Patents

Literature

1322results about How to "Won't wear out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

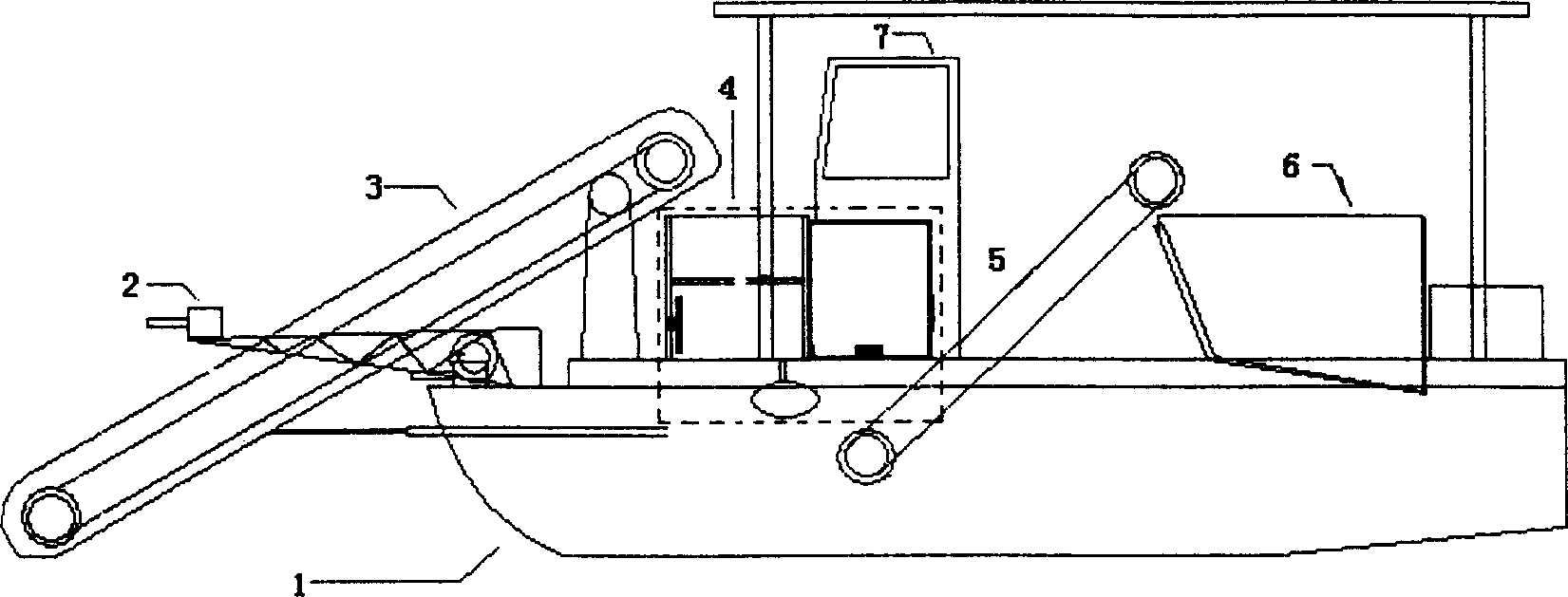

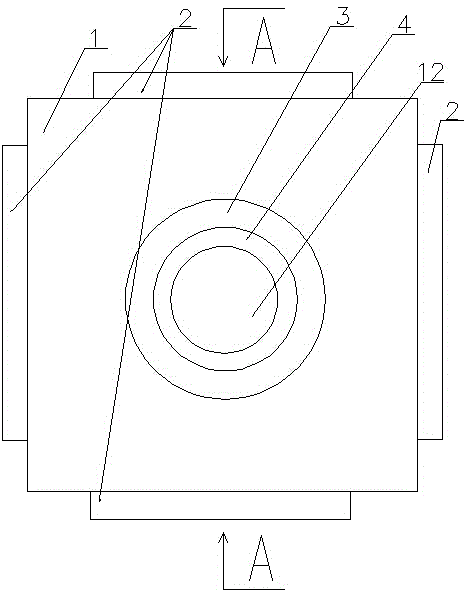

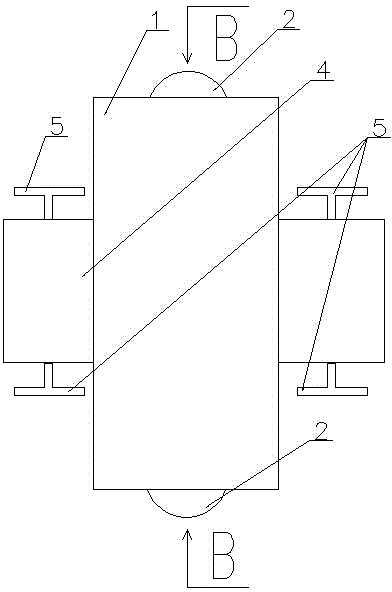

Ultrasonic cleaner

ActiveCN103878143AConsistent cleanlinessReduce replacement cycleCleaning using liquidsFiltrationWater storage tank

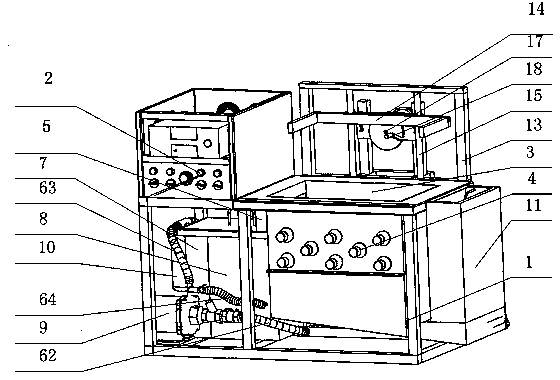

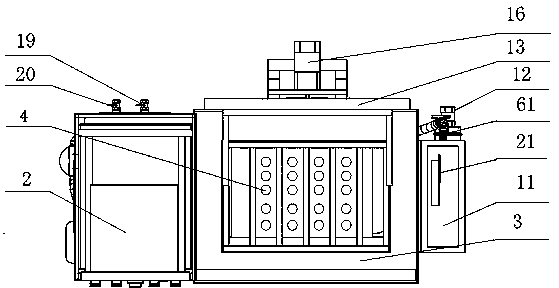

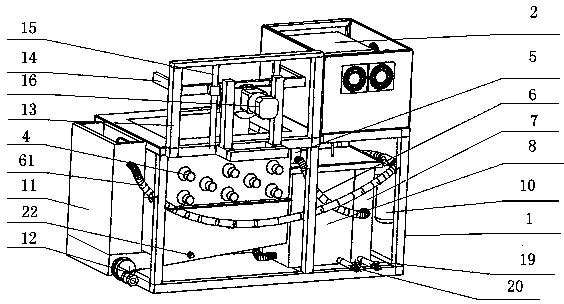

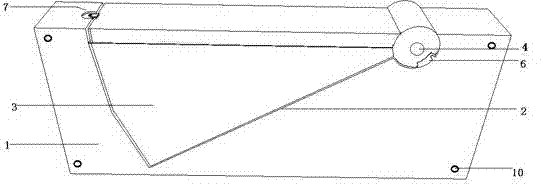

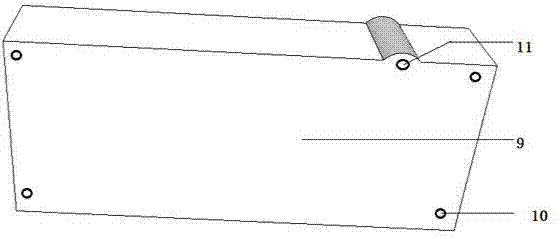

The invention discloses an ultrasonic cleaner and belongs to the field of mechanical equipment cleaning. The ultrasonic cleaner solves the problems that cleaning fluid in an existing ultrasonic cleaner cannot remove impurities in time, and the cleaning fluid is wasted. The ultrasonic cleaner comprises a rack (1), an ultrasonic generator (2), a cleaning tank (3) and ultrasonic vibrators (4). A water circulation device is arranged on the outer side of the cleaning tank (3) and comprises an overflow tank (5) arranged on one side of the cleaning tank (3). The water circulation device further comprises the overflow tank, an oil contamination tank (7), a water storage tank (8), a water pump (9), a filter (10) and a water injection tank (11). The bottom of the water injection tank (11) is communicated with the cleaning tank (3). The bottom of the cleaning tank (3) is an inclined plane. The ultrasonic cleaner integrates the functions of heating, ultrasonic waves, circulating filtration, oil-water separation and article movement, the cleaning speed is high, and the cleaning effect is good; besides, the ultrasonic cleaner is multifunctional, low in energy consumption and capable of prolonging the replacement cycle of the cleaning fluid and reducing environmental pollution, thereby being wide in application range.

Owner:台州鸿辰机械制造有限公司

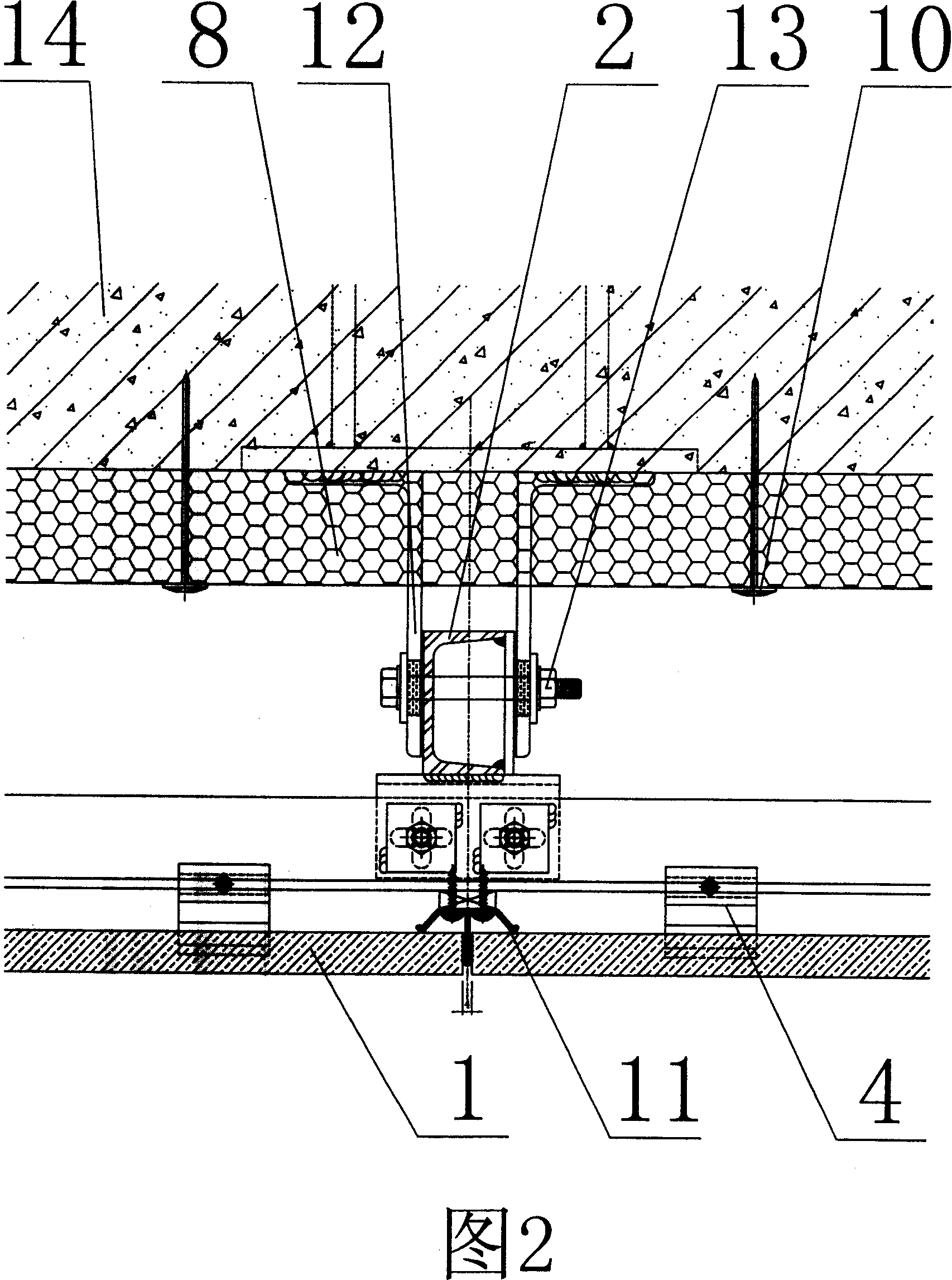

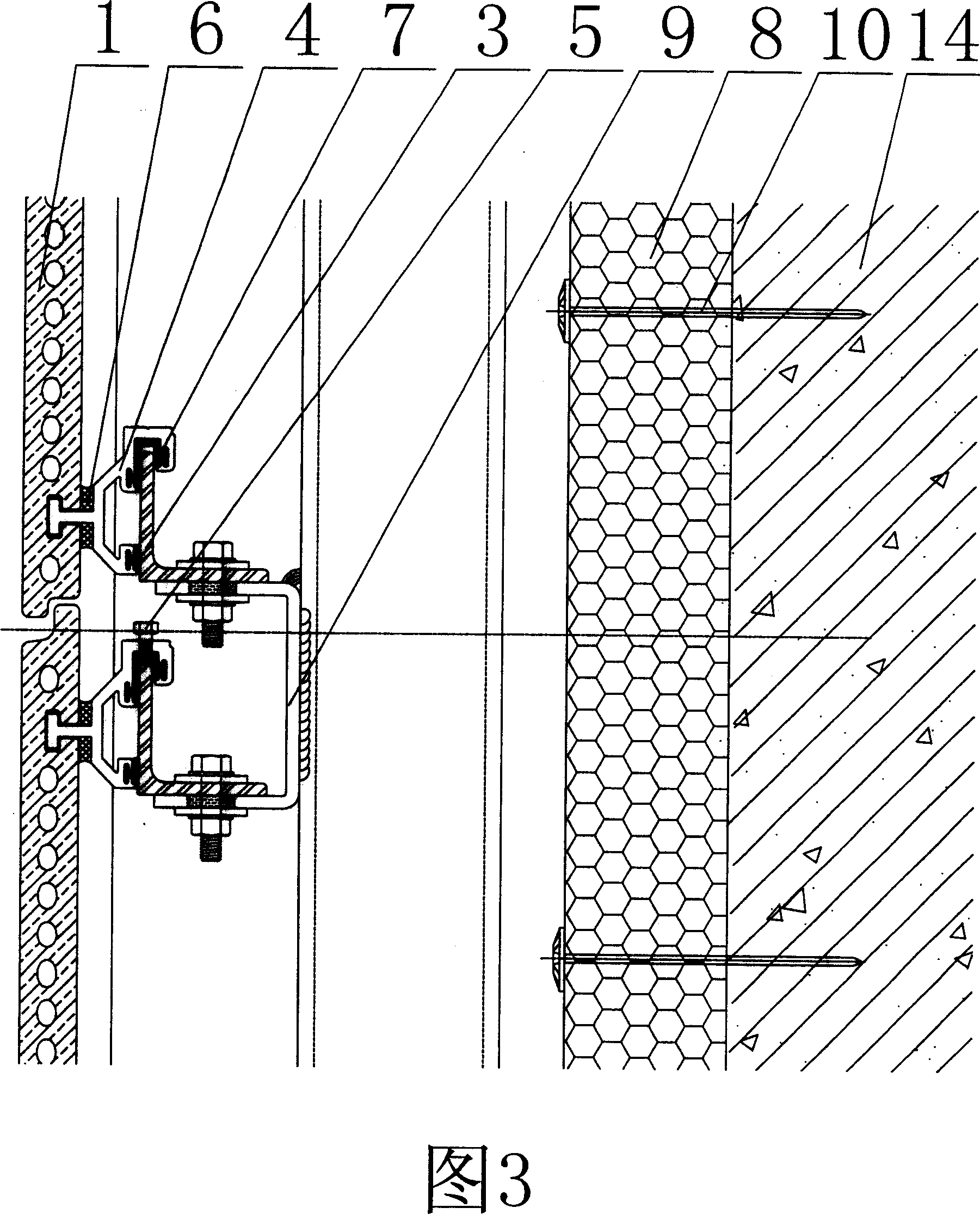

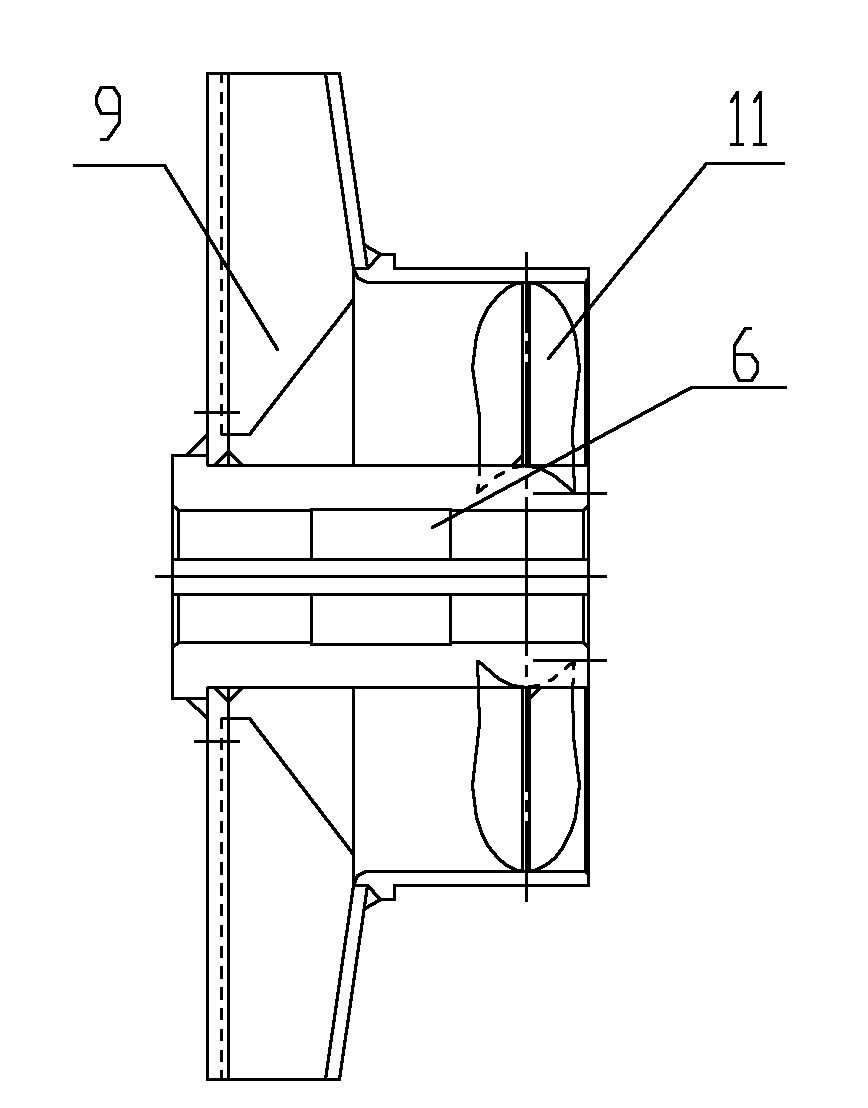

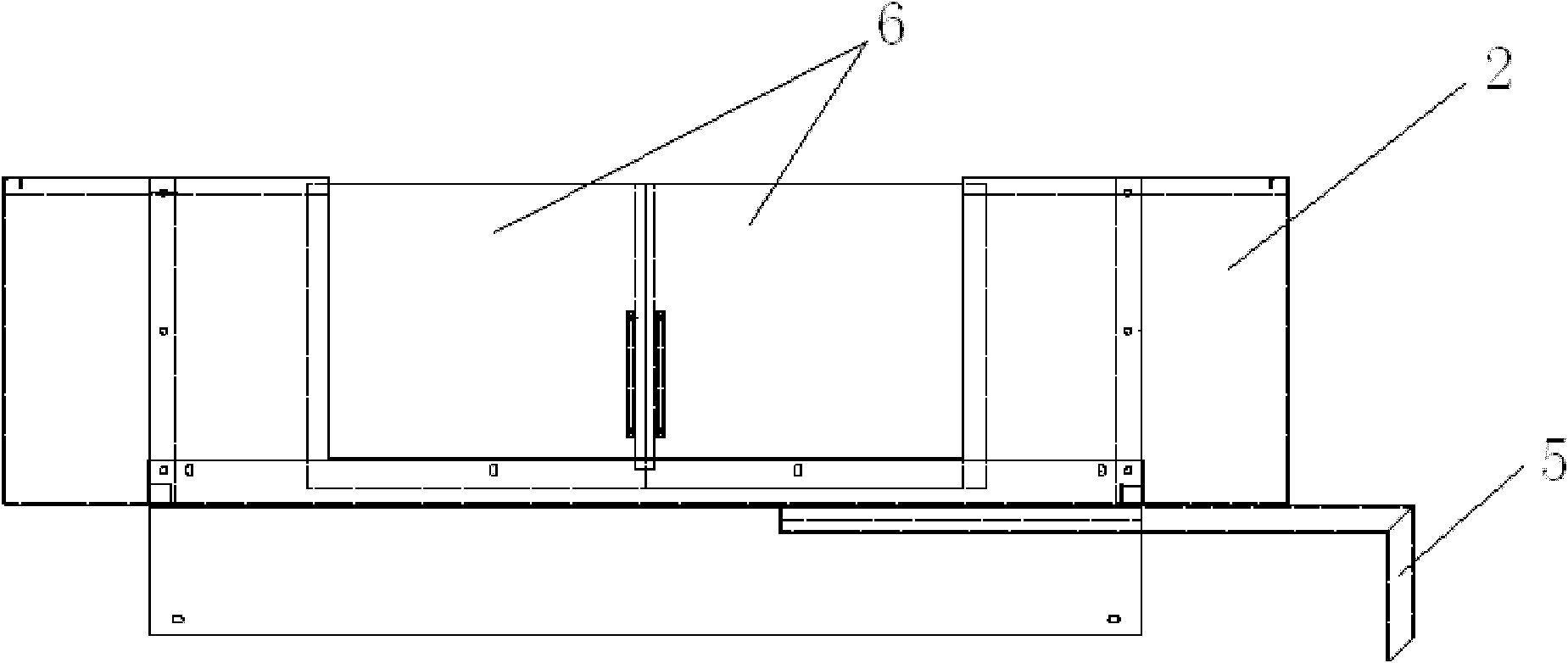

Mounting structure of figuline board curtain wall

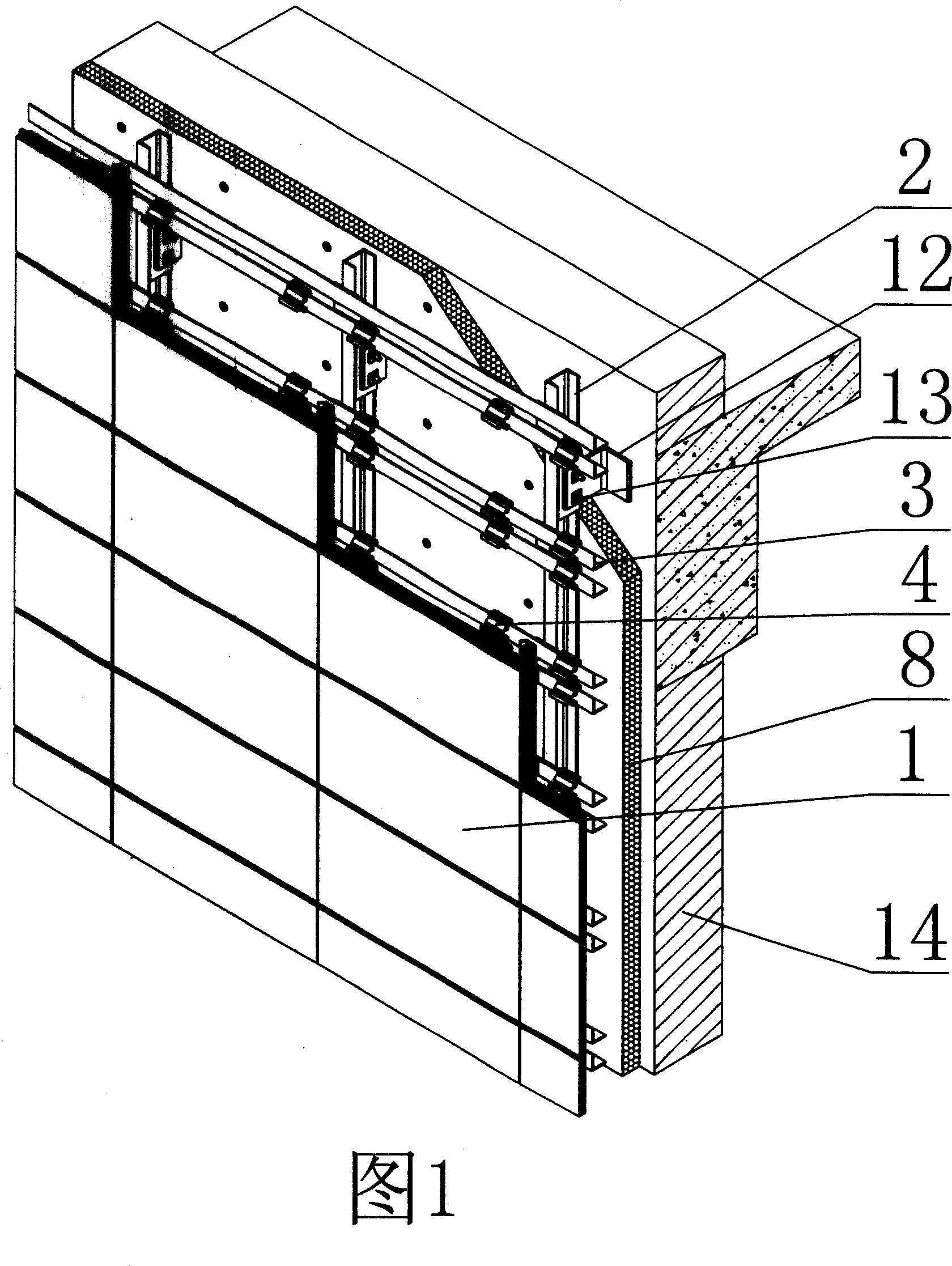

The invention discloses an installing structure for the curtain wall of ceramic plate, comprising a vertical skeleton, a horizontal skeleton, a parting connector and a linking part. The vertical skeleton is set vertically and the horizontal skeleton is set horizontally. The vertical skeleton is fixed with the horizontal skeleton in cross. The vertical skeleton is fixed on the wall and the linking part is installed on the horizontal skeleton. The front end of linking part is ligule and the back end is pothook shape. The invention also comprises an adjusting screw and a rubber strip. The rubber strip is set between the linking part and the horizontal skeleton. The adjusting screw passes through the linking part and is connected on the horizontal skeleton by screw connection. The parting connector is installed at the connecting position of horizontal beam of ceramic plate. The invention changes the rigid connection between the horizontal skeleton and the linking part into the flexible connection so as to avoid the noise and eliminate the deformation. Up and down directions of installed ceramic plate are adjusted by the adjusting screw to guarantee that the installed seam is smooth completely. The horizontal skeleton is made of profiled bar. So the material is saved and the cost is decreased.

