Patents

Literature

782results about How to "Uniform and stable dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Use of nanomaterials as effective viscosity modifiers in lubricating fluids

InactiveUS20070293405A1Uniform and stable dispersionHigh indexMaterial nanotechnologyBase-materialsViscosity indexGraphite

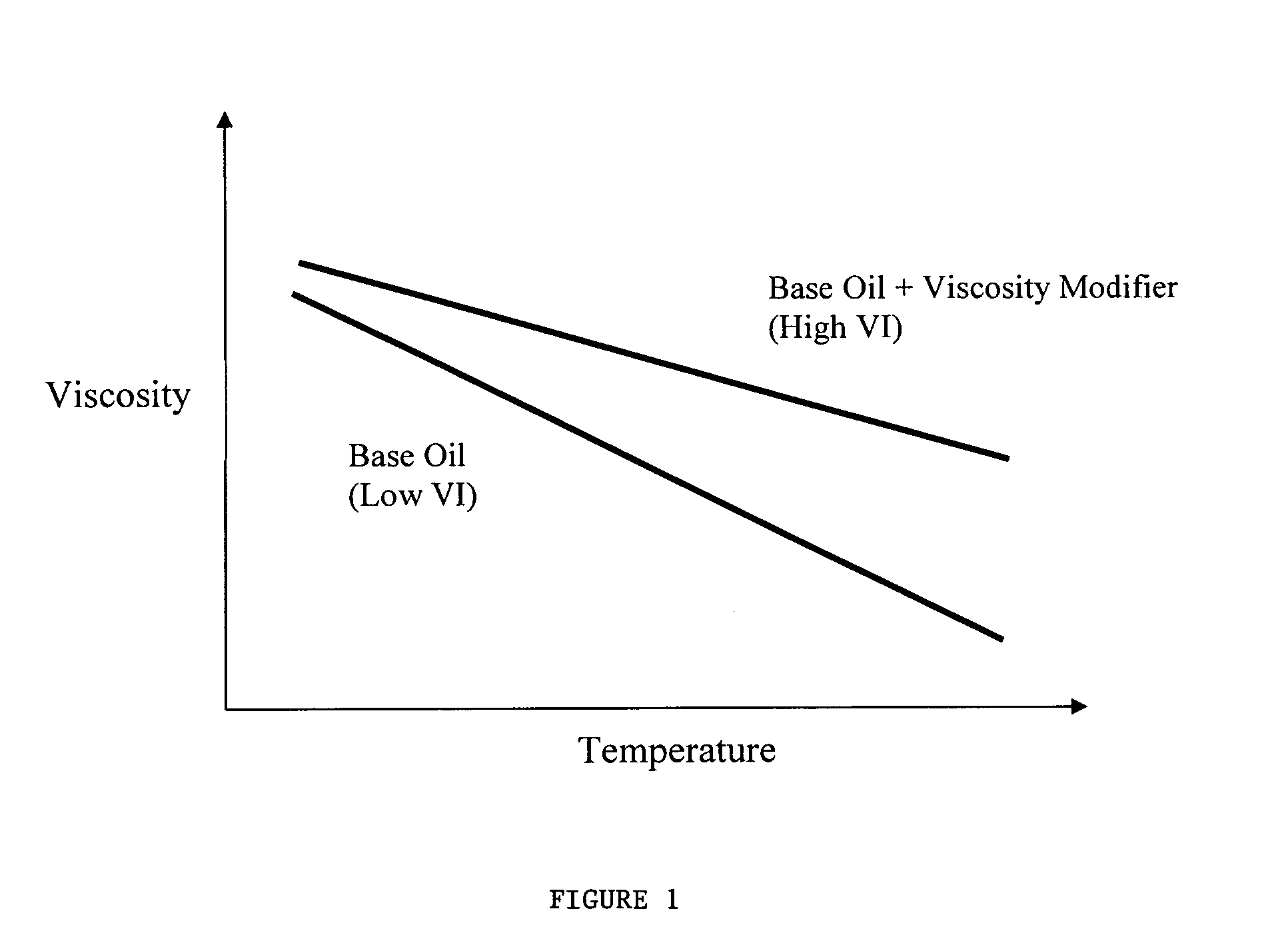

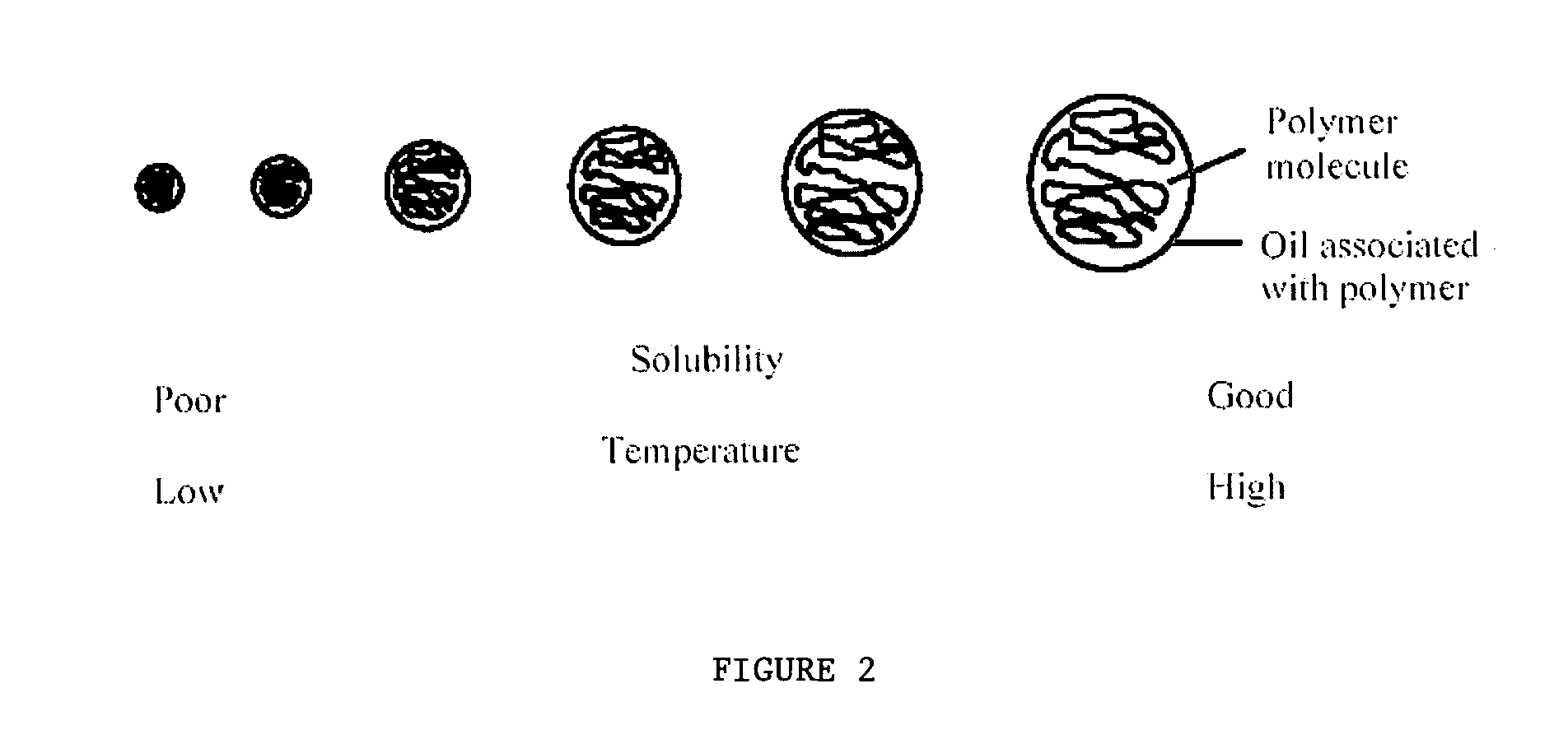

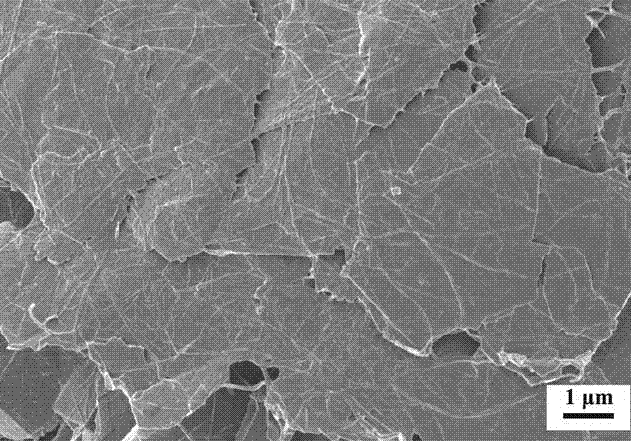

Nanomaterials have been used as a supplement or replacement of traditional polymer-based viscosity modifiers for lubricants and other related fluids. Compared with traditional polymer-based viscosity modifiers, nanomaterials possess better viscosity-index modification functions, i.e., more even viscosity increase across the whole temperature range. Meanwhile, a cost-effective way of making nanomaterials have been developed based on commercially available graphite materials, and the resulting nanoparticles of graphite are nanodisks (nanoplates). Furthermore, it provides a viscosity modifier which exhibits temporary shear loss, which can contribute to fuel economy, but no permanent shear loss.

Owner:ASHLAND LICENSING & INTPROP LLC

Lubricating oil composition and preparation method thereof

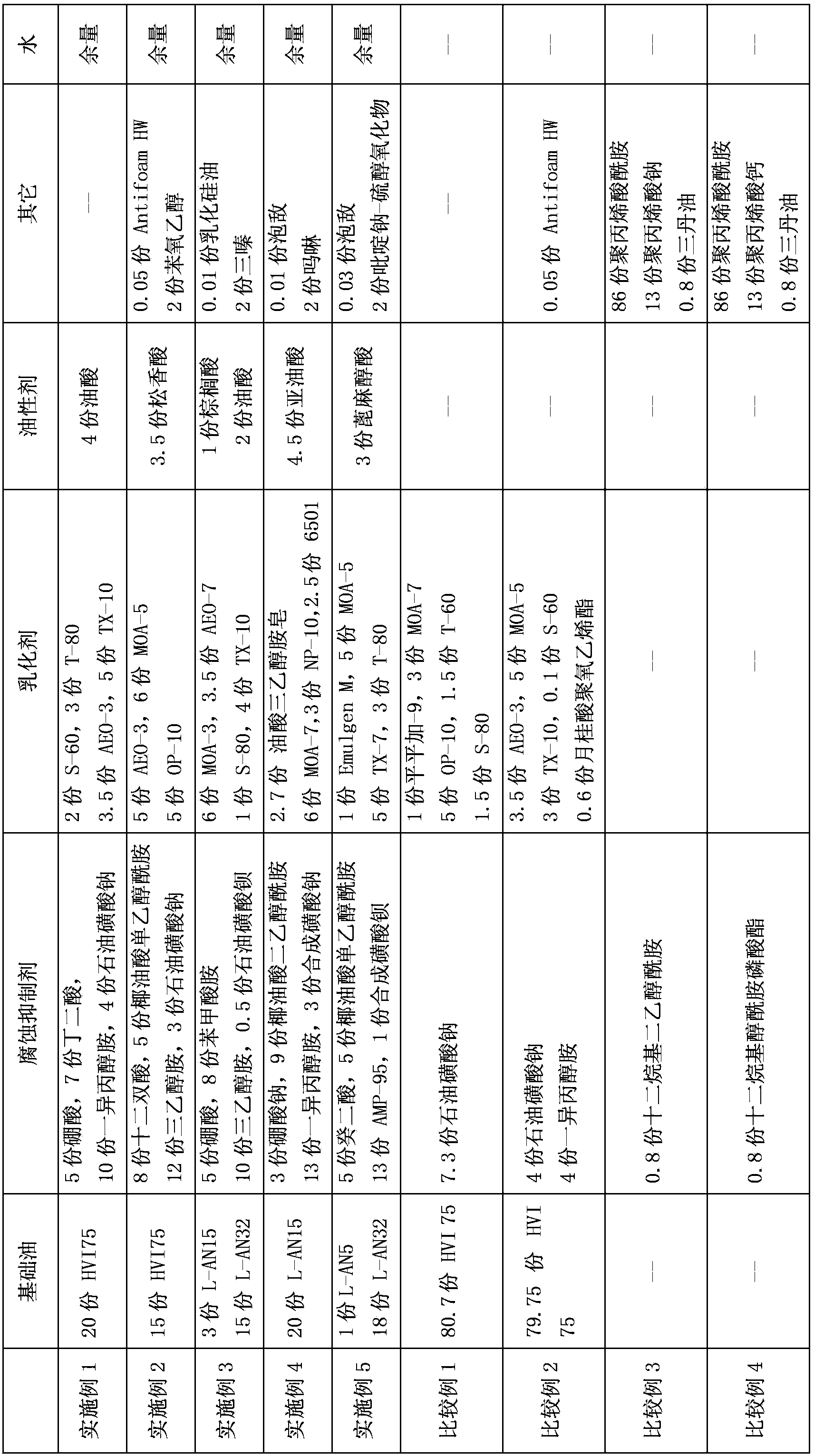

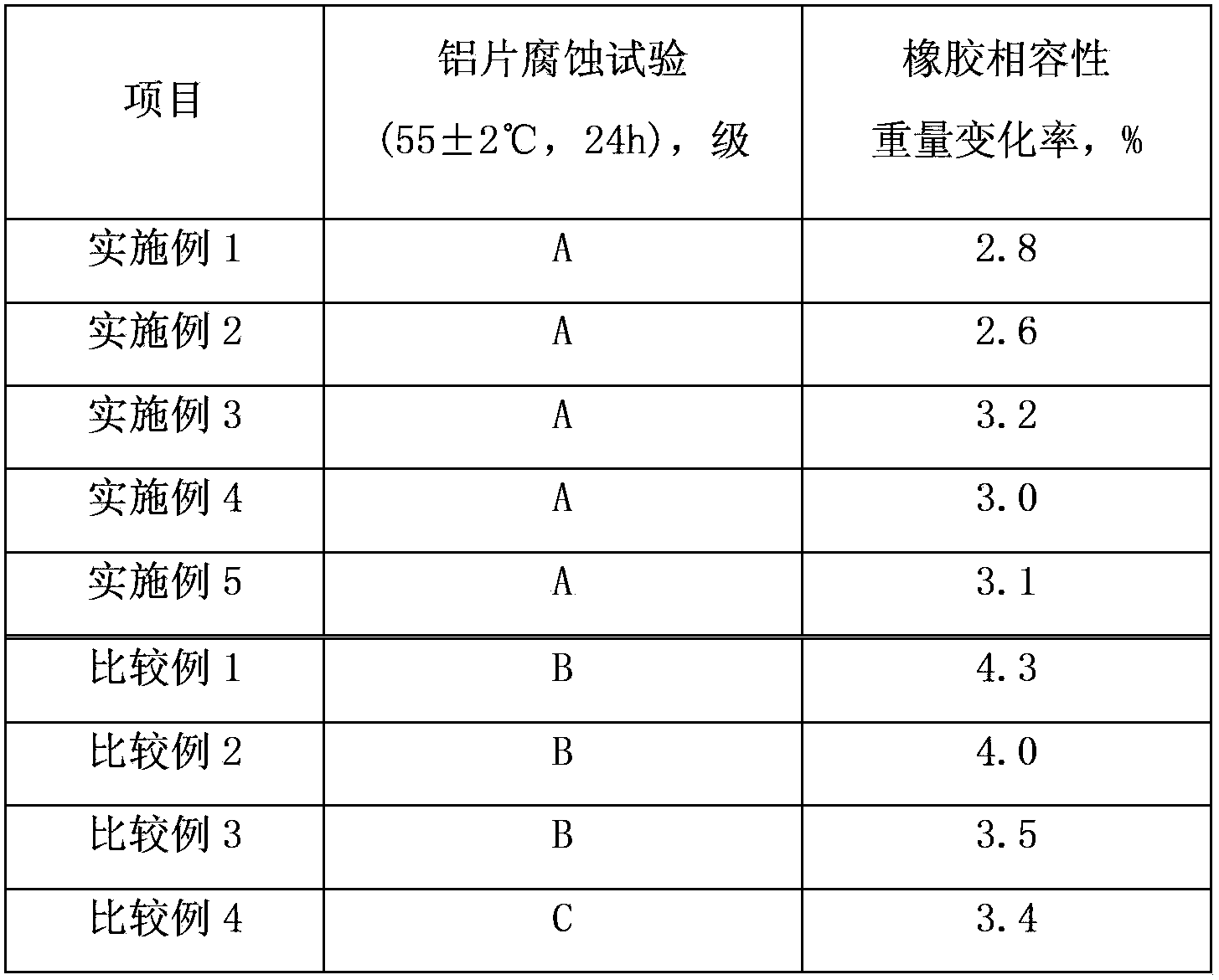

The invention relates to a lubricating oil composition and a preparation method thereof, and is mainly used for solving the problem that the lubricating oil in the prior art does not have anti-corrosive property to aluminum alloy and compatibility to rubber at the same time. The problem is well solved by the technical scheme that the lubricating oil composition comprises the following components in parts by weight: a) 10-30 parts of base oil, b) 15-35 parts of corrosion inhibitor, c) 8-20 parts of emulsifier, d) 1-6 parts of oil agent, and e) 5-40 parts of water. The lubricating oil composition can be applied to industrial production of the lubricating oil for automobile tire fitting.

