Patents

Literature

767 results about "Low protein" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

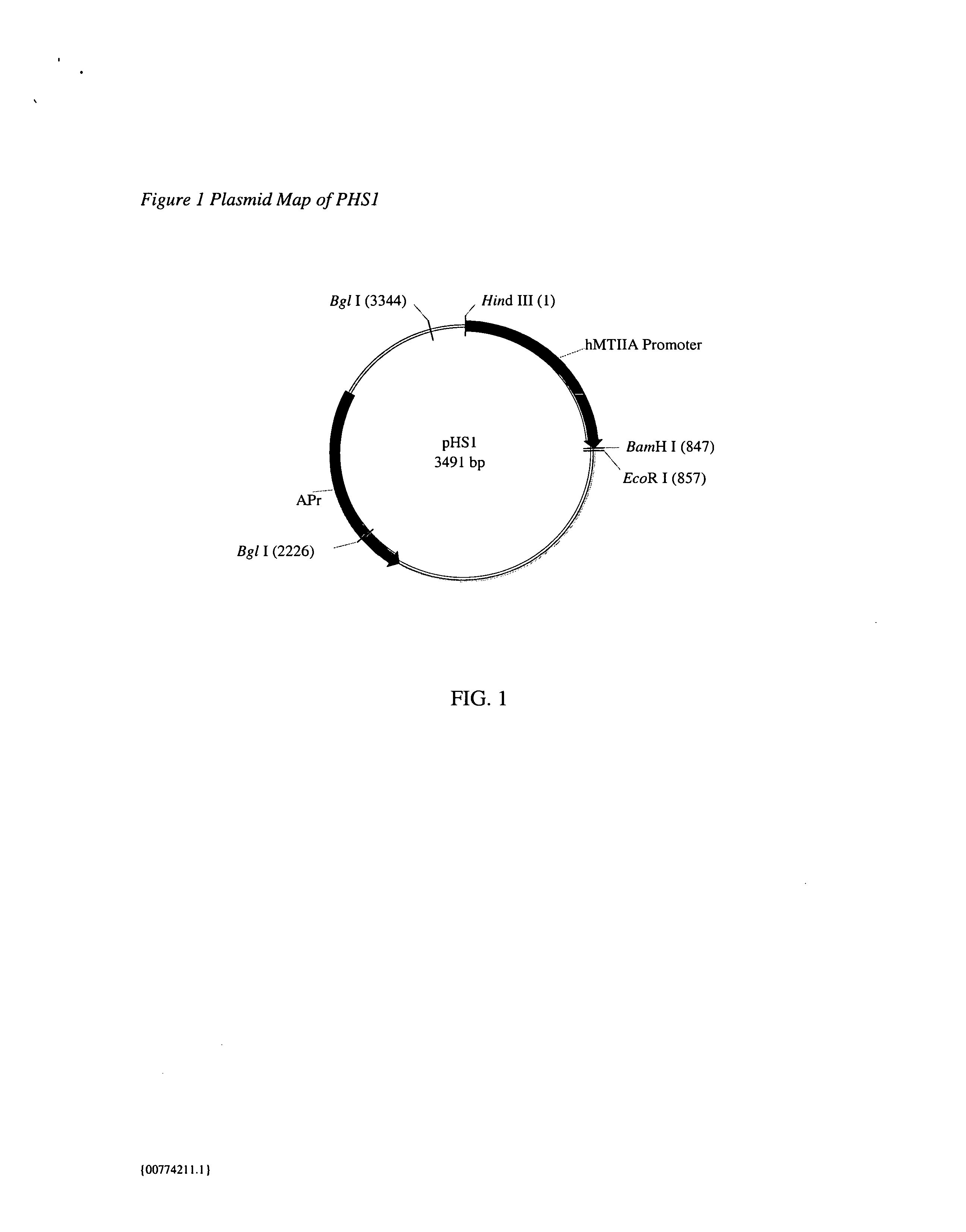

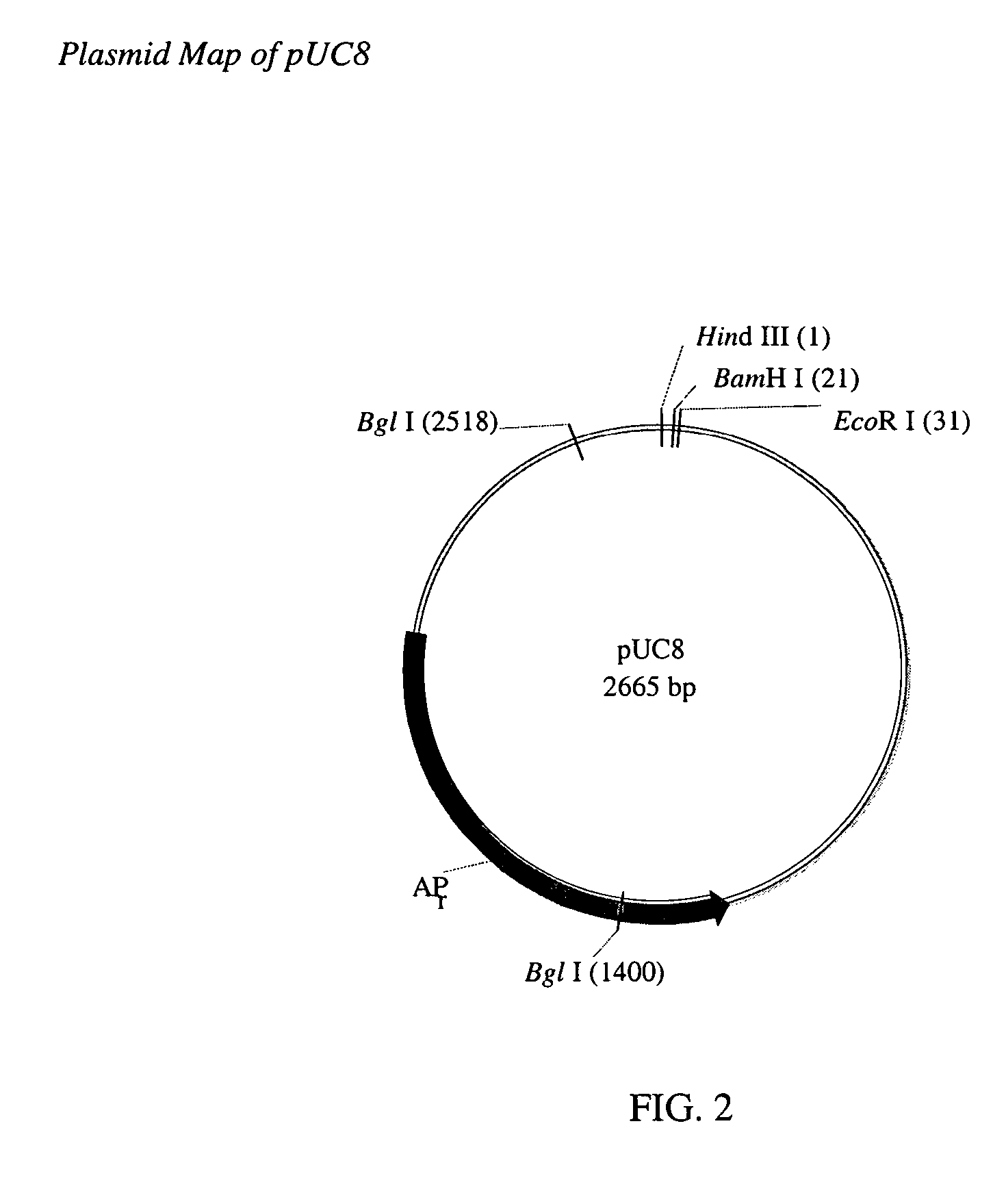

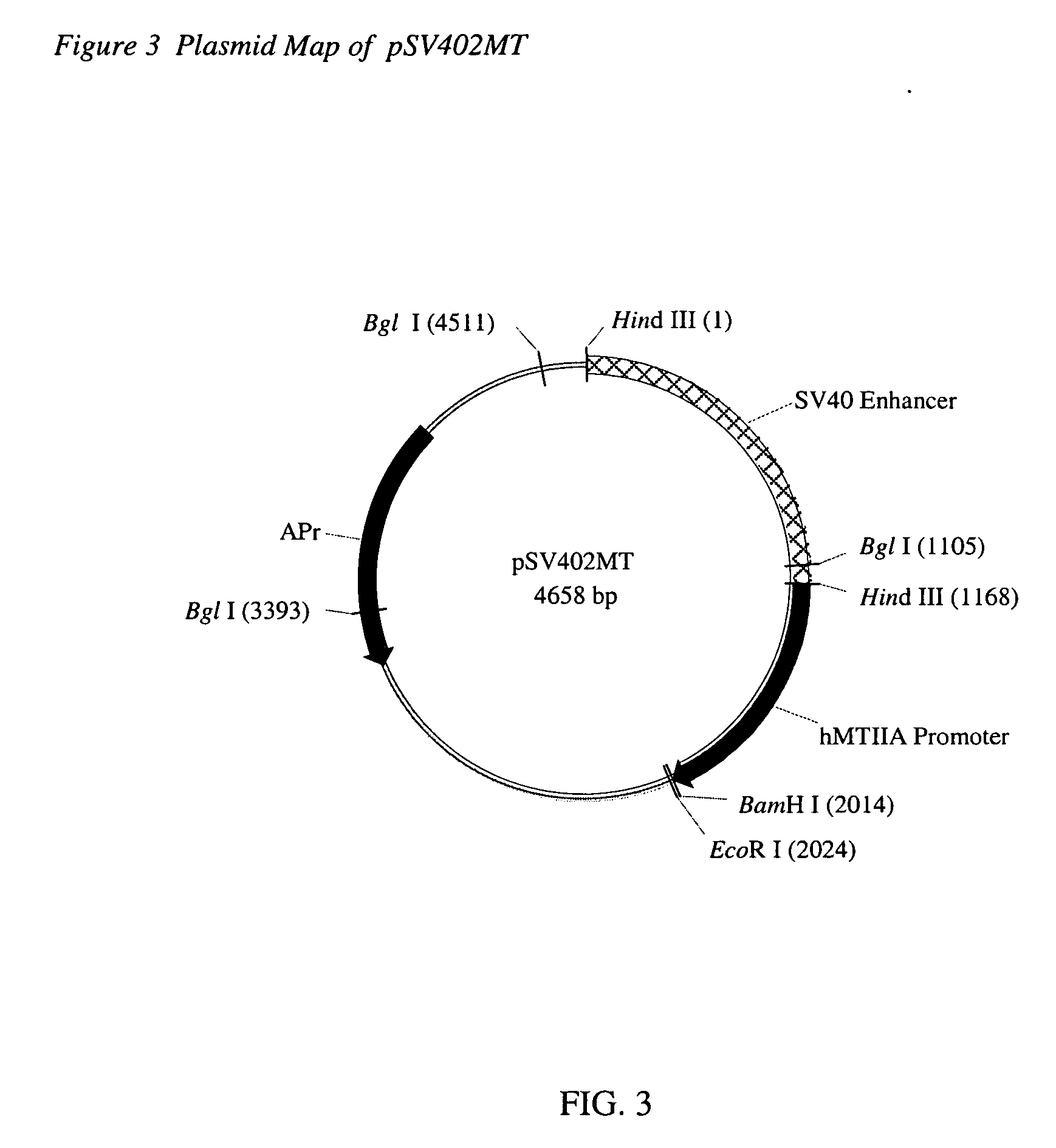

Cell lines for expressing enzyme useful in the preparation of amidated products

InactiveUS20060292672A1High expressionGood for survivalAnimal cellsSugar derivativesPeptidylglycine alpha-amidating monooxygenaseChemical compound

Cell lines are provided for expressing peptidylglycine alpha-amidating monooxygenase (PAM), or one of its two catalytic domains. High levels of enzyme expression are achieved while utilizing a non-animal source, low protein tissue culture medium. A robust two-step downstream purification results in high enzyme purity. Resulting PAM, or its PHM catalytic domain, is used to catalyze the enzymatic conversion of X-Gly to X-alpha-hydroxy-Gly or X—NH2 (X being a peptide or any chemical compound having a carbonyl group to which a glycine group can be covalently attached). Methods of preparing preferred cell lines are also set forth.

Owner:ENTERIS BIOPHARMA

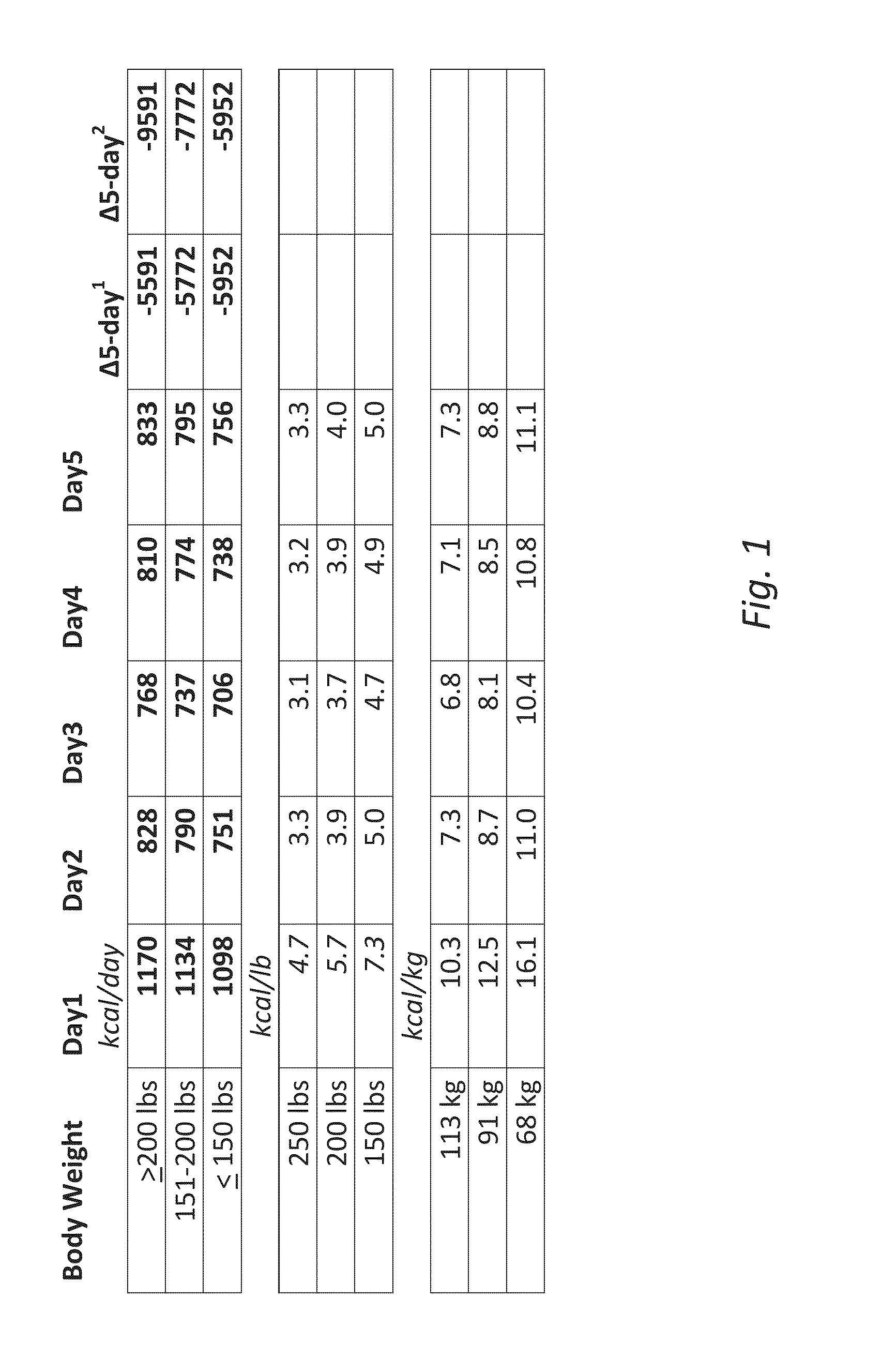

Methods and Diets to Protect Against Chemotoxicity and Age Related Illnesses

ActiveUS20140227373A1Relieve symptomsLowering glucoseHeavy metal active ingredientsBiocideAge related diseaseProtein intake

