Patents

Literature

1701results about How to "Reduce corrosion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degradable medical device

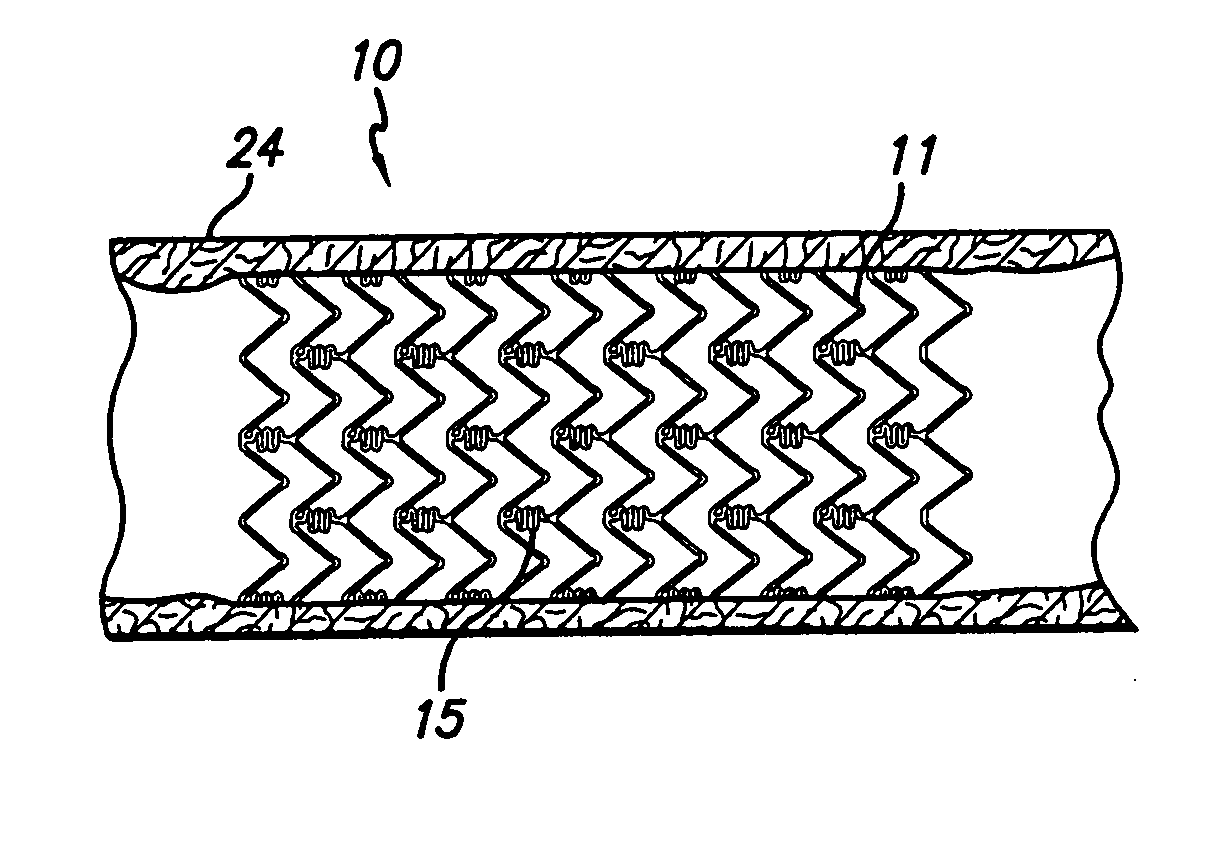

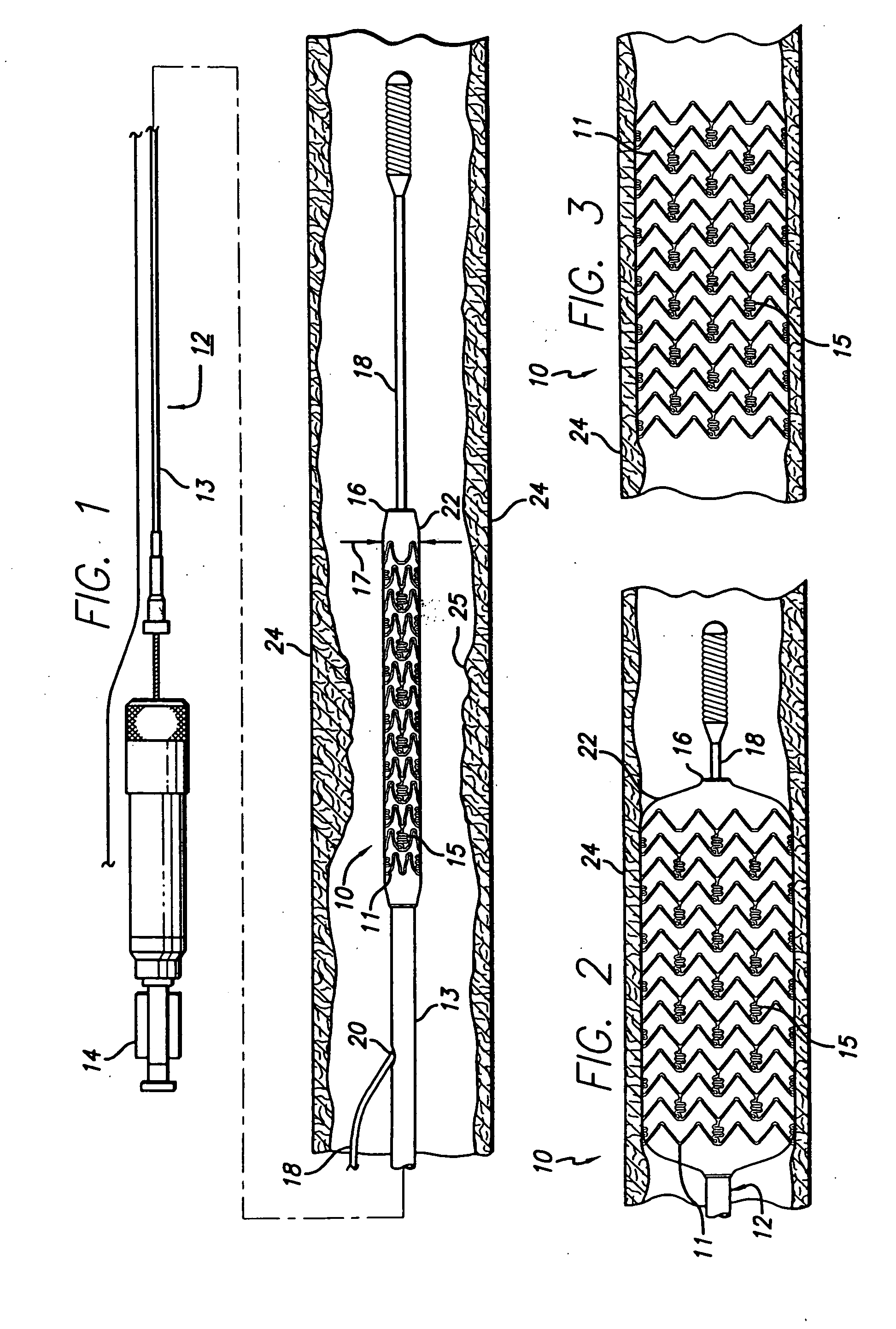

An implantable medical device is provided that degrades upon contact with body fluids so as to limit its residence time within the body. The device is formed of a porous corrodible metal to simultaneously provide high strength and an accelerated corrosion rate. The corrosion rate of a device formed of metal subject to self-dissolution or of a combination of metals subject to galvanic corrosion is accelerated by its porous structure. Coating the corrodible metallic device with a degradable polymer serves to delay the onset of corrosion of the underlying metallic structure.

Owner:KLEINE KLAUS +1

Metal surface treatment agent

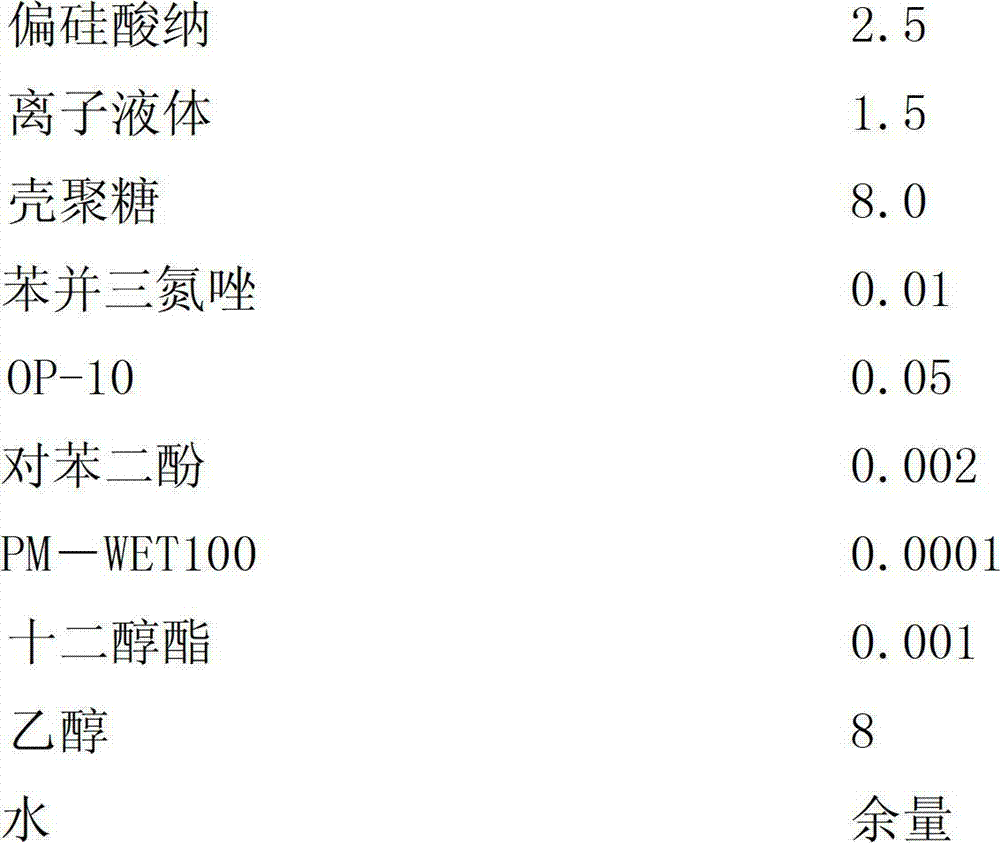

InactiveCN102787310AReduce corrosion rateReduce surface tensionMetallic material coating processesNitrogenous heterocyclic compoundIonic liquid

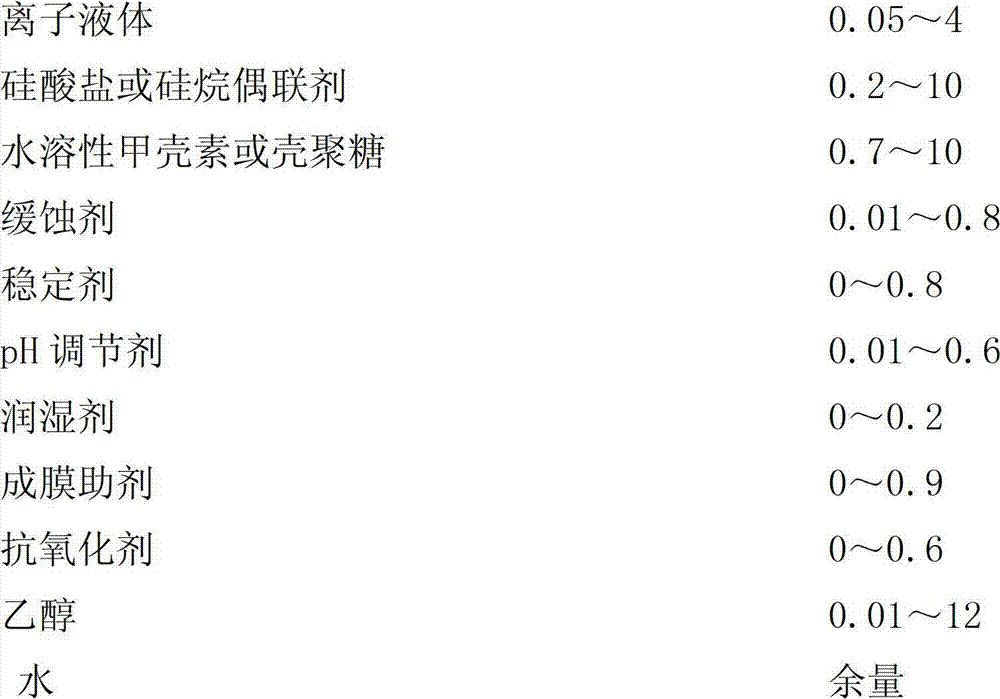

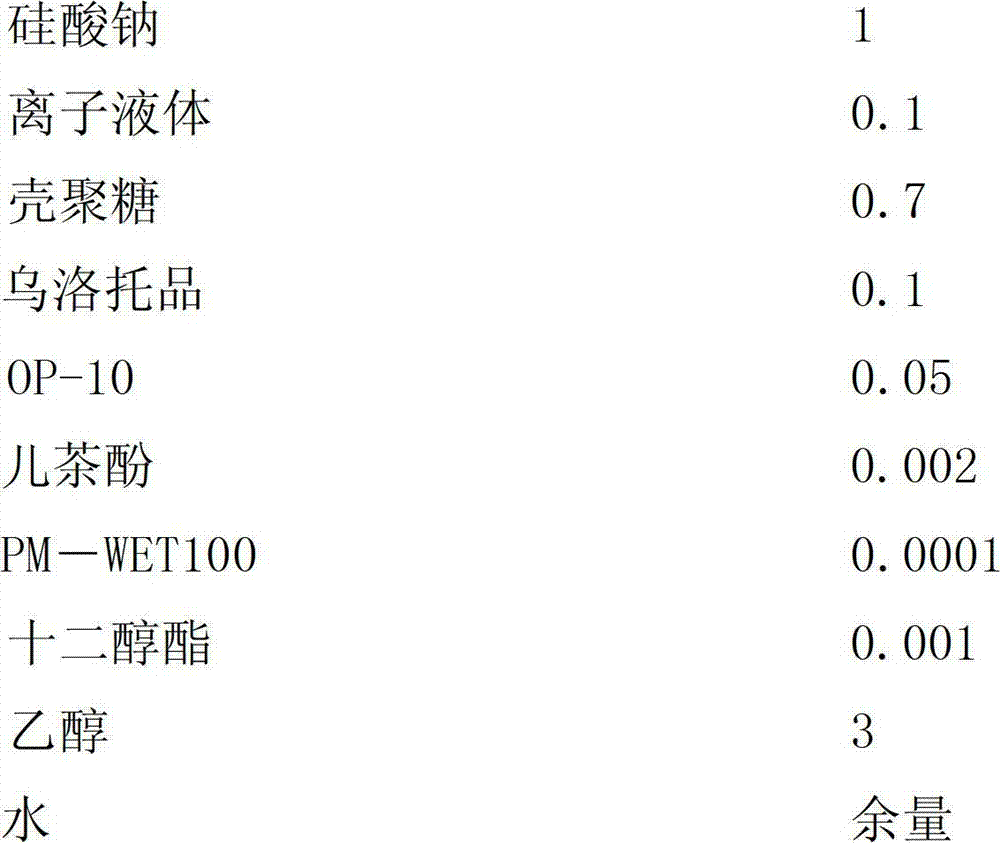

The invention provides a metal surface treatment agent composed of aqueous solution or aqueous emulsion containing ionic liquid. The metal surface treatment agent comprises the ionic liquid, silicate or silane coupling agent, water-soluble chitin or chitosan, corrosion inhibitor, stabilizer, pH modifier, wetter, coalescing agent, antioxidant, ethanol and water, the ionic liquid is room-temperature ionic liquid consisting of nitrogenous heterocyclic compound cations and inorganic or organic anions, one or more of nanoscale titanium dioxide, zirconium oxide or zirconium fluoride is uniformly mixed into the silicate or silane coupling agent by the weight equivalently accounting for 3%-25% of that of the silicate or silane coupling agent. A chemical conversion coating is formed on a metal surface by the metal surface treatment agent, can inhibit corrosion of the metal surface, and has a fine coating performance. The metal surface treatment agent is used for treating cold-rolled plates, galvanized plates and aluminum plates, and the metal surface treated by the metal surface treatment agent has the coating adhesion force equivalent to that of a metal surface treated by a phosphorus-containing metal surface treatment agent.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for electroplating magnesium and magnesium alloy

The present invention provides an electroplating method of magnesium and magnesium alloy. The technology comprises dehydrogen, chemical degreasing, shining, neutralization, activation, pre-plating, functional plating, decorative plating and post treatment. The cast workpiece must be water-washed between every two procedures. The current density of pre-plating is 5-15 A / dm2, cell voltage 4-12 V, pH value of pre-plating solution 1.0-1.2, and Baume degree at room temperature is 30-35. Pre-plating solution recipe contains: copper fluoborate, fluoboric acid, alanine, polyethylene glycol and alizarin dye, mixture of itaconic acid and MBT, 3-S isothiourea onium salt propane sulfonate ,R-S-S(CH2)SO3Na and deionization water. The pre-plating solution of the present invention is cyanogen free, non-toxic and non-hazardous. Bond strength between pre-plating layer and substrate material and between pre-plating layer and the post functional plating layer or decorative plating layer is good. The plating layer is bright and has good corrosion resistance, wear resistance and decorative effect.

Owner:SHENYANG POLYTECHNIC UNIV

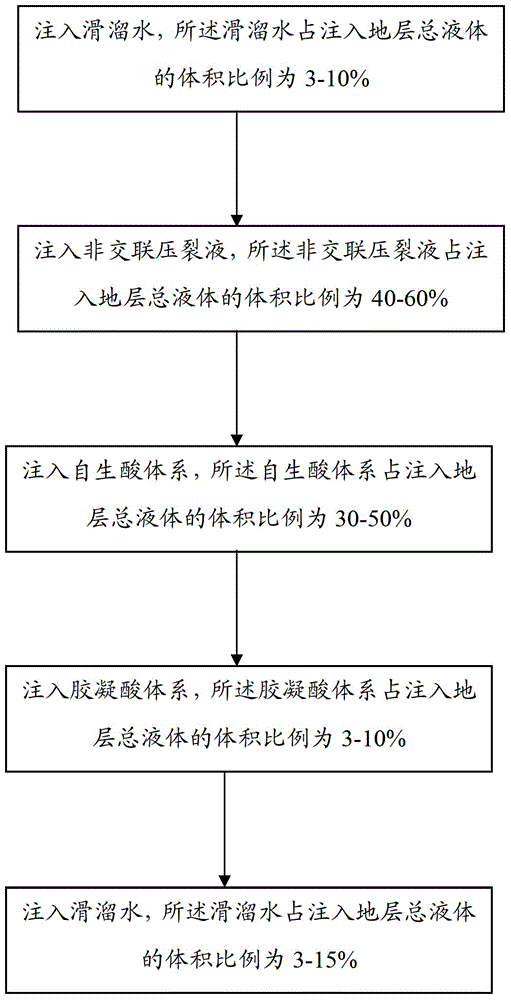

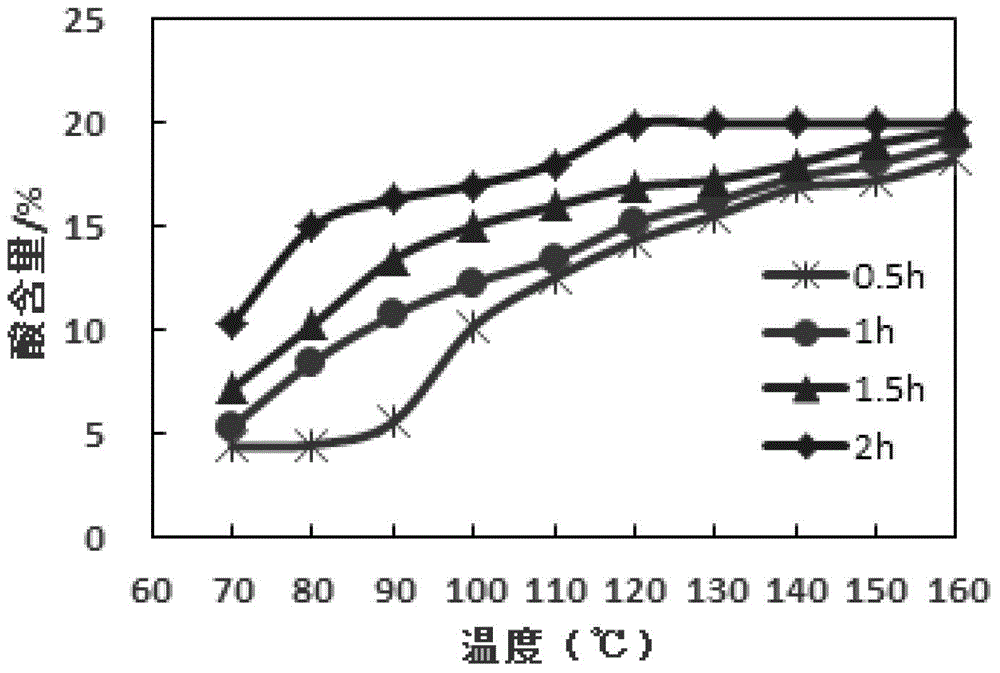

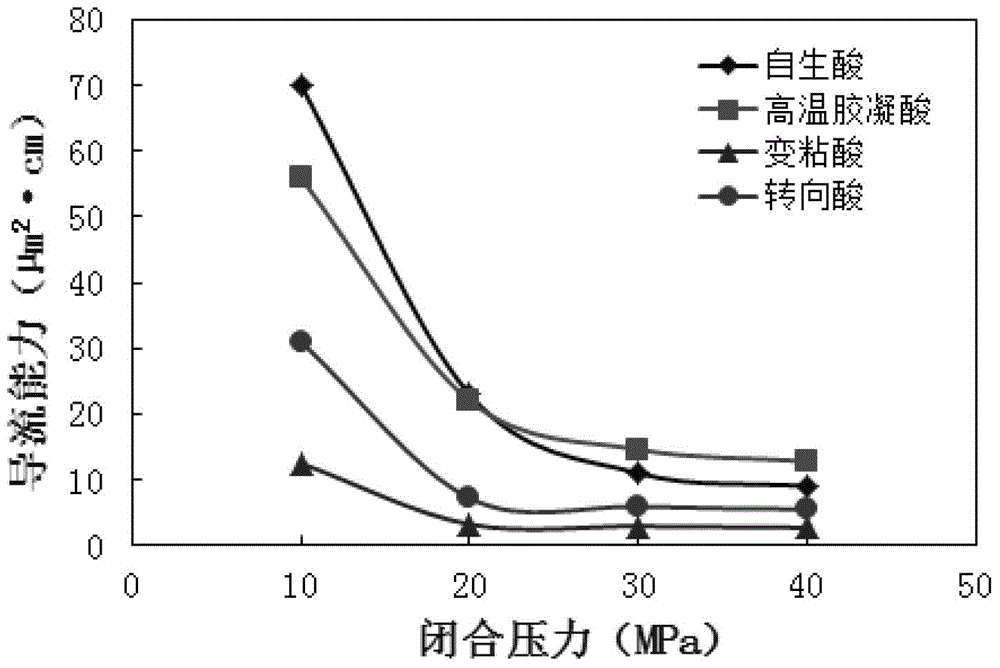

Self-born acid composite acid fracturing process for high-temperature deep well carbonate rock reservoir

