Patents

Literature

76results about How to "Small temperature coefficient of resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

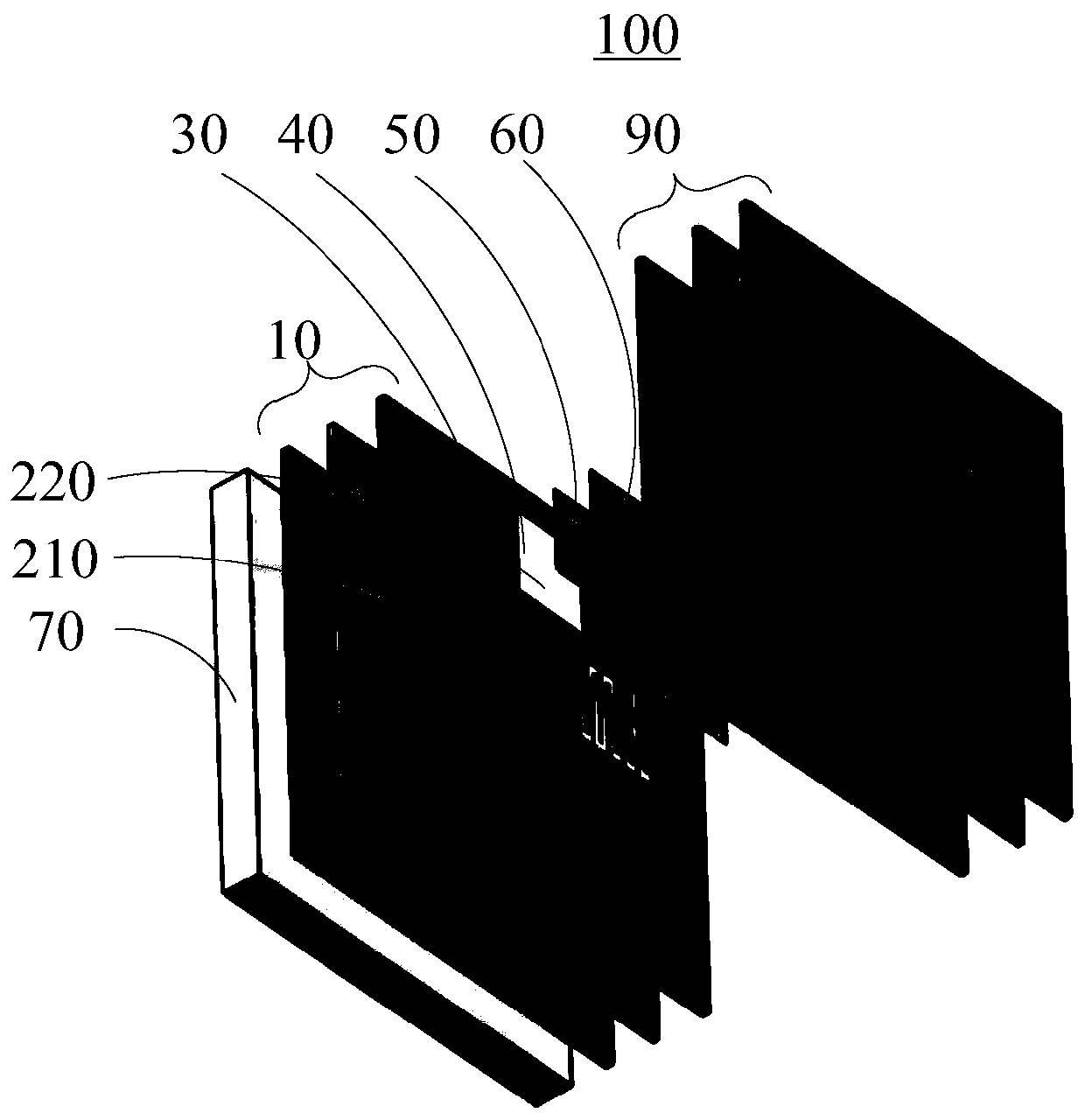

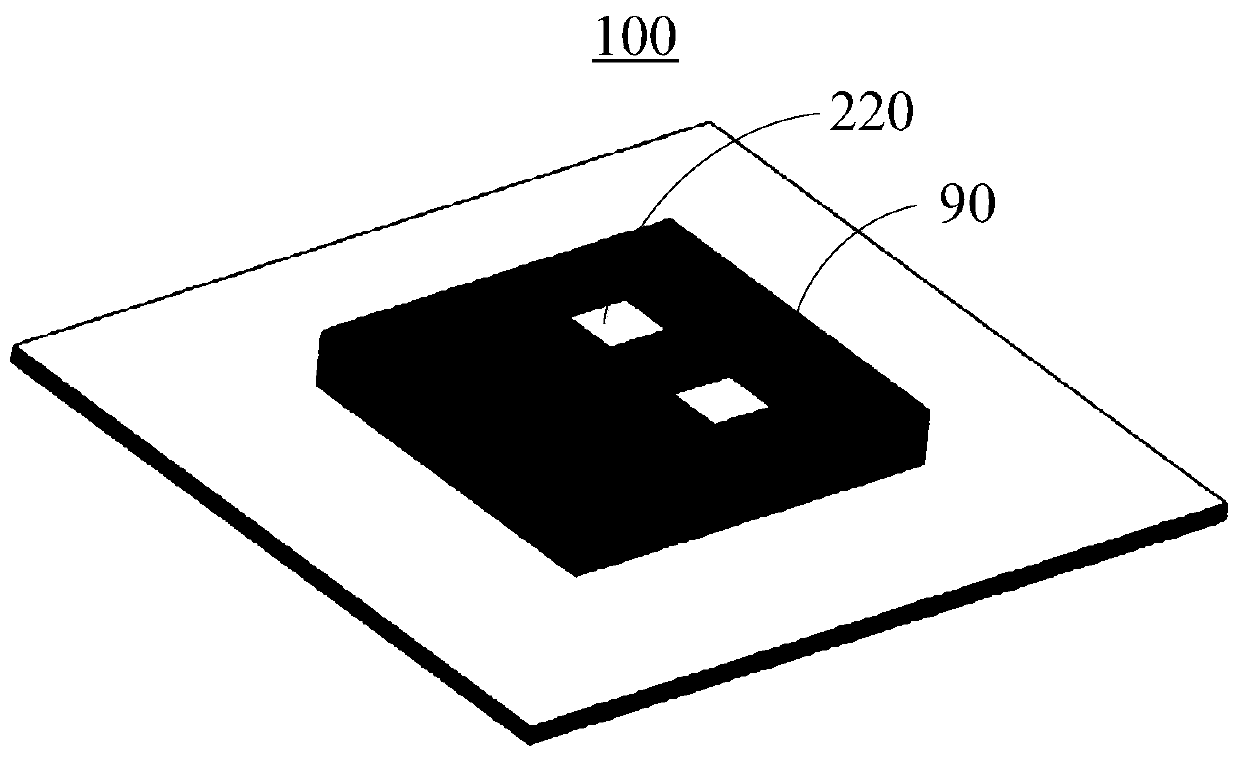

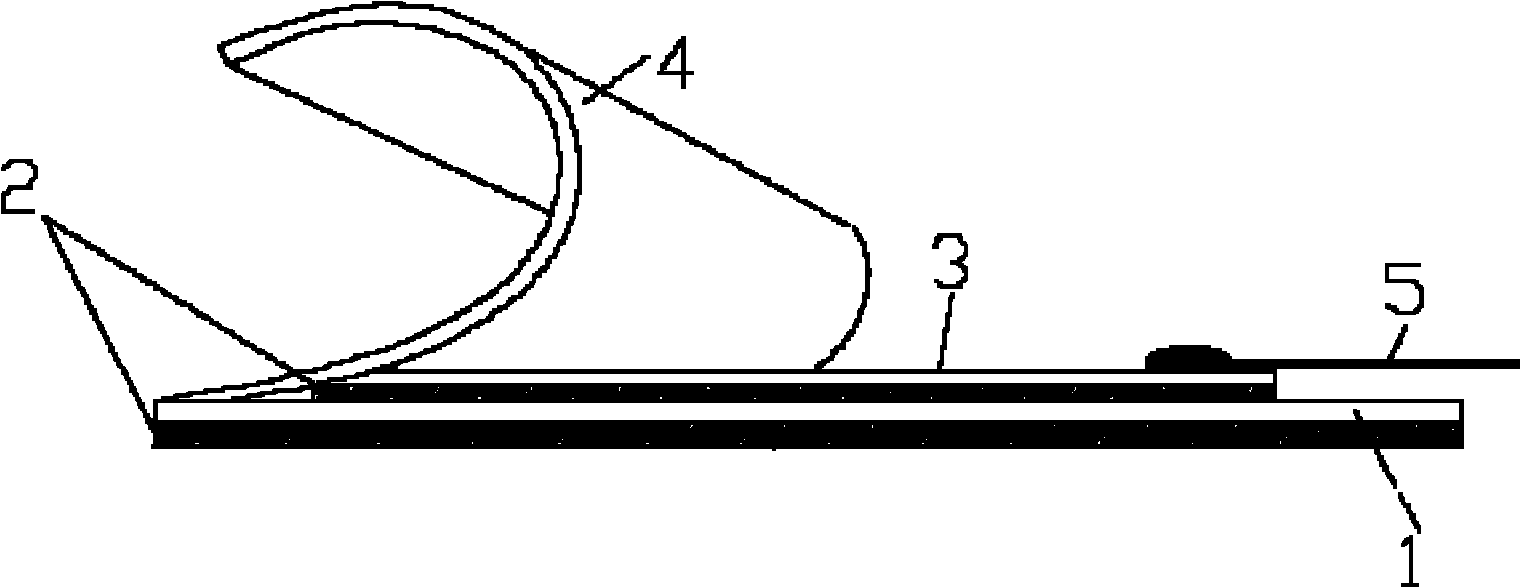

Microporous ceramic thick film heating element for electronic cigarette tar atomization core and manufacturing method of element

PendingCN110074463AImprove liquidityHigh bonding strengthTobacco devicesHeating element shapesElectrical resistance and conductanceTar

The invention relates to the technical field of electronic cigarettes, and particularly discloses a microporous ceramic thick film heating element for an electronic cigarette tar atomization core anda manufacturing method of the element. The microporous ceramic thick film heating element comprises a microporous ceramic base plate, a heating resistance film layer and an electrode layer, wherein the heating resistance film layer comprises a middle part and two connecting parts; the electrode layer comprises two electrode films arranged at intervals; the two connecting parts are respectively connected with the upper ends of the two electrode films; the middle part is connected with the upper surface of the microporous ceramic base plate; the heating resistance film layer is used for heatingthe microporous ceramic base plate so that the cigarette tar of an electronic cigarette is atomized and escapes through micropores of the microporous ceramic base plate. The microporous ceramic thickfilm heating element disclosed by the invention has the advantages that the use is safe and reliable; the service life is long; the cigarette tar reducing degree is high; the user experience and the mouthfeel are good, and the like; the manufacturing method of the element is simple and efficient; the operation and control are convenient; the product quality is stable; industrialized production isfacilitated.

Owner:东莞市东思电子技术有限公司

Rare-earth resistance paste of medium- and low-resistance high-power thick film circuit and preparation method of rare-earth resistance paste

InactiveCN105810291ASmall temperature coefficient of resistanceImprove featuresNon-conductive material with dispersed conductive materialCable/conductor manufactureOrganic solventRare earth

The invention discloses a rare-earth resistor slurry for high-power thick-film circuits in the medium-low resistance section and a preparation method thereof. The rare-earth resistor slurry for high-power thick-film circuits in the medium-low resistance section includes a functional phase, an inorganic bonding phase, and a sintering accelerator , organic carrier, the functional phase is composed of nano-silver powder and ruthenium dioxide powder, and the inorganic bonding phase is composed of SiO 2 , CaO, B 2 o 3 、A1 2 o 3 、 Bi 2 o 3 , rare earth oxides, and crystal nucleating agents; the organic carrier is composed of organic solvents, polymer thickeners, dispersants, defoamers, and thixotropic agents; Low and adjustable, low and adjustable resistance temperature coefficient, excellent printing and firing characteristics, and can match the insulated stainless steel substrate. The process steps of the preparation method are the preparation of the inorganic bonding phase, the preparation of the functional phase, the preparation of the organic carrier, and the preparation of the resistance slurry, and the preparation method can effectively produce and prepare the above-mentioned rare earth resistance slurry.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Heating ceramic slurry and preparation method thereof

InactiveCN109090709ASmall temperature coefficient of resistanceRapid heating responseTransportation and packagingMetal-working apparatusTemperature coefficientTungsten

The invention provides heating ceramic slurry, comprising a composite functional phase, an inorganic additive and an organic support. The composite functional phase includes a main functional phase and a TCR (temperature coefficient of resistance) adjusting phase. The main functional phase includes, but not limited to, one of or mixture of any of tungsten powder, molybdenum powder, manganese powder, silver powder, copper powder, nickel power, cobalt powder, titanium powder, chromium powder, and zinc powder; the TCR adjusting phase includes, but not limited to, one of or mixture of any of platinum powder, ruthenium powder, palladium powder, rhodium powder, osmium powder, iridium powder, germanium powder, and lanthanum powder or their oxides; the TCR adjusting phase accounts for 0.1-10% by weight of the main functional phase so that TCR of the heating ceramic slurry is kept to 1500 ppm / DEG C to 4000 ppm / DEG C. The heating ceramic slurry has low temperature coefficient of resistance and has delayed heating.

Owner:HUBEI CHINA TOBACCO IND

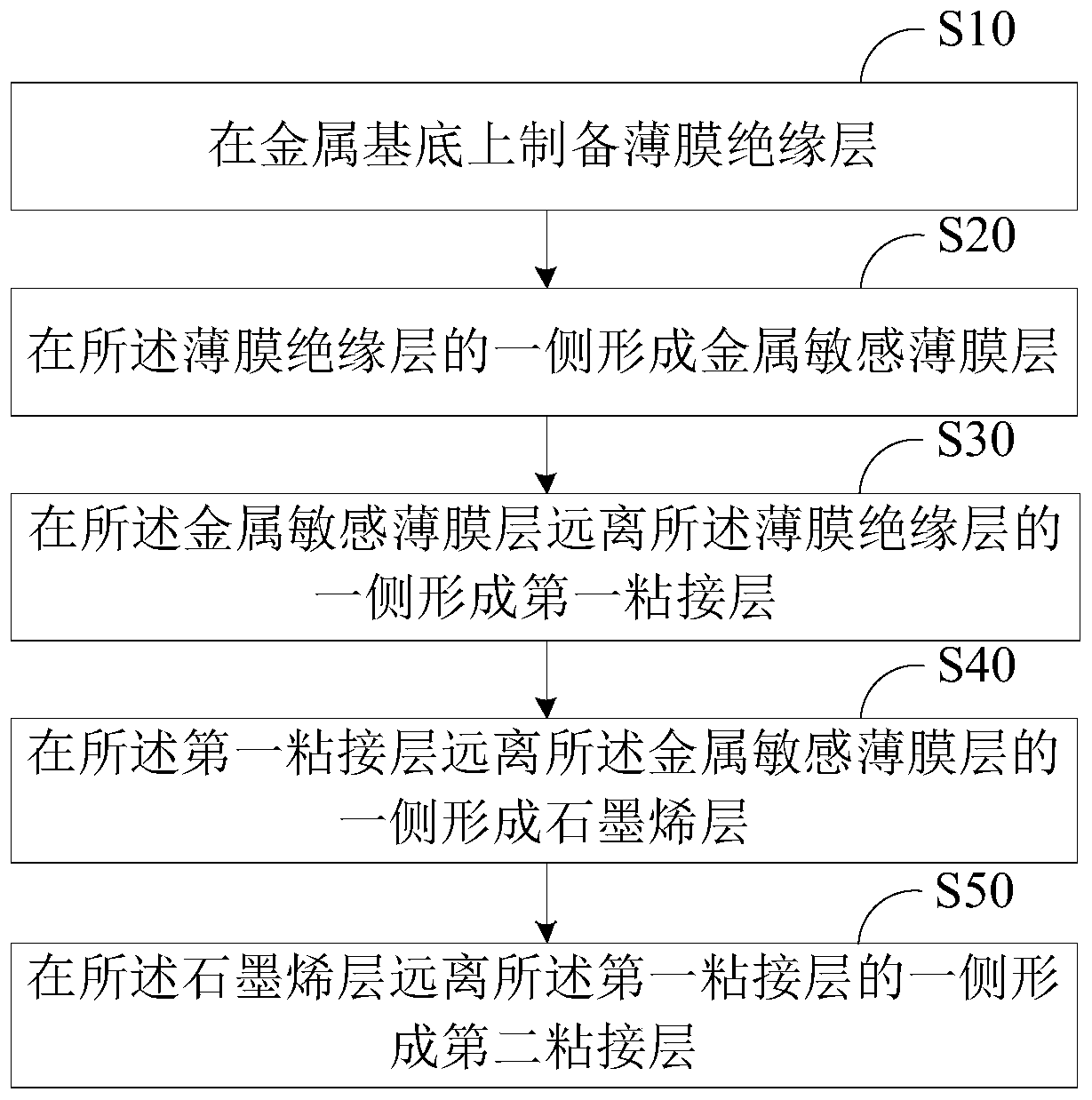

Method for preparing film strain sensor

ActiveCN110487166AIncreased strain sensitivitySmall temperature coefficient of resistanceForce measurement using piezo-resistive materialsElectrical/magnetic solid deformation measurementOptoelectronicsGraphene

The invention relates to a method for preparing a film strain sensor. The method comprises steps that a film insulating layer is prepared on a metal substrate. A metal sensitive film layer is formed on one side of the film insulating layer. A first bonding layer is formed on a side of the metal sensitive film layer away from the film insulating layer. A graphene layer is formed on a side of the first bonding layer away from the metal sensitive film layer. A second bonding layer is formed on a side of the graphene layer away from the first bonding layer. The metal sensitive film layer, the first bonding layer, the graphene layer and the second bonding layer have the same shape and are stacked in order to form a resistance grid and an electrode connection structure. The method is advantagedin that the film strain sensor can have the characteristics of both metal and graphene, so the film strain sensor has both excellent electrical conductivity and strong physical property, has advantages of high sensitivity and a wide range of installation environments and can be used in harsh environments such as acid and alkali, salt spray, and high and low temperature alternation.

