Patents

Literature

57 results about "Spinodal decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

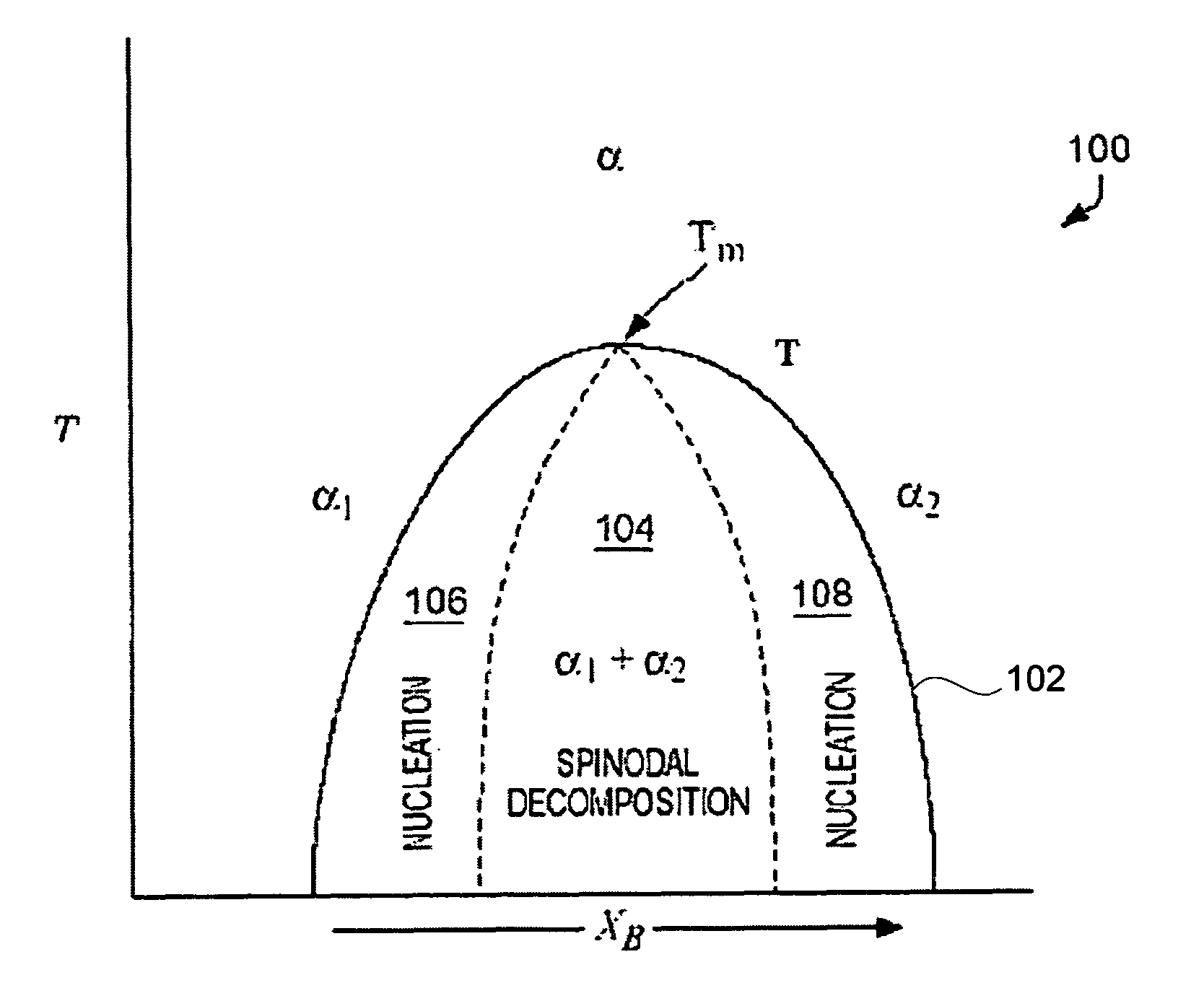

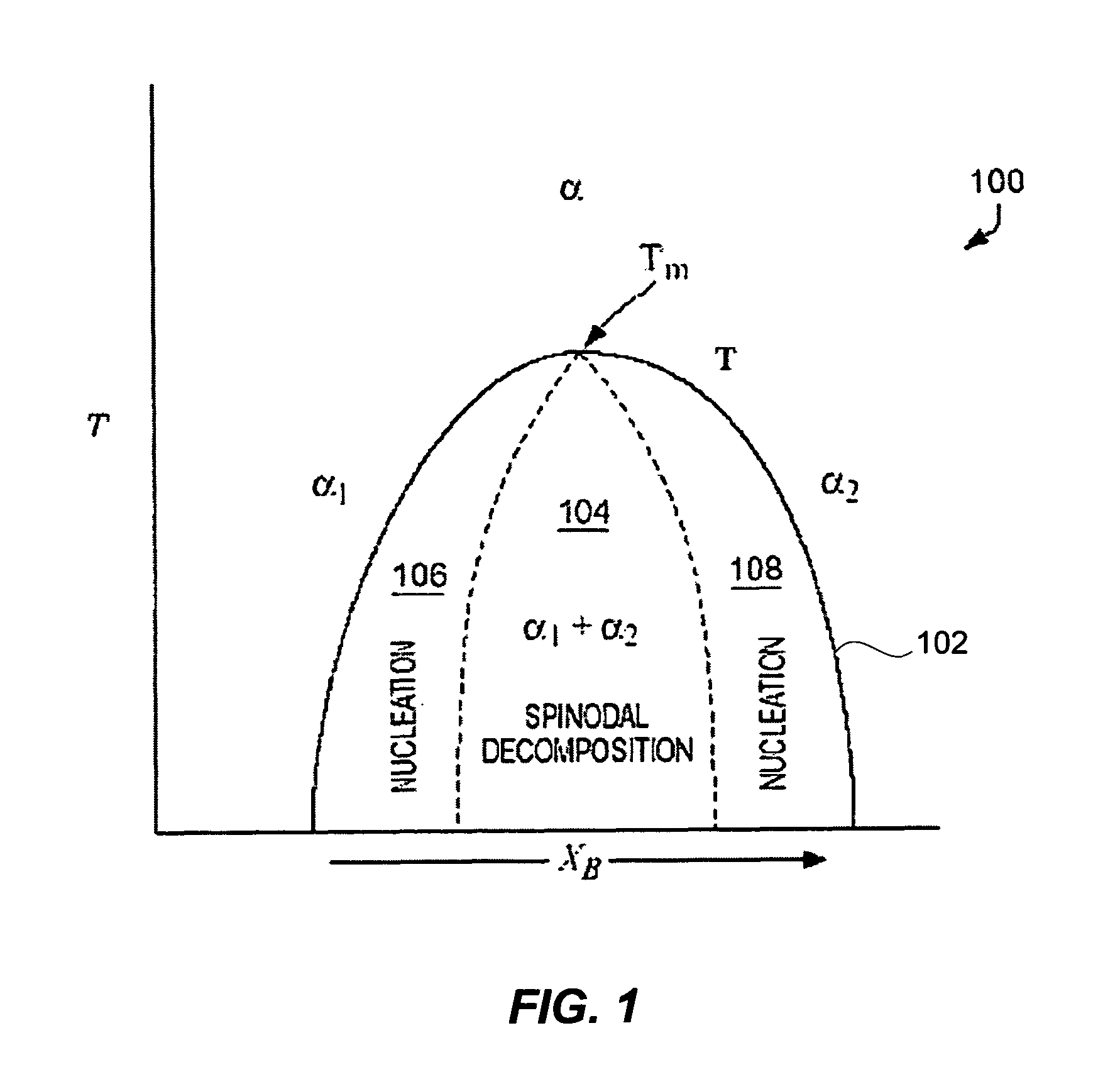

Spinodal decomposition is a mechanism for the rapid unmixing of a mixture of liquids or solids from one thermodynamic phase to form two coexisting phases. As an example, consider a hot mixture of water and an oil. At high temperatures the oil and the water may mix to form a single thermodynamic phase in which water molecules are surrounded by oil molecules and vice versa. The mixture is then suddenly cooled to a temperature at which thermodynamic equilibrium favours an oil-rich phase coexisting with a water-rich phase. Spinodal decomposition then occurs when the mixture is such that there is essentially no barrier to nucleation of the new oil-rich and water-rich phases. In other words, the oil and water molecules immediately start to cluster together into microscopic water-rich and oil-rich clusters throughout the liquid. These clusters then rapidly grow and coalesce until there is a single macroscopic oil-rich cluster, the oil-rich phase, and a single water-rich cluster, the water-rich phase.

Low-k dielectric material system for IC application

InactiveUS20050200025A1Reduced characteristicsHigh levelSemiconductor/solid-state device detailsSolid-state devicesSilicate glassPhysical separation

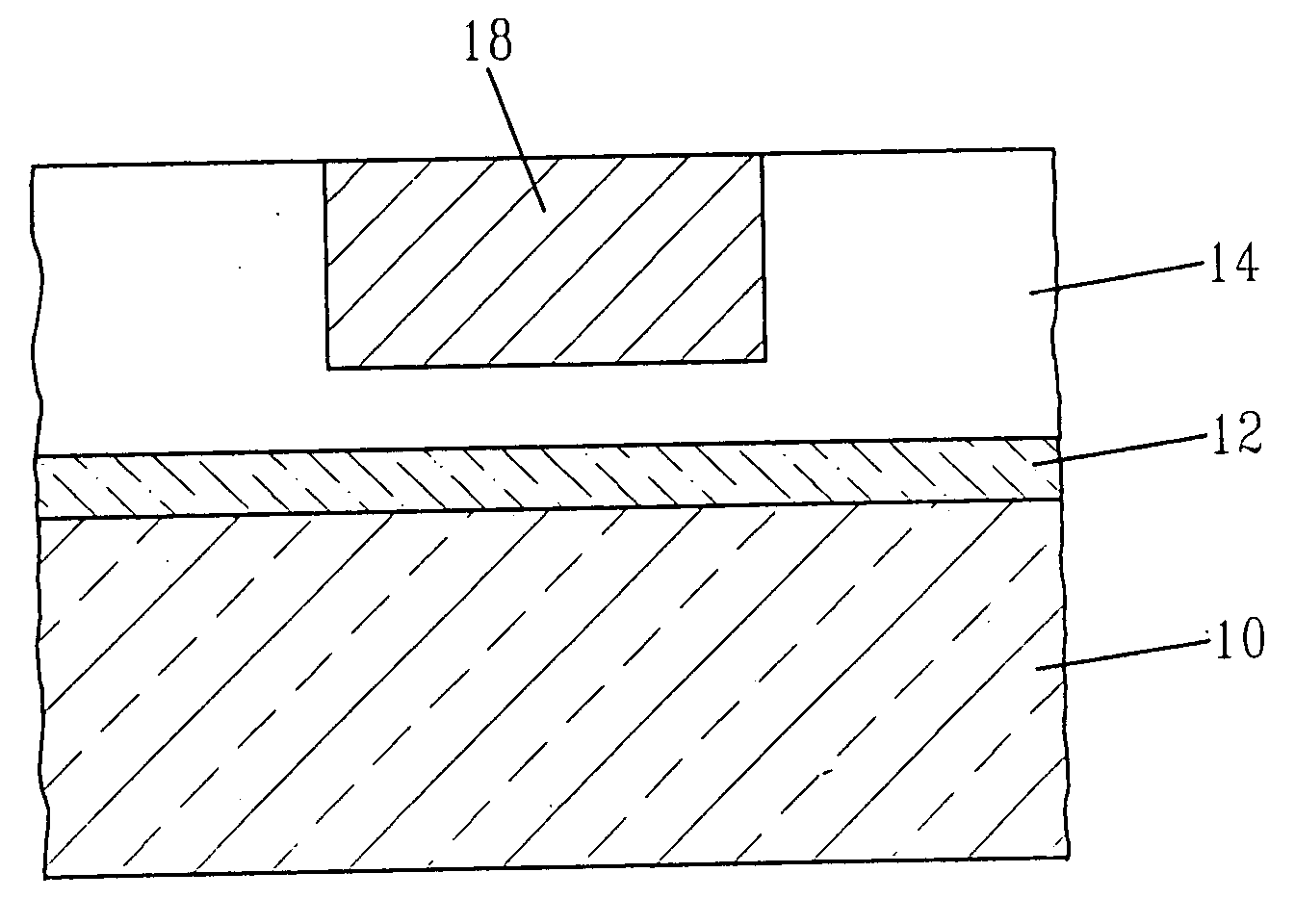

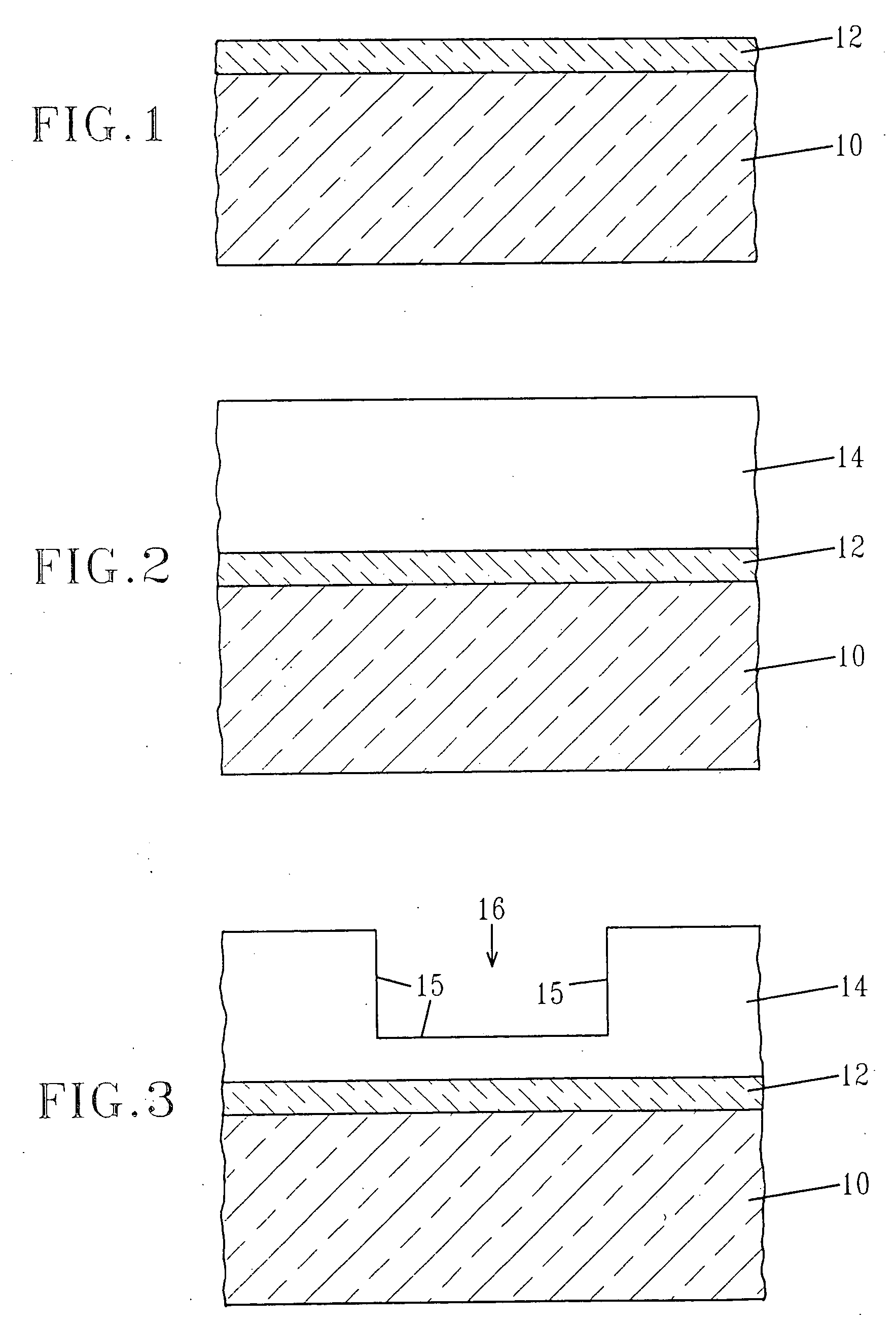

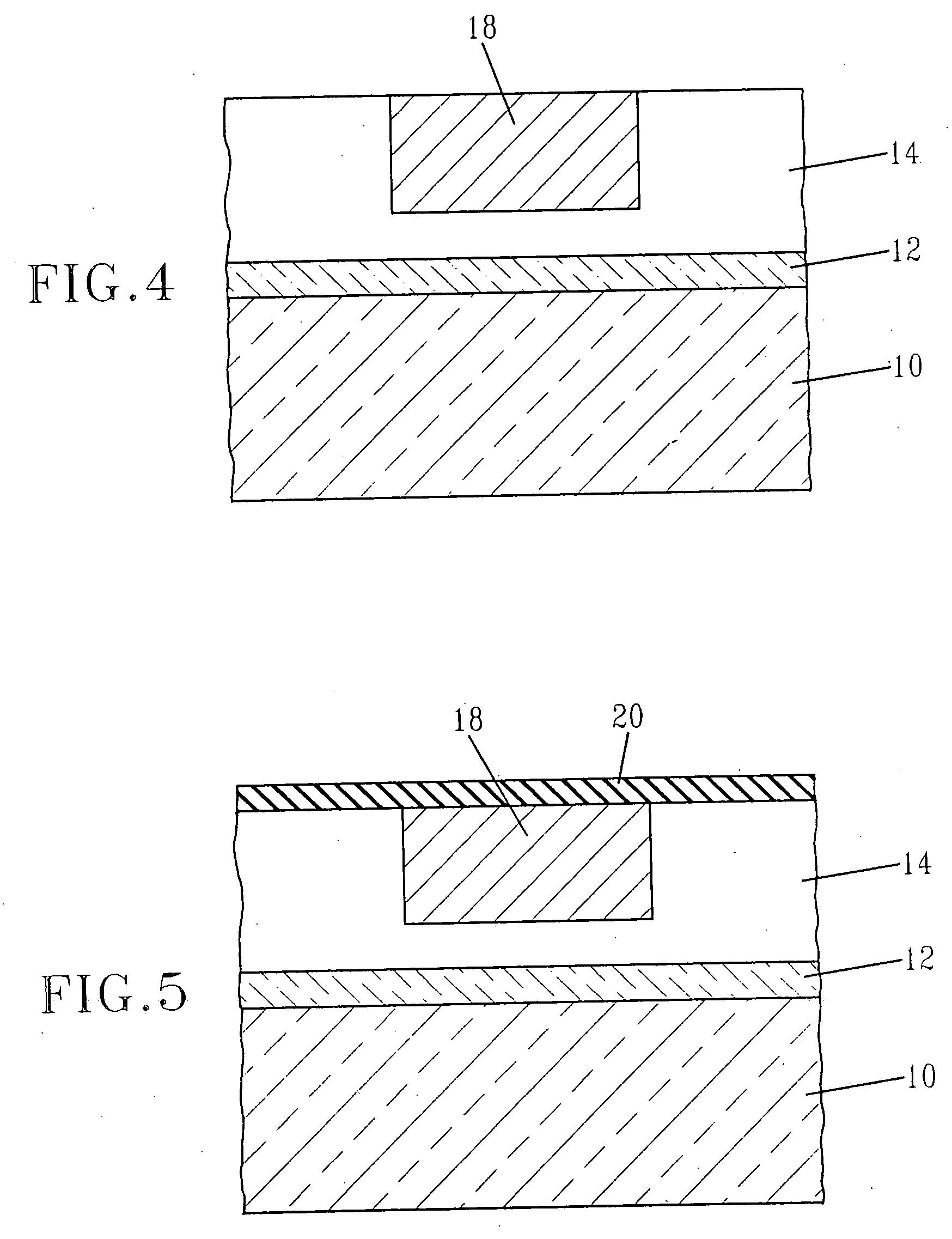

A low-k dielectric for use as an interlayer for an interconnect structure is provided. The dielectric of the present invention is an alkaline boron silicate glass which when formulated in certain compositional ranges can undergo spinodal decomposition when processed using certain thermal profiles. Spinodal decomposition is a chemical and physical separation of the silicate glass into a distinct interpenetrating microstructure which contains a substantially pure silicon dioxide network and a boron-rich network. The dimension (i.e., scale), and the amount of separation can be controlled through compositional and thermal control during the processing of the silicate glass.

Owner:GLOBALFOUNDRIES U S INC

Anti-glare film

InactiveUS7128428B2High anti-glareAvoid reflectionsLiquid crystal compositionsDiffusing elementsDisplay deviceRefractive index

