Patents

Literature

845 results about "Co2 absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plants absorb some of the carbon dioxide (CO2) released into the atmosphere by burning fossil fuels. But increasing deforestation and other changes in land use will reduce the CO2 absorption capacity of these areas in the future.

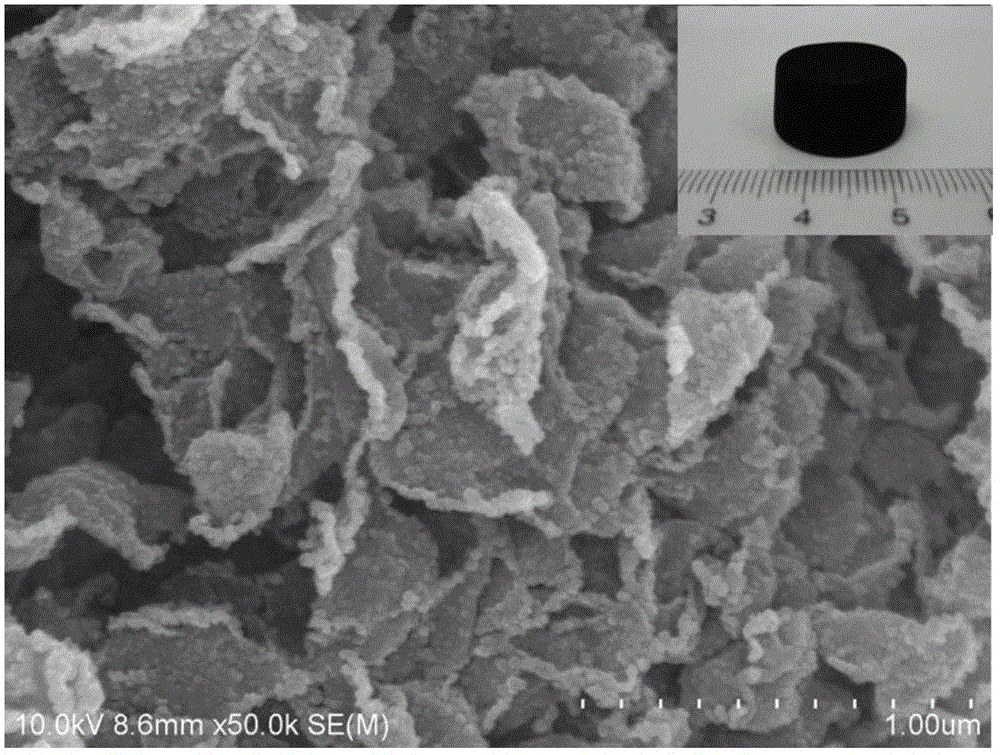

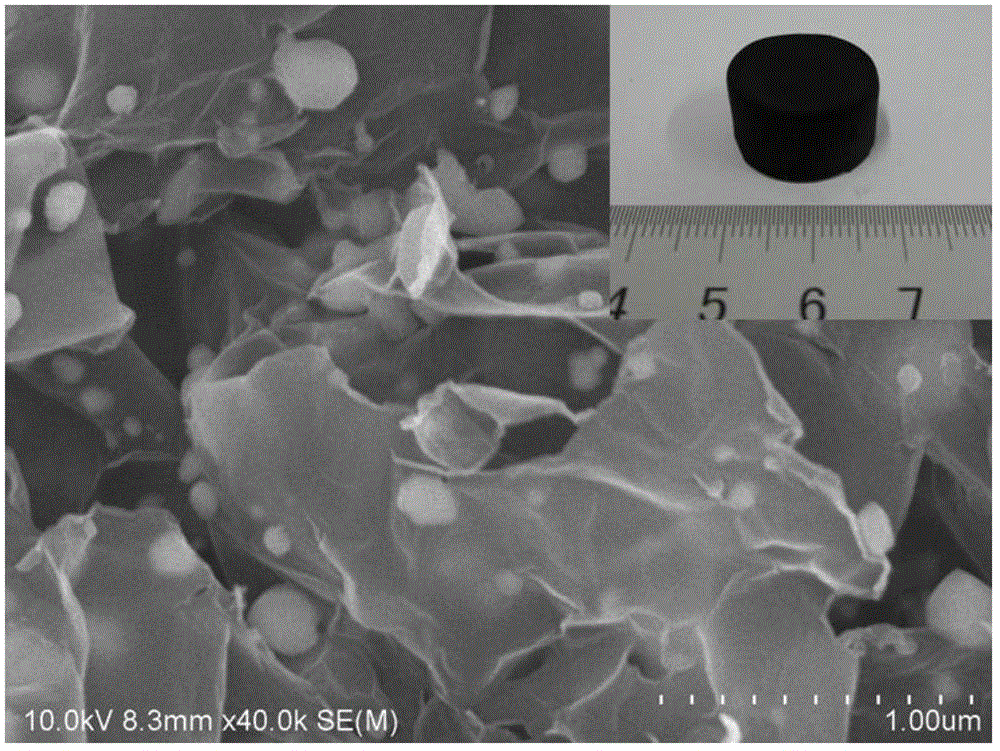

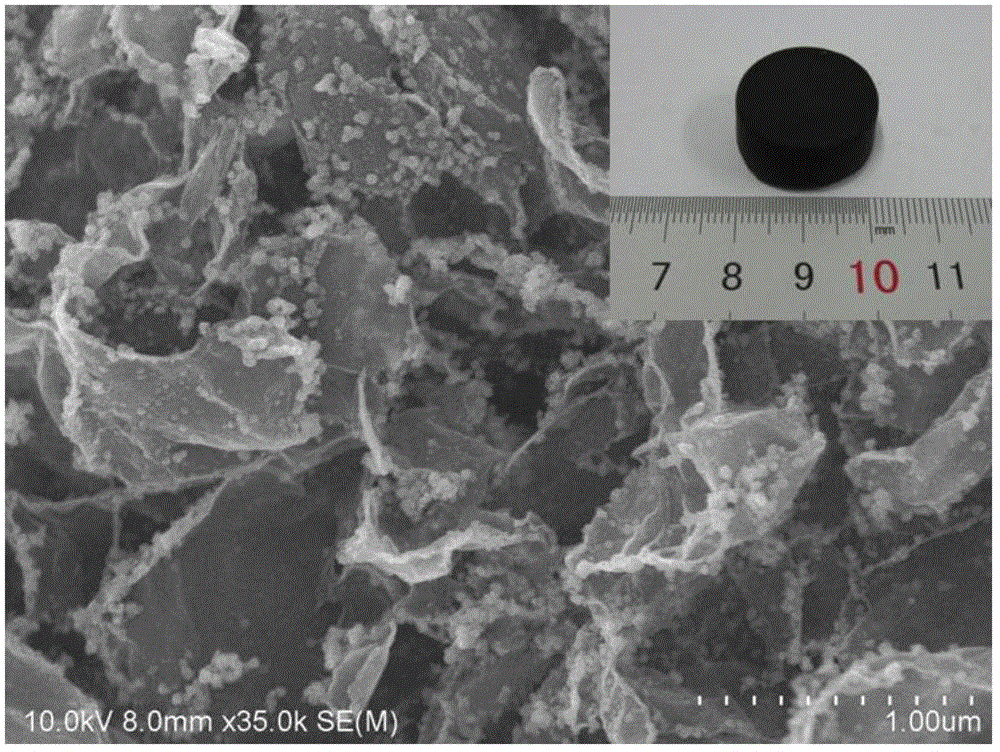

Graphene/metal oxide hybrid aerogel, preparation method and applications thereof

ActiveCN102941042AExcellent ultra-light porous propertiesExcellent physical and chemical propertiesOther chemical processesHybrid capacitor electrodesCo2 absorptionElectromagnetic shielding

The present invention relates a graphene / metal oxide hybrid aerogel, a preparation method and applications thereof, and belongs to the field of nanometer material applications. The hybrid aerogel comprises a graphene network and a metal oxide network, wherein the two networks are mutually wound to form a hybrid aerogel, and the metal oxide network is further a crystalline state. The hybrid aerogel preparation comprises: preparing a graphene oxide organic solution, adding a soluble metal salt and an epoxide to obtain a uniform non-flowing hybrid wet gel, and carrying out drying and charring to obtain the graphene / metal oxide hybrid aerogel. The hybrid aerogel can be used as an energy storage material, an electromagnetic shielding material, a biological enzyme catalysis carrier and a CO2 absorption material, and has wide applications.