Owner:北京石墨烯技术研究院有限公司

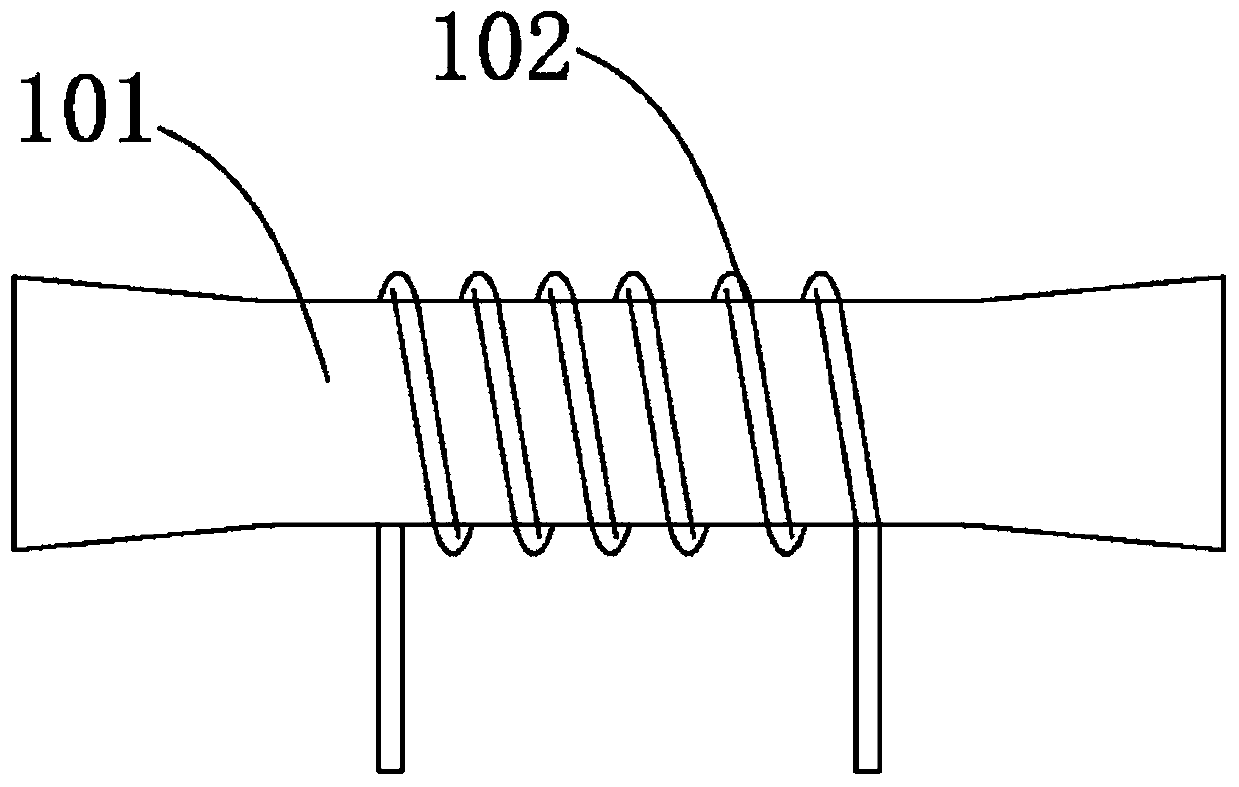

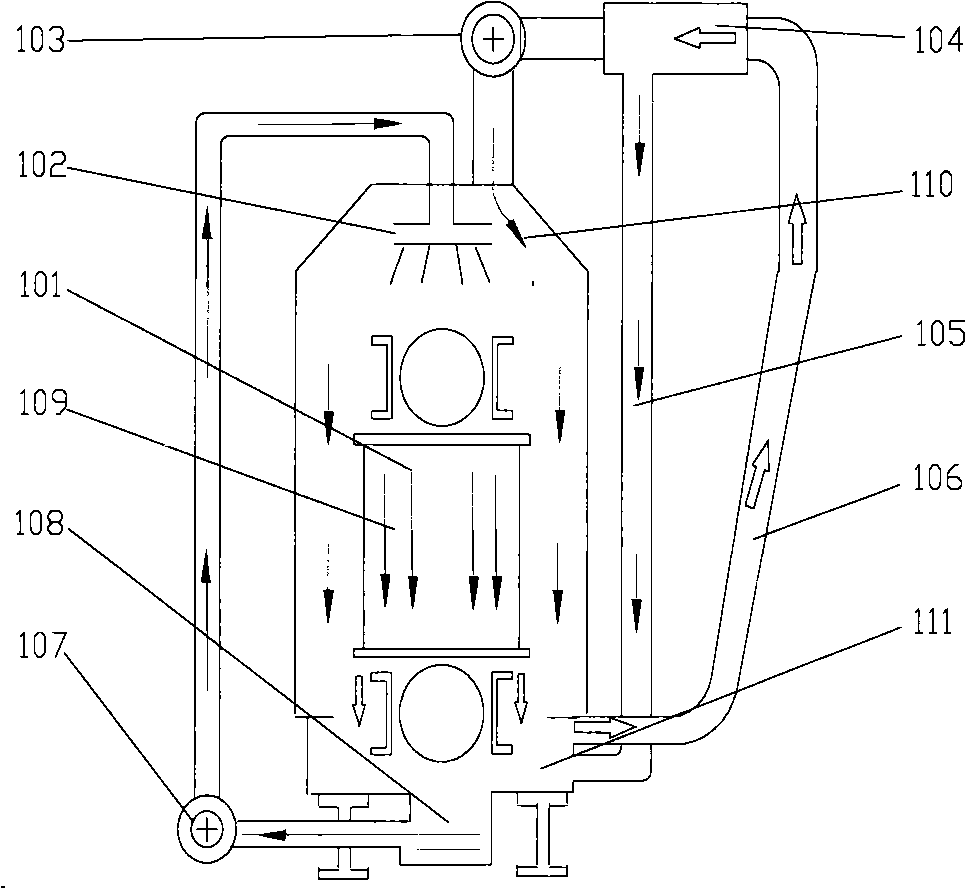

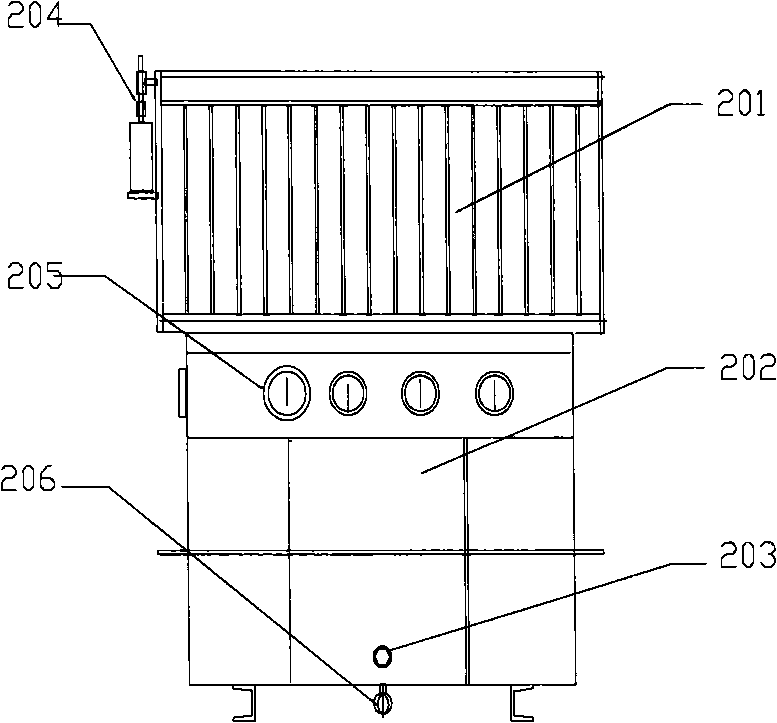

Non-homogeneous phase type power transformer for evaporative cooling

ActiveCN101303930AWith fire extinguishing propertiesLower operating temperatureTransformers/inductances coolingTransformerSulfur hexafluoride

The invention relates to an evaporative cooling non-homogenous power transformer and aims at solving the problems existing in cooling technology of the transformer in prior art, the transformer of the invention comprises a box body, a transformer in the box body, and an evaporative cooling medium loaded in the box body, wherein, the evaporation temperature of the cooling medium is between 30 DEG C to 123 DEG C. The transformer body is immersed in the evaporative cooling medium and provided with a cooling device which is used for cooling the air medium flowing out by evaporation from the box body to condense the air medium into liquid which reflows into the cooling device in the box body. When the transformer works, the whole process of evaporation and condensation of the cooling medium does not need external power. Good and effective automatic circulating cooling is realized; operation temperature of the transformer is reduced and operation efficiency of the transformer is enhanced. The cooling medium (A HFC-8160) used in the process has good environmental protection ability and is much better than the sulfur hexafluoride used in the traditional technology.

Owner:深圳市奥电高压电气有限公司

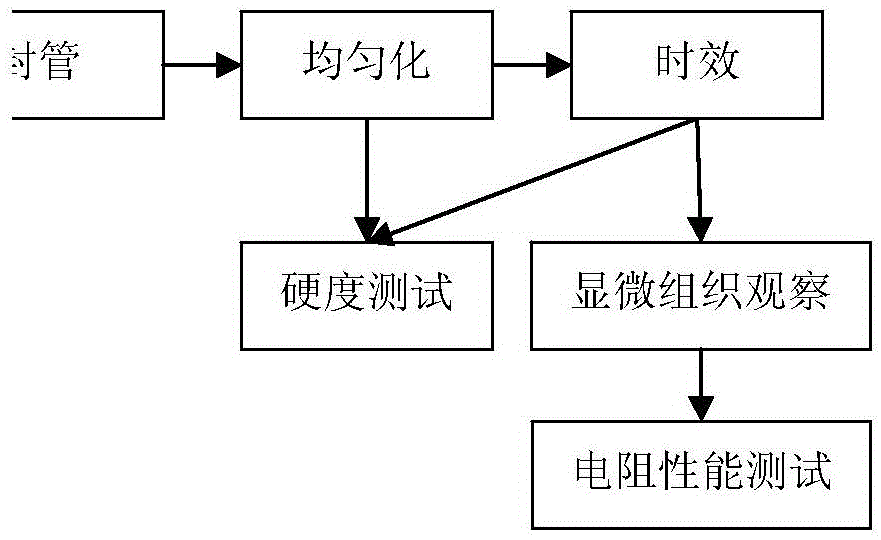

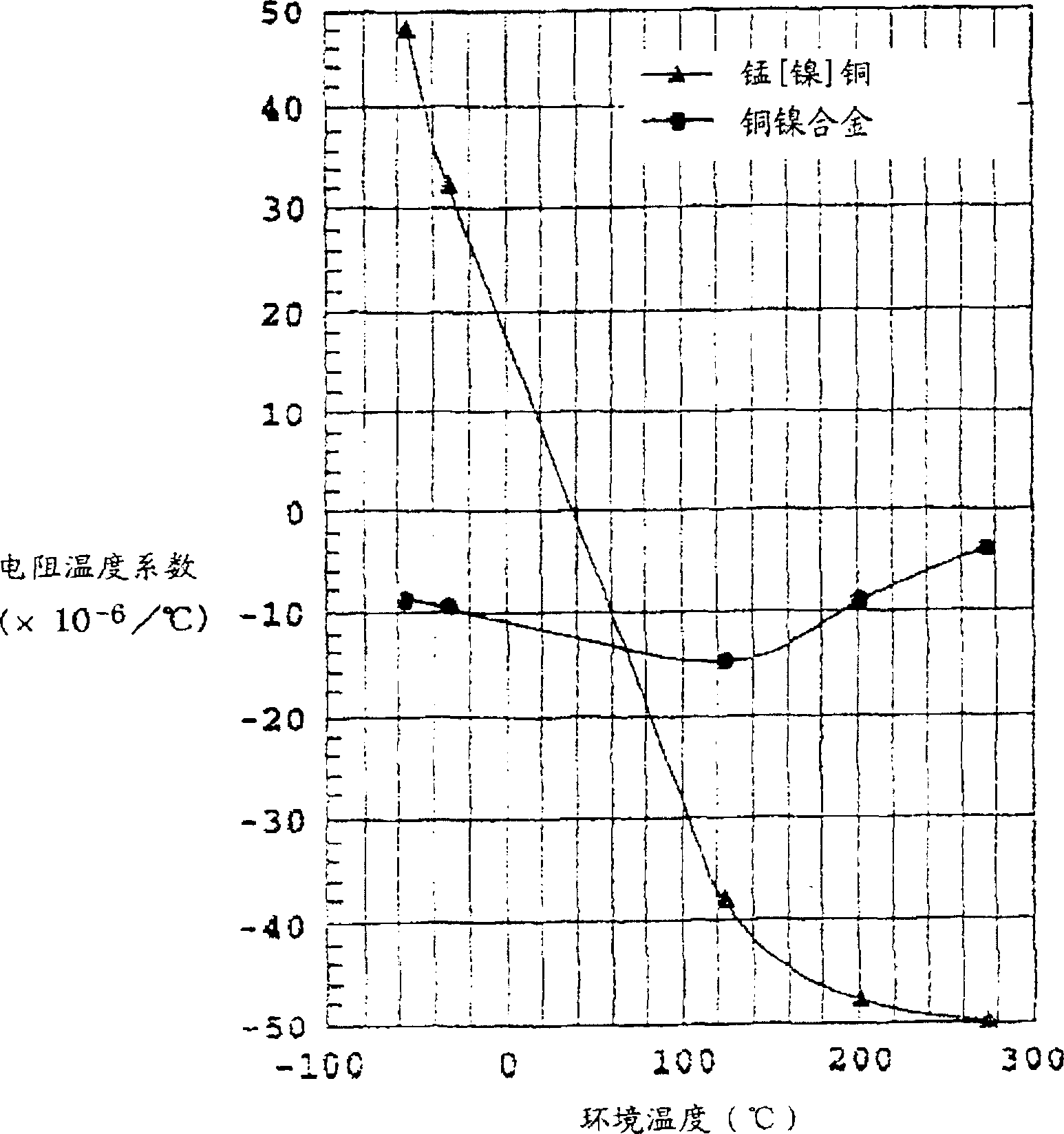

Copper-nickel system precision resistor alloy foil and preparation method thereof

The invention provides copper-nickel system precision resistor alloy foil which comprises the following components in percentage by weight: 40-48% of Ni, 1.4-1.8% of Mn, 0.1-0.3% of Fe, 0.3% of Si and balance of Cu. The preparation method comprises the steps of homogenizing treatment, hot forging, face milling, hot rolling, pickling, cold rolling in steps and annealing of finished products. The technical method is simple and convenient to operate, and the prepared foil is 0.005mm thick, can meet the operating requirements of a sensitive grid of a bridge fatigue life gauge, and can be used as a material of the sensitive grid of a bridge fatigue life gauge.

Owner:CENT SOUTH UNIV

Carbon rubber embedded resistance paste and preparation method of carbon rubber embedded resistance material

InactiveCN103295707AImprove performanceWide resistance rangeResistor manufactureNon-adjustable resistorsPolymer scienceMethyl benzene

The invention discloses a carbon rubber embedded resistance paste and a preparation method of a carbon rubber embedded resistance material. The carbon rubber embedded resistance paste comprises adhesive resin, a conductive filler, a curing agent, an accelerator, a coupling agent and a stability accelerant. Specifically, the adhesive resin is o-methyl phenolic epoxy resin; the conductive filler is a mixture of graphite and carbon black; the stability accelerant is a mixture of benzotriazole (BTA) and tolytriazole (TTA). The method is the preparation method of the paste. Compared with the prior art, the carbon rubber resistance material obtained according to the formula has the advantages of wide resistance range, high precision, good environmental stability, heat resistance and storage stability, and excellent mechanical properties, and can well meet the material characteristic requirements for embedding resistance in a circuit board.

