Patents

Literature

90results about How to "Reduce production labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rice dry-farming direct-seeding planting method

InactiveCN101785414ASimplify field operationsReduce production laborClimate change adaptationOrganic fertilisersNutrientDecomposition

The invention provides a rice dry-farming direct-seeding planting method, which is characterized by comprising the following: a, a step of preparing land, which is to level and harrow land before sowing, replenish pre-sowing water and keep soil moisture between 75 and 85 percent; b, a step of sowing, which is to uniformly sow rice seeds on the land finished in a step a, wherein the amount of seeds per each Mu of land is 2.5 to 5.4 kg; c, a step of earthing up, which is to earth up at a height of 1.5 to 3 centimeters after sowing is finished; d, a step of compacting, which is to compact after earthing up; and e, a step of spraying film, which is to add 0.03 to 0.06 kilogram of 2-methyl-4-chlorophenoxy acetic acid serving as herbicide to 60 to 80 liters of water, mix and stir the materials and uniformly spraying the obtained product on the compacted land so as to finish the dry farming and direct seeding of rice. The rice dry-farming direct-seeding planting method can leave out two work links of cultivating seedlings and transplanting. After multifunctional degradable liquid mulching film is sprayed on ground, effective accumulated temperature can be increased; rice water shortage is alleviated; the physical and chemical properties of soil are improved; microbial activity is improved; the decomposition and release of soil organic substances are accelerated; the transfer of effective nutrient to plants is accelerated; and the photosynthetic efficiency and nutrient conveying rate of rice are improved. The method has the advantages of ensuring exuberant tillering tendency, low positions of tillering knobs and numerous big ears, saving water by 50 to 70 percent and increasing yield by about 10 percent.

Owner:于飞

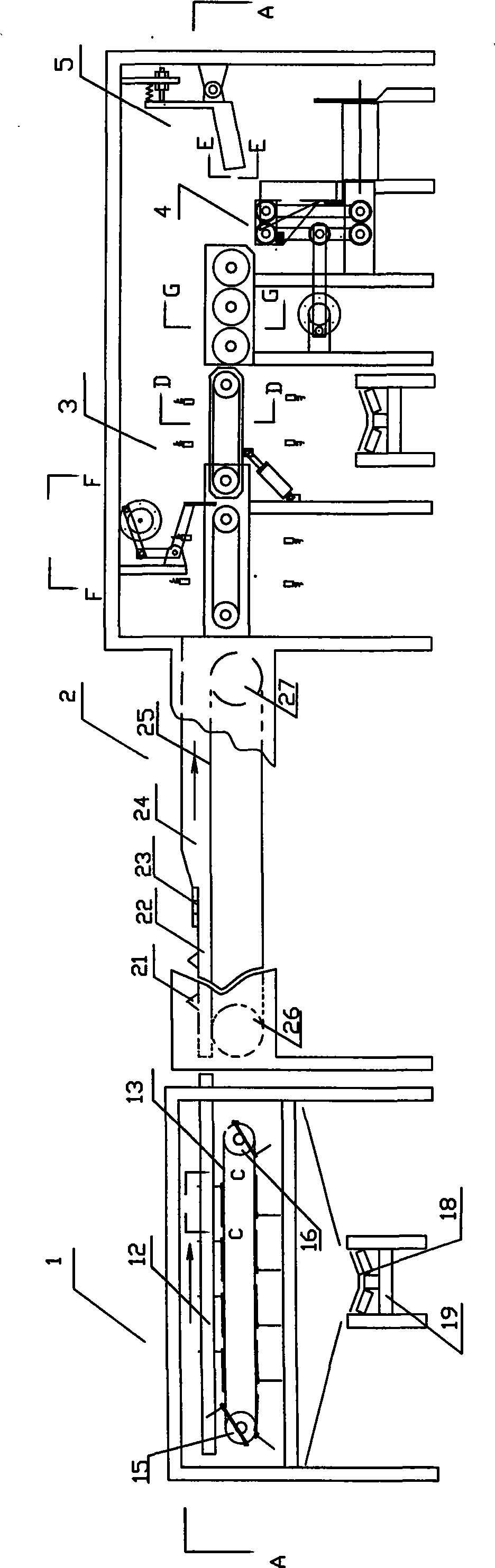

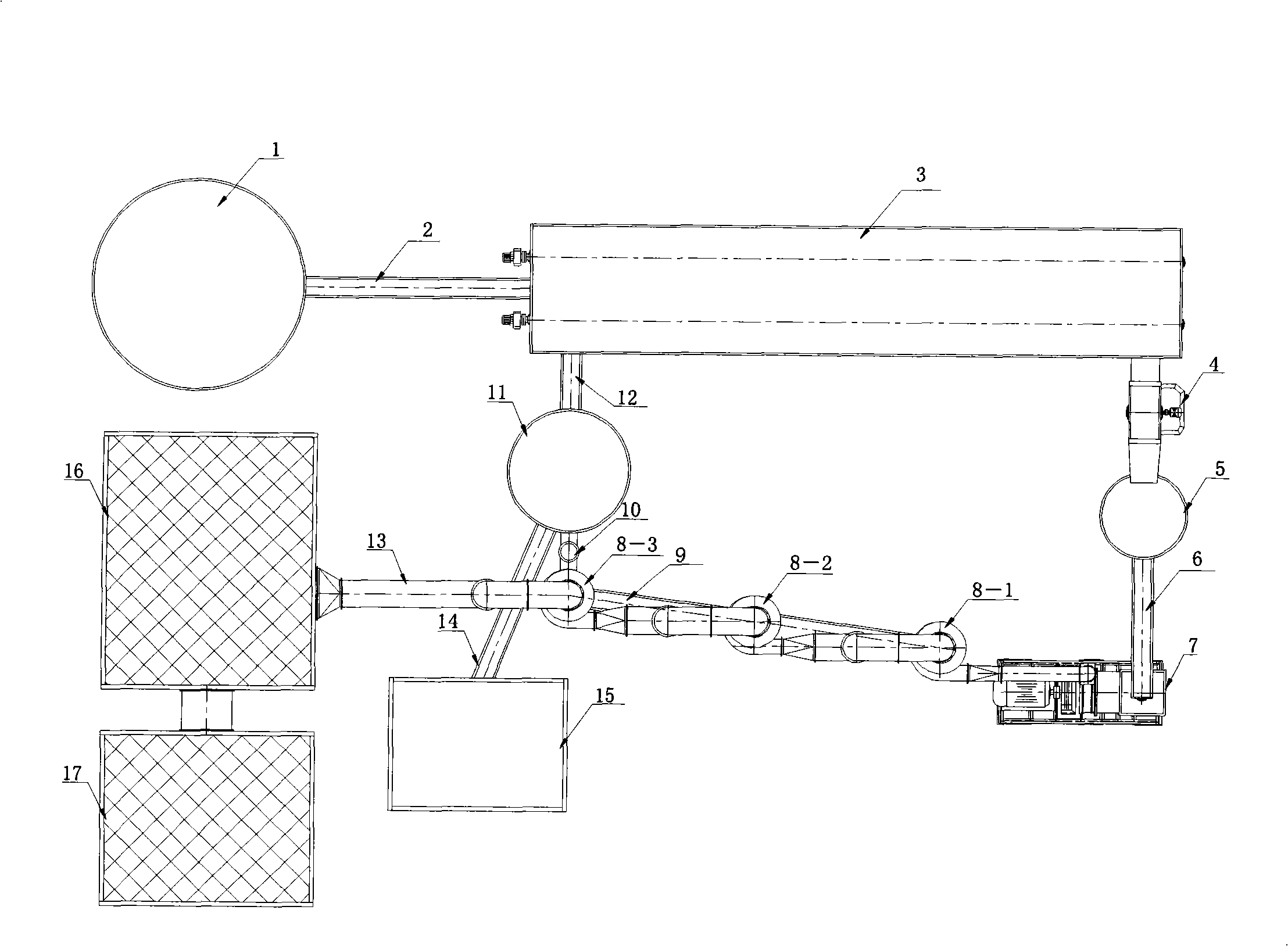

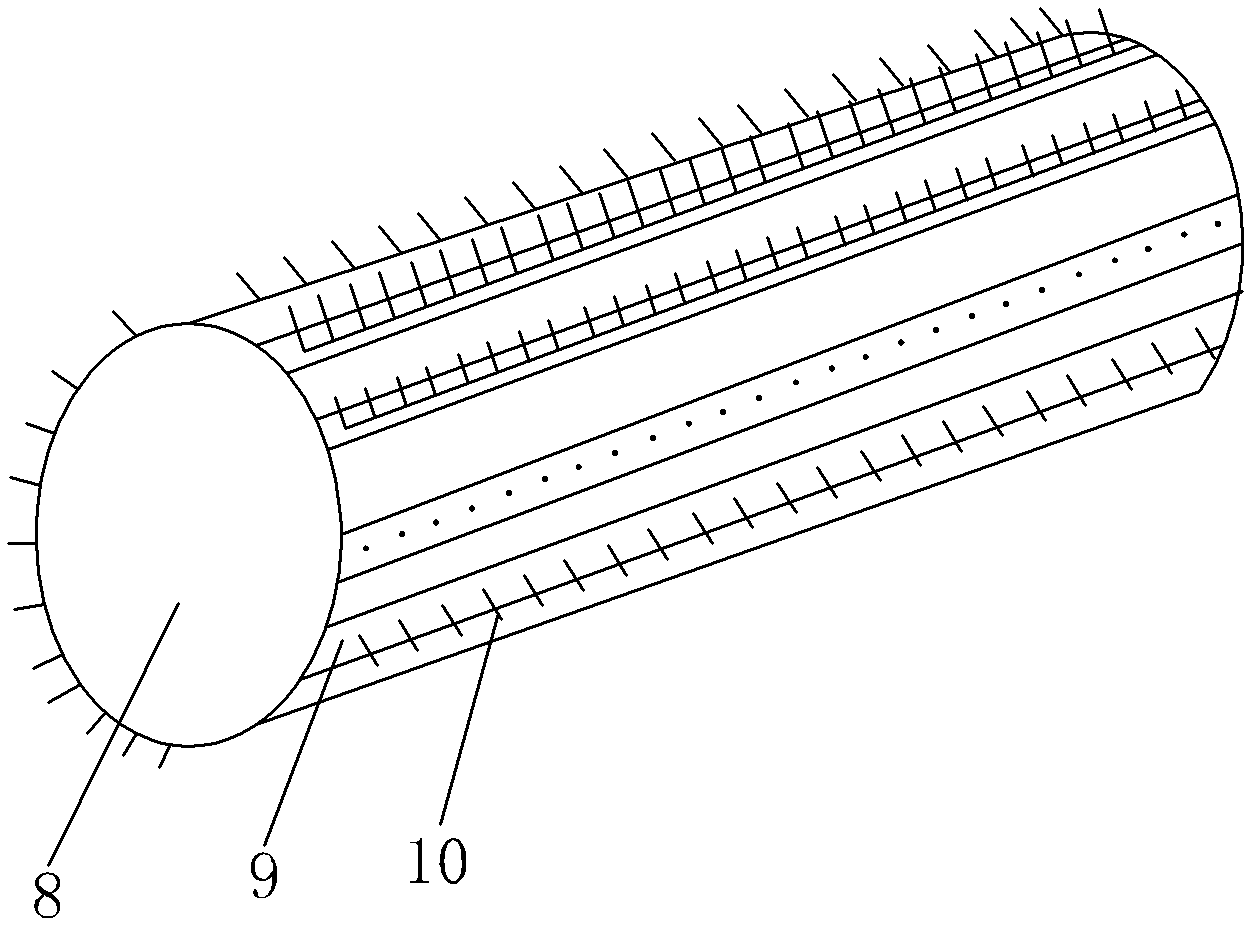

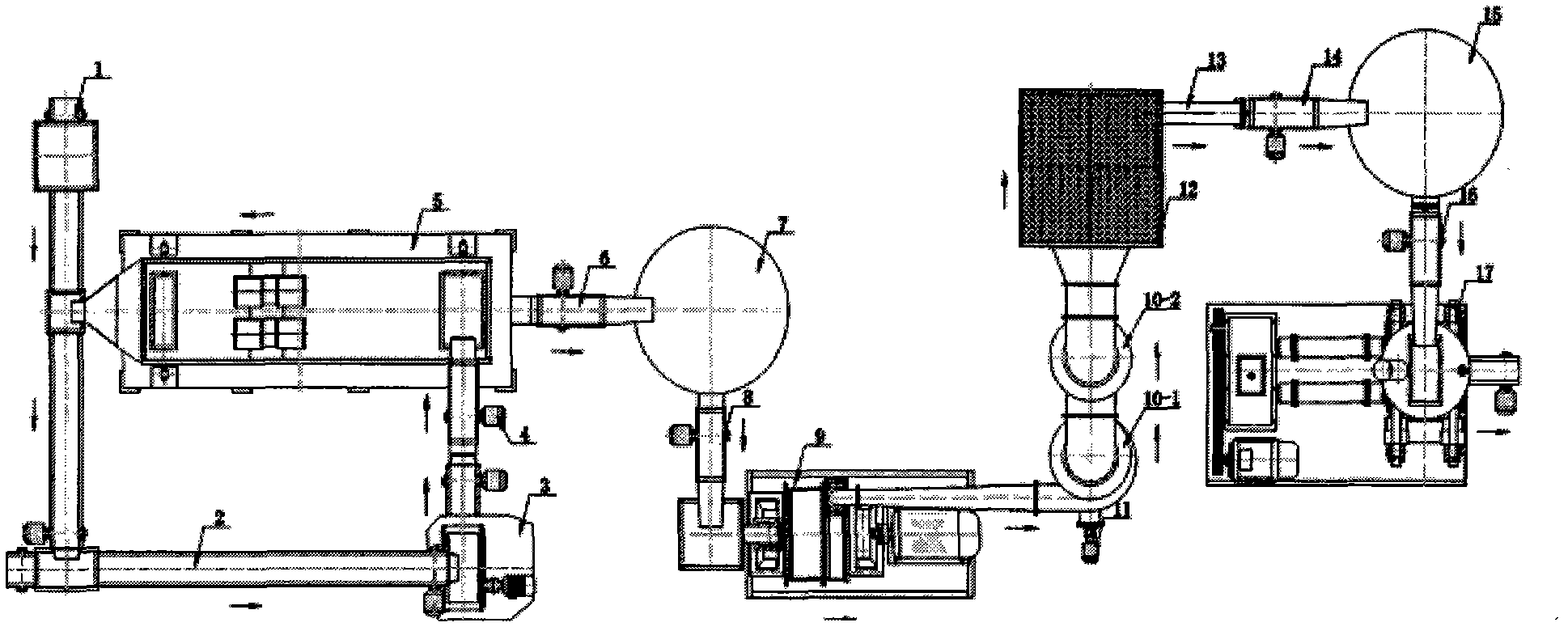

Beer bottle sorting machine

InactiveCN101519161AReduce physical laborReduce production laborControl devices for conveyorsMechanical conveyorsMicrocomputerAutomatic control

A beer bottle sorting machine comprises a conveying belt driven by a motor and a program automatic control system managed by a microcomputer, wherein the conveying belt is provided with a bottle sorting and conveying mechanism, a bottle separating and detecting mechanism, a defected bottle eliminating mechanism and a bottle standing or overturning standing mechanism. The invention automatically sorts scattered beer bottles on the conveying belt into a line to move forwards one by one, the scattered beer bottles stand one by one after the defected bottles are detected and eliminated one by one or stand after being overturned, and then are turned one by one to enter the next production stream line, the automatic operations are all completed by the program automatic control, therefore, the invention changes the manual labour into the automatic production line operation, can lighten the heavy labor of workers, and saves the production workers and the production cost in an enterprise.

