Patents

Literature

232results about How to "Measure security" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

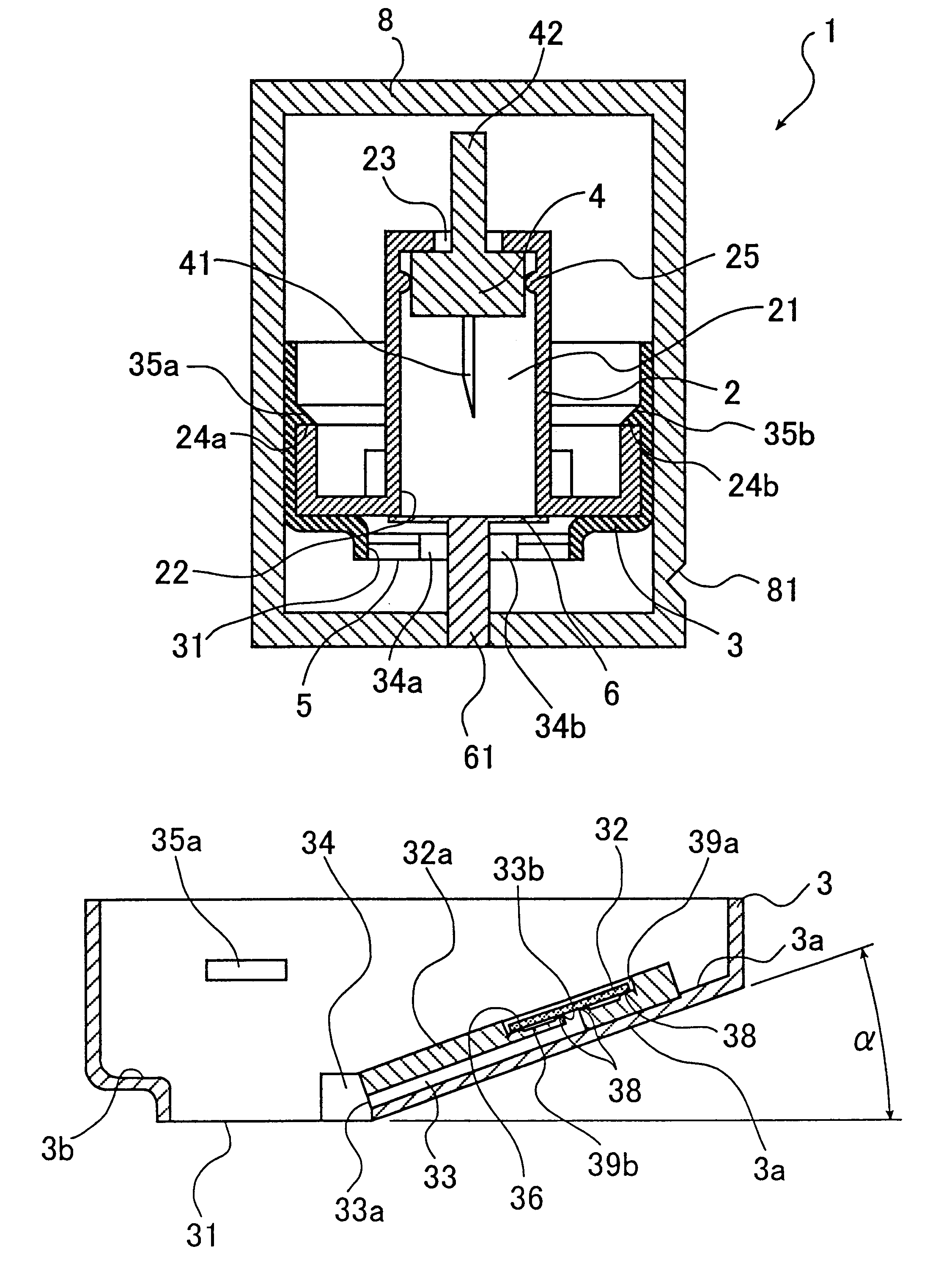

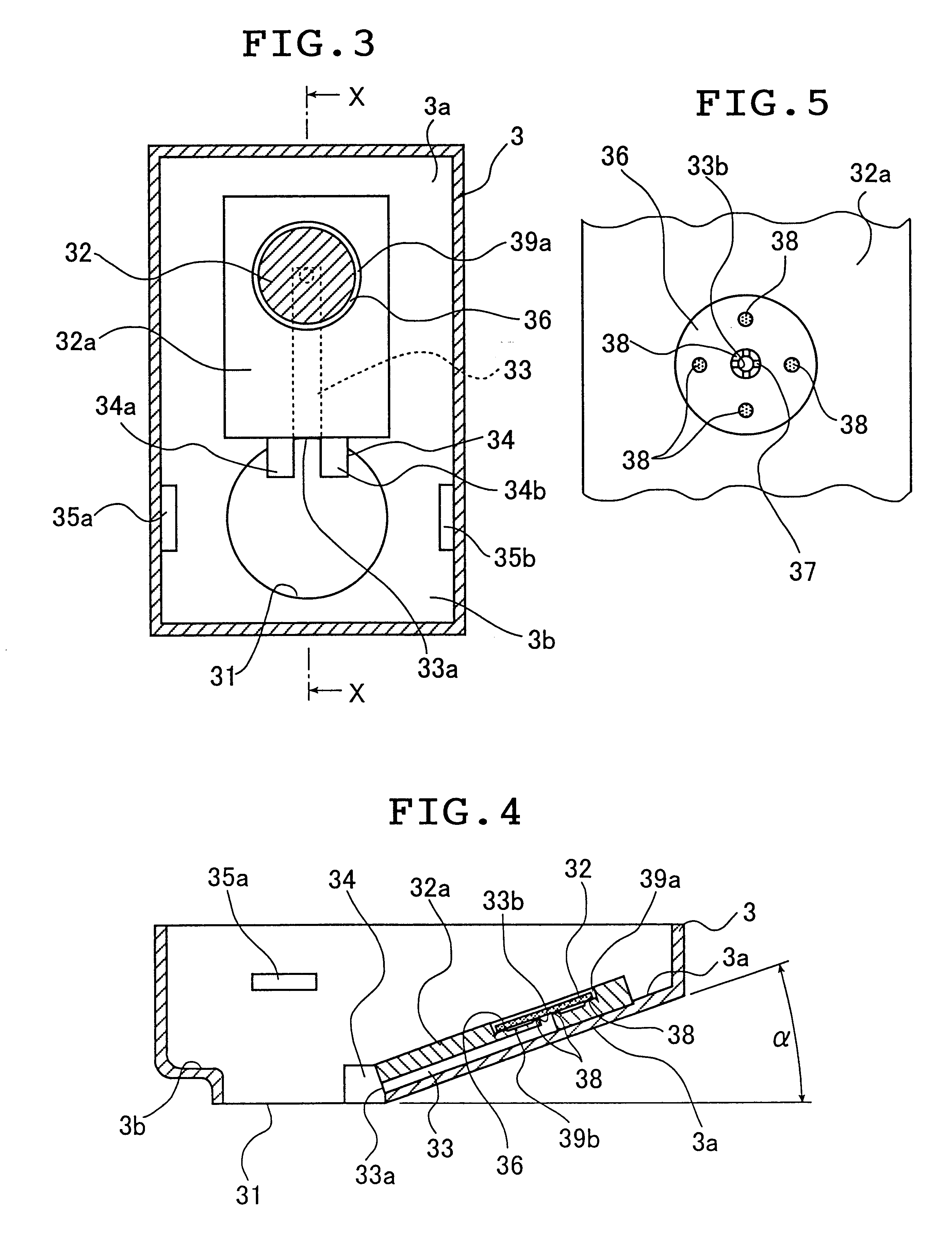

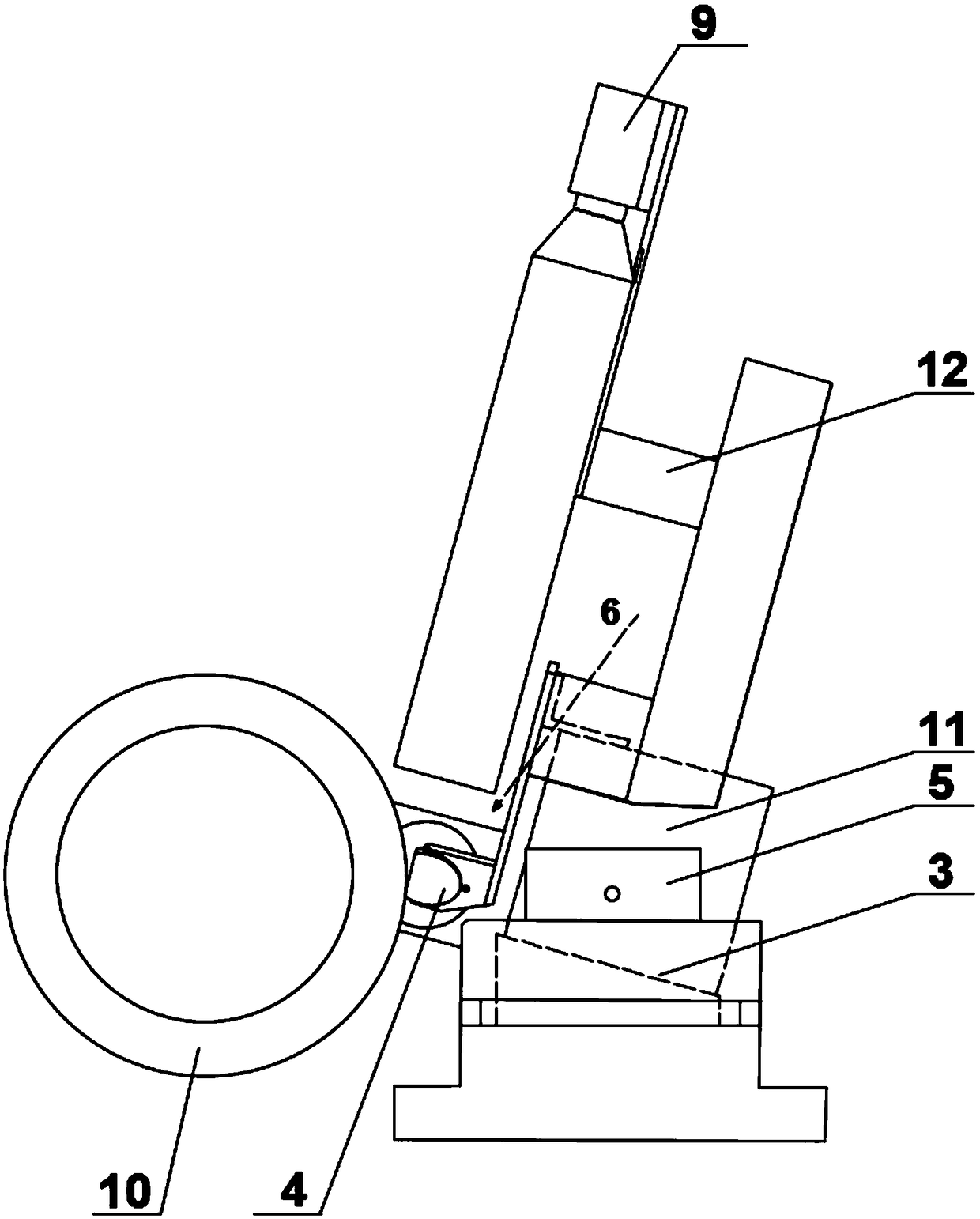

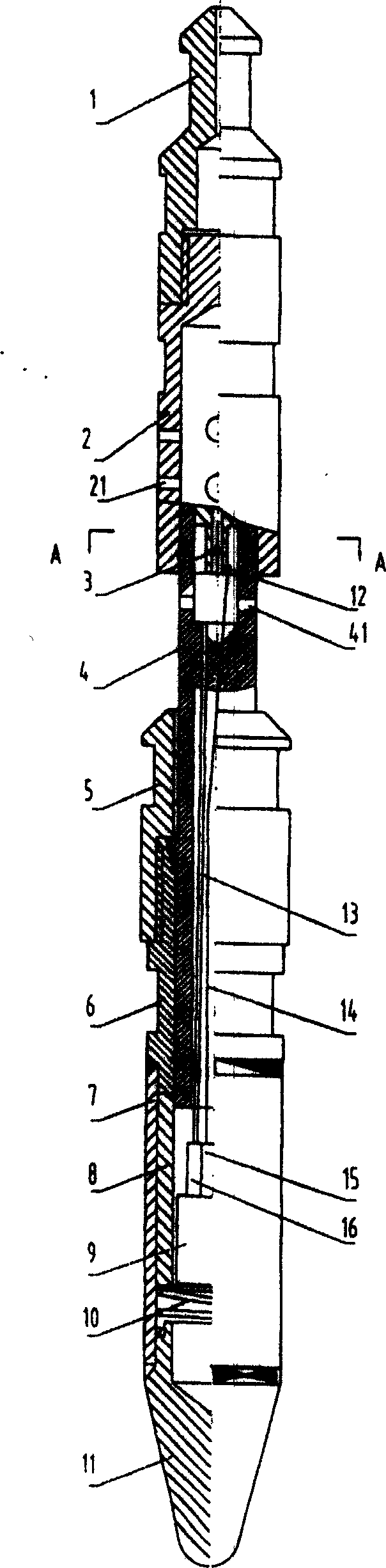

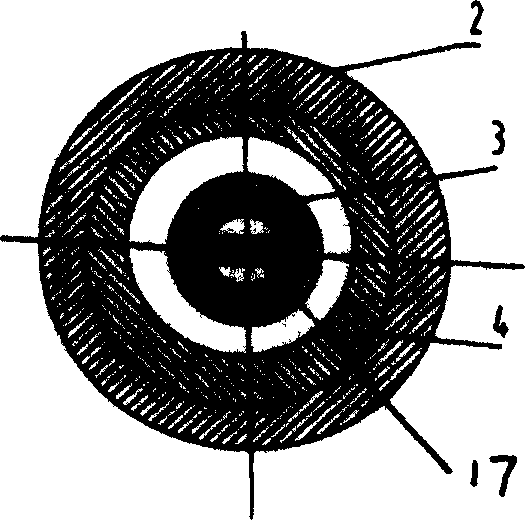

Assembly having lancet and means for collecting and detecting body fluid

An assembly to be detachably mounted on a body fluid monitoring system is provided. The assembly has a lancet and a device for collecting and detecting a body fluid. The lancet has a puncture needle. In this assembly, the puncture needle is maintained in sterilized conditions until its use, and the sterilization can be conducted with no adverse effects on the detection device. A readily sterilizable lancet unit and a body fluid-collecting and detecting unit adapted for use in such an assembly as well as a body fluid-monitoring system including such an assembly are also provided. The assembly comprises a first housing having a sleeve which movably accommodates the lancet in its interior, and a second housing having the body fluid detection device. The first housing and the second housing share an opening. The lancet is sterilized before the assembly. The body fluid-collecting and detecting section has a body fluid guide on the periphery of the inlet.

Owner:TERUMO KK

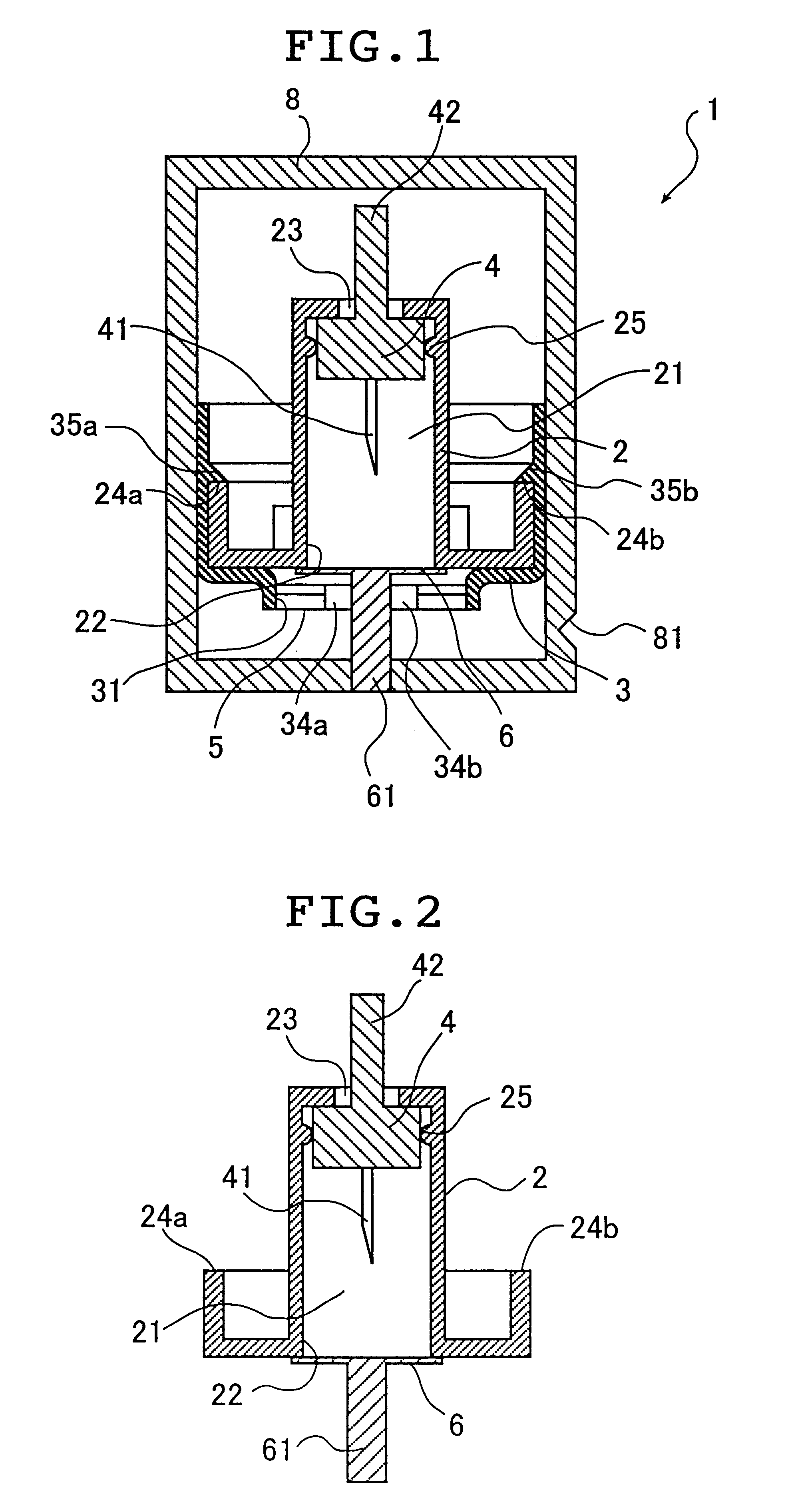

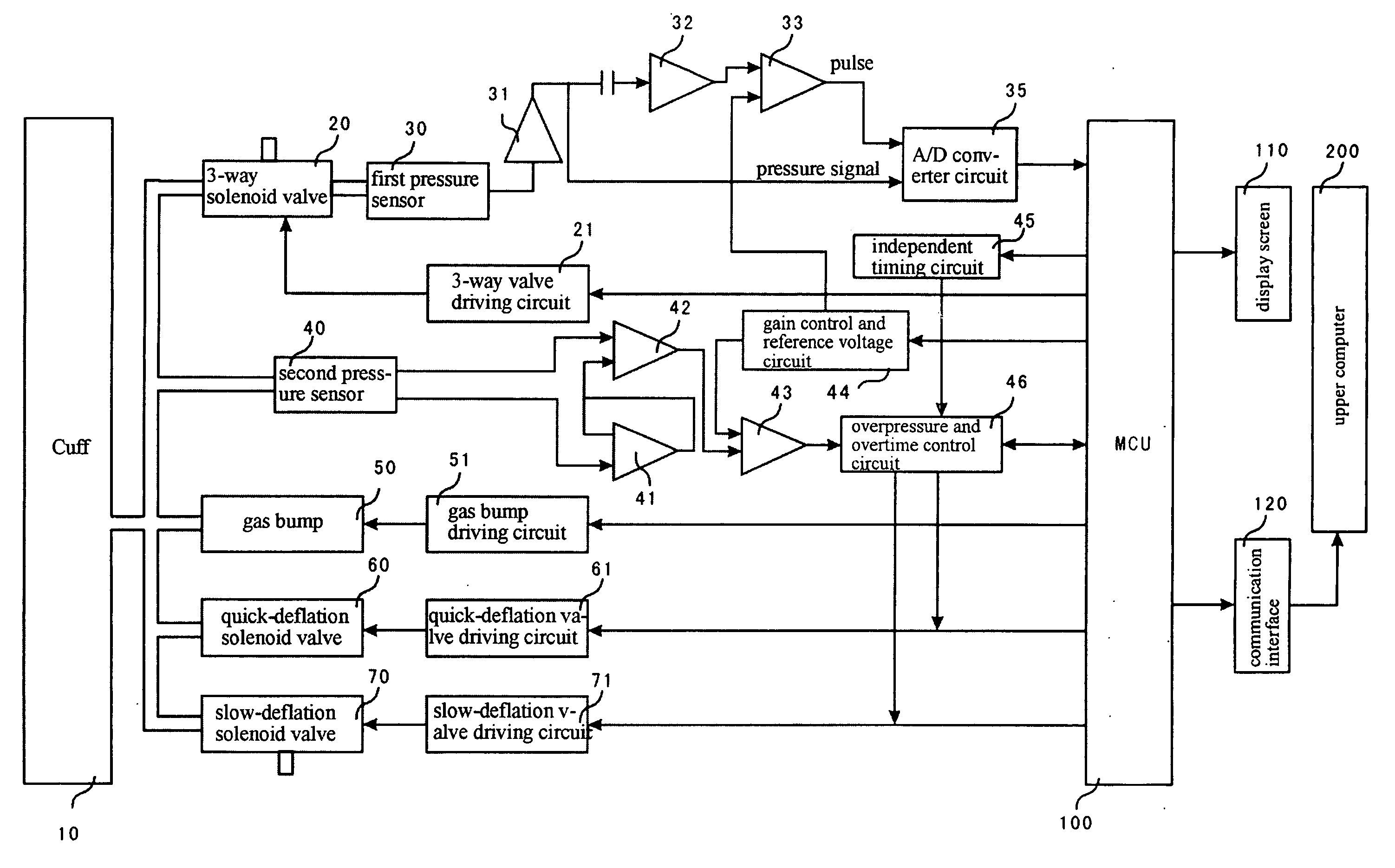

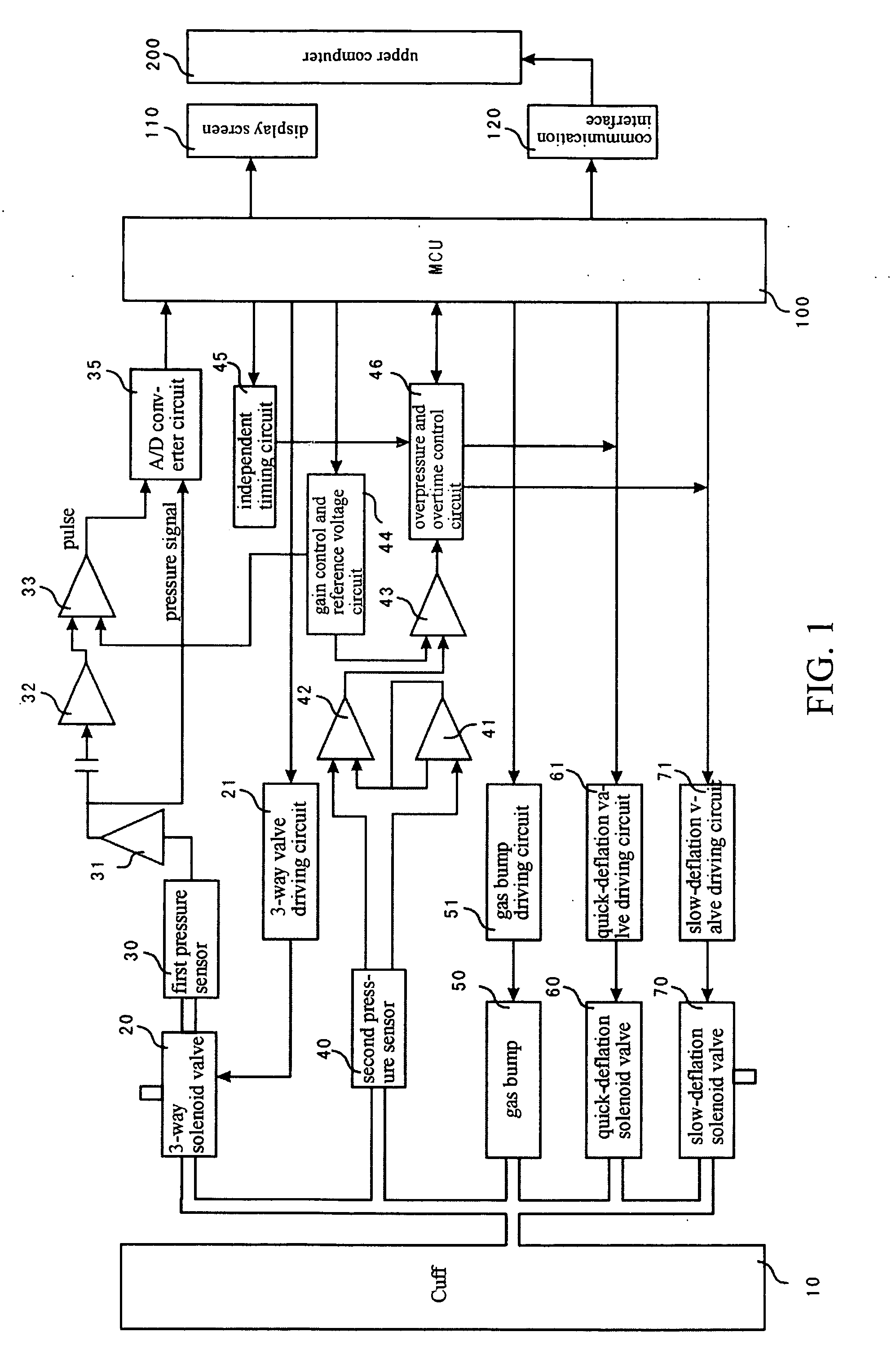

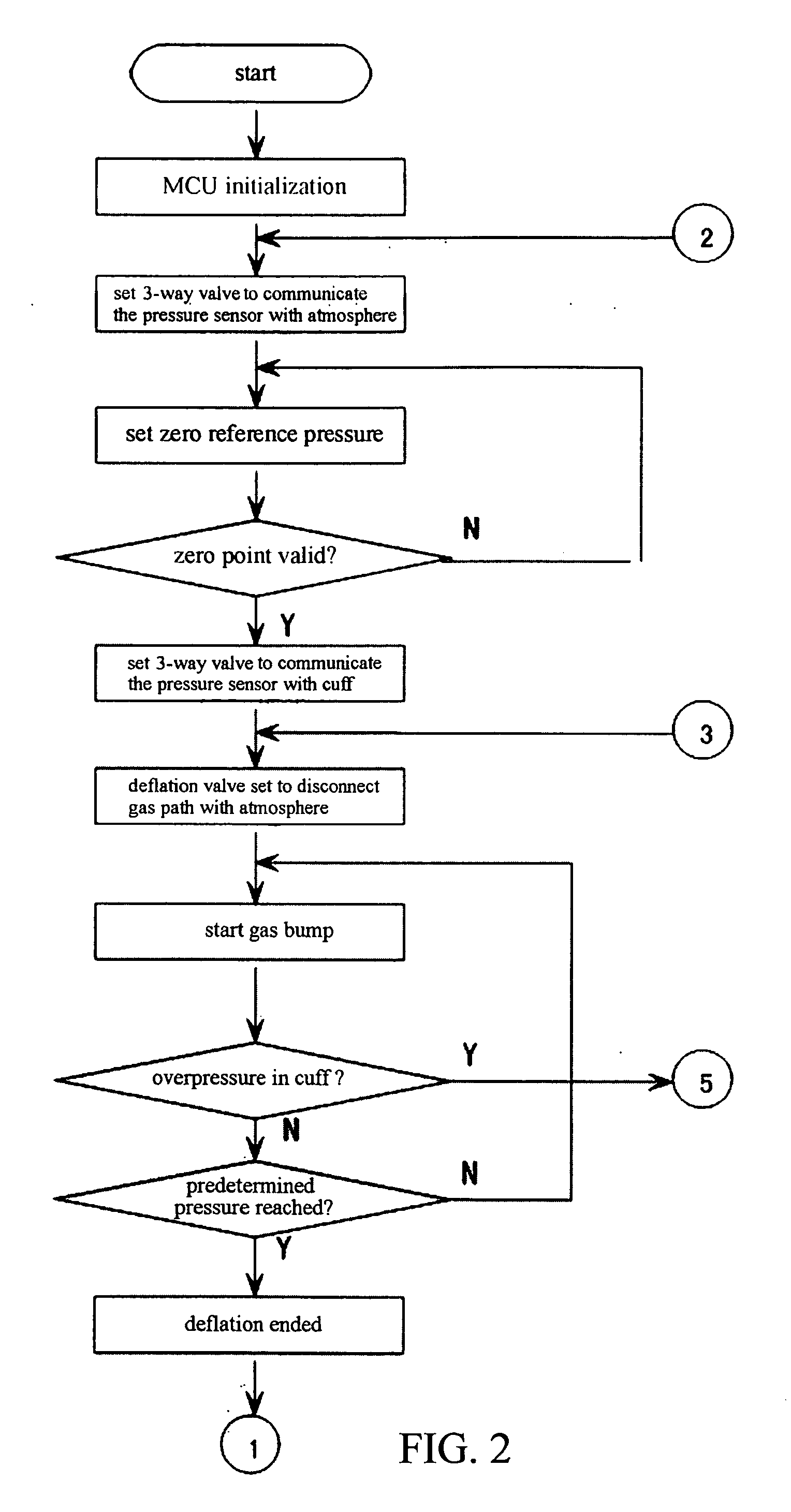

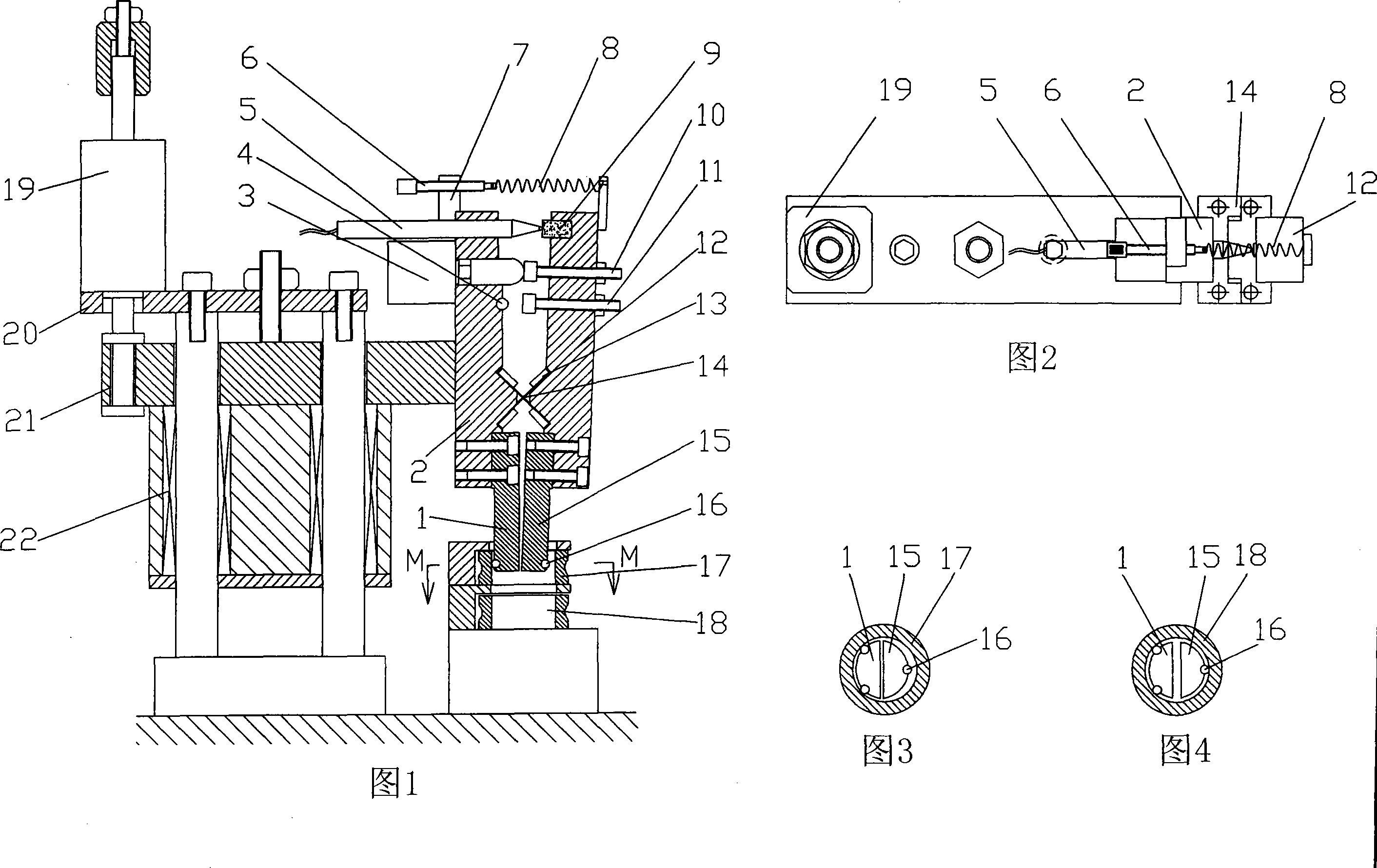

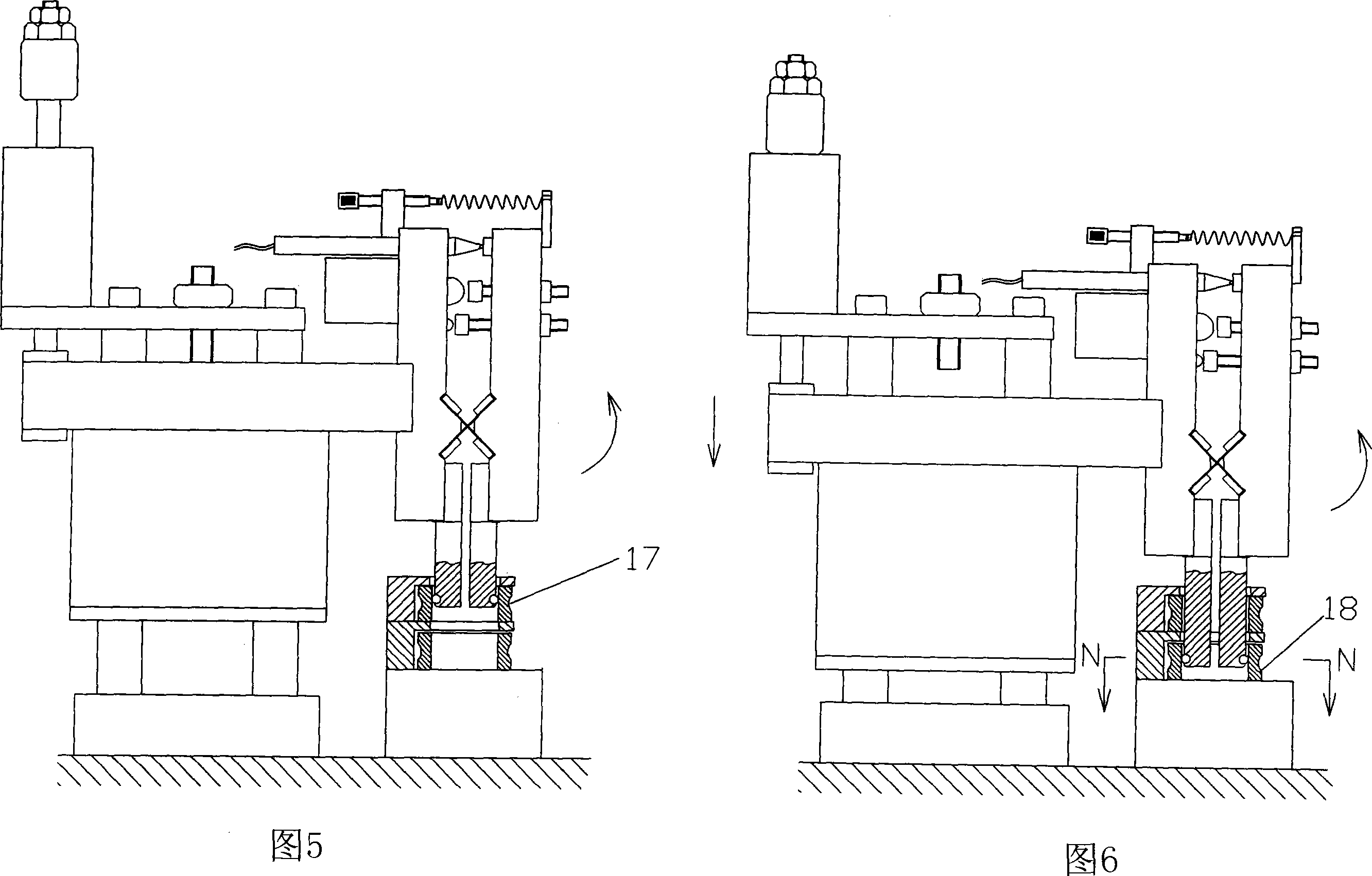

Non-invasive electronic method and apparatus for measuring blood pressure

ActiveUS20070142731A1Improve securityImprove consistencyCatheterDiagnostic recording/measuringAir atmosphereSolenoid valve