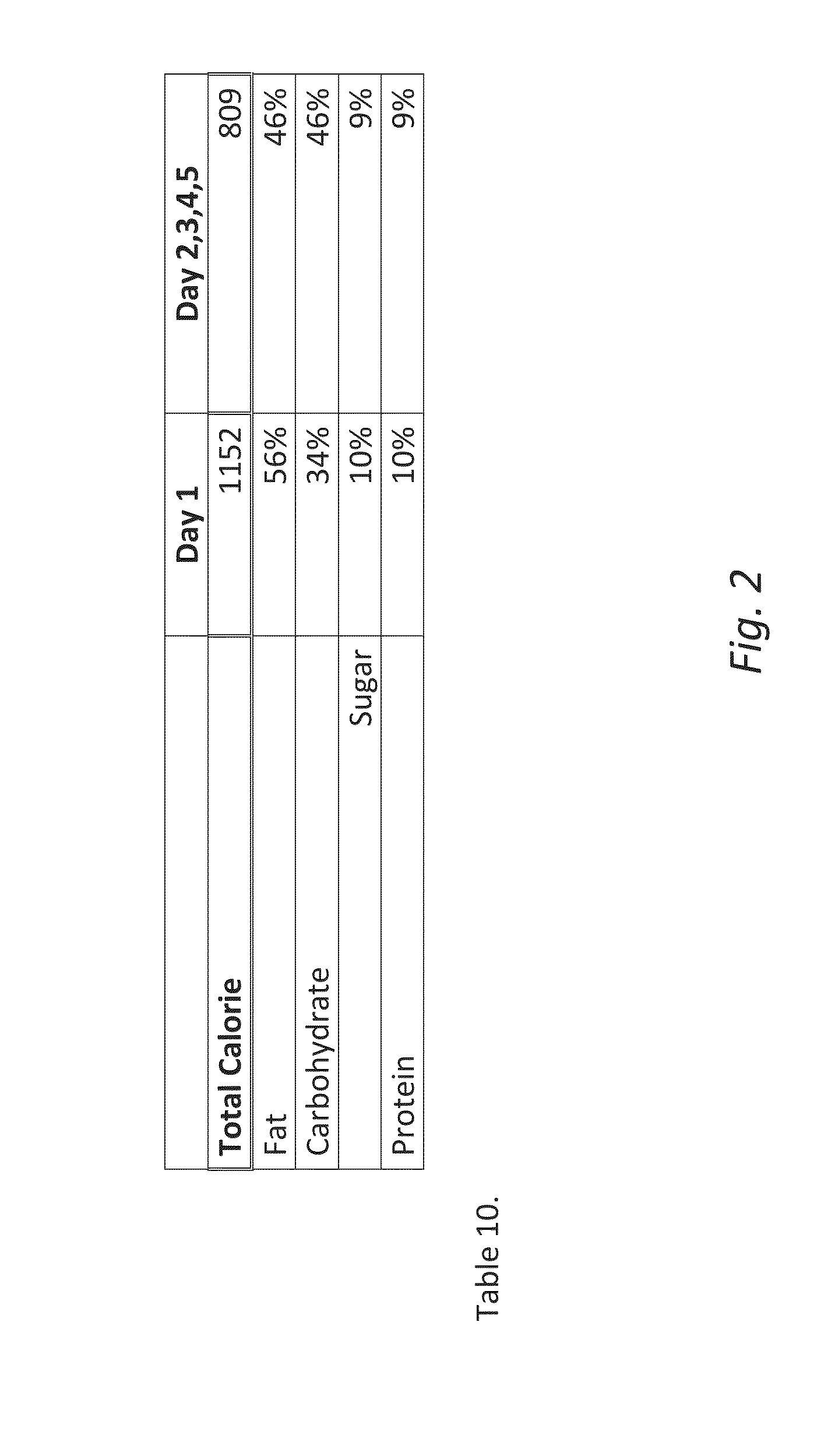

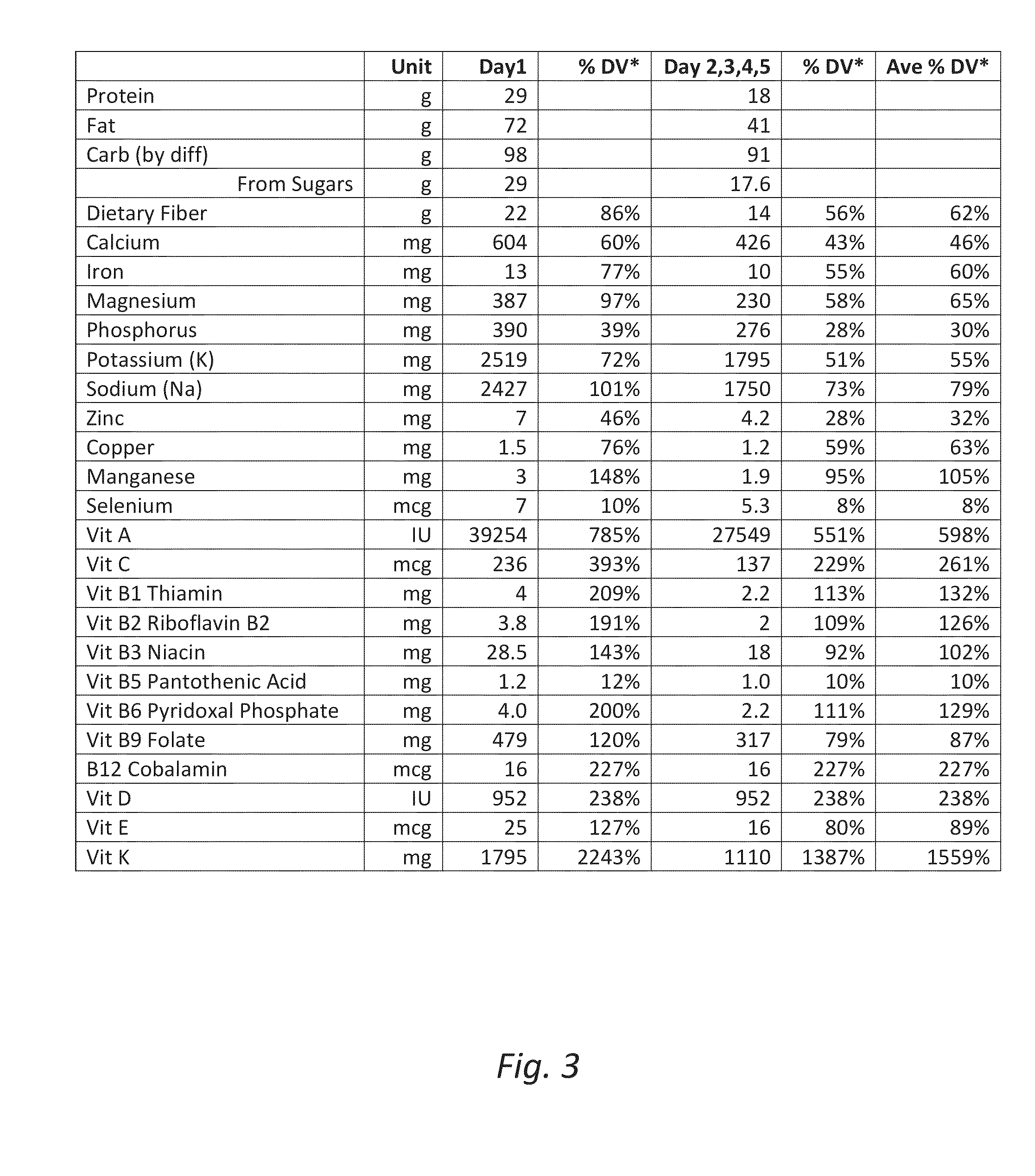

A method of improving longevity and / or alleviating a symptom of aging or preventing age related diseases is provided. The method includes a step in which the subject's average and type of daily protein intake, IGF-I, and IGFBP1 levels, and risk factors for overall mortality, cancer and diabetes are determined. With respect to protein consumption, the relative amounts of protein calories from animal and plant sources are determined. A periodic normal calorie or low calorie but low protein fasting mimicking diet with frequencies of every 2 weeks to 2 months is provided to the subject if the subject's average daily protein intake level and type and / or IGF-I levels, and / or IGFBP1 levels is identified as being greater or lower than a predetermined cutoff intake / level and if the subject is younger than a predetermined age. The method is also shown to alleviate symptoms of chemotoxicity.