Owner:周飞 +1

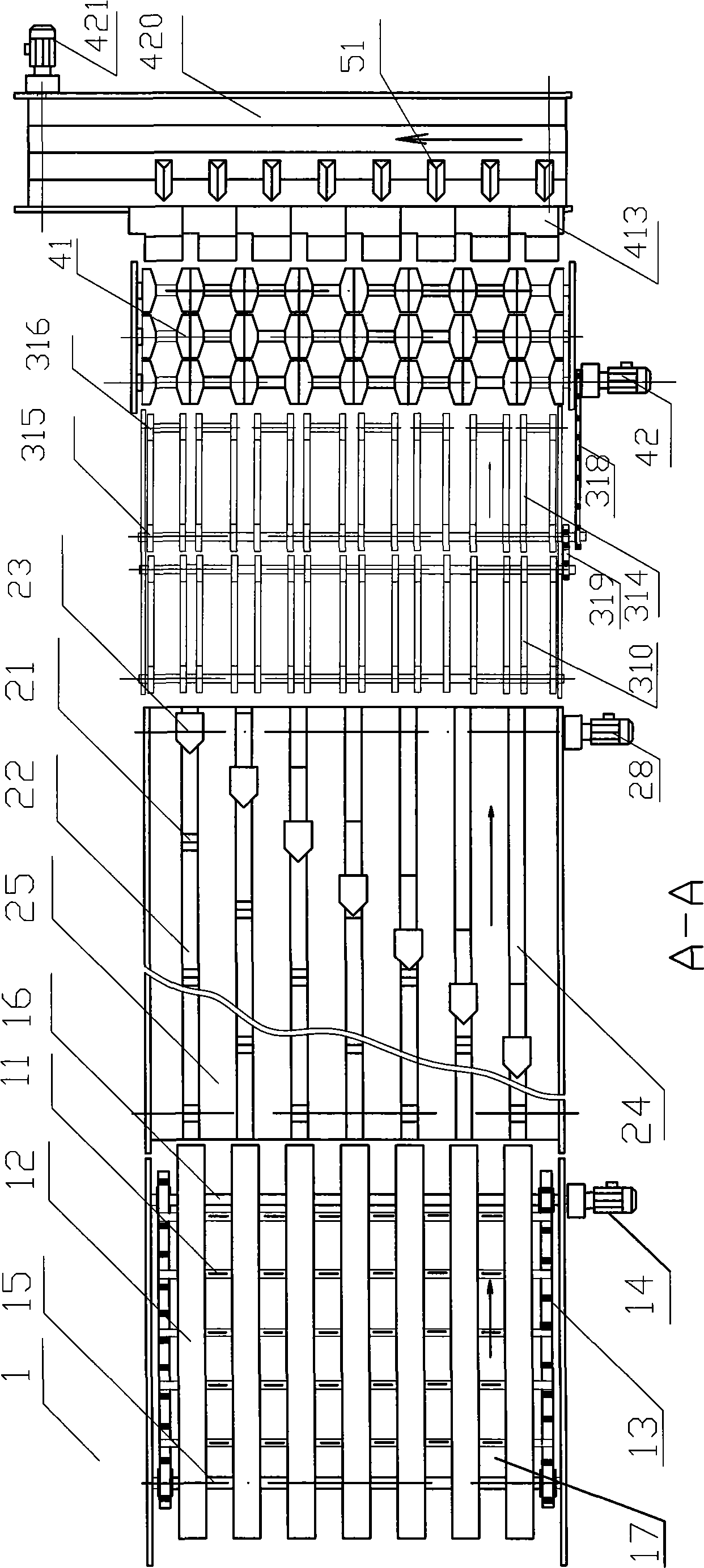

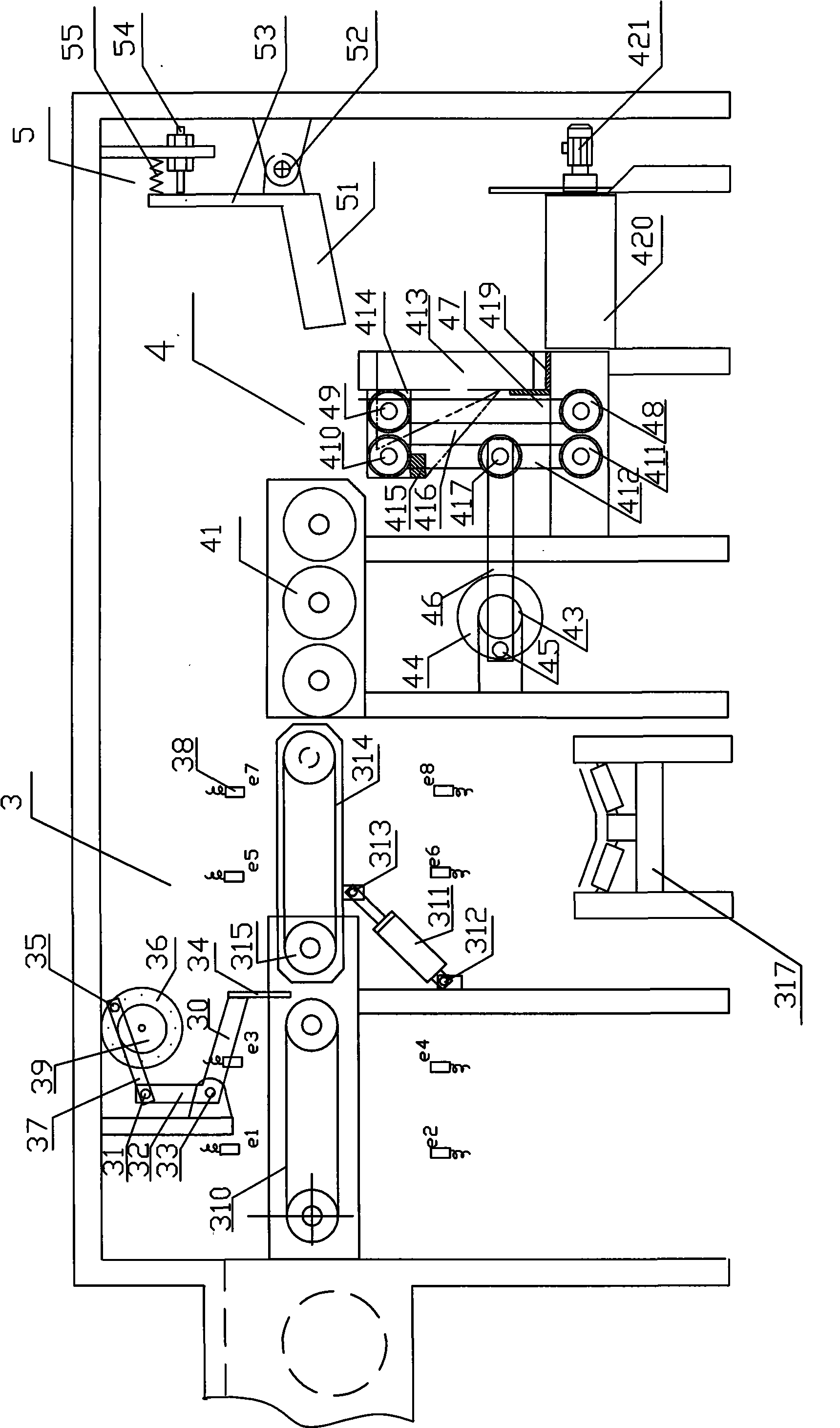

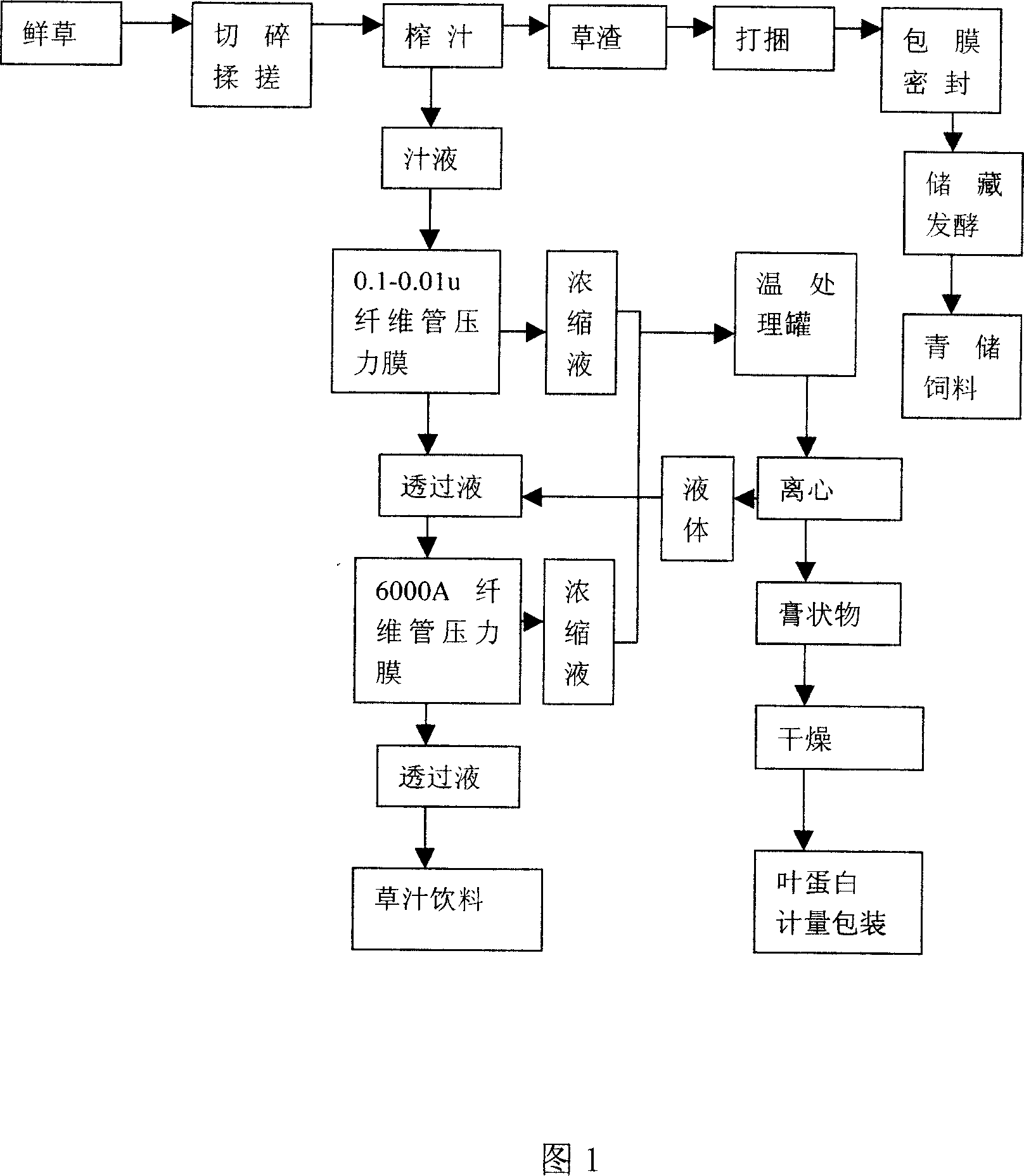

Composite extracting method for plant leaf protein and its use on hybrid giant napier

InactiveCN1943391AImprove extraction efficiencyReduce energy consumptionAnimal feeding stuffFood scienceVitamin CCarotenoid

The present invention discloses a method for extracting protein from plant leaf, it belongs to feed production and food processing areas. The invention includes such steps as chopping, kneading, pulping and squeezing. The concentrated liquid and the penetration liquid can be obtained by pressing juice through a filter. The plant leaf protein prepared through the concentrated liquid heating or cooling, centrifugal separating, drying. Residue can be made into meal or feed and so on. The penetration liquid can be made into beverage. The leaf protein can be obtained wherein the content of protein is 30-60%, and is rich in vitamin C, vitamin E, fat and carotenoids.

Owner:武汉光盛生物工程技术开发有限公司 +1

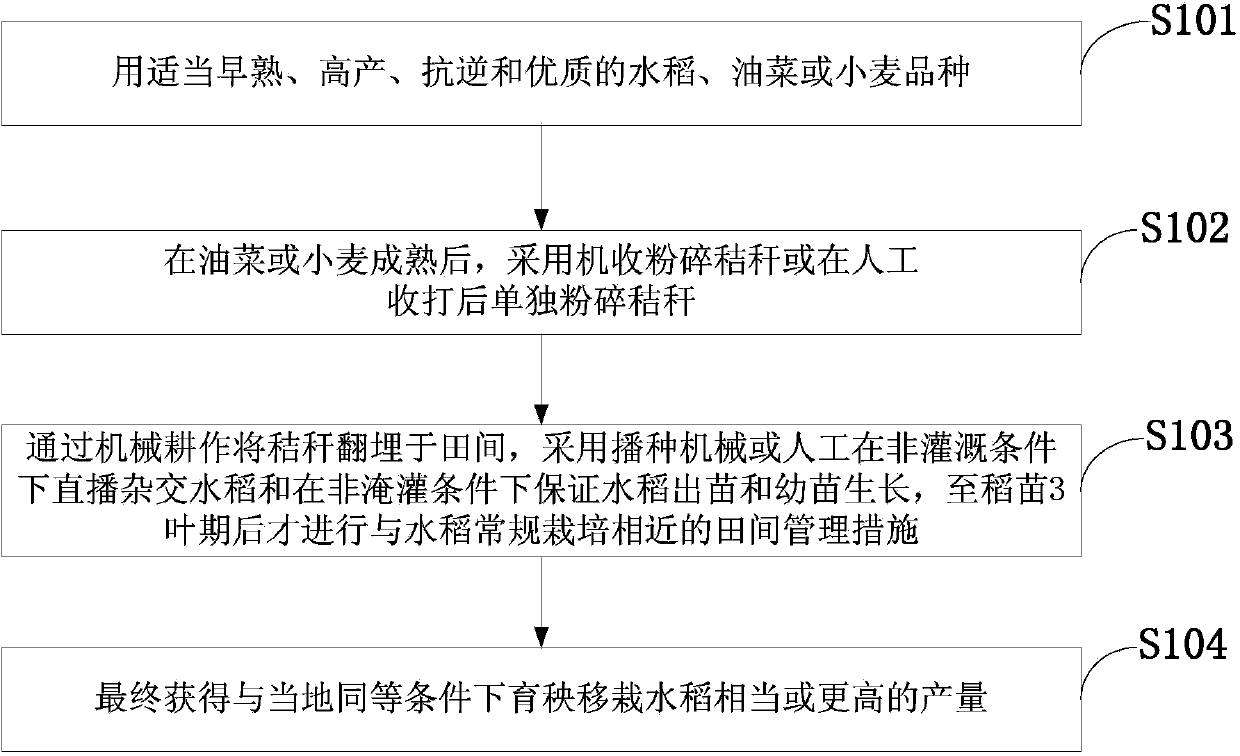

Hybrid rice water saving direct sowing cultivation method based on smashing, burying and retuning to field of preceding crop straw

The invention discloses an oilseed rape and wheat stubble hybrid rice water saving direct sowing cultivation method based on smashing, burying and retuning to field of preceding crop straw, wherein the cultivation method combines agricultural machinery with the agricultural technology closely. Appropriately-precocious, high-yield, stress-resistant and high-quality rice and oilseed rape or wheat varieties are selected, after the oilseed rape or wheat is mature, straw smashing during machine harvesting or separate straw smashing after harvesting is adopted, the smashed straw is buried in the field through mechanical farming, direct sowing of hybrid rice is carried out through sowing machines or workers under non-irrigation conditions, emergence and growth of rice seedlings are guaranteed under non-basin irrigation conditions, field management measures similar to normal rice cultivation are not taken until the three-leaf stage of the rice seedlings, and the yield equal to or higher than that of local seedling raising and transplanting rice under equal conditions is obtained finally. The hybrid rice water saving direct sowing cultivation method based on smashing, burying and retuning to field of the preceding crop straw realizes light and simple returning to field and effective utilization of oilseed rape and wheat straw, can substantially save water for rice irrigation and avoid seasonal water consumption peaks and water competition contradictions in rice production in arid regions, and realizes cost-reducing efficient ecological rice cultivation.