Owner:沈英 +1

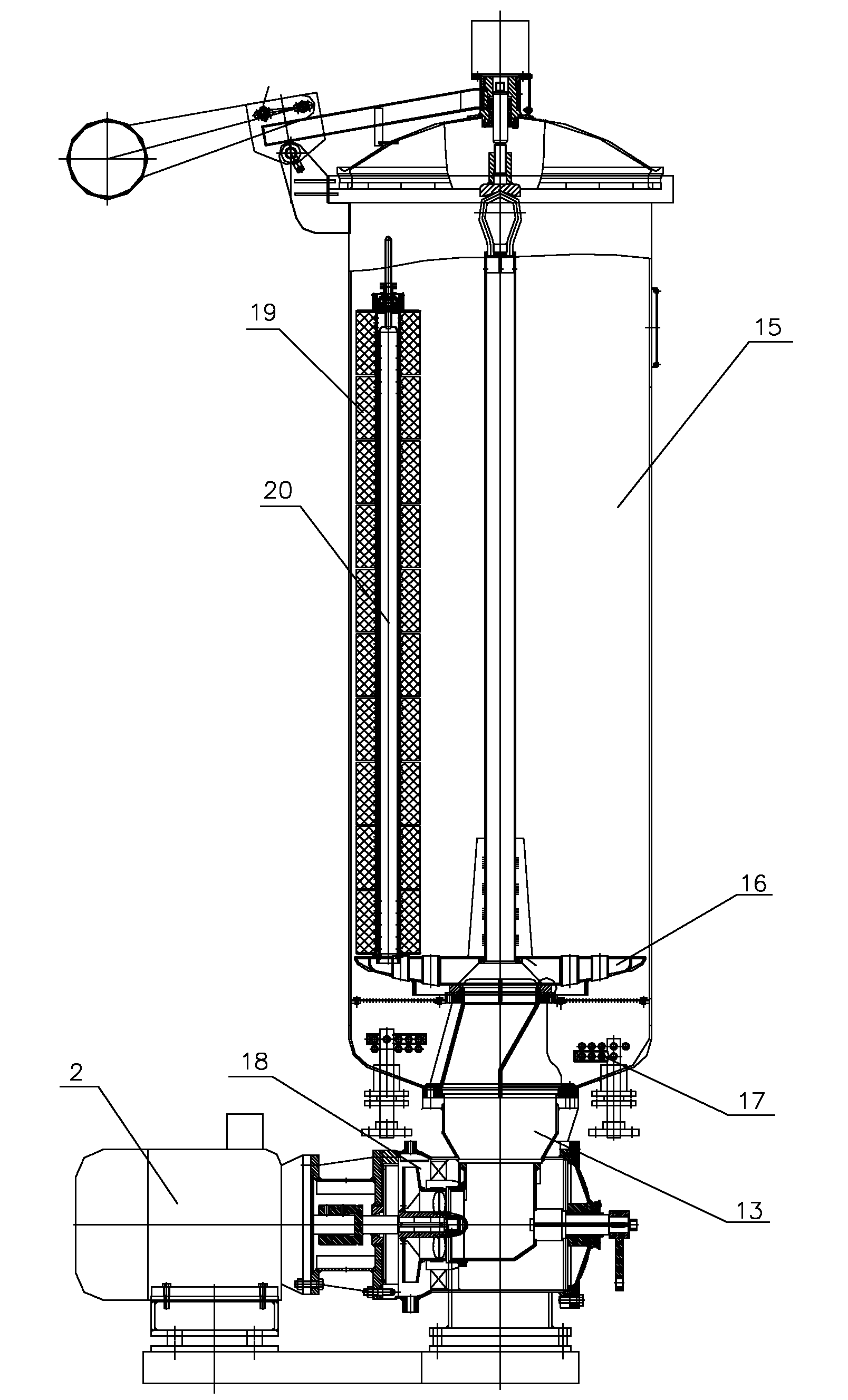

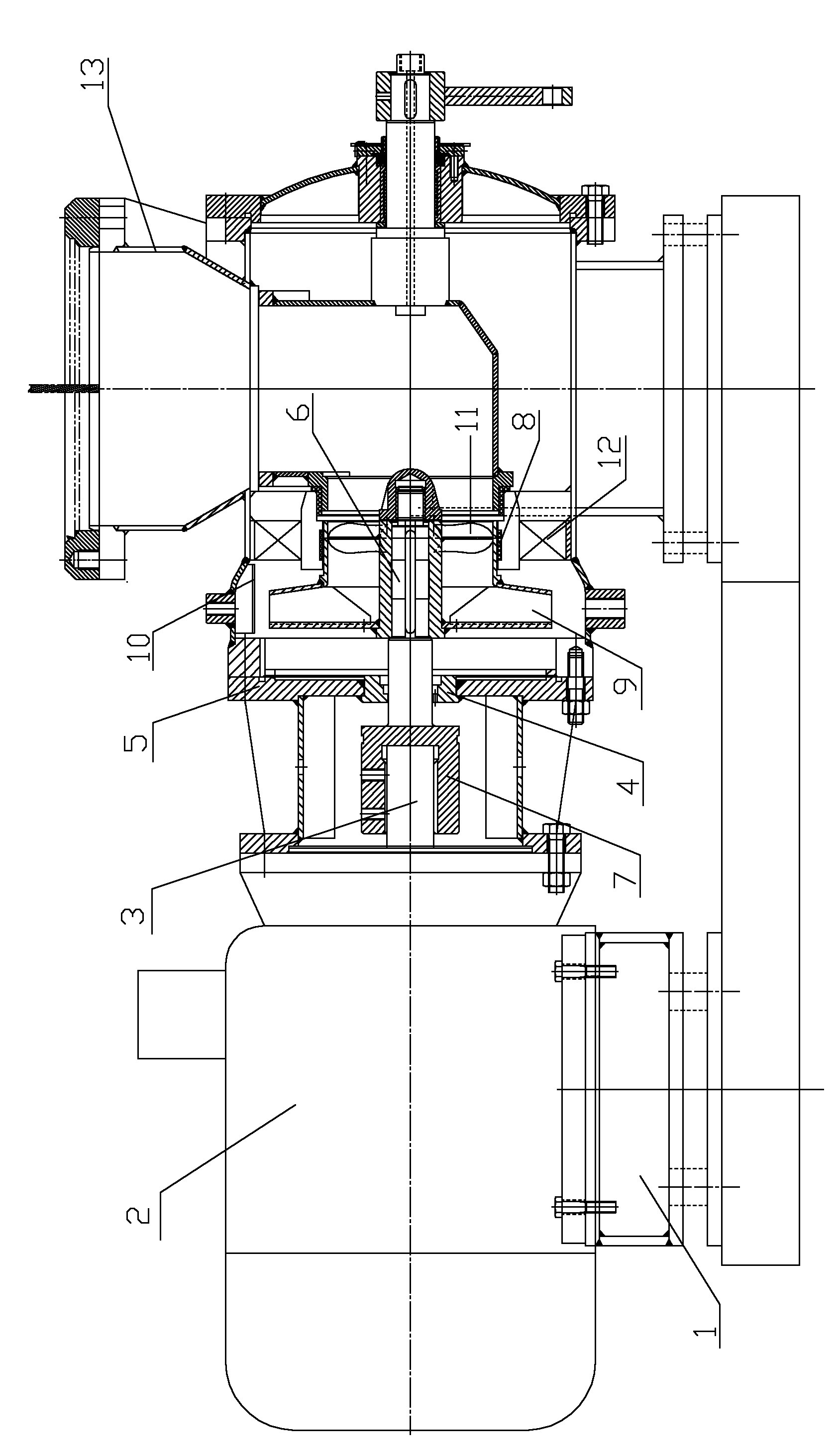

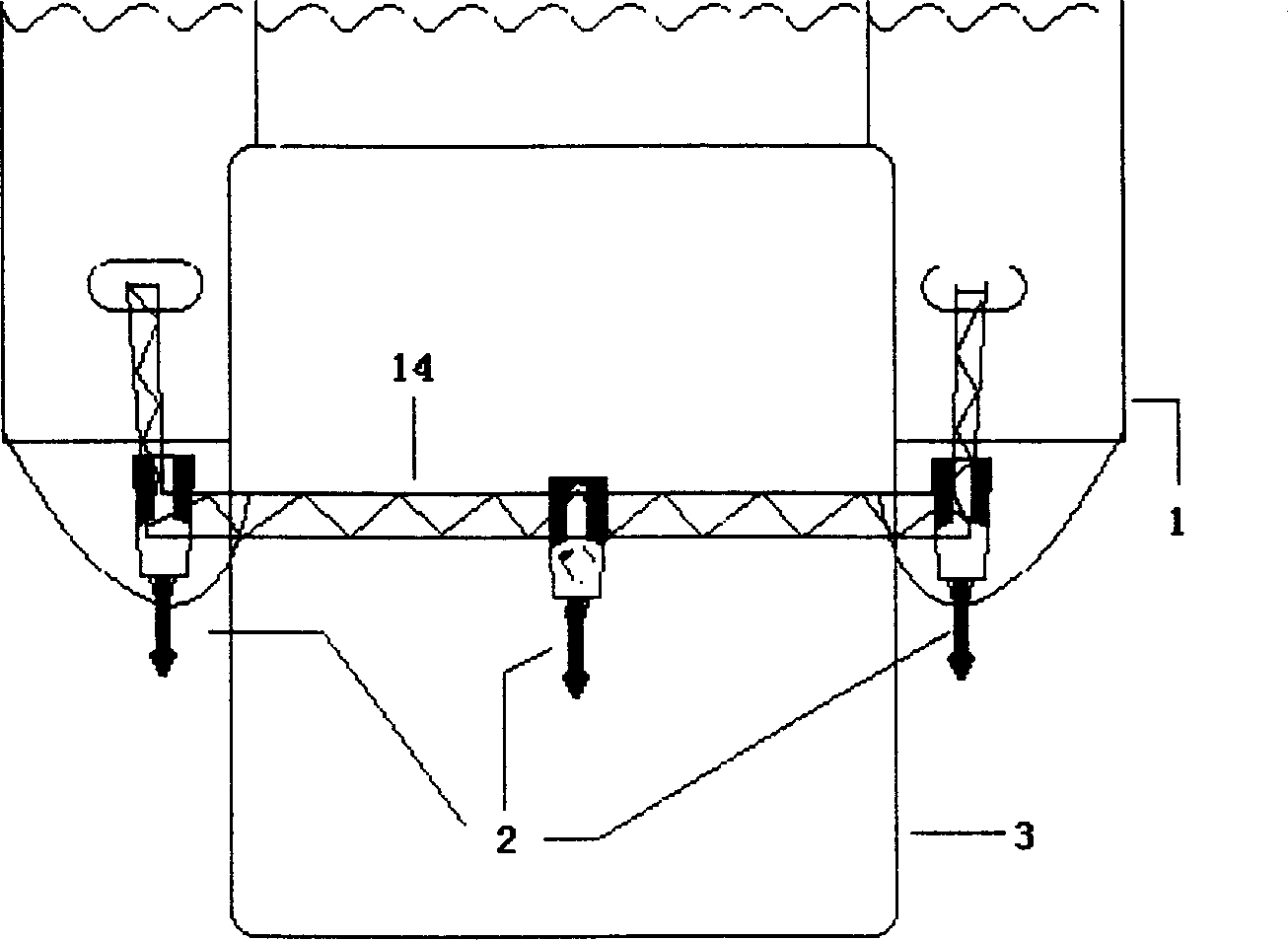

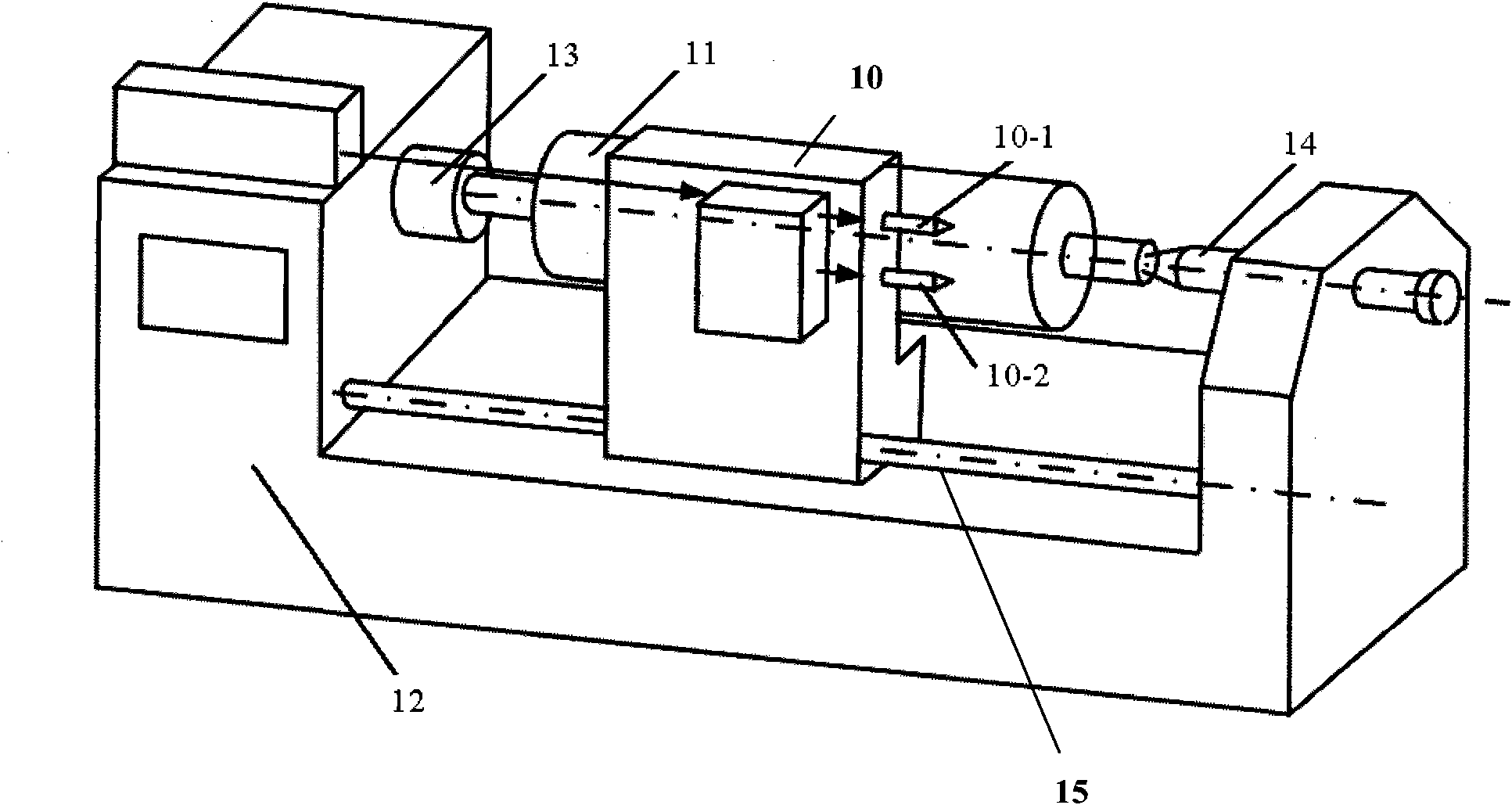

Ultralow bath-ratio yarn dyeing machine with three-level vane pump

InactiveCN102134793ACycle fastAvoid layer chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment machine arrangementsYarnThree level

The invention discloses an ultralow bath-ratio yarn dyeing machine with a three-level vane pump, comprising a dye vat, a yarn stand and a vane pump, wherein the bottom of the yarn stand is a yarn stand disk; the yarn stand disk is provided with a hole communicated with a dye liquor input channel in the dye vat; the vane pump is arranged below the whole dye vat and is a three-level vane pump; a shaft of the three-level vane pump is connected with an internal motor shaft coaxially; the dye vat is connected with the inlet of the three-level vane pump; the three-level vane pump comprises an axial flow level, a centrifugal level and a fixed guide vane level; the axial flow level and the centrifugal level are connected with the motor in sequence through the same transmission shaft; dye liquor flows into the axial flow level through an in-flow channel; the dye liquor flowing out of the axial flow level directly enters the inlet of the centrifugal level; and the dye liquor flowing out of the centrifugal level enters an out-flow channel after passing through the fixed guide vane level. During work, the dye liquor in the dye vat does not exceed the yarn stand disk all the time and the bath ratio is lower than 1:3. The ultralow bath-ratio yarn dyeing machine can achieve required lift when the dye liquor in the yarn dyeing machine is lower than a spindle, so as to realize the low bath ratio of the yarn dyeing machine as well as the purpose of saving energy and reducing emission.

Owner:高勋绿色智能装备(广州)有限公司

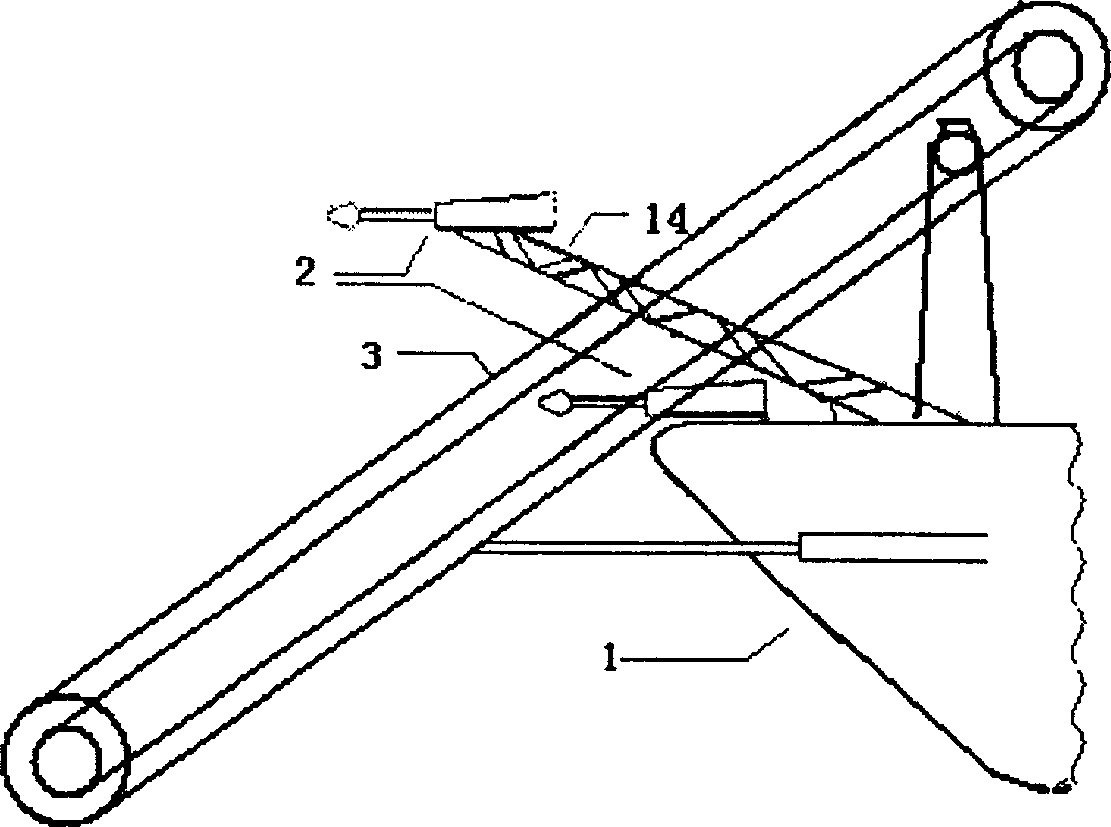

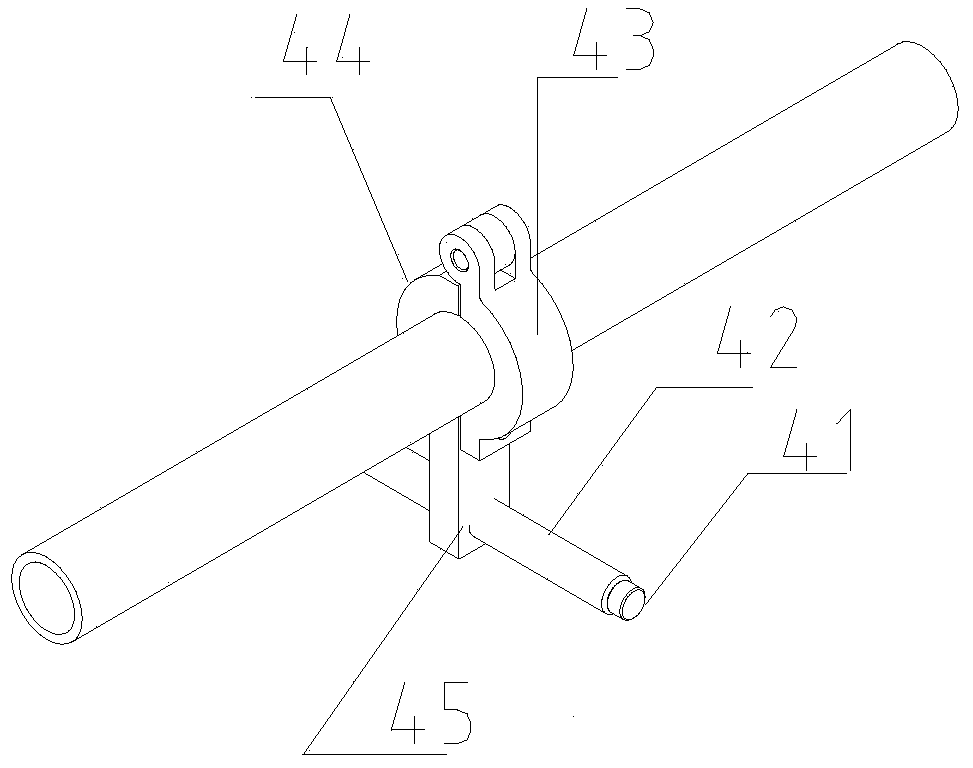

Pipeline apparatus for hyacinth salvage boat

InactiveCN1522932AWon't wear outNovel cutting methodWaterborne vesselsSpecial purpose vesselsMarine engineeringWork cycle

The present invention relates to a water hyacinth rescure vessel flow line equipment, belonging to the field of environment protection technology. Said invention includes double-body vessel vessel-body, high-pressure water gun, telescopic crawler wheel, press-filtering cabin, fixed crawler wheel, storage cabin and drive cabin. Said invention also provides their connection mode and working mode. Said invented cutting mode is novel, does not wear cutting tool and can prevent serious secondary pollution, and can raise working efficiency by 30%-50%.