Owner:陶丽

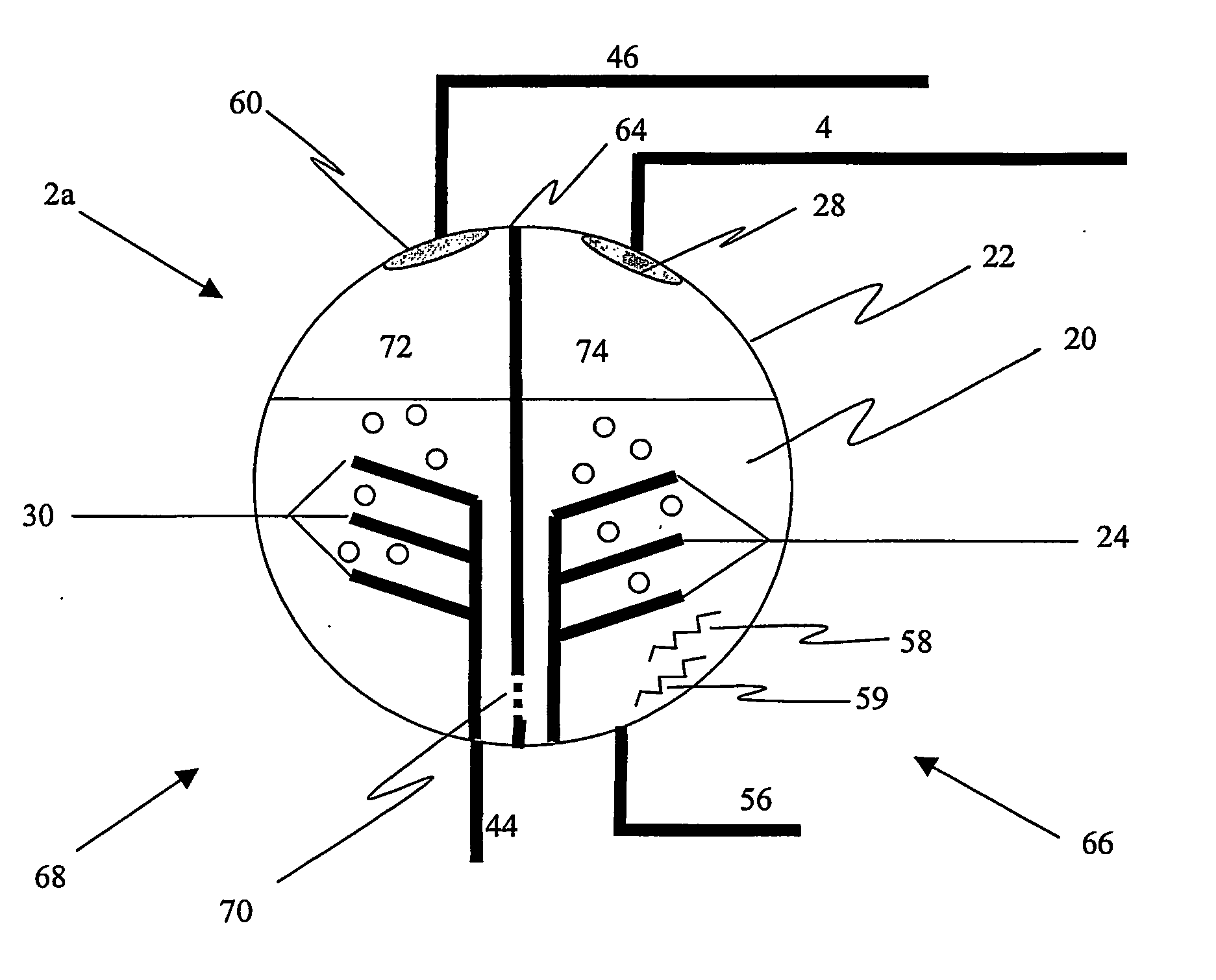

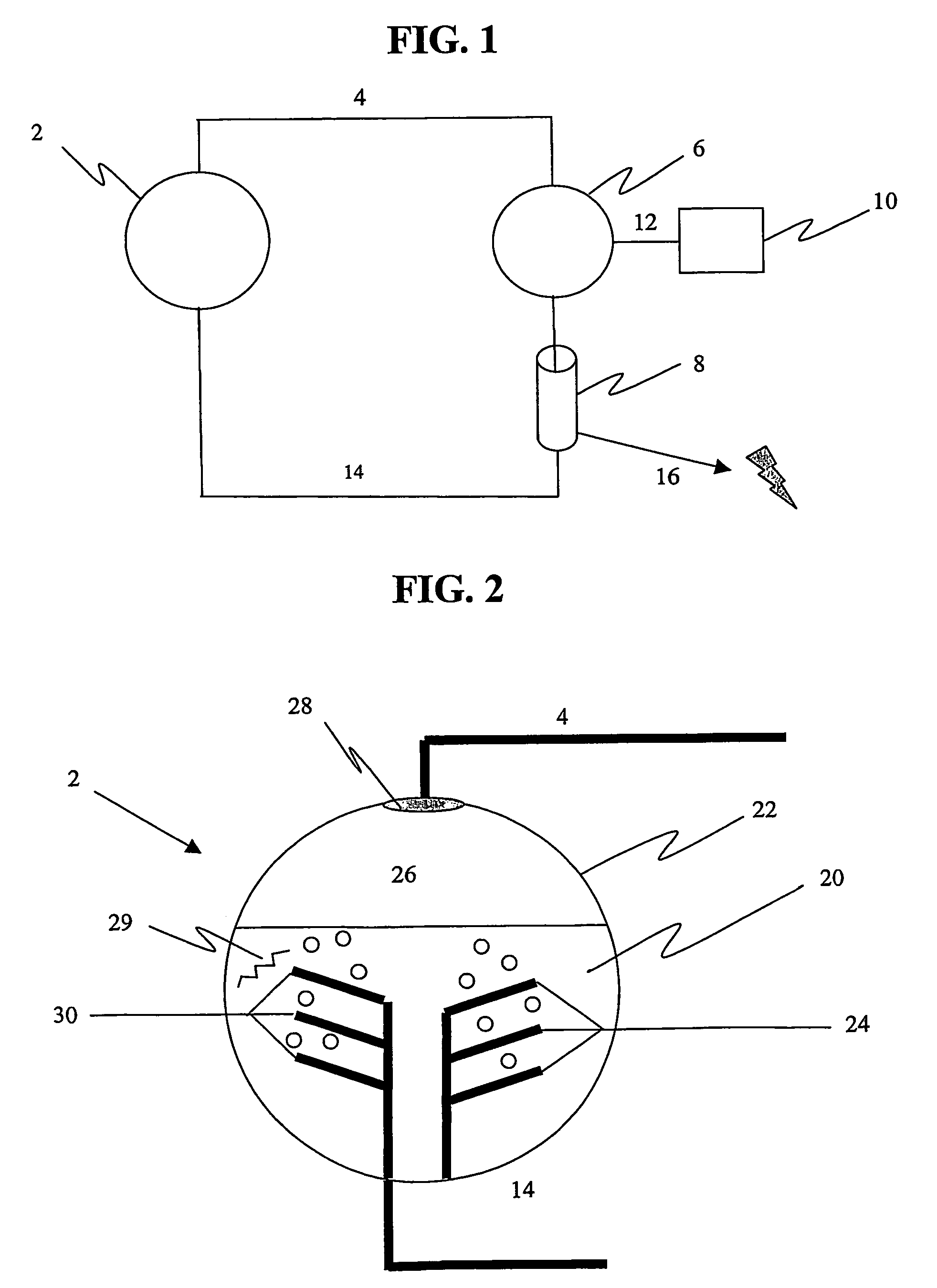

Integrated oxygen generation and carbon dioxide absorption method apparatus and systems

InactiveUS20050031522A1Improvement in mission durationLower acquisition costsFuel cell auxillariesMachines/enginesChemical speciesCo2 absorption

A method for producing oxygen and absorbing carbon dioxide in a single operation using a solution that contains an oxygen source and a redox partner that can react to form oxygen and a chemical species that can form an insoluble carbonate to precipitate and chemically store carbon dioxide. Carbon dioxide is introduced into the solution and the carbonate precipitates as the oxygen is generated. In particular, the invention uses an aqueous solution of permanganate and hydrogen peroxide that react in the presence of a catalyst to produce oxygen and manganese (II) ions. Carbon dioxide gas introduced into the solution reacts with the manganese (II) ions to precipitate manganese carbonate. Other cations capable of reacting with carbon dioxide to form an insoluble carbonate, for example calcium, barium and magnesium, may also be added to the solution to precipitate carbonate salts. Calcium permanganate may used as a source of both calcium and permanganate.

