Patents

Literature

175results about How to "No pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for determining a fluid flow rate with a fluid control valve

InactiveCN103307342ALow costRealize the adjustment functionOperating means/releasing devices for valvesVolume/mass flow by electric/magnetic effectsFluid controlValve actuator

A method for determining a fluid flow rate with a fluid control valve utilizes inherent characteristics of a particular valve in conjunction with easily measured parameters in order to determine a flow rate through the valve. A valve flow characteristic equation, a flow coefficient, and a rangeability for the valve are known and hardcoded into a chipset that controls the valve. A differential pressure transducer measures the pressure drop across the valve. A valve actuator controls the valve opening fraction. The differential pressure transducer and the valve actuator provide feedback signals to the chipset. The known and measured parameters are used to calculate an instantaneous valve characteristic and a fully-open flow rate for the valve. The instantaneous flow rate through the valve is then calculated from the instantaneous valve characteristic and the fully-open flow rate.

Owner:冯经娟

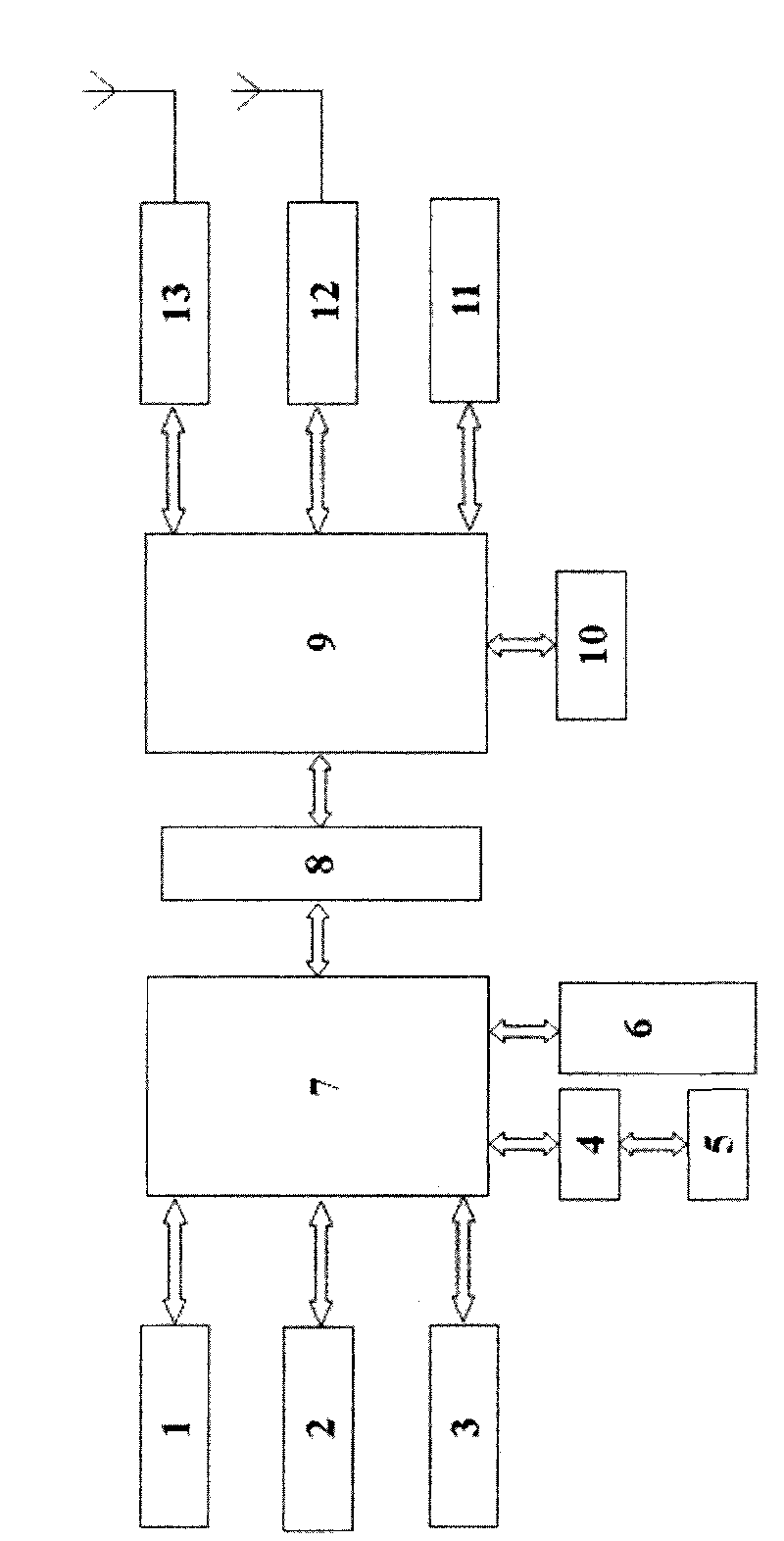

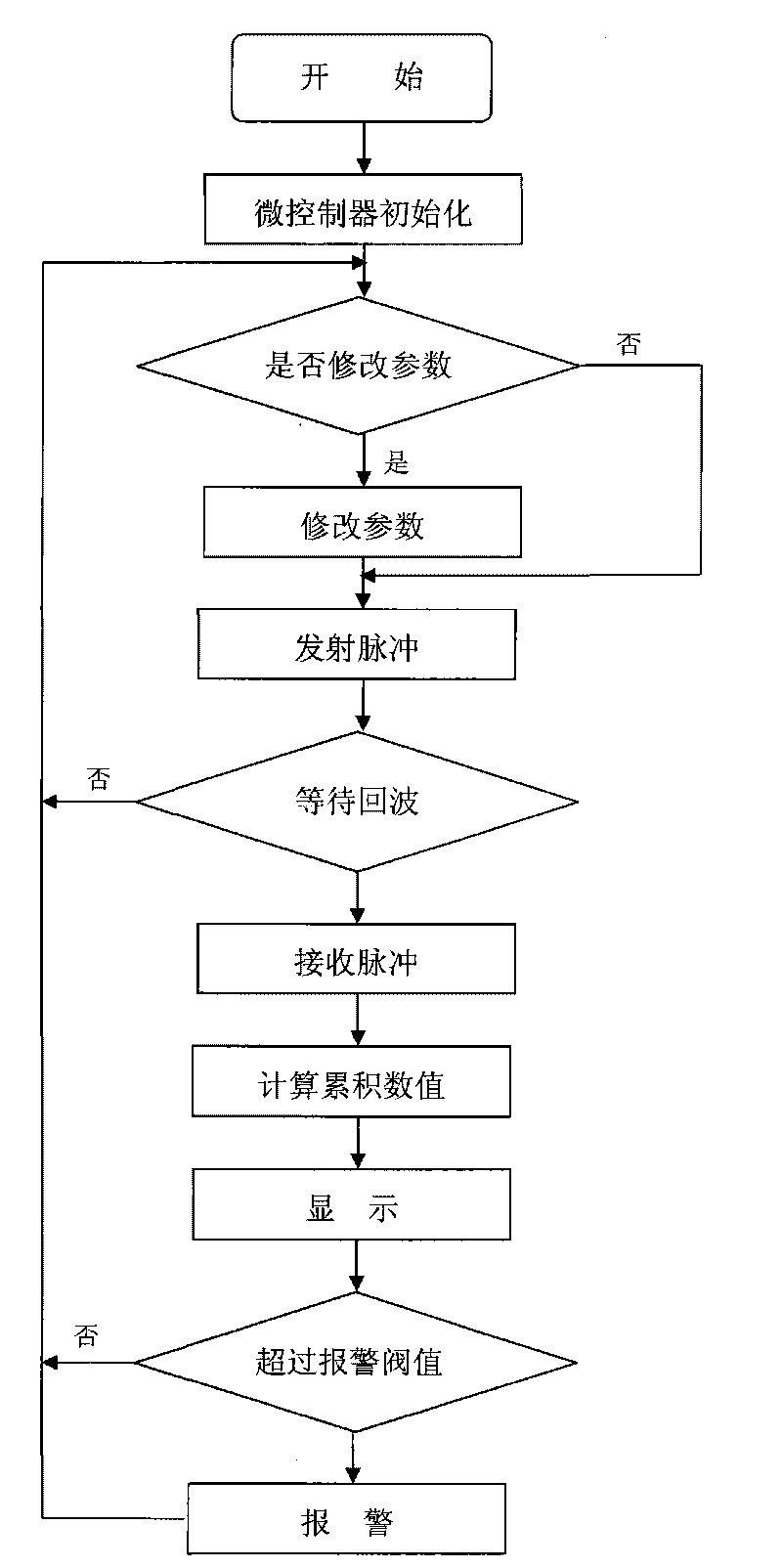

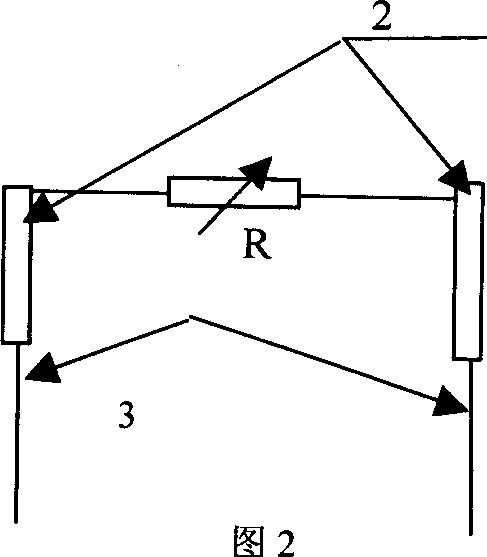

Wireless management system for oil and gas transportation metering and leakage alarming

InactiveCN101749542ANo Flow Obstruction DetectionNo pressure lossPipeline systemsMicrocontrollerUltrasonic sensor

The invention discloses a wireless management system for oil and gas transportation metering and leakage alarming, which includes an ultrasonic transducer, an ultrasonic transmitting and receiving module, a singlechip, a memorizer, a LCD, a keyboard control module, a sound and light alarming module, a communication module and a GPS + GPRS system based on microcontroller. The ultrasonic transducer is used to convert electric energy into ultrasonic energy, and transmit the ultrasonic energy into a detected fluid; an ultrasonic signal received by a receiver, measured instant flux and accumulated flux value after receiving the data processing of a microcontroller are converted into digital signals representing flux; one signal is supplied to the LCD to display data and the other signal transmits data through the command center of the GPS + GPRS system. If leakage occurs, the singlechip of the detecting unit thereof transmits an alarming signal to the command center through data comparison, and the command center confirms the accident position through a GPS positioning system immediately, and the staff nearby are informed to process through the SMS platform and voice system of the GPRS system.

Owner:谭汉卿

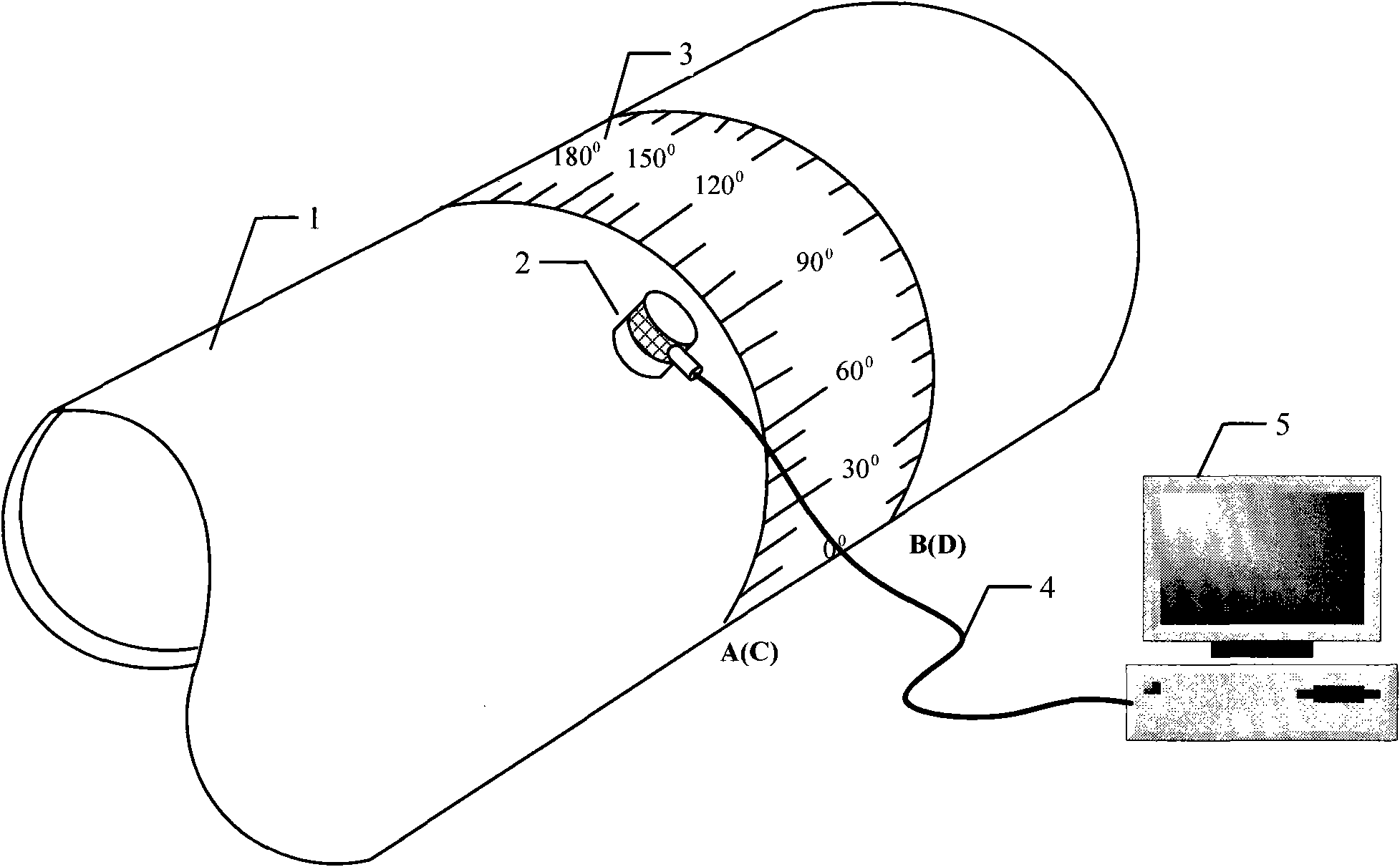

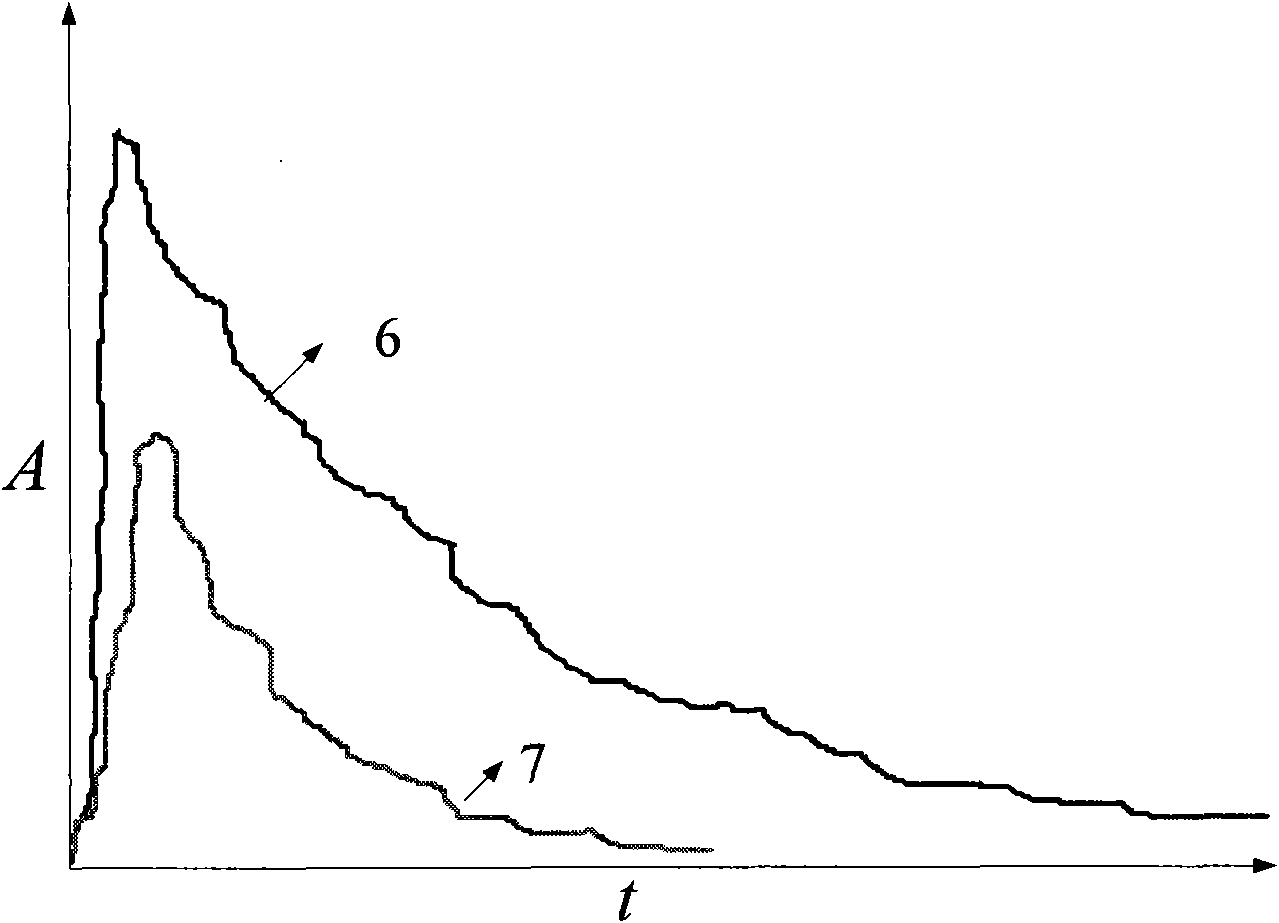

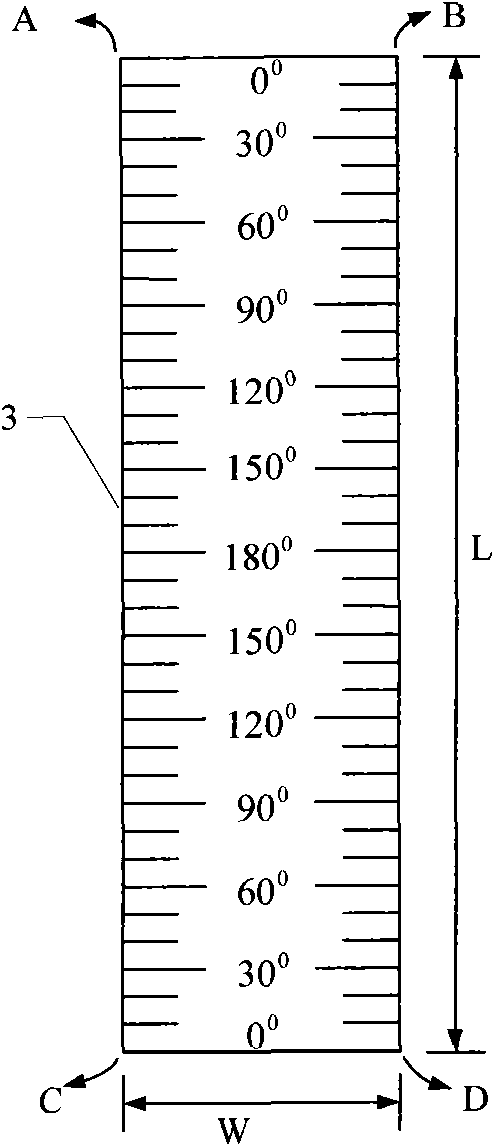

Method and device for measuring accumulated liquid of natural gas pipeline

InactiveCN101839746ASave energyNo security issuesMachines/enginesLevel indicatorsLiquid mediumLine tubing

The invention discloses a method and a device for measuring accumulated liquid of a natural gas pipeline. The method comprises the following steps of: vertically transmitting high-frequency ultrasonic wave into the pipeline by an ultrasonic probe coupled to the outer wall of the measured pipeline, wherein the energy of reflection echo has great difference due to different properties of gas and liquid media; judging that the pipe inner wall is contacted with gas or liquid at the position of the probe according to the characteristic of echo received by the ultrasonic probe and reflected by the pipe inner wall; gradually adjusting the measurement position of the ultrasonic probe on the pipe outer wall along the circumferential direction; and recording a circumferential angle of the ultrasonic probe by a circumferential angle ruler when the echo has mutation, and further calculating the height of the accumulated liquid. The method is a non-intrusive accumulated liquid measurement method, does not change the structure of the conventional pipeline, has no medium leakage risk, does not affect the operation such as cleaning the pipeline and the like, meanwhile is not affected by the composition of gas and liquid phase media in the pipeline and parameters such as temperature, pressure and the like, overcomes the defect that the conventional ultrasonic technology needs complex sound velocity correction, and is particularly suitable for measuring the accumulated liquid inside the pipeline for conveying corrosive and toxic media.

Owner:SINOPEC ZHONGYUAN PETROLEUM ENG DESIGN

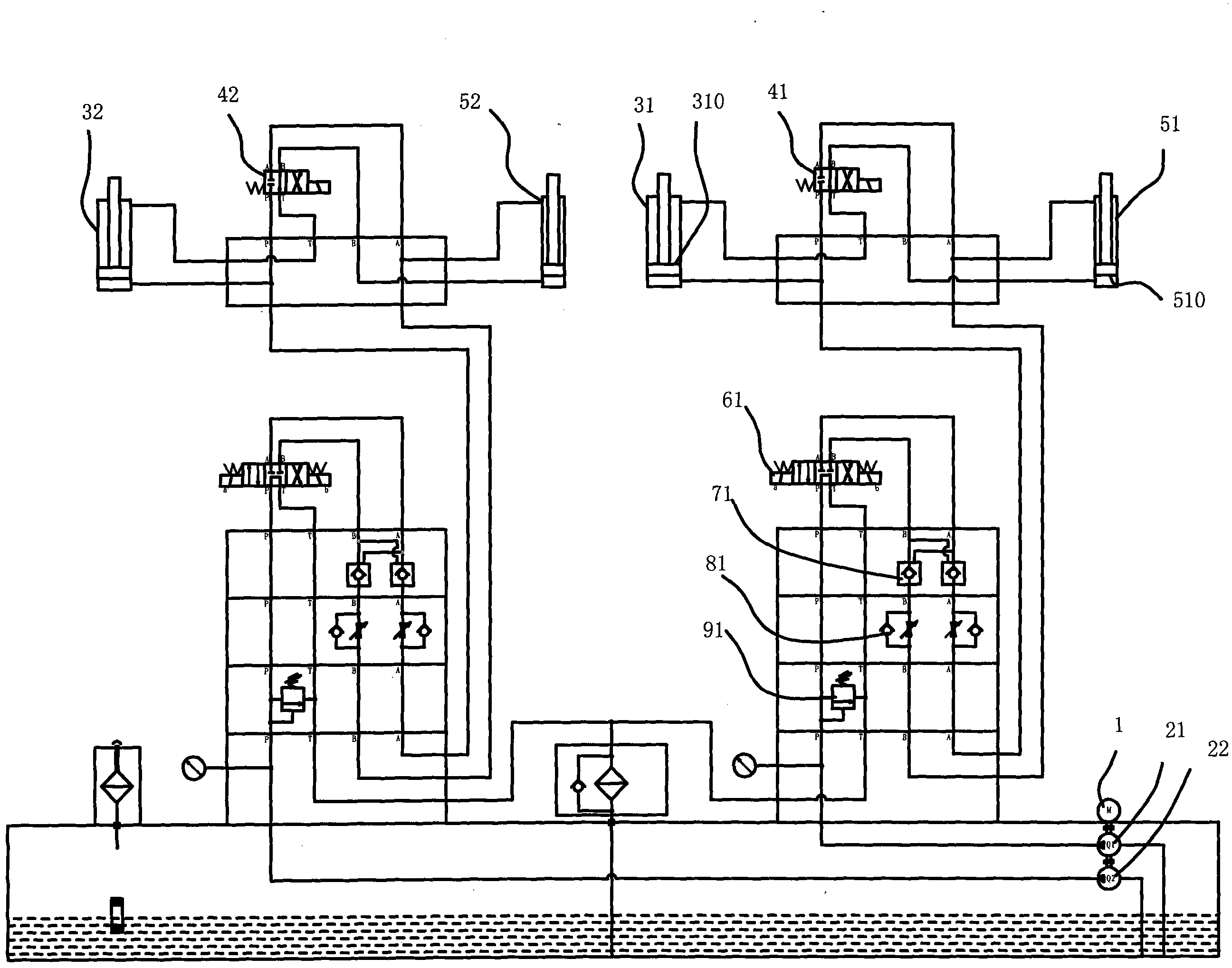

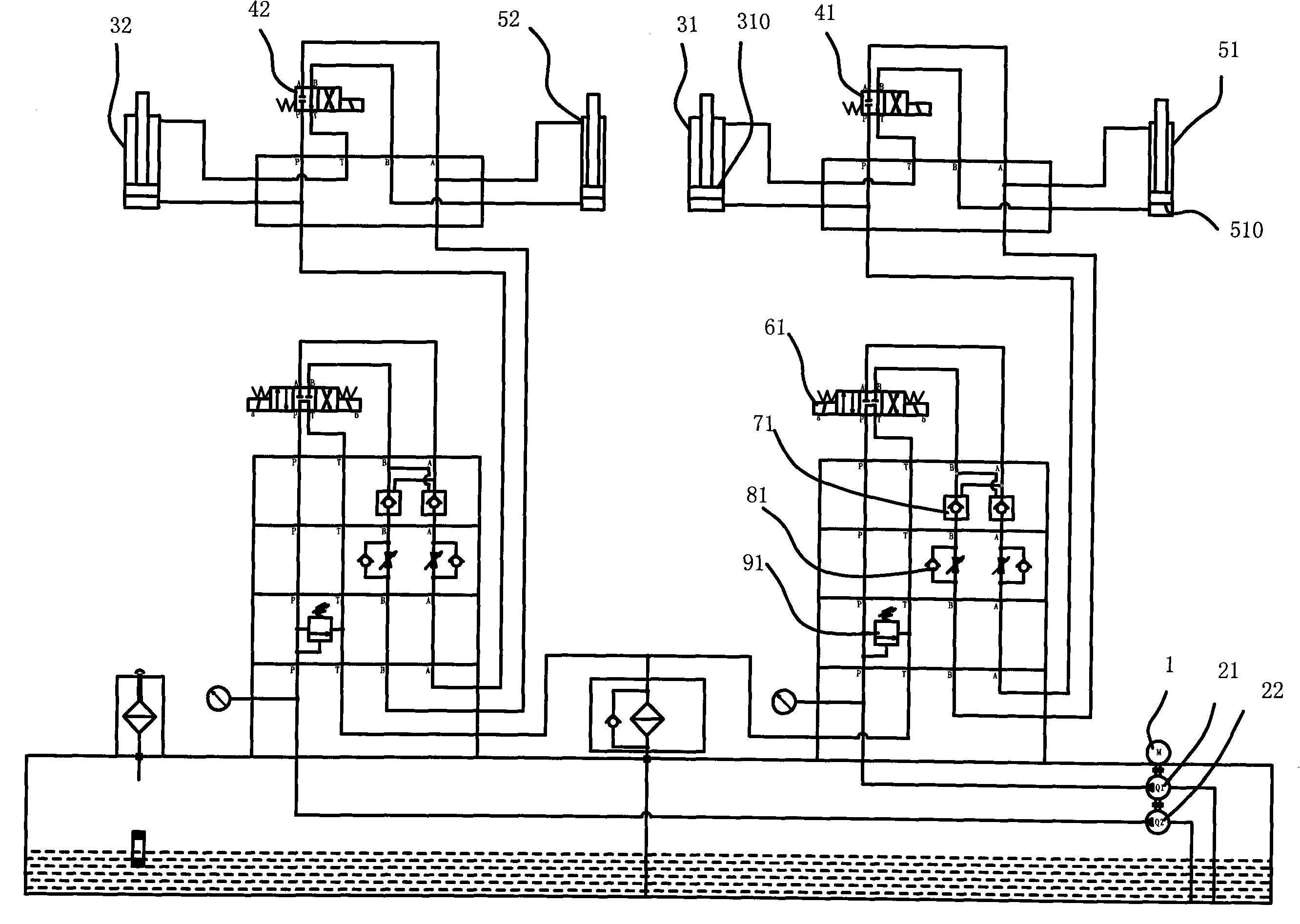

Four-cylinder synchronous hydraulic system

InactiveCN102022392ANo pressure lossReduce temperature riseServomotorsTop dead centerMaster cylinder

The invention discloses a four-cylinder synchronous hydraulic system relating to a synchronous hydraulic system synchronously lifting through a four-corner driving platform. The system can carry out online automatic compensation to ensure four-point synchronous lifting. The four-cylinder synchronous hydraulic system comprises a master cylinder A, a slave cylinder A, a master cylinder B, a slave cylinder B, an oil pump, two oilway reversing control valve banks and a hydraulic oil tank, wherein the master cylinder A, the slave cylinder A, the master cylinder B and the slave cylinder B respectively drive four corners of a horizontal table top, and the two oilway reversing control valve banks are arranged between the oil pump and the master cylinder and the slave cylinder; the rod cavities and the rodless cavities of the master cylinders and the rodless cavities and the rod cavities of the slave cylinders are in serial and parallel switching connection through a two-position four-way solenoid valve, and the working areas of the rod cavities of the master cylinders are equal to those of the rodless cavities of the slave cylinders. The four-cylinder synchronous hydraulic system comprises two same independent serial / parallel cylinder synchronous circuits; under the normal condition, master oil cylinders and slave oil cylinders in each circuit are synchronous through serial connection. When the master oil cylinders and the slave oil cylinders are asynchronous due to the leakage of the oil cylinders, the four oil cylinders can be lifted to top dead centers, and the master oil cylinders and the slave oil cylinders are switched into a parallel mode through the two-position four-way solenoid valve and then are switched to a serial mode after the four oil cylinders are synchronous.