Owner:CHINA PETROLEUM & CHEM CORP

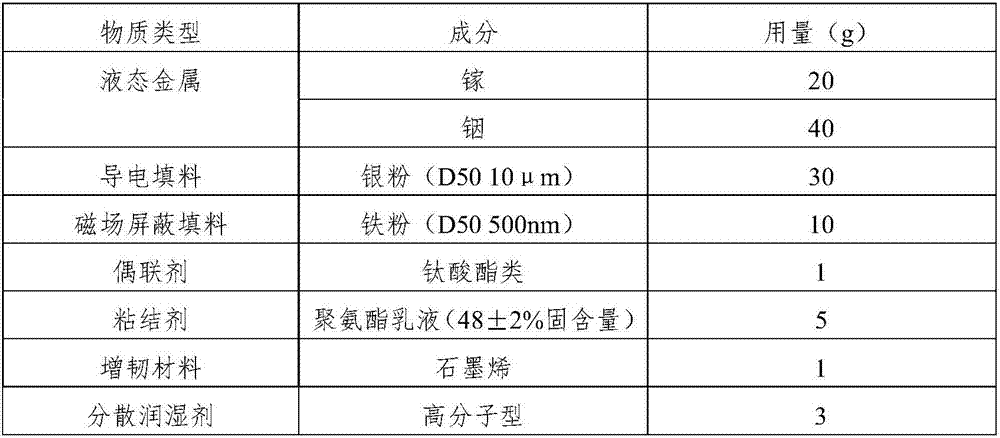

Electromagnetic shielding coating material and preparation method thereof

ActiveCN107573745AGood compatibilityImprove dispersion stabilityMagnetic/electric field screeningElectrically-conductive paintsHazardous substanceLiquid metal

The invention provides an electromagnetic shielding coating material. The electromagnetic shielding coating material comprises 40-70% of liquid metal, 10-40% of a conductive filler, 5-15% of a magnetic shielding filler, 0.5-2% of a coupling agent, 1-10% of a binder, 0.5-2% of a toughening material and 0.5-2% of a wetting dispersing agent, wherein the liquid metal is low-melting-point metal with the melting point of 300 DEG C or below or a conductive nanofluid formed by mixing low-melting-point metal nanoparticles with a fluid dispersant. For the first time, the concept of taking the liquid metal as a conductive auxiliary binder and a conductive auxiliary flow aid is put forward and implemented, and the liquid metal replaces a non-conductive solvent and a non-conductive binder to form the electromagnetic shielding coating material system. Besides, the electromagnetic shielding coating material neither contains any toxic or harmful substances nor produce any volatile organics, is high infilm forming speed, has the characteristics of being safe and environmentally friendly, convenient to construct and low in cost, and can be widely applied to a plurality of fields including militaryscience, electronics, aerospace, buildings and the like.

Owner:BEIJING DREAM INK TECH CO LTD

Lubricants with enhanced thermal conductivity containing nanomaterial for automatic transmission fluids, power transmission fluids and hydraulic steering applications

InactiveUS20080287326A1Low viscosityUniform and stable dispersionBase-materialsShear fieldViscosity index

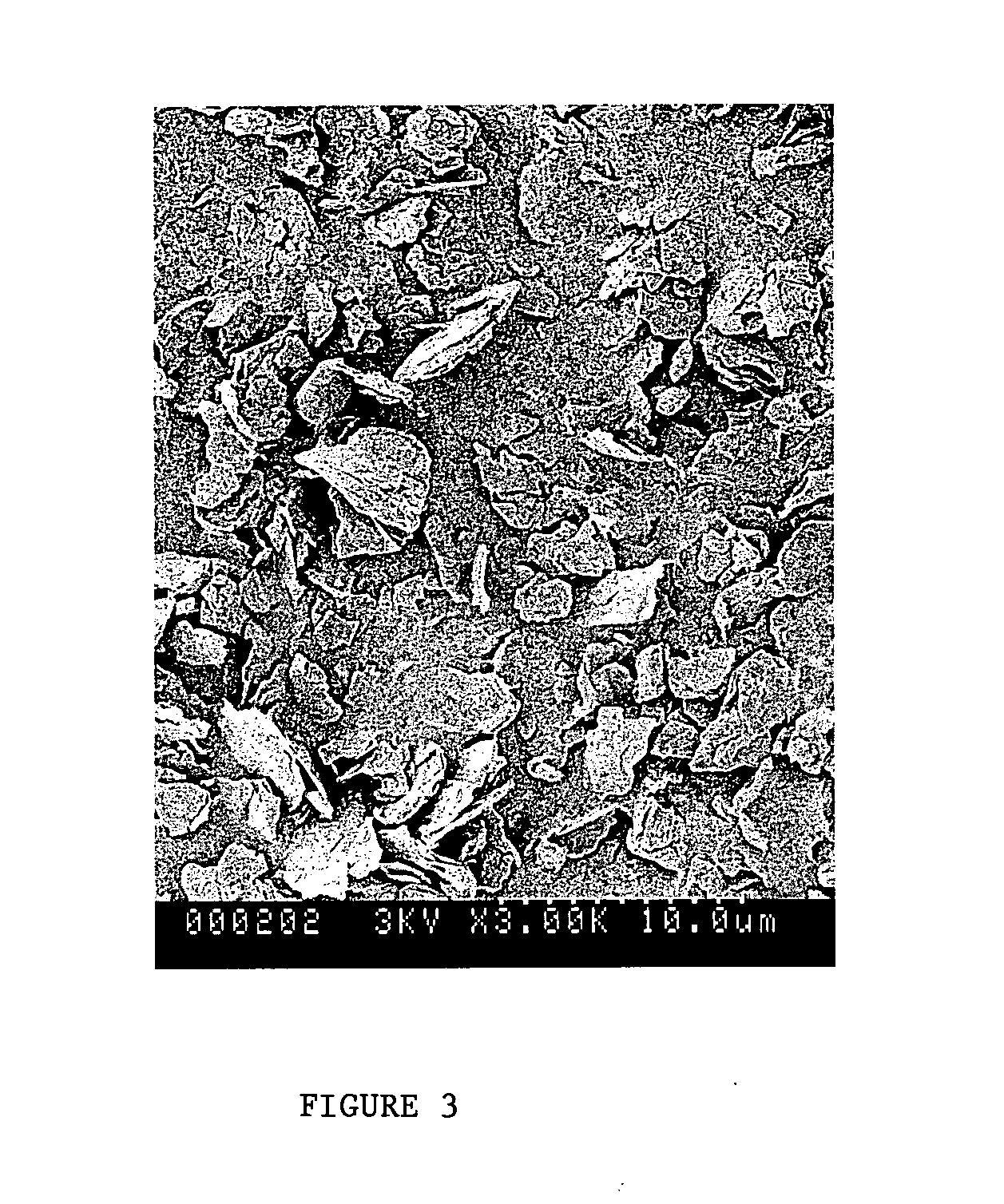

A lubricant composition having an enhanced thermal conductivity, up to 80% greater than its conventional analogues, and methods of preparation for these fluids are identified. One preferred composition contains a base oil, nanomaterial, and a dispersing agent or surfactant for the purpose of stabilizing the nanomaterial. One preferred nanomaterial is a high thermal conductivity graphite, exceeding 80 W / m in thermal conductivity. The graphite is ground, milled, or naturally prepared to obtain a mean particle size less than 500 nm in diameter, and preferably less than 100 nm, and most preferably less than 50 nm. The graphite is dispersed in the fluid by one or more of various methods, including ultrasonication, milling, and chemical dispersion. Carbon nanostructures such as nanotubes, nanofibrils, and nanoparticles are another type of graphitic structure useful in the present invention. Other high thermal conductivity carbon materials are also acceptable. To confer long-term stability, the use of one or more chemical dispersants or surfactants is useful. The thermal conductivity enhancement, compared to the fluid without graphite, is proportional to the amount of nanomaterials added. The graphite nanomaterials contribute to the overall fluid viscosity, partly or completely eliminating the need for viscosity index improvers and providing a very high viscosity index. Particle size and dispersing chemistry is controlled to get the desired combination of viscosity and thermal conductivity increase from the base oil while controlling the amount of temporary viscosity loss in shear fields. The resulting fluids have unique properties due to the high thermal conductivity and high viscosity index of the suspended particles, as well as their small size.

Owner:ZHANG ZHIQIANG +2

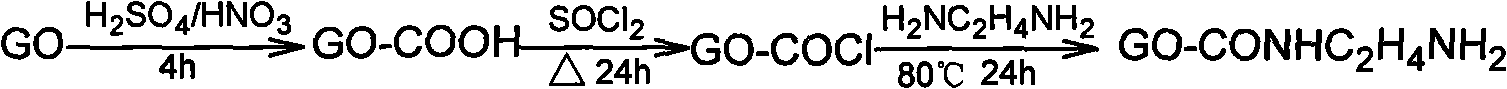

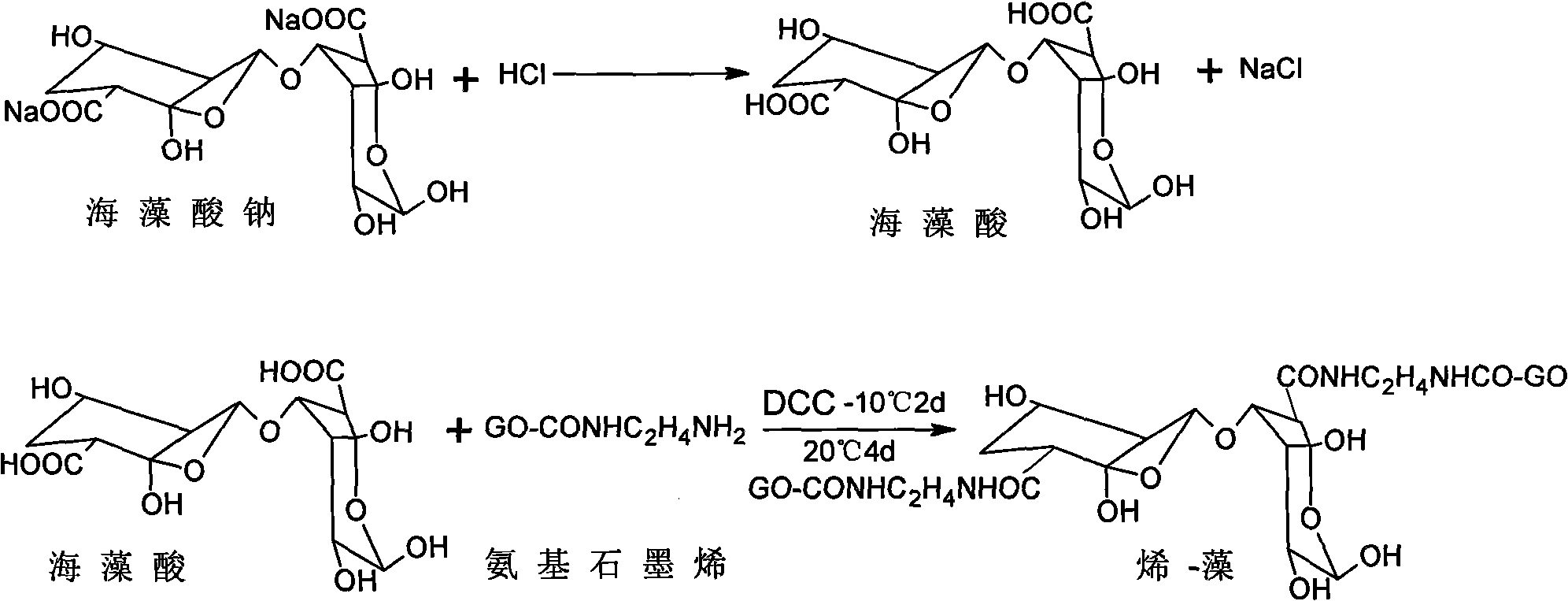

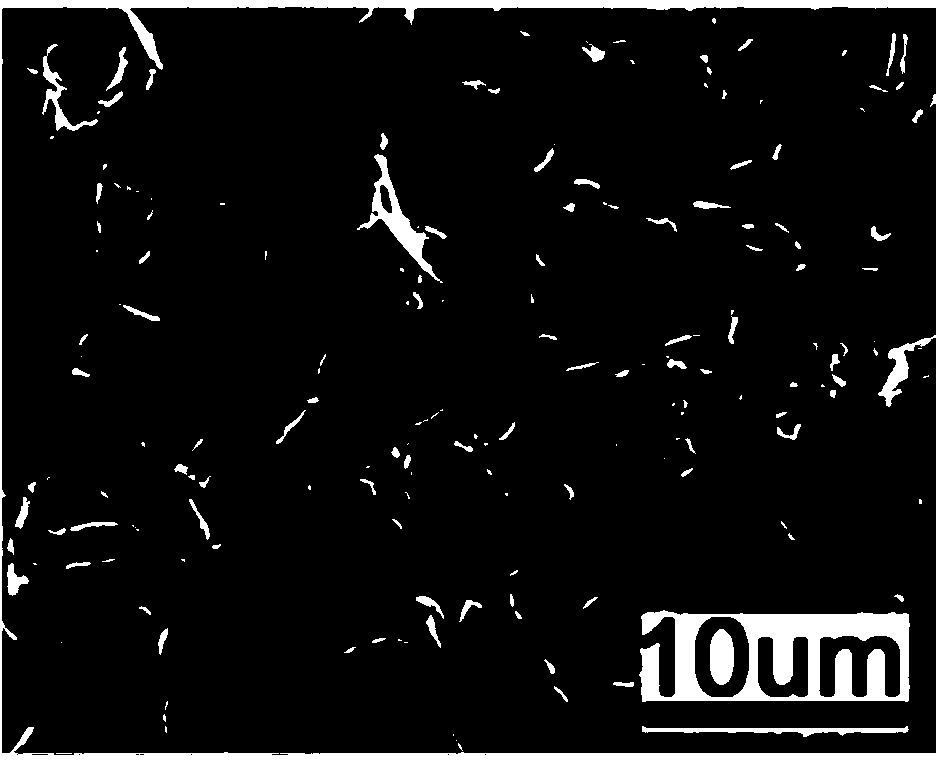

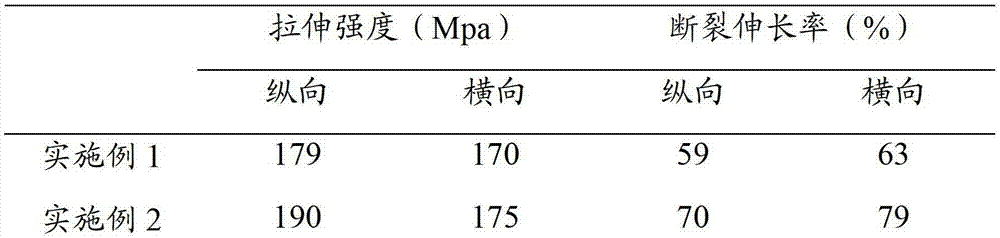

Method for preparing graphene functionalized alginate fibers

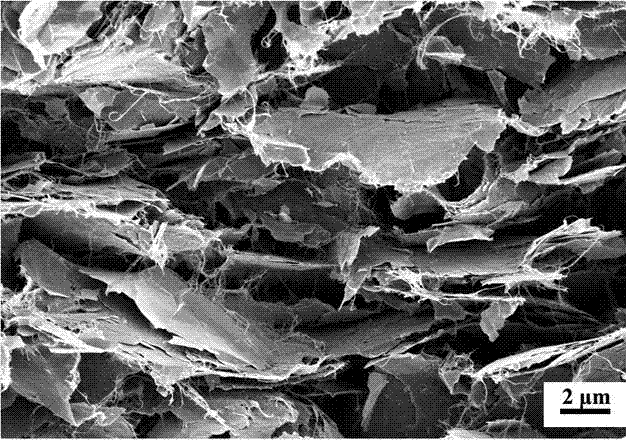

ActiveCN102181961AEffective orientationUniform and stable dispersionAlginate artificial filamentsWet spinning methodsFiberChemical reaction

The invention discloses a method for preparing graphene functionalized alginate fibers. The method comprises the following steps: firstly adding a defined amount of graphene to a sodium alginate solution to obtain a graphene / alginate spinning solution; or aminating the defined amount of graphene and then ensuring the aminated graphene to covalently bind with sodium alginate through a chemical reaction to obtain a graphene-alginate spinning solution; then ensuring the graphene / alginate spinning solution or the graphene-alginate spinning solution to respectively undergo a coagulation bath to obtain graphene / alginate as-spun fibers or graphene-alginate as-spun fibers; and then drawing, setting and oiling the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers after ensuring the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers to undergo a preheating bath and a drawing bath respectively to obtain graphene / alginate functionalized fibers or graphene-alginate functionalized fibers which are called graphene functionalized alginate fibers. The prepared graphene functionalized alginate fibers integrate the excellent performances of the graphene and the sodium alginate and have the excellent performances such as high tensile strength, good biocompatibility, antistatic performance, light weight, high elasticity, antibacterial performance and the like.

