Patents

Literature

38results about How to "High sensitivity factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

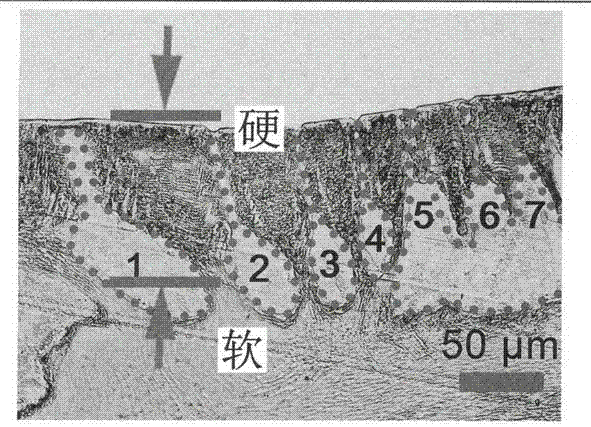

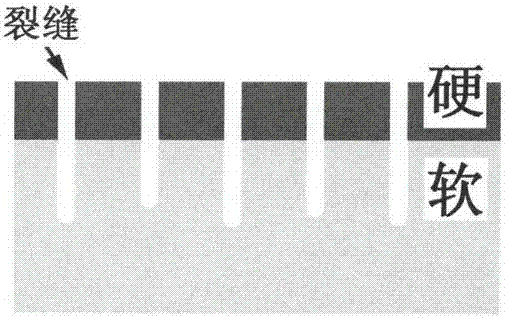

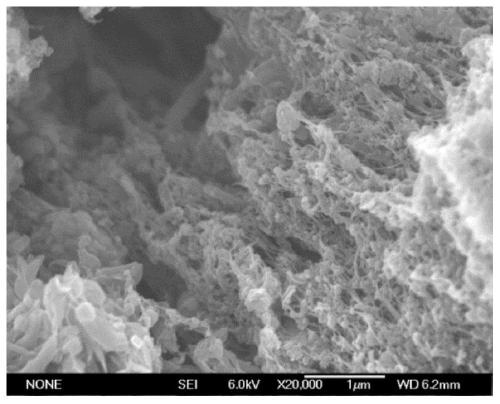

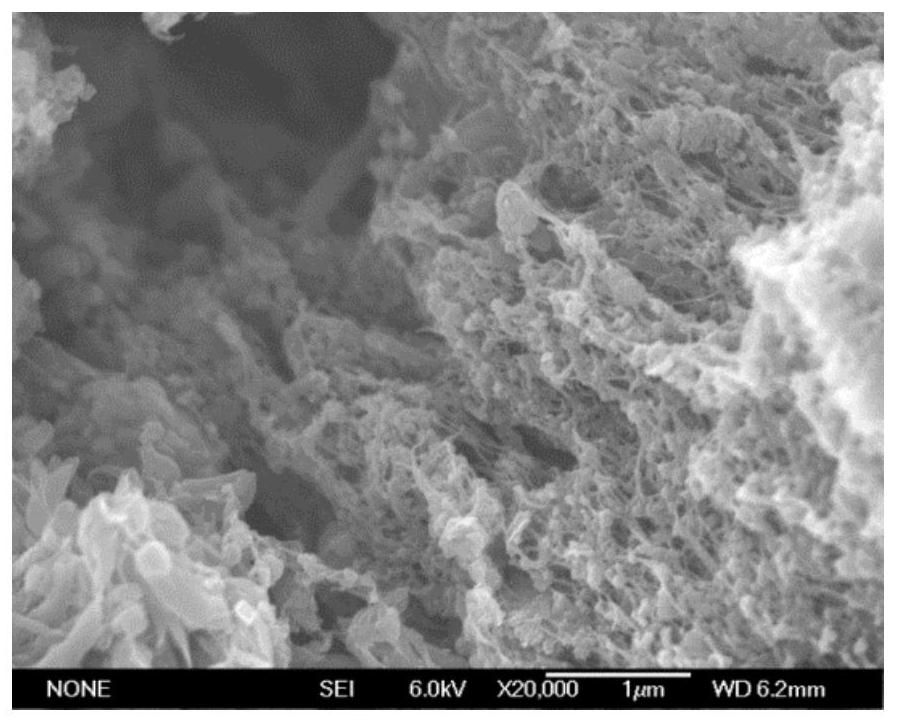

Bionic stress sensing structure and formation method thereof

ActiveCN106959071ALow costHigh sensitivity factorElectrical/magnetic solid deformation measurementStress sensingConductive ink

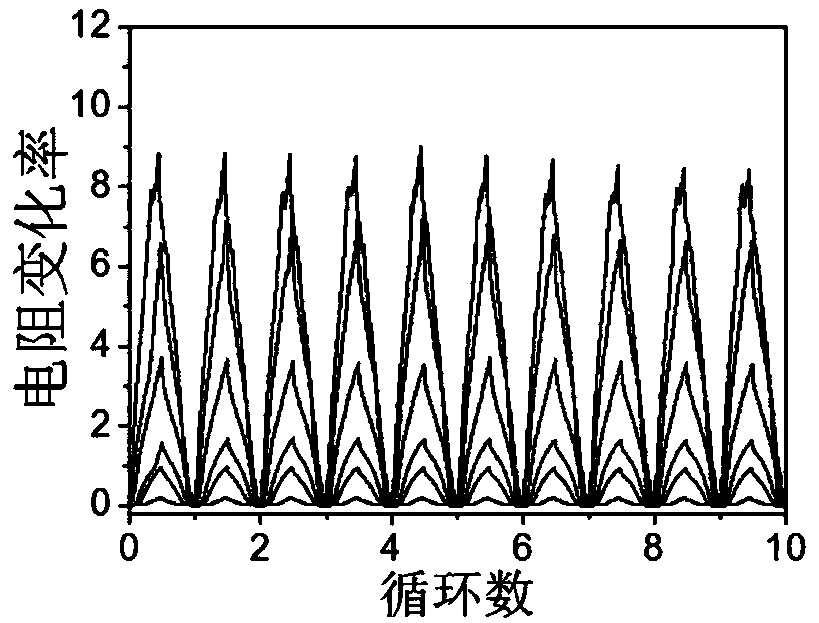

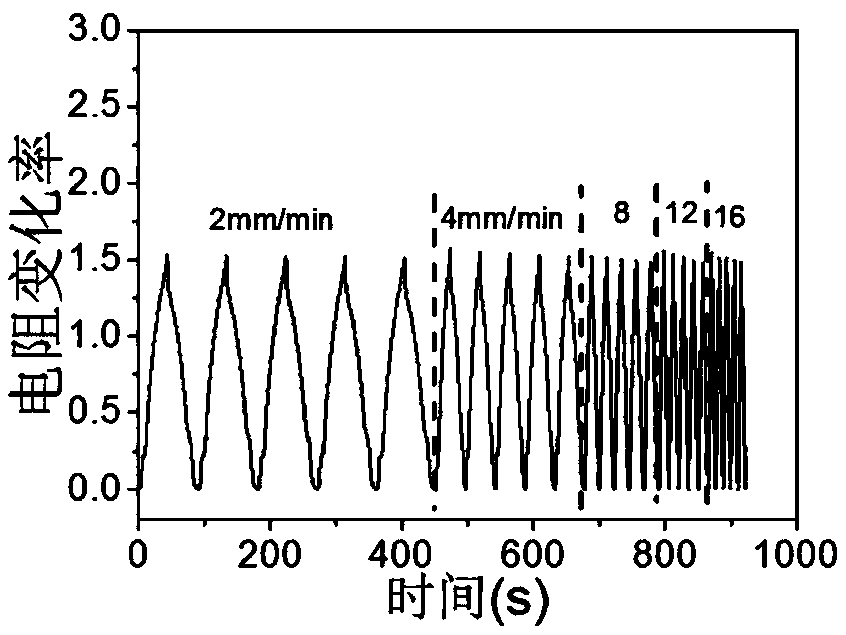

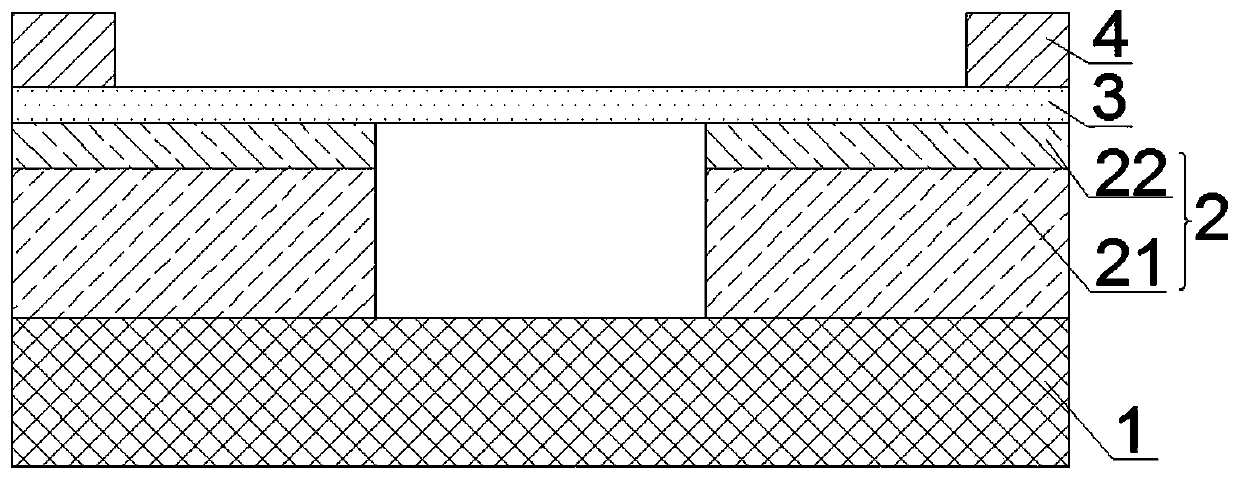

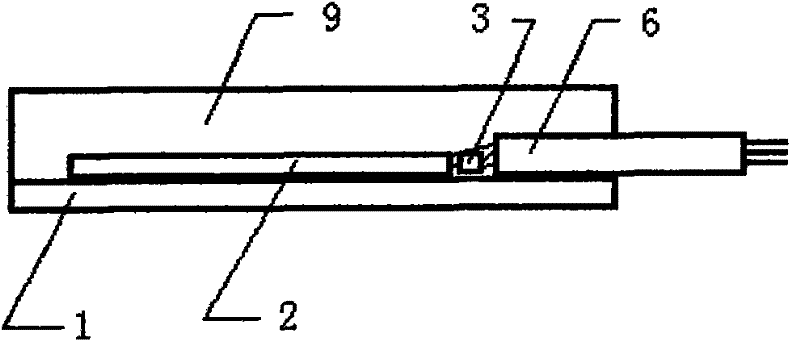

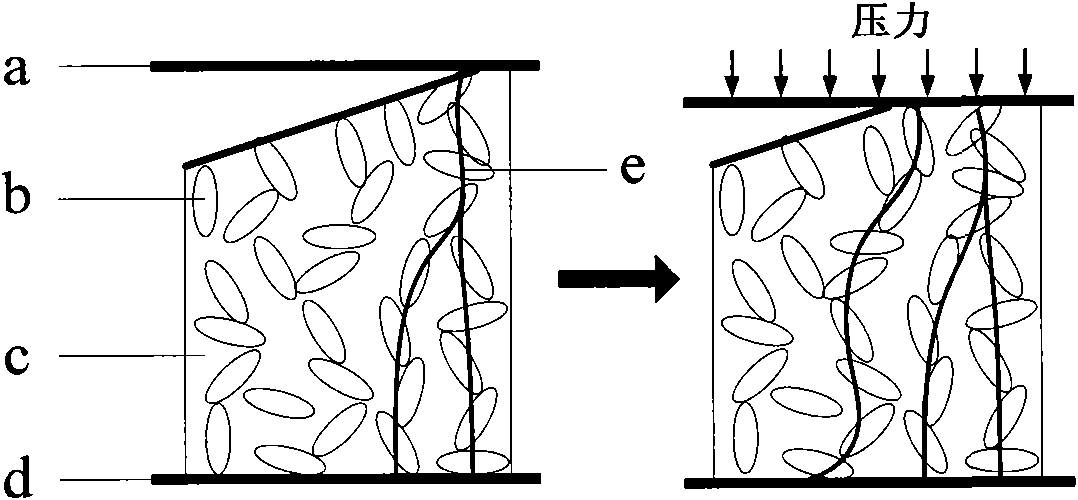

The invention discloses a bionic stress sensing structure and a formation method thereof. According to the bionic stress sensing structure, a conducting ink layer with strip-shaped parallel slit bands is formed on a paper substrate. The conducting ink layer is compact and rigid while the paper substrate is porous and soft. The formation method of the bionic stress sensing structure includes printing a layer of conducting ink on the paper substrate, wherein the conducting ink forms the dry conducting ink layer which is compact and rigid after drying up; and bending the paper substrate so as to make the dry conducting ink layer to break in the bending process. In this way, a plurality of slits are formed in the dry conducting ink layer and the slits form the slit band bionic structure. The dry conducting ink layer becomes the conducting ink layer with the strip-shaped slit bands, so that the bionic stress sensing structure is formed. When the paper substrate is stressed and deformation occurs, the contact degree of the slit walls of the strip-shaped slits of the slit band bionic structure changes, so that the resistance of the conducting ink layer varies. Therefore, the stress sensing function is achieved.

Owner:JILIN UNIV

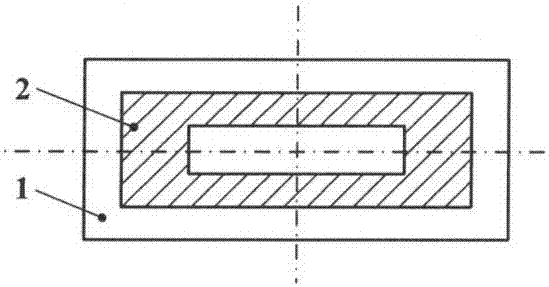

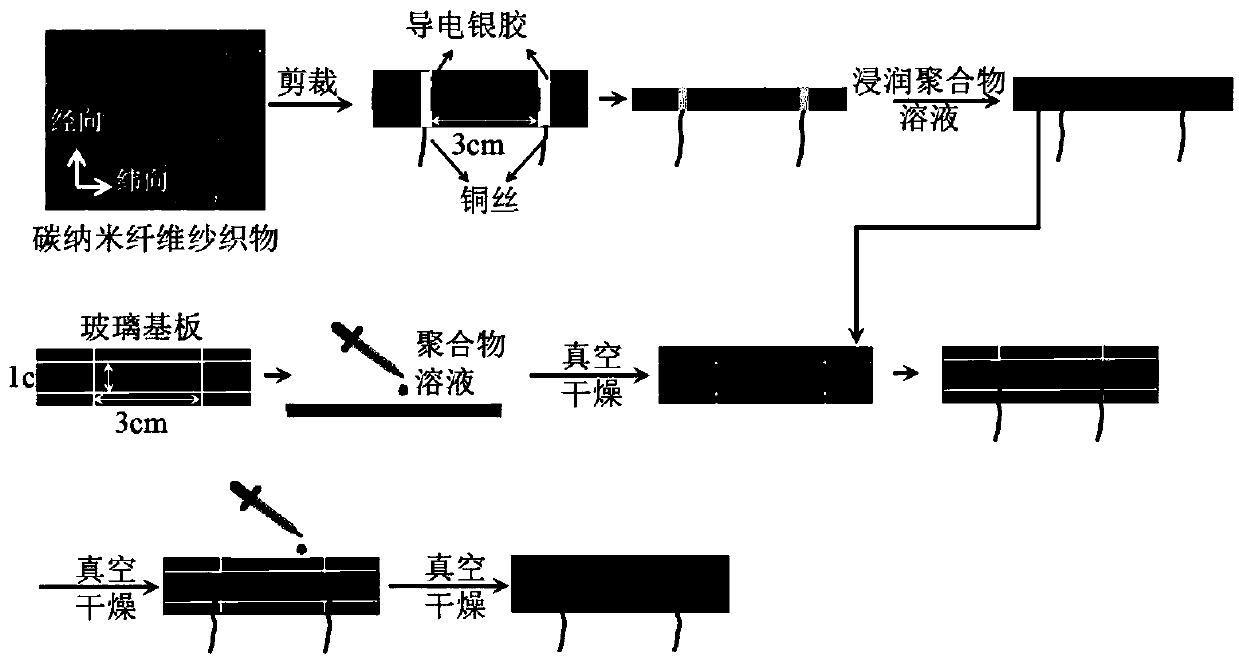

Flexible strain transducer based on carbon nanofiber yarn woven fabric and preparation method thereof

ActiveCN108680095ALarge specific surface areaReduce thicknessHeating/cooling textile fabricsElectrical/magnetic solid deformation measurementYarnLinear correlation

The invention relates to a flexible strain transducer based on carbon nanofiber yarn woven fabric and a preparation method thereof. The preparation method includes the following steps: uniformly spreading a polymer solution or a liquid polymer, and drying the polymer solution or the liquid polymer to prepare base film; connecting the carbon nanofiber yarn woven fabric with extraction electrodes, infiltrating the carbon nanofiber yarn woven fabric into the polymer solution or the liquid polymer, placing the carbon nanofiber yarn woven fabric on the base film, and performing drying treatment; applying the polymer solution or the liquid polymer to the surface of the carbon nanofiber yarn fabric once, and preparing the flexible strain transducer based on the carbon nanofiber yarn woven fabricthrough drying. Final products include the carbon nanofiber yarn woven fabric, two extraction electrodes communicating with the carbon nanofiber yarn woven fabric, and polymer film covering the upperand lower surface of the carbon nanofiber yarn woven fabric. A sensitivity coefficient of is 30-200 when cyclic stretch is performed at elongation ranging from 0 to 5-12%; and a linear correlation coefficient is more than or equal to 0.995 when the elongation is 9% or below when stretch is performed. The preparation method is simple in a process, and low in cost.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Graphene-based piezoresistive pressure sensor and preparation method thereof

InactiveCN110174197AMaintain structural integrityEasy to operateFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsSic substrateCvd graphene

The invention relates to a graphene-based piezoresistive pressure sensor and a preparation method thereof. The preparation method of the sensor comprises the following steps of preparing a graphene film on a metal substrate to form a metal / graphene film; coating PMMA on the surface of the graphene film to form a metal / graphene film / PMMA; carrying out bubbling and stripping on the graphene film coated with the PMMA on the metal substrate by an electrochemical method in order to obtain the graphene film / PMMA; transferring the graphene film / PMMA to an SiO2 / Si substrate and removing the PMMA to obtain the graphene film / SiO2 / Si; transferring the graphene film / SiO2 / Si to an SiC substrate; etching the SiO2 / Si substrate; patterning the graphene film; and evaporating a metal electrode on the graphene thin film to obtain the graphene-based piezoresistive pressure sensor. The graphene-based piezoresistive pressure sensor has the characteristics of good piezoresistive property, high sensitivity and fast response speed, and has wide market application value and prospect.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

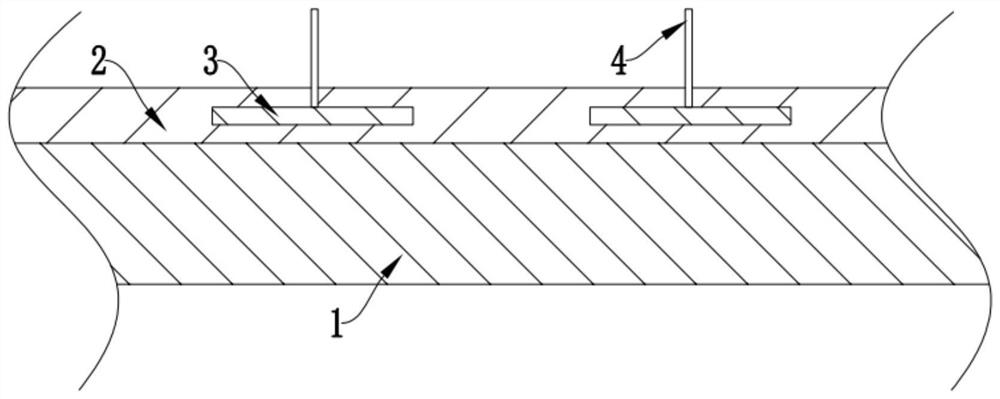

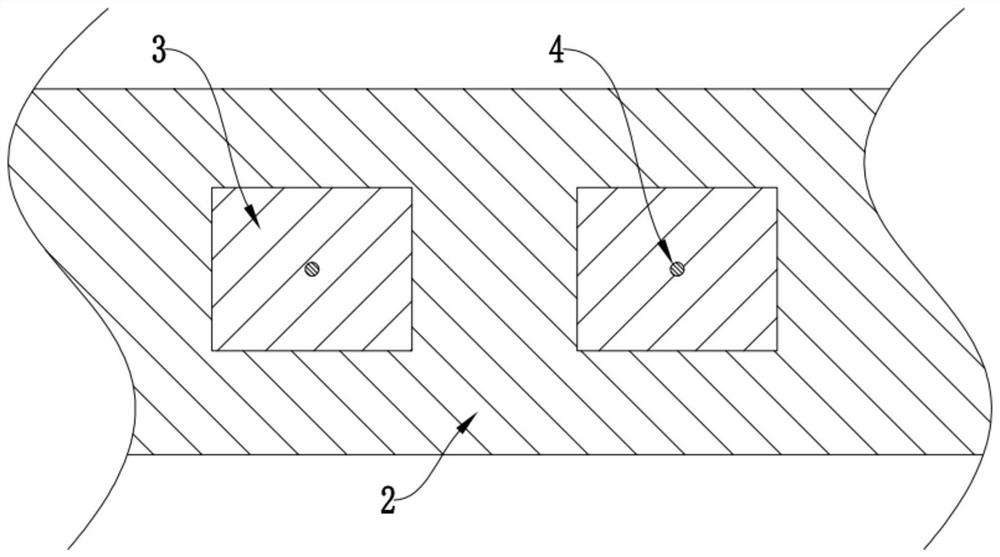

A self-compensating concrete-integrated strain gauge

InactiveCN102269567AReduce volumeEliminate the effect of detection sensitivityElectrical/magnetic solid deformation measurementFiberElectrical resistance and conductance

The invention discloses a self-compensating concrete integrated strain gauge, which is mainly characterized in that a compensation resistor is provided on the strain gauge, the compensation resistor and the working piece form a half-bridge or full-bridge working mode, and the compensation resistor adopts a high-precision resistor with no stress output Or small grid strain gauges, which can automatically compensate the influence of temperature on the bridge and wires, overcome the difficulty that it is impossible to equip each measuring point with a compensation block and ensure that its temperature and change are consistent; it can also eliminate the influence of wire length on detection sensitivity At the same time, the reinforced fiber insulation base and flexible waterproof sealing material are used to carry out the overall waterproof sealing treatment, which not only ensures the technical requirements of the insulation resistance of the strain gauge, but also has the effect of convenient, fast, accurate and safe on-site installation. .