ActiveCN104975840AImprove diversion capacityReduce corrosion rateFluid removalAcid fracturingHot Temperature

The invention relates to a self-born acid composite acid fracturing process for a high-temperature deep well carbonate rock reservoir. The process comprises the following work procedures of: (1) injecting slick water into a stratum through an oil pipe; (2) injecting non-crosslinked fracturing liquid into the stratum through the oil pipe; (3) injecting a self-born acid system into the stratum through the oil pipe; (4) injecting a gelled acid system into the stratum through the oil pipe in a low-displacement mode; and (5) injecting the slick water into the stratum through the oil pipe, wherein the volume proportions of liquid, accounting for the total liquid injected into the stratum, injected in the first to fifth work procedures are shown as follows: the slick water in the first work procedure accounts for 3 to 10 percent; the non-crosslinked fracturing liquid in the second work procedure accounts for 40 to 60 percent; the self-born acid system in the third work procedure accounts for 30 to 50 percent; the gelled acid system in the fourth procedure accounts for 3 to 10 percent; the volume proportion of the slick water in the fifth work procedure is 3 to 15 percent; and the volume unit is m<3>. Through the self-born acid composite acid fracturing process, the flow guide capability is improved by more than 140md.m, and the deep penetration effect of the high-temperature deep well carbonate rock reservoir is obvious.

Owner:CHINA PETROLEUM & CHEM CORP

Anti-corrosive paint of epoxy resin based on aqueous bitumen, and preparation method

InactiveCN1760291AReduce corrosion rateStrong corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsChemistryEmulsion

A kind of anticorrosion asphalt-based epoxy resin water paint is proportionally prepared from modified asphalt emulsion, epoxy resin emulsion, solidifying agent emulsion, filler, assistant and water. Its advantages are high hardness, resistance to corrosion and abrasion, adhesion and softening point, and low pollution.

Owner:NORTHWEST NORMAL UNIVERSITY

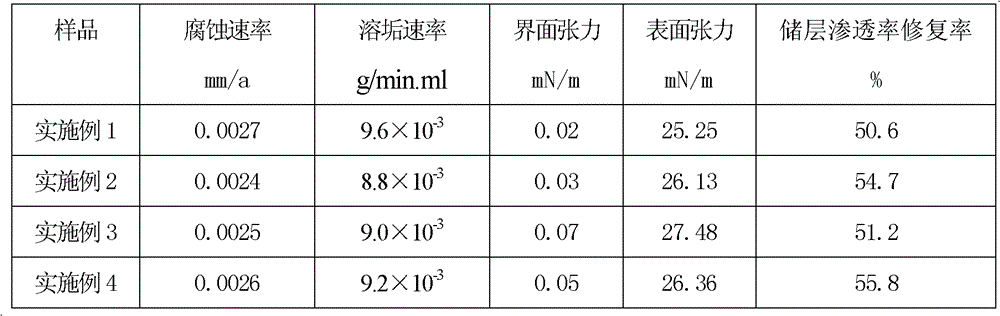

Blocking remover of gas well shaft

The invention relates to a blocking remover of a gas well shaft. The blocking remover comprises, by weight, 5-25% of an alcohol ether compound, 0.5-10% of a dispersant, 1-10% of a cleaning agent, and 0.5-5% of chelating agent, with the balance being a nitrogen-containing polar solvent, wherein the nitrogen-containing polar solvent is one selected from N,N dimethyl formamide, N,N dimethyl acetamide, and N-methyl pyrrolidone, the alcohol ether compound is one selected from glycol-ether, glycol-propyl ether, glycol-butyl ether, and diglycol-ether, the disperant whose micelle particle size is from 20nm to 100nm is a middle-phase microemulsion-type dispersant mixed by kerosene, water, a surfactant and a cosurfactant, the cleaning agent is one selected from allene diamine, acetonitrile and pentylamine, and the chelating agent is one selected from sodium citrate and EDTA. The blocking remover has the advantages that corrosivity is weak, that the speed of dissolving blockage is fast, that the product performance is stable in high temperatures, and that the blocking remover can reduce damages caused by water locking and fouling in areas close to gas wells, and can recover the permeability of storing layers.

Owner:PETROCHINA CO LTD

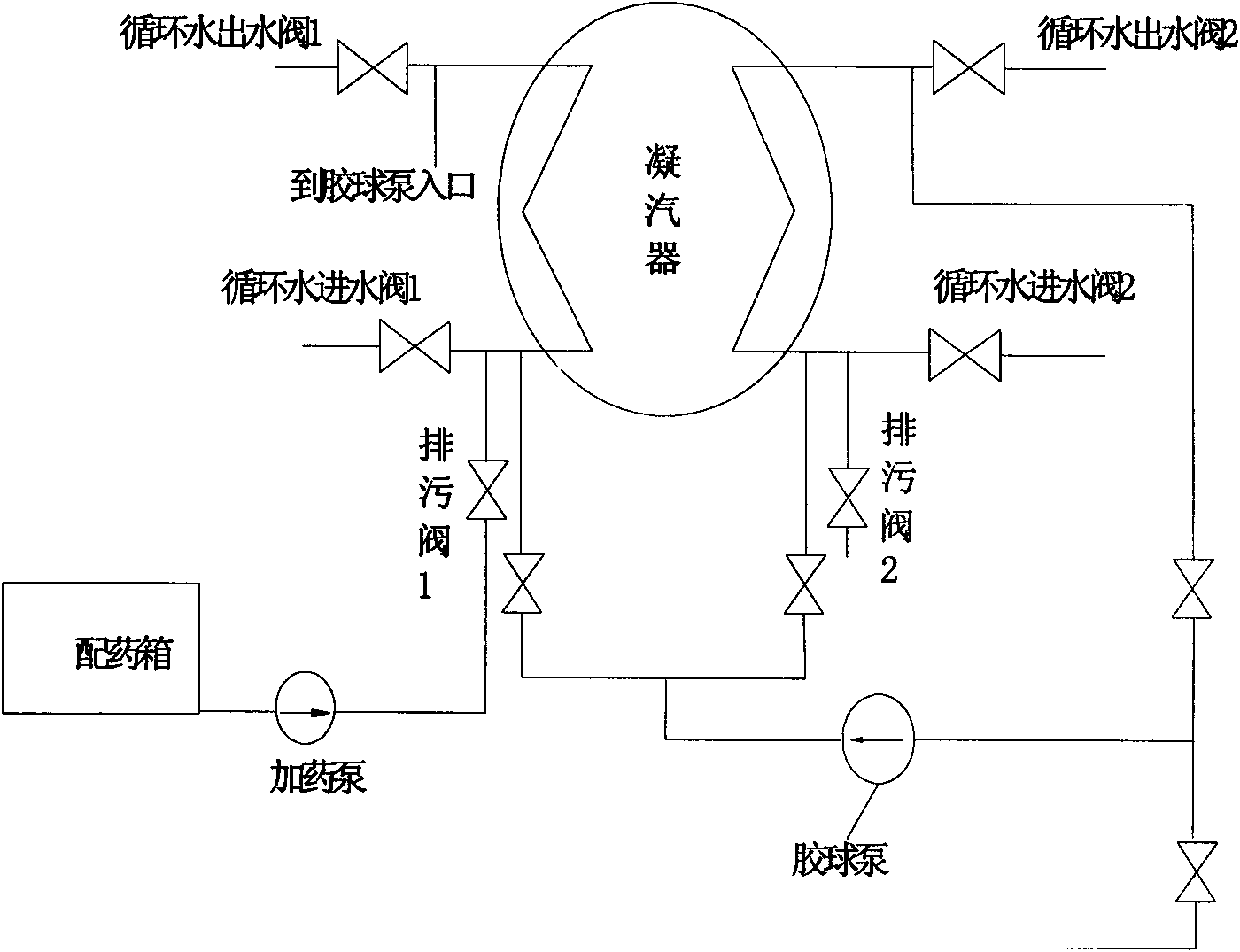

Method for cleaning copper tubes of condenser

A method for cleaning copper tubes of a condenser relates to the cleaning of heat transfer pipelines. The method comprises the following steps: the first step, closing an inlet valve and an outlet valve of circulating water after a turbine condenser is shut down; the second step, flushing the copper tubes of the condenser with clean water; the third step, injecting acid chemical cleaning liquor at water side of the condenser for soak cleaning; the fourth step, neutralizing soak solution with sodium hydroxide; the fifth step, flushing the copper tubes of the condenser with clean water; the sixth step, rinsing the copper tubes of the condenser with clean water; and the seventh step, replacing membrane, and commissioning after cleaning. Compared with the original method of cleaning with chemical agents to be added to a circulating water tank, the method is characterized in that chemical cleaning liquor is added to a single turbine condenser, which can help clean fouling off the copper tubes and improve vacuum degree of the turbine while ensuring no corrosion of the copper tubes, and has the advantages of low agent consumption, low cost, low corrosion rate, good cleaning effect and saving cleaning time. The method can be widely applied to cleaning and maintenance of the copper tubes of the condensers in power plants.

Owner:WENGFU (GRP) CO LTD

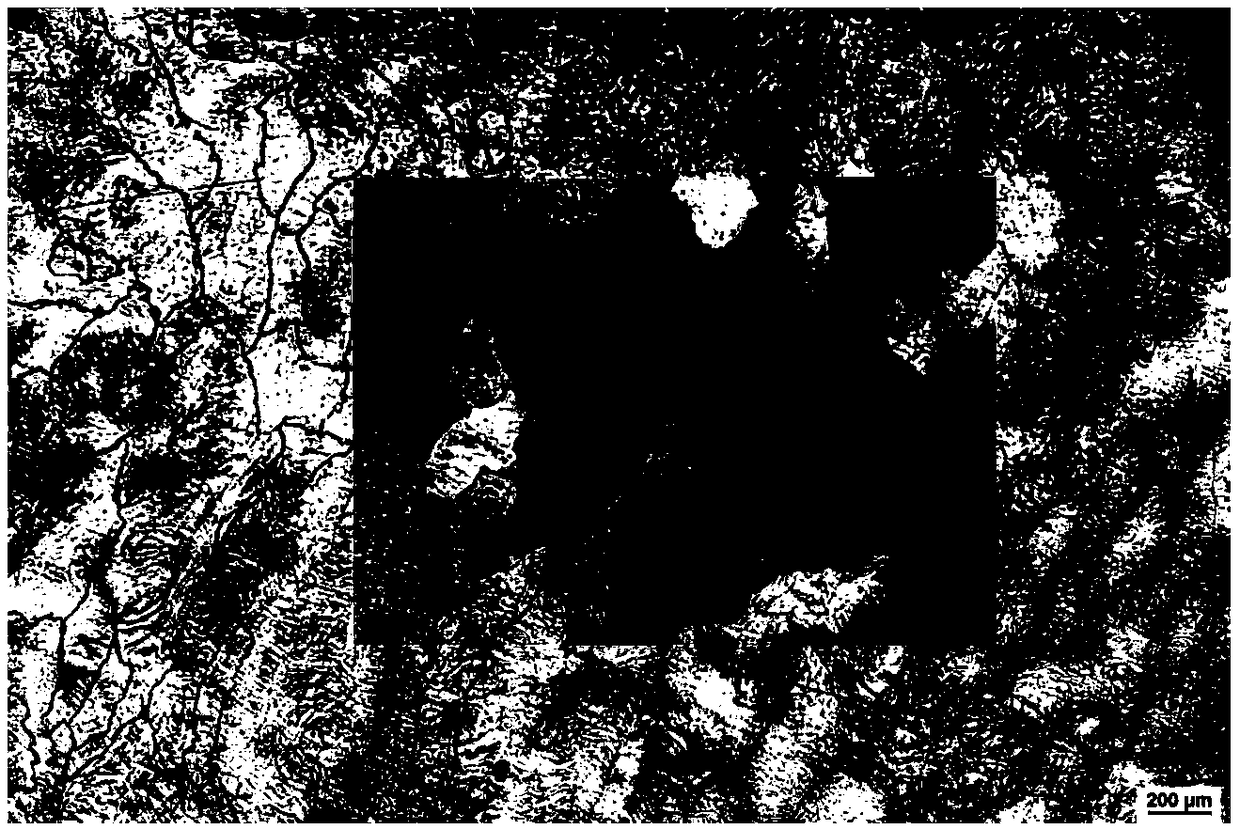

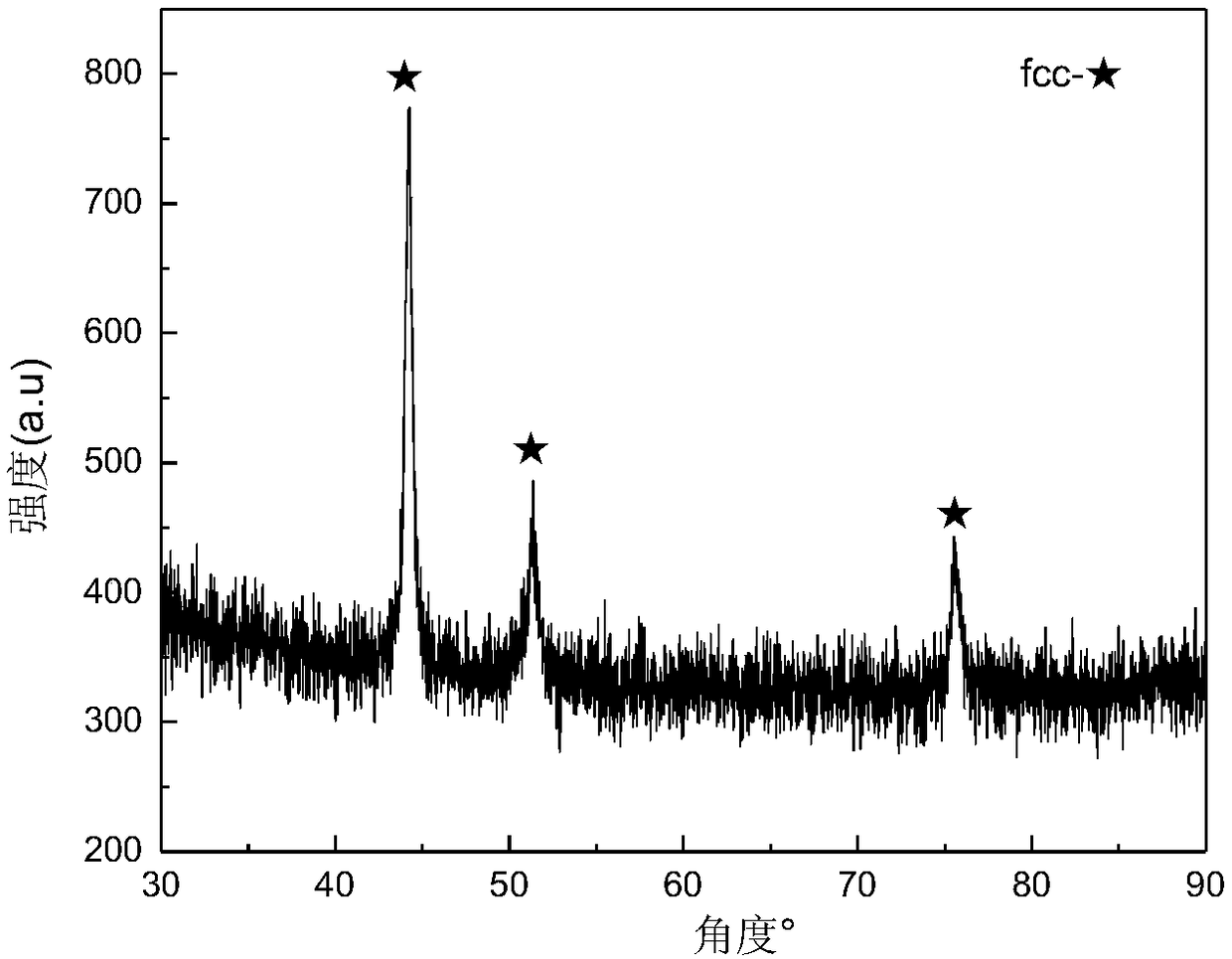

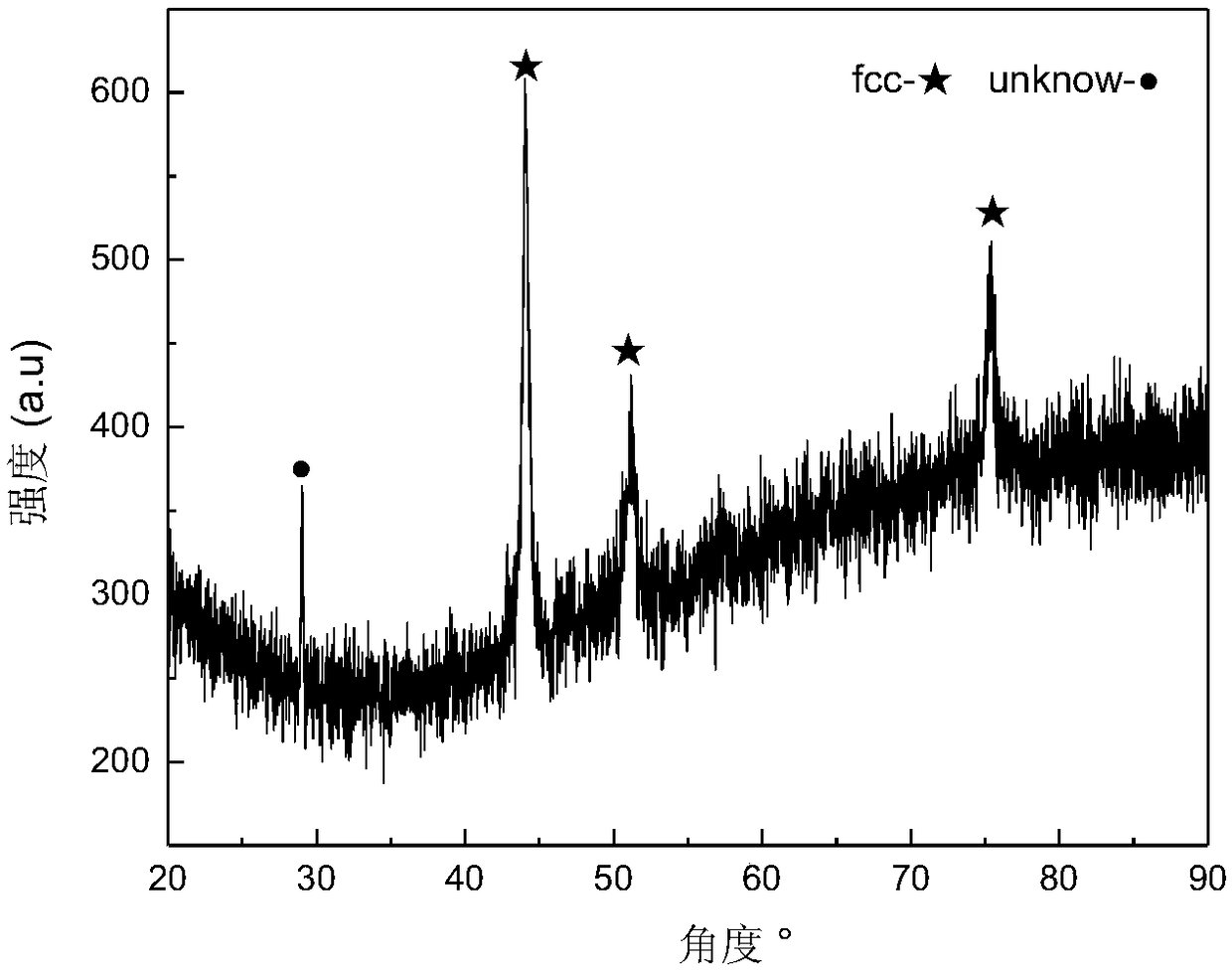

High-strength, corrosion-resistant and medium-entropy alloy and preparation method thereof

The invention discloses a high-strength, corrosion-resistant and medium-entropy alloy and a preparation method thereof. The component of the medium-entropy alloy is (CoCrNi)(100-x)Mnx, the atomic ratio of Co to Cr to Ni is (0.5-1):(0.5-1):(0.5-1), the value range of x is 1at%-10at%, , the alloy is formed through mixing, smelting, homogenizing treatment, rolling and heat treatment machining, the grain size of the alloy ranges from 30 mu m to 200 mu m, the manganese-rich phase is separated out of the grain boundary, the tensile strength of the alloy is higher than 1,200 MPa, the ductility is higher than 10%, the corrosion potential ranges from negative 0.43 V to negative 0.26 V, and the medium-entropy alloy is applicable to marine engineering equipment. The preparation process route of the alloy includes vacuum smelting, suction casting, homogenizing annealing, cold rolling and heat treatment. Co, Cr and Ni with the purity being 99% or higher are selected and weighed according to the proportion and are smelted repeatedly in a vacuum smelting furnace, suction casting forming is performed after the component is uniform, multi-pass cold rolling is adopted after annealing treatment, a plate which is 1-2 mm thick is obtained, the tensile strength of the plate is higher than 1,200 MPa, the ductility is higher than 10%, and the corrosion potential ranges from negative 0.43 V to negative0.26 V.