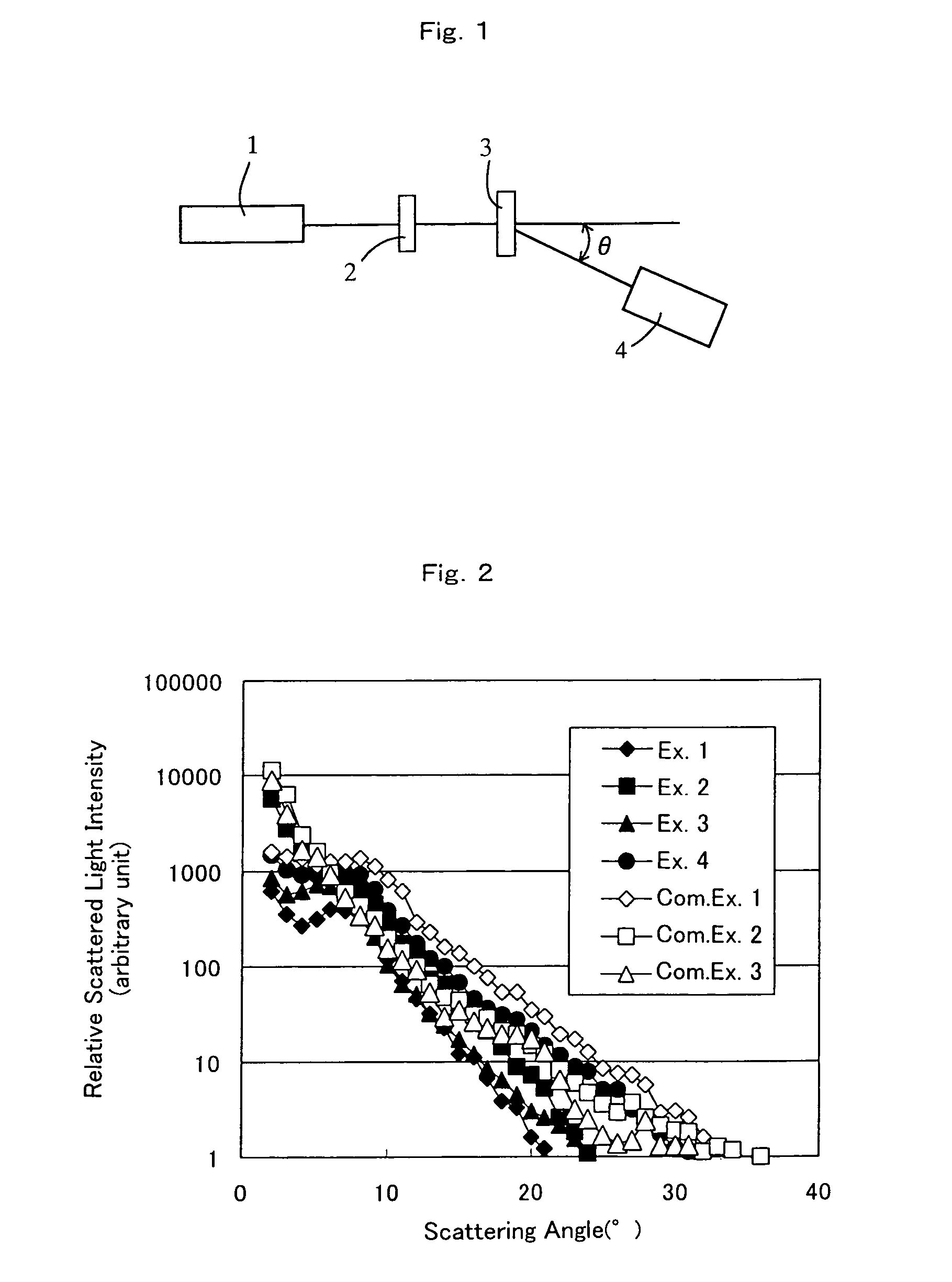

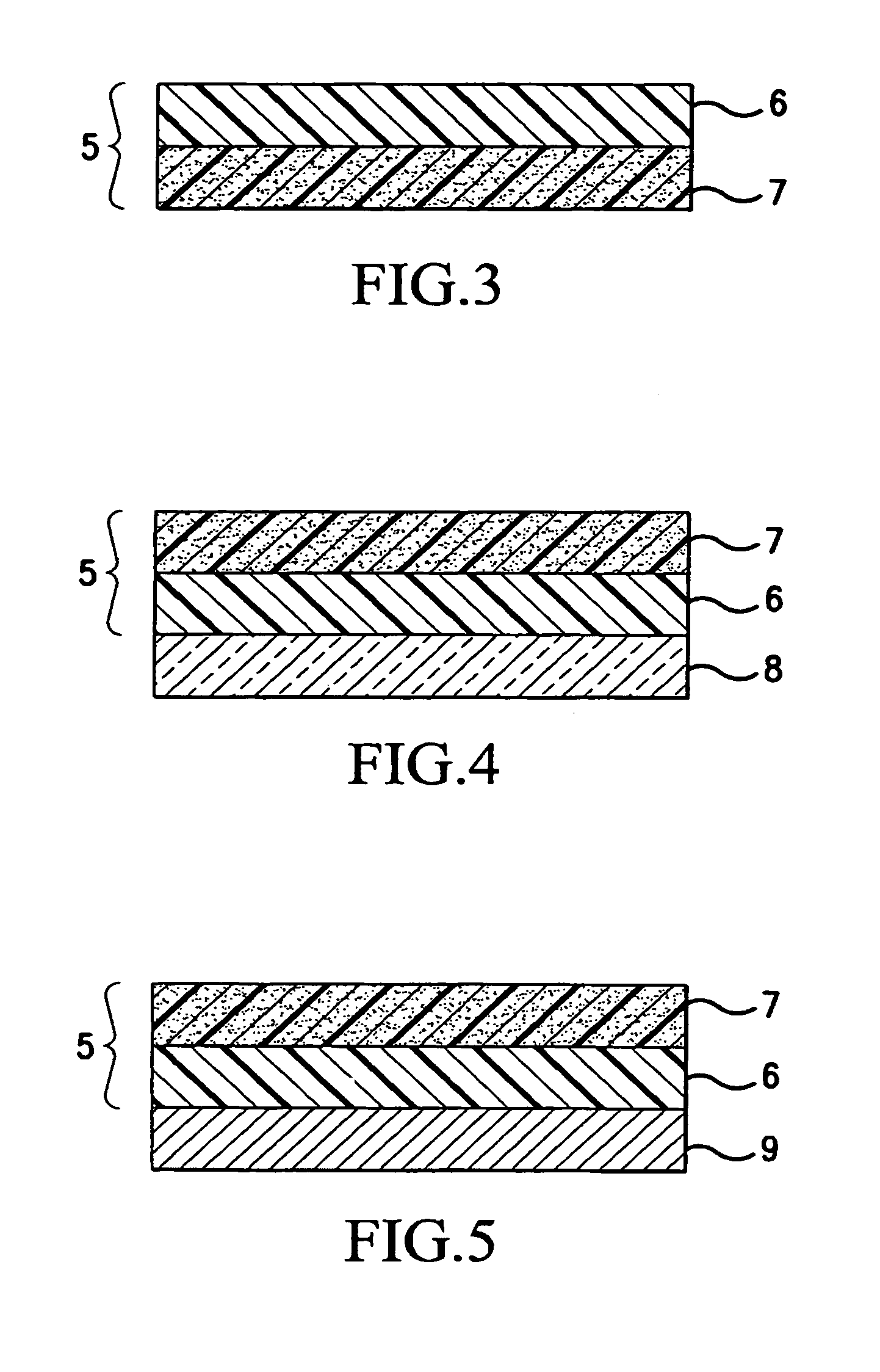

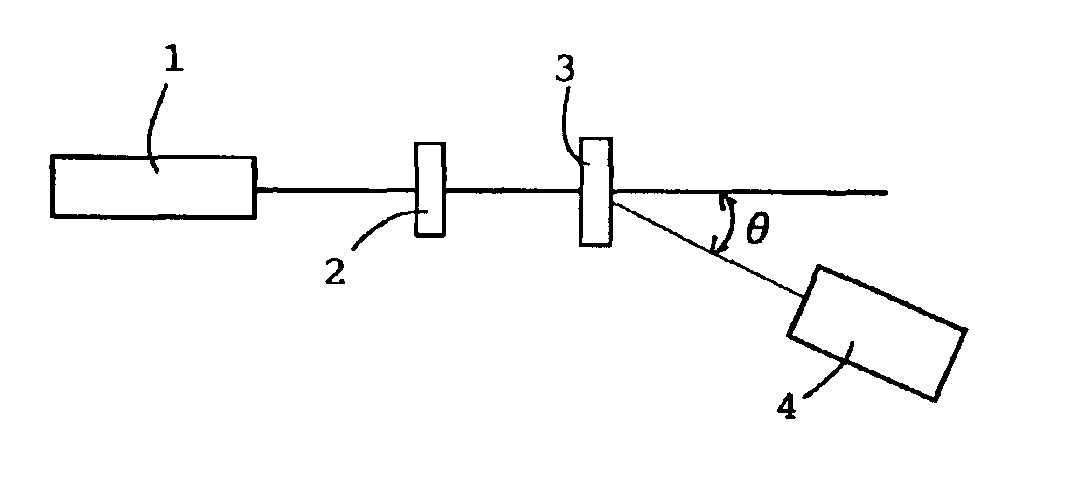

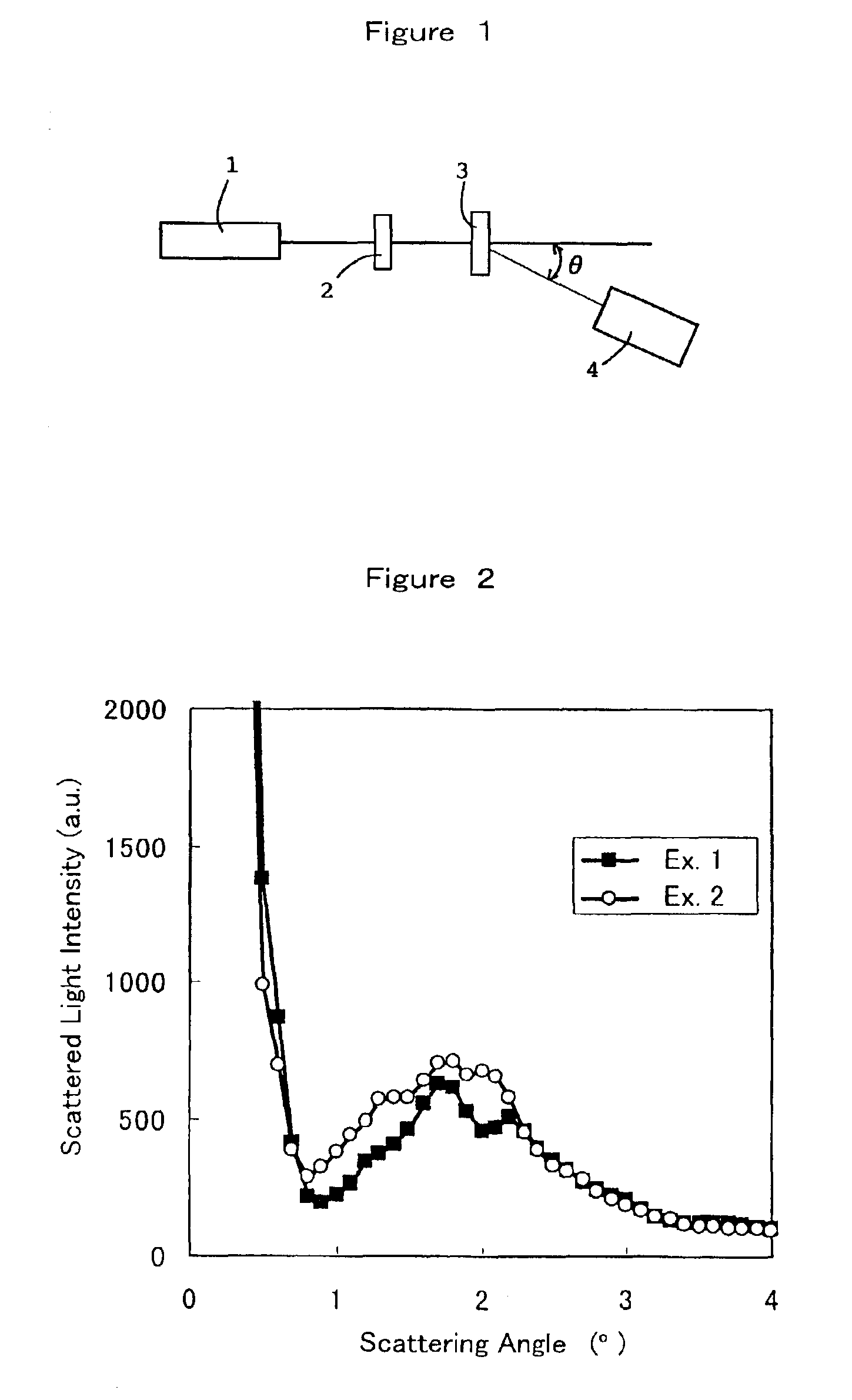

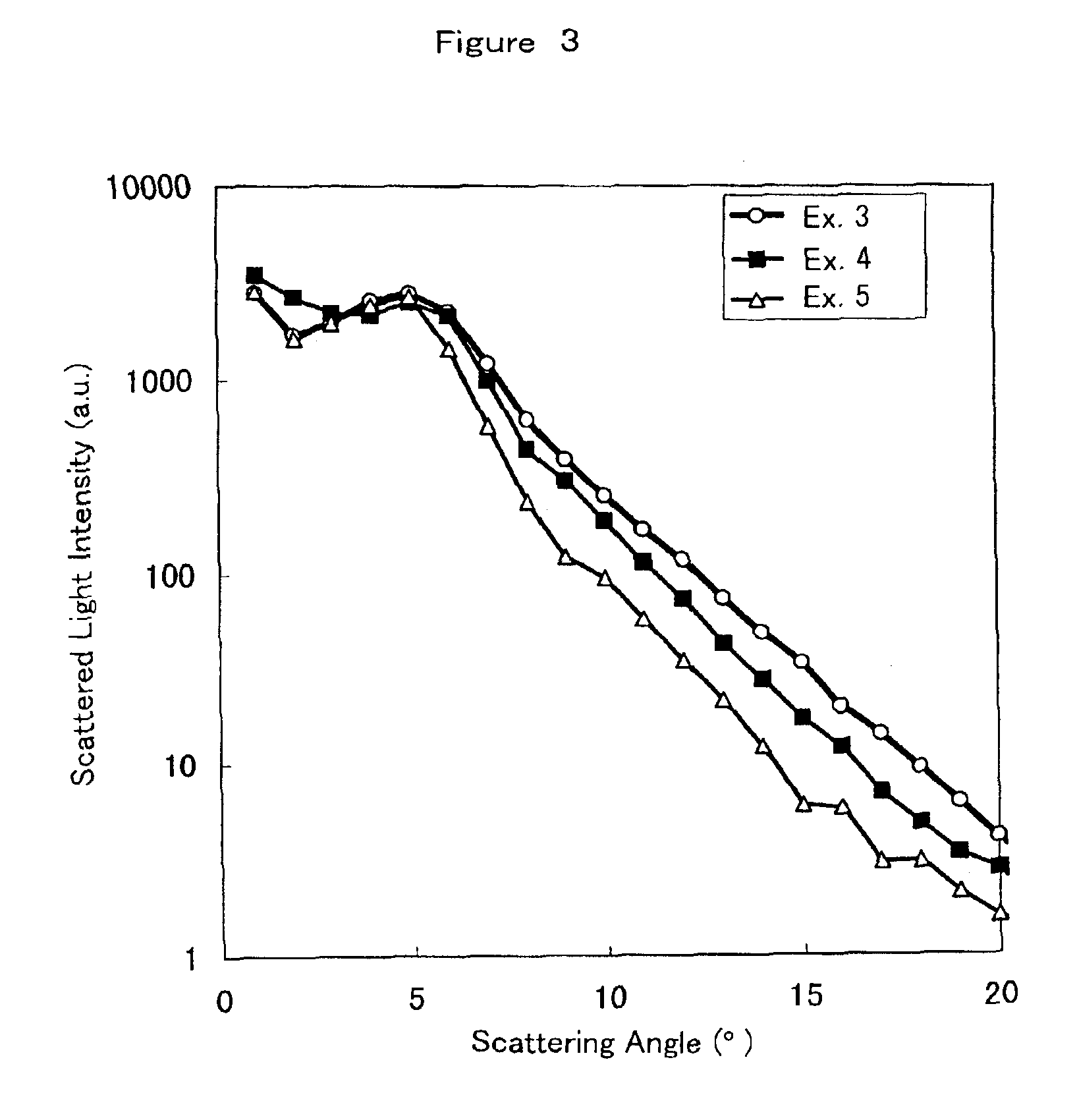

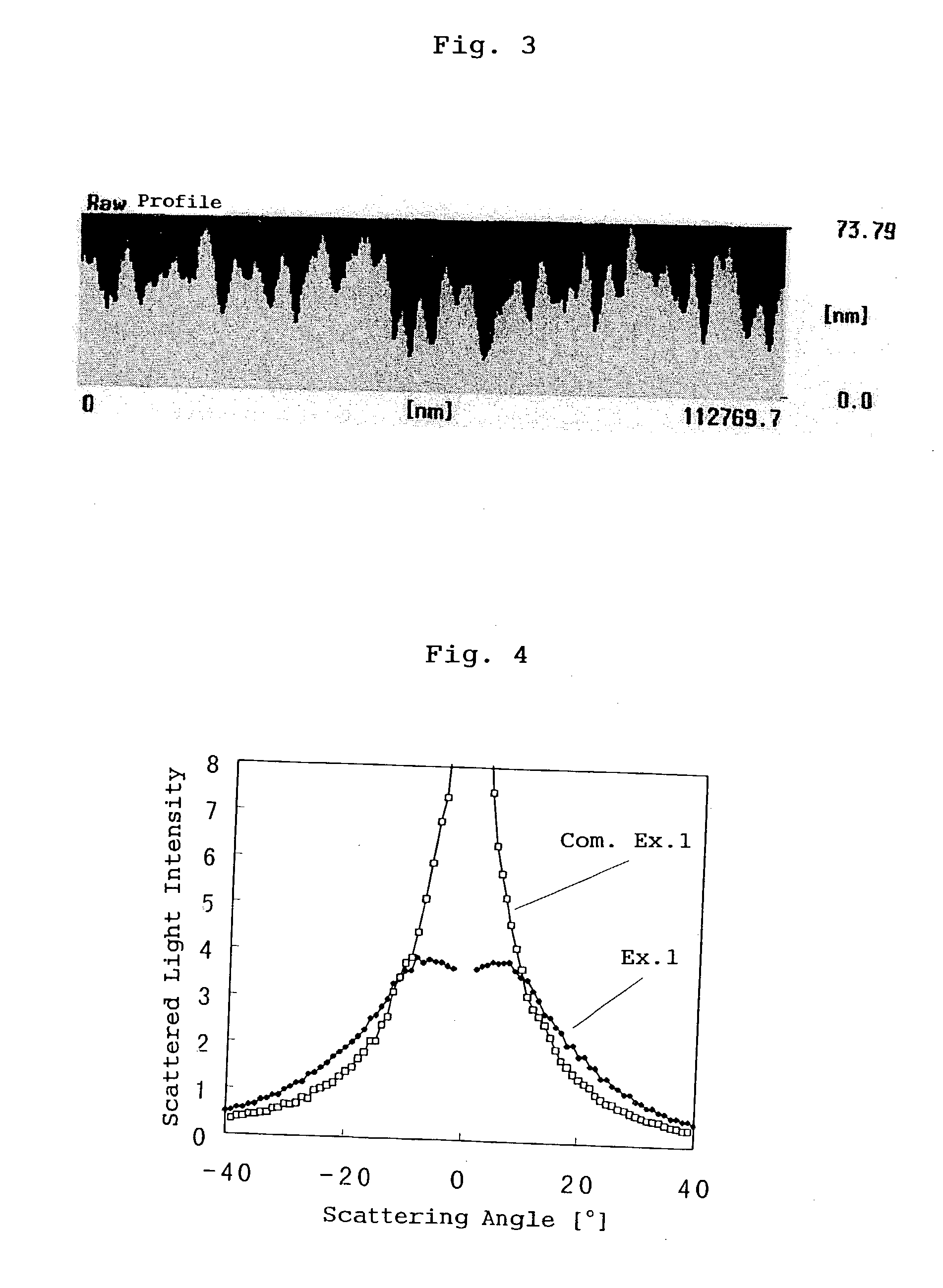

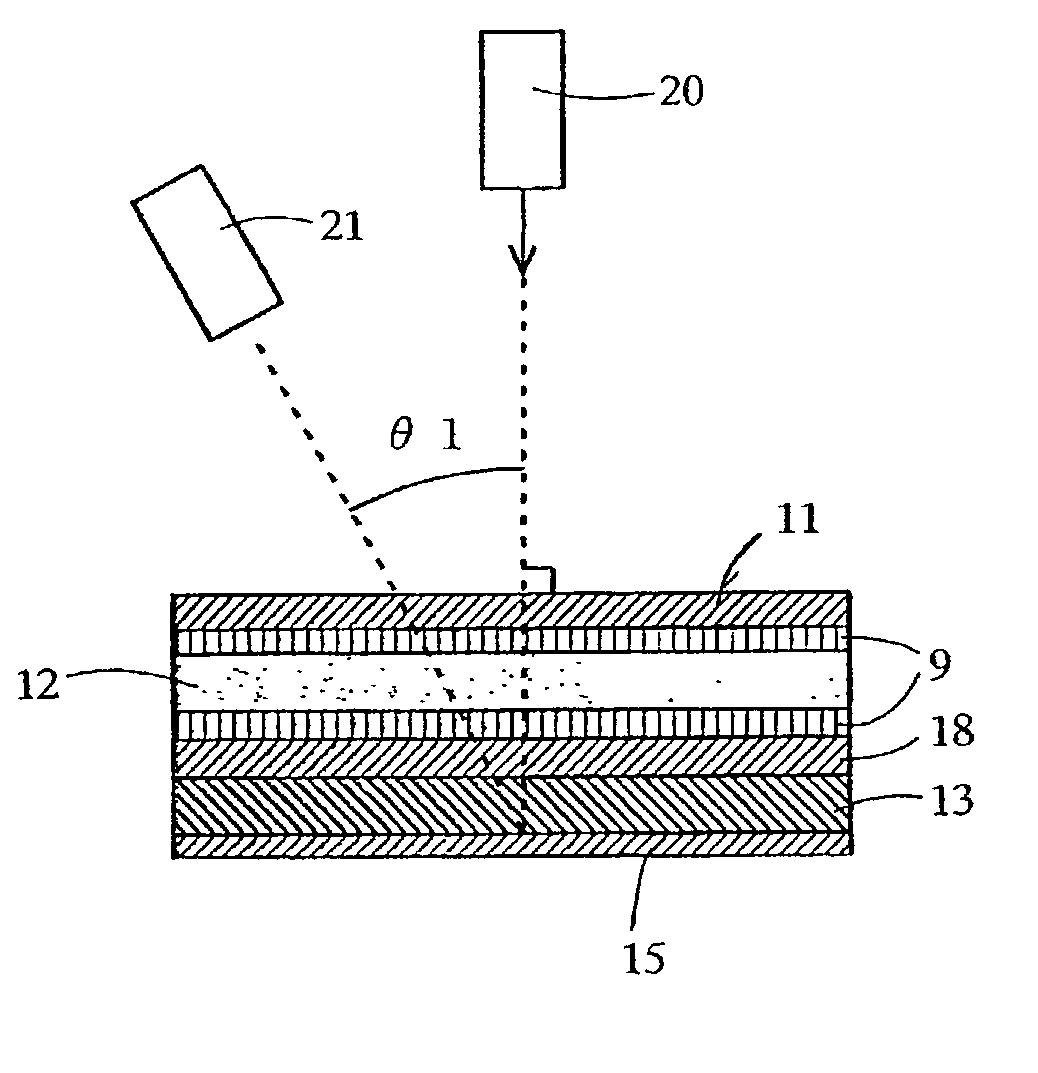

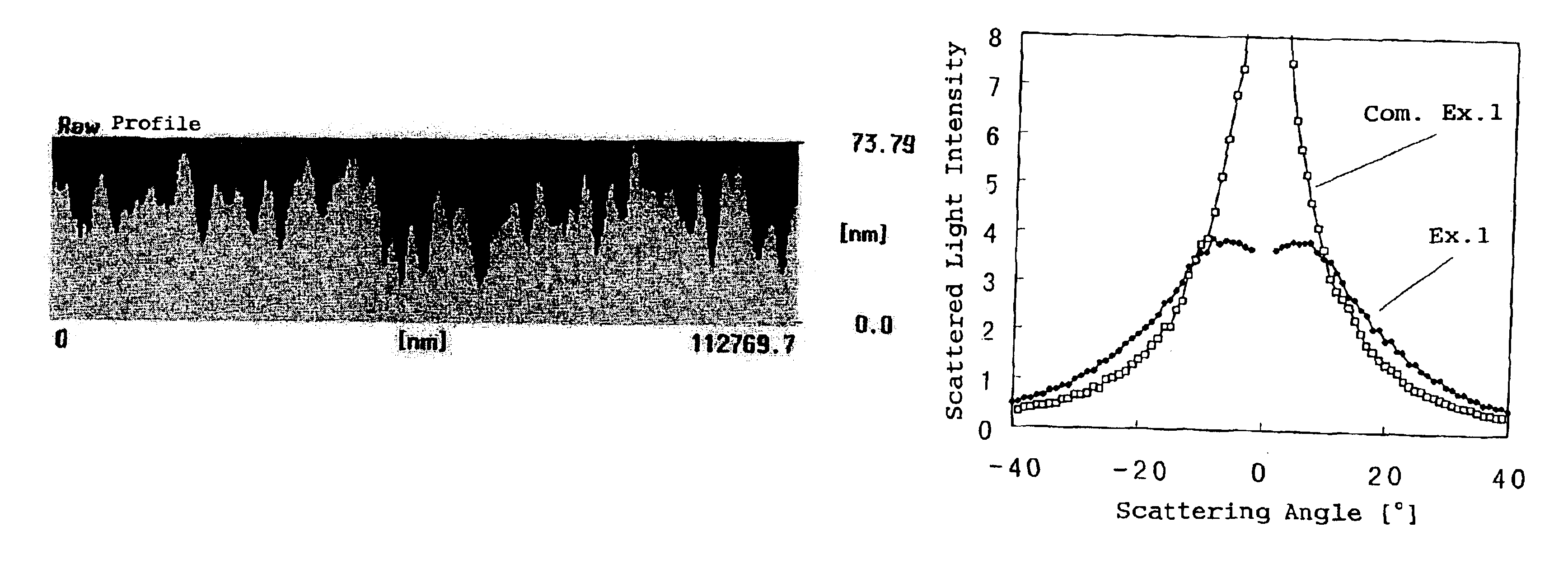

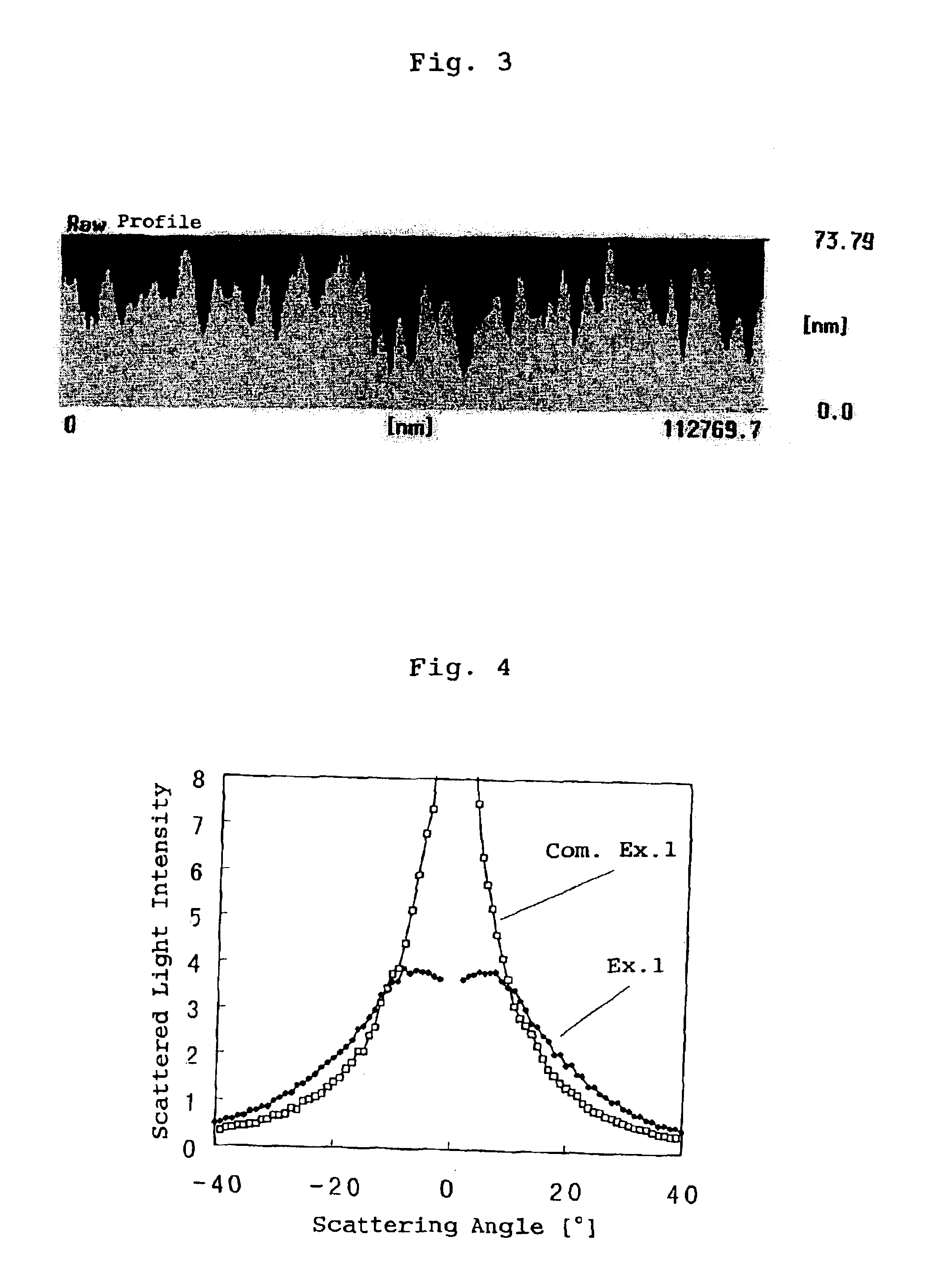

An anti-glare film is obtained by forming a resin layer having a low refraction index on an anti-glare layer is obtained by coating a transparent plastic film with a liquid composition containing a polymer, a curable resin precursor, and a solvent, evaporating the solvent, forming a phase separation structure by spinodal decomposition, and curing the precursor with light irradiation. The anti-glare film has an uneven surface structure in the anti-glare layer, isotropically transmits and scatters an incident light to show the maximum value of the scattered light intensity at a scattering angle of 0.–10°, and has a total light transmittance of 70–100%. The film prevents dazzle or blur of images on a display surface, and reflection of a surrounding scenery, and improves contrast with reducing whitening of the display, even in a high definition display apparatus.