Owner:陈彦平

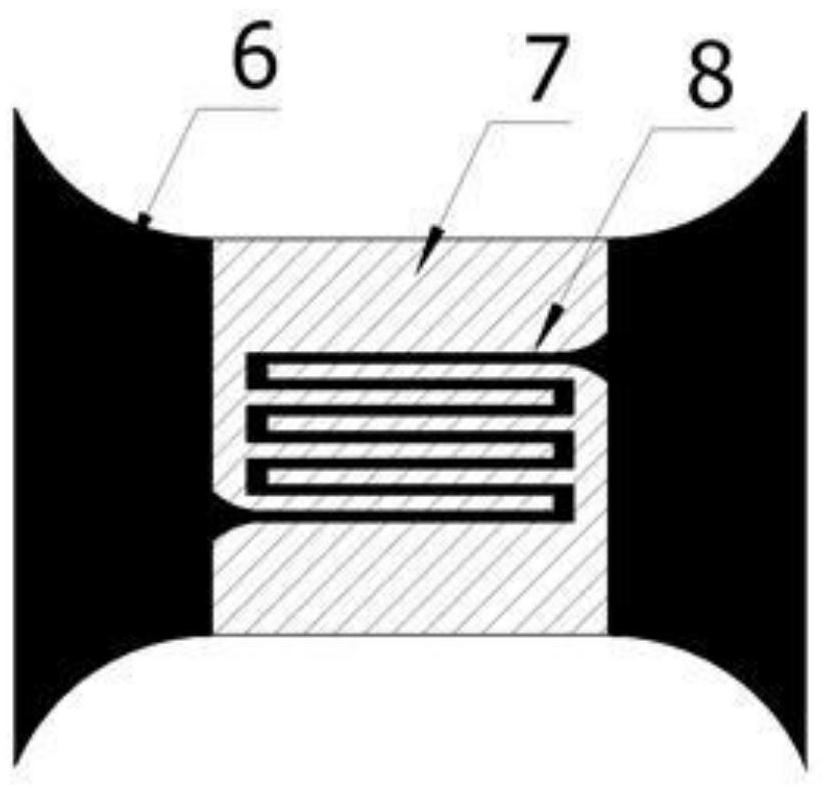

Contact stress sensor

InactiveCN103411712AApplicable measurementHigh sensitivity factorForce measurementLead bondingEngineering

The invention discloses a contact stress sensor. The contact stress sensor comprises a flexible supporting base, a strainmeter, a flexible transmission line and a flexible medium, wherein the flexible supporting base is provided with a plurality of through holes and located at the bottommost position, the strainmeter and the flexible transmission line adhere to the upper surface of the flexible supporting base after being connected into a whole in a lead bonding mode, and the flexible medium covers and adheres to the upper surface of a combination of the strainmeter and the flexible transmission line. Due to the adoption of the flexible supporting base, the flexible transmission line and the flexible medium, the contact stress sensor is capable of bending and deforming along with changes of installation environments, and particularly applicable to measuring contact stress of an upper contact surface and a lower contact surface of an article located in a curved surface structure; due to the fact that the through holes are formed in the supporting base, the contact stress sensor can be used for measuring not only pulling stress but also compressive stress, and measuring accuracy is enhanced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

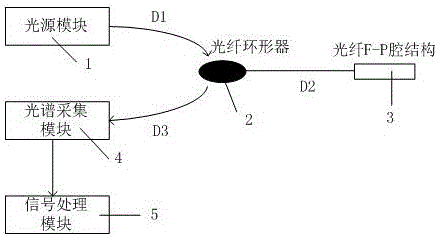

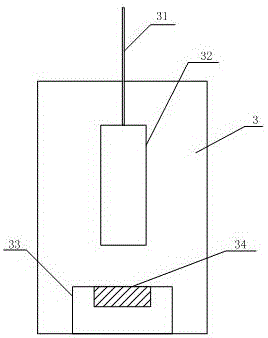

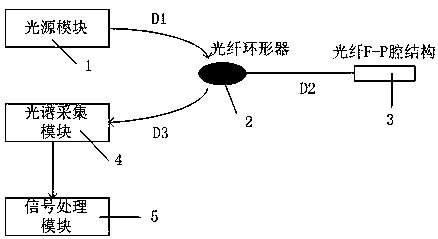

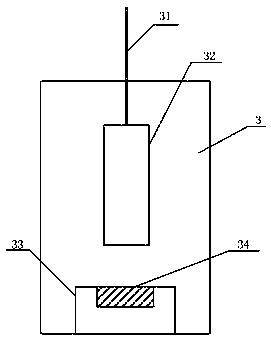

Hydrogen sulfide gas sensing device on basis of optical fiber F-P (Fabry-Perot) interferometer

InactiveCN106248602AImprove anti-interference abilityHigh sensitivity factorColor/spectral properties measurementsRefractive indexOptical pathlength

The invention provides a hydrogen sulfide gas sensing device on the basis of an optical fiber F-P (Fabry-Perot) interferometer. The concentration of external hydrogen sulfide gas can be perceived by an optical fiber F-P cavity of the hydrogen sulfide gas sensing device which is a measuring device, and the optical fiber F-P cavity is formed by an optical fiber collimator and a metal groove filled with hydrogen sulfide sensitive organic polymer materials. The refractive index of the organic polymer materials can be changed when the concentration of the external hydrogen sulfide gas is changed, optical paths of transmitted optical waves in the optical fiber F-P cavity can be changed, and accordingly spectral characteristics of interference signals outputted by the optical fiber F-P cavity can be changed. Data of the spectral characteristics of the reflected interference signals of the optical fiber F-P cavity are analyzed, so that the concentration of the hydrogen sulfide gas can be accurately measured. The hydrogen sulfide sensing device has the advantages of simple structure, miniaturization, high sensitivity and precision, electromagnetic interference resistance, intrinsic safety and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

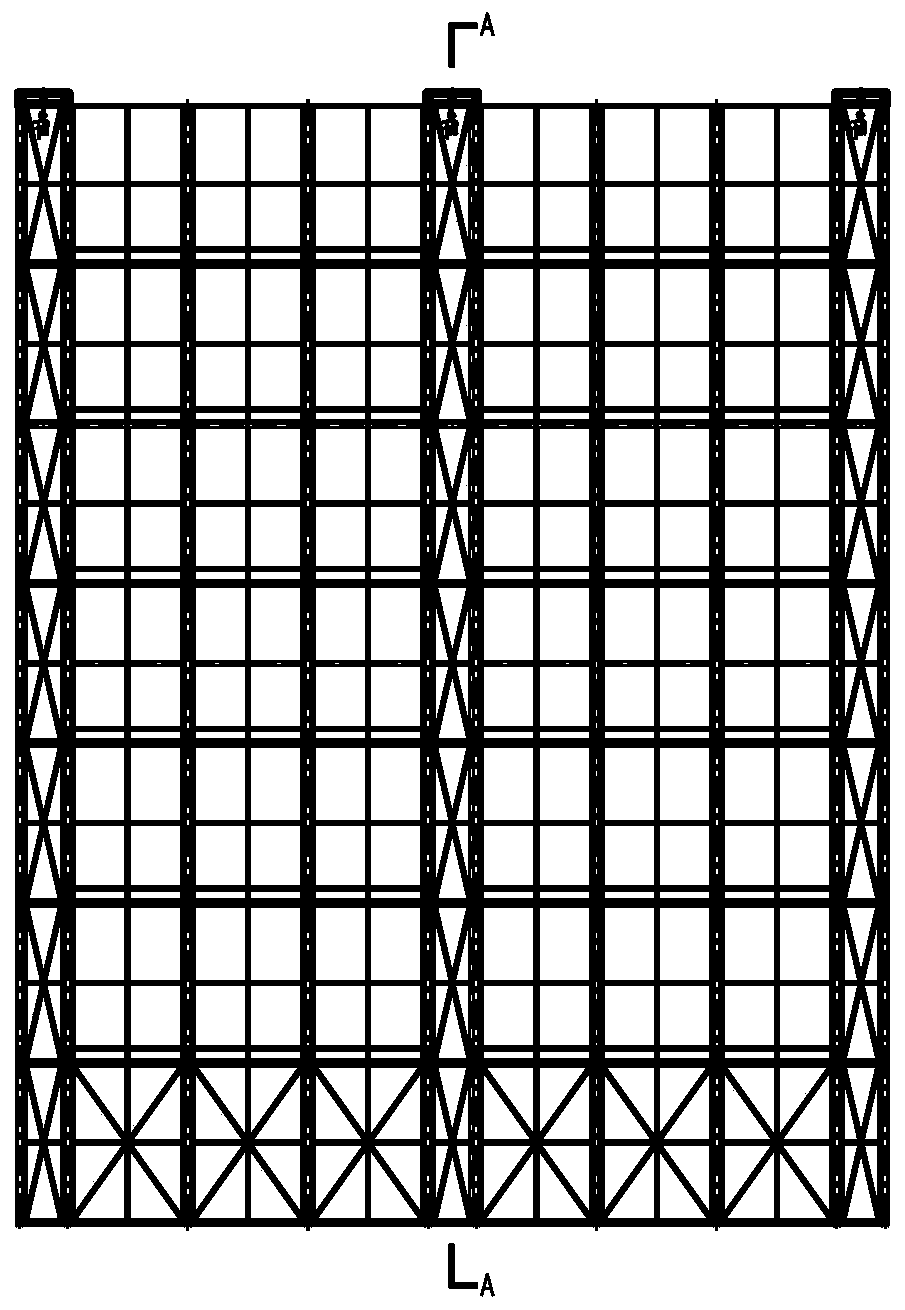

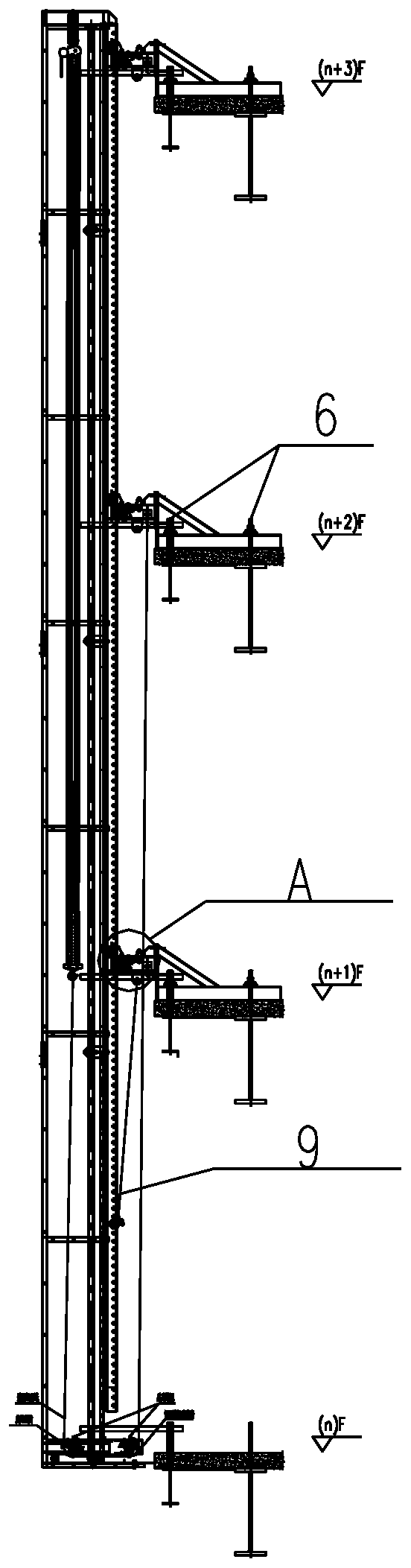

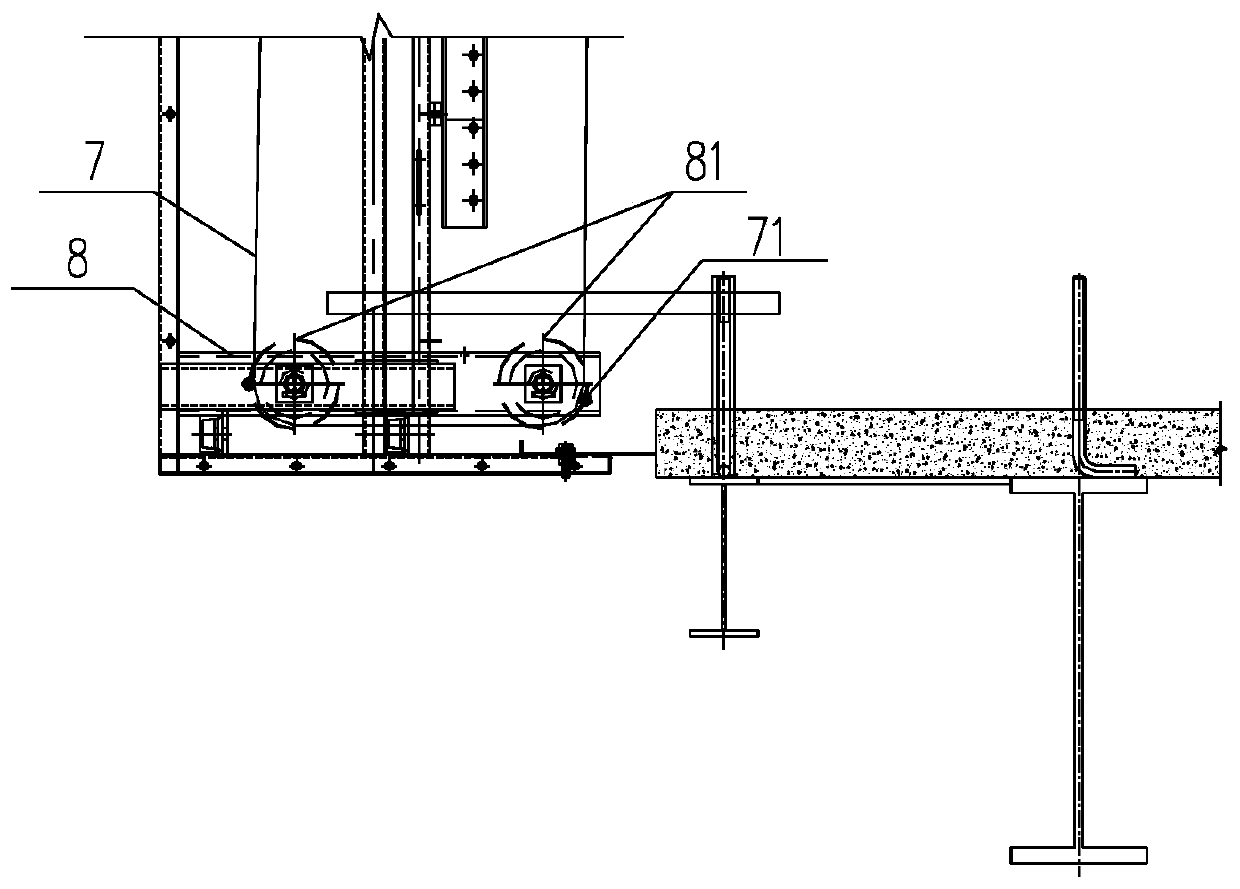

Light self-climbing shield frame system and construction method thereof

PendingCN110043020ASimple structureSmall sizeBuilding material handlingScaffold accessoriesSupporting systemEngineering

The invention discloses a light self-climbing shield frame system and a construction method thereof, and relates to the technical field of formwork systems. The light self-climbing shield frame systemand the construction method thereof are used for solving the problems of the tedious lifting process of a lifting system and an anti-falling device and low safety. The light self-climbing shield frame system includes a scaffold system, a supporting system, a lifting system and an anti-tilting and anti-falling system. The supporting system includes a bearing frame which is fixed on a structural steel beam; the lifting system includes an electric block, a bottom guiding wheel and a steel wire rope, wherein the electric block is arranged at the top of the scaffold system, the bottom guiding wheel is fixed to the bottom of the scaffold system, one end of the steel wire rope is connected with the electric block, and the other end of the steel wire rope passes through the bottom guiding wheel to be arranged at the bottom of the bearing frame in a hung mode; the anti-tilting and anti-falling system includes a guiding rail installed on a scaffold frame body, and an anti-falling pawl wheel, alimiting spring, an anti-falling pawl and a limiting baffle are arranged on the bearing frame; the anti-falling pawl wheel meshes with the guiding rail, the limiting spring is used for limiting the stroke of the anti-falling pawl, and the anti-falling pawl and the limiting baffle are used for preventing the anti-falling pawl wheel from rotating counterclockwise. Therefore, falling of the scaffoldframe body and the guiding rail is prevented, and the anti-falling effect is achieved advantageously.

