Patents

Literature

137 results about "Grammage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grammage and basis weight, in the pulp and paper and the fabric industries, are the areal density of a paper or fabric product, that is, its mass per unit of area.

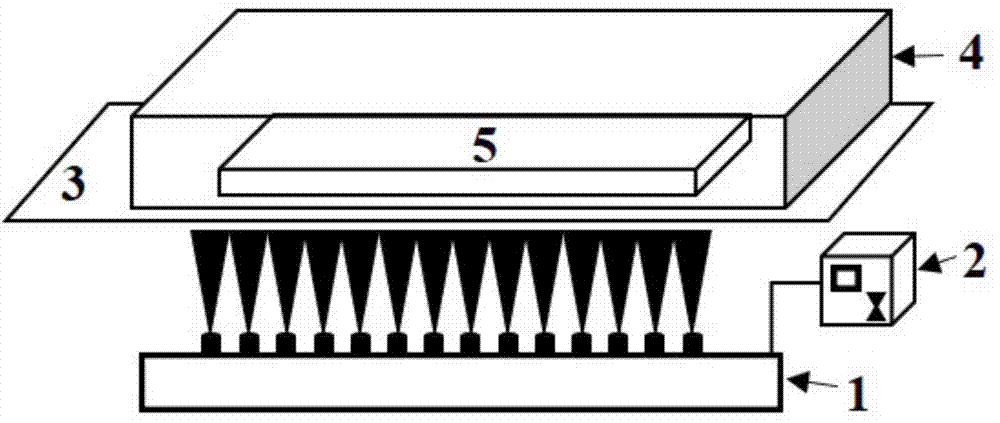

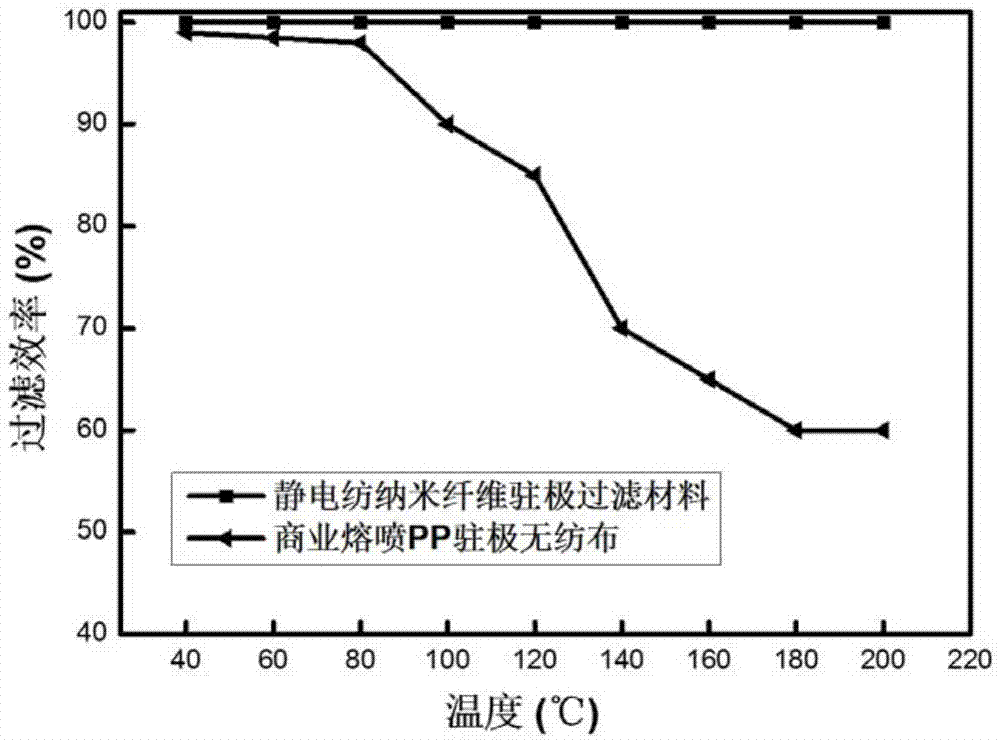

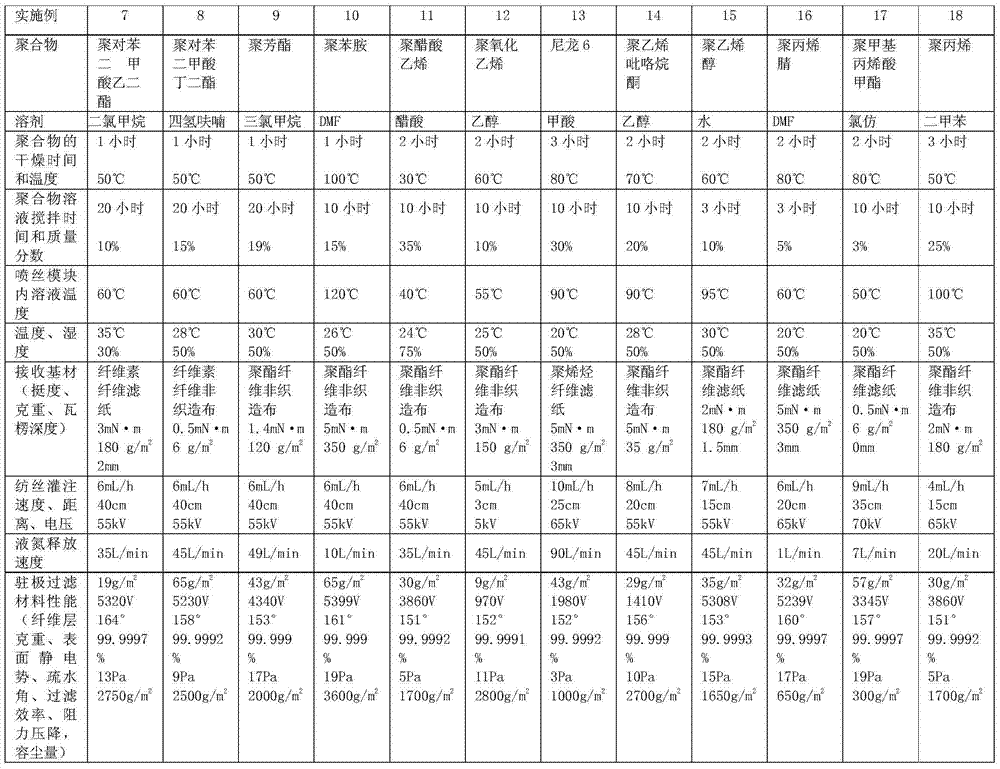

Electrospinning nano-fiber electret filtering material and its preparation method

ActiveCN104289042AHigh surface electrostatic potentialHigh super strong electrostatic adsorption performanceSynthetic resin layered productsFiltration separationPorosityFiber

The invention relates to an electrospinning nano-fiber electret filtering material and its preparation method. The high-efficiency and low-resistsance nano-fiber electret filtering material having no interfibrous adhesion and having a fluffy three-dimensional netted intercommunication structure is prepared through controlling the component and the temperatures of a polymer solution in an electrospinning process and carrying out one-step forming in the nano-fiber forming rapid cooling process, wherein the gram weight of the above nanofiber layer is 0.01-70g / m<2>, and the porosity is not less than 80%. The surface electrostatic potential of the nano-fiber electret filtering material is 800-6000V, and the surface charges have lasting storage stability, the hydrophobic angle is greater than 150DEG, the filtering efficiency of the material to particles of 0.006-1[mu]m can reach above 99.999%, the piezoresistance is less than 20Pa, and the dust containing capacity is 300-3600g / m<2>. The preparation method is simple, and the filtering material has wide application prospects in the fields of individual protection mouth mask filtration, indoor air purification and filtration, and high efficiency / ultrahigh efficiency air filtration.

Owner:DONGHUA UNIV

Terylene coral fleece blanket fabrics and processing method thereof

The invention relates to terylene coral fleece blanket fabrics and a processing method thereof, which belongs to the technical field of terylene fiber products and comprises voile weave and ground weave, the raw material used by the voile weave is DTY terylene filament in 133dtex / 192f, 111dtex / 192f or 111dtex / 144f, and the raw material used by the ground weave is FDY terylene filament of 75dtex / 24f, wherein the mass percentage of the DTY terylene filament occupied in the fabrics is 60-70 percent, and the mass percentage of the FDY terylene filament occupied in the fabrics is 30-40 percent. The invention can lead villus of the fabrics to be straight so as to have excellent lodging resistance and warmth retention property, and can obtain 150-250g / m<2> of gram weight of thread count and be suitable to fabricate household wares such as bathrobe, sleepwear, sheet, and the like. The method can ensure the advantages of the terylene coral fleece blanket fabrics, and can lead the terylene coral fleece blanket fabrics to have better sterilizing, antistatic and anti-allergic effects so as to meet the serviceability.