Owner:DAICEL CHEM IND LTD

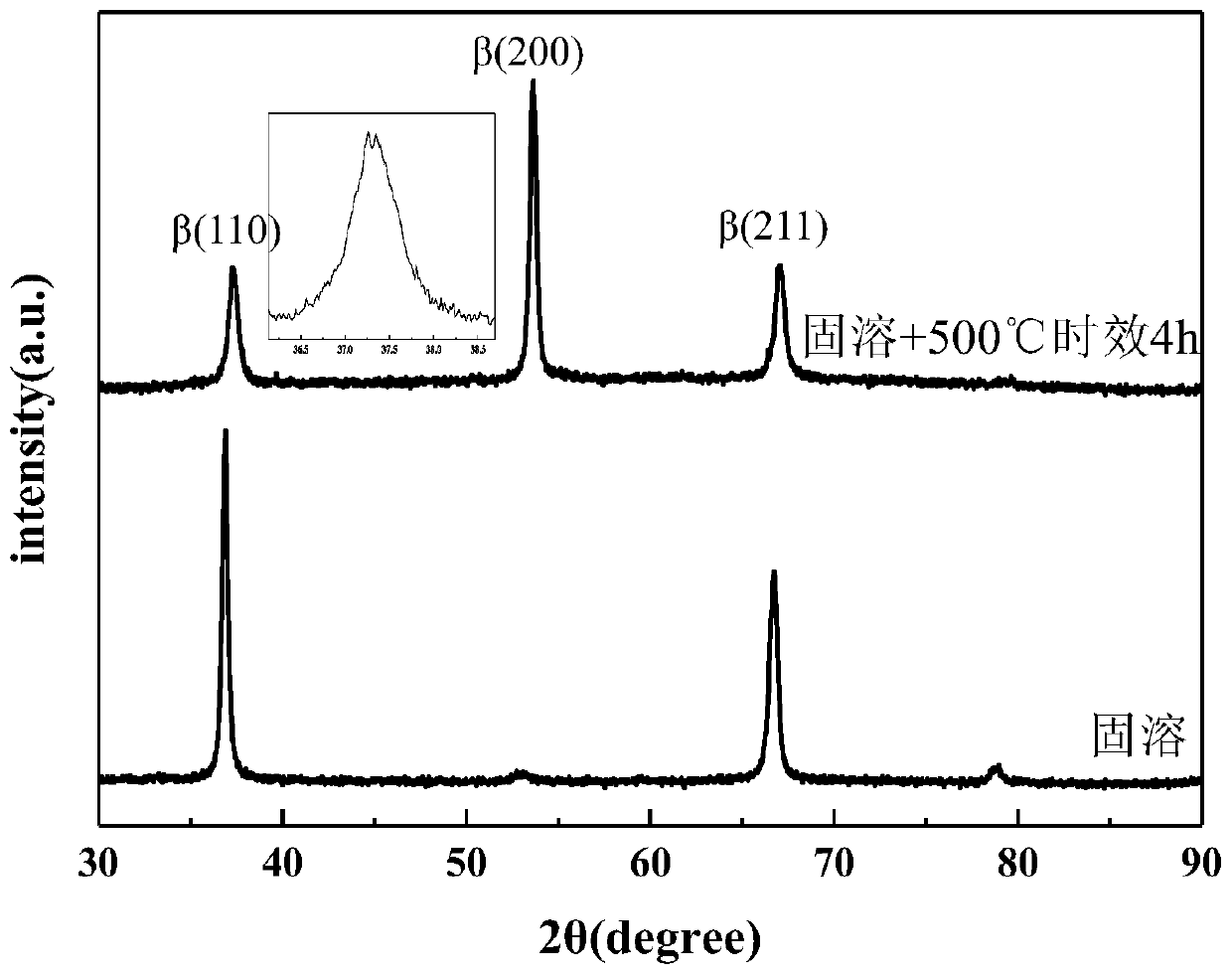

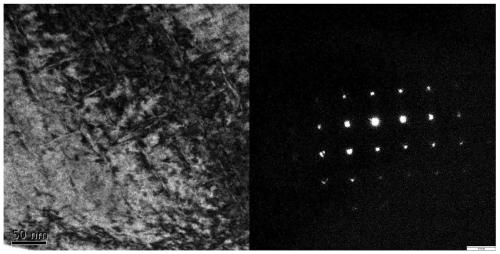

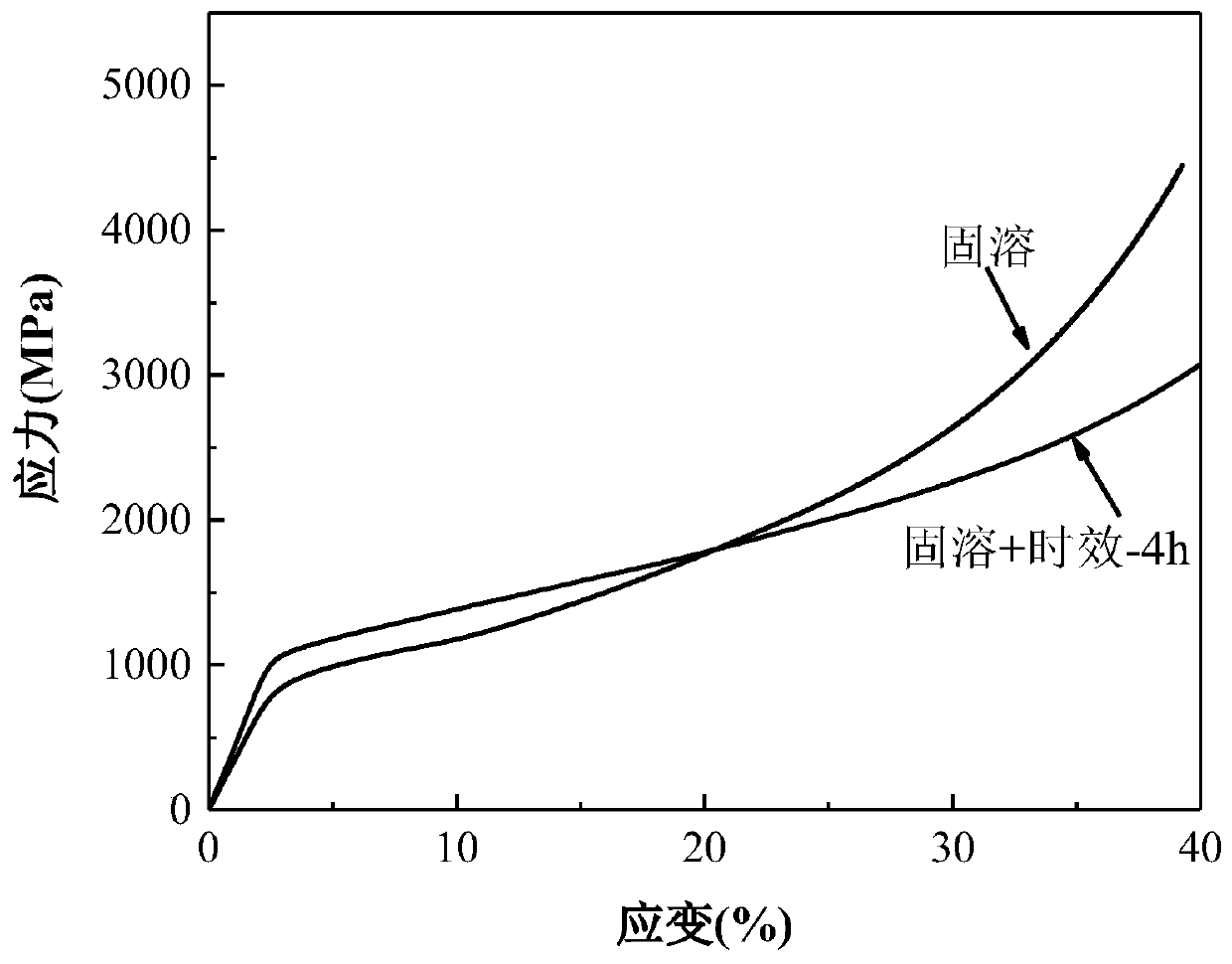

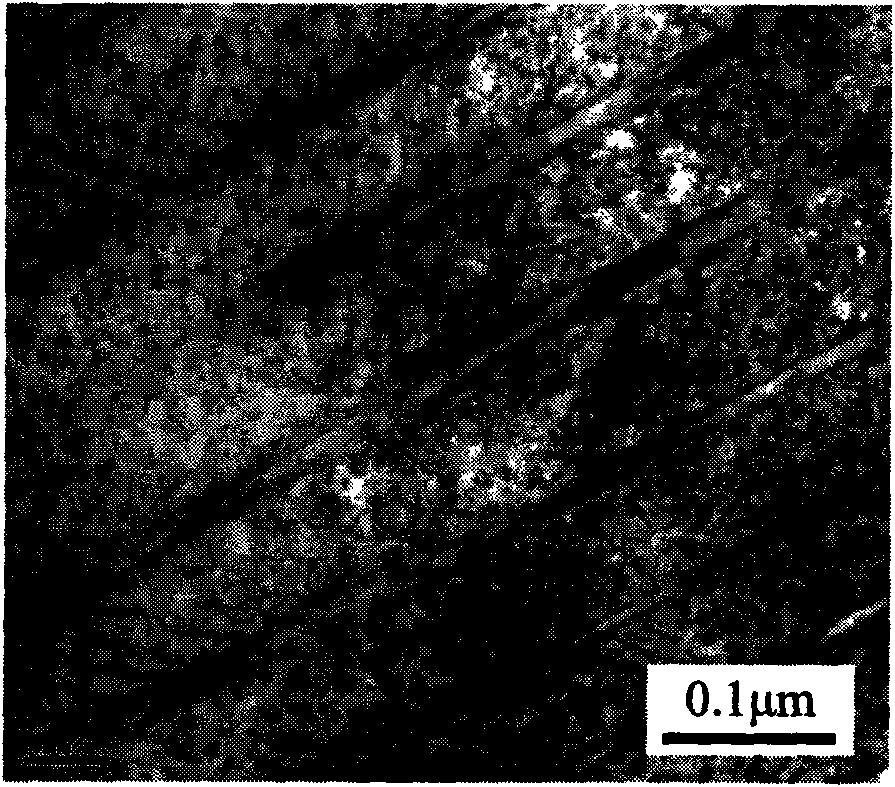

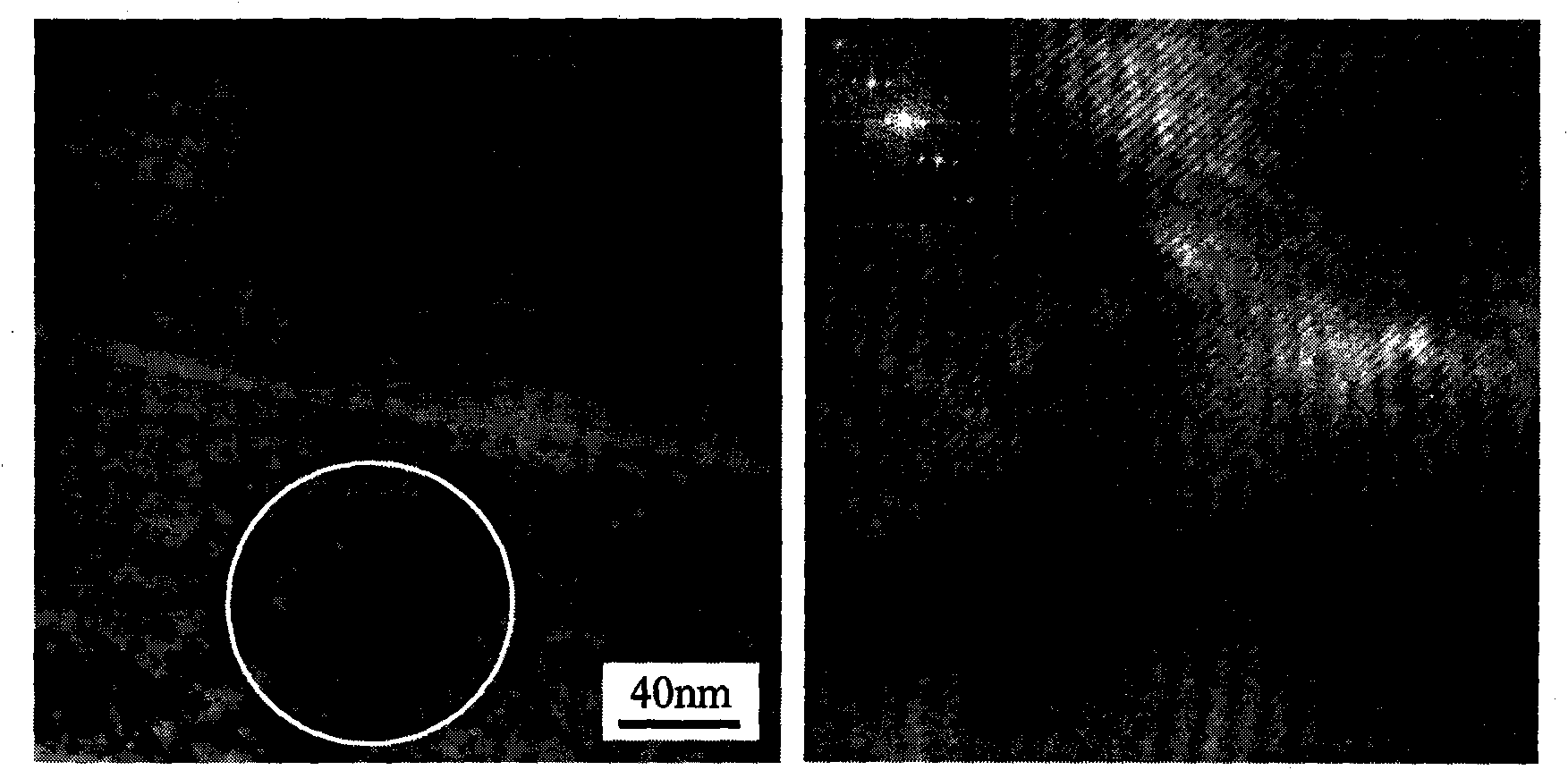

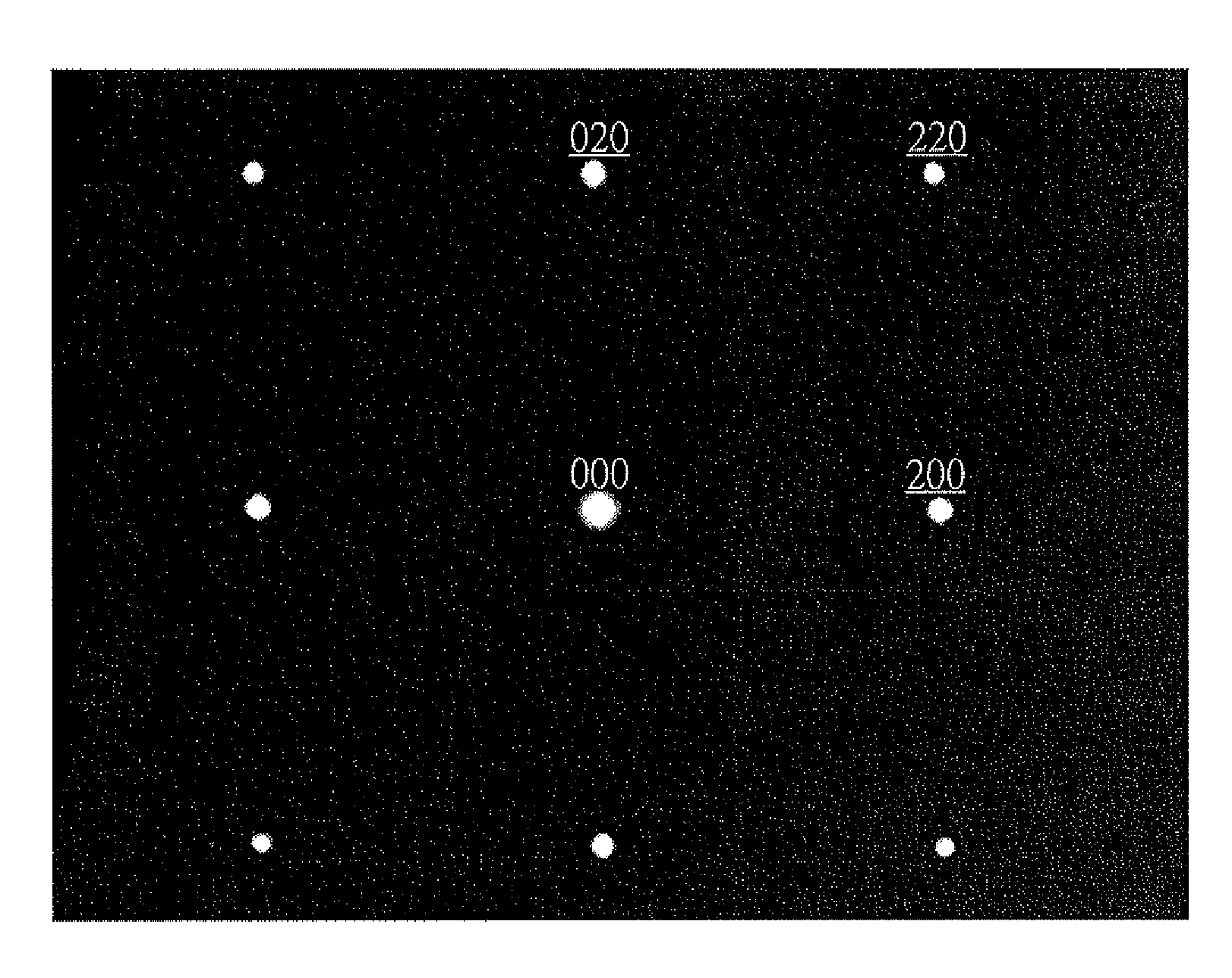

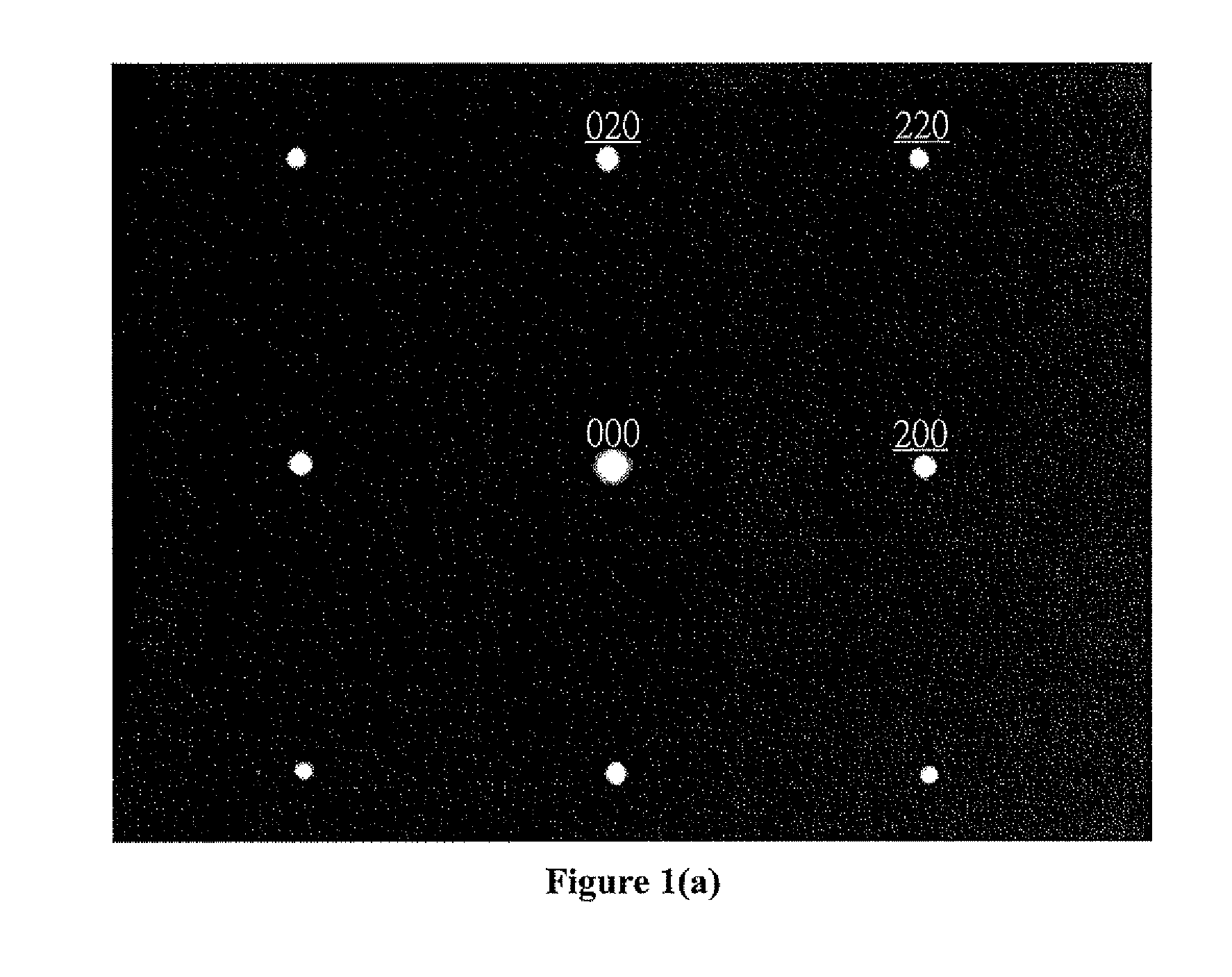

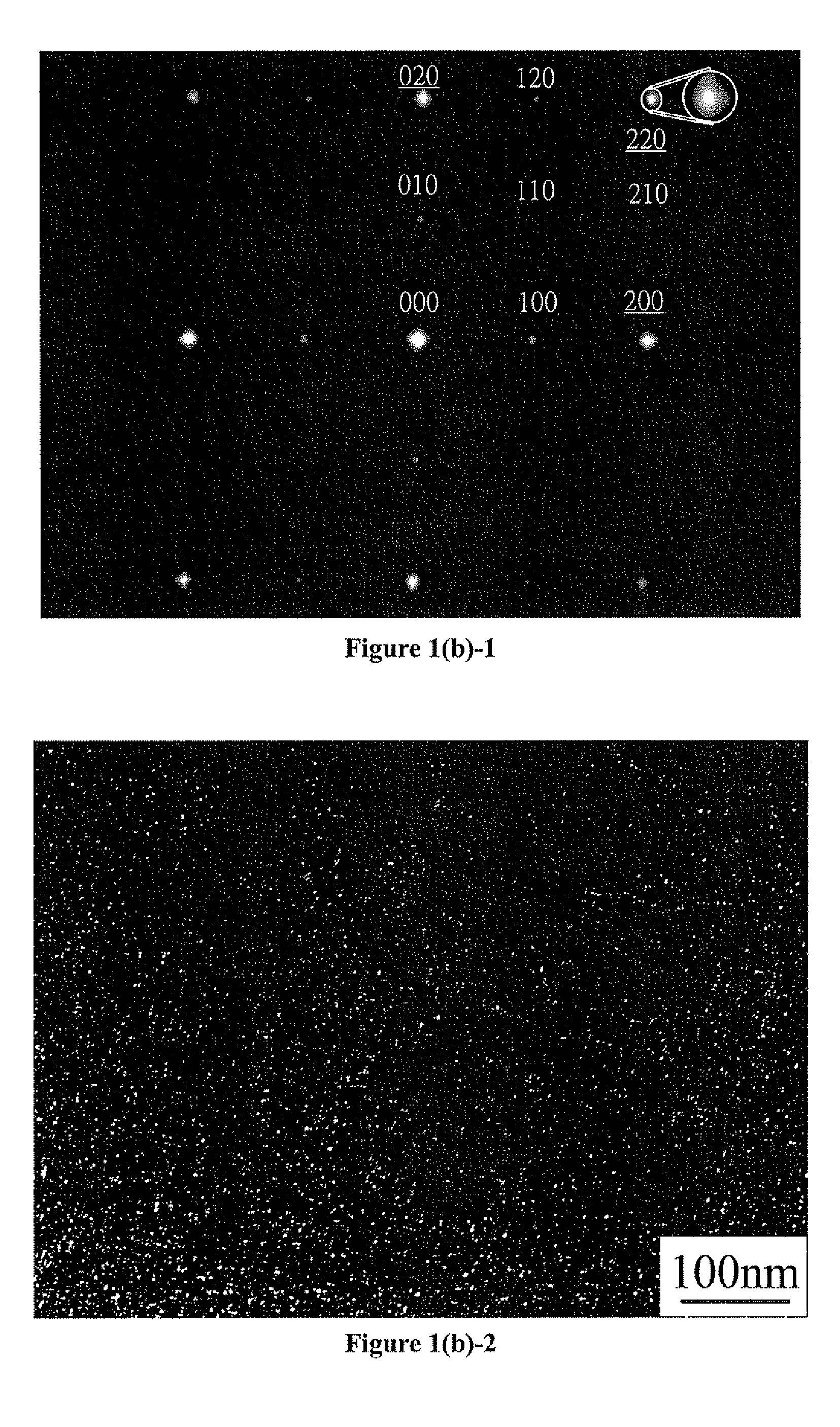

Composition design and processing methods of high strength, high ductility, and high corrosion resistance FeMnAlC alloys

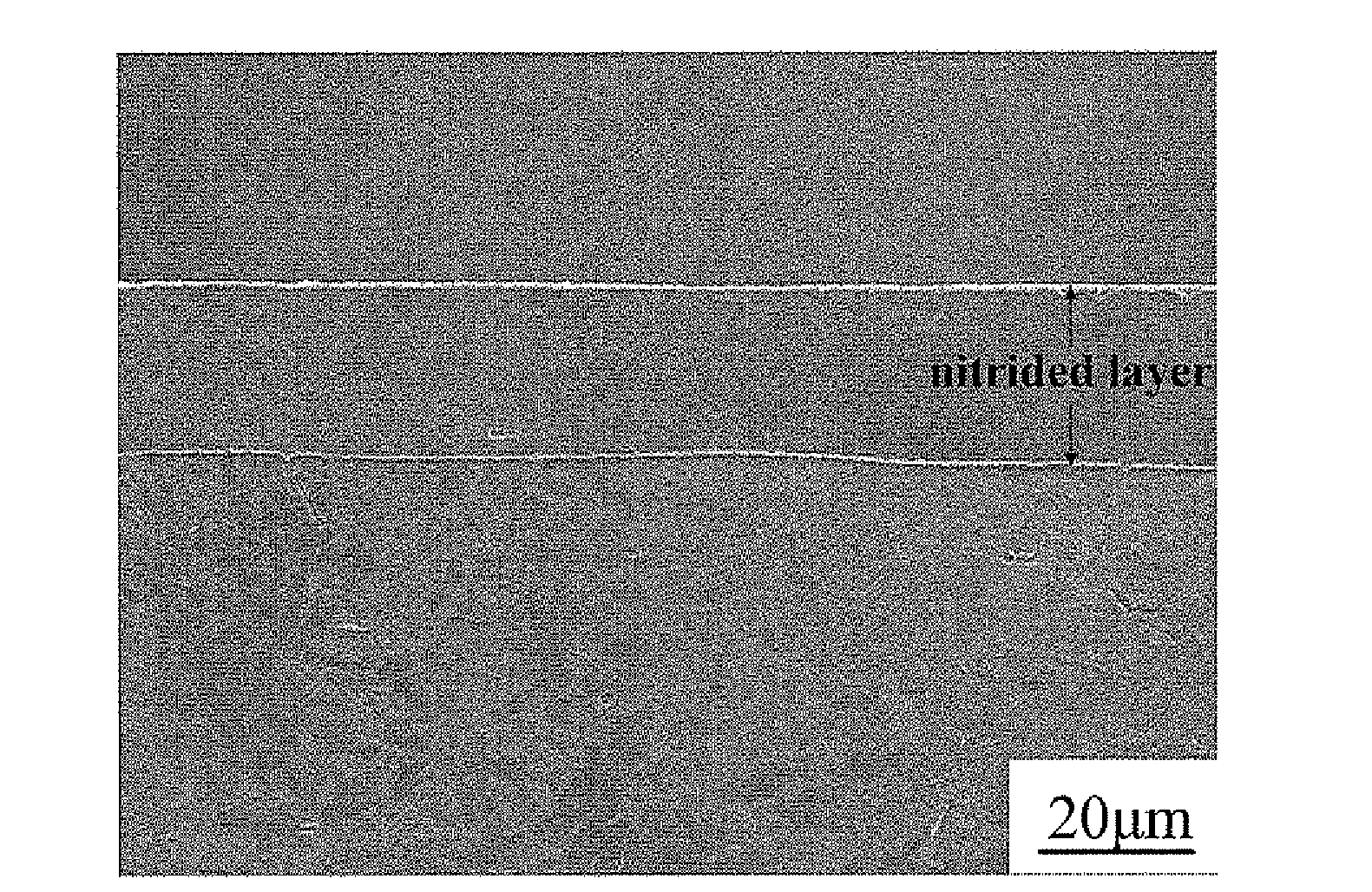

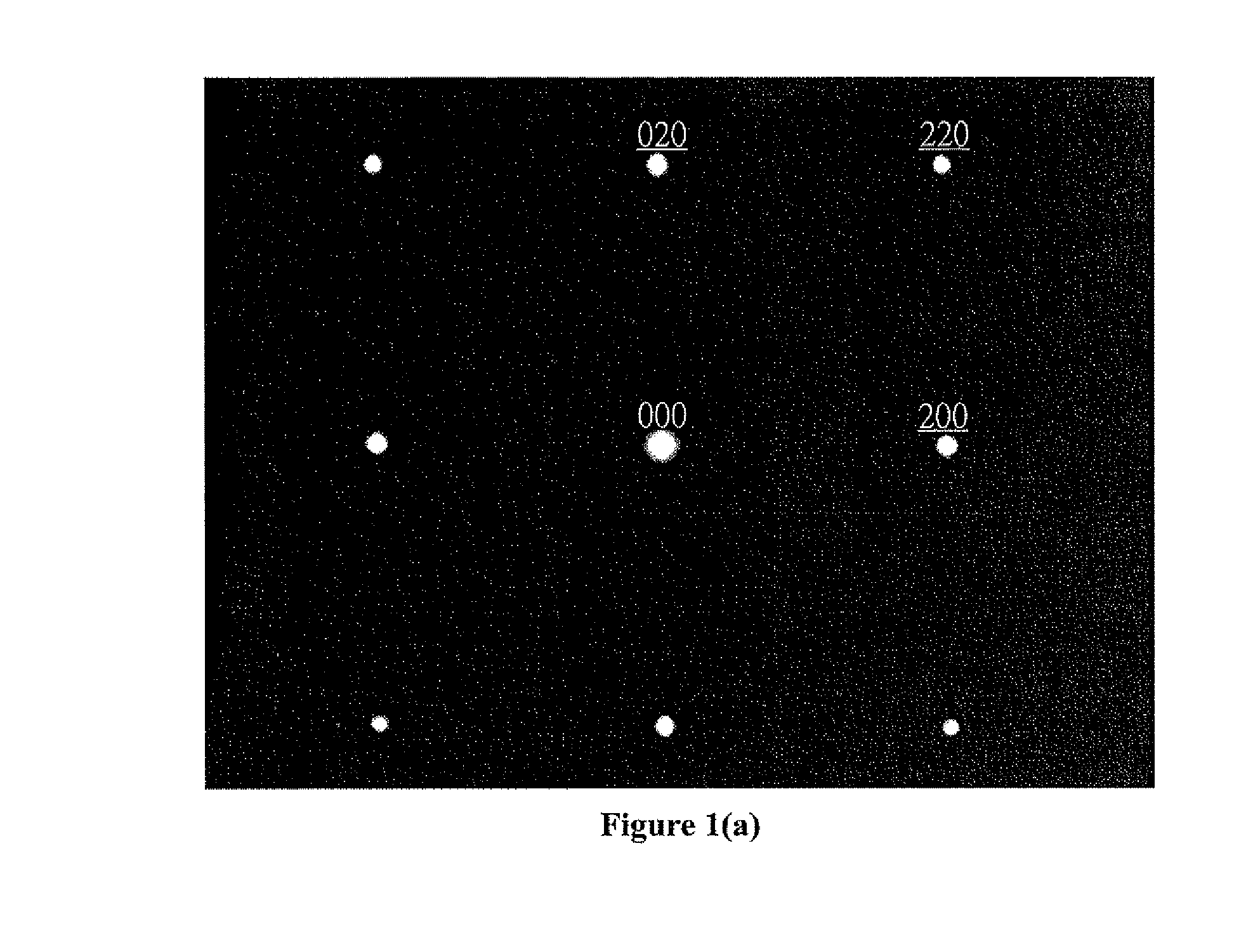

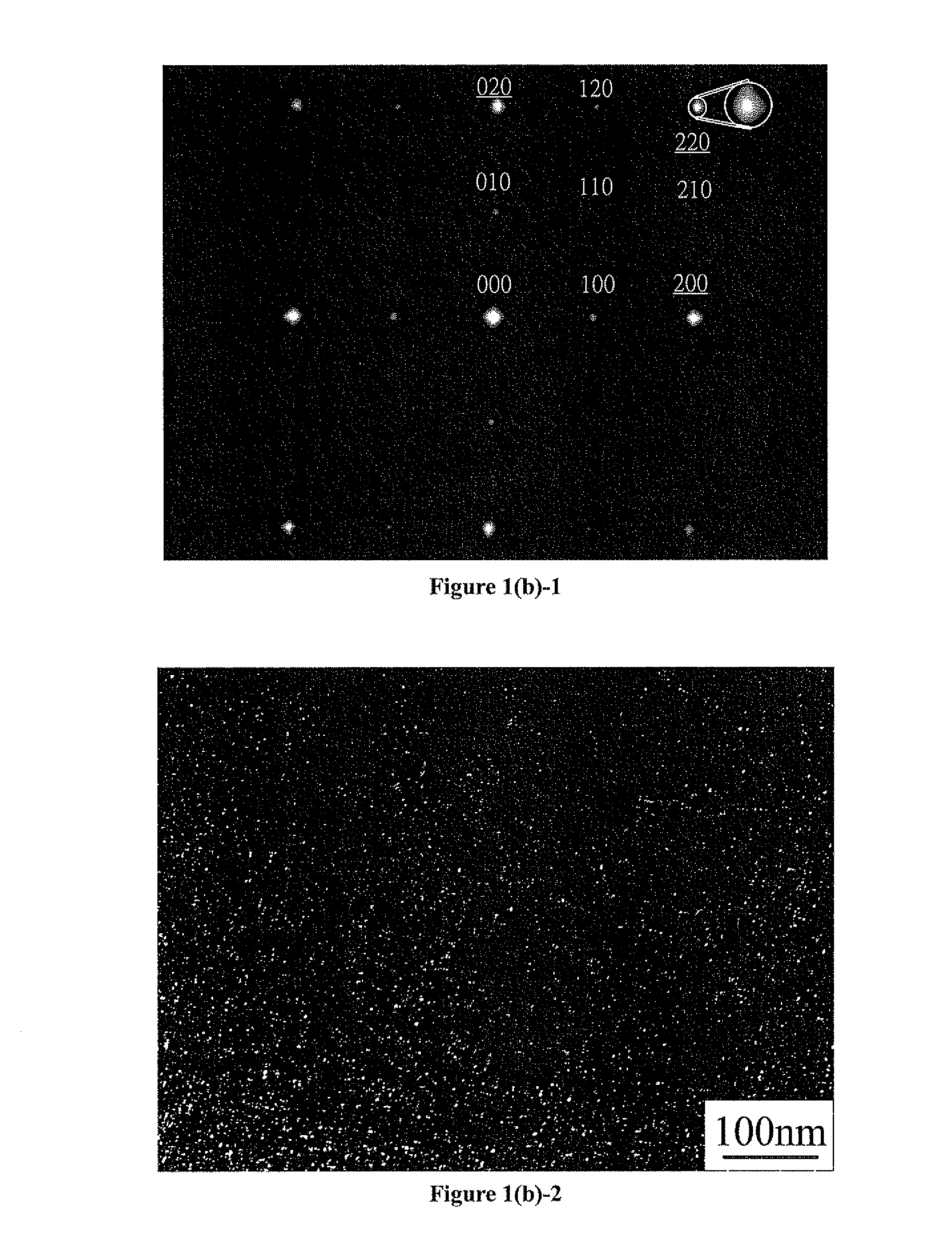

ActiveUS20130081740A1Improve ductilityHigh mechanical strengthSolid state diffusion coatingQuenching agentsHigh densityCarbide

A novel FeMnAlC alloy, comprising 23˜34 wt. % Mn, 6˜12 wt. % Al, and 1.4˜2.2 wt. % C with the balance being Fe, is disclosed. The as-quenched alloy contains an extremely high density of nano-sized (Fe,Mn)3AlCx carbides (κ′-carbides) formed within austenite matrix by spinodal decomposition during quenching. With almost equivalent elongation, the yield strength of the present alloys after aging is about 30% higher than that of the optimally aged FeMnAlC (C≦1.3 wt. %) alloy systems disclosed in prior arts. Moreover, the as-quenched alloy is directly nitrided at 450˜550° C., the resultant surface microhardness and corrosion resistance in 3.5% NaCl solution are far superior to those obtained previously for the optimally nitrided commercial alloy steels and stainless steels, presumably due to the formation of a nitrided layer consisting predominantly of AlN.

