Patents

Literature

343 results about "Calcium nitrate tetrahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium nitrate, also called Norgessalpeter (Norwegian saltpeter), is an inorganic compound with the formula Ca(NO3)2. This colourless salt absorbs moisture from the air and is commonly found as a tetrahydrate. It is mainly used as a component in fertilizers but has other applications.

Soiless culture nutrient solution

InactiveCN103172438AInhibition of reproductionIncrease resistanceFertilizer mixturesCalcium nitrate tetrahydrateManganese

The invention relates to the soiless culture field and in particular relates to a soiless culture nutrient solution; every liter of water comprises the following components by weight: major constituents consisting of 900mg-2200mg of much EM (Effective Microorganisms) probiotics liquid, 900mg-2200mg of brown sugar, 900mg-1000mg of calcium nitrate tetrahydrate, 700mg-900mg of potassium nitrate, 150mg-220mg of ammonium dihydrogen phosphate and 300mg-500mg of magnesium sulfate heptahydrate; micro constituents consisting of 20mg-25mg of EDTA (Ethylene Diamine Tetraacetic Acid) chelated iron, 2mg-3mg of boric acid, 2mg-3mg of manganese sulfate monohydrate, 0.1mg-0.5mg of zinc sulfate heptahydrate, 0.01mg-0.1mg of copper sulfate and 0.01mg-0.08mg of ammonium molybdate tetrahydrate. The soiless culture nutrient solution provided by the invention can be used for improvising the immunity of the soiless culture nutrient solution for resisting plant diseases and insect pests of the crops.

Owner:北京天食和谷农业科技有限公司

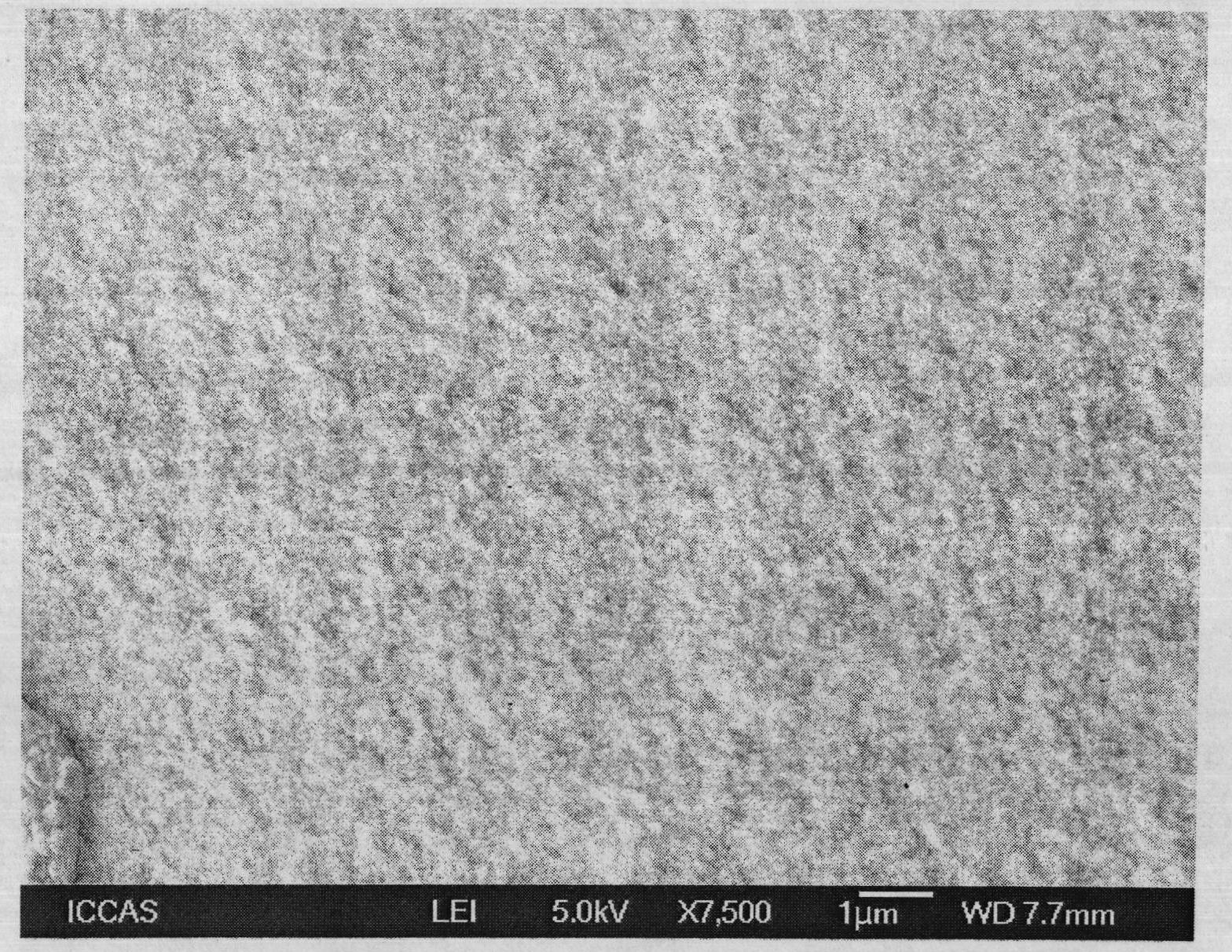

Nanometer hydroxyapatite powder preparation method

InactiveCN1544318AGood crystallizationSmall granularityEnergy based chemical/physical/physico-chemical processesPhosphorus compoundsCalcium nitrate tetrahydrateApatite

A process for preparing nano hydroxyapatite powder comprises the steps of, mixing Ca(NO3)-2-4H20 and NH4-2HPO-4 according to the mol ratio of Ca:P = 1.67-2.5:1, dissolving by charging distilled water, making the concentration of the Ca2++ ion to be 0.01-0.1 mol / L, charging aquadrate powder into the solution according the ratio of Ca(NO3)-2-4H2O : NH4-2HPO-4 = 1:5-12, conducting sound chemo synthesis through multiple frequency phonochemical generator, filtrating and washing the suspending liquid, placing the filtered material into vacuum drying oven for drying at the temperature of 80-100 deg. C, thus the nano hydroxyapatite powder can be obtained.

Owner:SHAANXI UNIV OF SCI & TECH

Aqueous culture method of anoectochilus

InactiveCN102100171AAbsorb evenlyAdequately meet nutritional needsCultivating equipmentsSoilless cultivationBiotechnologyCalcium nitrate tetrahydrate

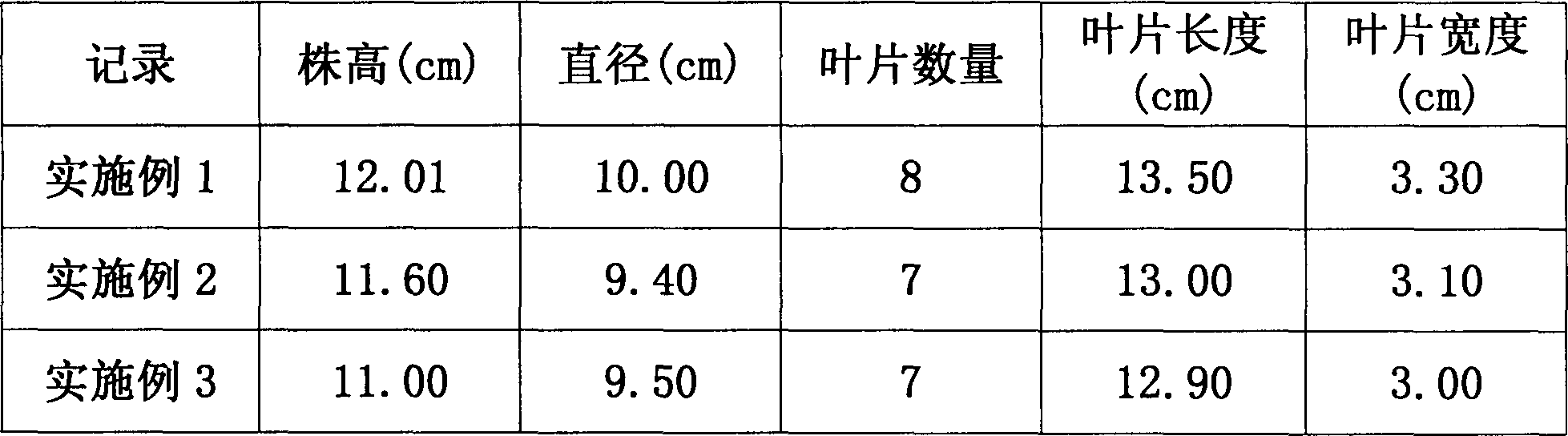

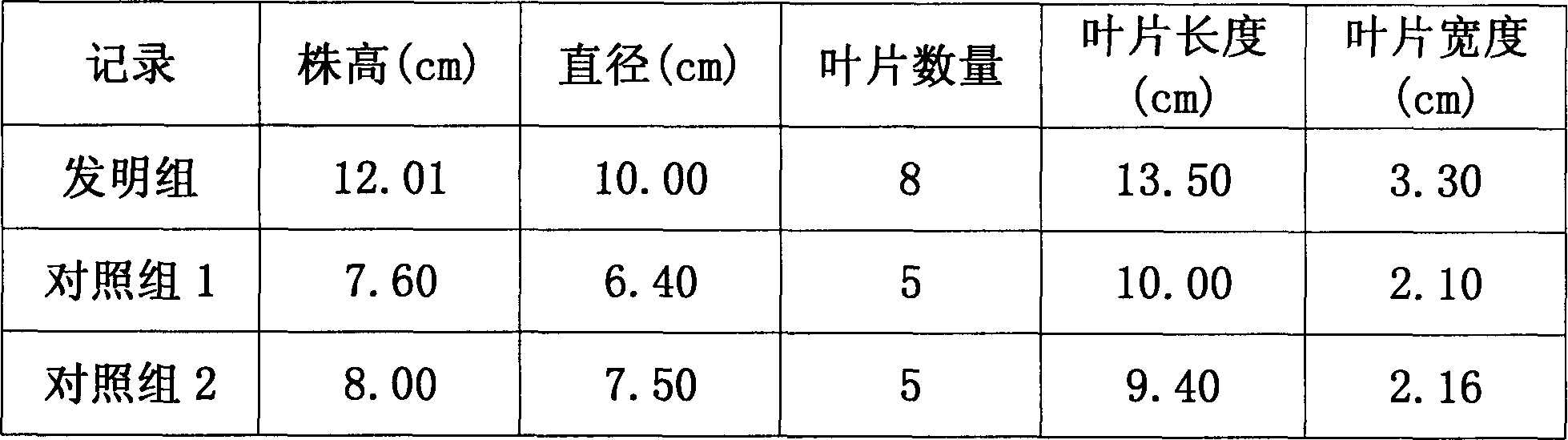

The invention relates to an aqueous culture method of anoectochilus. In the method, anoectochilus germchits are cleaned and sterilized, transplanted in a culture dish and cultured in a culture groove filled with an aqueous culture solution; each 10L of aqueous culture solution contains the following components: 650 to 800mg of calcium nitrate tetrahydrate, 50 to 60mg of ammonium nitrate, 280 to 350mg of potassium nitrate, 100 to 130mg of potassium dihydrogen phosphate, 350 to 380mg of magnesium sulfate, 0.5 to 0.8mg of potassium iodide, 2 to 5mg of manganese sulfate, 0.2 to 0.3mg of sodium molybdate, 0.1 to 0.2mg of cobalt chloride, 2 to 4mg of boric acid, 0.5 to 1mg of zinc sulfate, 0.3 to 0.5mg of copper sulfate and 3 to 5ml of iron salt solution, wherein the iron salt solution is prepared by mixing water, green vitriol and ethylenediamine tetraacetic acid disodium. The method has the advantages of lowering production cost, simplifying production process, improving the growth of anoectochilus plants and improving the survival rate of anoectochilus plants.

