Patents

Literature

771results about How to "Good environmental stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal oxynitride semiconductor containing zinc

ActiveUS8274078B2High mobility and environmental stabilityImprove mobilityPhotovoltaic energy generationSemiconductor devicesNitrogen oxideOxygen

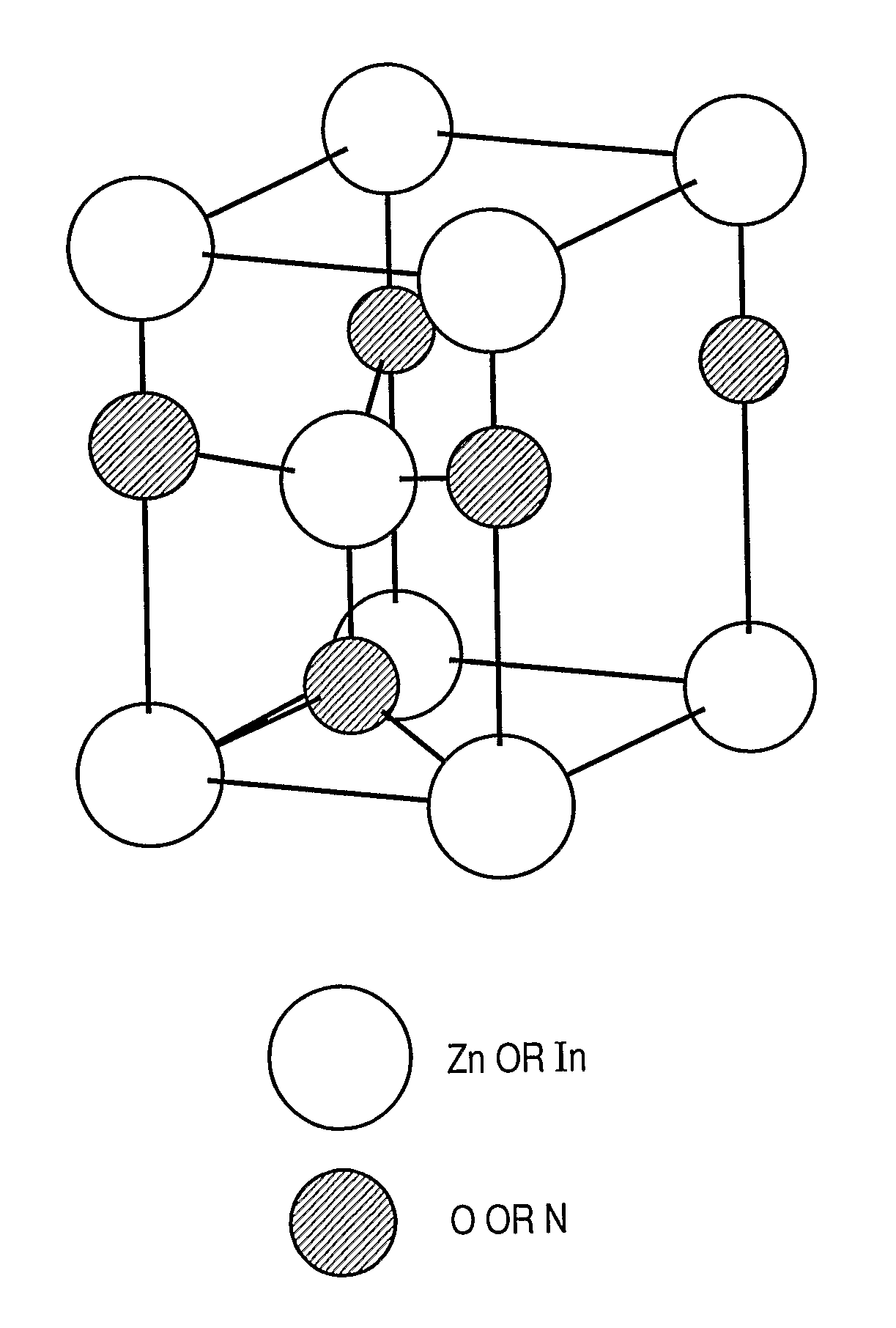

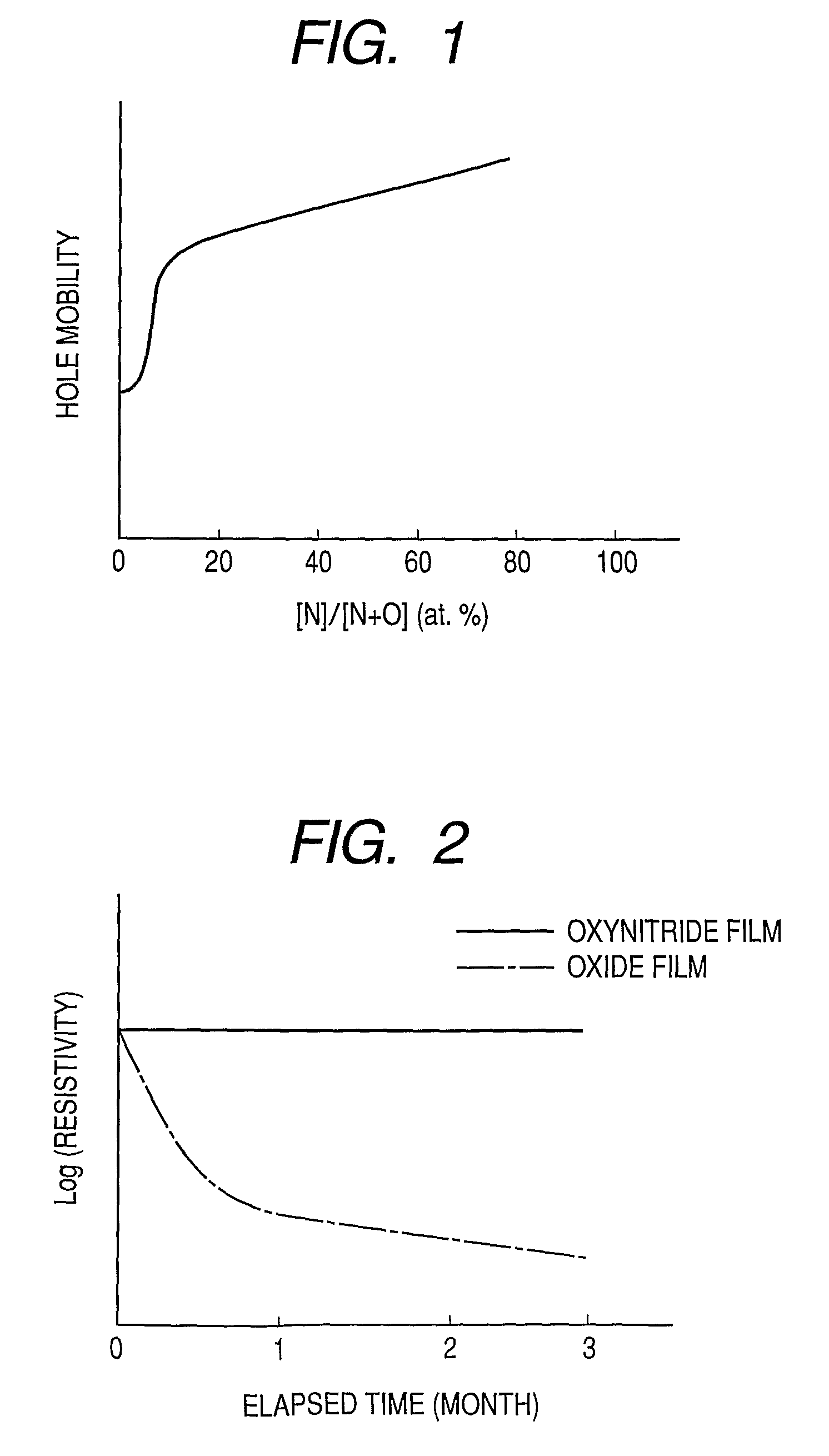

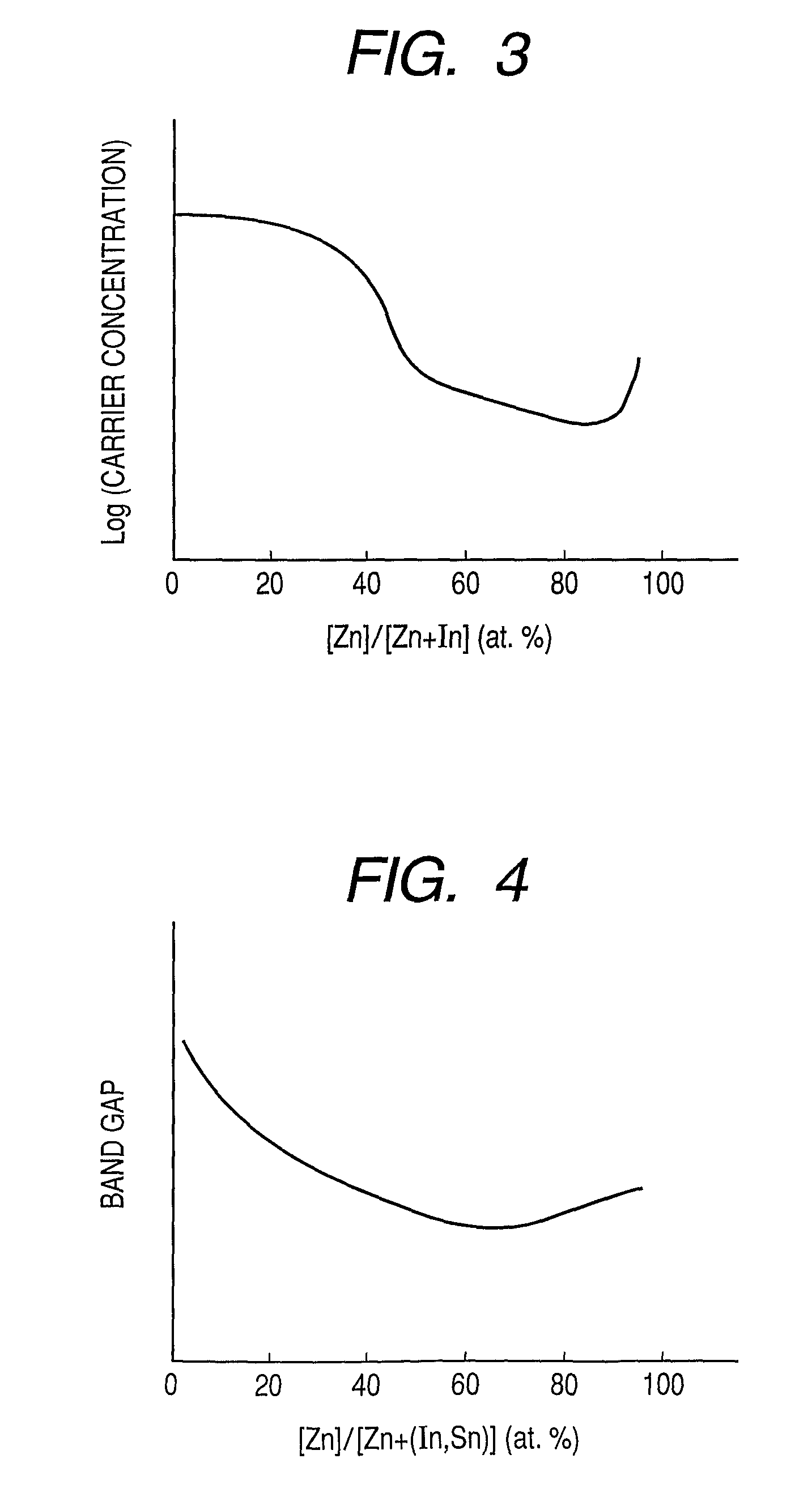

Provided is an oxynitride semiconductor comprising a metal oxynitride. The metal oxynitride contains Zn and In and at least one element selected from the group consisting of Ga, Sn, Mg, Si, Ge, Y, Ti, Mo, W, and Al. The metal oxynitride has an atomic composition ratio of N, N / (N+O), of 7 atomic percent or more to 80 atomic percent or less.

Owner:CANON KK

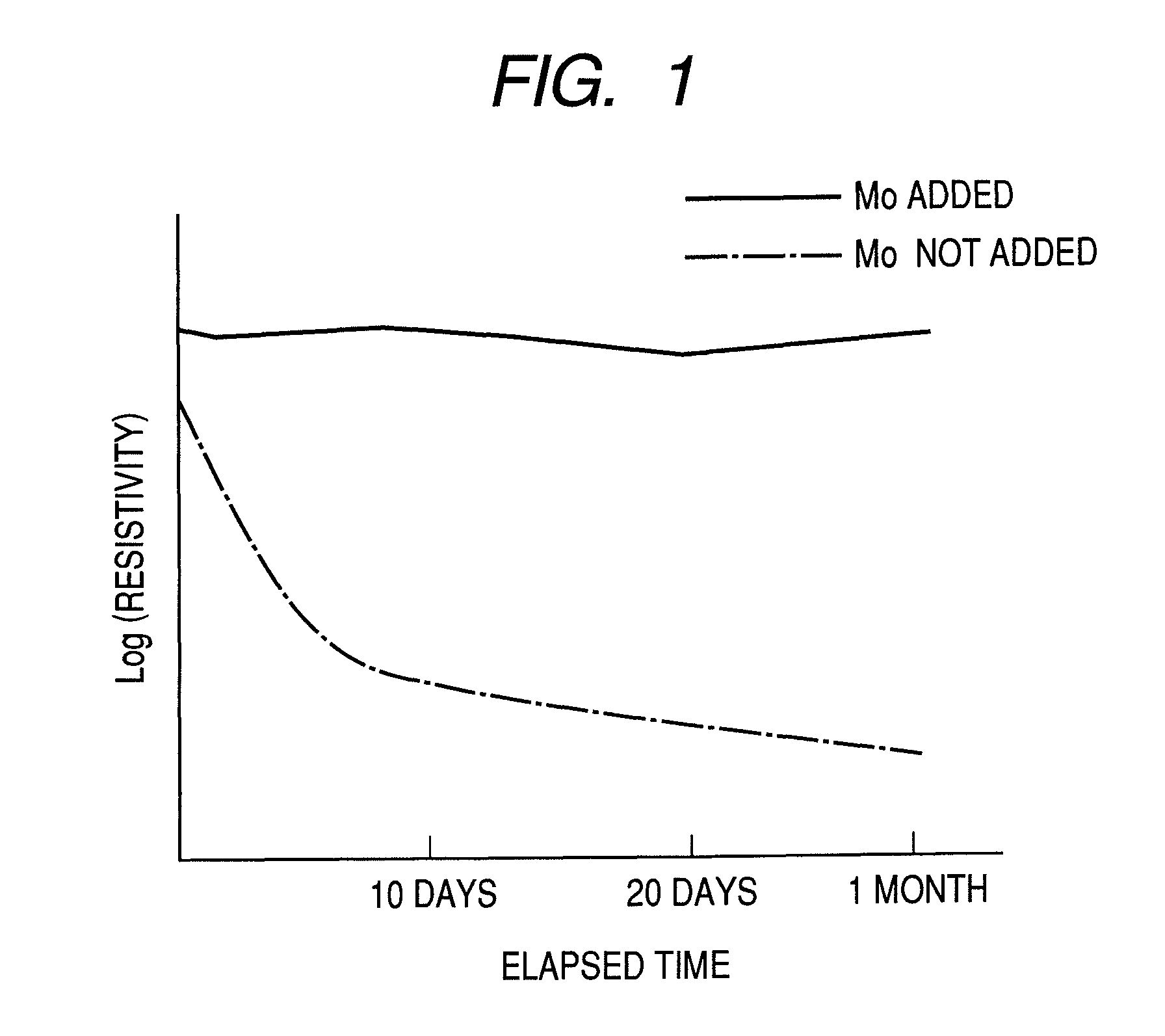

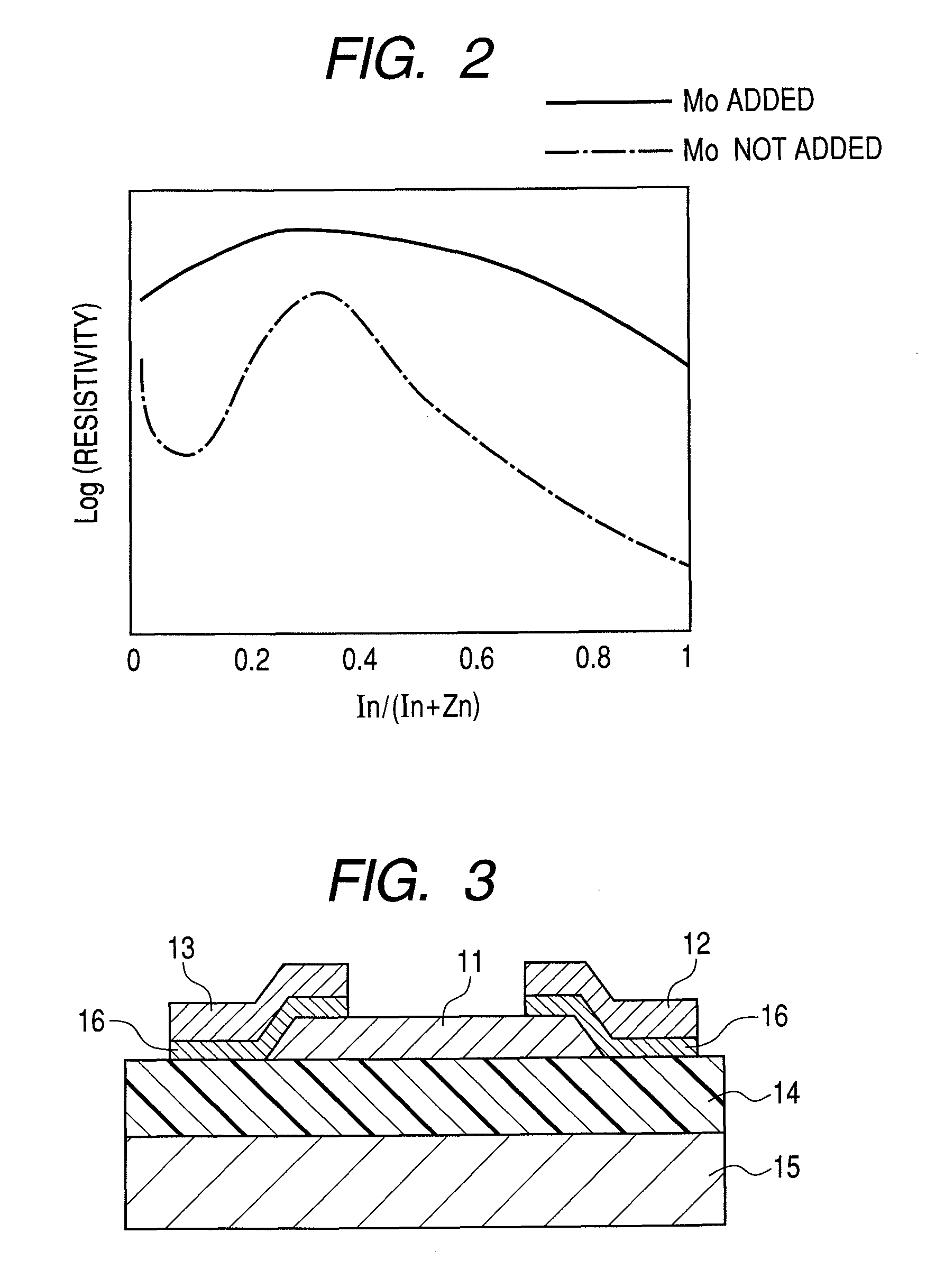

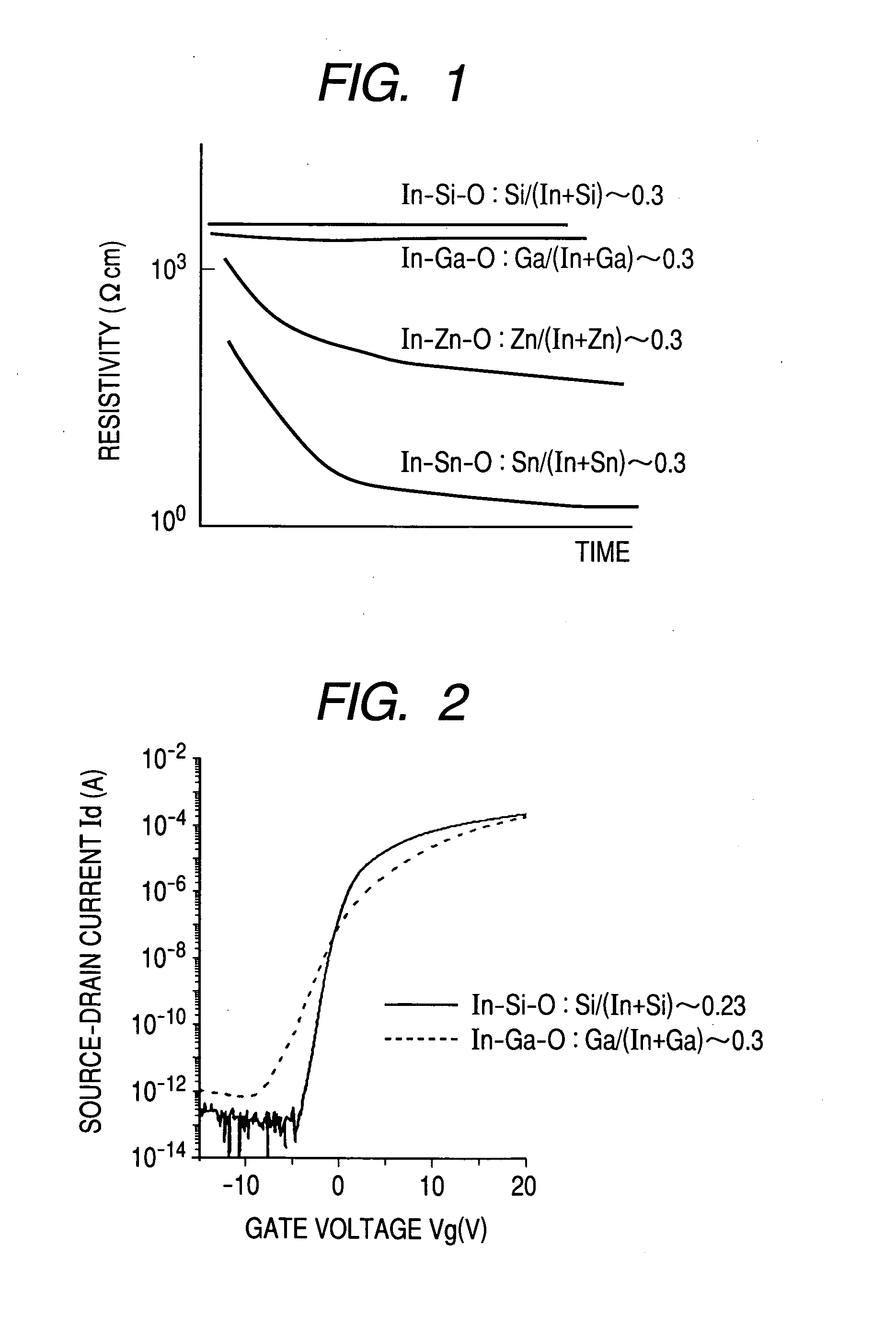

Amorphous oxide and field effect transistor

ActiveUS8212248B2Improve featuresIncrease profitSemiconductor devicesField-effect transistorAtomic composition

An amorphous oxide at least includes: at least one element selected from the group consisting of In, Zn, and Sn; and Mo. An atomic composition ratio of Mo to a number of all metallic atoms in the amorphous oxide is 0.1 atom % or higher and 5 atom % or lower.

