Patents

Literature

83results about How to "Increase delivery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

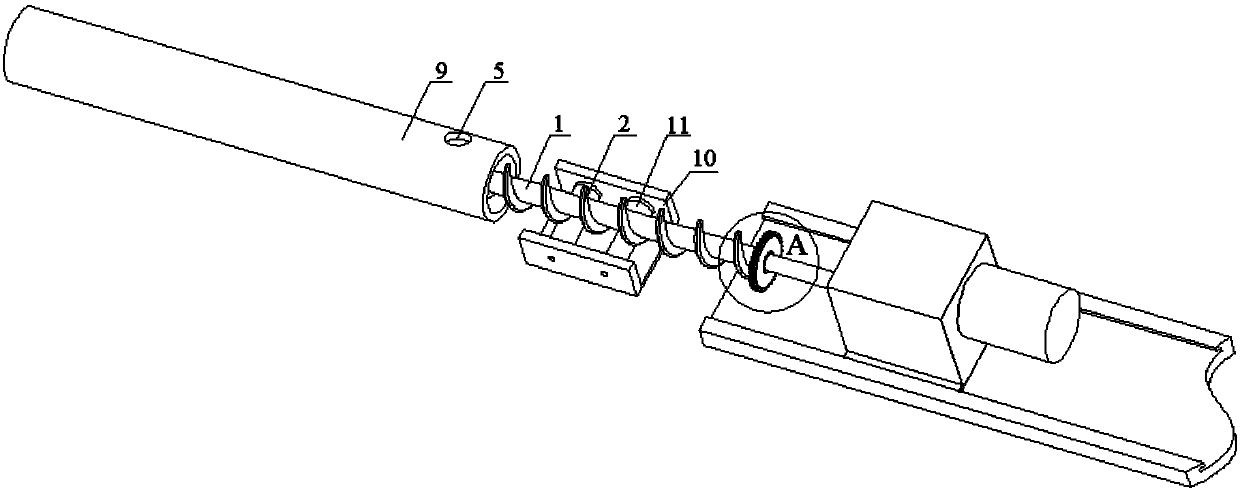

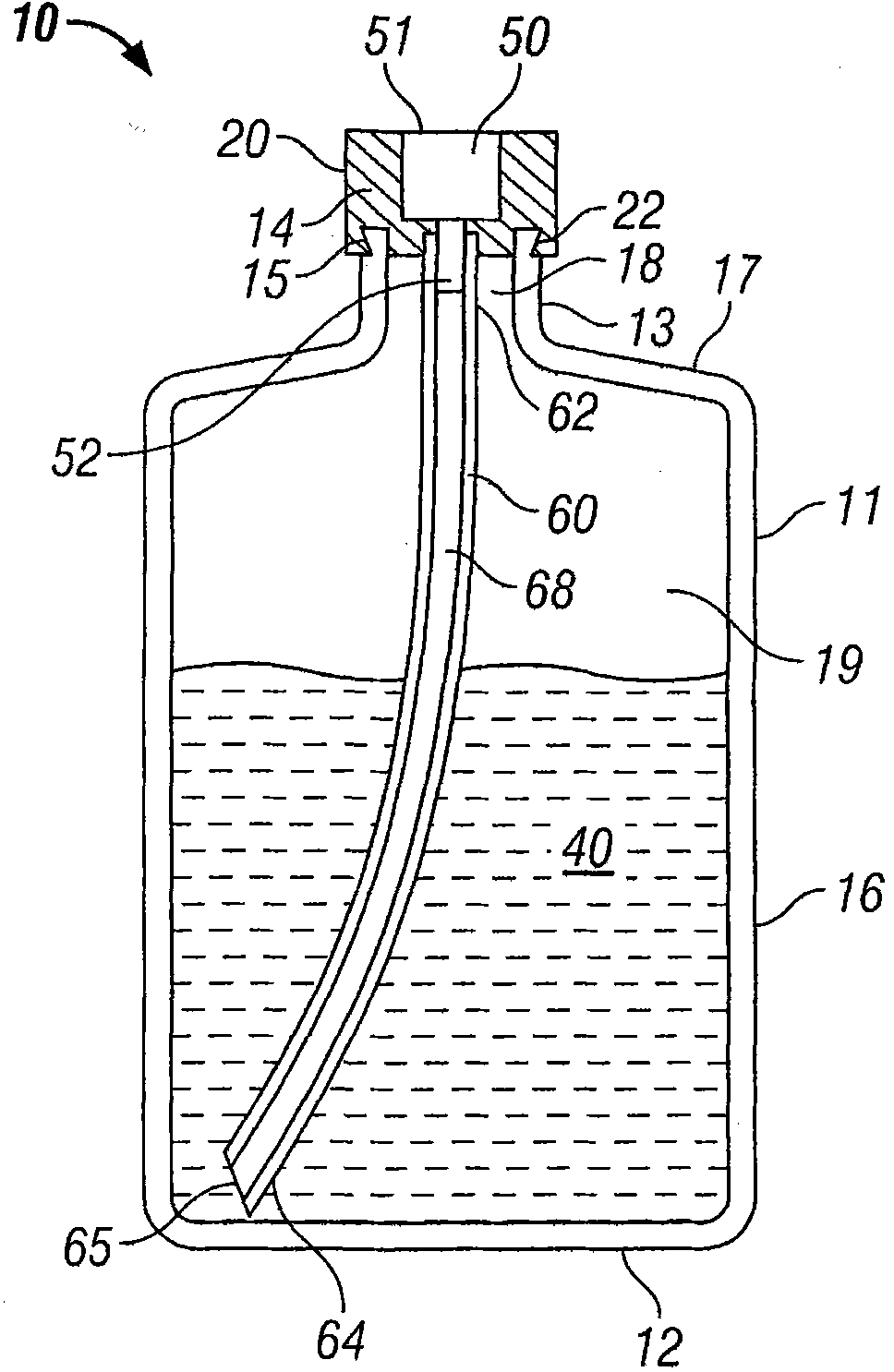

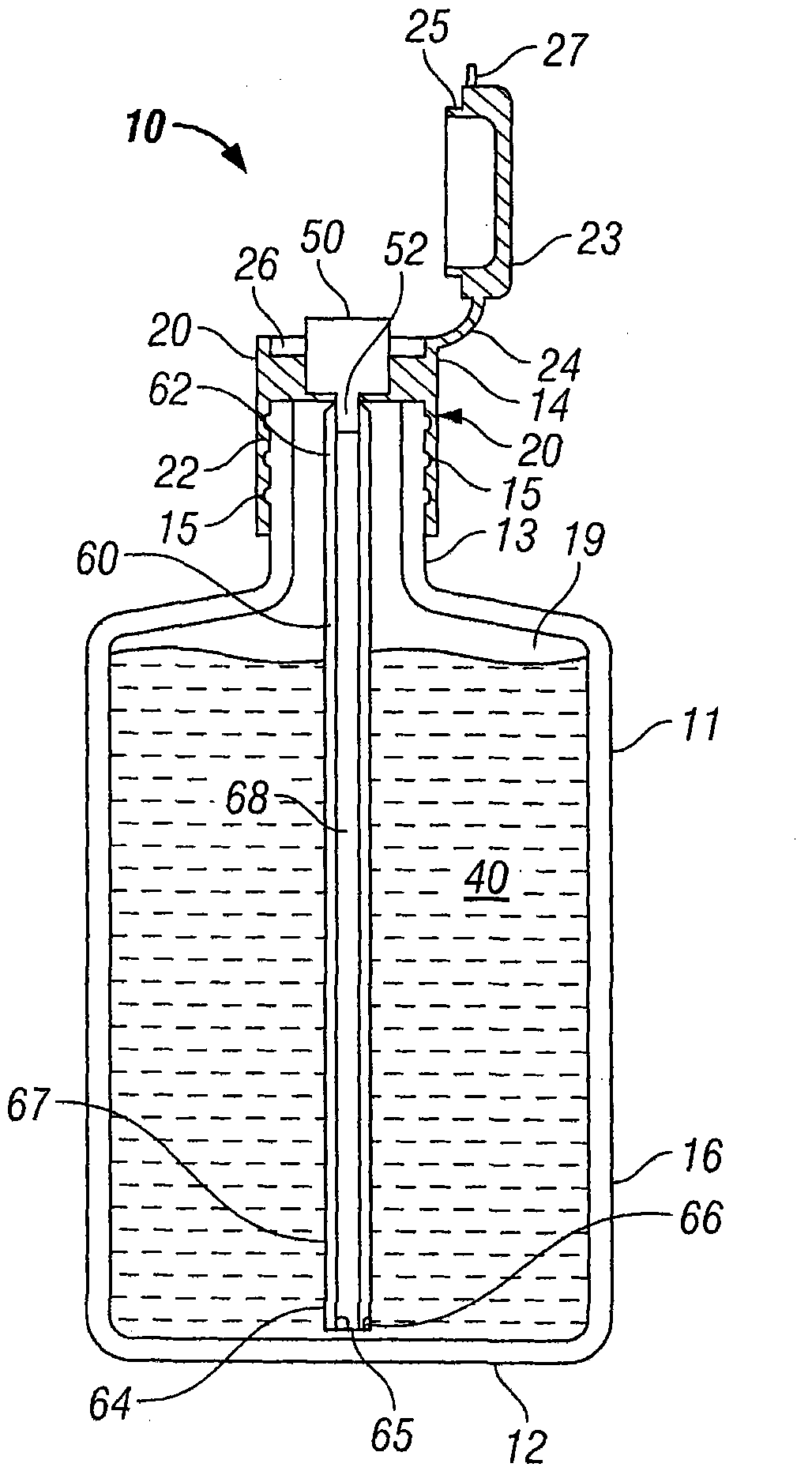

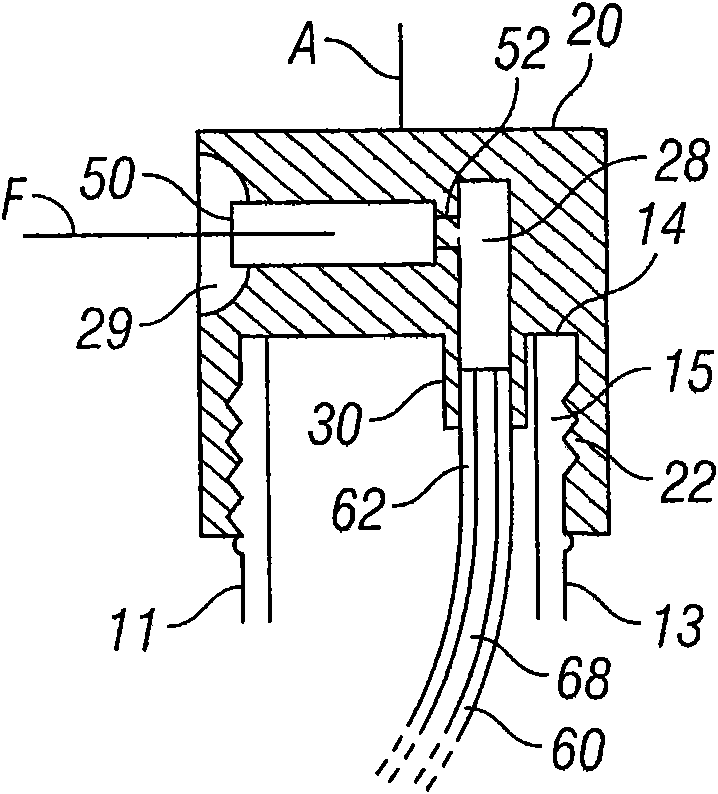

Fluid material dispensing syringe

InactiveUS20070250010A1Increase delivery rateAmpoule syringesMedical devicesDental syringeEngineering

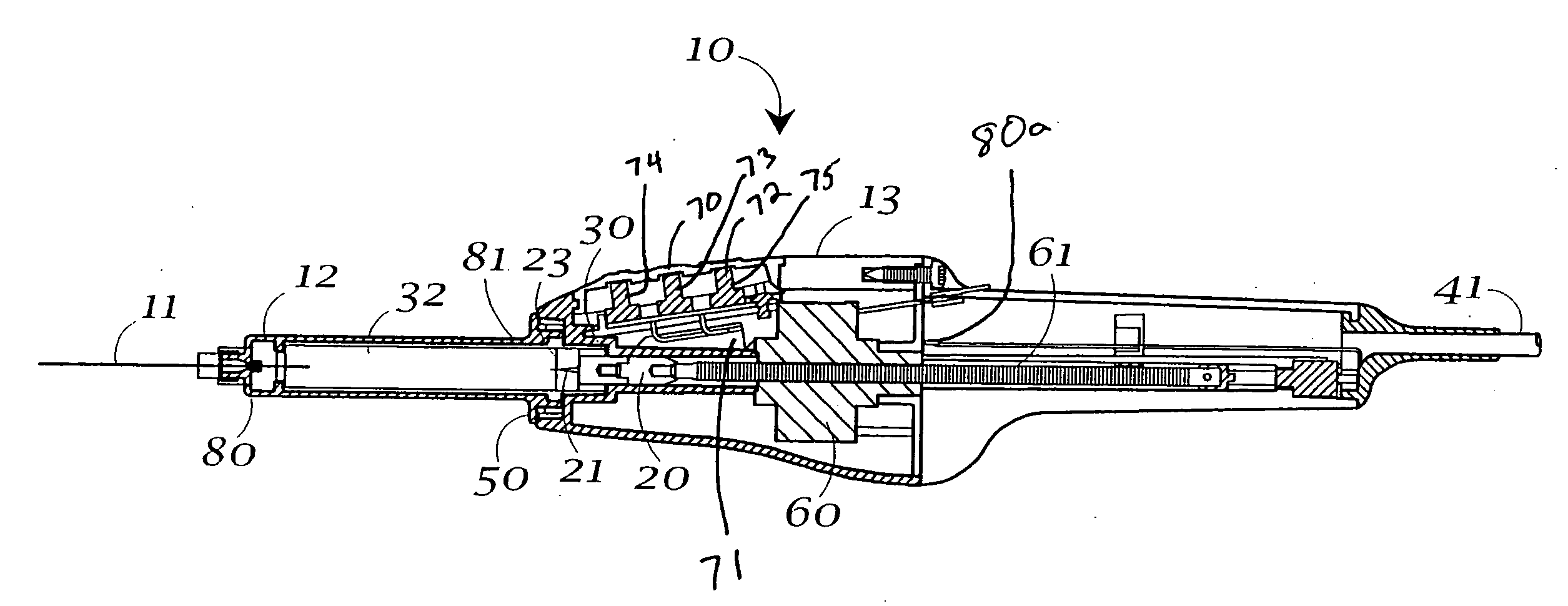

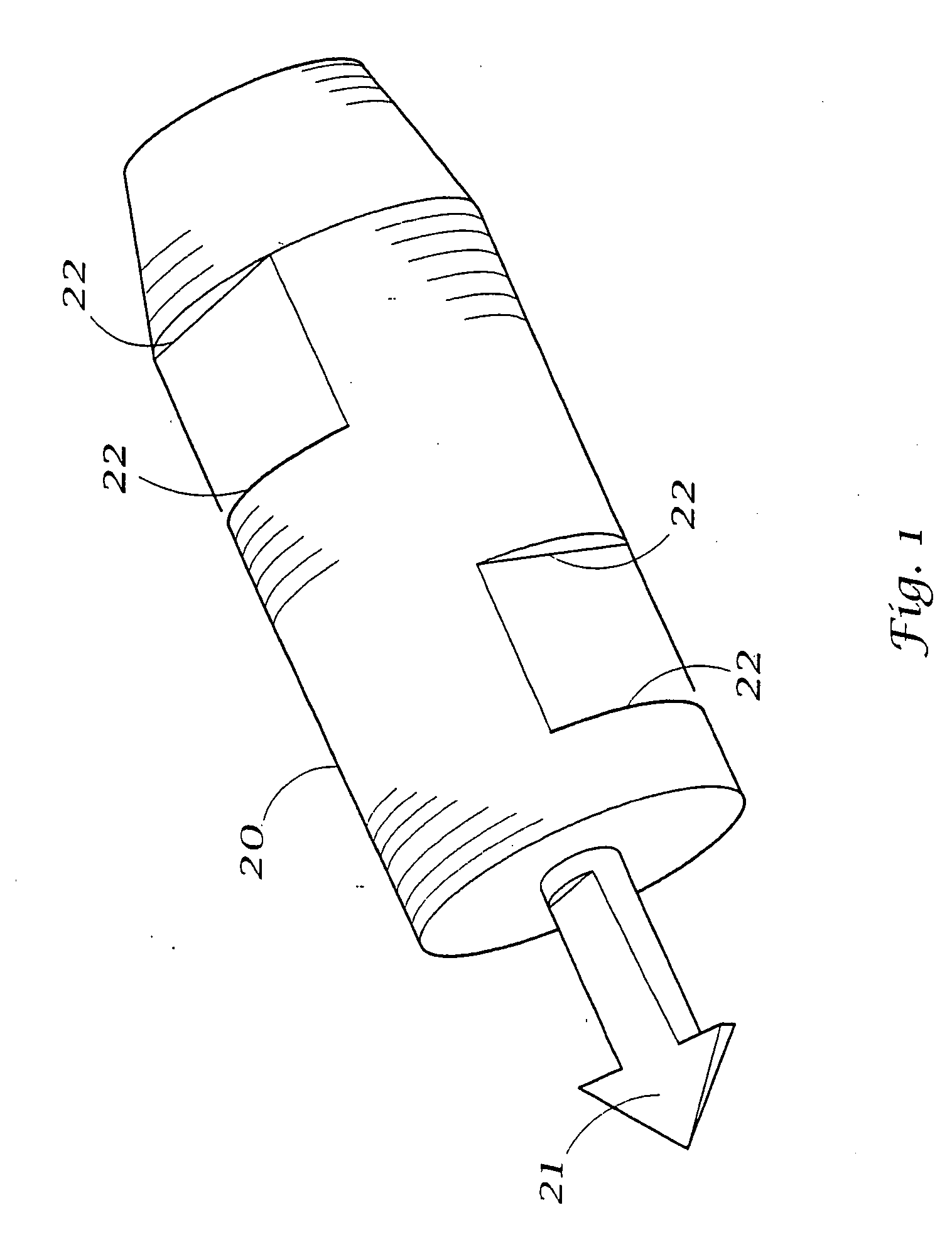

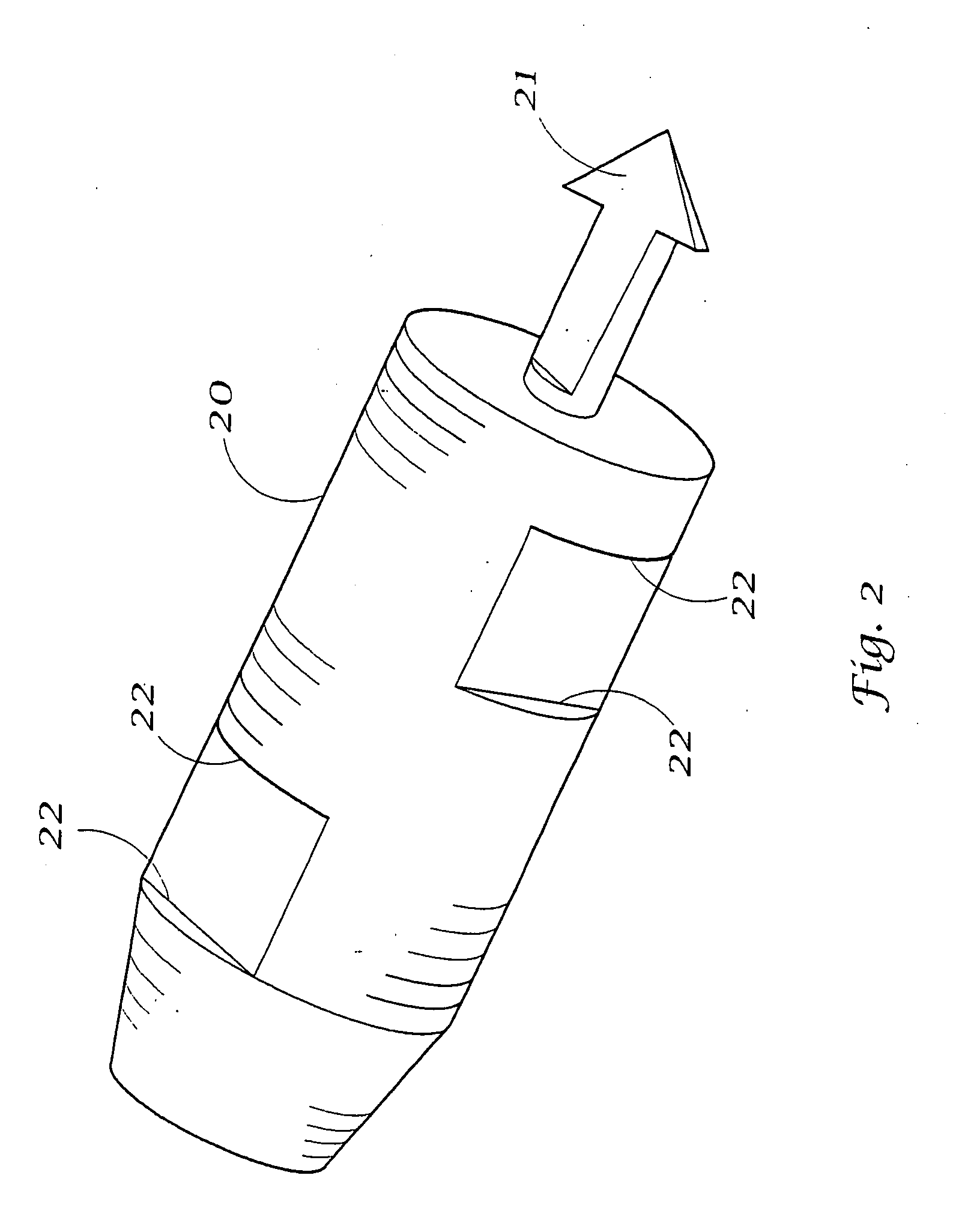

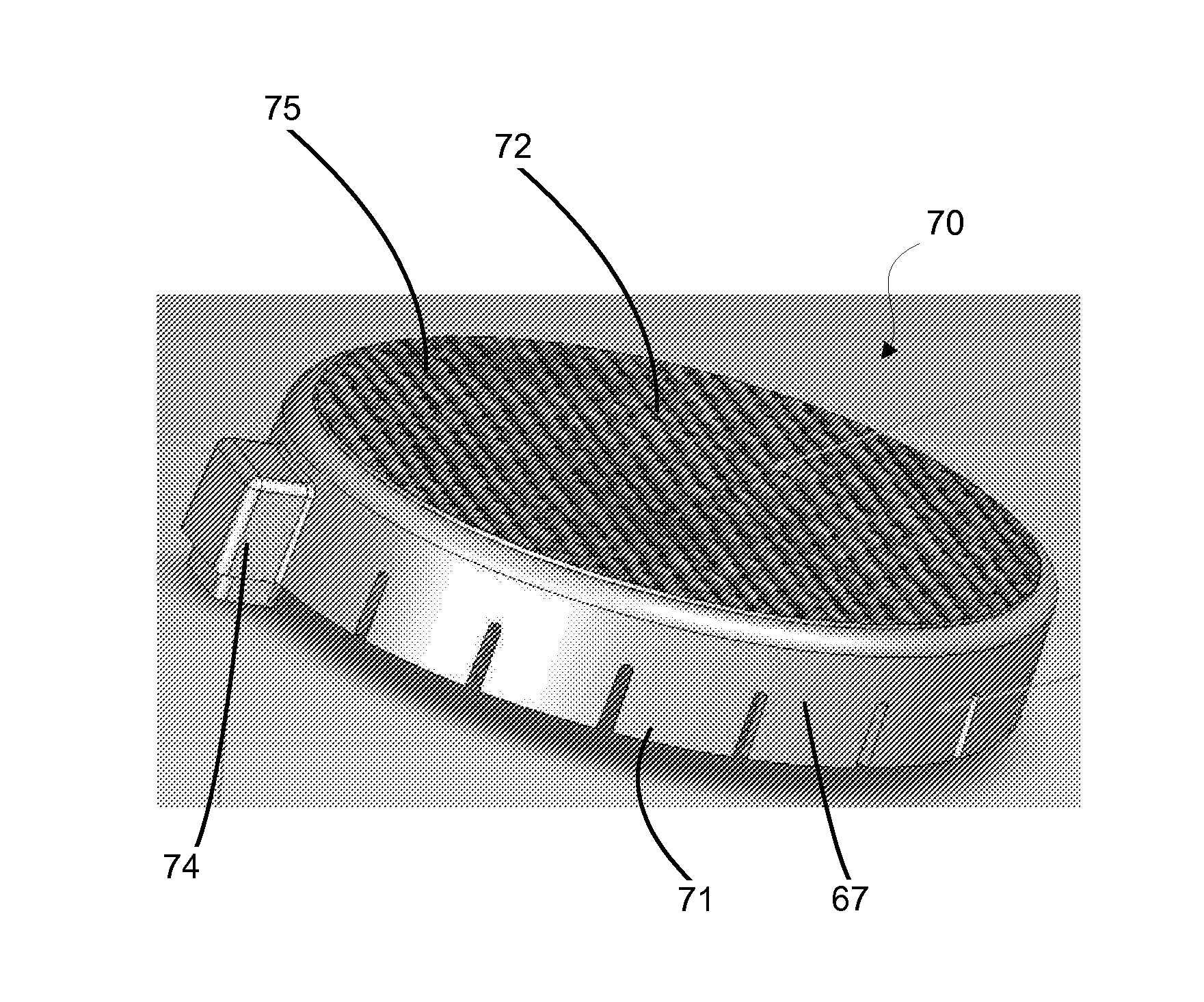

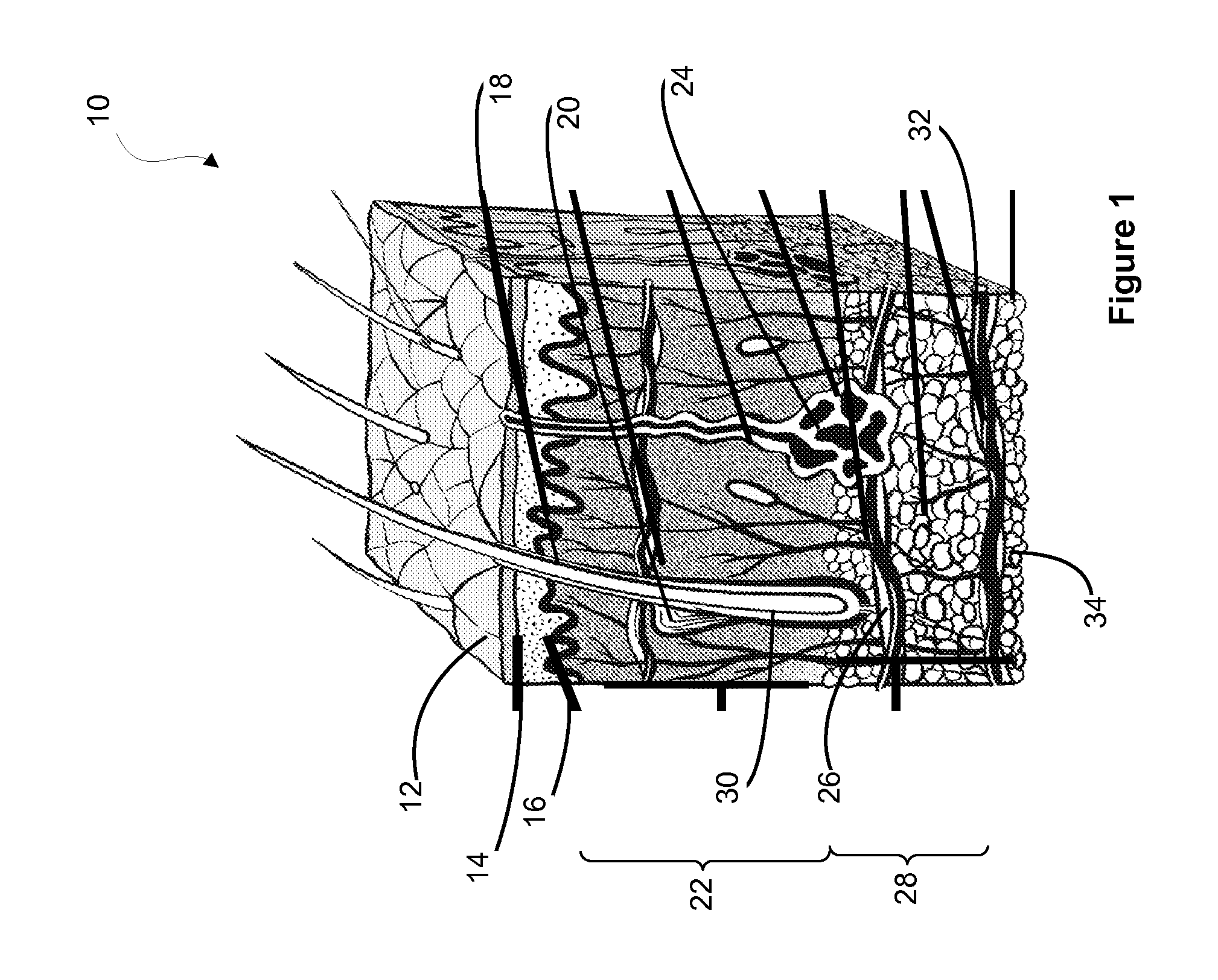

A dental syringe (10) has a needle (11) affixed to a carpule holder (12), which carpule holder (12) is affixed to a power drive unit (13). A harpoon (20) is provided to affix the drive unit to the carpule plunger (32). The harpoon (20) is made of stainless steel or other hard, corrosion resistant, sterilizable, material. Harpoon 20 has a unique barb geometry and hardened, knife-like, edges (21). The syringe (10) may operate to divide the delivery of anesthesia into two phases. According to the method, during the first about 10 seconds of the injection, anesthetic is delivered at an extremely slow rate to maximize patient comfort. The injection rate then automatically increases to the preprogrammed rate associated with the injection type selected.

