Patents

Literature

69 results about "Smart composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

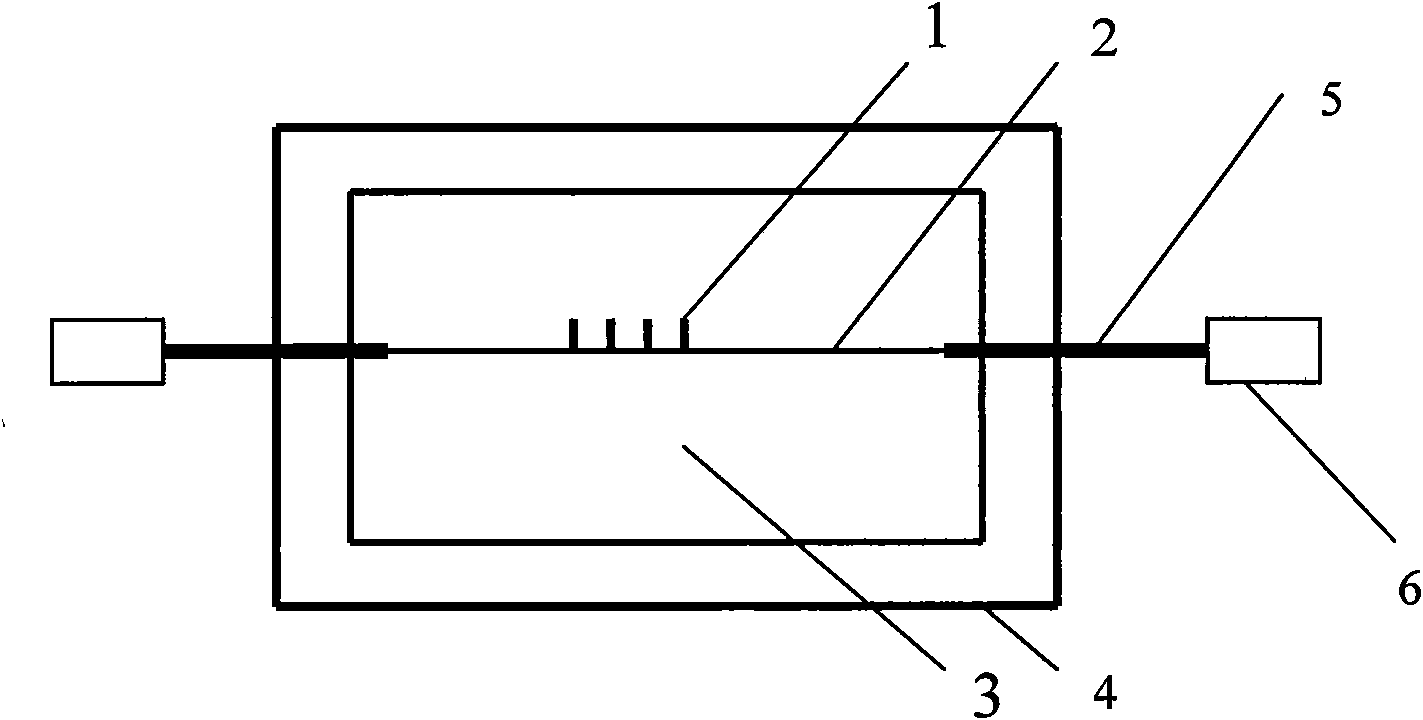

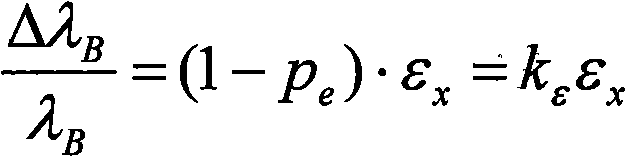

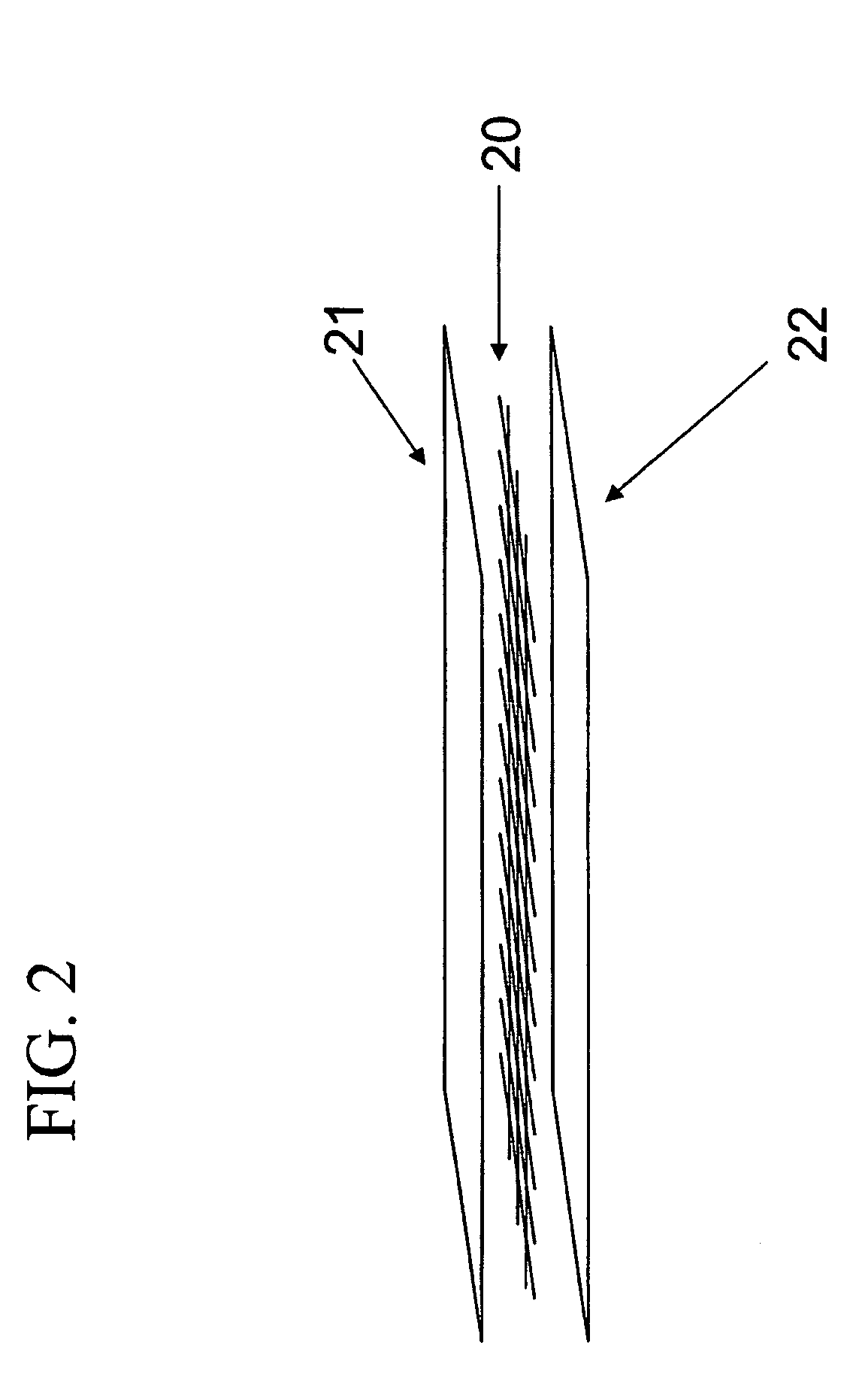

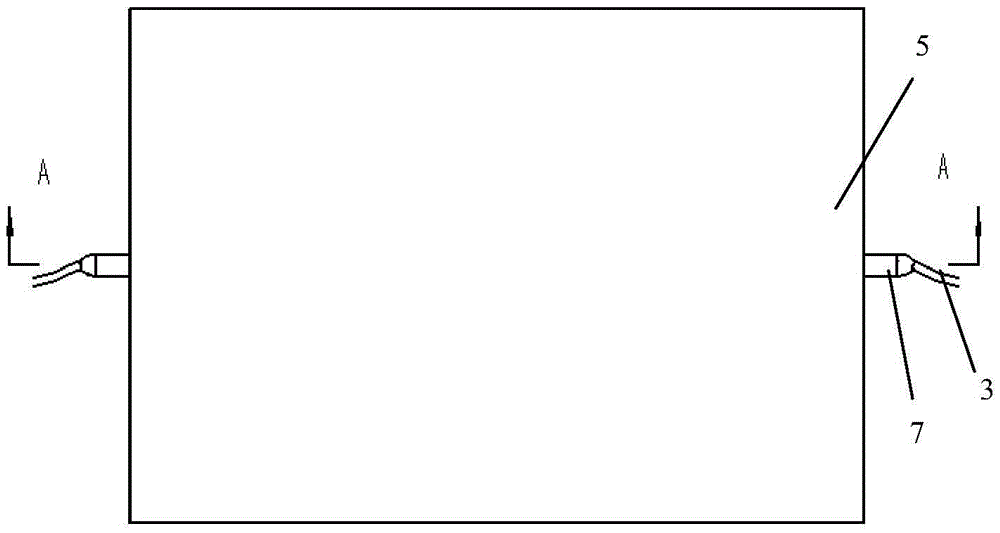

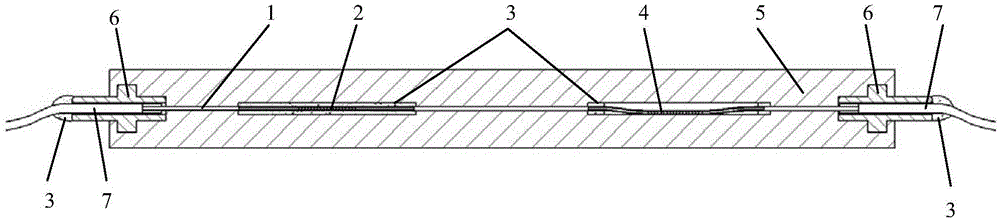

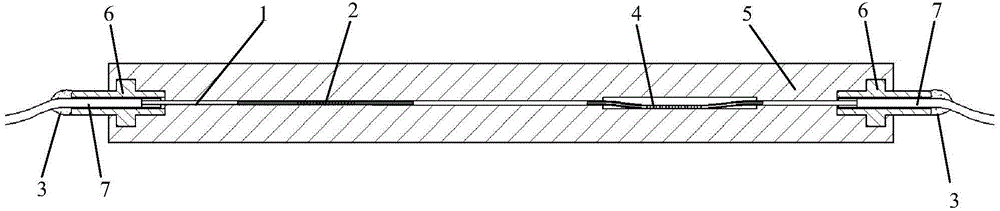

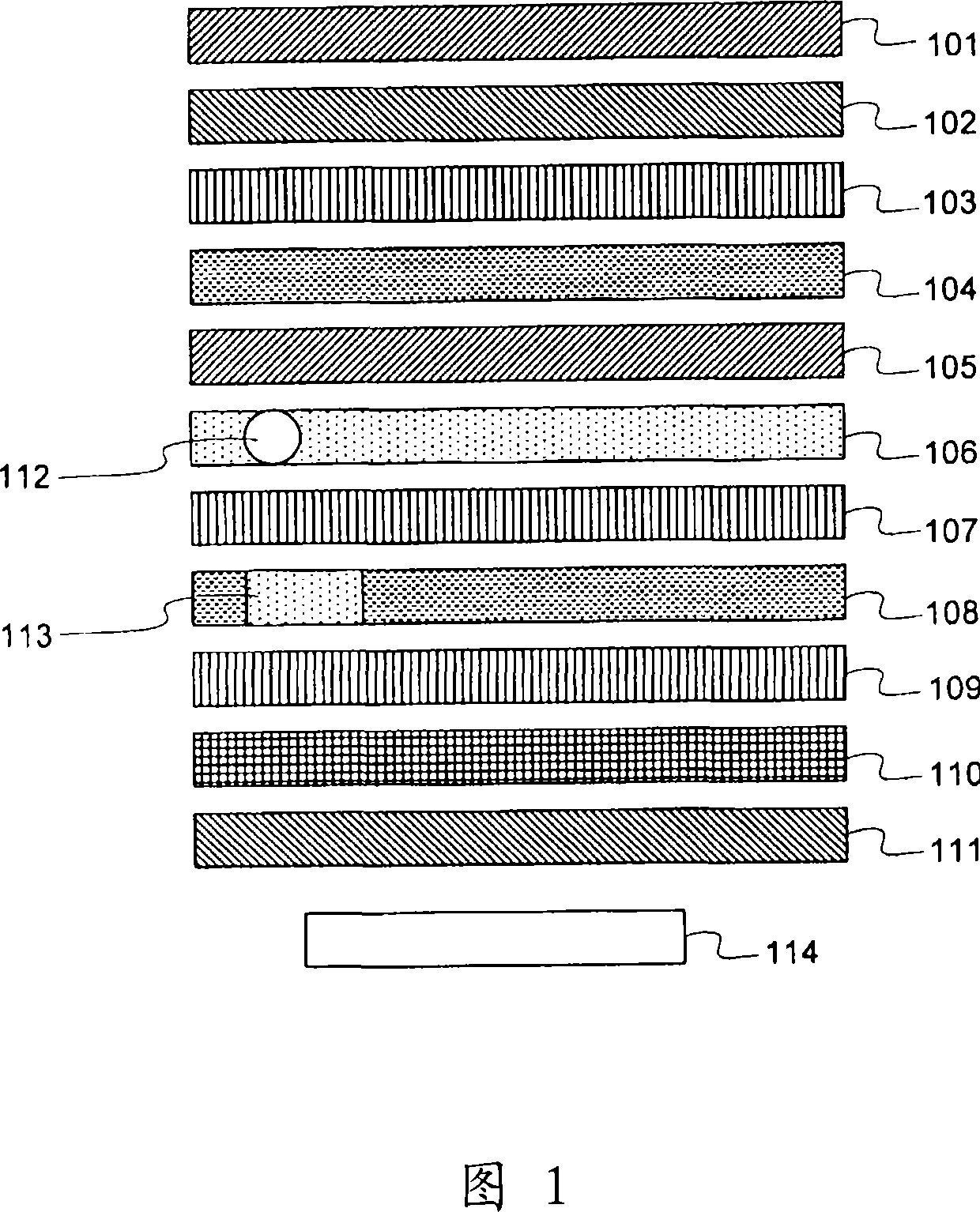

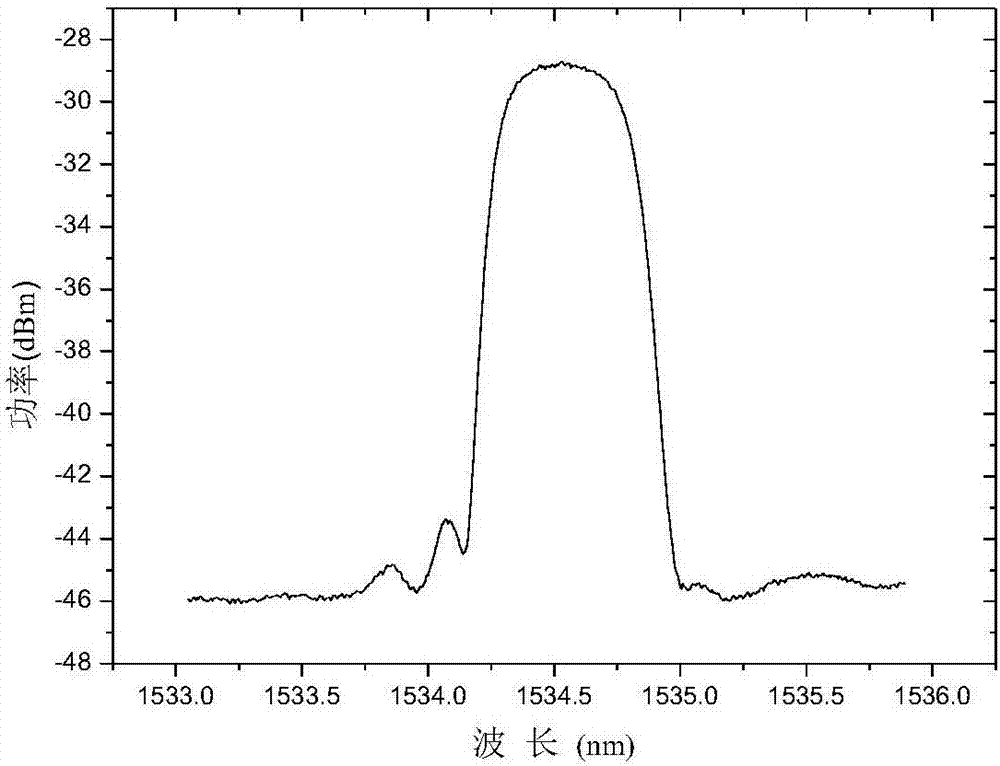

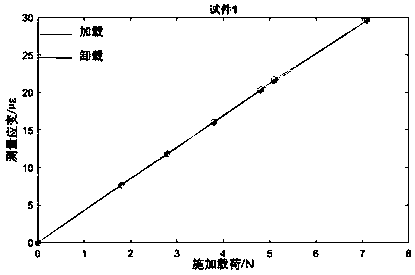

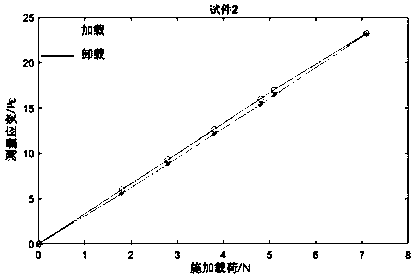

Method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain

The invention provides a method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain. In order to solve the technical problems that as fiber grating sensors are bonded to the surface of a structure through polyimide resin or epoxy resin commonly used in the prior engineering, optic fiber in service is easily destroyed; the optic fiber can get encapsulation protection but cause the concentration of surrounding stress / strain thereof if the optic fiber is directly embedded in a composite-material structure; and thermal residual stress produced in a material-curing process can cause chirp phenomena of fiber grating reflection spectrum to affect the measurement accuracy of grating strain, and the like, the invention provides the method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain. In the method, the fiber grating sensors are embedded in composite-material layers to replace resistance strain gauges commonly used in the field of monitoring structural health; by applying prestress to embedded fiber gratings, the influence of the curing residual stress of composite material on the fiber grating reflection spectrum is reduced so as to avoid the chirp phenomena; and the stability and repeatability of the sensors are improved. In addition, the composite material plays a good role in encapsulating and protecting bare fiber gratings, and meets engineering construction requirement on sensor sensitivity.

Owner:SHENYANG INST OF AERONAUTICAL ENG +1

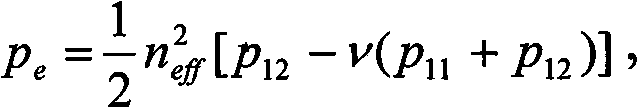

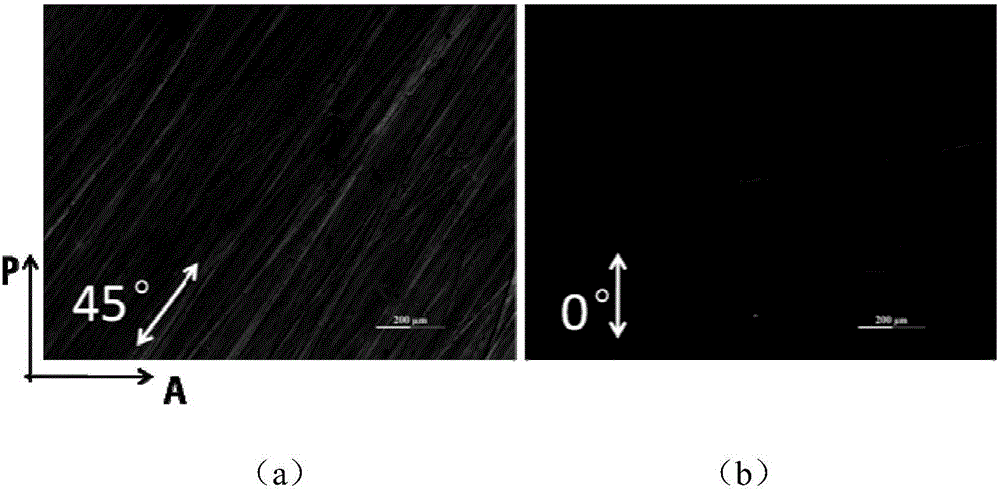

Intelligent composite material based on crystal photo-induced phase transformation and preparation method thereof

The invention discloses an intelligent composite material based on crystal photo-induced phase transformation and a preparation method thereof. A polymer film is used as a flexible substrate, the surface of the flexible substrate is subjected to friction treatment to obtain a micro groove structure, the surface of the substrate is coated with a micromolecular photoresponse crystal material capable of generating photo-induced phase transformation, and annealing is carried out to obtain a photically driven composite film capable of converting optical energy into mechanical energy. After being cut, the composite film can generate specific deformation, such as bending, curling, spiraling and moving, under specific wavelength illumination, and the process is reversible. The preparation method is simple, and the material is easy to obtain, large in deformation, high in response speed, controllable, functional and wide in application range, can be used for a flexible environment such as muscles and joints of an artificial mechanical system and can also be applied to the field of micromechanical systems.