Owner:GUANGDONG DANBOND TECH

Polyaniline/carbon conducting composite material with low resistance temperature coefficient, as well as preparation method and application thereof

InactiveCN103031037AGood environmental stabilityImprove linearityPolyurea/polyurethane coatingsEpoxy resin coatingsPotentiometerTemperature coefficient

The invention discloses polyaniline / carbon conducting composite material with low resistance temperature coefficient, as well as a preparation method and the application thereof, and solves the disadvantage that the resistance change rate of a resistor body of a precision potentiometer is large under high temperature in the prior art. The composite material comprises the following components in weight percentage: 5 to 60 wt% of conductive polyaniline solution, 3 to 35 wt% of conducting carbon material, 10 to 30 wt% of matrix resin, and the balance of solvent. The invention further provides a preparation method of the composite material and the application in manufacturing the resistor body of the precision potentiometer. The resistance temperature coefficient of the resistor body is smaller than 350 ppm / DEG C within the temperature range from minus 55 to plus 125 DEG C, and the resistance change rate is smaller than 5 percent after the resistor body is stored for 48h at 125 DEG C or stored for 24h at minus 55 DEG C, and the service life of the resistor body is longer than 4 million times.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

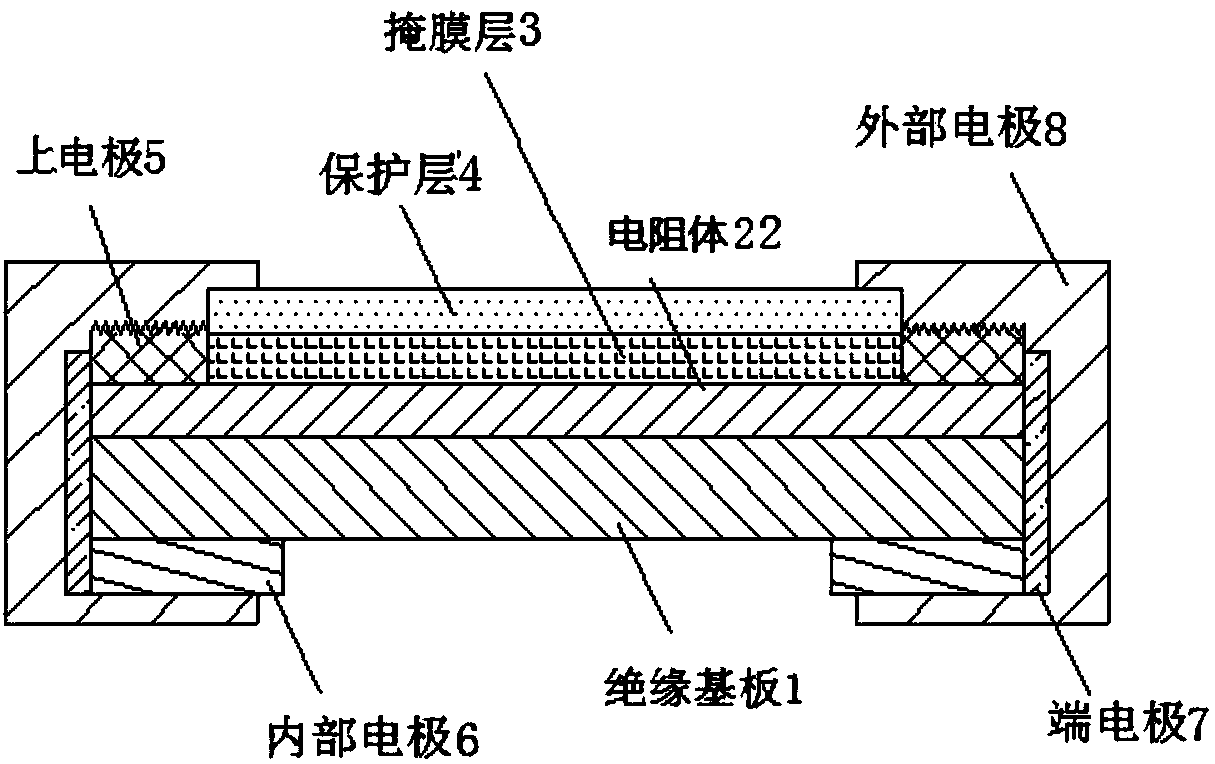

Tantalum nitride sheet-type thin film resistor and manufacturing method thereof

ActiveCN102800448AHigh precisionSmall temperature coefficient of resistanceResistor manufactureNon-adjustable resistorsTantalum nitrideEconomic benefits

The present invention discloses a tantalum nitride sheet-type thin film resistor, including an insulating substrate, two surface electrodes and two back electrodes respectively disposed on the front and rear surfaces of the insulating substrate, terminal electrodes disposed on both ends of the insulating substrate and connected with the surface electrodes and the back electrodes, an intermediate electrode covering the surfaces of the surface electrodes, the back electrodes and the terminal electrodes, an external electrode covering the surface of the intermediate electrode, a resistive layer arranged between the two surface electrodes and connected with the two surface electrodes, and an insulating encapsulating layer covering the surface of the resistive layer, wherein the resistive layer is a tantalum nitride thin film. The tantalum nitride sheet-type thin film resistor of the present invention has the characteristics of high precision, small temperature coefficient of resistance, moisture resistance, high stability and good high-frequency performance. Compared with other thin film products, the tantalum nitride thin film has the advantages of higher stability and lower temperature coefficient of resistance, and can be applied under more harsh natural conditions, therefore the tantalum nitride thin film resistors of high power can bring higher economic benefit.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

Foil type sensor with function of automatically accumulating resistance

InactiveCN102023179AImprove heat resistanceEasy to joinMaterial resistanceFatigue damageElectrical resistance and conductance

The invention relates to a foil type sensor with a function of automatically accumulating resistance. The senor comprises a foil type sensitive grid, a base, a covering layer and a lead, wherein the surface of the base is sequentially provided with the foil type sensitive grid and the covering layer, and the foil type sensitive grid is connected with the lead; and the foil type sensitive grid is made of a foil material of copper-nickel-manganese-iron-silicon alloy through a photochemical method according to the designed sensor structure. Under the effect of fatigue loading, the sensor has the function of automatically accumulating resistance, is suitable for monitoring the accumulation of fatigue damages of a bridge structure, has the capacity of temperature self-compensation and is suitable for complicated and variable climatic environments of bridge structures. The sensor has larger resistance accumulation increment and excellent fatigue service life and can be guaranteed to work for a long time without being frequently changed. The sensor also has a lower resistance accumulation strain threshold value and can be directly bonded on the surface of a structure for use. The sensor has low production cost and can be industrially applied in a large scale.

Owner:CENT SOUTH UNIV

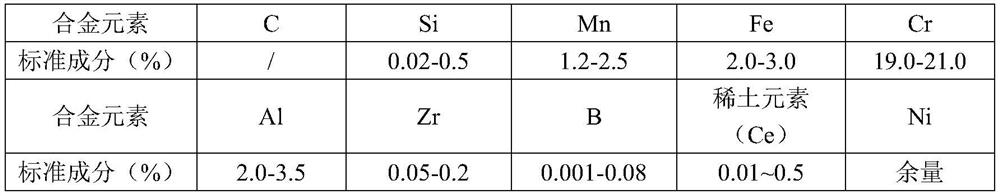

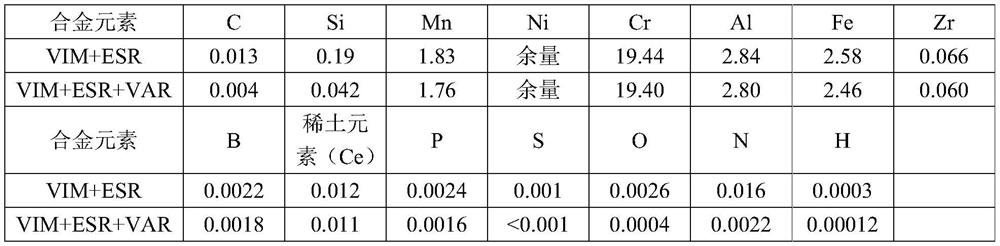

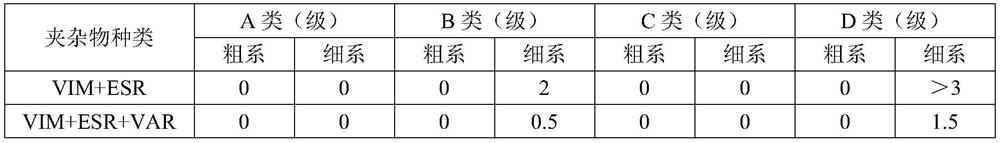

Preparation method of microalloyed high-strength precision nickel-chromium resistance alloy material

InactiveCN111621674AHigh temperature strengthImprove fatigue lifeIncreasing energy efficiencyNichromeMetallic materials

The invention belongs to the field of metal materials, and particularly relates to a microalloyed high-strength precision nickel-chromium resistance alloy material. A preparation method of the microalloyed high-strength precision nickel-chromium resistance alloy material comprises the steps of vacuum induction melting, electroslag remelting, vacuum consumable remelting and forging cogging. The material prepared by the method has high resistivity, low temperature coefficient of resistance, excellent heat resistance, corrosion resistance and mechanical properties, and good processing performance, can meet the processing requirements of high-precision foils and fine wires, improves the processing accuracy and surface quality of finished products, and is used for the production of high-precision electronic components, the products, namely precision resistance alloys, are made by the VIM+ESR+VAR smelting process, due to the precise control over the content of alloy elements, impurities andgas in the products, the electrical properties and the processing performance of the products meet the requirements, and the products can face the high-end precision resistance alloy market at home and abroad.

Owner:CHONGQING MATERIALS RES INST

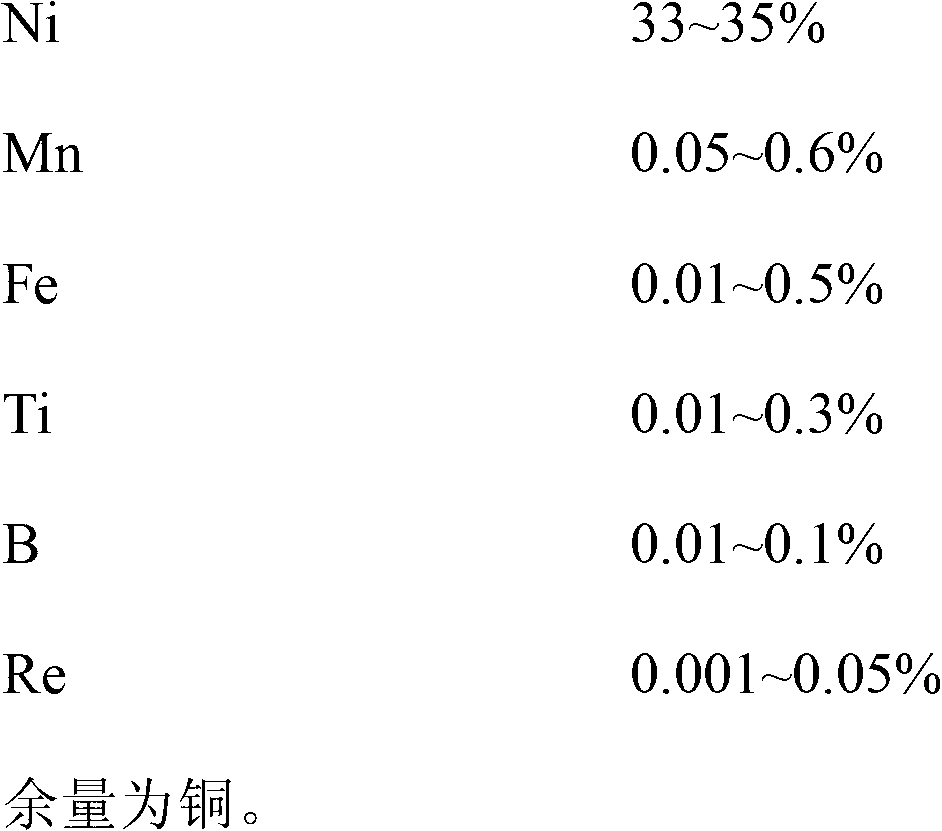

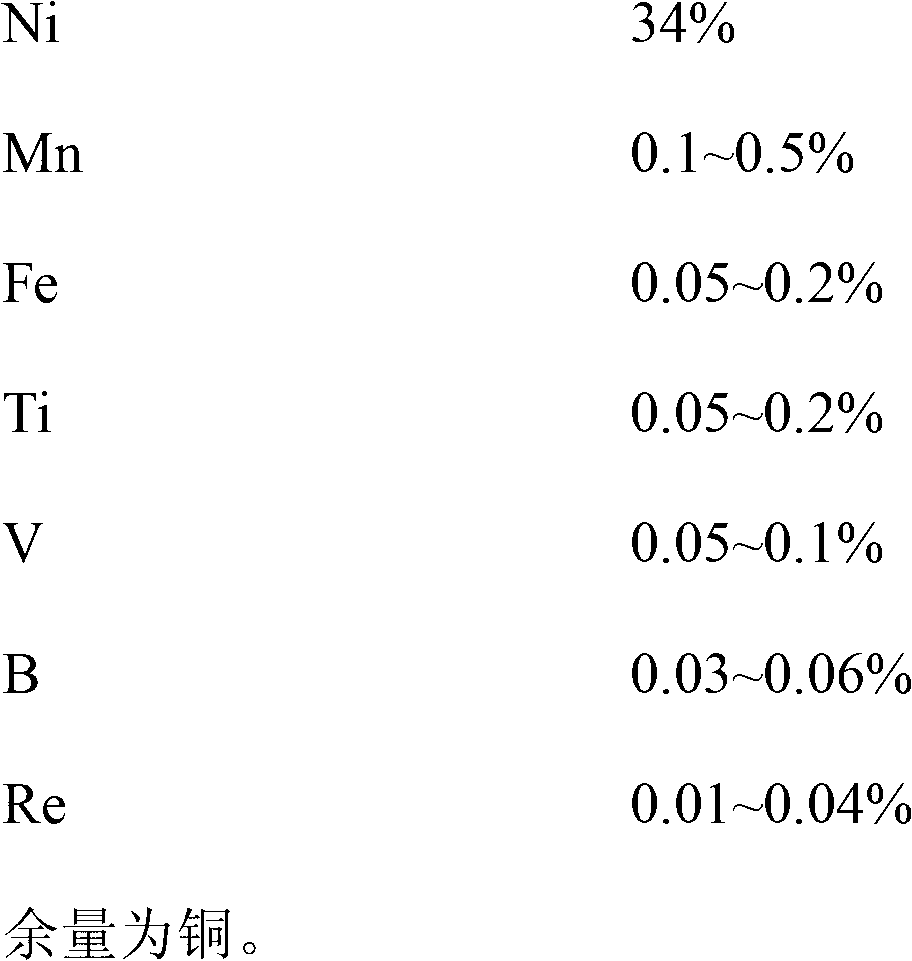

Copper-nickel 34 metal wire and preparation method thereof

InactiveCN102851535ASmall temperature coefficient of resistanceImprove corrosion resistanceMetal/alloy conductorsResistor detailsIngotTemperature coefficient

The invention relates to a relates to the field of copper-nickel alloy, and in particular relates to a copper-nickel 34 metal wire and a preparation method thereof. The copper-nickel 34 wire comprises, by weight, 33-35% of Ni, 0.05-0.6% of Mn, 0.01-0.5% of Fe, 0.01-0.3% of Ti, 0.01-0.1% of B, 0.001-0.05% of Re, and the balance of copper. The preparation method of the copper-nickel 34 metal wire comprises the following steps: conducting mixed melting according to the formula; peeling the obtained ingot and forging; drawing the forged blank; and repeating drawing and annealing for at least 2 times, until the copper-nickel 34 metal wire with desired specifications is obtained. The copper-nickel 34 metal wire prepared by the method of the invention has low resistance temperature coefficient, excellent corrosion resistance, good welding performance and processing performance, high tensile strength and elongation rate, and resistivity about 0.40 ohm.mm<2> / m.