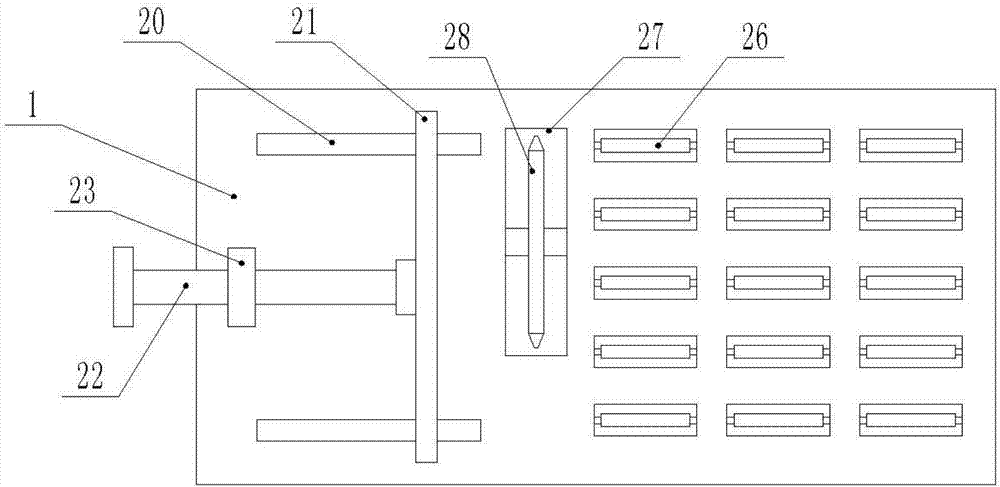

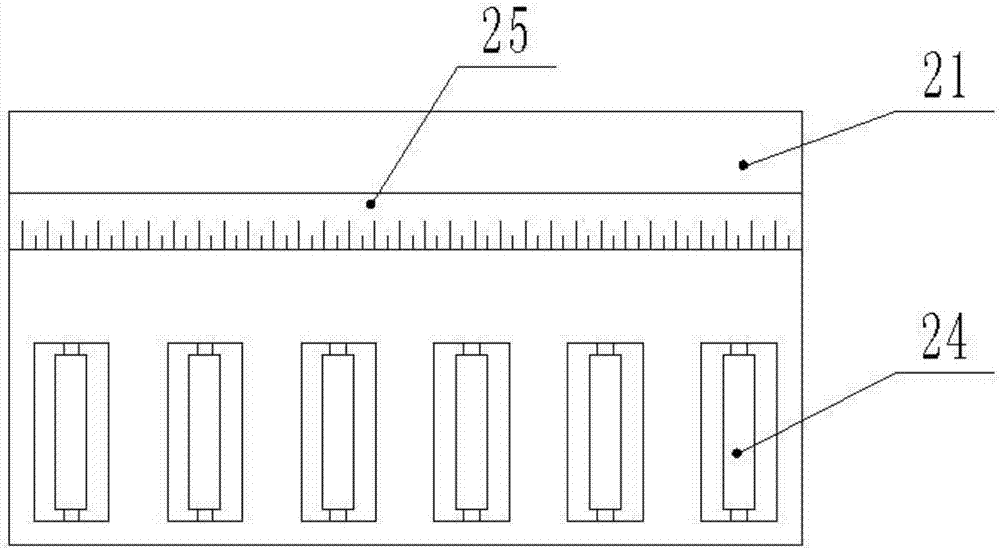

Provided is a non-invasive electronic method and apparatus for measuring blood pressure, in which the data is processed with an algorithm of non-linear fitting for recovering trend envelope of an oscillating PW by a firmware, so that the trend envelope of PW amplitude can be recovered accurately, and the obtained average pressure shows higher degree of agreement with the real situation in clinic. In this apparatus, a 3-way solenoid valve (20) is arranged between a cuff (10) and a first pressure sensor (30), wherein the common port of the 3-way solenoid valve (20) is connected with the first pressure sensor (30), the normally open port thereof connected with the cuff (10), and the normally closed port thereof connected with the air atmosphere during zeroing process. Moreover, an independent timing circuit (45) is provided additionally. In the measurement method of the present invention, the zeroing is performed with the help of the 3-way solenoid valve (20). Once a state of overtime or overpressure occurs, an air bump (50) is immediately closed, and a quick-deflation solenoid valve (60) is opened so that the pressure in the cuff (10) is released to ensure safe application.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

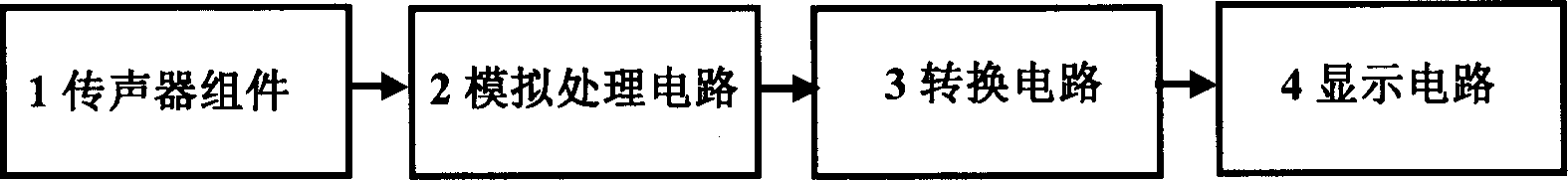

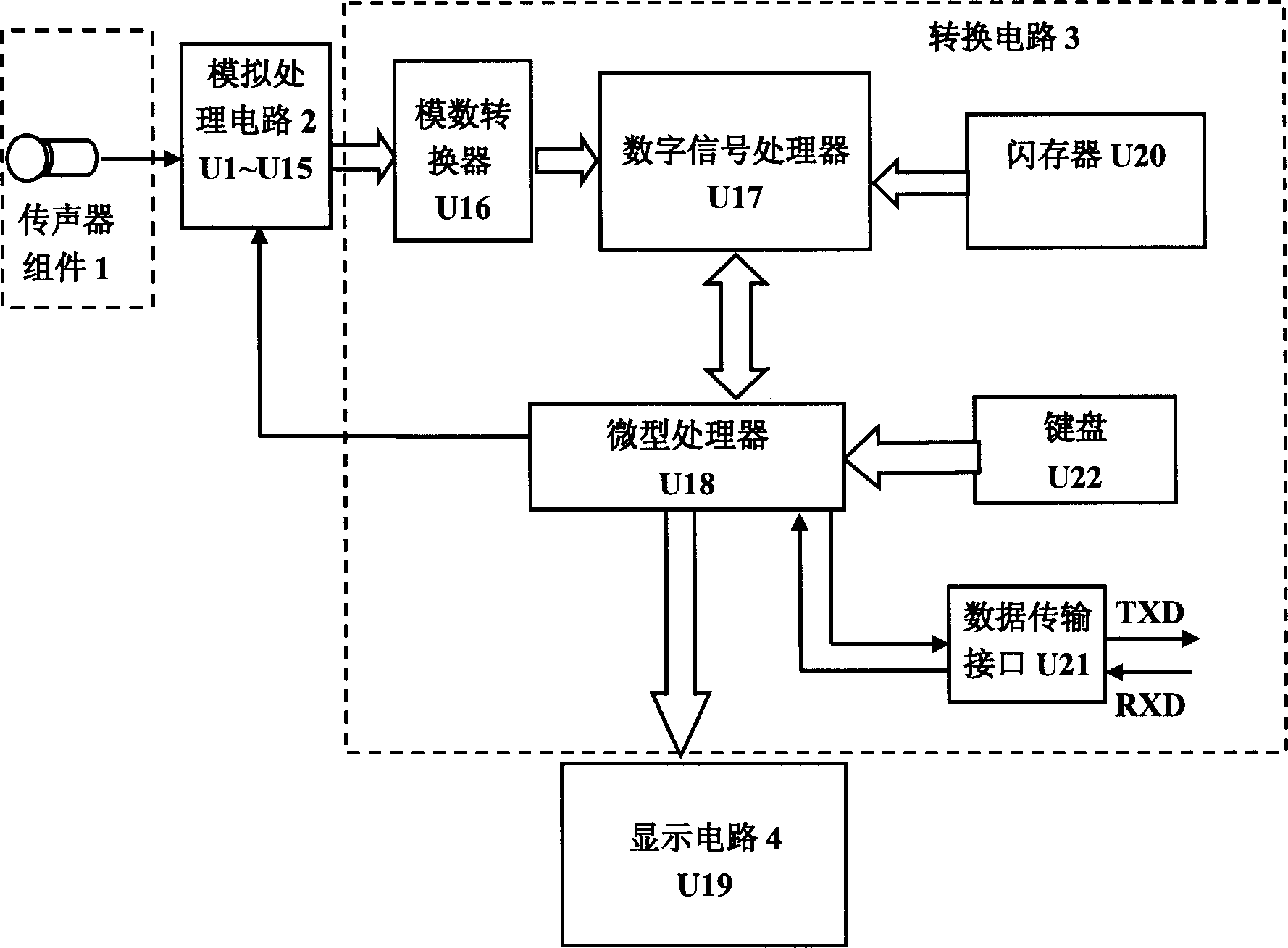

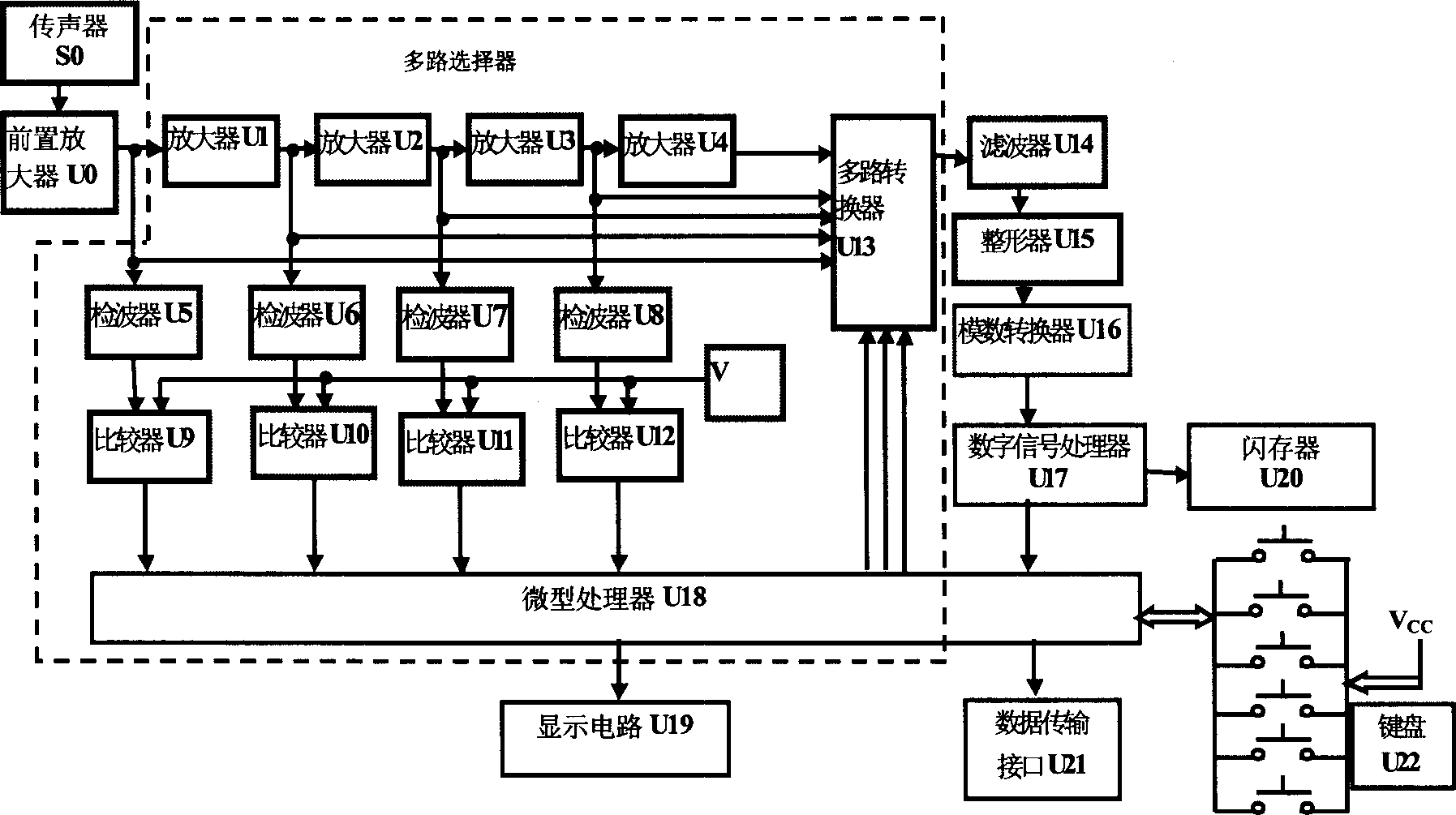

Automobile engine speed measurement apparatus and method

InactiveCN1704760ARealize the censusRealize monitoringDevices using electric/magnetic meansAutomatic controlEngineering

This invention discloses a car engine rotational velocity test device and a method including an analog process circuit and a converting circuit connected with the output of a microphone assembly and the input of a display circuit orderly, among which, the noise signal at the air vent is received by the microphone assembly and processed to become an engine rotational velocity signal or a value or a noise signal quantity value by the analog process circuit and the converting circuit. The analog process circuit includes a multiple selector for automatically controlling amplified output level to ensure a large dynamic sphere test and its accuracy.

Owner:曹广忠

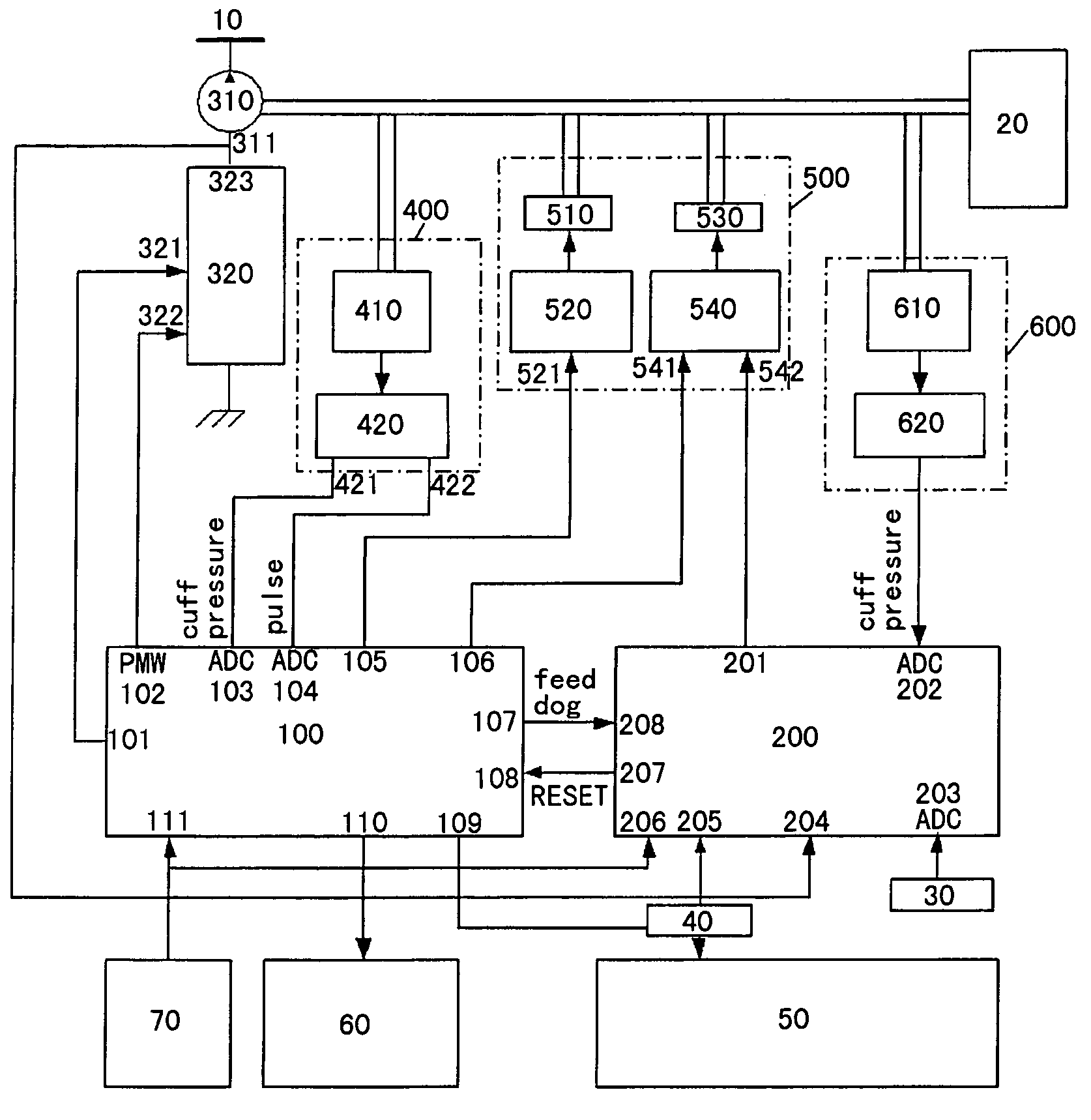

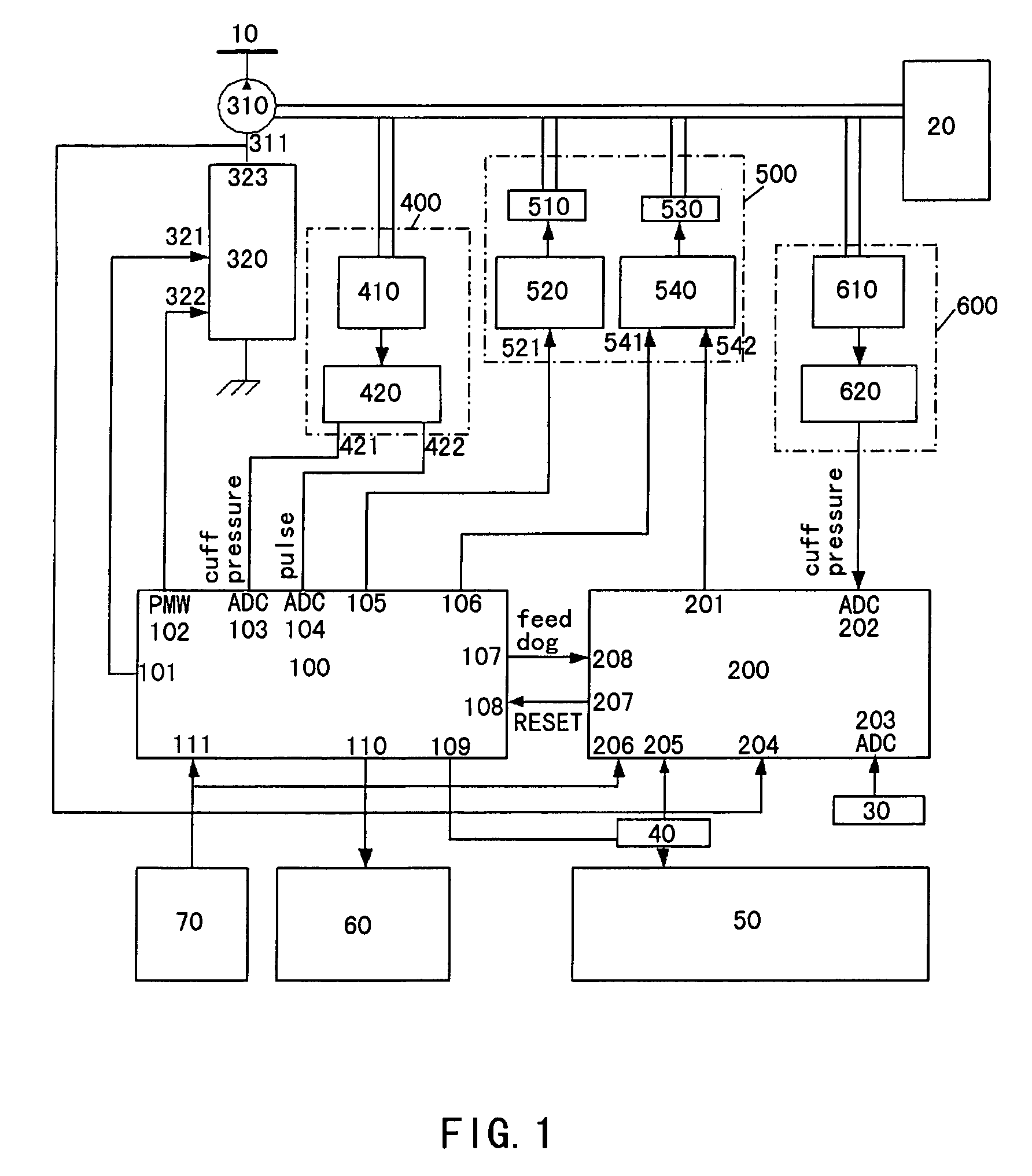

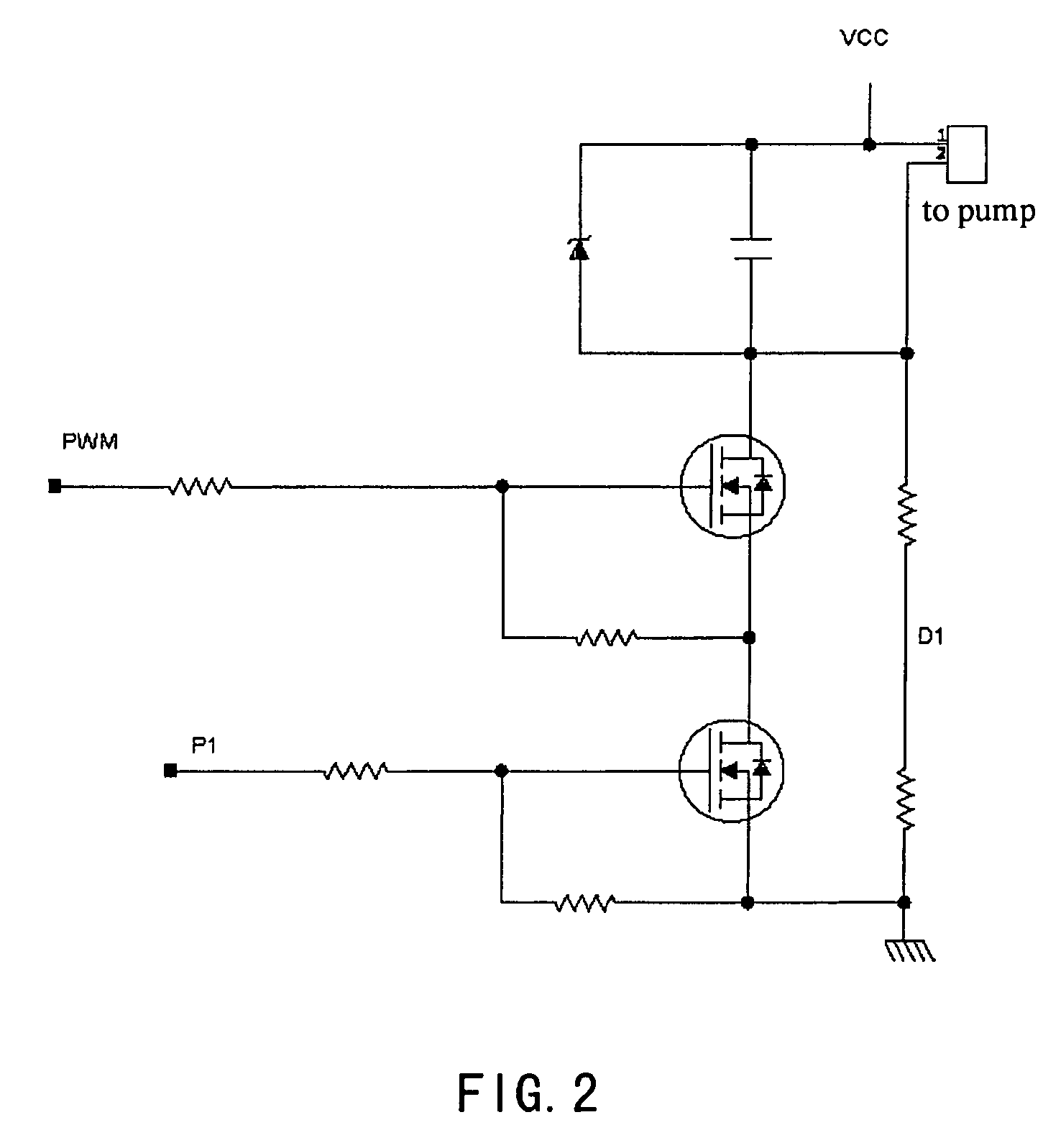

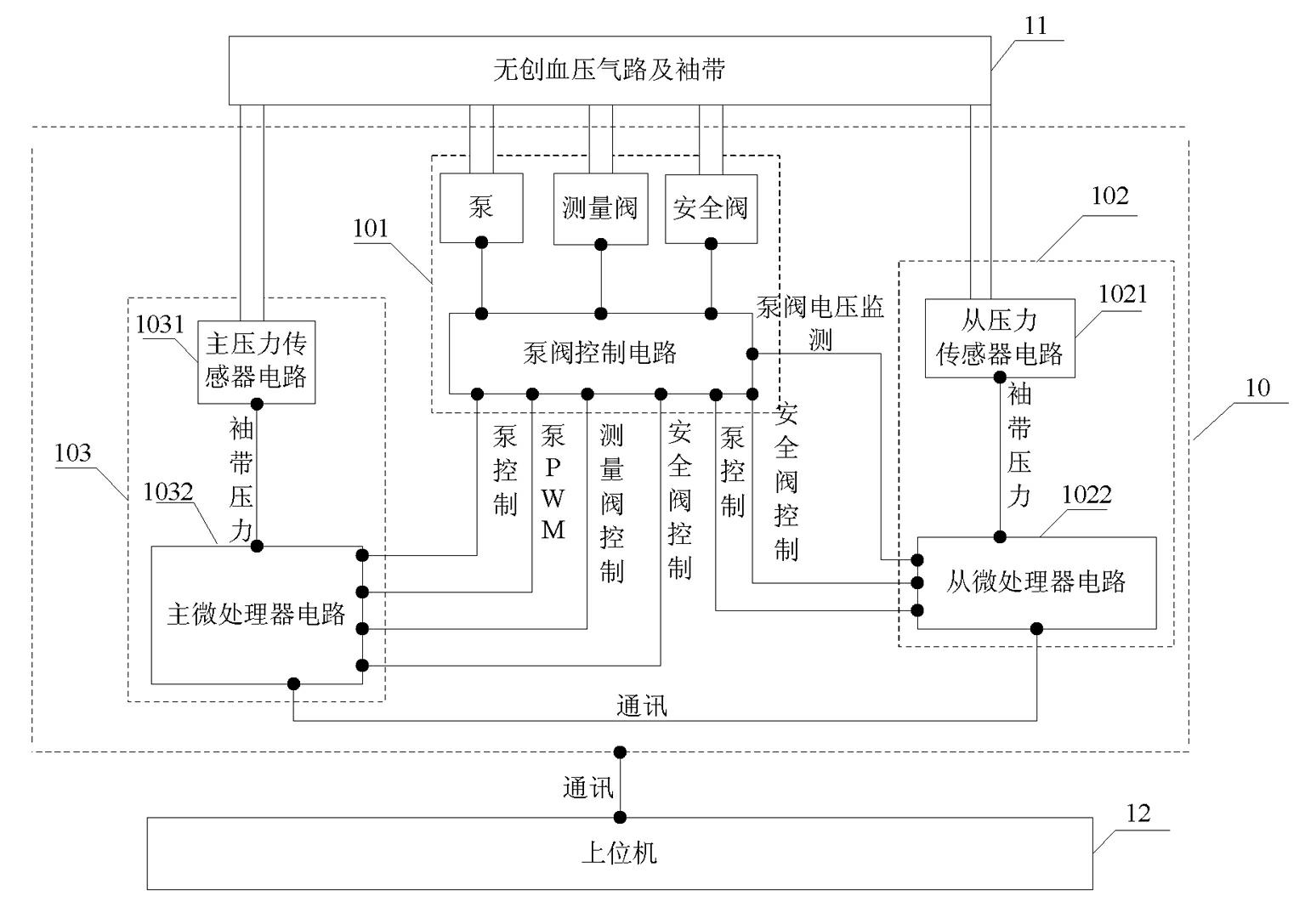

Non-invasive blood pressure measurement apparatus and safety protection method

ActiveUS7594892B2Improve accuracyEliminate the effects ofCatheterDiagnostic recording/measuringMeasurement deviceControl signal

The present invention discloses a non-invasive blood pressure measurement apparatus and a safety protection method. In addition to a main pressure measurement circuit and a main microprocessor circuit, the measurement apparatus also includes an independently disposed assist pressure measurement circuit and an independently disposed assist microprocessor circuit. In normal measurement, the assist microprocessor circuit periodically samples a cuff pressure via the assist pressure measurement circuit, and compares the measured cuff pressure with a specified overpressure protection value, and if the cuff pressure exceeds the specified overpressure protection value, the assist microprocessor circuit outputs a control signal to open a deflation valve until the pressure falls to below the safety pressure. Compared with the prior art, the method for overpressure protection of the present invention is more direct and has higher accuracy of decision, leading to higher reliability of the overpressure protection and higher safety of the measurement apparatus.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