Owner:福建永安天奇健金线莲生态实业有限公司

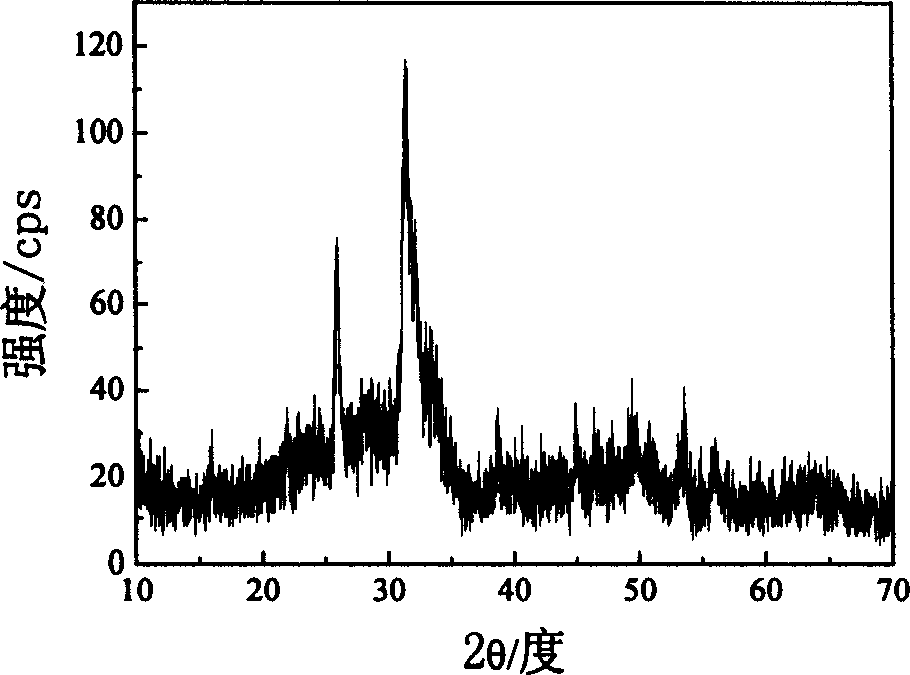

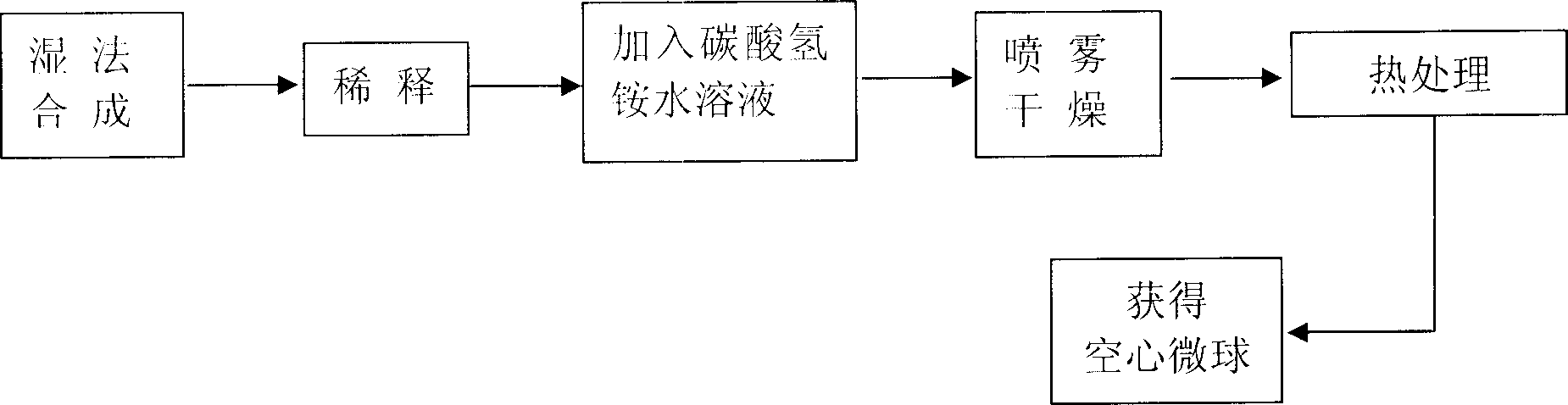

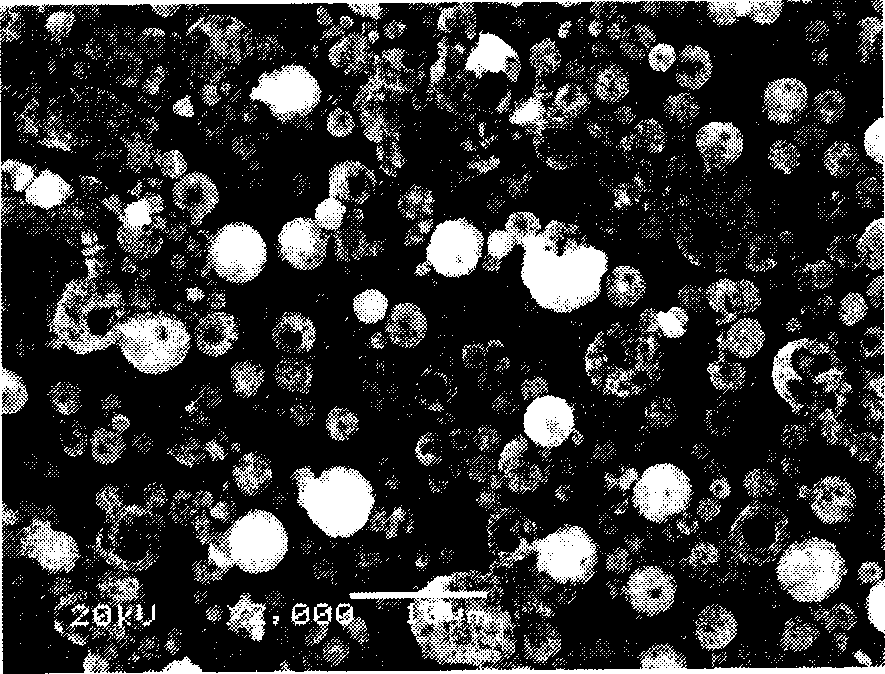

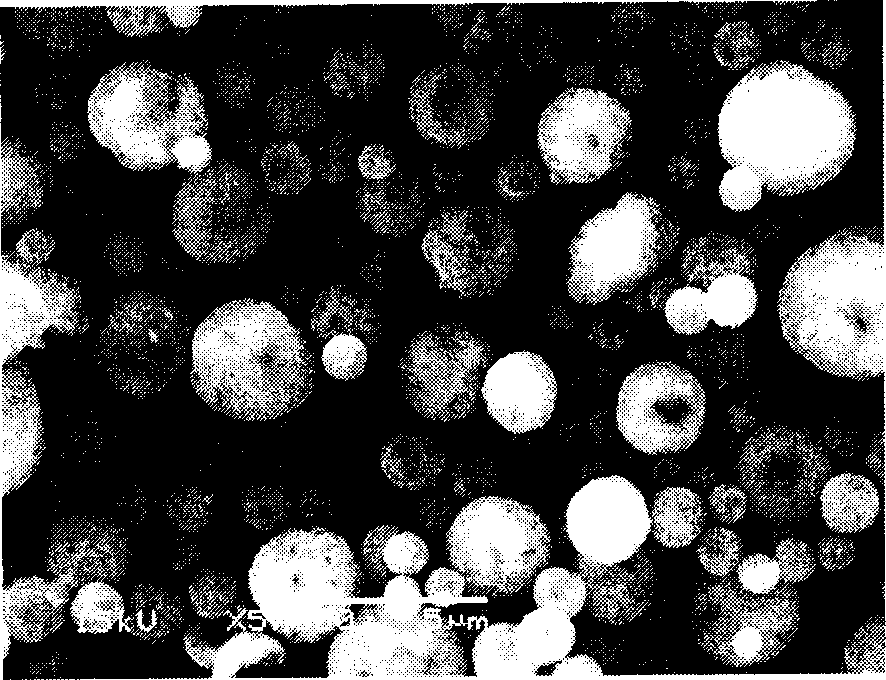

Preparation method of hydroxy phosephorite hollow microball

InactiveCN1903706AHigh purityReduce crystallinityPhosphorus compoundsProsthesisCalcium nitrate tetrahydrateApatite

The present invention discloses a method for preparing hydroxyapatite hollow microsphere. Said method includes the following steps: using tetrahydrate calcium nitrate and ammonium hydrogen phosphate as raw material, adopting chemical precipitation method to prepare hydroxyapatite slurry, then diluting said hydroxyapatite slurry by using distilled water, adding ammonium hydrogen carbonate as additive, uniformly stirring them, spray drying, making following heat treatment so as to obtain the hydroxyapatite hollow microsphere formed from nano grains.

