Method and device for measuring accumulated liquid of natural gas pipeline

A technology for natural gas pipelines and measurement methods, which is applied in the field of measuring the height of liquid accumulation inside natural gas pipelines. It can solve the problems of high pressure in natural gas pipelines, non-intrusive detection of liquid accumulation in collection and transportation pipelines, and high toxicity, so that no replacement is required. , good explosion-proof performance, small energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method principle and device structure proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings.

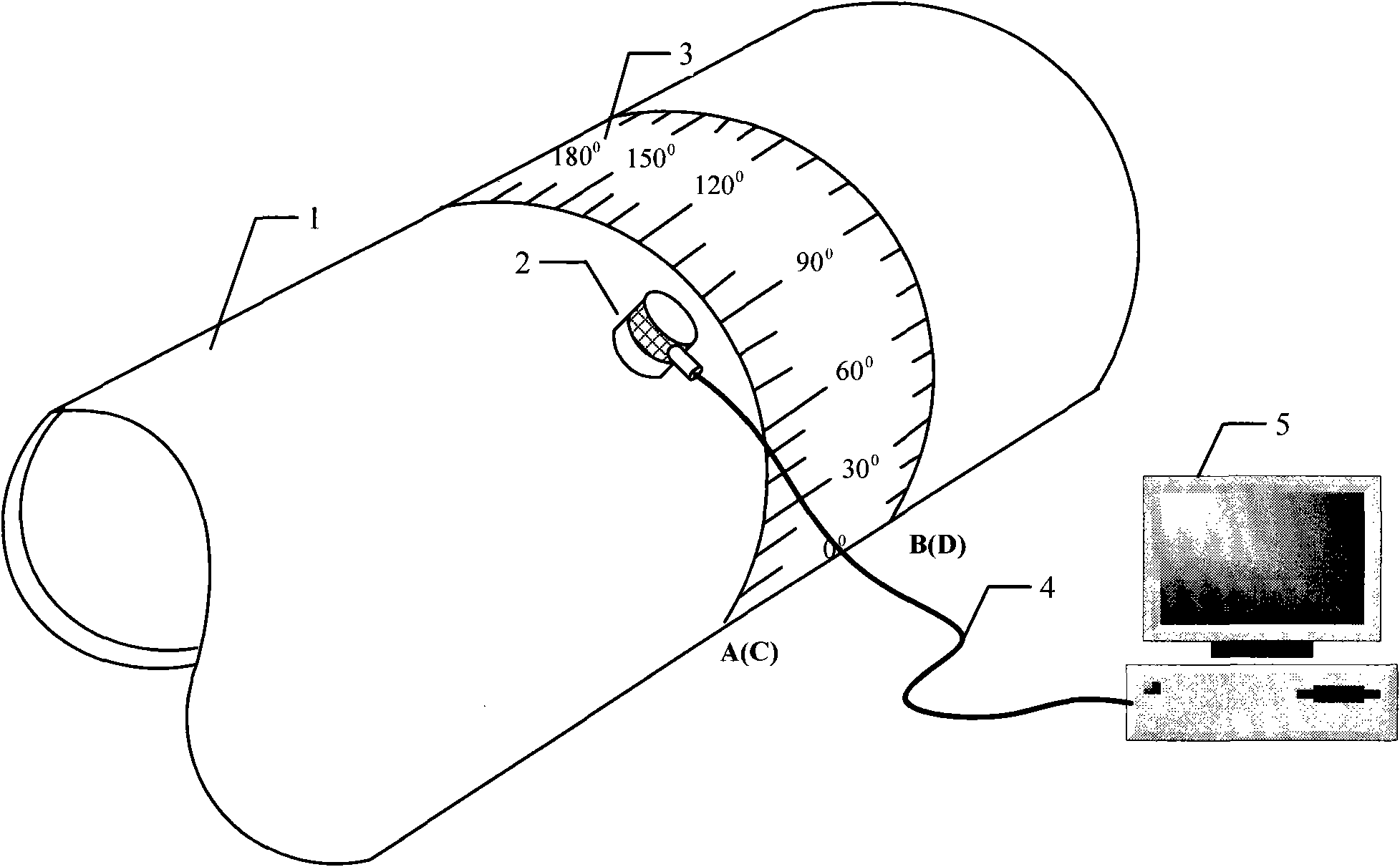

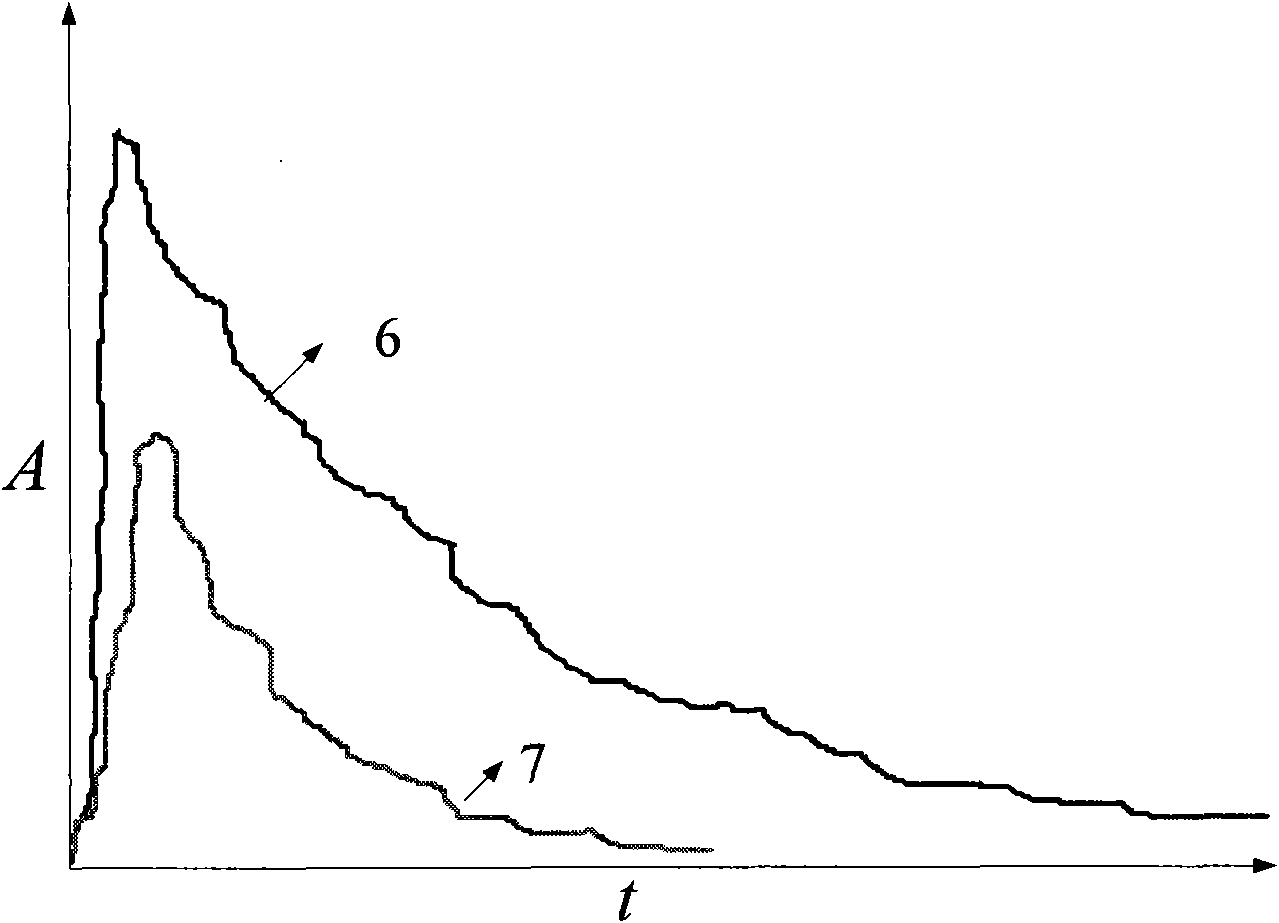

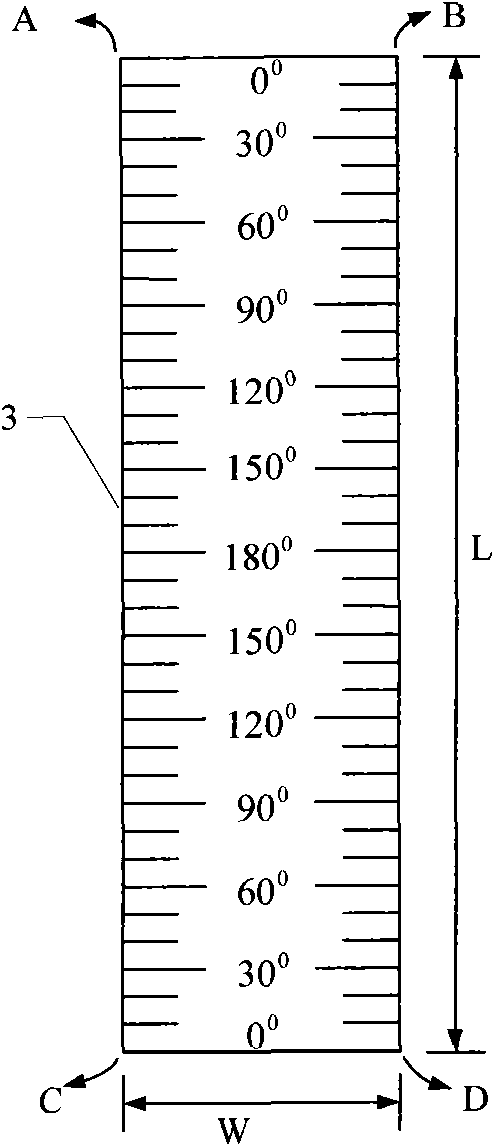

[0031] see figure 1 , The effusion monitoring device proposed by the present invention mainly includes an ultrasonic probe 2, a circumferential angle ruler 3, a signal line 4, and a effusion monitoring computer 5. The ultrasonic probe 2 proposed by the present invention is coupled on the outer wall of the pipeline 1 to be tested, and the ultrasonic probe has the function of transmitting and receiving ultrasonic signals at the same time. The ultrasonic probe 2 vertically emits high-frequency ultrasonic waves from the outside of the tube to the inside of the tube. The ultrasonic wave is reflected at the interface between the inner wall of the tube and the inner medium, and the reflected echo signal is received by the ultrasonic probe again. The end of the ultrasonic probe 2 is connected to the effusion mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com