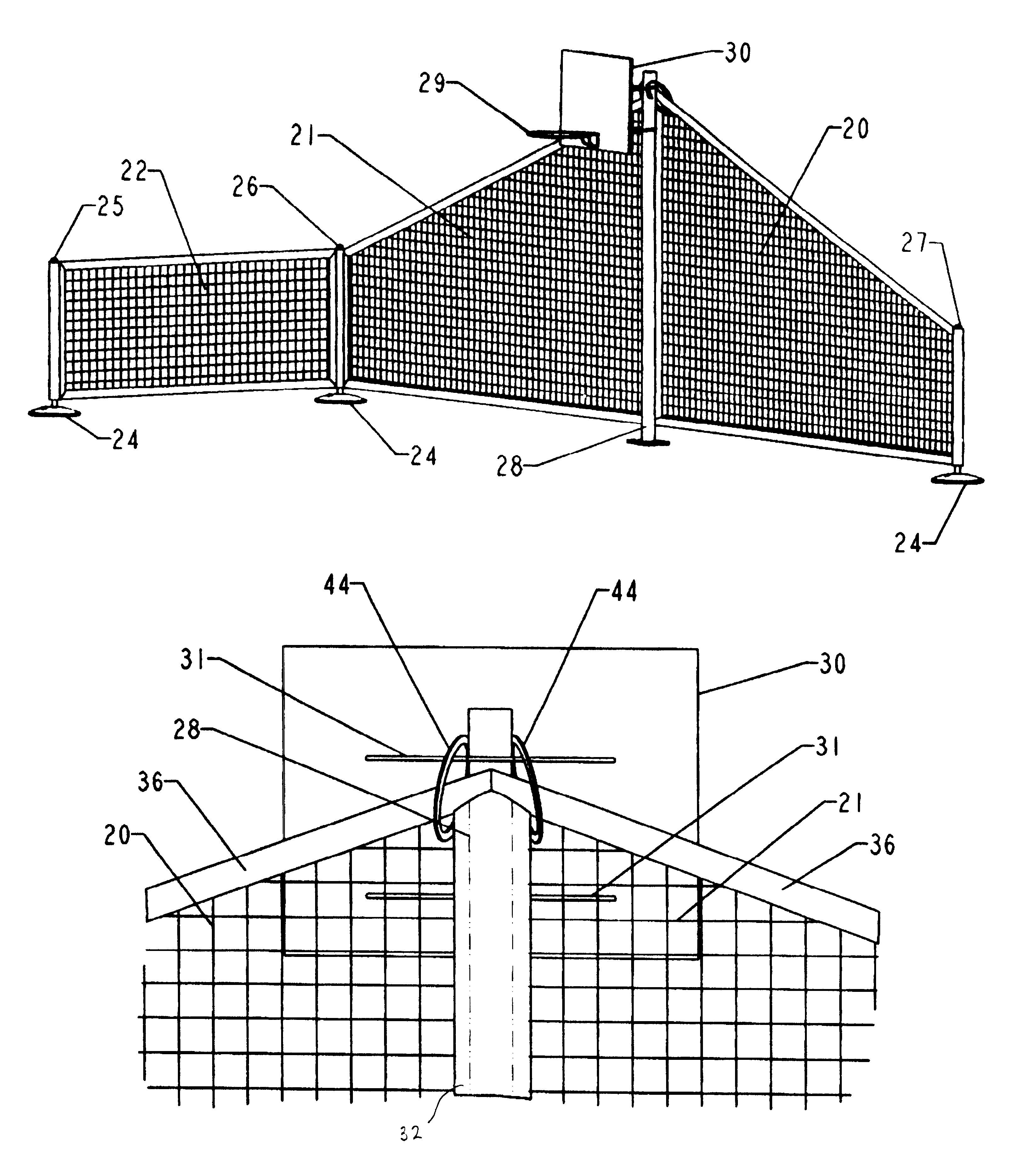

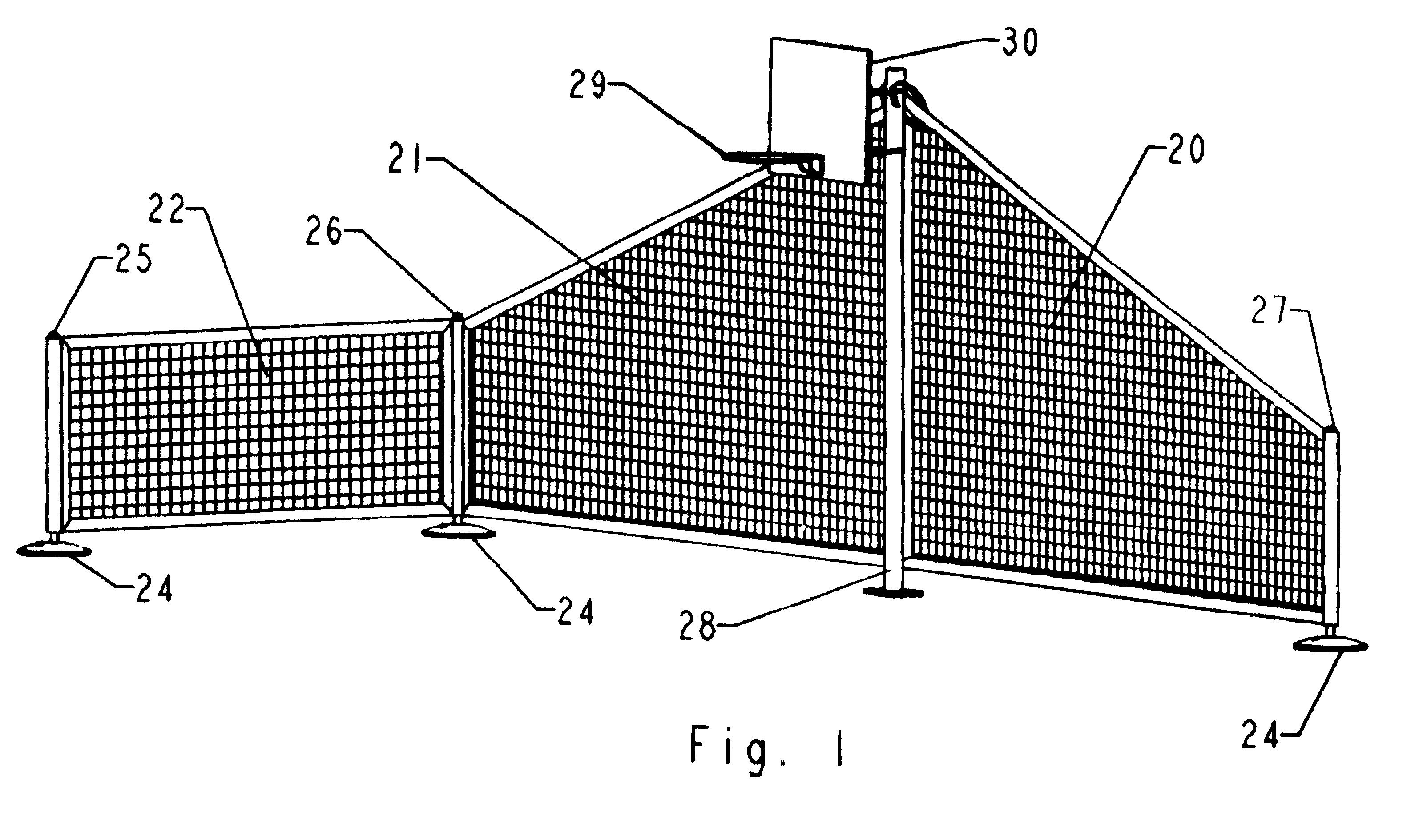

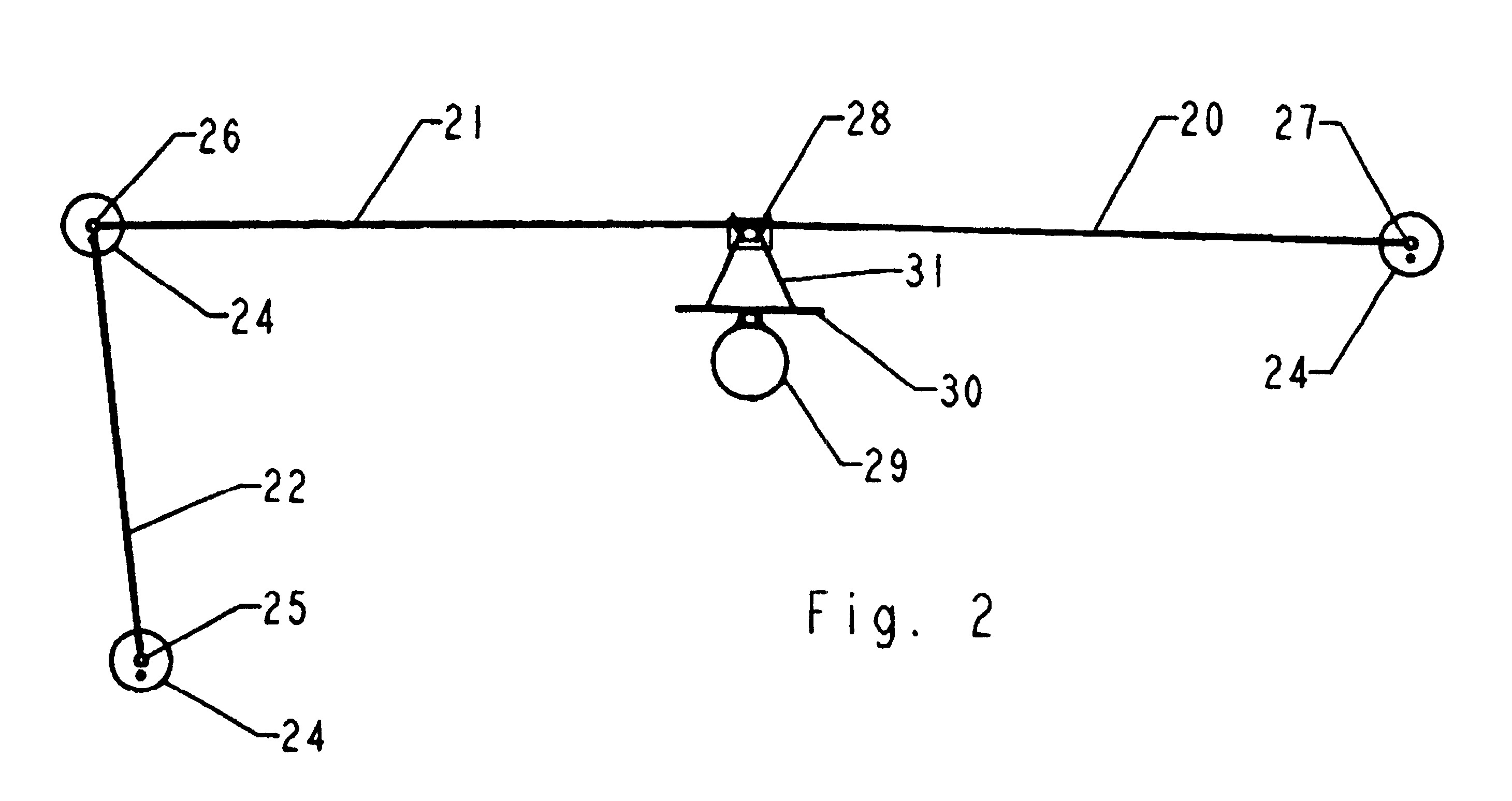

Basketball safety return II

A basketball safety apparatus which comprises sections of netting adapted to be used in conjunction with a basketball goal, movable pole support bases which are adapted to be positioned in proximity to the basketball goal and a driveway that connects to a street, and a plurality of poles adapted to be mounted vertically in the pole support bases. The sections of netting are connected to the vertically mounted poles or to the basketball goal. The netting has mesh size is sufficiently small to stop a basketball, and the poles and bases are mounted and arranged so that the netting forms a barrier in one or more directions from the basketball goal and across the driveway.

Owner:KEEHN SR GORMAN E +1

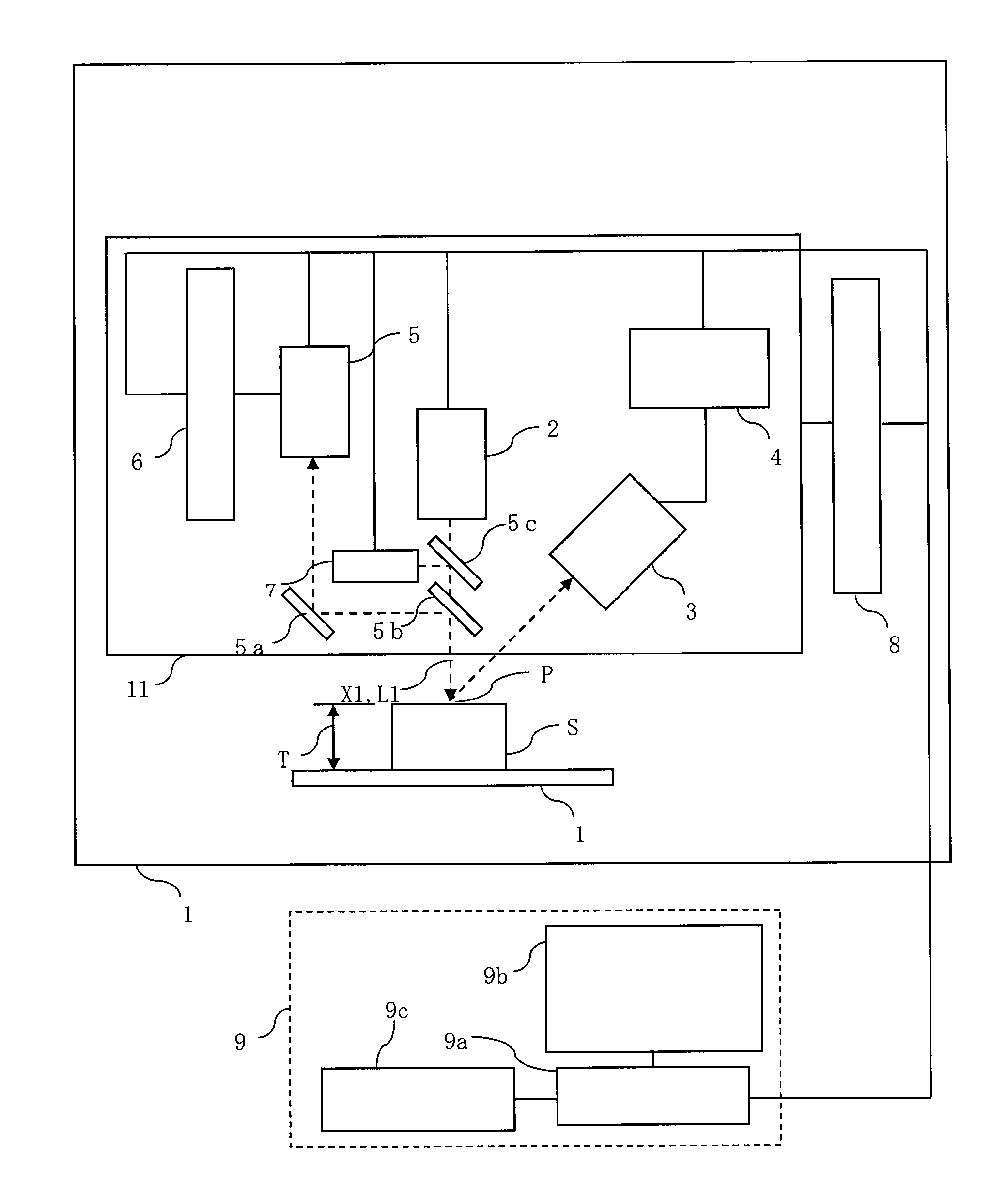

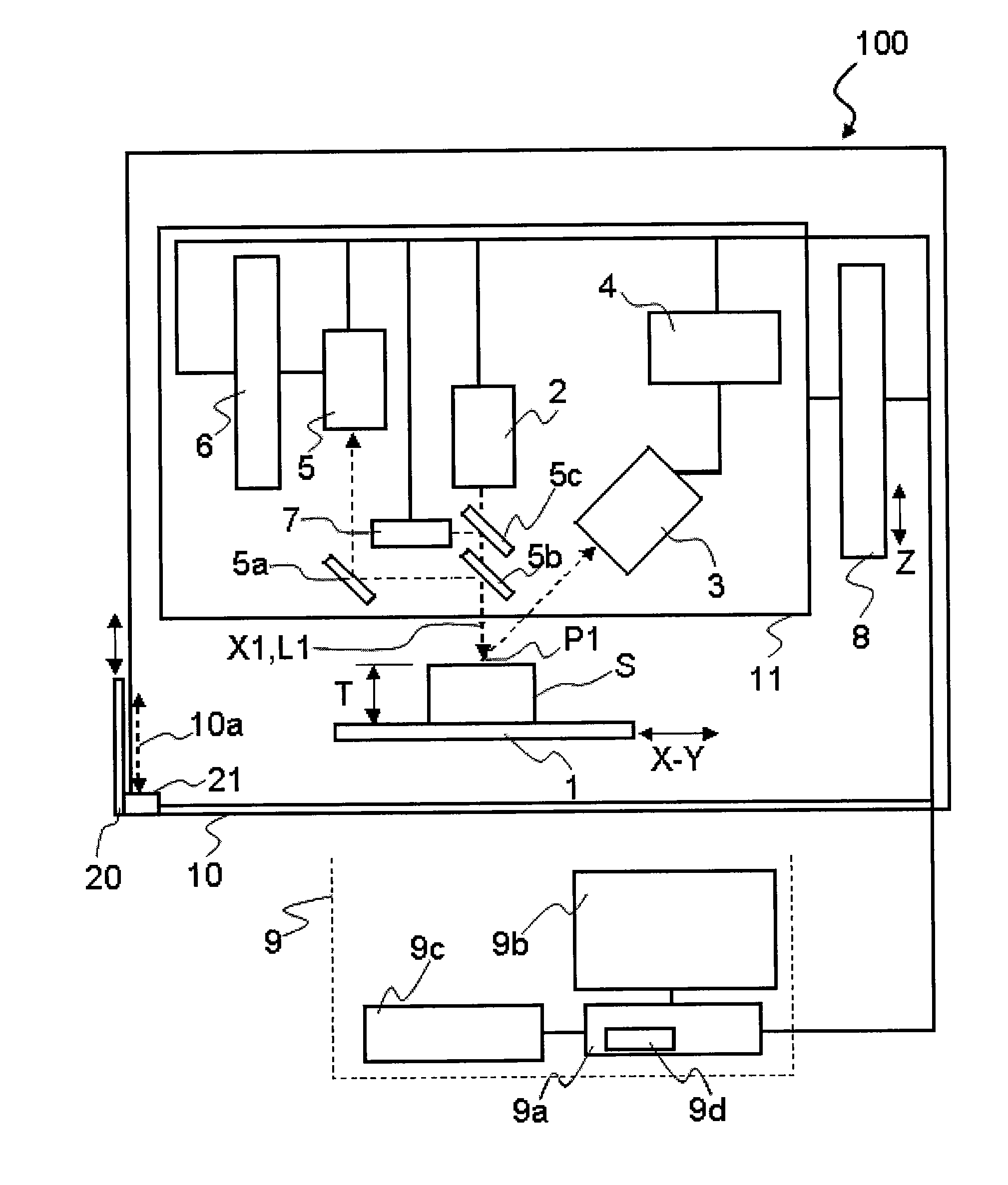

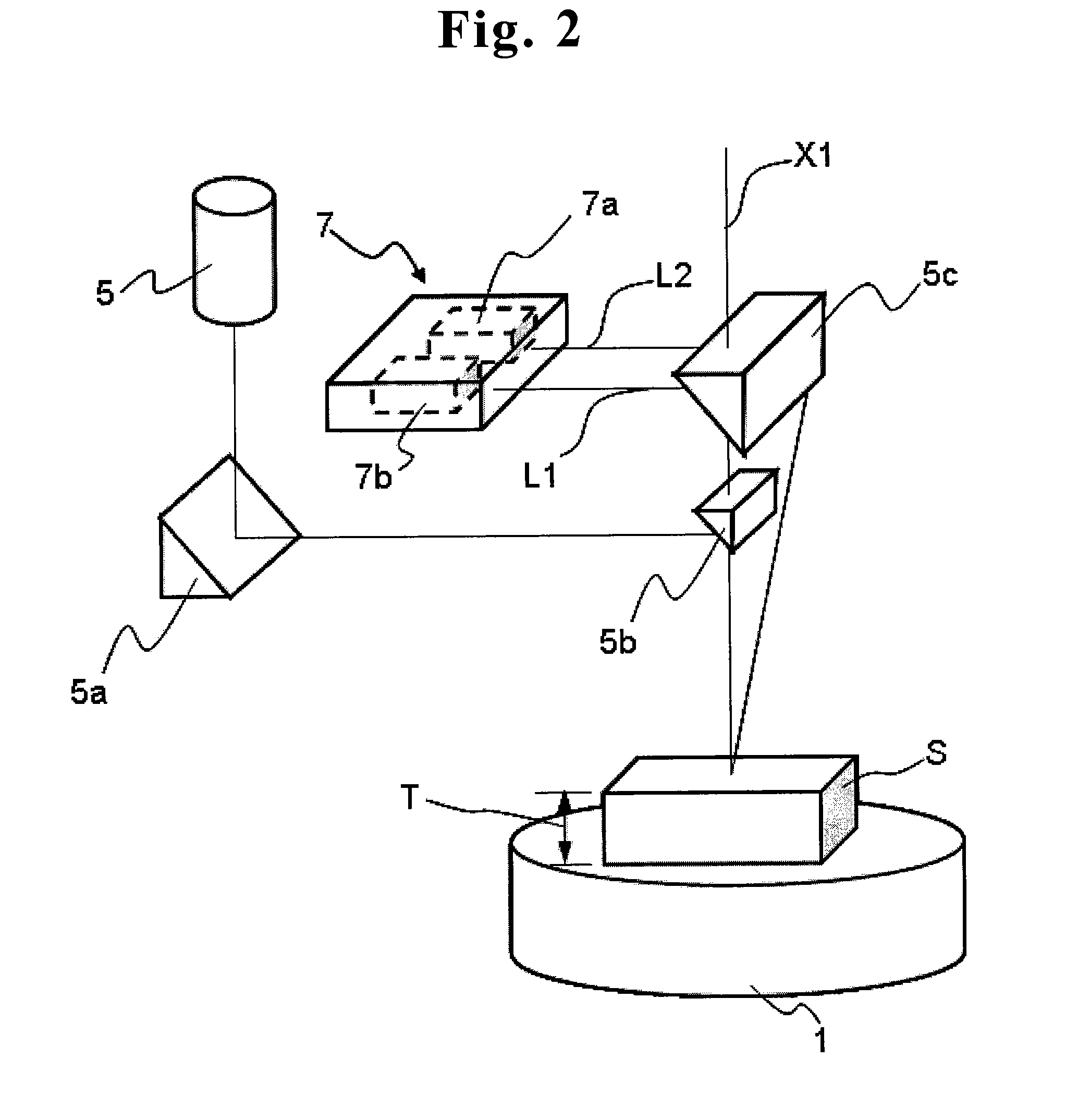

X-ray analysis apparatus and x-ray analysis method

ActiveUS20110051894A1Accurate quantitative analysisHigh work efficiencyUsing optical meansRadiation beam directing meansPhysicsSoft x ray

An X-ray analysis apparatus including: a radiation source configured to irradiate an irradiation point on a sample with radiation; an X-ray detector configured to detect a characteristic X-ray emitted from the sample, and output a signal including energy information about the characteristic X-ray; an analyzer configured to analyze the signal; a sample stage configured to allow placement of the sample thereon; a shifting mechanism being capable of relatively shifting the sample on the sample stage and the radiation source and the X-ray detector with respect to each other; a height measuring mechanism being capable of measuring the height of the irradiation point on the sample; and a controller configured to control the shifting mechanism on the basis of the measured height of the irradiation point on the sample and adjust the distance of the sample with respect to the radiation source and the X-ray detector is used.