Owner:HOHLFELDER INGRID ELAINE +3

Rice dry-farming direct-seeding planting method

InactiveCN101785414ASimplify field operationsReduce production laborClimate change adaptationOrganic fertilisersNutrientDecomposition

The invention provides a rice dry-farming direct-seeding planting method, which is characterized by comprising the following: a, a step of preparing land, which is to level and harrow land before sowing, replenish pre-sowing water and keep soil moisture between 75 and 85 percent; b, a step of sowing, which is to uniformly sow rice seeds on the land finished in a step a, wherein the amount of seeds per each Mu of land is 2.5 to 5.4 kg; c, a step of earthing up, which is to earth up at a height of 1.5 to 3 centimeters after sowing is finished; d, a step of compacting, which is to compact after earthing up; and e, a step of spraying film, which is to add 0.03 to 0.06 kilogram of 2-methyl-4-chlorophenoxy acetic acid serving as herbicide to 60 to 80 liters of water, mix and stir the materials and uniformly spraying the obtained product on the compacted land so as to finish the dry farming and direct seeding of rice. The rice dry-farming direct-seeding planting method can leave out two work links of cultivating seedlings and transplanting. After multifunctional degradable liquid mulching film is sprayed on ground, effective accumulated temperature can be increased; rice water shortage is alleviated; the physical and chemical properties of soil are improved; microbial activity is improved; the decomposition and release of soil organic substances are accelerated; the transfer of effective nutrient to plants is accelerated; and the photosynthetic efficiency and nutrient conveying rate of rice are improved. The method has the advantages of ensuring exuberant tillering tendency, low positions of tillering knobs and numerous big ears, saving water by 50 to 70 percent and increasing yield by about 10 percent.

Owner:于飞

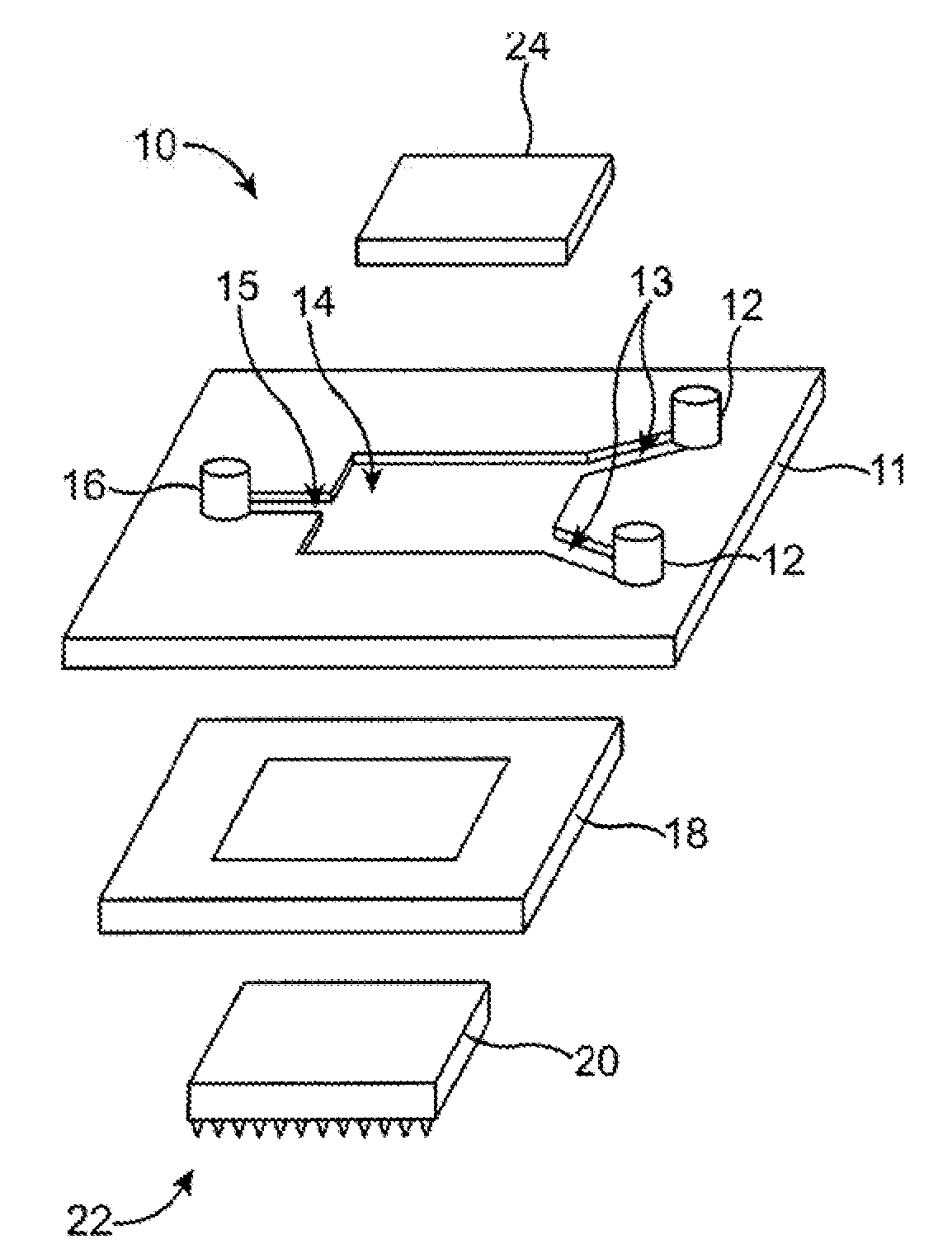

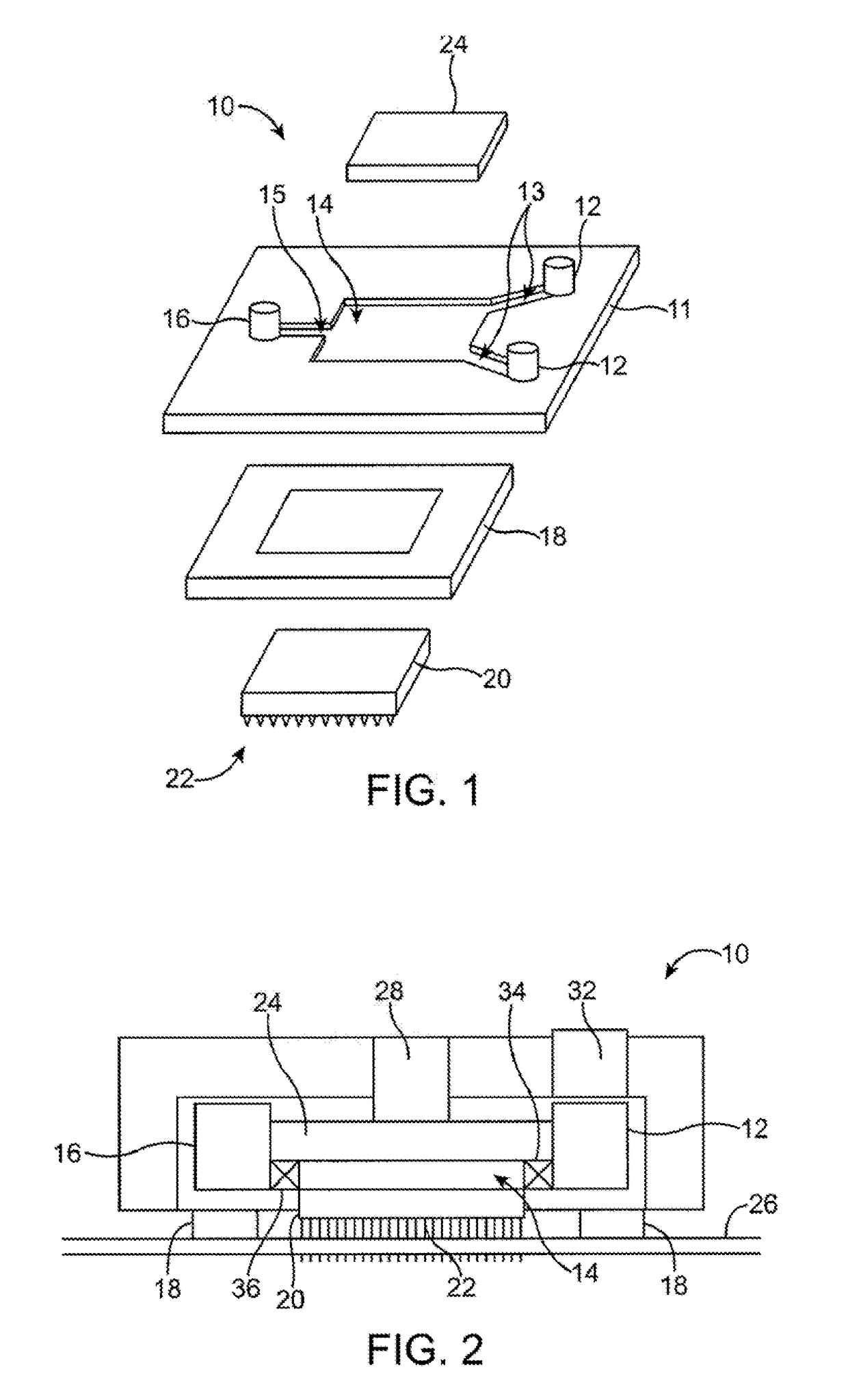

Systems and Methods for Enhancing the Delivery of Compounds to Skin Pores using Ultrasonic Waveforms

InactiveUS20140114234A1Efficient deliveryIncrease delivery rateSurgeryMedical devicesAcoustic energyAbsorption (skin)

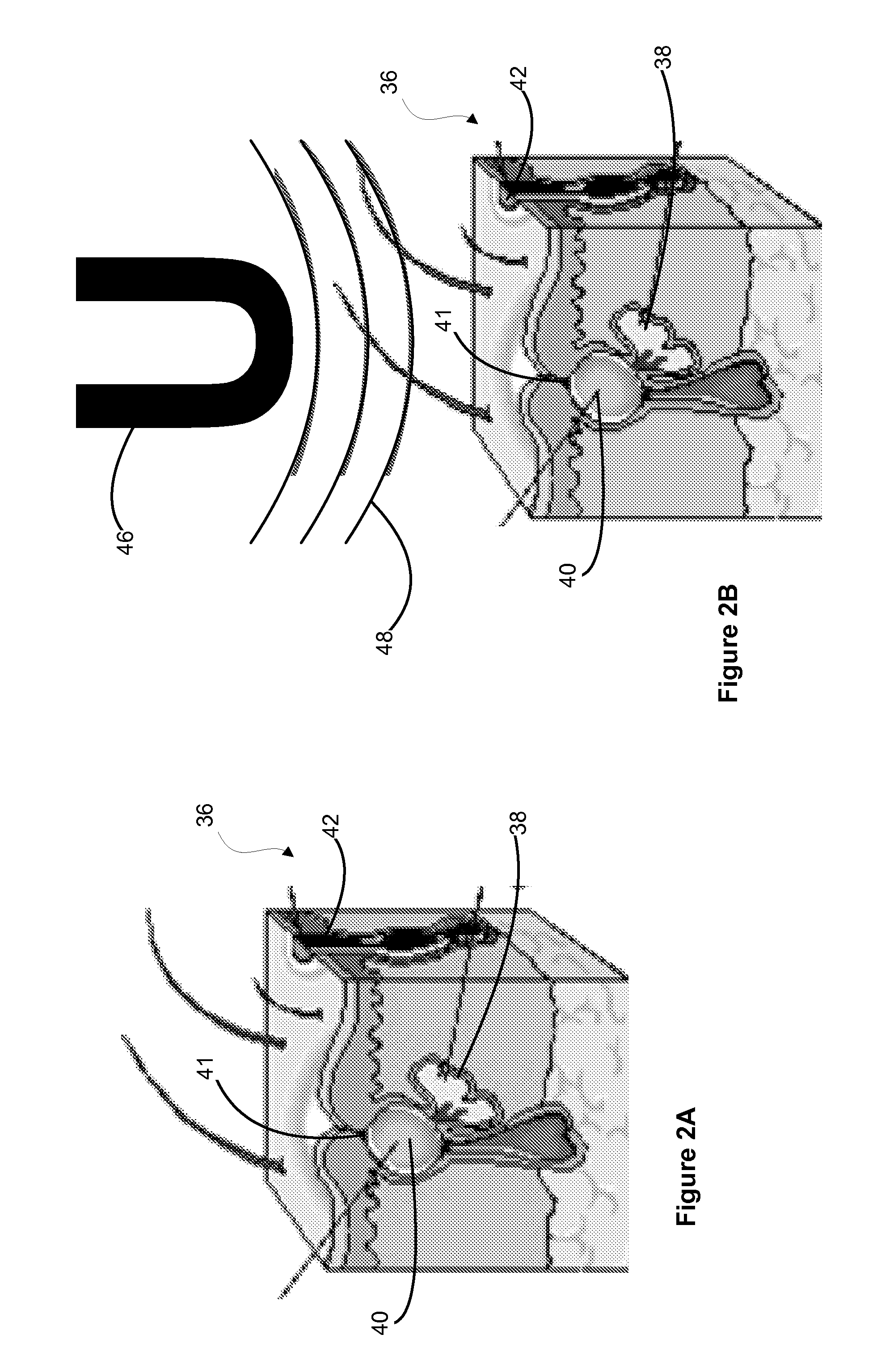

The invention is a device for transmitting acoustical energy through the surface of the skin of a patient, coupled with the administration of a compound, for example an acne medication, for the purpose of temporarily expanding the patient's pore size and enhancing the delivery of the compound to the patient's pores. The ultrasonic transducer emits a sonic transmission of variable intensity and frequency for the purpose of enhancing the absorption of compounds that have first been deposited onto the surface of the skin and into skin pores that have been expanded by the ultrasound transmission.

Owner:REDDING JR BRUCE K

Lithium iron phosphate battery auto-discharge screening method

ActiveCN107561449AShorten the production cycleShorten the resting timeElectrical testingLow voltageElectrical battery

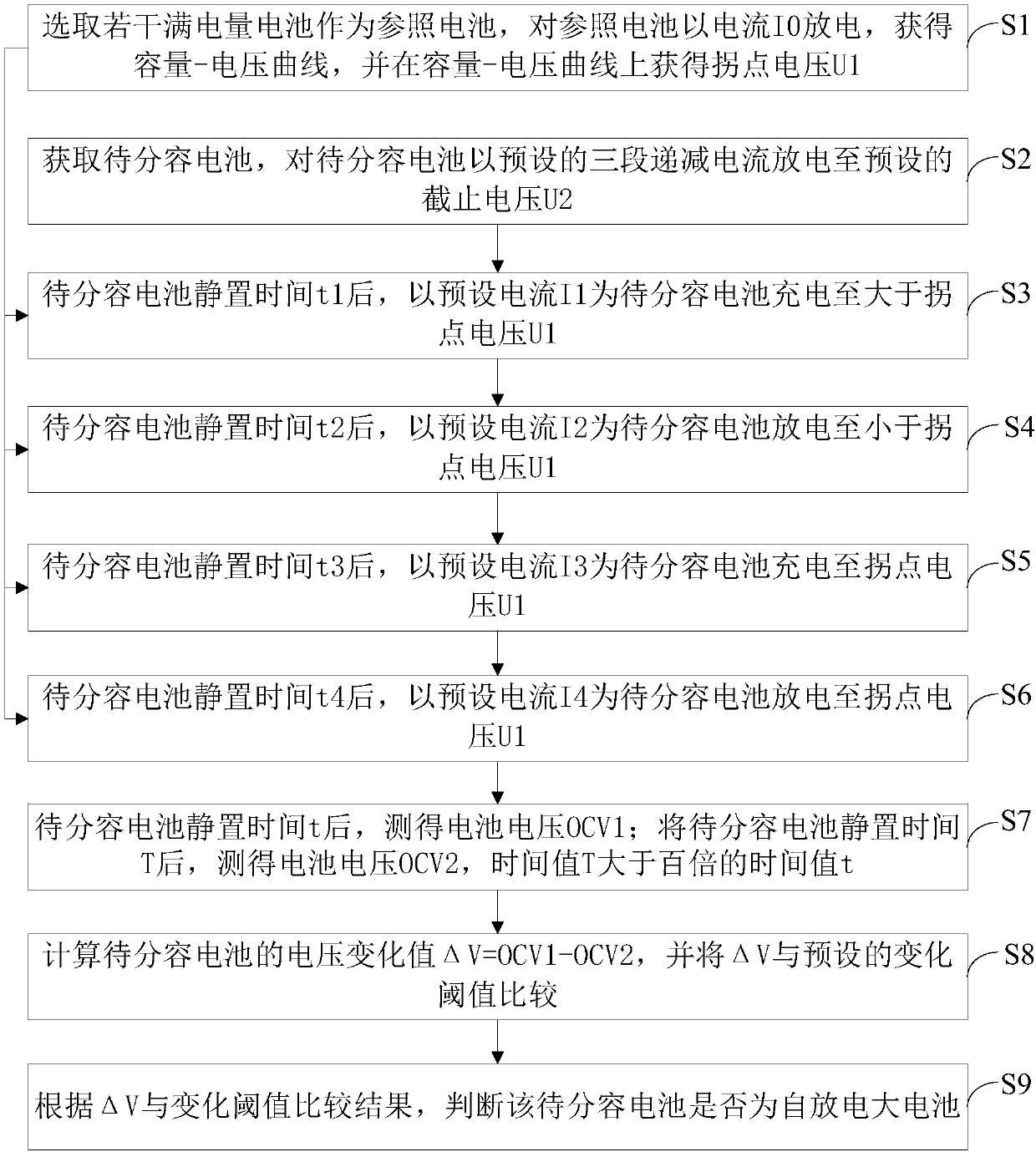

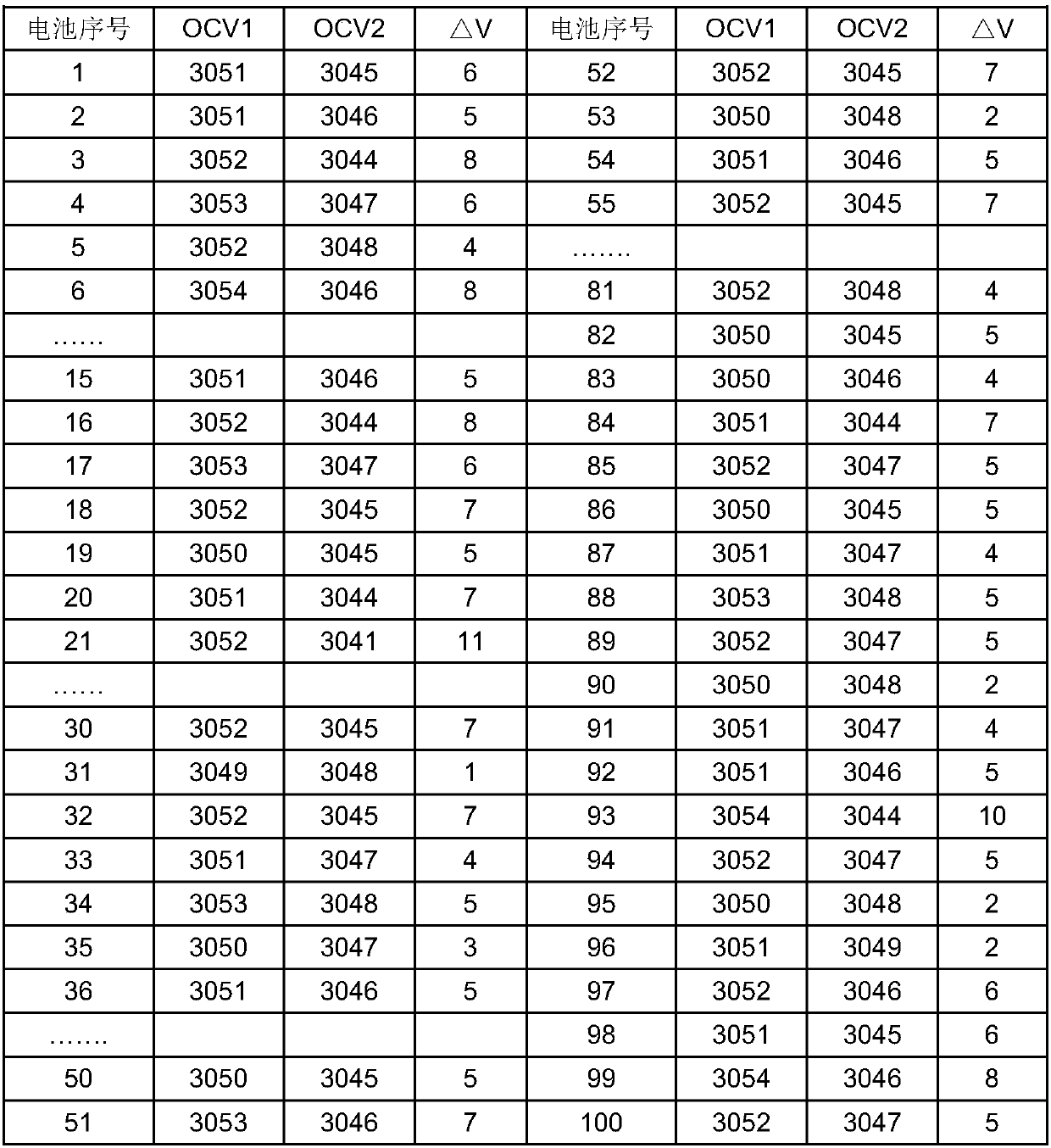

The invention discloses a lithium iron phosphate battery auto-discharge screening method. First, batteries are selected, and the voltage sudden change points of the batteries in the low-voltage stateare determined through low-current discharge. A produced battery is discharged at three currents decreasing gradually to a preset cutoff voltage, and is then charged and discharged at a low current within a narrow voltage range, in order to eliminate battery polarization to the greatest extent, make the final real voltage a sudden change voltage, and increase the accuracy of auto-discharge screening based on voltage drop. Through the method, whether a lithium iron phosphate battery meets the requirements can be determined in a short time, the production cycle of lithium batteries can be shortened, judgment is accurate, zero error can be basically guaranteed, the standing time of batteries can be shortened, and the supply rate can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

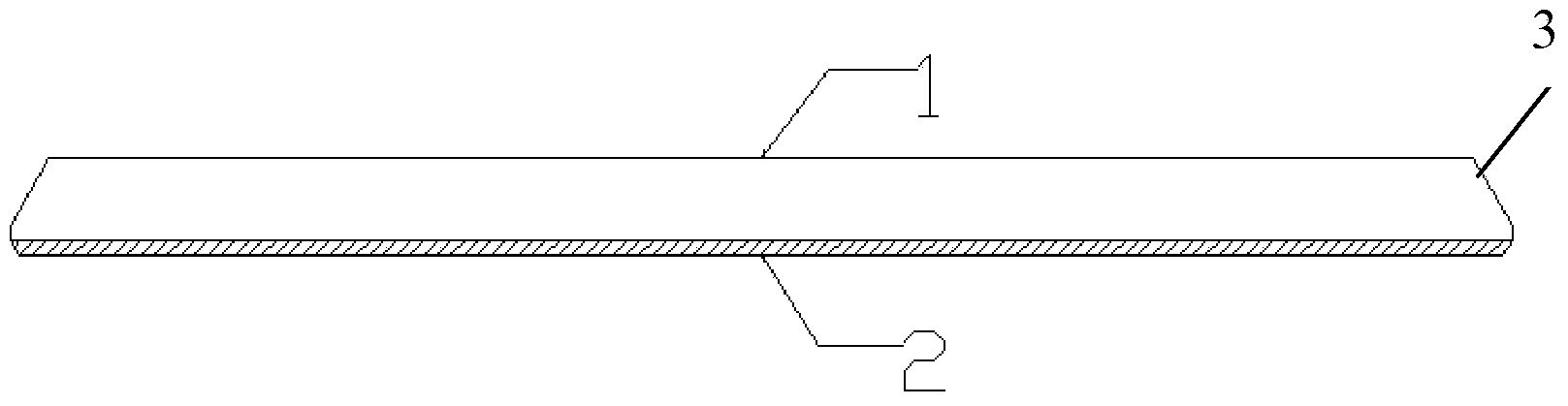

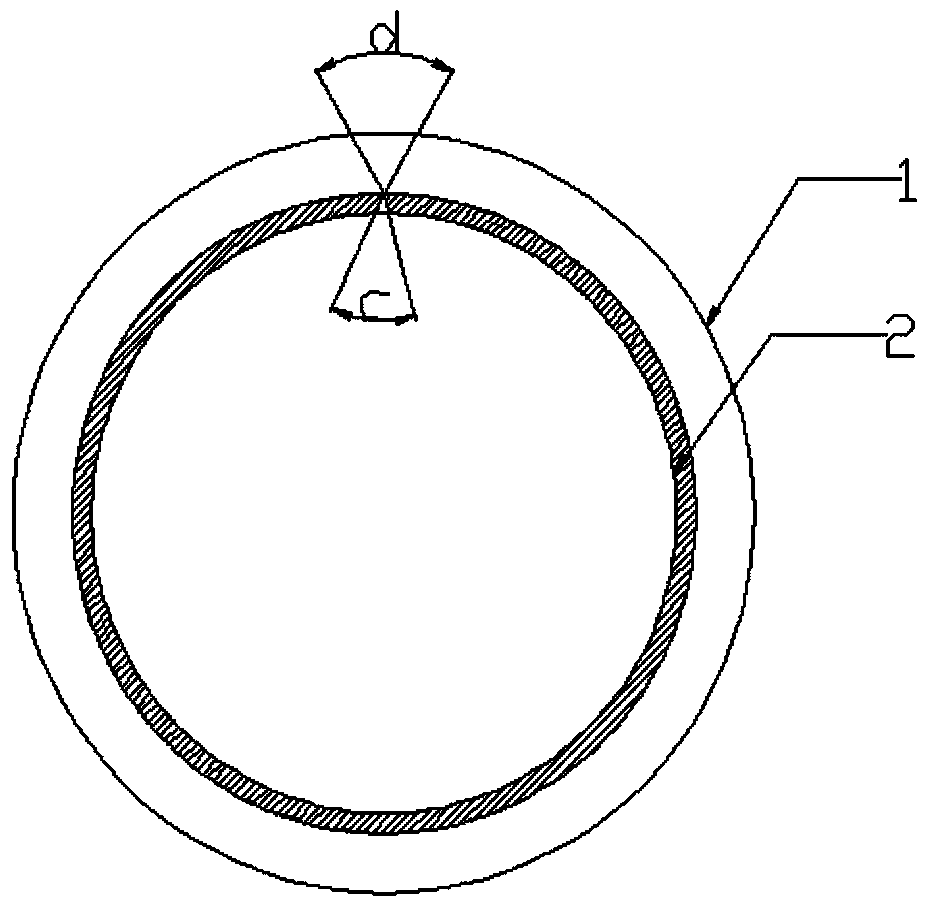

Method for manufacturing straight-line thermometal composite welded pipe

Disclosed is a method for manufacturing a straight-line thermometal composite welded pipe. The method comprises the steps that a thermometal hot rolling composite board produced by the explosion or hot rolling process is taken as raw materials, longitudinal edge pre-bending and stamping are carried out on the materials, stamping is based on the three-point bending basic principle, forming is achieved according to the sequence of J shape -> C shape -> O shape, and the product is manufactured through welding. According to the method for manufacturing the straight-line thermometal composite welded pipe, the forming mode is adopted to manufacture the straight-line thermometal composite welded pipe. Therefore, the method is suitable for industrialized mass production. In addition, due to the fact that the welding line is the straight line, therefore, compared with the length of a spiral welding line, length of the straight welding line is reduced by at least 30 percent, few welding materials are consumed, machining time is short, and the probability that a quality problem happens to the welding line is relatively small. In addition, due to the fact that in the use process, the resistance of the straight line in the pipe on conveyed media is small, the conveying speed of the liquid can be improved. Foreign matter is not easily hung on or happens to the welding line, and therefore the corrosive medium deposition cannot happen.