Owner:PEKING UNIV

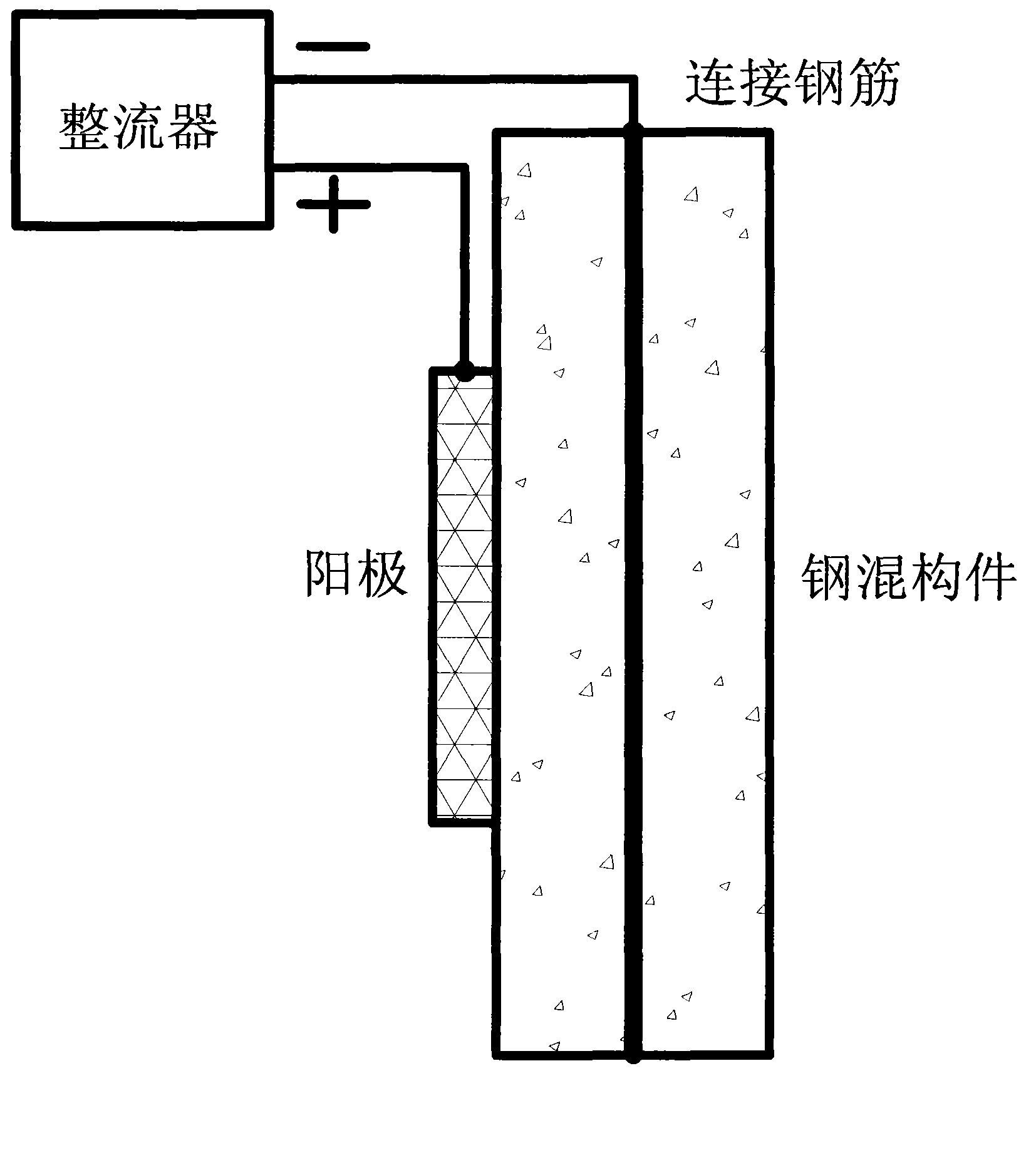

CP anode function and stress self-induction integral intelligent composite material

ActiveCN102797296AReal-time monitoring of stress distribution statusCapable of self-awareness of stressBuilding insulationsFiberCarbon fibers

The invention discloses a CP anode function and stress self-induction integral intelligent composite material comprising a Ti lath main anode, a Ti net auxiliary anode, a cement-based nanometer composite material and carbon fiber cloth; the Ti lath main anode is connected with the Ti net auxiliary anode, the cement-based nanometer composite material is covered on the Ti net auxiliary anode, and the carbon fiber cloth is paved on the cement-based nanometer composite material; and the preparation method of the cement-based nanometer composite material comprises the steps of uniformly mixing 5% of polyacrylamide, 0.5% of carbon fibers or nanometer carbon fibers, 15% of carbon black granules, 0.2% of pumping aid, 1.0% of nanometer SiO2 and 79.3% of P.0.42.5 according to mass percent, and constructing through traditional concrete pumping technology, wherein the weight ratio of water to the cement-based nanometer composite material is 0.4-0.6. The CP anode function and stress self-induction integral intelligent composite material disclosed by the invention is convenient in construction, capable of greatly prolonging the service life of the anode material, high in conductivity and is capable of monitoring the stress distribution state of the critical region of a steel concrete structure in real time.

Owner:HARBIN INST OF TECH

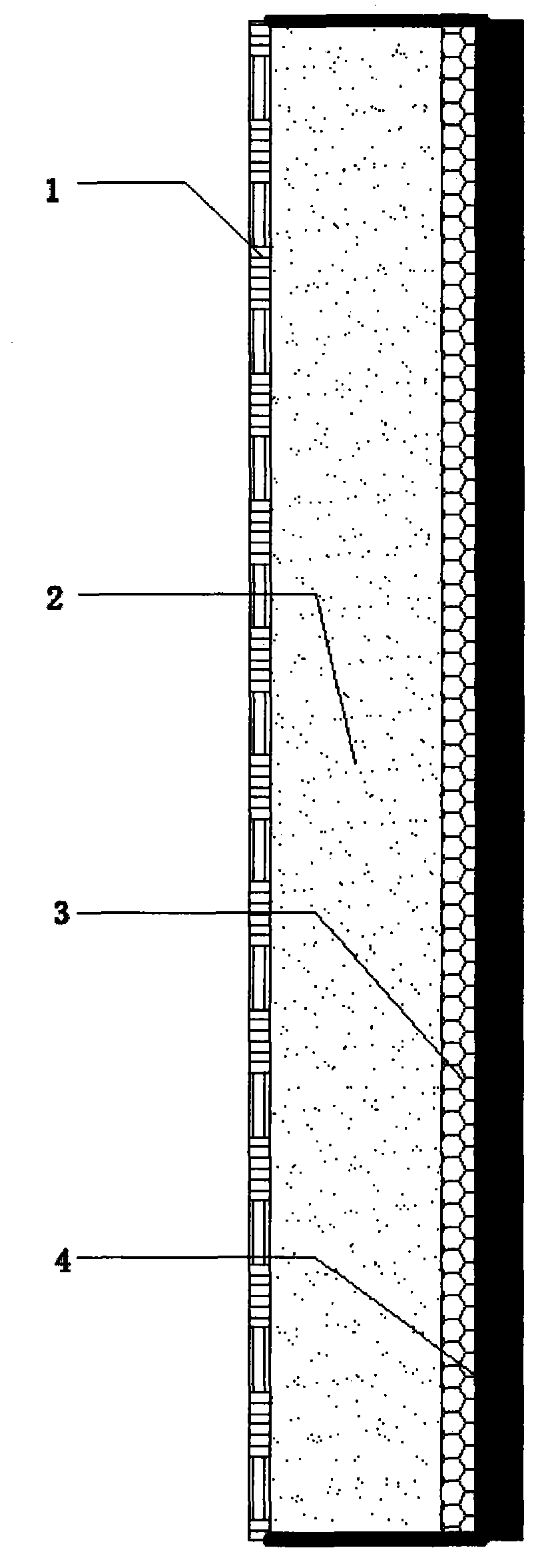

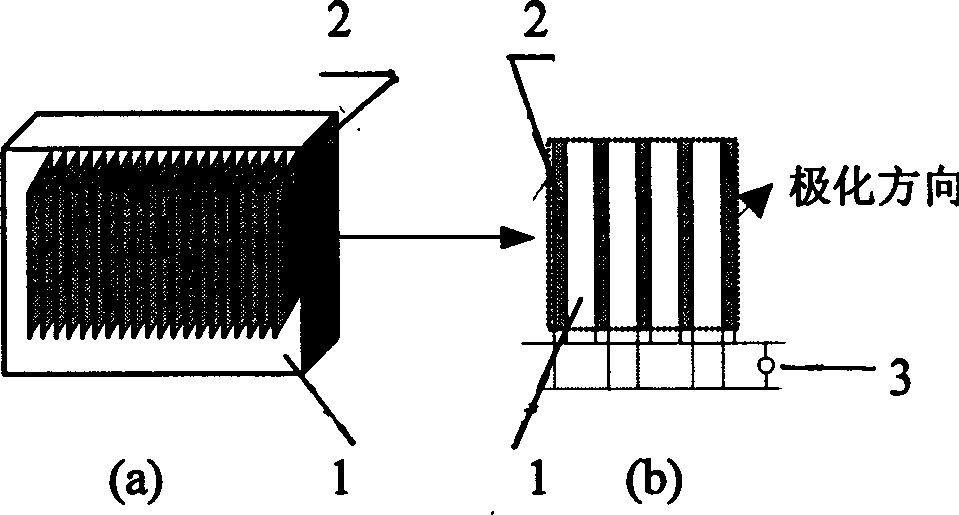

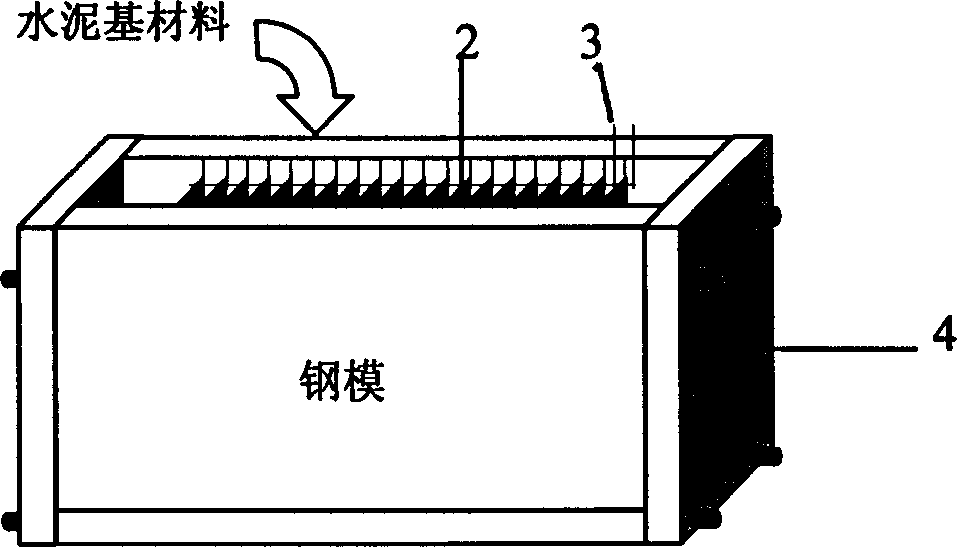

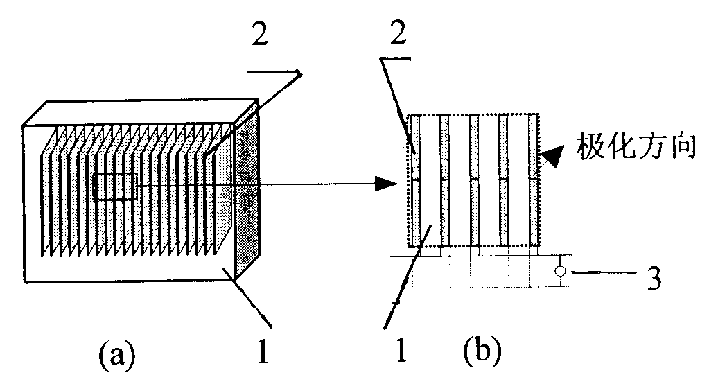

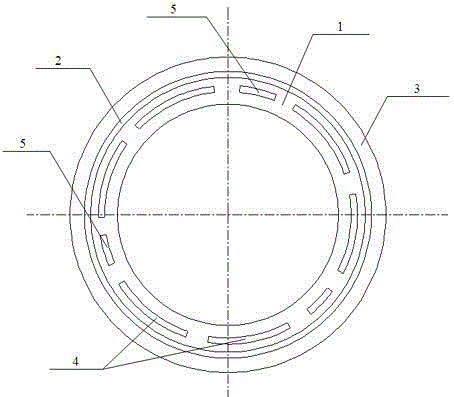

Layered cement base piezoelectric intelligent composite material and preparation method thereof

InactiveCN1450234APiezoelectricity is strong and stableImprove linearityMeasurement devicesBuilding componentsElectricityMetallurgy

The present invention relates to an intelligent composite material applicable to civil engineering. It is composed of sheet-layer cement base material and sheet piezoelectric ceramic material which are alternatively arranged. The piezoelectric ceramic sheets are connected in parallel mode by means of signal wire, and the polarization directions of adjacent two piezoelectric ceramic sheets are opposite. The preparation method of said composite material is convenient, its cost is low, its structure compatibility is good, response speed is quick, antijamming power is strong and it has the characteristics of sensing function and driving function multiplex.

Owner:TONGJI UNIV

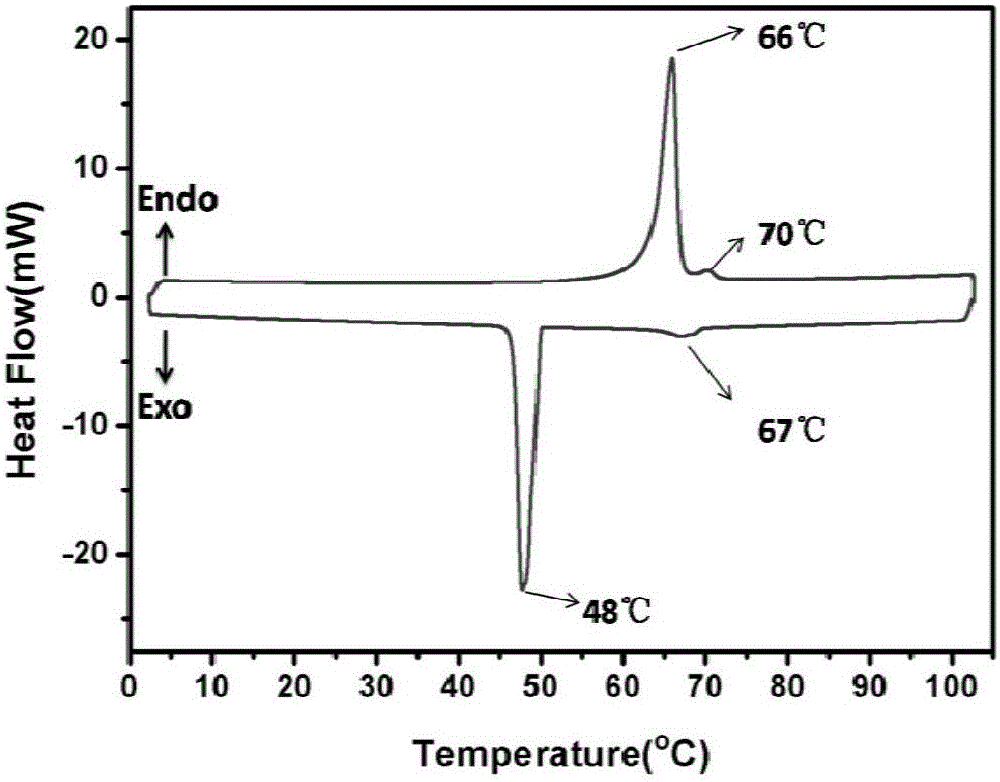

Method for preparing shape memory cyanate ester prepreg

The invention discloses a method for preparing shape memory cyanate ester prepreg, relates to a method for preparing shape memory prepreg for a fiber composite material, and aims to solve the problemsthat a conventional cyanate ester resin is single in structure, relatively high in melting point and relatively poor in manufacturability and cannot be adopted to prepare prepreg. The method comprises the following steps: I, preparing a modified cyanate ester resin prepolymer; II, preparing a shape memory cyanate ester resin; III, preparing a cyanate ester resin colloid membrane; IV, performing preimpregnation, thereby obtaining the shape memory cyanate ester prepreg, wherein the continuous fiber is a one-way continuous fiber or a fiber fabric. The method has the advantages that not only is the shape memory cyanate ester prepreg successfully prepared from a cyanate ester monomer, but also the cyanate ester prepreg has the characteristic of shape memory, and an appropriate material is provided for preparing high-performance intelligent composite materials. The mehtod is mainly used for preparing shape memory cyanate ester prepreg.