Owner:CAPITAL MANAGEMENT +1

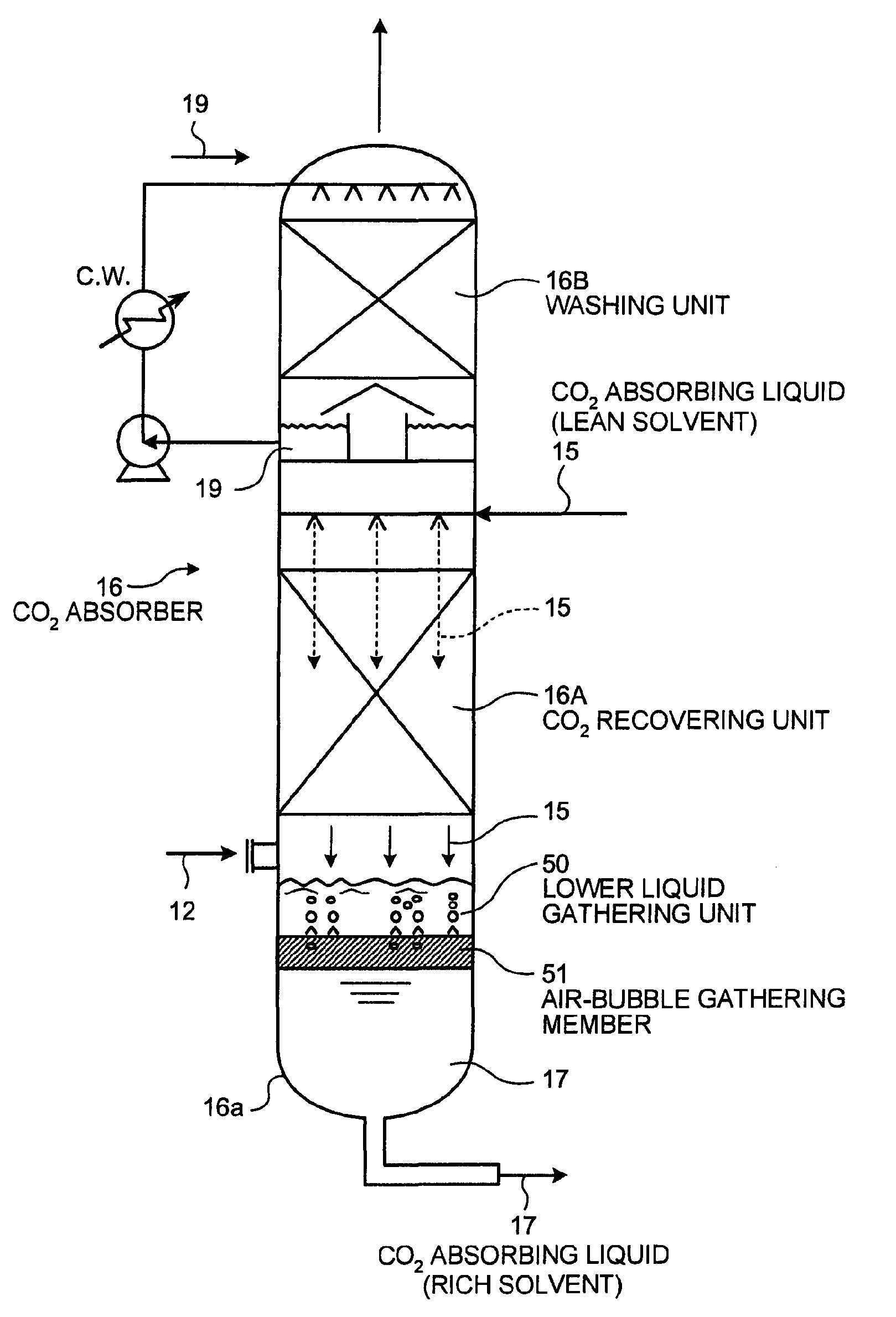

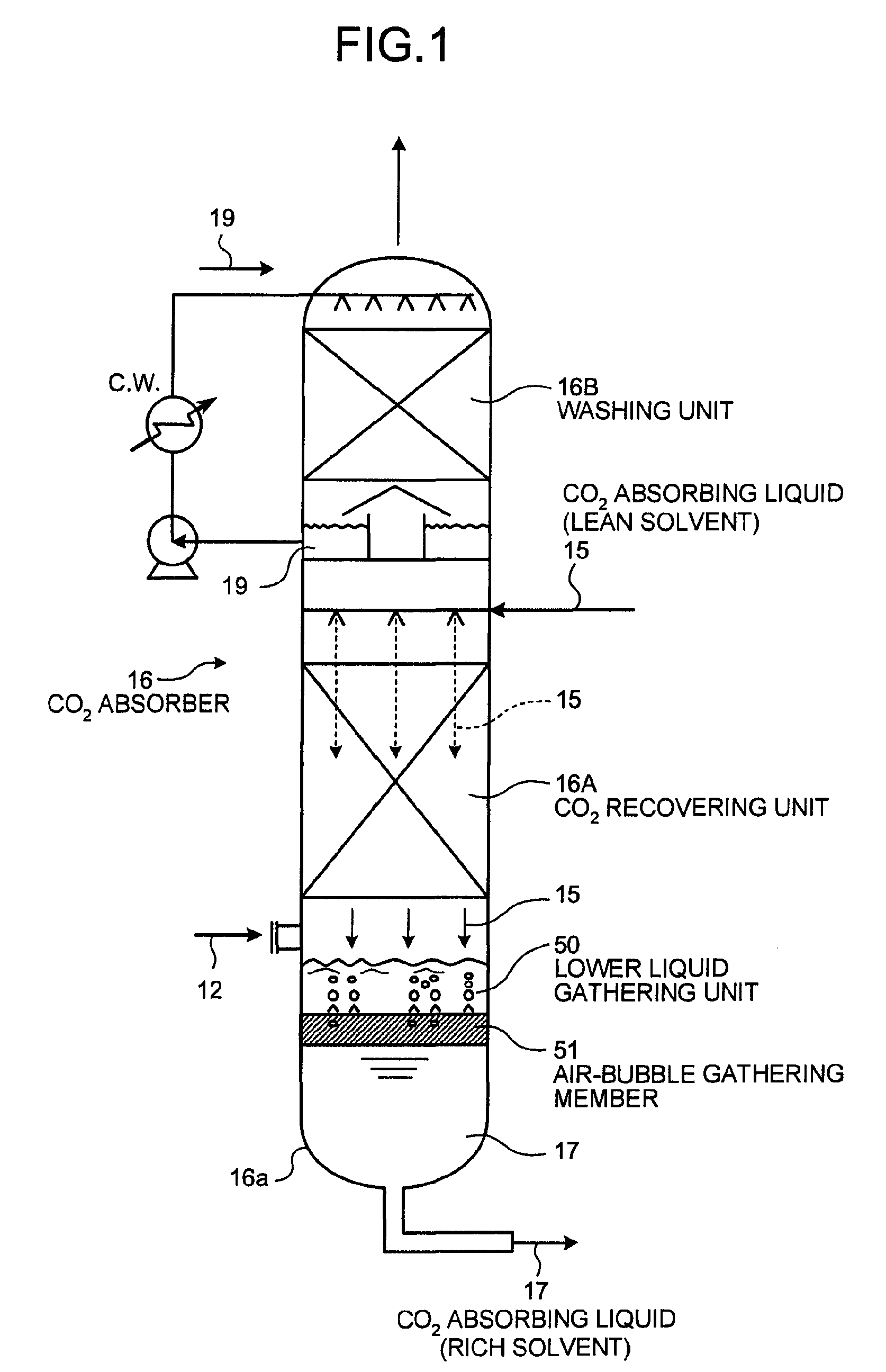

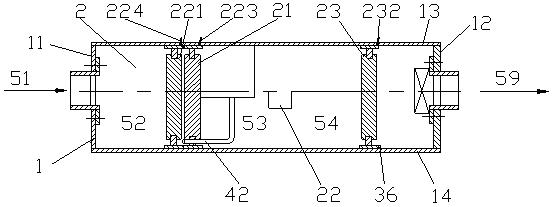

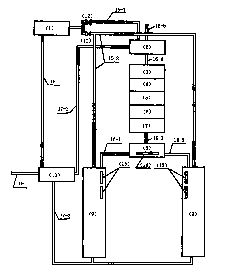

CO2 recovering apparatus

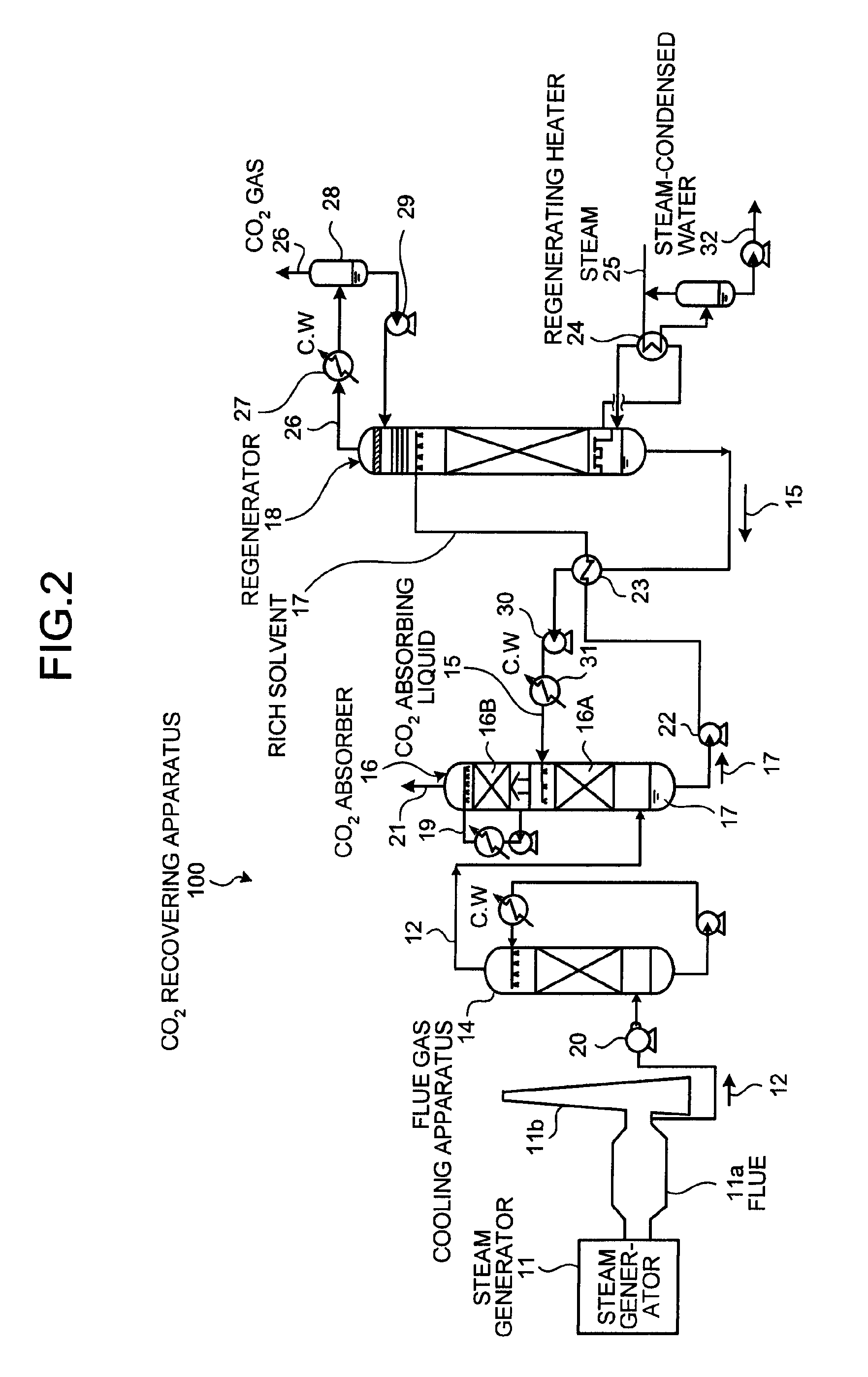

A CO2 recovering apparatus includes a CO2 absorber that brings flue gas containing CO2 and O2 into contact with CO2 absorbing liquid to reduce CO2 in the flue gas; and a regenerator that reduces CO2 in CO2 absorbing liquid (rich solvent) that absorbed CO2 in the CO2 absorber to regenerate the CO2 absorbing liquid, so that the regenerated CO2 absorbing liquid (lean solvent) having CO2 reduced in the regenerator is reused in the CO2 absorber. A lower liquid reservoir is located at the bottom of the CO2 absorber, and an air-bubble gathering member is arranged therein to gather air bubbles included in the absorbing liquid.