Owner:TIANJIN XUEYAN PIPES

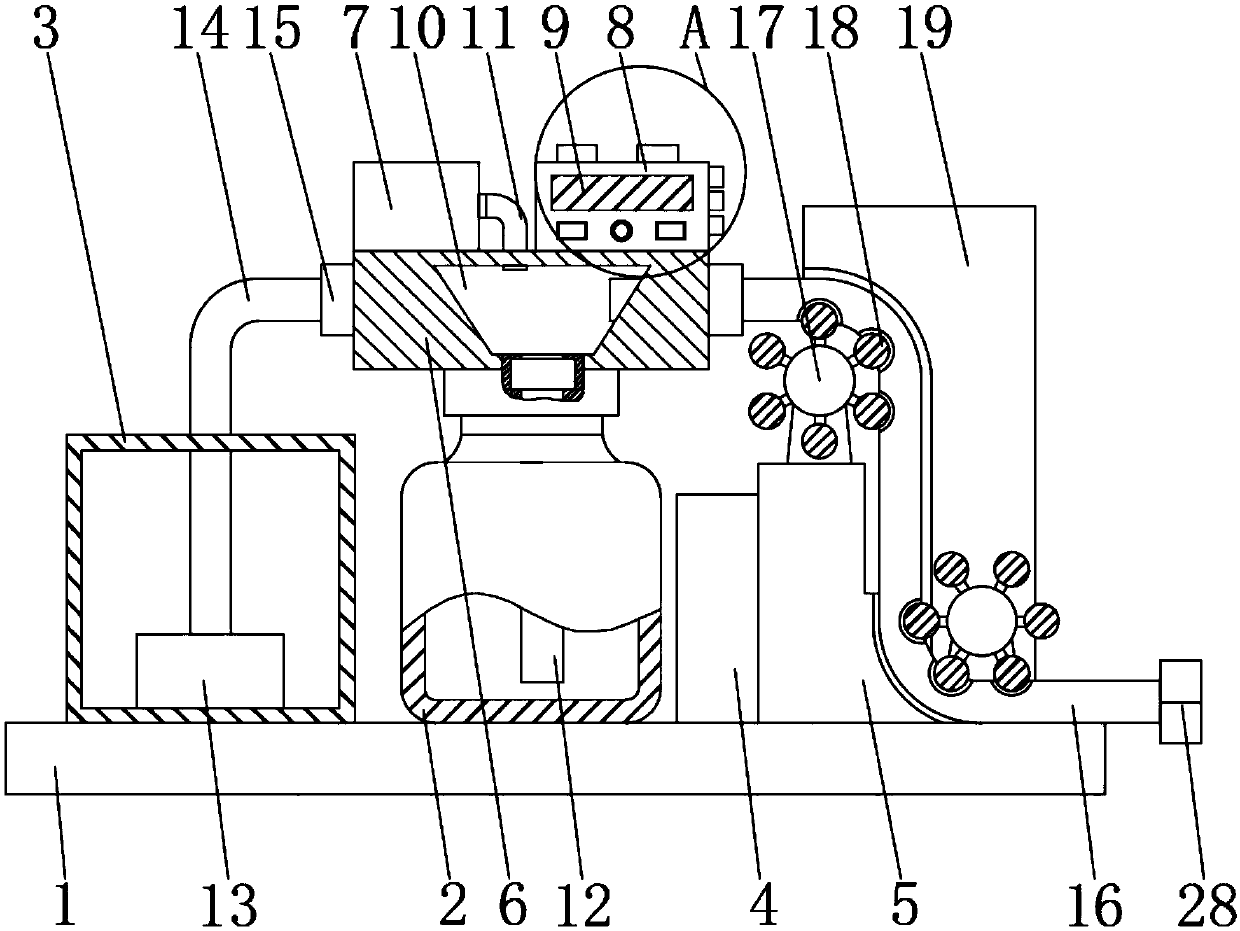

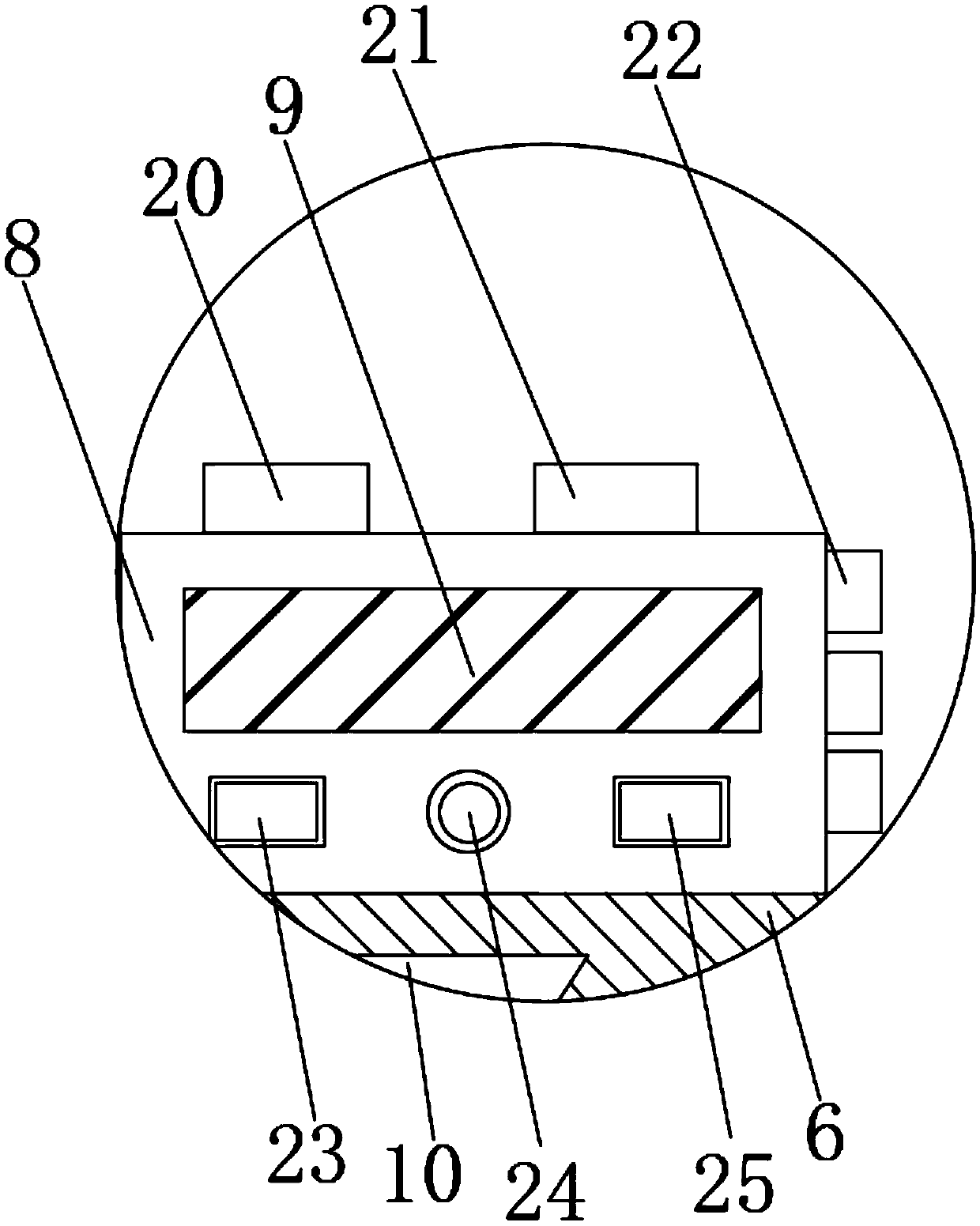

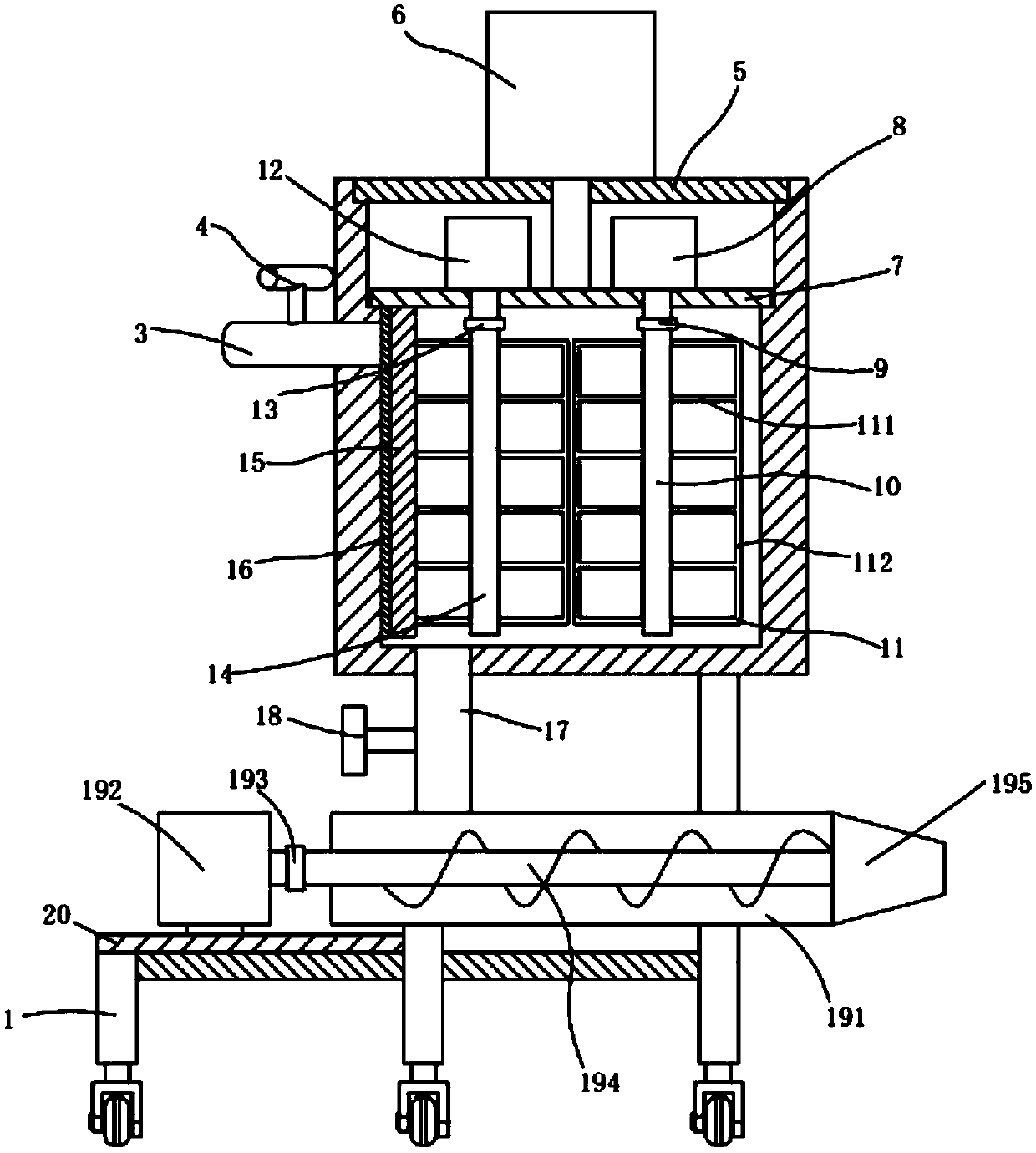

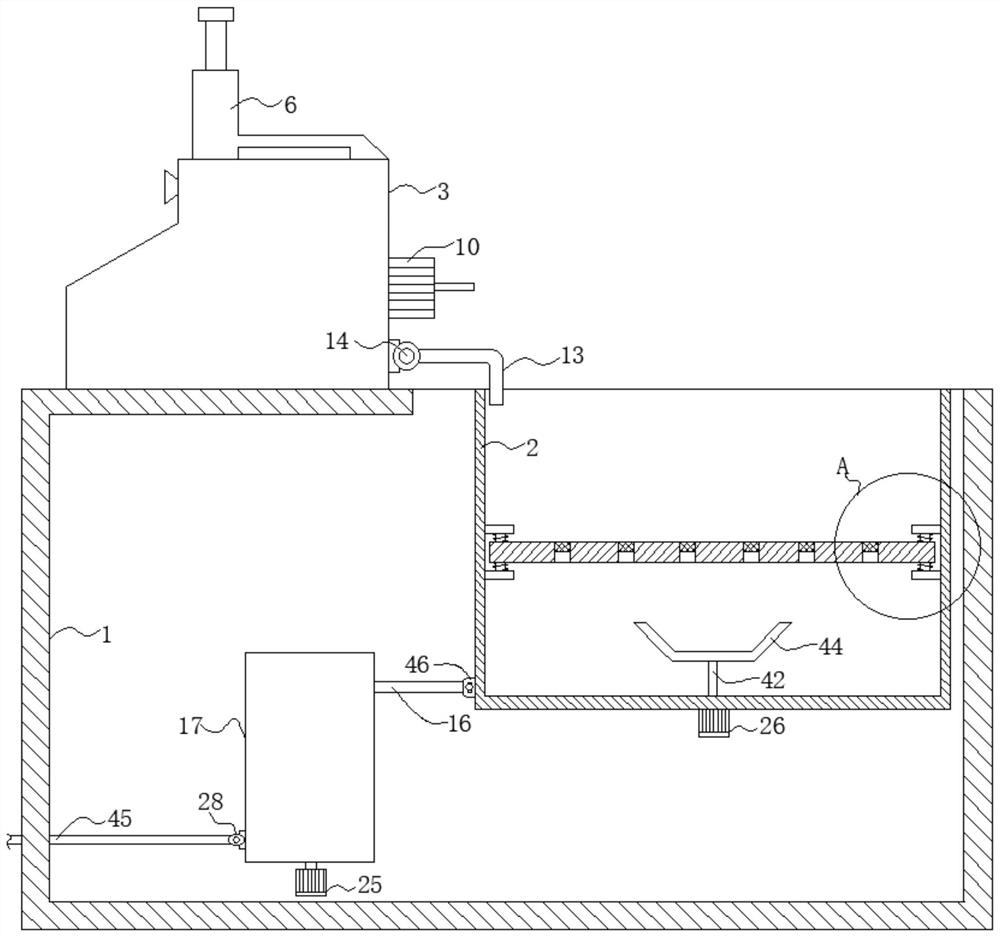

Anti-blocking electric drainage bottle used for hepatobilliary surgery department

InactiveCN108671273AIncrease delivery rateAvoid Difficult-to-Flow PhenomenaIntravenous devicesSuction drainage systemsDrainage cathetersAir pump

The invention discloses an anti-blocking electric drainage bottle used for a hepatobilliary surgery department. The anti-blocking electric drainage bottle comprises a bottom plate, a bottle body, a water tank, a storage battery, a first conduit pressing block, a top block, a speed-regulation miniature vacuum pump, a shell, a display screen, a cavity, an air pumping tube, a connecting tube, a submerged pump, a flushing tube, an electromagnetic valve, a drainage conduit, a rotary disc, a cylindrical block, a second conduit pressing block, an air pumping button, a water pump button, an electromagnetic valve button, a speed-increase button, a power button, a speed-decrease button, a motor, controllers and connectors. The anti-blocking electric drainage bottle is reasonable in structure; through the motor, the rotary disc and the cylindrical block, the conveying rate of calculi and foreign matter in bile during drainage is increased, it is avoided that the calculi and the foreign matter inthe bile have difficulty in flowing during drainage, and blocking occurs when the drainage conduit performs drainage, and the efficiency of drainage is improved; after the bile is drained, through thesubmerged pump, the water tank and the flushing tube, the cavity, the connecting tube and the drainage conduit can be flushed, the situation is avoided that residues of the bile and impurities existin the cavity and the bottle body, operation is simple, and using is convenient.

Owner:WUXI PEOPLES HOSPITAL

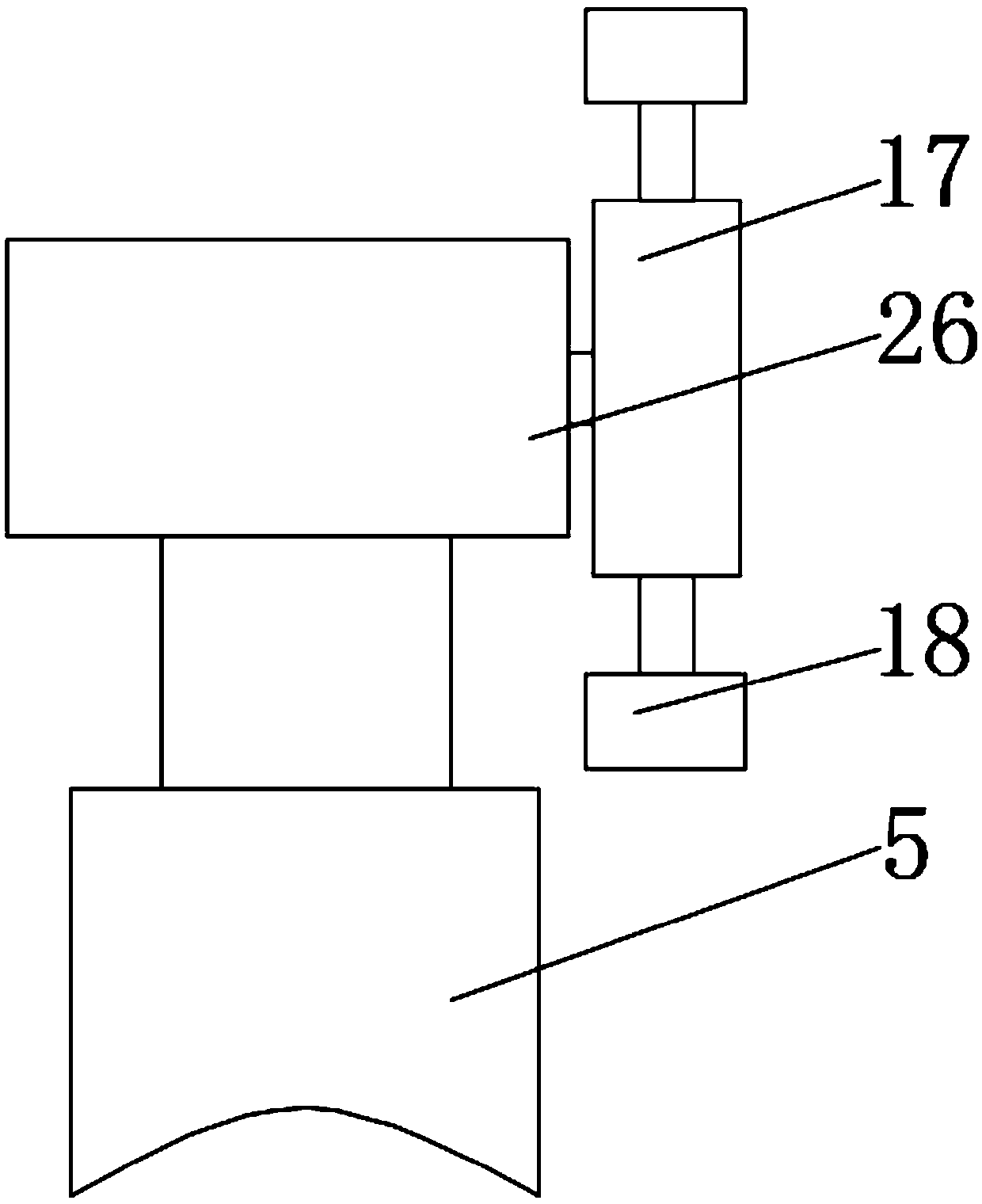

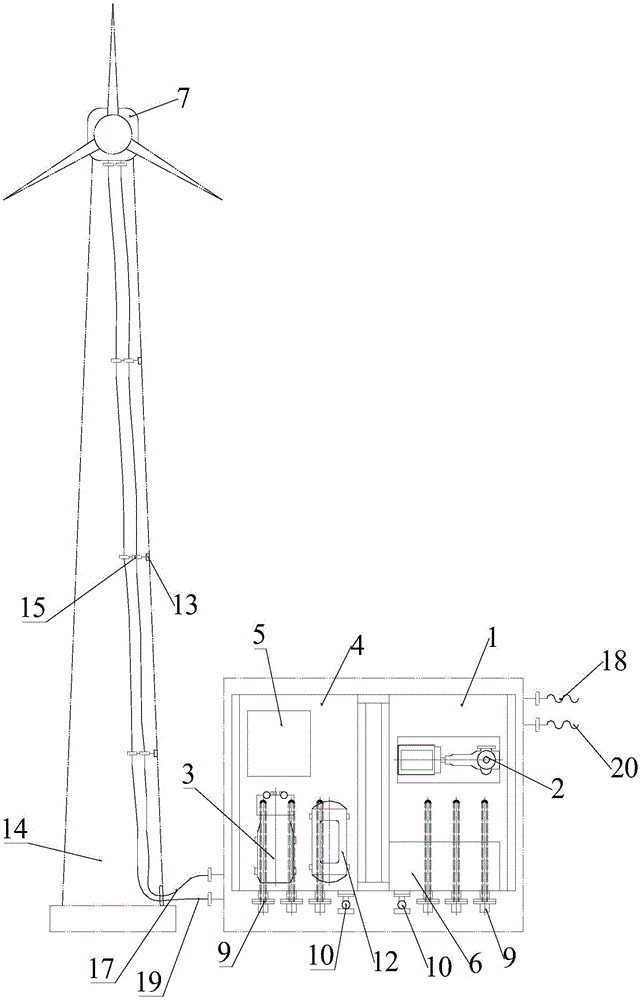

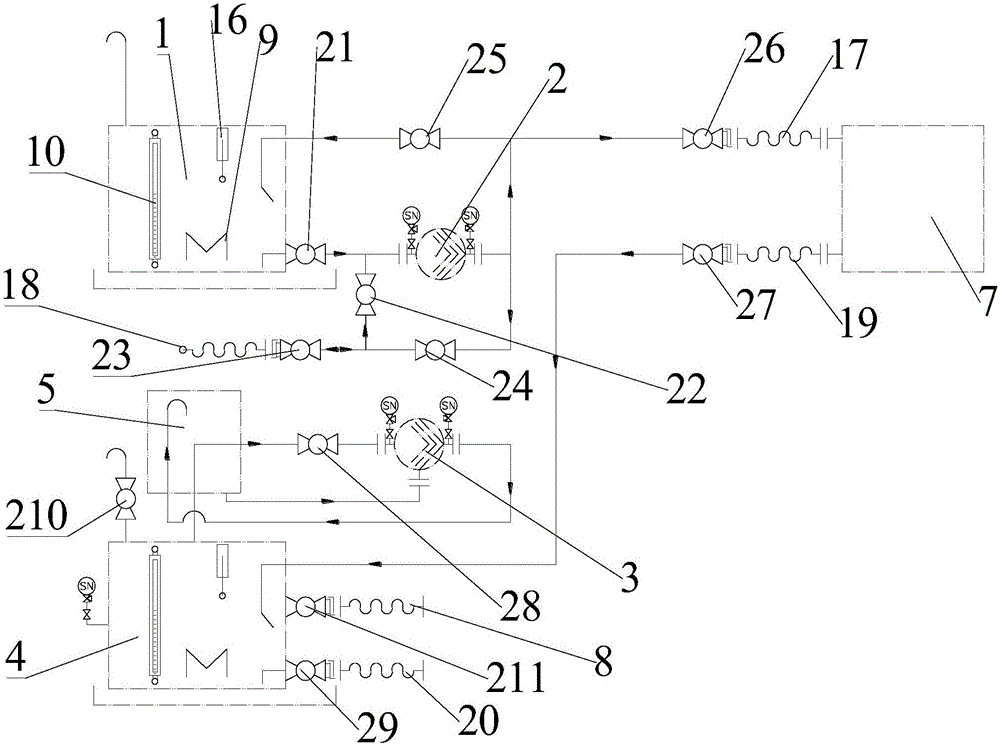

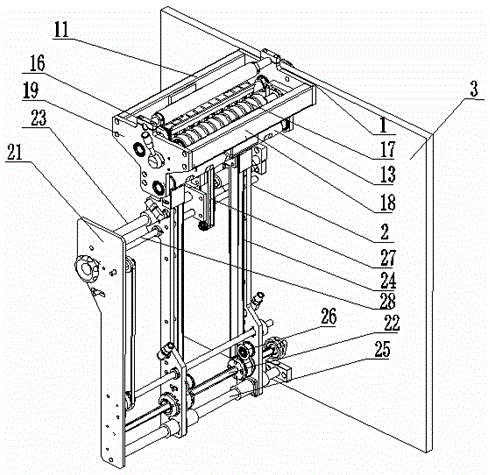

Efficient oil change device for wind power gear box

ActiveCN106439462AReduce operating and maintenance costsAvoid up and down transfersGear lubrication/coolingLubrication elementsControl systemFuel tank

The invention discloses an efficient oil change device for a wind power gear box. The efficient oil change device comprises a base, a lubricating oil box, a waste oil box, a lubricating oil conveying pump, a vacuum pump, a cooling water tank, an electric control box, a wind power tower barrel gear box, a wind power tower barrel, a control system and an air compressor. The waste oil box and the lubricating oil box are both internally provided with a liquid level meter, an electric heater and a temperature sensor. The wind power tower barrel gear box is connected to the lubricating oil box through a lubricating oil conveying hose, and the wind power tower barrel gearbox is connected to the waste oil box through a waste oil output hose. According to the device, lubricating oil is heated by the electric heater in the lubricating oil box, the viscosity of the lubricating oil is reduced, the conveying rate is increased, the operation of pumping out waste oil and adding new oil can be completed on the ground or an operation and maintenance ship only by connecting an oil inlet and outlet hose to an oil box connector of the wind power gear box, aerial work is reduced, up-and-down oil drum transfer is avoided, therefore, work safety is greatly improved, and the work intensity of maintenance staff is reduced.

Owner:重庆川东船舶重工有限责任公司

Film cutting and pulling method suitable for material packaging

ActiveCN105059606AReduce downtimeReduce laborWrapping material feeding apparatusEngineeringMechanical engineering

The present invention discloses a film cutting and pulling method suitable for material packaging, and relates to the technical field of material packing techniques. The film cutting and pulling method comprises cutting a packaging film in a transportation process of the packaging film. In comparison with the conventional packaging methods, film cutting time is saved, and the packaging speed is thus raised. When the method is used for packaging materials of different specifications, the position of a film cutting mechanism does not need to be adjusted, the length of the packaging film only needs to be set in the system, and thus precision cutting of the packaging film can be carried out; and during packaging of materials of different specifications, time for adjusting machinery equipment is saved, and thus the efficiency of the whole packaging process is raised.