Owner:HITACHI HIGH TECH SCI CORP

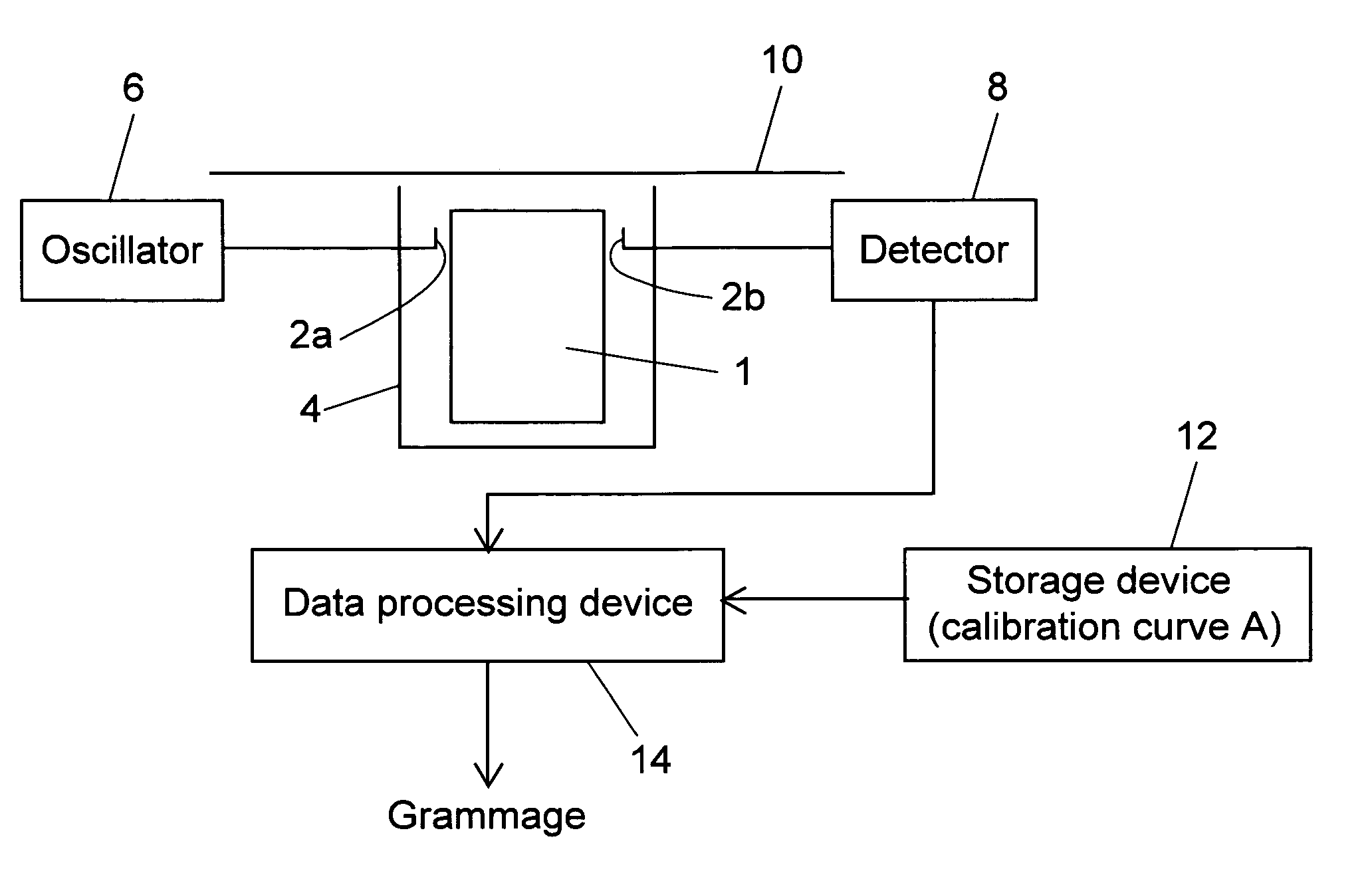

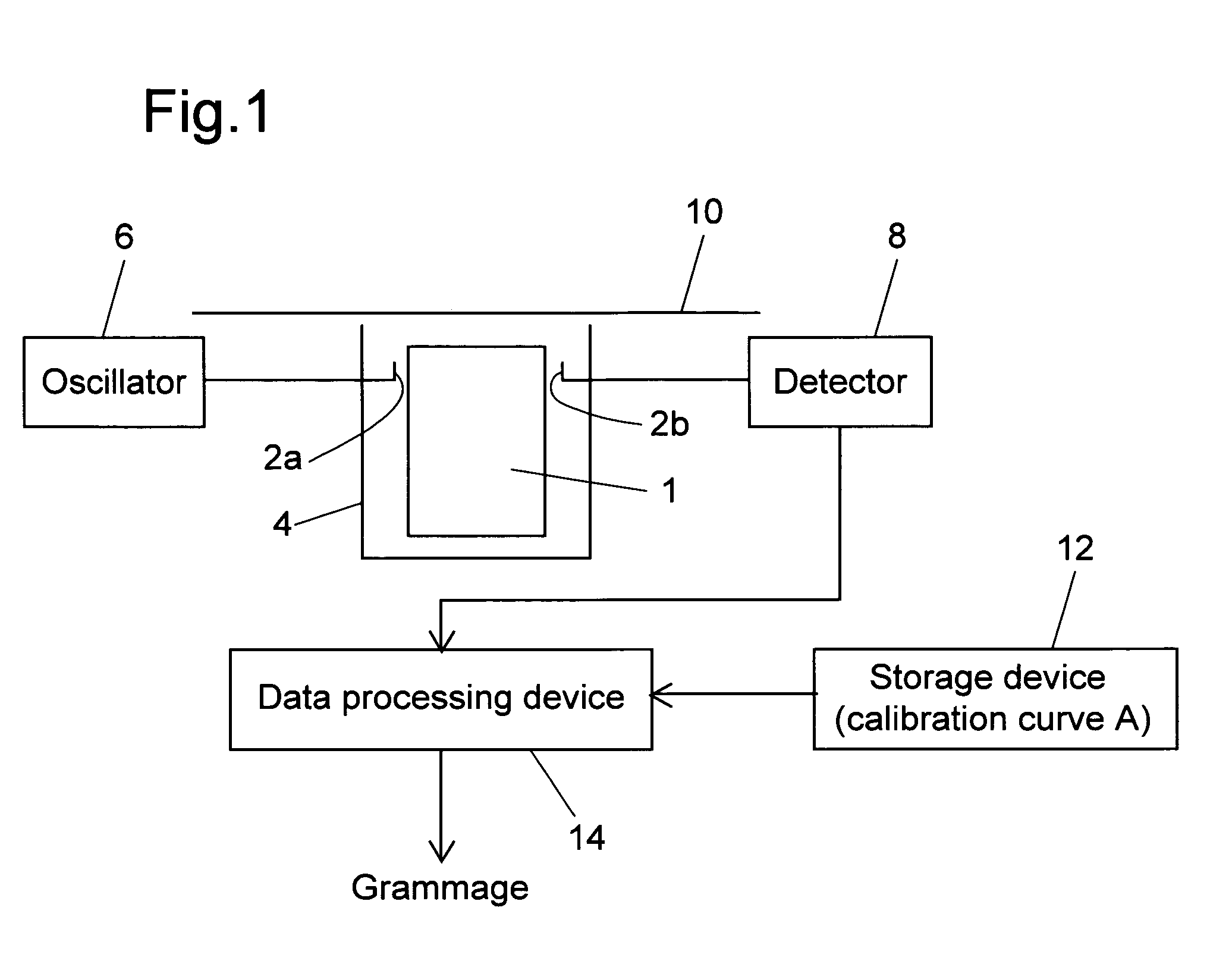

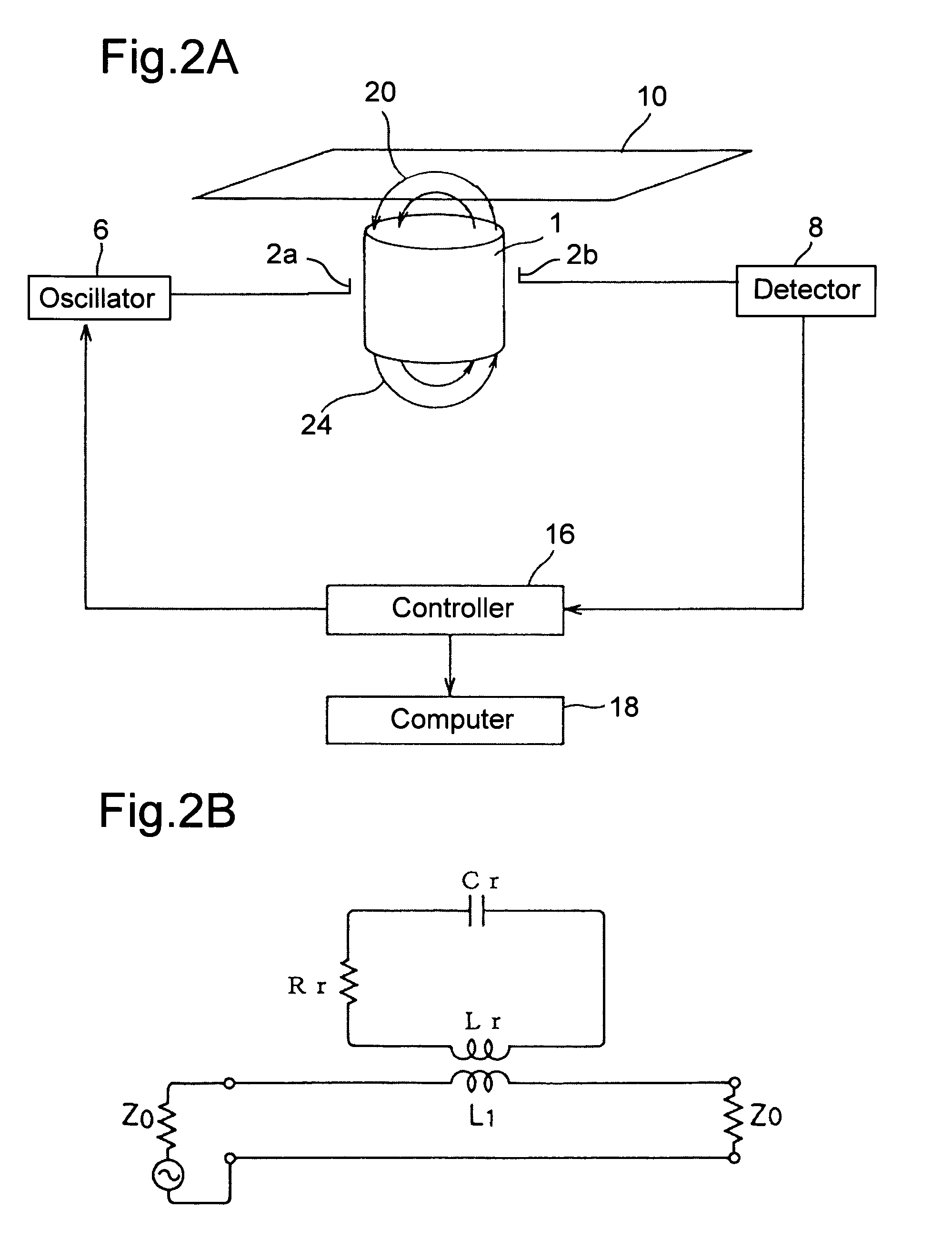

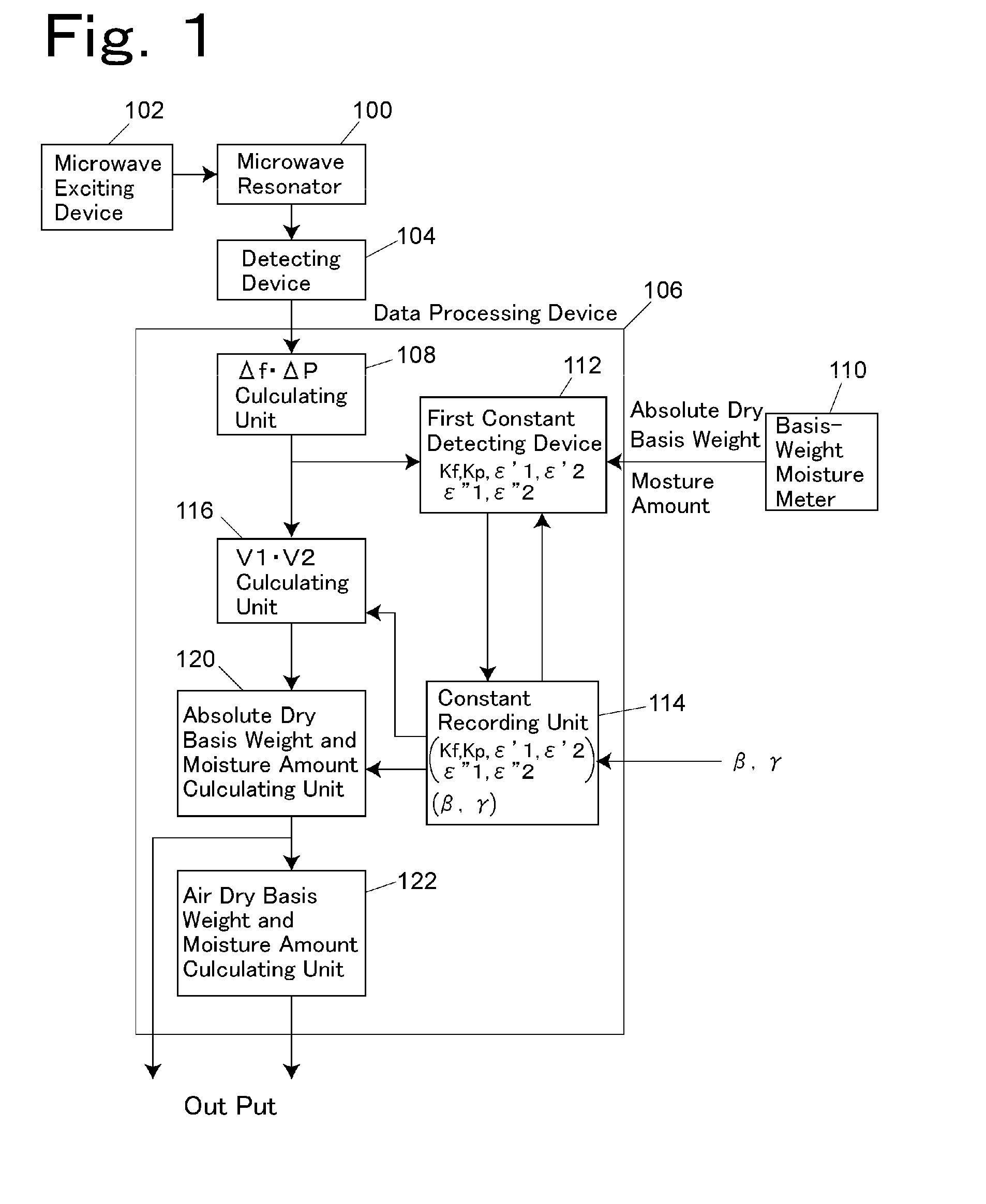

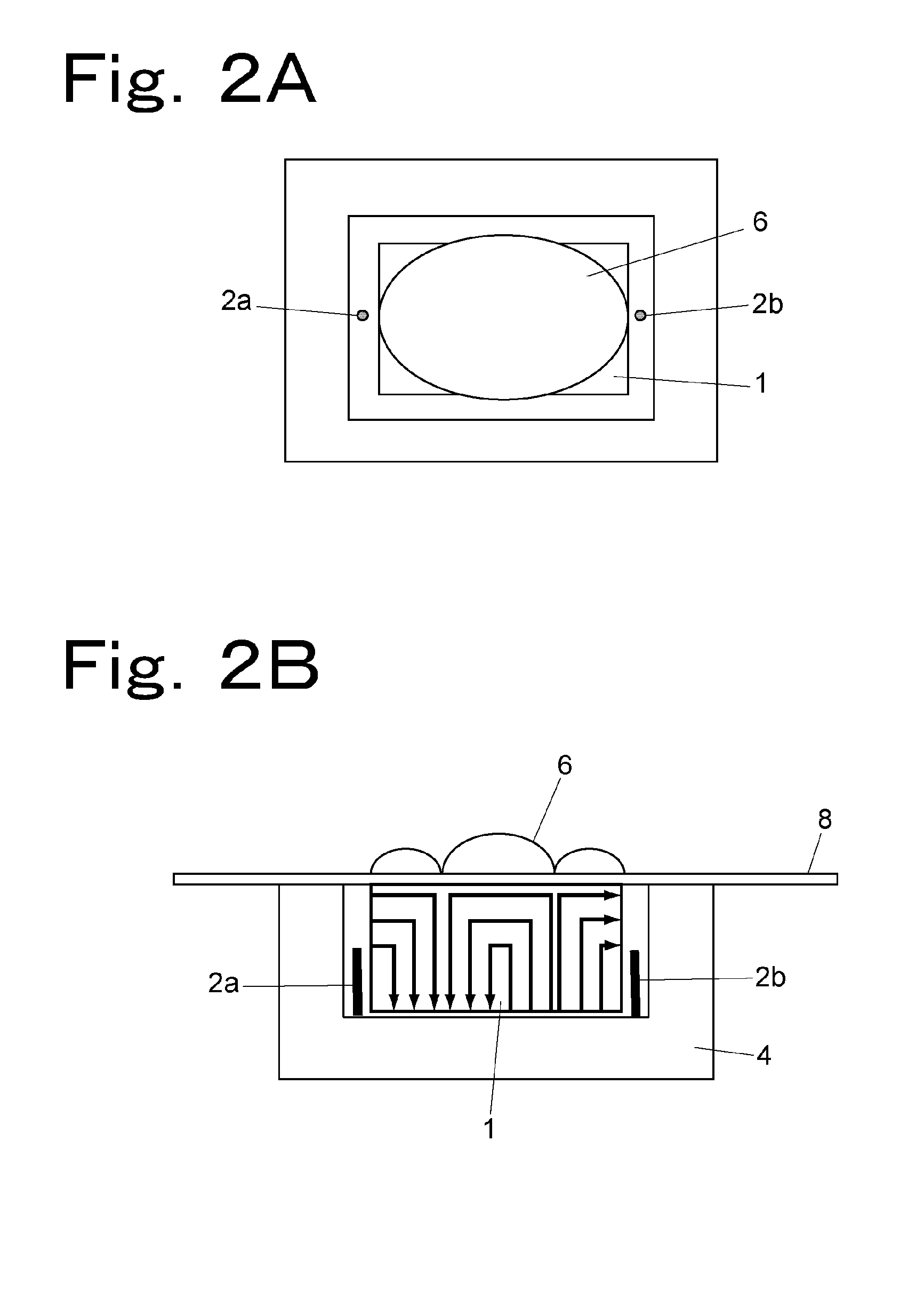

Method and apparatus for measuring grammage

InactiveUS7423435B2Easy to handleMeasure securityResistance/reactance/impedenceMoisture content investigation using microwavesMicrowaveSample Measure

A grammage measuring apparatus including a dielectric resonator which is arranged only at one side surface of a sample; a shielding container with which the dielectric resonator is substantially covered except for a sample measuring surface; a microwave excitation device which causes the dielectric resonator to generate an electric field vector; a detection device which detects transmission energy or reflection energy by the dielectric resonator; a storage device in which a calibration curve indicating a resonance frequency shift amount for a grammage is stored; and a data processing device which calculates the grammage of a measuring sample from the calibration curve and measurement result of the resonance frequency shift amount of the measuring sample.

Owner:OJI PAPER CO LTD

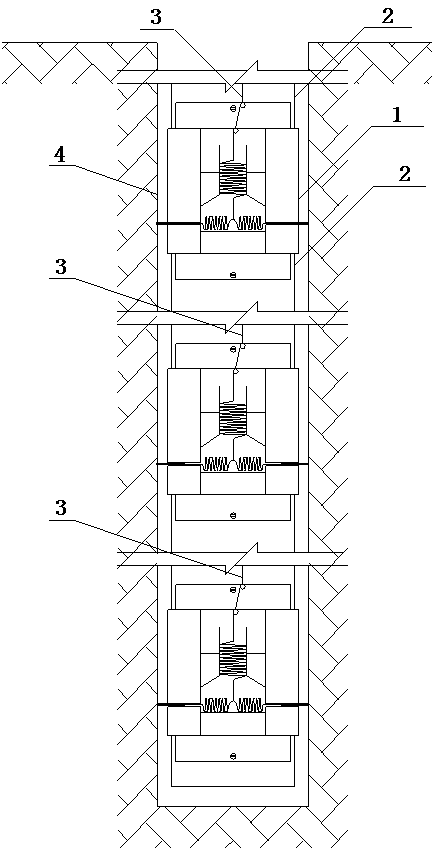

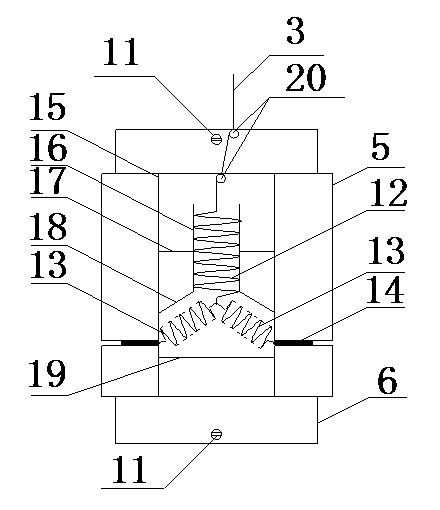

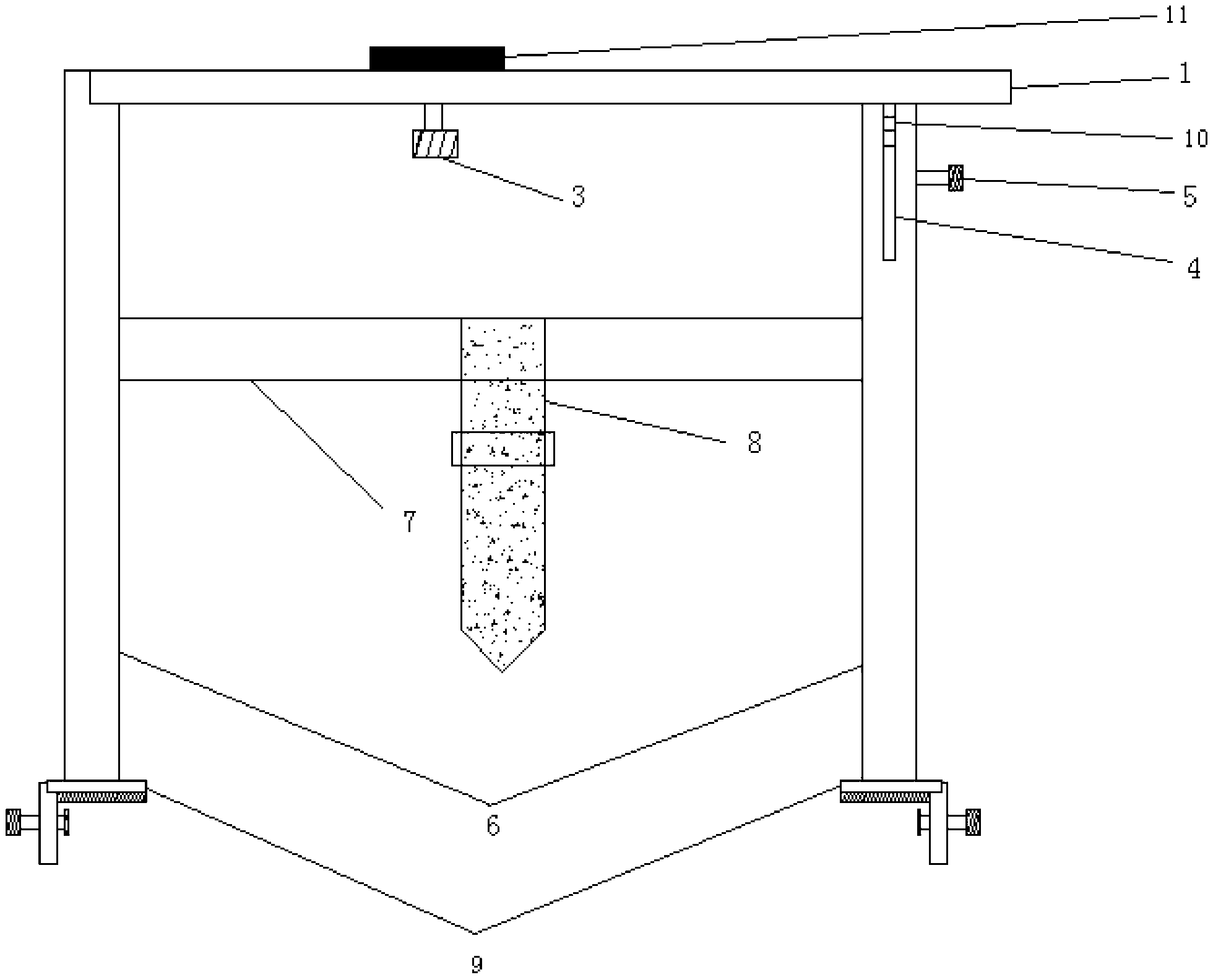

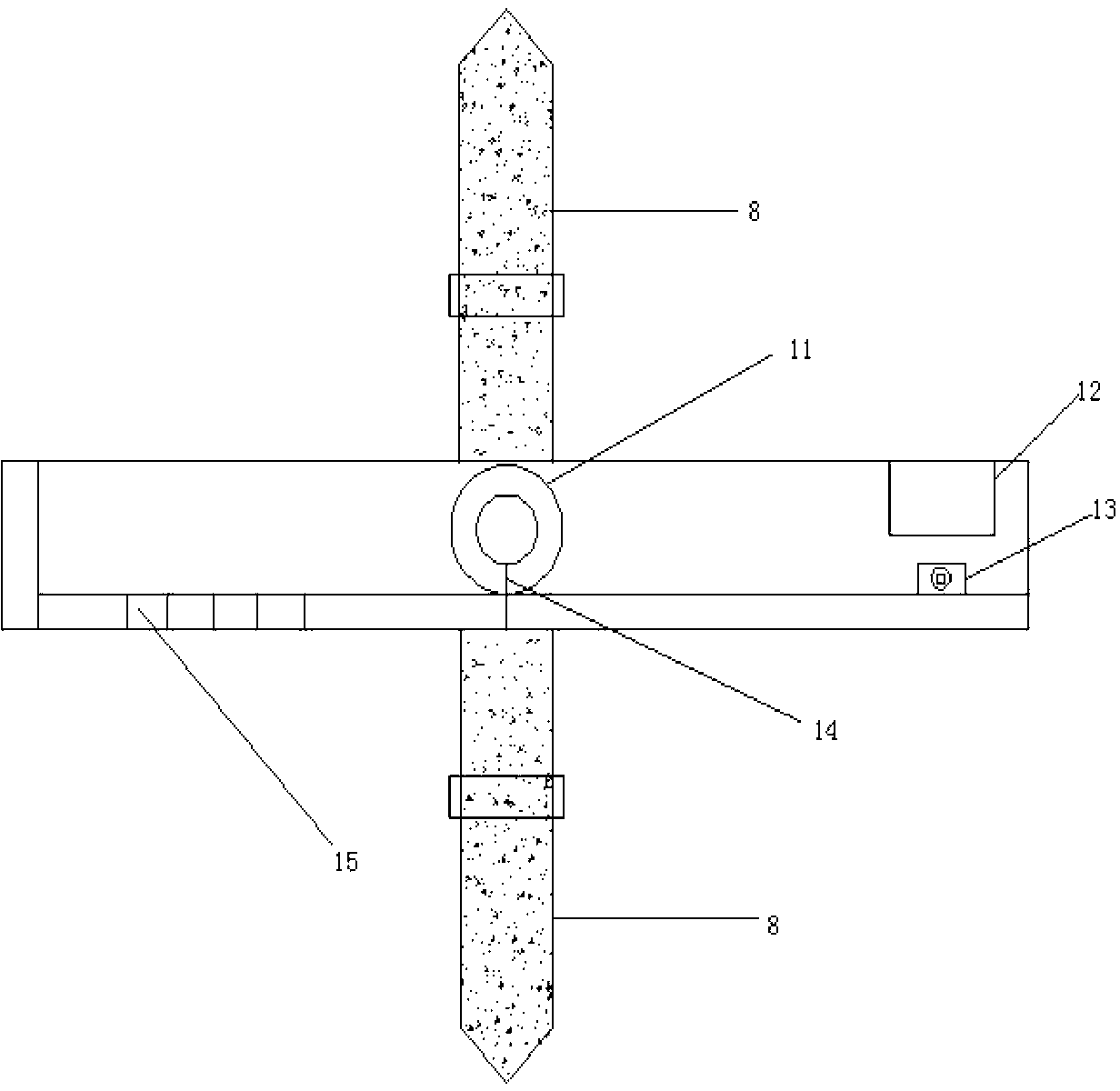

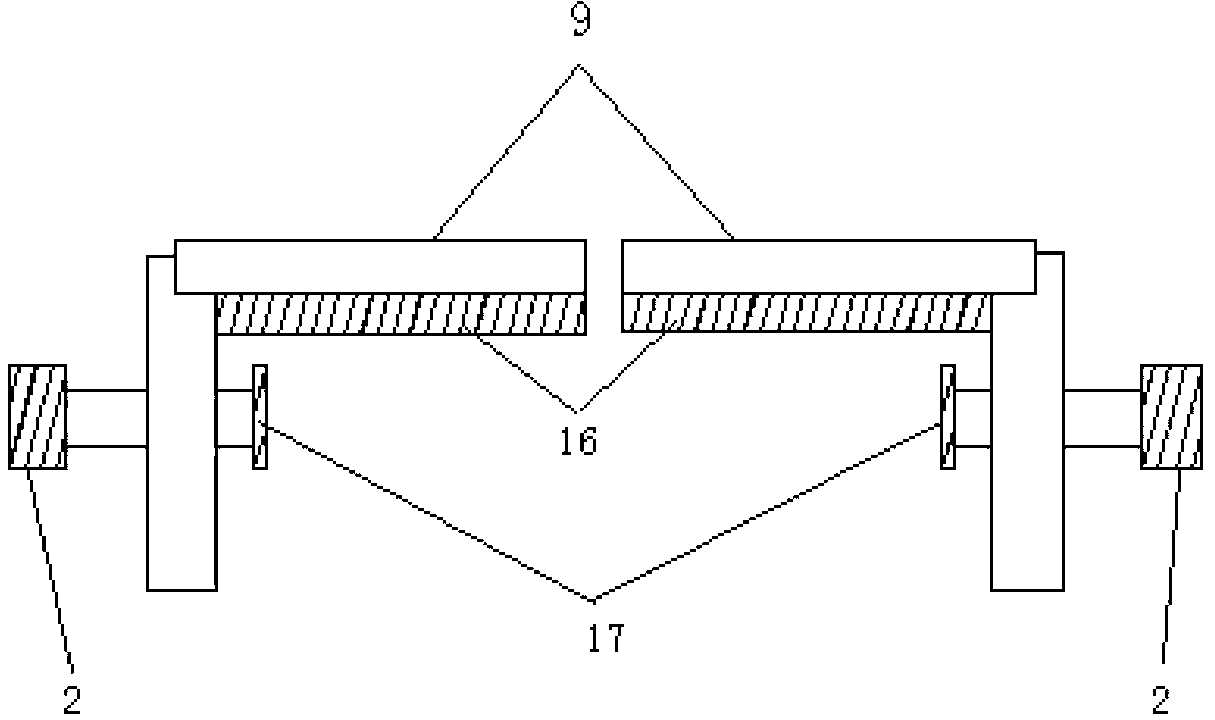

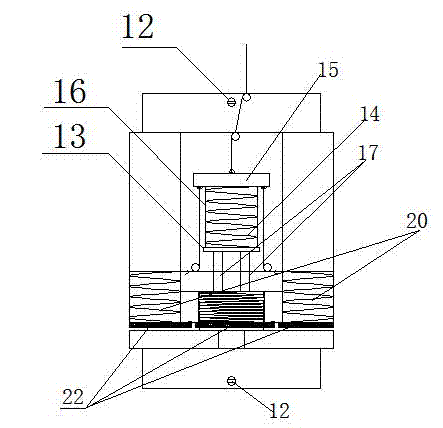

Multi-layer telescopic multi-point displacement meter anchor head for water-rich soft stratum

The invention relates to a multi-layer telescopic multi-point displacement meter anchor head for water-rich soft stratum. A plurality of in-hole measuring point anchor head units are arranged in the longitudinal direction one after another. Each in-hole measuring point anchor head unit is designed to be a surface contact type and comprises a main anchor head and an anchor head protective cover, wherein each main anchor head is connected with the corresponding anchor head protective cover by a positioning hole. Each main anchor head comprises an indium steel wire, a fixed pulley device, an external force conversion device and an anchor claw execution mechanism; each indium steel wire and each fixed pulley device receive external force; a contraction action is realized by each anchor claw execution mechanism through the conversion and the drive of each external force conversion device; each external force conversion device comprises a tension spring device and a plurality of special springs; each anchor claw execution mechanism comprises a plurality of triangular blade-type anchor claws; and the number of the special springs is the same as that of the anchor claws. The multi-layer telescopic multi-point displacement meter anchor head has the advantages of good anchoring effect, wide measuring range, simple structure, convenience in construction, high anti-sliding capacity, reliable performance and the like.