Owner:MITSUBISHI HEAVY IND LTD +1

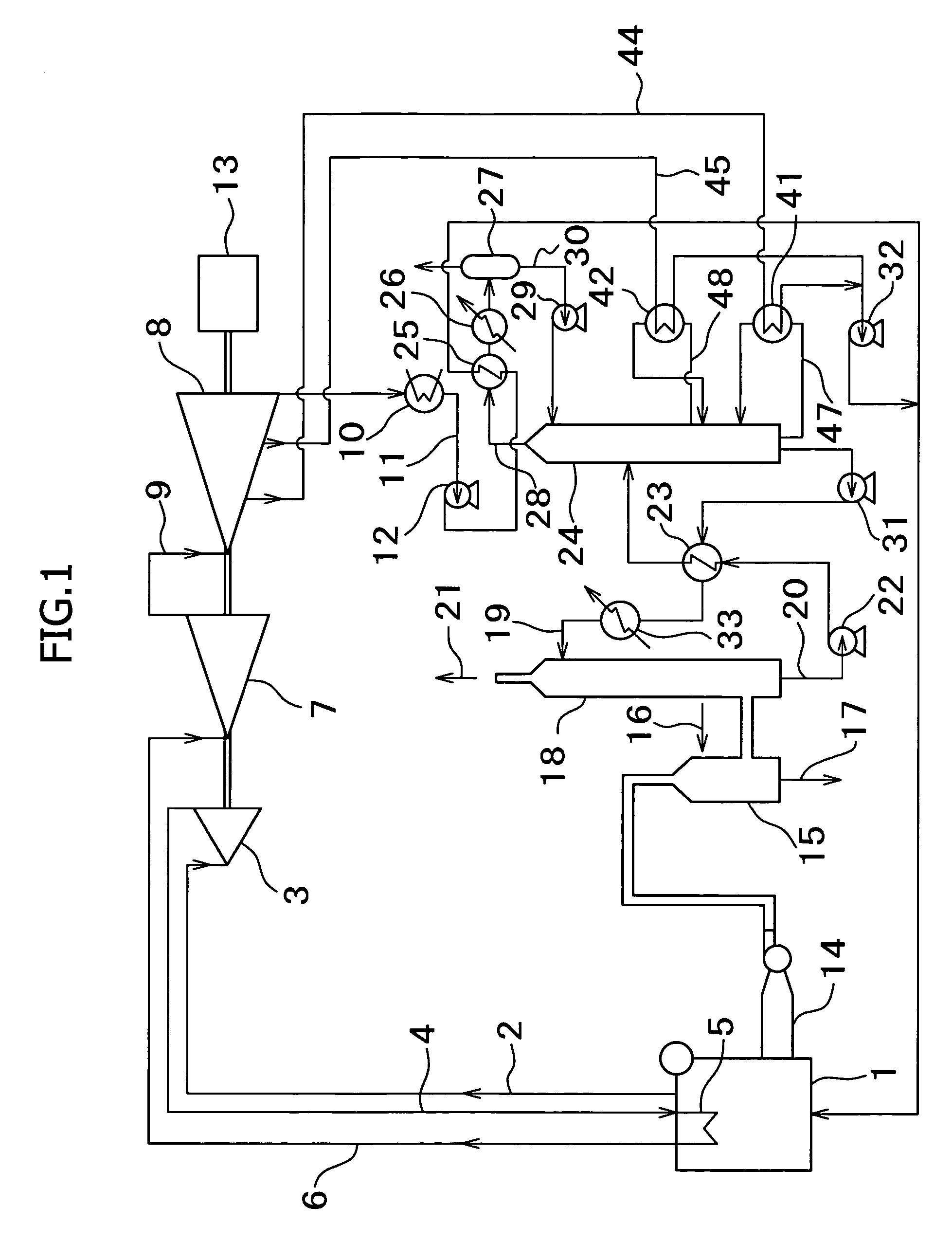

CO2 recovery apparatus and CO2 recovery method

ActiveUS8377184B2Reduce oxygen concentrationSuppression problemOxygen/ozone/oxide/hydroxideLiquid degasificationFlue gasCo2 absorption

