Preparation method of hydroxyapatite/polylactic acid composite coating on surface of medical magnesium alloy

A technology of hydroxyapatite and composite coating, which is applied to the device for coating liquid on the surface, metal material coating process, coating and other directions to achieve the effect of reducing corrosion rate, improving biocompatibility and avoiding local infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Simple pretreatment of the substrate: Cut the ZK60 magnesium alloy into moderate-sized samples with a wire cutting machine, and then polish them with 800# and 2000# alumina water-resistant sandpaper to remove the oxide layer on the surface of the magnesium alloy, and then use deionized water Ultrasonic cleaning with anhydrous ethanol for 10 minutes, and drying at room temperature for later use;

[0033] (2) Acid etching pretreatment: the magnesium alloy substrate obtained by simple pretreatment was etched in 90% (v%) phosphoric acid solution at 55°C for 30s, then placed in 1M NaOH solution for 90s, and then placed in Rinse in distilled water for about 30 seconds, and dry for later use.

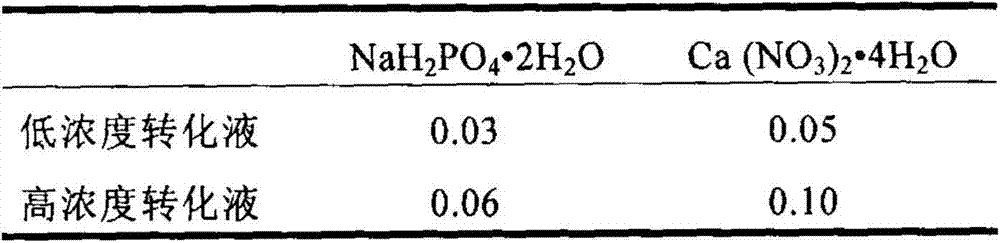

[0034] (3) Configuration of conversion solution: The conversion solution used was prepared from sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate, and a low-concentration conversion solution (as shown in Table 1) was prepared, wherein the solvent was deionized w...

Embodiment 2

[0041] (1) Simple pretreatment of the substrate: Cut the ZK60 magnesium alloy into moderate-sized samples with a wire cutting machine, and then polish them with 800# and 2000# alumina water-resistant sandpaper to remove the oxide layer on the surface of the magnesium alloy, and then use deionized water Ultrasonic cleaning with anhydrous ethanol for 10 minutes, and drying at room temperature for later use;

[0042] (2) Acid etching pretreatment: the magnesium alloy substrate obtained by simple pretreatment was etched in 90% (v%) phosphoric acid solution at 55°C for 40 seconds, then placed in 1M NaOH solution for neutralization treatment for 2 minutes, and then Rinse in distilled water for about 30 seconds, and dry for later use.

[0043] (3) Configuration of conversion solution: The conversion solution used was prepared from sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate, and a low-concentration conversion solution (as shown in Table 1) was prepared, whe...

Embodiment 3

[0050] (1) Simple pretreatment of the substrate: Cut the ZK60 magnesium alloy into moderate-sized samples with a wire cutting machine, and then polish them with 800# and 2000# alumina water-resistant sandpaper to remove the oxide layer on the surface of the magnesium alloy, and then use deionized water Ultrasonic cleaning with anhydrous ethanol for 20 minutes, and drying at room temperature for later use;

[0051] (2) Acid etching pretreatment: the magnesium alloy substrate obtained by simple pretreatment was etched in 90% (v%) phosphoric acid solution at 55°C for 30s, then placed in 1M NaOH solution for 90s, and then placed in Rinse in distilled water for about 30 seconds, and dry for later use.

[0052] (3) Configuration of conversion solution: The conversion solution used was prepared from sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate, and a high-concentration conversion solution (as shown in Table 1) was prepared, wherein the solvent was deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com