Owner:SHANGHAI JIAO TONG UNIV

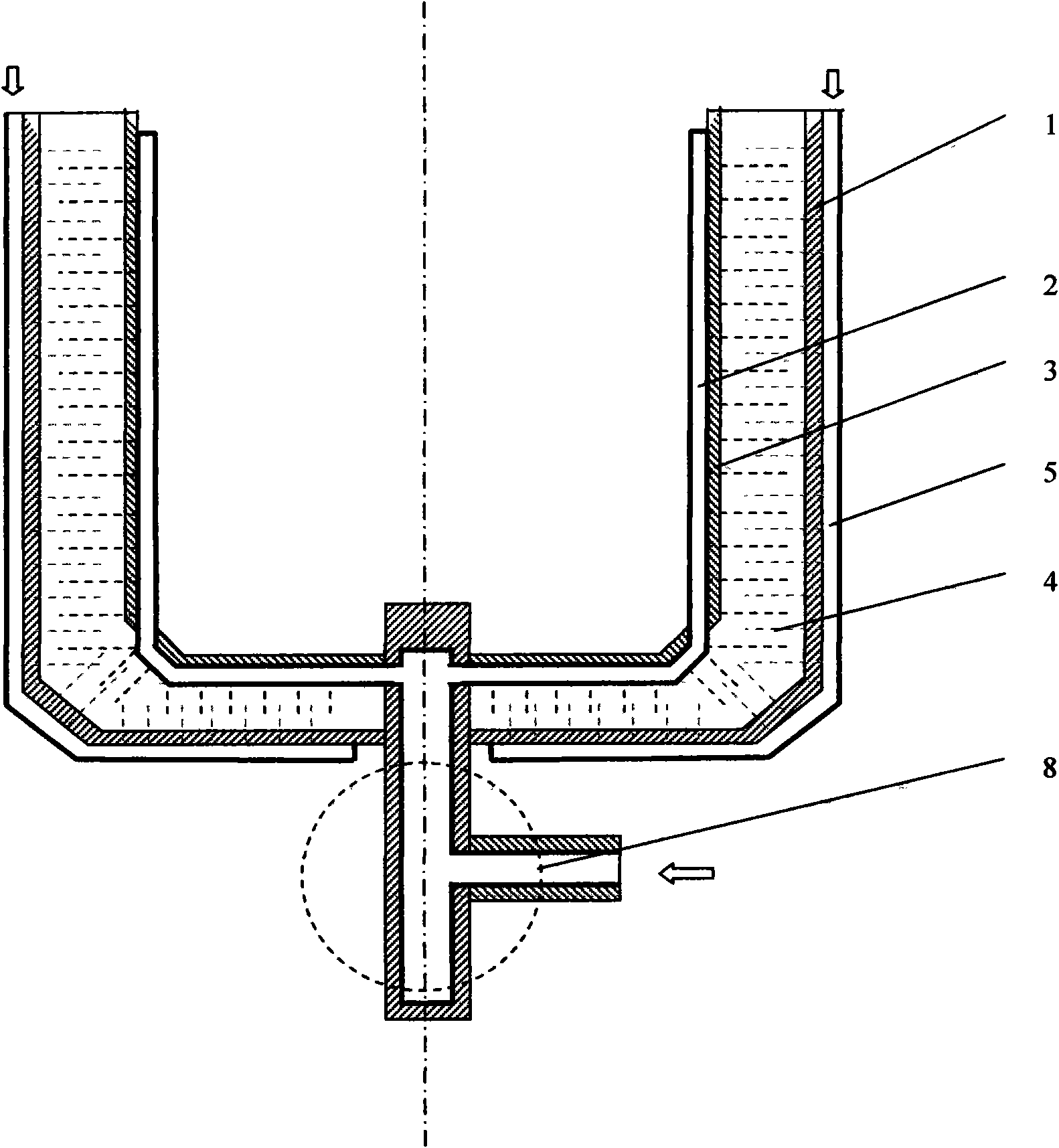

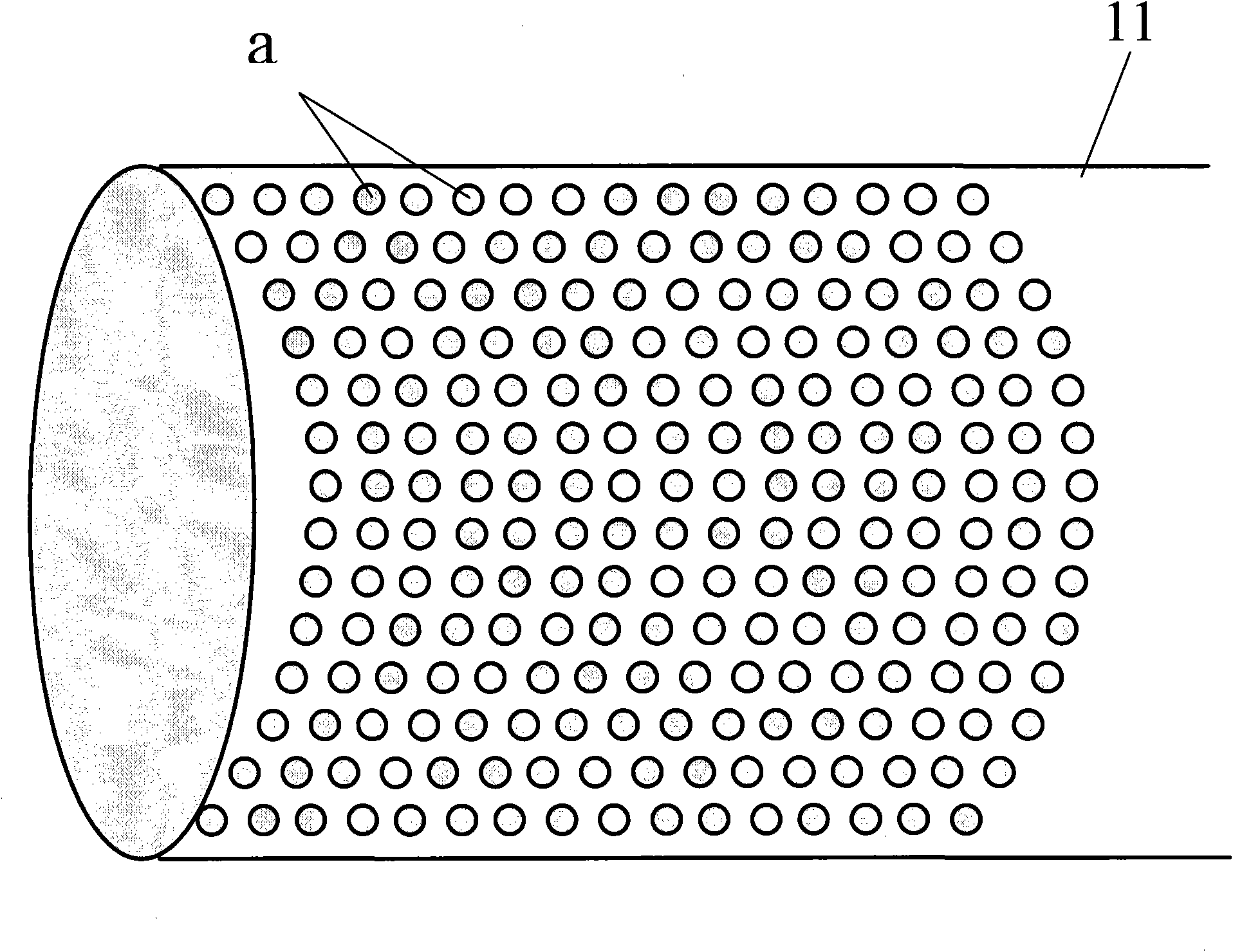

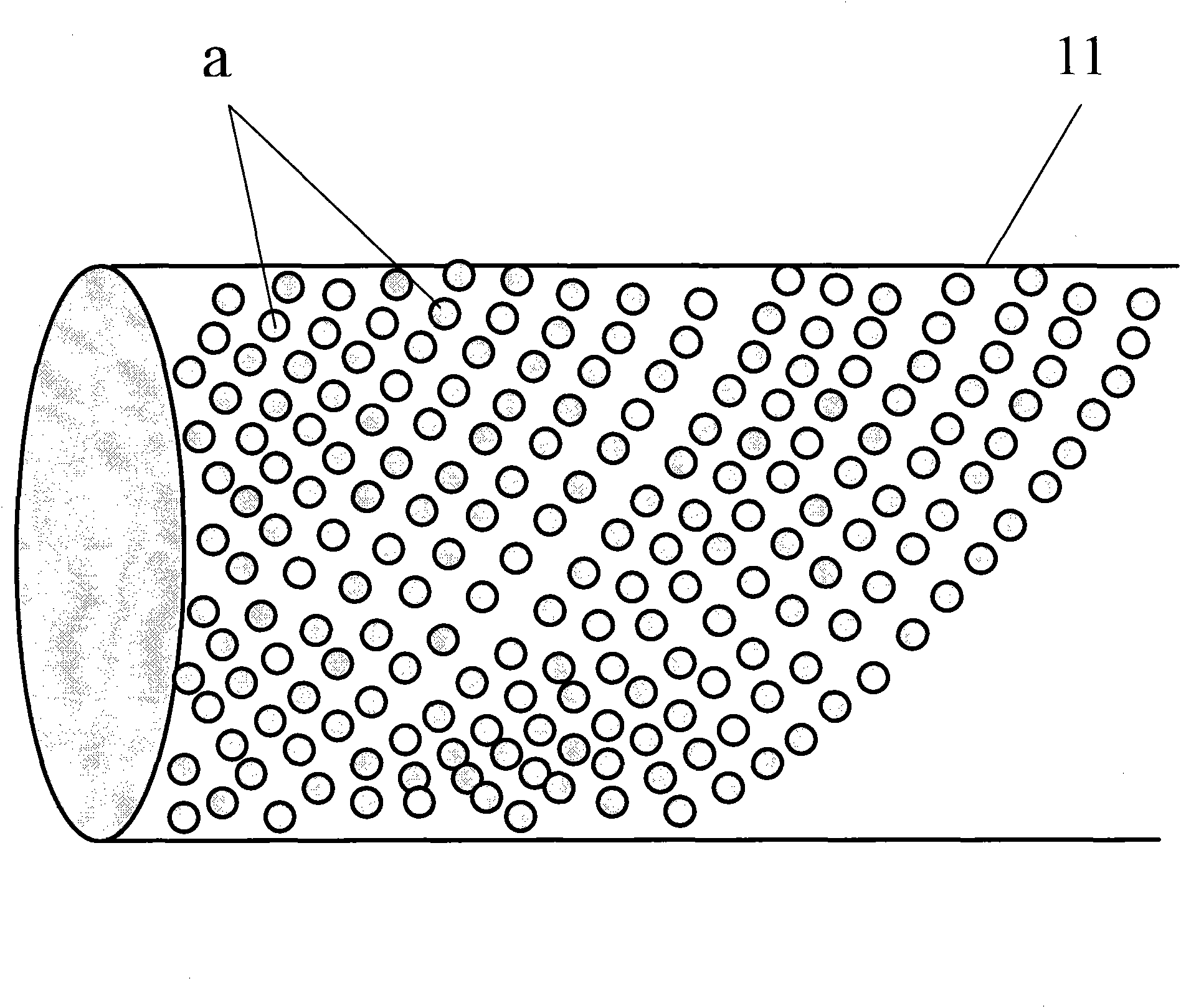

Self-cleaning device for dirt between barrels of washing machine

InactiveCN102134801AWon't wear outAvoid secondary pollutionOther washing machinesTextiles and paperWater flowPulp and paper industry

The invention relates to the technical field of washing machines, in particular to a method and device for simultaneously cleaning the outer wall of an inner barrel and the inner wall of an outer barrel of a washing machine, i.e., a self-cleaning device of a washing machine, which comprises water passages arranged on the inner barrel and the outer barrel of the washing machine; the passages can be integrated with the inner barrel or the outer barrel during manufacturing and can also be independent passages; many intensive holes in the water passages can form water curtains when water in the passages has pressure; a water curtain sprayed from the outer / inner barrel can respectively clean the inner / outer barrel of the washing machine so as to achieve the purpose of thoroughly cleaning dirt between the inner barrel and the outer barrel of the washing machine; cleaning water can be directly pressurized by running water or a booster pump; the water passage on the inner barrel of the washing machine can rotate together with the inner barrel of the washing machine; water in the water passage of the inner barrel is introduced through a rotating shaft of the washing machine; and a dynamic seal water supply device is used when the water is introduced into the rotating shaft, and the dynamic seal water supply device is characterized by supplying water to the hollow part of the shaft when the shaft rotates. A barrel cleaning program can be preset in a computer program when the washing machine is produced, so that the self-cleaning of dirt between the barrels of the washing machine is programmed. The device can be applied to impeller type washing machines and drum type washing machines.

Owner:朱雨轩 +1

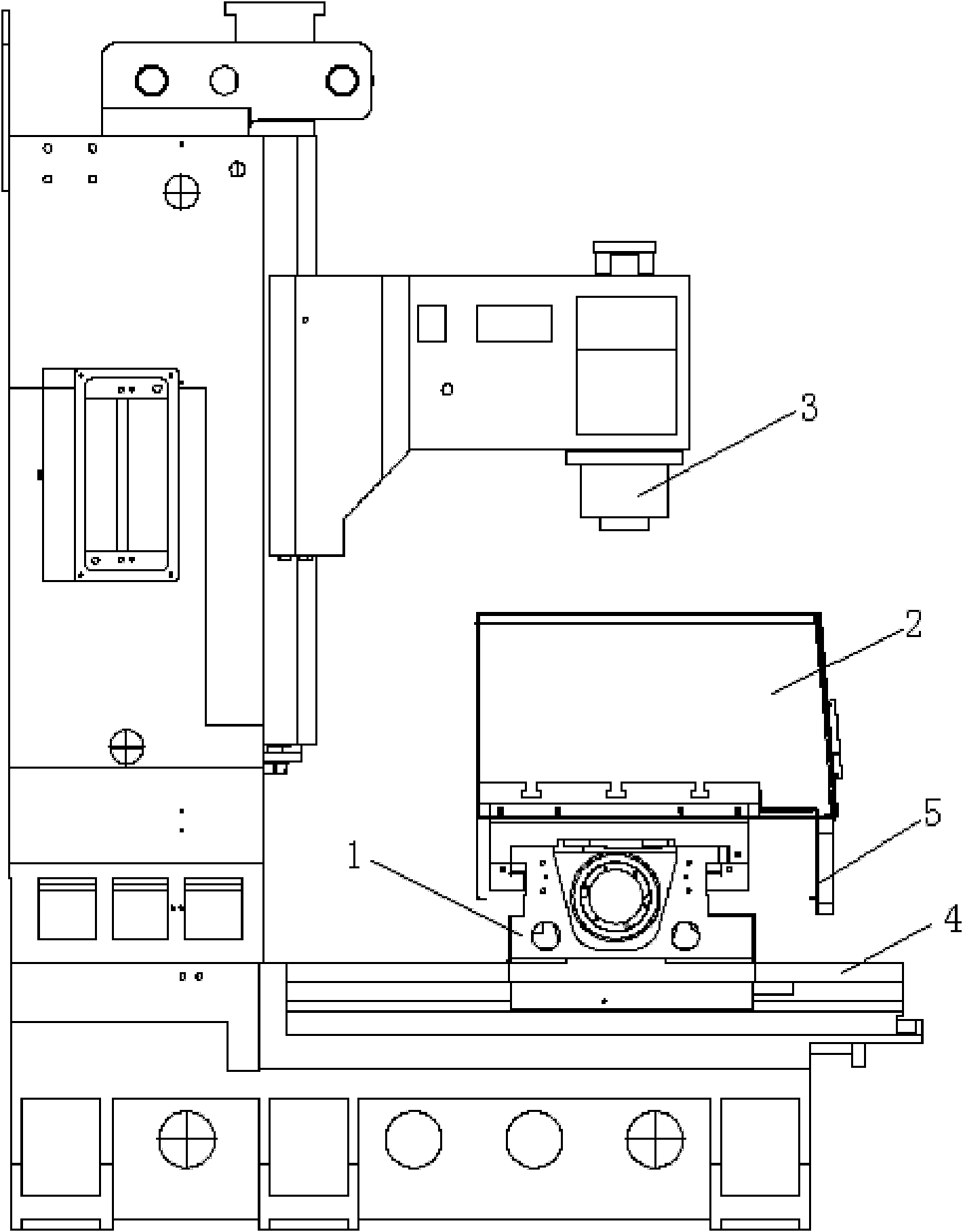

Vertical machining center

InactiveCN103100932AWon't wear outImprove protectionMaintainance and safety accessoriesEngineeringMachining

The invention discloses a vertical machining center which comprises a platform cover, wherein the platform cover is detachably and fixedly arranged on an operating platform. The platform cover is not provided with a top, the bottom of the platform cover is a sealing structure, and the sealing structure is arranged below a main shaft and above a guide rail stretching protective cover. A sealed platform cover is arranged on the operating platform and used for collecting cutting liquid, so that the cutting liquid with grains of sand does not fall on the guide rail stretching protective cover or a guide rail, does not produce abrasion on the guide rail, and well protects the guide rail. Improvement at low cost on a common vertical machining center can obtain the function of multiple grinding machines machined by the vertical machining center, so that the vertical machining center is economic, practical, and reliable in function.