Owner:SHANDONG UNIV

Leaf vegetable nutrient solution formula

InactiveCN103012004AMeet nutritional needsReduce nitrateFertilizer mixturesCalcium nitrate tetrahydrateNutrient solution

The invention discloses a leaf vegetable nutrient solution formula. The leaf vegetable nutrient solution formula is characterized in that leaf vegetable nutrient solution comprises fertilizers and citric acid; the leaf vegetable nutrient solution comprises the following components: major elements of calcium nitrate tetrahydrate 450-500 mg / L, potassium nitrate 180-250 mg / L, monopotassium phosphate 50-80 mg / L, magnesium sulfate heptahydrate 400-620 mg / L and ammonium nitrate 20-70 mg / L; trace elements of boracic acid 1-5 mg / L, manganous sulfate 1-4 mg / L, zinc sulphate 0.1-1 mg / L, ammonium molybdate 0.005-0.05 mg / L, copper sulphate heptahydrate 0.01-1 mg / L and ethylene diamine tetraacetic acid disodium ferric salt 5-40 mg / L; citric acid 3-20 mg / L; and the balance of water. The leaf vegetable nutrient solution formula disclosed by the invention is reasonable in components, good in stability and wide in range of application.

Owner:湖南壹叶都市农业发展有限公司

Preparation method of hydroxyapatite/polylactic acid composite coating on surface of medical magnesium alloy

InactiveCN103933611AHigh strengthReduce corrosion ratePretreated surfacesMetallic material coating processesAcid etchingCalcium nitrate tetrahydrate

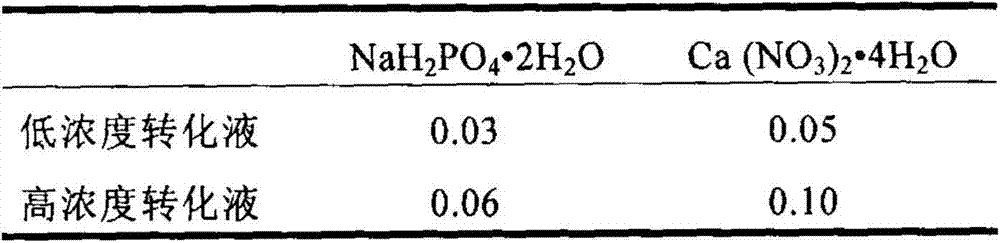

The invention relates to a preparation method of a hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy, which comprises the following steps of polishing a magnesium alloy basal body to remove an oxidation layer on the surface; carrying out acid etching pretreatment and neutralizing treatment on the magnesium alloy basal body; preparing transfer solution from sodium dihydrogen phosphate dihydrate and calcium nitrate terahydrate; preparing a biomimetic calcium-phosphate coating; dissolving polylactic acid in a chloroform solvent to prepare polylactic acid solution; immersing the prepared magnesium alloy / hydroxyapatite composite material in the polylactic acid solution, and coating the polylactic acid coating on the surface of the magnesium alloy / hydroxyapatite composite material by adopting the solution dip-coating method; and putting the magnesium alloy material for 2-3 days till chloroform in the polylactic acid solution is completely volatilized, thereby obtaining the composite material of which the surface of magnesium alloy is wrapped with the hydroxyapatite / polylactic acid composite coating. Compared with the prior art, the preparation method of the hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy overcomes the disadvantages of the single coating, and therefore, the corrosion resistance and the biocompatibility of magnesium alloy are obviously increased.

Owner:TONGJI UNIV

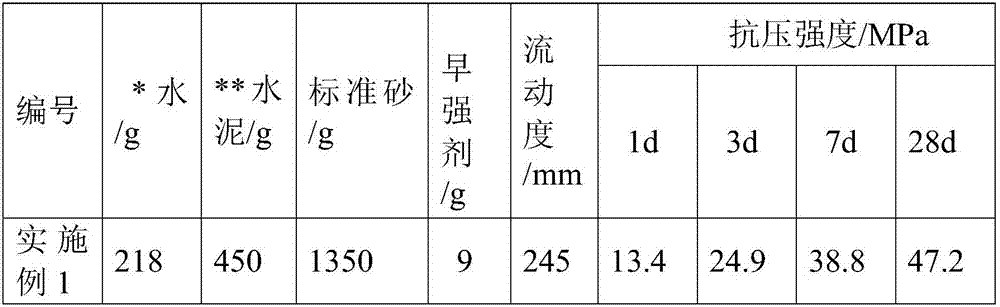

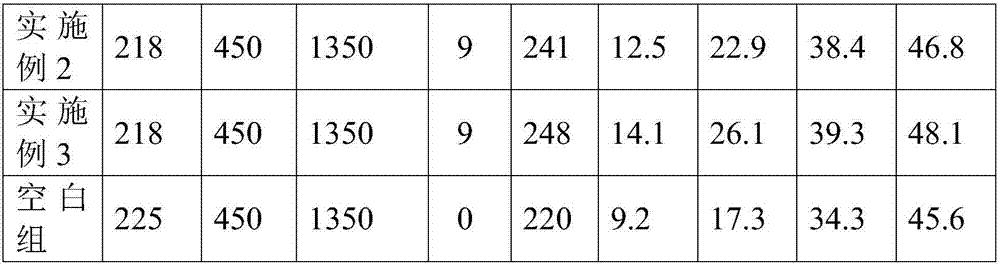

Crystal nucleus concrete early strength agent and preparation method thereof

The invention discloses a crystal nucleus concrete early strength agent and a preparation method thereof. 1,000 parts of crystal nucleus concrete early strength agent are prepared from the following raw materials in parts by weight: 100-150 parts of a polymer, 20-50 parts of sodium metasilicate pentahydrate, 60-90 parts of calcium nitrate tetrahydrate and the balance of deionized water. The preparation method comprises the steps of firstly adding the polymer to a three-neck flask, adding the deionized water to form a base solution, putting the flask into a hot water bath, controlling the temperature and stirring; taking the sodium metasilicate pentahydrate, and adding the deionized water to prepare a solution A; taking the calcium nitrate tetrahydrate and adding the deionized water to prepare a solution B; dropwise adding the solution A and the solution B to the base solution at the same rate, carrying out heat preservation on the product, stirring and reacting; and finally quickly cooling a product to a room temperature to obtain the final product, namely the crystal nucleus concrete early strength agent. The crystal nucleus concrete early strength agent is good in performance, is capable of making concrete solidified quickly, is short in demolding time and not easy to collapse and has a certain water reducing effect, and the later strength loss of the concrete is small.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Water culture nutrient solution of blueberry and preparation method thereof

InactiveCN102101803APromote absorptionReturn to normal growthFertilizer mixturesBiotechnologyCalcium nitrate tetrahydrate

The invention belongs to the technical field of fruit tree culture, in particular to a water culture nutrient solution prescription of a blueberry and a preparation method thereof. In the technology, the water culture nutrient solution of a blueberry comprises the following elements: 95-110mg / L of N, 10-15mg / L of P, 125-135mg / L of K, 80-90mg / L of Ca, 20-28mg / L of Mg, 4-6mg / L of Fe, 0.3-0.6mg / L of B, 0.4-0.6mg / L of Mn, 0.04-0.06mg / L of Zn, 0.02-0.04mg / L of Cu and 0.002-0.004mg / L of Mo. A pH value of the water culture nutrient solution is 4.8 to 5.5. The preparation method of the nutrient solution comprises the following steps of: weighing EDTA (Ethylene Diamine Tetraacetic Acid) ferrisodium, boric acid, manganese sulfate tetrahydrate, zinc sulphate heptahydrate, copper sulfate pentahydrate and ammonium molybdate tetrahydrate for dissolving into water and blending into 100 times of trace element mother liquor for storage and later use; additionally weighing calcium nitrate tetrahydrate, potassium nitrate, monopotassium phosphate and magnesium sulfate heptahydrate for dissolving into water; absorbing the trace element mother liquor into the solution according to the consumption; adding water for quantifying to needed volume; uniformly stirring; and adjusting the pH value of the solution to be 4.8 to 5.5 with 0.1mg / L dilute H2SO4 or dilute NaOH. By utilizing the technology, the water culture aims of growing a plurality of aquatic roots in 20 days after a blueberry seedling is transplanted and having the plant survival rate of more than 90 percent can be achieved.

Owner:JINLING INST OF TECH

Recycling method of circuit board tin stripping wastewater

InactiveCN102086073AReduce processing costsEasy to handleTin compoundsMultistage water/sewage treatmentCalcium nitrate tetrahydrateTreatment effect

The invention provides a recycling method of circuit board tin stripping wastewater and the method can be used in the resource treatment of the tin stripping wastewater of the circuit board factory, belonging to the technical field of environmental protection. The method has the following process flows: adding refined lime slurry in the tin stripping wastewater to adjust the pH value to be alkaline and ensure that a part of beta-stannic acid sol with positive charges is coagulated, another part of beta-stannic acid sol is converted to beta-stannic acid sol with negative charges, and adding the tin stripping wastewater to adjust the pH value to be neutral and ensure that the beta-stannic acid sol with negative charges performs charge neutralization with the beta-stannic acid sol particles with positive charges and is completely coagulated, performing solid-liquid separation, and rinsing to obtain solid beta-stannic acid precipitate which is used as the raw material of tin smelting to produce metal tin. The separated solution is mixed with the same rinse water and then the mixture is evaporated and concentrated to obtain a calcium nitrate tetrahydrate product. The recycling method is characterized by low treatment cost, simple treatment process, good treatment effect, high treatment efficiency, total recycling, zero emission and the like and is suitable for the resource treatment of the tin stripping wastewater of the circuit board factory.

Owner:HUIZHOU DAYAWAN HUILU ENVIRONMENT PROTECTION SERVICE +1

Method for preparing strontium-containing hydroxyapatite coating on surface of biodegradable magnesium alloy

InactiveCN104888271AGood biocompatibilitySimple processMetallic material coating processesProsthesisCalcium nitrate tetrahydrateCalcium phosphate coating

The invention relates to a method for preparing a strontium-containing hydroxyapatite coating on the surface of a biodegradable magnesium alloy. The method comprises the following steps: polishing a magnesium alloy matrix to remove a surface oxidation layer, and cleaning; preparing a hydrothermal solution from calcium nitrate tetrahydrate, EDTA-2 Na, sodium dihydrogen phosphate dihydrate and strontium nitrate; and placing the well treated magnesium alloy matrix into the hydrothermal solution for hydrothermal reaction to obtain the strontium-containing hydroxyapatite coating, a biomimetic calcium phosphate coating, wrapping the magnesium alloy matrix. Compared with the prior art, as the hydrothermal method is adopted to prepare hydroxyapatite, not only is the degradation rate of the magnesium alloy in a human body effectively slowed down, but also the biocompatibility of the magnesium alloy is further improved. As strontium element is added into the hydroxyapatite coating, and as one of trace elements of the human body, strontium has the functions of promoting bone formation and inhibiting bone breakage, both the biological activity and the biocompatibility are improved.