Owner:APOGEAN METAL CO LTD

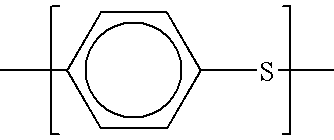

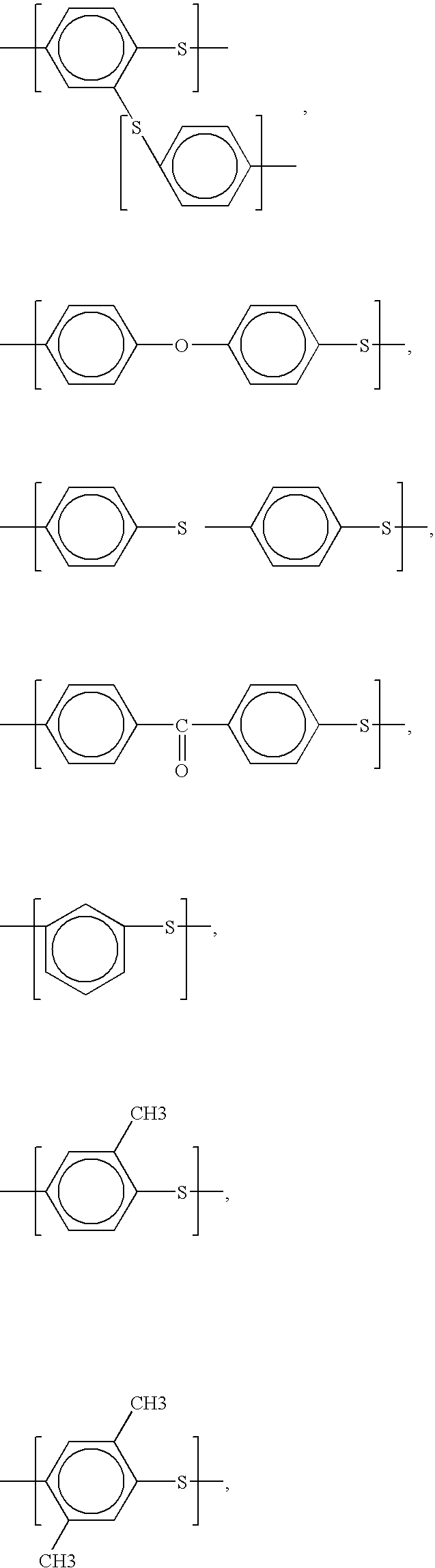

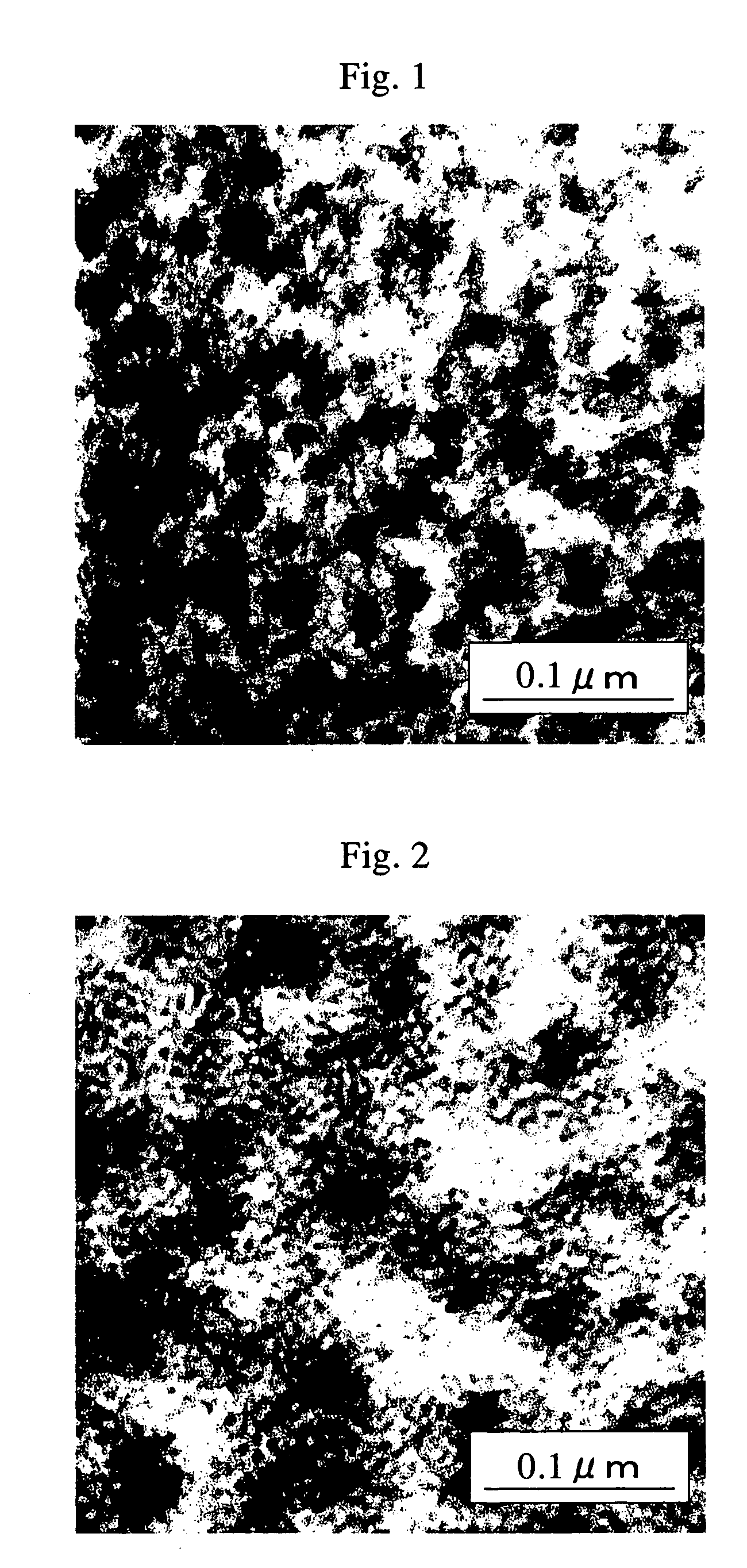

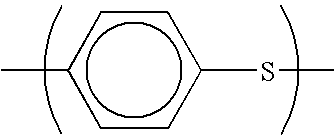

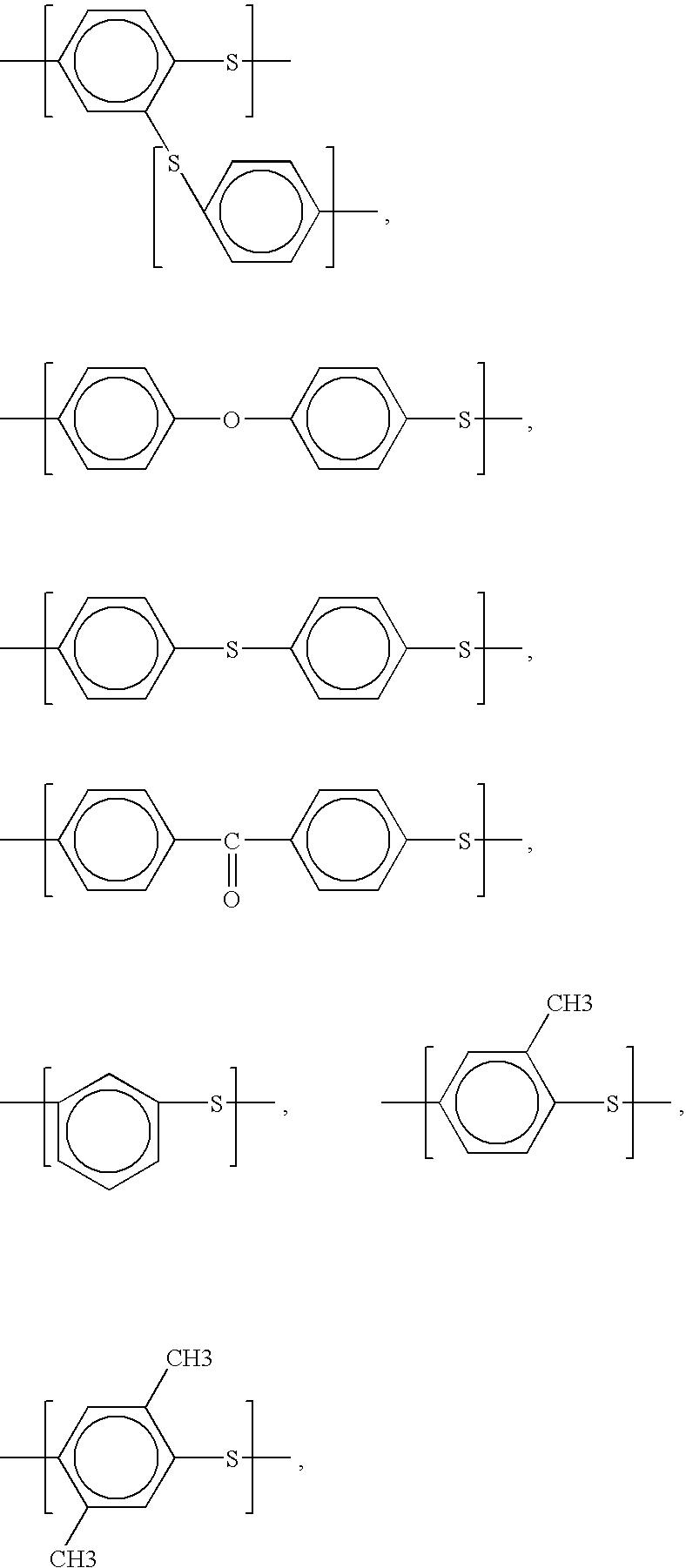

Polymer alloy and method for manufacturing polymer alloy

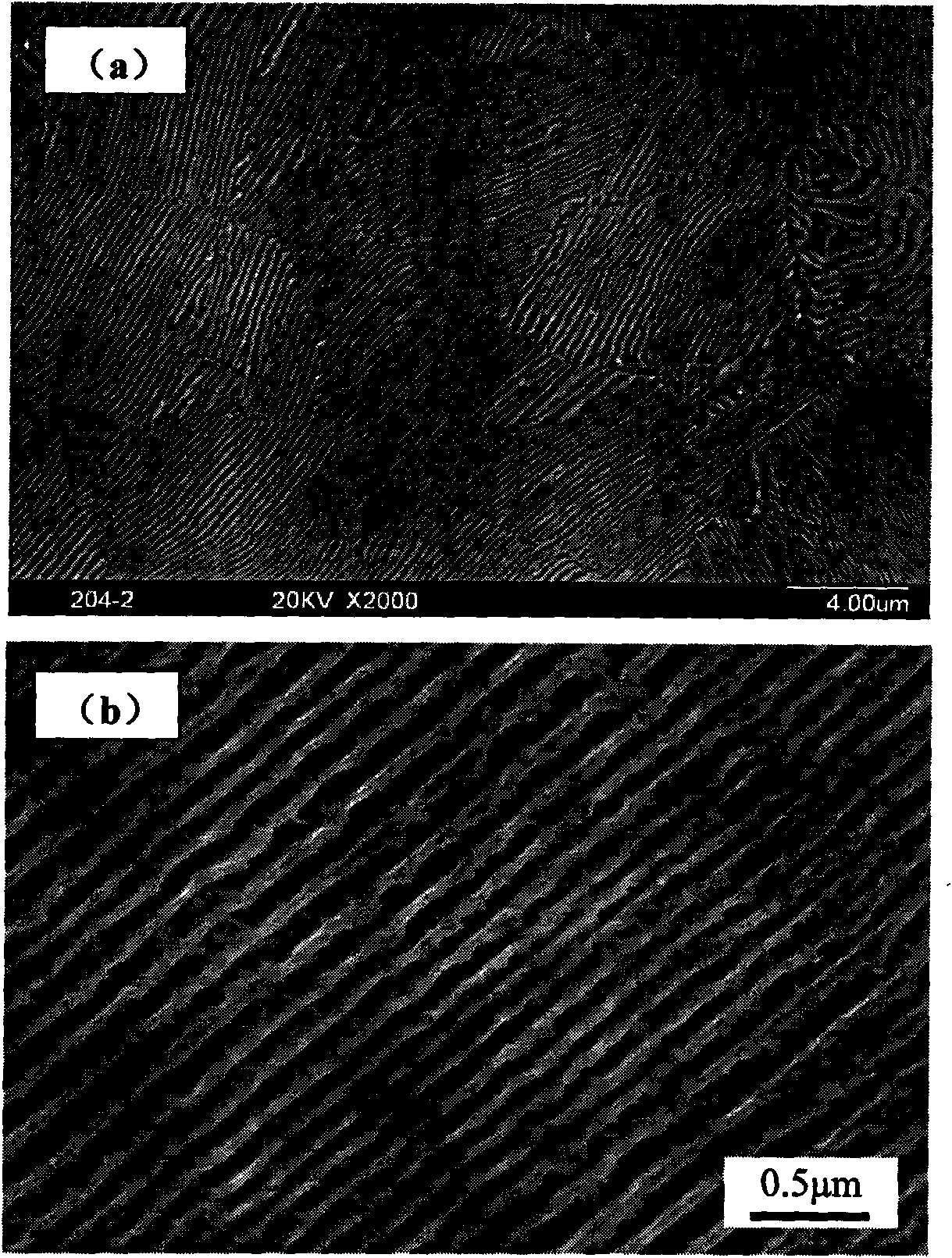

This invention is a method for manufacturing a polymer alloy, by making at least two resins used as components miscible, and inducing the spinodal decomposition for causing phase separation, for forming a co-continuous structure with a wavelength of concentration fluctuation of 0.001 to 1 mum or a dispersed structure with a distance between particles of 0.001 to 1 mum. This invention is also a polymer alloy manufactured by the method. The polymer alloy of this invention can provide a molded article, film, fibers and the like respectively with excellent mechanical properties at high productivity.

Owner:TORAY IND INC

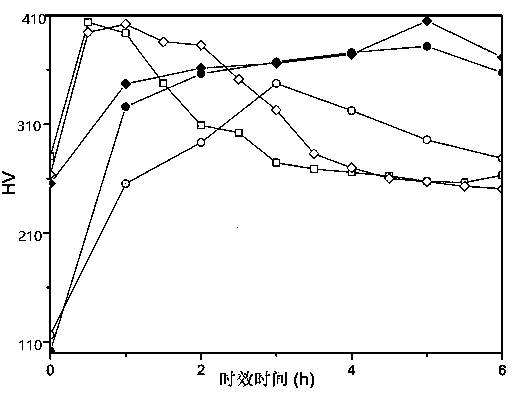

Titaniferous cuprum-nickel-stannum spinodal decomposition type anti-friction bearing alloy and preparation method thereof

A titanium containing Cu-Ni-Sn spinodal decomposition type anti-friction bearing alloy and method for making same, wherein the right amount of the fourth quadruple Ti into ternary Cu-Ni-Sn alloy by using copper peptide intermediate alloy mode, and vacuum induction electric furnace smelting or nonvacuum smelting casting are utilized for machining element through homogenization, quench and agehardening under casting state. The invention realizes high alloy strength, high expandability and high-wearing feature, thus can be applied to slide shaft sleeve of rock bit, or situations needing abrasion resistance for bearing high speed and heavy-duty bearing.

Owner:SHANGHAI JIAO TONG UNIV +1

Hydrogen-absorbing alloy

InactiveUS6258184B1Excellent hydrogen absorptionExcellent desorption characteristicHydrogenCell electrodesFine structureLattice constant

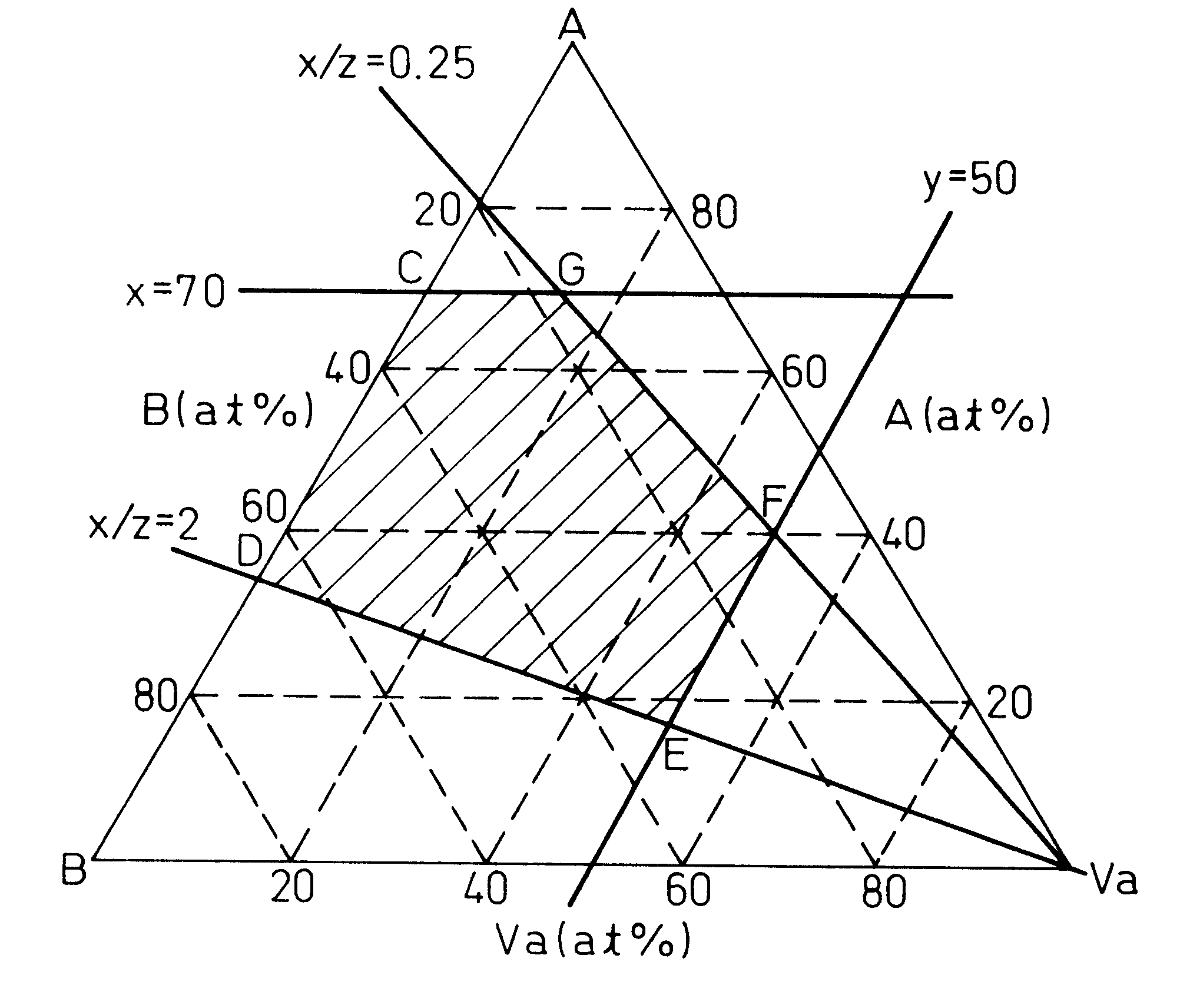

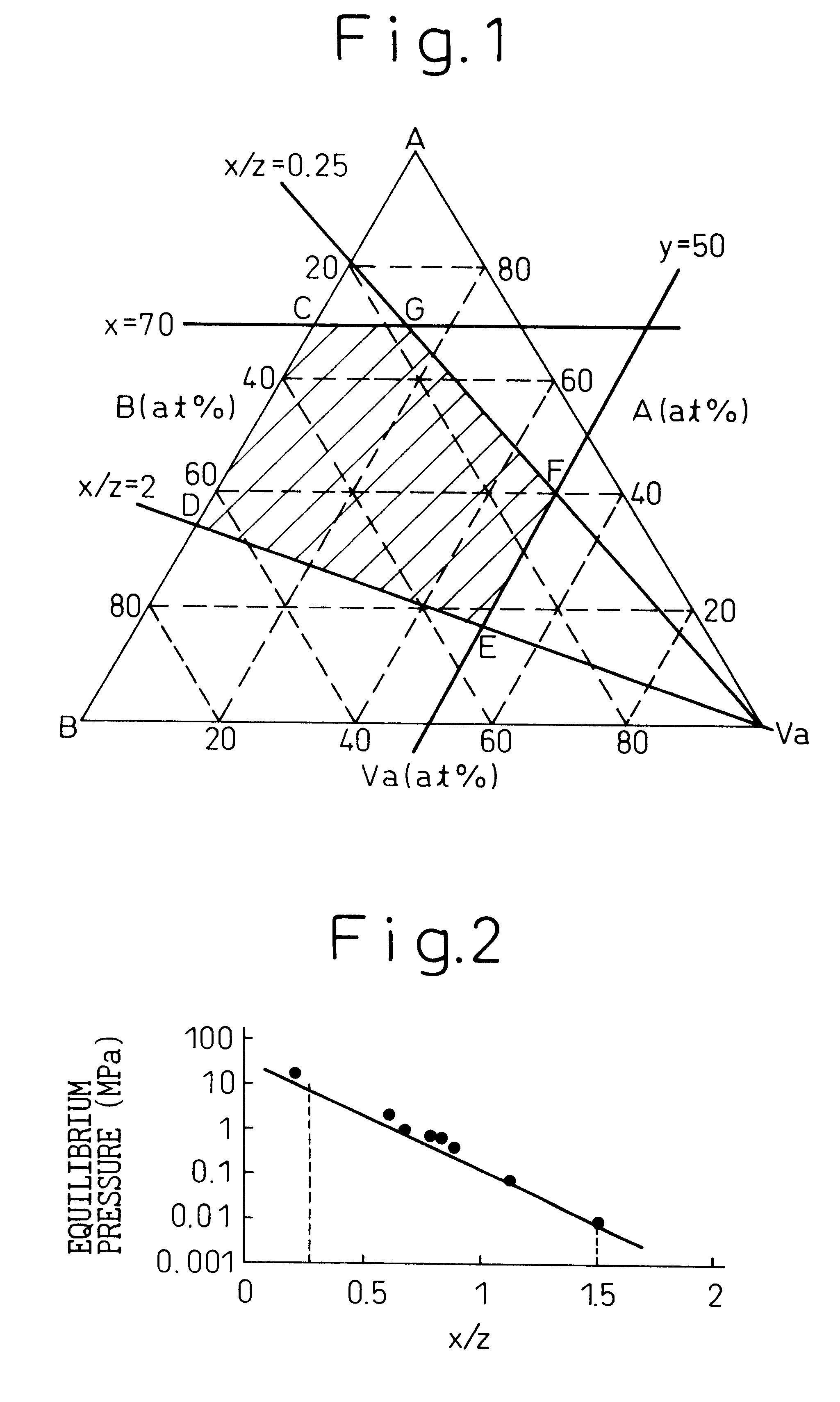

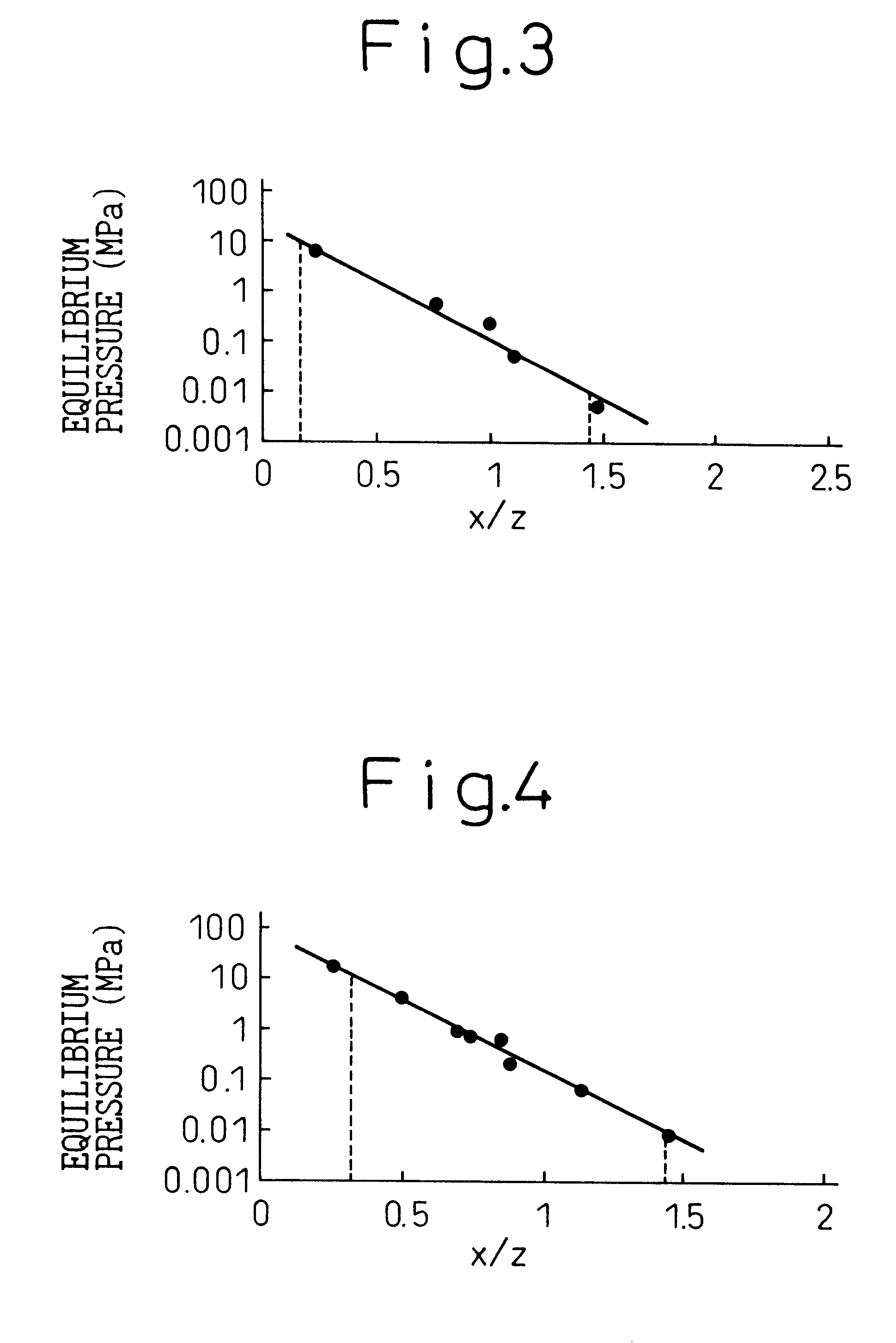

A BCC type hydrogen-absorbing alloy, which uses a ferroalloy, is advantageous from the aspect of the production cost and exhibits excellent hydrogen absorption and desorption characteristics due to a fine structure constituted by spinodal decomposition even when the iron component is increased. The hydrogen-absorbing alloy is expressed by the general formula AxVayBz, where A is at least one of Ti and Zr, Va is at least one member of the Group Va elements of the Periodic Table consisting of V, Nb and Ta, and B contains at least Fe and is at least one member selected from the group consisting of Cr, Mn, Co, Ni, Cu, Al, Mo and W, each of x, y and z satisfies the relation, in terms of of the atomic number ratio, 0<=x<=70, 0<=y<=50, x+y+z=100, and x / z=0.25 to 2.0, the phase of the body-centered cubic structure is at least 50% in terms of the phase fraction and its lattice constant is at least 0.2950 nm but not greater than 0.3100 nm.

Owner:TOYOTA JIDOSHA KK

Permanent hydrophilic polymer film with high mechanical property and preparation method thereof

ActiveCN105778363AAvoid decompositionStrong mechanical propertiesMembranesSemi-permeable membranesPolymer scienceDecomposition

The invention discloses a permanent hydrophilic polymer film with a high mechanical property and a preparation method thereof. A porous film is prepared from a hydroxyl-containing polymer which serves as a blend polymer and has high compatibility with polyvinylidene fluoride and a strong adhesion effect with a melt spinning method or coating-rolling preparation method through solid-liquid phase separation of a thermally-induced phase separation technology, so that the porous film with a three-dimensional penetrated mesh-shaped structure can be obtained or controlled easily under control by adjusting the adding amount of the polymer blend; the film is prepared at a temperature which is lower than a curing temperature of a polymer material, so that the problem of decomposition of the blend polymer under the conventional spinodal decomposition film-preparing condition is solved; the blend polymer has a strong adhesion effect, so that the blend polymer can be combined with the polyvinylidene fluoride with high adhesion without falling easily, the adhesion effect is equivalent to binding crosslinking, and the mechanical property of the film can be improved remarkably. Meanwhile, the preparation process of the porous film is simple, has high adaptability, does not require equipment updating, is convenient to popularize and has good industrial prospect.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

Polymer alloy and method for manufacturing polymer alloy

This invention is a method for manufacturing a polymer alloy, by making at least two resins used as components miscible, and inducing the spinodal decomposition for causing phase separation, for forming a co-continuous structure with a wavelength of concentration fluctuation of 0.001 to 1 mum or a dispersed structure with a distance between particles of 0.001 to 1 mum. This invention is also a polymer alloy manufactured by the method. The polymer alloy of this invention can provide a molded article, film, fibers and the like respectively with excellent mechanical properties at high productivity.

