Patents

Literature

745 results about "Injection rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

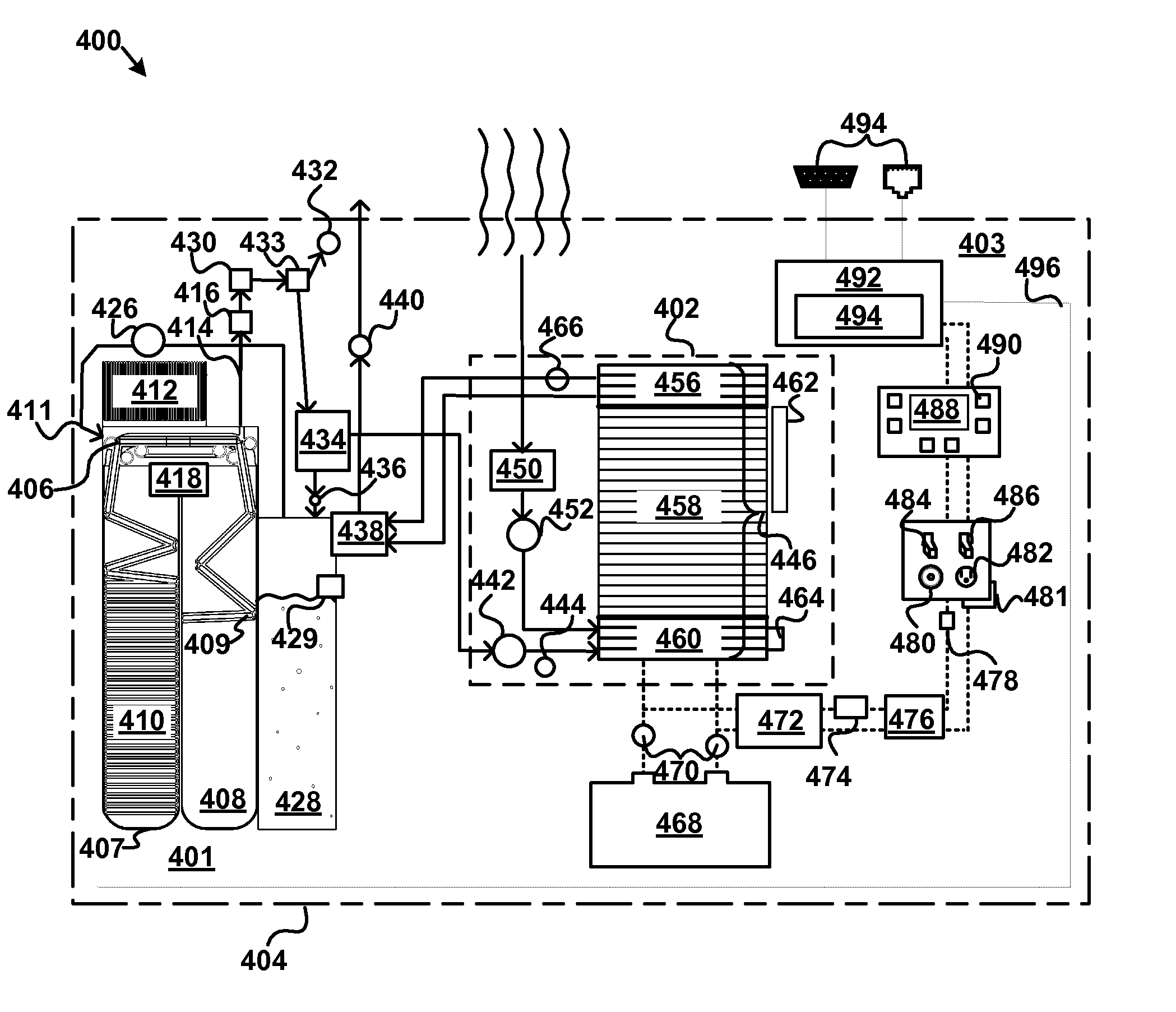

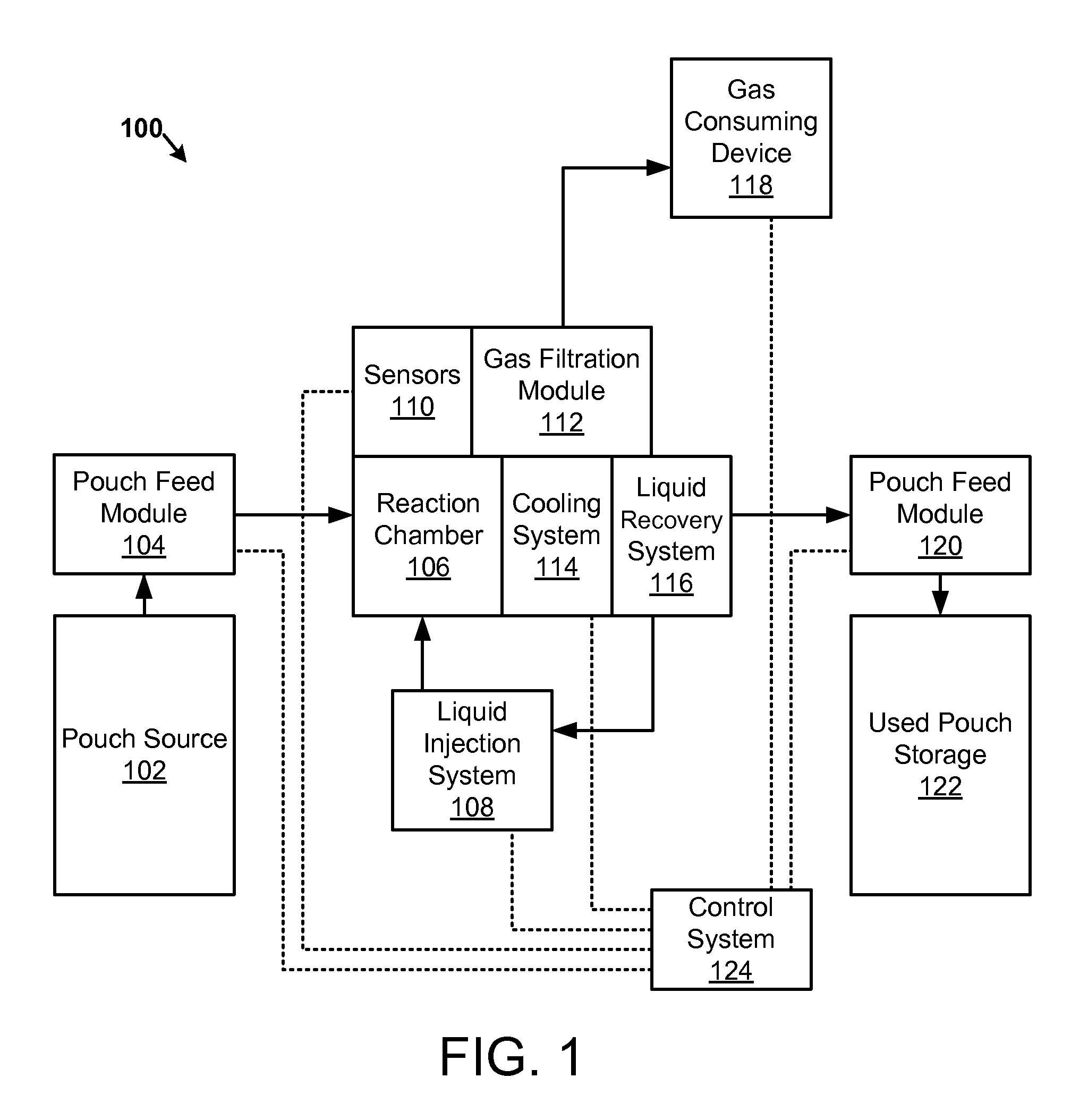

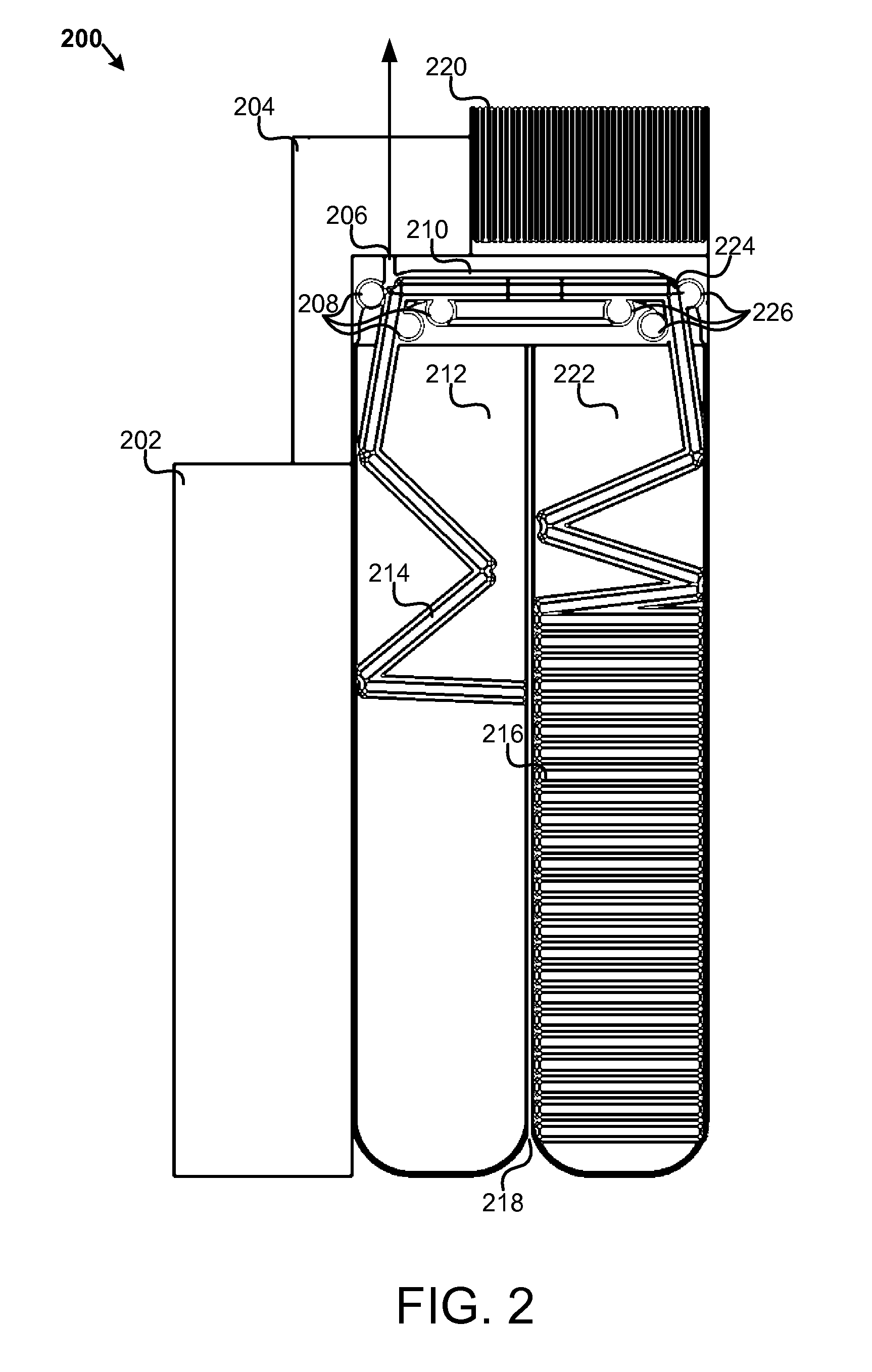

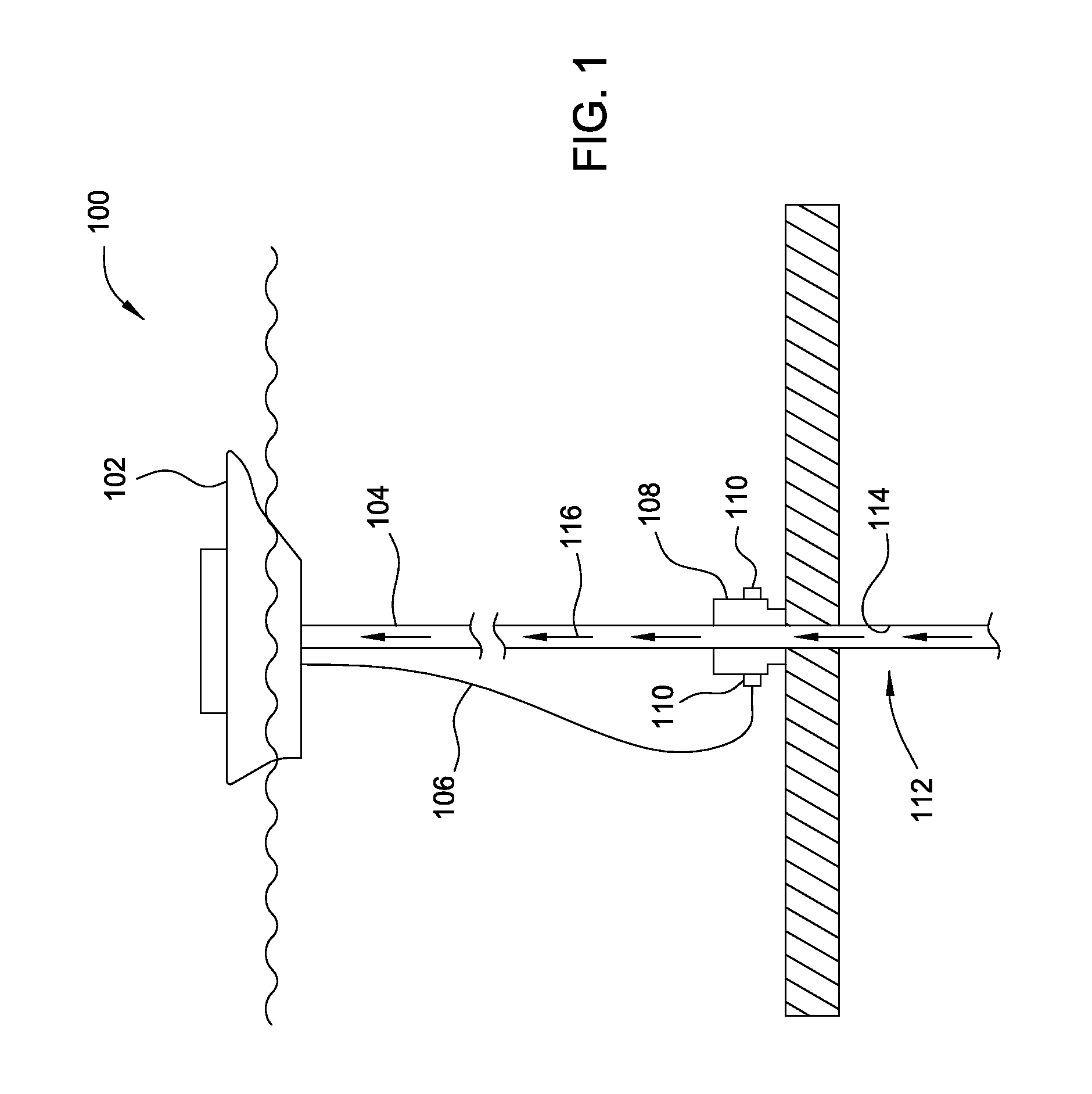

Apparatus, system, and method for generating a gas from solid reactant pouches

An apparatus, system, and method are disclosed for generating a gas. One or more liquid permeable pouches each define a cavity that contains a solid anhydrous reactant, such as a chemical hydride. A reaction chamber made of a heat, chemical and / or pressure resistant material receives the one or more pouches from a pouch feeder that transfers the one or more pouches into the reaction chamber successively at a feed rate. One or more liquid sources inject a liquid reactant into the reaction chamber so that the liquid reactant contacts a portion of the one or more pouches. The one or more liquid sources inject the liquid reactant at an injection rate that corresponds to the feed rate. A gas outlet releases a gas, such as hydrogen, oxygen, ammonia, borazine, nitrogen, or a hydrocarbon, that is produced by a reaction between the solid reactant and the liquid reactant.

Owner:TRULITE INC

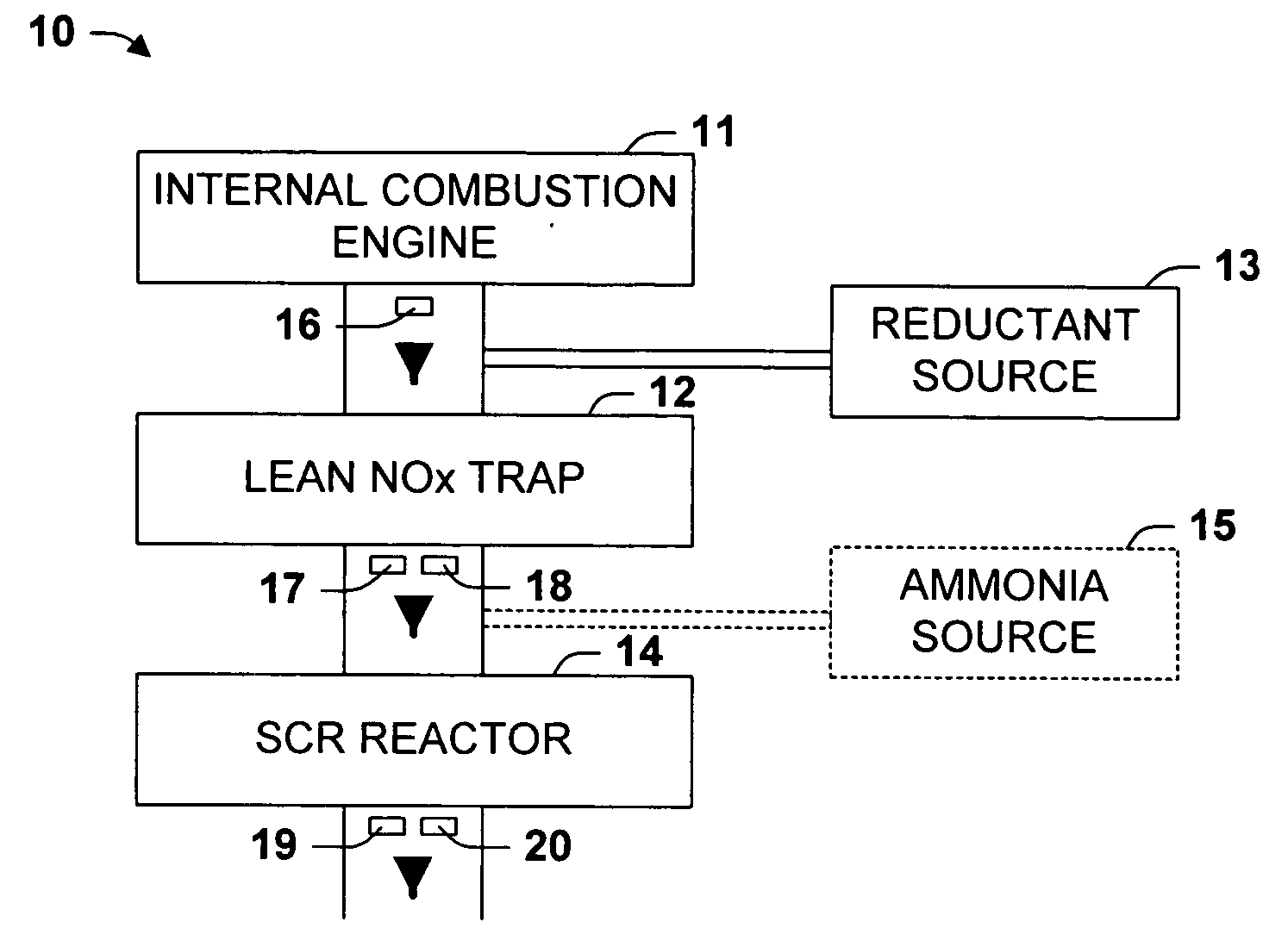

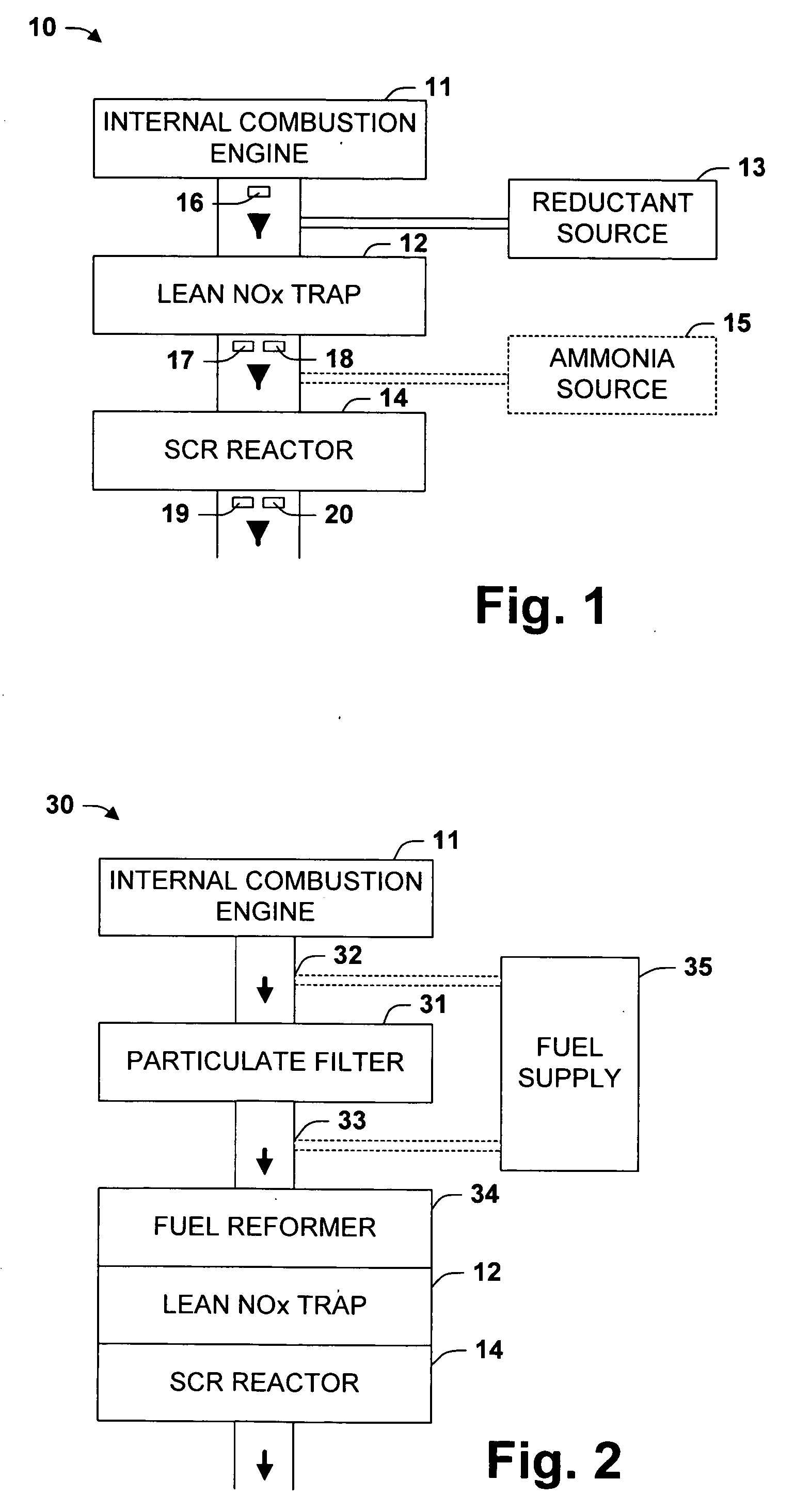

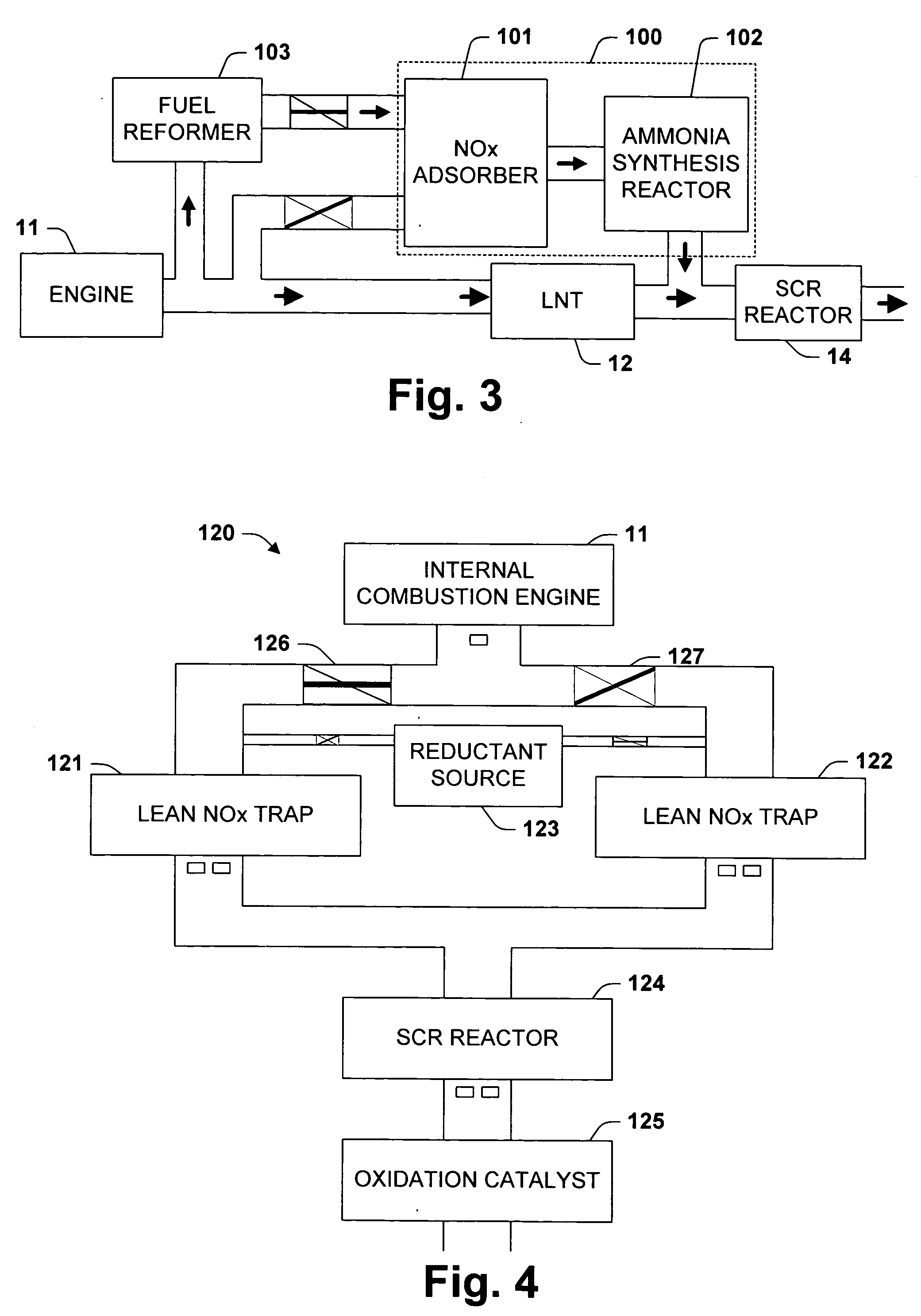

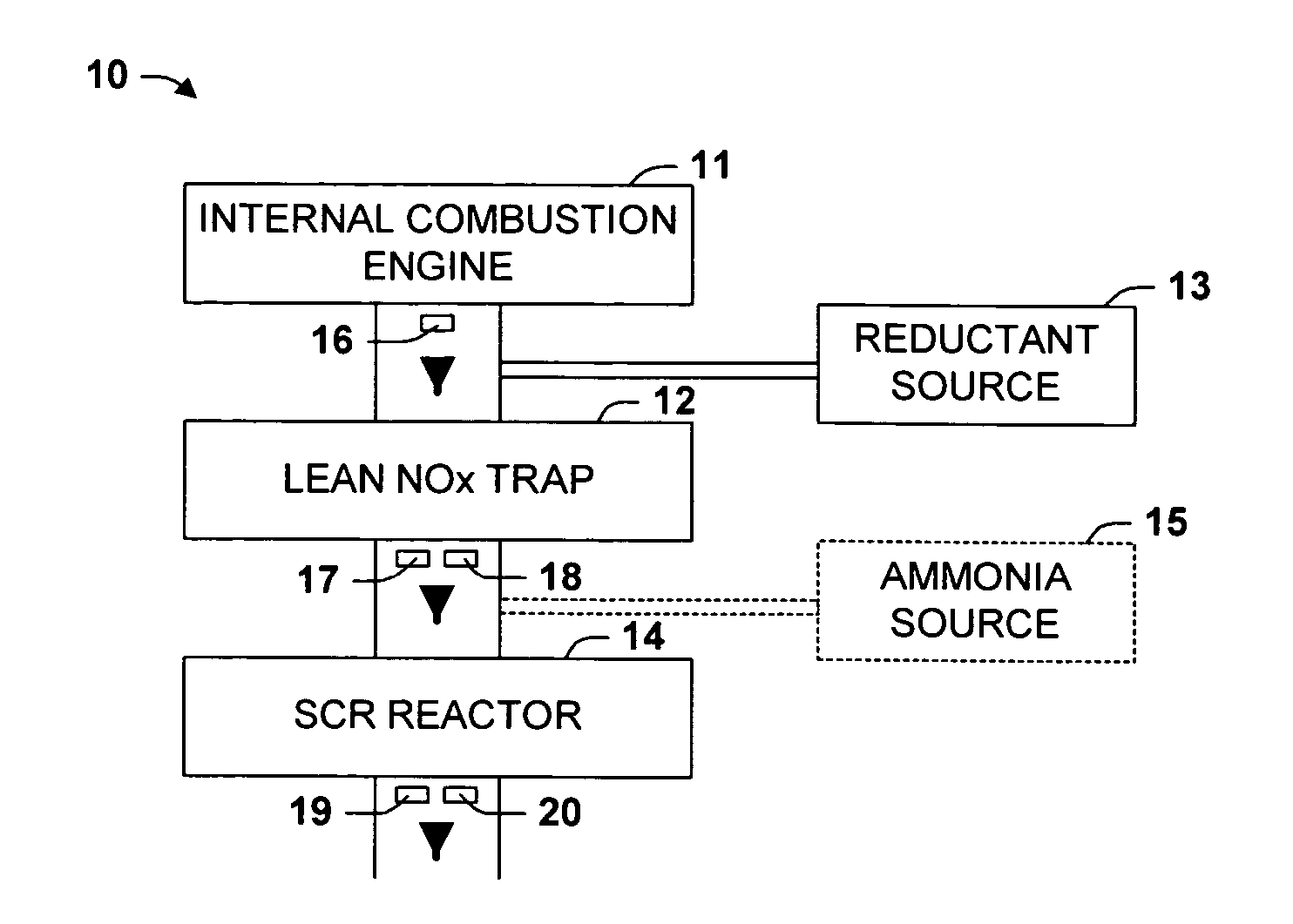

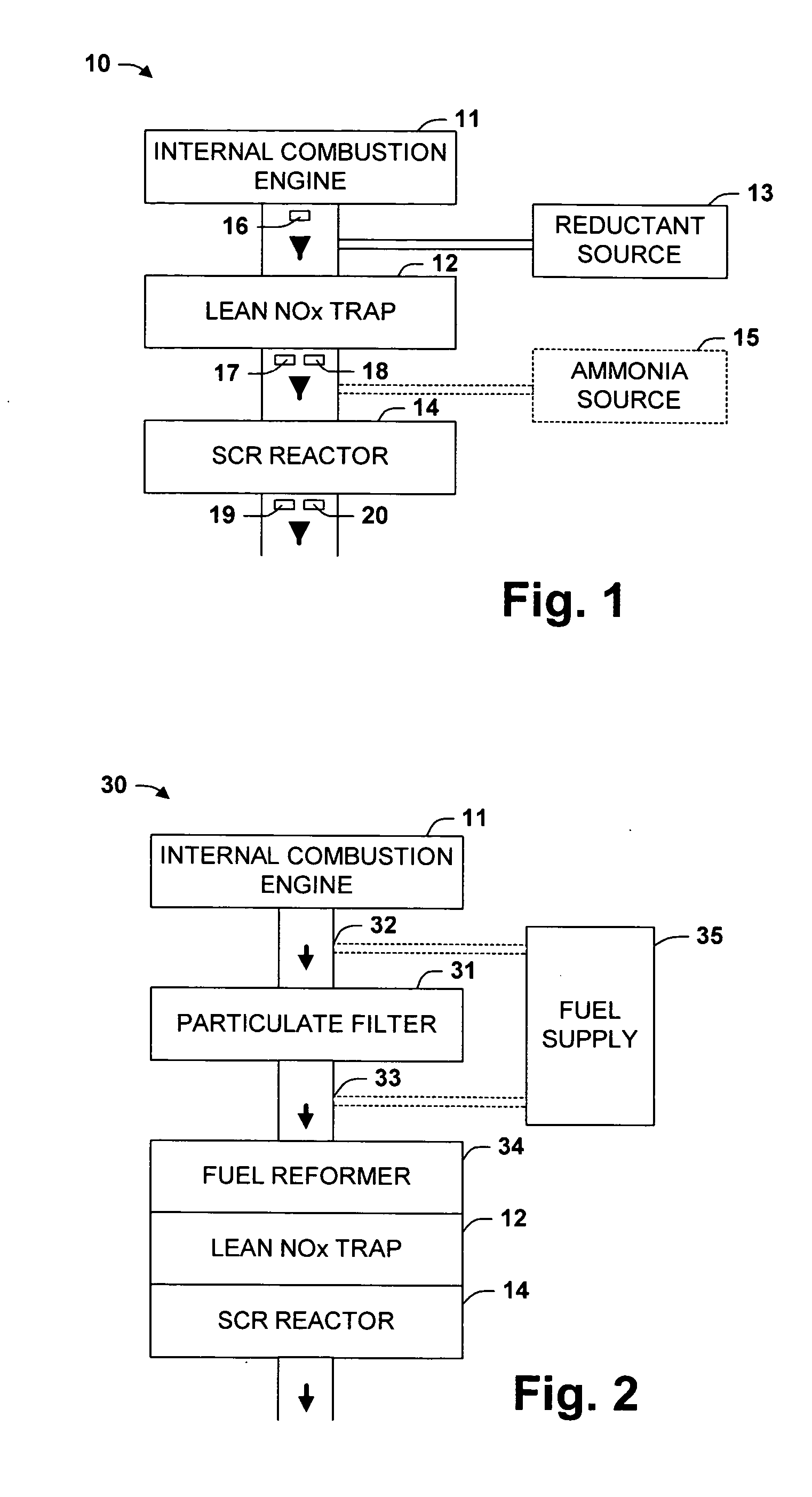

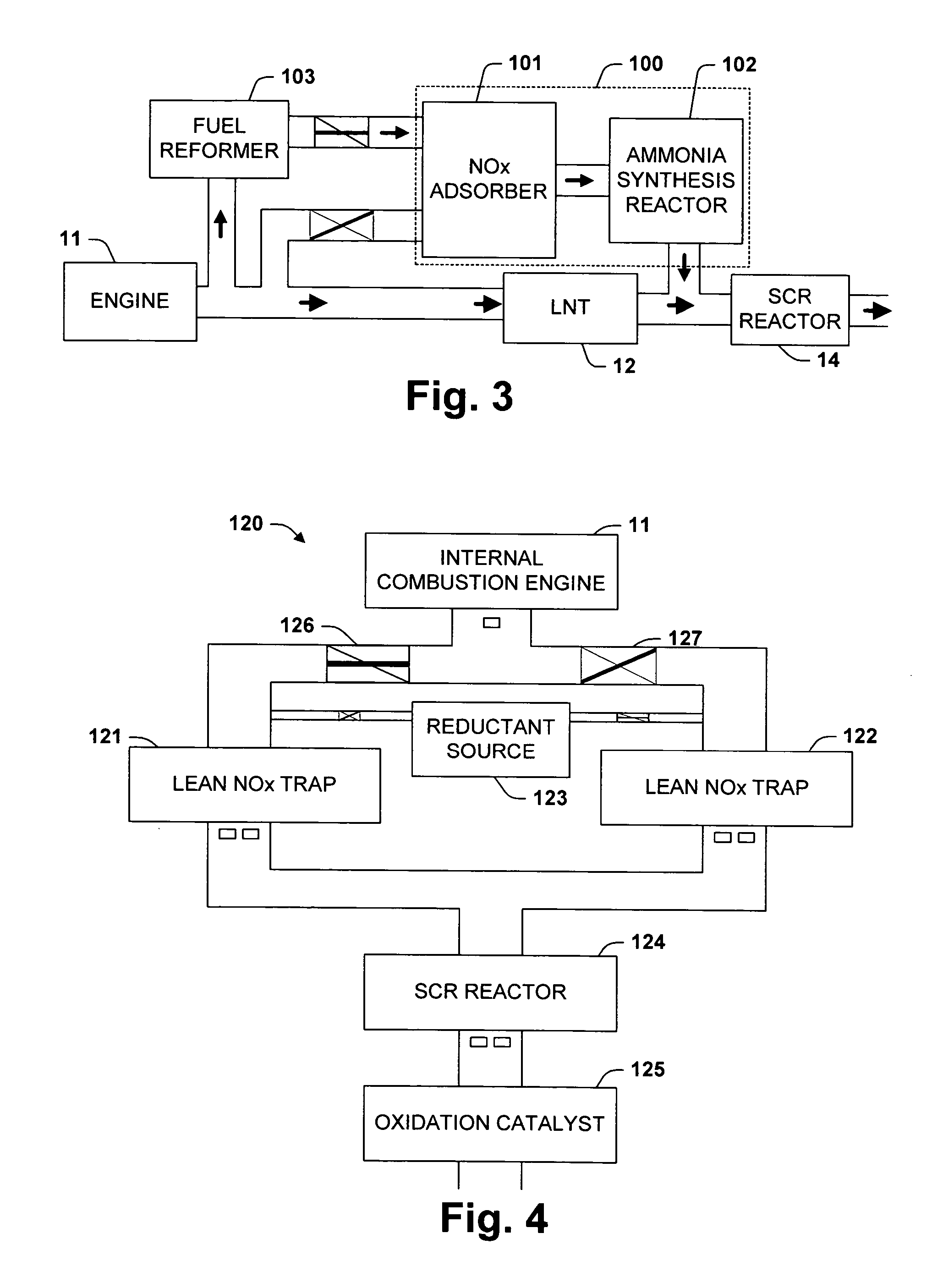

Hybrid catalyst system for exhaust emissions reduction

InactiveUS20060010857A1Improve efficiencySpeed up the conversion processHydrogenGas treatmentExhaust fumesEngineering

One aspect of the invention relates an exhaust treatment system having an SCR reactor following a NOx adsorber. Syn gas is used to regenerate the NOx adsorber. Another aspect relates to an LNT / SCR provided with an ammonia source separate from the LNT. A further aspect relates to a system comprising first and second LNTs and one or more SCRs downstream of the LNTs. A still further aspect relates to a device comprising first and second NOx adsorbers contained in a single housing. Another aspect relates to coating a surface of a moving part in an exhaust system with an oxidation catalyst to mitigate fouling. Additional aspects of the invention relate to strategies for controlling one or more of the time to initiate a regeneration cycle, the time to terminate a regeneration cycle, and the reductant injection rate during regeneration of LNT / SCR exhaust treatment systems.

