Preparation method of photoresponse adhesive with strong adhesion under water and prepared photoresponse adhesive

A binder and light-responsive technology, applied in the field of polymer materials, can solve problems such as poor adhesion, and achieve the effects of improved adhesion, biocompatibility, good hydrophobicity, and excellent adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

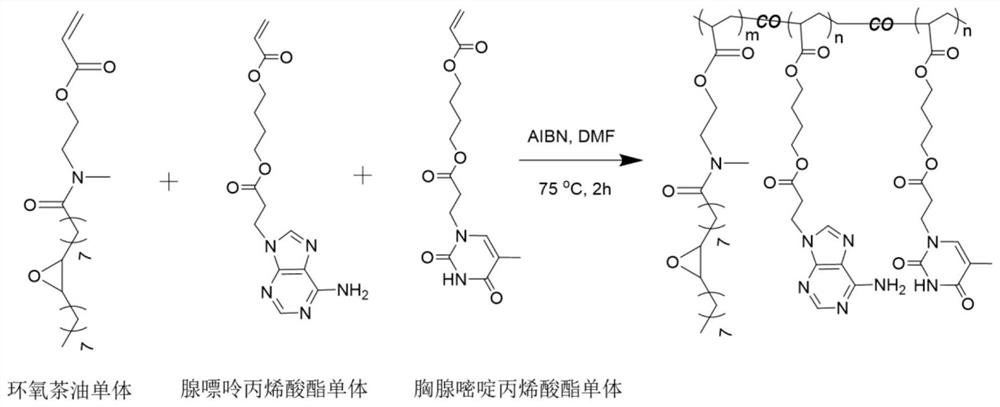

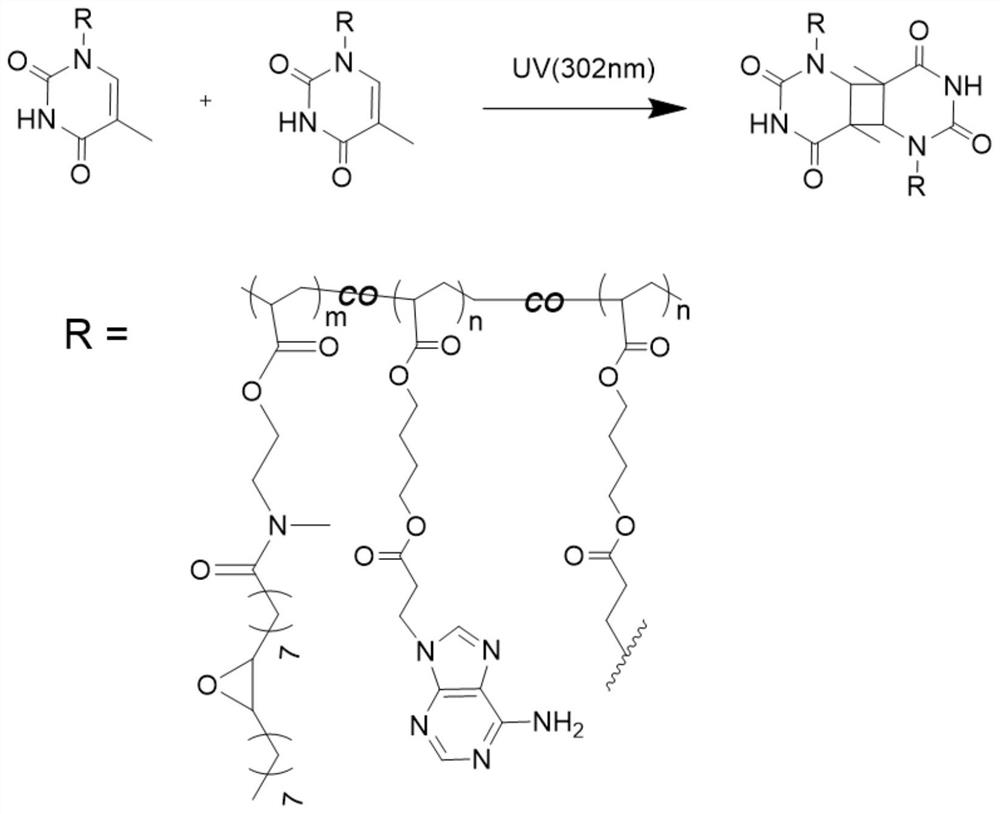

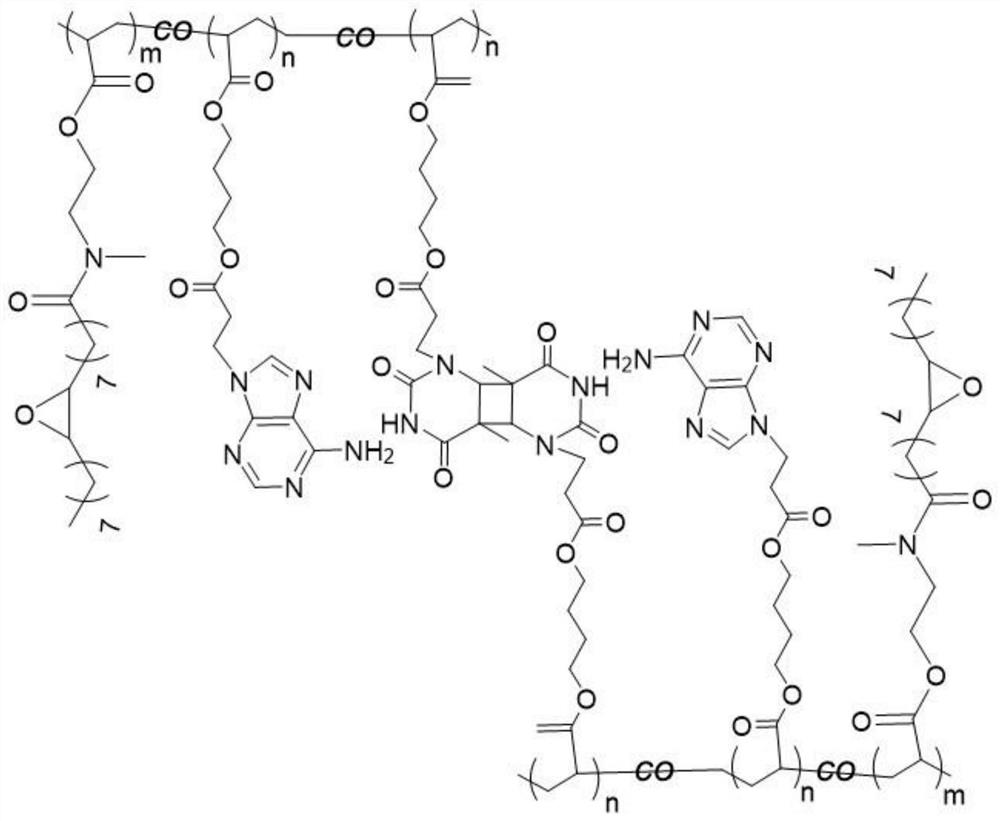

[0055] Preparation method of photoresponsive adhesive with strong adhesion under water, the preparation route is as follows figure 1 As shown, the degree of polymerization of the polymer is 600, m+2n=600, m is 420, n is 90, figure 1 The co represents the abbreviation of copolymerization.

[0056] Specifically include the following steps:

[0057] (1) Add 1.68mL epoxy camellia oil monomer (ECO) into the ampoule, add 291mg (TAc) thymine acrylate monomer and 300mg adenine acrylate monomer (AAc) to dissolve in 2.9mL N,N-di In methyl formamide (DMF); The structural formula of epoxy camellia oil monomer (ECO) is as follows in the present embodiment: ECO:AAc:TAc (molar ratio)=0.7:0.15:0.15 in the present embodiment, monomer AAc, The solid content of TAc and ECO is 45.8%, and the calculation method of solid content is: (0.291+0.300+1.68*1.024) / (2.9*0.945+0.291+0.300+1.68*1.024).