Owner:上海松川峰冠包装自动化有限公司

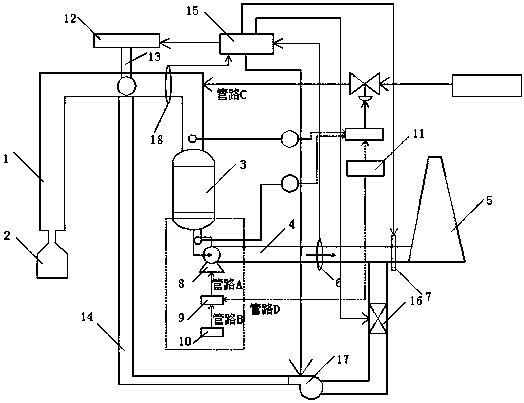

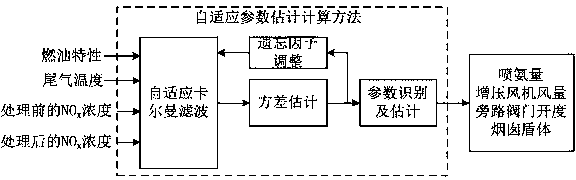

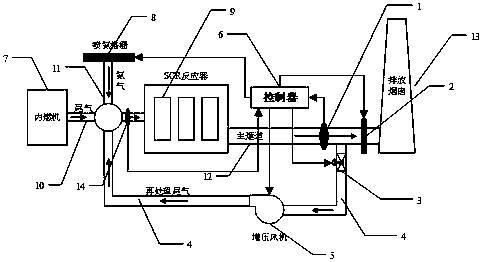

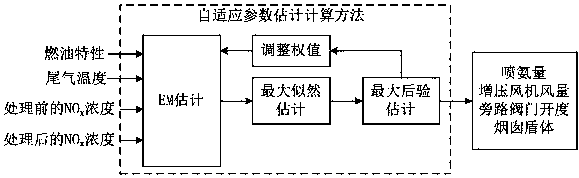

Tail gas circulating treatment system of ship denitrating system based on SCR

PendingCN107829804AMeet job requirementsSolve power lossGas treatmentInternal combustion piston enginesFlue gasEmission standard

The invention relates to a tail gas circulating treatment system of a ship denitrating system based on SCR. The ail gas circulating treatment system of the ship denitrating system based on SCR comprises a power releasing device and a tail gas circulating retreatment device. The power releasing device comprises an air extracting device which is arranged at an outlet of a flue gas denitrating pipeline. The air extracting device comprises a sucking pump, a sucking pump starting and stopping controller, a sucking pump power detecting device and a diesel engine load detecting device. The tail gas circulating retreatment device comprises an ammonia spraying grille and the ammonia spraying grille communicates with the flue gas denitrating pipeline through an ammonia gas pipeline. The system has the advantages that the problem of diesel engine power loss caused by a SCR denitrating device can be well solved and the tail gas after reaction can be retreated by circulating denitrating to reach anemission standard when the concentration of nitrogen oxide in the tail gas subjected to SCR treatment does not reach the emission standard.

Owner:JIANGSU UNIV OF SCI & TECH +1

Fixing device for medicine feeding for animals

InactiveCN107374771AIncreased drug delivery rateSolve fixed instabilityAnimal fetteringEngineeringMotherboard

The invention discloses a fixing device for animal drug delivery, including a fixing frame, a main board and a neck fixing device. Four supporting legs are arranged at four corners of the fixing frame, and fixing sleeves are arranged on the side of the fixing frame. The fixing sleeve is provided with two fastening ropes, the main board is provided with two leg fixing devices, the upper end of the leg fixing device is provided with a first leg fixing device and a second leg fixing device, the first leg fixing device The fixing device and the second leg fixing device are symmetrically arranged in two parts with respect to the main board, and the neck fixing device is fixed on the fixing frame. The invention is used for the fixing device for animal drug delivery, and the lower ends of the animal's limbs have no supporting points, which solves the problem of unstable animal fixation when the veterinarian feeds the animal medicine, improves the drug delivery rate, and has high drug feeding efficiency .

Owner:泉州森泸玩具有限公司

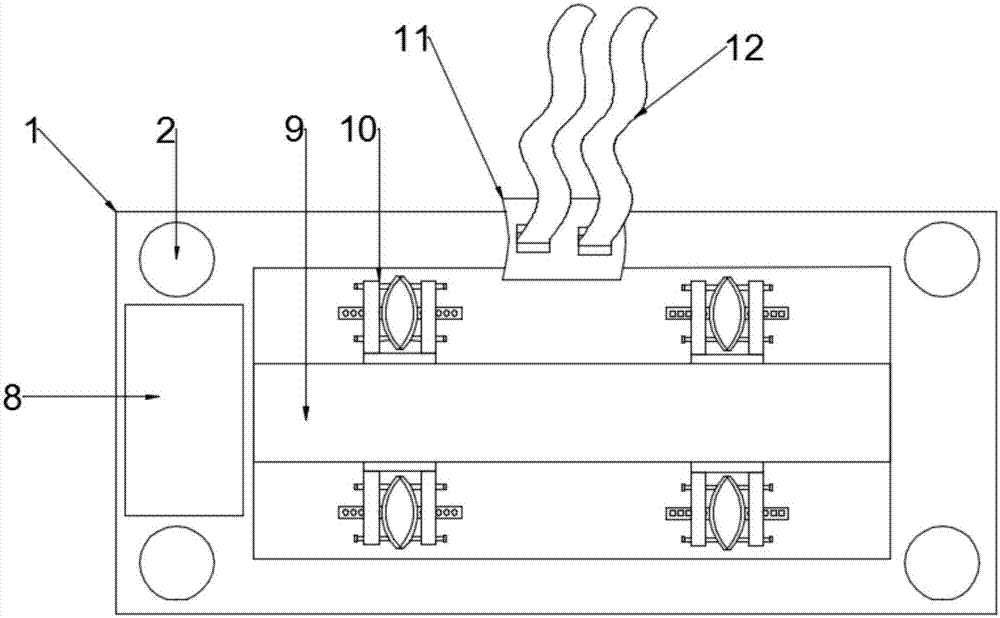

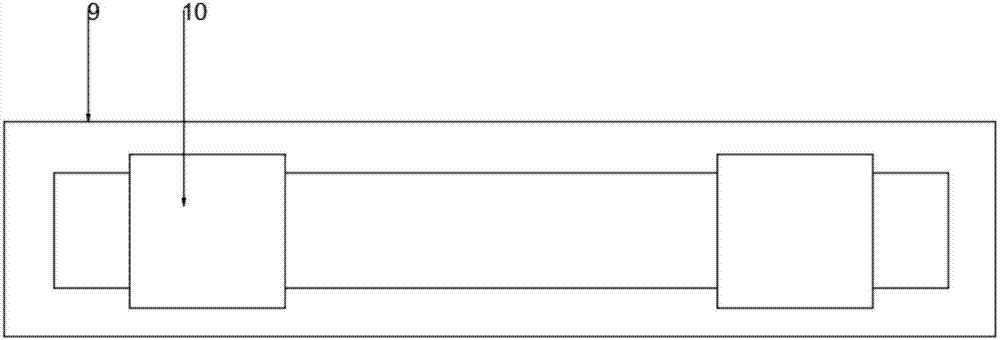

SCR (selective catalytic reduction)-based ship denitration system tail gas cyclic retreatment device

PendingCN107754608AAvoid emissionsEmission reductionInternal combustion piston enginesExhaust apparatusNitric oxideNitrogen oxide

The invention relates to an SCR (selective catalytic reduction)-based ship denitration system tail gas cyclic retreatment device. The SCR-based ship denitration system tail gas cyclic retreatment device comprises an internal combustion engine, an ammonia injecting grid and an SCR reactor; the gas discharge end of the SCR reactor is communicated with a discharge chimney through a main flue; a NOx concentration sensor and a chimney shield are arranged in the main flue sequentially from the gas inlet end to the gas outlet end; the SCR-based ship denitration system tail gas cyclic retreatment device also comprises a circulating bypass flue and a controller; the gas inlet end of the circulating bypass flue is communicated with the main flue between the NOx concentration sensor and the chimney shield; the gas discharge end of the circulating bypass flue is communicated with a tail gas pipeline; a circulating bypass valve is arranged on the flue at the gas inlet end of the circulating bypassflue; and the controller is connected with the ammonia injecting grid, the NOx concentration sensor, the chimney shield and the circulating bypass valve separately through pipelines. The SCR-based ship denitration system tail gas cyclic retreatment device has the following advantages: the denitration rate of the tail gas of the ship internal combustion engine is increased, the nitric oxide in thedischarged gas is reduced, and discharge of the treated gas not up to the standard is avoided.

Owner:JIANGSU UNIV OF SCI & TECH +1

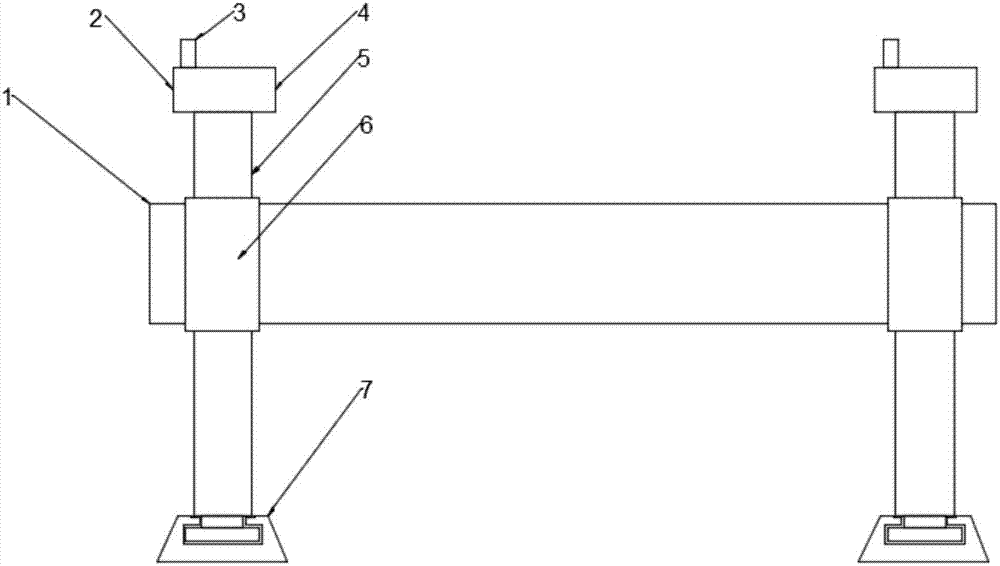

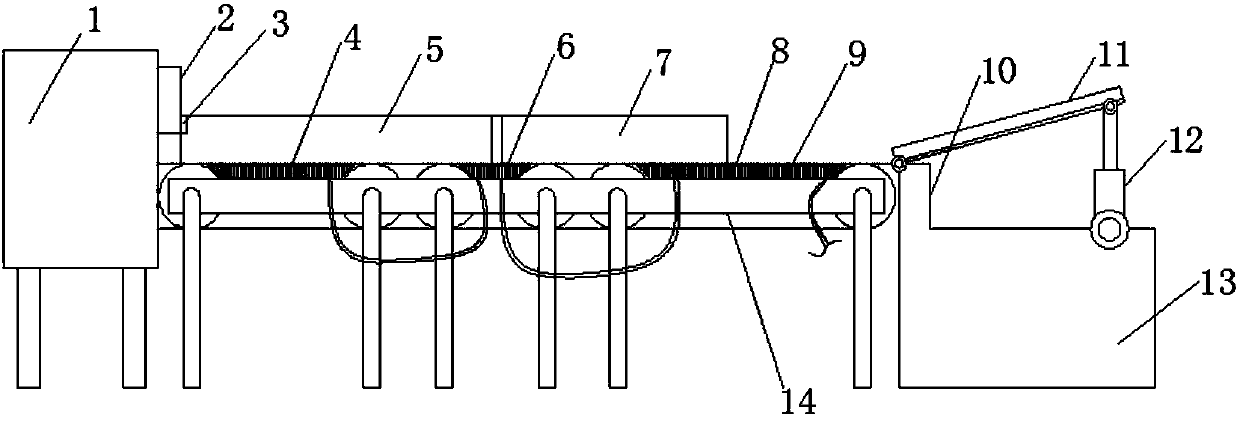

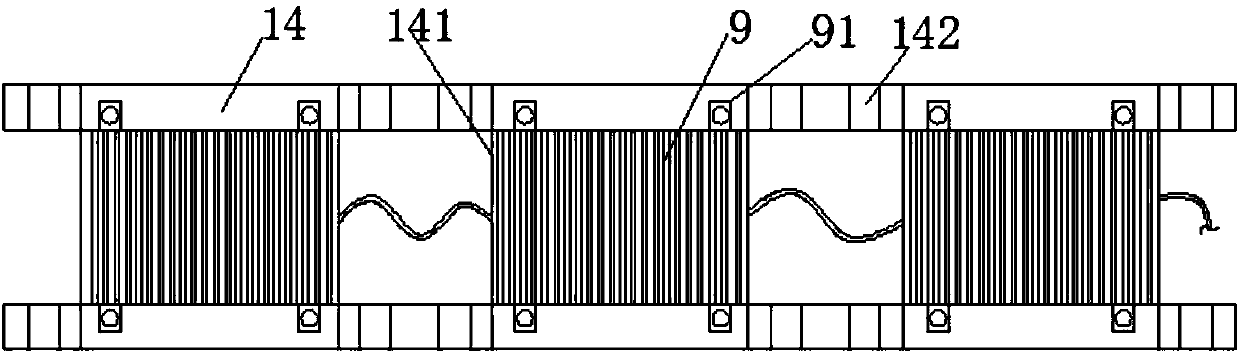

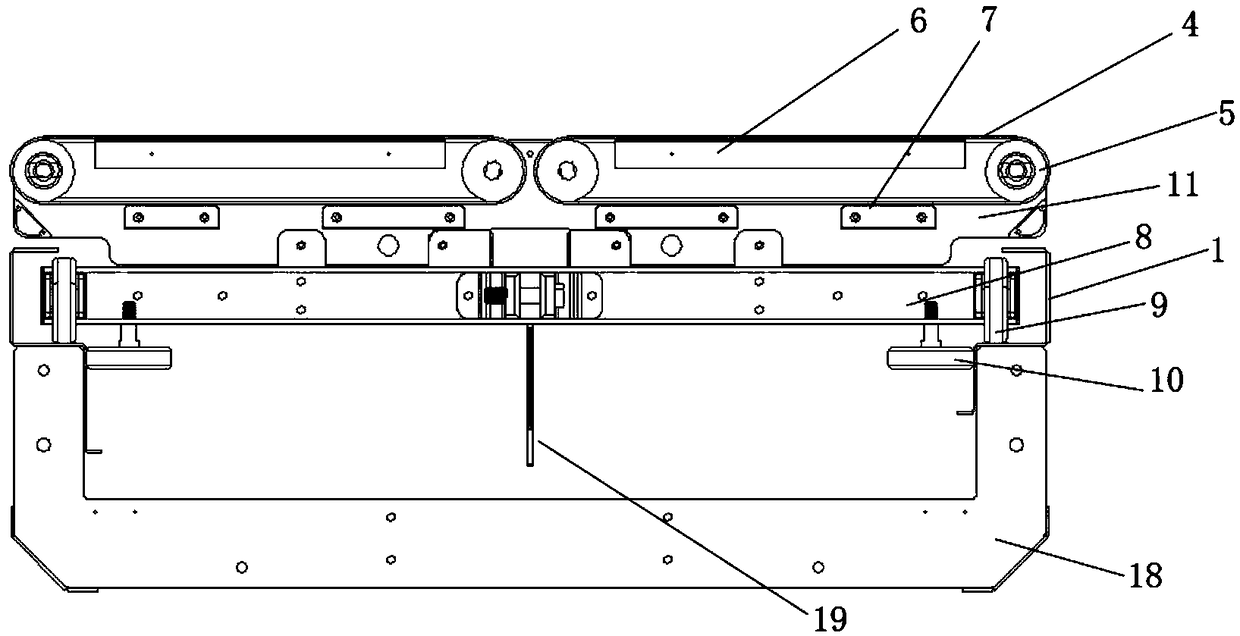

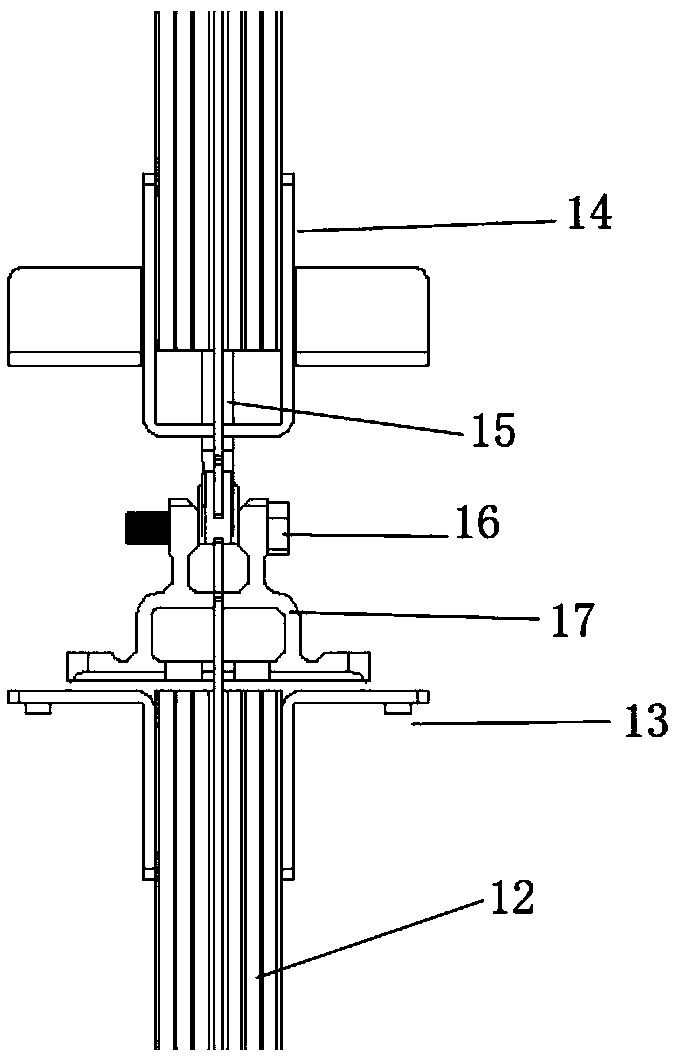

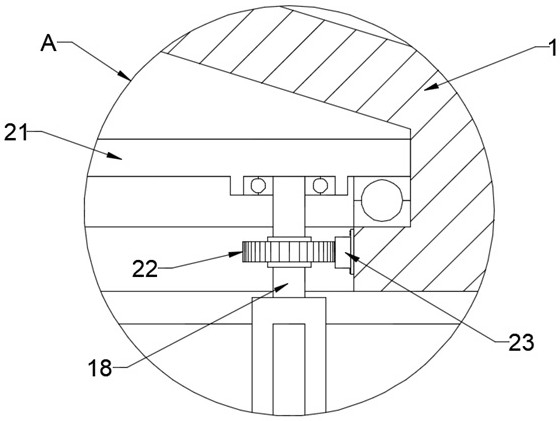

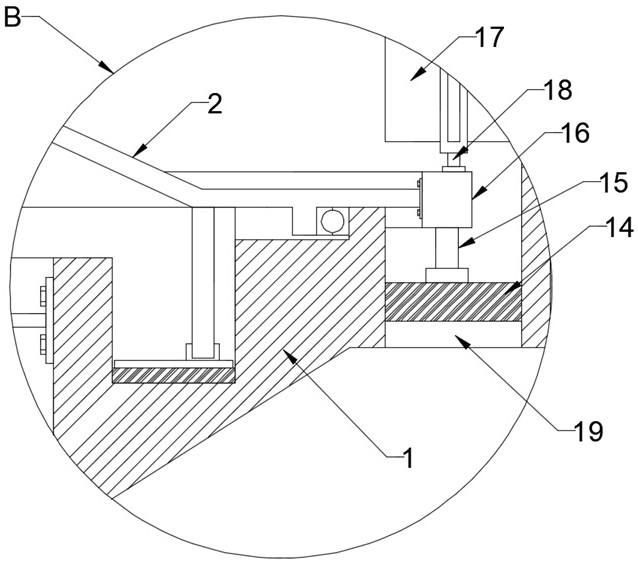

Mechanical part machining guiding device

InactiveCN107792627AIncrease delivery rateIncrease frictionConveyorsConveyor partsMachine partsDrive motor

The invention belongs to the field of injection molding machines and particularly relates to a mechanical part machining guiding device. The mechanical part machining guiding device is used for solving the problem that existing mechanical parts which have smooth surfaces and are small in size are difficult to guide and convey. The following scheme is put forwards at present; the mechanical part machining guiding device comprises a conveying rack and a second installation table located on one side of the conveying rack; a first guiding conveying belt, a second guiding conveying belt and a feeding conveying belt are sequentially arranged on the conveying rack; second installation tables which are symmetrically arranged are arranged on the two sides of the conveying rack; and the top end of one of the second installation tables is provided with a driving motor. By means of the mechanical part machining guiding device, mechanical guiding conveying can be achieved in the mechanical part machining process, parts are not likely to slide on the a conveying belt in the conveying process, metal mechanical parts which have different surface smooth degrees or are small in size can be guided and transported, selection space is increased, in addition, the machining efficiency is greatly increased, guiding conveying can be conducted on different specifications of parts, and practicability ishigh.