Owner:INT ENGINE INTPROP CO LLC

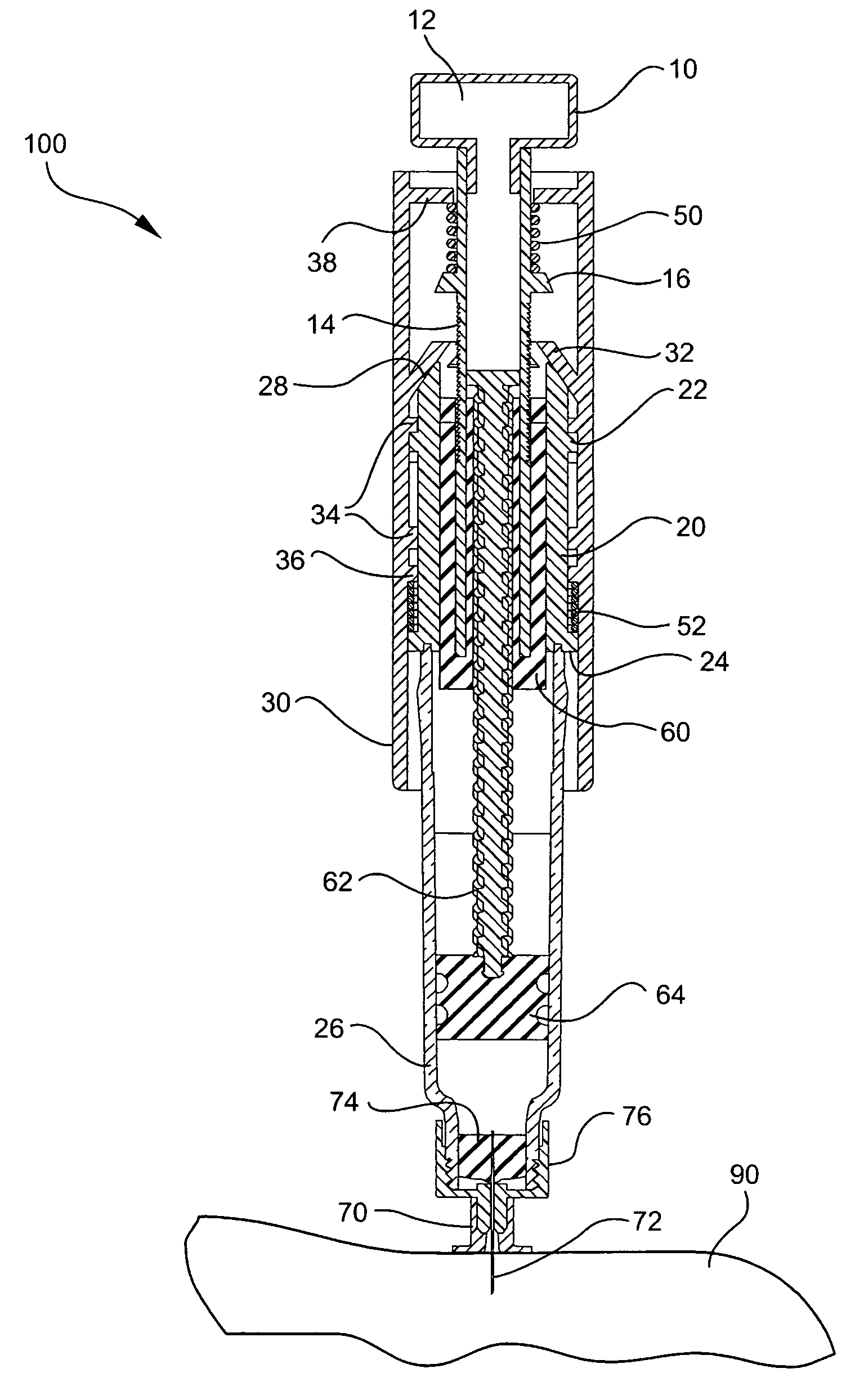

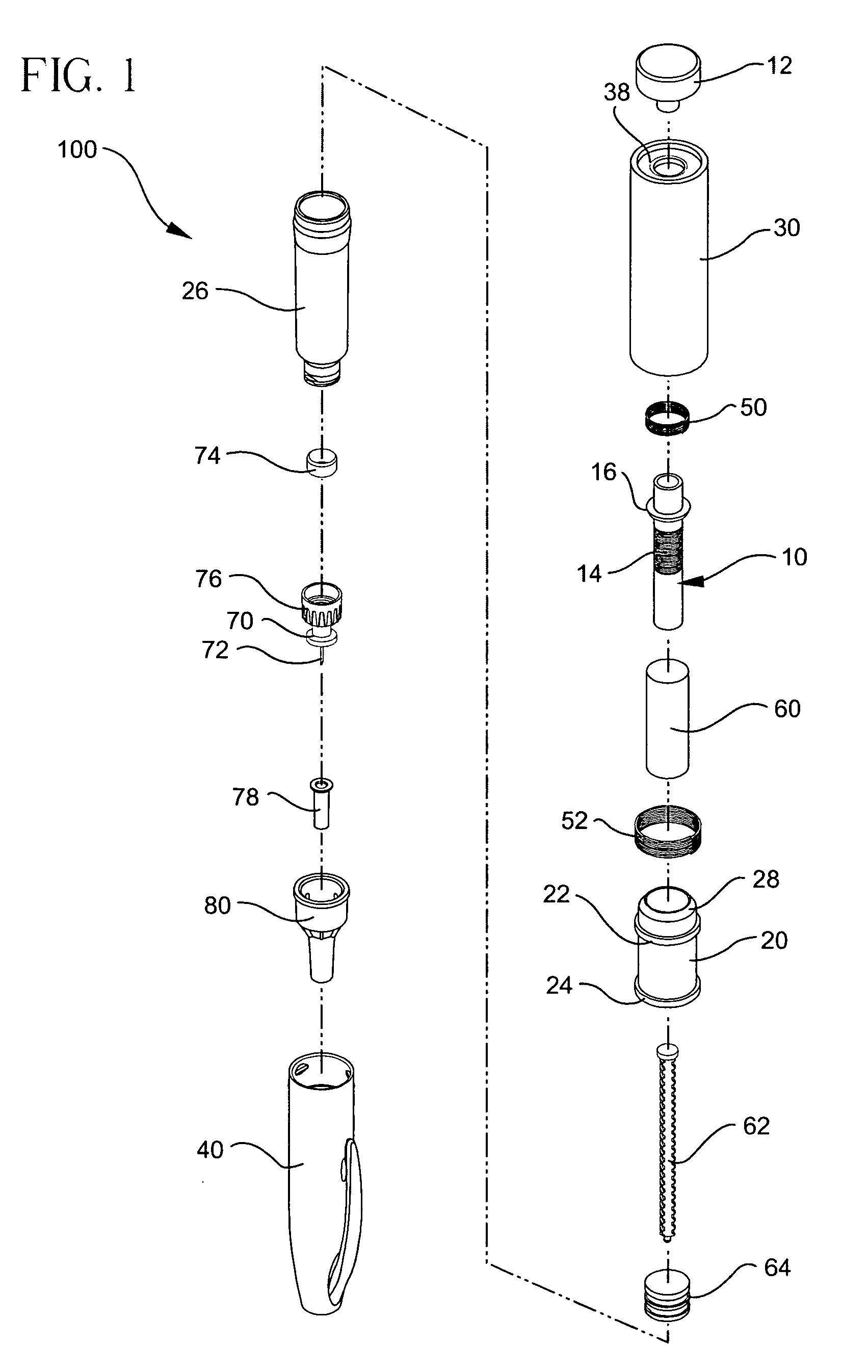

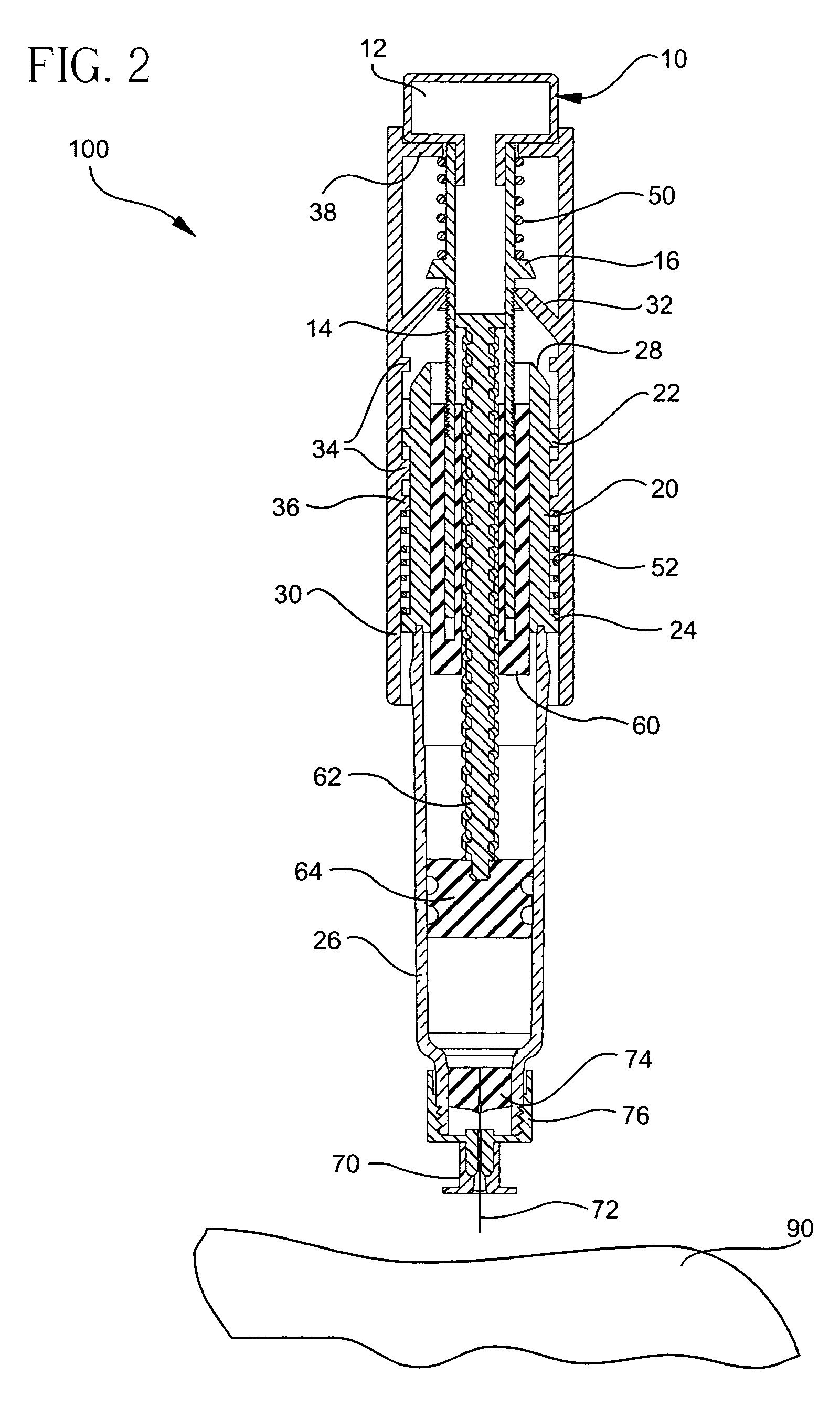

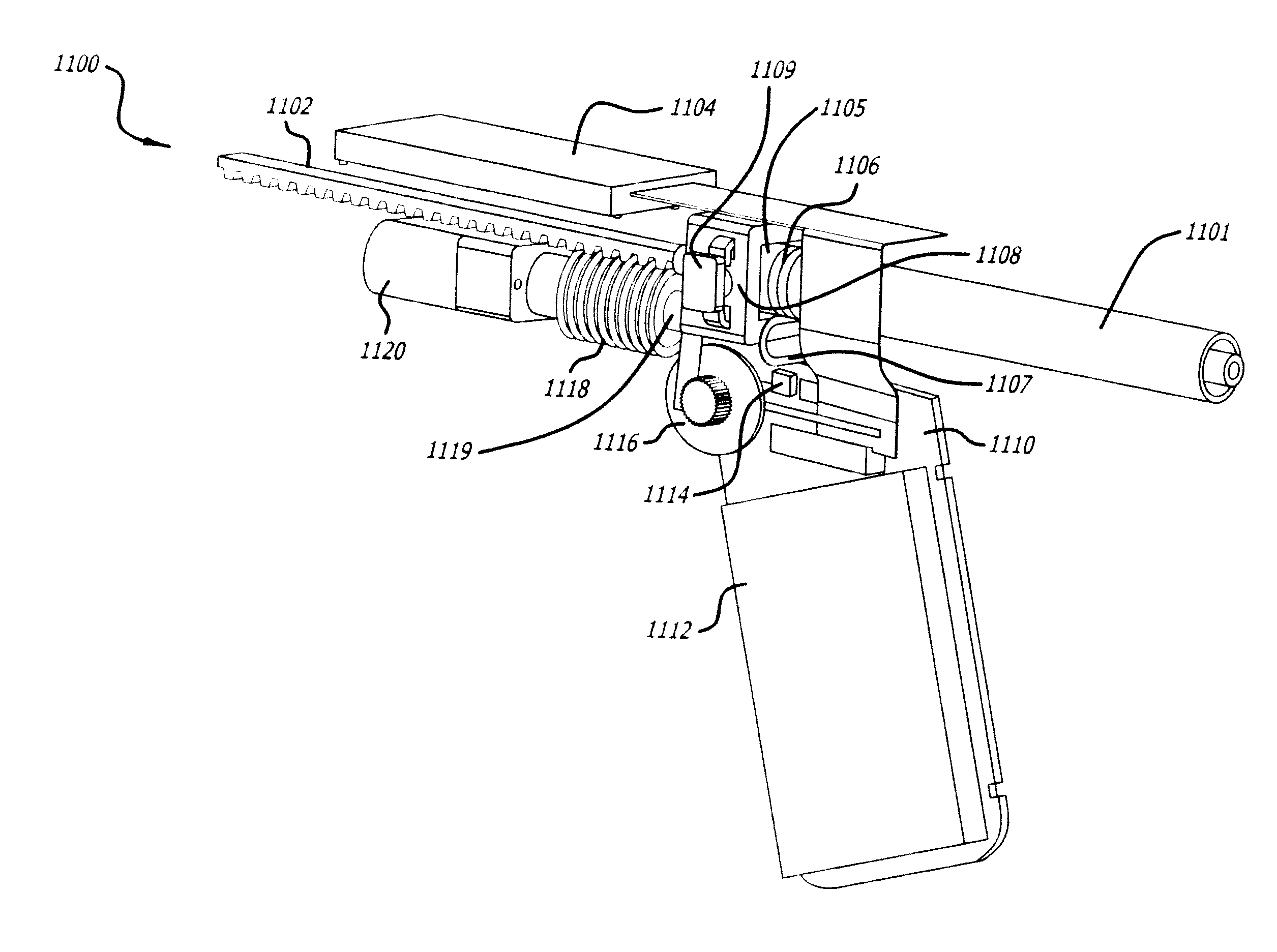

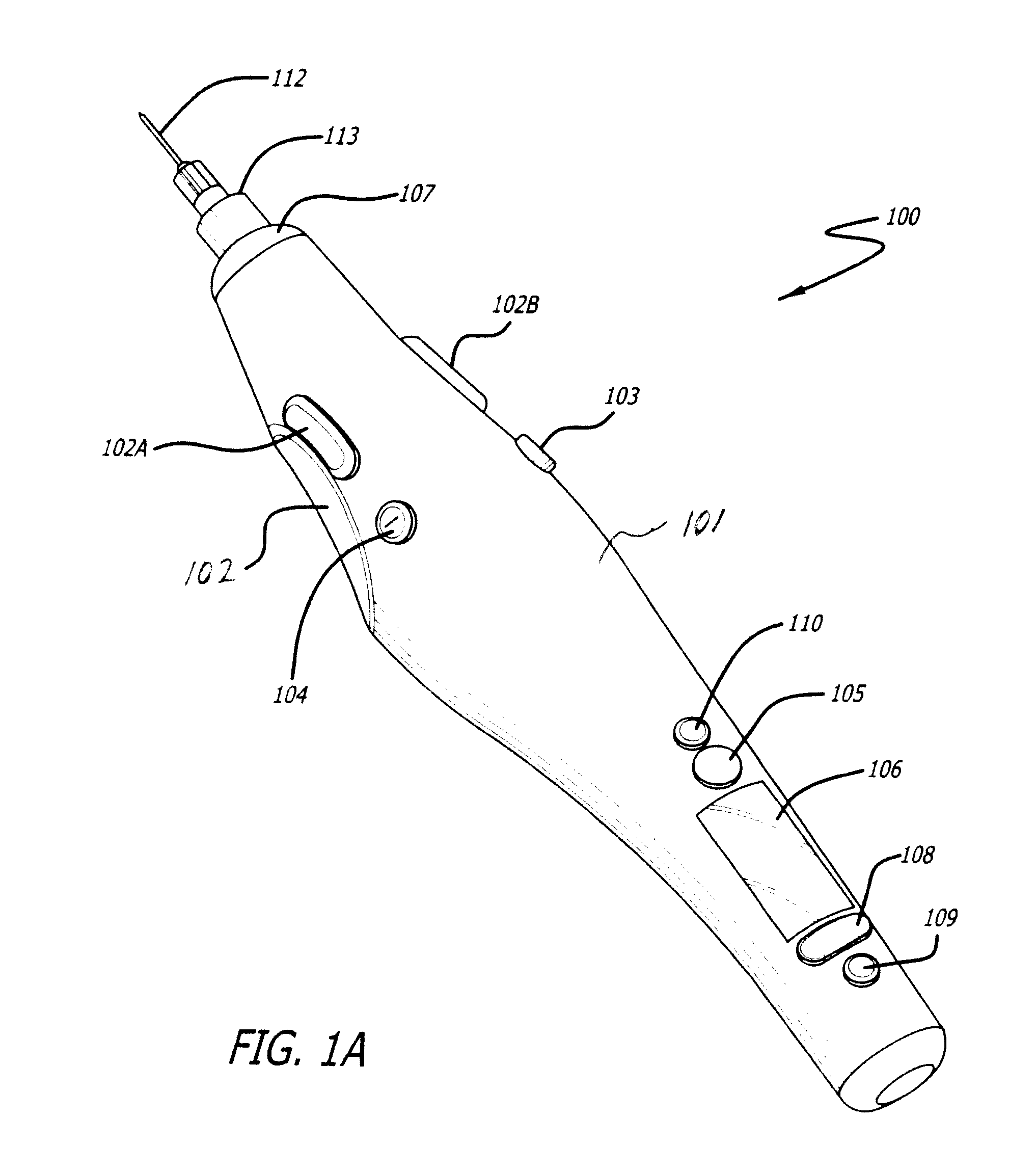

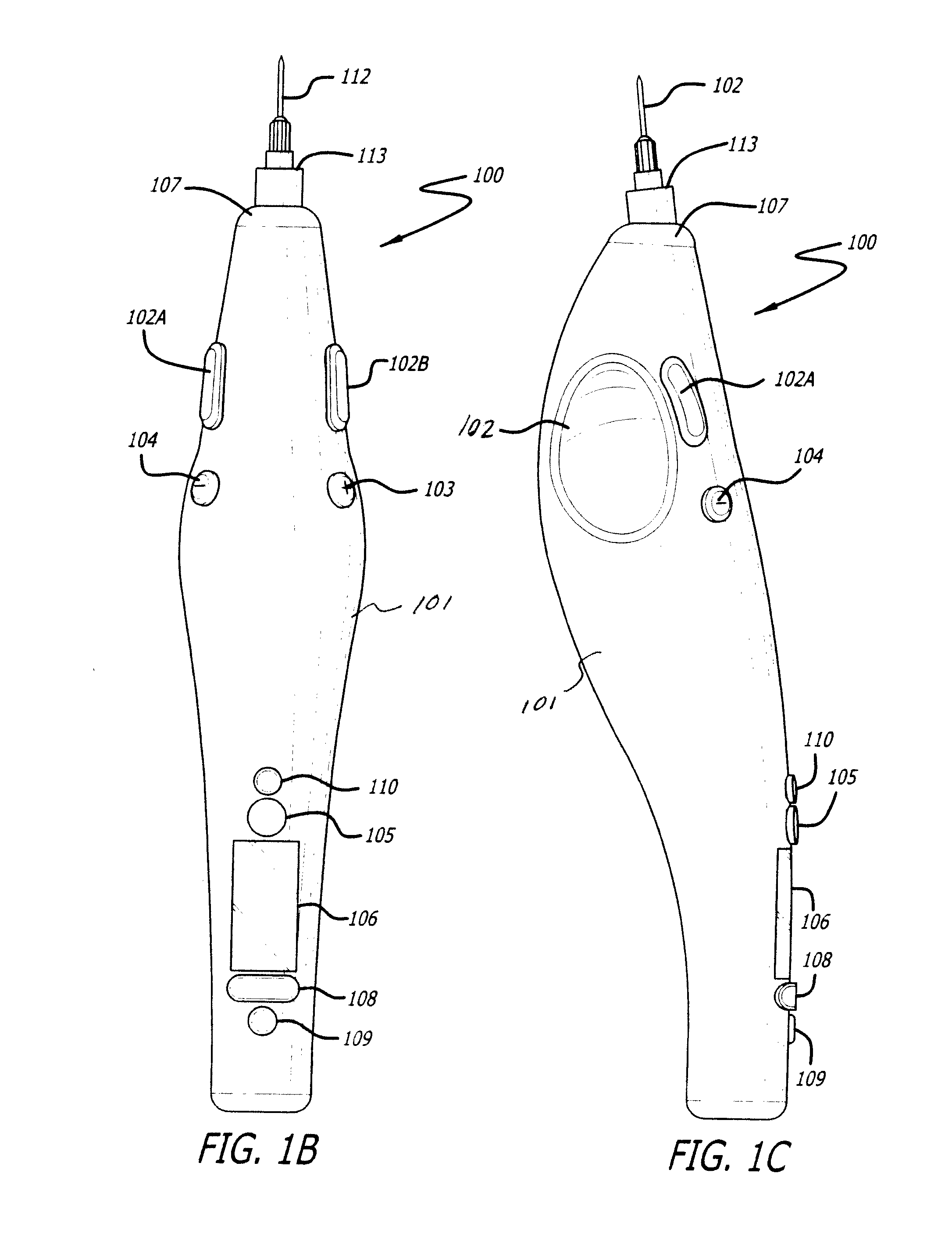

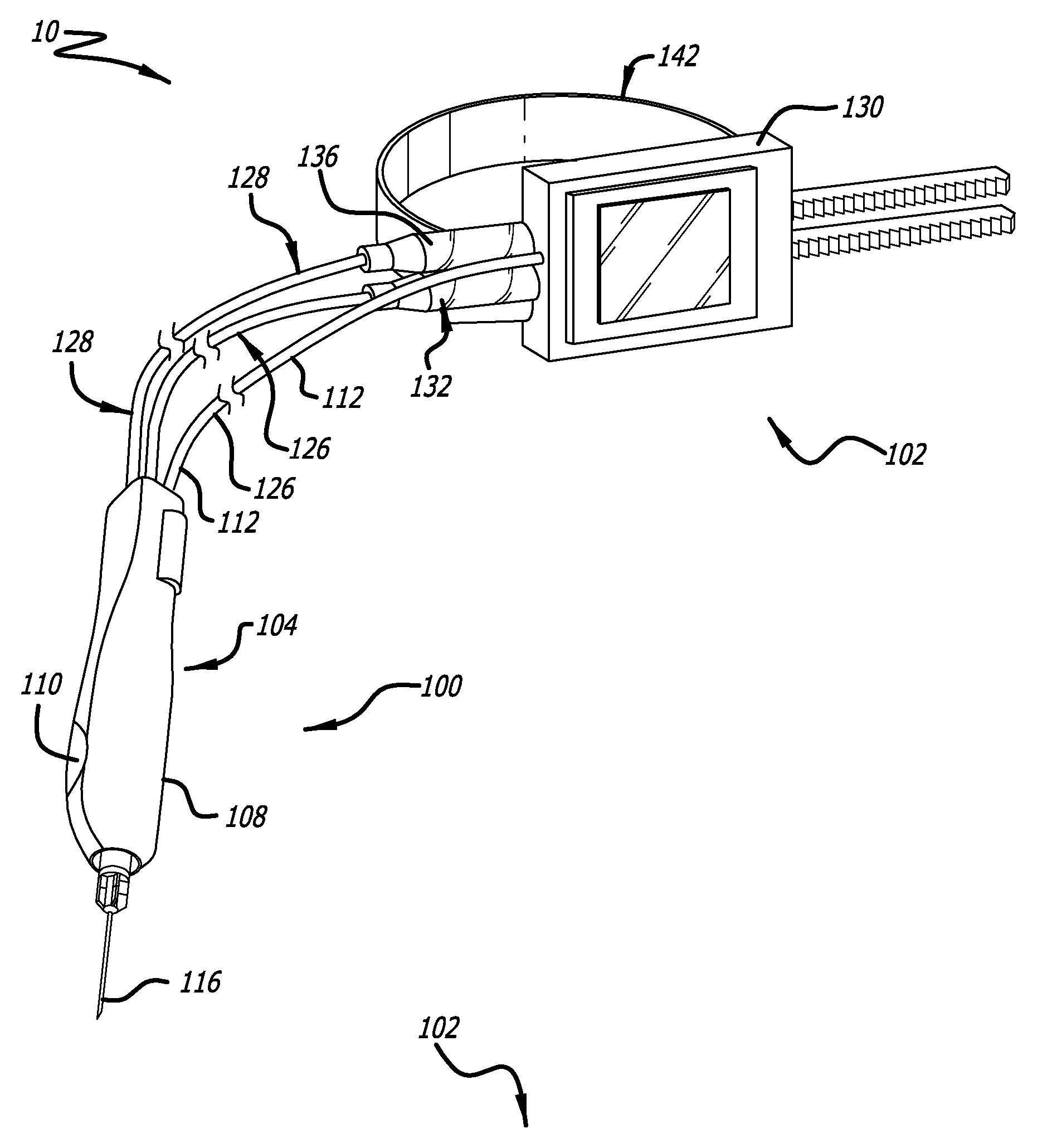

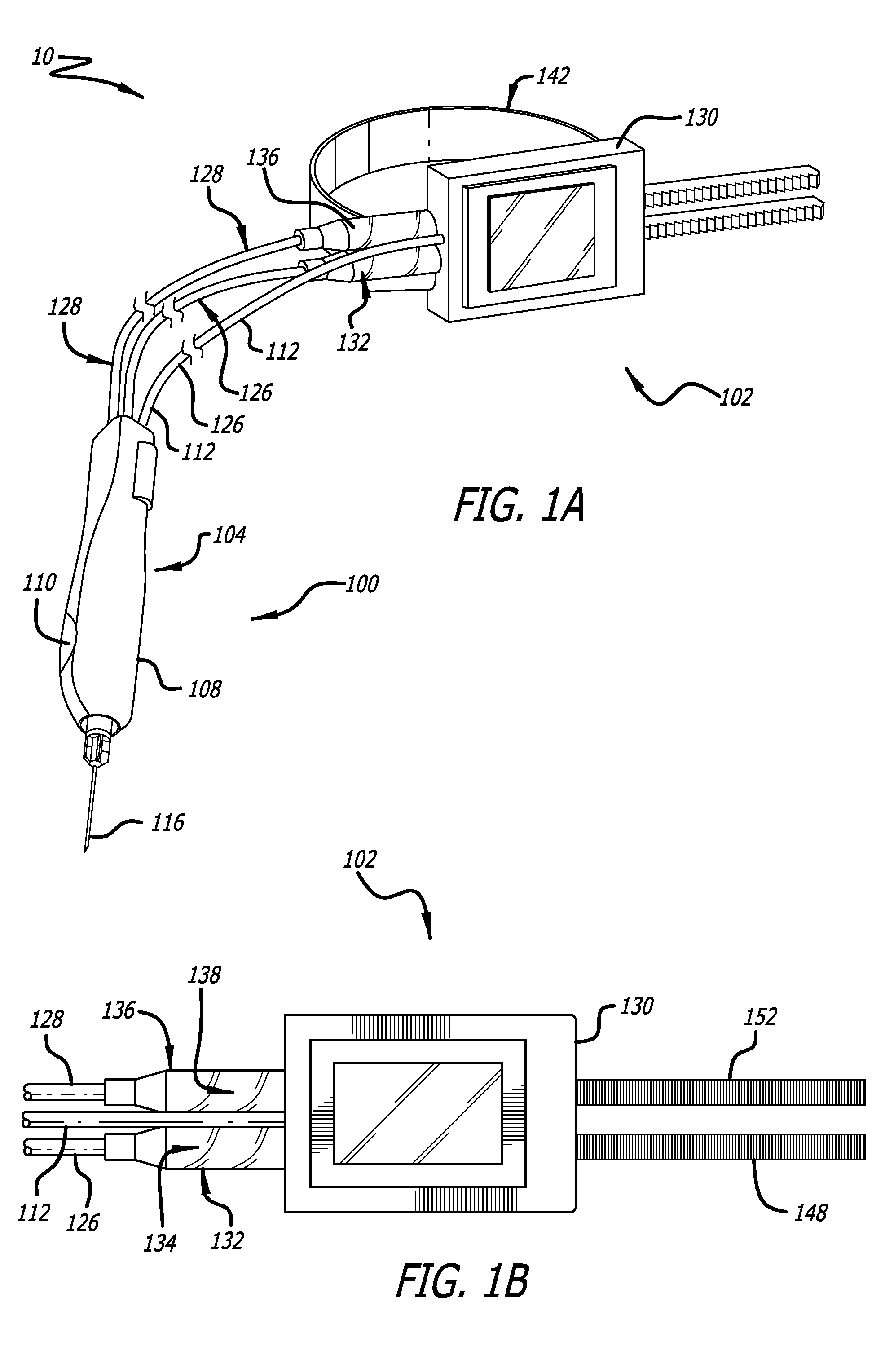

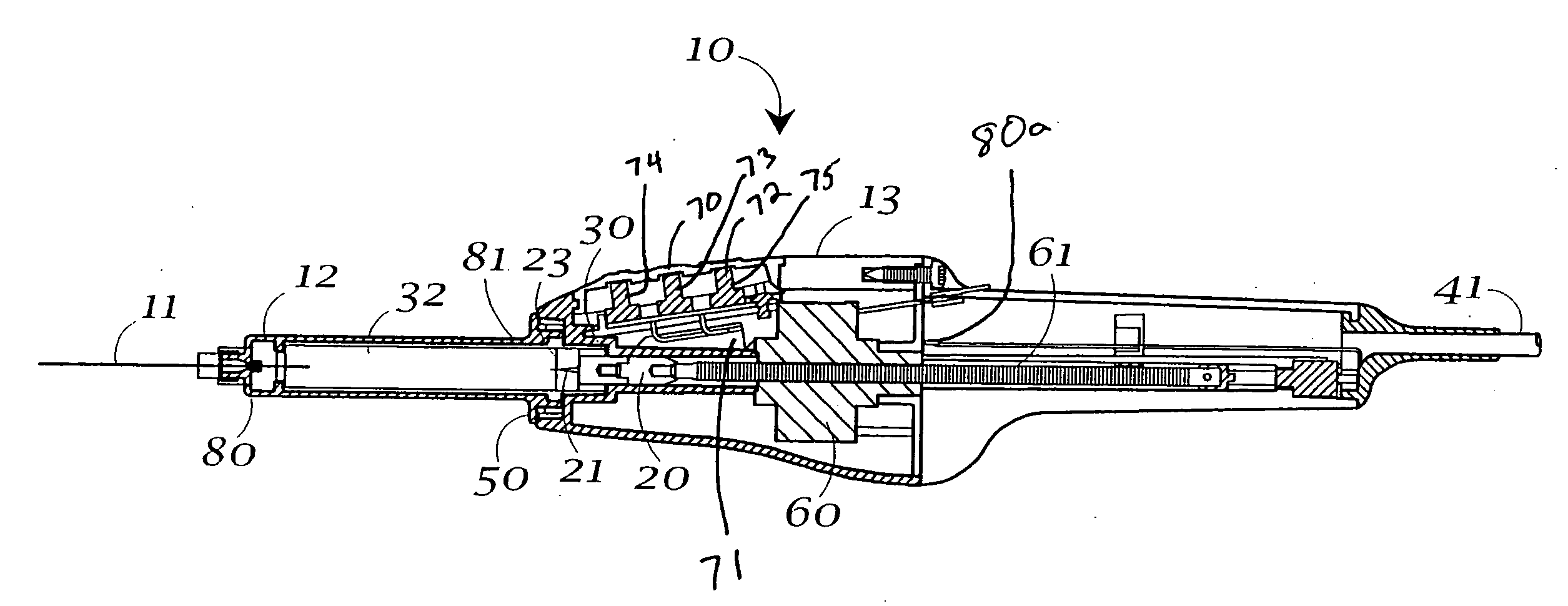

Injector device with force lock-out and injection rate limiting mechanisms

ActiveUS20060229570A1Inhibit injectionEliminate and minimize leakageAmpoule syringesAutomatic syringesRate limitingNeedle puncture

An injectable substance delivery device comprising a pen device body, a cartridge, a plunger, a drive mechanism, and at least one of a lock-out mechanism and a rate-limiting mechanism. The lock-out mechanism is provided through a ratchet engagement between the body and the plunger to restrict plunger movement and to ensure that the required needle puncture depth is realized prior to injection by locking out the injection mechanism from advancing until a specified force is applied to the skin. A rate-limiting mechanism is also provided through a user compressed plunger drive spring to ensure that a specific rate of injection is realized during the injection of a medicament.

