Patents

Literature

64results about How to "No bend" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

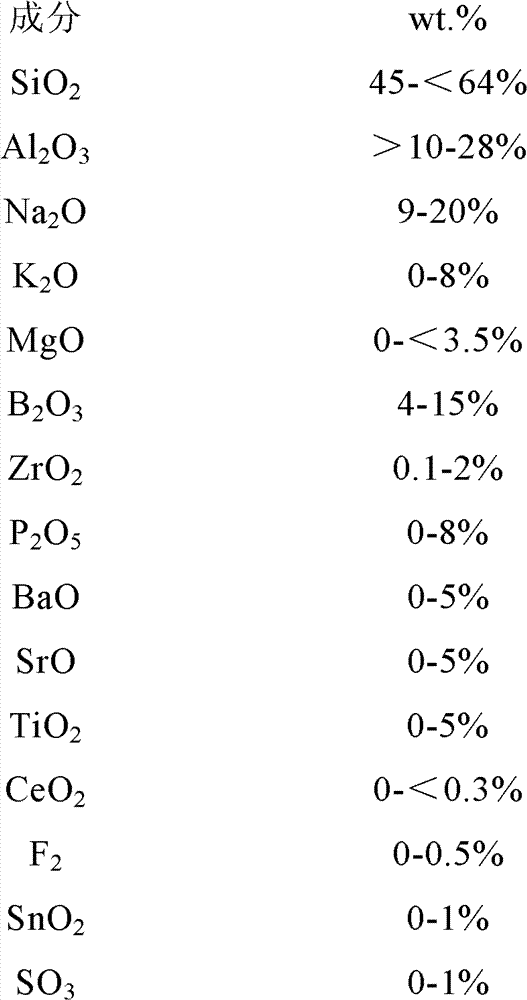

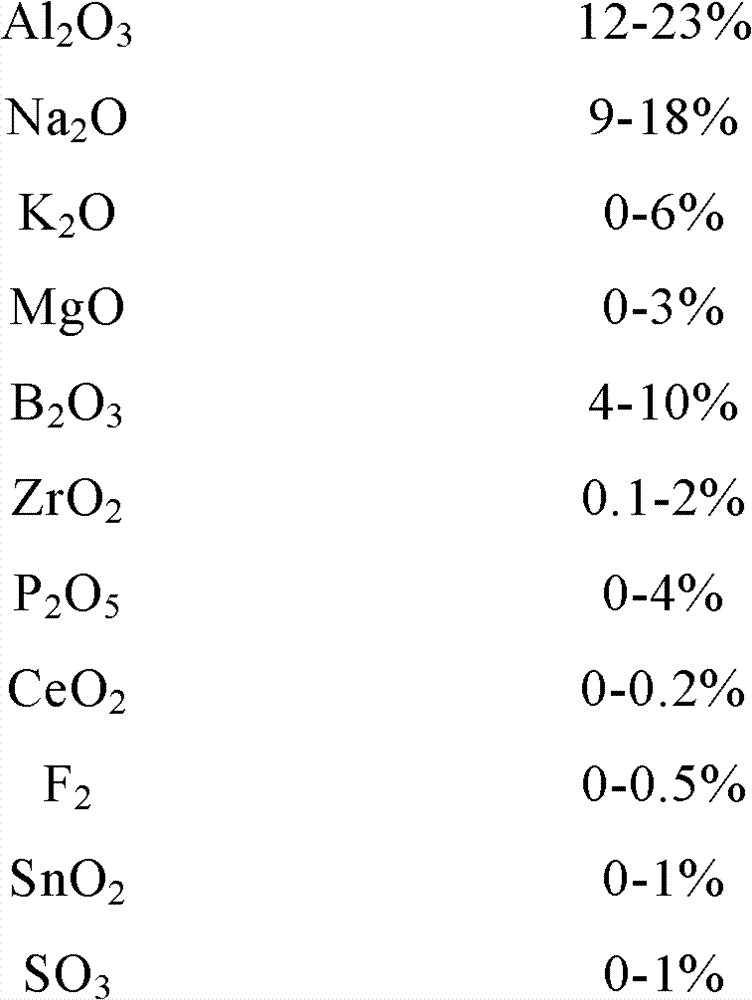

Deformation-resistant high-yield-point and light zirconium boron-alumina silicate glass

ActiveCN103359934ALow densityHigh elastic modulusGlass forming apparatusSurface stressSilicate glass

The invention relates to deformation-resistant high-yield-point and light zirconium boron-alumina silicate glass and particularly relates to alumina silicate glass containing ZrO2 and B2O3. The glass has the characteristics that the elasticity modulus E is more than or equal to 60 GPa and less than or equal to 78 GPa after the glass is chemically tempered; the yield point At is more than or equal to 620 DEG C and less than or equal to 850 DEG C; the coefficient of thermal expansion (CET) is more than or equal to 7.5*10<-6> / K and less than or equal to 9.8*10<-6> / K; the density is less than or equal to 2.5 g / cm<3>; the surface pressure stress is at least 700 MPa; and the thickness of a surface stress layer is at least 25 microns. The glass has deformation resistance, is high in yield point and is light in weight.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

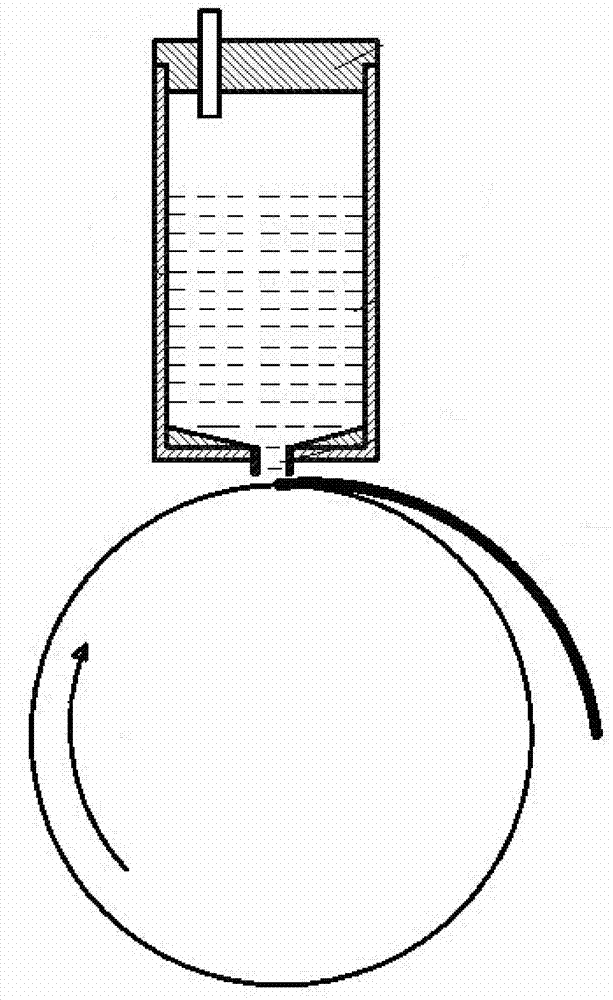

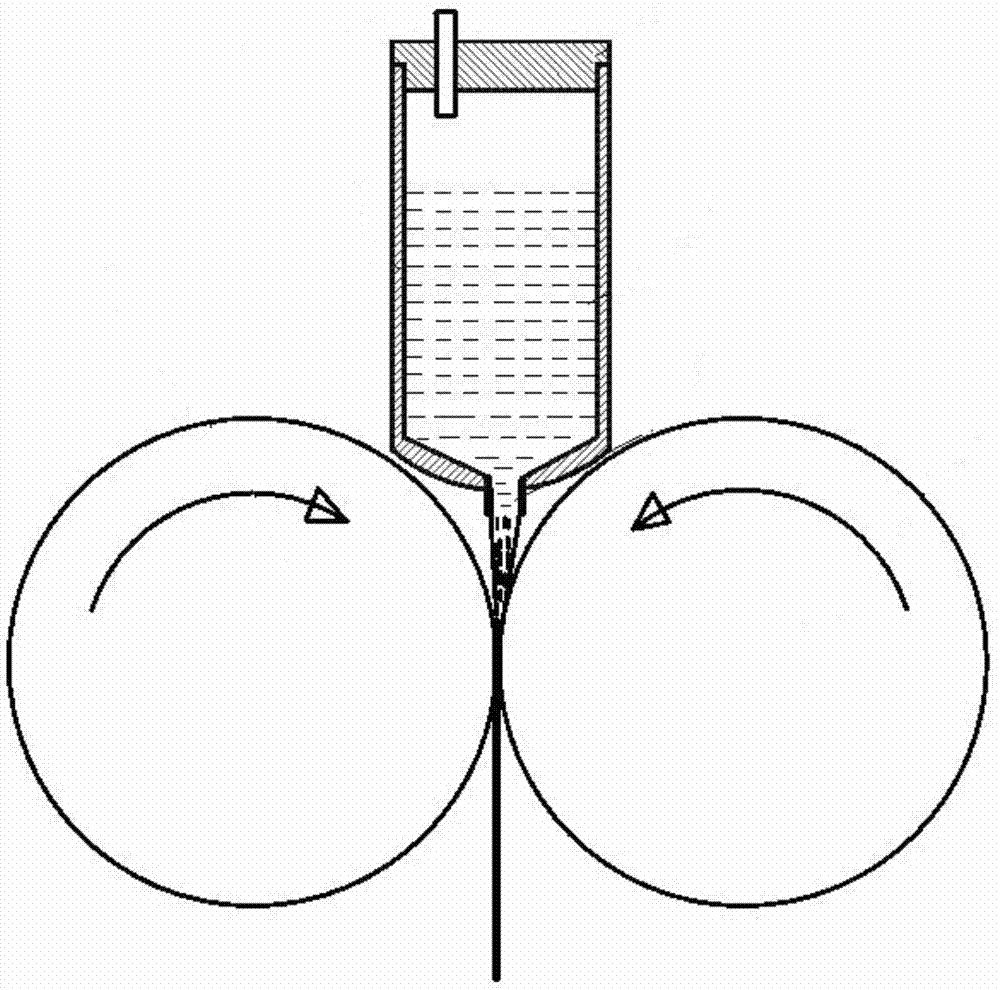

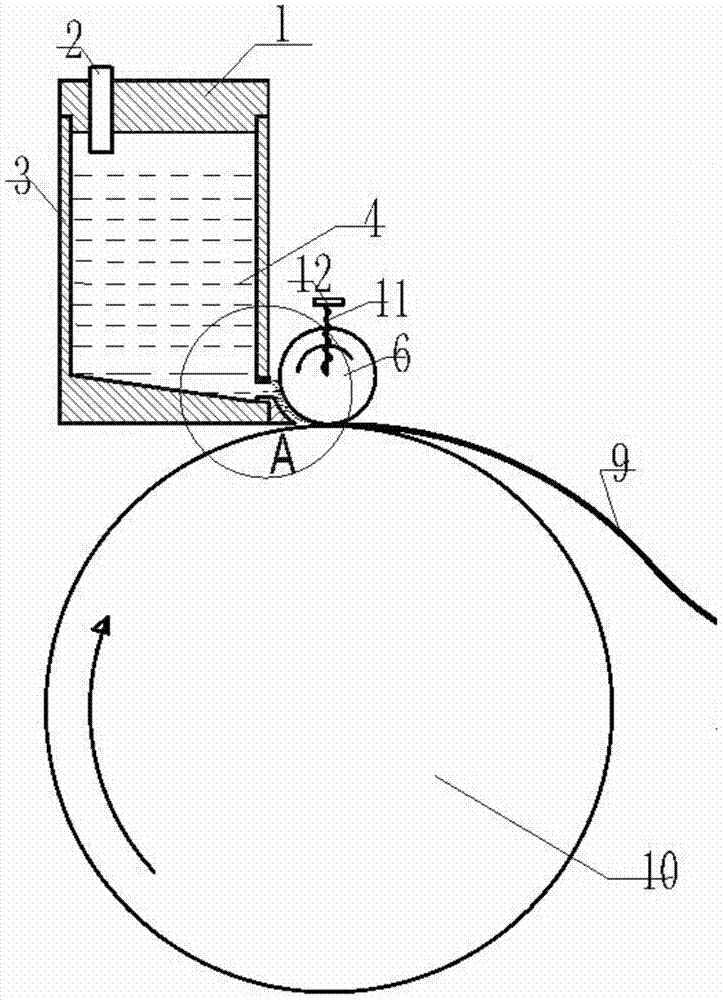

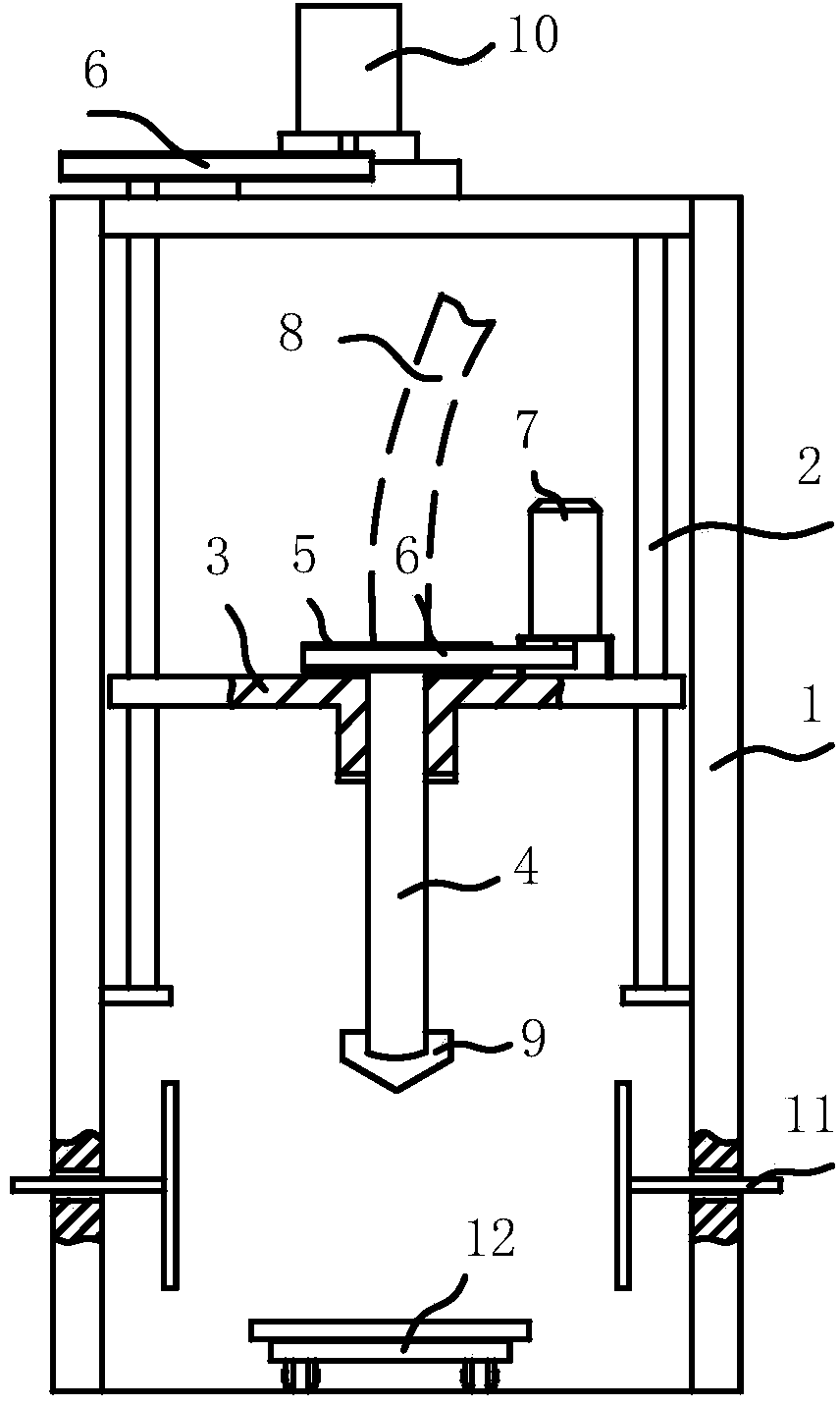

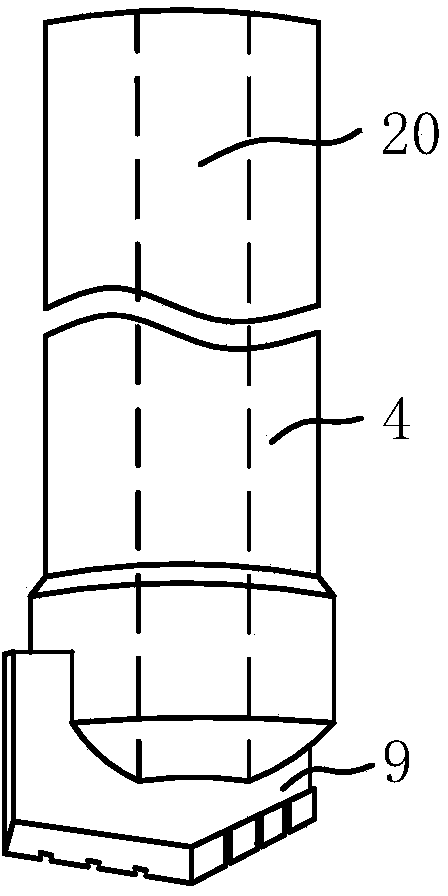

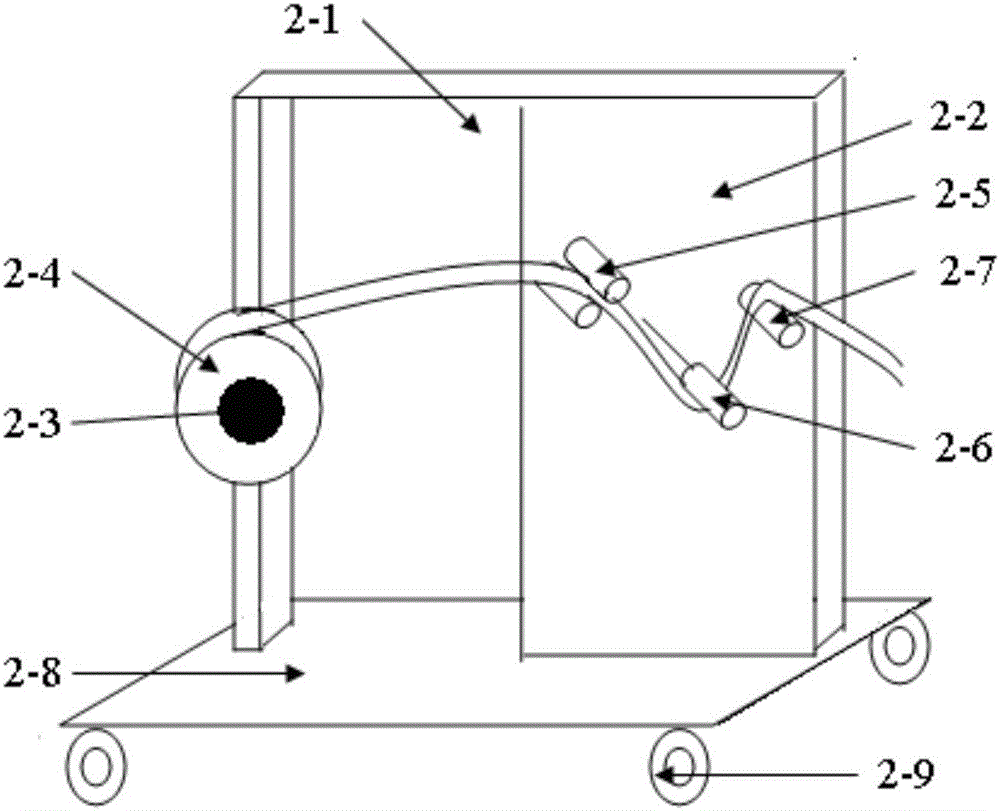

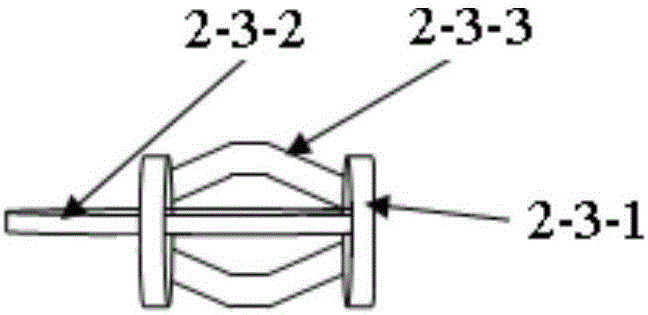

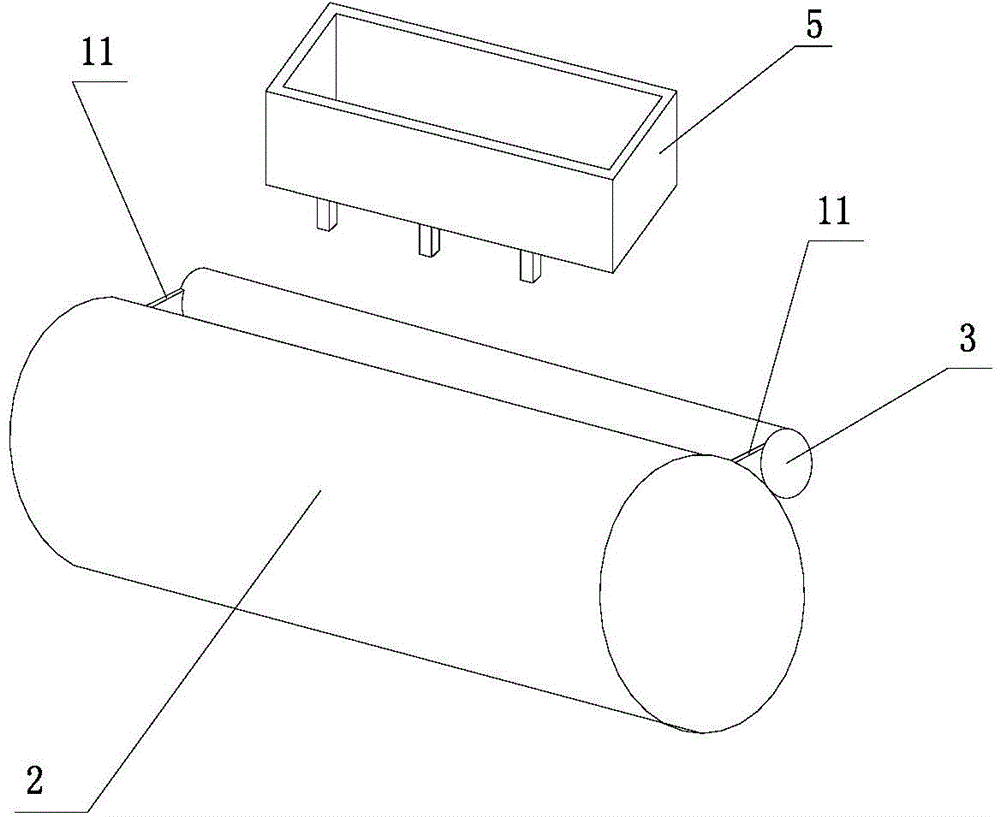

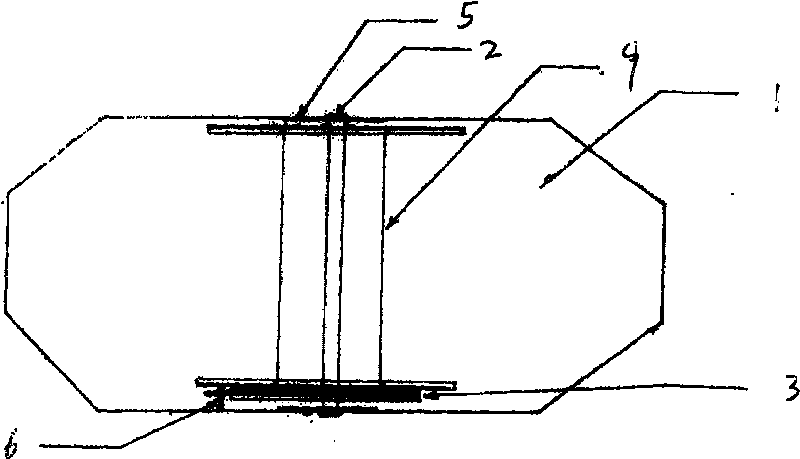

Jet preparation device of amorphous alloy strip and preparation method thereof

ActiveCN104493116ALarge span of thicknessWide range of applicationsMelt-holding vesselsQuenchingCopper

The invention discloses a jet preparation device of an amorphous alloy strip and a preparation method thereof. The preparation device comprises a sealing cover, a pneumatic tube, a steel ladle, a nozzle opening, a press wheel, a molten steel guide groove, a cooling copper roller, a pressure adjusting spring and a limiting device. According to the device and the method for preparing the amorphous alloy strip through the molten steel guide groove, the fixed-thickness press wheel and lateral pressure jet, the amorphous alloy molten steel jetted through the nozzle opening can easily form a larger liquid storage buffer puddle between the press wheel and the molten steel guide groove, accurate limiting is performed by using the press wheel, and the molten steel is squeezed through the press wheel to a certain extent at the moment of rapid quenching cooling, so the flat surface and the fine texture of the amorphous alloy strip prepared through jet are improved better, and accurate controllable thickness of the amorphous alloy strip is realized. Both the ultrathin strip of 15 mum and the relative thick strip of 40 mum can be prepared, the thickness span of the amorphous alloy strip is large, and the application scope is wide.