Owner:SOUTHWEAT UNIV OF SCI & TECH

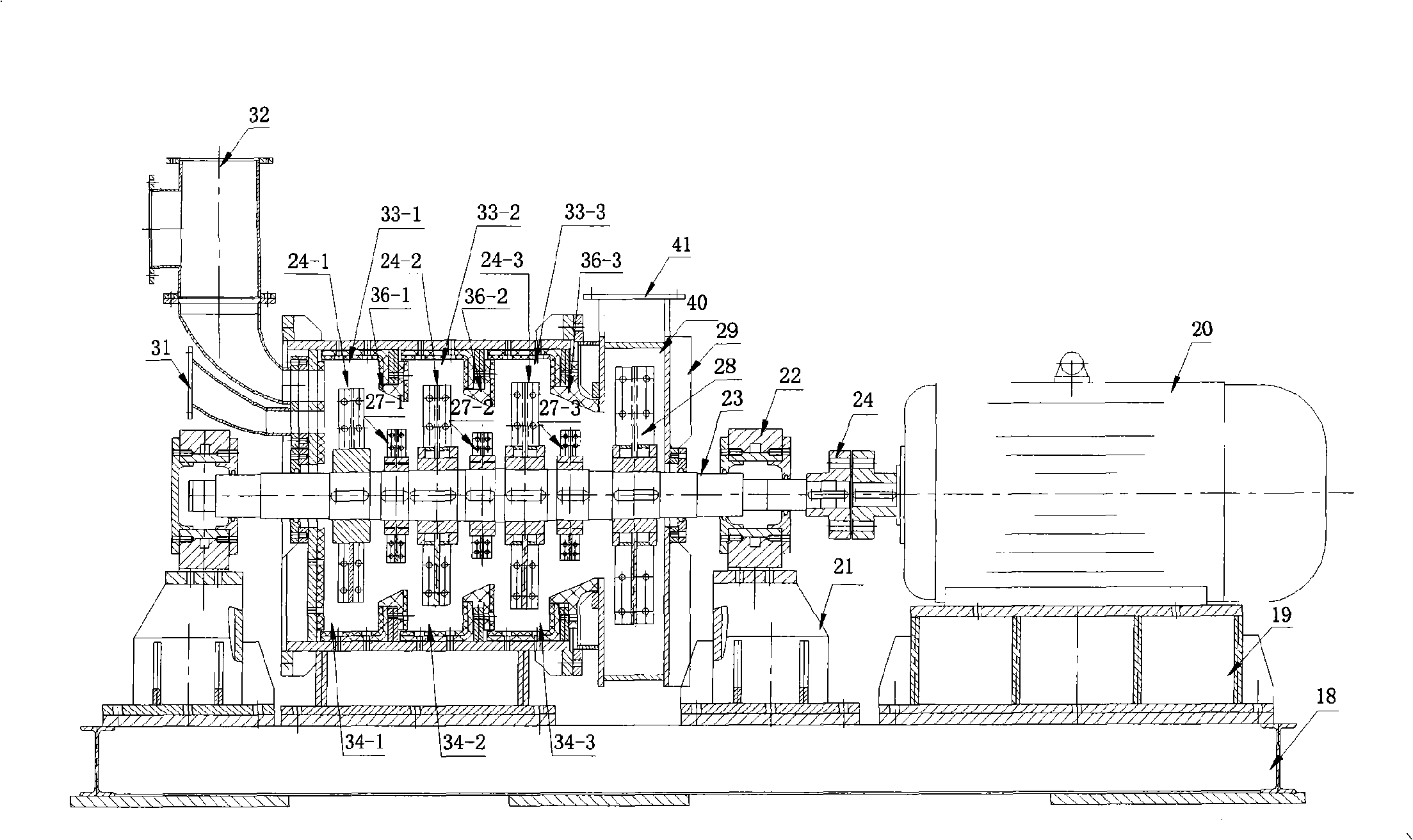

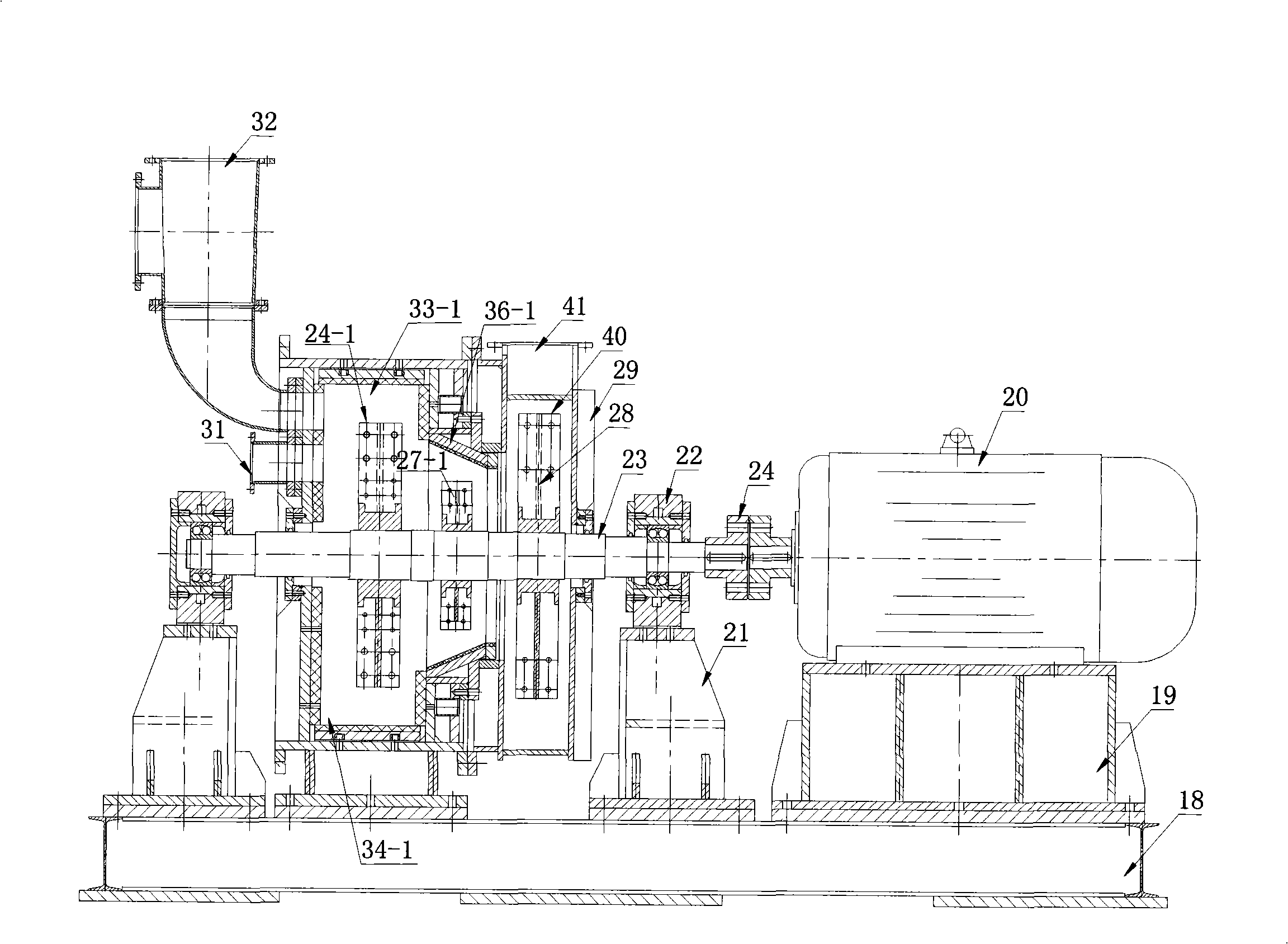

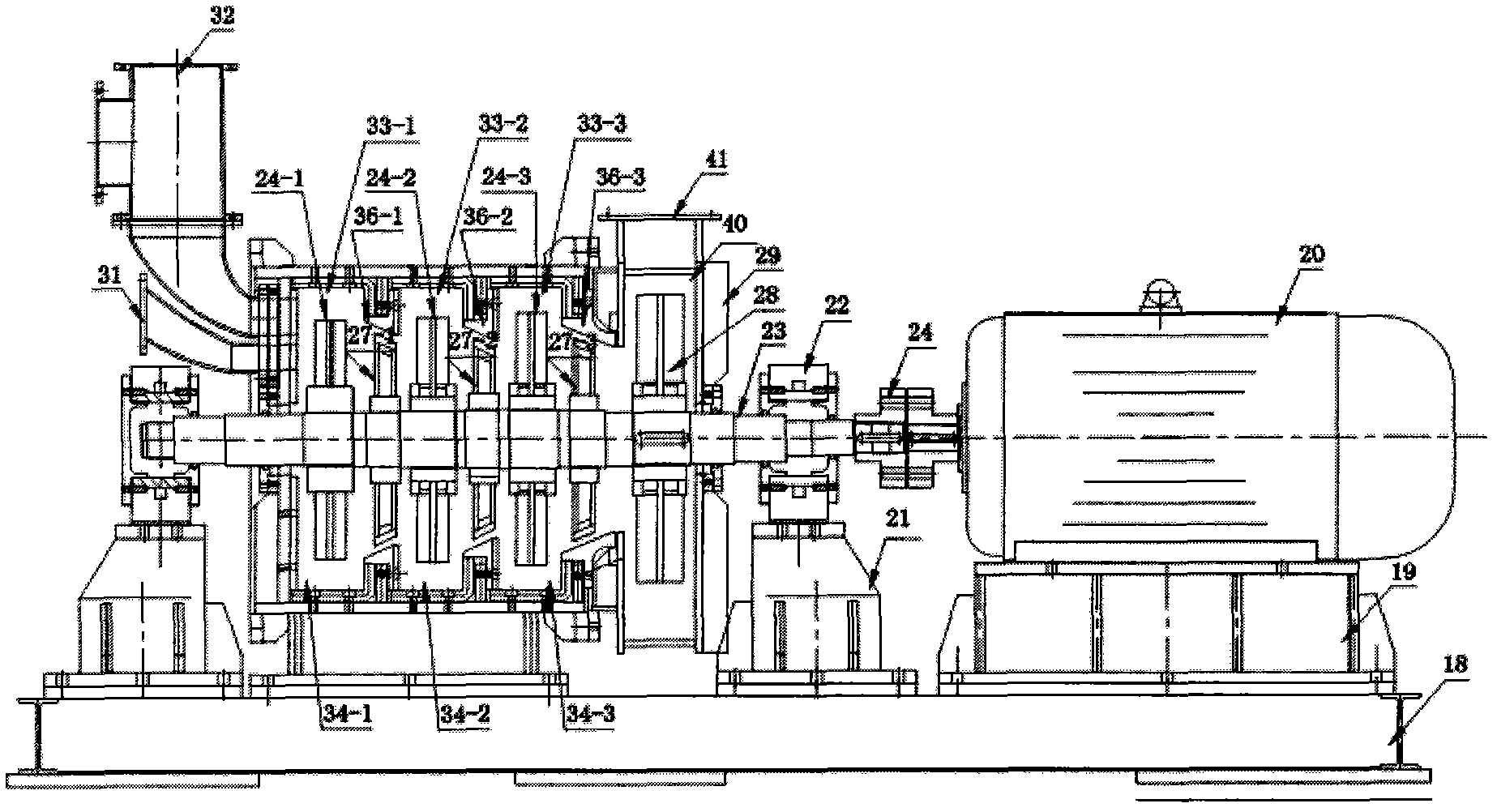

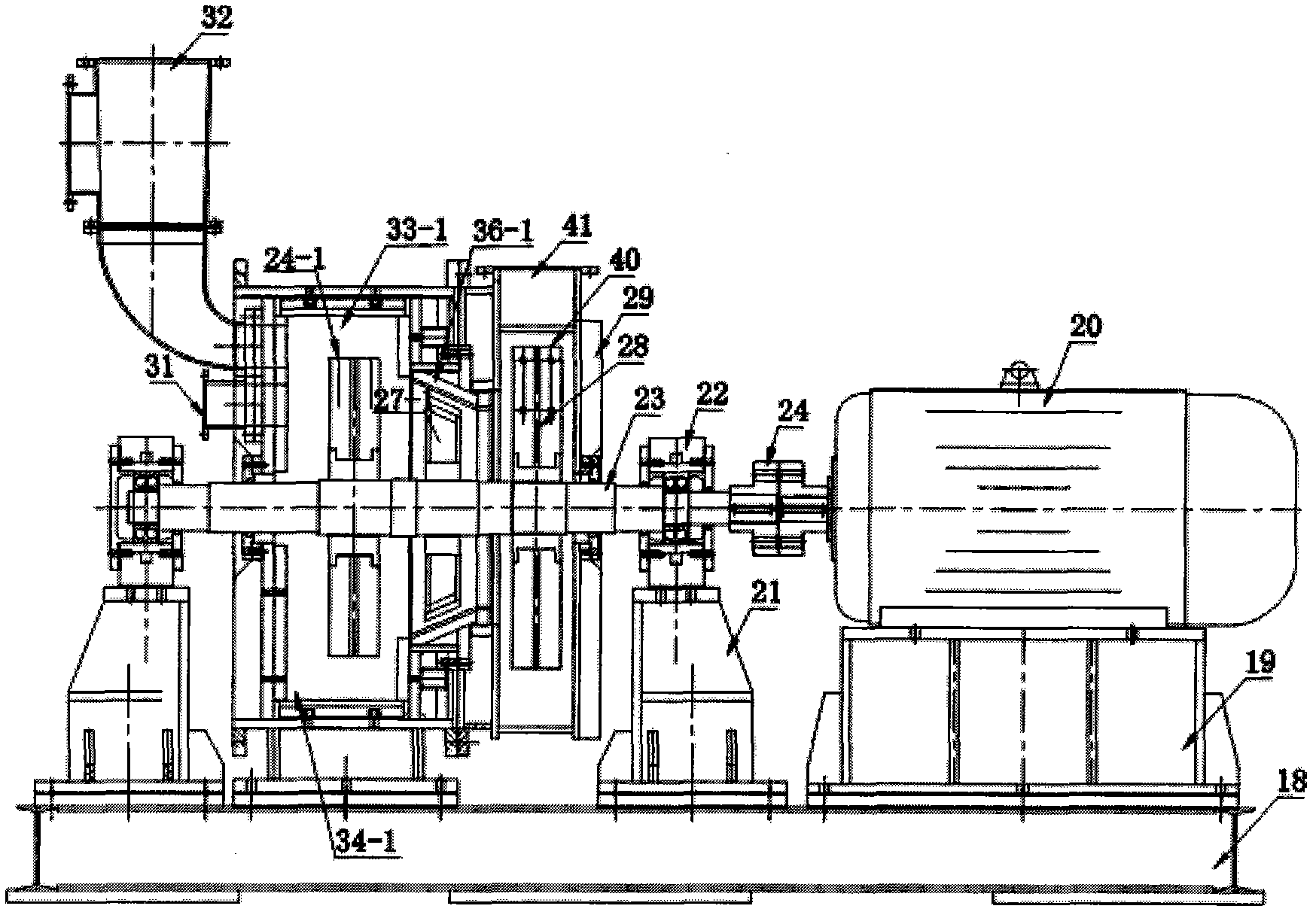

Industrial automatic method and device for producing sludge dry powder by sludge dehydration

InactiveCN101265010ARealize fully closed productionNo waste waterSludge treatment by de-watering/drying/thickeningGrain treatmentsWater contentSludge dewatering

The invention relates to an industrial automatic production method of sludge dry powder by sludge dewatering and equipment thereof. The method realizes industrial automatic production in industrial automatic production equipment of sludge dry powder by sludge dewatering, particularly sludge dewatering machine as main equipment. The sludge of water content below 85 wt% is dewatered to obtain sludge of water content below 5 wt%. The inventive method and equipment realize harmlessness, stabilization and reclamation of sludge dewatering; and can be widely used for dewatering domestic sludge or sediments, industrial sludge or sediments, lake and river course sludge or sediments.

Owner:何治国 +1

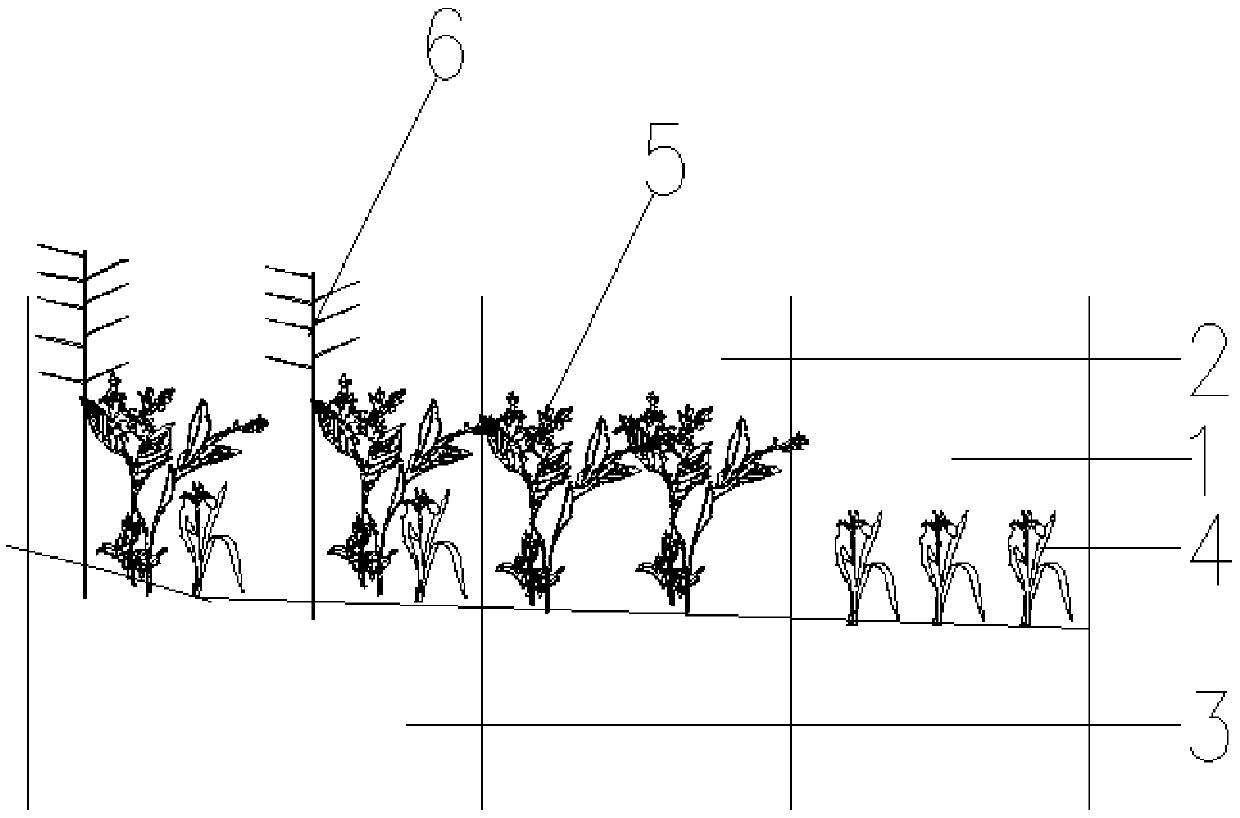

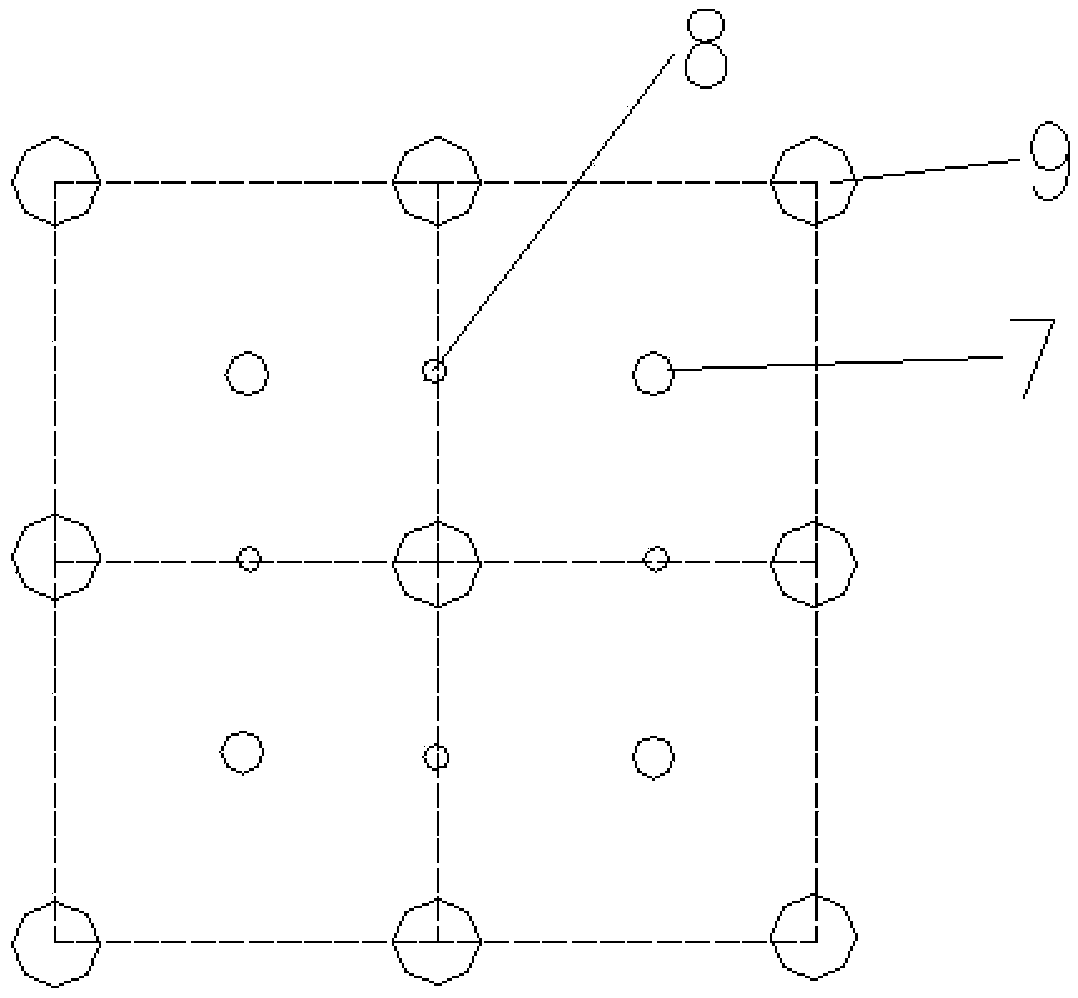

Construction method of amphibious plant community with water body purification function

ActiveCN105502666AGrowth inhibitionGood plastic effectSustainable biological treatmentBiological water/sewage treatmentBiological propertyPlant community

The invention discloses a construction method of an amphibious plant community with a water body purification function. The construction method comprises the following steps: dividing planting regions on a land-lake ecotone in a manner of being parallel to a river way; selecting amphibious plants, which have a good purification effect and a high survival rate, are amphibious and have a good landscape effect, and planting the amphibious plants into the planting regions to construct a plant community, wherein the amphibious plants are selected from more than three of bamboo reeds, iris wilsonii, cyperus altrnlifolius, reeds, cannas and lythrum salicaria; managing the plants according to growth conditions of the plants. Properties of absorbing pollutants of the plants are combined with biological properties of the different plants, and an attractive landscape is created at the same time; an amphibious plant community system is constructed by using ecological niches of the different plants, so that the effect of purifying a water body is improved; meanwhile, withered plants are harvested and external pollutants are not introduced, so that rotted plants are prevented from entering the water body, and furthermore, the content of the pollutants in the water body is reduced.

Owner:北京东方利禾景观设计有限公司

Direct seeding planting method for rice on dry field

InactiveCN105409661ASatisfy physiological water needsImprove permeabilityRice cultivationObserved SurvivalSurvival rate

The invention relates to a direct seeding planting method for rice on dry field. The method comprises the following steps: S1, soil preparation stage before seeding; S2, seed soaking and seeding; S3, coverage of covering; and S4, management after seeding. According to the direct seeding planting method for the rice on dry land provided by the invention, seeds are directly mixed with a drought resistant agent and water uniformly to form gelatinous substances containing the seeds, the gelatinous substances are planted in the dry land, and then a layer of covering covers the dry land. The direct seeding planting method for the rice on dry field has the beneficial effect that according to the planting method, the seedling stage after direct seeding is short; emergence rate and survival rate of seedlings are increased; drought resistant level of the rice in the whole production process is improved remarkably; frequent watering and irrigation are not required; and labor management cost is low.

Owner:FENGDU COUNTY URBAN AGRI DEV SPECIALIZED COOP

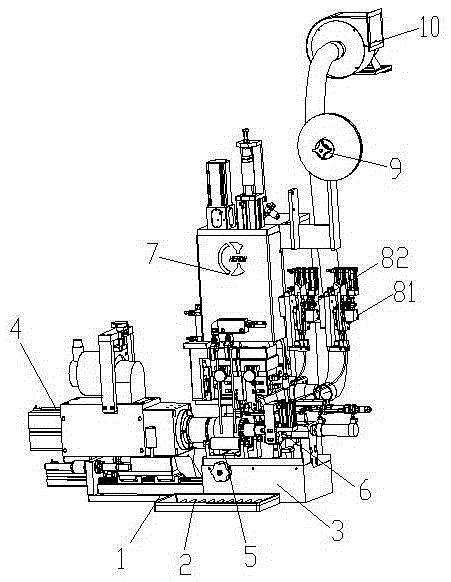

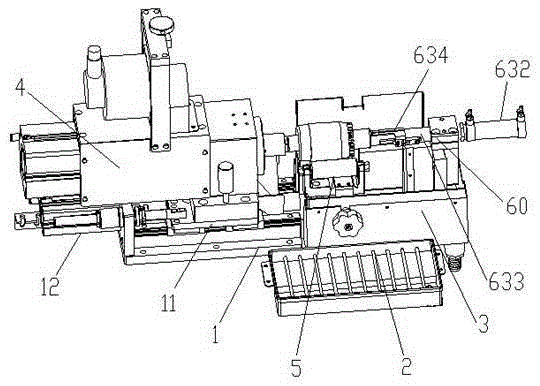

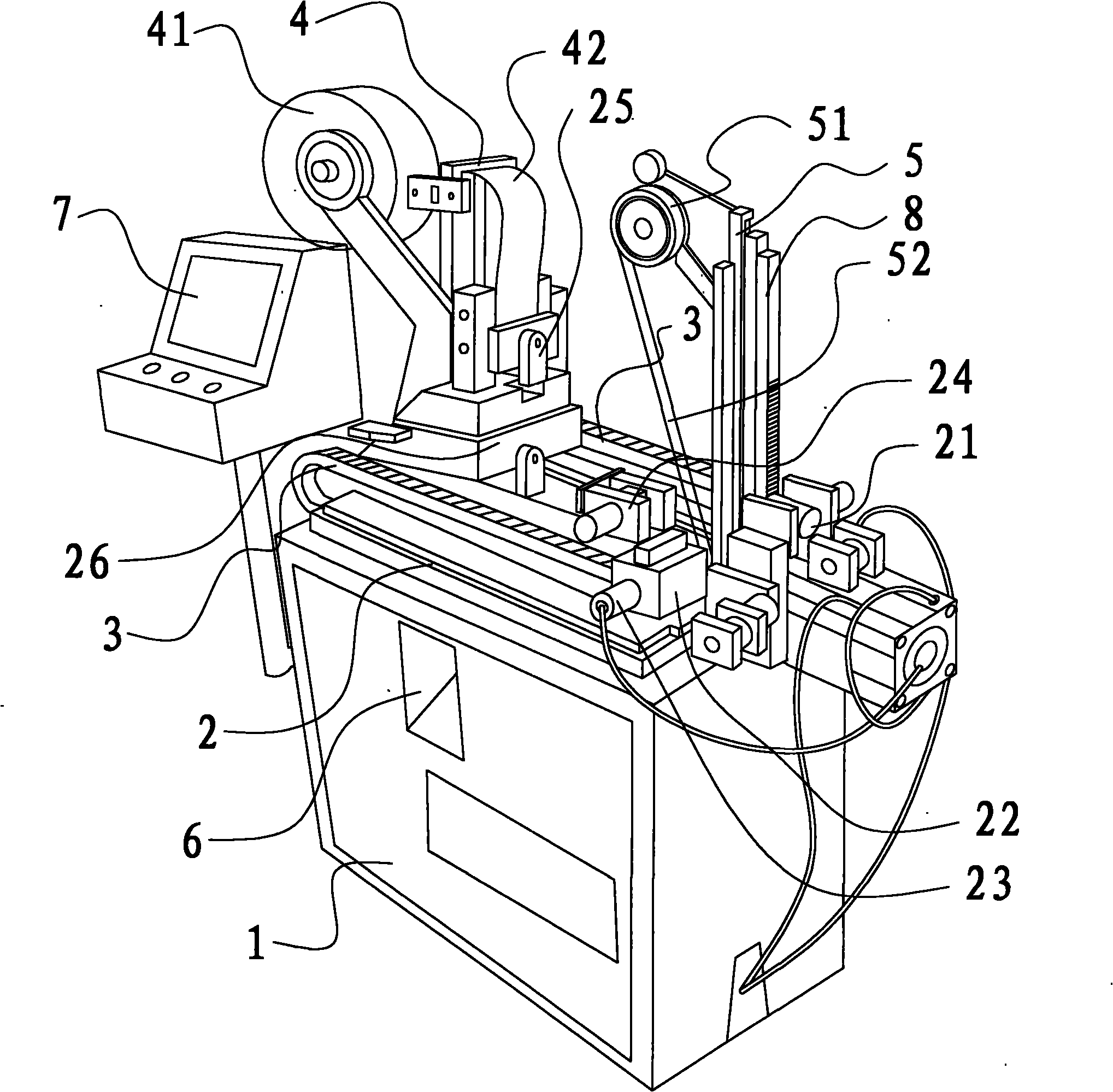

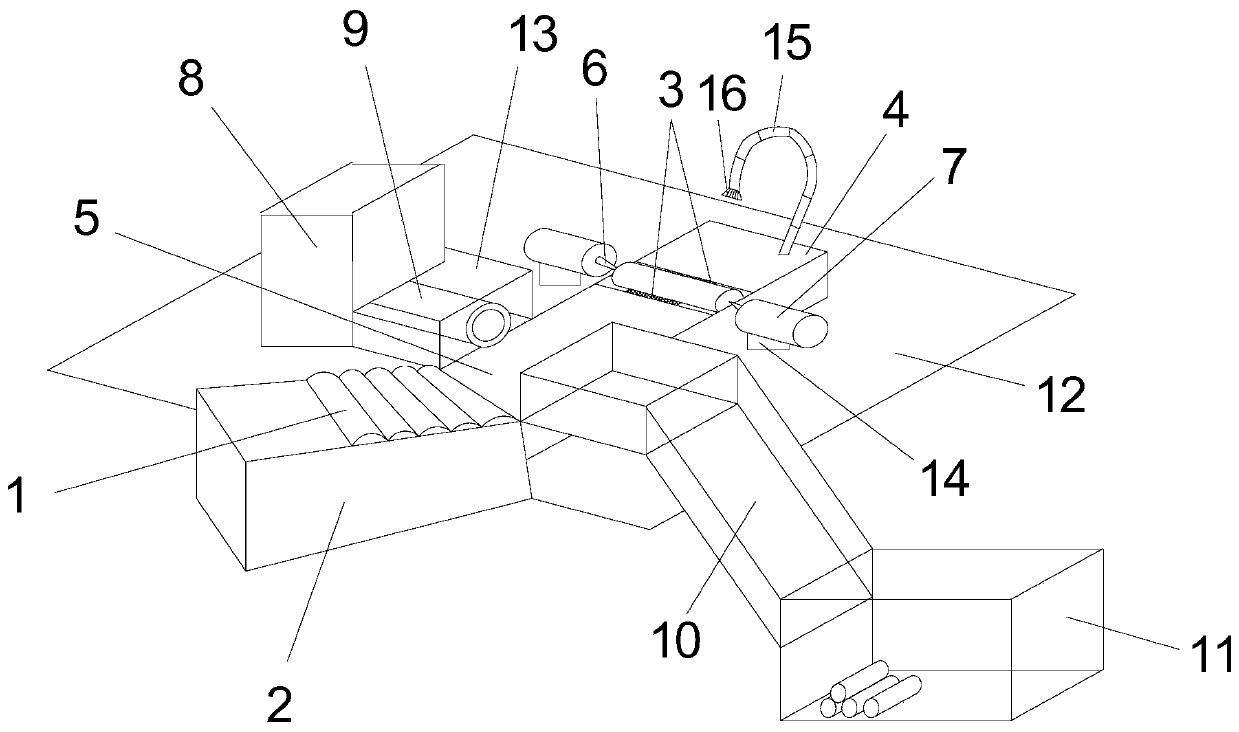

Inverse armature brazing machine with double feeding of brazing wire belts and welding technology thereof

ActiveCN105397229ANo consumptionRealize automatic alignmentMetal working apparatusSolder feeding devicesEngineeringFiller metal

The invention discloses an inverse armature brazing machine with double feeding of brazing wire belts and a welding technology thereof. The inverse armature brazing machine comprises an armature preparation plate, a machine base, a loading supporting base, a servo clamping and indexing mechanism, an armature loading supporting roller mechanism, an armature supporting rectification mechanism, a wire pressing and welding mechanism, a first brazing wire belt feeding mechanism, a second brazing wire belt feeding mechanism, a brazing filler metal plate and a smoke absorption mechanism. According to the machine, the brazing wire belts can be fed to the welding areas between outer-layer wires and inner-layer wires and the welding areas between the inner-layer wires and a commutator segment at the same time so as to be located in the middle of a conducting loop in welding and become the largest heat emission spot, and therefore the problem that a commutator emits heat excessively and then becomes expanded and deformed in the traditional lateral brazing wire belt feeding and welding process is solved, and the problems that temperature rise is excessive and the service life is short due to the small sectional area of arc welding connection and welding spot connection caused by single feeding of the brazing wire belts are solved; two wire processes of argon arc welding are eliminated in the armature welding process, the welding efficiency is high, welding is more reliable, less brazing filler metal is used, and the welding benefit is better.