Owner:CHANGZHOU TRANSCEND CNC MACHINE TOOL

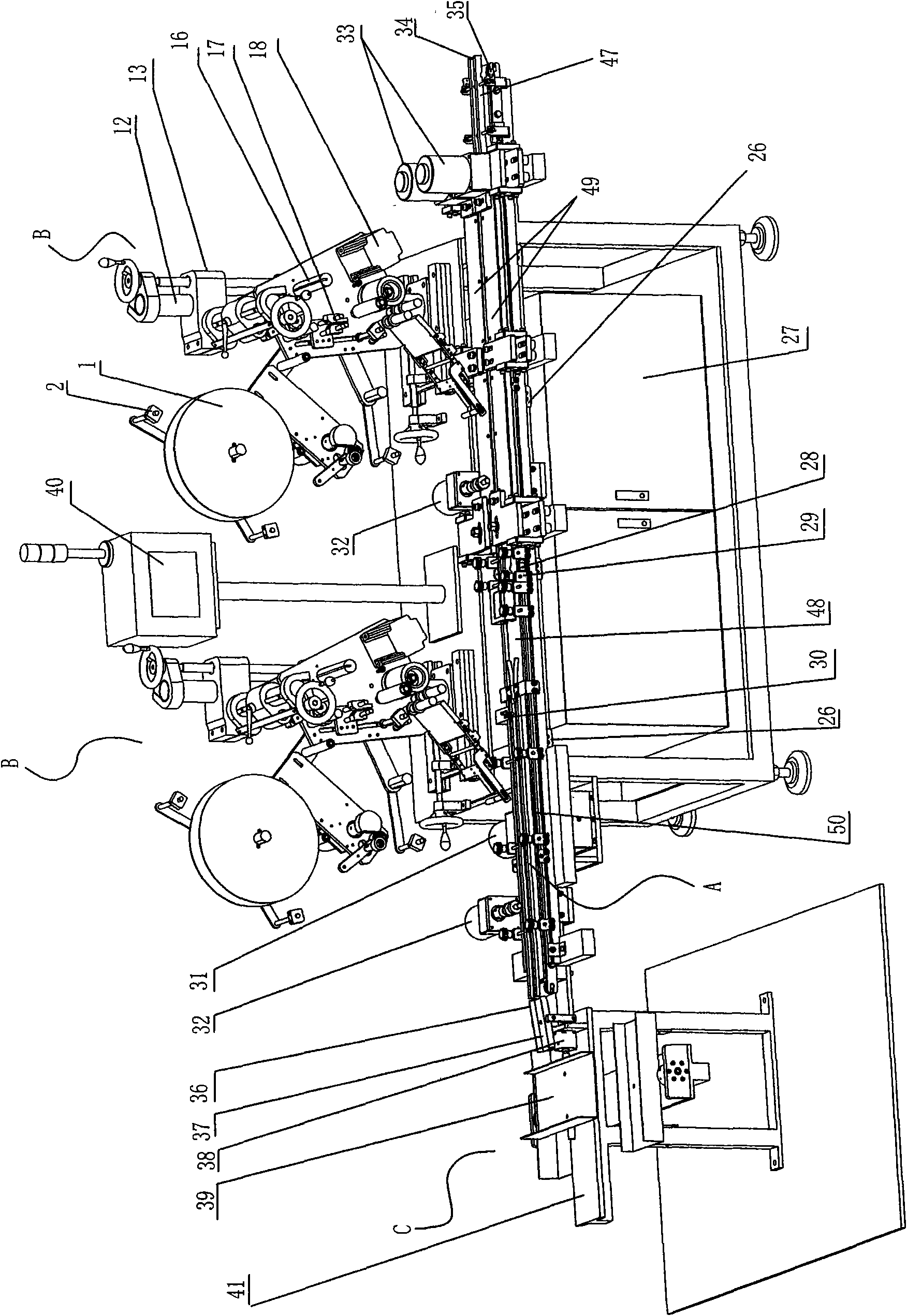

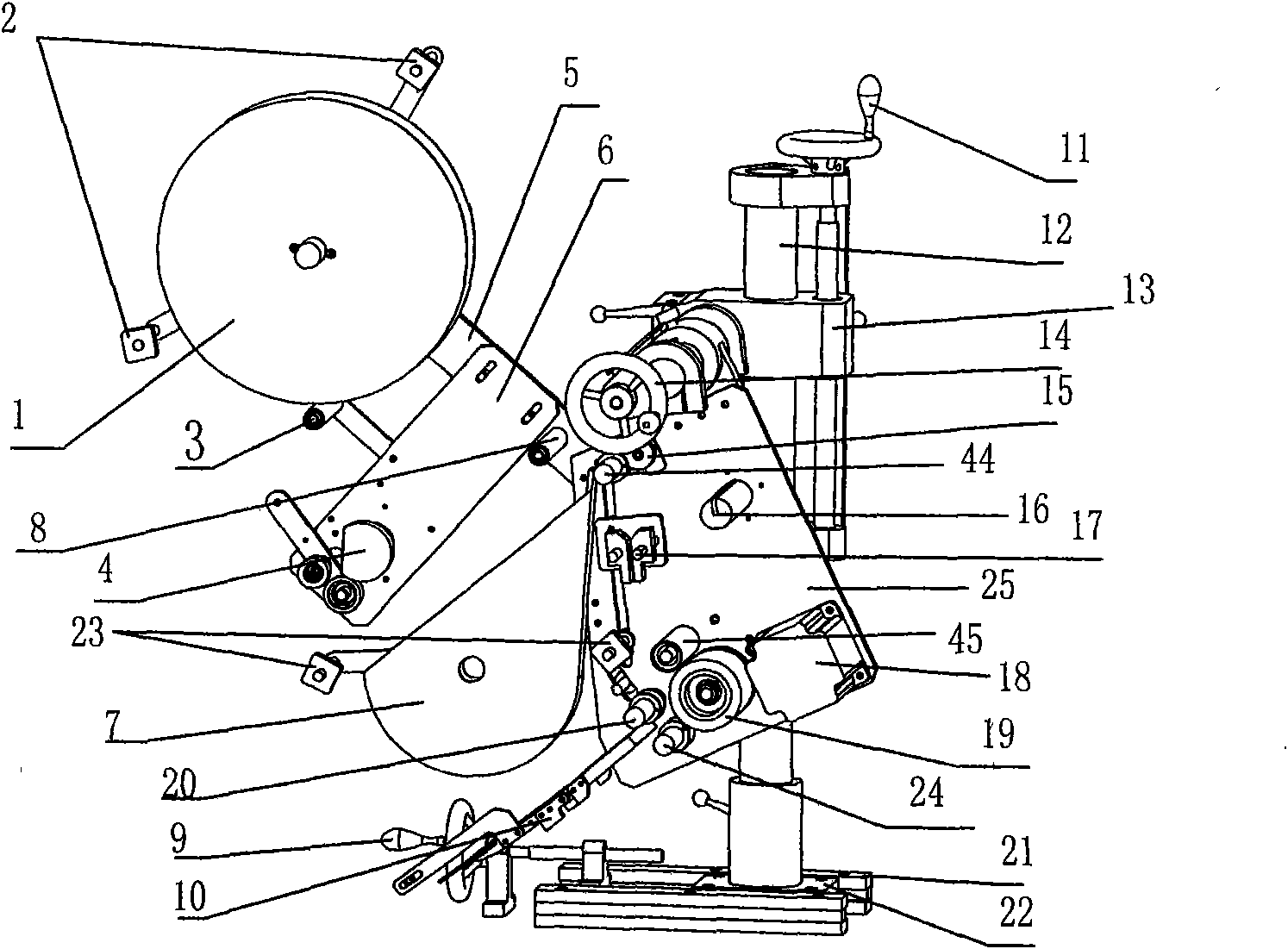

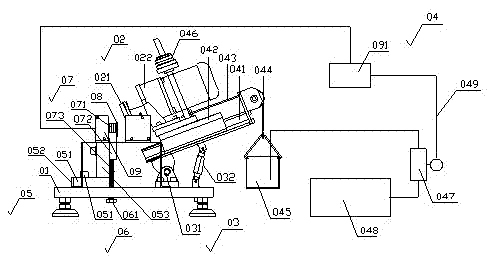

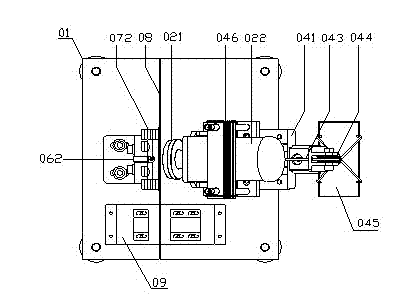

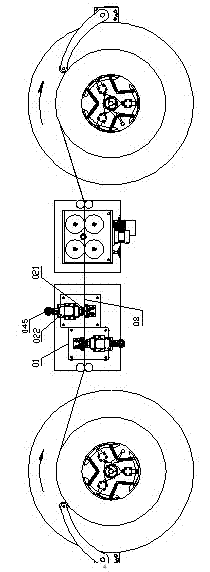

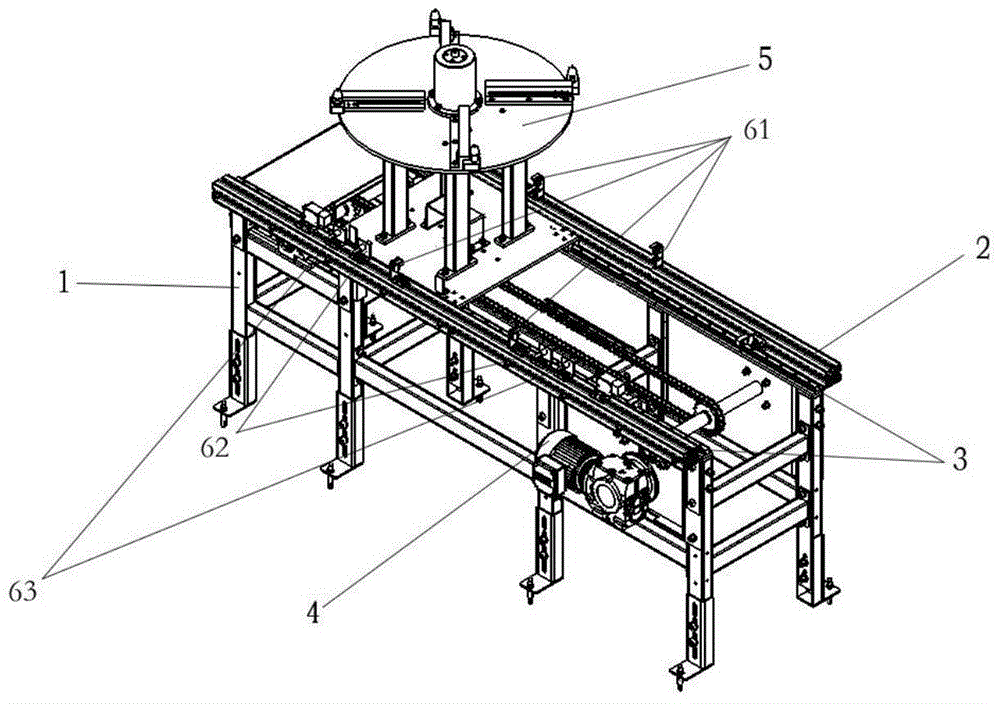

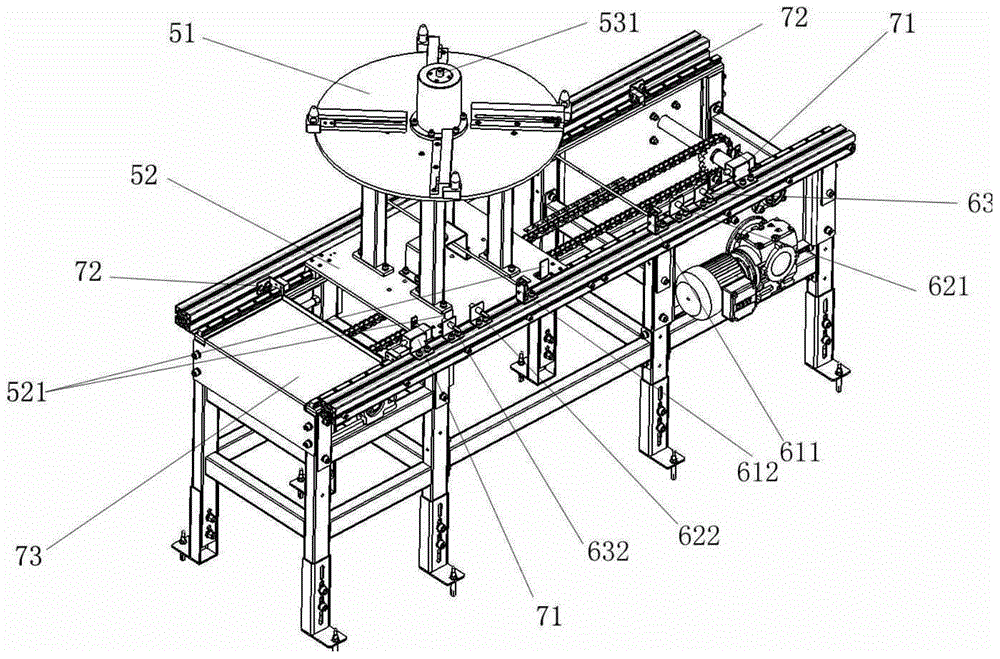

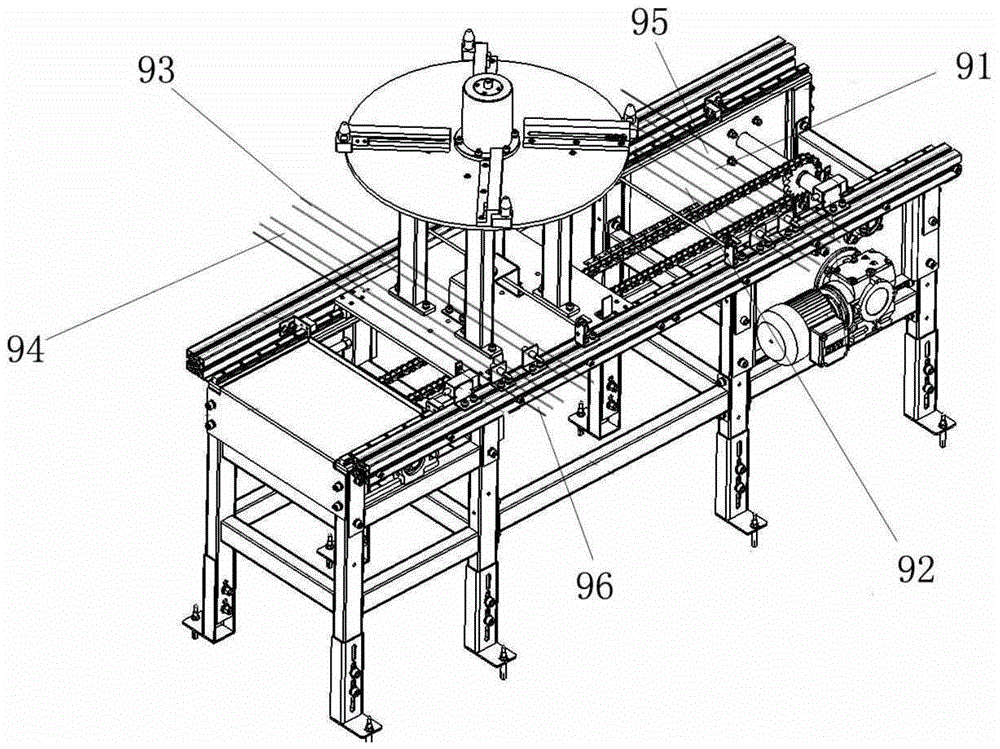

Labeler of lighter

ActiveCN101643120ARealize online monitoringGuaranteed unityLabelling flat rigid surfacesLabelling machinesCombustible gasElectric machinery

The invention relates to a labeler of a lighter. The existing labelers have no special clamps or conveying devices for clamping the shell of the lighters, and the gas storage tanks of the lighters areinternally provided with combustible gas or combustible liquid, which is dangerous. The invention comprises a labeler frame, on which a horizontally-placed conveying device and a vertically-placed labeling mechanism are arranged. The invention is characterized in that the conveying device comprises a bottom conveying component and a lateral conveying component; the bottom conveying component comprises a bottom conveying belt driven by a bottom conveying motor, and the bottom conveying belt is horizontally placed on the labeler frame; the lateral conveying component comprises lateral conveyingbelts driven by a lateral conveying motor, and the two lateral conveying belts are arranged at two sides of the bottom conveying belt to form a clamping channel; and the labeling mechanism is positioned above the clamping channel. The invention has a clamping channel for clamping the shell of the lighter, thus ensuring security during labeling process, simultaneously improving labeling efficiency, ensuring uniform labeling position and reducing production cost.

Owner:XINHAI TECH GRP CO LTD

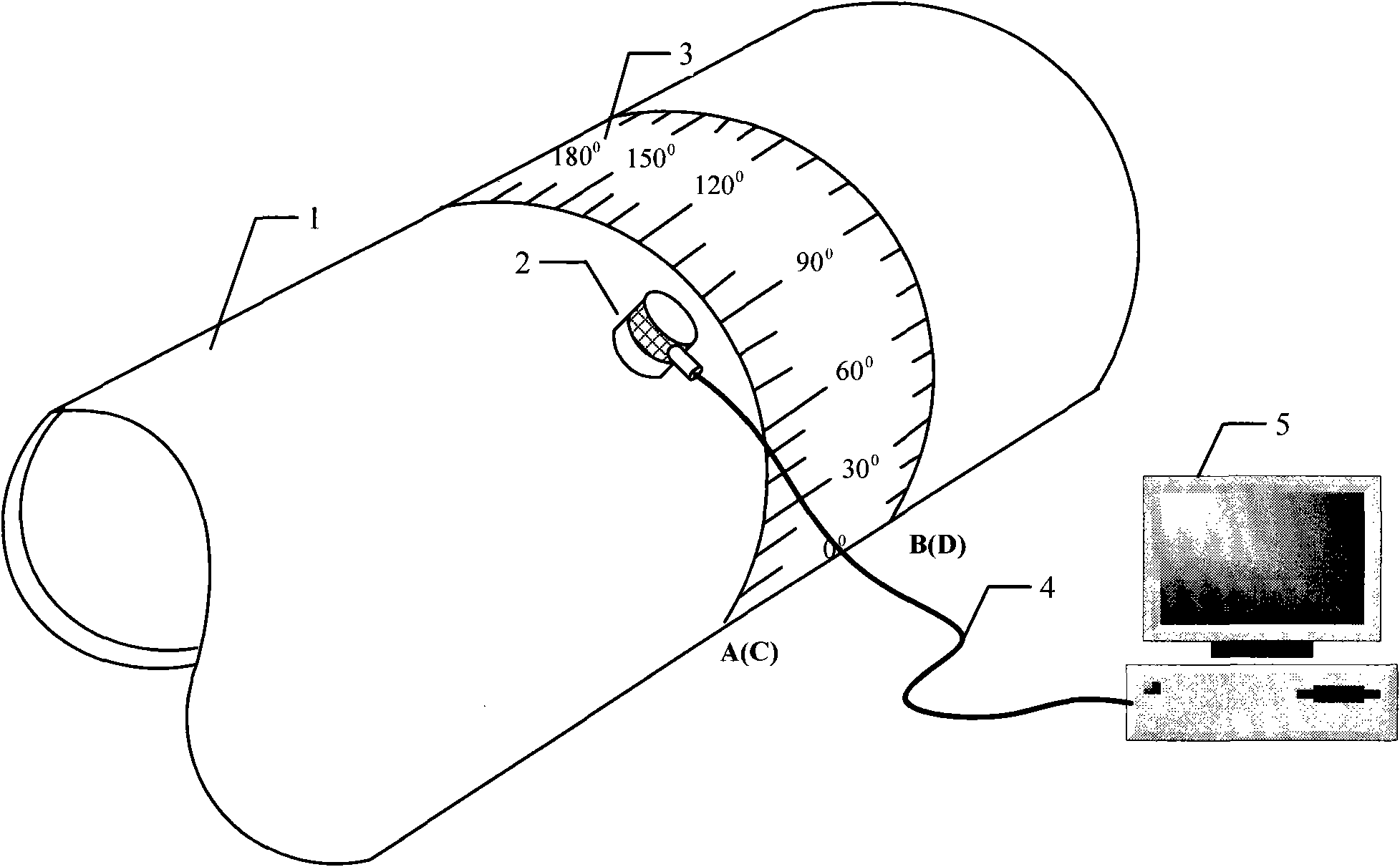

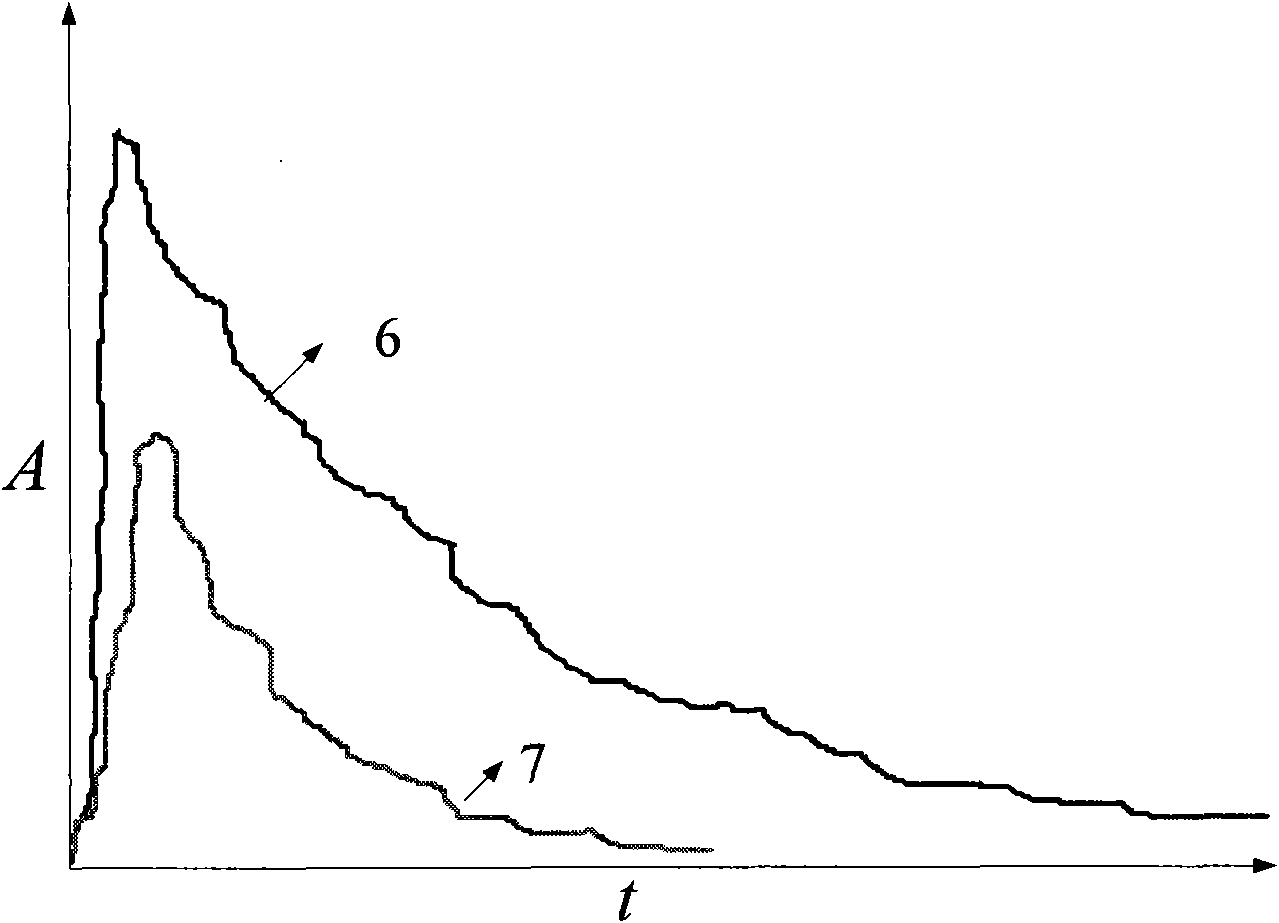

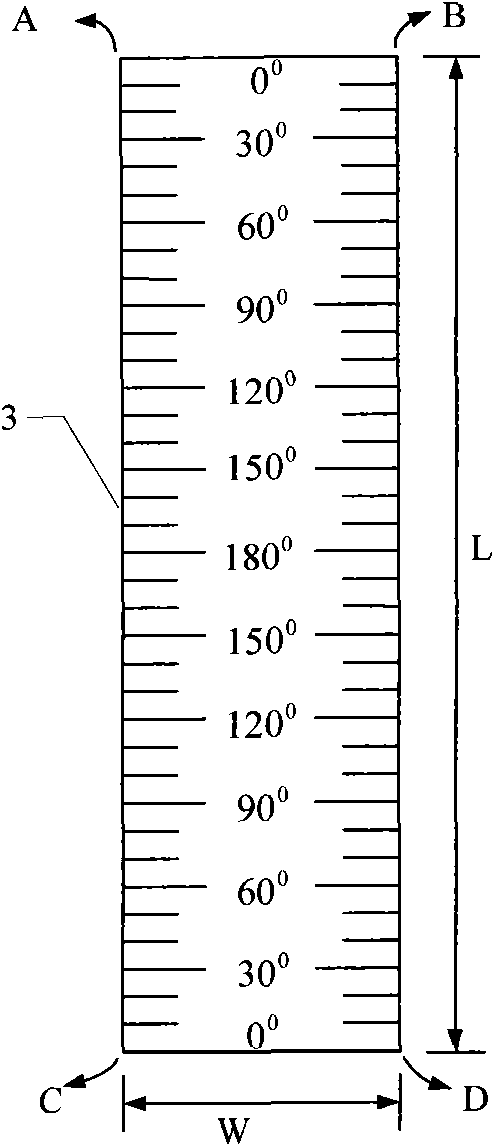

Method and device for measuring accumulated liquid of natural gas pipeline

InactiveCN101839746ASave energyNo security issuesMachines/enginesLevel indicatorsLiquid mediumLine tubing

The invention discloses a method and a device for measuring accumulated liquid of a natural gas pipeline. The method comprises the following steps of: vertically transmitting high-frequency ultrasonic wave into the pipeline by an ultrasonic probe coupled to the outer wall of the measured pipeline, wherein the energy of reflection echo has great difference due to different properties of gas and liquid media; judging that the pipe inner wall is contacted with gas or liquid at the position of the probe according to the characteristic of echo received by the ultrasonic probe and reflected by the pipe inner wall; gradually adjusting the measurement position of the ultrasonic probe on the pipe outer wall along the circumferential direction; and recording a circumferential angle of the ultrasonic probe by a circumferential angle ruler when the echo has mutation, and further calculating the height of the accumulated liquid. The method is a non-intrusive accumulated liquid measurement method, does not change the structure of the conventional pipeline, has no medium leakage risk, does not affect the operation such as cleaning the pipeline and the like, meanwhile is not affected by the composition of gas and liquid phase media in the pipeline and parameters such as temperature, pressure and the like, overcomes the defect that the conventional ultrasonic technology needs complex sound velocity correction, and is particularly suitable for measuring the accumulated liquid inside the pipeline for conveying corrosive and toxic media.