Owner:UNIV OF SOUTHERN CALIFORNIA

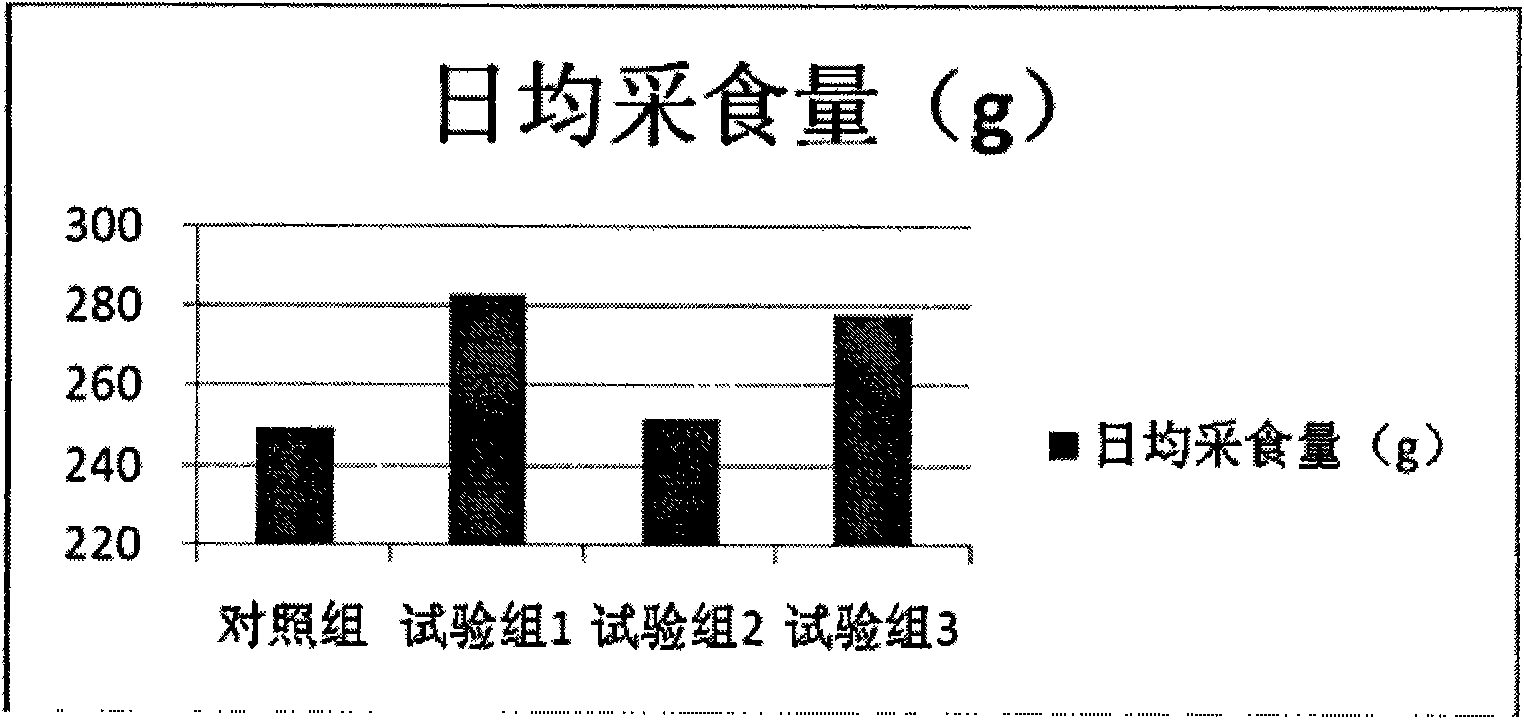

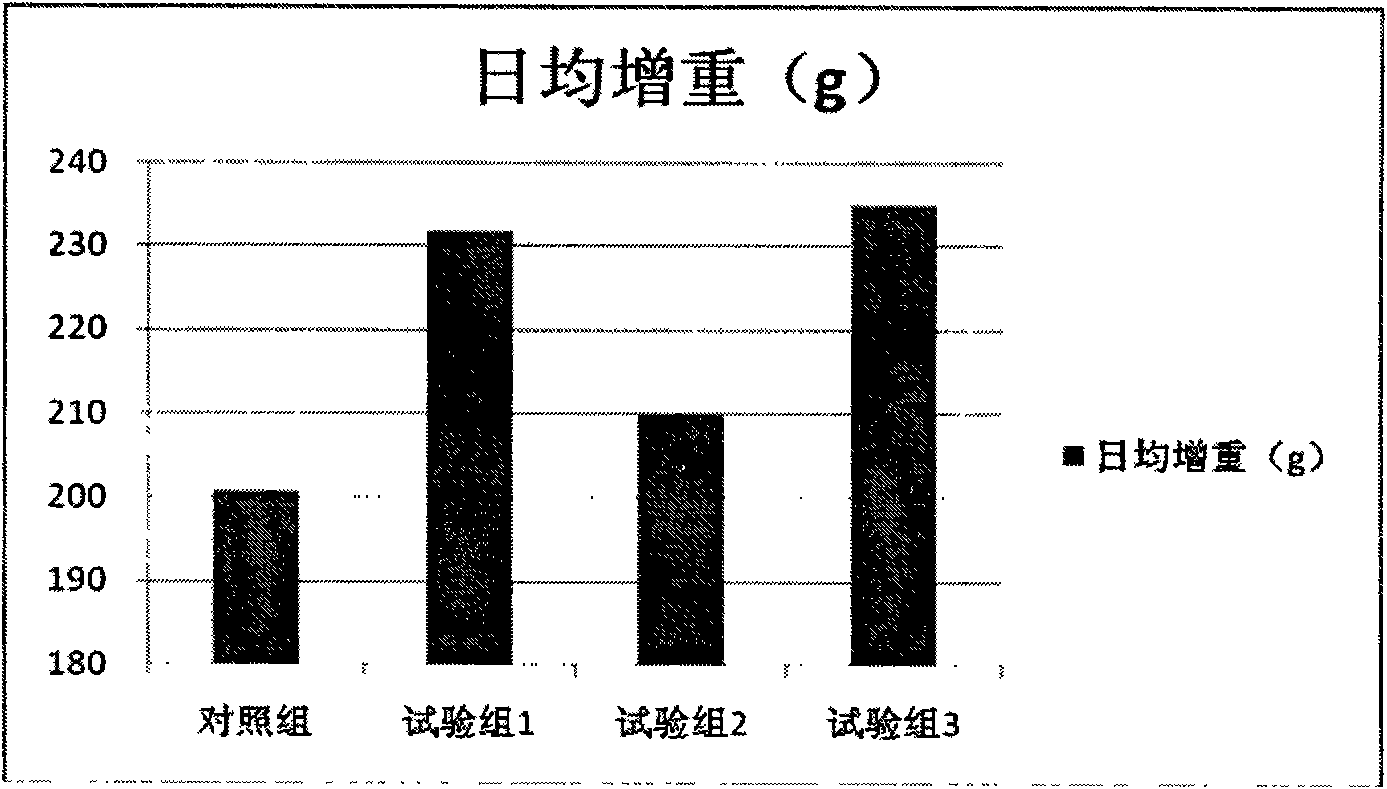

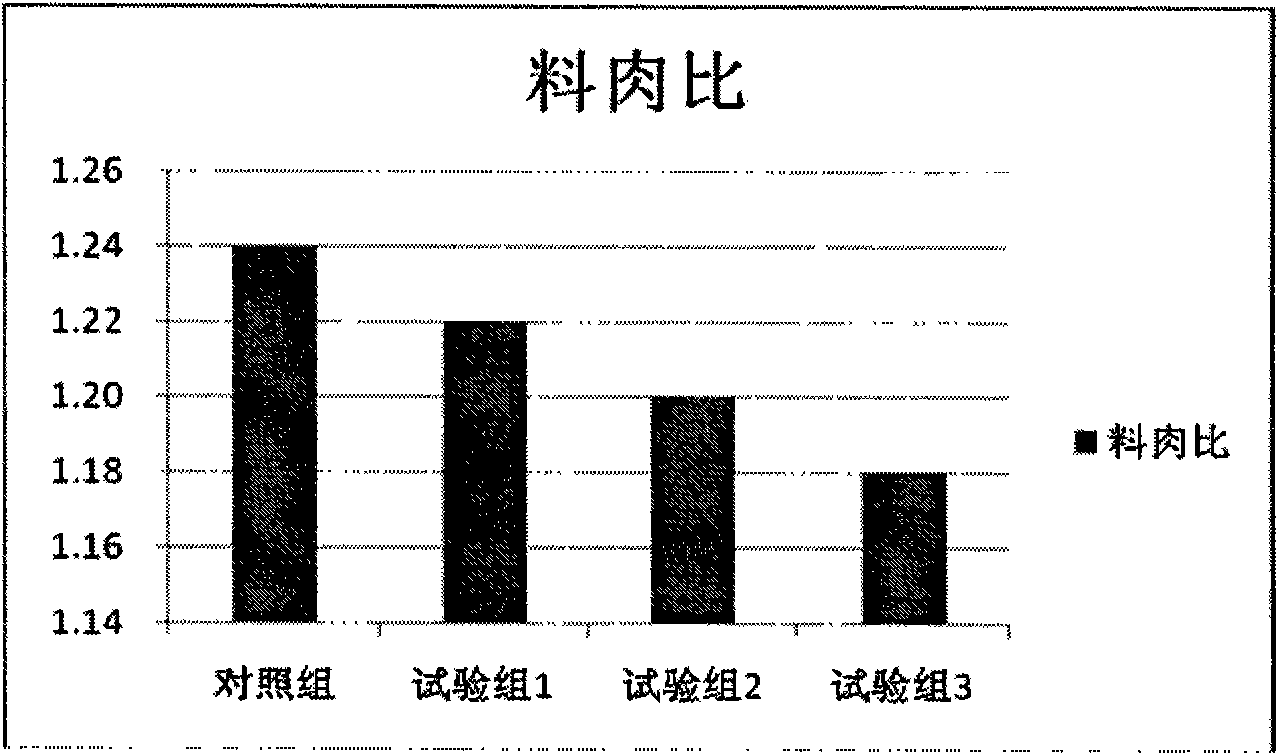

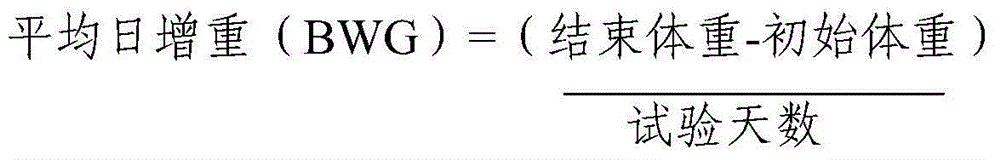

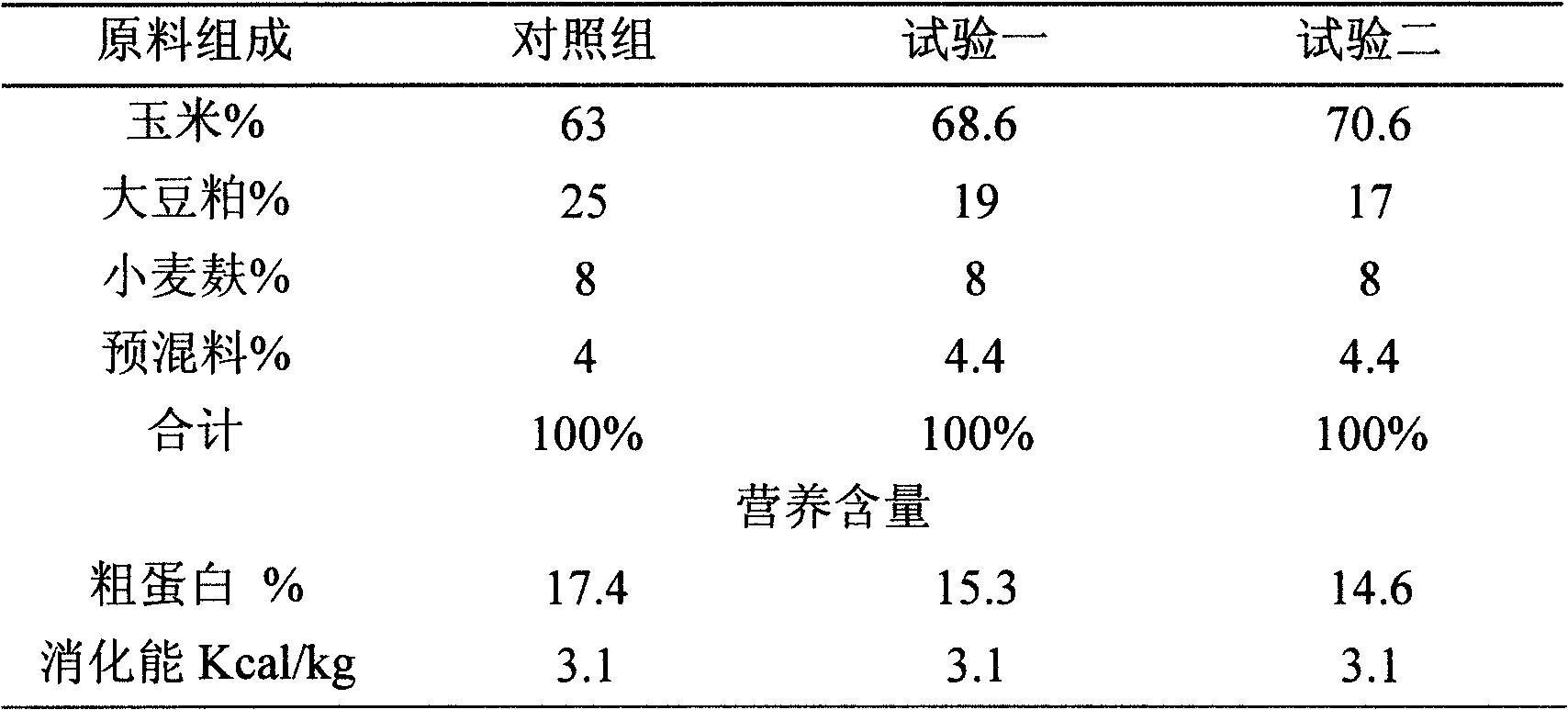

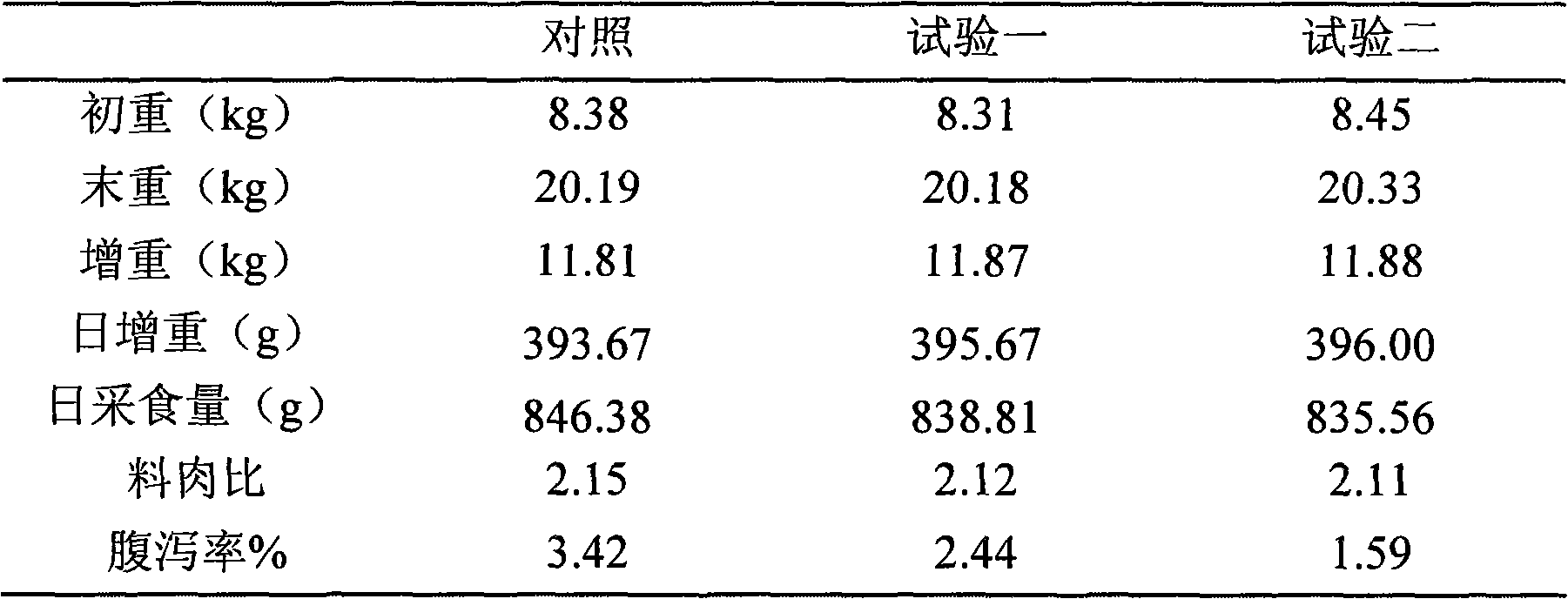

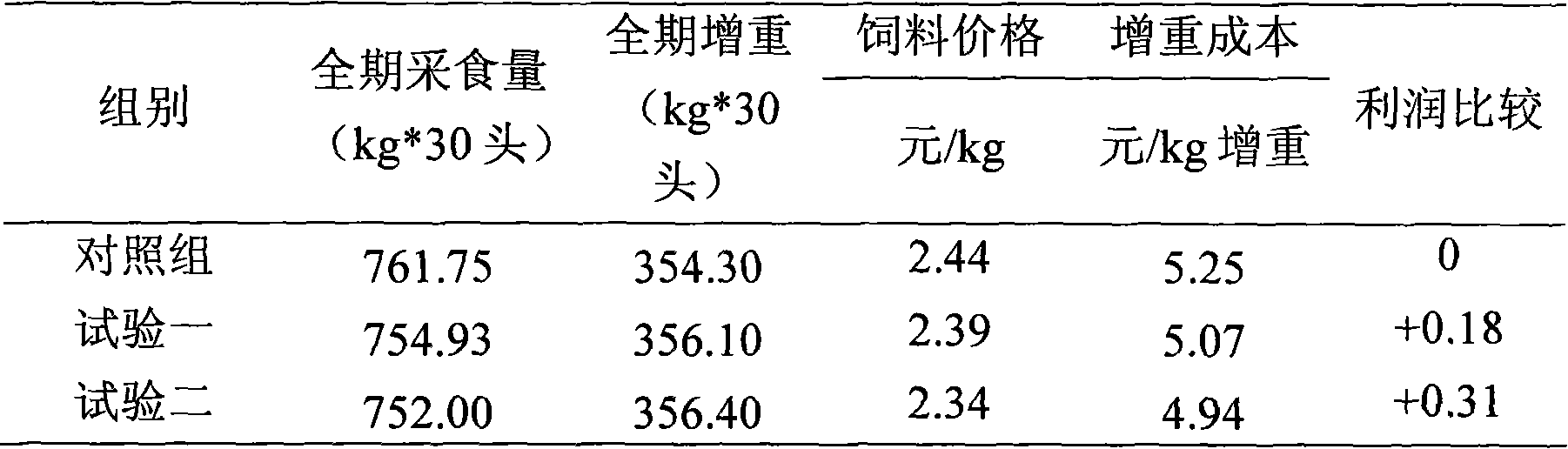

Low protein ration premix compound for growing pigs and using method thereof

The invention provides a low protein ration premix compound for growing pigs and a using method thereof. The low protein ration premix compound consists of mountain flour, calcium hydrophosphate, salt, sodium bicarbonate, L-lysine hydrochloride, DL-methionine, L-threonine hydrochloride, L-tryptophan hydrochloride, an antioxidant and the like. The crude protein content of the prepared growing and fattening pig ration is respectively reduced from 16.4 percent to 14.5 percent and from 15.4 percent to 12.5 percent. The invention aims to add commodity amino acid to produce the low protein ration premix compound to enlarge the applicability of the low protein ration technology and improves the conversion efficiency of the ration, reduces the use of the protein raw materials, reduces the feeding cost and reduces discharge by reducing the concentration of the crude protein of the prepared ration.

Owner:北京资源亚太饲料科技有限公司

Microporous membrane substrate having caustic stable, low protein binding surface

The present invention provides porous media or membranes having a surface coating that includes a first coating of a cross-linked terpolymer and a second coating comprising a copolymer or a terpolymer modified with a hydrophilic or hydrophobic functional group which has a superior combination of properties, including heat stable biomolecule resistant adsorptive properties, resistance to strong alkaline solutions, and low levels of extractable matter.

Owner:MILLIPORE CORP

Microporous membrane substrate having caustic stable, low protein binding surface

InactiveUS20050133441A1Superior combination of propertyLow levelMembranesUltrafiltrationCross-linkPorous medium

The present invention provides porous media or membranes having a surface coating that includes a first coating of a cross-linked terpolymer and a second coating comprising a copolymer or a terpolymer modified with a hydrophilic or hydrophobic functional group which has a superior combination of properties, including heat stable biomolecule resistant adsorptive properties, resistance to strong alkaline solutions, and low levels of extractable matter.

Owner:MILLIPORE CORP

Porket premix compound and porket creep feed prepared by the premix compound

ActiveCN101584417AIncrease feed intakeImprove microenvironmentFood processingAnimal feeding stuffWeaningDigestion

The present invention provides a porket premix compound and a porket creep feed prepared by the porket premix compound. The porket premix compound is composed of the components of a yeast powder, an energy-nutrient accelerating agent, a flavoring agent, minor elements, etc. The porket creep feed is composed of the components of swelled corn flour, swelled soybean flour, swelled wheat flour, low-protein whey powder, porket premix compound, etc. The porket premix compound of the invention fully takes the electrolyte balance into consideration; supplies various minor elements and vitamins required by the porket, promotes the growth and is used for preparing the excellent proket creep feed. The general dosage is 1% of the weight of the porket creep feed. At least 85% of the porket creep feed passes through a 60 mesh sieve so that the granularity of the feed stuff is smaller and the absorption of the porket to the nutrition substance is facilitated. The porket creep feed further has the advantages of sustaining the integrality of the mucous membrane, overcoming the weaning stress, increasing the feed intake, increasing the digestion and absorption rate, reducing the feed-meat ratio, realizing the effect of continuous body weight growing after the weaning.

Owner:河南雄峰科技股份有限公司

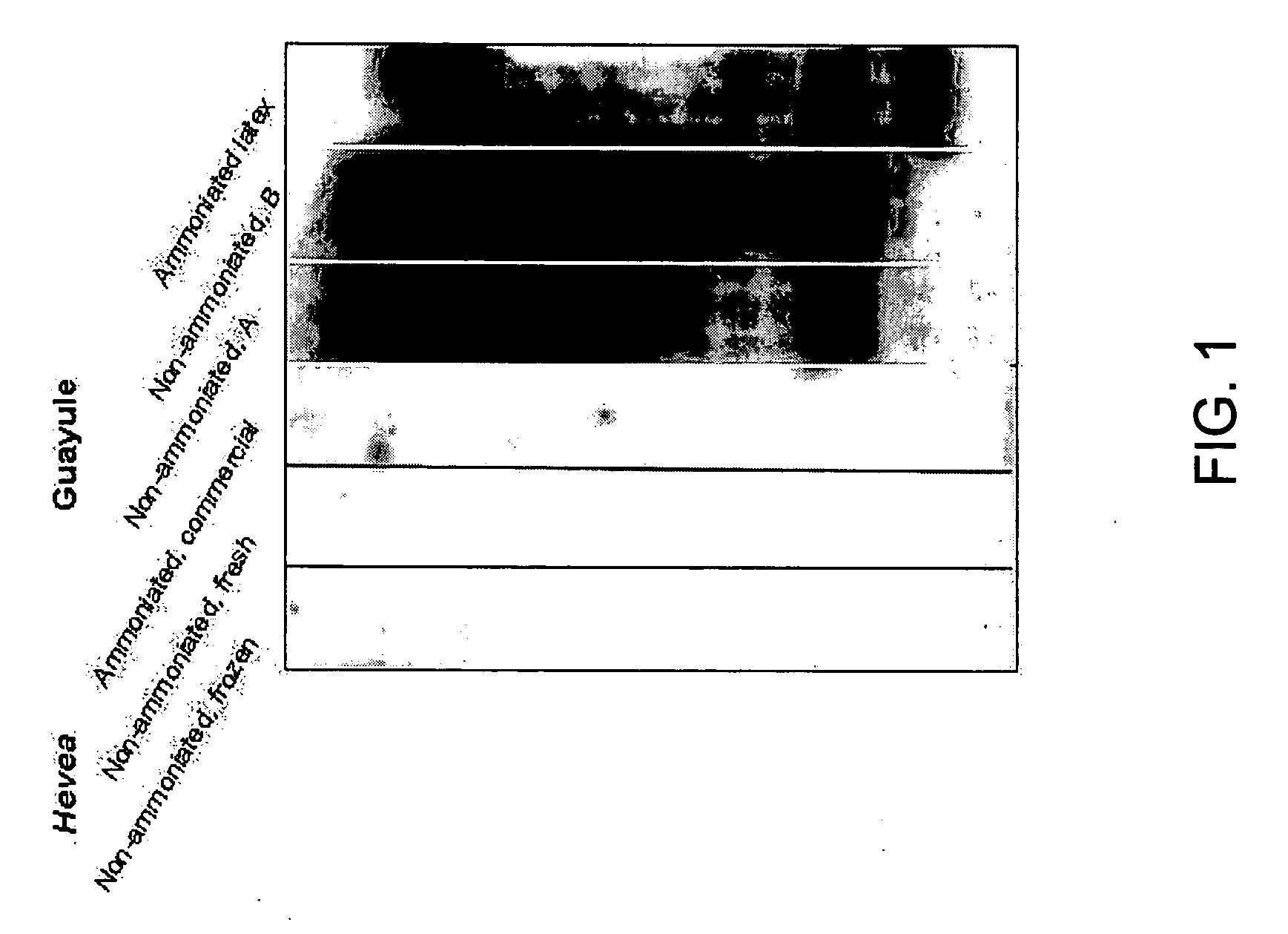

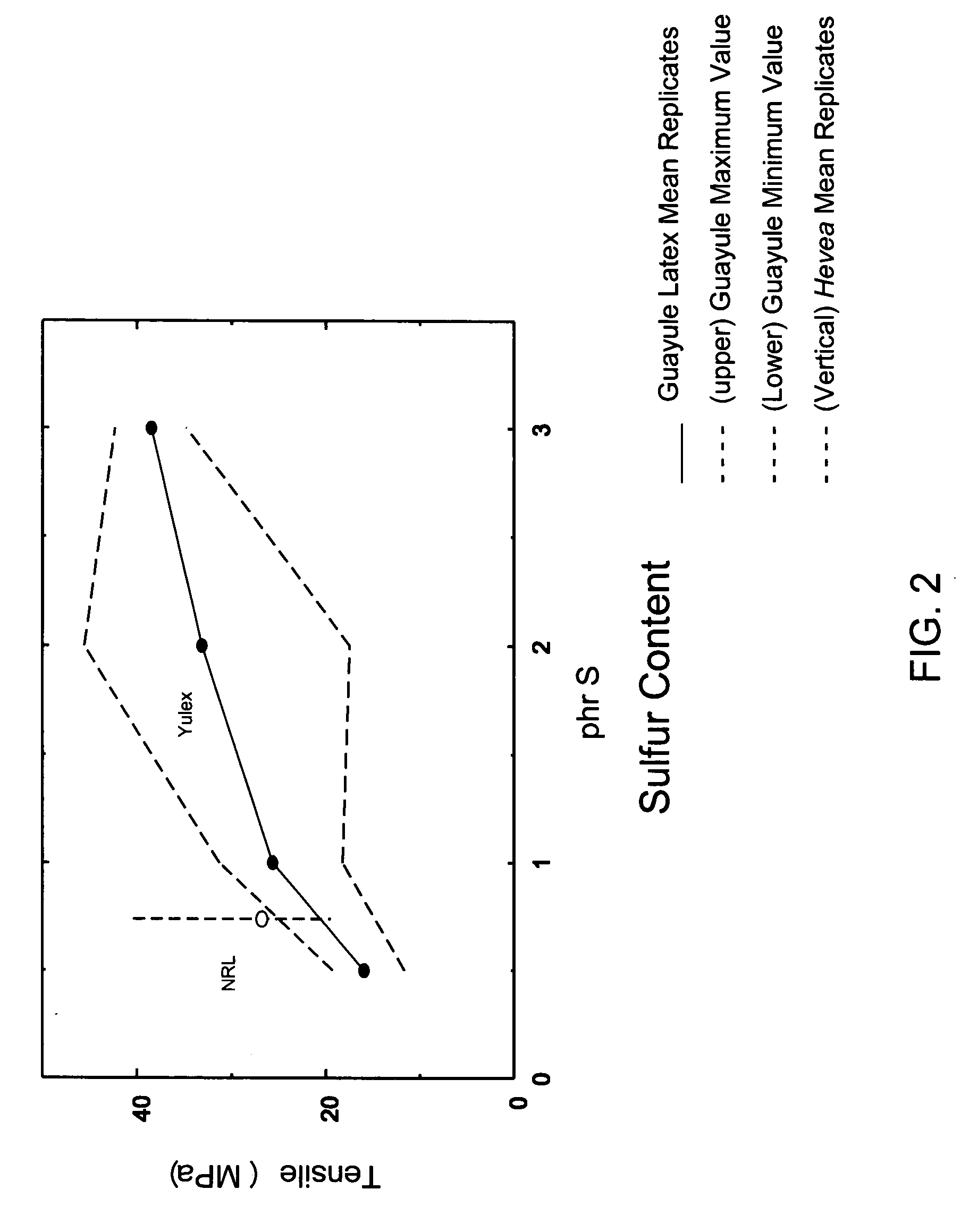

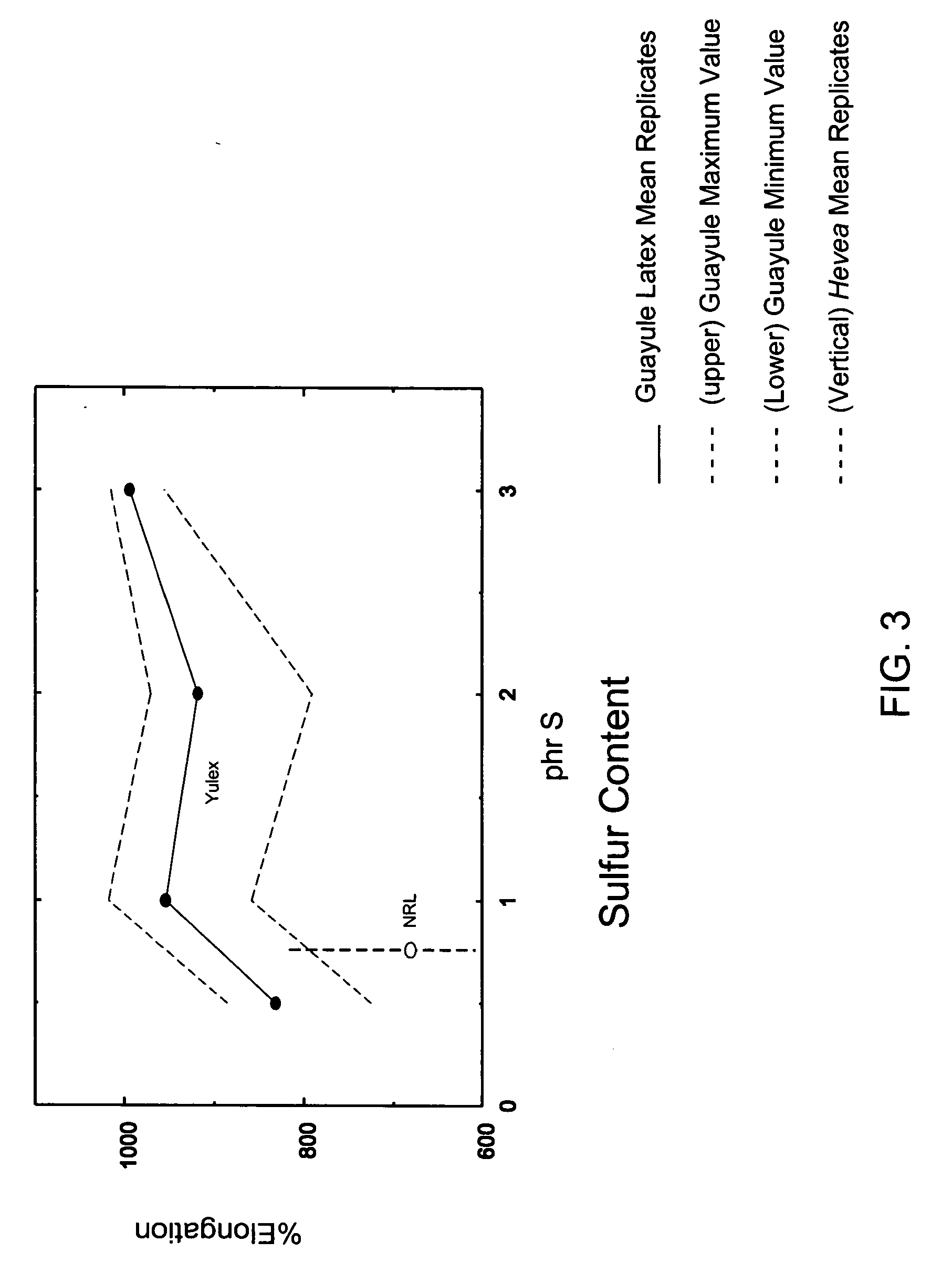

Non-synthetic low-protein rubber latex product and method of testing

The present invention discloses a non-Hevea, non-synthetic, low-allergenic, low-protein latex product that conforms to the standards published by the American Society for Testing Materials for Hevea latex products, and a new method and standard for determining the qualitative and quantitative properties of such products, including the substitutability of and superiority to Hevea and synthetic latex products.