Owner:TORAY IND INC

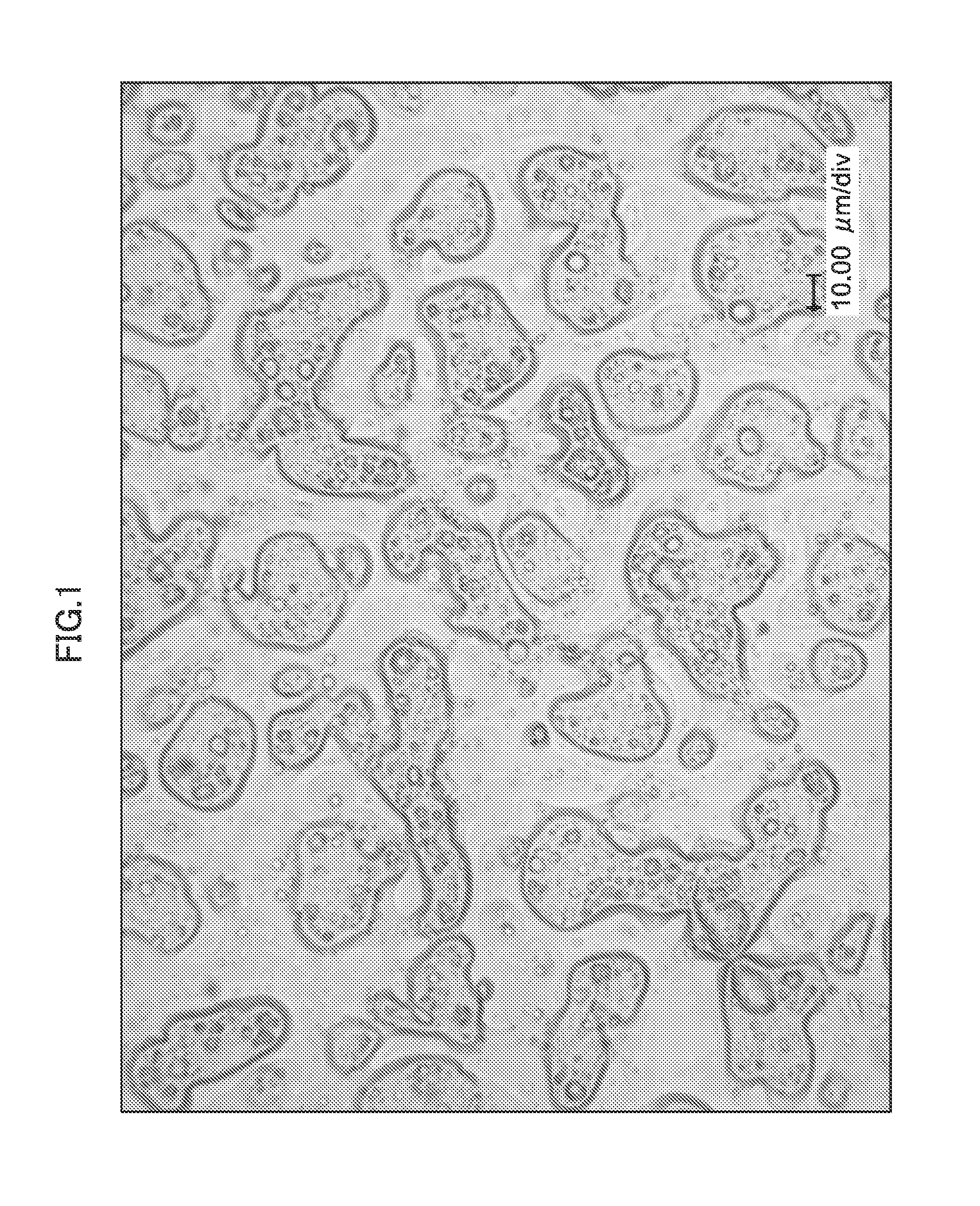

Anti-glare film, and optical member and liquid crystal display apparatus using the same

An anti-glare film comprising an anti-glare layer is obtained by coating or casting a liquid composition containing a polymer, a curable resin precursor (e.g., an ultraviolet curable resin) and a solvent, on a transparent plastic film; evaporating the solvent; forming a phase separation structure by spinodal decomposition; and curing the curable resin precursor by a light irradiation to form the anti-glare layer. The result anti-glare layer has an uneven structure on the surface thereof, isotropically transmits and scatters an incident light to show the maximum value of the scattered light intensity at a scattering angle of 0.1 to 10°, and has the total light transmittance of 70 to 100%.

Owner:DAICEL CHEM IND LTD

Low-elasticity-modulus and high-strength spinodal decomposition type Zr-Nb-Ti alloy material and preparation method thereof

The invention discloses a low-elasticity-modulus and high-strength spinodal decomposition type Zr-Nb-Ti alloy material and a preparation method thereof. The Zr-Nb-Ti alloy material comprises the following components in atomic percentage: 20-50% of Ti, 15-45% of Nb and the balance of Zr. The preparation method comprises the following steps: a titanium source, a niobium source and a zirconium sourceare prepared according to designed ratios; zirconium alloy ingots are obtained through multiple times of smelting; zirconium alloy rods are obtained through the zirconium alloy ingots by suction casting; and solid-solution treatment and aging treatment are performed on the zirconium alloy rods in sequence to obtain the Zr-Nb-Ti alloy material. The zirconium alloy material is higher in strength and low in elasticity modulus; the highest strength can reach 1130.8+ / -8.5 MPa; and the elasticity modulus is maintained between 40-50 GPa, and is near the elasticity modulus of human bodies.

Owner:XIANGTAN UNIV

Light scattering sheet and method for producing the same

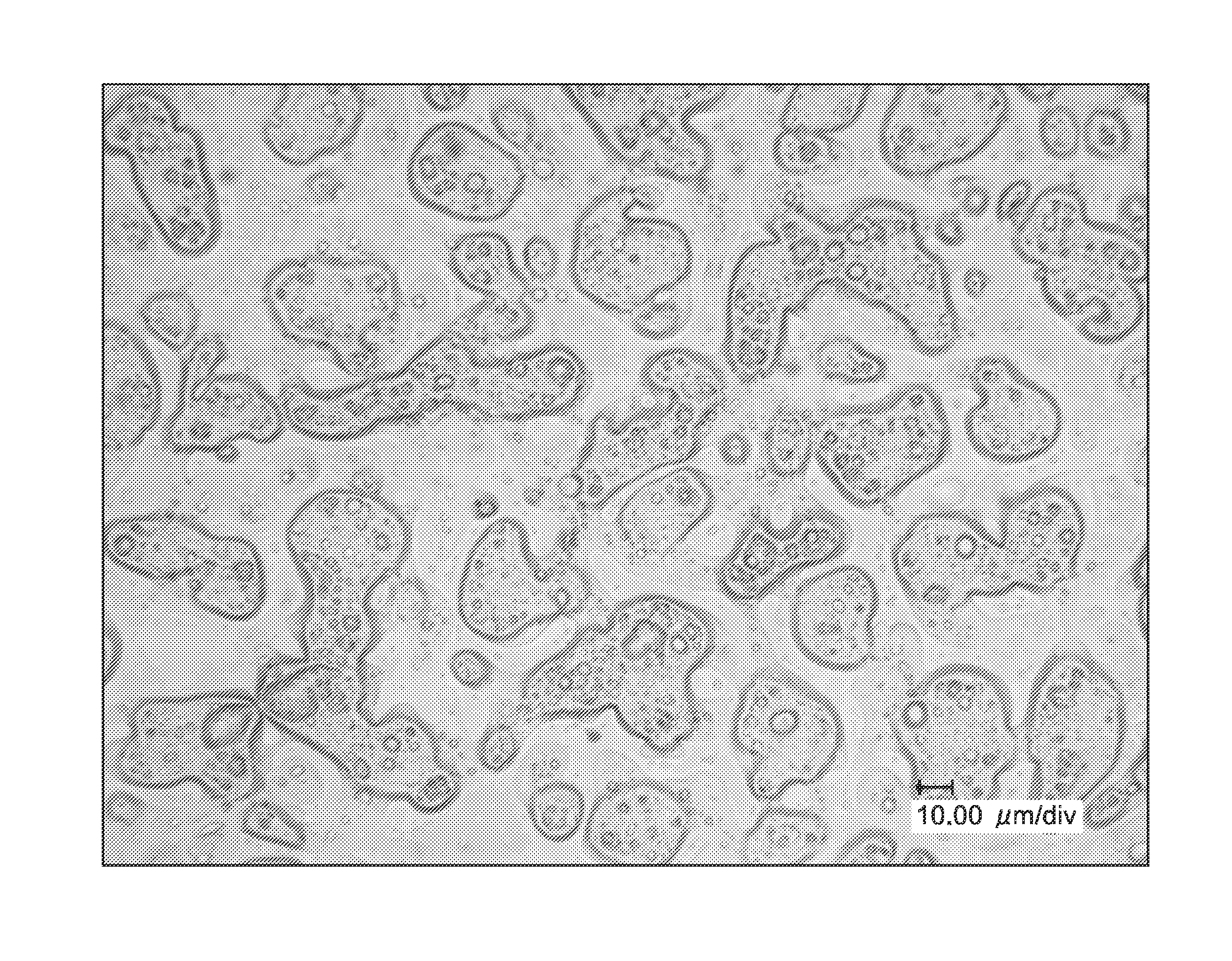

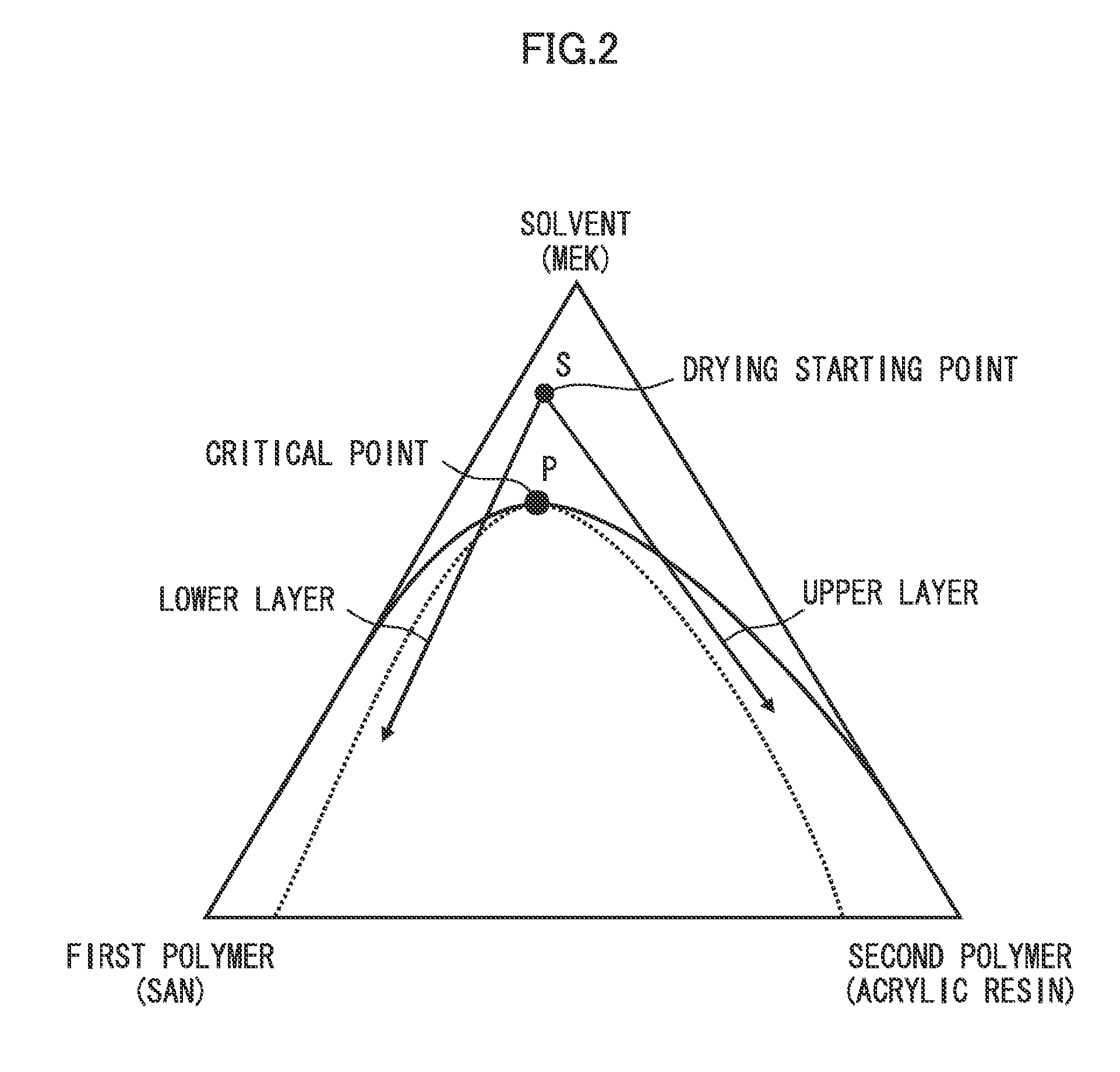

InactiveUS20120013987A1Excellent in moire-eliminating performanceReduction in thickness of liquidDiffusing elementsPretreated surfacesAcrylonitrileSolvent

A light scattering sheet includes: a transparent support; and a light scattering layer on the transparent support, the light scattering layer having a phase-separated convexo-concave structure formed by spinodal decomposition of a solution containing two or more resin materials capable of phase-separation from each other are dissolved in a solvent. In the light scattering layer, the phase-separated convexo-concave structure is formed into a sea-island structure of two or more resin materials including a styrene-acrylonitrile copolymer, and a plurality of domains constituting the islands have random shapes mainly having a string shape, and a transmitted image definition measured according to JTS K 7374 using an optical comb having a width of 2.0 mm is 10% or more and less than 25%.

Owner:FUJIFILM CORP

Polymer alloy and method for manufacturing polymer alloy

Owner:TORAY IND INC

Transmission light-diffusing layer

InactiveUS20030179456A1High scatterationImprove directivityLayered productsDiffusing elementsRefractive indexLiquid composition

Owner:DAICEL CHEM IND LTD

Transmission light-scattering layer sheet and liquid crystal display

InactiveUS20030025856A1Improve directionalityHigh diffusibilityDiffusing elementsNon-linear opticsRefractive indexUltimate tensile strength