Owner:SOUTHEAST UNIV

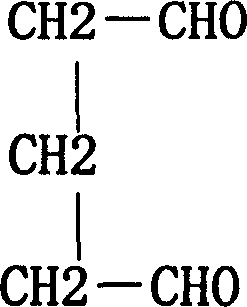

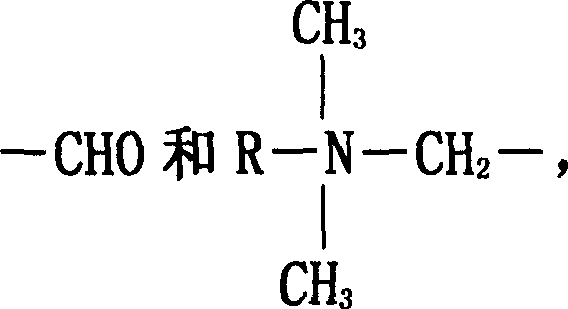

Composite efficient aldehyde insecticide

ActiveCN1853468AHas bactericidal and algae killing effectStrong penetration, peeling effectBiocideAnimal repellantsAlgaeBiology

An efficient composite biocide for killing the bacteria, fungi, algae, legionella, etc in circulated cooling water system is proportionally prepared from glutaric dialdehyde, quaternary ammonium salt, assistant, etc.

Owner:上海久安水质稳定剂厂 +1

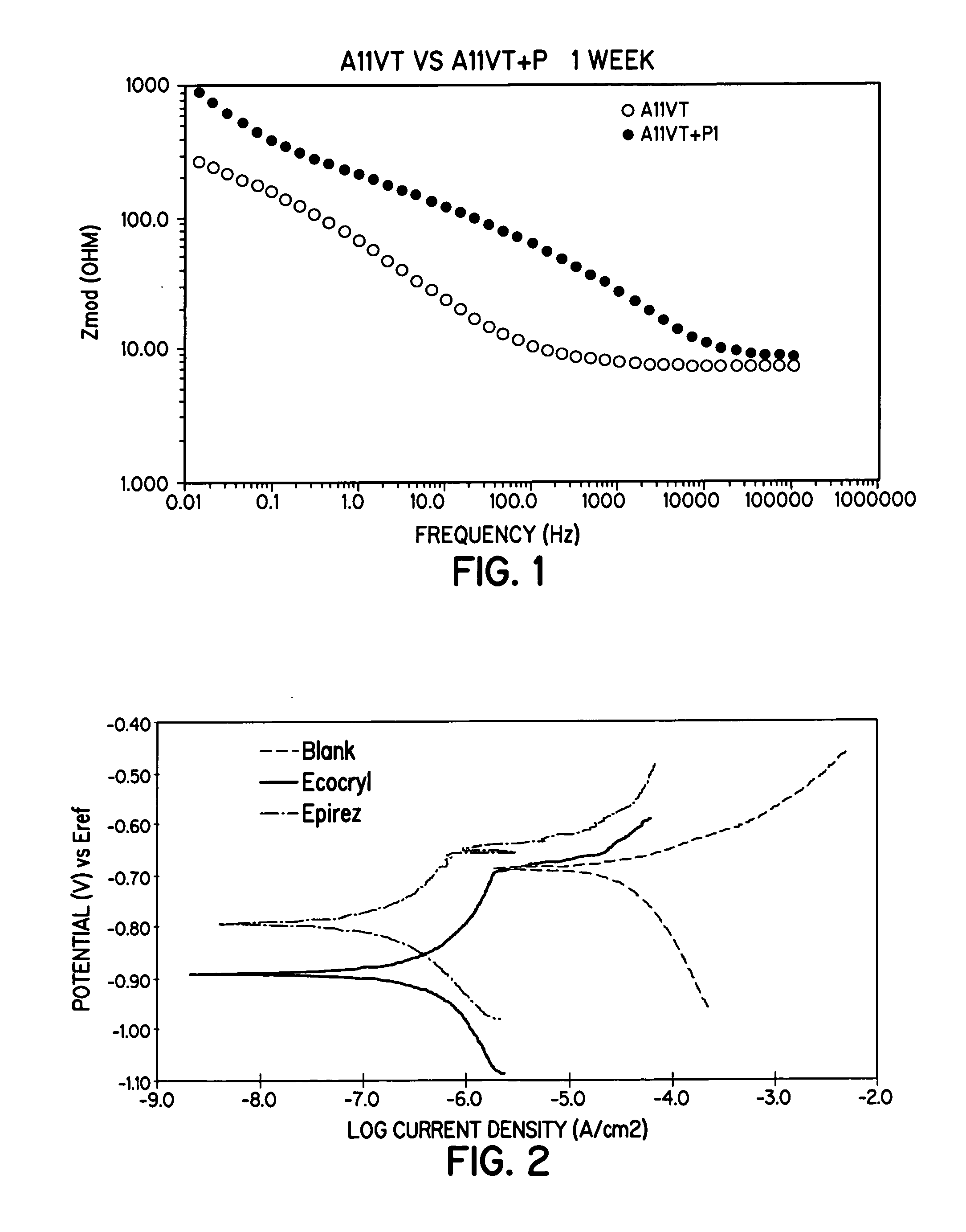

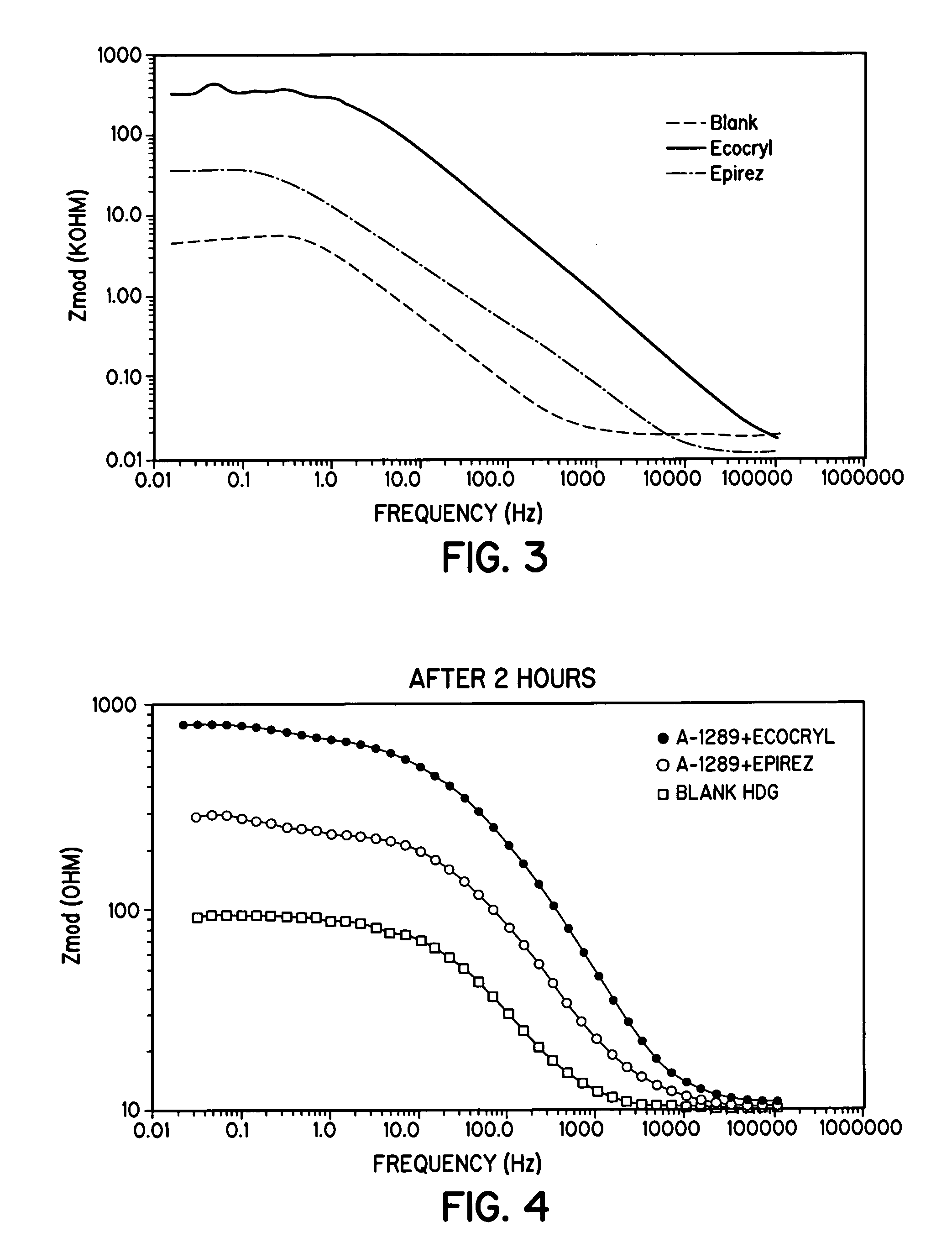

Silane coating compositions and methods of use thereof

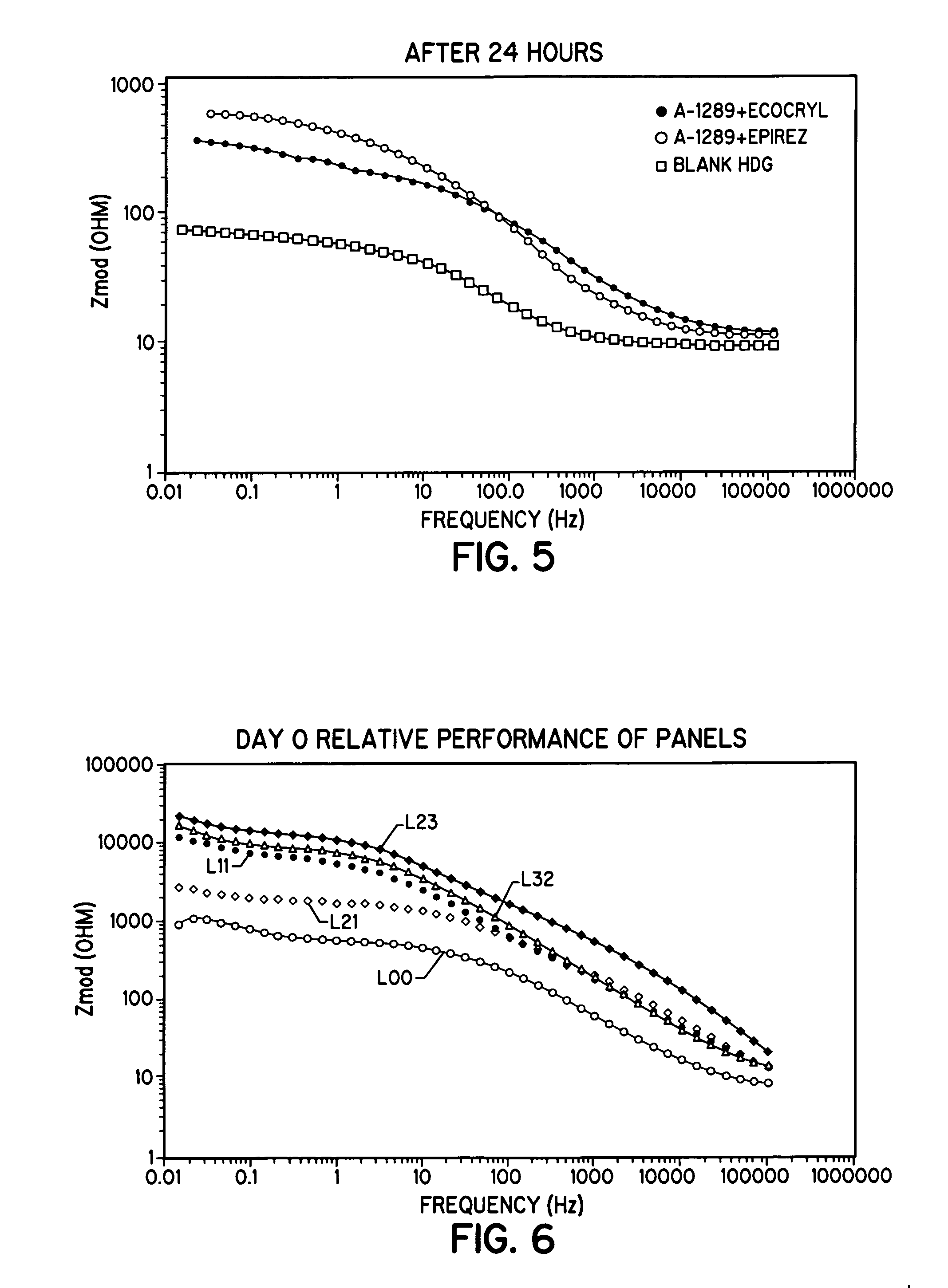

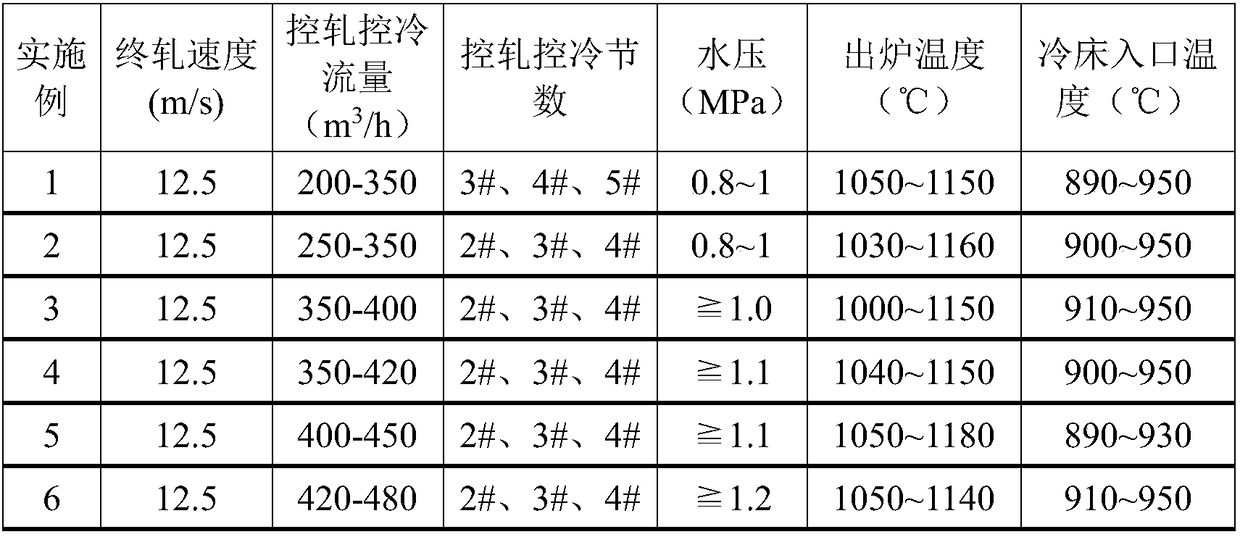

ActiveUS20070056469A1Slow ratePromote adhesionGroup 4/14 element organic compoundsSpecial tyresWater solubleCorrosion

A method of treating a substrate, such as a metal surface, by application of a silane coating composition containing at least one water-soluble or dispersible silane and a polymeric resin, which may be provided as a water-based dispersion of polymeric resin, the polymeric resin being present in an amount less than 10% by weight of the composition to slow the rate of corrosion of the metal surface and / or to promote adhesion of rubber thereto. The at least one silane can include a bis-amino silane, a vinyl silane, a bis-sulfur silane, or mixtures thereof and the polymeric resin may include an epoxy resin, acrylate resin, polyurethane resin, novolac resin, or mixtures thereof. The silane coating compositions may be either water or solvent based.

Owner:ECOSIL TECH +1

Seamless copper alloy pipe with excellent anti-corrosion performance for heat exchanger and preparation method thereof

The invention relates the seamless copper alloy pipe and preparing method used for corrosion resistant heat exchanger. The copper alloy comprises 0.002-0.02wt% boron, 0.1-0.6% nickel, 0.05-0.2% manganese, 69.0-71.0% copper, 0.8-1.3% tin, 0.03-0.06% arsenic, left zinc and impurity. The method comprises the following steps: adding raw material into brass-melting furnace to get copper alloy, shifting the copper alloy into holding furnace, adding the manganese copper alloy into copper alloy, adding copper boron alloy, making the melting copper alloy liquid, horizon continuous casting system driving copper alloy hollow strand, carrying out hot extrusion, tension and intermediate annealing, using the N2+H2 protective gas annealing furnace, and getting the product. The invention has the advantages of good corrosion resistance and simple technology.