Owner:YULEX CORP

Frozen confectionery product with a natural stabiliser

A frozen confectionary product comprising a natural stabilizer composition is an object of the invention. The frozen confectionary product has an overrun of preferably 0%-120%. The frozen confectionary product comprises a relatively low protein content. The stabilizer composition comprises egg yolk, a gum and preferably an acidifier. Use of the stabilizer composition is described. A method for the manufacture of the frozen confectionary product is also described.

Owner:SOC DES PROD NESTLE SA

Frozen confectionery product with a natural stabiliser

A frozen confectionary product comprising a natural stabiliser composition is an object of the invention. The frozen confectionary product has an overrun of preferably 0%-120%. The frozen confectionary product comprises a relatively low protein content. The stabiliser composition comprises egg yolk, a gum and preferably an acidifier. Use of the stabiliser composition is described. A method for the manufacture of the frozen confectionary product is also described.

Owner:SOC DES PROD NESTLE SA

Animal origin-free low-protein culture medium suitable for animal cell product production

ActiveCN101603026AEasy to separate and purifySuitable for productionTissue cultureFermentationLipid formationAntioxidant

The invention relates to an animal origin-free low-protein culture medium suitable for animal cell product production, comprising 24 basic metabolism nutrients, 11 vitamins, 3 transferrin substitute compounds, 5 lipid compounds, 2 nucleic acid compounds, 4 hormones and growth factors, 3 antioxidants, 1 shear-resistant protective agent, 1 pH indicator, 2 pH buffers, 9 other inorganic salts, soy hydrolysates adopted to substitute animal origin component, and composition of ferrous sulfate, ferric nitrate and EDTA-2Na adopted to substitute transferrin. The culture medium can be made by dissolving the aforementioned components in triply distilled water. The positive effects of the culture medium are as follows: the culture medium contains no animal origin component, the total protein content is lower than 10mg / L, which helps separate and purify products and is suitable for production of recombinant protein medicaments; the culture medium supports normal growth and long-term subculturing of animal cells; the culture medium can be used without adaptation, is easily prepared and is suitable for massive production of animal cell products.

Owner:EAST CHINA UNIV OF SCI & TECH

Non-antibiotic sucking pig milk replacer and preparation method

ActiveCN103598447ALess nutrient lossMaximize utilizationFeeding-stuffAnimal feeding stuffDiseaseSucrose

The invention discloses a non-antibiotic sucking pig milk replacer, which comprises various raw materials as follows: puffed corn, puffed soybean, plasma protein powder, steamed fish meal, soybean protein concentrate, low protein whey powder, lactose, fermented soybean meal, glucose, cane sugar, salt, anti-oxidant, lysine, threonine, methionine, tryptophan, zinc oxide, butyrin, microecology preparation, compound acidifying agent, compound enzyme preparation, compound vitamin premix and compound mineral matter premix. The invention employs synergism between butyrin, zinc oxide, acidifying agent and microecology preparation, and in the prerequisite that the antibiotics are not used, the product can help pigling to realize early stage weaning and get rid of weaning stress, and adjust sucking pig gastrointestinal tract health, control diarrhea, increase survival rate, and comprehensively improve immunity and disease resistance of sucking pig.

Owner:哈尔滨大北农牧业科技有限公司 +1

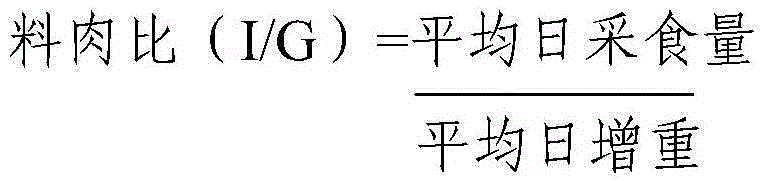

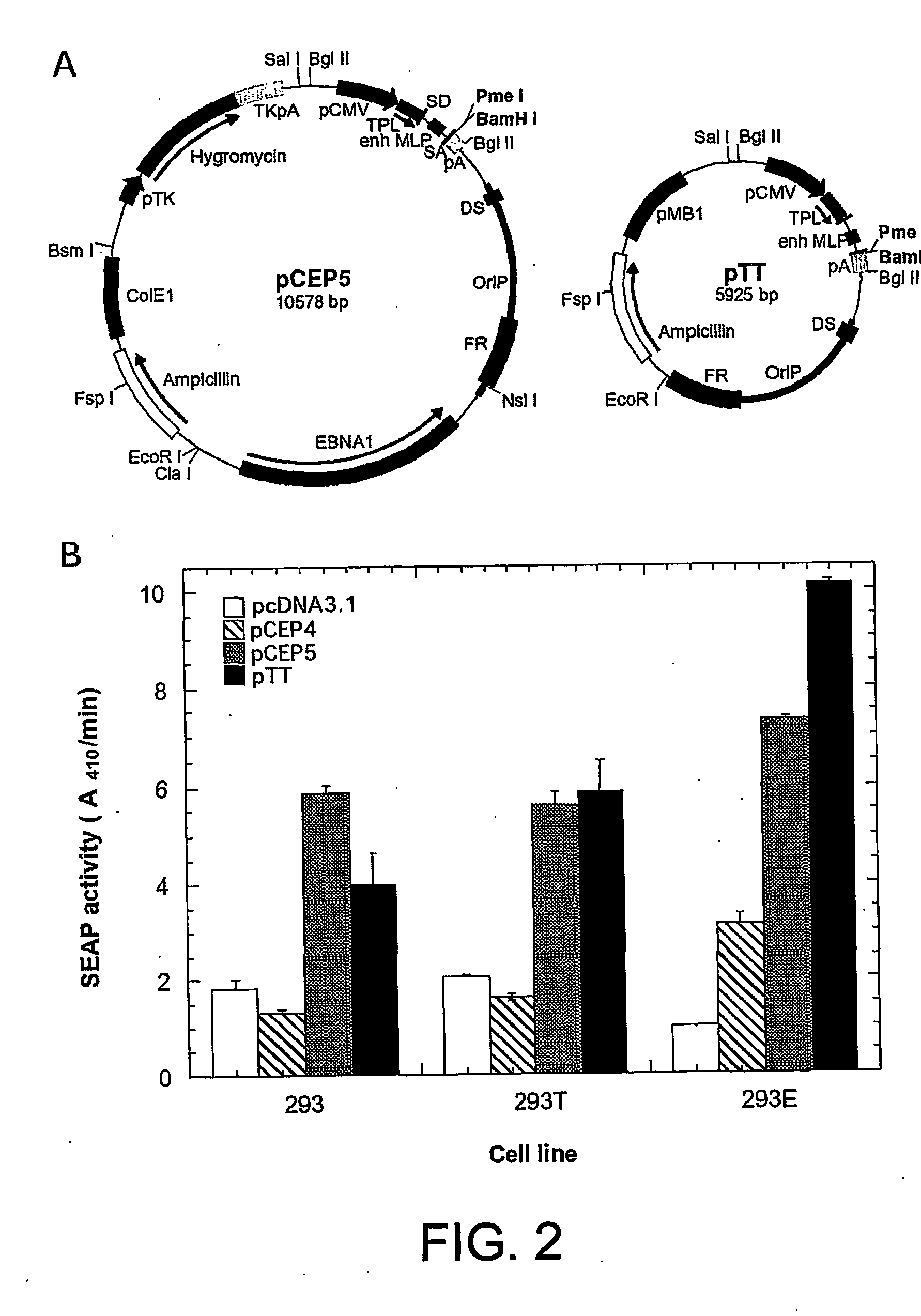

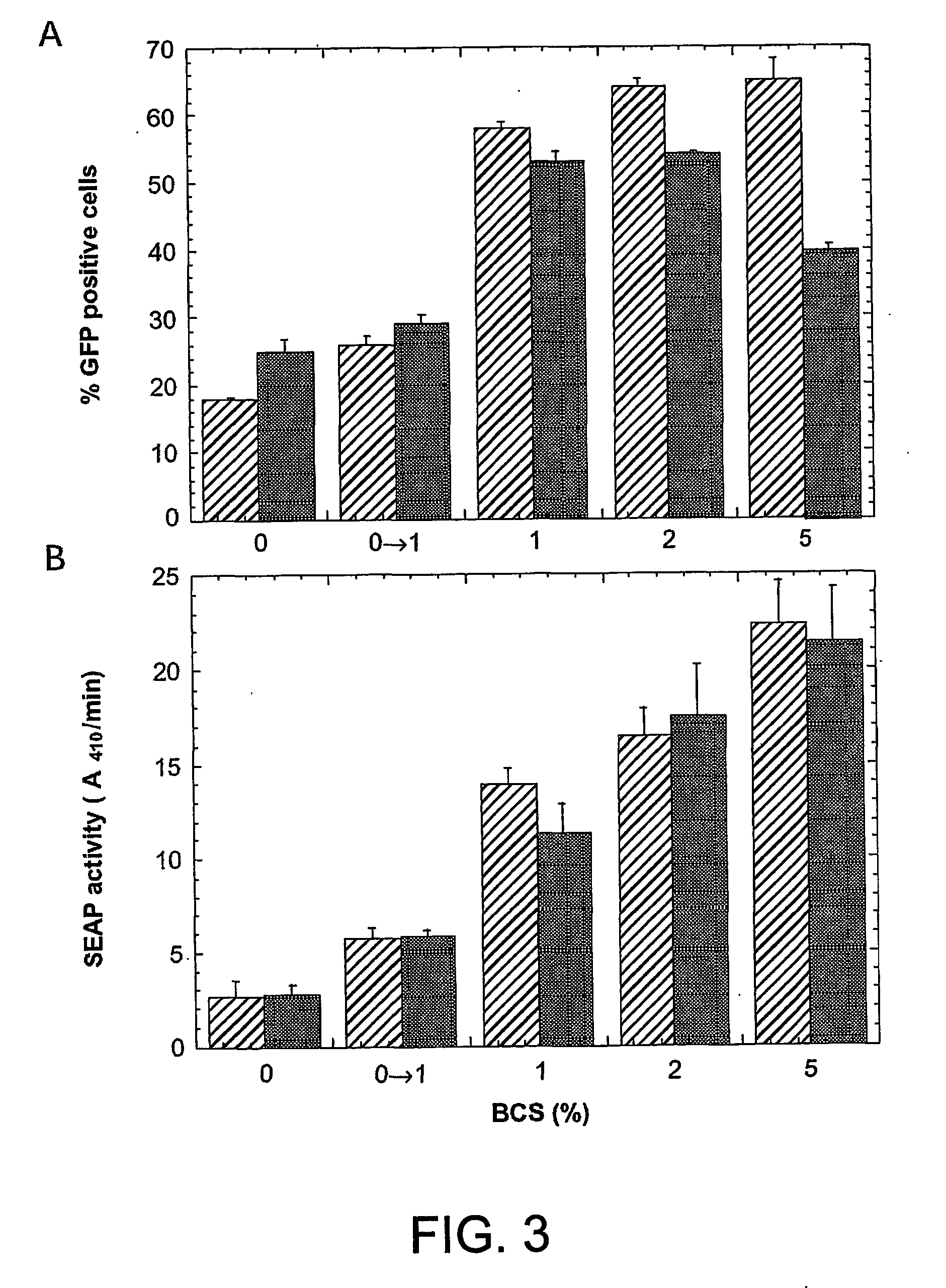

Enhanced production of recombinant proteins by transient transfection of suspension-growing mammalian cells

ActiveUS20050170450A1Increase transcriptional activityIncreasing nuclear importGenetically modified cellsVirus peptidesEpstein–Barr virusGene Variant

Disclosed is a new process for the production of recombinant proteins, by transient transfection of suspension-grown human embryonic kidney cells (293 cell line and its genetic variants) with an expression vector, using polyethylenimine (PEI) as a transfection reagent. In a preferred embodiment, the process uses 293E cells expressing the Epstein-Barr virus (EBV) EBNA 1 protein, in combination with an oriP-based episomal expression vector having an improved cytomegalovirus expression cassette comprising the CMV5 promoter. The process combines in a single step the cell growth, transfection and protein expression, is carried out without changing the culture medium, and allows to achieve high expression levels in a short period of time. The process may be carried out in a serum-free, low-protein culture medium, is easily scalable, compatible with continuous production processes, and fully adapted to high-throughput production of milligram quantities of recombinant proteins.