Owner:TONGJI UNIV

Plant infusion nutrient solution and preparation method thereof

InactiveCN101811909AImprove stress resistanceHigh activityFertilizer mixturesCalcium nitrate tetrahydrateHigh absorption

The invention discloses plant infusion nutrient solution and a preparation method thereof and aims to provide nutrient solution which can be directly infused into the plants, stimulate the tree activity, promote the plants to rapidly take root and sprout, quickly supply nutrition to the trees, and enhance the tree stress resistance, and a preparation method of the nutrient solution. The proportion of the nutrient solution is that: every 1,000ml of deionized water contains 0.05 to 0.1g of monopotassium phosphate, 0.02 to 0.045g of potassium nitrate, 0.15 to 0.3g of calcium nitrate tetrahydrate, 0.11 to 0.2g of magnesium sulfate heptahydrate, 0.03 to 0.06g of ferrous sulphate heptahydrate, 0.07 to 0.15g of disodium ethylene diamine tetraacetate, 0.015 to 0.025g of manganese sulfate tetrahydrate, 0.012 to 0.018g of zinc sulfate heptahydrate, 0.04 to 0.06g of copper sulfate pentahydrate, 0.015 to 0.022g of ammonium molybdate, 0.015 to 0.02g of indolebutyric acid, and 0.008 to 0.015g of 6-benzylaminopurine. The plant infusion nutrient solution satisfies the needed nutrient in the process of transplanting big trees, has high absorption utilization ratio, quick response, stable form, high activity, and is easily absorbed by the plants.

Owner:TIANJIN LVDONG PLANT NUTRITION TECH DEV

Nutrient solution for improving transplanting survival rate of trees

InactiveCN103193545AImprove transplant survivalImprove survival rateFertilizer mixturesCalcium nitrate tetrahydrateMonopotassium phosphate

The invention relates to a nutrient solution for improving the transplanting survival rate of trees. The nutrient solution comprises the following components in parts by weight: 0.2-0.4 part of calcium nitrate tetrahydrate, 0.03-0.05 part of ferrous sulfate heptahydrate, 0.0001-0.0003 part of ferric citrate, 0.03-0.05 part of monopotassium phosphate, 0.07-0.09 part of ethylene diamine tetraacetic acid disodium, 0.04-0.06 part of anhydrous cupric sulfate, 0.12-0.15 part of magnesium sulfate heptahydrate, 0.0005-0.0009 part of potassium chloride, 0.002-0.004 part of ammonium molybdate, 0.012-0.014 part of ammonium sulfate, 0.0025-0.0029 part of boric acid, 0.0012-0.0015 part of indolebutyric acid and 1000-1050 parts of water. The invention aims at providing the nutrient solution which can be used for rapidly and comprehensively replenishing nutrients for various trees, motivating the activities of the trees, promoting rapid development of root systems and further improving the transplanting survival rate of the trees.

Owner:万少侠

Water culture nutrient solution of spinach beet

InactiveCN103626559APromote growthShorten the growth cycleFertilizer mixturesCalcium nitrate tetrahydrateManganese

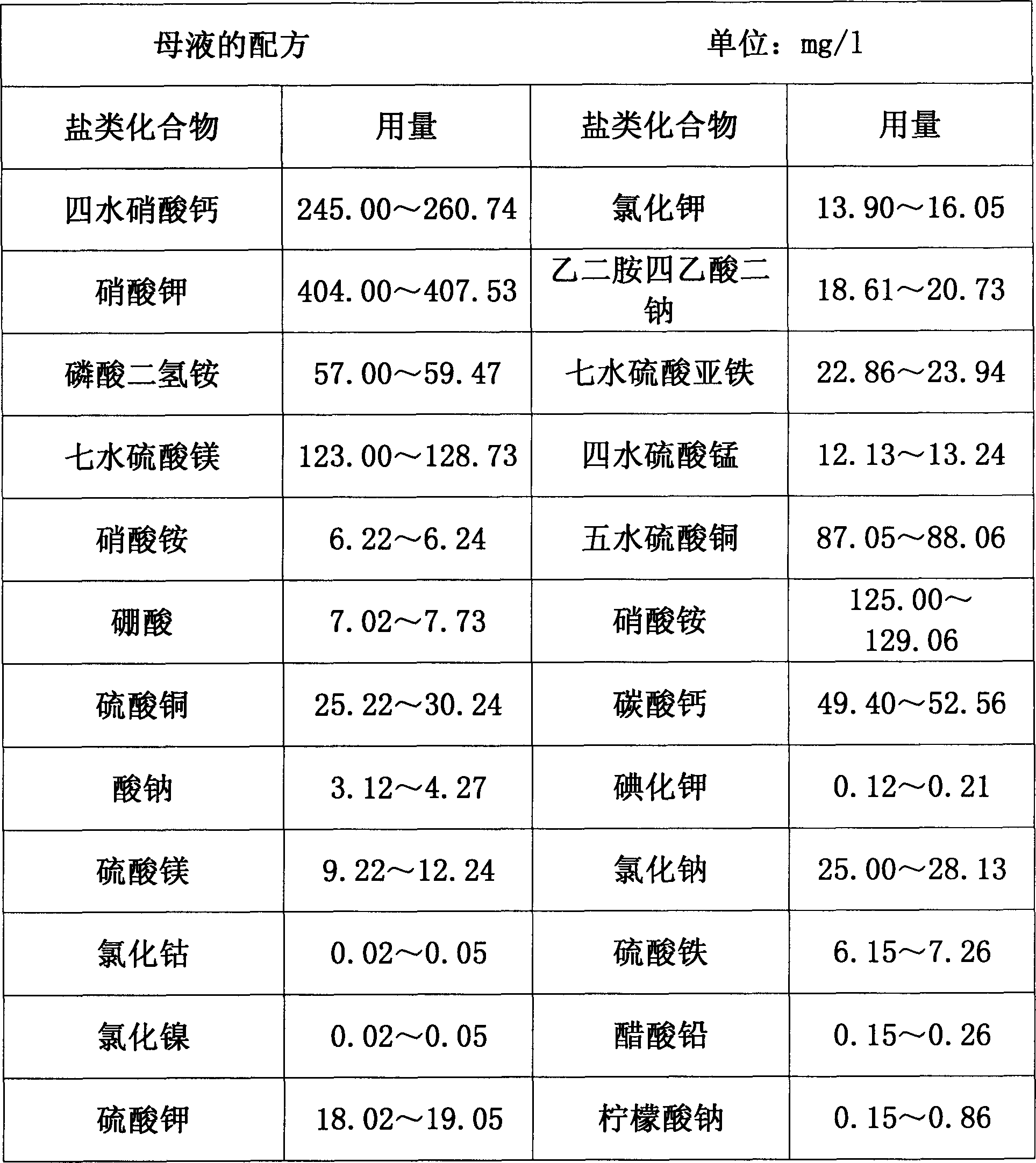

The invention discloses a water culture nutrient solution of spinach beet. The water culture nutrient solution comprises macroelements, microelements and water as well as calcium nitrate tetrahydrate, potassium nitrate, ammonium dihydrogen phosphate, magnesium sulfate heptahydrate, ammonium nitrate, boric acid, copper sulfate, sodium silicate, magnesium sulfate, cobalt chloride, nickel chloride, potassium sulfate, potassium chloride, ethylene diamine tetraacetic acid, ferrous sulfate septihydrate, manganese sulfate tetrahydrate, copper sulfate pentahydrate, ammonium nitrate, calcium carbonate, potassium iodide, sodium chloride, ferric sulfate, lead acetate and sodium citrate. According to the water culture nutrient solution of the spinach beet, the absorption utilization rate is high and the waste caused by nutrition excess or deficiency resulted by no pertinence of a water culture nutrient solution of the spinach beet in the past is avoided.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Method for treating waste liquid of chitin and chitosan production

InactiveCN101177328ATo achieve full resource utilizationEliminate pollutionClimate change adaptationSewage/sludge fertilisersCalcium nitrate tetrahydrateLiquid waste

The invention provides a novel technology to eliminate environmental pollution by resourceful treatment of the waste liquors of chitin and chitosan. First, the protein of shrimp and crab shells is removed by dilute alkali liquor and the dilute alkali liquor is used for two to four times; secondly, the waste alkali liquor after deporteinization is neutralized by acid with the fertilizers of N, P, K in proper quantity added to prepare protein peptide water flush fertilizer; thirdly, the deproteinized shell is de-calcified with 5 to 10% dilute nitric acid solution and the nitric acid solution is used for two to four times; fourthly, the waste acid liquor containing calcium nitrate is used to extract calcium nitrate tetrahydrate or directly used as fast-released calcium fertilizer; at the same time, the technology of continuous countercurrent washing is adopted to rinse the deproteinized, decalcified and de-acetylate materials so as to realize the ''zero-discharge'' of wastewater.

Owner:大连利健甲壳素股份有限公司

Method for preparing biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating

InactiveCN103463681AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

The invention relates to a method for preparing a biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating. The method comprises the following steps of: pretreating a magnesium alloy substrate, wherein the adopted transfer solution is prepared from sodium dihydrogen phosphate dehydrate and calcium nitrate tetrahydrate; soaking a substrate sample obtained by pretreatment in the transfer solution for 5-100 hours, thus obtaining a calcium-phosphorus coating; soaking a calcium-phosphorus coating sample in an alkali fluoridated transfer solution for 10-48 hours, so as to obtain a fluoridated calcium-phosphorus coating, wherein the alkali fluoridated transfer solution is prepared from sodium hydroxide and sodium fluoride, the concentration of the sodium hydroxide is 3-4g / L, the concentration of the sodium fluoride is 4-5g / L, and heat treatment is not performed; performing heat treatment on the fluoridated calcium-phosphorus coating at the temperature of 300-350 DEG C for 2-5 hours, thus obtaining the fluoridated hydroxyapatite. According to performance detection, the fluoridated hydroxyapatite (FHA) coating prepared by combining a heat treatment process is shaped like a slender sheet and is divergently arranged from the center to the periphery; the electrochemical test proves that the self-corrosion potential of the substrate is improved through the FHA coating; the immersed corrosion experiment proves that an actual protective effect of the FHA coating on the magnesium alloy substrate is better than that of a fluoridated apatite (FA) coating.