Owner:HENAN COLLEGE OF IND & INFORMATION TECH +1

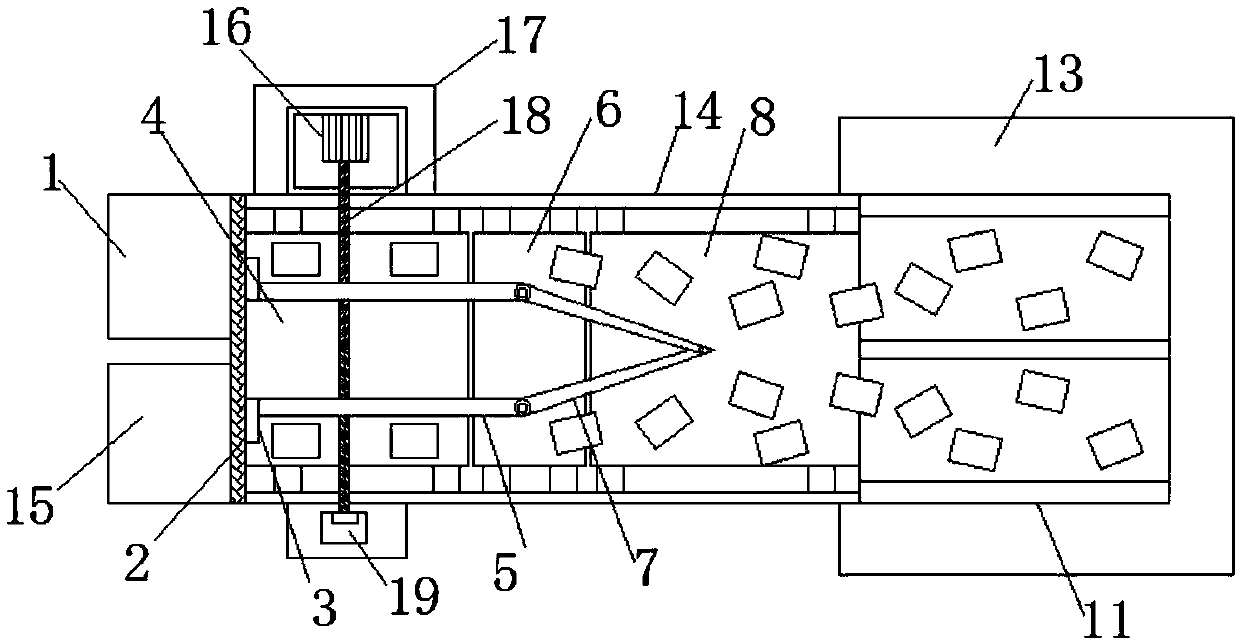

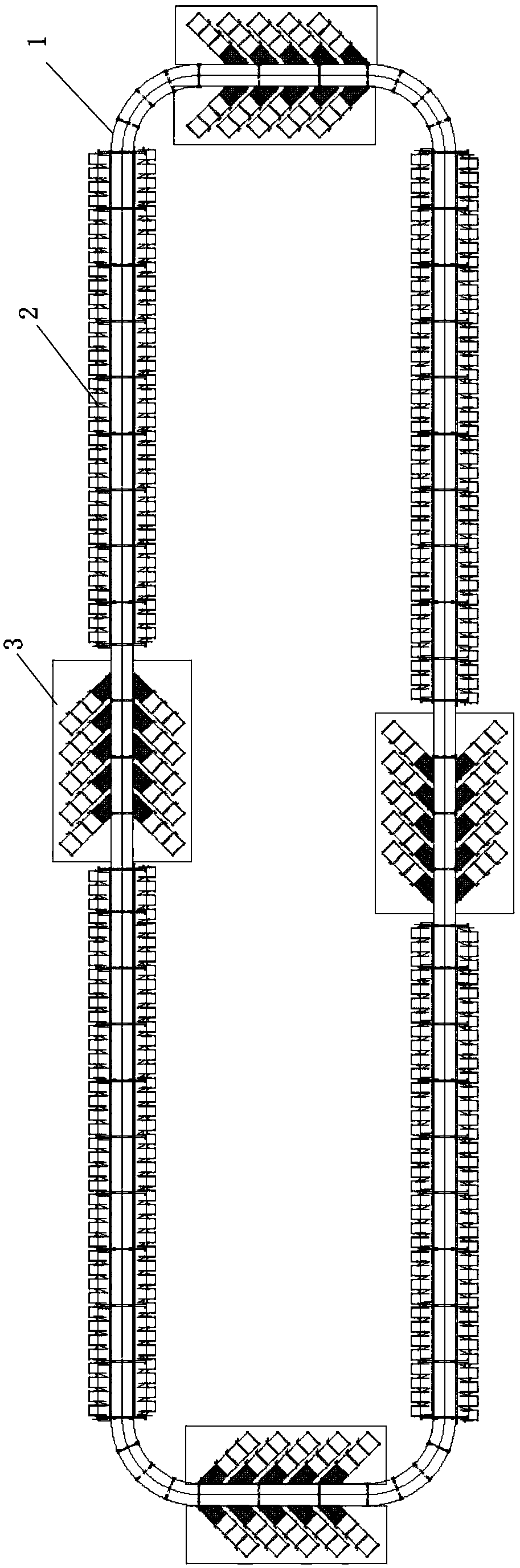

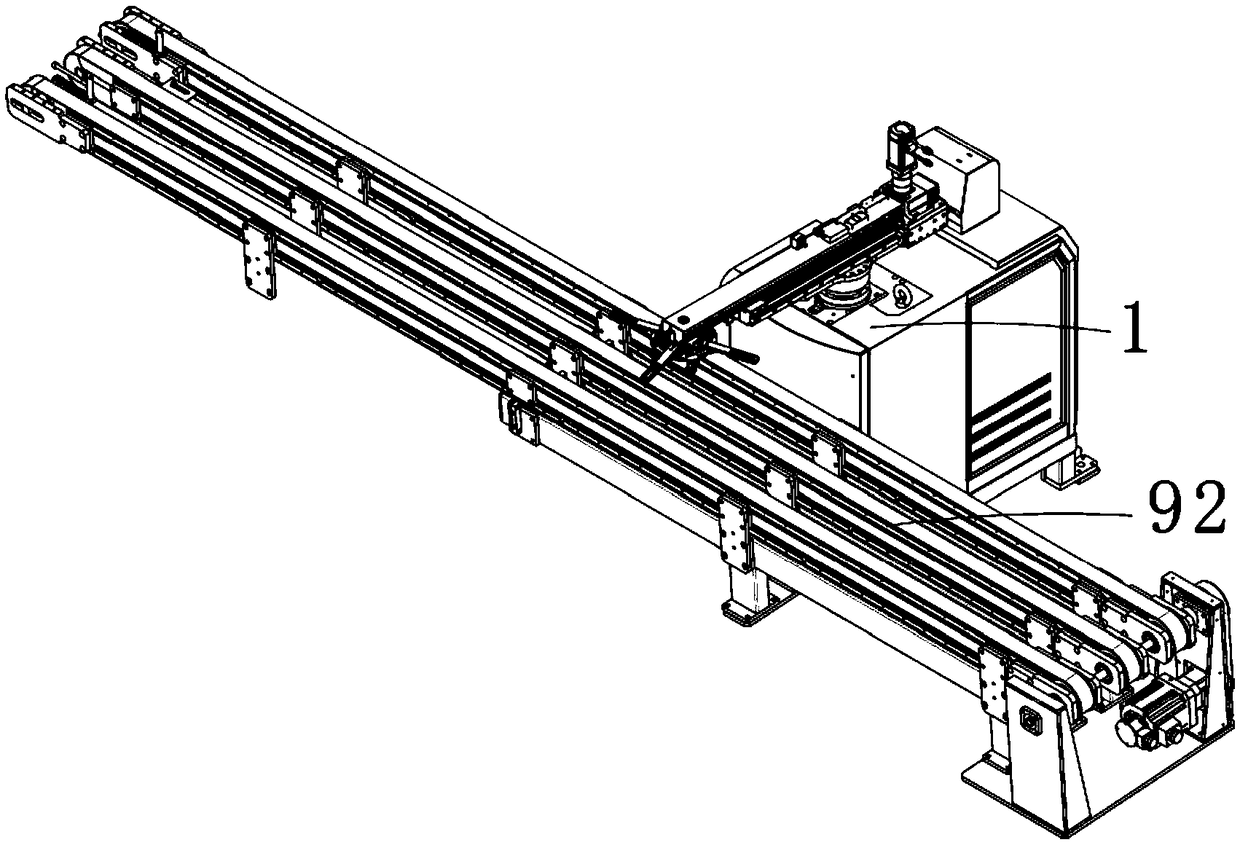

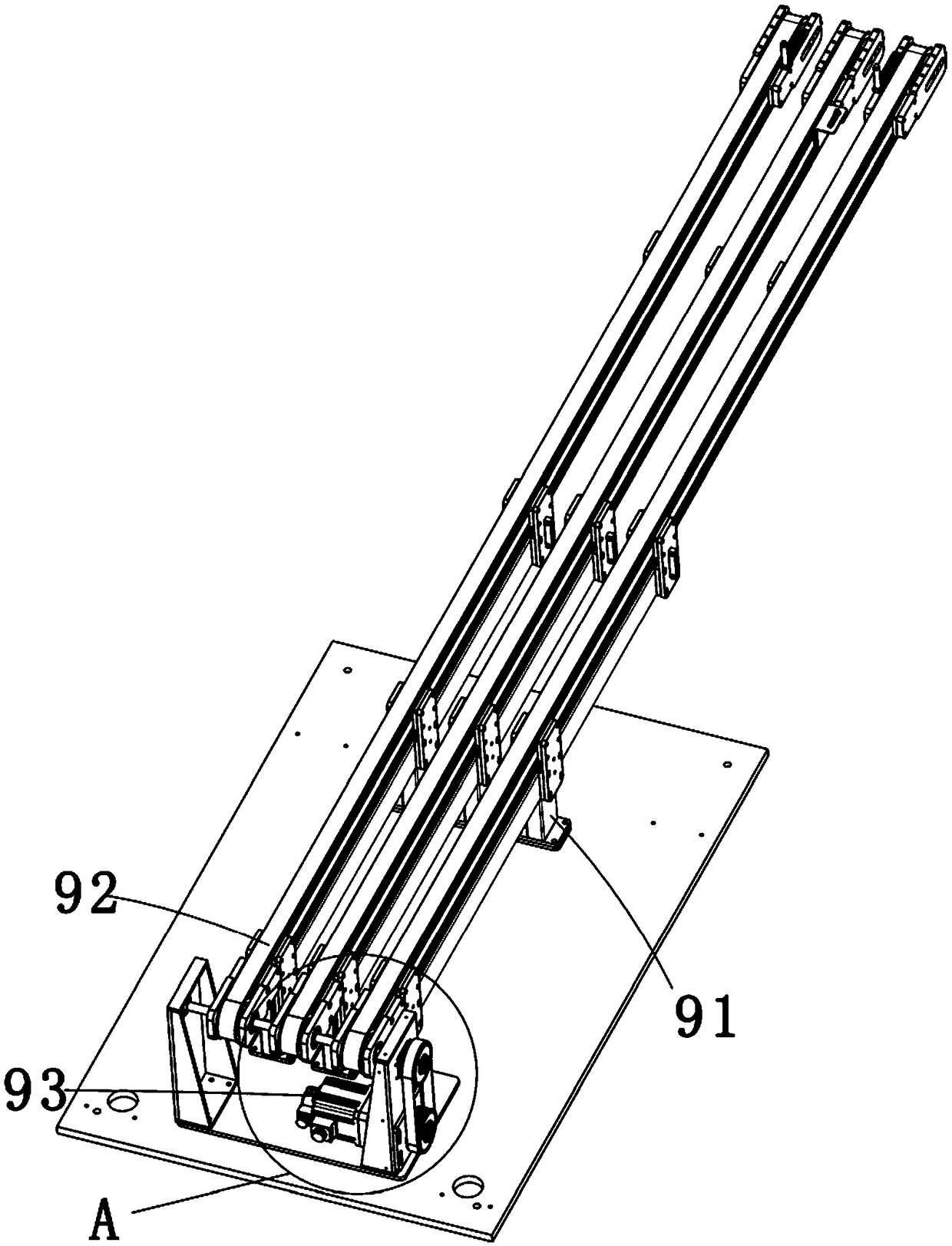

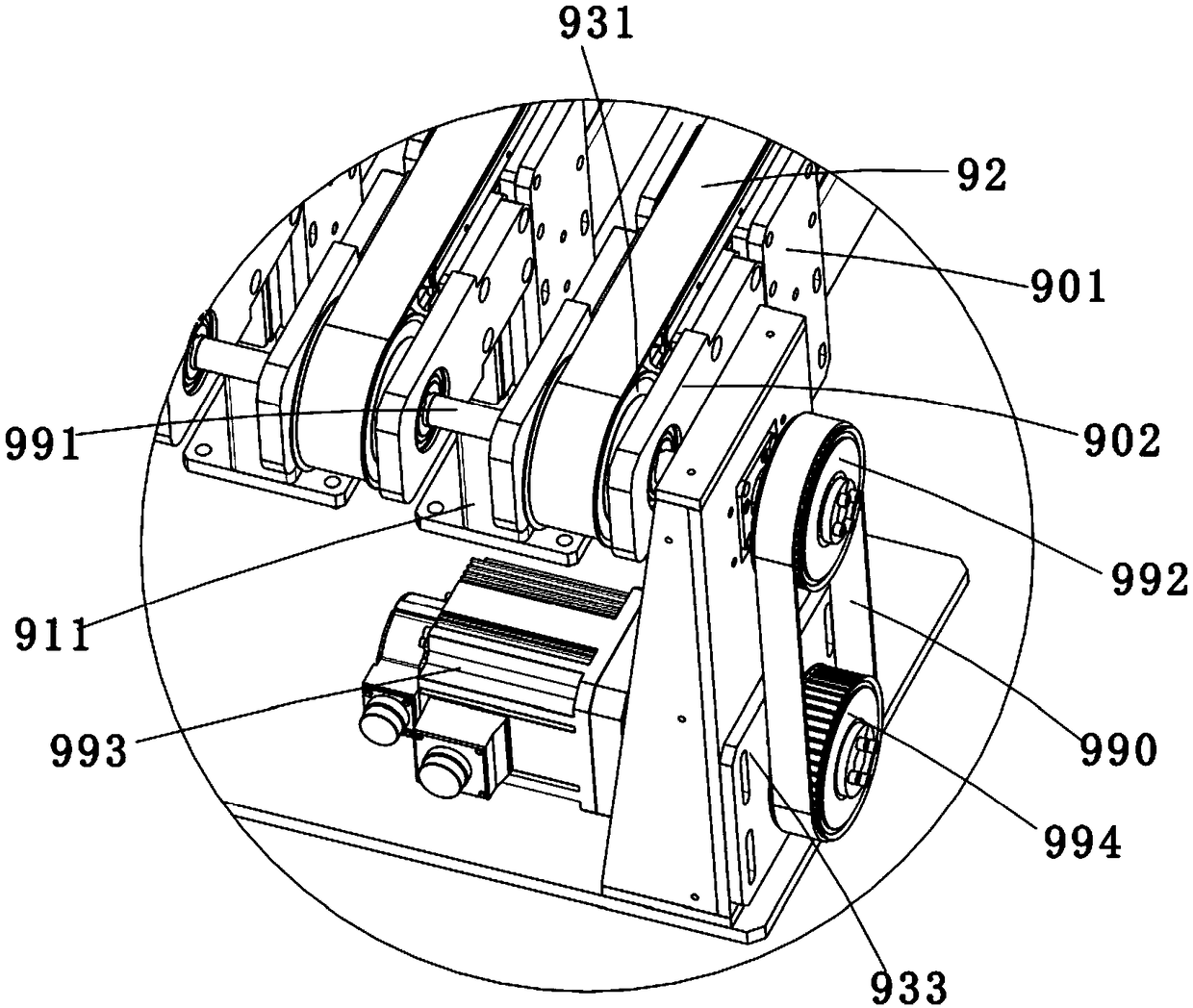

Double-side and double-trolley intelligent sorting and conveying system

PendingCN109178873AIncrease delivery rateThe connection is not damagedControl devices for conveyorsSortingTurning framesDelivery system

The invention provides a double-side and double-trolley intelligent sorting and conveying system. The double-side and double-trolley intelligent sorting and conveying system comprises a ring-shaped closed rail, a sorting double-side and double-trolley line running on the ring-shaped closed rail, package loading modules and package unloading modules, wherein the package loading modules and the package unloading modules are arranged on the inner side and the outer side of the ring-shaped closed rail, the inner direction and the outer direction of sorting trolley racks are provided with sorting trolleys correspondingly, the sorting trolleys are divided into inner-direction sorting trolleys and outer-direction sorting trolleys, the ring-shaped closed rail is provided with a horizontal supporting surface and a vertical steering surface, two sides of the sorting trolley racks are both provided with supporting walking wheels and position-limiting walking wheels, circulation sorting on the sorting trolleys can be guaranteed, the conveying speed rate of the sorting trolleys is increased, the sorting trolleys are made to swerve stably on the ring-shaped closed rail, connection of the sortingtrolley racks is not damaged, the inner-direction sorting trolleys and the outer-direction sorting trolleys on one same sorting trolley rack can perform sorting simultaneously, sorting tasks of the sorting trolleys are treated separately, accurate sorting is performed, a sorting trolley conveying belt is not prone to shifting, and packages are supported more stably.

Owner:GUANGZHOU GENYE INFORMATION TECH

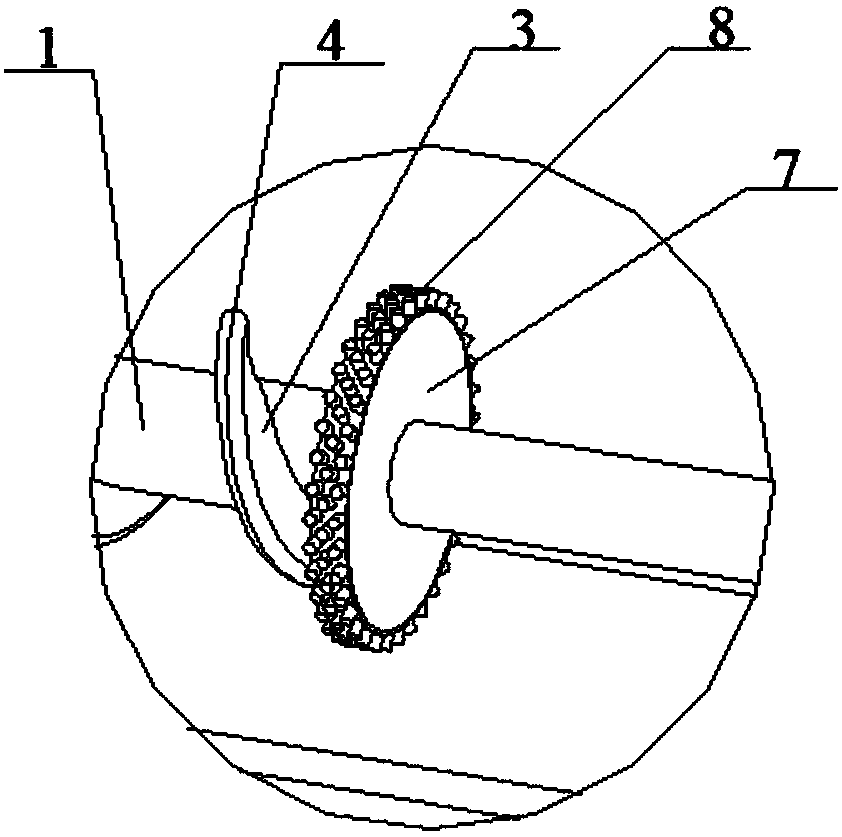

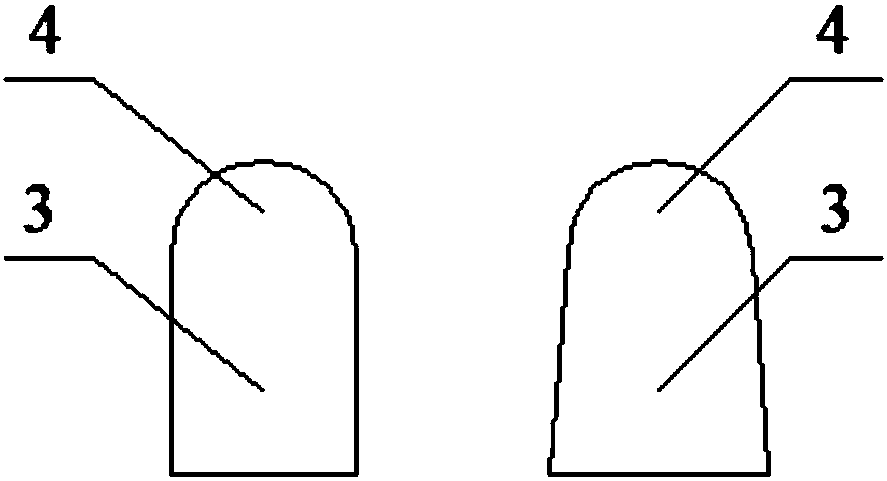

Devices and methods for enhanced skin perforation for continuous glucose monitoring

The efficacy of tissue piercing elements in the area of transdermal drug delivery is well-documented. Multiple studies have shown that enhancement of skin permeation via creation of microscopic pores in the stratum corneum can greatly improve the delivery rates of drugs. However, skin perforation with tissue piercing elements is not the only factor affecting the rate of drug transport. Other factors including such as the formulation of the drug and rate of closure of the micropores closure also need to be considered. Similarly micro tissue piercing elements have been used with less success by several workers for continuous glucose monitoring.

Owner:ARKAL INC

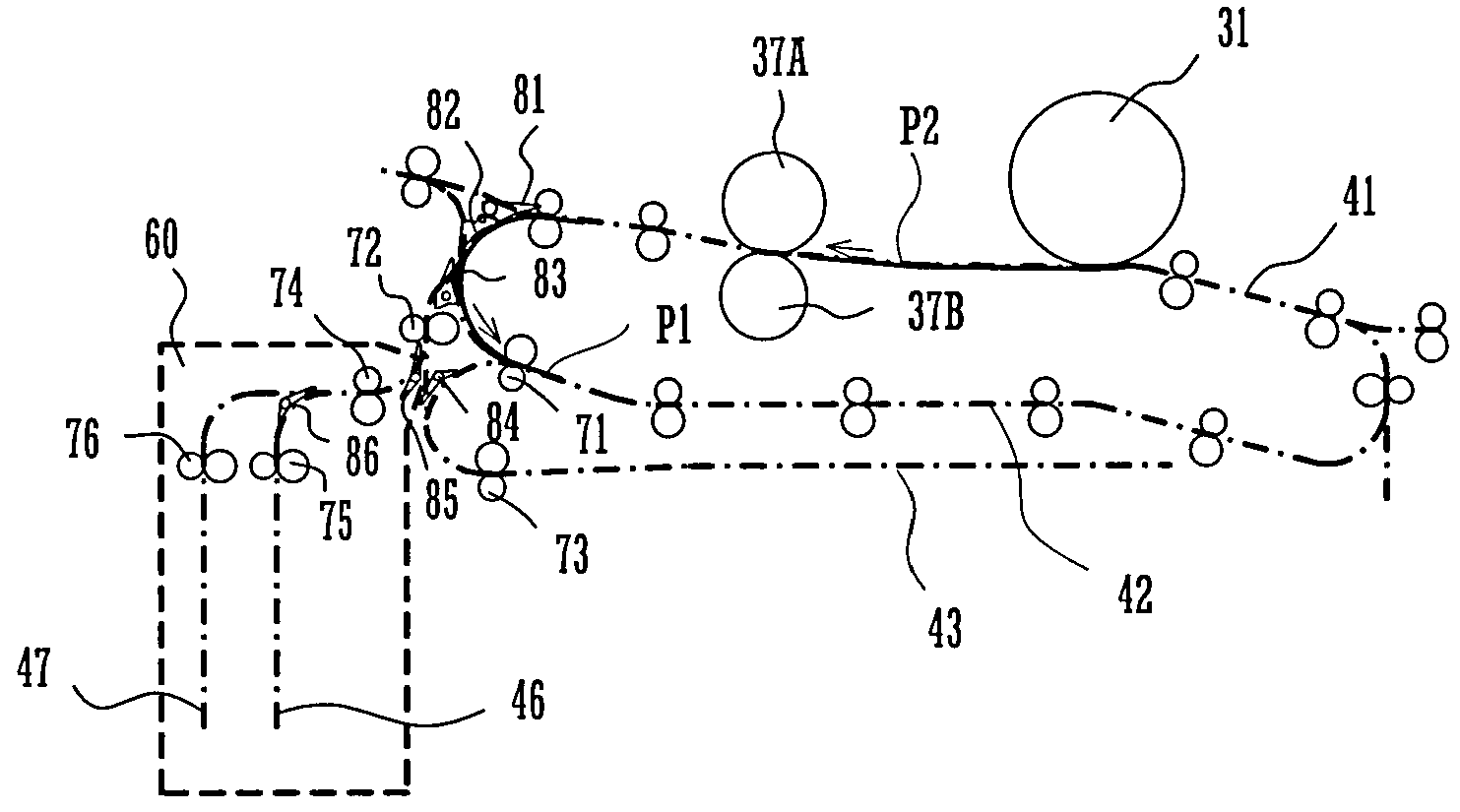

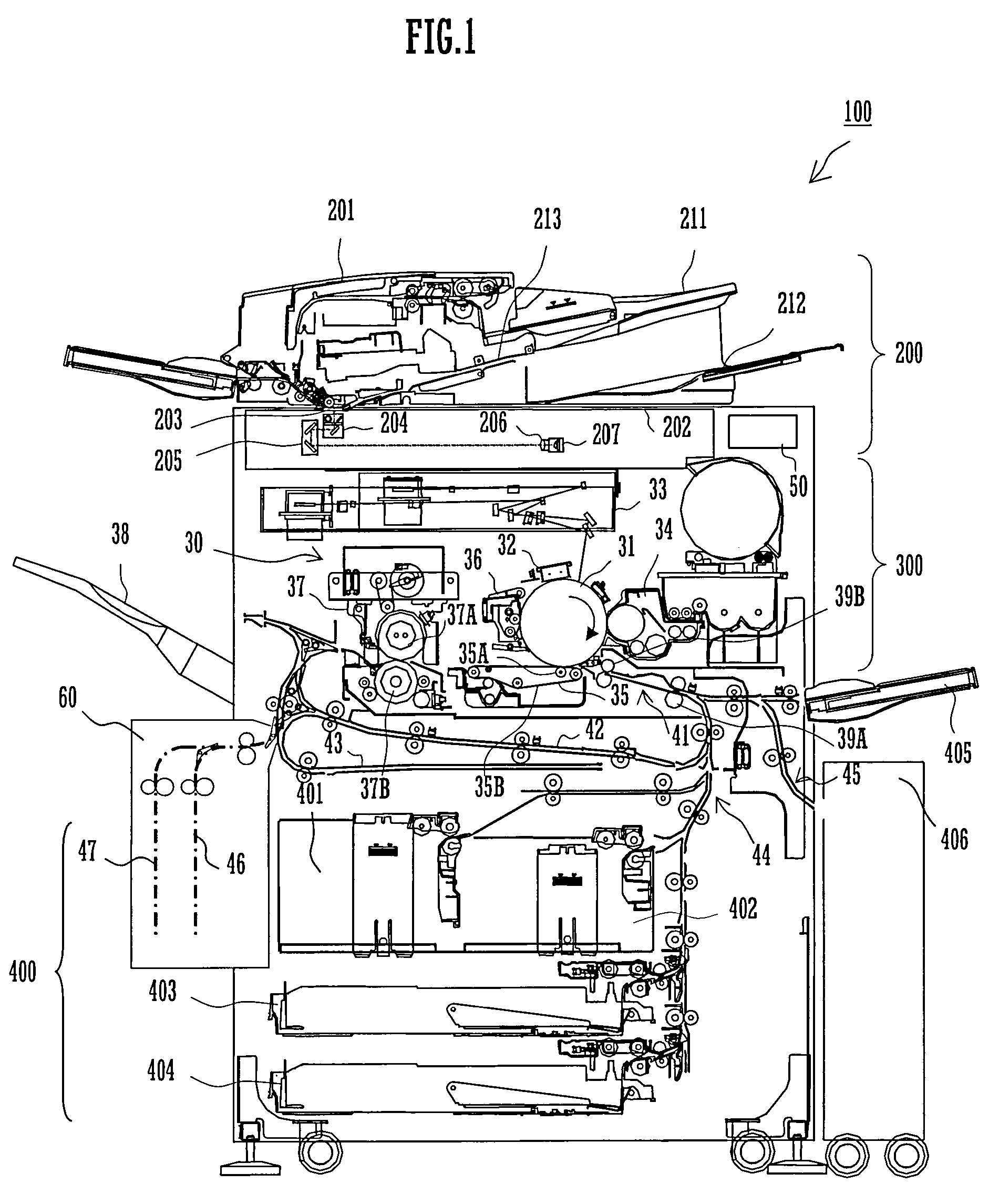

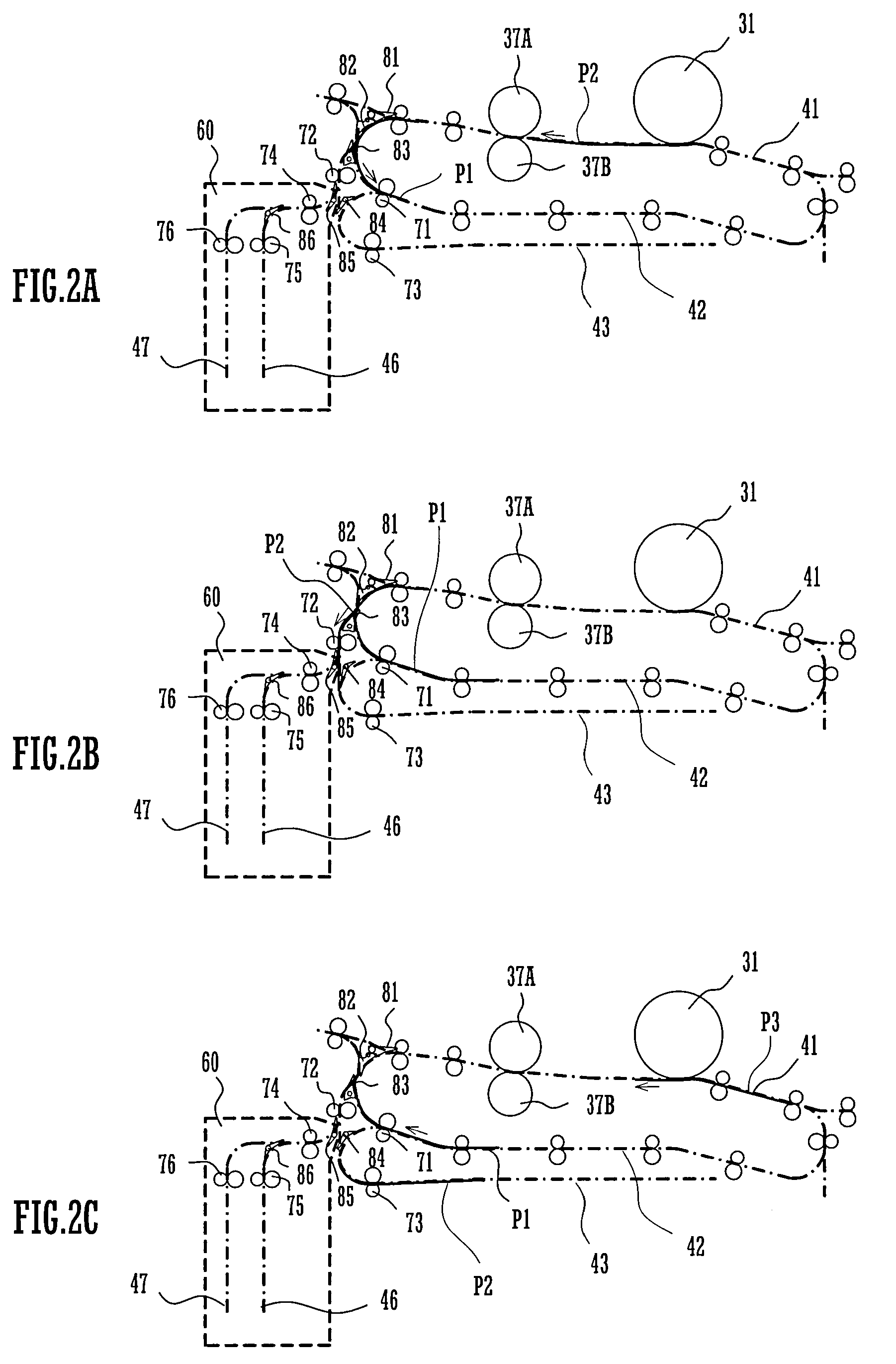

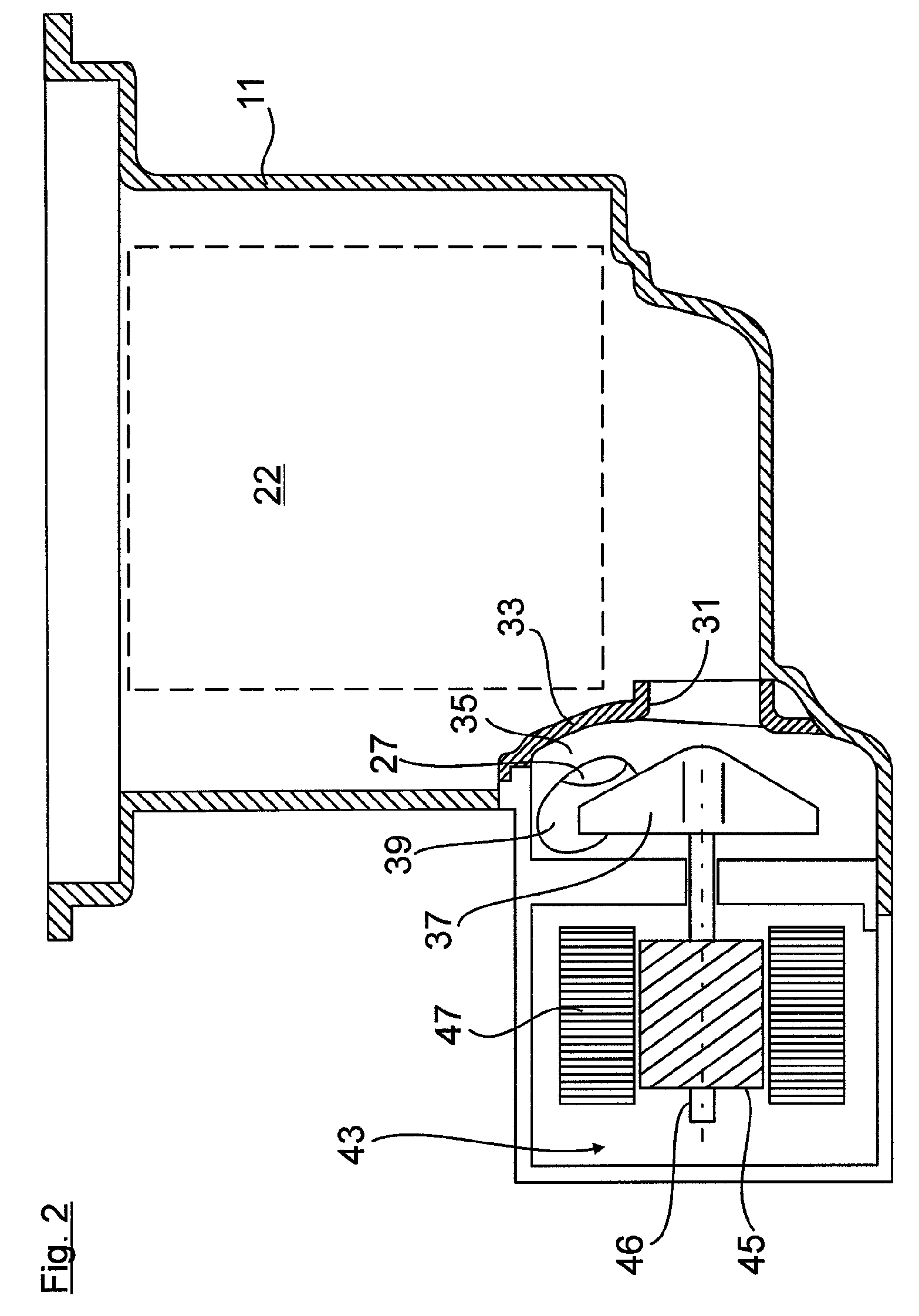

Image forming apparatus

InactiveUS20090148213A1Increase delivery rateReduce spaceElectrographic process apparatusArticle deliveryElectrical and Electronics engineeringPerformed Imaging

An image forming apparatus includes: an image forming section on a main feed path for performing image formation on a first recording medium to be subjected to single-side printing and on a second recording medium to be subjected to double-side printing; and an output section for delivering these recording media. The apparatus has first to third positions between the apparatus and the output section at each of which a feed path branches off the main feed path. The apparatus further includes: a subsidiary feed path extending from the first position and joining the main feed path at an entrance of the main feed path; a first switchback feed path formed in a place extending from the second position for turning the second recording medium upside down; and a second switchback feed path formed in a place extending from the third position for turning the first recording medium upside down.