Owner:HARBIN INST OF TECH

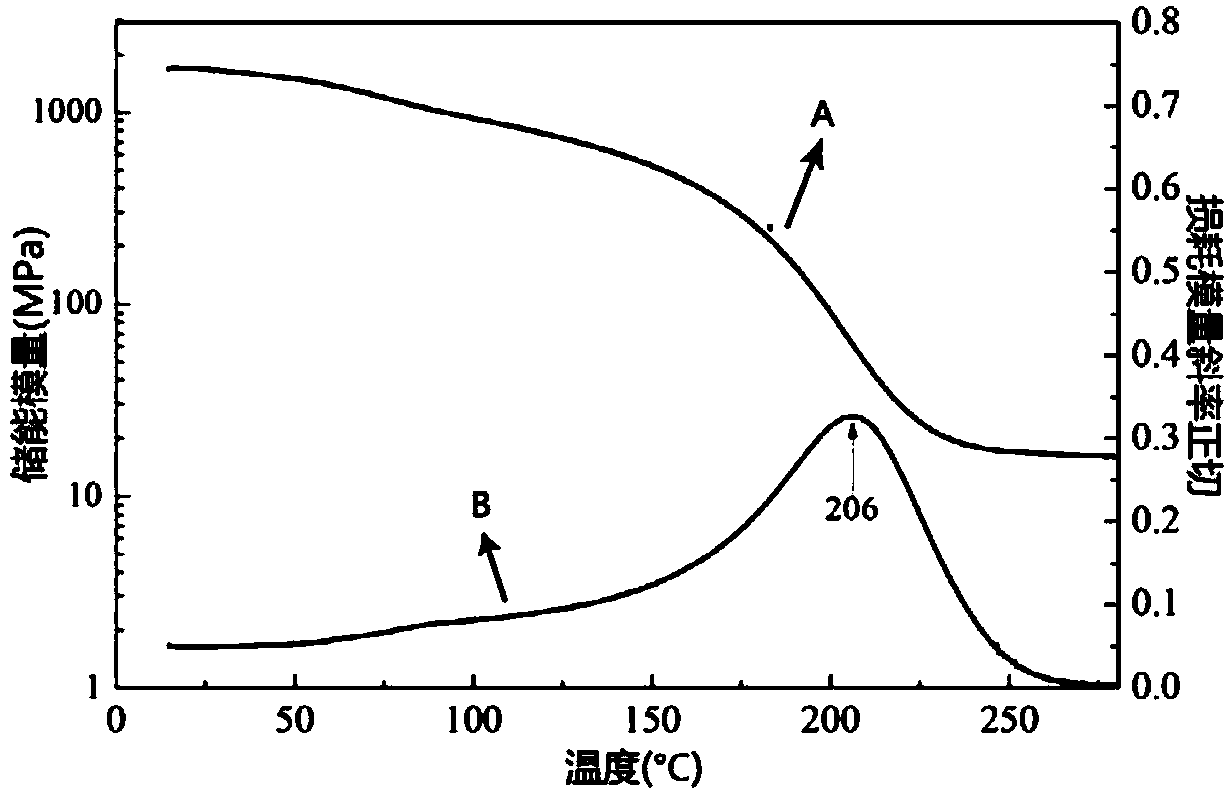

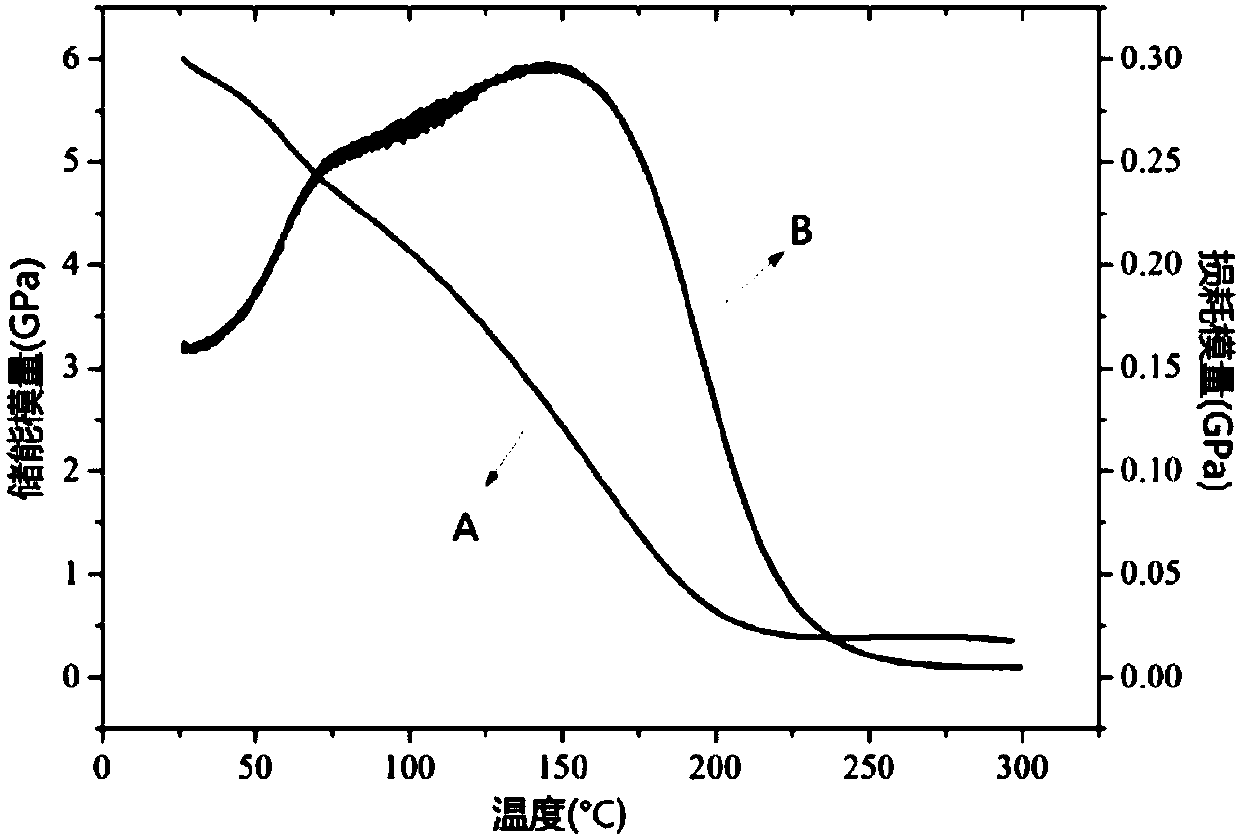

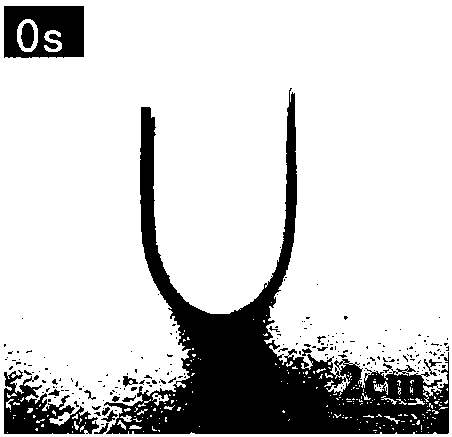

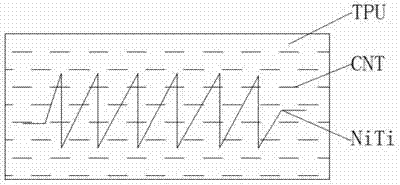

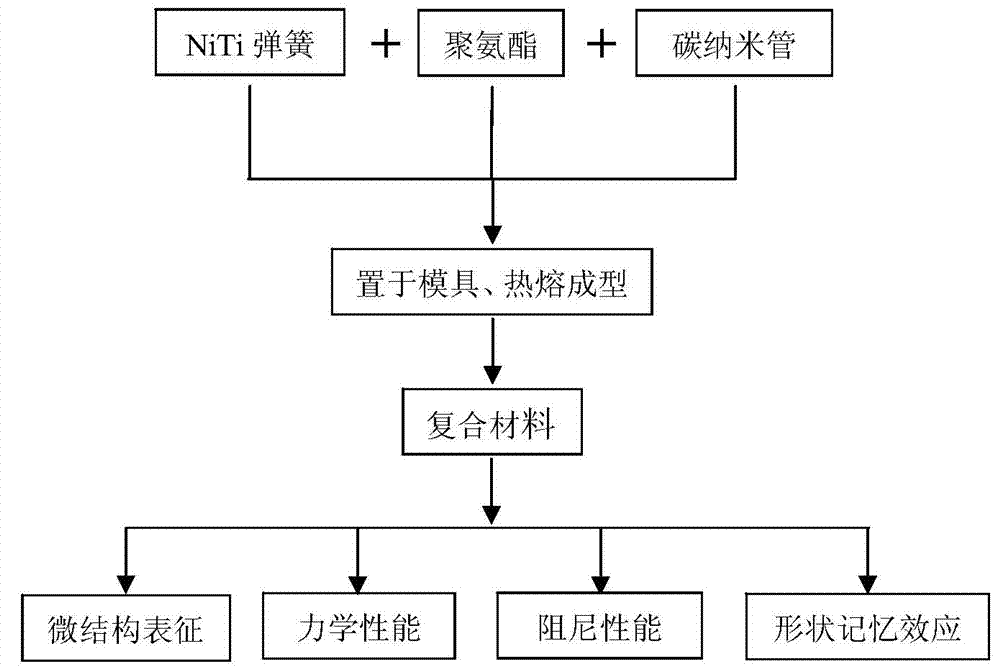

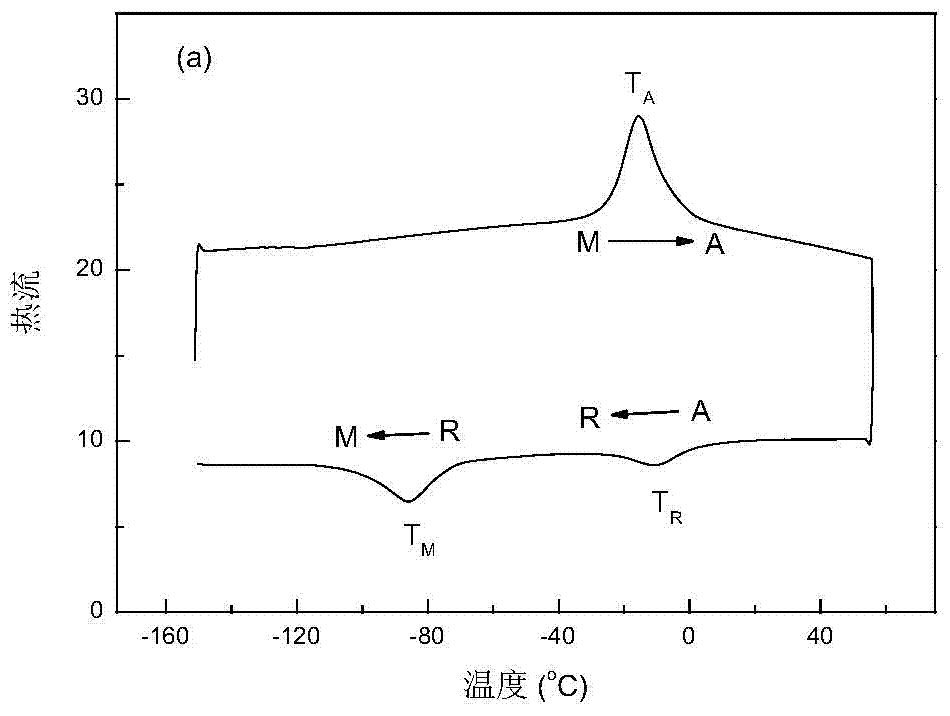

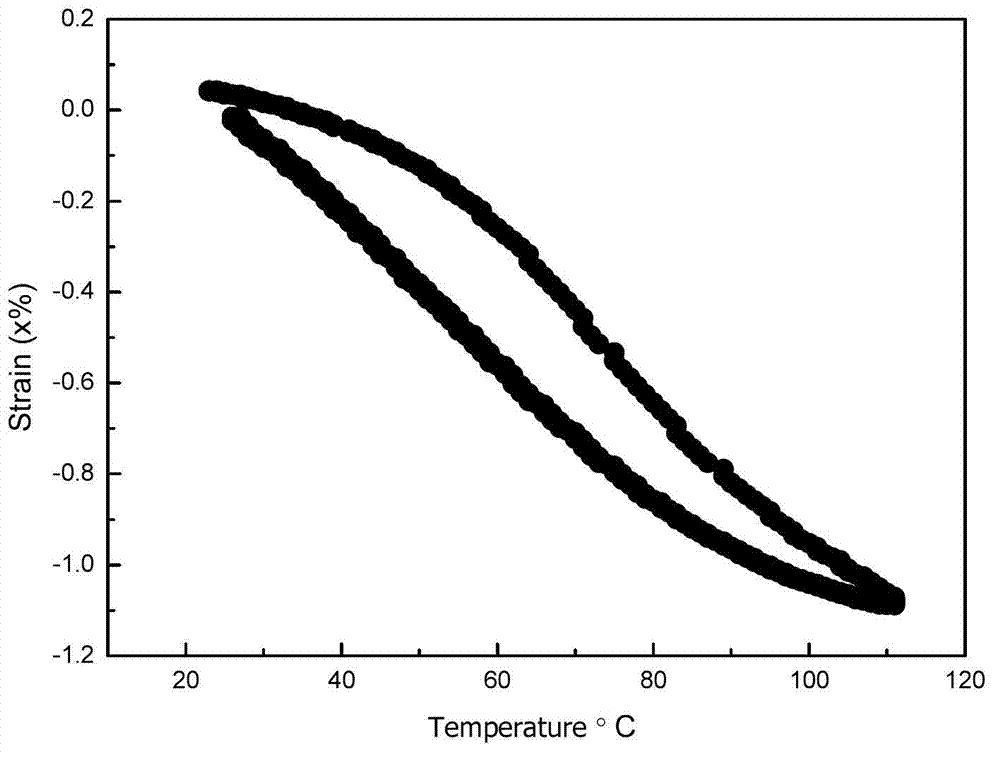

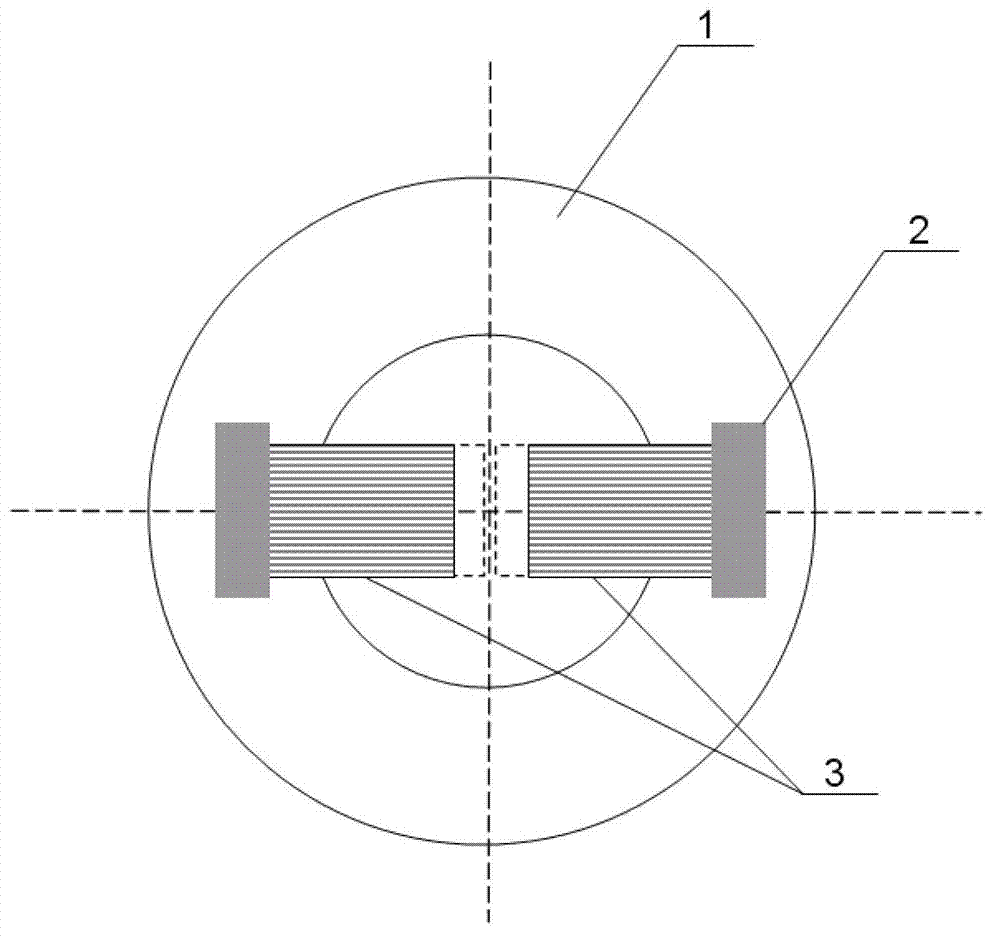

Polyurethane composite material doped by nickel-titanium memory alloy and carbon nanotube and preparation method thereof

The invention provides a polyurethane composite material doped by a nickel-titanium memory alloy and carbon nanotube, and a preparation method thereof. The preparation method comprises the following steps: (1) winding NiTi alloy wires around a spring winding machine to form a spring structure; (2) subjecting the obtained spring to a thermal treatment with a temperature of 400 to 500 DEG C; (3) mechanically stirring and mixing carbon nanotubes and polyurethane elastomer particles; (4) painting a demoulding agent on the inner surface of a mould; (5) placing the mixture obtained in the step (3) into the mould, melting the mixture at a temperature of 190 to 220 DEG C, and moulding; (6) evenly placing the NiTi alloy springs on the layer prepared in the step (5), then dispersing the mixture of carbon nanotubes and polyurethane elastomer around the NiTi springs until the springs are totally covered; (7) finally carrying out composite material melting and moulding in an air blast constant temperature oven. The prepared material is a damping intelligent composite material having a shape memory effect, is capable of adapting to the environmental and temperature changes, and can be applied to the vibration damping field.

Owner:黑龙江恒河沙科技开发有限公司

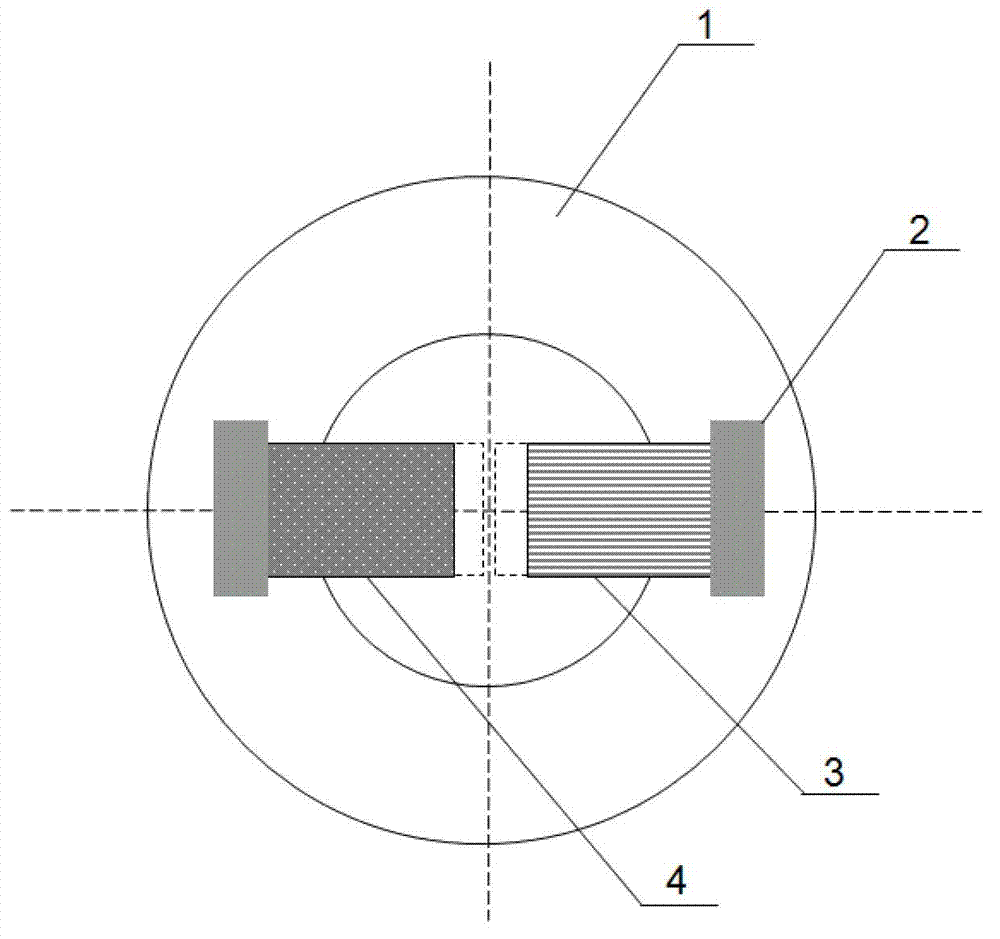

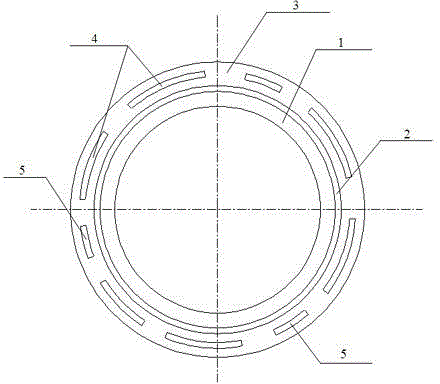

Thermally driven transmission electron microscope grid made of intelligent composite material

InactiveCN102779712AEasy to manufactureImprove performanceElectric discharge tubesElectron microscopeMetal sheet

The invention provides a thermally driven transmission electron microscope grid made of an intelligent composite material. The grid is composed of a driving portion and a support portion, wherein the support portion is a metal ring; the driving portion comprises first slide glass and second slide glass, the first slide glass is a composite material sheet or a rigidity metal sheet, the second slide glass is a composite material sheet, and the first slide glass and the second slide glass are symmetrically arranged relative to a circle center of the metal ring; and one ends of the outer sides of the first slide glass and the second slide glass are fixed on the metal ring through pressing sheets or gluing materials respectively, and one ends of the inner sides of the first slide glass and the second slide glass are not fixed. The transmission electron microscope grid can be used on standardized transmission electron microscope heating stages in various brands and is capable of achieving tilting in an X direction and a Y direction, applying in situ tensile tests to nanometer materials and larger and thicker samples, axially producing larger strain on the samples and achieving high resolution electron microscopic analyses on required zone axes.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of intelligent self-lubricating composite material containing electromagnetic trigger microcapsules

ActiveCN108410350AImprove self-lubrication efficiencyEnables tunable stimulus responsesMicroballoon preparationElectrically-conductive paintsConductive polymer compositeElectromagnetic shielding

The invention relates to a preparation method of the intelligent self-lubricating composite material containing the electromagnetic trigger microcapsules. The intelligent self-lubricating composite material comprises a conductive polymer matrix and the electromagnetic trigger microcapsules. According to the invention, the release of core-material active substances by the microcapsules are remotelyregulated and controlled through external electromagnetic stimulation, and self-repairing of lubrication and corrosion resistance of the conductive polymer composite material is realized. Compared with existing self-lubricating composite materials, the composite material provided by the invention has continuously variable electric current and magnetic field intensity which are triggered by electromagnetic stimulation, so that tunable stimulation response is realized. The intelligent composite material system and a self-repairing / self lubricating strategy thereof provided by the invention havelarge application potential and market value in the fields of self-lubricating bearings, anti-corrosion coatings, battery electrode materials and the like.

Owner:TSINGHUA UNIV

Smart composites and method of use thereof

Devices, systems, and methods for monitoring the condition of components, such as components of airframes, and in particular devices, methods, and systems for detecting faults and warning of faults in components using transmission mechanisms, such as optically or electrically conductive material incorporated in the construction of the components, added to a laminate material.

Owner:GKN AEROSPACE SERVICES STRUCTURES CORP

Method for preparing aluminum based intelligent composite material by ultrasonic welding

InactiveCN101879656AImprove protectionImprove high temperature resistanceNon-electric welding apparatusCross sensitivityGrating

The invention relates to a method for preparing an aluminum base intelligent composite material by ultrasonic welding. The method is characterized by comprising the following steps of: (1) intercepting an aluminum alloy foil; (2) pre-protecting an optical fiber Bragg grating (FBG) metal coating; (3) carrying out joint protection on a tetrafluoroethylene soft capillary; (4) adjusting an ultrasonic metal welding equipment parameter; and (5) embedding an FBG with sensing property by ultrasonic welding. The invention has the advantages that an optical fiber grating sensor embedded into a metal matrix by ultrasonic welding improves the high temperature resistance and the corrosion resistance of a sensor and has a favorable protecting function on the optical fiber grating; and the metal based intelligent composite material manufactured by ultrasonic welding effectively inhibits the cross sensitivity of the FBG, plays a role of temperature sensitivity improvement and obtains a temperature sensor with higher resolution and test precision.