Owner:TONGJI UNIV

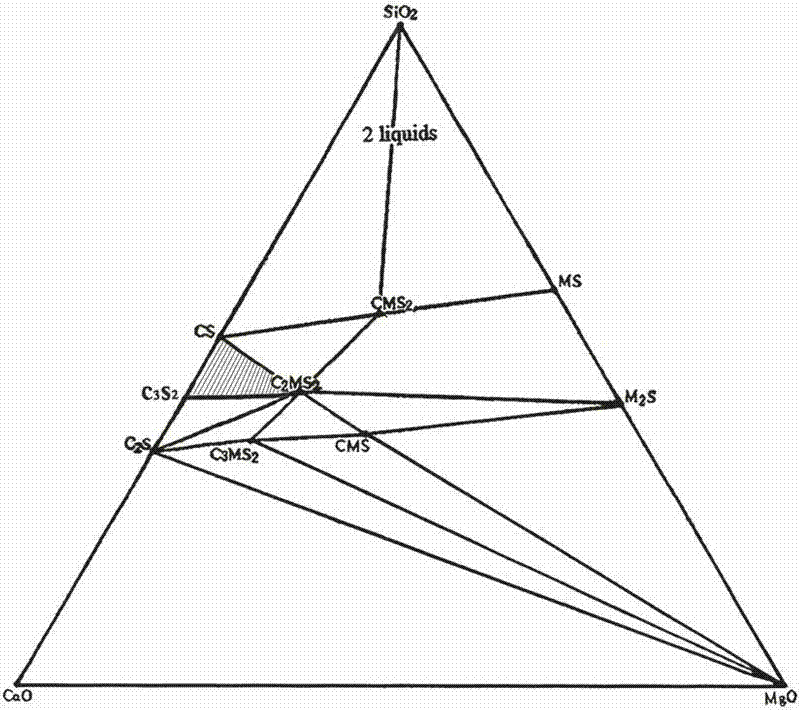

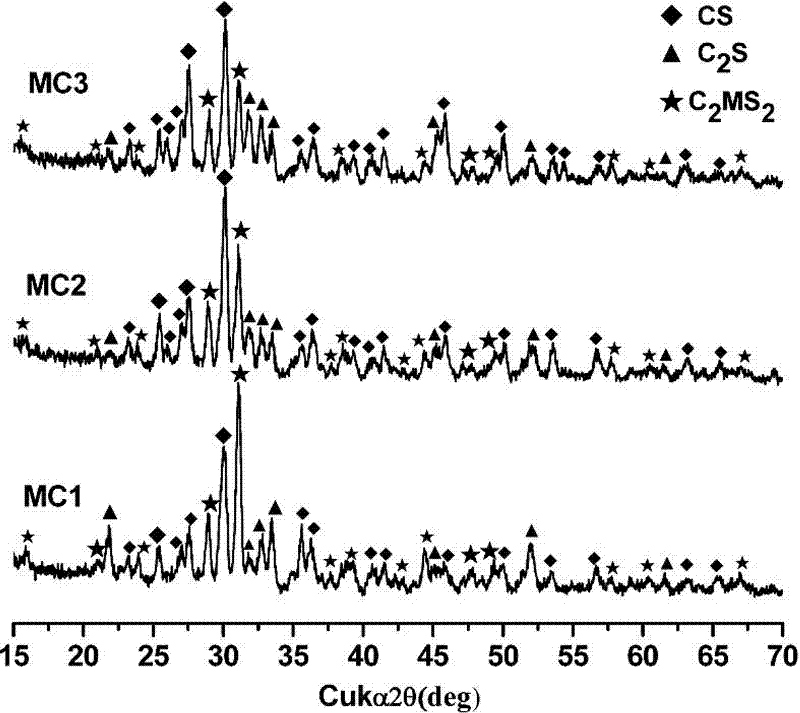

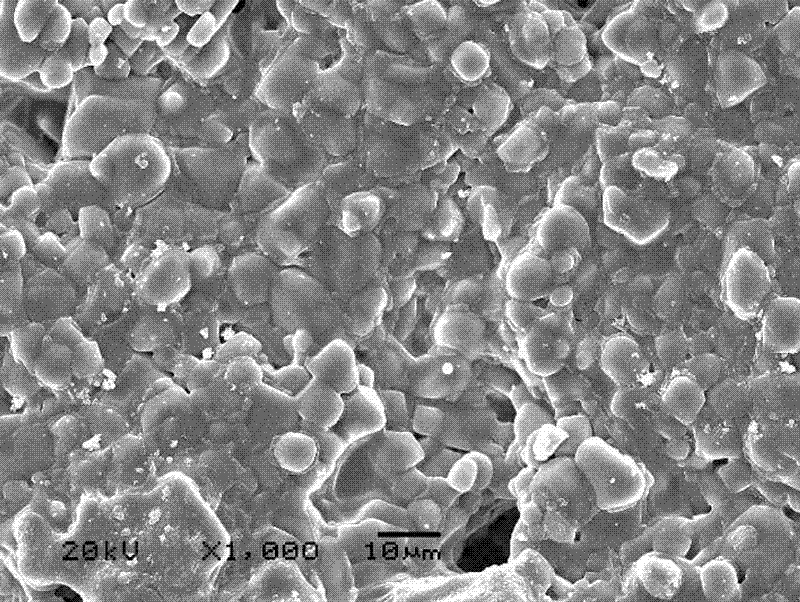

Design and preparation method for novel calcium-magnesium-silicon multiphase bioactive ceramic, and use thereof

InactiveCN102357260AHigh bonding strengthMeet the design requirementsCoatingsProsthesisOsteoblastTitanium alloy

The present invention relates to a design and preparation method for a novel calcium-magnesium-silicon multiphase bioactive ceramic, and a use thereof. According to the present invention, chemical compositions of three novel calcium-magnesium-silicon multiphase bioactive ceramics are firstly designed based on preliminary experimental results and theoretical analysis of phase diagrams; then tetraethoxysilane, water, magnesium nitrate hexahydrate and calcium nitrate tetrahydrate are adopted as raw materials, a sol-gel method is adopted for synthesis of three novel calcium-magnesium-silicon multiphase bioactive ceramic powders; the powders are subjected to dry-pressing and forming to obtain a material bisque; the bisque is subjected to sintering for 2 hours at a temperature of 1300-1350 DEG C to obtain a compact ceramic block body. According to the present invention, the multiphase ceramic MC2 is prepared by the method provided by the present invention, wherein the thermal expansion coefficient of the multiphase ceramic MC2 matches with titanium alloy TC4; because the intrinsic stress between the metal and the ceramic is reduced, the metal-ceramic bonding strength can be improved when the multiphase ceramic MC2 is adopted as the titanium-based bioactive coating; the ceramic has good mechanical property, good biological activity and good osteoblast compatibility; the novel calcium-magnesium-silicon multiphase ceramic MC2 is a potential bioactive ceramic material, and can be used in the surface modification fields of titanium implants in orthopedics, dentistry or plastic surgery, and human body hard tissue repairing and implanting materials; the method provided by the present invention has characteristics of simple process, easily-controlled components and conditions, and is easy to popularize.

Owner:SICHUAN UNIV

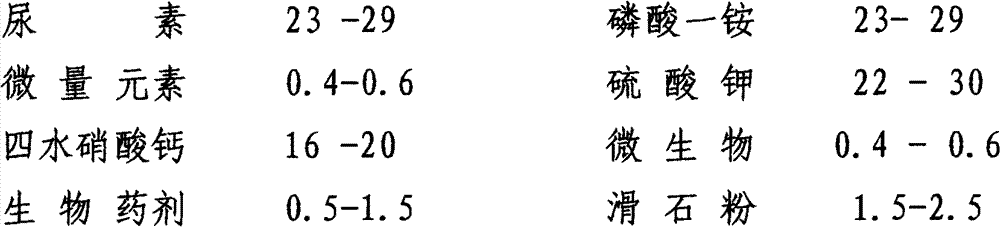

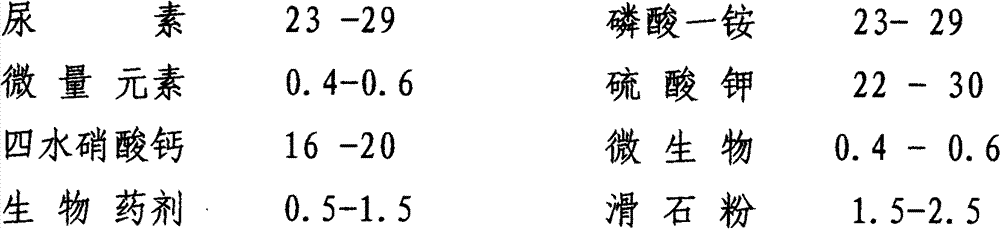

Novel citrus fertilizer for special purpose and its preparation method

InactiveCN102731220AHigh nutrient contentIncrease concentrationFertilizer mixturesFruit treeCalcium nitrate tetrahydrate

The invention relates to a novel citrus fertilizer for special purpose and its preparation method, and relates to the technical field of the agricultural fertilizer, the novel citrus fertilizer for special purpose of the invention is composed of 23-29 parts of urea, 23-29 parts of monoammonium phosphate, 0.4-0.6 parts of trace elements, 22-30 parts of potassium sulfate, 16-20 parts of calcium nitrate tetrahydrate, 0.4-0.6 parts of microbes, 0.5-1.5 parts of biopharmaceutical agent and 1.5-2.5 parts of talcum powder according to weight part; the citrus fertilizer for special purpose possesses the advantages of strong effect, obvious production enhancement effect, labor and time saving, environmental protection and the like, and can be used for spraying on leaves during the growth season of South citrus, and also can be used as a foliar-fertilizer for vegetables, flowers, fruits, tea leaves and other fruit trees.