Owner:江苏扬力数控机床有限公司

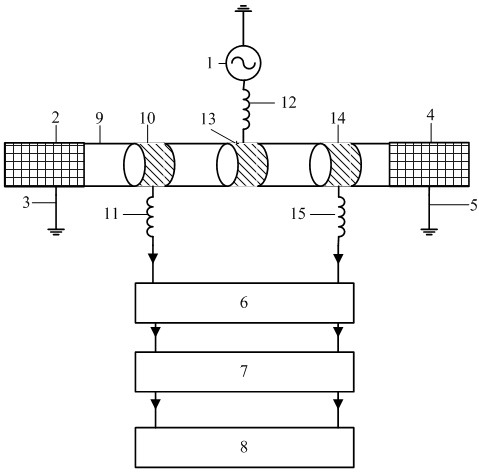

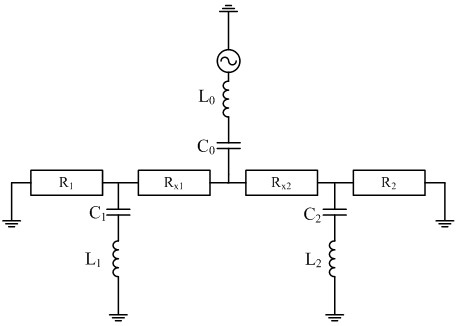

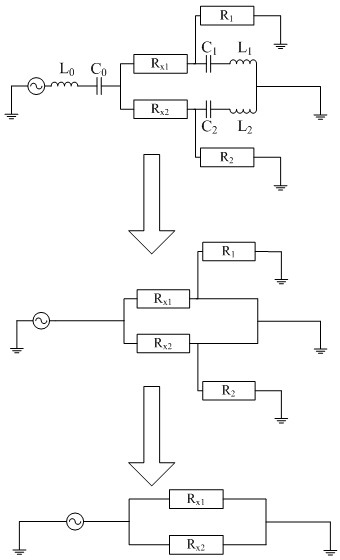

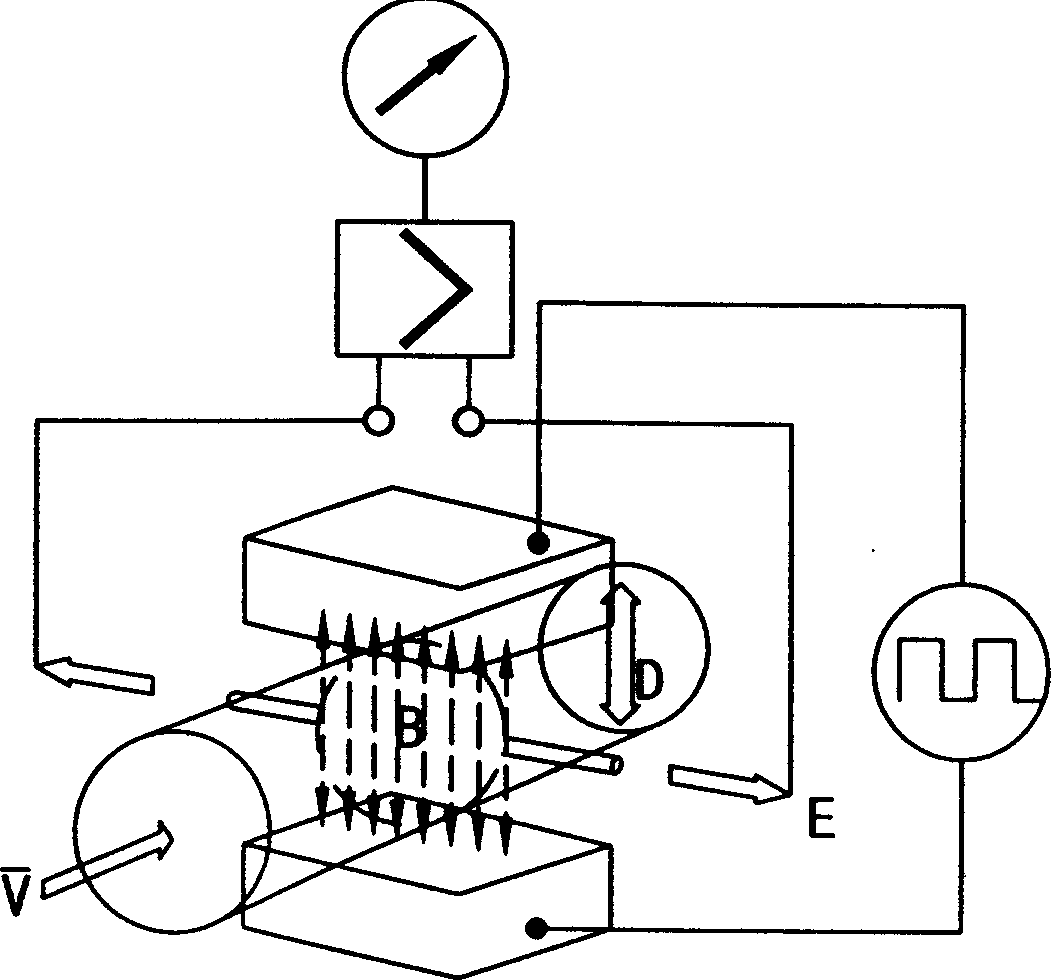

Fluid flow rate and flow measurement device and method

InactiveCN102323442AReduce adverse effectsDoes not affect flow characteristicsVolume/mass flow measurementFluid speed measurementCapacitanceAlternating current

The invention discloses a fluid flow rate and flow measurement device and method. The fluid flow rate measurement device comprises an alternating current excitation source, a three-electrode noncontact type conductivity sensor, a two-end grounding structure, a signal processing module, a data acquiring module and a microcomputer. The invention realizes that a noncontact conductivity measurement technology is used in fluid flow rate and flow measurement. Two groups of independent conductivity signals are obtained by using the three-electrode noncontact type conductivity sensor, and processed by adopting relevant technologies to obtain fluid flow rate and flow. According to the adopted series resonance method, the adverse influences on the measurement range and the sensitivity of a coupling capacitor are effectively eliminated. By adopting the two-end grounding structure, the adverse influences to the measurement precision by floating voltages at two ends of a pipeline are eliminated, and an insulation measurement pipeline is facilitated to be connected with an industrial site metal pipeline. The fluid flow rate and flow measurement device has the advantages of simple structure, low cost, non contact, no pressure loss, wide application range and the like, and provides an effective path for measuring the flow rate and the flow in the pipeline.

Owner:ZHEJIANG UNIV

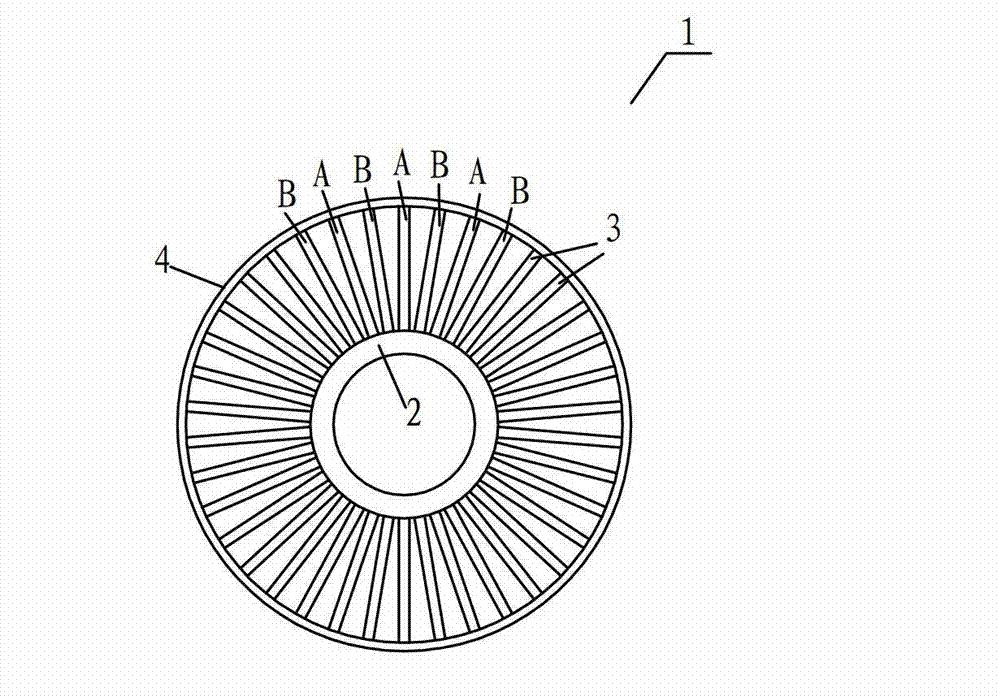

Guide blade or stator blade, and air treatment device having the same

ActiveCN102728470AReduce power consumptionNo pressure dropExternal electric electrostatic seperatorElectrostatic separation detailsLow noiseAir treatment

The invention relates to a guide blade or a stator blade, and an air treatment device having the guide blade or the stator blade. The guide blade or the stator blade comprises a wheel hub, blades and a wheel cover, wherein the blades are distributed on the wheel hub and / or the wheel cover at certain intervals along the circumferential direction. Structural characteristics of the guide blade or the stator blade are that: the blades comprise a first group of blades and a second groups of blades; the two groups of the blades have conductive properties; the first group of the blades and the second group of the blades are staggeredly distributed and insulated, and are not conducted; the first group of the blades and the second group of the blades are respectively applied with high potential and low potential so as to form a charged high voltage space between the first group of the blades and the second group of the blades, the high voltage space forms a dust removing channel, and the dust removing channel can effectively adsorb dust particles flowing through the dust removing channel. The blade and the device of the present invention have characteristics of simple and reasonable structure, high dust absorption efficiency, low resistance, low power consumption, low noise and no pressure loss. In addition, with the blade and the device of the present invention, air delivery, air pressure and efficiency of a fan can be effectively improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

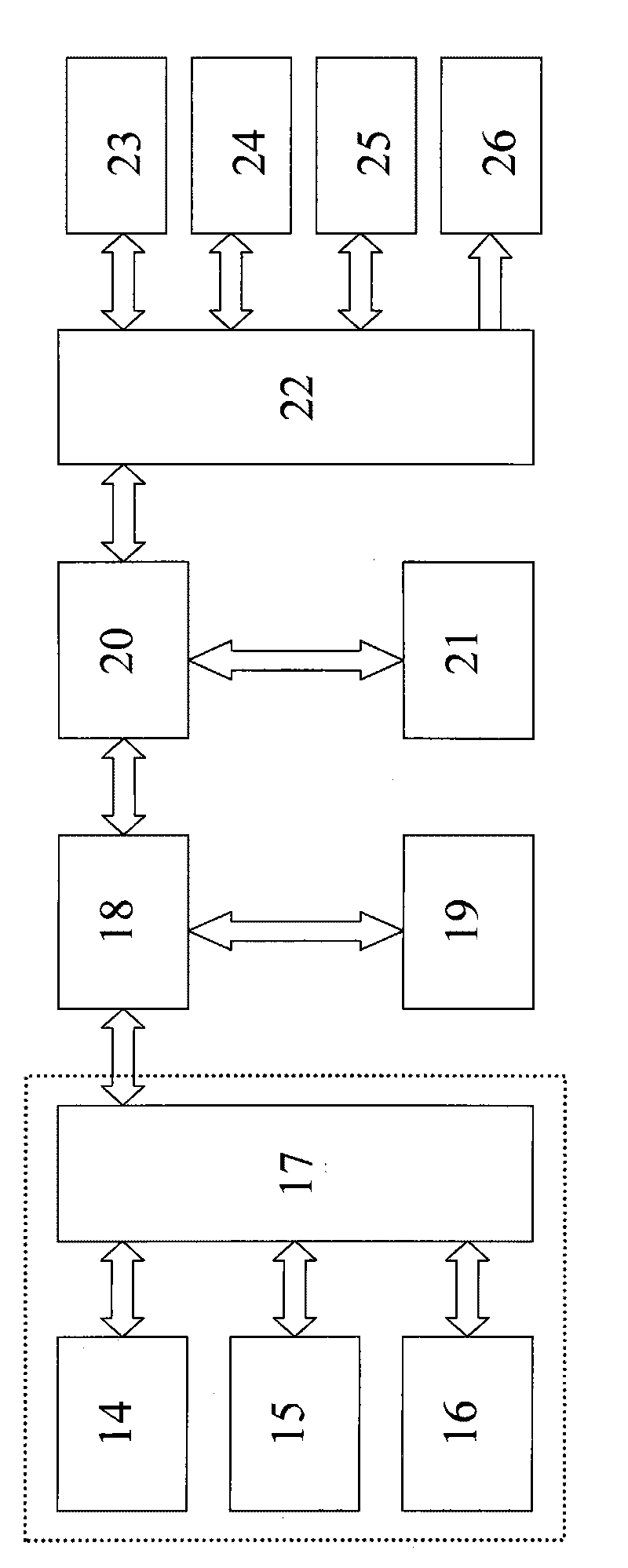

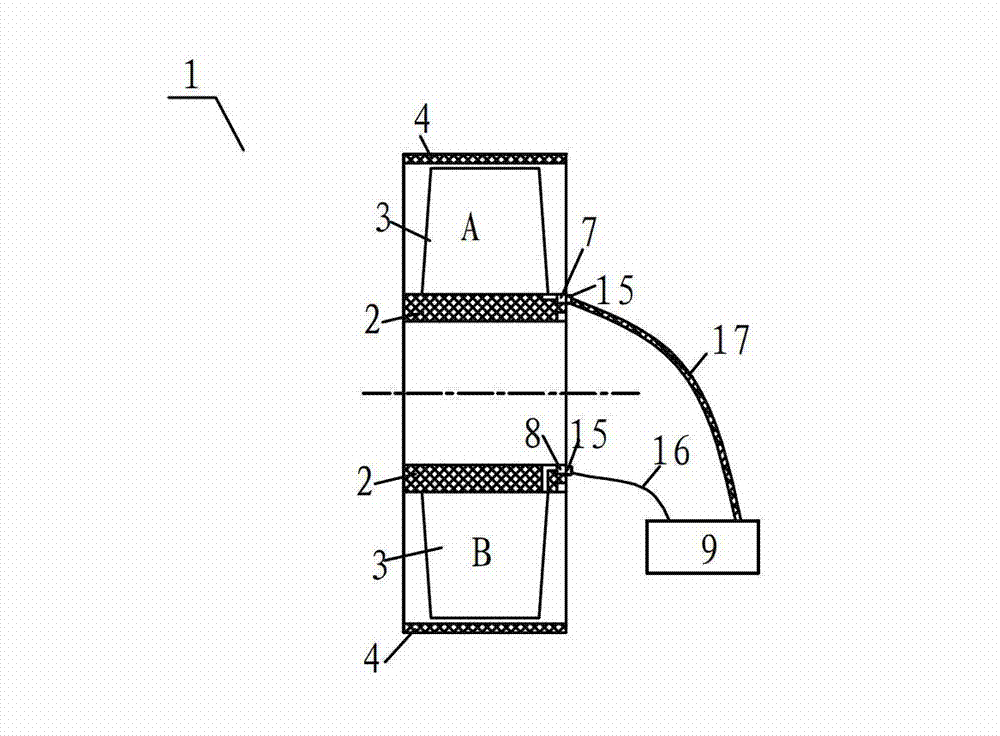

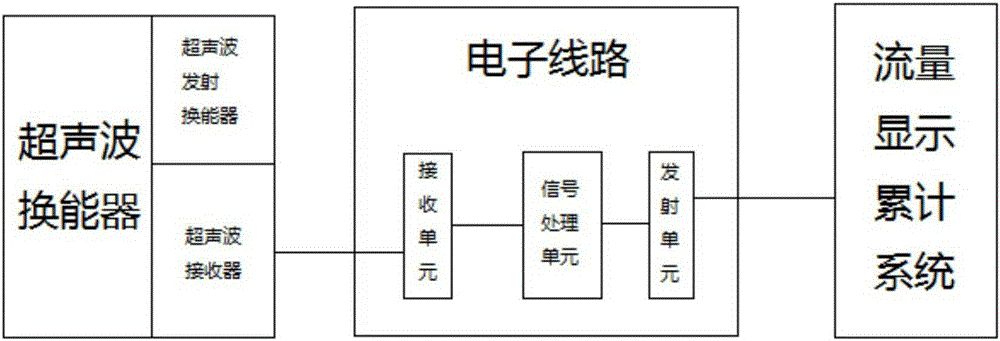

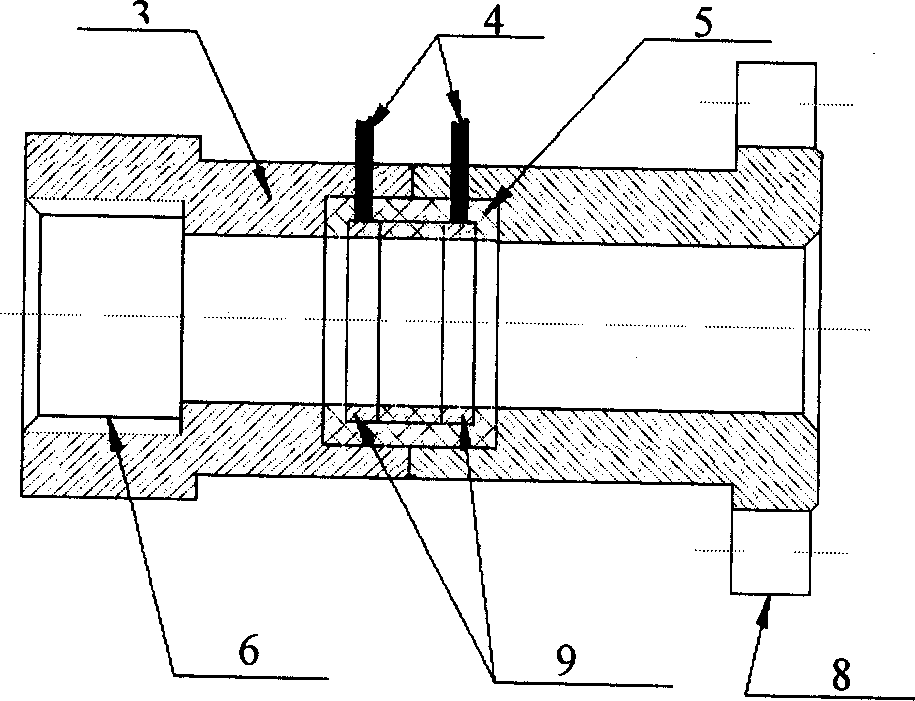

Non-contact ultrasonic flow velocity meter and non-contact flow velocity detection method

InactiveCN105181997AImprove stabilityImprove accuracyFluid speed measurementNon-contact ultrasoundWater flow

The invention discloses a non-contact ultrasonic flow velocity meter. The non-contact ultrasonic flow velocity meter comprises an ultrasonic transducer, an electronic circuit and a flow display and accumulation system, wherein the ultrasonic transducer comprises an ultrasonic emission transducer and an ultrasonic receiver; the ultrasonic emission transducer is used for converting electric energy into ultrasonic energy, and emitting the ultrasonic energy to the detected flow; the ultrasonic receiver is used for receiving ultrasonic signals and sending the ultrasonic signals to the electronic circuit; the electronic circuit comprises an emission unit, a receiving unit and a signal processing unit; the receiving unit is used for receiving the ultrasonic signals sent from the ultrasonic receiver and sending the ultrasonic signals to the signal processing unit to process the signals; and the emission unit sends the signals processed by the signal processing unit to the flow display and accumulation system. As the non-contact ultrasonic flow velocity meter installs the ultrasonic emission transducer and the ultrasonic receiver on the outer wall of a pipeline to be detected, flow detection when the water flow is opened wide can be performed, and no detection elements are required to be installed in the flow while the flowing state of the flow is not changed.