Owner:NAT RES COUNCIL OF CANADA

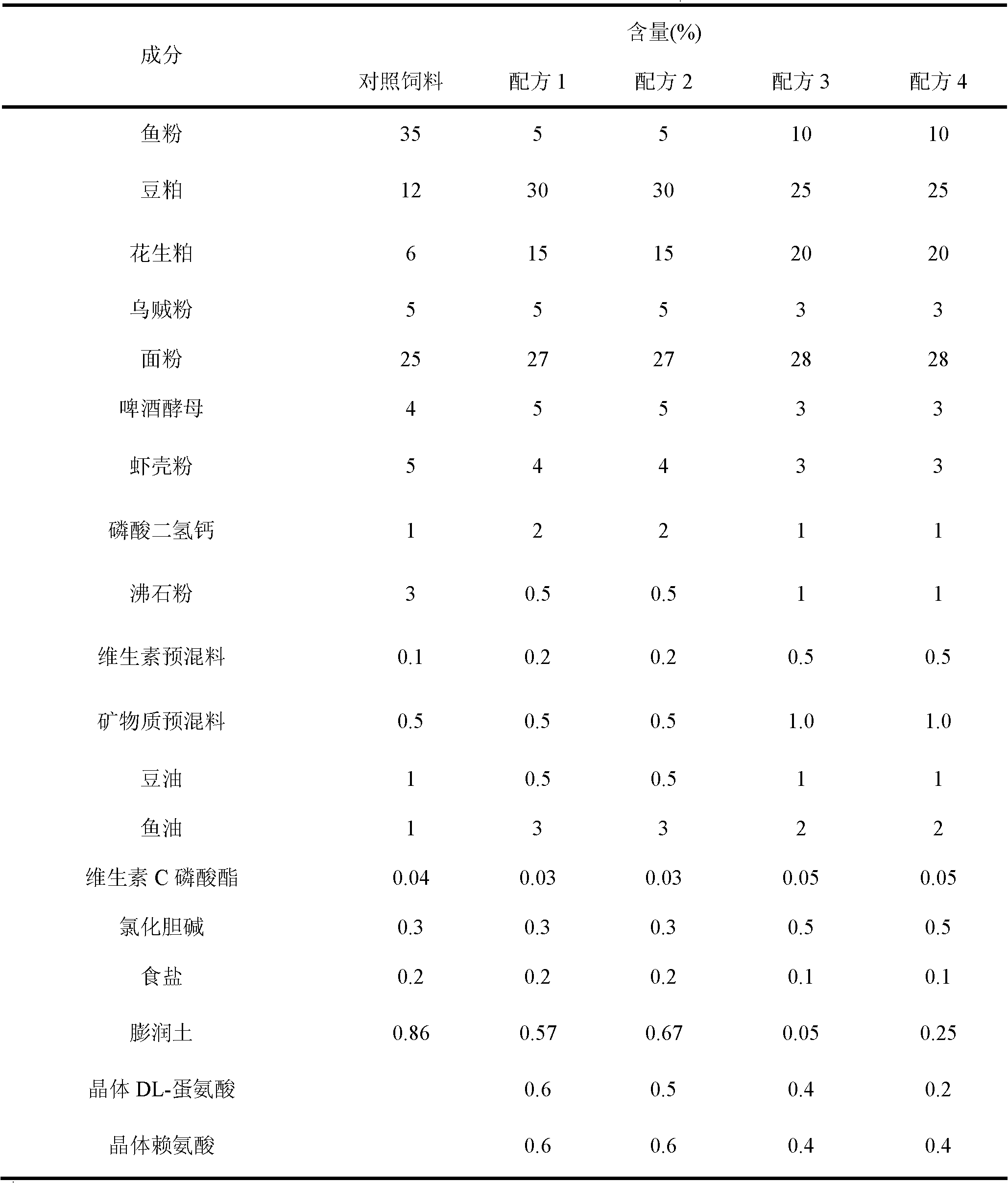

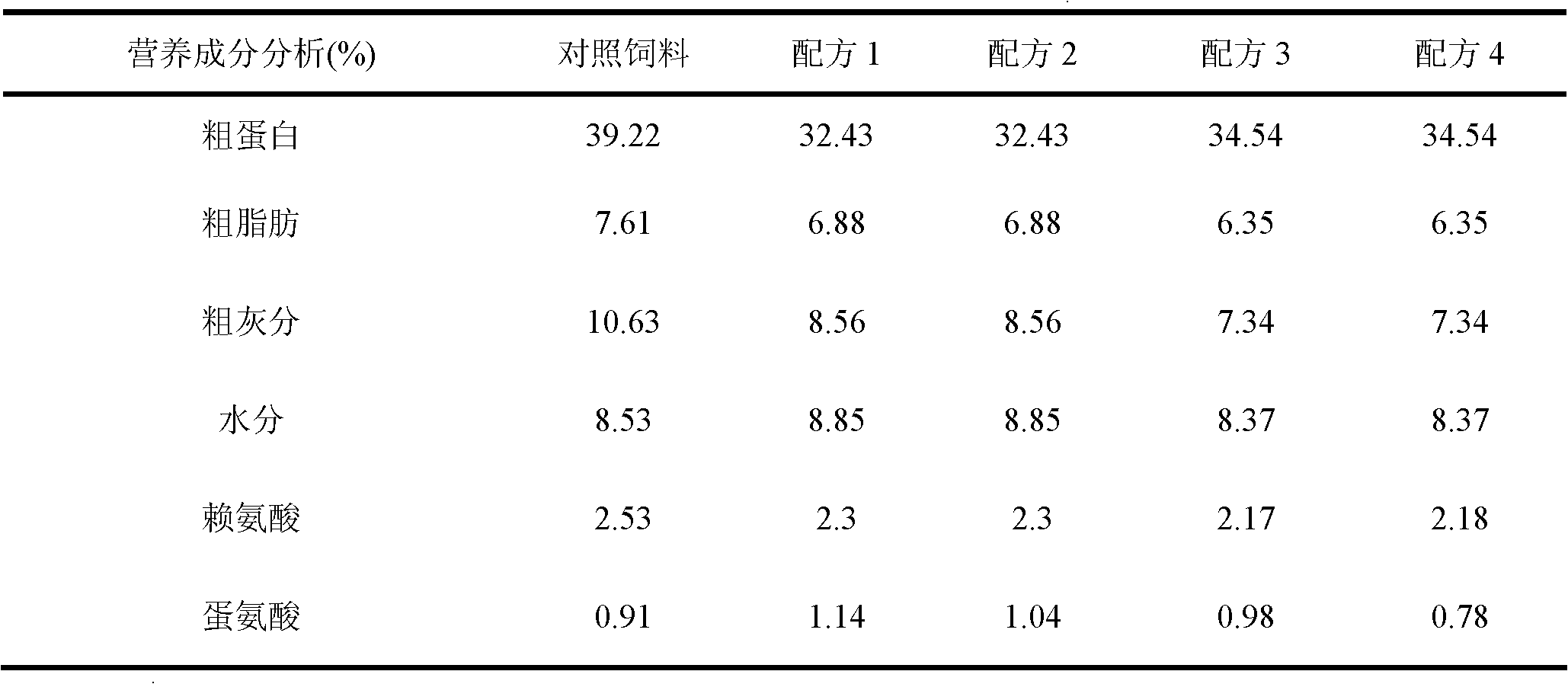

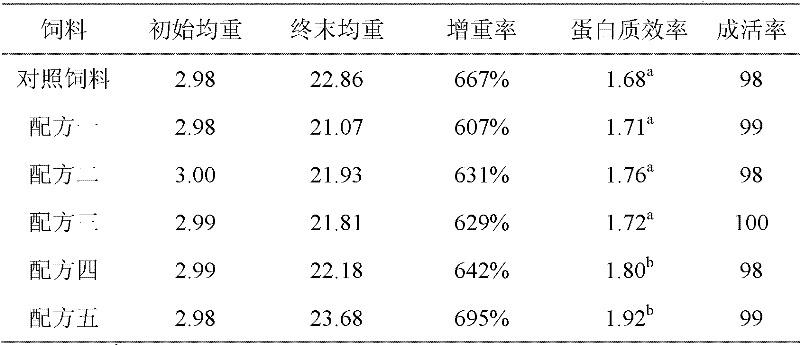

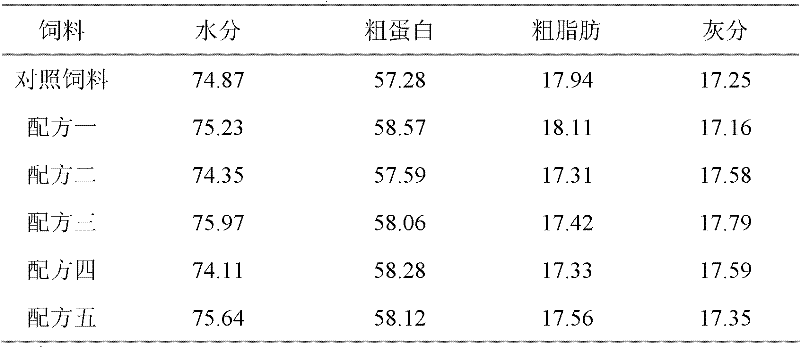

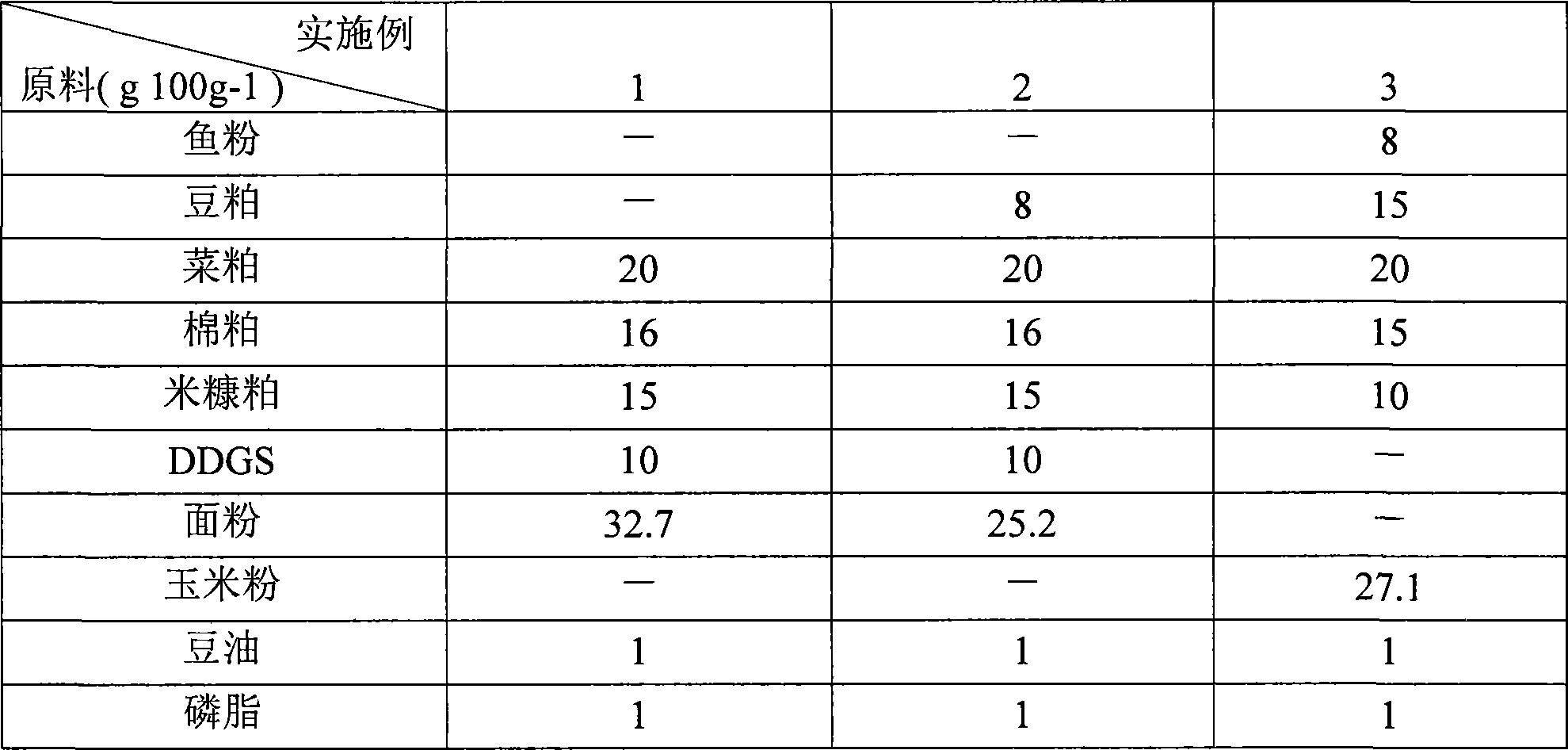

Low-protein low-fish meal feed for Litopenaeus vannamei

InactiveCN102217741ALower protein contentReduce excretionClimate change adaptationAnimal feeding stuffBiotechnologyPeanut meal

The invention discloses a low-protein low-fish meal feed for Litopenaeus vannamei. The content of proteins in a Litopenaeus vannamei feed is reduced by supplementing exogenous methionine, the content of fish meal in the feed is reduced by utilizing bean pulp with plant protein sources and peanut meal, and then the exogenous methionine, the bean pulp and plant protein sources and other raw materials are mixed according to a reasonable proportion to form the low-protein low-fish meal feed for the Litopenaeus vannamei. The using amount of the fish meal in the feed is reduced to be less than 10 percent to the maximum extent, and the problem that amino acid is unbalanced in a single protein source is solved by adding a plurality of kinds of plant protein sources. The content of the fish meal and the content of the proteins in the Litopenaeus vannamei feed are remarkably reduced, and the feed is favorable for reducing the cost, improves the utilization rate of the feed, and reduces the discharge of nitrogen and phosphorus in the aquaculture process so as to reduce environmental pollution. Through feeding experiments for a long time, the results show that when the Litopenaeus vannamei is fed by using the low-protein low-fish meal feed for the Litopenaeus vannamei, the feed has no adverse effect on the growth performance and feed coefficient of the Litopenaeus vannamei, and the discharge amount of nitrogen and phosphorus in water bodies can also be reduced.

Owner:广东省农业科学院畜牧研究所 +1

Low-protein amino acid balance daily ration, preparation method and application thereof

ActiveCN101658237AGuarantee product qualityImprove utilization efficiencyAnimal feeding stuffPhytaseData information

The invention discloses a low-protein amino acid balance daily ration, a preparation method and the application thereof. The daily ration comprises the components based on parts by weight: 68-80 partsof corn, 3-20 parts of bean pulp, 6-20 parts of wheat bran and 4-5 parts of pre-mixed material, wherein the pre-mixed material comprises the following components: pig multi-vitamin, pig compound trace element, lysine, methionine, threonine, tryptophan, choline chloride, calcium carbonate, calcium hydrogen phosphate, phytase, common salt, ethoxy quinoline, trimethylamine B lactone, sodium glutamate and zeolite powder. Based on summary of the existing experimental data, the low-protein daily ration combines the actual conditions of China, utilizes the latest data information of raw materials made in China, fully takes the organic combination of the pre-mixed material and the main raw materials into account, and adopts a net energy system structure and a new nutrition model, thus developingthe utilization rate of feed to the utmost extent on the premise of ensuring the quality of animal products.

Owner:北京挑战牧业科技有限公司

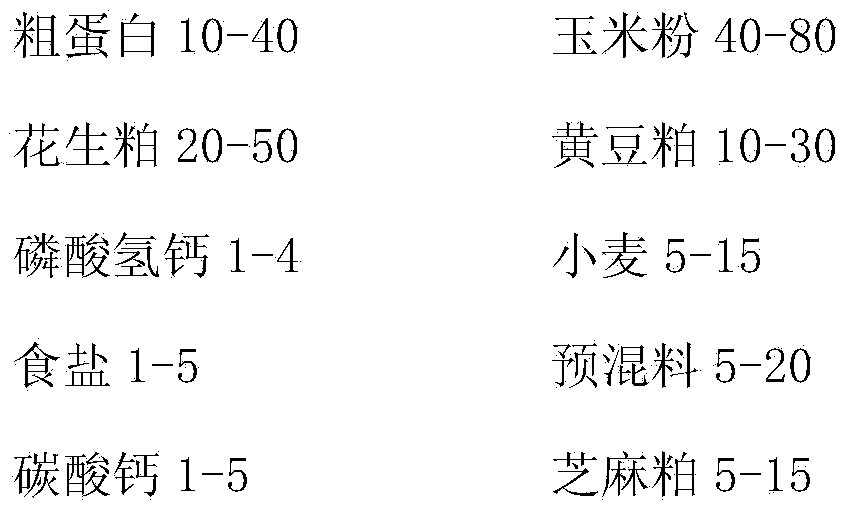

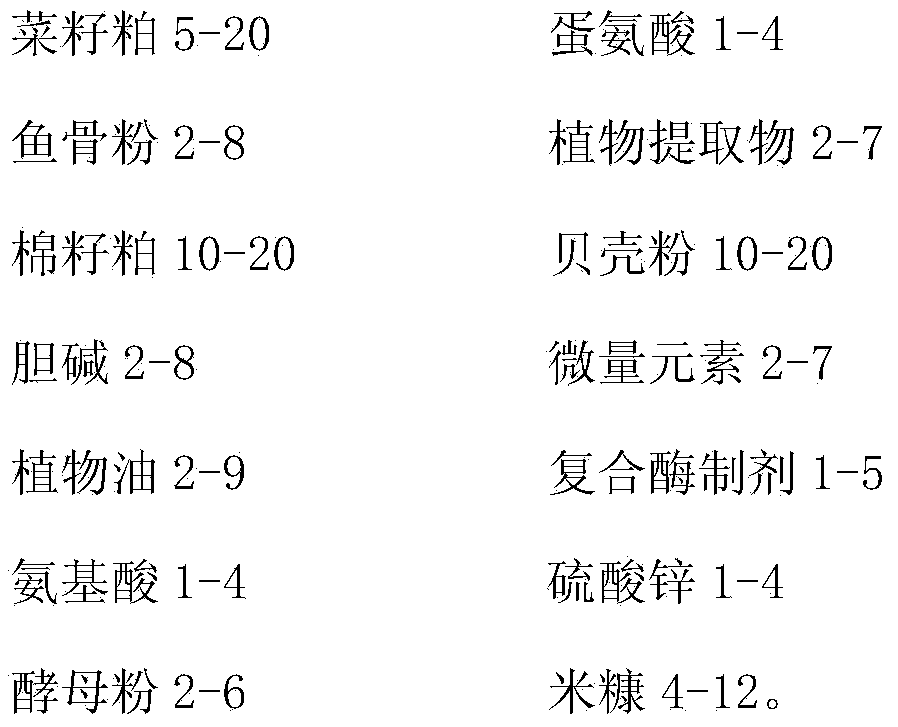

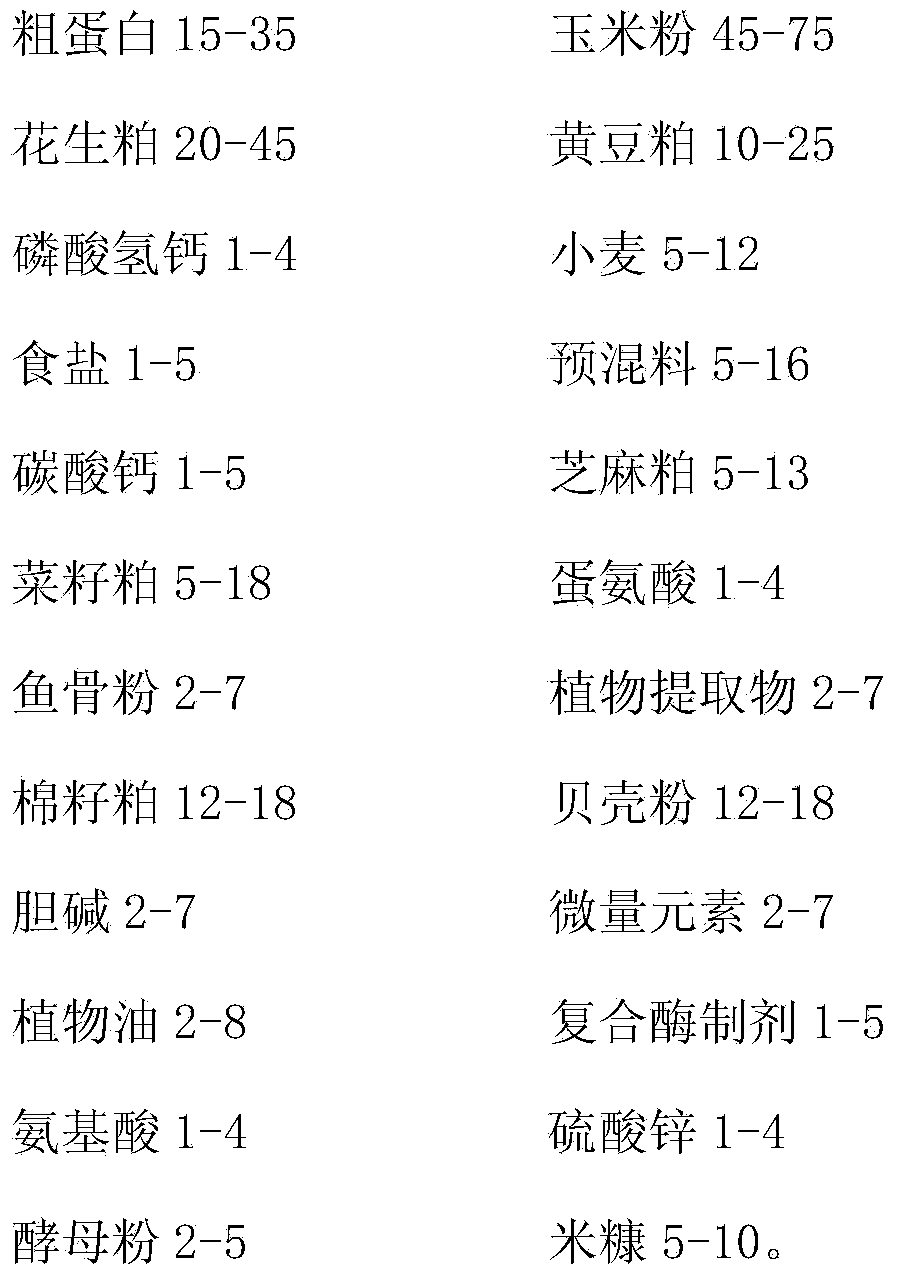

Feed for meat duck

ActiveCN103652476AImprove immunityImprove disease resistanceAnimal feeding stuffBiotechnologyDisease

The invention belongs to the field of feeds, in particular to a feed for meat duck. The feed comprises the following components by weight: 10 to 40 parts of crude protein, 40 to 80 parts of corn flour, 20 to 50 parts of peanut meal, 10 to 30 parts of soybean meal, 1 to 4 parts of calcium hydrogen phosphate, 5 to 15 parts of wheat, 1 to 5 parts of salt, 5 to 20 parts of a premix, 1 to 5 parts of calcium carbonate, 5 to 15 parts of sesame meal, 5 to 20 parts of rapeseed meal, 1 to 4 parts of methionine, 2 to 8 parts of fish bone meal, 2 to 7 parts of plant extract, 10 to 20 parts of cottonseed meal, 10 to 20 parts of shell powder, 2 to 8 parts of choline, 2 to 7 parts of trace elements, 2 to 9 parts of plant oil, 1 to 5 parts of a compound enzyme preparation, 1 to 4 parts of amino acid, 1 to 4 parts of zinc sulfate, 2 to 6 parts of yeast powder and 4 to 12 parts of rice bran. According to the invention, amino acid is balanced and the plant extract is added on the basis of original common daily ration so as to improve immunity of meat duck; a protein feed or amino acid balanced feed especially applicable to duck is a low-protein feed in essence; a variety of raw materials are cooperatively used in the invention, so protein content of the feed is reasonable, which enables meat duck to grow fast and a marketing cycle of meat duck to be shortened; addition of the plant extract improves disease resistance of meat duck.