Owner:CANON KK

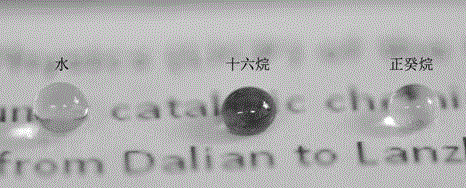

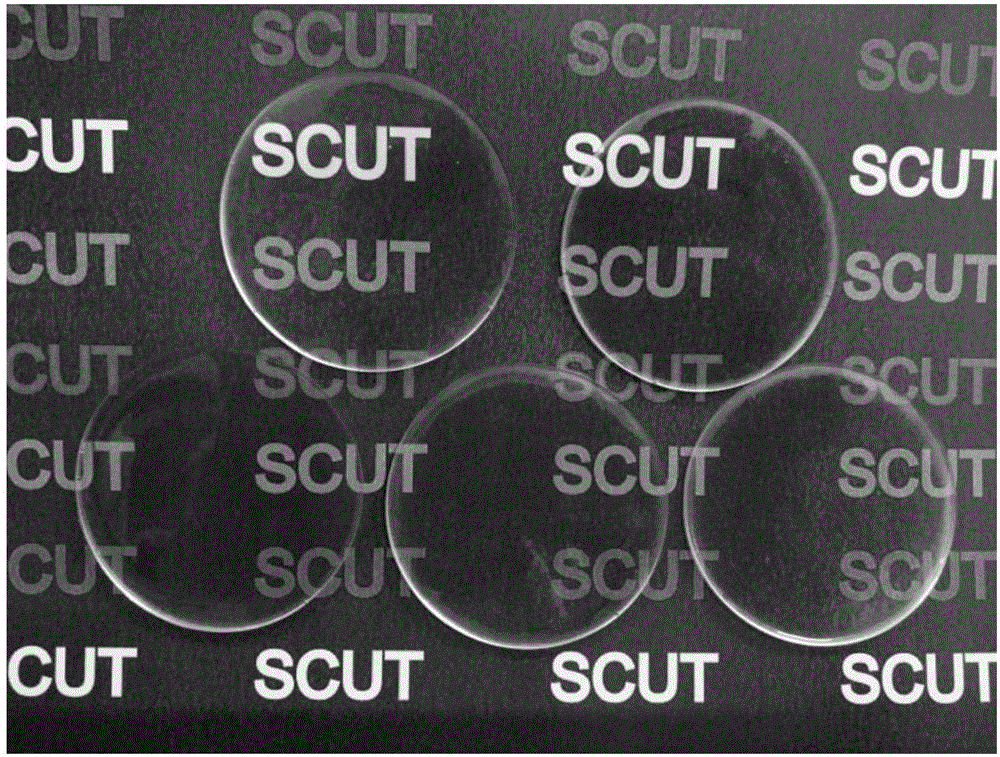

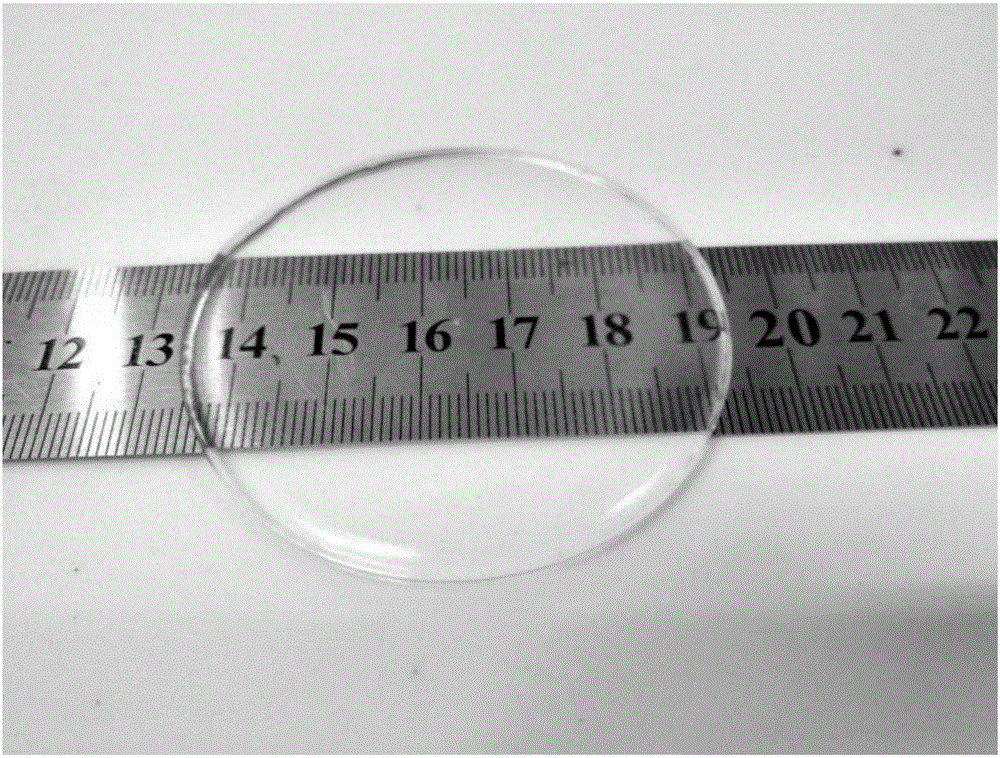

Large-scale preparation method of transparent super-hydrophobic/super-amphiphobic coating

InactiveCN106800885AExcellent superhydrophobic/superamphiphobic propertiesHigh transparencySpecial surfacesCoatingsNanoparticle ComplexAlcohol

The invention discloses a large-scale preparation method of a transparent super-hydrophobic / super-amphiphobic coating. The method comprises the steps of ultrasonically dispersing nano particles into an alcohol-water mixed system and carrying out hydrolysis and condensation reaction on the nano particles and fluoride-free or fluorine-containing organosilane under the acid or alkali catalysis action to prepare a transparent suspension liquid of a fluoride-free or fluorine-containing organosilane polymer-nano particle compound; and applying the transparent suspension liquid of the compound on the surface of a substrate material through spraying or dip-coating to obtain the transparent super-hydrophobic / super-amphiphobic coating with good performance. Preparation of the transparent super-hydrophobic / super-amphiphobic coating of 10-100m<2> can be completed within an hour; large-scale preparation of the large-area transparent super-hydrophobic / super-amphiphobic coating is achieved for the first time; the preparation method is low in cost and simple in process; and the prepared coating has excellent super-hydrophobic or super-amphiphobic property, relatively good mechanical stability, chemical stability and environment stability, and has a wide application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

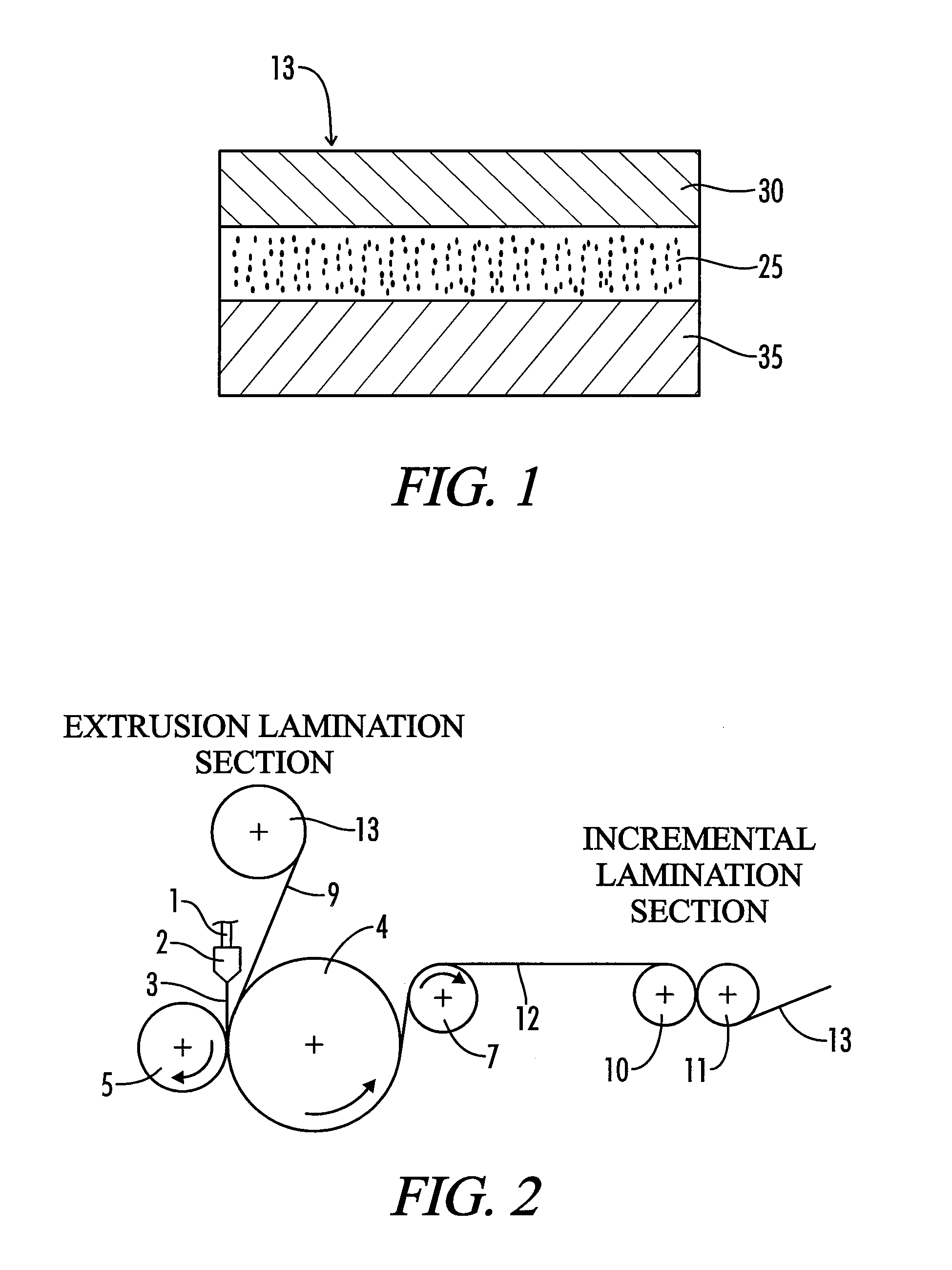

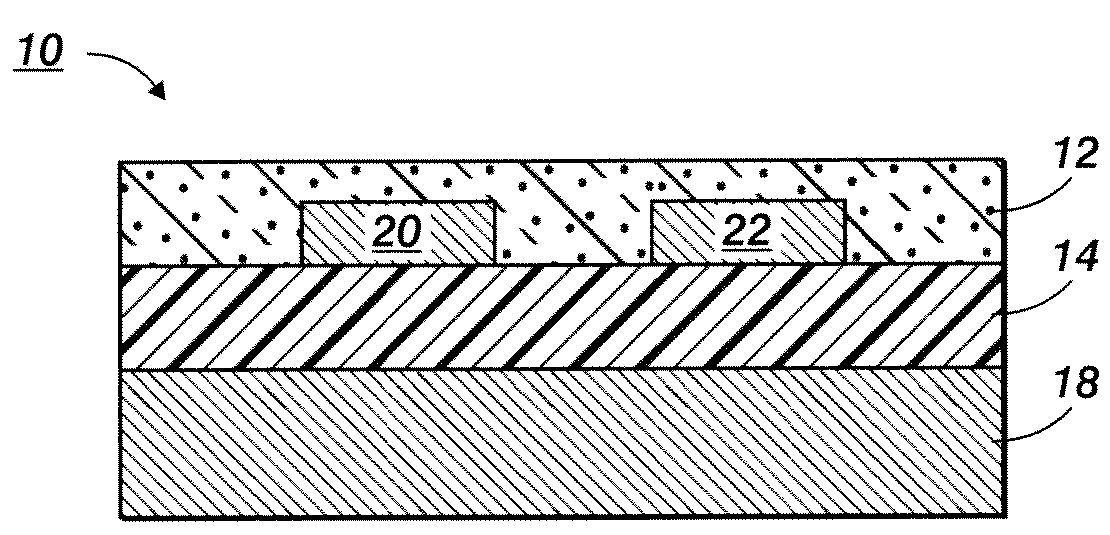

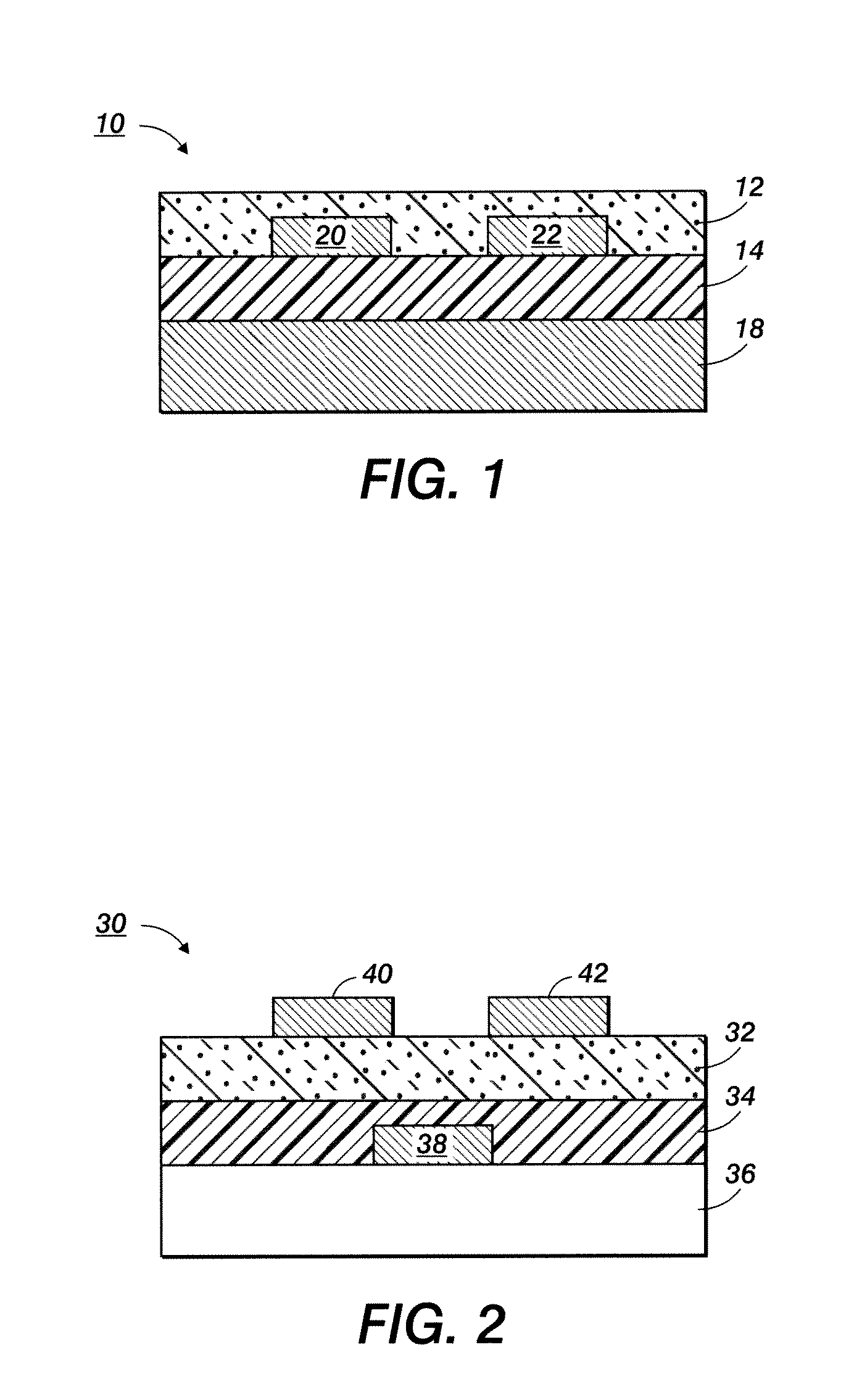

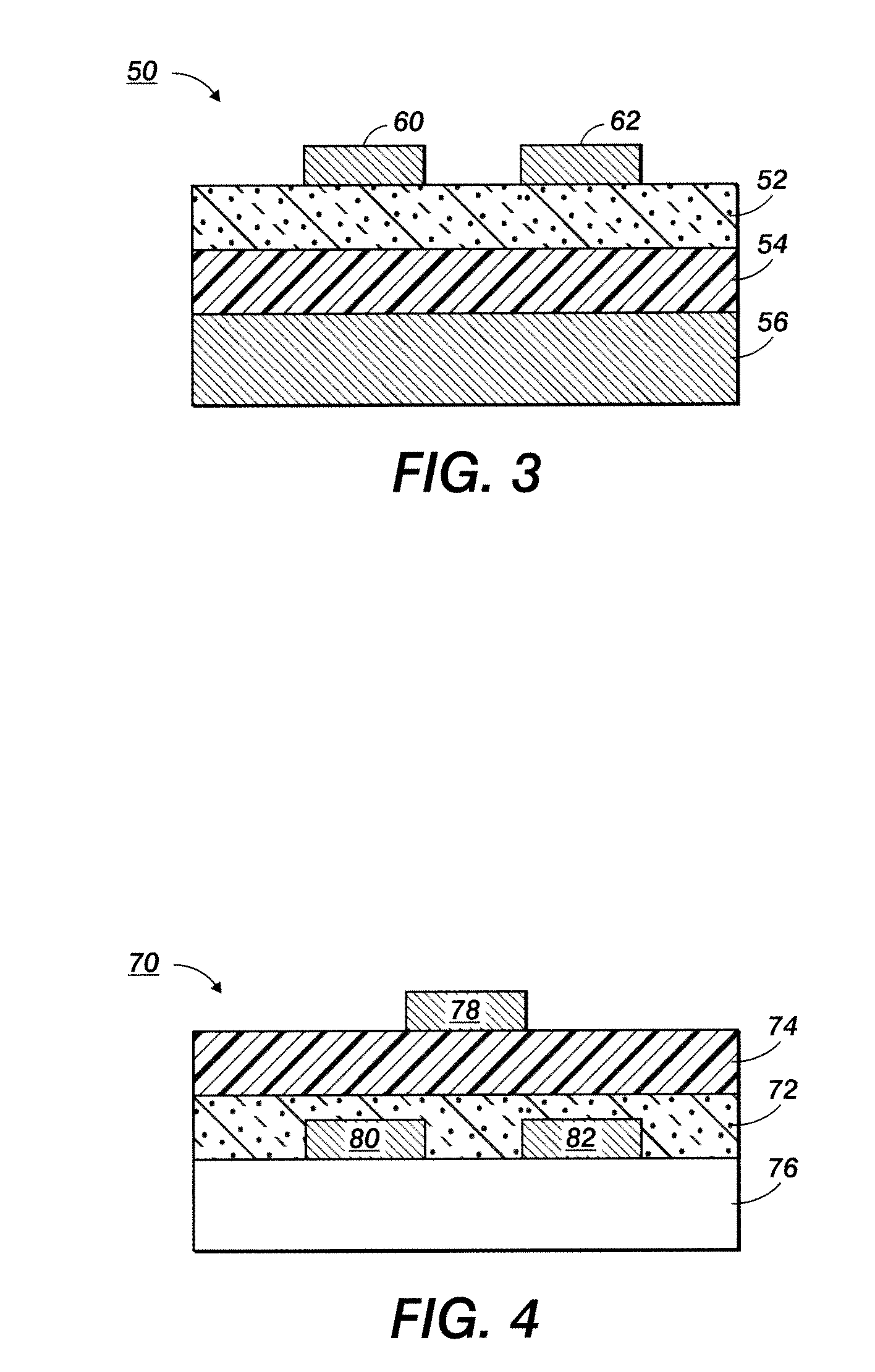

Weatherable multilayer articles and method for their preparation

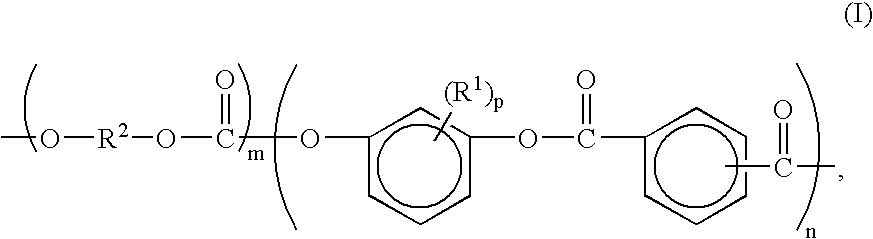

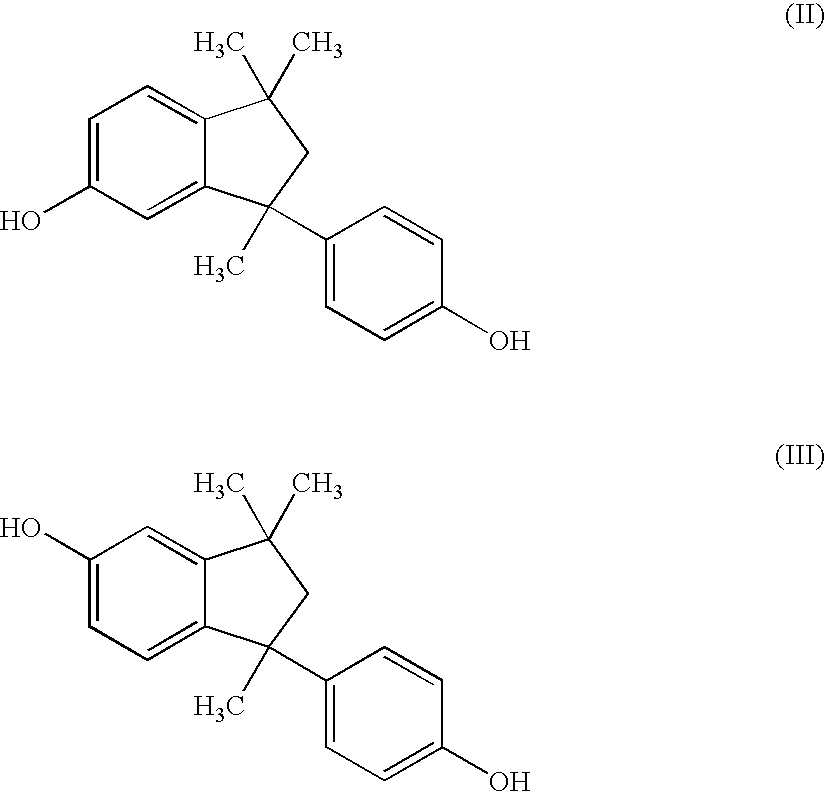

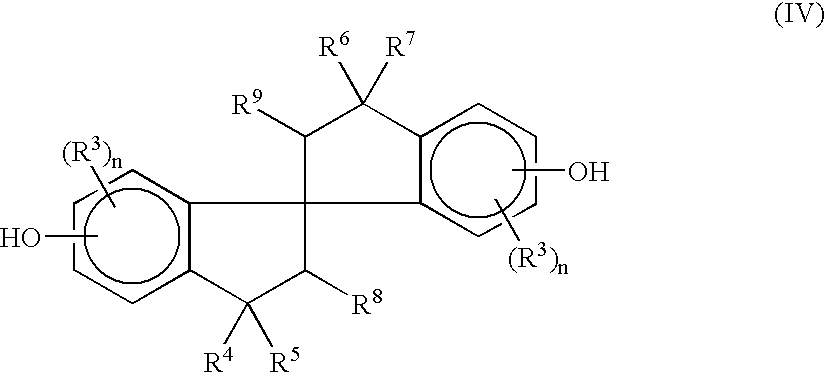

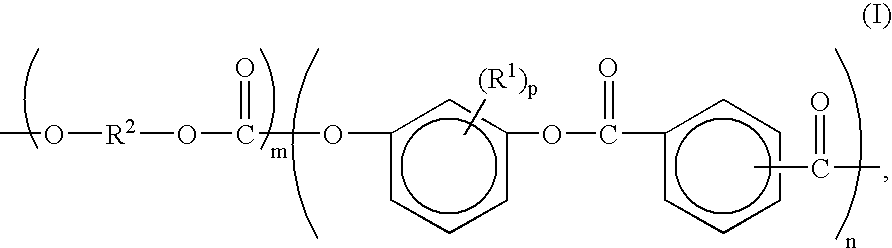

InactiveUS20040253428A1Avoid insufficient thicknessRelieve stressSynthetic resin layered productsThin material handlingPolyesterPolymer science

Disclosed are weatherable multilayer articles comprising (i) a coating layer comprising a block copolyestercarbonate comprising structural units derived from at least one 1,3-dihydroxybenzene and at least one aromatic dicarboxylic acid, (ii) a second layer comprising a polymer comprising carbonate structural units, (iii) an adhesive layer comprising a polyester with structural units derived from at least one glycol and at least one dibasic carboxylic acid, and (iv) a substrate layer, wherein the coating layer is in contiguous contact with the second layer, and the adhesive layer is in contiguous contact with the second layer and the substrate layer. Also disclosed is a method for making the multilayer article.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Method for improving environmental stability of cathode materials for lithium batteries

InactiveUS20090194747A1Good environmental stabilityQuality improvementConductive materialElectrode collector coatingCo2 absorptionNickel–lithium battery

A method for improving the environmental stability of cathode materials used in lithium-based batteries. Most currently used cathode active materials are acutely sensitive to environmental conditions, e.g. leading to moisture and CO2 pickup, that cause problems for material handling especially during electrode preparation and to gassing during charge and discharge cycles. Binder materials used for making cathodes, such as PVDF and PTFE, are mixed with and / or coated on the cathode materials to improve the environmental sensitivity of the cathode materials.

Owner:TIAX LLC

Weatherable multilayer articles and method for their preparation

InactiveUS20040028907A1Improve adhesionAvoid insufficient thicknessAutomatic/semiautomatic turning machinesPolyureas/polyurethane adhesivesPolymer scienceDicarboxylic acid

Disclosed are weatherable multilayer articles comprising (i) a coating layer comprising a block copolyestercarbonate comprising structural units derived from at least one 1,3-dihydroxybenzene and at least one aromatic dicarboxylic acid, (ii) a second layer comprising a polymer comprising carbonate structural units, (iii) an adhesive layer comprising a polyurethane, and (iv) a substrate layer, wherein the coating layer is in contiguous superposed contact with the second layer, and the adhesive layer is in contiguous contact with the second layer and the substrate layer. Also disclosed is a method for making the multilayer article.