Owner:CHANGSHU XINXIN WARP & KNITTING

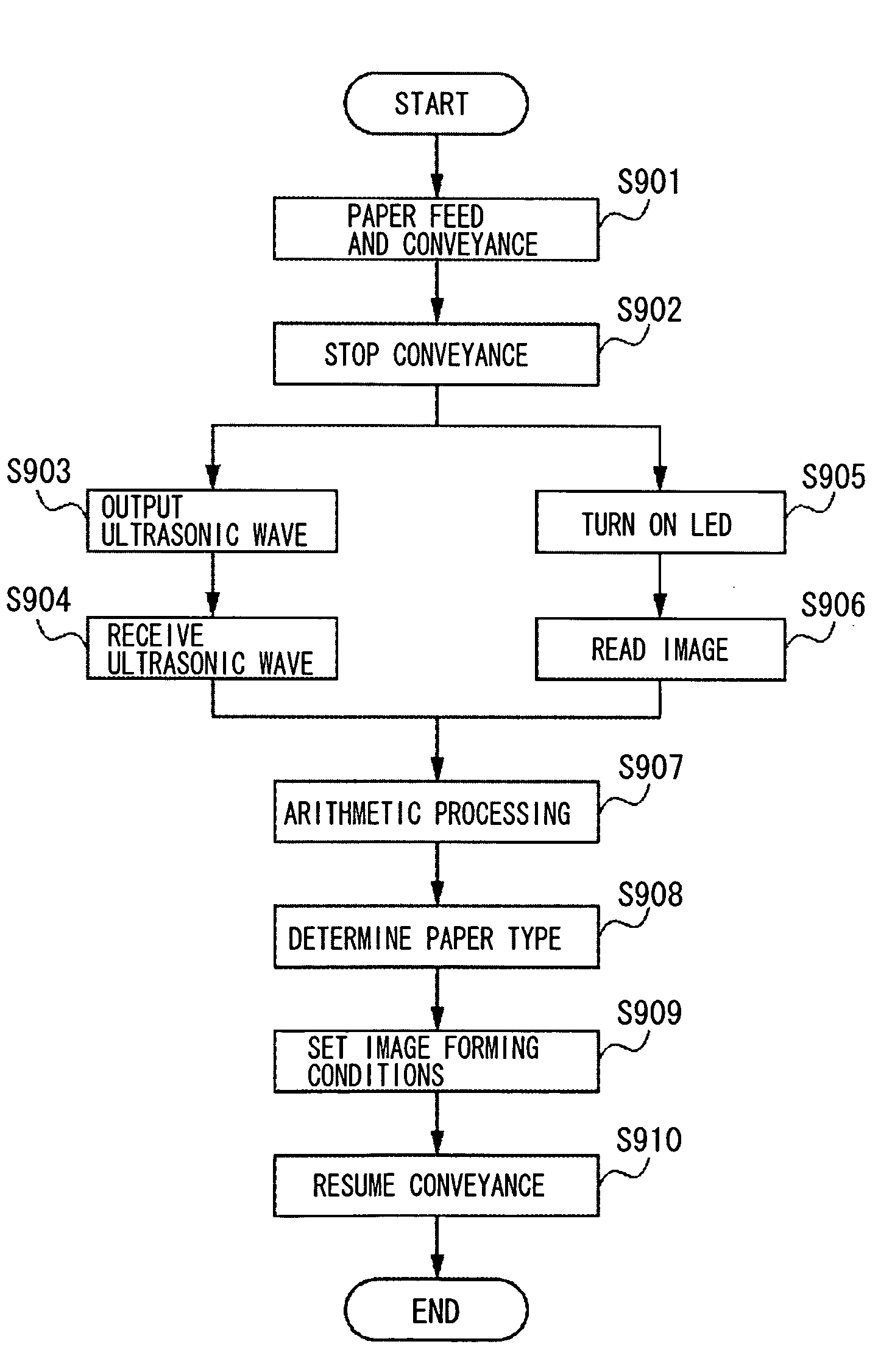

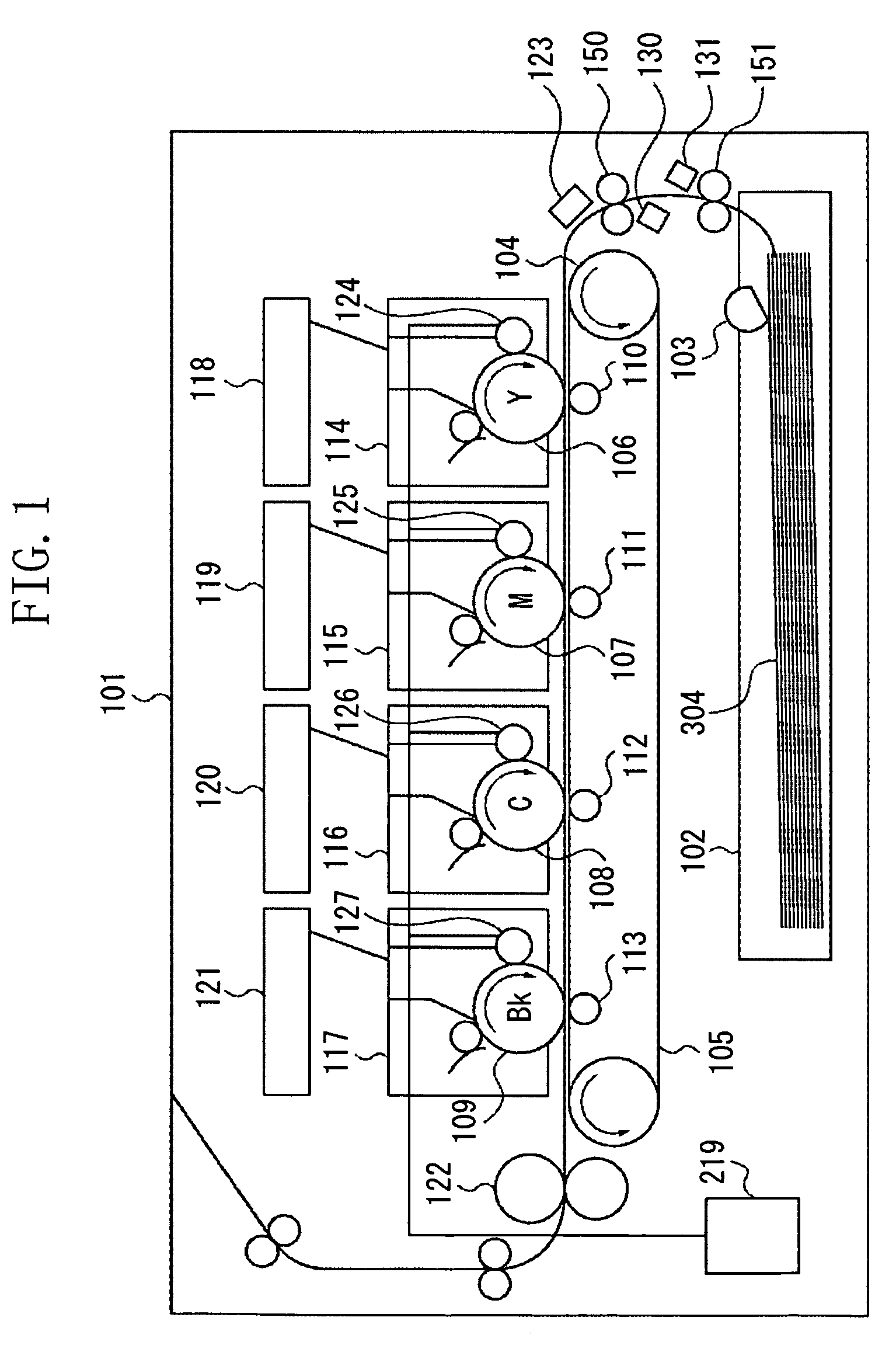

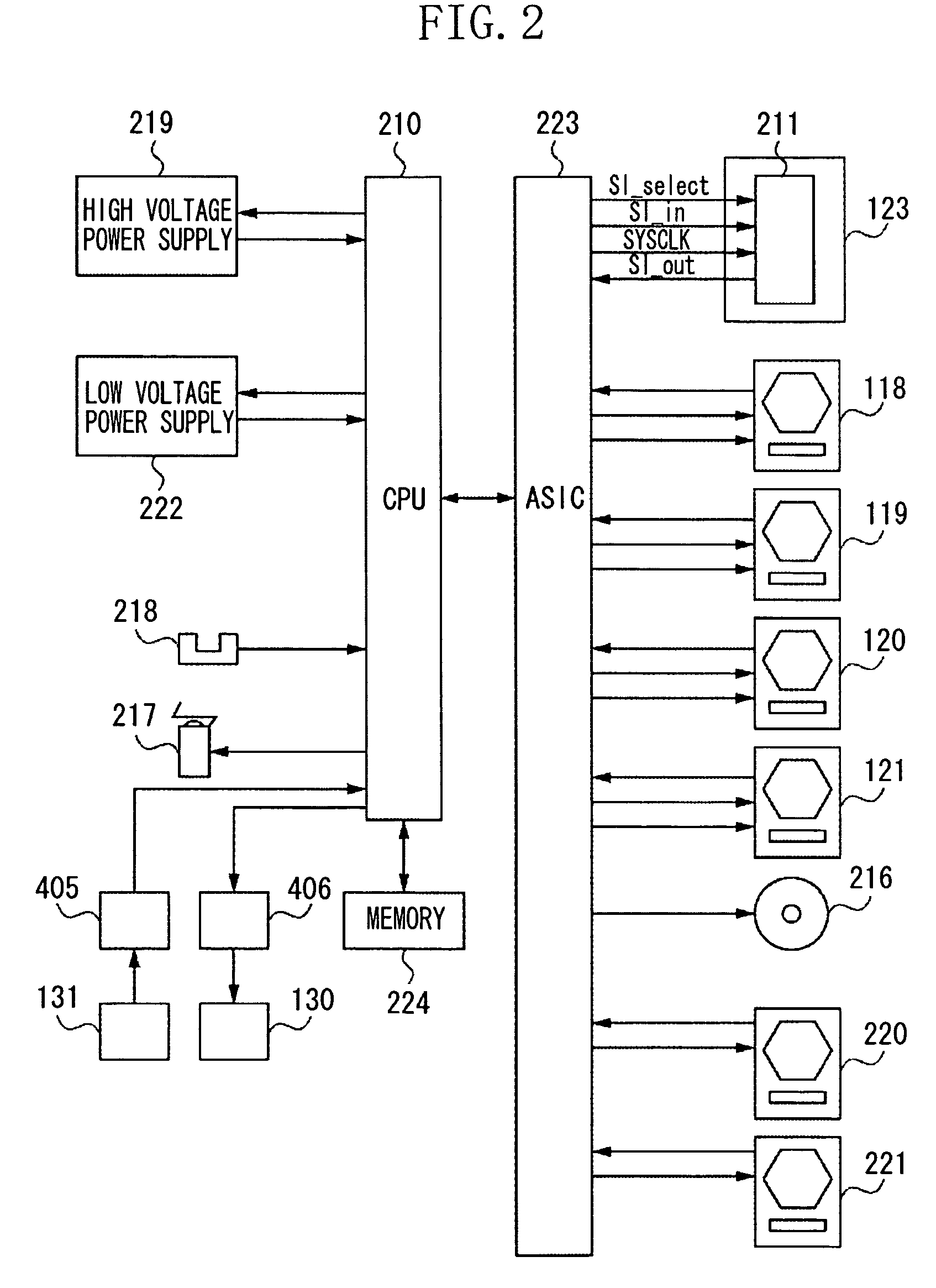

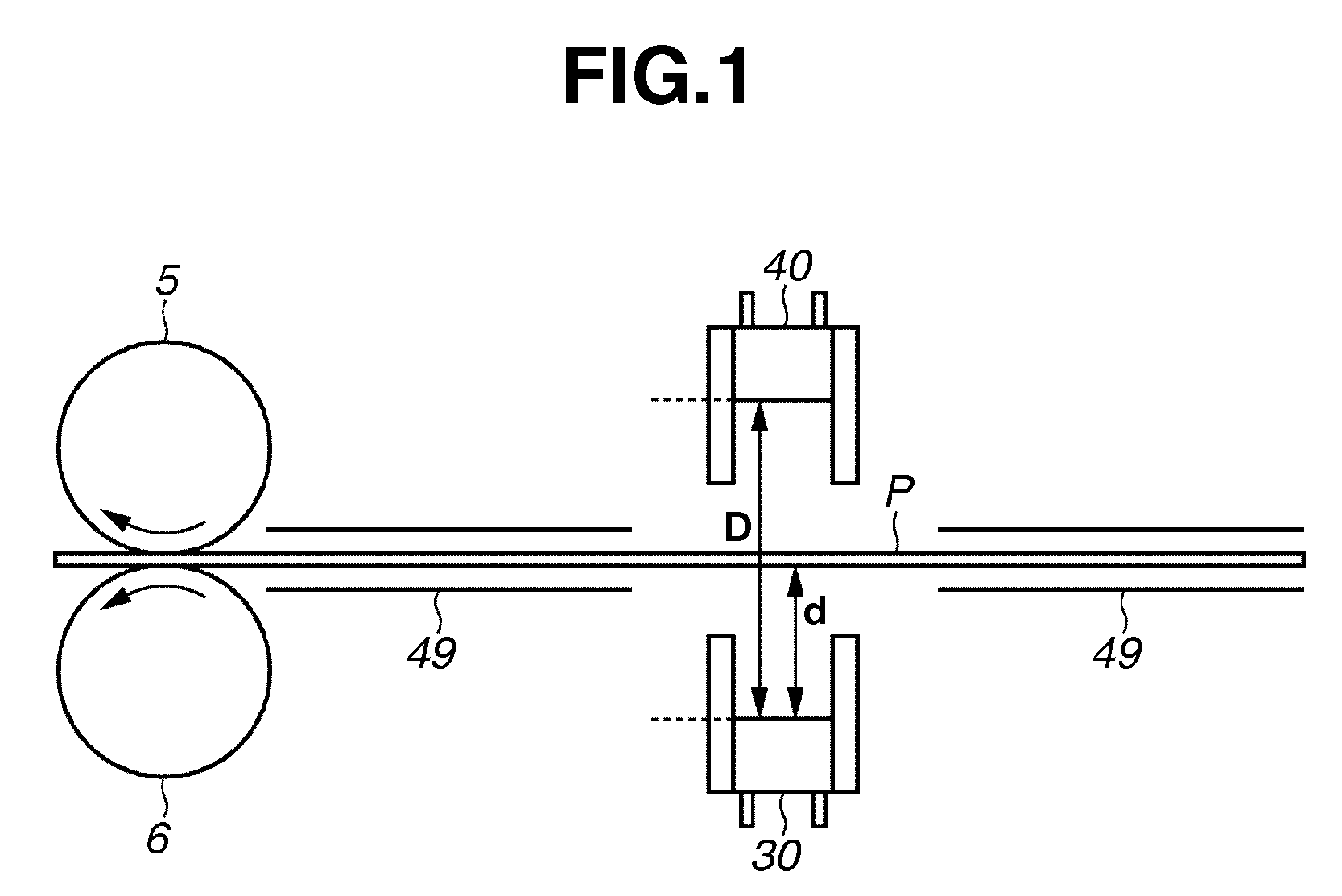

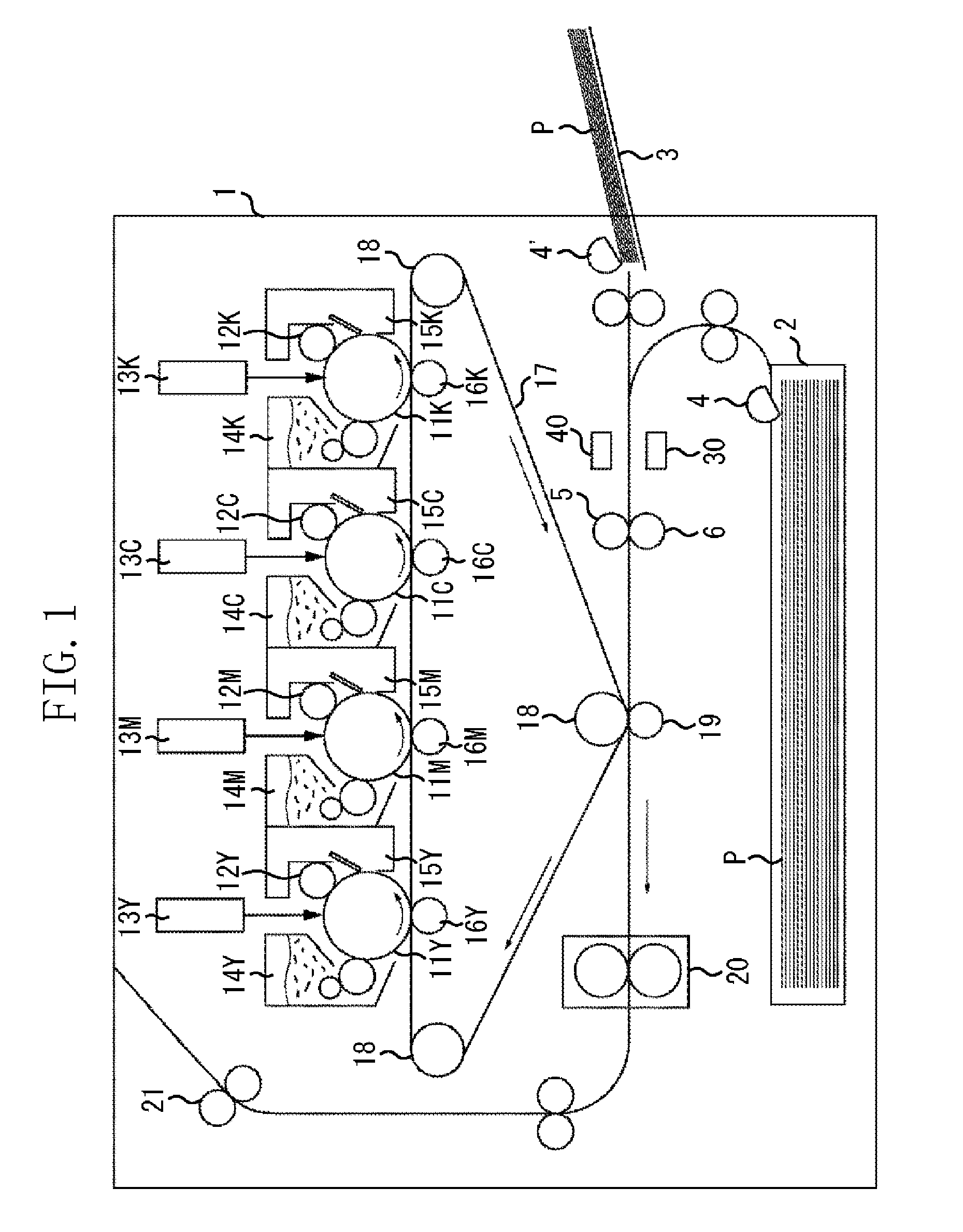

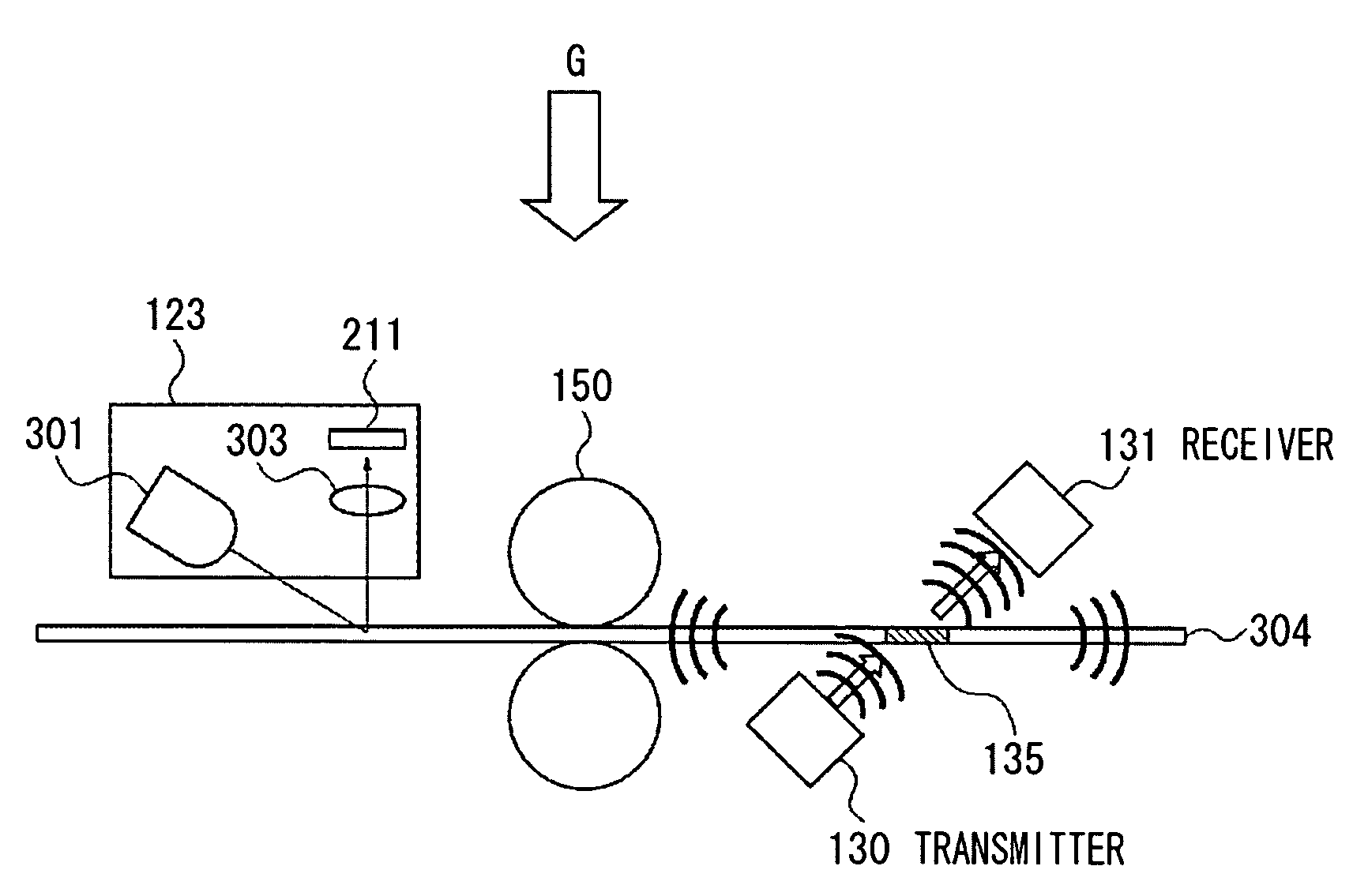

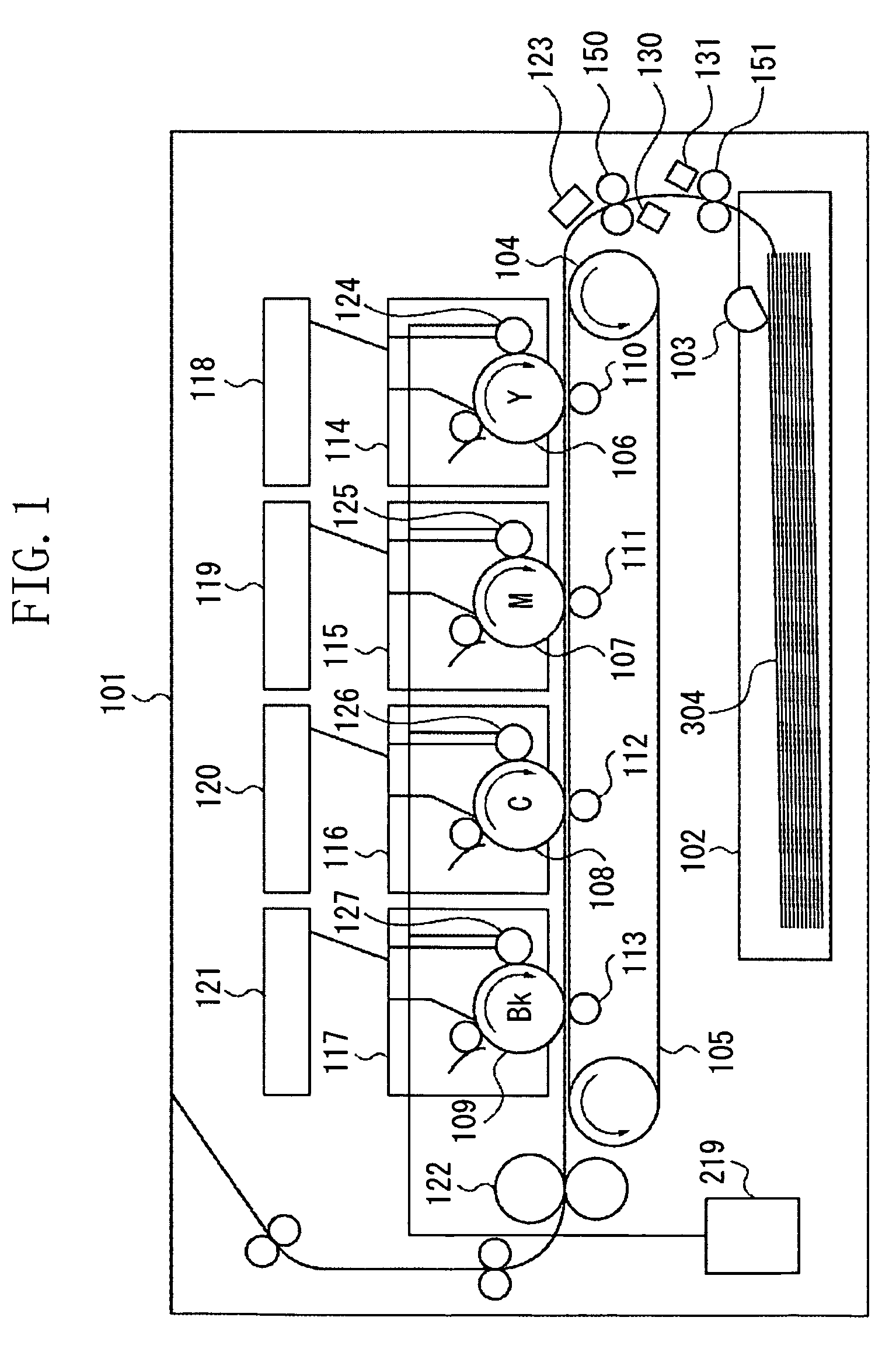

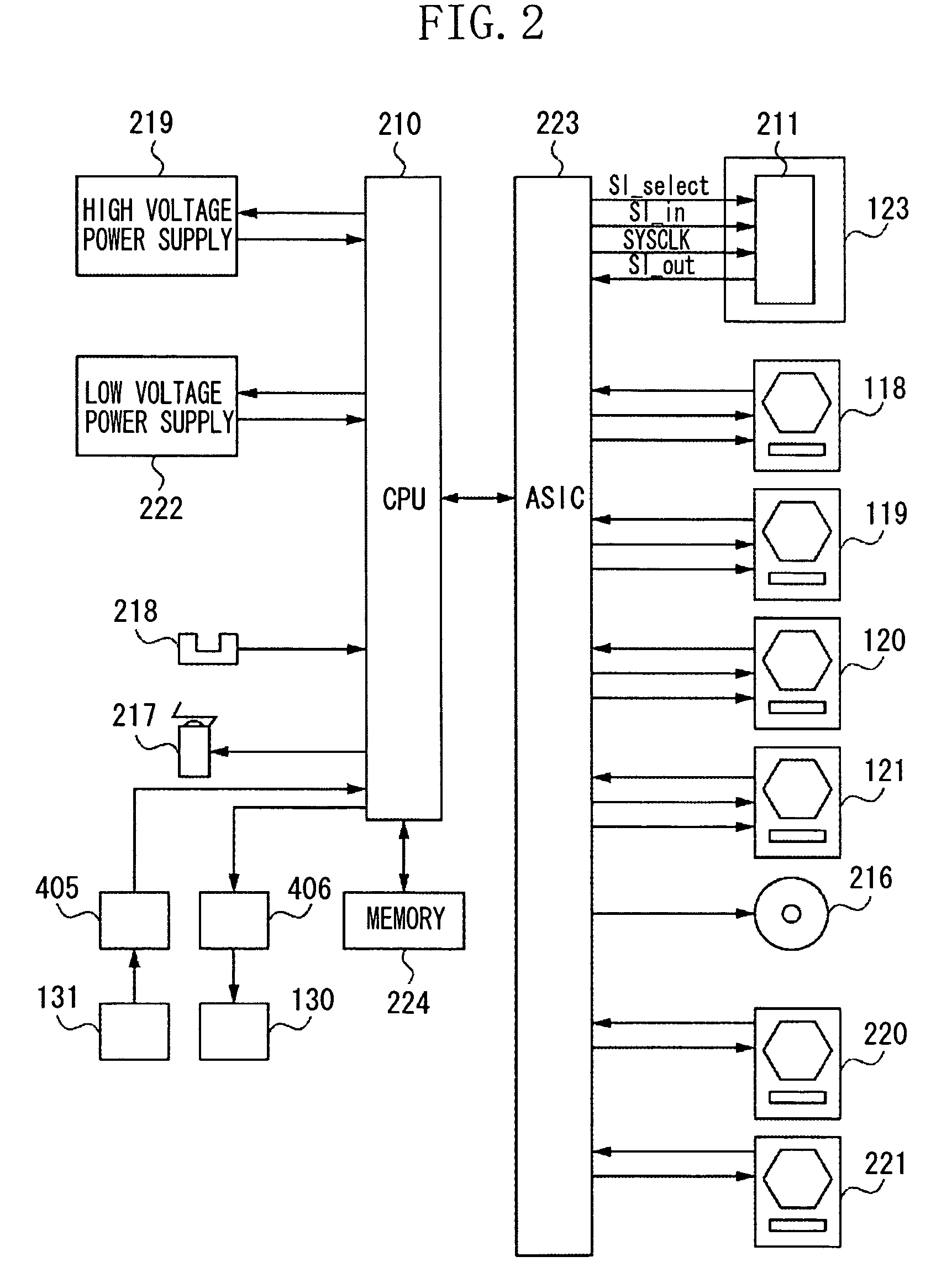

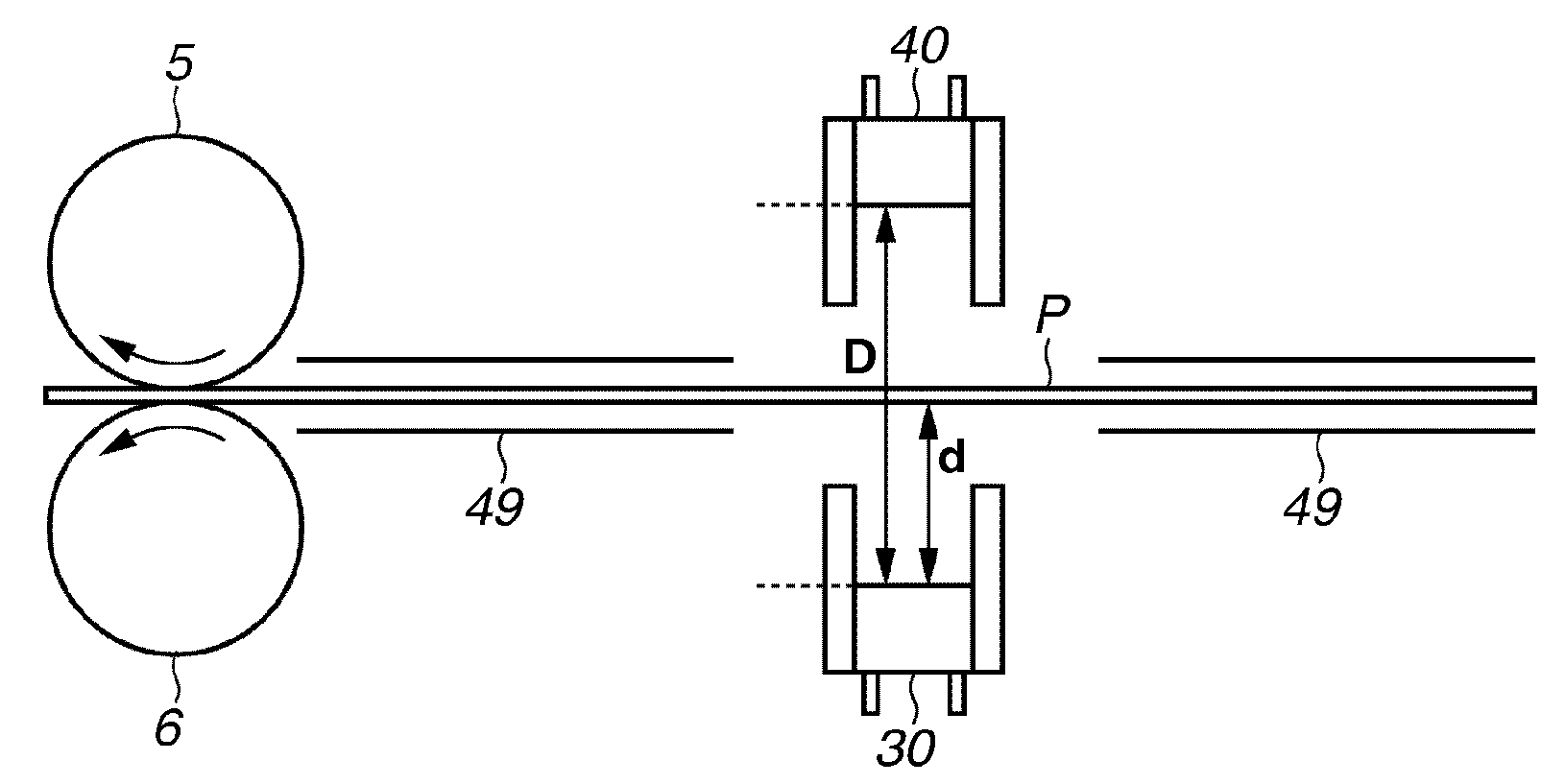

Recording material determination apparatus andimage forming apparatus

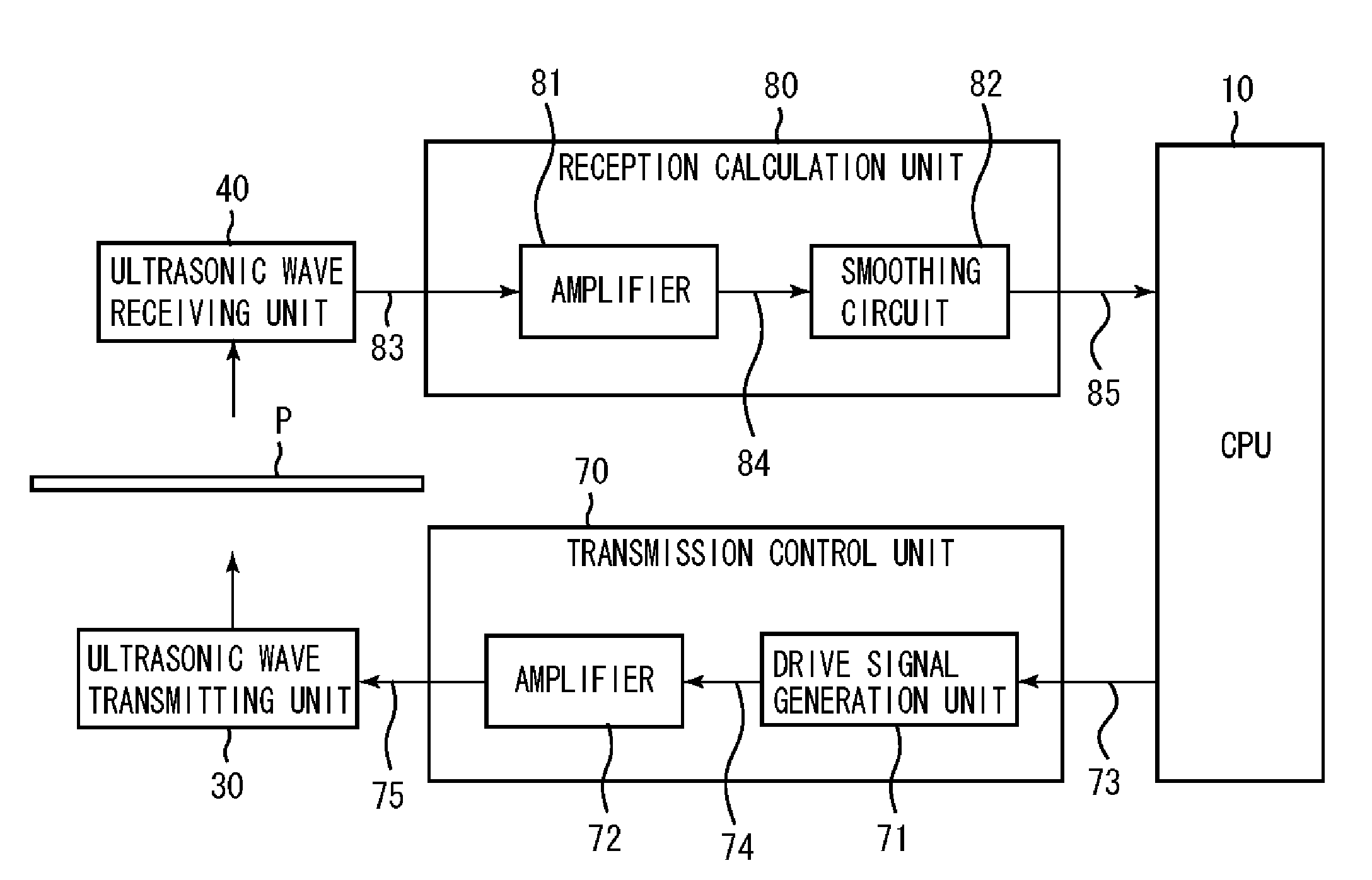

InactiveUS20090003857A1Shorten the timeFunction indicatorsElectrographic process apparatusGrammageSurface conditions

A recording material determination apparatus includes a first detection unit configured to detect a characteristic corresponding to a surface condition of a recording material based on a captured image of a surface of the recording material, a second detection unit configured to detect a characteristic corresponding to a grammage of the recording material based on an ultrasonic wave detected via the recording material by irradiating the recording material with an ultrasonic wave, and a conveyance unit configured to convey the recording material. The first detection unit and the second detection unit are located opposite each other with respect to the conveyance unit.

