Titanium-copper alloy material, and heat-treating or hot-rolling method of titanium-copper alloy

a technology of titanium-copper alloy which is applied in the field of titanium-copper alloy material and heat treatment or hot rolling method of titanium-copper alloy, can solve the problems of difficult to completely lessen the hardness dispersion, unstable quality and subsequent working, and unelucidated which production factor mast significantly influences anisotropy, etc., and achieves the effect of facilitating post-forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

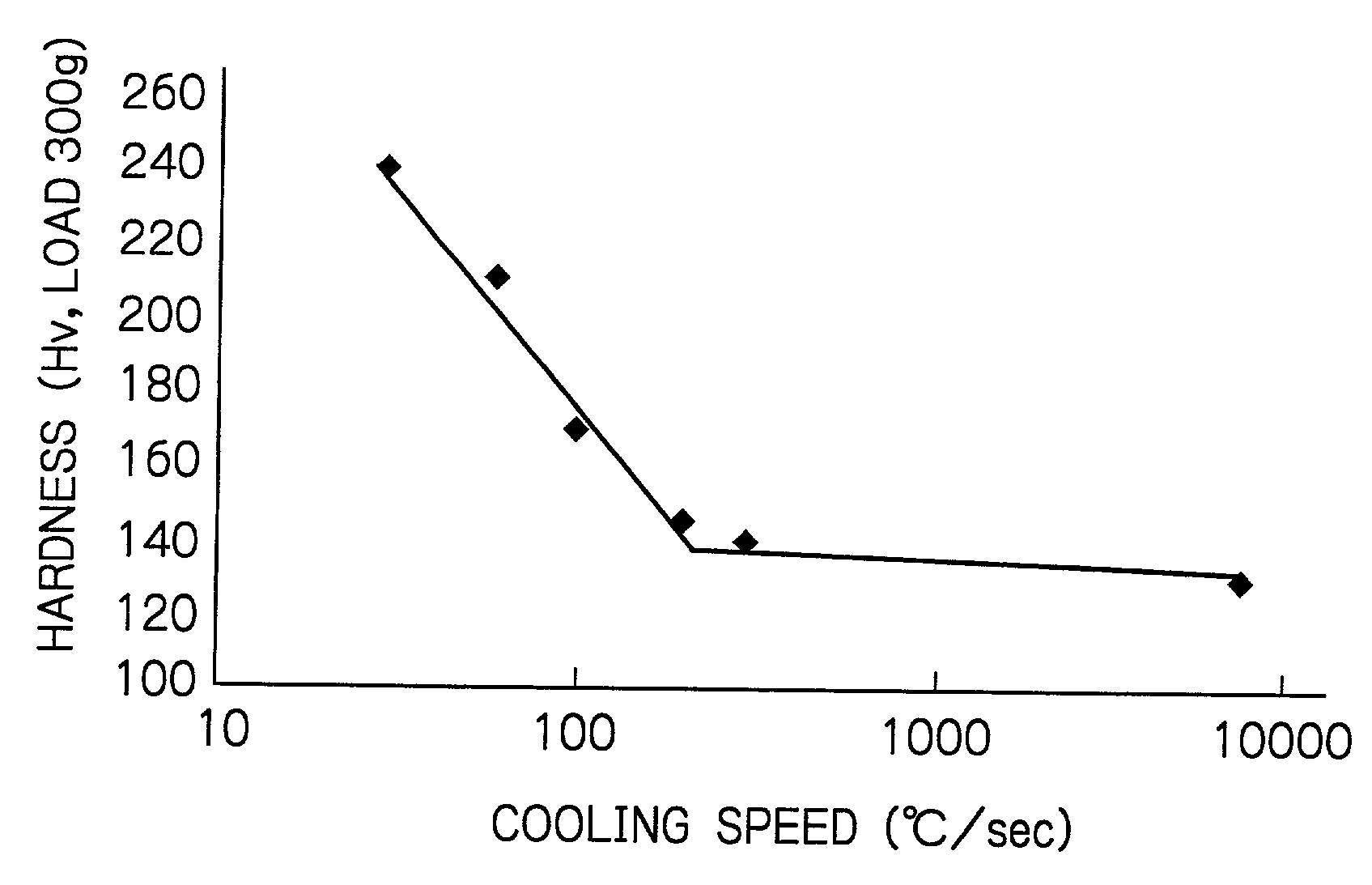

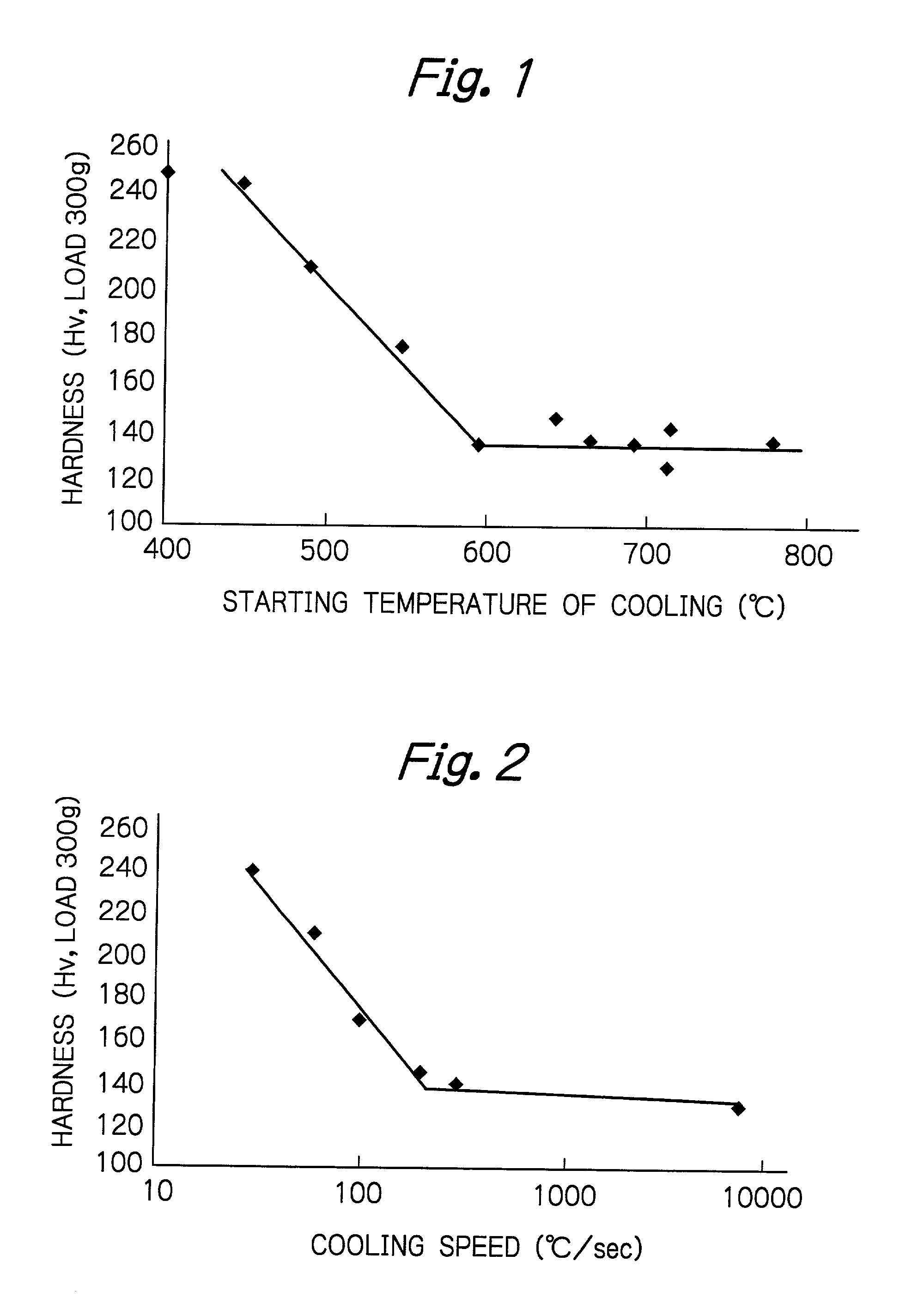

[0043] Titanium-copper alloys, which contain a specified mass % of Ti shown in Table 1, were used as the samples. The predetermined components were blended and melted in a vacuum melting-furnace to provide the titanium-copper alloys. The melt was cast into an ingot to provide a 3.5 kg ingot (30 mmt.times.80 mmw.times.150 mml). The riser portion of the ingot was cut off and subjected to scalping and milling of the edges in the transversal direction (10 mm at both edges). The scalped ingot was soaking-annealed in air at 1123K (850.degree. C.) for 1 hour. Hot rolling was then carried out to reduce the thickness from 27 mm to a predetermined thickness usually 8 mm thickness (8 mmt.times.70 mmw.times.562.5 mml). During the rolling, the surface temperature of the material was measured by a two-color type radiation thermometer. When the temperature of the material was lowered to a predetermined temperature, water cooling was carried out. Hardness of the material was then measured (referred...

example 2

[0048] A 3.5 kg titanium-copper alloy ingots (30 mmt.times.120 mmw.times.100 mml) having the components blended as shown in Table 1 were hot-rolled under the same process and conditions as in Example 1 to produce an 8-mm thick sheet.

[0049] Although the titanium-copper alloy {circle over (4)} was subjected to the production process until the final aging, the required properties, i.e., 800 N / mm.sup.2 or more of tensile strength and 2% or more of elongation, were not obtained. Cracks were generated during the hot-rolling of the comparative titanium-copper alloy {circle over (5)}, the subsequent working of which was therefore impossible.

[0050] The solution-treatment was carried out at 1173K (900.degree. C.) for 1 hour. The scalping was then again carried out. The cold-rolling was carried out to reduce thickness from 7.5 mm to 1.0 mm. Then, the final solution-treatment was carried out at a predetermined temperature under various conditions using a Greeble testing device, which can option...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com