Owner:BECTON DICKINSON & CO

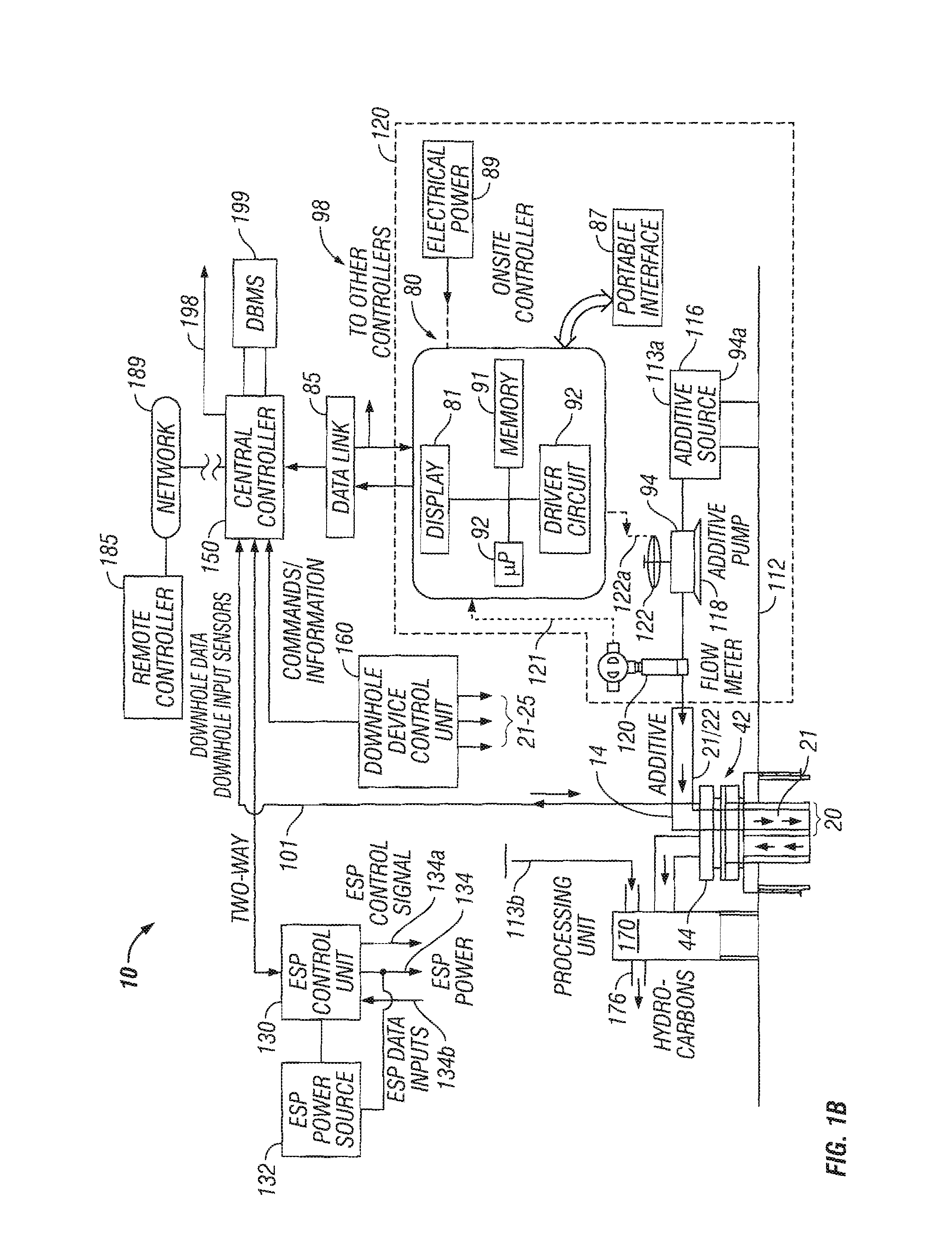

Apparatus and Method for Managing Supply of Additive at Wellsites

A system and method for supplying an additive into a well is disclosed that includes estimating injection rates for the additives and setting of one or more fluid flow control devices in the well based on a computer model. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:BAKER HUGHES INC

Method of optimizing the design, stimulation and evaluation of matrix treatment in a reservoir

InactiveUS6668922B2Easy to optimizeSimple calculationSurveyPackage sterilisationMathematical modelTreatment strategy

A method for designing acid treatments provides for the selection of optimal treatment for well stimulation wherein reservoir characteristics are obtained to further select the reaction kinetic data on the minerals of interests, the treatment to the reservoir is scaled up using a mathematical model and real time damage are computed based on bottomhole pressure and injection rate and compared to that predicted by the mathematical model to adjust the treatment. The model generated facilitates optimization of matrix treatments by providing a rapid quantitative evaluation of various treatment strategies for a formation. Stimulation with non-traditional fluid recipes containing mixtures of inorganic and organic acids, and chelating agents can be readily computed. The computed values can then be used in an economic model to justify the additional costs associated with the use of the non-traditional fluids. Apart from optimizing matrix treatments, the method can be used as a development tool for new fluid systems, as a tool for prediction and removal of inorganic scale and for fluid compatibility testing such as that required in water flooding projects.

Owner:SCHLUMBERGER TECH CORP

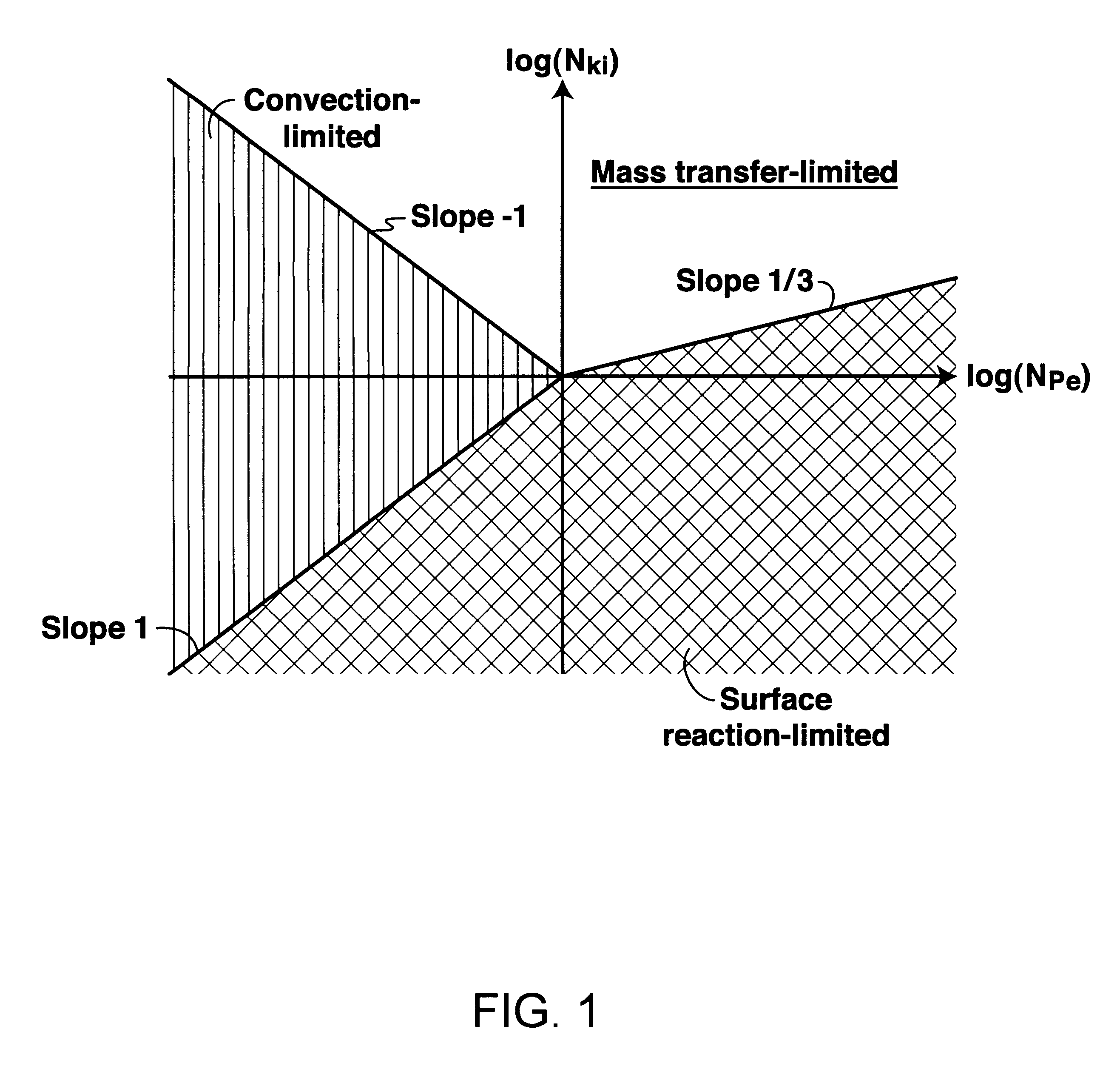

Method for optimizing acid injection rate in carbonate acidizing process

A method for optimizing the rate at which a given acid should be injected into a carbonate-containing rock formation during an acid injection process. The first step of the method calculates the Damkohler numbers for regimes in which kinematic force, diffusion rate and reaction rate control. The Damkohler numbers are then used to calculate the rate of growth of wormholes as a function of flux, taking into account compact dissolution, wormholing, and uniform dissolution. The calculated function is used to calculate an optimum flux for the formation. The optimum flux is then used to calculate an optimum injection rate at a given point in the acid injection process.

Owner:MOBIL OIL CORP

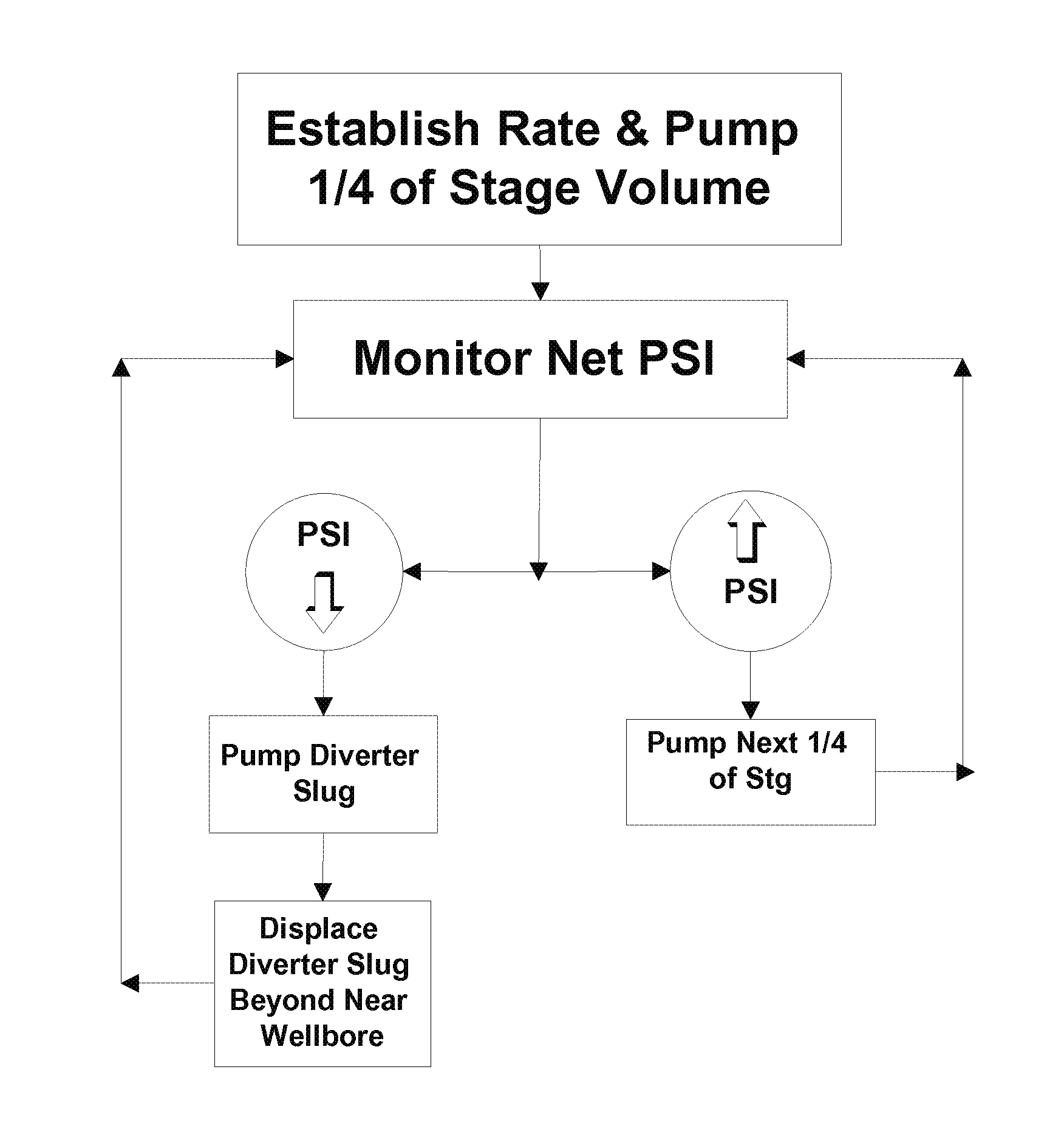

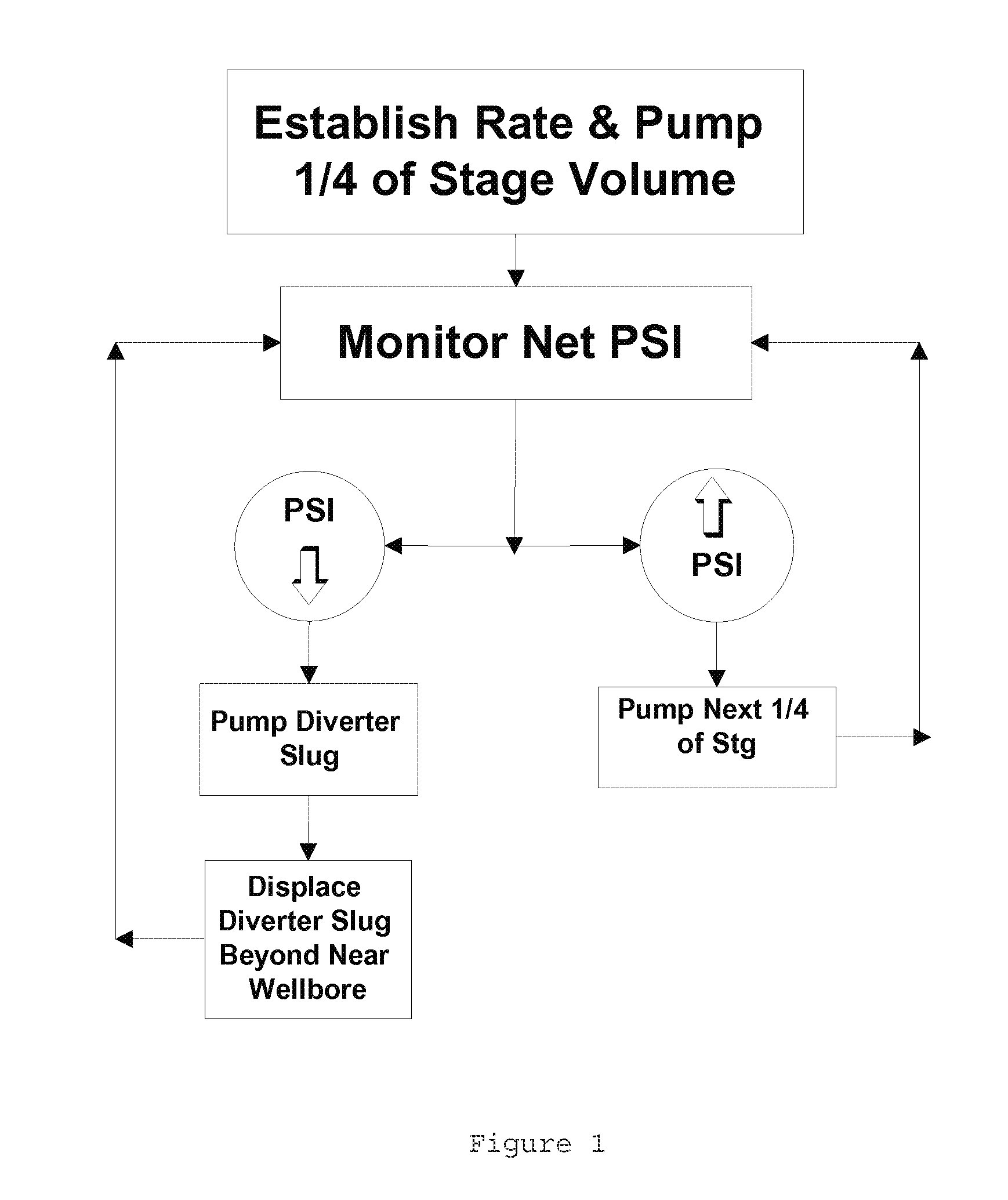

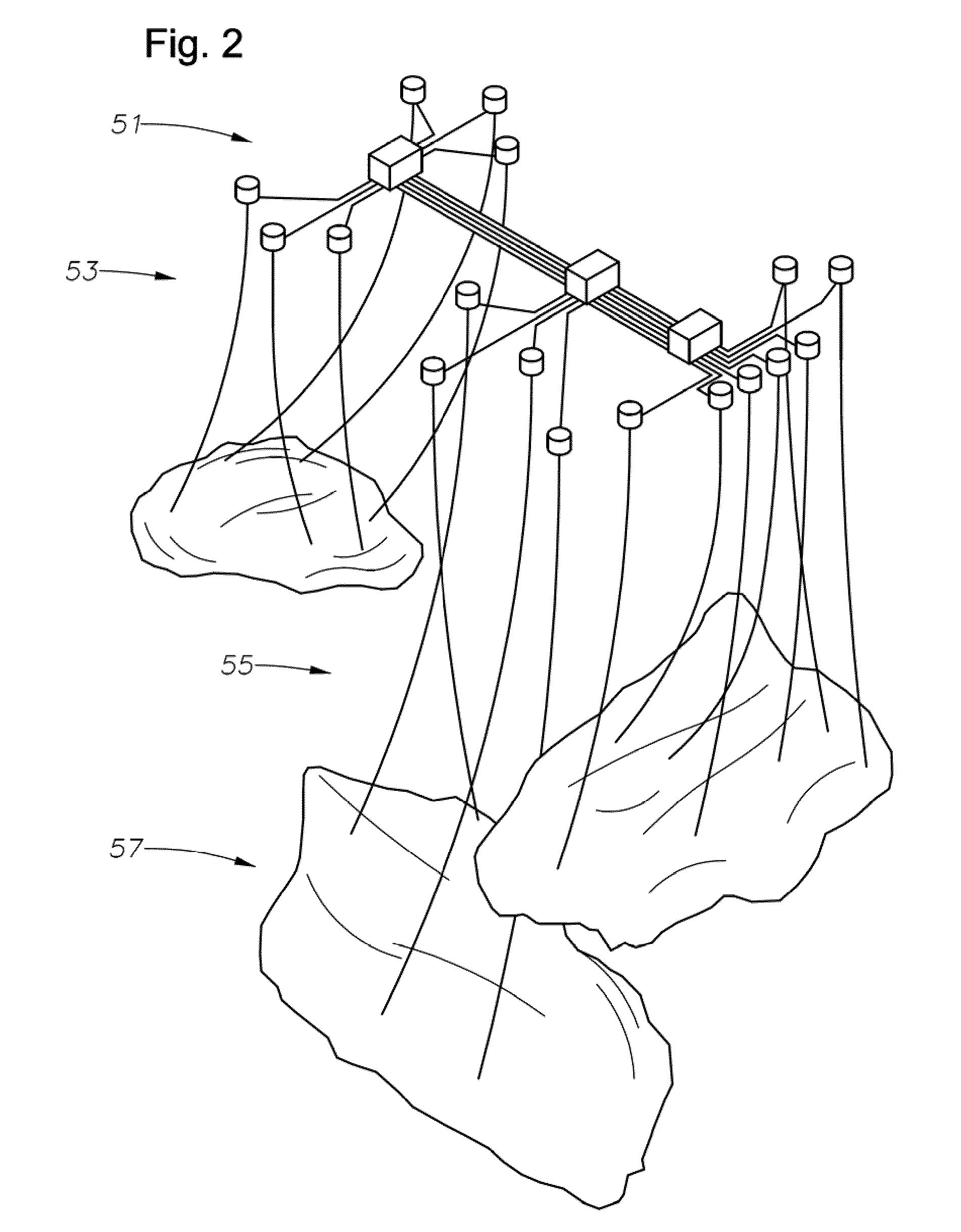

Methods of improving hydraulic fracture network

ActiveUS20130341030A1Optimize networkIncrease surface areaFluid removalDrilling compositionStress conditionsReservoir volume

The complexity of a fracture network may be enhanced during a hydraulic fracturing operation by monitoring operational parameters of the fracturing job and altering stress conditions in the well in response to the monitoring of the operational parameters. The operational parameters monitored may include the injection rate of the pumped fluid, the density of the pumped fluid or the bottomhole pressure of the well after the fluid is pumped. The method provides an increase to the stimulated reservoir volume (SRV).

Owner:BAKER HUGHES INC

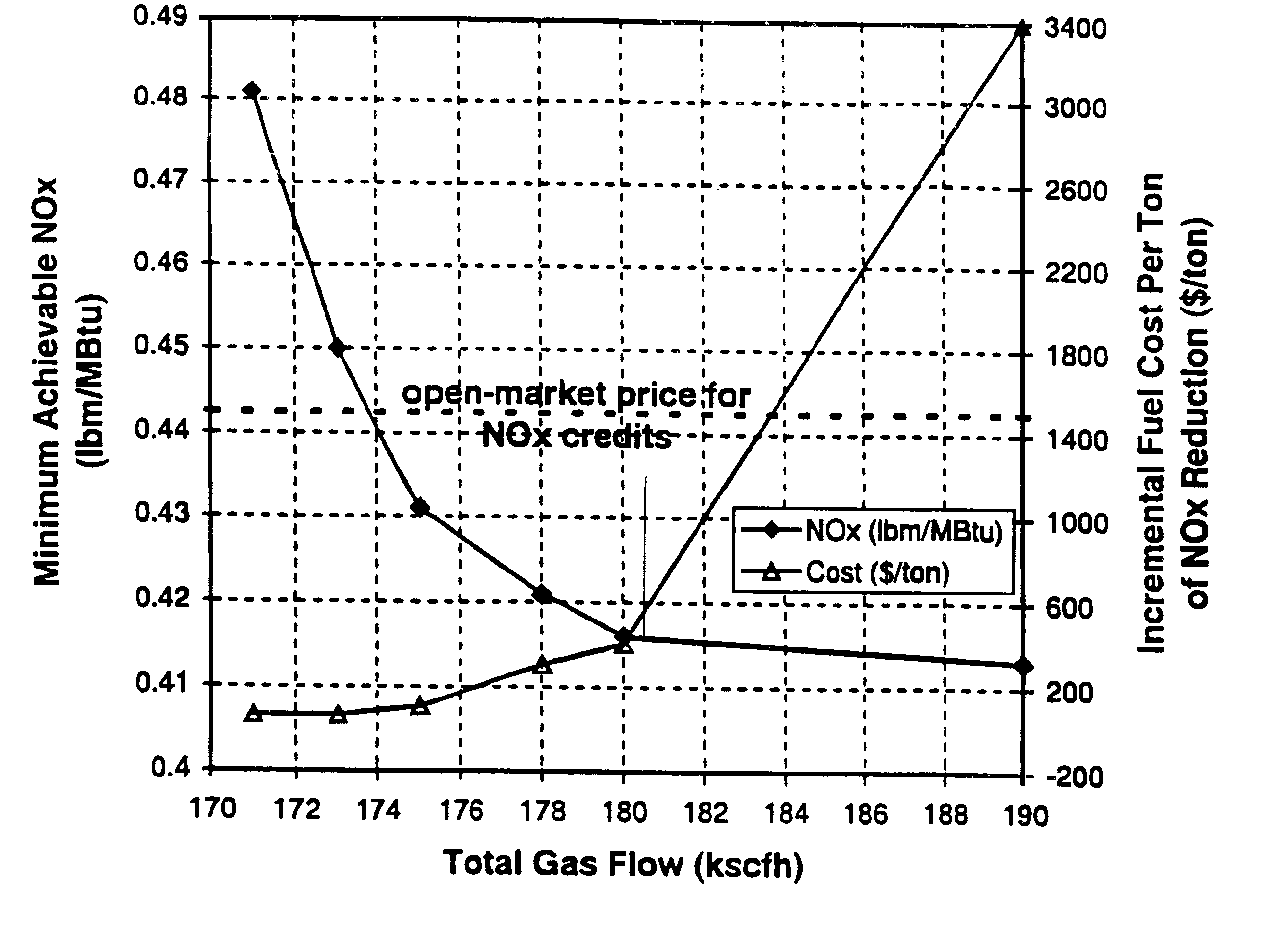

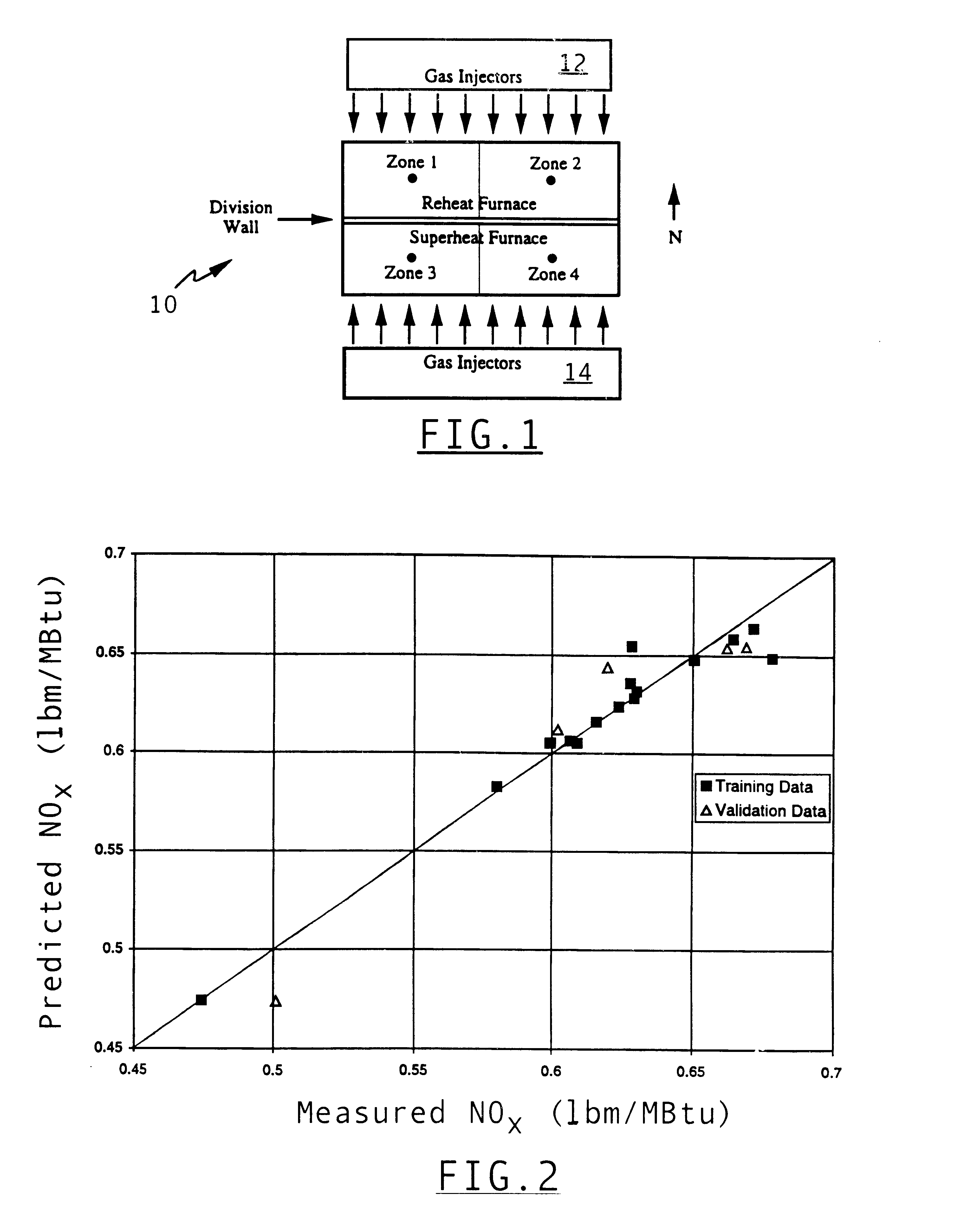

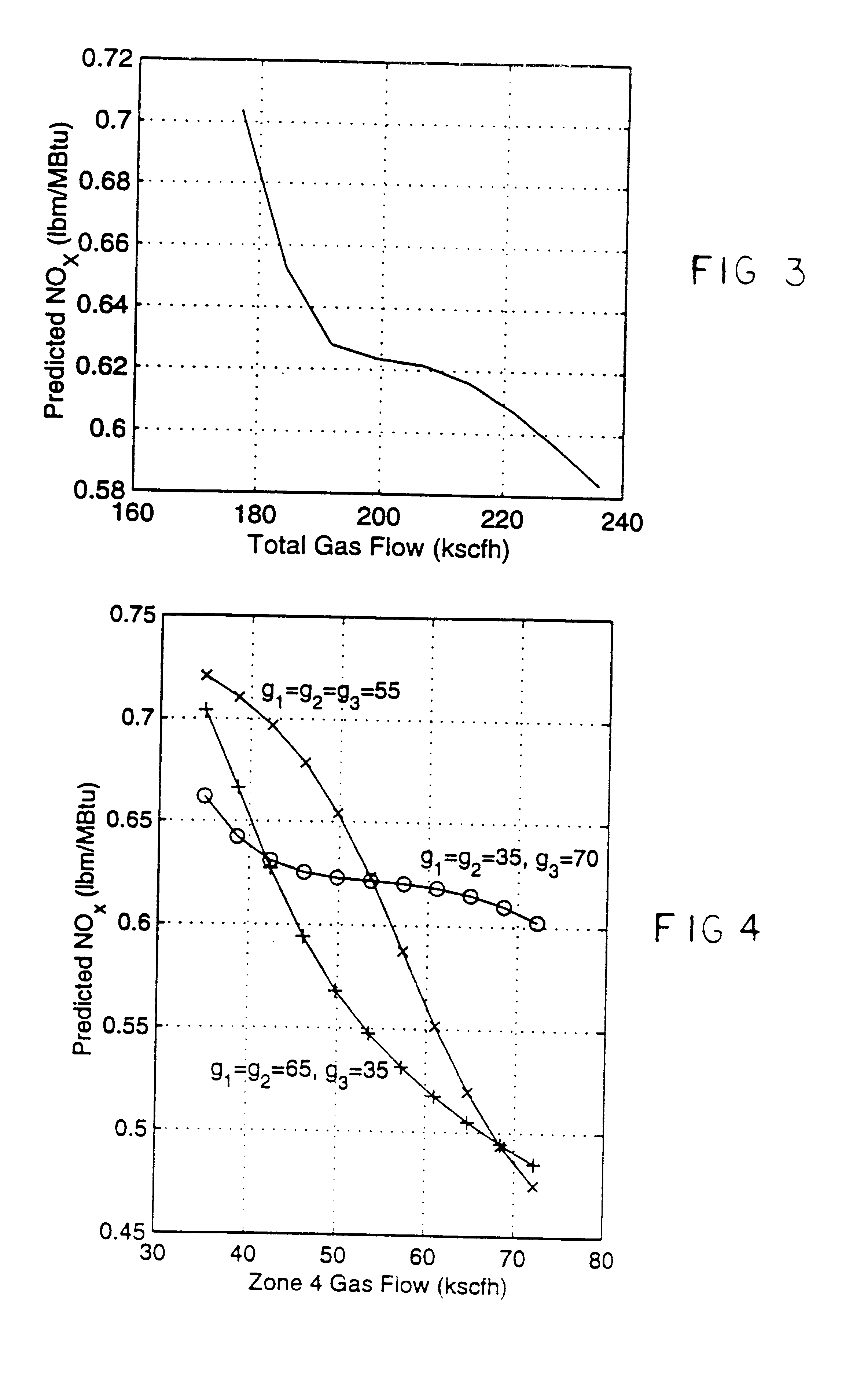

Intelligent emissions controller for substance injection in the post-primary combustion zone of fossil-fired boilers

InactiveUS6507774B1Emission reductionReduce pollutant emissionsSampled-variable control systemsCombustion signal processingWater oil emulsionU s economy

The control of emissions from fossil-fired boilers wherein an injection of substances above the primary combustion zone employs multi-layer feedforward artificial neural networks for modeling static nonlinear relationships between the distribution of injected substances into the upper region of the furnace and the emissions exiting the furnace. Multivariable nonlinear constrained optimization algorithms use the mathematical expressions from the artificial neural networks to provide the optimal substance distribution that minimizes emission levels for a given total substance injection rate. Based upon the optimal operating conditions from the optimization algorithms, the incremental substance cost per unit of emissions reduction, and the open-market price per unit of emissions reduction, the intelligent emissions controller allows for the determination of whether it is more cost-effective to achieve additional increments in emission reduction through the injection of additional substance or through the purchase of emission credits on the open market. This is of particular interest to fossil-fired electrical power plant operators. The intelligent emission controller is particularly adapted for determining the economical control of such pollutants as oxides of nitrogen (NOx) and carbon monoxide (CO) emitted by fossil-fired boilers by the selective introduction of multiple inputs of substances (such as natural gas, ammonia, oil, water-oil emulsion, coal-water slurry and / or urea, and combinations of these substances) above the primary combustion zone of fossil-fired boilers.

Owner:ENERGY SYST ASSOCD +1

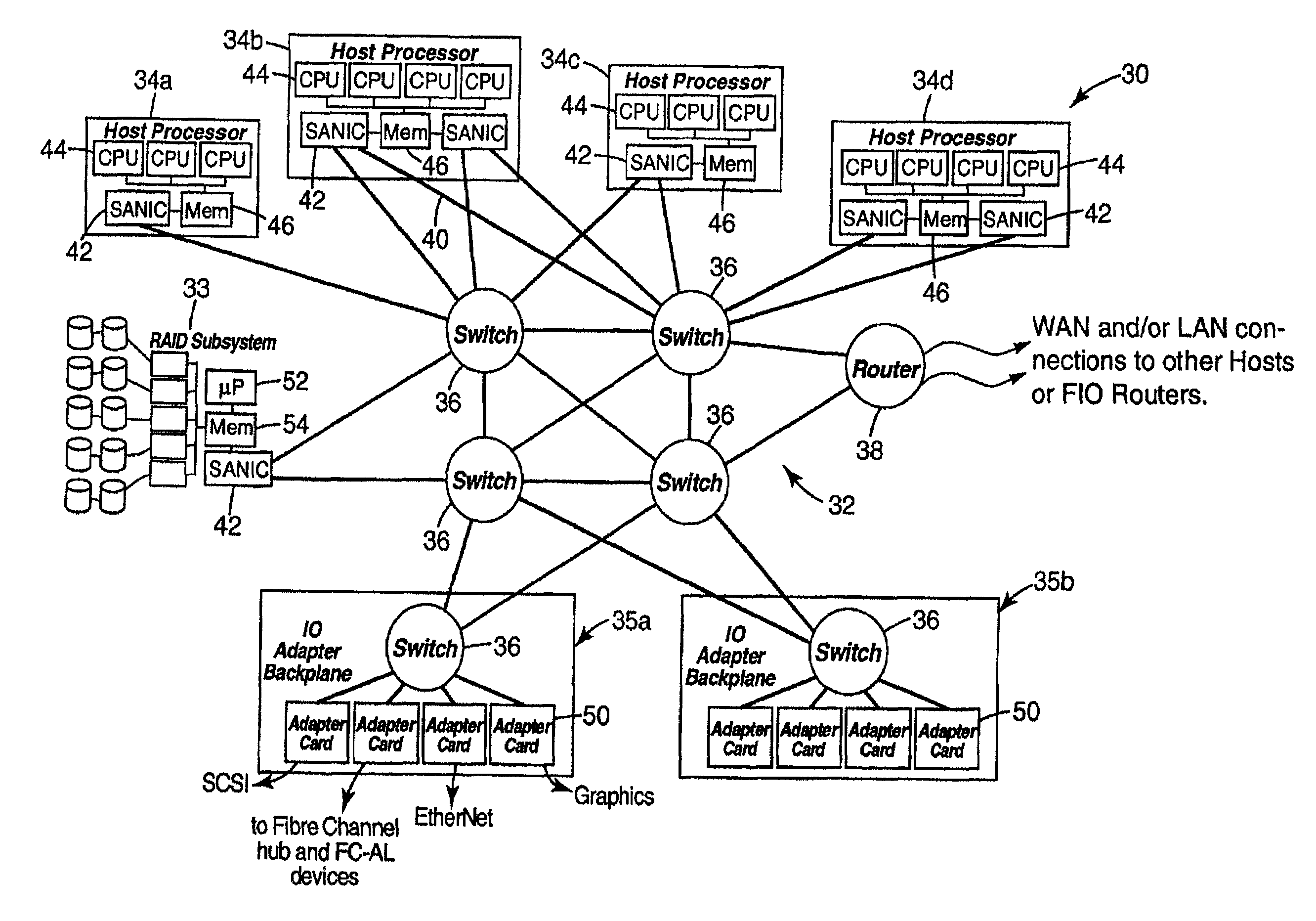

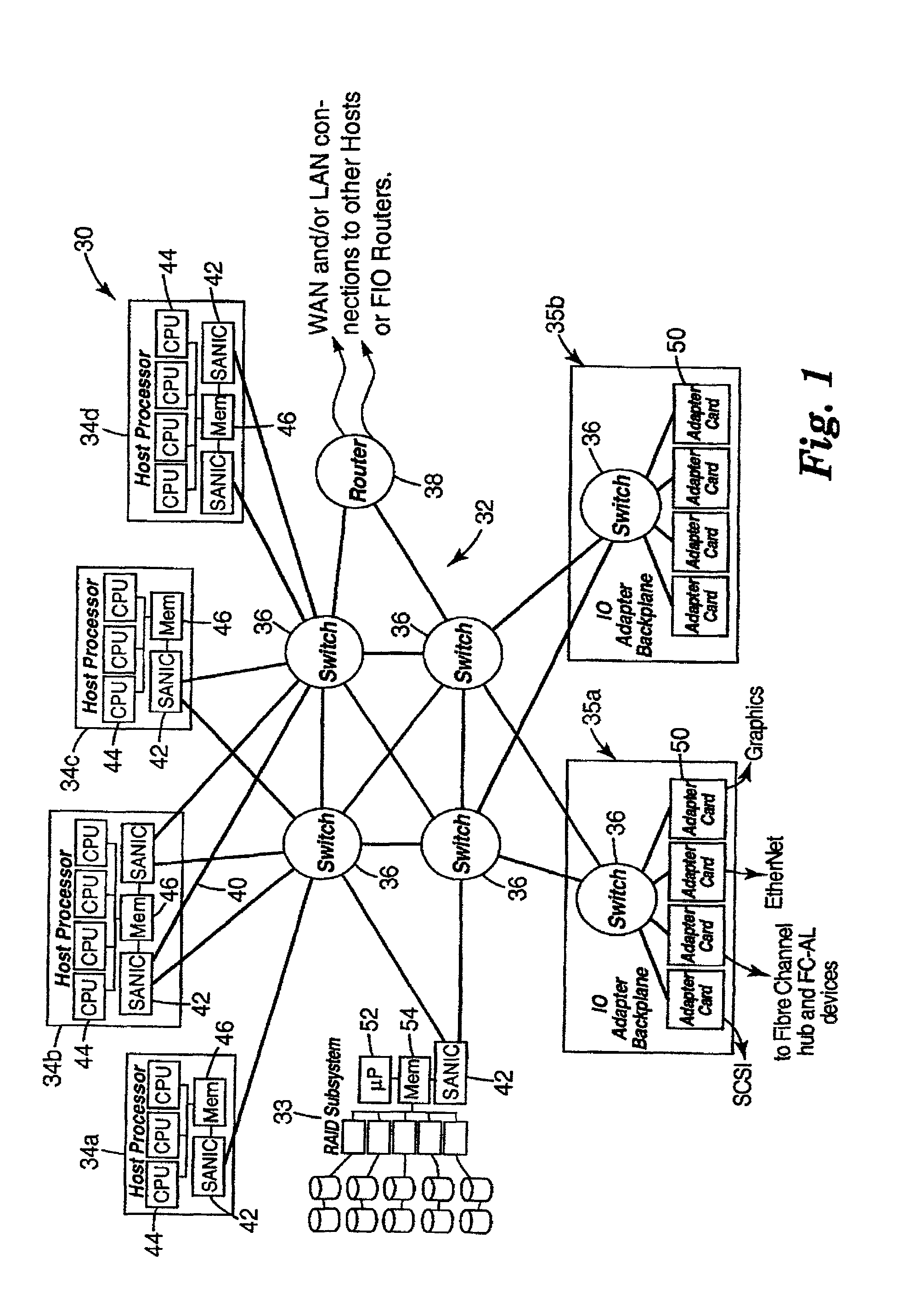

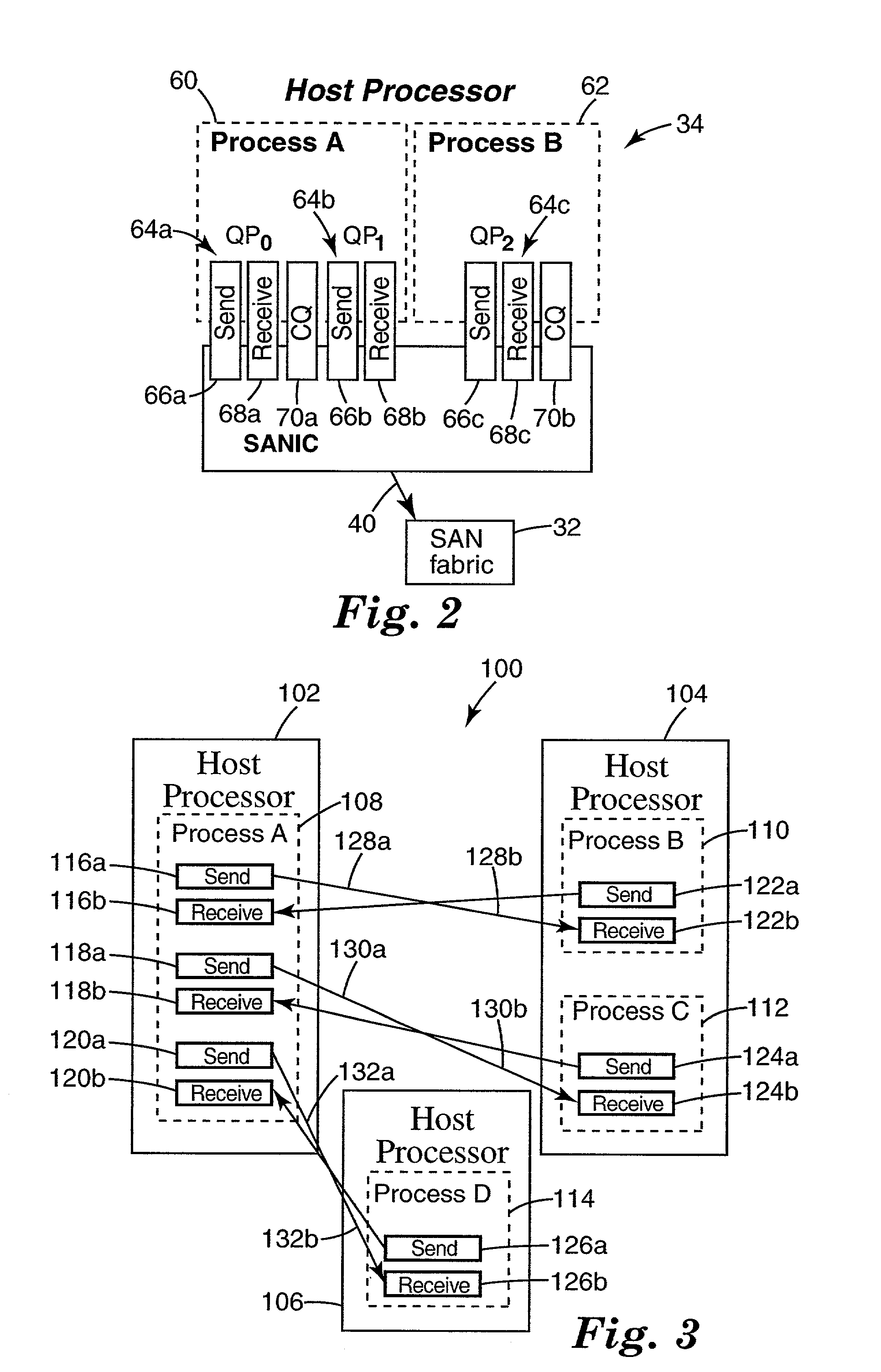

Congestion management in a distributed computer system multiplying current variable injection rate with a constant to set new variable injection rate at source node

InactiveUS7016971B1Reduce the injection rateReduce rateMultiple digital computer combinationsTransmissionComputerized systemInjection rate

A distributed computer system includes links and routing devices coupled between the links and routing frames between the links. Each of the routing devices includes a congestion control mechanism for detecting congestion at the routing device and responding to detected congestion by gradually reducing an injection rate of frames routed from the routing device.