Owner:SHANGHAI CONSTR NO 1 GRP

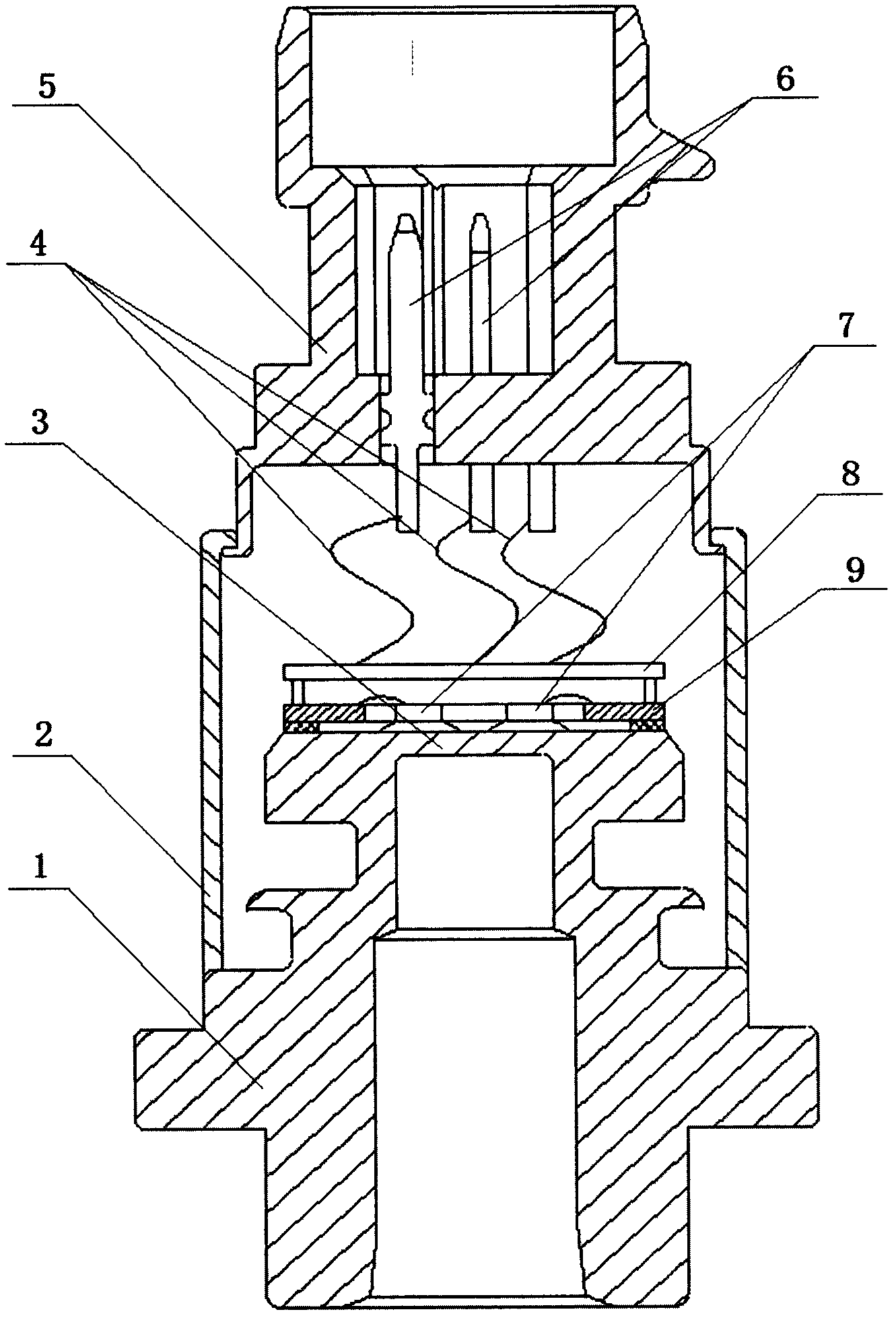

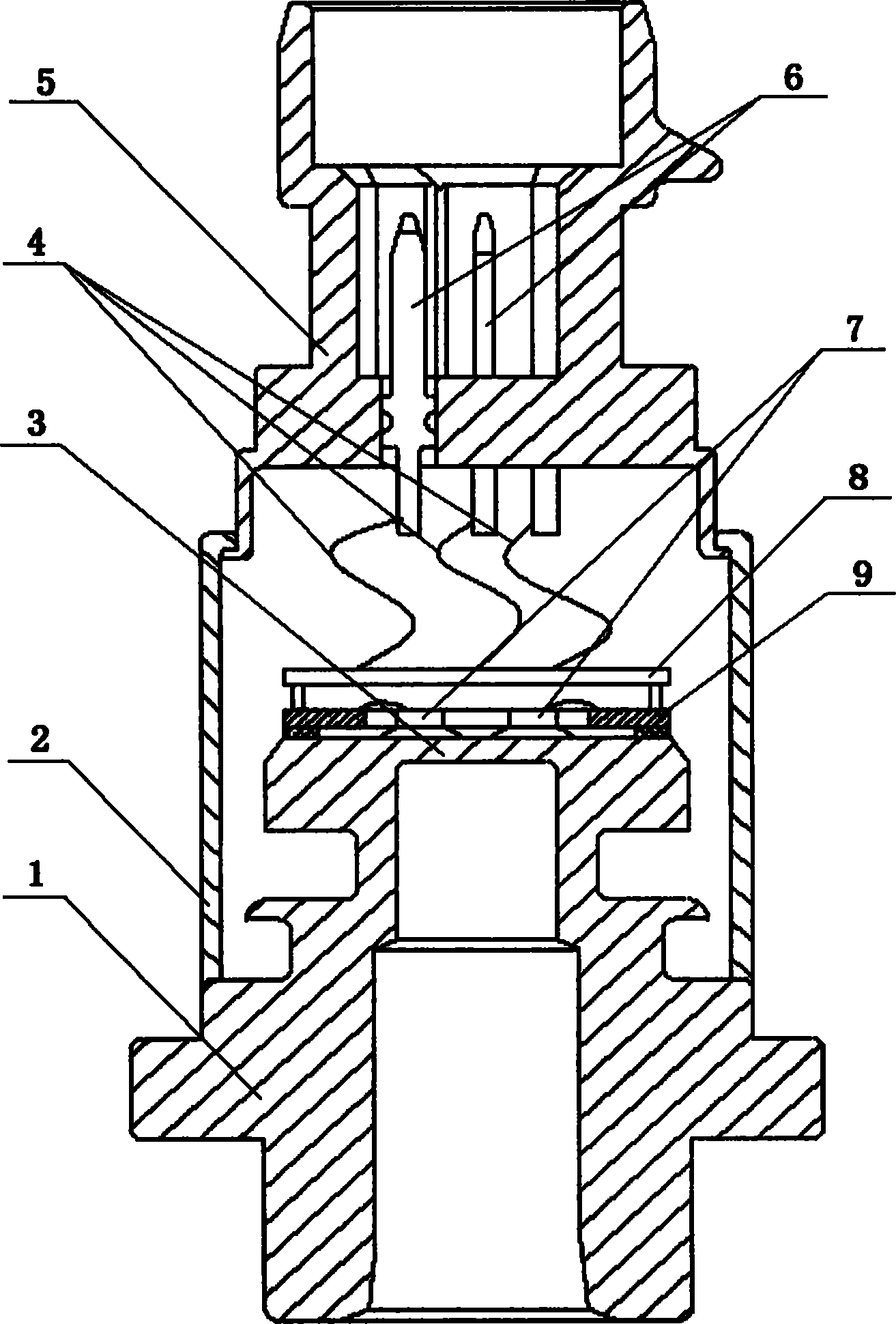

Silicon strain foil metallic packaging sensor

InactiveCN102661822AHigh sensitivity factorSmall mechanical hysteresisForce measurementFlexible circuitsEngineering

The invention relates to a silicon strain foil metallic packaging sensor sensing pressure output through a silicon strain foil. The sensor comprises a metal barrel. A plastic socket and a pressure port are respectively arranged at the upper end and the lower end. An inner cavity is arranged in the pressure port, the lower end of the pressure port is opened, and the upper end of the pressure port is closed to form an elastic diaphragm. A plurality of metal contact pins are arranged on the plastic socket, and the lower ends of the metal contact pins penetrate into the metal barrel. The silicon strain foil metallic packaging sensor is characterized in that the silicon strain foil is bonded to the upper portion of the elastic diaphragm, a first circuit board is arranged above the pressure port, and the first circuit board is connected with the silicon strain foil through a lead to form a bridge circuit. A second circuit board is arranged above the first circuit board, and the second circuit board and the first circuit board are welded through welding points. The second circuit board is connected with the metal contact pins into a series connection circuit through a flexible circuit board. The sensor is high in working efficiency and measuring accuracy. The silicon strain foil metallic packaging sensor does not require to be vacuumized, does not require oil injection and is simple in manufacture process.

Owner:无锡永阳电子科技有限公司

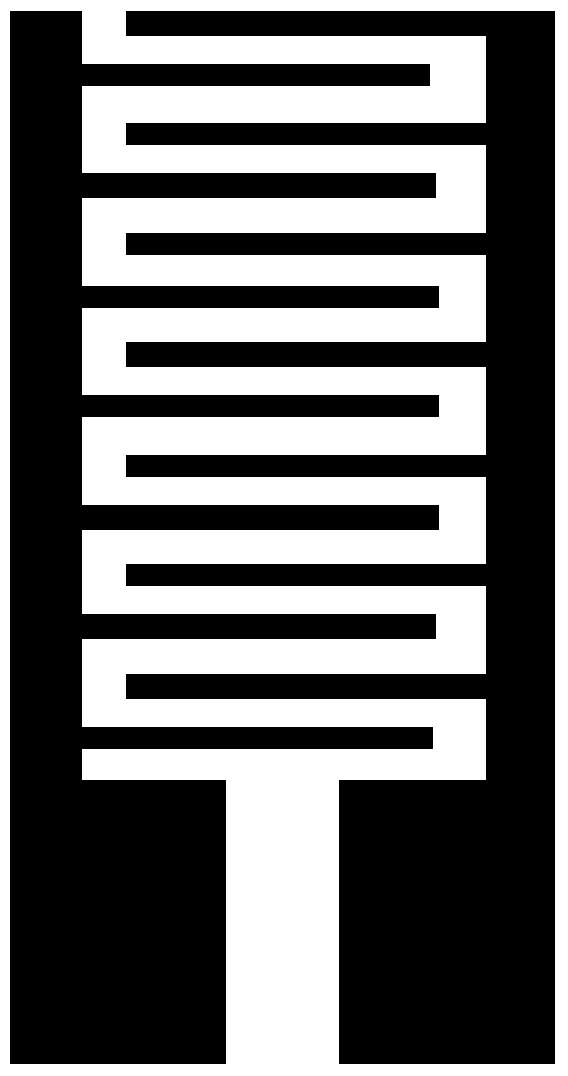

A kind of capacitive strain sensor and preparation method thereof

ActiveCN105021120BIncreased strain sensitivityLarge GF factorElectrical/magnetic solid deformation measurementDielectricCapacitance

The invention provides a capacitive strain sensor and a preparation method thereof, which belong to the technical field of sensor design and production. The capacitive strain sensor consists of a substrate, a first barium strontium titanate dielectric film layer, a PdCr electrode layer, a second barium strontium titanate dielectric film layer, and an Al strontium barium titanate dielectric film layer from bottom to top. 2 o 3 The protective layer, wherein the PdCr electrode layer is an interdigitated electrode structure. The present invention adopts the planar structure of interdigitated capacitance, and barium strontium titanate (Ba 0.5 Sr 0.5 TiO 3 ) as the dielectric material, PdCr as the electrode material, and the preparation technology of magnetron sputtering coating and photolithography technology are used to realize the higher temperature (500℃) of the capacitive strain sensor under the larger strain (2500με). The purpose of stabilizing work.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