Owner:CANON KK

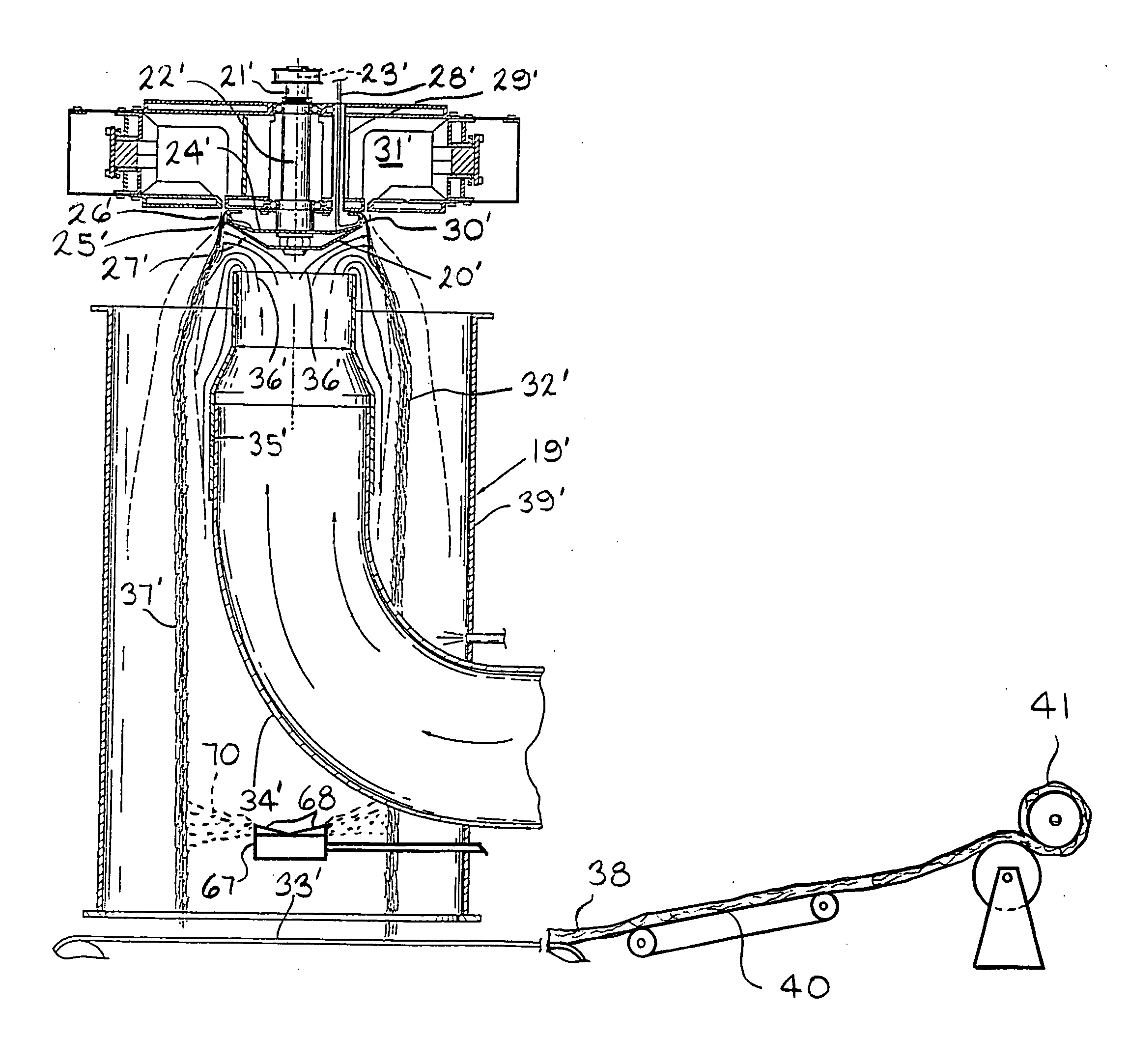

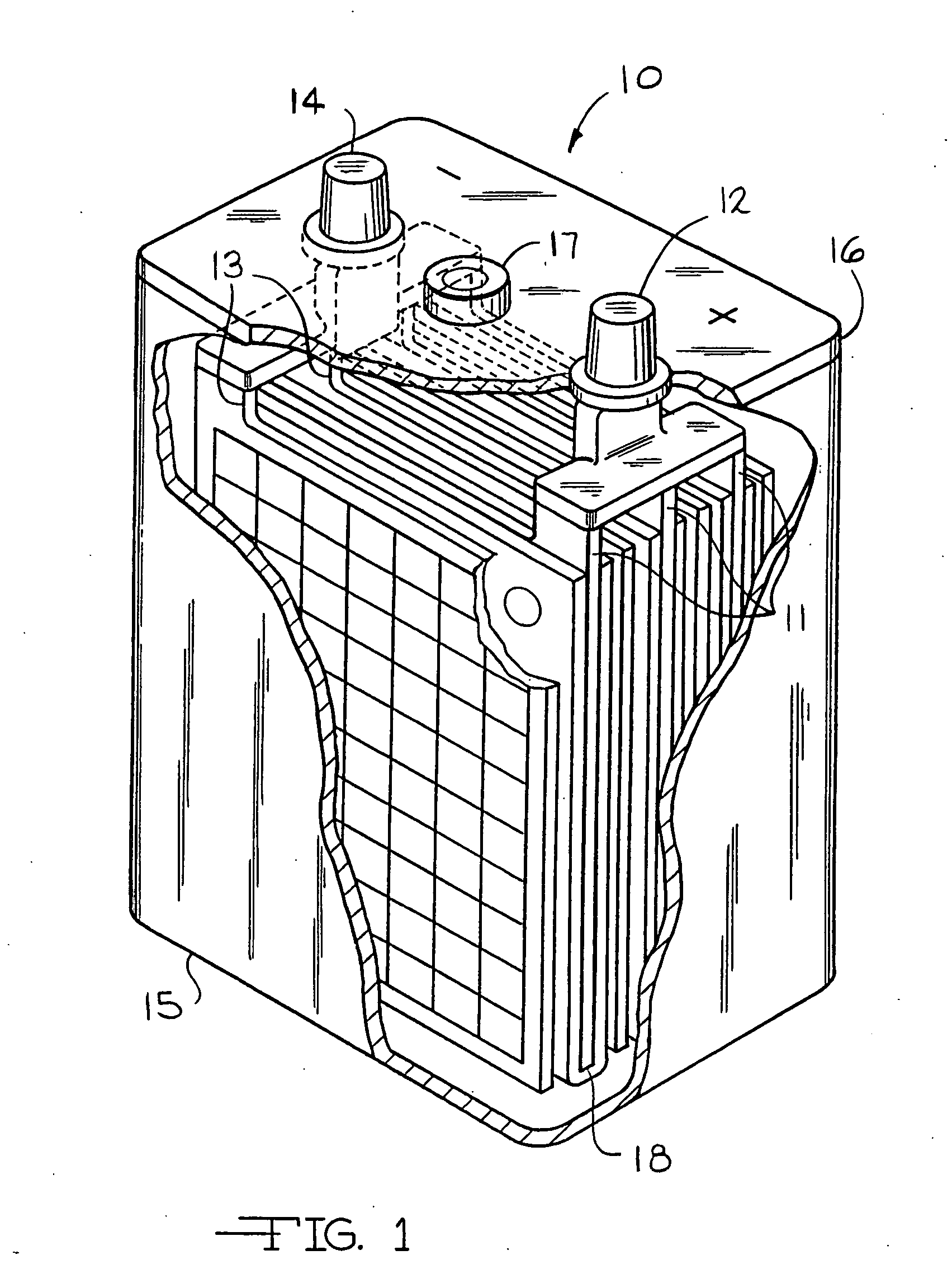

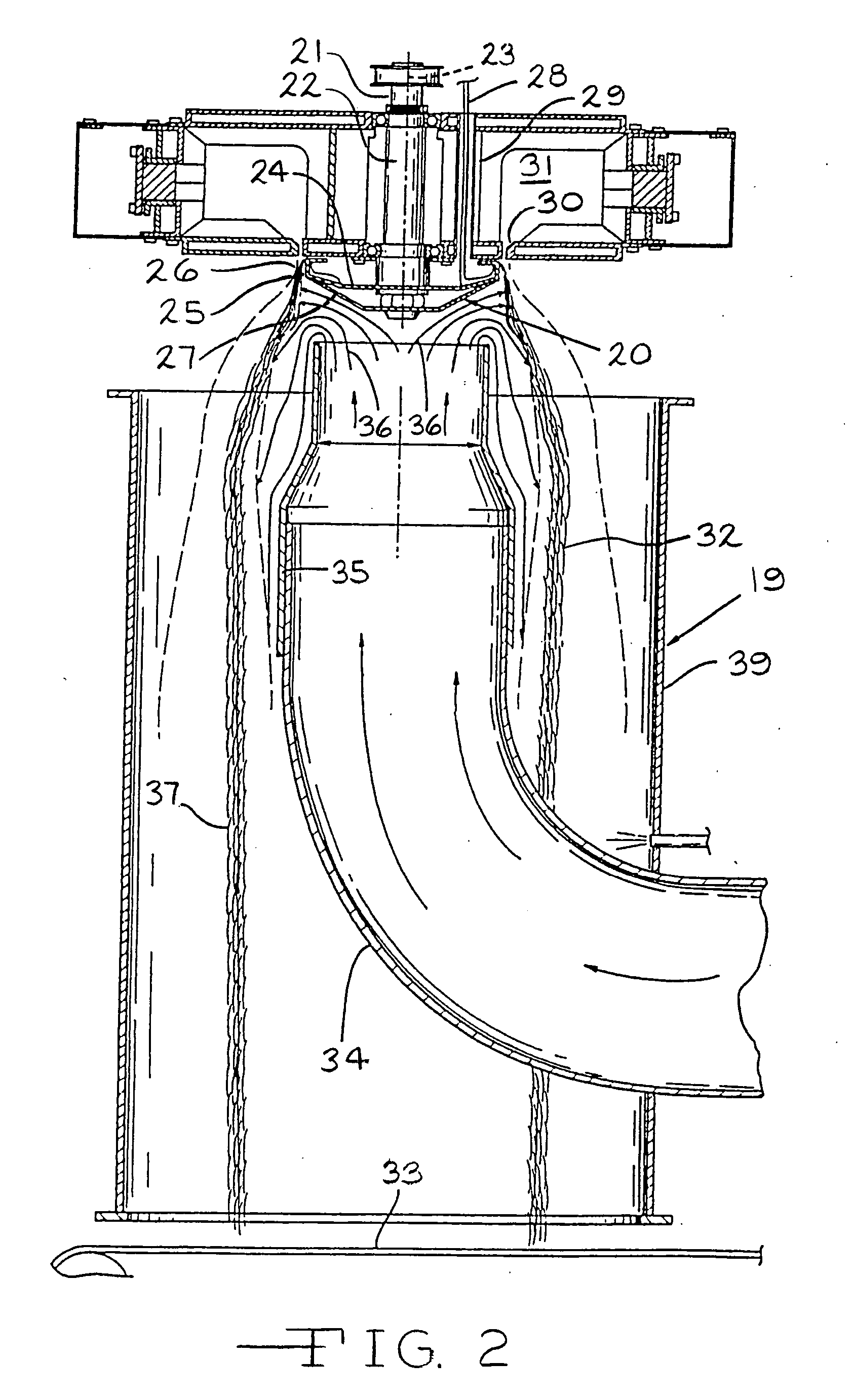

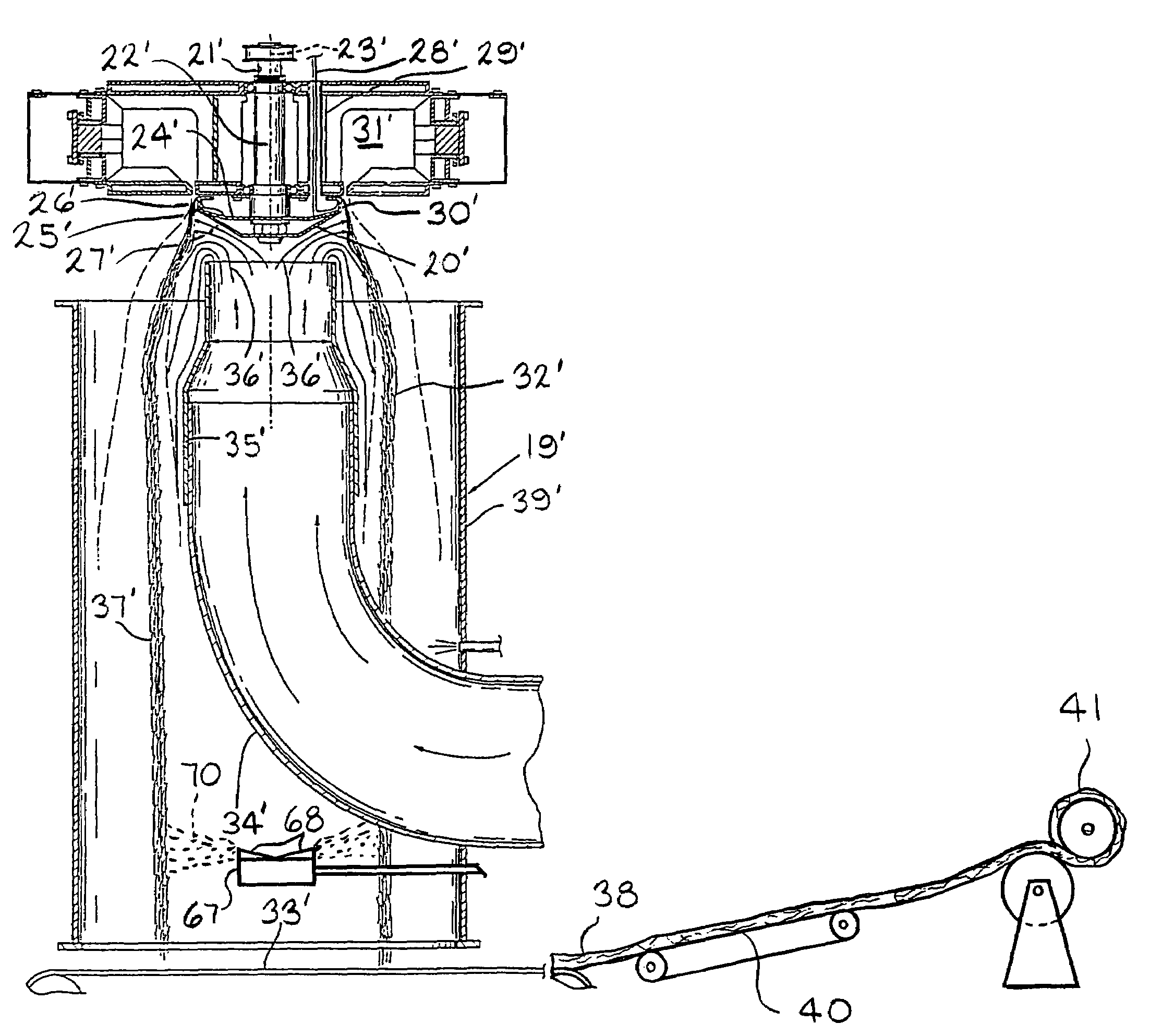

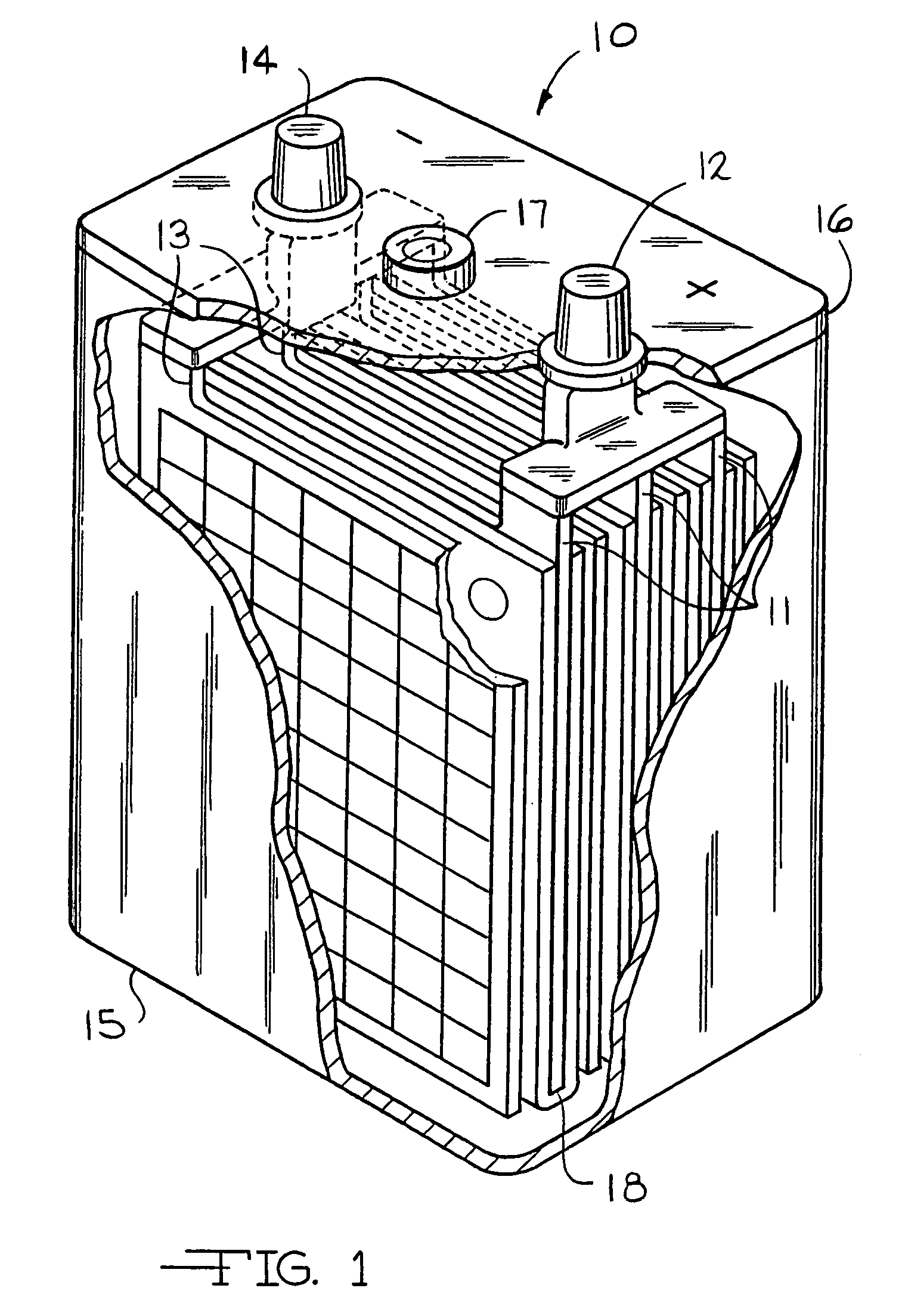

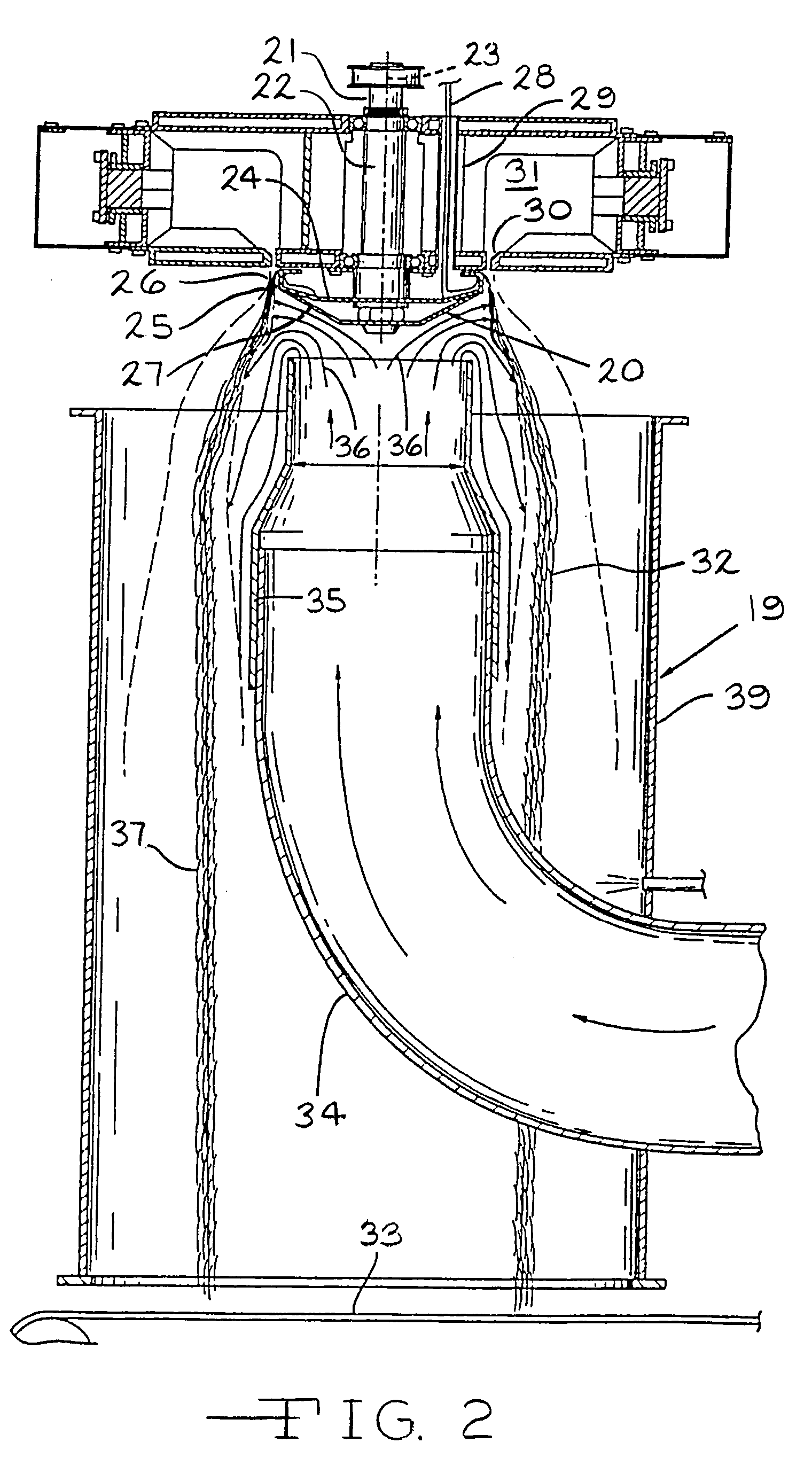

Mat of glass and other fibers and method for producing such mat

InactiveUS20050130031A1Enhance drip rateIncrease surface areaCell component detailsWoven fabricsGlass fiberFiber

A binderless glass fiber mat suitable for use as a separator for valve regulated (“recombinant”) lead acid (“VRLA”) batteries is disclosed. The separator is produced by a dry process by collecting the fibers from fiberizing apparatus, without subjecting them to a wet paper making or other post forming process, and selecting portions of the collected fibers which are sufficiently uniform in thickness and grammage for use as battery separators. The fibers can be entwined to produce a superior separator material. Additives can be introduced during the collection process to enhance the properties of the separator. A battery comprises at least one stack of alternating positive and negative plates, with the separator between adjacent plates. Separators according to the invention are significantly more resilient and have longer fibers than otherwise identical separators made from different samples of the same glass fibers, but by a conventional wet paper making process.

Owner:HOLLINGSWORTH VOSE

Cardboard having great reigidity

InactiveUS6221212B1Low densityHigh tensile stiffness indexNon-fibrous pulp additionWrappersCardboardVolumetric Mass Density

Owner:STORA ENSO AB

Mat of glass and other fibers and method for producing such mat

InactiveUS7288338B2Increase elasticityGreat percentageNon-fibrous pulp additionNatural cellulose pulp/paperFiberGlass fiber

A binderless glass fiber mat suitable for use as a separator for valve regulated (“recombinant”) lead acid (“VRLA”) batteries is disclosed. The separator is produced by a dry process by collecting the fibers from fiberizing apparatus, without subjecting them to a wet paper making or other post forming process, and selecting portions of the collected fibers which are sufficiently uniform in thickness and grammage for use as battery separators. The fibers can be entwined to produce a superior separator material. Additives can be introduced during the collection process to enhance the properties of the separator. A battery comprises at least one stack of alternating positive and negative plates, with the separator between adjacent plates. Separators according to the invention are significantly more resilient and have longer fibers than otherwise identical separators made from different samples of the same glass fibers, but by a conventional wet paper making process.

Owner:HOLLINGSWORTH VOSE

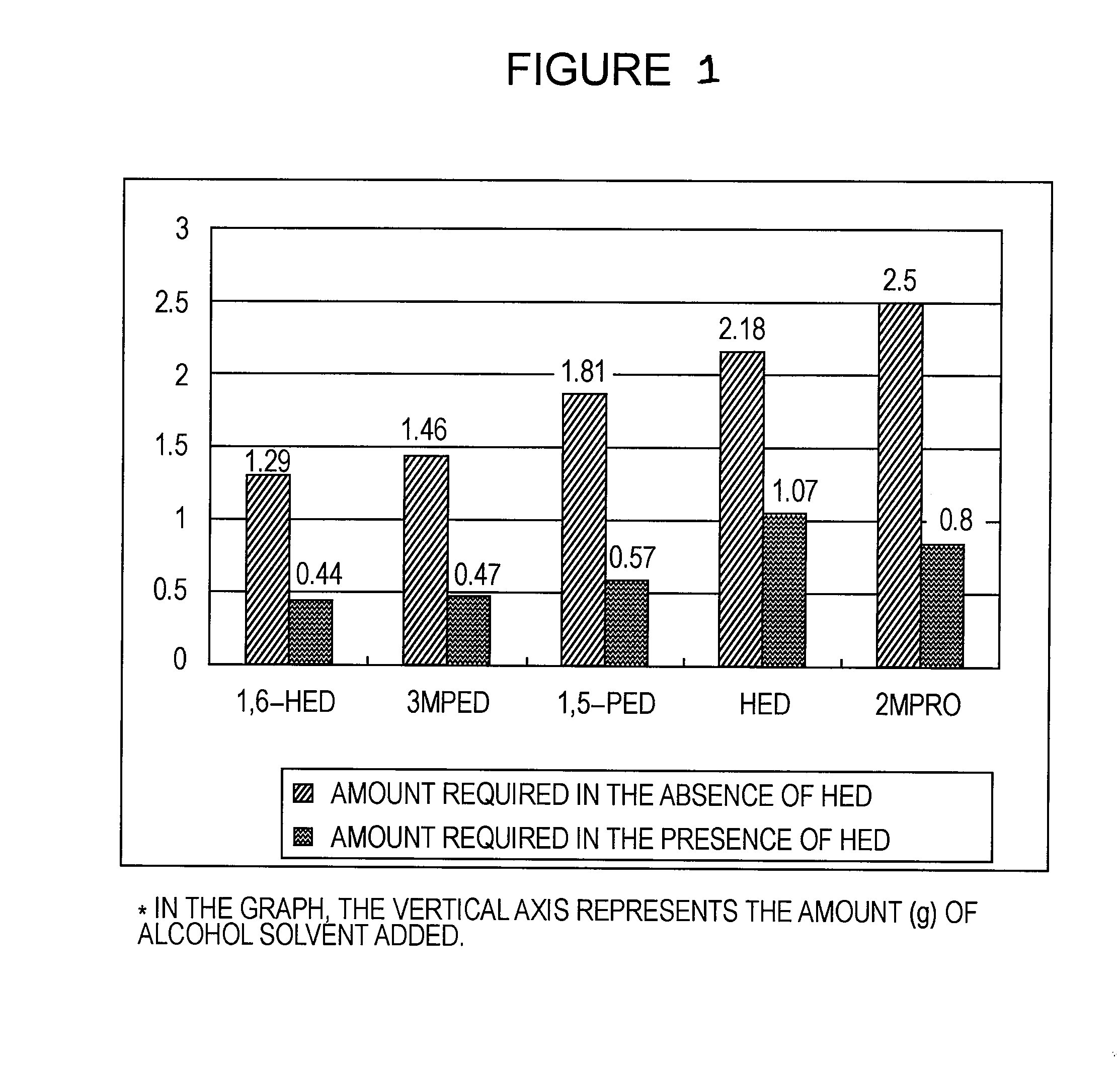

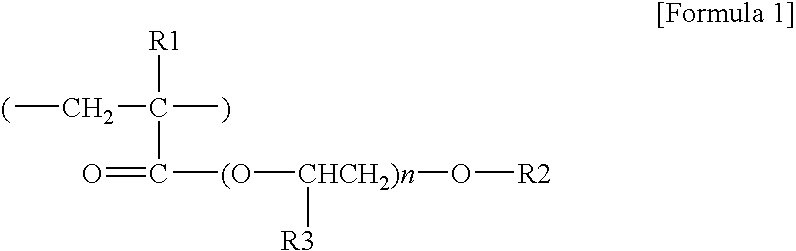

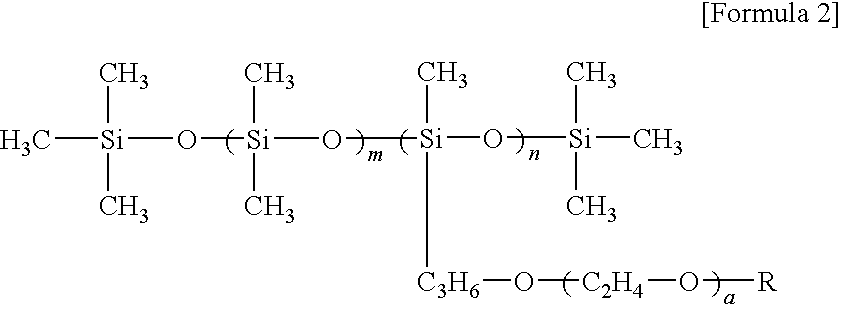

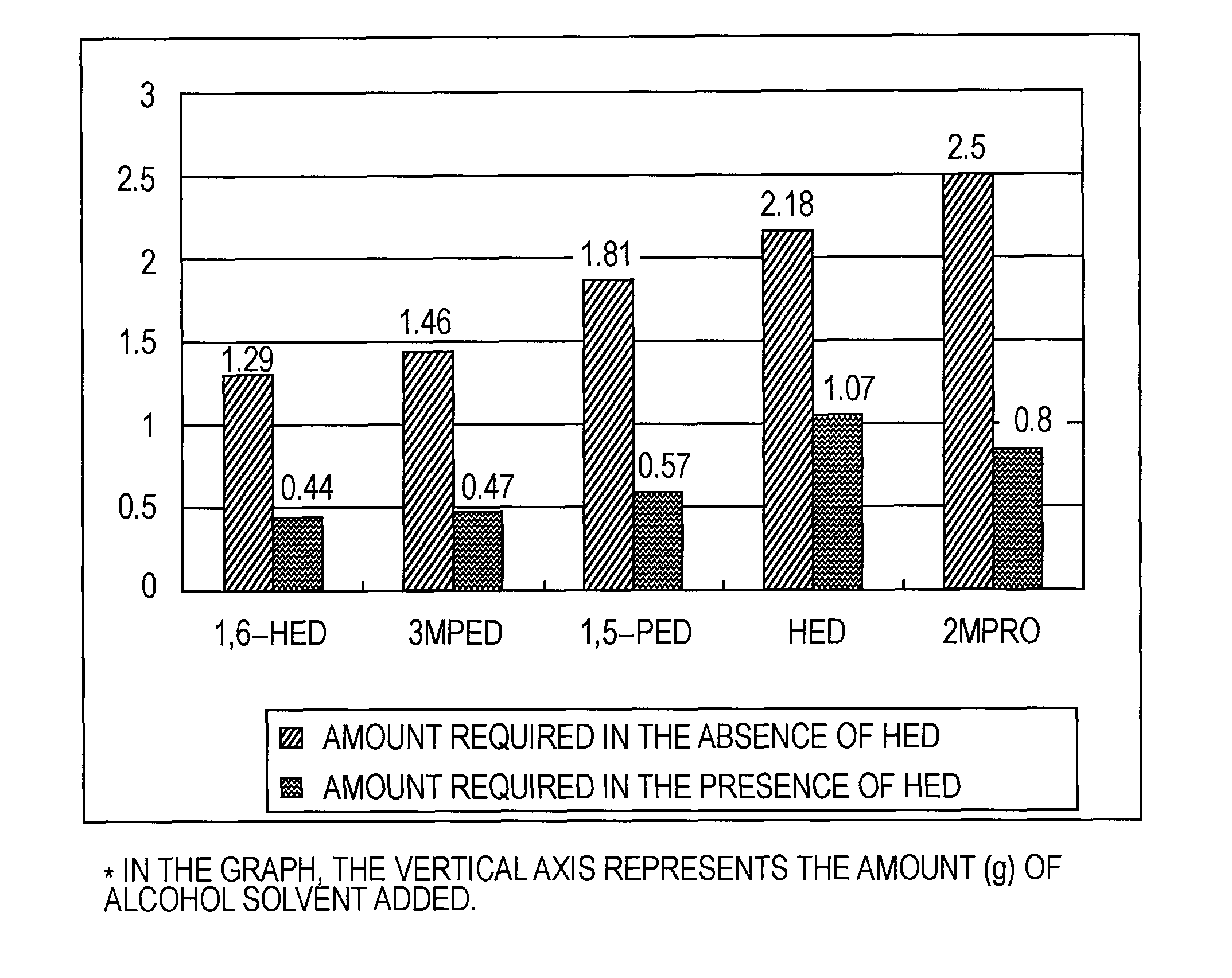

Ink composition for ink jet recording

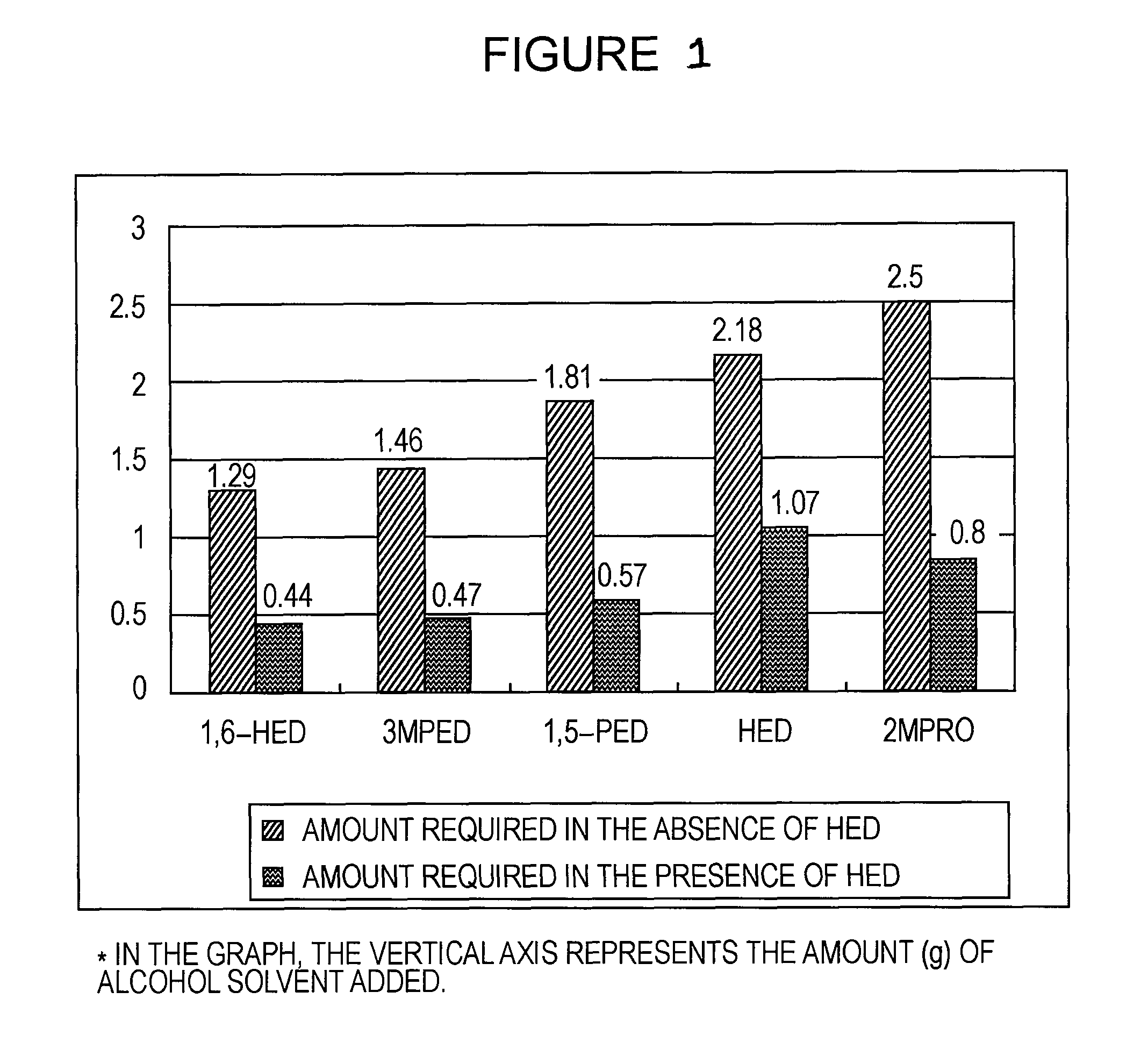

InactiveUS20090308279A1High quality imagingLow liquid absorbencyDuplicating/marking methodsInksAlcoholImage resolution

An ink composition that can form high-quality images free of white streaks and harshness on actual printing paper, such as art paper, even at low resolution and that can reduce the occurrence of curling even with thin actual printing paper having a low grammage is provided.An ink jet printing ink composition includes at least a colorant, water, an alcohol solvent, and a surfactant, wherein the alcohol solvent contains a poorly water-soluble alkane diol, a water-soluble 1,2-alkane diol, and a water-soluble symmetrical alkane diol having a hydroxy group at both ends.

Owner:SEIKO EPSON CORP

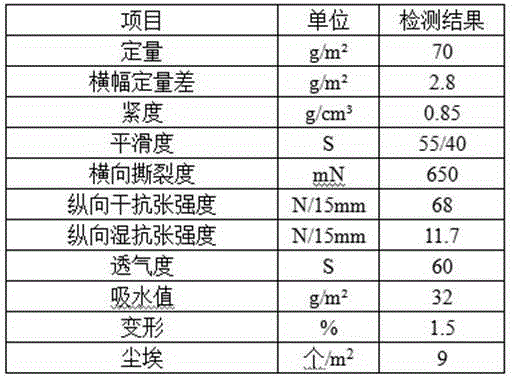

Raw paper for thermal transfer paper and preparation process thereof

ActiveCN104085214AImprove tightnessControl the concentration of plagiarism onlinePulp beating methodsDuplicating/marking methodsApparent densityGrammage

The invention provides raw paper for thermal transfer paper and a preparation process thereof. The raw paper for the thermal transfer paper has grammage of 70 to 95 g / m2, cross file grammage tolerance of no more than 5 g / m2, apparent density of 0.8 to 0.85 g / cm3, smoothness of 45 / 36S, transverse tearability of no less than 600 mN, vertical dry tensile strength of no less than 70 N / 15mm, vertical wet tensile strength of no less than 12 N / 15 mm, air permeability of no less than 60 S, a water absorption value of 30 to 50 g / m2, a deformation rate of no more than 1.5% and dust of no more than 10 / m2. The preparation process for the raw paper for the thermal transfer paper comprises the steps consisting of pulping, mixing, beating and rewinding so as to prepare the raw paper for the thermal transfer paper, and then packaging is carried out, wherein a surface sizing solution and a filling material are added during beating. The raw paper for the thermal transfer paper prepared in the invention has the advantages of low cost, good paper formation, great apparent density, small air permeability, high tensile strength, high heat resistance, etc.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

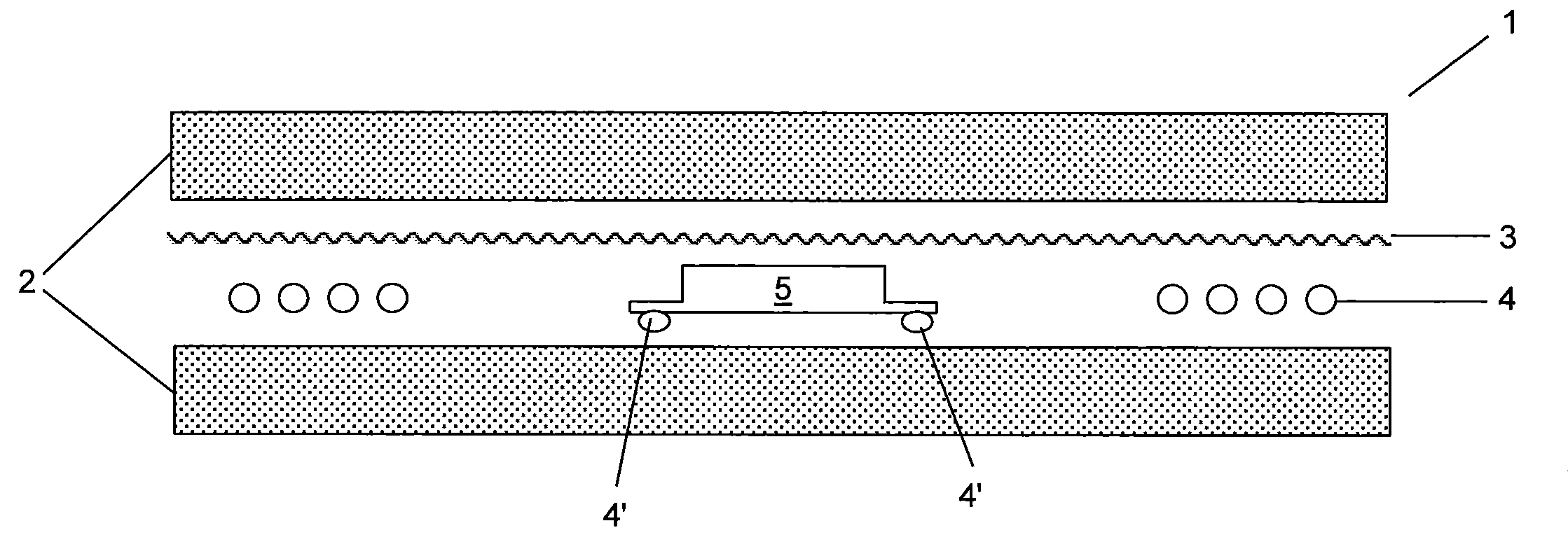

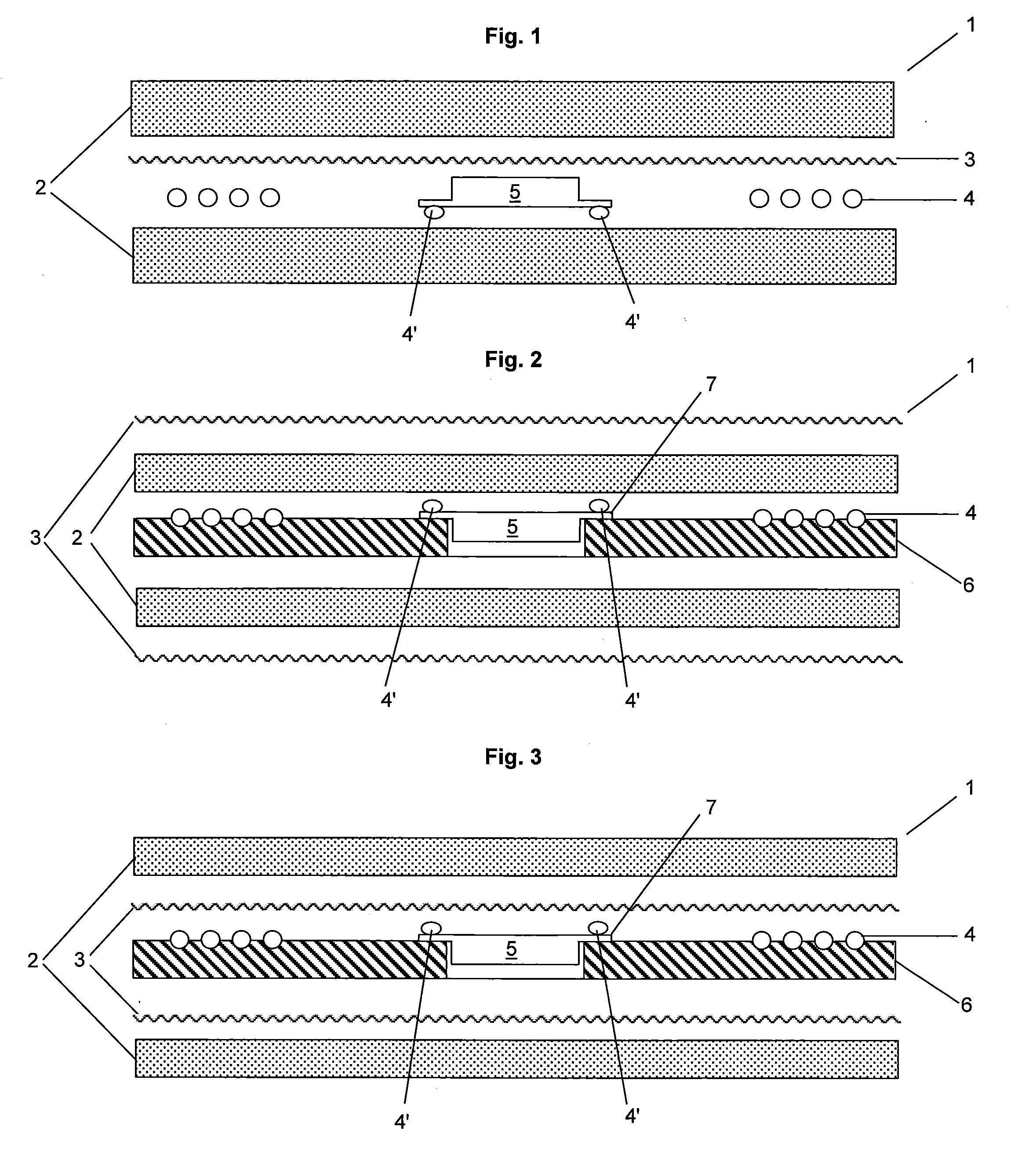

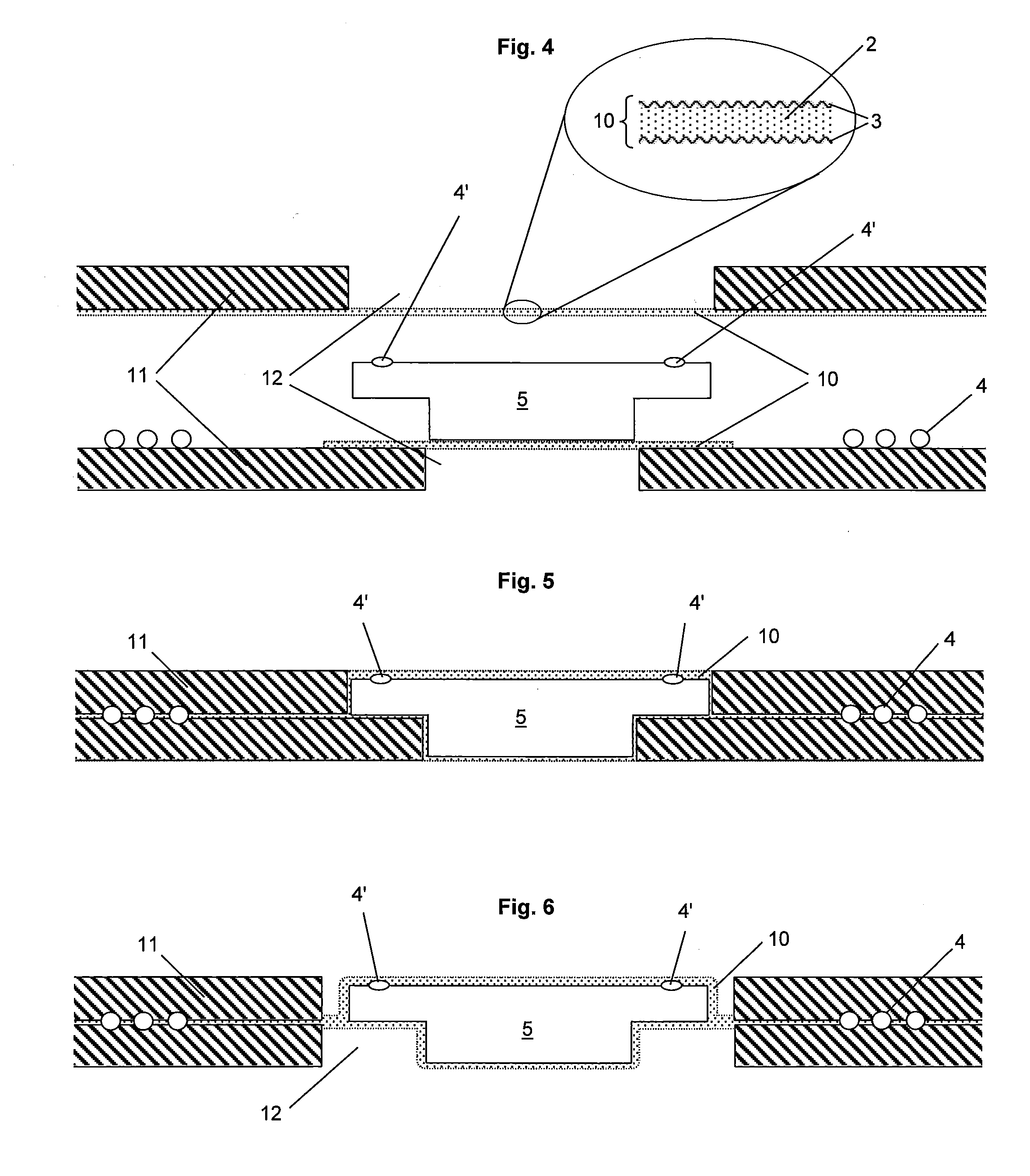

Transponder embedded in a flexible multilayer support

ActiveUS20080131669A1Improve permeabilityLess timeOther printing matterSynthetic resin layered productsThermoplasticGrammage

The transponder with an electronic unit comprising an antenna coil (4) connected to a chip module (5) embedded in a multi-layer laminate support (1) comprises at least one flexible thermoplastic layer (2) disposed on both sides of the electronic unit wherein the multi-layer laminate support further comprises a non-woven foil (3) with a grammage of less than 25 g / m2.