Owner:PMC-SIERRA +3

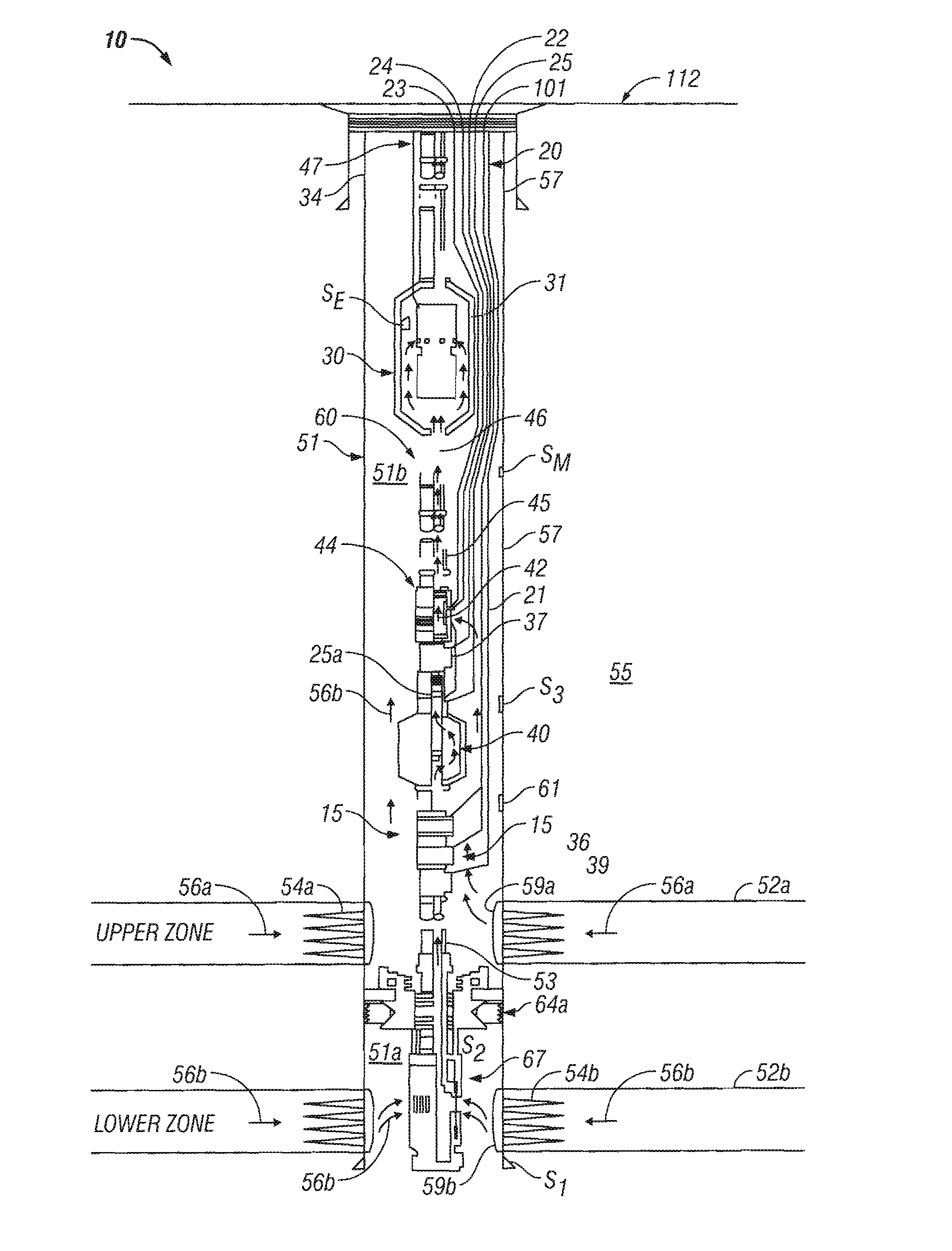

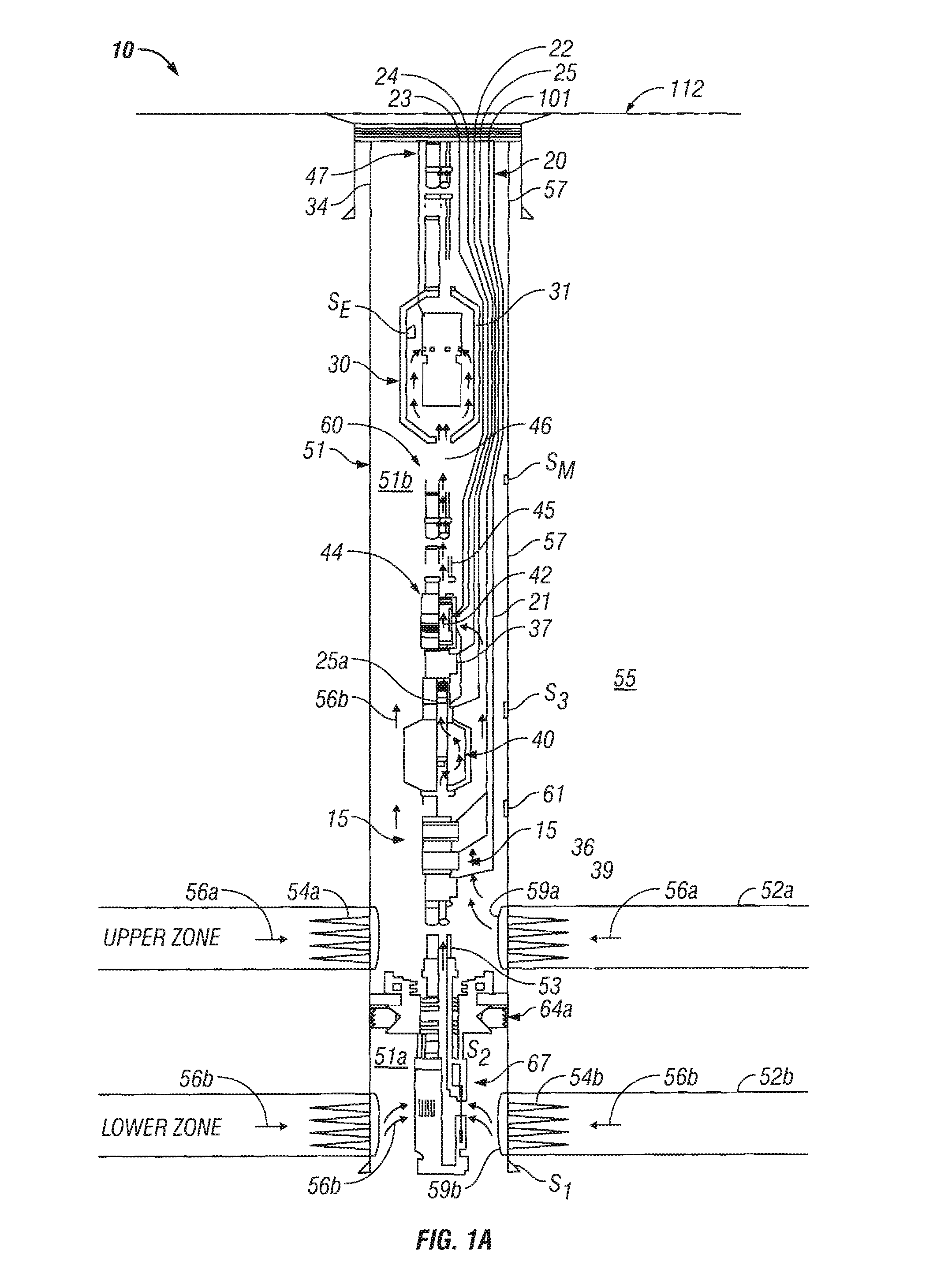

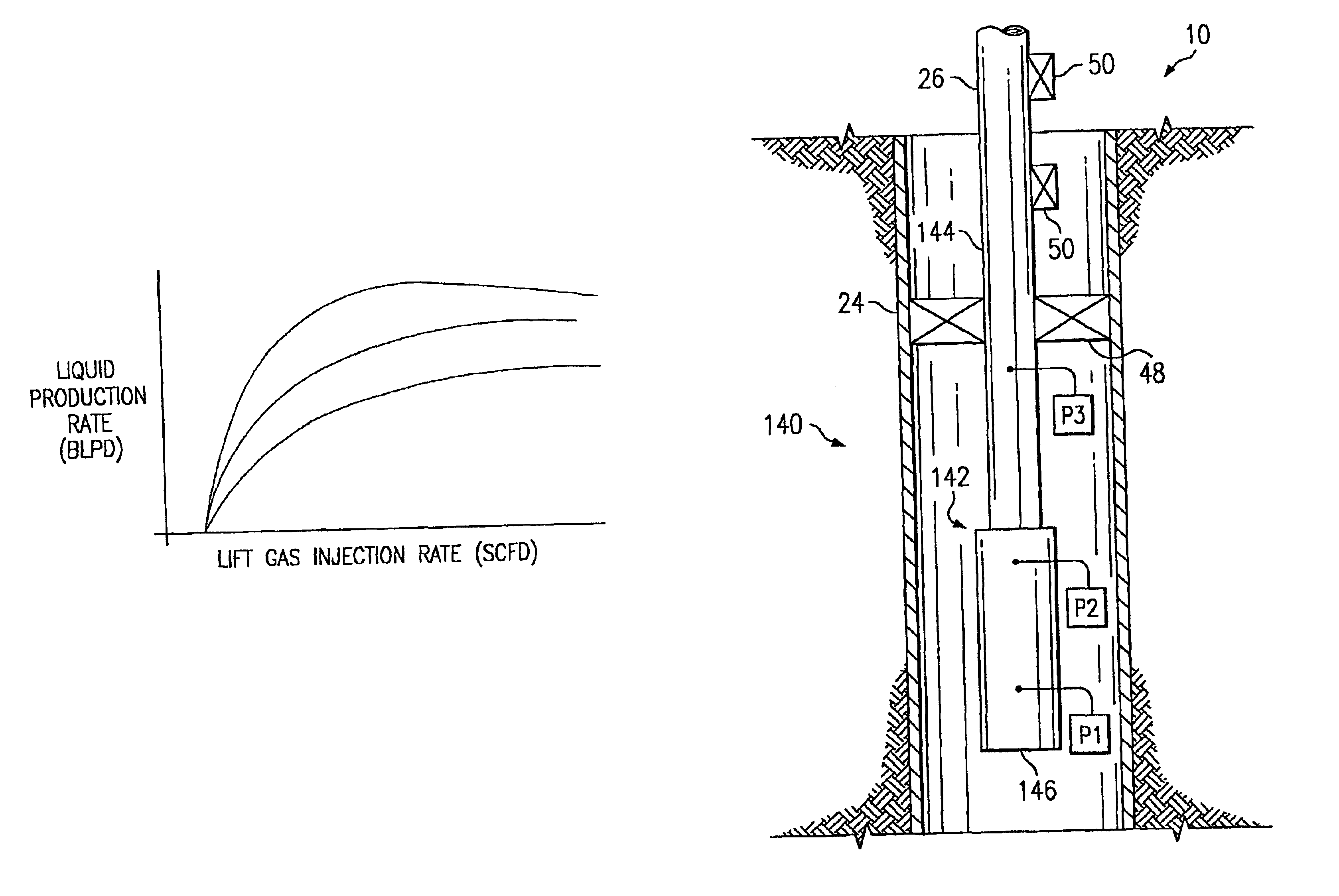

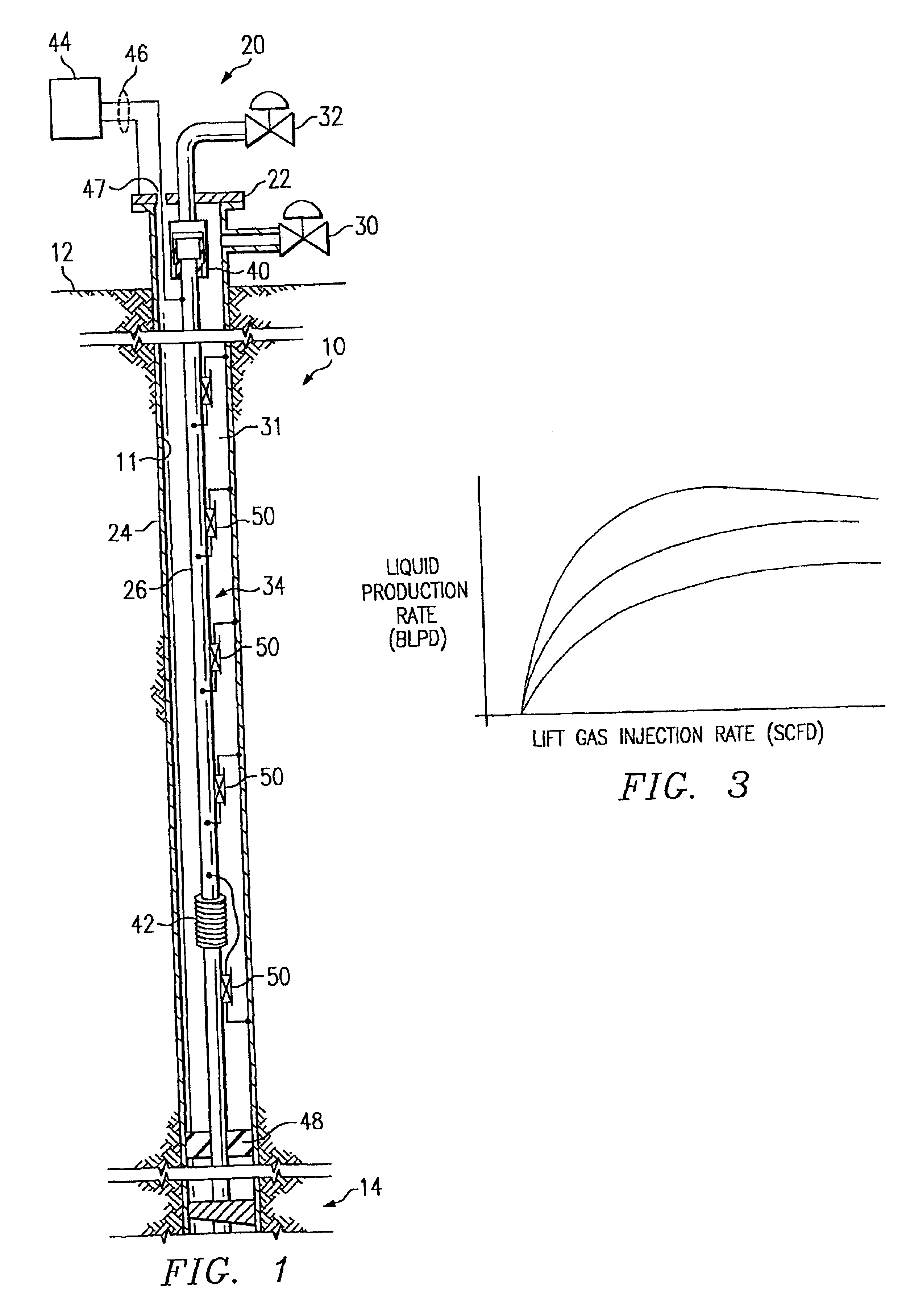

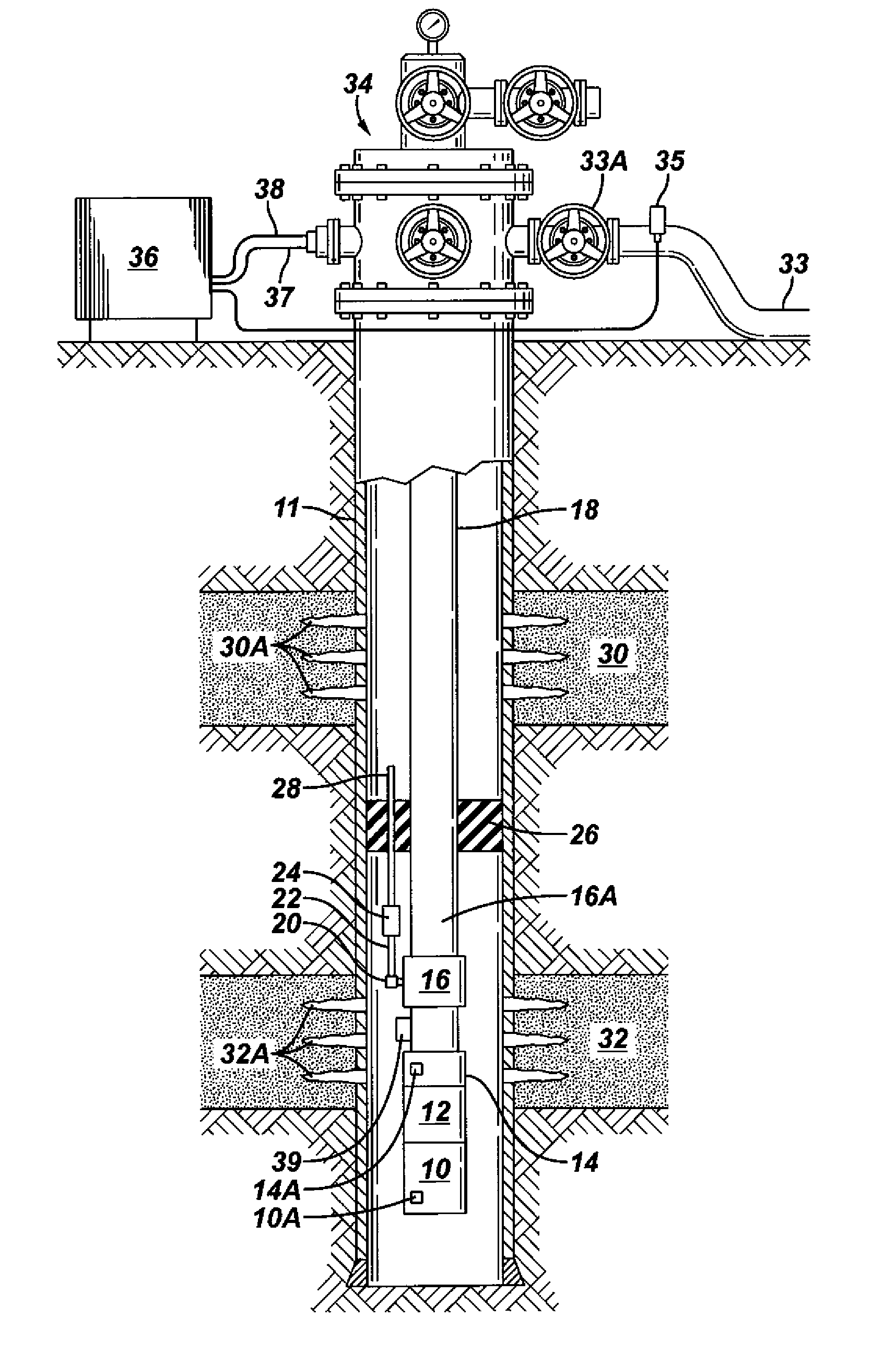

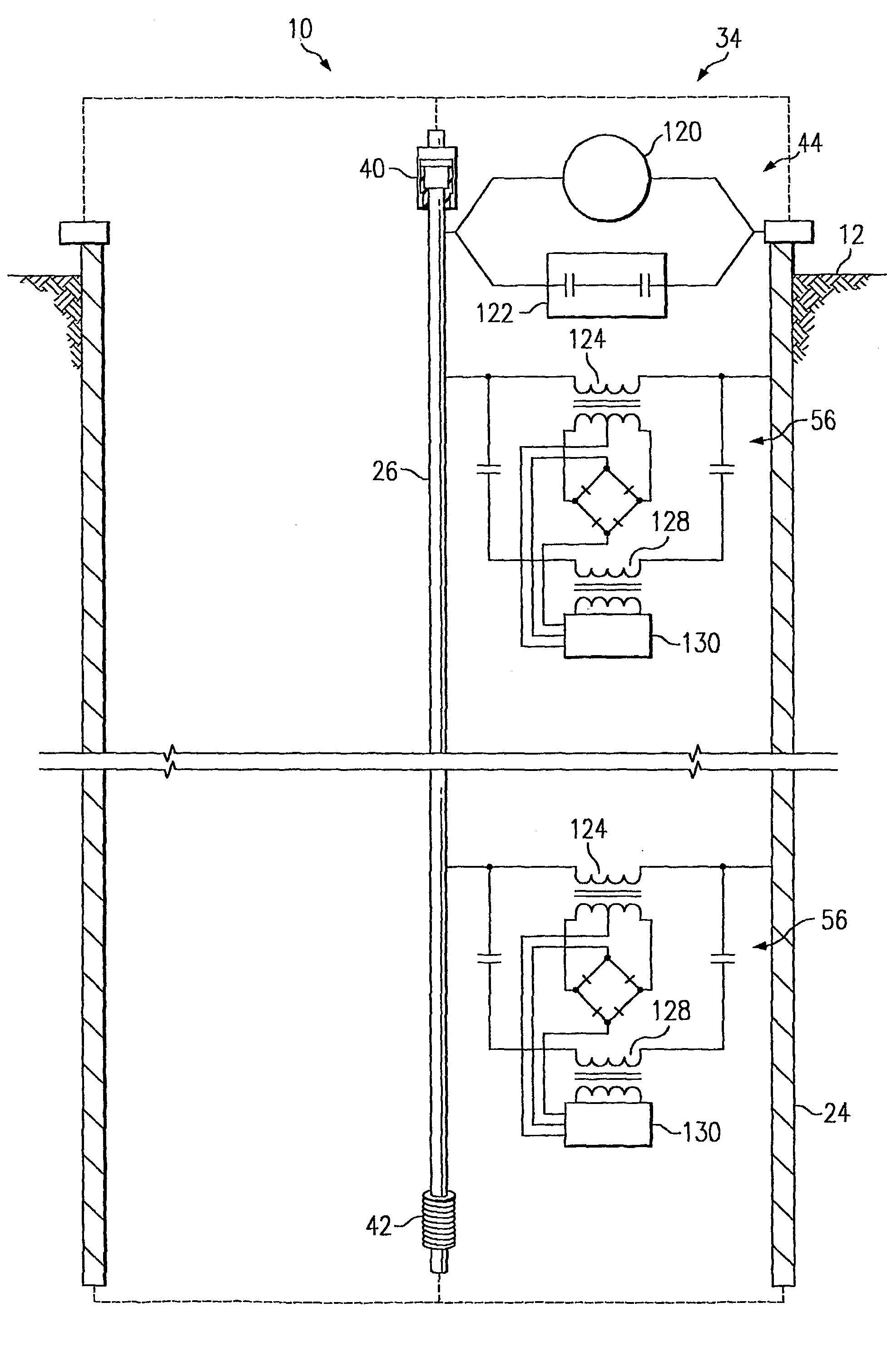

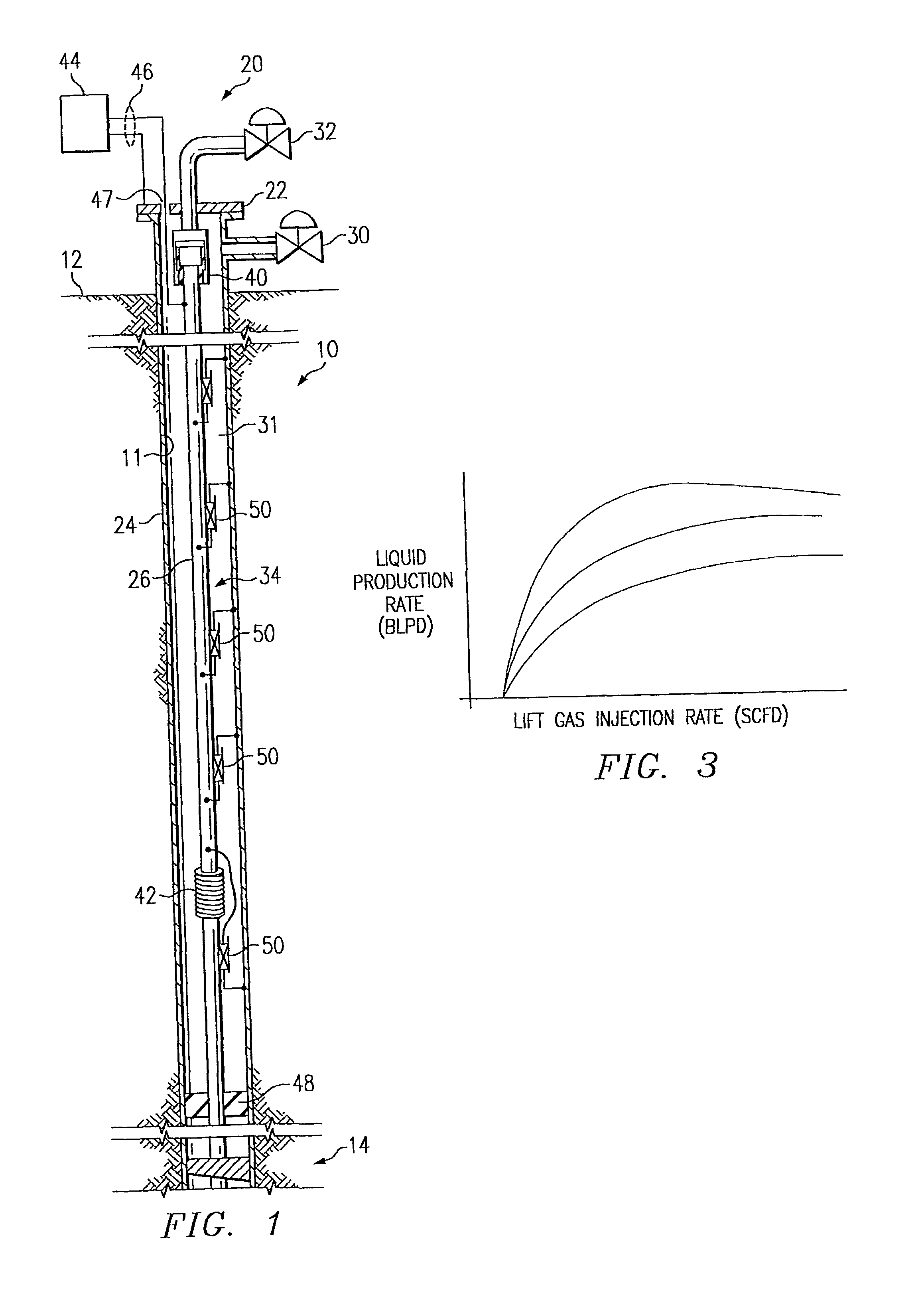

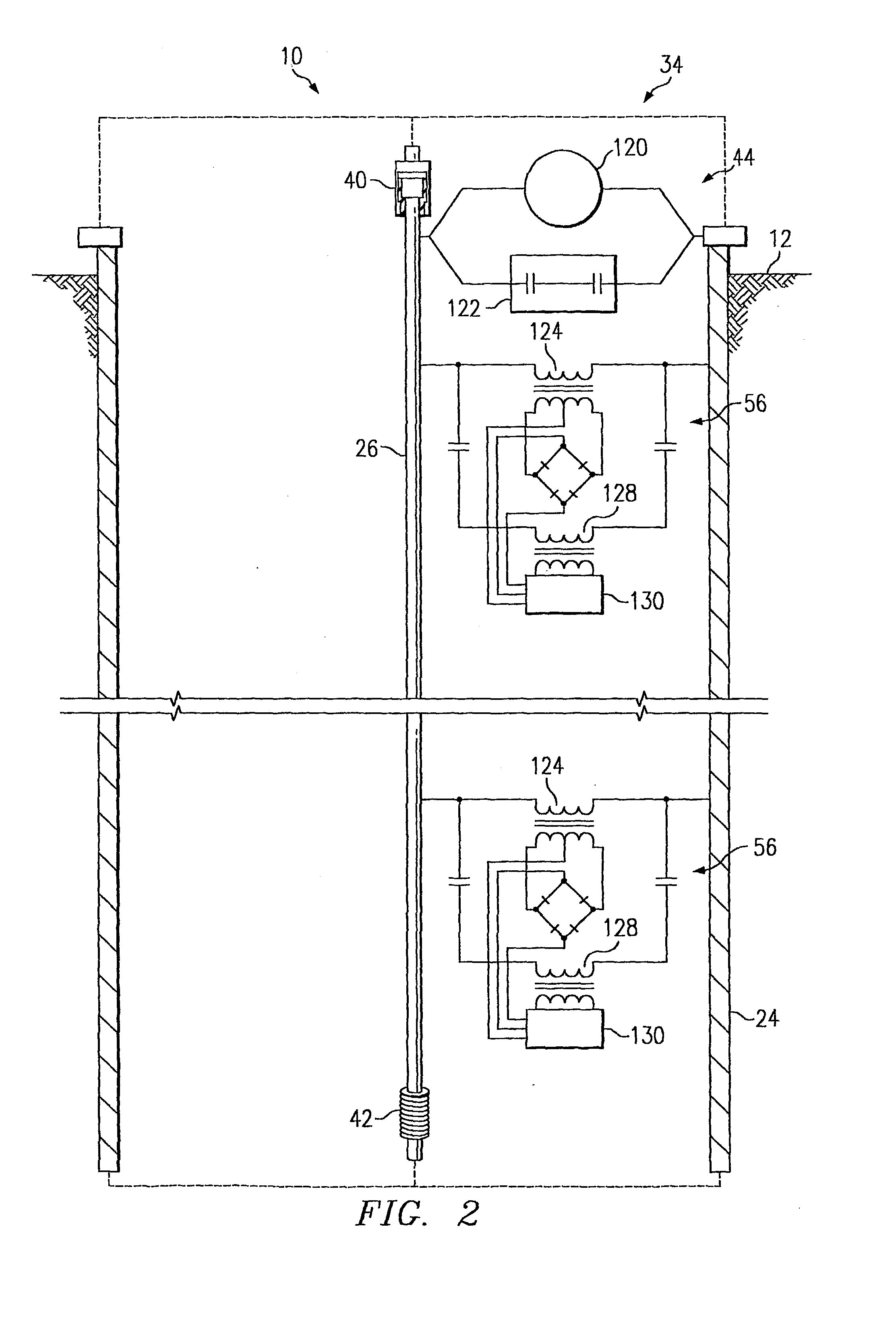

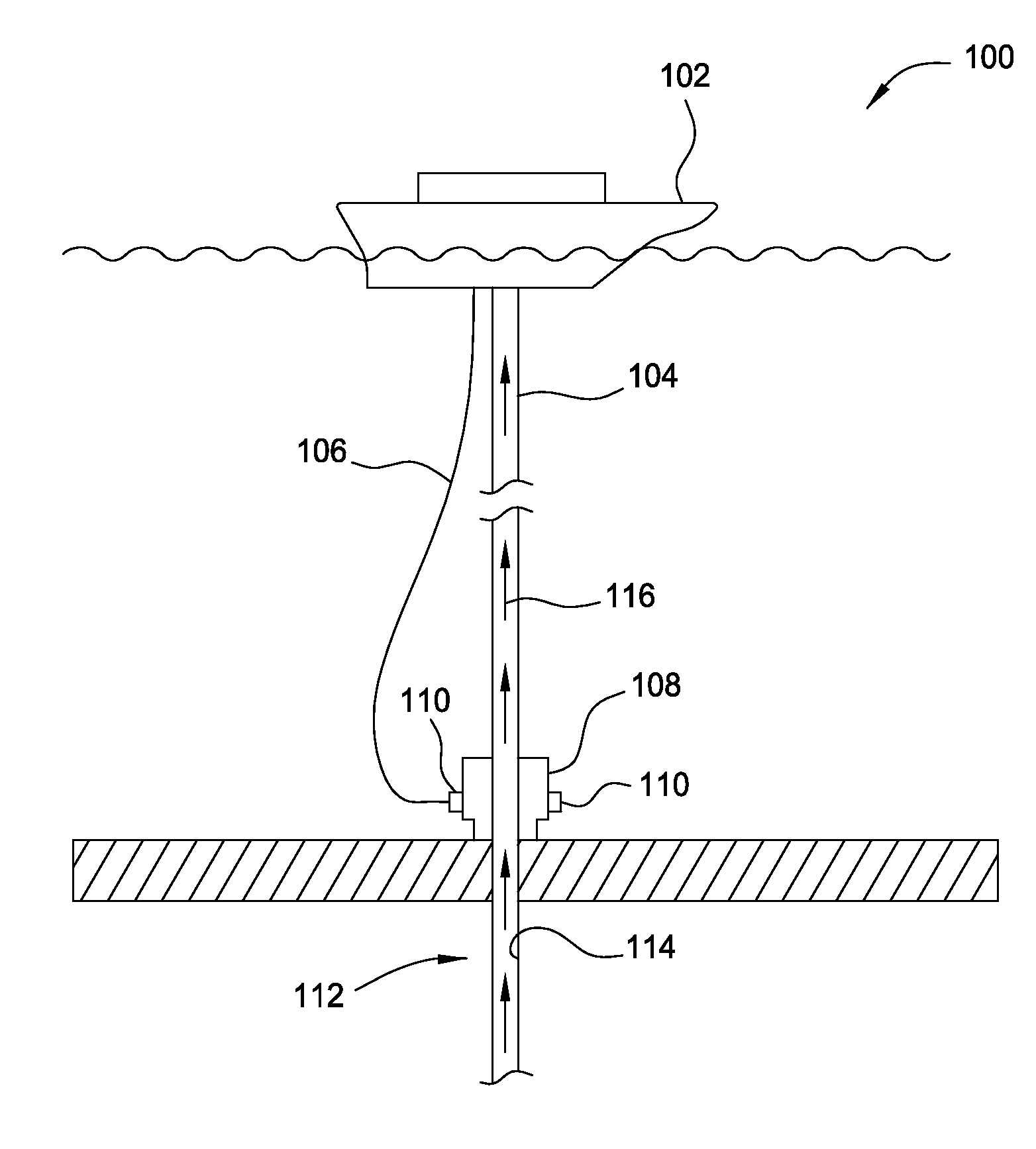

Wireless downwhole measurement and control for optimizing gas lift well and field performance

A method for optimizing the production of a petroleum well is provided. The petroleum well includes a borehole, a piping structure positioned within the borehole, and a tubing string positioned within the borehole for conveying a production fluid. Production of the well is optimized by determining a flow rate of the production fluid within the tubing string and determining a lift-gas injection rate for the gas being injected into the tubing string. The flow rate and injection rate data is communicated along the piping structure of the well to a selected location, where the data is collected and analyzed. After analysis of the data, an optimum operating point for the well can be determined.