Owner:HUNAN TIANJIN TECH

Wheat grass germination agent and soilless culture nutrient solution

ActiveCN103314997AImprove growth characteristicsImprove featuresBiocidePlant growth regulatorsHydrolysatePhosphate

The invention discloses a wheat grass soilless culture nutrient solution. The wheat grass germination agent adopts the technical scheme as follows: the following components of calcium nitrate terahydrate, nitrate of potash, monoammonium phosphate, epsom salt, ammonium nitrate, boric acid, manganese sulfate, heptahydrate, ammonium molybdate, heptahydrated copper sulfate, ethylenediamine tetraacetic acid disodium iron, yeast hydrolysate, chitosan, humic acid and sodium selenite are mixed and dissolved into distilled water to prepare the soilless culture nutrient solution according to parts by weight. The wheat grass germination agent and the soilless culture nutrient solution are simple in preparation method, and ideal in product modality; the soilless culture nutrient solution of wheat grasses not only contains nutrient substances required for plant growth, but also contains active ingredients such as an amount of amino acid, glutathione, glucosan, nucleic acid, the chitosan, the humic acid, selenium and the like; the current situation that practical techniques and methods for high production of the wheat grasses are in shortage in the present market is changed; the wheat grass germination agent has a wide economic development prospect.

Owner:GUANGZHOU YIXI DRINK

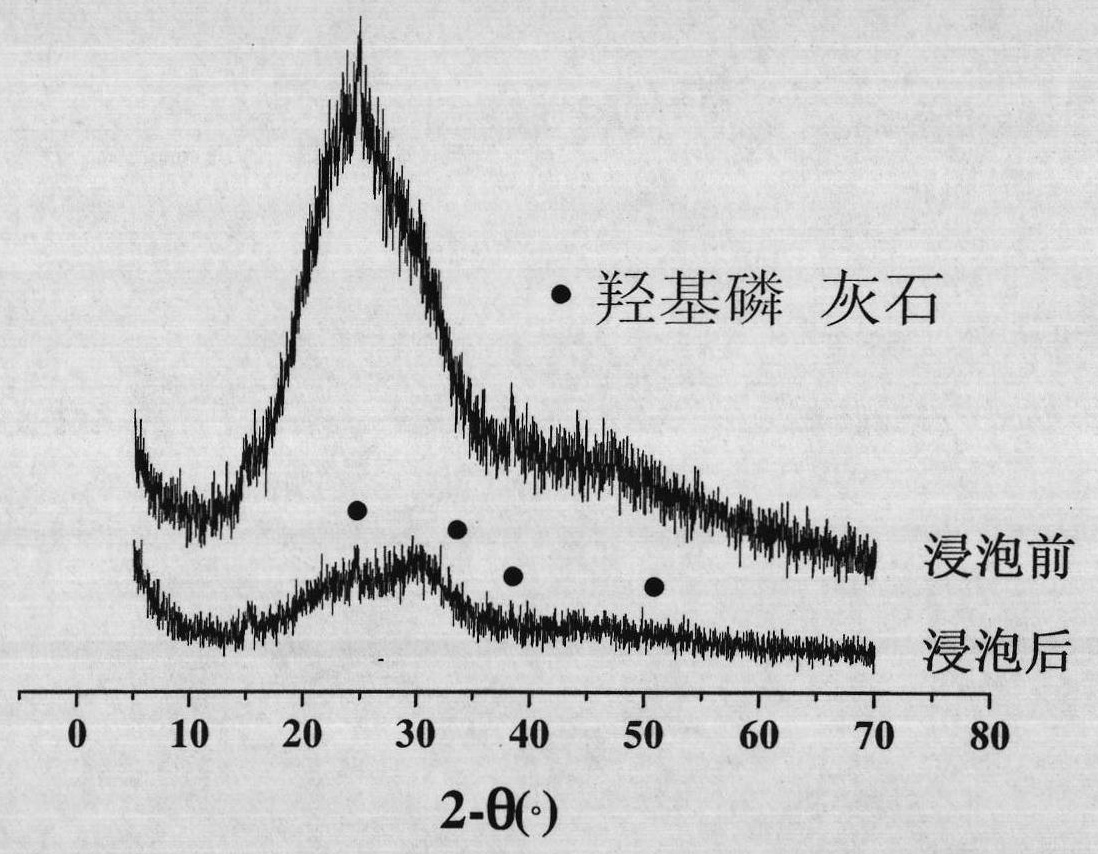

Preparation method of biodegradable magnesium alloy surface-modified hydroxyapatite coating

InactiveCN103446627AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

The invention relates to a preparation method of a biodegradable magnesium alloy surface-modified hydroxyapatite coating. The method specifically comprises the following steps: cutting the magnesium alloy into samples; polishing the samples by aluminum oxide water-resistant abrasive paper to remove surface oxide layers of the magnesium alloy; sequentially ultrasonic-cleaning with deionized water and absolute ethyl alcohol for 5-30 minutes, and drying at room temperature; preparing a conversion liquid by adopting sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate; controlling the molar ratio of calcium and phosphorus at (1:1)-(2:1), the concentration of Ca<2+> at 0.01-0.2M and the P<5+> concentration at 0.01-0.2M; placing pre-treated matrix sample in the conversion liquid to be soaked for 5-100 hours to obtain a calcium and phosphorus coating; preparing the hydroxyapatite coating through the calcium and phosphorus coating by adopting a thermal treatment process: soaking the samples in calcium and phosphorus liquor for 24-72 hours; taking out and directly placing in a Muffle furnace; carrying out thermal treatment at 250-350 DEG C for 2-5 hours; detecting performance. According to the method provided by the invention, the samples taken out from the calcium and phosphorus liquor are placed in the Muffle furnace for direct thermal treatment, so that the method is simpler and easier to operate and control, and the samples can be converted into the hydroxyapatite coating to achieve a considerable corrosion resistant effect.

Owner:TONGJI UNIV

Method for preparing phosphosilicate based glass

The invention belongs to the field of materials, and in particular relates to a method for preparing phosphosilicate based glass. The method takes water, ethanol or mixture of ethanol and water as solvent, and comprises the following steps: phytic acid, ethyl orthosilicate or calcium chloride are mixed to prepare gel precursor sol solution, and gel precursor sol solution is placed until becoming sol; the sol is aged at 60 DEG C, and is baked in an oven to ensure that the solvent is completely volatilized, and is cooled to room temperature; the temperature rises from the room temperature to the temperature of between 300 and 400 DEG C; and the dry gel is sintered at constant temperature of between 300 and 400 DEG C for at least 10 minutes, and is naturally cooled so as to obtain the phosphosilicate based glass. Compared with the conventional phosphorous precursor, the phytic acid serving as the precursor of phosphorous has smaller toxicity, so the biocompatibility of the material is improved, and the phosphosilicate based glass can be prepared in the conditions of low temperature, low toxicity and low cost, and the method can successfully prepare in a larger component range the phosphosilicate based glass with biodegradation speed which can be regulated in a wider range.

Owner:华魁科技泰州有限公司

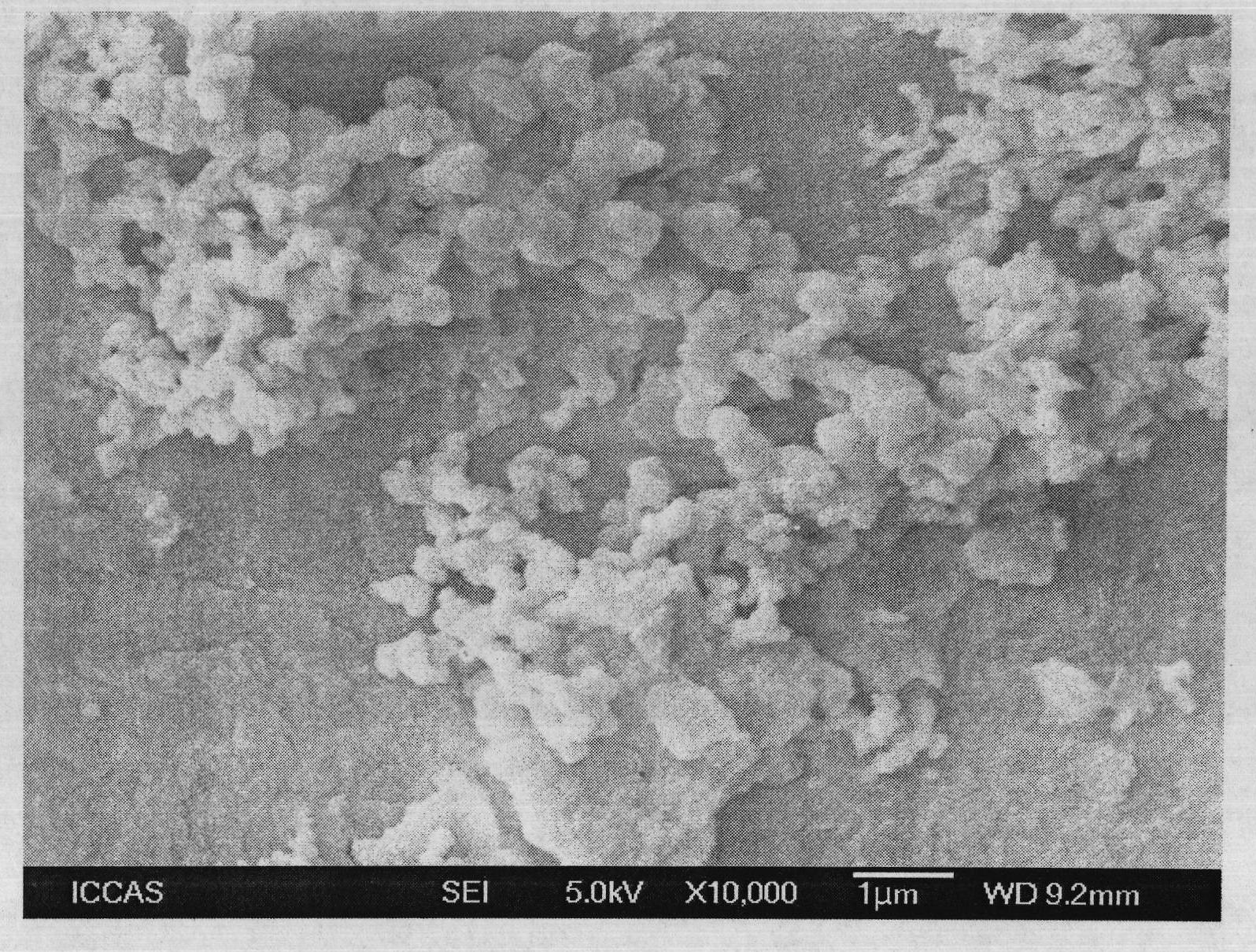

Synthesizing method of amorphous calcium phosphate

InactiveCN102320586AThe preparation method is mildLow costPhosphorus compoundsCalcium nitrate tetrahydrateCalcium biphosphate

The invention relates to a synthesizing method of amorphous calcium phosphate (ACP). According to the invention, tetrahydrated calcium nitrate and diammonium hydrogen phosphate are prepared into a solution; the solution is precipitated under an ultrasonic condition with a temperature of 0 DEG C; and the precipitate is vacuum-filtered and is dried, such that ACP powder is obtained. According to the method, no stabilizer is needed, and the method is simple and applicable. With the method, calcium phosphate powder with an adjustable Ca / P ratio and good bioactivity can be prepared. The prepared ACP powder can be applied in the field of biomedical materials.