Owner:江西中磁科技协同创新有限公司

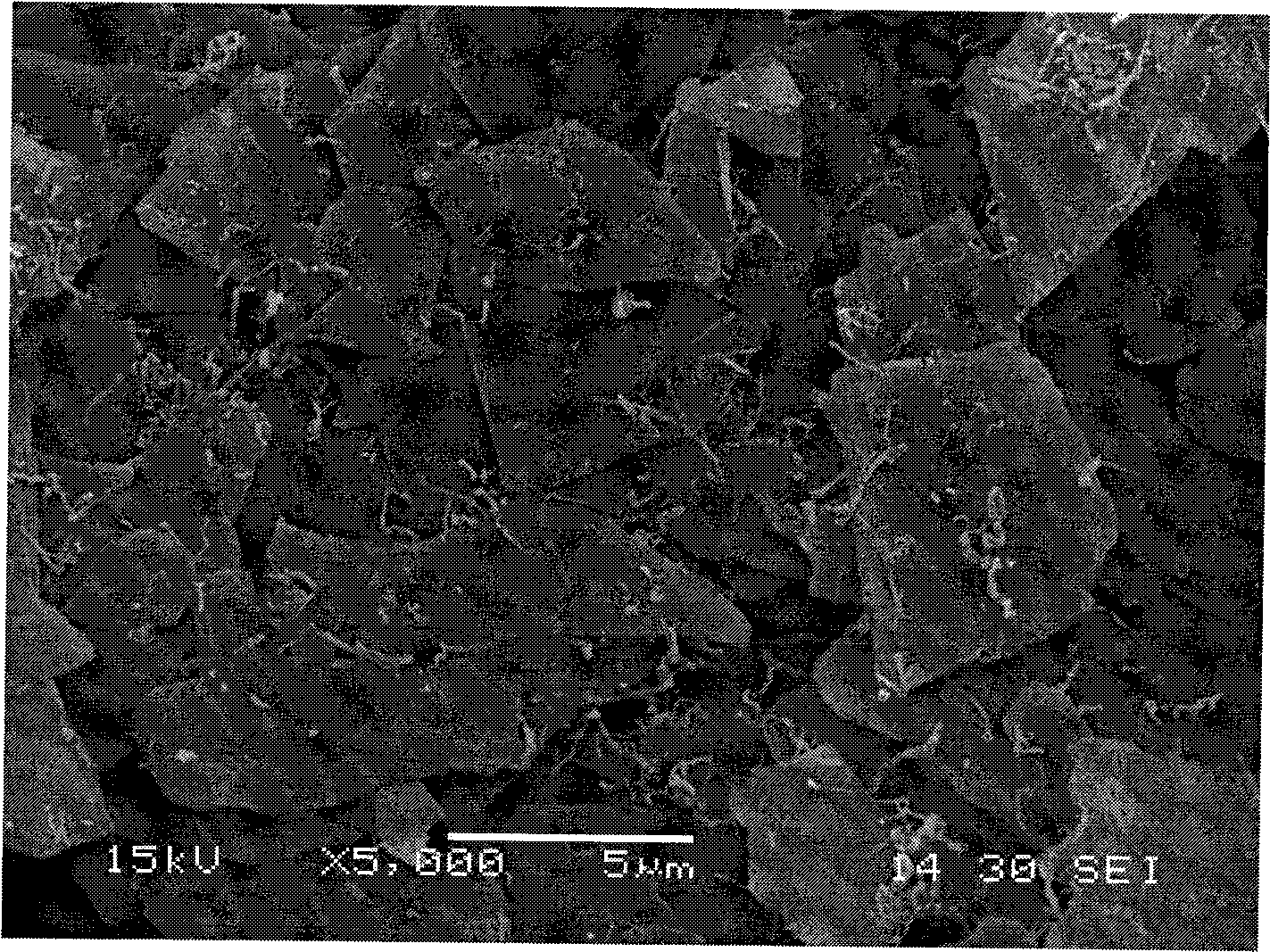

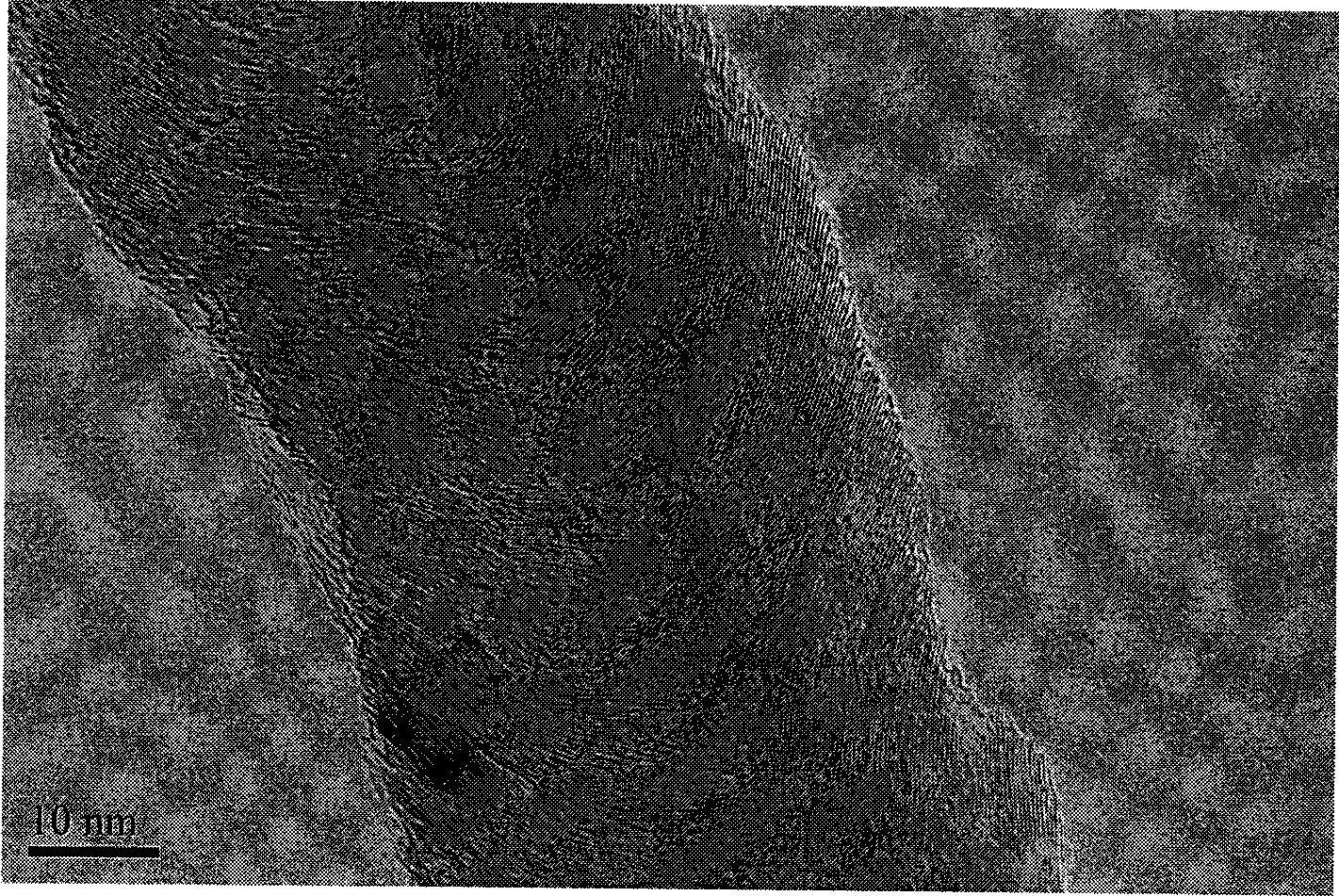

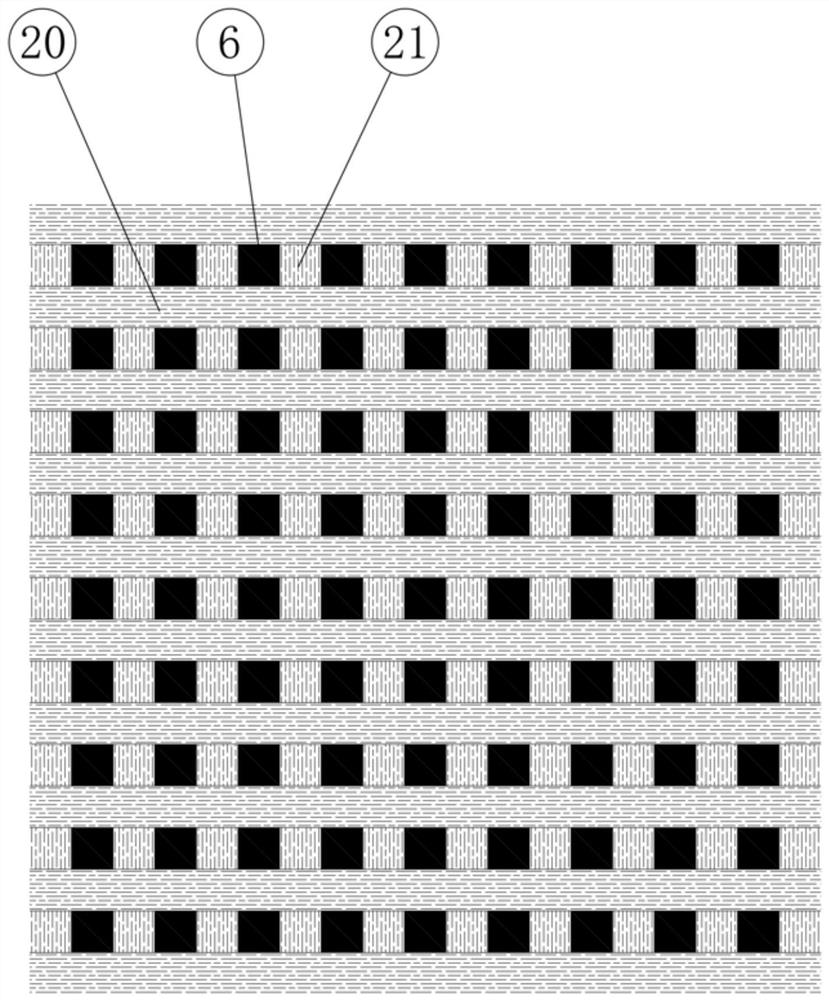

Method for improving carbon nano tube parallel array density

ActiveCN103964413ARaise Parallel ArrayOvercoming the problem of not being able to slide directly on the substrateMaterial nanotechnologyCarbon compoundsPolyesterHigh density

The invention discloses a method for improving the density in the process of carbon nano tube transfer. The method comprises the following steps: firstly, transferring the carbon nano tube parallel array growing on a substrate to a retractable membrane capable of shrinking in a single direction, such as the retractable materials of silicone rubber, polyester, a shape memory alloy and the like; secondly, shrinking the membrane in the direction perpendicular to the extension direction of the carbon nano tube to improve the density of the carbon nano tube parallel array; finally, transferring the carbon nano tube parallel array to a target substrate through the adoption of chemical methods. According to the method provided by the invention, the efficiency is high, the cost is low, the high-quality high-density carbon nano tube parallel array can be obtained, and the difficulty of transferring the conventional carbon nano tube can be solved successfully.

Owner:PEKING UNIV

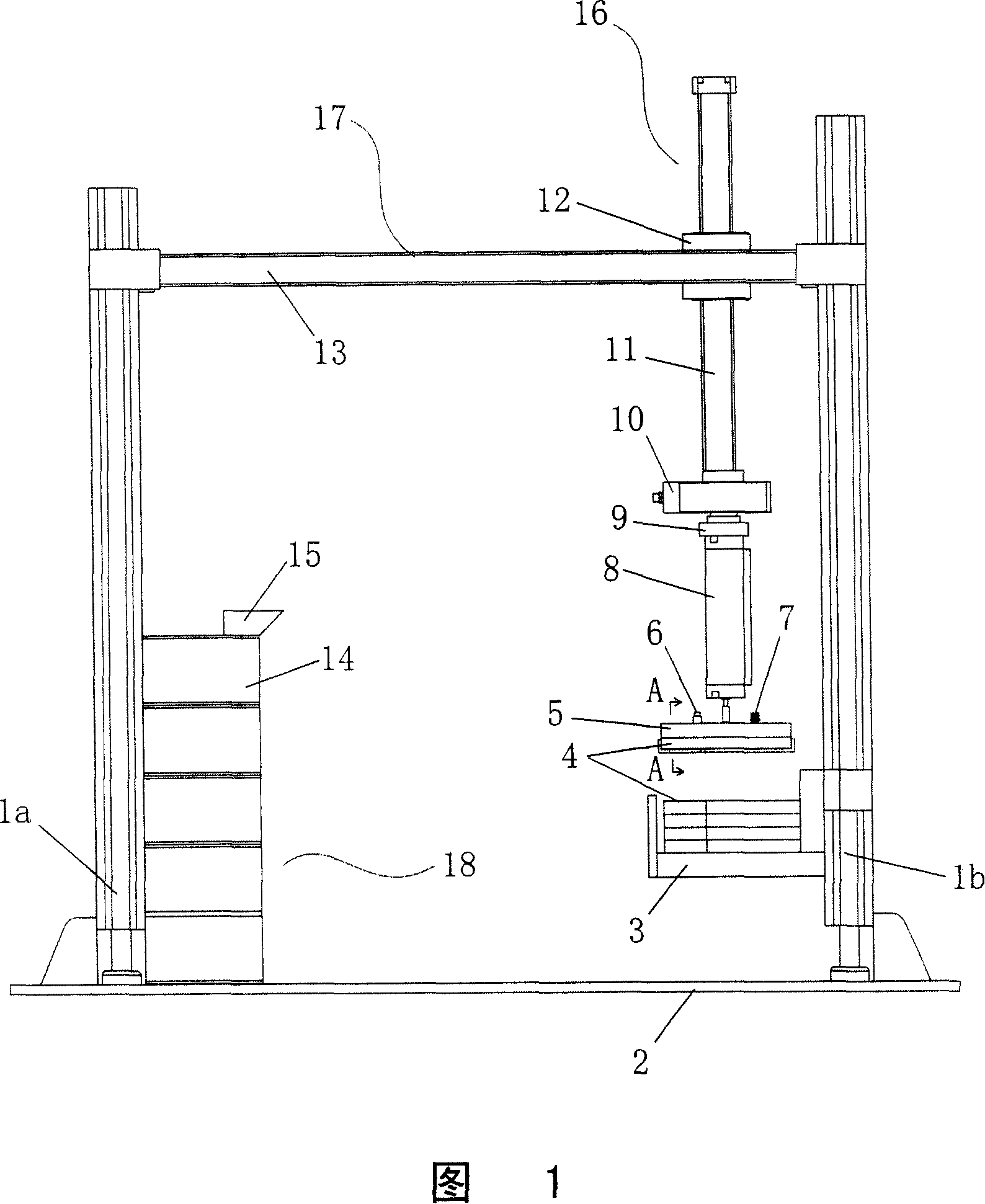

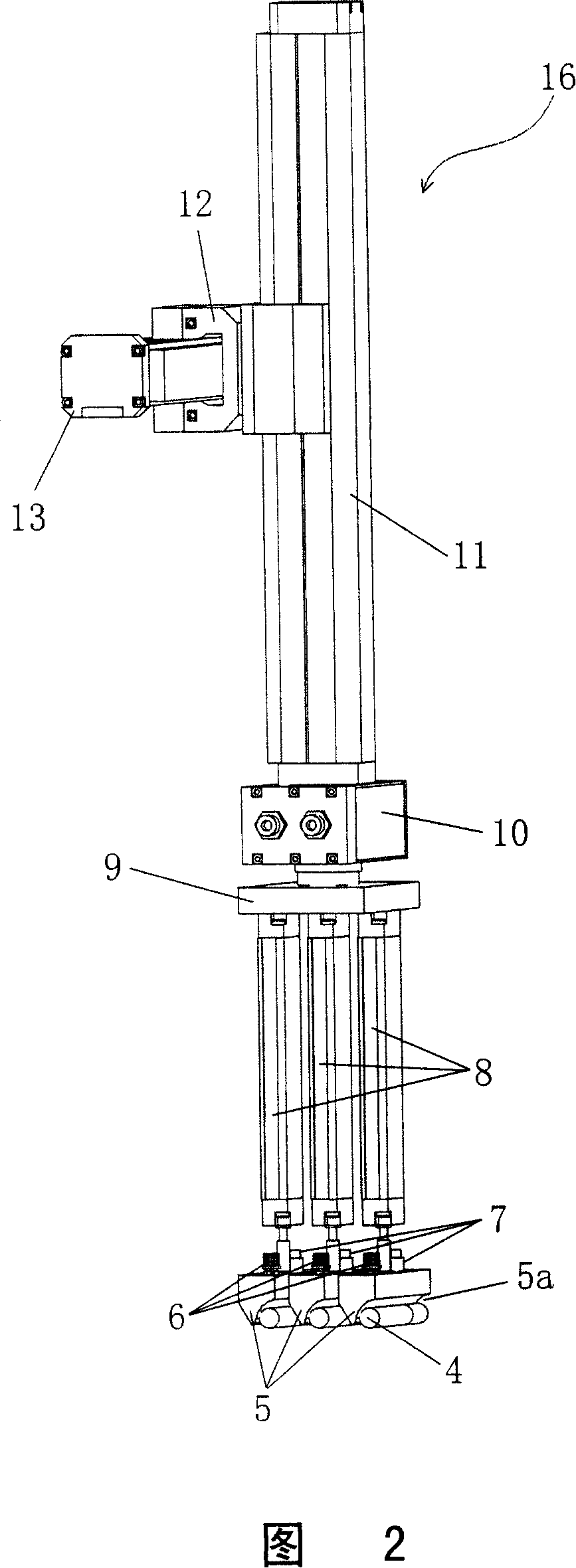

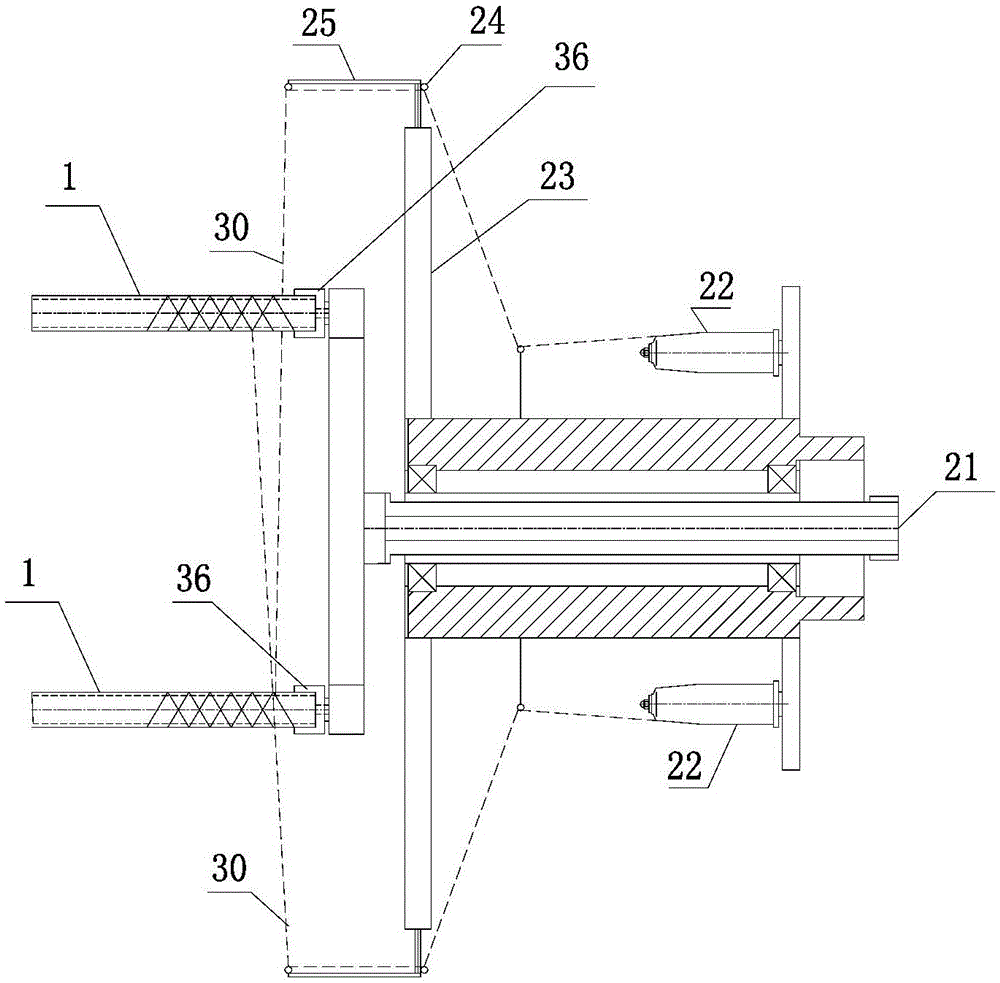

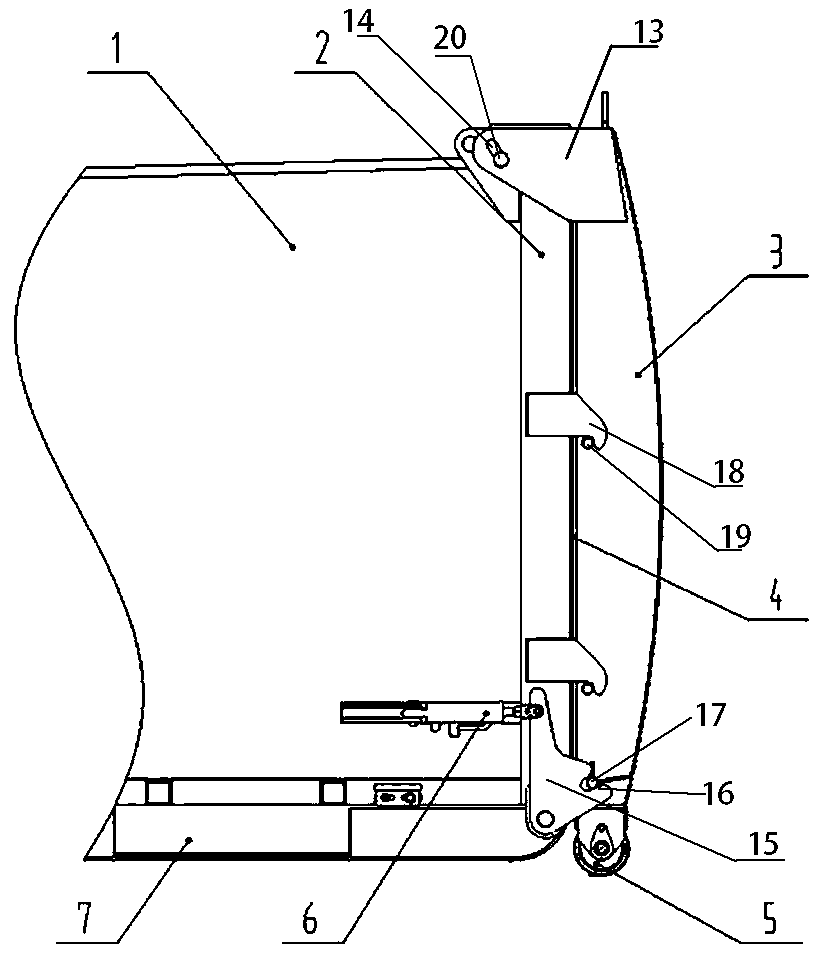

Cigarette/ filter candle sampling system

InactiveCN101126683AQuality is not affectedAvoid harmWithdrawing sample devicesCombined testSample integrity

The utility model relates to a tobacco rod / filter rod sampling system. The sampling system is provided with a plurality of gripper devices, and grips a plurality of tobacco rod / filter rod samples from an outlet channel through negative pressure suction and air cylinder motions; therefore, the utility model can simultaneously collect a or a plurality of tobacco rod / filter rod samples at one time, and convey the tobacco rod / filter rod samples gripped by the sampling system to an integrative test system through the level-transmission air cylinder without any damage to the samples; the sampling speed and sample integrality are far higher than manpower and any existing sampling method. The sampling system of the utility model conveys samples through mechanical method, and can convey samples with a long distance and free of damages; therefore, two or more tobacco rod / filter rod forming machines only need one integrative test system to complete the test task, thus the utilization rate of the integrative test system is improved and the production cost is reduced.