Owner:SHELL OIL CO

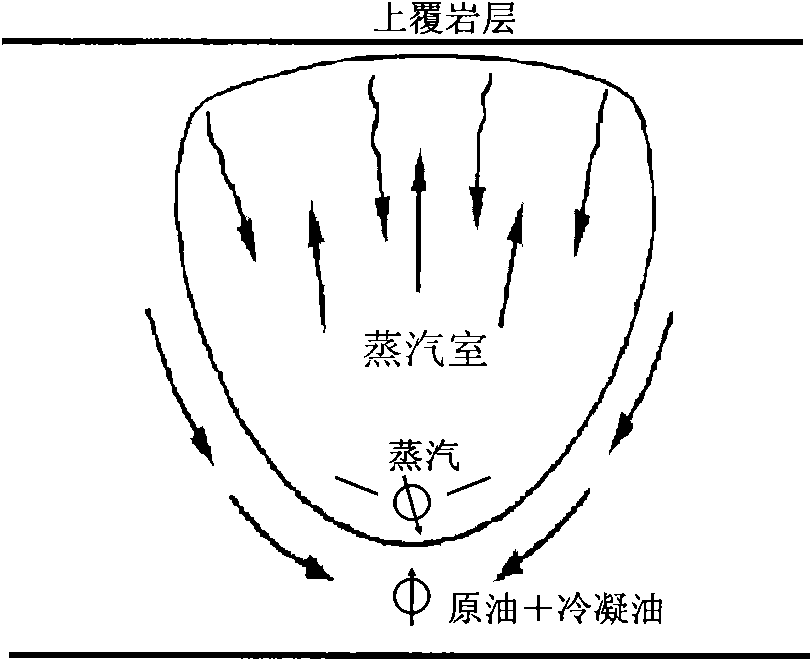

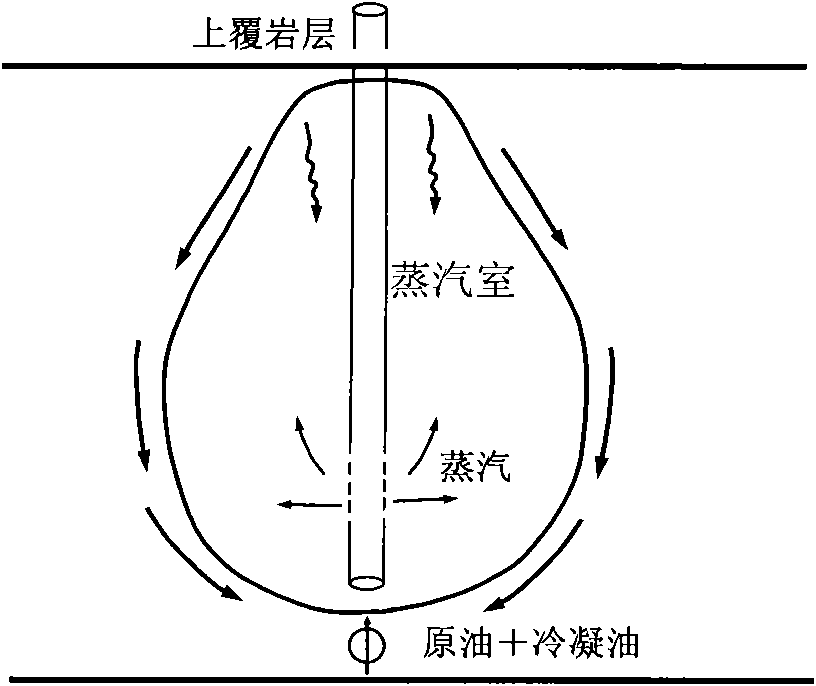

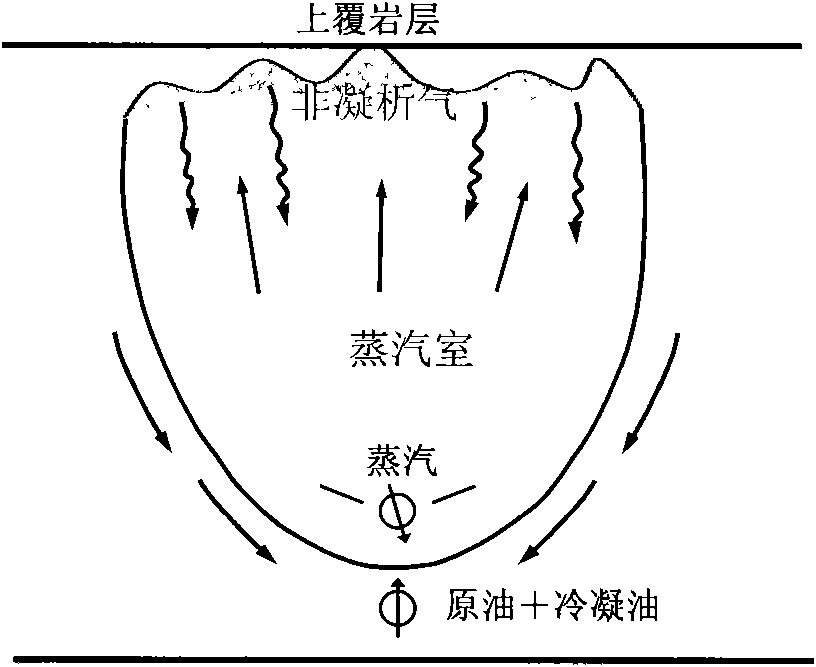

Gas-assisted SAGD method for exploiting super heavy oil

The invention relates to a gas-assisted SAGD method for exploiting super heavy oil; the selecting layer thickness is 530m, remaining oil saturation is more than 0.50, oil layer thickness is more than 10.0m, horizontal permeability is more than 250md, the ratio of the vertical permeability to the horizontal permeability is more than 0.1, the oil layer porosity is more than 0.20, continuous distributed impermeable clay and intercalated shale oil pools do not exist in the oil layer; a horizontal well is drilled between soaking vertical wells, the well spacing is 35m or a pair of horizontal wells are drilled at the bottom of the oil layer, the vertical distance is 6m; swallowing is carried out for 3 stages, when the hot communication is formed between the wells, the vertical wells is used to inject steam continuously, the production of horizontal wells is 3 years, then the vertical wells is used to inject nitrogen and steam until the underground volume ratio is 0.5 and the total injection rate of nitrogen is 0.10PV, then the steam is injected continuously, the steam injection rate is 1.4m / d.ha.m, the dryness of steam at the bottom of wells is 70%, the production-injection ratio is maintained at 1.2; the recovery percent is increased by 6.0-9.0% and the oil-steam ratio is improved by 0.02-0.05.

Owner:PETROCHINA CO LTD

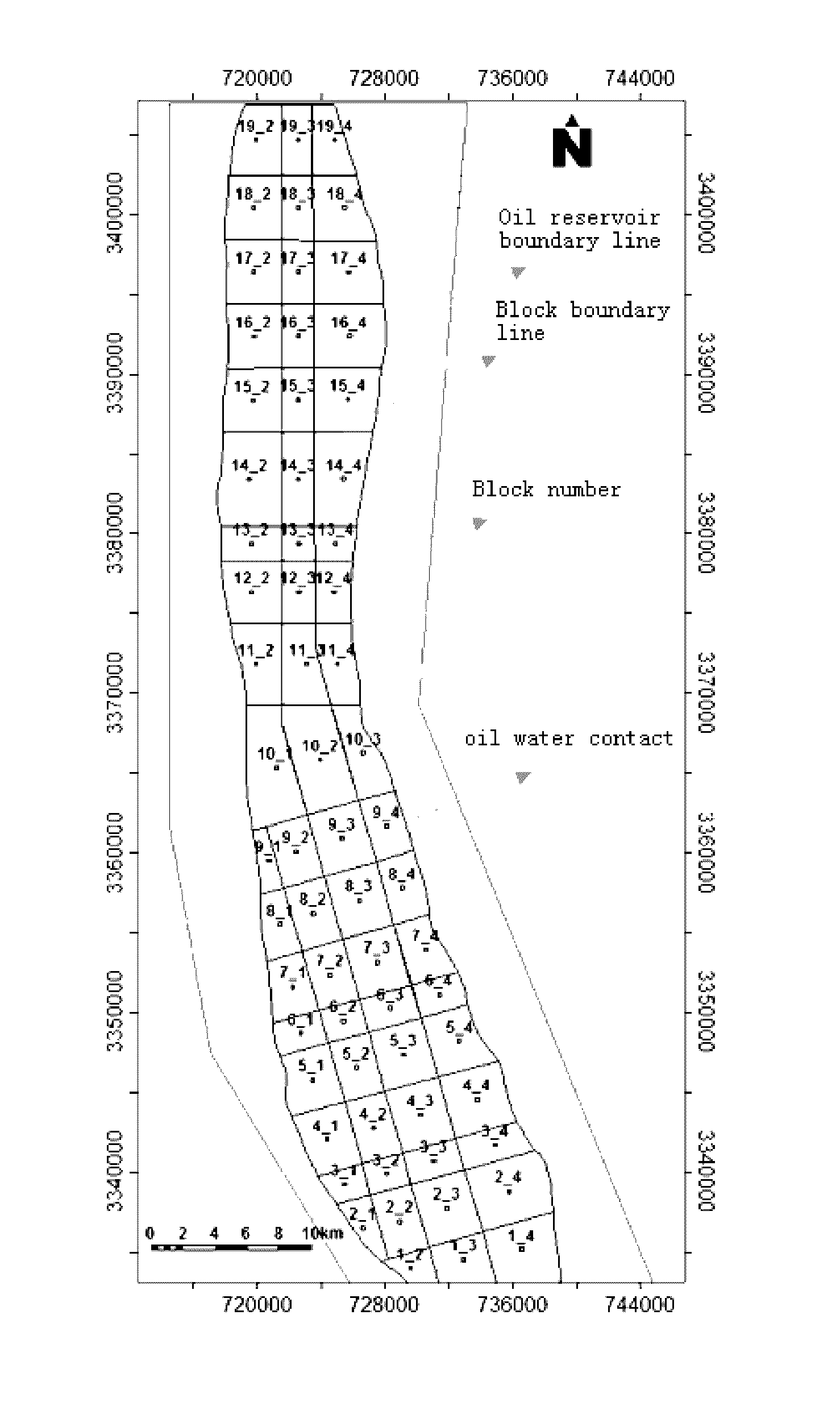

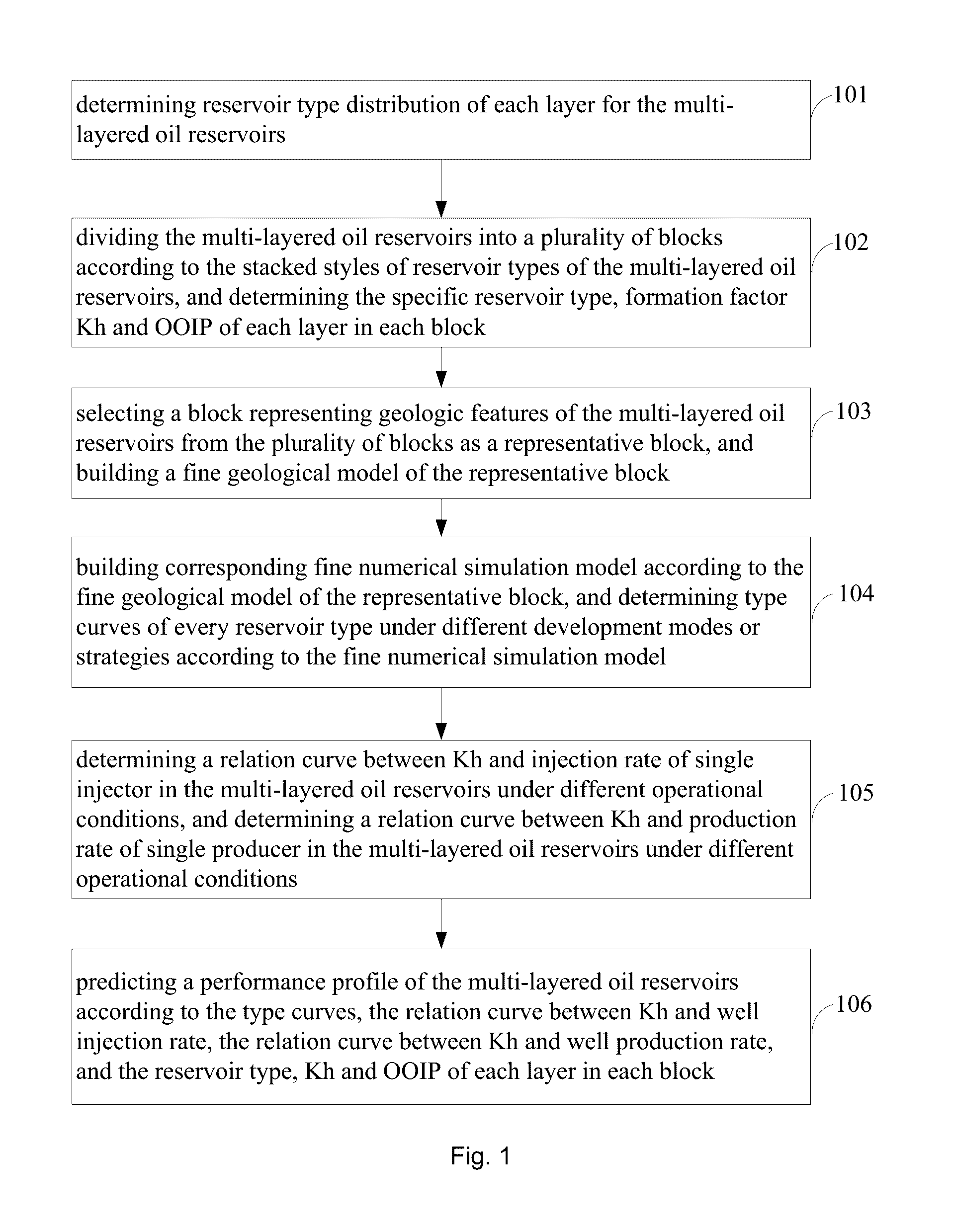

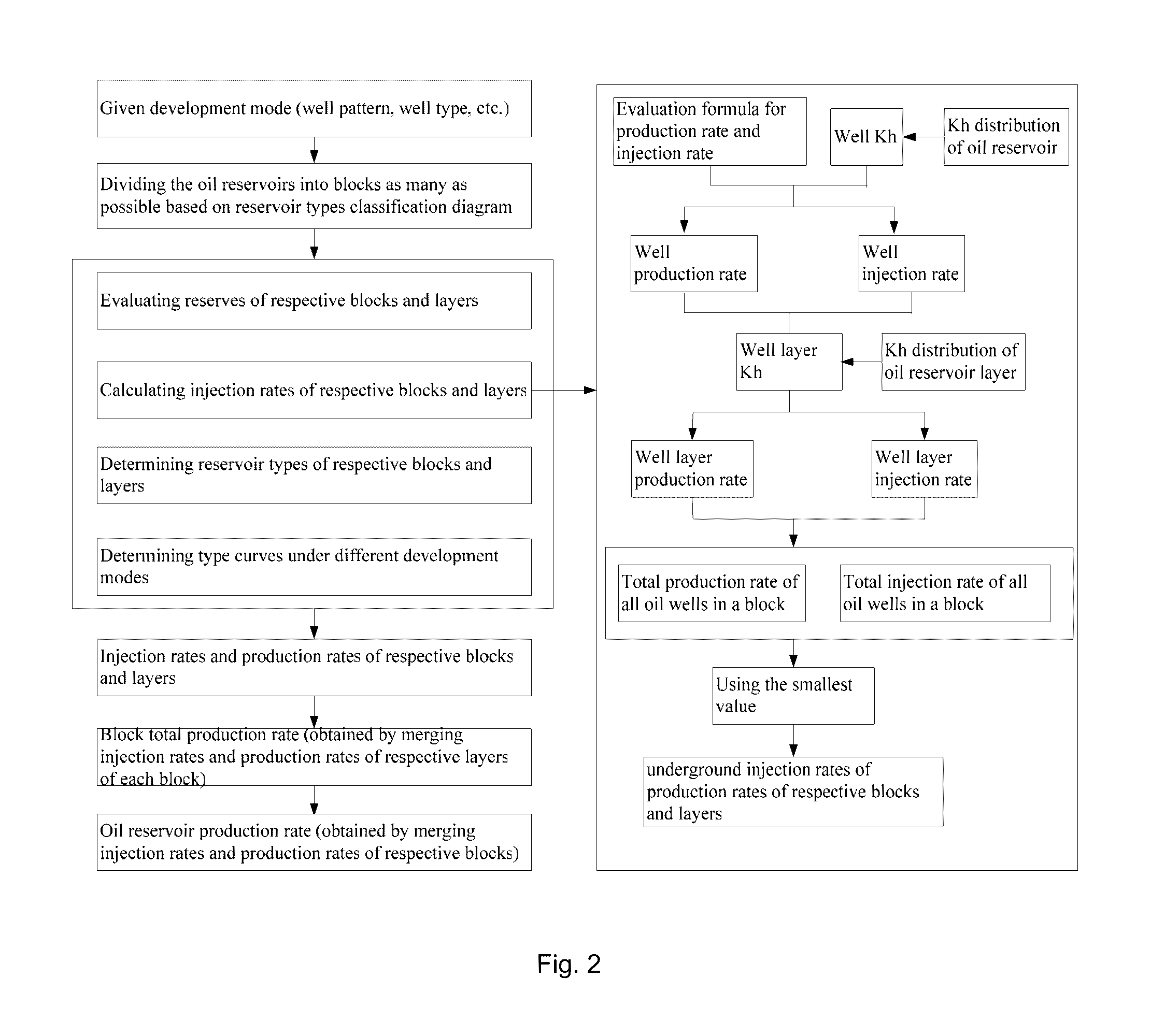

Method and Apparatus for Performance Prediction of Multi-Layered Oil Reservoirs

InactiveUS20160376885A1Decreasing man-powerConvenience to workElectric/magnetic detection for well-loggingConstructionsReservoir typeProduction rate

The present invention discloses a method and an apparatus for predicting performance profiles of multi-layered oil reservoirs, wherein the method comprises: dividing the multi-layered oil reservoirs into a plurality of blocks, and determining a reservoir type, formation factor Kh and an evaluated reserves of each layer in each block; selecting a block representing geologic features of the multi-layered oil reservoirs from the plurality of blocks as a representative block, to build a fine geological model of the representative block; building corresponding fine numerical simulation model according to the fine geological model of the representative block, and determining type curves of different reservoir types under different development strategies; determining a relation curve between Kh and well injection rate for injectors and a relation curve between Kh and well production rate for producers in the multi-layered oil reservoirs under different restrictive conditions; predicting performance of the multi-layered oil reservoirs according to the type curve, the relation curve between Kh and well injection rate, the relation curve between Kh and well production rate, and the reservoir type, formation factor Kh and evaluated reserves of each layer in each block.

Owner:PETROCHINA CO LTD

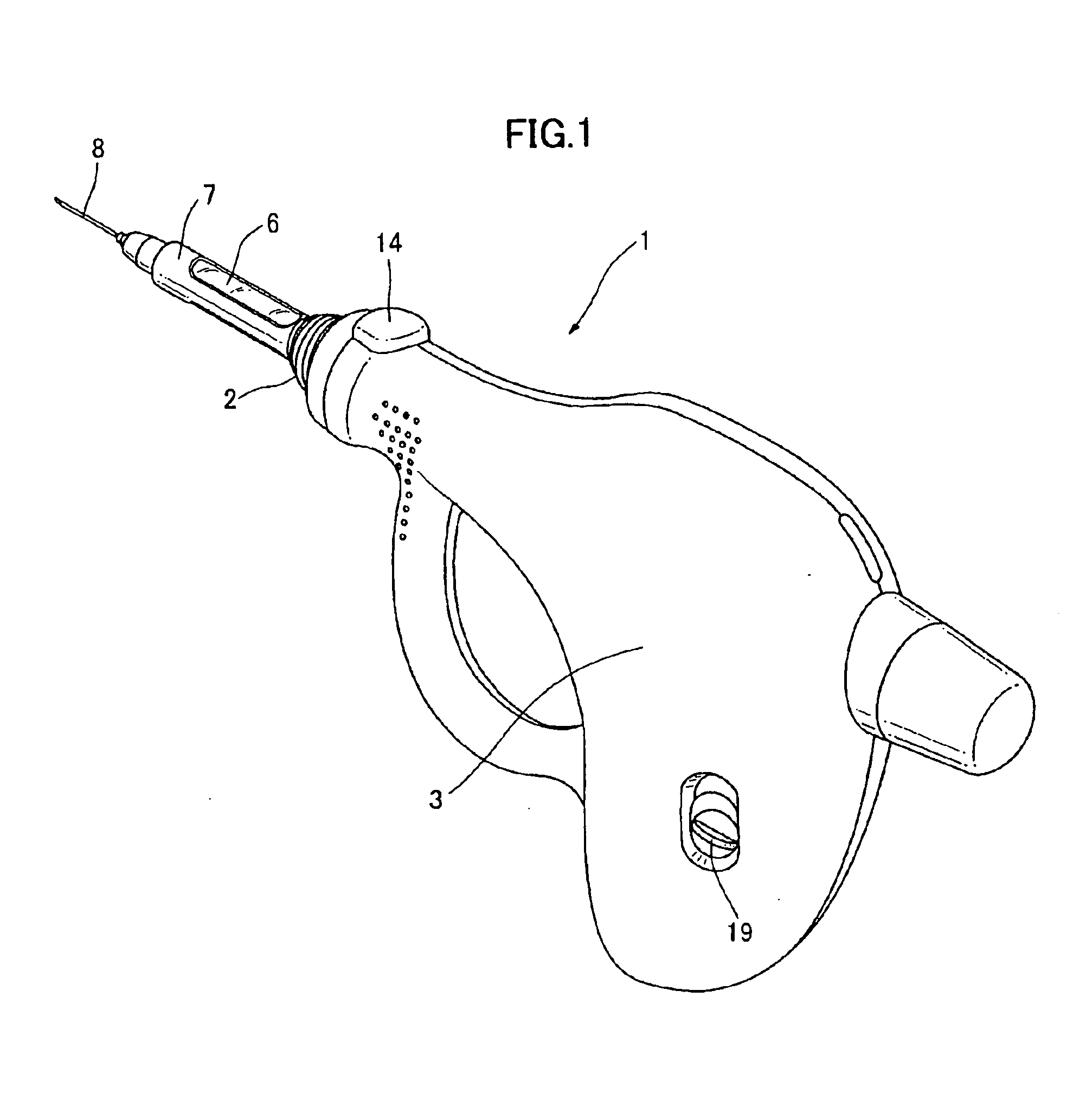

Injection device for soft-tissue augmentation fillers, bioactive agents and other biocompatible materials in liquid or gel form

Described herein are injection devices capable of automatically injecting substances into the soft tissue of a patient. The devices can inject low to high viscosity materials at predetermined, user selected injection rates, allowing the operator more control than a traditional syringe. The devices can allow mixing of more than one substance and / or reconstitution of a solid substance for injection. The injection devices described herein can allow the operator to easily inject one or more low to high viscosity liquid or gel soft-tissue augmentation fillers, one or more drugs, one or more other biocompatible materials, or combinations thereof.

Owner:ALLERGAN INC

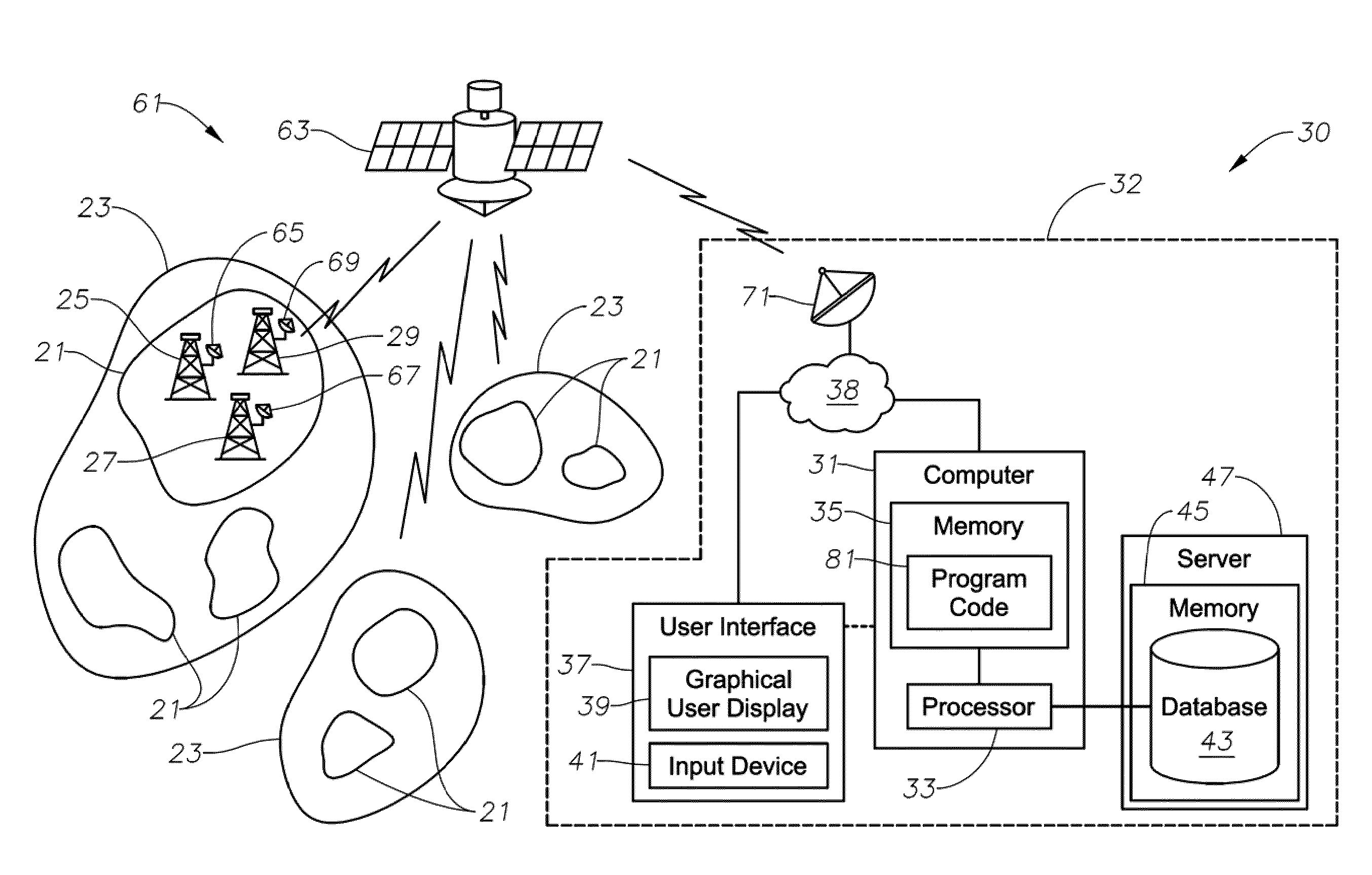

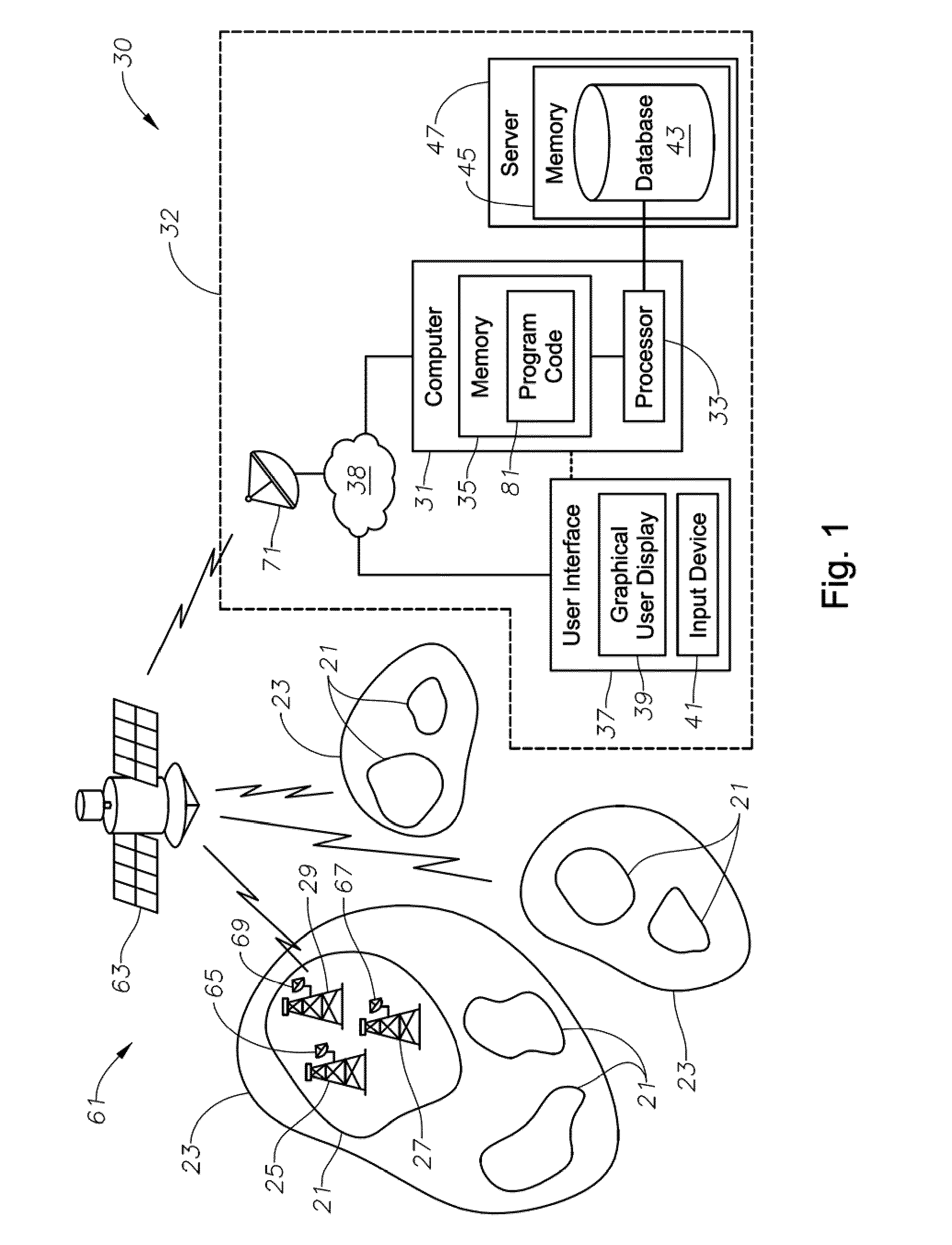

System, program product, and related methods for performing automated real-time reservoir pressure estimation enabling optimized injection and production strategies

ActiveUS20090276100A1Understand reservoir performanceMonitor performanceSurveyFlow control using electric meansStorage managementPressure data

Systems, program product, and methods for providing real-time reservoir management of one or more reservoirs across one or more fields are provided. A system can include multiple monitoring wells and at least one injection well in communication with a central facility including a reservoir management computer or server positioned to provide real-time reservoir management of the one or more reservoirs. The computer can include, stored in memory, reservoir management program code, which when executed, can cause the computer to perform the operations of calibrating an injection well model for each of one or more injection wells positioned in a reservoir responsive to real-time injection rate and wellhead pressure data associated therewith, calculating static reservoir pressure for each of the injection wells responsive to the respective calibrated injection well model and responsive to respective surface injection rate and wellhead pressure data, and generating real-time automated isobaric pressure maps.