Owner:SABIC INNOVATIVE PLASTICS IP BV

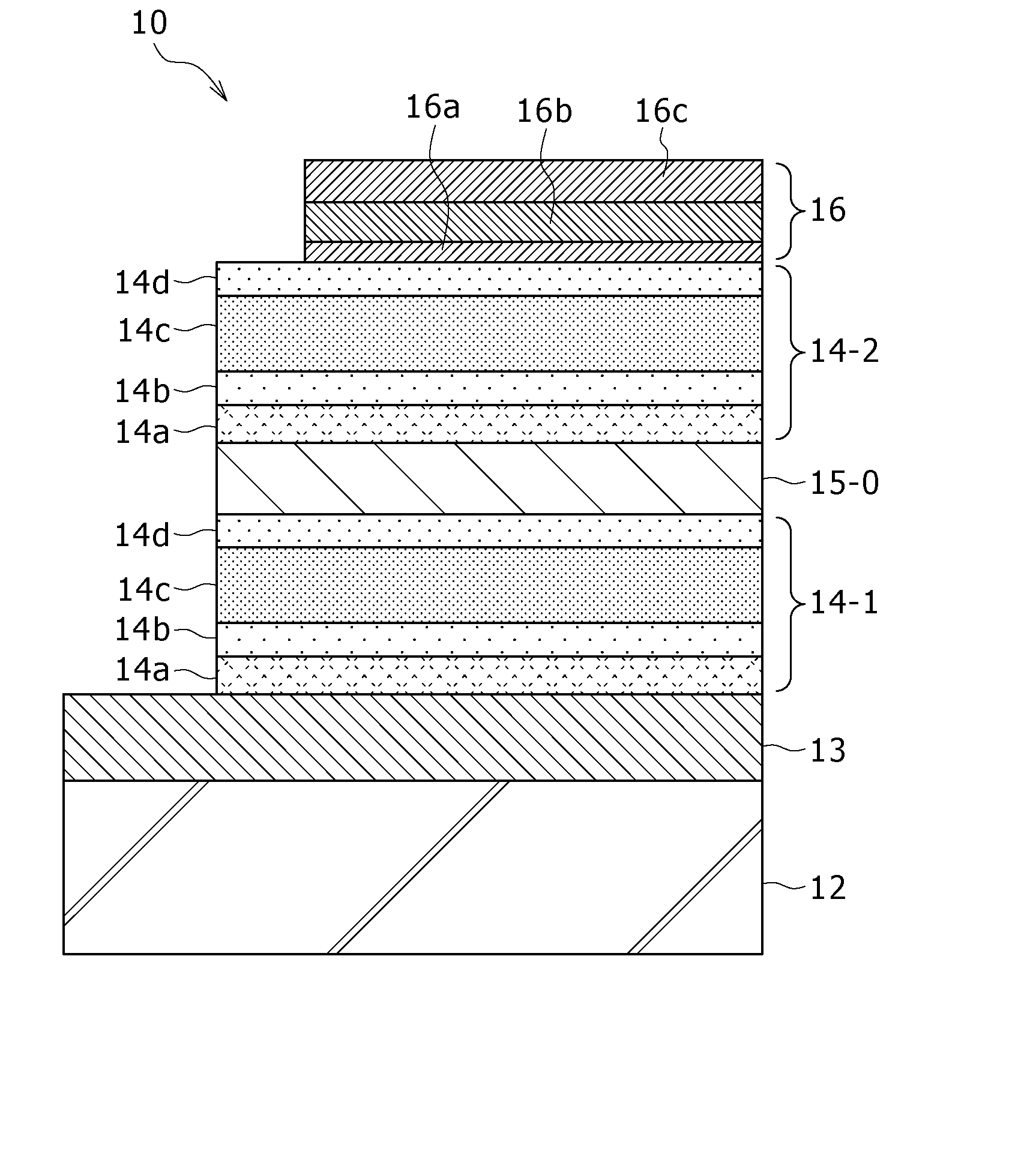

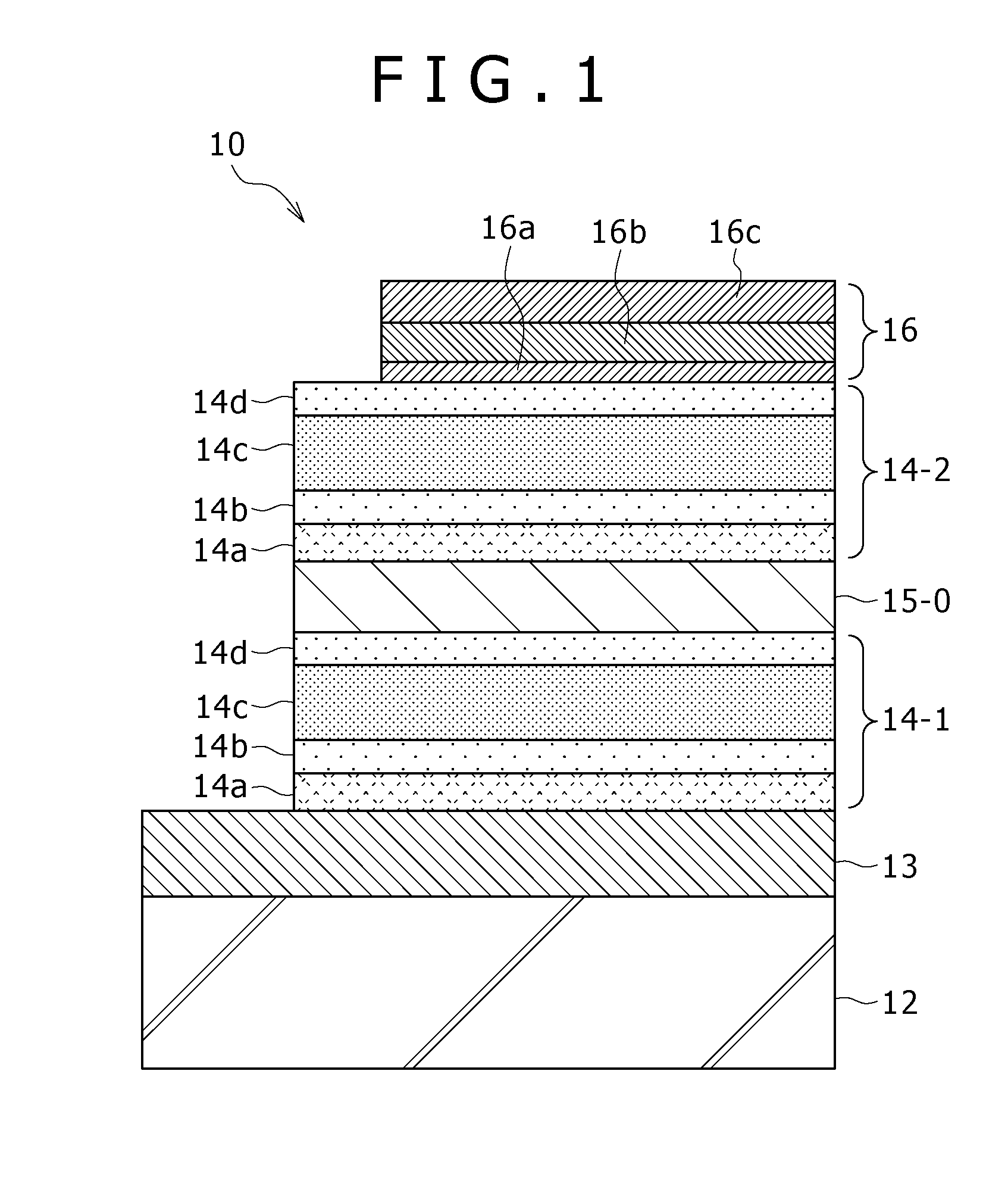

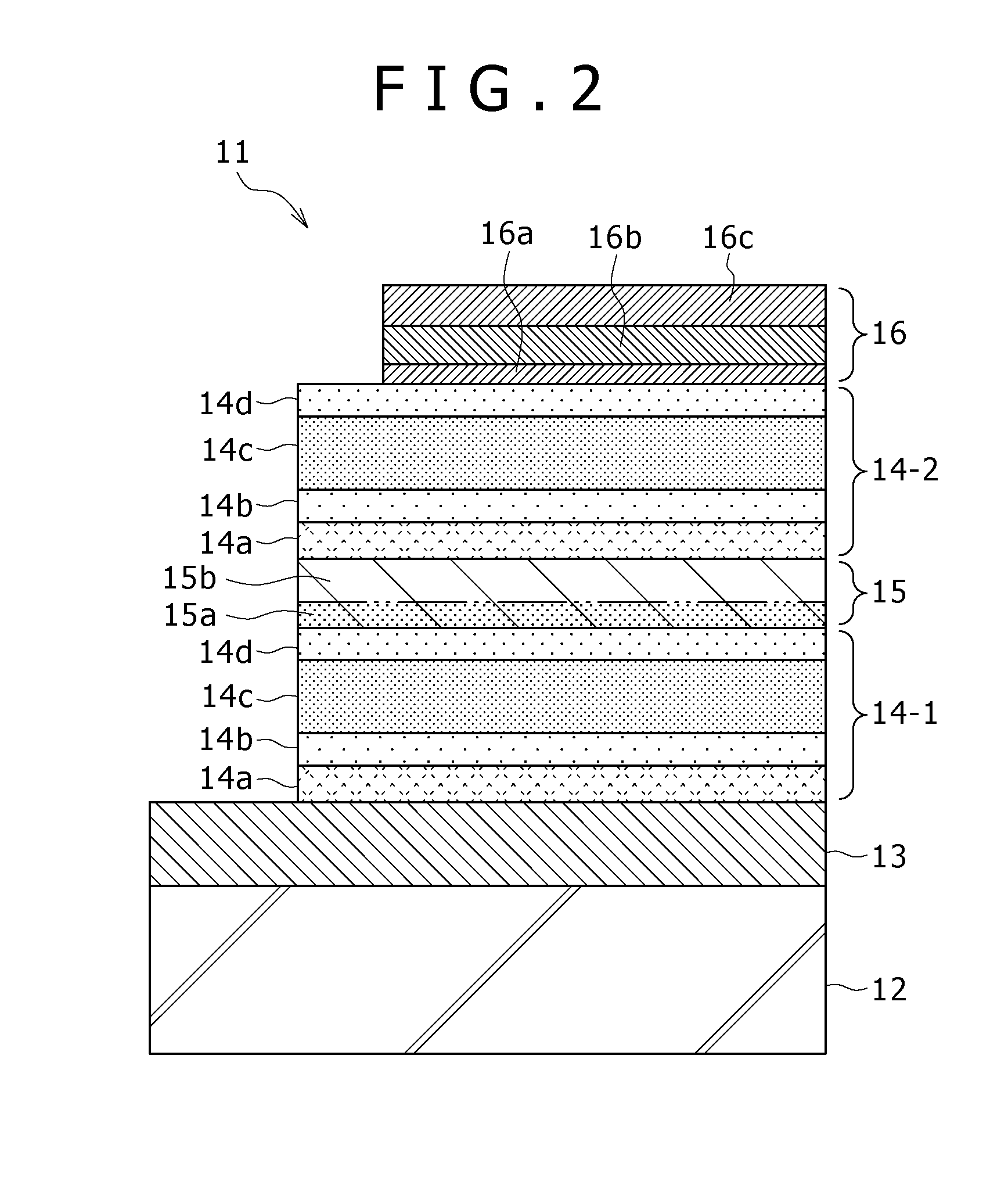

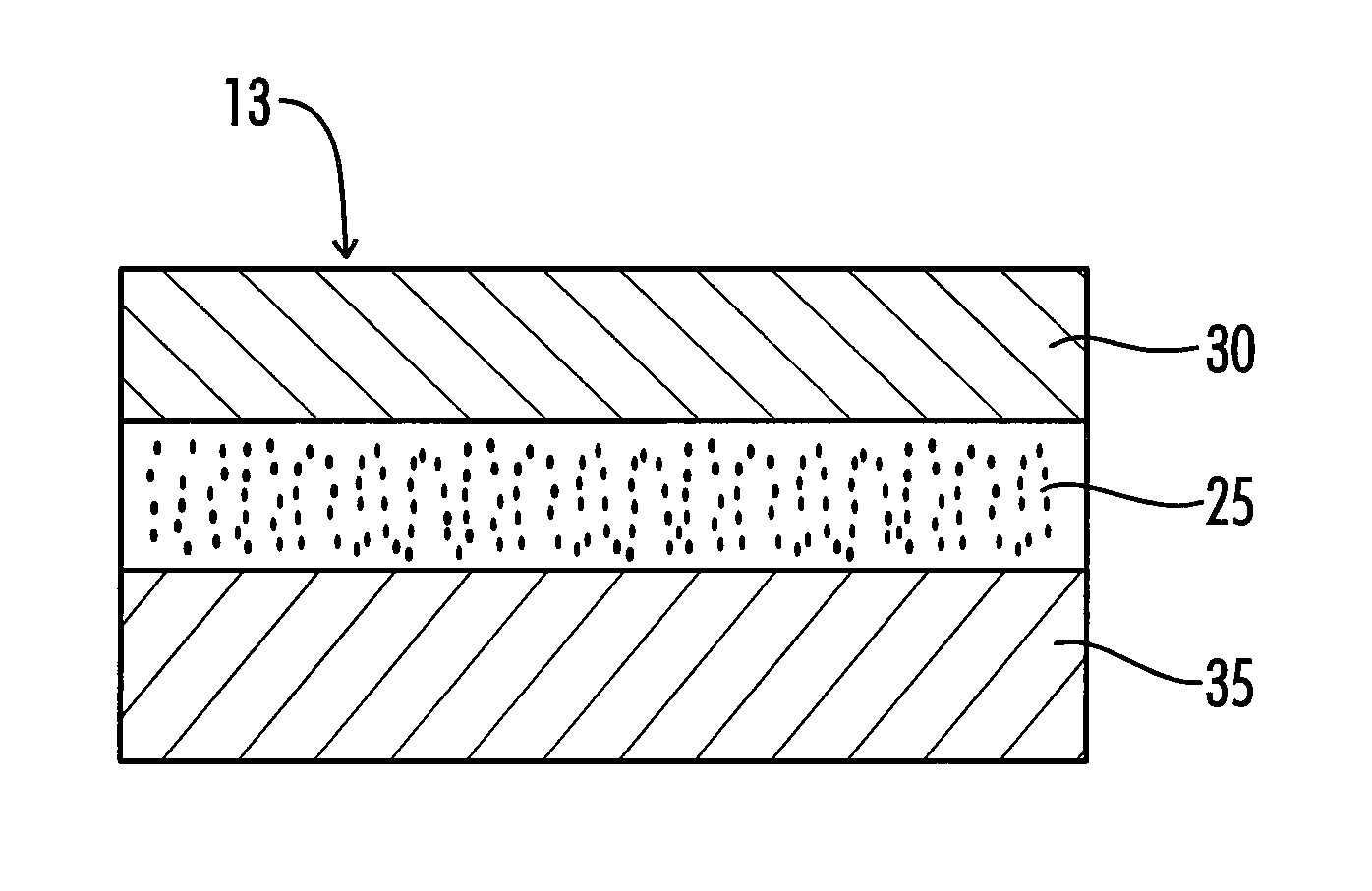

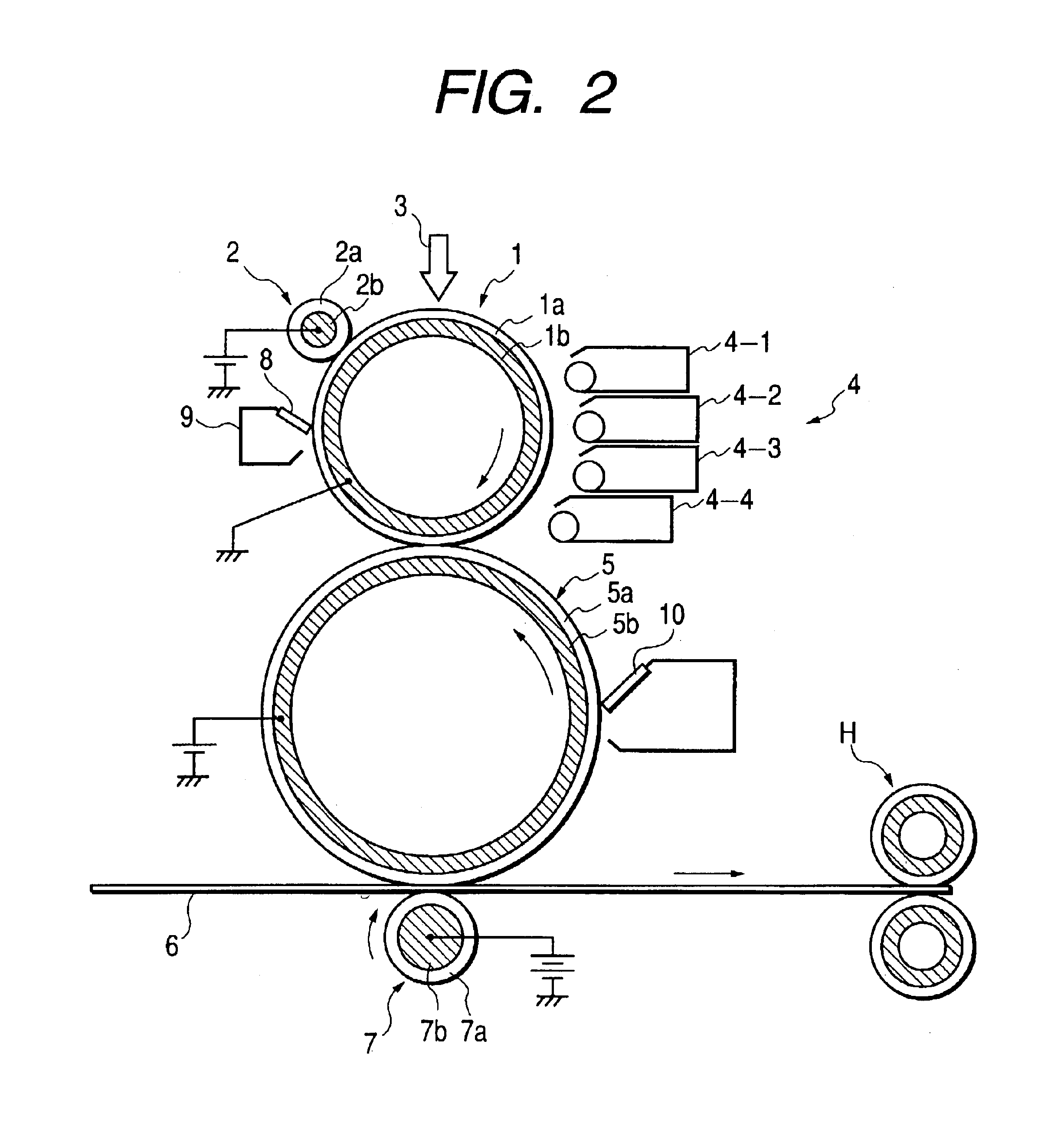

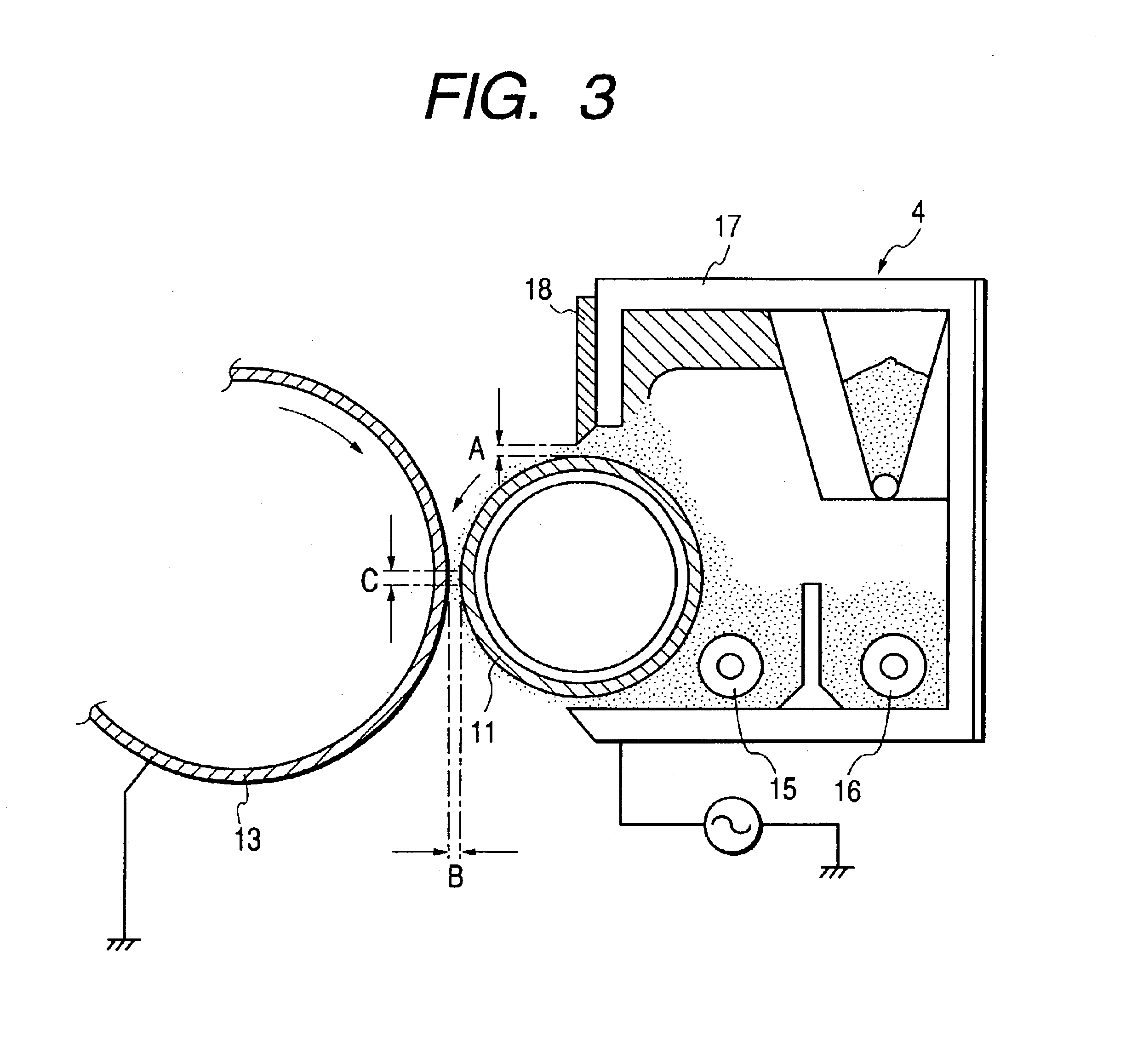

Display device

ActiveUS20070181887A1Increase brightnessImprove charging efficiencyElectroluminescent light sourcesSolid-state devicesAlkaline earth metalDisplay device

In a stacked display device with light-emitting units composed of organic layers and stacked together, the use of a stable material in at least a portion of a charge generation layer makes it possible to achieve improvements in environmental stability and also to attain an improvement in the efficiency of injection of charges from the charge generation layer into the light-emitting units. The display device can be readily fabricated. In a display device (11) provided with a plurality of light-emitting units (14-1)(14-2), each of which includes at least an organic light-emitting layer (14c), stacked together between a cathode (16) and an anode (13), and also with a charge generation layer (15) held between the respective light-emitting units (14-1)(14-2), at least a portion of the charge generation layer (15) is composed of an oxide or fluoride which contains at least one of alkali metals and alkaline earth metals.

