A preparation method of a photoresponsive adhesive with strong adhesion under water and the prepared photoresponsive adhesive

A binder and adhesion technology, which is applied in the field of polymer materials, can solve problems such as poor adhesion, and achieve the effects of improved adhesion performance, excellent adhesion performance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

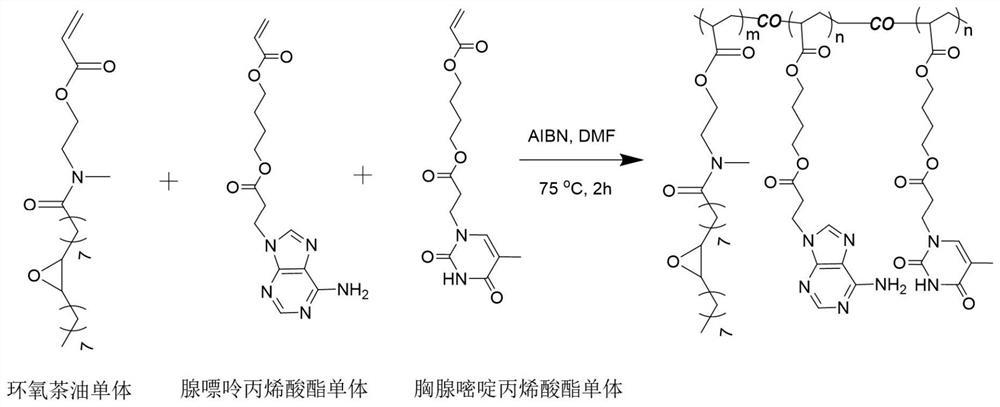

[0055] Preparation method of photoresponsive adhesive with strong adhesion under water, the preparation route is as follows figure 1 As shown, the degree of polymerization of the polymer is 600, m+2n=600, m is 420, n is 90, figure 1 The co represents the abbreviation of copolymerization.

[0056] Specifically include the following steps:

[0057] (1) Add 1.68mL epoxy camellia oil monomer (ECO) into the ampoule, add 291mg (TAc) thymine acrylate monomer and 300mg adenine acrylate monomer (AAc) to dissolve in 2.9mL N,N-di In methyl formamide (DMF); The structural formula of epoxy camellia oil monomer (ECO) is as follows in the present embodiment: ECO:AAc:TAc (molar ratio)=0.7:0.15:0.15 in the present embodiment, monomer AAc, The solid content of TAc and ECO is 45.8%, and the calculation method of solid content is: (0.291+0.300+1.68*1.024) / (2.9*0.945+0.291+0.300+1.68*1.024).

[0058] What adopt is that publication number is the epoxy camellia oil monomer of record in the pate...

Embodiment 2

[0061] Preparation method of photoresponsive adhesive with strong adhesion under water, the preparation route is as follows figure 1 As shown, the degree of polymerization of the polymer is 600, m+2n=600, m is 480, n is 60, figure 1 The co represents the abbreviation of copolymerization.

[0062] Specifically include the following steps:

[0063] (1) Measure 1.92mL ECO into the ampoule, add 194mg TAc and 200mg AAc and dissolve in 2.6mL DMF; The content is 49%, and the calculation method of the solid content is: (0.194+0.200+1.92*1.024) / (2.6*0.945+0.194+0.200+1.92*1.024).

[0064] (2) Prepare AIBN into 8.2 mg / mL DMF solution, add 200 μL into the ampoule in step (1), and seal the ampoule. After the mixed solution was subjected to multiple freeze-thaw cycles, it was reacted at 75° C. for 2 h under nitrogen gas. The obtained polymer was purified in methanol to obtain a light-responsive binder.

Embodiment 3

[0066] The difference between this example and Example 1 is that the molar ratio of ECO, AAc, and TAc is 0.9:0.05:0.05, and the solid content of AAc and TAc is 51.5%. correspond figure 1 m in is 540, and n is 30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com