Intelligent composite material core wire and preparation method thereof

A composite material core and wire technology, which is applied in the field of wires, can solve the problems that wires do not have the ability to measure and monitor stress and temperature, do not have communication functions, and have a small current carrying capacity, and achieve high wire density and filling rate, and no color appearance. Defects, the effect of large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

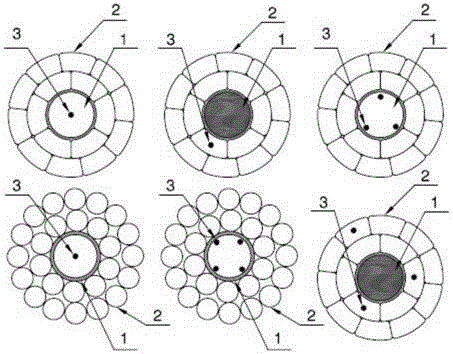

[0056] Such as figure 1 with image 3 As shown, a smart composite material core wire includes: a composite material core (1) and a single wire (2) twisted on the outer periphery of the composite material core (1); the composite material core (1) or the single wire (2) ) Is provided with one or more optical fibers (3) for communication or monitoring.

[0057] The above-mentioned smart composite material core wire is characterized in that the material of the single wire is copper, aluminum, aluminum-magnesium-silicon alloy or aluminum-zirconium alloy, and the cross-sectional shape of the single wire is circular or trapezoidal.

[0058] In the above-mentioned smart composite material core wire, the diameter of the composite material core (1) is 0.1 mm to 15 mm.

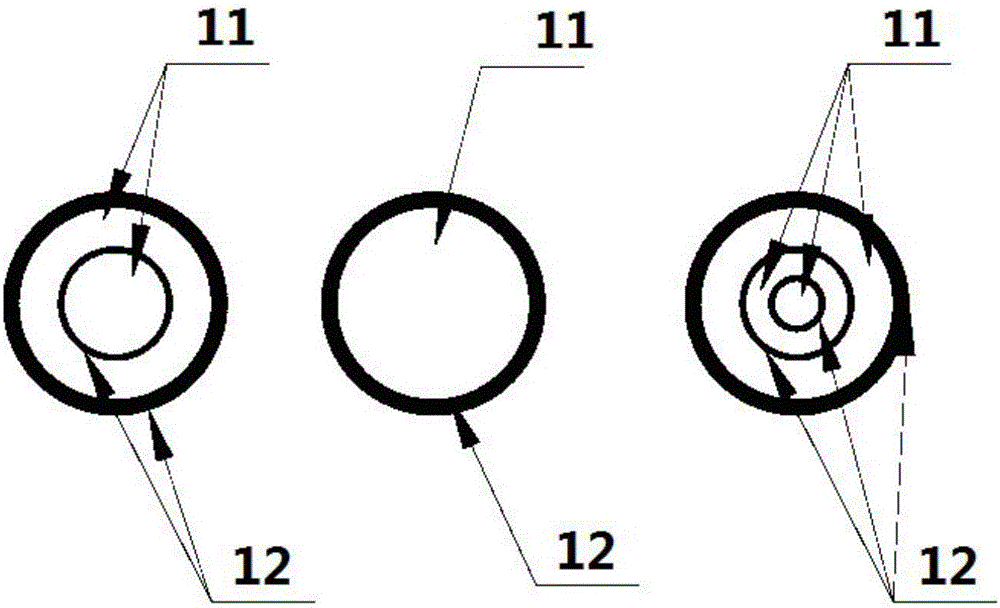

[0059] The above-mentioned smart composite material core wire, the composite material core (1) includes a high-strength fiber (11) and a fiber or fabric (12) with high breaking elongation wrapped around the high-strength fiber ...

Embodiment 2

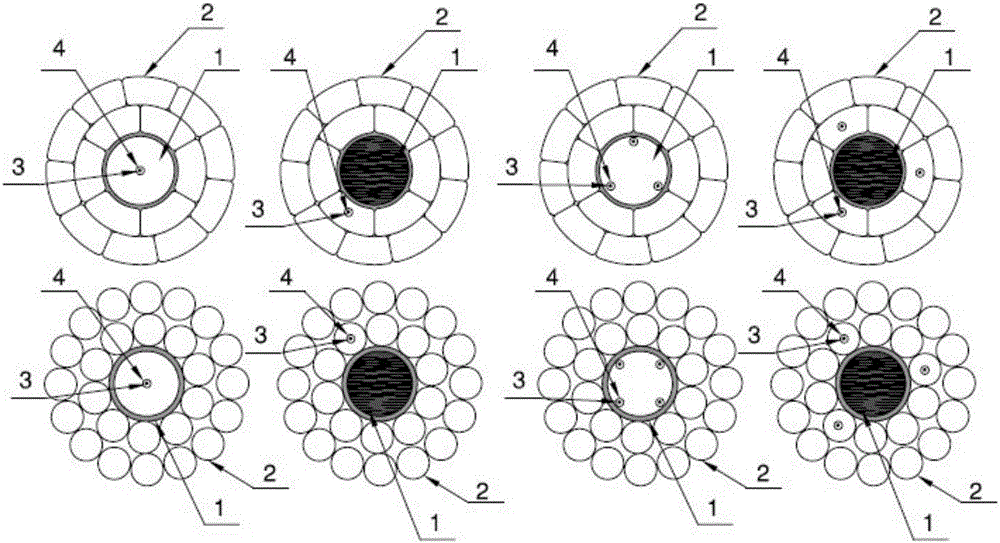

[0061] Such as figure 2 with image 3 As shown, a smart composite material core wire includes: a composite material core (1) and a single wire (2) twisted on the outer periphery of the composite material core (1); the composite material core (1) or the single wire (2) One or more optical fiber protection tubes (4) are arranged in the optical fiber protection tube (4), and one or more optical fibers (3) for communication or monitoring are arranged in the optical fiber protection tube (4).

[0062] In the above-mentioned smart composite material core wire, the material of the single wire is copper, aluminum, aluminum-magnesium-silicon alloy or aluminum-zirconium alloy, and the cross-sectional shape of the single wire is circular or trapezoidal.

[0063] In the above-mentioned smart composite material core wire, the diameter of the composite material core (1) is 0.1 mm to 15 mm.

[0064] The above-mentioned smart composite material core wire, the composite material core (1) includes a ...

Embodiment 3

[0067] Such as Figure 4 with Image 6 As shown, a method for preparing a smart composite core wire includes the following steps:

[0068] (1) Preparation of composite material core (1):

[0069] First, the high-strength fiber (11) and the high-breaking elongation fiber or fabric (12) are placed on the creel (1-1), pulled out by the tractor (1-5), and then passed through the dehumidifier (1-2) ) Dehumidification, and then fully infiltrate the resin glue through the glue tank (1-3); the high-strength fiber (11) is drawn into the pre-curing mold and preheated into the curing mold (1-4), and then the high elongation at break After the fiber or fabric (12) passes through the rectangular yarn dividing plate and the flat yarn guide in turn, it enters the curing mold (1-4) with the high-strength fiber (11) at the same time, and at the same time, add one or Multiple optical fibers (3) or optical fiber protection tubes (4); making high-strength fibers (11) and optical fibers (3) or optica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com