Owner:江阴和宏精工科技有限公司

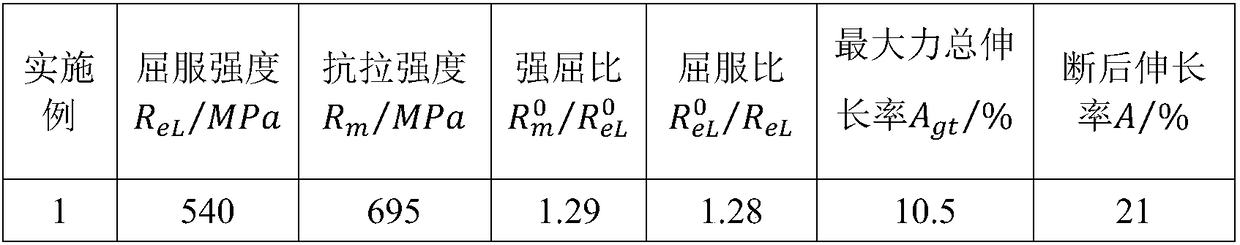

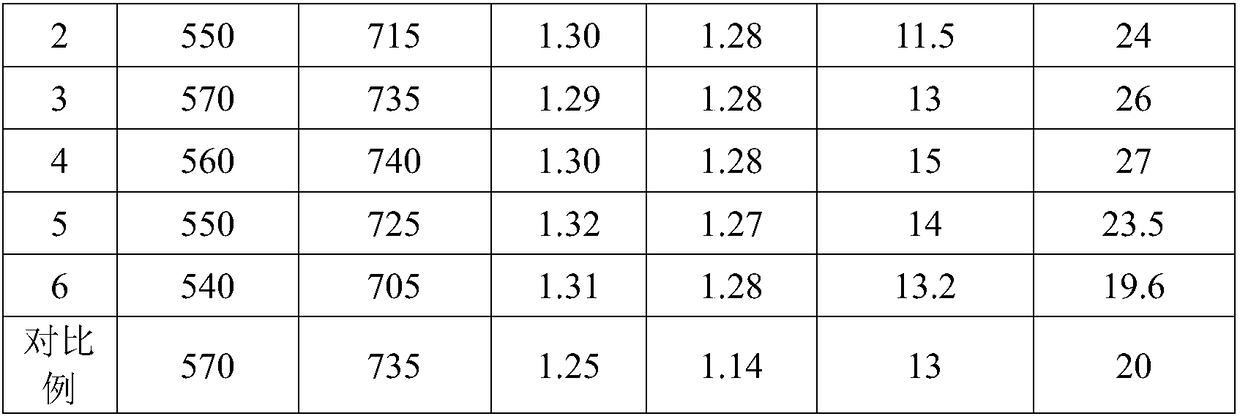

Steel bar with high weather resistance, low cost and seawater corrosion resistance and production process

ActiveCN108251746AGood weather resistanceLow costProcess efficiency improvementWeather resistanceRebar

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

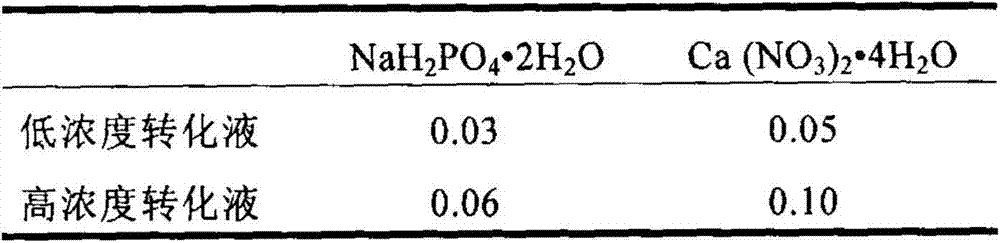

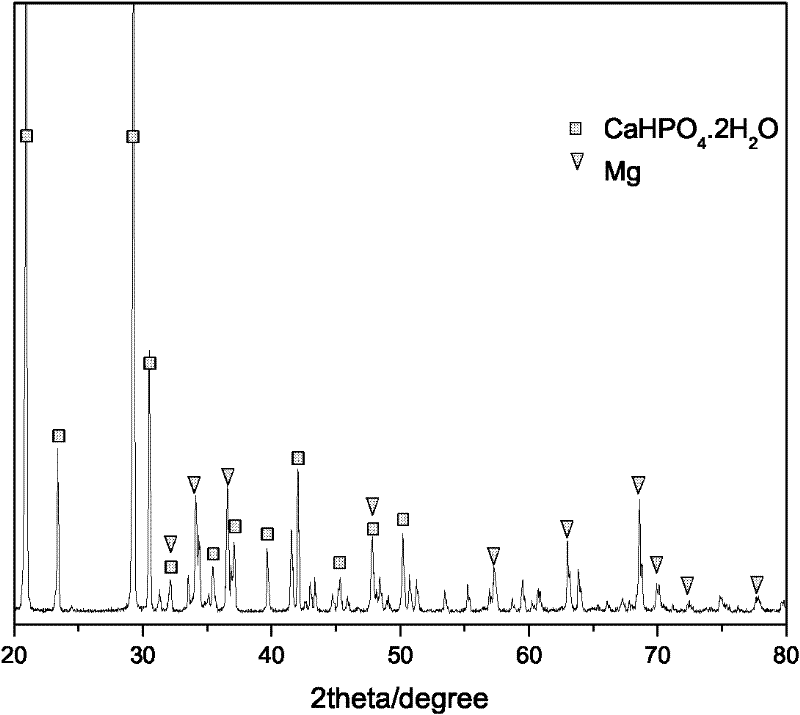

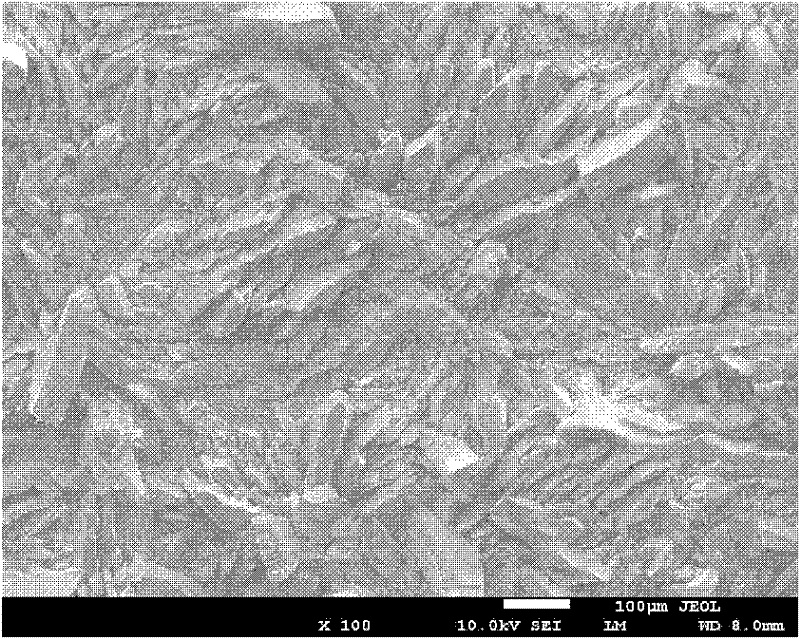

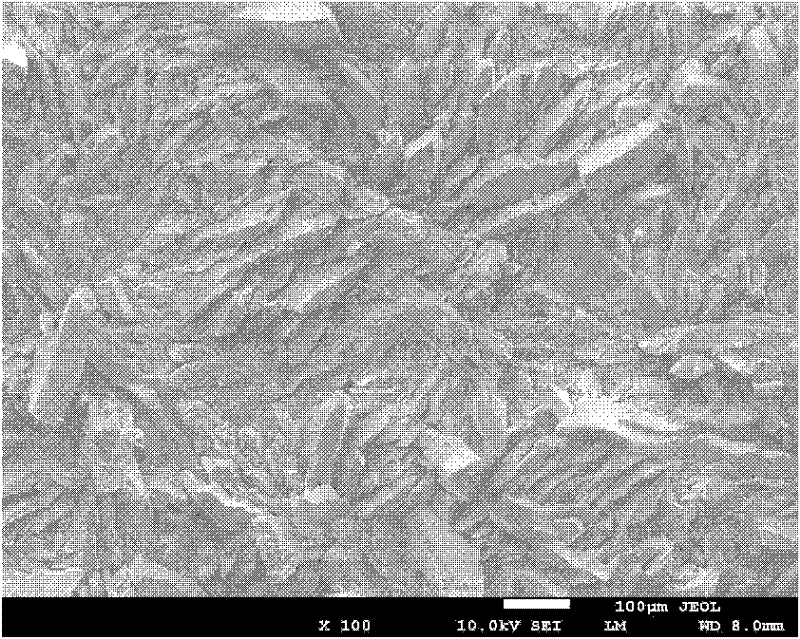

Preparation method of hydroxyapatite/polylactic acid composite coating on surface of medical magnesium alloy

InactiveCN103933611AHigh strengthReduce corrosion ratePretreated surfacesMetallic material coating processesAcid etchingCalcium nitrate tetrahydrate

The invention relates to a preparation method of a hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy, which comprises the following steps of polishing a magnesium alloy basal body to remove an oxidation layer on the surface; carrying out acid etching pretreatment and neutralizing treatment on the magnesium alloy basal body; preparing transfer solution from sodium dihydrogen phosphate dihydrate and calcium nitrate terahydrate; preparing a biomimetic calcium-phosphate coating; dissolving polylactic acid in a chloroform solvent to prepare polylactic acid solution; immersing the prepared magnesium alloy / hydroxyapatite composite material in the polylactic acid solution, and coating the polylactic acid coating on the surface of the magnesium alloy / hydroxyapatite composite material by adopting the solution dip-coating method; and putting the magnesium alloy material for 2-3 days till chloroform in the polylactic acid solution is completely volatilized, thereby obtaining the composite material of which the surface of magnesium alloy is wrapped with the hydroxyapatite / polylactic acid composite coating. Compared with the prior art, the preparation method of the hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy overcomes the disadvantages of the single coating, and therefore, the corrosion resistance and the biocompatibility of magnesium alloy are obviously increased.

Owner:TONGJI UNIV

Method for preparing bioactive calcium phosphate coating on magnesium alloy surface for endosseous implant

ActiveCN102206819AControl degradation rateReduce corrosion rateMetallic material coating processesProsthesisCalcium phosphate coatingChemical reaction

The invention belongs to the technical field of medical material, and relates to a method for preparing a bioactive calcium phosphate coating on a magnesium alloy surface for an endosseous implant. The method comprises: sequential soaking the magnesium alloy surface layer for the endosseous implant in hydrofluoric acid and a mixed solution containing phosphate at a constant temperature to preparethe bioactive calcium phosphate coating. With adopting a chemical deposition method provided by the present invention, surface bioactivity of the magnesium alloy is improved, and corrosion rate of the magnesium alloy substrate is reduced. The method has simple operation process, easy operation and no requirement of special equipment. The bioactive calcium phosphate coating prepared by the method has strong combining power with the magnesium alloy substrate, and has controllable thickness.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

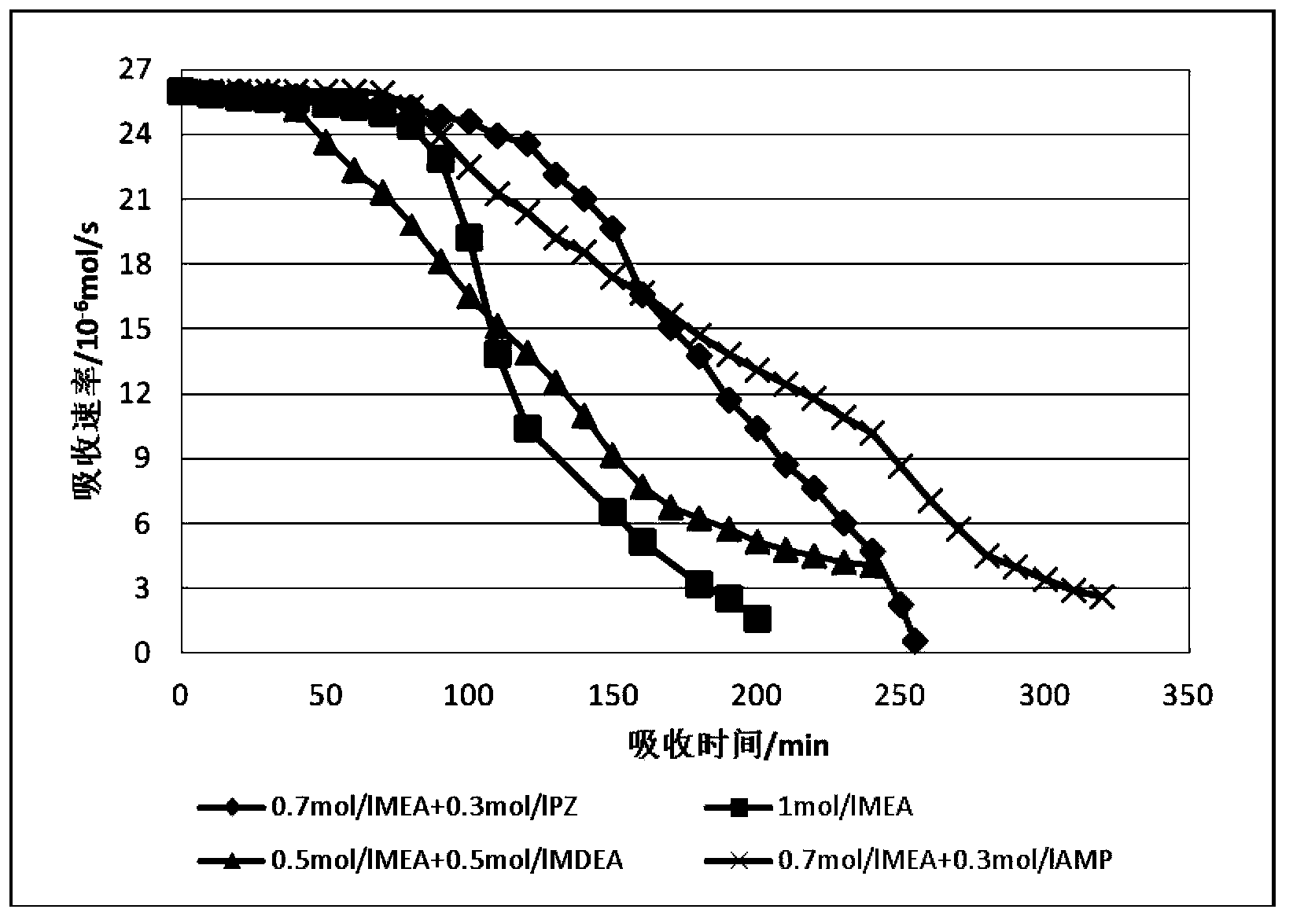

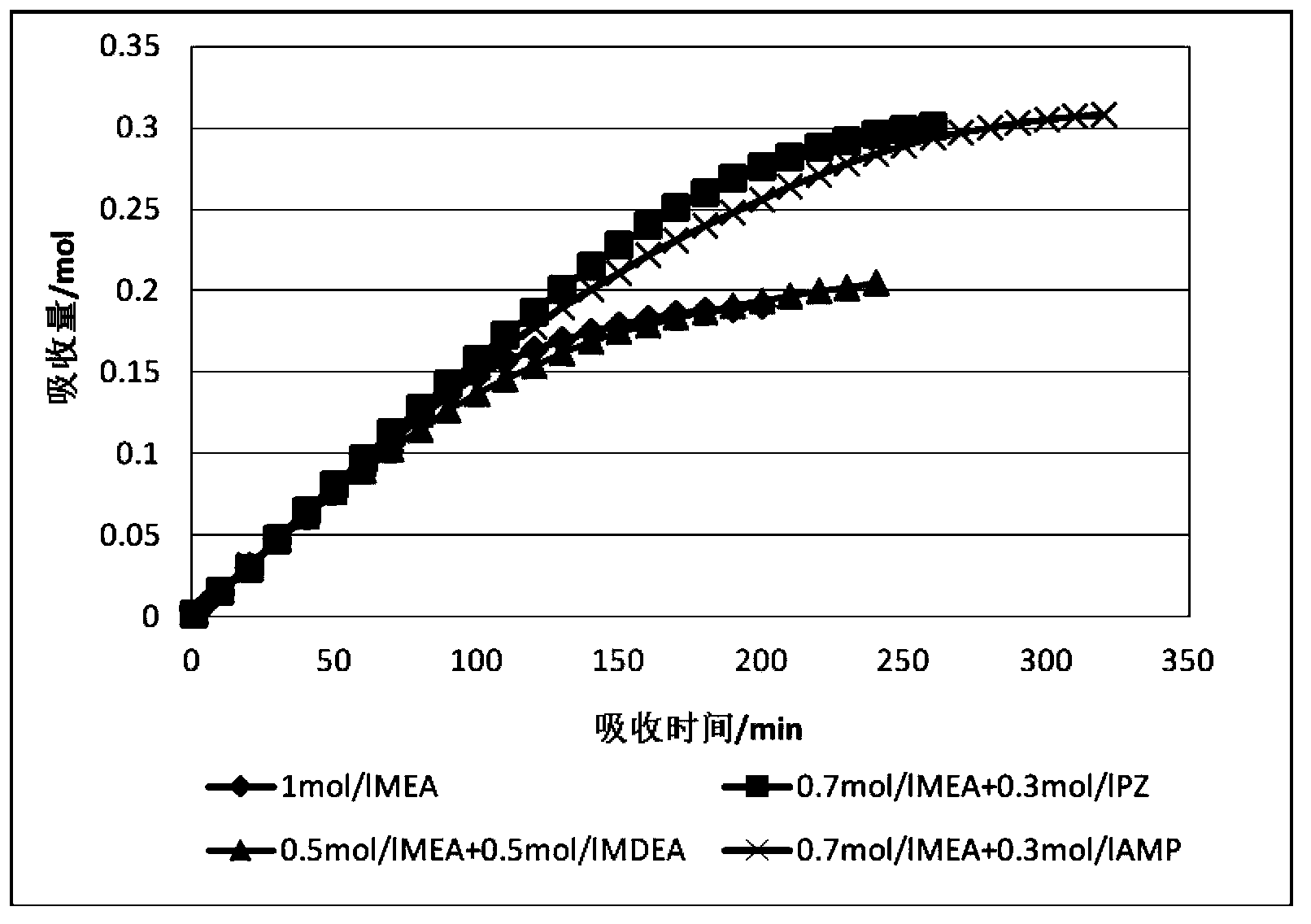

Organic amine compound absorbent for removal of carbon dioxide in fire coal flue gas

ActiveCN103394277AImprove protectionSolving Corrosion ProblemsDispersed particle separationBy chemical separationSulfolaneAbsorption capacity

The invention discloses an organic amine compound absorbent for removal of carbon dioxide in fire coal flue gas; the organic amine compound absorbent comprises the following components: by mass, 10%-45% of a main absorbent component, 0-10% of an assistant absorbent component, 0.01%-6% of a corrosion inhibitor, 0.01-3% of an antioxidant, 0-5% of a defoaming agent and the balance of water; wherein the main absorbent component comprises the following components: account for the total mass percentage of the organic amine composite absorbent, 3%-20% of monoethanolamine MEA, 0-12% of 2-amino-2-methyl-1-propanol AMP, 1%-15% of sun of piperazine PZ and N-aminoethyl piperazine AEP and 1%-12% of sum of aminoethyl ethanolamine AEEA and N-methyl monoethanolamine MMEA; and the assistant absorbent comprises one or a plurality of component selected from the group comprising diethanol amine DEA, diethylenetriamine DETA, triethylene tetramine TETA, N-methyldiethanolamine MDEA, sulfolane and tertbutylaminoethoxyethanol TBEE. The organic amine compound absorbent has the advantages of good stability, large absorption capacity, high purification degree, low regeneration energy consumption, good desorption effect, great reduction of degradation loss of the compound absorbent in the process of using, and the like.

Owner:STATE GRID CORP OF CHINA +1

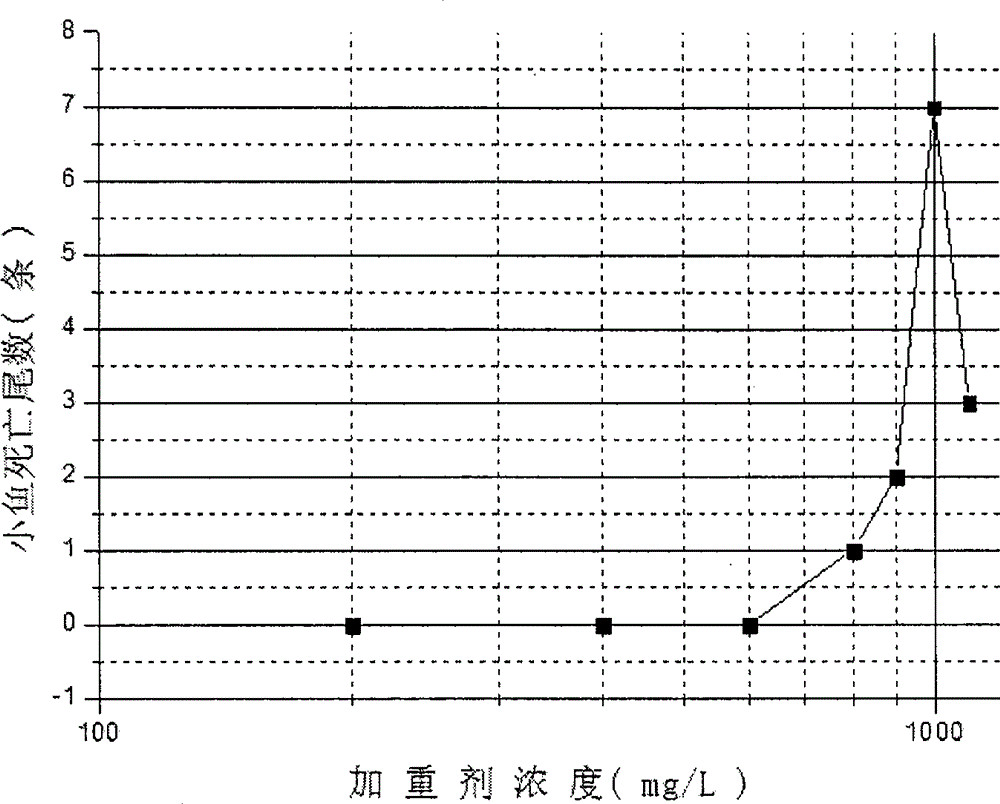

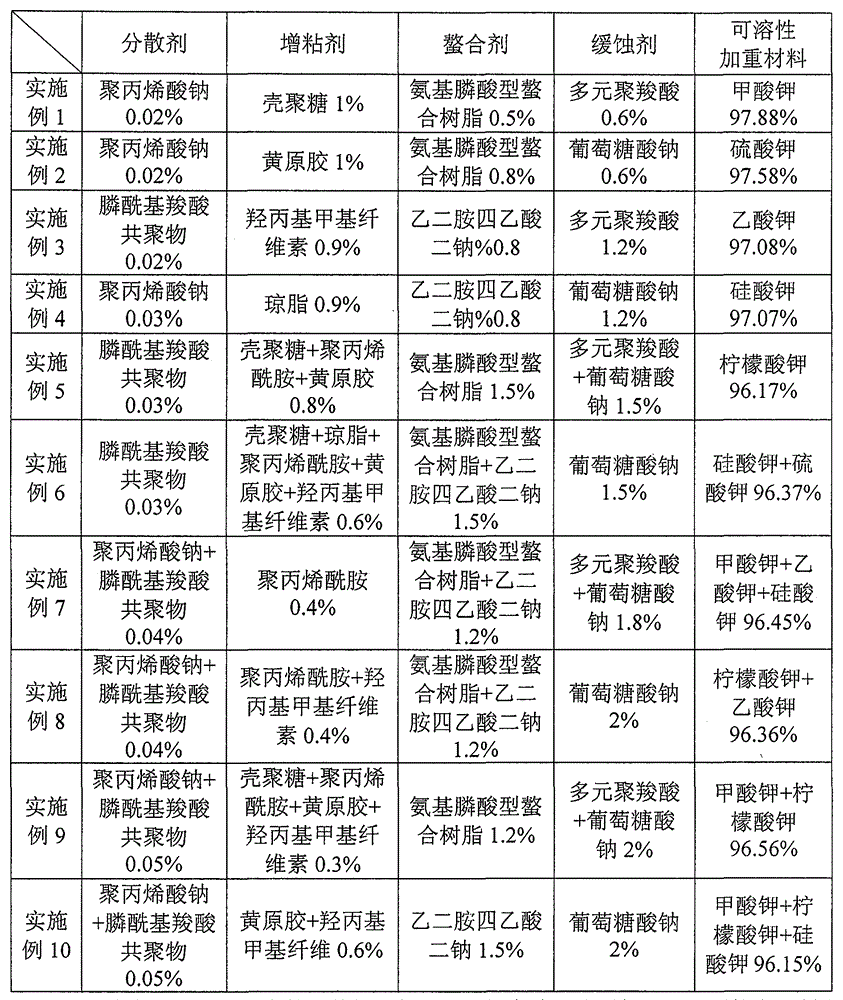

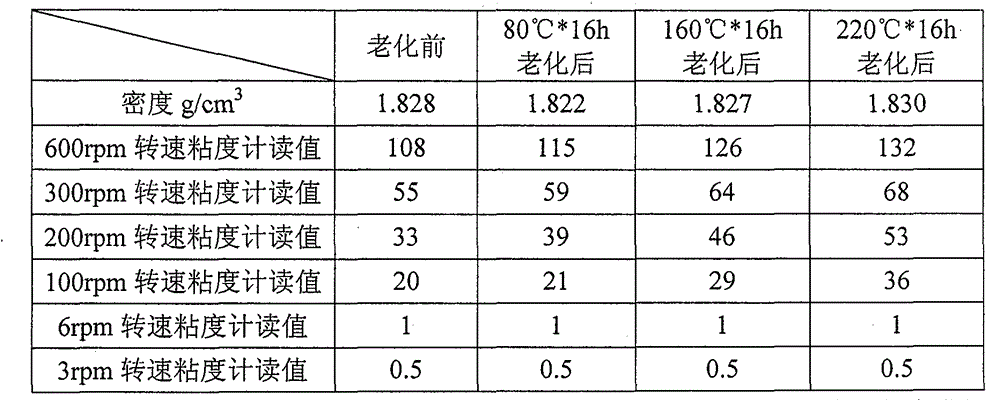

Environment-friendly high-density solid-free weighting agent and preparation method