Owner:NANCHANG UNIV

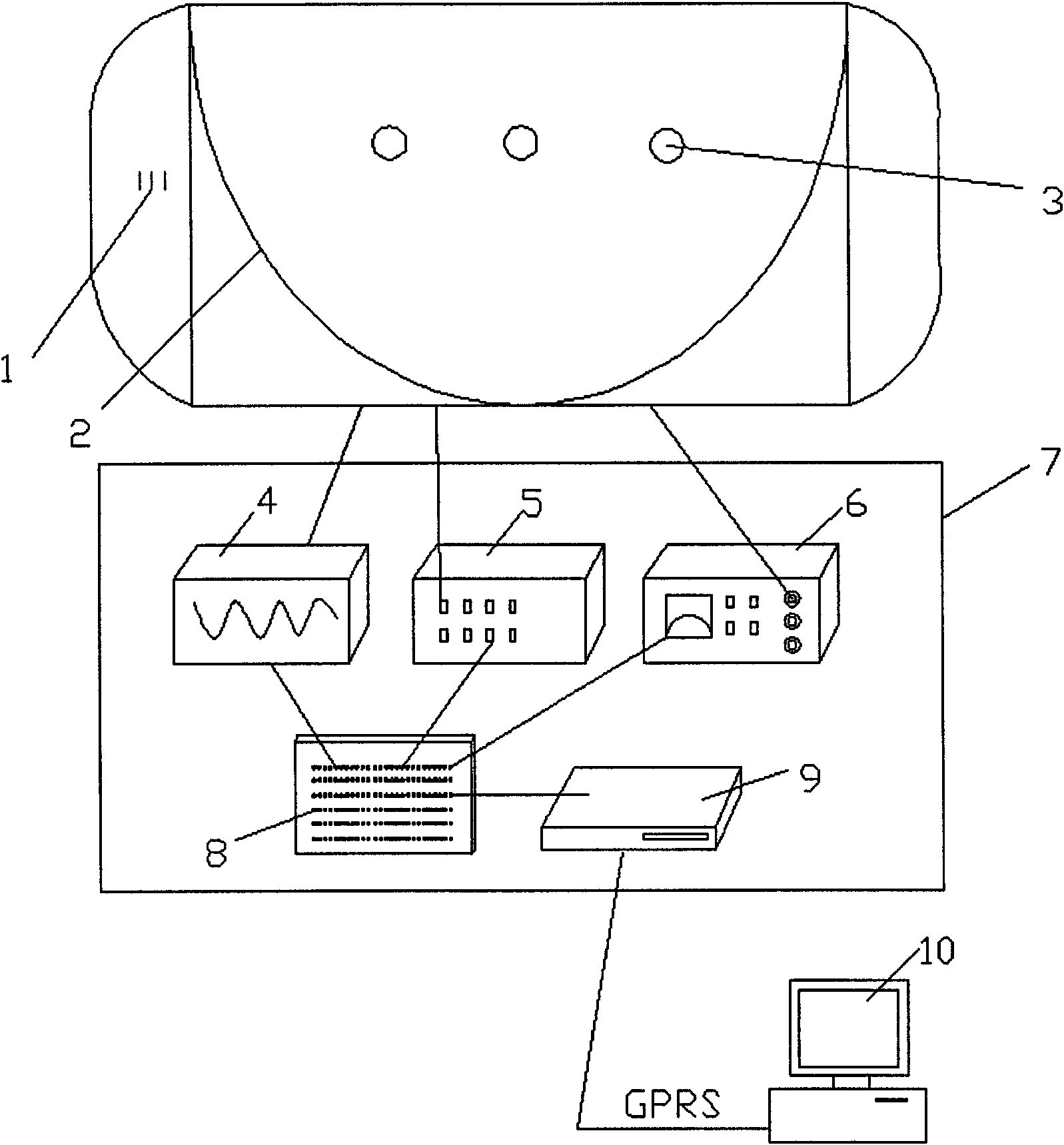

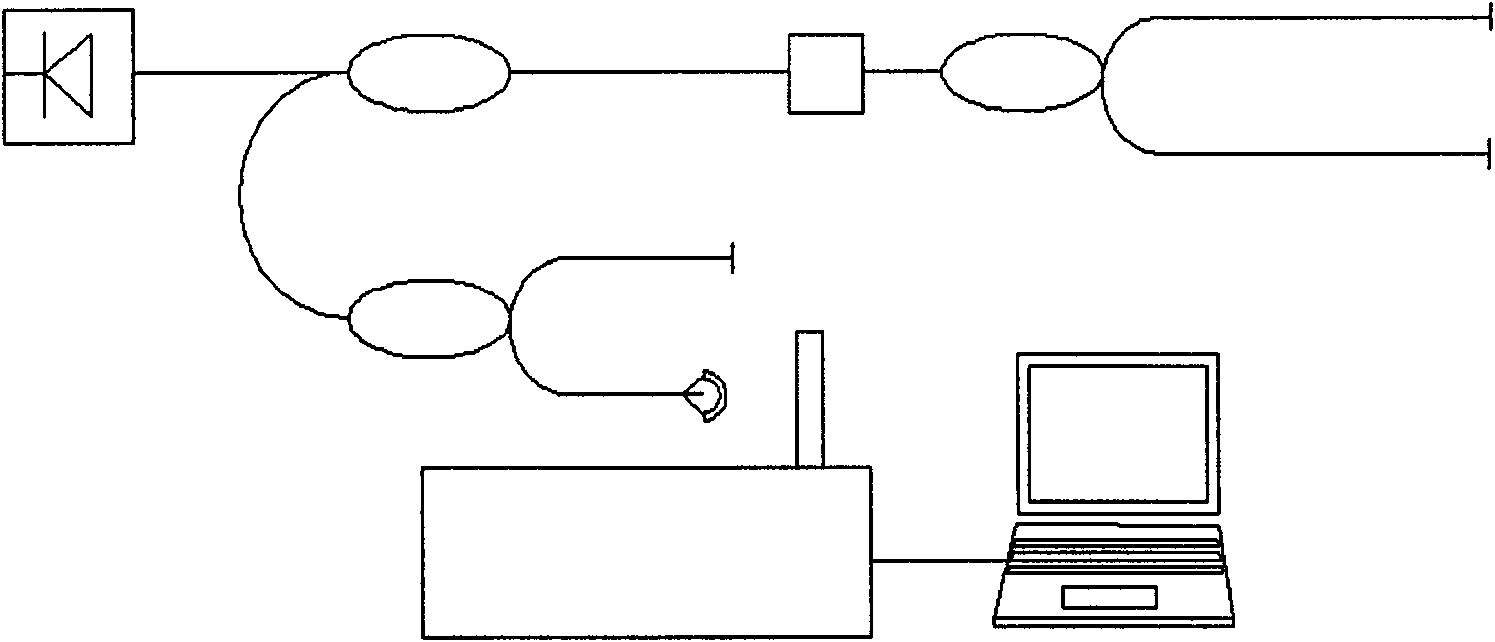

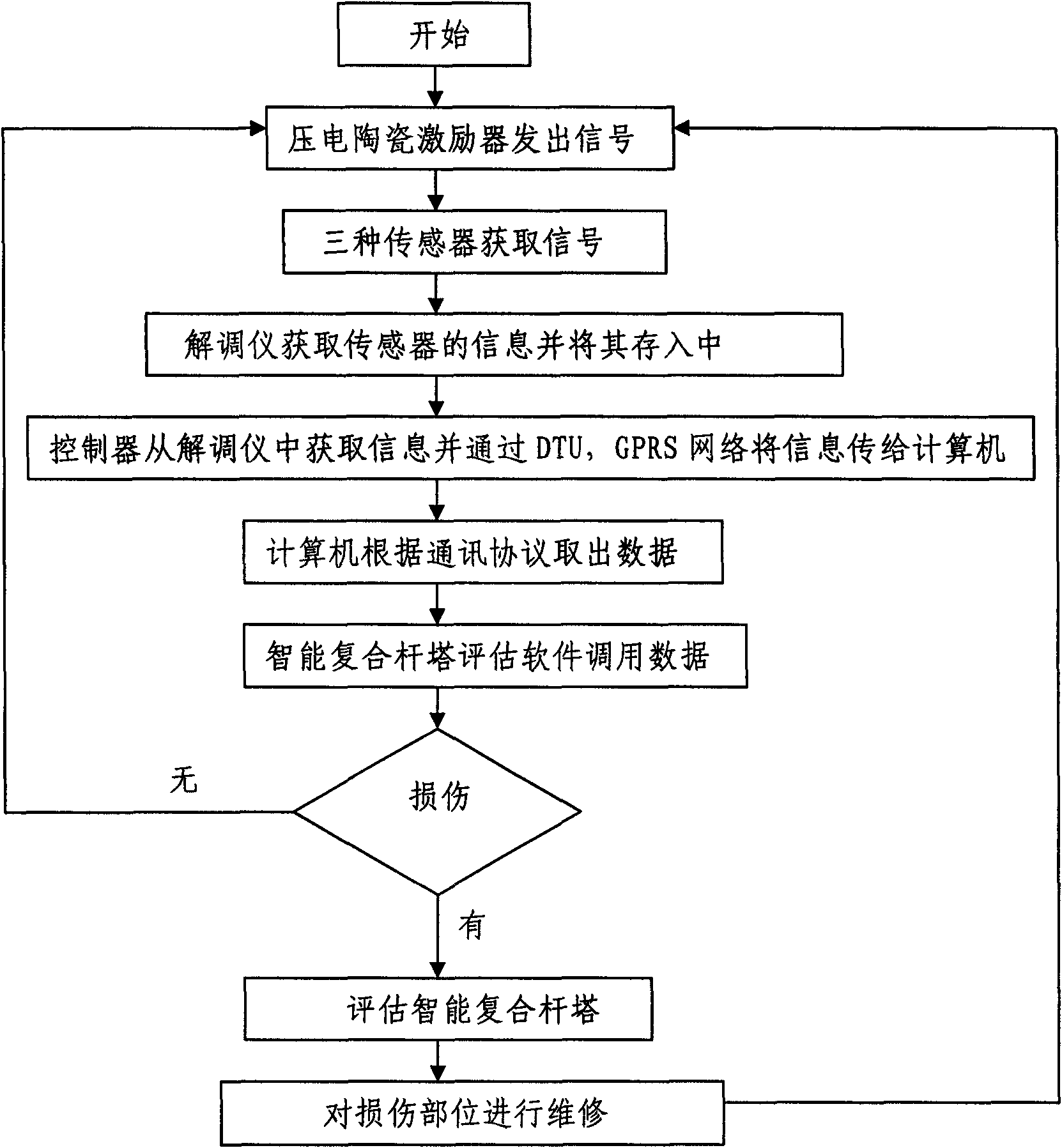

Intelligently composite material pole tower health monitoring device

InactiveCN101608976ARealize active online monitoringPhase-affecting property measurementsStructural/machines measurementData terminalElectricity

The invention relates to an intelligently composite material pole tower health monitoring device, belonging to the intelligent electrical appliance field; the monitoring device comprises a fiber grating sensor, an interference-typed optical fiber sensor and a piezoceramics. The fiber grating sensor, the interference-typed optical fiber sensor and the piezoceramics are respectively connected with a fiber grating demodulation instrument, an interference-typed demodulation instrument and a piezoceramics demodulation instrument; a main-control case internally comprises the fiber grating demodulation instrument, the interference-typed demodulation instrument, the piezoceramics demodulation instrument, a controller, a DTU (a data terminal unit) and a computer, wherein the controller obtains information from the demodulation instrument, transmits the information to other computers by a GPRS network and the information is processed by the computer. The monitoring device not only can carry out detection in the normal temperature, also can carry out the detection in the high temperature and low temperature, can well evaluate the health condition of the intelligently composite material and guarantees the using safety of the pole tower.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

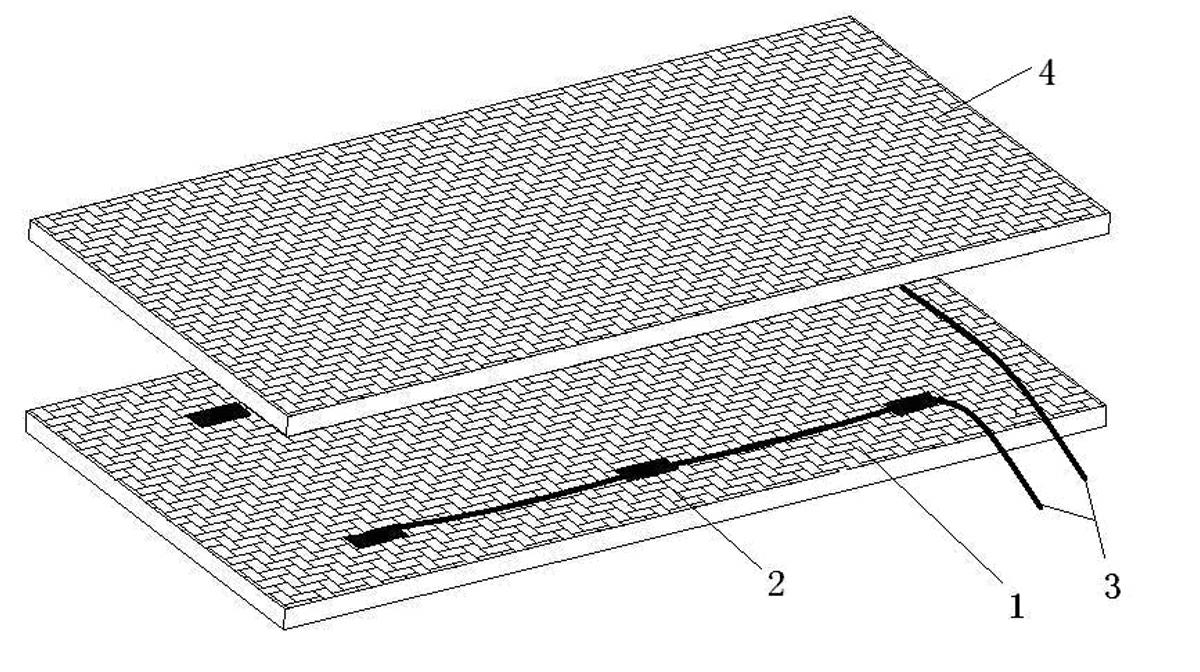

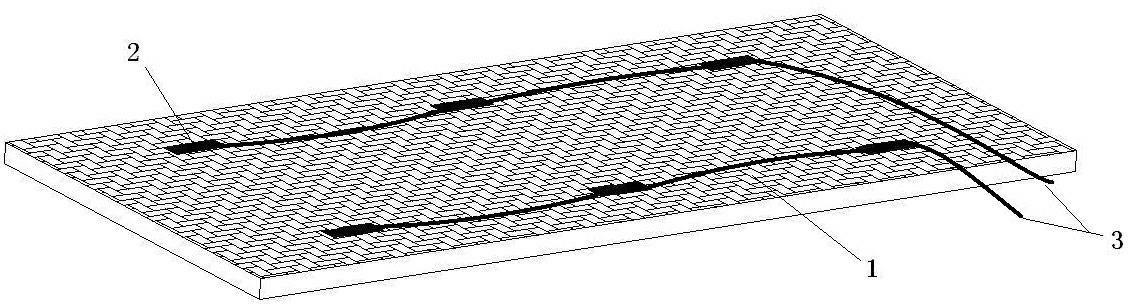

Fiber grating intelligent composite material structure based on 3D printing and preparation method thereof

ActiveCN105467513ARealize intelligent health monitoringEasy layoutFibre mechanical structuresOptical waveguide light guideFiberGrating

The invention provides a fiber grating intelligent composite material structure based on 3D printing, and the intelligent composite material structure comprises a composite material matrix and a fiber inside the composite material matrix; the fiber comprises a grating and a signal transmission tail fiber; the signal transmission tail fiber is lead out from the composite material matrix; part of the composite material matrix is printed through 3D printing and the rest of the composite material matrix is printed after adding the fiber through 3D printing. The composite material structure is printed through 3D printing; the intelligent healthy monitoring of the composite material structure that has a complex structure is realized by embedding the fiber grating in the material printing process; the installation position and the installation state of the fiber grating can be controlled because the 3D printing process can be interrupted at any time; the temperature and strain at any position of a composite material member can be monitored, and therefore the healthy real time monitoring of the composite material structure that has a complex structure is realized.

Owner:绍兴市上虞区武汉理工大学高等研究院

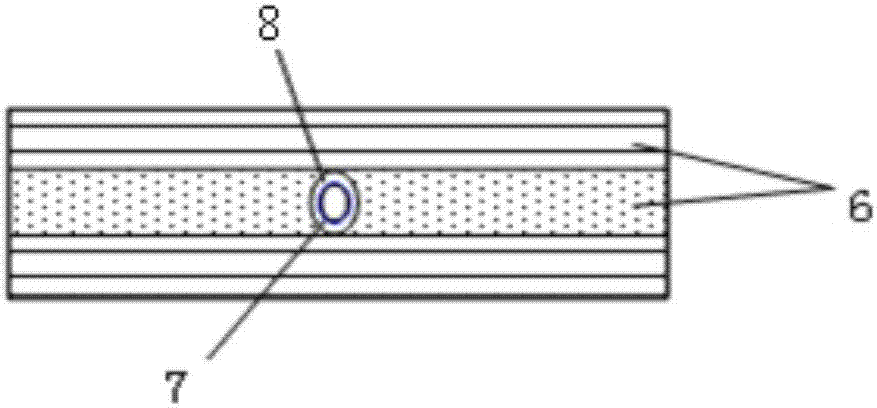

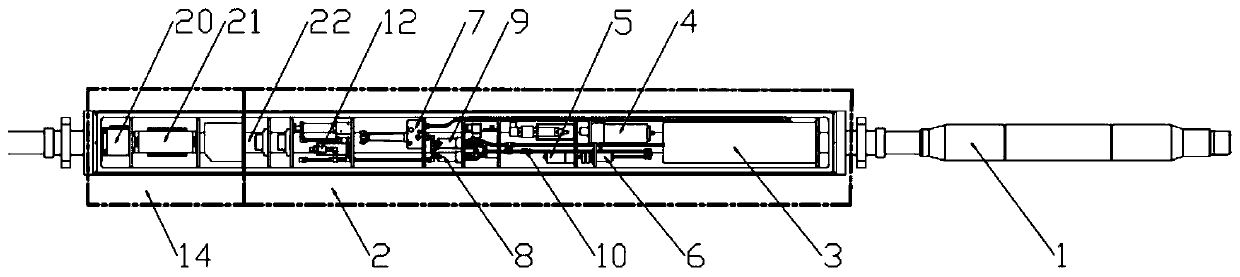

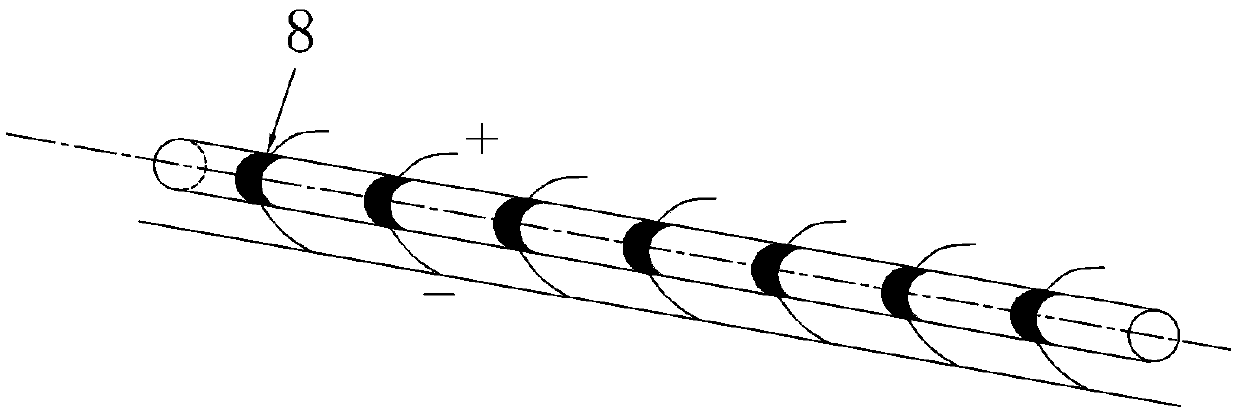

Intelligent composite material continuous pipe

InactiveCN104563897ASolve the real problemIncrease productionDrilling rodsDrilling casingsFiberCoiled tubing

The invention relates to an intelligent composite material continuous pipe for petroleum drilling and production, in particular to an intelligent composite material continuous pipe, which is used for intelligent petroleum drilling and production, electric energy transmitting, parameter measuring and real-time monitoring. The intelligent composite material continuous pipe comprises an inner pipe pressure sealing layer, a resin fiber reinforcing layer, an outer protecting layer, a power source line and an optical fiber data line, wherein the inner pipe pressure sealing layer, the resin fiber reinforcing layer and the outer protecting layer respectively adopt a whole continuous oil pipe, the power source line and the optical fiber data line respectively adopt a whole line, the resin fiber reinforcing layer is wound at the exterior of the inner pipe pressure sealing layer, the outer protecting layer coats the exterior of the resin fiber reinforcing layer, the power source line is embedded in the outer protecting layer, and the optical fiber data line is embedded in the outer protecting layer. The intelligent composite material continuous pipe has the beneficial effects that the operation cost is low, the productivity of an oil well is increased, an oil layer is protected, the safety operation and directional operation are convenient, the mechanical property is good, the intelligence effect is realized, the drilling and production advantages of deep wells and offshore platforms are more obvious, and the operation is simpler and more convenient.

