Endoporus measuring device

A technology of measuring device and inner hole, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of large volume, time-consuming and labor-intensive, poor reliability of detection quality, etc., and achieve high measurement accuracy, easy operation and regulation, measurement safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

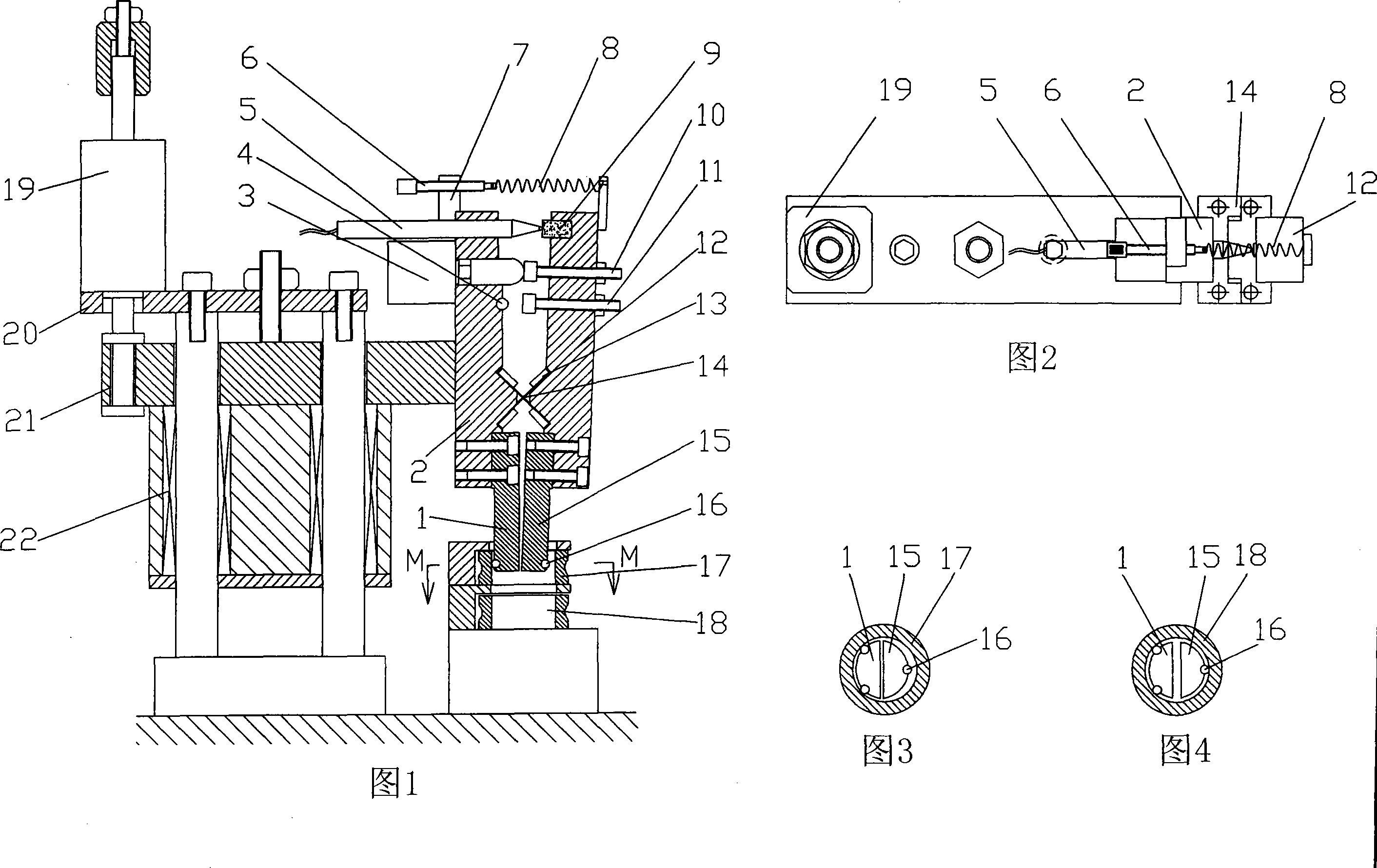

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] The measuring head is composed of two petals of the same shape and size, the dynamic measuring head 15 and the static measuring head 1. The outer circular surface of the static measuring head 1 is embedded with two measuring points 16 made of hard alloy or ceramics. 15 is embedded with a measuring point 16, as shown in Fig. 3 and Fig. 4 .