Owner:HID GLOBAL GMBH

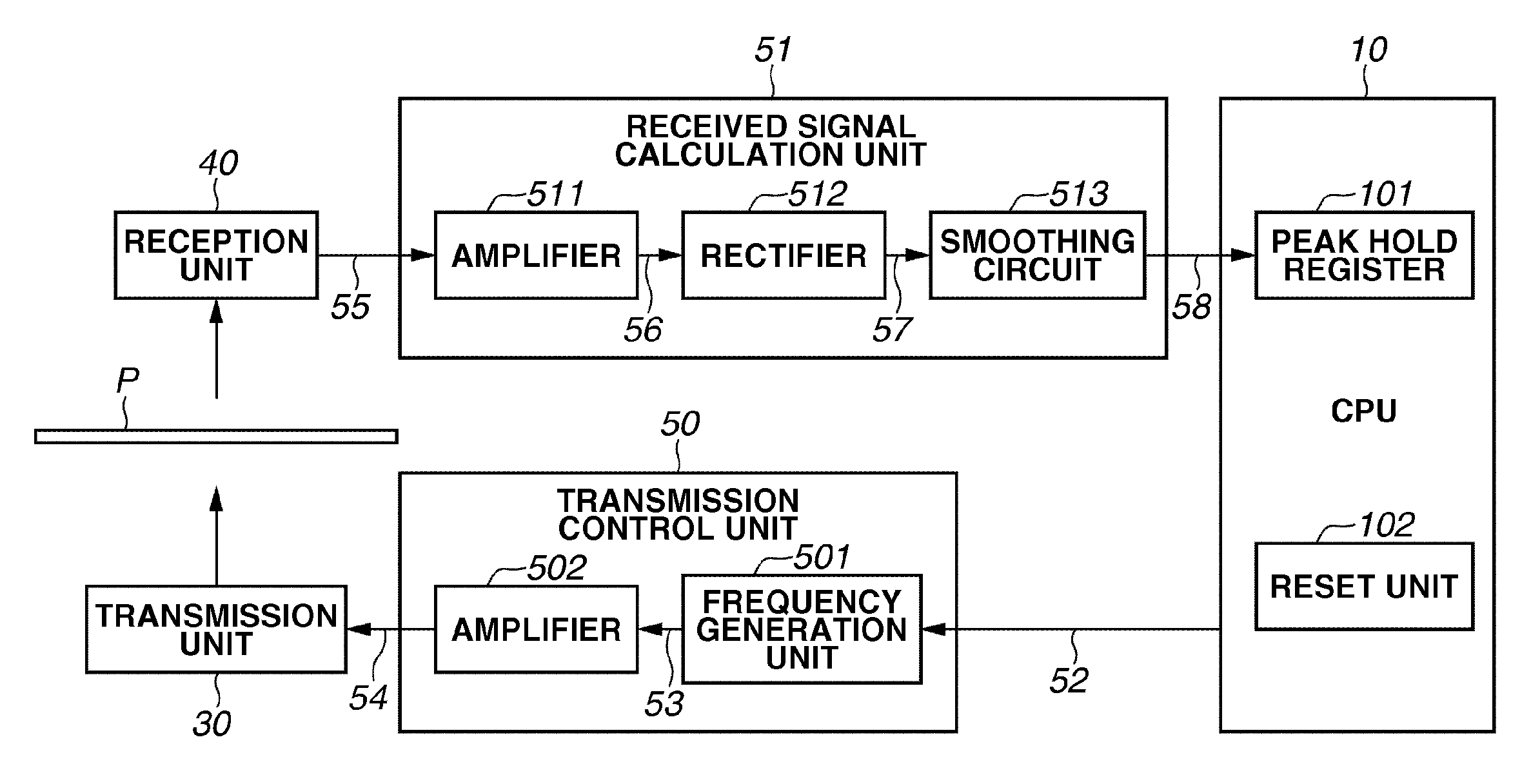

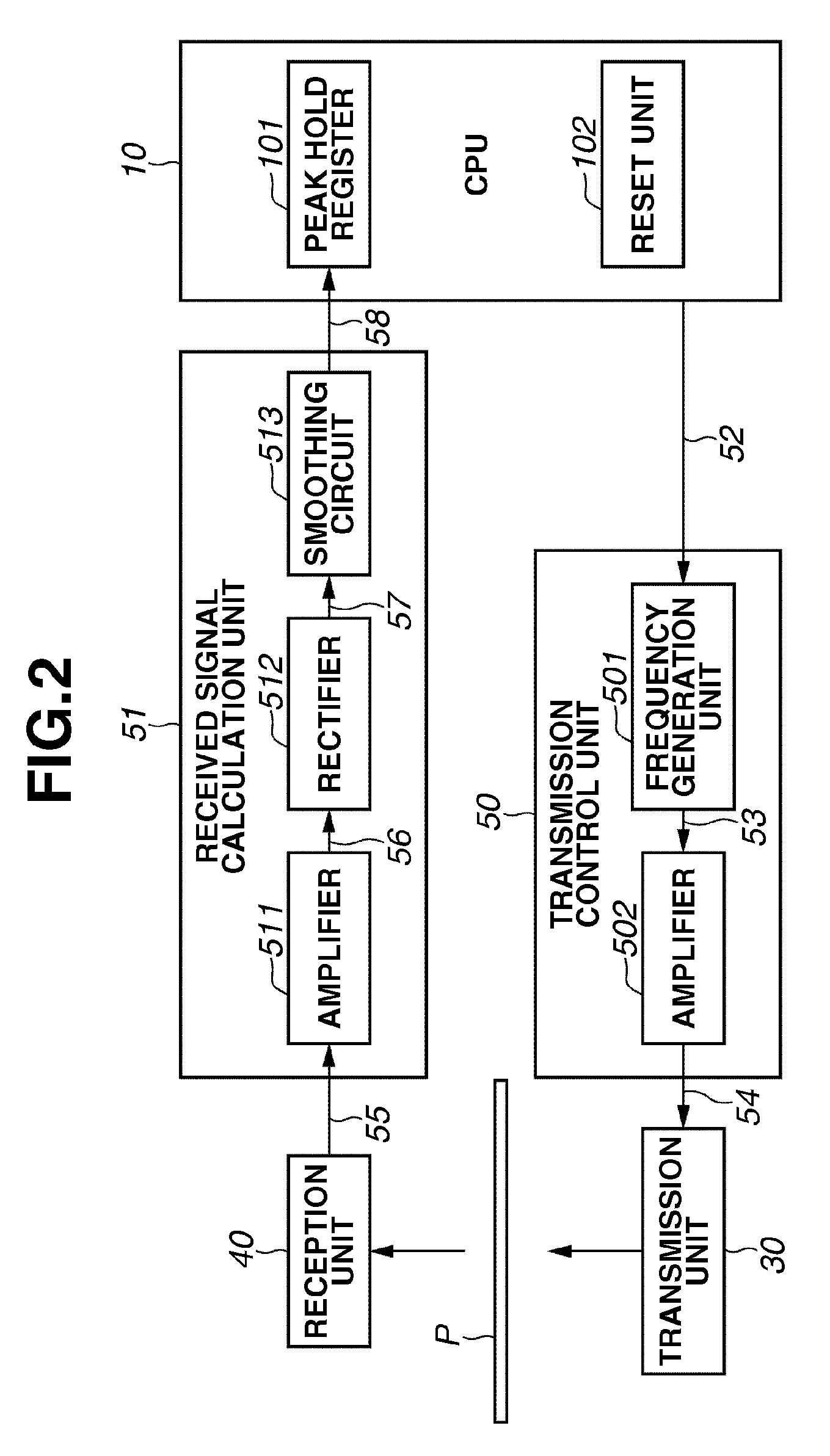

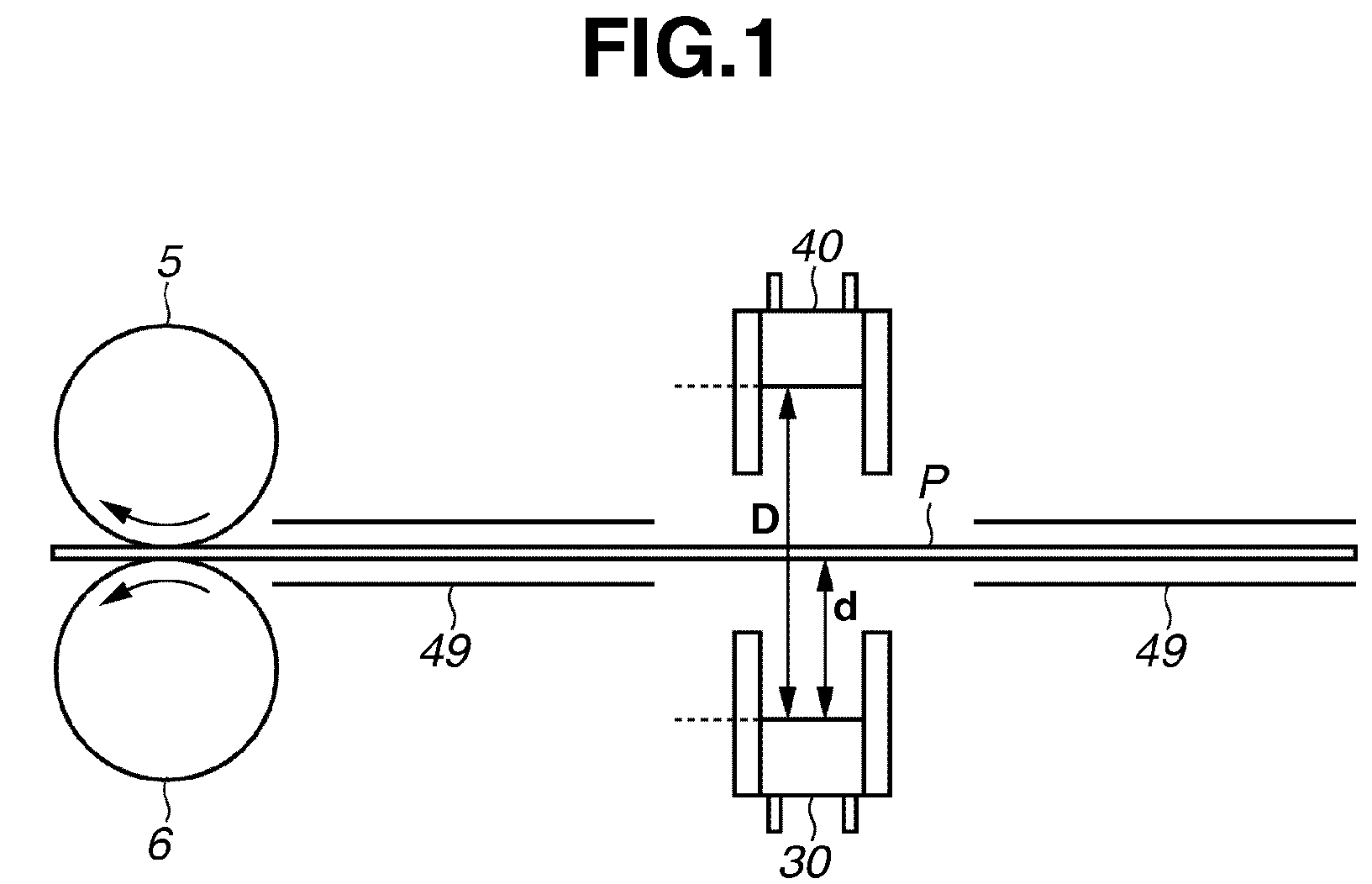

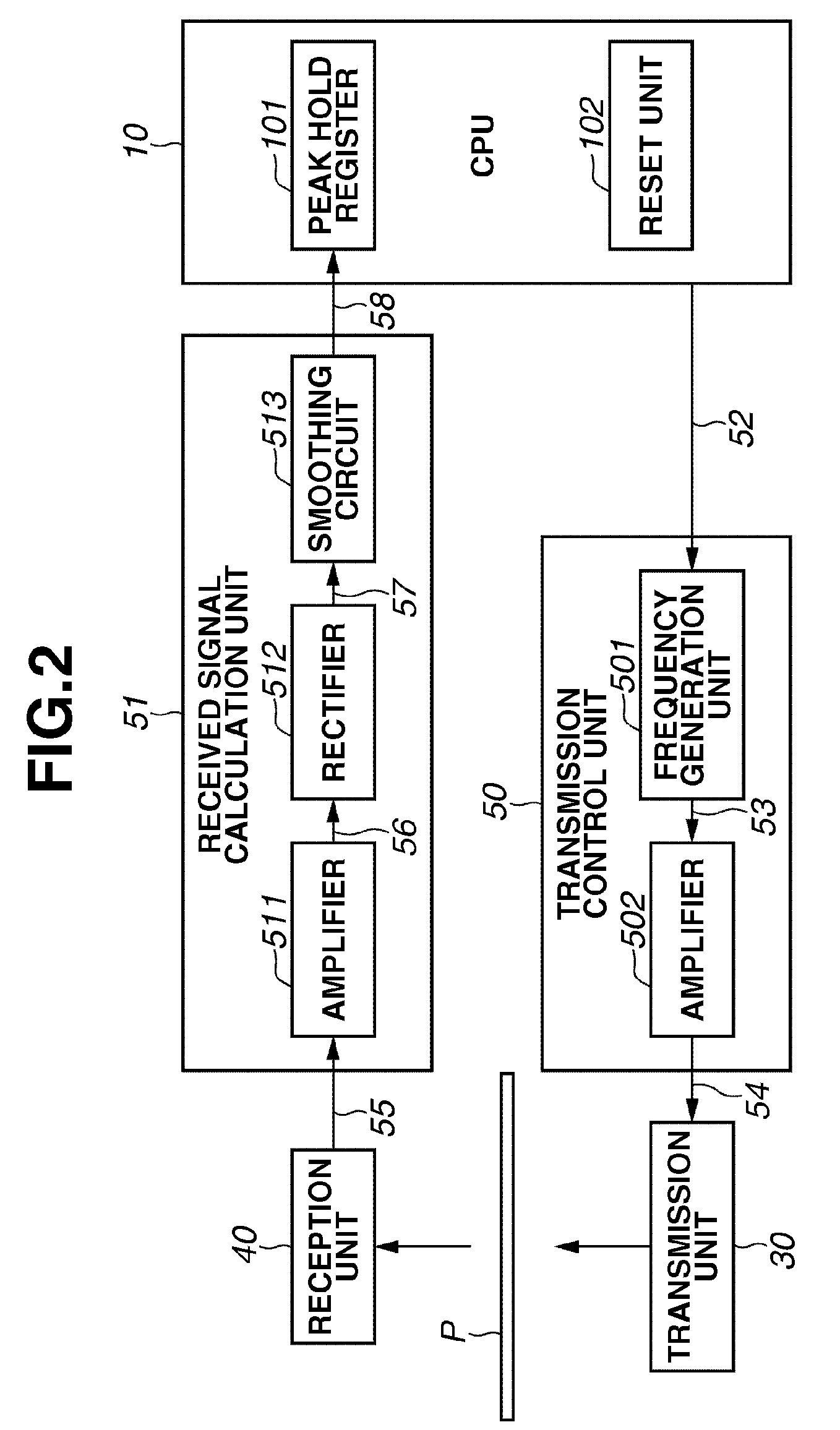

Recording medium determination apparatus and image forming apparatus

InactiveUS20090310992A1Digital computer detailsElectrographic process apparatusImage formationEngineering

A recording medium determination apparatus that determines grammage of a recording medium by using an ultrasonic wave includes a transmission unit configured to output an ultrasonic wave having a predetermined frequency, a reception unit configured to receive the ultrasonic wave output from the transmission unit and transmitted through the recording medium and output a received signal, a calculation unit configured to calculate a signal having a peak component according to a cycle of the received signal, and a determination unit configured to determine the grammage of the recording medium based on the signal calculated by the calculation unit.

Owner:CANON KK

High-wear-resistant anti-stripping electrostatic spinning nanofiber composite filter material and spinning method thereof

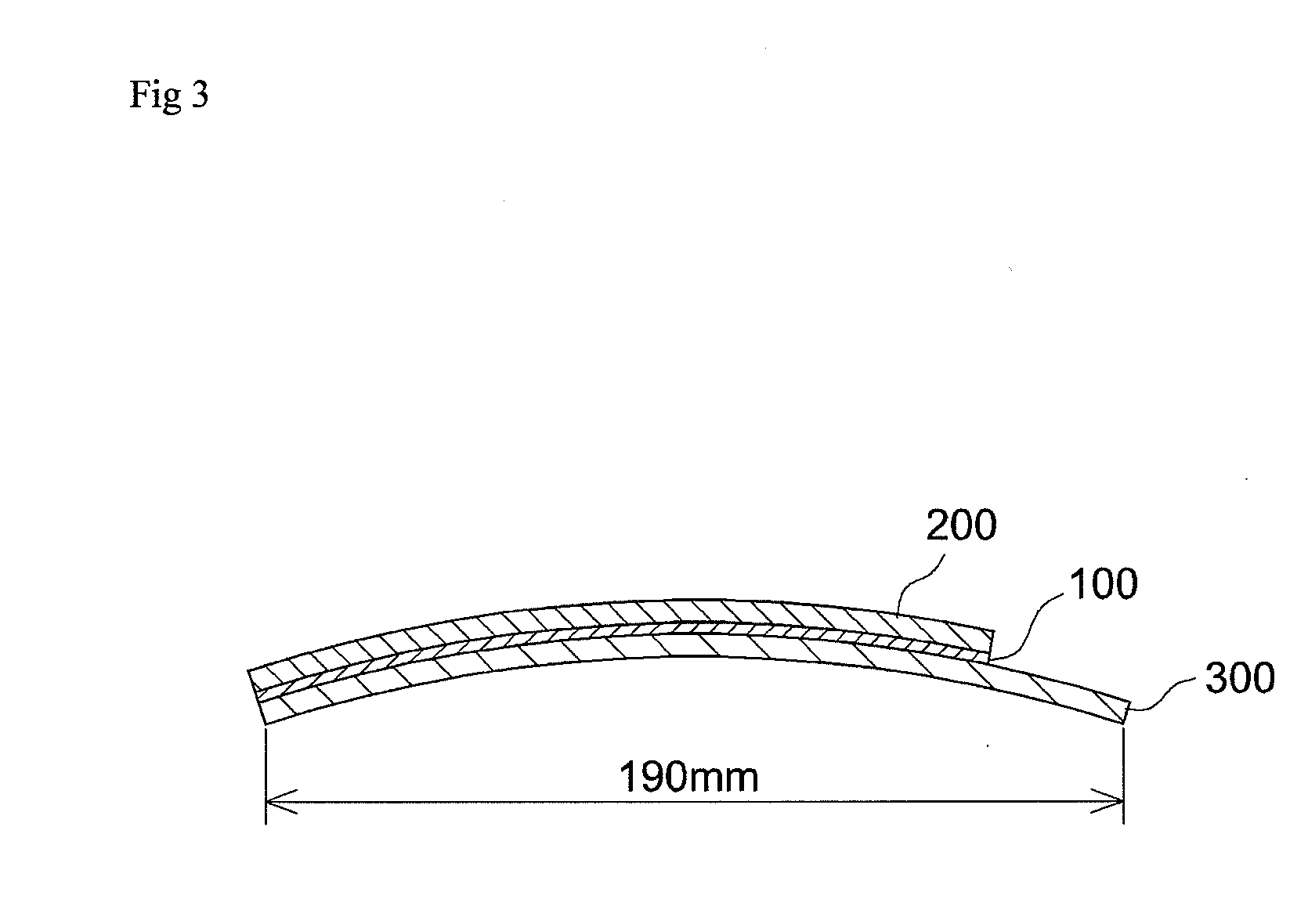

ActiveCN104028047ACompact structurePrecise control of bulk densitySynthetic resin layered productsLaminationFiberWear resistant

The invention relates to a high-wear-resistant anti-stripping electrostatic spinning nanofiber composite filter material and a spinning method thereof. The preparation method comprises the following step: in the electrostatic spinning process, performing one-step forming by controlling and regulating the solvent concentration / pressure difference / melting points of two different polymers / an electrostatic spray solvent, so as to obtain dense three-dimensional arc-hole structural composite filter material fully adhered to fiber lapping points, wherein the gram weight of a fiber layer is 0.01 to 30 g / m<2>, the wear resistance of the composite filter material is 600 to 3,000 circles, the anti-stripping intensity is 5 to 100 MPa, the filter efficiency to 0.008-2-mircon particles reaches more than 99.99%, the resistance pressure drop is below 25 Pa, and the clogging capacity is 100 to 3,000 g / m<2>. The spinning method has the advantages of simple preparation process and low cost, and the prepared composite filter material has wide application prospects in the fields of engine filtration, air compressor filtration, gas turbine filtration, indoor air purification and filtration, high-efficiency filtration and the like.