ActiveCN104610937AWide range of densitiesReduce pollutionDrilling compositionCarboxylic acidPotassium formate

An environment-friendly high-density solid-free weighting agent comprises components in parts by weight as follows: 0.02-0.05 parts of a dispersant, 0.3-1 part of a tackifier, 0.5-1.2 parts of chelating agent, 0.6-2 parts of a corrosion inhibitor and the balance of soluble weighting materials, wherein the dispersant is one or two of sodium polyacrylate and copolymer of phosphono and carboxylic acid; the tackifier is one or more of chitosan, agar, polyacrylamide, xanthan gum and hydroxypropyl methyl cellulose; the chelating agent is one or two of aminophosphonic acid chelate resin and ethylenediamine tetraacetic acid disodium; the corrosion inhibitor is one or two of multiple polycarboxylate and sodium gluconate; the soluble weighting materials are one or more of potassium formate, potassium citrate, potassium acetate, potassium silicate and potassium sulfate. The process steps are as follows: the raw materials are taken in weight proportion, mixed and uniformly stirred; the raw materials are added to water and dissolved at the high temperature of 70-80 DEG C; a product is evaporated to dryness, and solid is obtained; the obtained solid is ground into powder, and the solid weighting agent is obtained.

Owner:成都西油华巍科技有限公司

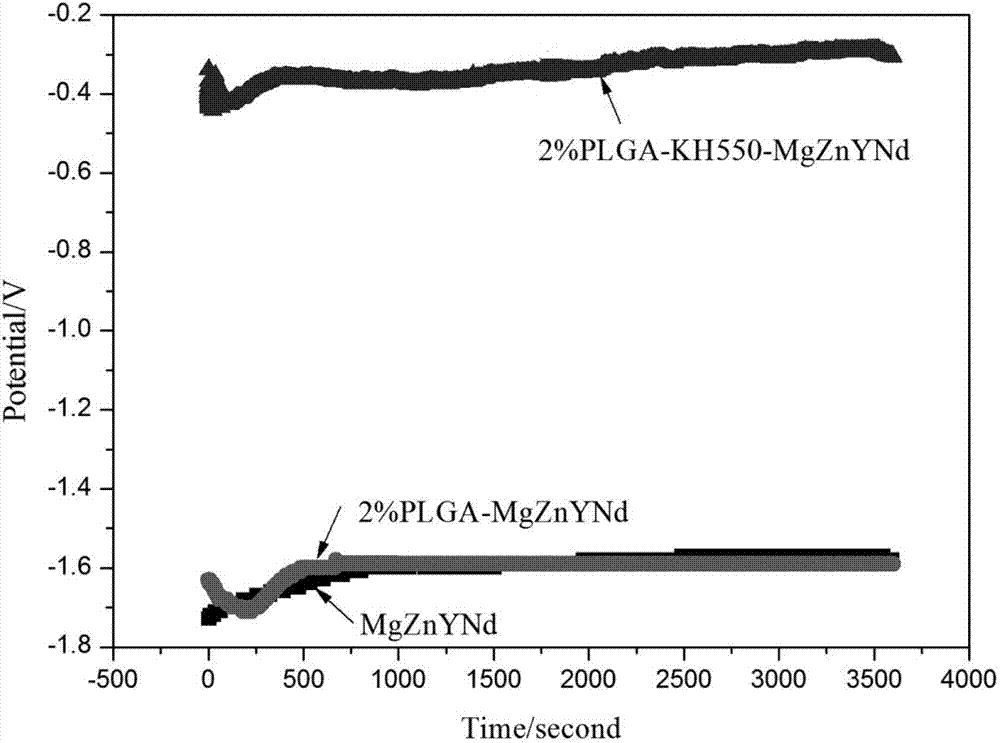

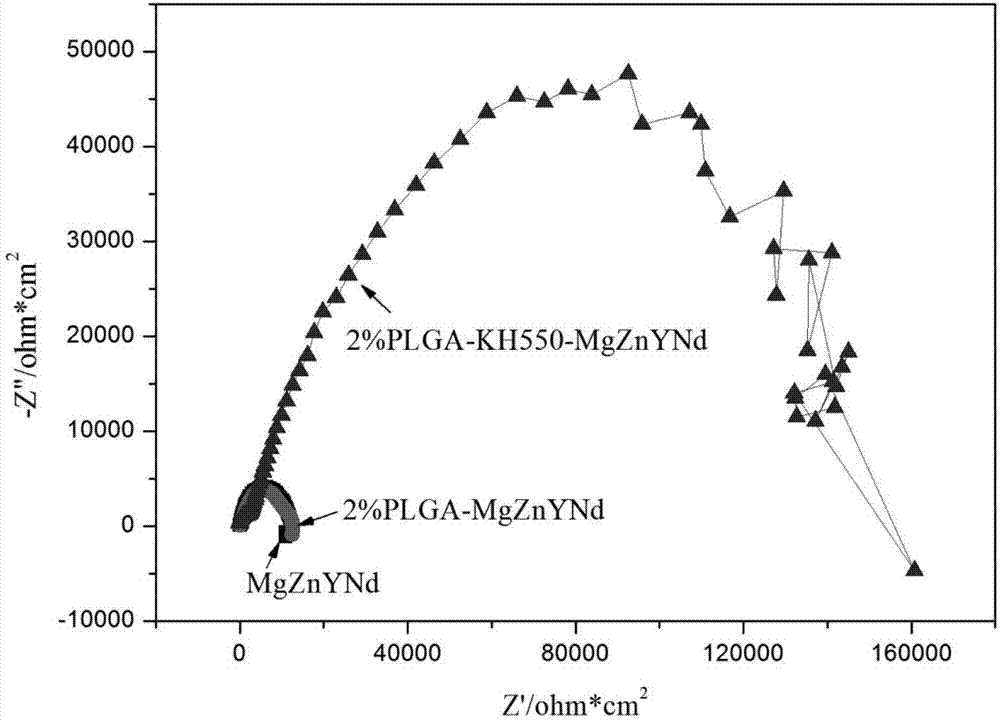

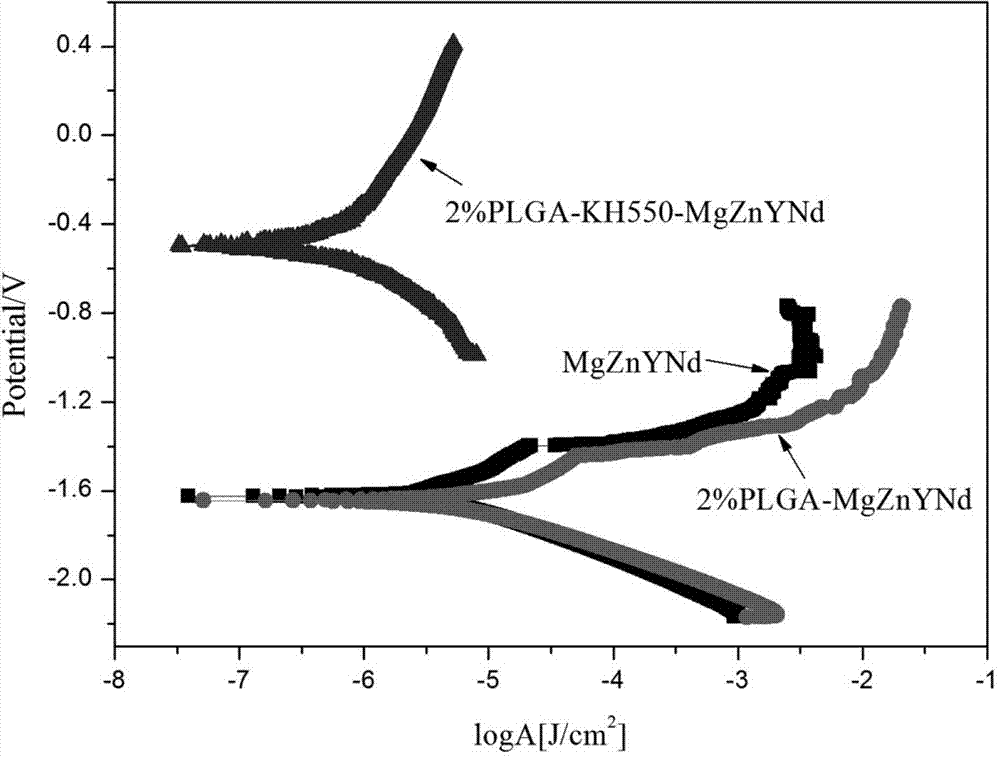

Preparation method of surface coating capable of lowering degradation rate of fully-degradable magnesium alloy vascular stent

ActiveCN104189963AReduce the degradation rateReduce sheddingSurgeryCoatingsMg alloysBiocompatibility

The invention relates to a preparation method of a surface coating capable of lowering the degradation rate of a fully-degradable magnesium alloy vascular stent. The method comprises the following steps: preparing a silane coupling agent on a magnesium alloy surface in a way that a silane coupling agent and an organic solvent are mixed, the silane coupling agent is grafted to the magnesium alloy surface of a biodegradable vascular stent by adopting a dip coating method and heating and curing are performed to form a coating; and preparing a polymer coating on the surface pre-treated by the silane coupling agent in a way that a spin-coating method is adopted to coat a polymer on a sample surface treated by the silane coupling agent, vacuum drying is realized and the polymer coating is formed after solvent volatilization. Through the technical scheme, a strong binding force exists between the polymer coating on the magnesium alloy surface pre-treated by the silane coupling agent and the surface of the fully-degradable magnesium alloy vascular stent, so that the magnesium alloy base body is prevented from excessively quick degradation, and the biocompatibility is improved; and as the coating is completely degraded with the base body at last, no toxic or side effects are brought to a human body.

Owner:JIANGSU FENGYUAN MEDICAL DEVICES CO LTD

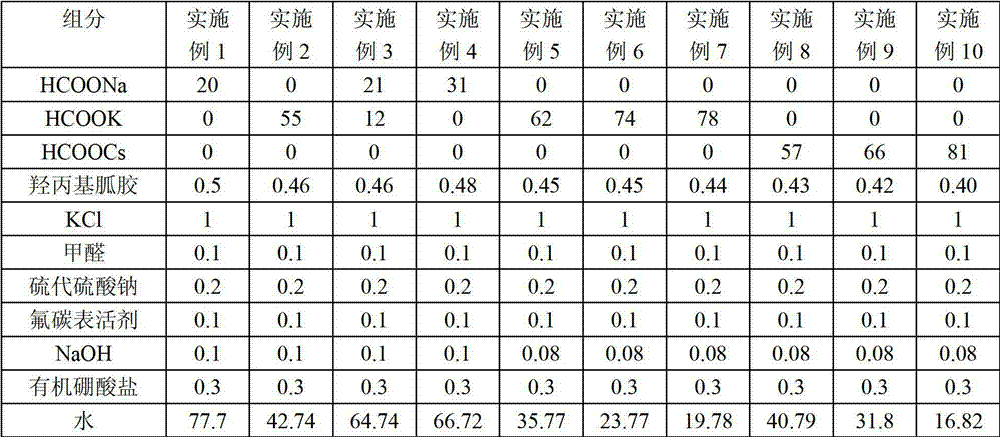

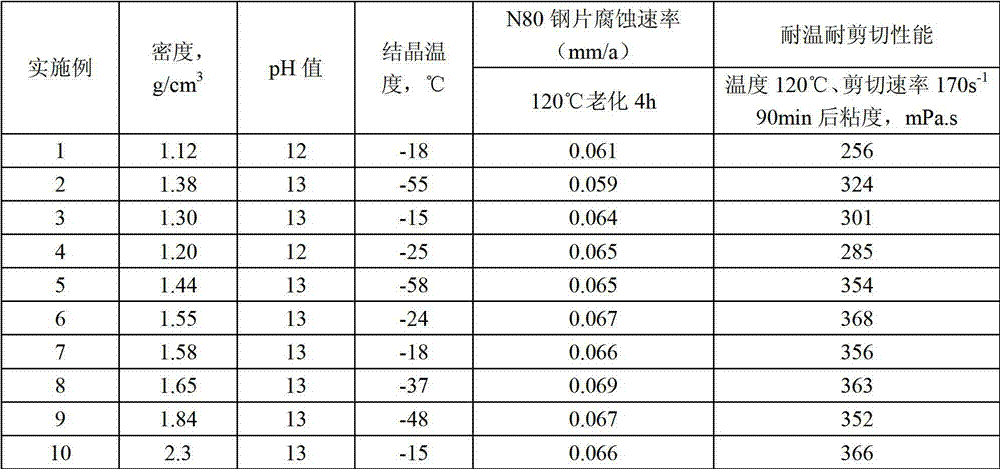

Weighted fracturing fluid

InactiveCN102876314AWide density adjustment rangeReduce corrosion rateDrilling compositionOrganic acidChemistry

The invention relates to weighted fracturing fluid and belongs to the technical field of oilfield chemistry. The weighted fracturing fluid comprises organic acid salt weighting agents, thickening agents, cross-linking agents, pH (potential of hydrogen) conditioning agents, discharge aiding agents, bacteriacide, clay stabilizers and high-temperature stabilizers by mixing. The organic-salt weighted fracturing fluid is adjustable within a wider density adjustment range of 1.05g / cm<3>-2.3g / cm<3> and lower in crystallization temperature to meet the requirements of low-temperature construction in winter due to the fact that the crystallization temperature of inorganic salt solution is generally above minus 20 DEG C but the crystallization temperature of formate solution even can be lower than about minus 60 DEG C. Besides, the weighted fracturing fluid has low corrosion rate so as to reduce corrosion to equipment, pipes and the like, has low toxicity and a biodegradable characteristic so as to reduce harm of bromide toxicity to human bodies and the environment, and has better temperature and shear resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

