A composite non-woven battery separator and its preparation method

A battery separator, non-woven technology, applied in the field of composite non-woven battery separator and its preparation, can solve the problems of insufficient liquid absorption rate, large resistance, poor strength of battery separator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

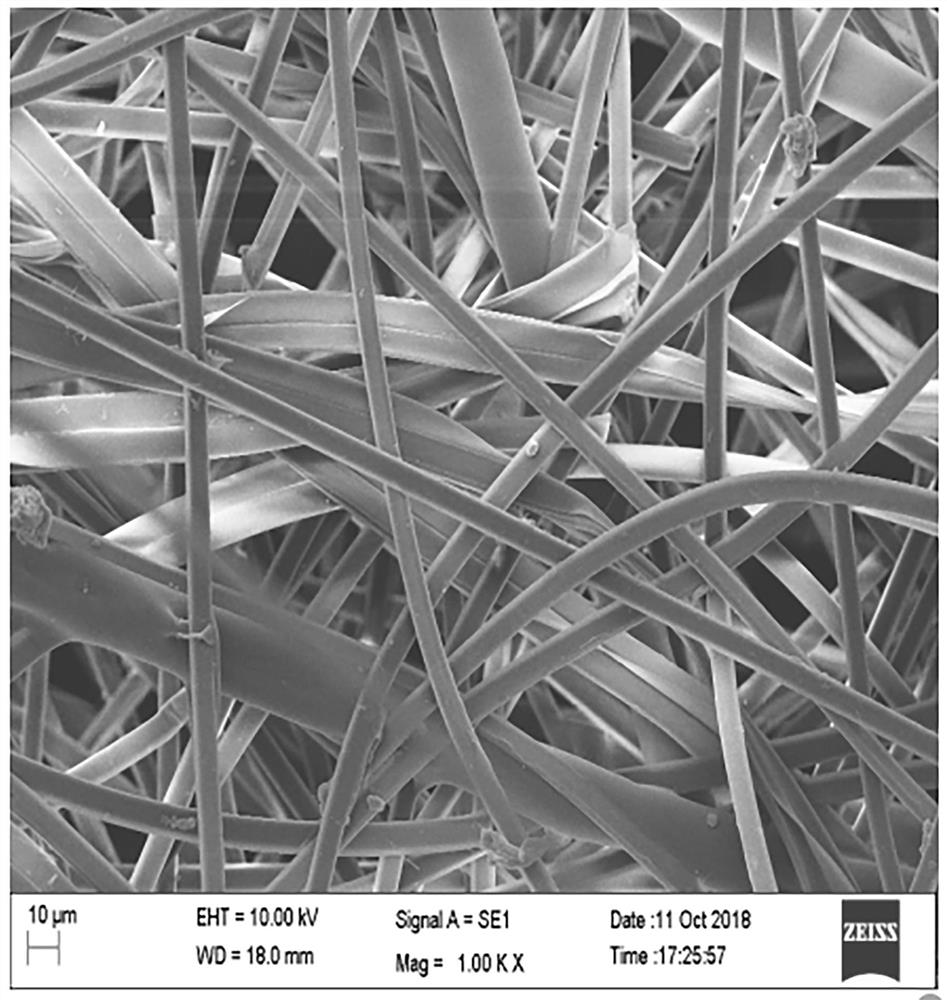

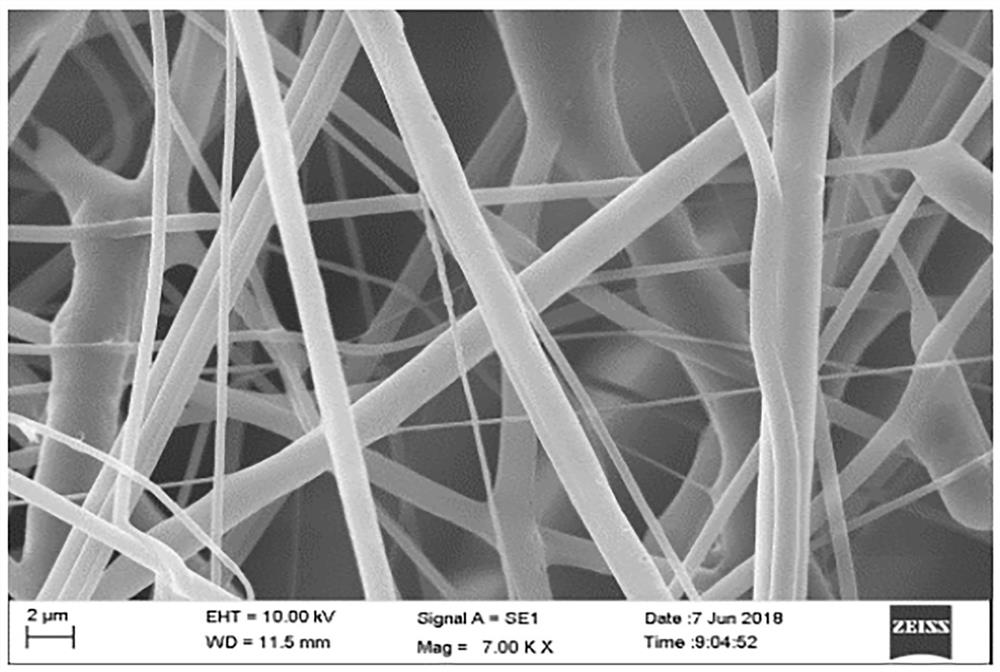

[0038] A composite nonwoven battery separator, the battery separator is based on a composite nonwoven material composed of a short fiber wet layer, a coarse denier filament layer, an ultrafine fiber layer and a fine denier filament layer. A composite diaphragm formed by branched carboxyl and / or sulfonic acid functional groups, wherein the short fiber wet-laid layer is made of PE / PP sheath-core bicomponent fiber with a fiber fineness of 0.5-0.8 denier (purchased from Jiangnan Gao Fiber Co., Ltd.) and polypropylene fibers with a fiber fineness of 1.6 to 2 deniers, the mass fraction of PE / PP sheath-core bicomponent fibers in the short fiber wet layer is 60 to 75%, and the length 6~16mm, the mass fraction of polypropylene fiber is 25~40%, and the length is 6~16mm, and the thickness of the short fiber wet layer is 0.05~0.06mm; 6~8 denier polypropylene filament, the weight of the coarse denier filament layer is 20~50g / m 2 , with a thickness of 0.04~0.06mm, the superfine fiber layer...

Embodiment 2

[0053] Such as Figure 1-5 As shown, a composite nonwoven battery separator, the battery separator is based on a composite nonwoven material composed of short fiber wet layer, coarse denier filament layer, ultrafine fiber layer and fine denier filament layer, A composite diaphragm formed by radiation