Water-soluble cross-linking agent, preparation method thereof and prepared electrospun collagen fibers

A cross-linking agent, water-soluble technology, applied in the field of electrospun collagen fiber preparation, can solve the problems of poor electrospinning, poor structural stability of electrospun collagen fibers, difficult molecular chain entanglement, etc., and achieves increased chain entanglement and good structure. Effects of stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

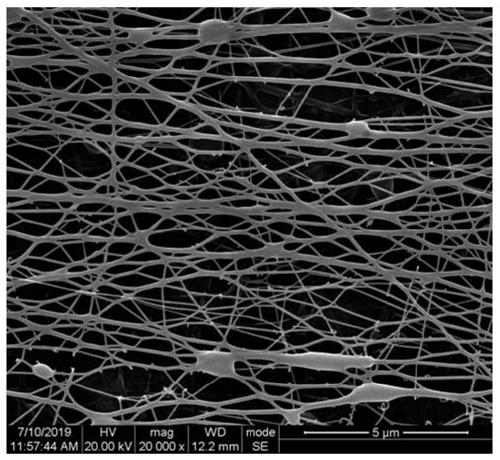

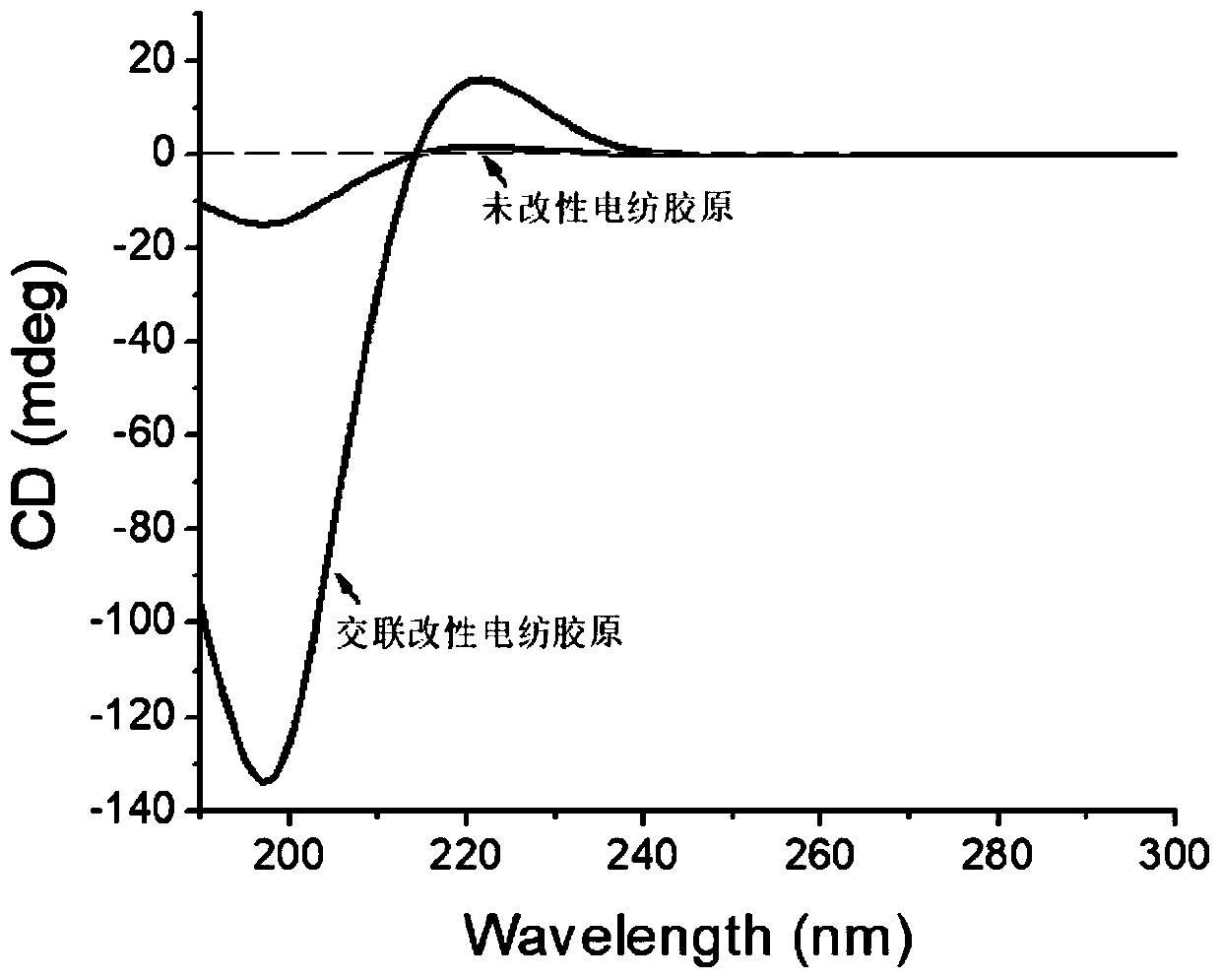

[0039] A preparation method of electrospun collagen fibers, comprising the following steps:

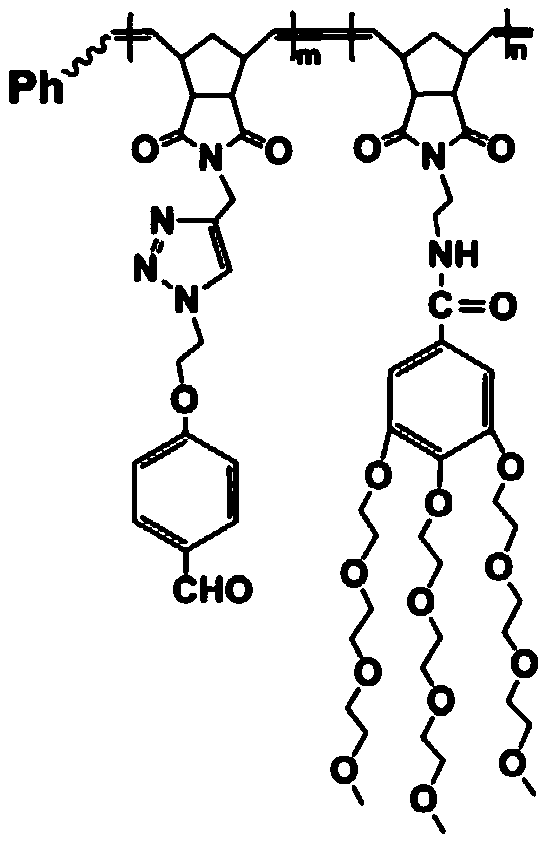

[0040] (1) Dissolve 0.025 parts of aldehyde-containing norbornene-based hydrophobic monomer NCHO and 0.5 part of norbornene-based hydrophilic monomer NTEG containing triethylene glycol structure in 0.25 and 5 parts of dry dichloromethane, respectively ;

[0041] (2) the 3rd generation catalyst of 0.01 part of Grubbs is dissolved in the flask that 0.3 part of dry dichloromethane is housed under nitrogen protection; Stir vigorously at room temperature and react under nitrogen protection for 20 minutes;

[0042] (3) Add the norbornene-based hydrophilic monomer solution containing triethylene glycol structure into the reaction system quickly, and further react vigorously at room temperature for 20 minutes; then inject 0.5 parts of vinyl ether into the flask to deactivate the catalyst, Diethyl ether was used to promote product precipitation, and the precipitate was collected by filtratio...

Embodiment 2

[0046] A preparation method of electrospun collagen fibers, comprising the following steps:

[0047] (1) Dissolve 0.05 parts of aldehyde-containing norbornene-based hydrophobic monomer NCHO and 1 part of norbornene-based hydrophilic monomer NTEG containing triethylene glycol structure in 0.5 and 10 parts of dry dichloromethane, respectively ;

[0048] (2) the 3rd generation catalyst of 0.015 part of Grubbs is dissolved in the flask that 0.4 part of dry dichloromethane is housed under nitrogen protection; Stir vigorously at room temperature and react under nitrogen protection for 10 minutes;

[0049] (3) Add the norbornene-based hydrophilic monomer solution containing triethylene glycol structure quickly into the reaction system, further react vigorously at room temperature for 10 minutes, then inject 0.5 parts of vinyl ether into the flask to deactivate the catalyst, Diethyl ether was used to promote product precipitation, and the precipitate was collected by filtration, com...

Embodiment 3

[0053] A preparation method of electrospun collagen fibers, comprising the following steps:

[0054] (1) Dissolve 0.04 parts of aldehyde-containing norbornene-based hydrophobic monomer NCHO and 0.8 parts of norbornene-based hydrophilic monomer NTEG containing triethylene glycol structure in 0.4 and 8 parts of dry dichloromethane, respectively ;

[0055] (2) the 3rd generation catalyst of 0.012 parts of Grubbs is dissolved in the flask that 0.32 parts of dry methylene chloride is housed under nitrogen protection; Stir vigorously at room temperature and react under nitrogen protection for 15 minutes;

[0056] (3) Add the norbornene-based hydrophilic monomer solution containing triethylene glycol structure quickly into the reaction system, further react vigorously at room temperature for 15 minutes, then inject 0.5 parts of vinyl ether into the flask to deactivate the catalyst, And use diethyl ether to promote the precipitation of the product, filter to take the precipitate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com