Owner:HERON INTELLIGENT EQUIP CO LTD

Automatic separation equipment of waste mixed plastics and method thereof

InactiveCN105312255ARealize automatic sortingEasy to identifyPlastic recyclingSortingAutomatic controlEngineering

The invention discloses automatic separation equipment of waste mixed plastics and a method thereof. The equipment comprises an automatic control system, an electromagnetic vibration feeding system, a conveying belt, a color inductor array, a pneumatic nozzle, a pure material collecting bin, an automatic push rod and a waste collector. The method comprises the following steps: (1) crushed and deironed piece-shaped or particle-shaped plastic products are fed onto the conveying belt by the electromagnetic vibration feeding system; (2) mixed plastic particles supported by the conveying belt are screened with colors through different color inductors in the color inductor array and the pneumatic nozzle in sequence, and are collected by the pure material collecting bin; and (3) wastes not identified by the color inductor array on the conveying belt are pushed into the waste collector by the automatic push rod after passing through the final color inductor. The method adopts a high-tech method to replace manual sorting, so that the production labor force is reduced; and compared with manual sorting, the method is faster in speed, is stronger in continuity, and greatly improves the production efficiency.

Owner:森蓝环保(上海)有限公司

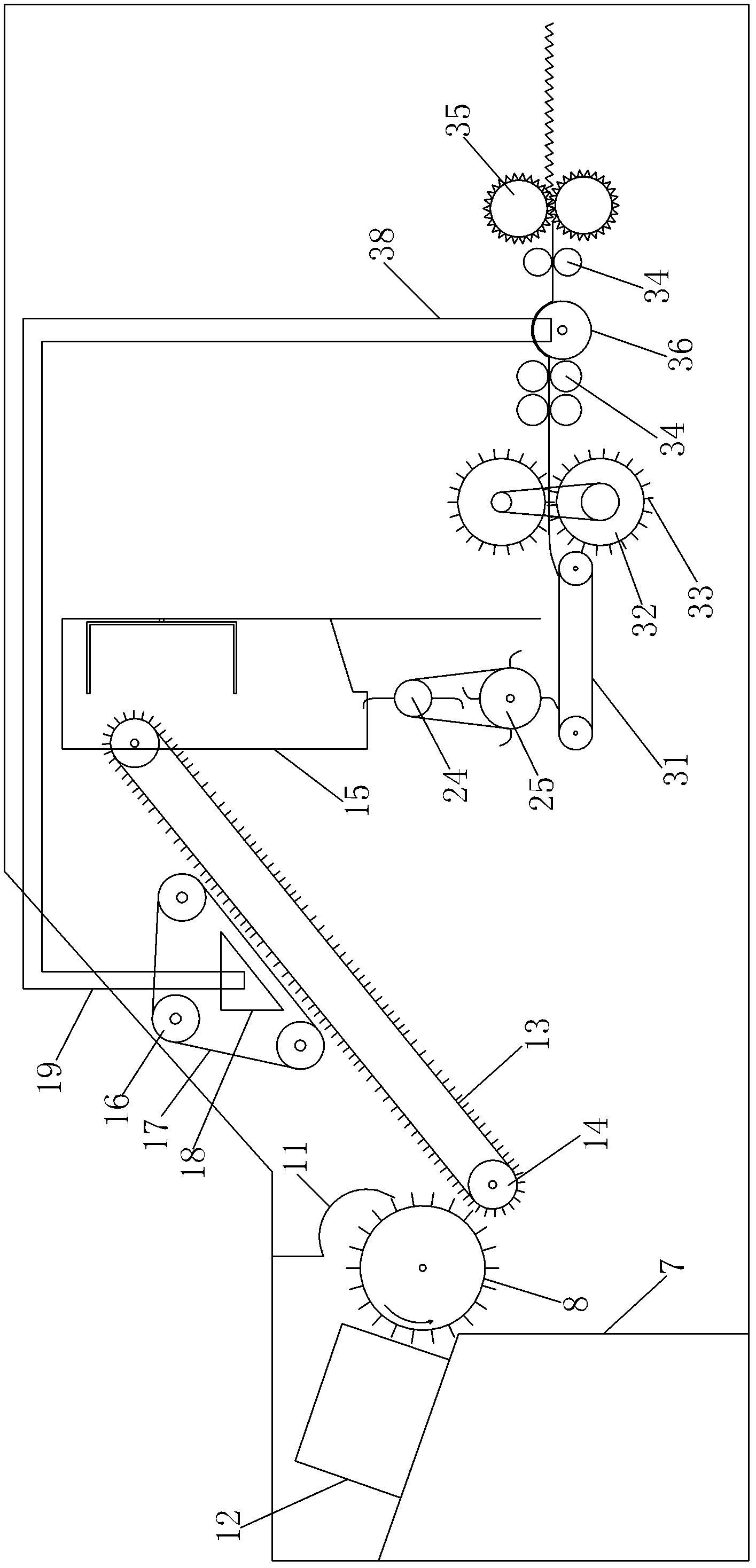

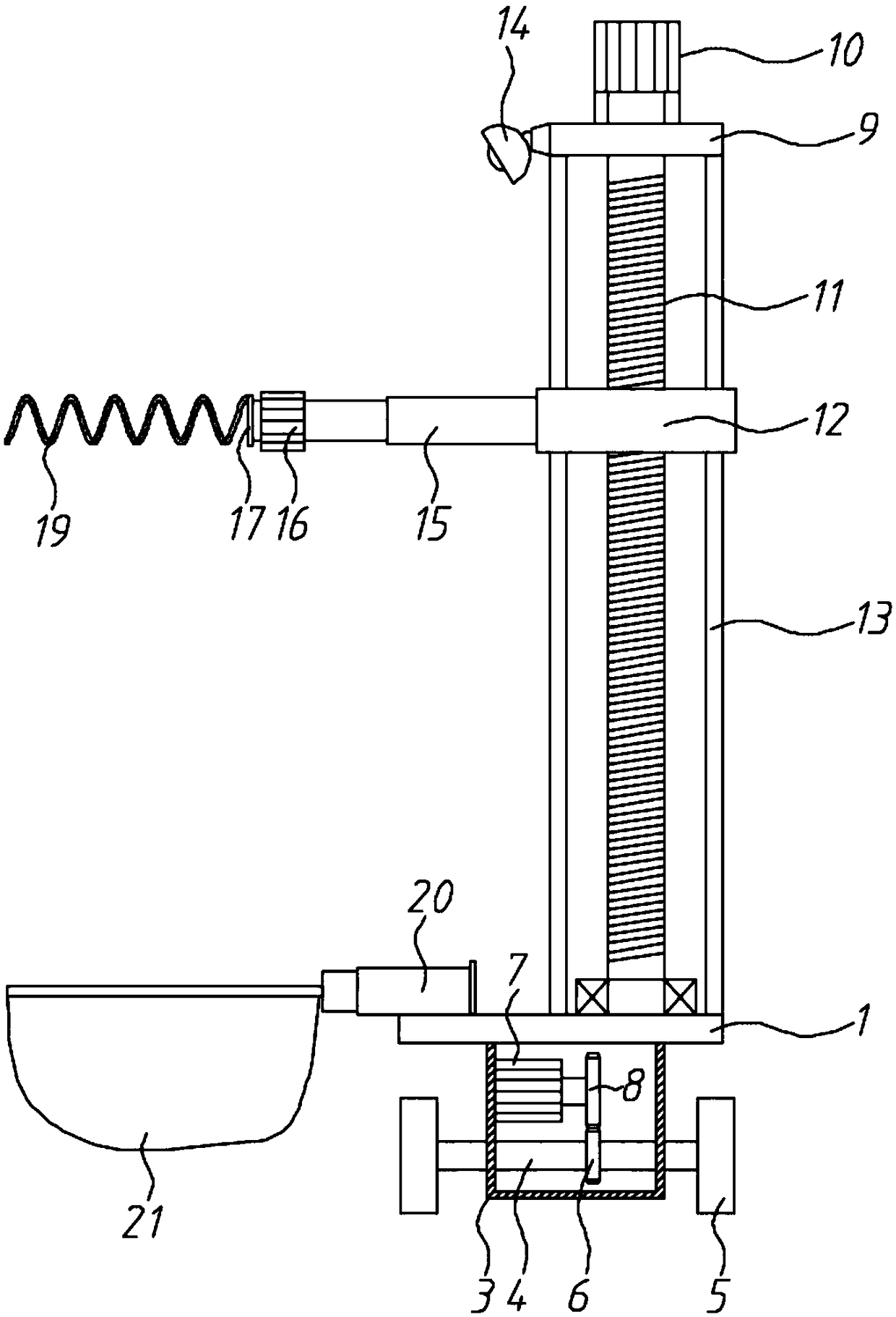

Automatic feeding machine for Monofilament mattress

InactiveCN102583212AFully automatedReduce production laborUpholstery manufactureUpholstery fillingWave shapeEconomic benefits

The invention discloses an automatic feeding machine for a monofilament mattress. According to the automatic feeding machine, a monofilament bag is arranged on a monofilament bag feeder with certain inclination, the monofilament bag slides downwards to contact with a monofilament roller with small teeth, the monofilament is loosened by pulling, carried to a toothed conveyer belt, and conveyed to a feeding bin by the toothed conveyer belt, a material pulling mechanism pulls the monofilament in the feeding bin to drop on the below conveyer belt, then the monofilament is pulled to be smooth and straight by a pair of toothed rollers and then is flattened through two compression rollers and finally are rolled by a pair of gears meshed together to be in a wave shape, and the wave-shaped monofilament is transmitted to a swing machine of the monofilament mattress to complete the feeding process. According to the automatic feeding machine for the monofilament mattress, the automatic monofilament feeding is realized completely, not only are the production time and the production cost saved, but also the uniformity of the product, the quality, the attractiveness and the technological content of the product are improved, and the application of the feeding machine has obvious social and economic benefits.

Owner:褚建祥

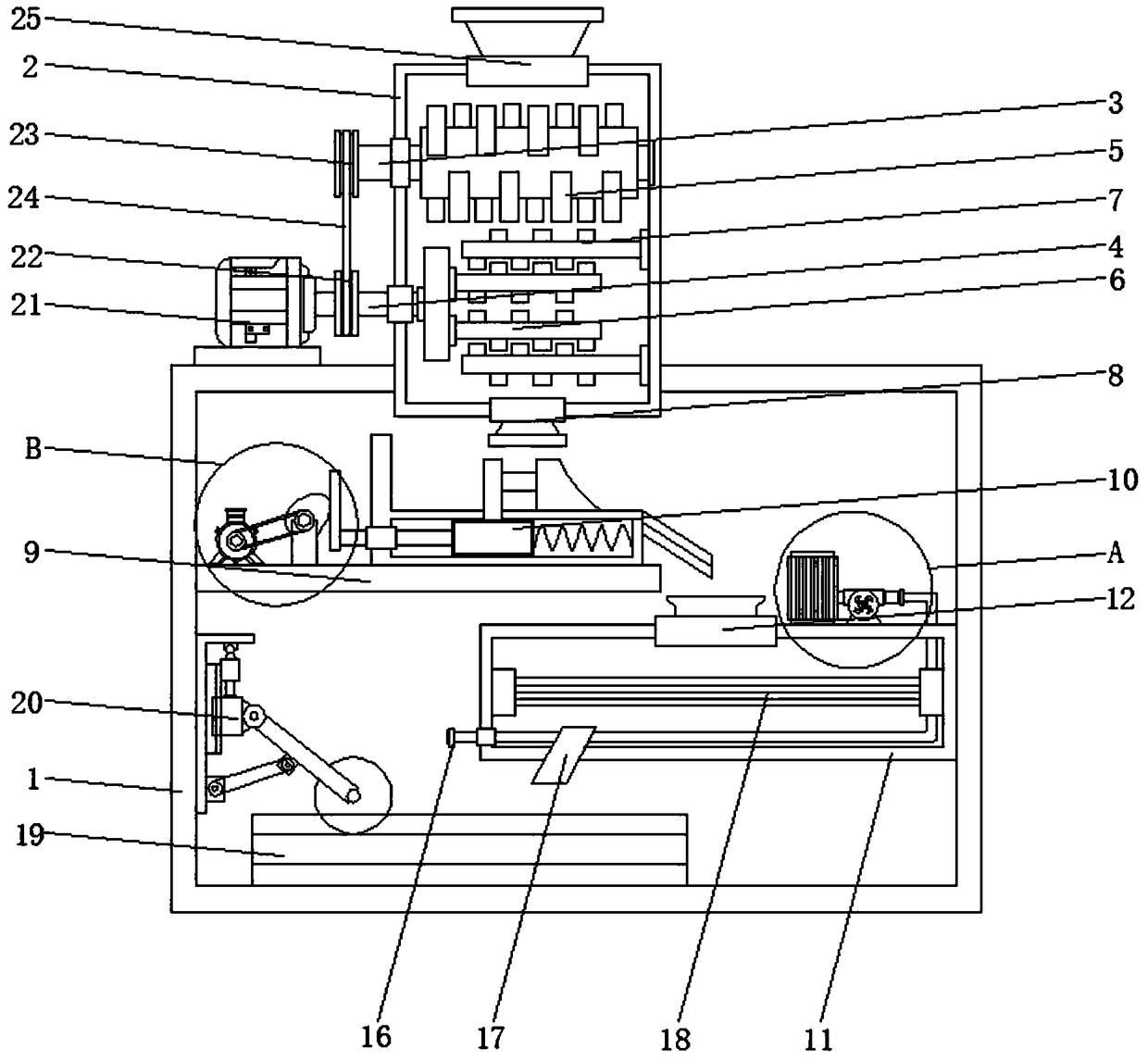

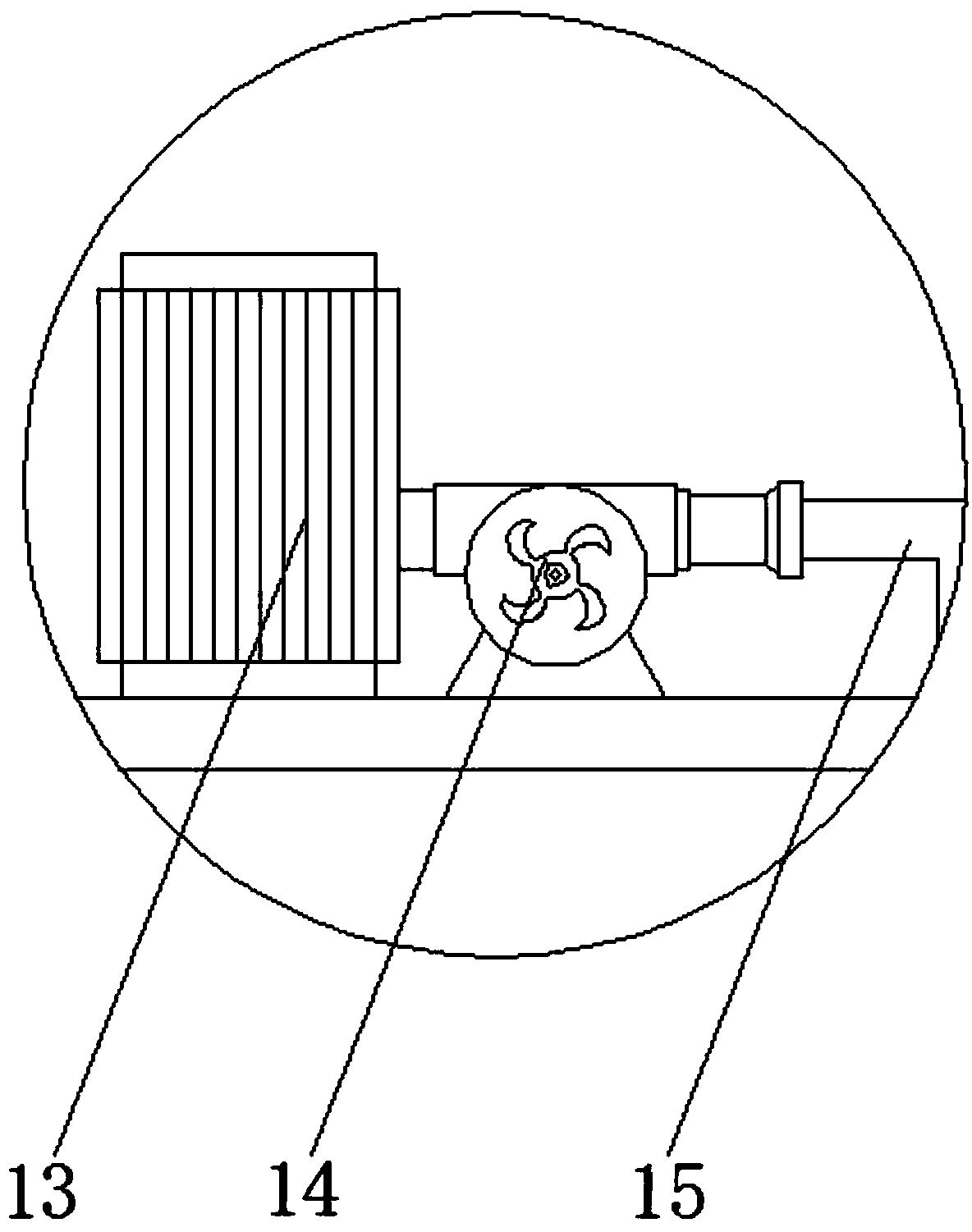

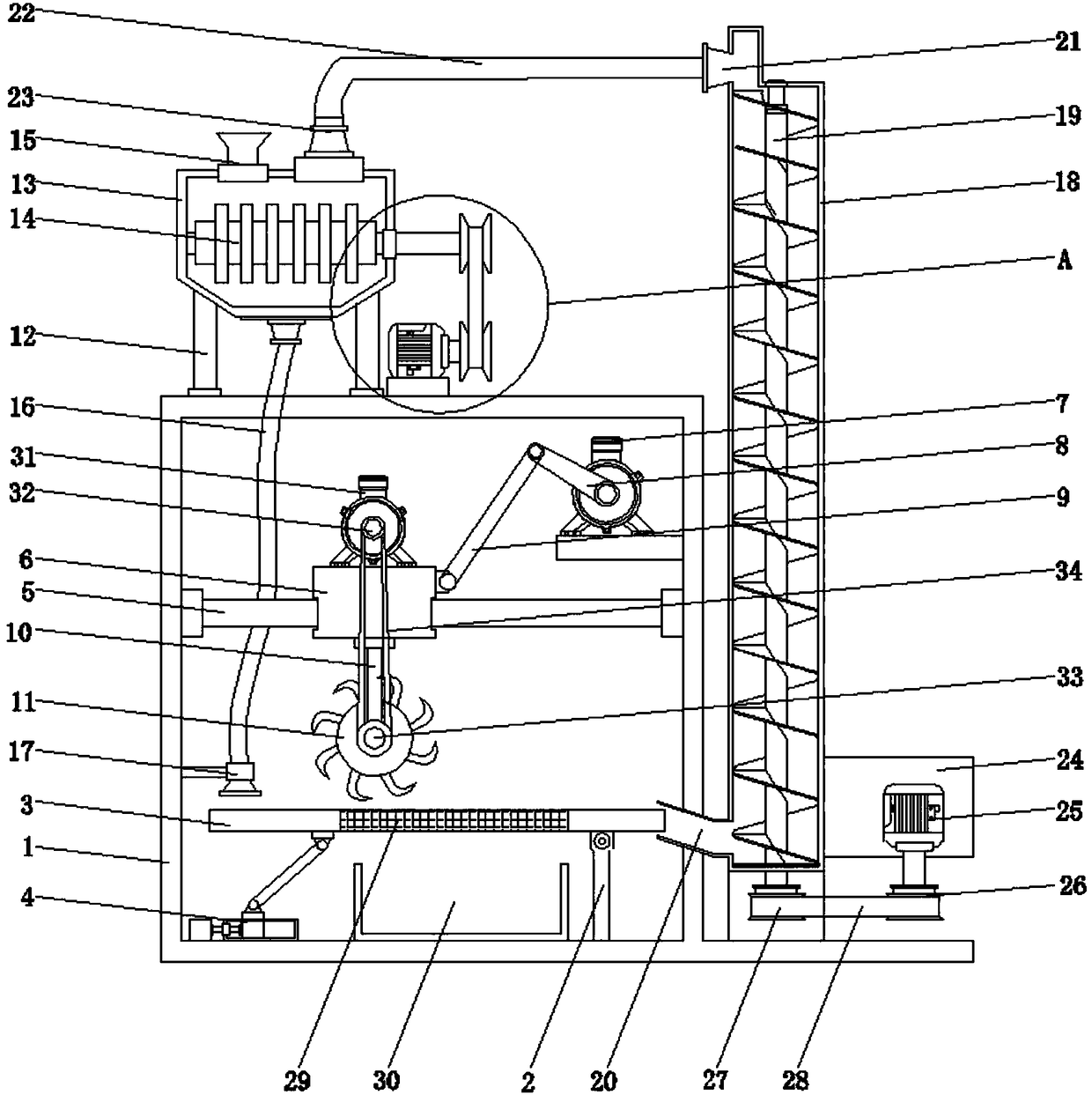

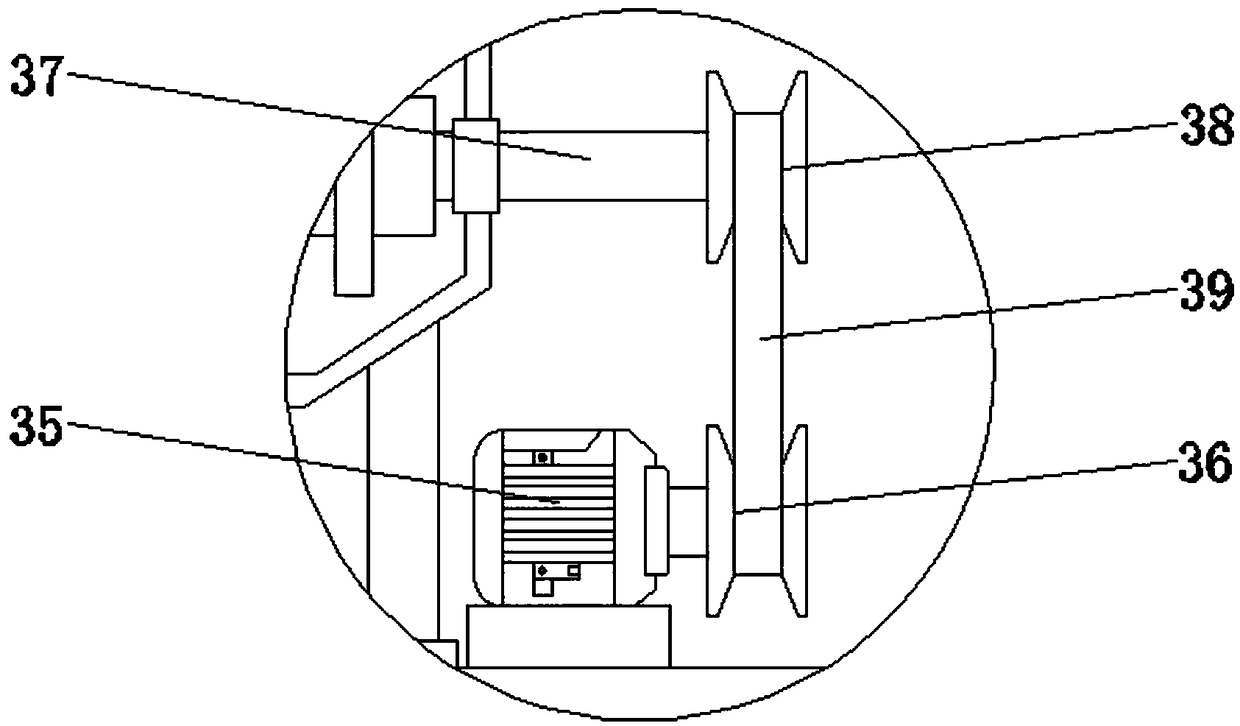

Waste plastic recycling regenerating device

InactiveCN108372606AImprove melt qualityReduce production laborPlastic recyclingGrain treatmentsAir heaterEngineering