Owner:SHANDONG UNIV

Culture medium of rapid propagation and tissue culture of Prunus serrulata Lindl. and method of rapid propagation and tissue culture

InactiveCN101584299AHigh reproductive coefficientImprove survival rateCultivating equipmentsPlant tissue cultureSucroseMonopotassium phosphate

The invention belongs to the field of rapid propagation and tissue culture method of plant, more particularly relates to a culture medium of Prunus serrulata Lindl. and a method of rapid propagation and tissue culture. The culture medium consists of a large number of elements, micro elements, ferric salt, organic components, sycrose, agar and a plant growth regulating agent, a large number of elements thereof comprise: ammonium nitrate, potassium sulfate, monopotassium phosphate, magnesium sulfate heptahydrate, calcium nitrate tetrahydrate and calcium chloride dehydrate; the ferric salt thereof comprises: ferrous sulfate heptahydrate and dihydrate sodium ethylene diamine tetracetate; the plant growth regulating agent is 6-benzyladenine and has concentration of 0.5-1.0 milligram / liter; other components are the same as MS culture medium. The pH value of the culture medium is 5.6-5.8. The culture medium of rapid propagation and tissue culture and the method of rapid propagation and tissue culture, provided by the invention, are simple, convenient and easily feasible aiming at characteristics of Prunus serrulata Lindl.. The tissue culture seedling is free from malformation, elongated in internode, enhanced in propagation coefficient, short in propagation period, which is about 50 days, good in culture effect and high in survival rate.

Owner:HENAN ACAD OF AGRI SCI

Method for extracting phosphorite co-production gypsum whisker by utilizing nitric acid

ActiveCN102352528AReduce utilizationIncrease profitPolycrystalline material growthFrom normal temperature solutionsCalcium nitrate tetrahydrateSulfate

The invention discloses a method for extracting a phosphorite co-production gypsum whisker by utilizing nitric acid, which comprises leaching phosphorite powder by taking a nitric acid solution of which the mass percent concentration is 50-60 percent as a raw material, wherein the mass ratio of the nitric acid to the phosphorite powder is 0.9-1.31; reacting for 50-70 minutes at the temperature of50-55 DEG C at the stirring speed of 350 turns per minute to obtain mixed liquor, filtering the mixed liquor, and then, performing freeze crystallization on the mixed liquor at the temperature of minus 5-0 DEG C for 280-300 minutes to obtain a product: tetrahydrated calcium nitrate; and adding a sulfuric acid solution and magnesium sulfate to a tetrahydrated calcium nitrate solution under the conditions of controlling the reaction temperature to be 40-90 DEG C, the stirring speed to be 150-250 turns per minute and the reaction time to be 30-60 minutes to obtain mixed liquor, filtering the mixed liquor, and then, drying filter residues at the temperature of 60 DEG C for 2 hours to obtain the product: a calcium sulfate whisker. The method for extracting the phosphorite co-production gypsum whisker by utilizing the nitric acid can improve the use ratio of the raw material, has low energy consumption and low production cost and is green and environmentally friendly.

Owner:WENGFU (GRP) CO LTD

Potato spray culture nutrient solution and preparation method thereof

InactiveCN101781148AMeet the needs of growth and developmentIncrease productionFertilizer mixturesEthylenediamineCalcium nitrate tetrahydrate

The invention discloses potato spray culture nutrient solution and a preparation method thereof. The potato spray culture nutrient solution comprises mother solution A, mother solution B, mother solution C, mother solution D and mother solution E. The mother solution A comprises the following raw materials in weight volume ratio: 30 to 40 g / L of potassium nitrate, 20 to 30 g / L of monopotassium phosphate, 4.0 to 5.0 g / L of ferrisodium ethylenediamine tetracetate trihydrate, 3.0 to 4.0 g / L of sodium ethylenediamine tetracetate dehydrate, and the balance of water. The mother solution B comprises the following raw materials in weight volume ratio: 45 to 55 g / L of calcium nitrate tetrahydrate, and the balance of water. The mother solution C comprises the following raw materials in weight volume ratio: 0.8 to 0.9 g / L of potassium iodide, 6.0 to 7.0 g / L of boric acid, 22 to 23 g / L of manganese sulfate tetrahydrate, 8.0 to 9.0 g / L of zinc sulfate heptahydrate, 0.2 to 0.3 g / L of sodium molybdate dehydrate, 0.025 to 0.03 g / L of cobalt chloride hexahydrate, 0.02 to 0.03 g / L of copper sulfate pentahydrate, and the balance of water. The mother solution D comprises the following raw materials in weight volume ratio: 100 to 200 g / L of urea, and the balance of water. The mother solution E comprises the following raw materials in weight volume ratio: 100 to 200 g / L of monopotassium phosphate, and the balance of water.

Owner:庞淑敏

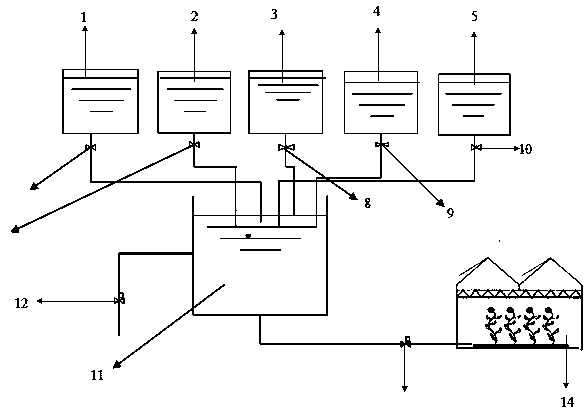

Nutrient solution fertilizing device and nutrient solution irrigation method

InactiveCN103503621ASolve the problem that the price is expensive and not suitable for my country's national conditionsLow priceFertilising methodsPressurised distribution of liquid fertiliserCalcium nitrate tetrahydrateMonopotassium phosphate

The invention discloses a nutrient solution fertilizing device and a nutrient solution irrigation method. The fertilizing device comprises five mother liquor tanks, one liquor preparation tank, pipelines, an underground water power pump, a nutrient solution pump and on / off valves, wherein the five mother liquor tanks are respectively provided with ferric salt, microelements, calcium nitrate tetrahydrate, potassium nitrate, monopotassium phosphate and magnesium sulfate heptahydrate. The irrigation method specifically comprises the following steps: predicating the daily demand of greenhouse plants on elements of nitrogen, phosphorus, potassium, calcium and magnesium in a next day, calculating the demand amount of the mother liquor according the predication result, preparing a nutrient solution, and subsequently starting or stopping the irrigation according to the water content of a medium. The nutrient solution fertilizing device and the nutrient solution irrigation method are simple to operate and low in cost, and can be applied to nutrient solution fertilization and nutrient solution irrigation.

Owner:JIANGSU UNIV

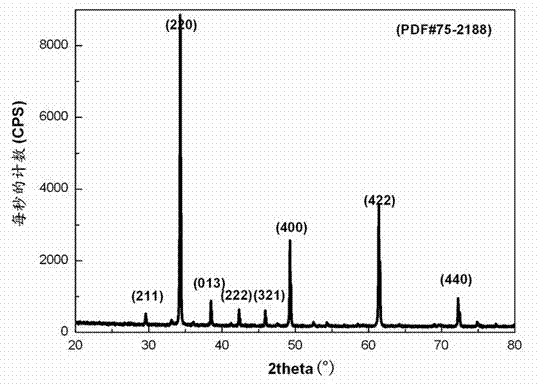

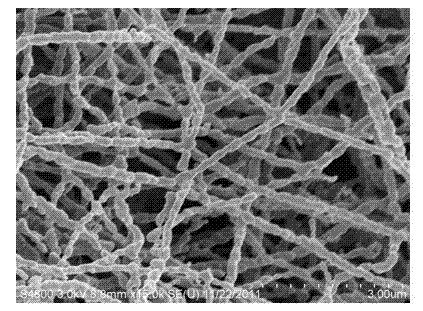

CaCu3Ti4O12 micro nano sized fiber and its preparation method

InactiveCN102515744AControl the hydrolysis processThe electrospinning process went smoothlyFilament/thread formingSpinning solutions preparationFiberCalcium nitrate tetrahydrate

The invention discloses a CaCu3Ti4O12 micro nano sized fiber and its preparation method, which belongs to the inorganic material technical field. The CaCu3Ti4O12 micro nano sized fiber comprises the elements of Ca, Cu, Ti and O with the mol ratio of 13412, and the diameter is 200-300 nanometers. The preparation method comprises the following steps mixing anhydrous ethyl alcohol, calcium nitrate tetrahydrate and copper acetate monohydrate to obtain a solution A; mixing anhydrous ethanol, butyl titanate and a spinning auxiliary agent to obtain a solution B; slowly adding the solution B in the solution A, and using a static spinning technology to prepare the CaCu3Ti4O12 micro nano sized fiber. The method of the invention can effectively control the hydrolysis process of the raw materials by selecting and adjusting the ratio of raw materials and the spinning auxiliary agent, the obtained static spinning solution possesses spinnability, and the method of the invention provides the novel CaCu3Ti4O12 micro nano sized fiber. The preparation method has the advantages of simple process, mild condition, easy control and wide applicability.