Owner:常丰(无锡)金属制品有限公司

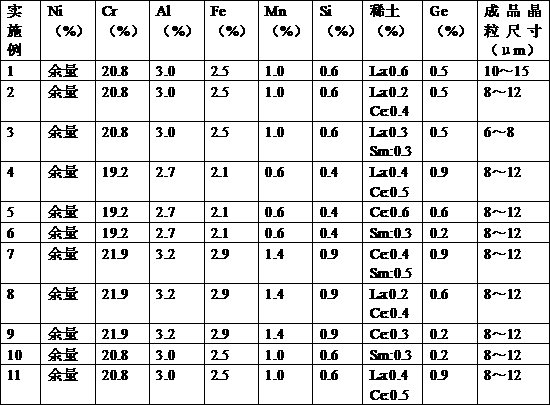

Nickel-chromium-aluminum-iron alloy with high resistance long-term stability

ActiveCN111363952AEasy to processSmall temperature coefficient of resistanceRare-earth elementNichrome

Owner:CHONGQING CHUANYI AUTOMATION

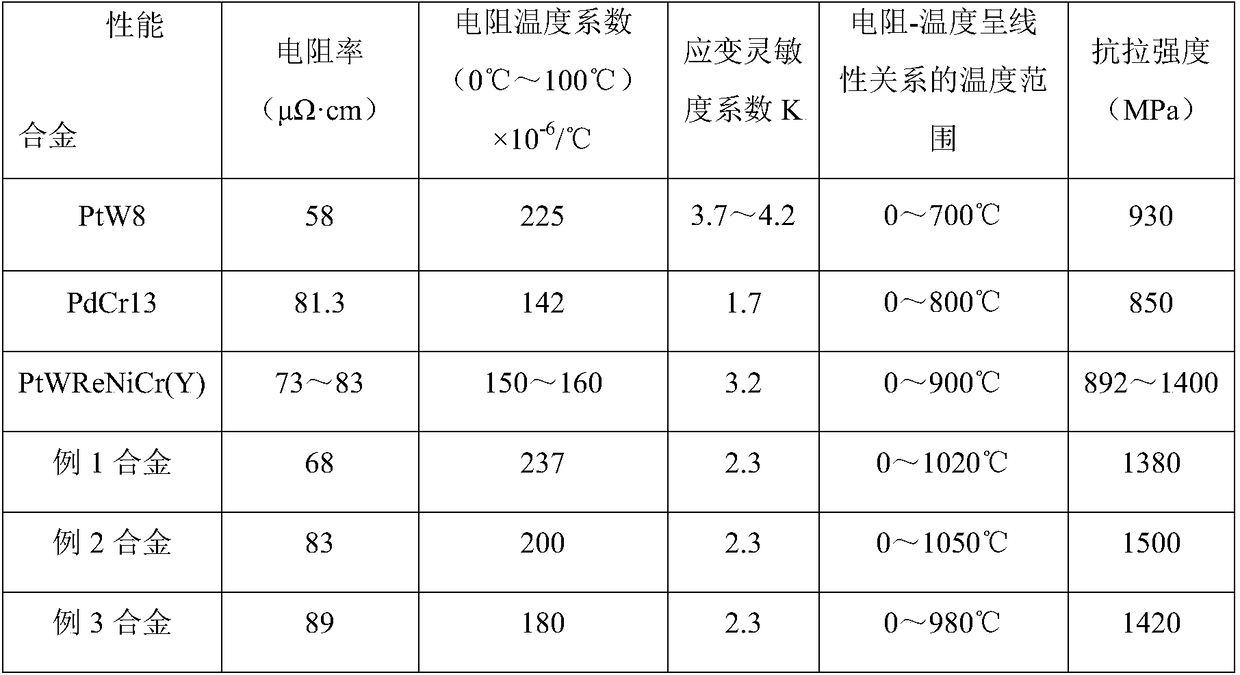

Novel platinum-based high-temperature resistance strain alloy and preparation method thereof

ActiveCN108179303AStable mechanical propertiesImprove electrical performancePetrochemicalOxidation resistant

The invention discloses novel platinum-based high-temperature resistance strain alloy and a preparation method thereof. The alloy is prepared from the following chemical components in percentage by mass: 15 to 40 percent of Rh, 4 to 10 percent of Mo, 2 to 8 percent of Re, 0.5 to 3 percent of Cr, and the balance of Pt. The alloy can also be added with 0 to 2 percent of M (M is at least one of Ni, Zr, Y and Sc). A finish product is prepared by adopting the processes of preparing an alloy ingot in a high-frequency induction smelting furnace, hammer cogging at a high temperature, performing stableheat treatment and the like. The alloy material has high tensile strength and electrical resistivity, low resistance temperature coefficient, excellent high-temperature mechanical properties and oxidation resistance, and resistance-temperature characteristic is linear in the temperature range of 0 to 1,050 DEG C, the novel platinum-based high-temperature resistance strain alloy can be widely applied to the stress-strain test of a hot end component at over 1,000 DEG C in the fields, such as spaceflight, aviation, heavy machinery, petrochemical industry and nuclear industry, and ensures the safety and reliability of an operating system.

Owner:SINO PLATINUM METALS CO LTD

Palladium base alloy resistance strain material and preparation method thereof

InactiveCN107841647AHigh tensile strengthHigh resistivityAviationElectrical resistance and conductance

The invention discloses a palladium base alloy resistance strain material and a preparation method thereof, and relates to a water cooling silver mold quick solidification process for preparing the palladium base alloy resistance strain material. The palladium base alloy resistance strain material comprises the following components in percentage by mass: 0-10 of Ni, 0-10 of Zr, 0-5 of Ta, 5-15 ofW, and the balance of Pd. At least one of 0-5 of Ag, 0-5 of Ru, 0-2 of Ir and 0-2 of Rh can be added in the palladium base alloy resistance strain material. The alloy nucleation speed is accelerated;the alloy grain is refined; and the alloy component segregation is improved. The prepared material is higher in tensile strength and resistivity and lower in resistance temperature coefficient, and can be used for precise potentiometers in such fields as aviation electric appliances, precise instruments and high-reliability instruments; the tensile strength reaches 1200-1800 MPa; the resistivity reaches 80-95 u omega.cm; and the resistance temperature coefficient is reduced to 40-55 ppm / DEG C.

Owner:KUNMING INST OF PRECIOUS METALS

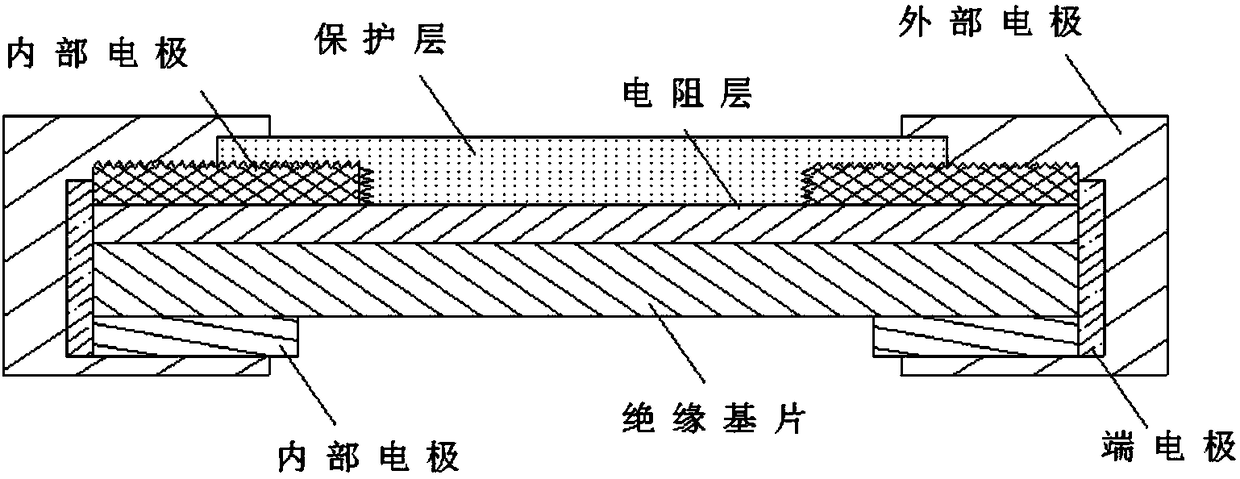

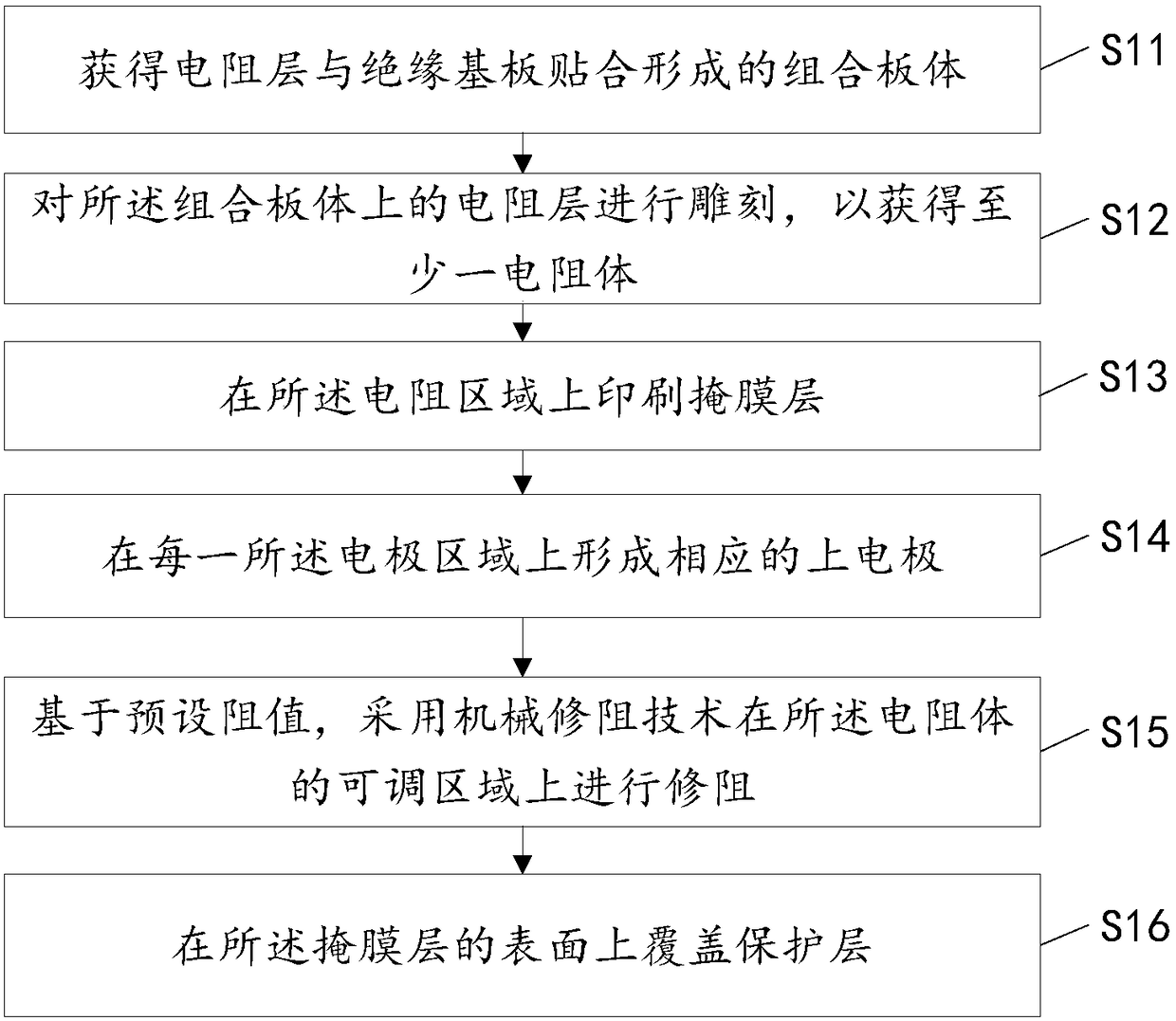

Manufacturing method of resistor as well as resistor

ActiveCN108109795AIncrease resistanceHigh precisionEnvelope/housing resistor manufactureResistors adapted for applying terminalsEngineeringResistor

The invention discloses a manufacturing method of a resistor. The manufacturing method of the resistor comprises the following steps: obtaining a combined plate body which is formed by sticking a resistance layer and an insulating substrate; engraving the resistance layer on the combined plate body to obtain at least one resistor body, wherein the upper surface of the resistor body comprises a resistance area and two electrode areas, and the resistance area and the two electrode areas are not overlapped; printing a mask layer on the resistance area; forming a corresponding upper electrode on each electrode area; and covering the surface of the mask layer with a protective layer to obtain the resistor. Correspondingly, the invention also provides the resistor. High-precision resistance value and low TCR value of the resistor can be realized effectively.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

High-conductivity high-elasticity palladium-based alloy, heat treatment process and application

The invention discloses a high-conductivity high-elasticity palladium-based alloy, a heat treatment process and application. The palladium-based alloy comprises, by mass, 40-60 wt.% of Pd, 25-45 wt.%of Cu, 5-15 wt.% of Ag, 1.5-5 wt.% of Ru and 0-2.0 wt.% of modified elements, wherein the modified elements are one or two of La, Ce, Gd, Y, Ga, Zr and B. The heat treatment process comprises the steps of carrying out burdening, carrying out smelting, carrying out casting, carrying out rolling, carrying out annealing, carrying out drawing and carrying out intermediate annealing, and after the intermediate annealing step is completed, aging solution strengthening treatment needs to be carried out on a prepared alloy wire. The conductivity of the palladium-based alloy ranges from 15% to 25%IACS,the elasticity modulus ranges from 115 GPa to 125GPa, the hardness Hv0.1 ranges from 360 to 460, the resistance temperature coefficient ranges from 2.0 to 4.0x10<-4>K<-1>, the yield strength ranges from 1075 MPa to 1125MPa, and the ductility ranges from 2% to 10%. The high-conductivity high-elasticity palladium-based alloy can be used for a micromotor electric brush wire, a potentiometer electricbrush wire and a semiconductor test probe, wherein the probe can be a Cobra probe or a cantilever type probe or a vertical type probe or a spring type probe.

Owner:昆明贵研新材料科技有限公司

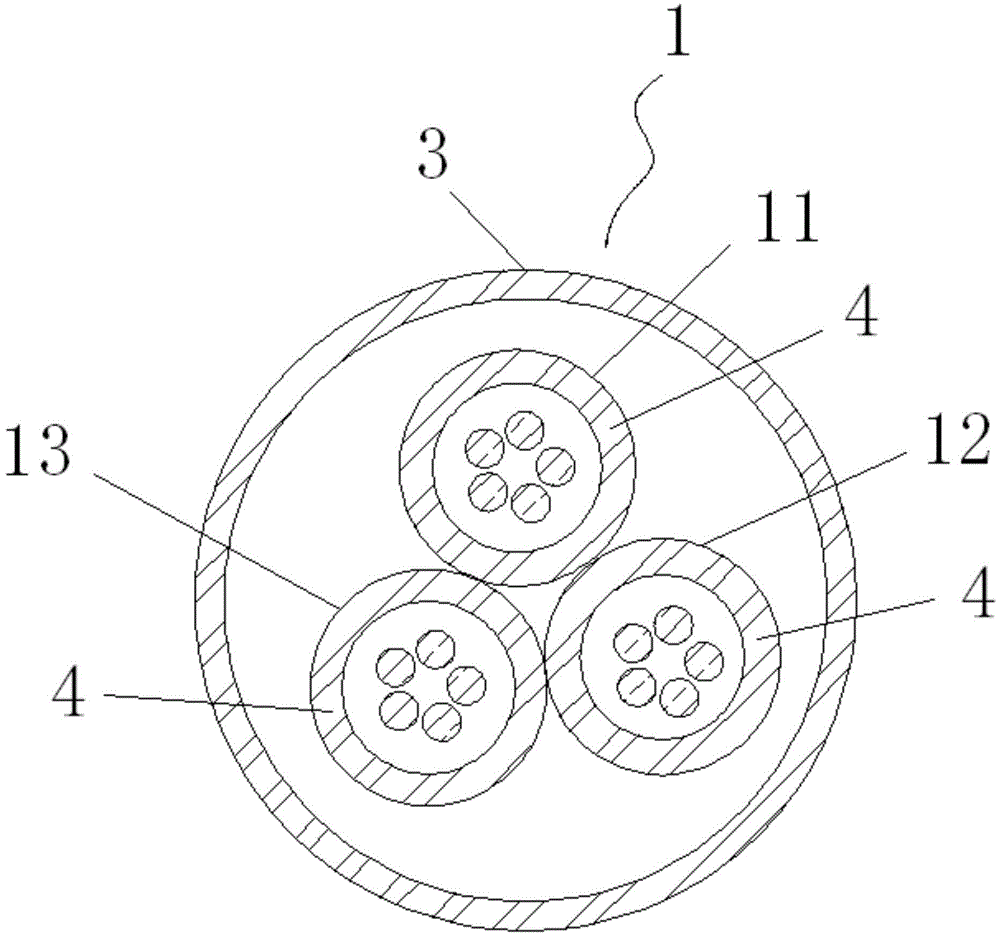

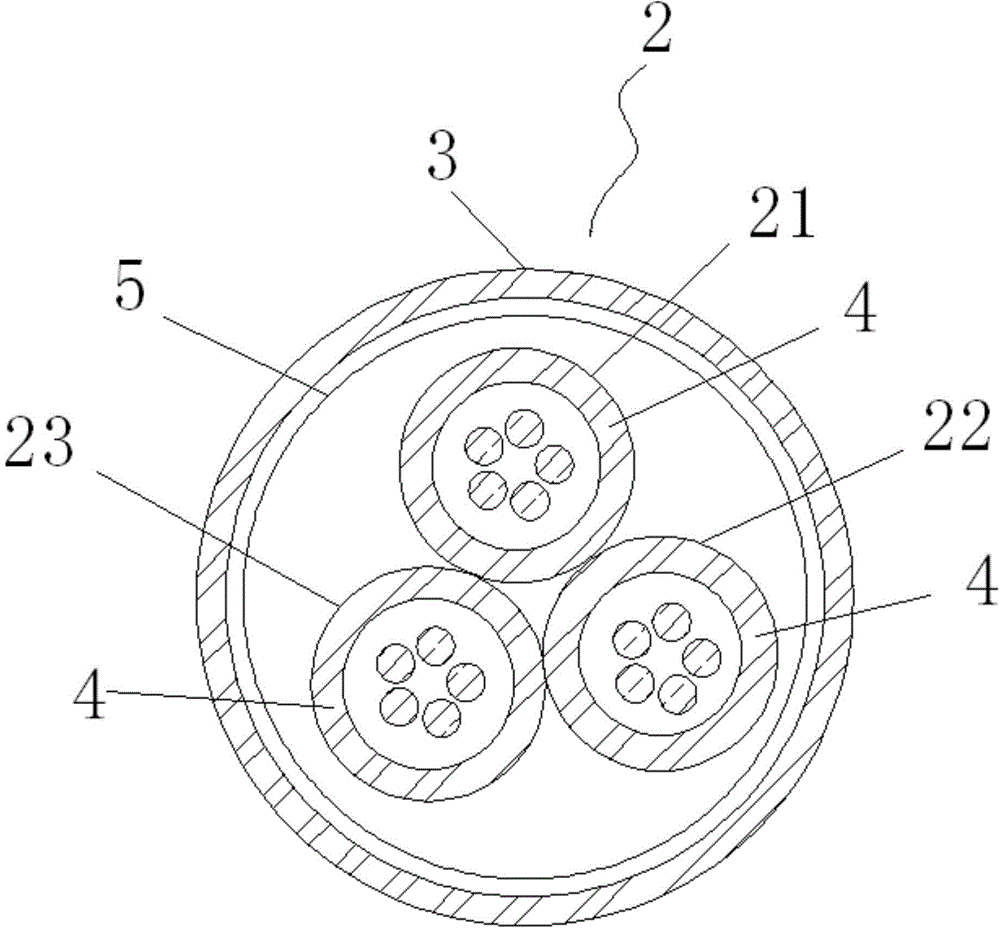

Carbon-fiber double-conductor grounding heating cable

The invention provides a carbon-fiber double-conductor grounding heating cable. The carbon-fiber double-conductor grounding heating cable comprises a main wire and heating wires. The heating wires are connected with the main wire. The heating wires are connected in parallel. The main wire comprises a live wire body, a first null wire body and a first grounding wire body. Each heating wire comprises a second null wire body, a second grounding wire body and an electric heating wire body. The carbon-fiber double-conductor grounding heating cable has the advantages of being safe to use and good in electrical property.