Owner:张敏 +3

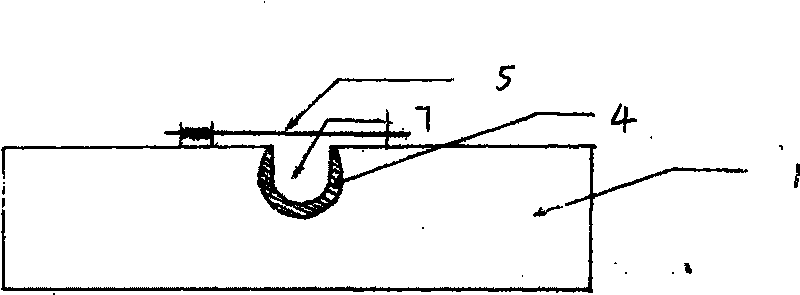

Two ends straight through type all glass vacuum heat collection tube of solar energy

InactiveCN1959293AGuaranteed working lifeTake advantage ofSolar heating energySolar heat devicesDegasserWave form

A glass vacuum solar heat collection tube of through two-end type consists of external glass tube, internal tube with corrugated body, absorption coated layer, elastic support and degasser. It is featured as setting space between two said tubes to be vacuum cavity, melt-jointing two ends of two said tubes to be an integral body for sealing two ends with each other and setting circular wave form ledges on internal tube to be distributed in mode of group wave ledges being not continuously set.

Owner:罗赞继 +2

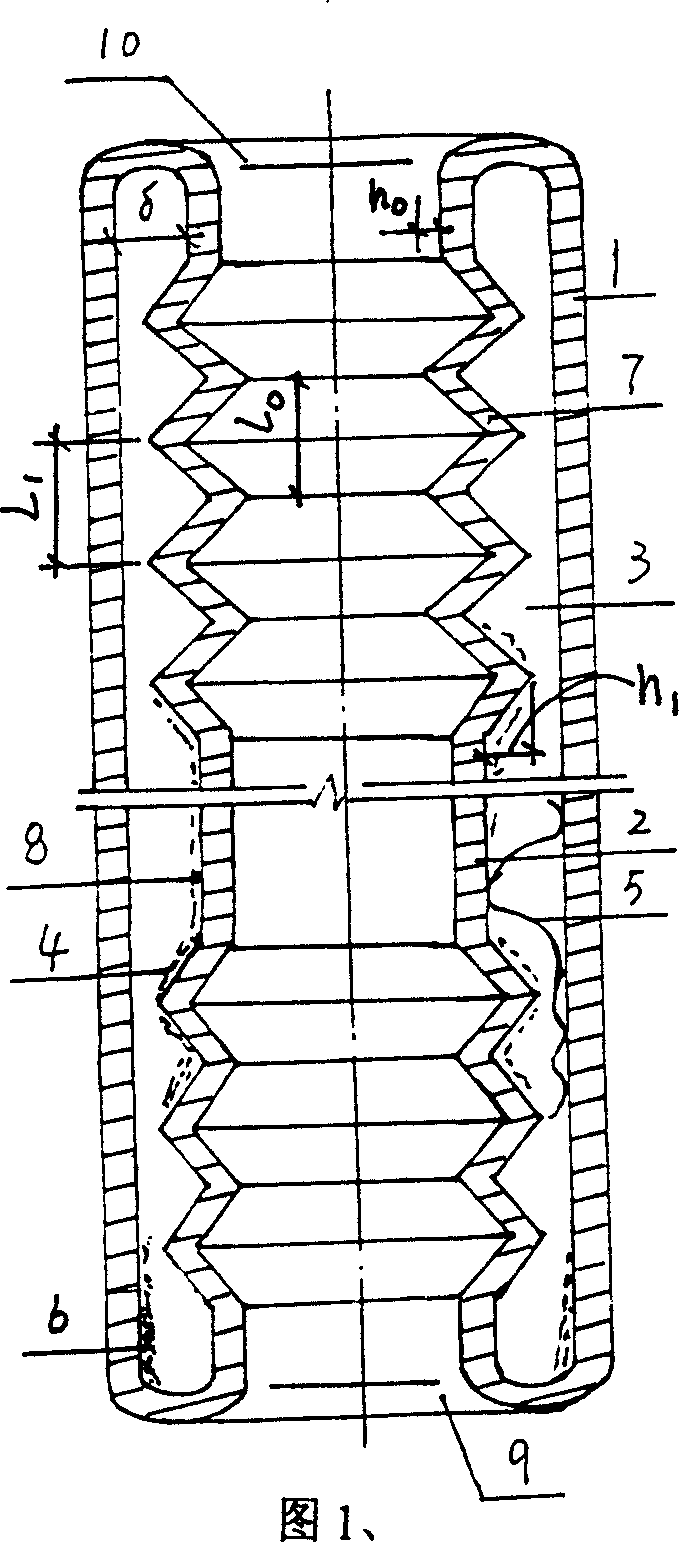

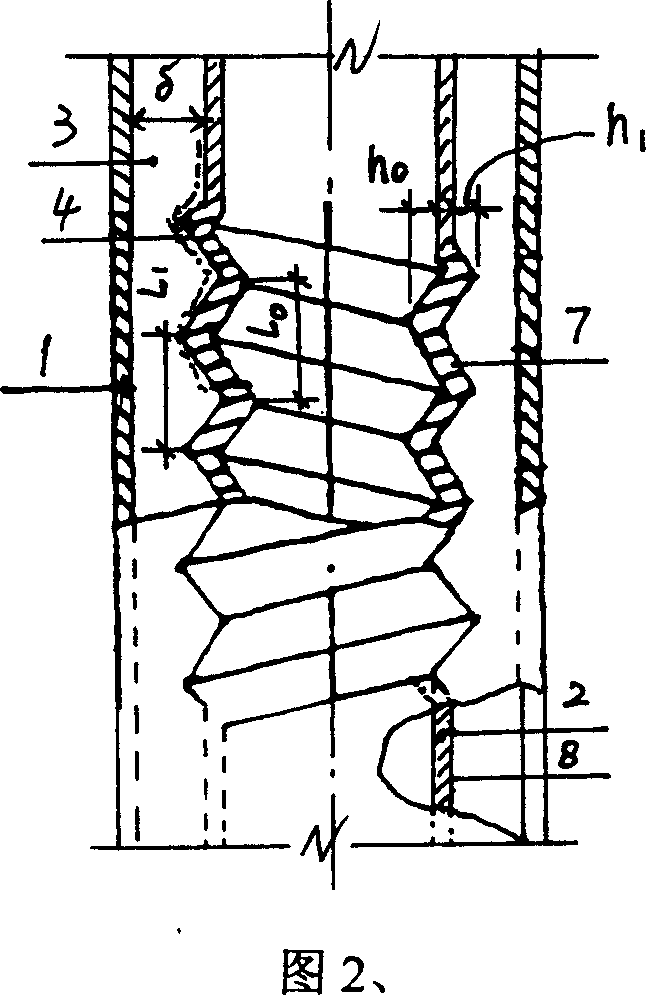

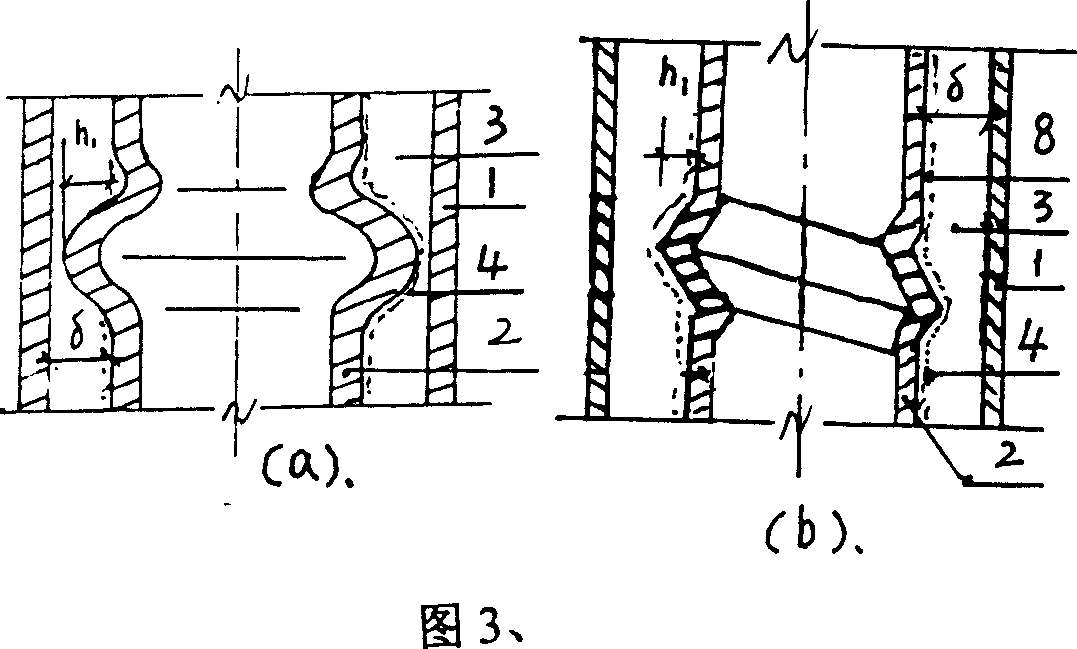

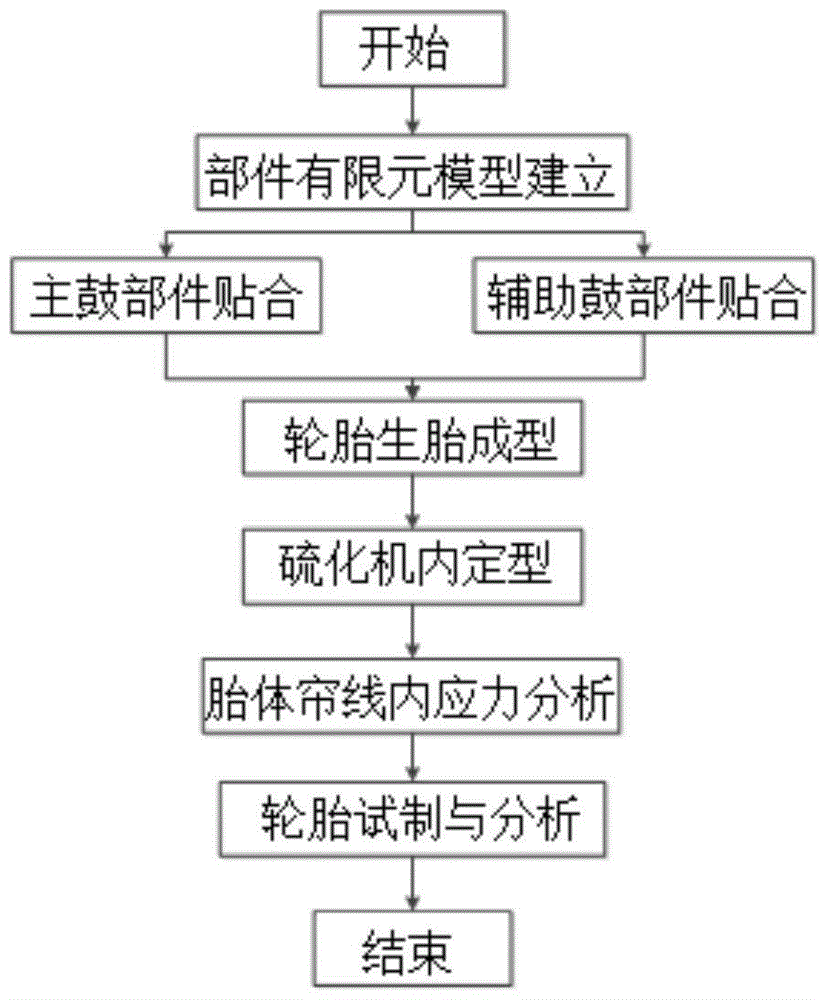

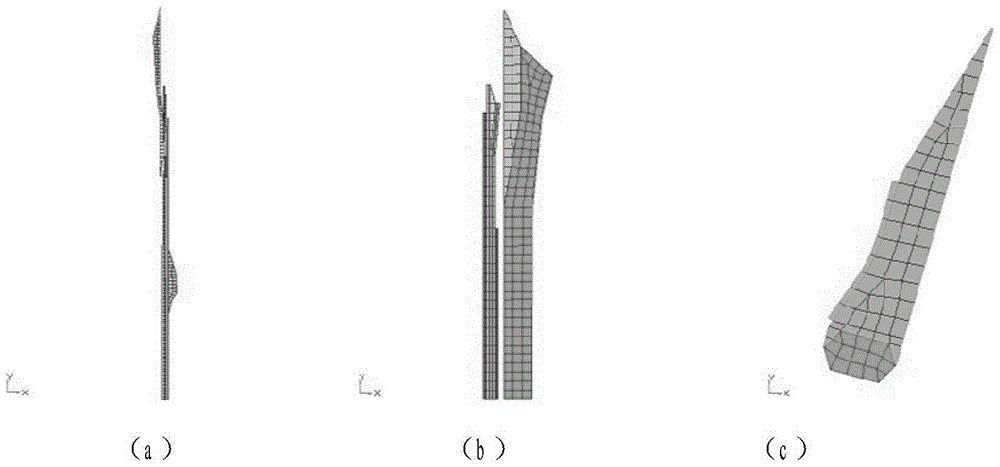

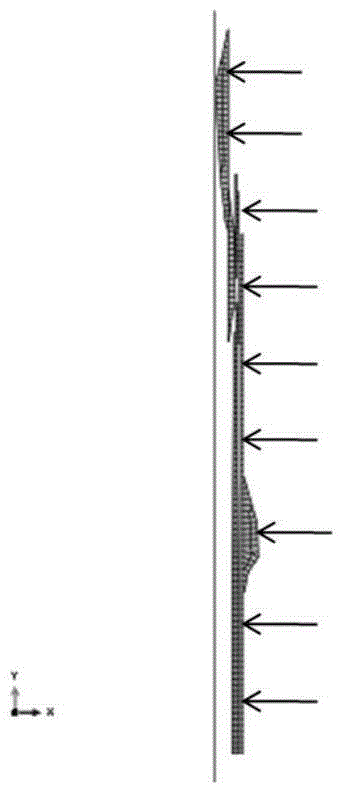

Method for judging bending of carcass cord of wide base radial tire

ActiveCN105205243ASolve the bendImprove product qualitySpecial data processing applicationsTweelElement analysis

The invention provides a method for judging the bending of a carcass cord of a wide base radial tire. The method is characterized in that a finite element analysis method is used for establishing a raw tire model of the tire, simulated analysis is carried out on the forming process of the wide base radial tire and a process of converting a raw tire of the tire into a finished tire by a mode of shaping inside a vulcanizing machine; positive and negative internal forces of the carcass cord at a crown of the finished tire are used as a method for judging whether the carcass cord is bent or not. According to the method disclosed by the invention, whether the carcass cord is bent or not is judged by using the positive and negative internal forces of the carcass cord of the finished tire after shaping is performed in the vulcanizing machine, so that the problem that the carcass cord is bent in a production process of the wide base radial tire is effectively solved, and theoretical guidance and technical support are laid for improving the properties of the wide base radial tire.

Owner:SHANDONG LINGLONG TIRE

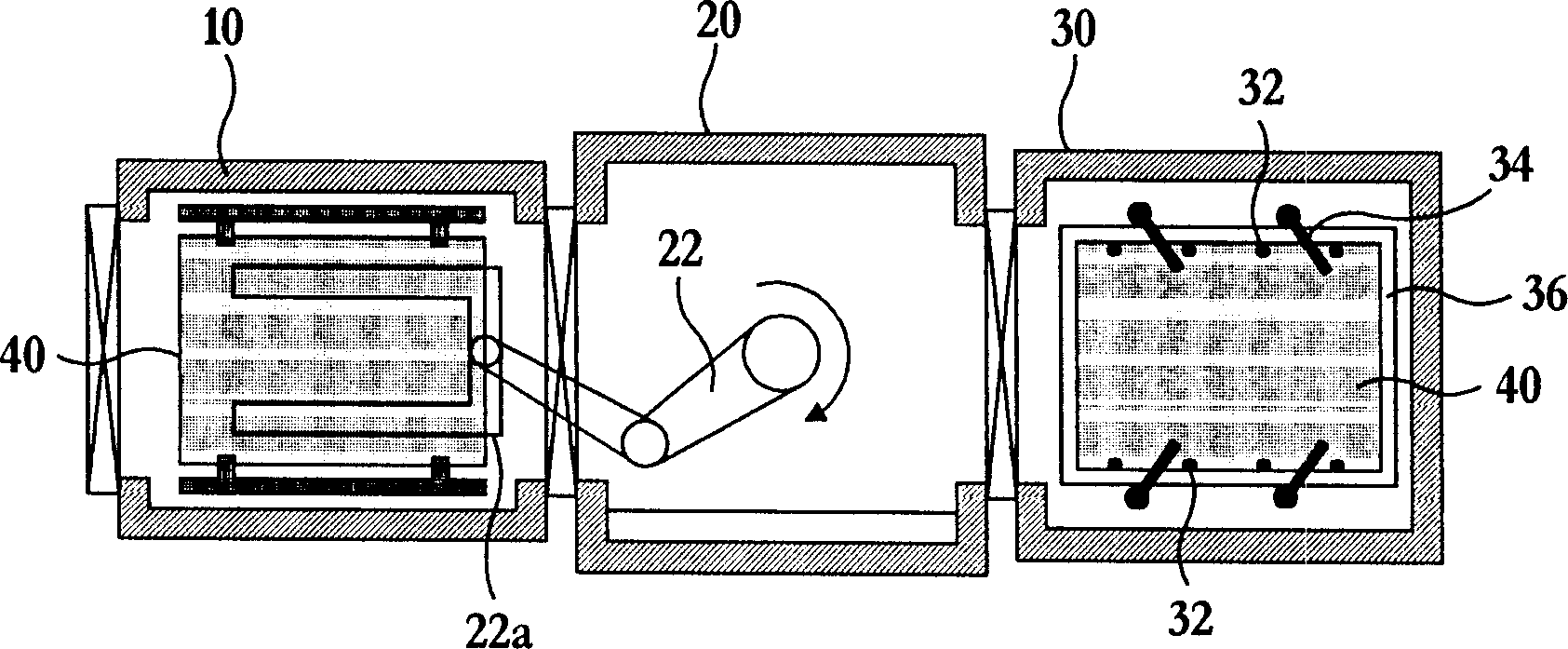

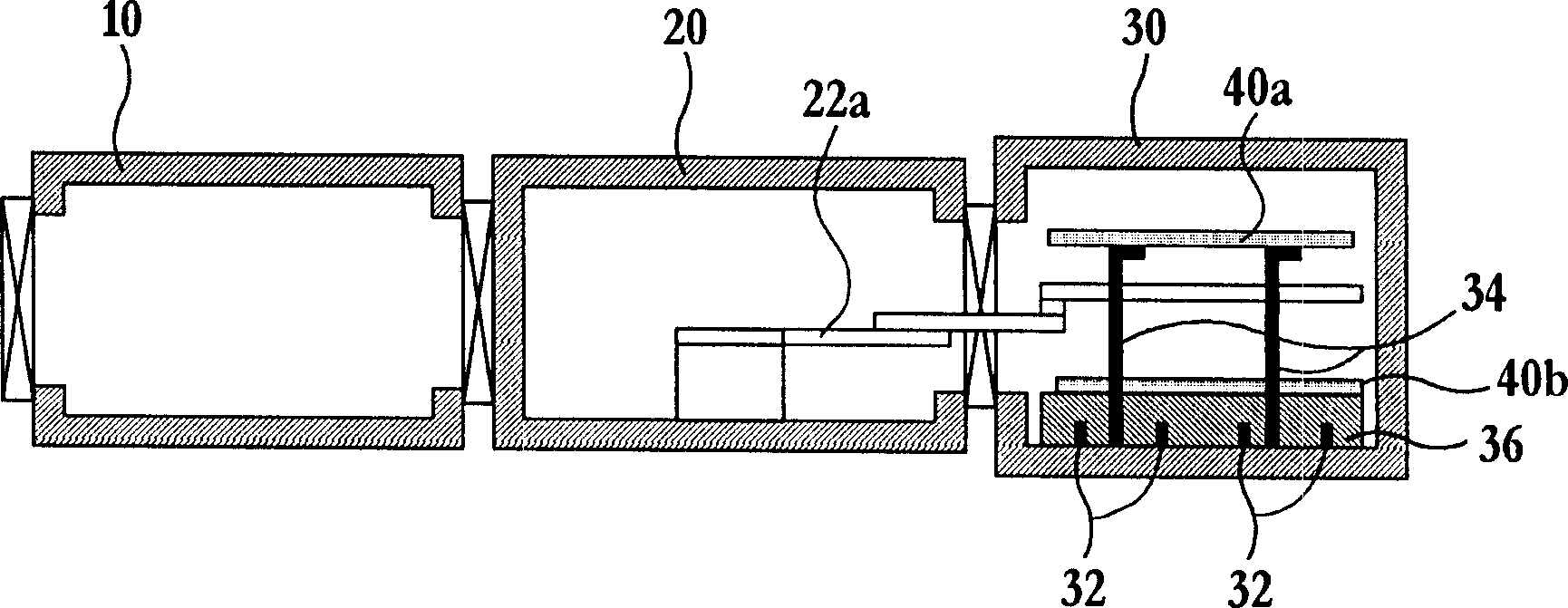

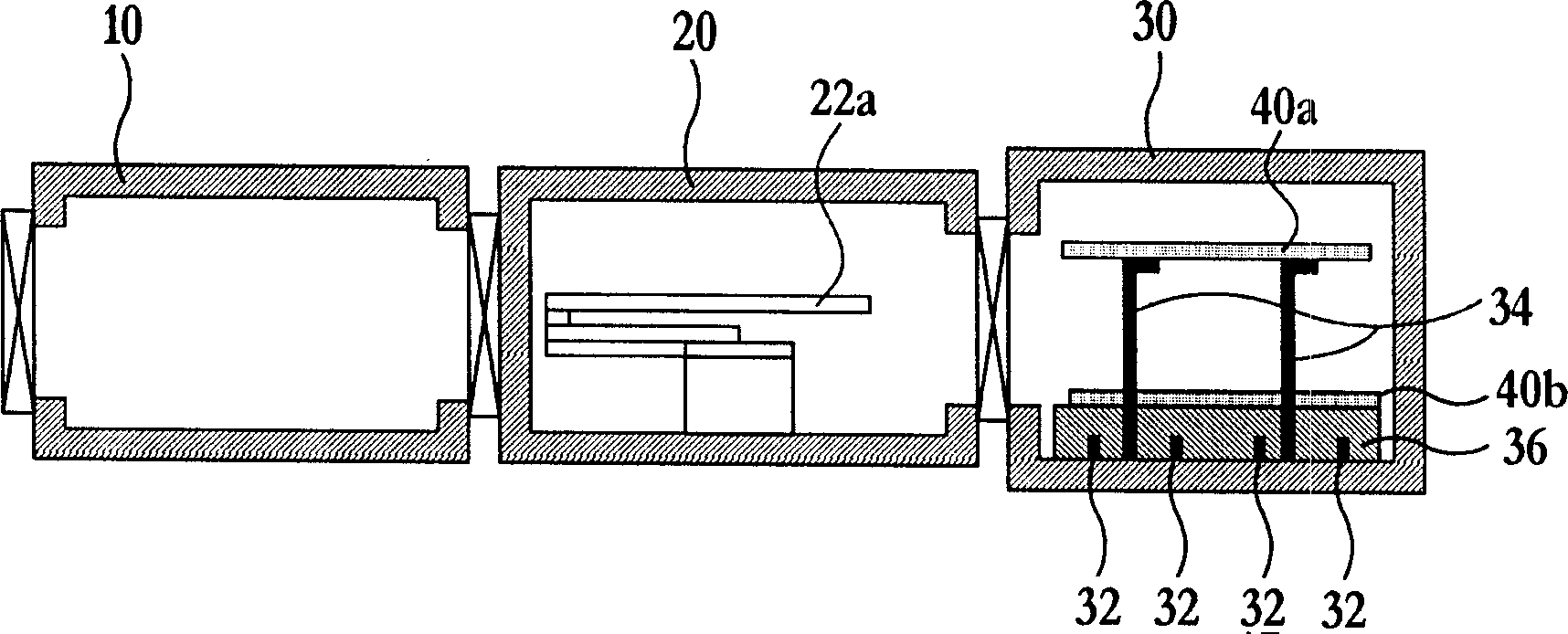

Plate display producing apparatus

InactiveCN1506207ASave spaceLow costSolid-state devicesVacuum evaporation coatingDisplay deviceManipulator

An FPD fabricating apparatus according to the present invention comprises two chambers of a process chamber 130 and a transfer chamber 120. The substrate 140 is mounted on and transferred by one of two carrier plates 150a and 150b, each of which have a forked shape. The carrier plate lift pins 160b are raised up and fallen down while avoiding contact with the forked prongs of the robot arm 122a, so that the carrier plates 150a and 150b can be raised up and fallen down. The substrate lift pins 160a which are raised up and fallen down while avoiding contact with all the forked prongs of the robot arm 122a and the carrier plates 150a and 150b, so that only the substrate 140 mounted on the carrier plates 150a and 150b can be raised up and fallen down. According to the present invention, a load-lock chamber for transferring a substrate and a transfer chamber is incorporated into a single transfer chamber, so that space of the apparatus can be remarkably reduced and cost of the apparatus can be reduced. In addition, since the substrate is raised up and fallen down by using the carrier plates 150a and 150b, even large-area substrate can be stably transferred at high speed without bending, disrupting or vibration of the substrate.

