Nitrogenous heterocyclic quaternary ammonium salt acidizing corrosion inhibitor and preparation method thereof

A technology of acidifying corrosion inhibitor and quaternary ammonium salt, which is applied in the field of metal anti-corrosion, can solve the problems of insufficient stability of dissolution and dispersion, high corrosion speed of oil pipe steel, and large addition of corrosion inhibitor, so as to be suitable for large-scale industrial production and application, low corrosion rate, and less harsh synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

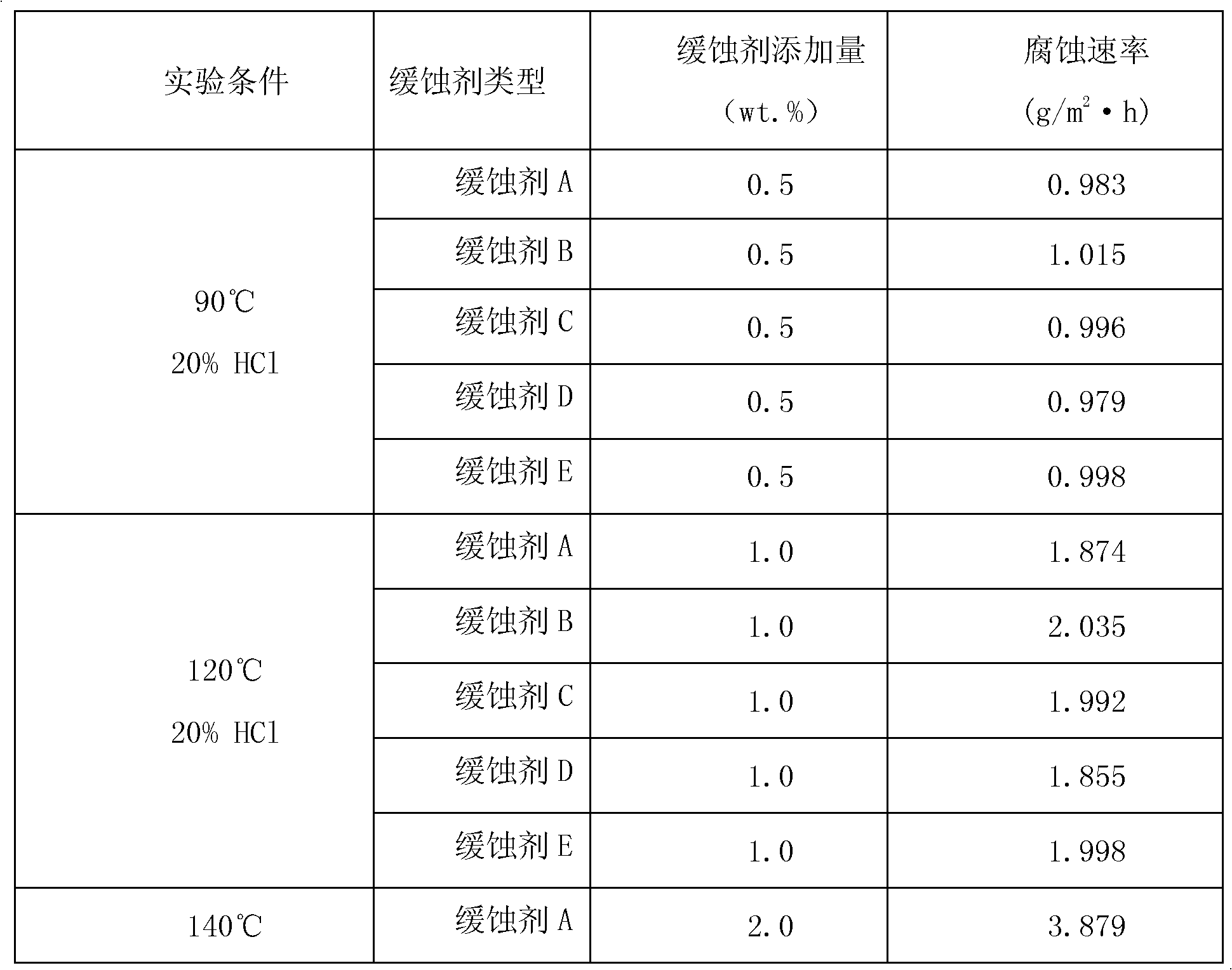

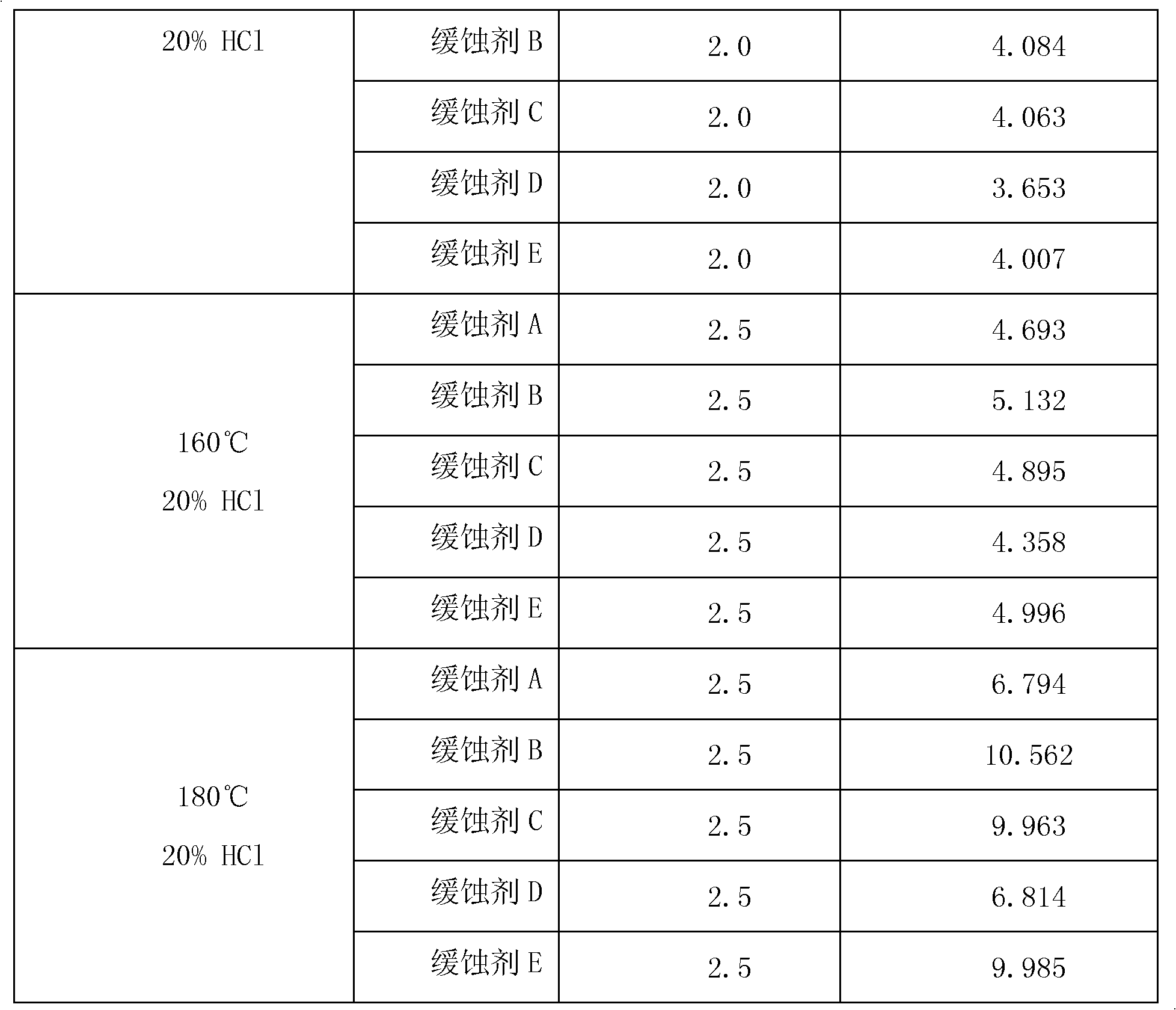

[0024] Add benzyl chloride and industrially synthesized pyridine residues above 180°C under normal pressure to the reaction kettle at a weight ratio of 1:1, and react at 160°C for 4 hours to obtain N-benzyl-R-pyridine chloride Quaternary ammonium salt; prepared N-benzyl-R pyridinium chloride quaternary ammonium salt, propynyl alcohol, formaldehyde, potassium iodide, antimony trichloride, O-15, methanol by weight ratio 40:5:5:1:15: 15:19, the corrosion inhibitor A was obtained after stirring evenly.

Embodiment 2

[0026] Benzyl chloride and industrial quinoline were added to the reactor according to the weight ratio of 1:1, and reacted for 4 hours at 160 ° C to obtain N-benzyl-R-quinoline quaternary ammonium chloride; the prepared N-chloride -Benzyl-R-quinoline quaternary ammonium salt, propynyl alcohol, formaldehyde, potassium iodide, antimony trioxide, O-15, and methanol in a weight ratio of 40:5:5:1:15:15:19, stir evenly Afterwards, corrosion inhibitor B was obtained.

Embodiment 3

[0028] Get N-benzyl-R-pyridine quaternary ammonium chloride and N-benzyl-R-quinoline quaternary ammonium chloride obtained in Example 1 and Example 2; Chloride N-benzyl-R-pyridine quaternary Ammonium salt (prepared in Example 1), chloride N-benzyl-R-quinoline quaternary ammonium salt (prepared in Example 2), propynyl alcohol, formaldehyde, potassium iodide, antimony trioxide, O-15, methanol by weight The ratio is 20:20:5:5:1:15:15:19, and the corrosion inhibitor C is obtained after uniform stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com