Owner:SINOPEC ZHONGYUAN PETROLEUM ENG DESIGN

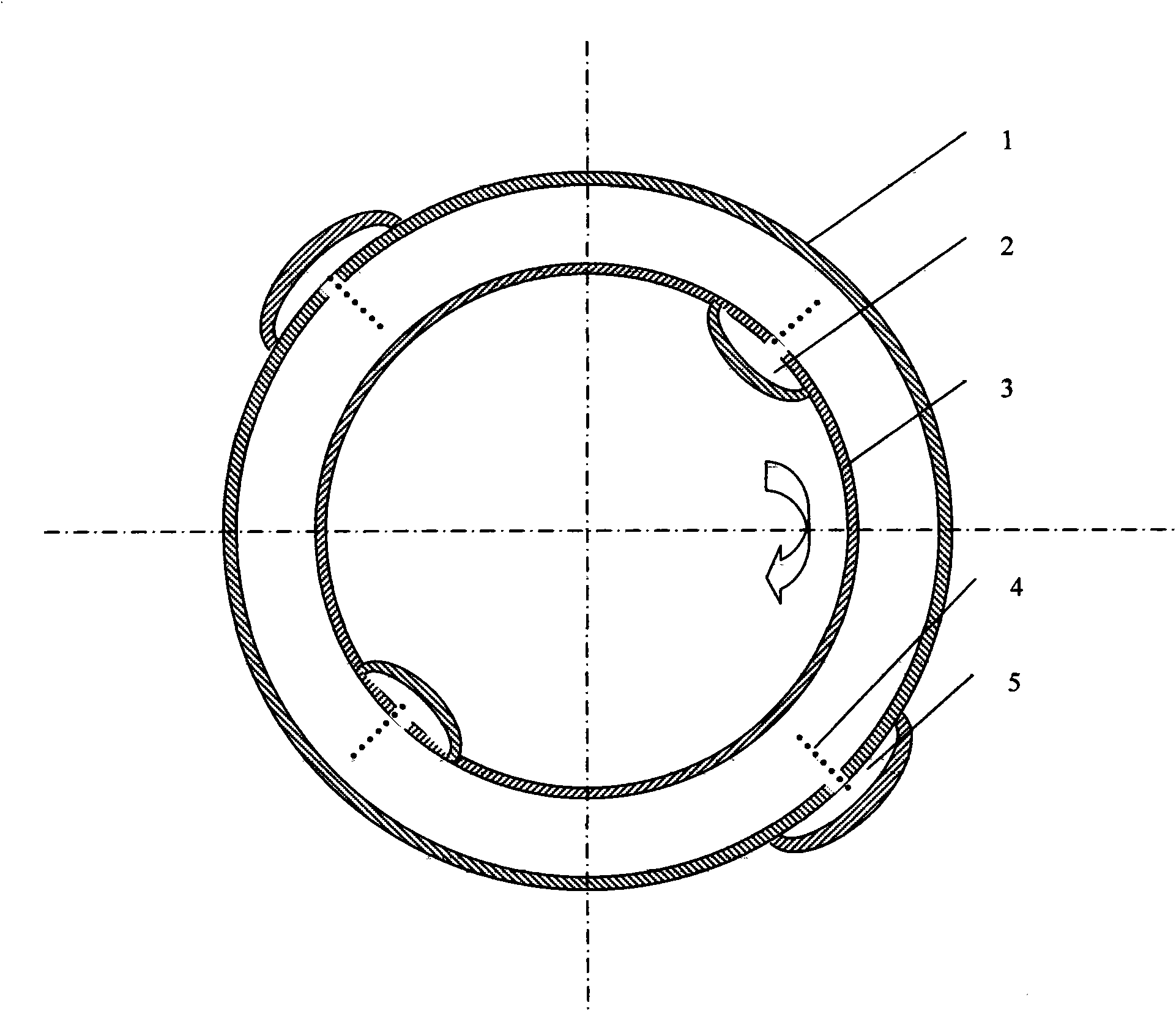

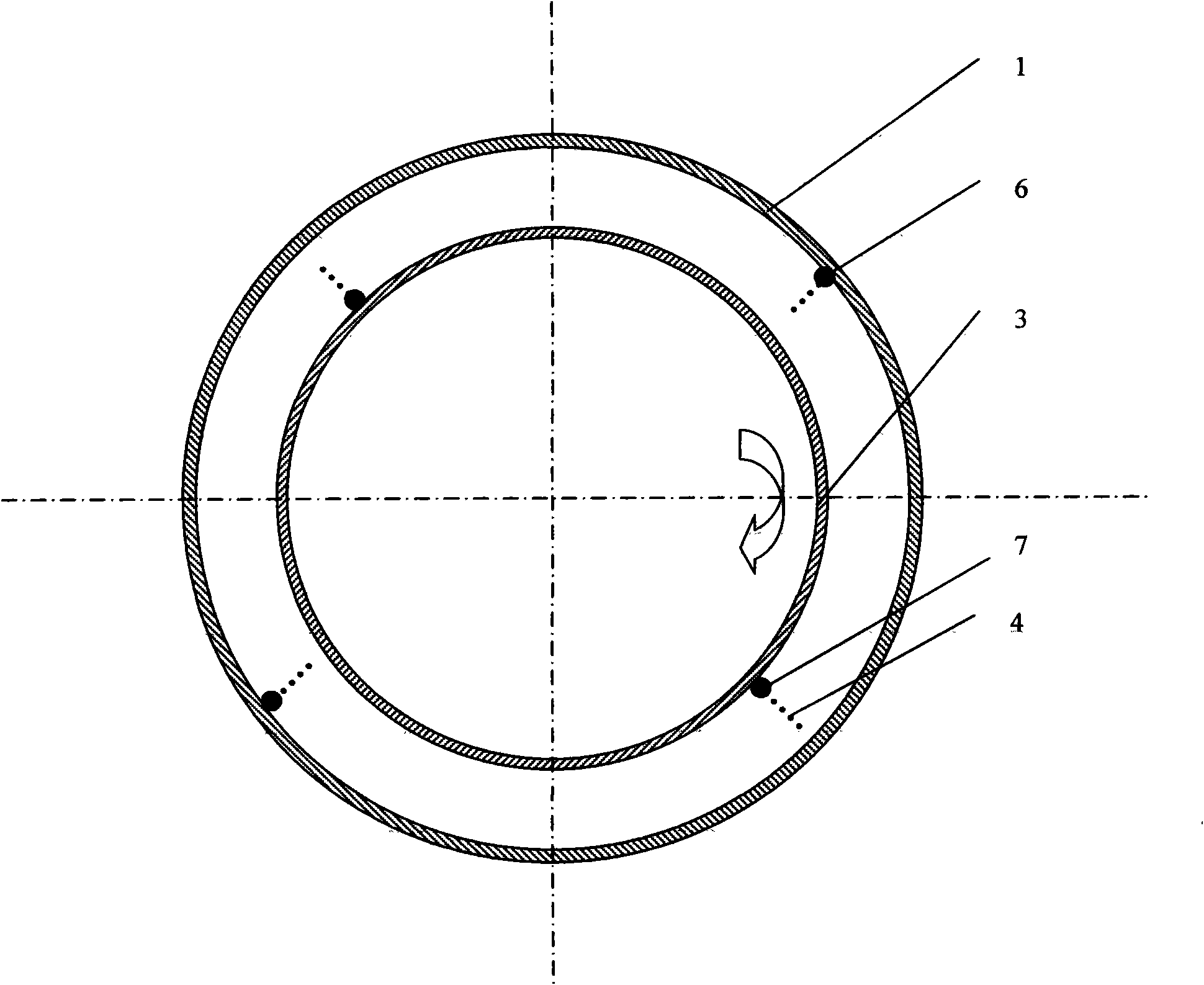

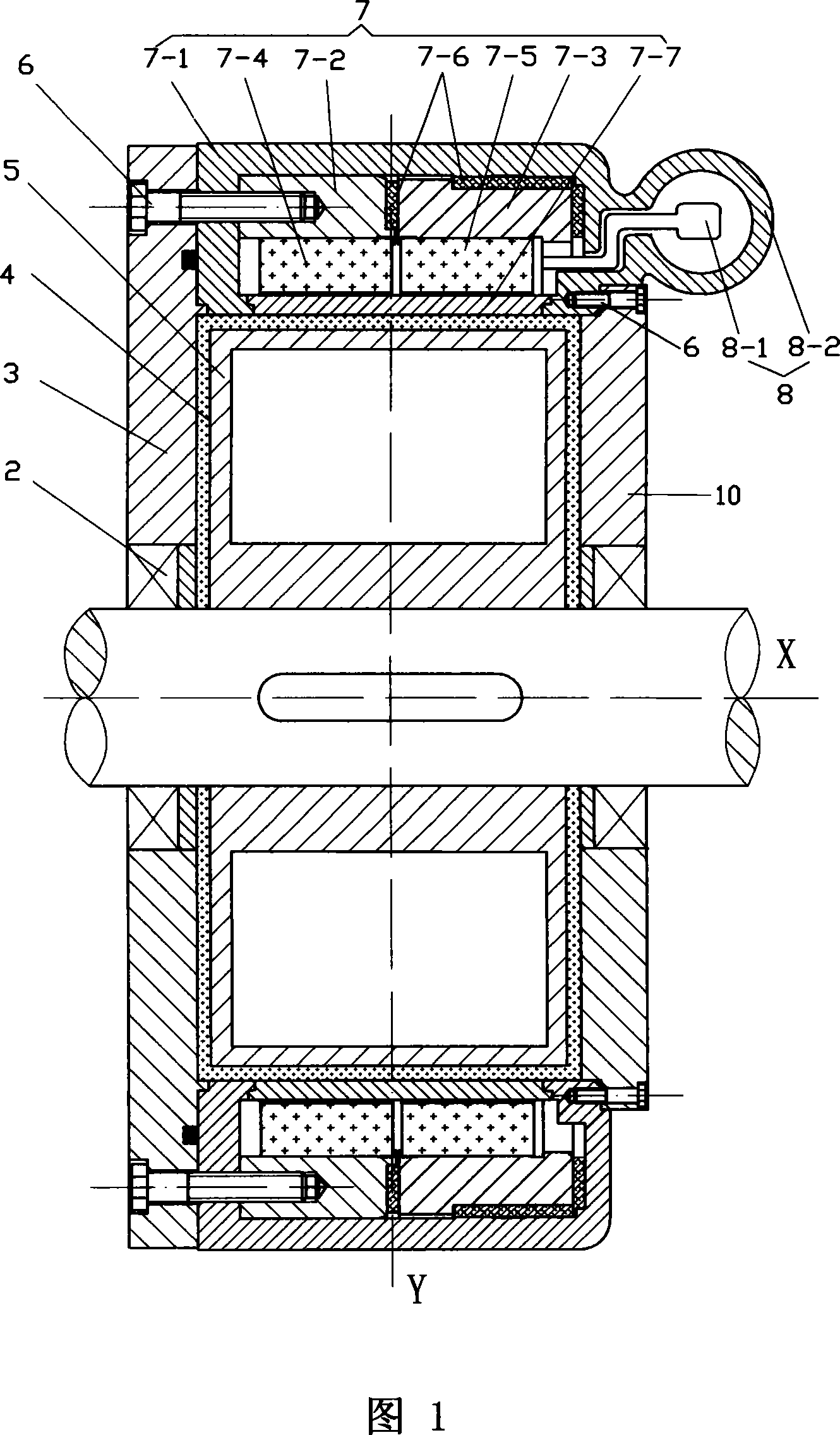

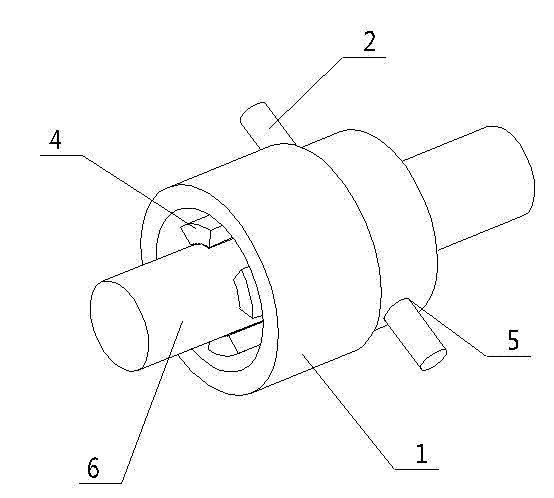

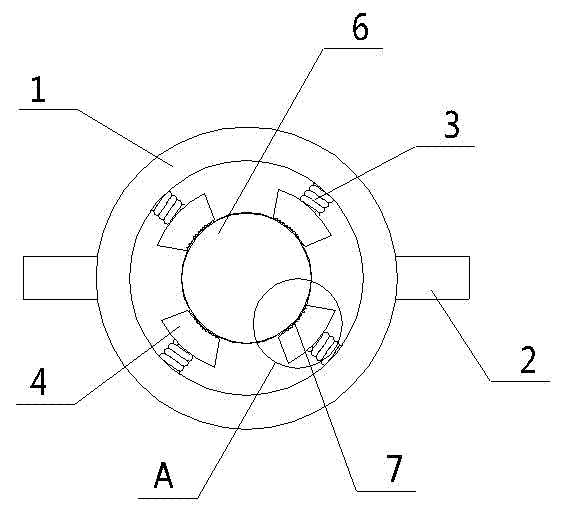

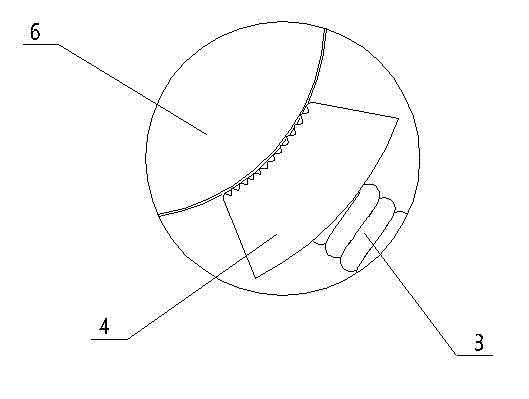

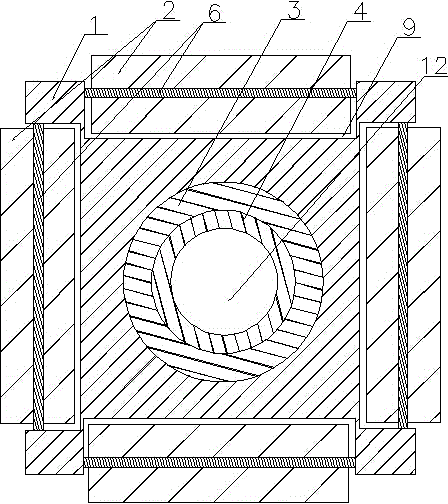

Magneto-rheologic liquid brake

InactiveCN101225859AEasy to implementEasy to operateLiquid resistance brakesMagnetic sourceDrive shaft

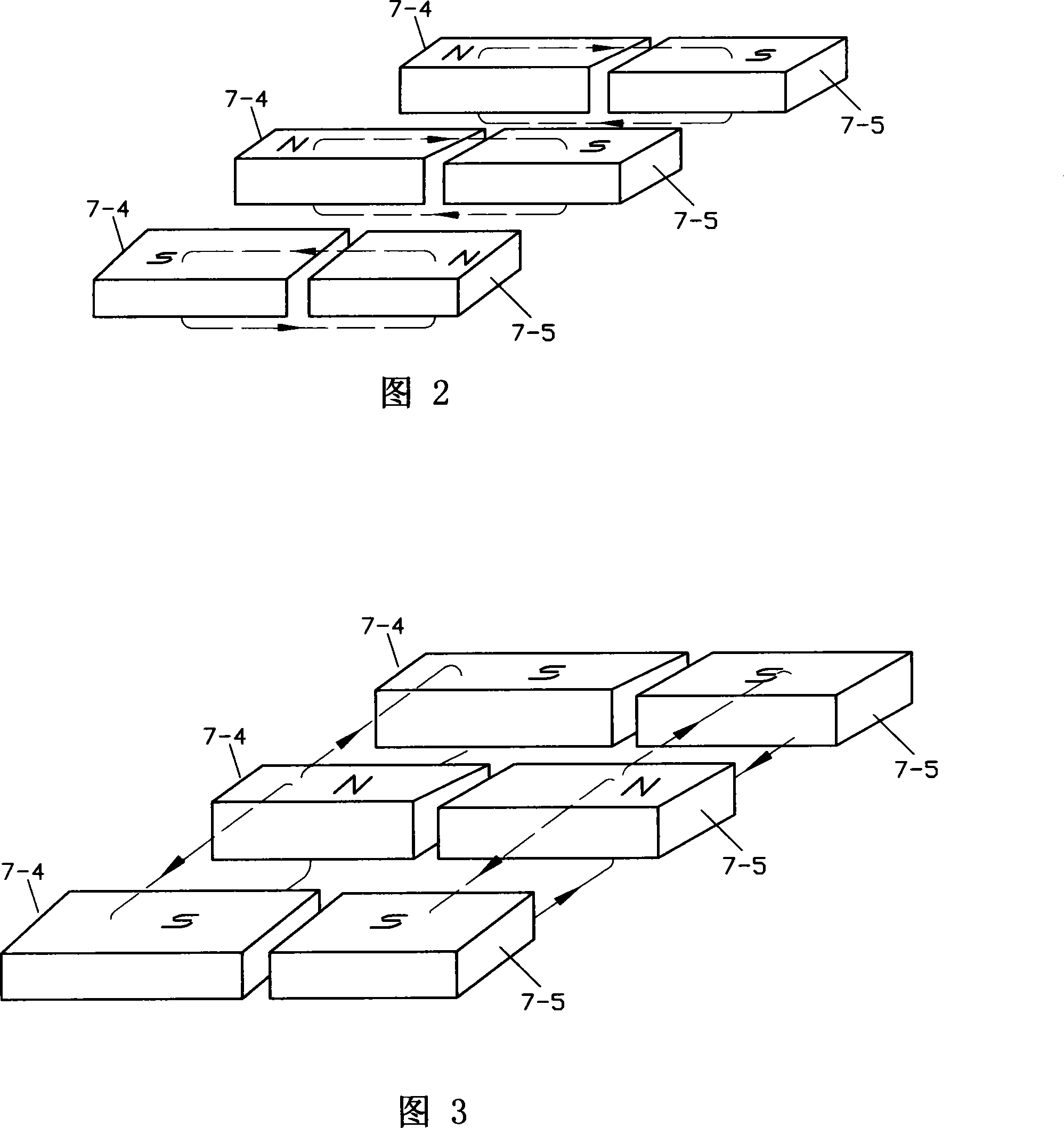

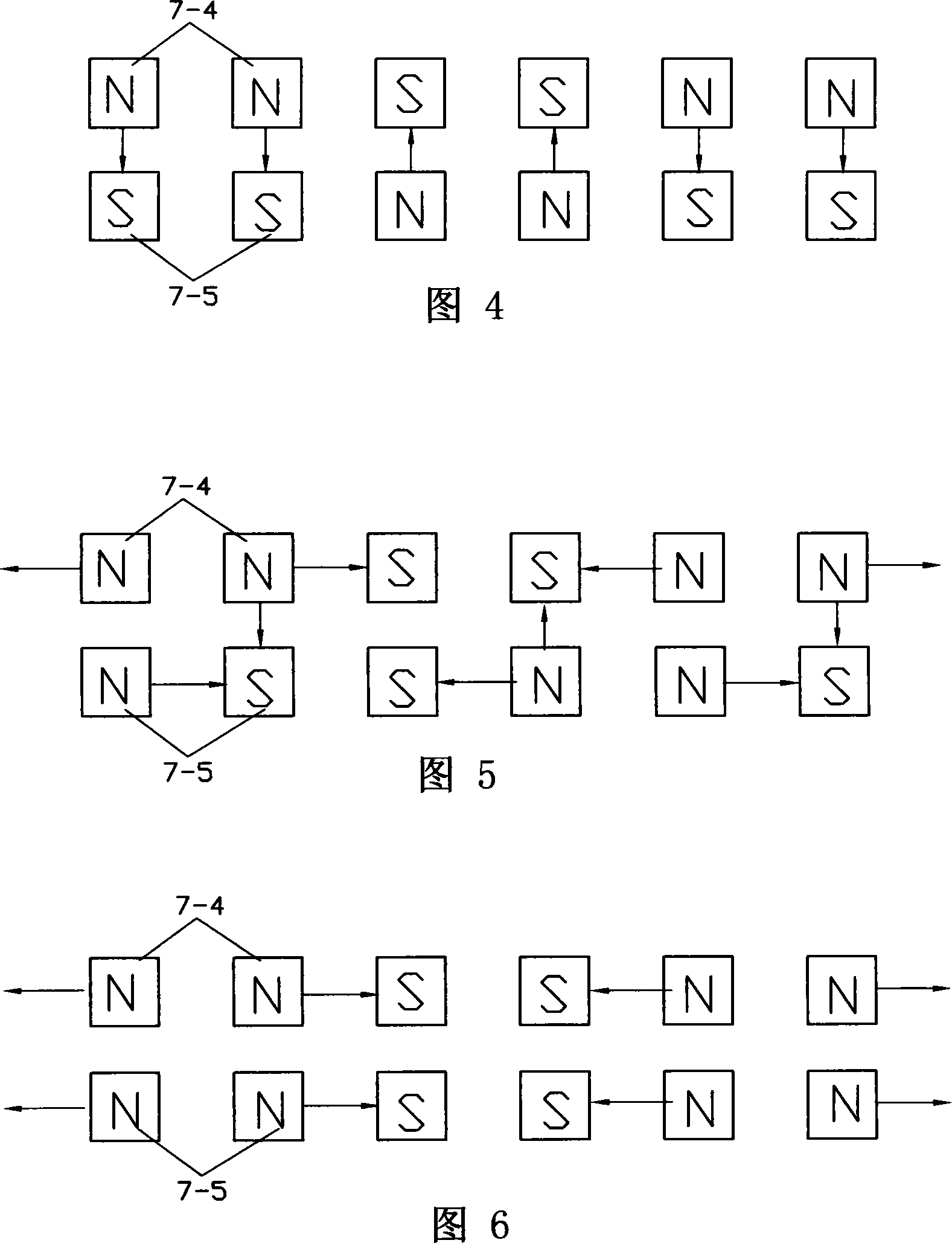

The invention relates to a magneto-rheological fluid brake, comprising a rotor, a stator, a sealing cover, and a transmission shaft, which is characterized in that a plurality of closed cavities filled with magneto-rheological fluid are arranged around the rotor; the stator is composed of an annular hollow housing, an annular fixed retainer, and an annular movable retainer; a plurality of permanent magnets uniformly distributed in circumferential direction with the same regularity are fixed on the inner side surfaces of the fixed retainer and the movable retainer; the fixed retainer and the movable retainer with permanent magnets are axially paralleled in the casing; a plurality of windows are uniformly distributed on the inner side surface of the casing; two axially adjacent permanent magnets belonging to the fixed retainer and the movable retainer respectively share the same window; a magnetic-inductive plate is embedded in each window; the fixed retainer and the movable retainer are made of magnetic conducive materials, and the other parts of the casing are made of non-magnetic materials. The magneto-rheological fluid brake has the advantages of realization of brake, power saving, convenient operation and actualization, reliable brake performance by adopting permanent magnets as magnetic source, and changing direction of closed magnetic circuit through rotation of the movable retainer.