Owner:TONGJI UNIV

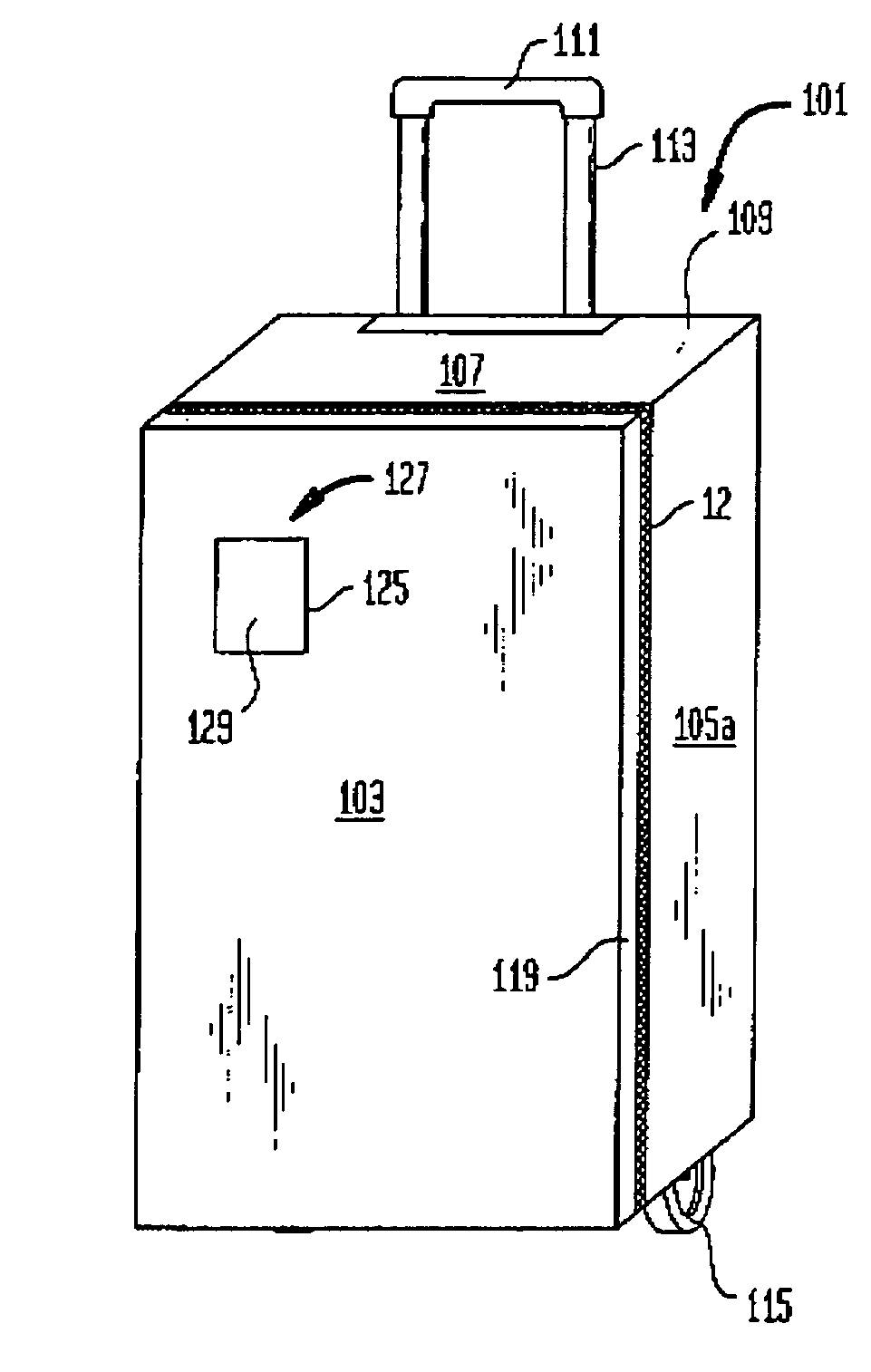

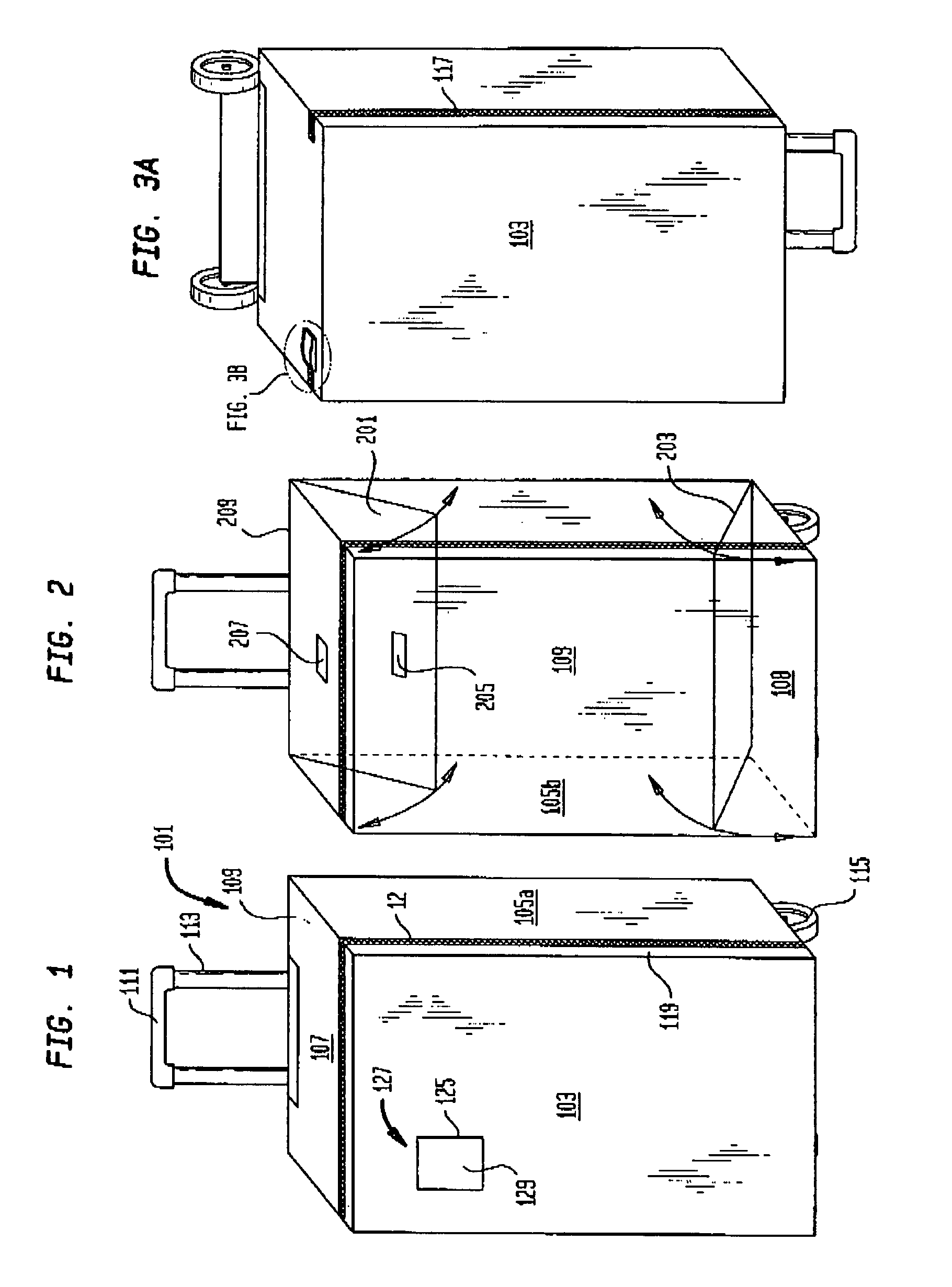

Collapsible, wheeled security luggage

Owner:A RIFKIN

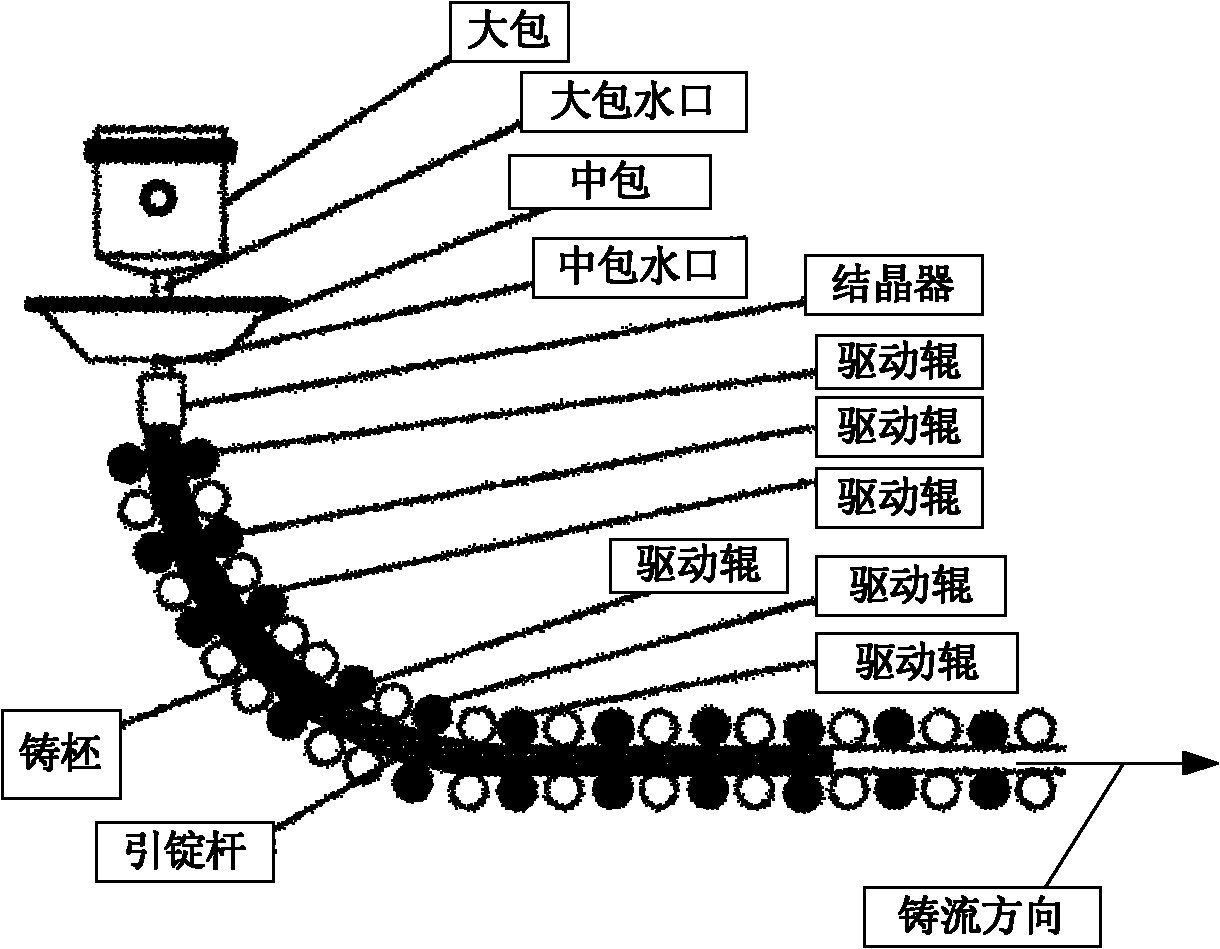

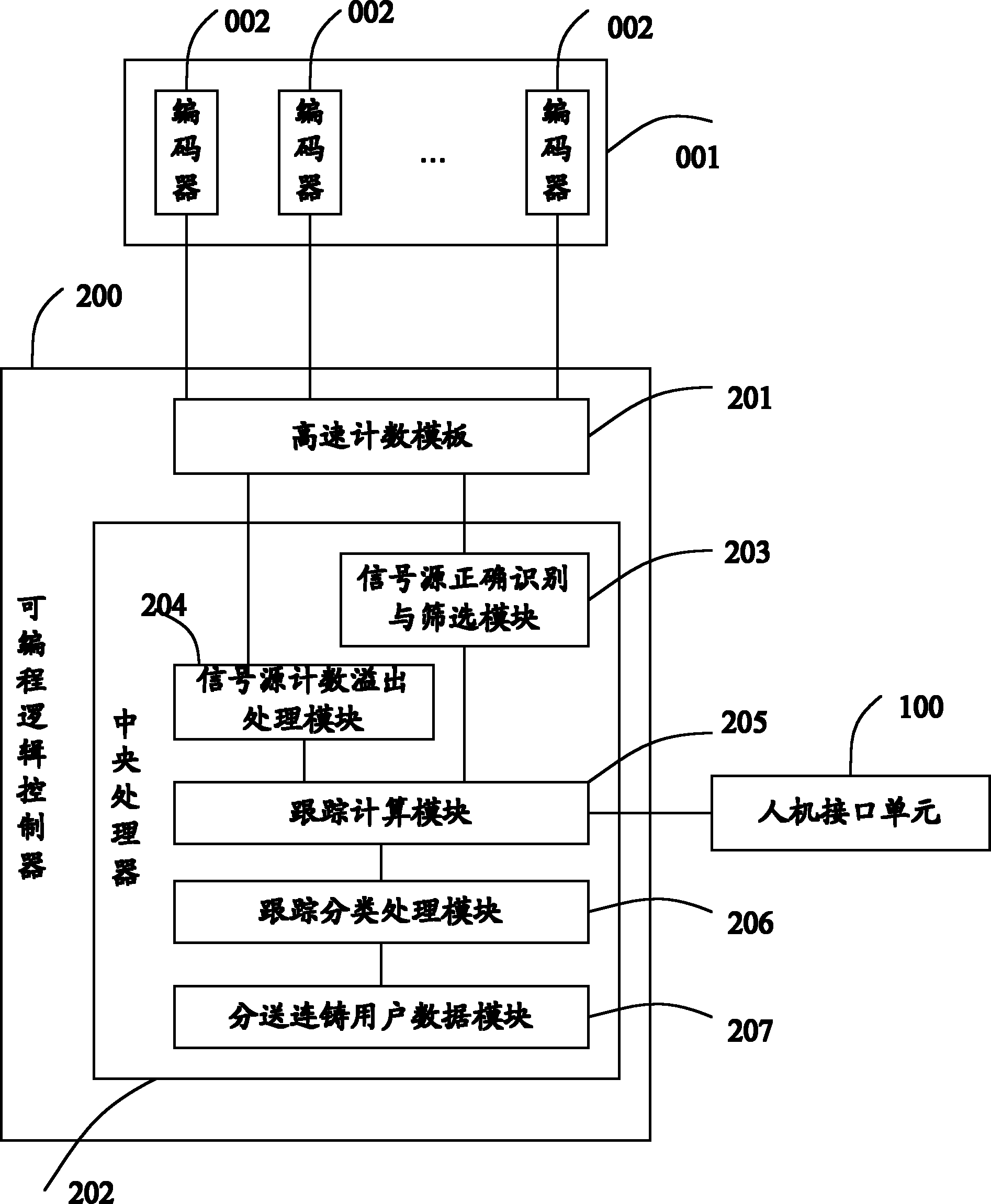

Casting flow tracking system of continuous casting machine

The invention discloses a casting flow tracking system of a continuous casting machine, which is used for successfully measuring actual positions of a blank and a dummy bar in a sector section and casting length of a casting blank through a plurality of encoders, a high-speed calculation template, a signal source counting overflow processing module, a signal source correct recognition and screening module and a tracking calculation module, wherein the plurality of encoders are arranged at a plurality of sector sections to drive a rear shaft of a drive motor, and the measuring process is safe,and is safer and more reliable compared with single-point detection; the signal source counting overflow processing module improves the reliability and the tracking precision of the signal source; and the signal source correct recognition and screening module recognizes a reference signal source from the plurality of encoders to overcome the defect of signal distortion of the signal source causedby using the selected fixed signal source as the reference signal. A human-computer interface unit determines the actual diameter of a drive roller according to the abrasion condition of a mechanicalroller and solves the problem of error compensation of the tracking data caused by the abrasion of the mechanical roller. A tracking classification processing module and a delivery continuous castinguser data module can realize the application of the calculation result.

Owner:WUHAN IRON & STEEL ENG TECH GROUP

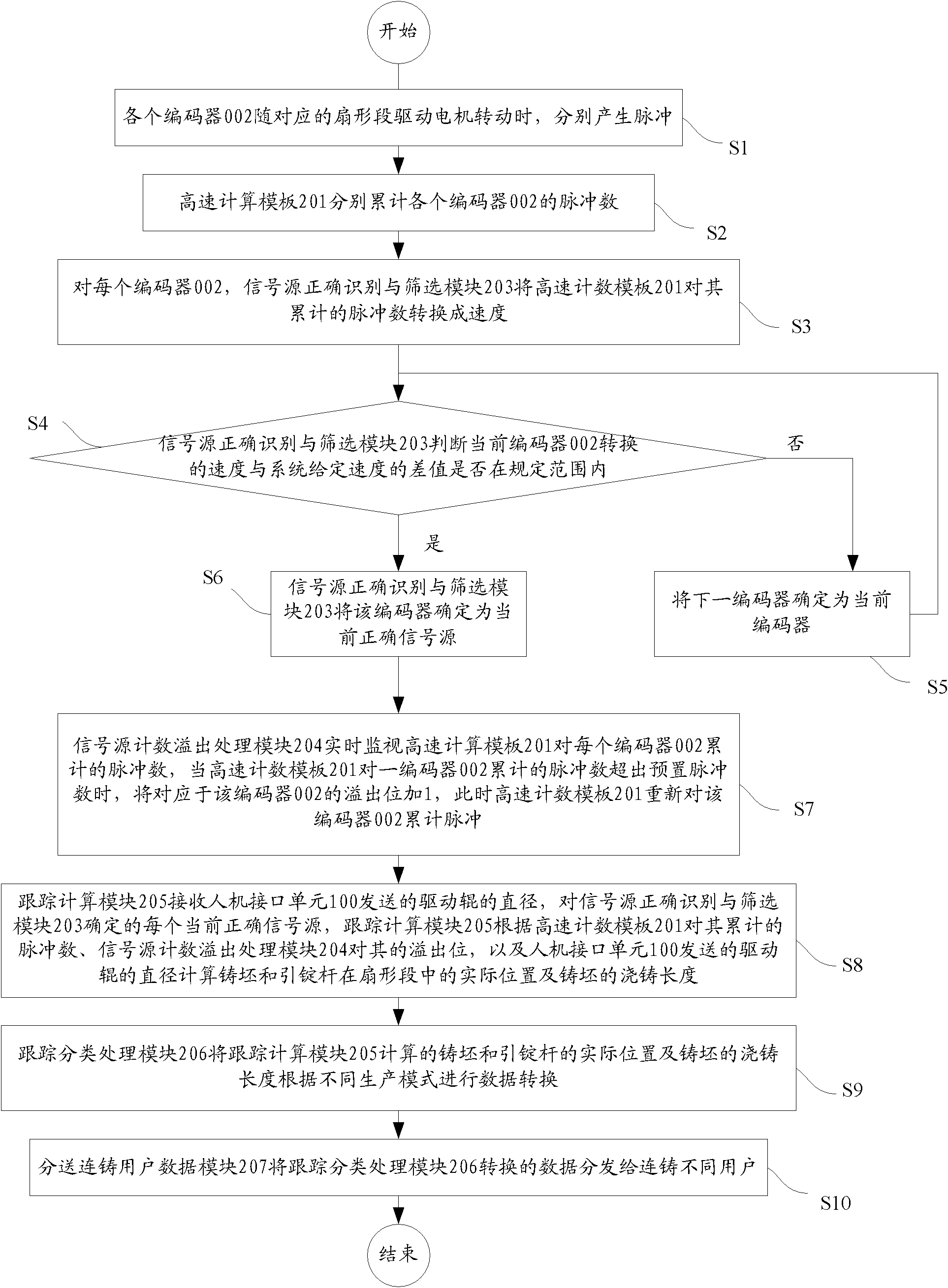

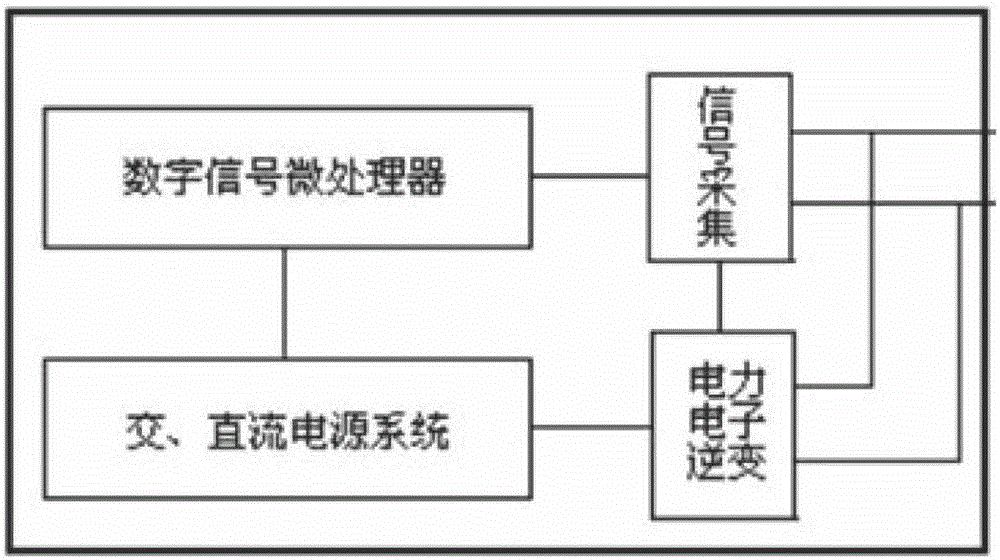

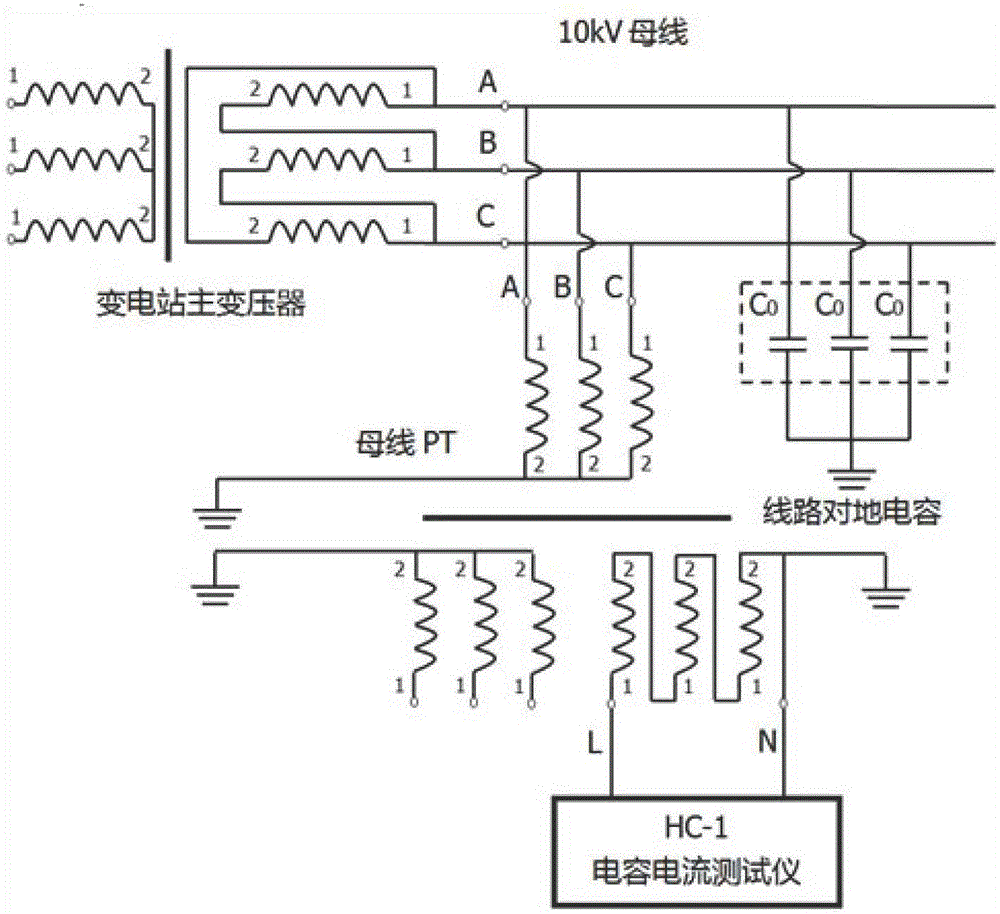

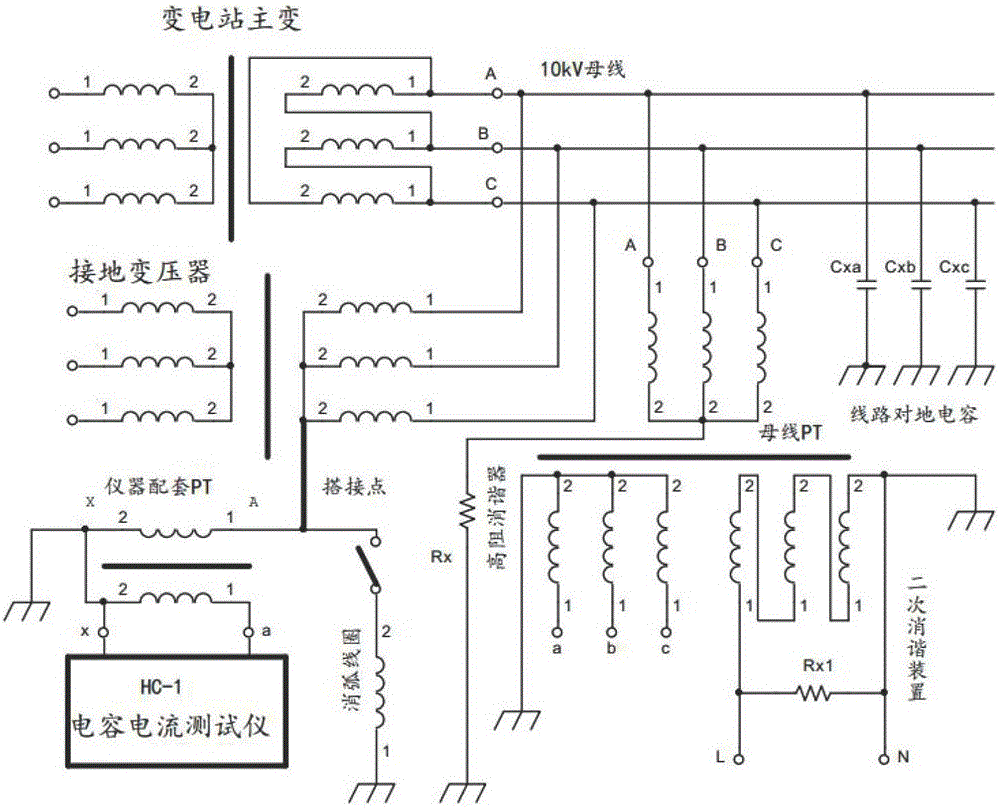

Method for measuring capacitive current of low-current grounding power grid

InactiveCN106771647AReduce the impact of measurement accuracyMeasure securityCapacitance measurementsMeasurement using digital techniquesDigital signal processingCapacitance

The invention relates to a method for measuring capacitive current of a low-current grounding power grid. The method comprises an HC-1 capacitive current tester and a measurement device, wherein the HC-1 capacitive current tester injects a 5Hz constant-current square wave signal into a zero-sequence circuit of a power distribution network, carries out charging and discharging on a grounding capacitor of a line to measure the grounding capacitive current of the power distribution network; the measurement device comprises an AC / DC power supply system, a digital signal microprocessor, a signal collection unit and a power electronic inverter circuit; the digital signal microprocessor controls the power electronic inverter circuit to generate the 5Hz constant-current square wave signal, and injects the 5Hz constant-current square wave signal into the zero-sequence circuit of the system through a bus open delta of the system, a grounded variable neutral point or a neutral point of a capacitor bank; and a high-performance A / D sampling circuit and digital signal processing are adopted by a signal collection system.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

Fast lofting method for connecting points of overhead line system of railway tunnel and automatic measuring system

InactiveCN103076009AMeasure securityQuick measurementSurveying instrumentsRailway tunnelSteering angle

The invention discloses a fast lofting method for connecting points of an overhead line system of a railway tunnel and an automatic measuring system. The method includes the following steps: producing a foot stool of the automatic measuring system; installing and moving the automatic measuring system to an occupied station; regulating the foot stool to enable a worktable to be horizontal and a total station to be placed on a central line between two rails; calculating to obtain a steering angle; enabling the total station to aim at a back viewing point and turning over the steering angle to obtain a vertical surface where connecting point positions of the overhead line are located; rotating the lens of the total station in the vertical surface by a measurer and enabling the total station to measure continuously, obtaining a plurality of groups of measurement data, substituting each group of the measurement data into a formula in real time by the total station and alarming when the formula holds; then stopping the measurement, recording the laying-off angle of the group and corresponding laying-off distance; and displaying a point, namely the lofting point, on a tunnel wall by a laser sent by the total station and marking the point on the tunnel wall by the measurer to finish lofting. The method and the system can achieve high-efficiency and high-precision lofting point of the connecting points of the overhead line.

Owner:CHANGAN UNIV

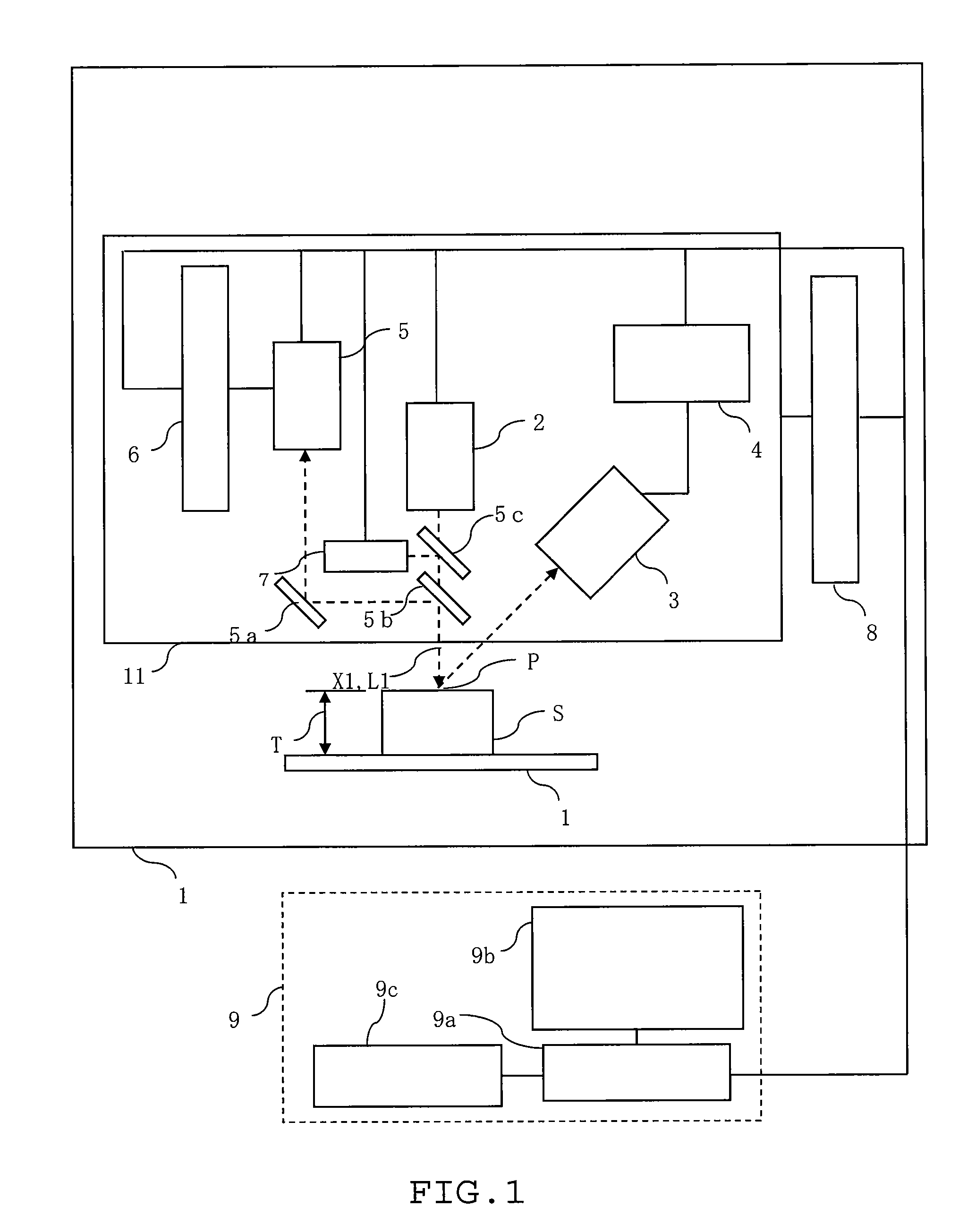

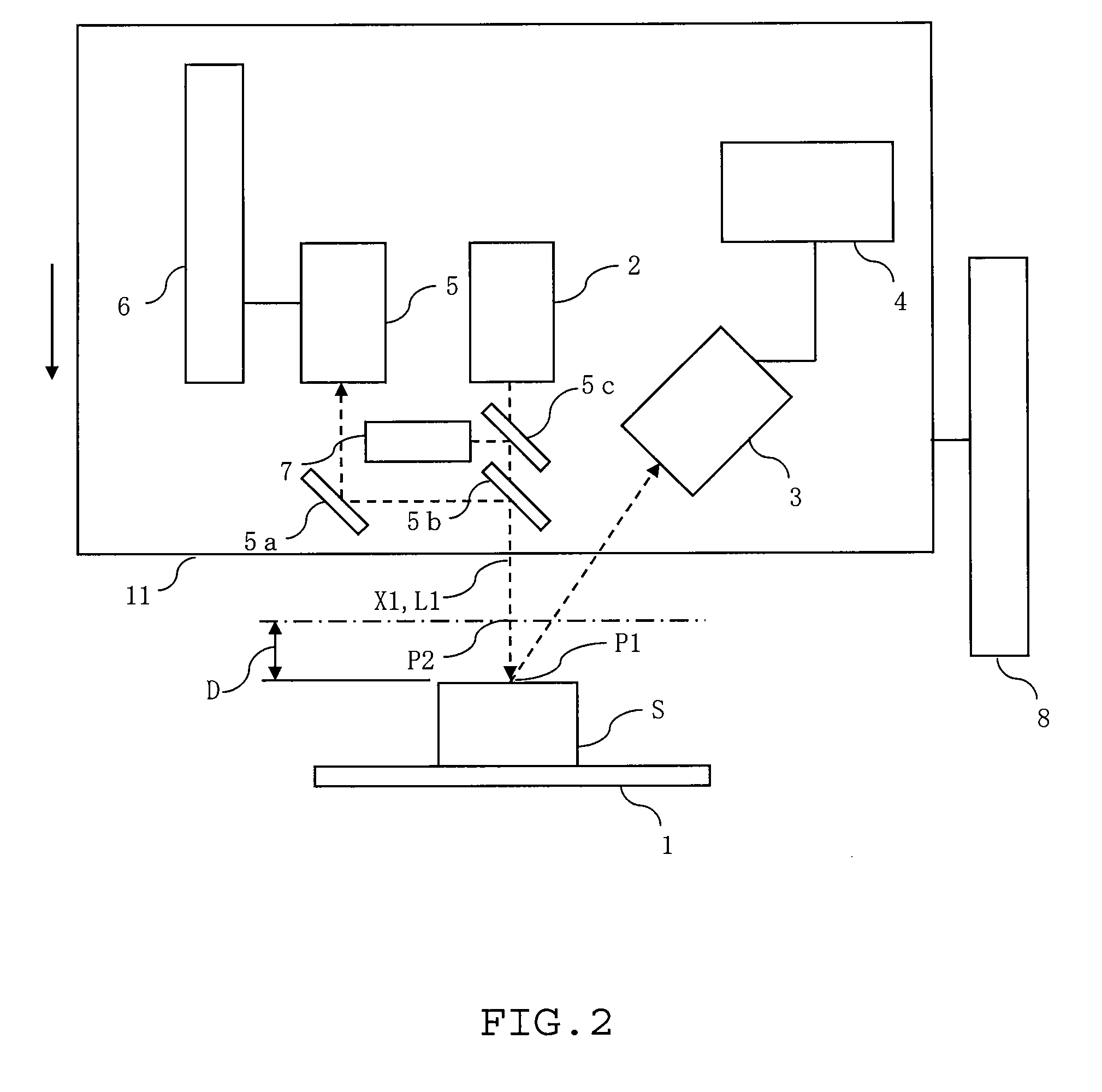

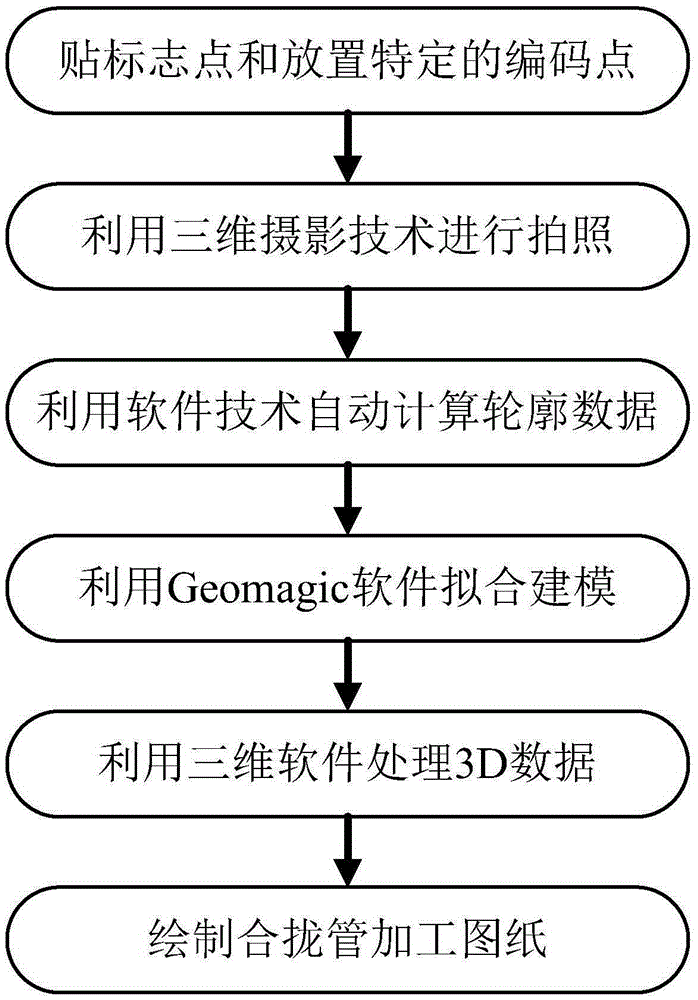

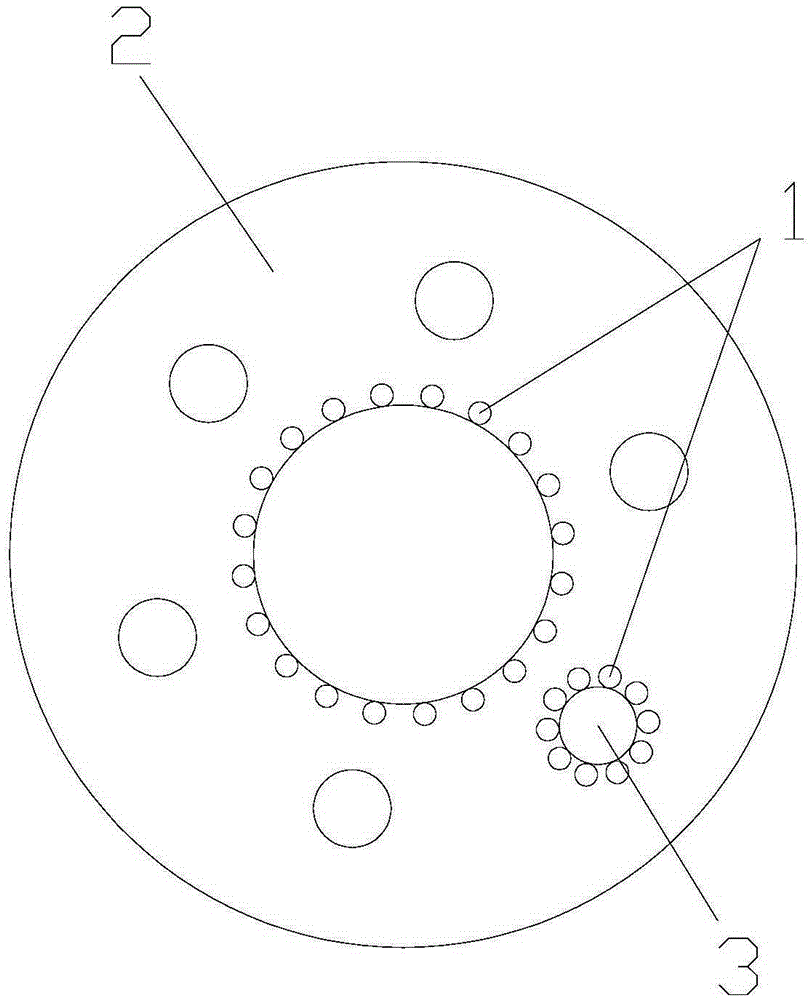

Three-dimensional photography technology based folded pipe field measurement method

InactiveCN105302961AEasy to measureShorten the timeUsing optical meansSpecial data processing applicationsAnti jammingMeasurement precision

The invention discloses a three-dimensional photography technology based folded pipe field measurement method. The method comprises the following steps: (1) arranging a plurality of mark points on a flange and a pipe, and placing encoded points in a spatial position near to-be-measured flange and pipe; (2) performing multi-angle shooting around the pipe and the flange by using a camera or a video camera; (3) copying and storing all shot photos in a computer, and automatically and quickly calculating contour data and spatial relative position data of the pipe and the flange by utilizing three-dimensional photography software; (4) importing the obtained data into Geomagic software, and performing fitting modeling by utilizing the software to form required pipe and flange; and (5) performing analytic processing on 3D data by utilizing related three-dimensional drawing software, drawing a required folded pipe processing drawing, and outputting the drawing in a PDF format. The measurement method is simple, convenient and high in measurement precision, is slightly influenced by factors such as environment and the like, is not influenced by factors of space and light, and is relatively high in anti-jamming capability.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

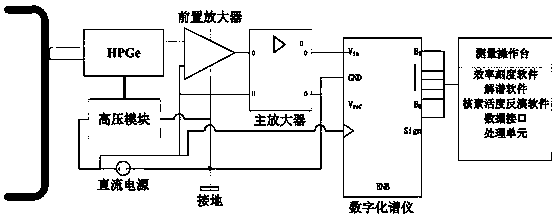

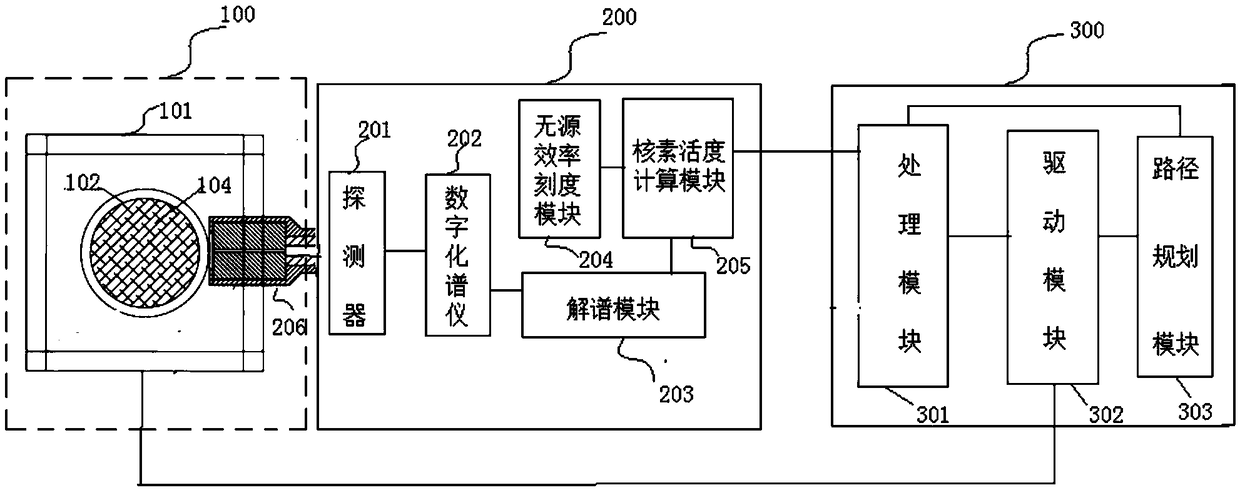

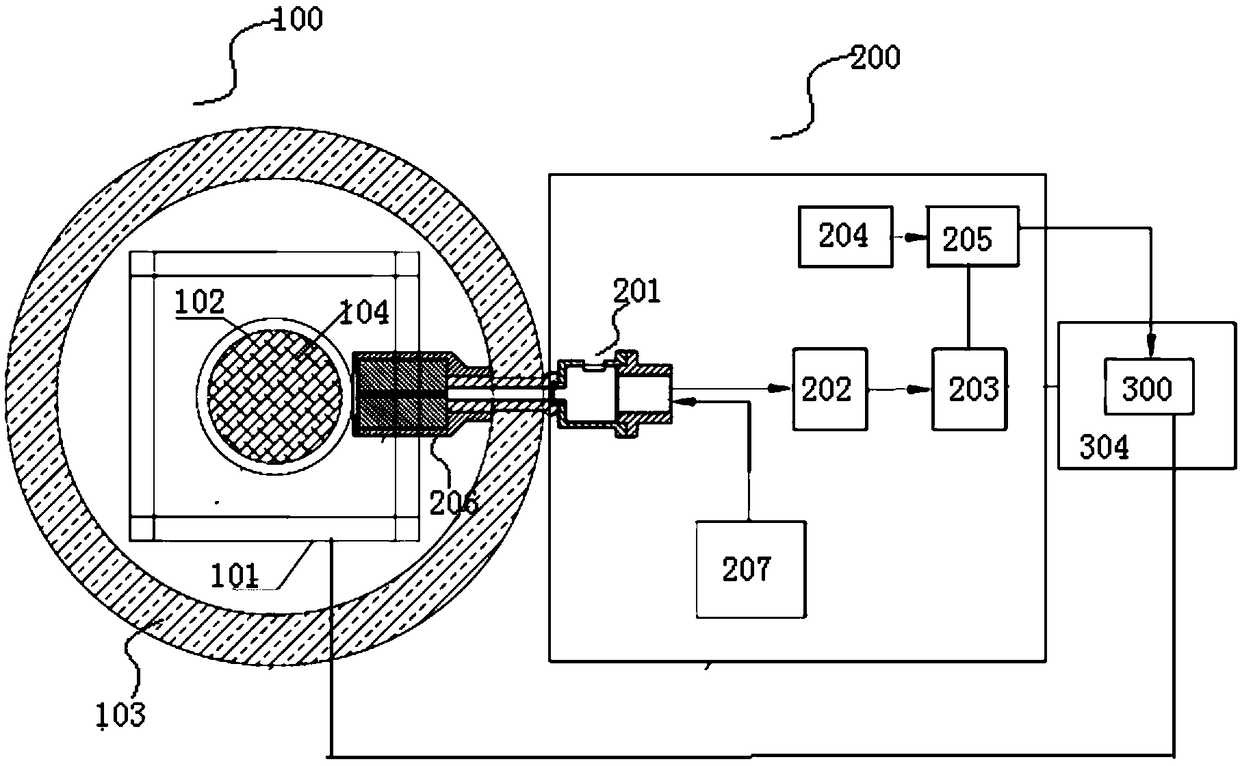

Radioactive water filter waste filter core measuring system and method

ActiveCN109283568AAccurate assessmentSatisfy requirements related to disposalX-ray spectral distribution measurementAutomatic controlWater filter

The invention provides a radioactive water filter waste filter core measuring system and method. The method comprises the following steps that a machinery stand drives a waste filter core to be testedto do three-dimensional movement; a gamma spectrometer and gamma rays released by radionuclides in the waste filter core to be tested act on each other; the distribution of each radionuclide in the waste filter core to be tested, the total activity and the activity ratio are obtained through the total energy peak count rate analysis of each section of the waste filter core to be tested obtained through measurement; and a control unit selects a measuring point, plans a measuring path, automatically controls the movement of a rotating table and visually displays the measuring result. The systemand the method have the advantages that the sectioned multi-point detection on the waste filter core is realized; and a more precise and detailed gamma spectrum type of the waste filter core can be obtained. The guarantee is provided for nuclear power plants to more accurately evaluate the types and the activity of the radionuclides in waste filter core waste barrels by a dose rate reckoning method so that the radiation safety of measuring personnel is ensured and the relevant requirements on national radioactive waste treatment and disposal can be met.