Owner:JOLED INC

Toner and heat-fixing method

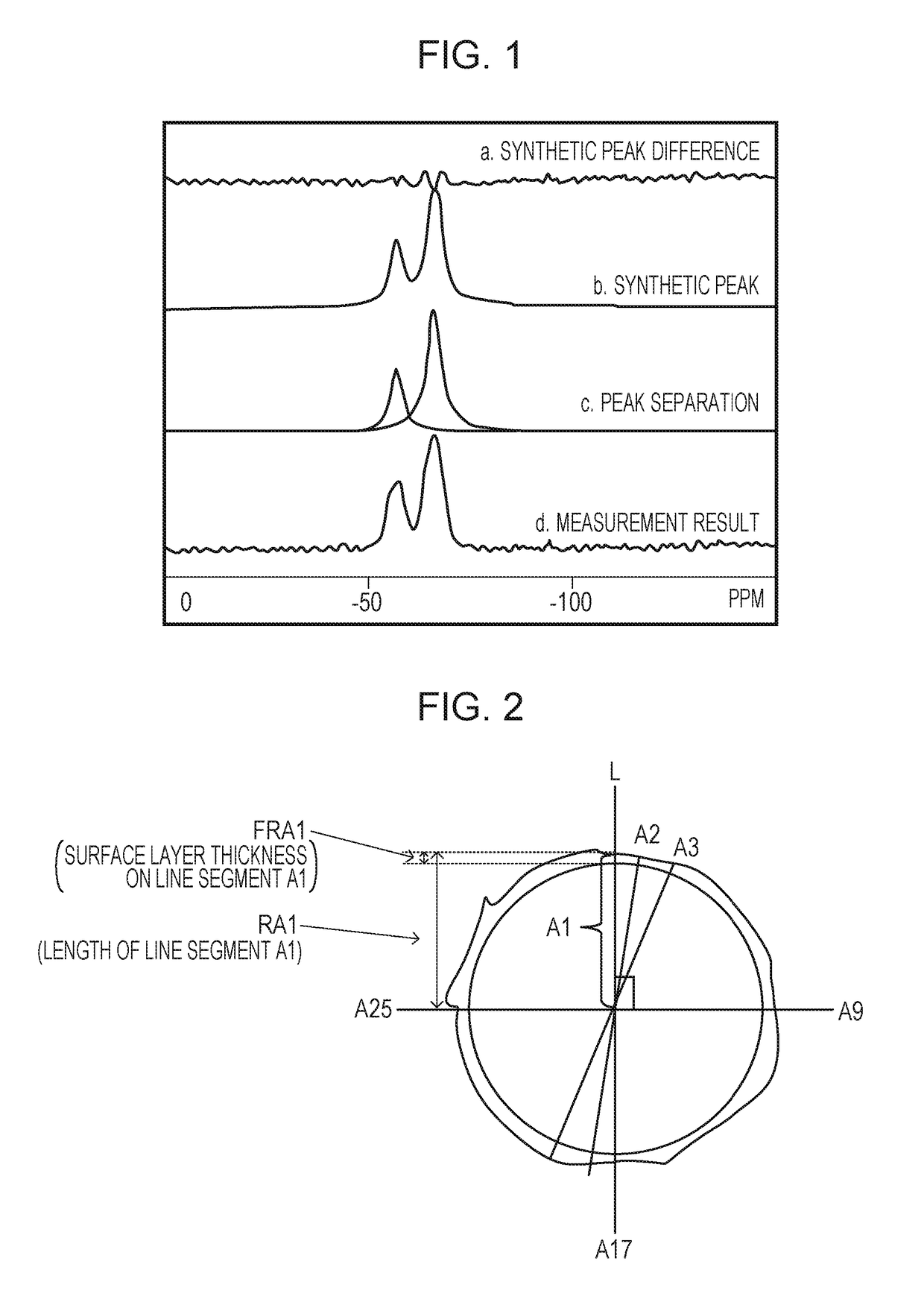

InactiveUS6808852B2Excellent low temperature fixabilityHigh quality imagingDevelopersElectrographic processes using charge patternMethacrylatePolyester

A toner characterized by improved fixing performances with no or minimum oil application is formed of: (i) a binder resin, (ii) a colorant, (iii) a hydrocarbon wax, (iv) a resin composition formed by copolymerization of a styrenic monomer together with at least one of nitrogen-containing vinyl monomers, carboxyl group-containing monomers, hydroxyl group-containing monomers and (meth)acrylate ester monomers, in the presence of a hydrocarbon unit; and (v) an organometallic compound. The binder resin (i) comprises a polyester component in a proportion of at least 60 wt. % of the binder resin. The toner has a GPC molecular weight distribution including a weight-average molecular weight (Mw) of at least 4.0x10<4 >an a ratio Mw / Mn of at least 50 between the Mw and a number-average molecular weight (Mn).

Owner:CANON KK

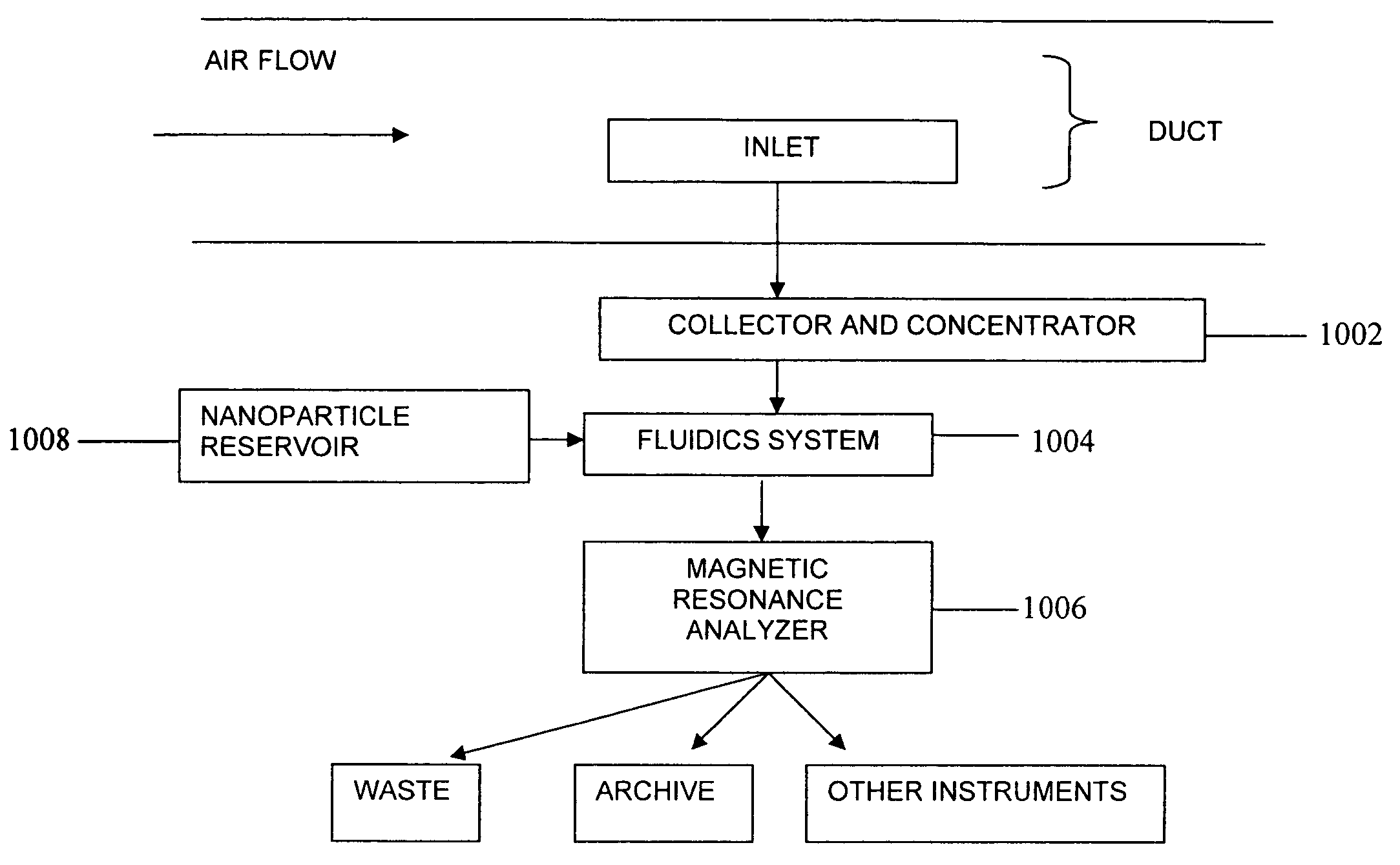

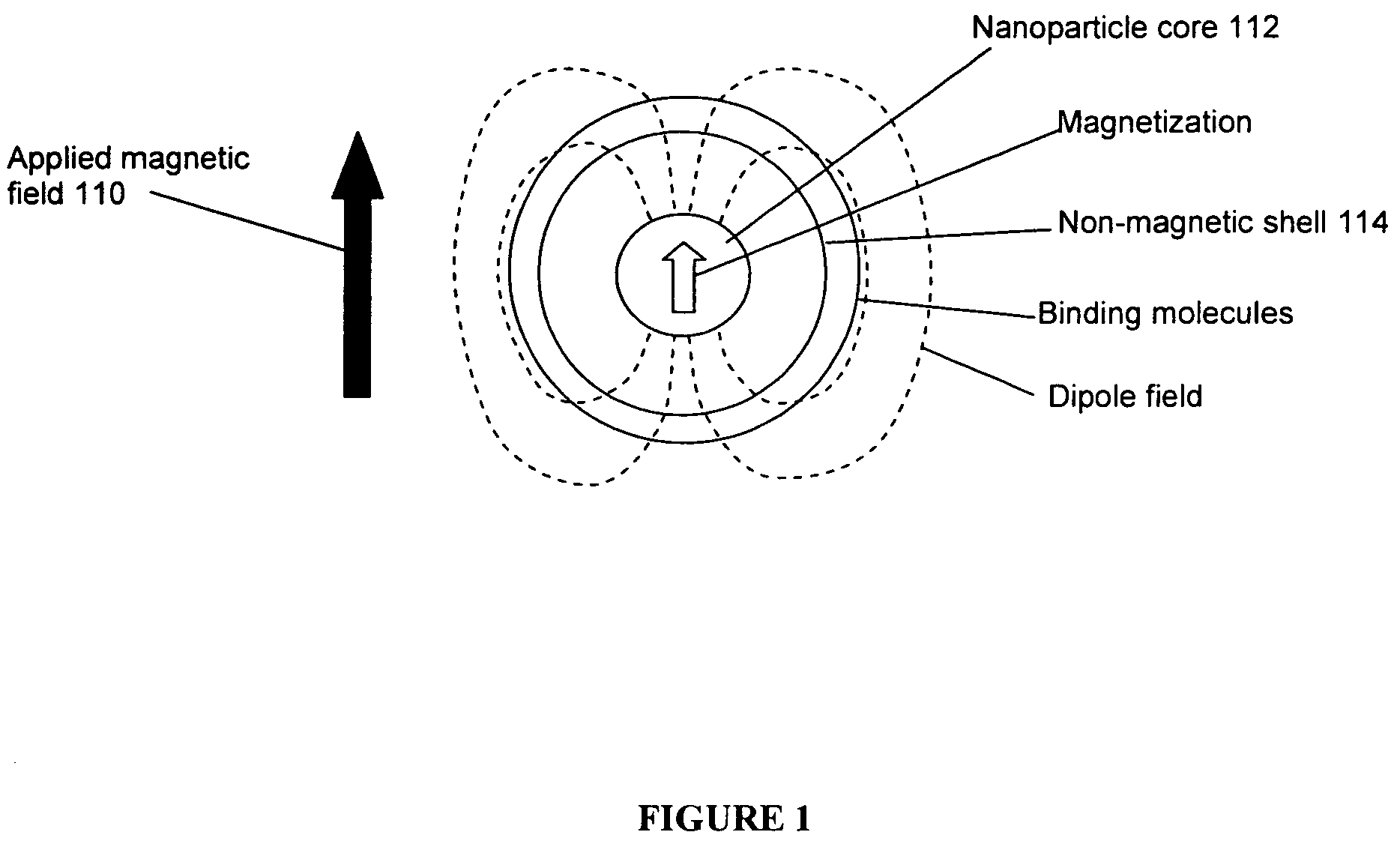

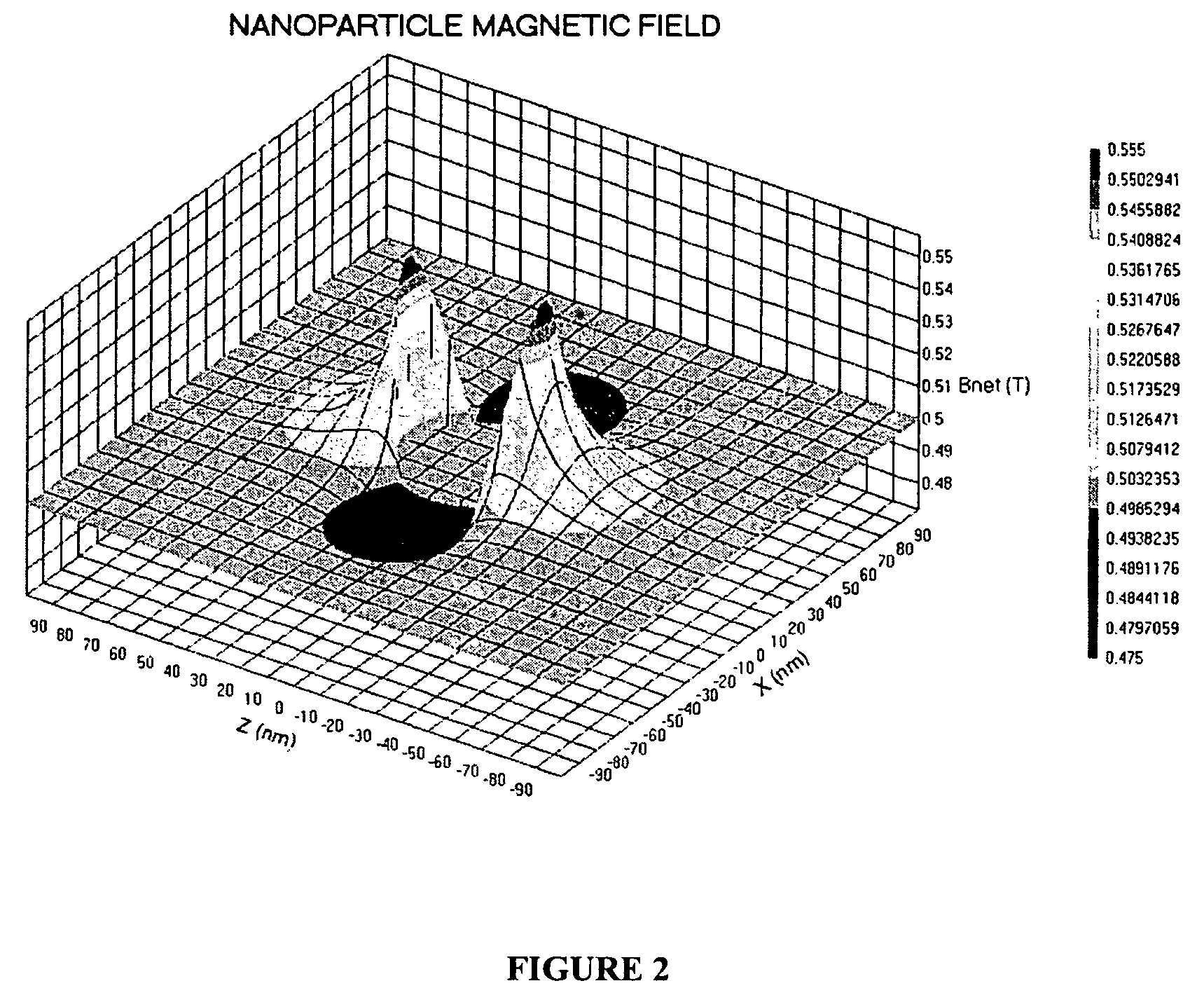

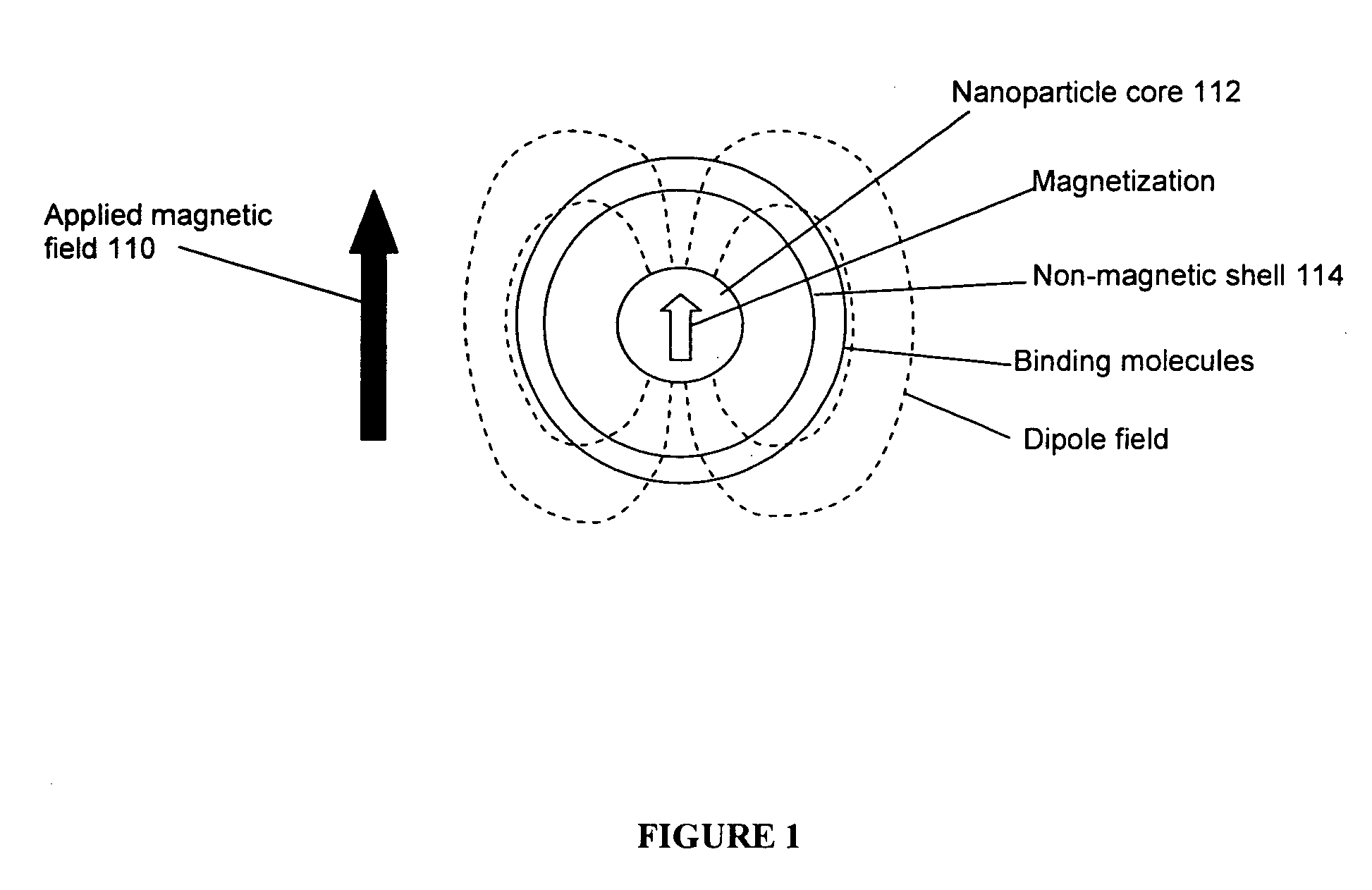

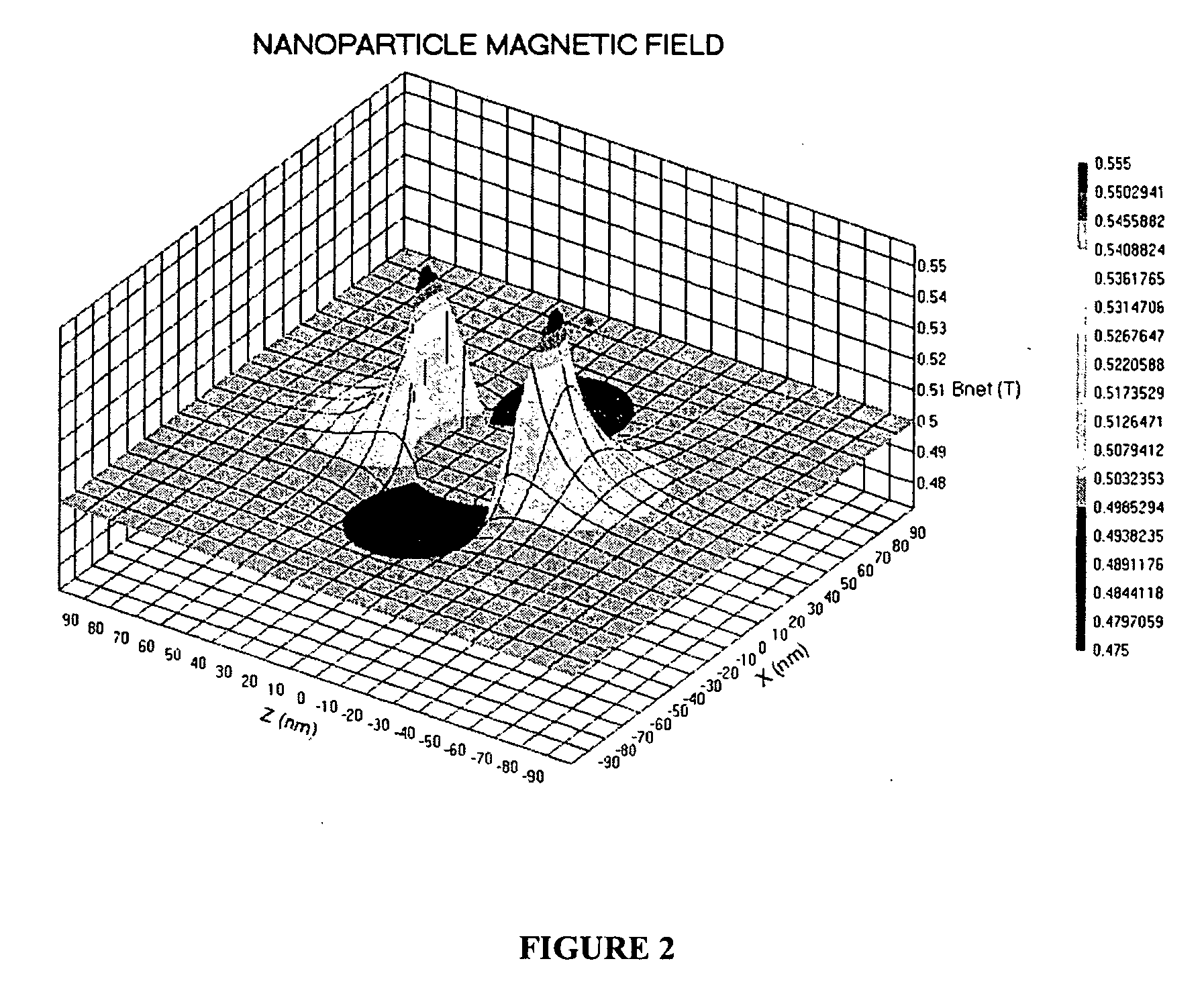

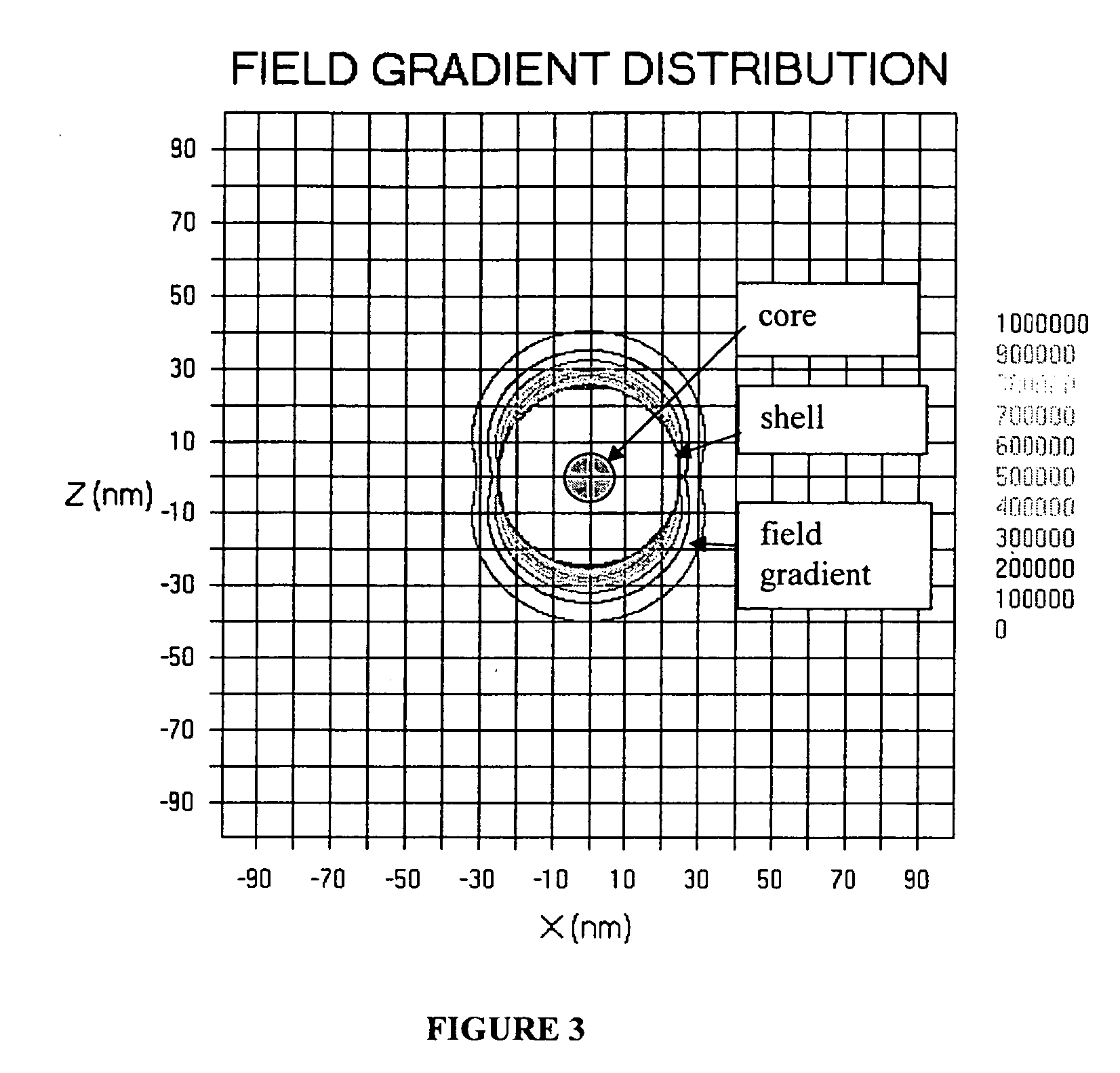

Magnetic resonance system and method to detect and confirm analytes

ActiveUS7781228B2Improve bindingReduce activity timeNanotechMagnetic measurementsResonance measurementProton magnetic resonance

A system and method are provided to detect target analytes based on magnetic resonance measurements. Magnetic structures produce distinct magnetic field regions having a size comparable to the analyte. When the analyte is bound in those regions, magnetic resonance signals from the sample are changed, leading to detection of the analyte.