Owner:广西九翔农牧有限责任公司

Low-protein carp feed and processing method

InactiveCN101991007AAvoid the disadvantage of low effective utilizationImprove use valueFood processingClimate change adaptationMonocalcium phosphateRapeseed

The invention relates to a low-protein carp feed. The feed comprises wheat-middlings, wheat bran, rapeseed cake, soya bean meal, corn germ meal, alfalfa meal, spouting corn bran, fish meal, meat and bone meal, sesame seed meal, monocalcium phosphate, bentonite, soybean oil, lysine, methionine, choline chloride and a premix and is characterized in that: alternanthera philoxeroides, parthemum powder, garlic powder, pine needle meal and rhubarb powder are added into the feed. A processing method for the low-protein carp feed comprises the following steps of: smashing and / or grinding various components in the feed; adding various raw materials into a stirring machine for stirring; and packaging the stirred feed. The feed can enhance the immunity and disease resistance of low-protein carp, effectively lower the morbidities of enteritis, gill breaking, red skin disease and explosive bleeding disease of the low-protein carp, increase fry survival rate, promote growth and effectively lower the bait coefficient of the low-protein carp.

Owner:HENAN MUHE GROUP FEED

Amino acid humanized infant formula milk powder and preparation method thereof

ActiveCN104012657APromote absorptionPromote growth and developmentMilk preparationVegetable oilTyrosine

The present invention relates to amino acid humanized infant formula milk powder and a preparation method thereof. The amino acid humanized infant formula milk powder comprises the following materials by a certain weight percent: lactose, demineralised whey powder, vegetable oil, skimmed milk powder, hydrolyzed whey protein, galactooligosaccharides, fructo oligosaccharide, a mineral premix, ARA, casein hydrolysate, whey protein concentrate, soybean phospholipids, DHA, a water-soluble vitamin premix, casein phosphopeptides, lactoferrin, L-tyrosine, nucleotide, a lipid soluble vitamin premix, L-tryptophan, L-methionine and taurine. The present invention also includes a method for preparing the amino acid humanized infant formula milk powder. The present invention can effectively solve the problem of pool protein absorption and digestion effect and the low protein utilization rate of infants during infant period.

Owner:AUSNUTRIA DAIRY CHINA

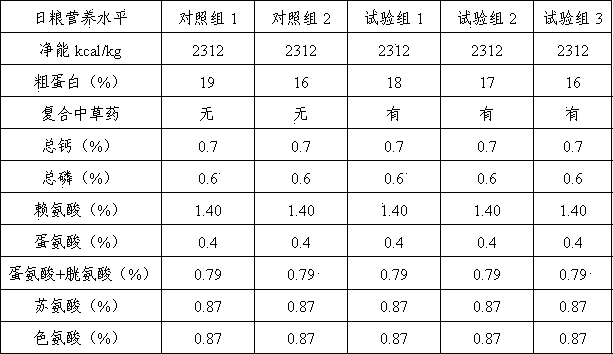

Low-protein weanling piglet feed and preparation method thereof

ActiveCN103960547AReduce dosageReduce manufacturing costFood processingAnimal feeding stuffPhytaseAntioxidant

The invention discloses a low-protein weanling piglet feed which comprises the following raw materials: corns, bean pulp, calcium hydrogen phosphate, dried porcine soluble, fermented bean pulp, fish meal, soybean oil, a premix, sodium chloride, phytase, a compound antioxidant, a compound acidifier, a compound enzyme preparation, a microecological preparation, limestone, L-lysine hydrochloride, L-threonine, DL-methionine, L-tryptophan and a compound traditional Chinese medicine preparation. According to the feed, the crude protein content of piglet full-price daily ration is reduced to 16% from 19%; the compound acidifier, the compound enzyme preparation, the microecological preparation and the compound traditional Chinese medicine preparation are added, so that the immunity of piglets is comprehensively improved and the use of antibiotic drugs is reduced; low-protein high-growth piglet ration is prepared, so that the misunderstanding to the feed consumption caused by farmers is eliminated, the low-protein ration formula technology is really popularized in local, the use of protein raw materials and the diarrhea of the piglets are reduced, and the cost and the N discharge are reduced.

Owner:哈尔滨大北农牧业科技有限公司 +1

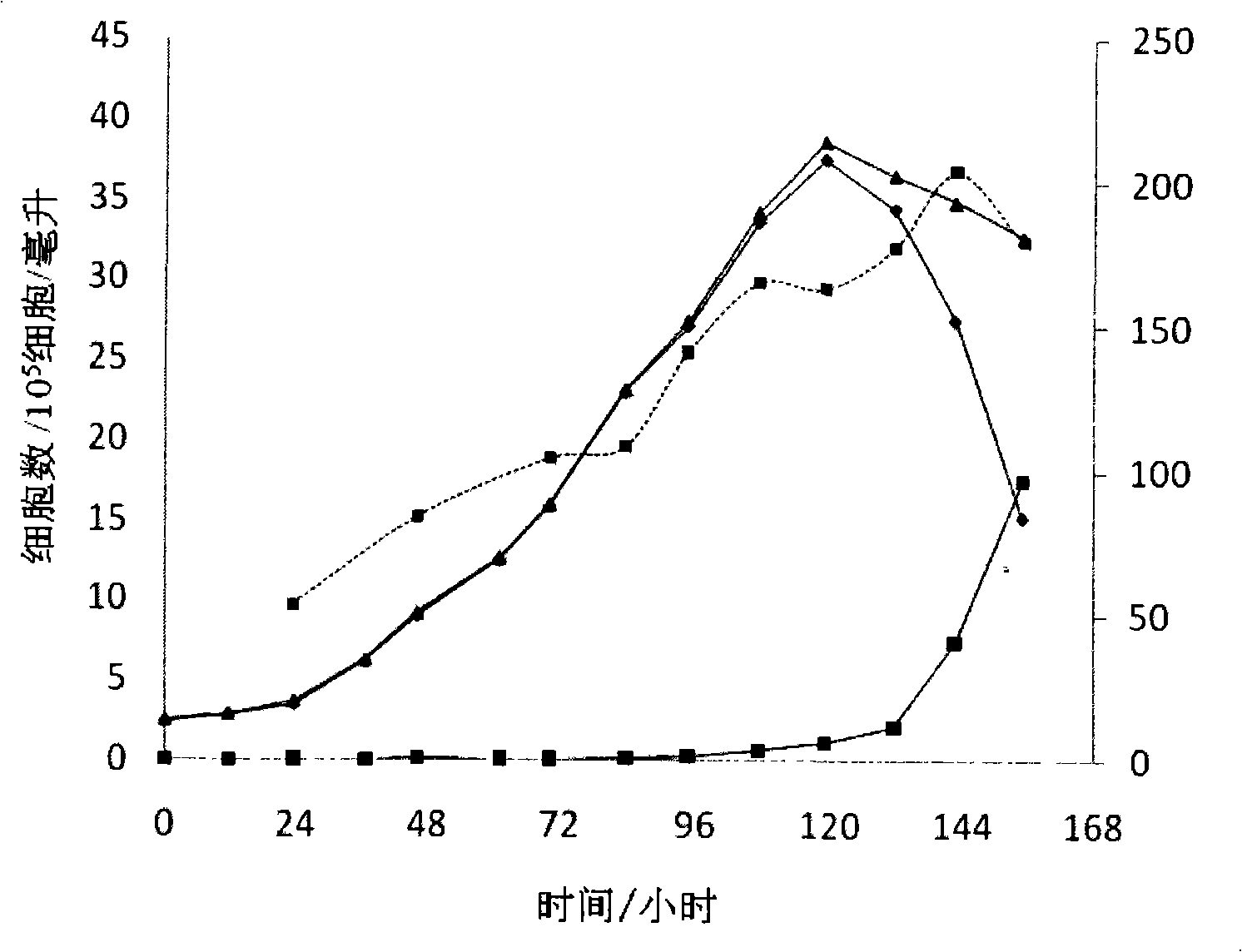

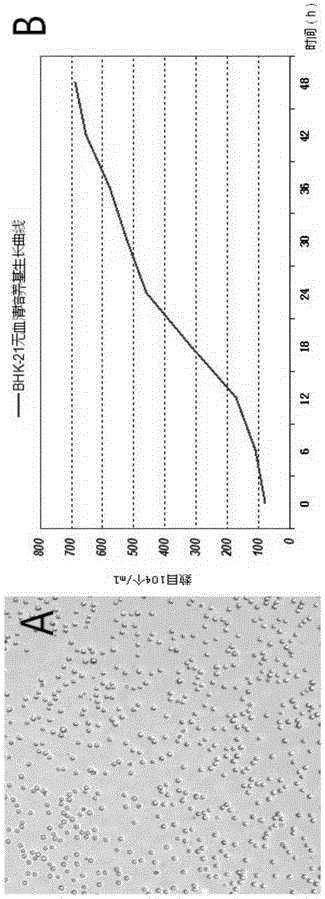

Serum-free animal origin-free culture medium for suspension culture of BHK-21 cells and preparation method of serum-free animal origin-free culture medium

ActiveCN105018416AProliferate fastIncrease vitalityArtificial cell constructsVertebrate cellsAntigenDouble-time

The invention discloses a serum-free animal origin-free culture medium for suspension culture of BHK-21 cells and a preparation method of the serum-free animal origin-free culture medium. According to the serum-free animal origin-free culture medium for suspension culture of the BHK-21 cells and the preparation method of the serum-free animal origin-free culture medium, through the addition and component optimization of amino acids, inorganic salt, vitamins, lipids, hydrolysates and the rest of additives in the culture medium, the multiplication speed of the BHK-21 cells is remarkably improved, the doubling time is shortened, and the high activity is maintained while the cells reach higher growth density. The culture medium is suitable for high-density suspension culture of the BHK-21 cells, low in cost, free of serum, free of animal origins and low in protein, the biological function of the serum is completely replaced through the addition of the ingredients including the lipids, the vitamins, the microelements, recombinant protein and the hydrolysates,, and some negative effects caused by the serum to later purification and separation of an antigen are avoided. Through optimization on the components of the culture medium, the multiplication speed of the BHK-21 cells in suspension culture is higher, the cell density is higher, the cell activity is higher, and the BHK-21 cells are more suitable for large-scale industrial production.

Owner:内蒙古金源康生物工程股份有限公司

A high-sugar and low-protein tilapia feed

InactiveCN102265983AIncrease dosageLow in proteinFood processingClimate change adaptationRapeseedVitamin B6 synthesis

The invention discloses a high-sugar and low-protein tilapia feed. Based on the total mass fraction of 100%, it consists of the following components: fish meal: 0-3%, soybean meal: 16-20%, rapeseed meal: 18-21%, cotton meal: 12-16%, secondary meal: 39- 42%, soybean oil: 2-3%, choline chloride: 0.2-0.5%, sodium chloride: 0.1-0.5%, calcium dihydrogen phosphate: 1-2%, vitamin B1: 0.004-0.006%, vitamin B6: 0.002-0.004%, zinc sulfate: 0.02-0.04%, chromium chloride: 0.0001-0.0003%, vitamin premix: 0.1-0.2% and mineral premix: 0.5-1%. The invention maximizes the amount of secondary powder in the feed, adds several plant protein sources to overcome the problem of amino acid imbalance of a single protein source, and at the same time significantly reduces the amount of fish meal. By optimizing and adjusting the feed formula, supplementing suitable vitamin and mineral premixes to adjust the sugar utilization ability of tilapia, so that the tilapia can make good use of the sugar compound of the present invention, avoiding the damage of fish liver caused by high sugar, Fatty liver is formed, and even the fish body becomes obese, and the symptoms of "big belly" appear.

Owner:广东省农业科学院畜牧研究所 +1

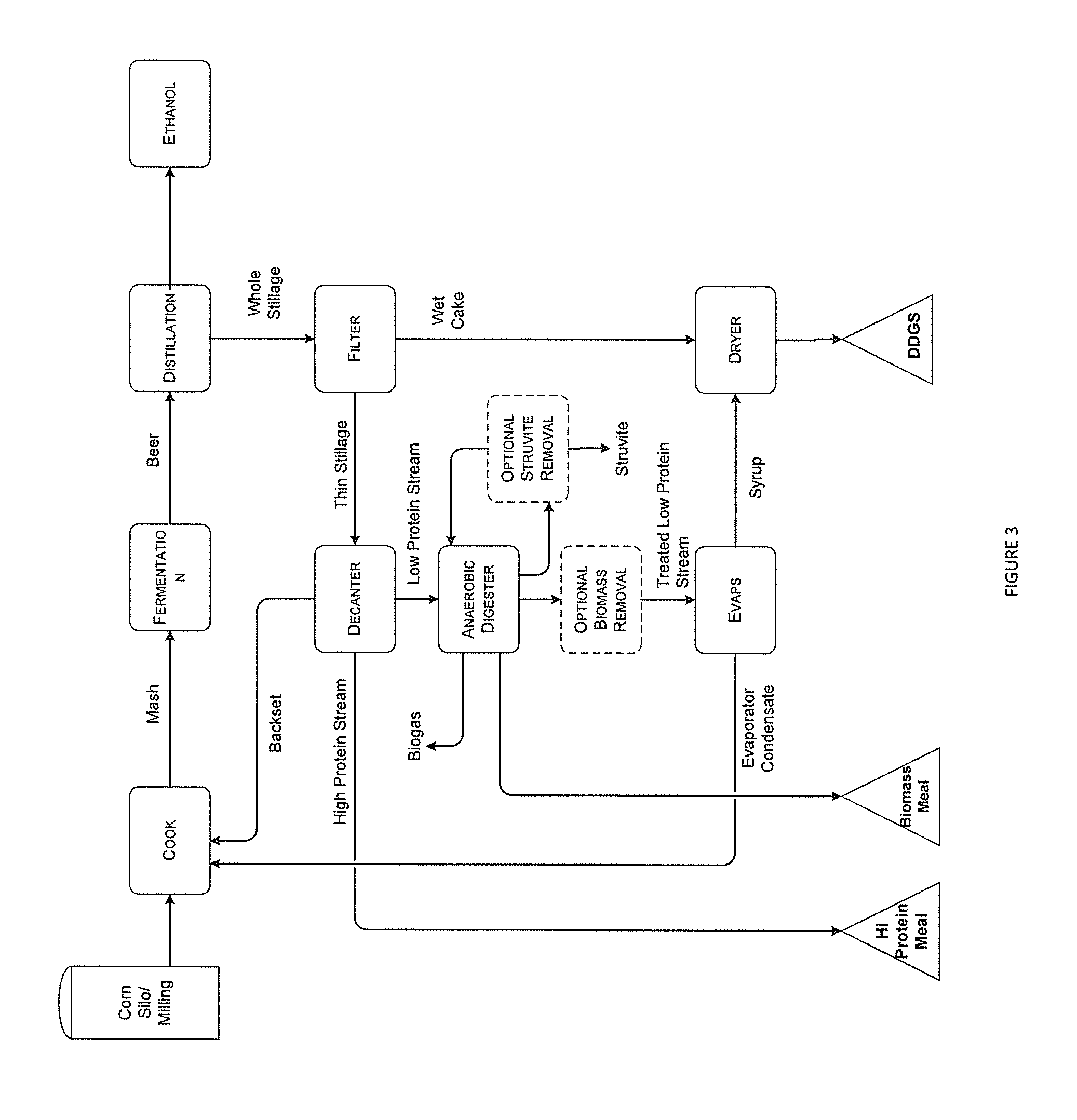

Methods for managing the composition of distillers grain co-products

The present invention provides for methods of managing the protein content of multiple distiller's grain co-products of a fermentation process. A valuable protein rich distiller's grain co-product having greater than 40 wt % protein on a dry basis can be removed from whole stillage or spent grains; however the protein content in the residual wet cake is reduced. The present invention provides for methods to mitigate protein depletion in wet cake by removing non-protein components from the wet cake stream, from the low protein thin stillage stream added to wet cake, or both streams. The present invention provides for blending protein depleted and protein enriched streams to meet the protein specifications of multiple distiller's grain co-products.

Owner:VALICOR

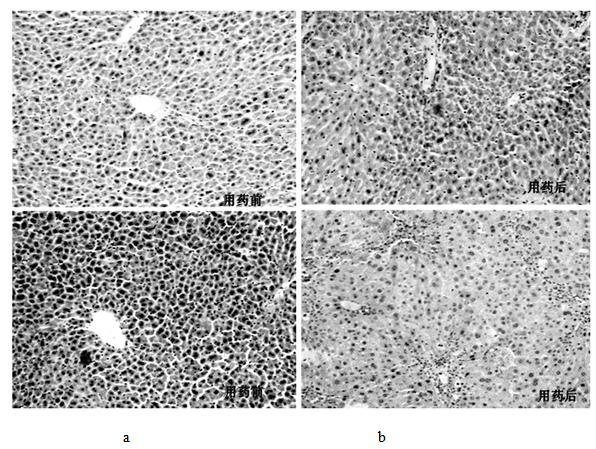

Preparation method and application of physiologically active notoginseng polysaccharide

ActiveCN102585029AImprove transfer rateReduce contentOrganic active ingredientsMetabolism disorderBiotechnologyBlood glucose decreased

The invention provides a preparation method and application of physiologically active notoginseng polysaccharide. The method comprises the steps of refining and purifying by applying resin column chromatography, activated carbon and membrane separation and purification technology, and the like, so as to obtain the notoginseng polysaccharide. The notoginseng polysaccharide obtained by the preparation method provided by the invention has the characteristics of low protein, heavy metal and ash contents and stable quality, has the physiological activities of immunity regulation, liver injury protection, blood glucose decrease, tumor resisting and the like, and can be used singly or combined as raw materials for natural medicines and health products. The preparation method of the notoginseng polysaccharide, provided by the invention, is simple to operate, applicable for industrial production and low in cost and reaches the purposes of energy saving and consumption reduction and realizing comprehensive development and sustainable utilization of the rare Chinese traditional medicine, namely, notoginseng.