Owner:CHINA PETROCHEMICAL CORP +1

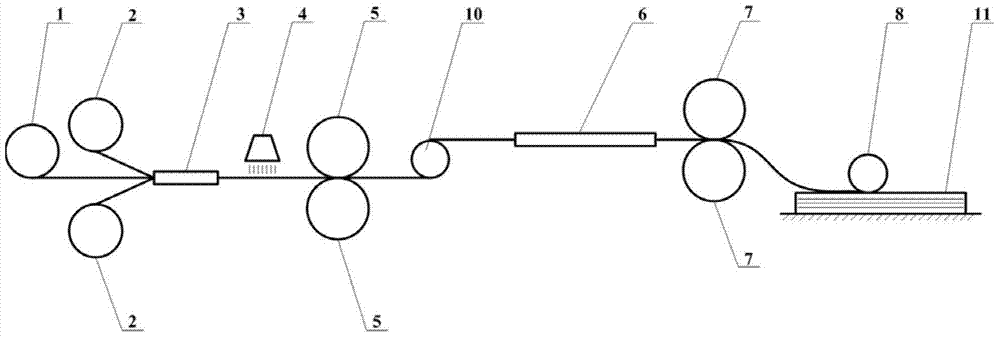

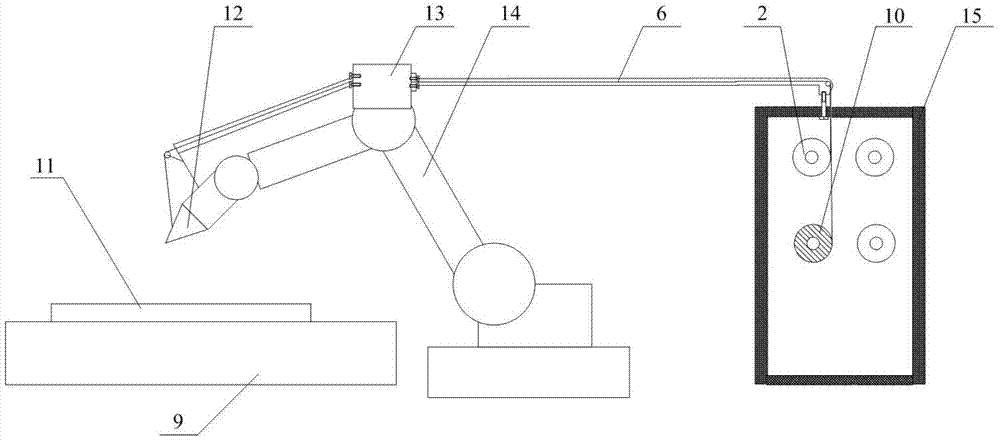

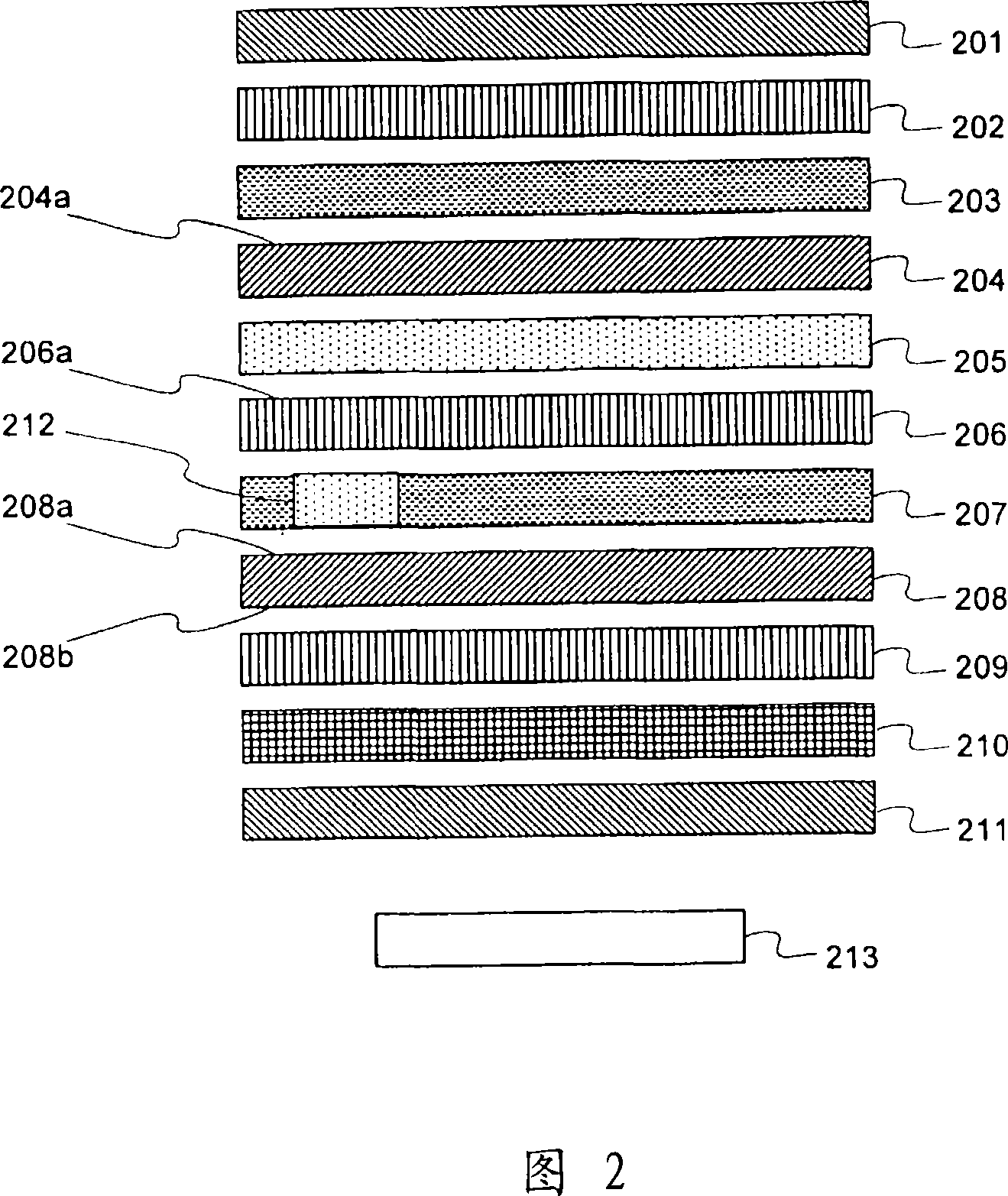

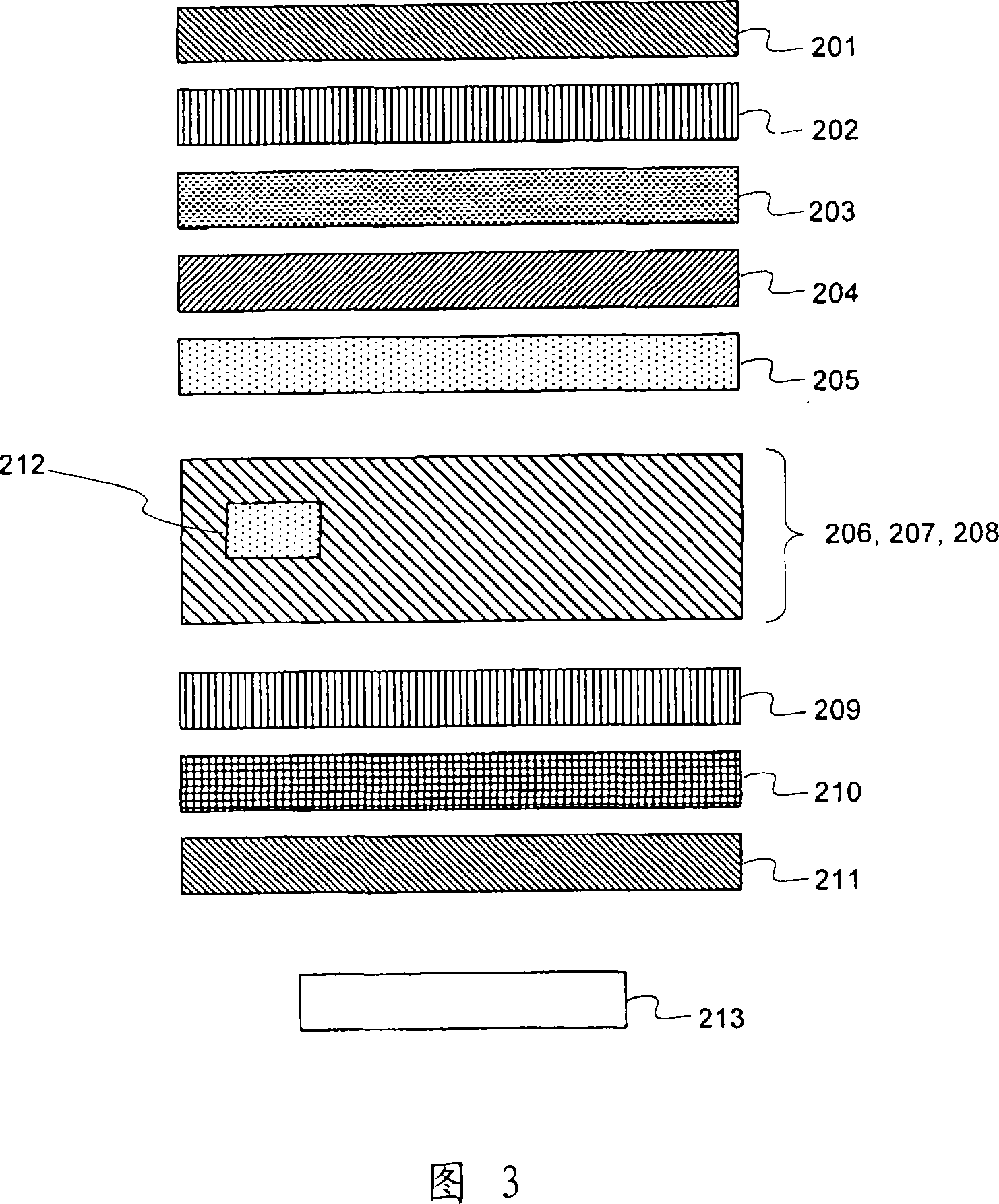

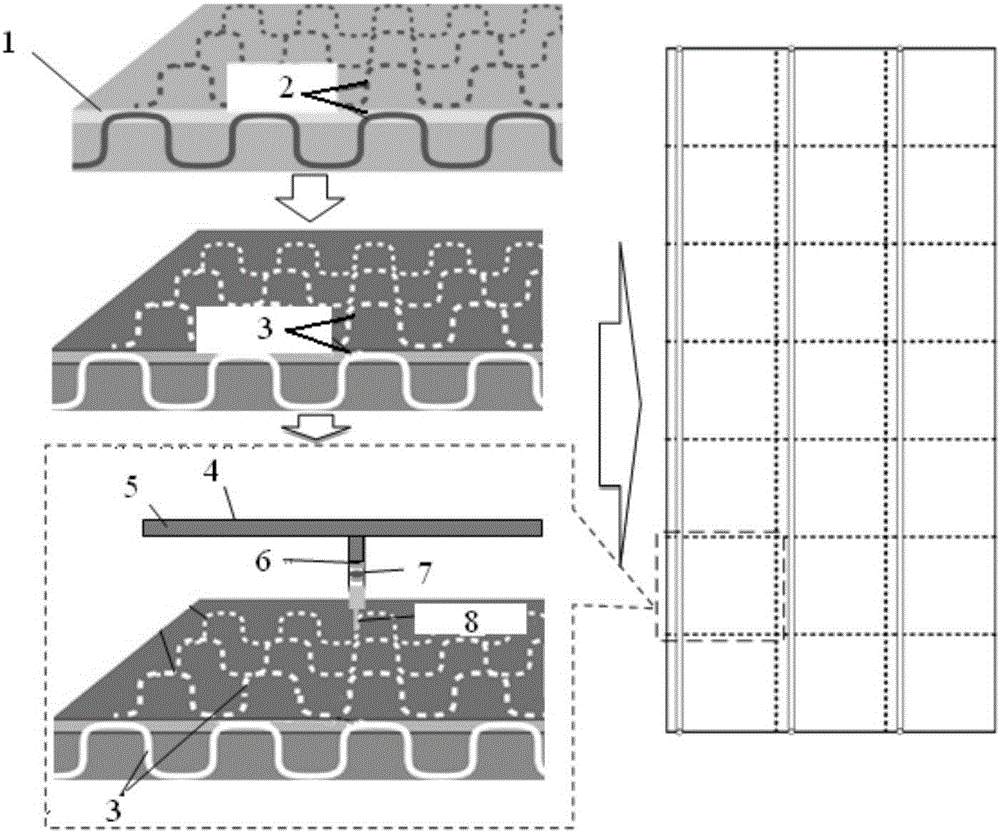

Method and device for automatically planting optical fiber into composite materials based on fiber laying and placing

InactiveCN103792033AAvoid destructionAvoid torsional deformationForce measurement by measuring optical property variationFiberEngineering

The invention discloses a method and device for automatically planting optical fiber into composite materials based on fiber laying and placing. The device comprises a manipulator used for laying and placing single-layer prepreg tape and double-layer prepreg tape with the middle wrapped by the optical fiber, a laying and placing head is arranged at the front end of the manipulator, and a prepreg tape conveying channel used for conveying prepreg is arranged on the manipulator. In the laying and placing process, the optical fiber to be planted in is placed between two pieces of single-layer prepreg tape, and the optical fiber is wrapped in the double-layer prepreg tape so as to effectively improve the survival rate for planting the optical fiber into the composite materials. The automatic panting-in technology is adopted in the process for planting the optical fiber into the composite materials, the single-layer prepreg tape is laid and placed on a substrate to a required thickness by the laying and placing head, then the double-layer prepreg tape with the middle wrapped in optical fiber is laid and placed at the required position, then the single-layer prepreg tape is laid and placed a required thickness continuously, and namely the intelligent composite materials can be obtained. With the method, the optical fiber can be effectively prevented from twisting and shifting in the conveying process, and therefore the positioning accuracy for planting the optical fiber into the composite materials is not affected, and the planting-in efficiency and quality of the optical fiber can be improved.

Owner:XI AN JIAOTONG UNIV +1

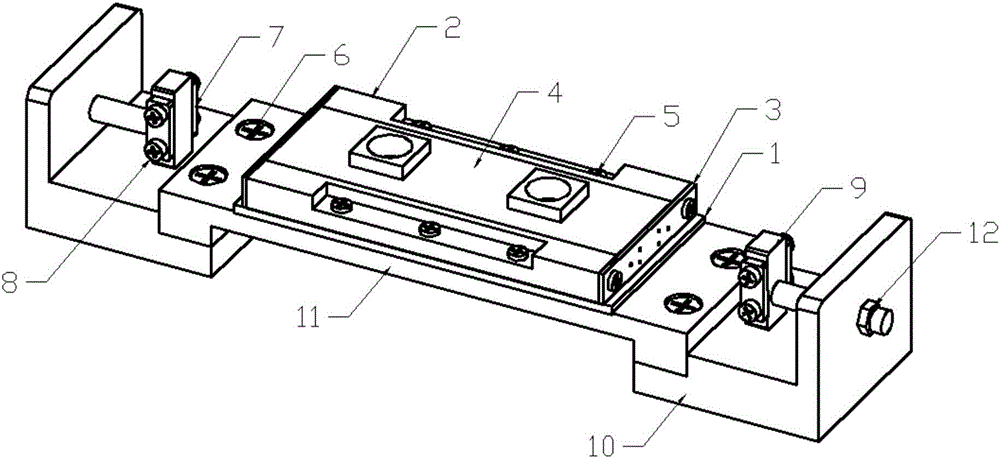

Die and tool assembly and manufacturing method of intelligent composite material actuator

The invention discloses a die and tool assembly and manufacturing method of an intelligent flexible composite material actuator. The die and tool assembly of the intelligent flexible composite material actuator comprises a die and a tool. To manufacture the actuator, an SMA wire needs to be subjected to tensioning memory training firstly; aluminum alloy clamps need to be clamped in the middle section of the SMA wire after tensioning is completed, specifically, the interval between the aluminum alloy clamps is 5-10 mm smaller than the length of the actuator die; and the SMA wire is placed in the die after penetrating through a through hole of a short baffle, the aluminum alloy clamps are located on the inner side of the die, then vacuumized PDMS glue is slowly and evenly injected when the SMA wire is in the tensioned state, and die parts can be detached step by step in the demolding process of the actuator. According to the die and tool assembly and manufacturing method of the intelligent composite material actuator, the SMA wire can be tensioned in advance, and the tensioning prestress of the SMA wire is worked out finally through marking and measurement; the manufacturing process of the intelligent composite material actuator has the advantages that operation is easy and controllability is high; and by the adoption of the assembly type die, the die parts are easy to manufacture, and the actuator die is more convenient to disassemble.