Owner:YANGJIANG NUCLEAR POWER +1

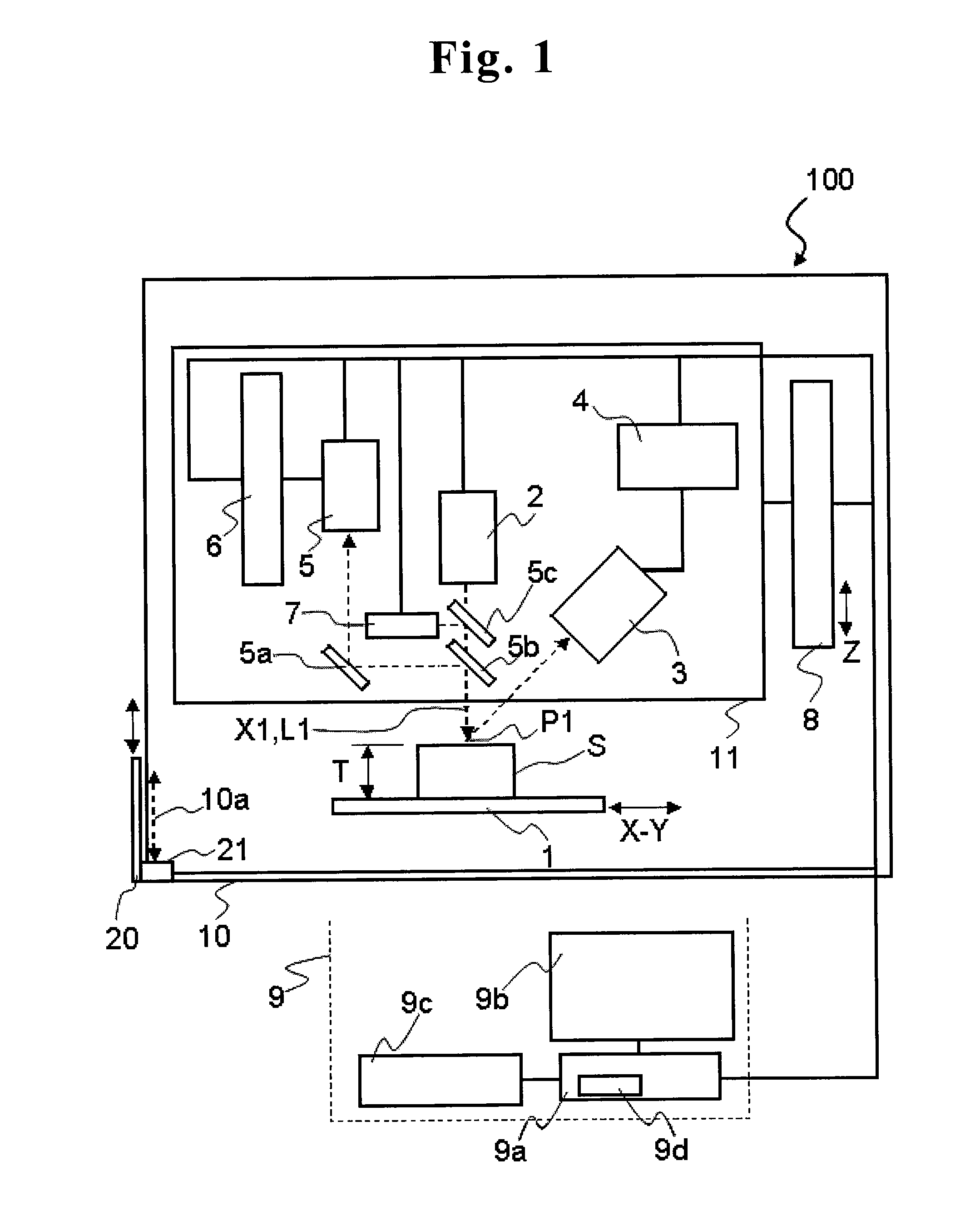

X-ray fluorescence analyzer and x-ray fluorescence analysis method

ActiveUS20120051507A1Work efficiency be superiorSecurity measureMaterial analysis using wave/particle radiationX-ray spectral distribution measurementLight laserRadiation

The X-ray fluorescence analyzer (100) includes: an enclosure (10); a door (20) for putting the sample into and out of the enclosure; a height measurement mechanism (7) capable of measuring a height at the irradiation point; a moving mechanism control unit (9) for adjusting a distance between the sample and the radiation source as well as the X-ray detector based on the measured height at the irradiation point; a laser unit (7) for irradiating the irradiation point with a visible light laser beam; a laser start control unit (9) for irradiating the visible light laser beam by the laser unit (7) when the door is open state; and a height measurement mechanism start control unit (9) for starting the height measurement mechanism to measure the height at the irradiation point when the door is opened.

Owner:HITACHI HIGH TECH SCI CORP

Endoporus measuring device

InactiveCN101226046AReduce contact surfaceReduce volumeAngles/taper measurementsMechanical counters/curvatures measurementsIntegratorMeasurement device

The invention relates to an inner-hole measuring unit, which is a critical component at the testing equipment for measuring bearing inner hole in full automation or the inner of hardware cutting piece. The inner-hole measuring unit is an integrator which is formed by connecting a driver with a measuring mechanism. The measuring mechanism is composed of dynamic and static measuring benches, dynamic and static measuring heads with measuring point, a sensor, a measuring cylinder, an adjusting screw, a measuring plane, a pressing board, a crossing reed, a spring and a standard working piece; the measuring positions of the dynamic and static measuring benches are three measuring points; a change ring surface contact is a three point contact and self centering; the measuring mechanism is arranged on the dynamic and static measuring benches; the inner-hole measuring unit has the advantages of simple and compact structure, compact size, easy assembly and maintenance. The dynamic and static measuring heads are connected as a whole by the crossing reed, so that a lever measuring pivot is constant; simultaneously, the sensor which is arranged at the measuring bench can be changed along the tiny change of the measuring bench; the measuring accuracy is high and the measuring effect can not be affected. An original position automatic standard piece, a measuring protection limit and a force-measuring governing device are also arranged to ensure the safety and accuracy of the measurement.

Owner:黄津

Adjustable board cutting equipment for building decoration

InactiveCN107443495AGuaranteed stabilityReduced stabilityProfiling/shaping machinesBark-zones/chip/dust/waste removalDrive shaftGear wheel

The invention discloses an adjustable plate cutting device for building decoration, which comprises a casing, a motor, a mounting frame and a cutting knife; The driving gear is fixed coaxially, the driving gear is meshed with the driven gear, the driven gear is coaxially fixed and connected with the horizontal transmission shaft, the cutting knife is coaxially fixed on the transmission shaft, and the connecting rod is fixed with a fixed wedge block. The screw rod is respectively provided with a first thread and a second thread, and a movable wedge block is threadedly connected to the first thread and the second thread, and the top of the housing is provided with a limiting device. The present invention can adjust the height of the installation frame and the cutting knife through the wedge-shaped block, and adjust the extent of its extension, so as to cut wood boards of different thicknesses, and has a wide application range; Measure, measure accurately, apply safely.

Owner:广西东创智能科技有限公司

Method for measuring polymer-base foam material linear expansion coefficient by displacement sensor

InactiveCN1779452ALow costImprove deformation measurement accuracyMaterial thermal coefficient of expansionElectrical/magnetic solid deformation measurementElectrical resistance and conductanceThermodynamics

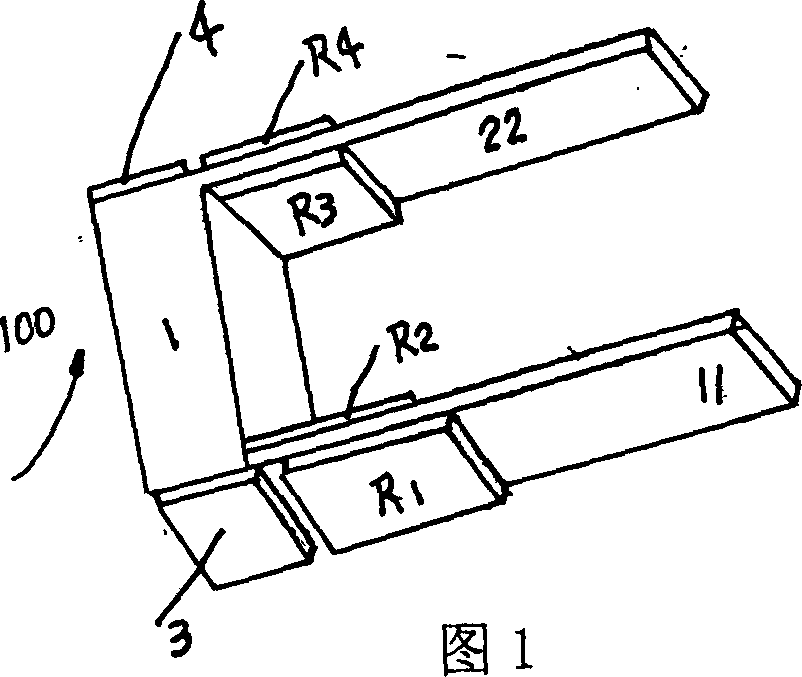

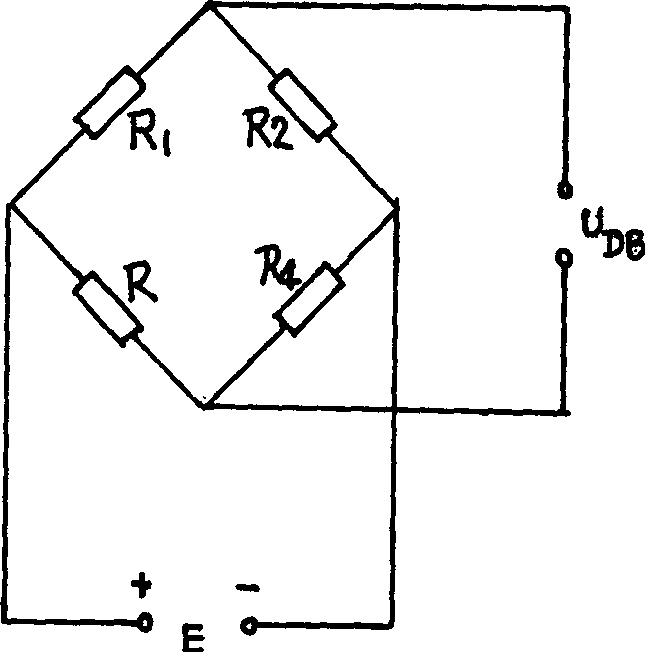

A method for measuring linear expansion coefficient of polymer based foam material by using displacement transducer includes fixing measurement zone of material to be measured on two pincer arms of said transducer and setting it in temperature zone of 4.2 ¿C 300 K, connecting resistance foil gauge forming Wheatstone bridge to resistance strain gauge, collecting deformation of material to be measured and clamping force on said transducer then converting displacement amount to be electric amount, sending these data to computer for obtaining curve of strain to temperature variation and furthermore to obtain expansion coefficient of material to be measured from the curve.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

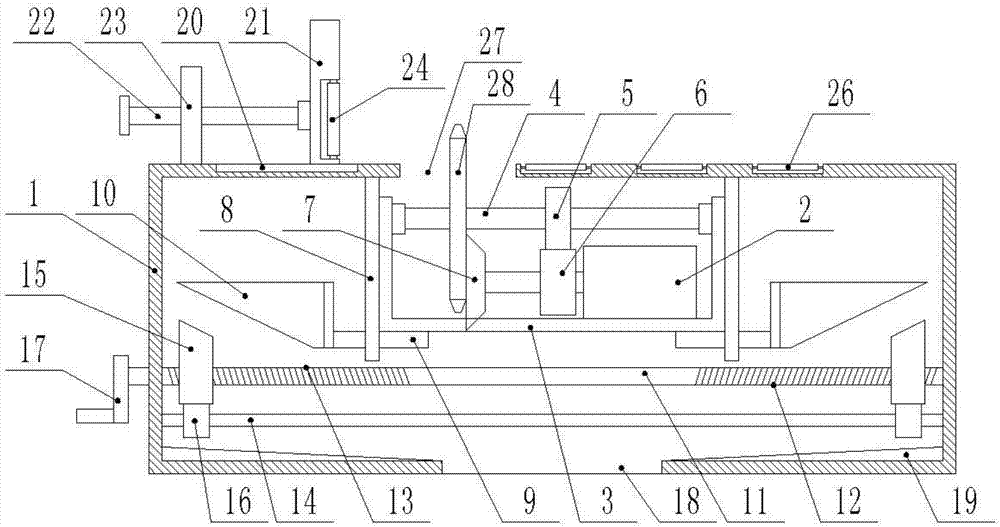

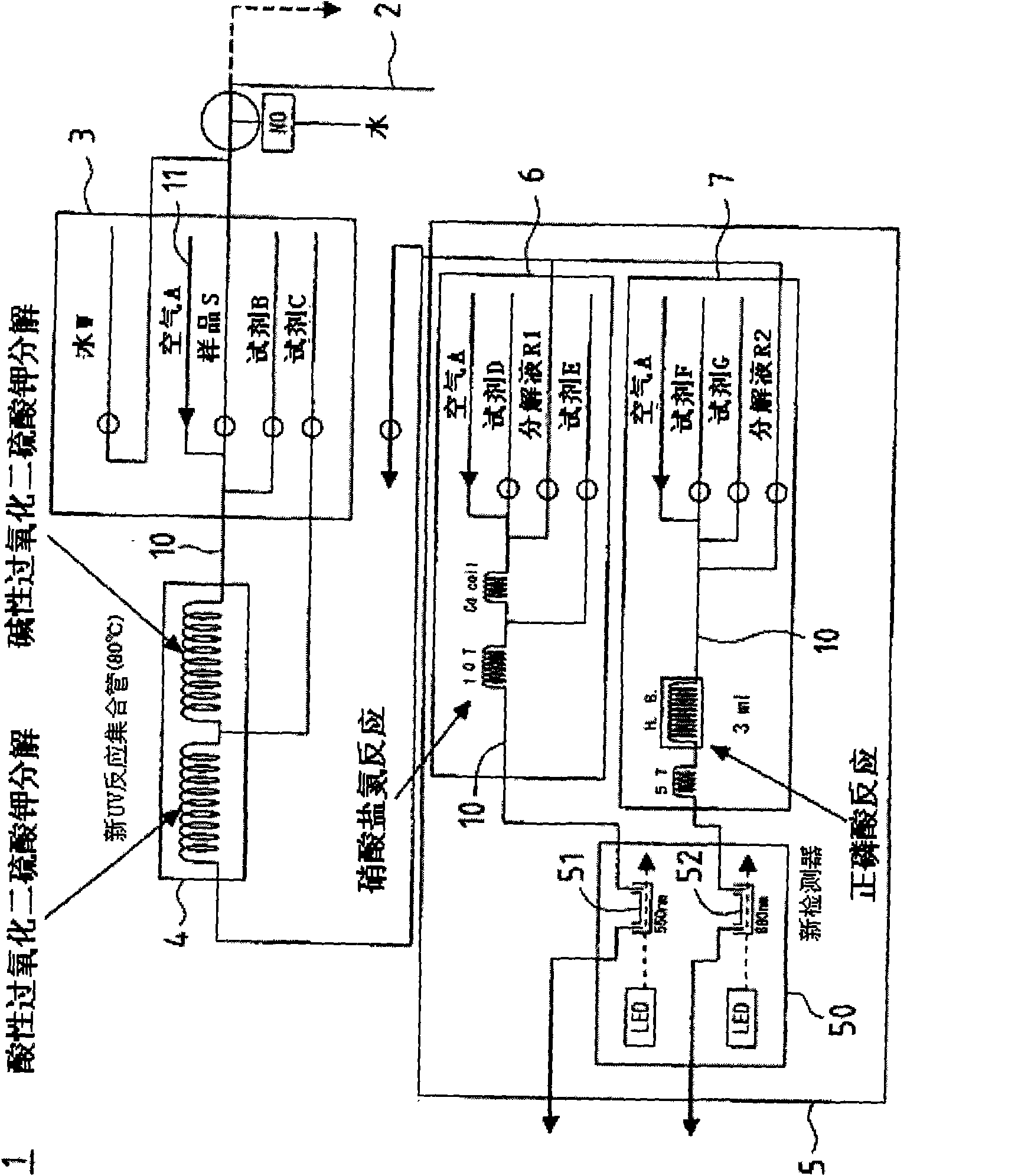

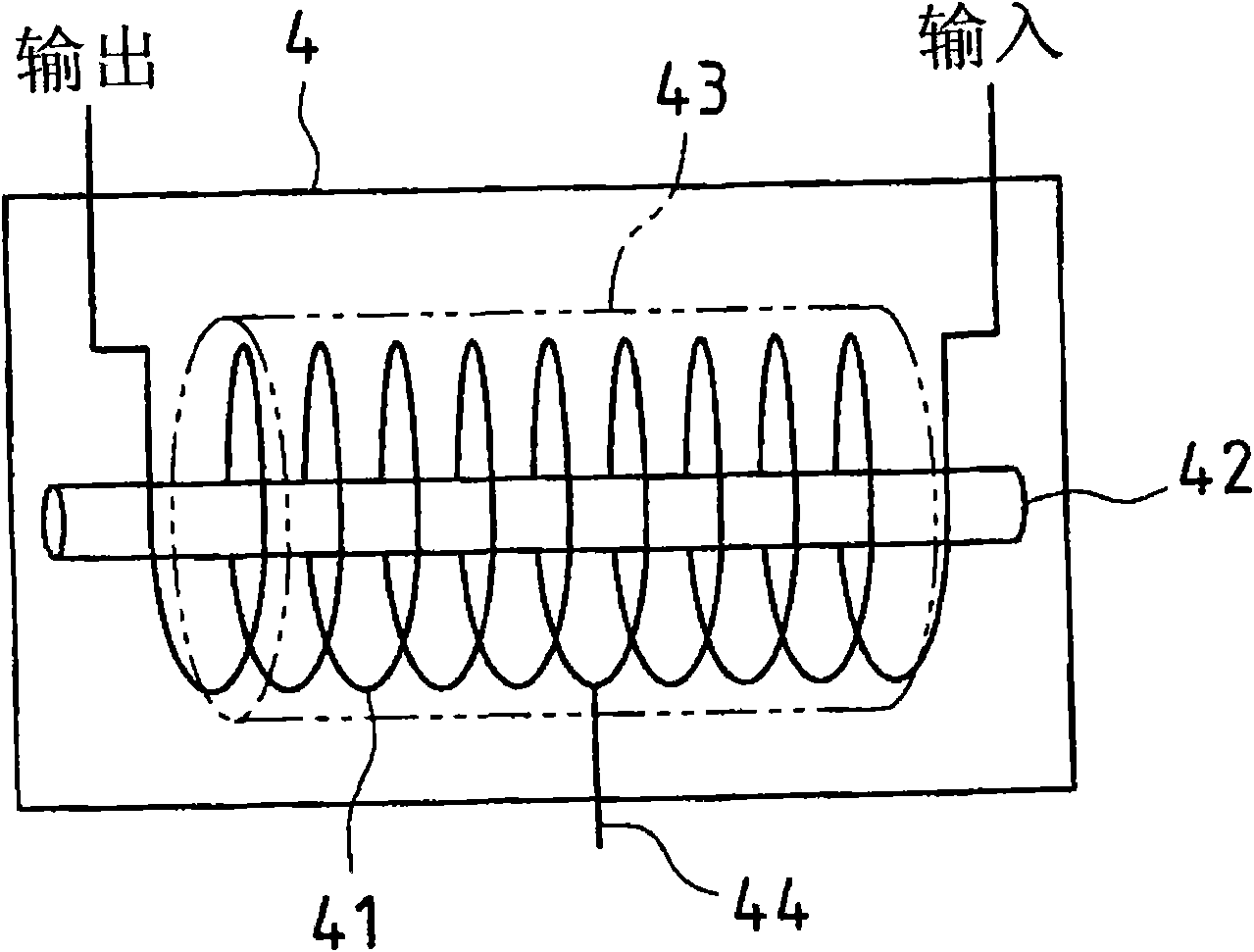

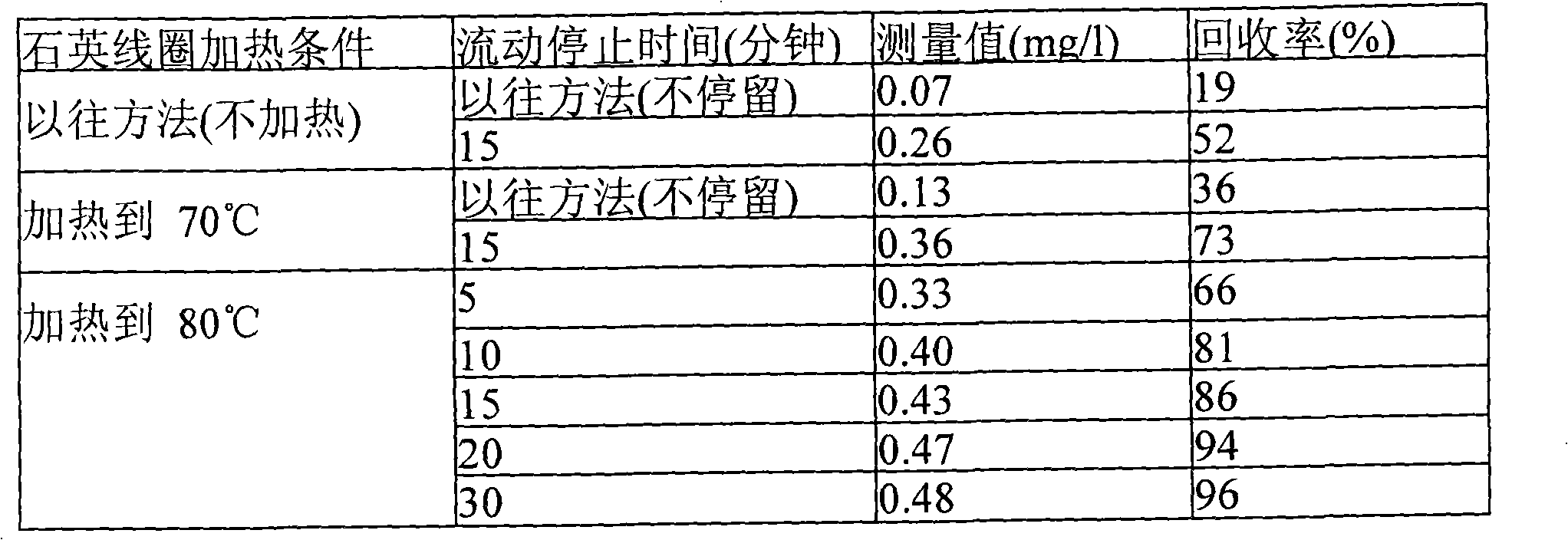

Automatic analysis quantitatively measure method and automatic analysis quantitatively measure apparatus

InactiveCN101592670AMeasure securityExcellent decomposabilityAnalysis using chemical indicatorsPreparing sample for investigationTotal nitrogenReagent

The invention relates to a total nitrogen content and a total phosphorus total content automatic analysis quantitatively measure apparatus and an automatic analysis quantitatively measure method, wherein the method adopts continuous streaming analytical method, which comprises the following procedures: separate a sample (S) by using air (A); inject the separated sample and a reagent (B,C) into a tube (10) together continuously for quantity determination and mixture; after analysis of the obtained mixed liquor in a reaction collecting tube (4), analyze in usual way by a detector (5), and sample the sample (S) at a certain time interval to supply to the tube (10); in the reaction collecting tube (4), the mixed liquor is remained for 10-30 min, heat and decompose the mixed liquor under the temperature from 80 to 90 DEG while irradiating UV; analyze the mixed liquor that generated repeatedly at a certain time interval so as to quantitatively measure total nitrogen content and total phosphorus total content of a sampling position.

Owner:BLTEC KOREA

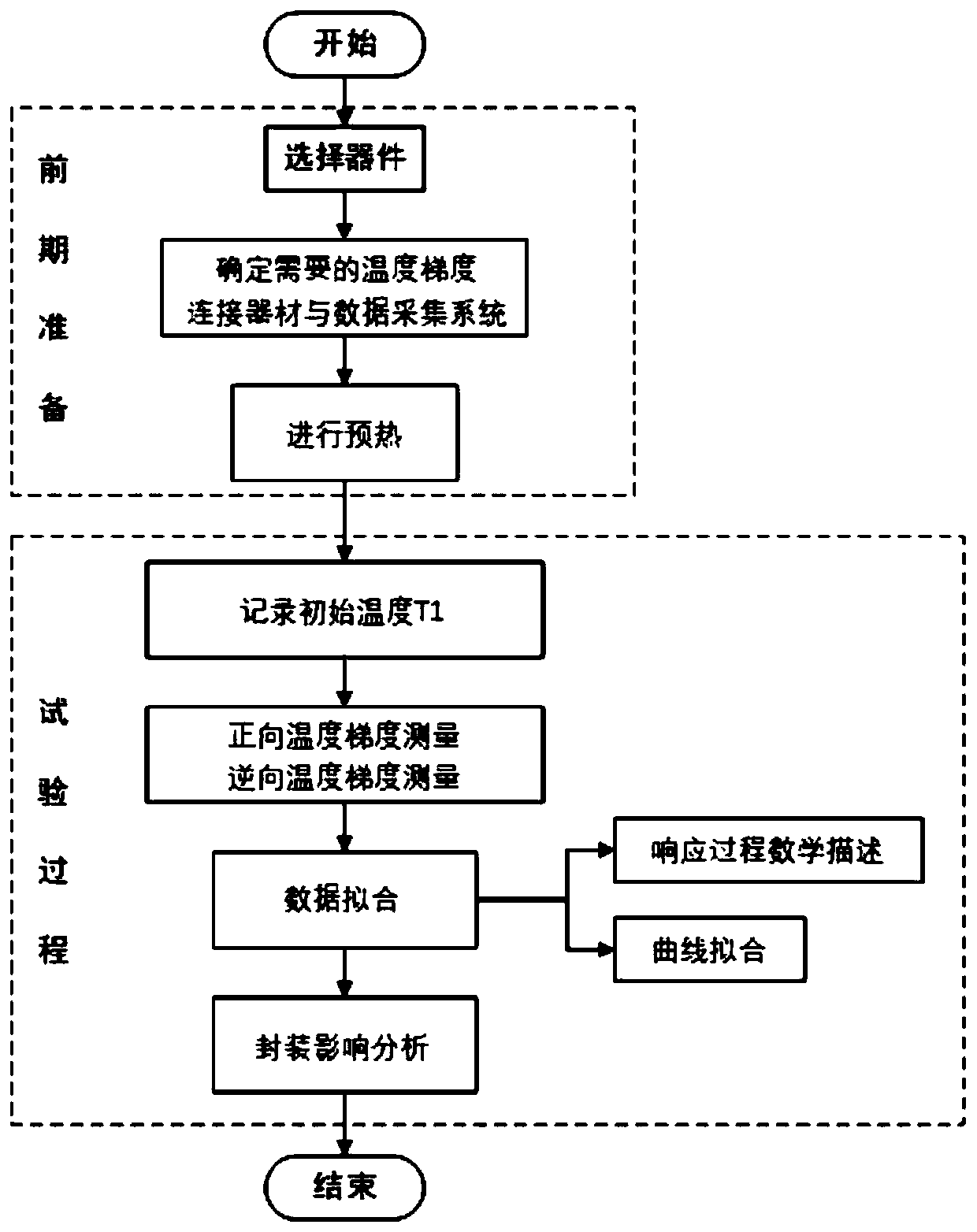

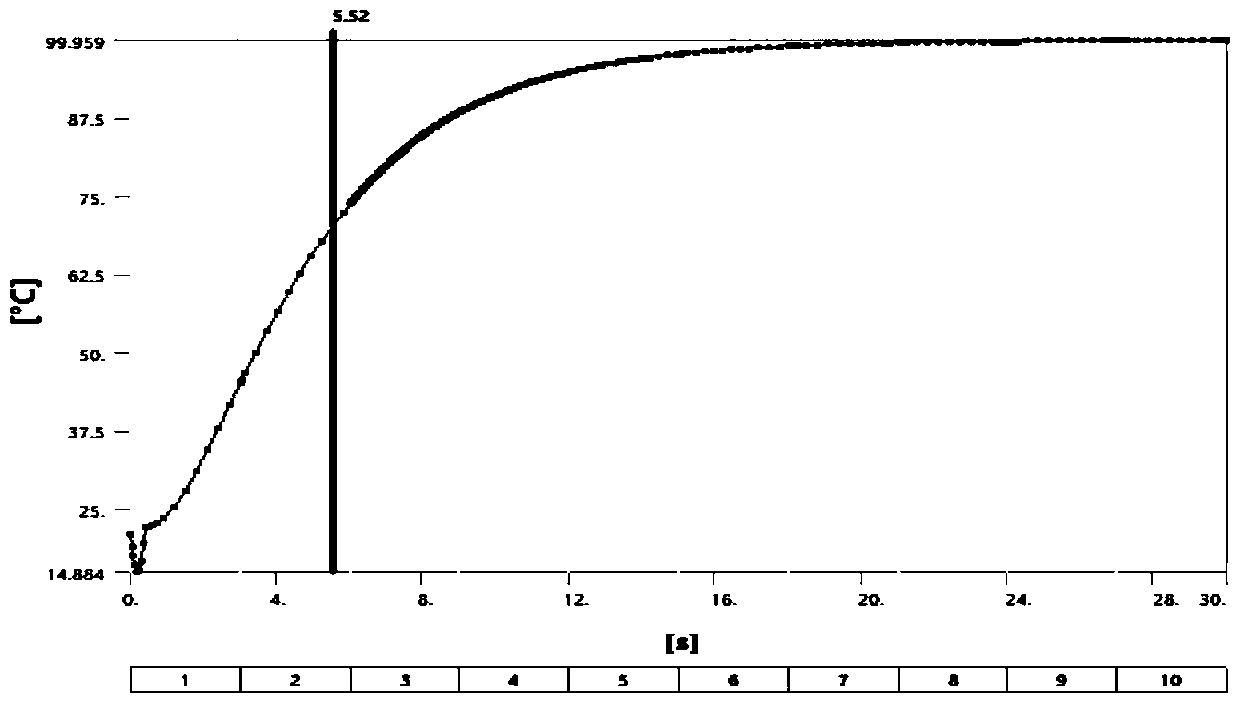

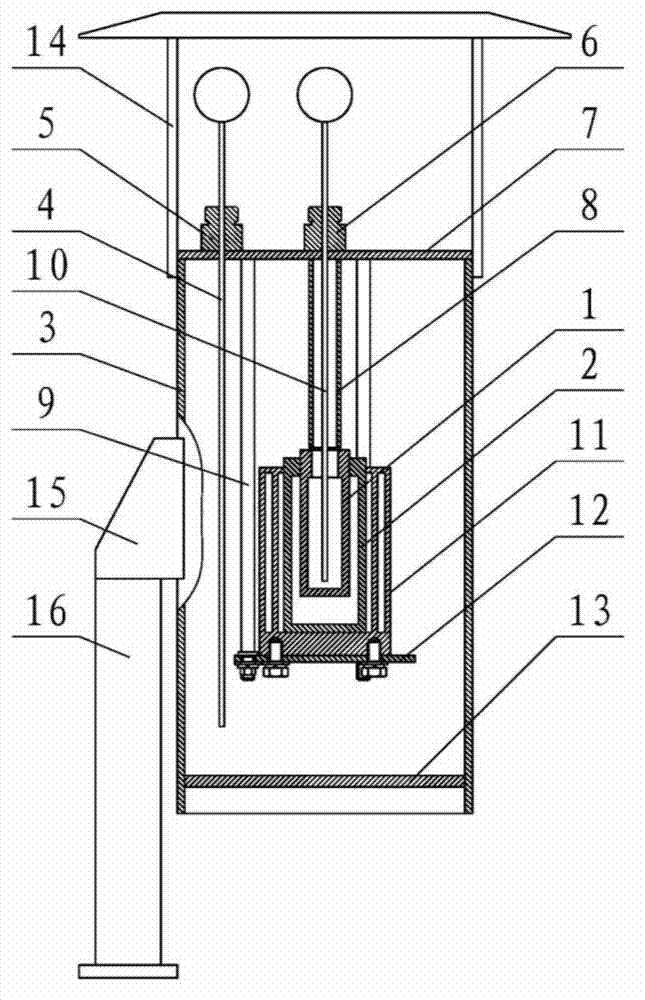

K-type armored thermocouple response time measuring method based on heat pipe method

InactiveCN111006793ARich temperature rangeMeasure securityThermometer testing/calibrationThermodynamicsData acquisition

The invention provides a K-type sheathed thermocouple response time measurement method based on a heat pipe method, and the method comprises the following steps: 1, selecting a to-be-measured K-type sheathed thermocouple, and determining a needed temperature gradient; 2, connecting a to-be-tested device, a data acquisition instrument and a computer system, and opening a heat pipe thermostatic bathfor preheating; 3, recording initial temperature T1; 4, measuring forward temperature gradient response time and recording data; 5, measuring reverse temperature gradient response time; and 6, performing data fitting and packaging influence analysis. Through the steps, the response time of the K-type sheathed thermocouple can be measured and calculated by utilizing a heat pipe method and data processing and analysis; an accurate method for measuring the response time is provided, and accurate thermal performance parameters of the K-type sheathed thermocouple are provided for a device user.