Owner:QINGDAO UNIV

Graphene conductive coating material, preparation method therefor and application of graphene conductive coating material

ActiveCN105778740AUniform and stable dispersionEasy to prepareAnti-corrosive paintsPolyurea/polyurethane coatingsChemical reactionMetallic materials

The invention discloses a graphene conductive composite coating material. The graphene conductive composite coating material contains macromolecular film-forming resin, graphene and a graphene dispersant; and the graphene dispersant contains an aniline oligomer or a derivative thereof or soluble polyaniline which can be combined with the graphene through PI-PI interaction so as to enable the graphene to be uniformly and stably dispersed in the macromolecular film-forming resin or a mixture of the macromolecular film-forming resin and water and / or an organic solvent. The invention also discloses a preparation method for the coating material. According to the coating material disclosed by the invention, the graphene can be uniformly and stably dispersed in a coating material matrix, so that the application of the coating material in the aspects of conductive macromolecular coatings and the like can be greatly promoted; the preparation process is simple, does not need complex chemical reactions and is easy to control, and the coatings made from the coating material have good bonding capability on surfaces of macromolecular materials, metallic materials, textile materials and ceramic materials; and meanwhile, the coating material also has the characteristics of radiation resistance, electrostatic resistance, corrosion prevention, wave absorbing, wear resistance and the like, thereby being broad in application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-quality graphene dispersion method and film preparation method

ActiveCN103449420AHigh dispersible concentrationNo dispersant residueGrapheneHigh concentrationProtonation

The invention relates to the field of graphene, particularly a high-quality graphene dispersion method and a method for preparing a film from a corresponding graphene dispersion solution or slurry. Graphene powder or aggregation-state slurry is added into a micromolecule amine compound solution to carry out dispersion treatment, so that the three amine micromolecule compounds are utilized to implement dispersion of the graphene; and in the dispersion solution, the molecules of the compounds are combined with the graphene under the pai-pai interaction, the amino group protonation is utilized to electrically charge the graphene, and the electrostatic repulsion action is utilized to prevent aggregation, thereby implementing the stable dispersion of the graphene. The dispersion solution or slurry can be subjected to spray coating, roller coating, scratch coating or any other conventional coating preparation method to obtain a graphene film on the substrate surface. The method can implement high-concentration efficient dispersion on high-quality graphene with the carbon / oxygen atom ratio of greater than 20 in multiple solvents; and after the film is formed and dried, no solvent or dispersant residue exists.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Lithium battery positive electrode slurry and preparation method thereof

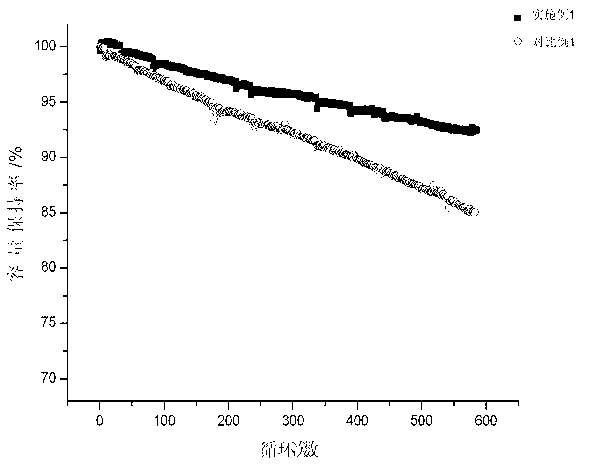

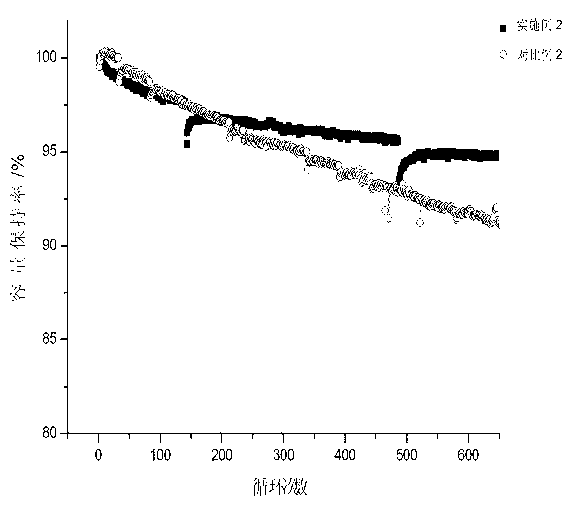

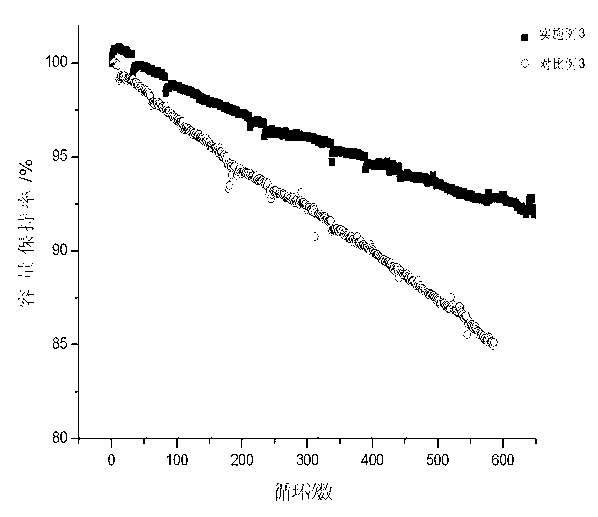

ActiveCN103208631AGood high temperature performanceHigh capacity retentionNon-aqueous electrolyte accumulator electrodesOrganic solventSlurry

The invention discloses lithium battery positive electrode slurry. The lithium battery positive electrode slurry is a mixture of a positive electrode material and an organic solvent. The positive electrode material is composed of, by mass, 60-97% of a positive electrode active material, 1-30% of a binding agent, 0-10% of a conductive agent, 1-5% of a conductive reinforcing agent and 0.1-3% of a dispersing agent. A lithium battery prepared by the lithium battery positive electrode slurry provided by the invention has the advantages of excellent high temperature performance, high capacity conservation rate, good cycle performance, long service life and the like. The invention also provides a preparation method of the lithium battery positive electrode slurry, enabling solid materials such as the conductive reinforcing agent to be distributed in the organic solvent uniformly and stably and to be directly stirred and mixed in a common stirring apparatus, so that the operation is convenient and the method can realize large-scale production.

Owner:WANXIANG 123 CO LTD

Method for preparing hydroxyapatite biodegradable aliphatic polyester composite material

The invention provides a process for preparing a novel nanometer / micrometer inorganic- biological degradable polyester composite material comprising, subjecting hydroxyapatite nanometer / micrometer particles and lactic acid to dewatering polycondensation reaction in organic solvent under the condition of heating and stirring, further reacting under toluene azeotropic dewatering condition, the dewatering polycondensation reaction can also be conducted to hydroxyapatite and lactic acid without the presence of solvent, grafting the hydroxyl of the particle surface of the hydroxyapatite to obtain the chemical constitution of lactic acid ester or low polylactic acid ester - hydroxyapatite, under the condition of waterless and oxygen free, using stannous octoate as initiating agent to trigger epsi-caprolactone, lactide, glycolide or cyclic ester monomer, and ring-opening polymerizing to obtain the homopolymer of epsi-caprolactone, lactide or glycolide biodegradable polyester and the nanometer / micrometer composite material of their dyadic and ternary copolymer.

Owner:CHANGCHUN SINOBIOMATERIALS

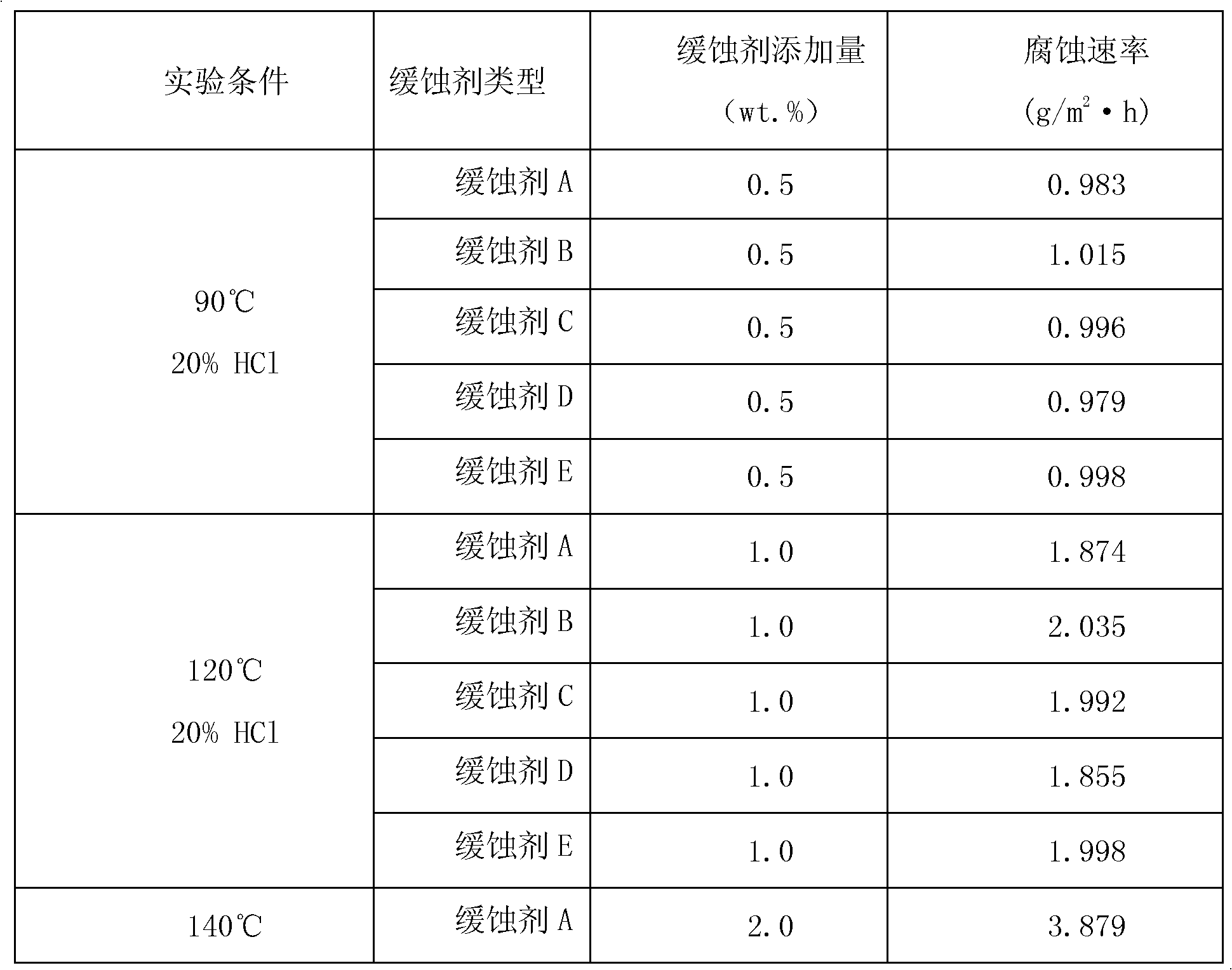

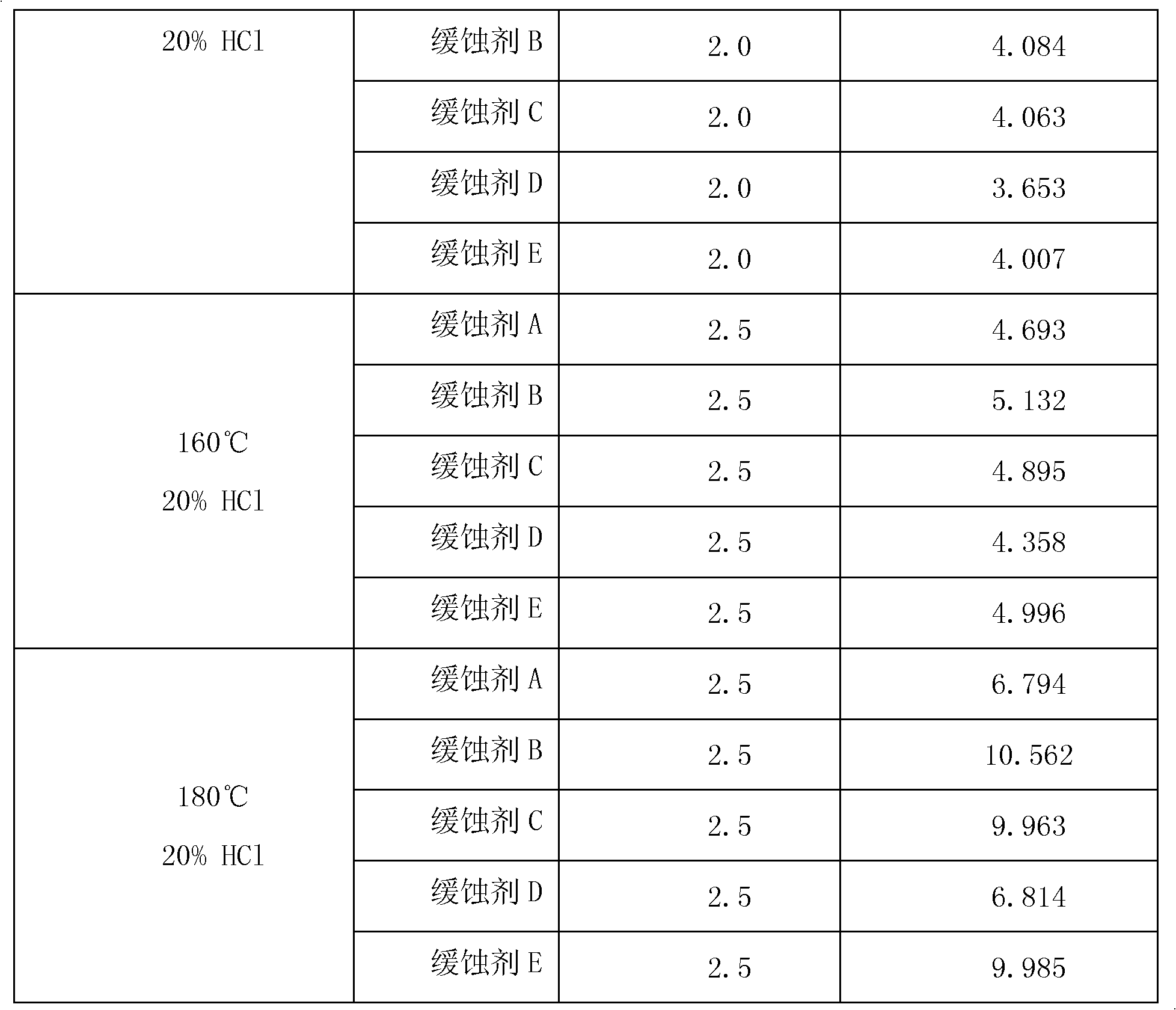

Nitrogenous heterocyclic quaternary ammonium salt acidizing corrosion inhibitor and preparation method thereof

The invention discloses a nitrogenous heterocyclic quaternary ammonium salt acidizing corrosion inhibitor and a preparation method thereof. The nitrogenous heterocyclic quaternary ammonium salt acidizing corrosion inhibitor comprises the following components in percentage by weight: component 1, propargyl alcohol, formaldehyde, urotropine, potassium iodide, antimonous oxide, antimony butter, surfactant and solvent in the ratio of (1-50) : (0-25) : (1-25) : (0-10) :(0-10) : (0-20) : (6-25) : (15-70), wherein the component 1 is selected from one or more of chlorinated N-benzyl-R-pyridine quaternary ammonium salt or chlorinated N-benzyl-R-quinoline quaternary ammonium salt. The nitrogenous heterocyclic quaternary ammonium salt acidizing corrosion inhibitor has the advantages of small addition amount, low cost, stable and uniform dispersion in acidic liquid, low corrosion speed, capability of resisting high temperature of over 160 DEG C and excellent performance. 0.5-2.5 percent of nitrogenous heterocyclic quaternary ammonium salt acidizing corrosion inhibitor disclosed by the invention is added into the acidic liquid, so that the corrosion speed is far lower than national primary standard.