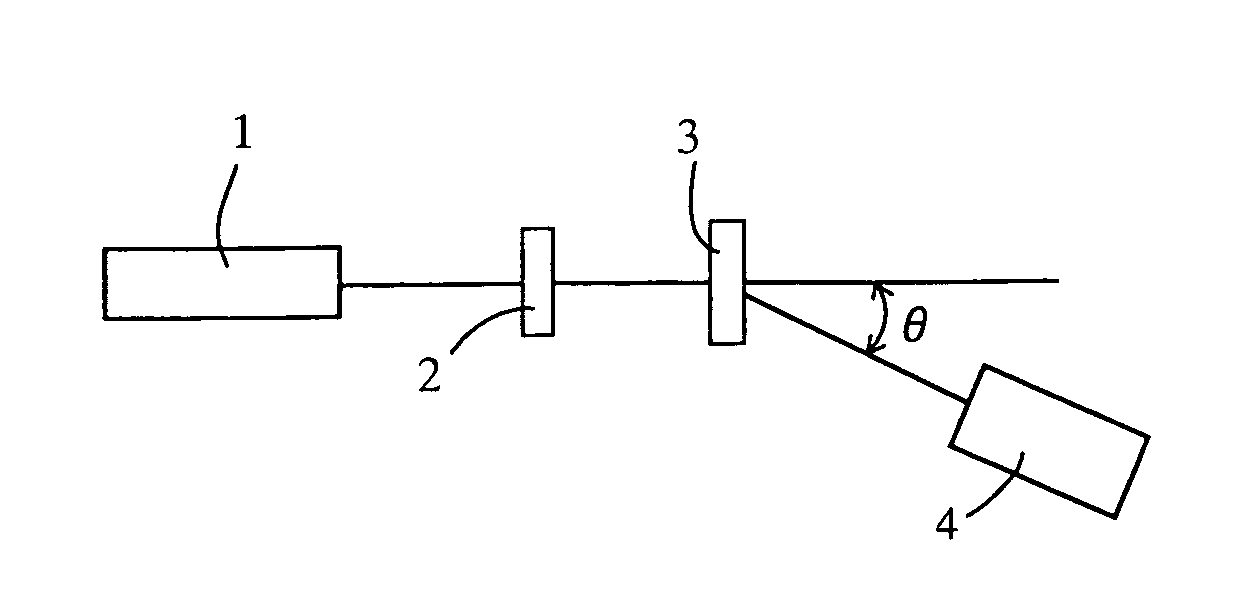

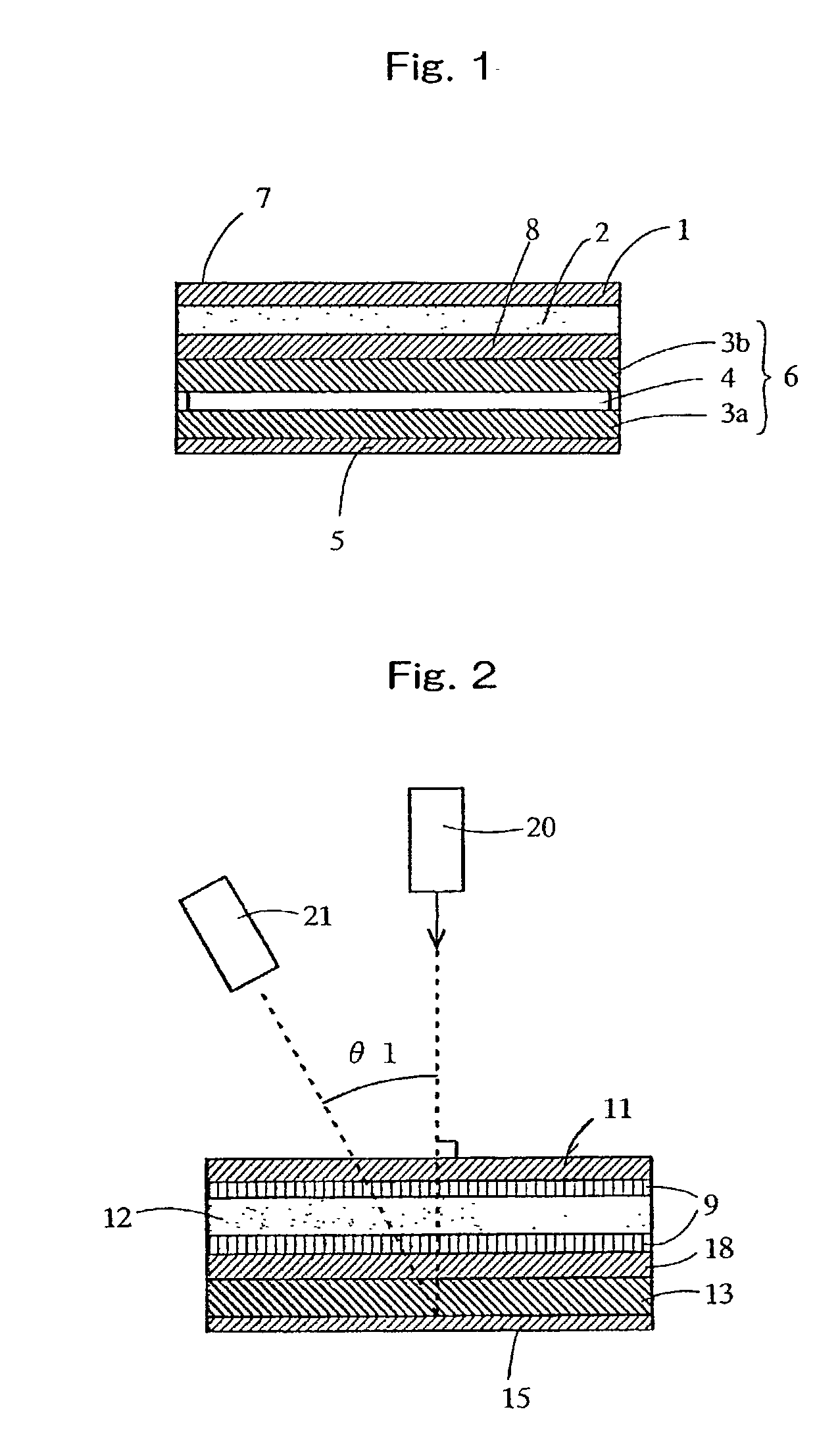

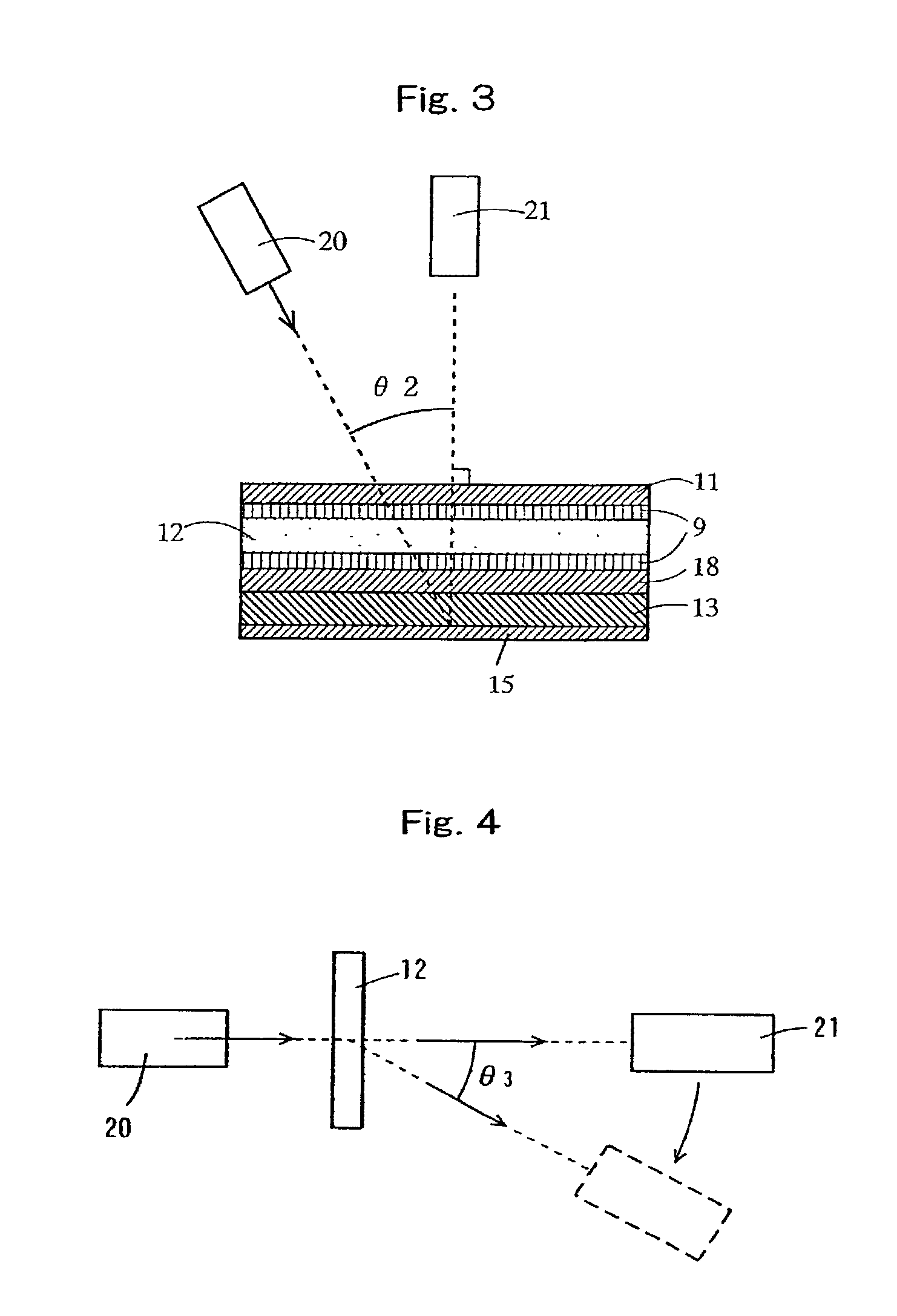

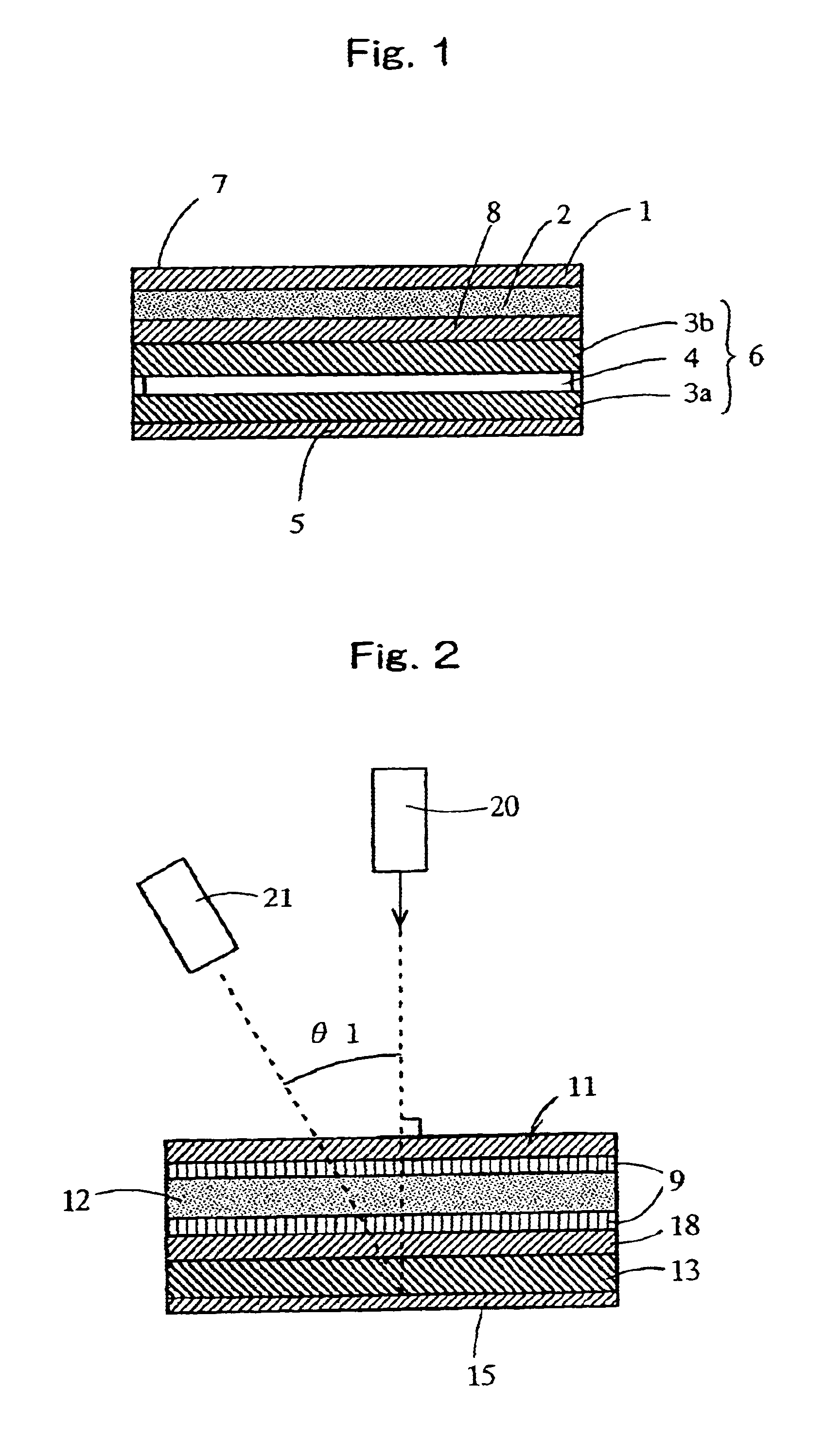

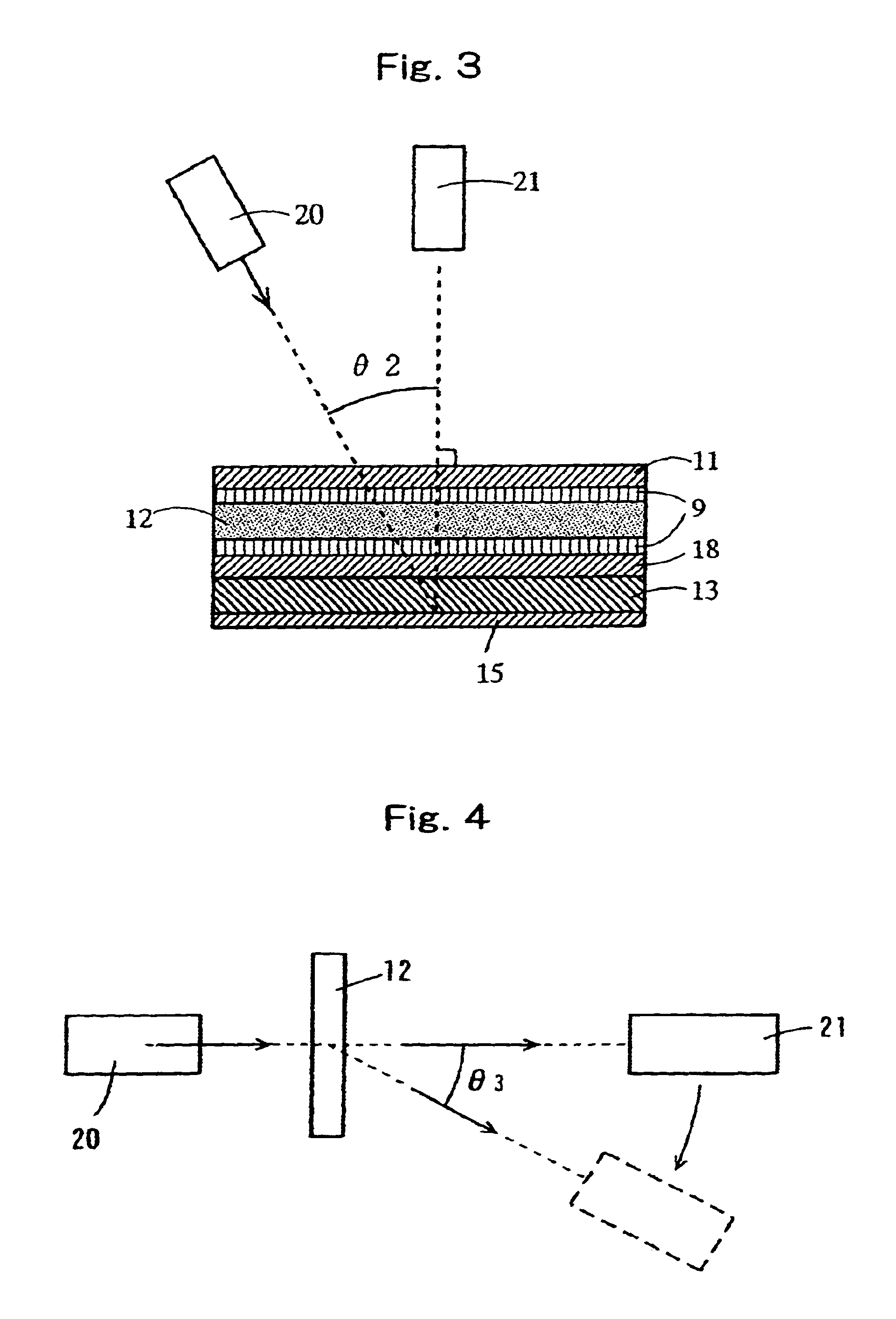

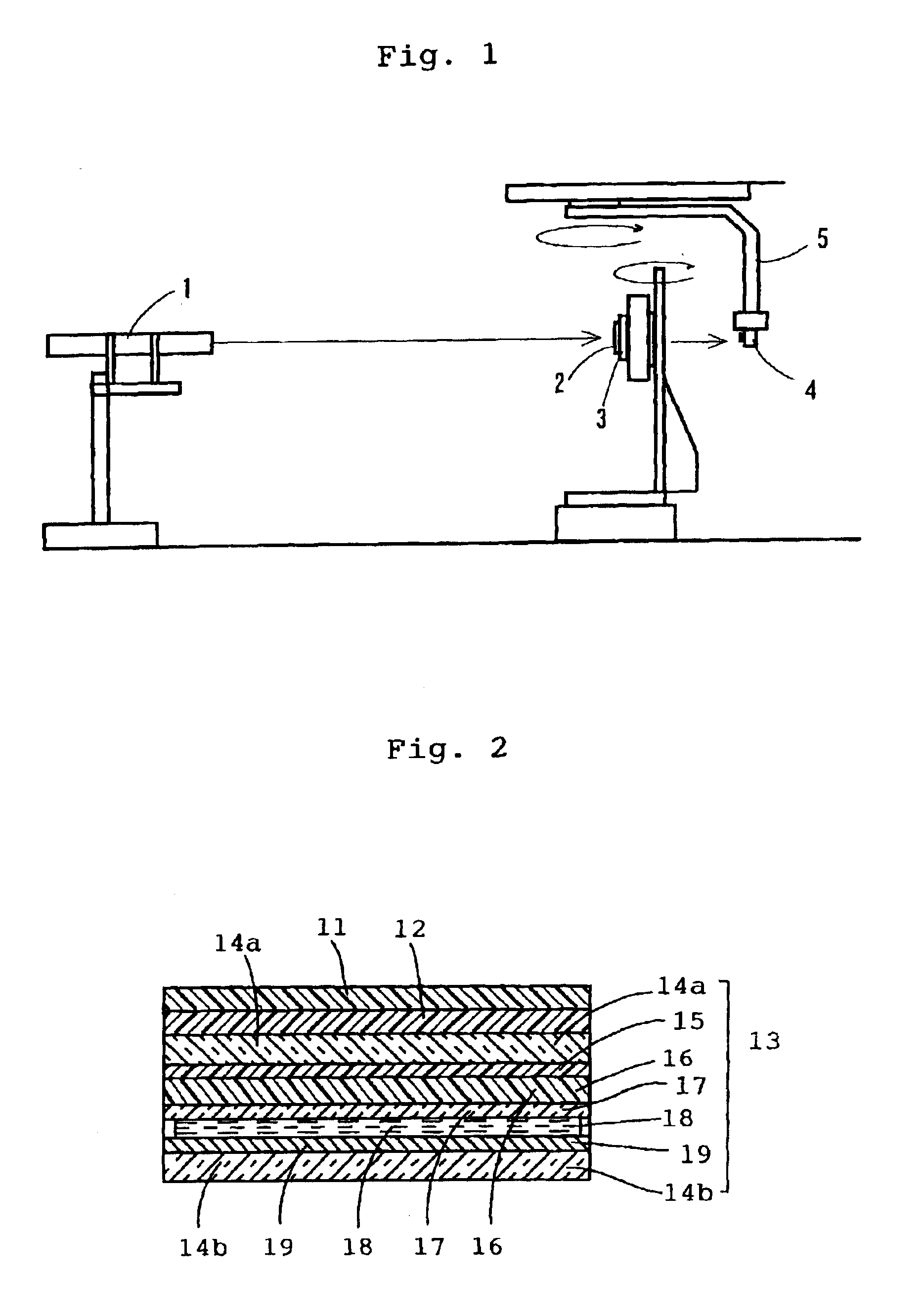

The reflective liquid crystal display device comprises a polarizing plate 1 disposed forwardly of the liquid crystal cell 6, a reflecting means 5 which is disposed on backside of the liquid crystal cell and reflects an incident light, and a light-scattering sheet 2 which is disposed forwardly of reflecting means and scatters the incident light isotopically. The light-scattering sheet can be prepared with the use of spinodal decomposition method comprising by coating a mixture liquid containing a plurality of polymers varying in refractive index on a transparent support and evaporating or removing a solvent to form a light-scattering layer having a droplet phase structure. The light-scattering layer includes a light-scattering layer showing a maximum intensity of the scattered-light at scattering angle of 3 to 40°, and a light-scattering layer showing maximums intensity of the scattered-light respectively at smaller angle of 2 to 20° and larger angle thetab.

Owner:DAICEL CHEM IND LTD

Intrinsic non-net secondary cementite steel and application method thereof

The invention discloses an intrinsic non-net secondary cementite steel and an application method thereof; the steel comprises the following components by weight percent: 0.8-1.8% of C, 0-3.0% of Al, 0-2.5% of Cr, 0.2-0.8% of Mn, 0-2.0% of Si, 0-0.8% of Mo, 0-0.1% of Nb, 0-0.1% of V, 0-0.1% of Ti, 0-0.05% of Re and the balance Fe. The steel does not have net-shaped secondary cementite in common casting state, annealed state and normalized state, secondary cementite is precipitated in pearlite in a dispersive form and the form of organization is pearlite and dispersive spinodal decomposition organization. The organization is easy for nodulizing which can be realized by heating the organization at 800 DEG C for 1-2h after the routine forging technology. The steel can be widely applied in the fields such as tools, abrasive tools, bearings, rail steels and the like and the steel can improve the carbon content, hardness and wear resistance and service life of traditional materials.

Owner:XI AN JIAOTONG UNIV

Preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy

The invention relates to a preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy. The Cu-Ni-Sn multi-element alloy is obtained through vacuum induction melting or covering protection type non-vacuum smelting. In the casting forming process, electromagnetic stirring is applied until alloy liquid is complete solidified, and then the as-cast alloy is subjected to homogenization annealing, hot rolling and cogging, solid solution treatment, cold deformation, spinodal decomposition and other processes. The preparation method of the Cu-Ni-Sn alloy is capable ofrefining crystalline grains, reducing dendritic spacing and eliminating alloy microscopic and macroscopic structure and component segregation, provides implementation conditions for follow-up alloy plastic processing, spinodal decomposition and other processes, and has the beneficial effects that energy is saved, the production efficiency is improved, the service life of the alloy is prolonged, and the production cost is reduced.

Owner:JIANGYIN SANLING METAL PROD

Composition design and processing methods of high strength, high ductility, and high corrosion resistance FeMnAlC alloys

ActiveUS9528177B2Improve ductilityHigh mechanical strengthSolid state diffusion coatingQuenching agentsHigh densityCarbide

A novel FeMnAlC alloy, comprising 23˜34 wt. % Mn, 6˜12 wt. % Al, and 1.4˜2.2 wt. % C with the balance being Fe, is disclosed. The as-quenched alloy contains an extremely high density of nano-sized (Fe,Mn)3AlCx carbides (κ′-carbides) formed within austenite matrix by spinodal decomposition during quenching. With almost equivalent elongation, the yield strength of the present alloys after aging is about 30% higher than that of the optimally aged FeMnAlC (C≦1.3 wt. %) alloy systems disclosed in prior arts. Moreover, the as-quenched alloy is directly nitrided at 450˜550° C., the resultant surface microhardness and corrosion resistance in 3.5% NaCl solution are far superior to those obtained previously for the optimally nitrided commercial alloy steels and stainless steels, presumably due to the formation of a nitrided layer consisting predominantly of AlN.

Owner:APOGEAN METAL CO LTD

Transmission light-scattering layer sheet and liquid crystal display

InactiveUS6788368B2Display screen can be highly brightenedAvoid reflectionsStatic indicating devicesDiffusing elementsRefractive indexSolvent

Owner:DAICEL CHEM IND LTD

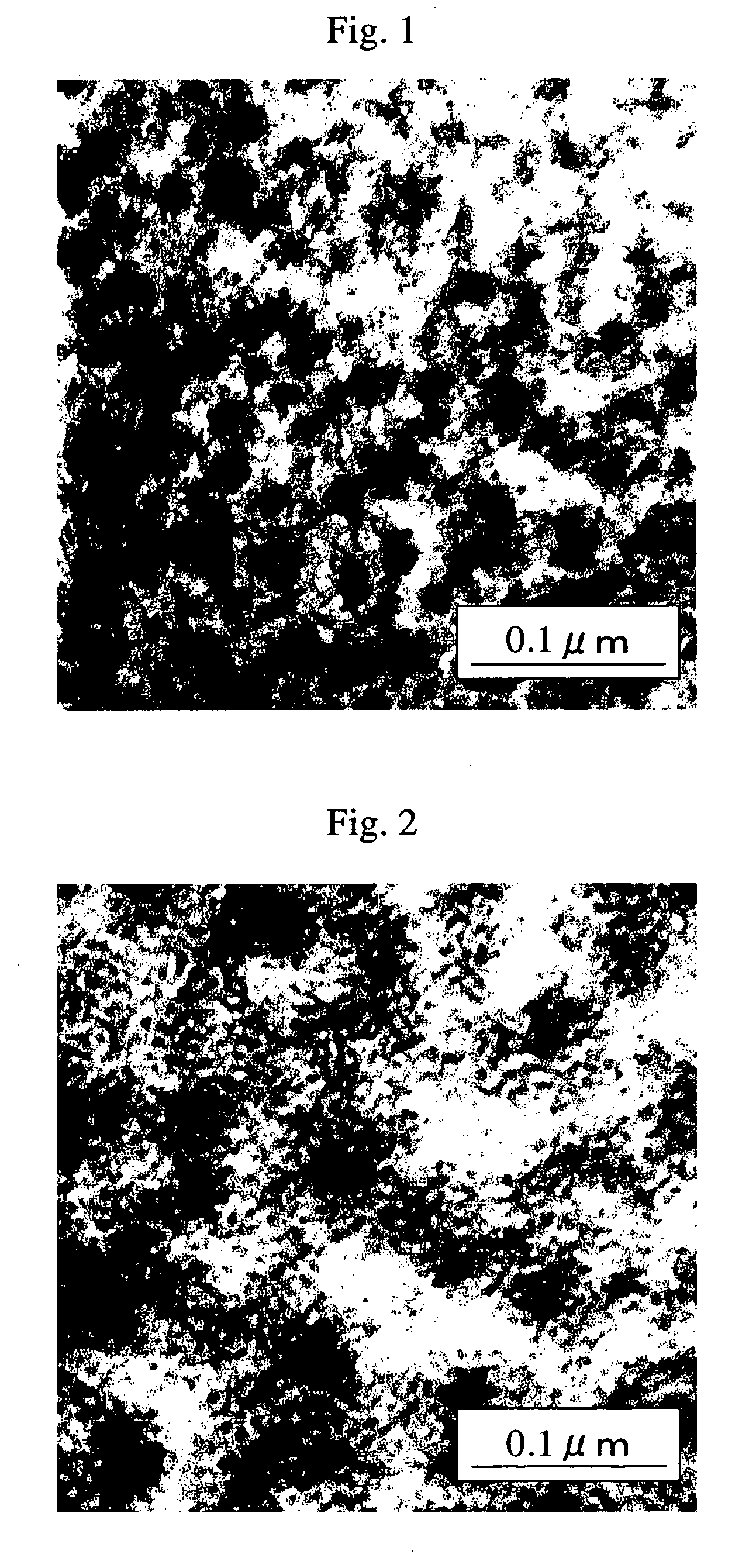

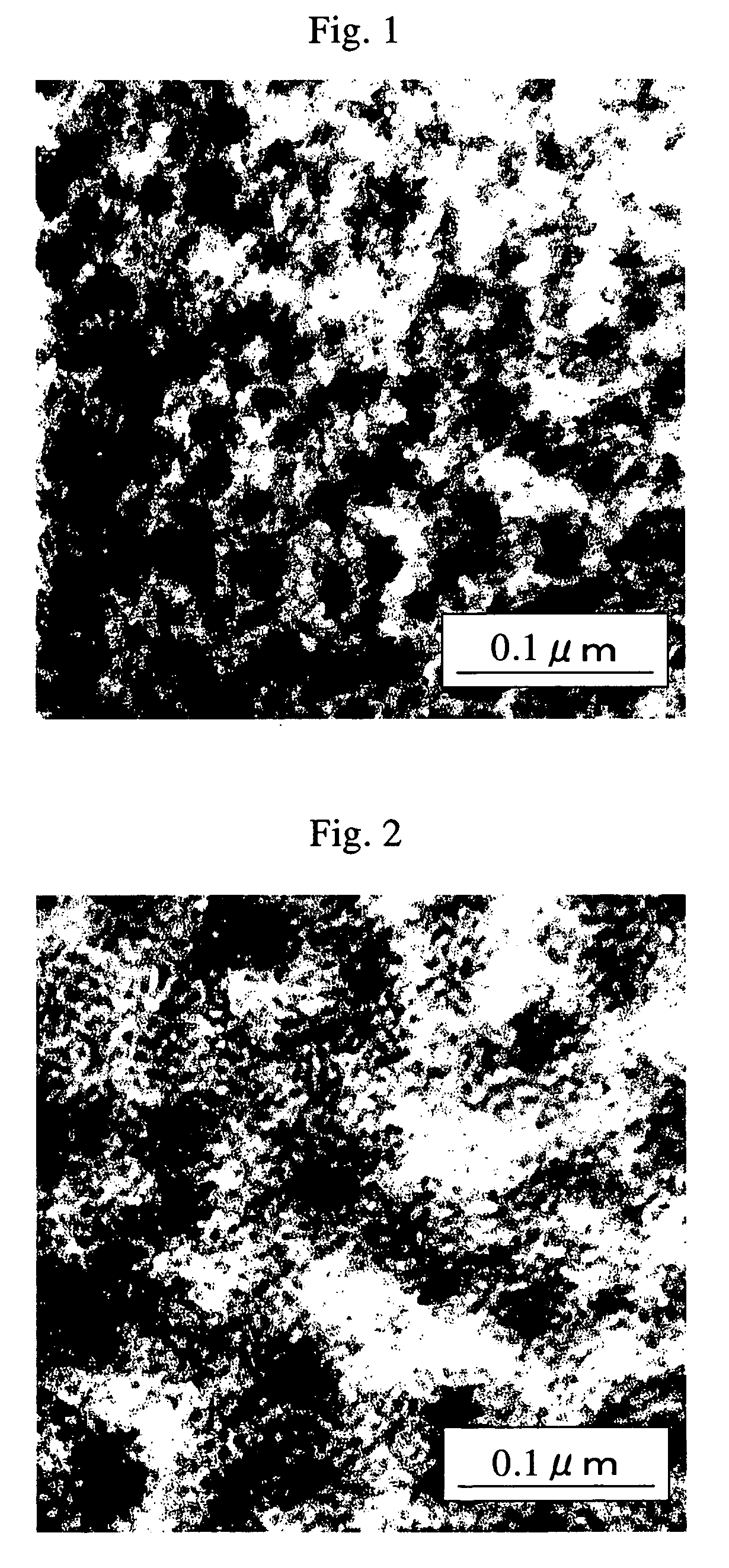

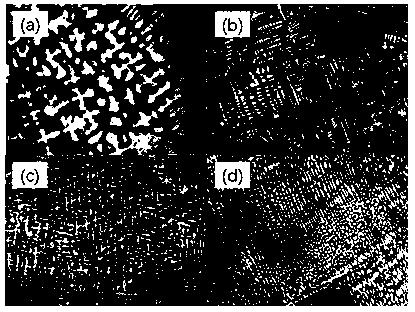

Polymer alloy and production method thereof

ActiveUS20100216946A1Improve compatibilityImprove regularitySynthetic resin layered productsThin material handlingThermoplasticChemical reaction

To provide a structure material having excellent mechanical characteristics and a functional material having excellent regularity, provided are a polymer alloy which is composed of at least two components of thermoplastic resins and of which the structure can be controlled finely and evenly dispersed and a production method of the polymer alloy. With respect to a polymer alloy composed of at least two or more components of thermoplastic resins, a precursor (A) of at least one thermoplastic resin among the thermoplastic resin components composing the polymer alloy is chemically reacted in the co-presence of the remaining thermoplastic resin component (B1) and / or a precursor (B2) of the thermoplastic resin component to induce spinodal decomposition, so that it is made possible to obtain a polymer alloy having excellent regularity and of which the structure is finely controllable and the structure is evenly dispersed.

Owner:TORAY IND INC

Polymer alloy and production method thereof

ActiveUS8338547B2Improve compatibilityImprove regularitySynthetic resin layered productsThin material handlingThermoplasticChemical reaction

To provide a structure material having excellent mechanical characteristics and a functional material having excellent regularity, provided are a polymer alloy which is composed of at least two components of thermoplastic resins and of which the structure can be controlled finely and evenly dispersed and a production method of the polymer alloy. With respect to a polymer alloy composed of at least two or more components of thermoplastic resins, a precursor (A) of at least one thermoplastic resin among the thermoplastic resin components composing the polymer alloy is chemically reacted in the co-presence of the remaining thermoplastic resin component (B1) and / or a precursor (B2) of the thermoplastic resin component to induce spinodal decomposition, so that it is made possible to obtain a polymer alloy having excellent regularity and of which the structure is finely controllable and the structure is evenly dispersed.

Owner:TORAY IND INC

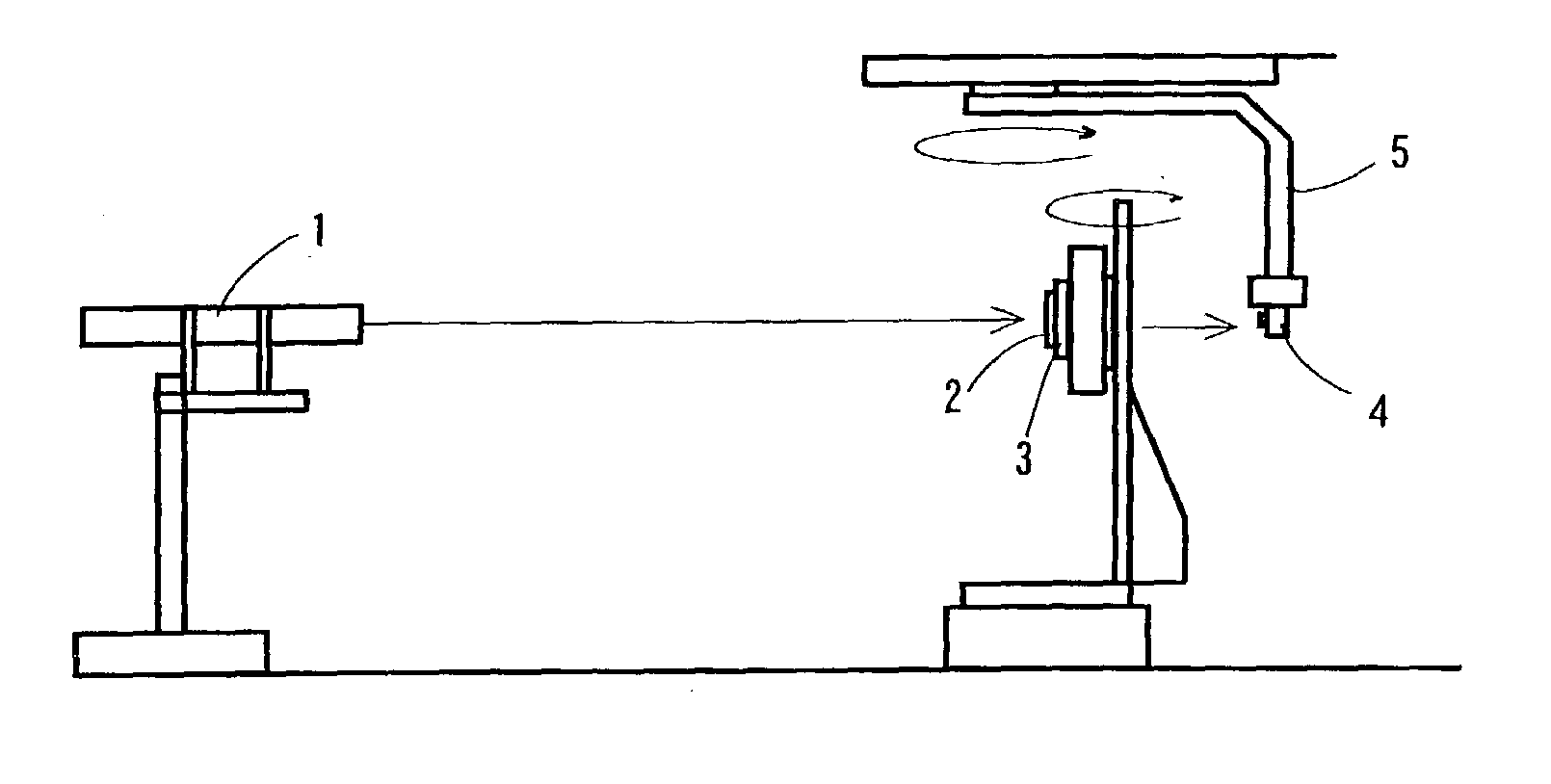

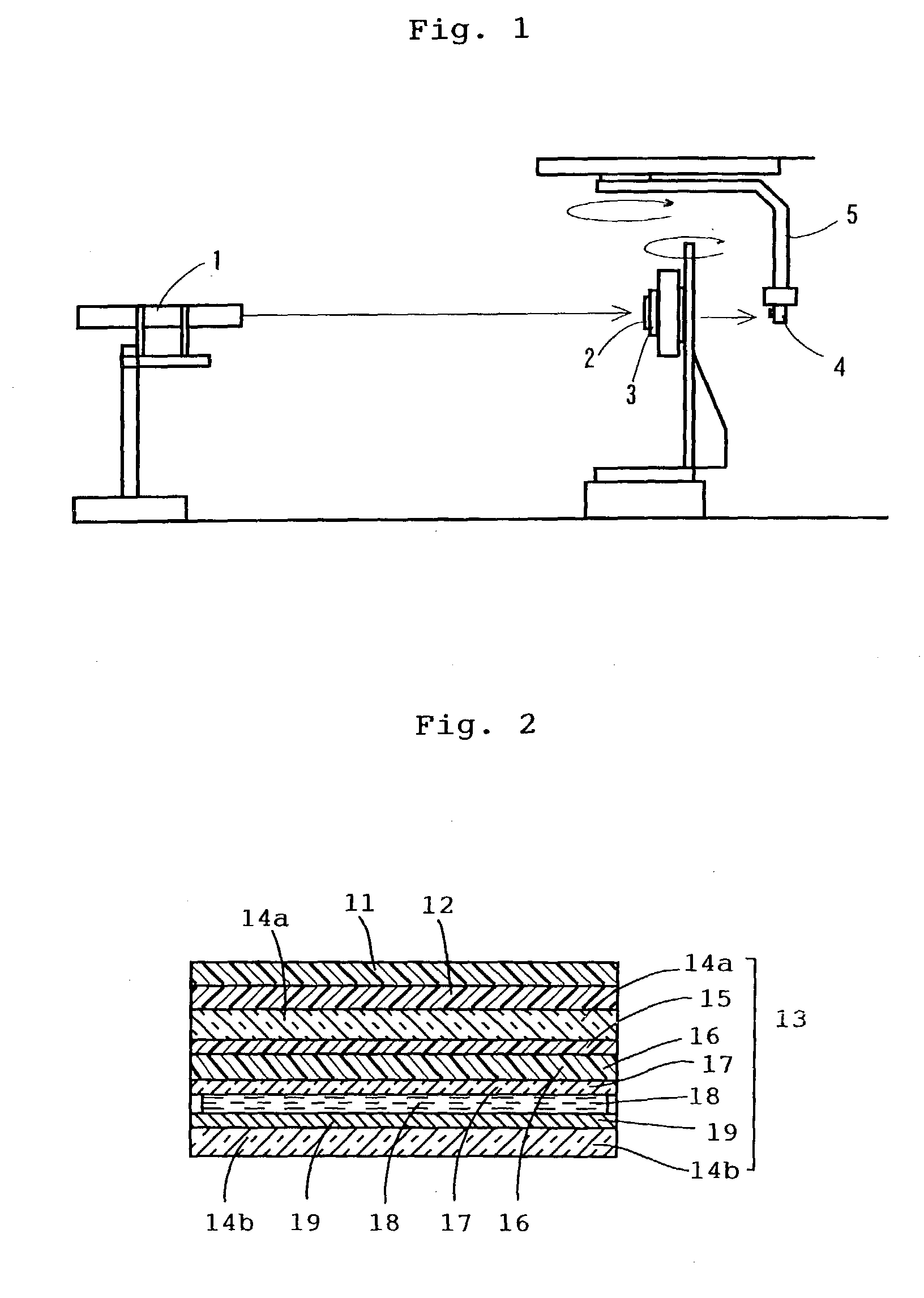

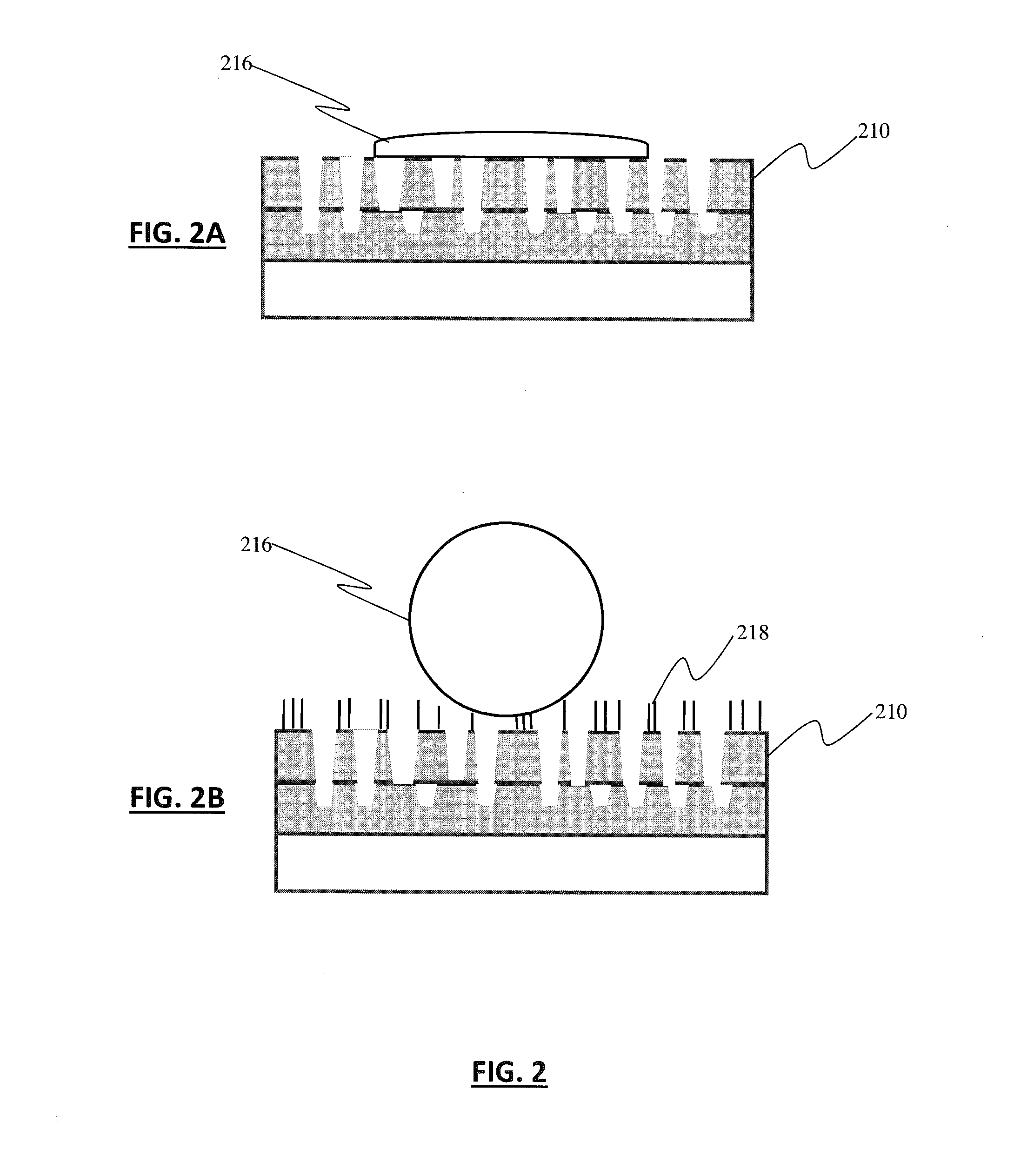

Transmissive light-diffusing layer

InactiveUS6856365B2Low costEasy to operateDiffusing elementsLayered productsRefractive indexLiquid composition