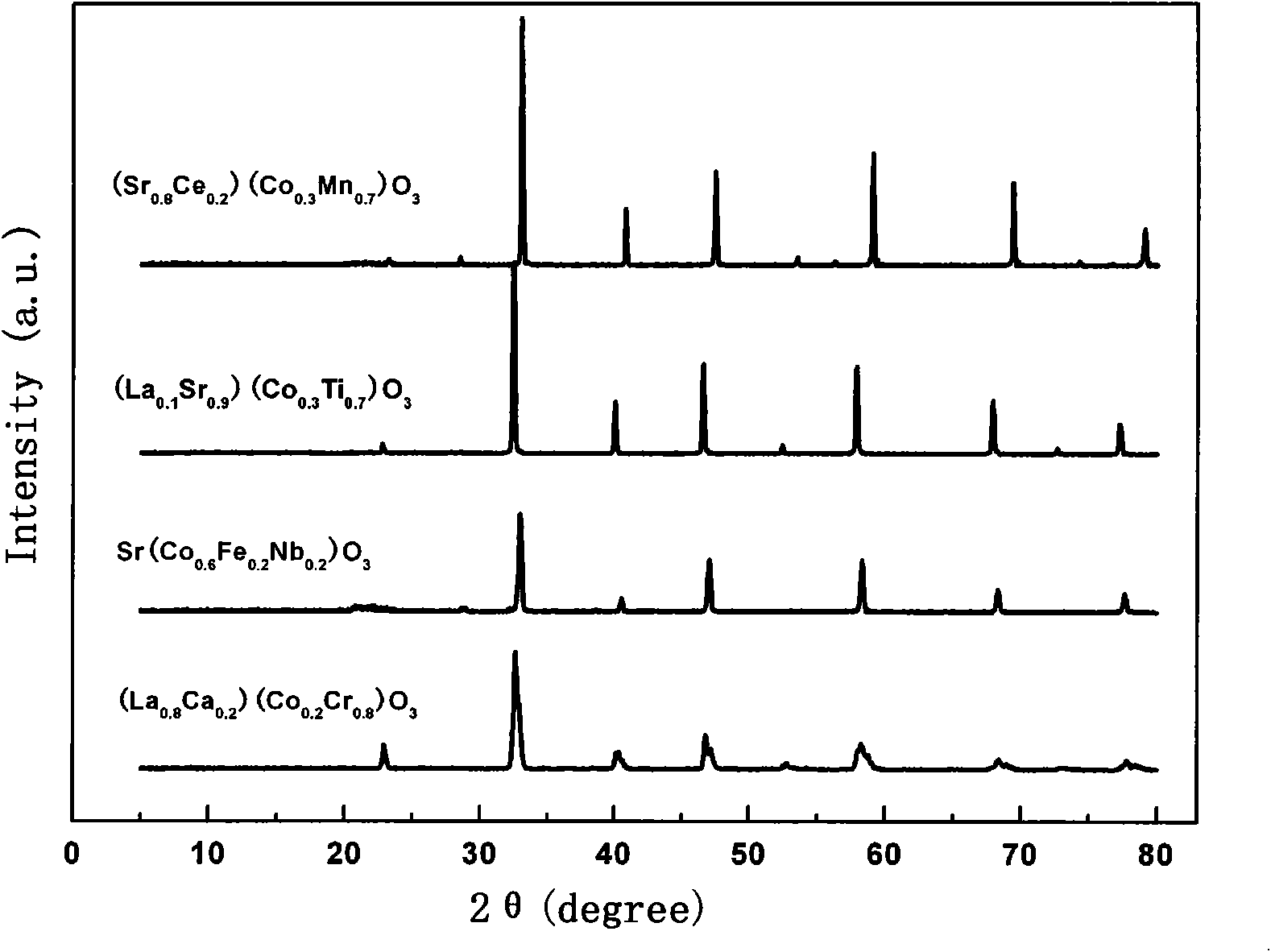

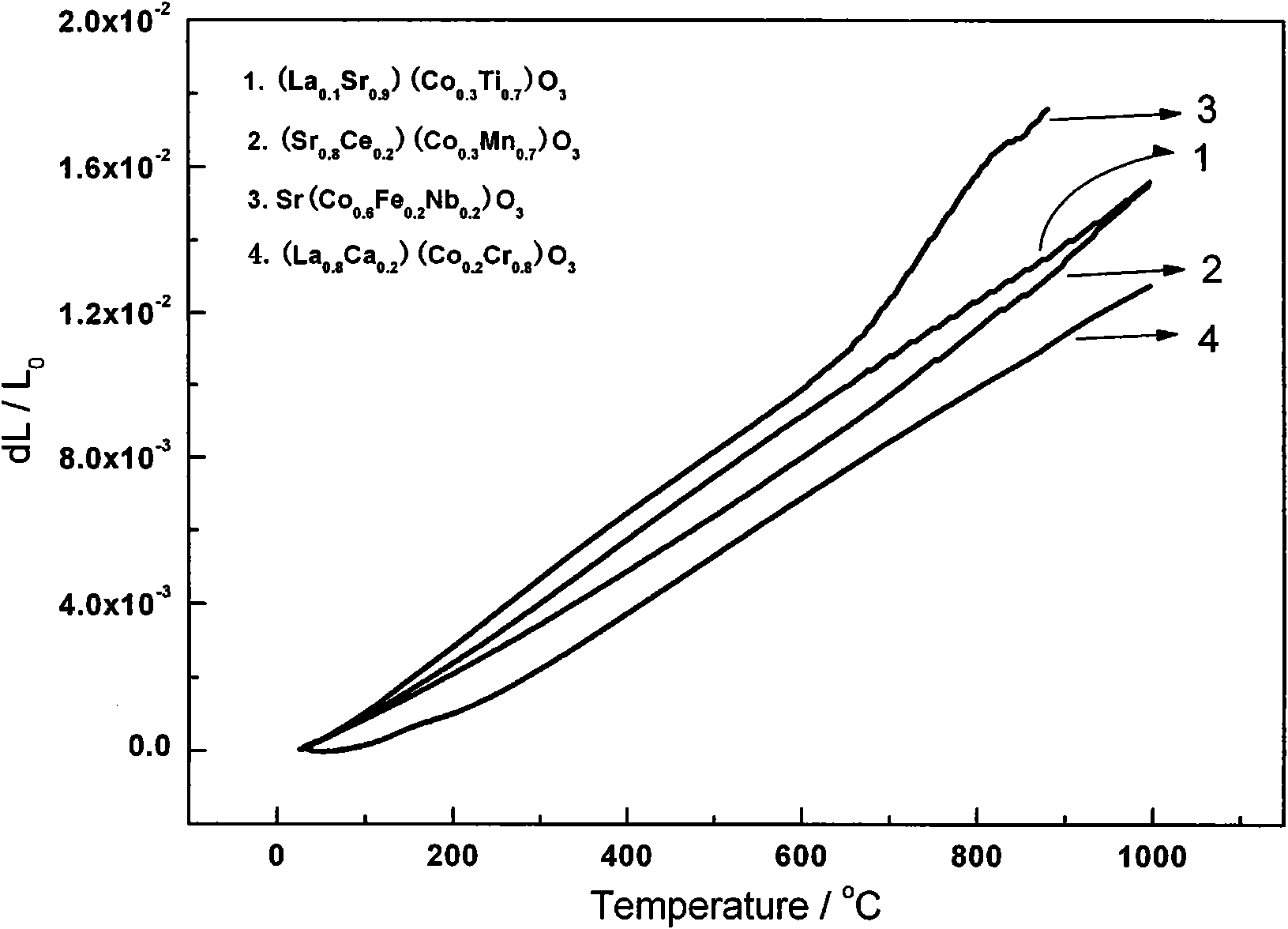

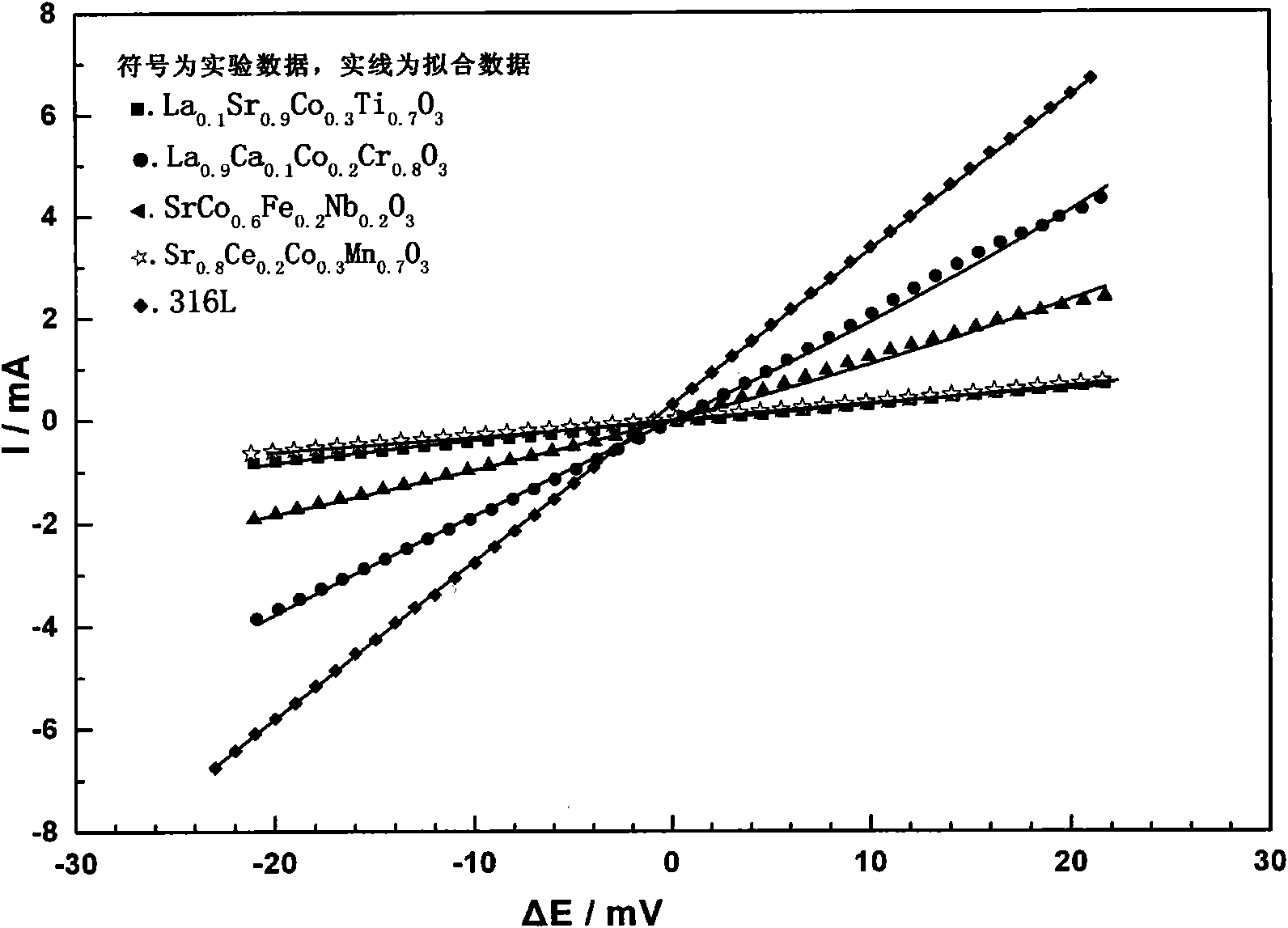

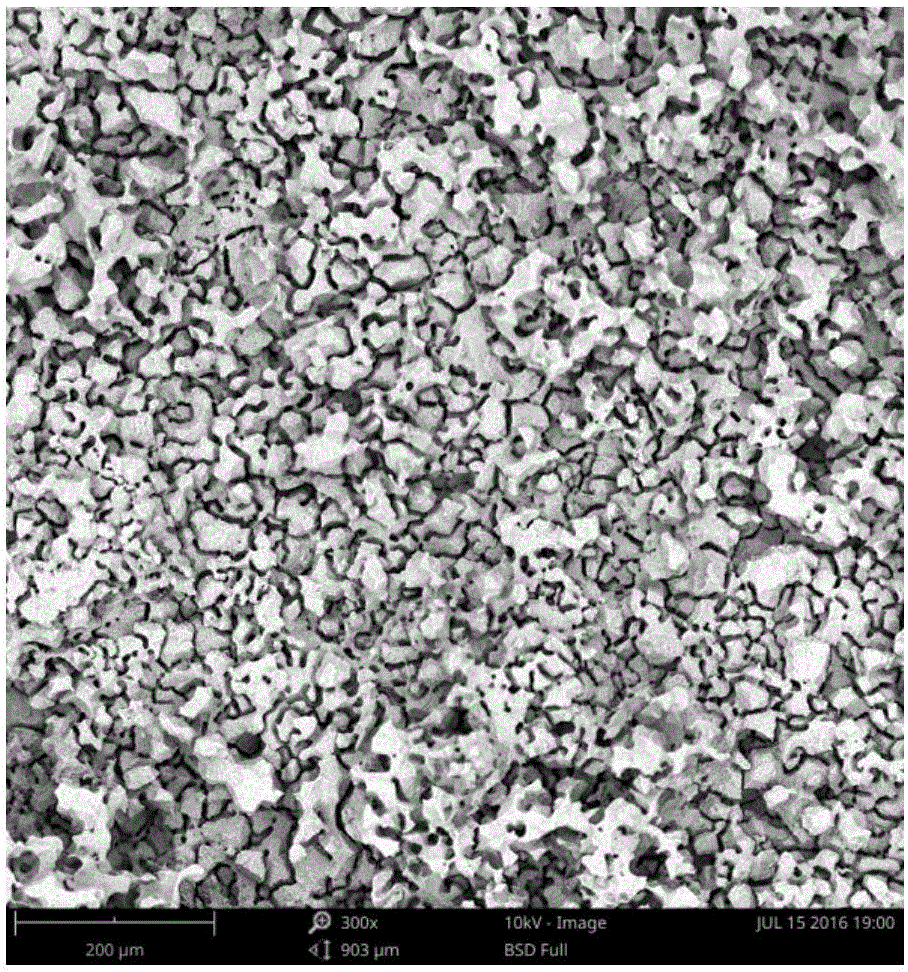

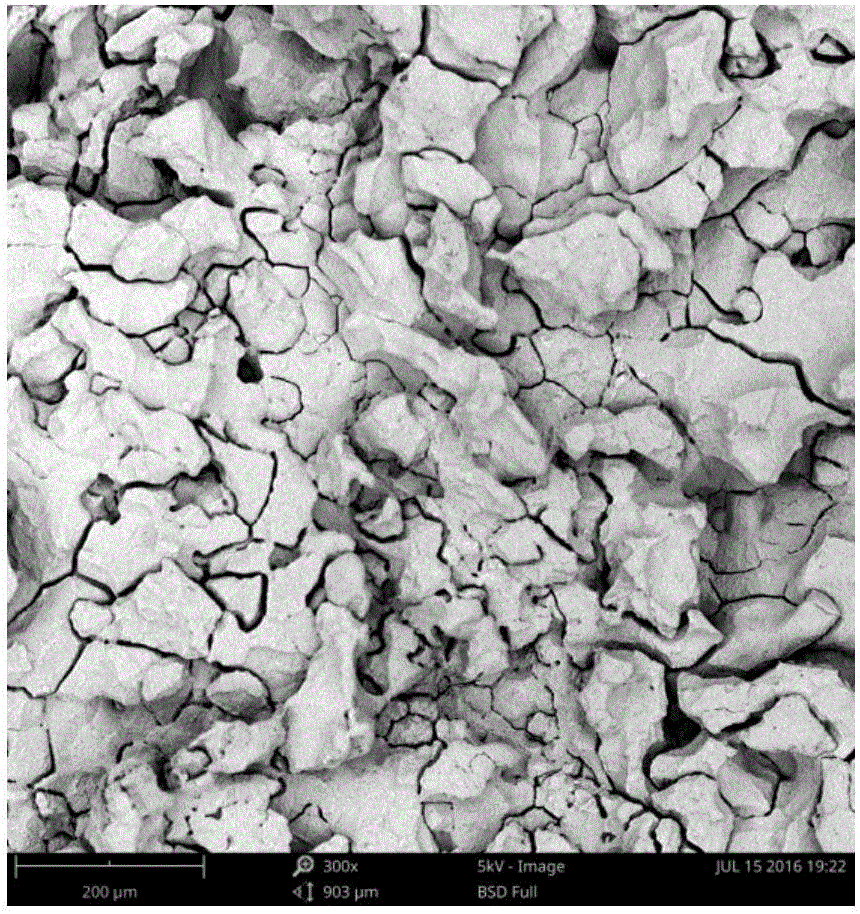

Perovskite structure material and preparation method thereof

InactiveCN101792304AImprove conductivityImprove stabilityCell component detailsRare-earth elementMischmetal

The invention relates to a conductive corrosion-resistant perovskite structure material which is characterized in that the chemical formula of the material can be represented by ABO3, wherein A is a rare earth element or an alkaline earth metal element, or the combination of a rare earth metal element and the alkaline earth metal element, and B is one or more transition metal elements. The conductive corrosion-resistant perovskite structure material has great electronic conductivity and excellent stability and corrosion resistance, in particular to the corrosion resistance against the molten salt environments. The material can be applied in the corrosion resistance of housings of sodium sulfur batteries and the corrosion resistance of devices in other molten salt environments.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Aluminum alloy electrode material and preparation method and application of aluminum alloy electrode material

ActiveCN106191571AUniform corrosionReduce corrosion rateFuel and primary cellsCell electrodesRare-earth elementCrystallite

The invention provides an aluminum alloy electrode material. The aluminum alloy electrode material comprises 0.1-3 wt% of Mg, 0.05-1 wt% of Sn, 0.01-0.5 wt% of Ga, 0.02-0.1 wt% of RE and the balance Al. According to the aluminum alloy electrode material, an aluminum substrate is doped with a certain amount of magnesium, stannum, gallium and the rare earth element, on the basis of improving the activity of an aluminum anode, through the refining function of the rear earth element on grains, corrosion of the aluminum anode is evener, and the corrosion rate is lowered; meanwhile on the one hand, due to addition of the elements, the electrochemical performance of the aluminum alloy is good; on the other hand, the added elements are free of contamination; and the rare earth element is added in the form of an aluminum rare earth master alloy, and the price is low. The invention further provides a preparation method of the aluminum alloy electrode material and application of the aluminum alloy electrode material in air batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

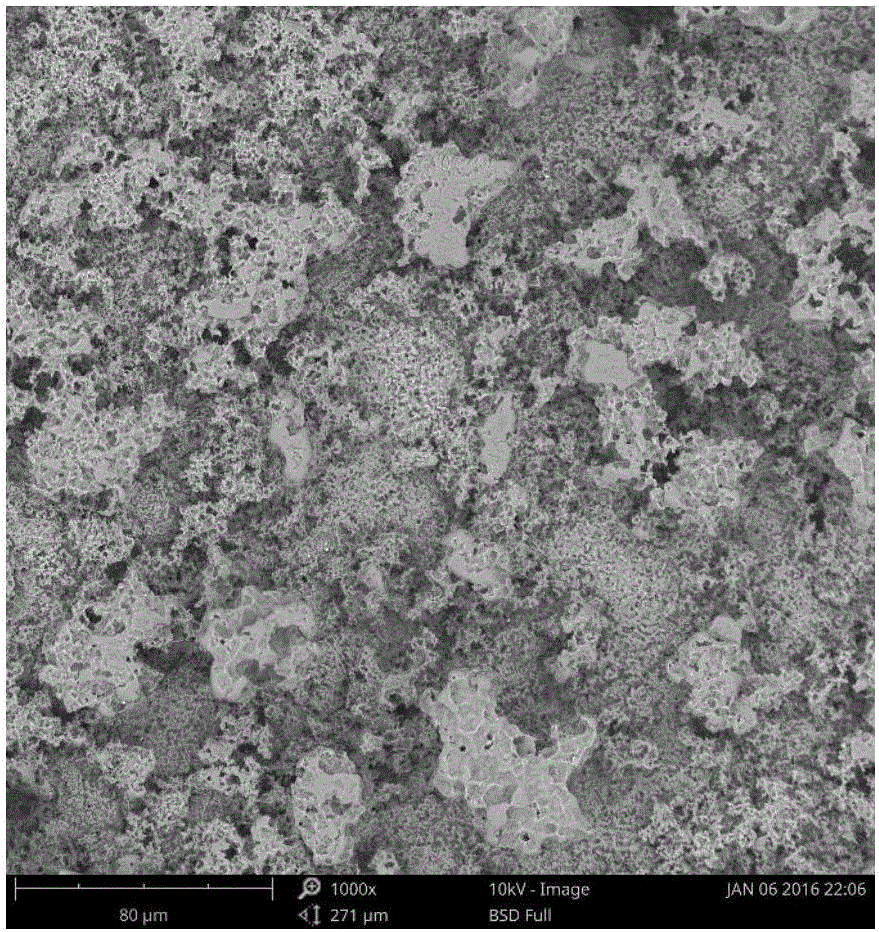

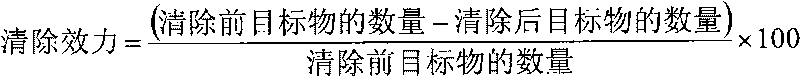

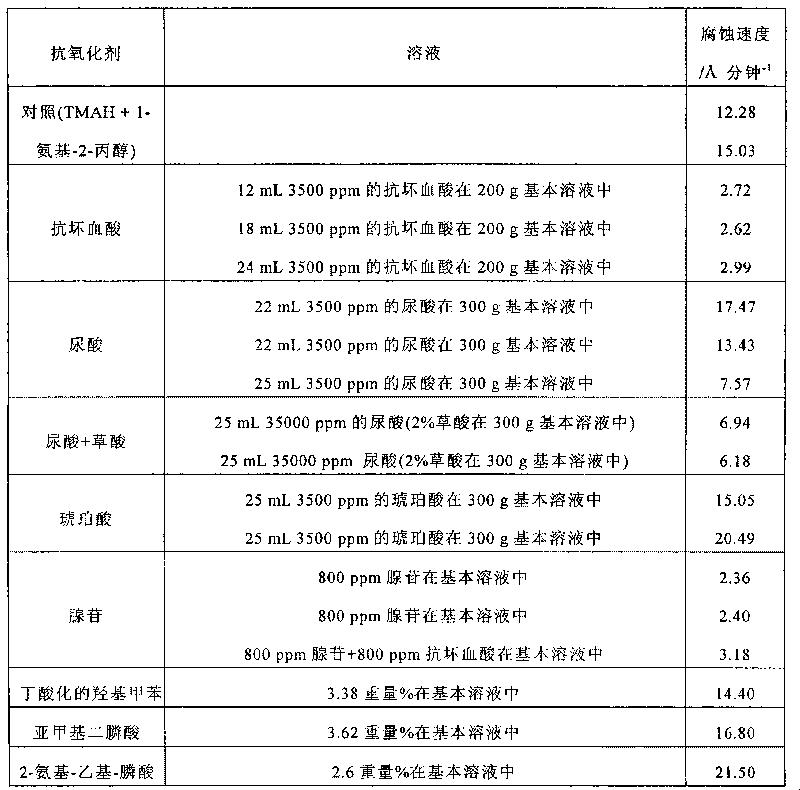

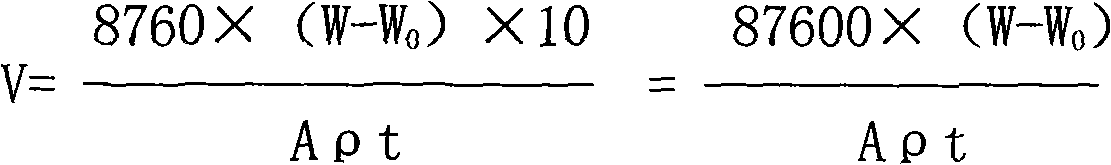

New antioxidants for post-cmp cleaning formulations

ActiveCN101720352AReduce corrosion rateCationic surface-active compoundsOrganic detergent compounding agentsCopper interconnectAntioxidant

An cleaning composition and process for cleaning post-chemical mechanical polishing (CMP) residue and contaminants from a microelectronic device having said residue and contaminants thereon. The cleaning compositions include novel corrosion inhibitors. The composition achieves highly efficacious cleaning of the post-CMP residue and contaminant material from the surface of the microelectronic device without compromising the low-k dielectric material or the copper interconnect material.

Owner:ENTEGRIS INC

Compound corrosion and scale inhibitor

InactiveCN101560022AGood sedimentationImprove the coordination effectScale removal and water softeningCalcium biphosphateSulfonate

The invention relates to a compound corrosion and scale inhibitor which comprises the following raw materials according to mass ratio: 15%-30% of organic phosphonic acid, 10%-20% of acrylic acid or acrylic acid copolymer, 2%-10% of poly-maleic acid, 1%-3% of azole ramifications, 15%-30% of multivariate organic sulfonate, 2%-6% of dimethyl formamide and 20%-35% of water. The compound corrosion and scale inhibitor of the invention is used for a system which employs normal water as circulating cooling water, so as to solve corrosion problem caused by circulating water of normal-water to equipment. Corrosion rate of copper product is lower than the national standard of 0.005mm / a, thereby generating no equipment scaling caused by calcium phosphate deposition. Compared with corrosion inhibitors of the same kind, the compound corrosion and scale inhibitor has a lower dosage and is effective in corrosion and scale inhibiting. The compound corrosion and scale inhibitor is simple in operation, convenient, quick, safe and efficient.