Owner:南京华洲新材料有限公司

Nano-silica/polyacrylate organic and inorganic hybrid water-dispersible resin and preparation method thereof

InactiveCN105061700AGood storage stabilityInhibit aggregationAntifouling/underwater paintsPaints with biocidesWater dispersibleIn situ polymerization

The invention discloses nano-silica / polyacrylate organic and inorganic hybrid water-dispersible resin and a preparation method thereof. According to the method, a silane coupling agent is adopted to modify a methyl methacrylate dispersion liquid of silica at first, and then in-situ polymerization of the modified methyl methacrylate dispersion liquid of silica and acrylate monomers is carried out in a solvent. The nano-silica / polyacrylate organic and inorganic hybrid water-dispersible resin comprises the following ingredients in parts by mass: 20-40 parts of a solvent, 10-40 parts of a modified methyl methacrylate dispersion liquid of silica, 8-14 parts of acrylate monomers, 2-6 parts of acrylic acid, 0.15-0.5 part of an initiator, 1.5-5.5 parts of a pH regulator and 10-30 parts of deionized water. The water-dispersible resin is a pale yellow or pale yellow and slightly-blue semitransparent liquid, is favorable in storage stability, high in coating transparency and good in stain resistance and water resistance, the hardness can be 4H or above and the adhesion can be 1 grade.

Owner:SOUTH CHINA UNIV OF TECH

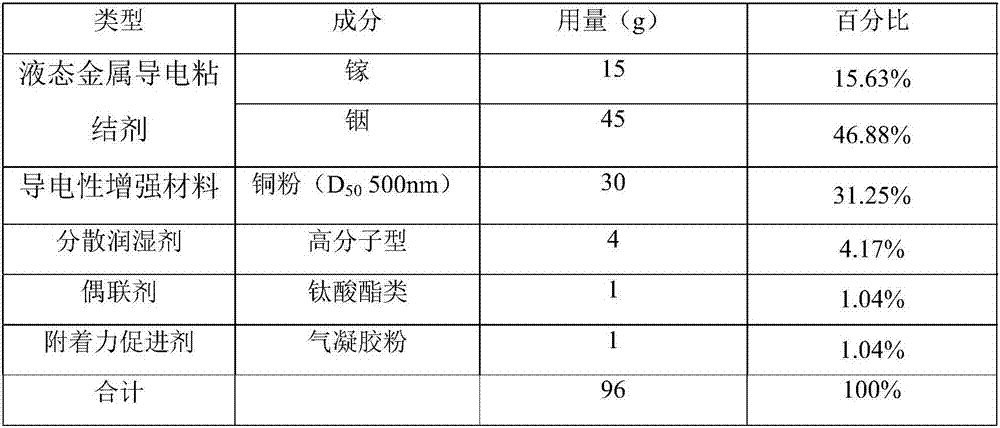

Polyimide film and preparation method thereof

The invention provides a preparation method of a polyimide film. The preparation method comprises the following steps of mixing and grinding a heat-conducting padding, a solvent and a coupling agent to obtain slurry; enabling diamine and dianhydride to react in a solvent, so as to obtain polyimide resin; mixing, defoaming and casting the slurry and the polyimide resin to obtain a polyamic acid film; conducting imidization on the polyamic acid film to obtain the polyimide film, wherein the heat-conducting padding includes a first heat-conducting padding of which the particle size is 100-200nm, a second heat-conducting padding of which the particle size is 50-100nm and a third heat-conducting padding of which the particle size is 10-50nm. The heat-conducting padding adopted by the polyimide film is different in particle size, so that the maximal packing degree is formed between the heat-conducting padding; an effective heat-conducting channel is formed; the heat-conducting property of the polyimide film is improved; the heat-conducting padding can be evenly dispersed in the solvent in a grinding manner; the prepared polyimide film is even to disperse, high in stability, and good in mechanical property in the presence of the coupling agent.

Owner:株洲时代华鑫新材料技术有限公司

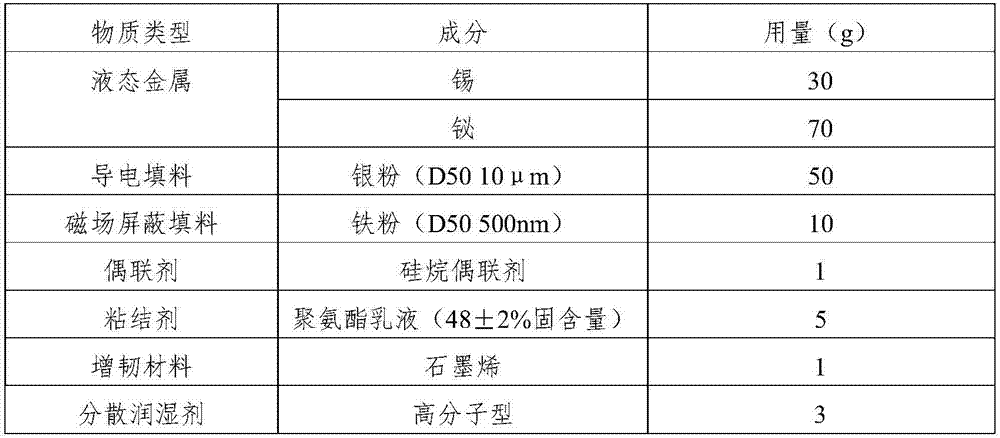

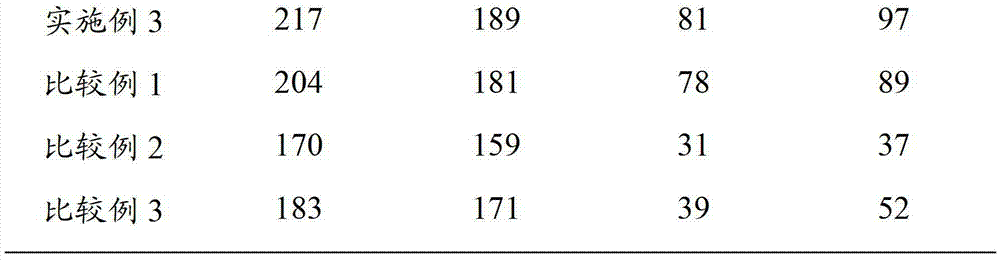

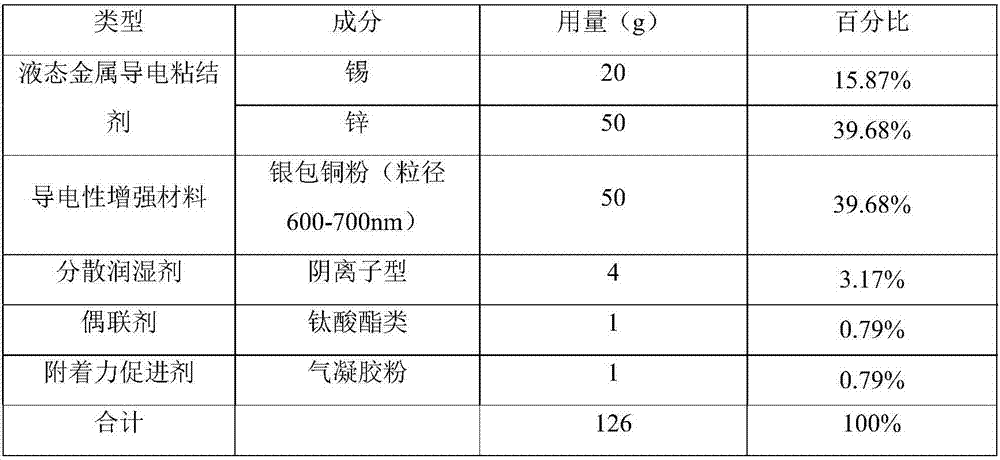

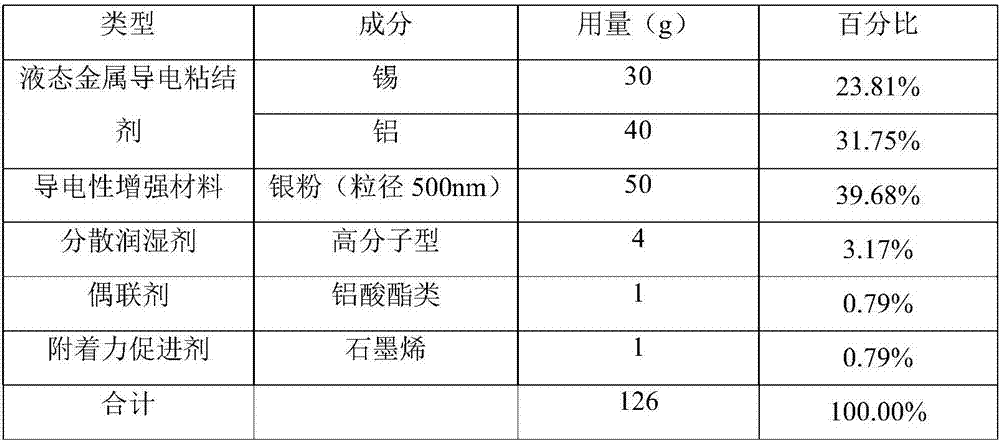

Low cost recyclable conductive paste and preparation method thereof

ActiveCN107578838AGood compatibilityImprove dispersion stabilityConductive layers on insulating-supportsMetal/alloy conductorsDispersion stabilityLiquid metal

The invention provides a low cost recyclable conductive paste. By weight percentage, 45-80% liquid metal conductive binder, 12-50% conductive reinforced material, 1-5% dispersant wetting agent, 0.5-2%coupling agent and 0.5-2% clunging promoter are comprised, wherein the liquid metal is a low melting point metal or alloy with a melting point below 300 DEG C or conductive nano-fluids formed throughmixing low melting point metal nano particles with fluid dispersant. The low cost recyclable conductive paste is advantaged in that the liquid metal conductive binder is utilized to replace a non-conductive high-molecular binder and solvent, under the synergism effect of small amount of coupling agent and the dispersant wetting agent, through adding small amount of the conductive reinforced filling material to realize uniform and stable dispersion, the low cost conductive paste with high compatibility and high dispersion stability is formed, and volume resistivity reaches 3*10<-5> Omega*cm.

Owner:BEIJING DREAM INK TECH CO LTD

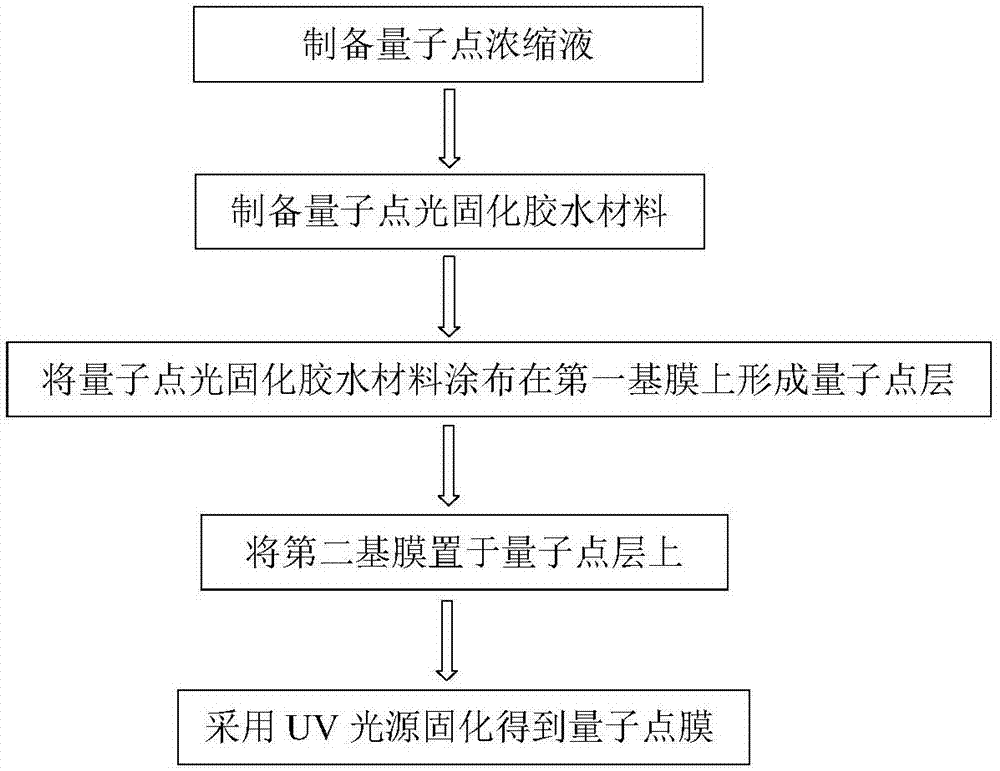

Quantum dot film and preparation method thereof

InactiveCN106863935AUniform and stable dispersionAvoid direct contactLamination ancillary operationsNon-macromolecular adhesive additivesQuantum dotSolid content

The invention relates to a quantum dot film and a preparation method thereof applied to the field of optical display. The quantum dot film comprises a first base film, a quantum dot layer and a second base film, wherein the quantum dot layer is positioned between the first base film and the second base film, and the quantum dot layer comprises photo-curing glue, a quantum dot nano-material dispersed in the photo-curing glue, and a light diffusing agent. The preparation method comprises the following steps: preparing a quantum dot concentrated liquid, preparing a photo-curing glue material, forming the quantum dot layer on the first base film, placing the second base film on the quantum dot layer and forming a film by photo-curing. The quantum dot film and the preparation method thereof provided by the invention have the beneficial effects that the quantum dot nano-material is uniformly and stably dispersed in a photo-curing glue system with 100% solid content, so that the obtained quantum dot film has high quantum luminescence efficiency; the film is formed by photo-curing without heat curing, quantum dots cannot be damaged due to high temperature; on the one hand, the working procedures are reduced, and the production efficiency is improved; on the other hand, the equipment investment and energy consumption are reduced, and the production cost is reduced.

Owner:WUHAN BAOLI LIANGCAI TECH CO LTD

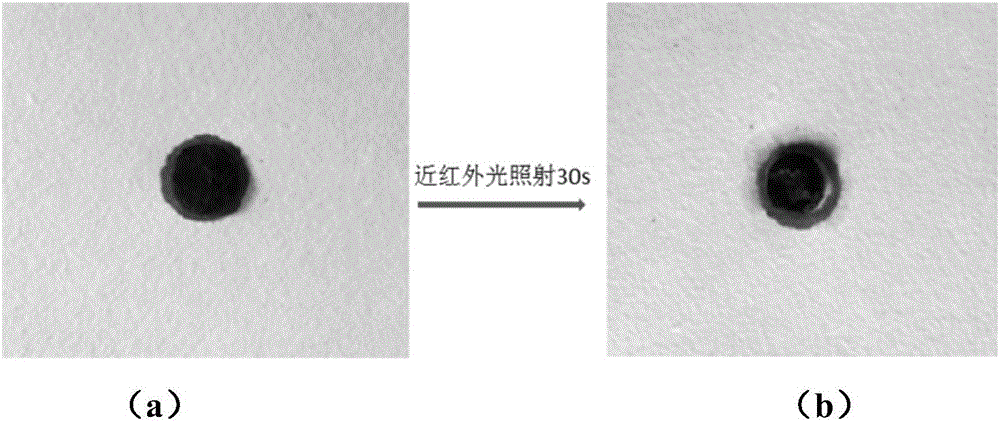

Preparation method of electrical stimulation-near infrared dual response high strength hydrogel

The invention discloses a preparation method of electrical stimulation-near infrared dual response high strength hydrogel. The preparation method comprises the following steps: with taking a thermosensitive polymer monomer as a main raw material, adding a natural polymer to prepare thermosensitive deformable hydrogel with a semi-interpenetrating network structure; and then sequentially adsorbing an oxidizing agent and a pyrrole monomer by utilizing the swelling effect of the hydrogel so that the pyrrole monomer sufficiently permeates into a hydrogel network and is oxidized into polypyrrole by the oxidizing agent. Due to the introduction of polypyrrole, the prepared hydrogel has conductivity and near-infrared responsibility. When the hydrogel is in an energized state or is irradiated by near infrared light, temperature of the hydrogel rises, and the thermosensitive polymer network in the hydrogel structure contracts, so that volume and shape change, and light-electricity dual stimulation response is realized; meanwhile, stimulation response behaviour of the hydrogel has good sensitivity. The prepared hydrogel also has good mechanical properties and biocompatibility and can be applied to multiple fields of drug controlled release systems, memory element switches and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Method for preparing superfine calcium carbonate compound particles

ActiveCN102020878AUniform and stable dispersionCompact structureInorganic pigment treatmentCalcium hydroxideSlurry

The invention discloses a method for preparing superfine calcium carbonate compound particles, which comprises the following steps of: (1) introducing carbon dioxide gas or carbon dioxide-containing gas in suspension of calcium hydroxide, and reacting to obtain slurry containing superfine calcium carbonate particles; (2) when the pH value is reduced to be between 7.1 and 10.5, adding soluble aqueous solution of silicate, so that the pH value in a reaction system is between 7.5 to 9.5, after adding the silicate, stopping introducing the carbon dioxide-containing gas, aging at the temperature of between 40 and 90 DEG C for 0.5 to 3 hours, and introducing the carbon dioxide-containing gas until the pH value is between 6.5 to 7.0; and (3) filtering the obtained serous fluid, and washing by water to obtain the products. By the method, silicon dioxide can be subjected to film-forming cladding on the surface of calcium carbonate uniformly; and the method is simple in operating conditions, and the prepared calcium carbonate compound particles have the advantages of compact structures, high acid-resisting capacity, high dispersibility and low cost.