Owner:YUXI WINHEY BIO TECH

Piglet low-protein feed and preparation method thereof

ActiveCN102132781AReduce usageReduce pollutionAnimal feeding stuffAccessory food factorsAnimal scienceThreonine

The invention relates to a piglet low-protein feed, in particular to a piglet low-protein feed with lower protein content. The piglet low-protein feed comprises the following compositions in portions by weight: 30-40 portions of corn, 25-35 portions of puffed corn, 2-4 portions of imported fish meal, 10-15 portions of dehulled soyabean pulp, 4-8 portions of enmolysis soyabean pulp, 2-6 portions of whey powder, 1-3 portions of soyabean oil, 1-2 portions of calcium hydrophosphate, 0.1-1 portions of mountain flour, 0.2-0.6 portion of lysine, 0.1-0.4 portion of methionine, 0.05-0.2 portion of threonine, 0.01-0.1 portion of tryptophane, and 2 portions of premixing compound. The invention reduce the use of protein raw materials during the preparation of the feed, and supplements crystal amino acid, thereby balancing the level of the amino acid in the feed, relieving the problem of lacking the protein raw materials on the premise of meeting the demand of piglets to a certain extent, loweringthe feed cost, reducing the environmental pollution of a farm, and reducing the diarrhea of the piglets.

Owner:GUANGDONG EVERGREEN FEED INDAL

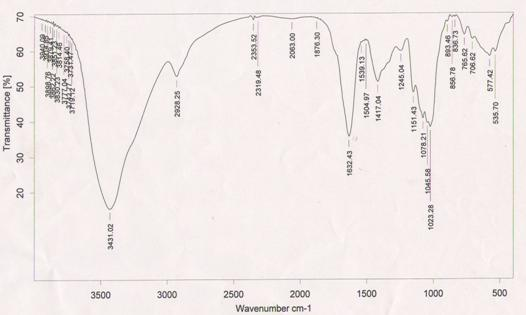

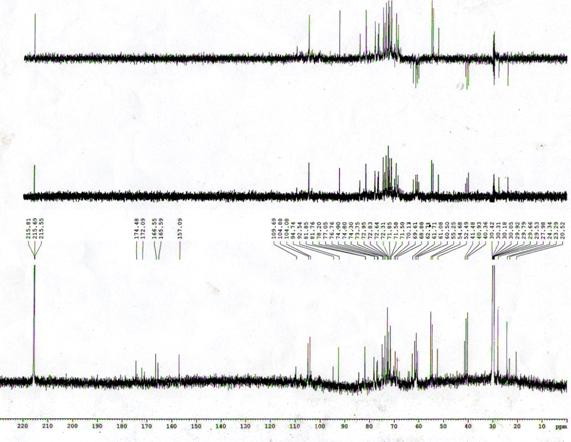

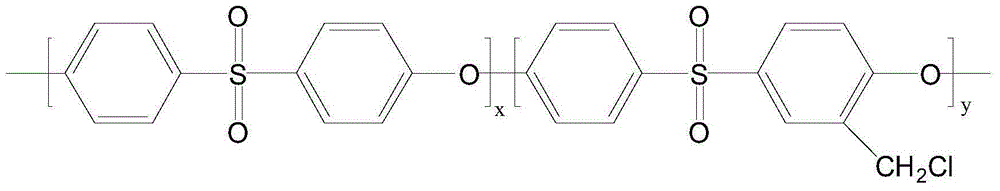

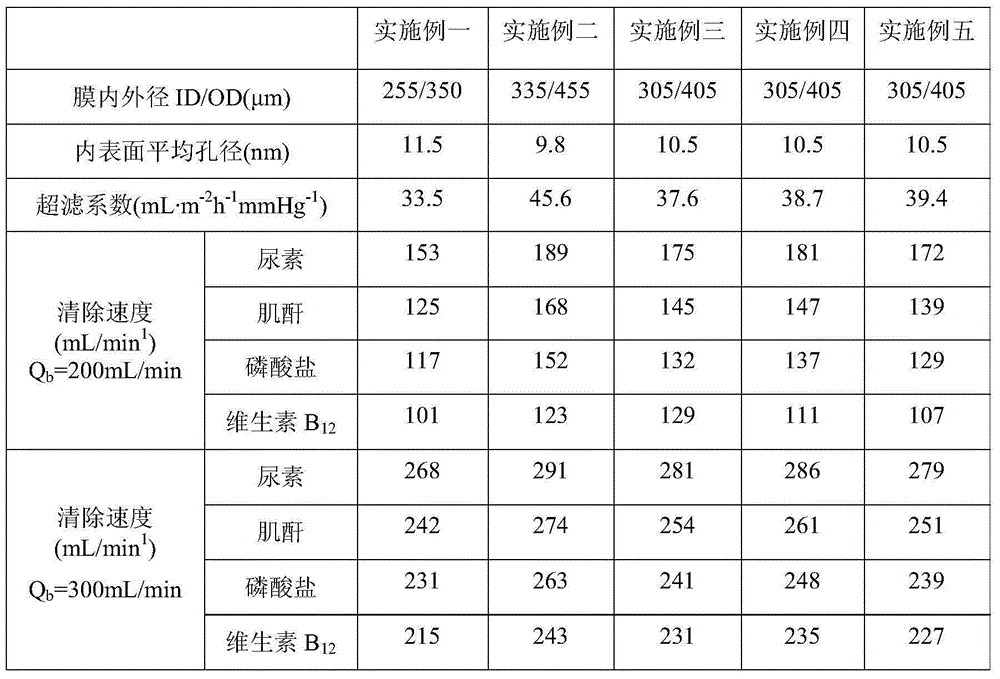

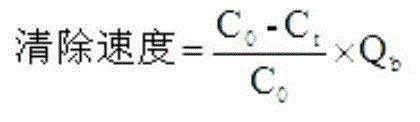

Method for preparing amino acid modified polyether sulfone hematodialysis membrane

InactiveCN104984664APermanent hydrophilicityLow protein adsorptionSemi-permeable membranesSuction devicesBiocompatibility TestingAmidogen

The invention relates to the technology of hematodialysis membranes, and aims at providing a method for preparing an amino acid modified polyether sulfone hematodialysis membrane. The method comprises the steps that chloromethyl group polyether sulfone, polarity aprotic organic solvent and a micromolecule pore-forming agent are taken and mixed to be stirred and dissolved to obtain a uniform and stable membrane casting solution; vacuum standing and bubble removing are carried out, and a chloromethyl group polyether sulfone hollow fiber membrane is prepared through a dry / wet phase inversion method and then immersed in hot water; finally, immersing is carried out through an ethanol solution, and drying is carried out; the chloromethyl group polyether membrane is immersed in a sodium hydroxide water solution to be reacted; the chloromethyl group polyether membrane is immersed in hot water; finally, the chloromethyl group polyether membrane is immersed in the ethanol solution, drying is carried out, and then the product is obtained. The chloromethyl group polyether sulfone hollow fiber membrane serves as a precursor material, and precise and controllable amidogen acidification modification can be carried out on the chloromethyl group polyether sulfone membrane through the electrophilic substitution policy. The polyether sulfone hematodialysis membrane modified through amino acid has the advantages of permanent hydrophilia, low-protein adsorbability and superior biocompatibility.

Owner:杭州汉膜新材料科技有限公司

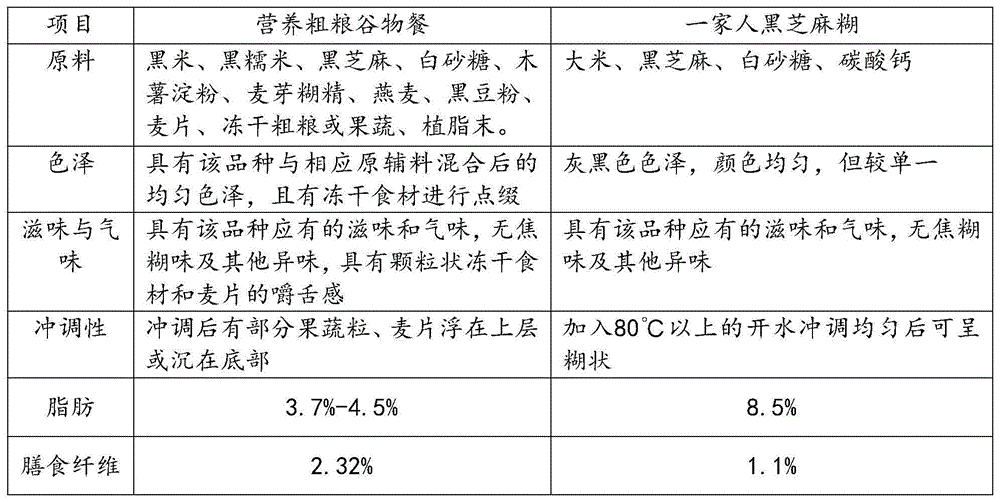

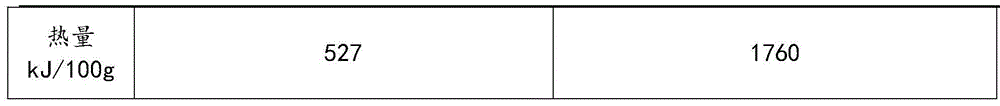

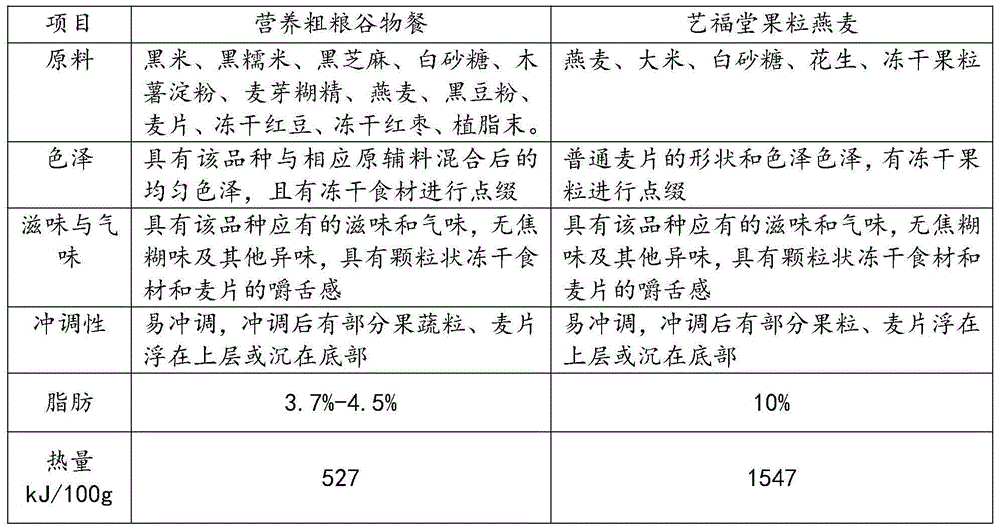

Nutritional whole-grain cereal meal and preparation method thereof

InactiveCN104642933AIn line with the concept of healthy eatingIncrease heatFood preparationFreeze-dryingSemen

The invention discloses a nutritional whole-grain cereal meal and a preparation method thereof, and belongs to the field of food processing. The nutritional whole-grain cereal meal is prepared from the following raw materials in parts by weight: 15-25 parts of black rice, 5-10 parts of semen sesami nigrum, 5-10 parts of oat, 1-5 parts of black glutinous rice, 1-5 parts of black bean flour, 1-5 parts of oatmeal, 1-2 parts of purple sweet potatoes and purple Chinese yam or 1-2 parts of freeze-drying raw materials. The preparation method comprises the following working procedures of frying the semen sesami nigrum, puffing the black rice and the black glutinous rice, crushing raw materials, mixing and the like. The nutritional whole-grain cereal meal has the characteristics of low content of fat, high content of proteins, dietary fibers and vitamins, relatively reasonable nutrition match, relatively convenience in preparation, and rich mouthfeel, can effectively remedy the problems of poor nutrition replenishment, low proteins, inconvenience in eating, poor mouthfeel and the like in existing foods (especially the food for breakfast), so that the dietary structure for the breakfast becomes reasonable.

Owner:GUANGXI HEIWULEI FOOD GRP

Preparation process of intravenous injection human immunoglobulin

ActiveCN101972479AHigh yieldHigh purityAntibody ingredientsImmunoglobulinsUltrafiltrationPhosphoric acid

The invention relates to a preparation process of intravenous injection human immunoglobulin, belonging to the field of pharmaceuticals. On a basis of a traditional preparation process of intravenous injection human immunoglobulin with the low protein concentration of 5 percent, a filter pressing method is adopted instead of a centrifuging method in an extraction process. During hyperfiltration, the protein concentration is adjusted to 3-6 percent, a pH value is adjusted to 6.4-6.6 with 0.5 mol / L of NaOH; then, 1 mol / L phosphoric acid-NaOH buffer solution is added to adjust the electrical conductivity which is measured to be 0.175-0.205 s / m at a temperature T of 19 DEG C; and a chromatography method is adopted to carrying out column chromatography and purification by using upper ion exchange columns after the electrical conductivity is adjusted. The protein impurities can be effectively removed, the protein purify and the product yield are improved; maltose or glycin is used as a protector, which benefits the improvement of the stability of the intravenous injection human immunoglobulin; and the glycin is used as the protector, which satisfies the clinical use of diabetics. According to the invention, the intravenous injection human immunoglobulin with the protein concentration of 5-11 percent can be obtained.

Owner:华润博雅生物制药集团股份有限公司

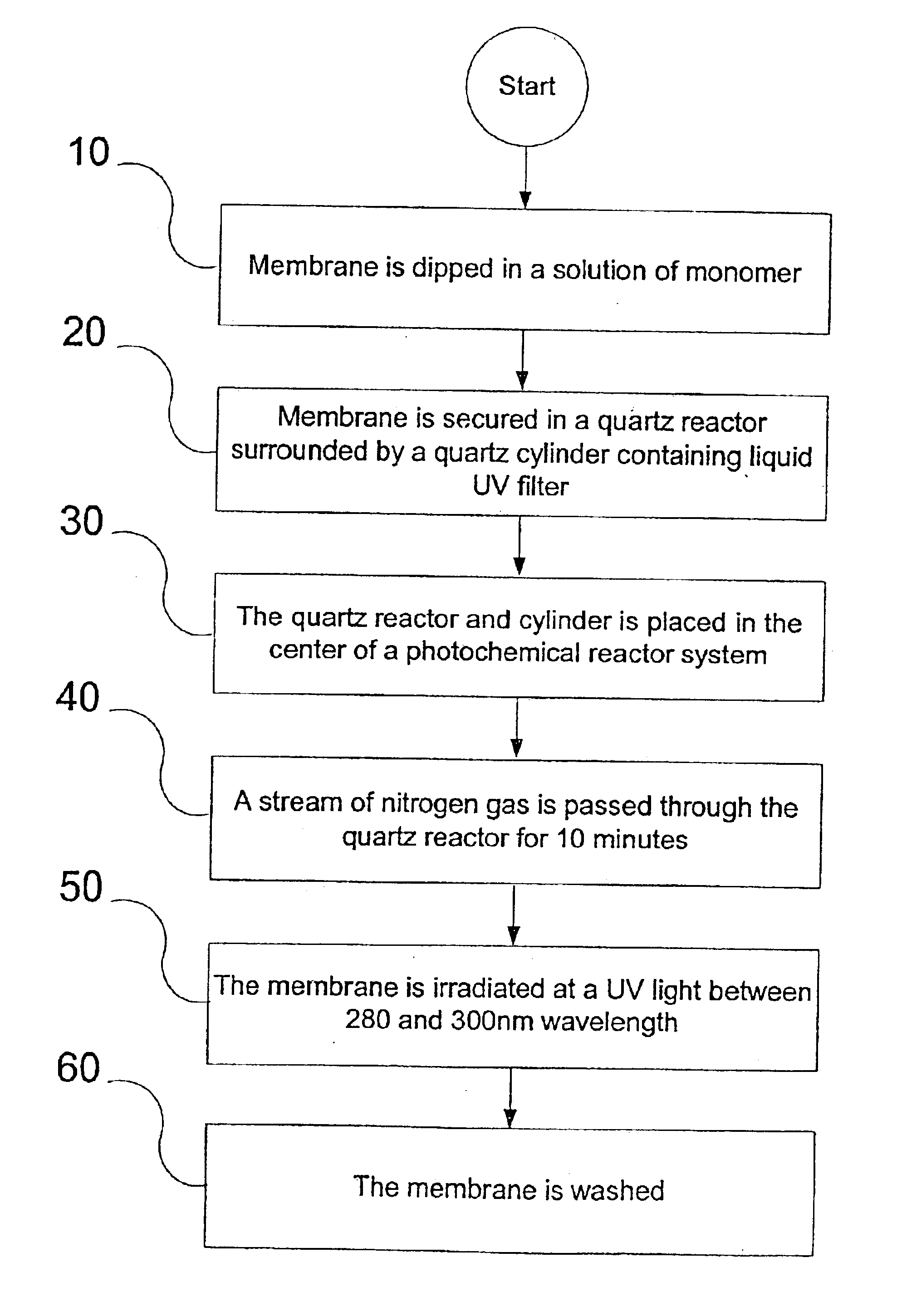

UV-assisted grafting of PES and PSF membranes

InactiveUS6852769B2Low protein foulingGreat fraction of original membrane permeability and retention propertySemi-permeable membranesMembranesUltrafiltrationPhotochemistry

An ultrafiltration membrane is modified to exhibit low protein fouling and yet maintains a greater fraction of the original membrane permeability and retention properties after modification. This is achieved by grafting monomer onto the surface of a highly photoactive membrane such as polyethersulfone, via the process of dipping the polymeric membrane into a solution containing one or more monomers and a chain transfer agent, removing the membrane from the solution, securing the membrane inside of a quartz vessel contained within another vessel of liquid filter, and irradiating the membrane with a UV light at a wavelength between the range of 280 nm and 300 nm. High density grafting and shorter grafted monomer chain length result in low protein fouling and retention of permeability.