Owner:SHANGHAI JIAO TONG UNIV

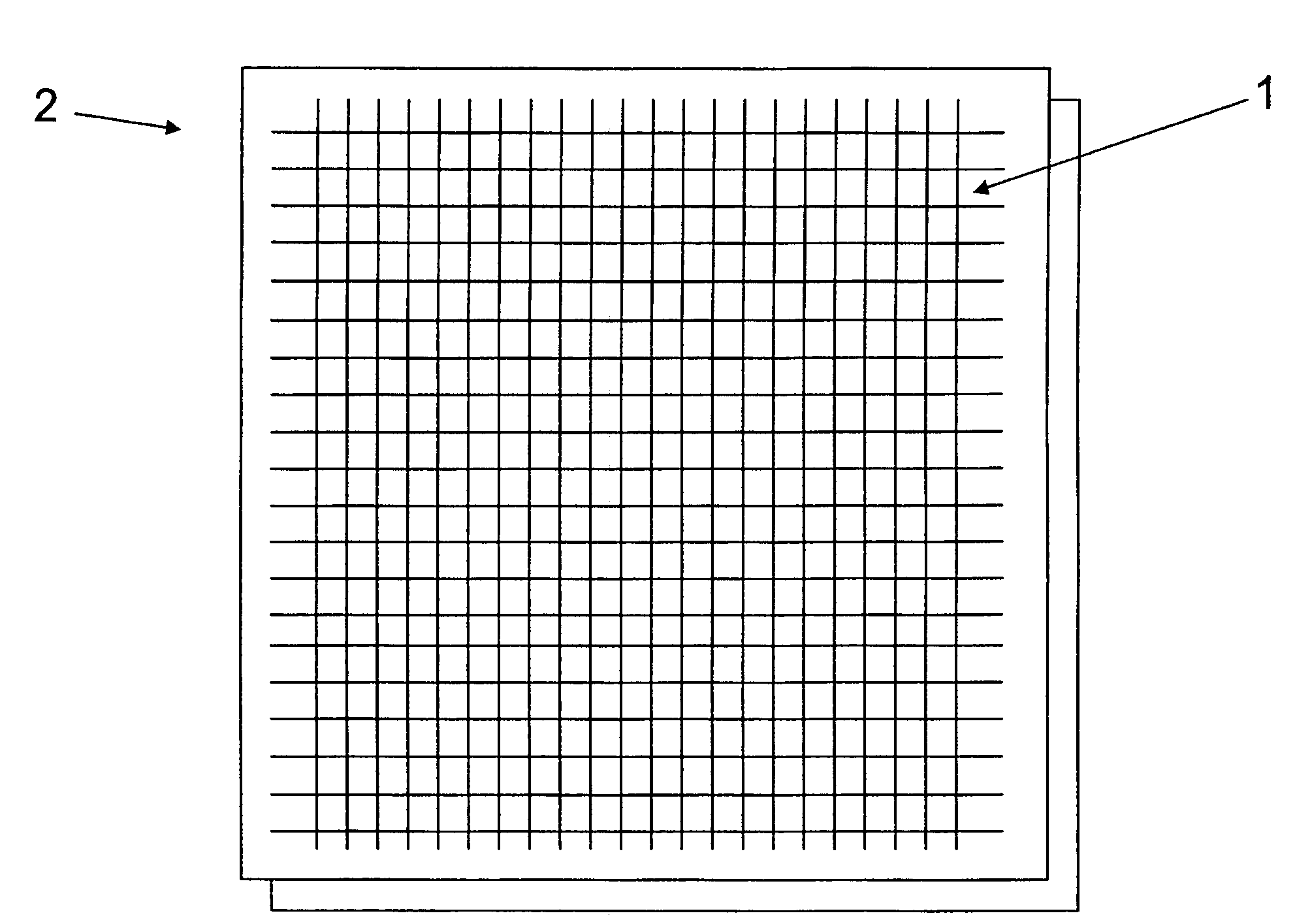

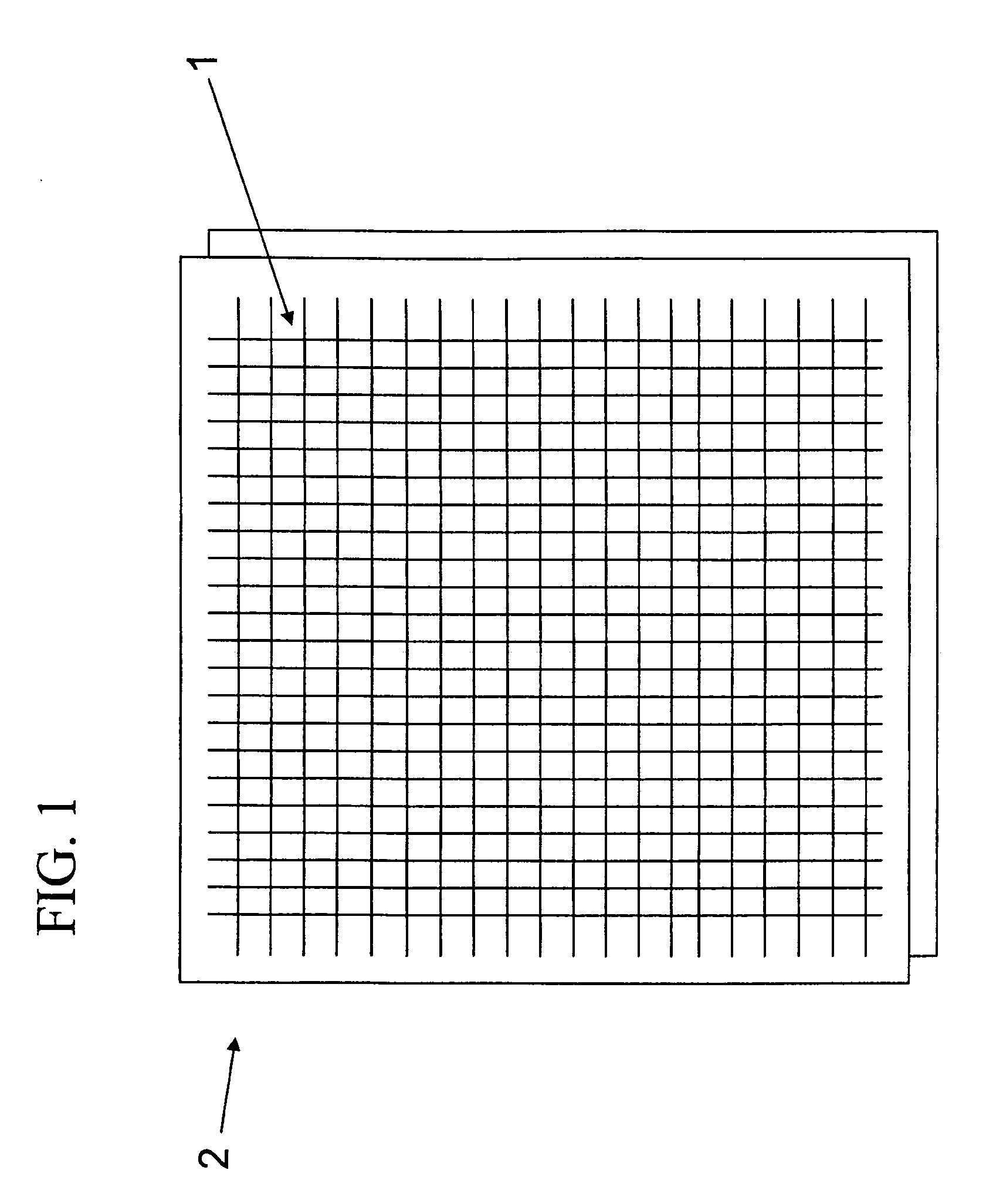

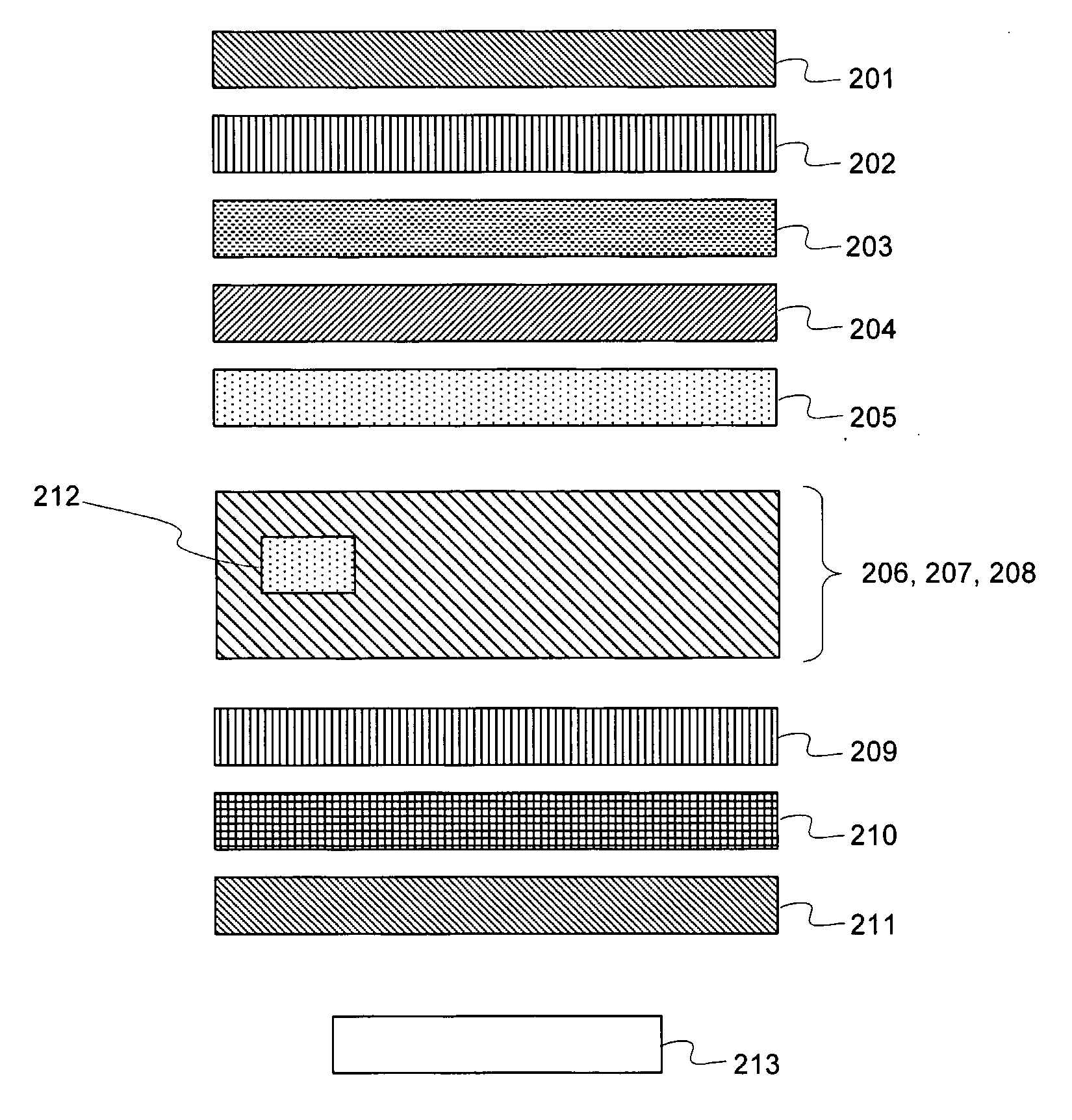

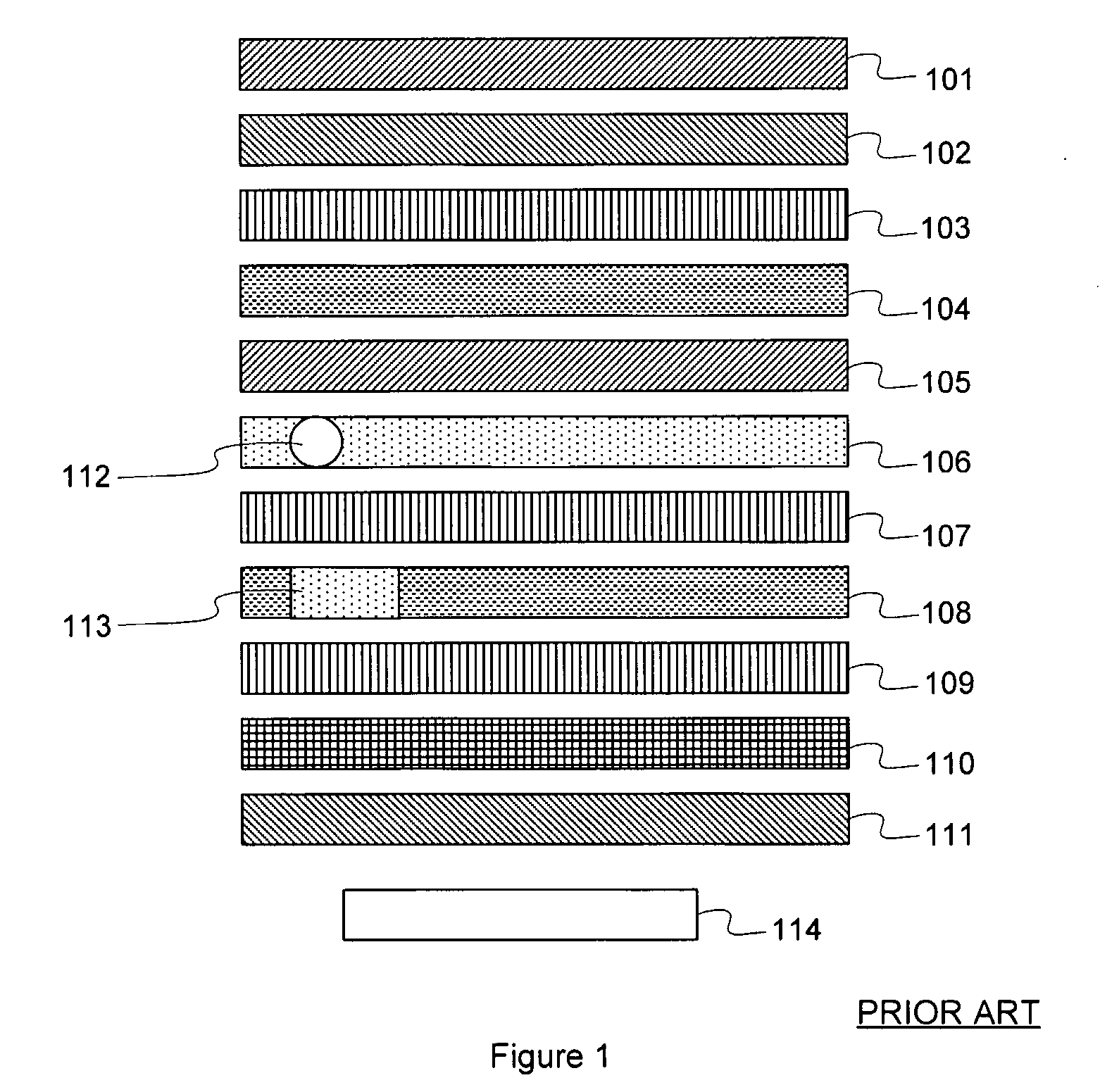

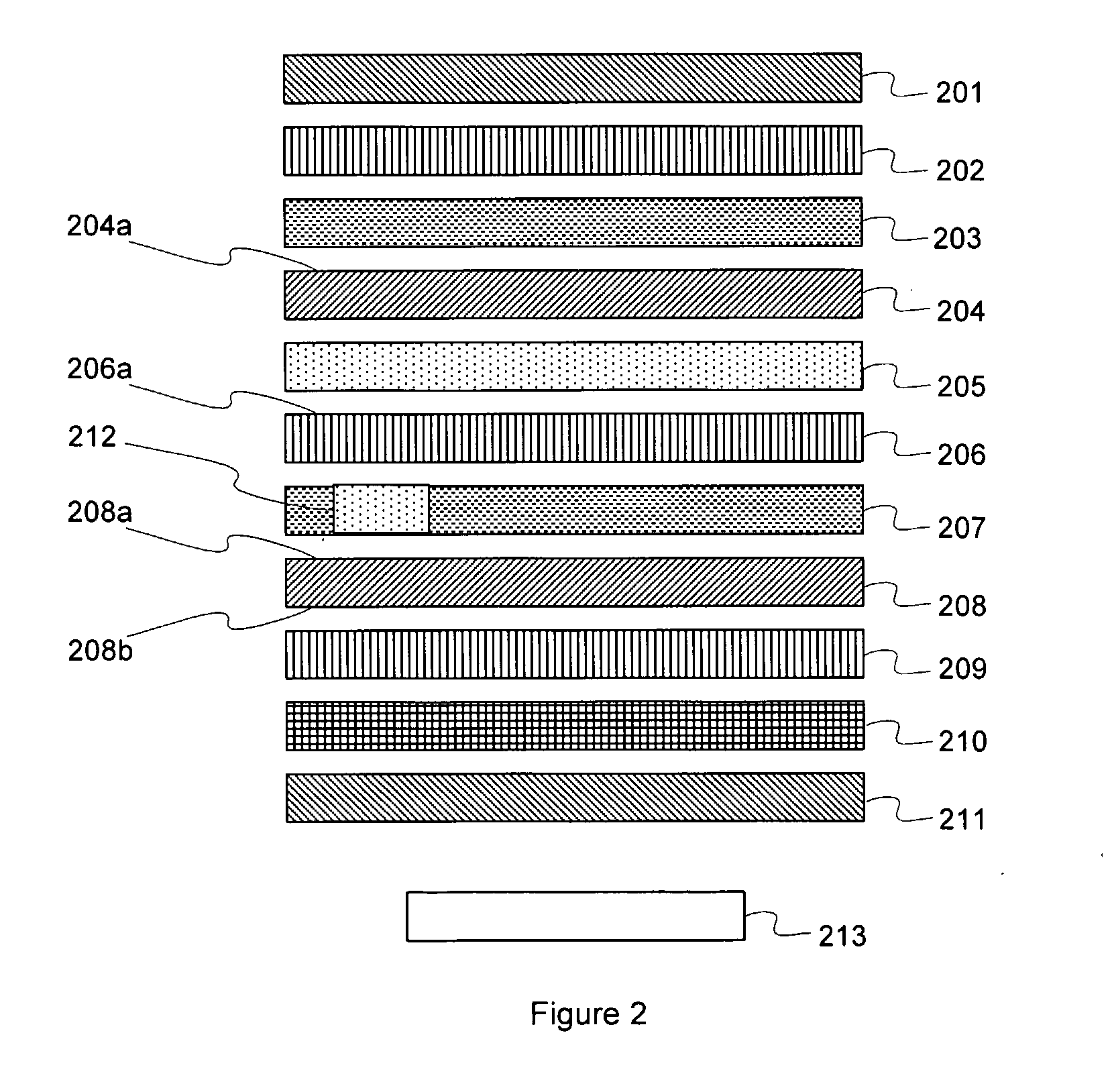

Smart composite materials for plastic substrates

InactiveCN101056763ALiquid crystal compositionsSynthetic resin layered productsPolymer scienceLiquid-crystal display

The present invention provides a shapeable multilayer composite, and method of making same, having dimensional stability. The composite comprises at least two polymer substrates, each polymer substrate having a first and a second surface and each of the at least two polymer substrates being positioned sequentially such that each two consecutive polymer substrates are bonded together. Furthermore, a shapeable composite material, and method of making same, for use in the fabrication of liquid crystal displays using a shapeable multilayer composite as described above.

Owner:SILK DISPLAY

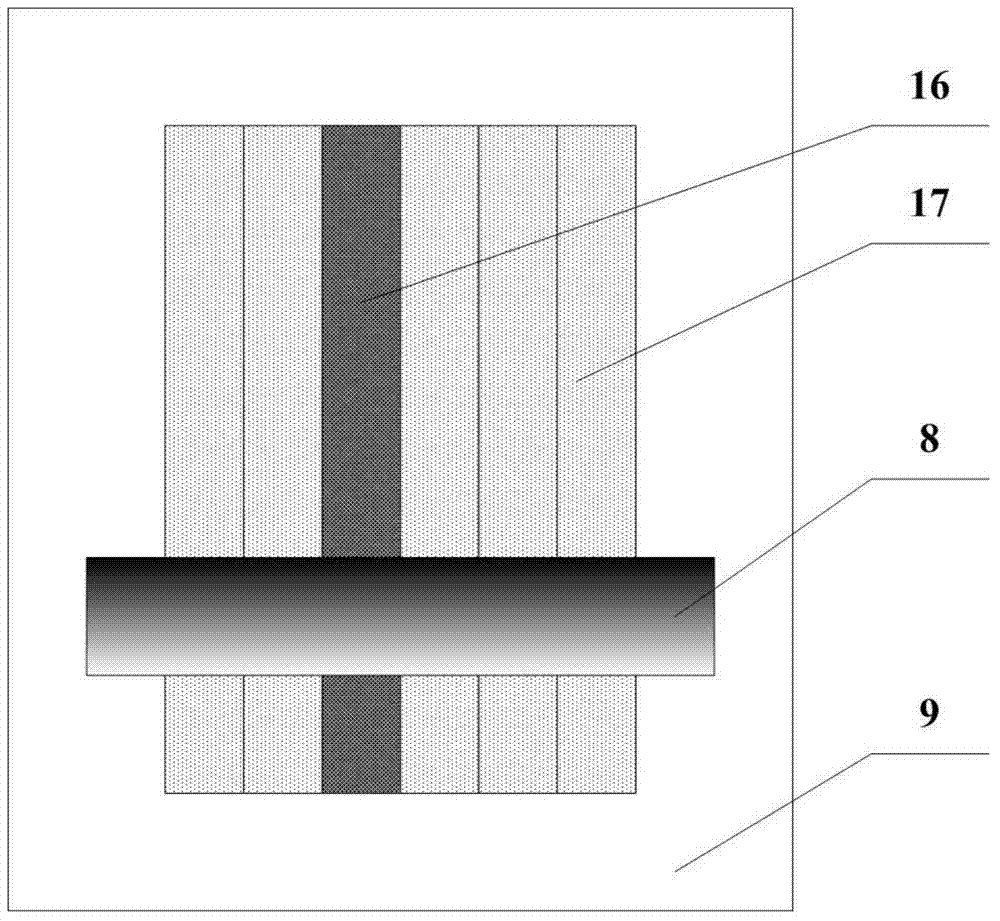

High-performance optical-fiber built-in intelligent composite material and preparation method thereof

PendingCN107503525AReliable embeddingReal-time monitoring of tension and pressureForce measurement by measuring optical property variationBuilding repairsFiberGrating

The invention discloses a high-performance optical-fiber built-in intelligent composite material with an engineering structure strengthening function and a sensing function and a preparation method thereof. According to the high-performance optical-fiber built-in intelligent composite material and the preparation method thereof, optical fiber gratings are coated with polymers, the outer layers of grid areas of the optical fiber gratings are coated with high-temperature resistant resin adhesive coatings, after the optical fiber gratings are protected by the coatings, resin adhesive films are arranged outside the optical fiber gratings to conduct pre-fixation, the leading-out tail fiber portions of optical fibers are sleeved with tail-fiber protection sleeves, therefore, it can be ensured that the optical fiber gratings are embedded reliably in arbitrary directions and among arbitrary layers in the composite material, it is guaranteed that spectra of the optical fiber gratings do not distort, the compatibility and mechanical matching performance of the optical fibers and the composite material are improved, the survival rate of the built-in optical fiber gratings is significantly increased, and the service life of the built-in optical fiber gratings is significantly prolonged; on the basis of completing the functions of engineering structure strengthening and reinforcing, the prepared intelligent composite material can be used for measuring the tensile compression and bending of key areas and has excellent popularization and application value.

Owner:SHANDONG UNIV

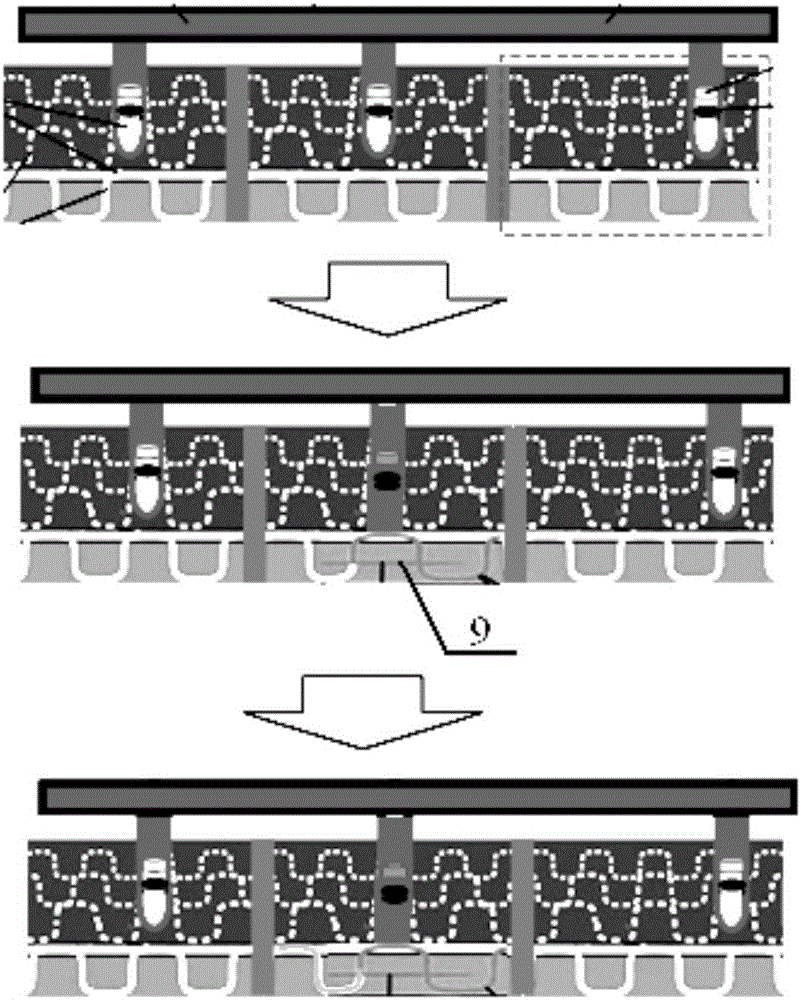

Self-induction repairing resin matrix composite structure and preparing repairing method

ActiveCN106626454ALittle negative impact on mechanical propertiesAchieving Self-Sensing RepairResin matrixSelf induction

The invention belongs to the field of intelligent composites and particularly relates to a self-induction repairing resin matrix composite structure and a preparing repairing method. Currently, an impairment awareness sensing system and a repairing agent supply system which are separated are adopted in various principle schemes currently proposed. System connectors are complex, and the additional weight increment is large. The resin matrix composite comprises multiple composite units, hollow vessel pipes which communicate with one another are arranged in each composite unit. The structure further comprises a repairing agent conveying pipeline arranged on the surface of the resin matrix composite, and the repairing agent conveying pipeline is filled with a repairing agent. The repairing agent conveying pipeline communicates with the hollow vessel pipes in all the composite units, and a connecting pipeline is internally provided with a one-way check valve and a flow detection element. Two sets of separated systems which are the impairment awareness sensing system and the repairing agent supply system are not needed, repairing agent supplying and impairment sensing are integrated, the system complexity is greatly lowered, the mechanical performance of a material body is slightly reduced, and the structure is simple and reliable.

Owner:AVIC BASIC TECH RES INST

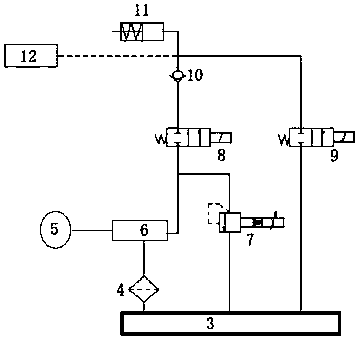

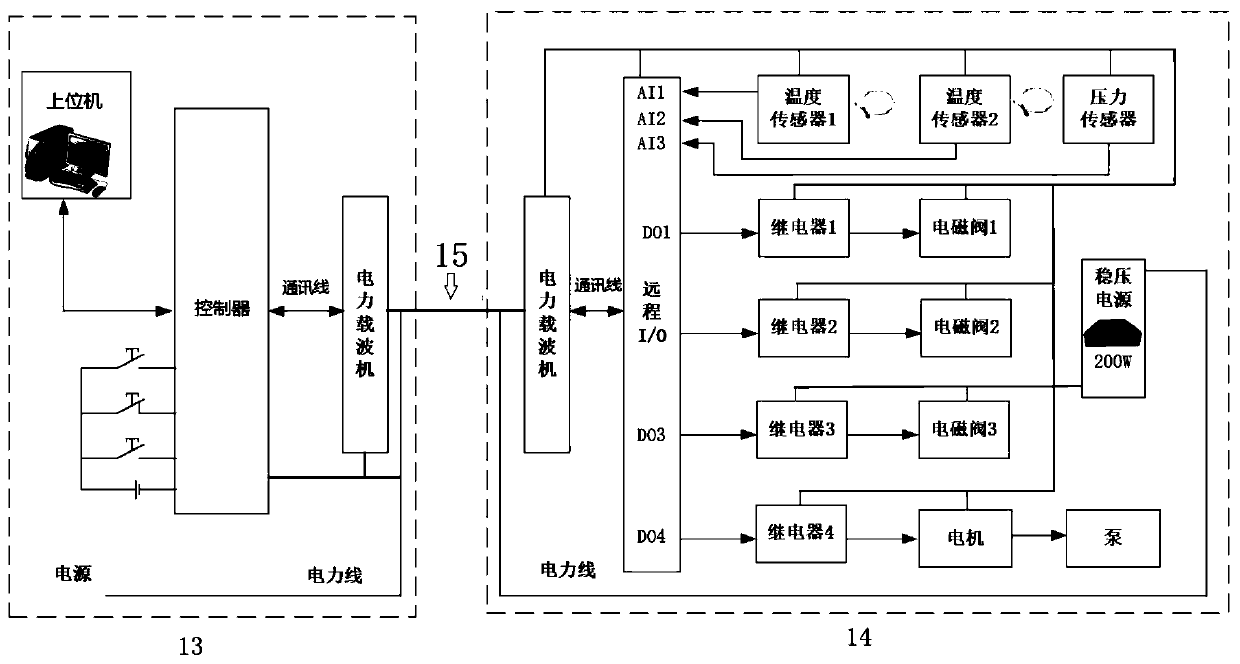

Micro downhole liquid station

PendingCN111577201AImprove control delayReal time monitoringDrilling rodsWell/borehole valve arrangementsControl systemElectrical control

The invention relates to a micro downhole liquid station, and belongs to the technical field of downhole production equipment. The micro downhole liquid station comprises an up-hole electric control system, a smart composite continuous casing pipe, a downhole electric control system and a downhole micro liquid station, wherein the up-hole electric control system is connected with the downhole electric control system through the smart composite continuous casing pipe; the downhole electric control system is connected with the downhole micro liquid station; and the downhole electric control system and the downhole micro liquid station are arranged in the same semi-cylindrical box. According to the micro downhole liquid station, an up-hole electric system is used for controlling the downholeliquid station to open a downhole safety valve, so that the problem of control delay of a conventional safety valve is improved greatly. In addition, the working state of the downhole safety valve ismonitored accurately in real time, so that the downhole potential safety hazard is eliminated, and the workover operation is avoided. The micro downhole liquid station is designed into a form in whicha petroleum pipeline is surrounded by a semi-cylindrical body in order to adapt to the downhole narrow working space.

Owner:STARSE ENERGY & TECH GROUP

Method for preparing polytetrafluoroethylene-based three-dimensional orthogonal composite material

The invention relates to a method for preparing polytetrafluoroethylene-based three-dimensional orthogonal composite material, which includes the following steps: (1) a three-dimensional orthogonal woven fabric is dried and weighed; the three-dimensional orthogonal woven fabric is then socked in polytetrafluoroethylene dispersing agent, evened up by a roller, turned over, evened up, dried and weighed; the process is repeated; after weighing, the presoaked three-dimensional orthogonal woven fabric is put into a die, and receives the pressure of 30 MPa to 40MPa; after evening, the evened presoaked three-dimensional orthogonal woven fabric is put into an oven with the temperature of 80 DEG C, and the temperature is increased to 200 DEG C; (2) the temperature continues to increase for agglomeration; (3) the three-dimensional orthogonal woven fabric is cooled along with the oven, taken out and trimmed, and thereby the polytetrafluoroethylene-based three-dimensional orthogonal composite material is obtained. The invention has the advantages of simplicity, low cost and stable performance, and is suitable for industrialized production; the invention can be used to shape structures related to intelligent composite material; the resin content in the obtained composite material is high and stable, and the bonding property of the fibers and the polytetrafluoroethylene resin is good.

Owner:DONGHUA UNIV

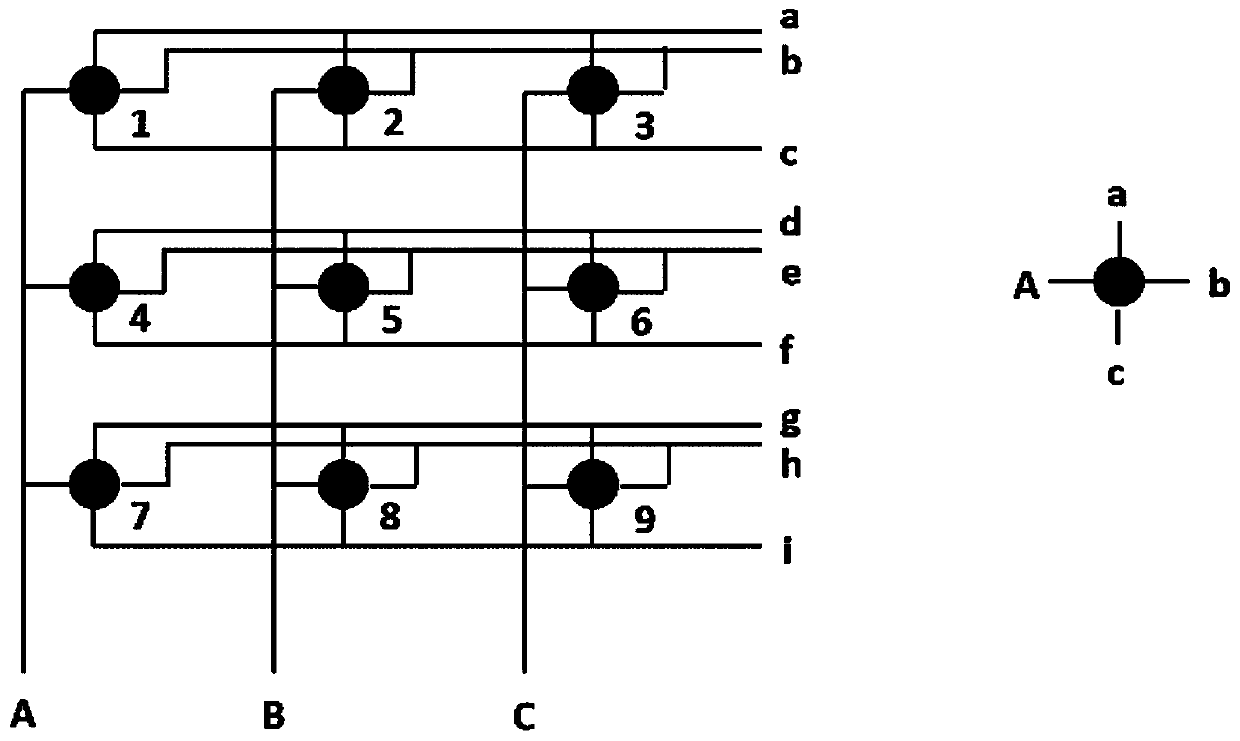

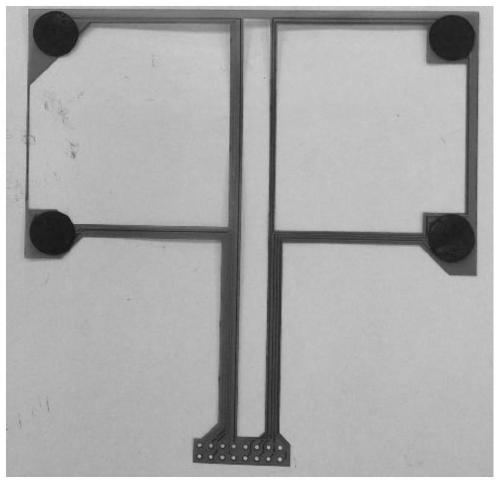

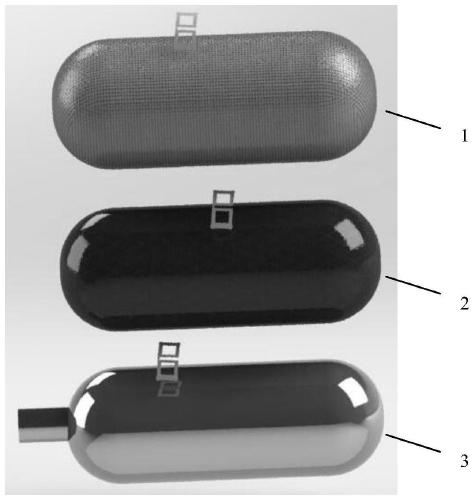

Intelligent composite overwrapped pressure vessel relating to micro-nano sensors and manufacturing method of intelligent composite overwrapped pressure vessel

ActiveCN111237456AImprove wetting propertiesOvercome the problem of introducing defectsPressure vesselsMaterial resistanceFiberMicro structure

The invention provides an intelligent composite overwrapped pressure vessel relating to micro-nano sensors and a manufacturing method of the intelligent composite overwrapped pressure vessel, and relates to the technical field of manufacturing of intelligent overwrapped composite pressure vessels. The intelligent composite overwrapped pressure vessel comprises a composite overwrapped pressure vessel bottle body and a flexible sensor array. Through a flexible printed circuit, the number of wires is decreased, and arrangement of the wires is simplified; composites and the micro-nano sensors areintegrally formed, so that any tiny damage of a composite structure in the service process of the composite overwrapped pressure vessel is transmitted to the microstructures of the micro-nano sensorsin real time, the change of the residual resistance of the micro-nano sensors is shown, and great sensitivity is achieved. Compared with a traditional resistance strain gauge and a fiber grating sensor, the intelligent composite overwrapped pressure vessel has the advantages of large-deformation monitoring, high sensitivity coefficient, high service temperature, multi-directional monitoring and curved surface structure health monitoring and the like.