grafting of carboxyl and / or sulfonic acid functional groups, wherein the short fiber wet-laid layer is made of PE / PP sheath-core bicomponent fibers with a fiber fineness of 0.6 denier and fiber fineness It is composed of polypropylene fibers with a denier of 1.8, the mass fraction of PE / PP sheath-core bicomponent fibers in the short fiber wet-laid layer is 68%, the length is 11mm, and the mass fraction of polypropylene fibers is 32%, The length is 11mm, and the thickness of the short fiber wet layer is 0.055mm; the coarse denier filament layer is made of polypropylene filament with a fiber fineness of 7 deniers, and the grammage of the coarse denier filament layer is 35g / m 2 , w...

Embodiment 3

[0065] A composite nonwoven battery separator, the battery separator is based on a composite nonwoven material composed of a short fiber wet layer, a coarse denier filament layer, an ultrafine fiber layer and a fine denier filament layer. A composite diaphragm formed by branched carboxyl and / or sulfonic acid functional groups, wherein the short fiber wet-laid layer is made of PE / PP sheath-core bicomponent fibers with a fiber fineness of 0.8 denier and a fiber fineness of 1.7 denier Neil's polypropylene fiber composition, the mass fraction of PE / PP sheath-core bicomponent fiber in the short fiber wet-laid layer is 70%, the length is 8mm, the mass fraction of polypropylene fiber is 30%, and the length is 8mm , the thickness of the short fiber wet layer is 0.053mm; the coarse denier filament layer is made of polypropylene filament with a fiber fineness of 6 deniers, and the grammage of the coarse denier filament layer is 25g / m 2 , with a thickness of 0.046mm, the ultrafine fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com