Owner:MENON BIOSENSORS

Magnetic resonance system and method to detect and confirm analytes

ActiveUS20070020701A1Improve detectionEnhance qualityNanotechMagnetic measurementsNuclear magnetic resonanceResonance signal

A system and method are provided to detect target analytes based on magnetic resonance measurements. Magnetic structures produce distinct magnetic field regions having a size comparable to the analyte. When the analyte is bound in those regions, magnetic resonance signals from the sample are changed, leading to detection of the analyte.

Owner:MENON BIOSENSORS

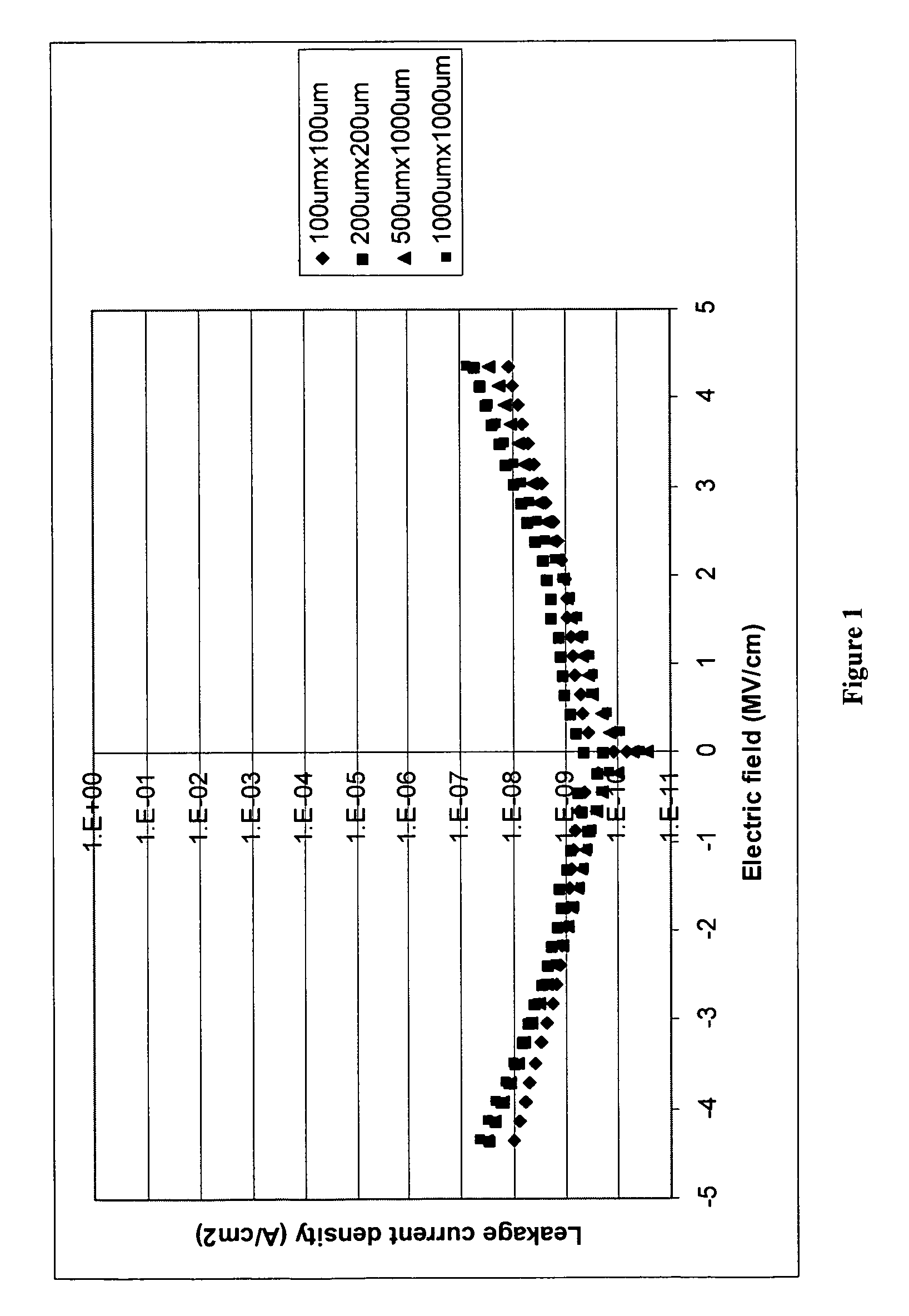

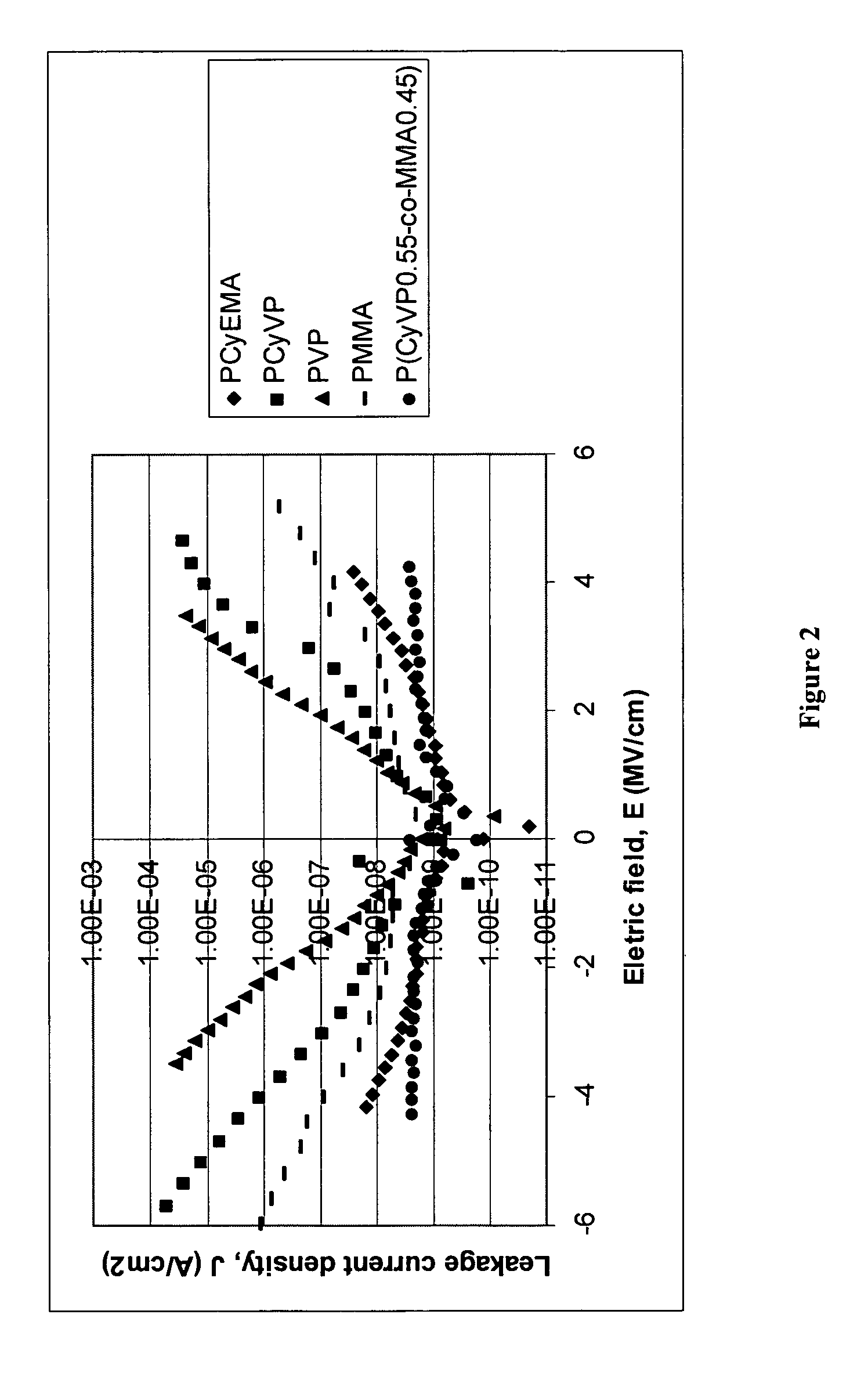

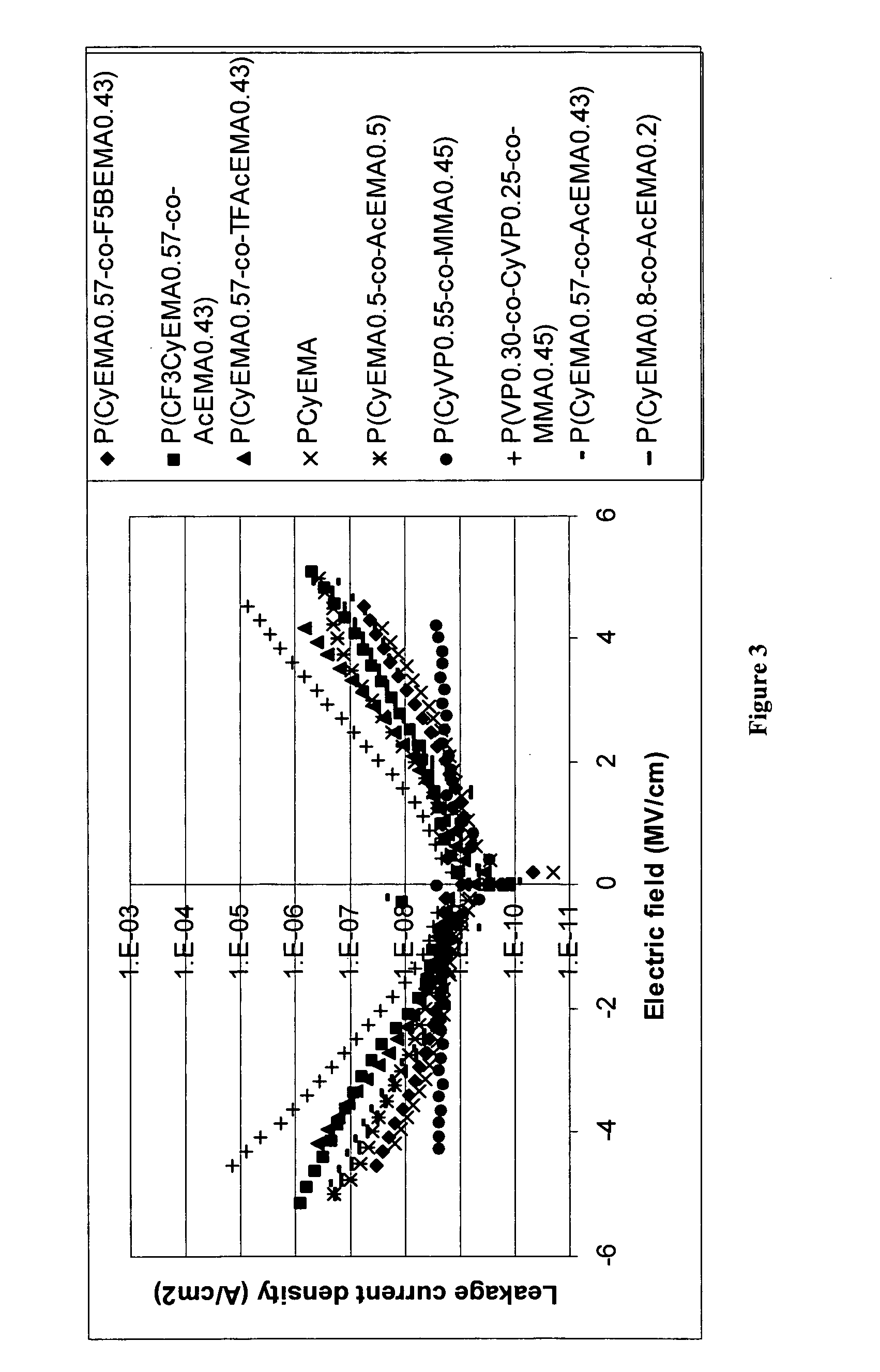

Photopolymer-based dielectric materials and methods of preparation and use thereof

Photopolymer-based dielectric materials are provided with methods for preparing the same. Composites and electronic devices including such dielectric materials also are provided.

Owner:FLEXTERRA INC

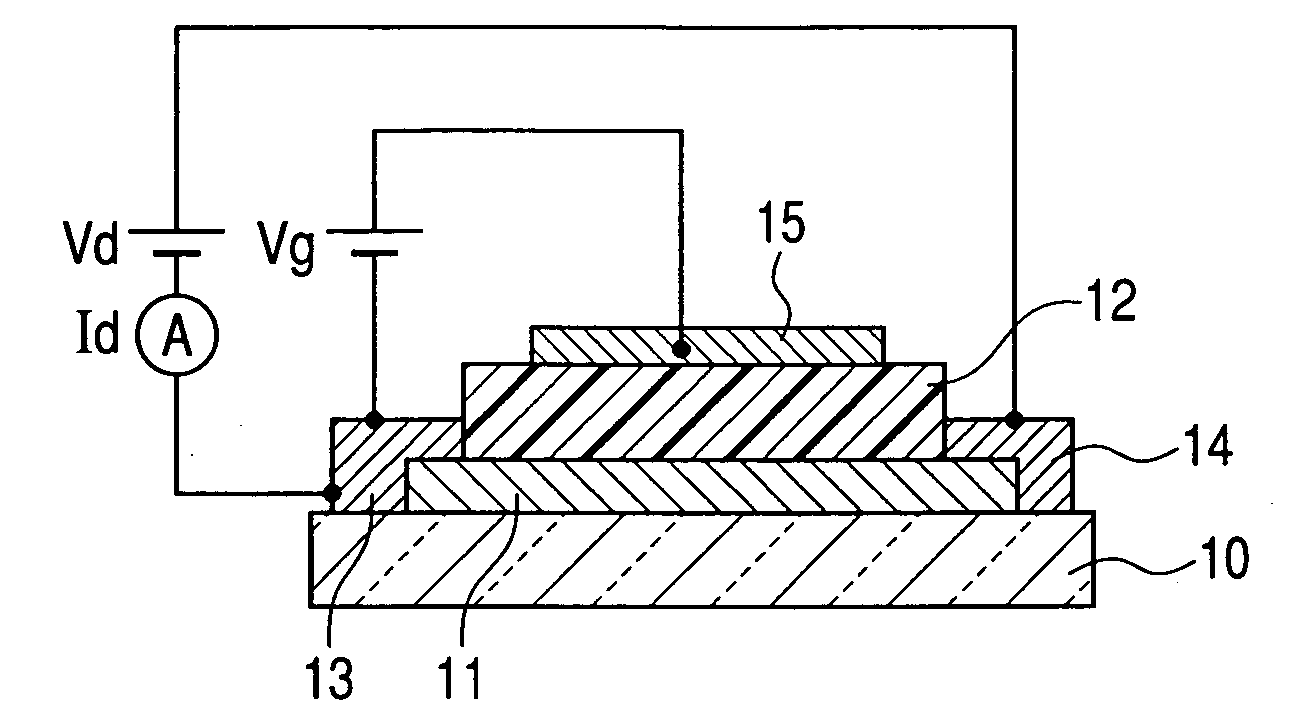

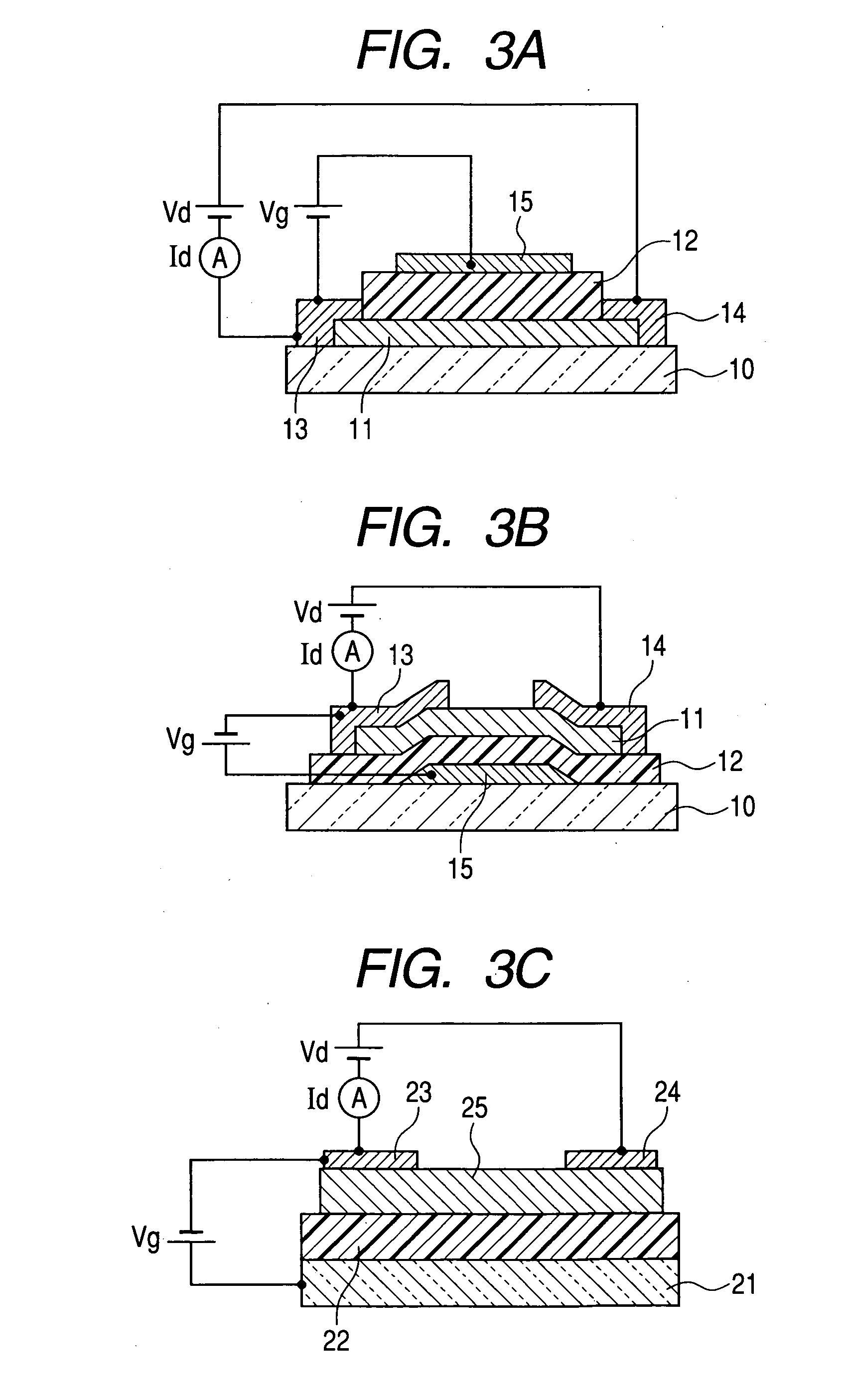

Field effect transistor

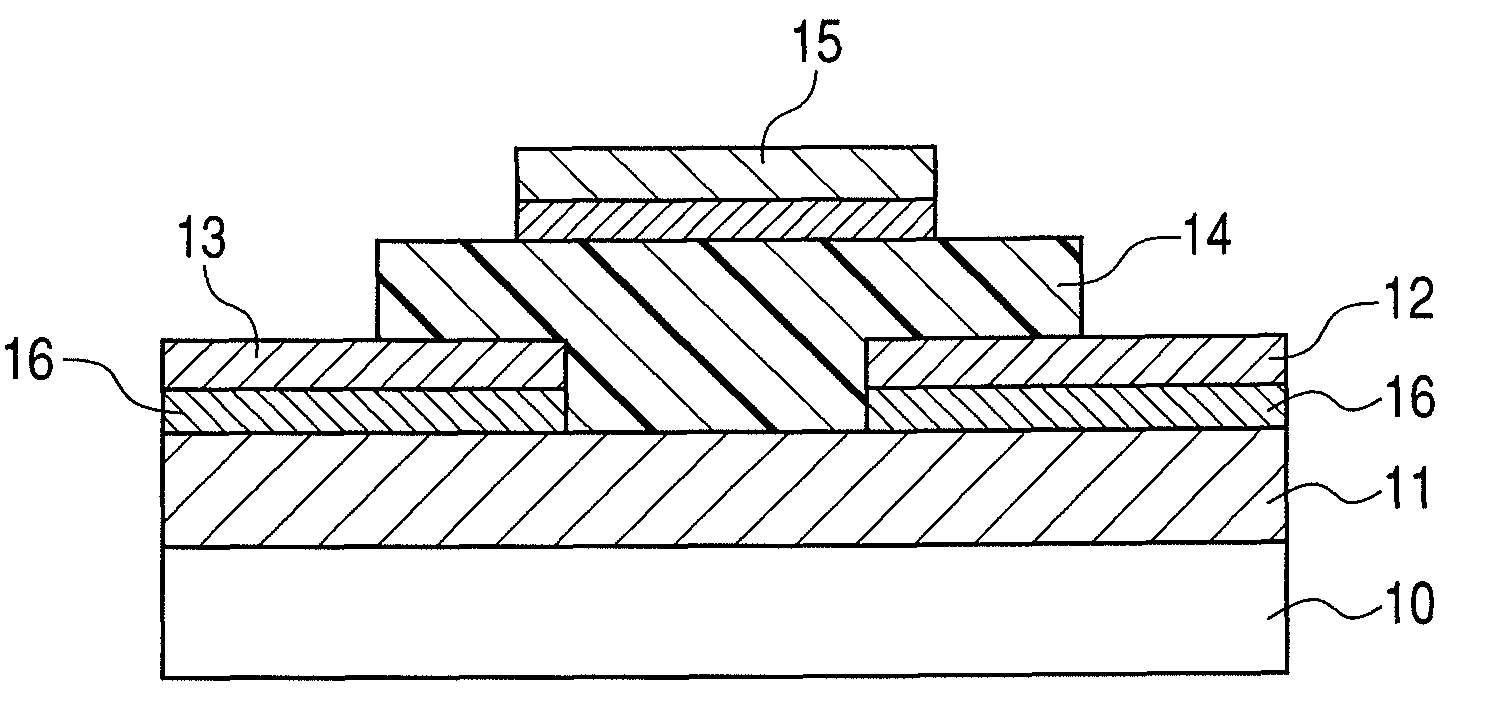

ActiveUS20100258794A1Good environmental stabilityImprove featuresTransistorVacuum evaporation coatingPhysicsAmorphous oxide

A field effect transistor is provided including a gate electrode (15), a source electrode (13), a drain electrode (14) and a channel layer (11) to control current flowing between the source electrode (13) and the drain electrode (14) by applying a voltage to the gate electrode (15). The channel layer (11) is constituted of an amorphous oxide containing In and Si and having a compositional ratio expressed by Si / (In+Si) of not less than 0.05 and not more than 0.40.

Owner:CANON KK

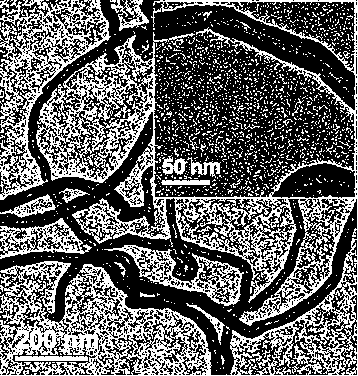

Manufacturing method of carbon nano tube paper

A carbon nanotube paper is prepared from carbon nanotubes through adding them to acid, heating or thermal reflux, and / or ultrasonic stirring, removing impurity, diluting in water, filtering, washing the filtered cake, dispersing the carbon nanotubes in water by ultrasonic stirring, spreading on carrier, and drying. It has regular structure, high uniformity, purity and electric conductivity, and enough mechanical strength.