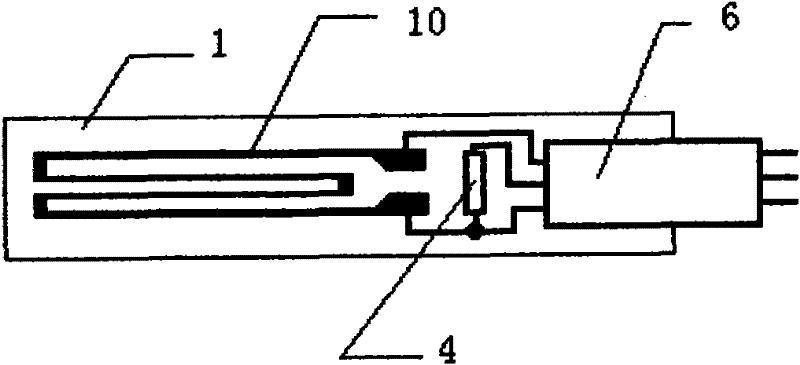

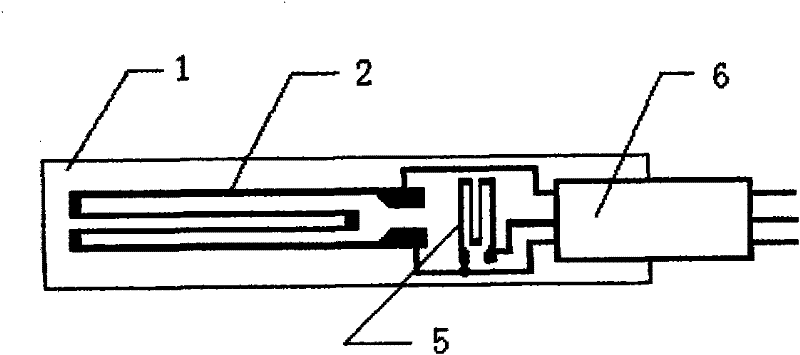

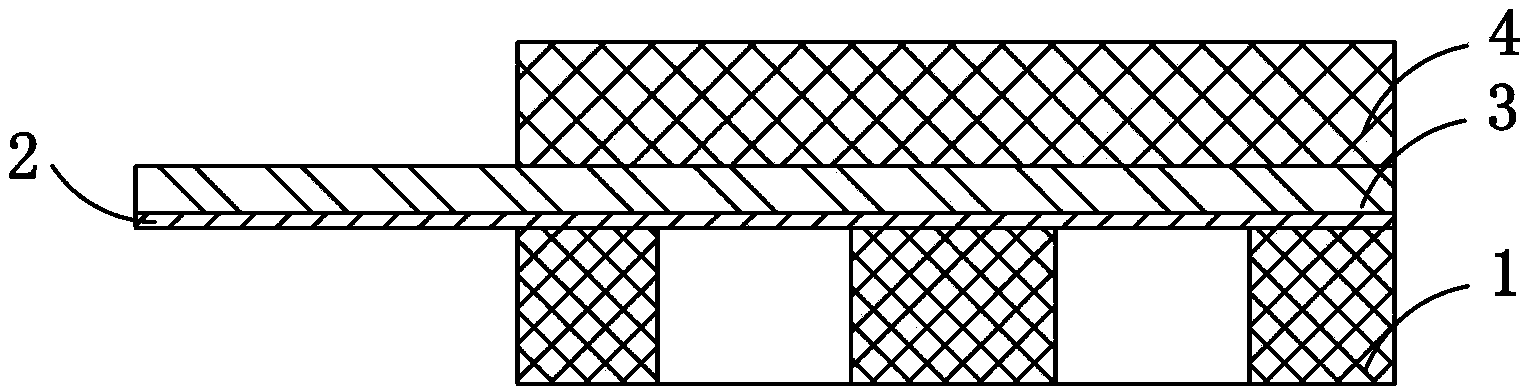

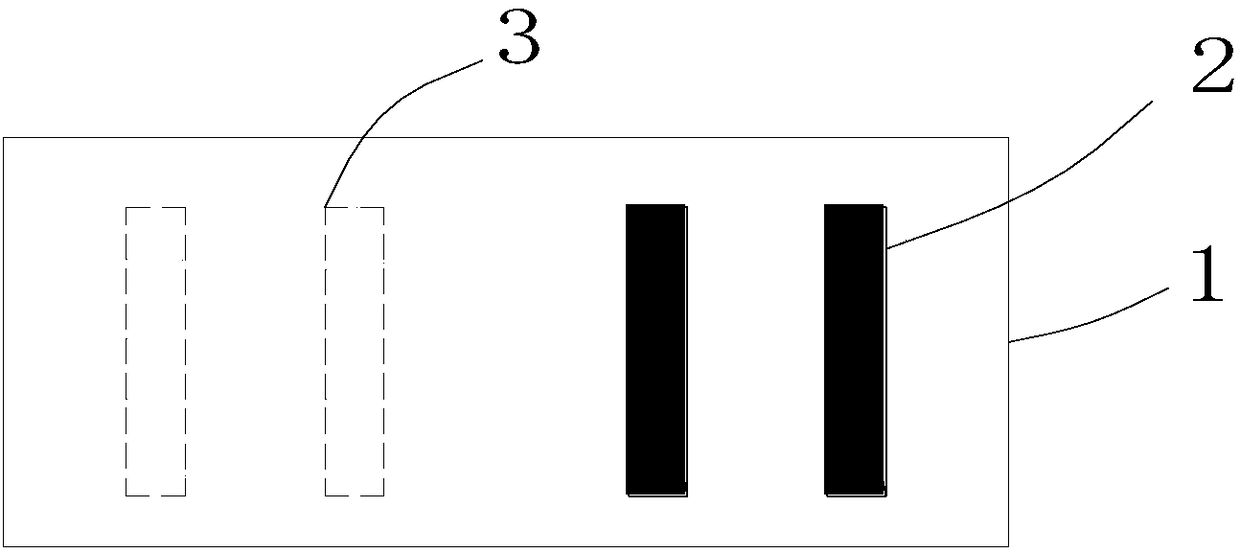

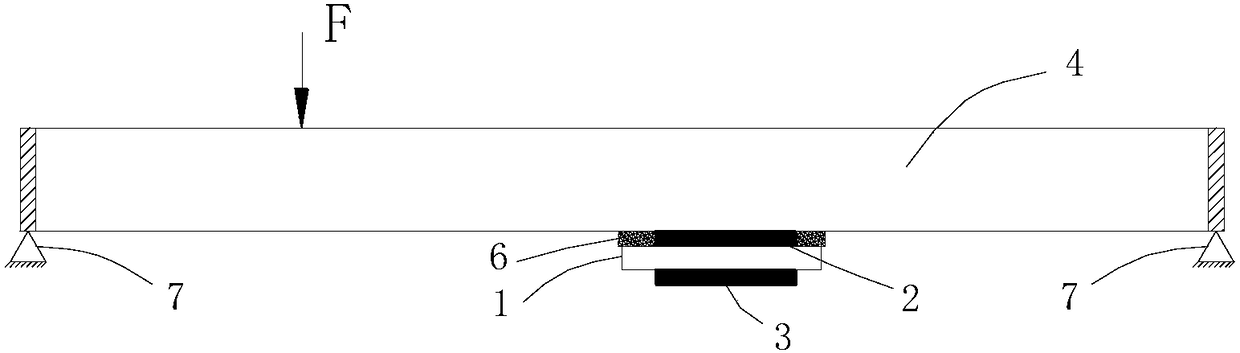

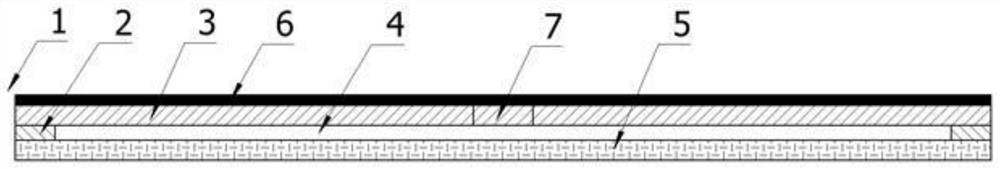

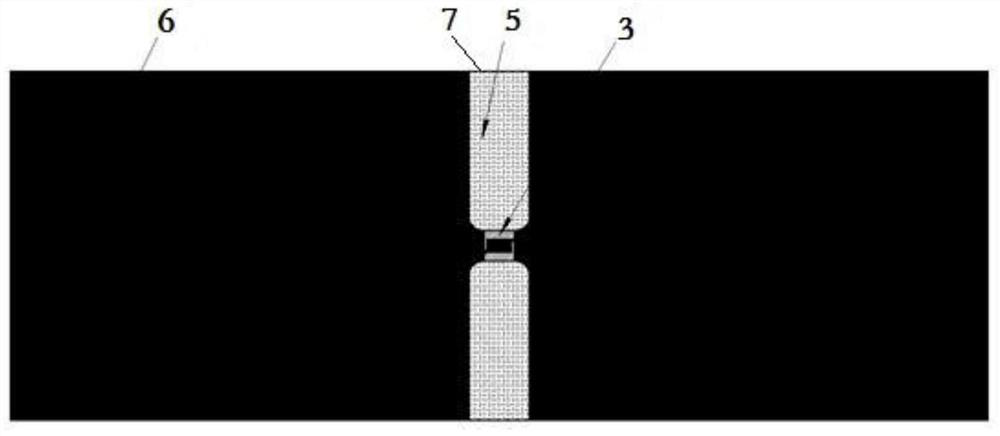

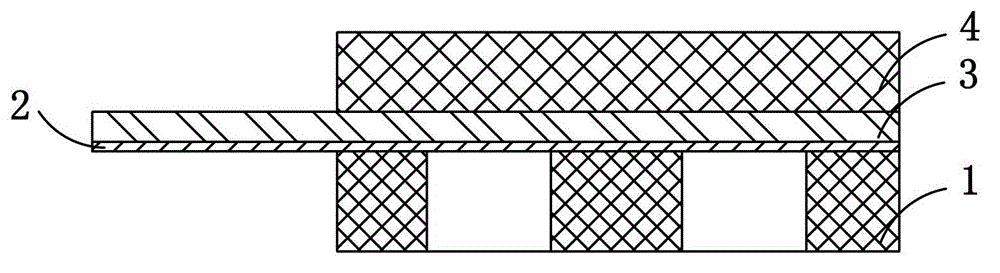

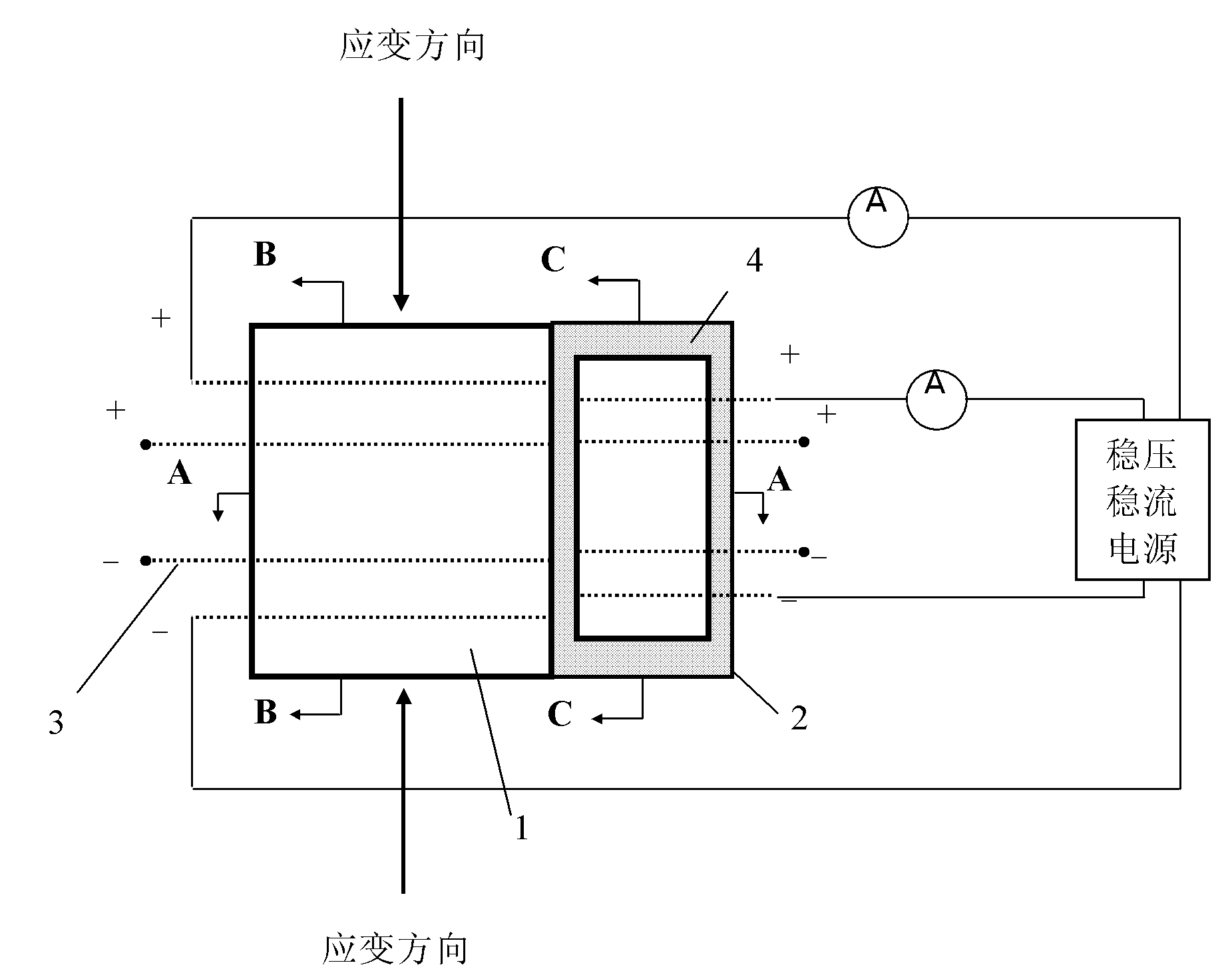

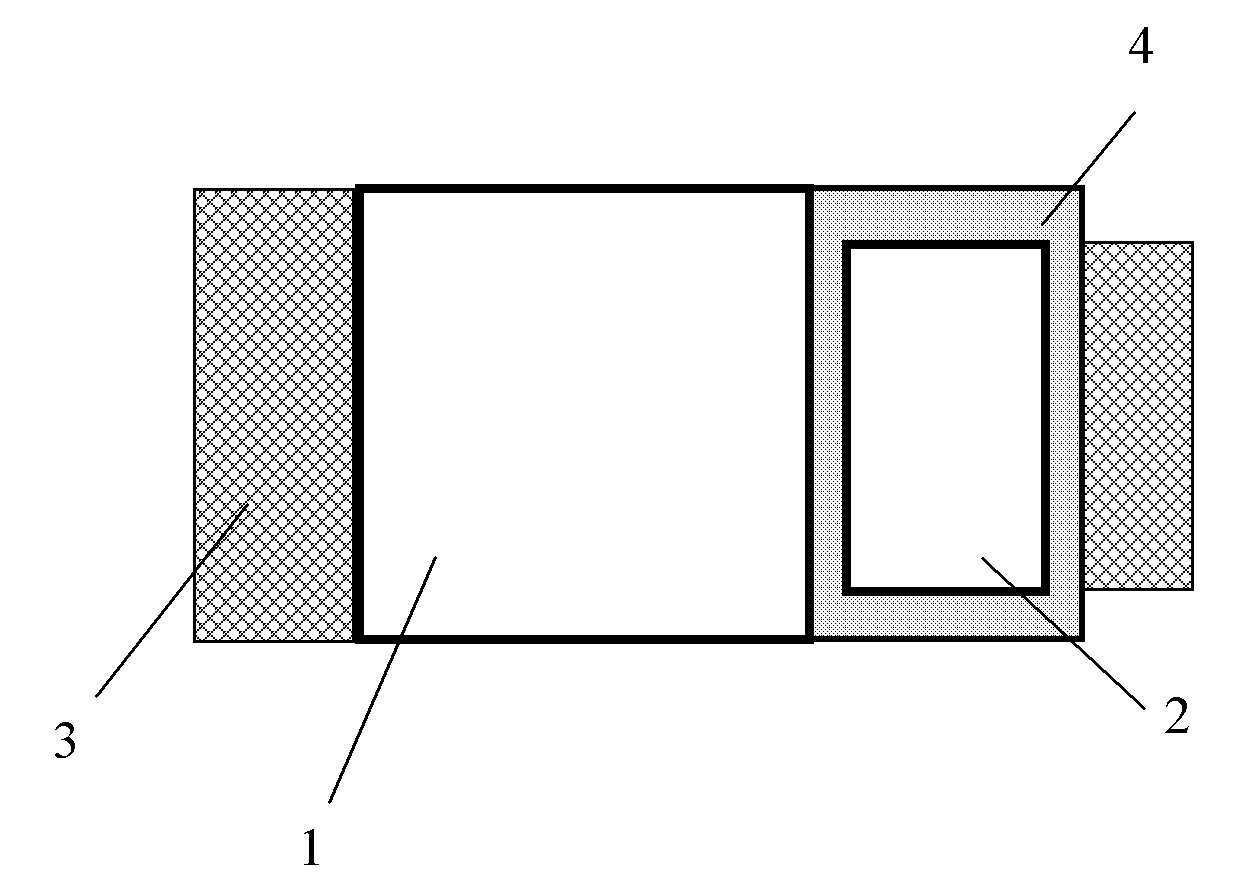

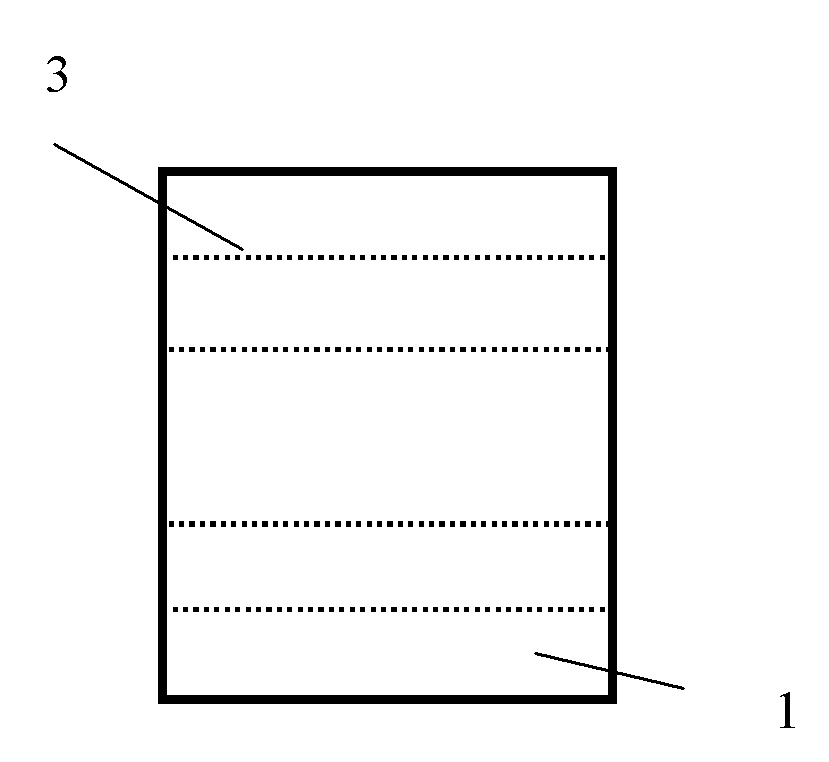

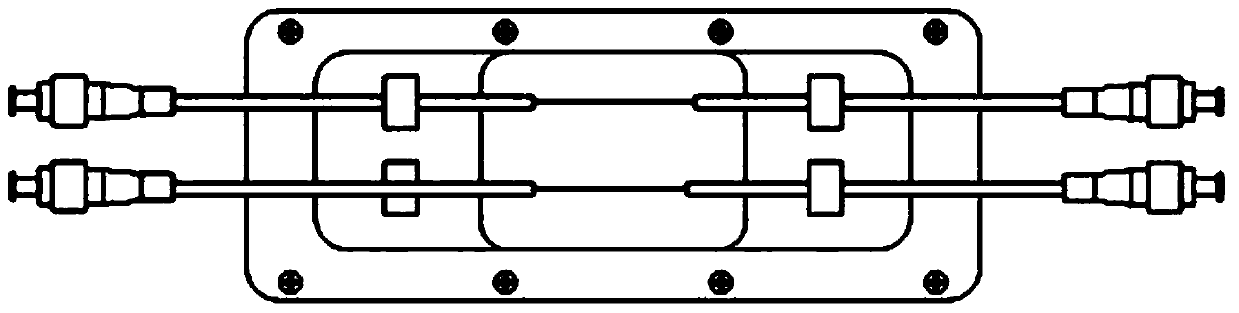

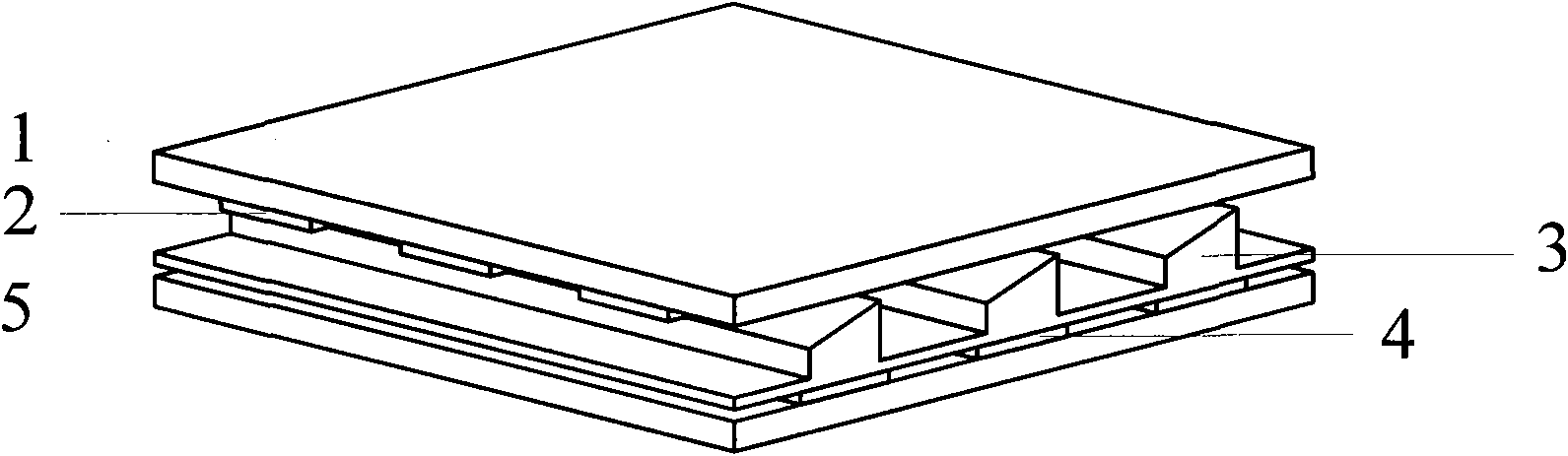

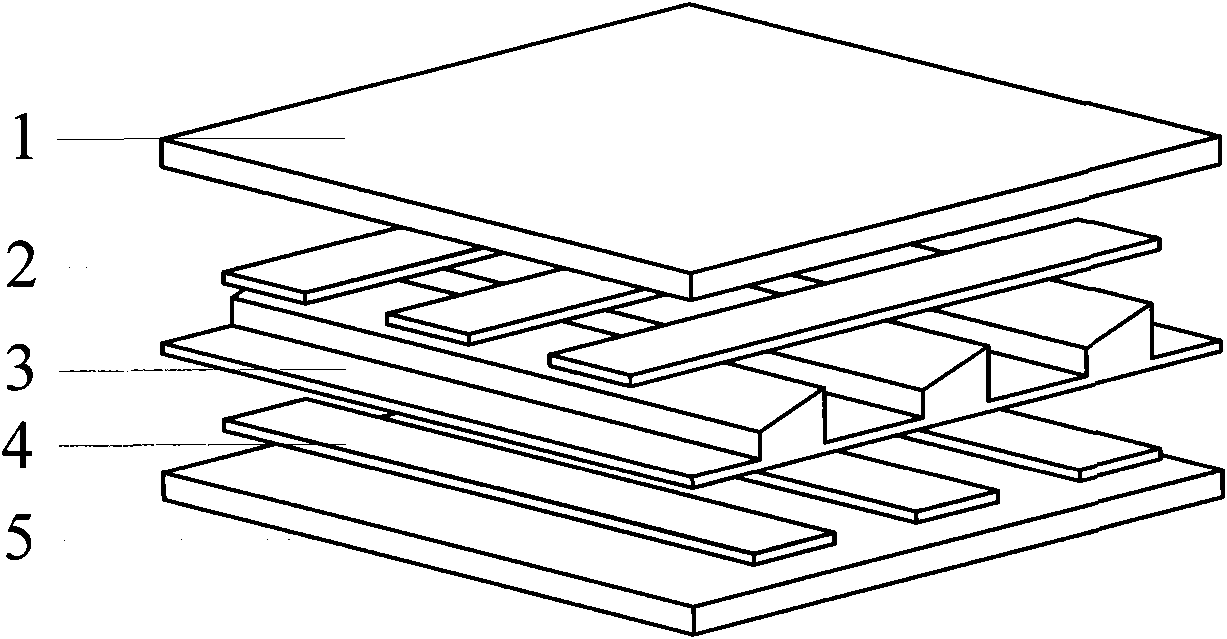

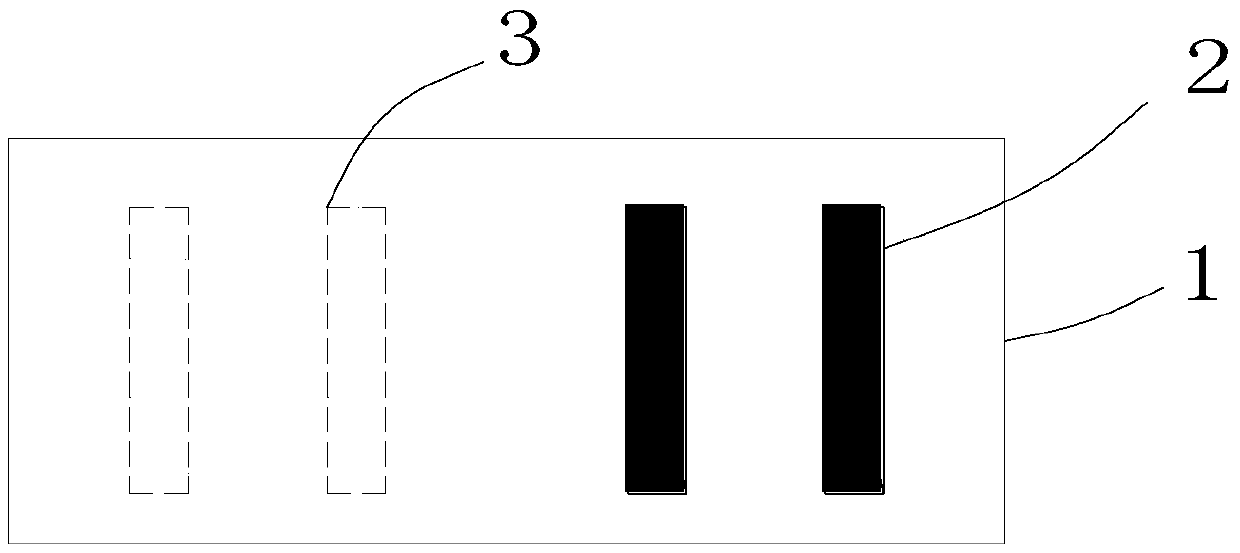

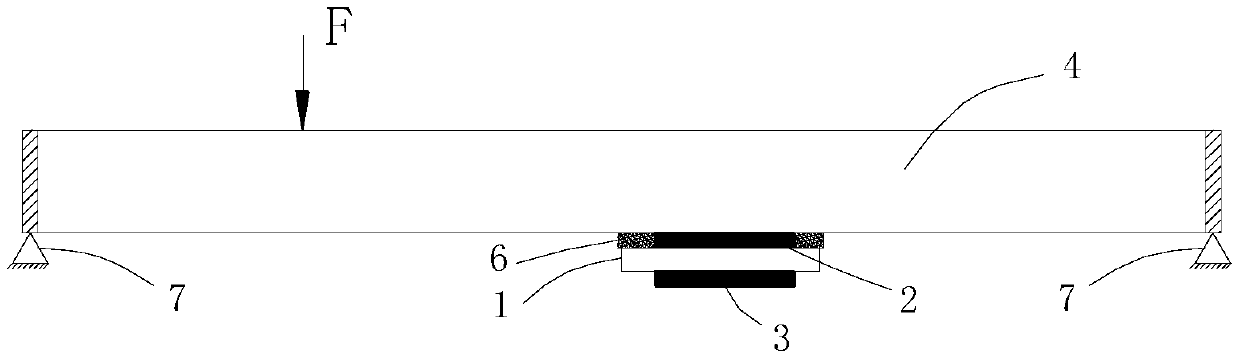

Strain sensor, method using strain sensor to acquire high sensitivity and measuring device

ActiveCN108709490AHigh sensitivityEasy to manufactureElectrical/magnetic solid deformation measurementStrain sensorStrain measurement

The invention belongs to the technical field of sensors and particularly relates to a strain sensor, a method using the strain sensor to acquire high sensitivity and a strain measuring device comprising the strain sensor. The strain sensor comprises a flaky carrier and is characterized in that a first sensitive grid and a second sensitive grid are respectively arranged on two sides of the flaky carrier, and the projections of the first sensitive grid and the second sensitive grid on the flaky carrier do not coincide with each other. The method can double the sensitivity of the sensor and is convenient to operate. The strain measuring device has the advantages that the strain measuring device is compact in structure by using a FPC connector to connect with the strain sensor, the strain measuring device is simple to operate, convenient to use and capable of saving cost, and plug type electric connection with an external signal receiving device can be formed conveniently.

Owner:2D CARBON CHANGZHOU TECH INC

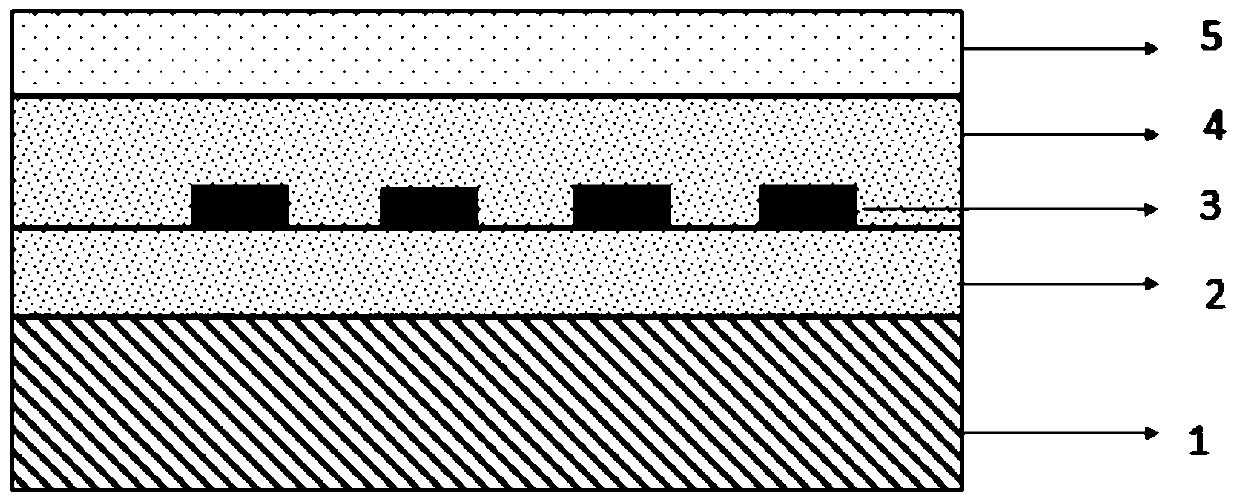

Multi-layer structure strain sensor with high sensitivity

ActiveCN113959327AReduce stiffnessIncrease stiffnessElectrical/magnetic solid deformation measurementThin membraneStrain sensor

The invention relates to the technical field of strain sensors, and provides a multilayer structure strain sensor with high sensitivity, which comprises a sensor body that comprises a first thin film layer, the first thin film layer is connected with a second thin film layer, and the second thin film layer far away from the first thin film layer is connected with a third thin film layer, wherein cavities are formed among the first thin film layer, the second thin film layer and the third thin film layer, and a strain core area is arranged on the first thin film layer; The second thin film layer enables the first thin film layer and the third thin film layer to be indirectly connected; the rigidity of the strain core area on the first thin film layer is lower than the rigidity of the areas on the two sides by combining with the parameter design of the strain core area, so that larger strain is generated on the strain core area of the first thin film layer. Therefore, even if the deformation of the measured object is small, the accurate measurement requirement can be met.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

contact stress sensor

InactiveCN103411712BApplicable measurementHigh sensitivity factorForce measurementLead bondingTension stress

