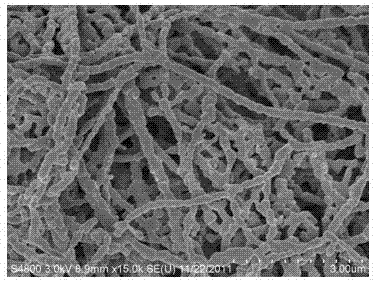

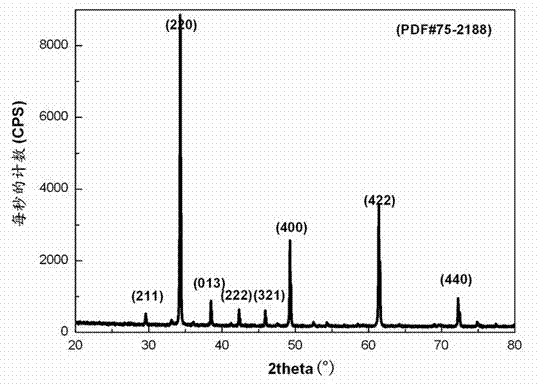

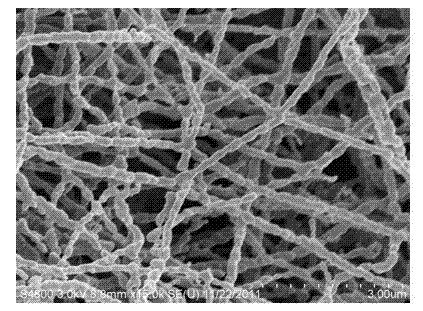

CaCu3Ti4O12 micro nano sized fiber and its preparation method

A micro-nano fiber technology, applied in fiber processing, spinning solution preparation, filament/thread forming, etc., can solve problems such as inability to carry out electrospinning, difficult electrospinning process, and increased viscosity of spinning solution. Achieve the effect of easy control, mild conditions and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Under stirring conditions, add 10 ml of absolute ethanol, 1.04 g of calcium nitrate tetrahydrate and 2.63 g of copper acetate monohydrate into the reaction vessel, and react at a constant temperature of 30°C for 2 hours to obtain solution A;

[0027] 2. Under stirring conditions, add 1.5 g of polyvinylpyrrolidone, 10 ml of absolute ethanol, 3 ml of acetic acid and 6 ml of butyl titanate into the reaction vessel, and react at a constant temperature of 30 ° C for 1 hour to obtain a solution B;

[0028] 3. Under stirring conditions, all the solution B prepared in step 2 was slowly added dropwise to solution A at a rate of 100 ml per hour to obtain solution C;

[0029] 4. Electrospinning solution C, the voltage used for electrospinning is 16.50 kV, the injection rate is 6.5 ml / hour, the curing distance is 12 cm, the receiving device is aluminum foil, and the electrospinning time is 3 hours. corresponding fibers;

[0030] 5. Dry the fiber obtained by electrosp...

Embodiment 2

[0034] 1. Under stirring conditions, add 15 ml of absolute ethanol, 1.04 g of calcium nitrate tetrahydrate and 2.63 g of copper acetate monohydrate into the reaction vessel, and react at a constant temperature of 45°C for 3 hours to obtain solution A;

[0035] 2. Under stirring conditions, add 2.5 grams of polyvinylpyrrolidone, 15 milliliters of absolute ethanol, 1.5 grams of tetramethylammonium hydroxide and 6 milliliters of butyl titanate into the reaction vessel, and react at a constant temperature of 45°C for 3 Hour, obtain solution B;

[0036] 3. Under stirring conditions, slowly add all the solution B prepared in step 2 to solution A at a rate of 200 ml per hour to obtain solution C;

[0037] 4. Electrospinning solution C, the voltage used for electrospinning is 19.50 kV, the injection rate is 8.5 ml / hour, the curing distance is 15 cm, the receiving device is aluminum foil, and the electrospinning time is 2 hours. corresponding fibers;

[0038] 5. Dry the fib...

Embodiment 3

[0040] 1. Under stirring conditions, add 20 ml of absolute ethanol, 2.08 g of calcium nitrate tetrahydrate and 5.26 g of copper acetate monohydrate into the reaction vessel, and react at a constant temperature of 50° C. for 1 hour to obtain solution A;

[0041] 2. Under stirring conditions, add 3 grams of polyvinylpyrrolidone, 20 milliliters of absolute ethanol, 3 grams of tetramethylammonium hydroxide and 12 milliliters of butyl titanate into the reaction vessel, and react at a constant temperature of 50 ° C for 1 Hour, obtain solution B;

[0042] 3. Under stirring conditions, all the solution B prepared in step 2 was slowly added dropwise to solution A at a rate of 150 ml per hour to obtain solution C;

[0043] 4. Electrospinning solution C, the voltage used for electrospinning is 23.50 kV, the injection rate is 9.5 ml / hour, the curing distance is 15 cm, the receiving device is aluminum foil, and the electrospinning time is 2 hours. corresponding fibers;

[0044] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com