Owner:SHARP KK

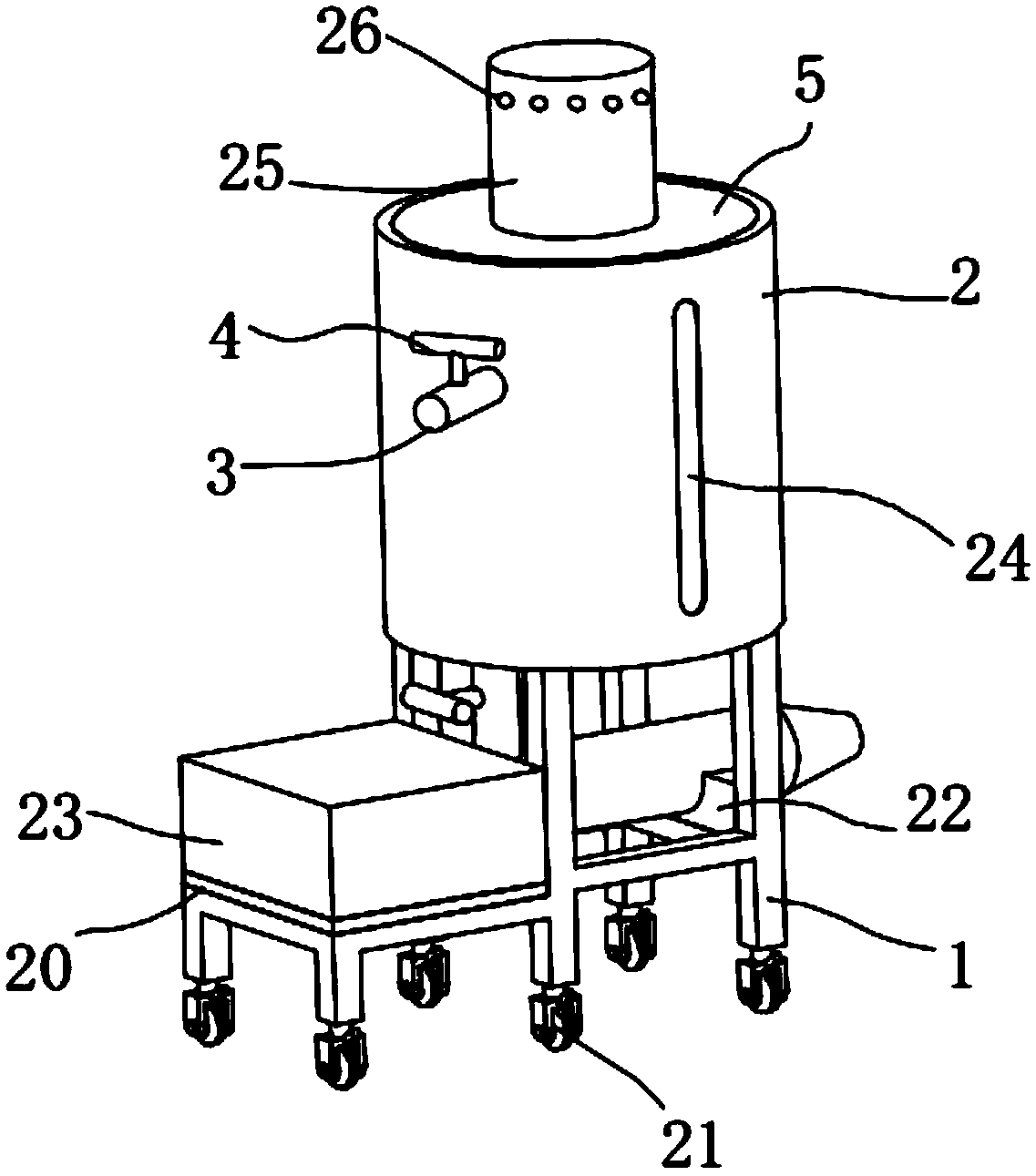

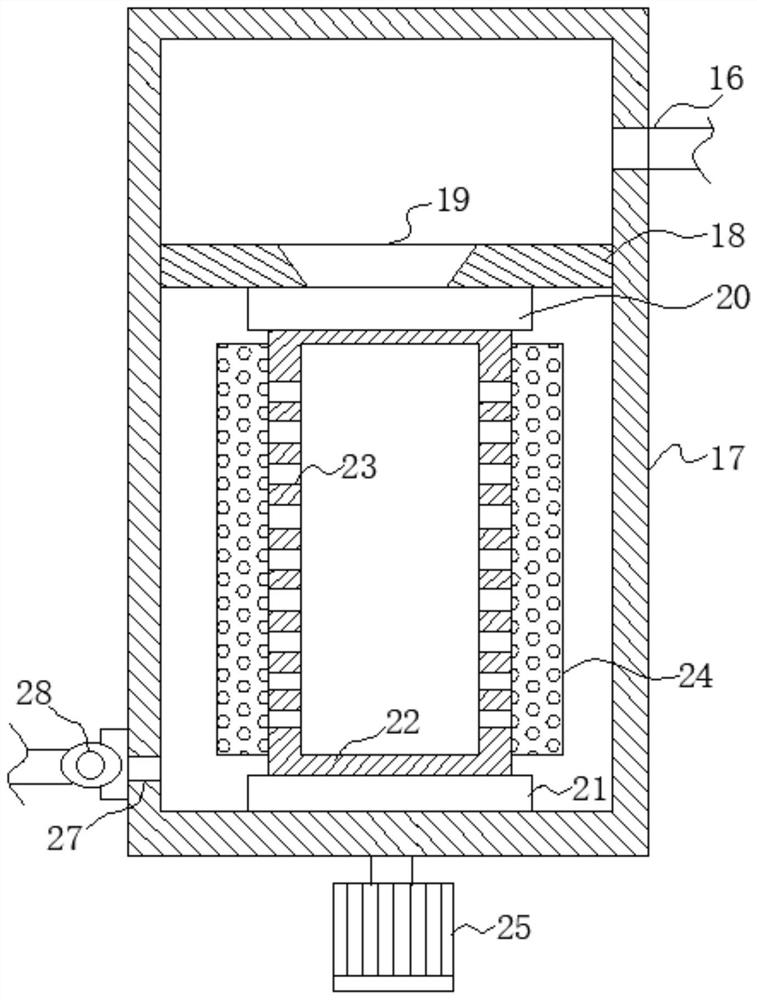

Papermaking pulping machine capable of uniformly pulping and automatically cleaning inner wall

InactiveCN109554949ABeat evenlyConvective Relative Stress IncreasePulp beating methodsElectric machineryPulp and paper industry

The invention discloses a papermaking pulping machine capable of uniformly pulping and automatically cleaning the inner wall. The papermaking pulping machine comprises a rack, wherein a pulping barrelis fixed on the upper end of the rack, a cover plate is fixed on the upper end of the pulping barrel, a first motor is fixed on the upper end of the cover plate, a rotating disc is fixed on the end portion of the output shaft of the first motor, a second motor is fixed on the upper end of the rotating disc, a first rotating shaft is fixed on the end portion of the output shaft of the second motor, a pulping mechanism is fixed on the outer circumference of the first rotating shaft, hair brush installing plates are fixed on both sides of the lower end of the rotating disc, hair brushes are fixed on the hair brush installing plates, the inner cavity of the pulping barrel is communicated to a material inlet pipeline, the bottom end of the pulping barrel is communicated to a material dischargechannel, and the lower end of the material discharge channel is communicated to a material conveying mechanism. According to the present invention, the paper pulp in the pulping barrel forms convection by using the structure, such that the pulping speed is increased, the pulping uniformity is improved, and the paper pulp quality is good; and the inner wall of the pulping barrel is cleaned by driving the hair brushes through the rotating disc so as to achieve the advantages of convenience and rapidness.

Owner:台州洪挺食品有限公司

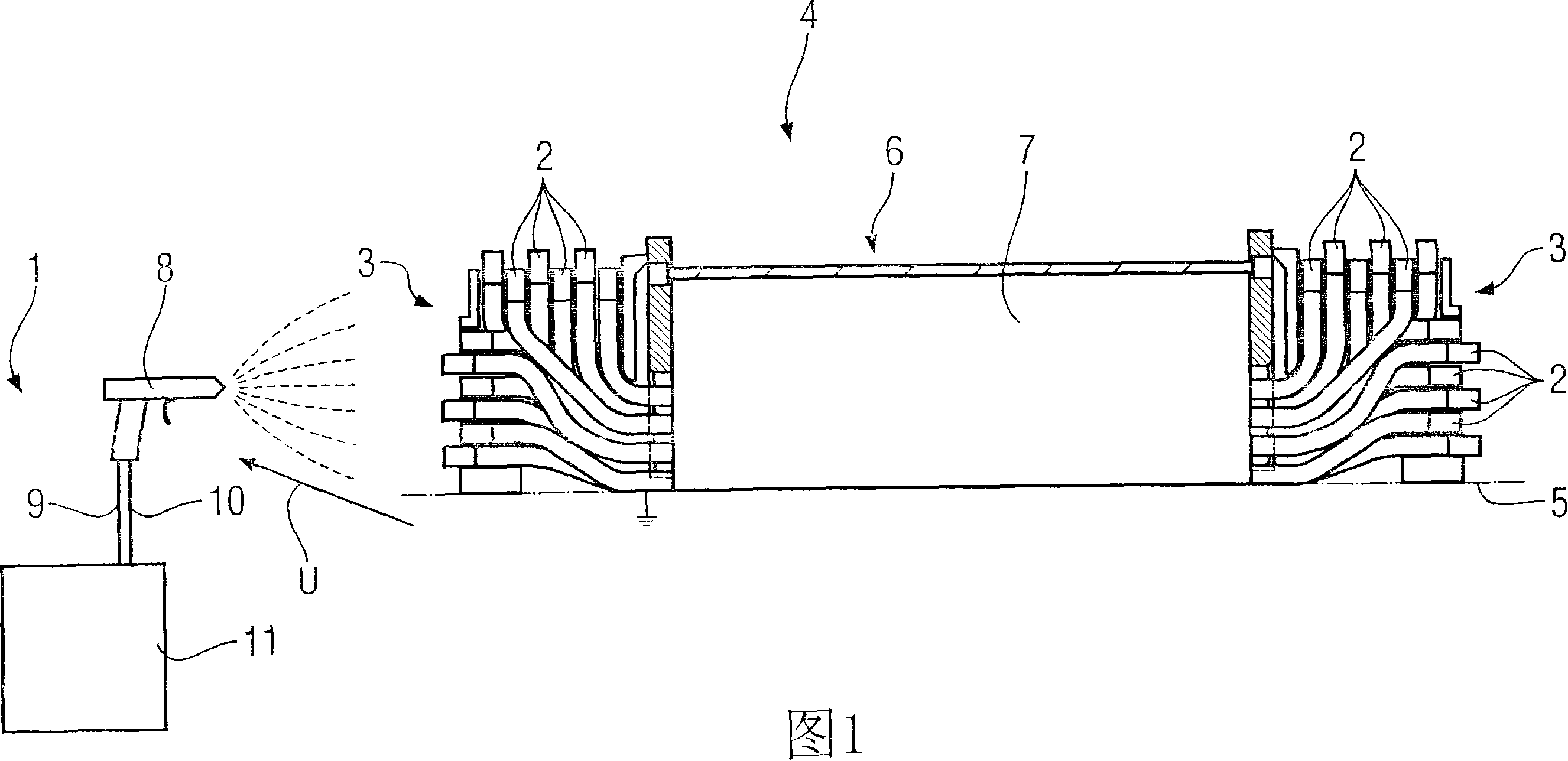

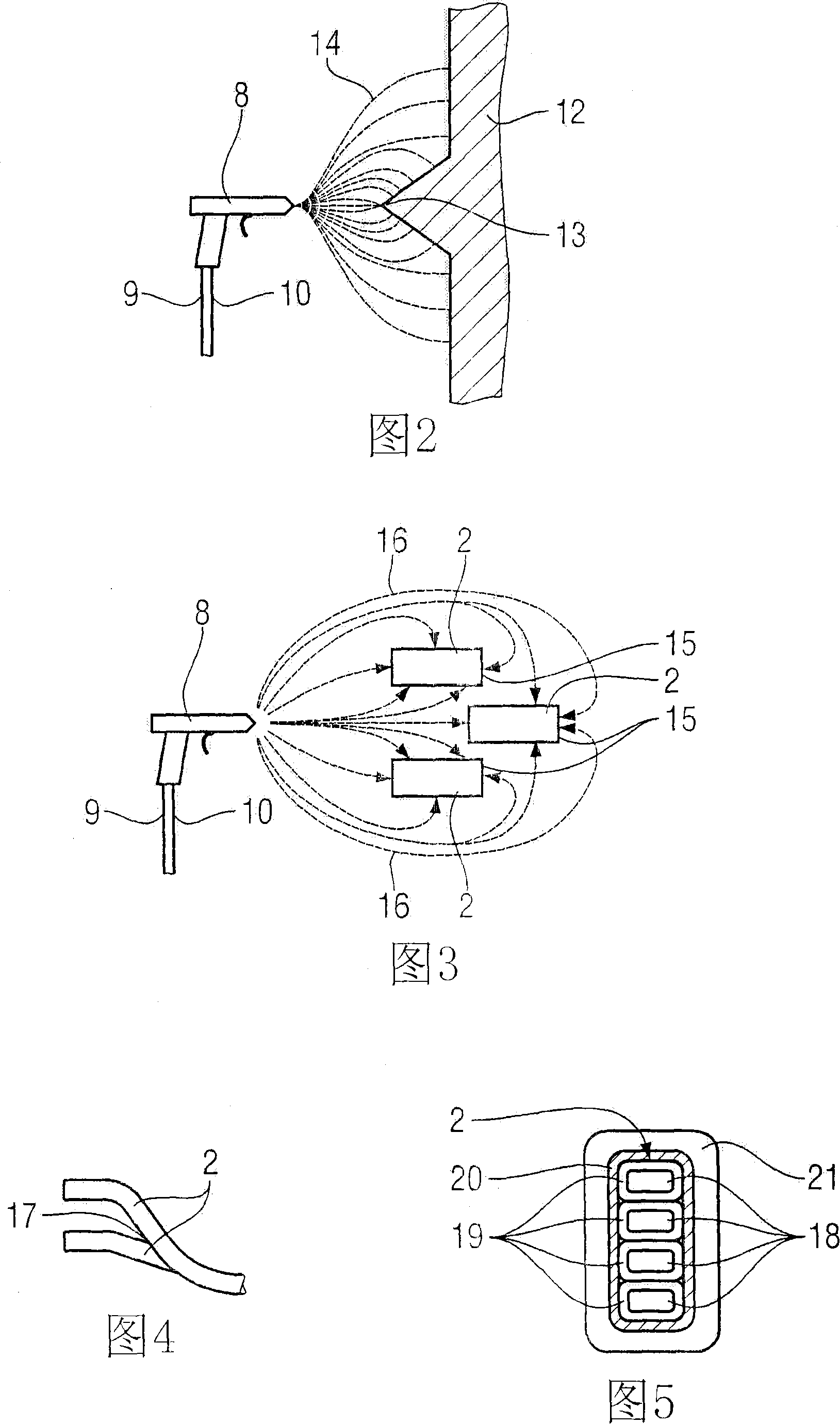

Coating method for an end winding of an electric motor

InactiveCN101156301AHigh densityIncrease delivery rateLiquid surface applicatorsManufacturing winding connectionsPotential differenceEngineering

The coating method is for application to the coating of an end winding (3) of an electric motor (4), whereby the end winding (3) comprises several conductor arrangements (2) for coating. The coating material for application is atomised by means of a spray device (1). An electrostatic potential difference (U) is applied between the spray device (1) and the conductor arrangements (2) for spraying, such that atomised particles of the coating material are transported along the forming electrical field lines in the direction of the conductor arrangements (2) of the end windings (3) for coating.

Owner:SIEMENS AG

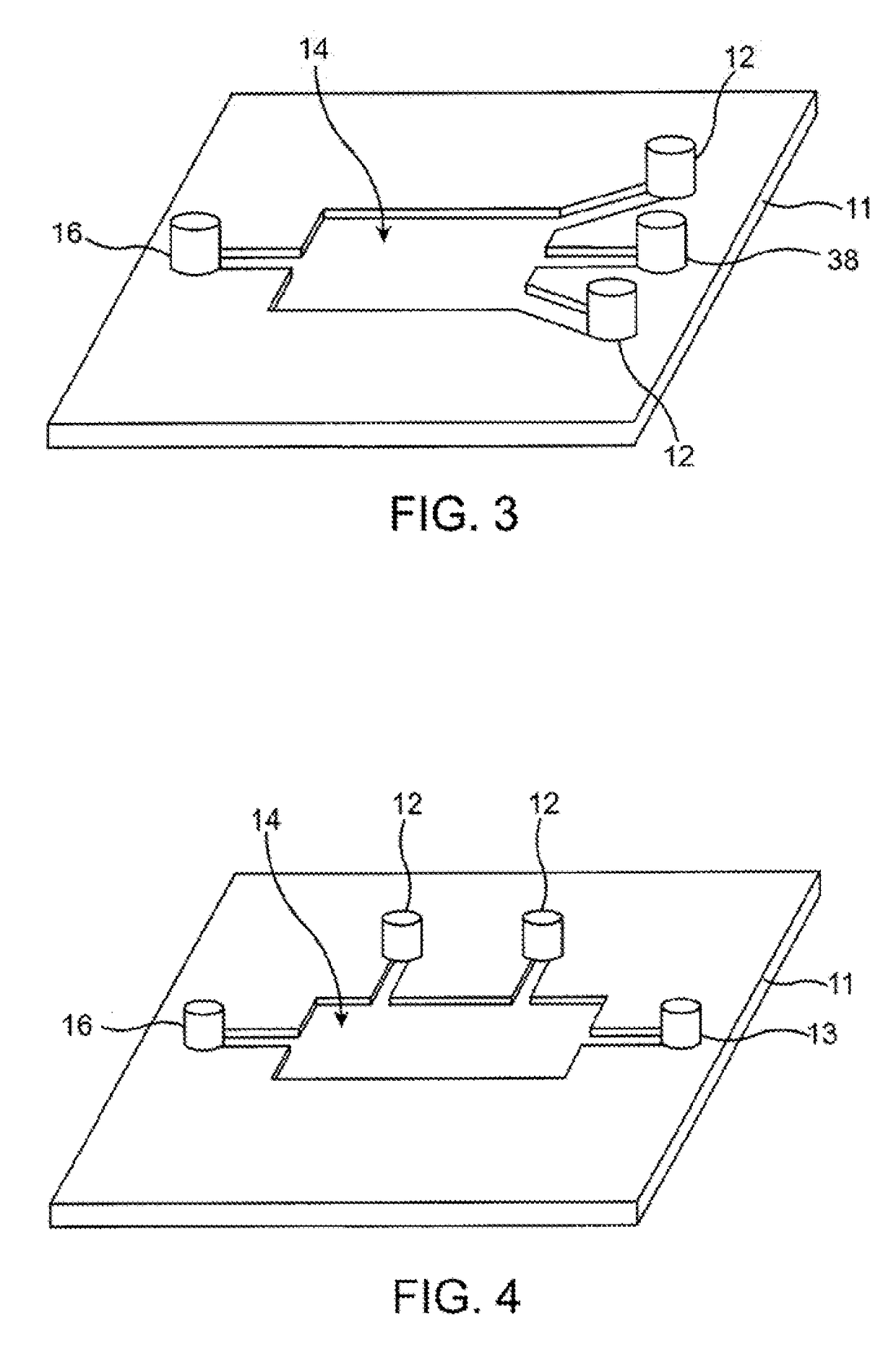

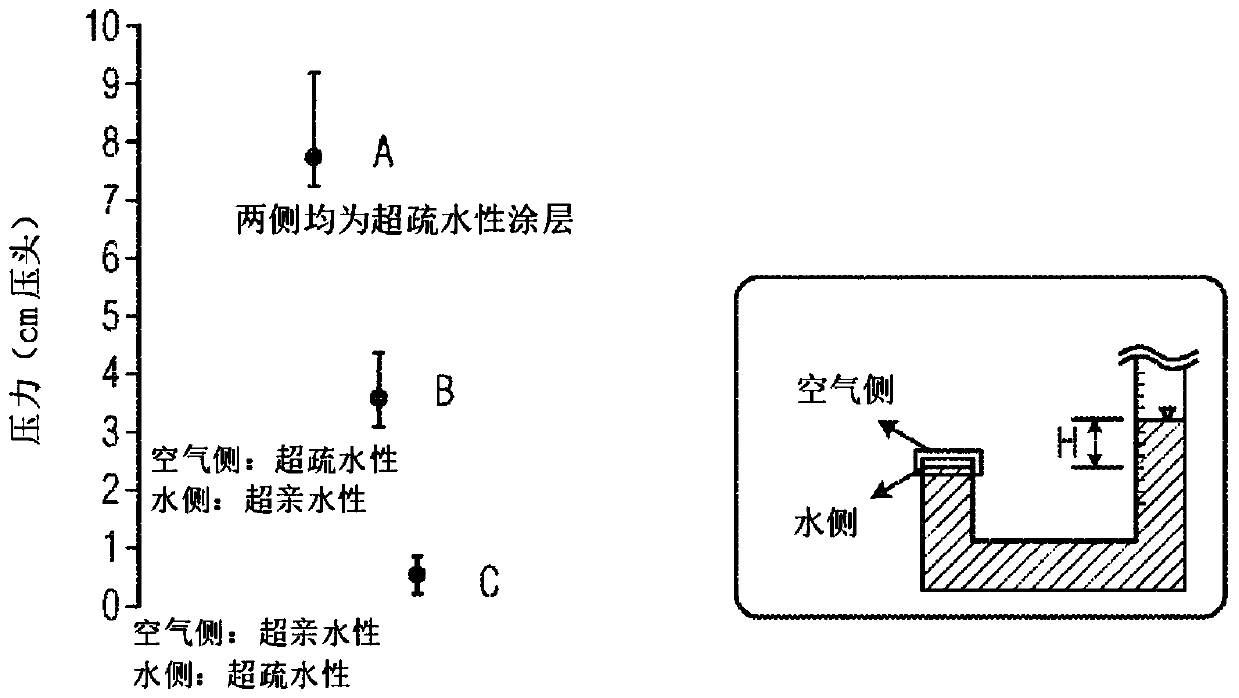

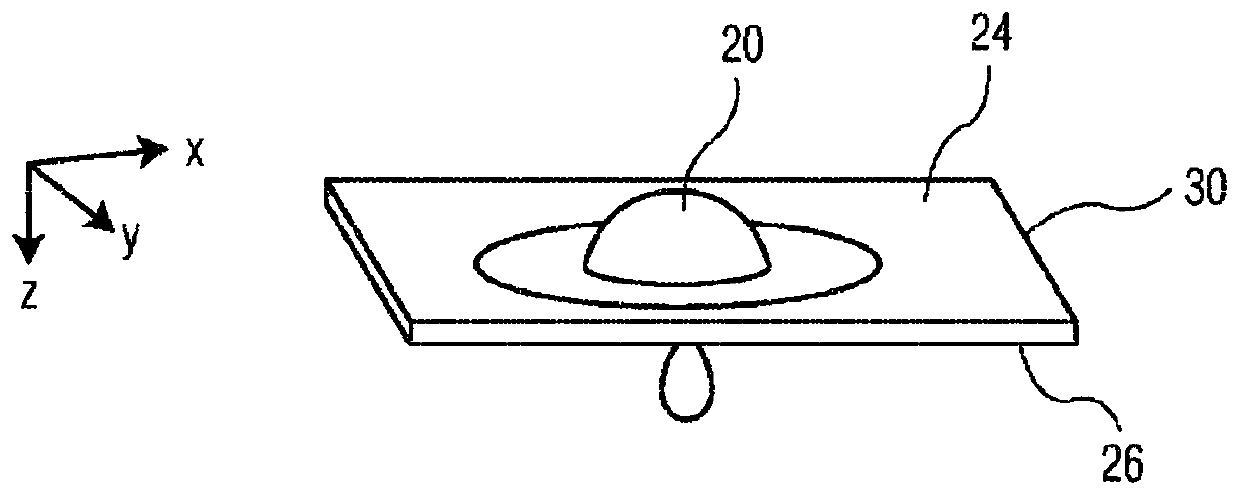

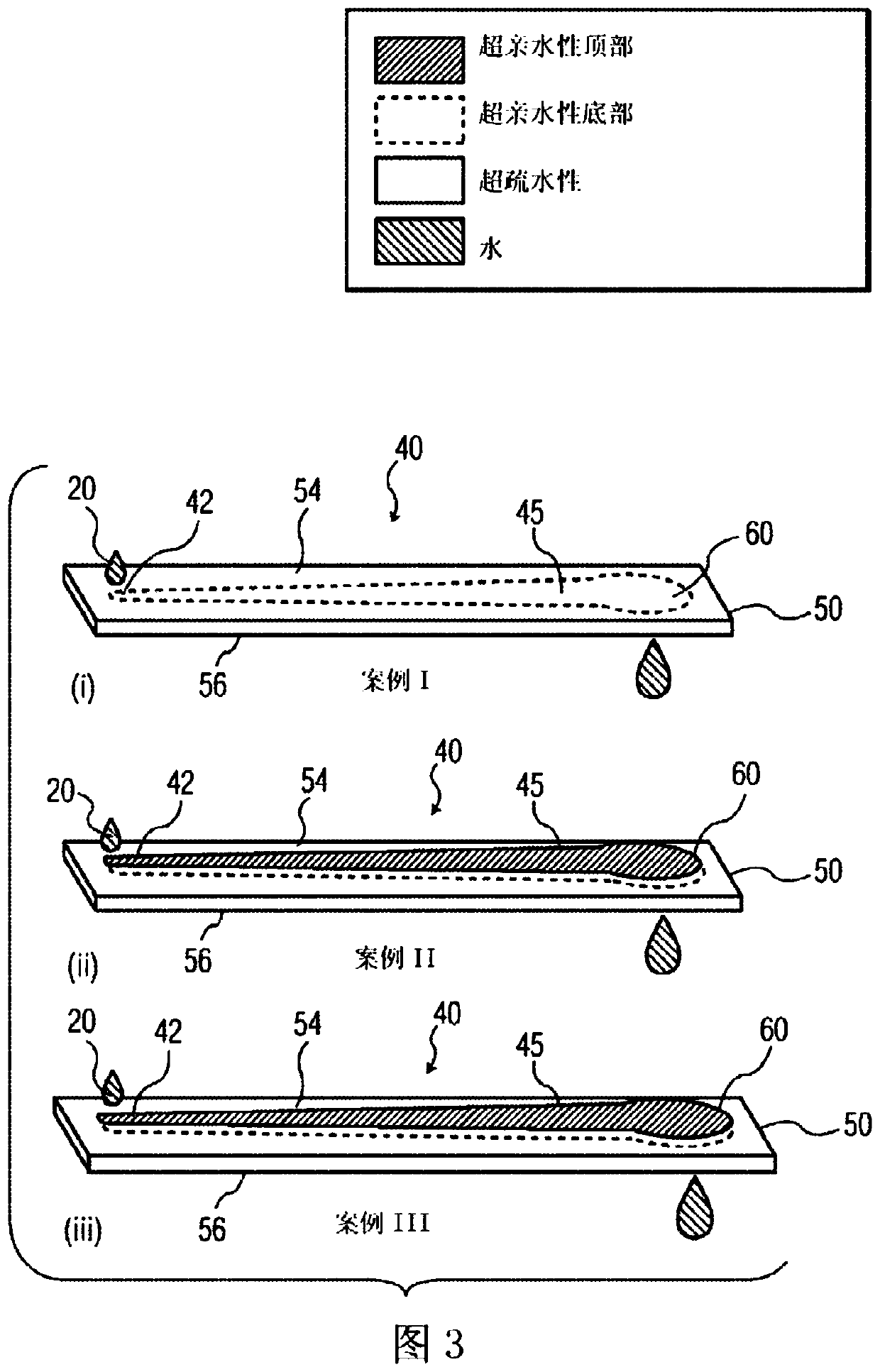

Wettability-patterning method and designs for pumpless transport and precise manipulation of liquid volumes on and through porous materials

PendingCN109963651AIncrease delivery rateFast liquid handlingLaboratory glasswaresFluid controllersSuperhydrophobePorous substrate

A material for manipulating liquid includes a porous substrate having first and second surfaces; and a wedge-shaped transport element disposed on one of the first and second surfaces, wherein the wedge-shaped transport element has a narrow end and a wide end, the wide end connected to a first reservoir, wherein the wedge-shaped transport element is configured to pass liquid from the narrow end tothe wide end to the first reservoir, regardless of gravity, and wherein the first reservoir is configured to pass liquid away from the substrate in a z-direction opposite from the surface on which a liquid is deposited. The surface on which the wedge-shaped transport element is disposed is one of hydrophobic or superhydrophobic, and the wedge-shaped transport element is one of a) superhydrophilicwhen the first surface is hydrophobic, b) superhydrophilic when the first surface is superhydrophobic, and c) hydrophilic when the first surface is superhydrophobic.

