Composite extracting method for plant leaf protein and its use on hybrid giant napier

An extraction method and composite extraction technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of low protein extraction rate, high energy consumption and high production cost, and achieve low production labor, low energy consumption and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

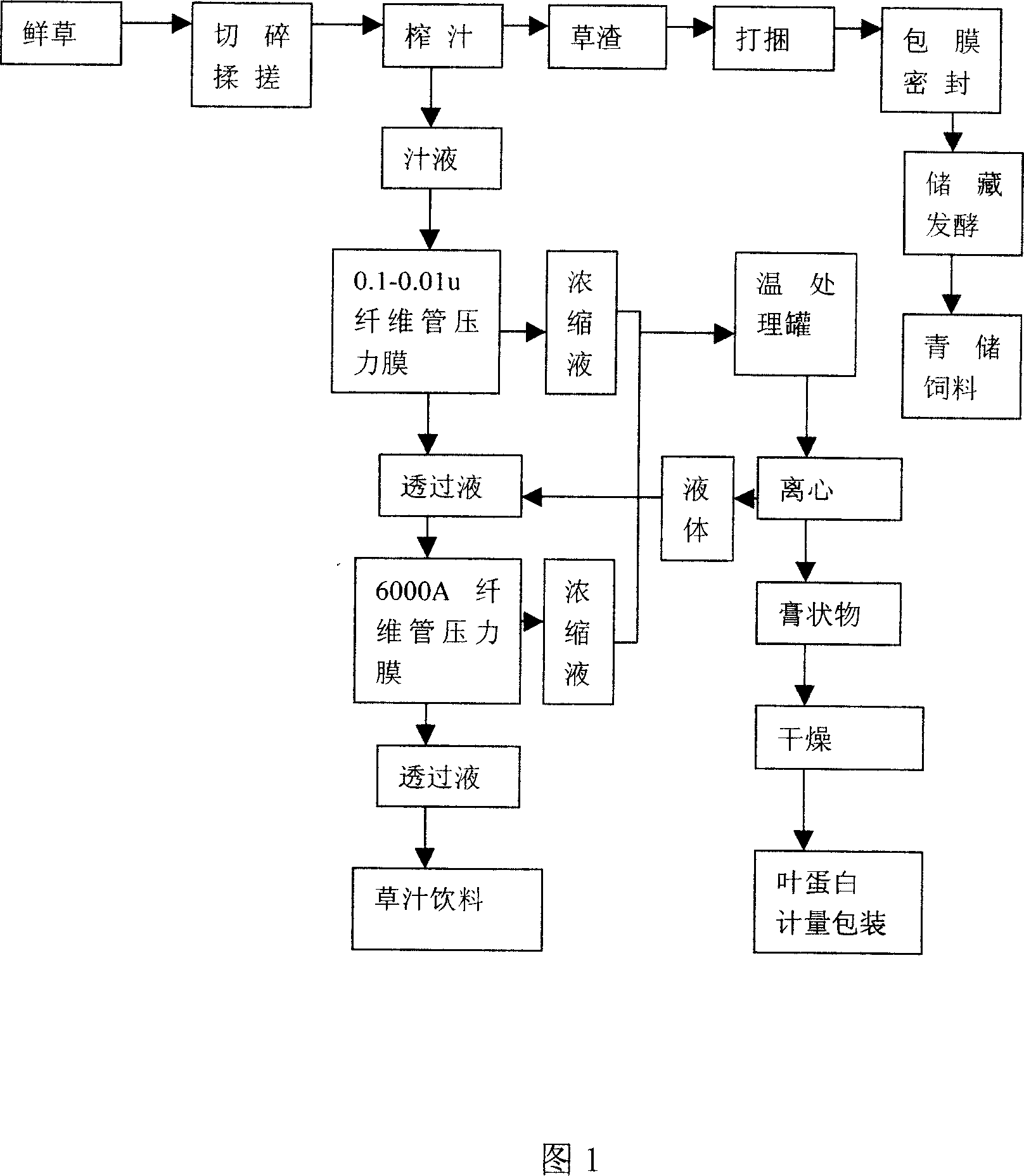

[0031] Cut off the 1.3-1.5m high bamboo grass plant, wash the dust and soil with a high-pressure water gun, send 1 ton of fresh grass to the chopping and kneading machine, and transport the kneaded material to the hydraulic juicer to squeeze the juice. The obtained juice is 600-700kg, and the residue is 300-400kg. The grass residue is directly used to make silage feed with a baler and a coating machine. Filtration through a pressure membrane with a fiber tube with a diameter of 0.540-640kg is used to make the sports drink of Huangzhucao grass juice. ), 45°C (10 minutes), and 75°C (5-8 minutes) are the three best coagulation points, and then enter the stacked high-speed centrifuge (4000-7000r / m), centrifugal separation, the liquid part returns to 6000 Dal Filtrate again in the film, and the paste part enters the spray drying tower for drying (inlet air temperature 190-220°C, outlet air temperature 75-85°C, the dried product is light green to light yellow powder product, weight ...

Embodiment 2

[0033] Cut off the alfalfa plants in full flowering stage, wash the dust and soil with a high-pressure water gun, send 1 ton of fresh grass to the chopping and kneading machine, and send the kneaded material to the beater, and add water according to the grass-to-water ratio of 1:1 for beating , and then send the slurry into a plate and frame filter press to press and squeeze the juice to obtain 1600-1650kg of juice and 350-400kg of grass residue. The grass residue is directly used to make silage feed with a baler and a coating machine. Filtration and concentration in a 0.1-0.01u fiber tube pressure membrane, and the permeate is filtered through a 6000-dalton pore diameter fiber tube pressure membrane. The permeate is about 1540-1640kg and used to make Huangzhu grass juice sports drinks. The concentrate is twice Combine about 60kg together, transport to the temperature treatment tank for temperature treatment, 55°C (10 minutes), 80°C (5-8 minutes) are the two best coagulation po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com