Owner:上海迅江科技有限公司

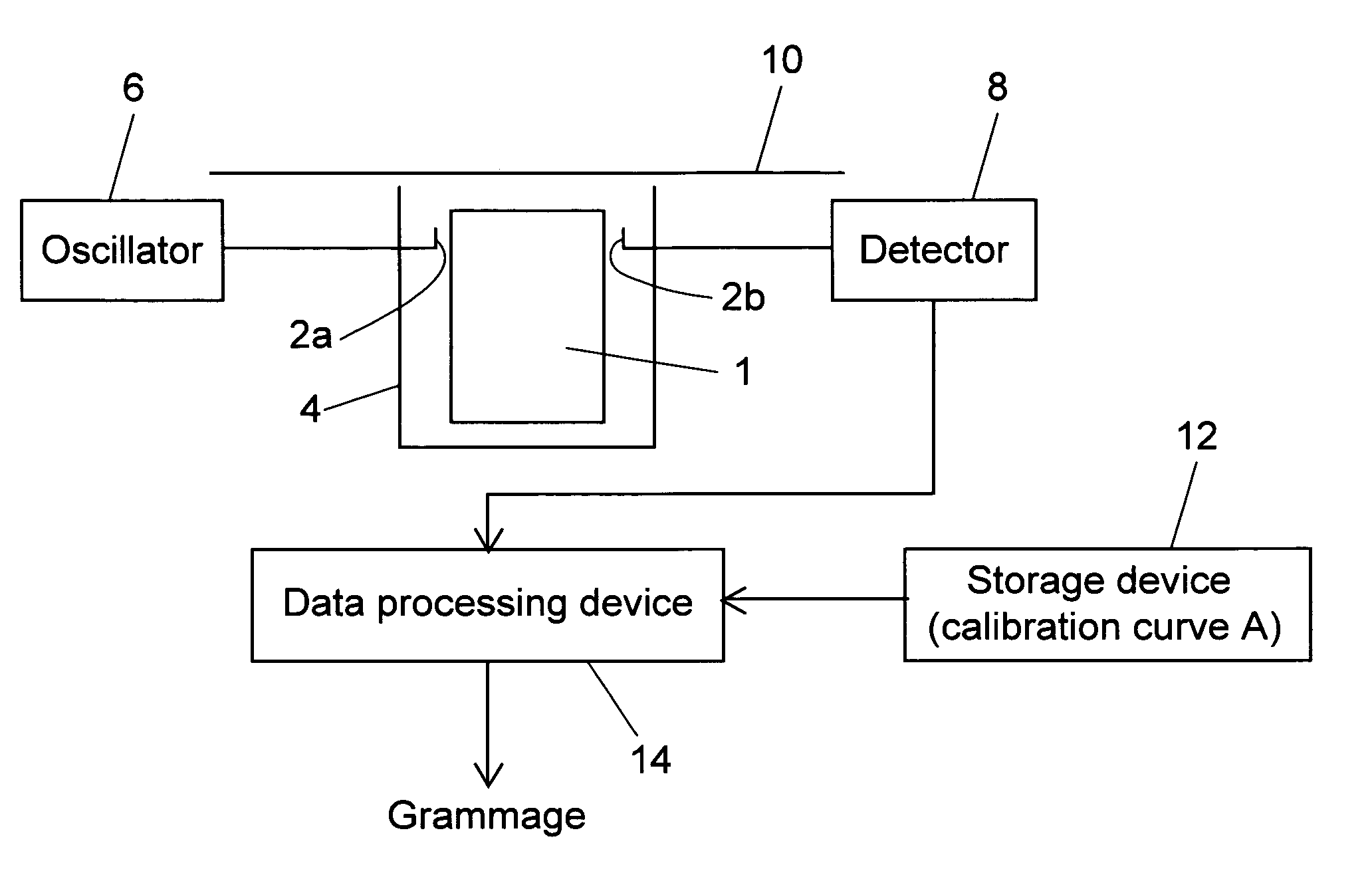

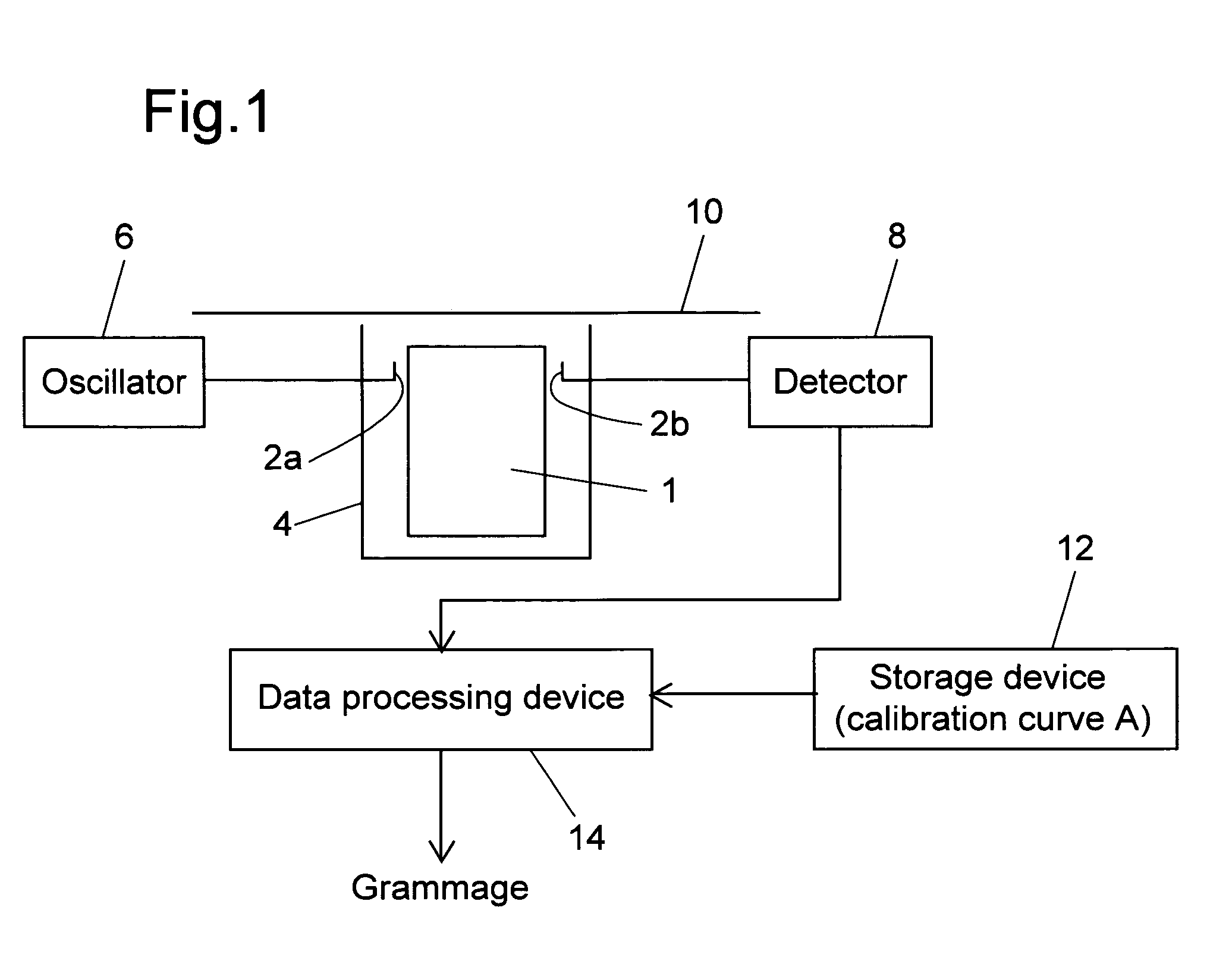

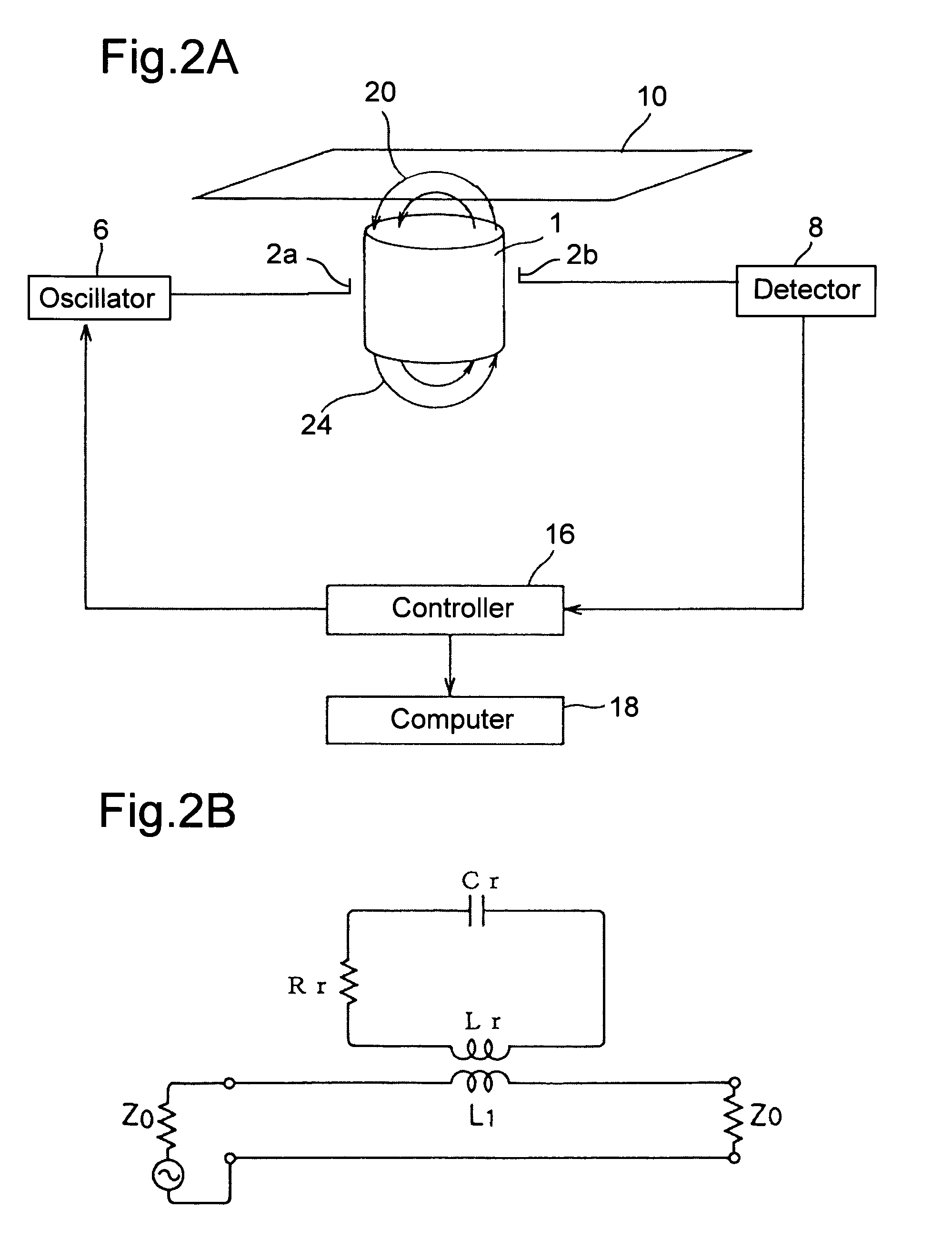

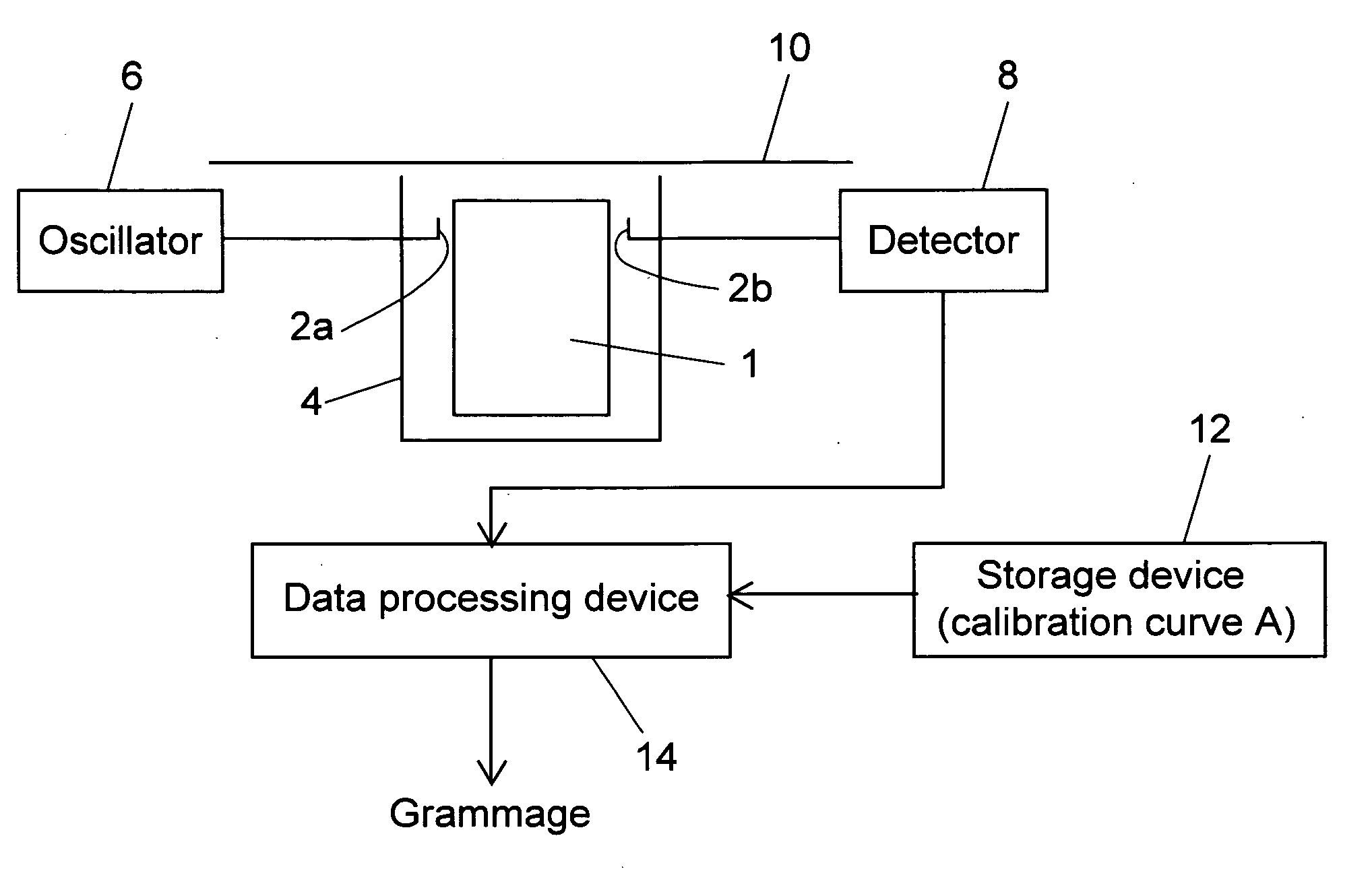

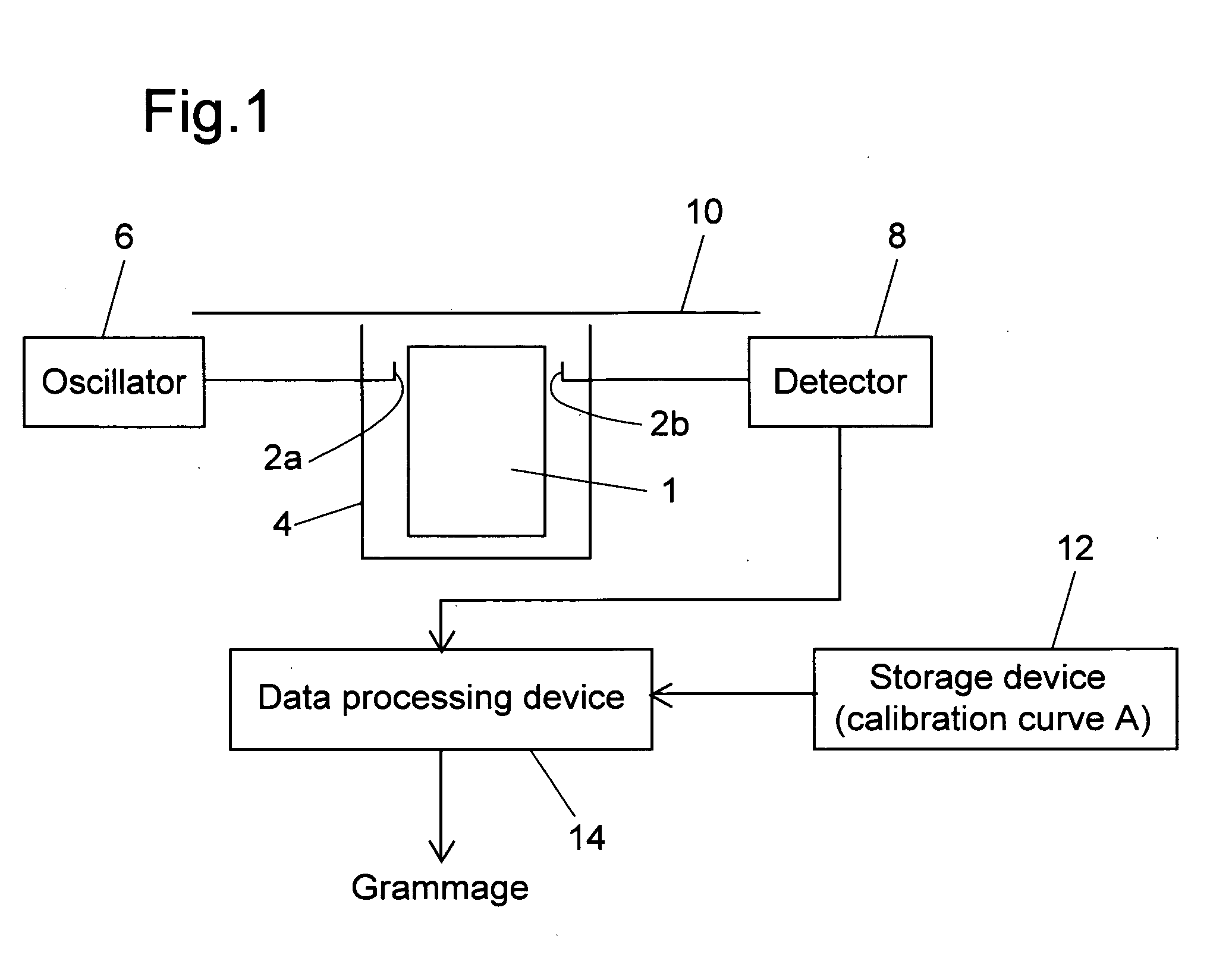

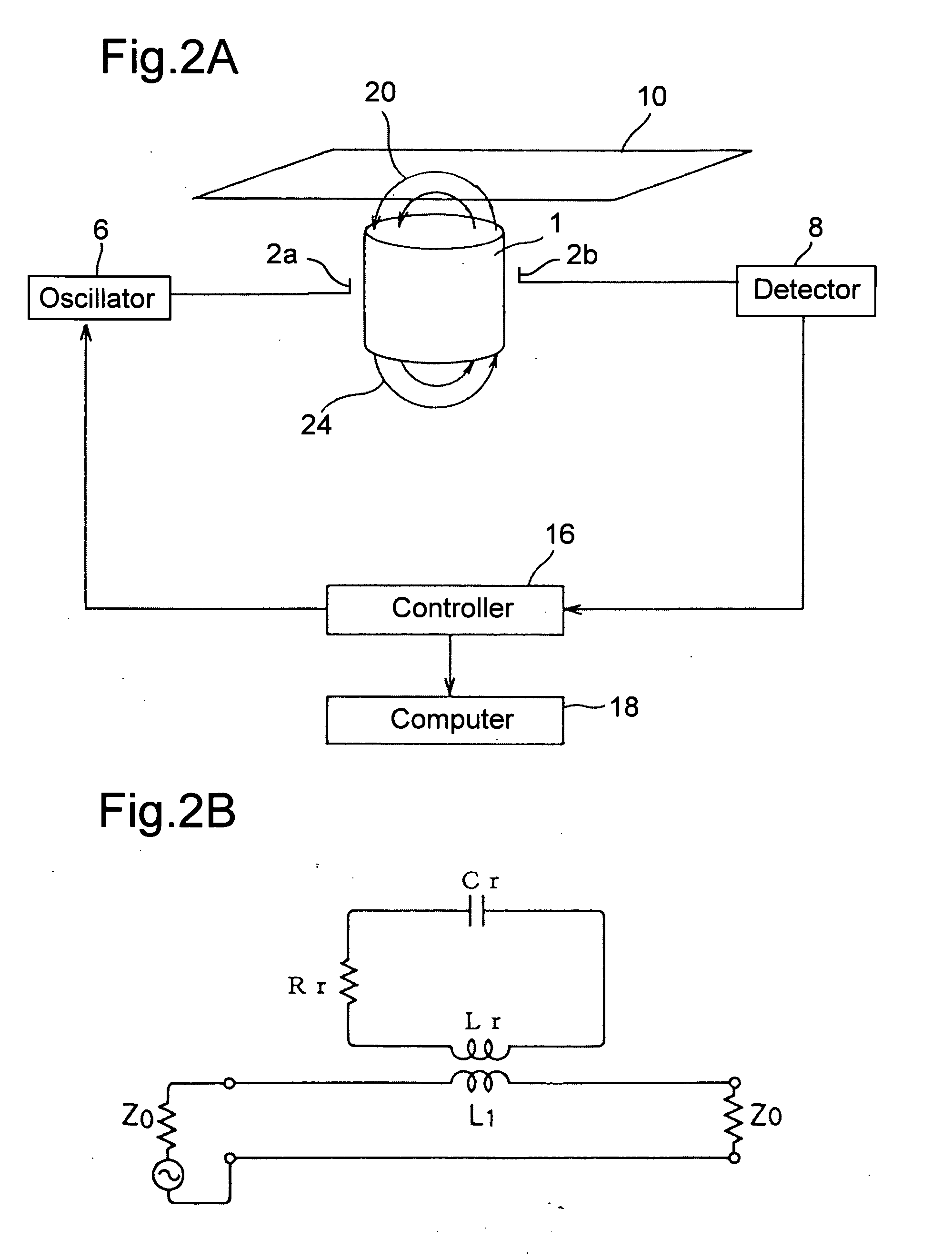

Method and apparatus for measuring grammage

InactiveUS7423435B2Easy to handleMeasure securityResistance/reactance/impedenceMoisture content investigation using microwavesMicrowaveSample Measure

A grammage measuring apparatus including a dielectric resonator which is arranged only at one side surface of a sample; a shielding container with which the dielectric resonator is substantially covered except for a sample measuring surface; a microwave excitation device which causes the dielectric resonator to generate an electric field vector; a detection device which detects transmission energy or reflection energy by the dielectric resonator; a storage device in which a calibration curve indicating a resonance frequency shift amount for a grammage is stored; and a data processing device which calculates the grammage of a measuring sample from the calibration curve and measurement result of the resonance frequency shift amount of the measuring sample.

Owner:OJI PAPER CO LTD

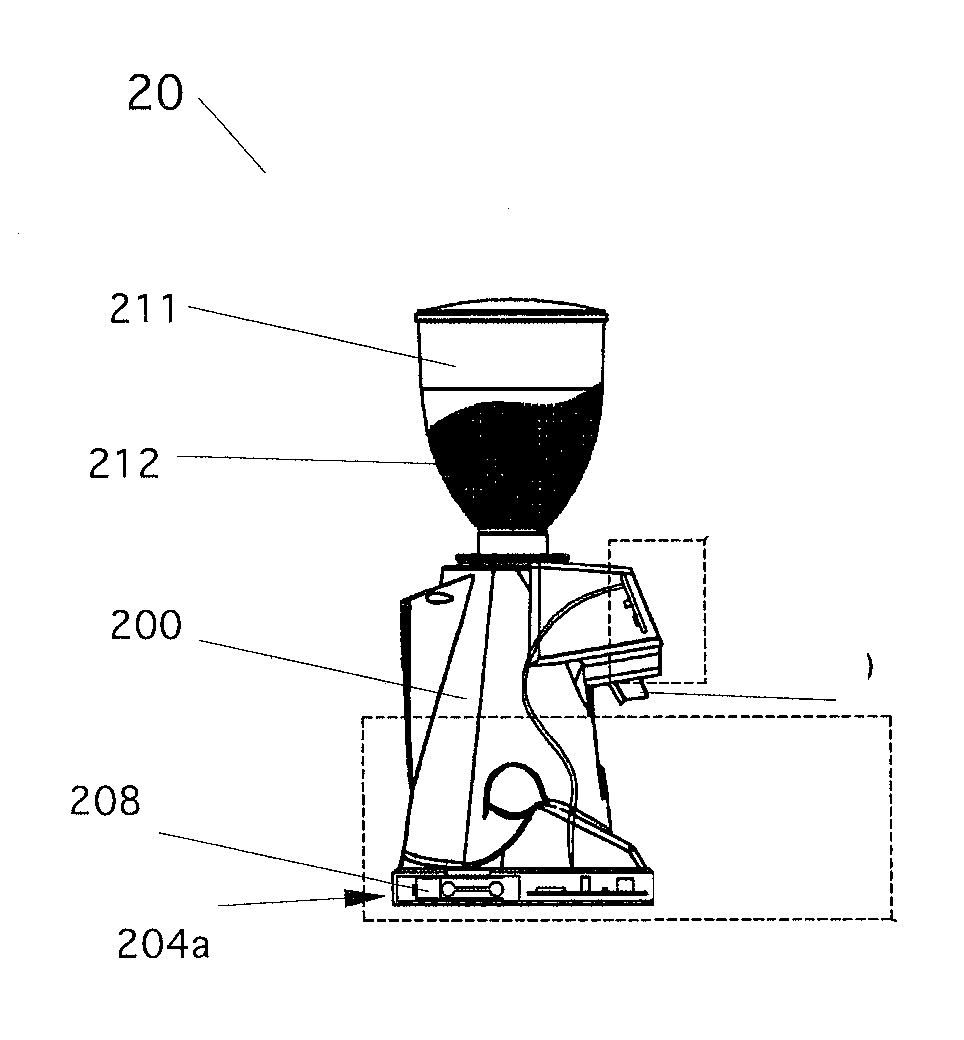

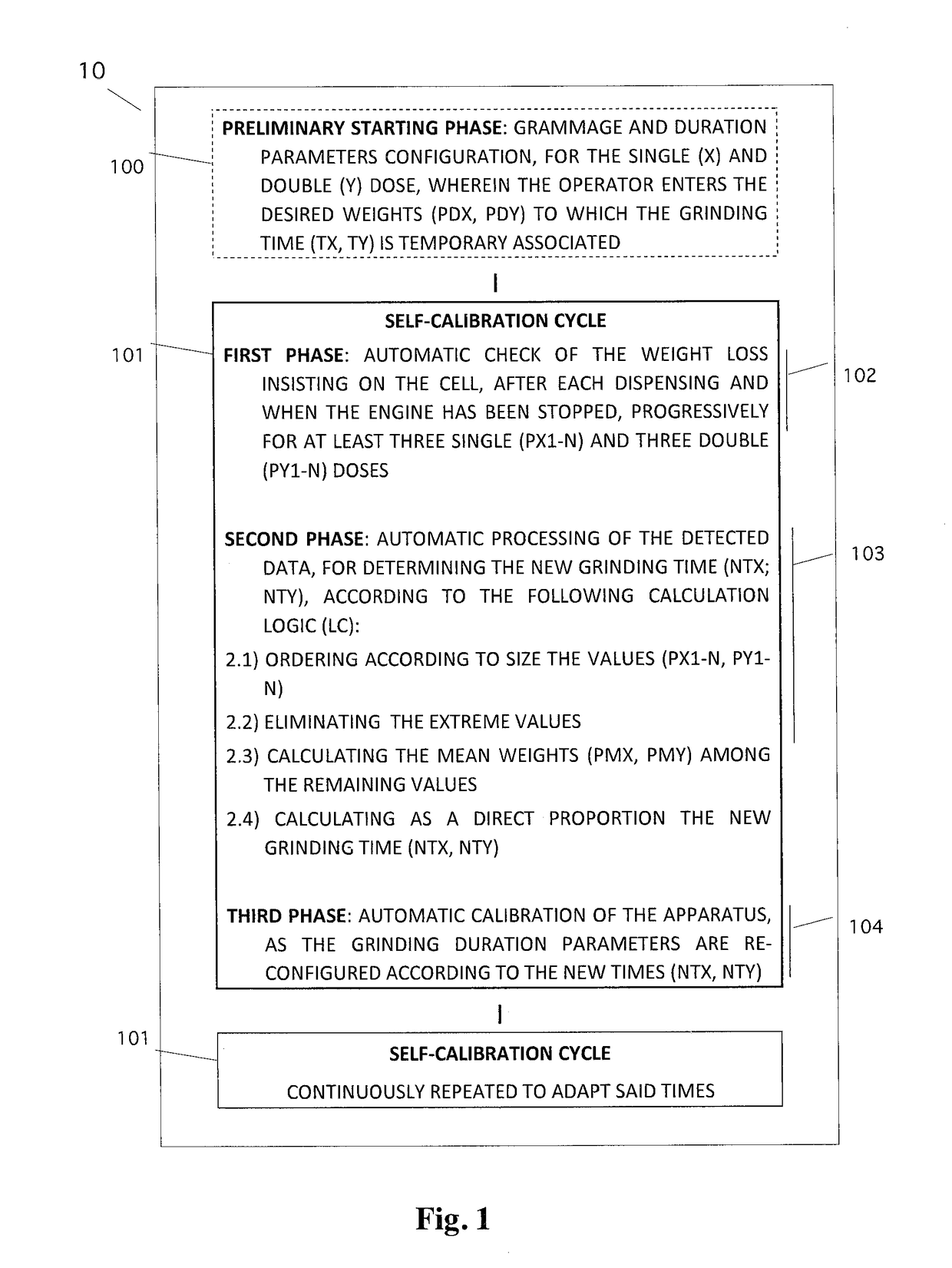

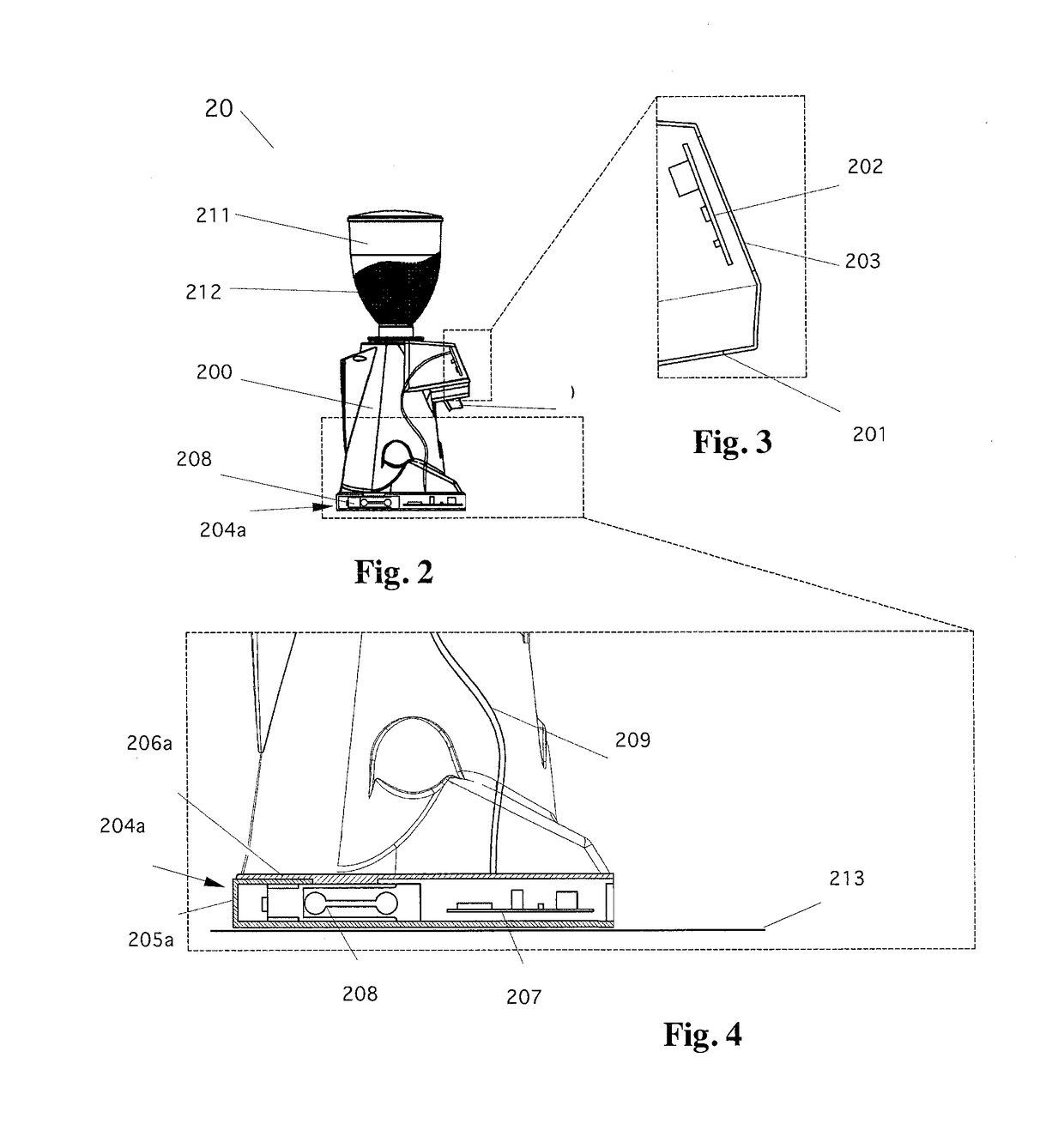

Process and apparatus for grinding and dosing coffee beans with automatic and continuous dose calibration

Automatic process for calibrating the single and double dose of ground and dispensed coffee by means of a specific grinder-doser integrating a weighing device with a load cell. The process is automatically and steadily carried out during the ordinary activity, with no interruptions, adapting the grinding time according to the actually detected grammages, in order to get closer as much as possible to the desired grammage in any use condition. The process, after a preliminary phase for temporary configuring the desired grammages and the grinding time, conceives self-calibration cycles continuously repeated, each of them comprising three sequential phases: a first phase for automatically checking the dispensing with progressive weight detections, a second phase for automatically processing the detected data for determining the correct grinding time, a following third phase for the automatic setting.