Owner:SHENYANG GAS CYLINDER SAFETY TECH +1

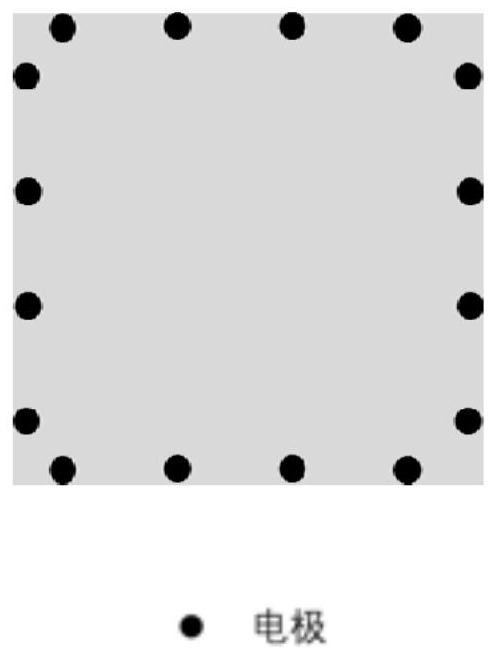

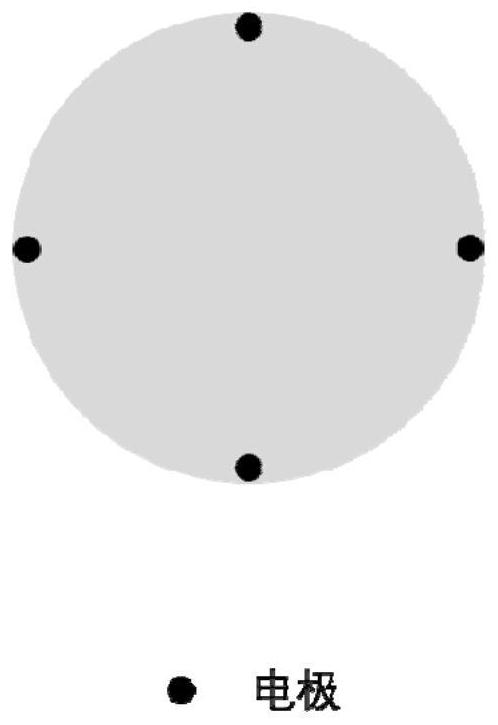

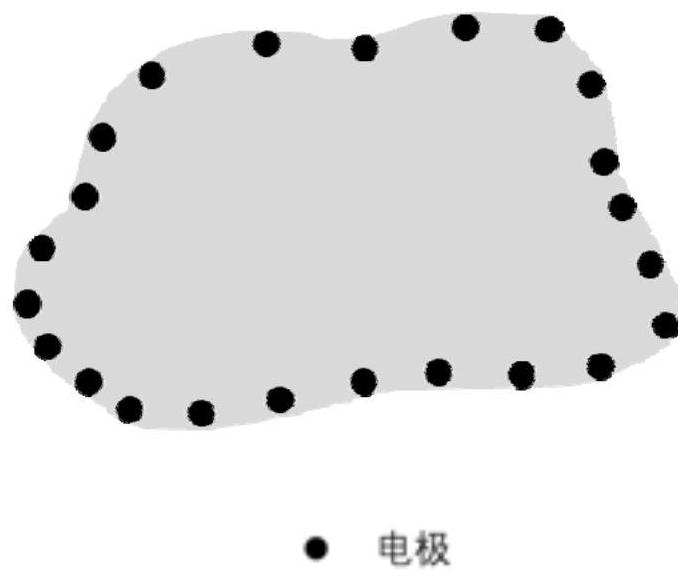

Intelligent composite material and preparation method and application thereof

ActiveCN112700908AOptimize layoutIncrease movement rateConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersNetwork structureThin membrane

The invention discloses an intelligent composite material as well as a preparation method and application thereof. The preparation method comprises the following steps of: arranging an electrode at the edge of a porous conductive network structure to prepare a conductive material film sensor; and compounding the conductive material film sensor with a resin-based material, or compounding a conductive medium or a porous conductive network structure formed by the conductive medium with a resin-based material and curing the compound to obtain a composite material, and then arranging an electrode at the edge of the composite material to obtain the intelligent composite material. The film-shaped network structure is made of the conductive material, and damage can be detected and positioned through the conductive network structure; meanwhile, the composite material is easily compounded with a resin-based material, and the mechanical property of the composite material is not reduced; moreover, the intelligent composite material disclosed by the invention can be used for self-monitoring, positioning the damage and displaying the damage in an imaging manner, and can further be used for carrying out fixed-point self-repairing on the specified damage without influencing other regions.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

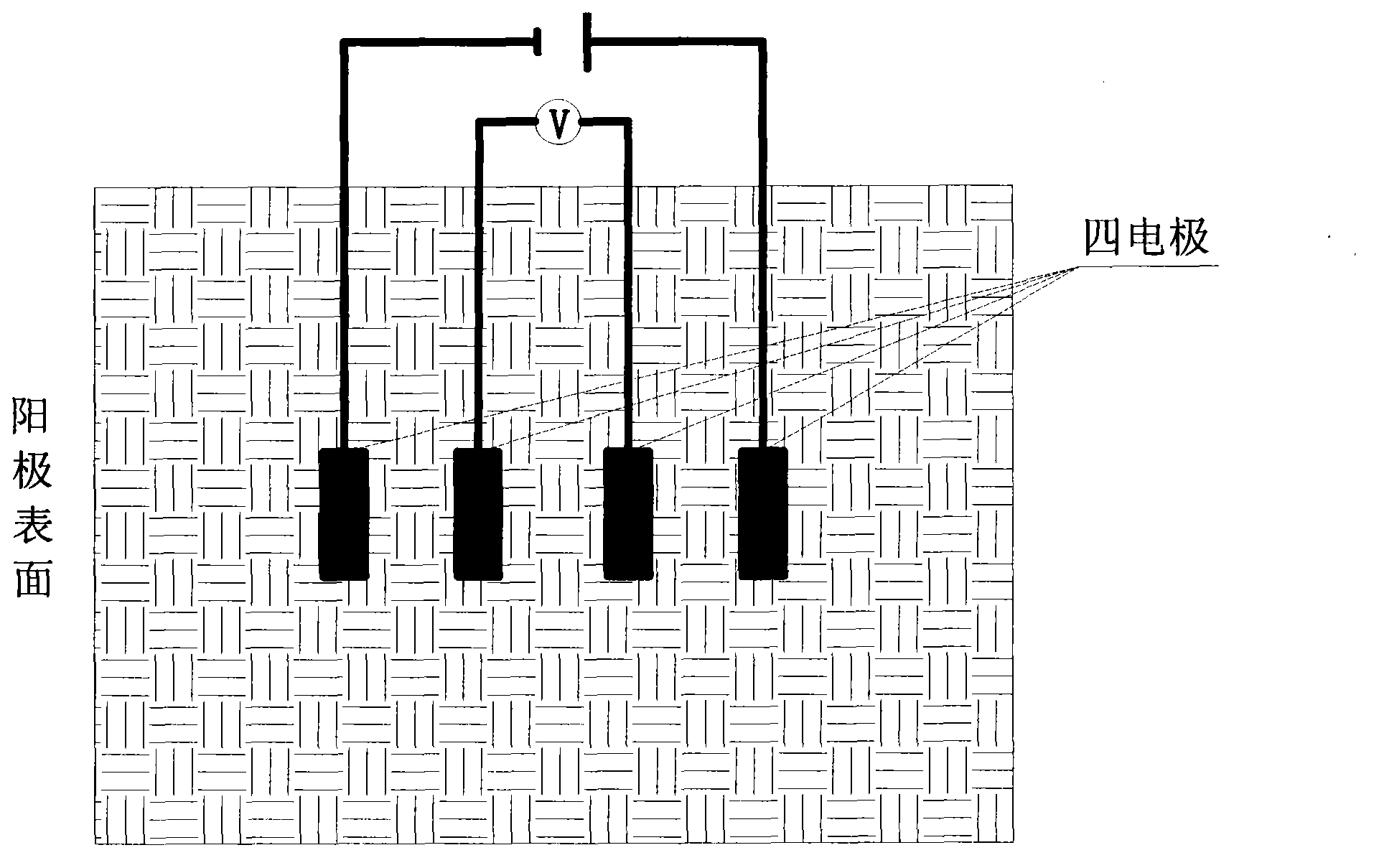

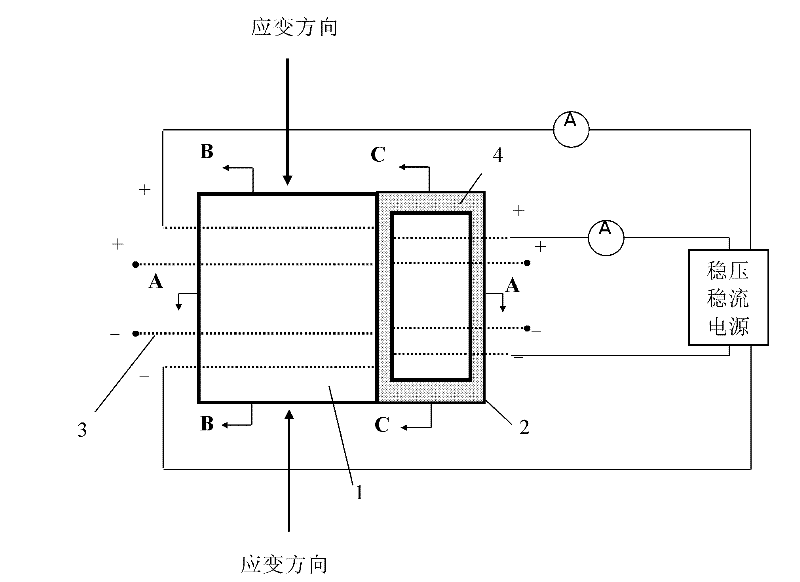

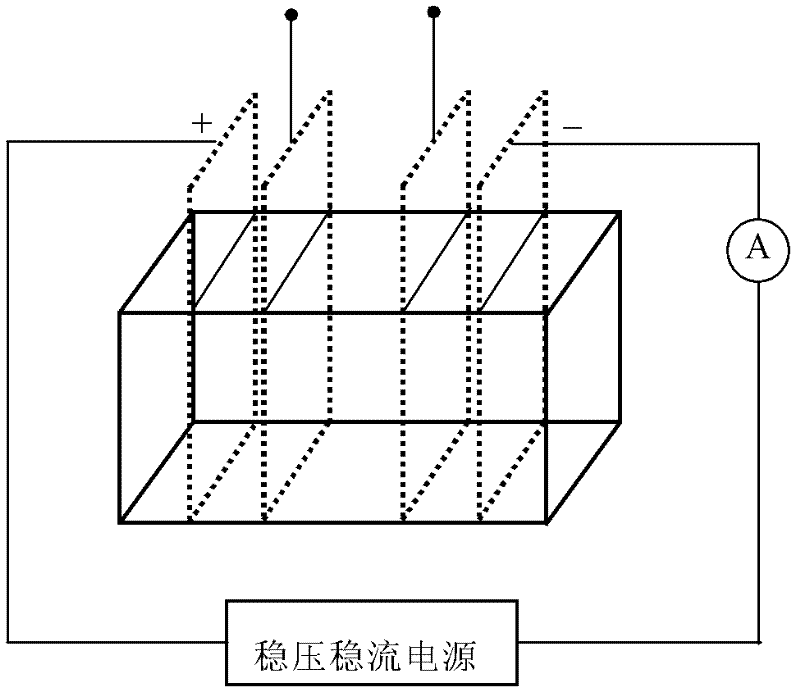

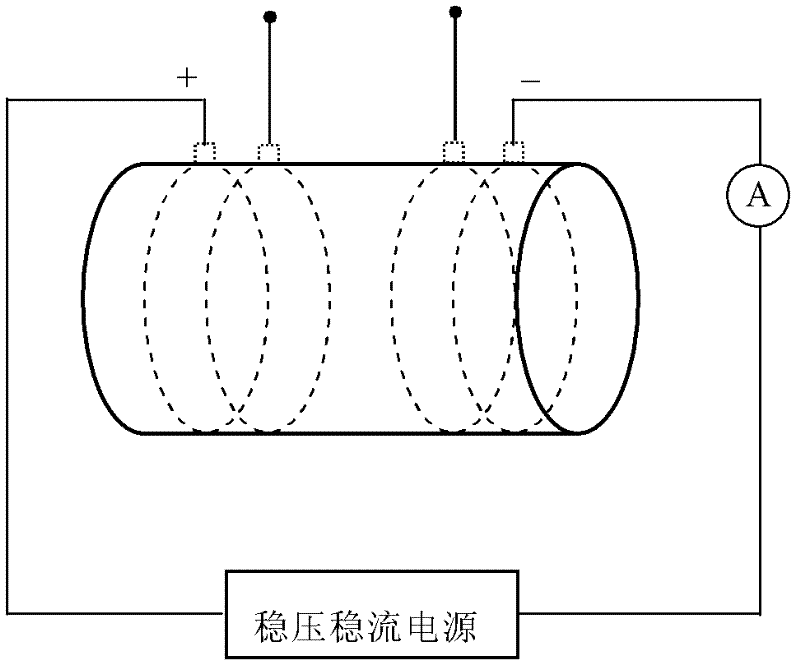

Cement-based intelligent composite material strain sensor with temperature compensation function

ActiveCN102506691AWith temperature compensation functionHigh sensitivity factorElectrical/magnetic solid deformation measurementFiberCarbon fibers

The invention discloses a cement-based intelligent composite material strain sensor with a temperature compensation function, which comprises a strain monitoring module and a temperature monitoring module, wherein the strain monitoring module and the temperature monitoring module are formed by carbon-fiber cement-based intrinsic intelligent composite material and four parallel electrodes arranged on the composite material; and the strain monitoring module and the temperature monitoring module are connected and are respectively provided with four parallel electrodes. The cement-based intelligent composite material strain sensor has the advantages of temperature compensation function, high sensitivity coefficient, high voltage-sensitive and good performance stability, is applicable to strain monitoring of concrete structures under various environment conditions, avoids the defect of poor technical effect of a thermoelectric couple for directly measuring the temperature and carrying out temperature function, has the characteristics of high temperature compensation accuracy and simple technology and simultaneously improves the temperature compensation effect and the strain monitoring accuracy of the sensor under various strain conditions.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