Owner:ADVANCED DISPLAY PROCESS ENG

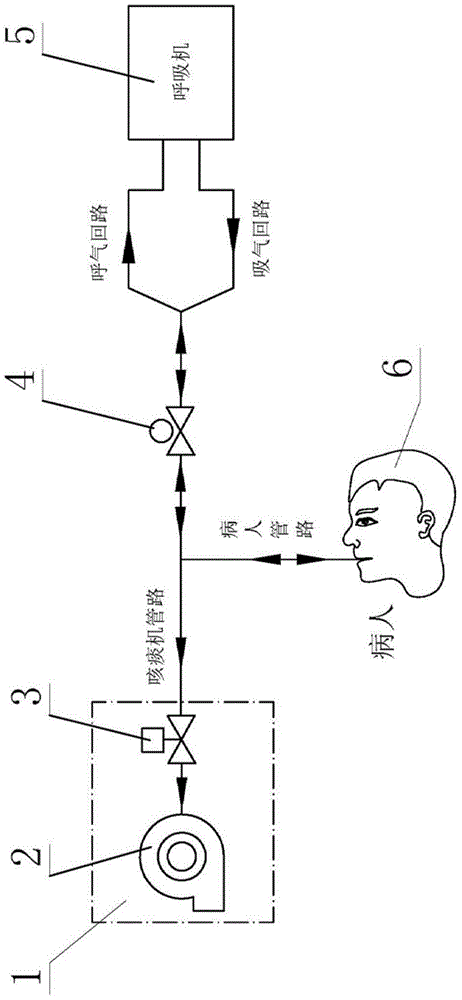

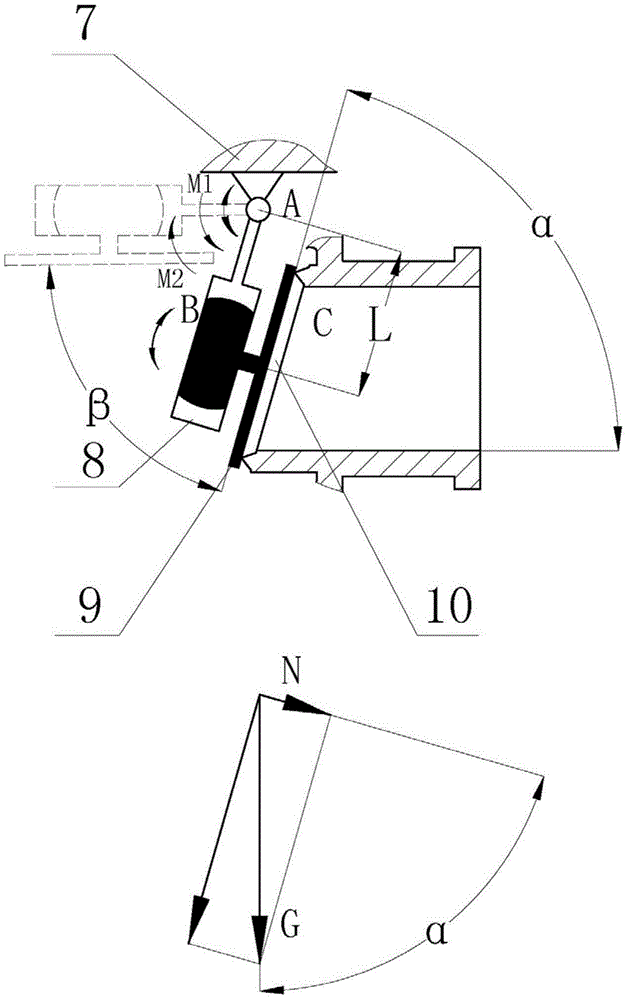

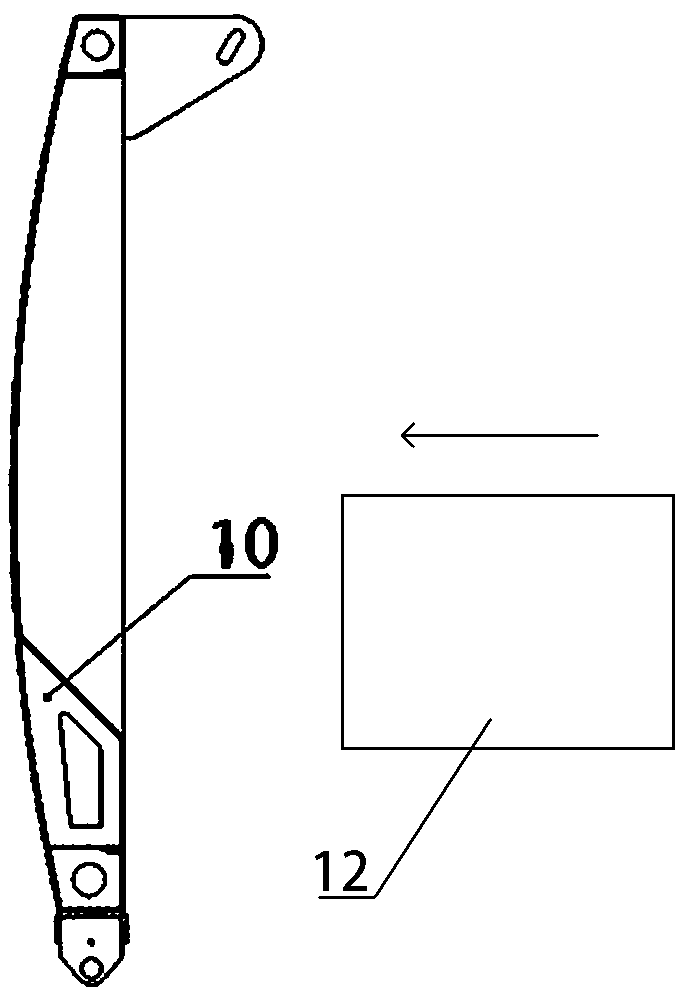

Quick valve

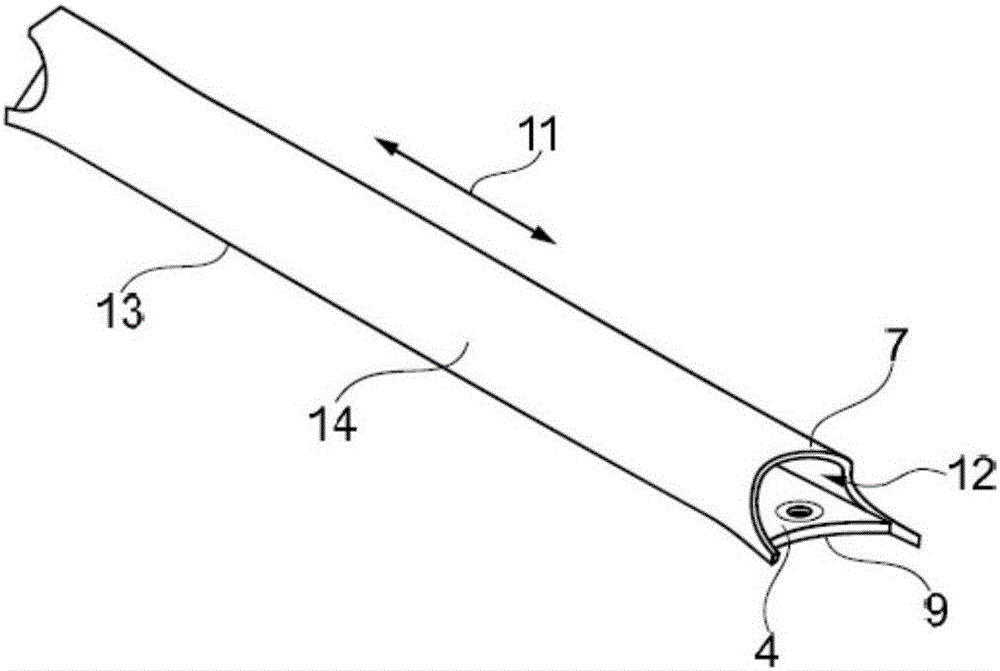

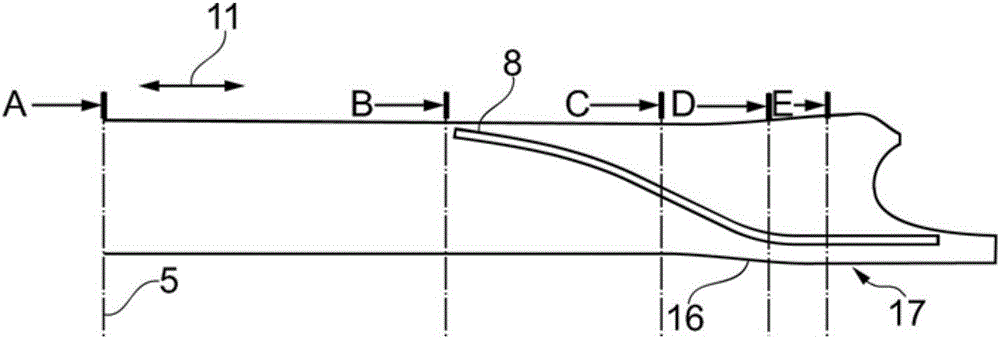

ActiveCN104879506AGuaranteed high frequencyNo bendRespiratorsOperating means/releasing devices for valvesEngineeringMechanical engineering

A quick valve (3) comprises a swing member (8) and an angle adjusting member (9). The swing member (8) can be rotatingly fixed on a valve body (7), the valve body (7) has a valve port (10), the swing member (8) can rotate along the direction that clings to or far away from the valve port (10). The angle adjusting member (9) can cover the valve port (10), the angle adjusting member (9) is combined with the swing member (8), and the angle adjusting member (9) can adjust an angle between itself and the valve port (10). The quick valve is simple in structure, easy to process, high in sealing reliability, quick in switch and with no abrasion during rotation and no pressure loss.

Owner:王淑萍

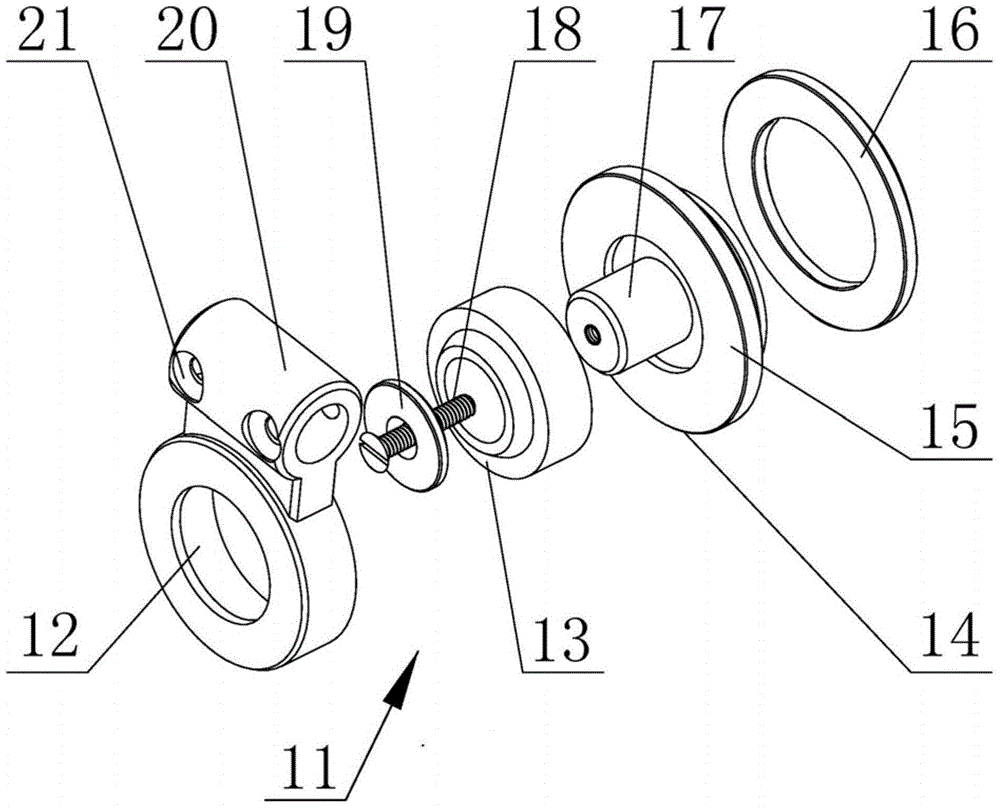

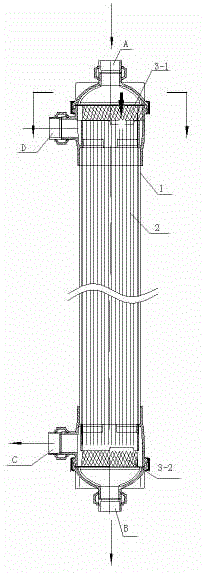

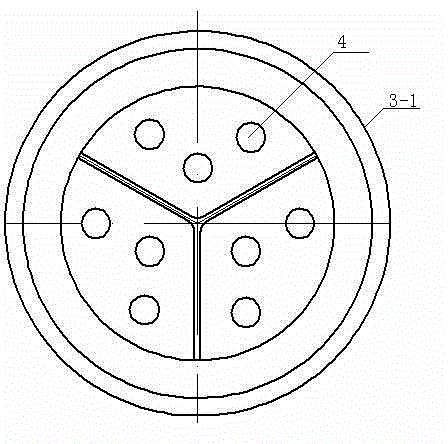

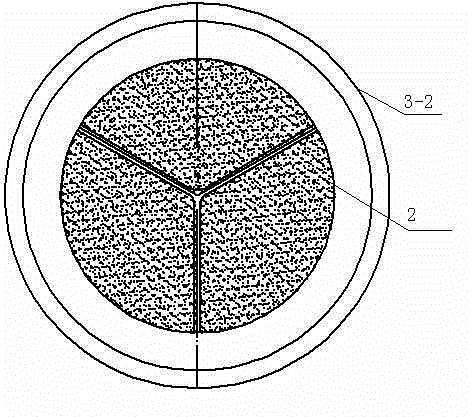

Static pouring column type membrane component and machining method thereof

InactiveCN104524977AHigh bonding strengthNo bendSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWire cuttingWater processing

The invention relates to a water processing device and a machining method of the water processing device, in particular to a static pouring column type membrane component and a machining method of the static pouring column type membrane component. The membrane comprises a shell, membrane wires, a water inlet, a water outlet, a spare opening and a concentrated solution outlet. The water inlet and the water outlet are provided with resin ends. The water processing device and the machining method are characterized in that the resin at the resin ends is flexible resin and fixes the two ends of the membrane wires, the diameter of water inlet holes ranges from 8 mm to 20 mm, and the number of water inlet holes ranges from 5 to 20. The machining method of the membrane component includes the steps of membrane wire drying, membrane wire fixing, membrane wire cutting, membrane wire pouring and resin solidification. The membrane wires of the column type membrane component are evenly distributed, firmly fixed at the ends and not prone to damage, and the membrane wire utilization rate and the long service life of the membrane component are effectively guaranteed; by means of the machining method, the problems that the membrane wires are unevenly distributed, high in number adjustment difficulty and unsmooth and not straight are solved effectively, and effective input and output of original water are guaranteed.