Owner:TIANJIN ZHONGZHONG SCI & TECH CO LTD

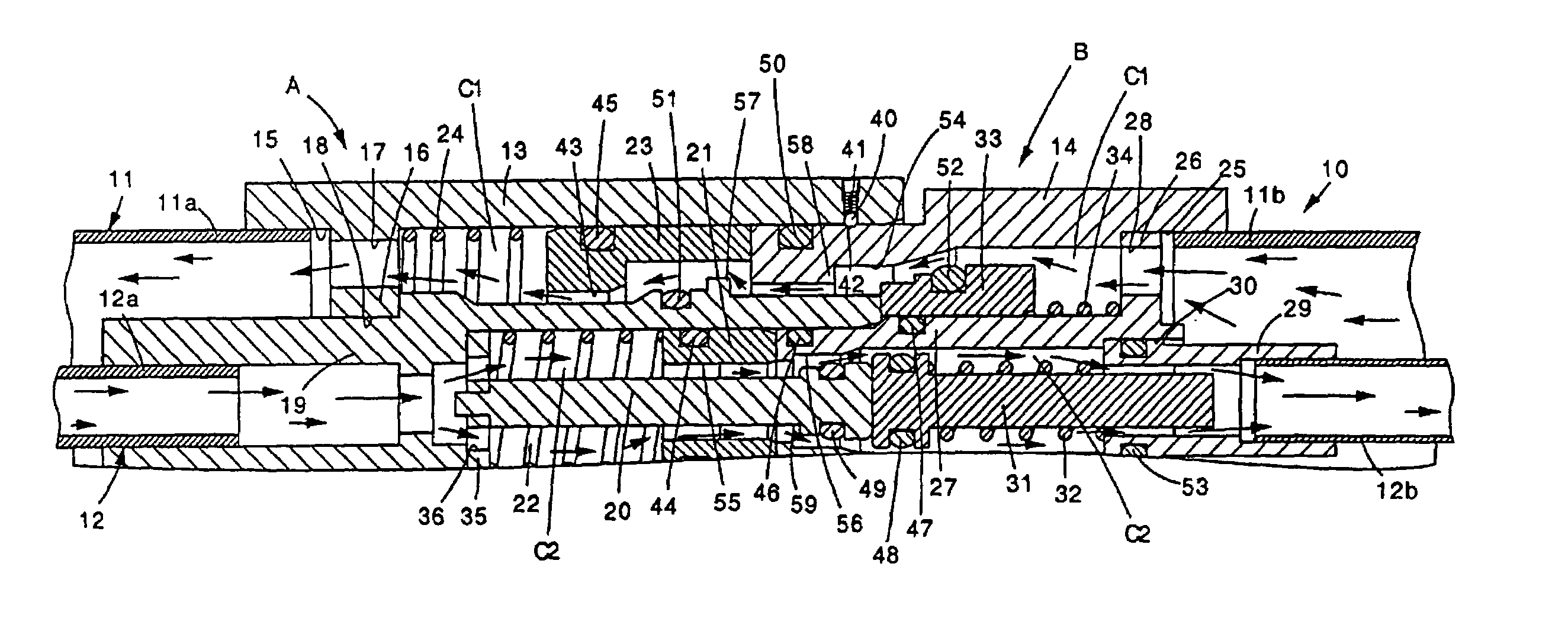

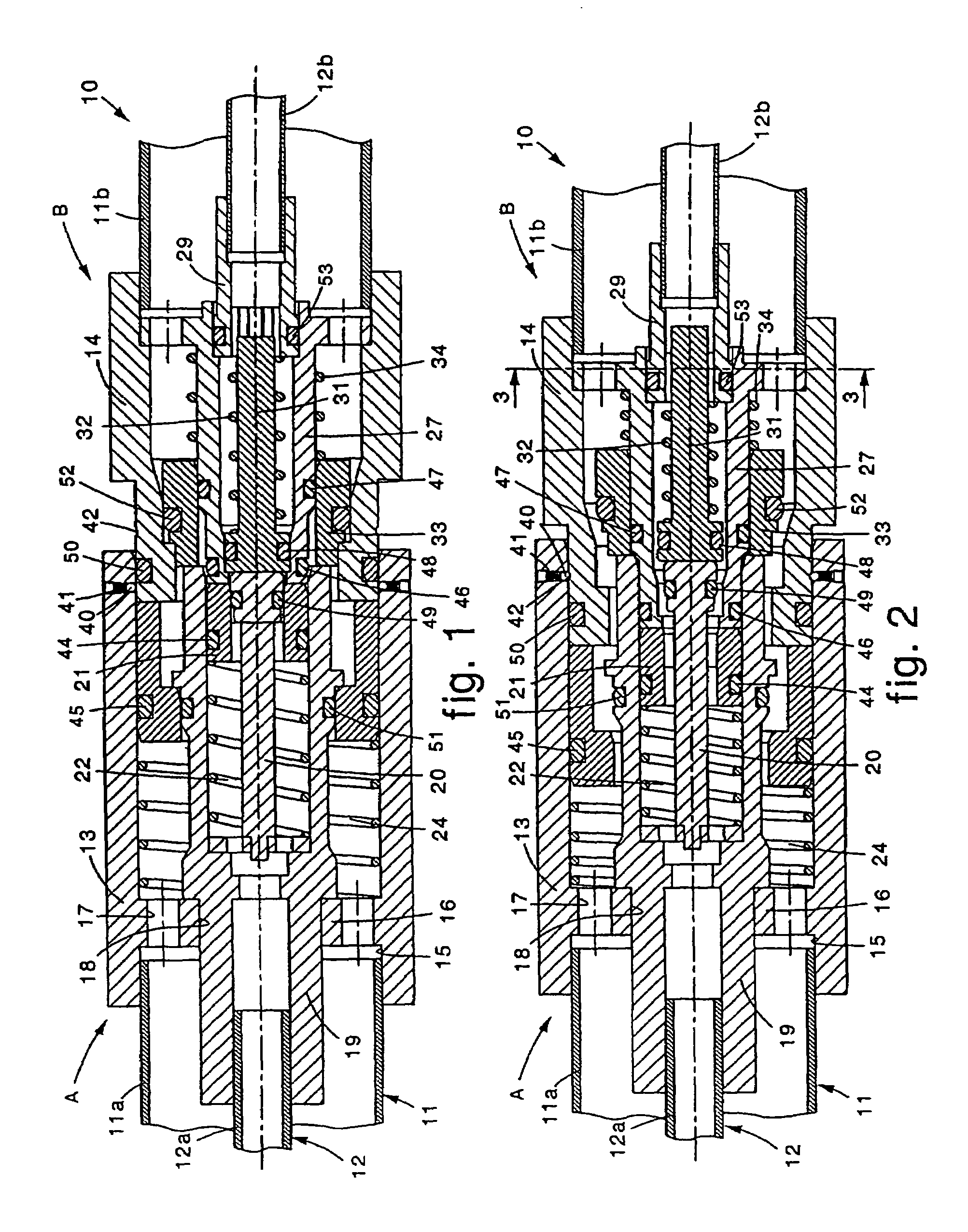

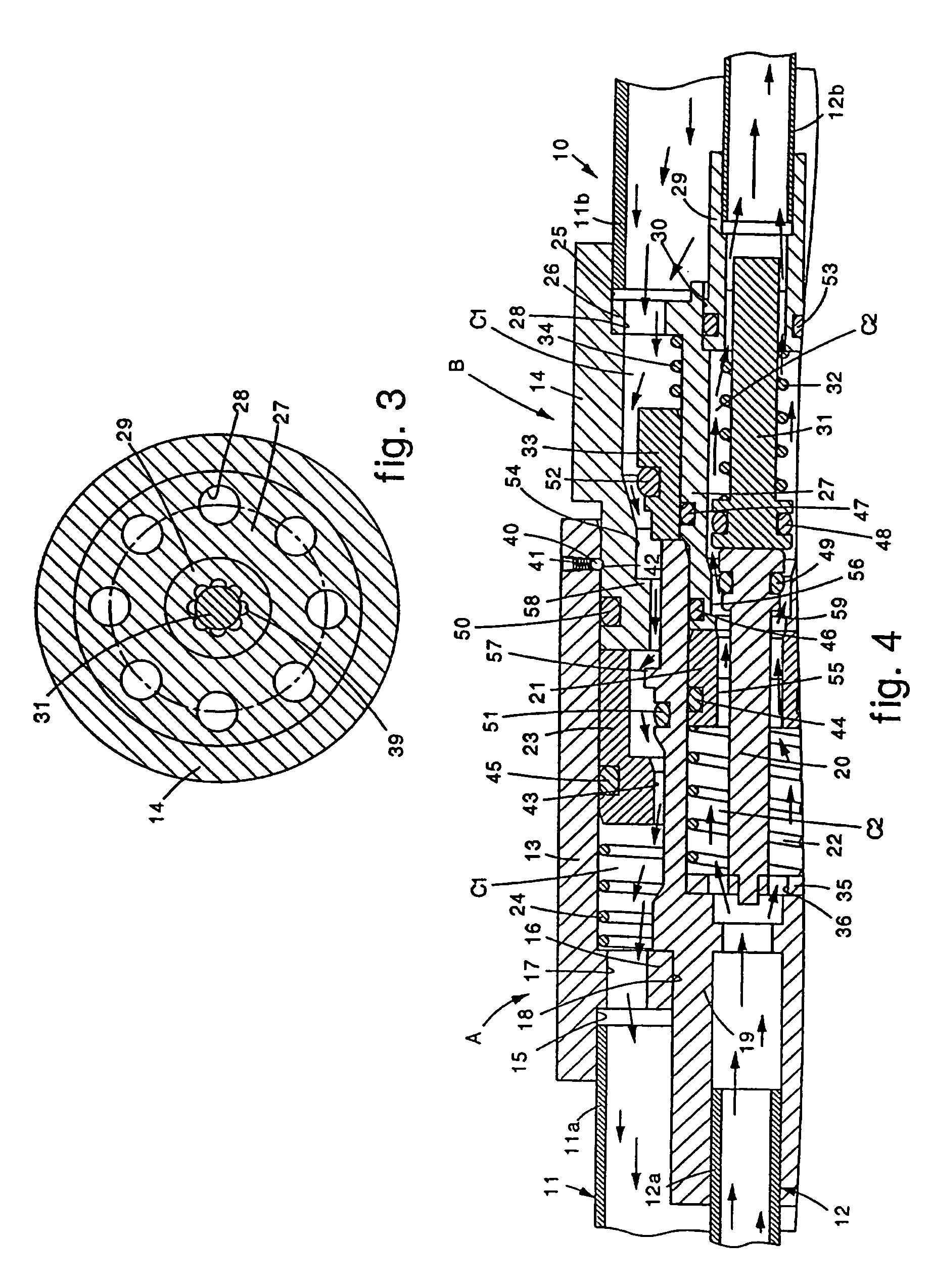

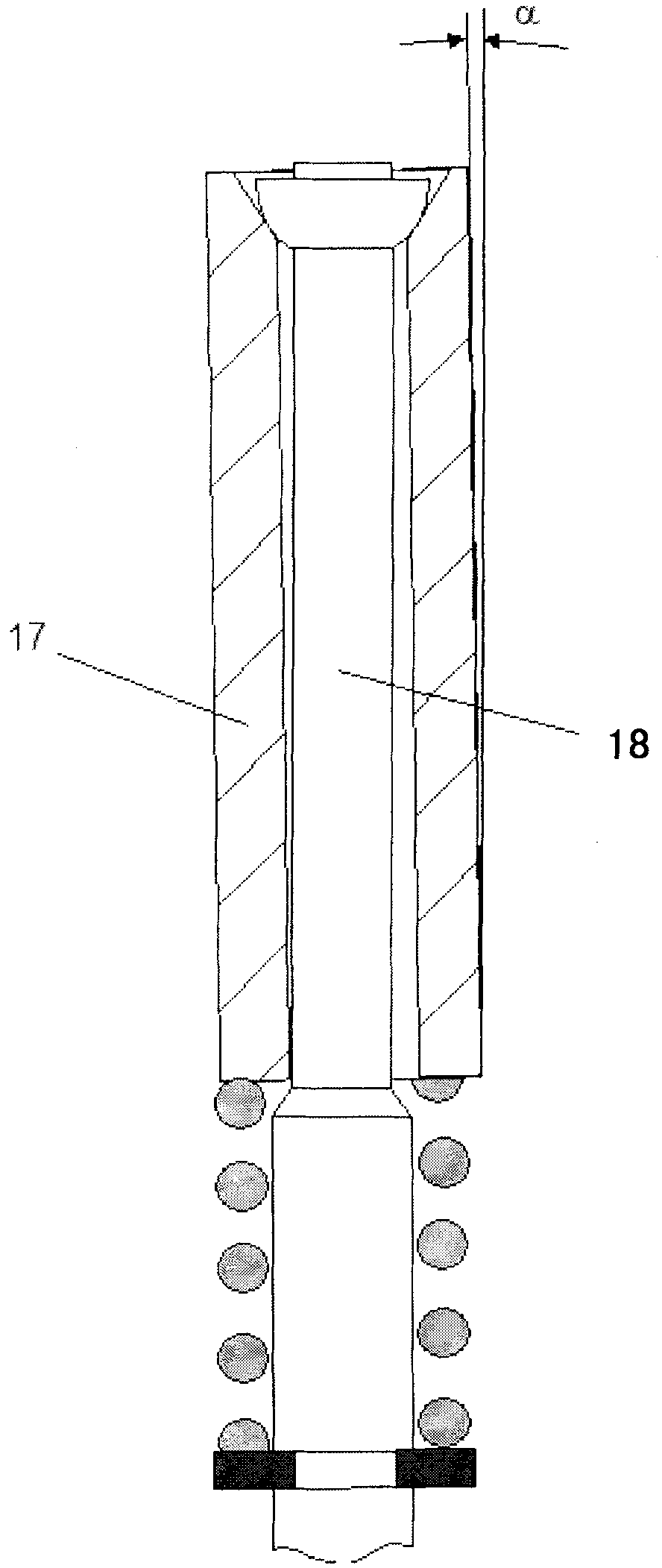

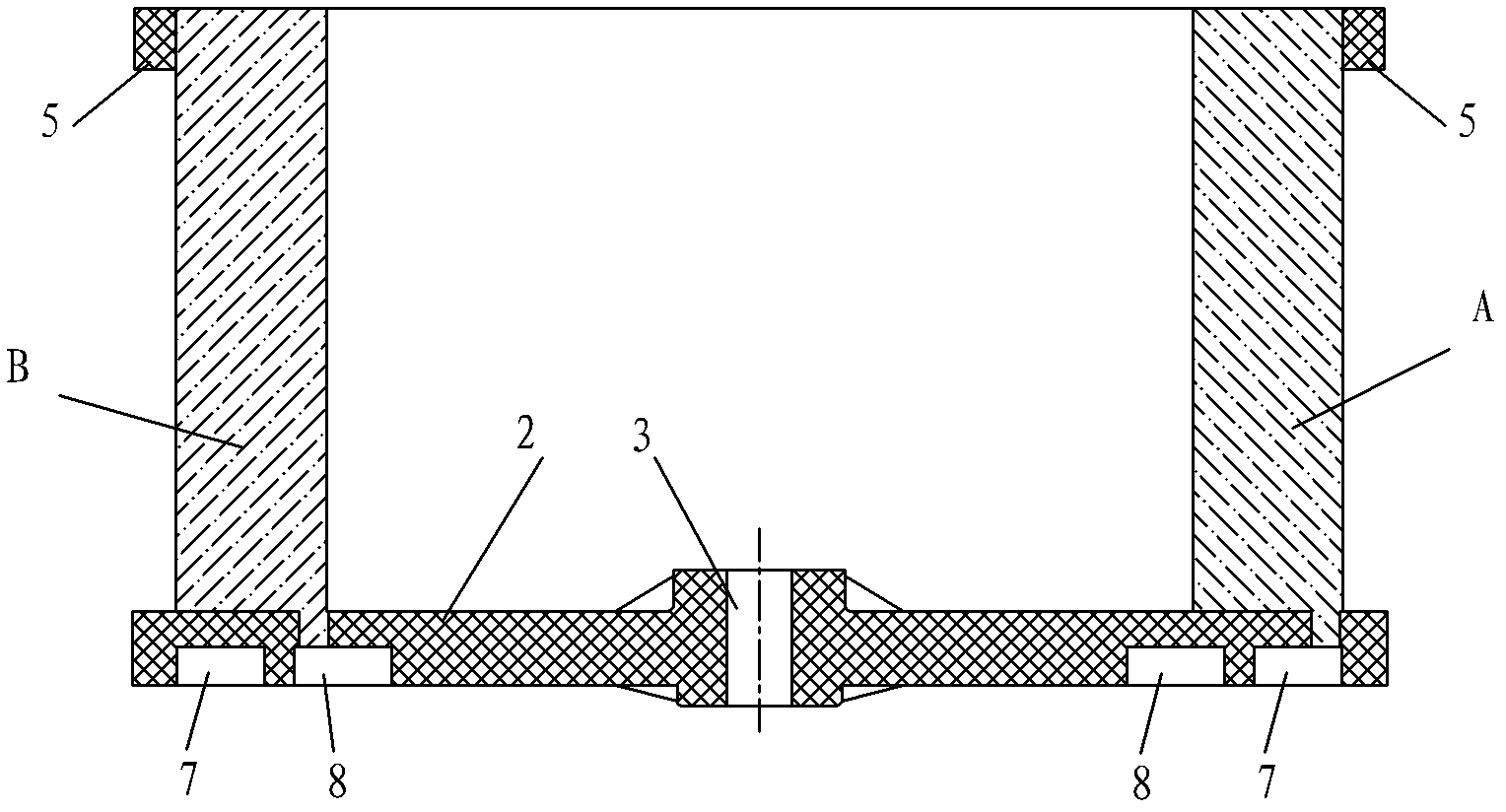

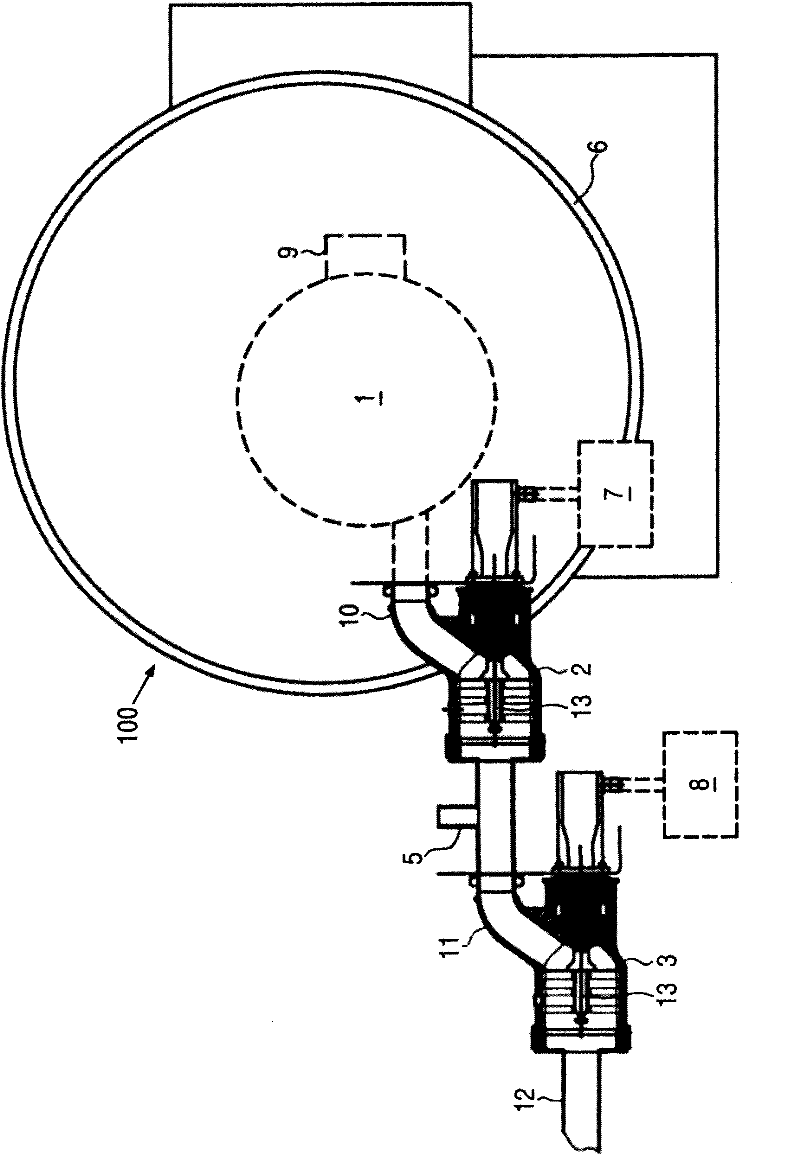

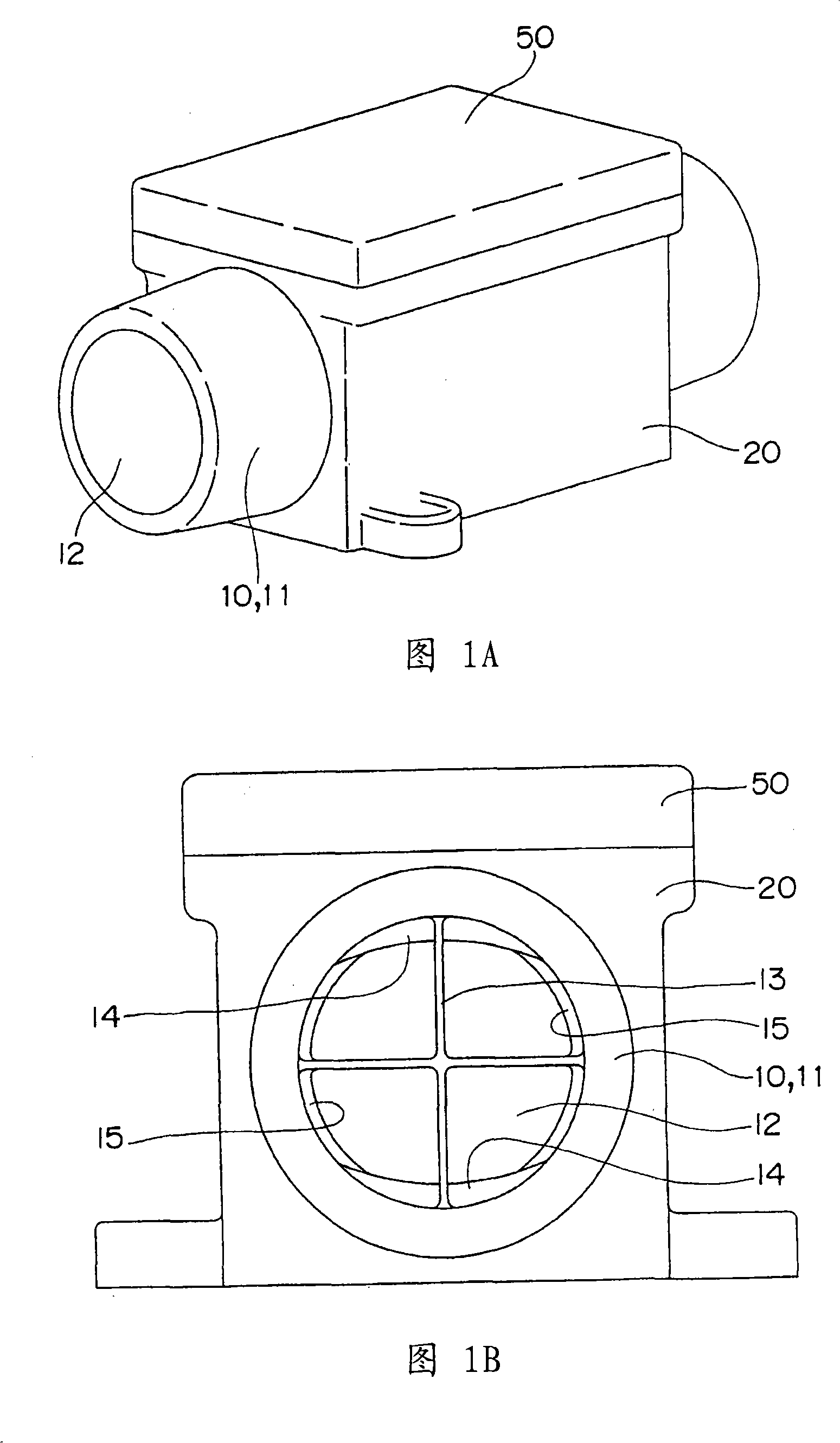

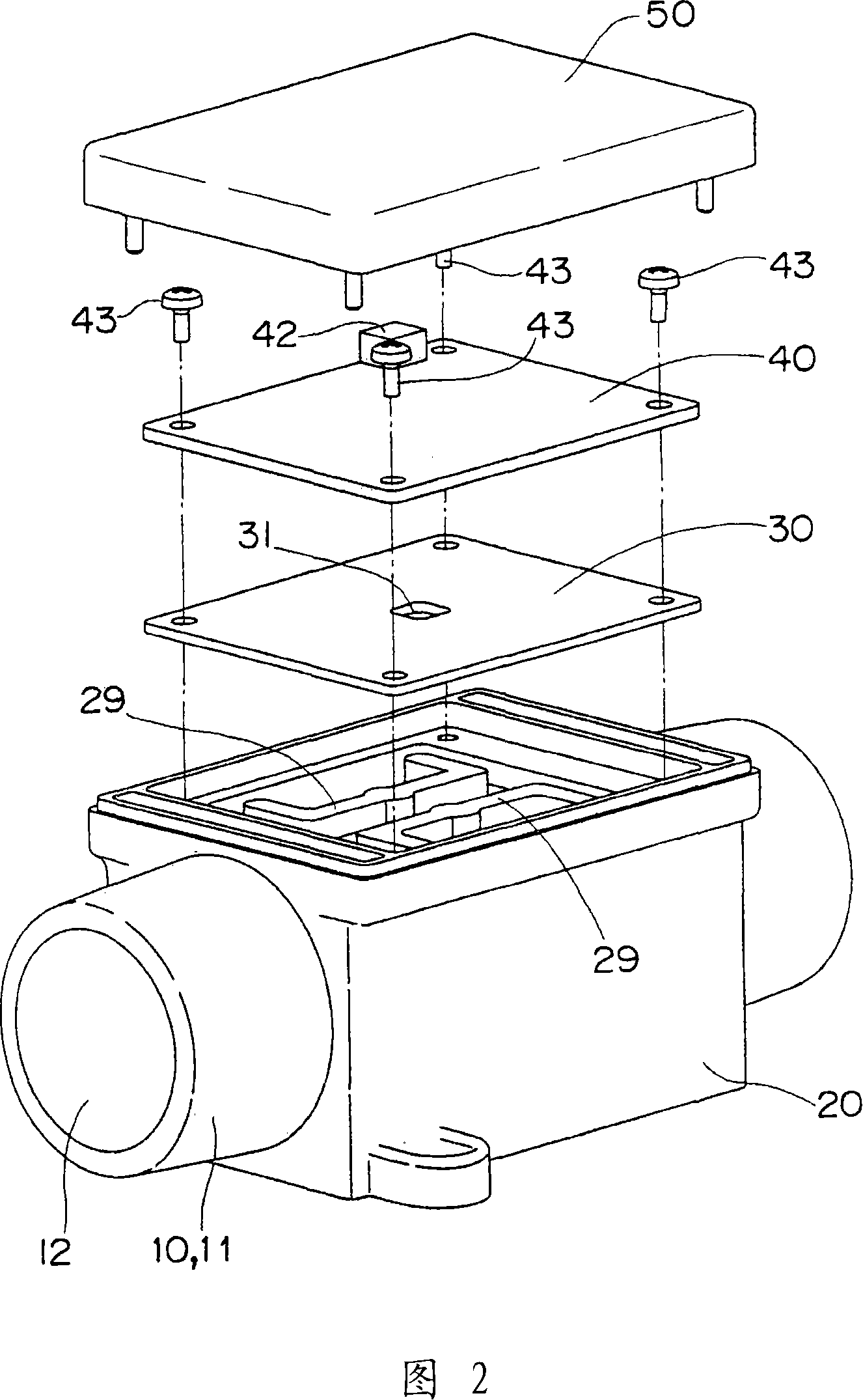

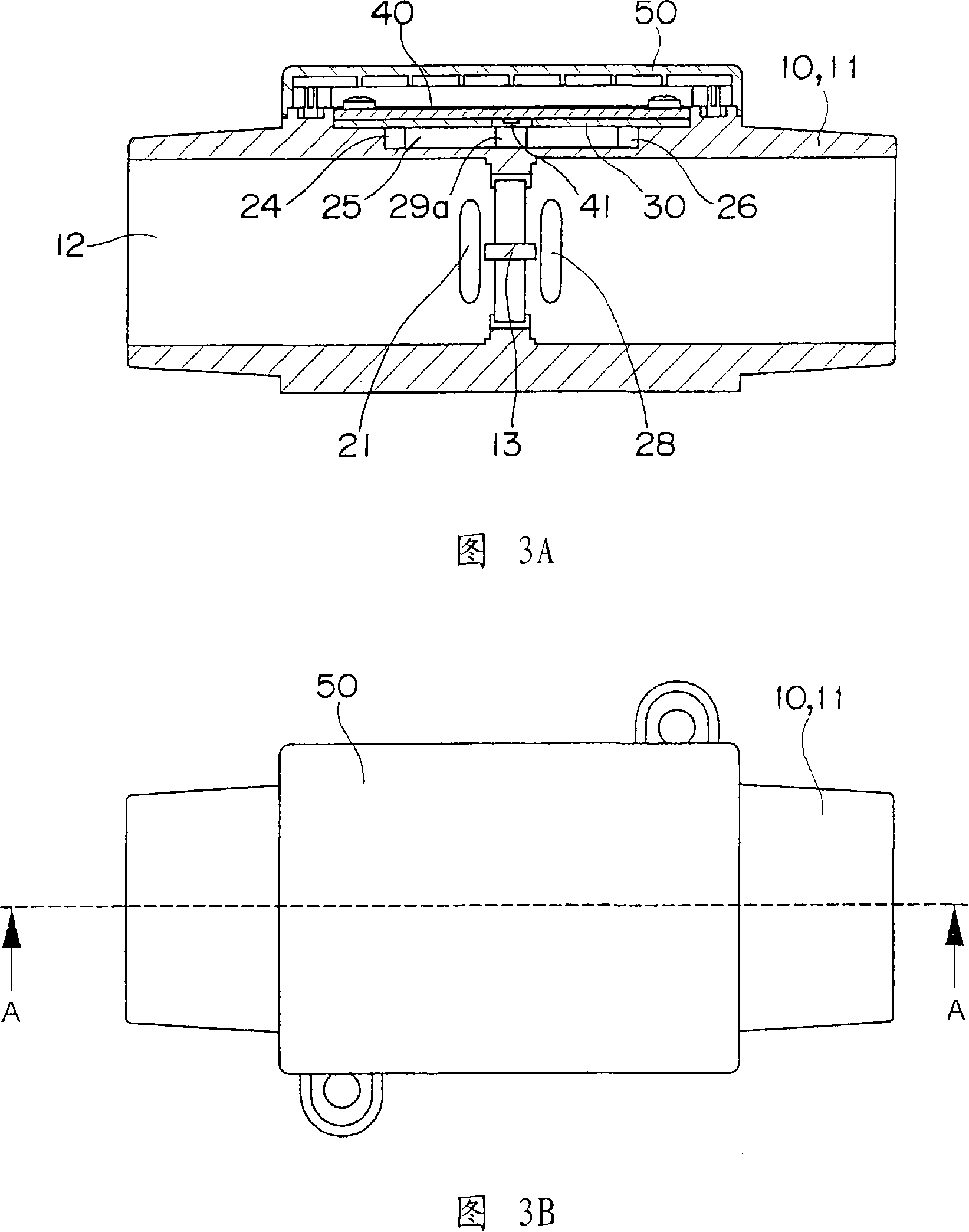

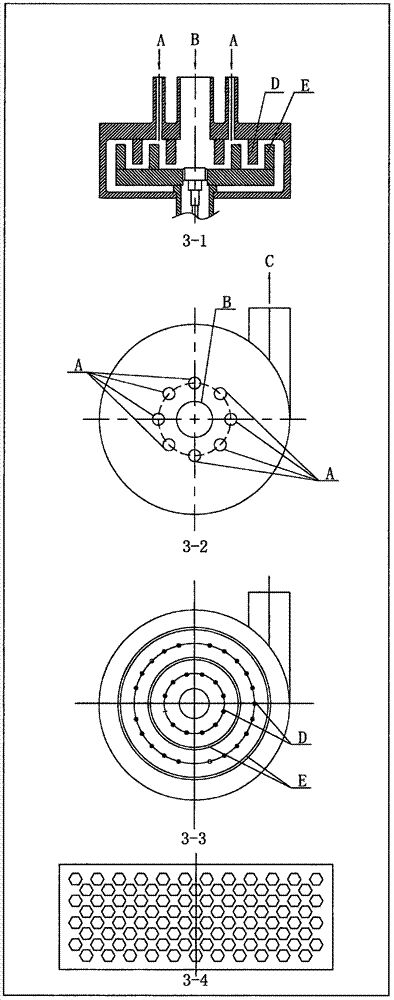

Joint-type coaxial connection

InactiveUS7044155B2No pressure lossFlow interruptionValve members for heating/coolingPipe heating/coolingEngineeringJoints types

Joint-type coaxial connection (10) to connect / disconnect to / from each other two elements (A, B) defining coaxial tubular pipes inside which a respective fluid flows. The connection (10) defines two respective coaxial paths for the passage of the fluid, one internal and one external, able to be selectively opened / closed substantially simultaneously so as to connect pairs (11a, 11b; 12a, 12b) of tubular pipes, respectively inner and outer. In the connection step the two elements (A, B), located coaxial and with the front faces in contact, have a reciprocal approaching travel with the sealing means (44, 45, 46, 47, 48, 49, 50, 51, 52) which close every passage between the inner pipe and the outer pipe, and between the outer pipe and the part of the joint outside the outer pipe, before achieving the reciprocal fluid-dynamic continuity of the two coaxial pipes of the connection.