Owner:SAUDI ARABIAN OIL CO

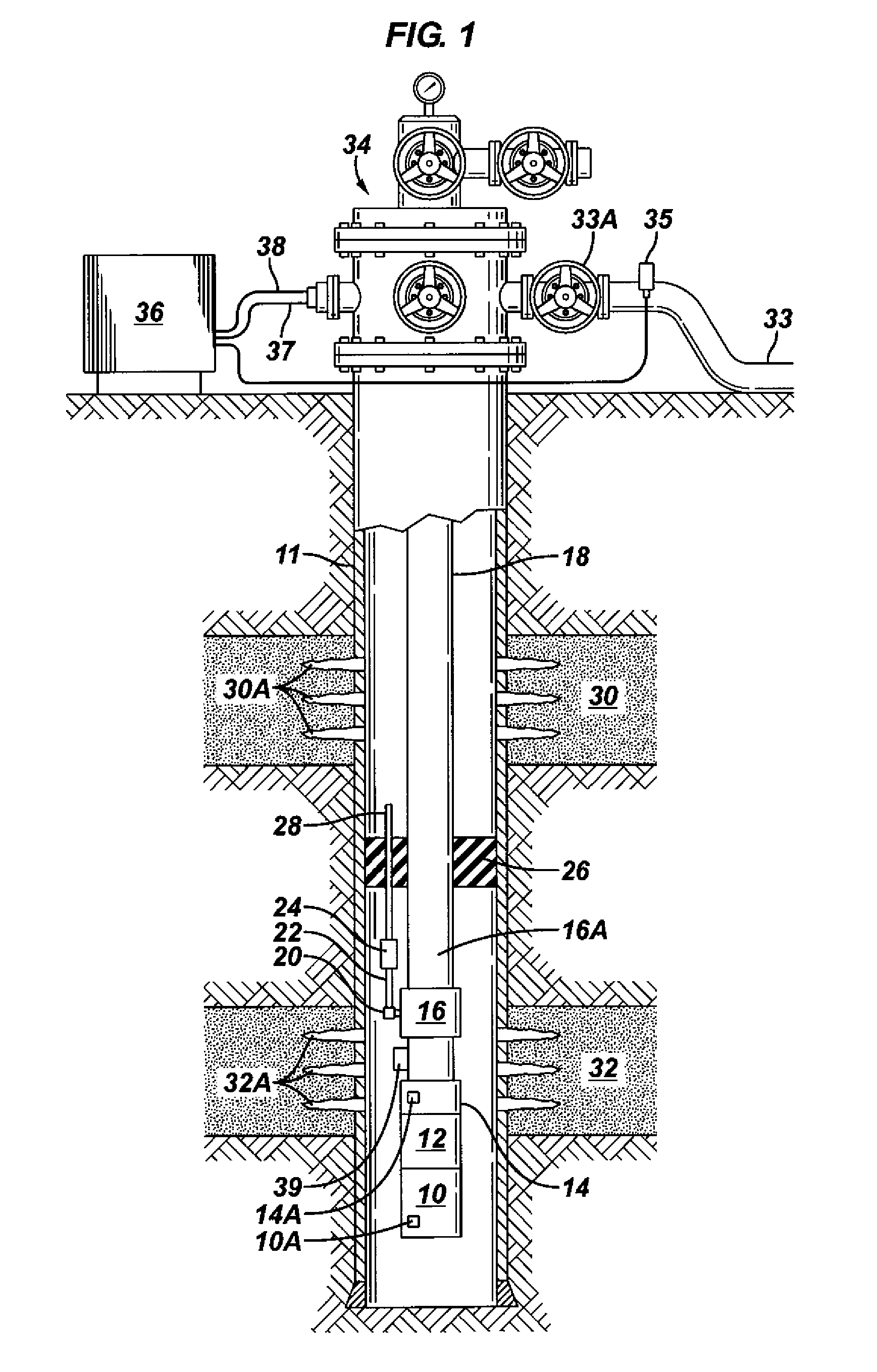

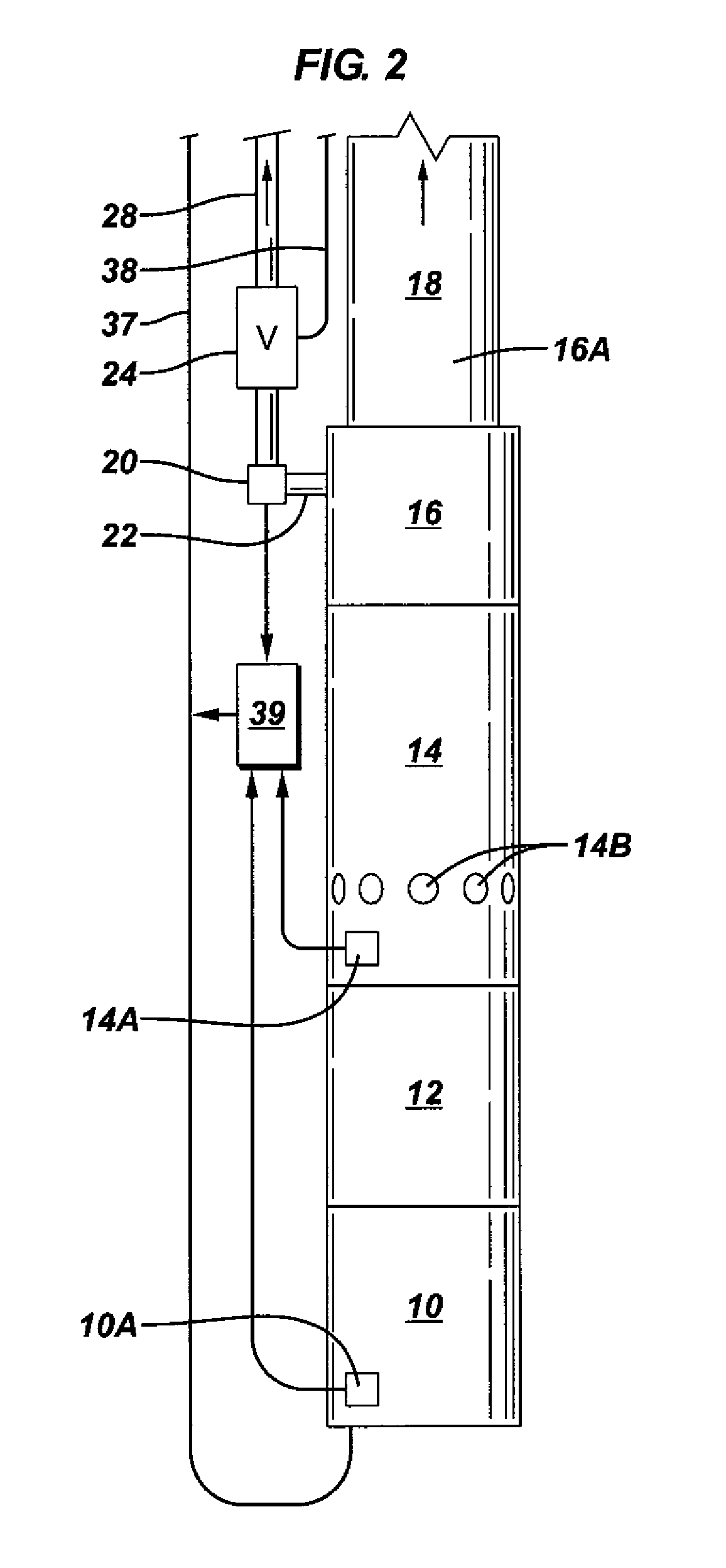

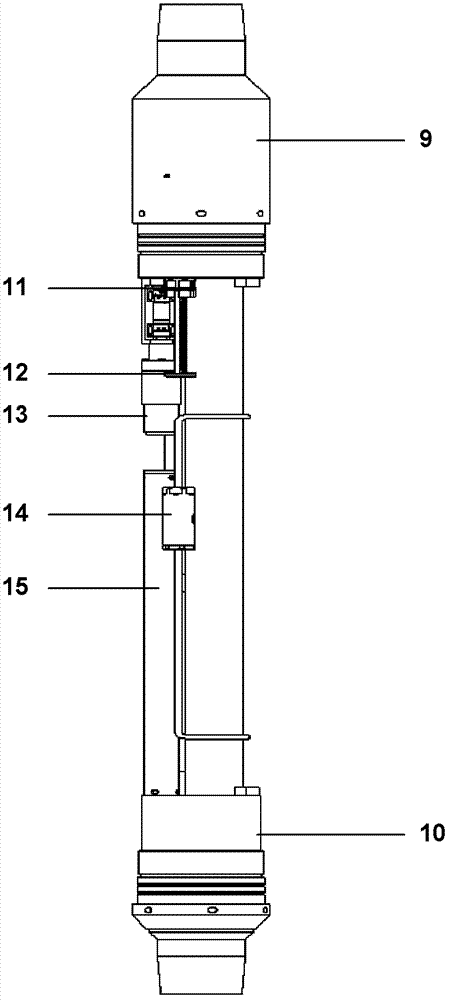

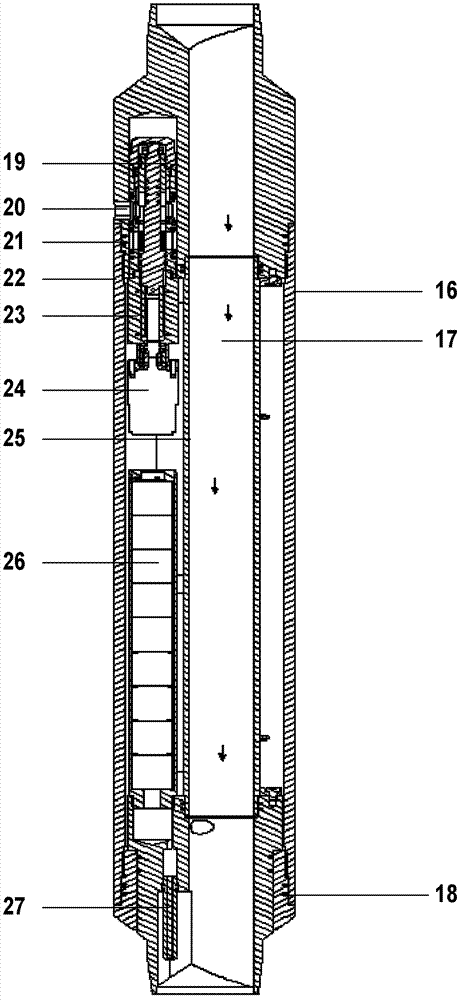

Monitoring and automatic control of operating parameters for a downhole oil/water separation system

A method for operating a downhole oil water separator and electric submersible pump includes measuring fluid pressure proximate one of the pump intake, separator intake and a bottom of a wellbore. At least one of flow rate and pressure is measured at the separator water outlet. Pump and a water outlet restriction are controlled to maintain an optimum fluid pumping rate and an optimum injection rate of separated water. A flow control system includes a controllable valve disposed in a water outlet of the separator. At least one of a pressure sensor and a flowmeter is operatively coupled to the water outlet. A controller is in signal communication with the at least one of a pressure sensor and flowmeter and in operative communication with the valve. The controller operates the valve to maintain at a selected pressure and / or a selected flow rate through the water outlet.

Owner:SCHLUMBERGER TECH CORP

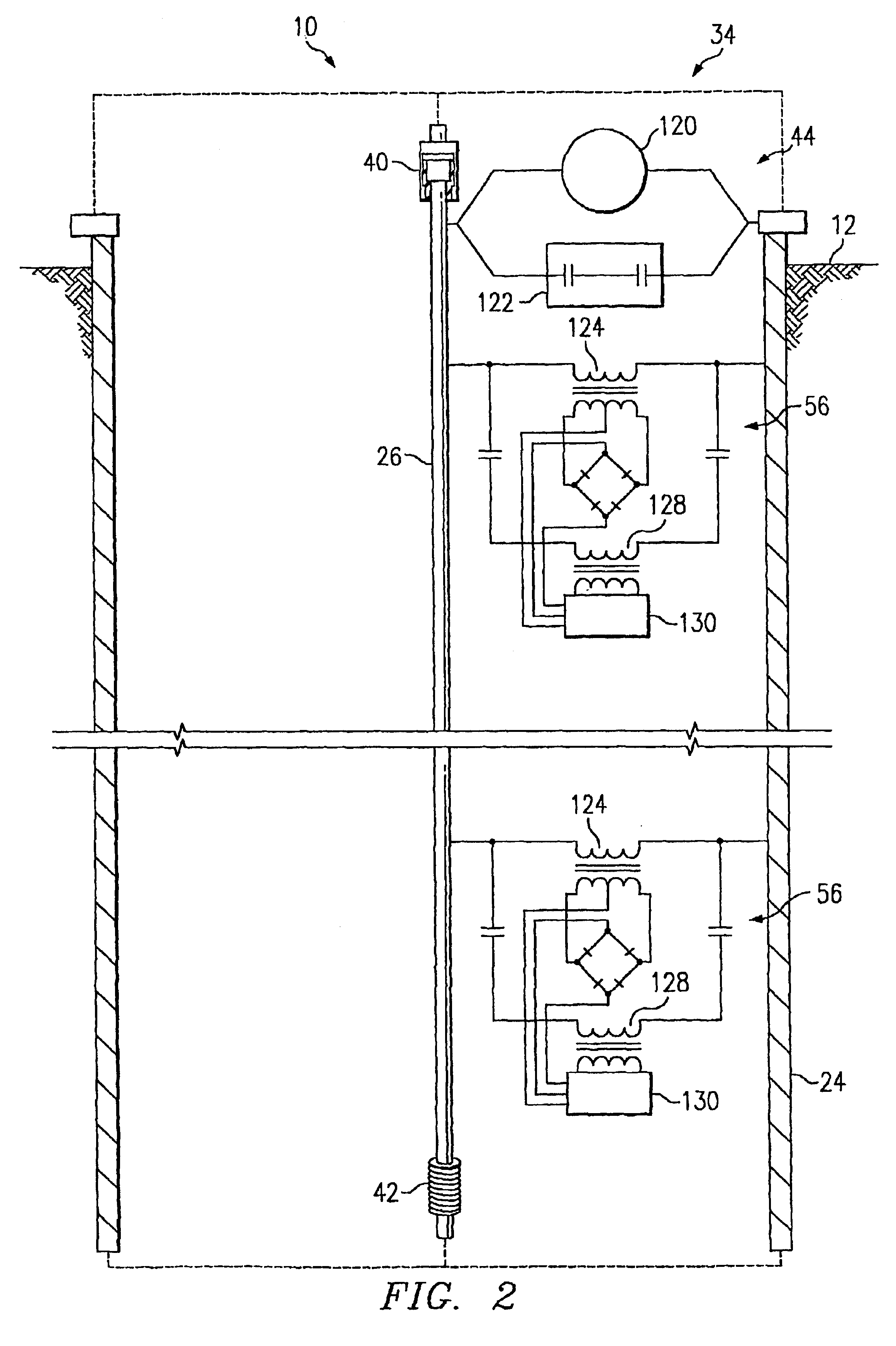

Wireless downwhole measurement and control for optimizing gas lift well and field performance

A method for optimizing the production of a petroleum well is provided. The petroleum well includes a borehole, a piping structure (24) positioned within the borehole, and a tubing string (26) positioned within the borehole for conveying a production fluid. Production of the well is optimized by determining a flow rate of the production fluid within the tubing string (26) and determining a lift-gas injection rate for the gas being injected into the tubing string. The flow rate and injection rate data is communicated along the piping structure of the well to a selected location (44), where the data is collected and analyzed. After analysis of the data, an optimum operating point (152) for the well can be determined

Owner:SHELL OIL CO

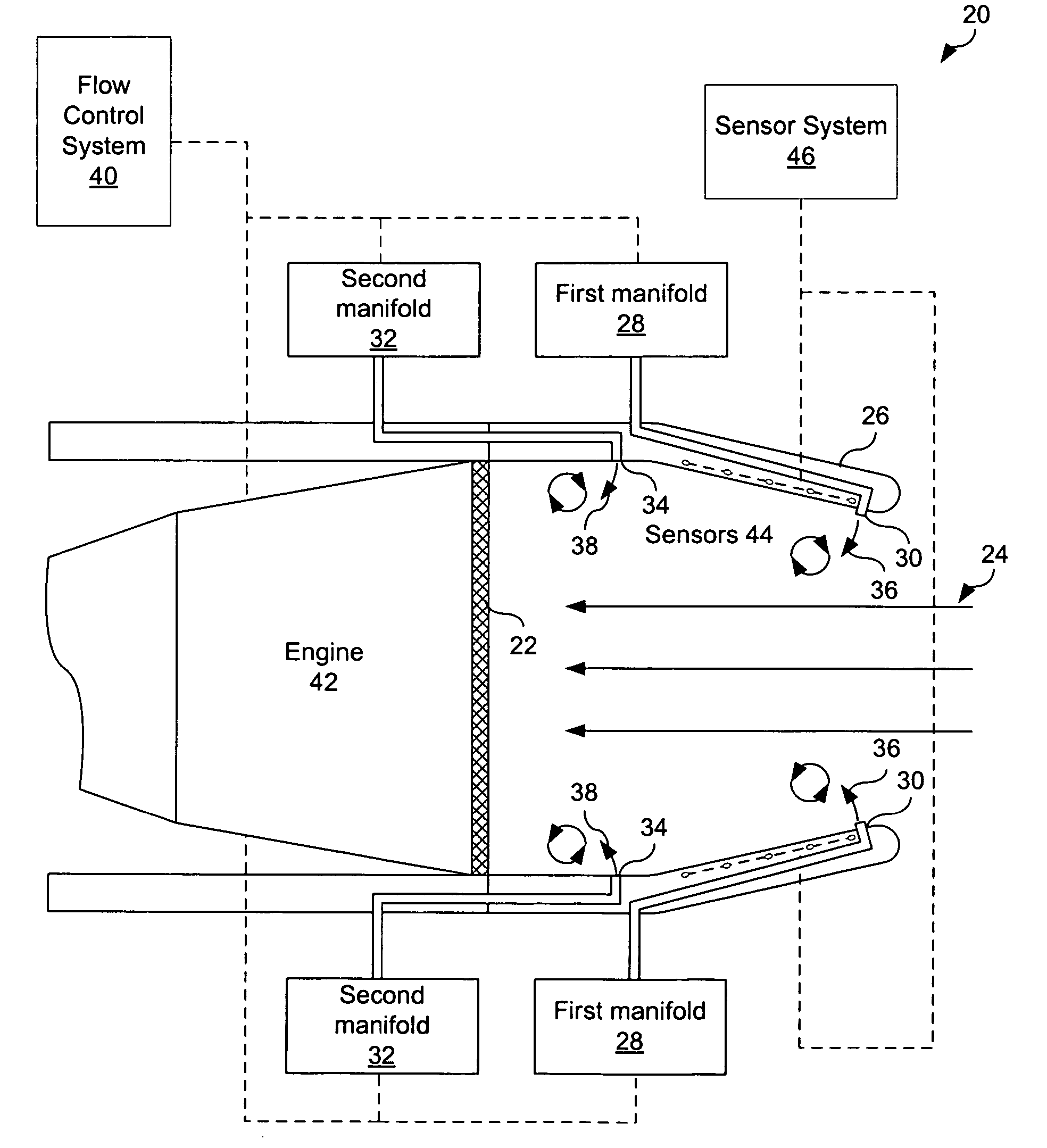

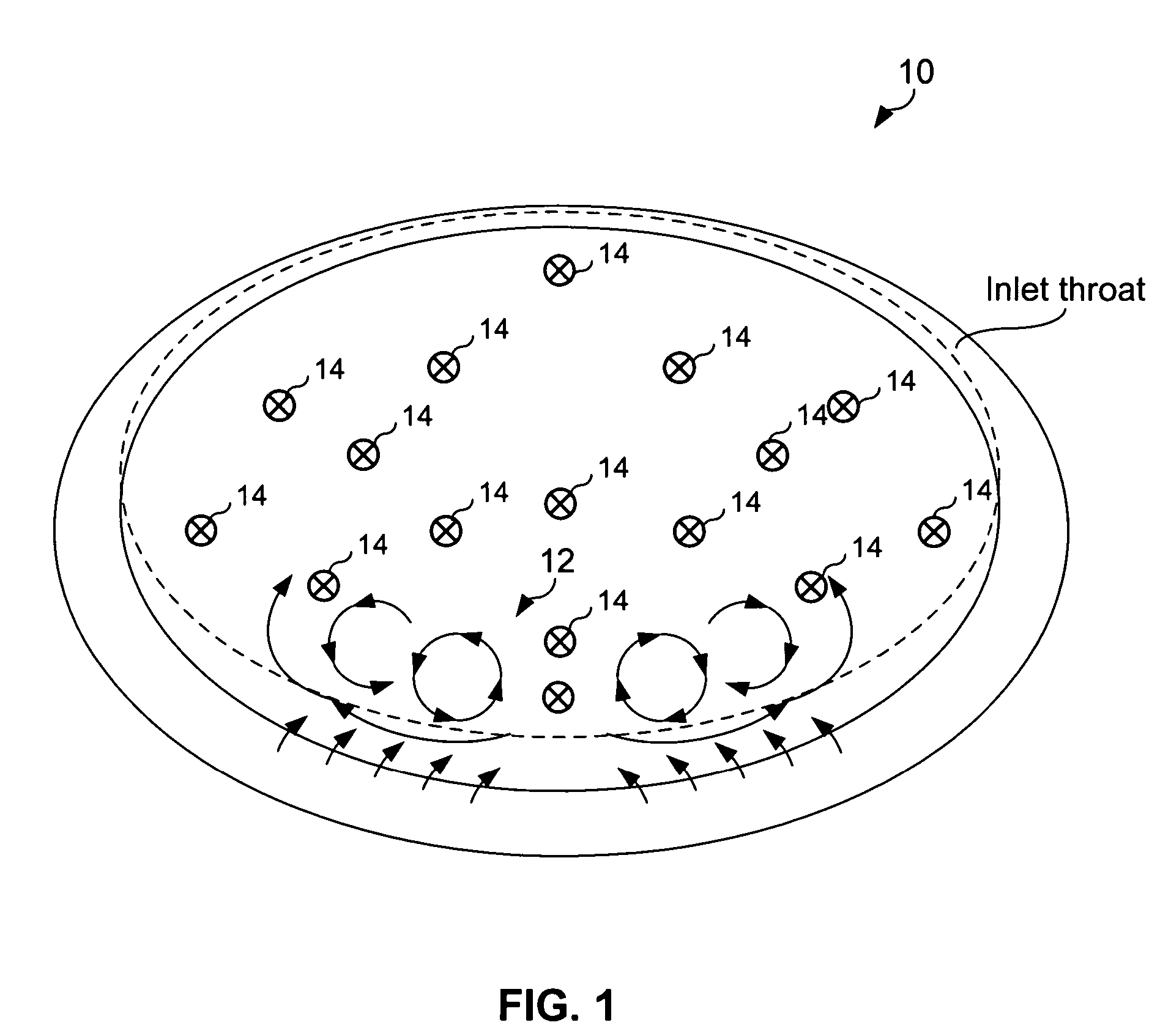

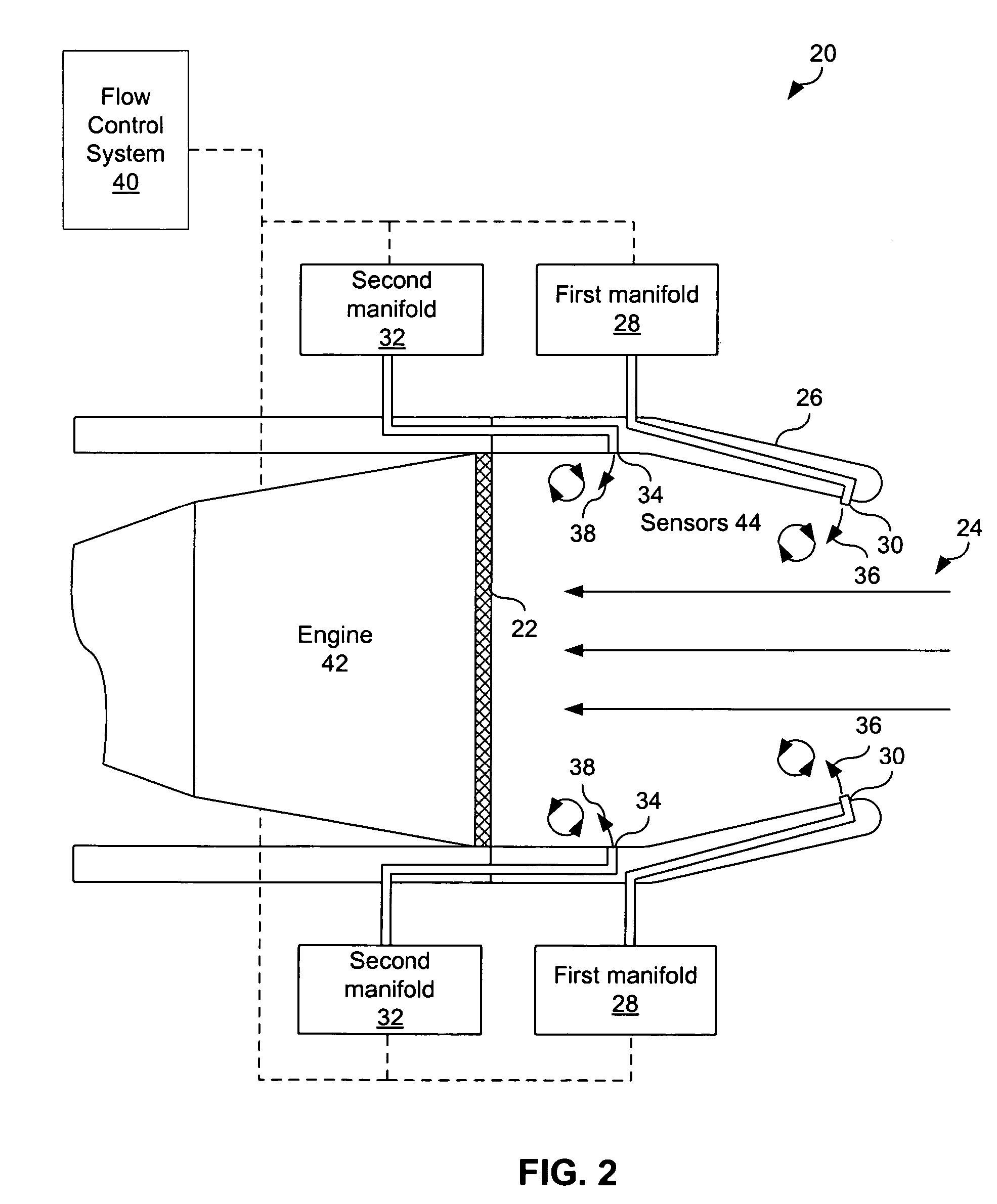

Flow control redistribution to mitigate high cycle fatigue

ActiveUS7617670B2Improve distortionPromote recoveryCombustion enginesGas turbine plantsEngineeringLow-cycle fatigue

A method operable to improve pressure recovery and / or distortion within engine inlet is disclosed. A first fluid flow is provided to primary jet vortex generator(s) operable to inject fluid at a first injection rate into a boundary layer of a primary fluid flow within the inlet. A secondary fluid flow is injected by secondary jet vortex generator(s) at a second injection rate into the boundary layer of the primary fluid flow, The fluid injected at the first injection rate and second injection rate is operable to induce secondary flow structures within the boundary layer. These secondary close structures are then operable to improve or manipulate the pressure recovery of the inlet. At specific engine conditions, this method may redistribute the ratio of the first injection rate and second injection rate in order to improve pressure recovery and / or distortion of the inlet when the particular engine conditions.

Owner:LOCKHEED MARTIN CORP

Method for improving oil well yields by means of oil pool indigenous microorganisms

ActiveCN103291267ASave on-site testing costsStrong targetingFluid removalDrilling compositionRecovery methodInjection rate

The invention relates to a microorganism enhanced oil recovery method, in particular to a method for improving oil well yields by means of oil pool indigenous microorganisms. The method includes the following steps of (1) screening of a test oil well, (2) screening of activating agents, (3) confirming of the injection rate of the activating agents, (4) confirming of well closing time and (5) on-site testing. By means of the indigenous microorganisms existing in the activated oil well, on-site test cost is thereby saved, different formulas of the activating agents are chosen according to the different indigenous microorganisms, activating effects and on-site test effects are effectively improved, the stratum cannot be damaged and the environment cannot be polluted when nutrient substances are injected, and therefore the method can be widely used for microorganism enhanced oil recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

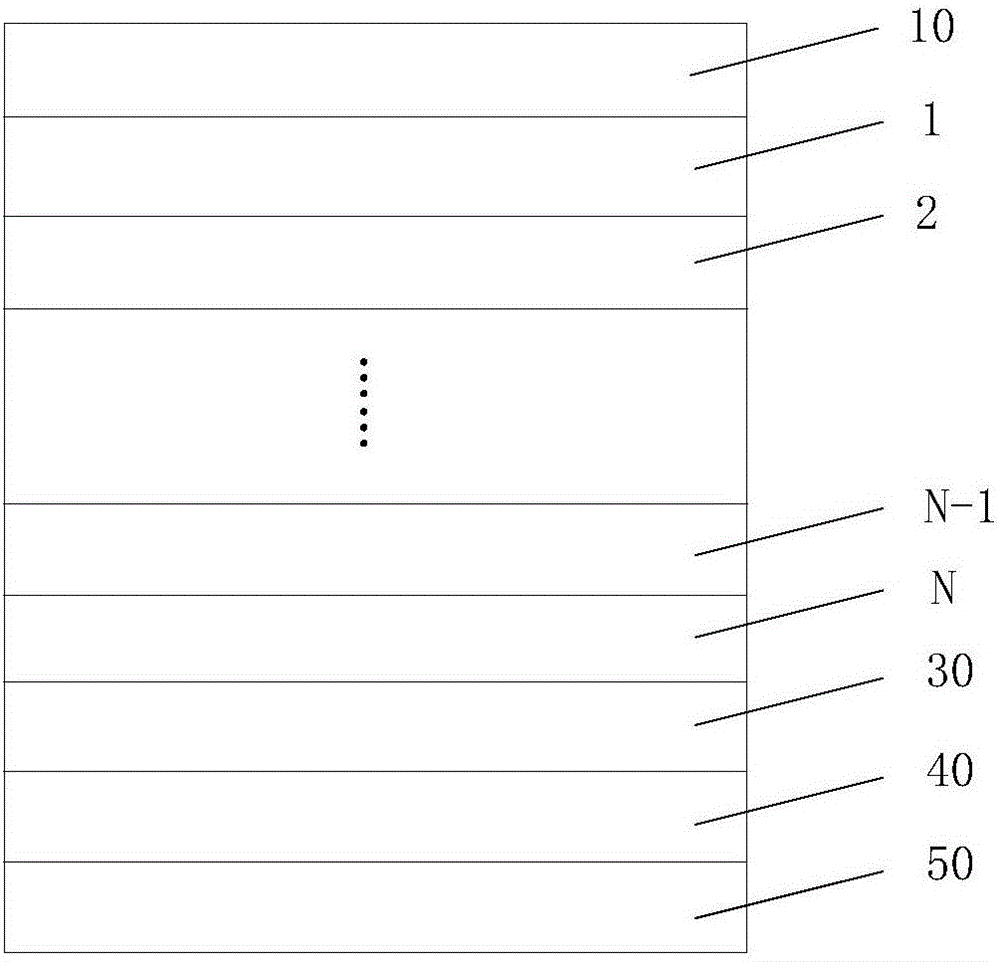

Quantum dot light-emitting device and display device and lighting device with same

ActiveCN106654026ALow transfer rateConsistent injection rateStatic indicating devicesSolid-state devicesElectron injectionDisplay device

The invention provides a quantum dot light-emitting device and a display device and lighting device with the same. The quantum dot light-emitting device comprises a negative electrode, a first electron transmission layer to an n(th) electron transmission layer, a quantum dot light-emitting layer and a positive electrode which are sequentially arranged, wherein n is an integer and is more than or equal to 2 but less than or equal to 6, and in the first electron transmission layer to the n(th) electron transmission layer, the electron mobility rate of at least one layer in a second electron transmission layer to the n(th) electron transmission layer is smaller than the electron mobility rate of the first electron transmission layer. The electron mobility capability of the whole transmission layer material is reduced, thus, the electron mobility rate is reduced from the overall, the electron injection rate and the hole injection rate approximate to be relatively consistent, the luminous efficiency of the light-emitting device is improved, and the service lifetime of the light-emitting device is prolonged.

Owner:NANJING TECH CORP LTD

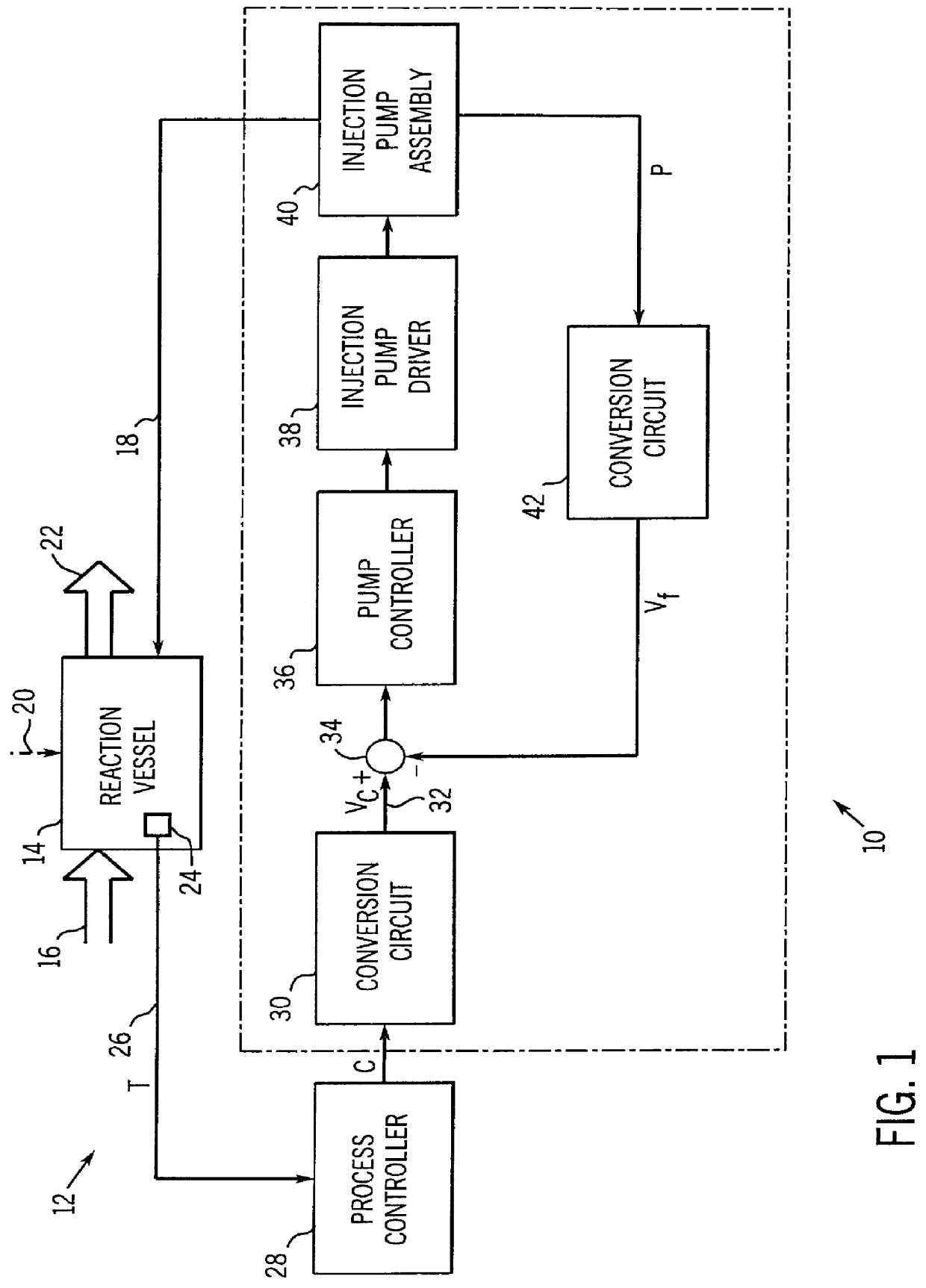

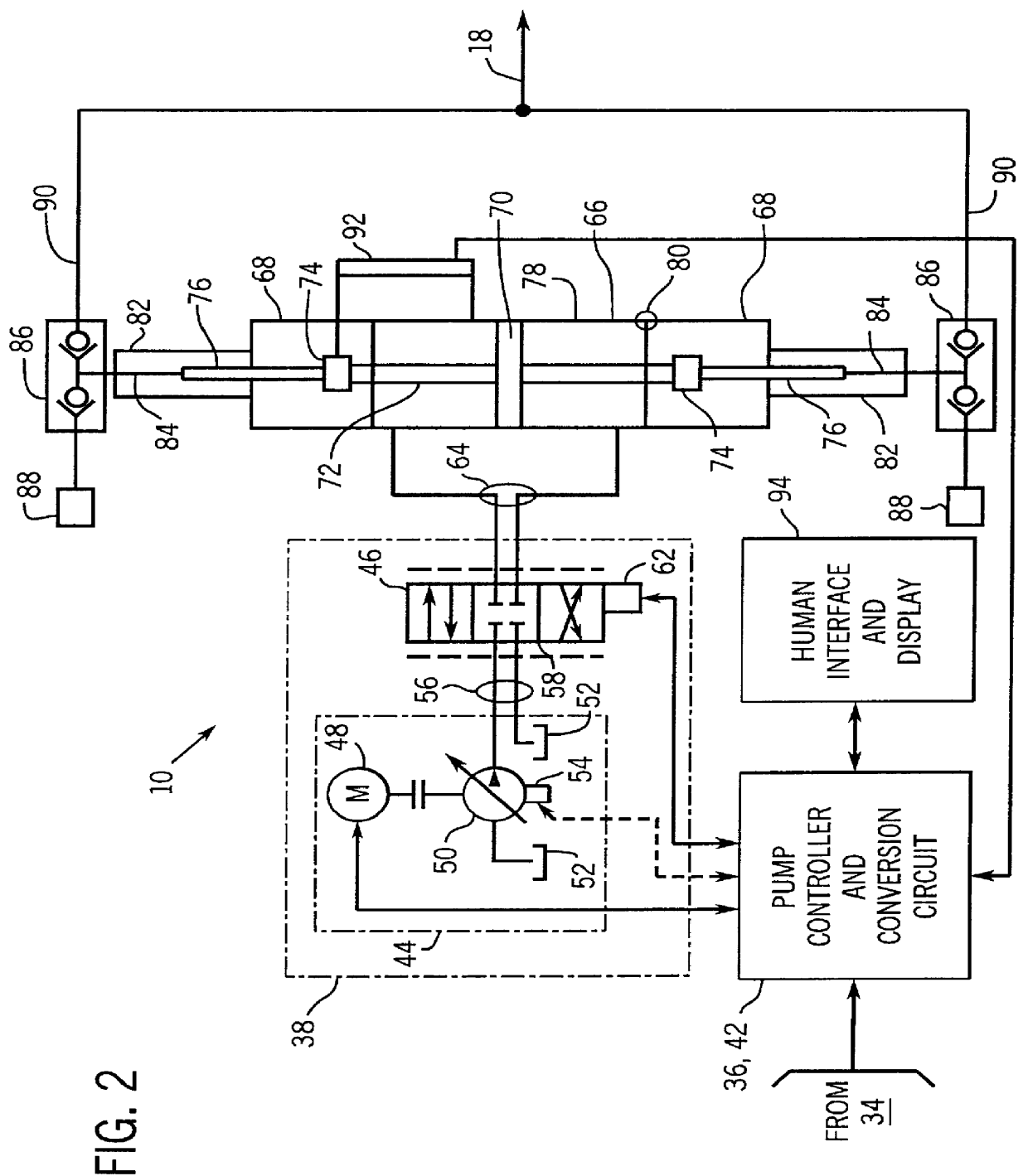

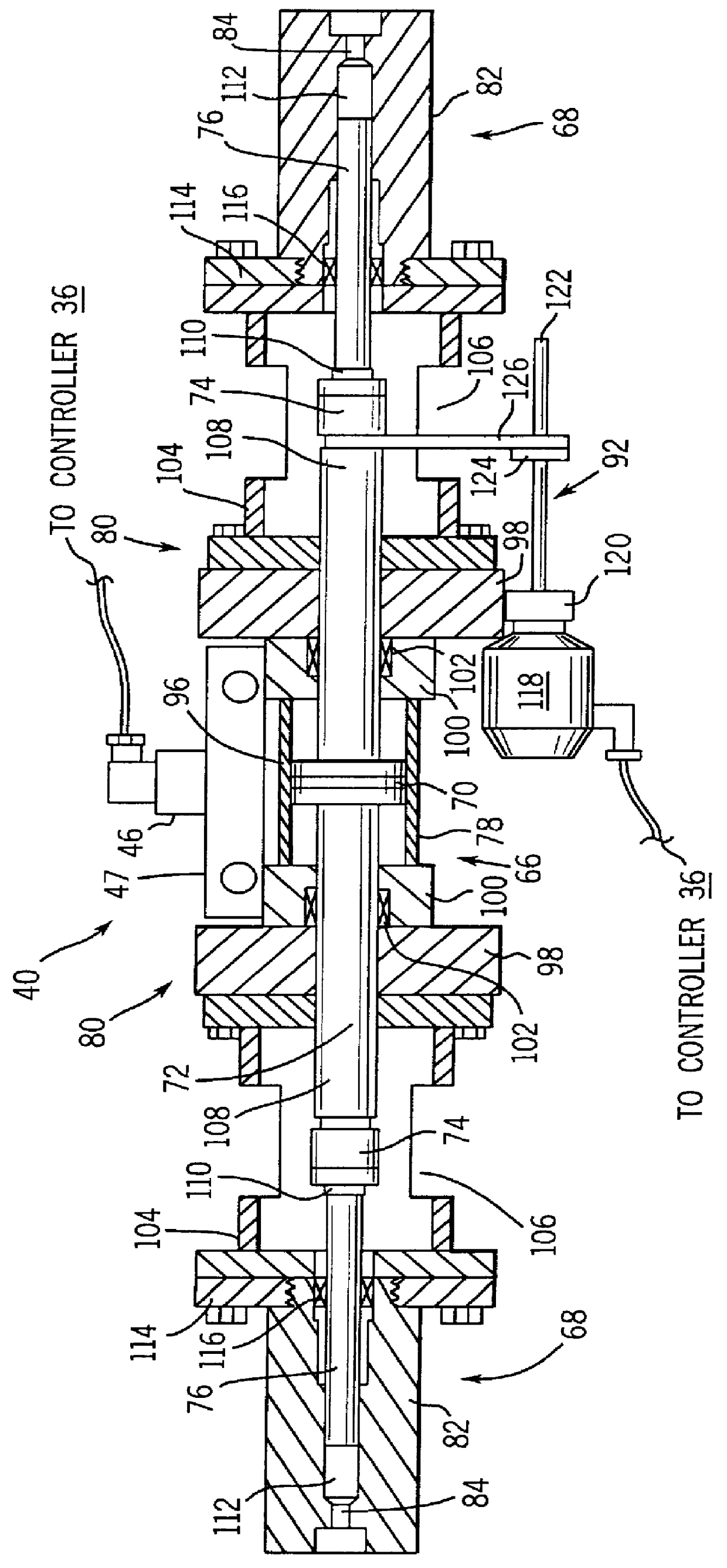

Method and apparatus for metering injection pump flow

InactiveUS6135719AReliable indicatorValve arrangementsFlow control using electric meansControl flowReciprocating motion

A system for metering a fluid, such as a catalyst in an industrial chemical process plant, includes a controller, a drive pump assembly and an injection pump assembly. The drive pump assembly forces reciprocation of the injection pump assembly via a controlled flow of hydraulic fluid. The injection pump assembly includes a drive cylinder and at least one injection section. The drive cylinder receives pressurized fluid from the drive pump assembly and causes metered fluid to be drawn into and expelled by the injection section. The position of reciprocating components of the injection pump assembly is detected between stroke limits and converted to a velocity signal. Closed-loop control of the flow from the injection pump assembly is implemented by the controller via the drive pump assembly based upon the actual velocity of the reciprocating components of the injection pump assembly and a commanded velocity. The closed-loop injection rate control may be incorporated in a nested fashion with a process parameter control loop to maintain a desired level of a process parameter, such as temperature in a reaction vessel.