Owner:TSINGHUA UNIV

Environment-friendly water-based nano coating material used for concrete protection, and preparation method thereof

ActiveCN103275616AStable performanceGood environmental stabilityAntifouling/underwater paintsPaints with biocidesSilane couplingOrganosilicon

The invention provides an environment-friendly water-based nano coating material used for concrete protection, and a preparation method thereof. The environment-friendly water-based nano coating material comprises 15%-65% of an organic silane coupling agent, 0.5-10% of nano silica, 0.5-5% of nano titanium dioxide, 0.4%-4% of an organosilicon oligomer, 0.3%-3% of an emulsifier, 0.1%-0.6% of a bactericidal anti-algae agent, 0.01%-0.1% of a regulator, and the balance being deionized water. The environment-friendly water-based nano coating material used for the concrete protection takes advantages of a nanometer effect of nanoparticles and a hydrophobic effect of long-chain organosilicone coupling agent. The prepared environment-friendly water-based nano coating material used for the concrete protection has excellent protection performance.

Owner:江苏道成不锈钢管业有限公司

Vapor permeable, liquid impermeable composite fabric and fabrication process

InactiveUS7501357B2Improve stabilityGreat abrasionLamination ancillary operationsSynthetic resin layered productsEnvironmental resistancePolyolefin

A flexible, vapor permeable, liquid impermeable composite fabric comprising a ultraviolet light stabilized and thermally stabilized microporous-formable polyolefin barrier layer extrusion laminated to an ultra-violet light stabilized and thermally stabilized polyolefin nonwoven fabric, the composite of which has been incrementally stretched to induce sufficient moisture vapor transmission characteristics while maintaining adequate resistance to water penetration, and methods of making the composite. This composite may be further laminated to one or more layers of either woven or nonwoven materials offering strength and environmental resistance characteristics sufficient for various outdoor applications including covers and building construction products. Embodiments of the above mentioned components have been shown to offer improved liquid resistance, environmental stability, and abrasion resistance as compared to existing commercially available materials.

Owner:CLOPAY PLASTIC

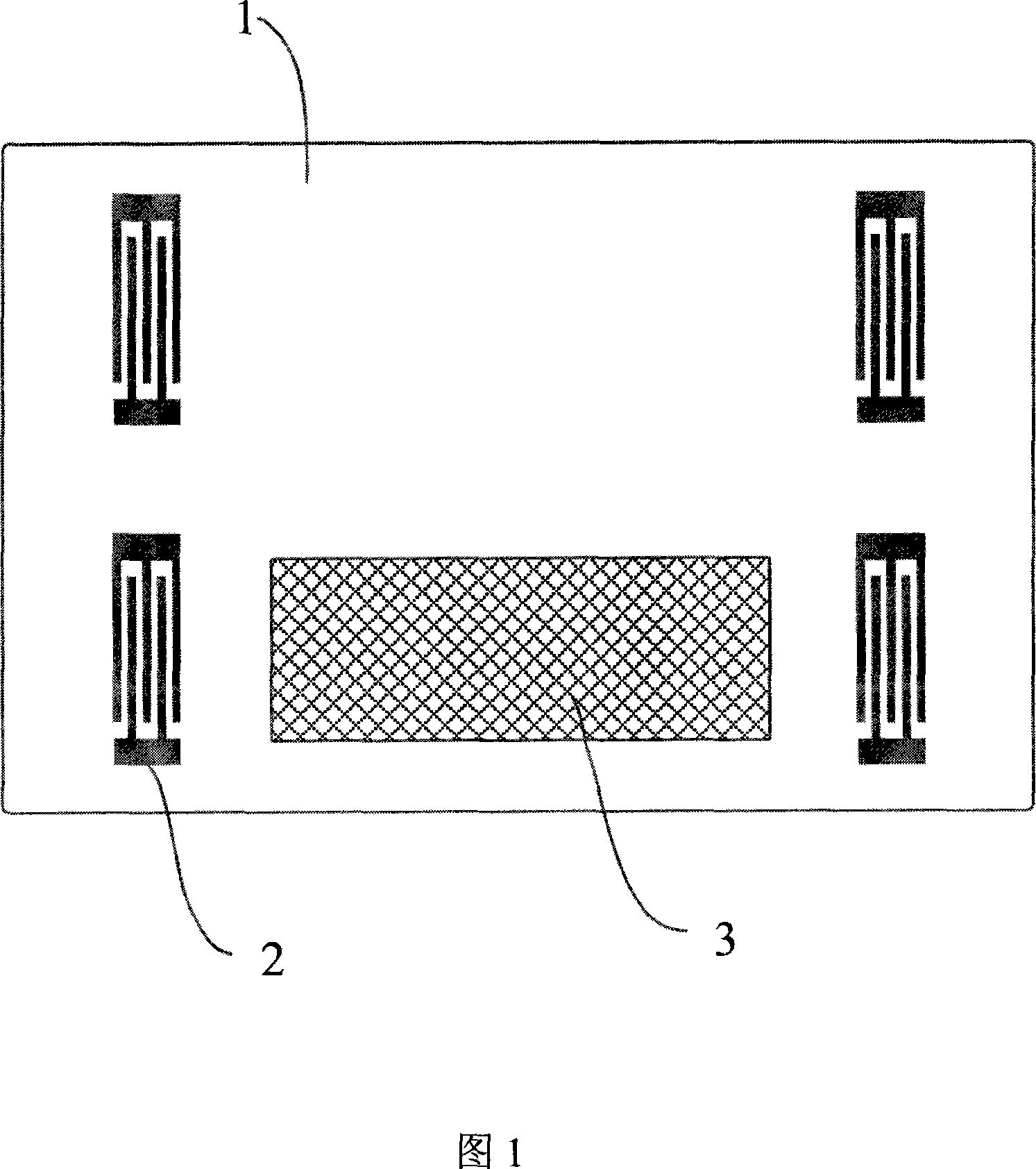

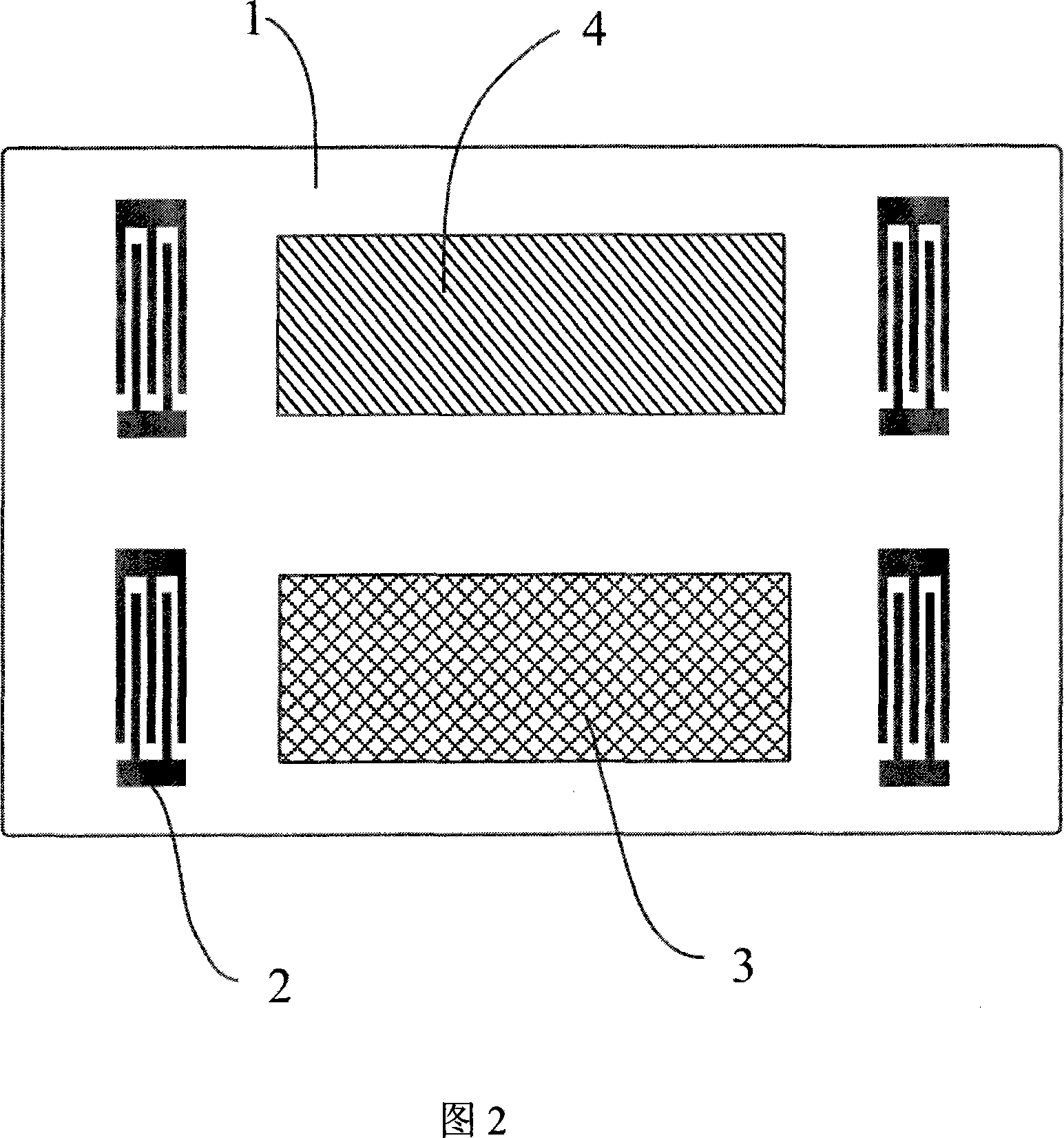

Two-channel sonic surface wave gas sensors having humidity compensate function

InactiveCN101135670AGood environmental stabilityReduce temperature drift gapAnalysing fluids using sonic/ultrasonic/infrasonic wavesElectricityAcoustics

The invention comprises a piezoelectric baseboard and two pairs of interdigital electrodes; said interdigital electrodes are located on the piezoelectric baseboard to construct both parallel acoustic surface wave measuring channel and reference channel. It features the following: coating a sensitive film on the measuring channel; coating a temperature compensation film on the reference channel.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Toner for electrophotographic processes and electrostatic printing processes

Disclosed is a toner including toner particles each including a core portion that contains a binder resin, and a surface layer containing an organosilicon polymer, in which each of the toner particles contains a polyvalent metal element having a resistivity of 2.5×10−8 Ω·m or more and 10.0×10−8 Ω·m or less at 20° C., and when the toner particles are subjected to X-ray fluorescence analysis, a net intensity originating from the polyvalent metal element is 0.10 kcps or more and 30.00 kcps or less.

Owner:CANON KK

Organic semiconductor materials and methods of preparing and use thereof

ActiveUS7947837B2High operating requirementsIncrease speedTransistorOrganic chemistrySemiconductor materialsOrganic semiconductor

Owner:FLEXTERRA INC

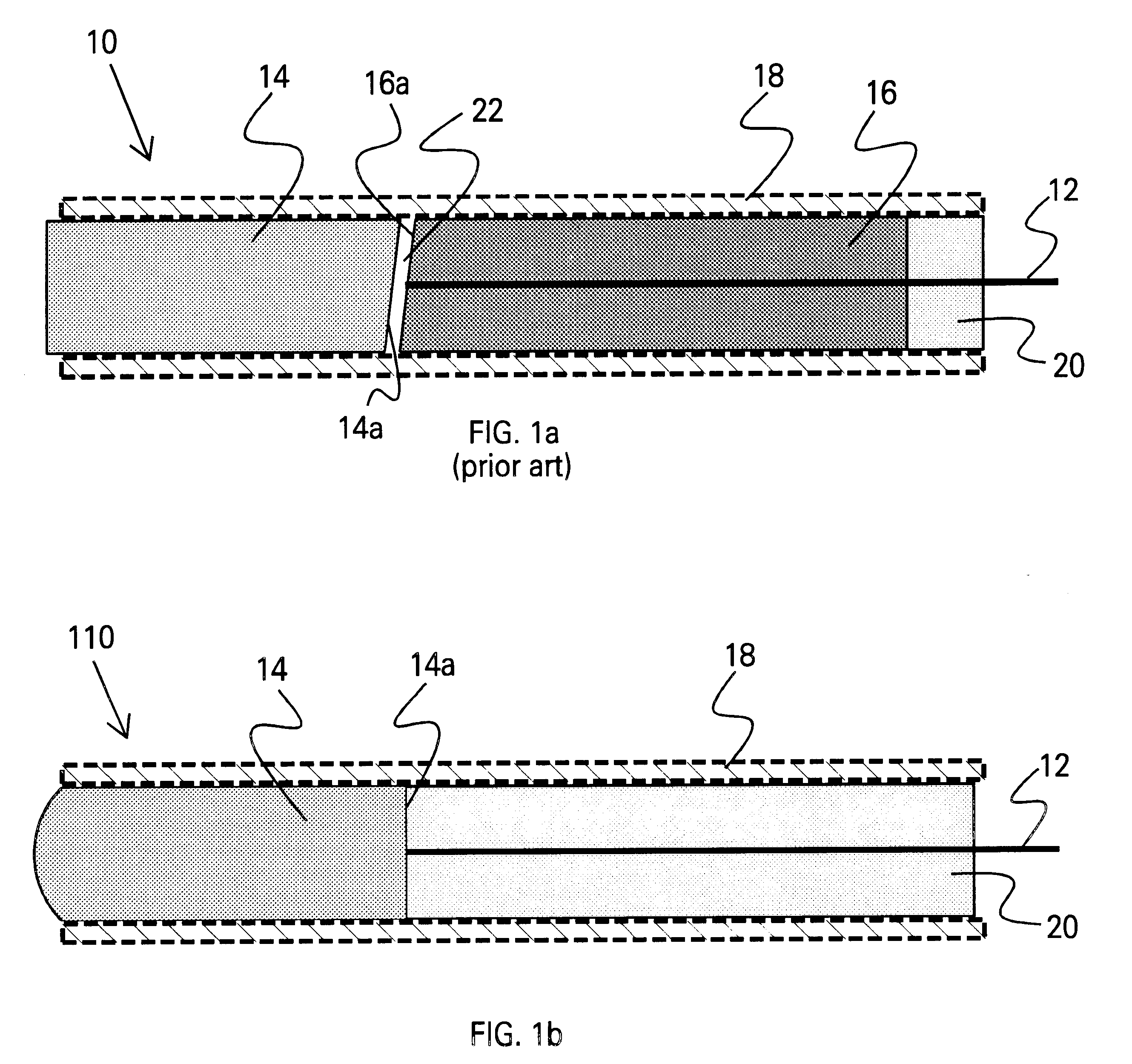

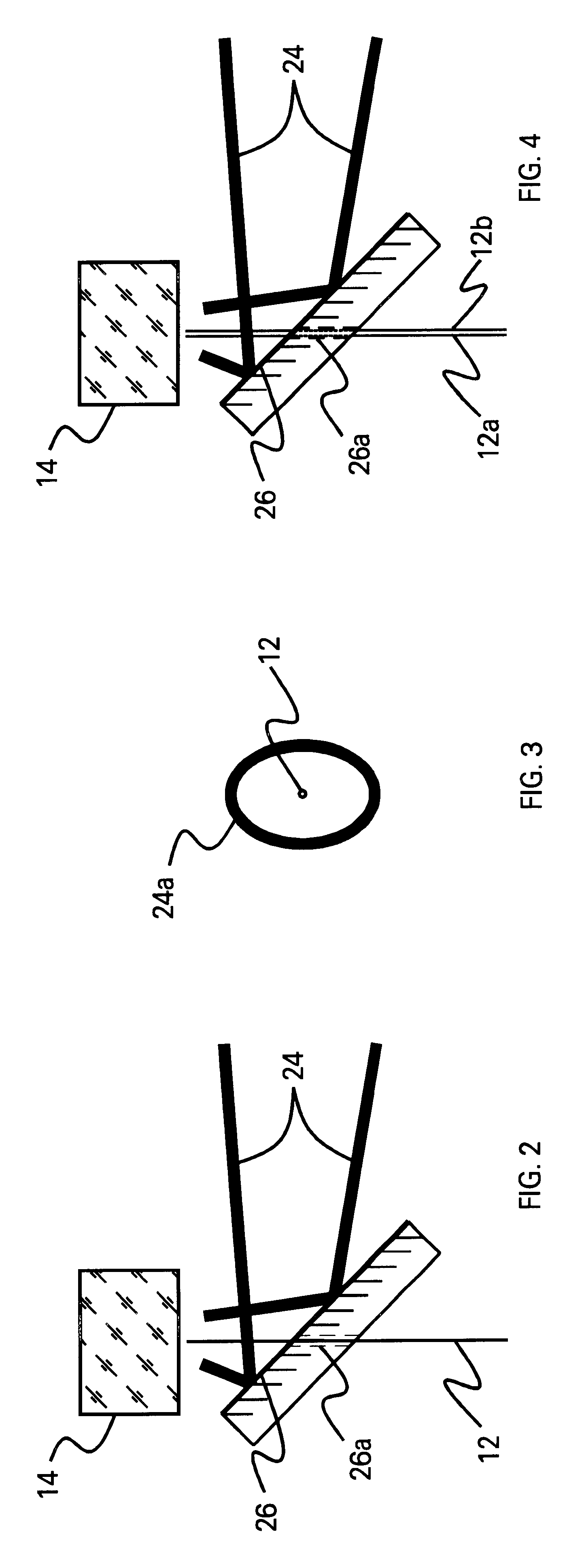

Fabrication of collimators employing optical fibers fusion-spliced to optical elements of substantially larger cross-sectional areas

InactiveUS6360039B1Reduce back reflectionImprove pointing accuracyLamination ancillary operationsLaminationRefractive indexFusion splicing

A fiber collimator is provided, comprising at least two optical components, one of the optical components (e.g., an optical element such as a collimating lens or a plano-plano pellet) having a surface that has a comparatively larger cross-sectional area than the surface of the other optical component(s) (e.g., at least one optical fiber). The optical components are joined together by fusion-splicing, using a laser. A gradient in the index of refraction is provided in at least that portion of the surface of the optical element to which the optical fiber(s) is fusion-spliced or at the tip of the optical fiber. The gradient is either formed prior to or during the fusion-splicing. Back-reflection is minimized, pointing accuracy is improved, and power handling ability is increased.