Owner:DE LONGHI SPA

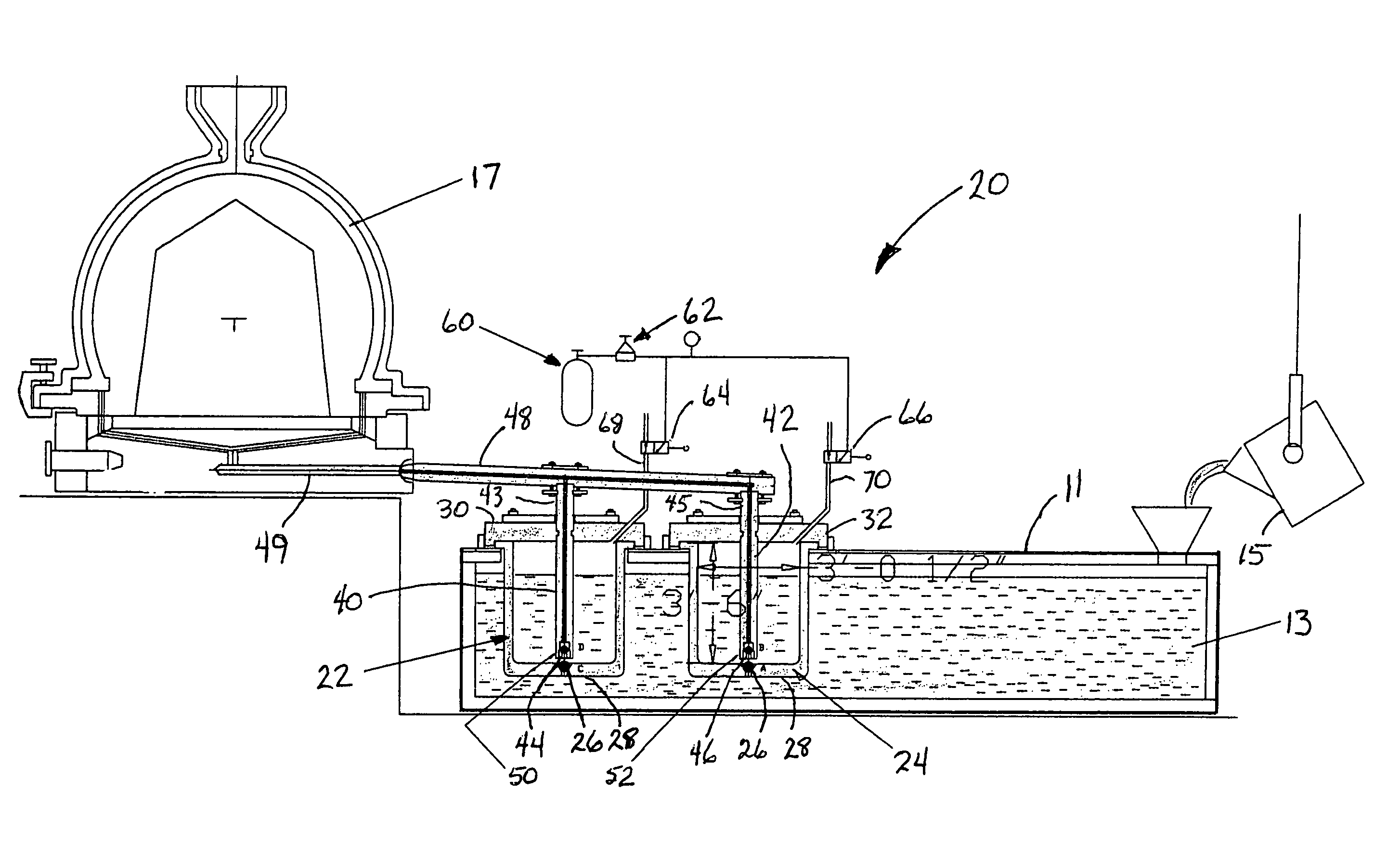

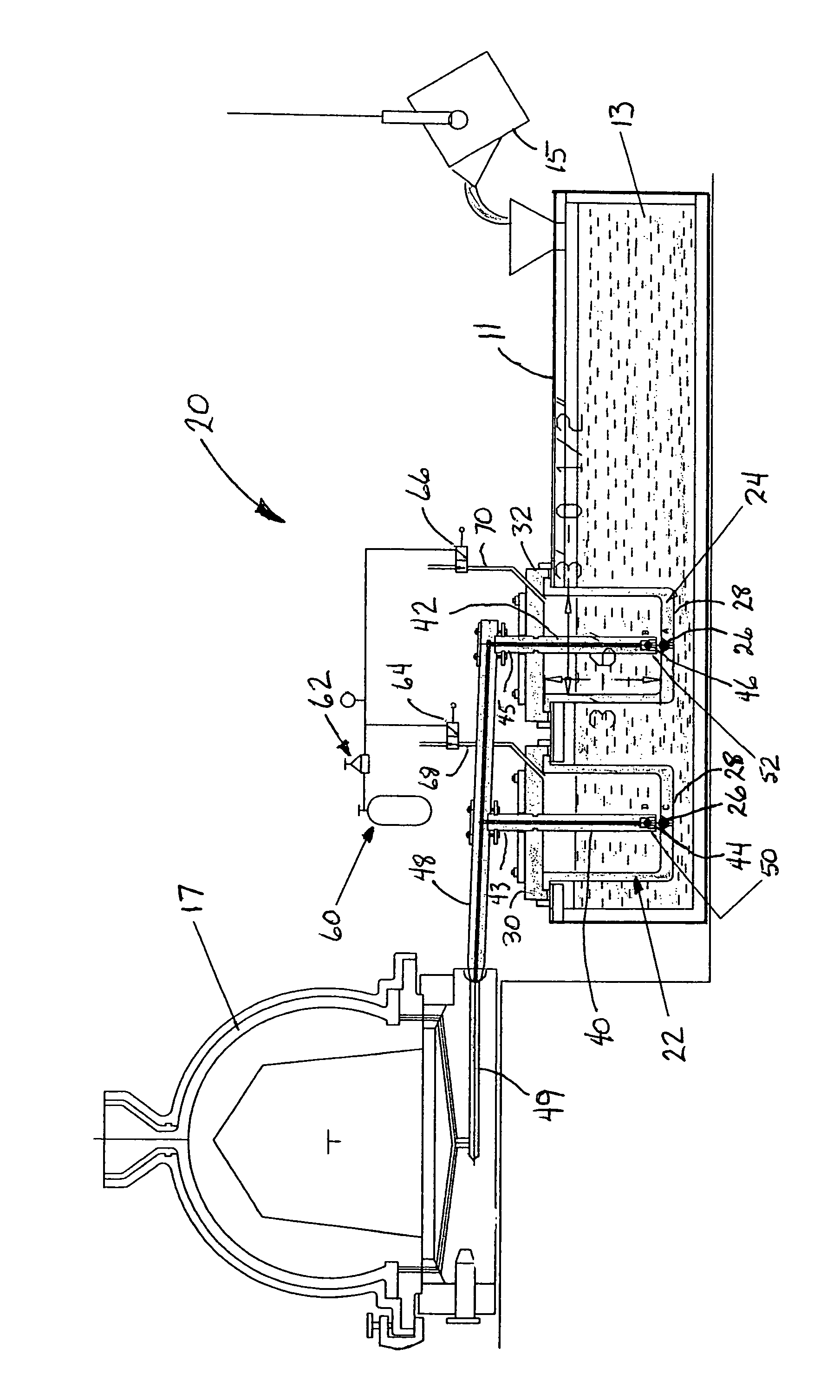

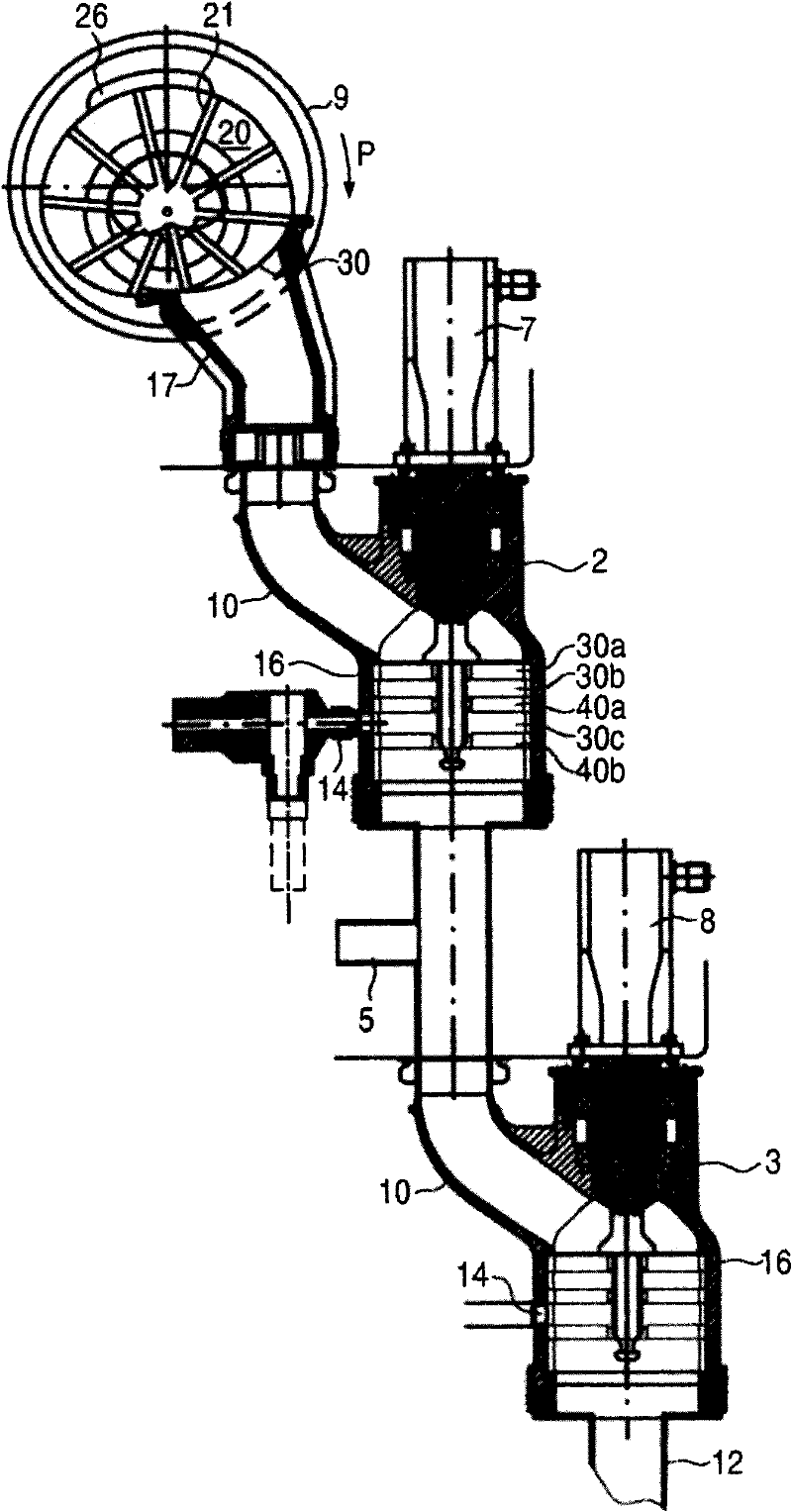

Method and system for pumping molten metal

InactiveUS7841379B1Prevent downward flowNo pressure lossMelt-holding vesselsMolten metal pouring equipmentsCrucibleGraphite

Method and apparatus for pumping molten metal from a reservoir into a preferably bottom-filled mold includes a pair of graphite pump crucibles partially submerged in a reservoir of molten metal. Check valves in the bottom of each crucible enable them to be filled to the same level as the reservoir. A high pressure inert gas supply operating through a pressure regulator, forces the molten metal from one of the crucibles up a riser tube to a horizontally extending runner and through a fill port into the mold. The pressure supply is then connected to the other crucible while the first refills.

Owner:EVANS DWIGHT

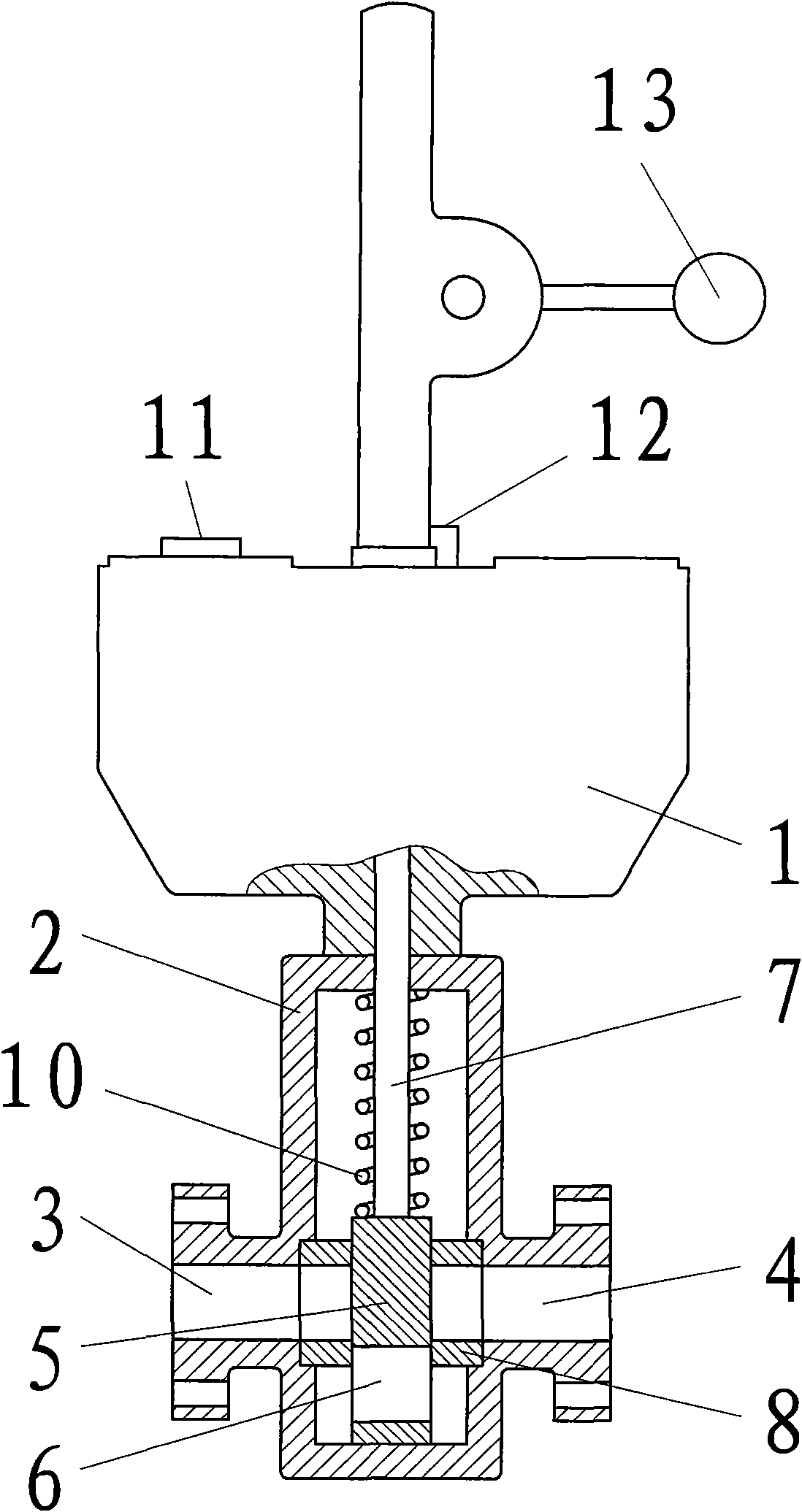

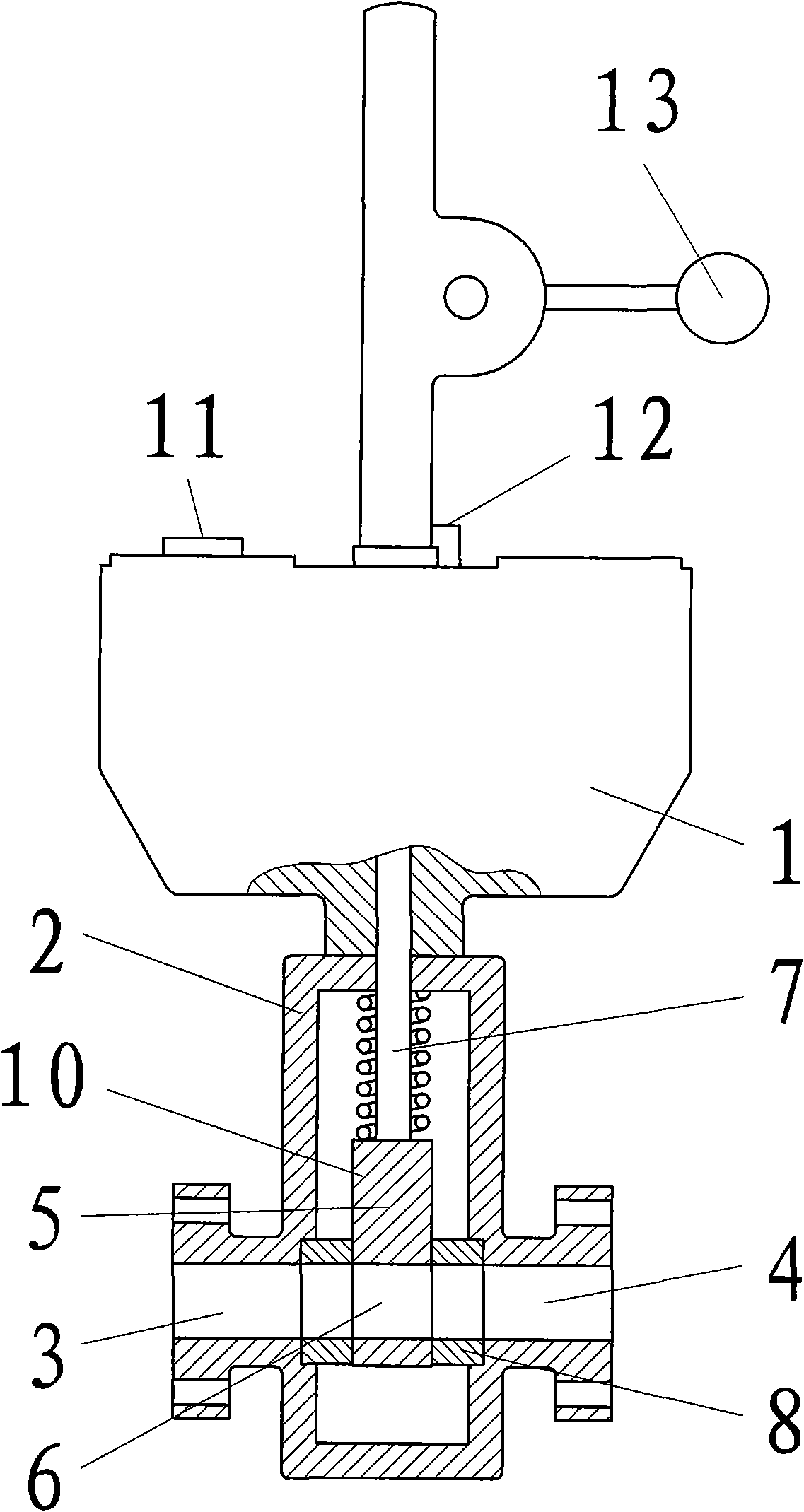

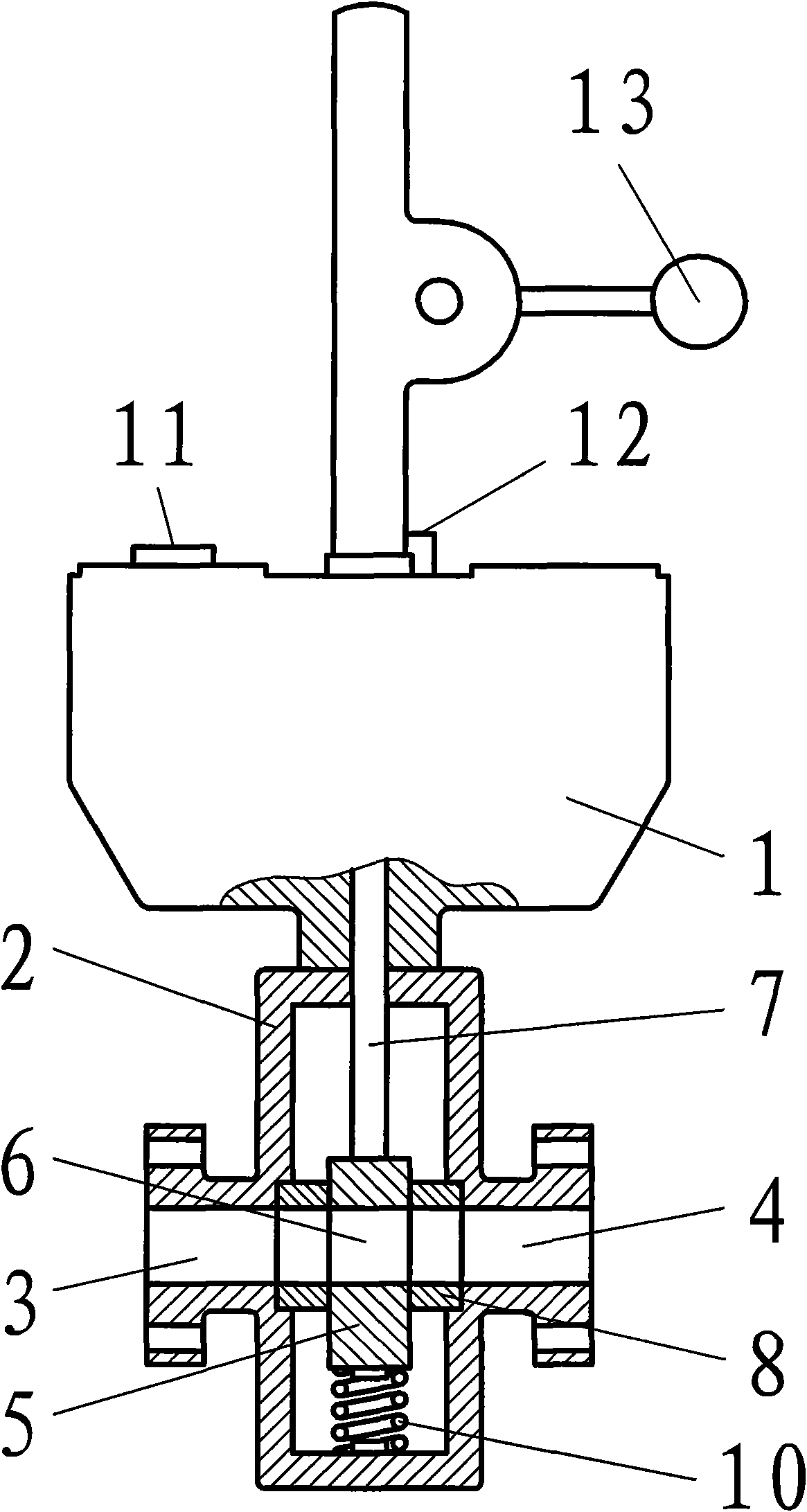

Self-operated emergency cutting method of fluid pipe and self-operated flat-plate emergency cut-off valve

ActiveCN101586737ANo precipitationEasy to cleanPipeline systemsSlide valveProcess engineeringOil production

The present invention discloses a self-operated emergency cutting method of oil-gas pipe. According to the method of the invention, the emergency cutting-off to the pipe is realized through a triggering mechanism and a straight-through gate valve which is controlled by the triggering mechanism for opening and closing. The invention also discloses a self-operated emergency cutting valve for realizing the method. According to the invention, as the triggering mechanism is adopted for controlling the opening and the closing of the straight-through gate valve for realizing the emergency cutting-off so that the oil-gas inlet pipe is directly communicated with the oil-gas outlet pipe, so that the throttling and pressure loss are not generated. The cleaning to the pipe and the valve by the cleaning ball is facilitated and the impurity deposit is prevented. Furthermore the cut-off valve has the advantages of simple structure, reliable safety and low production cost. The method and the cut-off valve of the invention are not only suitable for conveying the natural gas, but also are suitable for conveying other liquid or gas medium of oil, steam, etc. The method and the cut-off valve of the invention can also be used for the initial product of oil-gas containing sand, water and sulfur, and can also be used for the oil production and gas production wellhead and the middle and downstream pipe network.

Owner:GATO OIL & GAS TECH (SHANGHAI) CO LTD

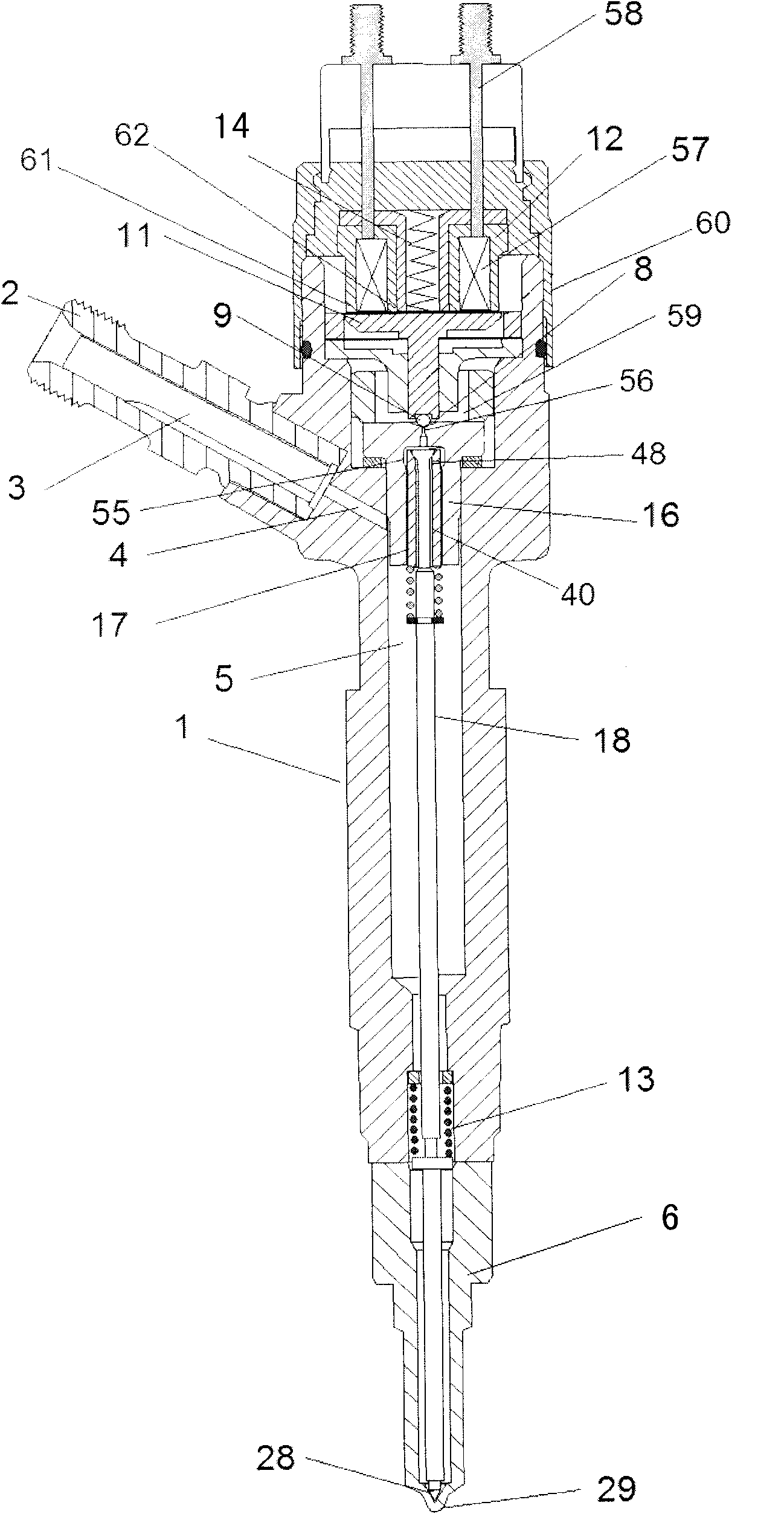

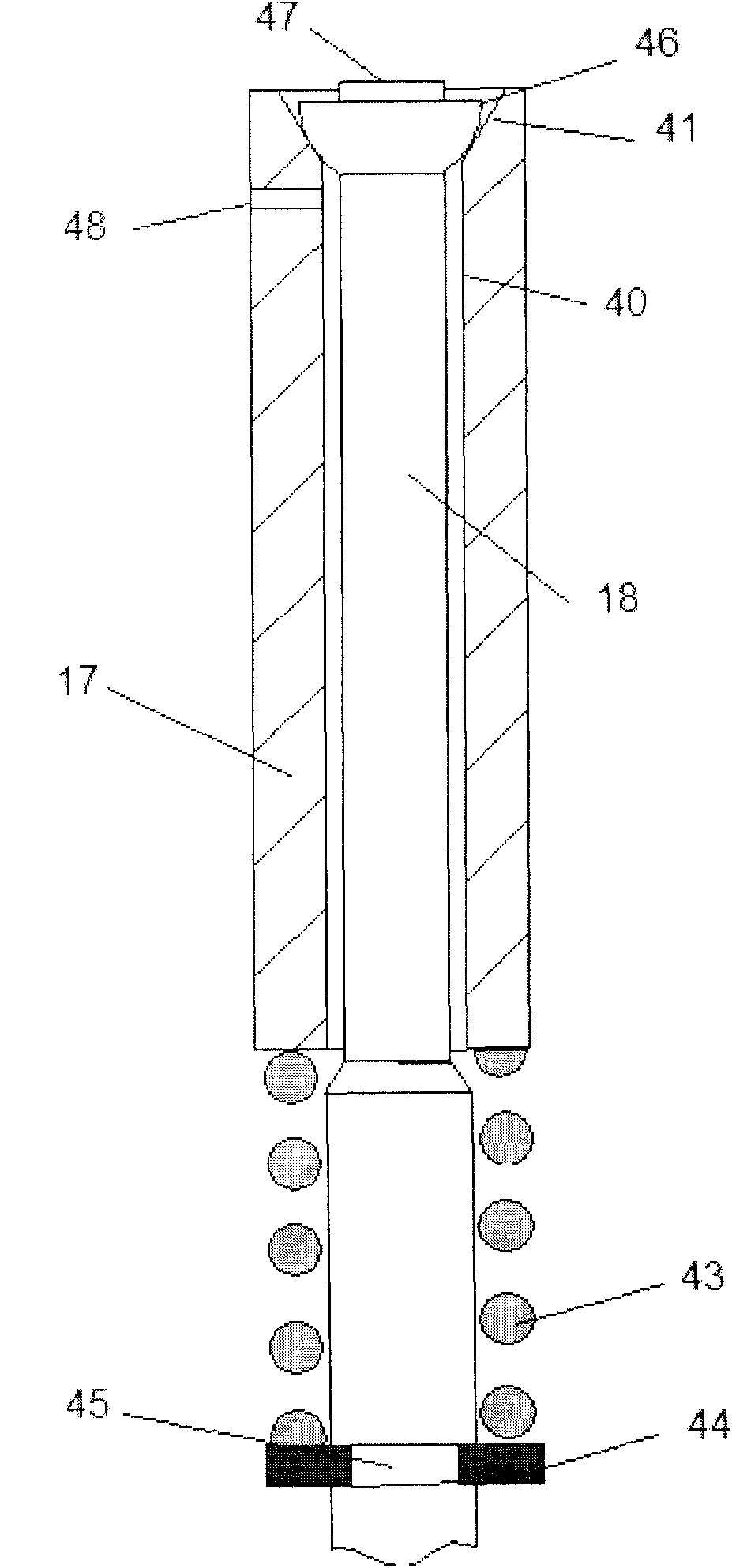

High pressure common rail electronic control fuel injector

ActiveCN102213165AGuaranteed stabilityReduced Dimensional Tolerance AccuracyFuel injection apparatusMachines/enginesCombustion chamberEngineering

The invention discloses a high pressure common rail electronic control fuel injector which is characterized in that a control cavity is communicated with the transition cavity of a control valve through an oil outlet, the transition cavity is connected with the oil return pipe of the fuel injector, the top of a ball valve is arranged in the oil outlet which is positioned on a seat surface by a magnetic valve spring through an armature, a magnetic valve coil is arranged above the armature, the top of a control plunger is provided with a conical surface which is axially slant outward, a hemispherical connector is arranged on the top of an oil pin, the oil pin is clamped and matched with the conical surface through the connector and is arranged in the control plunger in a penetrating manner,an oil pin groove is arranged on the bareness part, penetrating through the control plunger, of the oil pin, a snap ring is embedded into the oil pin groove, and an elastic part is clamped between the control plunger and the snap ring. The high pressure common rail electronic control fuel injector in the invention has the advantages of providing flexible timing, accurate control, repeatability, high voltage and good fuel oil pulverization function for a diesel motor combustor and having good stability of small-oil-mass jet.