Owner:XIAN XIELI POWER TECH

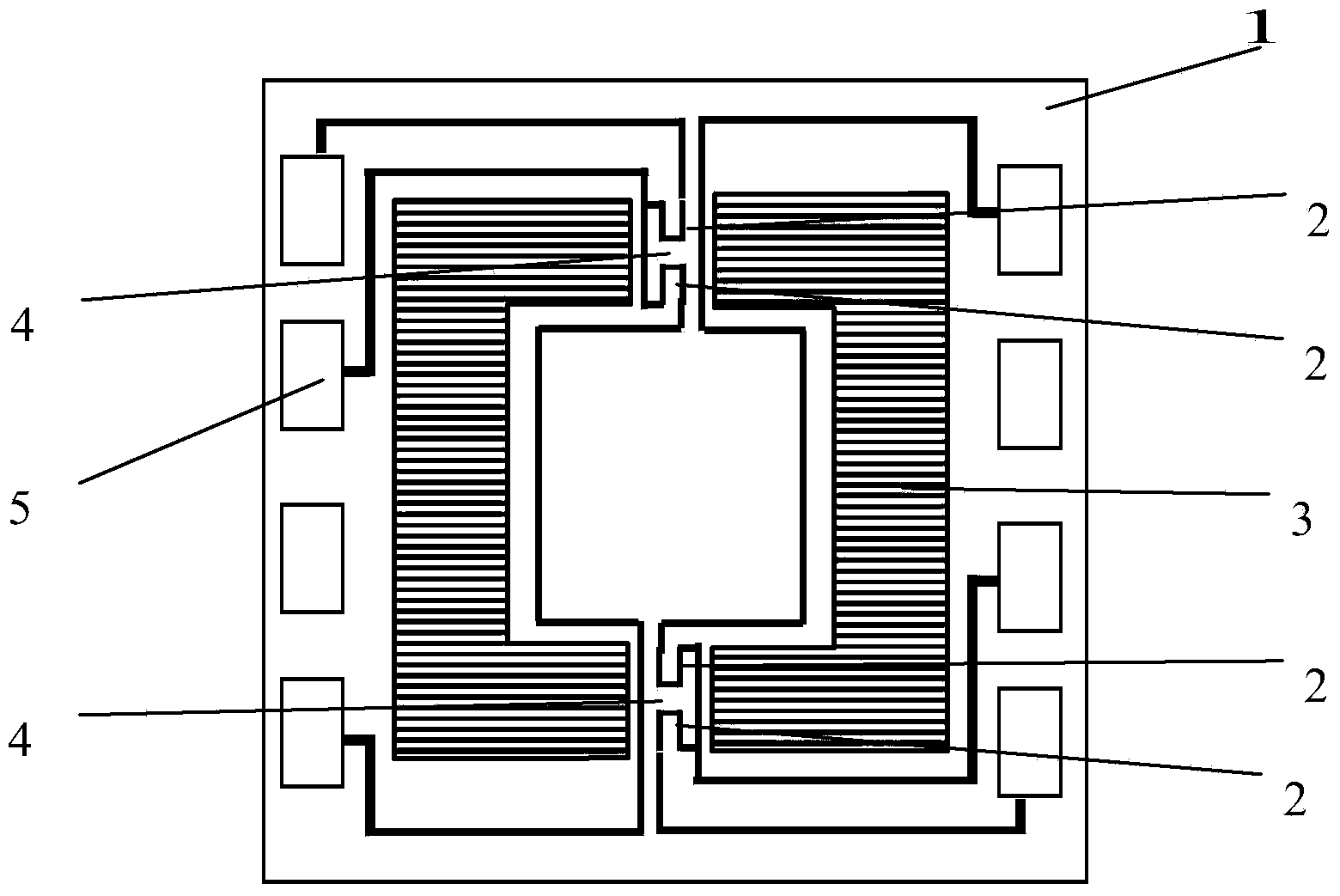

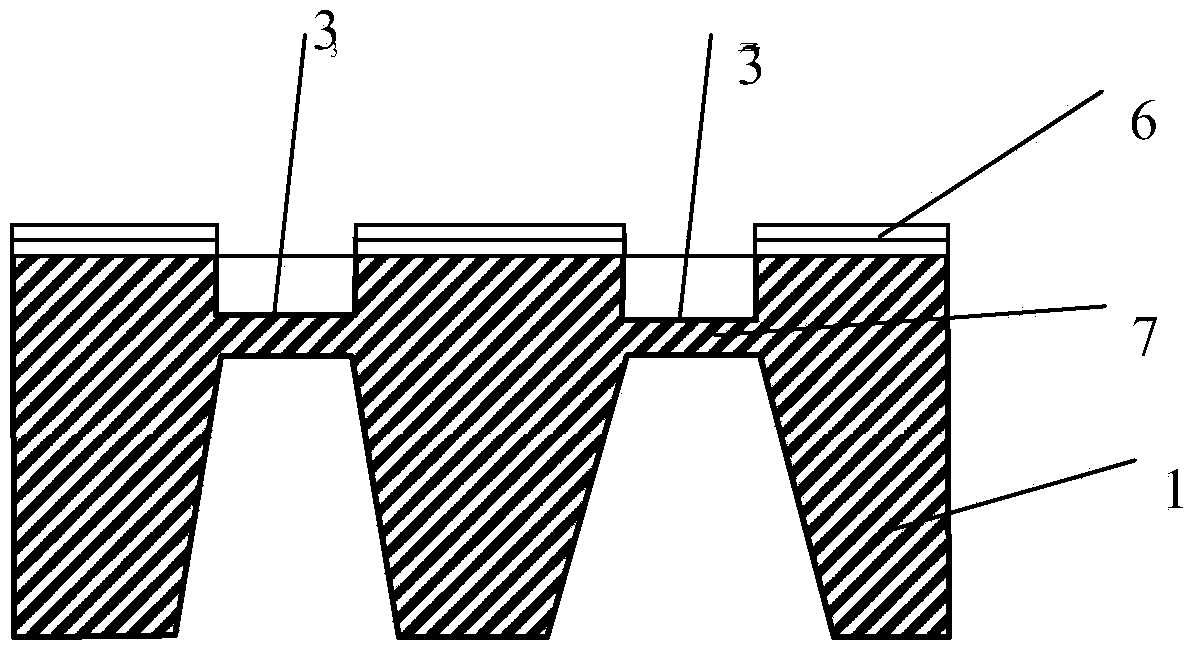

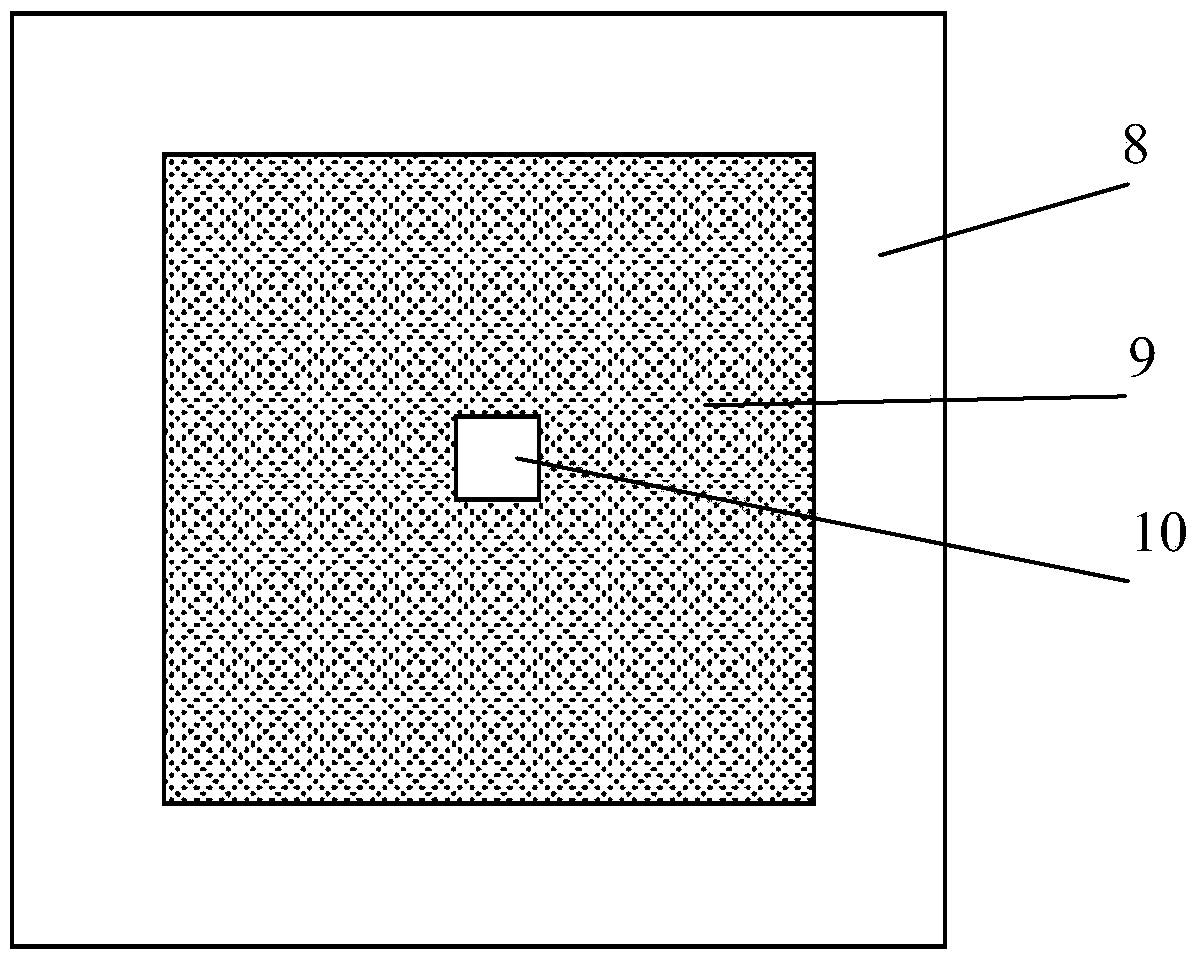

High-power overload 1KPa silicon micropressure sensor chip and manufacturing method

InactiveCN103487178ALow costProcess is easy to implementFluid pressure measurement using ohmic-resistance variationForce measurementBatch productionMicro structure

Provided are a high-power overload 1KPa silicon micropressure sensor chip and a manufacturing method. The high-power overload 1KPa silicon micropressure sensor chip is characterized by being of a beam-single-island double-sided double-piece micro structure. A U-shaped pressure sensitive resistor is arranged on an I beam in the front side of an upper chip body, an aluminum electrode lead and a lead welding pad are arranged at the periphery of a shallow groove, a residue membrane is connected with a central square support on the back side of the upper chip body at the portion opposite to the shallow groove to form a single hard core-shaped sensitive membrane, a peripheral sealing face and an overpressure stopping groove are arranged on the front side of a lower chip body, a pressure tap through hole is formed in the center of the front side of the lower chip body, the upper chip body and the lower chip body are sealed by rubber and are divided in a scribing mode to form the single micropressure sensor chip. An MEMS technique is utilized to manufacture the pressure sensitive resistor and the I beam structure, a KOH wet method is used for etching and manufacturing the single hard core-shaped sensitive membrane, and the KOH wet method is further used for etching the structure of the lower chip body. The high-power overload 1KPa silicon micropressure sensor chip has the advantages that due to the stress concentration effect of a beam structure, the pressure sensitive resistor can obtain the largest strain; the flexibility for acquiring a micropressure range can reach to 20mV / 1KPa (1mA excitation); the linearity reaches to 0.05%FS; the overpressure stopping groove achieves 50-time overpressure resistance protection in 1KPa pressure measurement; batch production of wafers is achieved.

Owner:SHENYANG ACAD OF INSTR SCI

Phosphorus-free environment-friendly carbon steel composite corrosion inhibitor by using seawater circulating cooling water as well as preparation and use methods thereof

ActiveCN102642934AAchieving Corrosion InhibitionGood value for moneyTreatment using complexing/solubilising chemicalsHigh concentrationSolubility

The invention discloses a phosphorus-free environment-friendly carbon steel composite corrosion inhibitor using seawater circulating cooling water as well as preparation and use methods of the carbon steel composite corrosion inhibitor. The composite corrosion inhibitor is prepared by molybdate or tungstate, gluconate, rare-earth salts, zinc salts and a stabilizing agent. Based on the characteristic of difficulty in passivation of carbon steel in the seawater, the characteristic of the seawater circulating cooling process and the system economic operation requirement, a compound multi-element pretreatment filming agent with high concentration is firstly adopted, and then, a process for multi-element compound treatment of corrosion inhibitor with low concentration during normal operation is adopted, so that the purposes that the corrosion inhibitor with high concentration is quickly film-formed and the corrosion inhibitor with low concentration keeps running and repairing films are fulfilled; and moreover, the corrosion velocity of the carbon steel is controlled to be less than 0.02mm / a, and the corrosion inhibition rate is controlled to be more than 98 percent. The corrosion inhibitor product has wide sources of raw materials, is good in solubility and high in cost performance, does not pollute ocean environment, and belongs to low-poisonous grade industrial products; and moreover, the corrosion inhibitor is compatible to seawater scale inhibition and dispersion agents and bacteria-algae inhibitors.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

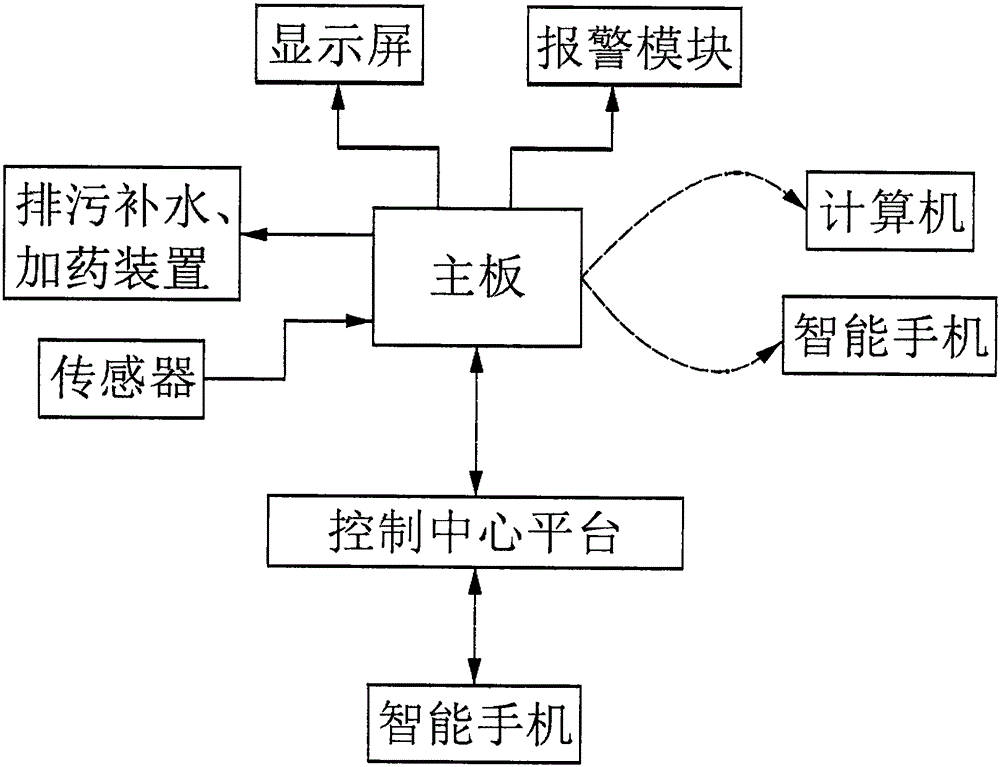

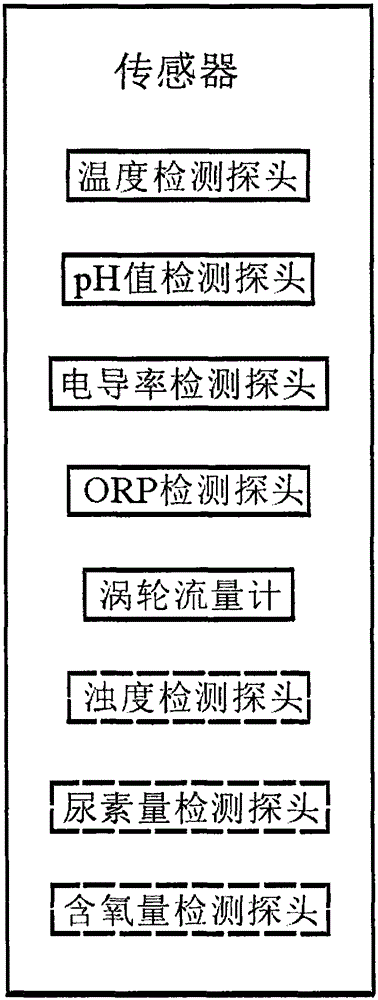

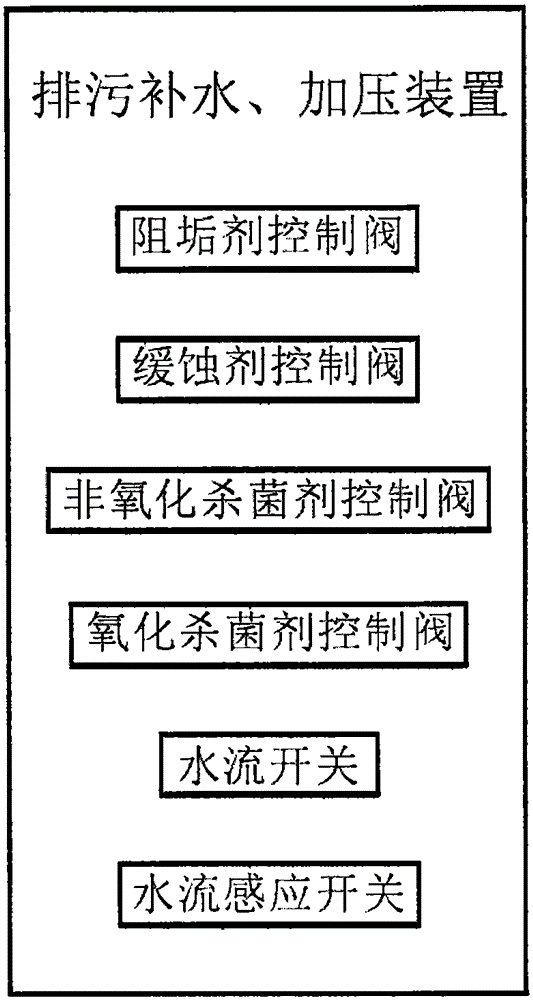

On-line intelligent network automatic water treatment detection and control system

InactiveCN105152364AImprove utilizationIncrease the concentration factorScale removal and water softeningWater/sewage treatment by neutralisationElectricityIntelligent Network

The invention discloses an on-line intelligent network automatic water treatment detection and control system which comprises a control center platform, a main board, a sensor, a pollution discharge, water replenishing and dosing device, an alarm module, a display screen, a computer and an intelligent mobile phone, wherein the output port of the sensor is connected with the input end of the main board, the output port of the main board is connected with the input end of the pollution discharge, water replenishing and dosing device, the output end of the main board is respectively connected with the display screen and the alarm module, the output end of the main board is connected with the computer or the intelligent mobile phone through the Internet or GPRS network, the main board and the control center platform are in bilateral interaction, and the control center platform and the intelligent mobile phone are in bilateral interaction. According to the invention, the sensor is used for detecting water quality data, and the opening and closing of the pollution discharge, water replenishing and dosing device are remotely controlled through the Internet, so that the electricity, water and chemical agents are furthest saved, the service life of an air conditioner is prolonged, the running cost of the air conditioner is lowered, and the environmental pollution is reduced.

Owner:中环清新人工环境工程技术(北京)有限责任公司

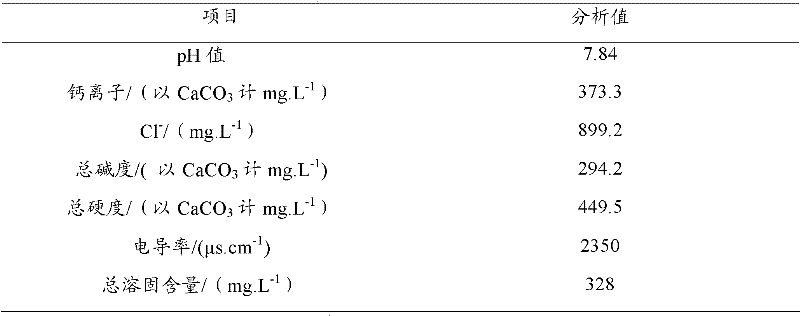

Ascorbic acid phosphorus-free corrosion and scale inhibitor, and preparation method thereof

ActiveCN102225809ADoes not cause eutrophicationWide variety of sourcesScale removal and water softeningGluconatesPollution

The invention discloses an ascorbic acid phosphorus-free corrosion and scale inhibitor which is applicable for treatment of industrial circulating cooling water. The corrosion and scale inhibitor is prepared by compounding a maleic acid compound, an acrylic acid terpolymer, ascorbic acid, a sulfamic acid compound, a zinc salt, a gluconate and distilled water. The ascorbic acid phosphorus-free corrosion and scale inhibitor provided by the present invention provides good corrosion inhibition and scale inhibition effects for carbon steel equipment. The dosage of the phosphorus-free corrosion and scale inhibitor is 20 mg.L<-1> - 50 mg.L<-1> in the industrial circulating cooling water having an alkalinity less than 400 mg.L<-1>, a hardness less than 500 mg.L<-1>, a pH value less than 8.2, a conductance controlled from 0[mu]s.cm<-1>-2400[mu]s.cm<-1>. A plurality of experiment results show that the corrosion and scale inhibitor provides a annual corrosion rate lower than 0.04 mm.a<-1> and a calcium carbonate inhibition rate higher than 98% for the A3 carbon steel. Advantages of the ascorbic acid phosphorus-free corrosion and scale inhibitor and the preparation method are as follows: the discharged waste water during using the corrosion and scale inhibitor does not provide a eutrophic pollution caused by phosphor for water body; the environment is environment-friendly; agent cost for treating each ton of the water is less than 0.12 yuan; the product preparation process is simple.