The invention discloses a waste plastic recycling regenerating device, and relates to the technical field of resources. The waste plastic recycling regenerating device comprises an outer frame; the top end of the outside of the outer frame is fixedly connected with a smashing frame; a first rotary shaft is fixedly connected with a smashing gear; the inner wall of the right side of the smashing frame is fixedly connected with fixed smashing engaging teeth; the bottom end of the smashing frame is provided with a smashing outlet; the top end of a supporting plate is fixedly connected with a propulsion device; the right side of the interior of the outer frame is fixedly connected with a heating frame; the middle of the top end of the heating frame is provided with a melting inlet, the right side of the top end of the heating frame is fixedly connected with an air heater, and the middle of the interior of the heating frame is fixedly connected with a melter; and the inner wall of the left side of the outer frame is fixedly connected with a press roll device. According to the waste plastic recycling regenerating device, the purposes that double smashing and sufficient smashing of plasticcan be conducted, the plastic melting quality is improved, the production labor force is reduced, the plastic regenerative quality is improved, and wasted plastic resources are decreased are achieved.

Owner:佛山杰致信息科技有限公司

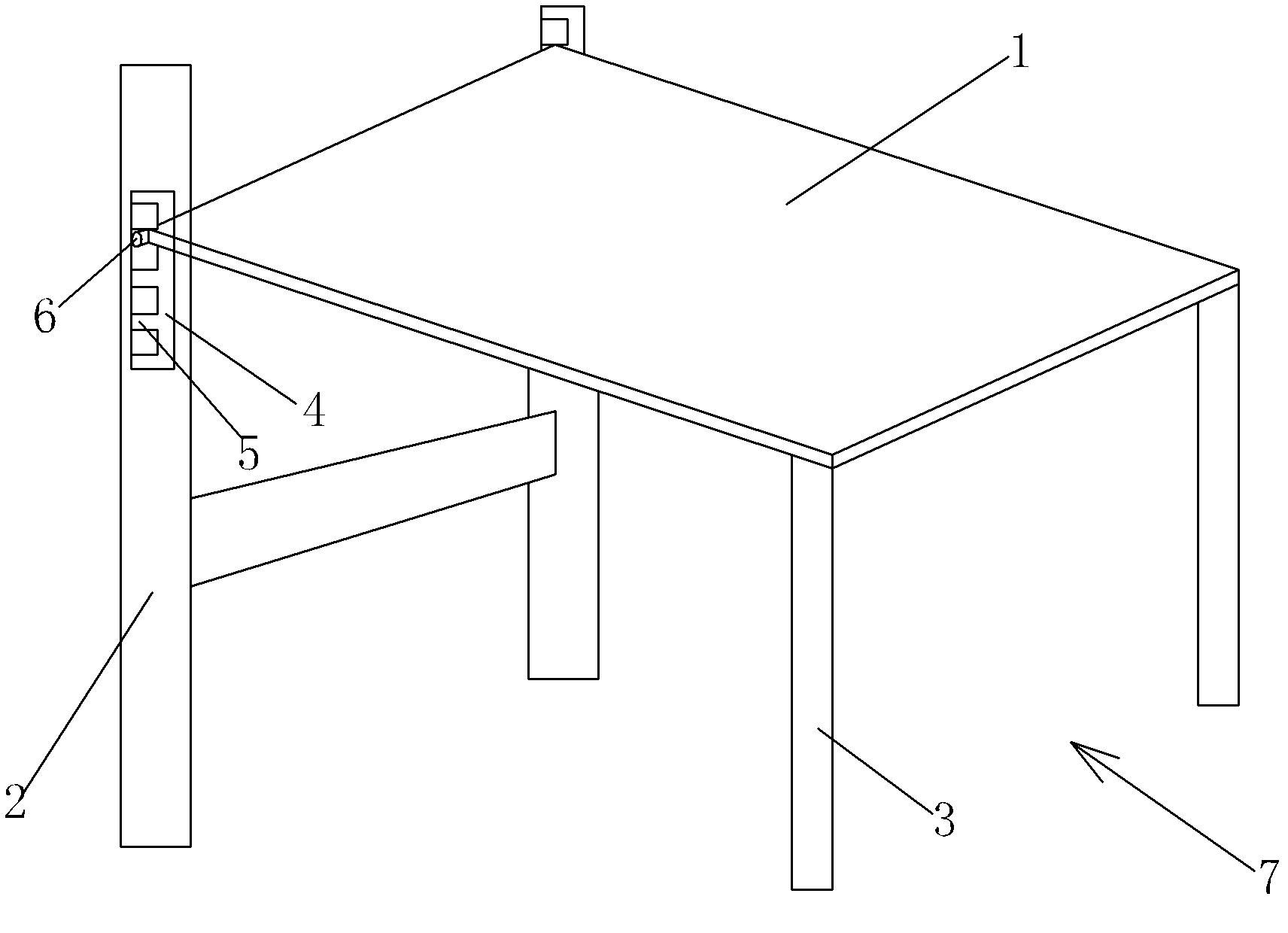

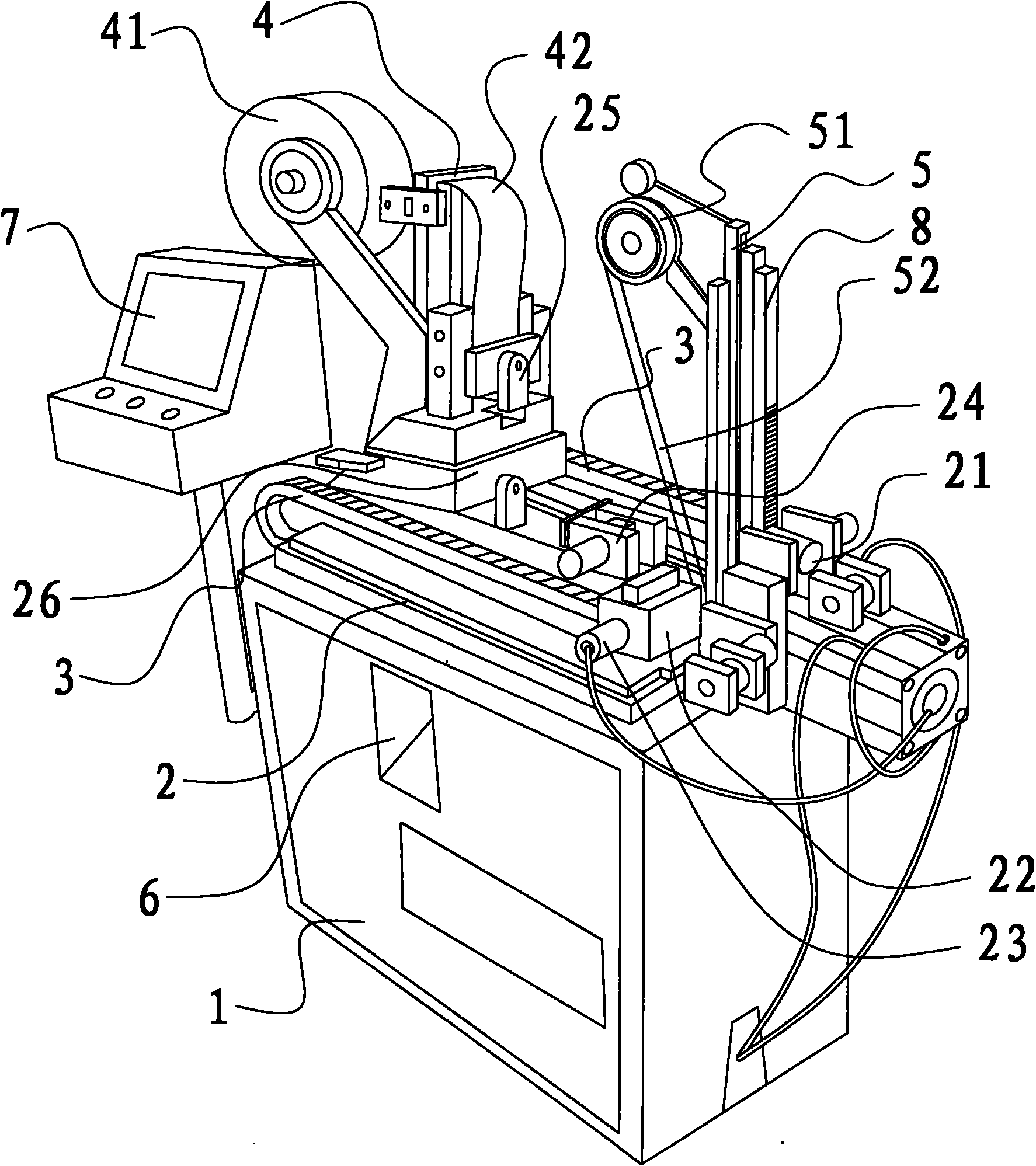

Banding machine

InactiveCN102133932ACompact structureReduce production laborPaper article packagingBundling machine detailsMicrocomputerAdhesive belt

The invention discloses a banding machine comprising a machine box, a power assembly arranged in the machine box, and a working platform arranged at the top of the machine box, wherein the working platform is provided with two parallel transmission belts and a sliding rail positioned between the two transmission belts; the front end of one transmission belt is provided with an emptying frame and an adhesive tape frame in sequence, and the rear end of the transmission belt is provided with a cutting mechanism and a paper belt frame in sequence; a feeding mechanism positioned on the sliding rail is arranged between the cutting mechanism and the adhesive tape frame; a bundling mechanism is arranged between the feeding mechanism and the cutting mechanism; the paper belt frame and the adhesive tape frame are respectively arranged on a paper belt wheel and an adhesive belt wheel; an ejecting mechanism is arranged at the bottom end of the emptying frame; two sides of the feeding mechanism are respectively provided with a clamping mechanism positioned on the transmission belt; a supporting platform positioned at the bottom end of the adhesive tape frame is arranged between the ejecting mechanism and the feeding mechanism; and a limiting stopper is arranged at the front end of the supporting platform. In the bundling machine, the actions of pushing, feeding, cutting and banding are smartly combined together comprehensively, and the accurate control of banding can be realized by a microcomputer.

Owner:李少洪

Candy and production technique thereof

InactiveCN101310609AShort processing timeSimple preparation processConfectionerySweetmeatsAdditive ingredientHigh fructose

The invention provides a candy and a production manufacturing process thereof, which contains the following components: 10 percent to 30 percent of white sugar, 20 percent to 60 percent of malt syrup, 0 percent to 30 percent of high fructose syrup, 0 percent to 30 percent of concentrated juice, 3 percent to 10 percent of preserved fruit cubes, 0.1 percent of calcium chloride, 1 percent to 15 percent of water, 10 percent to 30 percent of modified starch, 0.2 percent to 5 percent of acidity regulator, 0 percent to 0.01 percent of coloring matter and 0 percent to 0.5 percent of essence. The manufacturing process of the candy comprises five steps, including mixing ingredients, extruding, curing and seasoning, quantitative filling, sealing and parting, cooling and packaging. The production manufacturing process of the candy of the invention is simple, low in energy consumption, sanitary and reliable, good in taste and beautiful in appearance.

Owner:朱先洪

Waste plastic pulverizing and collecting device

InactiveCN108357026AExpedited screeningImprove crushing collection efficiencySievingScreeningPulp and paper industryProduction quality

The invention discloses a waste plastic pulverizing and collecting device and relates to the technical field of resources. The device comprises an outer frame. The bottom end of the interior of the outer frame is fixedly connected with a shaking device. The middle of the interior of the outer frame is fixedly connected with a limit slide bar, and a limit slide block is connected to the limit slidebar in a sliding mode. The end, away from a first motor, of an output connecting rod is rotationally connected with a transmission rod. The bottom end of the limit slide block is fixedly connected with a hanging rod. The bottom end of the hanging rod is rotationally connected with a stirring rotating wheel. The top end of the exterior of the outer frame is fixedly connected with a fixing rod. Pulverizing gears are rotationally connected into a pulverizing frame. The middle position of the bottom end of the pulverizing frame communicates with a communication pipeline. A pulverizing outlet is formed in the end, away from the pulverizing frame, of the communication pipeline. According to the waste plastic pulverizing and collecting device, the purposes that screening of plastic particles isaccelerated, the pulverizing and collecting efficiency is improved, cyclic pulverizing and pelleting are achieved, the production quality is improved, and the production labor is reduced are achieved.

Owner:佛山杰致信息科技有限公司

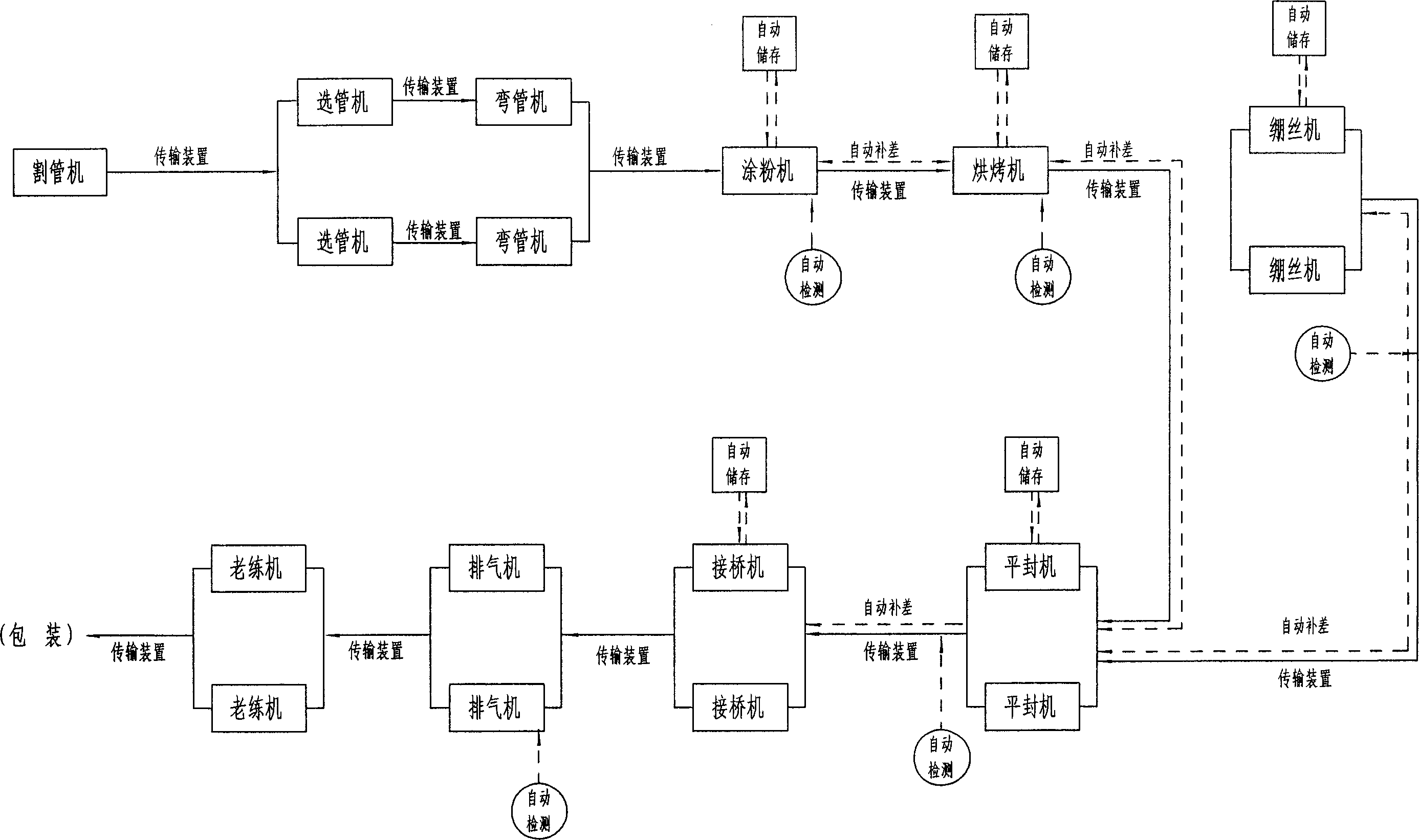

Automatic production system for energy saving luminous tube

InactiveCN1873883AMinus the phenomenon of multi-employmentReduce clutterVessels or leading-in conductors manufactureCold cathode manufactureProcess engineeringWork in process

The disclosed automatic system for fabricating energy-saving luminous tube arranges following facilities in order: tube cutter, tube selection unit, tube bender, powder coating machine, roasting unit, capper, air exhauster and aging machine etc. Transmission equipment is set up between each unit of machine. Through transmission equipment, each unit of machine is cascaded. Thus, half-finished product from previous working procedure enters to unit of machine at next working procedure automatically. Advantages are: reducing manual work and number of worker, reducing breakage of half-finished or finished products in each working procedure so as to save ground area needed for production.