Owner:建德华明科技有限公司

Magnesium-aluminum based layered double hydroxide aging resistant SBS (Styrene-Butadiene-Styrene Block Copolymer) modified asphalt and preparation method thereof

ActiveCN102174269AImproves UV resistanceImproved performance against UV agingBuilding insulationsAluminium oxides/hydroxidesPolymer modifiedAging resistance

The invention relates to aging resistant SBS (Styrene-Butadiene-Styrene Block Copolymer) modified asphalt and a preparation method thereof. The aging resistant SBS modified asphalt is a magnesium-aluminum based layered double hydroxide aging resistant SBS modified asphalt prepared from the following raw materials by weight percent: 86.7%-94.95% of base asphalt, 3%-5% of polymer modifier SBS, 2%-8% of magnesium-aluminum based layered double hydroxide and 0.05%-0.3% of vulcanizer. In the preparation method, the magnesium-aluminum based layered double hydroxide with the ultraviolet physical shielding and chemical absorption functions is mixed with the SBS modified asphalt so as to obviously increase the ultraviolet aging resistance of the SBS modified asphalt.

Owner:WUHAN UNIV OF TECH

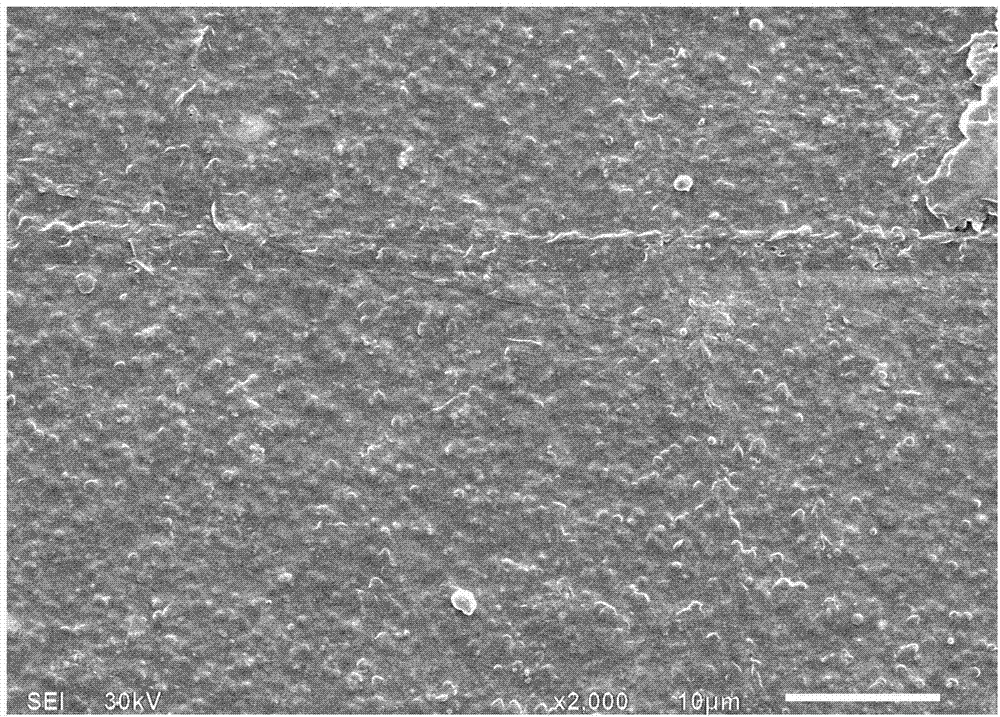

Manufacturing method of inorganic particle filled polyimide film

InactiveCN101805517AUniform and stable dispersionOvercoming dispersionGrain treatmentsOrganic solventInorganic particle

The invention discloses a manufacturing method of an inorganic particle filled polyimide film, in particular to a manufacturing method of an inorganic particle filled polyimide film which adopts a small-sized grinding ball as a grinding medium and also adopts a grinding machine to uniformly and stably disperse inorganic particles into an organic solvent, thereby improving the transparency and mechanical properties of the film. The manufacturing method comprises the following steps: adding a grinding ball with the diameter no more than 6mm into the grinding bucket of a grinding machine with a moving medium, and adding and grinding part of organic solvent, inorganic particles and surfactant until the inorganic particles are uniformly dispersed in the organic solvent, thereby obtaining inorganic particle / organic solvent suspension; adding the inorganic particle / organic solvent suspension, the remaining organic solvent and diamine and dianhydride with identical molar numbers into a reactor, and preparing inorganic particle / polyamic acid solution suspensoid in a conventional method; and preparing the inorganic particle filled polyimide film with the inorganic particle / polyamic acid solution suspensoid according to the production process of the conventional flow casting method. The film has the advantages of good transparency and excellent mechanical properties.

Owner:天津恒通时代电工材料科技有限公司 +1

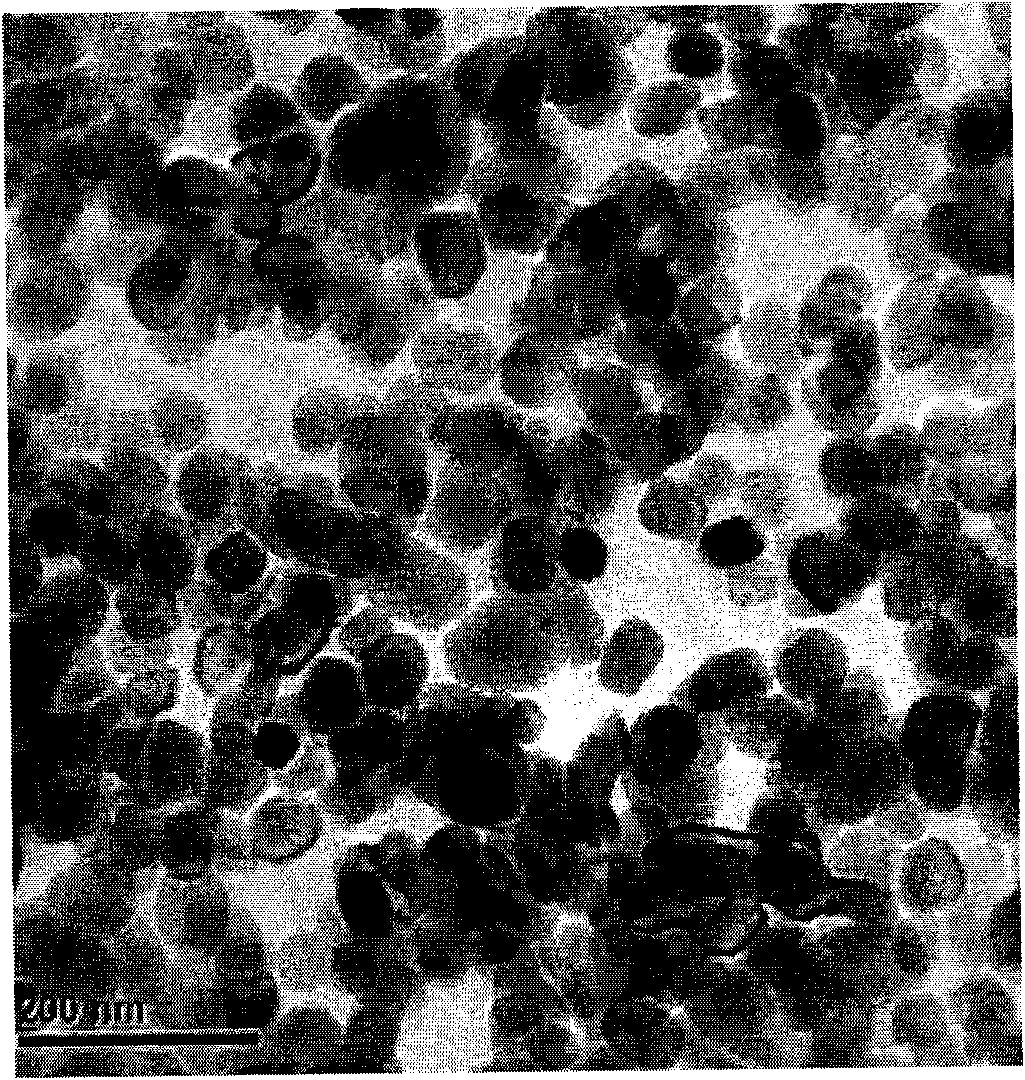

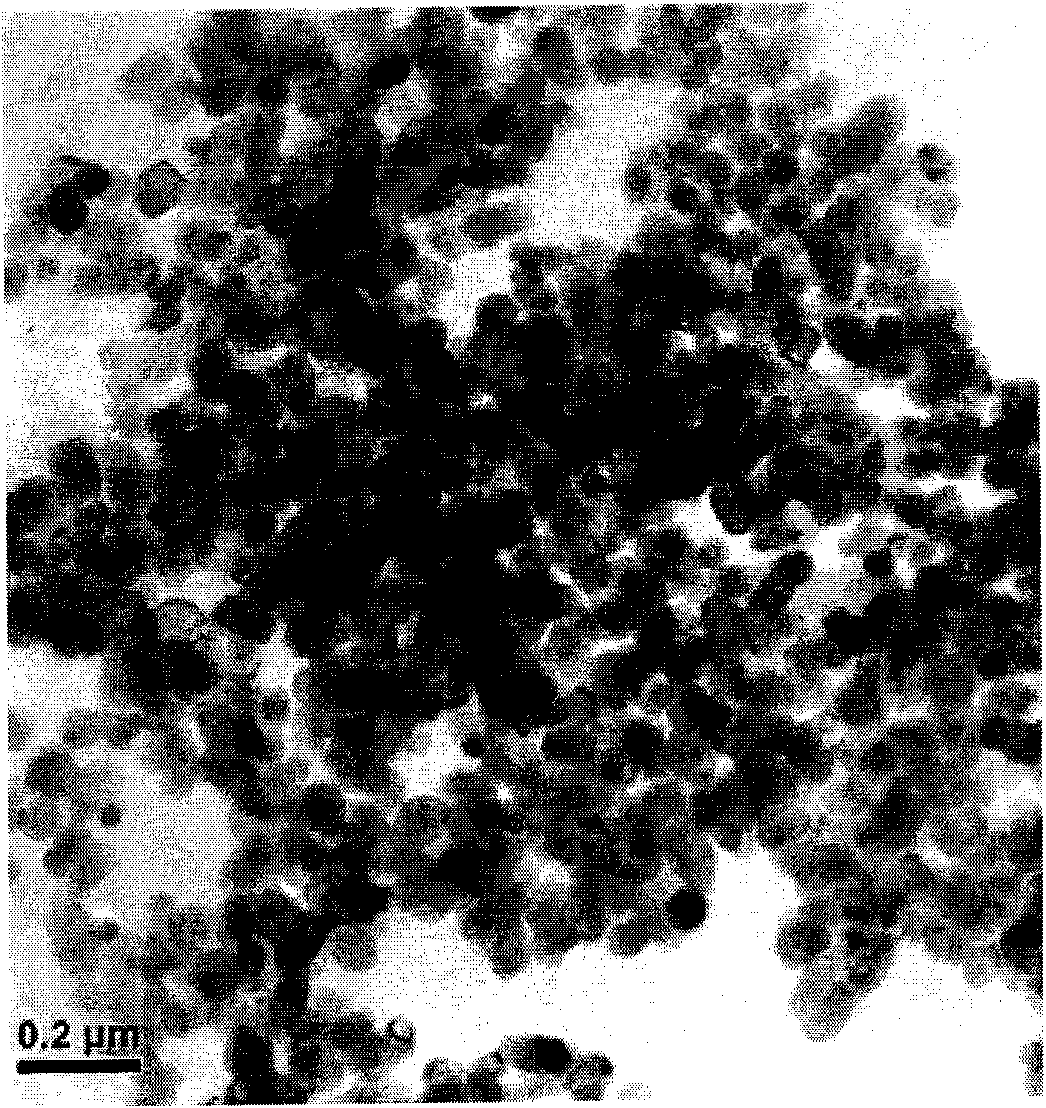

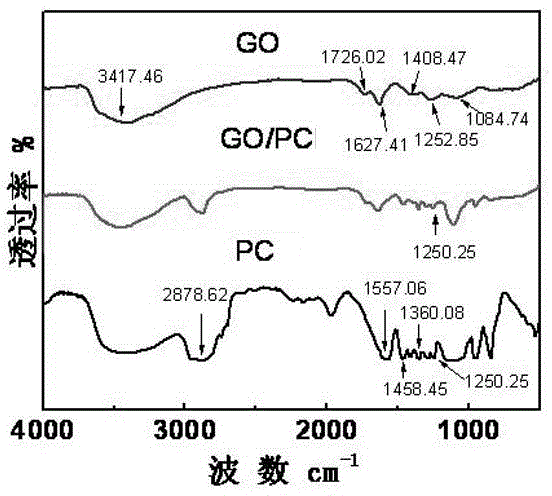

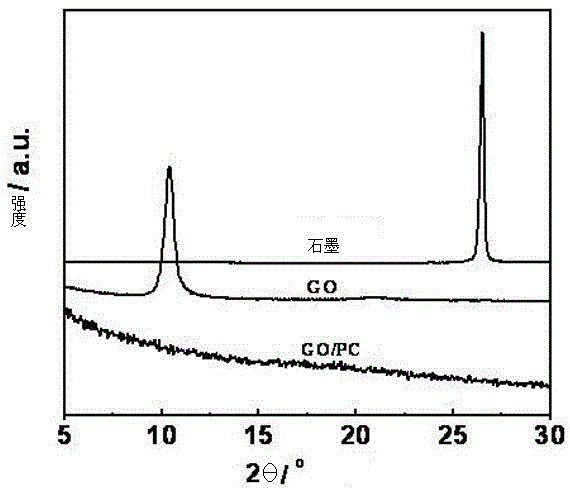

Method for modifying graphene oxide

The invention discloses a method for modifying graphene oxide. According to the method, the surface of graphene oxide is modified, so that graphene oxide can be uniformly dispersed in cement paste. The method mainly comprises the following steps: putting a 0.2-5mg / ml graphene oxide dispersed liquid into a water bath pot of 60-80 DEG C, dropwise adding a polycarboxylate-type high-efficiency water reducing agent of which the mass is 6-8 times that of graphene oxide while the graphene oxide dispersed liquid is stirred, and after the reaction is completed, performing ultrasonic treatment for 0.5-1 hour, thereby obtaining modified graphene oxide. As the polycarboxylate-type high-efficiency water reducing agent is adopted to modify graphene oxide, PC is grafted on the surface of graphene oxide through covalence action, and the adsorption degree of a graphene oxide nanosheet layer to Ca<2+> is reduced, the problem that a graphene oxide adhesive can be coagulated in the presence of positive charge Ca<2+> can be solved, and furthermore the graphene oxide can be uniformly and stably dispersed in early-age cement paste.