Owner:JIANGSU UNIV OF TECH

Overhead line cross wiring device

ActiveCN103441451AWon't wear outExcellent wire qualityApparatus for overhead lines/cablesEngineeringOverhead line

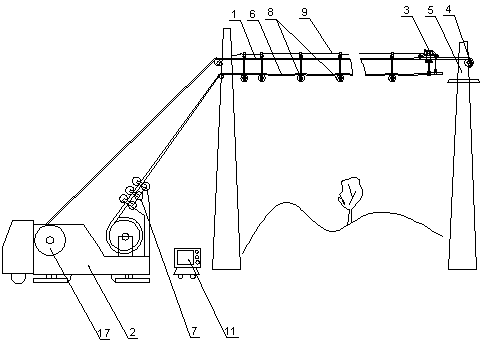

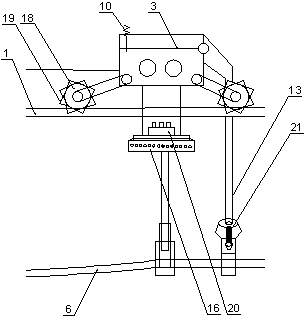

The invention discloses an overhead line cross wiring device which comprises an overhead suspension wire, a wire barrow, a traction tackle with a drive mechanism, and suspension wire supporting wheels, wherein the front end of the overhead suspension wire is connected to a fixed object in front of a crossing object through a tensioning mechanism, the traction tackle pulls wires to be laid to move on the overhead suspension wire, the suspension wire supporting wheels support the wires and are suspended on the overhead suspension wire, a wire anti-twisting device is arranged at the outgoing line end of the wire barrow, and the lower portion of the traction tackle is provided with a counterweight balancer. According to the overhead line cross wiring device, firstly, the overhead suspension wire is erected, the traction tackle is installed to pull the wires to be laid to move on the overhead suspension wire, advancing of the wires is prevented from being affected by overlarge droop through the suspension wire supporting wheels, the counterweight balancer is utilized to ensure stable movement of the traction tackle, remote cross stringing is achieved conveniently, meanwhile, abrasion between the wires and the ground does not exist, the stringing quality is superior, and the overhead line cross wiring device is suitable for not only line laying but also line repairing, and has high degree of automation.

Owner:STATE GRID CORP OF CHINA +1

Fixture

The invention discloses a fixture which comprises a sleeve and a fixing pin. Four springs are fixed on the inner periphery wall of the sleeve and are evenly arranged on the inner wall of the sleeve. A clamp block is fixed to the other end of each spring. The section of each clamp block is arced. A clamping surface of each clamp block, in contact with a workpiece, is corrugated. The tail end of the sleeve is provided with a fixing hole. The fixing pin matching with the sleeve is disposed in the fixing hole. A rotor is fixed with the clamp blocks and is further locked with the fixing pin, so that twisting is convenient and fast and installation is compact. In addition, the corrugated clamping surfaces enable friction to be increased and wearing of workpieces to be avoided. The fixture is simple in structure and convenient to operate and can be higher in efficiency and quality.

Owner:郁祥林

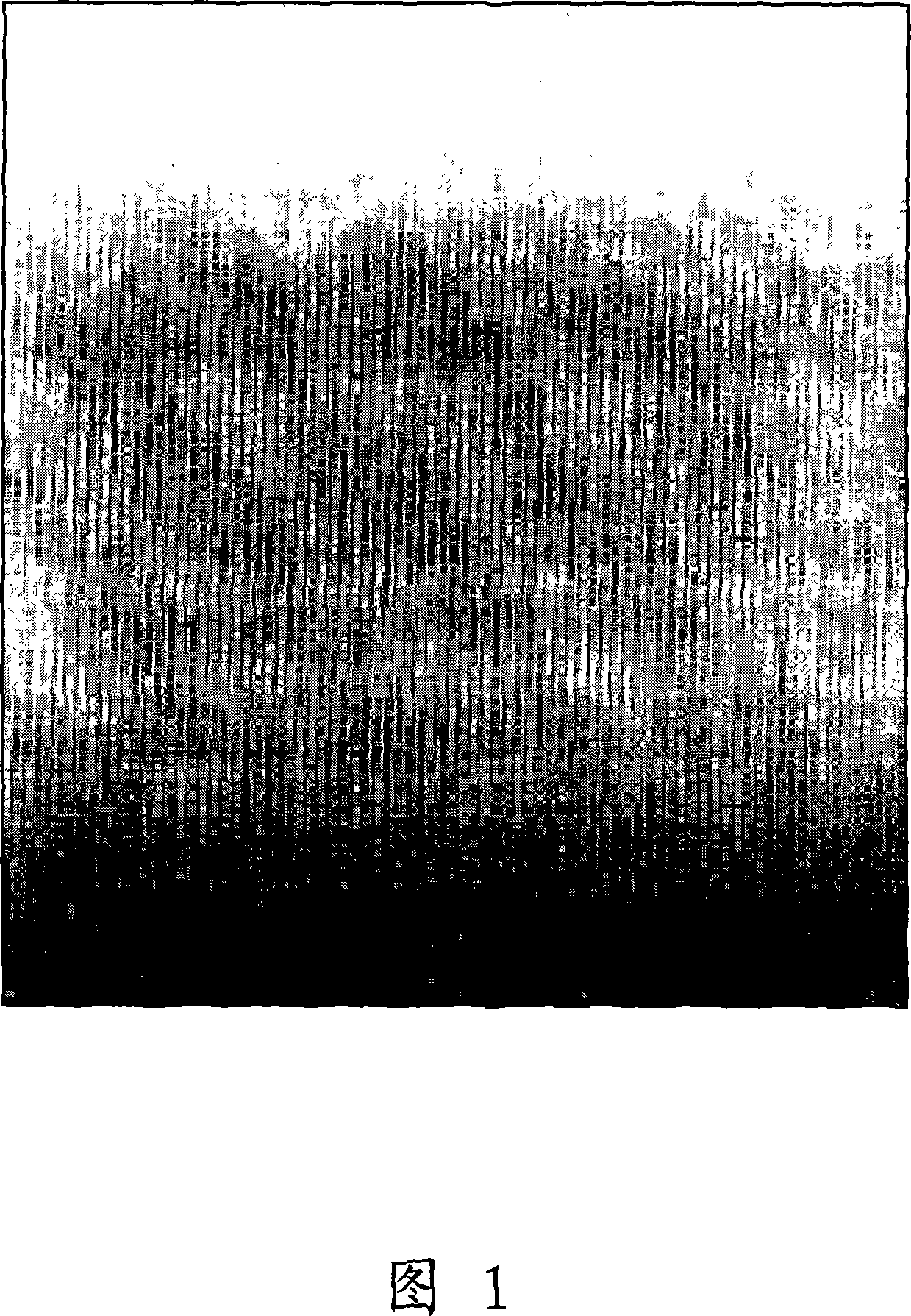

Laser texturing processing method on surface of roller

InactiveCN101642778AImprove rolling qualityImprove wear resistanceRolling equipment maintainenceLaser beam welding apparatusHelical lineSheet steel

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; simultaneously, leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized in that by accelerating the moving speed V of the laser texturing head along the axial direction of the roller, the texturing spots are distributed along the high inclination-angle helical line with the thread pitch of delta being equal to 2-200mm on the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbedby texturing concave holes crisscross distributed on the peripheral direction of the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