Owner:OILQUIP

Hybrid catalyst system for exhaust emissions reduction

InactiveUS20070033928A1Improve efficiencySpeed up the conversion processHydrogenGas treatmentExhaust fumesEngineering

One aspect of the invention relates an exhaust treatment system having an SCR reactor following a NOx adsorber. Syn gas is used to regenerate the NOx adsorber. Another aspect relates to an LNT / SCR provided with an ammonia source separate from the LNT. A further aspect relates to a system comprising first and second LNTs and one or more SCRs downstream of the LNTs. A still further aspect relates to a device comprising first and second NOx adsorbers contained in a single housing. Another aspect relates to coating a surface of a moving part in an exhaust system with an oxidation catalyst to mitigate fouling. Additional aspects of the invention relate to strategies for controlling one or more of the time to initiate a regeneration cycle, the time to terminate a regeneration cycle, and the reductant injection rate during regeneration of LNT / SCR exhaust treatment systems.

Owner:INT ENGINE INTPROP CO LLC

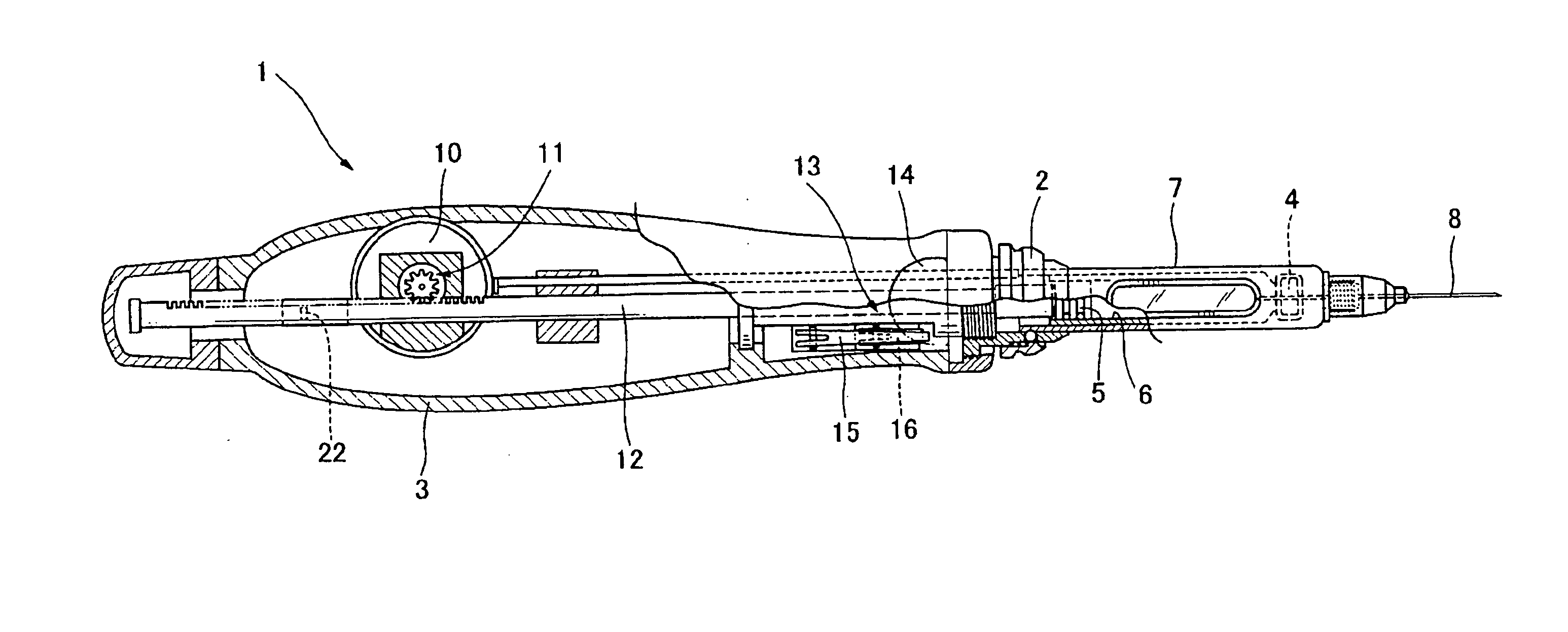

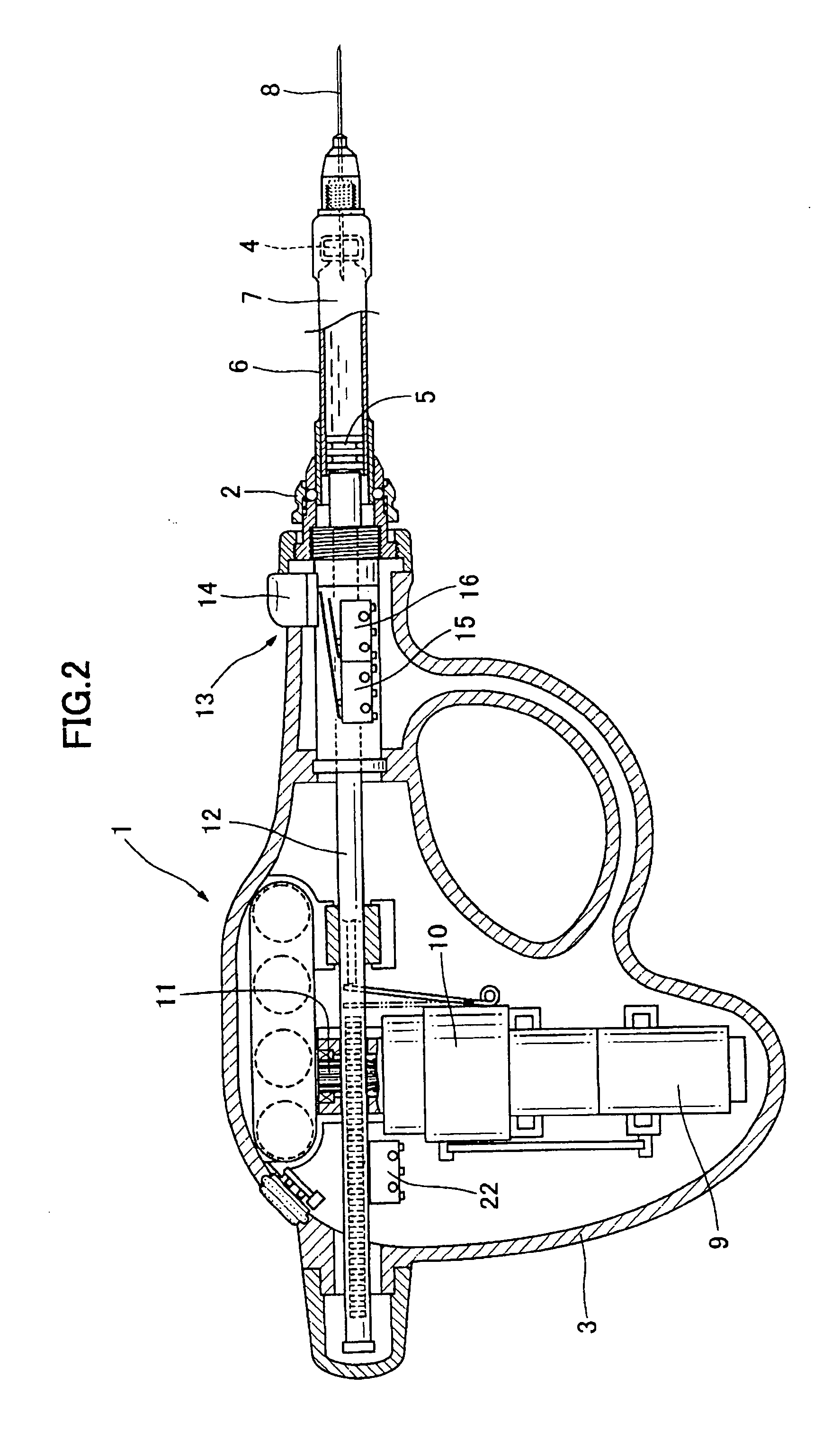

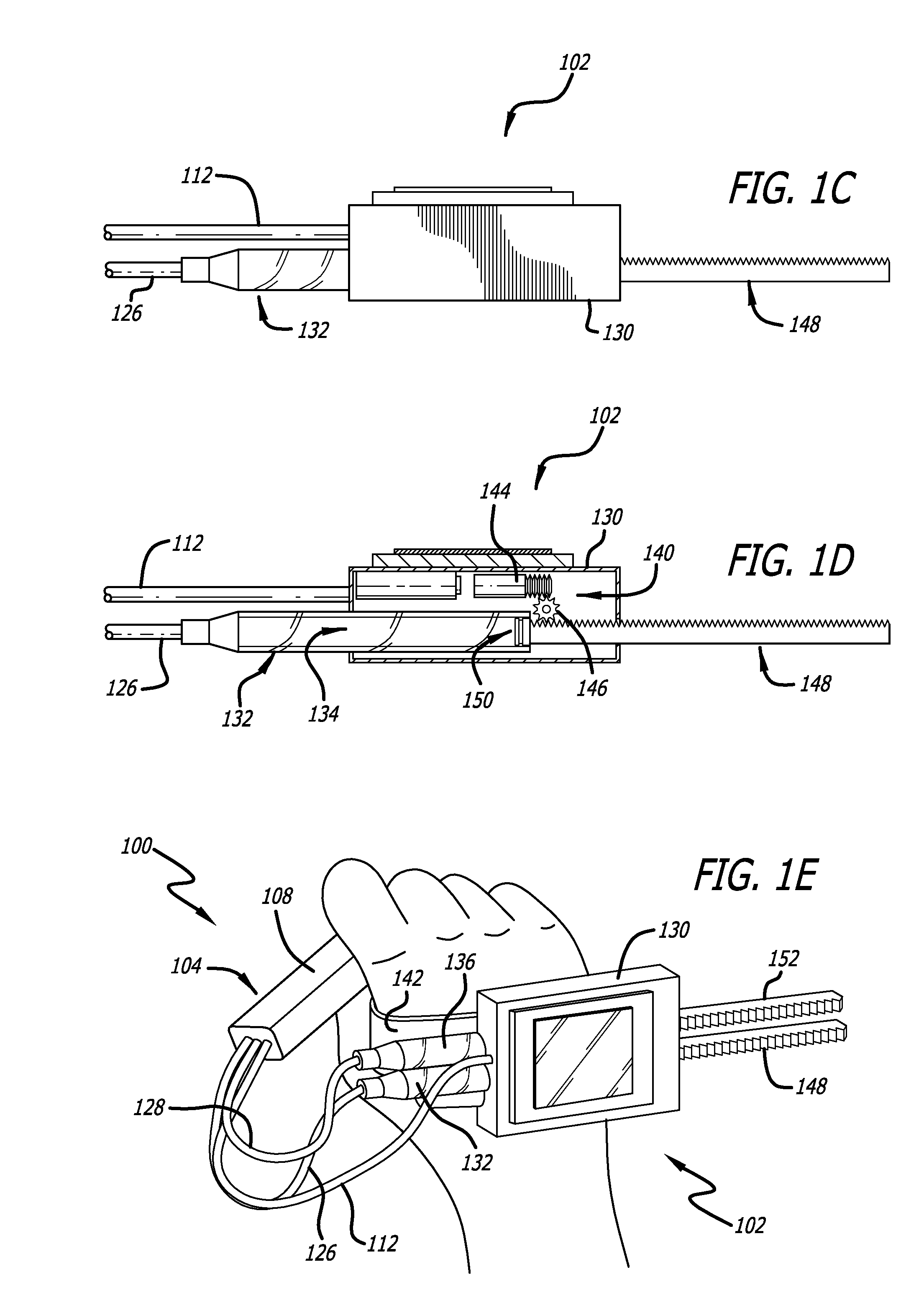

Method and apparatus for controlling the injection rate of a drug solution in a cartridge type motor-driven dental injection syringe

InactiveUS20080097325A1Low injection rateAmpoule syringesAutomatic syringesDrugs solutionMotor drive

Disclosed are a method and apparatus for controlling the injection rate of an anesthetic solution in a cartridge type motor-driven injection syringe for dental use, particularly beginning with the “Low” rate injection at the outset, and switching to the “Medium” or “High” injection rate at an arbitrarily selected time in the course of injection. The speed of revolution of the electric motor is changed among the low, medium and high speed, and a two-step operable type of switch is used as a starter switch 13. The first depression of the starter switch makes the electric motor 9 start at the low speed, thereby making the plunger rubber 5 initially move at the “Low Speed” in the cartridge 6 via the plunger rod 12, and the second depression of the switch makes the electric motor 9 run at the low, medium or high speed, and accordingly the plunger rod moves at the selected “Low Speed”, “Medium Speed” or “High Speed”.

Owner:SHOWA YAKUHIN KAKO

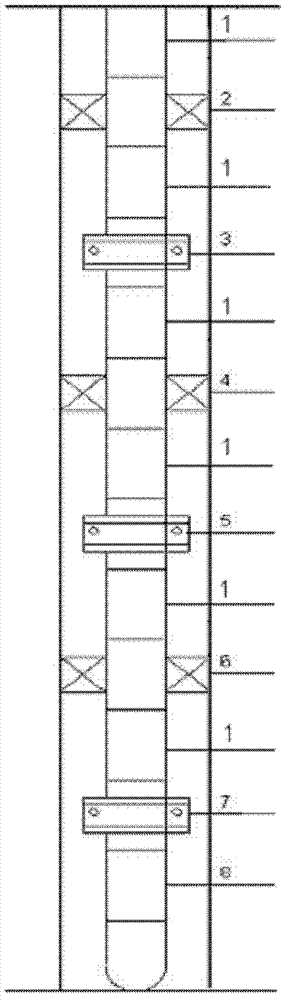

Digital underground layering water injection testing and adjusting process pipe column and operation method thereof

The invention discloses a digital underground layering water injection testing and adjusting process pipe column and an operation method thereof. According to the purpose, the instantaneous flow rate and the accumulative total injection rate of a single reservoir stratum can be monitored and recorded in real time underground, pressure of the reservoir stratum is monitored in real time, underground well shut-in layering pressure drop is tested, and bi-directional transmission of data and orders between a down-hole and the ground is carried out in a wireless mode. The process pipe column is formed by connecting a multistage digital water distributor and an Y344 water injection packer through an oil pipe, and eliminates steps of testing and allocating steel wires of the flow rate compared with an existing water distributor and a packer used for layering water injection. Meanwhile, the instantaneous flow rate and the accumulative total injection rate of the single reservoir stratum can be monitored and recorded in real time underground, the pressure of the reservoir stratum is monitored in real time, and the underground well shut-in layering pressure drop is tested. The pipe column can greatly reduce workloads of matching tests and pressure-drop tests of an oil field layering water injection well, provides the true and reliable accumulative total injection rate of the single stratum, and provides reliable evidence for policy adjustment of the oil field development technology.

Owner:PETROCHINA CO LTD

Modular injection system and method for diluting an injectable fluid

A modular injection system enables a user to control the dilution ratio of mixed injectable fluid. In one embodiment, modular injection system includes a handheld injection device operatively connected to a separate control device. In one embodiment, the control device includes a drive unit configured to apply extrusion forces to fluids. In another embodiment, the handheld injection device includes the drive unit. In one embodiment, the modular injection system produces the mixed injectable fluid based on a selected dilution ratio. In one embodiment, the modular injection system produces the mixed injectable fluid based on selected injection rates.

Owner:ALLERGAN INC

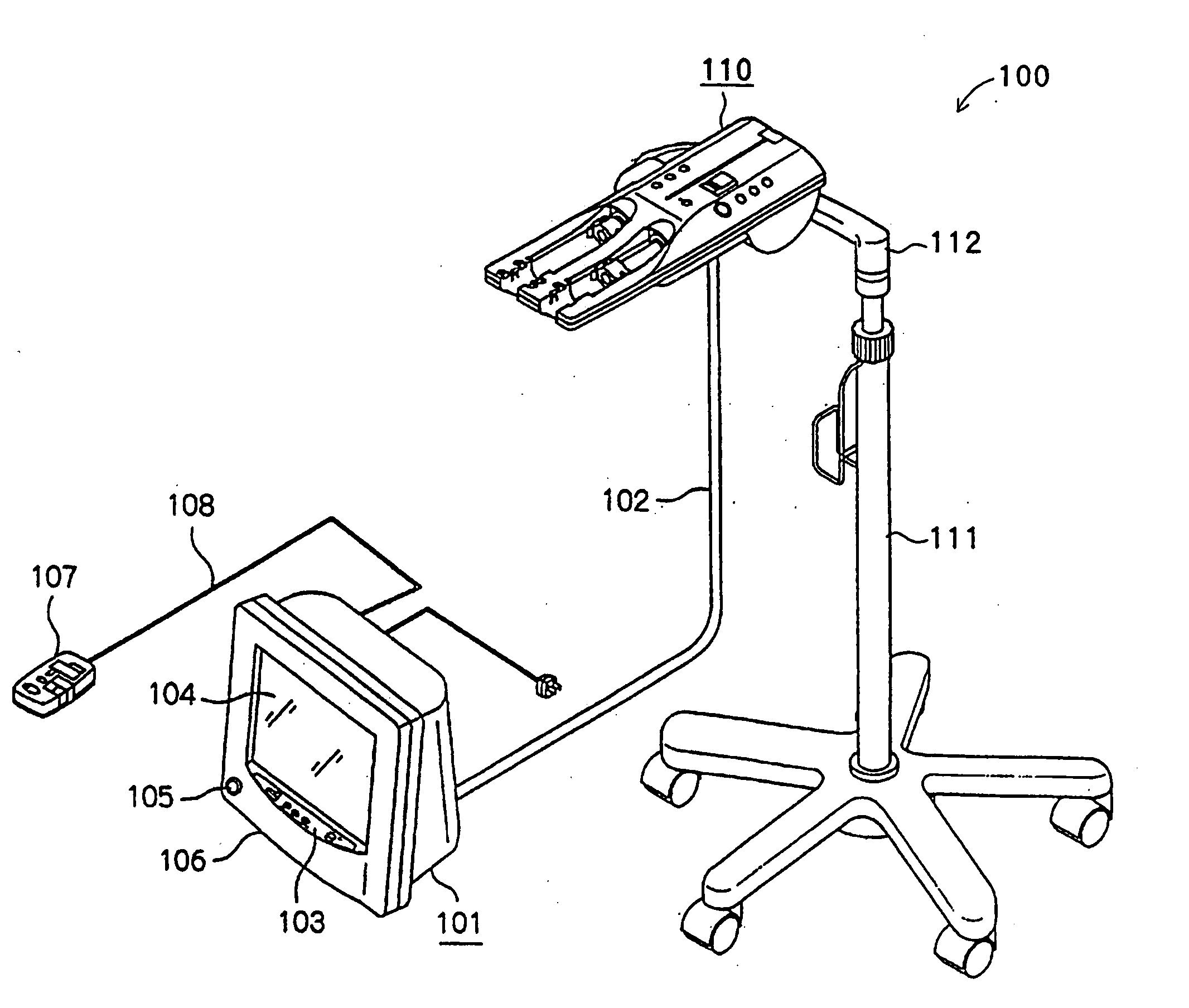

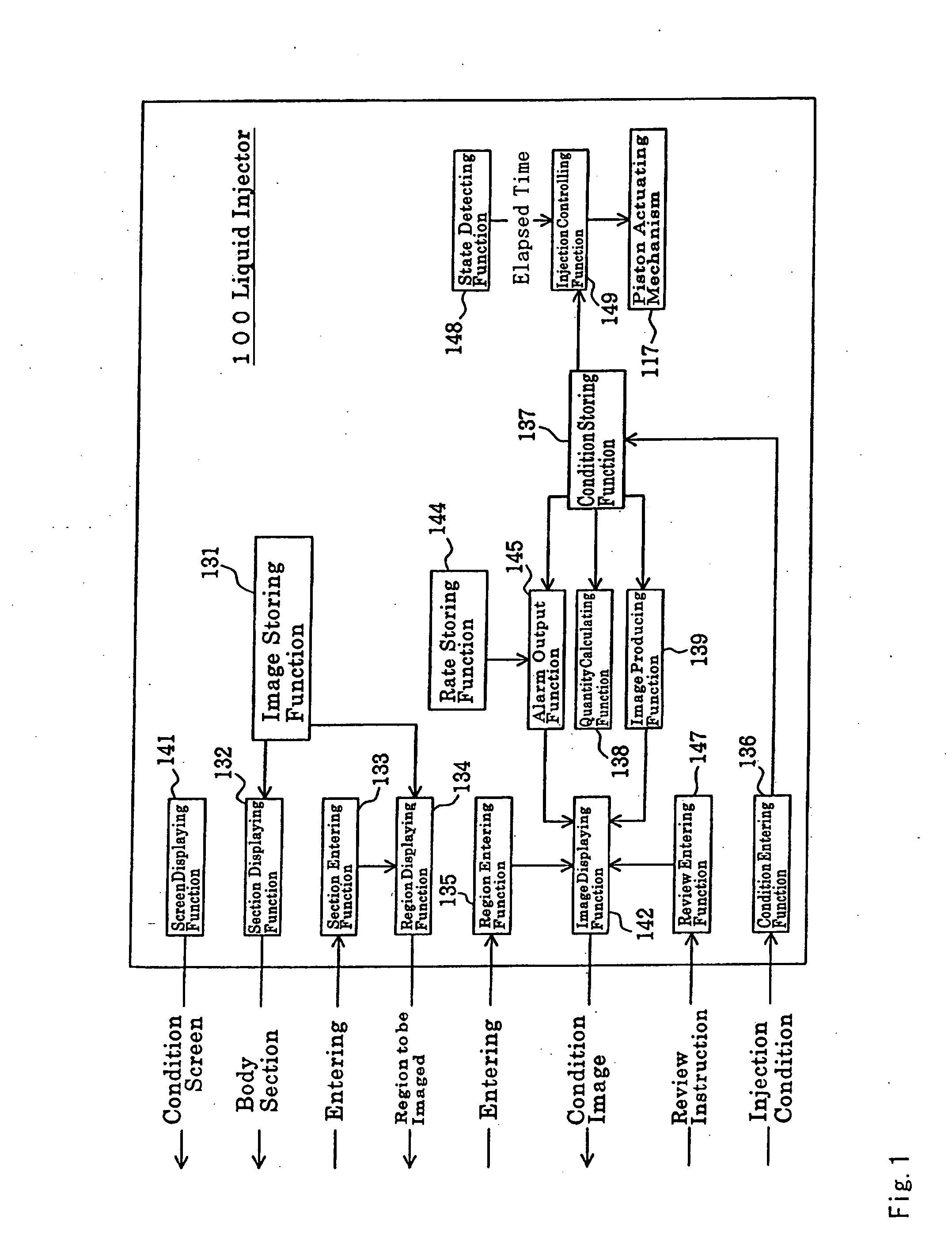

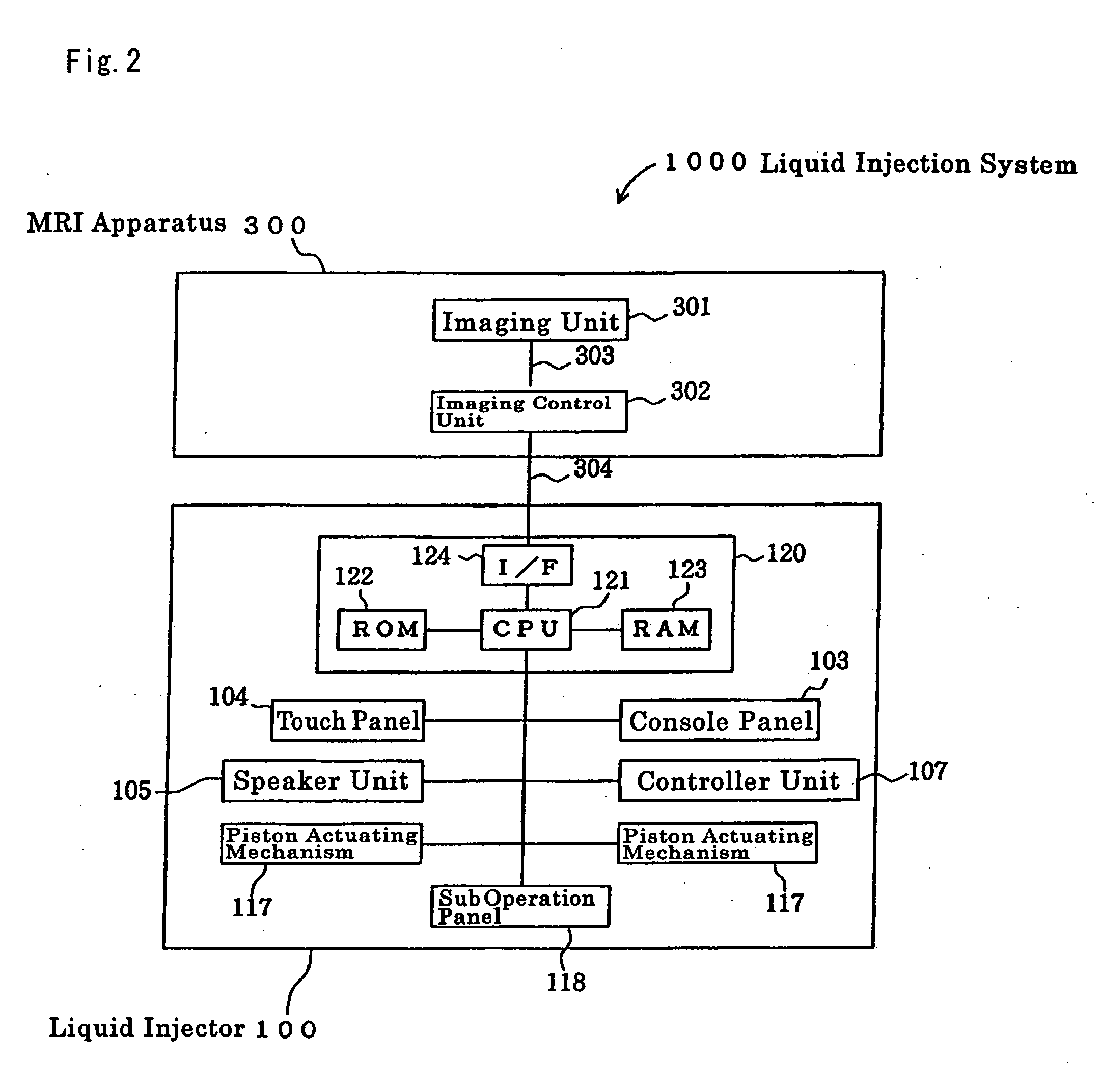

Medicine infuser for displaying image of entered infusion condition

ActiveUS20060184122A1Simple and easy input actionQuick checkMedical devicesPressure infusionData operationsHorizontal axis

The preset invention provides a liquid injector in which, when an injection time period and an injection rate are entered as an injection condition, a condition image having a horizontal width corresponding to the injection time period and including the injection rate as text data is displayed in a condition screen with its vertical axis representing the injection rate and its horizontal axis representing the injection time period at a vertical position in association with the injection rate and a horizontal position in association with the injection time period. The operator easily understands instinctively the injection condition from the horizontal width and the position of the condition image, and since the condition image includes the injection rate as text data, the operator can check quickly the numerical values. Thus, the liquid injector can be provided which allows simple entry and review of the injection condition.