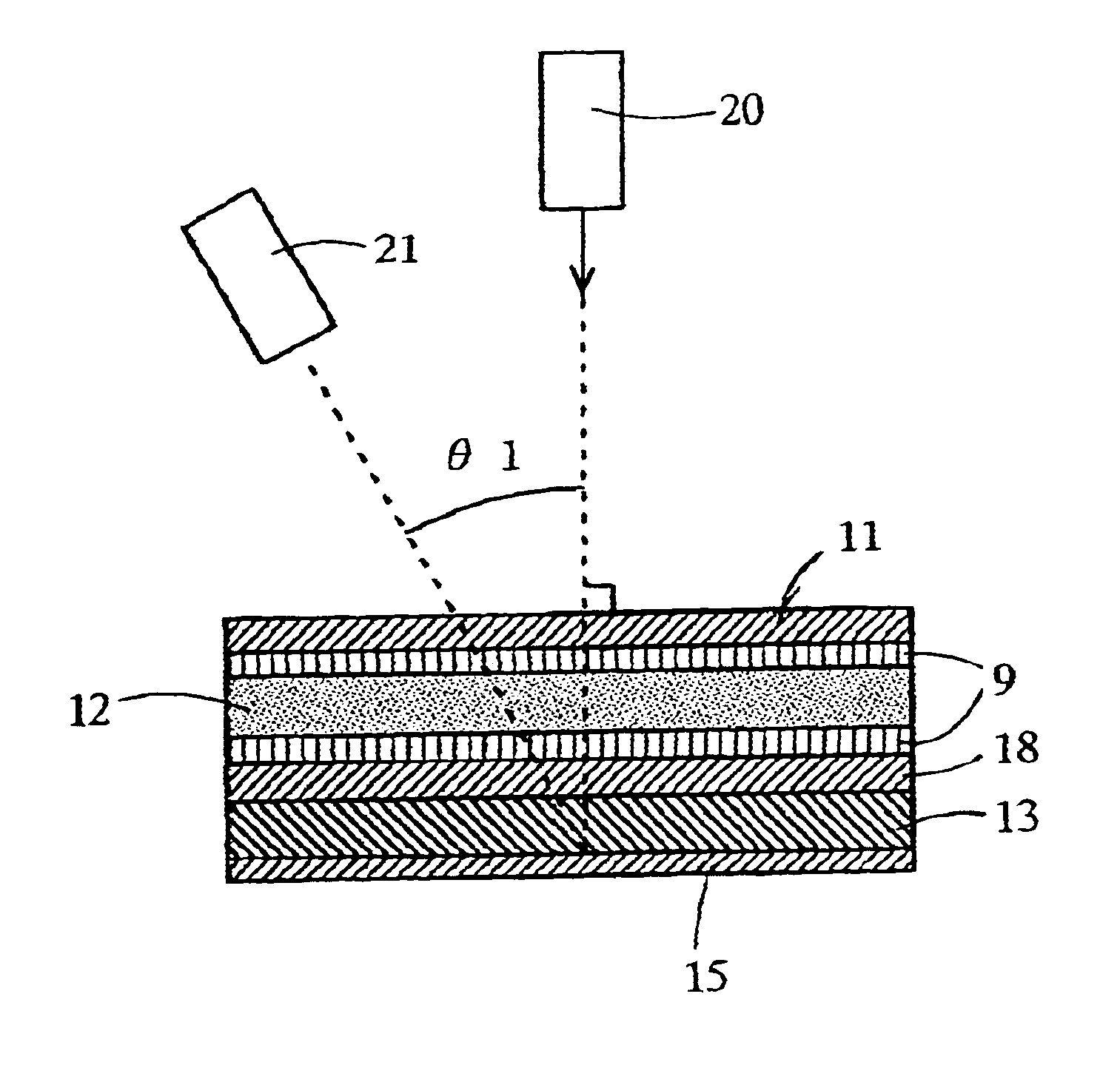

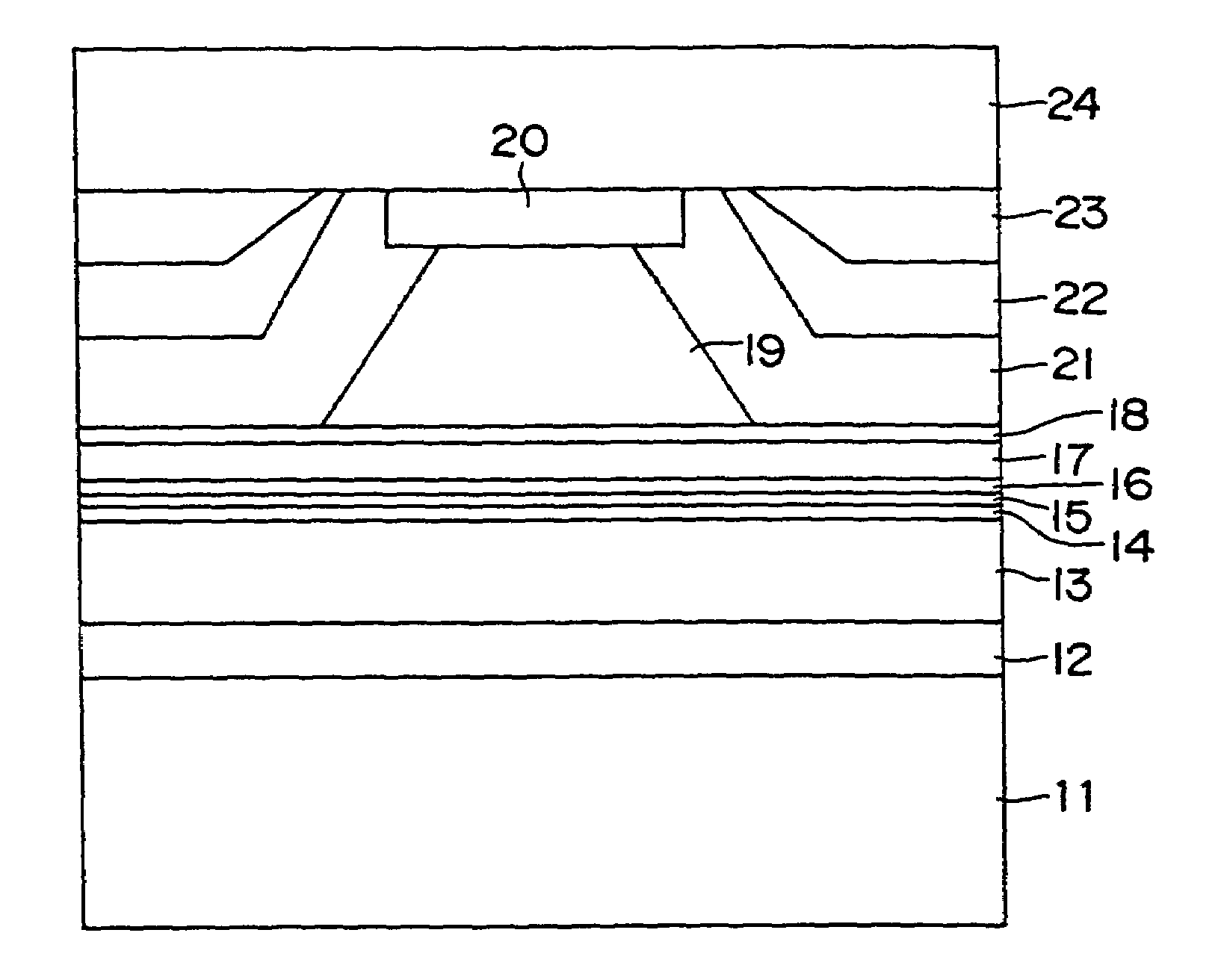

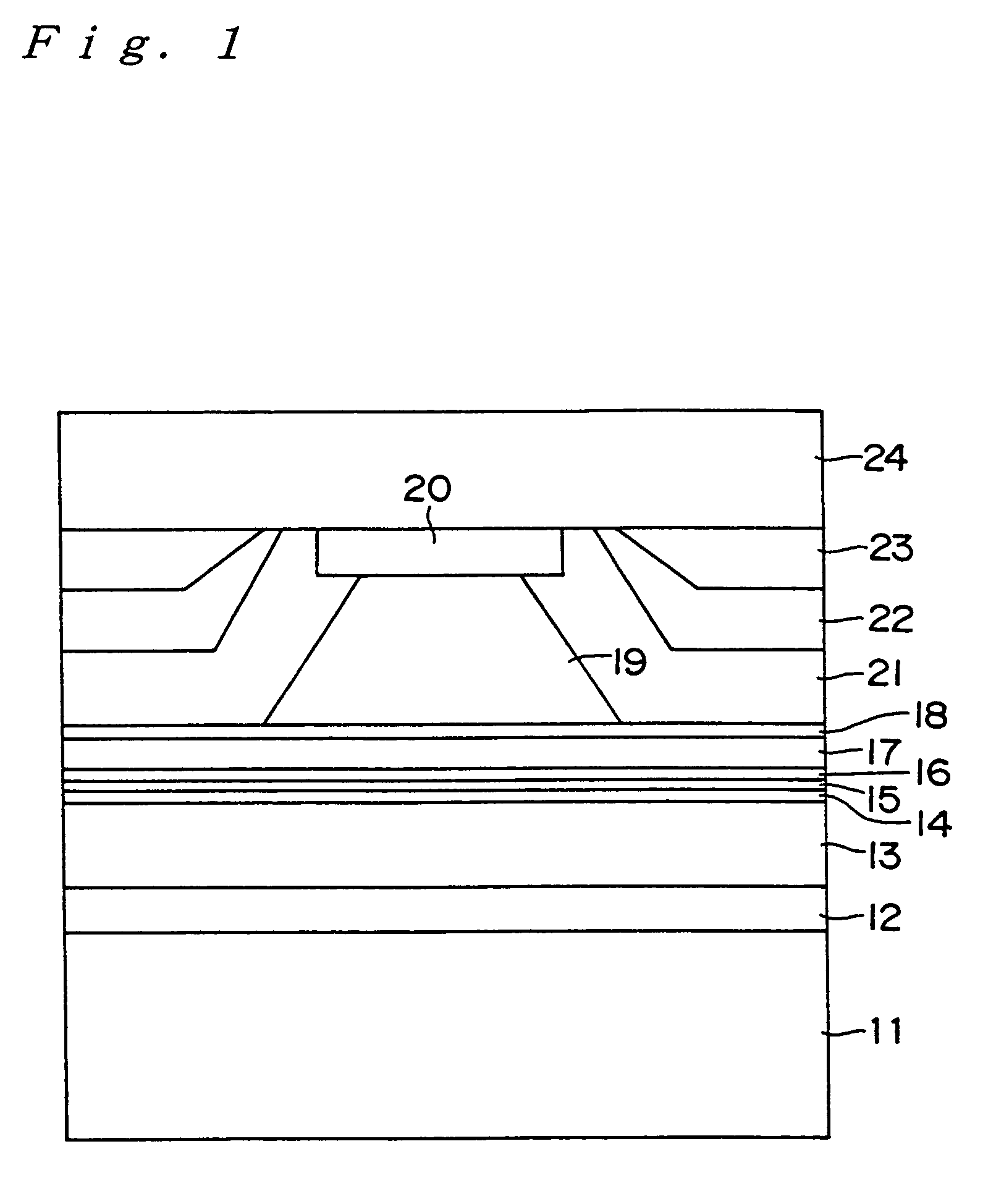

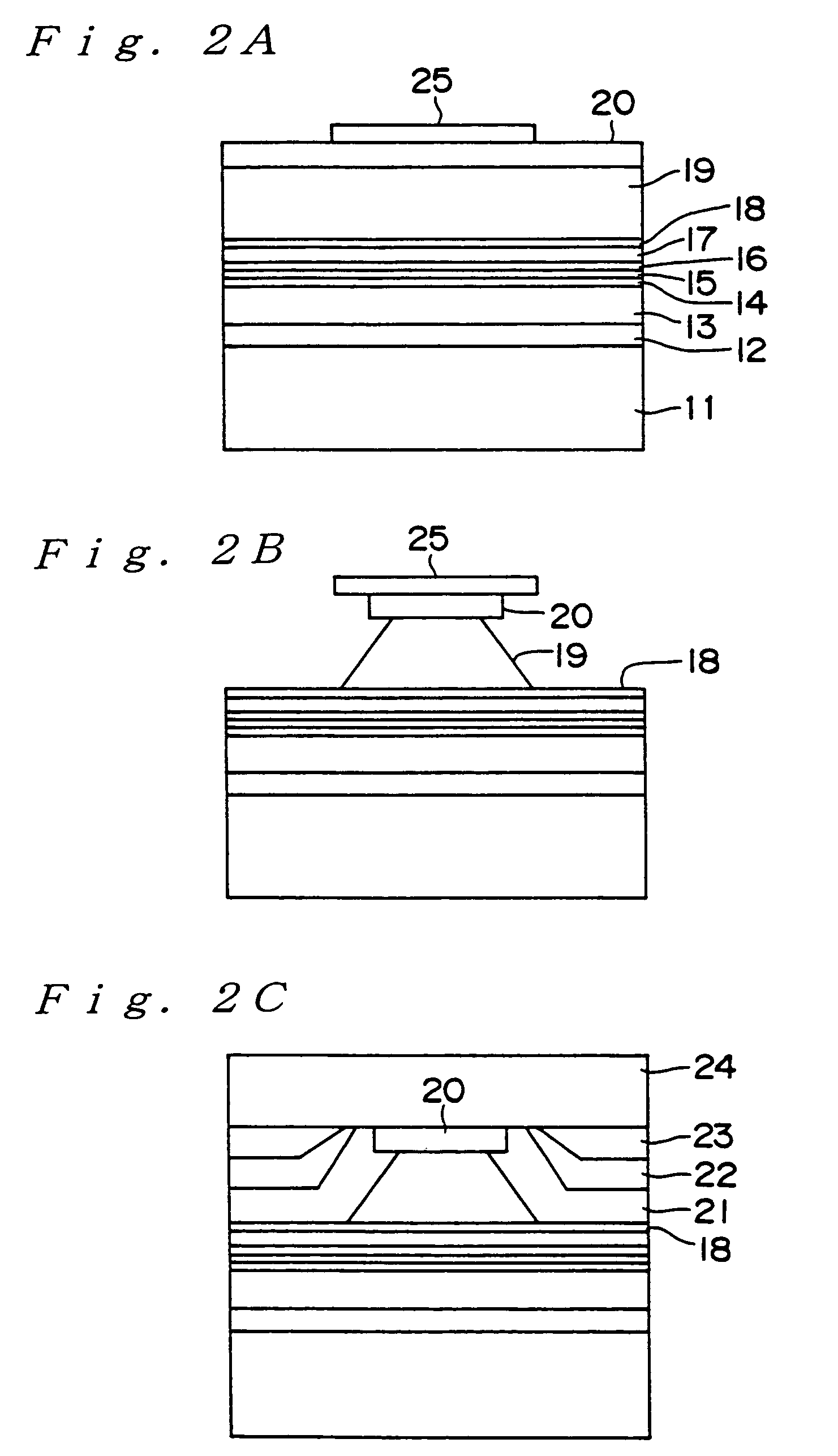

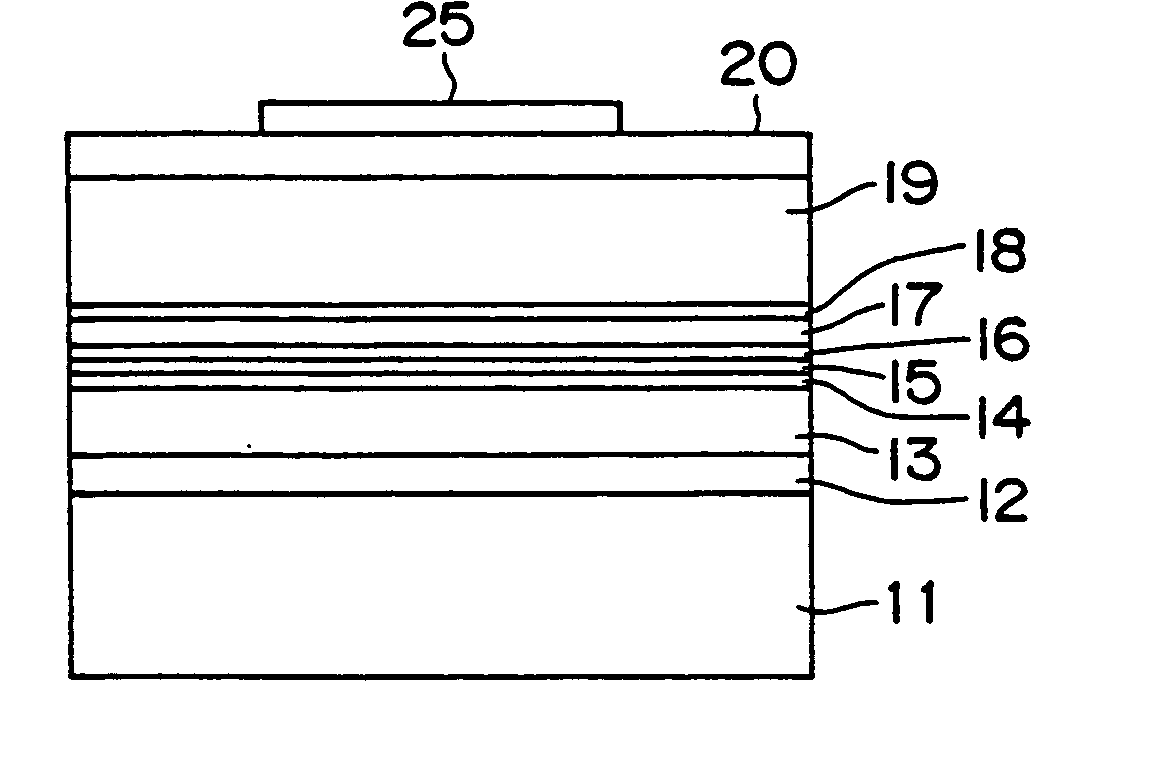

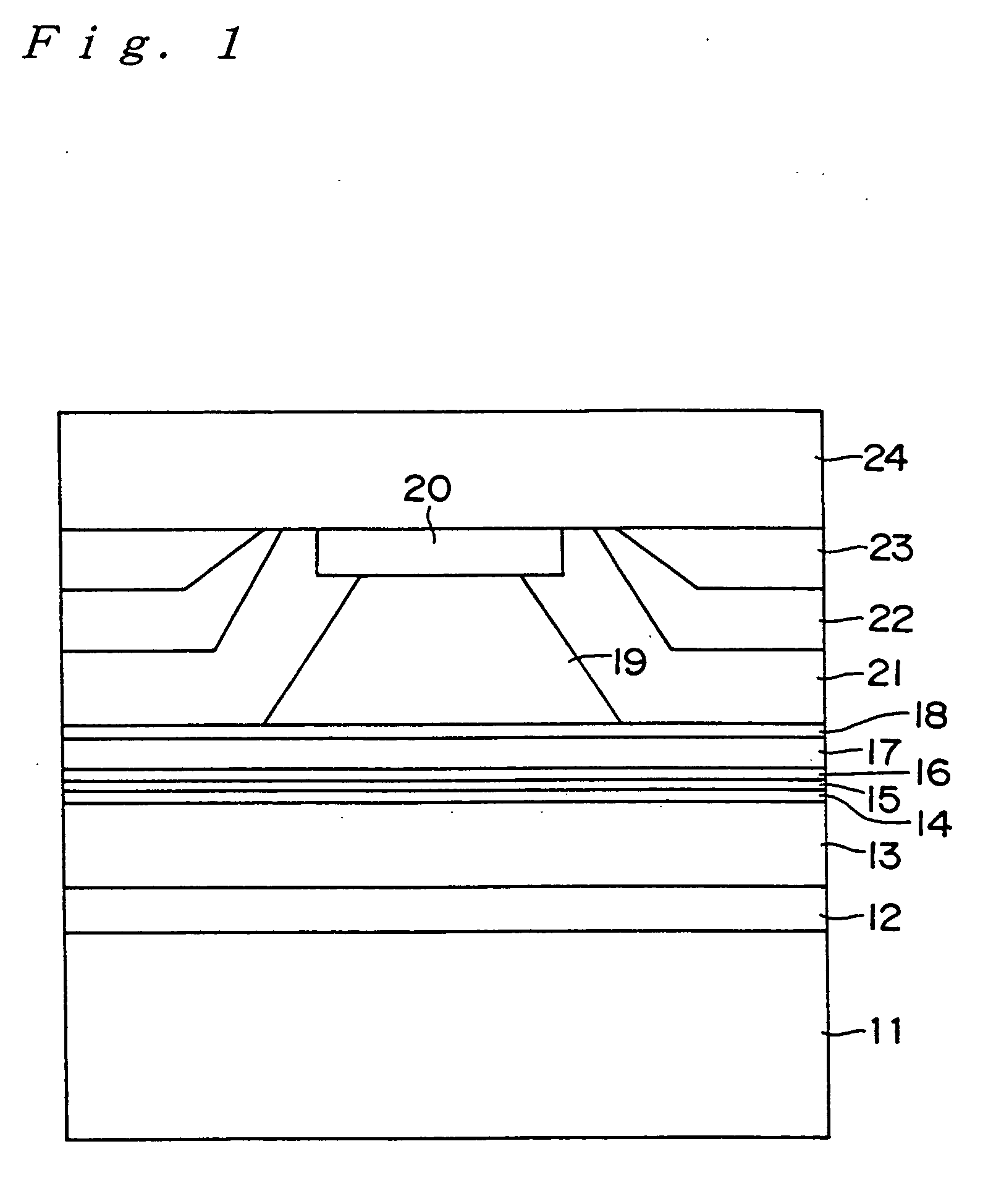

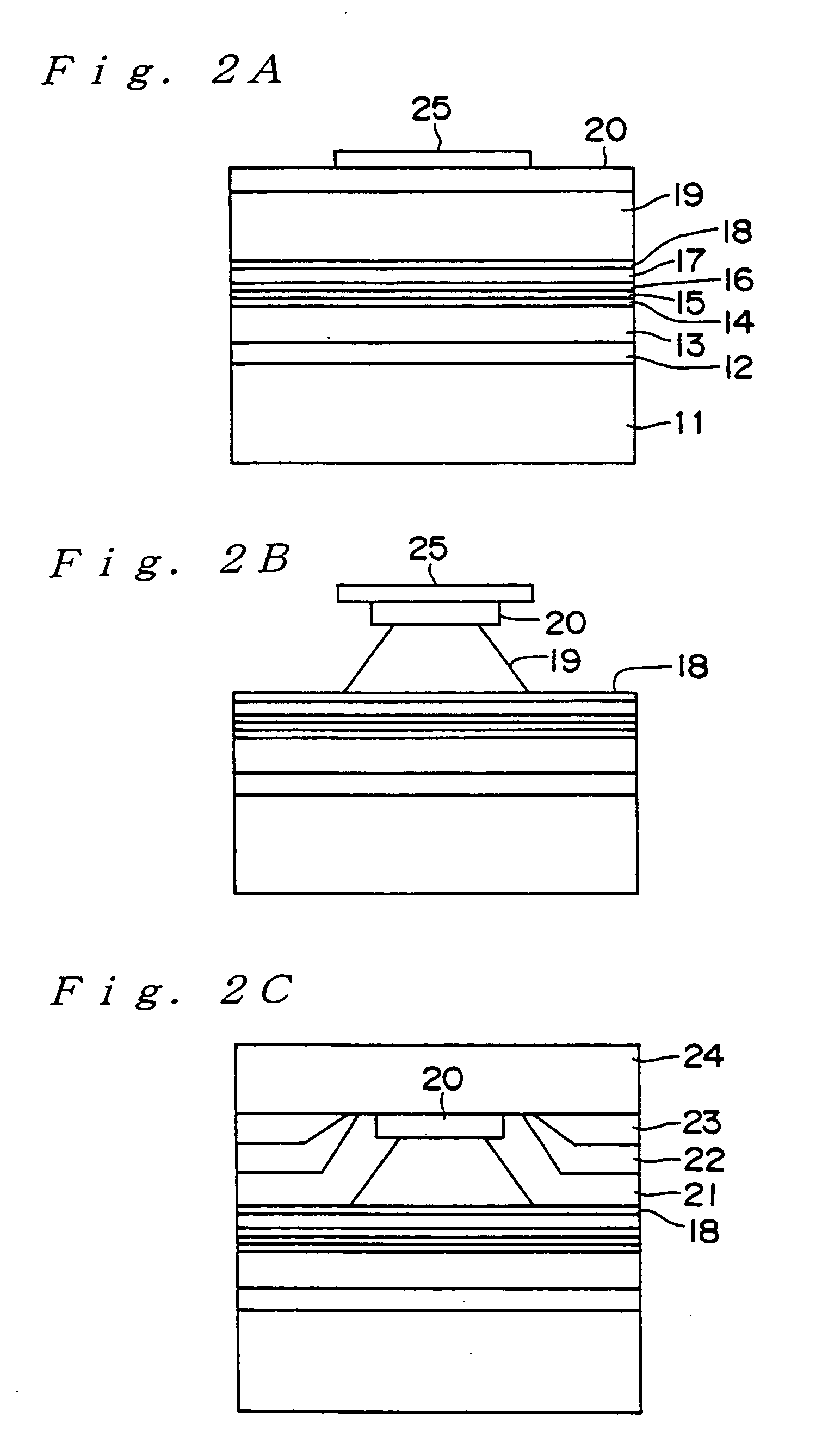

A light-diffusing layer 16 having at least a bicontinuous phase structure is formed by coating a substrate 14a with a coating liquid composition containing a plurality of resins being different in refractive index with each other, drying the substrate, and heating the resultant to cause spinodal decomposition from the resin-containing layer on a transparent substrate. A transparent conductive layer (or a transparent electrode) 17 may be formed on the light-diffusing layer 16 of the substrate 14a. A liquid crystal cell 13 of a reflective liquid crystal display apparatus may be formed by facing the transparent conductive layer 17 with a reflection electrode 19 formed on the other substrate 14b, and sealing a liquid crystal 18 between a pair of electrodes, 17 and 19. The present invention, therefore, provides a light-diffusing layer capable of uniformly and brightly displaying an image on a screen in a reflective liquid crystal display apparatus of an internal light-diffusing layer system in which the light-diffusing layer is formed on a substrate of a liquid crystal cell.

Owner:DAICEL CHEM IND LTD

Novel gold-based composite electrical brush material and preparation method thereof

InactiveCN105925830AHigh strengthRotary current collectorBrushes manufactureHardnessSolid solution strengthening

The invention discloses a novel gold-based composite electrical brush material and a preparation method thereof. The novel gold-based composite electrical brush material is characterized in that a coating layer is gold alloy; a core part is copper alloy; the coating layer of the electrical brush material adopts gold as a matrix and contains a certain mass friction of Cu and Ag; a base layer adopts copper as a matrix; a coating layer material contains alloy with Au and Cu elements; AuCu ordered phases generated from ordering of Au-Cu exert an ageing strengthening function; and the added Ag elements can exert a solid solution strengthening function. According to the novel gold-based composite electrical brush material, a copper alloy core part material is liable to precipitate (CuNi)3Sn phases during the ageing process, the strength of the alloy is improved, and the alloy is strengthened through spinodal decomposition; and composite electrical brush materials with different hardness and different coating layer thicknesses can be obtained through controlling the processing deformation amount, an intermediate annealing technology and an ageing technology, and the highest performances can reach as follows: the hardness HV is larger than or equal to 240 Hv, the coating layer thickness is smaller than or equal to 0.07 mm, and the outer diameter is 0.5 mm.

