Preparation method of intelligent composite material containing delamination damage

A composite material and intelligent technology, applied in the field of materials, can solve the problems of indistinguishable damage signal and noise signal, X-ray damage to human body, complicated experimental procedures, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

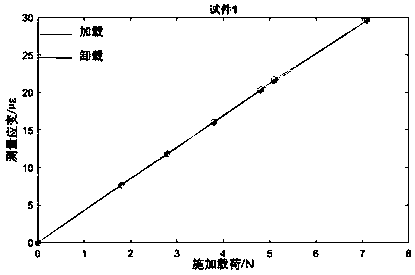

Embodiment 1

[0030] Example 1, prepare a prefabricated 22-layer carbon fiber epoxy resin-based composite laminate test piece with a damage area of 10mm×10mm and a surface size of 200mm×25mm.

[0031] Step 1: Prepare before making

[0032] 1.1) Prepare the basic materials used:

[0033] Basic materials include: disinfectant, fiber cloth, PTFE film, fully transparent epoxy resin glue, fiber grating sensor, high temperature silicone, high temperature tape, flat mold, isolation film, air felt, vacuum bag and high temperature sealant;

[0034] 1.2) Prepare the equipment used:

[0035] Equipment includes: fiber cloth cutting machine, autoclave

[0036] 1.3) Scrub the work surface with a disinfectant to ensure the surface of the material is clean.

[0037] Step 2: Cut the fiber cloth.

[0038] The main technical material of the present invention is carbon fiber epoxy resin-based composite material fiber cloth. First, a whole piece of carbon fiber epoxy resin-based composite material fiber c...

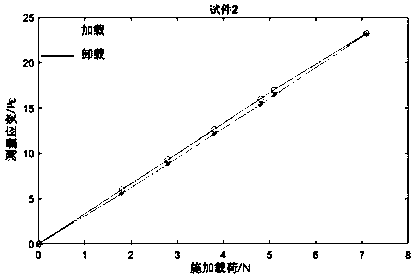

Embodiment 2

[0062] Embodiment 2, the preparation of a prefabricated damage area is 15mm * 15mm, and the surface size of the test piece is a 22-layer carbon fiber epoxy resin-based composite laminate test piece of 200mm * 25mm;

[0063] Step 1: Preparation before making.

[0064] The specific implementation of this step is the same as Step 1 of Example 1.

[0065] Step 2: Cut the fiber cloth.

[0066] The specific implementation of this step is the same as step 2 of embodiment 1.

[0067] Step 3: Lay the optical fiber layer.

[0068] The specific implementation of this step is the same as step 3 of embodiment 1.

[0069] Step 4: Make a prefabricated damage layer.

[0070] In this embodiment, a polytetrafluoroethylene film with an area of 15 mm×15 mm is used as the prefabricated damaged layer of the test piece, and the remaining implementation methods are the same as Step 4 of Embodiment 1.

[0071] Step 5: Overall compounding.

[0072] The specific implementation of this step is th...

Embodiment 3

[0073] Embodiment 3, the preparation of a prefabricated damage area is 10mm * 10mm, and the surface size of the test piece is a 44-layer carbon fiber epoxy resin-based composite laminate test piece of 200mm * 25mm;

[0074] Step A: Preparation before making.

[0075] The specific implementation of this step is the same as Step 1 of Example 1.

[0076] Step B: cutting the fiber cloth.

[0077] In this example, 16 pieces of fiber cloth strips with a ply angle of 0°, 12 pieces of fiber cloth strips with a ply angle of 45°, 8 pieces of fiber cloth strips with a ply angle of -45°, and 8 pieces of fiber strips with a ply angle of 90° Cloth strips, all the other implementations are the same as step 2 of embodiment 1.

[0078] Step C: laying the optical fiber layer.

[0079] The specific implementation of this step is the same as step 3 of embodiment 1.

[0080] Step D: making a prefabricated damage layer.

[0081] The specific implementation of this step is the same as step 4 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com