Owner:SHANDONG ZHAOJIN MOTIAN

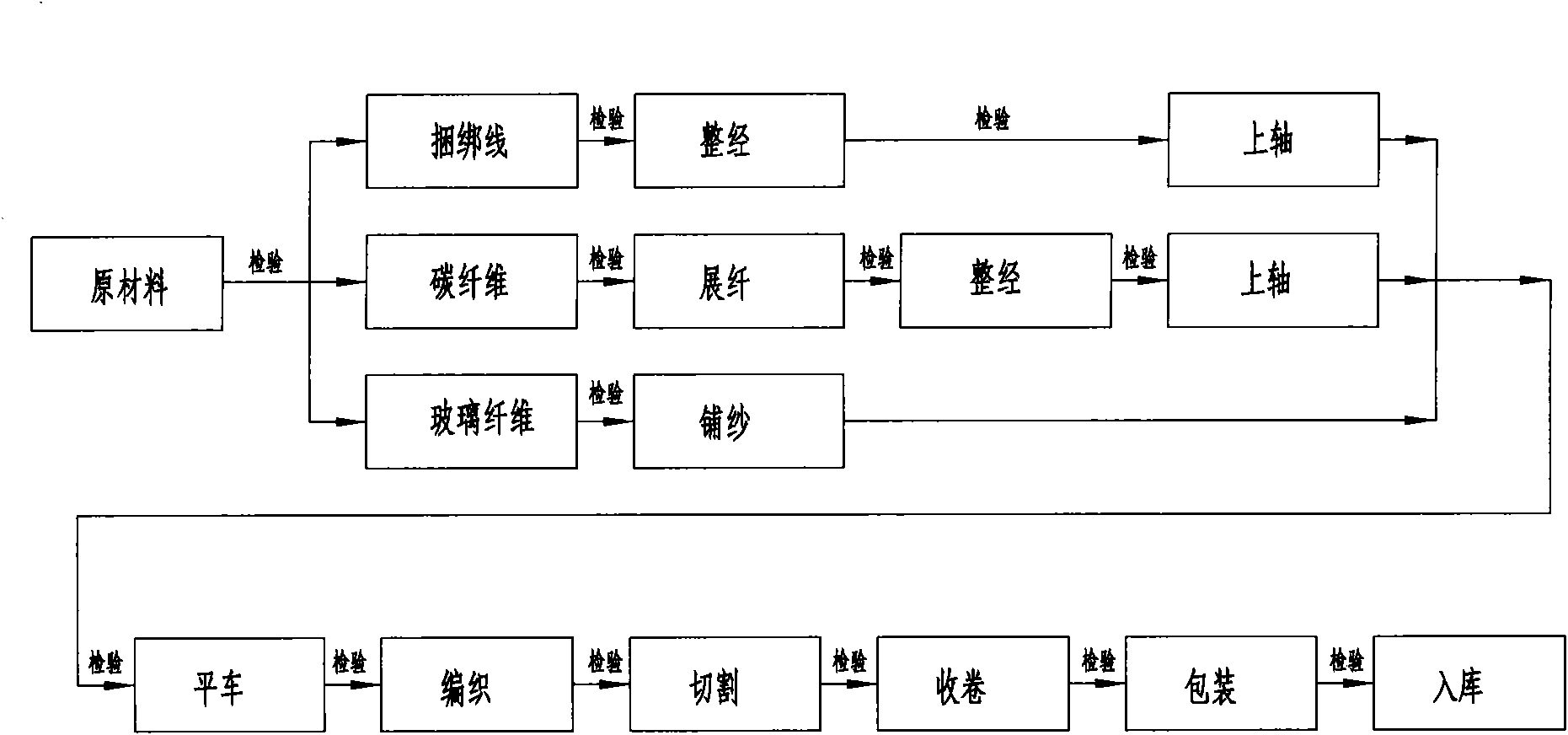

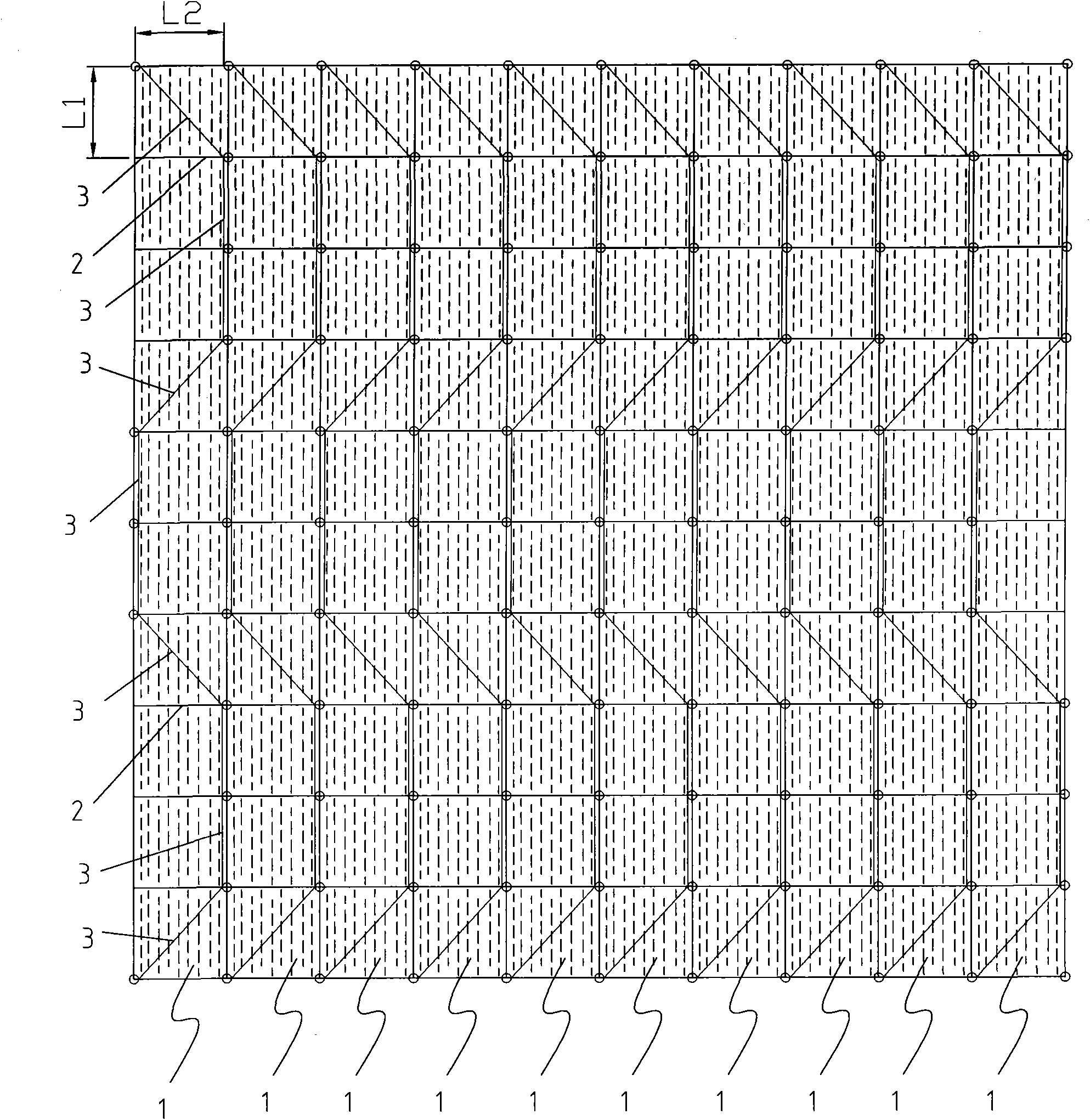

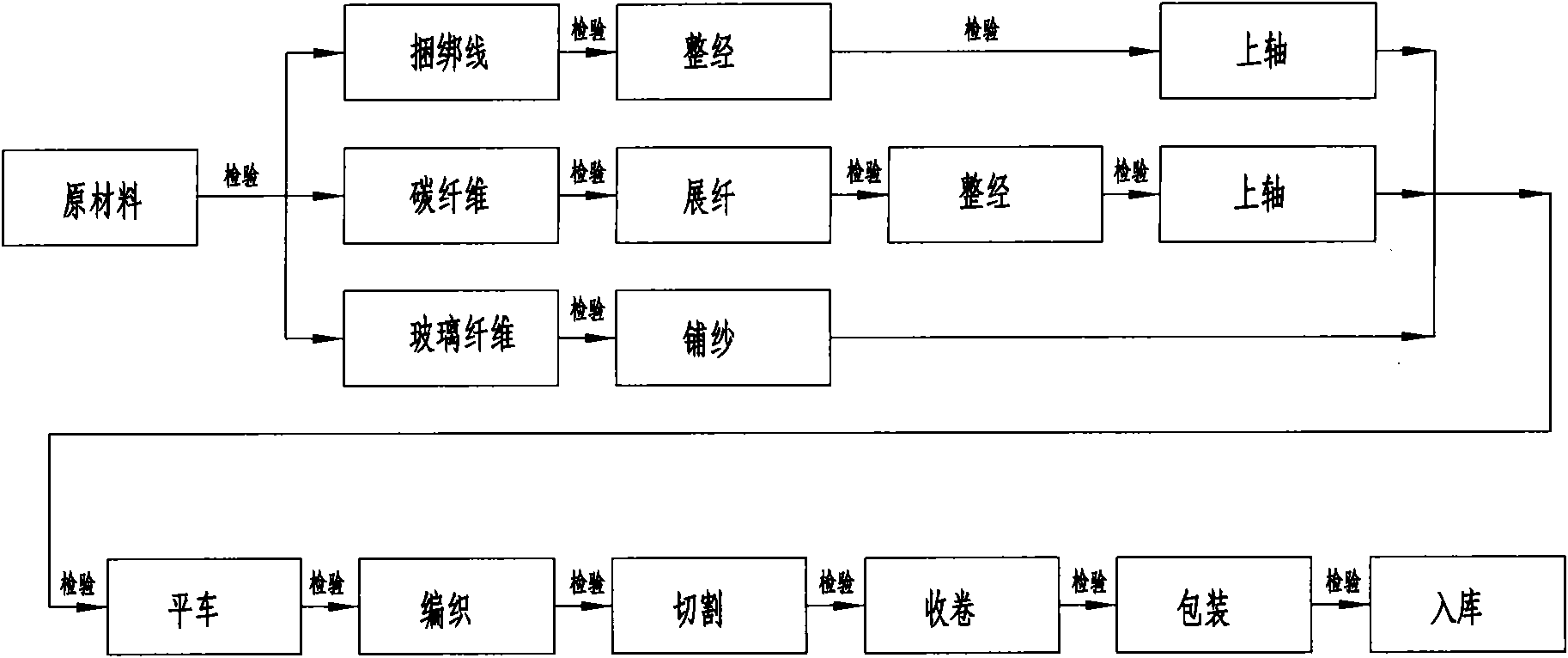

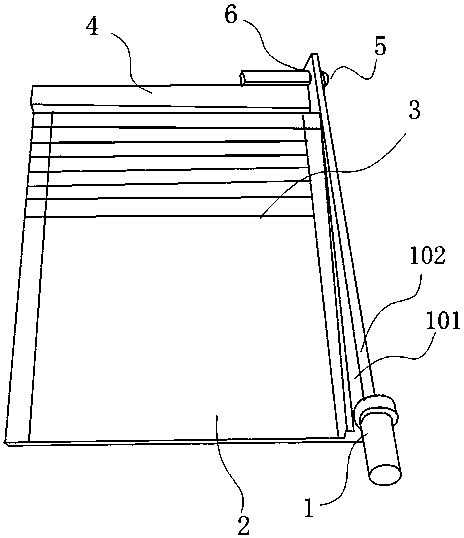

Production process of carbon fiber warp-knitting unidirectional cloth

ActiveCN101818408AExtended Raw MaterialsUniform and gap-free unwindingWarp knittingTextile fiberGlass fiber

The invention discloses a production process of carbon fiber warp-knitting unidirectional cloth, comprising the following steps: warping and shaft-arranging a binding line 3; laying glass fiber weft 2; spreading, warping and shaft-arranging carbon fiber warp 1 to weave with the binding line 3 together; and finally cutting, rolling and packaging the weaved cloth. The textile fiber produced by the process has no bending, good stability and good properties.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

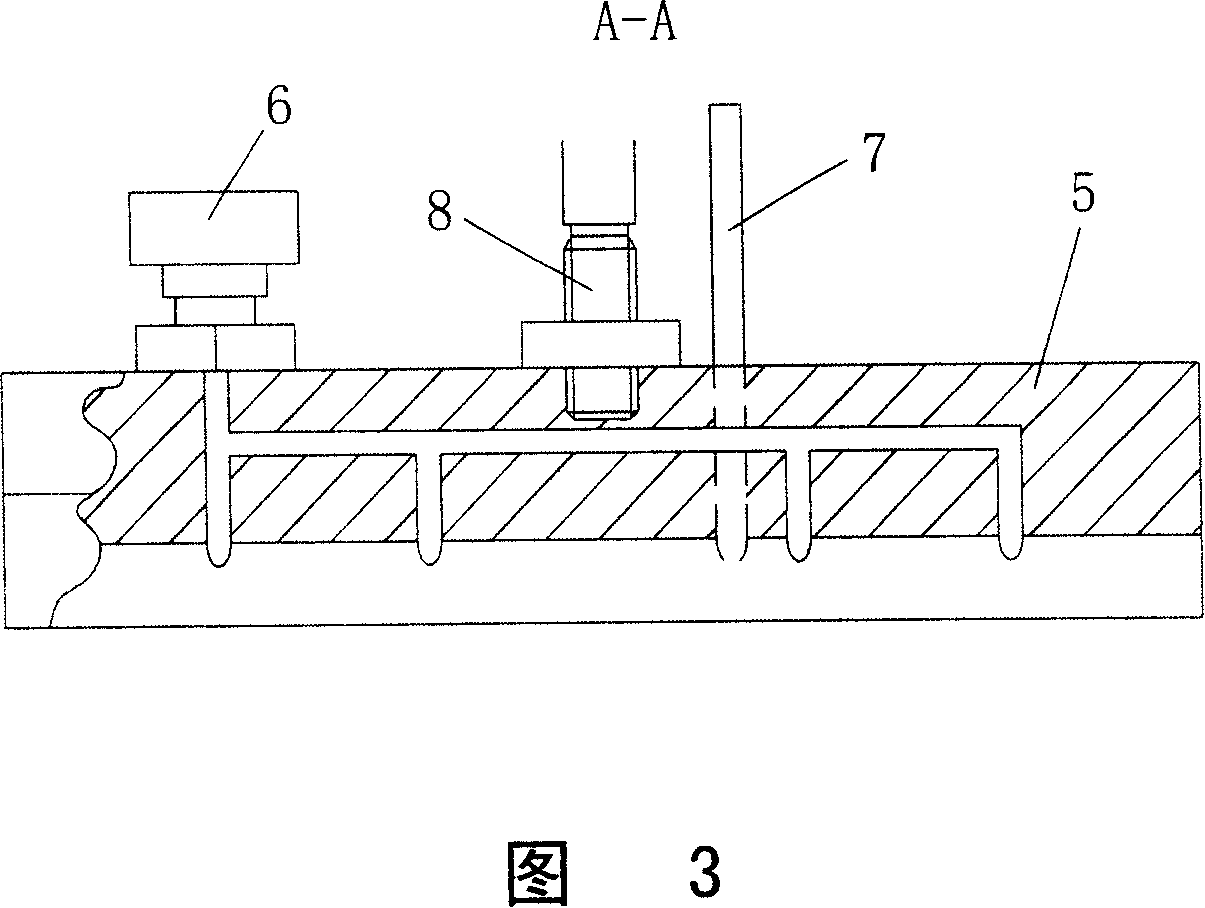

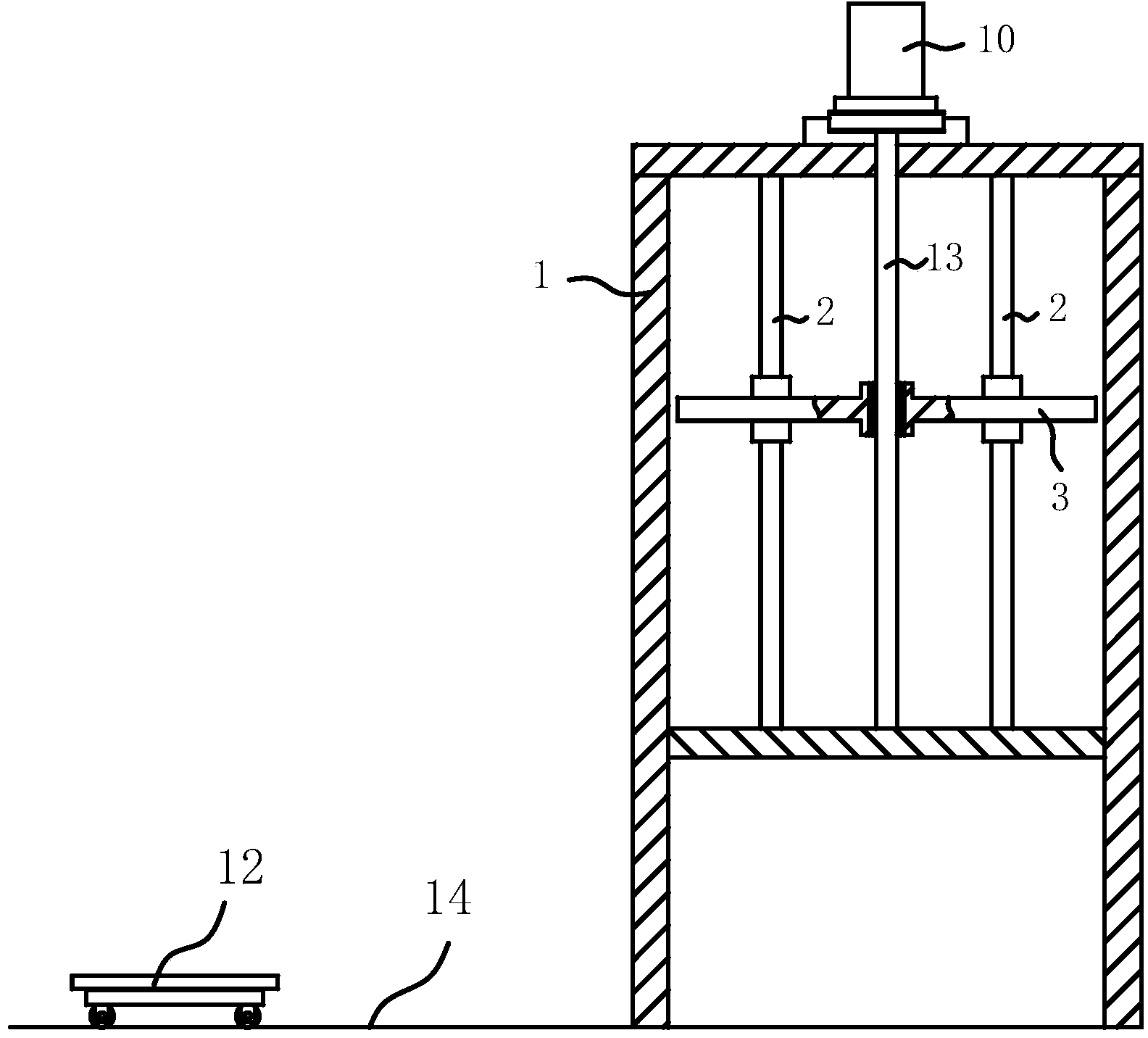

Multi-drill-bit graphite machining equipment

ActiveCN104227852AMeet processing needsSimple structureWorking accessoriesStone-like material working toolsGear wheelElectric machinery

The invention relates to the field of multi-drill-bit graphite product drilling equipment. The multi-drill-bit graphite machining equipment comprises a vertical frame and a lifting platform arranged on the frame, wherein the lifting platform is arranged on a polished lever on the upper part of the frame, and is driven to ascend and descend through the rotation of a lead screw; the lead screw is connected with a lifting motor; a main revolving shaft and a plurality of auxiliary revolving shafts are vertically arranged on the lifting platform; the main revolving shaft is arranged in the center of the lifting platform; the auxiliary revolving shafts uniformly surround the periphery of the main revolving shaft; the main revolving shaft and the auxiliary revolving shafts are connected through a gear; the main revolving shaft and the auxiliary revolving shafts are provided with through holes along the axis direction respectively; the upper end part of the main revolving shaft is provided with a belt wheel, and is connected with a driving motor arranged on the upper end face of the lifting platform through a belt; the upper end parts of the main revolving shaft and the auxiliary revolving shafts are connected with a dust sucking device respectively through suction pipes; plate-like tools are arranged on the lower end heads of the main revolving shaft and the auxiliary revolving shafts; the revolving shaft through holes are isolated symmetrically by the tools. The multi-drill-bit graphite machining equipment is simple in structure, has a good dust-removing effect, and is equipment special for deep-hole machining of large and medium-sized graphite crucibles.