Owner:北油电控燃油喷射系统(天津)有限公司

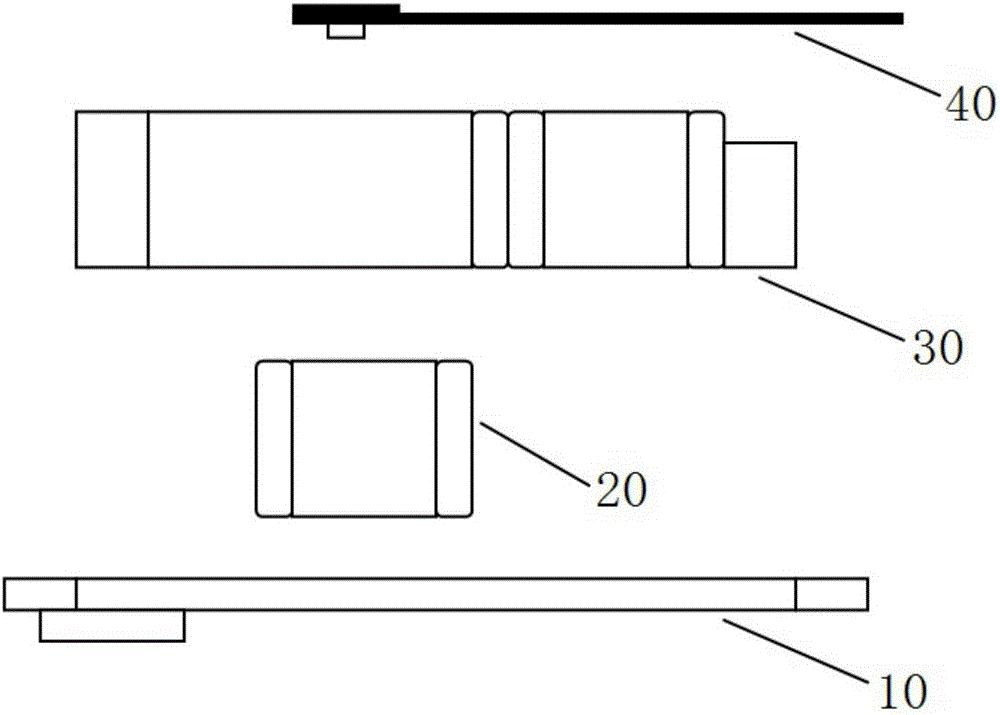

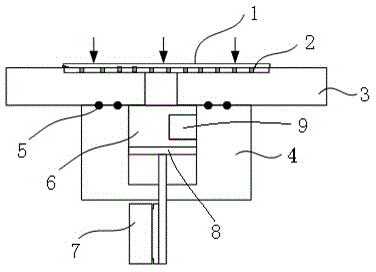

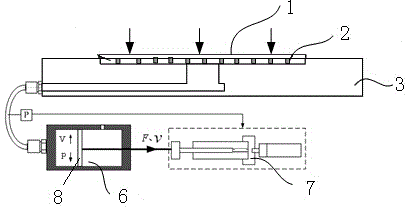

Circuit board testing device

InactiveCN106597254APressure/low pressureNo pressure lossPrinted circuit testingCircuit under testComputer module

The invention discloses a circuit board testing device which comprises a switching module, a conductive module, a supporting module and a control unit. The switching module is provided with a plurality of testing points. The bottom surface of the conductive module is connected with the switching module so that the plurality of testing points of the switching module are electrically connected with a plurality of conductive paths of the conductive module in a one-to-one correspondence manner. The top surface of the conductive module is used for making contact with a to-be-tested circuit board so that the conductive paths of the conductive module are electrically connected with electric connecting pins of a device on the tested circuit board in a one-to-one correspondence manner. According to the circuit board testing device, the conductive module realizes electric connection between the testing points of the switching module and pins of a to-be-tested product through the plurality of conductive paths, thereby realizing a good testing effect. Furthermore compared with a prior-art probe, the conductive module has advantages of lower pressure in making contact with the pins of the product, and effective prevention for pressing damage, stab and deformation of pins of the product.

Owner:SHENZHEN YANMADE TECH CO LTD

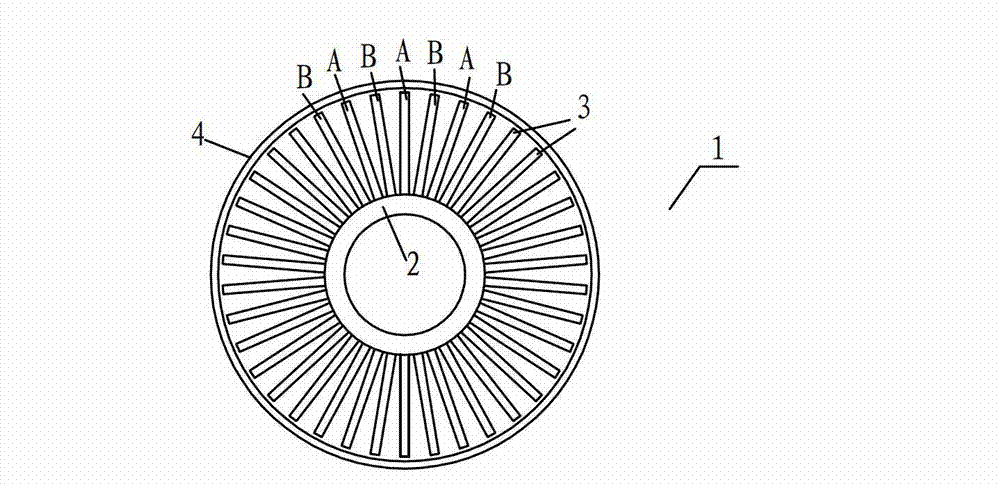

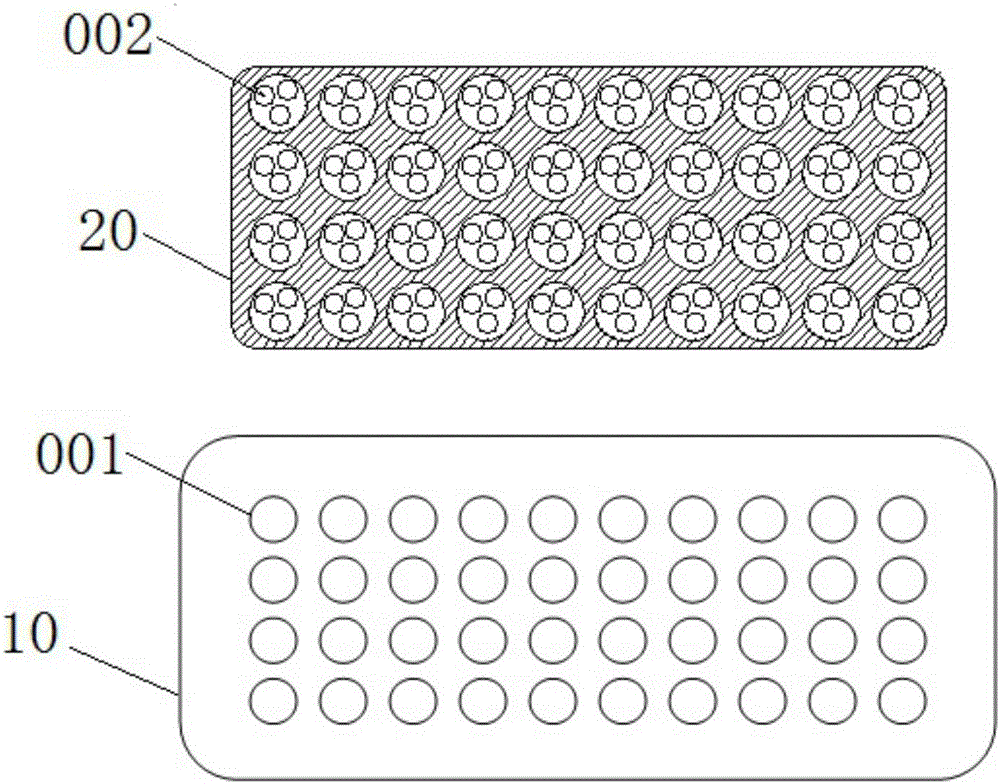

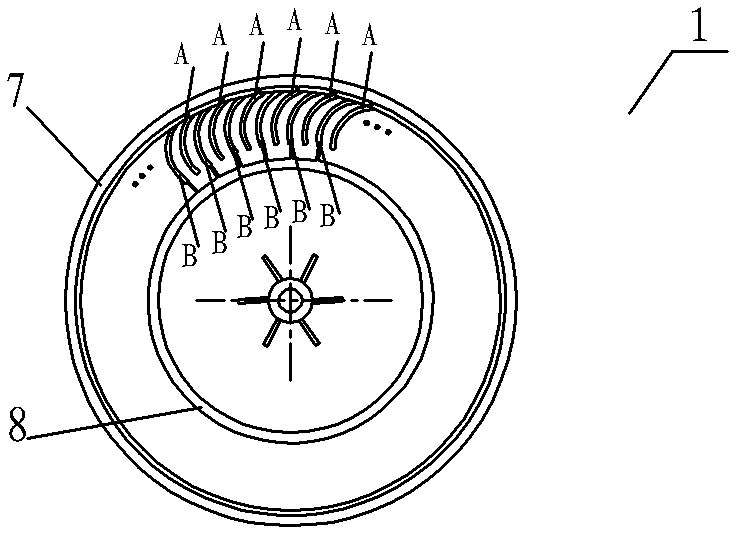

Centrifugal wind wheel and air treatment device with same

ActiveCN102614987AReduce power consumptionNo pressure dropExternal electric electrostatic seperatorElectrostatic separation detailsHigh potentialElectricity

Disclosed are a centrifugal wind wheel and an air treatment device with the same. The centrifugal wind wheel comprises a base plate, a motor mounting hole, blades and a reinforcing frame or wheel cover, one ends of the blades are distributed on the base plate at certain intervals along a peripheral direction, the other ends of the blades are fixed on the reinforcing frame or wheel cover along the peripheral direction, the blades comprise a first group of blades and a second group of blades, both the two groups of blades have conduction characteristics, and the first group of blades and the second group of blades are distributed in a mutually staggered manner, are insulated from each other and are not conducted; and high potential and low potential are respectively applied to the first group of blades and the second group of blades, a high-voltage charging place is formed between the first group of blades and the second group of blades which are staggered mutually and forms a dust removal channel, and the dust removal channel can effectively absorb dust particles in airflow flowing through the dust removal channel. The centrifugal wind wheel and the air treatment device with the same have the advantages of simple and reasonable structure, high dust absorption efficiency, low resistance, electricity consumption and noise and zero pressure loss.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

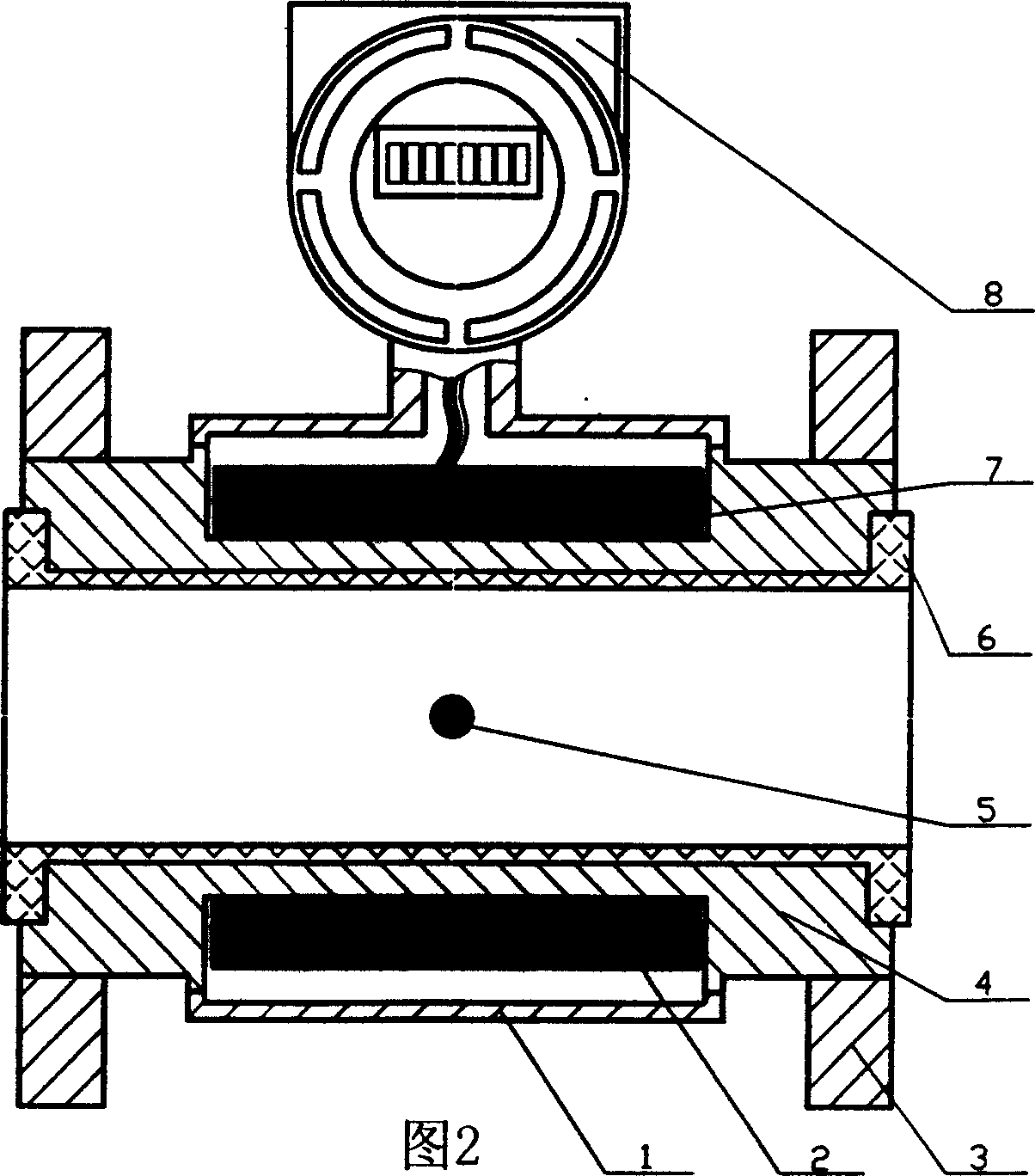

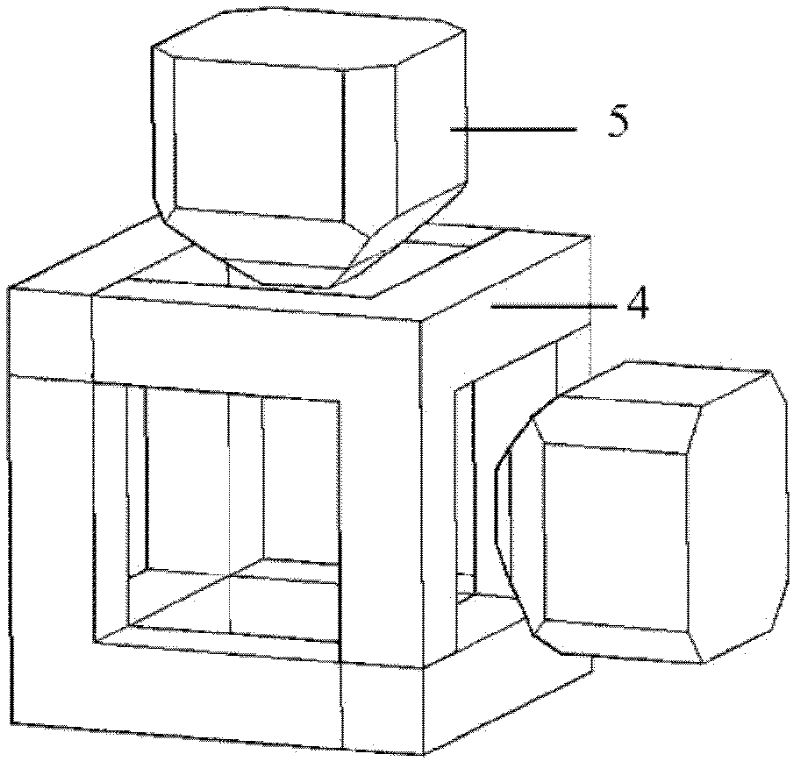

Permanent-magnet small bore flowmeter

InactiveCN1560569ANot easy to blockEasy to blockVolume/mass flow by electromagnetic flowmetersDisplay deviceElectromagnetic interference

The invention is a permanent magnetism small caliber flow meter, which includes a flow sensor, conversion monitor and power. The keys of the technology are: the straight pipe segment of the flow sensor measuring pipe is lined with a insulating cover, the permanent magnetisms are arranged in the concave slots along the external circle of the measuring pipe, there has a pair of compound conductor electrode at two side of the position vertical to the magnetic lines on the inner surface of the lined insulating cover in the straight pipe segment of the measuring pipe. A temperature sensor is attached onto one conductor electrode. It maintains the merits of the traditional electromagnetic flow meter that not apt to be blocked, no pressure loss, and it solves the problem that the circuit is complex, the cost is high, and apt to be affected by electromagnetic disturbance, the measurement is not precise.

Owner:SHENYANG SENSOR TECH INST

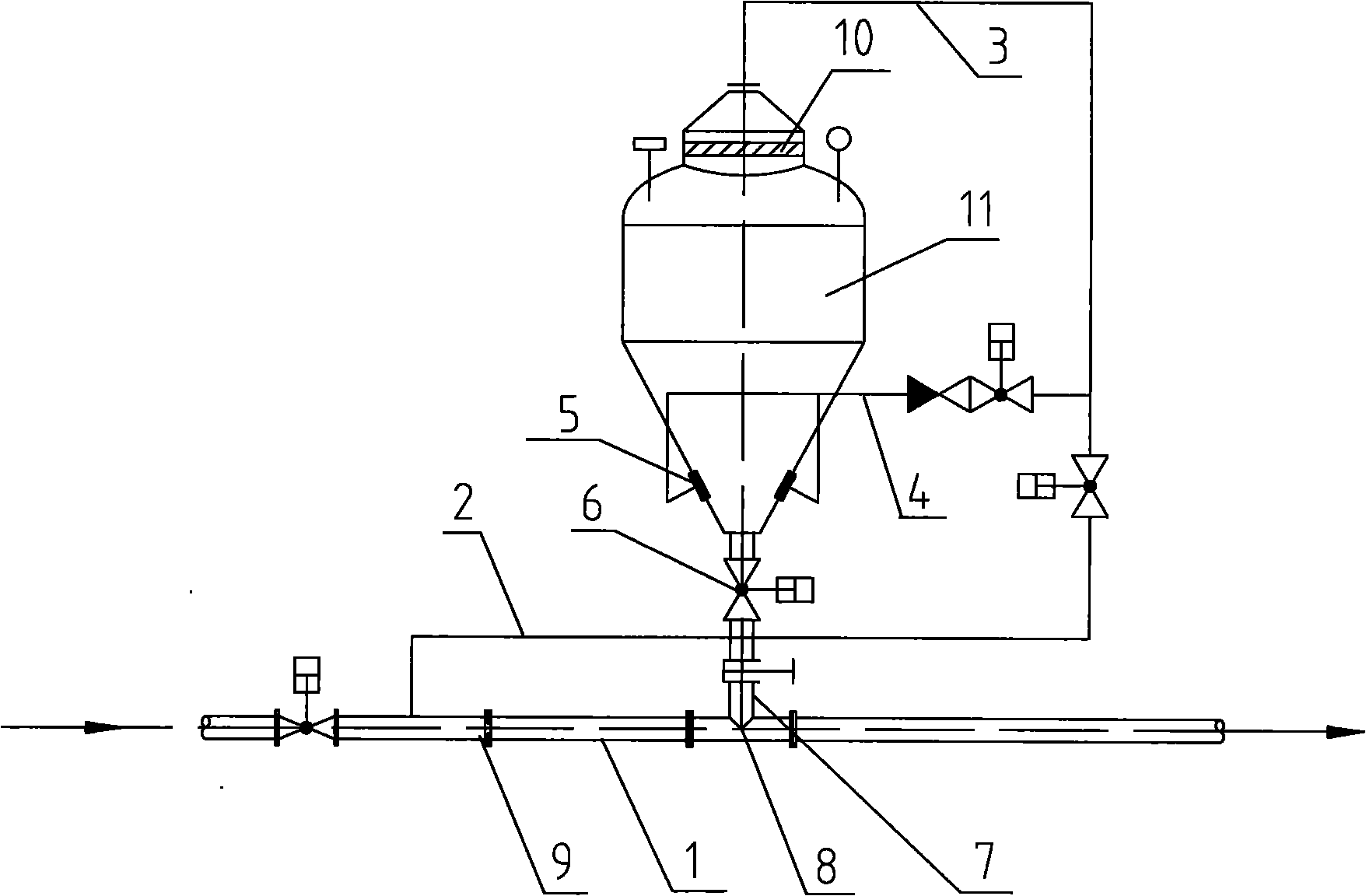

Conveying method for bottom discharge bin pump

InactiveCN102009851ANo pressure lossReduce transportation energy consumptionBulk conveyorsPositive pressureEngineering

The invention discloses a conveying method for a bottom discharge bin pump, which comprises the following steps of: 1, enabling a compressed air to enter a pressurized and fluidized pipeline, and pressurizing a bin pump through the pressurized pipe; 2, enabling the compressed air to enter a fluidizing device in the bin pump through the fluidized pipeline for fluidizing dry ash in the bin pump; and 3, when the pressure in the bin pump reaches the preset value, opening a pneumatic discharge valve, enabling the dry ash to enter a positive pressure ash conveying pipeline through a feeding hole of an ash conveying pipeline, regulating a flow regulating device on the positive pressure ash conveying pipeline, and controlling the discharge speed of the dry ash until the dry ash is conveyed completely, thereby improving the ash discharge and conveying reliability of the bottom discharge bin pump, increasing the conveying efficiency, and lowering the conveying unit gas consumption and the unit energy consumption.

Owner:ZHENJIANG CITY POWER STATION AUXILIARY MACHINERY PLANT

Device and method for producing and filling fine sausage meat, in particular an emulsion

ActiveCN102217666AShorten the timeReduce manufacturing costSausage filling/stuffing machinesMeat mixing apparatusEmulsionEngineering

A device and a method of manufacturing and filling up product in the form of fine sausage meat, in particular an emulsion, with a feed means for the product, a feed pump for transporting the product, at least one downstream fine mincer as well as a filling and / or portioning means arranged downstream of the fine mincer for filling up the produced fine sausage meat or the emulsion, respectively.