Owner:LIGHTPATH TECH INC

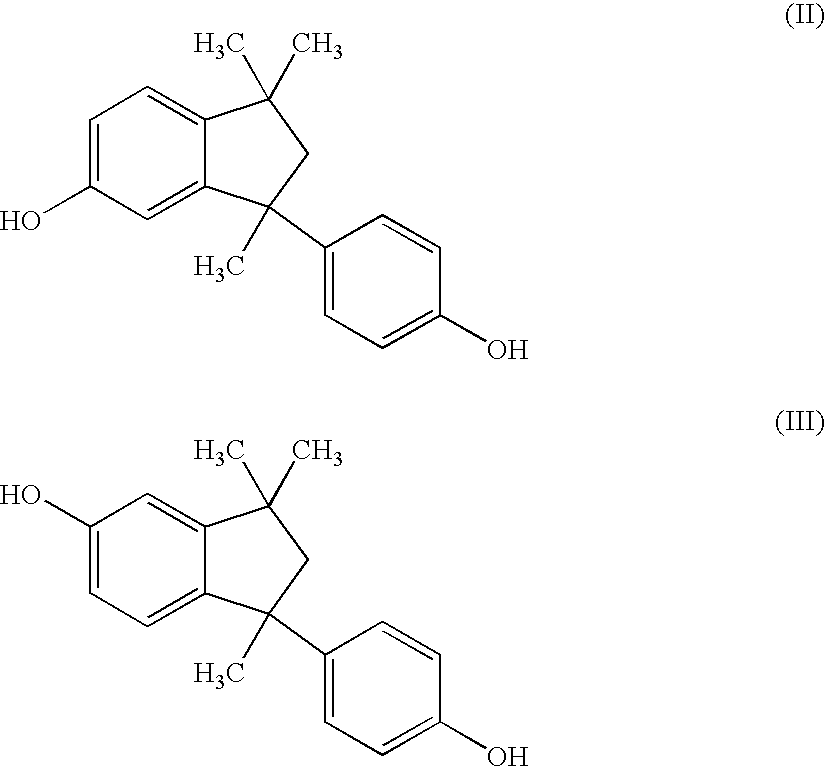

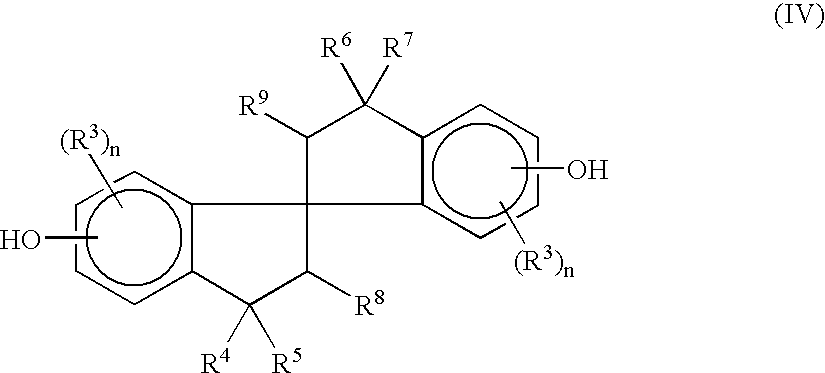

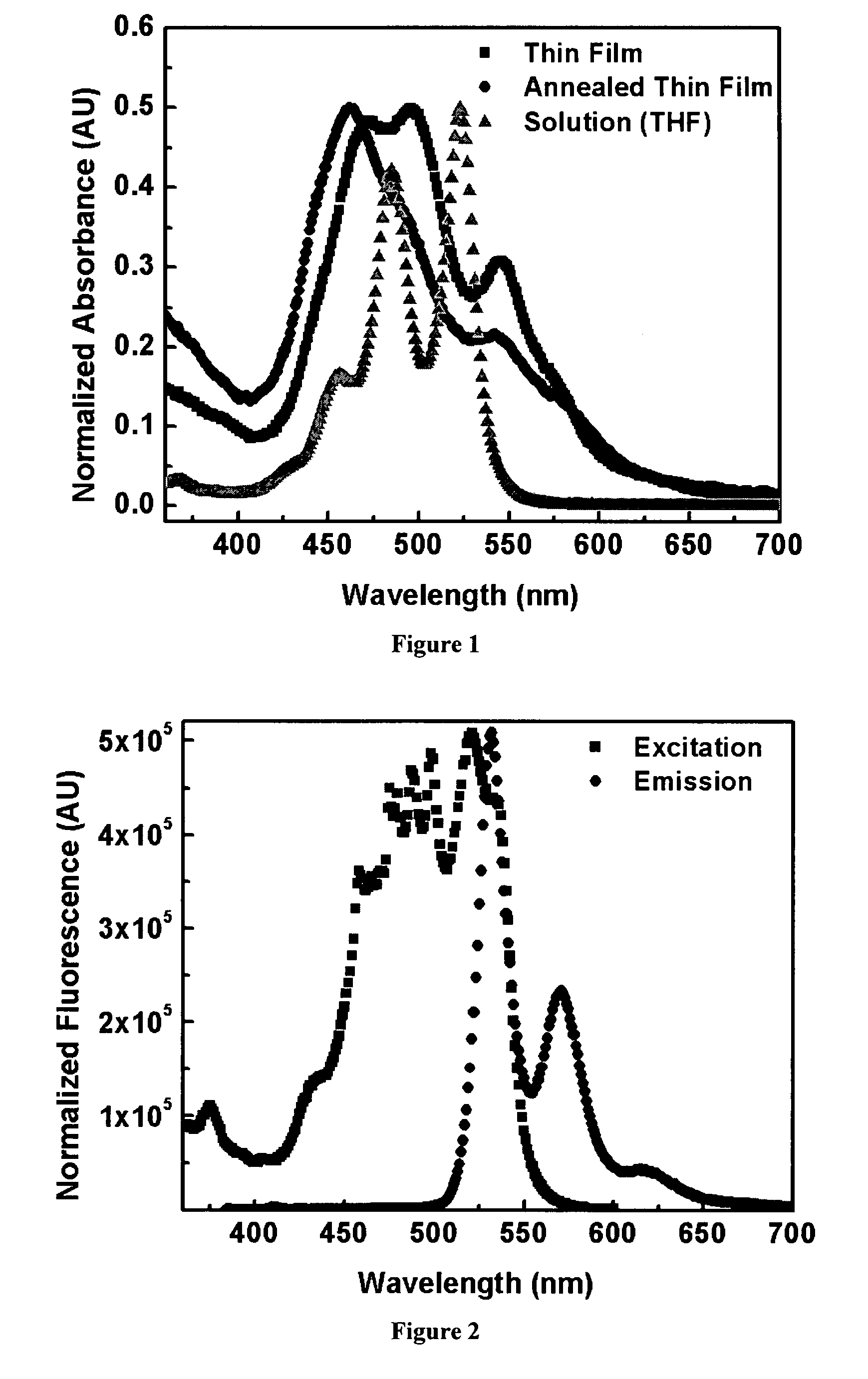

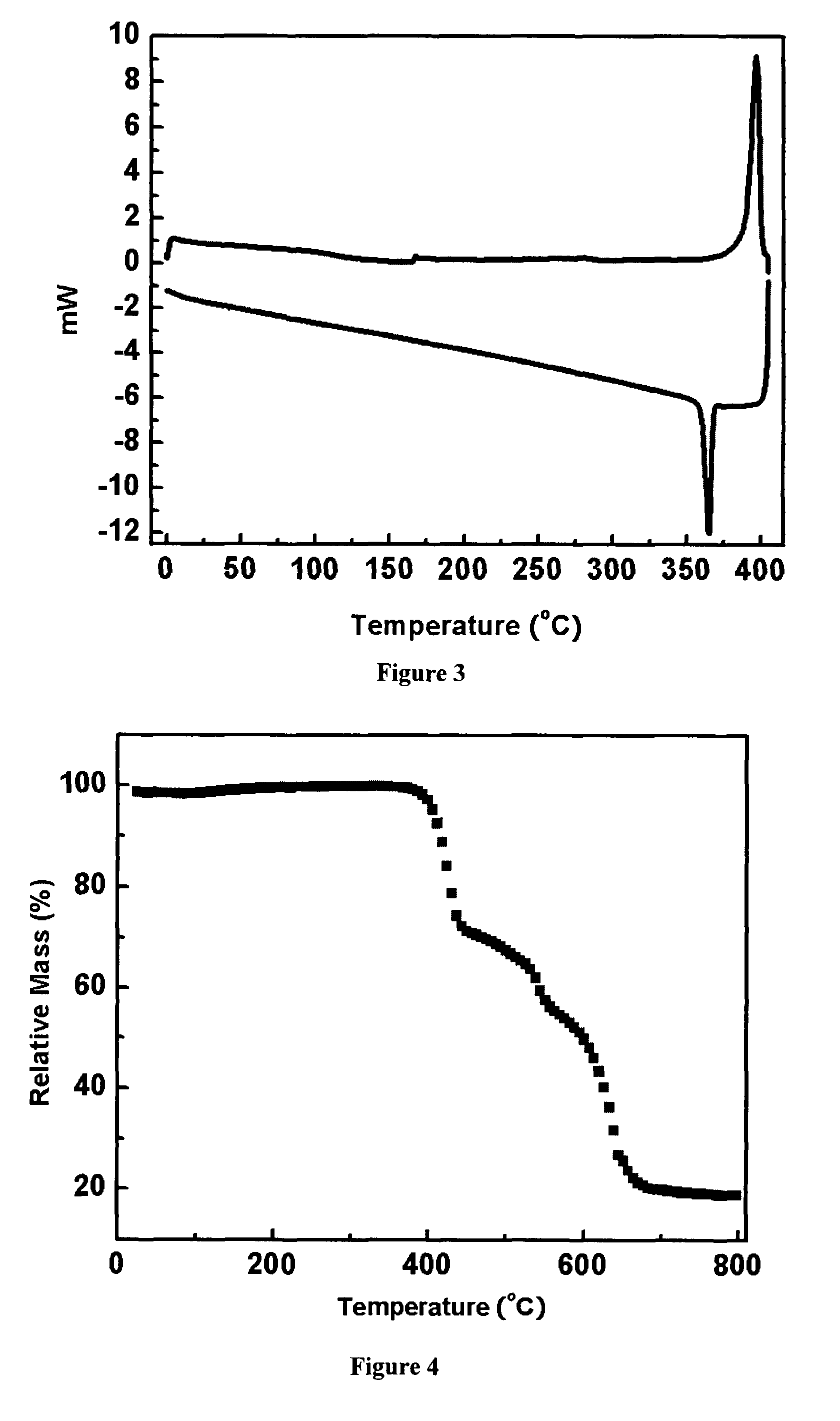

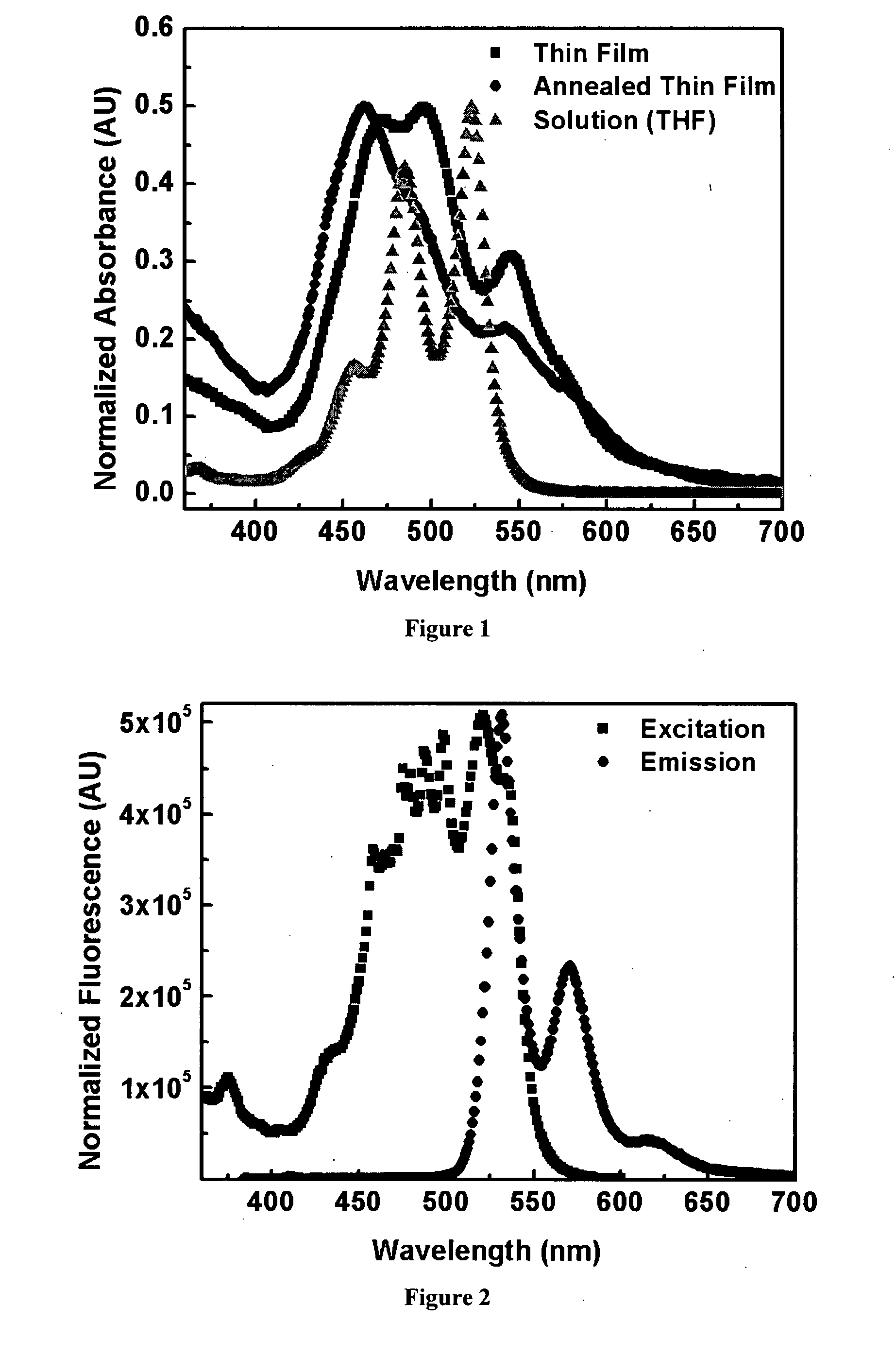

Organic semiconductor materials and methods of preparing and use thereof

ActiveUS20080167435A1Useful electrical propertyWide viscosity rangeOrganic chemistrySolid-state devicesOrganic semiconductorSemiconductor materials

Solution-processable organic n-type semiconductor materials are provided with processes for preparing the same. Composites and electronic devices including the organic n-type semiconductor materials also are provided.

Owner:FLEXTERRA INC

Polyhydroxyalkanoate having amide group and sulfonic group, method of producing the same, charge controlling agent containing novel polyhydroxyalaknaote, toner binder, toner, and image forming apparatus using the toner

InactiveUS6908721B2Improved melt processabilityGood biocompatibilityDevelopersElectrographic processes using charge patternHalogenAliphatic hydrocarbon

A polyhydroxyalkanoate comprises a unit of formula (1): —(O—CH((CH2)mSASO2R)CH2C(═O))— wherein R is selected from the group consisting of OH, a halogen atom, ONa, OK, OCH3 and OC2H5; A represents a substituted or unsubstituted aliphatic hydrocarbon structure; m is an integer number selected from 1 to 8; and in the case where a plurality of units exist in the same molecule, R, A and m in one unit can be different from them in another unit respectively. A method of producing the polyhydroxyalkanoate comprises the step of reacting a polyhydroxyalkanoate comprising a unit of formula (18): —(O—CH((CH2)mBr)CH2C(═O))—, wherein m is an integer number selected from 1 to 8, and in the case where a plurality of units exist in the same molecule, m in one unit can be different from that in another unit, with at least one type of compounds of formula (19): HS-A1-SO2R15 wherein R15 is selected from the group consisting of OH, a halogen atom, ONa, OK, OCH3 and OC2H5 and A1 is a substituted or unsubstituted aliphatic hydrocarbon structure, and in the case where a plurality of types of compounds exist in the same molecule, R15 and A1 in one unit can be different from them in another unit respectively.

Owner:CANON KK

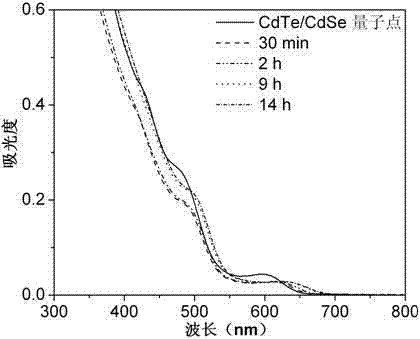

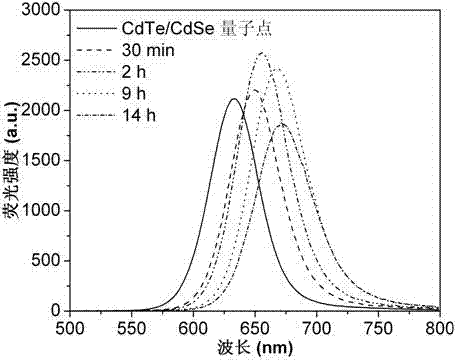

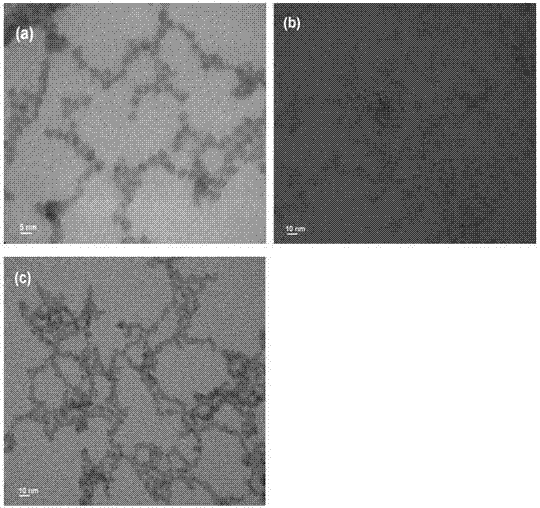

Multi-shell-structure quantum dot composite particle, and high-fluorescent-brightness quantum dot probe and preparation method thereof

InactiveCN102925158AHigh fluorescence brightnessIncrease brightnessBiological testingLuminescent compositionsFluoProbesBio molecules

The invention discloses a multi-shell-structure quantum dot composite particle, and a high-fluorescent-brightness quantum dot probe and a preparation method thereof. The composite particle uses a quantum dot as a core, a semiconductor shell is coated outside the quantum dot, and a composite silicon dioxide shell is coated outside the semiconductor shell. A biological molecule can be connected to the composite silicon dioxide shell to form the probe. The composite particle and probe with required fluorescent wavelength can be obtained by controlling the reaction conditions. The method has strong operability. The obtained composite particle has favorable chemical and physical stability, biocompatibility and environmental stability. The formed probe has high stability and high fluorescent brightness, can have high application value in the fields of medicine and biology, and can be used as a common fluorescent probe, immunologic detection agent or any other biosensor.

Owner:UNIV OF JINAN

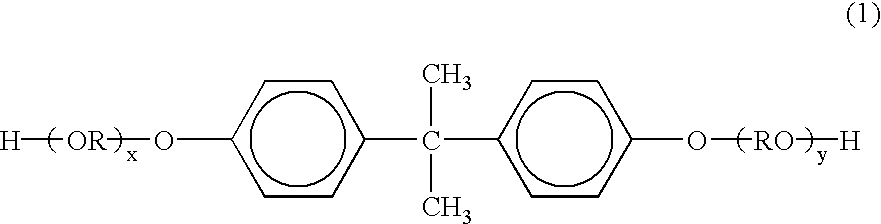

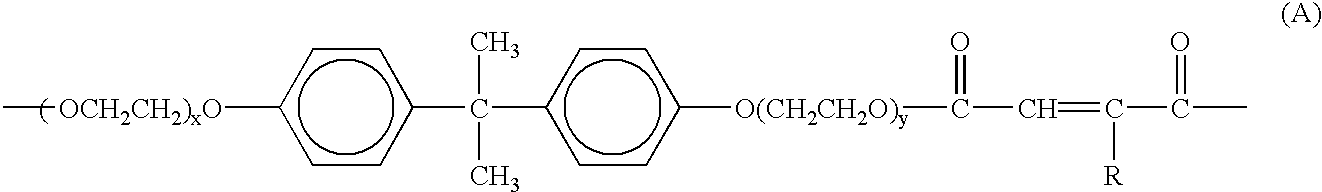

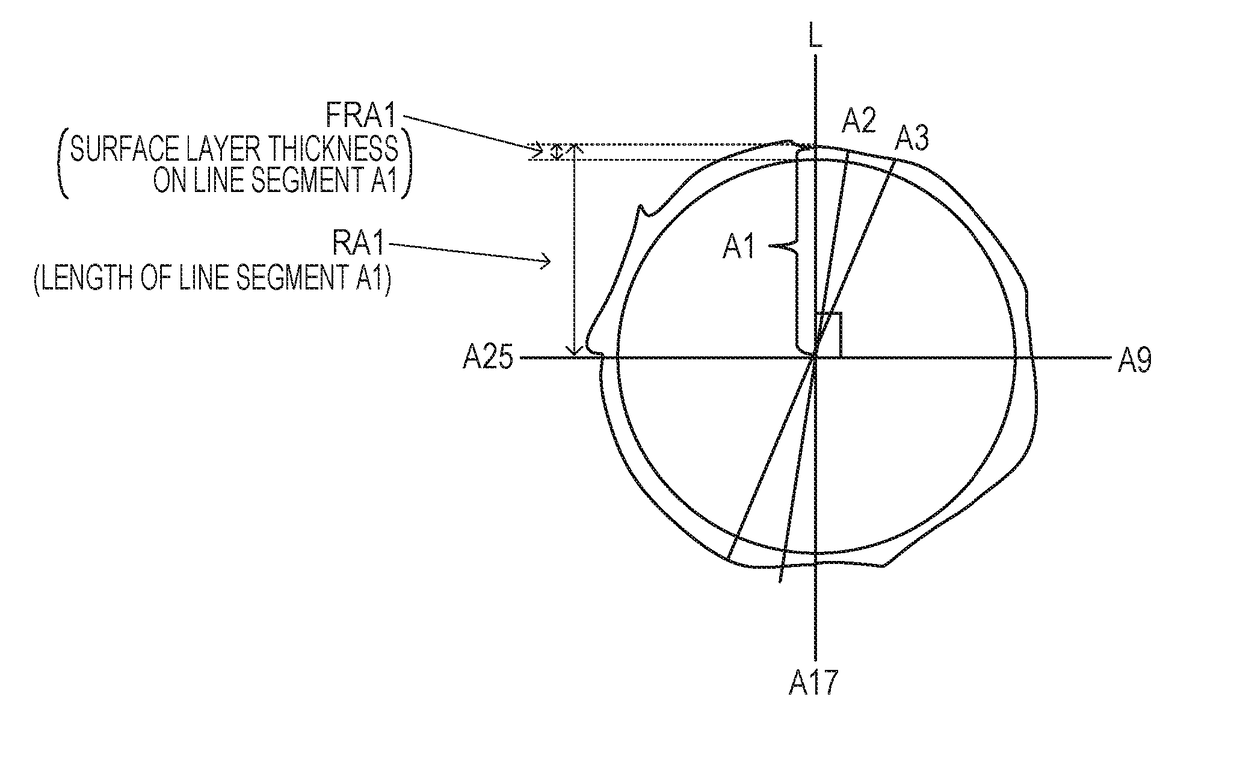

Toner

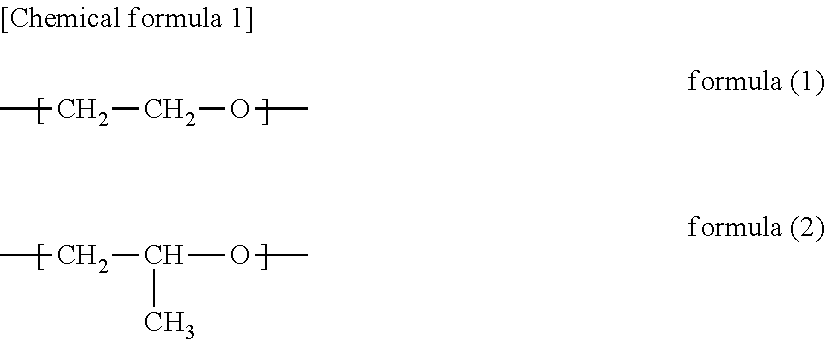

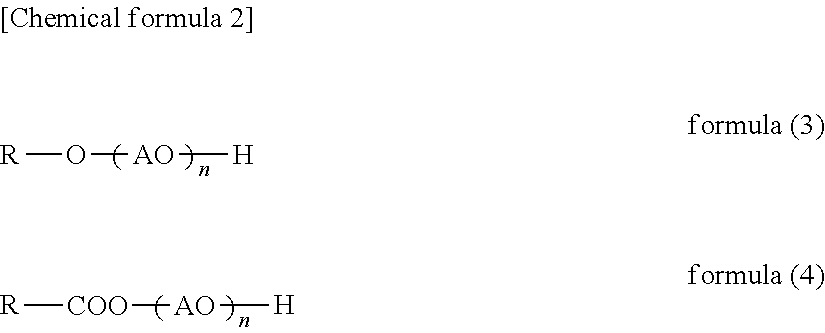

A toner is provided that exhibits a high long-term image stability even during high-speed printing and that also exhibits an excellent environmental stability. The toner comprises a binder resin, a colorant, and a nonionic surfactant, wherein the nonionic surfactant has an oxyethylene group (EO) and an oxypropylene group (PO) and has a ratio of the number of moles of the oxypropylene group to the number of moles of the oxyethylene group (PO / EO) of at least 0.01 and not more than 5.00; and when A (μg / g) is defined as a nonionic surfactant content on the surface of the toner that can be extracted by methanol from 1 g of the toner and B (m2 / g) is defined as a theoretical specific surface area determined from a toner particle diameter distribution obtained by a precision particle diameter distribution analyzer that operates based on an aperture electrical resistance method, a ratio A / B is at least 100 μg / m2 and not more than 9000 μg / m2.

Owner:CANON KK

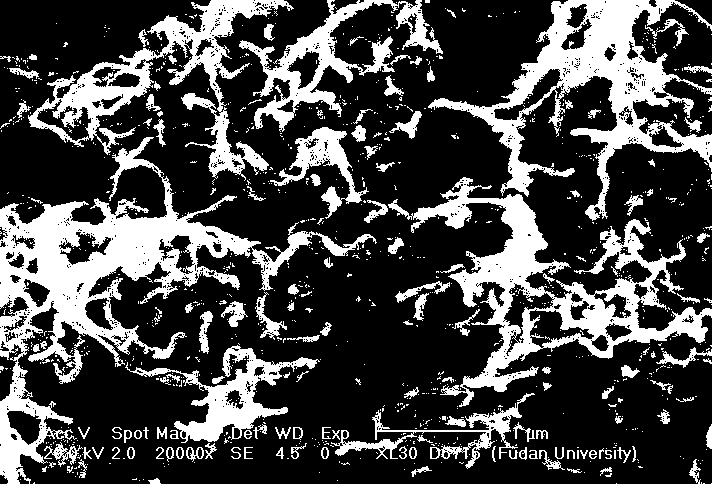

Synthetic method and application of polydopamine-modified carbon nanotube composite material

InactiveCN103012806AHigh sensitivityGood reproducibilityMaterial analysis by electric/magnetic meansModified carbonBiocompatibility

The invention belongs to the field of nanotechnology, and particularly relates to a synthetic method and application of a polydopamine-modified carbon nanotube composite material. The synthetic method comprises the following steps in sequence: dispersing carbon nanotubes into dopamine-containing aqueous solution; quickly adding trismetyl aminomethane buffer solution into the dopamine-containing aqueous solution in which the carbon nanotubes are uniformly dispersed under magnetically stirring; mechanically stirring for 10 hours at room temperature; washing by water; and centrifugally separating to obtain the carbon nanotube composite material of which the surface is modified by polydopamine, wherein the carbon nanotube composite material shows high dispersibility in water. The polydopamine-modified carbon nanotube composite material adopts the carbon nanotubes as the framework, and therefore, a large specific surface area is provided; the polydopamine-modified carbon nanotube composite material is excellent in environmental stability and biocompatibility and high in dispersibility in water; the synthetic method is simple and low in cost; and the polydopamine-modified carbon nanotube composite material can be used as the substrate for analyzing metabolite micromolecule under high-throughput MALDI-TOFMS (Matrix Assisted Laser Desorption Ionization Time of Flight Mass Spectrometry).