Owner:SOUTHEAST UNIV

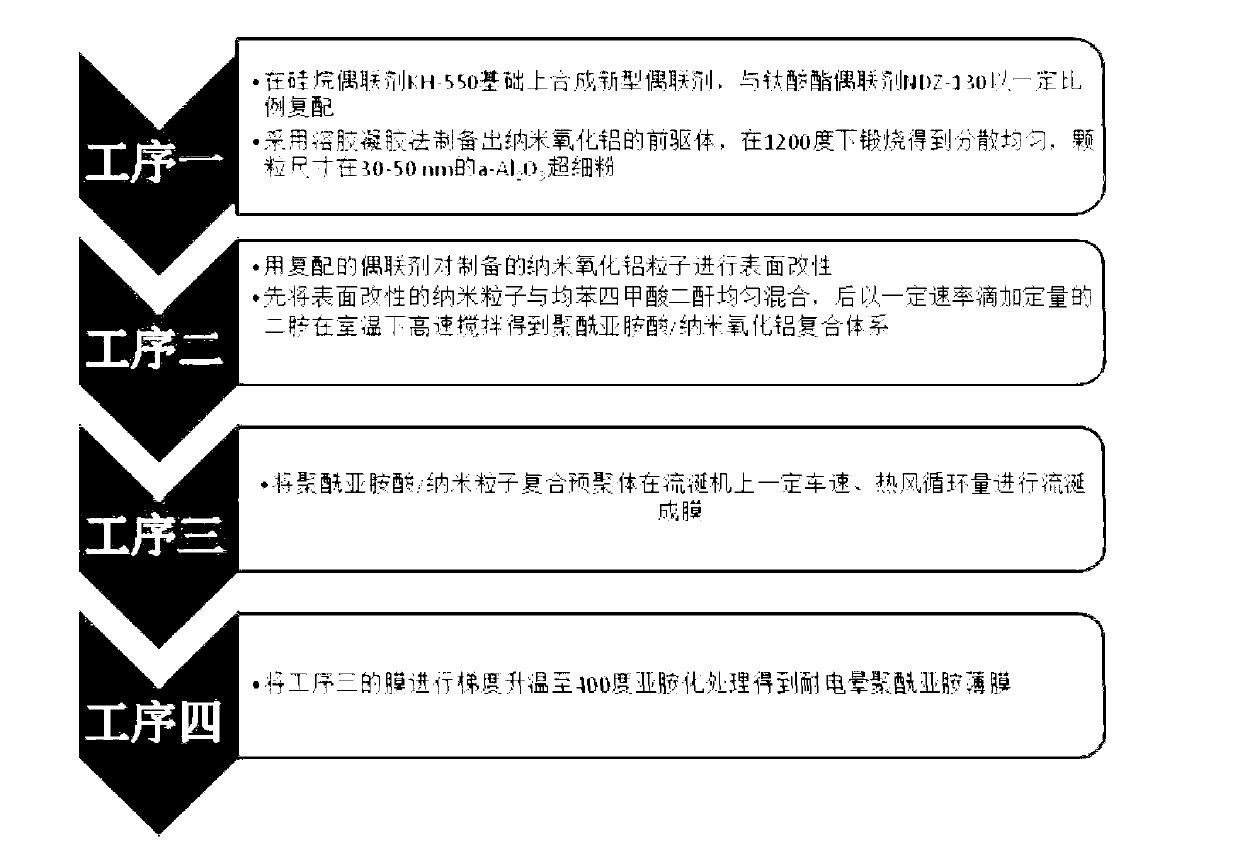

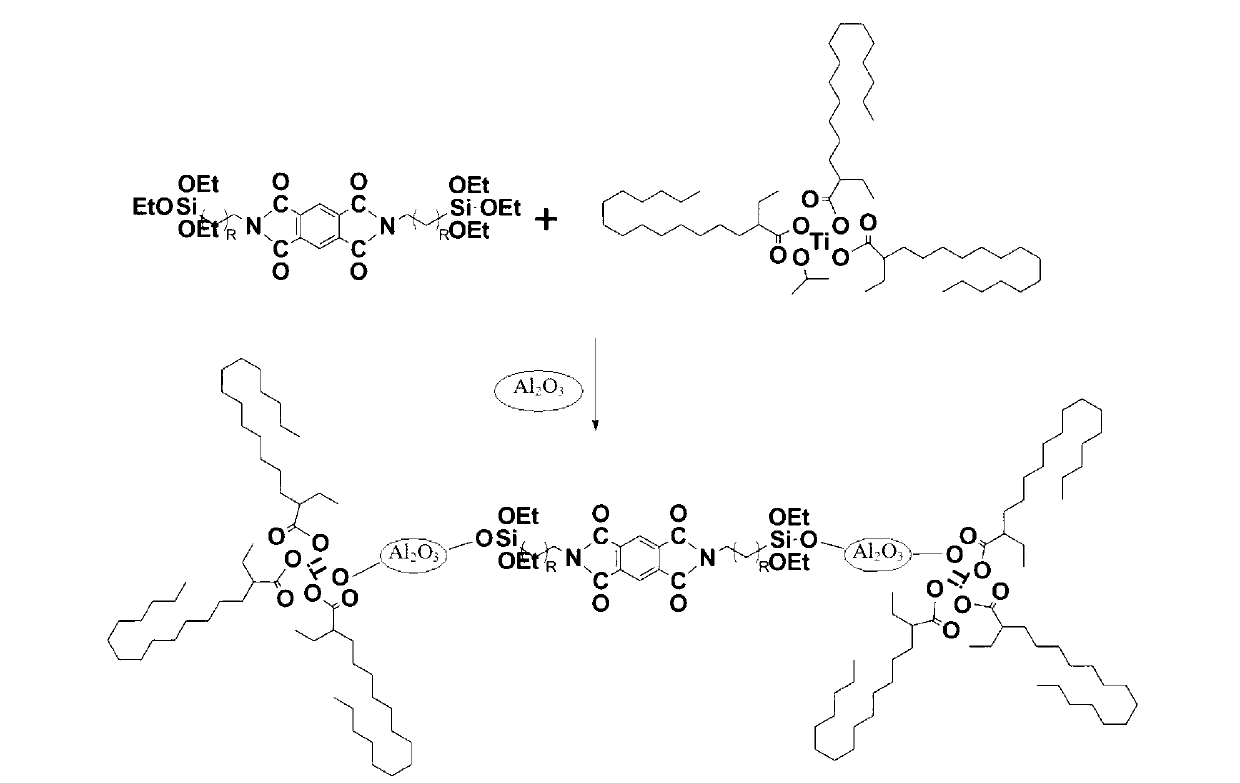

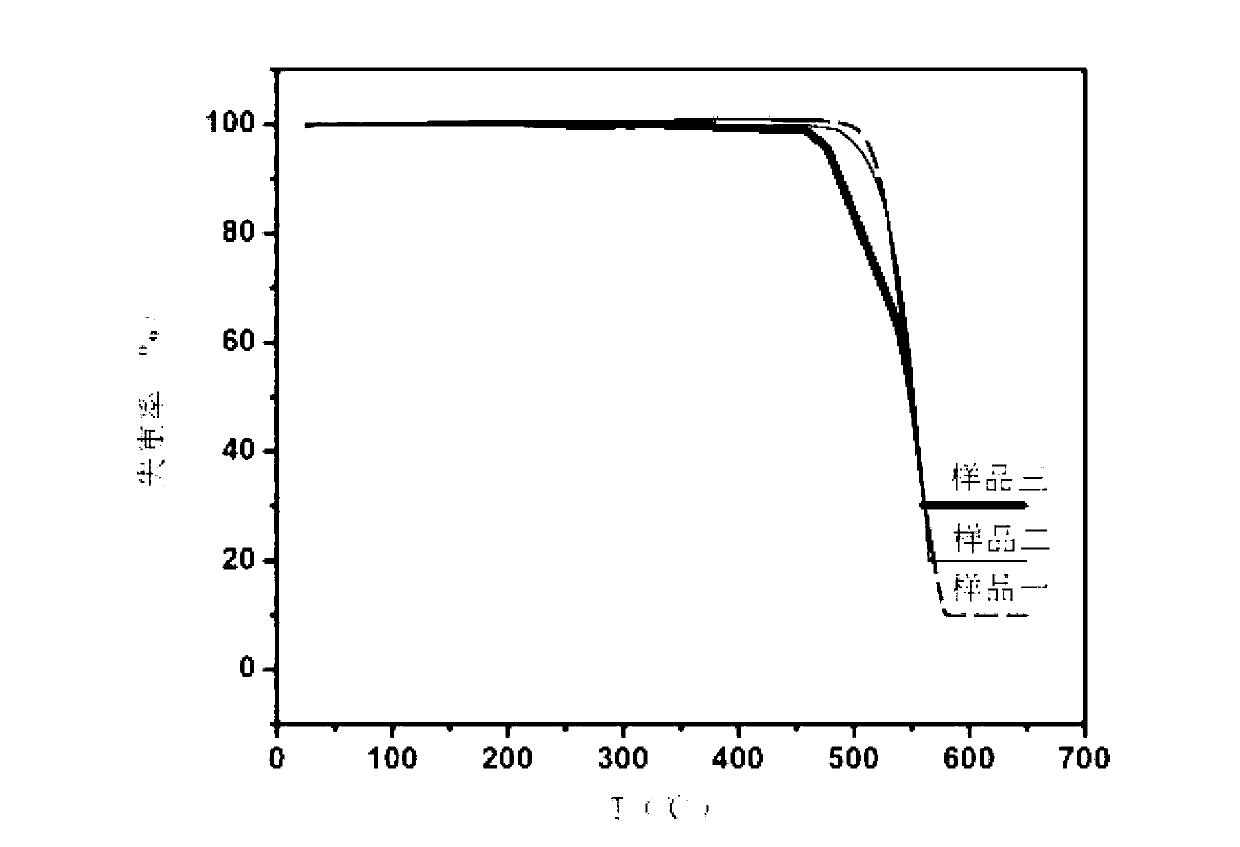

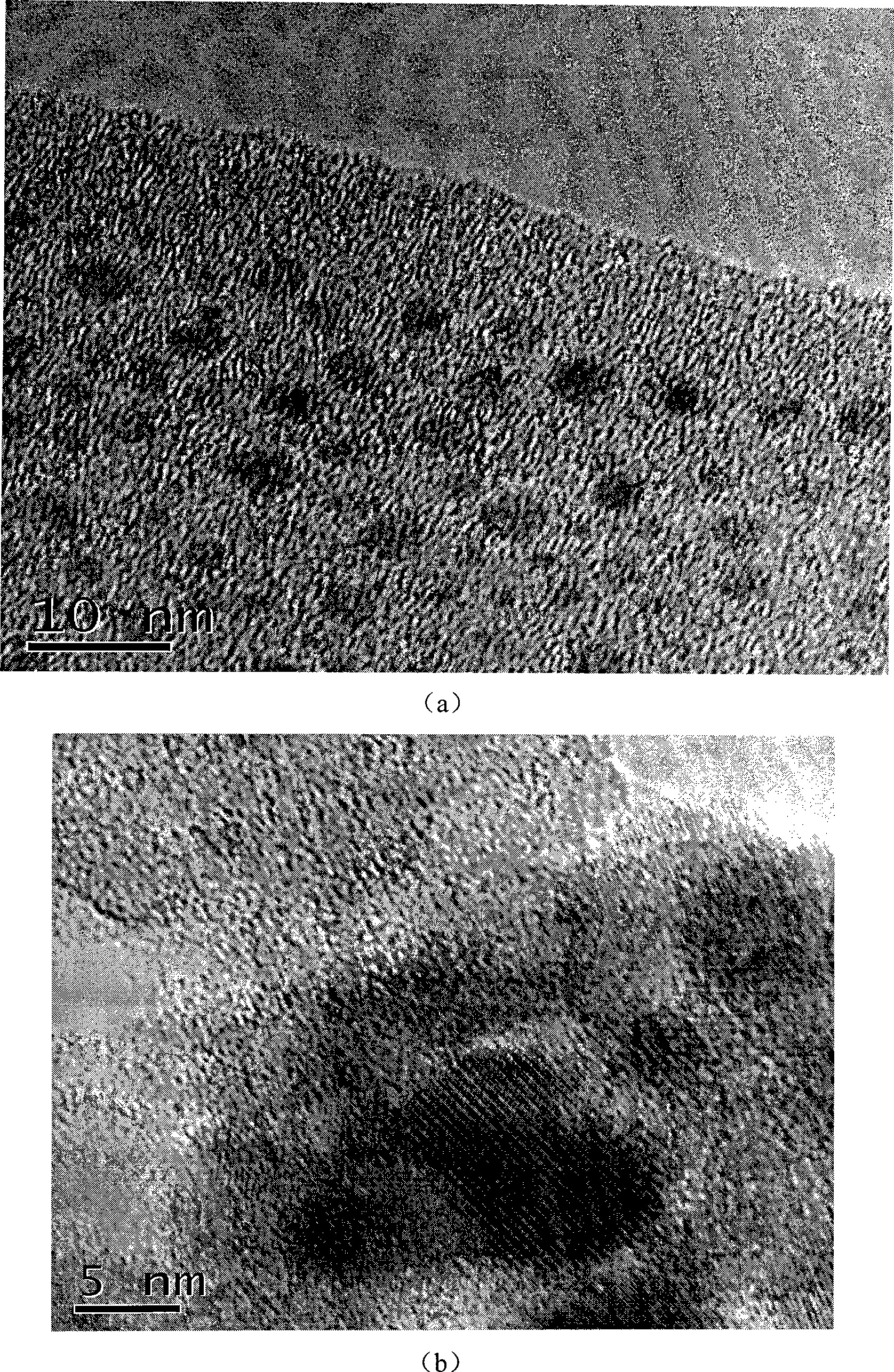

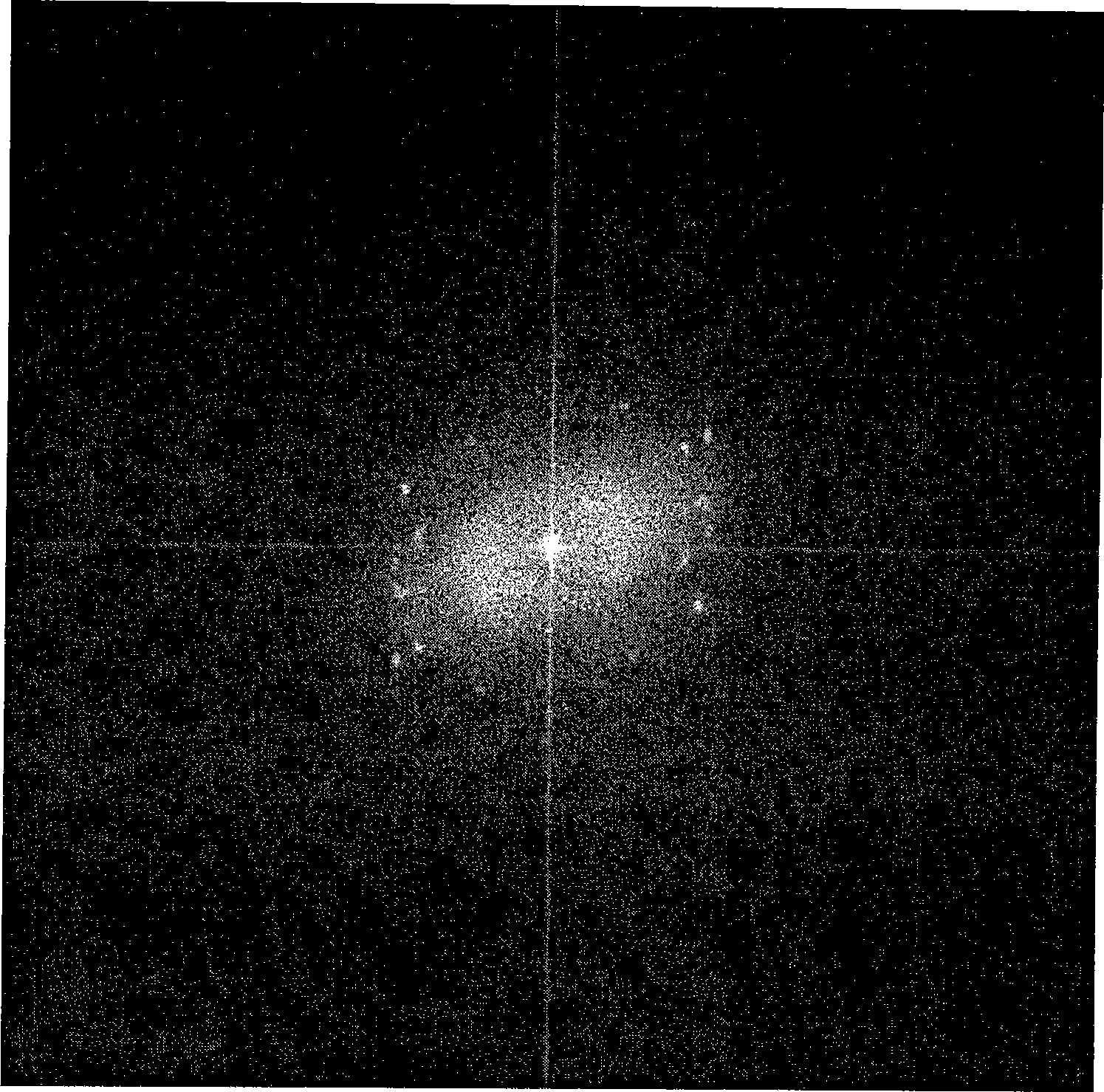

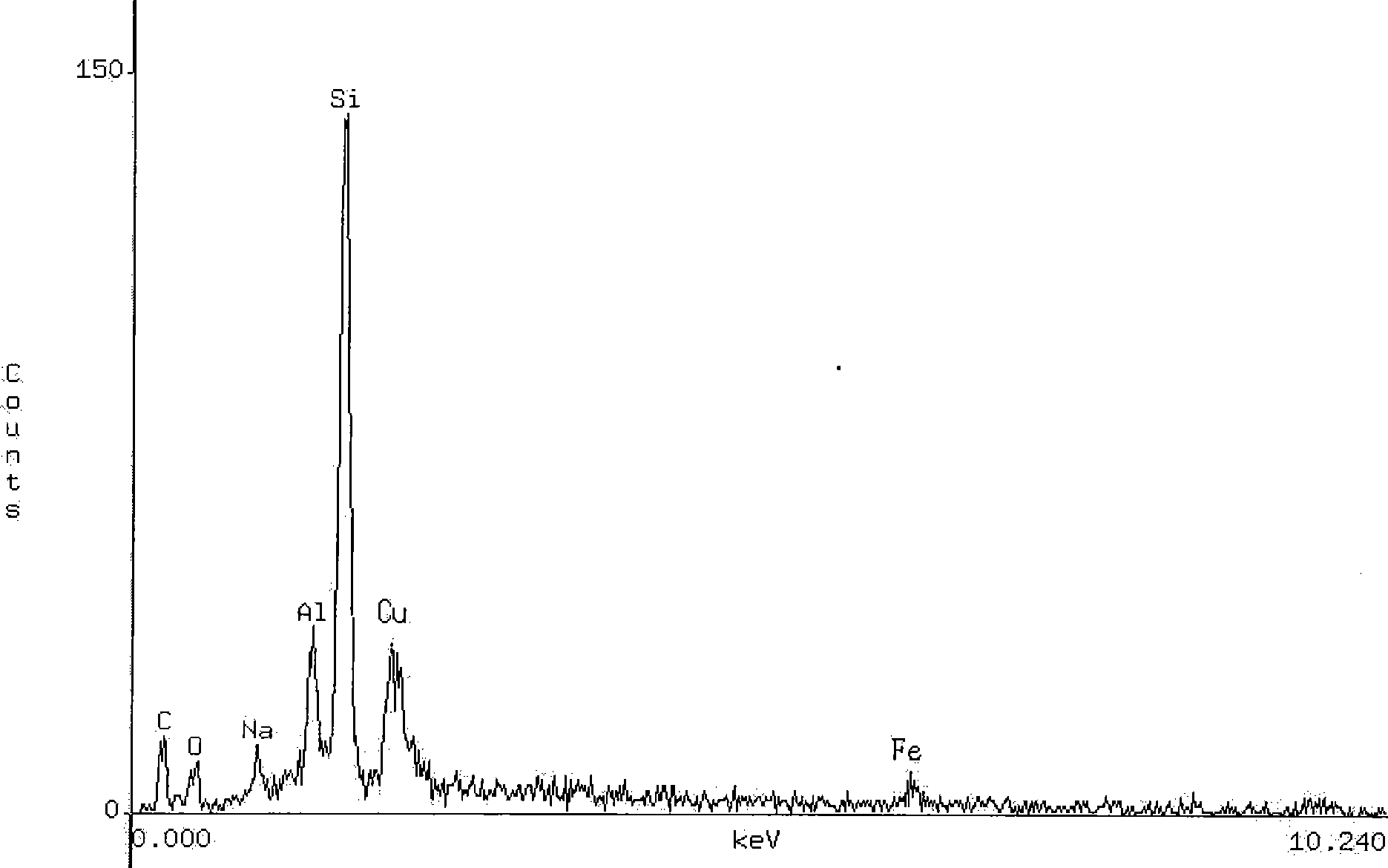

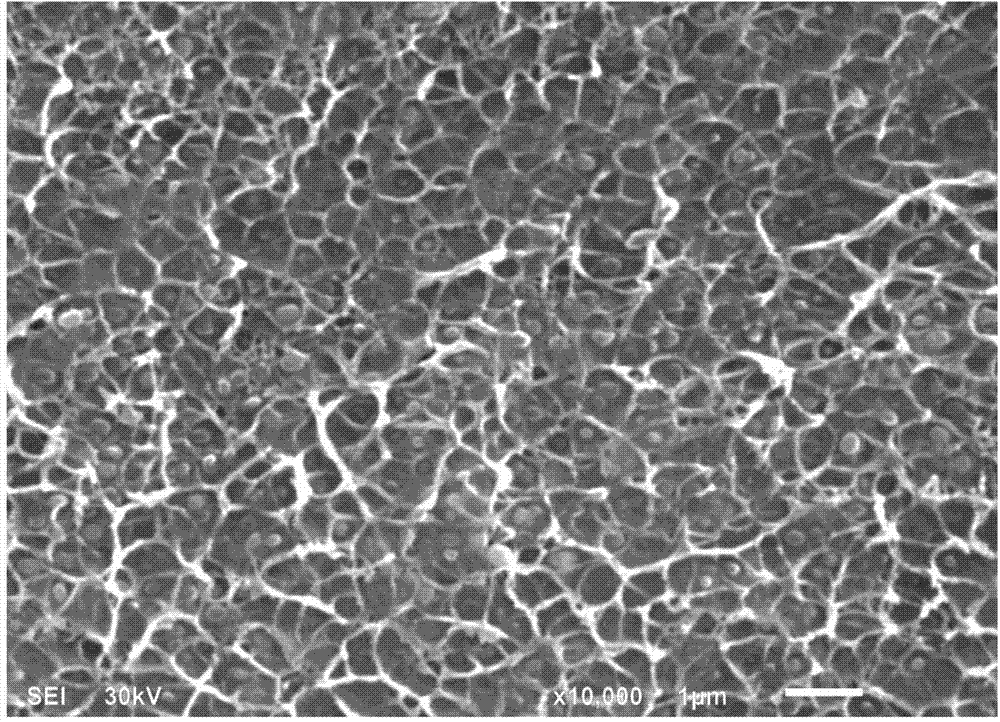

Nano Al2O3 composite corona-resistant polyimide film

The invention relates to a corona-resistant polyimide film containing high-concentration nano metal oxide, which comprises the following main components: benzenetetracarboxylic anhydride, 4, 4'-diamino diphenyl ether and nano-scale aluminum oxide, wherein the particle size of the nano-scale metal oxide is in the range from 30nm to 50nm. The film provided by the invention has the following outstanding advantages that a novel coupling agent is synthesized and is compounded with titanate coupling agent NDZ-130 to conduct surface modification on prepared alpha-Al2O3, thus the modified nano-particles can be steadily and uniformly dispersed in the substrate polyimide film with relatively high mass percentage (can reach 30wt%). By adoption of the above novel technical scheme of the invention, the technical problem that high-concentration nano-metal oxide is very difficultly doped uniformly in the corona resistant polyimide film according to the prior art is solved well, and meanwhile the mechanical strength of the film is kept from dropping.

Owner:UNIV OF SCI & TECH BEIJING

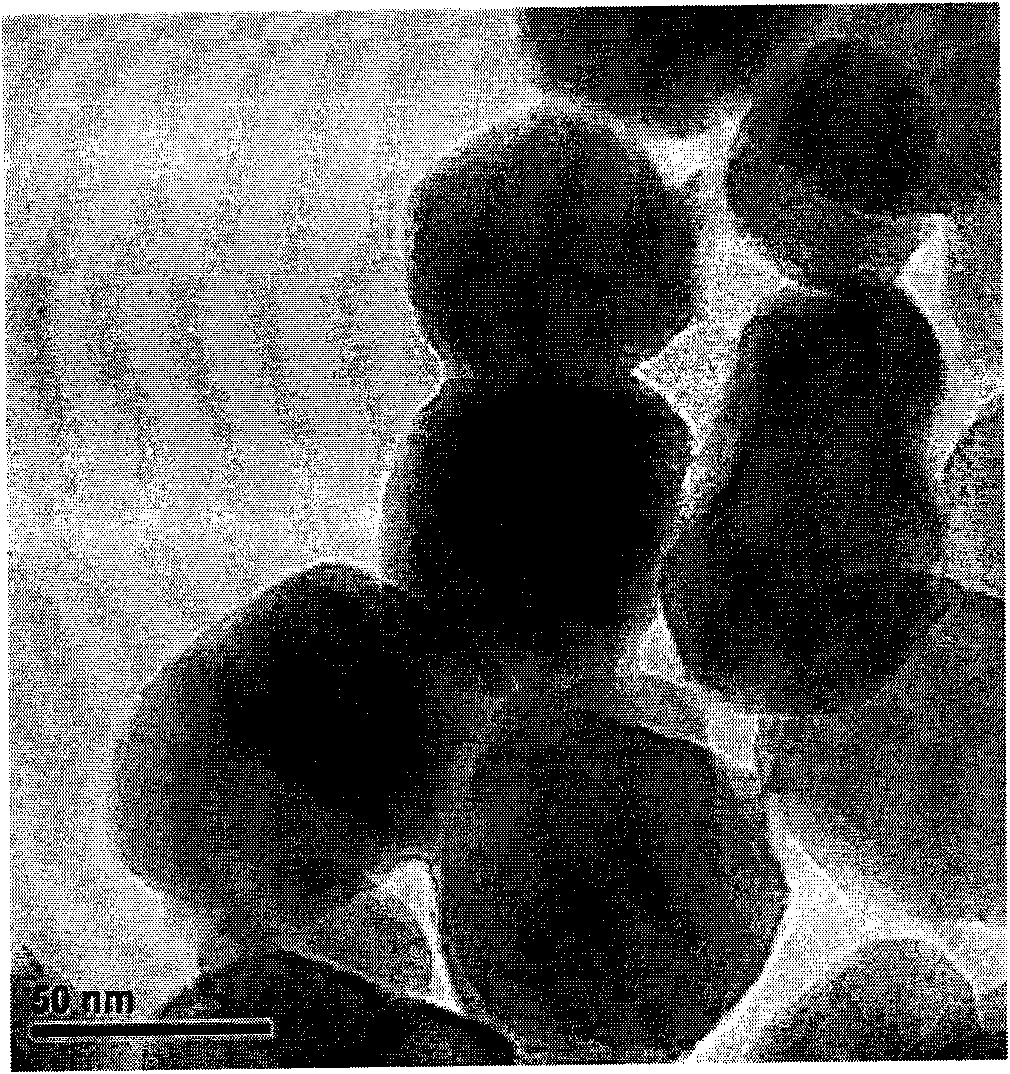

Method for preparing nano Fe3O4/SiO2 composite aerogel granule by supercritical process

ActiveCN101485969AUniform and stable dispersionStrong Fe—O—Si bondColloidal chemistry detailsSupercritical dryingSol-gel

The invention relates to a method for preparing a nanometer Fe3O4 / SiO2 composite aerogel particle by a supercritical method. The method is characterized in that: firstly, by utilizing a sol-gel method, precursors-Fe(OH)2 and Fe(OH)3 of a Fe3O4 crystal are prepared, and the precursors are added in a precursor of SiO2 aerogel, subjected to ultrasound for a few minutes, stirred at a high speed and added with certain amount of alkali solution to be gelled so as to obtain a composite wet gel system; by utilizing a supercritical drying method, a nanometer magnetic Fe3O4 / SiO2 composite aerogel material is prepared by drying, and a nanometer magnetic Fe3O4 / SiO2 composite aerogel material with stable dispersion, no obvious agglomeration and even distribution is further prepared; and finally, the composite aerogel material is ball-milled to obtain the nanometer magnetic Fe3O4 / SiO2 composite aerogel particle. The preparation method has the advantages of simple and practical process and easy control of the preparation process, and the prepared nanometer magnetic Fe3O4 / SiO2 composite material is stable in quality.