Owner:JIANGSU HAOMING PHOTOELECTRIC TECH

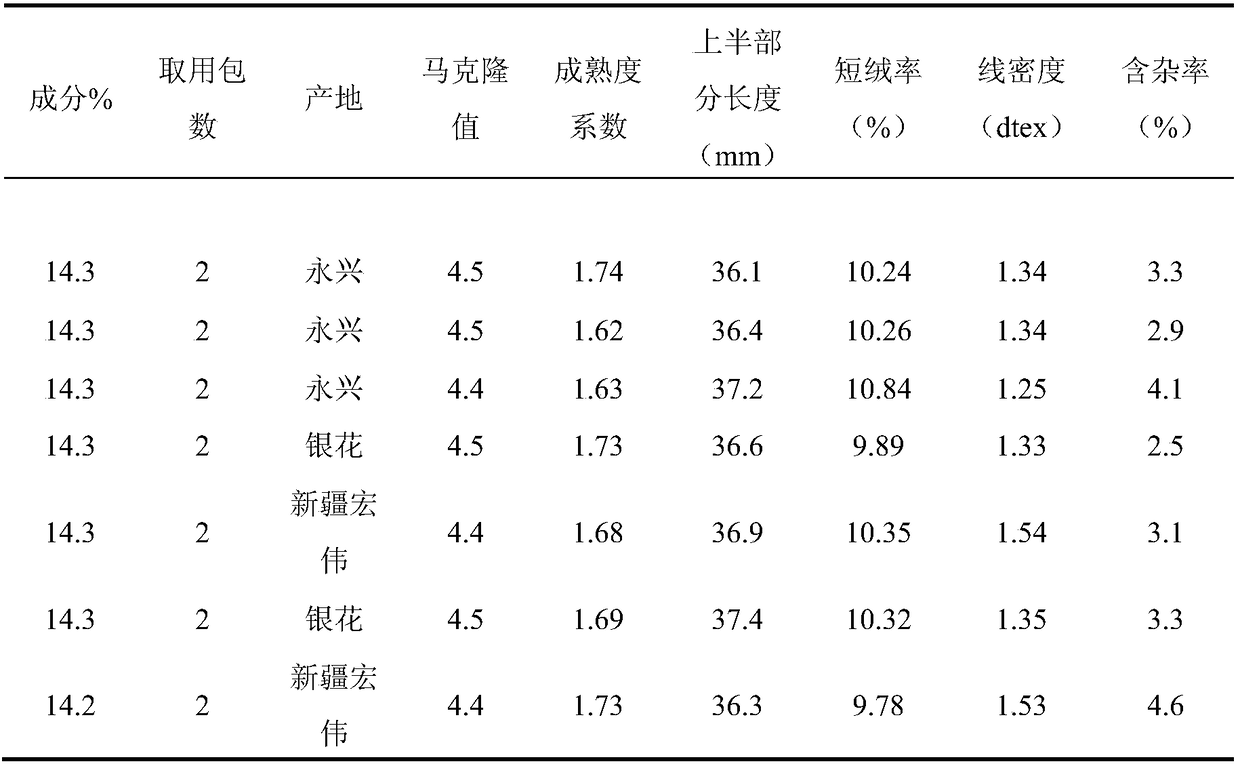

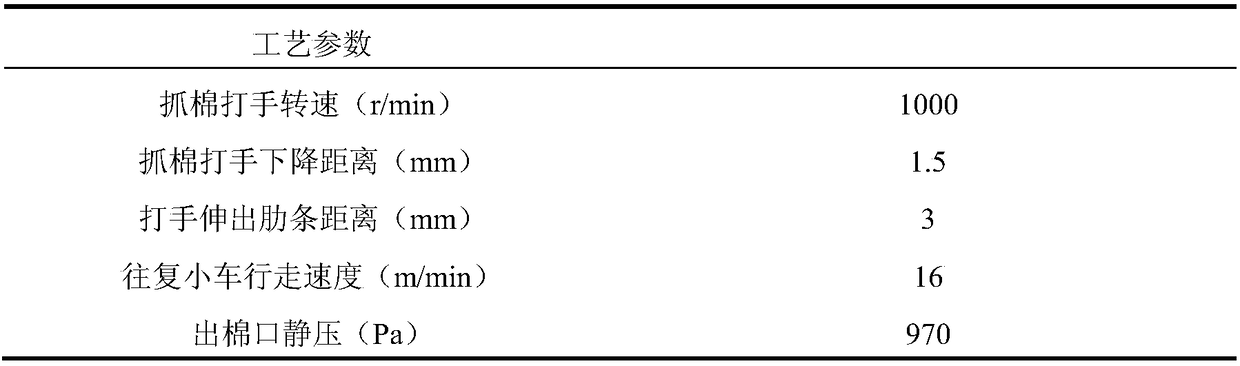

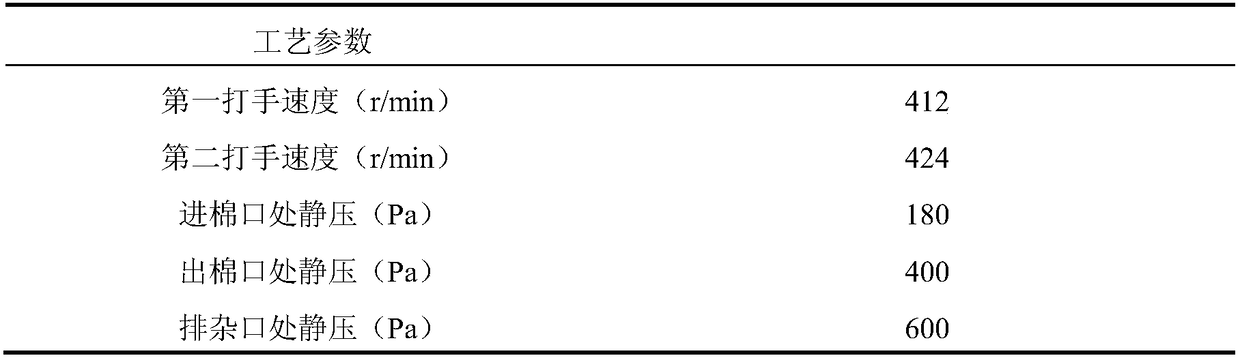

Pure cotton yarn production method utilizing seamless joint of roving and finespinning

ActiveCN108998867AAchieve seamless connectionRealize the continuous production of thicknessYarnYarnManufacturing engineering

The invention discloses a pure cotton yarn production method utilizing seamless joint of roving and finespinning. Through reasonable raw cotton matching and through an automatic doffing roving frame,an all-digital integrated spinning automatic doffing finespinning machine and an automatic roving and finespinning conveying system, seamless joint of the roving process and the finespinning process in the pure cotton yarn production process is realized, continuous roving and finespinning production is realized, production labor is significantly reduced, moreover, influence of yarn faults and hairiness caused by touch, friction, collision and the like in the transporting process of a roving drum in the operation process is reduced, labor is reduced, and work efficiency is improved.