Owner:FUDAN UNIV

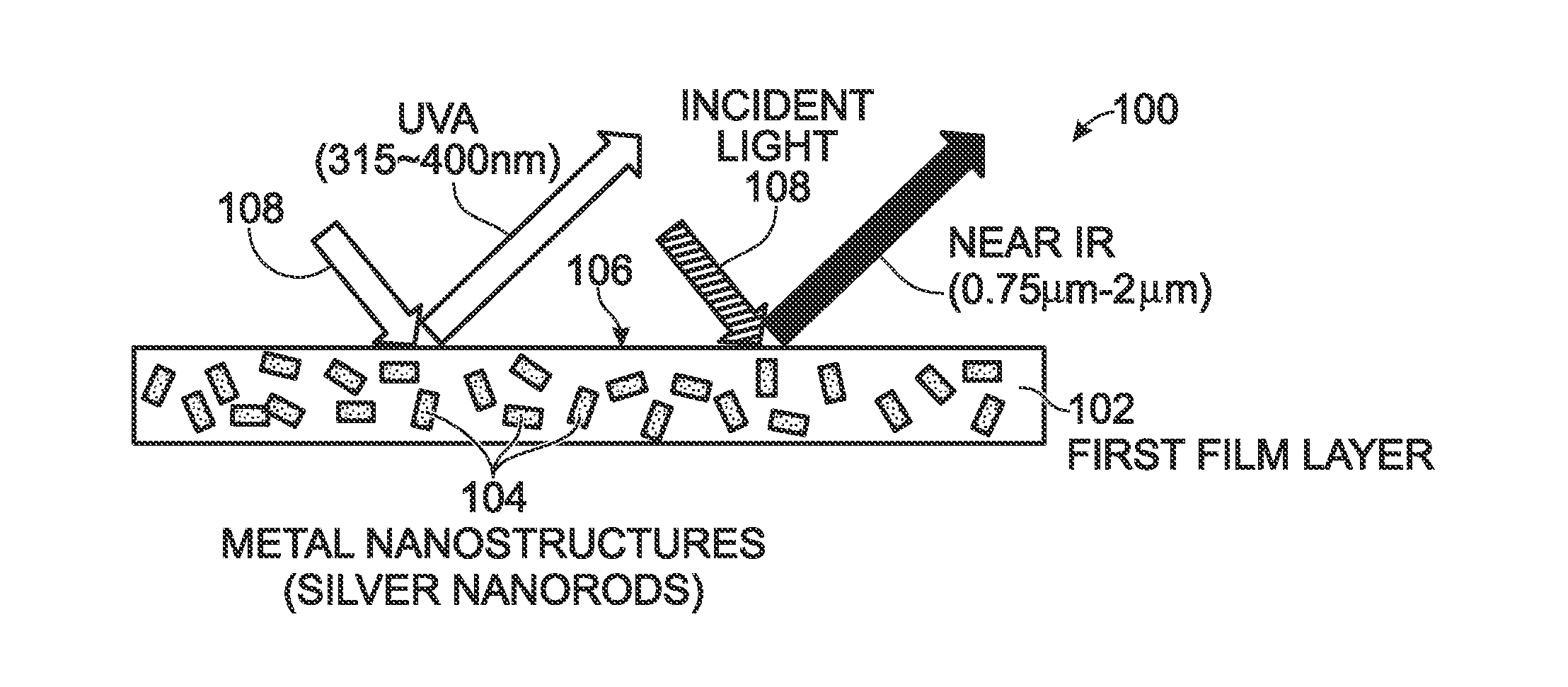

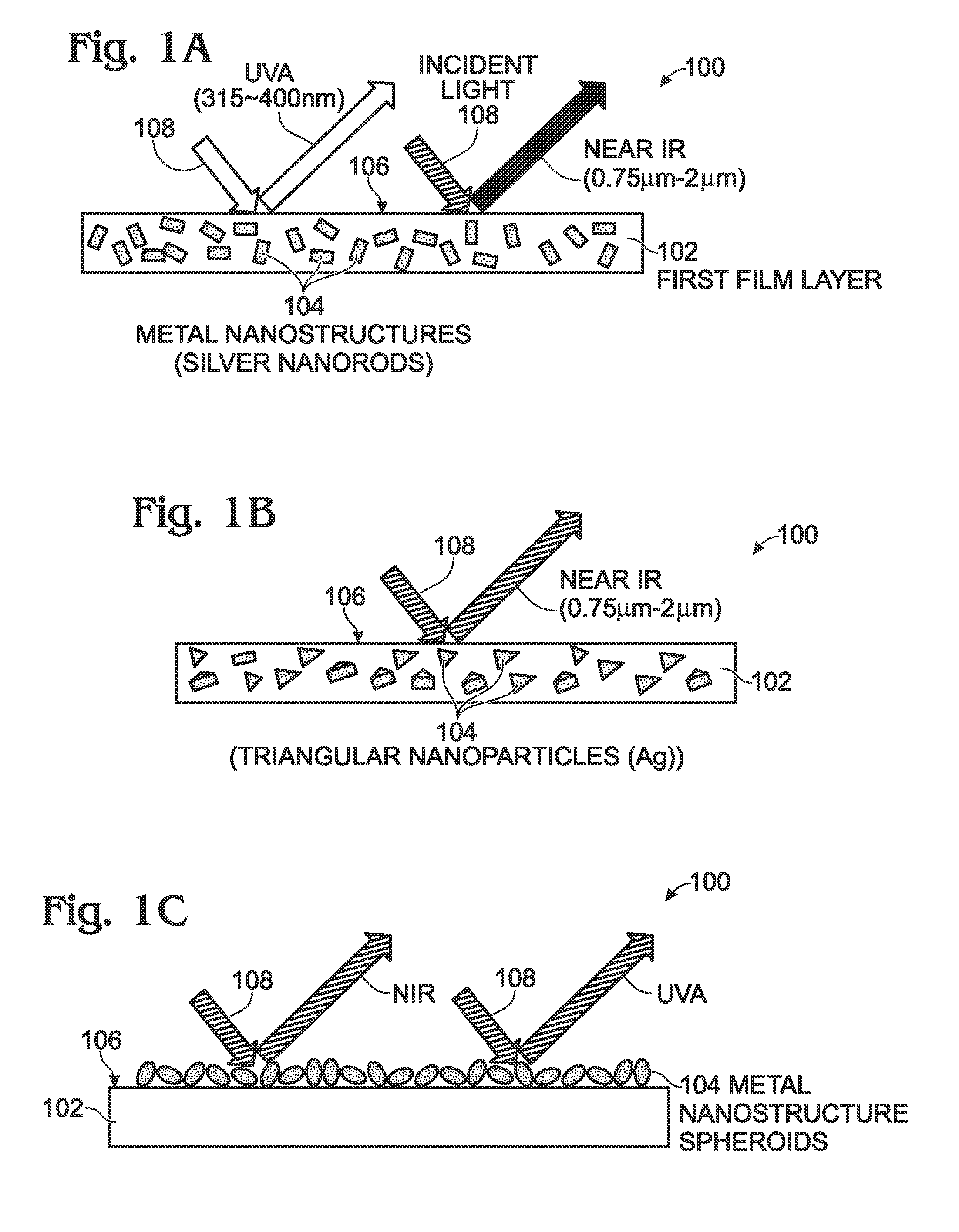

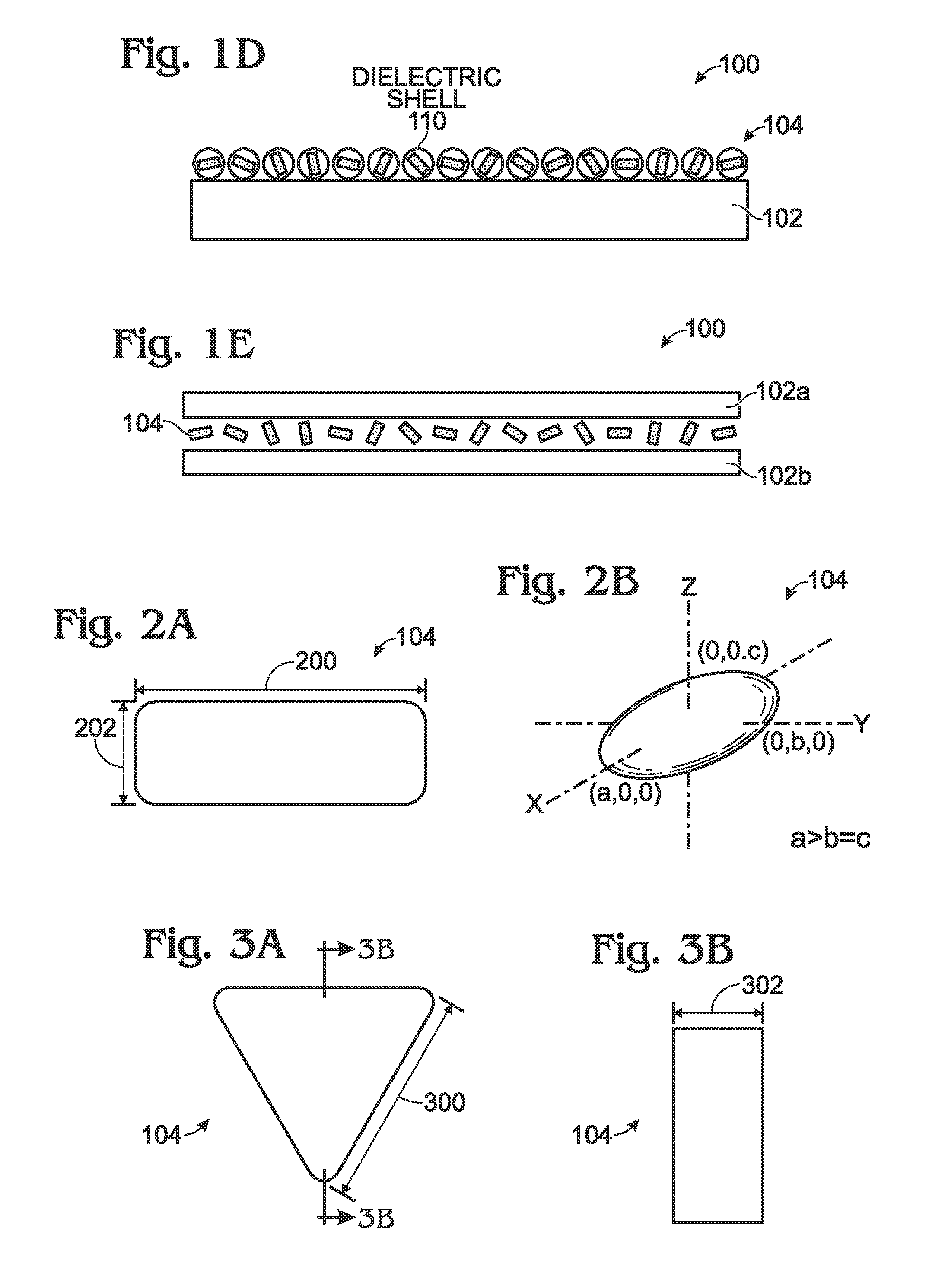

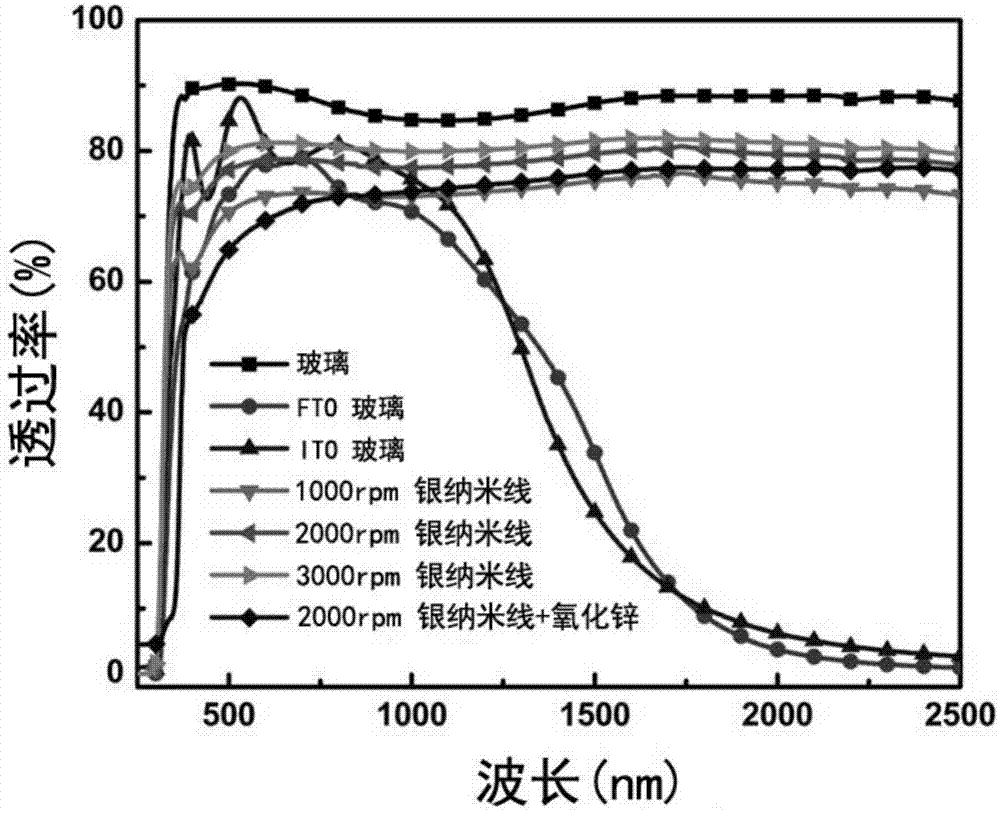

Energy-Efficient Transparent Solar Film

InactiveUS20130258456A1Improve stabilityImprove efficiencyMaterial nanotechnologyMirrorsResonanceLength wave

An energy-efficient transparent solar film is presented. The solar film has a first film layer with metal nanostructures. The metal nanostructures have plasmon resonances in wavelength bands greater than, or both less than and greater than visible wavelengths, depending on size and shape. The metal nanostructures have no plasmon resonance at visible wavelengths. In another aspect, metal oxide nanocrystals are formed with the first film layer. The metal oxide nanocrystals have absorption in a band of wavelengths less than visible wavelengths, and absorption in a band of wavelengths greater than visible wavelengths. Also provided is a solar film window and fabricating method.

Owner:SHARP KK

Preparation method of high-thermal-conductivity low-leakage phase-change composite

InactiveCN104371666AHigh phase change heat storage capacityLow phase change heat storage capacityHeat-exchange elementsMass ratioLow leakage

The invention discloses a preparation method of a high-thermal-conductivity low-leakage phase-change composite. The method includes: taking a phase-change material and thermal-conductive filler in the mass ratio of 0.1%-1% for melt mixing at the temperature above the melt temperature of the phase-change material for 10min, and taking out the mixture for cooling prior to breaking into granules to obtain modified filler; taking the phase-change material and a support material in the mass ratio of 0.1%-10% for melting at the temperature above the melting temperature of the support material and the phase-change material for 20min, and taking out the molten materials for cooling prior to breaking the materials into granules to obtain a modified support material; adding the modified thermal-conductive filler and the modified support material in the proportion of 1:9-9:1 into the phase-change material counting for 40-50% of total mass for melting the the temperature above the melting temperature of the support material and the phase-change material for 30min prior to obtaining a mixed composite; pouring the mixed composite into a preheated mould, applying certain pressure to the mould, maintaining the pressure for 20min, and performing cooling and demoulding to obtain the high-thermal-conductivity low-leakage phase-change composite. Compared with the prior art, the preparation method has the advantages of simplicity, low cost and chip and available raw materials.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Silver nanoparticles and process for producing same

ActiveUS20100037731A1Low costGood environmental stabilityMaterial nanotechnologyMetal-working apparatusHydrazine compoundCarboxylic acid

Processes for producing silver nanoparticles are disclosed. A reaction mixture comprising a silver compound, a carboxylic acid, an amine compound, and an optional solvent is optionally heated. A hydrazine compound is then added and the mixture is further reacted to produce the silver nanoparticles.

Owner:XEROX CORP

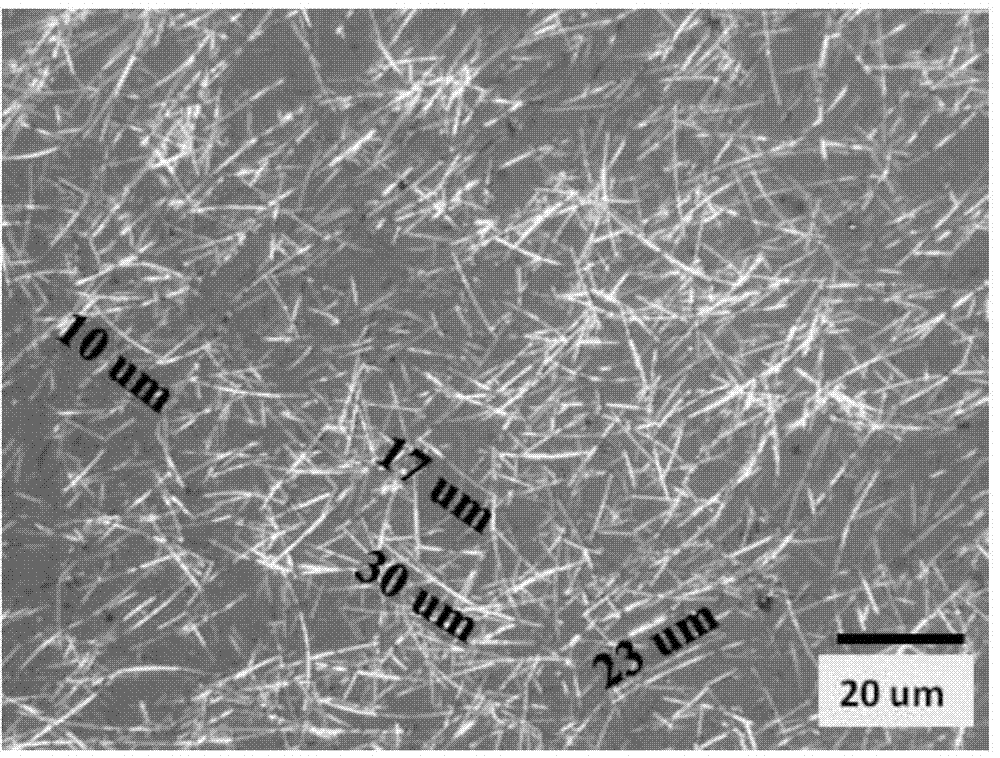

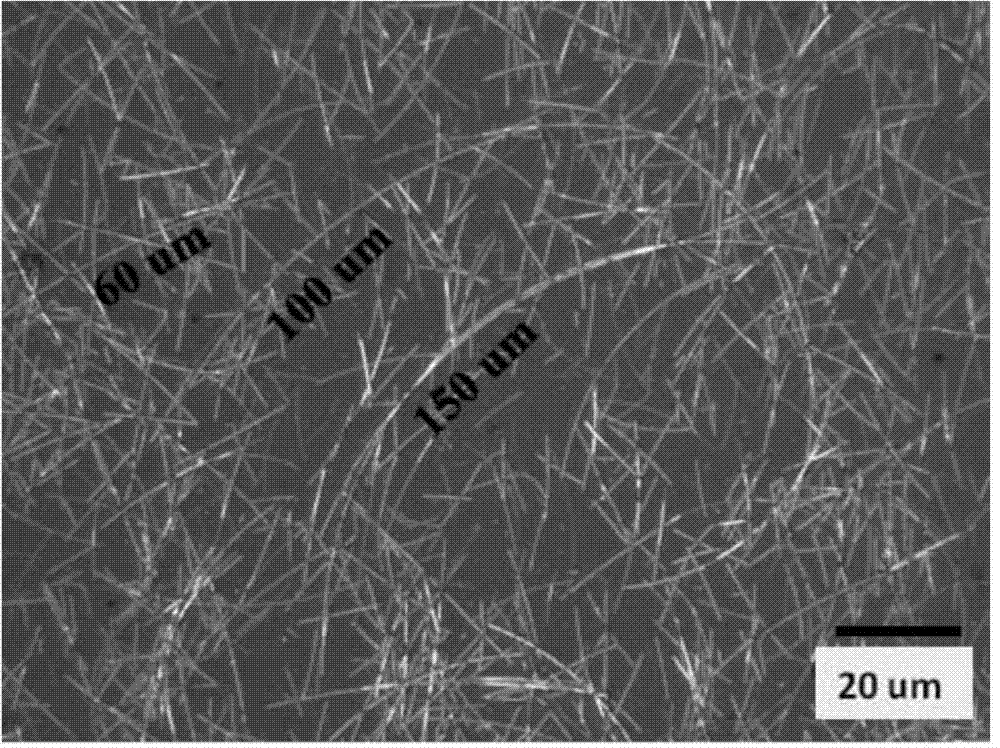

Preparation method of silver nanowire-zinc oxide composite transparent electrode

InactiveCN103700446AAvoid clustersHigh viscosityCable/conductor manufactureOxide compositeZinc nanoparticles

The invention belongs to the field of application of a nano material, particularly relates to a preparation method of a silver nanowire-zinc oxide composite transparent electrode and aims to simplify process, reduce cost and obtain the silver nanowire-zinc oxide composite transparent electrode with excellent light transmission and electrical conductivity, high wear resistance and environmental stability. The invention adopts the following technical scheme: 1, an ultra long silver nanowire is prepared by an improved polyol reduction method; 2, the silver nanowire is processed by a post-processing process; 3, a silver nanowire transparent conductive film is prepared; 4, zinc oxide nano particles are filled. The preparation method has various advantages of simple process, high repeatability, easiness for operation and control and the like.

Owner:XI AN JIAOTONG UNIV

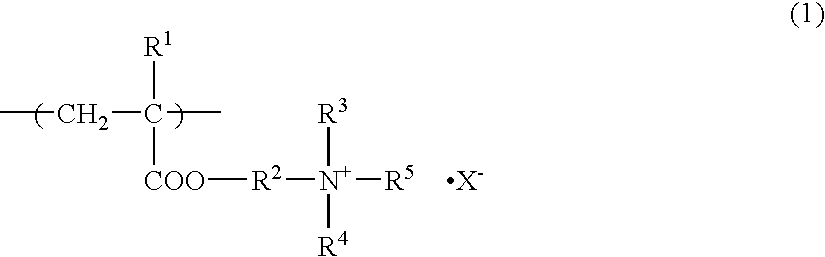

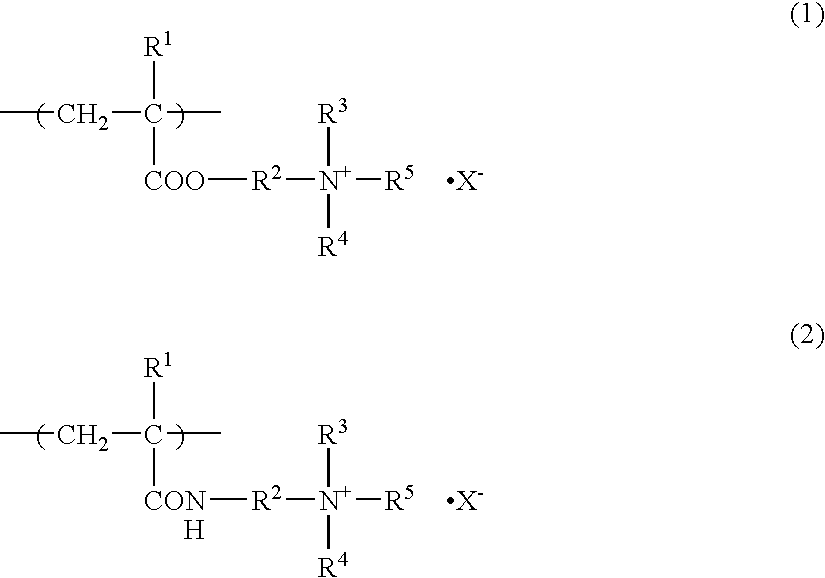

Positively charged developer for development of electrostatic image and production process thereof

ActiveUS20100173240A1Easy to cleanPrinting property is not impairedDevelopersInorganic particleInorganic particles

A positively charged developer for development of electrostatic images, comprising positively charged toner particles and an external additive, wherein the positively charged toner particles are colored resin particles composed of aggregated and fusion-bonded particles of fine binder resin particles and fine colorant particles and having a shape factor SF-1 of 115 to 150 and a shape factor SF-2 of 110 to 140, and the external additive is an external additive containing positively charged inorganic particles subjected to a hydrophobization treatment with an amino group-containing compound, and a production process thereof.

Owner:ZEON CORP

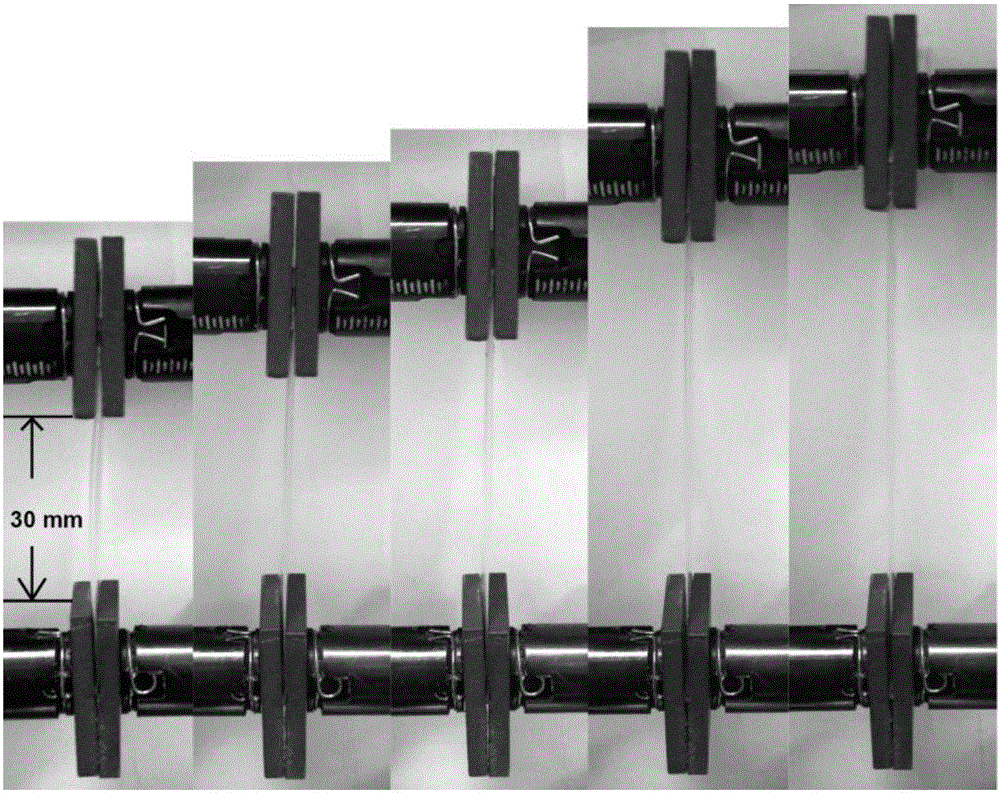

Application of polymerizable deep-eutectic solvents to preparing transparent conductive elastomers

The invention discloses application of polymerizable deep-eutectic solvents to preparing transparent conductive elastomers. Hydrogen bond receptors and hydrogen bond donors are mixed with one another at the temperatures of 60-100 DEG C to obtain the polymerizable deep-eutectic solvents, a molar ratio of the hydrogen bond donors to the hydrogen bond receptors is not smaller than 1:1, and the hydrogen bond donors comprise acrylic acid or methacrylic acid. The polymerizable deep-eutectic solvents, cross-linking agents and photoinitiators are mixed with one another to obtain mixed solution, and the mixed solution can be cured in polytetrafluoroethylene culture dishes under ultraviolet irradiation to obtain the transparent conductive elastomers. The application has the advantage that the transparent conductive elastomers are high in light transmission and conductivity, excellent in tensile property and bendability and good in environmental stability.

Owner:广州纽楷美新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com