Owner:江苏安珈新材料科技有限公司

Method for preparing polymer modified asphalt by one-step method

ActiveCN101457023ASimple processEasy to operateBuilding insulationsPolymer modifiedStabilizing Agents

The invention relates to a method of preparing polymer asphalt with one step to modify the asphalt by adopting the polymer as a modifying agent. In a peptizator of 80 to 160 DEG C which account for 5 to 27 percent of the total weight of the raw materials, the polymer modifying agent and 0.1 to 2 percent of stabilizer which account for 2 to 9 percent of the total weight of the raw materials are added, and then is poured into a plastic extruder where the rotating speed is 300 to 800 rotations per second to be extruded; the extruding temperature is controlled to be 130 to 210 DEG C; the extruded polymer is directly and mixingly stirred for 0.5 to 6 hours together with the asphalt which accounts for 62 to 89.9 percent of the total weight of the raw materials, then the polymer modified asphalt is gained, which is provided with good heat preservation function, good low temperature expanding performance, anti-fatigue and anti-tearing function and relatively good weatherproof function. After being mixed with the stones, the mixed materials perform good water stability and high and low temperature stability, which can effectively improve the using performance of the asphalt pavement and prolong the service life.

Owner:PETROCHINA CO LTD +1

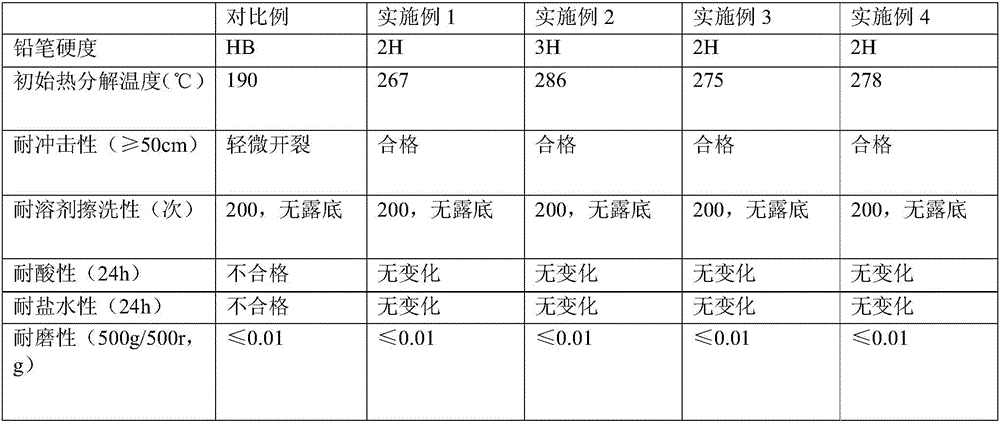

Preparation method of graphene modified waterborne polyurethane

The invention relates to the field of a new material, in particular relates to the technical field of preparation and application of a functional high-polymer material, and discloses a preparation method of graphene modified waterborne polyurethane. According to the method disclosed by the invention, firstly, graphene is modified by a coupling agent and then is blended with waterborne polyurethane so as to implement excellent dispersion; meanwhile, a secondary chain extension mode is adopted and an interpenetrating network structure is introduced; after resin prepared by the method is formed into a film, the film has excellent hardness, flexibility, compactness, impact resistance, corrosion resistance, water resistance, aging resistance, pollution resistance and the like, and can be applied to the fields of automobile coating, wood lacquer, buildings, office furniture, leather and the like.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

