Method for preparing amino acid modified polyether sulfone hematodialysis membrane

A technology of hemodialysis and chloromethyl polyethersulfone, applied in the field of hemodialysis membrane, can solve the problems of larger membrane pore structure regulation, membrane surface shedding, difficulty, etc., and achieve excellent biocompatibility and low protein adsorption. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

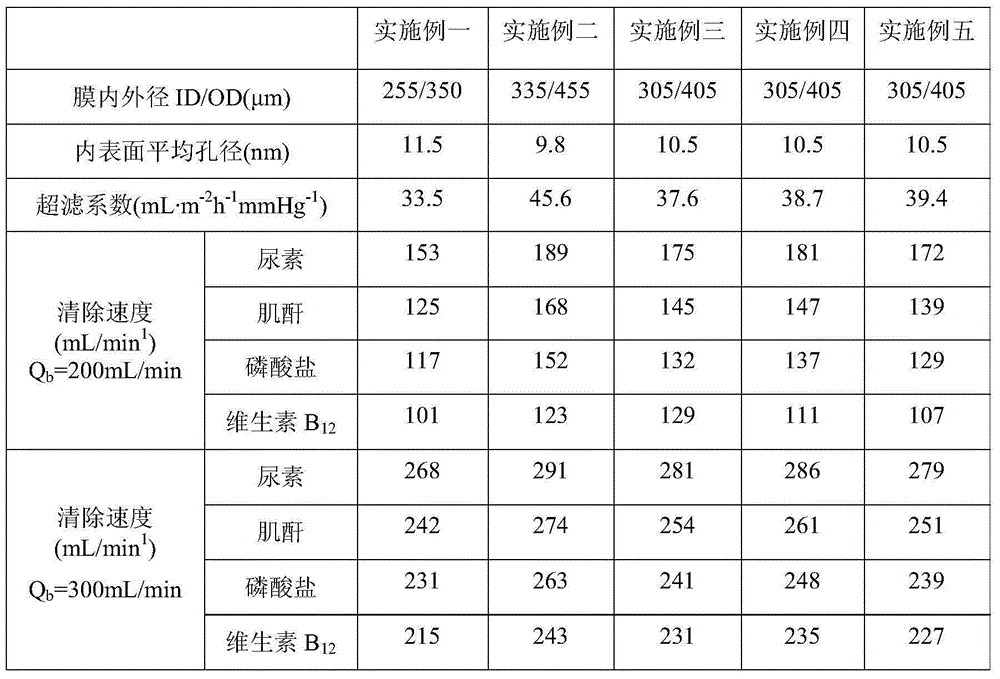

Embodiment 1

[0023] step one:

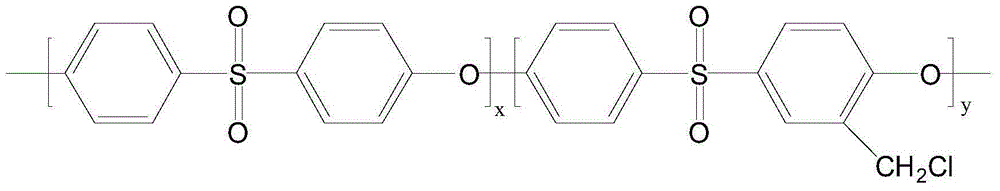

[0024] Weigh 10% chloromethyl polyethersulfone (x is 200, y is 2; degree of chloromethylation is 1%, Hangzhou Xiaoshan Jiangcheng Chemical Co., Ltd.), dimethylacetamide 80%, isopropanol 5% by mass fraction %, lithium chloride 5%, stirring and dissolving at 25°C for 10 hours to obtain a uniform and stable casting solution, vacuum standing for defoaming and keeping at the required spinning temperature of 25°C, prepared by dry / wet phase inversion method Chloromethyl polyethersulfone hollow fiber membrane; then soaked in hot water at 40°C for 10 hours to remove small molecule pore-forming agents and residual solvents on the surface of the membrane and in the pores, and finally soaked in ethanol solution for 2 hours, at 60°C Dry and set aside.

[0025] Step two:

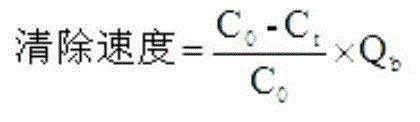

[0026] The chloromethyl polyethersulfone membrane prepared in step (1) was immersed in an aqueous sodium hydroxide solution with a pH of 8 and a glycine concentration of 2.0 mol / L, reacted at 20°C for...

Embodiment 2

[0028] step one:

[0029] Weigh 30% of chloromethyl polyethersulfone (x is 160, y is 40; degree of chloromethylation is 20%, Hangzhou Xiaoshan Jiangcheng Chemical Co., Ltd.), dimethylformamide 50%, butanol 10% by mass fraction , Lithium perchlorate 10%, stirring and dissolving at 85°C for 6 hours to obtain a uniform and stable casting solution, standing in vacuum for defoaming and keeping at the required spinning temperature of 85°C, by using the dry / wet phase conversion method Prepare the chloromethyl polyethersulfone hollow fiber membrane; then soak it in hot water at 60°C for 5 hours to remove the small molecule pore-forming agent and residual solvent on the surface of the membrane and in the pores, and finally soak it in ethanol solution for 5 hours, at 60°C Tumble dry and set aside.

[0030] Step two:

[0031]Immerse the chloromethyl polyethersulfone membrane prepared in step (1) into an aqueous sodium hydroxide solution with a pH of 10 and an aspartic acid concentratio...

Embodiment 3

[0033] step one:

[0034] Weigh 20% chloromethyl polyethersulfone (x is 180, y is 20; chloromethylation degree 10%, Hangzhou Xiaoshan Jiangcheng Chemical Co., Ltd.), N-methylpyrrolidone 50%, molecular weight 400 poly 15% ethylene glycol, 15% lithium nitrate, stirring and dissolving at 40°C for 8 hours to obtain a uniform and stable casting solution, vacuum standing for defoaming and keeping at the required spinning temperature of 40°C, passing through the dry / wet phase The chloromethyl polyethersulfone hollow fiber membrane was prepared by the conversion method; then soaked in hot water at 50°C for 8 hours to remove the small molecule pore-forming agent and residual solvent on the surface of the membrane and in the pores, and finally soaked in ethanol solution for 3 hours, Dry at 60°C for later use.

[0035] Step two:

[0036] Immerse the chloromethyl polyethersulfone membrane prepared in step (1) into an aqueous sodium hydroxide solution with a pH of 9 and a lysine concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com