Owner:浙江万舟控股集团有限公司

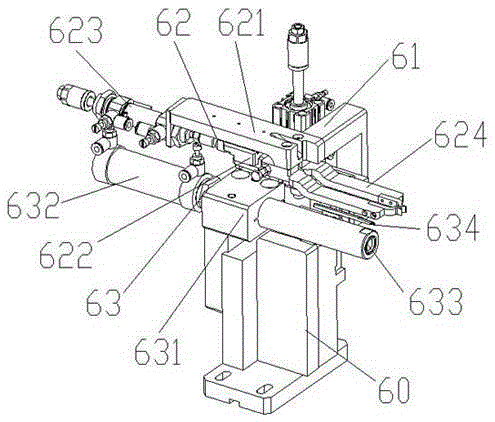

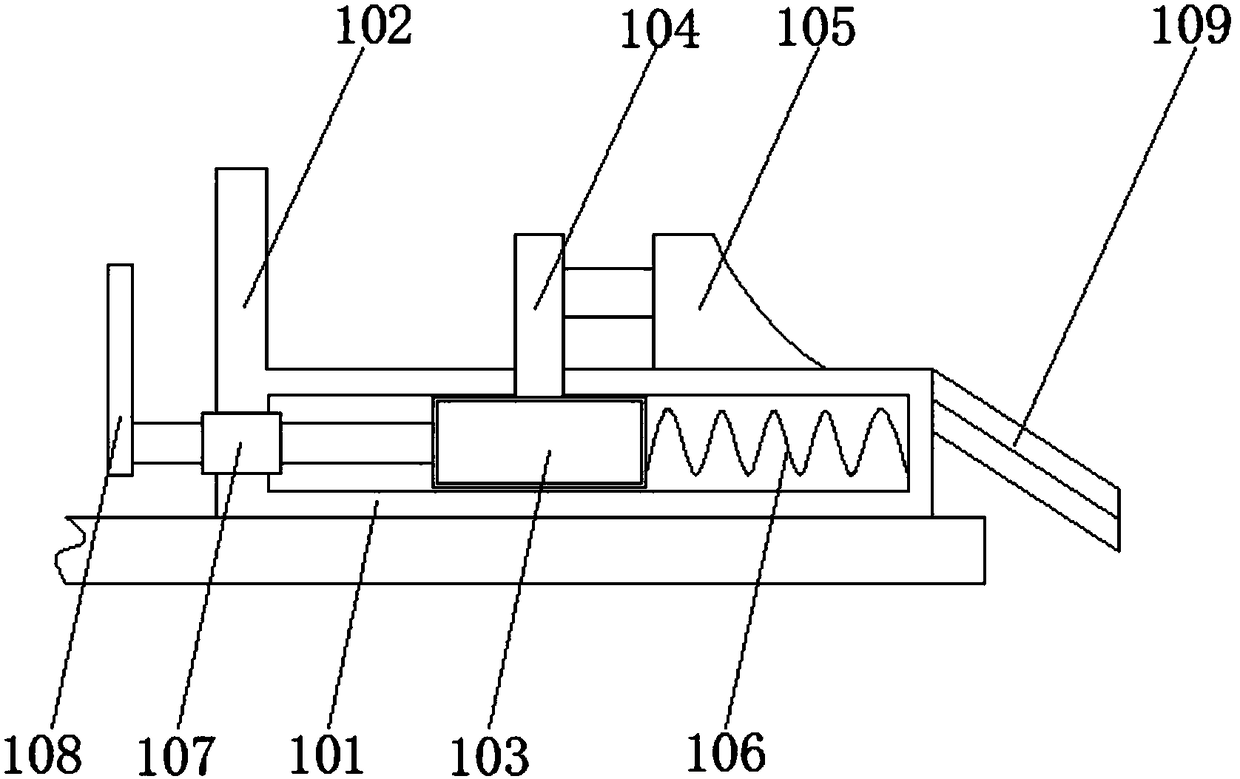

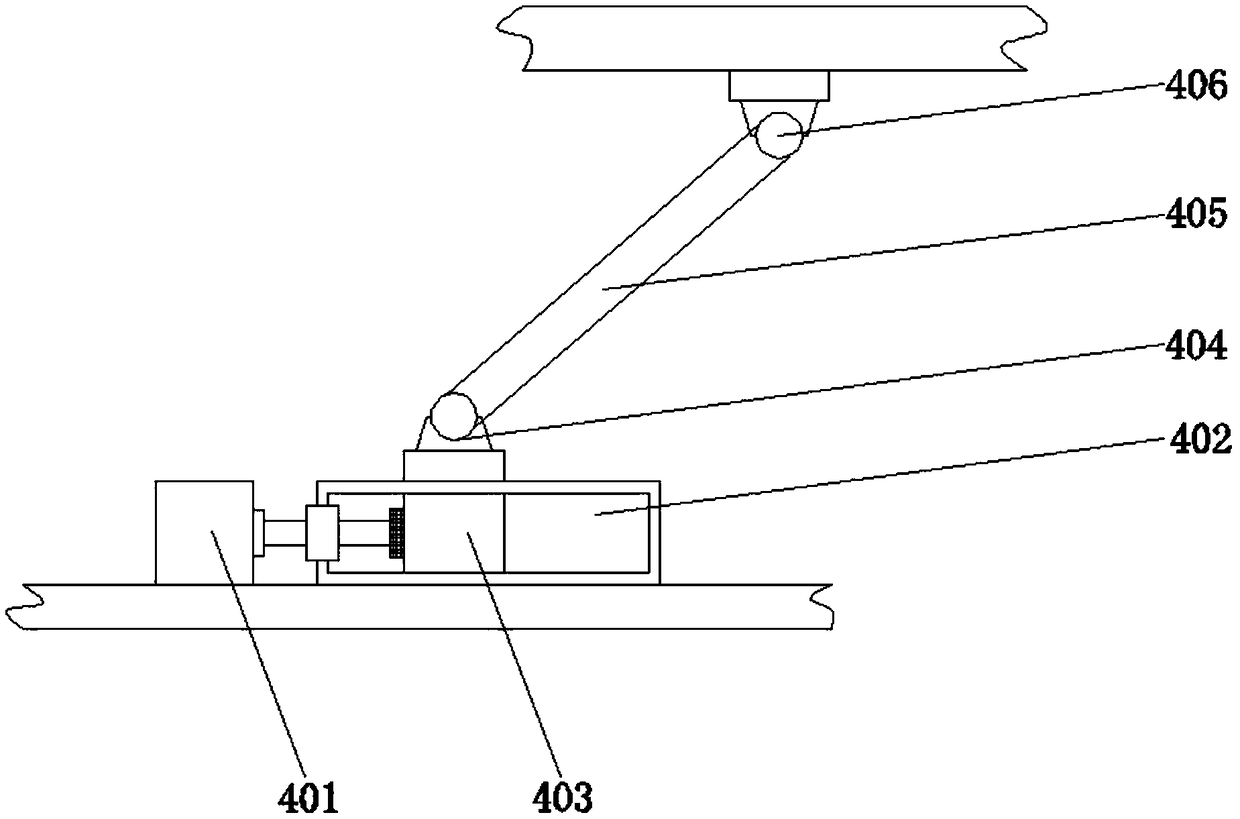

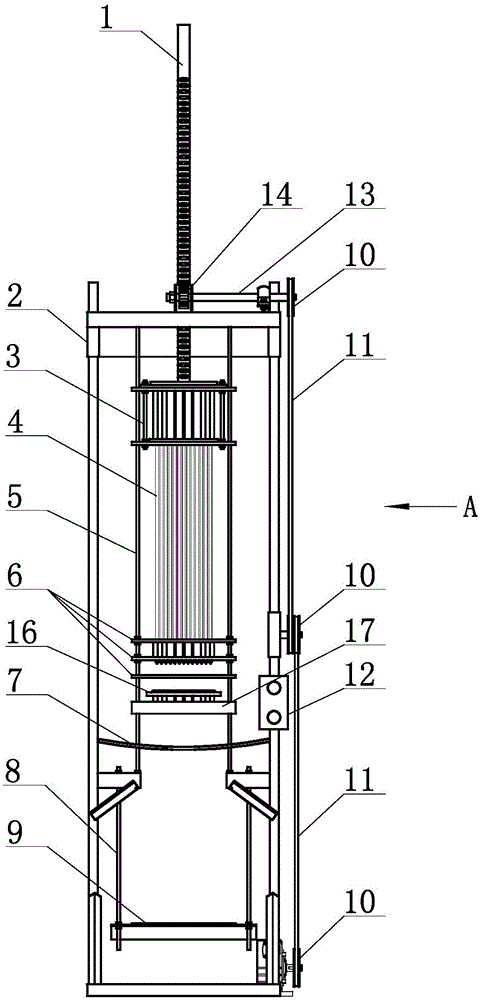

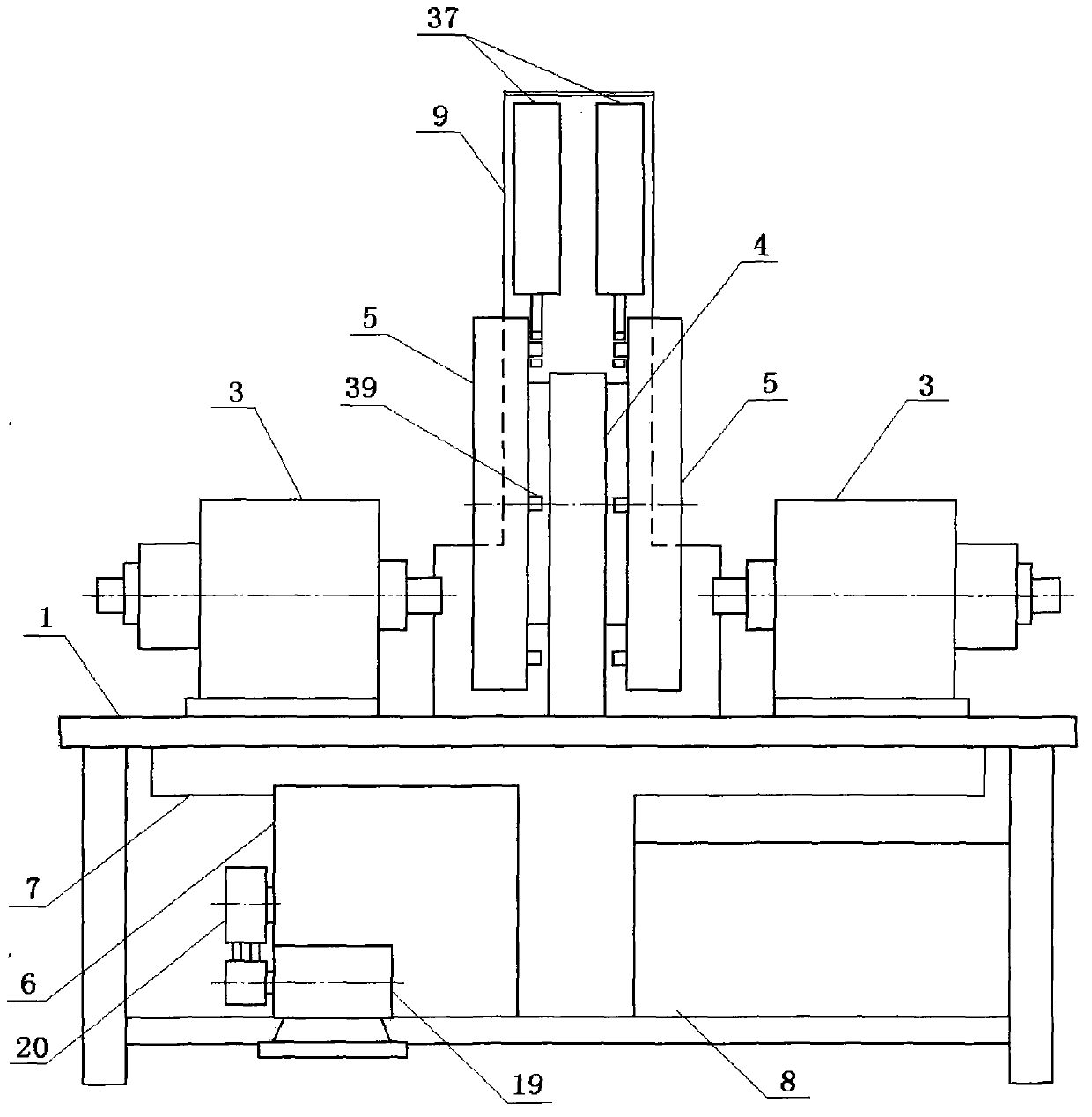

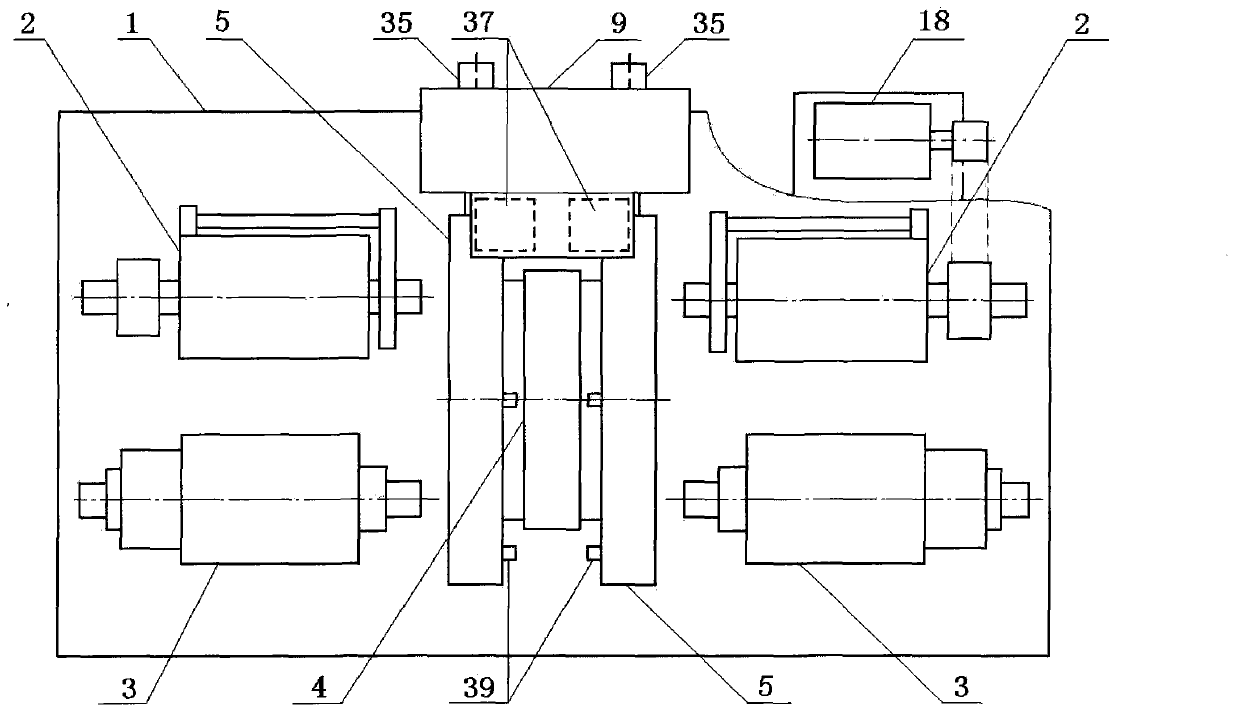

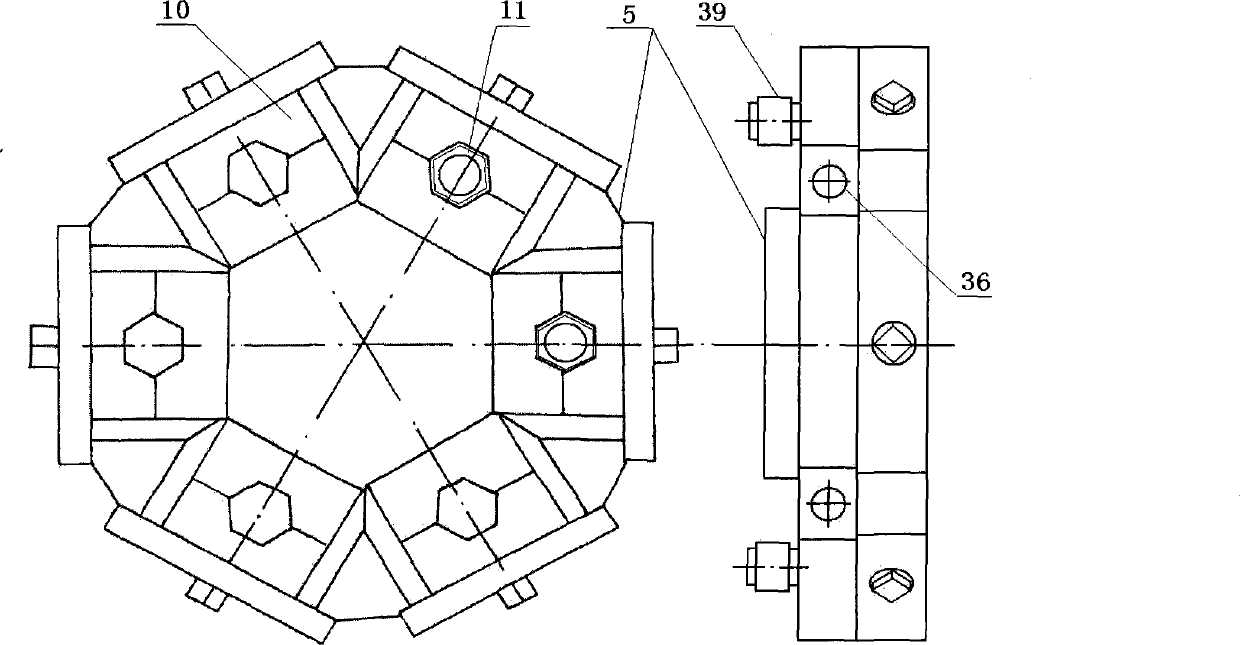

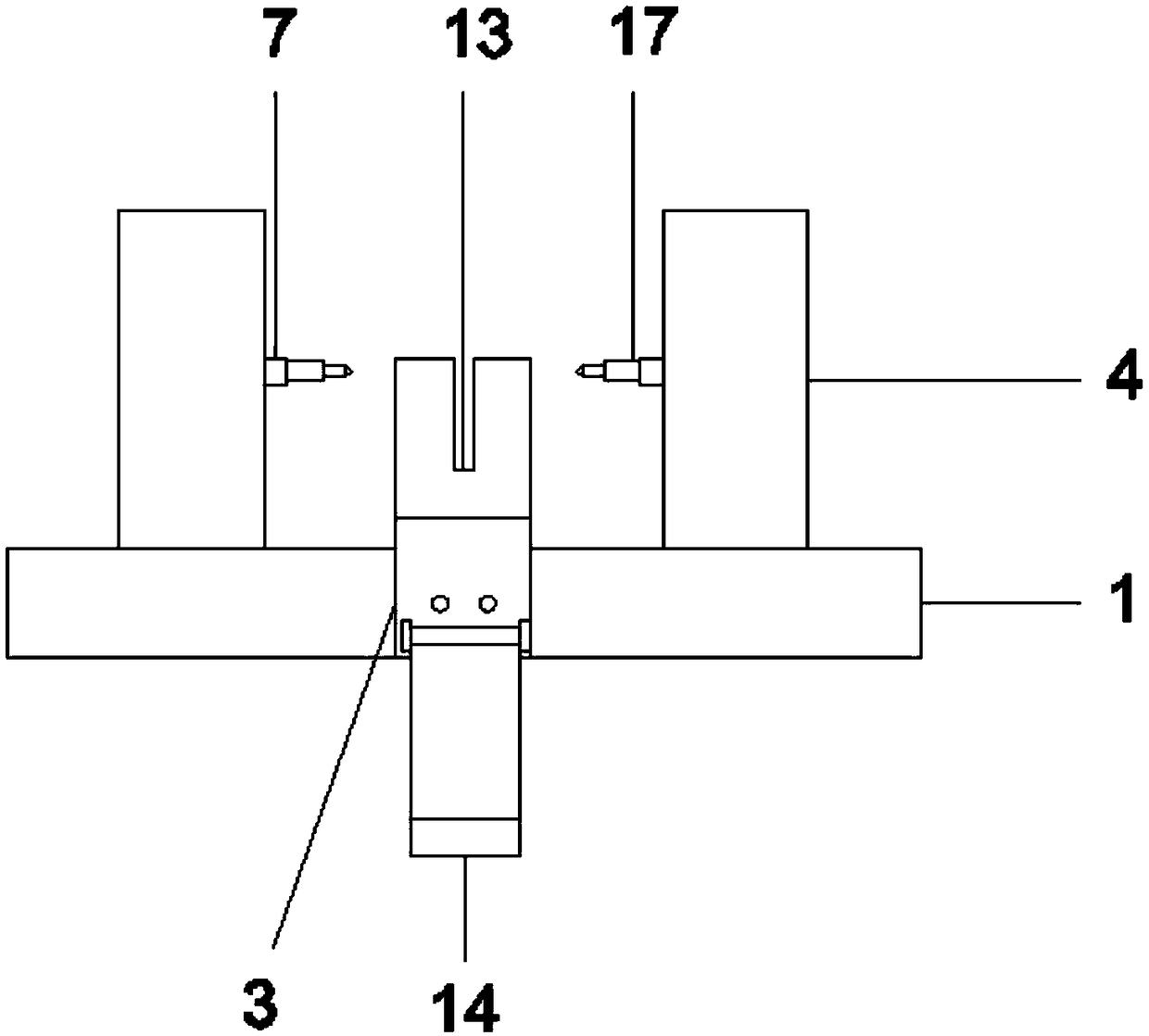

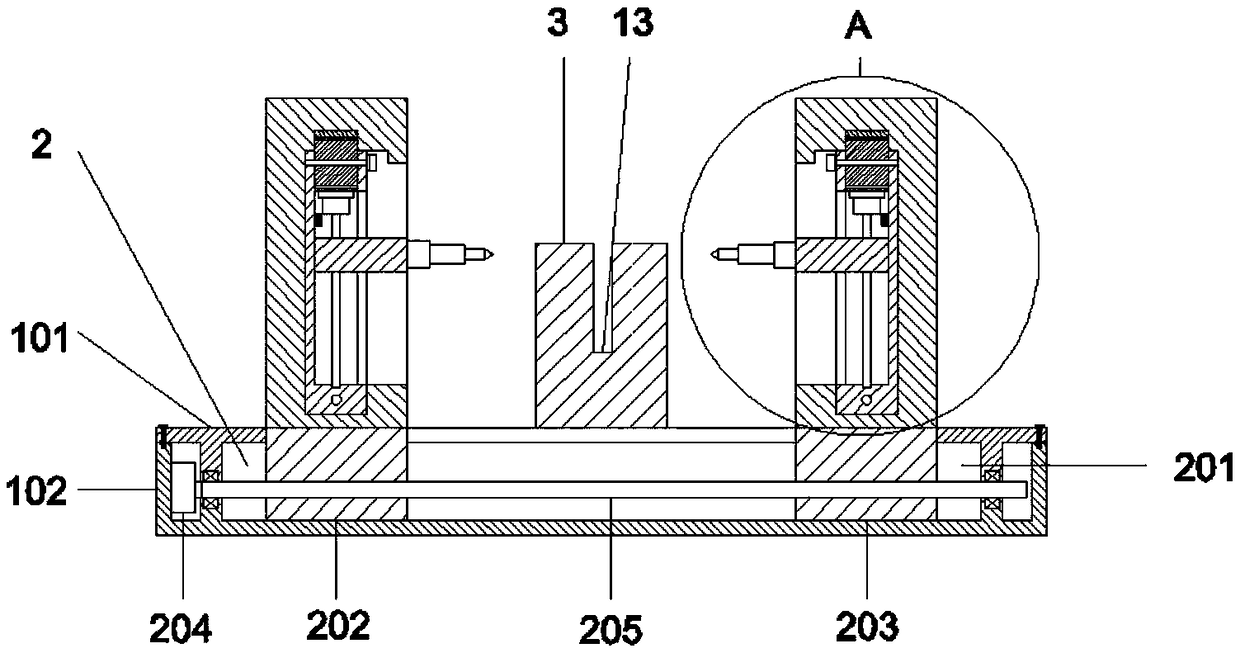

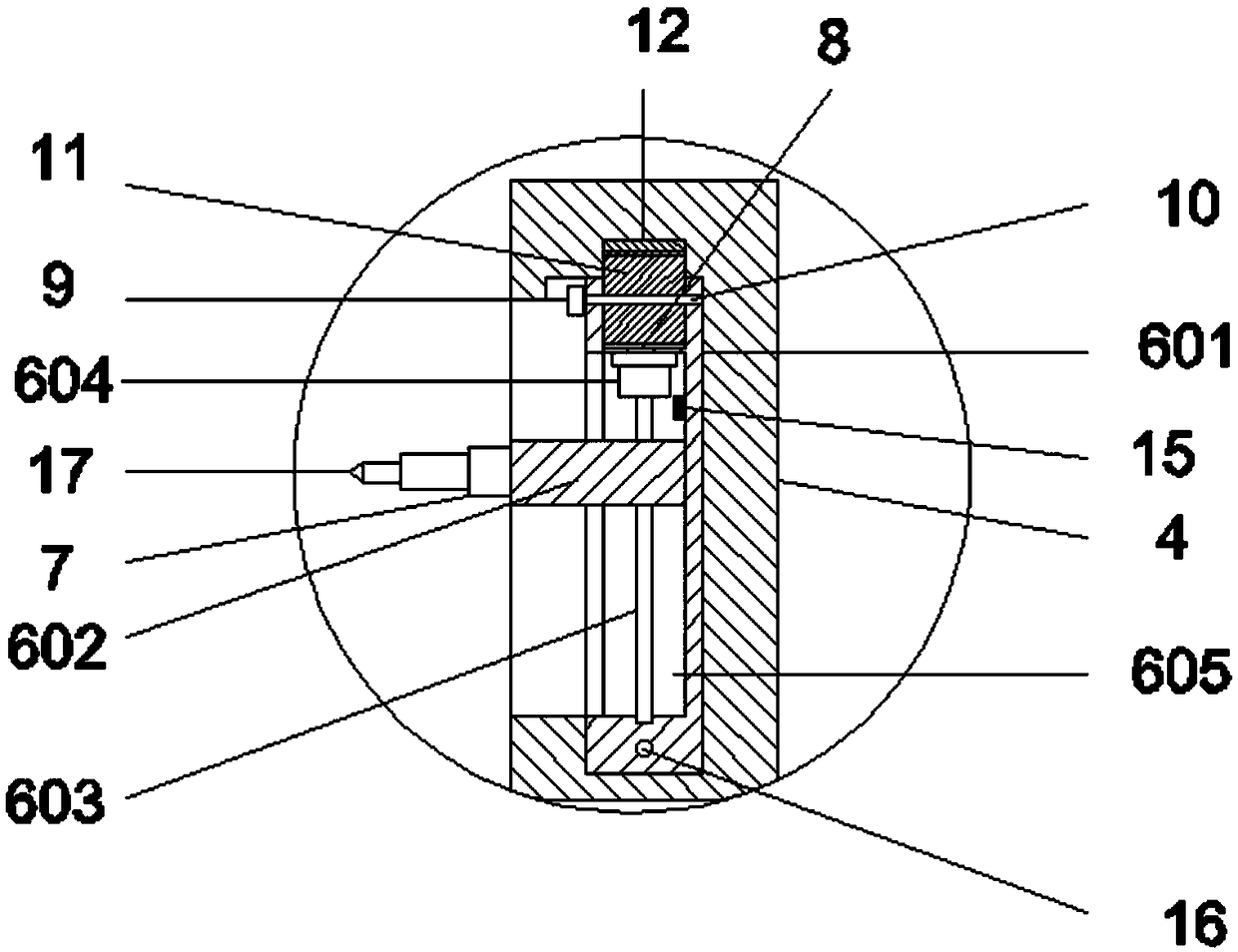

Central hole drilling machine

InactiveCN110560724ACompact structureEasy to operateMetal working apparatusBoring/drilling componentsEngineeringContact position

The invention discloses a central hole drilling machine. The central hole drilling machine comprises a feeding mechanism, a clamping and moving mechanism, a hole processing mechanism, an ejection mechanism and a discharging mechanism; a plurality of to-be-processed workpieces are placed on the feeding mechanism, the clamping and moving mechanism can move to close to the feeding mechanism and clampthe one of the to-be-processed workpieces, the to-be-processed workpiece is moved to a machining area of the hole processing mechanism, and the hole processing mechanism carries out central hole drilling operation on the to-be-processed workpiece; a blowing pipe is arranged on the clamping and moving mechanism, one end of the blowing pipe is fixed on the clamping and moving mechanism and communicates with a gas supply pipeline, and the other end of the blowing pipe extends towards the contact position of the hole processing mechanism and the to-be-processed workpiece and blows gas; and the ejection mechanism can eject the to-be-processed workpiece after the drilling operation from the clamping and moving mechanism, and to-be-processed workpiece falls into the discharging mechanism for storage. The central hole drilling machine is compact in structure, convenient to operate, high in safety coefficient, and time-saving and labor-saving, the production labor force is saved, and the production efficiency is improved.

Owner:芜湖欣艾特机电有限公司

Fermentation method and production method of liquor

InactiveCN102994304AIncrease aromaMaintain nutritional contentAlcoholic beverage preparationAlcoholAdditive ingredient

The invention discloses an alcoholic beverage, and in particular relates to a fermentation method and a production method of liquor. The method comprises steps of dipping raw materials, stewing, carrying out liquid state fermentation and solid state fermentation, distilling and purifying, and preparing the liquor. The method has the effects that the liquor production method disclosed by the invention, in comparison with the conventional solid fermentation distillation technology, can improve the liquor yield by 10-15%; the sewage discharge is reduced by 80%, the labor environment is improved, the production labor is saved, and specifically turbidity can be eliminated in producing low-alcohol liquor; in addition, the product reserves nutrition ingredient and amino acid of the yellow wine, and keeps the style of the liquor; and the product has the advantages of being smooth, mellow and soft in mouthfeel and the liquor 'will not go to the head' after being drunk.

Owner:绍兴国稀酒酿造有限公司

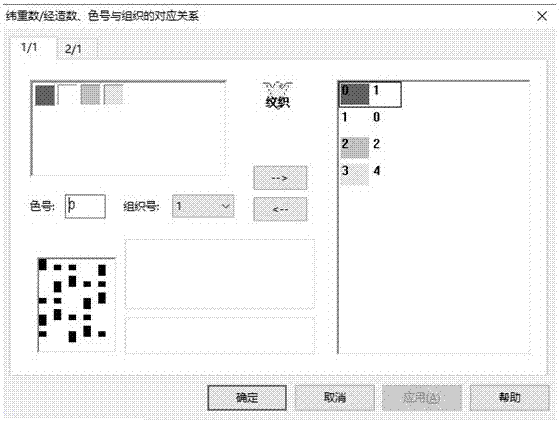

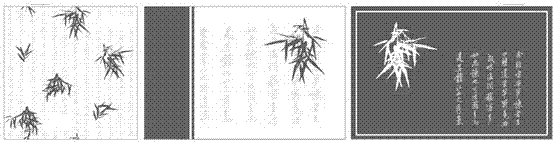

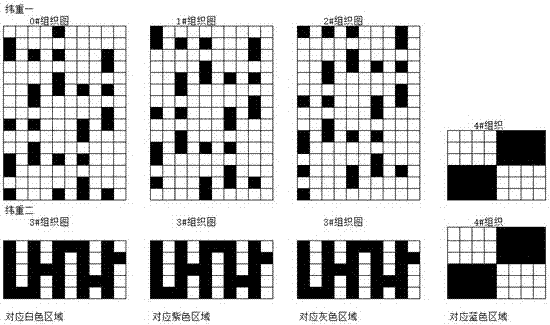

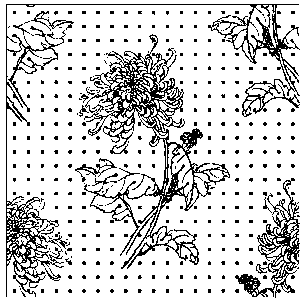

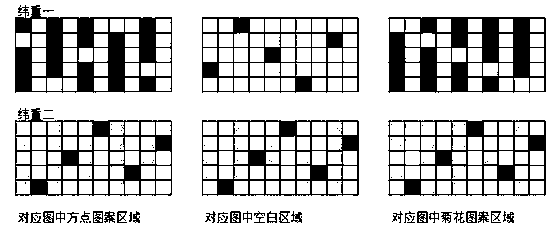

Preparing method of weaving molding home textile products

ActiveCN107299442AReduce production laborLow manufacturing costMulti-ply fabricsDesign innovationWoven fabric

The invention discloses a preparing method of weaving molding home textile products. The method comprises the steps that a woven fabric organizational structure design innovation is combined with a figured weaving technology, a large jacquard loom is used for preparing a stereo structure, home textile set products such as bedding bags and pillowcases are directly woven out, most steps such as cutting, splicing and sewing in home textile production processing are saved, and the preparing method has overturning value significance for the home textile manufacturing industry.

Owner:WEIQIAO TEXTILE

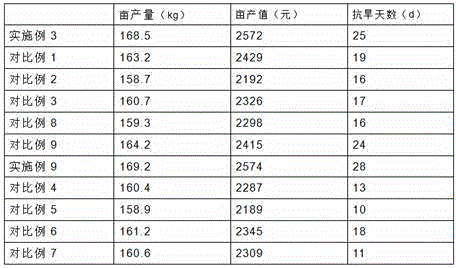

Ratoon rice directly-seeding cultivation method

ActiveCN108432579AReduce production labor intensityReduce labor intensityRice cultivationDiseaseIntermittent irrigation

The invention discloses a ratoon rice directly-seeding cultivation method. The method comprises the following steps: (1) selecting a medium and early-maturing fine variety; (2) finely preparing the soil; (3) directly seeding main rice crop by a precision machine at the appropriate period of the main rice crop from the last ten-day period of March to the first ten-day period of April, and arrangingthe heading and flowering phase of the ratoon rice ratooning season at the latest in the middle of September; (4) carrying out intermittent irrigation; (5) carrying out fertilization in the main cropping season; (6) applying a seedling fertilizer to the ratooning season; (7) harvesting the main rice crop by machine, wherein a low-pile machine harvesting mode is adopted for the main rice crop of ashort growth period variety and a high-pile machine harvesting mode is adopted for the main rice crop of a long growth period variety; (8) treating diseases and pests; and (9) removing weeds. According to the method, the agricultural production labor intensity is greatly reduced, the problems that the labor intensity for rice production is high and the benefit is low are solved. According to themethod, the rice production cost is reduced by 400 yuan per mu, and the labor for rice production is reduced by 70%, so that the production profits of the rice can be more than 500 yuan per mu, and the rapid improvement of the production mechanical level of the regenerated rice is realized.

Owner:福建省农业科学院水稻研究所

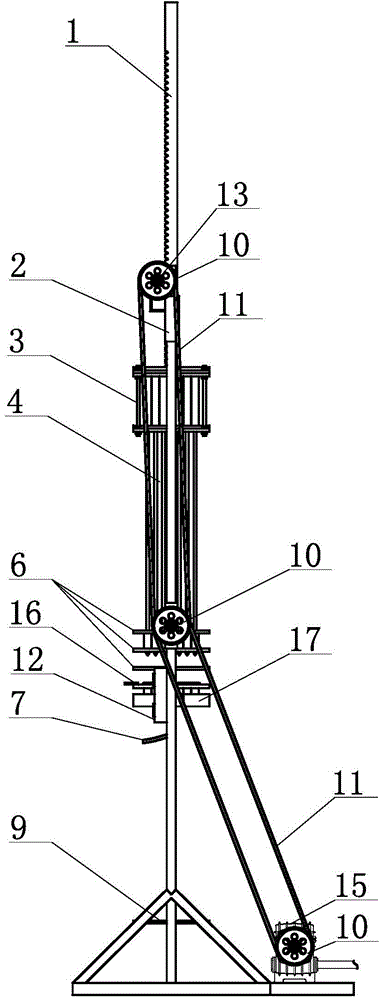

Handheld firework mounting machine

The invention discloses a handheld firework mounting machine, which comprises a frame, a lifting shaft rod which is inserted into the center of the top of the frame, two support connecting pull rods which are fixed on both sides in the frame and are connected vertically, a transmission mechanism which is positioned on one side of the frame and is connected with a driving power structure, and a combined barrel which is arranged in the center of the lower part of the inner side of the frame. The handheld firework mounting machine is characterized in that the two support connecting pull rods in the center segment of the upper part of the inner side of the frame are provided with a mounting structure which is connected with the lifting shaft rod; a carrying plate for carrying the combined barrel is arranged below a corresponding mounting mechanism; a shaping plate is arranged on the lower-middle parts of the two support connecting pull rods respectively; the shaping plates can be used for shaping and fixing the combined barrel below the shaping plates in cooperation with a shaping brazing plate; a combined barrel fixing belt is arranged below each shaping plate; a plurality of mounting accessories are connected with the lower ends of the combined barrel and the mounting mechanisms in sequence in a matching way. The handheld firework mounting machine has the advantages of simple design structure, convenience in operation and use, high production efficiency, reliable product mounting quality, high mechanical running stability, and the like.

Owner:刘宗献

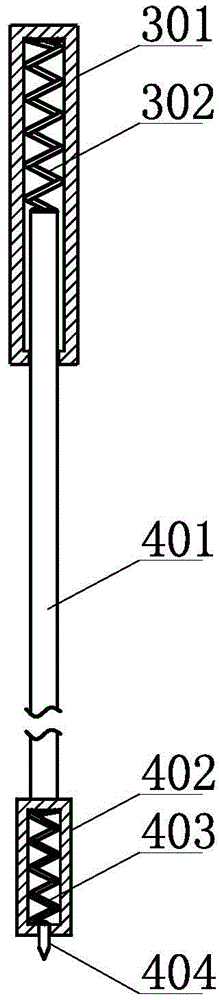

Method for drought resisting transplanting of flue-cured tobacco through agriculture and forestry water-retaining agent

InactiveCN106561231AGuaranteed drought resistance timeHigh transplant survival rateFertilising methodsPlant cultivationEcological environmentBiology

The invention relates to a method for drought resisting transplanting of flue-cured tobacco through an agriculture and forestry water-retaining agent and belongs to the technical field of cultivation of the flue-cured tobacco. The method for drought resisting transplanting of the flue-cured tobacco through the agriculture and forestry water-retaining agent comprises the four steps of determining the dosage of the agriculture and forestry water-retaining agent for flue-cured tobacco cultivation, selecting soil and the agriculture and forestry water-retaining agent, preparing gel of the agriculture and forestry water-retaining agent, and transplanting flue-cured tobacco seedlings. The method is simple and reliable, and by adopting the method to carry out drought resisting cultivation of the flue-cured tobacco, it can be ensured that the drought resisting time after the flue-cured tobacco is transplanted reaches 20 days or over, the yield per mu can be increased by 9.8-13.3 kg, and the output value per mu can be increased by 327.6-448.2 CNY. Meanwhile, the method relieves white pollution, protects the ecological environment of tobacco fields and is easy to apply and popularize.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Semi-automatic hoop machining technology

InactiveCN104209755AReasonable process designEasy to operateAutomatic control devicesFeeding apparatusLow speedControl system

The invention discloses a semi-automatic hoop machining technology which is achieved by the adoption of a semi-automatic hoop machining machine. The semi-automatic hoop machining machine comprises a machine tool, a reaming power head, a tapping power head, a fixed support, a rotary turnplate, a rotary braking control system, an electromagnetic transmission box, a main transmission shaft box, an electrical control system and a power system which is composed of a reaming motor and a tapping motor. The semi-automatic hoop machining technology comprises the steps that a workpiece to be machined is well clamped and pressed, cutting and reaming are conducted through a reaming tool at a low speed after rapid idling feeding of the reaming tool, the reaming tool returns to the original position after reaming, a screw tap rotate forwards to achieve idling feeding and tapping and then returns to the original position when a predetermined tapping length is achieved, the machined workpiece is taken down, another workpiece to be machined is well clamped and pressed, the rotary turnplate is unlocked, transferred to another station and then is locked for standby, and then a whole technological process is completed. According to the semi-automatic hoop machining technology, multi-station synchronous machining can be achieved, two machines can be operated by one worker, the production efficiency can be improved by over one time, the product quality can be effectively improved, the qualified rate of finished products can be effectively increased, labor is saved, and labor intensity is relieved.