Owner:SHANGHAI HEIMAN ENERGY TECH

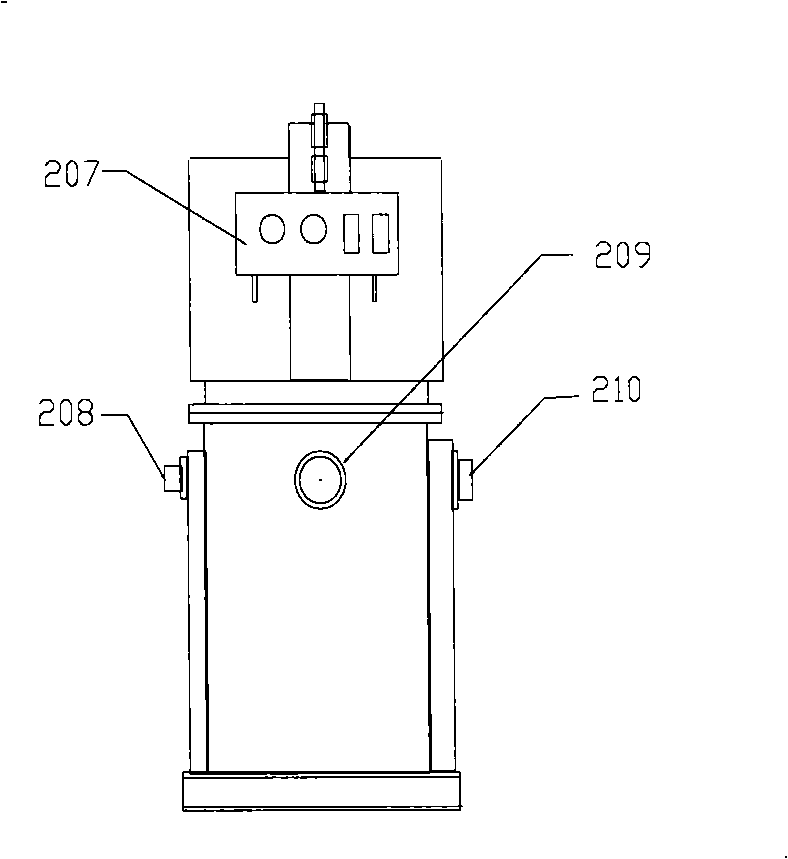

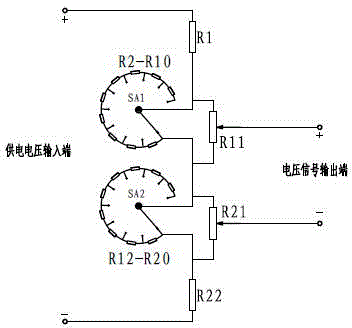

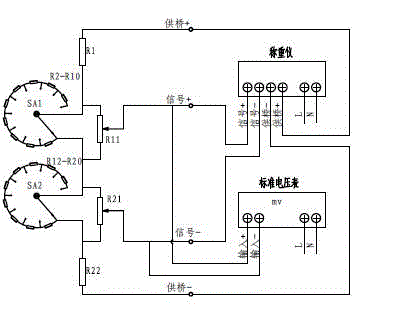

Tester of simulating weighing sensor weighing precision

ActiveCN103604491AGive quicklyGiven preciselyWeighing apparatus testing/calibrationPotentiometerVoltage regulation

The invention discloses a tester of simulating weighing sensor weighing precision and belongs to the electronic measurement instrument technology field. The tester comprises an output voltage regulation circuit. The output voltage regulation circuit is divided into a fine tuning voltage circuit and a coarse tuning voltage circuit. The fine tuning voltage circuit and the coarse tuning voltage circuit are connected in series and then are connected with a supply voltage input terminal. Structures of the fine tuning voltage circuit and the coarse tuning voltage circuit are the same. Each structure comprises a resistance box and a potentiometer which are connected in parallel. A gear resistance ratio of the resistance boxes in the fine tuning voltage circuit and the coarse tuning voltage circuit is 1:5-20. Center taps of the two potentiometers are voltage signal output terminals. The tester possesses the following advantages that the structure is simple; manufacturing cost is low; voltage signal output precision is high; operation is convenient and so on. By using the tester to verify a weighing instrument, through coarse tuning and fine tuning knobs, any voltage signal output values can be rapidly and accurately provided so that instrument verification precision and working efficiency are increased.

Owner:DALIPAL PIPE

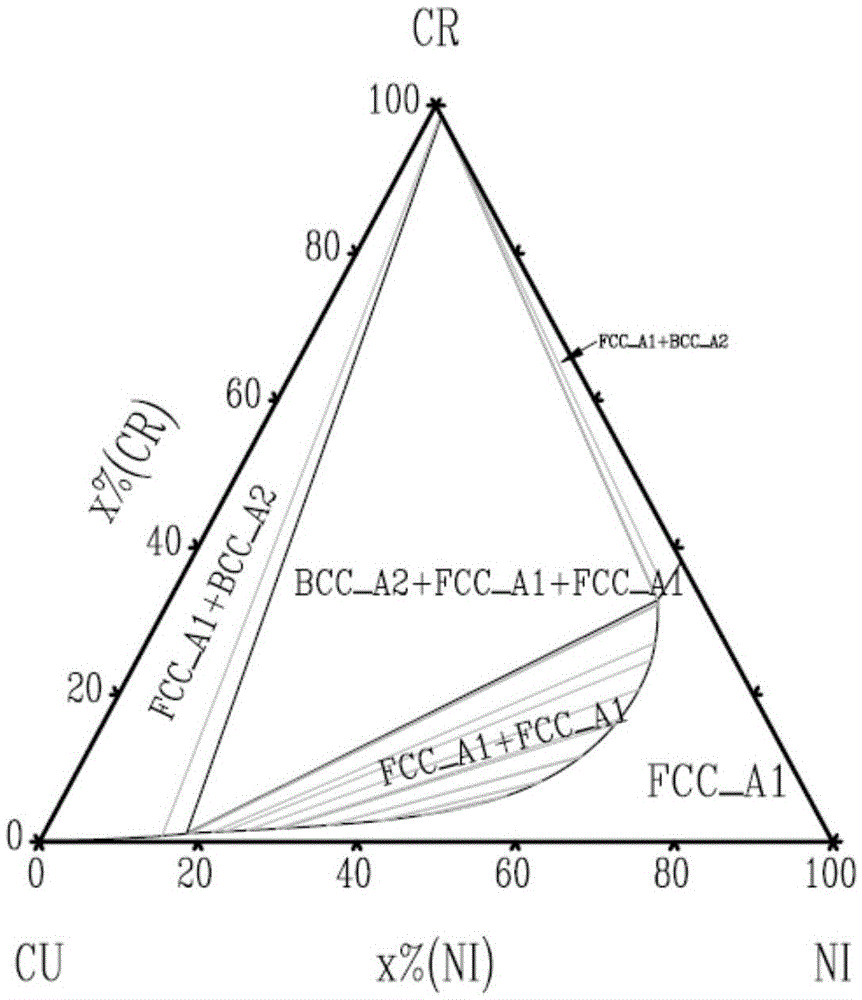

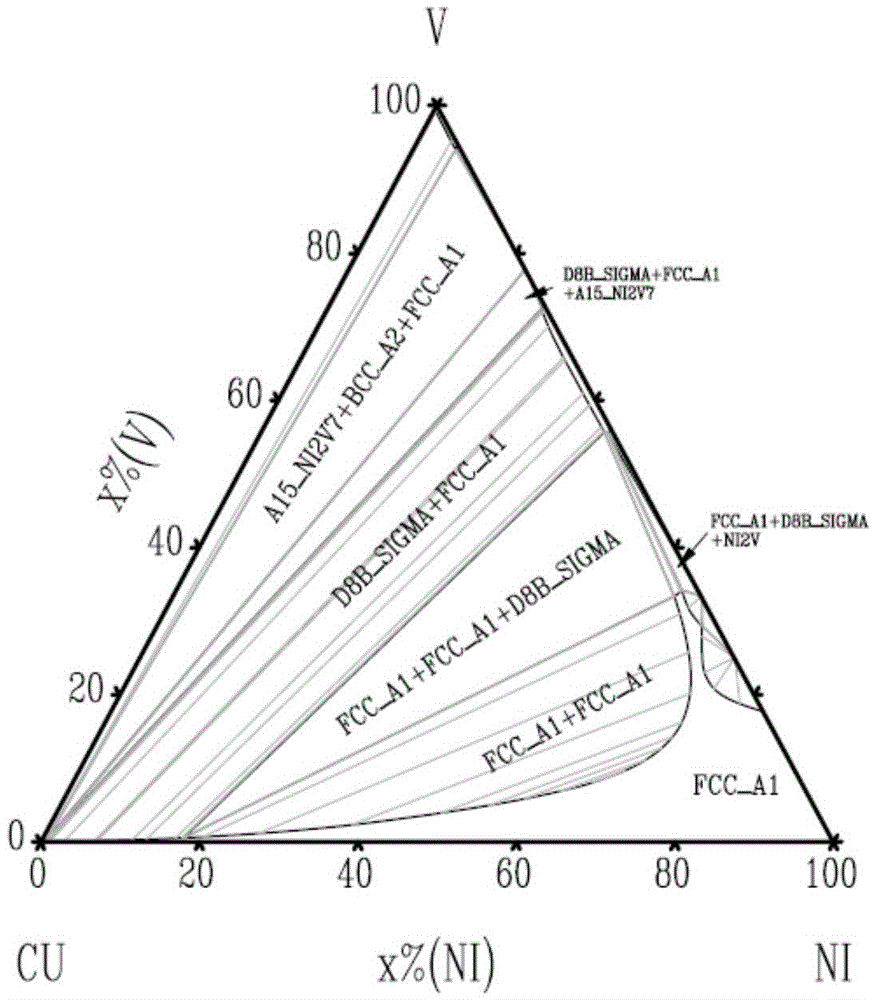

Application of copper-nickel alloy based on spinodal decomposition as reinforced constant-resistivity alloy

ActiveCN105603252AHigh strengthSmall temperature coefficient of resistanceTemperature coefficientCopper nickel alloy

The invention discloses application of a copper-nickel alloy based on spinodal decomposition as a reinforced constant-resistivity alloy. The copper-nickel alloy is composed of copper, nickel and an optional element, the optional element is chromium or vanadium, an atomic ratio of copper to nickel is 25-75:25-75, total amount of copper and nickel in the copper-nickel alloy is 82-98at%, and amount of the optional element is 2-18at%. Strength of the copper-nickel alloy is improved remarkably, resistance temperature coefficient is small and is about 200 ppm / K at most and about 50 ppm / K at least, and the copper-nickel alloy is still a good constant-resistivity alloy material.

Owner:XIAMEN UNIV

Palladium molybdenum precision resistance alloy and preparing method thereof

ActiveCN110453105AReduce oxidationReduce volatilityFurnace typesHeat treatment furnacesShort range orderHeat treated

The invention discloses a palladium molybdenum precision resistance alloy and a preparing method thereof. Chemical components of the alloy comprise, by mass, 30-40% of Mo, 0.5-6% of M (at least one ofZr, Cr and Y), and the balance Pd. Cast ingots are prepared through high-frequency induction smelting, and a finished product is prepared through the procedures of high-temperature forging, short-range order transition heat treatment and the like. The alloy has high specific resistance and tensile strength, a low temperature coefficient of resistance, high oxidation resistance and high abrasive resistance, is a precision resistance alloy material with good comprehensive performance, and has wide application prospects in the cutting-edge technical fields of computer technology, aerospace and aviation, and the like.

Owner:SINO PLATINUM METALS CO LTD

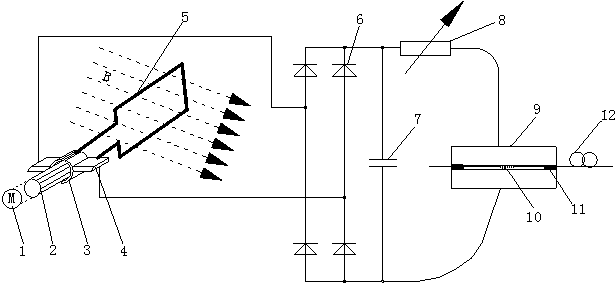

A fiber Bragg raster magnetic field sensor based on a current heat effect and an application method thereof

ActiveCN103645446AAdjust the size of the measurement rangeAdjust measurement sensitivityMagnetic field measurement using galvano-magnetic devicesFiberGrating

The invention relates to a fiber Bragg raster magnetic field sensor based on a current heat effect and an application method thereof, and belongs to the technical field of photoelectron measurement. The fiber Bragg raster magnetic field sensor of the invention comprises a direct current asynchronous motor, an electric motor rotary shaft, a commutator, an electric brush, a rectangular coil, bridge type rectifier diodes, a filtering capacitor, a variable resistor, a fiber Bragg raster, a constantan piece, polytetrafluoroethylene, and an externally connected lead-out fiber. The direct current asynchronous motor, the electric motor rotary shaft and the commutator are fixed together with the rectangular coil. The electric brush contact with the commutator, and a contact of the electric brush is connected with the bridge type rectifier diodes through a conductive wire. A leading-out end of the bridge type rectifier diode is connected with the filtering capacitor and the variable resistor. The fiber Bragg raster is bonded to the constantan piece in an adhesive mode through the polytetrafluoroethylene, and is externally connected with the lead-out fiber. According to the invention, the size of a measurement scope of a magnetic field and the measurement sensitivity of the sensor can be adjusted; the resistance will not change as the temperature changes; the anti-interference capability is strong; the structure is simple; and the usage is convenient.