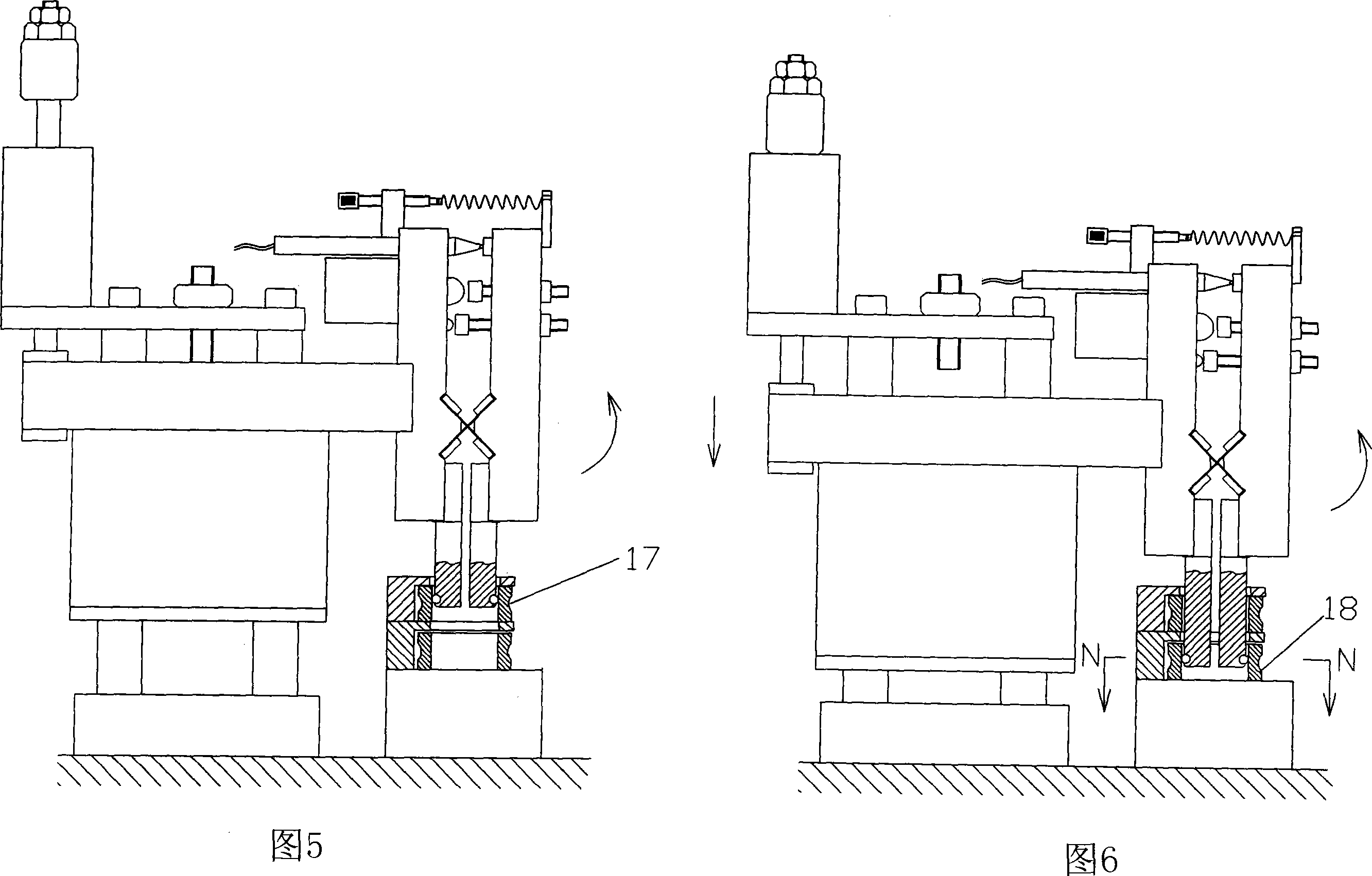

[0016] When measuring, the dynamic probe 15 moves outward, and its section is a circle with a gap in the middle, as shown in FIG. 4 .

[0017] The power cylinder 19 is fixed on the fixed plate 20, and the guide post and the guide sleeve 22 connect the fixed plate 20 and the movable plate 21 into an integral power source.

[0018] Through the movable plate 21, the power source and the moving measuring frame 12 on the measuring mechanism are fixed as a whole, as shown in Fig. 1 and 2 .

[0019] Connect one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com