Owner:BEIHANG UNIV

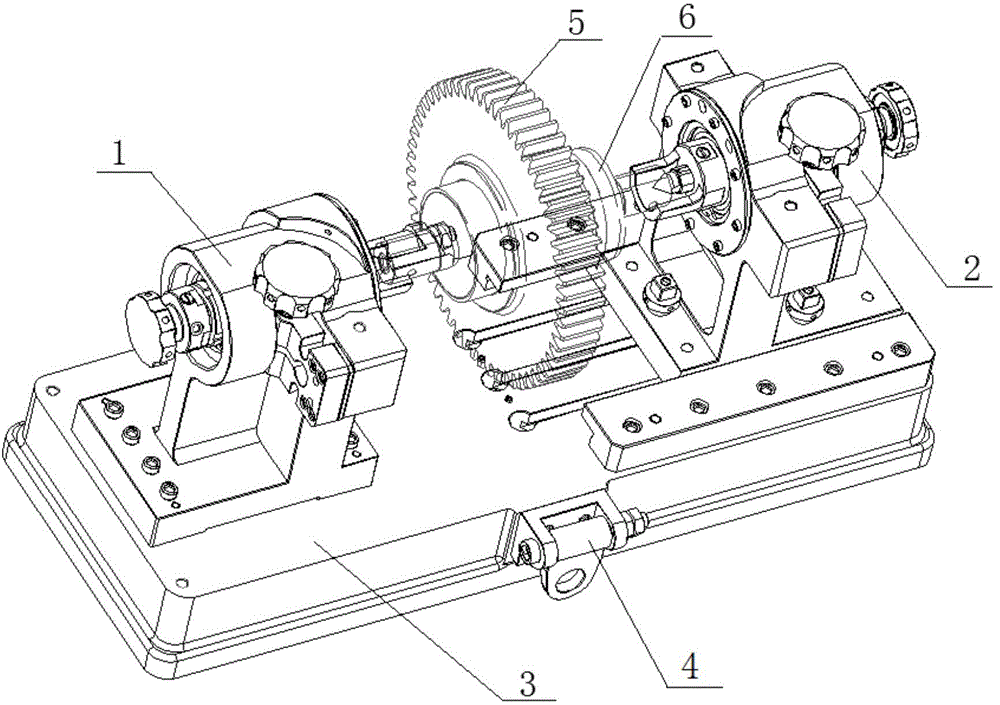

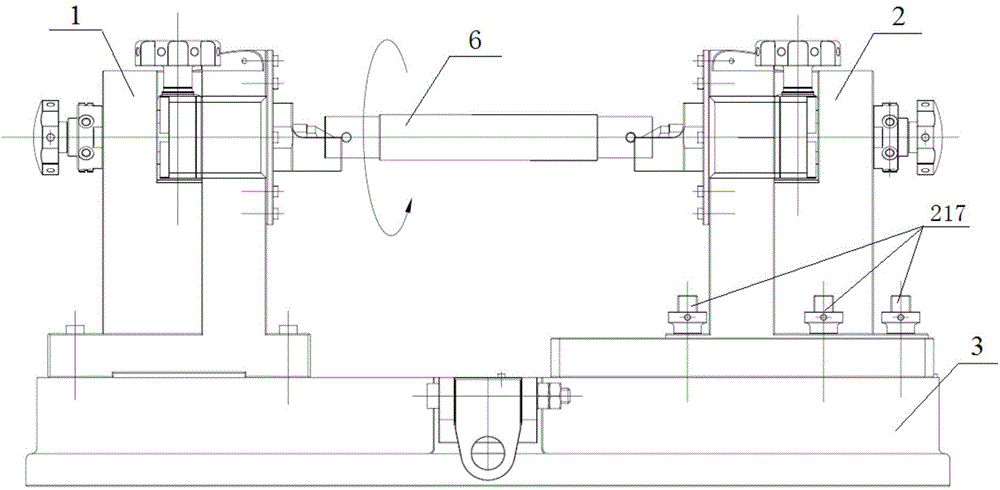

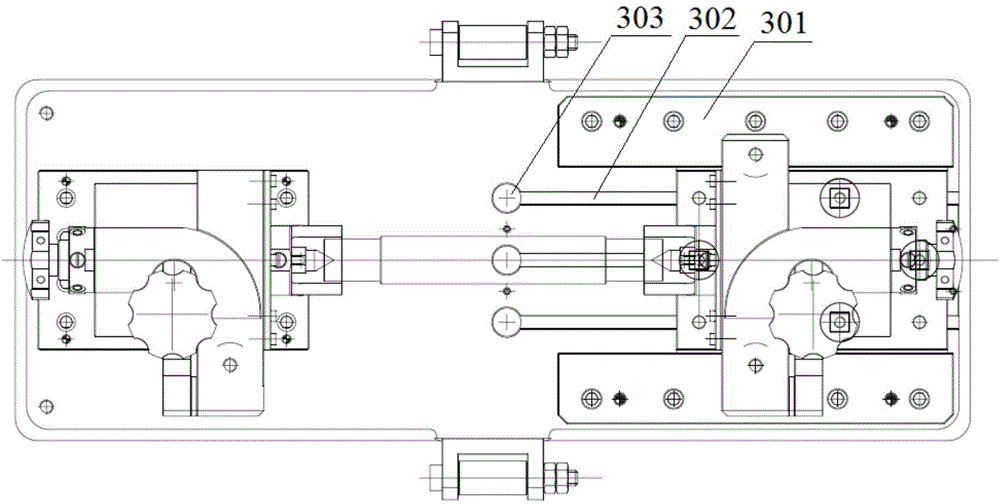

Device for measuring runout of rotating member

ActiveCN104406478APlay a fine-tuning roleEasy to installMechanical measuring arrangementsMechanical engineering

The invention discloses a device for measuring runout of a rotating member, which comprises a base, a fixing component and a sliding component, wherein the internal part of a body of the fixing component is rotatably provided with a first shaft, a center hole of the first shaft is slidably provided with a first tip and a first adjusting screw, one end of the first tip is in threaded connection with the first adjusting screw, a screw cap of the first adjusting screw is isolated at the external part of the first shaft through a first cap tightening nut, and the first cap tightening nut and the first adjusting screw are provided with a first rolling bearing therebetween; the internal part of a body of the sliding component is rotatably provided with a second shaft, a center hole of the second shaft is slidably provided with a second tip and a second adjusting screw in sequence, one end of the second tip is in threaded connection with the second adjusting screw, a screw cap of the second adjusting screw is isolated at the external part of the second shaft through a second cap tightening nut, and the second cap tightening nut and the second adjusting screw are provided with a second rolling bearing therebetween. The device disclosed by the invention is applicable to core shafts with the length being various, and the stability of a gear assembly under an installation state is improved through a fine adjusting mechanism.

Owner:GUANGXI YUCHAI MASCH CO LTD

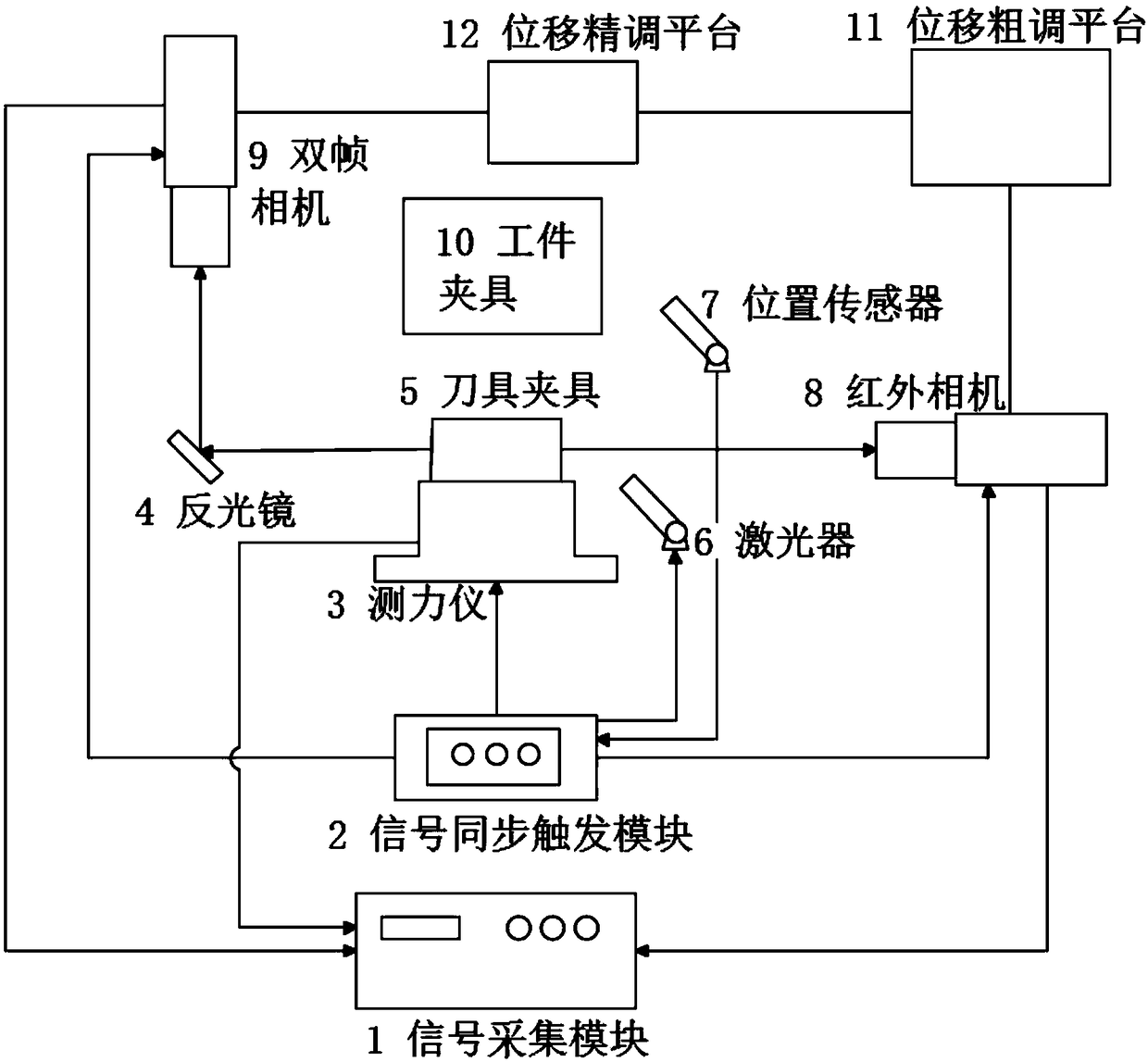

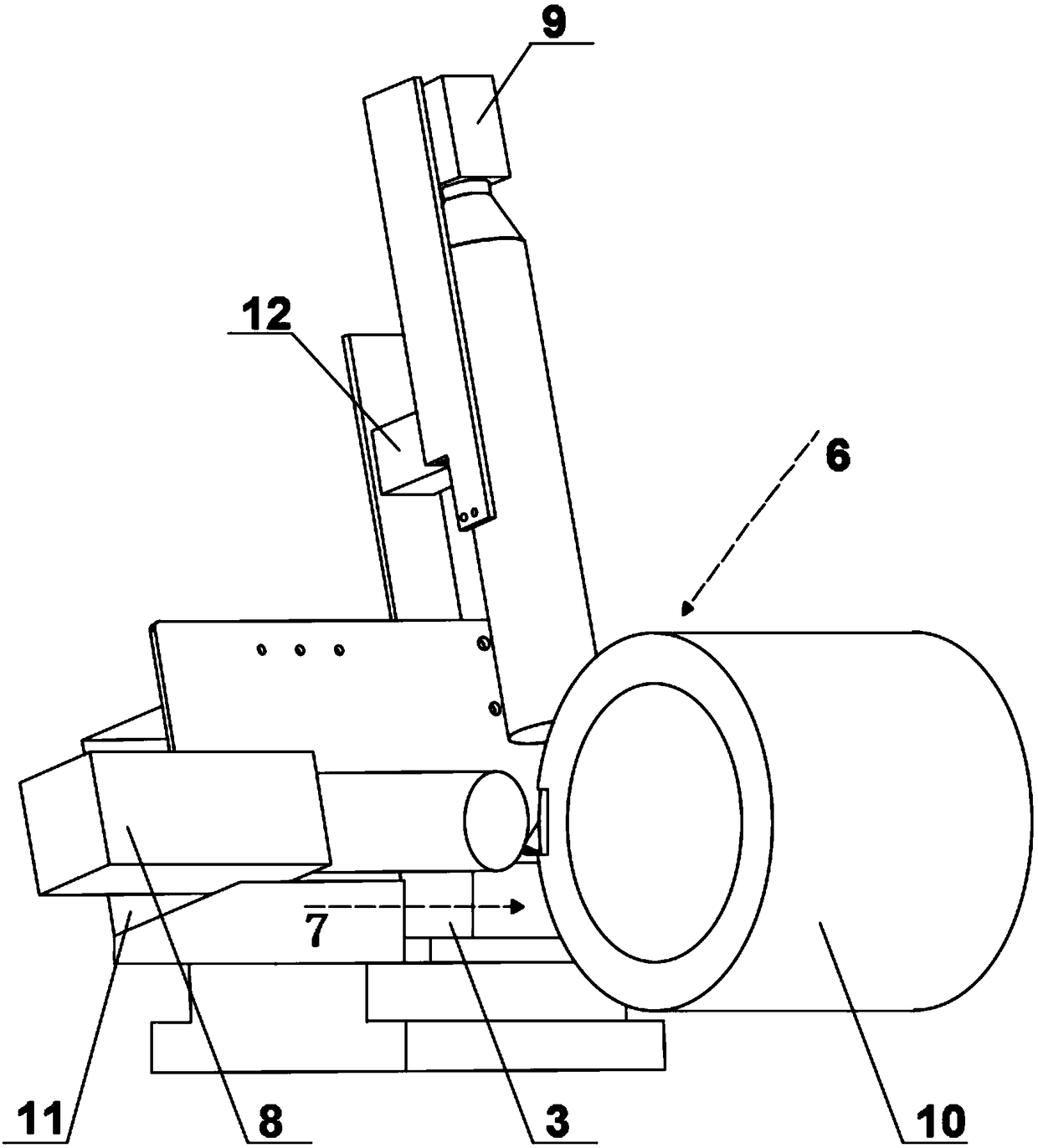

Online measuring system for high-speed cutting deformation field and method thereof

ActiveCN109333162AKeep clearAvoid approximationMeasurement/indication equipmentsTime delaysTransient deformation

The invention belongs to the field of metal machining, and discloses an online measuring system for a high-speed cutting deformation field and a method thereof. The online measuring system comprises adynamometer, an infrared camera, a dual-frame camera, a position sensor, a signal synchronous triggering module and a signal acquisition module, wherein the dynamometer is used for measuring the cutting force of a workpiece to be measured in real time; the infrared camera is used for measuring the temperature field of the workpiece to be measured in real time; the double-frame camera is used formeasuring the displacement field of the workpiece to be measured in real time; the position sensor is used for sending a measurement starting signal; after the signal synchronous triggering module receives the measurement starting signal, the signal synchronous triggering module controls the dynamometer, the infrared camera and the dual-frame camera to start measurement according to the preset time delay; and the signal acquisition module is used for acquiring results obtained by measurement, so that the online measurement of the cutting force, temperature field and displacement field of the workpiece to be measured in the high-speed cutting process is realized. Through the online measuring system and method thereof, the non-contact measurement of the transient deformation field and the temperature field under high speed and high strain is realized, the measurement process is safe and reliable, and the processing precision is guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

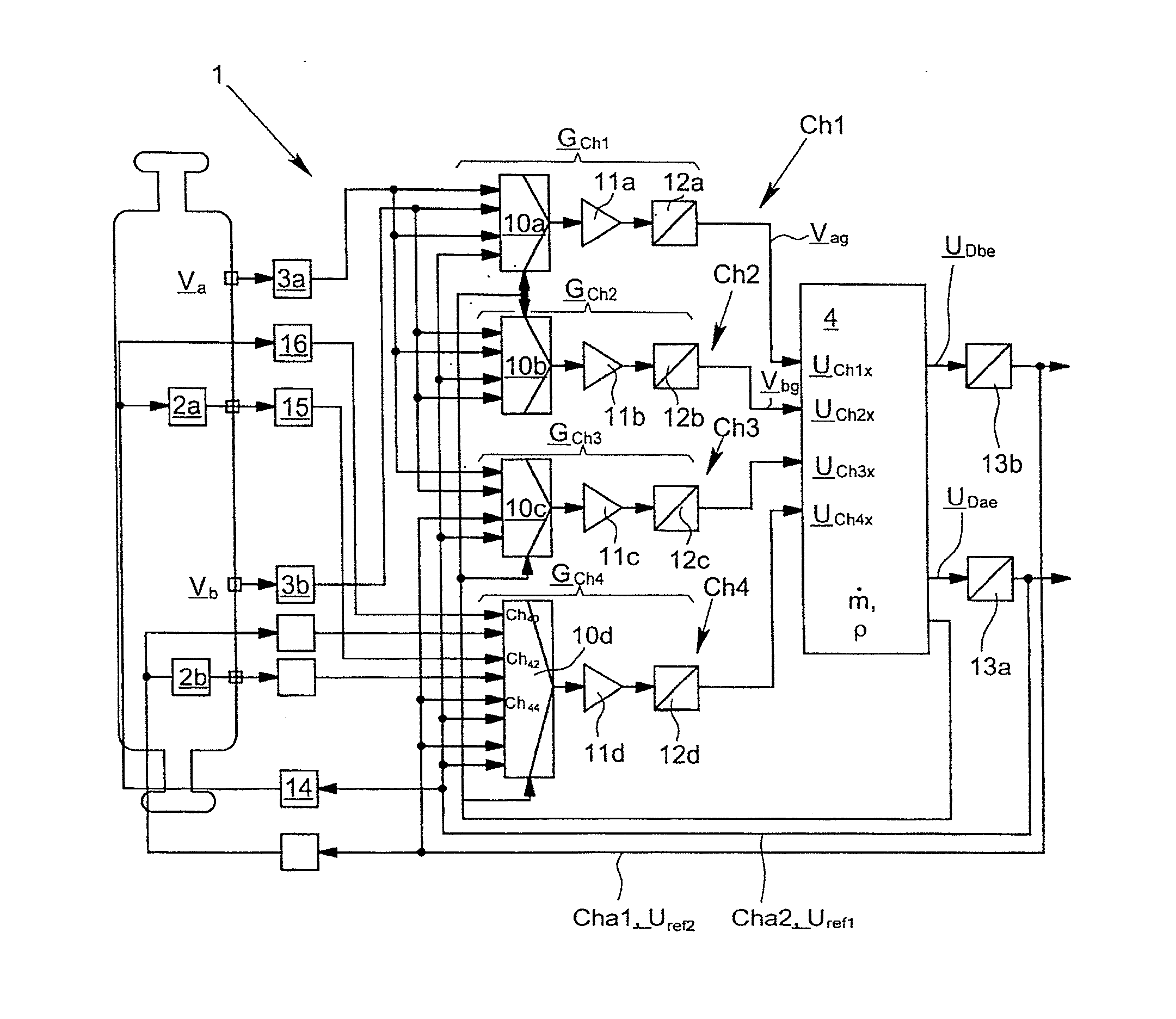

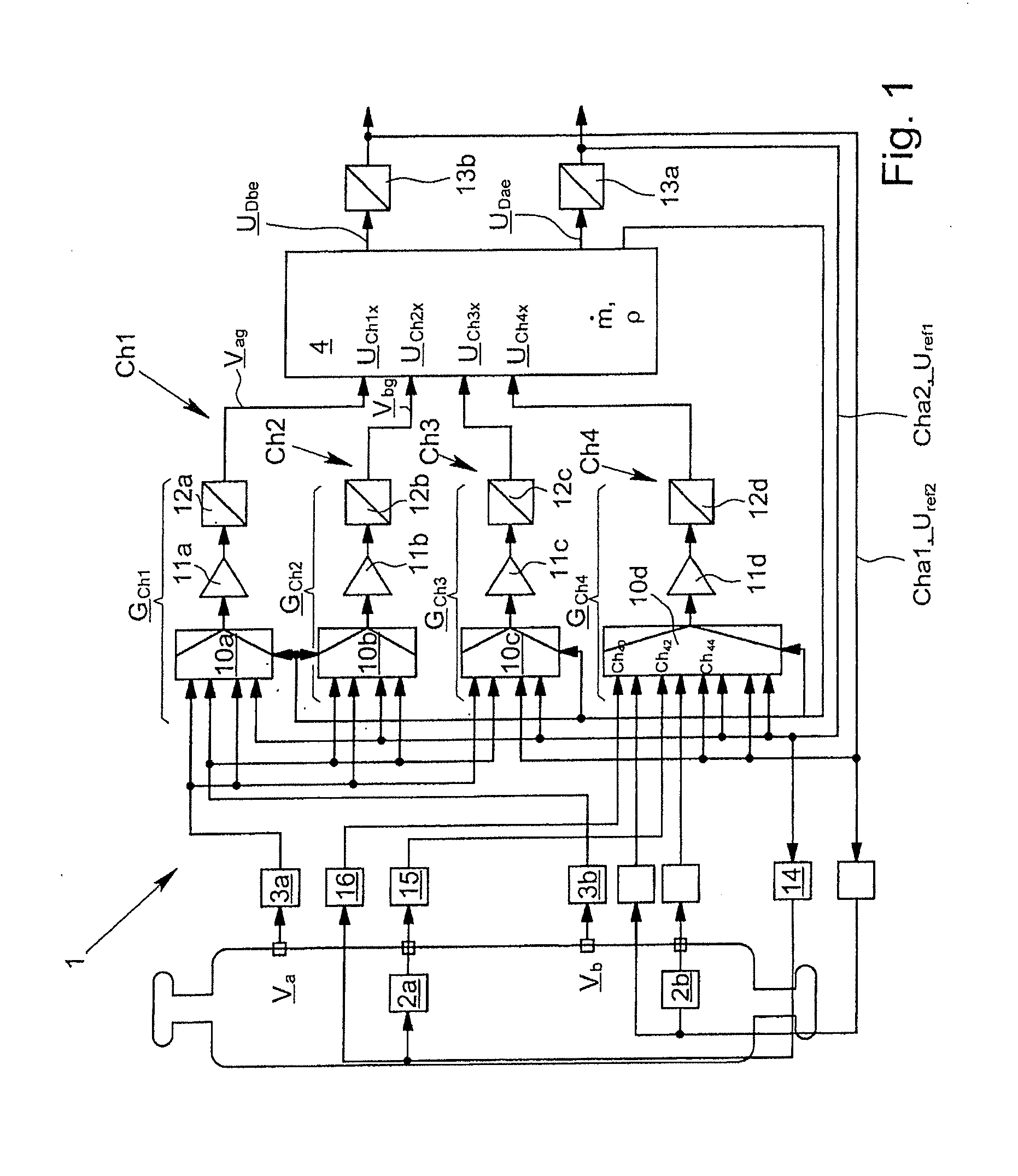

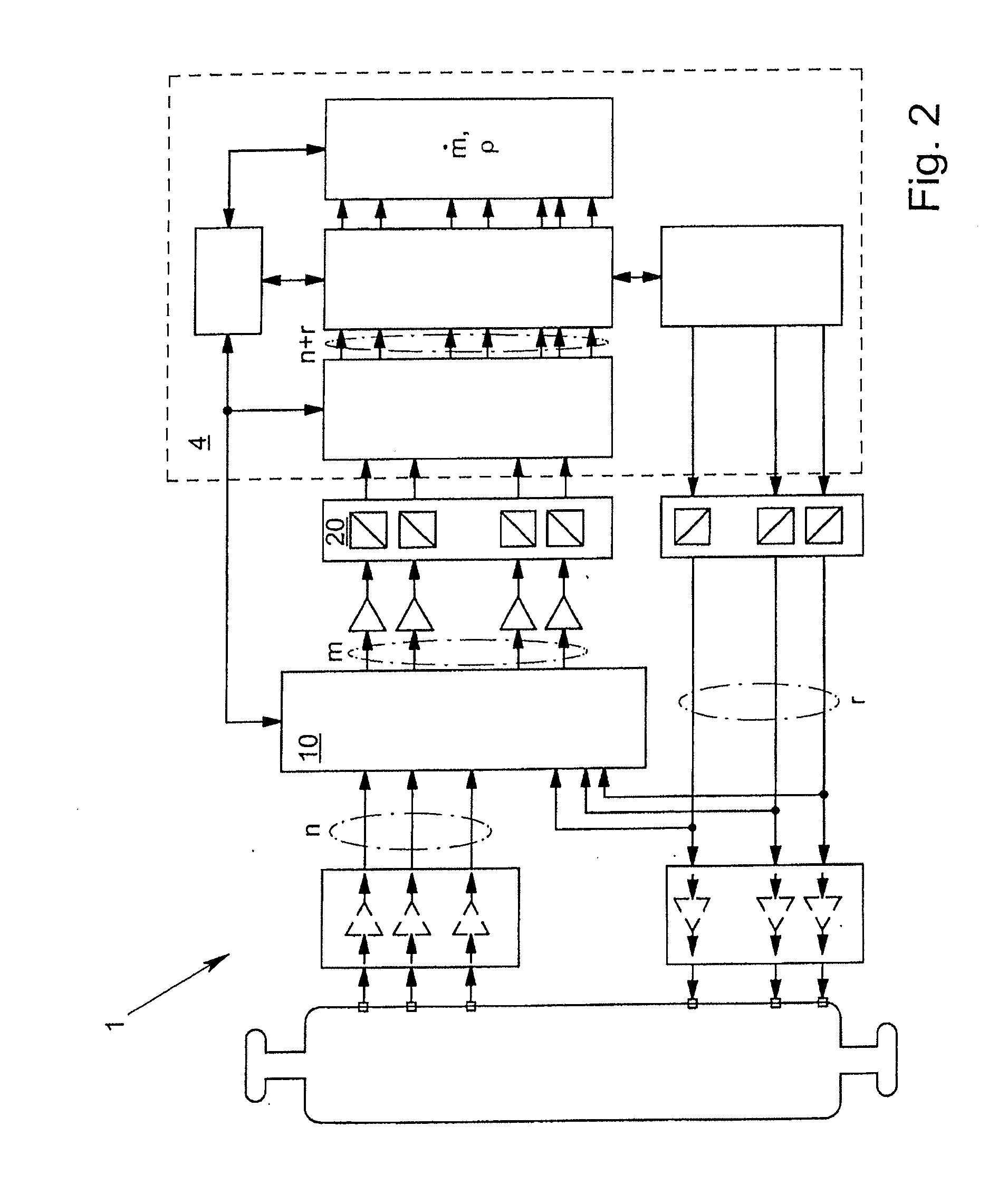

Method for operating a resonance measuring system

ActiveUS20130317760A1Improve accuracyMeasure securityFluid pressure measurementTesting/calibration for volume flowMeasurement deviceResonance

A method for operating a Coriolis mass flow measuring device having at least one measuring pipe through which a medium flows, at least one vibration generator, at least a first vibration sensor, at least a second vibration sensor and at least a control and analyzing unit. The detection of measurement variables or diagnosis parameters is achieved with increased accuracy and security in that the control and analyzing unit calculates, at least indirectly and in a ratiometric manner, at least a derived secondary variable based on a primary measurement, wherein interested primary measurement signals are transmitted alternately to the control and analyzing unit via different measurement channels and wherein, based on the various values obtained from the different measurement channels regarding the primary measurement signals, compensation values of the transmitted primary measurement signals are calculated and used as a basis for the calculation of the derived secondary variable.