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

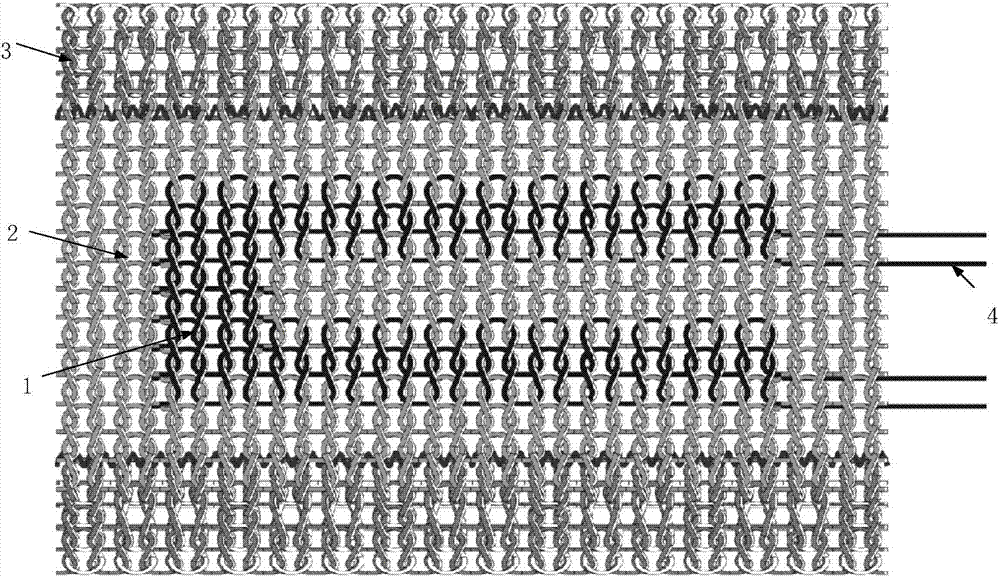

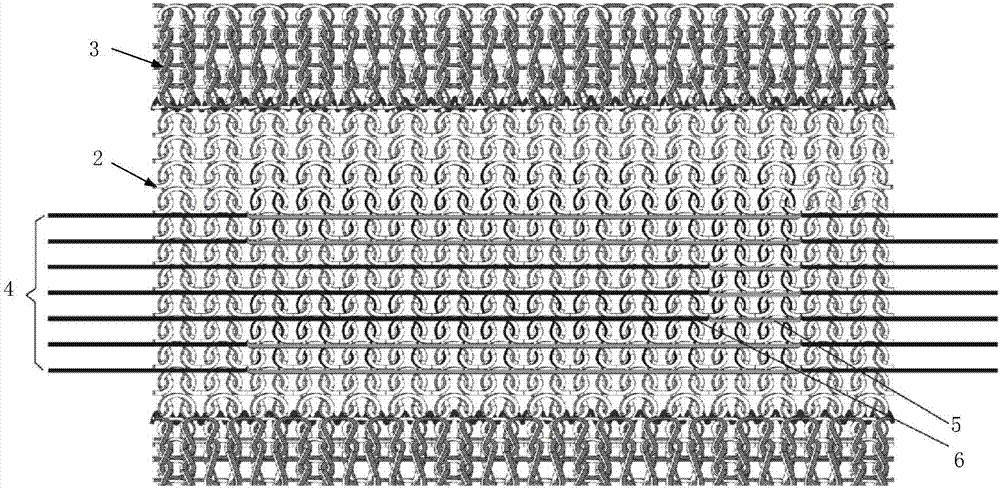

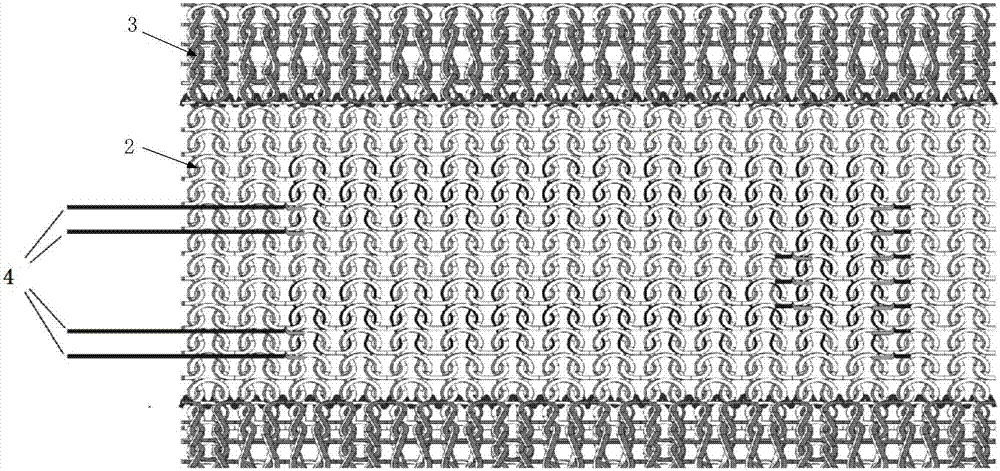

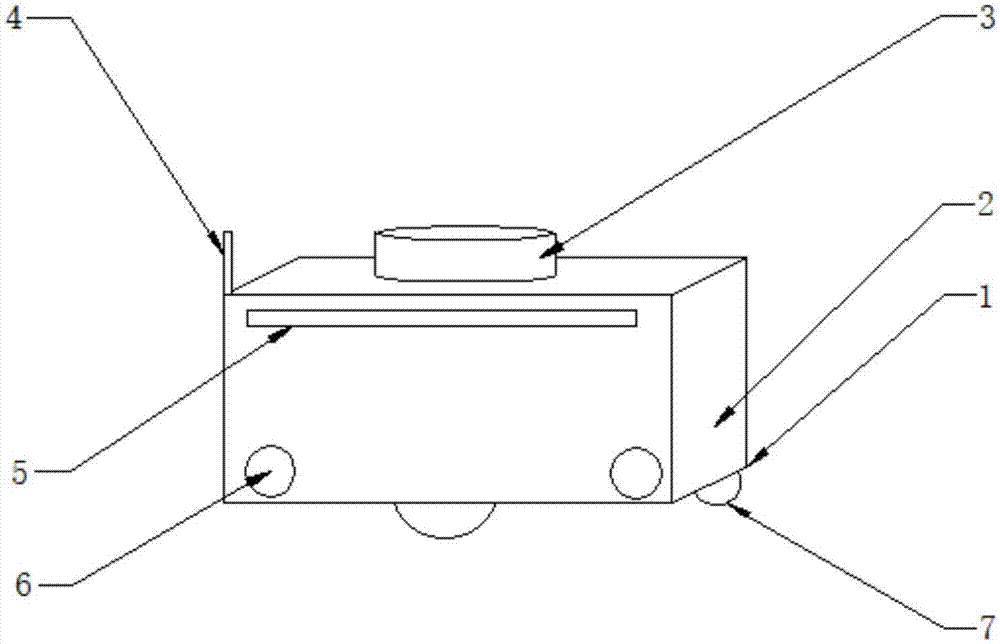

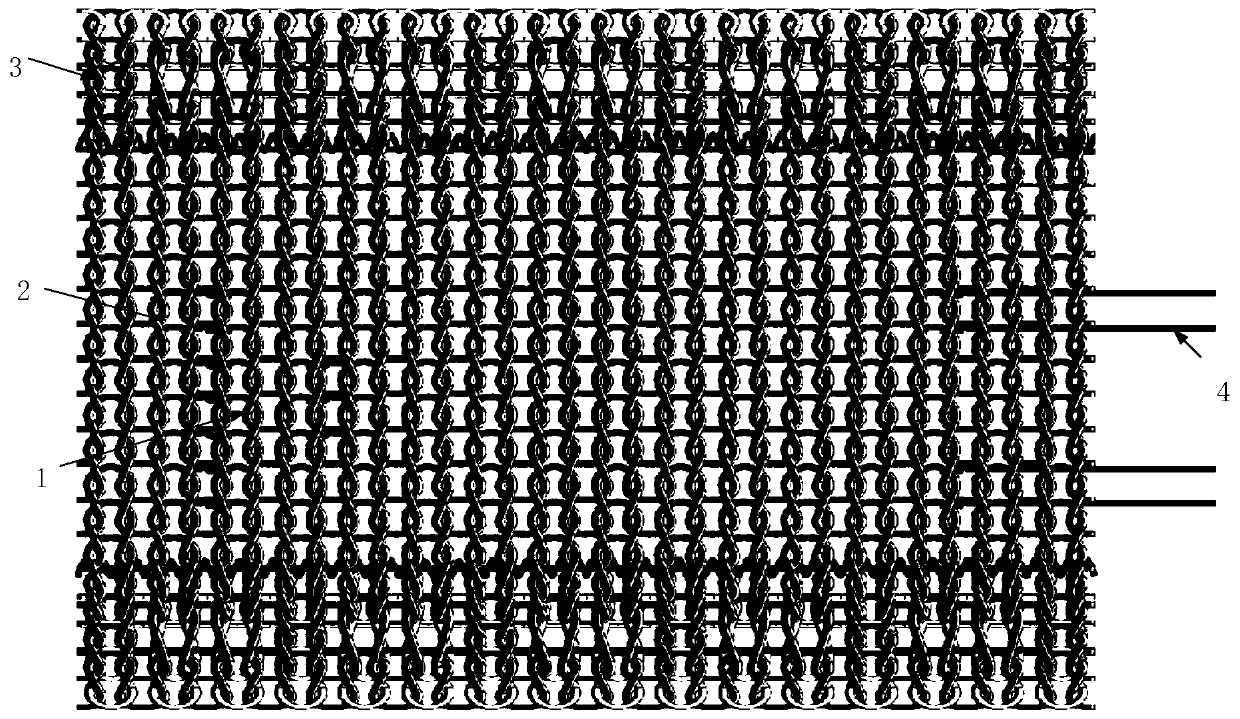

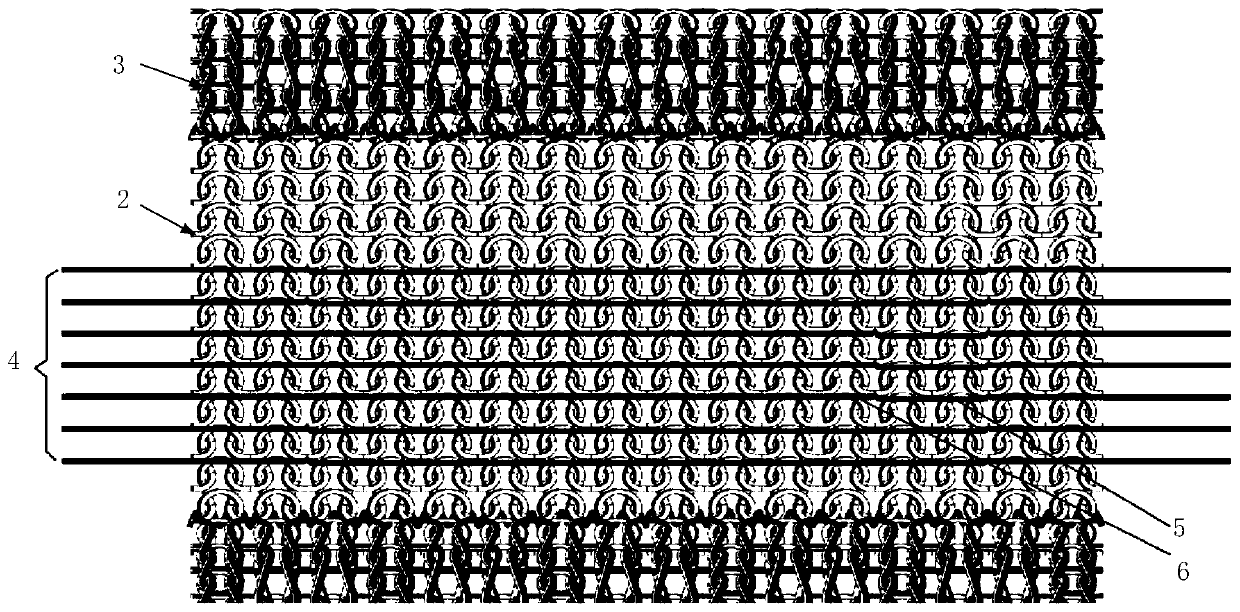

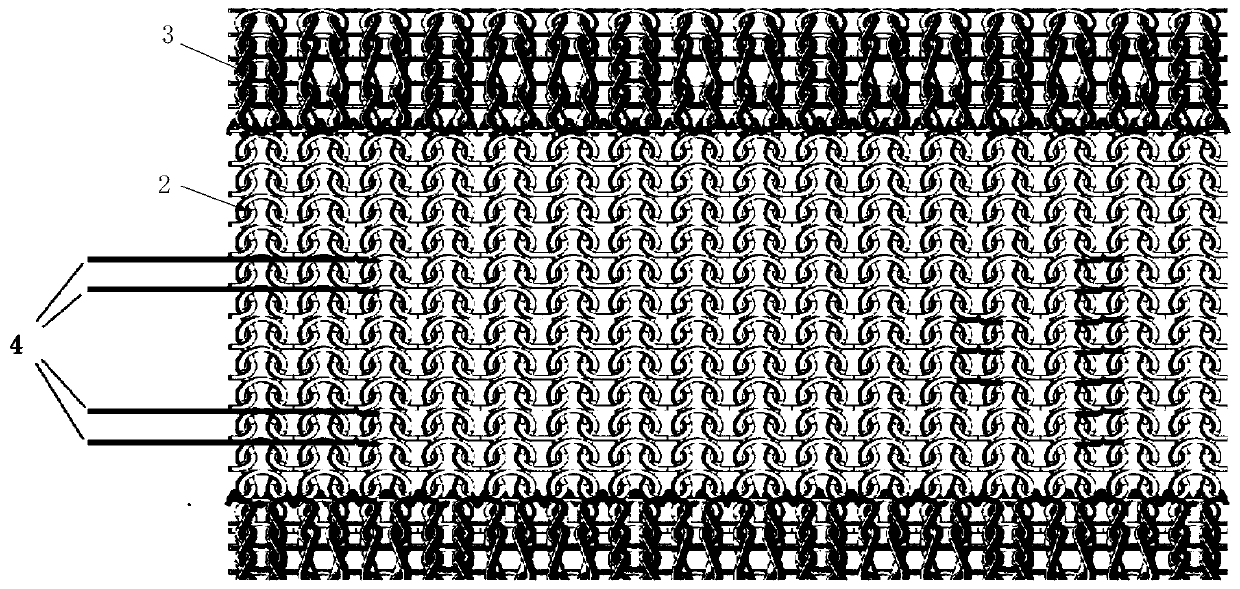

Strain sensor for weft knitted fabric and knitting method

The invention relates to a strain sensor for weft knitted fabric and a knitting method. The sensor comprises a sensing area and connecting areas. The sensing area comprises plain plaiting coils using face yarn as the conductive yarn and using ground yarn as the elastic yarn. The connecting areas are located at two sides of the sensing area. The connecting areas comprise plain plaiting coils using face yarn as the yarn and the ground yarn as the elastic yarn. Edge locking areas are located at the outer sides of corresponding connecting areas. The edge locking areas comprise plain plaiting coils using face yarn as the yarn and the ground yarn as the elastic yarn, wherein, the face yarn is exposed at the front sides of the sensing area, connecting areas and edge locking areas, and the ground yarn is exposed at the back sides of the sensing area, connecting areas and edge locking areas. The conductive yarn in the sensing area is in a bending structure. The sensor has a good extendability and elastic recovery, the equivalent resistance in the curved sensing area is larger than a rectangular area indicating the sensor has a high sensitivity coefficient.

Owner:李鹏 +1

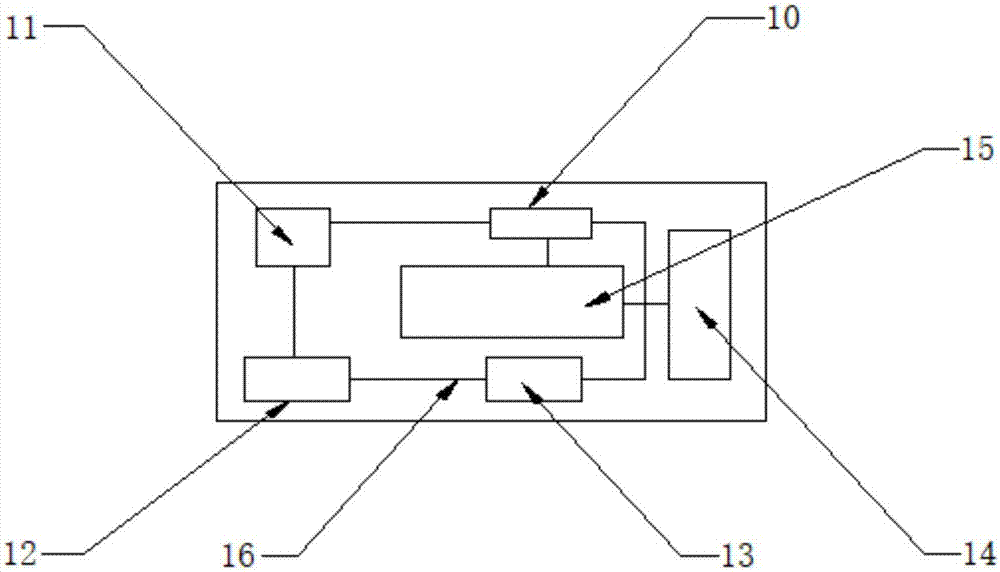

Parking lot system based on indoor positioning

InactiveCN107545781AImprove convenienceEasy to understandIndication of parksing free spacesComputer scienceClose contact

The invention discloses a parking lot system based on indoor positioning, comprising a server body and a geomagnetic locator. The server body is composed of a casing arranged on the outer surface of the server body and a fixing frame at the top of the casing, and the fixing frame is connected to the casing. The geomagnetic locator is closely connected with the server body. This indoor positioning-based parking lot system is equipped with an induction board, and the amorphous wire magneto-sensitive material used is made of Co-based or / and Ni-based or The amorphous wire is mainly made of materials such as Fe-based and Fe-based, and is processed by adding other one or more elements. Its diameter can be 1-200 microns, and its sensitivity coefficient is as high as 4000. , which can immediately feed back information to the server itself, update the parking space information in time, and have broad prospects for use in the future.

Owner:张思银

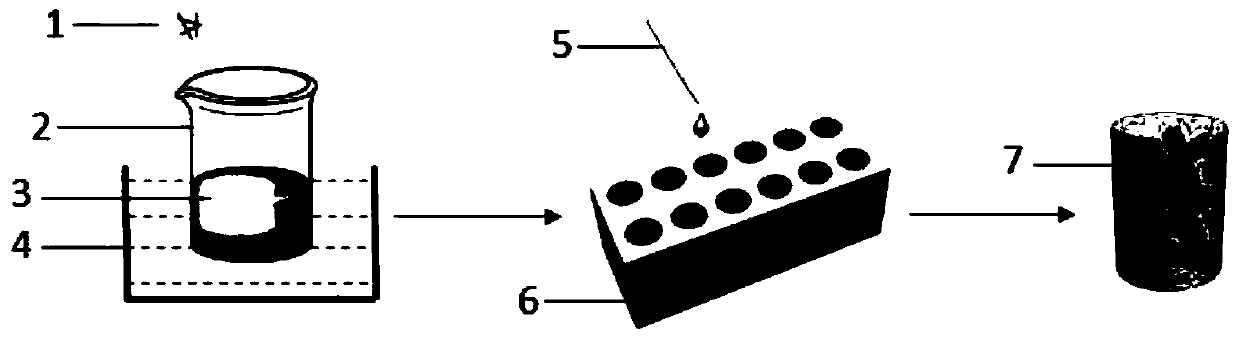

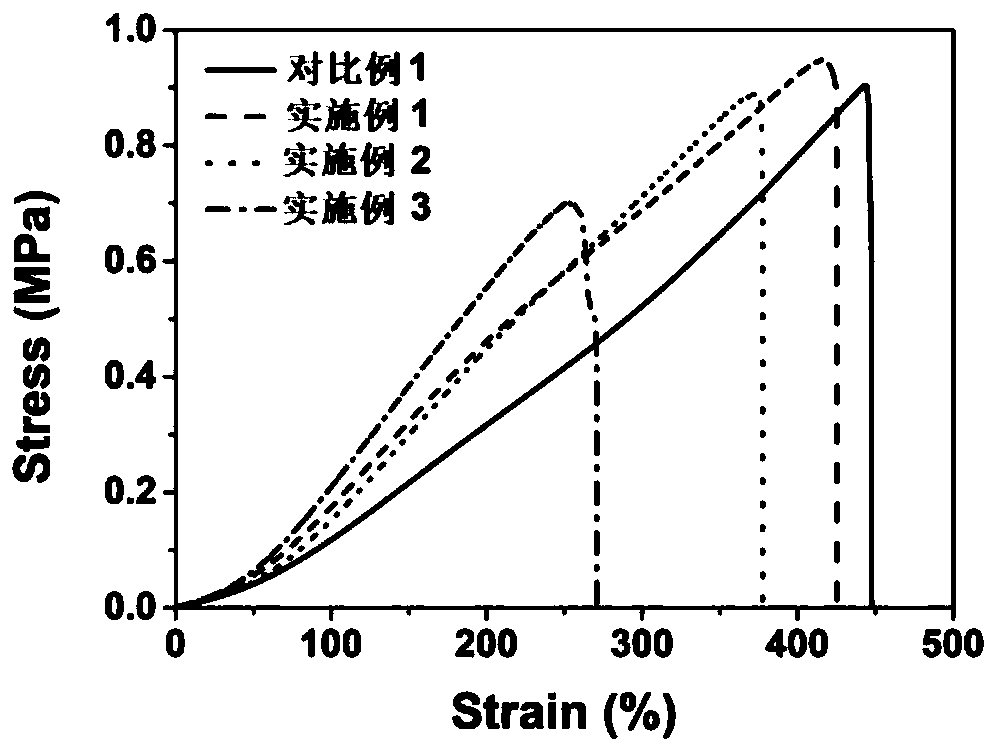

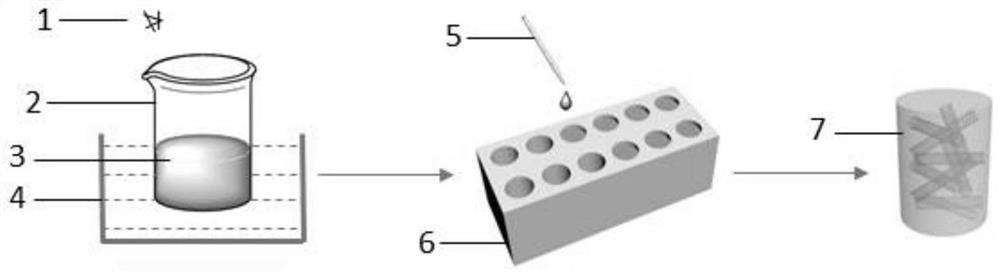

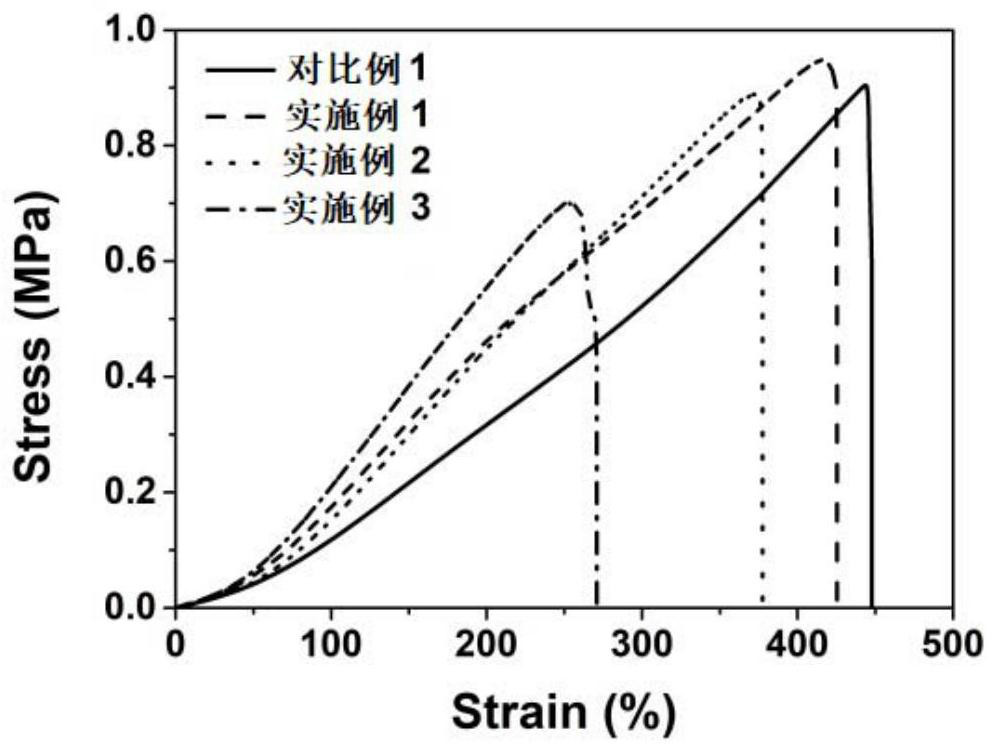

Preparation method and application of large strain superelastic PVA(polyvinyl alcohol)/MCNTS (multi-walled carbon nanotube) hydrogel

The invention provides a preparation method and application of a large strain superelastic PVA / MCNTS(multi-walled carbon nanotube) hydrogel. The preparation method comprises the following steps: 01. preparing disordered MCNTS powder by chemical vapor deposition; 02. acidifying, separating, drying and grinding the MCNTS powder; 03. preparing a PVA aqueous solution, adding the MCNTS powder treated in the step 02 into the PVA aqueous solution, and heating and stirring in a water bath to fully disperse the MCNTS powder to prepare a PVA / MCNTS mixed solution; and 04. pouring the PVA / MCNTS mixed solution in the step 03 into a mold, and then freezing and thawing for many times to obtain the PVA / MCNTS hydrogel. The polyvinyl alcohol / multi-walled carbon nanotube hydrogel prepared by the method has uniform components, has large tensile strain and compressive strain at the same time, and has superelasticity and sensitivity factors in the tensile process and the compression process. Due to excellent performance, the hydrogel can be used as a strain sensor in the field of flexible stretchable devices.