Owner:KIMBERLY-CLARK WORLDWIDE INC +1

Material processing system

ActiveCN109132370AImprove processing efficiencyNo offsetConveyorsConveyor partsMaterials processingPower component

The invention discloses a material processing system. The material processing system comprises material conveying equipment and material grabbing equipment, wherein the material conveying equipment comprises a support component, a conveying belt, a power component, a magnetic component and an adjusting structure, the conveying belt is used for conveying materials, the power component is used for driving the conveying belt to rotate so as to convey the materials, the magnetic component is arranged below the conveying belt and is used for sucking the materials located on the conveying belt, andthe adjusting structure is matched with the power component so as to adjust the tightness of the conveying belt. According to the material processing system, the material conveying equipment and the material grabbing equipment are arranged, so that the materials can be quickly grabbed and then are conveyed, the material processing efficiency can be effectively improved in the process, and manpoweris saved; the materials cannot deflect, remain, slip or fall off in the process, so that quick conveying is realized, and the material processing efficiency is improved.

Owner:HANGZHOU KINGNET ELECTROMECHANICAL

Pipeline cable conveying method with auxiliary supporting structure

ActiveCN107826872AEasy to transportReduce deliveryFilament handlingApparatus for laying cablesSpiral bladeEngineering

The invention provides a pipeline cable conveying method with an auxiliary supporting structure and belongs to the technical field of pipeline cables. The pipeline cable conveying method is completedby means of a cable conveying device, the cable conveying device comprises a horizontal drilling machine, a cable is fixedly connected with a drilling rod of the horizontal drilling machine, and the cable is fixedly sleeved with spiral blades. The spiral blades comprise blade roots and blade tips fixedly connected with the blade roots, the cross sections of the blade tips are circular, and the ratio of the thickness L of the blade roots to the diameter D of the blade tips is 1:(1-1.2). A spiral pipeline cable conveying structure is formed through the cable by means of driving of the horizontaldrilling machine and further comprises a supporting frame provided with a travelling mechanism and arranged between the drilling rod and a pipeline and a cable groove formed in the supporting frame,and a shaft roller for bearing the cable is arranged in the cable groove. On the basis of the spiral pipeline cable conveying structure, in the process that the cable is spirally conveyed to the otherend of the pipeline by means of the horizontal drilling machine, the pipeline is filled with plugging particles finally. According to the pipeline cable conveying method, the cable and the plugging particles can be easily, rapidly, and synchronously conveyed in place in good condition.

Owner:STATE GRID CORP OF CHINA +2

Filtering system with controller and oil conveying system

PendingCN108159763AIncrease volumeVariable volumeStationary filtering element filtersFilter systemMechanical equipment

The invention provides a filtering system with a controller and an oil conveying system, and relates to the technical field of mechanical equipment. According to the filtering system, oil in an oil storage container is guided into a filtering device to be filtered, and then is output into the next working procedure through an oil conveying device; a liquid level sensor on a shell is used for monitoring the liquid level in the shell in the filtering process, and alarming is carried out through an alarm device when a designated position is reached; then an operator takes bearing blocks in one ormore bearing grooves to reduce the overall mass of a top cover; a spring assembly in a concave groove stretches, then a first barrel and the top cover move upwards, so that the volume of the whole shell is increased and can adapt to a higher oil conveying speed. The oil conveying system comprises the filtering system with the controller. The filtering system and the oil conveying system can bothadapt to a higher oil conveying speed, the volume of the shell of the filtering device is adjustable, and the filtering system and the oil conveying system are convenient to operate and suitable for wide application.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

Liquid spray dispenser

InactiveCN101795779AImprove spray deliveryIncrease delivery rateClosuresSpray nozzlesFluidic oscillatorNozzle

The present invention provides a compressible spray dispensing container which includes a quantity of a liquid treatment composition contained therein, and a dispensing means which dispensing means includes a fluidic oscillator which provides for oscillation of the liquid exiting the dispensing means, and particularly via a nozzle.

Owner:RECKITT BENCKISER (UK) LTD

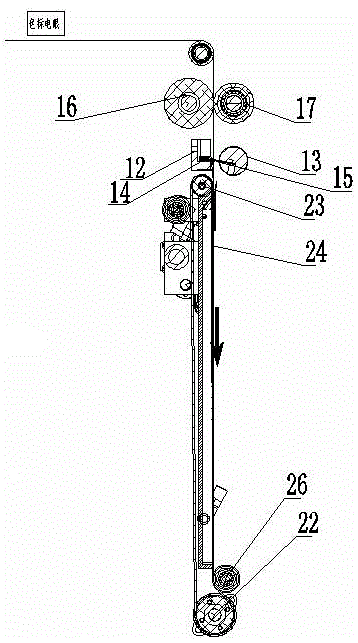

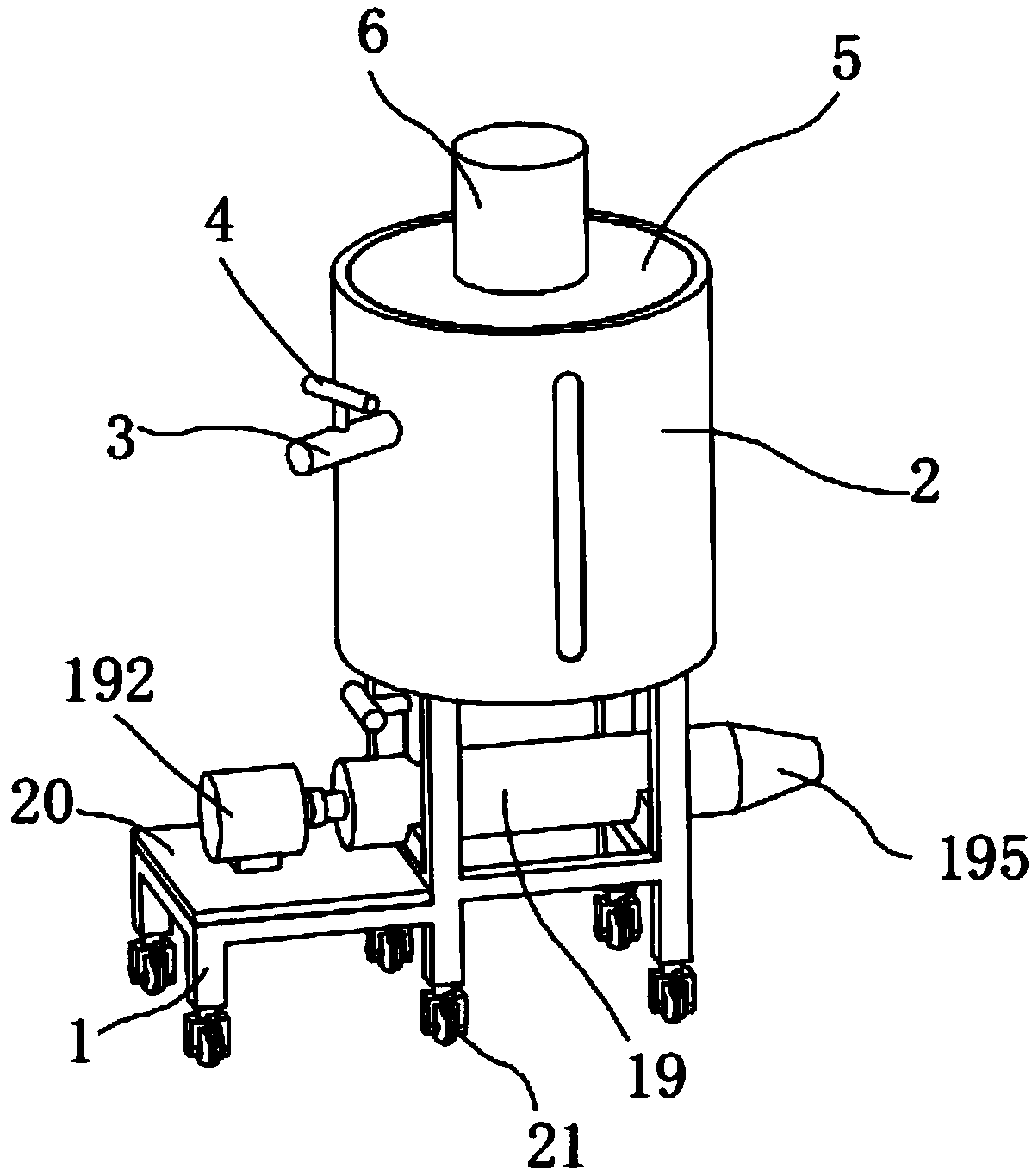

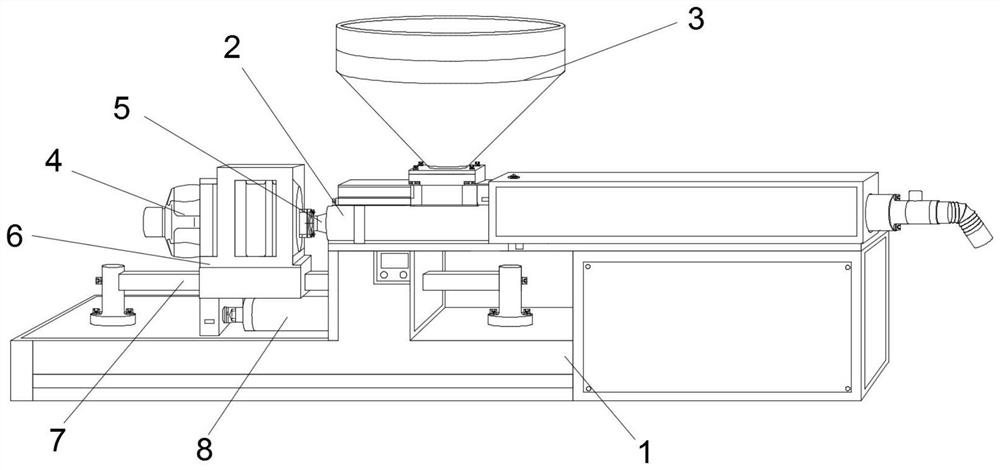

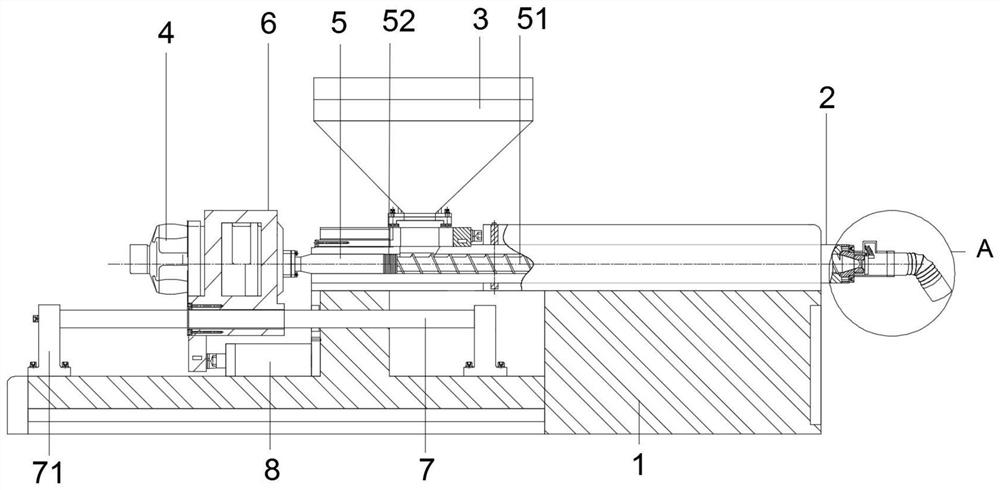

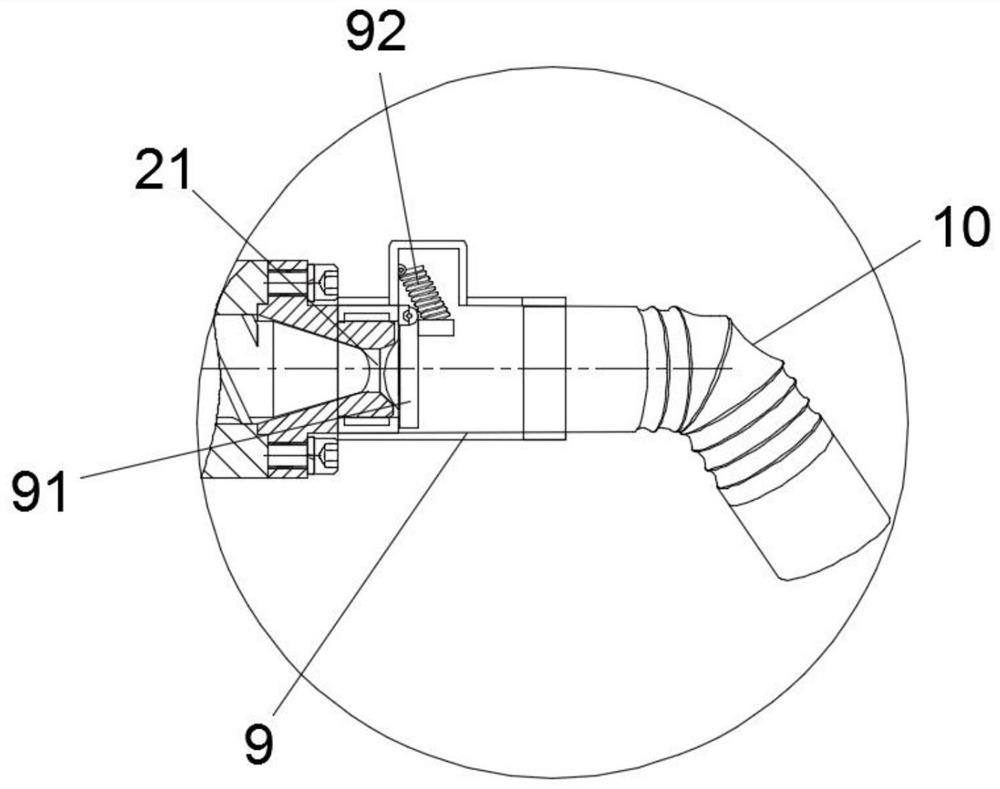

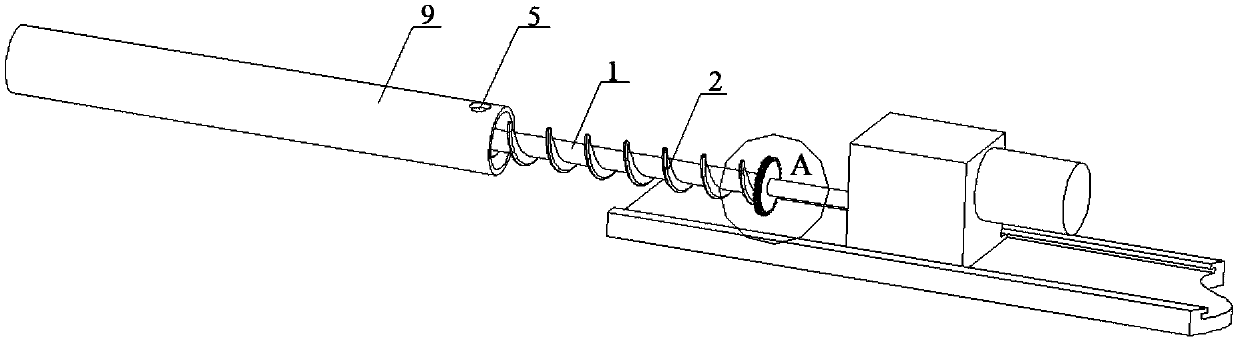

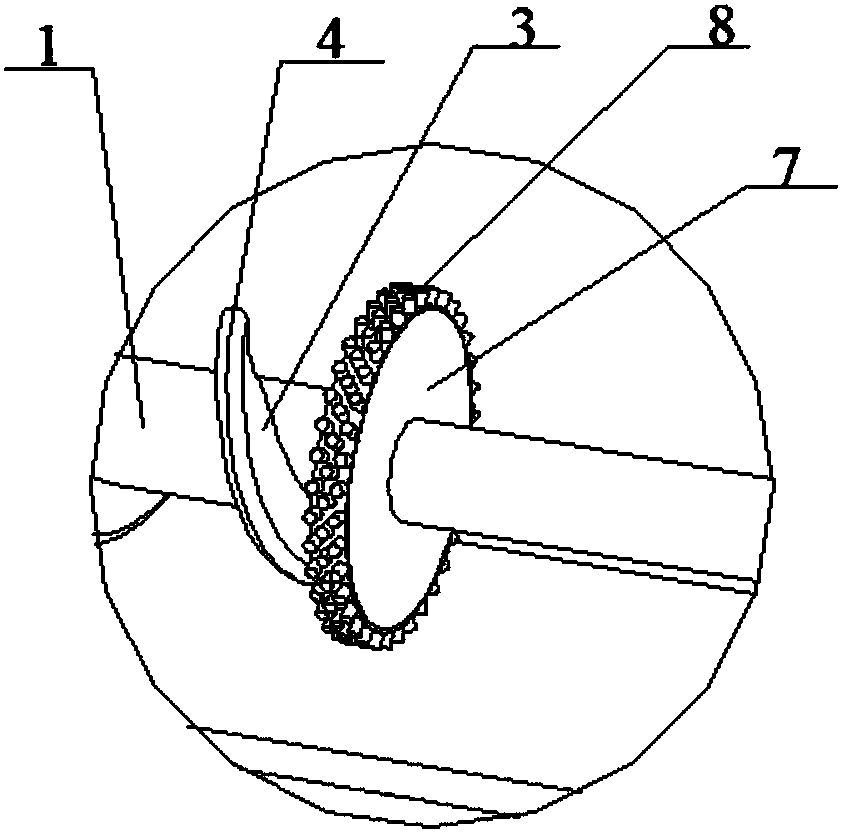

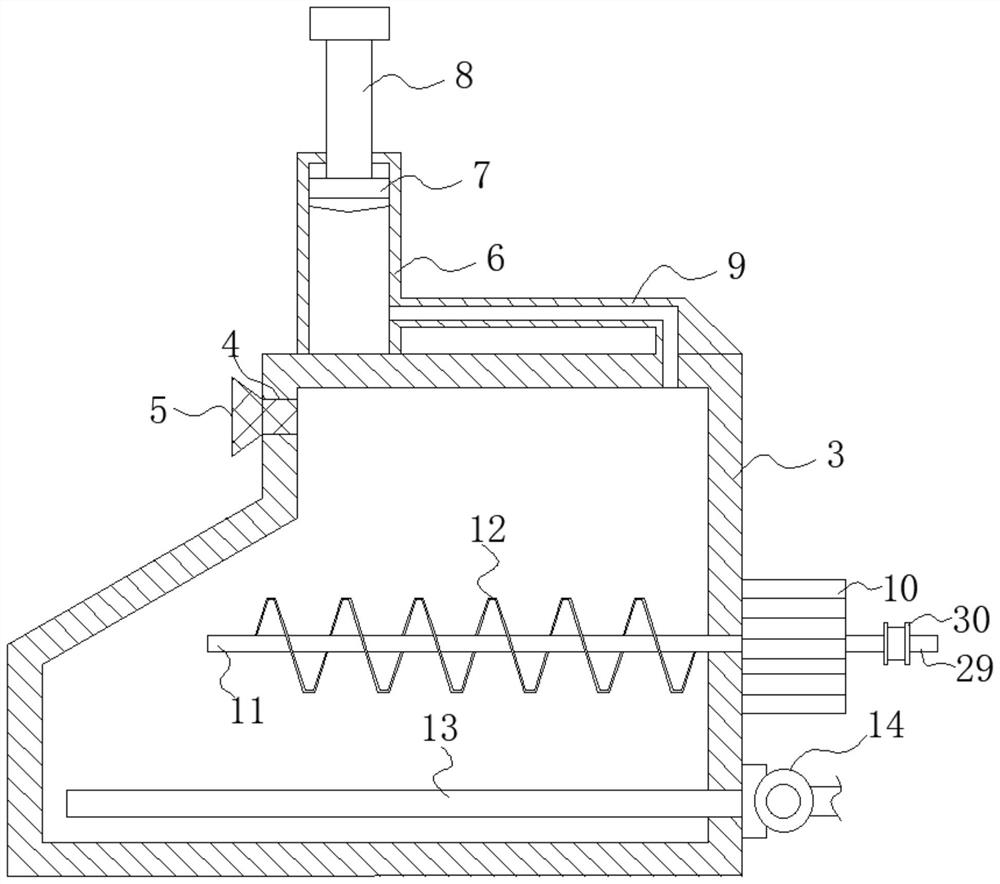

Rapid screw feeding equipment

InactiveCN111646124AIncrease delivery rateReduce cloggingPackagingConveyor partsElectric machineDrive motor

The invention relates to the technical field of feeding equipment, in particular to rapid screw feeding equipment. The rapid screw feeding equipment comprises a rack and a feeding pipe mounted on therack. A discharge port is formed in one end of the feeding pipe, a feed hopper is arranged in the middle of the feeding pipe, a drive motor is arranged on the other side of the feeding pipe, the drivemotor is connected with a rotary shaft through a shaft, the rotary shaft is slidingly embedded into the inner side of the feeding pipe, the rack is fixedly provided with a rectangular sliding rod, the rectangular sliding rod is slidingly provided with a fixing frame, the drive motor is fixedly arranged on the fixing frame, an electric push rod is arranged on the lower side of the fixing frame, the fixing frame is connected with the rack through the electric push rod, one end of the feeding pipe is connected with a connecting pipe, the other end of the connecting pipe is connected with a telescopic pipe, the drive motor is arranged on the fixing frame, the electric push rod of the drive motor can push the fixing frame to move left and right, thus, the rotary shaft connected with the motordrives a screw to move in the feeding pipe, and the screw generates thrust forwards while carrying out spiral conveying.

Owner:郭毅义

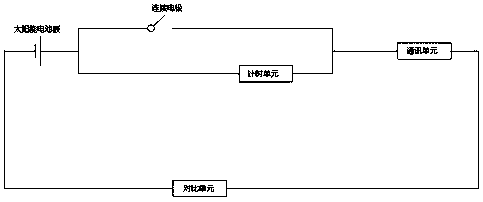

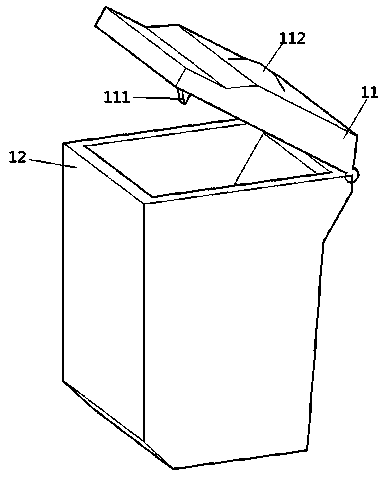

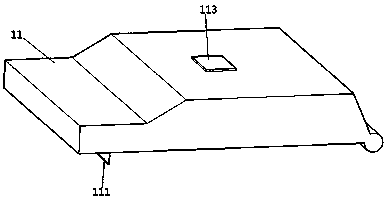

Garbage can monitoring system based on intelligent collection and transportation

PendingCN111047492AEffective detection of fullnessTimely notificationData processing applicationsRefuse receptaclesCommunication unitMonitoring system

The invention relates to the field of garbage collection and transportation management, in particular to a garbage can monitoring system based on intelligent collection and transportation. The systemcomprises a garbage can and a central server; a timing unit, a communication unit and a comparison unit are arranged in the garbage can; a connecting electrode is arranged between a cover body of thegarbage can and the can body; the connecting electrode is connected in parallel with the timing unit; the timing unit is used for recording the open circuit duration of the connecting electrode to obtain duration data; the comparison unit compares the duration data with preset data; and the communication unit outputs a full-load signal to the central server according to the comparison result of the comparison unit when the comparison result is that the duration data is greater than the preset data. In the prior art, garbage collection and transportation are monitored by detecting the weight ofgarbage, but a garbage truck cannot be informed of collecting and transporting a full garbage can in time. Compared with the prior art, whether the garbage can is full or not can be effectively detected through the connecting electrode, the comparison unit and the communication unit, and the garbage truck is informed of collecting and transporting the garbage can in time.

Owner:浙江旺能生态科技有限公司

Pipeline cable conveying method

ActiveCN107819298APlay a supporting roleAvoid frictional damageBiocidePest repellentsSpiral bladeEngineering

The invention relates to a pipeline cable conveying method, and belongs to the pipeline cable field. The pipeline cable conveying method is completed by means of a cable conveying device. The cable conveying device includes a horizontal drilling machine, wherein the cable is fixedly connected with a drilling pole of the horizontal drilling machine; spiral blades sleeve and are fixed on the cable;each spiral blade includes a blade root and a blade tip which is fixedly connected with the blade root; the cross section of the blade tip is circular; the ratio between the thickness L of the blade root and the diameter of the blade tip is 1: (1-1.2); the cable is driven by the horizontal drilling machine to form a spiral pipeline cable conveying structure, and based on the structure, the spiralblades sleeve the periphery of the cable and are fixed; the cable is fixedly connected with the drilling pole of the horizontal drilling machine; the end head of the cable is arranged in the end headof the pipeline; the horizontal drilling machine is started, and the blocking particles are injected into from a feed opening above the end head of the pipeline; and during the process that the cableis conveyed to the other end head of the pipeline, the blocking particles are filled in the pipeline; and then the horizontal drilling machine is closed, and the end head, with the feed opening, of the pipeline is cut off, and then the process is completed. The pipeline cable conveying method can easily, quickly and completely convey the cable and the blocking particles to be in place synchronously.