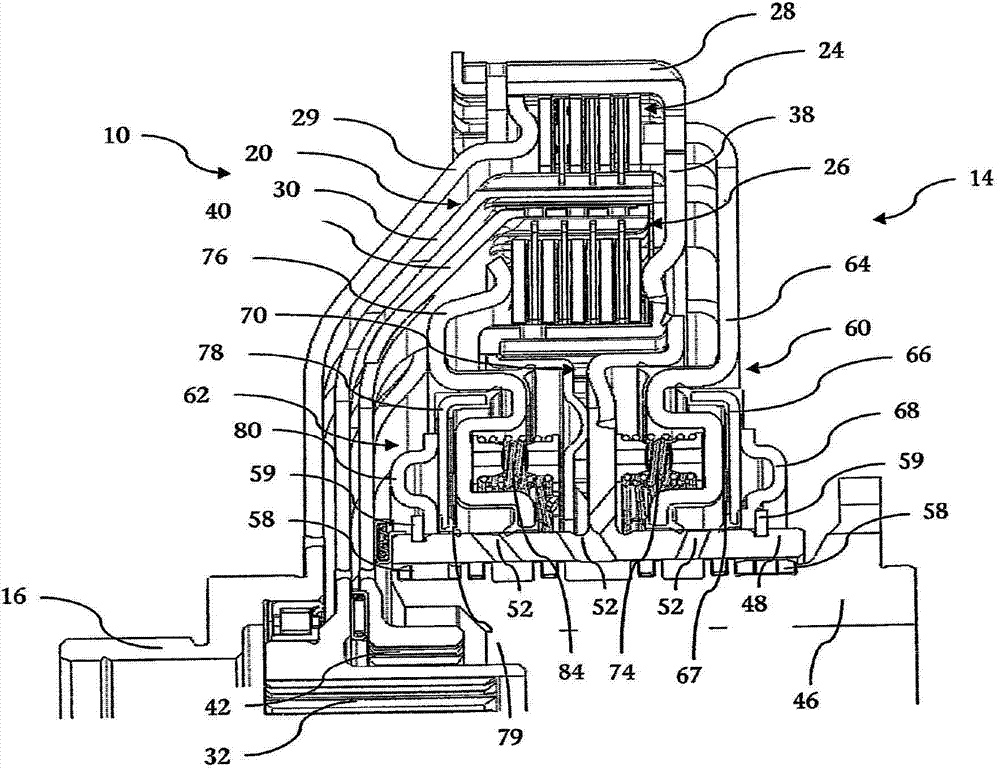

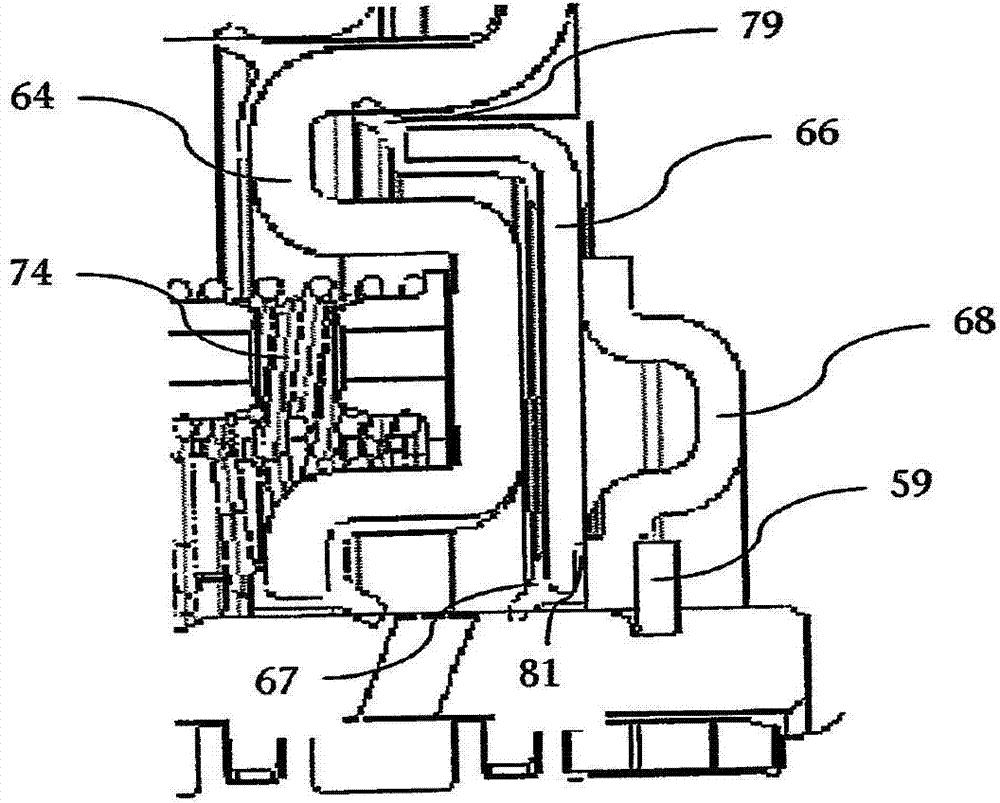

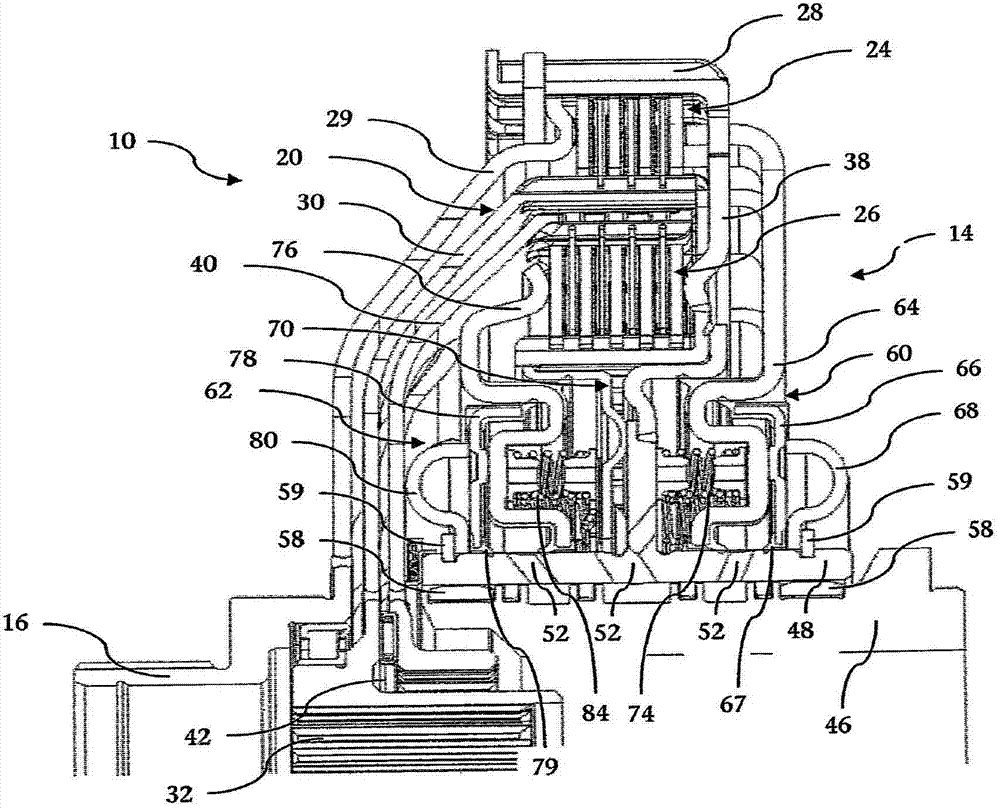

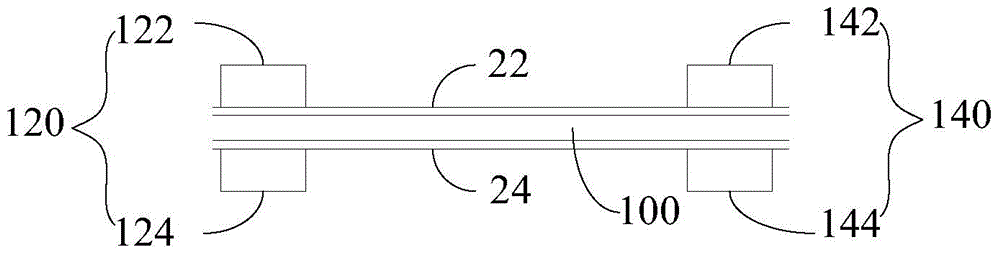

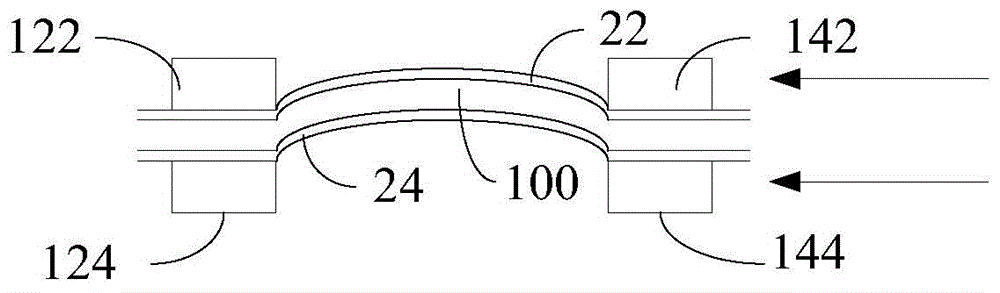

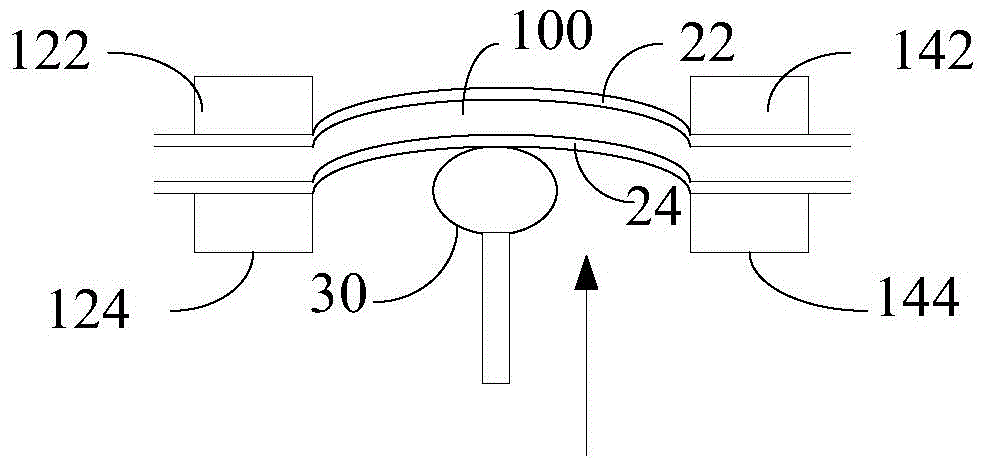

Dual-clutch assembly for a dual-clutch transmission

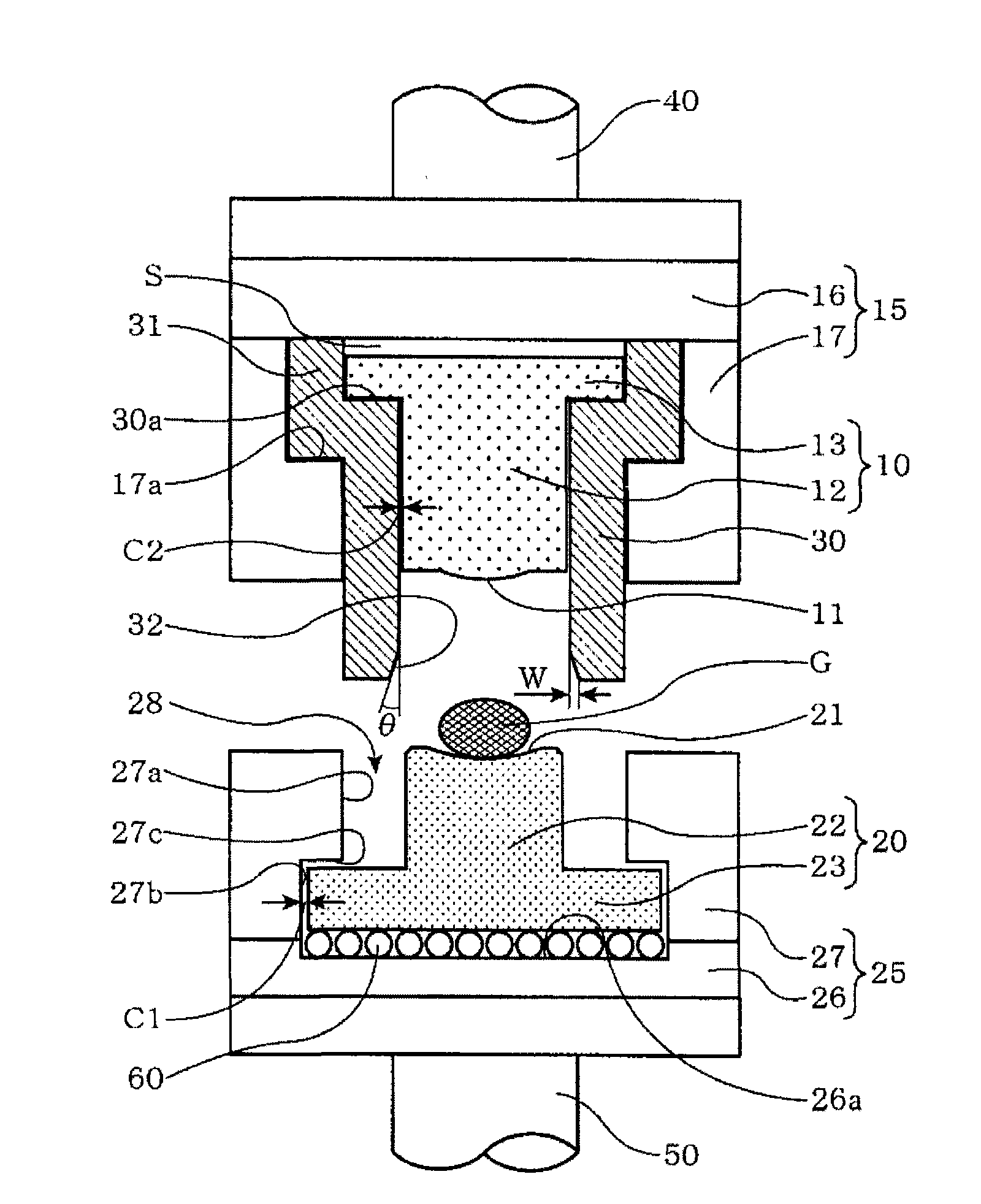

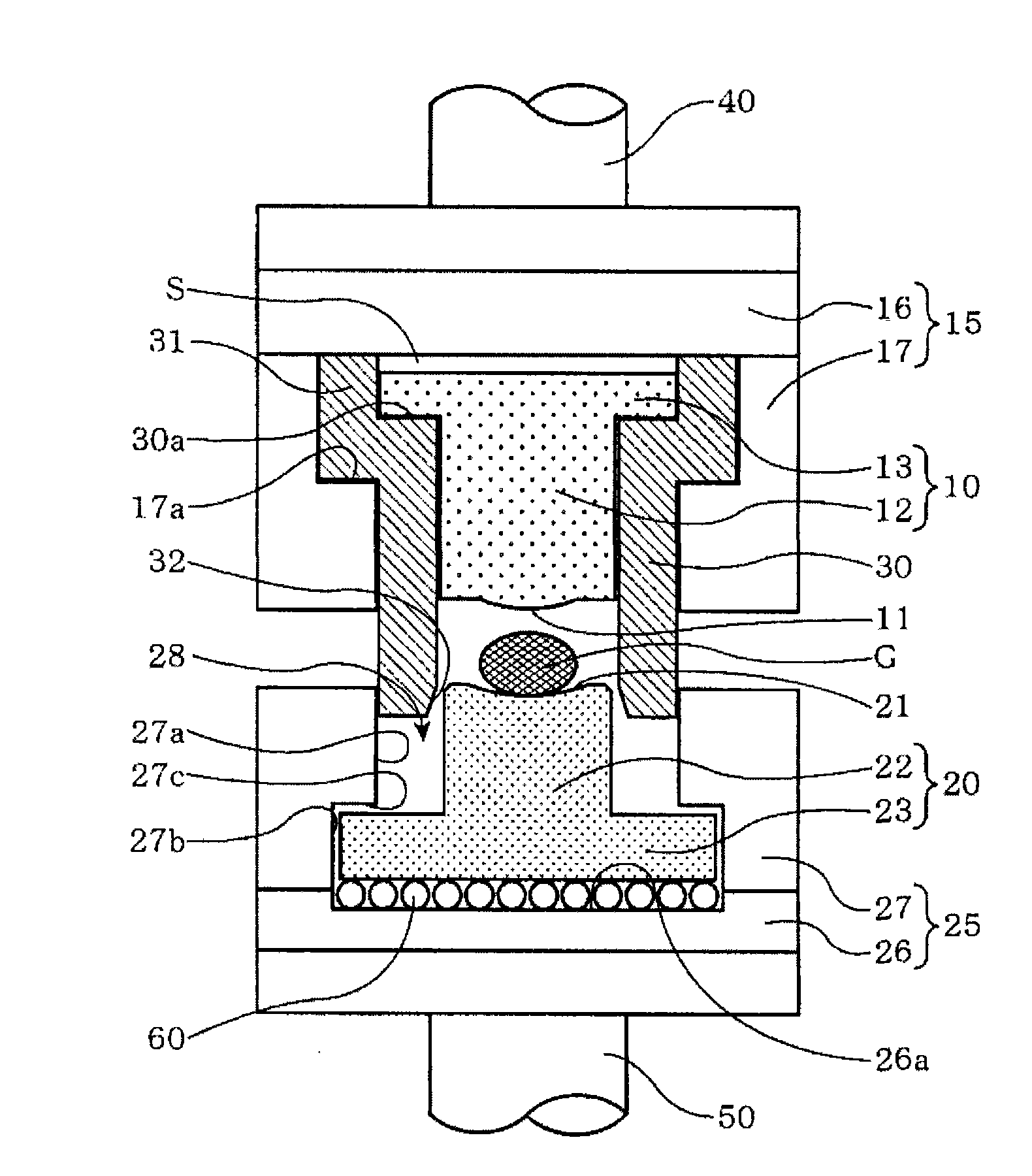

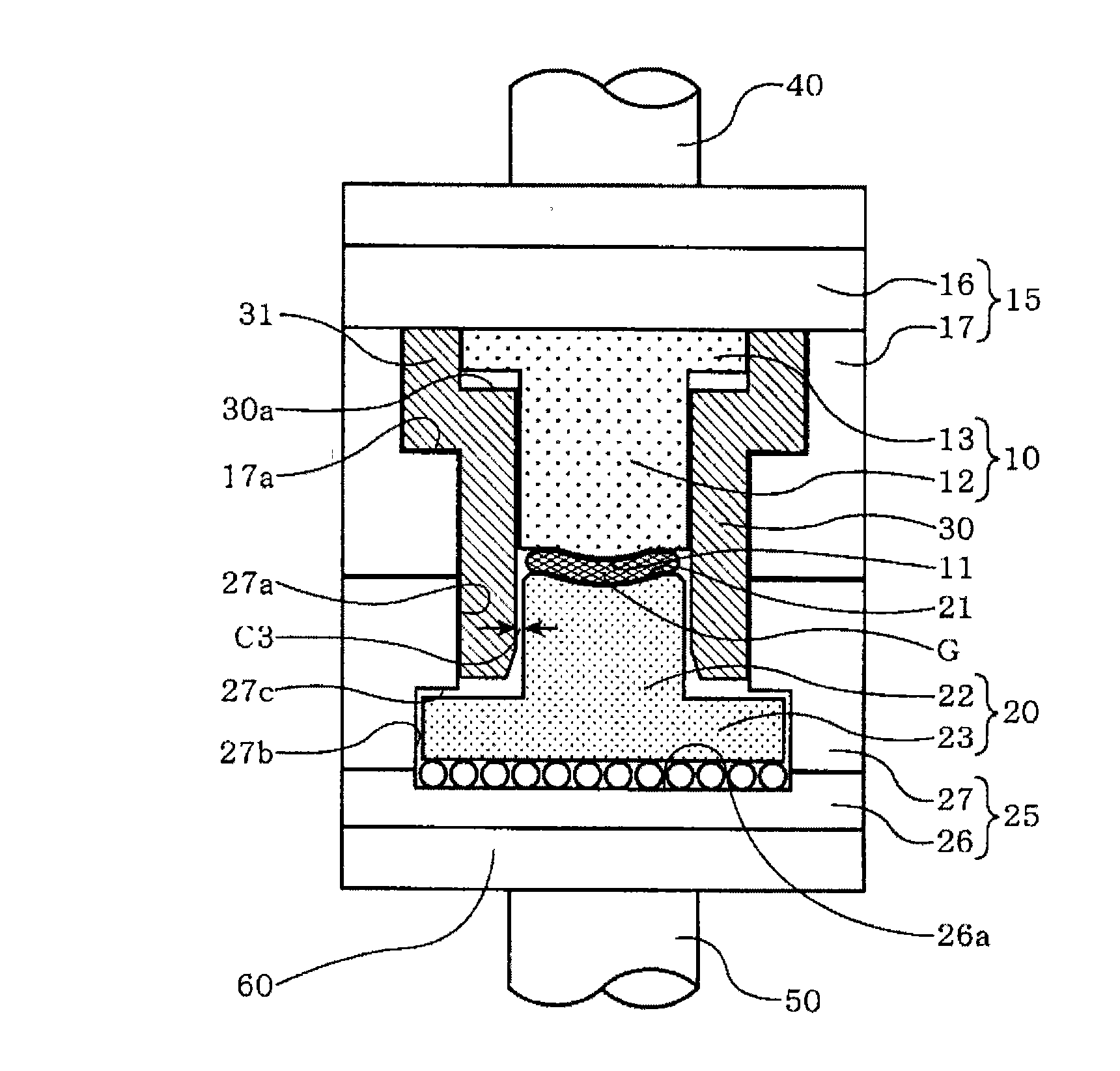

ActiveCN104768786ALow costSave installation spaceMechanical actuated clutchesFluid actuated clutchesEngineeringPiston

The invention relates to dual-clutch assembly (20) for a dual-clutch transmission (14), comprising an input shaft (16), a first friction clutch (24), a second friction clutch (26), a first output shaft (32), a second output shaft (42), a first piston / cylinder assembly (60), and a second piston / cylinder assembly (62); wherein input elements (28, 38) of the friction clutches (24, 26) are connected to the input shaft (16); wherein output elements (30, 40) of the friction clutches (24, 26) are each connected to one of the two output shafts (32, 42); wherein the friction clutches (24, 26) can each be actuated by means of one of the piston / cylinder assemblies (60, 62); wherein each piston / cylinder assembly (60, 62) has a piston (64, 76), which is supported so as to be axially movable in relation to an associated cylinder (66, 78); wherein each cylinder (66, 78) is supported on a support (68, 80) in a region lying radially outside on the side facing away from the piston (64, 76); and wherein each cylinder (66, 78) is distanced from the support (68, 80) in a region lying radially inside on the side facing away from the piston (64, 76).

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

Shell and manufacturing method thereof

InactiveCN101646316AWon't wear outDecorative surface effectsCasings/cabinets/drawers detailsProtection layerMaterials science

The invention relates to a shell which comprises a transparent substrate, a decoration layer formed on the transparent substrate and a transparent protection layer formed on the decoration layer, wherein hollowed-out patterns are formed on the decoration layer, and color ink is printed on the surface of the substrate, which is opposite to the decoration layer. A method for manufacturing the shellcomprises the following steps: providing the transparent substrate; arranging the decoration layer on the surface of the transparent substrate; arranging the transparent protection layer on the decoration layer; forming the hollowed-out patterns on the decoration layer; and printing color ink on the surface of the transparent substrate, which is opposite to the decoration layer.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Surface modified quartz glass crucible and its modification process

InactiveCN1448685AHigh strengthHigh dislocation-free ratioPolycrystalline material growthBy pulling from meltMaterials scienceSurface modified

A surface modified fused quarts crucible and method of modifying its surface. All or a part of the inner and / or outer surface of the surface modified fused quarts crucible, has a coating layer of a burned metal oxide. Preferably, the metal oxide comprises one or more selected from magnesium, calcium, strontium, and barium. The coating layer does not exfoliate easily and in which a good rate of single crystallization can be achieved.

Owner:JAPAN SUPER QUARTZ CORP

Under-glaze colored decoration method of bone china

The invention relates to an under-glaze colored decoration method of bone china. The method includes an under-glaze colored decoration firing process and a pigment preparation technology, which includes transferring figures through pigment paint or labels for porcelain to a biscuit after lower temperature biscuit firing at a temperature of 700-800 DEG C, covering a protective layer, buckling a decorated ware on a profiling kiln furniture, performing firing at a temperature of 1250-1290 DEG C, wherein figure surfaces cannot be bruised, performing polishing on figure bases after firing, spraying fritted glaze slip, and performing glaze firing at a temperature of 1170-1200 DEG C. The figure surfaces are arranged under a glaze layer completely, and the method is a novel color decoration different from bone china over-glaze color figure for in-glaze decoration. Blanks are performed biscuit firing at a low temperature, the figure bases are fired through oxidizing flames at a high temperature (1250-1290 DEG C), and vitreous enamels are fired through oxidizing flames at an intermediate temperature (1170-1200 DEG C). Compared with once-firing of under-glaze color figure through reducing flames at a high temperature, the method is a firing method in which the temperature and the flame property are completely different. Bottoms of high range gift porcelain products are glazed through lowtemperature glazes, and smooth and non-discoloring forever after firing at a temperature of about 800-850 DEG C.

Owner:湖南丰德利瓷业有限公司

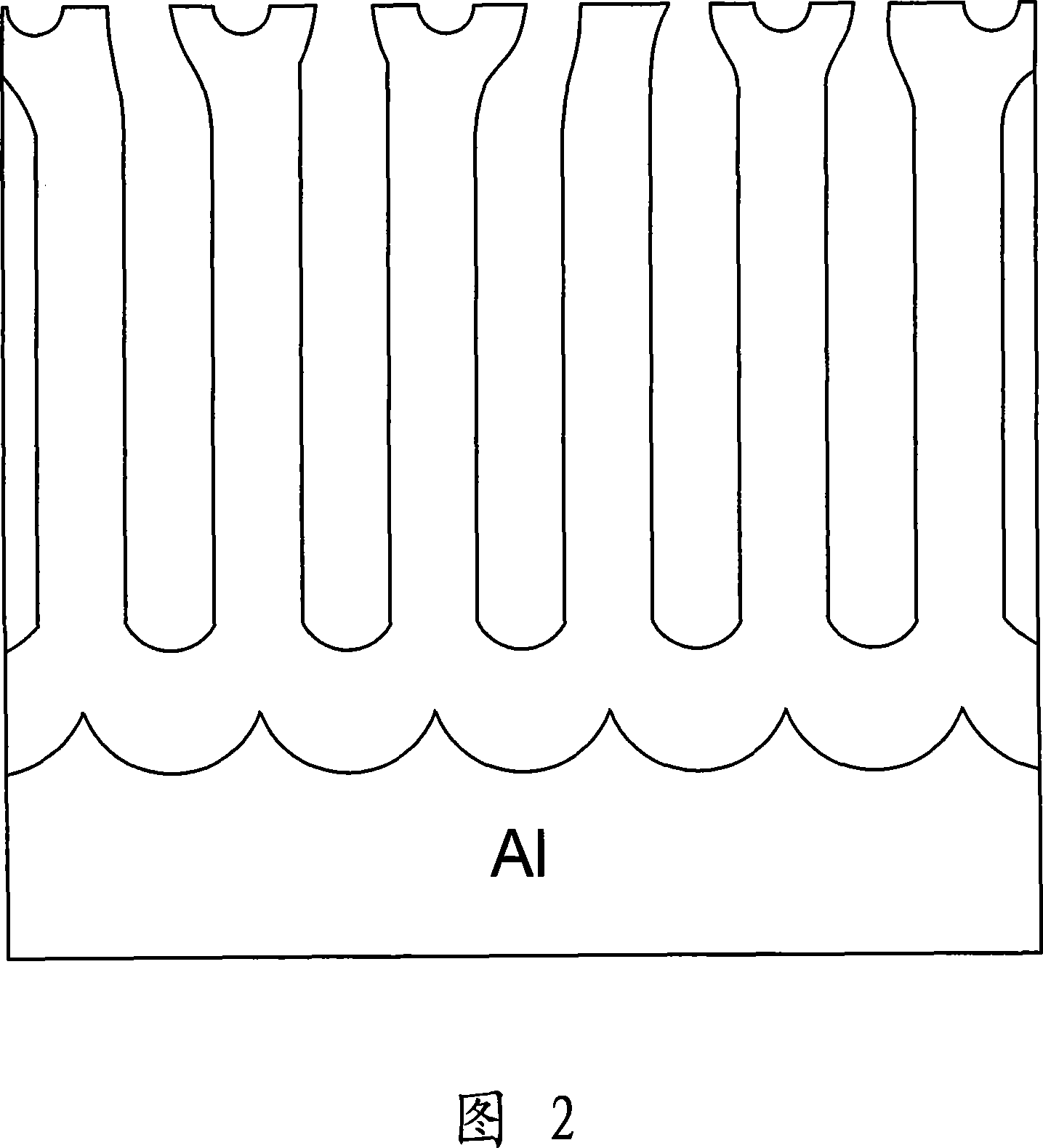

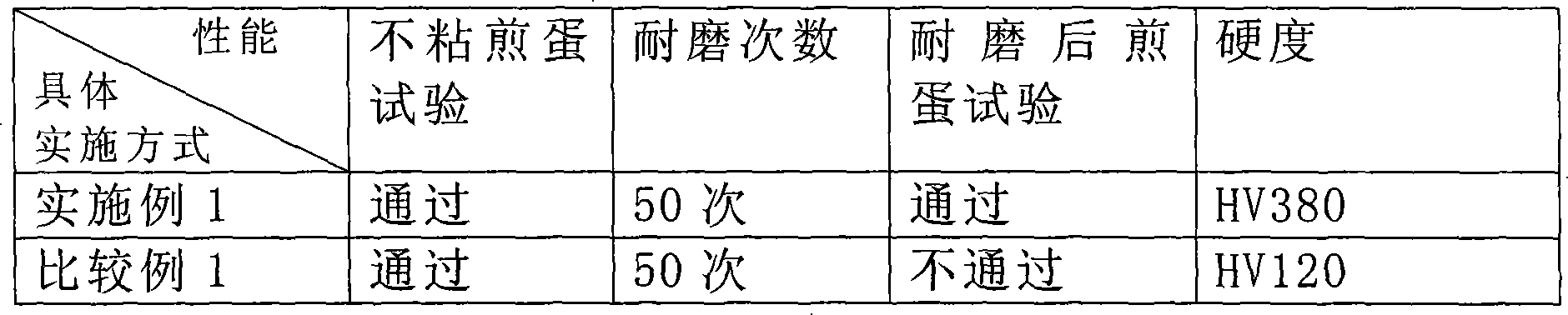

Making process of antiwear nonstick cooker

InactiveCN101019742ANot easy to produce oily smokeImprove thermal conductivityCooking-vessel materialsHardnessHigh wear resistance

The present invention is making process of antiwear nonstick cooker and belongs to the field of daily article making technology. The making process of antiwear nonstick cooker includes the following steps: forming, anode oxidation to form hard oxide layer, permeating, and pore sealing treatment. The antiwear nonstick cooker has the advantages of high nonstick performance, high hardness, high wear resistance and long service life. Besides, the cooker has fewer trend of generating oil smoke and easy cleaning.

Owner:严卫星 +1

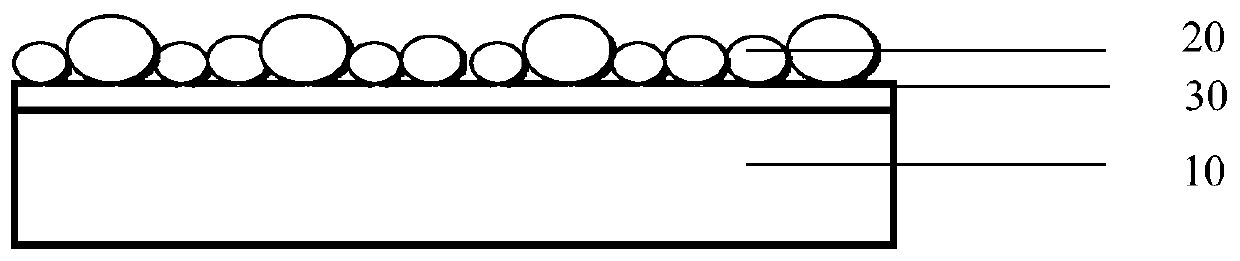

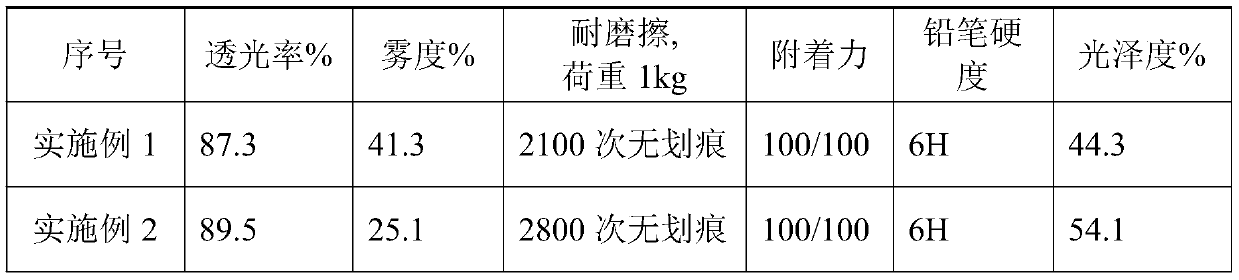

High-hardness and anti-dazzle hardening layer coating liquid and hardening film

The invention relates to the technical field of a hardening film, in particular to high-hardness and anti-dazzle hardening layer coating liquid and a hardening film. In order to solve the problems that the existing hardening film cannot realize high hardness or anti-dazzle performance at the same time, the invention provides the high-hardness and anti-dazzle hardening layer coating liquid and thehardening film. The hardening layer coating liquid contains 40 to 80 percent of acrylic ester prepolymers, 10 to 30 percent of acrylic ester monomers, 7 to 30 percent of silicon dioxide, 2 to 6 percent of photoinitiators and 0.1 to 0.5 percent of auxiliary agents in percentage by weight. The hardening layer coating liquid provided by the invention forms a hardening layer after the curing; high hardness and anti-dazzle performance are realized. The hardening film provided by the invention has high hardness and anti-dazzle protection effects.

Owner:NINGBO EXCITON TECH

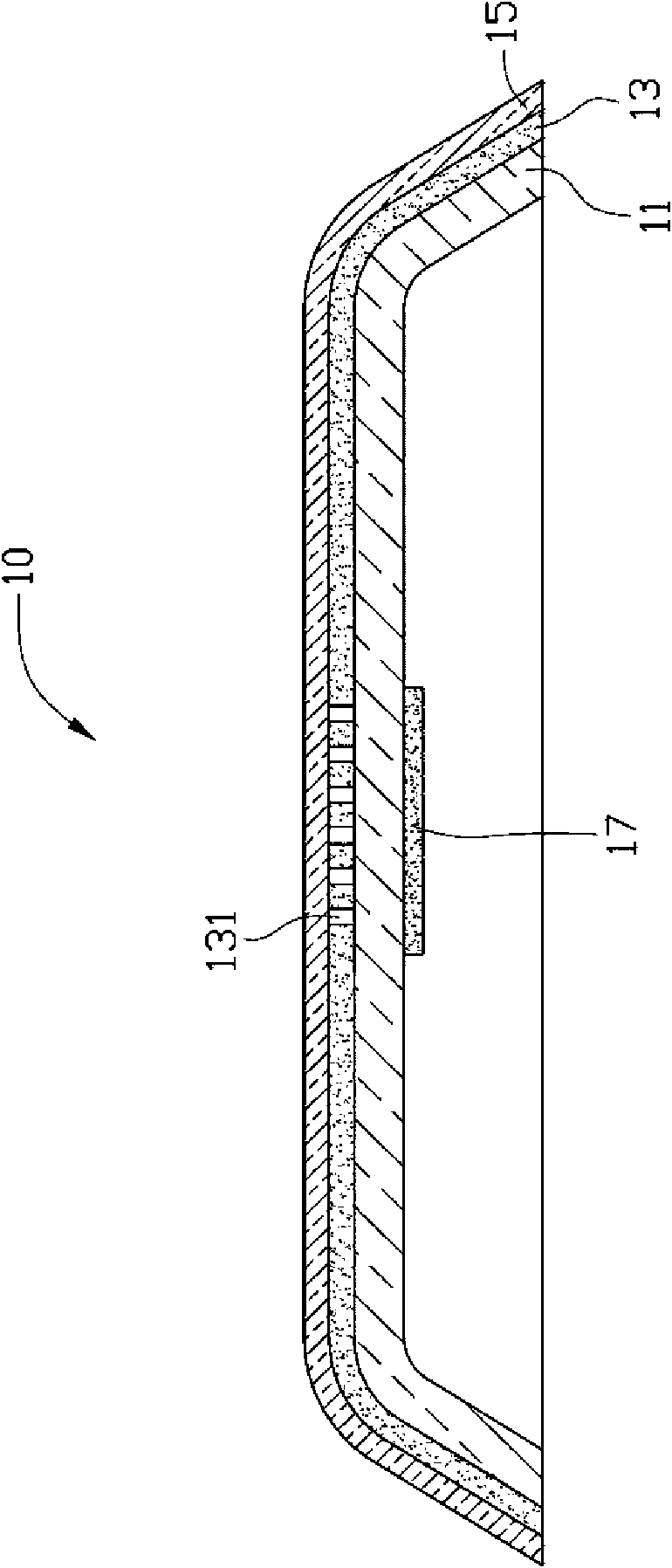

Outer casing of electronic product and preparation method thereof

InactiveCN101352947APlay a protective effectWon't wear outLamination ancillary operationsDecorative surface effectsComposite materialMetal coating

The invention relates to an electronic product shell, comprising a film layer, an injection layer and a pattern layer which is arranged between the film layer and the injection layer, wherein, the pattern layer is a metal coating. The invention also provides a preparation method of the electronic product shell. The pattern layer of the electronic product shell of the invention is a metal coating which is used for displaying patterns of the electronic product shell, and thereby the patterns of the electronic product shell are metallic. Besides, as the metal coating is arranged between the film layer and the injection layer, the film layer has contact with the outside for protecting the metal coating when used, and the metal coating is not worn.

Owner:BYD CO LTD

Protection device and protection method for cable sheath in power construction process

InactiveCN104158110AAvoid damageEasy to twist and twistCable installation apparatusMechanical engineeringElectric power

The invention discloses a protection device for a cable sheath in the power construction process. The protection device comprises a shell, wherein one or more rolling mechanisms are arranged at the upper end of the shell; a through hole axially perpendicular to a rotating shaft of each rolling mechanism is formed in the shell; a bearing is arranged in the through hole; an inner pipe is sleeved by the bearing; two ends of the inner pipe stretch out of the through hole; a conducting wire adjusting and fixing mechanism is arranged at each of the two ends of the inner pipe. By the adoption of the bearing arranged inside the shell, the cable moves forwards under the action of a dragger, a conducting wire is easy to automatically rotate due to the dead weight per se, and a twisted conducting wire is loosened to greatly facilitate moving or recycling of the conducting wire without damaging the wire sheath.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Casting method of SiO2-reinforced nodular cast iron-based brake disc

InactiveCN102367536AWon't wear outReduce hardnessBraking discsFriction liningDuctile ironWear resistance

The invention discloses a casting method of a SiO2-reinforced nodular cast iron-based brake disc. The casting method comprises five steps of SiO2 particle selection, nodular cast iron selection, sand mold preparation, melting and pouring, and cooling and cleaning. The casting method has the advantages that the SiO2-reinforced nodular cast iron-based brake disc obtained by the casting method does not wear brake blocks; SiO2 particles adopted by the casting method are combined according to different particle sizes, are uniformly distributed in a nodular cast iron matrix in a way that large particles and small particles are arranged alternately and have a certain support effect on the nodular cast iron matrix, and thus brake disc wear resistance is greatly improved and a brake disc service life is prolonged; and the casting method is simple and is easy.