Owner:FIORENZATO M C

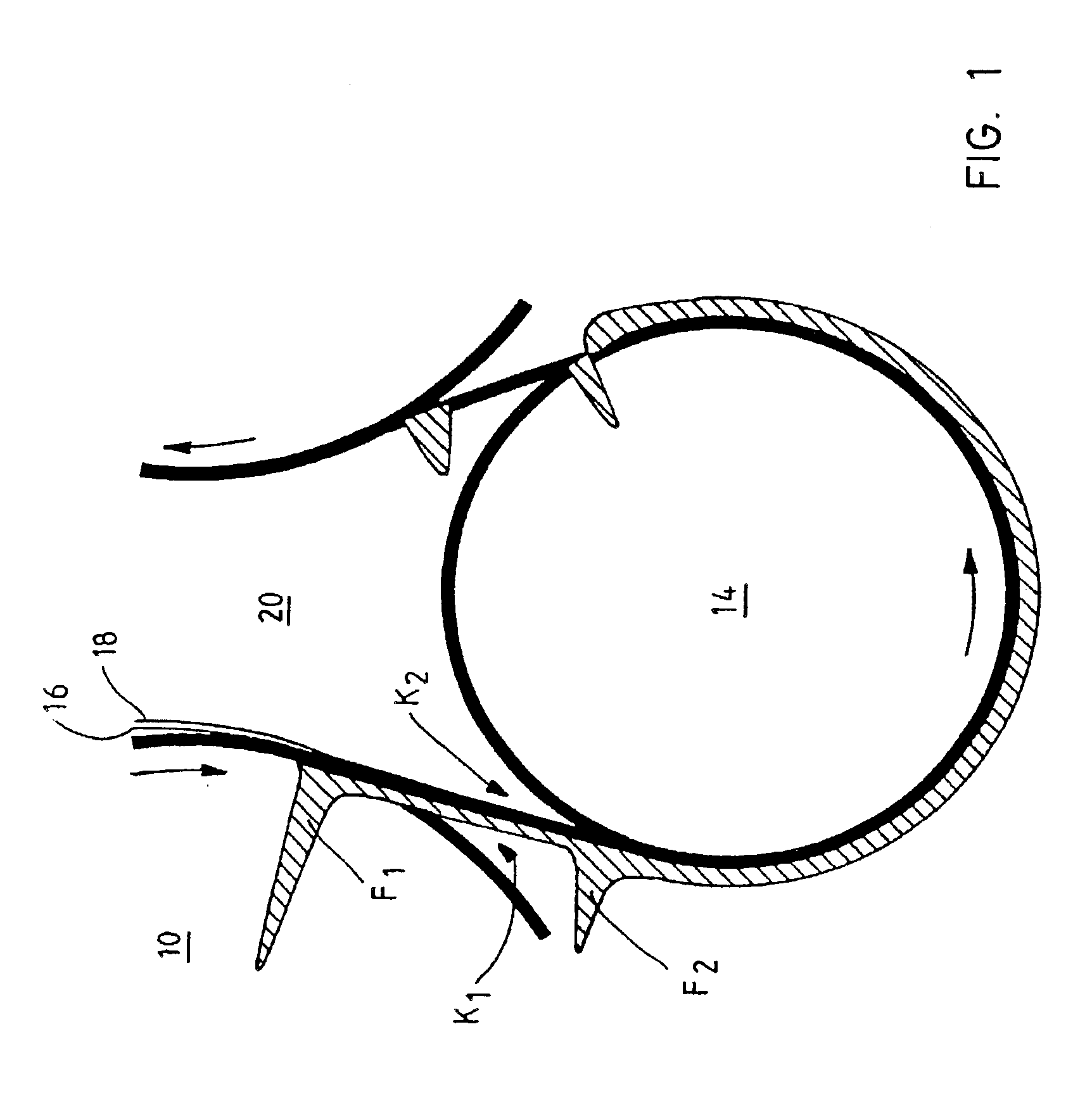

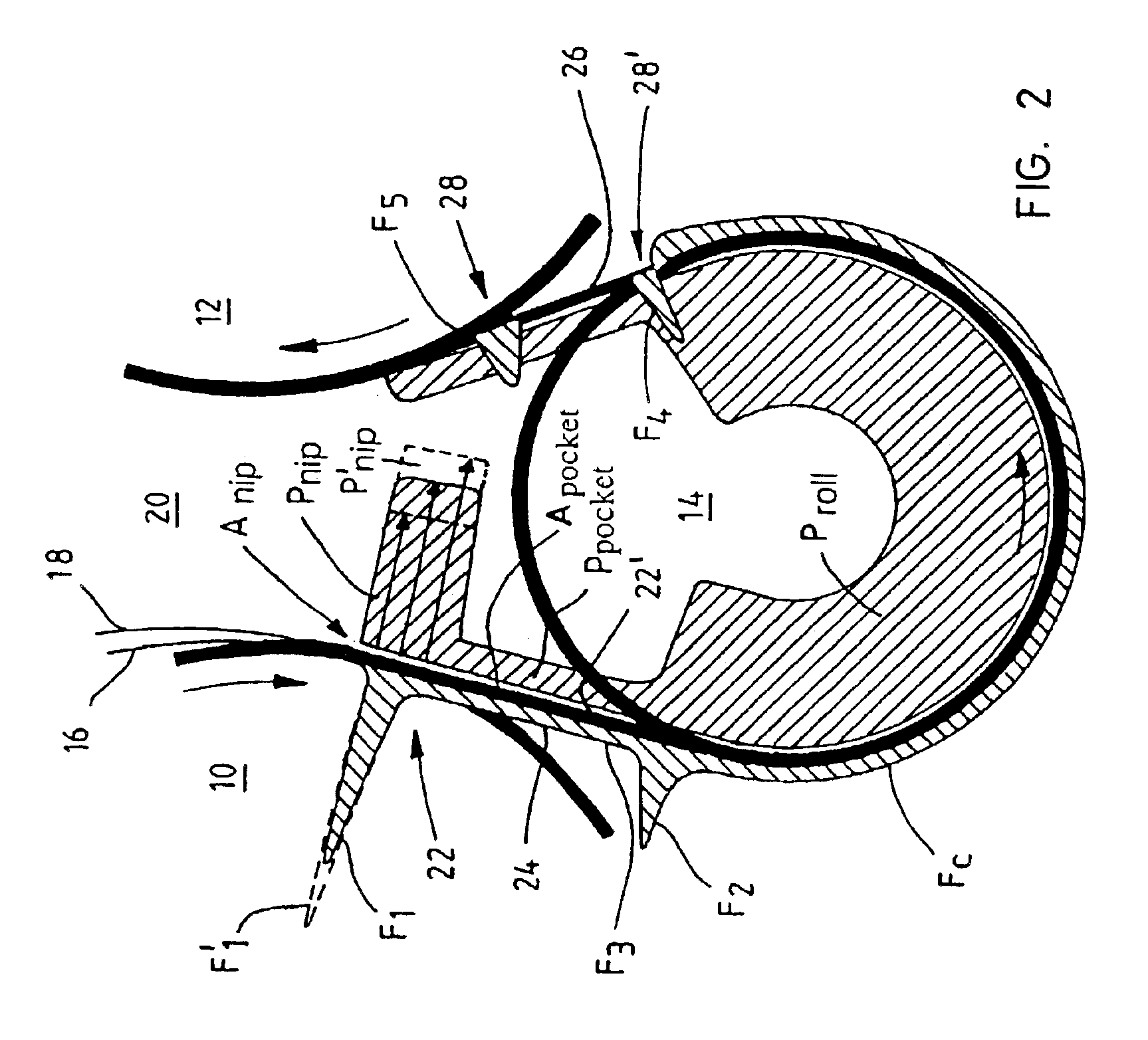

Method and apparatus in the drying section of a paper machine or the like

InactiveUS6910282B1Prevent penetrationEasy to useDrying solid materials with heatDryer sectionCardboardPorosity

Owner:VALMET TECH INC

Method and device for measuring grammage

InactiveCN1880947ASafe and easy to measureResistance/reactance/impedenceUsing wave/particle radiation meansMicrowaveSample Measure

A grammage measuring apparatus includes a dielectric resonator (1) which is arranged only at one surface side of a sample (10); a shielding container (4) with which the dielectric resonator (1) is substantially covered except for a sample measuring surface; a microwave excitation device (6,2a) which causes the dielectric resonator (1) to generate an electric field vector; a detection device (8,2b) which detects transmission energy or reflection energy by the dielectric resonator (1); a storage device (12) in which a calibration curve indicating a resonance frequency shift amount for a grammage is stored; and a data processing device (14) which calculates the grammage of a measuring sample from the calibration curve and measurement result of the resonance frequency shift amount of the measuring sample.

Owner:OJI PAPER CO LTD

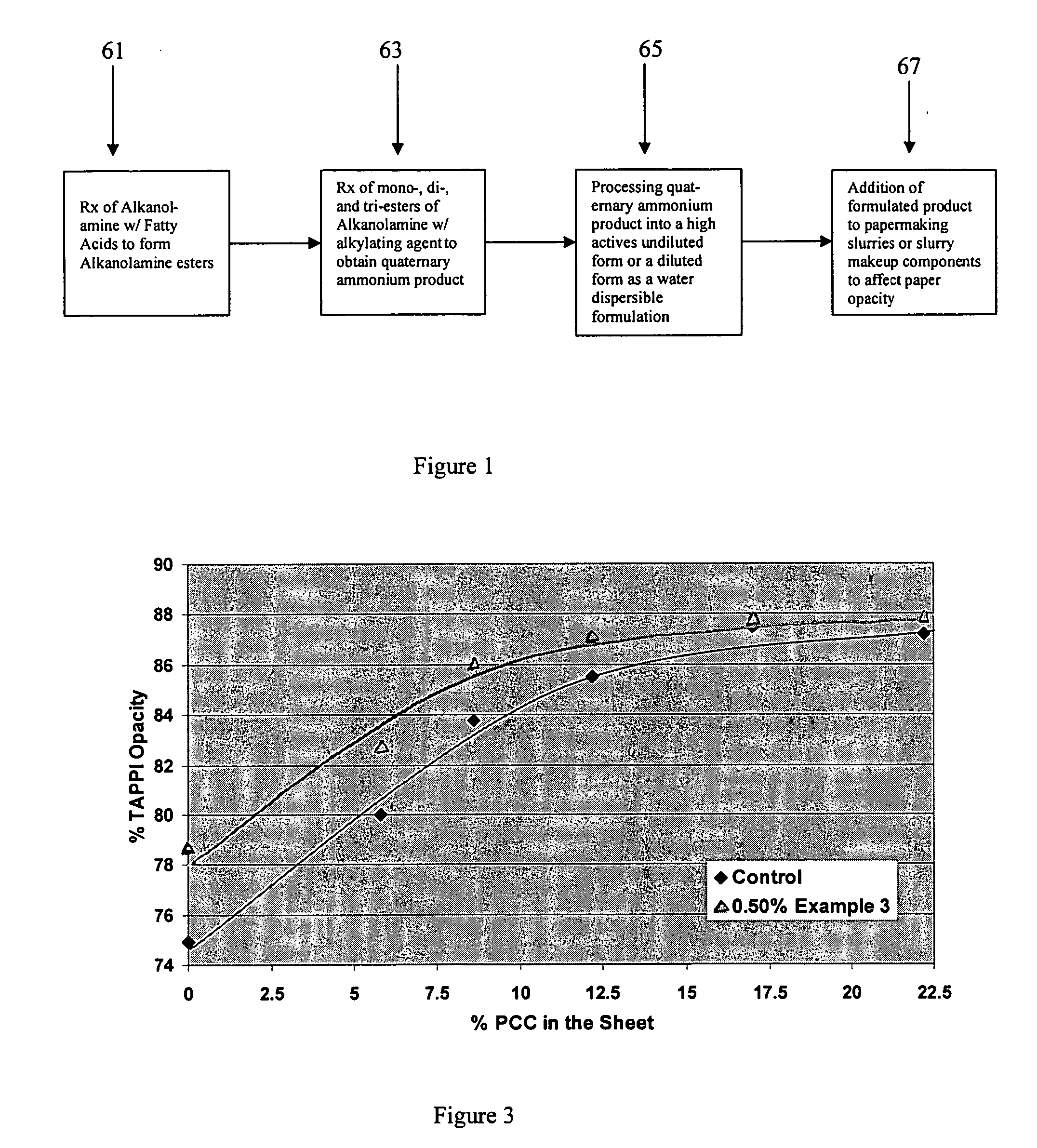

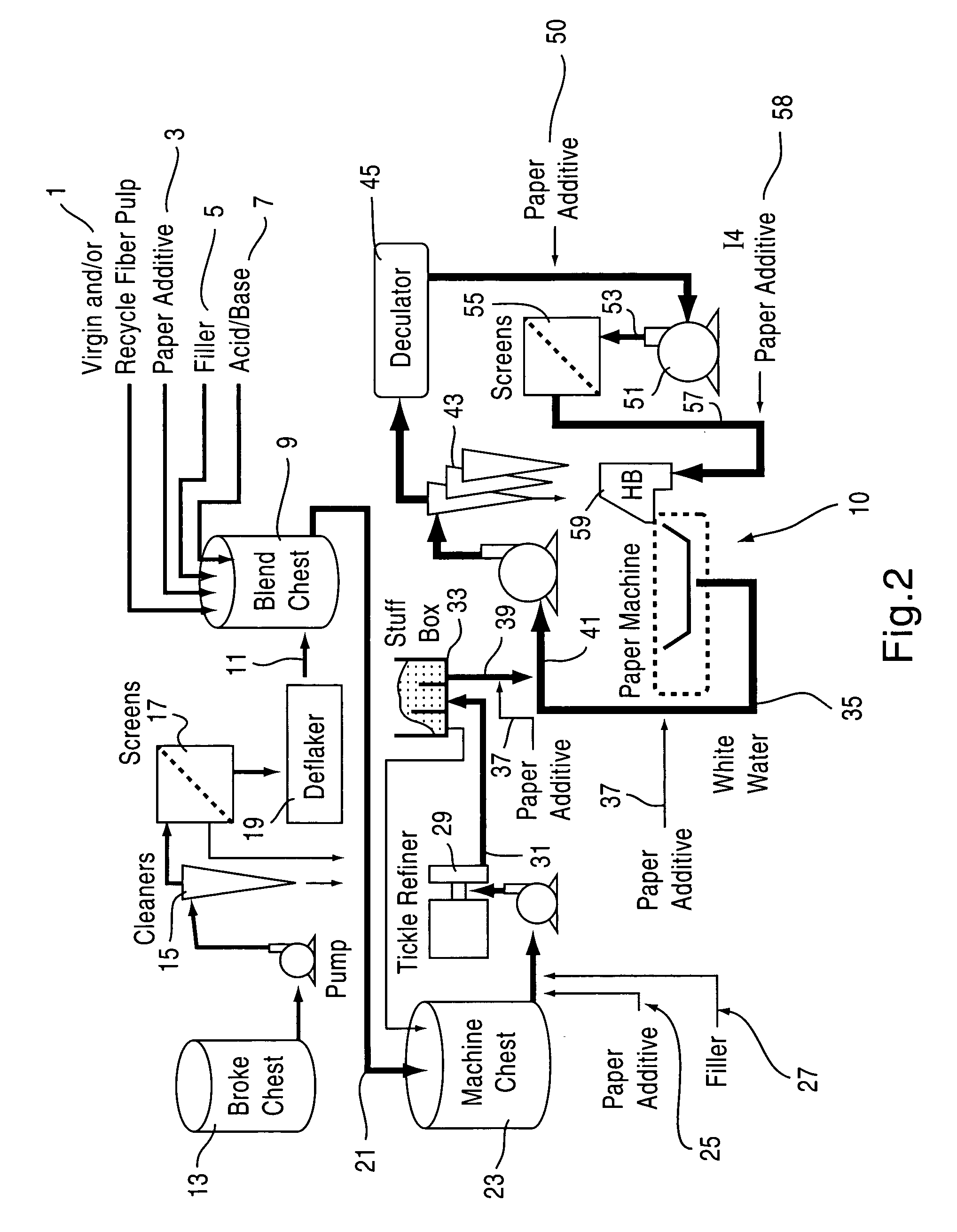

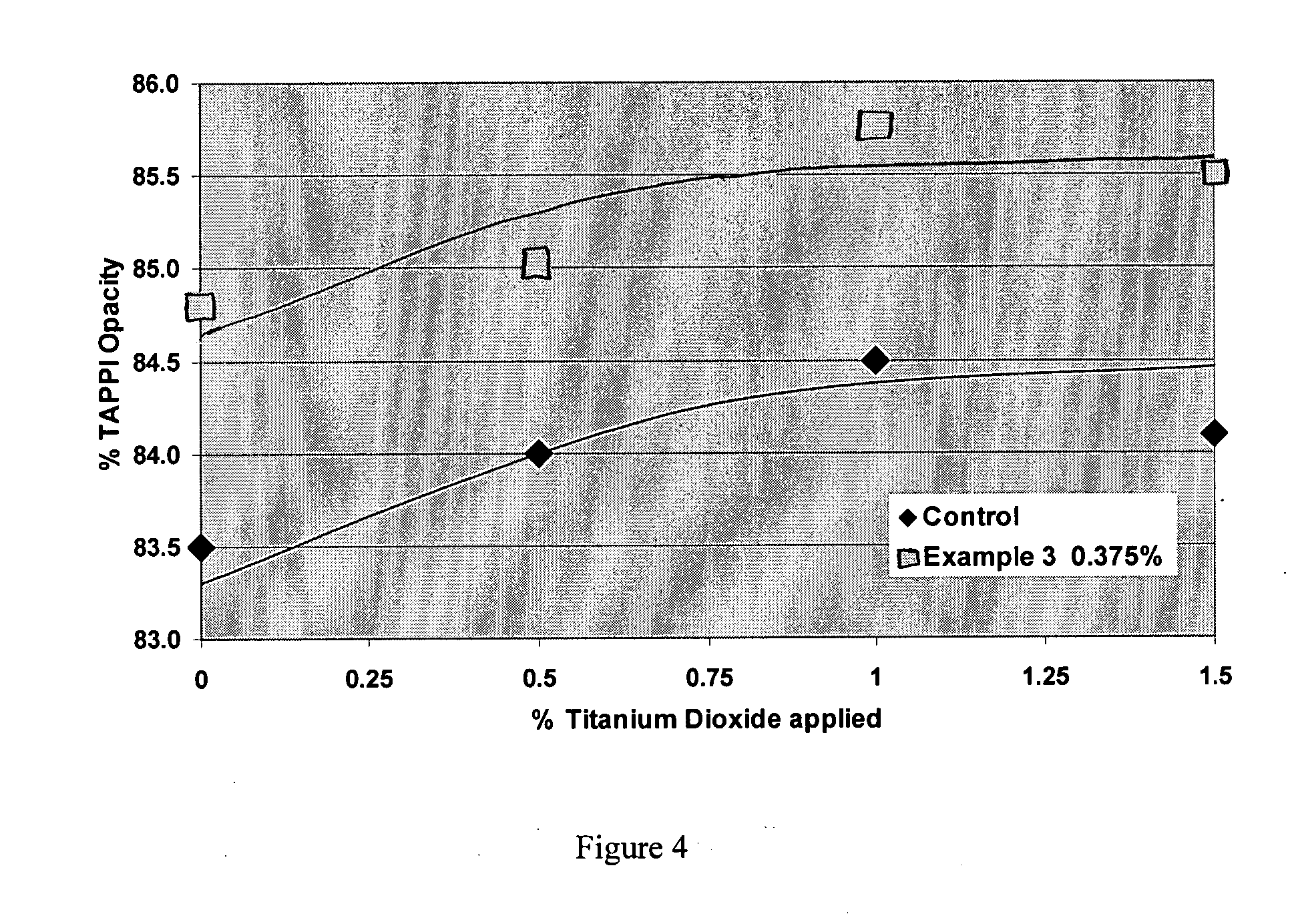

Papermaking method using opacification aid, and paper product made thereby

InactiveUS20060196624A1Reduce weightImprove strength propertiesNatural cellulose pulp/paperSpecial paperOptical propertyPaperboard

A method for making an opacity relevant grade paper or paperboard product, such as a communication type paper used for printing and writing applications, utilizes an effective amount of quaternized alkanolamine fatty acid ester compounds as an opacification aid to control the optical properties of the paper or paperboard product as a wet-end additive to a papermaking operation. Using the quaternized alkanolamine fatty acid ester compound can improve the opacity of the paper or paperboard product, maintain the opacity of the paper while reducing the use of other opacification aids, such as inorganic fillers and / or pigments, and allow for a reduction in paper grammage without a compromise in opacity. The improvements in paper optical properties are achieved without adversely affecting other characteristics of the paper product such as bulk value, tensile strength, tear index, and the like.

Owner:KEMIRA CHEM

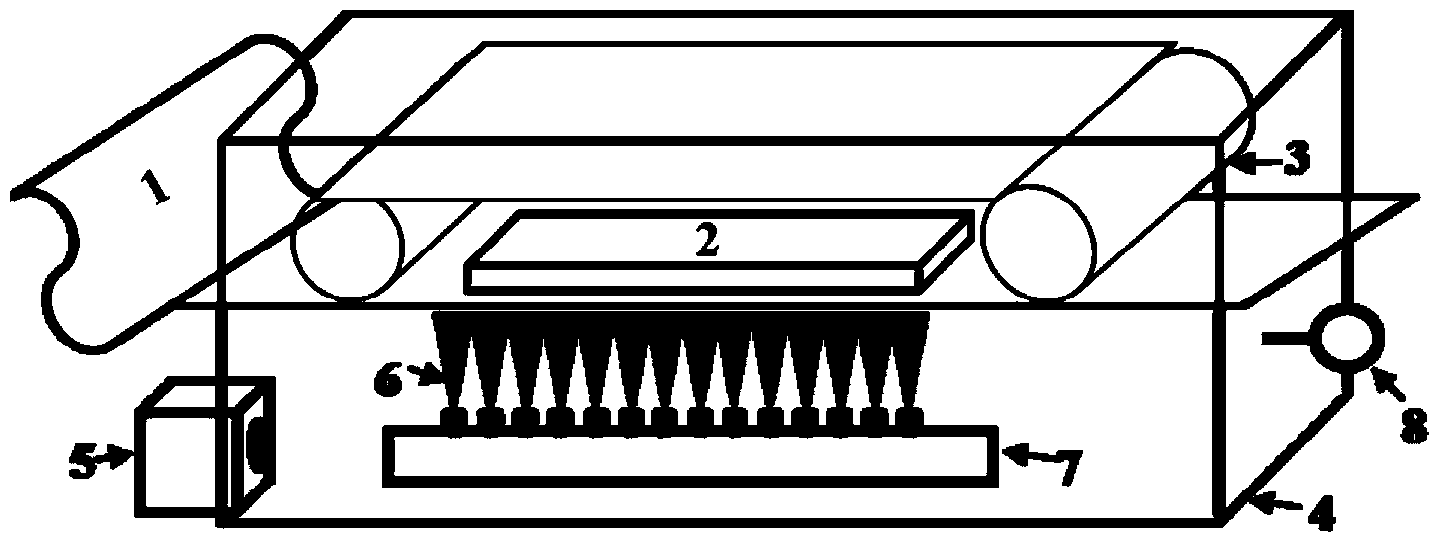

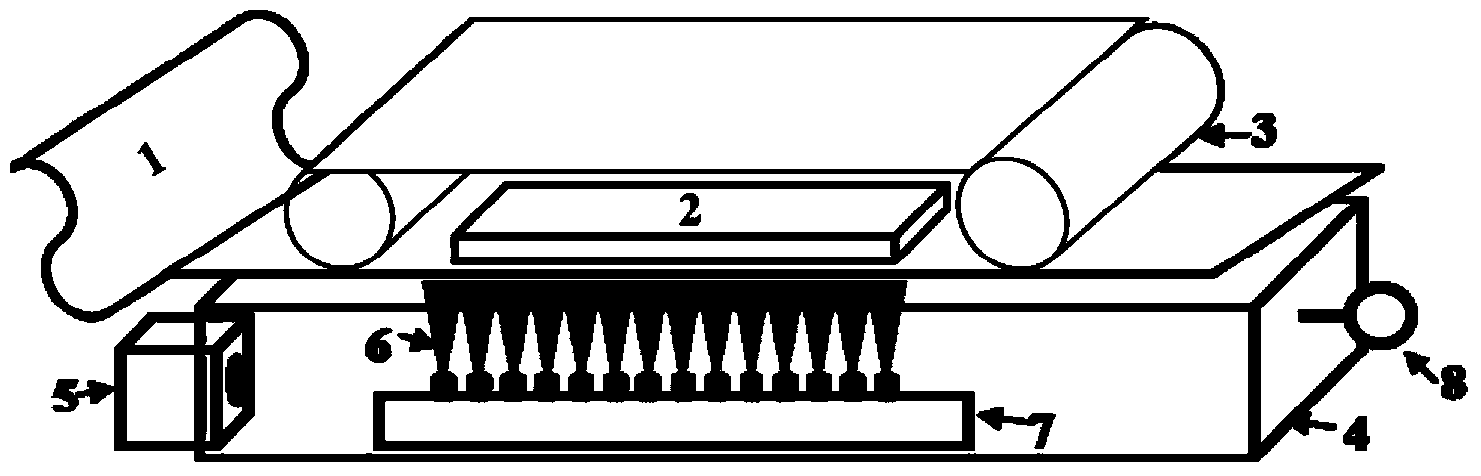

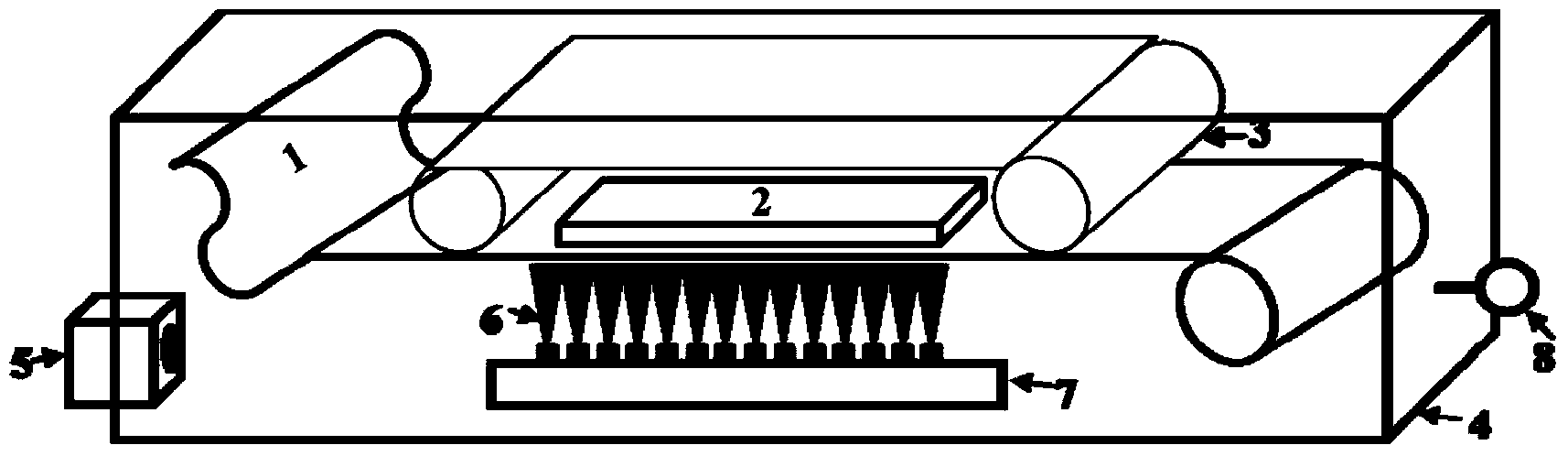

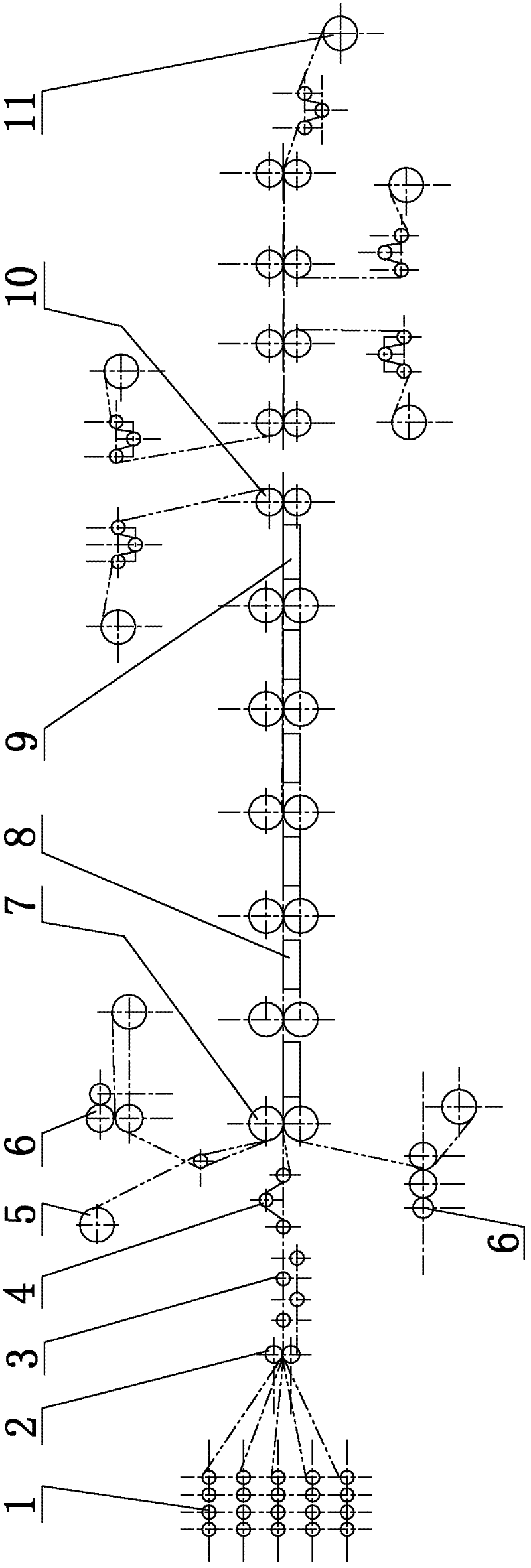

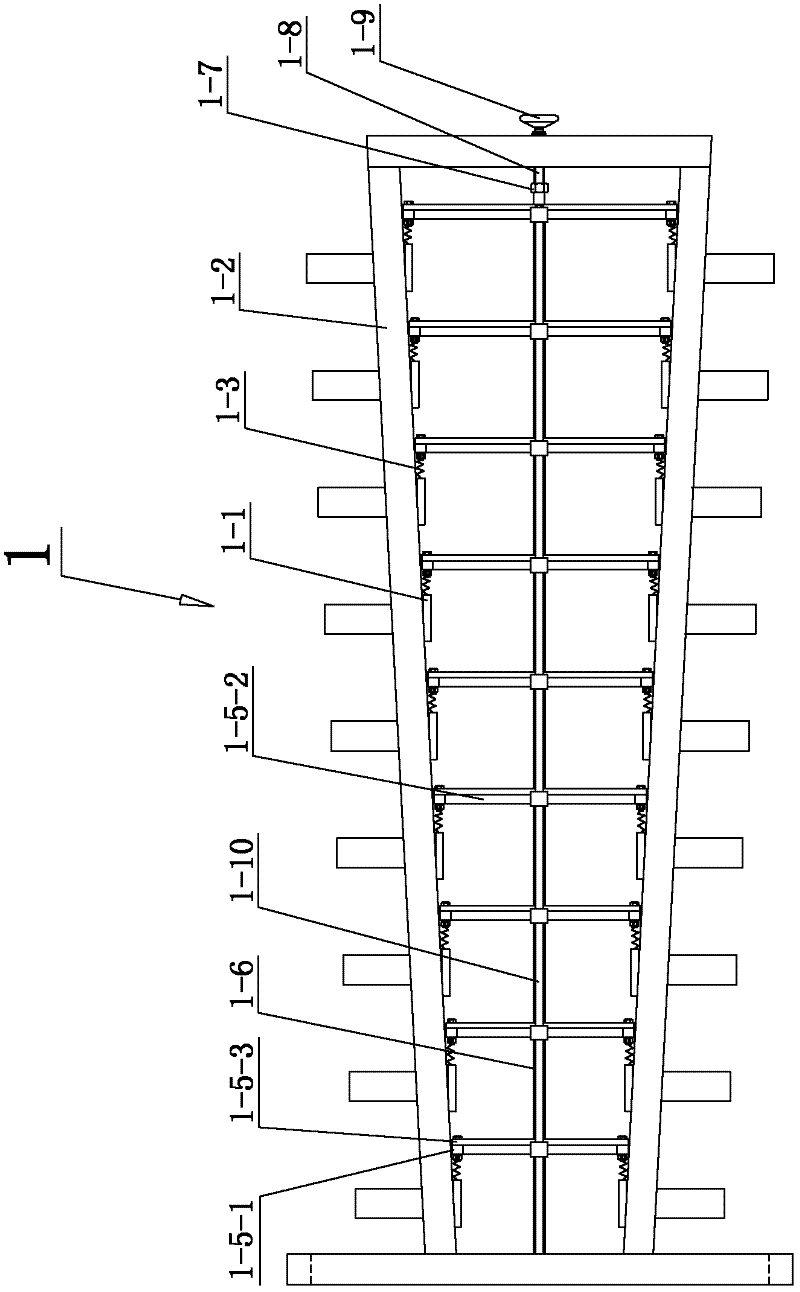

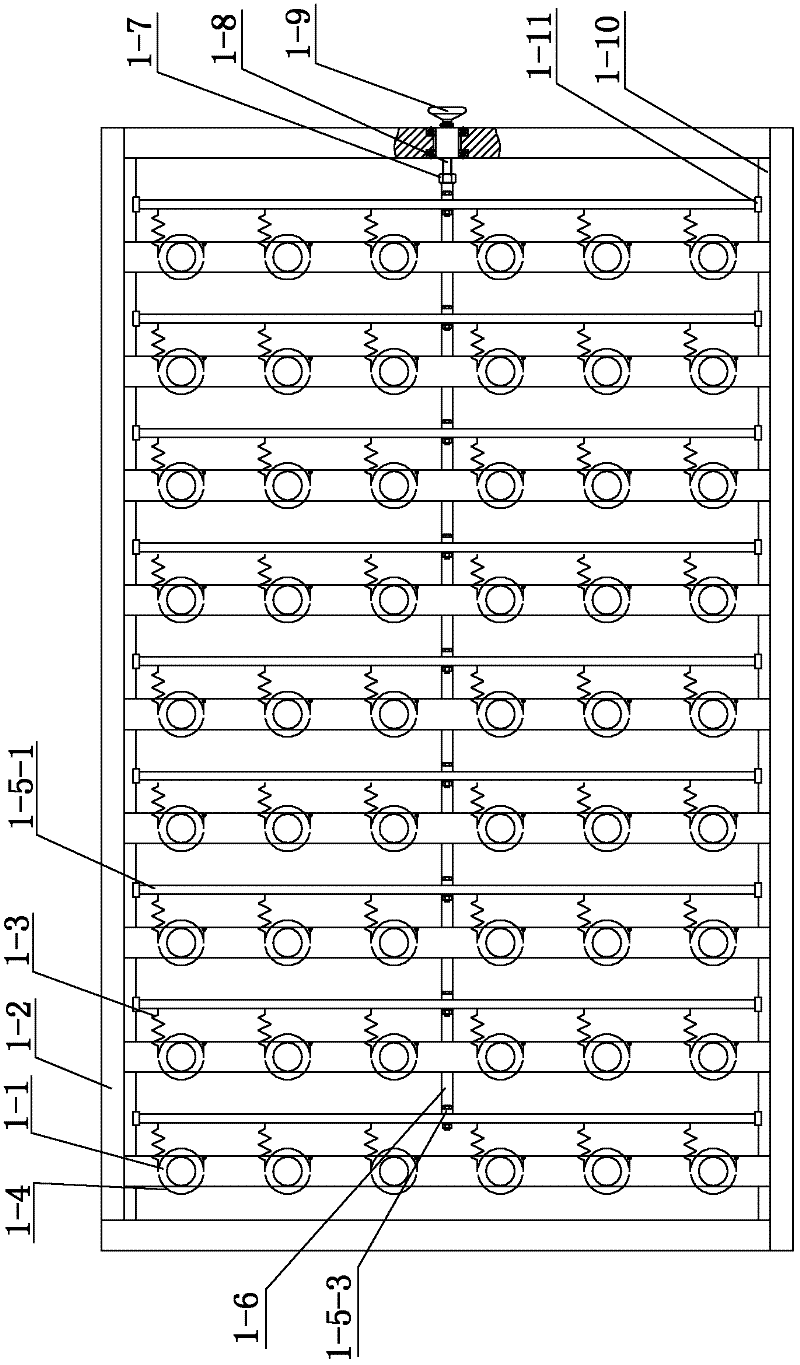

Large-tow carbon fiber and glass fiber composite preimpregnation equipment

The invention relates to large-tow carbon fiber and glass fiber composite preimpregnation equipment, which sequentially comprises a fiber bobbin cradle, a fiber sequencing device, a fiber thinning device, a traction device, a weft fabric unreeling device, a resin glue film generating device, a thermal compound compression roller device, a hot plate, a cooling plate, a shaping device and a finished product reeling device. The large-tow carbon fiber and glass fiber composite preimpregnation equipment is characterized in that the fiber thinning device comprises a motor, a transmission shaft, a crank slider mechanism and a spline shaft, large-tow carbon fibers are wound on the spline shaft in a vertically staggered manner, the spline shaft drives the large-tow carbon fibers to vibrate vertically and alternately so that the large-tow carbon fibers are thinned, the thermal compound compression roller device is provided with six groups of thermal compound compression rollers, the gap betweeneach two compression rollers is accurately reflected by two grating scales and adjusted by an adjustment positioning mechanism so that the needed gap is adjusted according to technological requirements, and the preimpregnation equipment is simple in operation, labor-saving and reliable in precision, and can be used for providing 500g / m2-1650g / m2 large-grammage glass fiber prepregs and carbon fiber prepregs for manufacturing wind energy blades.