Owner:ZHENGZHOU UNIV

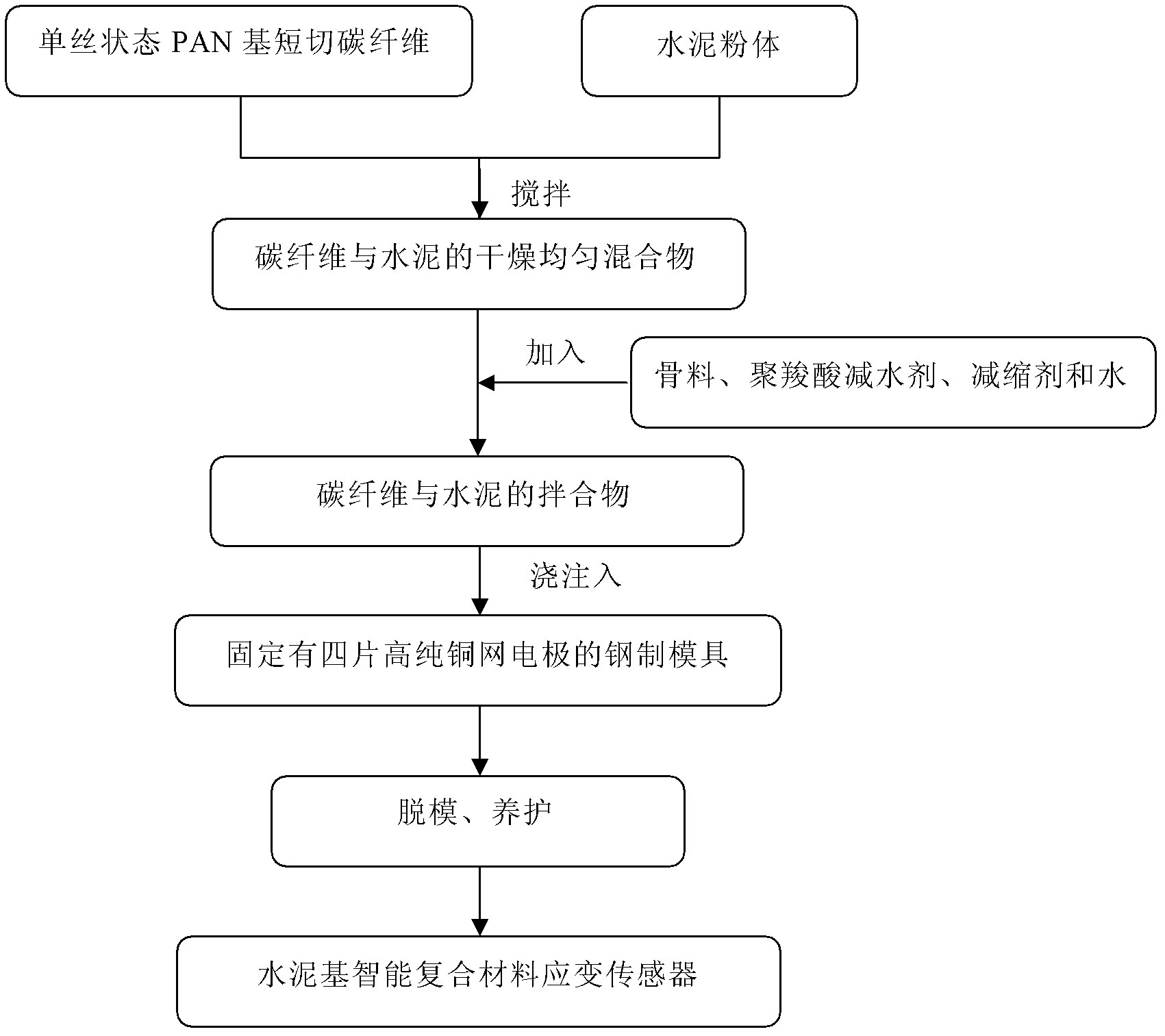

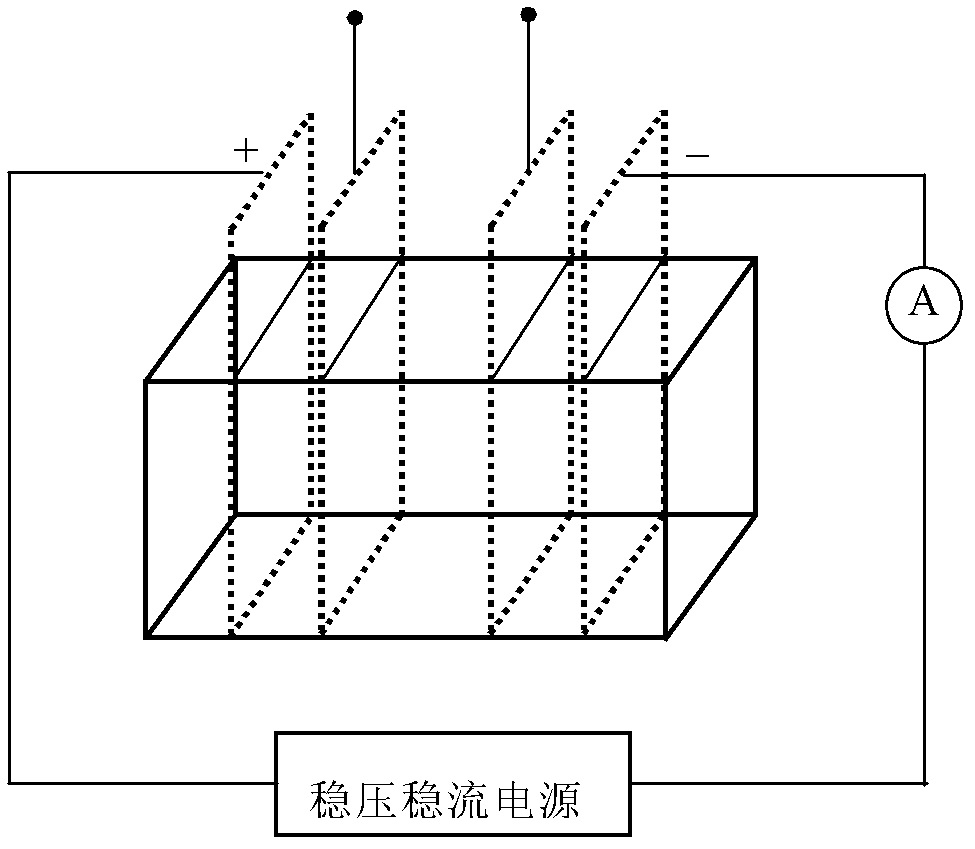

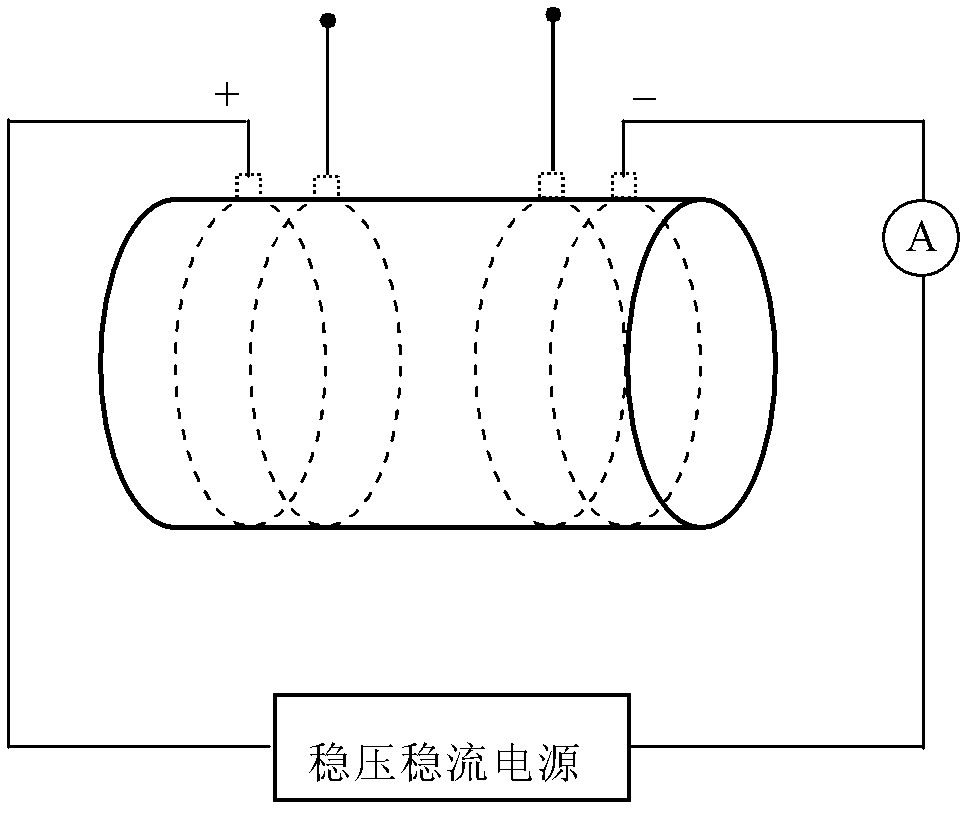

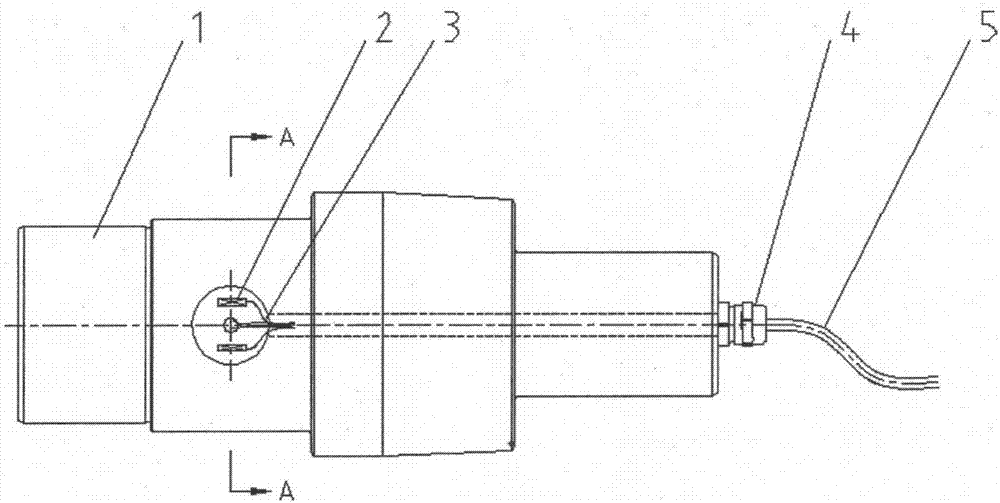

Cement-based intelligent composite material strain sensor and preparation method thereof

ActiveCN102506692BLinearity of High Pressure SensitivityGood pressure sensitive propertiesElectrical/magnetic solid deformation measurementCelluloseFiber

The invention discloses a cement-based intelligent composite material strain sensor, which comprises a carbon-fiber cement-based intrinsic intelligent composite material and four parallel electrodes arranged on the composite material, wherein the electrodes are high-purity copper meshes; the pore diameter of the high-purity copper meshes is larger than 2mm; and the main ingredients of the composite material are PAN-based short-cut carbon fiber and silicate cement, and the electrodes are combined together with the carbon-fiber cement-based intrinsic intelligent composite material by an embedding process. The cement-based intelligent composite material strain sensor has the characteristics of high sensitivity coefficient, high voltage-sensitive characteristic linearity and excellent mechanical property; and the preparation process adopts a drying and mixing process, so that the problems that due to use of cellulose, the strength of the sensor is reduced and the electric performance of the sensor becomes poor are avoided and no phenomenon of fiber agglomeration occurs.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Strained thin film used for thin film pressure sensor, preparation method thereof, core body of thin film pressure sensor

ActiveCN105547535BHigh melting pointSmall temperature coefficient of resistanceForce measurementFilm resistanceThin film sensor

The invention discloses a strain thin film for a thin film pressure sensor, a preparation method of a strain thin film, a thin film pressure sensor core. The strain thin film is a tantalum nitride thin film. The preparation method includes the following steps that: (1) an ion beam sputtering deposition method is adopted to bombard tantalum nitride targets, a tantalum nitride thin film preparation layer can be deposited on an elastic substrate required by a thin film sensor; and (2) annealing treatment is carried out, and the strain thin film for the thin film pressure sensor can be obtained. The thin film pressure sensor core comprises a buffer layer, an insulating layer and a tantalum nitride thin film resistance layer which are sequentially arranged on the elastic substrate. The strain thin film for the thin film pressure sensor and the strain thin film prepared by the preparation method of the invention have the advantages of high strain factor, low resistance temperature coefficient and excellent electrical conductivity. The thin film pressure sensor core has the advantages of high sensitivity and high reliability in a harsh environment.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

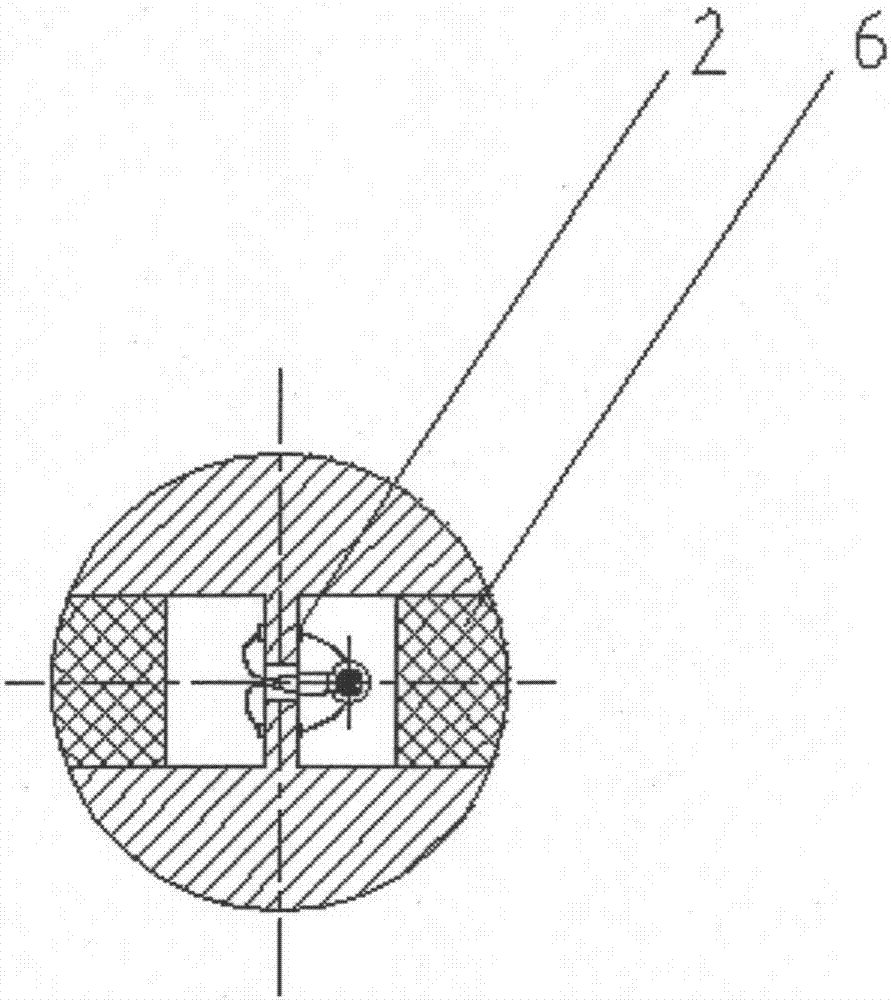

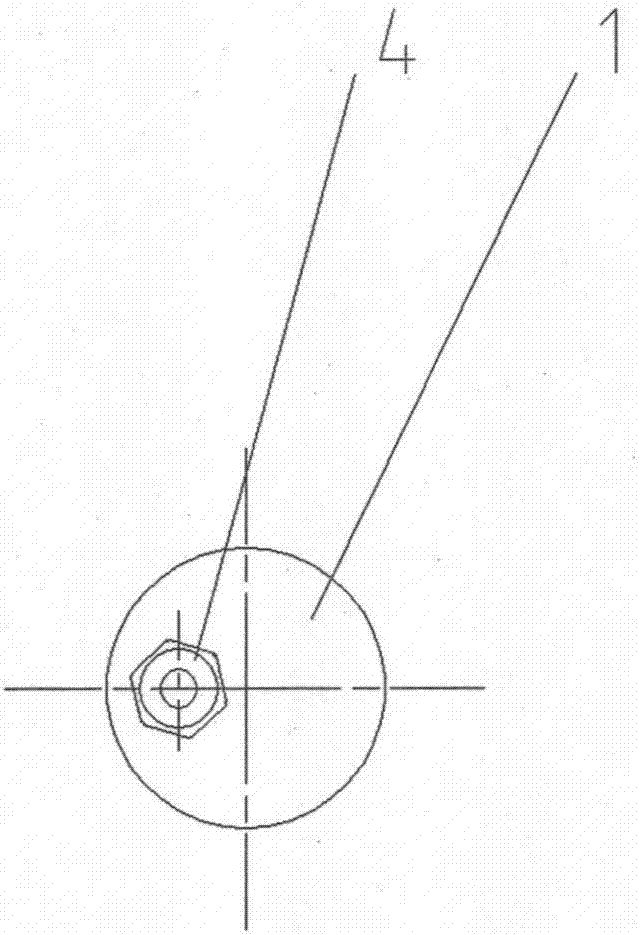

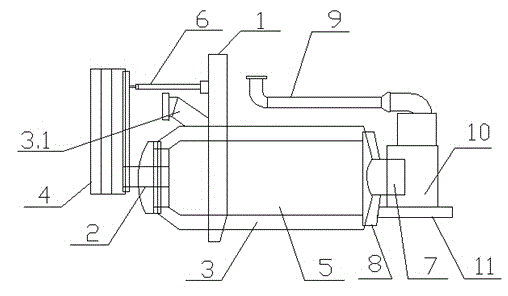

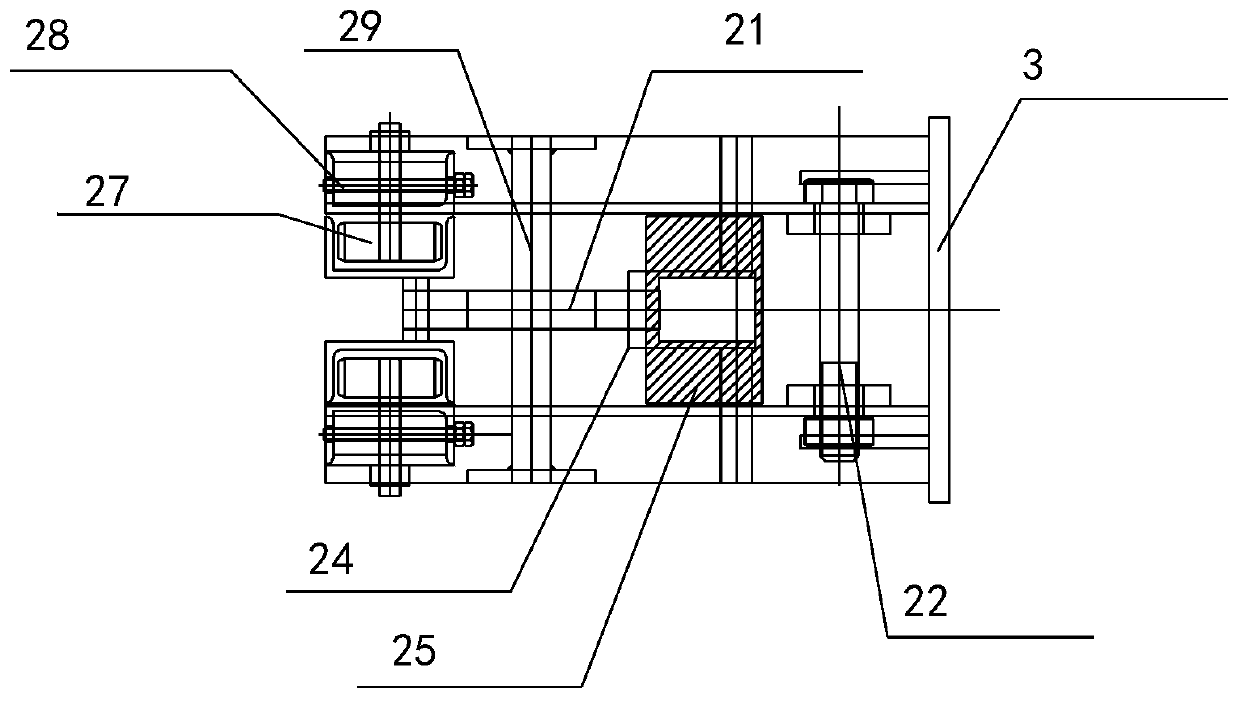

Pressure column pressure wheel axle structure with built-in pressure sensors

PendingCN107322972AHigh sensitivity factorSmall mechanical hysteresisForce measurementShaping pressStrain gaugeHysteresis