Owner:KUNMING UNIV OF SCI & TECH

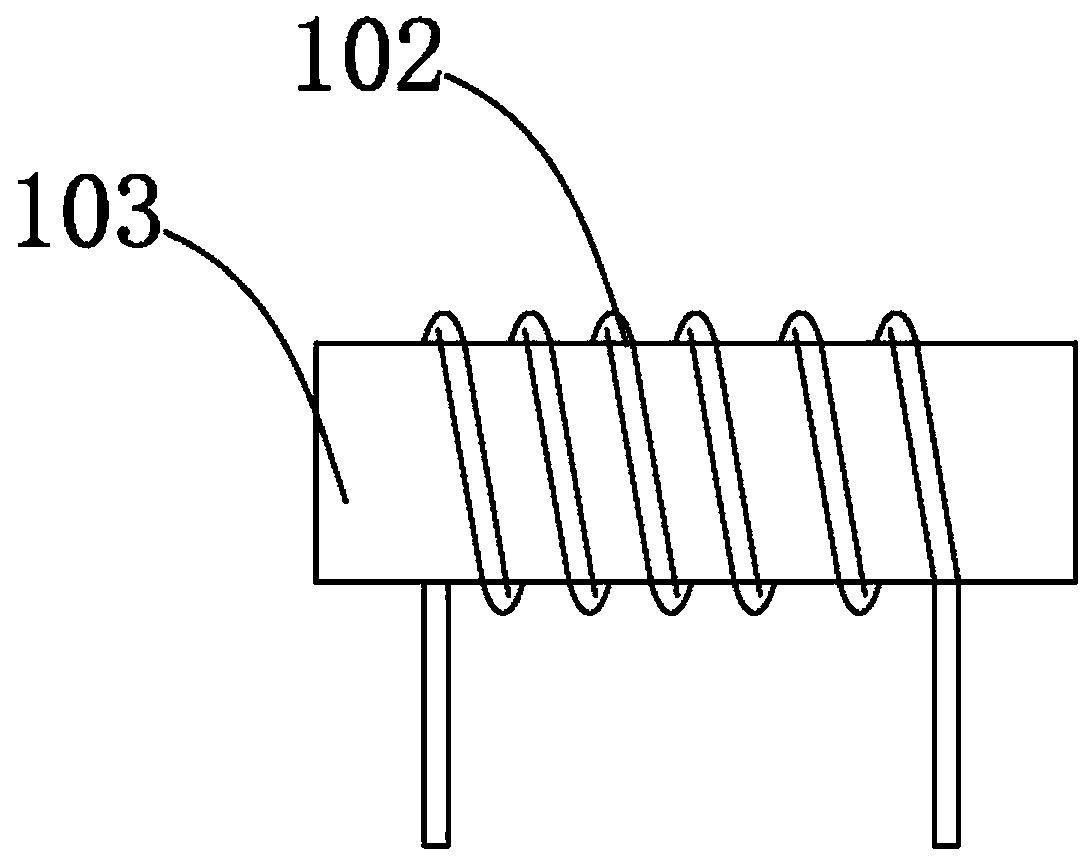

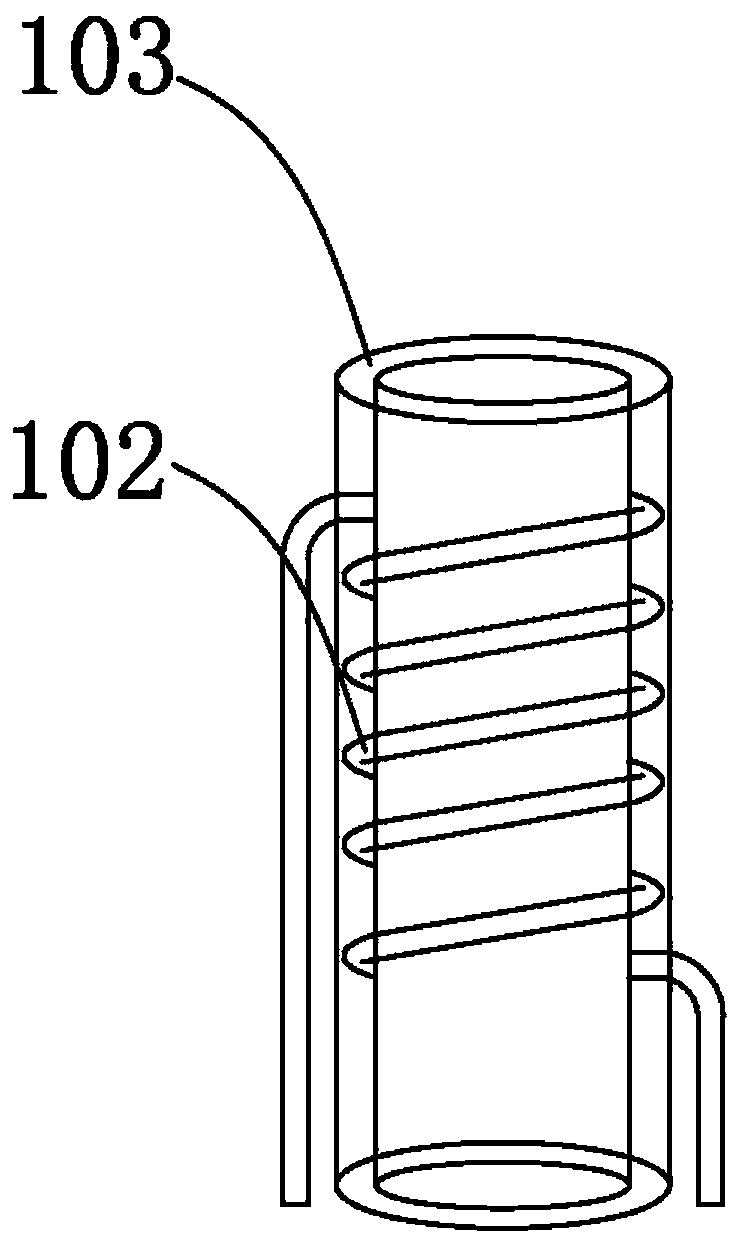

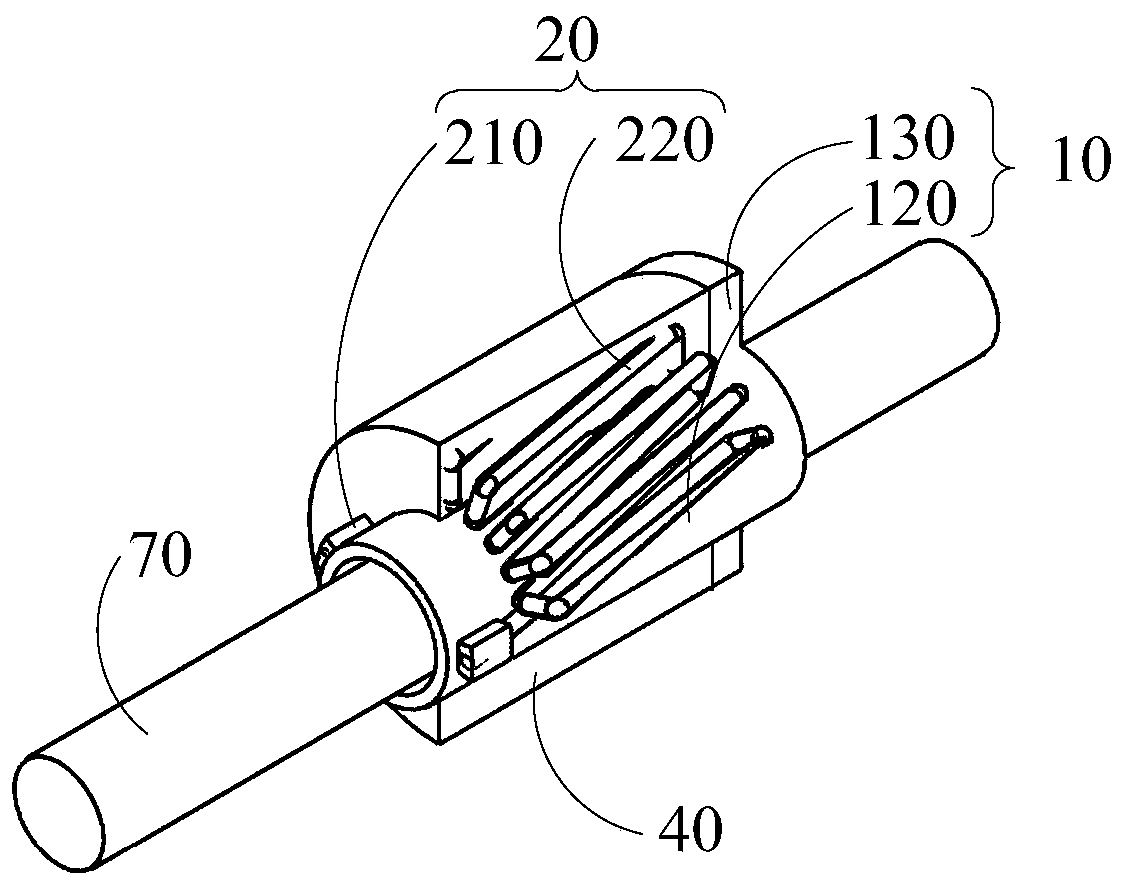

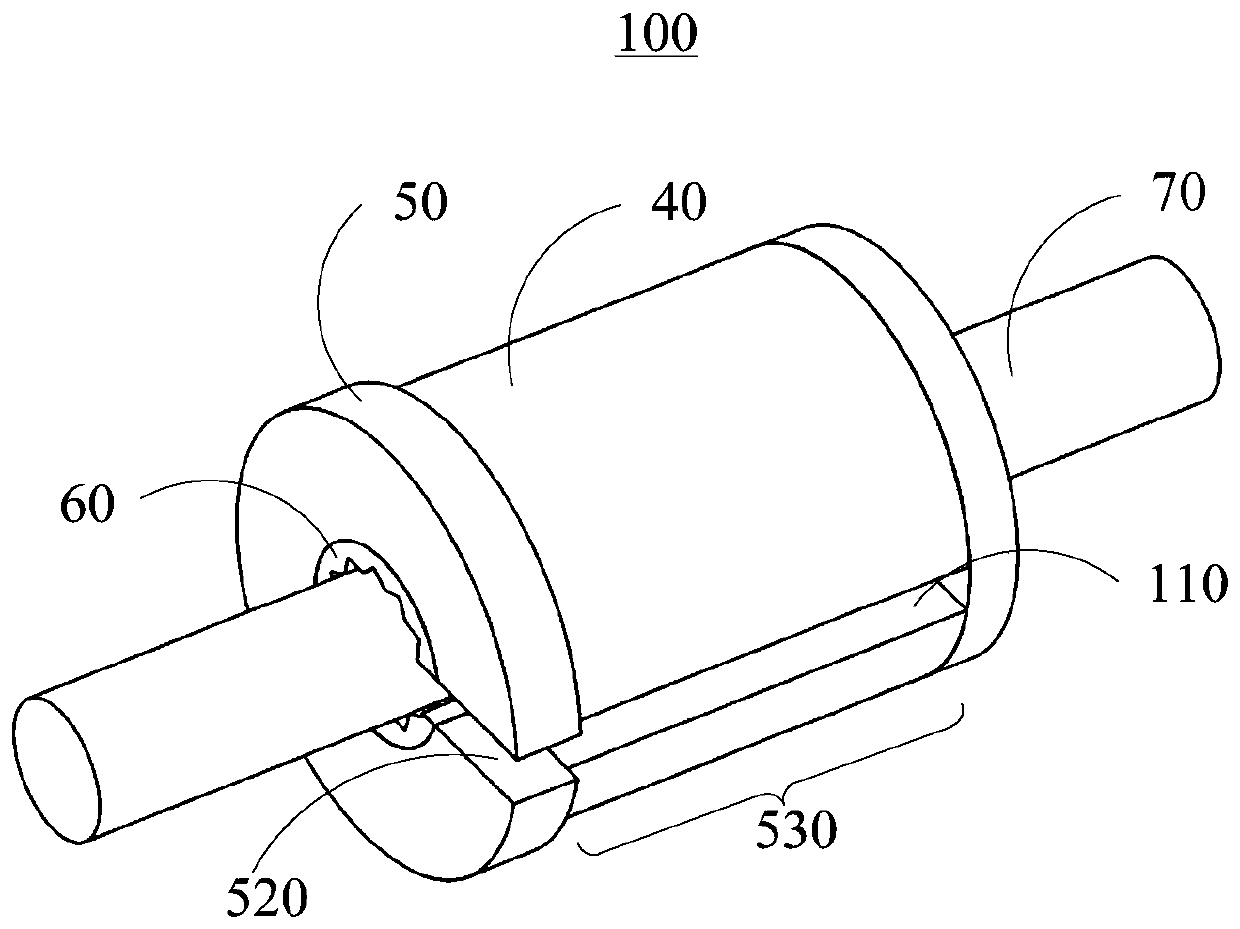

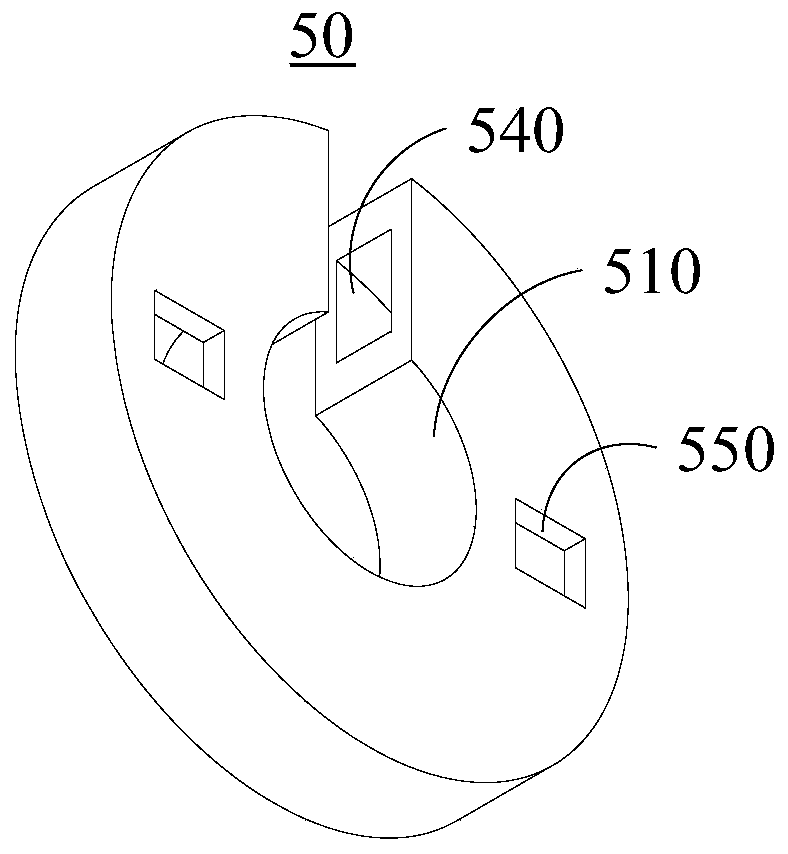

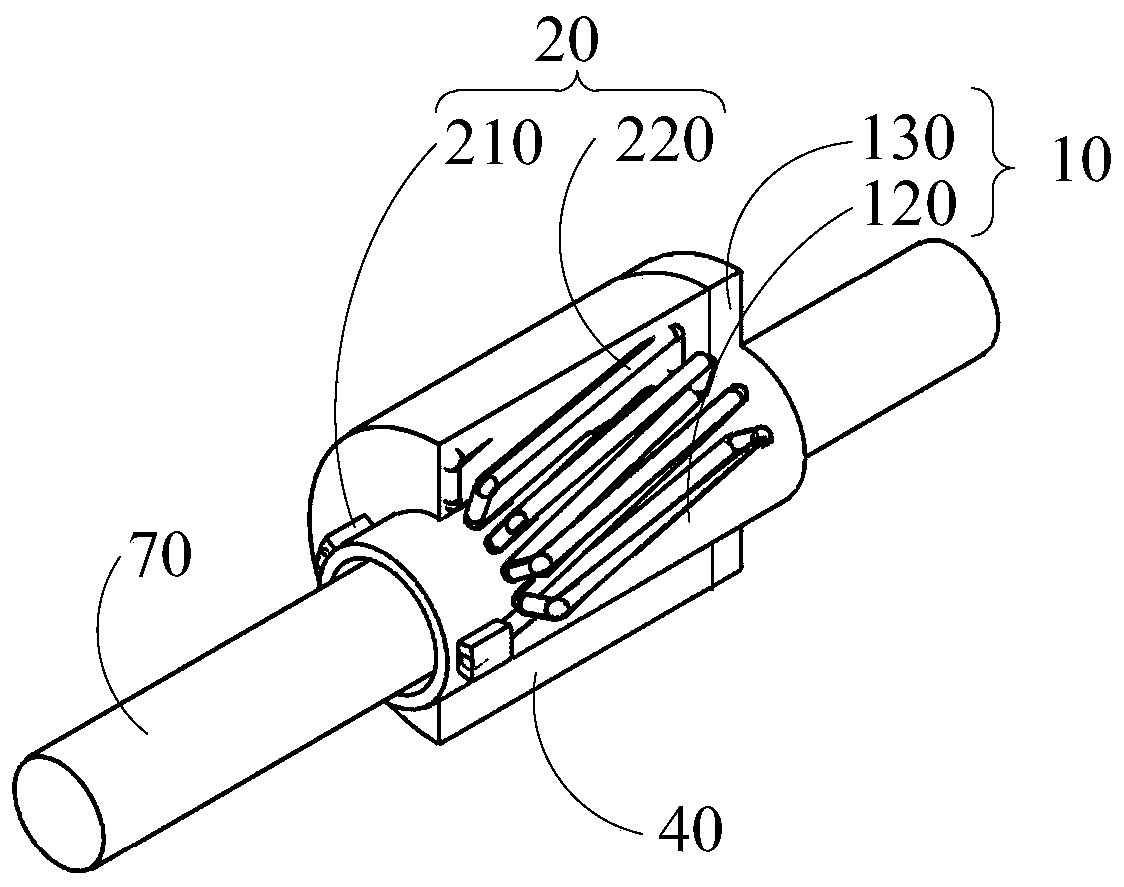

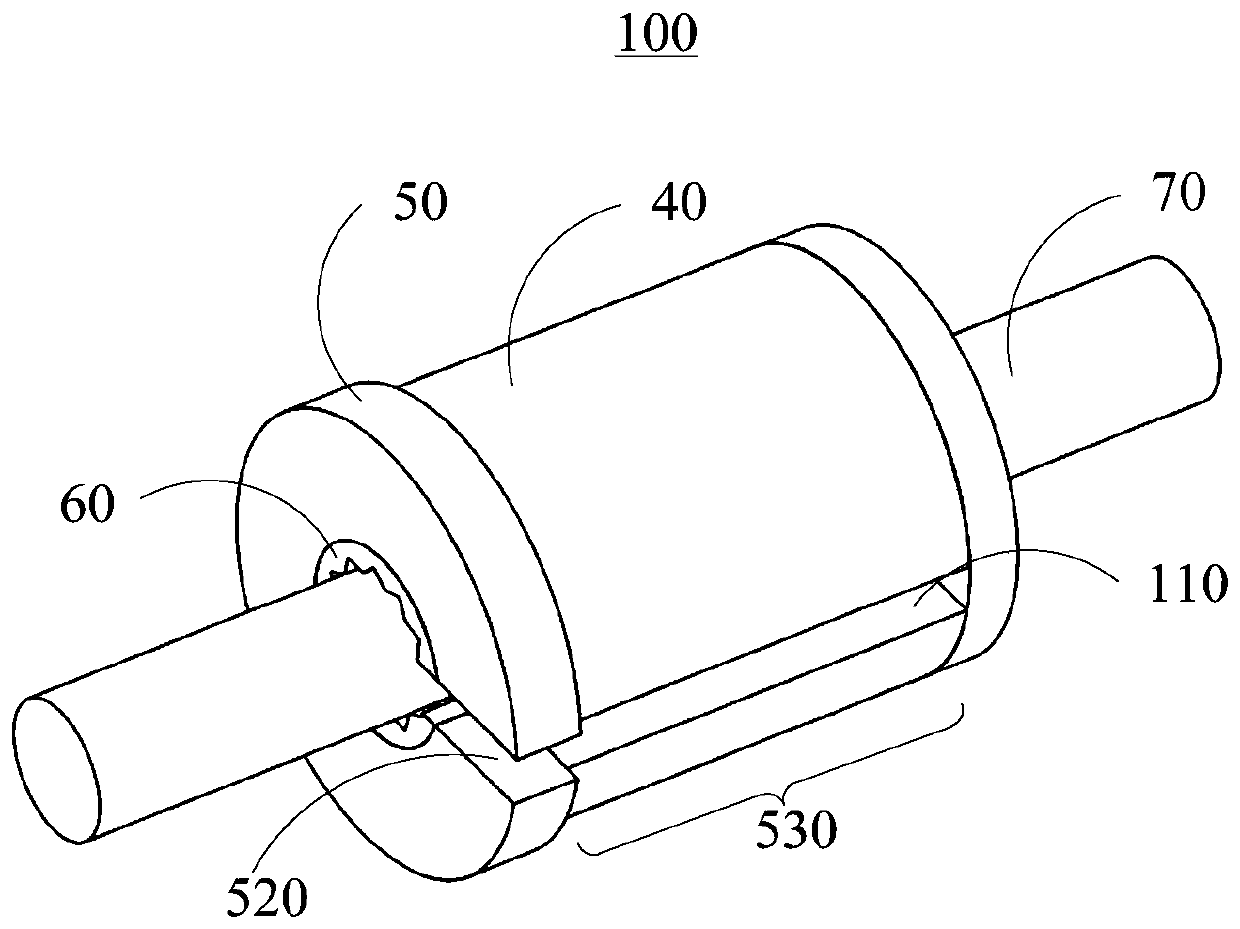

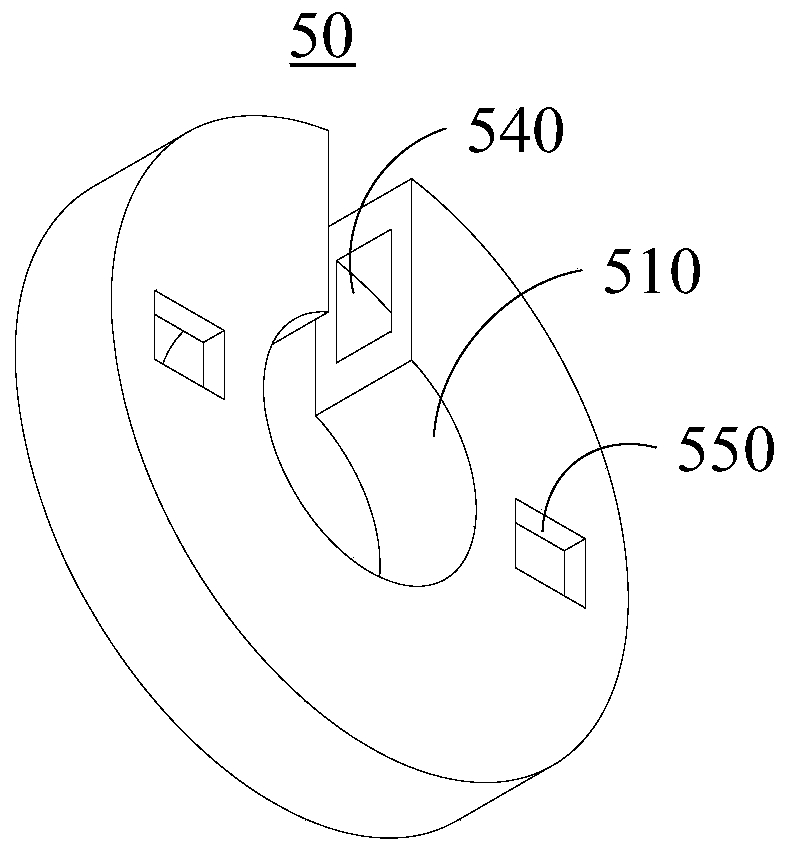

Graphene current sensor

ActiveCN110780105AHigh strengthImprove conductivityCurrent/voltage measurementBase element modificationsElectrical resistance and conductanceCurrent sensor

The application relates to a graphene current sensor comprising a sleeve, an induction wire and a detection circuit, wherein the inner side of the sleeve is used to fix the wire under test; the induction wire is disposed outside the sleeve and is used to generate an induced voltage according to an induced current generated by the wire under test; the detection circuit is electrically connected tothe induction wire and is configured to detect the induced voltage generated by the induction wire, and calculate the current of the wire under test according to a preset mapping relationship betweenthe induced voltage and the current of the wire under test, wherein the induction wire is made of a graphene metal composite material. Using induction wires to detect the current of the wire under test does not produce magnetic saturation and expands the application range of graphene current sensors. In addition, the use of graphene metal composite induction wires can improve the strength and conductivity of traditional metal wires, so that the induction wires have the advantages such as low resistance temperature coefficient, good resistance to heat dissipation, and high sensitivity.

Owner:北京石墨烯技术研究院有限公司

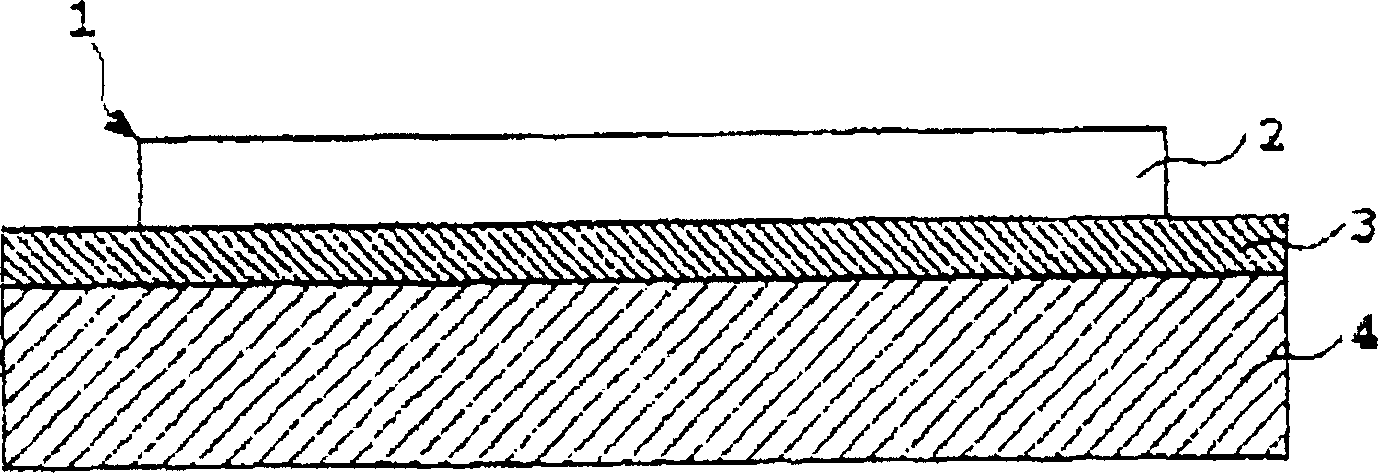

Film resistor structure and method for manufacturing same

ActiveCN101399101AHigh sheet resistanceSmall temperature coefficient of resistanceResistive material coatingNon-adjustable resistorsFilm resistanceComposite film

The invention relates to a film resistor structure which at least comprises a substrate and a composite film resistor which is formed at the substrate. The composite film resistor is formed by mixing semiconductor metal copper or / and nickel oxide which is provided with negative temperature coefficient of resistance (TCR) and conductive metal material which is provided with positive temperature coefficient of resistance in dispersed way. Thus, when the resistance value of a film resistance chip is improved to be larger than 1000 Omega / square area, the value of TCR can still be guaranteed to be less than 200ppm / DEG C effectively.

Owner:IND TECH RES INST +1

Graphene current sensor

ActiveCN110780105BHigh strengthImprove conductivityCurrent/voltage measurementBase element modificationsCurrent sensorElectrical connection

The application relates to a graphene current sensor comprising a sleeve, an induction wire and a detection circuit, wherein the inner side of the sleeve is used to fix the wire under test; the induction wire is disposed outside the sleeve and is used to generate an induced voltage according to an induced current generated by the wire under test; the detection circuit is electrically connected tothe induction wire and is configured to detect the induced voltage generated by the induction wire, and calculate the current of the wire under test according to a preset mapping relationship betweenthe induced voltage and the current of the wire under test, wherein the induction wire is made of a graphene metal composite material. Using induction wires to detect the current of the wire under test does not produce magnetic saturation and expands the application range of graphene current sensors. In addition, the use of graphene metal composite induction wires can improve the strength and conductivity of traditional metal wires, so that the induction wires have the advantages such as low resistance temperature coefficient, good resistance to heat dissipation, and high sensitivity.

Owner:北京石墨烯技术研究院有限公司

Precious metal alloy wire for precision resistance and manufacturing method thereof