Owner:于海东

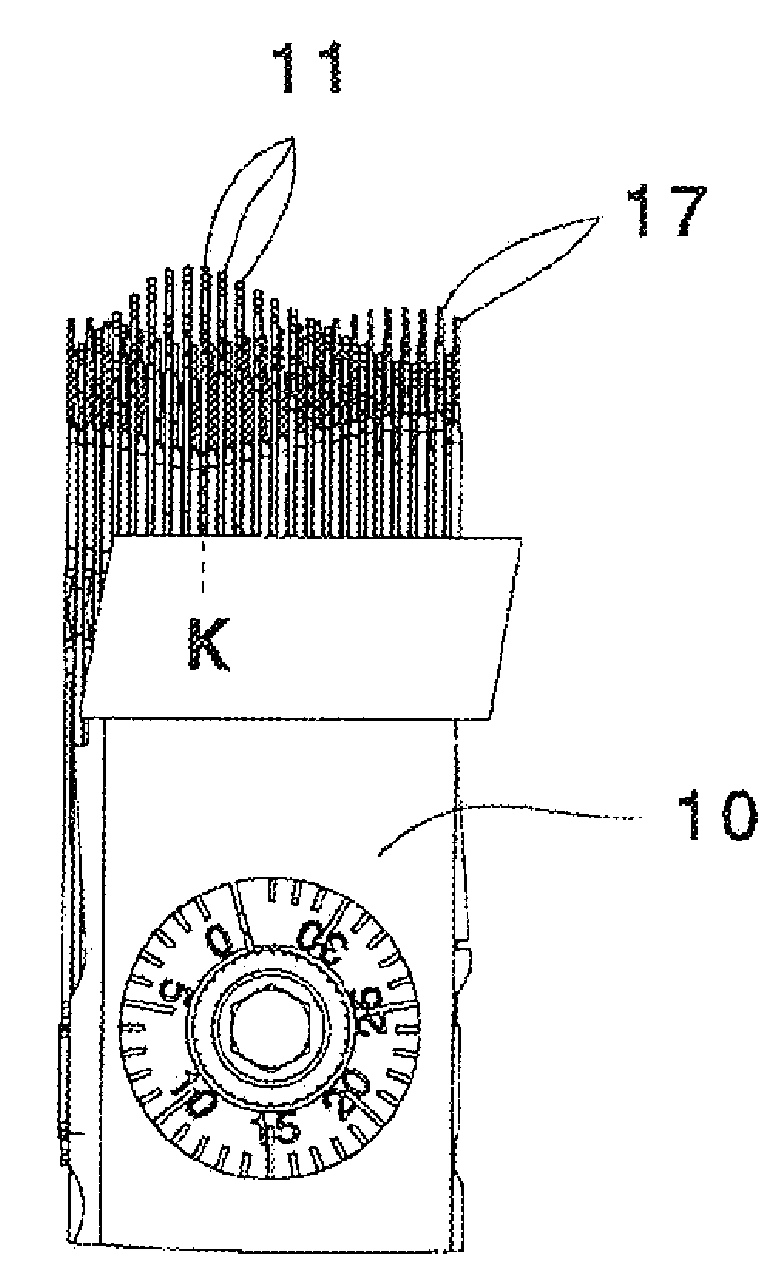

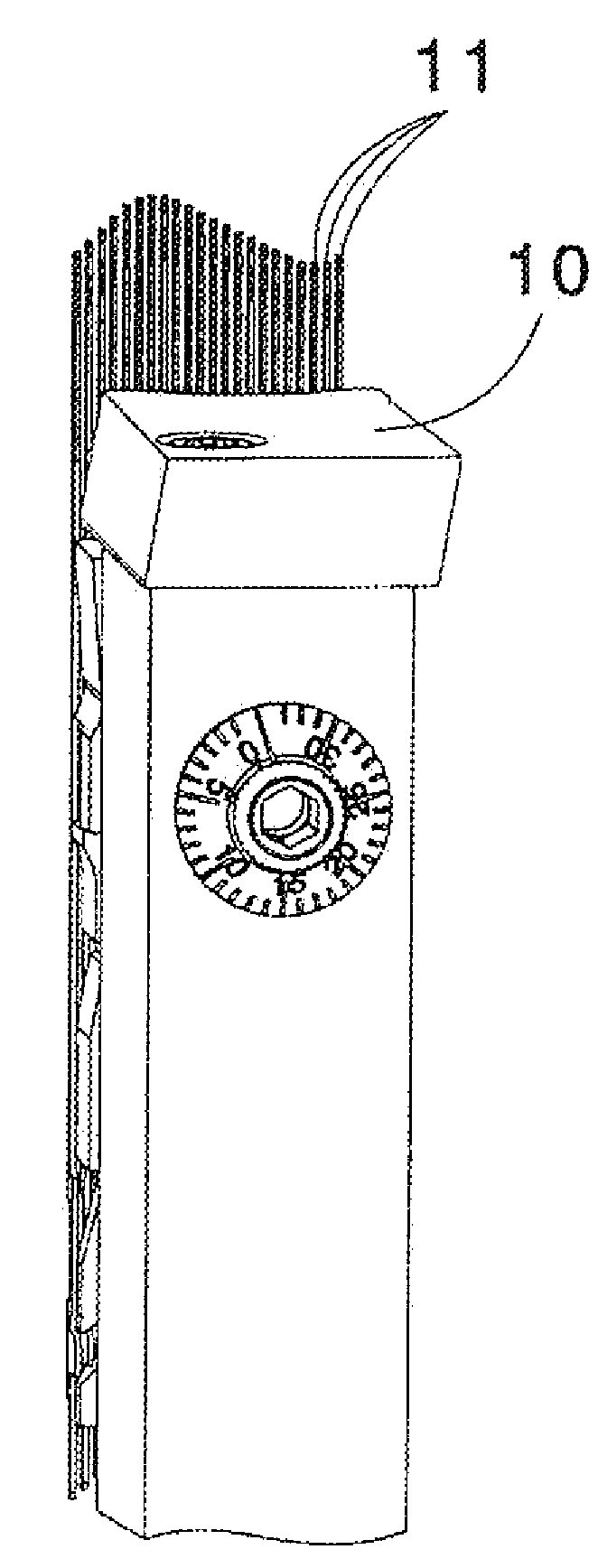

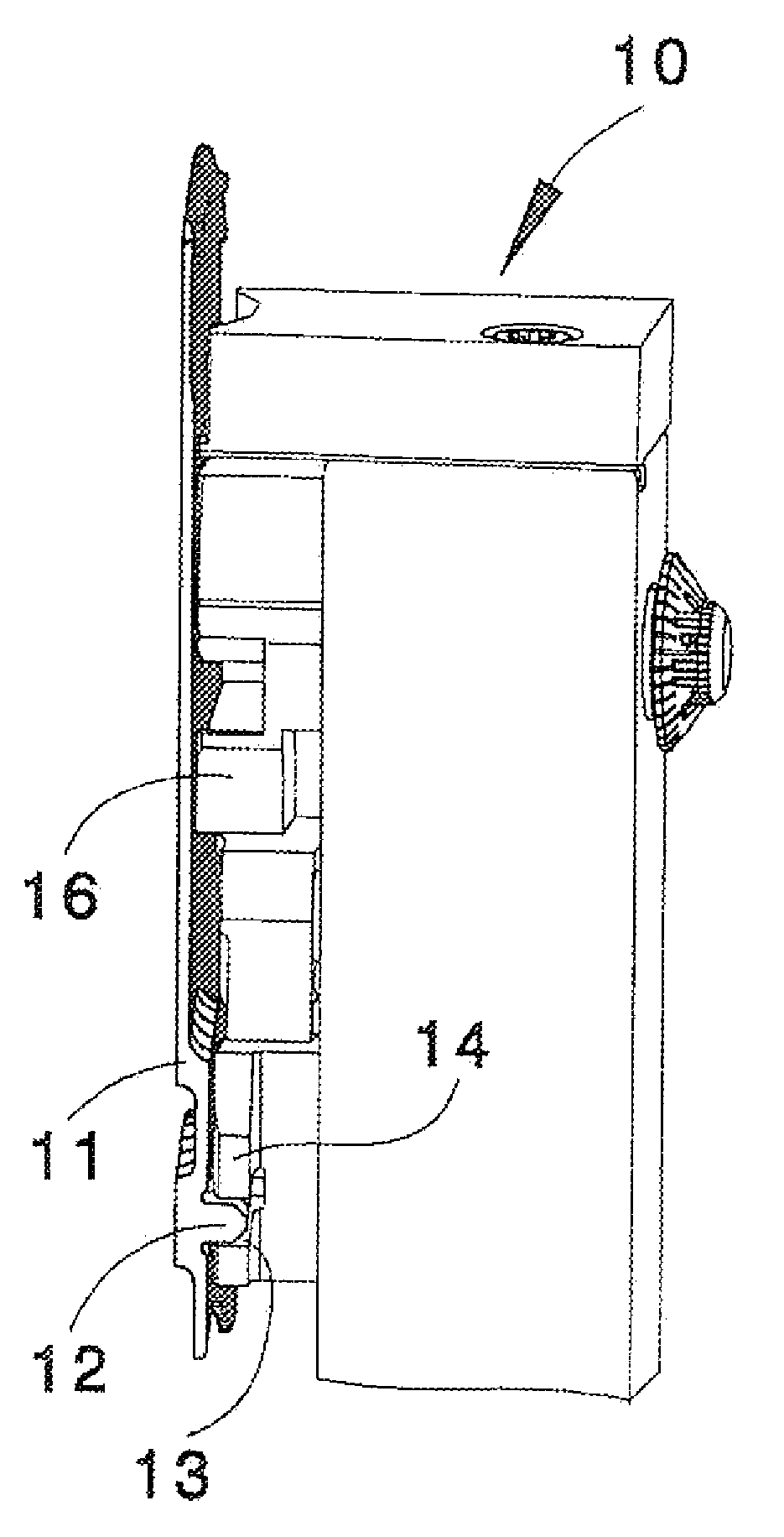

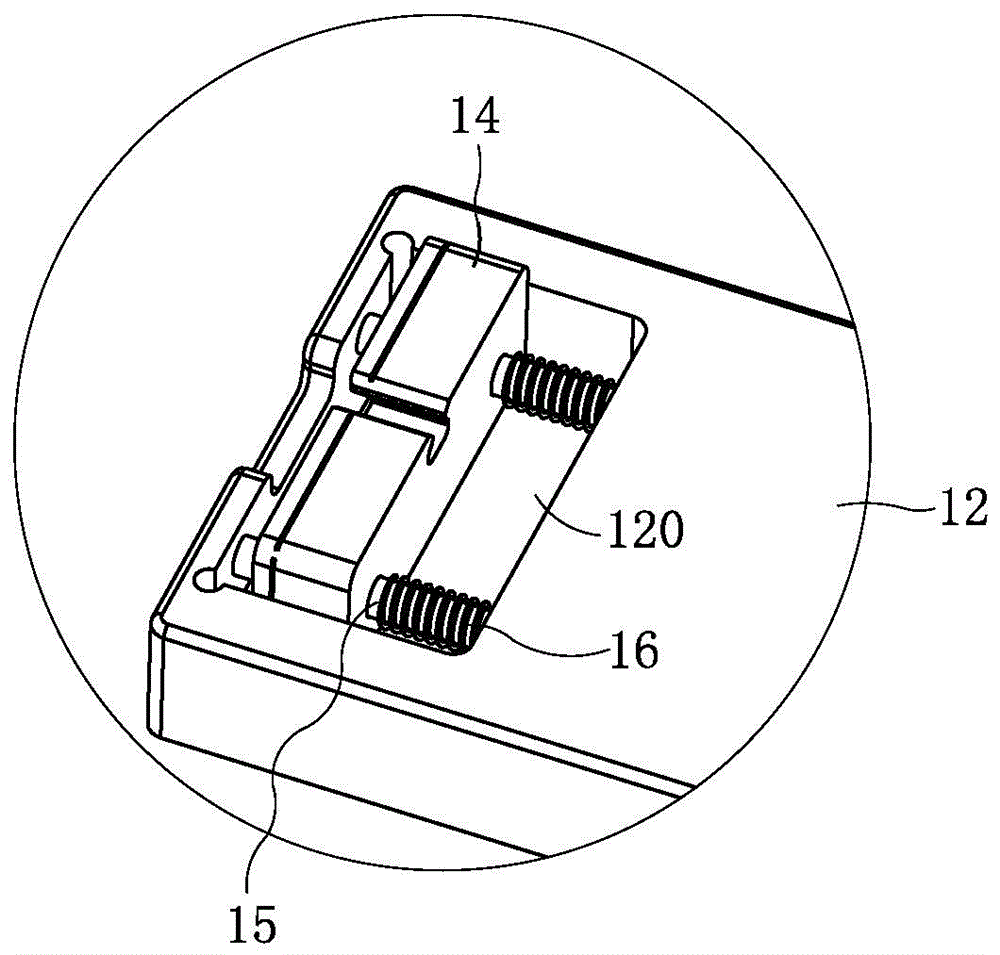

Knitting machine

A knitting machine having needles which are mounted to be longitudinally moveable and having needle cams (14) with a needle control curve (13) for moving the needles, the needle control curves (13), at least in the latch closure region (Z), having a withdrawal angle (alpha)@35°.

Owner:SIPRA PATENTENTWICKLUNGS & BET GMBH (DE)

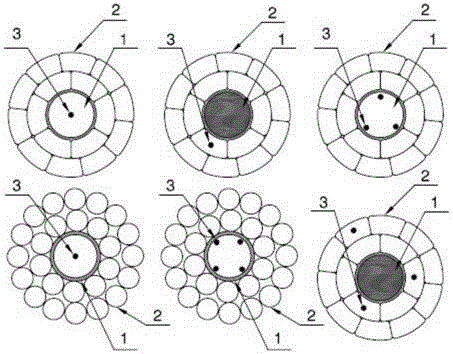

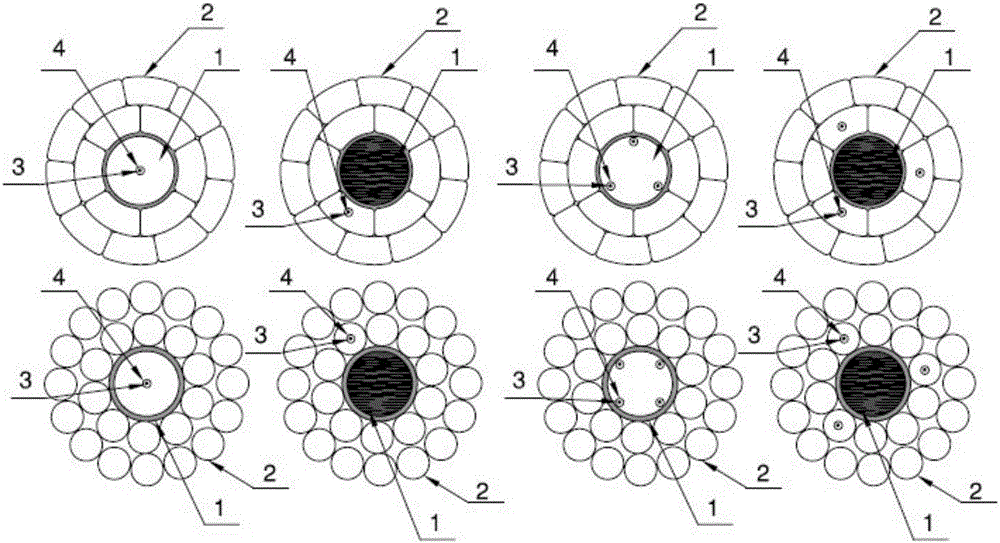

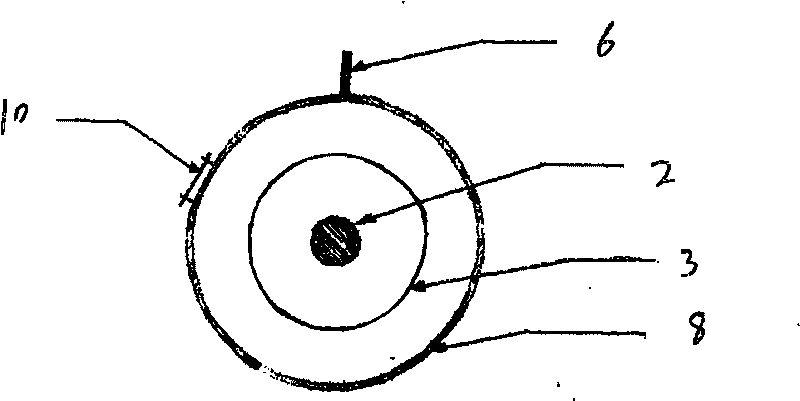

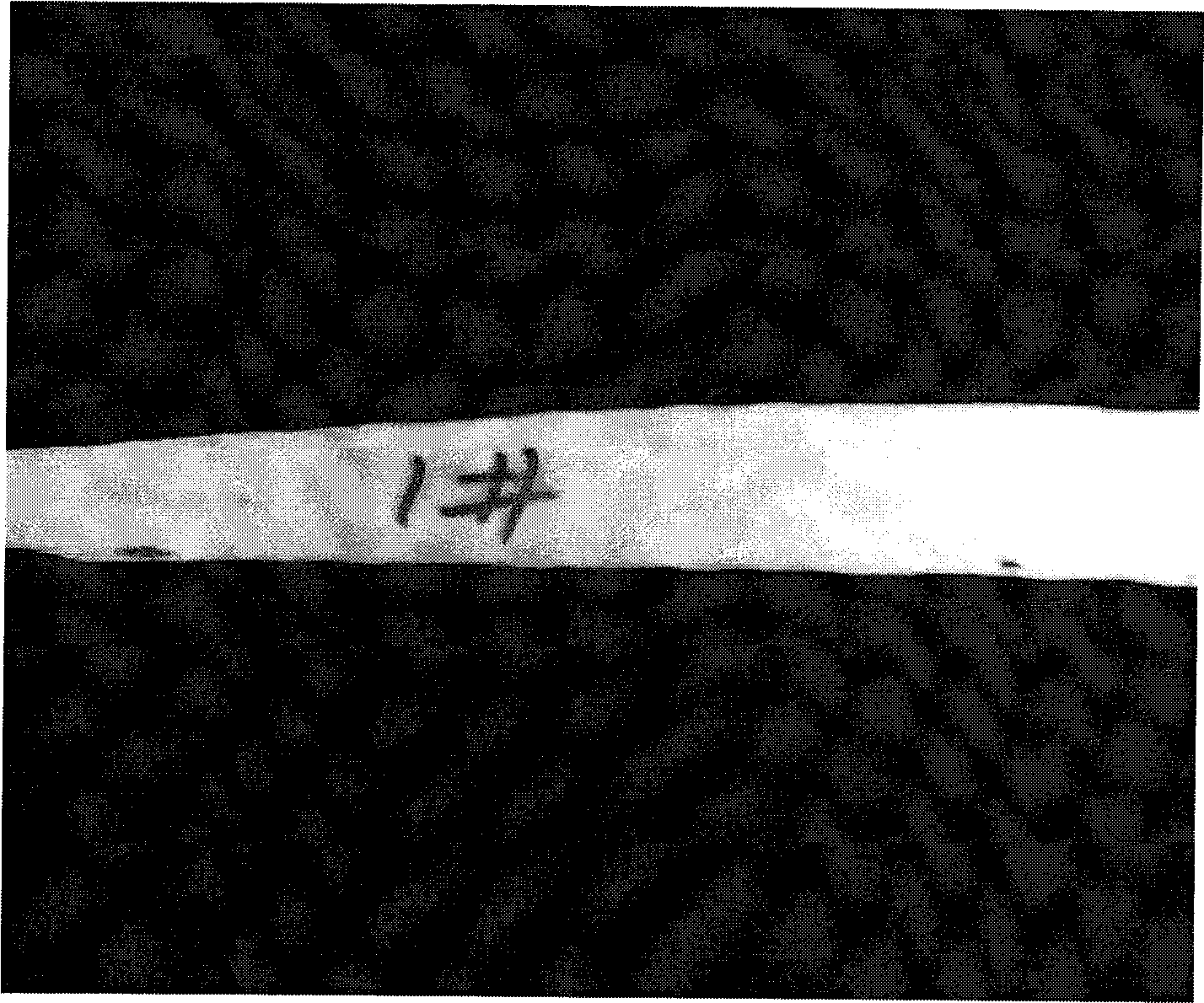

Intelligent composite material core wire and preparation method thereof

ActiveCN105825945AReasonable structural designHigh temperature resistantNon-insulated conductorsPower cables including optical transmission elementsCarrying capacityAging resistance

The invention discloses an intelligent composite material core wire and a preparation method thereof. The intelligent composite material core wire includes a composite material core (1) and single conductor wires (2) stranded at the periphery of the composite material core (1), wherein the composite material core (1) or the single conductor wires (2) are internally provided with optical fibers (3) or optical fiber protection pipes (4) for communication or monitoring; and the optical fibers (3) are arranged in the optical fiber protection pipes (4). The preparation method of the intelligent composite material core wire includes the steps of preparing the composite material core and stranding the single conductor wires (2) at the periphery of the composite material core (1). The preparation method of the intelligent composite material core wire has the advantages of being high in operability, being higher in production efficiency, being able to save a lot of manpower and material resources, and being low in production cost; the prepared composite material core has the advantages of being high in linearity and roundness, having no bending, being high in color consistency, being high in intensity, being long in the service life, having no eccentricity, and being high in aging resistance; and the prepared intelligent composite material core wire has the advantages of being higher in the wire compactness and filling rate, being resistant to high temperature, being high in current-carrying capacity and being small in sag.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

Unfolding process of green bamboo strips

PendingCN113927685AHigh strengthUniform thicknessWood treatment detailsCane mechanical workingPulp and paper industryComposite material

The invention discloses an unfolding process for green bamboo strips, and belongs to the technical field of bamboo processing. The unfolding process comprises the following steps that bamboos are segmented and sectioned bamboo strips with cambered sections; the bamboo strips are expanded in an equal-arc and fixed-thickness mode after being pressurized, heated and softened; then, double-face protection gradual flattening is conducted under the heat preservation condition till the bamboo strips are completely flattened, and a bamboo board is obtained; and the bamboo board is continuously cooled, then subjected to ballasting, shaping and drying until the moisture content is 6-10%, and then subjected to fixed-width trimming to obtain a green bamboo board finished product. According to the unfolding process for the green bamboo strips, the green bamboo strips can be unfolded on the premise that oblique notching and green planing are not conducted, the problems of cracking and rebounding cannot occur in the unfolding process, the obtained green bamboo strips are smooth and flat, the obtained green bamboo strips have the characteristic of high strength, and the application range and field of the bamboo wood are further widened through the unfolding process.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

Lead-type anode post lithium battery

InactiveCN101626092AAvoid bendingImprove toughnessNon-aqueous electrolyte cellsSecondary cellsTinningAlloy

The invention relates to the technical field of lithium batteries, in particular to a lithium battery structure with a leading-out wire. The invention relates to a lead-type anode post lithium battery comprising a battery housing; a lithium sheet, a side film and a carbon package are sequentially sheathed in the battery housing, wherein the port of the batter housing is provided with a cover film; the cover film is provided with a nut cap body which is connected with an anode leading-out structure, and the anode leading-out structure comprises a current collector performing the current collection function, an anode post and the leading-out wire; the current collector, the anode post and the leading-out wire are respectively independent components. The anode leading-out structure of the invention is characterized in that the current collector can choose pure nickel and alloy thereof with favourable electrical conductivity to manufacture and is manufactured into a flat structure, thus increasing the current output capacity of the battery and avoiding bending phenomenon when the current collector is inserted into the carbon package. The anode post adopts 4J28 alloy material to realize better sealing with glass, and the leading-out wire can adopt tinning alloy with strong tinning ability; in addition, the leading-out wire has favourable toughness and is not easy to break off.

Owner:EVE ENERGY CO LTD

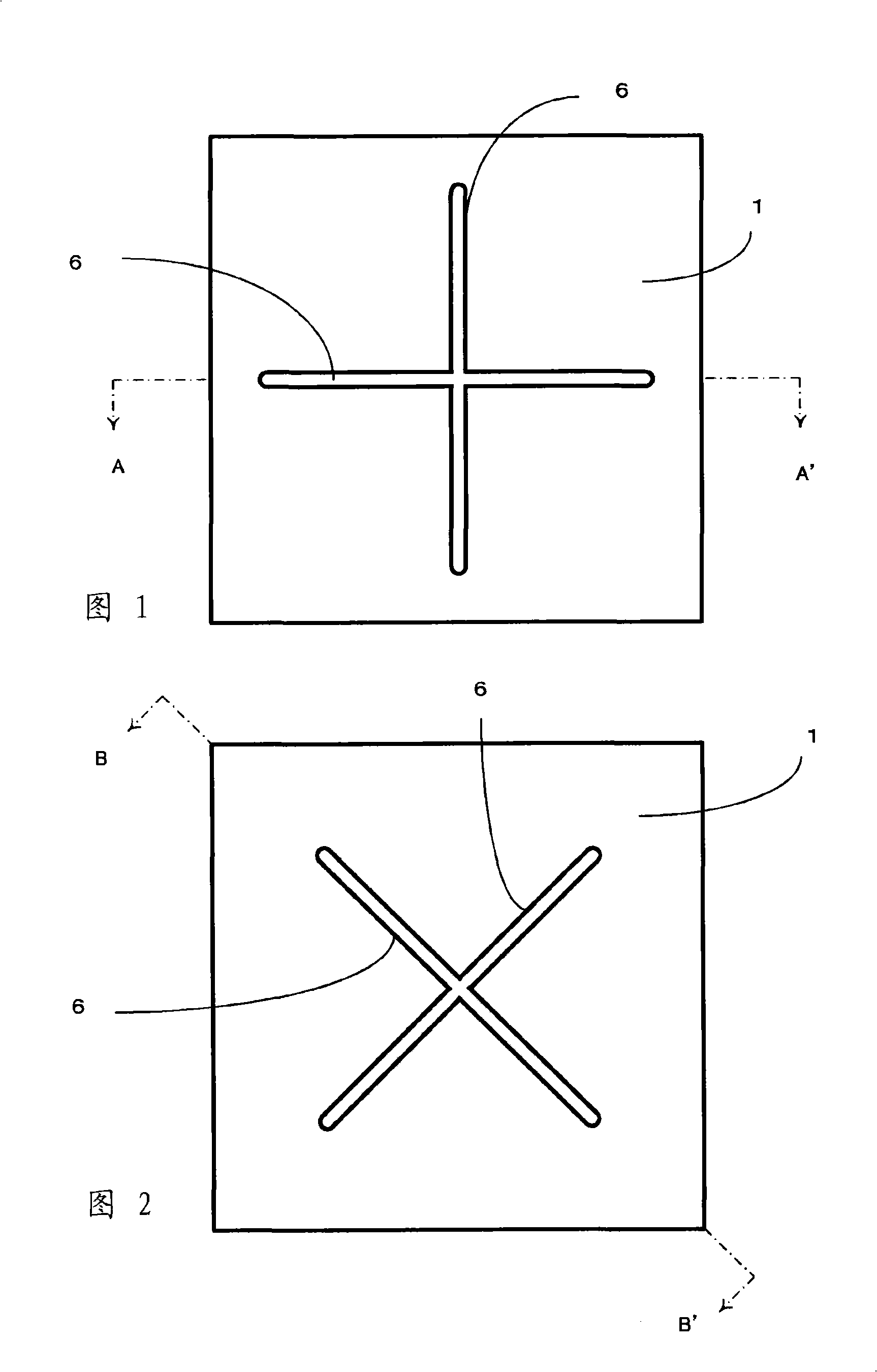

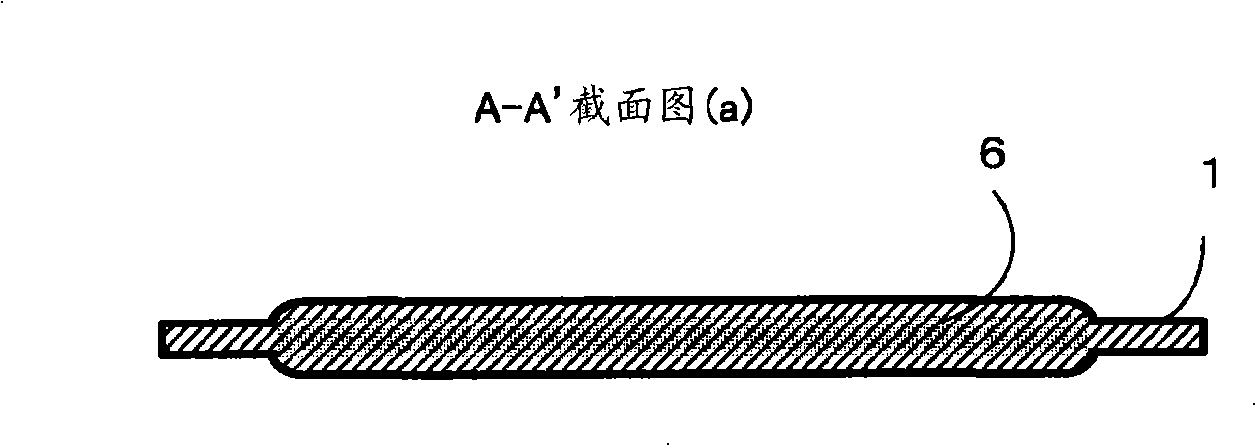

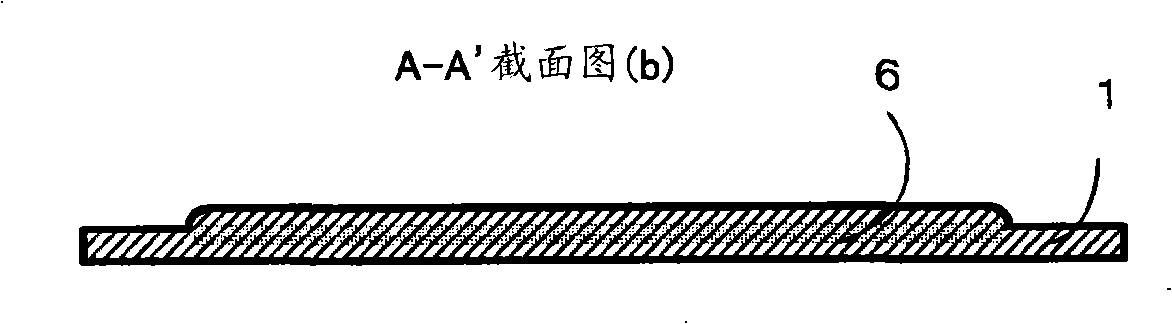

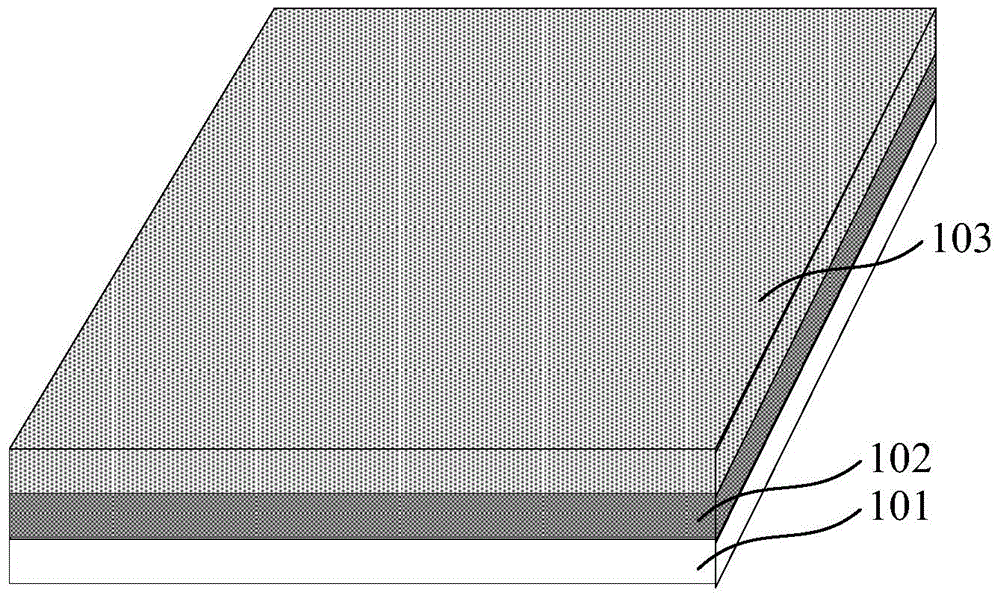

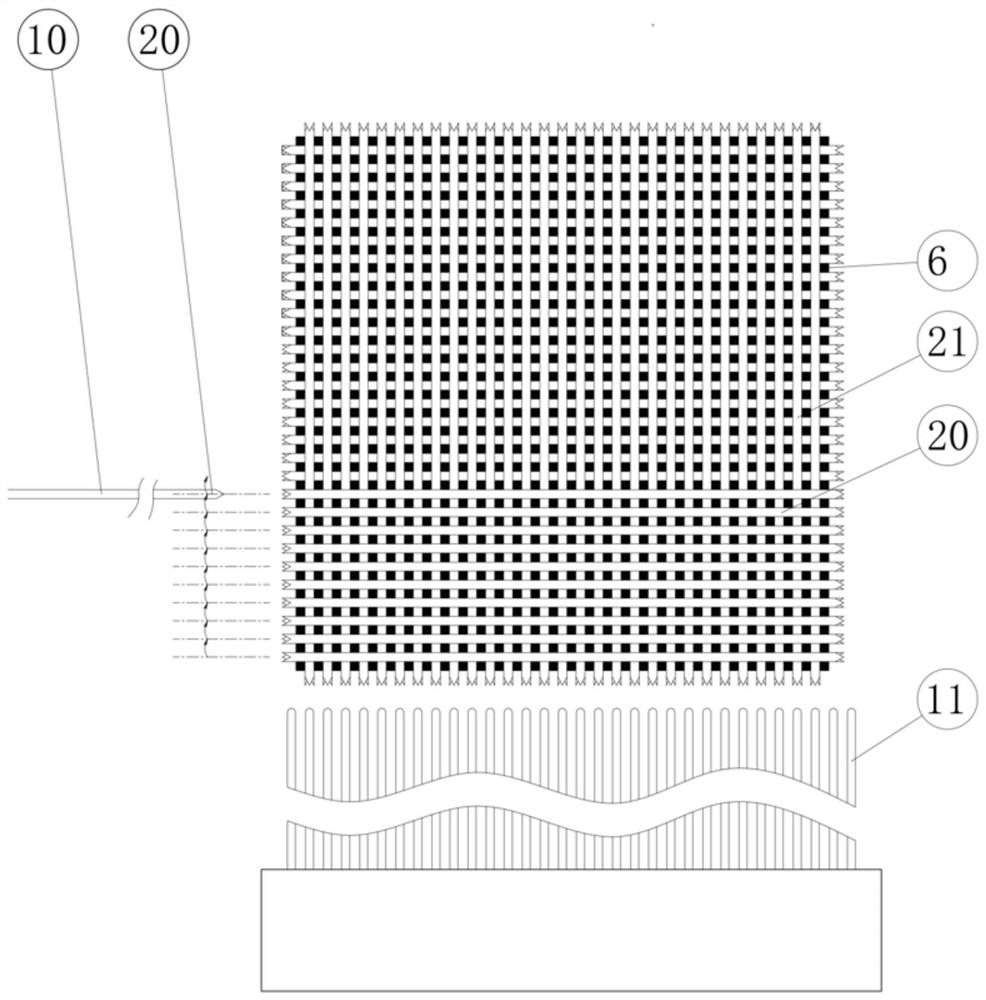

Thin molded article

The thin molded article of the present invention includes a thin flat plate 1 and dam / discharge ribs 6 provided on the thin flat plate having a shape in which bar-type ribs having wide or large diameters extend radially from the center of the molded article. The tips of the bar-type ribs having wide or large diameters have a shape that allows the molten resin injected from a gate into a cast to be accumulated temporarily before it flows into said thin plate, thereby providing a configuration in which the tips of said ribs do not reach the outer edge of the molded article.