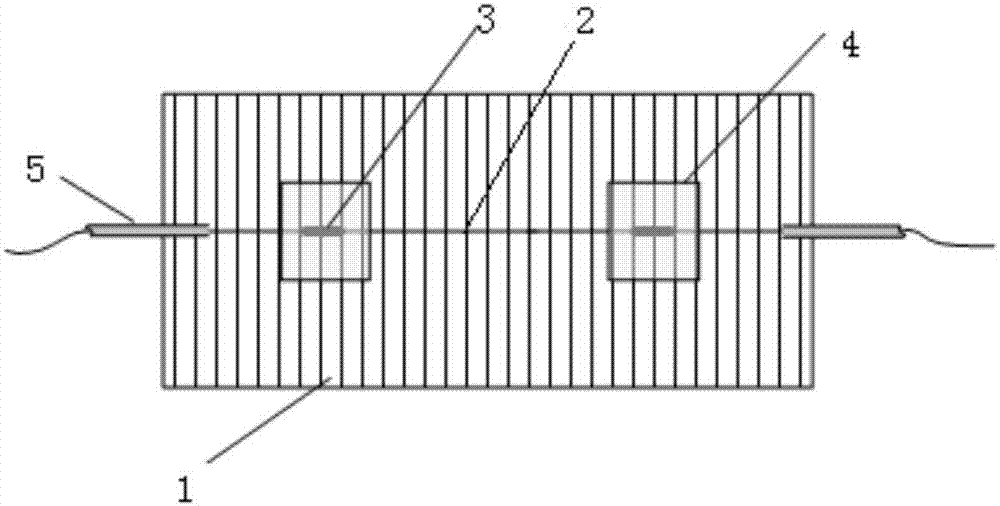

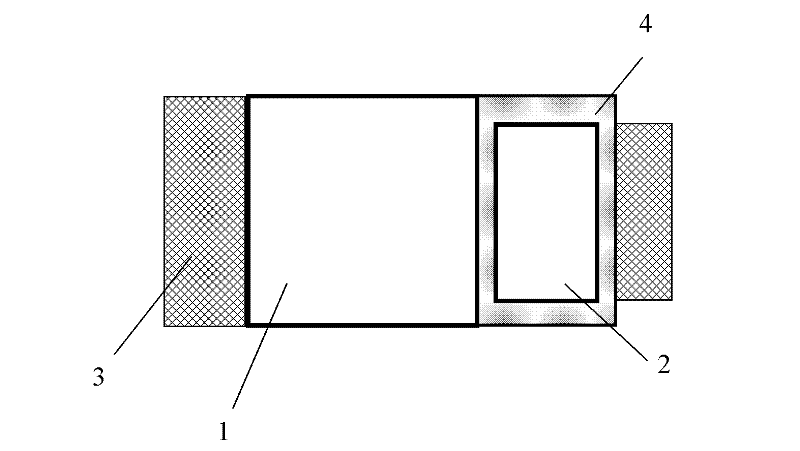

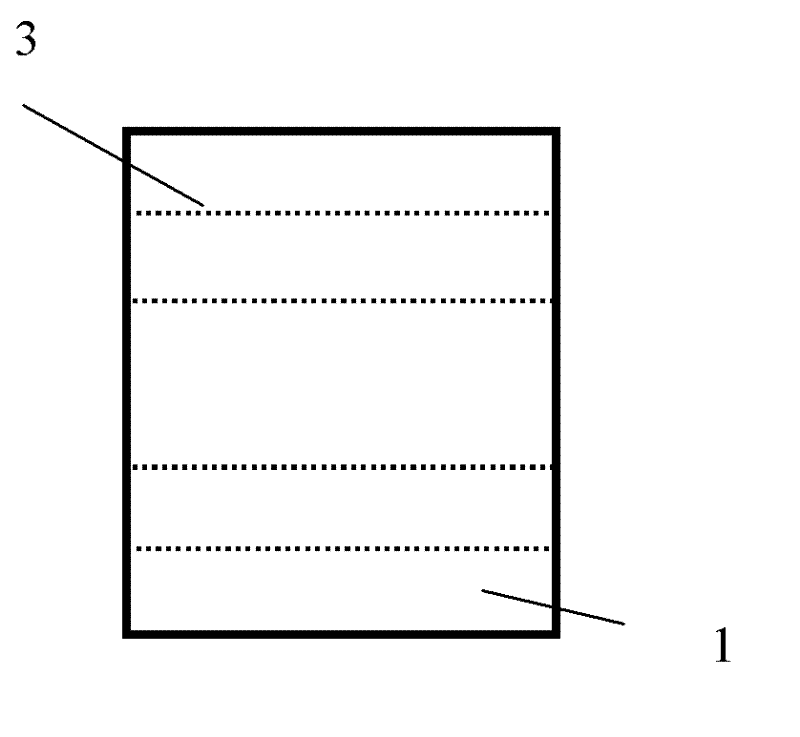

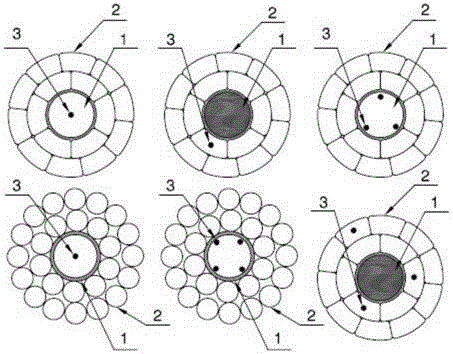

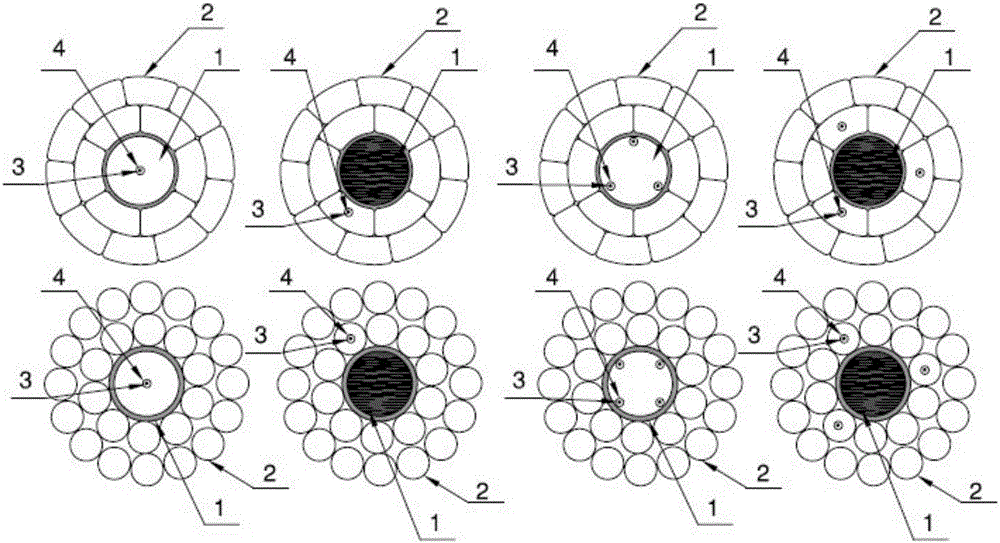

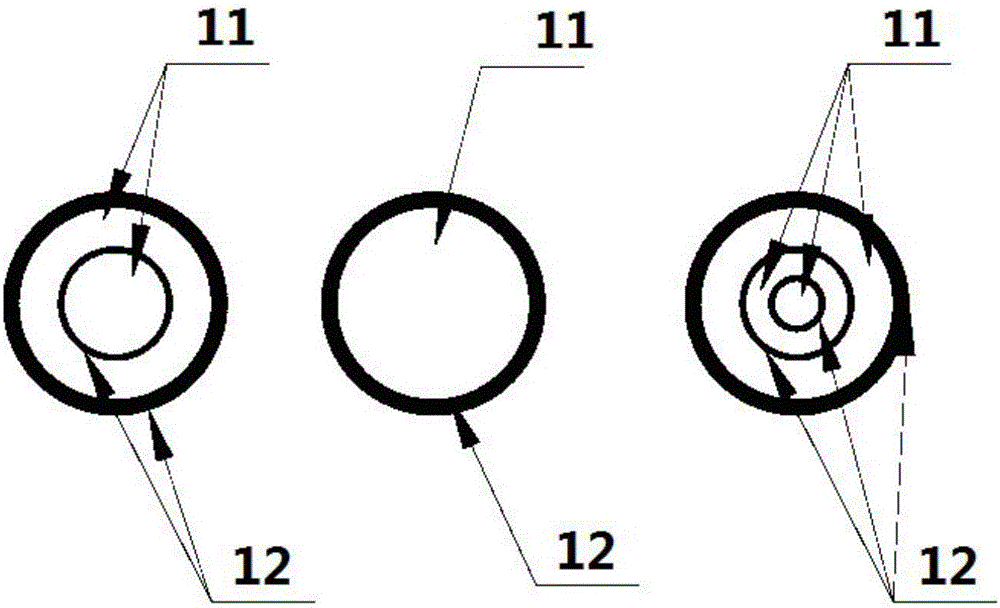

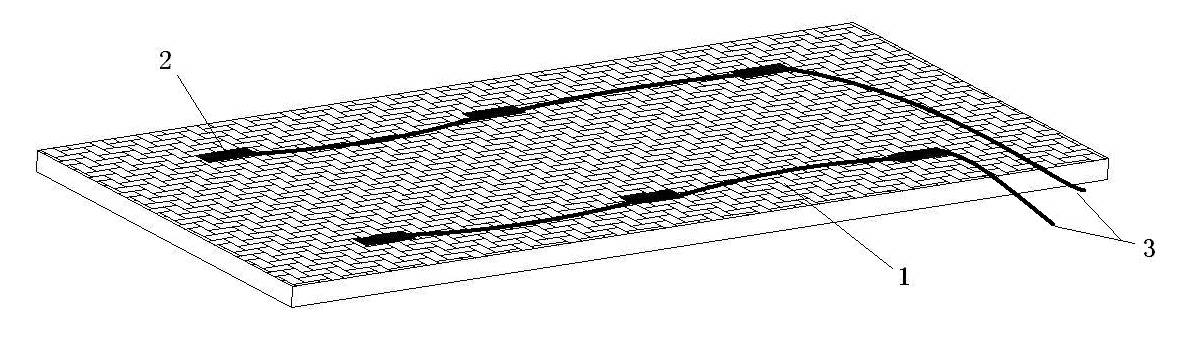

Intelligent composite material core wire and preparation method thereof

ActiveCN105825945AReasonable structural designHigh temperature resistantNon-insulated conductorsPower cables including optical transmission elementsCarrying capacityAging resistance

The invention discloses an intelligent composite material core wire and a preparation method thereof. The intelligent composite material core wire includes a composite material core (1) and single conductor wires (2) stranded at the periphery of the composite material core (1), wherein the composite material core (1) or the single conductor wires (2) are internally provided with optical fibers (3) or optical fiber protection pipes (4) for communication or monitoring; and the optical fibers (3) are arranged in the optical fiber protection pipes (4). The preparation method of the intelligent composite material core wire includes the steps of preparing the composite material core and stranding the single conductor wires (2) at the periphery of the composite material core (1). The preparation method of the intelligent composite material core wire has the advantages of being high in operability, being higher in production efficiency, being able to save a lot of manpower and material resources, and being low in production cost; the prepared composite material core has the advantages of being high in linearity and roundness, having no bending, being high in color consistency, being high in intensity, being long in the service life, having no eccentricity, and being high in aging resistance; and the prepared intelligent composite material core wire has the advantages of being higher in the wire compactness and filling rate, being resistant to high temperature, being high in current-carrying capacity and being small in sag.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

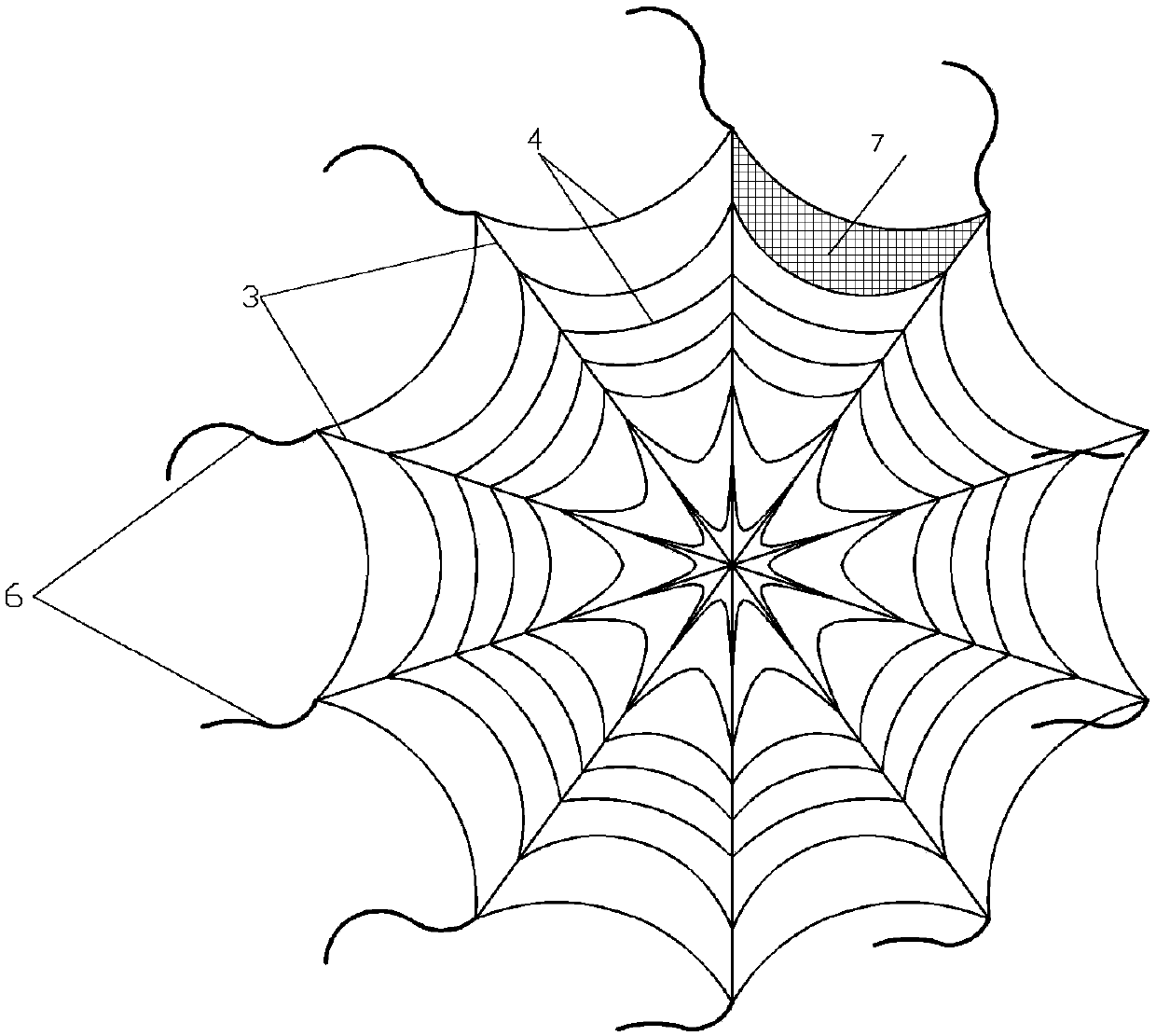

Cobweb capture structure based on intelligent composite materials

ActiveCN110510150AReduce vibrationLittle heating consumes energyCosmonautic vehiclesCosmonautic partsSilver pasteFiber

The invention provides a cobweb capture structure based on intelligent composite materials. The cobweb capture structure includes a cobweb structure woven by warps made of a shape memory polymer composite material and wefts made of a linear fiber driver and high-temperature nylon, and having a closed end and an open end. The open end and the weft at the middle of the cobweb structure are the linear fiber driver. The wefts at the other positions of the cobweb structure are the high-temperature nylon. The linear fiber driver is thermally-treated wound high-temperature nylon having a surface coated with silver paste. Each warp is uniformly covered with electric heating sheets spaced apart from one another in the longitudinal direction. Each warp at the open end of the cobweb structure is connected with an auxiliary cable. Adjacent warps and wefts are independent of each other. The cobweb capture structure based on intelligent composite materials according to the present invention can be autonomously driven and reused, has certain rigidity, and can racemize and orbit transfer a captured object.

Owner:HARBIN INST OF TECH

Preparation method of intelligent composite material containing delamination damage

InactiveCN110425993AMonitor strain changesChange the refractive indexUsing optical meansStrength propertiesFiberGrating

The invention discloses a preparation method of an intelligent composite material structure containing delamination damage and mainly solves the problems that influence on the material self is great when the intelligent composite material is prepared in the prior art and preparation cost is high. According to the scheme, the preparation method comprises the following steps: cutting fiber cloth byadopting a cutting machine, thus obtaining fiber cloth strips with different fiber ply angles; paving a fiber Bragg grating sensor on every two fiber cloth strips by adopting a trapezoid slide routingstructure, thus forming an optical fiber layer, placing two optical fiber layers back to back, and placing a polytetrafluoroethylene film in the middle as a prefabricated damaged layer; then taking the damaged layer as a starting point, respectively paving the same number of layers of the fiber cloth strips above and below the two optical fiber layers, thus forming a well-overlaid fiber cloth strip whole, then sequentially covering with an isolating membrane, a ventilated felt and a vacuum bag, and sealing with high temperature sealant; and finally transferring the well-sealed whole into a hot pressing tank, and curing at set technological conditions, thus obtaining the intelligent composite material containing the prefabricated damaged layer. The preparation method disclosed by the invention has small influence on the material self, is low in preparation cost and can be used for health detection on the composite material.

Owner:XIDIAN UNIV

Smart composite materials for plastic substrates

InactiveUS20100098886A1Liquid crystal compositionsTube/lamp screens manufacturePolymer scienceLiquid-crystal display

Owner:SILK DISPLAY

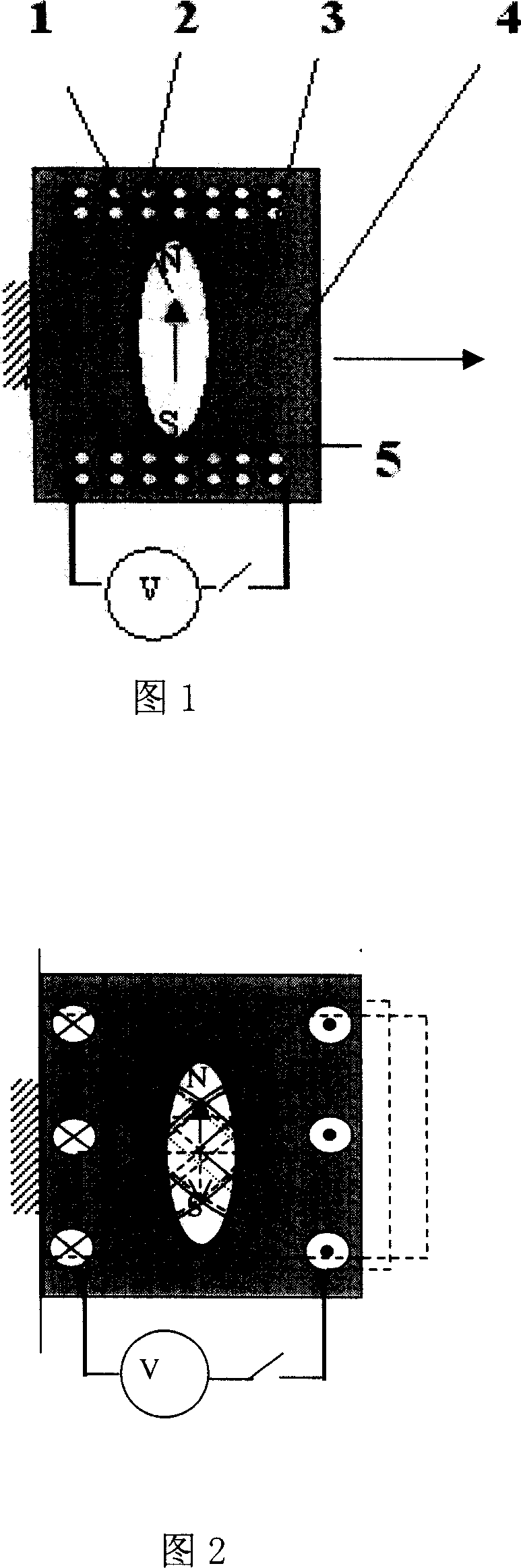

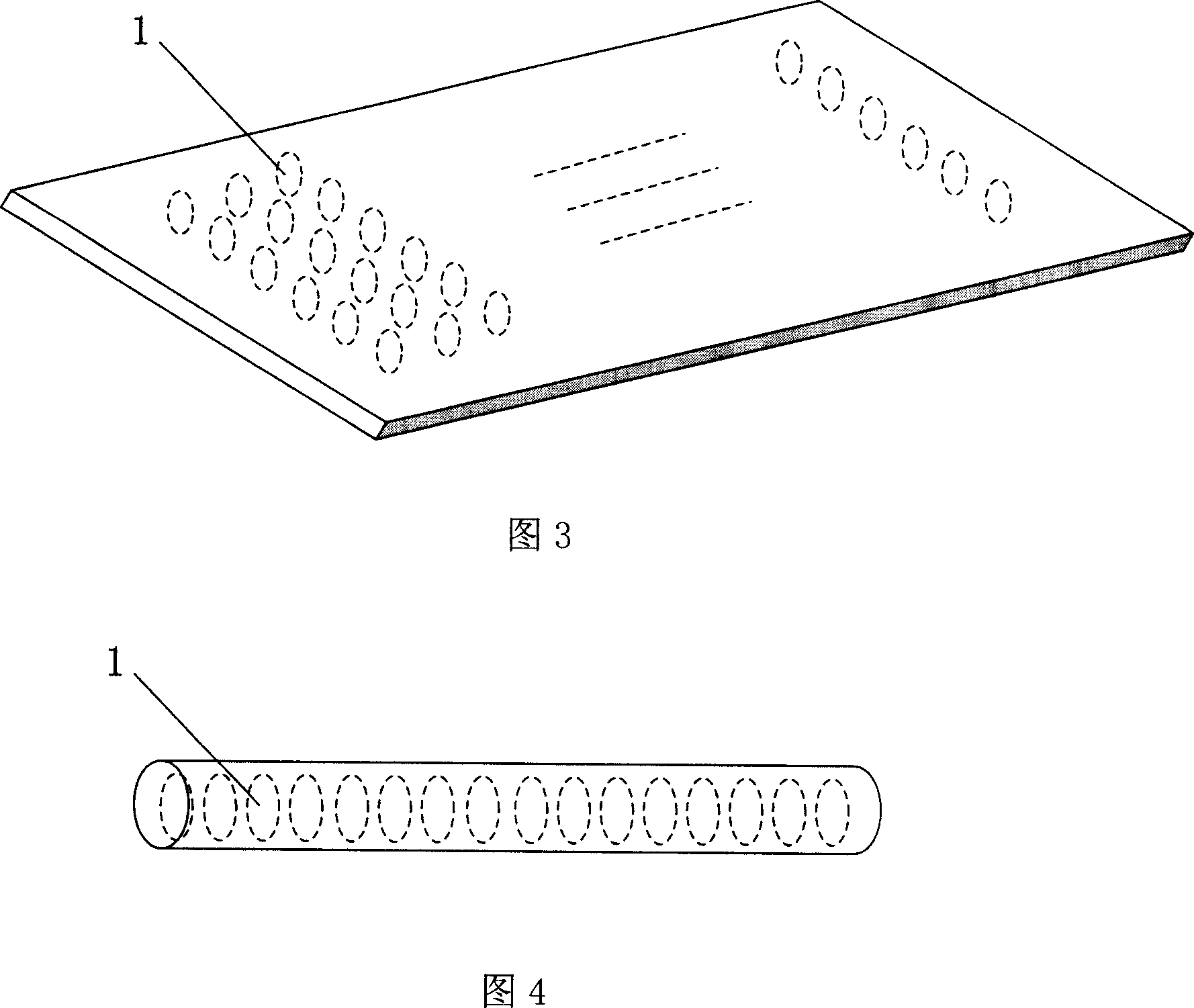

Electricity, magnetism excitated intellective composite material body with ultra large deformation

ActiveCN101093745AAchieving magnetostrictive strainAchieving electrostrictive strainElectromagnetsElectricityLarge deformation

Especially, the invention is related to intelligent composite material body capable of generating super large deformation by using electrical excitation and magnetic excitation. The intelligent composite material body includes magnetic body and basal body. Size of the magnetic body in length direction is different from the size in width. Being set up inside the basal body, cavities wrap basal bodies. At certain extent, replacing current magnetostrictive material, the composite material body can generate super large deformation. Possessing both characteristics of electrostriction and magnetostriction, the disclosed composite material makes appearance of stretching material body neat and integral structure compact.

Owner:杨斌堂

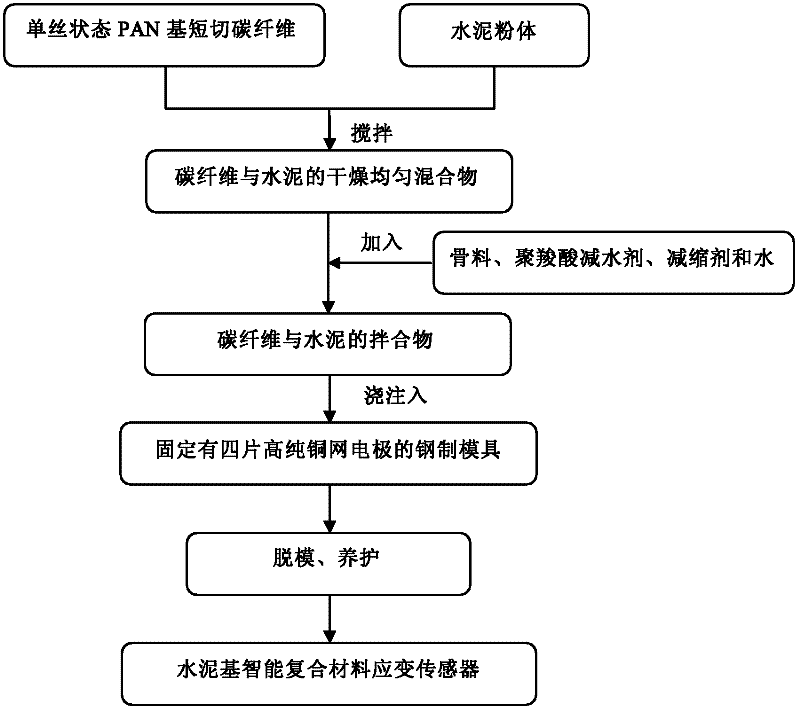

Cement-based intelligent composite material strain sensor and preparation method thereof

ActiveCN102506692ALinearity of High Pressure SensitivityGood pressure sensitive propertiesElectrical/magnetic solid deformation measurementCelluloseFiber

The invention discloses a cement-based intelligent composite material strain sensor, which comprises a carbon-fiber cement-based intrinsic intelligent composite material and four parallel electrodes arranged on the composite material, wherein the electrodes are high-purity copper meshes; the pore diameter of the high-purity copper meshes is larger than 2mm; and the main ingredients of the composite material are PAN-based short-cut carbon fiber and silicate cement, and the electrodes are combined together with the carbon-fiber cement-based intrinsic intelligent composite material by an embedding process. The cement-based intelligent composite material strain sensor has the characteristics of high sensitivity coefficient, high voltage-sensitive characteristic linearity and excellent mechanical property; and the preparation process adopts a drying and mixing process, so that the problems that due to use of cellulose, the strength of the sensor is reduced and the electric performance of the sensor becomes poor are avoided and no phenomenon of fiber agglomeration occurs.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Natural bamboo fiber optical intelligent composite material and preparation method thereof

InactiveCN102152549AHigh strengthGood weather resistanceConstruction materialForce measurement by measuring optical property variationSurface layerTransducer

The invention discloses a natural bamboo fiber optical intelligent composite material and a preparation method thereof. The natural bamboo fiber optical intelligent composite material consists of a bottom layer of a bamboo gluing strip, an optical fiber strain transducer, and a surface layer of the bamboo gluing strip. The optical fiber strain transducer is arranged between the bottom layer of the bamboo gluing strip and the surface layer of the bamboo gluing strip. The invention also discloses a preparation method of the natural bamboo fiber optical intelligent composite material. The natural bamboo fiber optical intelligent composite material inherits the characteristics of high strength and strong stability of a common bamboo fiber gluing material; meanwhile, the natural bamboo fiber optical intelligent composite material has the performances of automatically checking damages and detecting mechanical properties, provides conveniences for active, online and real-time monitoring on the damages of an intelligent bamboo fiber composite material building structure, and can be applied to industries like building industry, package industry, etc.

Owner:长沙凯森竹木新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com