Owner:山东国桥复合材料科技有限公司

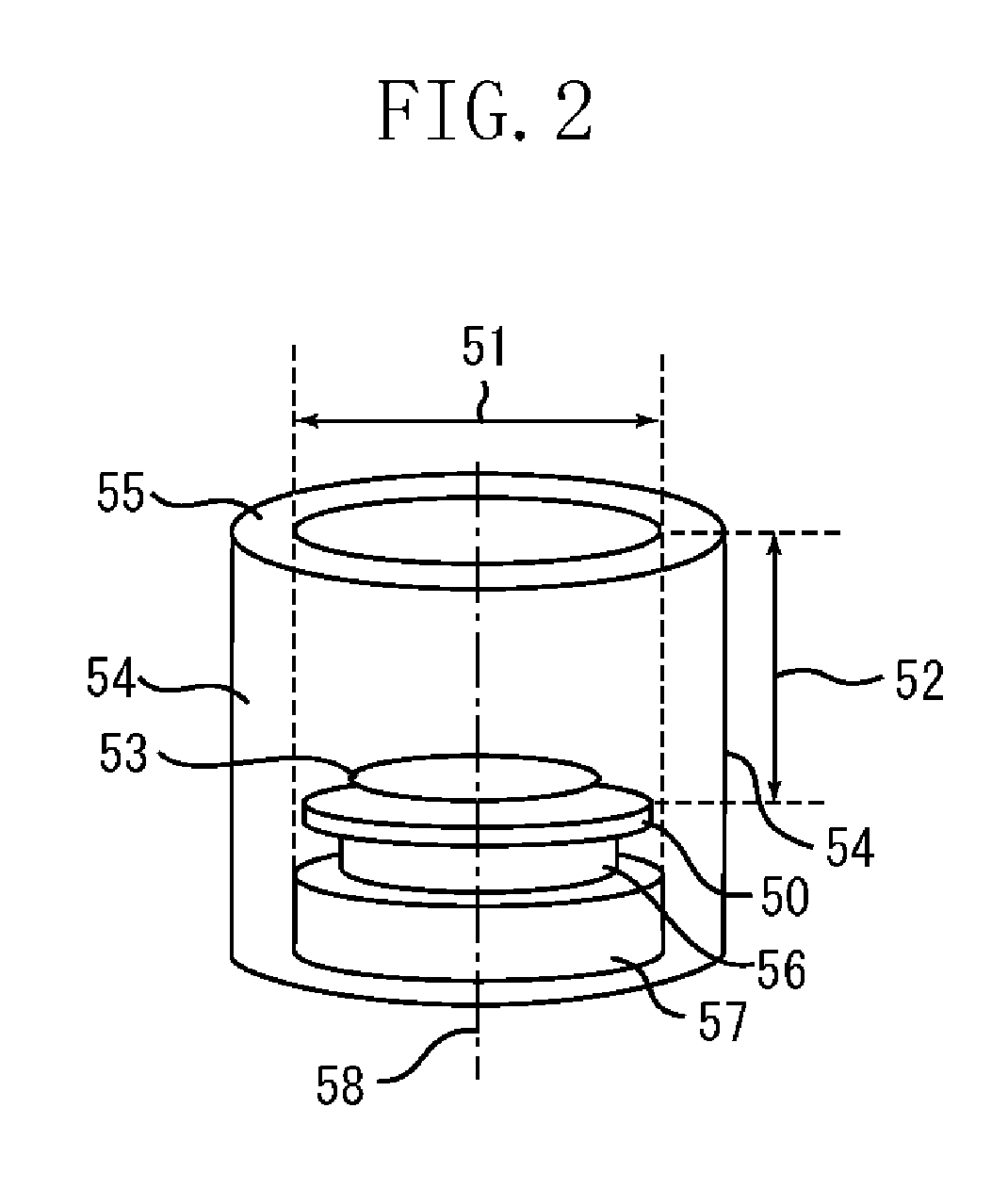

Grammage detection sensor of recording medium and image forming apparatus

ActiveUS20090310981A1Enhances grammage detection accuracyStable emissionsMultiple-port networksElectrographic process apparatusImage formationGrammage

A grammage detection sensor which detects a grammage of a recording medium using an ultrasonic wave includes a transmitting unit configured to transmit the ultrasonic wave and a receiving unit including a first vibration member configured to receive the ultrasonic wave that is transmitted from the transmitting unit and passes through the recording medium. The receiving unit includes a guide member configured to guide the ultrasonic wave that passes through the recording medium to the first vibration member. A length from a surface of the first vibration member to a plane including an end plane of the guide member along a line that passes through a center of the first vibration member and is perpendicular to the first vibration member is approximately n times of one-half wavelength of the ultrasonic wave transmitted from the transmitting unit where n is an integer of one or greater.

Owner:CANON KK

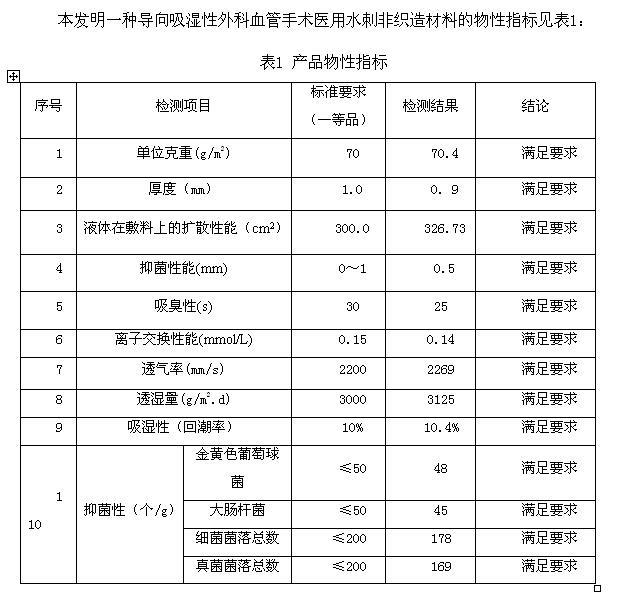

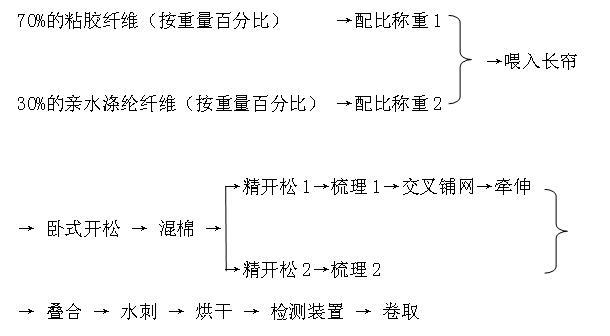

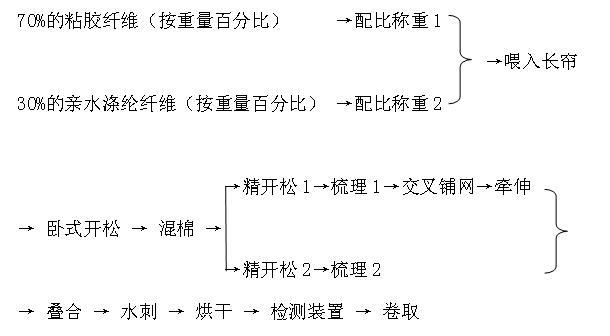

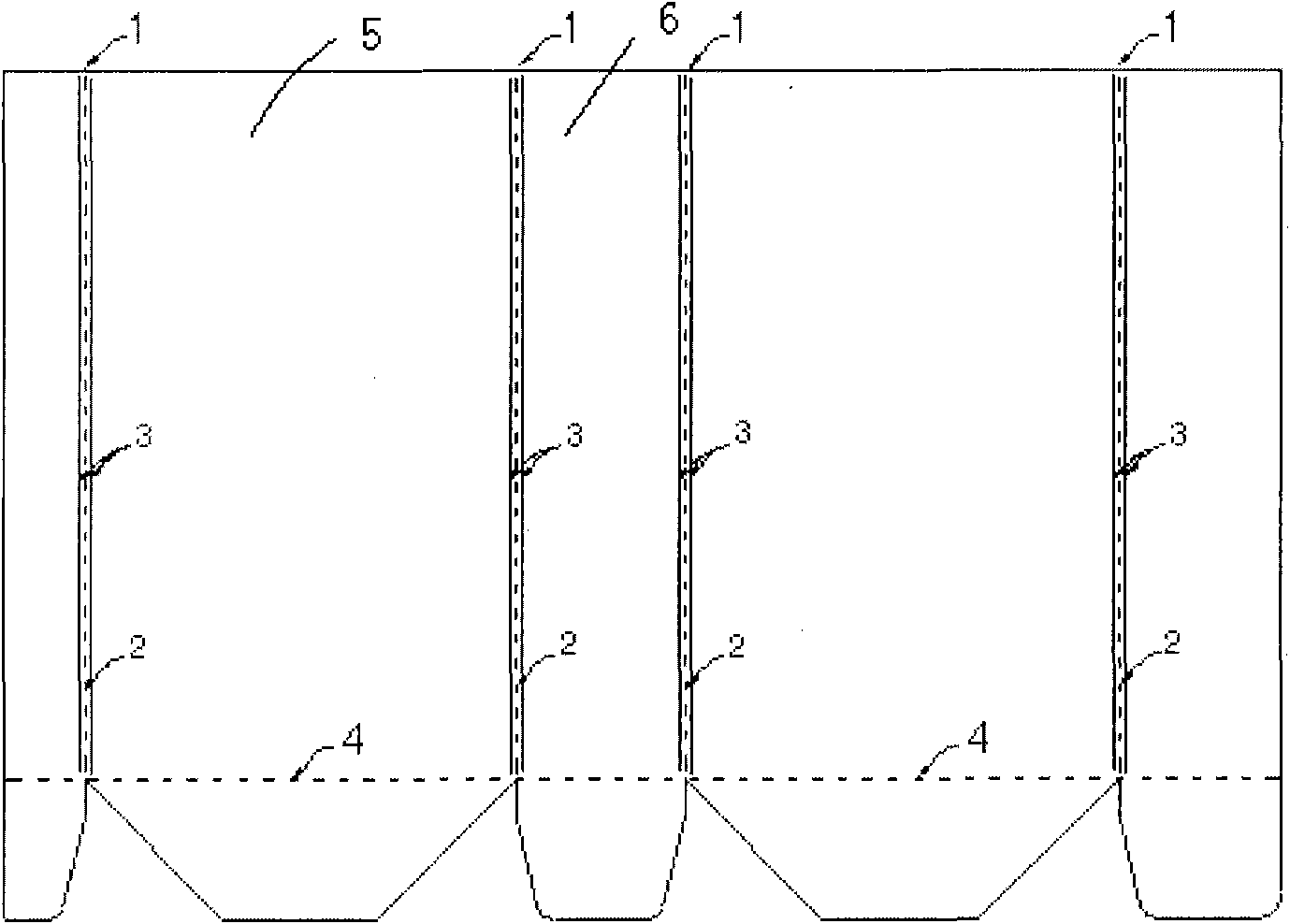

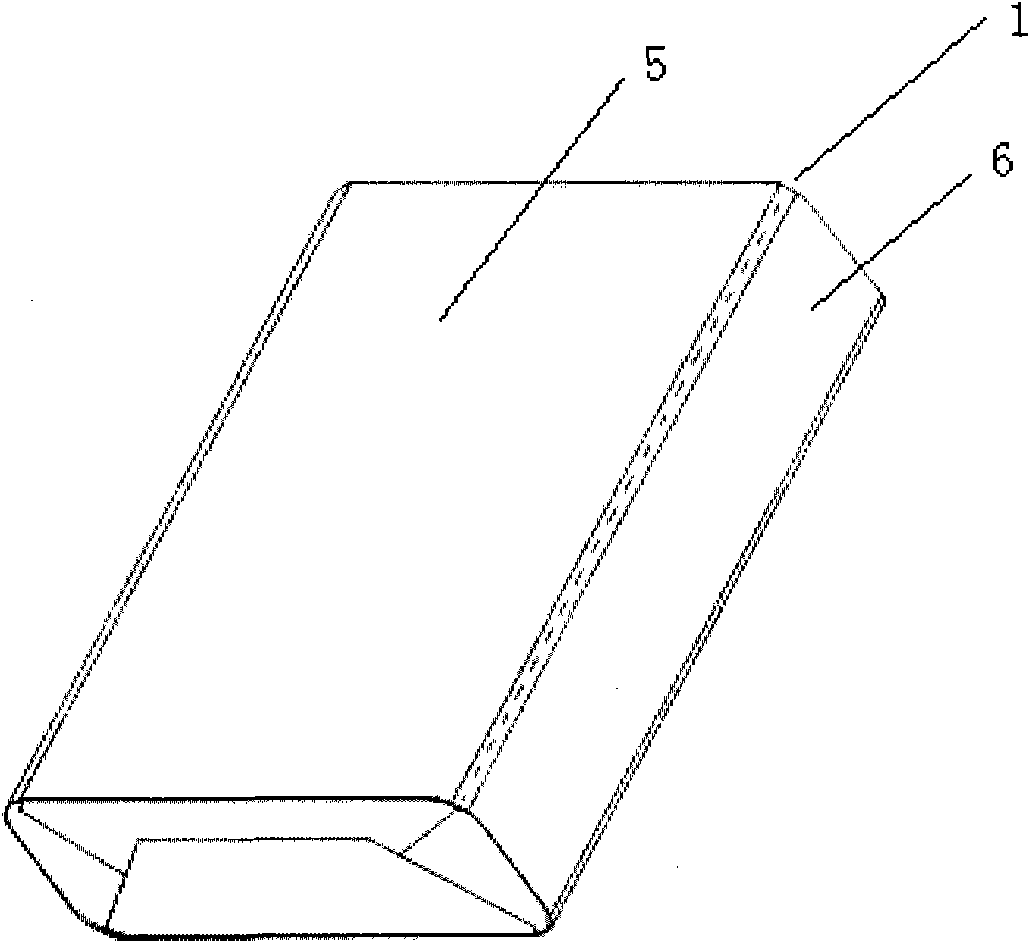

Guiding hygroscopic hydro-entangled non-woven fabric used for surgical blood vessel operation

ActiveCN102166872AThe overall thickness is thinFluff freeSynthetic resin layered productsAbsorbent padsBlood vessel operationsSurface layer

The invention relates to a type of guiding hygroscopic hydro-entangled non-woven fabric used for surgical blood vessel operation, belonging to the weaving material technical field, and the guiding hygroscopic hydro-entangled non-woven fabric comprises a surface layer made of pearl line non-woven fabric, an interface layer made of plastic film, and a bottom layer made of spunbonded non-woven fabric, combined via hot rolling and bonding, wherein the upper layer fibre web of the pearl line non-woven fabric, directly in contact with patients, adopts the straight-paving technology, with weight accounting for two thirds of the surface non-woven fabric grammage; the lower layer fibre web adopts cross lapping technology, with weight accounting for one third of the surface non-woven fabric grammage; and the upper layer fibre web and the lower layer fibre web form the surface layer via hydro-entangled method. The guiding hygroscopic hydro-entangled non-woven fabric of the invention features thinness, high hygroscopicity, excellent diversion performance, and great antibiosis function. Moreover, the guiding hygroscopic hydro-entangled non-woven fabric has no fluff, is lint-free, and does not stick to the wound.

Owner:ZHEJIANG BAOREN NONWOVEN CO LTD

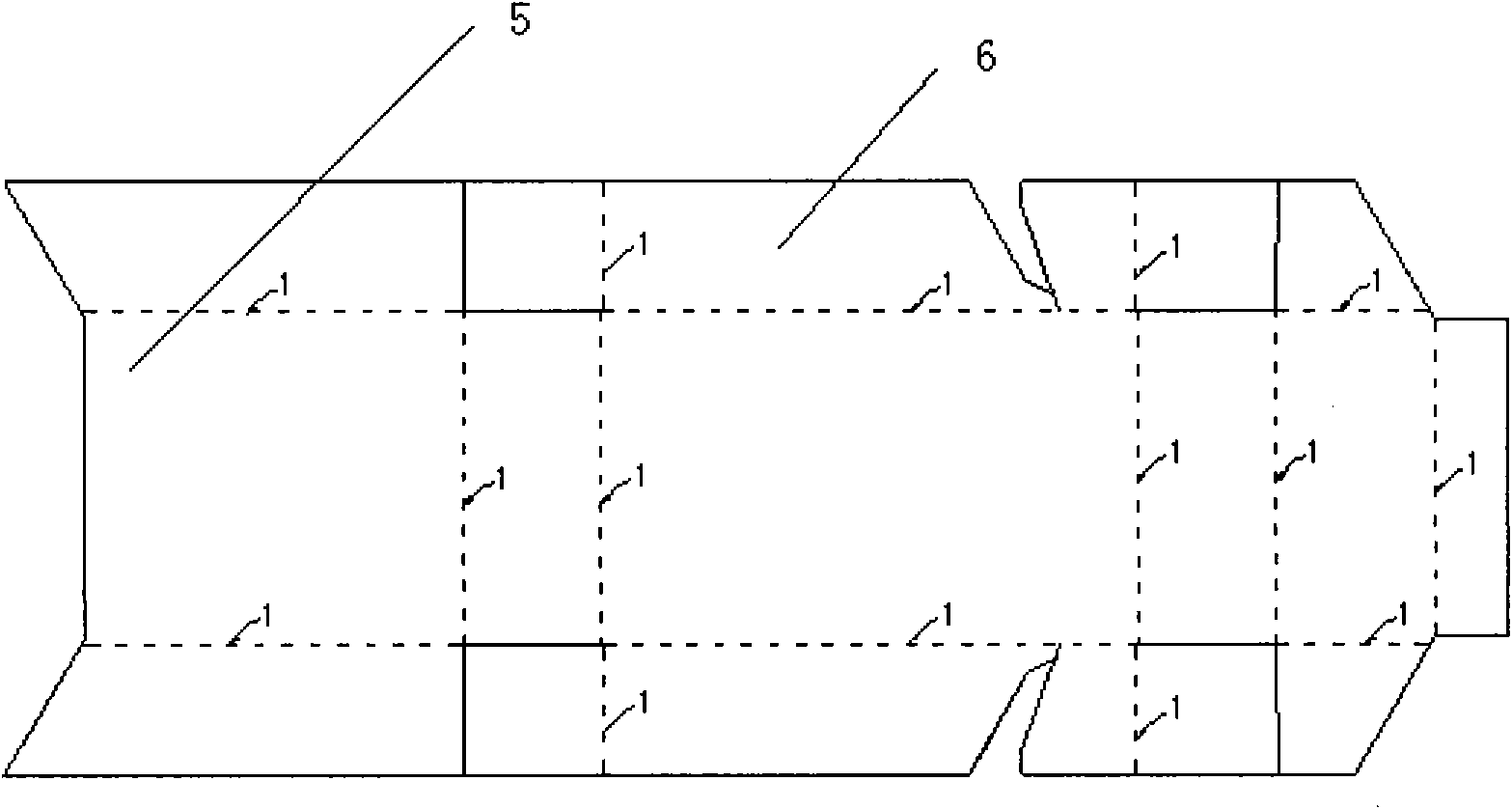

Parchment paper cigarette packing box and manufacturing method thereof

ActiveCN101643131AIt is not easy to cause the problem of poor paper feedingSolid paperContainers for flexible articlesFlexible coversScreen printingTransfer volume

The invention provides a parchment paper cigarette packing box, which comprises two wide side walls parallel to each other, two narrow side walls parallel to each other and a lower end surface, wherein the wide side walls are vertical to the narrow side walls and the lower end surface; and the paper used by the packing box is parchment paper of which the gram weight is 90 to 250 grams / m<2>. The invention also provides a method for preparing the packing box, which comprises the following steps: (1) selecting the parchment paper of which the gram weight is 90 to 250 grams / <2>; (2) printing pictures and texts on the parchment paper by combining various printing modes of offset printing, screen printing, gold stamping and the like, wherein a bar code spare space is printed with UV gloss oil first and then is printed with a flexographic plate white ink of which the ink-transferring volume is between 10.0 and 11.0 BCM so that the thickness of an overprint ink layer is between 20 and 50 mums,and then the well-printed parchment paper is obtained; and (3) performing back cross cutting molding on the well-printed parchment paper in the step (2) to finally mold and obtain the cigarette packing box, wherein a crease line is a point penetration pressure cutting line and two edges of the crease line are half-penetration pressure cutting lines.

Owner:SHENZHEN JINJIA GRP

Recording material determination apparatus and image forming apparatus

A recording material determination apparatus includes a first detection unit configured to detect a characteristic corresponding to a surface condition of a recording material based on a captured image of a surface of the recording material, a second detection unit configured to detect a characteristic corresponding to a grammage of the recording material based on an ultrasonic wave detected via the recording material by irradiating the recording material with an ultrasonic wave, and a conveyance unit configured to convey the recording material. The first detection unit and the second detection unit are located opposite each other with respect to the conveyance unit.

Owner:CANON KK

Method and apparatus for measuring grammage

InactiveUS20060288782A1Measure securityEasy to handleVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSample MeasureMeasurement device

A grammage measuring apparatus includes a dielectric resonator which is arranged only at one surface side of a sample; a shielding container with which the dielectric resonator is substantially covered except for a sample measuring surface; a microwave excitation device which causes the dielectric resonator to generate an electric field vector; a detection device which detects transmission energy or reflection energy by the dielectric resonator; a storage device in which a calibration curve indicating a resonance frequency shift amount for a grammage is stored; and a data processing device which calculates the grammage of a measuring sample from the calibration curve and measurement result of the resonance frequency shift amount of the measuring sample.

Owner:OJI PAPER CO LTD

Ink composition for ink jet recording

An ink composition that can form high-quality images free of white streaks and harshness on actual printing paper, such as art paper, even at low resolution and that can reduce the occurrence of curling even with thin actual printing paper having a low grammage is provided.An ink jet printing ink composition includes at least a colorant, water, an alcohol solvent, and a surfactant, wherein the alcohol solvent contains a poorly water-soluble alkane diol, a water-soluble 1,2-alkane diol, and a water-soluble symmetrical alkane diol having a hydroxy group at both ends.

Owner:SEIKO EPSON CORP

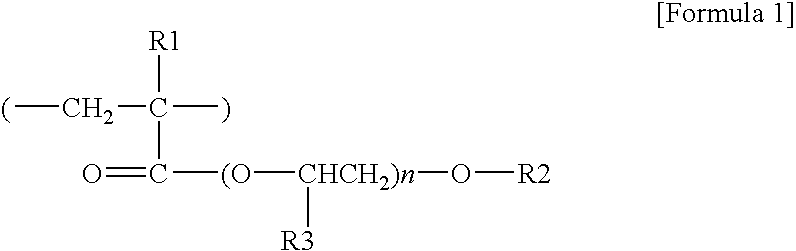

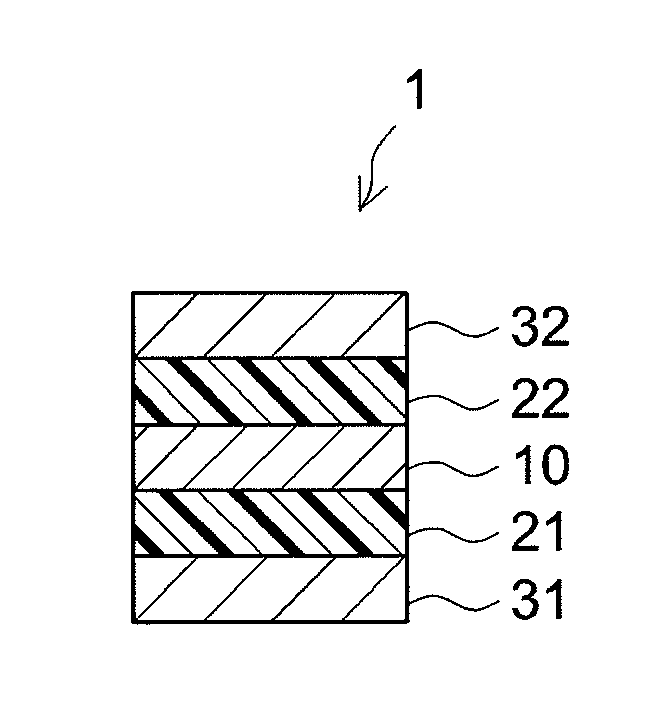

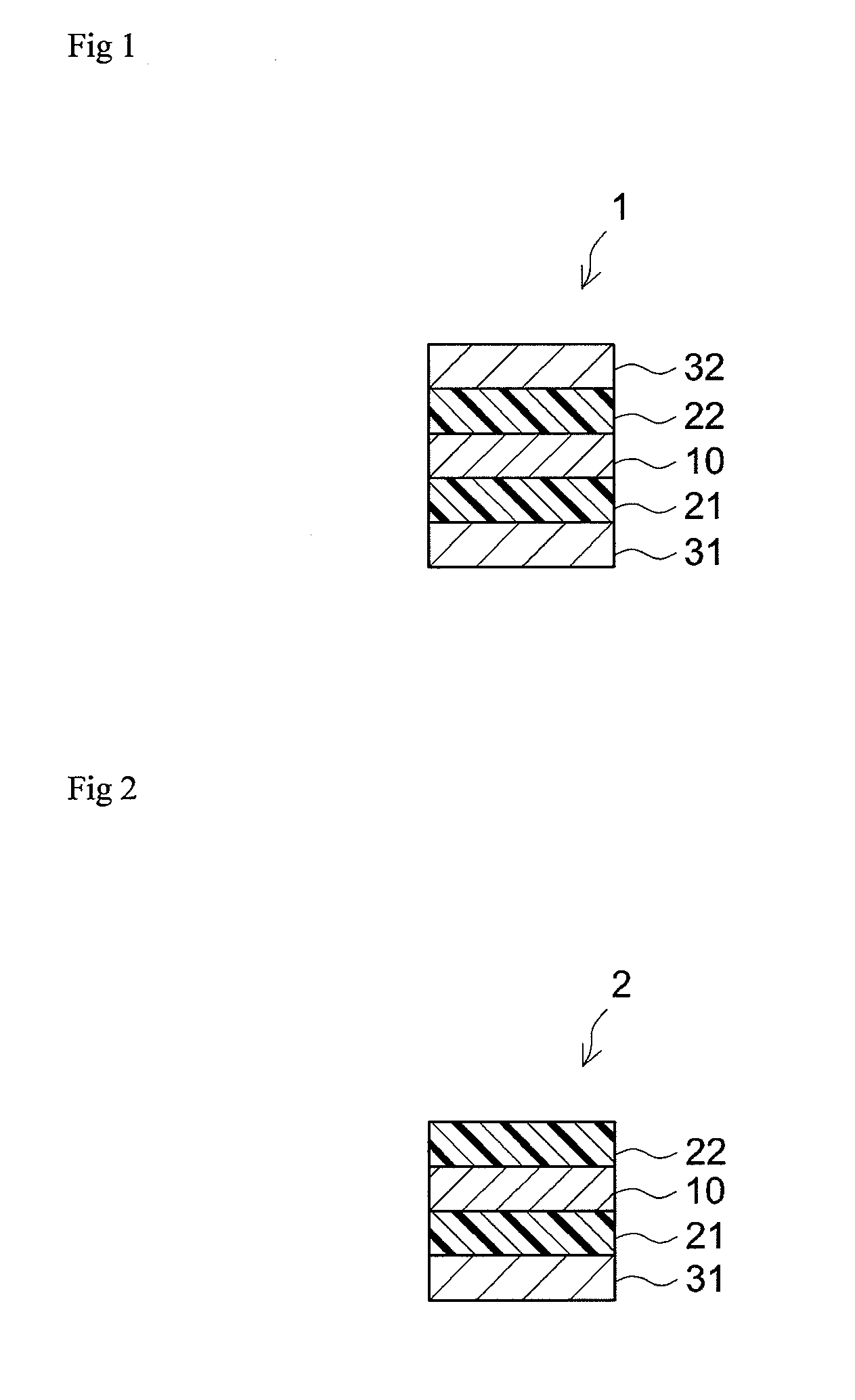

Double-sided pressure-sensitive adhesive sheet

InactiveUS20110059281A1Improve balanceAppropriate strengthLayered productsThin material handlingOrganic solventGrammage

The present invention provides a double-sided pressure-sensitive adhesive (PSA) sheet that is provided with both adhesion performance and re-peelability that enables the PSA sheet to be preferably used for scheduled recyclable parts. The double-sided PSA sheet 1 is provided with a substrate 10, PSA layers 21 and 22 each applied to each side of the substrate 10, and a release liner 31 laminated onto at least the PSA layer 21. The PSA layer 21 contains a PSA component synthesized in an organic solvent. The release liner 31 has a release layer composed of a silicone release agent on at least the side that contacts the PSA layer 21. The release layer has an amount of silicone transfer of 10 kcps or less per unit surface area equivalent to a 30 mm diameter circle. The substrate 10 is composed of a non-woven fabric which has a grammage of 10 to 25 g / m2, tensile strength in the lengthwise direction and tensile strength in the widthwise direction both falling within the range of 9 to 20 N / 10 mm, and a grain ratio of 70 to 140%.