Owner:DAISAN

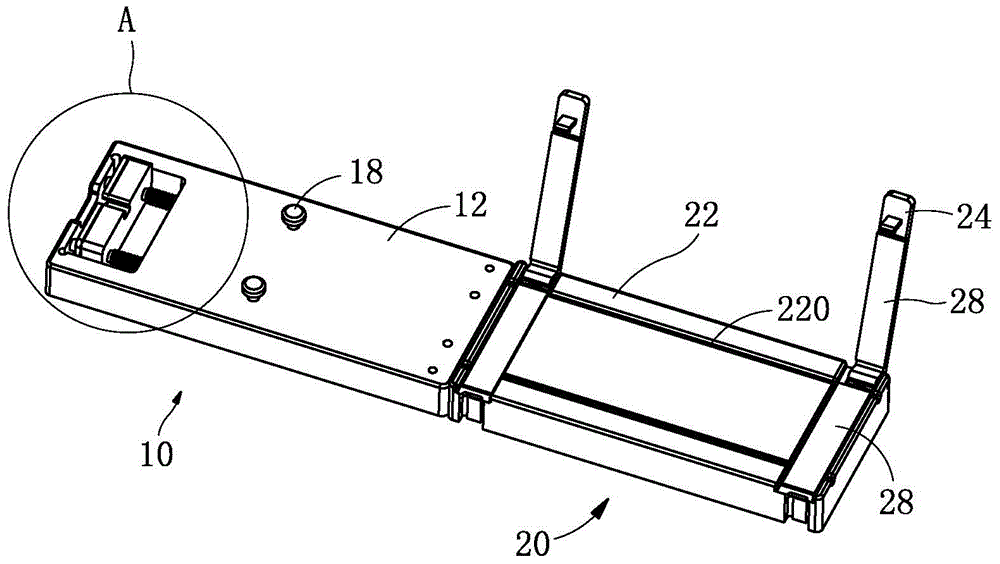

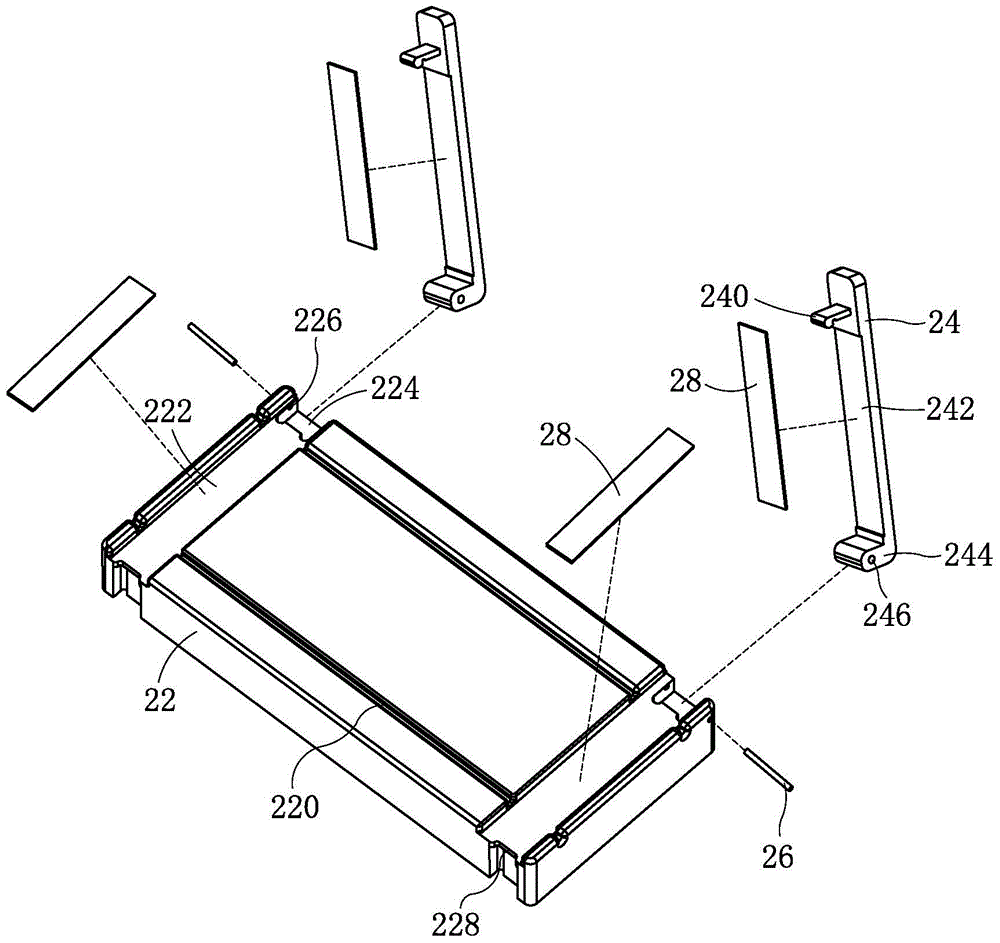

Wire fixing jig

The invention discloses a wire fixing jig, and relates to the technical field of wire processing molds. The wire fixing jig comprises a wire guide assembly and a wire clamp assembly. The wire guide assembly and the wire clamp assembly are connected with each other, the wire guide assembly comprises a wire guide base plate, the wire clamp assembly comprises a wire clamp base plate, and one end of the wire guide base plate is connected with an end of the wire clamp base plate; a slider is slidably mounted at the other end of the wire guide base plate, the sliding direction of the slider is consistent with the extending direction of the wire guide base plate, a clamp portion which is used for clamping a wire distributor for wires is arranged on the slider, and at least two wire distributing columns are arranged in the middle of the wire guide base plate; two wire clamp plates are respectively hinged to two ends of the wire clamp base plate, and the wires can be clamped between the wire clamp base plate and the wire clamp plates by the two wire clamp plates. The wire fixing jig has the advantages that the wire fixing jig is simple in structure and convenient to use, and the wires can be reliably fixed by the aid of the wire fixing jig and can be prevented from being damaged; the wire fixing jig is suitable for assembly line work, and the production efficiency of products can be effectively improved.

Owner:GOERTEK INC

All-bamboo unfolding process

ActiveCN113370332ANo deformationNo problem of crackingWood compressionWood treatment detailsProcess engineeringMachining process

The invention discloses an all-bamboo unfolding process, and belongs to the technical field of bamboo processing. The process comprises the following steps of: segmenting and sectioning all-bamboo into bamboo chips with radians; after being pressurized, heated and softened, unfolding the bamboo chips in a variable-arc and fixed-thickness mode, and planing off bamboo green and tabasheer; then, conducting double-face protection gradual flattening under the heat preservation condition till the bamboo chips are completely flattened, to obtain bamboo boards; and performing multi-layer ballasting shaping and compensation ballasting shaping drying on the cooled the bamboo board until the moisture content is 6-10% after being subjected to cooling treatment, and finally obtaining a bamboo board finished product after fixed-width trimming. According to the all-bamboo unfolding technology, unfolding treatment can be conducted on different sections of bamboo tubes, the effect that all-bamboo is unfolded through the same technology is achieved, it is not needed to configure multiple production technologies and corresponding production line in the unfolding process, the problem of cracking does not occur in the machining process, and the obtained bamboo board finished product is smooth and flat in surface and does not rebound.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

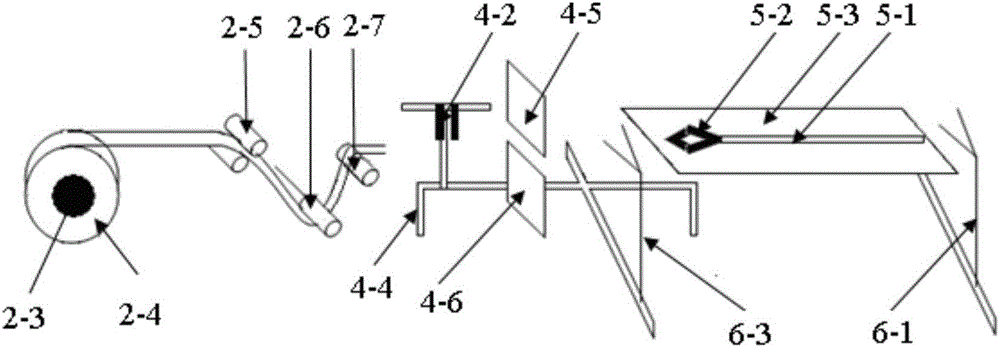

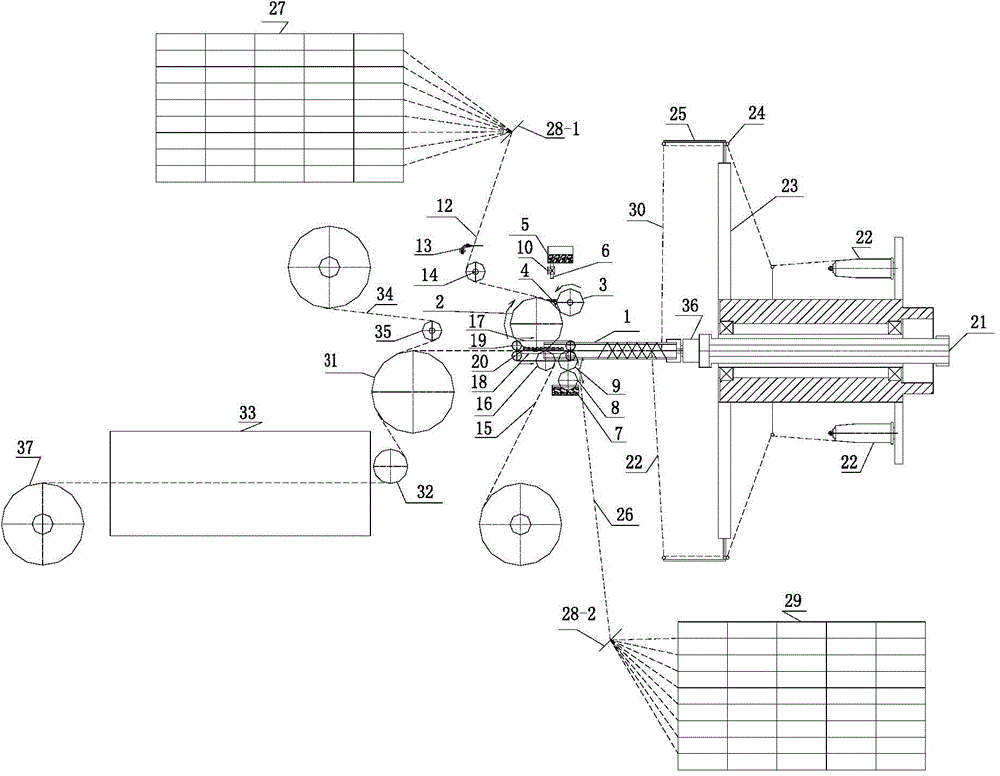

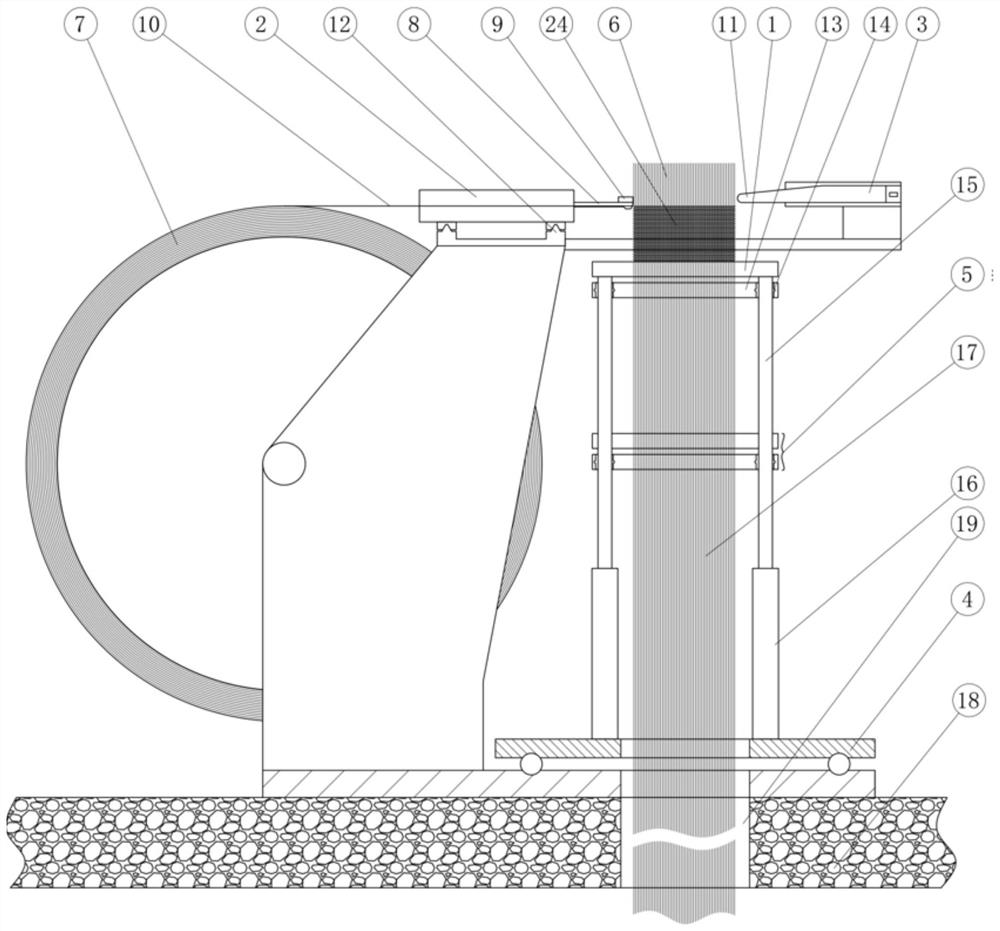

Zero-twist feeding system for flattened wefts of weaving

The invention provides a zero-twist feeding system for flattened wefts of weaving of weaving. The zero-twist feeding system comprises a picking back device, a weft insertion device, a weft receiving device and beating-up devices, wherein the picking back device is arranged at the front end of the weft insertion device, the weft receiving device is arranged at the rear end of the weft insertion device, and the beating-up devices are arranged at the inlet end and the outlet end of the weft receiving device. The motion of the zero-twist feeding system is controlled and sensed by combining pneumatic-electric drive with the light-sensing laser technology, the tension, thickness and width of the flattened wefts can be set and monitored according to needs so as to conveniently regulate the tension, thickness and width timely, the flattened wefts are fed into the cloth-fell of fabric without twist, bending, friction fluffing, edge curling and gaps during weaving, the requirements such as flatness, even yarn width, even thickness and low gap rate of the flattened fabric are satisfied while the shortest waste edge is achieved, and raw material loss and cost can be lowered to the maximum extent.

Owner:SHANGHAI CEDAR COMPOSITES TECH CO LTD +1

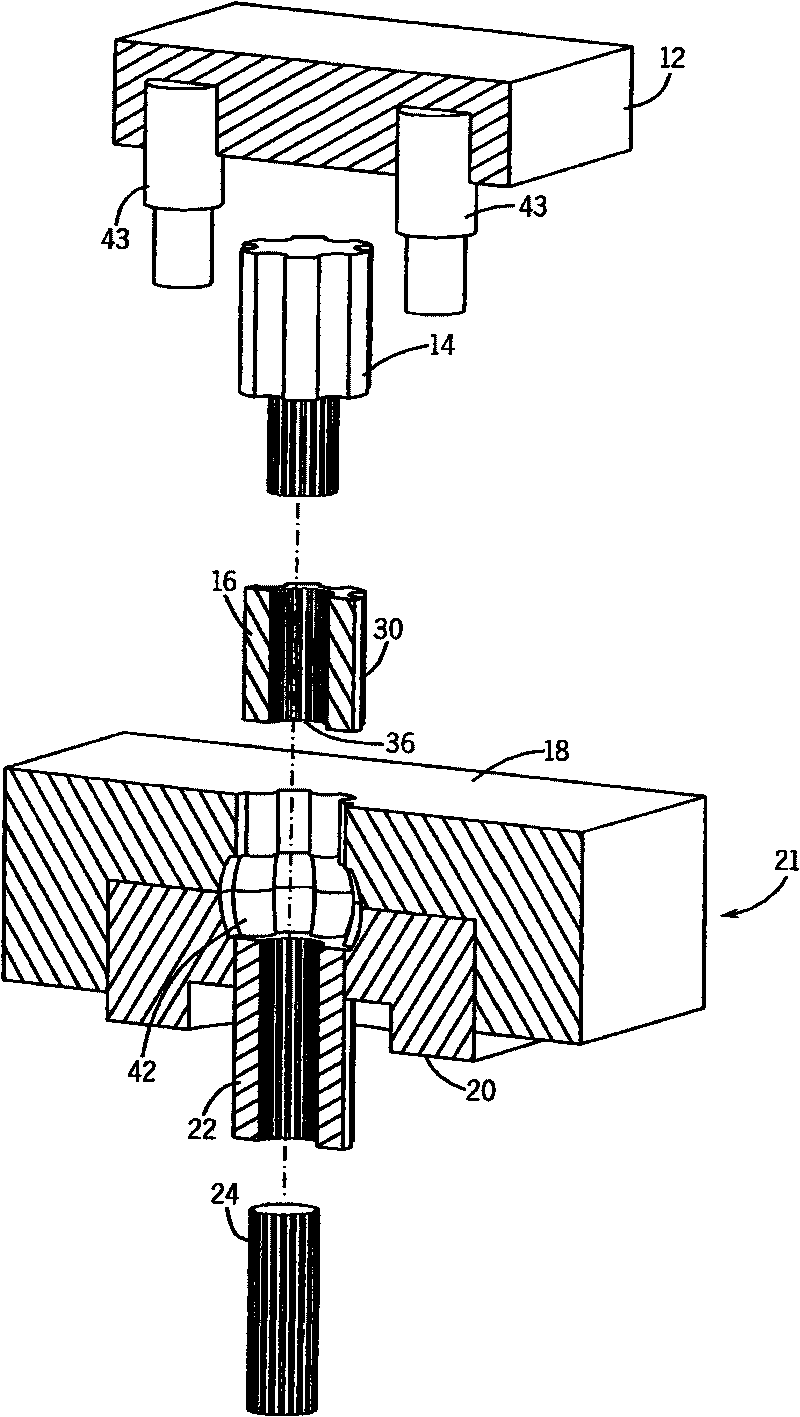

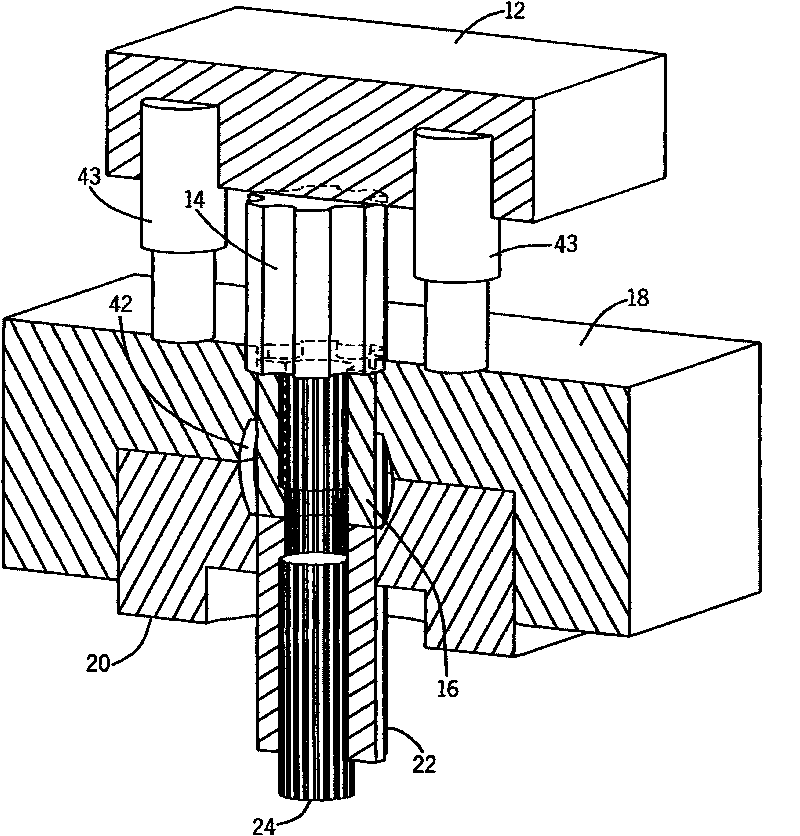

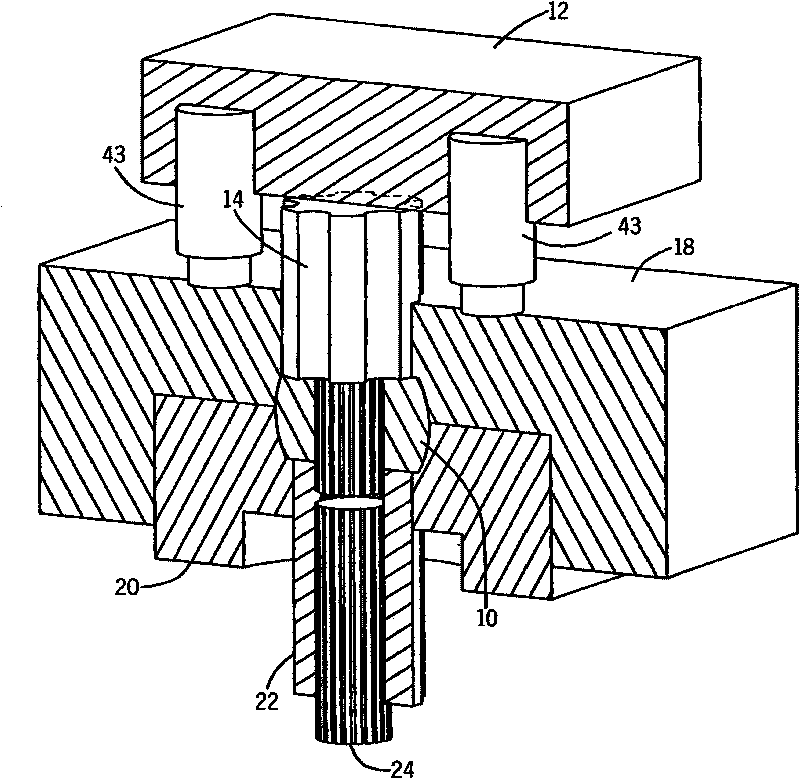

Powder metal forging and method and apparatus of manufacture

A method of forming a powder metal forging, including the steps of: forming a preform including a sintered powder metal composition; inserting the preform in a die set having a bottom die and a top die, the die set defining a forge form therewithin, the die set being in a closed position wherein the top die is contacting the bottom die; and compressing the preform in the forge form using an upper punch and a lower punch, the compressing step resulting in a formed part. The closed die set minimizes or eliminates flash in the formed part, particularly in the contoured surfaces, which allows the forging to be through hardened by direct quenching after the forging operation, without the need to remove hardened flash from these surfaces.