Owner:NEMOTO KYORINDO KK

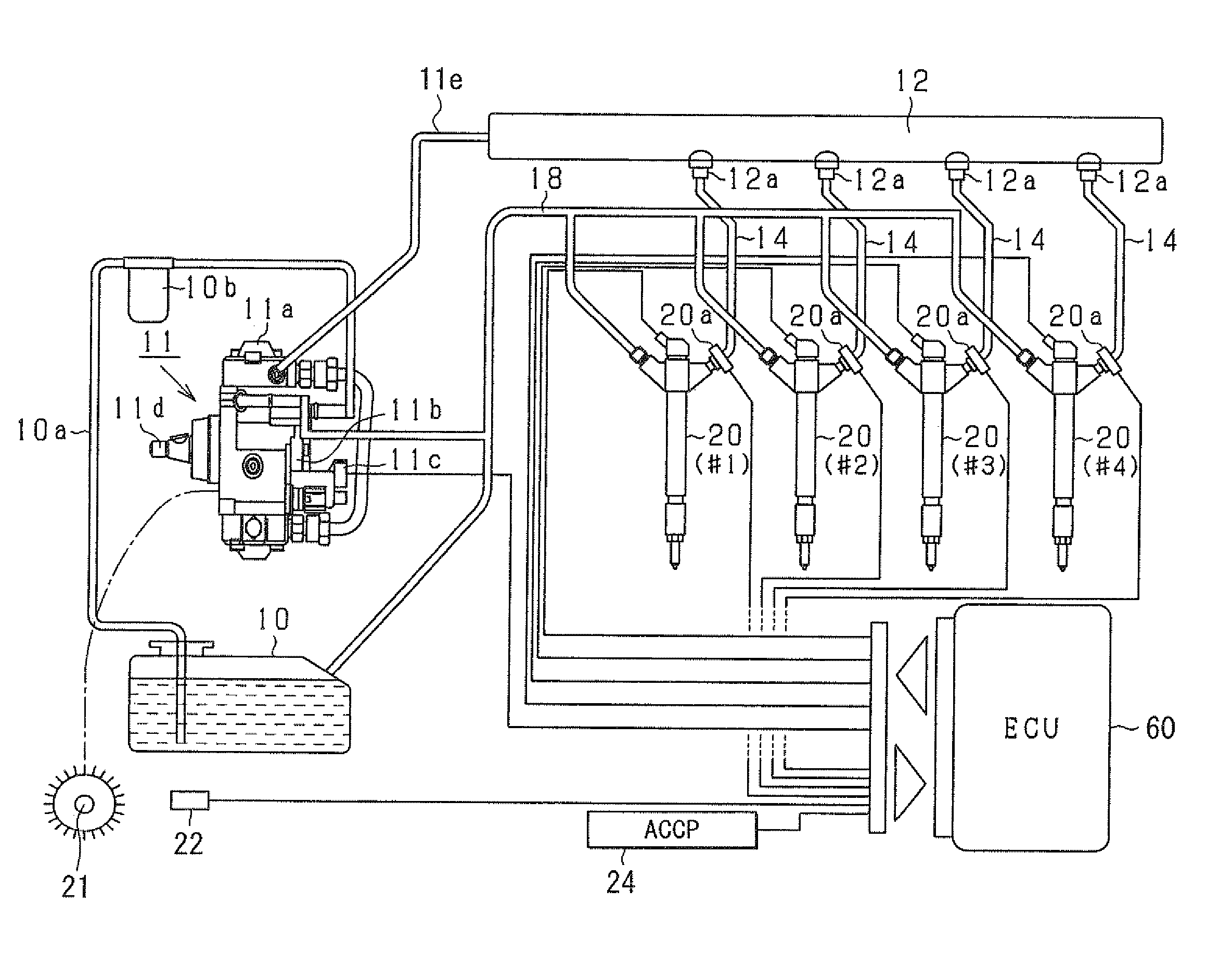

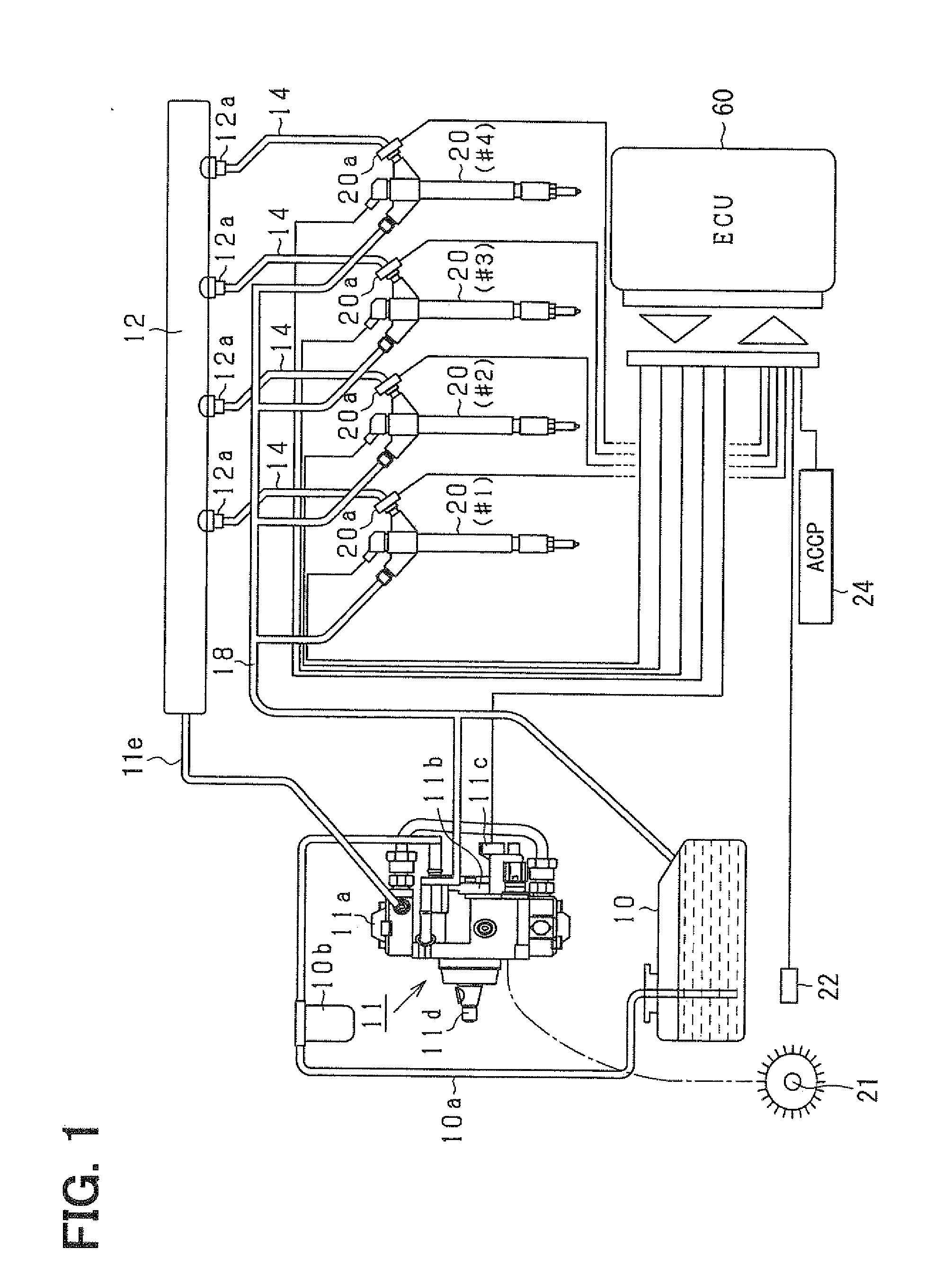

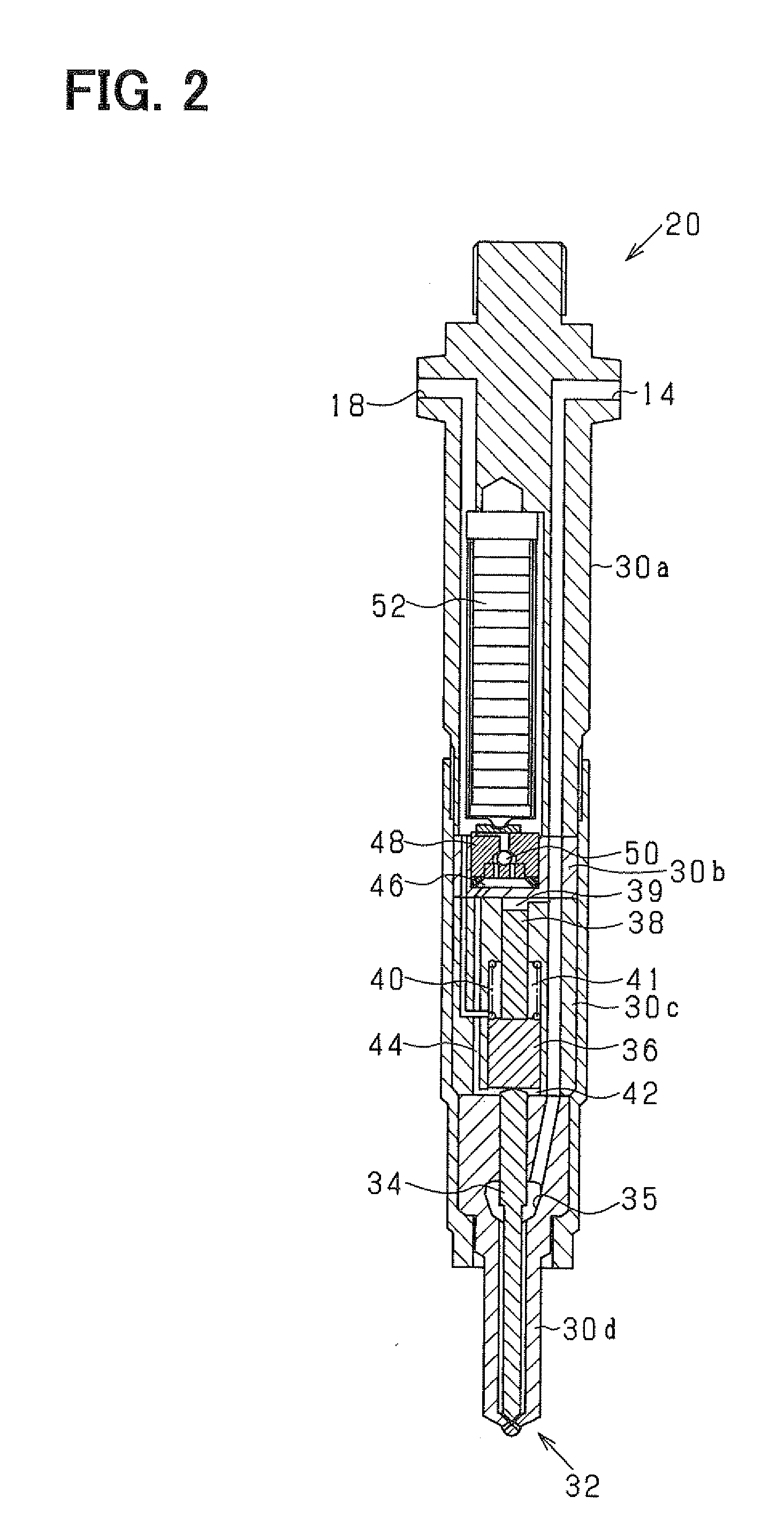

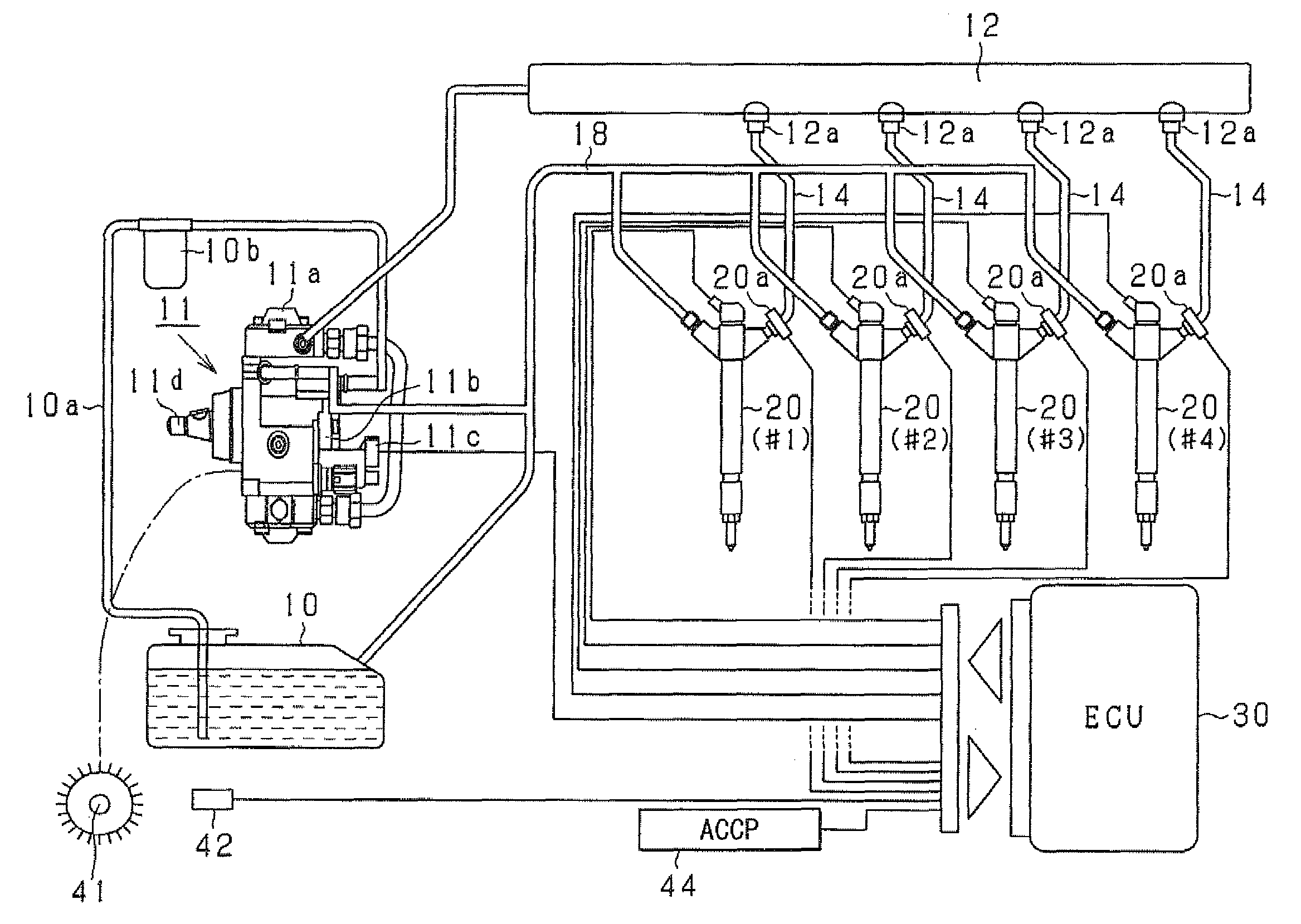

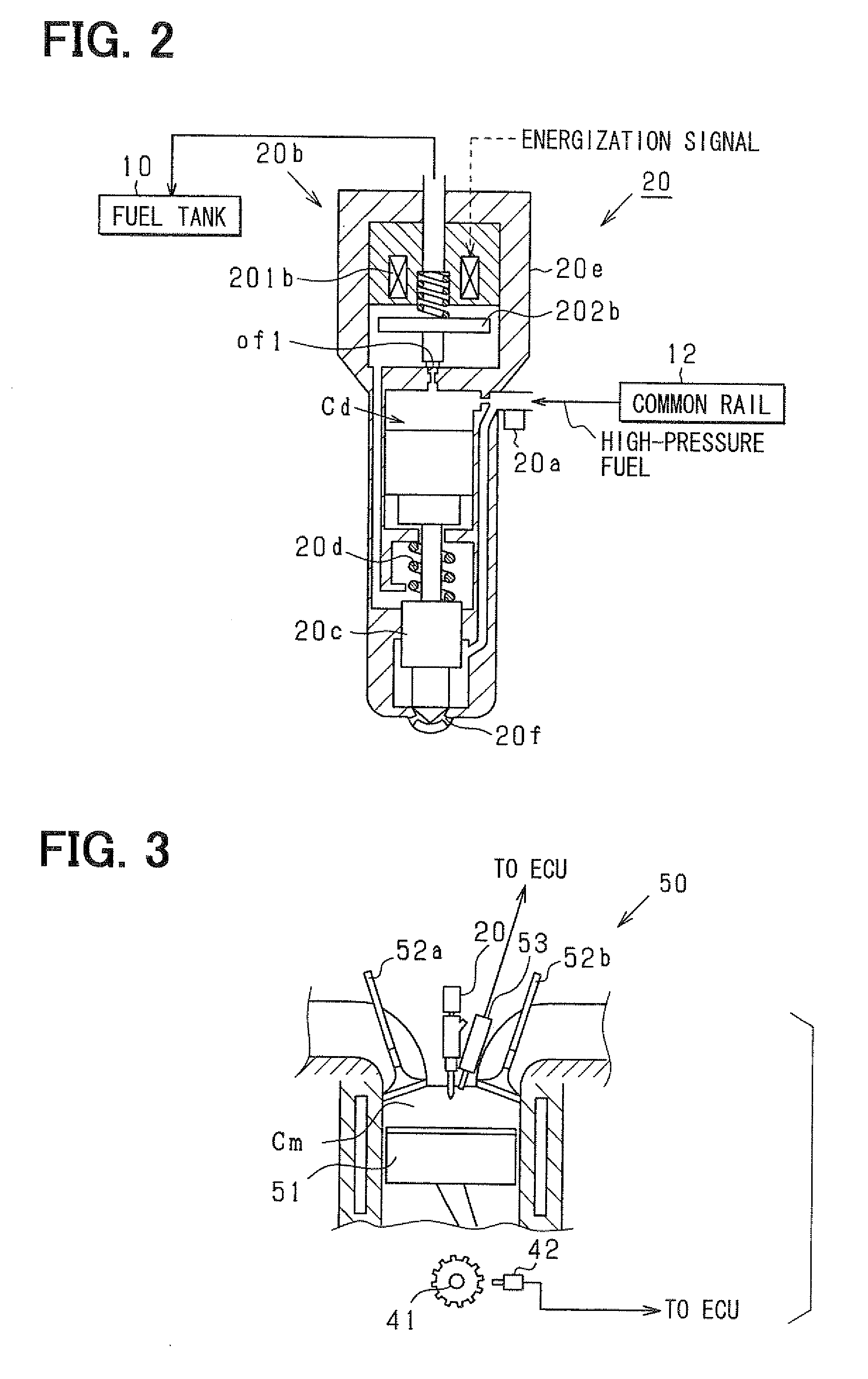

Injection control device of internal combustion engine

InactiveUS20090063016A1Controlled in a desired mode easily and appropriatelyImprove practicalityElectrical controlInternal combustion piston enginesReciprocating motionInternal combustion engine

A fuel injection control device (ECU) for controlling injection supply of fuel to an engine is applied to an injector that has a valve body formed with a fuel injection hole, a needle accommodated in the valve body for opening and closing the injection hole, and a piezoelectric element for driving the needle such that the needle reciprocates and that can continuously adjust an injection rate in accordance with an injection command signal to the piezoelectric element. The fuel injection control device senses a fuel pressure waveform indicating a transition of fuel pressure fluctuation accompanying a predetermined injection of the injector based on an output of a fuel pressure sensor and calculates an injection command signal for approximating a predetermined injection parameter concerning the predetermined injection to a reference value of the parameter based on the sensed fuel pressure waveform.

Owner:DENSO CORP

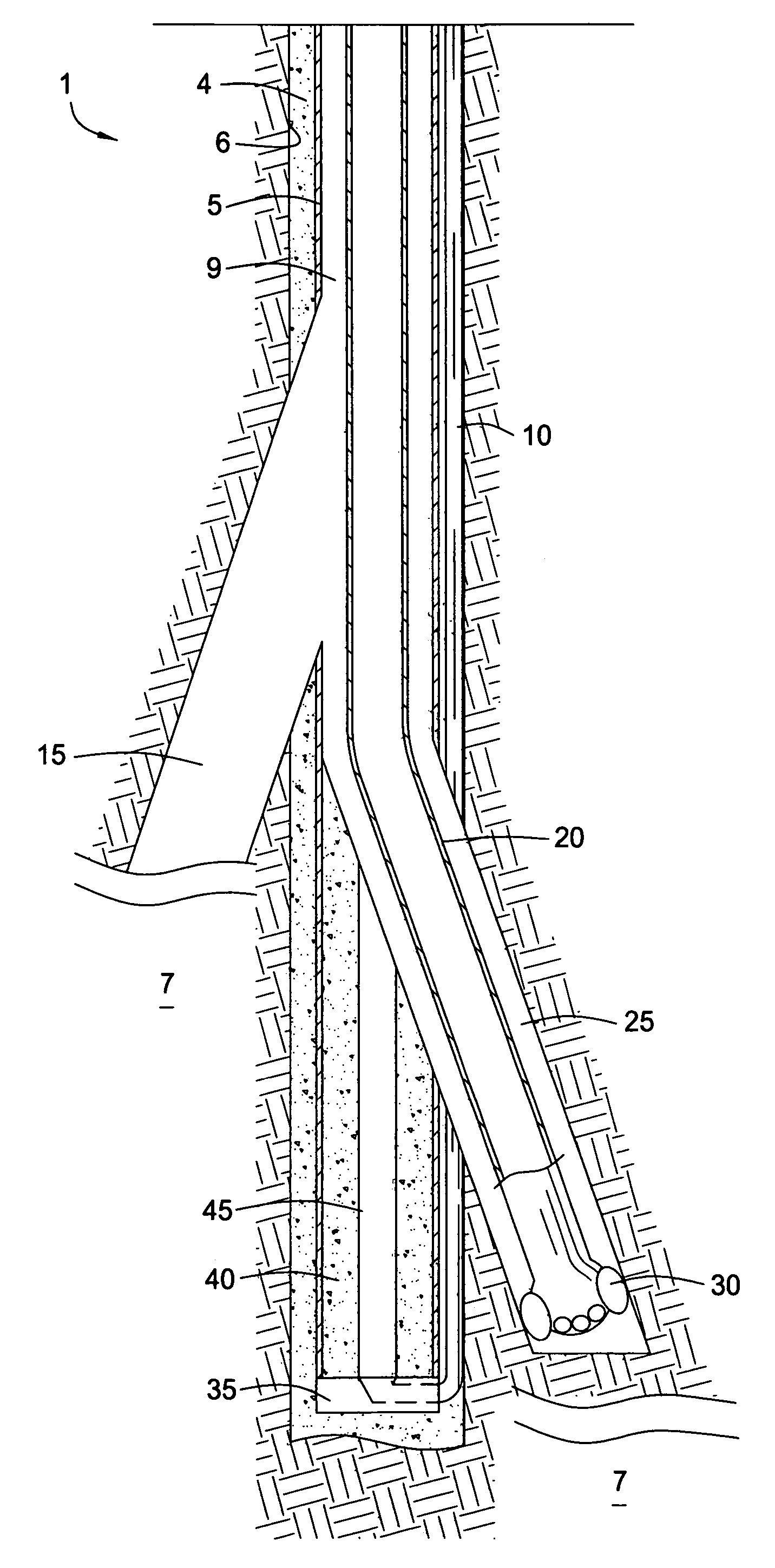

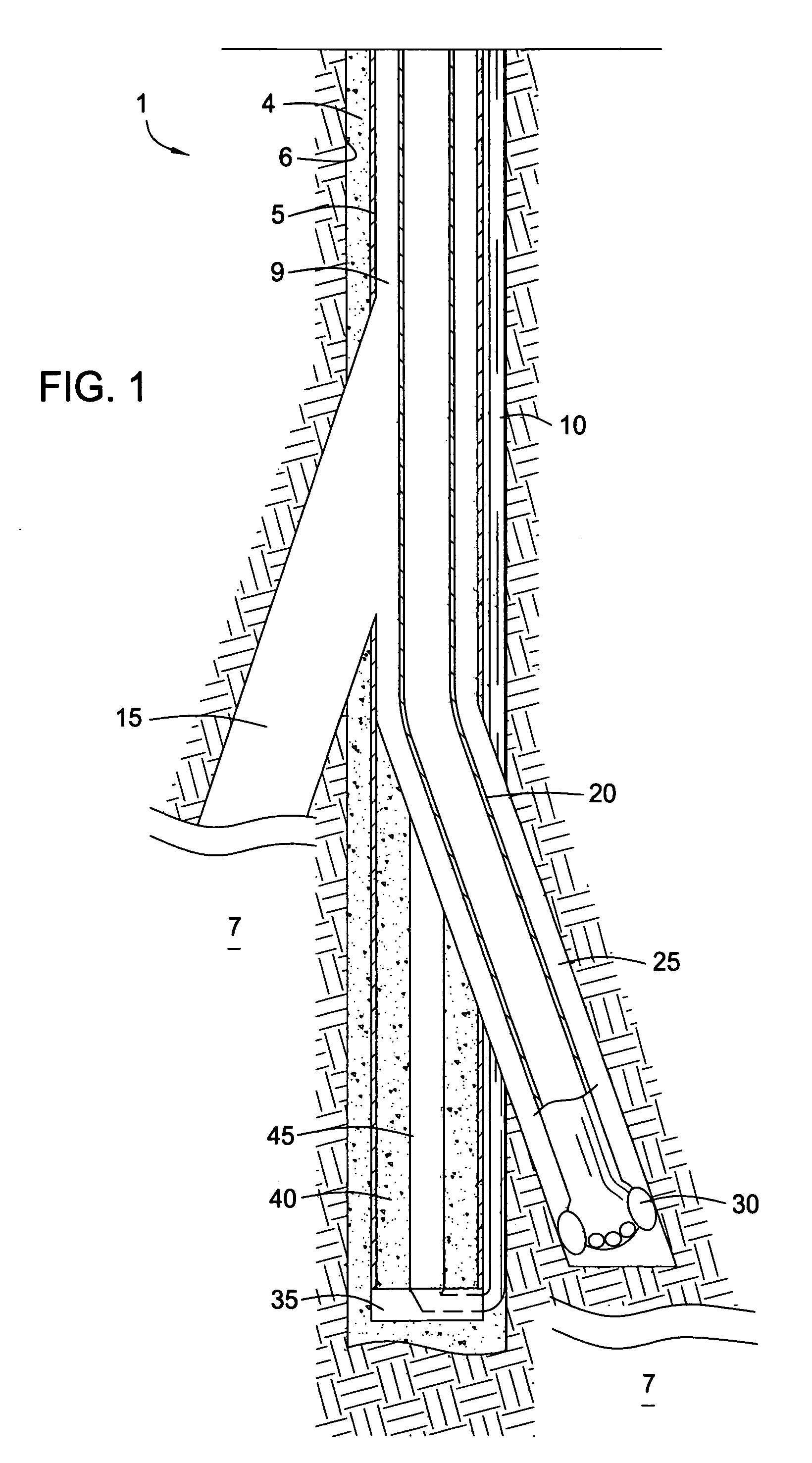

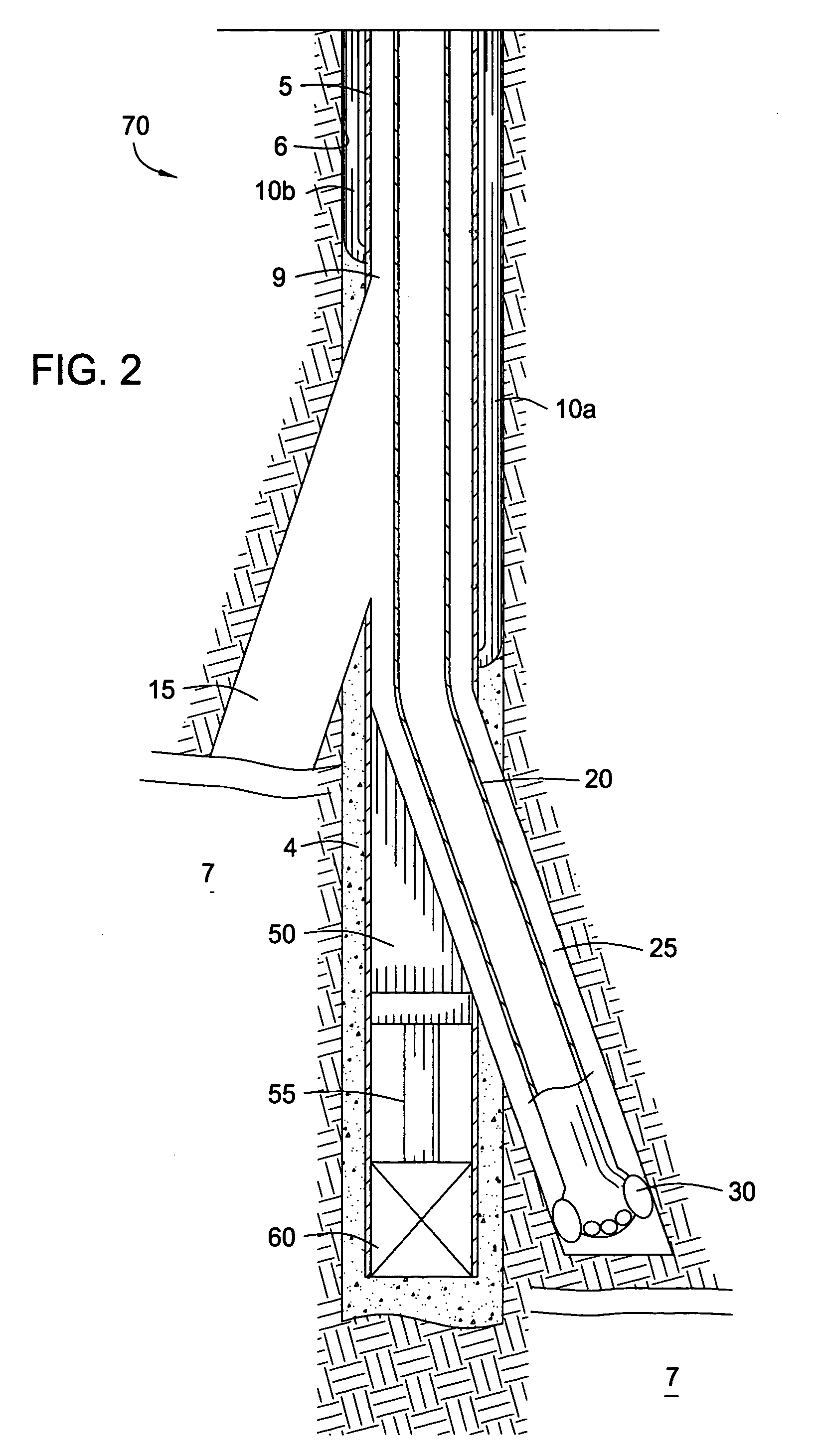

Method for extracting coal bed methane with source fluid injection

The present invention generally provides an inexpensive method for drilling a multilateral wellbore where the pressure exerted on a formation of interest by a column of drilling fluid may be controlled. In one aspect, a method for drilling a lateral wellbore from a main wellbore is provided, including running a string of casing with an injection line connected thereto into the main wellbore, wherein the injection line is disposed along an outer side of the casing and a portion of the casing corresponding to a starting depth of the lateral wellbore is made from a drillable material; running a drillstring through the casing to the starting depth of the lateral wellbore, wherein the drillstring comprises a drill bit; injecting drilling fluid through the drill sting; and injecting a second fluid, having a density less than that of the drilling fluid, through the injection line at a rate corresponding to an injection rate of the drilling fluid to control hydrostatic pressure exerted by a column of the drilling fluid and the second fluid returning through the casing.

Owner:WEATHERFORD TECH HLDG LLC

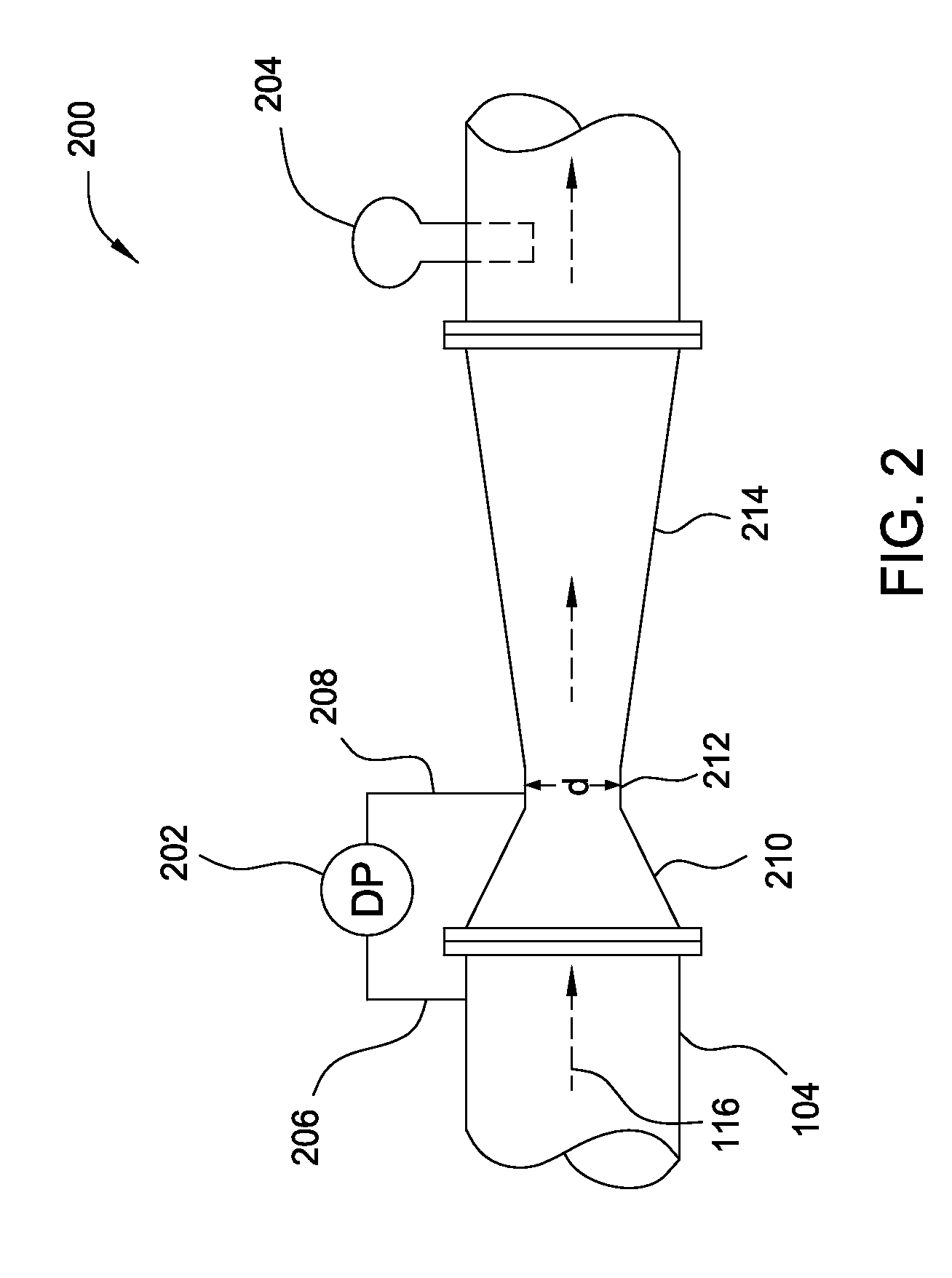

Multiphase flow meter for subsea applications using hydrate inhibitor measurement

ActiveUS20120046870A1Electric/magnetic detection for well-loggingSurveyDifferential pressureWater flow

Methods and apparatus for determining phase fractions (relative concentrations) within a multiphase fluid mixture, in the presence of an injected hydrate inhibitor. Combining this phase fraction information with a hydrate inhibitor injection rate (HIIR) enables resolving oil and water flow rates for the phase fractions. The liquid flow rates and a total combined flow rate of the fluid mixture—determined based on a differential pressure of the fluid mixture through a given area—enable resolving a gas flow rate.

Owner:WEATHERFORD TECH HLDG LLC

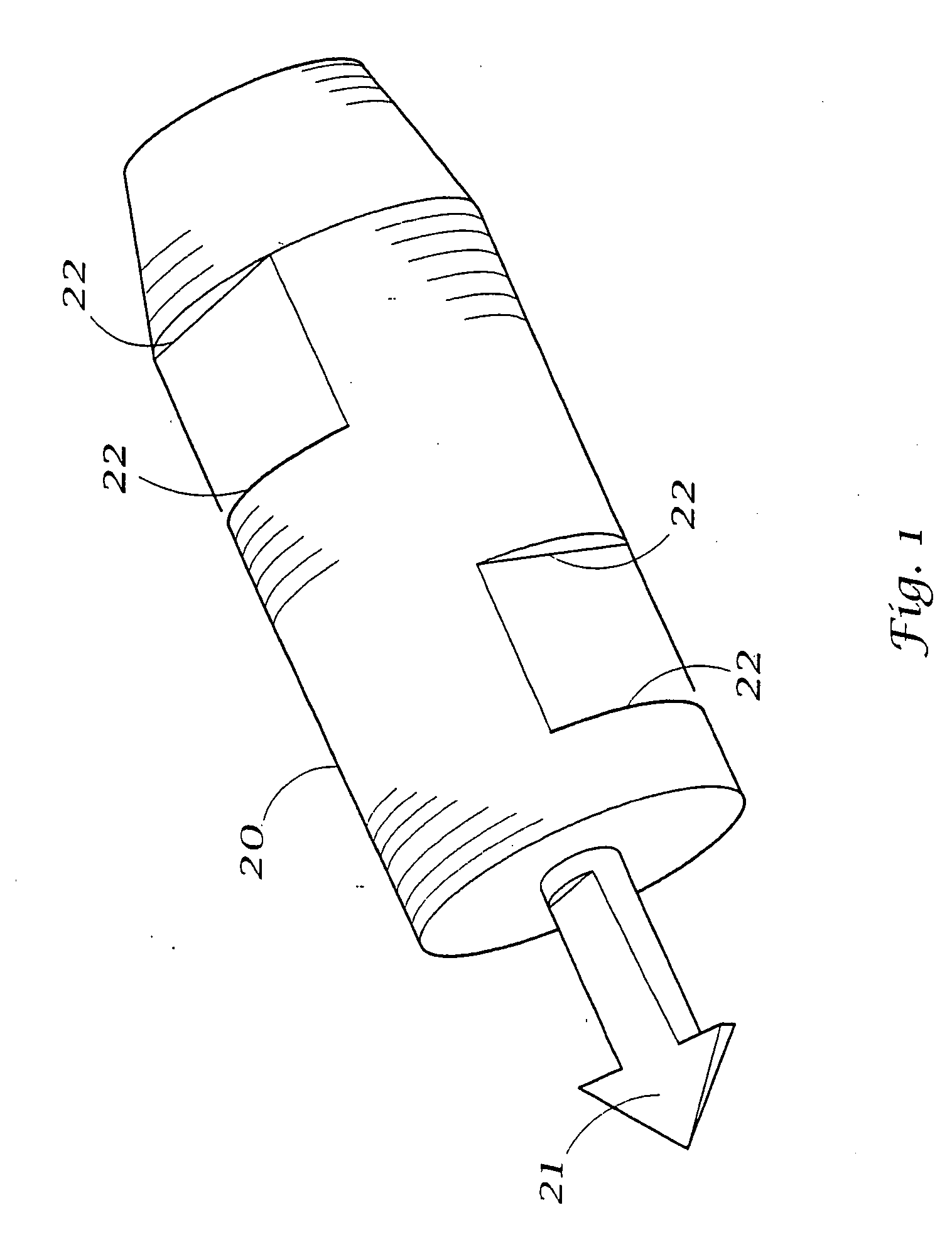

Fluid material dispensing syringe

InactiveUS20070250010A1Increase delivery rateAmpoule syringesMedical devicesDental syringeEngineering

A dental syringe (10) has a needle (11) affixed to a carpule holder (12), which carpule holder (12) is affixed to a power drive unit (13). A harpoon (20) is provided to affix the drive unit to the carpule plunger (32). The harpoon (20) is made of stainless steel or other hard, corrosion resistant, sterilizable, material. Harpoon 20 has a unique barb geometry and hardened, knife-like, edges (21). The syringe (10) may operate to divide the delivery of anesthesia into two phases. According to the method, during the first about 10 seconds of the injection, anesthetic is delivered at an extremely slow rate to maximize patient comfort. The injection rate then automatically increases to the preprogrammed rate associated with the injection type selected.

Owner:HOHLFELDER INGRID ELAINE +3

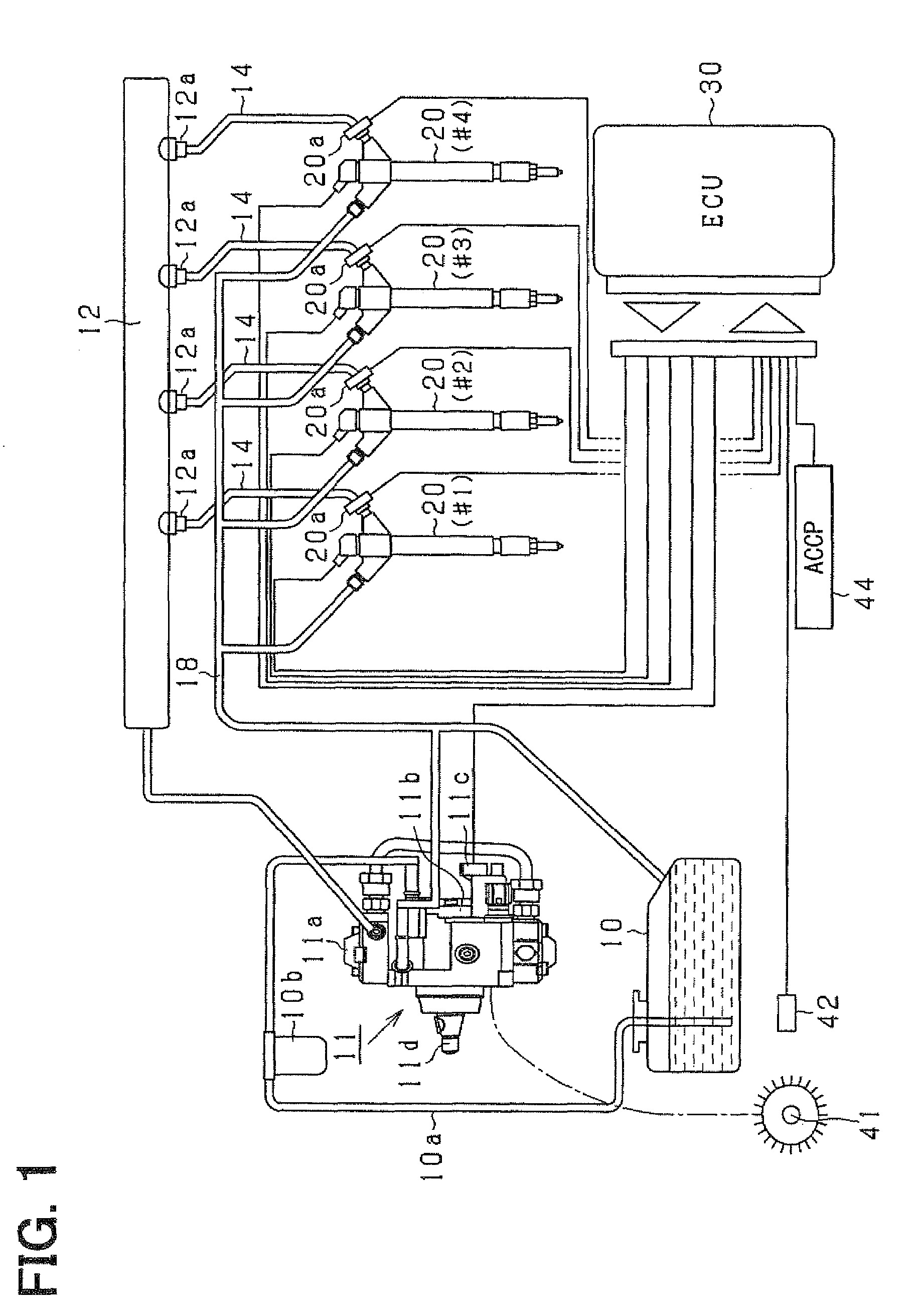

Fuel injection control device

ActiveUS20090063010A1Improve accuracyEasy maintenanceElectrical controlInternal combustion piston enginesEngineeringInjection rate

A fuel injection control device (ECU) for controlling injection supply of fuel to a target engine has a program for sequentially sensing fuel pressure fluctuating with injection of a predetermined injector a program for detecting an injection centroid of a diagram as a profile of a transition of an injection rate of the injector at a present time based on a transition of the sequentially sensed fuel pressure, and a program for varying an injection command (injection timing) of the injector based on the detected injection centroid and an injection centroid of a predetermined basic diagram such that a relative positional relationship between the injection centroids of the diagram as the actual profile of the injection rate transition and the basic diagram becomes a relationship, in which timings of the injection centroids are close to each other.

Owner:DENSO CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com