[0058] What adopt is that publication number is the epoxy camellia oil monomer of record in the pate...

Embodiment 2

[0061] Preparation method of photoresponsive adhesive with strong adhesion under water, the preparation route is as follows figure 1 As shown, the degree of polymerization of the polymer is 600, m+2n=600, m is 480, n is 60, figure 1 The co represents the abbreviation of copolymerization.

[0062] Specifically include the following steps:

[0063] (1) Measure 1.92mL ECO into the ampoule, add 194mg TAc and 200mg AAc and dissolve in 2.6mL DMF; The content is 49%, and the calculation method of the solid content is: (0.194+0.200+1.92*1.024) / (2.6*0.945+0.194+0.200+1.92*1.024).

[0064] (2) Prepare AIBN into 8.2 mg / mL DMF solution, add 200 μL into the ampoule in step (1), and seal the ampoule. After the mixed solution was subjected to multiple freeze-thaw cycles, it was reacted at 75° C. for 2 h under nitrogen gas. The obtained polymer was purified in methanol to obtain a light-responsive binder.

Embodiment 3

[0066] The difference between this example and Example 1 is that the molar ratio of ECO, AAc, and TAc is 0.9:0.05:0.05, and the solid content of AAc and TAc is 51.5%. correspond figure 1 m in is 540, and n is 30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com