Owner:GKN SINTER METALS GMBH & CO KG

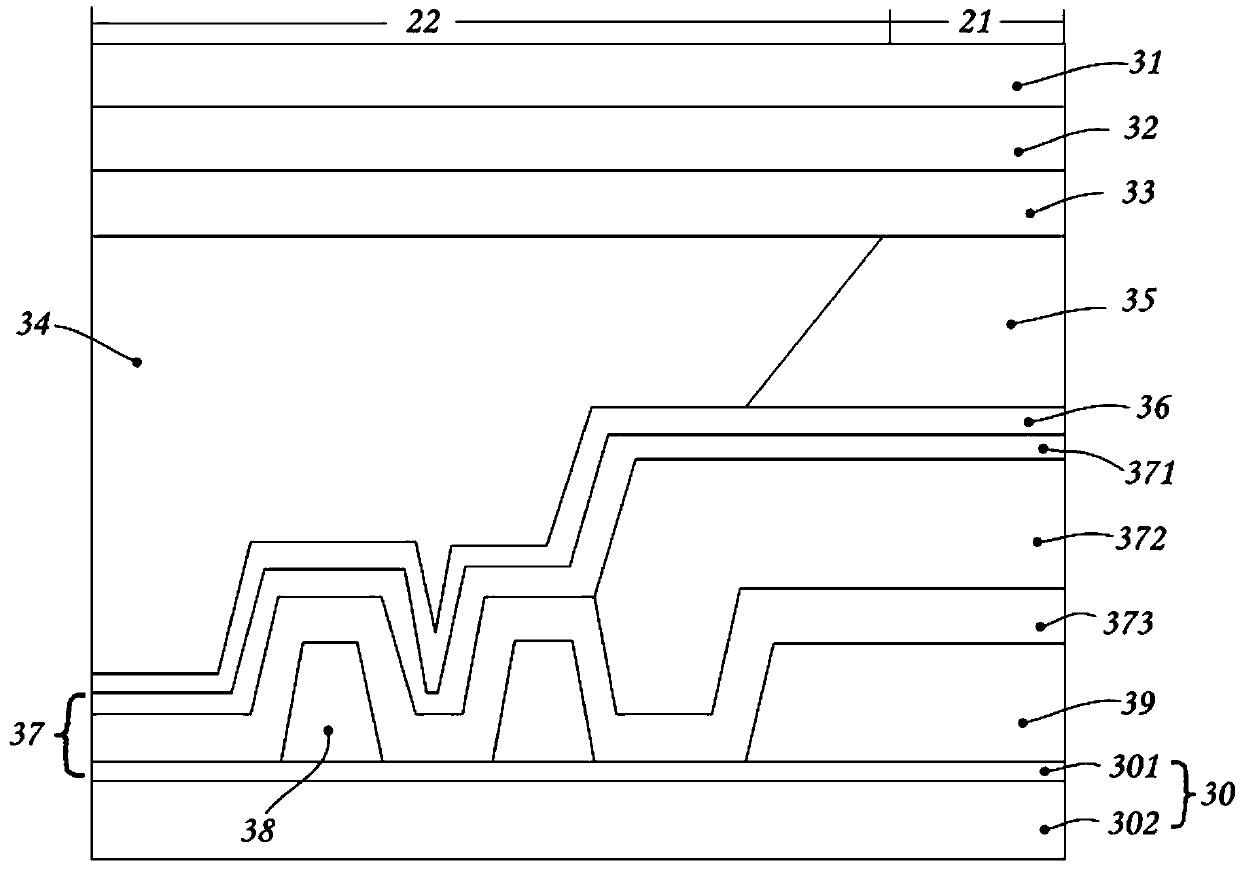

OLED display panel and manufacturing method thereof, and display device

ActiveCN111370442AEliminate gapsEffective occlusionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses an OLED display panel and a manufacturing method thereof, and a display device. The OLED display panel comprises an array substrate, a pixel light-emitting layer, a touch control layer, a planarization layer and a cover plate which are sequentially arranged in a stacked mode, and further comprises a first shielding layer is formed between the touch control layer and the cover plate and located on the same layer as the planarization layer, wherein the planarization layer is formed in a display area, and the first shielding layer is formed in the peripheral area surrounding the planarization layer. According to the invention, the first shielding layer is arranged between the polarization layer and the touch control layer, so that no step offset exists between the first shielding layer and the planarization layer so as to eliminate the offset of the shielding layer and effectively shield the non-display circuit at the bottom; and through the second shielding layerarranged between the touch control layer and the packaging layer, the bottom non-display circuit can be further shielded, and the touch layer can be free of bending, so that the circuit in the touch layer is prevented from being broken, and the flexibility of the touch layer is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

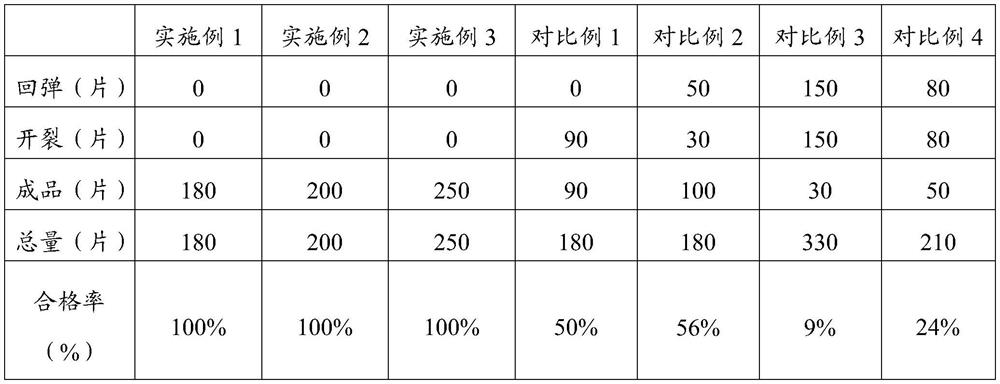

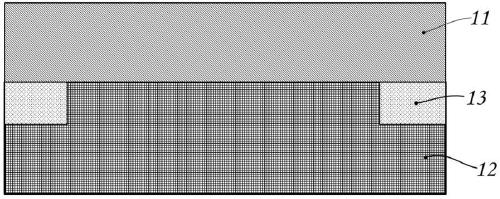

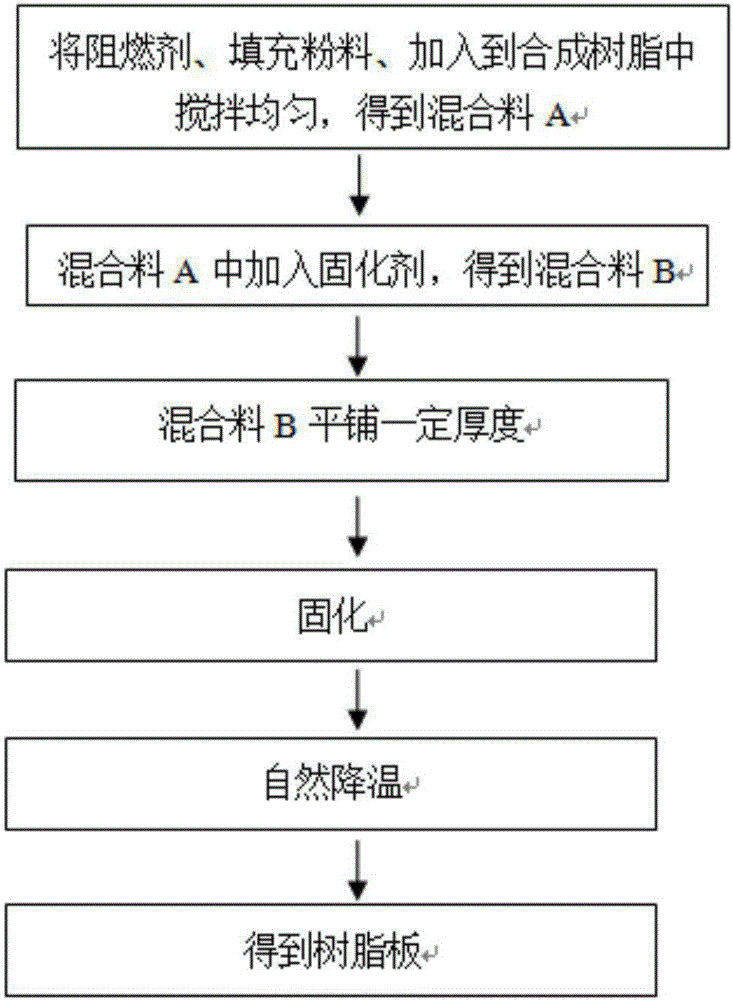

Resin material for cutting diamond wire and resin plate for cutting diamond wire

InactiveCN107523019AEasy to recycleImprove yieldWorking accessoriesFine working devicesNitrogenSlurry

The invention provides a resin material for cutting a diamond wire and a resin plate for cutting the diamond wire. The resin material for cutting the diamond wire comprises the following components in parts by weight: 20 to 70 parts of synthetic resin, 5 to 50 parts of a flame retardant, 10 to 70 parts of silicon powder and 1 to 20 parts of a curing agent; the flame retardant is selected from one or more of bromine-series flame retardants, nitrogen-series flame retardants, phosphorus-nitrogen-series flame retardants and silicon-series flame retardants. Compared with the prior art, the resin material for cutting the diamond wire takes the silicon powder as filler, and does not take a metal-containing compound as the filler, so that cutting slurry does not require subsequent treatment, environment-protection pressure is lightened, and the cutting slurry is beneficial to cyclic utilization; the characteristics of the resin material are close to the characteristics of a cut silicon rod, which is beneficial to cutting, so that the yield of silicon pieces is high. The shore hardness of the resin plate prepared by the resin material is 80 to 96, and does not have bending or deformation; the edge breakage rate of a silicon rod slice is about 1 percent.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

Method for making non-woven mesh composite non-woven fabric with rotary weft laying method

ActiveCN104674460ALeading technology levelIncrease line speedNon-woven fabricsEngineeringNonwoven fabric

The invention discloses a method for making a non-woven mesh composite non-woven fabric with a rotary weft laying method. In the method, continuous fibers, a non-woven fabric material and a colloidal bonding agent are taken as original auxiliary materials, and a brand-new rotary weft laying-sizing way is adopted, so that weaving of square and rhombus non-woven mesh composite non-woven fabric is realized. By adopting the method, the conventional weaving concept and compounding process are changed in a disruptive way, and the mechanical structural characteristics of a material are changed, so that the comprehensive performance and production efficiency of a product are greatly increased, and the material cost of a relevant strong fabric is greatly lowered.

Owner:CHANGZHOU NEWLAND COMPOSITE MATERIAL

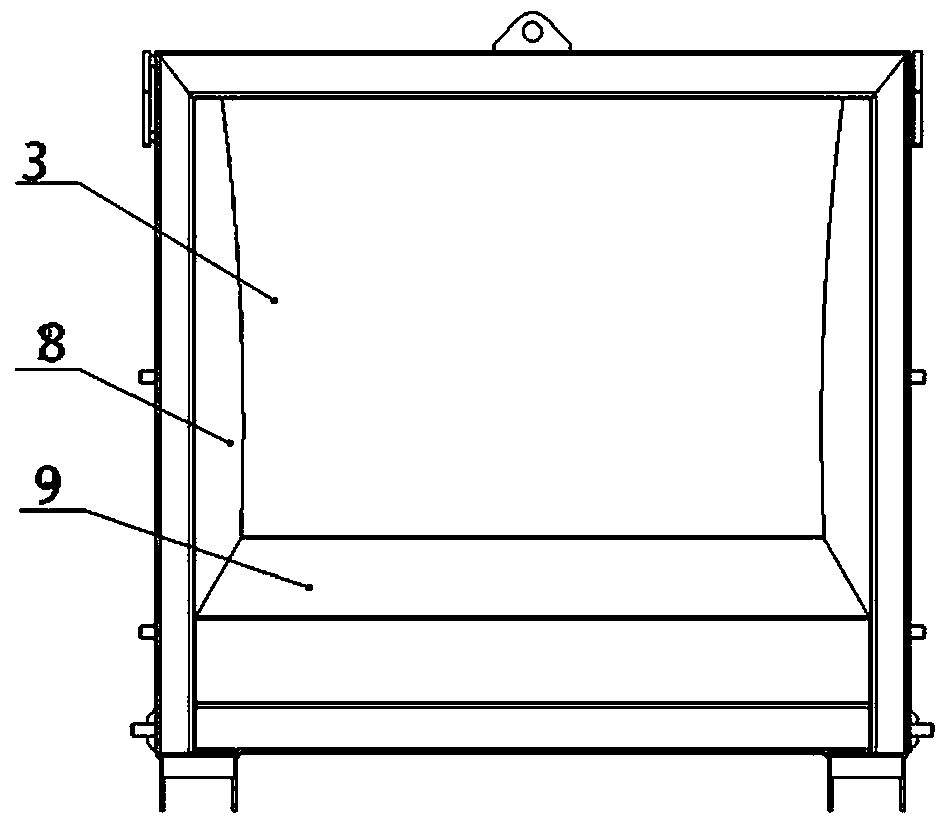

Rear door water leakage prevention structure of intelligent mobile rubbish compressor

InactiveCN109353731APrevent outflowPrevent overflowRefuse transferringLoading/unloadingHydraulic cylinderWater leakage

The invention discloses a rear door water leakage prevention structure of an intelligent mobile rubbish compressor. The structure comprises a box body, a rear door, a rear door frame and a rear door locking mechanism, wherein the rear door frame is installed in the box body; and the rear door locking mechanism comprises a hydraulic cylinder, a locking plate, a clamping column, a mounting plate anda fixing shaft, wherein a piston rod of the hydraulic cylinder is movably connected to the upper end of the locking plate. The structure has the beneficial effects that the problem of water leakage of the intelligent mobile rubbish compressor is solved, and the sanitation environment is protected.

Owner:江苏巨邦环境工程集团股份有限公司

Cradle with shaft

InactiveCN101756555AReduce wearOperational securityCradleRope making machinesProduction rateEngineering

Owner:张家港市汇金电力材料有限公司

Method for preparing nano carbon fiber/inorganic powder antistatic material additive

InactiveCN101544882AEvenly distributedSolve reunionOther chemical processesCoatingsFiberCarbon fibers

The invention discloses a nano carbon fiber / inorganic powder antistatic additive and a preparation method thereof. The antistatic additive is a composite material obtained by growing nano carbon fiber on inorganic powder. The preparation method for the antistatic material additive comprises the following steps: A, loading a metal catalyst on the surface of the inorganic powder; and B, growing the nano carbon fiber on the surface of the inorganic powder. The nano carbon fiber / inorganic powder conductive composite material can be directly mixed with paint to prepare antistatic paint without treatment.

Owner:EAST CHINA UNIV OF SCI & TECH

Directed self-assembly method for block copolymers with laser

ActiveCN105446074ASharp edgeNo glitchPhotomechanical exposure apparatusMicrolithography exposure apparatusOptoelectronicsStrong binding

The invention provides a directed self-assembly method for block copolymers with laser. The method comprises the following steps: a substrate with a block copolymer layer deposited on one surface is provided, wherein the block copolymers comprise two different kinds of block molecules; laser is irradiated on the surface of the block copolymers through a photomask for forming a laser power distribution, the position with the highest light intensity is the point with the lowest potential energy, block molecules which resonate with laser frequency in the block copolymers are captured by the point with the lowest potential energy, so that the two different kinds of block molecules are guided for carrying out a periodically ordered arrangement, and a directed self-assembly pattern is formed. The directed self-assembly method for block copolymers with laser belongs to a physical method, the laser irradiation generates an extremely strong binding effect for one kind of the block molecules, so that the directed ordered arrangement at regular intervals of the two kinds of block molecules of the block copolymers are carried out, and the edge lines of the self-assembly pattern are clear without burr, bending and defect.

Owner:SEMICON MFG INT (SHANGHAI) CORP

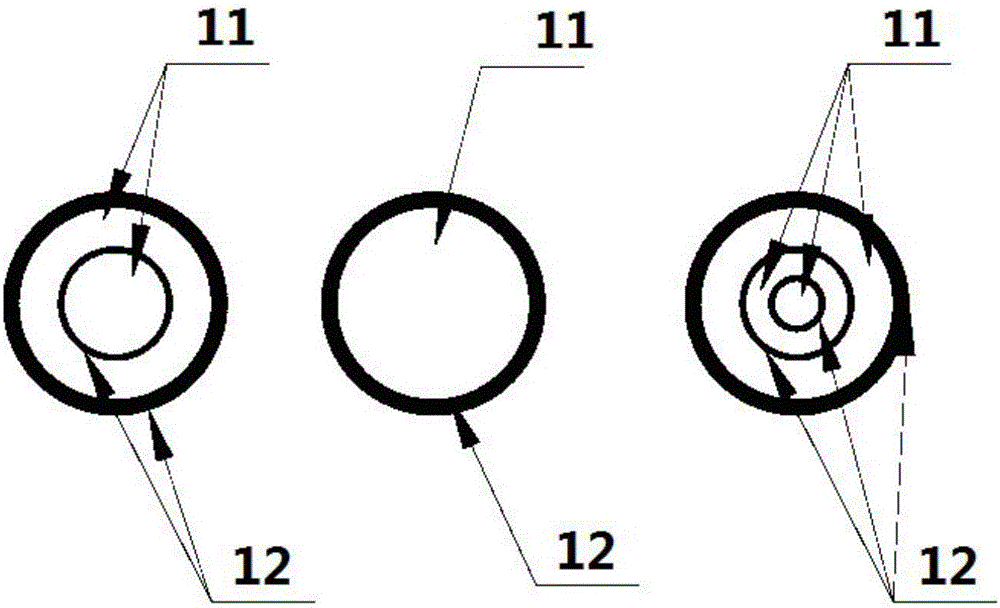

Knitting device and knitting method for carbon-carbon throat liner preform

The invention discloses a knitting device and knitting method for a carbon-carbon throat liner preform. The knitting device comprises a machine body, a flat rod reel, a vertical rod, a flat rod, a vertical rod tray, a flat rod insertion head, a knitted body pressing mechanism, a rotating mechanism and a vertical rod conveying mechanism; the flat rod reel, the knitted body pressing mechanism and the flat rod insertion head are all arranged on the machine body; the flat rod is wound on the flat rod reel and penetrates through the flat rod insertion head; the vertical rod is arranged on the vertical rod tray; the vertical rod conveying mechanism is arranged at the bottom of the vertical rod tray; the rotating mechanism is arranged at the bottom of the vertical rod conveying mechanism; and the vertical rod and the flat rod form a knitted body. When liquid phase densification is carried out, a hard rod-rod knitted preform can be placed in a vacuum impregnation container, vacuumizing is carried out firstly, then asphalt is injected, and then heating and pressurizing are carried out for a certain time, so that all gaps can be filled with the asphalt through the gaps in the edges and corners of a carbon rod. The smooth surface of the carbon rod can reduce the flowing resistance of asphalt liquid, and asphalt permeation during liquid phase densification is facilitated.

Owner:XIAN YINGLIKE ELECTRIC TECH CO LTD

Temperature sensor cutting device

The invention relates to a temperature sensor cutting device. The temperature sensor cutting device comprises a cutting knife body and a cutting platform. The cutting knife body is fixedly arranged onthe cutting platform. The cutting platform is provided with a scale label layer. One end of the cutting platform is provided with a boss, and one end of the boss is provided with a hinge device. Thecutting knife body is provided with a hinge hole, and the hinge device coordinates with the hinge hole. After the cutting device is adopted, CP cutting is rapid, cutting planes are tidy and accurate,and CP lines are not curved.

Owner:刘浩荫

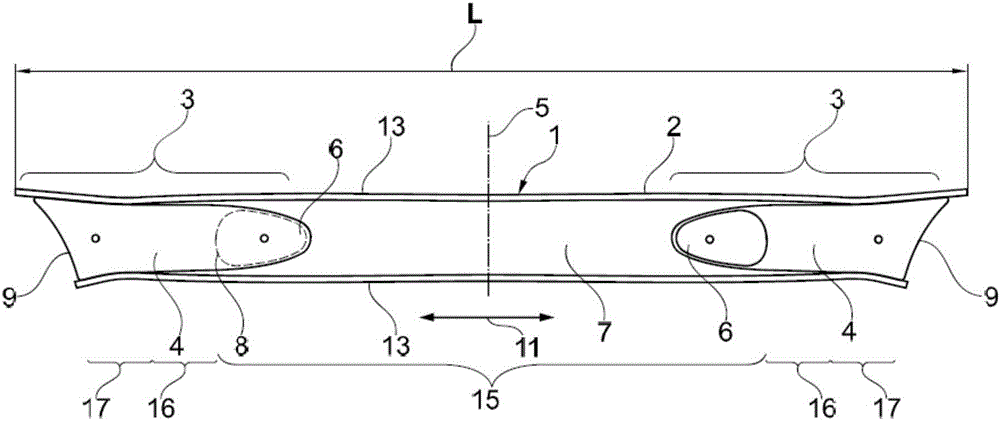

A torsion cross beam, in particular for a composite steering axle and a motor vehicle comprising the torsion cross beam

InactiveCN106314062AUniform tension distributionNo bendInterconnection systemsWheel manufactureEngineeringInsertion element

A torsion cross beam having a torsion cross beam profile in which the insert element is inserted into an end region of the torsion beam profile to form a closed cross-sectional space, wherein the insertion element is directed at the end of the longitudinal center of the torsion cross beam to form an abutment region of the torsion cross beam profile so as to fit the profile base of the torsion cross beam profile in the direction towards the end; at least in the abutment area of the torsion cross beam profile against the base of the profile, the profile base has a first cross-sectional space; the cross-section of the first cross-sectional space is curved and has a curvature greater than zero; the profile base has a curved cross-sectional space in the abutment region, and the torsion cross beam together with the insertion element form a substantially quadrilateral second cross-sectional space in the end region; and when viewed in the longitudinal direction, the torsion cross beam profile has a transition zone between the abutment region and the free end of the torsion cross beam.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com