Owner:ALBERT HANDTMANN MASCHFABRICK

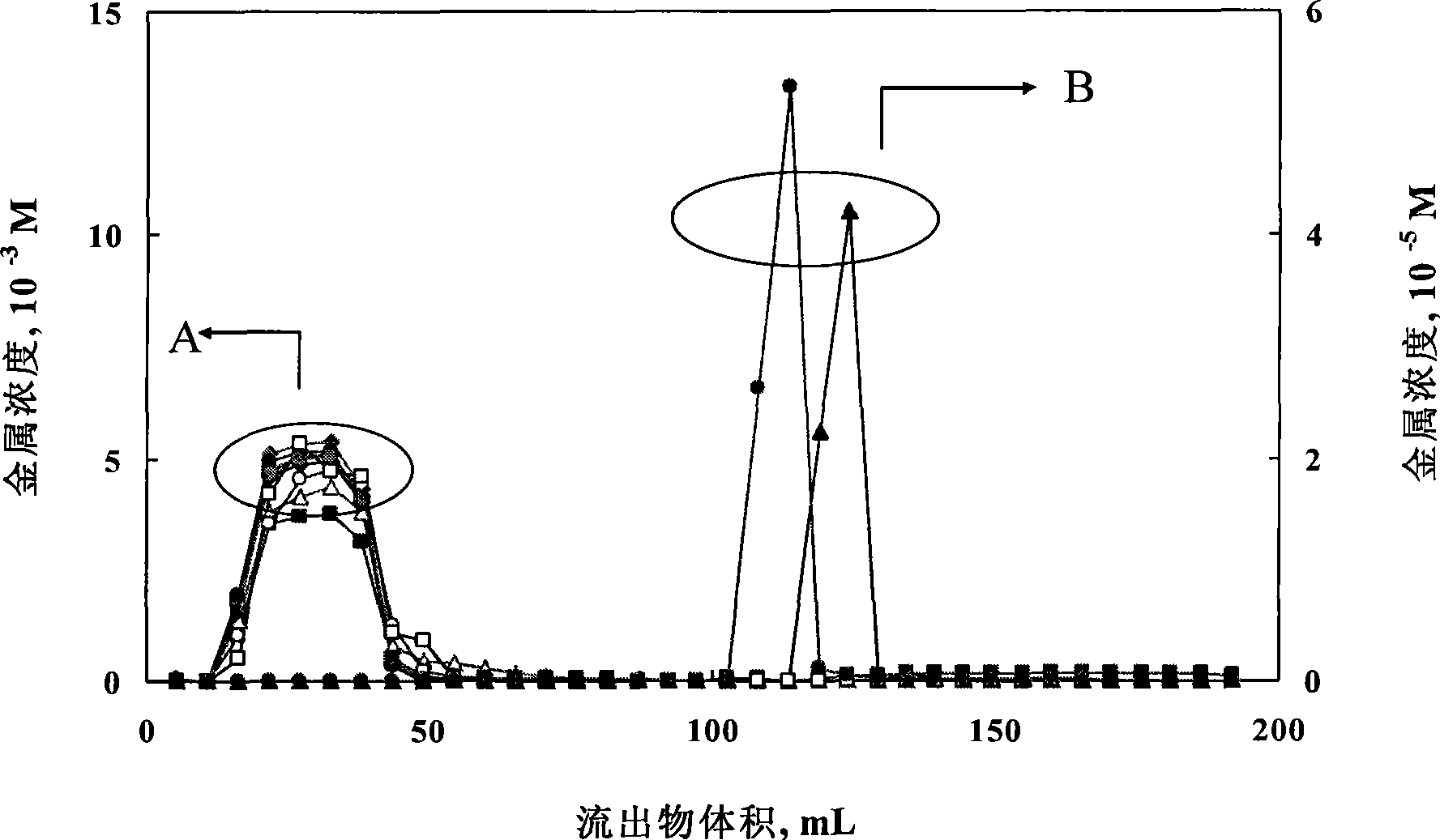

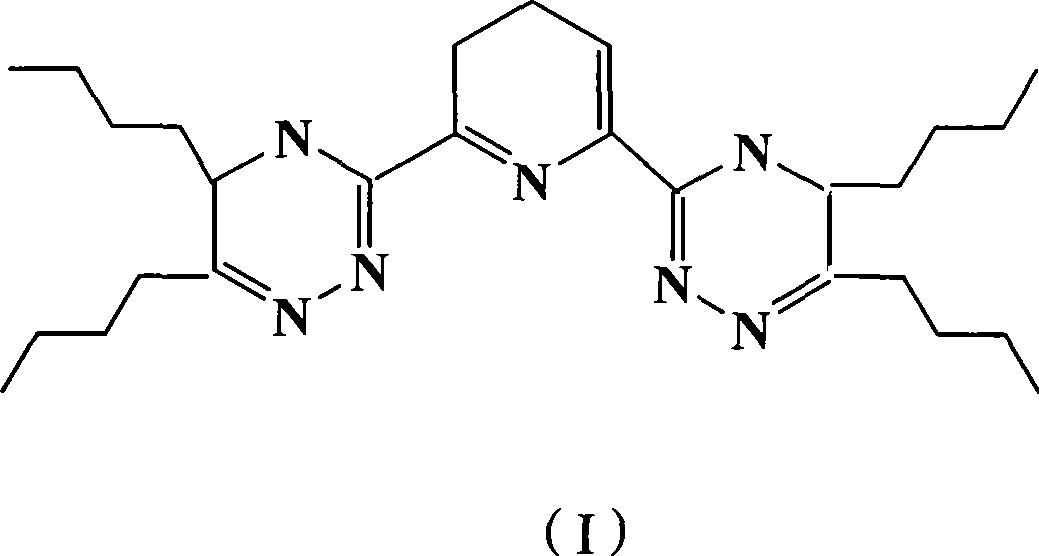

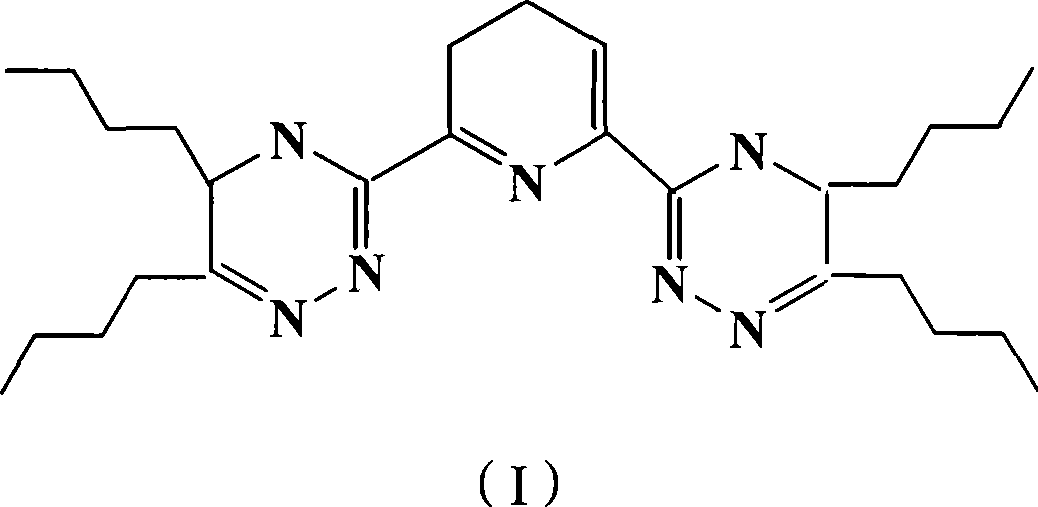

Sorbent for mutual separation of MA/RE in high-level waste and preparation thereof

InactiveCN101502790AEasy to identifyImprove adsorption capacityOther chemical processesSilicon compoundsMass ratioSorbent

The invention discloses a sorbent for MA / RE mutual separation in high-level waste and a preparation method thereof. The sorbent is prepared from 2, 6-di-(5, 6-di-n-butyl-1, 2, 4-triazine-3-radical)-pyridine loaded on macropore SiO2 of a coated polymer, and the mass ratio of the macropore SiO2 to R-BTP is (1-20):1. The sorbent has good identification capability on MA, high adsorption capacity and high recovering rate; when the sorbent is used in an adsorptive separation process, the sorbent does not need to be diluted or dissolved by with diluent of special performance, and can avoid introducing large amount of toxic solvent substances or generating secondary radioactive waste; and the ion diffusion, adsorption and desorption rate of the sorbent are remarkably improved, and the sorbent can run safely under the condition of high flow rate and is a safe and economic sorbent for efficiently mutually separating MA / RE in the high-level waste.

Owner:ZHEJIANG UNIV

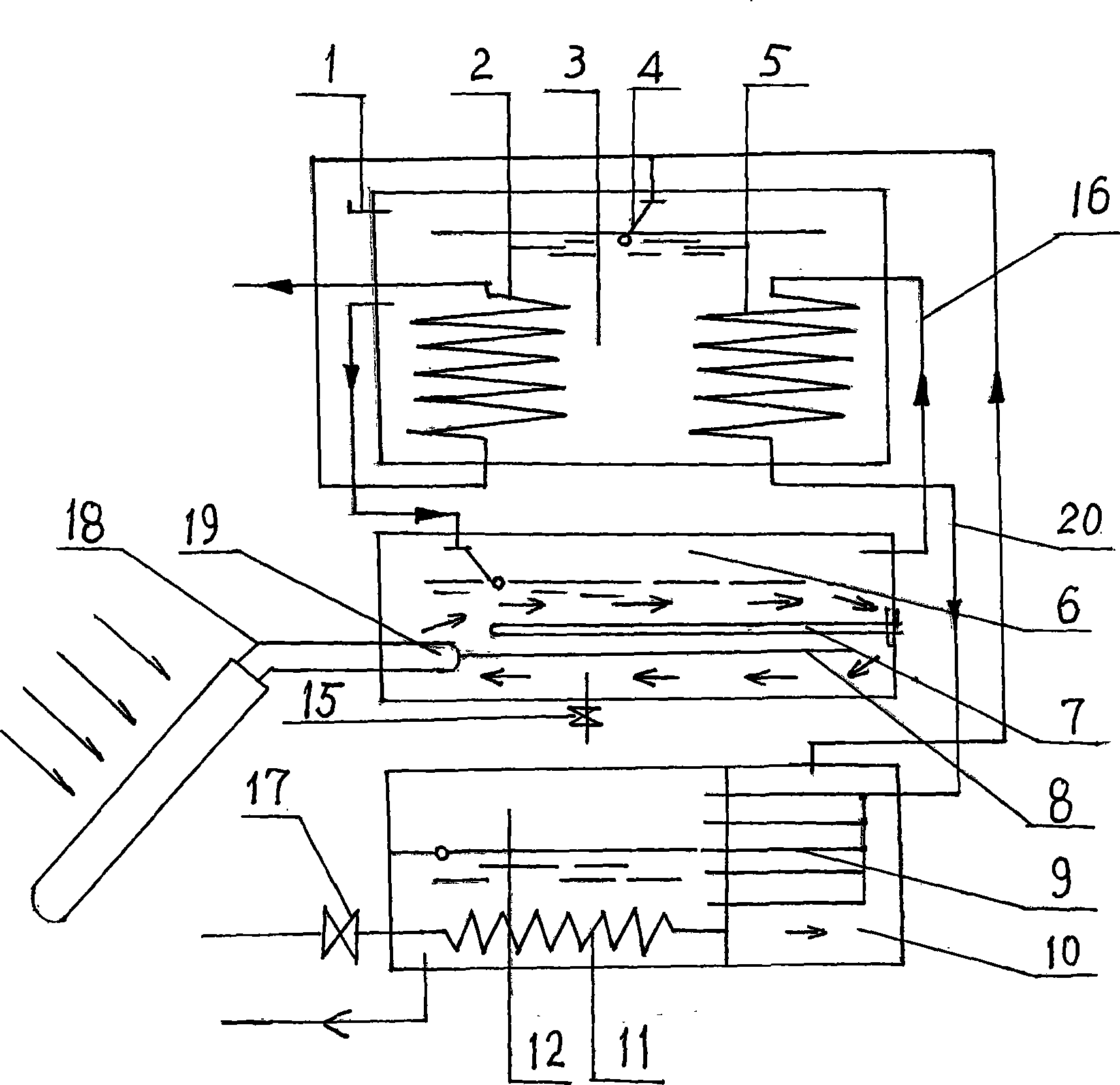

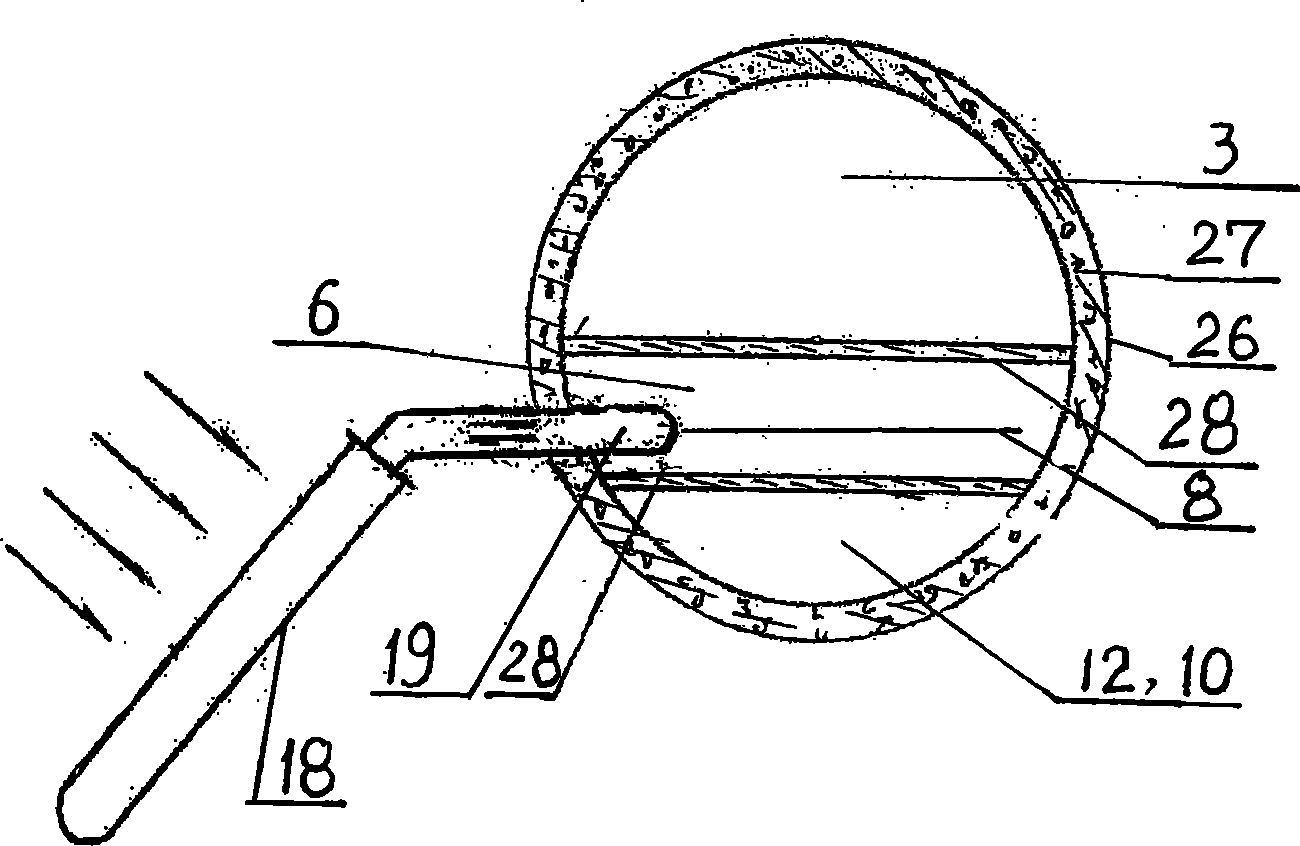

High-efficiency energy-saving multipurpose solar water heater

InactiveCN101373103AIncrease pressureSolve the following problemsSolar heating energySolar heat devicesSolar waterEngineering

An efficient energy-saving and multipurpose solar water heater comprises a hot water storage tank, an evaporation water tank, a preheating water tank, a distilled water tank and a full glass double-vacuum solar collector tube, wherein a vapor heat exchanger and a domestic hot water exchanger are installed in the hot water storage tank; an assisting electrical heating pipe and a flow deflector are installed in the evaporation water tank; a distilled water exchanger is installed in the preheating water tank; a tap water inlet heat exchanger is installed in the distilled water tank; the tap water inlet heat exchanger, the preheating water tank and the domestic hot water thermal exchanger are communicated with each other in sequence, so as to provide domestic hot water for users; the full glass double vacuum solar collector tube is communicated and connected with the evaporation water tank; and the evaporation water tank, the vapor heat exchanger, the distilled water heat exchanger and the distilled water tank are connected and communicated with each other in sequence, so as to provide drinking distilled water for the users. The invention has the advantages of novel structure, high heat efficiency, energy conservation, multiple purposes and excellent technical performance.

Owner:甘国华

Pipeline-free material adsorption apparatus and method used for high-precision workpiece table

ActiveCN105301911ANo pressure lossNo distractionPhotomechanical exposure apparatusMicrolithography exposure apparatusMotor driveElectric machinery

The invention discloses a pipeline-free material adsorption apparatus used for a high-precision workpiece table. The pipeline-free material adsorption apparatus is characterized by comprising a suction cup, an air cylinder, a piston and a motor; a pipeline in the suction cup is connected with the air cylinder; and the motor drives the piston to move to cause negative pressure in the internal of the air cylinder and to enable the suction cup to absorb materials. Compared with the prior art, the pipeline-free material adsorption apparatus has no external air source, so that pressure loss in a transmission path and the interference from a pipeline are avoided; and meanwhile, the pipeline-free material adsorption apparatus is not limited by the environment, so that the pipeline-free material adsorption apparatus can be applied to the atmospheric environment.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

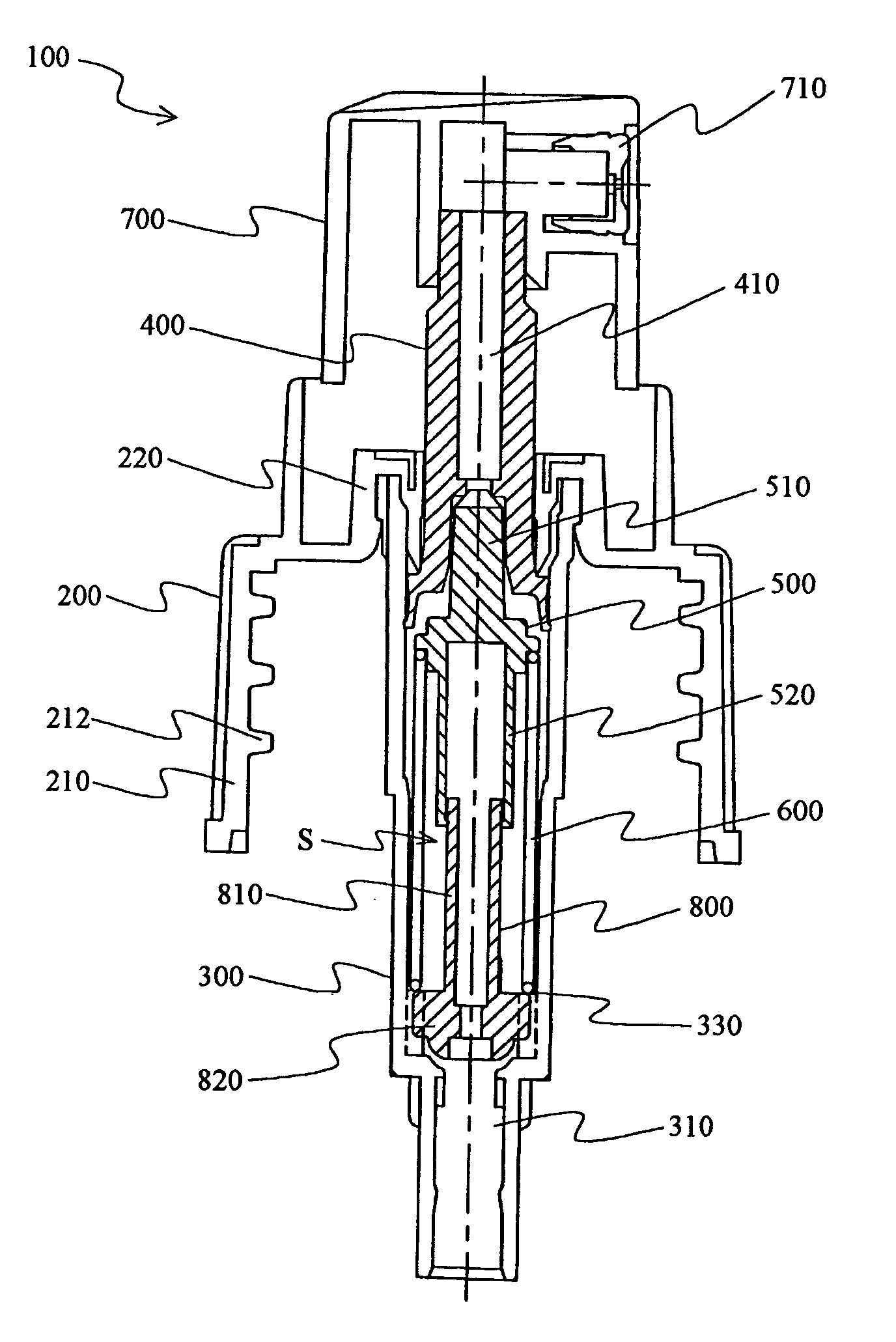

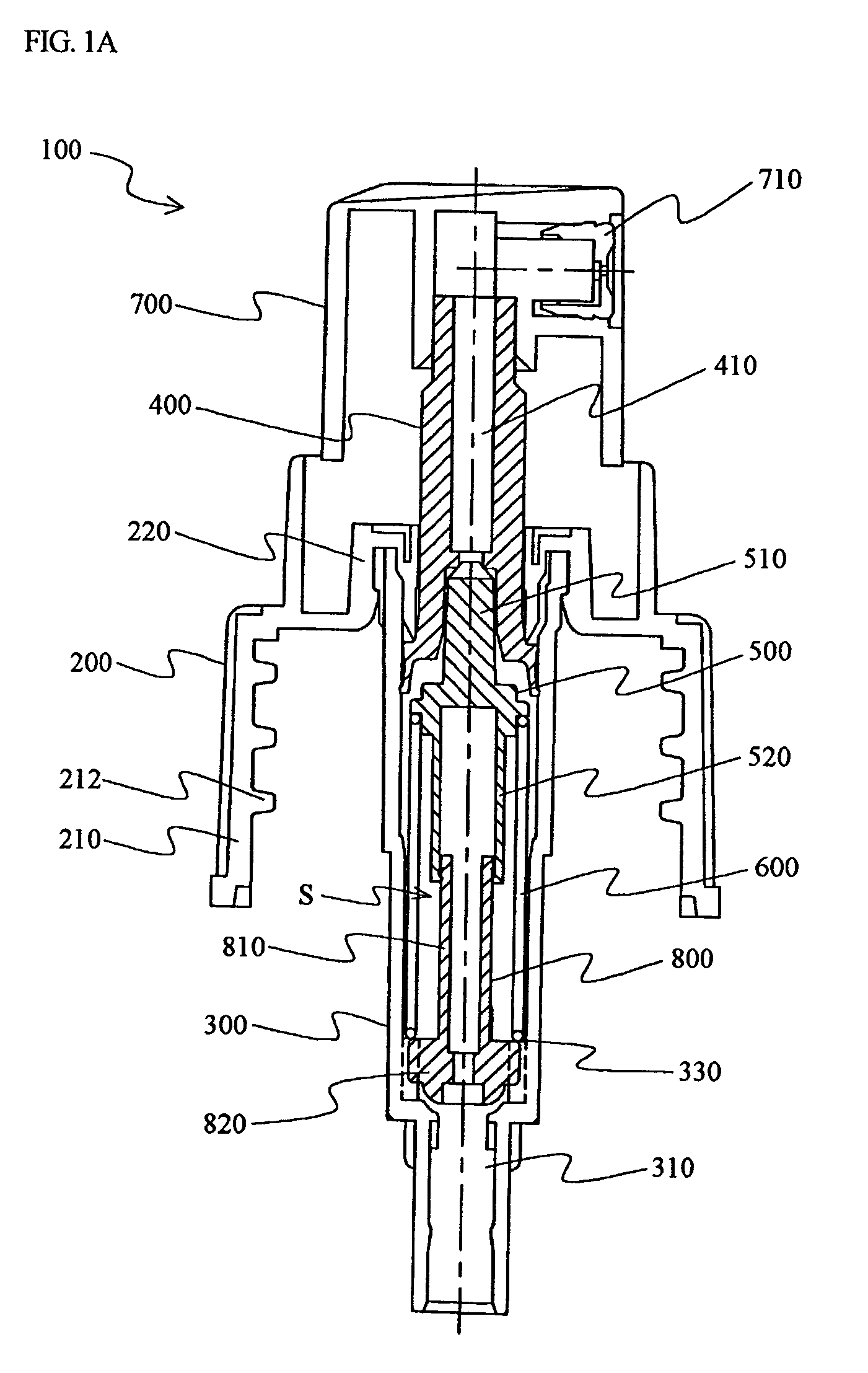

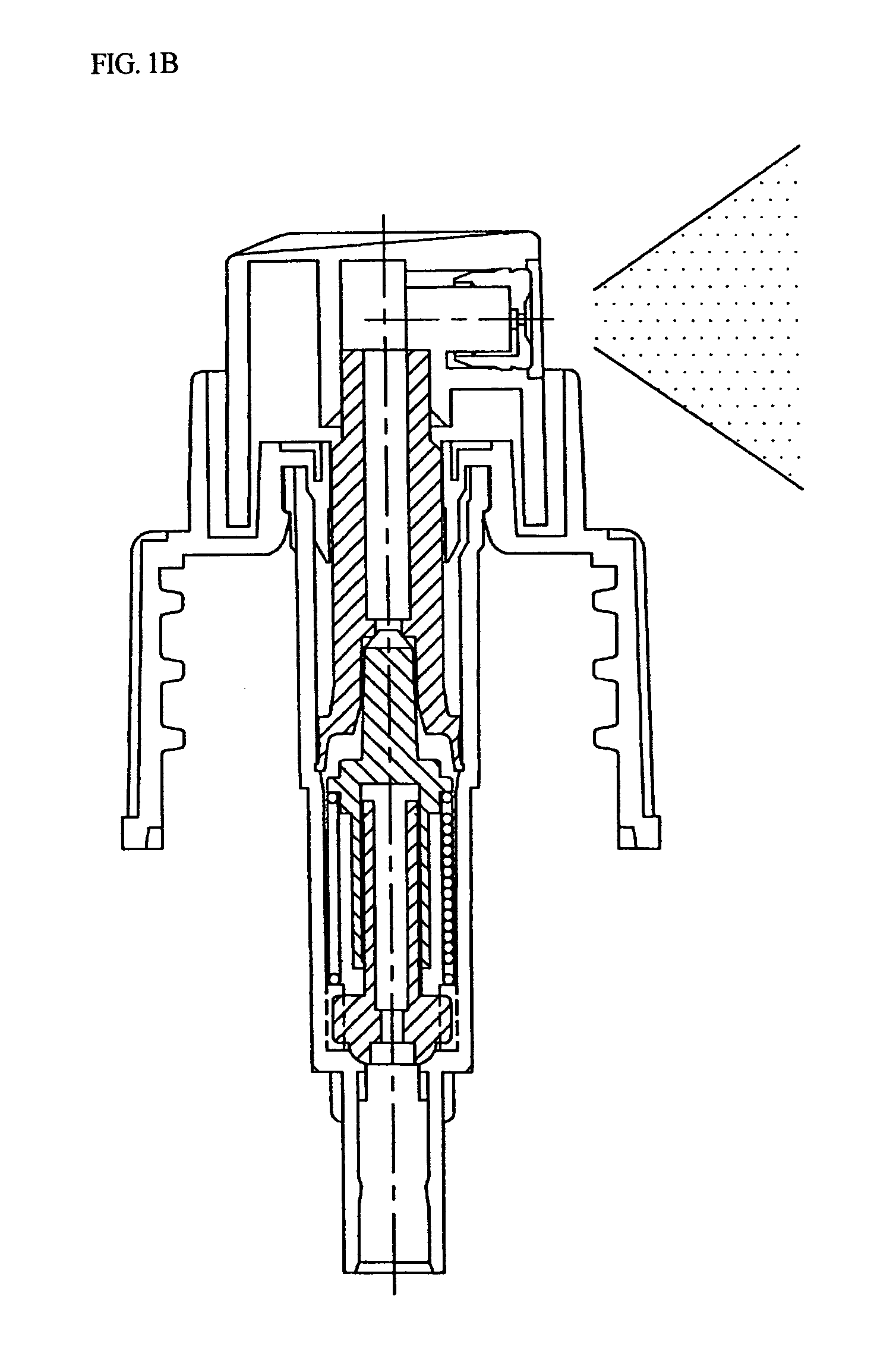

Low profile, fine mist, finger-operated, precompression-type spray pump

InactiveUS6913169B2Pumping procedure to be performed smoothlyReduce assemblyContracting/expanding measuring chambersLarge containersEngineeringPiston

The present invention relates to a low profile, fine mist, finger-operated, precompression-type spray pump, and more particularly to a spray pump provided with a second valve of the novel structure being moveable between a poppet valve and a bottom entrance of housing, to precompress the fluid as a liquid content and then spray, whereby the spray pump can be operated even with a short travel distance of a piston, which enables to make the height of a push button spaced from a closure to be shorter than the existing ones, and the pumping process can be smoothly performed without leakage and can also be started with small empty pumping numbers. In addition, the spray pump according to the present invention is constructed with small numbers of constituent parts, resulting in the significant reduction of manufacturing cost and assembly cost.