Owner:SINO PLATINUM METALS CO LTD

High-strength nanostructured alloys

Biphasic alloys, formed through a spinodal decomposition process, are disclosed. The alloys have improved strength and hardness, over single phase alloys, due to coherency strain between the phases. They are prepared from readily available transition metals, and they can be used to make large, high-strength parts, for example, of types that cannot be made by extrusion, forging or cold working techniques.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

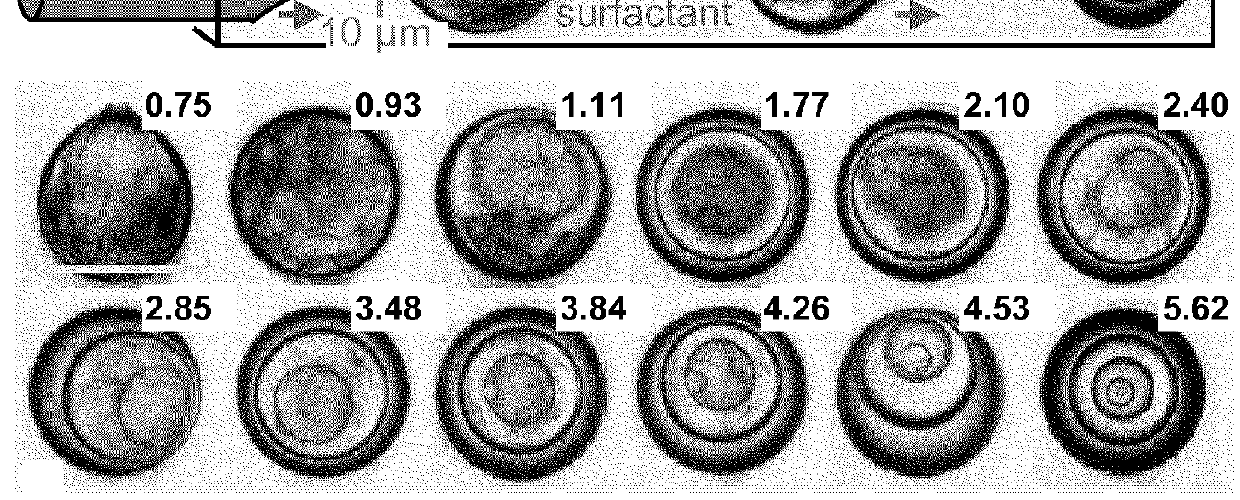

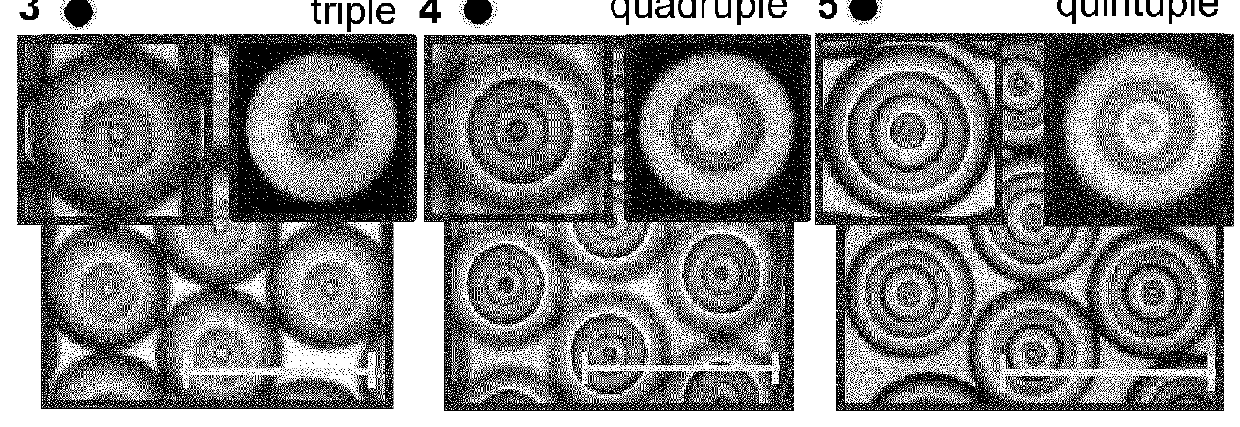

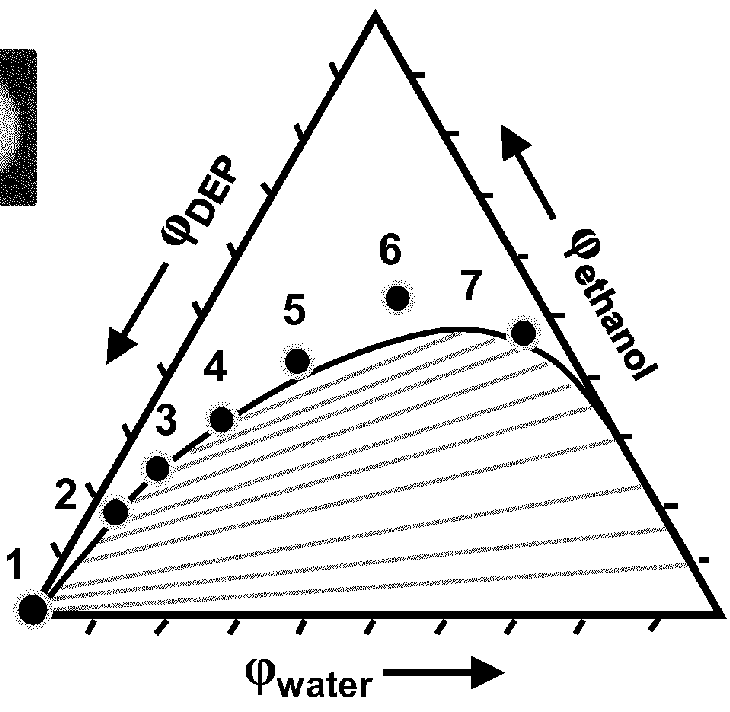

Higher order multiple emulsions

Multiple emulsions with an “onion” topology are useful vehicles for drug delivery, biochemical assays, and templating materials. They can be assembled by ternary liquid phase separation using microfluidics, but the control over their design is limited because the mechanism of their creation is unknown. Here it is shown that phase separation occurs via self-similar cycles of mass transfer, spinodal decomposition or nucleation, and coalescence into multiple layers. Mapping out the phase diagram demonstrates a linear relation between concentric layer diameters, whose slope depends on the initial ternary composition and the molecular weight of the surfactant. These general rules quantitatively predict the number of droplet layers (multiplicity). Further, self-assembly routes for polymer capsules and liposomes are provided with techniques to assemble lipid-stabilized droplets with ordered internal structures.

Owner:NEW YORK UNIV

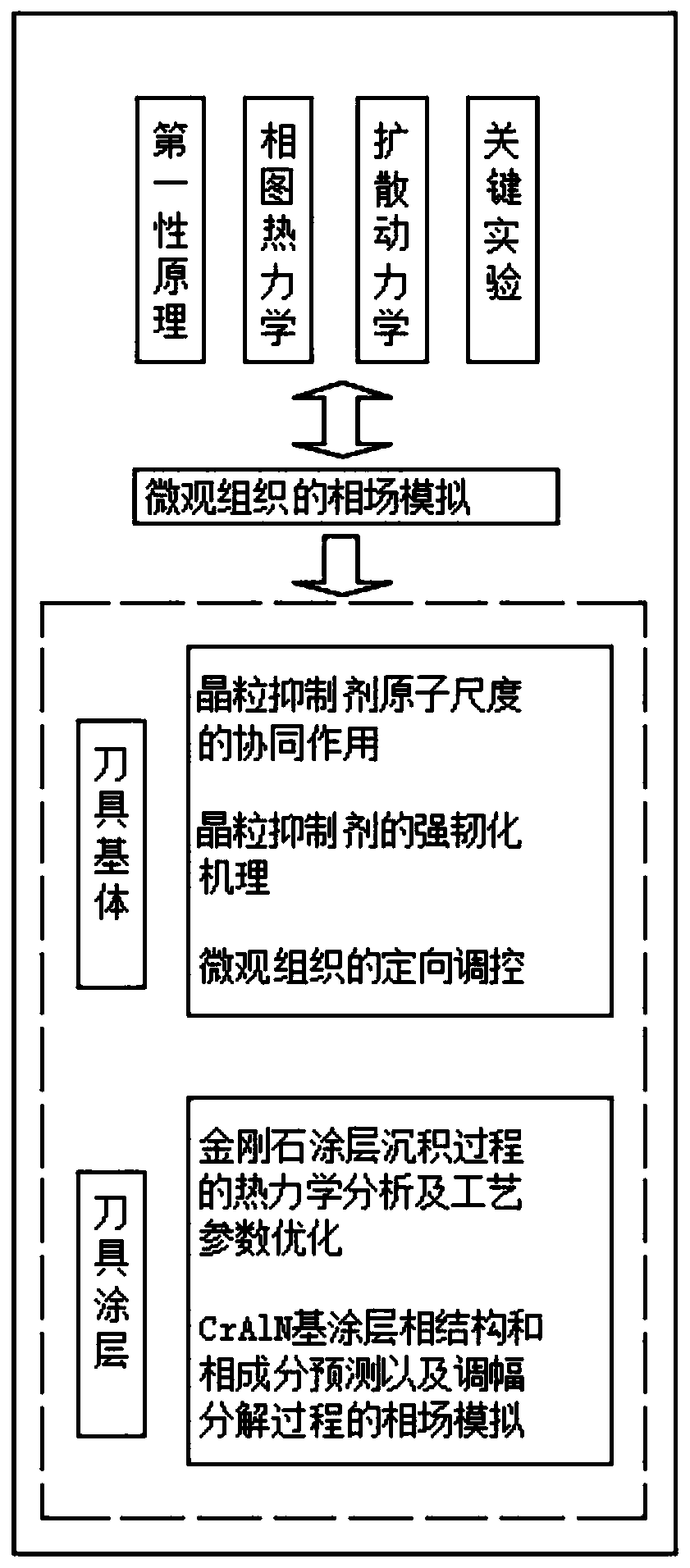

Directional regulating method for systematic tissue structure of high-strength high-toughness ultra-fine hard alloy material

PendingCN110265093ARealize Phase Field SimulationOptimizing the preparation process parametersComputational materials scienceInstrumentsSolubilityWear resistant

The invention discloses a directional regulating method for a systematic structure of a high-strength high-toughness ultra-fine hard alloy material. The method comprises the steps of establishing a researching platform for designing a hard alloy cutter substrate and a wearing-resistant coating microsturcture; performing directional regulating on distribution and dispersion of a crystal grain inhibitor and segregation thickness in a WC / Co interface according to a performance requirement; establishing thermodynamics information of a temperature interval, a solubility interval and phase stability in generating each deposit of a diamond coating, and researching influence of technical conditions such as precursor kind and component and deposition temperature and pressure to properties such as phase kind and component of the diamond coating; and based on a metastable phase graph of a pseudobinary CrN-AlN system and a phase change driving force of each phase, predicting the phase structure and the phase composition of sosoloid at different temperatures, thereby realizing phase field simulation of a CrAlN base coating spinodal decomposition process. According to the method of the invention, a cooperative function and a strengthening and toughening mechanism of the crystal grain growth inhibitor are disclosed in an atom scale, and furthermore directional regulating of the high-strength high-toughness ultra-fine hard alloy microstructure is realized through a thermal-dynamic analysis facility.

Owner:蓬莱市超硬复合材料有限公司

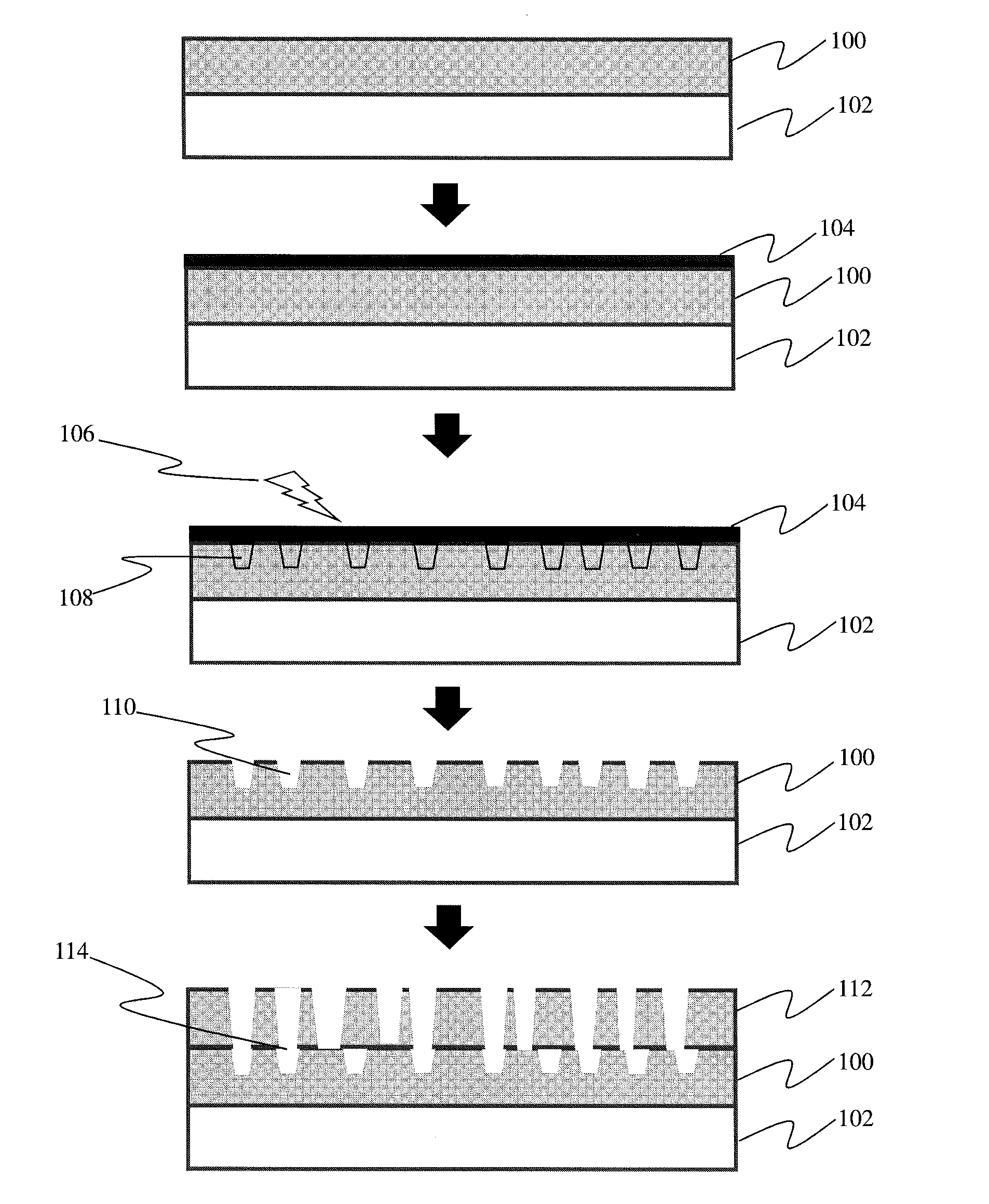

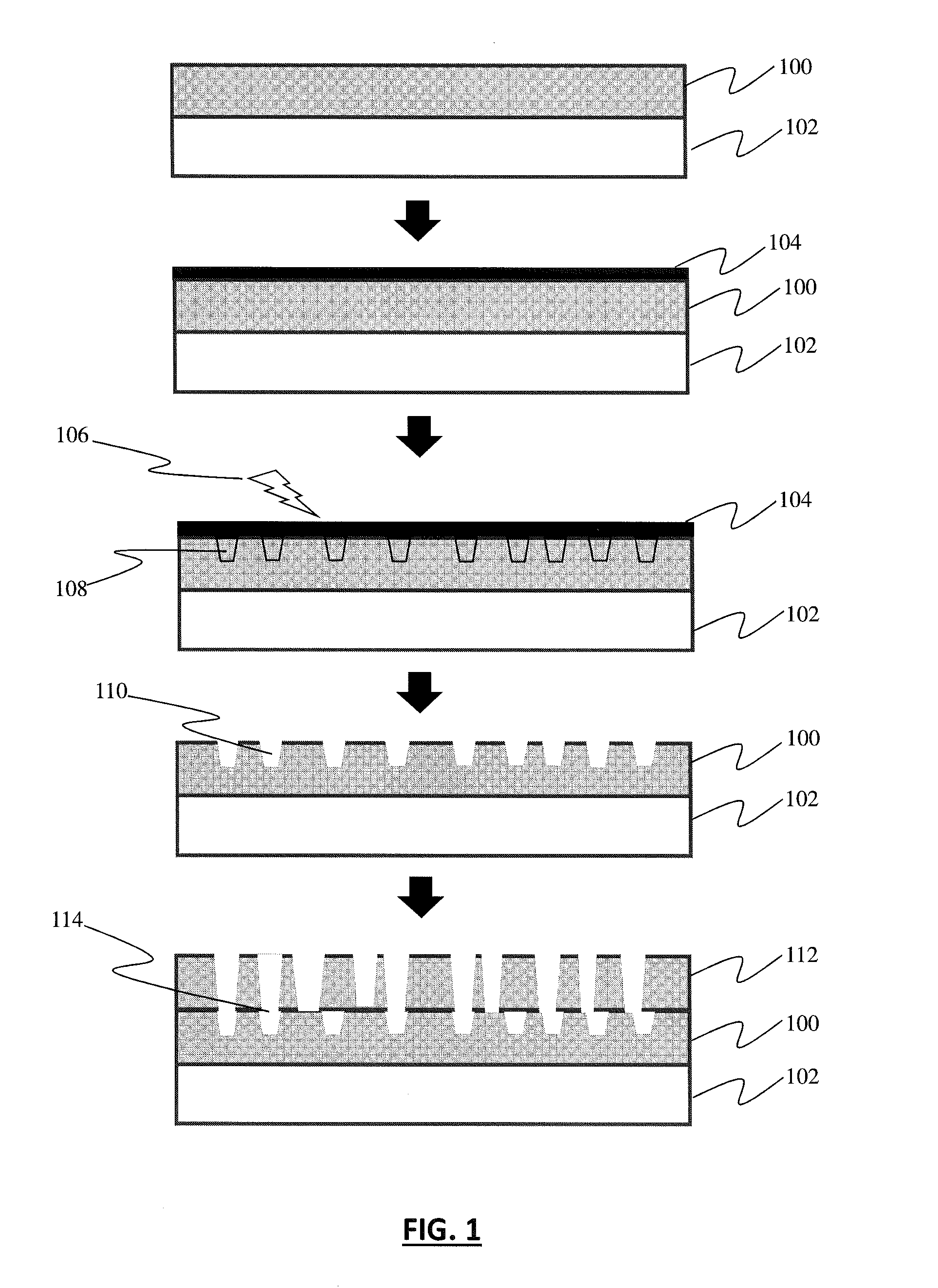

Fabricating highly durable nanostructured coatings on polymer substrate

ActiveUS20160200630A1Increased durabilityCellsDecorative surface effectsPolymer substrateSuperhydrophobic coating

A method of forming a coating that includes depositing a multicomponent glass layer on a polymer substrate and depositing a heat absorbing layer on the multicomponent glass layer. Inducing spinodal decomposition of the multicomponent glass layer by annealing the heat absorbing layer, and etching at least one of a phase separated component of the multicomponent glass layer. The spinodal decomposition may be achieved through a pulse thermal or electromagnetic assisted annealing process. The coating may then be used as a hydrophilic surface, or may be fluorinated using conventional methods to produce the superhydrophobic coating.

Owner:KONICA MINOLTA LAB U S A INC

Semiconductor laser device and optical disc drive

InactiveUS7197056B2Prevent degradationReduce the temperatureLaser detailsLaser active region structureTensile strainOptical power

Owner:SHARP FUKUYAMA LASER CO LTD

Titanium-copper alloy material, and heat-treating or hot-rolling method of titanium-copper alloy

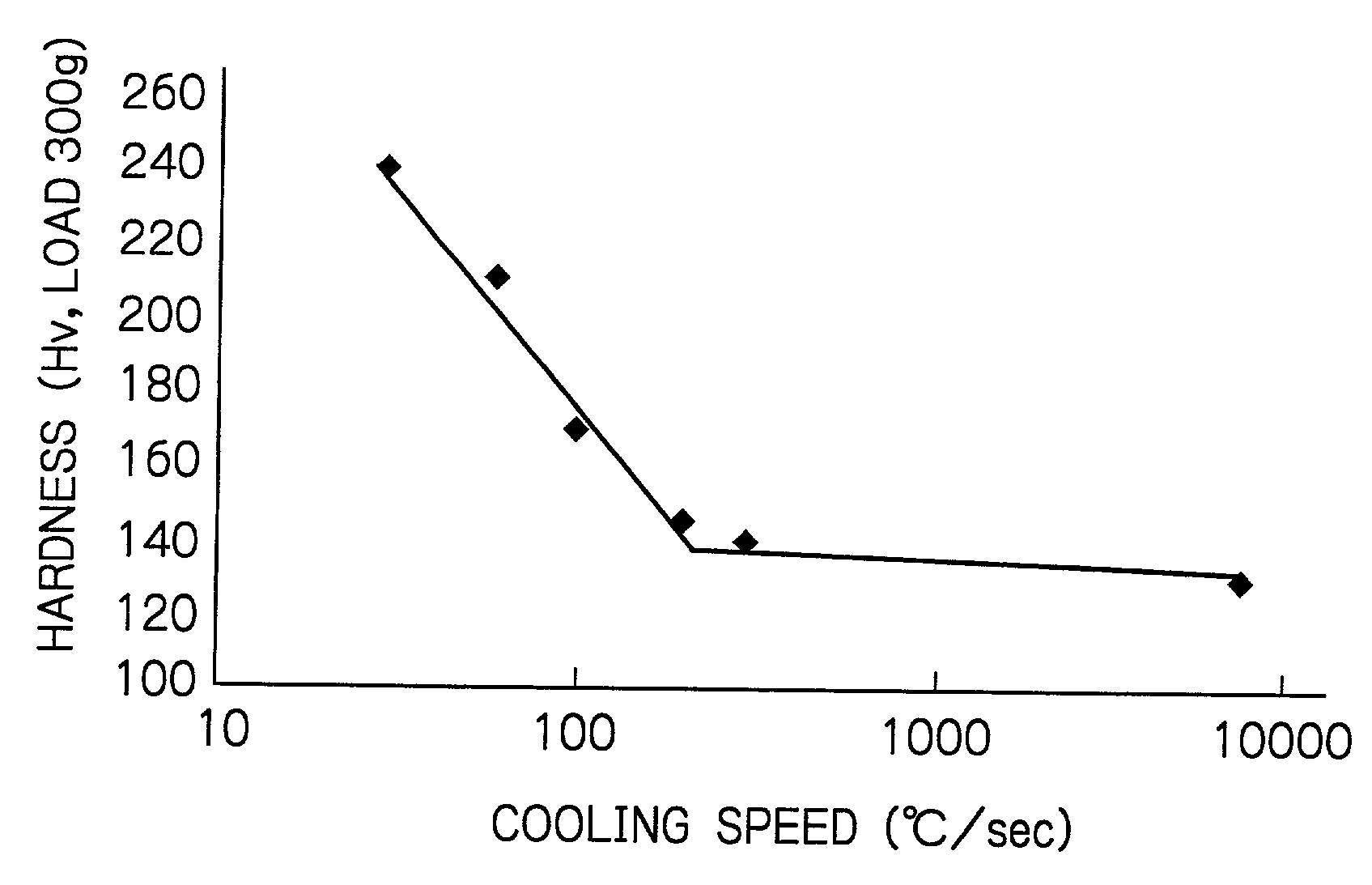

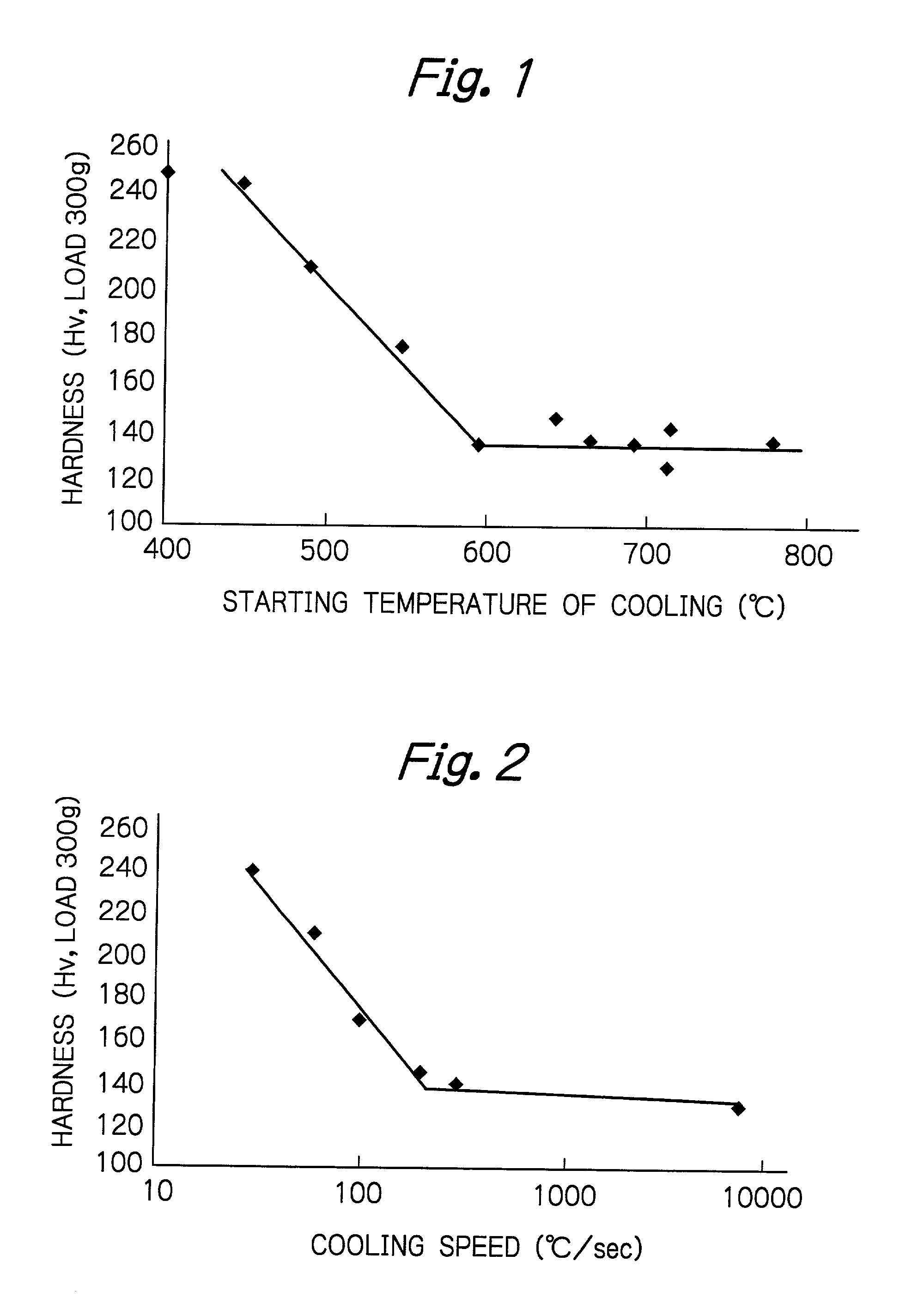

Spinodal decomposition of Cu alloy, which contains from 0.5 to less than 5.0% of Ti, is suppressed and a low hardness dispersion of Hv 40 or less is obtained over a sheet surface. In addition, an isotropy in terms of tensile strength in the vertical direction over the sheet surface is improved such that it is 50N / mm2 or less. In the hot-rolling of the alloy, it is cooled at a cooling speed of not less than 200K (200° C.) / second at least in a temperature range of between 773K (500° C.) and 573K (300° C.).

Owner:JX NIPPON MINING & METALS CO LTD

Semiconductor laser device and optical disc drive

InactiveUS20050041708A1Improve reliabilityPrevent degradationLaser detailsNanoopticsTensile strainOptical power

A 780 nm band semiconductor laser device has an InGaAsP well layer, phosphorous composition of which is 0.51 smaller than 0.55 to prevent spinodal decomposition in growing InGaAsP. A compressive strain of 0.65% less than 1% and more than 0.25% is introduced into the well layer to reduce threshold current thereof. Thus, the 0.78-μm band semiconductor laser device having the InGaAsP well layer stably operates for a long time even in outputting a high optical power of 100 mW or more. A tensile strain of 1.2% is also introduced into barrier layers within the active region so as to compensate the stress due to the compressive strain of the well layer. As a result, the reliability of the semiconductor laser device is further increased during a high output operation.

Owner:SHARP FUKUYAMA LASER CO LTD

Transfer mold releasing film and method for manufacturing mat-shaped molded body

PendingCN110621489AReduce glossIncrease production capacityMagnetic/electric field screeningSynthetic resin layered productsPolyresinMaterials science

The present invention addresses the problem of manufacturing a mat-shaped molded body by forming a concavo-convex shape that is an inverted shape of a transfer surface on a surface to be transferred of a molded body using a transfer mold releasing film in which a concavo-convex layer that does not contain fine particles of 1 [mu]m or more and includes the transfer surface having an arithmetic average roughness Ra of 0.1 to 2 [mu]m and 60-degree gloss of less than 5% is formed on at least one surface of a base material layer. The concavo-convex layer may be a cured product of a curable composition containing one or more types of polymer components and one or more types of curable resin precursor components. At least two components selected from the polymer components and the curable resin precursor components may be phase-separated from each other by wet spinodal decomposition. The transfer mold releasing film may have a haze of 50% or more. The mat-shaped molded body may be an electromagnetic wave shield film. When a concavo-convex shape is transferred using the transfer mold releasing film, a mat-shaped molded body having a low gloss can be manufactured.

Owner:DAICEL CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com