Tilapia feed formula

A feed formula, tilapia technology, applied in animal feed, animal feed, climate change adaptation and other directions, can solve the problem of increased costs for feed manufacturers and breeding producers, restricting the development and growth of the tilapia industry, and low feed protein conversion rate. and other problems to achieve the effect of improving feed utilization, optimizing feed efficiency and reducing protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

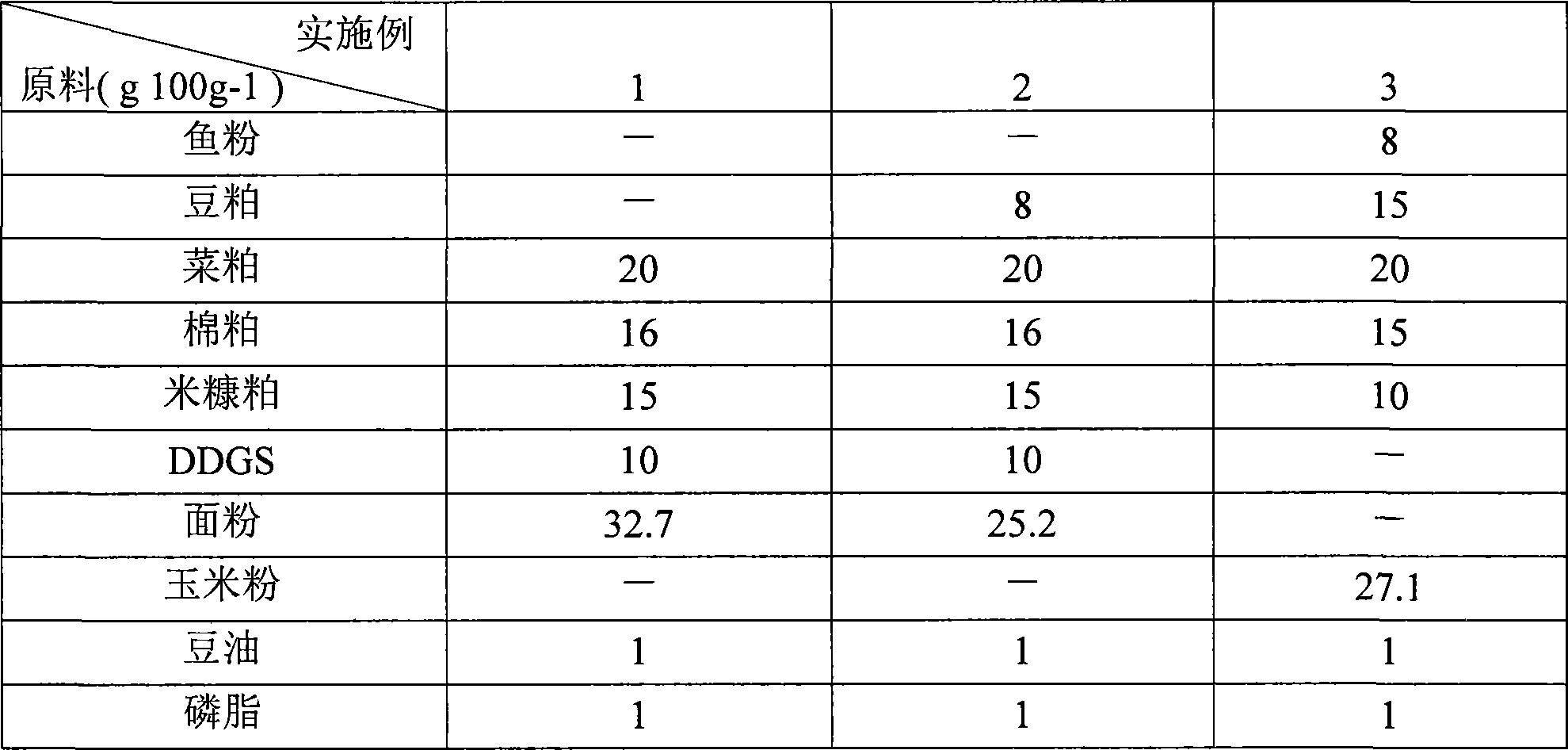

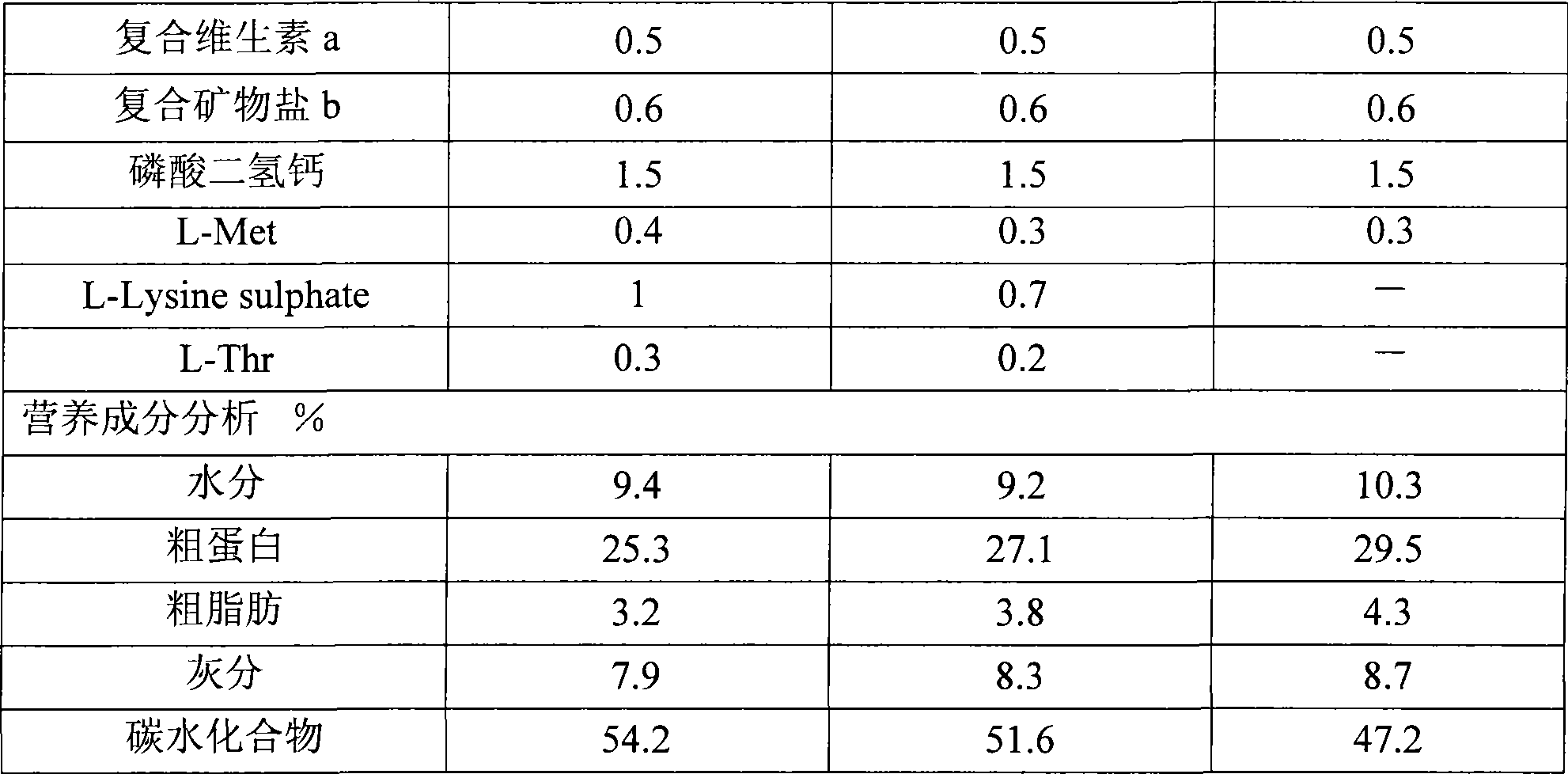

[0017] Embodiment 1: Feed (0% soybean meal, 32.7% flour) was formulated with Formula 1 shown in Table 1, and about 5.2 g of Gifu tilapia were raised for 64 days. After the experiment finished, the average weight of this group of tilapia was 46.3g, weight gain rate (WG) 815.1%, specific growth rate (SGR, %d -1 ) 3.69, all parameters were compared with high-protein low-starch feed (34% CP (crude protein content) group (24% soybean meal, 9.9% flour) and 32% CP group (16% soybean meal, 17.9% flour )) There is no significant difference. The protein efficiency of formula 1 was 2.36 slightly higher than 2.28 of 34% CP group and 2.34 of 32% CP group, but there was no significant difference.

Embodiment 2

[0018] Embodiment 2: Feed (8% soybean meal, 25.2% flour) was formulated with Formula 2 shown in Table 1, and about 5.2 g of Gifu tilapia were raised for 64 days. After the experiment finished, the average weight of this group of tilapias