Owner:CHONG WOO

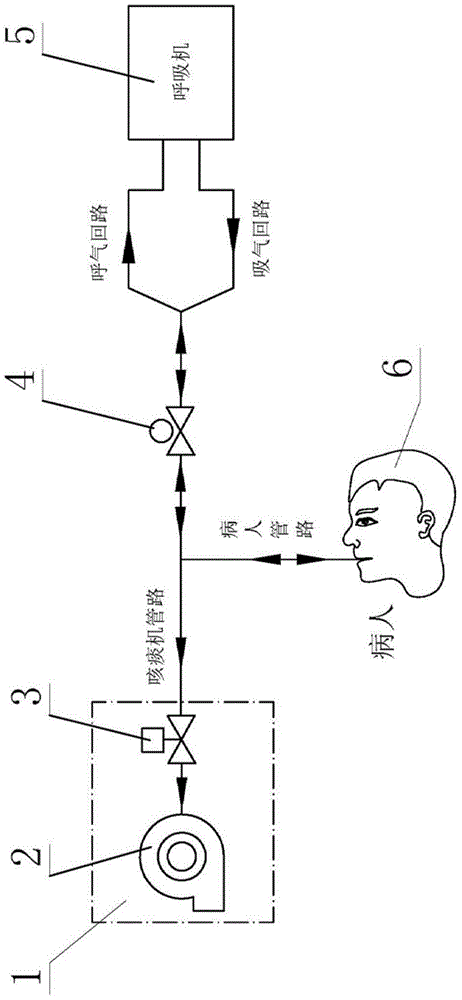

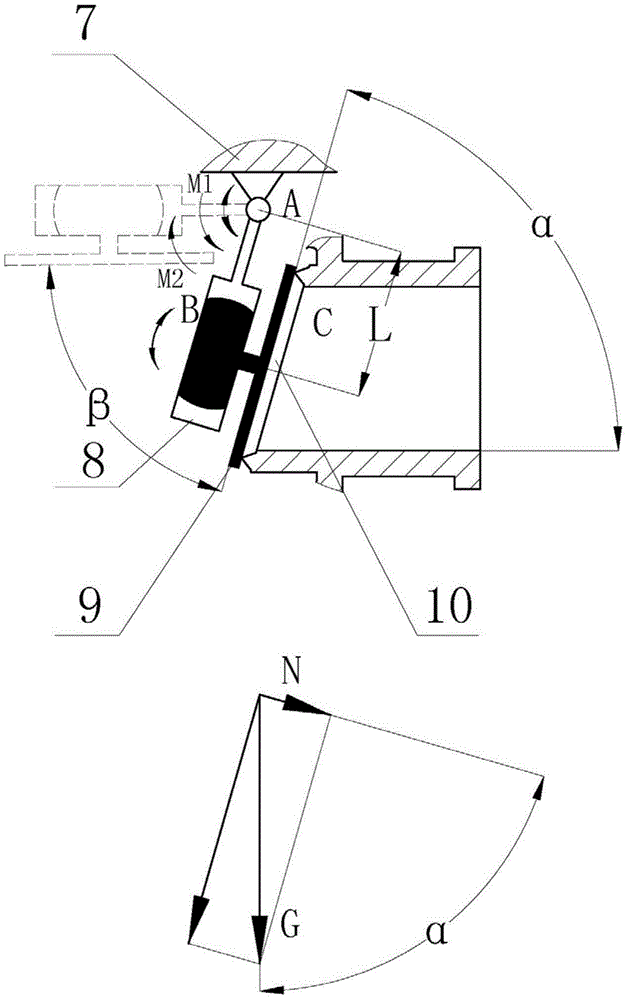

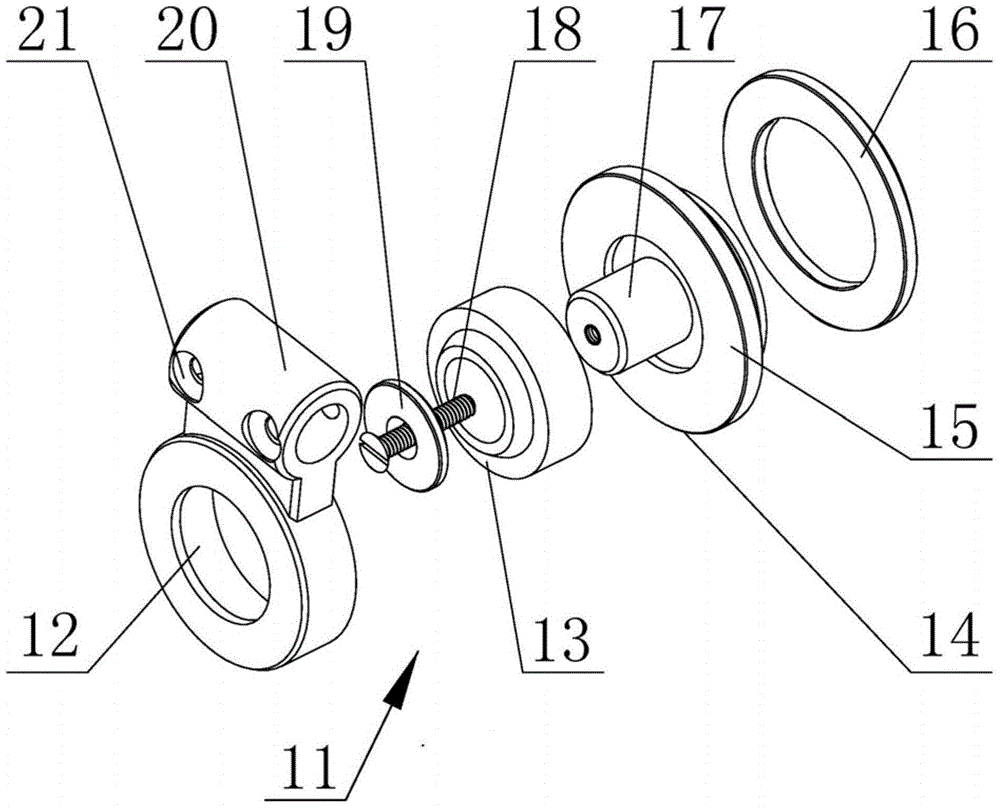

Quick valve

ActiveCN104879506AGuaranteed high frequencyNo bendRespiratorsOperating means/releasing devices for valvesEngineeringMechanical engineering

A quick valve (3) comprises a swing member (8) and an angle adjusting member (9). The swing member (8) can be rotatingly fixed on a valve body (7), the valve body (7) has a valve port (10), the swing member (8) can rotate along the direction that clings to or far away from the valve port (10). The angle adjusting member (9) can cover the valve port (10), the angle adjusting member (9) is combined with the swing member (8), and the angle adjusting member (9) can adjust an angle between itself and the valve port (10). The quick valve is simple in structure, easy to process, high in sealing reliability, quick in switch and with no abrasion during rotation and no pressure loss.

Owner:王淑萍

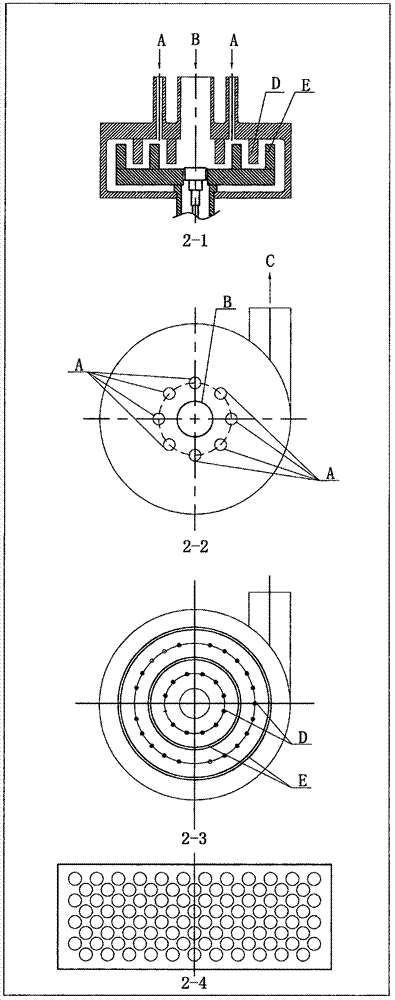

Flow rate measuring device

ActiveCN101194145AHigh measurement accuracySmall sizeVolume/mass flow by thermal effectsVolume flow proportion measurementMeasurement deviceEngineering

The invention discloses a flow rate measuring device which is small in size and in which dust and the like can hardly pass through, has high measurement accuracy, and has small pressure loss. The secondary flow channel includes: a guide channel 22, wherein the upstream side is communicated with the guide port 21 used as the first split point, and the downstream side is used as the second split point 20a; the first flow channel 23, wherein the upstream side is at the second split point. The diversion point 20a is divided and formed from the diversion channel 22 so that it is parallel to the main flow channel 12, and the downstream side communicates with the discharge port 28; 22 is divided and formed so as to cross the main flow channel 12; and the third flow channel (detection flow channel) 25, wherein the upstream side communicates with the downstream side of the second flow channel 24, the flow velocity detection member is provided, and the downstream The side communicates with the discharge port 28 .

Owner:OMRON CORP

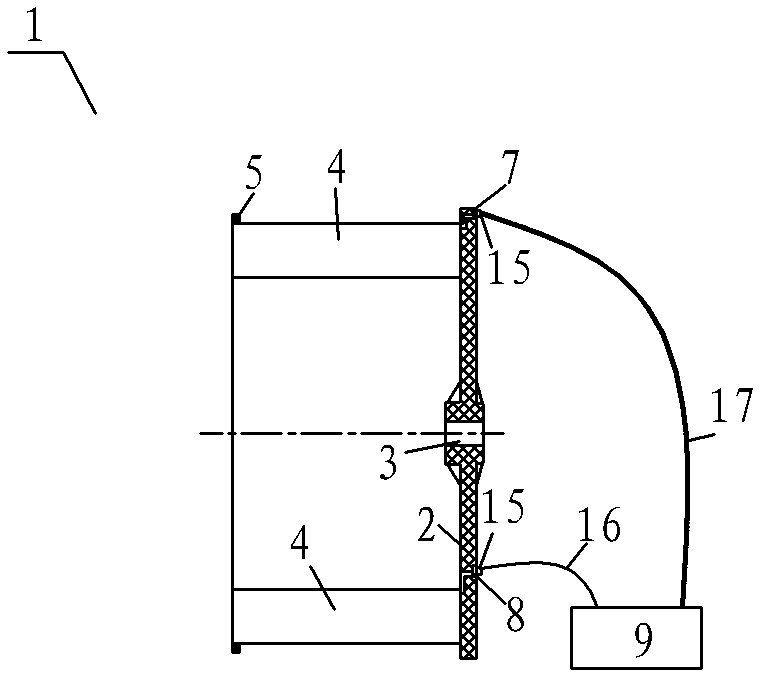

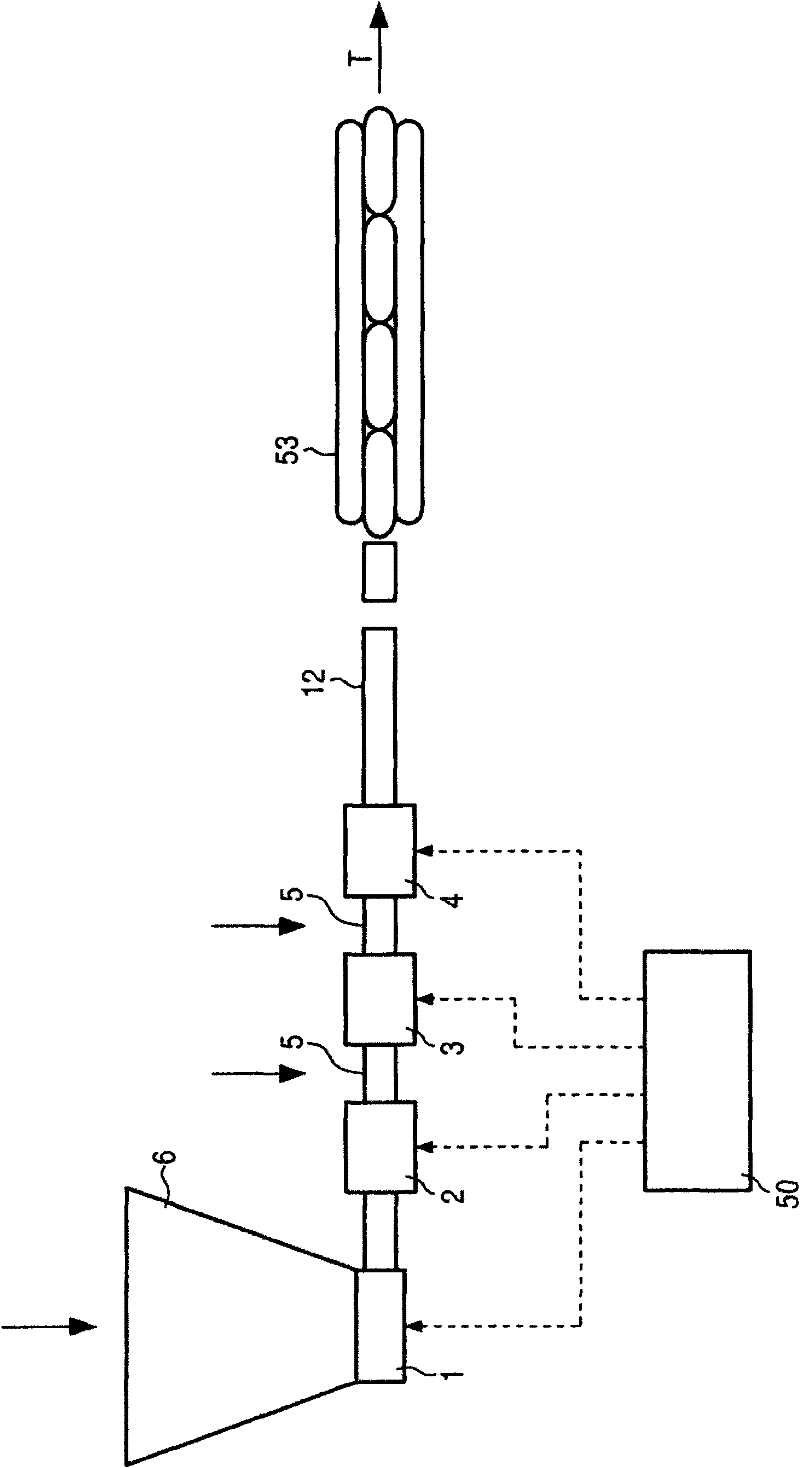

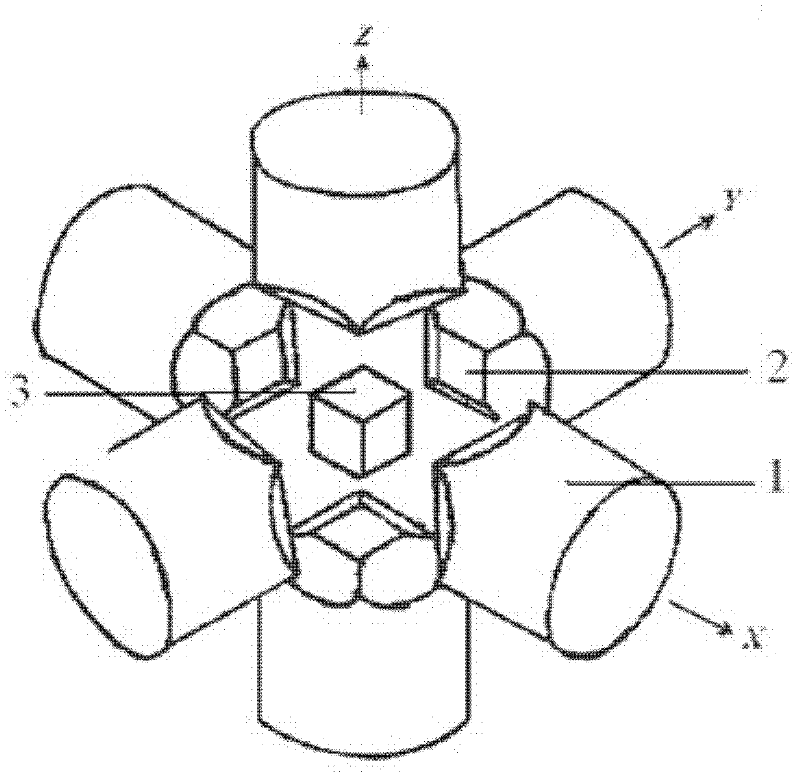

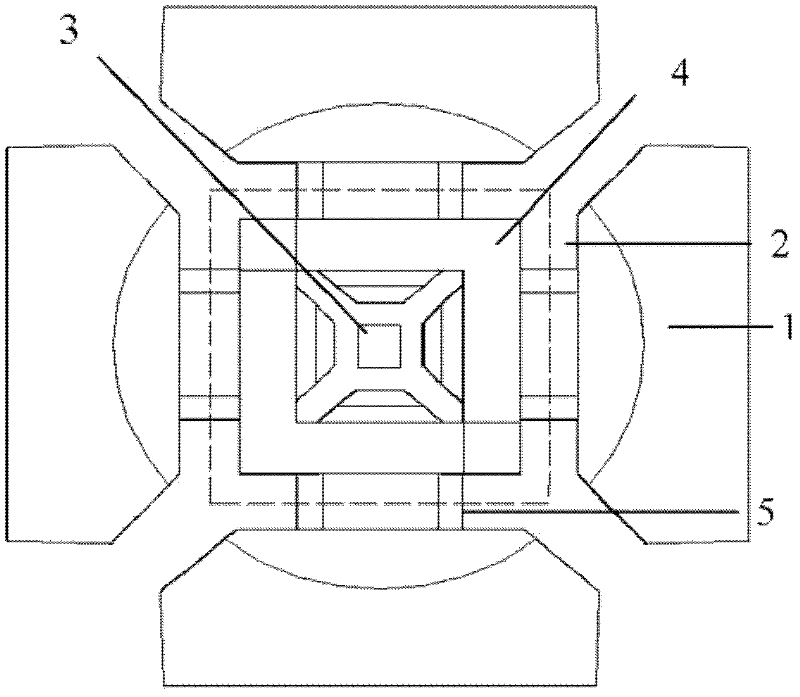

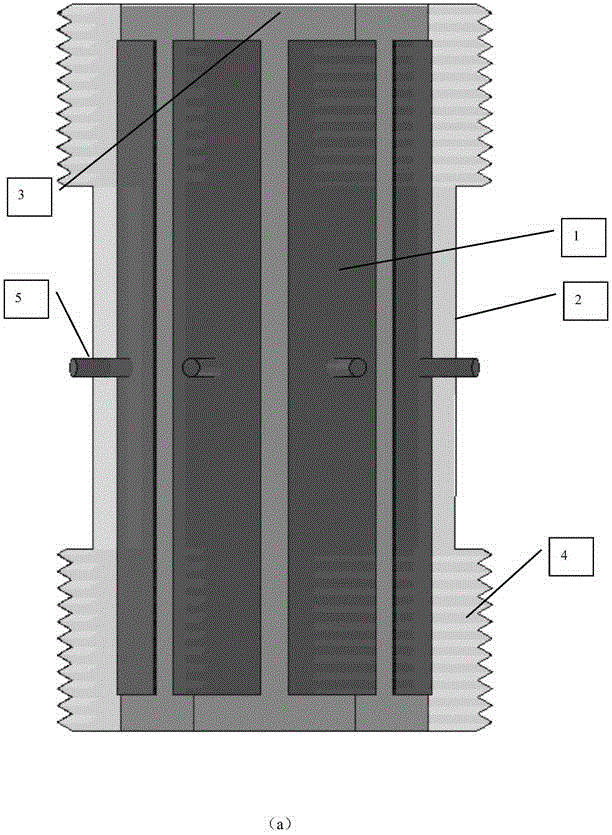

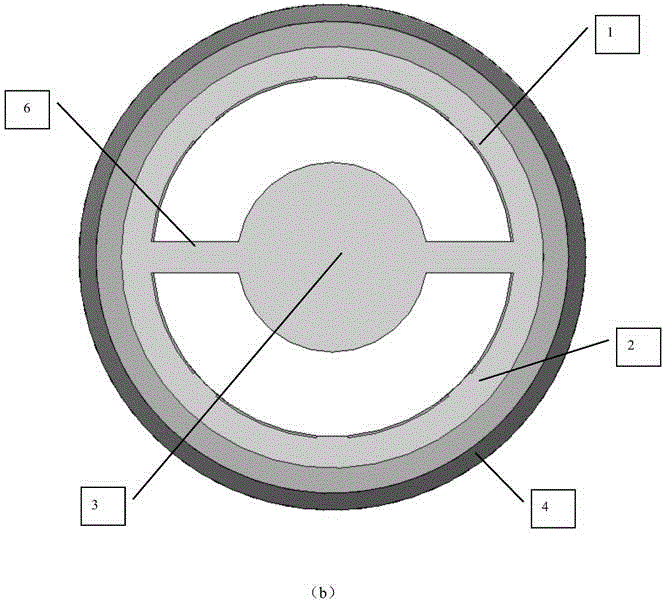

Ultra-high pressure device based on hinged-type hexahedral press

InactiveCN102389750AExcellent overall performanceFast installation and debuggingUltra-high pressure processesMaterial synthesisEngineering

The invention discloses an ultra-high pressure device based on a hinged-type hexahedral press and belongs to the technical field of ultra-hard material synthesis equipment. The ultra-high pressure device structurally comprises six press anvils (1) which are synchronously driven by a hexahedral press, a cubic synthesis block (3) and pressurization anvils (5) arranged between press anvil faces (2) and the plane of the synthesis block (3). The invention is characterized in that the ltra-high pressure device further comprises a cubic support frame (4) which is formed by assembly of four pressurization anvil holders (6), each pressurization anvil holder (6) is formed by three columns which are perpendicular to one another, and the pressurization anvils (5) can pass through the six planes of the cubic support frame (4) and move in the axial direction of the pressurization anvils (5) to apply a pressure to the synthesis block (3) or relieve the pressure of the synthesis block (3). The invention has the biggest advantage as follows: the six pressurization anvils (5) can be assembled on the cubic support frame (4) very easily and can be used directly without needing setting-up or alignment; the installation and set-up are rapid and accurate; and the time is saved.

Owner:JILIN UNIV

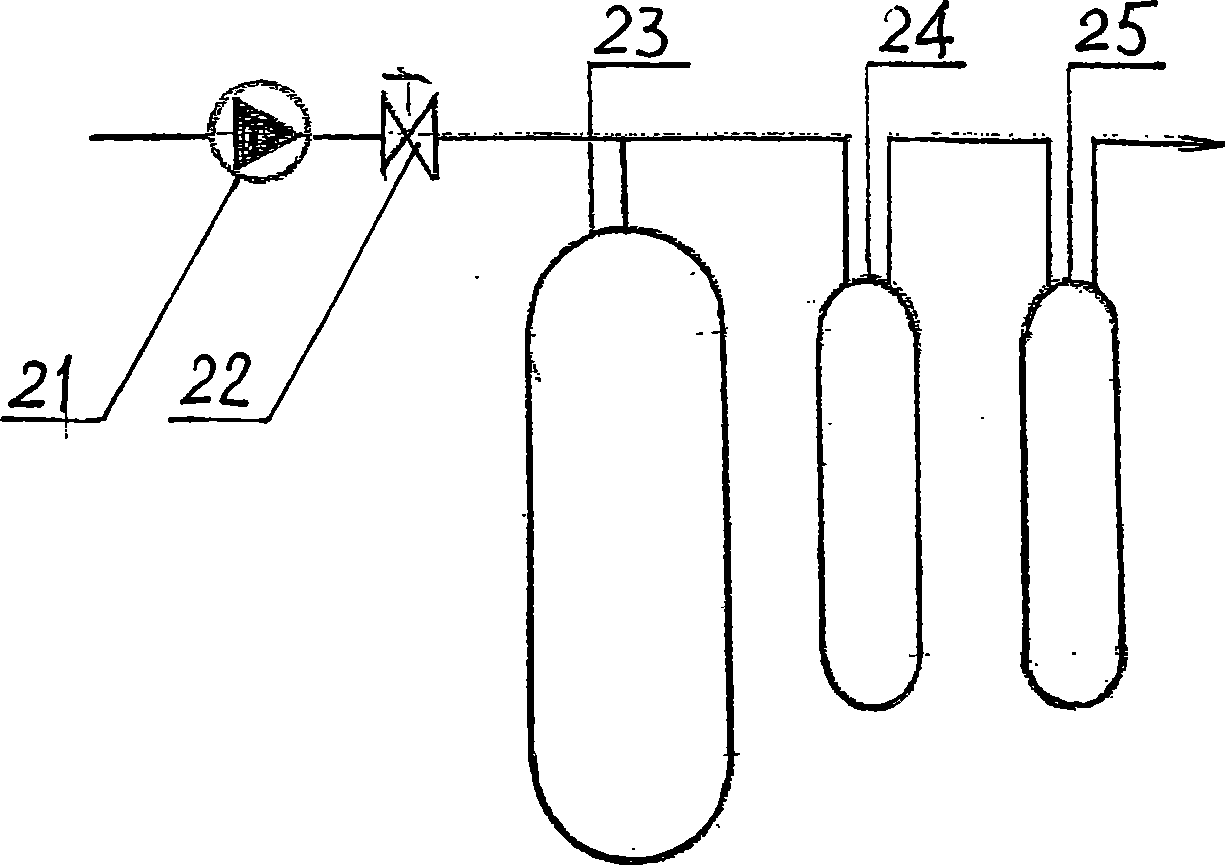

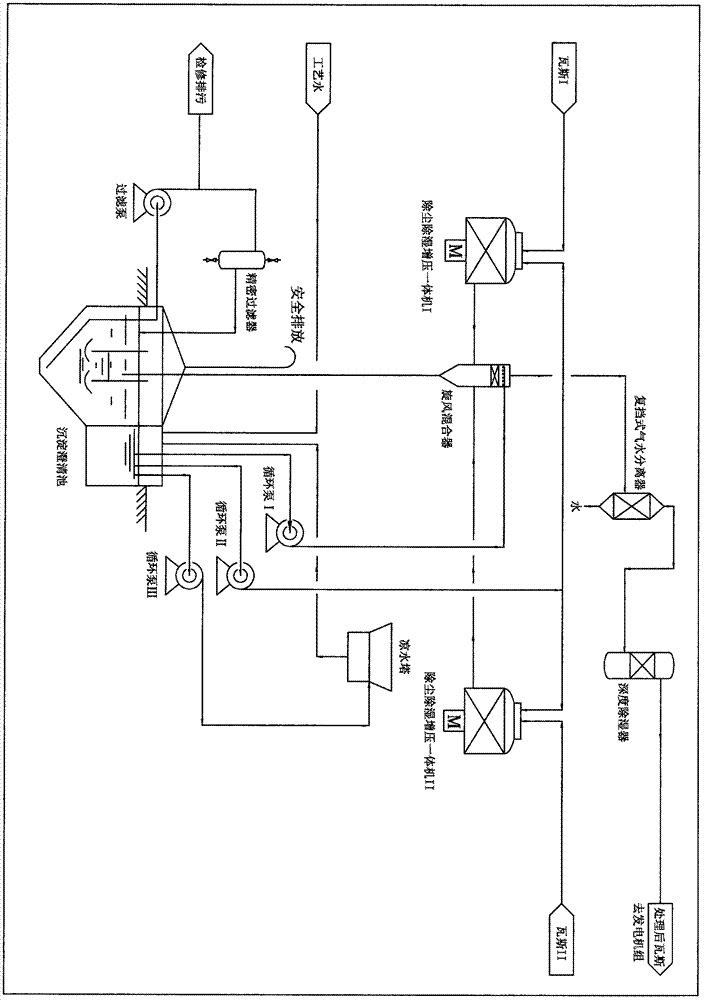

High-efficiency energy-saving pretreatment process used for generating gas

InactiveCN106906016ASmall footprintDust removal effect is stableGaseous fuelsPre treatmentProcess engineering

The invention relates to a high-efficiency energy-saving pretreatment process used for generating gas. The invention relates to a high-efficiency energy-saving pre-treatment method for generating gas. The method employs a dedusting, dehumidification and supercharging machine and integrated equipment to dedust, dehumidify and supercharge the gas sent to a generator set. The method has the advantages of high dehumidification efficiency, energy saving, and high efficiency of dust removal, and maximum dust particle size of from the outlet is not greater than 1.5 [mu]m, and pressurization mixing pressure is adjustable. By adopting the process method of the invention, pretreatment of gas is carried out, efficient utilization of resources can be satisfied, operation cost is reduced, and energy is saved and cost is reduced.

Owner:山西都宝新能源发展研究院 +3

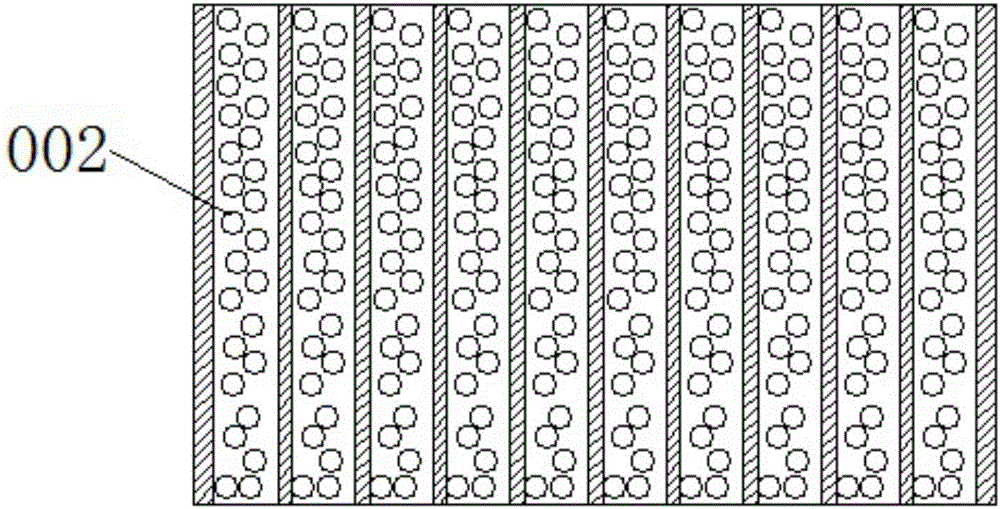

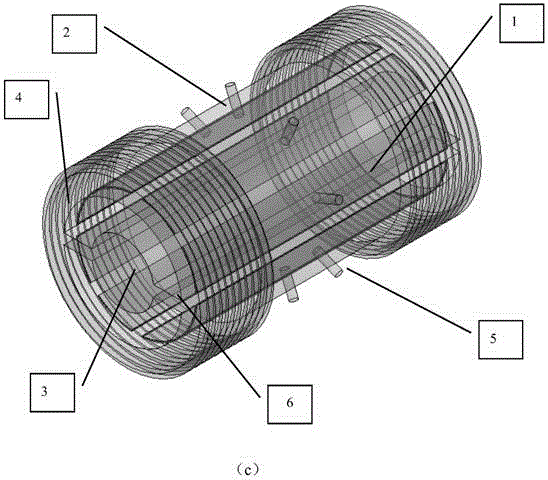

Online oil abrasive particle imaging and counting sensor for airplane engine and manufacturing method

InactiveCN105571995ANo pressure lossWill not cause false detectionMaterial analysis by electric/magnetic meansAirplaneParticle imaging

The invention discloses an online oil abrasive particle imaging and counting sensor for an airplane engine and a manufacturing method. The online oil abrasive particle imaging and counting sensor comprises a pipeline center. The pipeline center is embedded into a sensor pipe wall. The sensor pipe wall is circular and concentric with the pipeline center. A sensor inner core is embedded into the sensor pipe wall. A plurality of metal electrode plates are embedded into the sensor pipe wall. The sensor pipe wall is provided with an interface part and a metal lead. The metal electrode plates are used for imaging so as to detect abrasive particles. The manufacturing method includes: performing 3D printing on metal materials to allow the metal materials to be formed into the metal electrode plates; using polymer insulating materials to form the sensor pipe wall and the sensor inner core through integral injection molding so as to obtain a formed body; machining the interface part on the basis of the formed body; using static spraying to manufacture an outer shielding metal layer on the outer wall of the formed body. The online oil abrasive particle imaging and counting sensor and the manufacturing method have the advantages that the structure of the sensor is improved, the 3D printing is used, detection reliability is increased, and abrasive particle imaging detection and quantitative abrasive particle counting are achieved.