Owner:RENESSELAER POLYTECHNIC INST

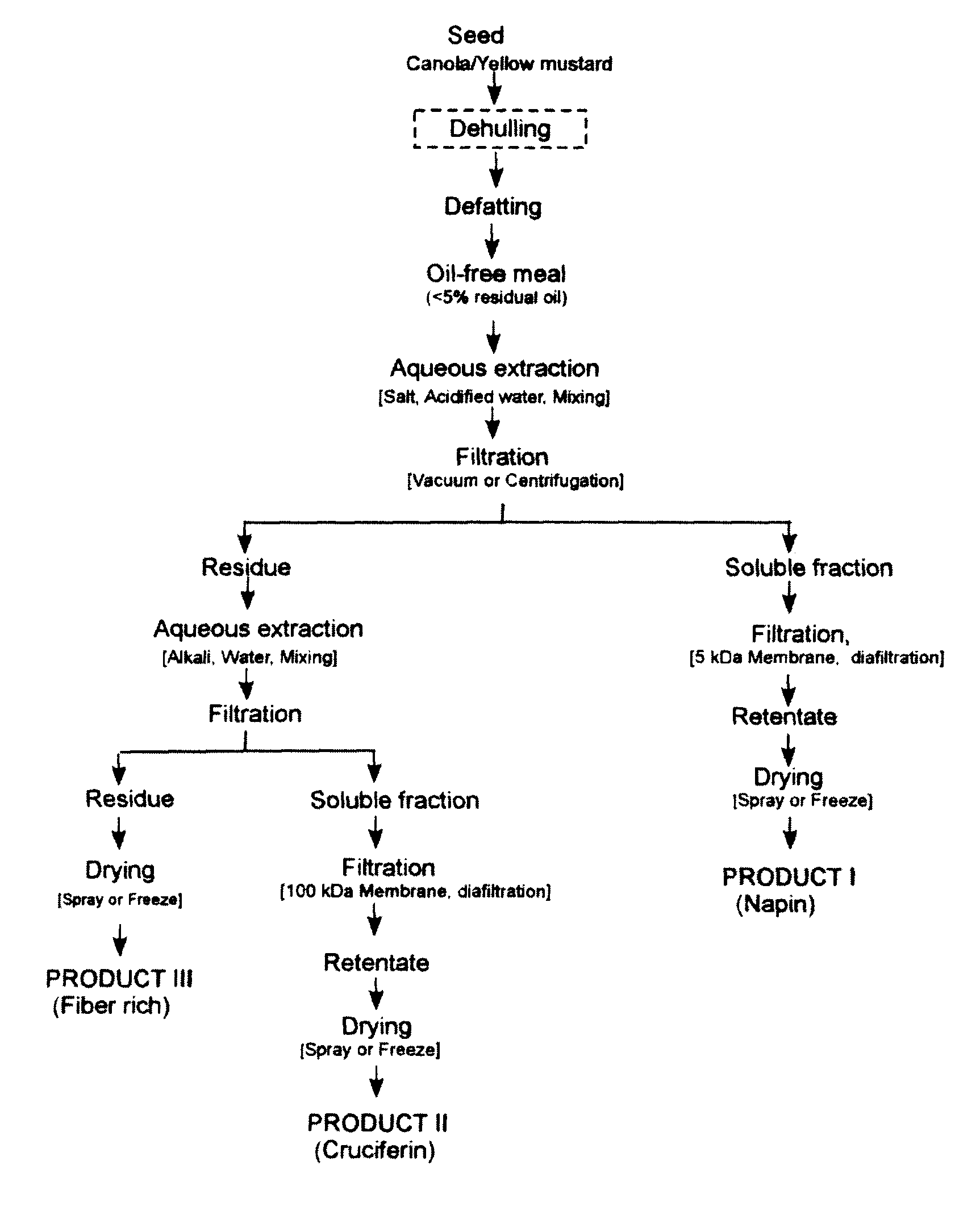

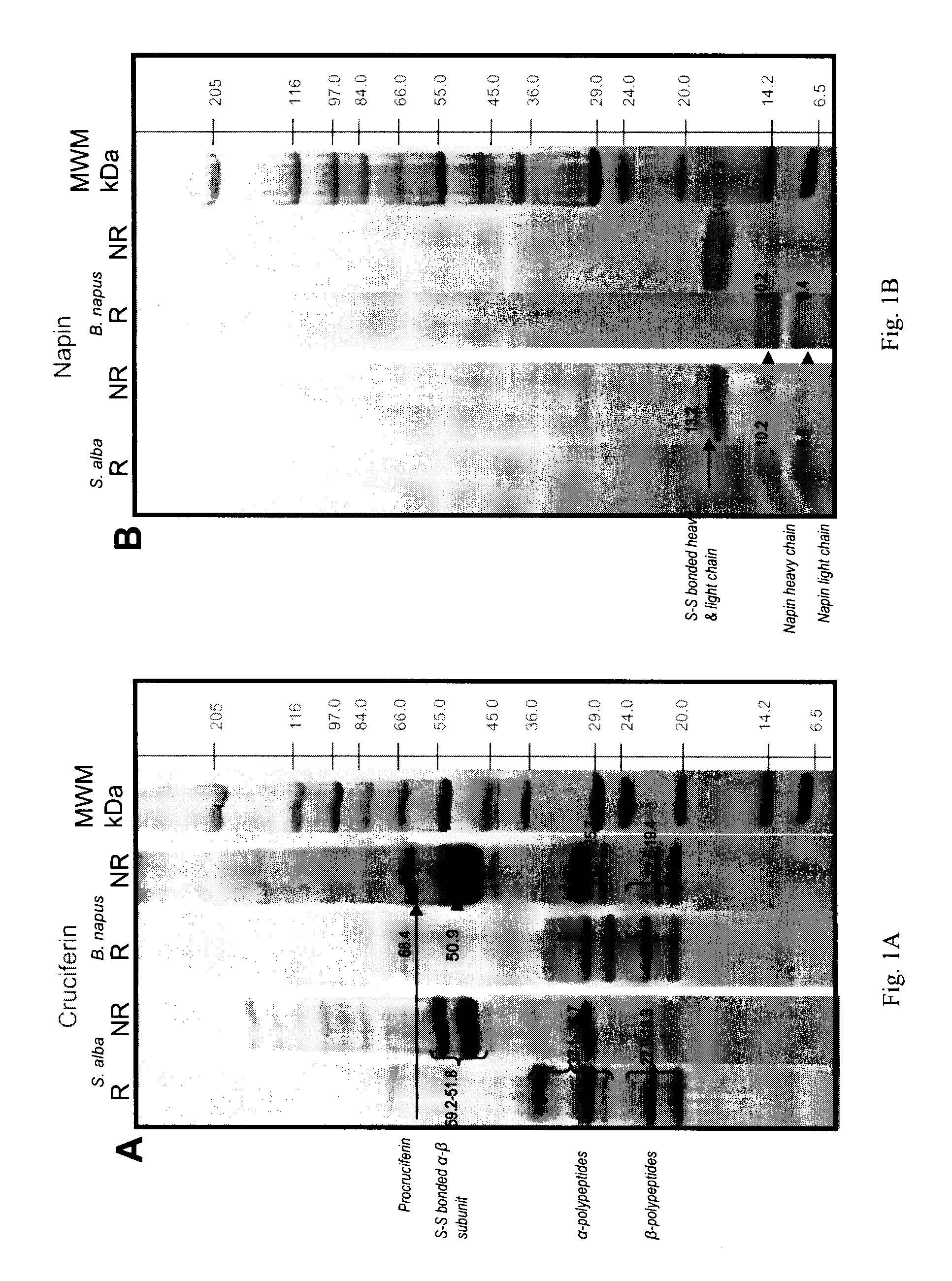

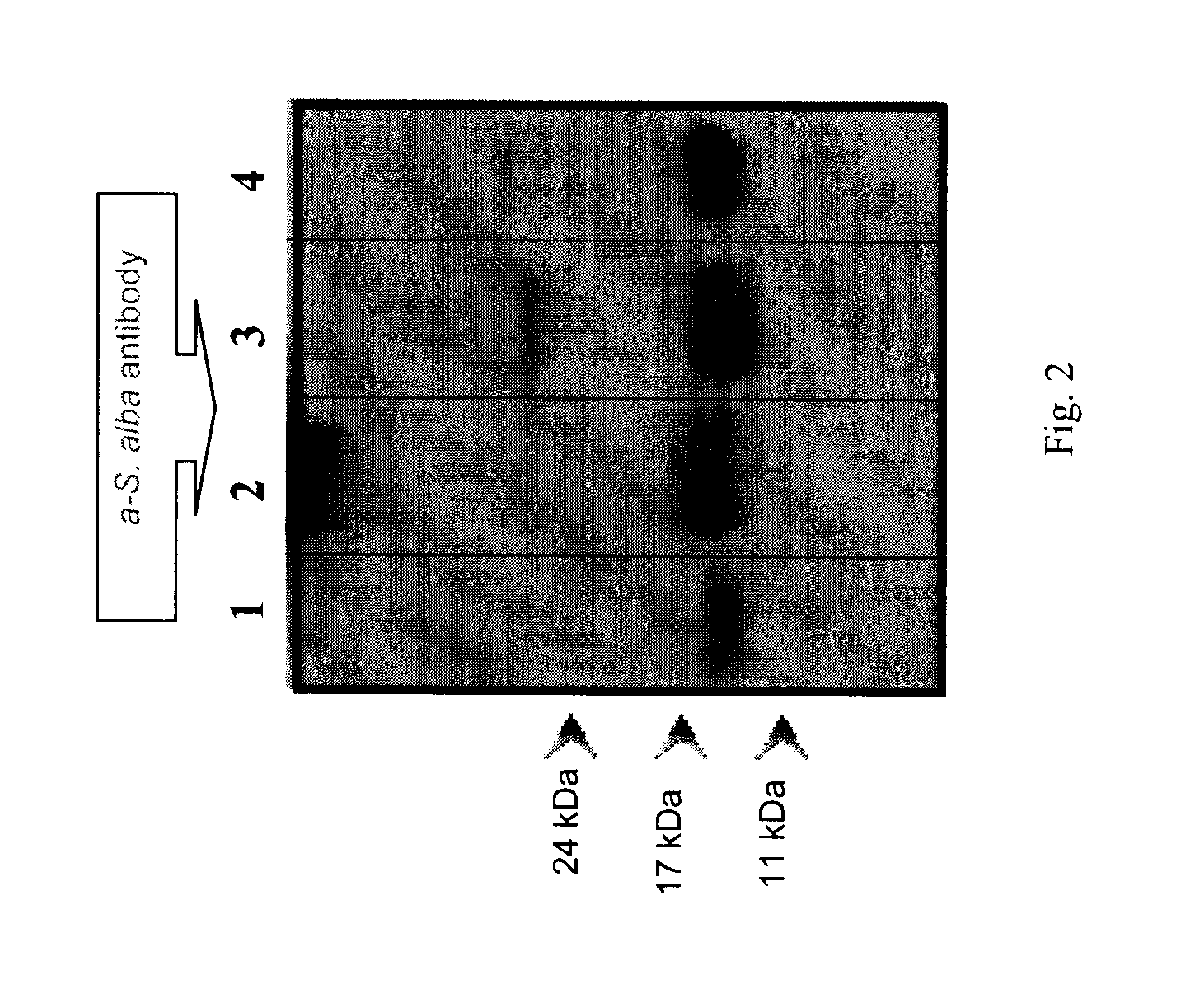

Process of aqueous protein extraction from brassicaceae oilseeds

InactiveUS20100249378A1Reduce extractionImprove solubilityProtein composition from vegetable seedsDepsipeptidesBrassicaceaeLow protein

A process of aqueous protein extraction from Brassicaceae oilseed meal, such as canola, commercial canola meal or yellow mustard, to obtain a napin-rich protein extract, a cruciferin-rich protein extract, and a low-protein residue. The process comprising the steps of performing aqueous extraction of the Brassicaceae oilseed meal at a pH of from about 2.5 to about 5.0 to obtain a soluble napin-rich protein extract and a cruciferin-rich residue followed by performing aqueous extraction of the cruciferin-rich residue to obtain a soluble cruciferin-rich protein extract and a low-protein residue. The cruciferin-rich residue may be treated with cell wall degrading enzymes to obtain a cruciferin-rich fraction The cruciferin-rich protein products may be substantially free of napin protein and may be useful as a non-allergenic food product for human consumption.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA

Preparation method of middle and large pig low-protein concentrated forage for wheat based diets

ActiveCN102726632AMeet nutritional needsImprove turnover metabolismFood processingAnimal feeding stuffAnimal sciencePhytase

The invention which discloses a preparation method of a middle and large pig low-protein concentrated forage for wheat based diets belongs to the technical field of concentrated forages. The preparation method comprises the following steps: uniformly mixing100wt% of raw materials, and packaging the raw materials, wherein the raw materials comprise the following components, by weight, 40-60 parts of soybean meal, 7-10 parts of peanut meal, 4-6 parts of cotton meal, 4-6 parts of corn lees, 4-6 parts of corn protein flour, 3-4 parts of rice bran meal, 2-4 parts of soybean oil, 4-6 parts of stone flour, 2-3 parts of calcium hydrogen phosphate, 1-3 parts of salt, 1-2 parts of 65% lysine, 0.2-0.5 parts of 98.5% threonine, 0.3-0.5 parts of 10% tryptophan, 0.05-0.1 parts of a composite enzyme, 0.01-0.02 parts of phytase, 0.01-0.02 parts of choline chloride and 0.5-1 part of a premix. The preparation method has a beneficial effect that unfavorable factors can be fully eliminated and a corn based diet effect can be reached through the improvement of a production technology and the application of exogenous nutrients and forage additives, so the preparation method has great grain saving and environmental protection meanings.

Owner:江苏中煤长江生物科技有限公司

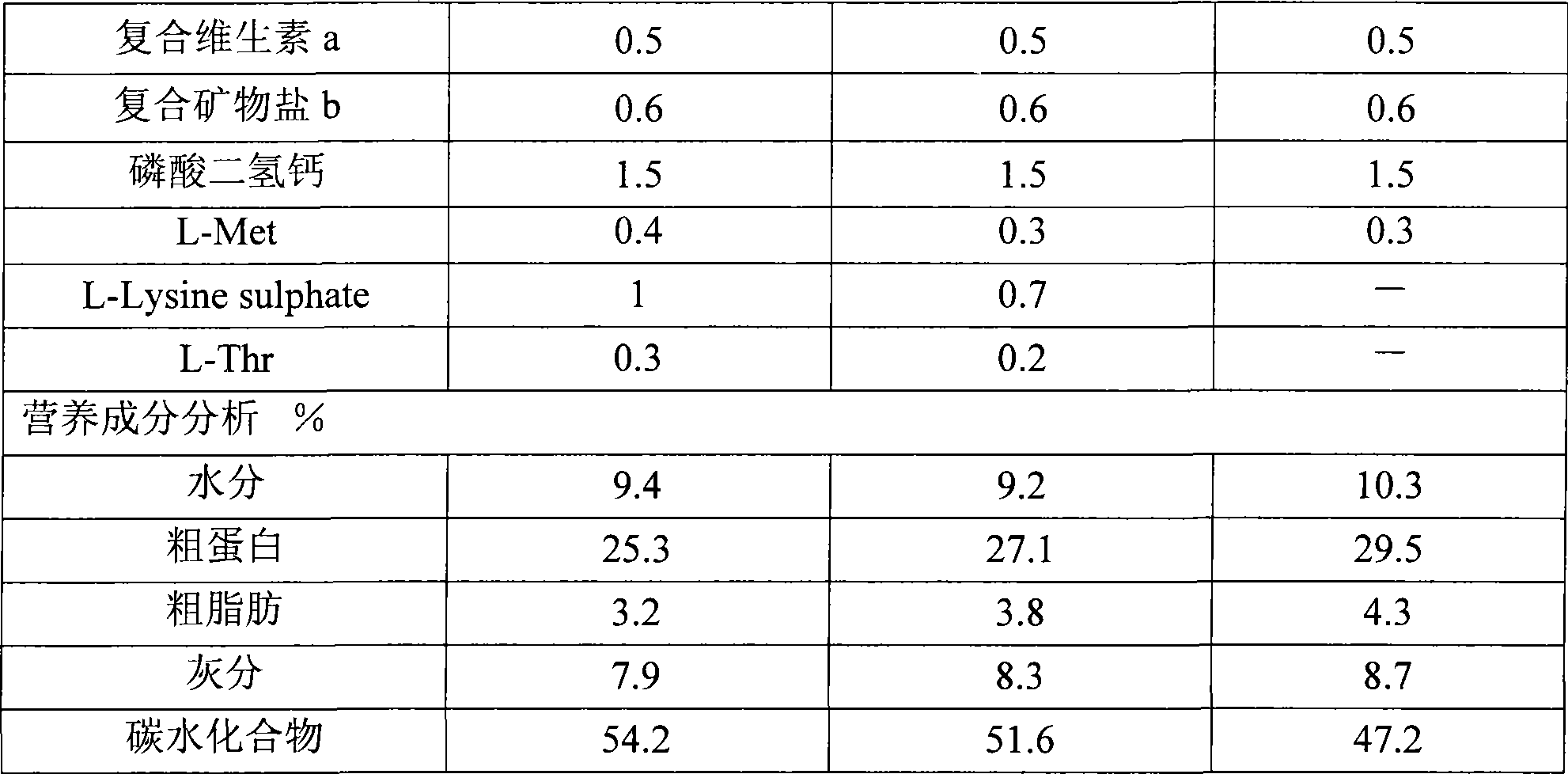

Tilapia feed formula

InactiveCN101473904ALow costImprove palatabilityFood processingClimate change adaptationAnimal scienceTransformation efficiency

The invention relates to a feed formulation for tilapia. The feed comprises the following nutrition components by weight percentage: crude protein, 25%-30%; crude fat, 3%-5%; ash content, 7%-9%; carbohydrate, 40%-55%; and moisture content, 9%-11%. The feed formulation of the invention increases the content of carbohydrate and reduces the content of protein, thus having the function of saving protein raw materials and reducing feed cost and pollution. Long-term raising experiments indicate that the feed produced by adopting the feed formulation of the invention has good palatability, and better growth effect is achieved in breeding of the tilapia. Compared with the feed of high protein contents, the low protein and high carbohydrate type feed for the tilapia can achieve considerably good growth effect and better feed efficiency; compared with feed with the same level of protein and fat, the feed for tilapia of the invention achieves better growth effect, higher protein transformation efficiency and lower ammonian discharge amount.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com