Owner:陈均

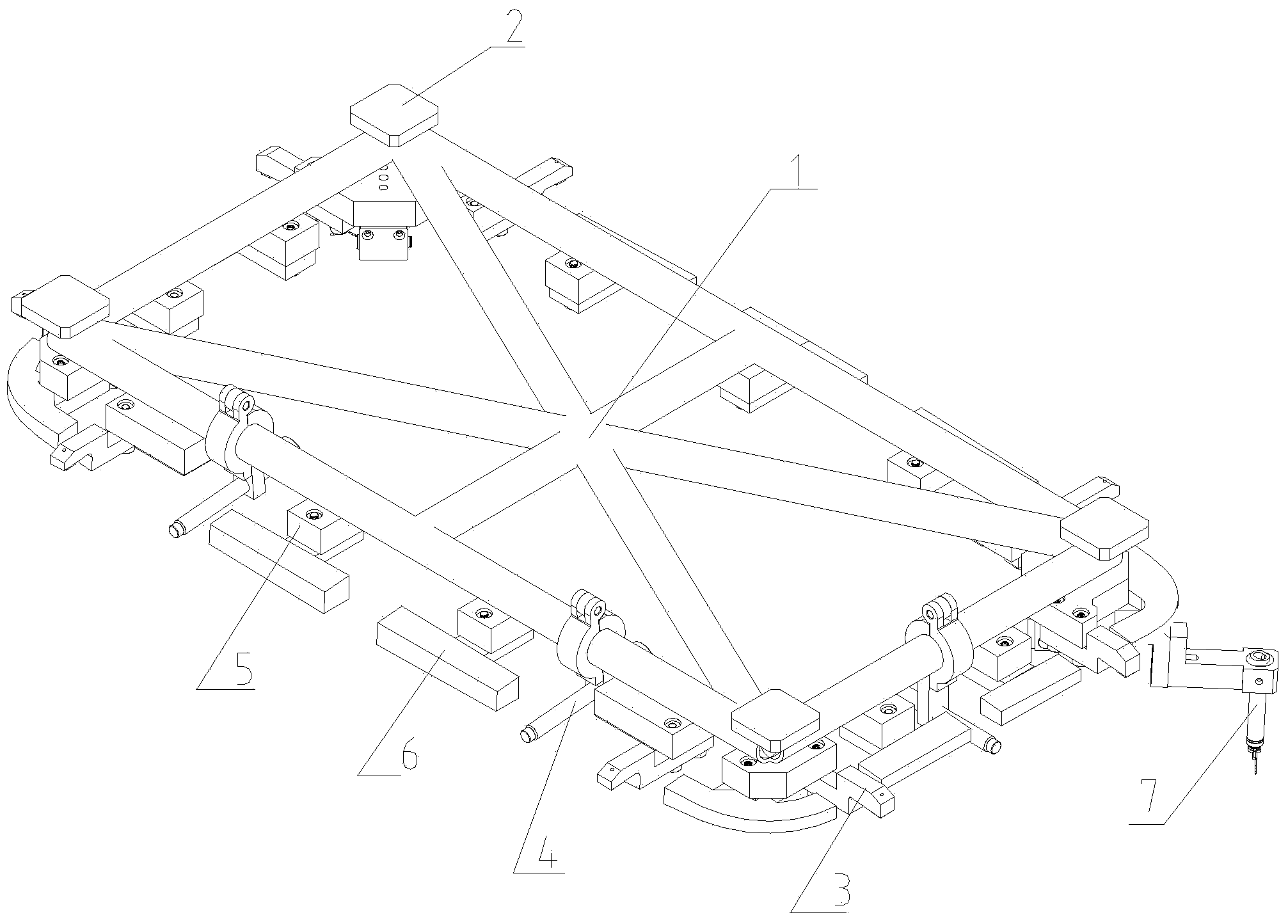

Automobile skylight opening detection tool and method for detecting skylight profile and gap by detection tool

ActiveCN103808225ATightly boundReduce detection errorMechanical counters/curvatures measurementsMechanical clearance measurementsReference blockEngineering

The invention provides an automobile skylight opening detection tool and a method for detecting a skylight profile and gap by the detection tool. The detection tool comprises a frame and a detection block, the detection block is connected with the frame through connection blocks, detection pins are arranged on the periphery of the frame and connected with the frame through the connection blocks, a plurality of positioning blocks are arranged on the periphery of the frame, connected with the frame through the connection blocks and used for axially and radially positioning automobile skylight plates, positioning compression mechanisms are arranged at two adjacent edges of the frame, and peripheral apexes of the frame are provided with reference blocks. The detection tool is placed at the corresponding position of an automobile skylight, a general rule detects whether a skylight opening gap is within a tolerance range or not, a segment difference rule detects whether a skylight opening profile is within a tolerance range or not, and the detection pins detect whether skylight mounting holes are within a tolerance range or not. The detection tool is closely matched with the automobile skylight, light in weight and firm, the detection method is simple to operate, and detection results are accurate.

Owner:铜陵市创威科技有限责任公司

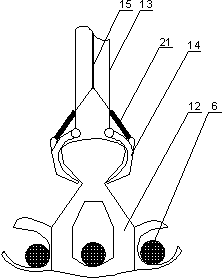

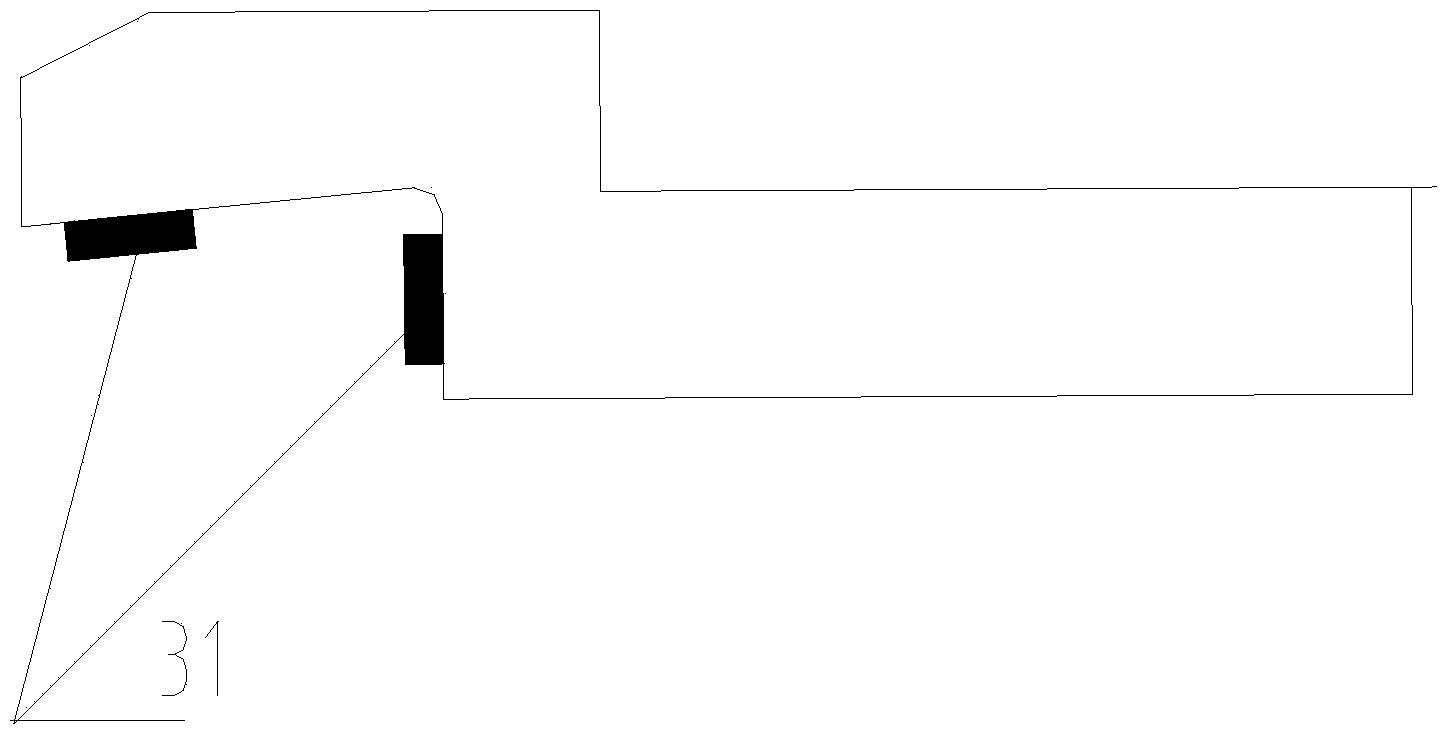

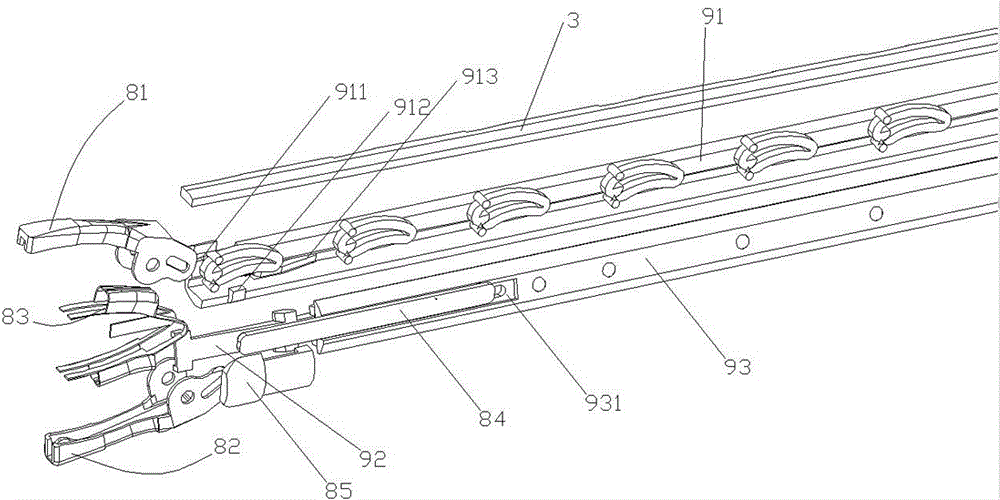

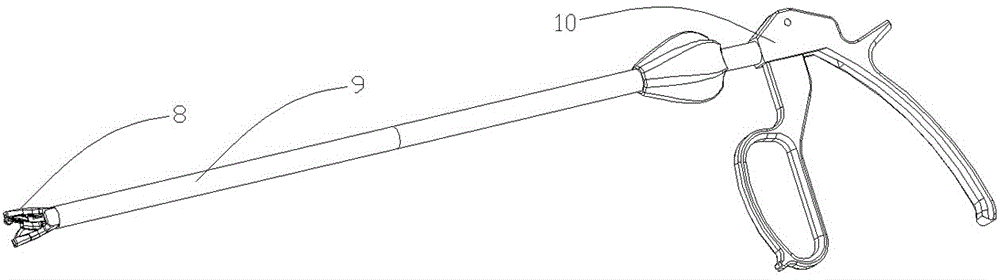

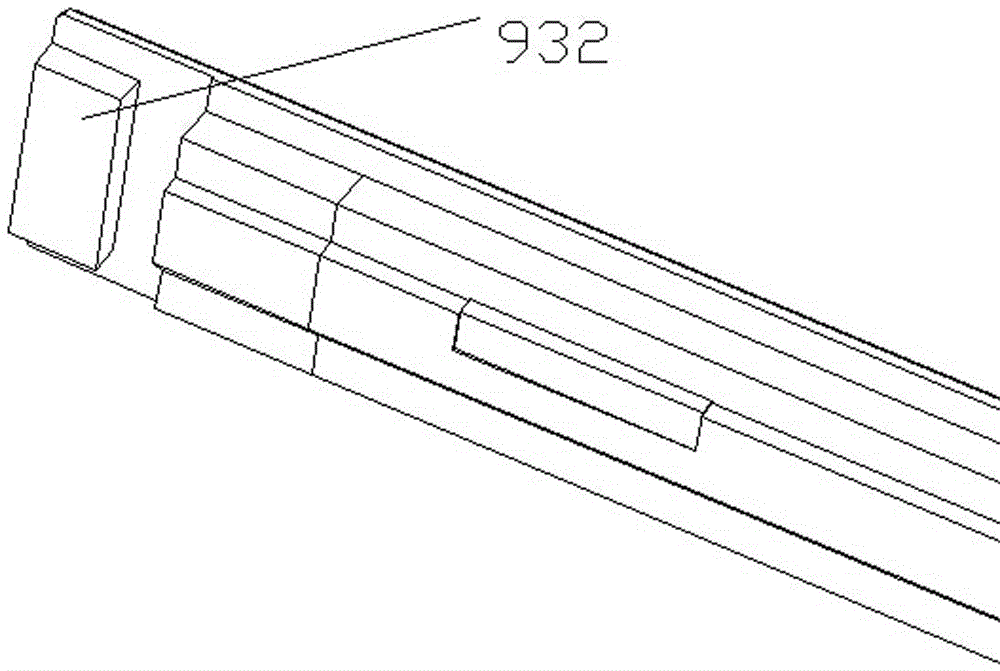

Hemostatic clip applier capable of continuously serving

InactiveCN106037866AShorten the timeImprove the effect of surgeryWound clampsContinuous usePower apparatus

The invention discloses a hemostatic clip applier capable of continuously serving, and belongs to the field of medical articles, aiming at solving the problems of an existing hemostatic clip applier which is slow to take effects, easy to cause accidents and poor in hemostatic clip fastening performance. The hemostatic clip applier comprises a clip head, a clip pipe which is connected to the clip head and a power device which is connected to the clip pipe, wherein the clip pipe comprises a cartridge holder, a clamping plate pushing device, a right side plate as well as a sleeve which sleeves the cartridge holder, the clamping plate pushing device and the right side plate; a passage, in which the hemostatic clip can advance, is surrounded by the cartridge holder, the clamping plate pushing device and the right side plate; a locating groove is formed in the cartridge holder; a pushing device for pushing the hemostatic clip to advance is arranged on the clamping plate pushing device; and the power device comprises a tail pipe.

Owner:CHENGDU IDING IND PROD DESIGN

Flexible part detecting device and method

ActiveCN104406520AWon't wear outNot easy to damageUsing optical meansEngineeringMechanical engineering

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

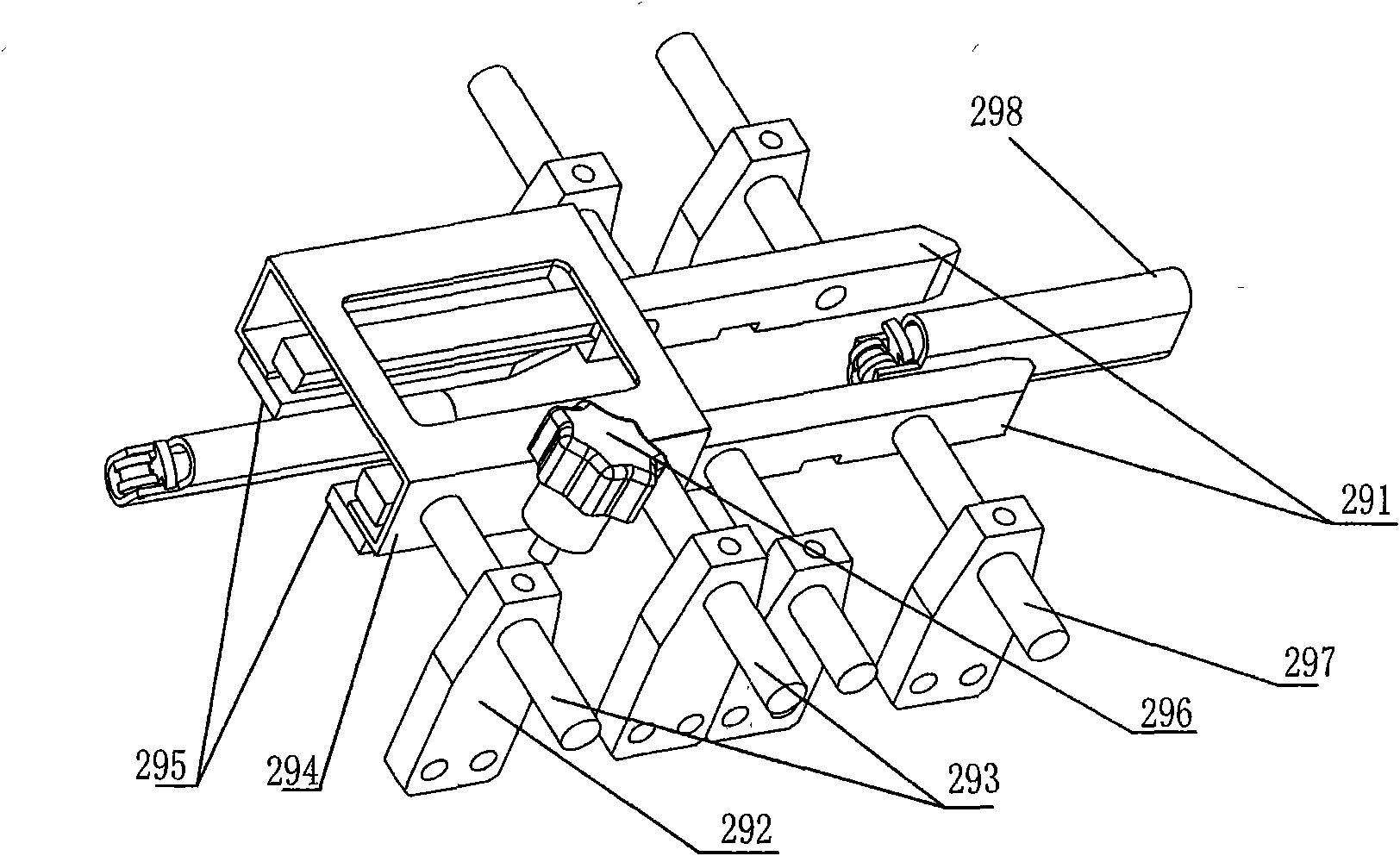

Cutter belt processing device and processing method thereof

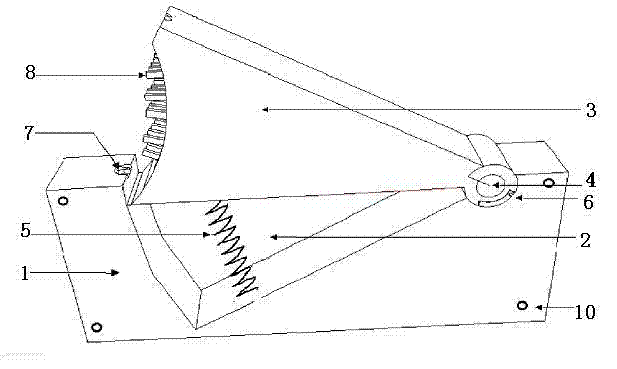

ActiveCN103358188ASolve the difficult problem of precise automatic feedingHigh precision grinding made easyGrinding drivesOther manufacturing equipments/toolsVertical planeDynamic positioning

A cutter belt processing device comprises a constant angle constant-pressure automatic compensating and feeding device and a dynamic positioning assembly, wherein the constant angle constant-pressure automatic compensating and feeding device and the dynamic positioning assembly are fixedly arranged on a base plate. The constant angle constant-pressure automatic compensating and feeding device comprises a grinder, an angle adjuster and a compensating feeder, wherein the grinder is arranged above the base plate through the angle adjuster, the grinder can rotate in a vertical plane above the base plate, and the compensating feeder is arranged on the grinder. The cutter belt processing device is strong in maneuverability, easy and convenient in angle adjusting and capable of meeting technological requirements for producing high-accuracy cutter belts, enables high-accuracy grinding of blades of the cutter belts to be easy and controllable, does not need manual or other types of intervention during service life of a grinding wheel, is high in dynamic positioning stability, cannot damage blades or abrade cutter bodies, guarantees technology and control stability of a cutter belt manufacturing process, avoids the time for replacing the positioning assembly when product specification needs to be changed and greatly reduces the preparation time for changing product specification.

Owner:SHANGHAI XINPENG PRINTING EQUIP

Negative ion wall brick ceramic ink and preparation method thereof

The invention discloses negative ion wall brick ceramic ink and a preparation method thereof. The wall brick ceramic ink comprises, by mass percentage, 35-45% of pigment, 3-8% of dispersing agent, 40-50% of solvent, 2-5% of surface additive, 0.1-0.5% of flatting agent, 0.3-0.8% of antifoaming agent, 0.5-1% of bonding agent, 0.08-0.1% of anti-settling agent, 4-8% of composite antistatic agent and 0.1-10% of composite negative ion powder. The ceramic ink can efficiently continuously release negative ions, have high abrasion resistance, prolong release of negative ions and have an anti-static function.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

Automatic transfer device and transfer method

The invention relates to an automatic transfer device. Existence sensors are set for sensing whether workpieces are arranged on a motion component or not so as to control operation time of a power component, speed reduction sensors are set for enabling the motion component to reduce speed before the stop position and reduce inertia of the motion component during stopping so as to improve operation stability of the transfer device and letting the motion component to stay in the accurate stopping position, and stop sensors are set for controlling the stopping time of the power component so as to enable the motion component to stop in the stop position. The existence sensors, the speed reduction sensors and the stop sensors realize automatic control motion process of circulating of workpieces from the feed position to the discharge position and to the feed position again. Furthermore, the invention provides an automatic transfer method of the automatic transfer device.

Owner:苏州久工自动化科技有限公司

Mold press forming die and molded article manufacturing method

ActiveCN101528616AGuaranteed coaxialityGood eccentricityGlass pressing apparatusGlass press-moulding apparatusEngineeringMechanical engineering

Owner:HOYA CORP

Roadblock for controlling one-way traffic and realizing shock absorption and speed reduction

InactiveCN102900032AWon't wear outAct as a deceleration warningTraffic signalsRoad signsEngineeringRoad traffic

The invention discloses a roadblock for controlling one-way traffic and realizing shock absorption and speed reduction. The roadblock comprises a roadblock body, wherein a balking bin is arranged in the roadblock body; the shape of the balking bin is matched with that of a balking block; the balking bin is used for accommodating the balking block; one end of the balking block is connected to the balking bin through a shaft, and the bottom of the other end of the balking block is connected to the balking bin through a spring; at least one end of the shaft is provided with an anti-inversion mechanism; a switch for controlling the balking block to be accommodated into the balking bin and clamped in the balking bin or controlling the balking block to be unfolded; the roadblock is also provided with a spacer body, wherein the shape and the size of the spacer are the same as those of the closed roadblock body; and connection holes are formed in corresponding positions. The roadblock can flexibly limit one-way traffic of vehicles and achieve effects of speed reduction and shock absorption; the traffic safety of a road is guaranteed, and abrasion of the vehicles can be reduced; and the roadblock is rational in design, comprehensive in function and suitable for popularization.

Owner:CHINA THREE GORGES UNIV

Multi-layer anti-flaming textile cloth and manufacturing method thereof

ActiveCN103361987AImprove flame retardant performanceIncreasing the thicknessSynthetic resin layered productsWoven fabricsSurface layerEmulsion

The invention relates to multi-layer anti-flaming textile cloth and a manufacturing method thereof. The multi-layer anti-flaming textile cloth comprises at least three surface layers which are adhered through anti-flaming emulsion; the surface layers are interwoven of warps and wefts up and down; before being woven, the warps and the wefts are soaked in a specific anti-flaming chemical medicinal solution; the warps comprise textile metal fibers, polyester cotton, polyamide filaments and 20D chinlon matt fully drawn yarn (FDY) filaments; the wefts comprise cotton, hemp, furs and 20D chinlon matt FDY filaments; the cross sections of all the warps and wefts are flat rectangular; the firmness of the cloth can be improved; the warps and the wefts are soaked in the anti-flaming chemical medicines, so that effects of retarding flames and preventing fire from spreading are achieved; hexa-bromine water media and deca-bromine-antimonous oxide are coated on the surface of the cloth; furthermore, the cloth is tightly woven and is low in ventilating property, so that the anti-flaming effect of the cloth can be enhanced; the manufacturing method for the cloth is simple; a plurality of warps or wefts are combined, so that the firmness and the air permeability of the cloth are improved.

Owner:陕西秦塬纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com