ActiveCN110578068BHigh resistivitySmall temperature coefficient of resistanceApparatus for heat treatmentExtrusion control devicesElectrical resistance and conductanceGrain structure

The invention belongs to the field of alloy wire manufacturing, and particularly discloses a precious metal alloy wire for a precision resistor and a manufacturing method thereof. The precious metal alloy wire contains gold, iron, aluminum, ytterbium and palladium, wherein the alloy wire containing the components has the advantages of high resistivity, low resistance temperature coefficient, stable resistance value, small resistance change range, good machining performance and the like; the manufacturing method comprises the steps that firstly, the gold, the iron, the aluminum, the ytterbium and the palladium are prepared and smelted to prepare a precious metal alloy rod; secondly, large deformation machining is carried out on the precious metal alloy rod to prepare a precious metal alloyrough wire, and then heat treatment is carried out on the precious metal alloy rough wire; and then wire drawing preparation, online heat treatment and fine machining are carried out to prepare a finished product of the precious metal alloy wire. The manufacturing method ensures the stability of the alloy components, and avoids the defects such as segregation, a transgranular structure, loosening,air holes generated in a traditional casting mode; and the large deformation machining ensures that the internal crystal grains are refined uniformly, the heat treatment enables alloy elements to befurther separated out, the internal crystal grain structure is stabilized, and the resistivity of the precious metal alloy wire is increased.

Owner:JIAOZUO UNIV +2

Resistor

InactiveCN1256736CImprove adhesionReduce thermal resistanceSolid-state devicesResistor cooling/heating/ventillationNickelDielectric strength

Provides a high precision current sensing resistor whose resistance does not change significantly with temperature. In this type of resistor, a resistance alloy plate and a heat-dissipating metal plate are laminated with a resin insulating layer. The resistance alloy plate is formed of an alloy containing nickel and copper. After etching the grain boundaries of the alloy into a concave shape, the resistance alloy plate is adhered to the resin. on the insulating layer.

Owner:FUJI ELECTRIC CO LTD

New type alloy material

InactiveCN1760391AImprove mechanical propertiesSmall temperature coefficient of resistanceCorrosionHigh resistance

An au-alloy is prepared from Pd (1-3 mass %), Gd (0.2-0.6) and Au (rest). Its advantages are the improved elasticity and yield point, low resistance temp coefficient, high recrystallizing temp, and high resistance to creep, electric corrosion and abrasion.

Owner:SINO PLATINUM METALS CO LTD

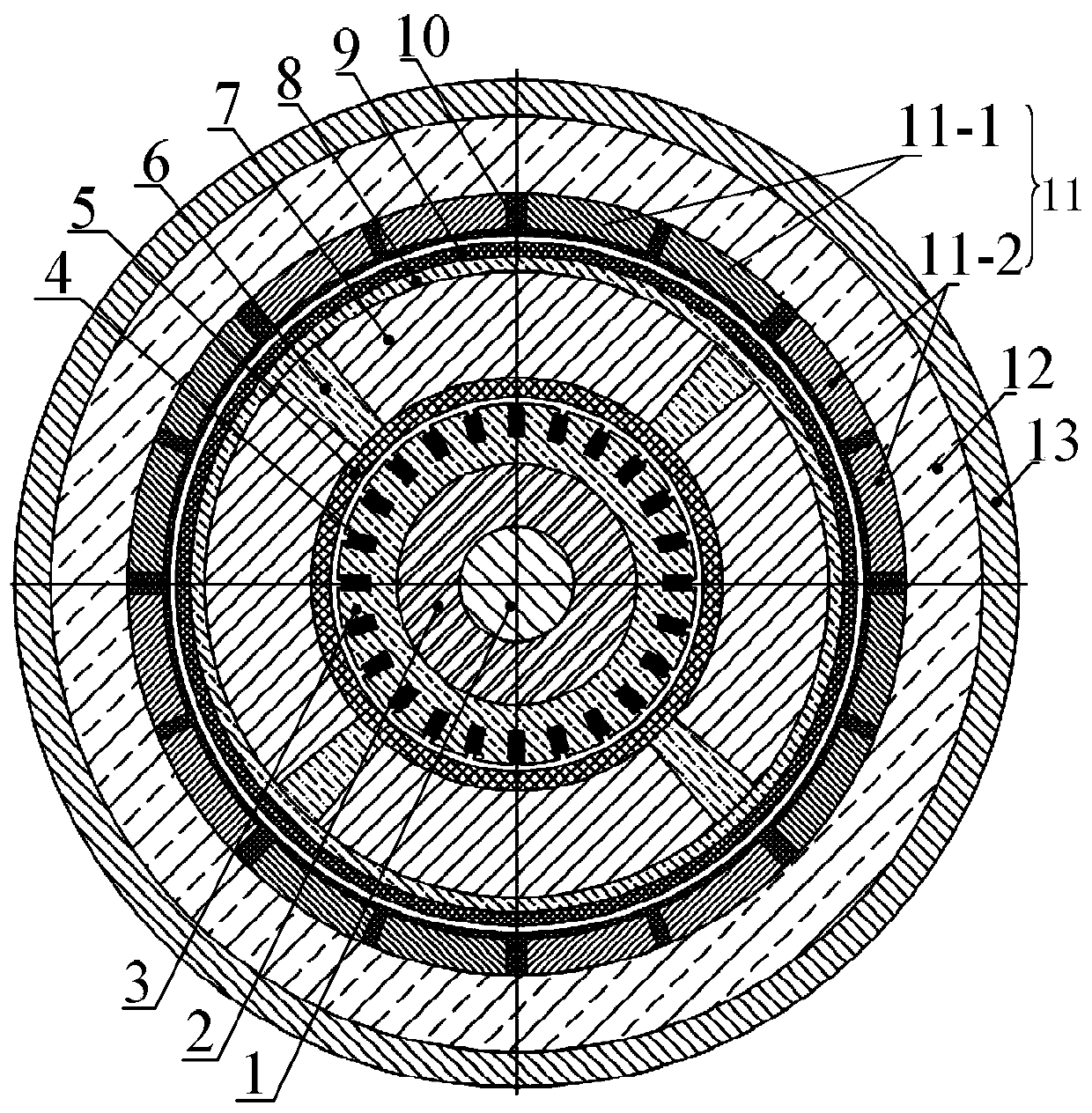

Radial coaxial integrated high-power-density inertia energy storage pulse power supply system

ActiveCN110729871AConducive to high-speed operationReduce volumeMagnetic circuit rotating partsAC/DC convertorsCopper wireCarbon nanotube

A radial coaxial integrated high-power-density inertia energy storage pulse power supply system relates to the technical field of inertia energy storage pulse power supplies. The invention aims to solve the problem that an existing traditional inertia energy storage pulse power supply system has large axial length, high mechanical noise, low power density and poor reliability due to the fact thata prime motor and a pulse generator are mechanically connected through a coupling and to solve the problem that the armature windings of the traditional system are made of copper wires and will be damaged due to the generation of a transient high current during discharging. An inner stator, a rotor and an outer stator are coaxially nested from inside to outside, an air gap exists between the innerstator and the rotor, and an air gap exists between the outer stator and the rotor. A motor armature winding and a generator armature winding are both made of copper-based carbon nanotube wires. Theradial coaxial integrated high-power-density inertia energy storage pulse power supply system is used as a pulse power supply.