Owner:NITTO DENKO CORP

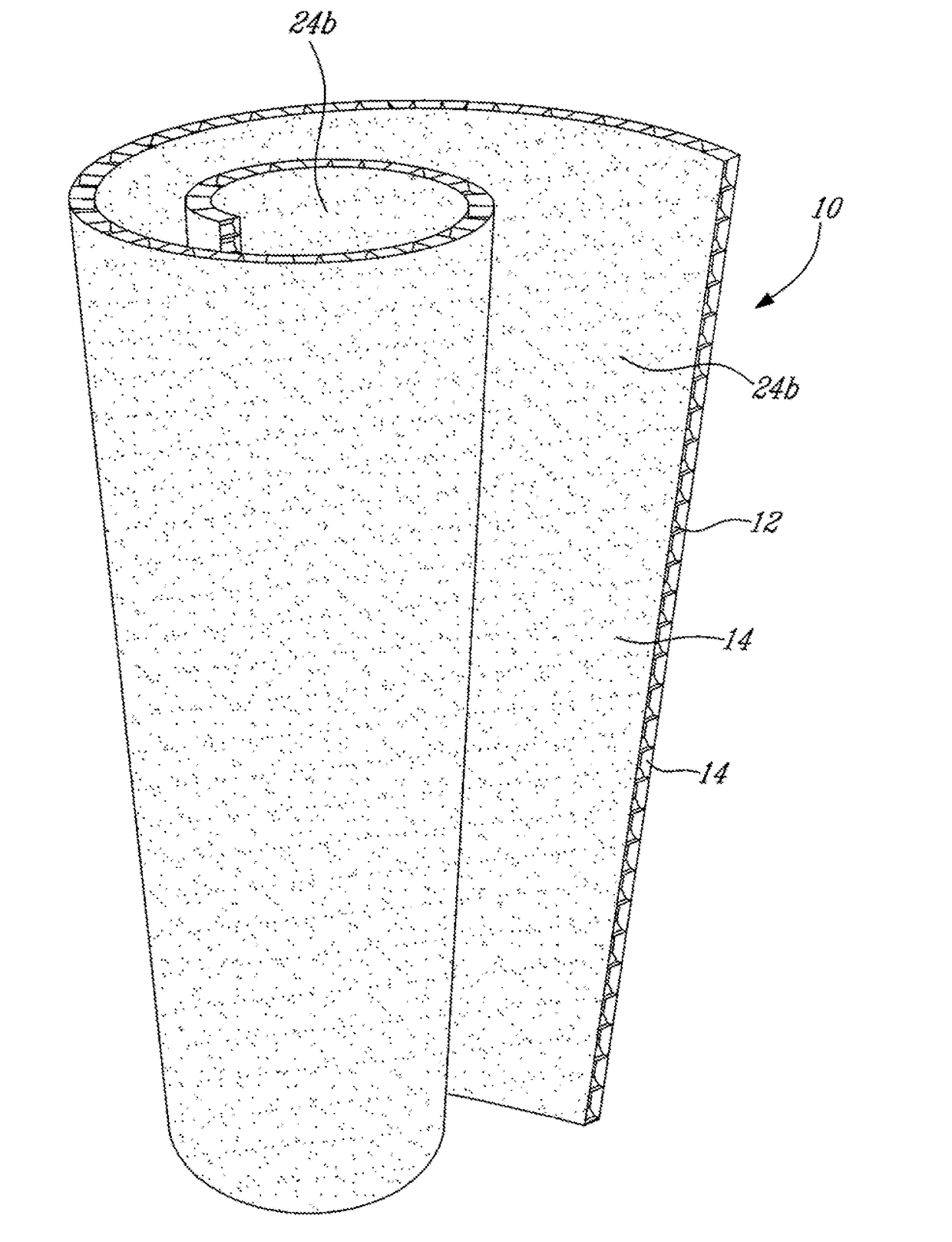

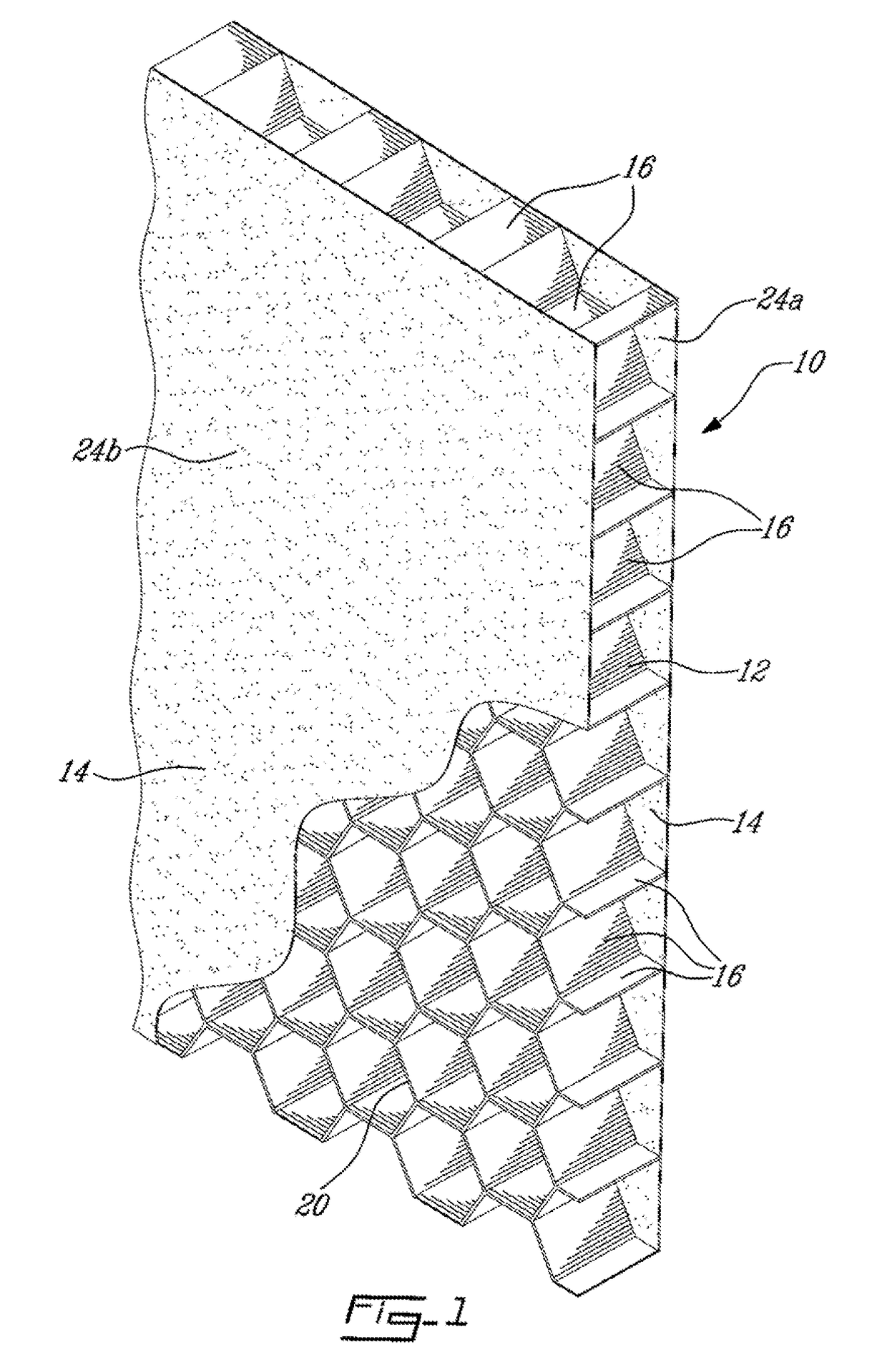

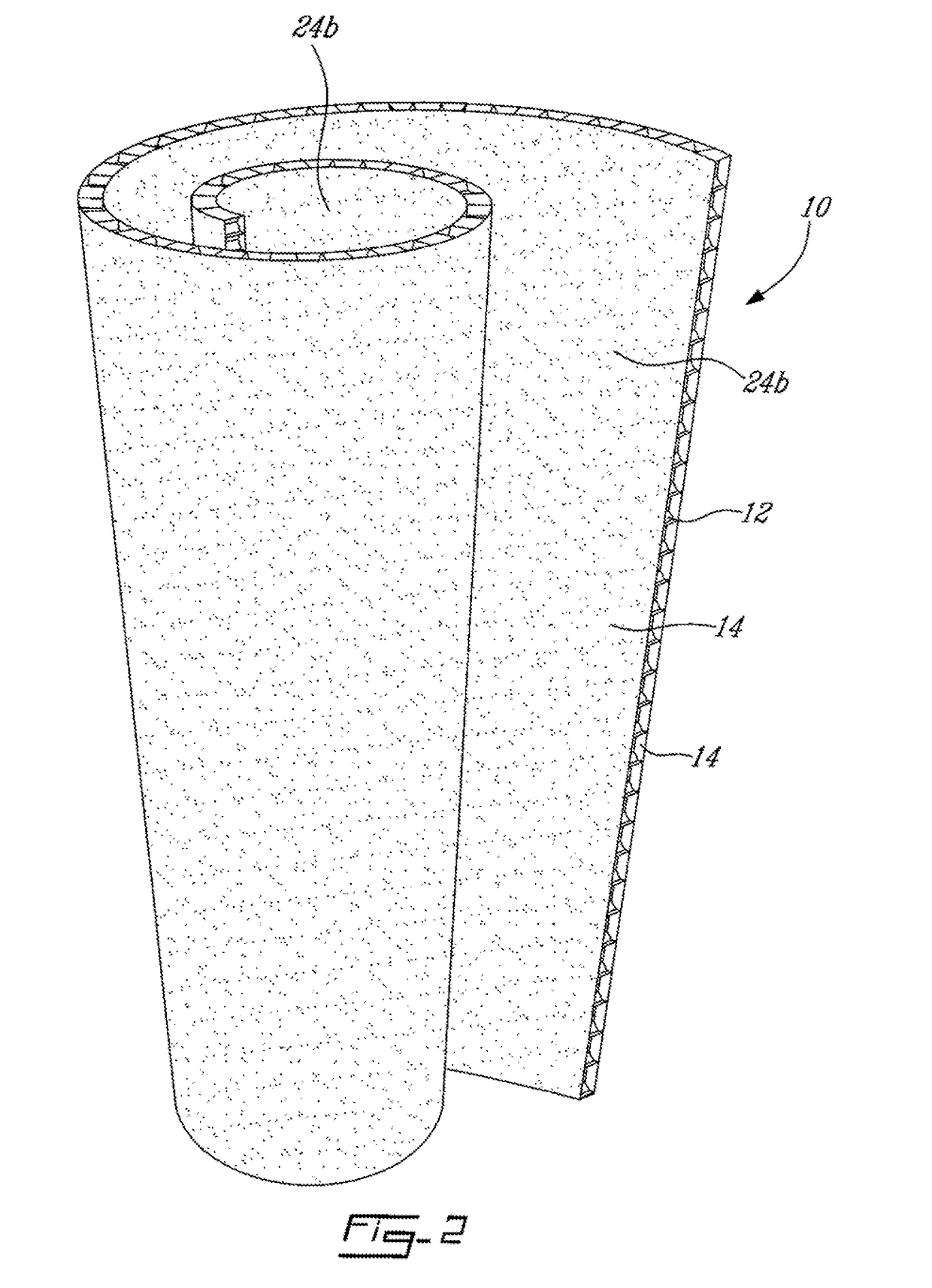

Flexible cellulosic fiber-based honeycomb material

A flexible packaging material including: a core portion having a geometrically patterned structure defining two spaced-apart substantially planar faces and providing air space therebetween, the core portion including cellulosic fiber-based walls having a core grammage; and at least one cellulosic fiber-based liner bonded to a respective one of the planar faces of the core portion and having a liner grammage lower than the core grammage, the material being flexible along a plane defined by the at least one liner.

Owner:CASCADES CANADA INC

Digital glaze for high grammage, without the use of Anti-settling agents

A digital glaze for high grammage, without the use of anti-settling agents, referred to as digital glazes for digital inkjet printing techniques to apply high grammage, maintaining the same aesthetic and technical characteristics obtained with traditional glazes and non-digital application techniques. No anti-settling agents are used in the composition to prevent the digital glaze from being thixotropic and creating problems in the inkjet printing. The composition includes at least one medium that is liquid at ambient temperature, formed by a mixture of water and polar solvents and / or solvents of medium to low polarity, having a percentage by weight of between 20 and 70% of the total weight of the digital glaze; and at least one mixture of ceramic raw materials and / or frits as a glaze-forming material, having a percentage by weight of between 30 and 80% of the total weight of the digital glaze.

Owner:TORRECID

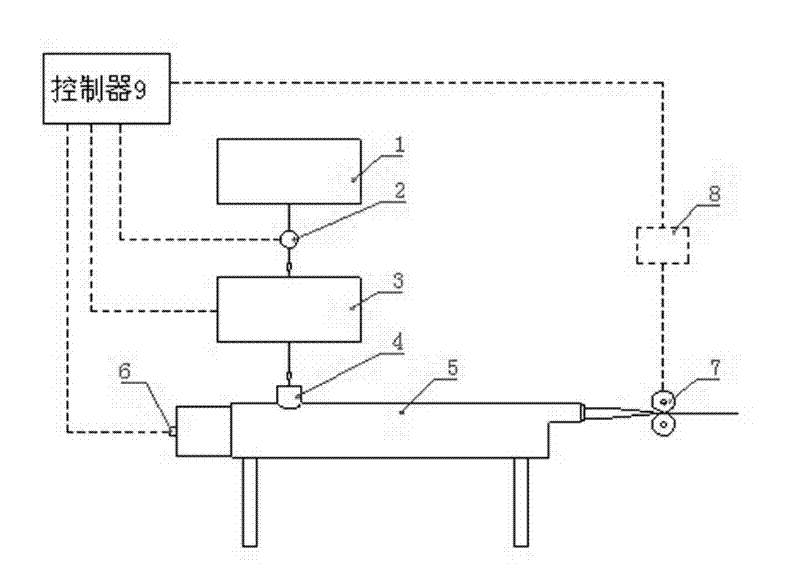

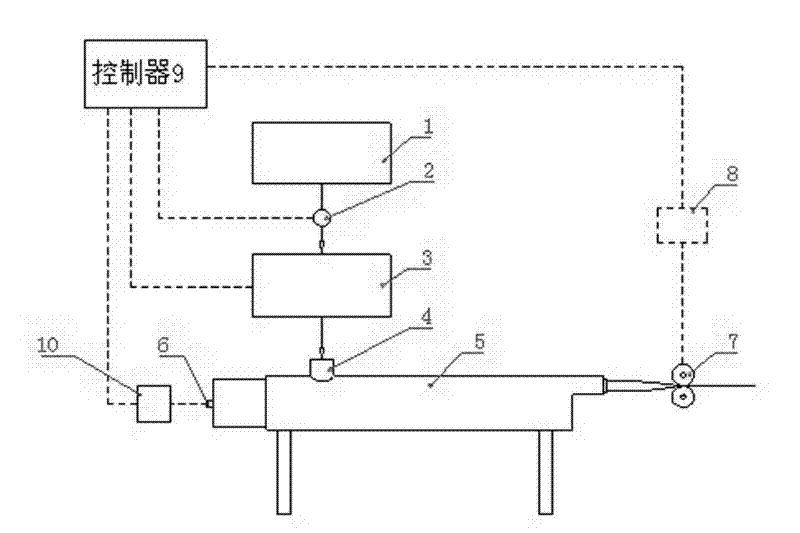

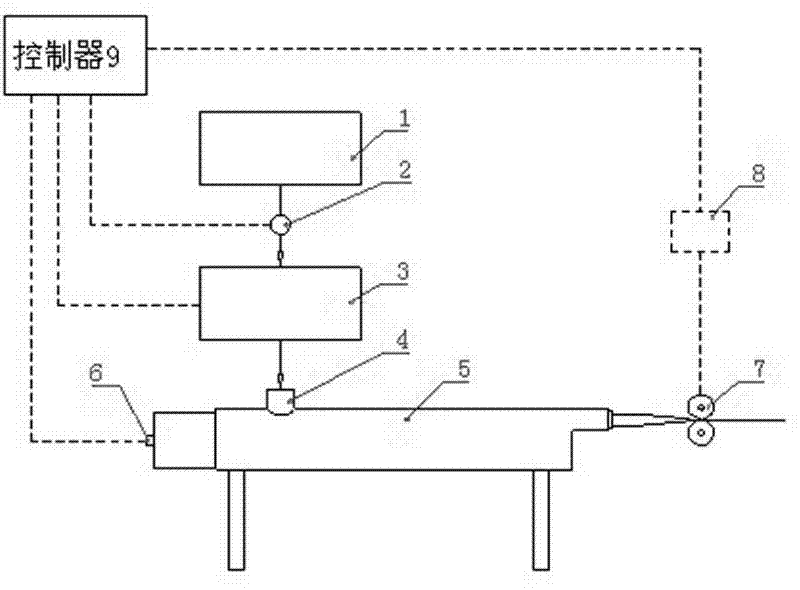

High-precision method for controlling uniformity of discharging of extruder

The invention discloses a high-precision method for controlling the uniformity of discharging of an extruder. The method comprises the following steps: inputting a grammage parameter of a product in a storage of a controller, utilizing the controller to collect and store the rotating speed of the screw of the extruder and the flow amount A of the raw materials in unit time metered by a weighing device at the last time; calculating the discharging amount B every time the screw of the extruder rotates for a circle based on the flow amount A of the raw materials in unit time, and utilizing the controller to adjust the rotating speed of a pull roll at any time according to the change of the B so as to meet the grammage parameter of the product. The method disclosed by the invention has the advantage of calculating the corresponding discharging amount every time the screw of the extruder rotates for a circle by using calculated weight (parameter A) of the raw materials entering the extruder in unit time in the prior art, thereby adjusting the rotating speed of the pull roll of the discharging port of the extruder; and when the discharging amount every time the screw of the extruder rotates for a circle has a certain deviation, the controller can adjust the rotating speed of the pull roll, thereby greatly improving the control precision which can be improved by one order of magnitude.

Owner:王根乐

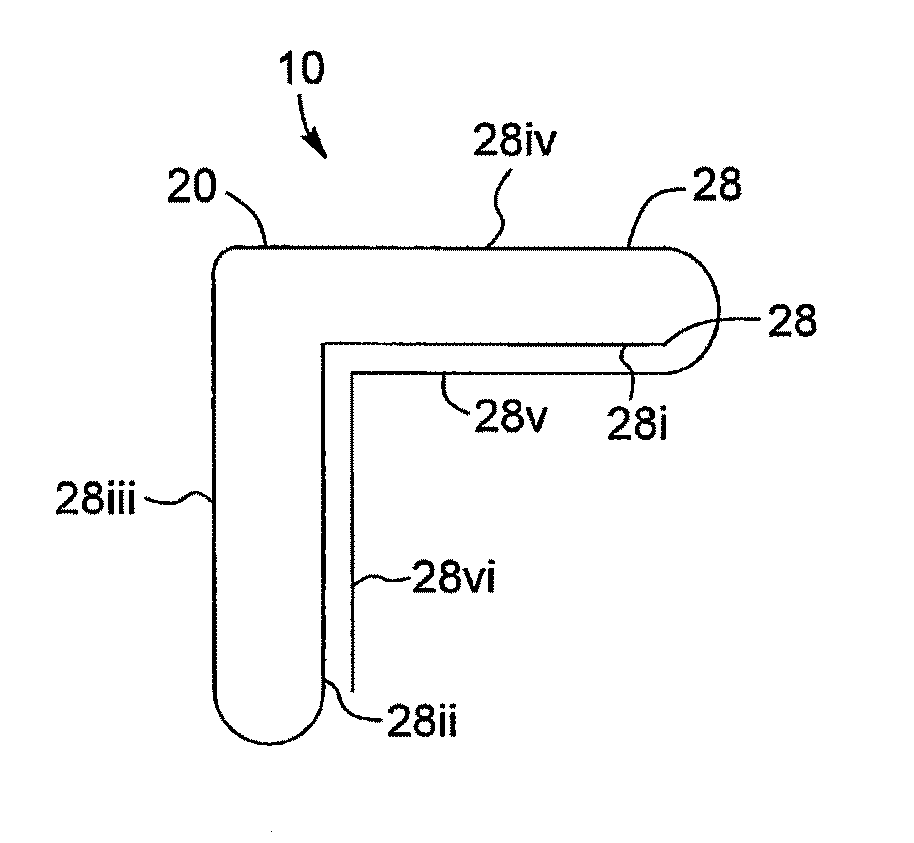

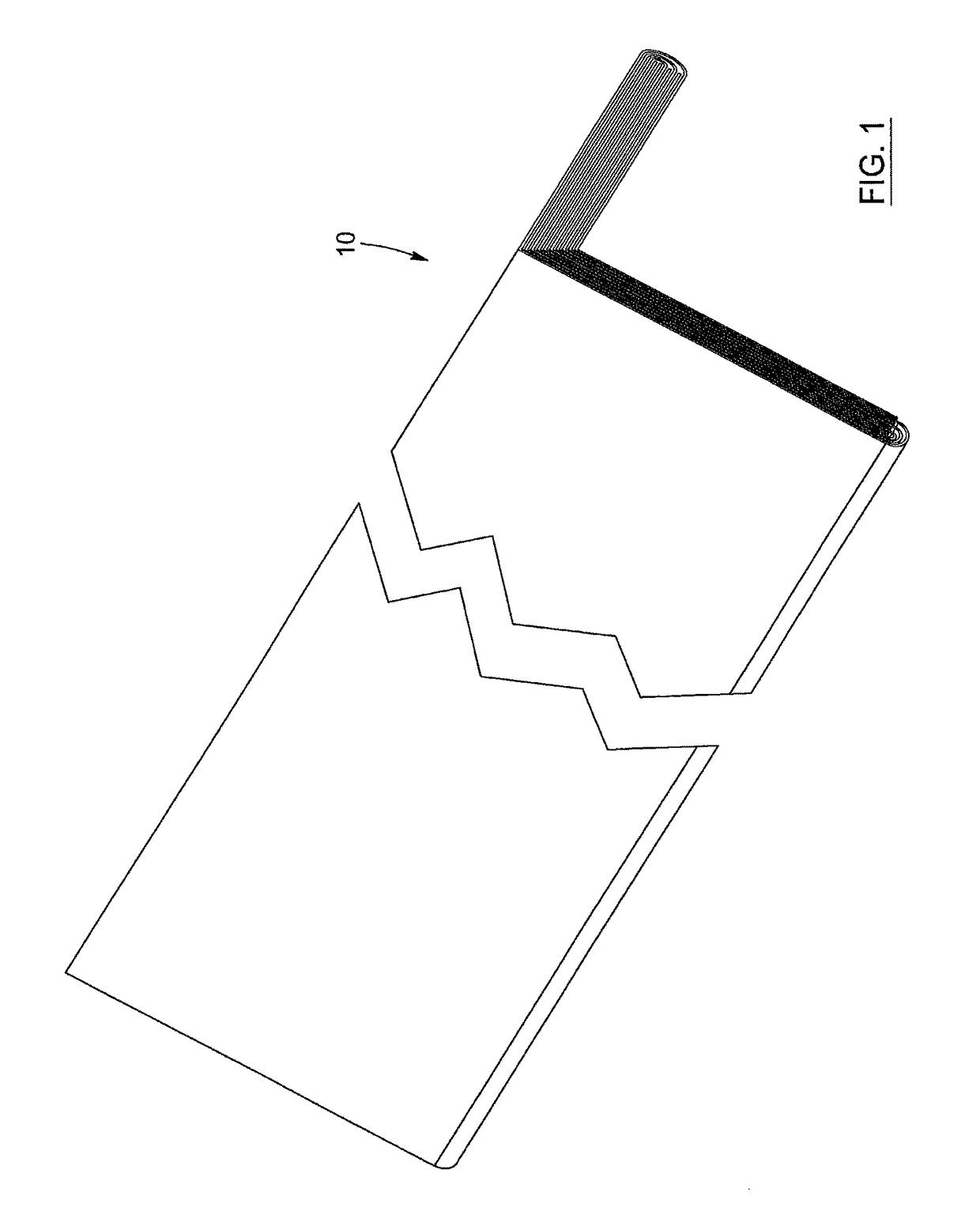

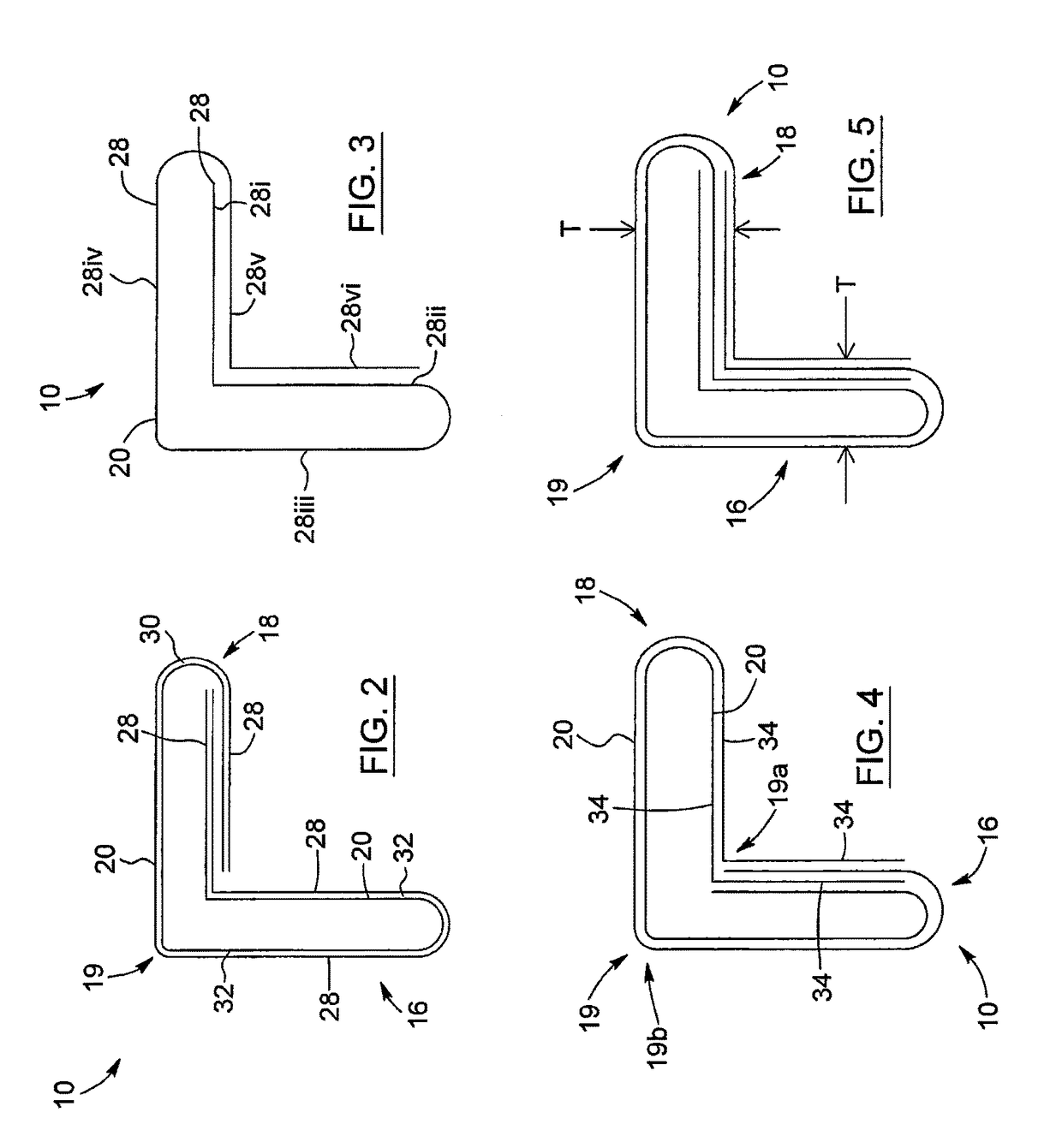

Paperboard corner, and method of manufacturing the same

ActiveUS9764527B2Improves Structural IntegrityProvides water resistancePaper/cardboard articlesPaper/cardboard wound articlesPaperboardEngineering

The invention concerns an elongated protective corner for the transport and / or packaging of products. The corner has at least two non-corrugated paperboard plies combined together to create two perpendicular wings and an apex. The plies form multiple ply sections, and at least one of the ply sections of a given ply overlaps another ply section of the same ply. This overlapping arrangement gives the apex a resistance force of about 100 to about 500 lbs. The thickness of the corner can vary, with each wing being in the range of about 100 to about 250 points, and each ply is made from paperboard having a grammage of about 120 to about 380 g / m2. The resistance force can be determined by mounting the corner upon two blocks, and applying a force to the apex at a middle of the corner until a fracture is detected.

Owner:ABZAC CANADA INC

A method for preparing warming composite material

The invention discloses a method for preparing warming composite material. The invention provided method using a widely-known method of producing cloth melt-blown with non-woven, Producing any one or two of polypropylene, polyethylene glycol terephthalate, polybutylene telephthalate or polylactic acid superfine fiber into superfine fiber then melting and spraying onto the cotton for non-weaving cloth, Denier range of the superfine fiber is one to five Mum, The average denier is three to four Mum, Gram weight of the melt-blown with non-weaving cloth is 30 to 50 gram for every square meters; The using the widely-known adhesive and a composite method to composing the superfine fiber melt-blown non-weaving cloth with polyfluortetraethylene micropore film together, And then the warming composite material is prepared; The gram weight of the polyfluortetraethylene micropore film is 15 to 25 gram for every square meters, Dosage for a certain unit area of the adhesive is two to four gram for square meters. Products produced by using the invention provided method has characteristics of warming, water proofing, wind proofing, ventilating, moisture permeable, comfortable and portable.

Owner:TIANJIN TEDA FILTERS

Recording medium determination apparatus and image forming apparatus

InactiveUS8774653B2Digital computer detailsElectrographic process apparatusImage formationEngineering

A recording medium determination apparatus that determines grammage of a recording medium by using an ultrasonic wave includes a transmission unit configured to output an ultrasonic wave having a predetermined frequency, a reception unit configured to receive the ultrasonic wave output from the transmission unit and transmitted through the recording medium and output a received signal, a calculation unit configured to calculate a signal having a peak component according to a cycle of the received signal, and a determination unit configured to determine the grammage of the recording medium based on the signal calculated by the calculation unit.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com