Owner:KROHNE MESSTECHNICK GMBH & CO KG

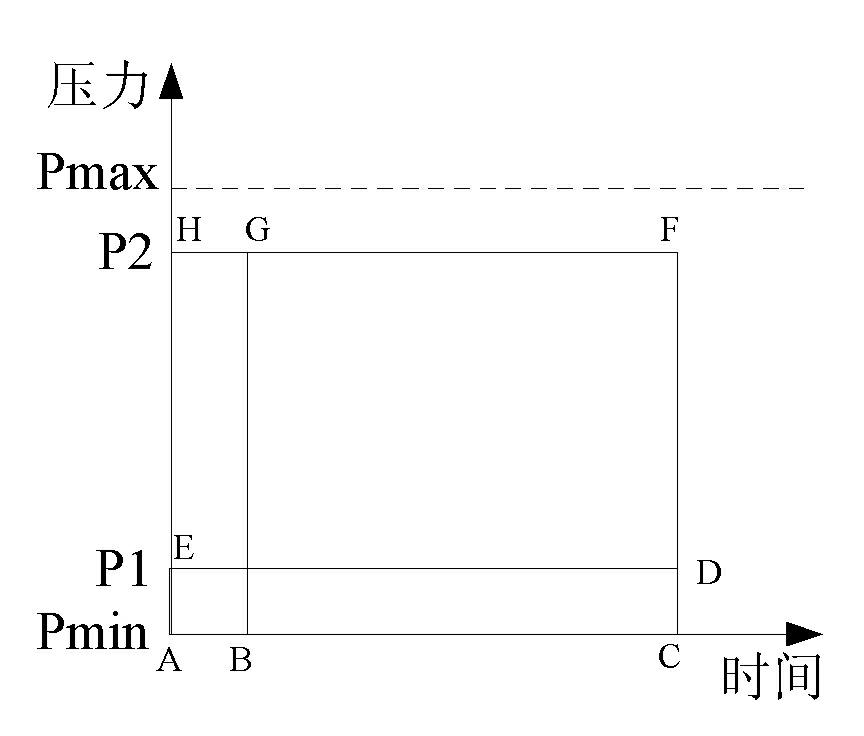

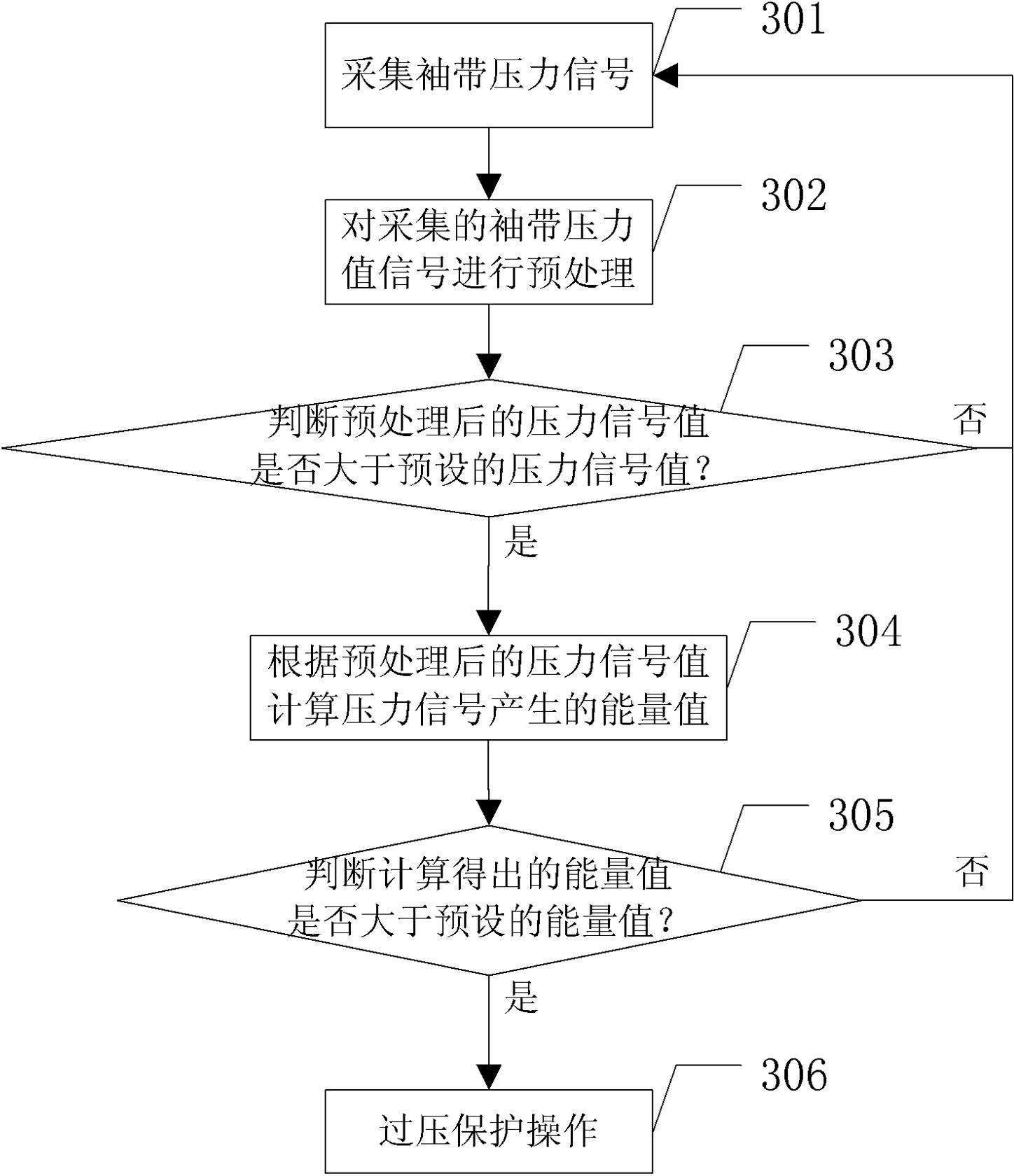

Pressure protection method and pressure protection apparatus used in non-invasive blood pressure measurement process

ActiveCN102579025AImprove measurement validityIncrease flexibilityAngiographyBiomedicineBiomedical engineering

The invention belongs to the field of biomedical signal processing, and particularly relates to a pressure protection method and a pressure protection apparatus used in the non-invasive blood pressure measurement process. Energy value of pressure generated in a cuff serves as a reference for pressure protection so that different types of patients can be protected. By the pressure protection method, measurement effectiveness of the non-invasive blood measurement device can be improved effectively, and harm to patients due to energy variation caused by pressure difference can be considered. The pressure protection method has the advantages of higher flexibility and more effective protection and higher safety in measurement.

Owner:EDAN INSTR

Method and device for measuring basis weight and moisture content amount

ActiveUS20130025350A1Measure securitySatisfy safety performance requirementsMaterial moisture contentMoisture content investigation using microwavesPeak valueMoisture

A resonance frequency shift amount Δf and a peak level change amount ΔP are measured using a microwave resonator, V1 and V2 are obtained based on V1=(Δf·∈″2 / Kf−ΔP·∈′2 / Kp) / (∈′1·∈″2−∈″1·∈′2), and V2=(Δf·∈″1 / Kf−ΔP·∈′1 / Kp) / (∈″1·∈′2−∈′1·∈″2), and an absolute dry basis weight and a moisture amount are obtained based on absolute dry basis weight=β·V1, and moisture amount=γ·V2. For the constants Kf, Kp, c′1, ∈′2, ∈″1 and ∈″2, the constants ∈′1, ∈′2, ∈″1 and ∈″2 are determined so that the variance values of Kf and Kp are smaller than a predetermined value.

Owner:OJI HLDG CORP

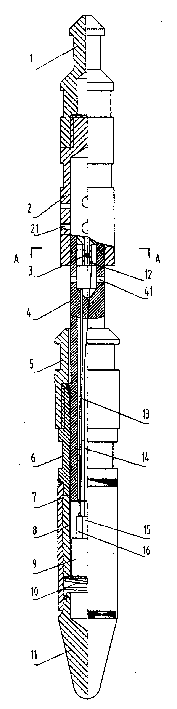

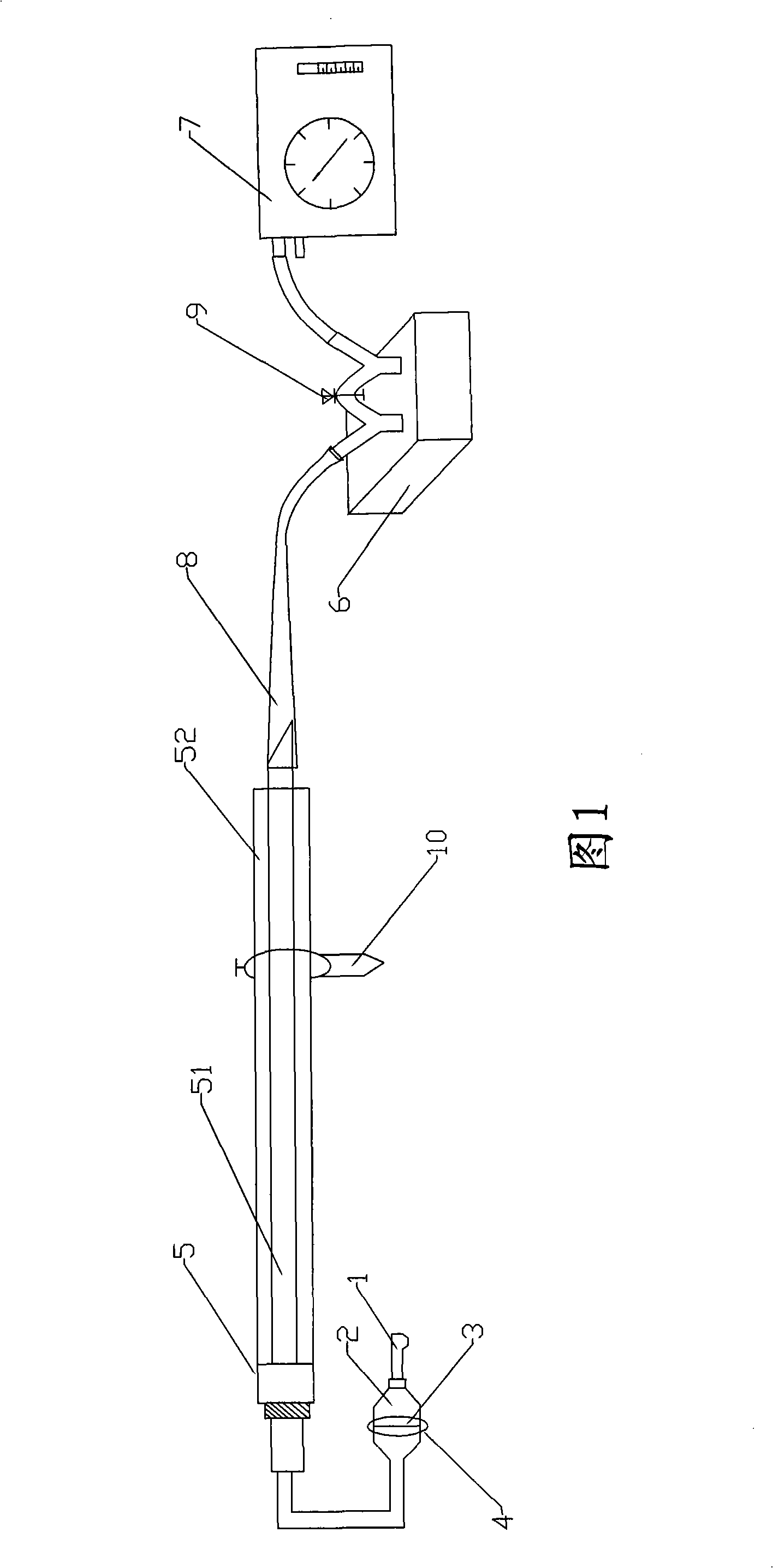

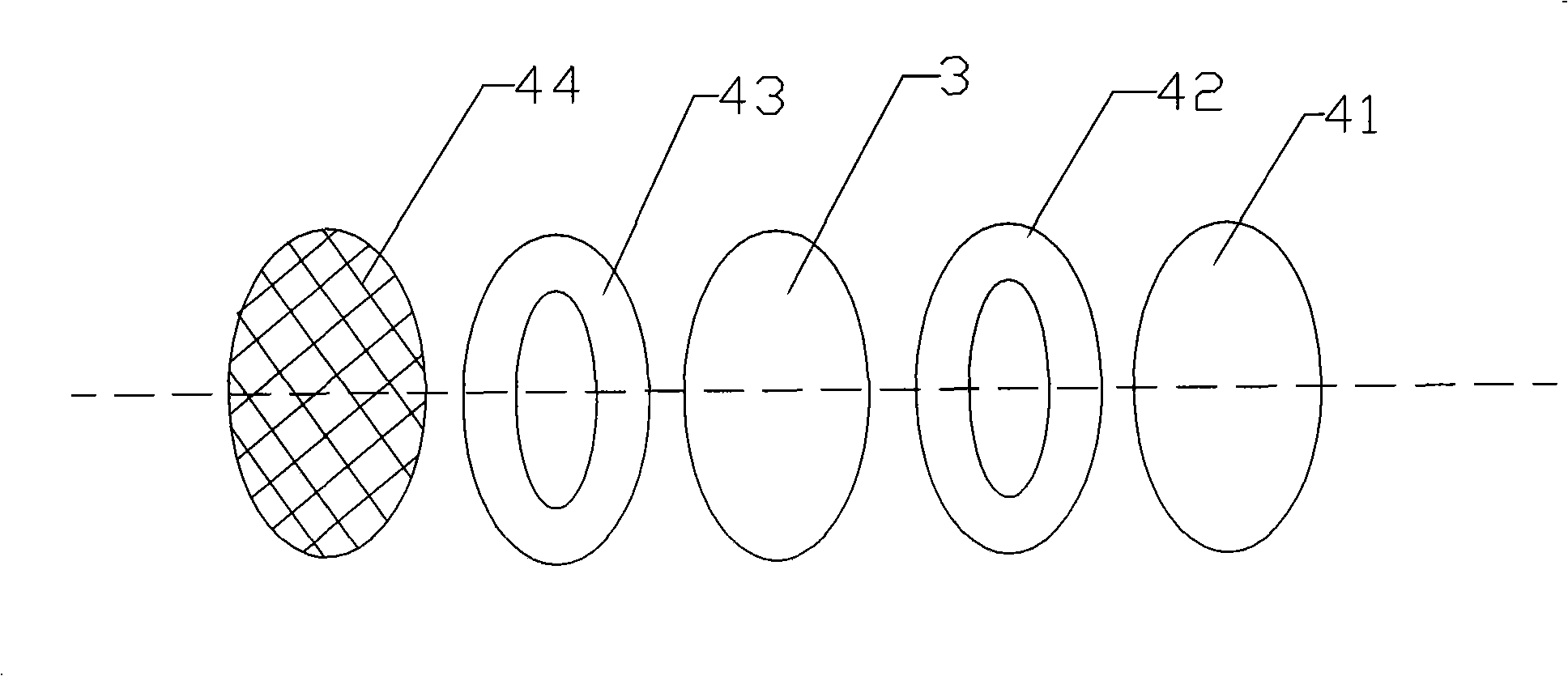

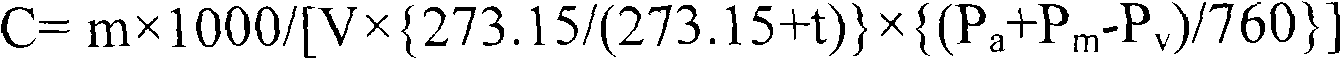

Downhole steam flow and mass dryness fraction measurement method and measurement instrument

InactiveCN1477375AIngenious methodReasonable designVolume/mass flow by differential pressureMaterial analysisImpulse frequencyMeasuring instrument

The present invention discloses a downhole steam flow and dryness fraction measurement method and its measuring instrument. The measurement method in includes measurement of difference pressure and vortex-shedding frequency. Its steps are: (A). the described measurement of difference pressure and vortex dropping frequency uses the integrated measuring instrument with vortex-shedding frequency generator, difference pressure sensor and vortex-shedding sensor to make measurement.; and (B) it utilizes the measured throttle difference pressure and vortex-shedding frequency and uses the two-phase flow measuring formula corrected simultaneously by using flow rate coefficient and density coefficient to make simultaneous resolution so as to obtain the downhole steam flow rate and dryness fraction.

Owner:OIL EXTRACTION TECH INST OF SINOPEC SHENGLI OILFIELD

Equipment and method for measuring dust content in flue gas

InactiveCN101408491AInvestigate the effect of dust removalAccurate analysisWithdrawing sample devicesWeighing by absorbing componentFlue gasEngineering

The invention discloses an apparatus for measuring dust content of flue gas and a method thereof. The apparatus comprises a dust collecting device, a sampling device and a suction device; an outlet end of the dust collecting device is connected with an inlet end of the sampling device, and the outlet end of the sampling device is connected with the inlet end of the suction device; in the method, the flue gas passes the dust collecting device under the condition of constant speed suction, the dust in the flue gas is filtered by filter paper, and the dust content of the flue gas is calculated by weighing the weight of the filter paper before filtering the dust and the weight of the filter paper after filtering the dust and putting the weights into a formula. By the device for measuring the dust content of the flue gas, the dust content of the flue gas can be accurately analyzed. The device has the advantages of novel design, simple structure and easy implementation, and is very applicable to large scale popularization and use. The method for measuring the dust content of the flue gas has the advantages of safe and reliable sampling, simple operation, accurate and reliable analysis result and fast detection.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

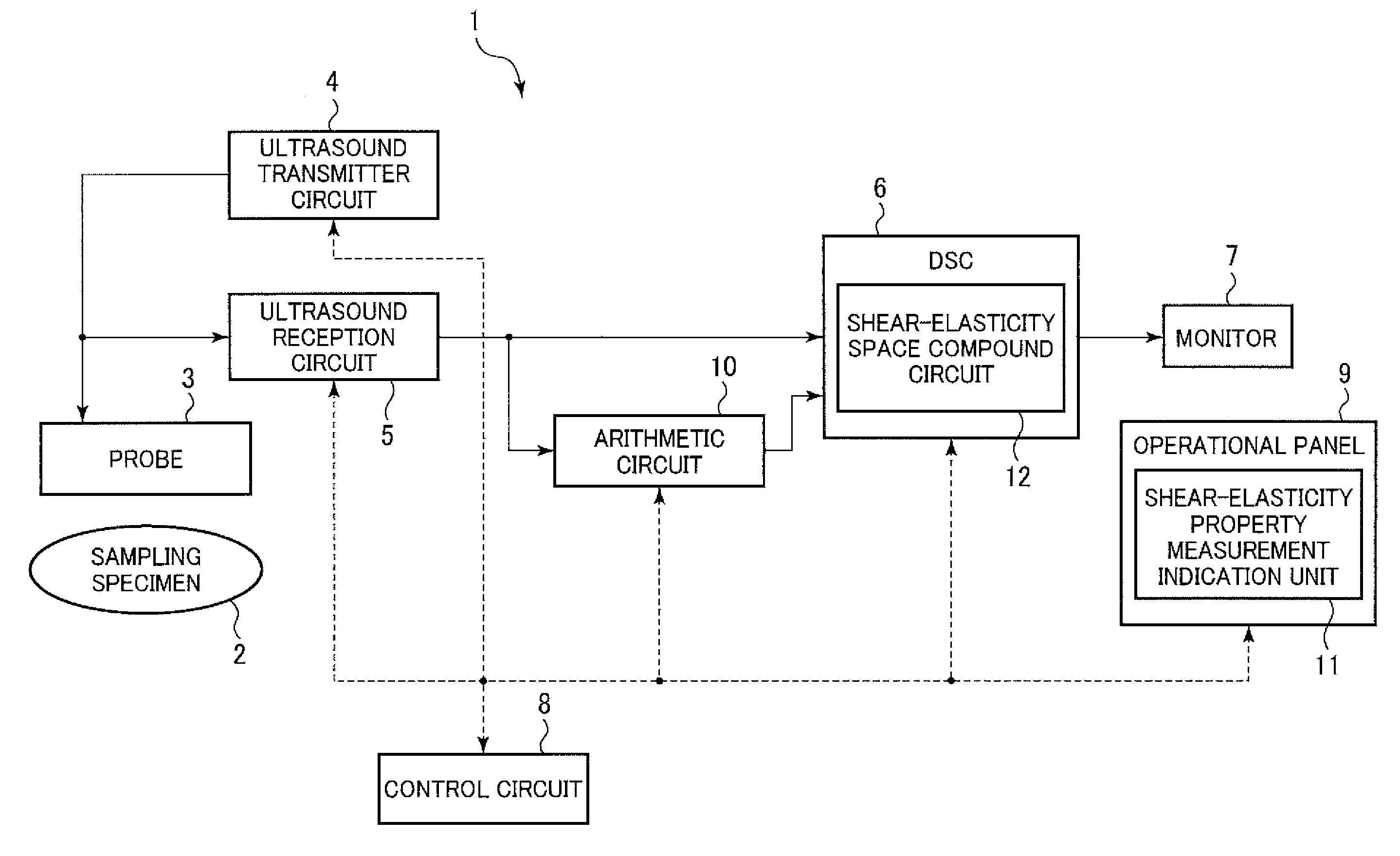

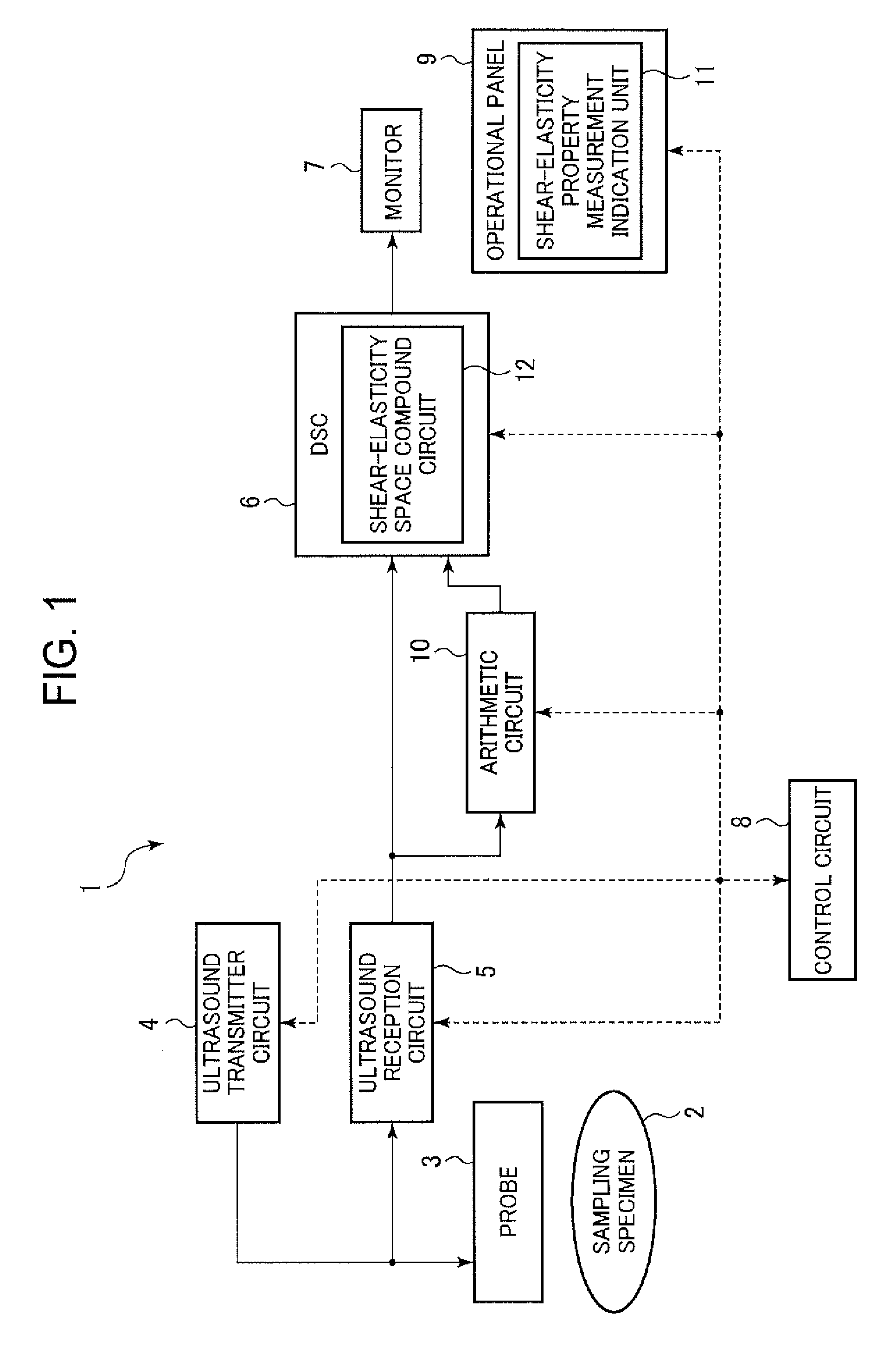

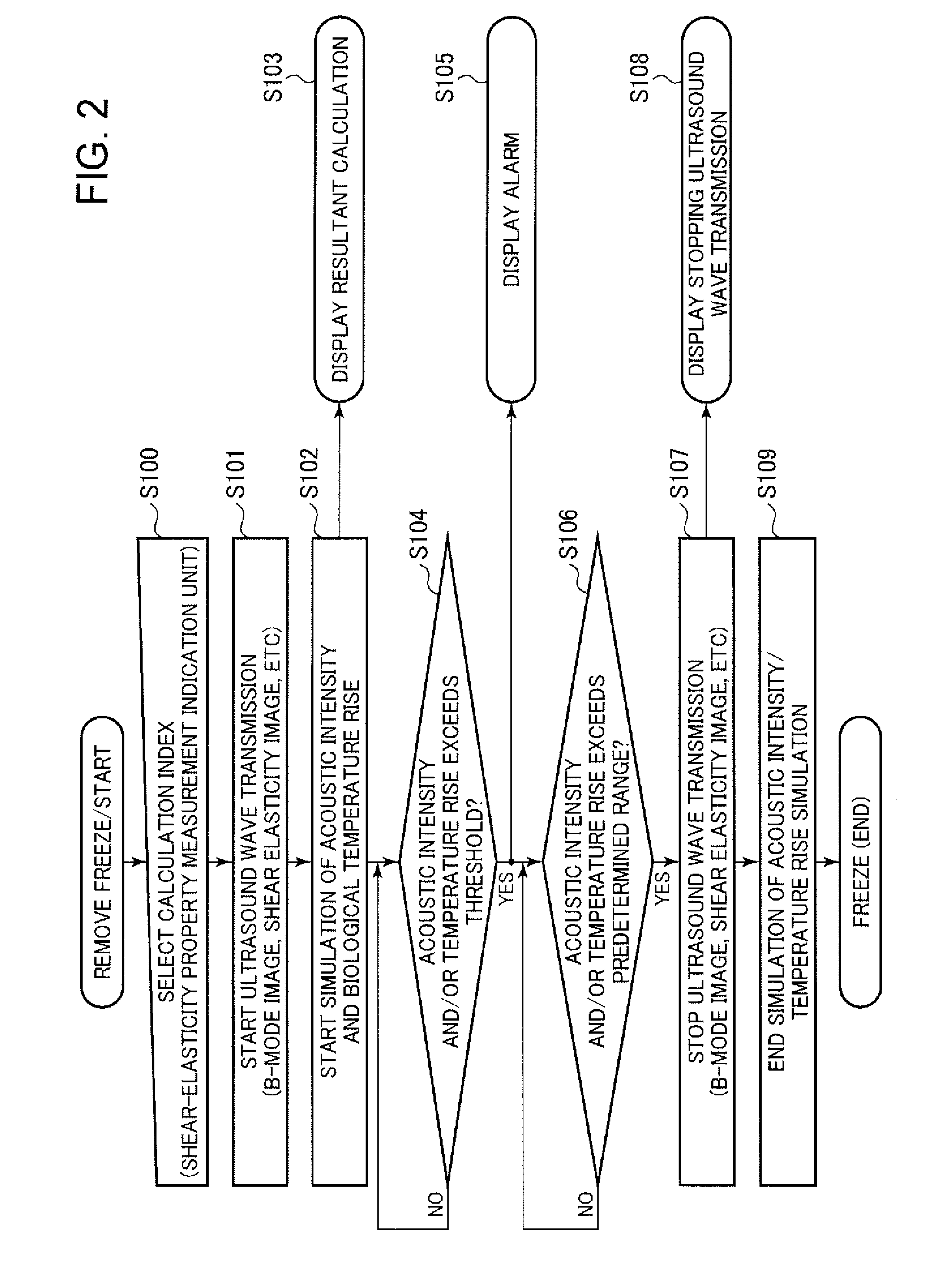

Ultrasound diagnostic apparatus and shear-elasticity measurement method therefor

InactiveUS20140148698A1Increase temperatureMeasure securityWave based measurement systemsOrgan movement/changes detectionBiological tissueUltrasonic radiation

An inventive ultrasound diagnostic device is provided, which can display information on the temperature rise in a biological object under ultrasound radiation for measurement of a shear elasticity of a biological tissue of interest, thereby drawing attention of an examiner of the device and enabling him to retain the temperature rise within a predetermined safe range while performing the shear elasticity measurement. The device is adapted to measure the shear elasticity of a tissue by ultrasonic waves emitted from a probe. The device has a calculation unit configured to calculate a rise in temperature of the biological tissue irradiated with a focused ultrasonic (US) beam, and a display unit configured to display the temperature information obtained.

Owner:HITACHI LTD

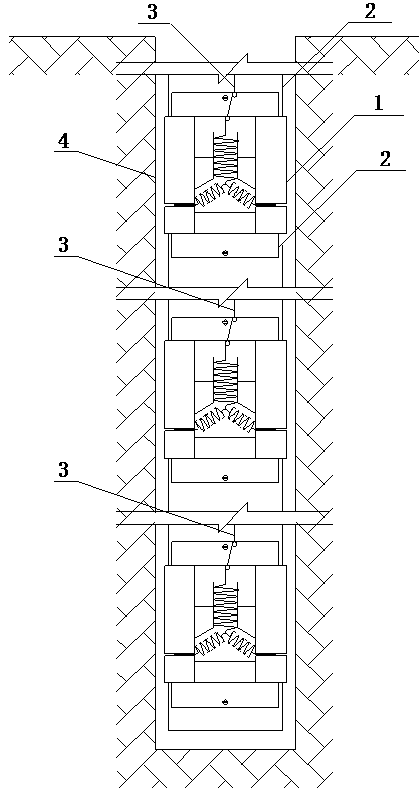

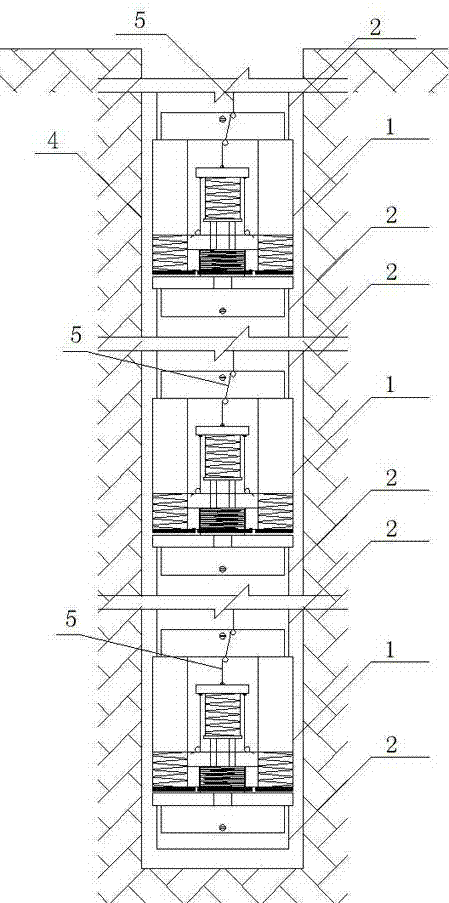

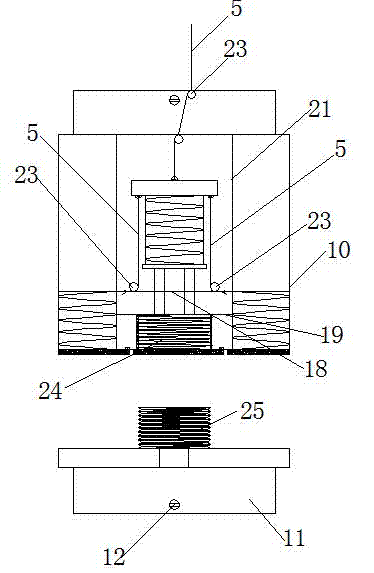

Multilayer blade-typed multipoint displacement metre anchor head used for soft soil layer

InactiveCN102953365AEasy to installSimple structureIn situ soil foundationField conditionsEngineering

The invention discloses a multilayer blade-typed multipoint displacement metre anchor head used for a soft soil layer, wherein the anchor head comprises a plurality of measuring point anchoring head units arranged in a drilling hole of a to-be-tested soil body; each measuring point anchoring head unit is orderly and vertical to each other and connected with each other through a casing pipe from head to tail; each measuring point anchoring head unit is fixed with one longitudinal measuring point of the drilling hole. Each measuring point anchoring head unit comprises a main anchoring head and an anchoring head protective cover, wherein each main anchoring head and each corresponding anchoring head protective cover are connected in thread. The multipoint displacement metre anchoring head in the invention can drive three blade-typed anchoring grasps synchronously with three springs; utilizes elastic energy released instantly to cut into the soft soil to finish anchoring; is not limited by field condition; and is convenient in installation, simple in structure, strong in reliability and stability, good in anchoring effect, strong in anti-skid ability and reliable in performance.

Owner:TONGJI UNIV

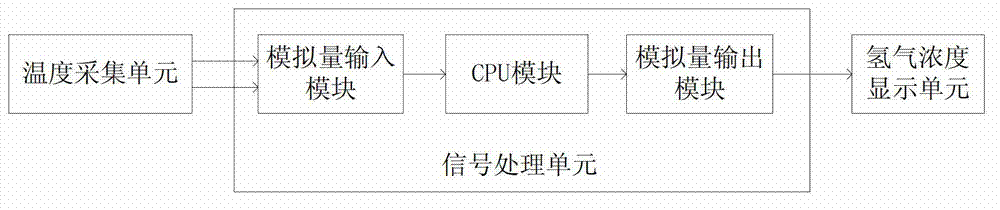

Concentration measuring system of hydrogen in containment vessel

ActiveCN102928463ASafe continuous measurementReduce energy consumptionMaterial heat developmentContinuous measurementHydrogen concentration

The invention discloses a concentration measuring system of hydrogen in a containment vessel, belonging to the technical field of concentration measurement of flammable and explosive gasses. The concentration measuring system comprises a temperature acquisition unit, a signal processing unit and a hydrogen concentration display unit, wherein the signal processing unit comprises an analog value input module, a CPU (Central Processing Unit) module and an analog value output module; and the temperature acquisition unit, the analog value input module, the CPU module, the analog value output module and the hydrogen concentration display unit are connected in sequence. The concentration measuring system is low in energy consumption, simple to assemble and capable of safely and reliably realizing continuous measurement of concentration of hydrogen in the containment vessel under accident conditions of a nuclear power plant.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com