Owner:HARBIN INST OF TECH

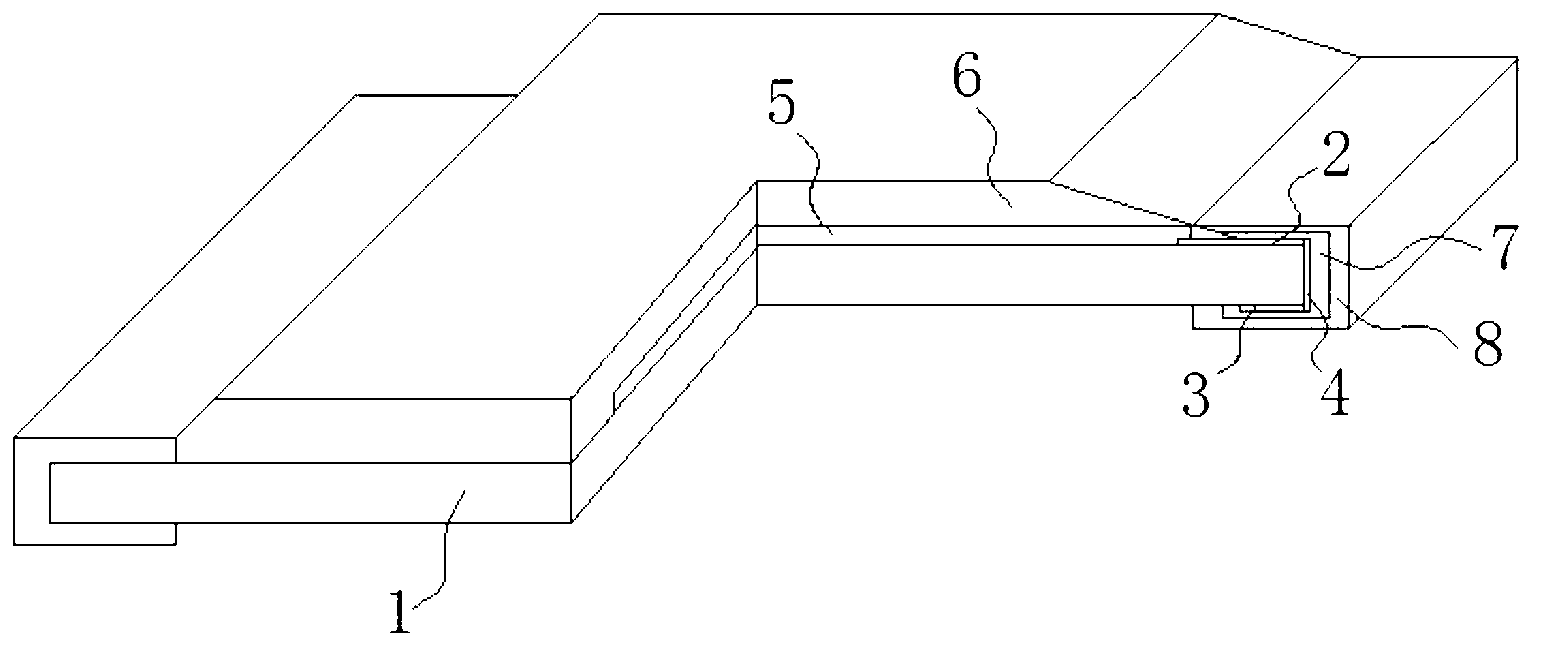

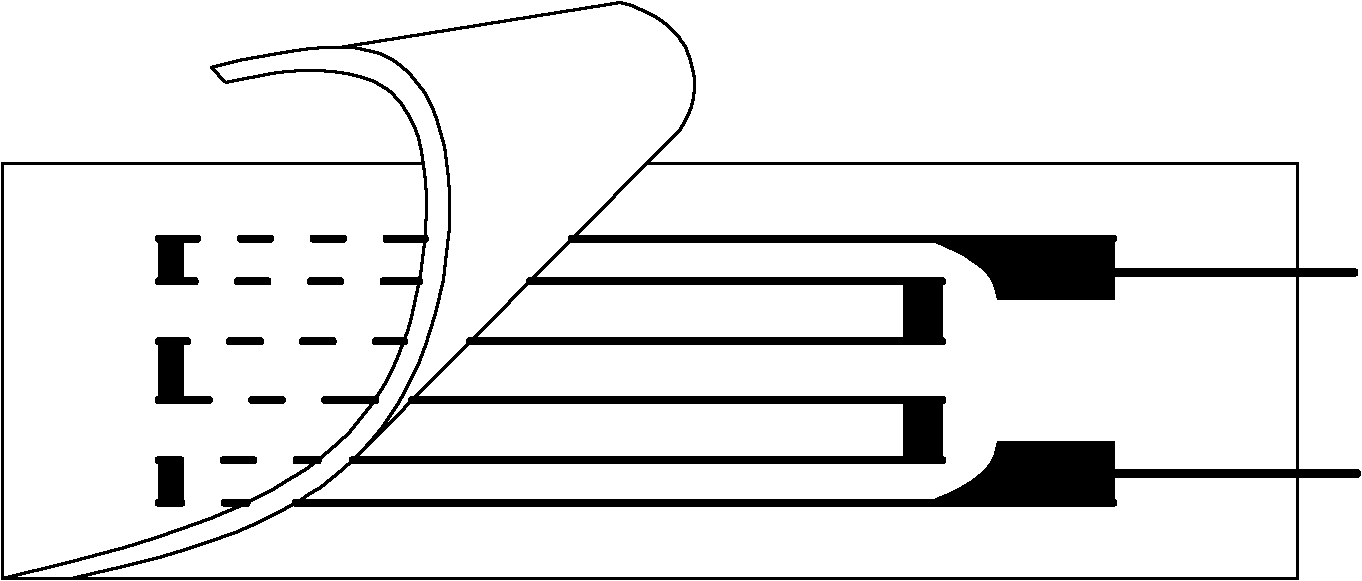

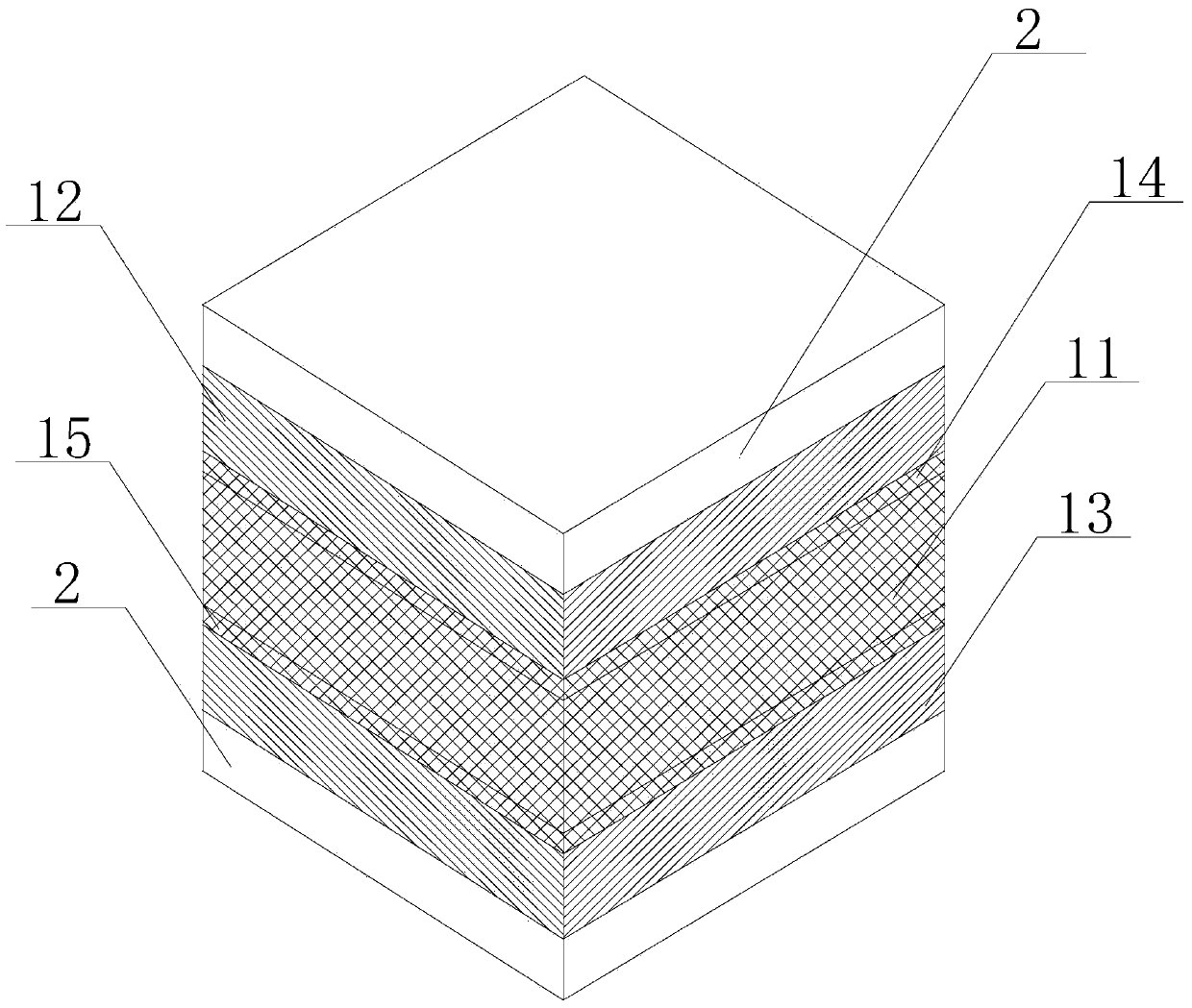

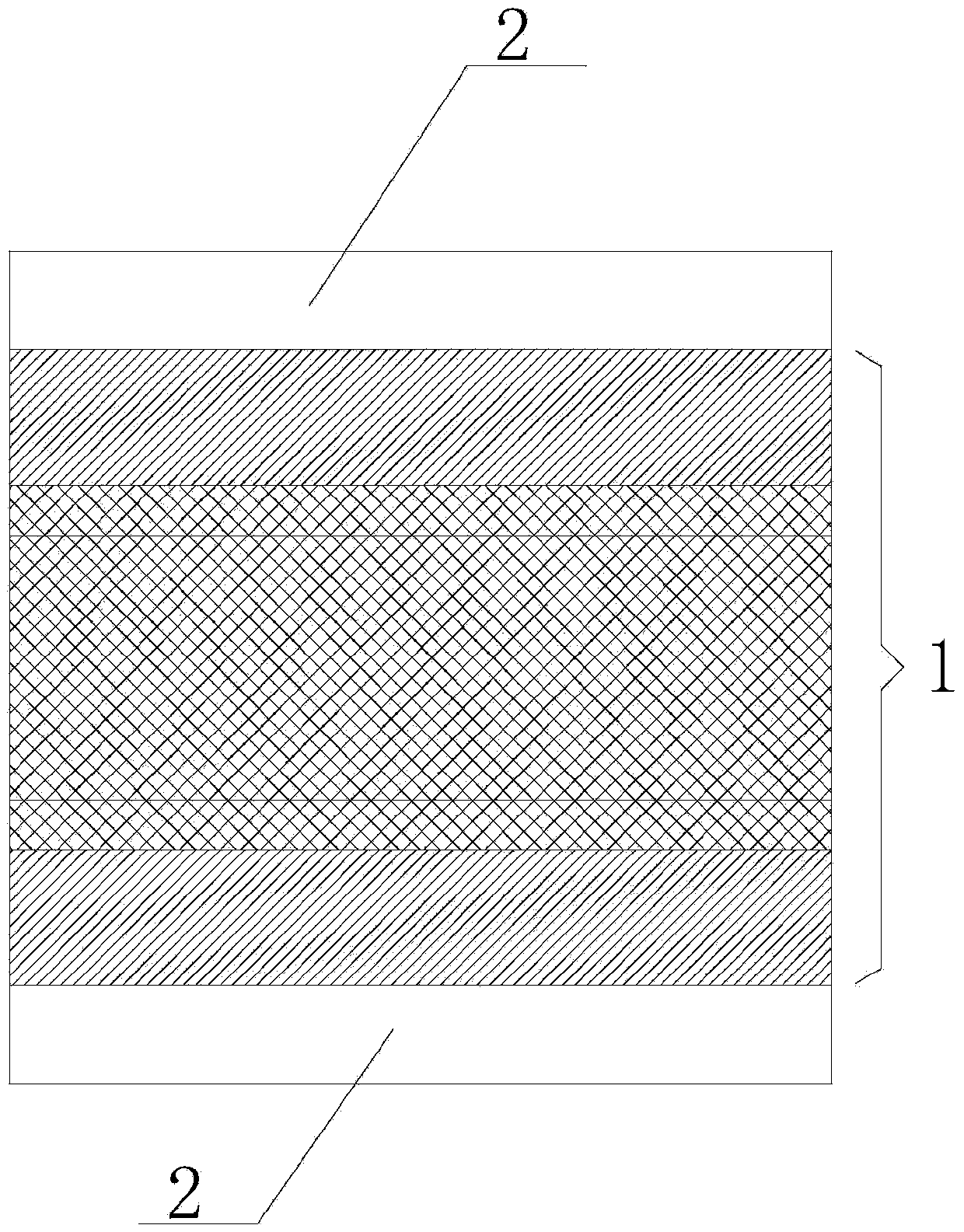

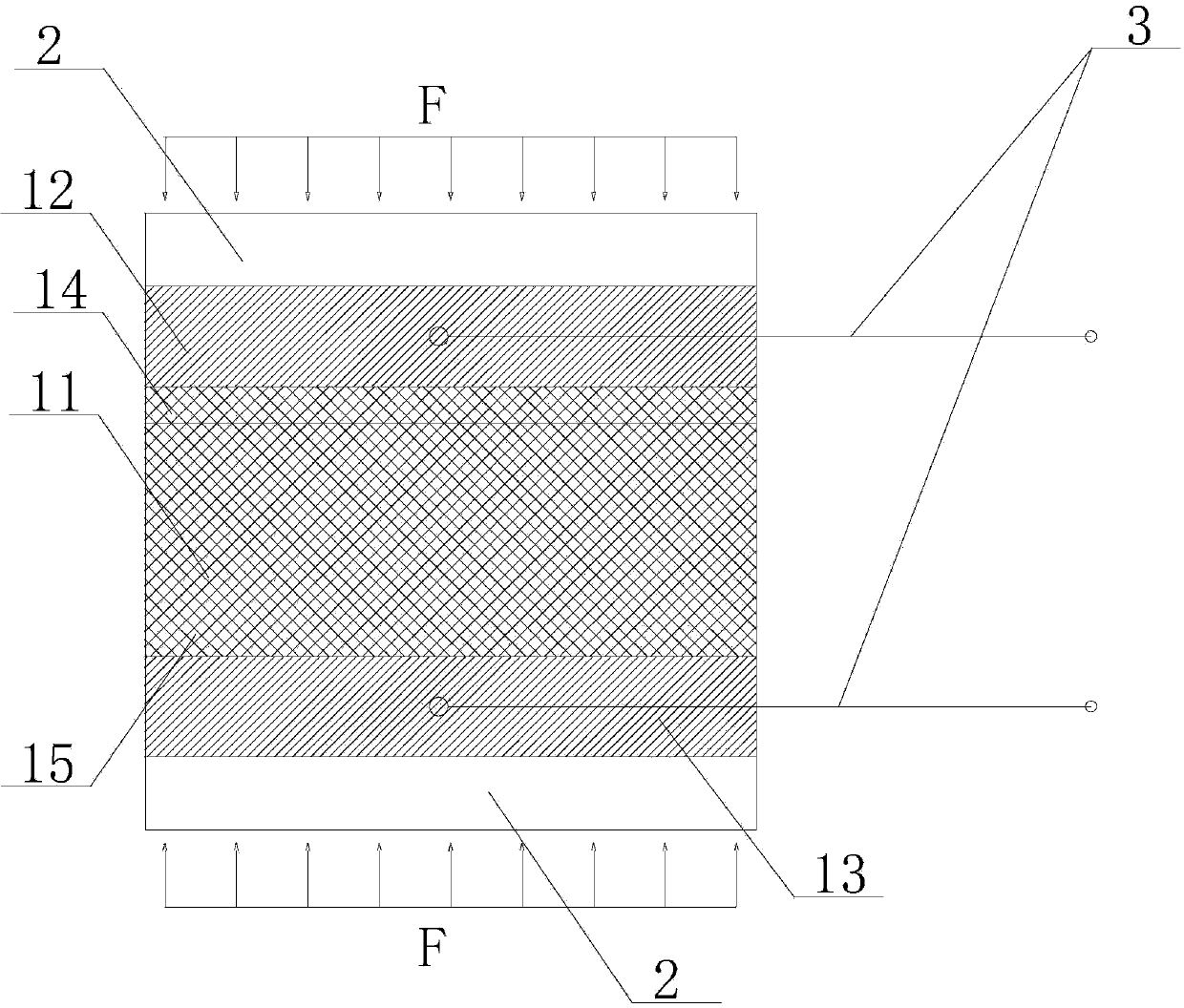

Embedded type thick-film resistor strain sensor and manufacturing method of embedded type thick-film resistor strain sensor

InactiveCN104006735AHigh sensitivitySmall temperature coefficient of resistanceElectrical/magnetic solid deformation measurementMechanical engineeringStrain sensor

The invention discloses an embedded type thick-film resistor strain sensor which is used for internal strain monitoring of a concrete structure. The embedded type thick-film resistor strain sensor comprises a stone substrate, a thick-film resistor area, a first electric conduction electrode area and a second electric conduction electrode area, wherein the thick-film resistor area is arranged on the lateral surface of the stone substrate, the first electric conduction electrode area is arranged on the lateral surface of the stone substrate and connected to one end of the thick-film resistor area, the second electric conduction electrode area is arranged on the lateral surface of the stone substrate and connected to the other end of the thick-film resistor area relative to the first electric conduction electrode area, a resistor electrode assembly is jointly formed by the second electric conduction electrode area, the first electric conduction electrode area and the thick-film resistor area, and wires are connected to the second electric conduction electrode area and the first electric conduction electrode area respectively. In addition, the invention further discloses a manufacturing method of the sensor. The embedded type thick-film resistor strain sensor has the advantages of being high in sensitivity, good in concrete matching performance, good in stability and good in durability.

Owner:ZHIXING S&T

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com