Owner:WUHAN UNIV OF TECH +1

Preparation method of surface coating capable of regulating degradation rate of magnesium alloy intravascular stent

ActiveCN103418035AReduce corrosion rateImprove the acidic microenvironmentSurgeryCoatingsSpray methodMetallurgy

The invention relates to a preparation method of a surface coating capable of regulating the degradation rate of a magnesium alloy intravascular stent. The preparation method comprises the following steps: step one, preparing a polymer solution : dissolving biodegradable high polymer material into organic solvent; step two: preparing dispersion liquid containing an additive: adding additive particles into the polymer solution, and performing ultrasonic dispersion; step 3: coating the dispersion liquid containing the additive on the surface of the biodegradable magnesium alloy intravascular stent by adopting a dip coating method or a spraying method so as to form a coating, and obtaining the surface coating after the coating is dried and baked. The coating containing the additive, which is prepared through the preparation method provided by the invention, has the advantages that acidic micro-environment at the periphery of the coating can be improved, the degradation of a basal body is inhibited, the basal body together with the coating is completely degraded in a human body finally, the side effects to human body are not be generated, meanwhile, the degradation speed of the coating can be controlled through regulating the content of the additive. Therefore, the degradation speed of the intravascular stent can be controlled.

Owner:SHANGHAI JIAO TONG UNIV

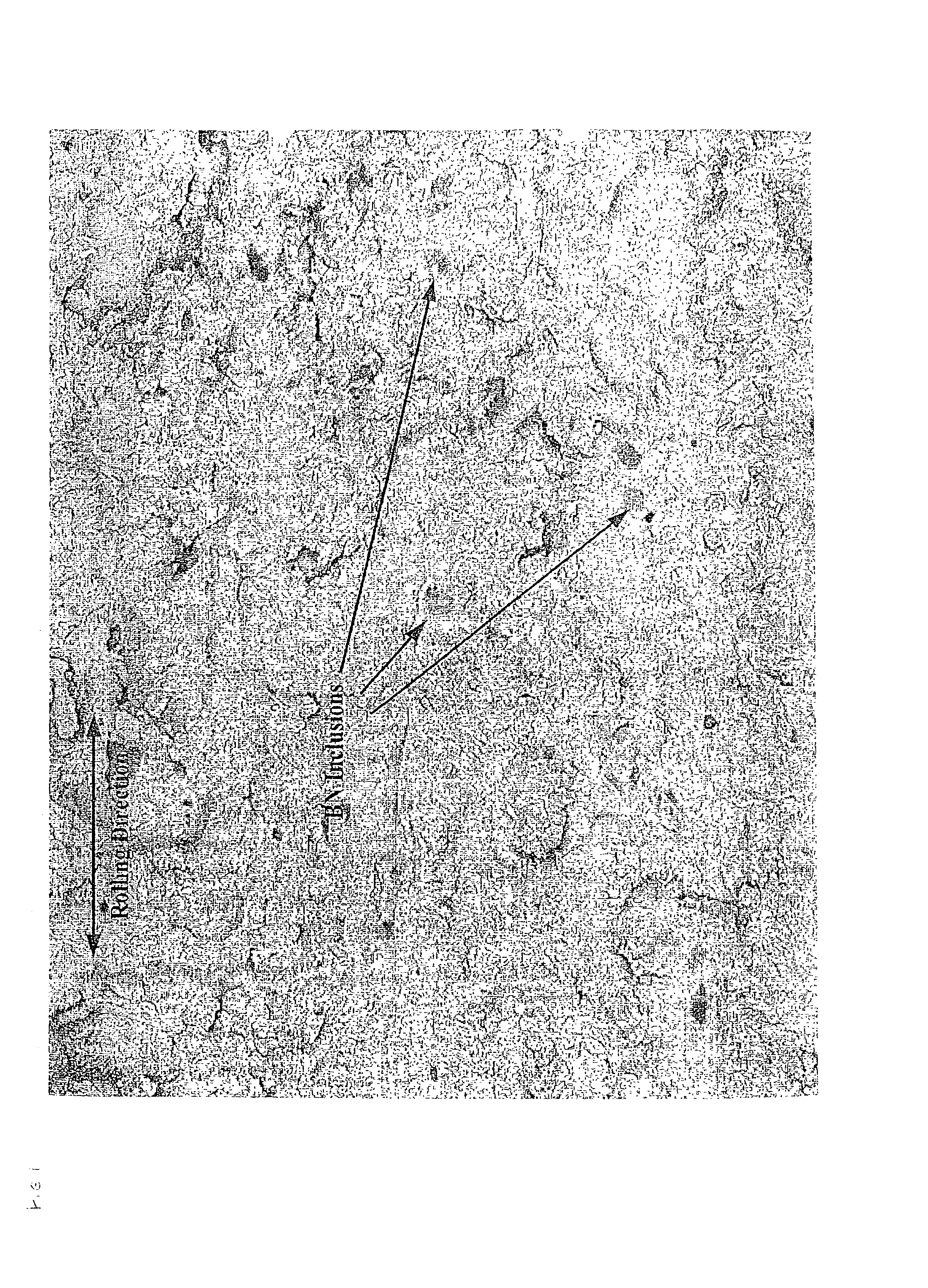

Hydrogen-induced-cracking resistant and sulphide-stress-cracking resistant steel alloy

The invention relates to a quench-and-temper steel alloy for use in casing for oil and gas wells wherein such casing is exposed to low pH environments. The steel alloy has a carbon range by weight of 0.15% to 0.35%, a manganese range by weight of 0.60% to 1.10%, a molybdenum range by weight of 0.15% to 0.65%, and a sulphur range by weight of less than 0.002%. The steel alloy has a quench-and-temper micro-structure and features precipitated spheroidal molybdenum carbides in manganese- and carbon-rich bands. The steel alloy also has, by weight, a chromium range of less than 0.50%, an aluminum range of less than or equal to 0.08% and a calcium range of less than or equal to 0.0045%.

Owner:IPSCO ENTERPRISES

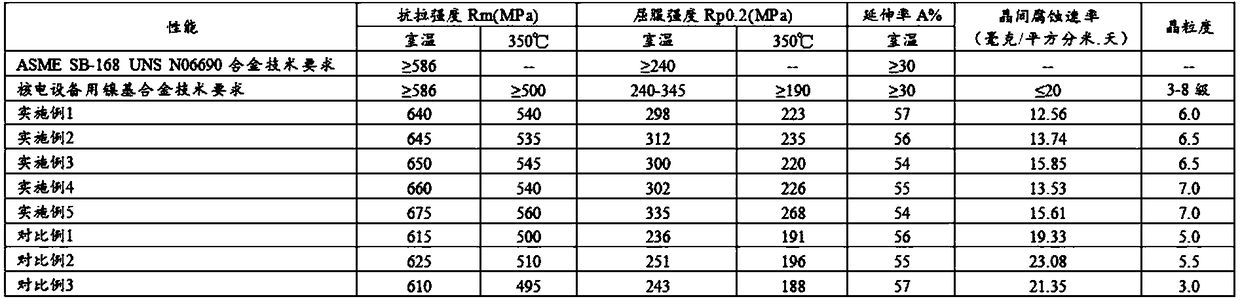

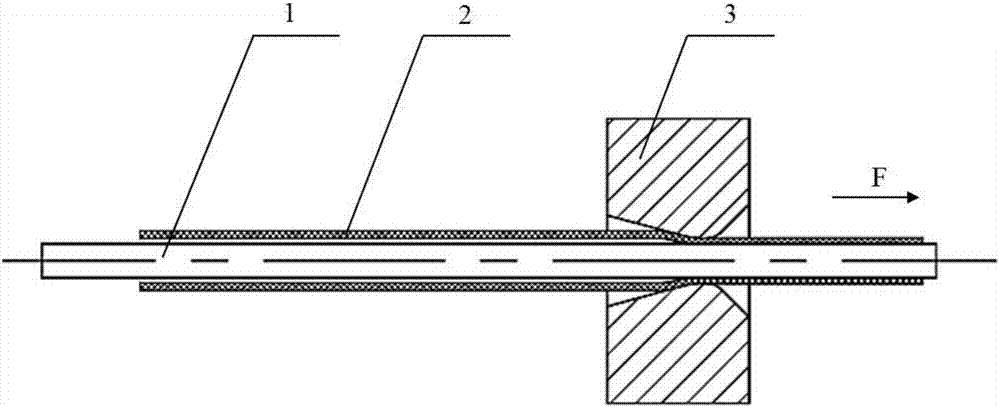

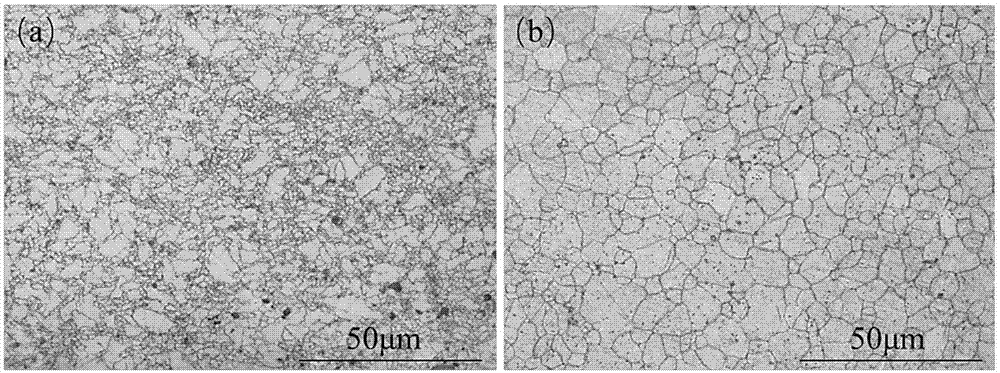

Nickel-base alloy for nuclear power equipment and manufacturing method for nickel-base-alloy hot rolled plate

ActiveCN109136653AImprove hot working plasticityImprove corrosion resistanceUltimate tensile strengthImpurity

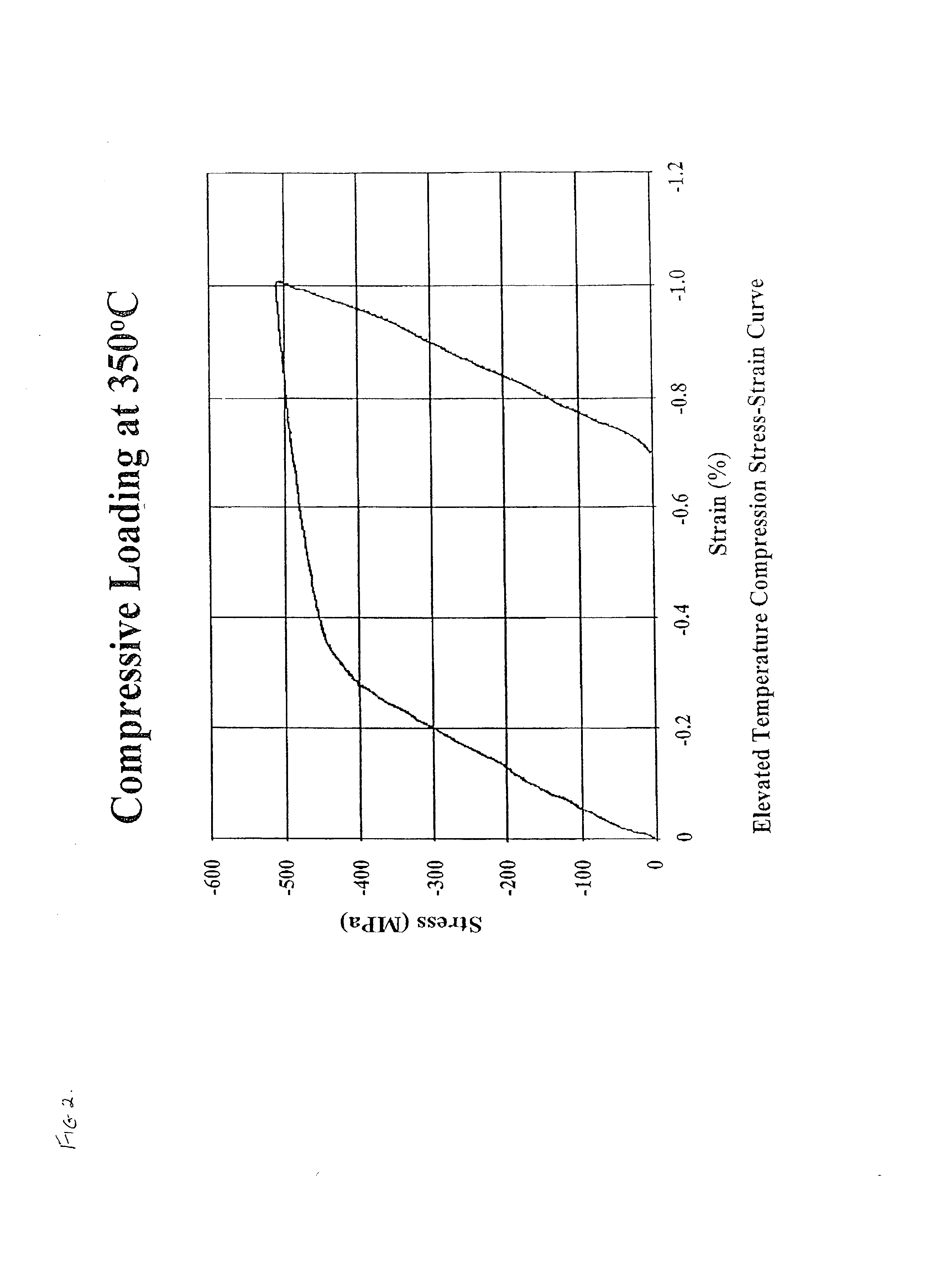

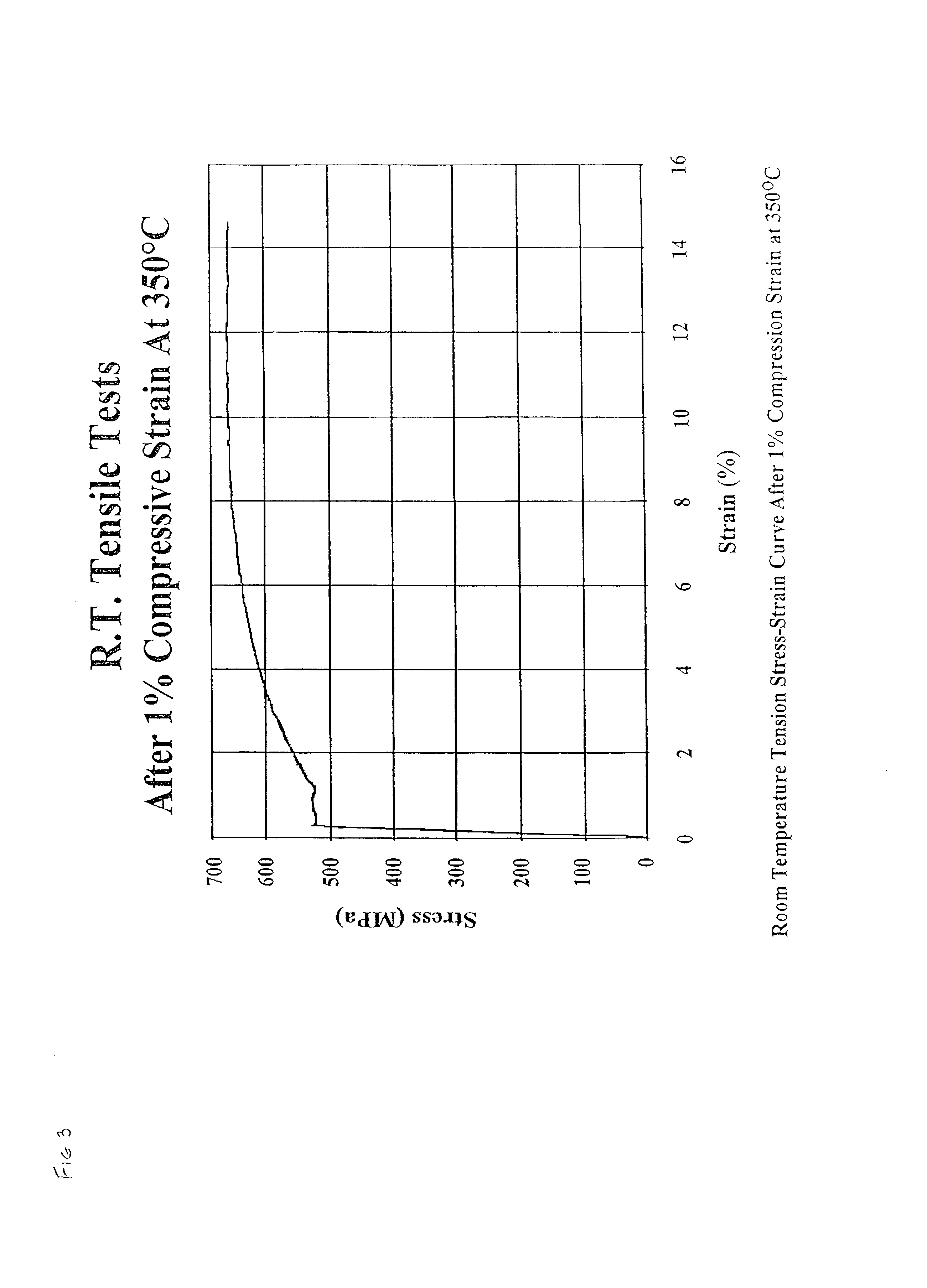

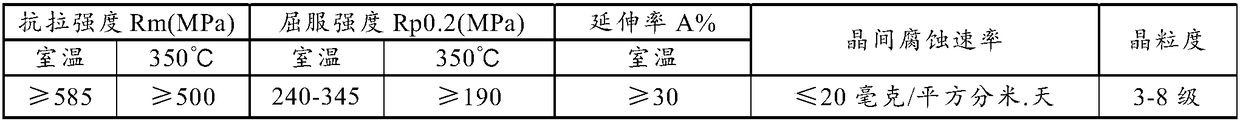

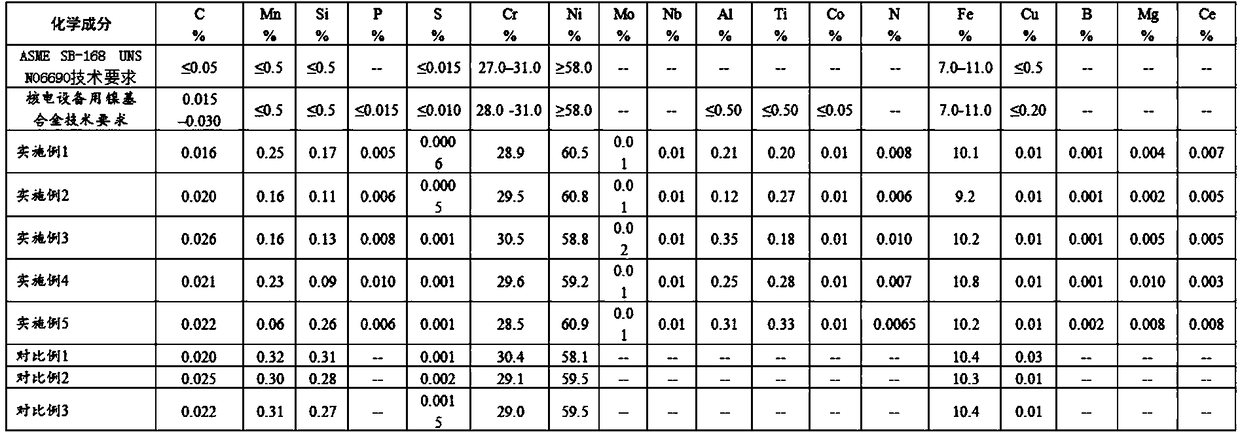

The invention provides nickel-base alloy for nuclear power equipment and a manufacturing method for a nickel-base-alloy hot rolled plate. The nickel-base alloy comprises C, Cr, Fe, Mg, Ce and the balance Ni and unavoidable impurities, wherein the content of the Ni is higher than or equal to 58%. The preparing method for the hot rolled plate includes the steps of nickel-base alloy manufacturing, plate hot rolling forming and plate heat treatment. Compared with the prior art, the nickel-base alloy for the nuclear power equipment and the manufacturing method for the nickel-base-alloy hot rolled plate have the advantages that compared with the performance of an ASME SB-168UNS N06690 alloy plate, the performance of the hot rolled plate manufactured with the nickel-base alloy and the method is remarkably improved, the tensile strength of the indoor temperature can be increased by 10% about, the plasticity (extending rate) is not reduced, the excellent 350-DEG C tensile performance meeting the using requirement is achieved, the intercrystalline corrosion rate is reduced by 30% about, the corrosion resistance is better, and the nickel-base alloy is more suitable for nuclear-power criticalequipment.

Owner:宝武特种冶金有限公司

Magnesium alloy microcapillary and preparation method thereof

The invention discloses a magnesium alloy microcapillary and a preparation method thereof and belongs to the field of metal material precision machining. The method comprises the following steps that(1) a magnesium alloy blank is extruded to obtain a seamless extruded pipe blank; (2) the obtained seamless extruded pipe blank is subjected to stress relief annealing; and (3) the annealed seamless extruded pipe blank is subjected to multiple passes of drawing and intermediate annealing, and the magnesium alloy microcapillary is obtained. The magnesium alloy microcapillary prepared through the preparation method provided by the invention is good in surface quality, precise in size, uniform in wall thickness and excellent in mechanical property; the machining method is simple in process, low in cost, high in machining efficiency, and capable of performing large-scale production; and the magnesium alloy microcapillary can be used as a structural component to be applied to the fields of automobiles and electronics, and can also be used as a medical implant used for preparing an intravascular stent.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com