Owner:SUZHOU UNIV

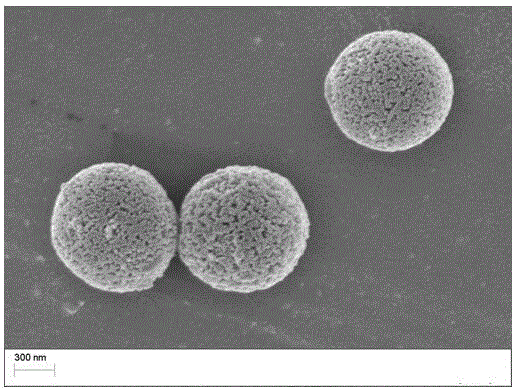

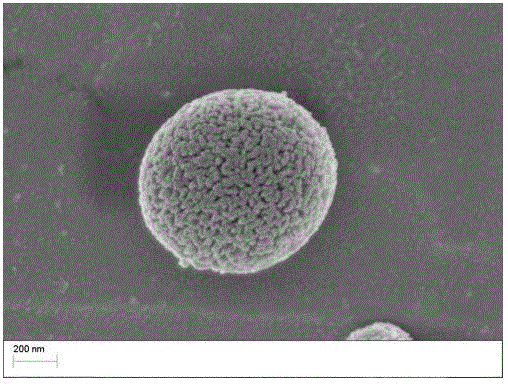

Micro-nano bioactive glass microsphere with surface nanometer pore structure and preparation method thereof

ActiveCN107522389AGood monodispersitySurface nanoporous structure is obviousGlass shaping apparatusTissue regenerationMicro nanoCalcium nitrate tetrahydrate

The invention discloses a micro-nano bioactive glass microsphere with a surface nanometer pore structure and a preparation method thereof. The method comprises the following steps of (1) mixing water, ethanol and calcium nitrate tetrahydrate into a water phase solution; mixing tetraethoxysilane and cyclohexane into an oil phase solution; (2) mixing the water phase solution and the oil phase solution; then, sequentially adding surfactants, catalysts and triethyl phosphate; performing uniform stirring to obtain a bioactive glass gel solution; (3) performing centrifugal separation on the bioactive glass gel solution; performing cleaning to obtain wet state gel precipitates; then, performing drying to obtain the bioactive glass gel powder; (4) performing heat treatment on the obtained bioactive glass gel powder to obtain the micro-nano bioactive glass microsphere with the surface nanometer pore structure. The micro-nano bioactive glass microsphere has the advantages of good dispersivity and high specific surface area, can be used for loading medicine, bioactive molecules and the like, and belongs to an ideal micro-nano bone restoration carrier microsphere.

Owner:SOUTH CHINA UNIV OF TECH

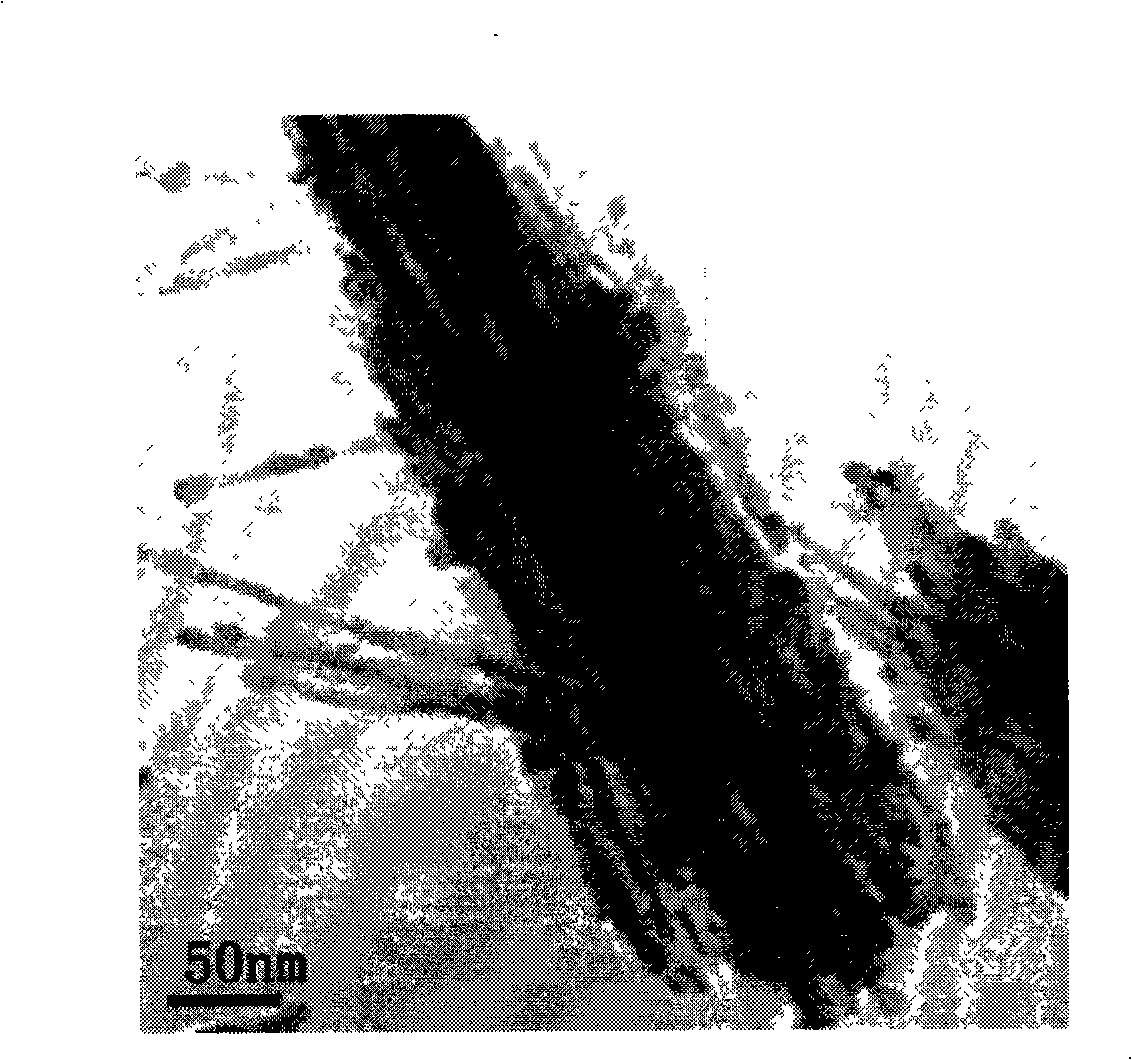

Method for preparing biological activity glass nano-fibre cluster

The invention relates to a preparation method of a bioactive glass nanofiber cluster, which is characterized in that A solution which is composed of tetraethyl orthosilicate and triethyl phosphate and B solution which is composed of calcium nitrate tetrahydrate, deionized water, a template agent and a catalyst are firstly prepared, the B solution is slowly dropped into the A solution to form a sol, the sol forms a gel by aging for 4 to 7 days, the gel is dried for 2 to 3 days at the temperature of 80 to 140 DEG C, and finally the nanofiber cluster material is obtained by heat treatment and solidification process at 400 to 700 DEG C and grinding. The weight percentage of the components of the nanofiber cluster is that: 60 to 80 percent of SiO2, 36 to 16 percent of CaO and 4 percent of P2O5. The bioactive glass nanofiber cluster prepared by the invention is composed of nano-fibers that are regularly arranged, thus showing good biological mineralization characteristics in simulated physiological solution and being used in the fields such as bone tissue repair and bone tissue engineering.

Owner:SOUTH CHINA UNIV OF TECH

Soilless tomato culture nutrient solution

InactiveCN103626585APromote growthIncrease productionFertilizer mixturesCalcium nitrate tetrahydrateMagnesium phosphate

The invention provides a soilless tomato culture nutrient solution, comprising calcium nitrate tetrahydrate, ethylenediaminetetraacetic acid sodium ferric salt, ammonium nitrate, an EM probiotic liquid, potassium nitrate, potassium magnesium phosphate, copper sulfate, manganese sulfate, boric acid, ammonium molybdate, EDTA (Ethylene Diamine Tetraacetic Acid) chelated iron and the balance of water. According to the soilless tomato culture nutrient solution provided by the invention, the EM probiotic liquid is added to propagate strains necessary for probiotics so as to form a good microbial circulation system for the nutrient solution, the system can fully decompose organic matters generated in the nutrient solution in a planting process to transform the organic matters into substances to be absorbed by plants, and the potassium nitrate, potassium magnesium phosphate, copper sulfate, manganese sulfate, boric acid, ammonium molybdate and EDTA chelated iron provide such elements necessary for tomatoes as potassium, magnesium, copper, manganese, boron, molybdenum, iron and the like so as to enable the tomatoes to achieve an optimal growth effect so as to increase the yield and improve the quality.

Owner:GUIZHOU PINGBA BAODI AGRI SCI & TECH IND

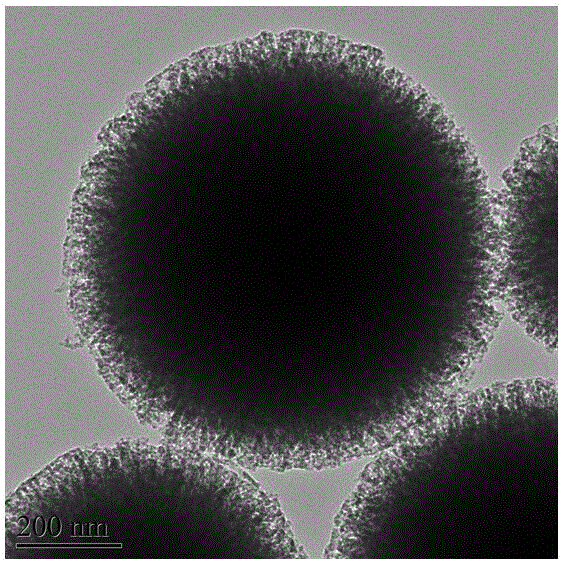

Biological active microsphere and preparation method thereof

ActiveCN103239756ANarrow and uniform particle size distributionUniform compositionMicroballoon preparationProsthesisCalcium nitrate tetrahydrateMicrosphere

The invention discloses a biological active microsphere and a preparation method thereof. Based on molar percentage, the microsphere is composed of 16- 36% of CaO, 4% of P2O5 and 60-80% of SiO2 composition; the particle size of the microsphere 1-5 [mu]m; and the microsphere is in a hollow ball shape. The preparation method of the biological active microsphere comprises the following steps of preparing an acid catalyst polyethylene glycol solution A according to a proportion, adding tetraethoxysilane, triethyl phosphate and calcium nitrate terahydrate into the solution A respectively in order according to a molar ratio of 60-80 : 4 : 16-36 to form a gel B; hydrothermal ageing the gel B at the temperature of 60 DEG C and drying at the temperature of 37 DEG C to obtain a dry gel; grinding the dry gel and performing heat treatment on the grinded dry gel at the temperature of 600 DEG C-800 DEG C to obtain a target product. Compared with a conventional biological active microsphere, the biological active microsphere provided by the invention is in regular sphere shape with a hollow structure and smooth surface; the particle size of the microsphere 1-5 [mu]m; a particle size distribution range is narrow and uniform; and the biological active microsphere has excellent fluidity, syringeability and security and is simple in preparation process.

Owner:佛山今兰生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com