Owner:STATE GRID CORP OF CHINA +2

Food cleaning table

InactiveCN111604317AGuaranteed cleaning effectUniform concentrationRotary stirring mixersTransportation and packagingProcess engineeringSewage

The invention relates to the technical field of food processing, and discloses a food cleaning table. The food cleaning table comprises an internal hollow table body, wherein an opening is formed in one side of the top of the table body, a cleaning tank with a top open is fixed in the opening, and a water outlet is formed in one side of the cleaning tank; and a liquid conveying assembly is arranged on the other side of the top of the table body, the liquid conveying assembly comprises a cleaning liquid box, an injection opening is formed in one side of the cleaning liquid box, and a plug cockused for plugging the injection opening is arranged at the injection opening. According to the food cleaning table, a traditional food cleaning device is replaced, a cleaning agent and a water body can be fully stirred and mixed through the liquid conveying assembly before food is cleaned, it is guaranteed that the concentration of a cleaning liquid is uniform, the cleaning liquid is gradually conveyed into the cleaning tank through a mode of pressing rod pressing to be used for food cleaning, and the food cleaning effect is guaranteed; and meanwhile, waste water after cleaning can be purifiedthrough a water purifying assembly, and the pollution to the external environment is avoided.

Owner:ANHUI XIAXING FOOD

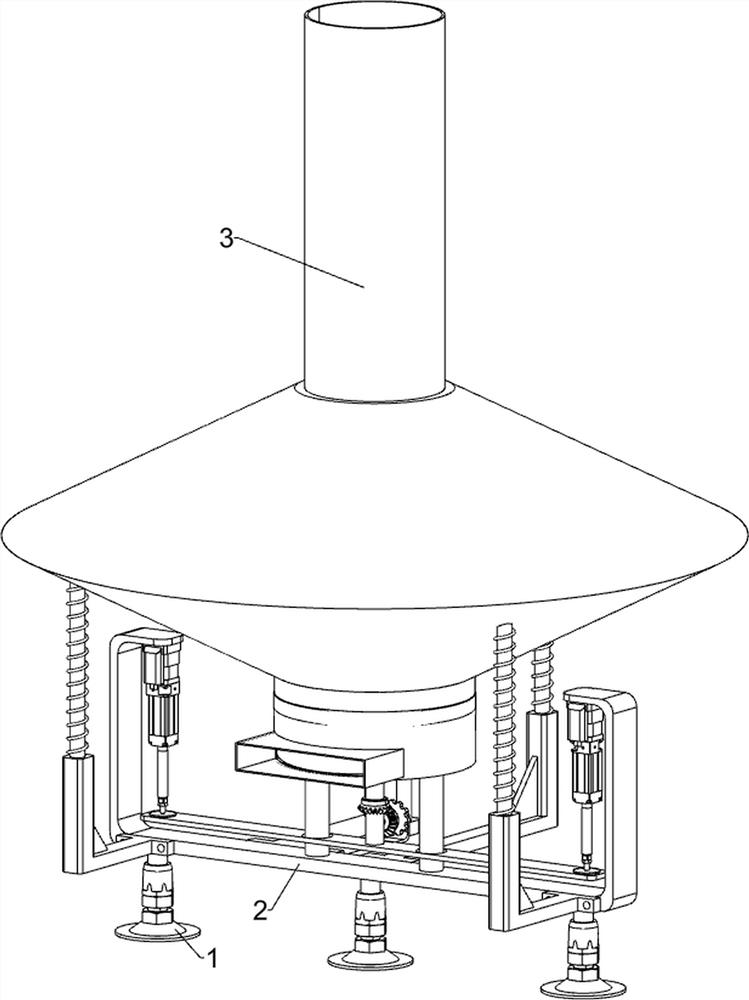

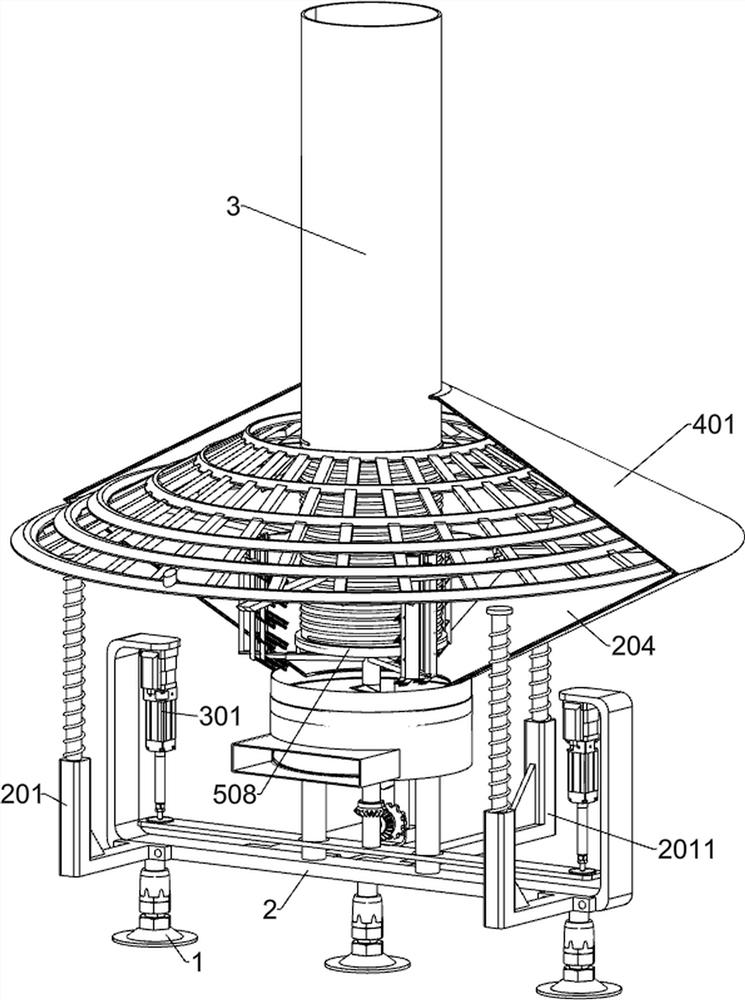

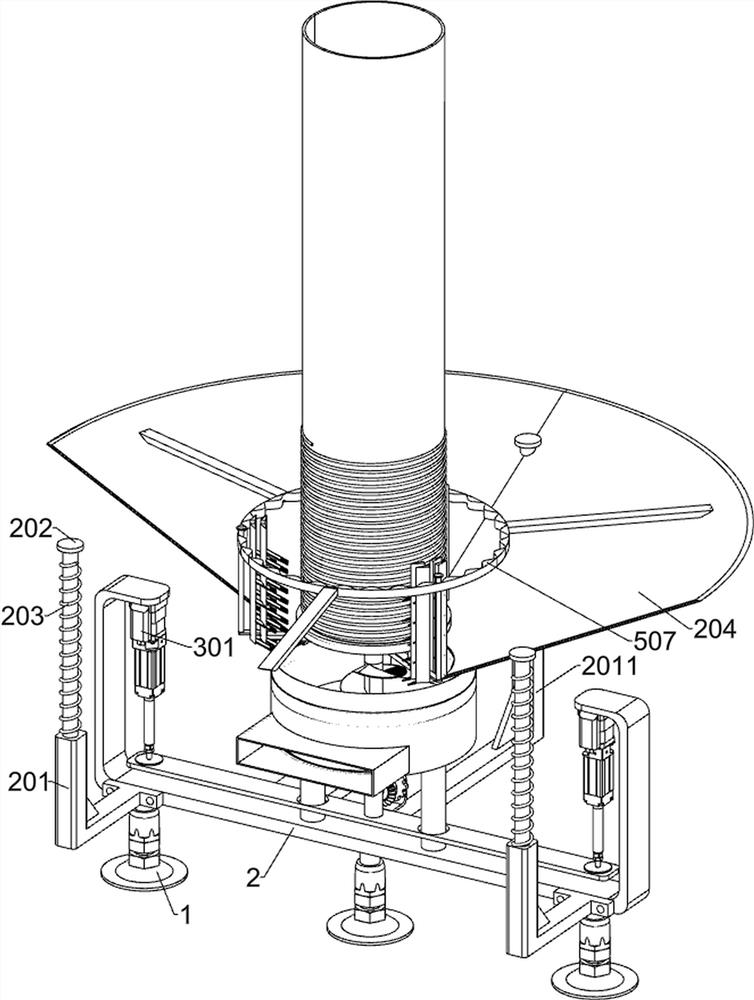

Feed conveying device with side leakage prevention function

ActiveCN114275568APrevent side leakageAvoid cloggingClimate change adaptationLarge containersStructural engineeringFodder

The invention relates to the field of feed conveying, in particular to a feed conveying device with a side leakage prevention function. The invention relates to a feed conveying device, and aims to solve the problems that accumulation and blockage of feed conveying are caused by existing feed conveying equipment, side leakage of the feed is caused, and side leakage of the feed is further caused under the action of airflow. According to the technical scheme, the feed conveying device with the side leakage prevention function comprises fixing bottom feet, a U-shaped fixing frame and the like; the number of the fixing bottom feet is three. A U-shaped fixing frame is fixedly connected to the upper surfaces of the three fixing bottom feet. When powdery feed is conveyed, in order to fundamentally solve the problem of side leakage of the feed, namely, the problems of feed blockage and diffusion and side leakage formed under the action of airflow, the feed accumulated in the funnel is automatically dredged, so that the feed cannot be blocked, the conveying speed of the feed is increased, and the conveying efficiency of the feed is improved. Meanwhile, the backflow grid plate is used for guiding and guiding the airflow, so that the airflow forms backflow.

Owner:XINXIANG ZHENGYUAN MACHINERY EQUIP

Aluminum condenser of gas steam-injection boiler

ActiveCN113418204AIncrease delivery rateLower discharge temperatureSteam/vapor condensersCombustion technology mitigationFlue gasSoot

The invention discloses an aluminum condenser of a gas steam-injection boiler, and relates to the field of condensers. The condenser comprises an aluminum shell body, and further comprises an auxiliary air supply mechanism and a movable cleaning mechanism, wherein the auxiliary air supply mechanism is installed on the side wall of the aluminum shell body and used for increasing the conveying rate of flue gas into the aluminum shell body; the movable cleaning mechanism comprises a movable frame body movably installed on the inner side wall of the aluminum shell body and a plurality of cleaning components movably installed on the movable frame body and used for carrying out auxiliary cleaning on soot on the inner side wall of the aluminum shell body, and the movable frame body is installed at one end of the auxiliary air supply mechanism; and the movable frame body is used for driving the plurality of cleaning components to rotate around the central axis of the aluminum shell body and rotate at the same time under driving of the auxiliary air supply mechanism. According to the invention, the soot on the inner wall of the condenser can be efficiently and dynamically removed and automatically discharged, and then the maintenance frequency and the manual maintenance cost of the whole device are effectively reduced, and the working effect of the whole device is improved.

Owner:SHENGLI OILFIELD SHENGJI PETROLEUM EQUIP

Supercritical water treatment method for arsenic-containing wastewater

ActiveCN109179621APromotes rapid oxidationIncrease delivery rateWater treatment parameter controlArsenic oxides/hydroxides/oxyacidsLiquid productHigh pressure

The invention relates to a supercritical water treatment method for arsenic-containing wastewater, belonging to the field of wastewater treatment. The supercritical water treatment method comprises the following steps of: adding an oxidizing agent, the arsenic-containing wastewater and additives to a high-temperature and high-pressure reaction kettle to obtain a reaction system, heating and pressurizing the reaction system under a closed condition until the reaction system reaches a supercritical state, and reacting for 8 to 115 minutes to obtain the reaction product system; when the temperature in the supercritical state is 460-630 DEG C, quickly releasing the pressure, carrying out gas-solid-liquid separation on the reaction product system, wherein a solid product in the kettle body is metal oxide, a gaseous product is cooled, and arsenic trioxide is converted from a gas into a solid to be settled, and a liquid product is a solution of nitric acid; and when the temperature in the supercritical state is 385-460 DEG C (excluding 460 DEG C), cooling the reaction product system in the high-temperature and high-pressure reaction kettle to be below 100 DEG C, introducing sulfur dioxidewaste gas and reacting to obtain a solid product and a liquid product, carrying out solid-liquid separation to obtain the arsenic trioxide solid and the liquid product, wherein the liquid product isa mixed acid solution containing metal cations.

Owner:KUNMING UNIV OF SCI & TECH

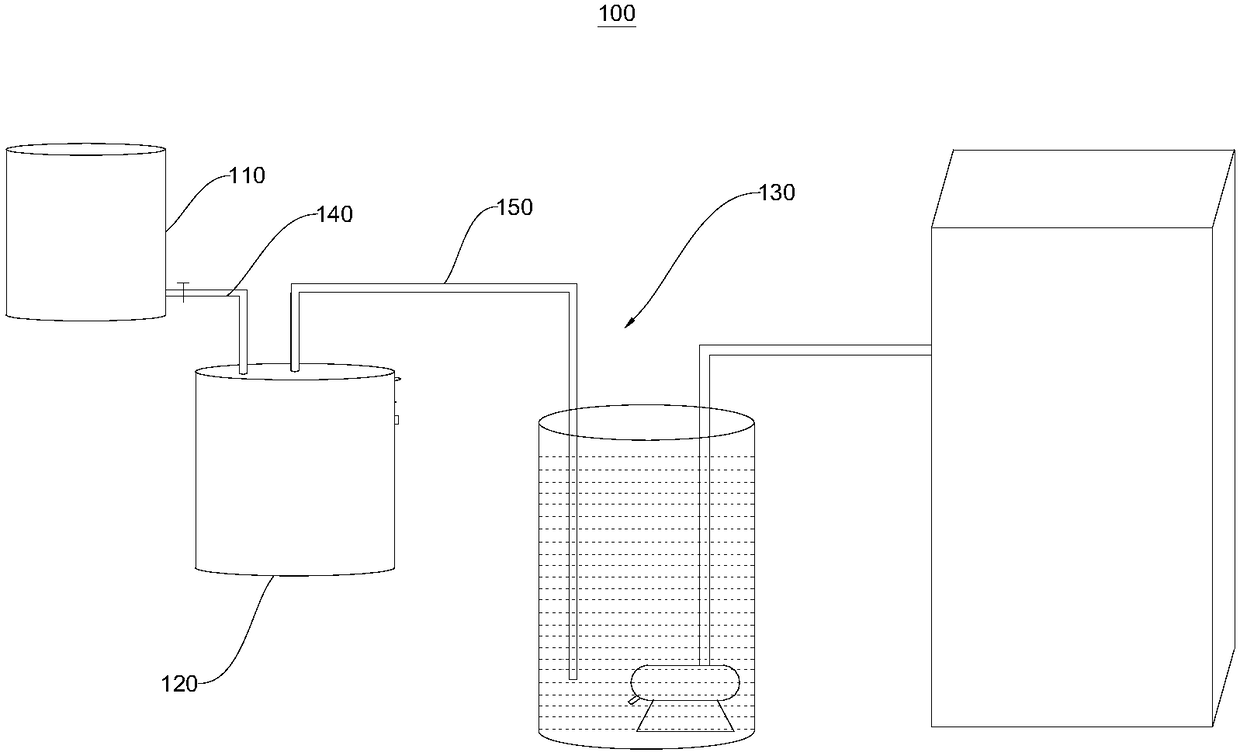

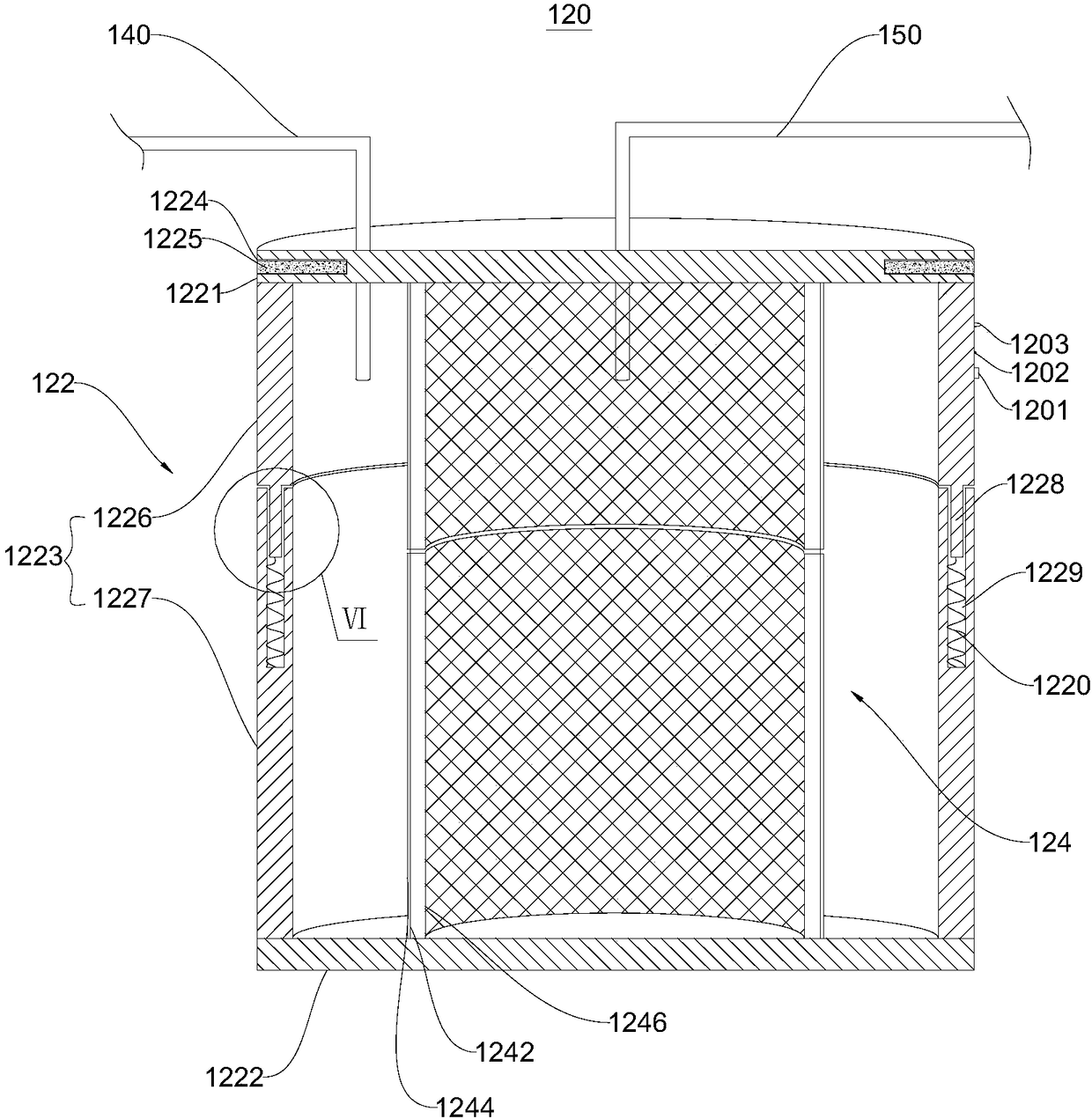

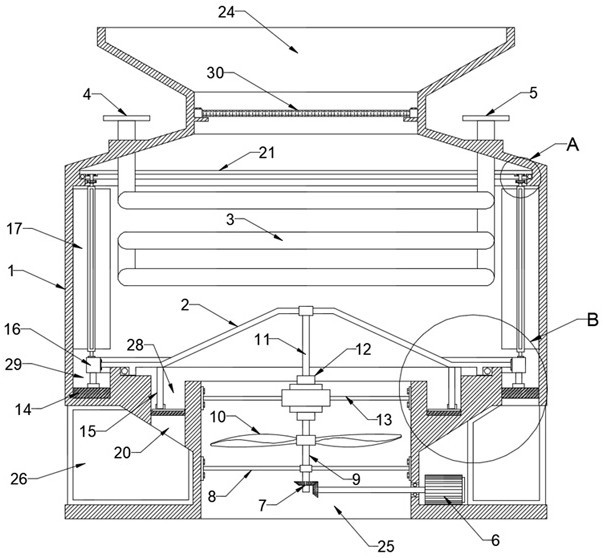

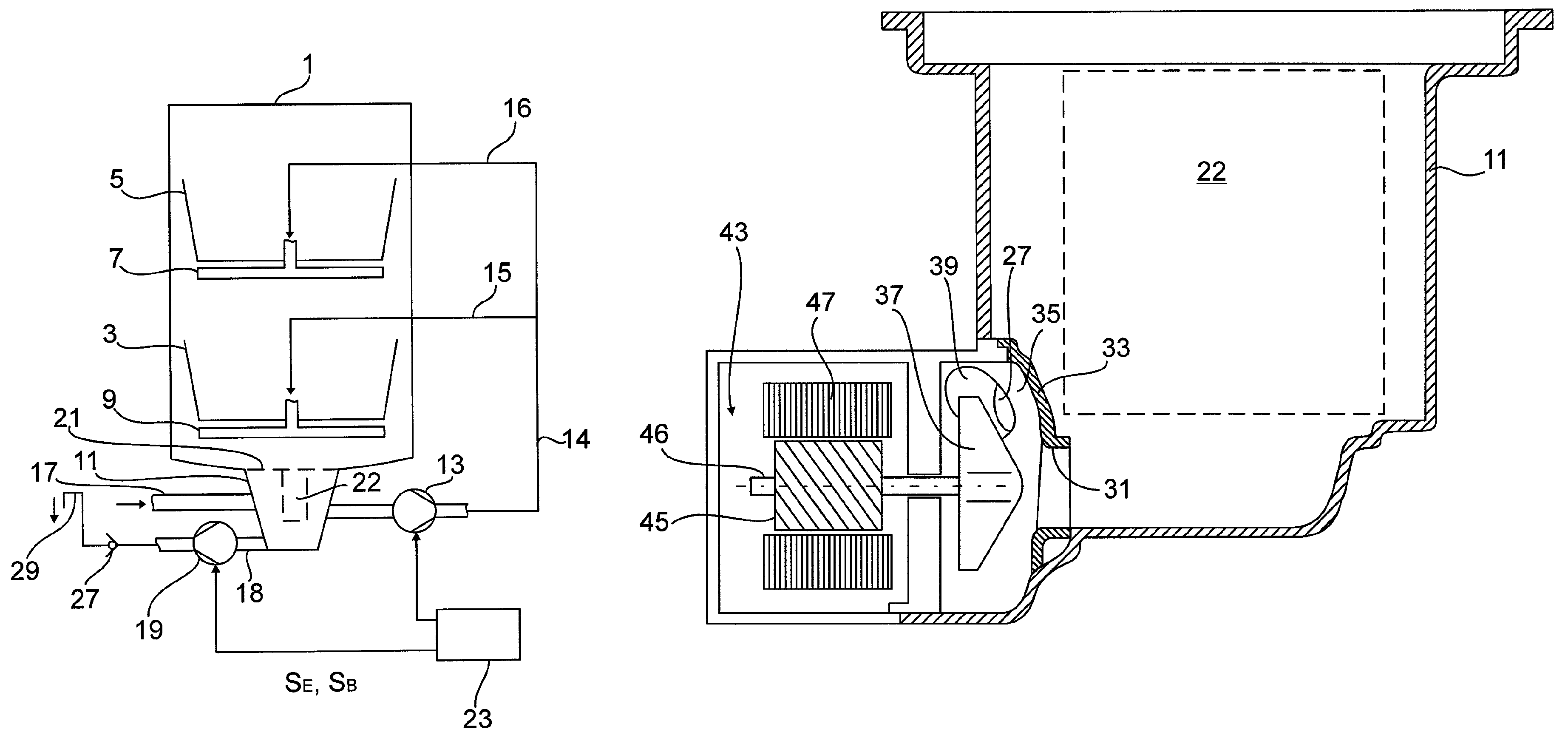

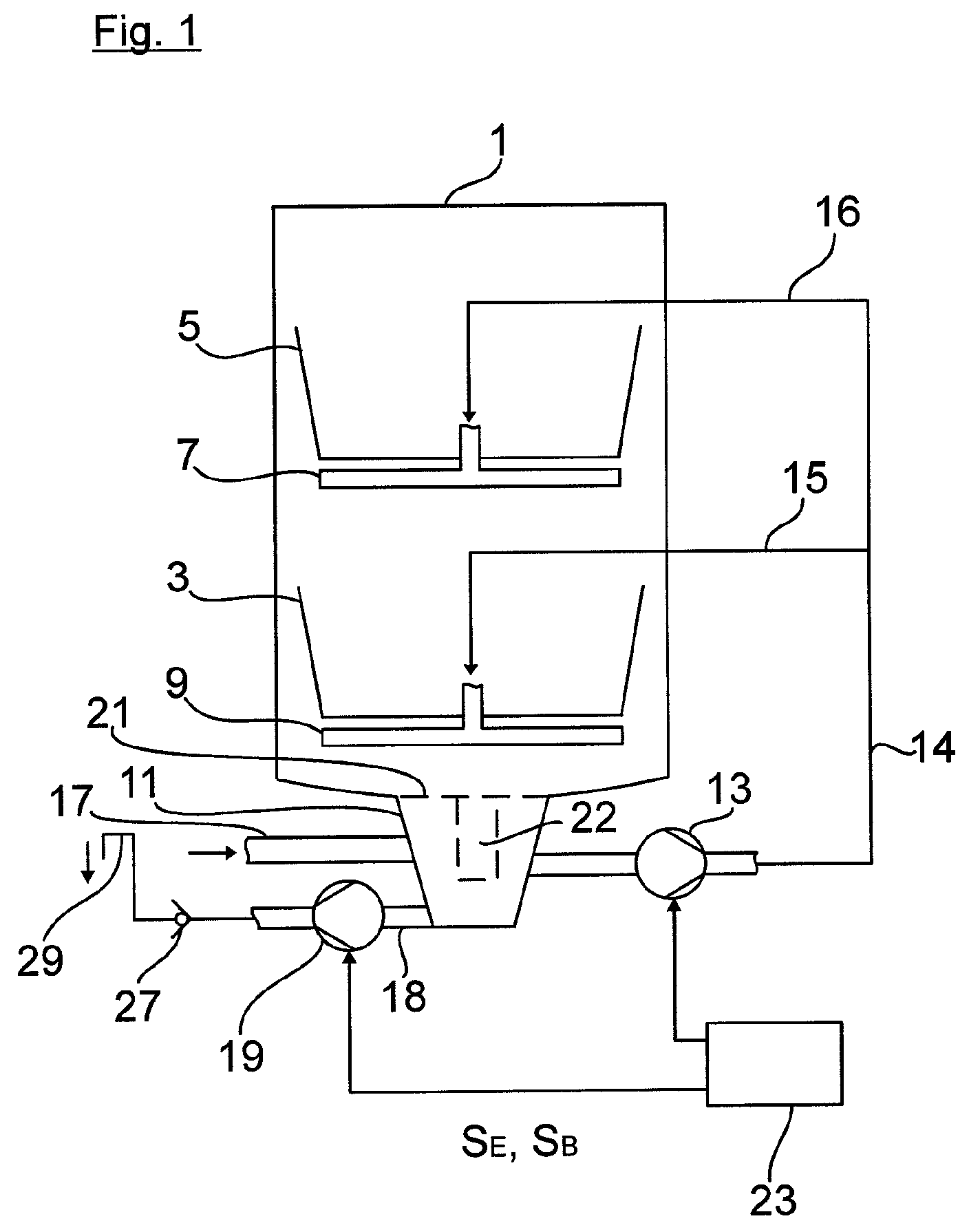

Water-conducting household appliance, particularly a dishwasher

ActiveUS8734136B2Increase delivery rateImprove delivery ratePositive displacement pump componentsOther washing machinesPump chamberOperation mode

A water-conducting household device, particularly a dishwasher, includes a pump having at least one normal operating mode in which fluid is pumped in a pumping direction, and a venting operating mode which can be carried out before the normal operating mode. The venting operating mode is provided to allow venting of the pump by pumping a gas bubble in opposition to the pumping direction during the normal operating mode at least partially out of a pump chamber of the pump to a fluid pump inlet of the pump.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com