Owner:TIANJIN UNIV

Supersonic wave-ozone-based flue gas desulphurization and denitration device

ActiveCN105363325AAvoid wastingPrevent leakageDispersed particle separationAir quality improvementActivation actionLiquid water

The invention discloses a supersonic wave-ozone-based flue gas desulphurization and denitration device. Air goes through a first valve and then enters a first dryer, the first dryer and a plasma ozone generator are connected by a flowmeter, the plasma ozone generator has two output paths, one path goes through a third valve and then is orderly connected to a second dryer and a first ozone concentration sensor, the other path goes through a second flowmeter and then is orderly connected to a second valve and a flue gas reaction chamber, flue gas is input into the flue gas reaction chamber, an ultrasonic generator is arranged in the flue gas reaction chamber, liquid water orderly goes through a forth valve, a third flowmeter and an ultrasonic oscillator and then is fed into the flue gas reaction chamber, through ultrasonic wave activation action on water and ultrasonic wave mass transfer enhancement effects, when flue gas and ozone go through water mist subjected to ultrasonic treatment and then enter the reaction chamber, gas and water mist in the reaction chamber are subjected to activation under ultrasonic wave action and produce a lot of hydroxyl radicals and other active particles and SO2 and NOX in the flue gas are removed.

Owner:JIANGSU UNIV OF SCI & TECH

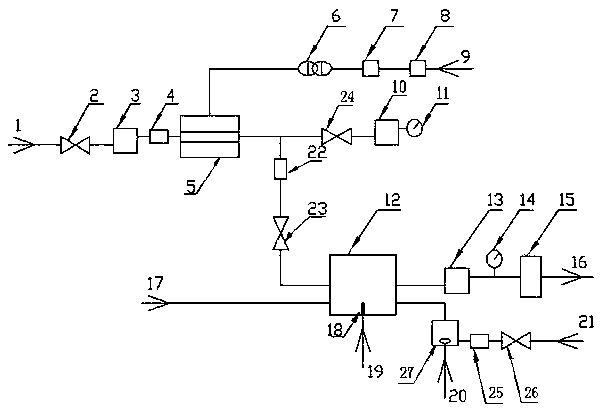

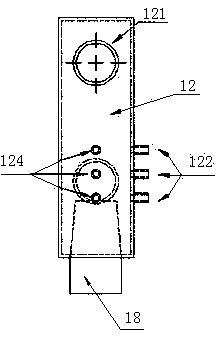

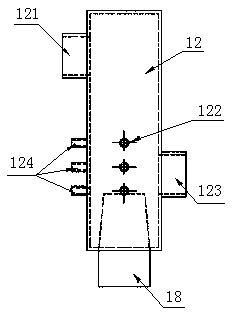

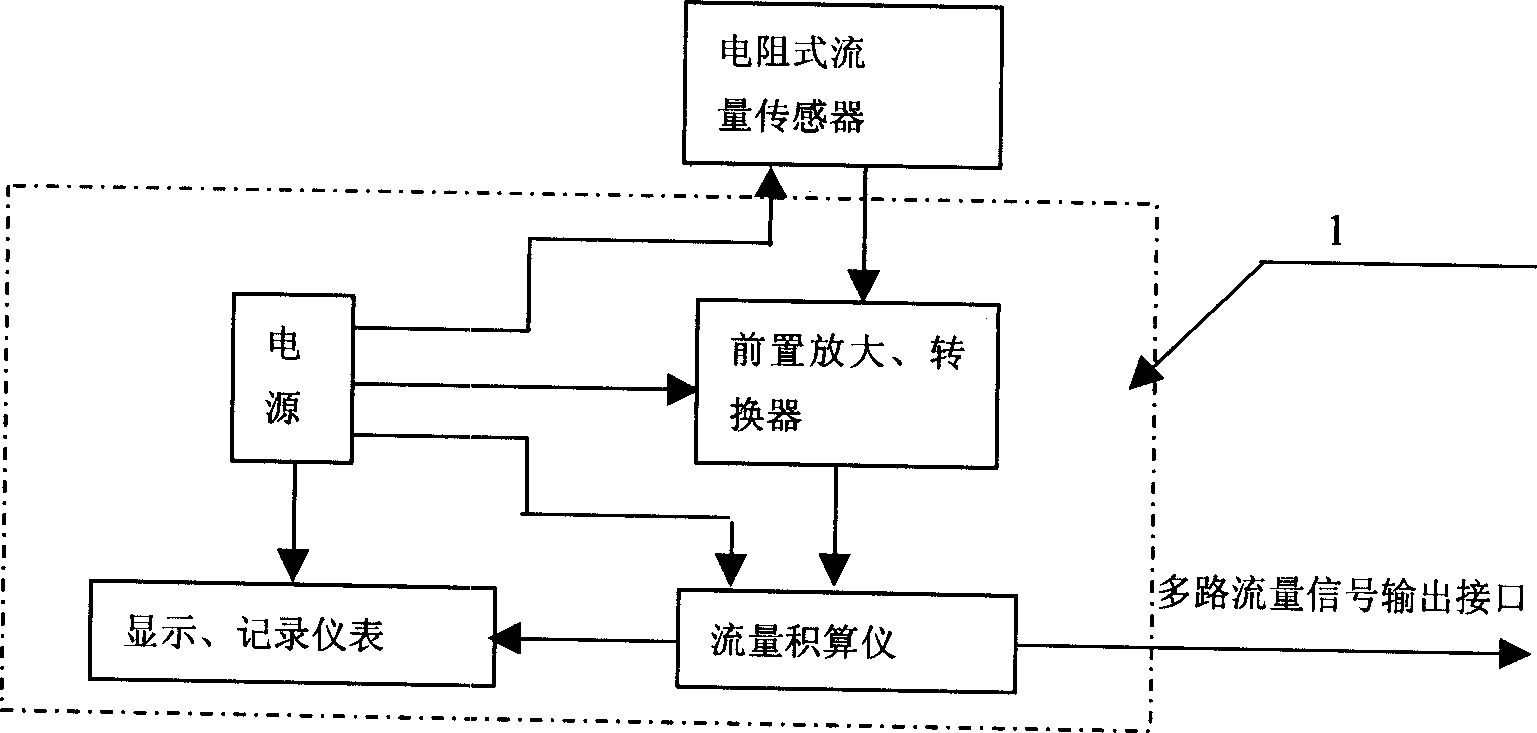

Flux measuring method based on negative resistance property and resistance flowmeter

InactiveCN1828230ASimple structureHigh strengthVolume/mass flow by electric/magnetic effectsElectrical resistance and conductanceIntegrator

The disclosed measurement method comprises: measuring the resistance variation between two fixed points in flow field and opposite liquid average flow rate to scale and find out the relation V=f(R), then calculating the flow rate by Q=AV=Af(x). Wherein, the flowmeter comprises a flow rate sensor, a front-end amplification converter, a flow rate integrator, a display and record device, an interface circuit, and a power. This invention has well application in lots of fields.

Owner:KUNMING UNIV OF SCI & TECH

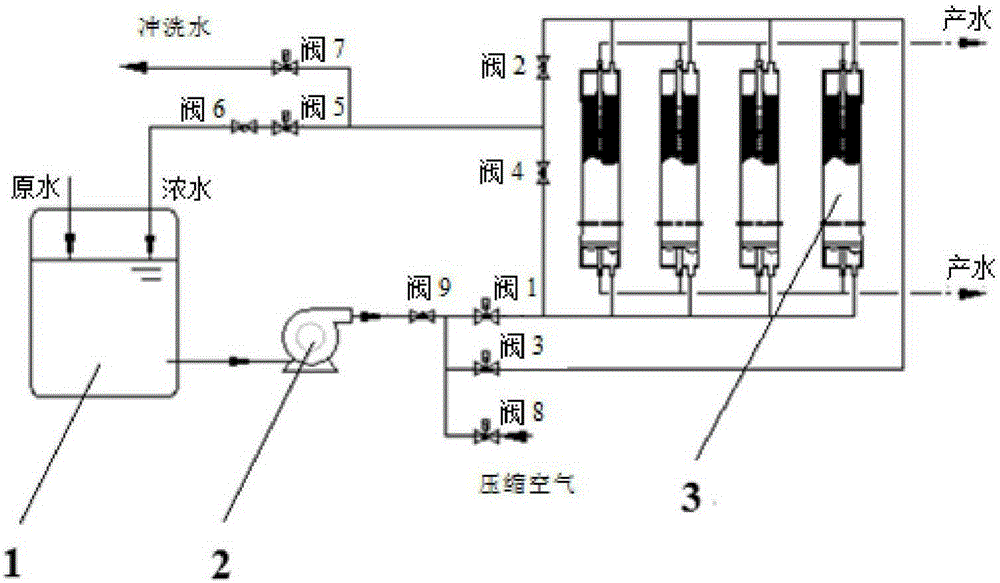

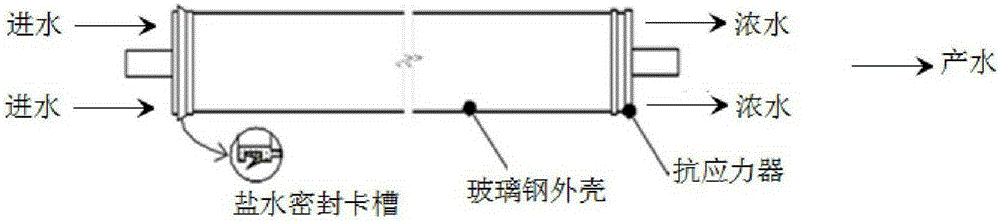

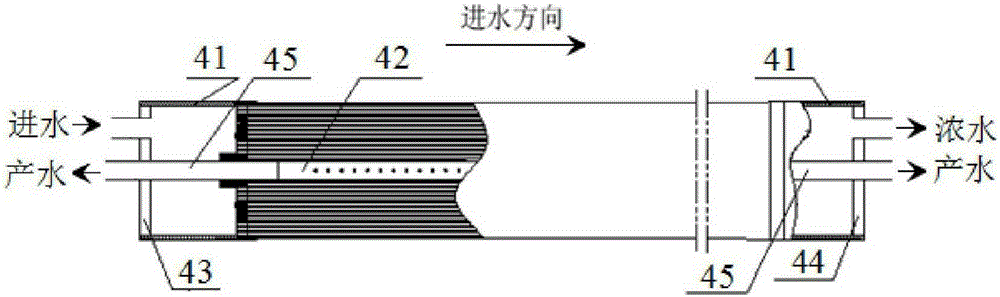

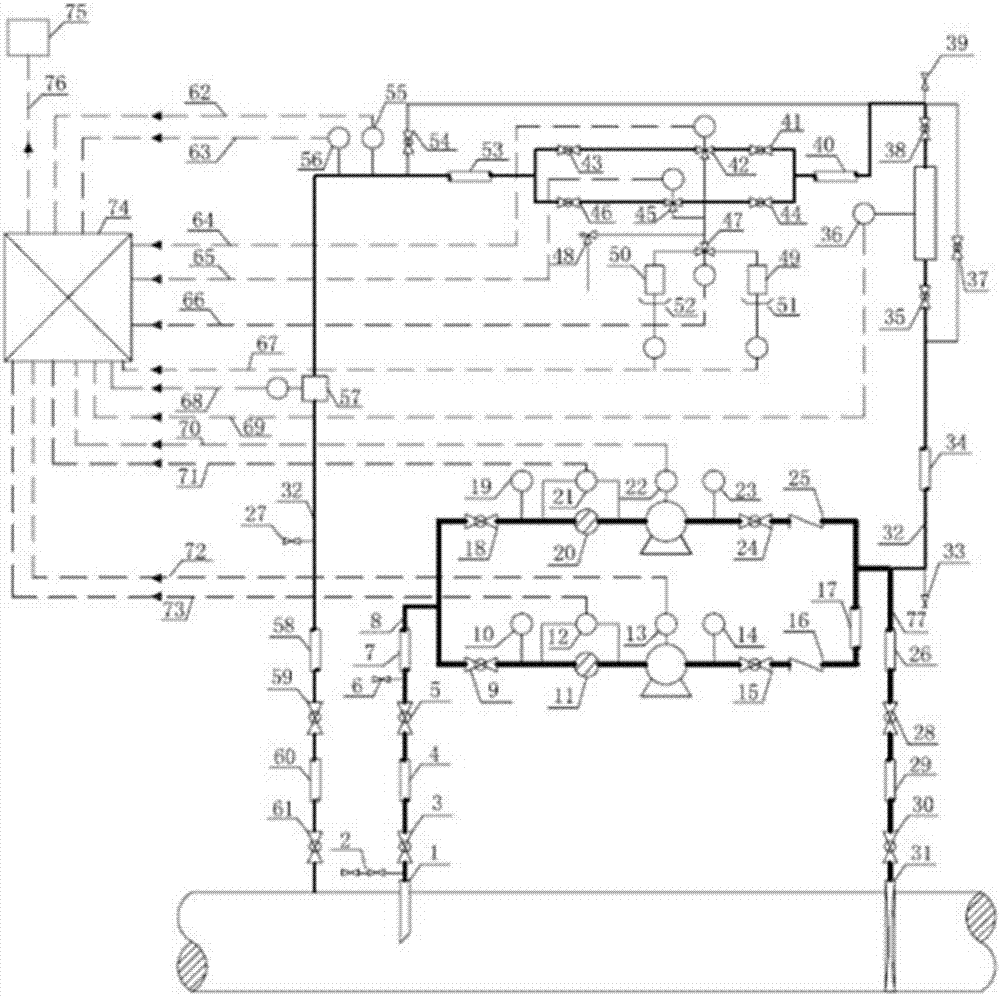

Bidirectionally-flowing nanofiltration membrane water treatment system and method

ActiveCN105217733ASame concentrationNo pressure lossReverse osmosisWater/sewage treatment bu osmosis/dialysisWater treatment systemNanofiltration

The invention provides a bidirectionally-flowing nanofiltration membrane water treatment system and method. The system comprises a water tank, a membrane component and a valve component, wherein the water tank is connected with the membrane component through the valve component; the membrane component comprises a component main body and a convergence pipeline, the component main body is formed by arranging multiple membrane elements in parallel, a water inlet pipeline and a water concentrating pipeline are arranged at the two ends of the membrane elements respectively; the valve component is communicated with the convergence pipeline. According to the bidirectionally-flowing nanofiltration membrane water treatment system, a bidirectionally-flowing mode is adopted for conducting nanofiltration membrane water treatment in an alternate mode, and the pollution resistance of the nanofiltration membrane elements is improved.

Owner:BEIJING ORIGIN WATER FILM TECH

Online sampling method for oil pipeline

InactiveCN106908276ASampling is representativeWith quantitative accuracyWithdrawing sample devicesMaterial testing goodsSpray nozzleEngineering

The invention relates to an online sampling method for an oil pipeline. The online sampling method comprises following steps: 1), a section of bypass pipeline is arranged on a main pipeline, and a liquid enters the bypass pipeline through a sampling probe; 2), pressure detection is performed; 3), filtering and pollution discharge are performed; 4), pressure difference detection is performed at two ends of a filter; 5), the liquid is pressurized by a sampling pump; 6), pressure detection is performed; 7), an outlet of the sampling pump is connected with a sampling loop and a jet loop, the liquid at an outlet end of the jet loop is sprayed into the main pipeline through a spray nozzle, and the liquid entering the sampling loop is subjected to follow-up processes continuously; 8), pollution is discharged; 9), online density detection is performed; 10), gas is exhausted; 11), a sample is taken and stored; 12), the residual liquid after the sample is taken is subjected to pressure detection, temperature detection and flow detection sequentially and is finally converged into the main pipeline. According to the online sampling method for the oil pipeline, reliable, real-time and continuous operation, accurate sample quantity and accurate loop flow control can be realized, and the requirements that the obtained sample is representative, the sampling process is automatic and the system control is accurate are met finally.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

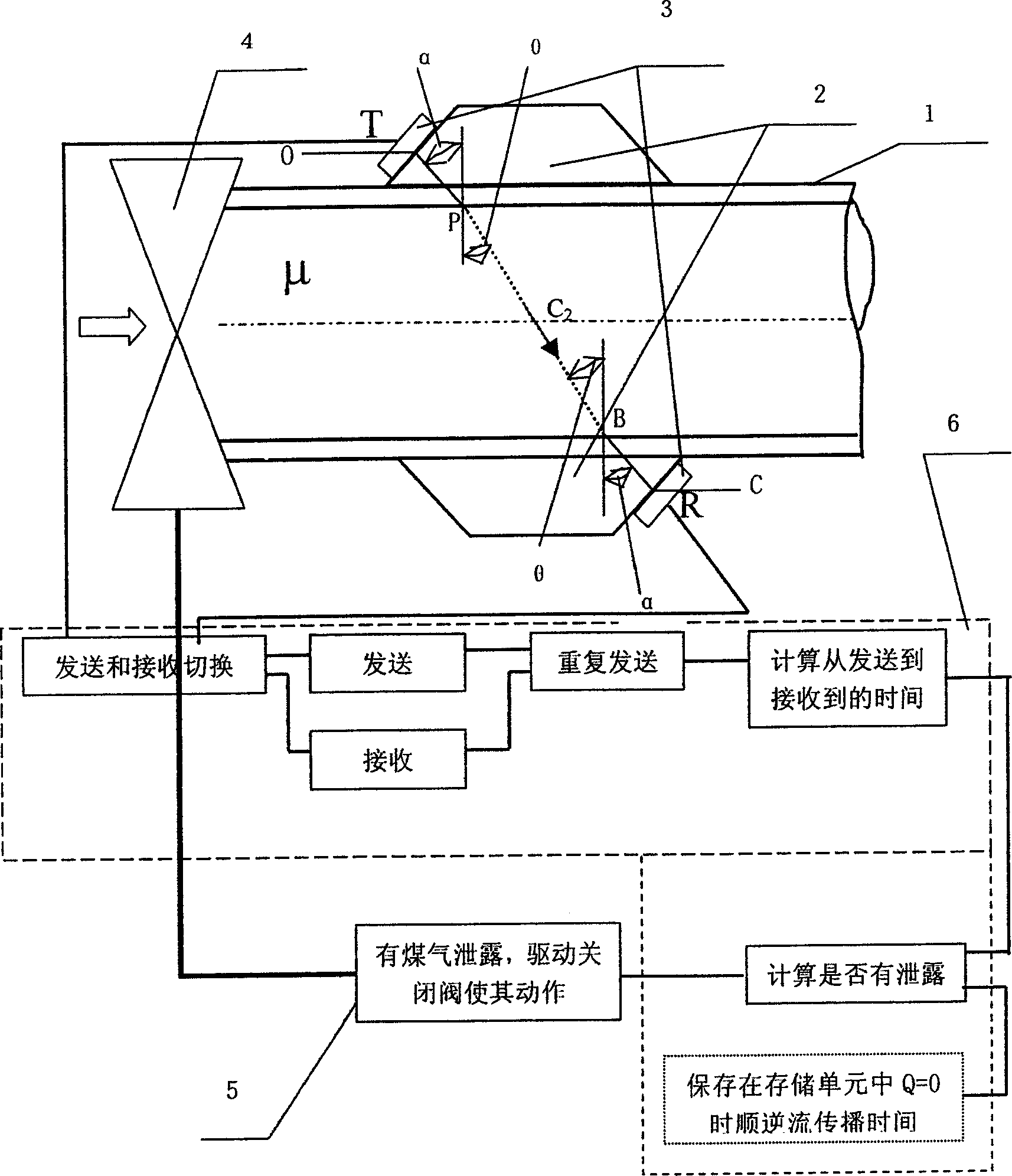

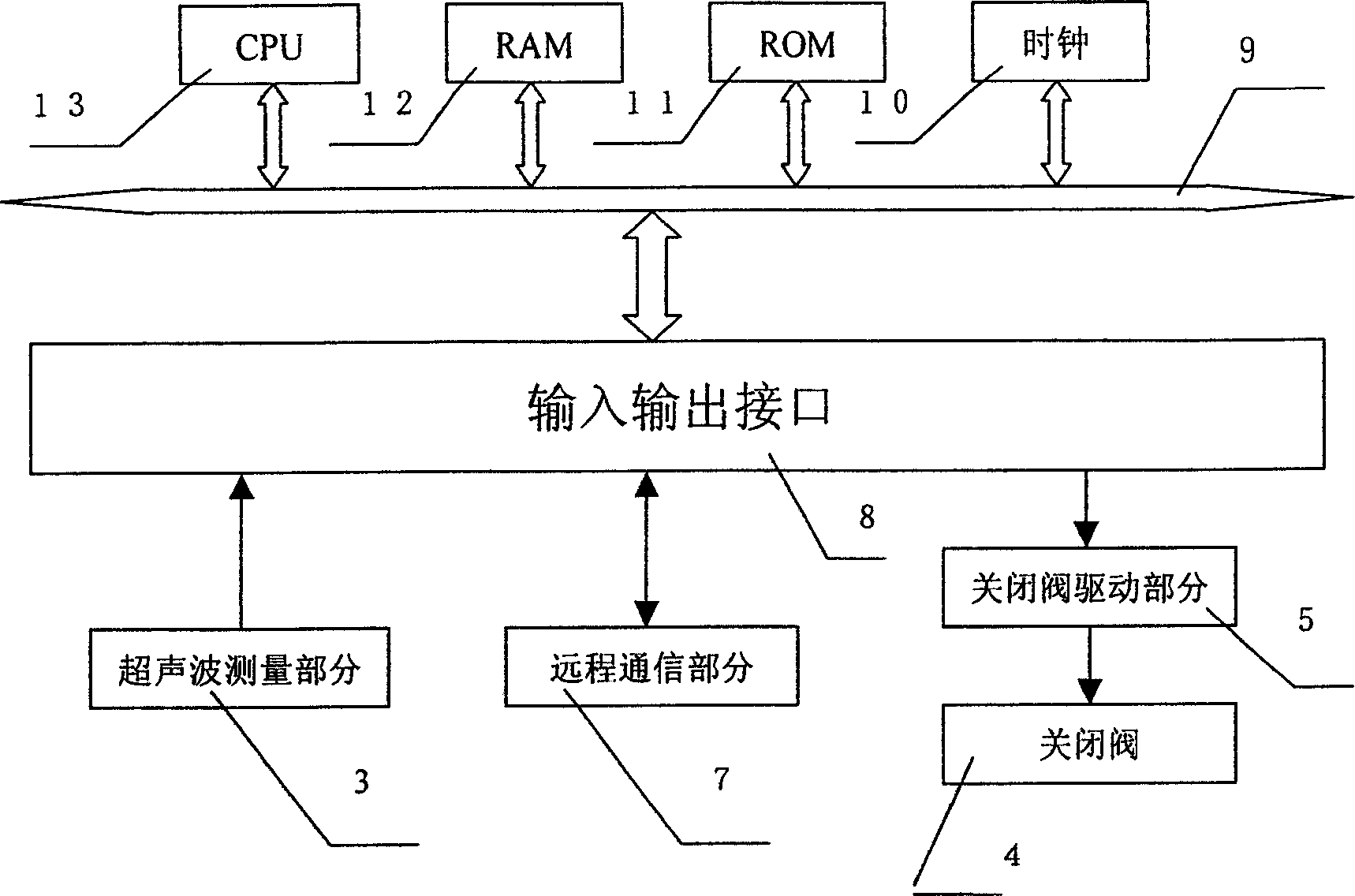

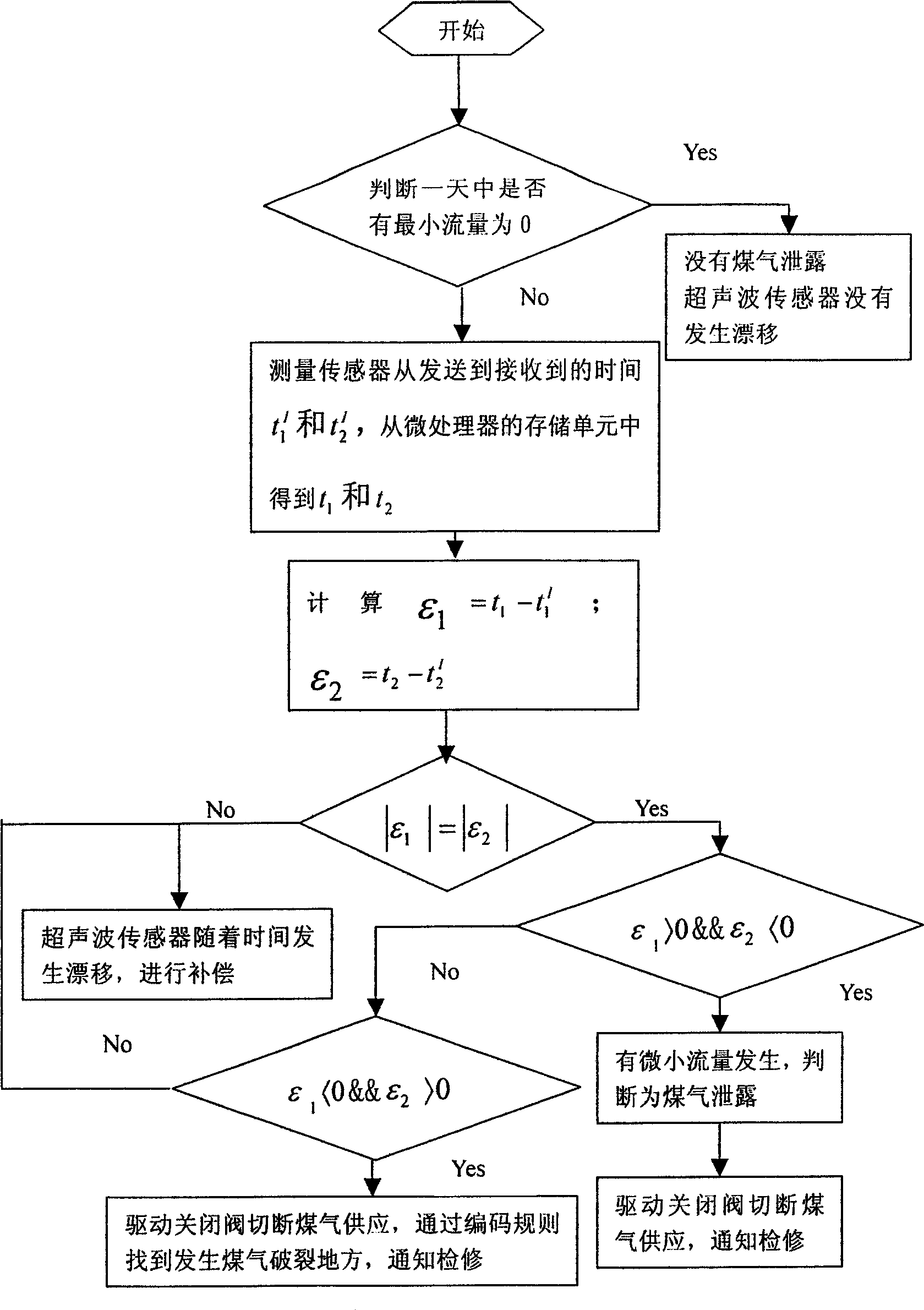

Intelligent gas leakage detecting apparatus

InactiveCN1773235AHigh sensitivityNo pressure lossDetection of fluid at leakage pointMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasonic sensorEngineering

The present invention relates to an intelligent gas leakage detection device. It includes gas pipeline mounting portion, gas pipeline control device mounted in the gas pipeline mounting portion, also includes two ultrasonic transducers, microprocessor and closing valve. Said invention also provides their connection mode. The described microprocessor includes transmitting and receiving switching unit, time metering unit, information storage portion, comparison analysis unit, closing valve driving unit and remote communication unit. Besides, said invention also provides its working principle and operation method.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com