The invention provides a pressure column pressure wheel axle structure with built-in pressure sensors. The pressure column pressure wheel axle structure comprises a pressure wheel axle body; two sensor holes which are coaxial but do not communicate with each other are formed in the pressure wheel axle body in the radial direction; a radial line penetrating hole which connects the two sensor holes in series is formed between the two sensor holes; and an axial line penetrating hole is formed from one end of the pressure wheel axle body to one of the sensor holes or the radial line penetrating hole in the axial direction. A pressure strain gauge is pasted on the side wall of each sensor hole; and two wires penetrate into the axial line penetrating hole from one end of the pressure wheel axle body and are welded to connectors of the two pressure strain gauges correspondingly. The pressure strain gauges are adopted as the pressure sensors, and the characteristics of large sensitivity coefficients and minimal mechanical lag are achieved; the pressure sensors and a pressure wheel axle are manufactured into a whole, the structure is concise, the size is small, and mounting is convenient; and a mechanical connection structure of a traditional sensor is omitted, the error caused by mechanical connection is avoided, the precision of pressure detection is improved, and the feedback speed of pressure detection is increased.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

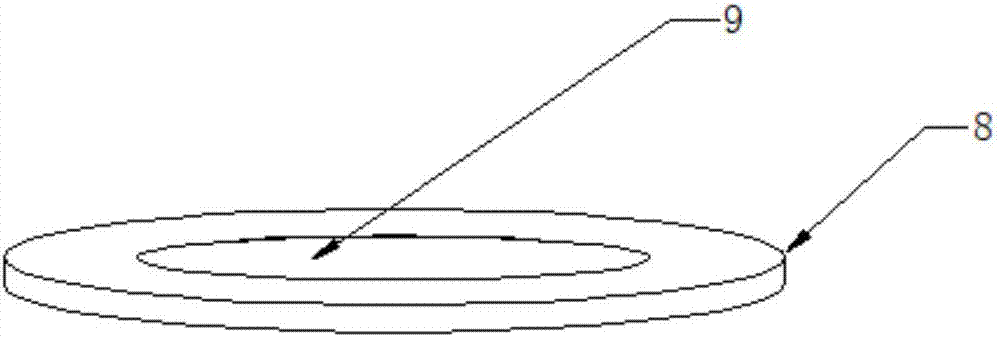

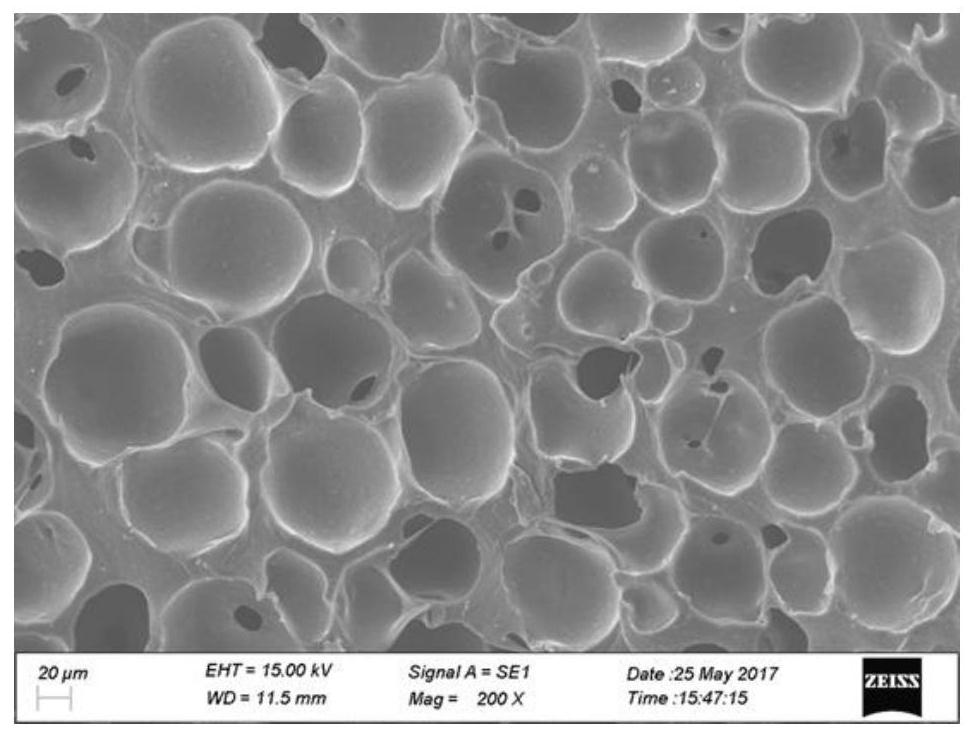

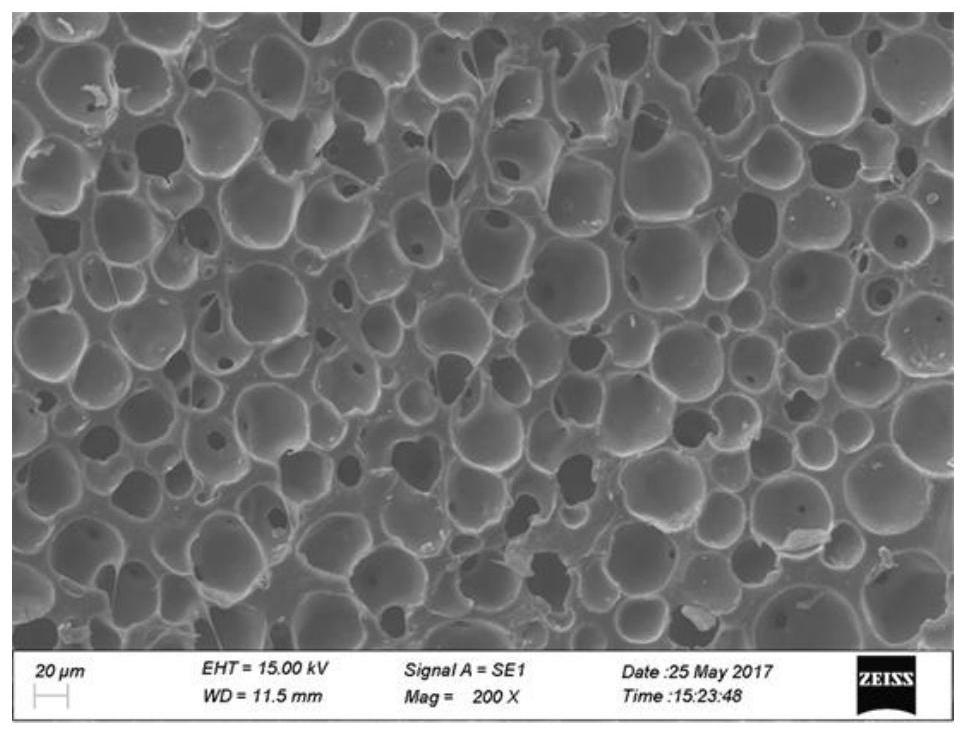

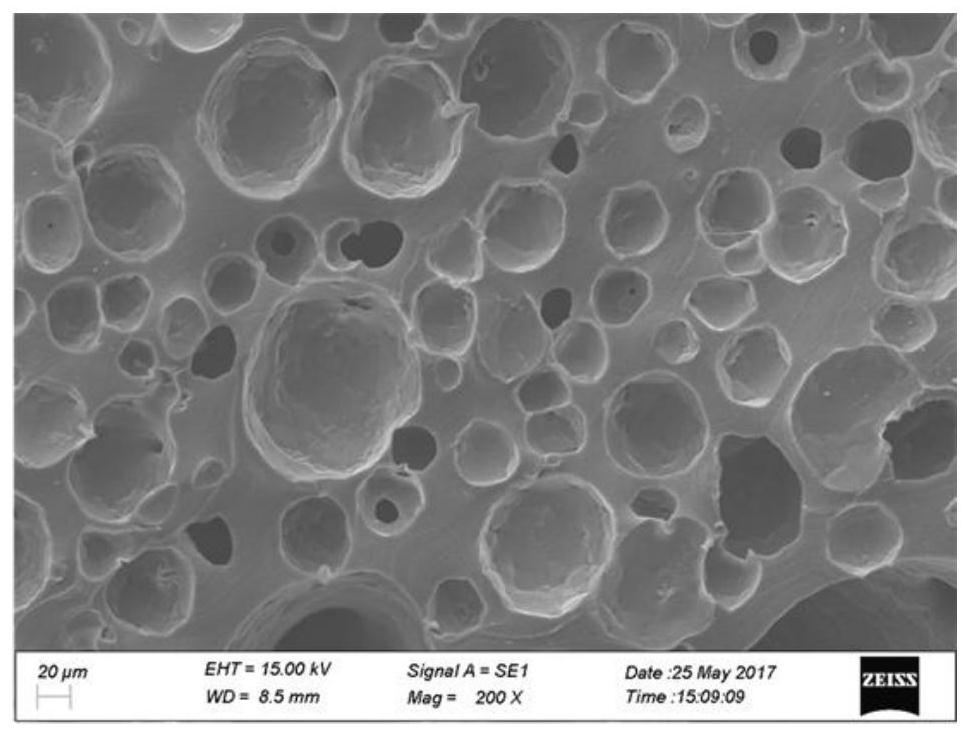

Porous impact-resistant tpu composite pressure sensing material, preparation method and application

ActiveCN111138835BExcellent impact resistance and energy absorption performanceImprove mechanical propertiesForce measurementOrganic solventAlcohol

The invention discloses a preparation method of a porous impact-resistant TPU composite pressure sensing material. The preparation method comprises the following steps: (1) preparing a uniform mixed solution from thermoplastic polyurethane, a conductive material and an organic solvent; (2) treating the mixed solution by a steam-induced phase separation method to obtain a molded TPU composite pressure sensing material; and (3) washing the molded TPU composite pressure sensing material with alcohol for multiple times, then washing the material with water for multiple times, and performing freeze-drying to obtain the porous impact-resistant TPU composite pressure sensing material. In the mixed solution in the step (1), the mass volume ratio of TPU to the organic solvent is 1g : (1-10) mL. Theporous impact-resistant TPU composite pressure sensing material provided by the invention has good mechanical properties, high sensitive factors and excellent impact resistance and energy absorptionproperties. The preparation method is simple in process, high in quality controllability and low in production cost.

Owner:CENT SOUTH UNIV

Cement-based intelligent composite material strain sensor with temperature compensation function

ActiveCN102506691BWith temperature compensation functionHigh sensitivity factorElectrical/magnetic solid deformation measurementFiberCarbon fibers

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Hydrogen Sulfide Gas Sensing Device Based on Optical Fiber f-p Interferometer

InactiveCN106248602BImprove anti-interference abilityHigh sensitivity factorColor/spectral properties measurementsIntrinsic safetyRefractive index

The invention provides a hydrogen sulfide gas sensing device on the basis of an optical fiber F-P (Fabry-Perot) interferometer. The concentration of external hydrogen sulfide gas can be perceived by an optical fiber F-P cavity of the hydrogen sulfide gas sensing device which is a measuring device, and the optical fiber F-P cavity is formed by an optical fiber collimator and a metal groove filled with hydrogen sulfide sensitive organic polymer materials. The refractive index of the organic polymer materials can be changed when the concentration of the external hydrogen sulfide gas is changed, optical paths of transmitted optical waves in the optical fiber F-P cavity can be changed, and accordingly spectral characteristics of interference signals outputted by the optical fiber F-P cavity can be changed. Data of the spectral characteristics of the reflected interference signals of the optical fiber F-P cavity are analyzed, so that the concentration of the hydrogen sulfide gas can be accurately measured. The hydrogen sulfide sensing device has the advantages of simple structure, miniaturization, high sensitivity and precision, electromagnetic interference resistance, intrinsic safety and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

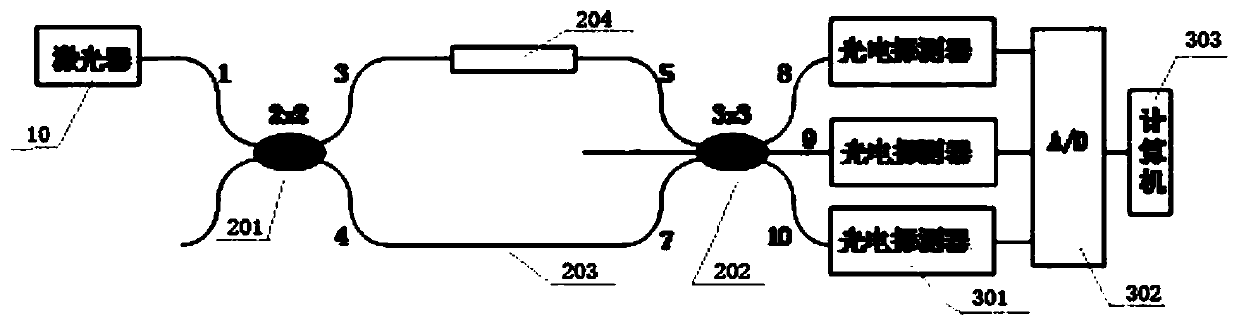

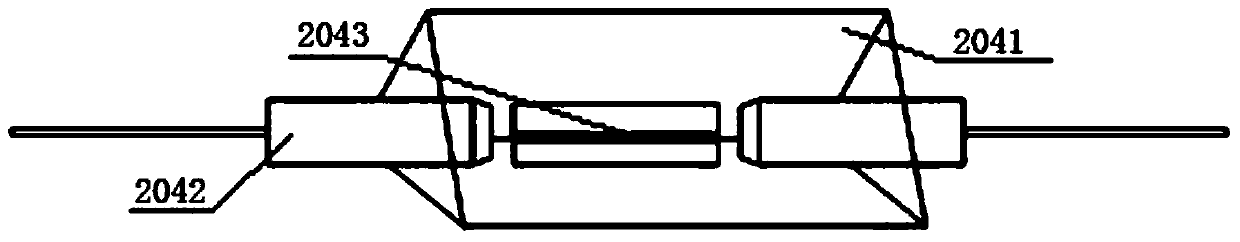

A device for detecting hydrogen sulfide gas based on optical fiber m-z interferometer

InactiveCN106323915BThe effect of transmitted light is obviousHigh sensitivityPhase-affecting property measurementsOrganic compoundLaser source

The invention relates to the technical field of optical fiber sensing, in particular to a device based on an optical fiber M-Z interferometer to detect hydrogen sulfide gas. The device comprises a laser device, a sensitive optical path structure and a signal processing module, the laser device is used for generating a laser source, the sensitive optical path structure is arranged at an output end of the laser device and comprises a first coupler, a gas chamber filled with the hydrogen sulfide gas and a second coupler, and two optical paths are arranged in the gas chamber and include a full-optical-fiber reference transmission arm optical path and a measuring transmission arm optical path composed of a V-shaped groove filled with an organic compound sensitive to the hydrogen sulfide gas and optical fiber collimation heads at two ends; the laser source splits a light beam into two beams of light through the first coupler, one beam of light is output through the reference transmission arm optical path, another beam of light is output through the measuring transmission arm optical path, the beams of light enter the second coupler to output three beams of light; the signal processing module is arranged at an output end of the second coupler and used for performing photoelectric signal conversion according to light beam output by the second coupler and utilizing a phase demodulation algorithm to calculate to acquire concentration of the hydrogen sulfide gas. By the device, measuring sensitivity is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method and application of a kind of large strain hyperelastic pva/mcnts hydrogel