was 54.7g, weight gain (WG) 951.6%, specific growth rate (SGR, %d -1 ) 3.92, feed coefficient is 1.34, each parameter has no significant difference with 34% CP group (24% soybean meal, 9.5% flour); and the protein efficiency of formula 2 is slightly higher than 34% CP group, but no significant difference sexual difference. All parameters of formula 2 were slightly better than those of the 32% CP group (16% soybean meal, 17.1% flour), but there was no significant difference.

Embodiment 3

[0019] Embodiment 3: Prepare feed (8% fish meal, 15% soybean meal, 27.1% corn meal) with Formula 3 shown in Table 1, and raise about 9.2 g of Oza tilapia for 64 days. After the experiment finished, the average weight of this group of tilapia was 63.8g, weight gain rate (WG) 589.5%, specific growth rate (SGR, %d -1 ) 3.45, the feed coefficient is 1.28, and all parameters are significantly better than the low-starch feed (8% fish meal, 15% soybean meal, 12% corn starch) of equal protein and fat.

[0020] Specific growth rate SGR (%d -1 )=100×(1n final average weight-ln initial average weight) / experimental days

[0021] Weight gain rate WG(%)=(final average weight-initial average weight)×100 / initial average weight

[0022] Survival rate SR (%) = number of remaining fish tails at the end of the experiment × 100 / number of fish tails at the beginning of the experiment

[0023] Feed coefficient (FCR) = feed amount / (final body weight-initial body weight)

[0024] Protein efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com