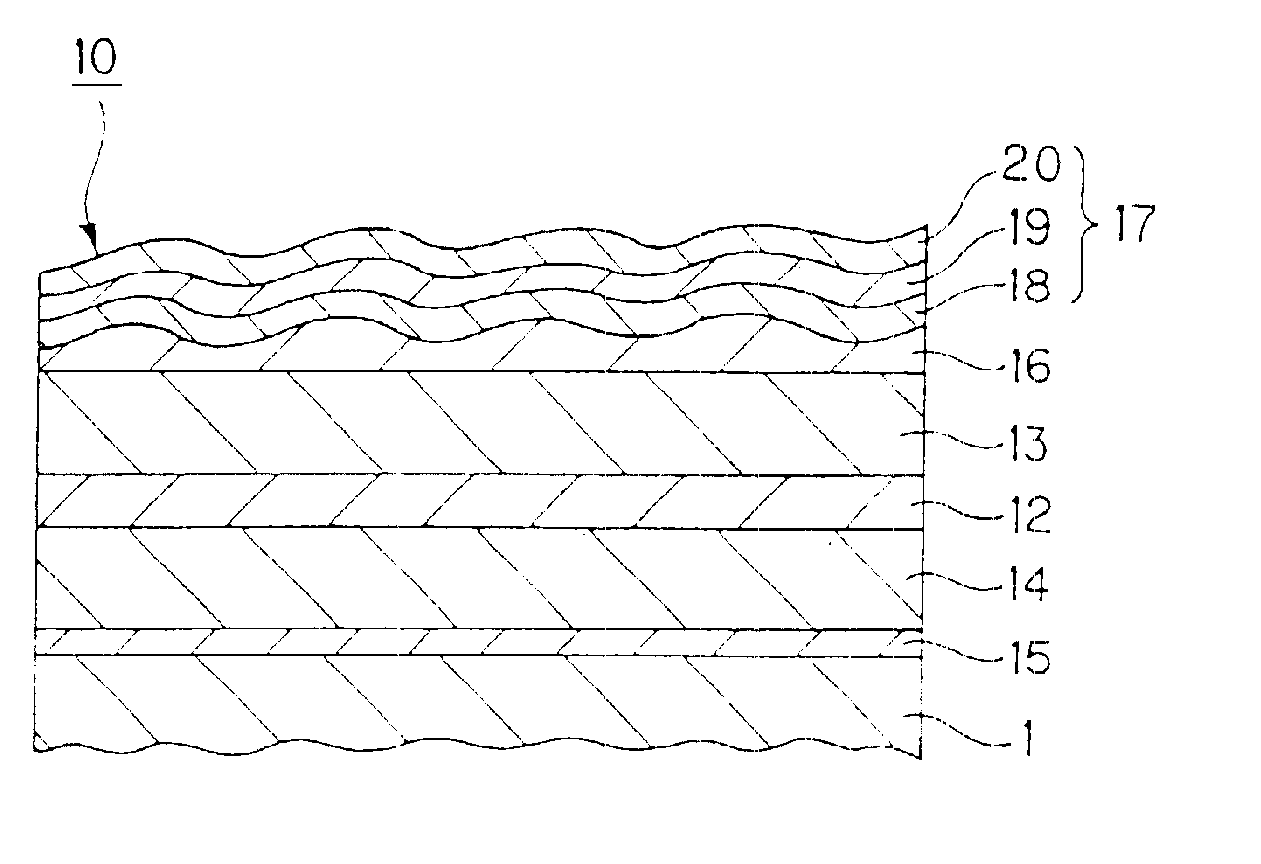

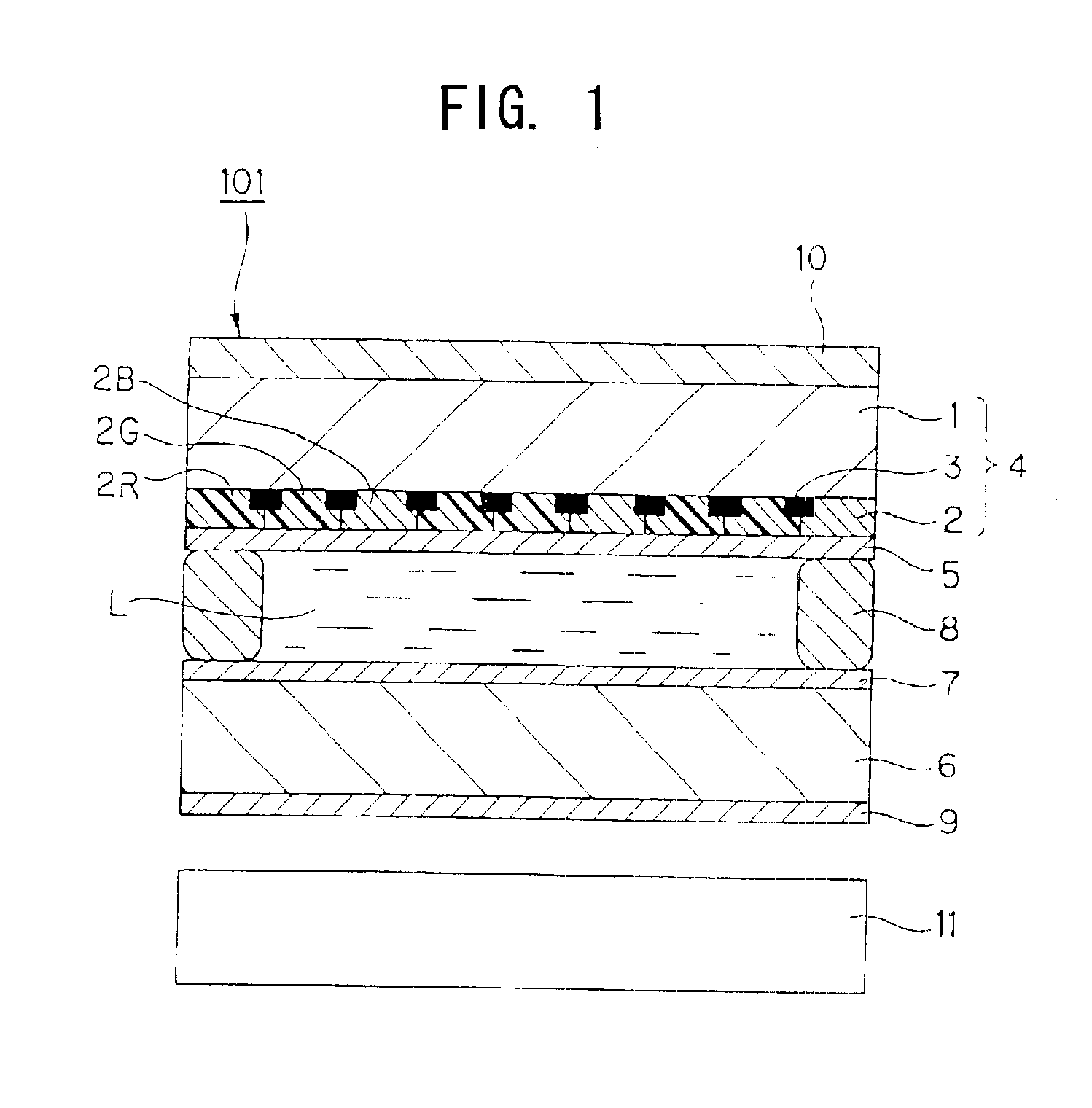

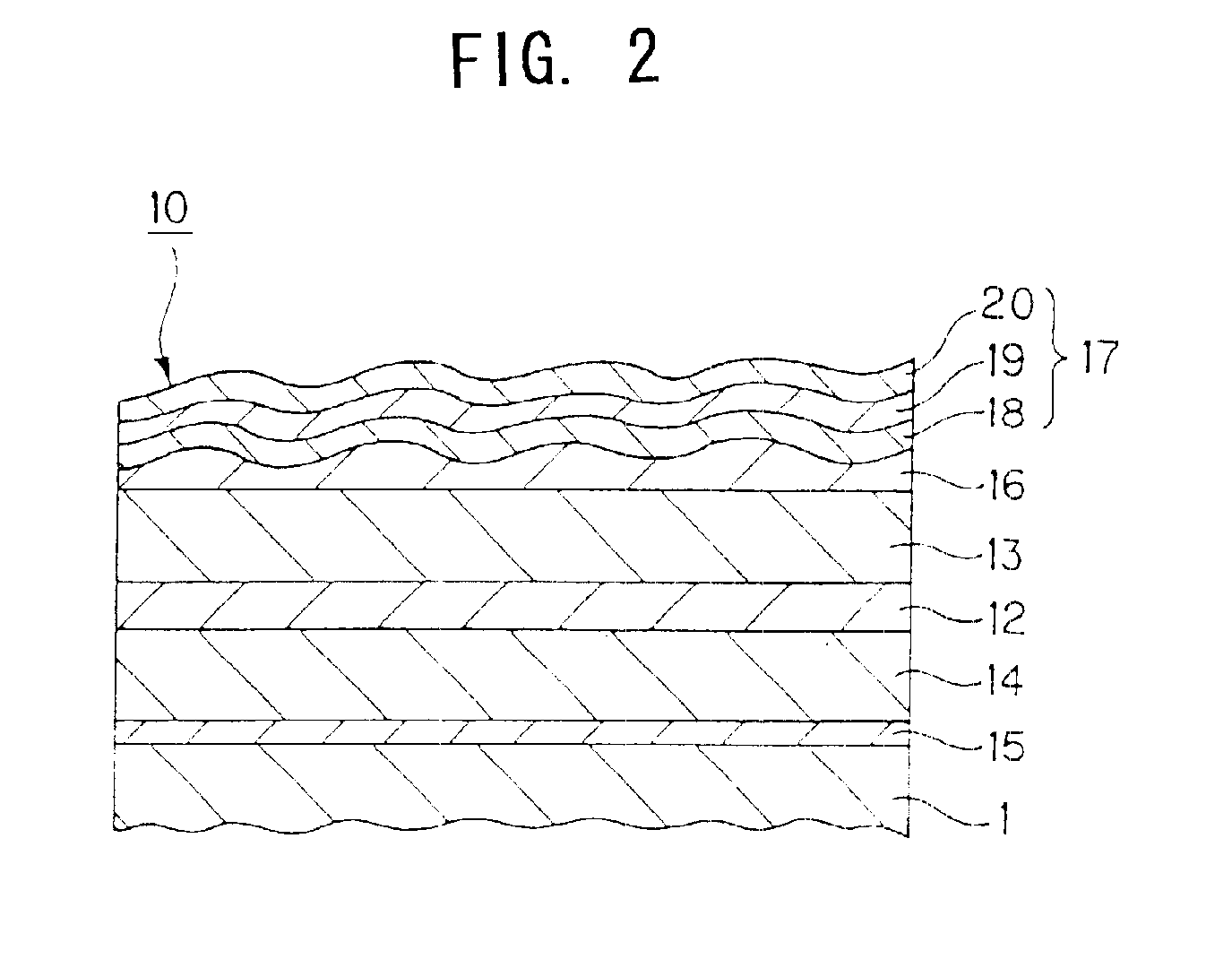

Coating composition, it's coating layer, antireflection coating, antireflection film, image display and intermediate product

InactiveUS6949284B2Refractive index is limitedHigh refractive indexSynthetic resin layered productsCellulosic plastic layered productsRefractive indexDisplay device

The present invention provides an application material capable of forming a thin layer of high quality having controlled refractive index, a coating layer formed by using said application material, an antireflection coating using said coating layer, an antireflection film and image display to which said antireflection coating is applied. A coating layer formed from a coating composition comprising (1) rutile type titanium oxide coated with an inorganic compound decreasing or eliminating a photocatalyst activity and an organic compound and / or organometal compound having an anionic polar group, and having a primary particle size in the range from 0.01 to 0.1 μm, (2) a binder component having an ionizing radiation-curing property, (3) a dispersing agent having an anionic polar group, and (4) an organic solvent is suitable for forming a light transmission layer constituting a single-layer type or multi-layer type antireflection coating 17, partucularly, a middle refractive index layer 18, high refracive index layer 19 or hard coat layer 16 having high refractive index (FIG. 2).

Owner:DAI NIPPON PRINTING CO LTD

Zinc oxide-based nanoparticle ink and electroluminescent device

InactiveCN107099190AVolatileEvenly dispersedMaterial nanotechnologySolid-state devicesAlcoholNanoparticle

The invention provides zinc oxide-based nanoparticle ink. The zinc oxide-based nanoparticle ink comprises a solvent and zinc oxide-based nanoparticles uniformly dispersed in the solvent. The zinc oxide-based nanoparticle ink comprises, by mass, 0.01 to 20.00% of the zinc oxide-based nanoparticles and 80.00 to 99.99% of the solvent. The zinc oxide-based nanoparticle ink is characterized in that the solvent comprises at least one alcohol ether ester compound. The zinc oxide-based nanoparticle ink can solve the problem that the existing zinc oxide-based nanoparticle ink is not suitable for ink-jet printing and has poor film-forming quality. The invention provides an electroluminescent device. An electron transport layer of the device is prepared from the zinc oxide-based nanoparticle ink through ink-jet printing.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

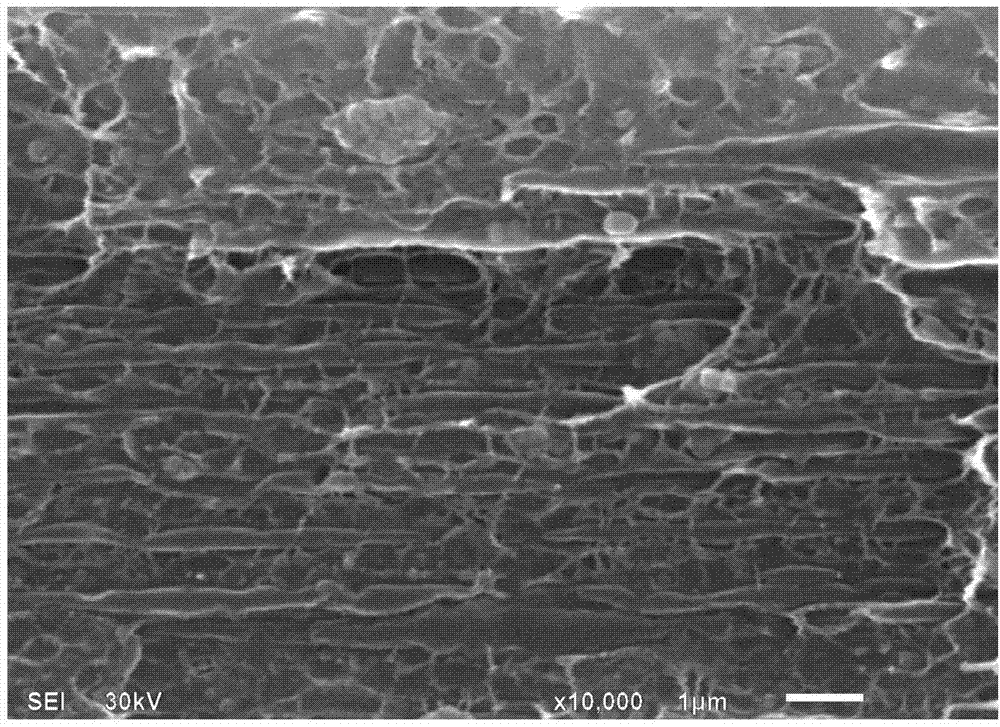

Preparation method of tough graphene/cellulose composite heat-conductive and electro-conductive film

InactiveCN107293377AReduce manufacturing costEasy to operateNon-conductive material with dispersed conductive materialCable/conductor manufactureCelluloseFiber

The invention discloses a preparation method of a tough graphene / cellulose composite heat-conductive and electro-conductive film. The preparation method of the tough graphene / cellulose composite heat-conductive and electro-conductive film comprises the following steps: firstly, dispersing the wood pulp into an aqueous solution to peel the wood pulp into single nano diameter single fibrous bundles under the action of liquid shear force; diluting the single fibrous bundles with deionized water and obtaining the low concentration cellulose aqueous solution through treating by a high-speed shearing machine for a certain period of time; then dispersing the industrial graphene nanosheets evenly into the aqueous solution containing the dispersant through ultrasonic treatment; then dripping the prepared cellulose aqueous solution gradually into the graphene dispersion; and preparing the graphene / cellulose composite film through ultrasonic mixing, suction filtration, drying and other processes. The obtained film has good flexibility, thermal conductivity and electrical conductivity, and the mechanical, thermal and electrical properties of the film can be further improved through hot pressing treatment. The preparation method of the tough graphene / cellulose composite heat-conductive and electro-conductive film has the advantages of simple process, low cost, green environment protection and wide application value in the field of functional composite materials.

Owner:QILU UNIV OF TECH

Preparation method of polyvinylidene fluoride-based thin film

The invention relates to a preparation method of a polyvinylidene fluoride (PVDF)-based thin film. According to the thin film forming process, through an extrusion casting and drawing method, PVDF, polymethyl methacrylate (PMMA), a rubber elastomer, titanium dioxide as well as other auxiliaries and fillers are mixed according to a certain ratio and are melted and extruded at certain temperature, and then the PVDF-based thin film is formed under guiding and stretching effects of casting traction equipment. The PVDF-based thin film prepared by the invention is uniform and easily controllable in thickness, good in barrier property as well as excellent in mechanical property and environmental aging resistance, and is easy to realize industrialization; the PVDF-based thin film, through modification treatment, is significantly improved in surface caking property and guarantees good adhesion with a solar cell packaging material; the thin film brings high convenience for assembly of a solar cell backboard film and is compact in structure; and the thin film has good application prospect in solar cell industry.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Zinc-oxide-based nanometer particle ink and preparation method thereof

The invention discloses a zinc-oxide-based nanometer particle ink and a preparation method thereof. The zinc-oxide-based nanometer particle ink comprises the following components, by weight percentage, 0.01-20.0% of zinc-oxide-based nanometer particles and 80.0-99.99% of a solvent. The solvent comprises at least one low-boiling-point alcohols solvent and at least one high-boiling-point alcohols solvent, wherein the amount of low-boiling-point alcohols solvent is 1.0-80.0% of the total amount of the solvent. According to an ink formula in the invention, zinc-oxide-based nanometer particles can be dispersed in the solvent, and the viscosity of the solvent is improved and the volatilization speed of the solvent is lowered by adjusting low-boiling-point alcohols with high-boiling-point alcohols. The ink can meet the index requirements, such as ink viscosity and volatilization speed, of ink-jet printing, and zinc-oxide-based nanometer particles of the ink can be uniformly stably dispersed in the solvent.

Owner:TCL CORPORATION

Electrocondution slurry and preparation method and application of electrocondution slurry

InactiveCN103839605AAvoid affecting charge transportGuaranteed normal transmissionNon-conductive material with dispersed conductive materialCable/conductor manufactureCross-linkMoisture resistance

The invention discloses electrocondution slurry and a preparation method and application of the electrocondution slurry. The slurry comprises, by mass percent, 30-40% of silver-graphene composite materials, 30-48% of organic resin, 5-10% of cross-linking agents and 12-26% of thinning agents. The method that the silver-graphene composite materials are prepared are as follows: graphite oxide and organic silver are added to a mixed system formed by organic solvents and deionized water, and ultrasonic dispersion is carried out on the mixture; hydrazine hydrate is dripped to the mixed system while the mixed system is stirred; after stirring is carried out for 20-30 min at room temperature, the temperature rises to 60-70 DEG C, reaction is conducted for 2-3 h, the mixture is cooled to be at the room temperature, filtered and rinsed by the deionized water, vacuum drying is carried out on the mixture, and the silver-graphene composite materials are obtained. The electrocondution slurry can meet the demands of photovoltaic devices for the electrical property under low silver content conditions and is suitable for flexible substrates, good in temperature and moisture resistance and excellent in filament printing performance, adhesive force of the electrocondution slurry and substrate ITO materials is high, and production cost of the slurry is remarkably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Stress and whitening-resistant filled/modified polypropylene and preparation method thereof

InactiveCN102020806APromote absorptionHigh propylene regularityPolypropylene compositesMechanical property

The invention belongs to the field of polypropylene compound materials, and relates to a stress and whitening-resistant filled / modified polypropylene. The stress and whitening-resistant filled / modified polypropylene comprises the following compositions in parts by weight: 50 to 80 parts of PP, 5 to 25 parts of toughening agent, 10 to 25 parts of minerals, 1 to 5 parts of compatibilizer, 0.1 to 1 part of dispersant; 0.1 to 1 part of antioxygen, and 0.1 to 1 part of light stabilizer, wherein sum of the weight parts of the PP, the toughening agent, the mineral and the compatibilizer is 100. The prepared polypropylene compound material in the invention both has a good stress and whitening-resistant performance and an excellent comprehensive mechanical property. The preparation method in the invention is simple and easy to operate without special processing methods, and can be promoted and applied in large scale.

Owner:SUZHOU SUNWAY POLYMER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com