Owner:ZHENGZHOU UNIV

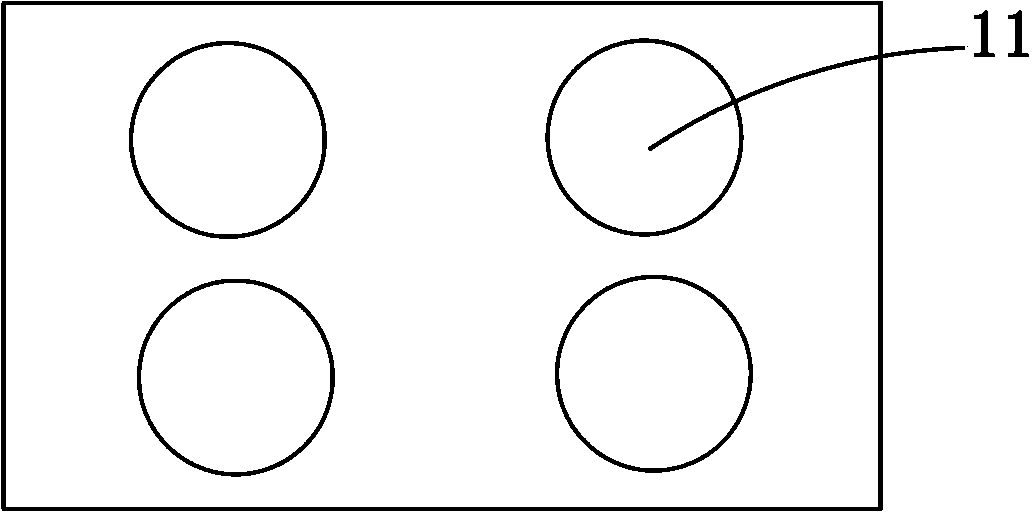

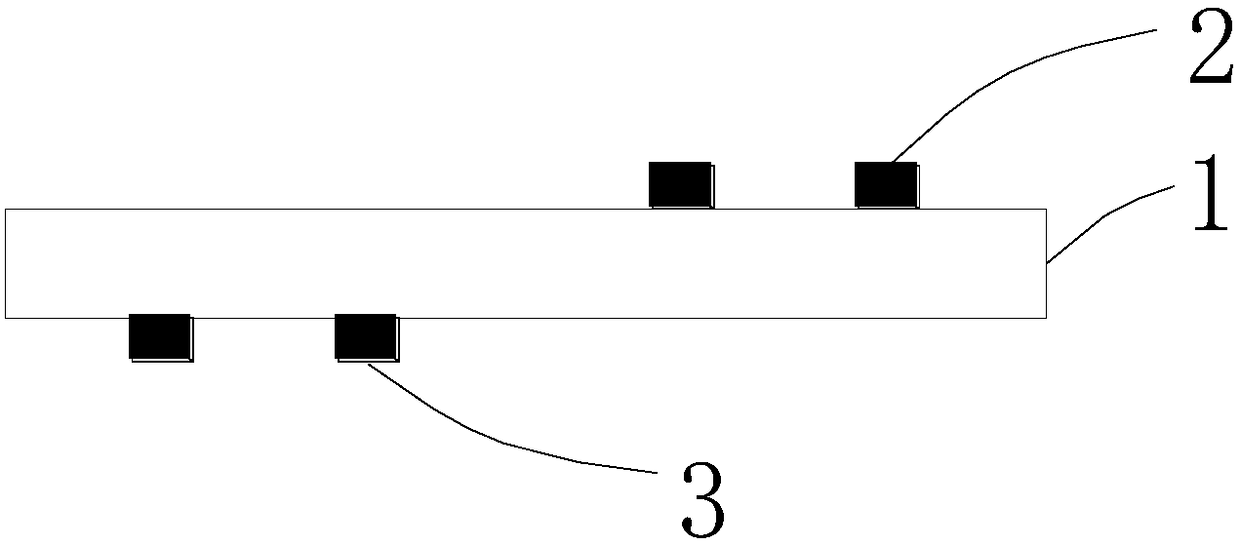

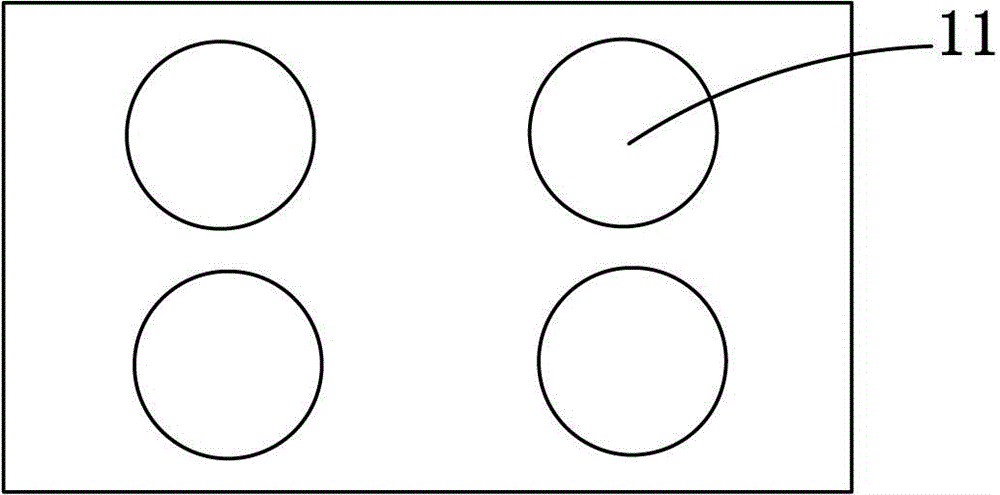

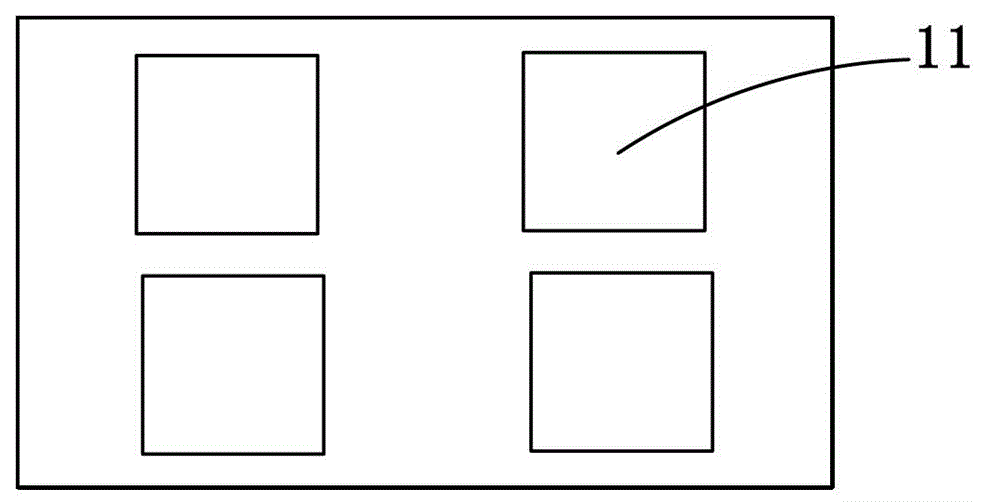

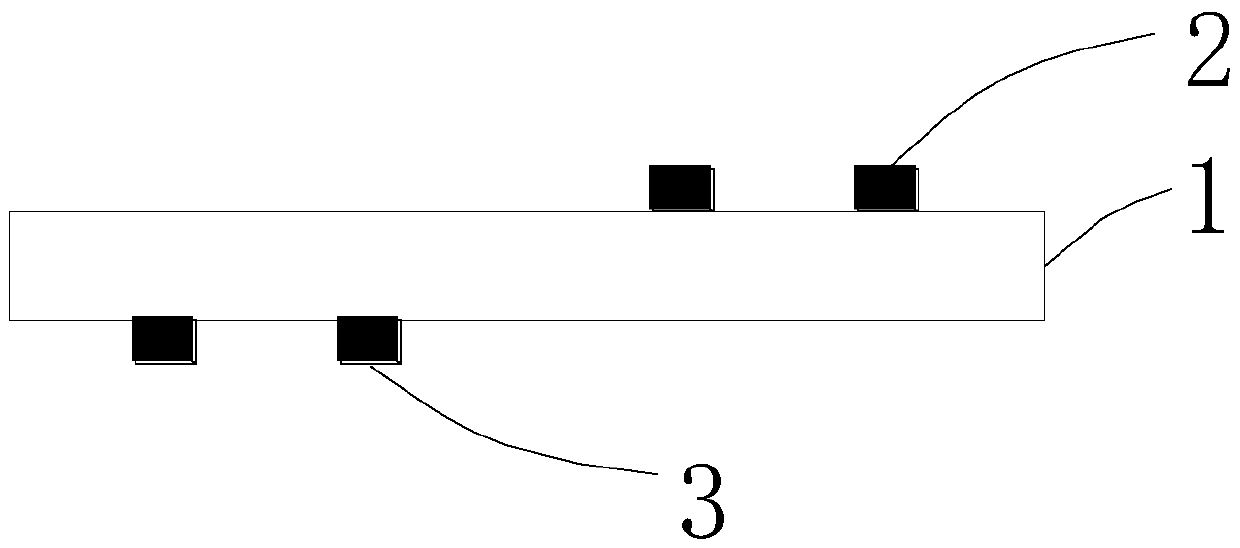

Array type flexible force sensor

InactiveCN102374911BHigh sensitivity factorSolution to short lifeForce measurement using piezo-resistive materialsEngineeringForce sensor

The invention relates to an array type flexible force sensor, which comprises an upper insulation protecting layer, a parallel metal row electrode graphically arranged on the lower surface of the upper insulation protecting layer, a lower insulation protecting layer, a parallel metal column electrode graphically arranged on the upper surface of the lower insulation protecting layer, and a first sensitive membrane layer positioned between the row electrode and the column electrode, wherein the first sensitive membrane layer consists of a filling type sensitive material layer and a filling typesensitive material convex strip or convex block adhered onto the upper surface of the filling type sensitive material layer, and the longitudinal section of the convex strip or convex block is in a wedge, conical or serrated shape; the convex strip or convex block is vertically aligned with the column electrode, and the row electrode and the column electrode are distributed in a spatial vertical intersection way; a spatial vertical intersection part and the first sensitive membrane layer contained in the spatial vertical intersection part form a force sensing unit, and the filling type sensitive material is a conductive composite material that conductive particles are uniformly dispersed in a flexible insulation matrix material. The array type flexible force sensor has the advantages of high sensitivity, stable performances, long service life and the like.

Owner:TSINGHUA UNIV

Strain gauge sensor, method and measuring device for obtaining high sensitivity using it

ActiveCN108709490BHigh sensitivityEasy to manufactureElectrical/magnetic solid deformation measurementMechanical engineeringStrain sensor

The invention belongs to the technical field of sensors and particularly relates to a strain sensor, a method using the strain sensor to acquire high sensitivity and a strain measuring device comprising the strain sensor. The strain sensor comprises a flaky carrier and is characterized in that a first sensitive grid and a second sensitive grid are respectively arranged on two sides of the flaky carrier, and the projections of the first sensitive grid and the second sensitive grid on the flaky carrier do not coincide with each other. The method can double the sensitivity of the sensor and is convenient to operate. The strain measuring device has the advantages that the strain measuring device is compact in structure by using a FPC connector to connect with the strain sensor, the strain measuring device is simple to operate, convenient to use and capable of saving cost, and plug type electric connection with an external signal receiving device can be formed conveniently.

Owner:2D CARBON CHANGZHOU TECH INC

Device for melting thermo-sensitive film master batch by adopting form of vacuum tank

The invention provides a device for melting a thermo-sensitive film master batch by adopting a form of a vacuum tank. The device for melting the thermo-sensitive film master batch comprises a fixed frame, a nitrogen inlet pipe, a circulation chamber, a three-level pressurizing chamber and a vacuum chamber. The fixed frame is installed on a wall. A tank body is fixed to the middle of the fixed frame. The three-level pressurizing chamber is controlled by a hydraulic rod above the fixed frame. The vacuum chamber is arranged in the circulation chamber. The gas inlet end of the nitrogen inlet pipe is arranged on the three-level pressurizing chamber. The gas outlet end of the nitrogen inlet pipe is directly connected with a gas inlet of the vacuum chamber. The tail end of the circulation chamber is further provided with a wind suction implement. According to the device for melting the thermo-sensitive film master batch, the form of the vacuum tank is adopted for melting the thermo-sensitive film master batch, so that the thermo-sensitive film master batch does not contain impurities of air any more, and accordingly the quality and the sensitivity coefficient of a finished film is effectively improved.

Owner:TIANJIN LVJINGYUAN ENVIRONMENTAL PROTECTION TECH

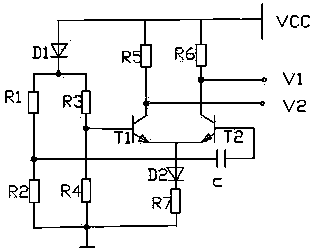

Pressure sensor with long service life and high sensitivity

InactiveCN103674356AHigh sensitivity factorHigh pressure resolutionForce measurementClosed loopEngineering

The invention discloses a pressure sensor with long service life and high sensitivity. The pressure sensor comprises a resistor R1, a resistor R2, a resistor R3, a resistor R4, a resistor R5, a resistor R6, a resistor R7, a transistor T1, a transistor T2, a diode D1, a diode D2 and a capacitor C, wherein the resistor R1, the resistor R2, the resistor R4 and the resistor R3 are sequentially connected to one another in series to form a closed loop; a common terminal of the resistor R2 and a common terminal of the resistor R3 are sequentially connected with an emitting electrode of the resistor R7, an emitting electrode of the diode D2 and an emitting electrode of the transistor T1; a base electrode of the transistor T1 is connected with a common terminal of the resistor R3 and a common terminal of the resistor R4; a collector electrode of the transistor T1 is sequentially connected with the resistor R5 and a power source VCC; an emitting electrode of the transistor T1 is connected with an emitting electrode of the transistor T2; a base electrode of the transistor T2 is sequentially connected with a common terminal of the capacitor C, a common terminal of the resistor R1 and a common terminal of the resistor R2 in series; a collector electrode of the transistor R2 is sequentially connected with the resistor R6 and the power source VCC in series; and a negative electrode of the diode D1 is connected with a common terminal of the resistor R1 and a common terminal of the resistor R3. By using the principle, the pressure sensor is simple in structure, high in sensitivity, high in pressure resolution ratio, high in overall precision and long in service life.

Owner:CHENGDU GKHB INFORMATION TECH

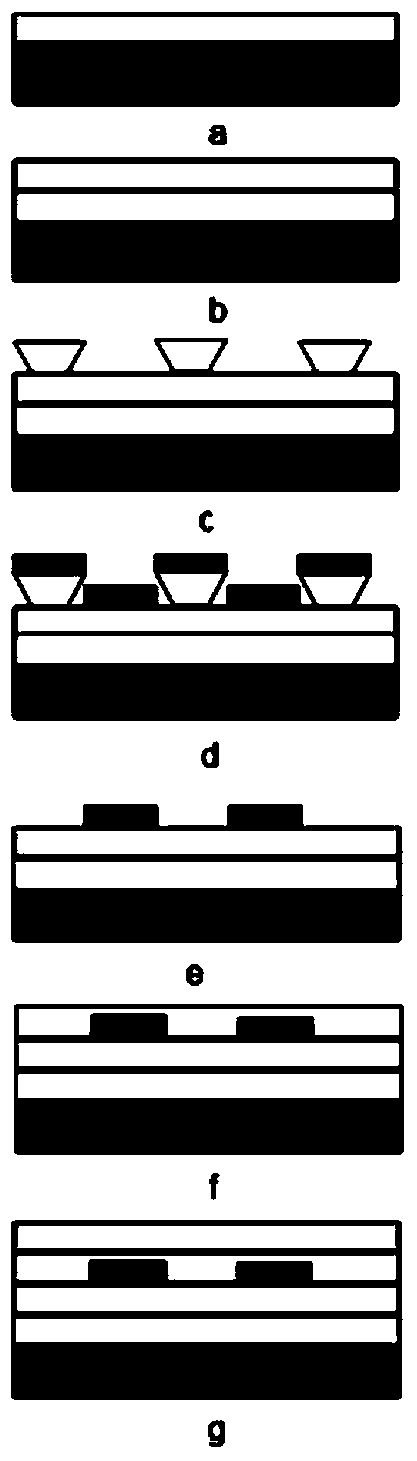

Geopolymer composite material, concrete surface strain gauge using same and preparation method

ActiveCN112521059BHigh room temperature gauge factorReduce measurementCement productionElectrical/magnetic solid deformation measurementGlass fiberSlag

The invention discloses a geopolymer composite material, a concrete surface strain gauge using the geopolymer composite material, and a preparation method thereof. The geopolymer composite material includes powder and a sodium-based alkali activator, and according to the mass ratio, the powder and the sodium The mixing ratio of the base activator is (4-5): (2-3); according to the mass parts, the powder includes 40-50 parts of granulated blast furnace slag, 30-40 parts of fly ash and 3 parts of glass fiber ~5 servings. The geopolymer composite material proposed in this technical solution uses the geopolymer as the substrate, covering layer, adhesive and resistance of the strain gauge, which is not easy to fail during the measurement process and is conducive to long-term observation of the concrete structure. Furthermore, a concrete surface strain gauge using the above-mentioned geopolymer composite material is proposed, which has a simple structure and reliable performance, and its precision can reach submicron level. In addition, a preparation method of the above-mentioned concrete surface strain gauge is also proposed, which has simple steps and strong operability.

Owner:广东至道先进土木工程材料技术研究有限公司

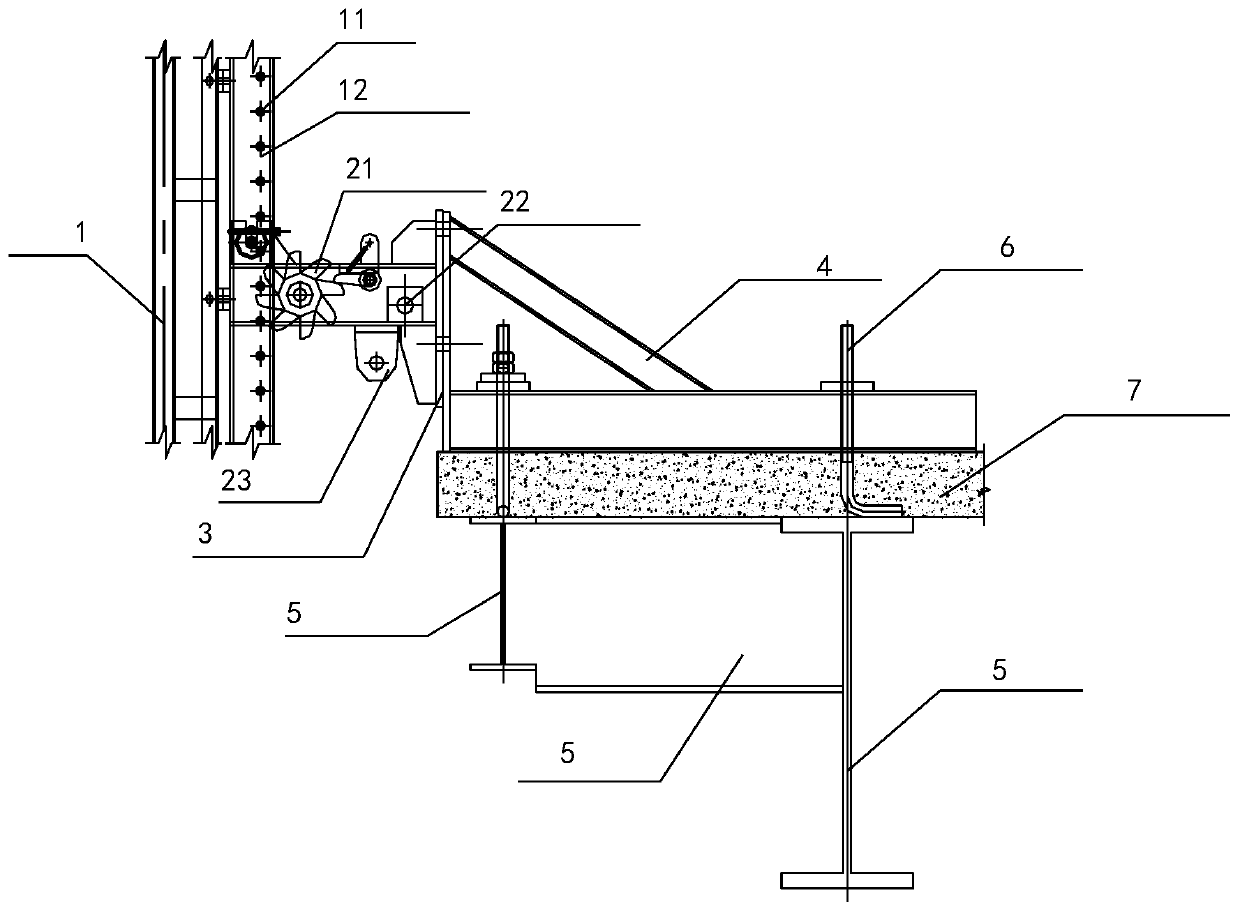

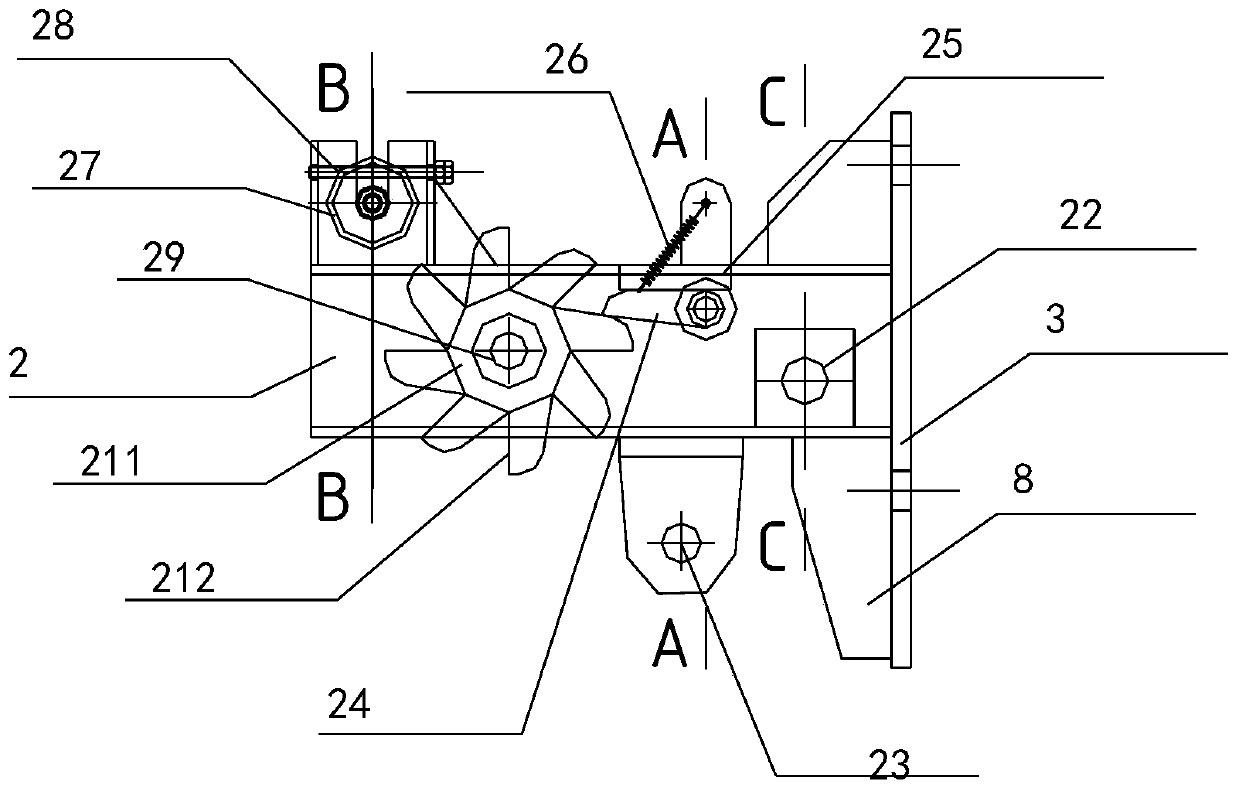

One-way stress conversion system and construction method thereof

PendingCN110005185AEnsure safetyReduce usageBuilding material handlingScaffold accessoriesEngineeringSafety coefficient

The invention relates to a one-way stress conversion system and a construction method thereof, and relates to the technical field of formwork systems. The one-way stress conversion system and the construction method thereof are used for solving the problems of complicated structures and low safety coefficients of the existing attached lifting scaffold anti-falling devices. As for the one-way stress conversion system, a guiding rail is installed on a scaffold body, a load-bearing frame is arranged on a steel structural beam of a building structure, a rotary gear, a limiting spring, a limiting tongue and a limiting baffle are arranged on the load-bearing frame, the rotary gear meshes with the guiding rail, the limiting spring is used for limiting the stroke of the limiting tongue, and the limiting tongue and the limiting baffle are used for preventing the rotary gear from rotating counterclockwise, thus the scaffold body and the guiding rail are prevented from descending, and then the anti-falling effect is achieved. The one-way stress conversion system is especially suitable for construction of super-high buildings with outer frames being of steel structures.

Owner:SHANGHAI CONSTR NO 1 GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com