Owner:TANGSHAN DAOCHENG PIPE IND +1

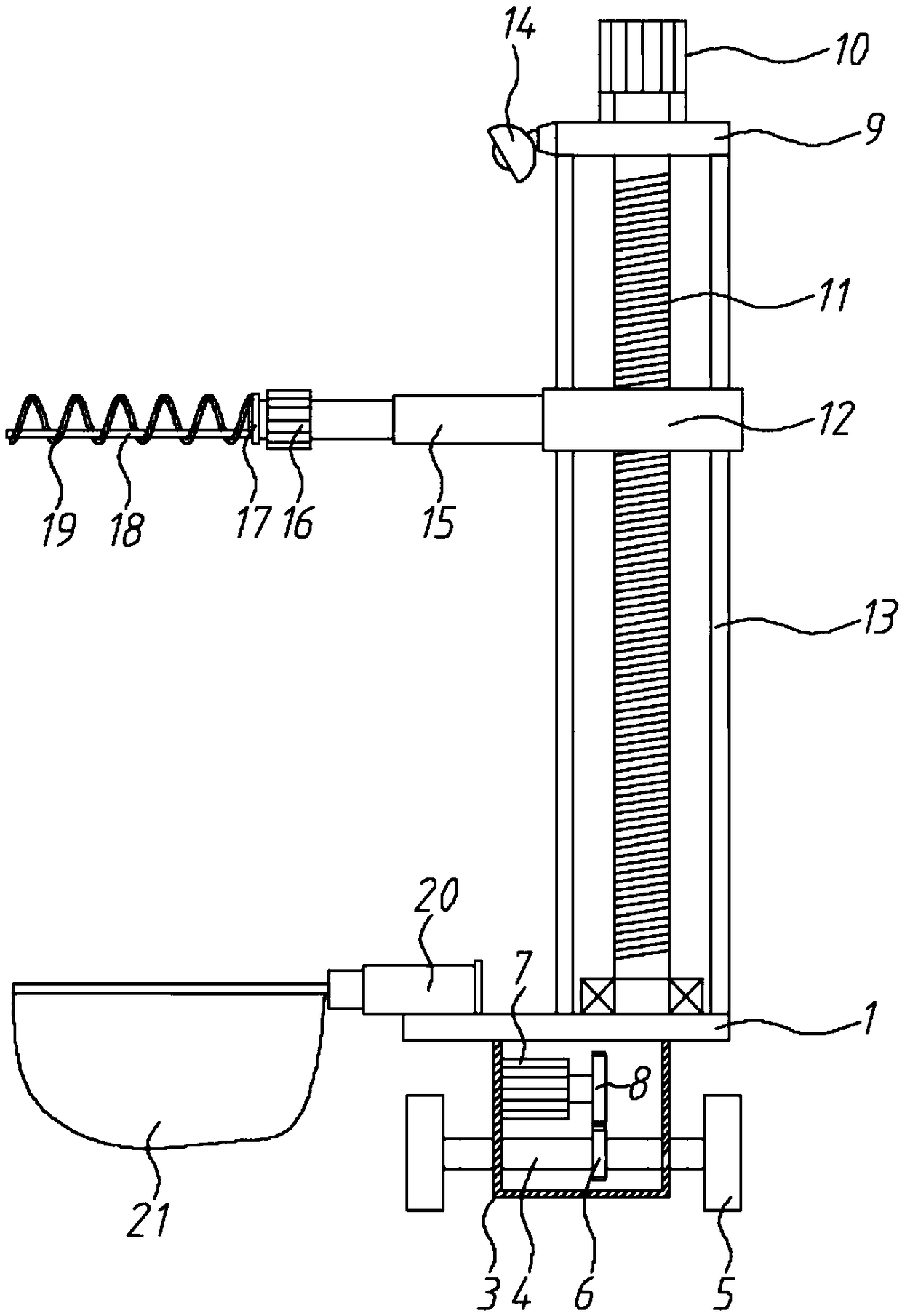

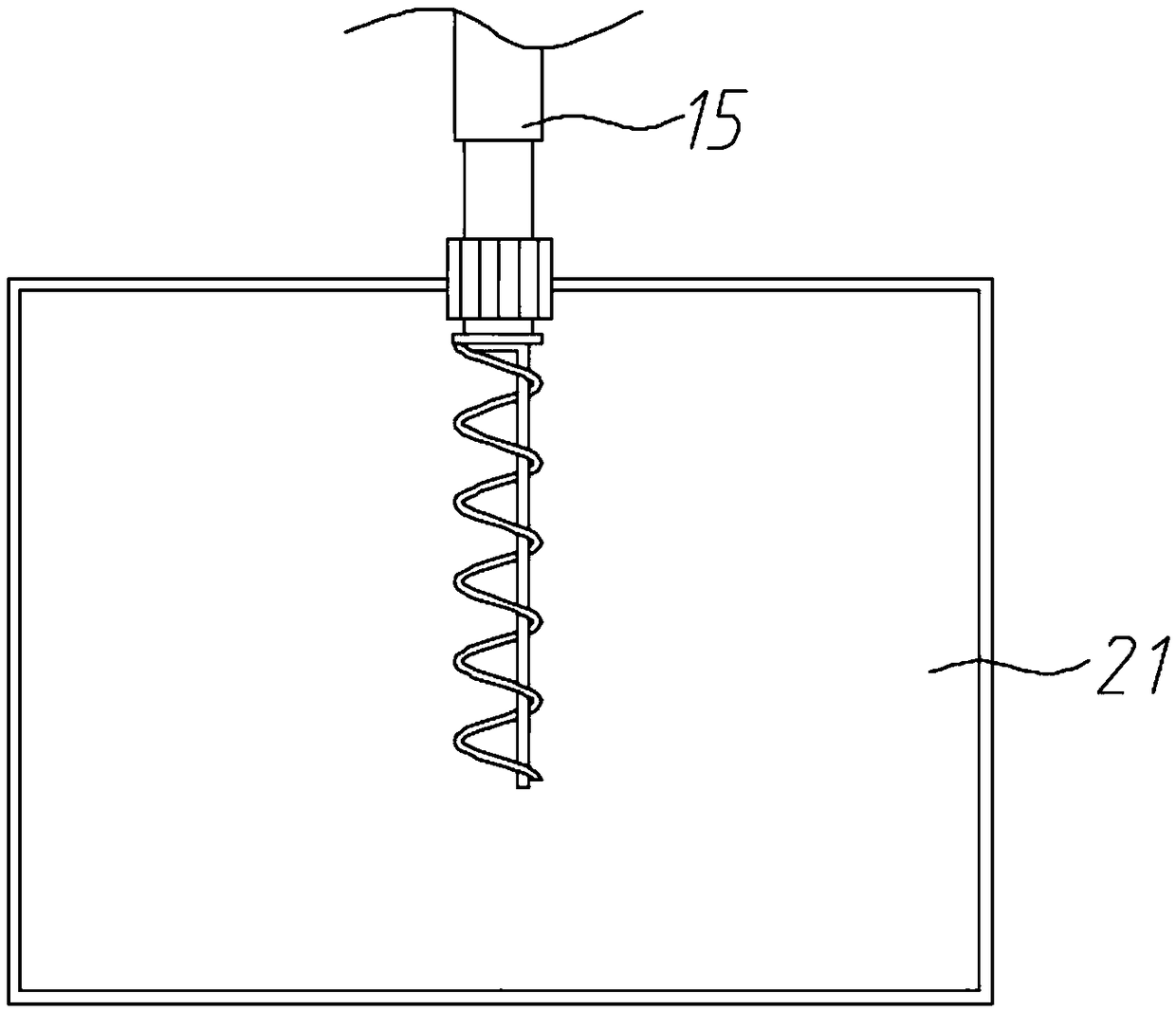

Mechanical blueberry harvesting device

PendingCN108934465AReduce production laborReduce the amount of manual laborPicking devicesEngineeringWorkload

The invention relates to the technical field of blueberry harvesting, in particular to a mechanical blueberry harvesting device. Blueberries are harvested mechanically, not only can manpower for production be greatly saved, but also the problems of manpower shortage and employment difficulty in rural orchards are solved, manpower costs are reduced, and the problem that manual picking is impeded ina plum rain season is effectively solved. A screw rod assembly is adopted for driving a shaking assembly to move up and down, and height adjustment within the height range from 0.5 m to 1.7 m is achieved. Mechanical harvesting is adopted, the shaking assembly drives branches with blueberry fruits to shake, the almost ripe or completely ripe fruits drop into a collecting device, and the manual workload is reduced.

Owner:INST OF GARDENING ANHUI ACADEMY OF AGRI SCI

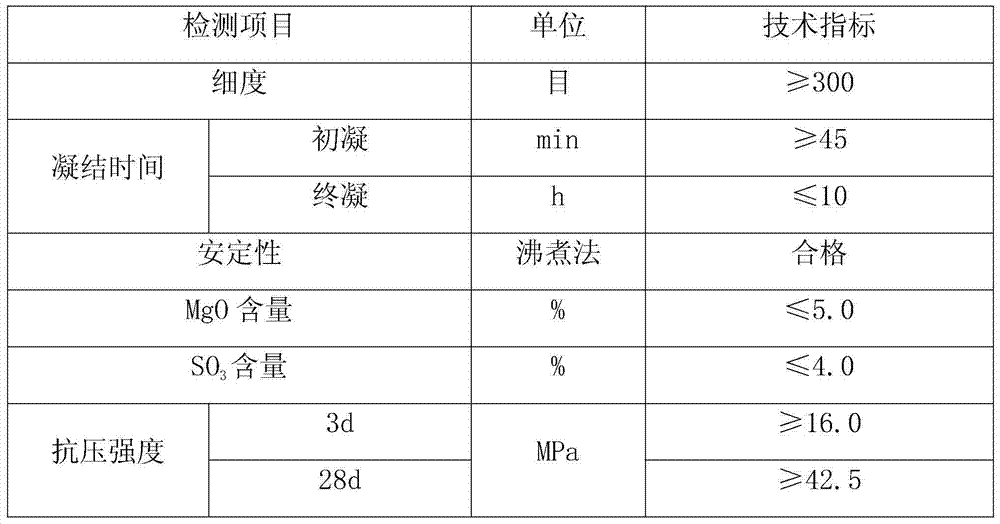

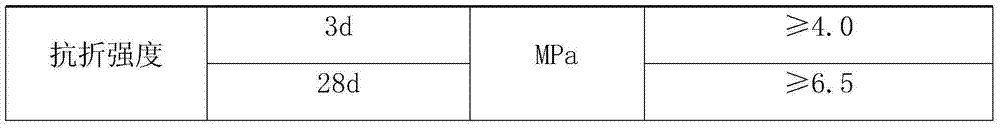

TK-JH mineral interface active material, and preparation method and application method thereof

ActiveCN104496255AOvercoming high heat of hydrationSpeed up the construction periodCircular economyConstruction industry

The invention discloses a TK-JH mineral interface active material, and a preparation method and application method thereof. The TK-JH mineral interface active material is composed of the following components in percentage by weight: 30-60% of sulfate, 20-30% of silicate, 20-30% of plasticizing and water reducing agent, 3-6% of phosphate and 1-3% of alkylol amine salt. The TK-JH mineral interface active material can perform green revolution on the cementing material and foundation work, can make great contribution to energy saving and environmental protection, protection of mine resources, utilization of waste resources, sustainable development of circular economy and great exploits of centuries, and can become historical transitions in sunrise industry of cementing material and application of construction industry new materials in construction industry.

Owner:苏笮斌

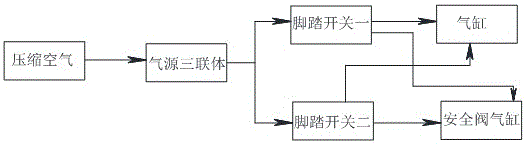

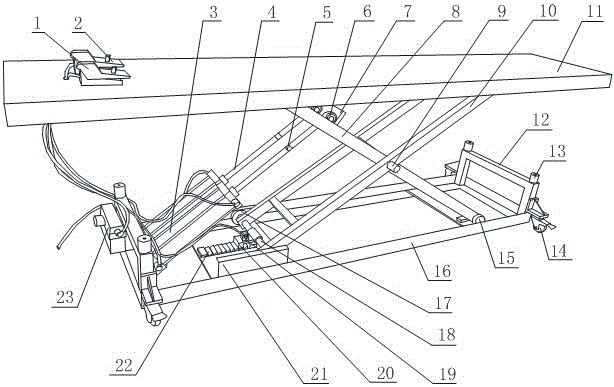

Pneumatic lift platform and lift control method thereof

ActiveCN106379849AImprove space usageIncrease productivityLifting framesUniversal jointSmall footprint

The invention discloses a pneumatic lift platform and a lift control method thereof. A movable support frame is arranged below the lift platform; an underframe is provided with position limiting frames; each position limiting frame is provided with an air source triplet; a connecting plate is arranged between support rods II; the connecting plate is provided with a universal joint; the underframe is provided with air cylinders; a mandril is arranged in each air cylinder; the underframe is provided with a mounting plate; a safety retaining slot is formed in the mounting plate; a safety plate is arranged in the safety retaining slot; a safety valve air cylinder mandril is arranged in a safety valve air cylinder; the safety valve air cylinder mandril is connected with a safety valve; the safety plate is provided with a mounting sleeve; a safety pin is arranged in the mounting sleeve; the safety pin is nested with a pulley; and the lift platform is provided with foot pedals. The pneumatic lift platform disclosed by the invention is capable of obviously increasing production efficiency, saving productive labor force, increasing production quality and ensuring continuity of production, and is small in occupied area, saving in used field, convenient to use, energy-saving, environmental friendly, high in safety factor, high in load and stable to operate.

Owner:SICHUAN TIANQIANG GLASS

Seamless home textile kit with three sutureless sides and preparation method of kit

InactiveCN108823730AReduce consumptionIncrease productivityBlanketBed linenManufacturing cost reductionEngineering

The invention relates to a seamless home textile kit with three sutureless sides. The home textile kit comprises a quilt cover and a pillowcase which are of a sleeve-shaped structure; in a texture structure, an upper fabric is of a jacquard structure, a lower fabric is of a plain weave structure, the upper and lower fabric structures are combined and interlaced into a single layer on the edge of the kit, and cutting lines are reserved between kits. According to the kit, a part of labor-consuming and time-consuming processes, such as cutting and sewing, in the process of manufacturing the hometextile kit are eliminated, the labor for production can be significantly reduced, and the manufacturing cost is reduced; the home textile processing time can be shortened by 23%, and the home textileprocessing cost is reduced by 20%.

Owner:WEIQIAO TEXTILE

Chamfering device of automobile chassis supporting frame

PendingCN109332750AEffectively fixedRealize chamferBoring/drilling machinesManufacturing technologyRolling chassis

The invention discloses a chamfering device of an automobile chassis supporting frame and relates to the technical field of automobile manufacturing. The chamfering device comprises a base. The base is provided with a sliding and moving mechanism. The middle of the base is fixedly provided with a clamping base. Supports are symmetrically arranged on the sliding and moving mechanism leftwards and rightwards. The supports are internally provided with sliding grooves. The sliding grooves are internally connected with lifting mechanisms in a sliding manner. The lifting mechanisms are connected with rotating motors. Output shafts of the rotating motors are provided with drill rods. The chamfering device is simple in structure and convenient to operate, chamfering can be carried out on holes indifferent positions of the automobile chassis supporting frame, it does not need to repeatedly move the automobile chassis supporting frame, the production labor force is reduced, and the production efficiency is improved.

Owner:WUHU YUANSHAN MACHINERY MFG CO LTD

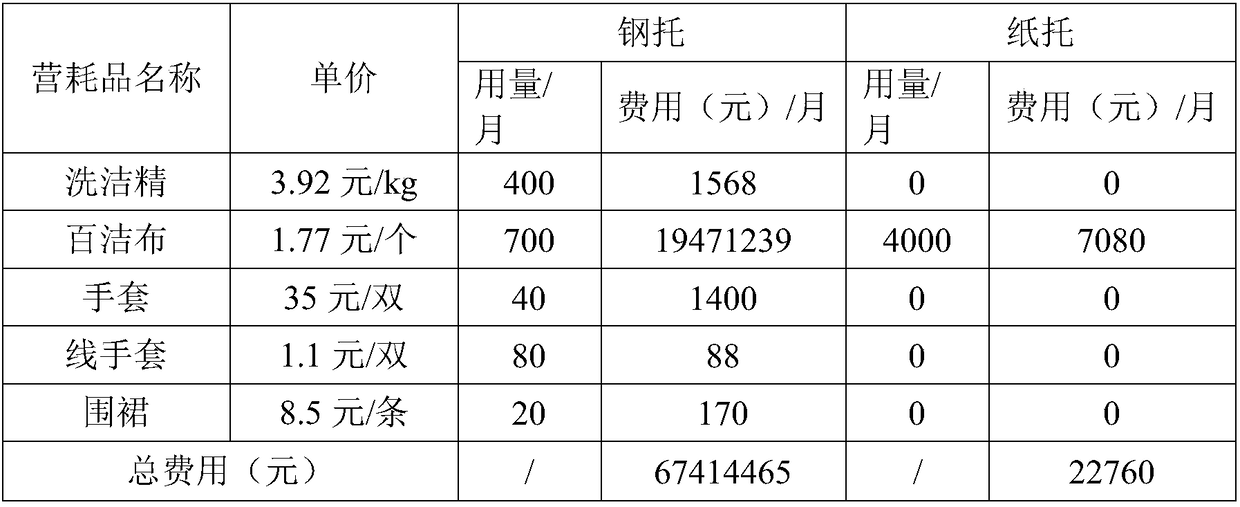

Technological method for preparing cake bases by using paper cake cups instead of steel moulds

InactiveCN108477269AReduce production laborSave mold footprintBakery productsBaking-tinsPlastic packagingCooking & baking

The invention discloses a technological method for preparing cake bases by using paper cake cups instead of steel moulds. The technological method for preparing cake bases by using paper cake cups instead of steel moulds comprises the following steps of filling flour paste into paper cake cups by using equipment, such as a stuffing filling machine and the like, or by manpower; directly carrying out high-temperature baking by using an oven so as to have cake bases shaped; putting the baked cake bases into cooling equipment or a cooling room, and carrying out cooling until the central temperature of the cake bases falls within the range of 5 DEG C below room temperature and 5 DEG C above room temperature; packing the cake bases by adopting a paper or plastic packaging material by using a packaging machine or by manpower; storing the cake bases at normal temperature or under refrigerated or frozen conditions; and distributing the stored cake bases to the customers. The cake bases can be directly eaten or processed by the customers by tearing off the paper cups outside the cake bases. The technological method for preparing cake bases by using paper cake cups instead of steel moulds improves mould turnover rate and cleanliness during production process, reduces production manpower, consumable supply cost and product loss rate, and ensures cake base quality; and thus, the technological method is applicable for preparation of cake bases.

Owner:武汉市仟吉食品有限公司

Industrial automation production equipment and production method used for lignite fine-drying and quality-improving moulding

InactiveCN102585954AReduce moisture contentHigh calorific valueSolid fuelsSpontaneous combustionBriquette

The invention relates to industrial automation production equipment and a production method which are used for lignite-drying and quality-improving moulding. The industrial automation production equipment mainly comprises a belt deironing conveyor, a belt conveyor, a coarse grinding machine, a classifying screen, a hoisting machine, main equipment 1-3-stage fine drying machine, a wet-type separating and aggregating device and a dust-removing purifying chamber, wherein a fine lignite dry powder storage silo and a moulding machine are successively arranged and connected in a technological process; and the lignite is converted into briquette, wherein the original all water of lignite is reduced to less than 10wt% from less than 65wt% by virtue of the 1-3-stage fine drying machine, hydrophilicity which is smooth outside and coarse inside and is compact outside and loose inside is changed into hydrophobicity, and surface property is converted into the property similar to excellent bituminite. The equipment provided by the invention has unique and novel structure, high drying efficiency and low cost; a product is difficult to absorb water, spontaneous combustion and heat value are greatly improved, and the problems of weathering, spontaneous combustion, transportation, storage, great investment and high cost are comprehensively solved. The equipment and method provided by the invention can be widely applied to lignite dehydration moulding in power plants at home and aboard and other boilers, and the equipment provided by the invention is dehydration drying and quality improving technical equipment of a new generation.

Owner:何永峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com