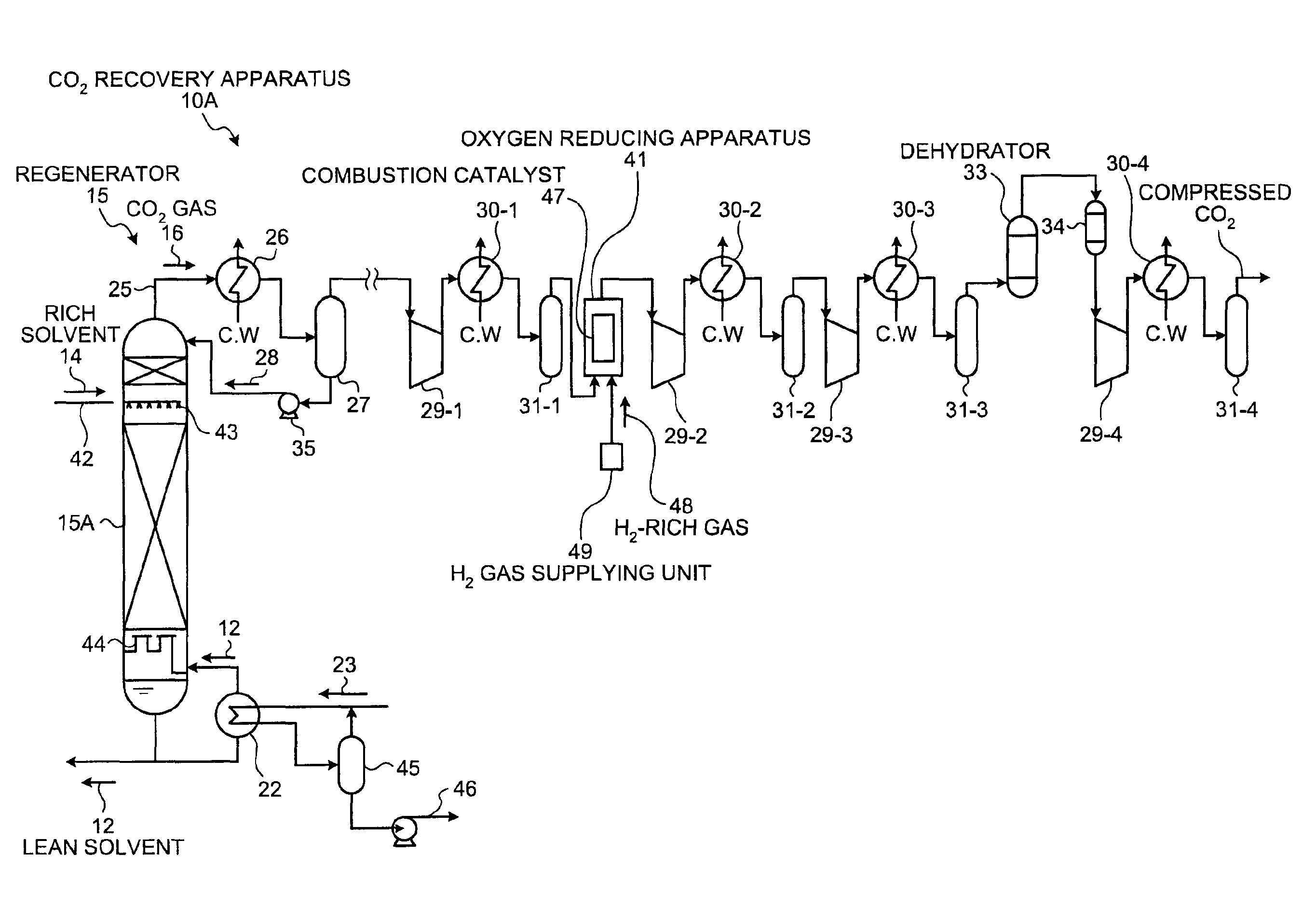

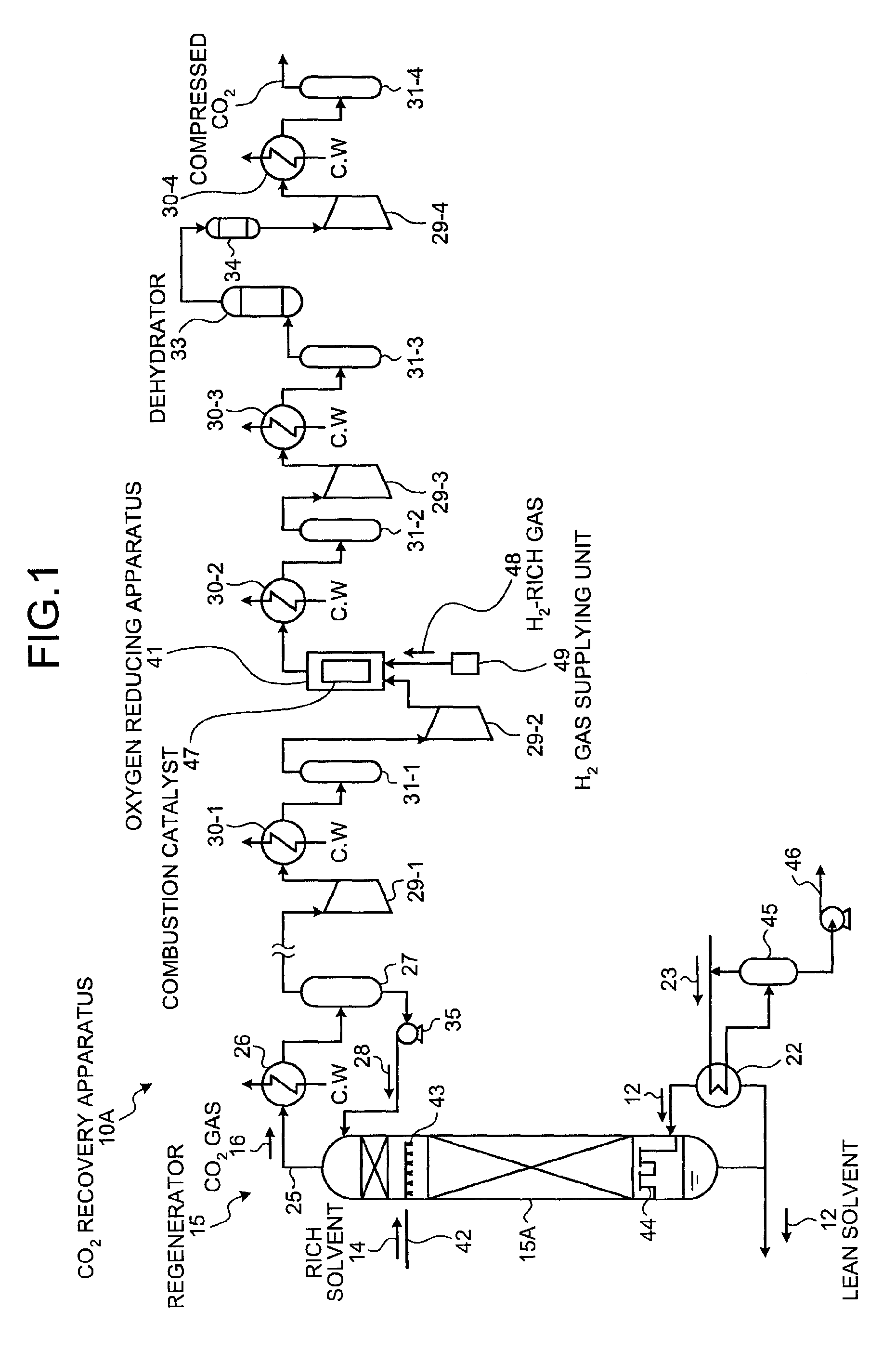

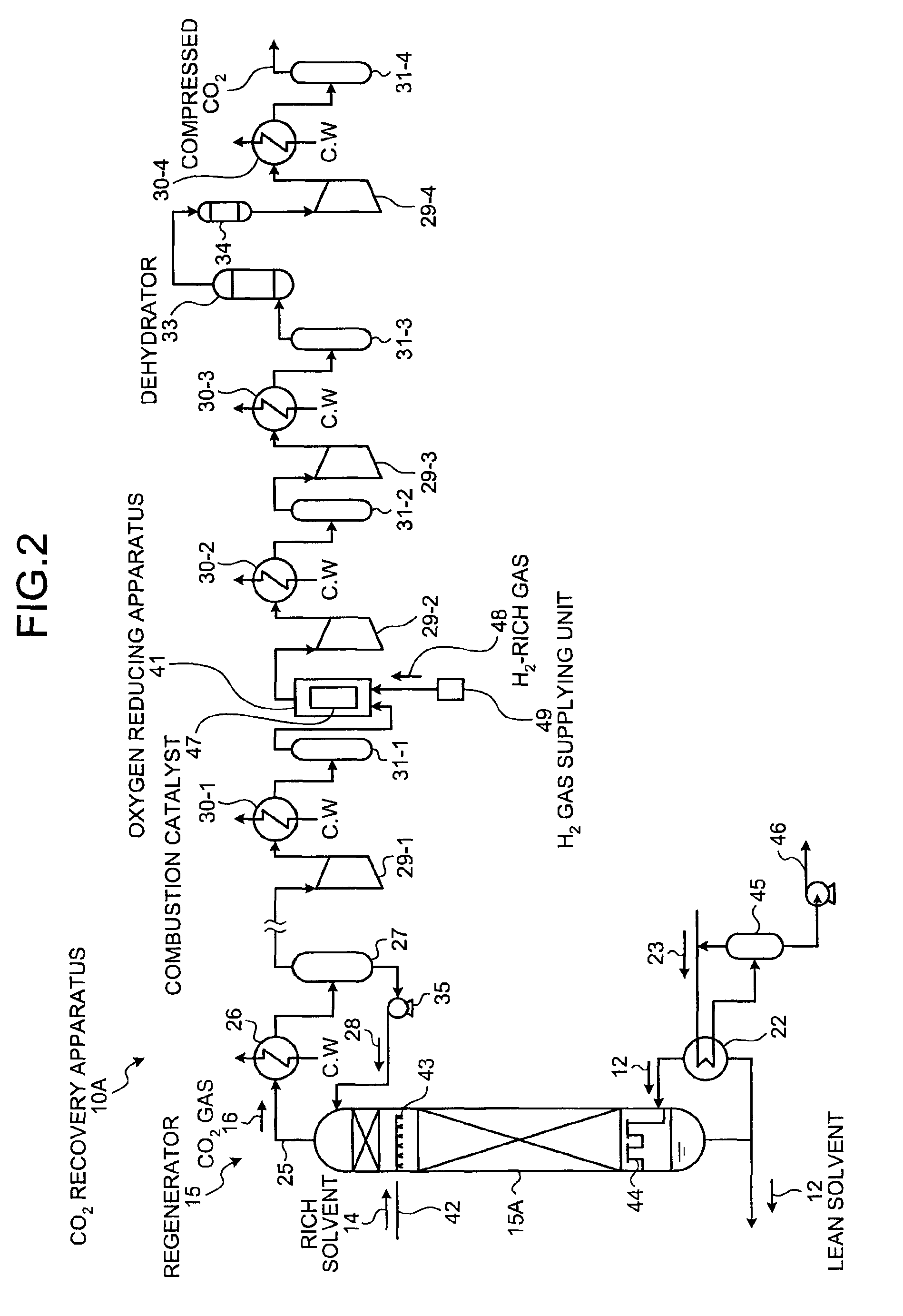

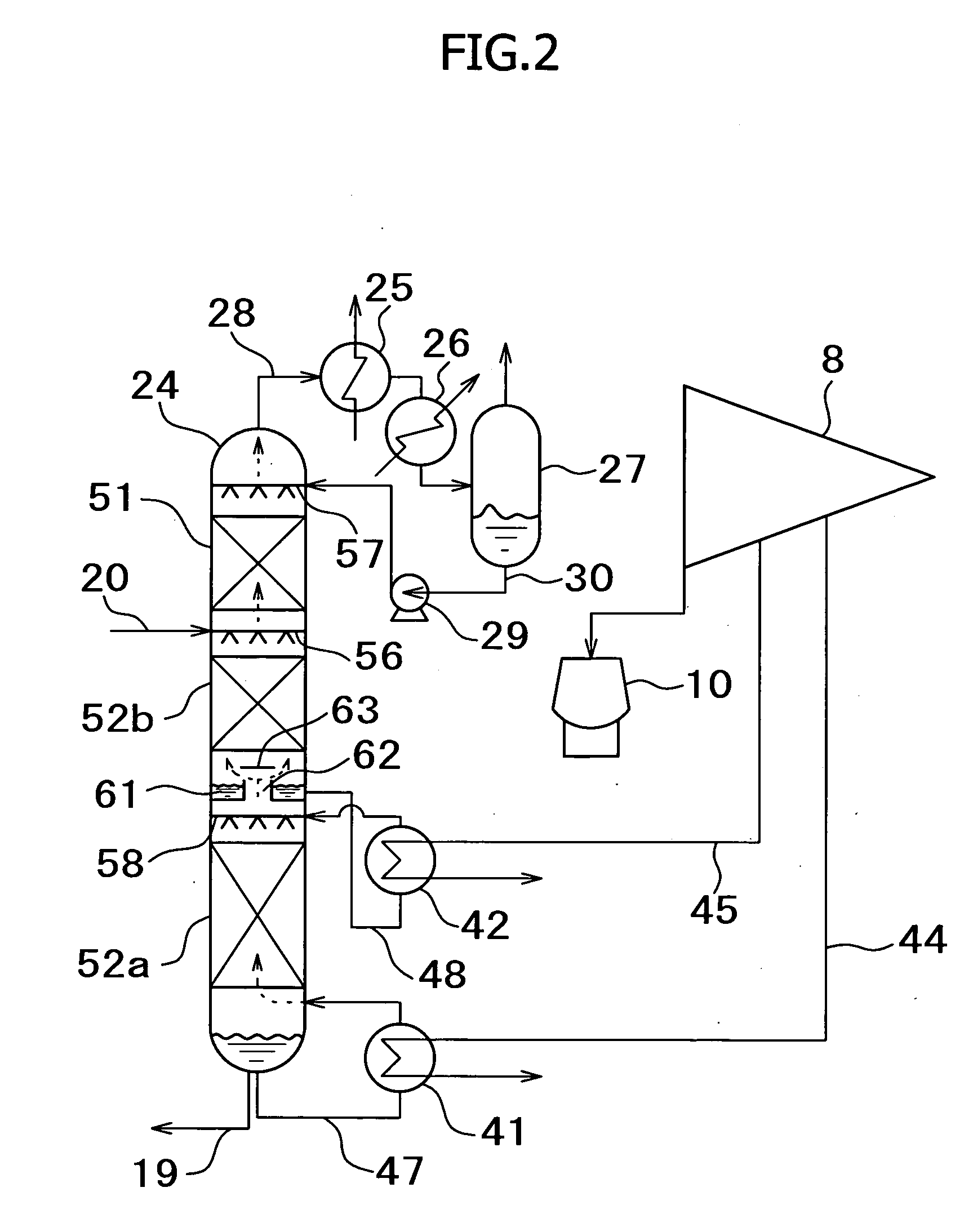

A CO2 recovery apparatus according to a first embodiment of the present invention includes: a CO2 absorber that brings flue gas containing CO2 into contact with CO2 absorbing liquid to reduce CO2 in the flue gas; a regenerator that reduces CO2 in CO2 absorbing liquid (rich solvent) that has absorbed the CO2 in the CO2 absorber to regenerate the CO2 absorbing liquid, so that the regenerated absorbing liquid (lean solvent), having CO2 reduced in the regenerator, is reused in the CO2 absorber; a first compressor to a fourth compressor that compress the CO2 gas released from the regenerator; and an O2 reducing apparatus arranged between the second compressor and a second cooler to reduce O2 in the CO2 gas.

Owner:MITSUBISHI HEAVY IND ENG LTD

Method for improving environmental stability of cathode materials for lithium batteries

InactiveUS20090194747A1Good environmental stabilityQuality improvementConductive materialElectrode collector coatingCo2 absorptionNickel–lithium battery

A method for improving the environmental stability of cathode materials used in lithium-based batteries. Most currently used cathode active materials are acutely sensitive to environmental conditions, e.g. leading to moisture and CO2 pickup, that cause problems for material handling especially during electrode preparation and to gassing during charge and discharge cycles. Binder materials used for making cathodes, such as PVDF and PTFE, are mixed with and / or coated on the cathode materials to improve the environmental sensitivity of the cathode materials.

Owner:TIAX LLC

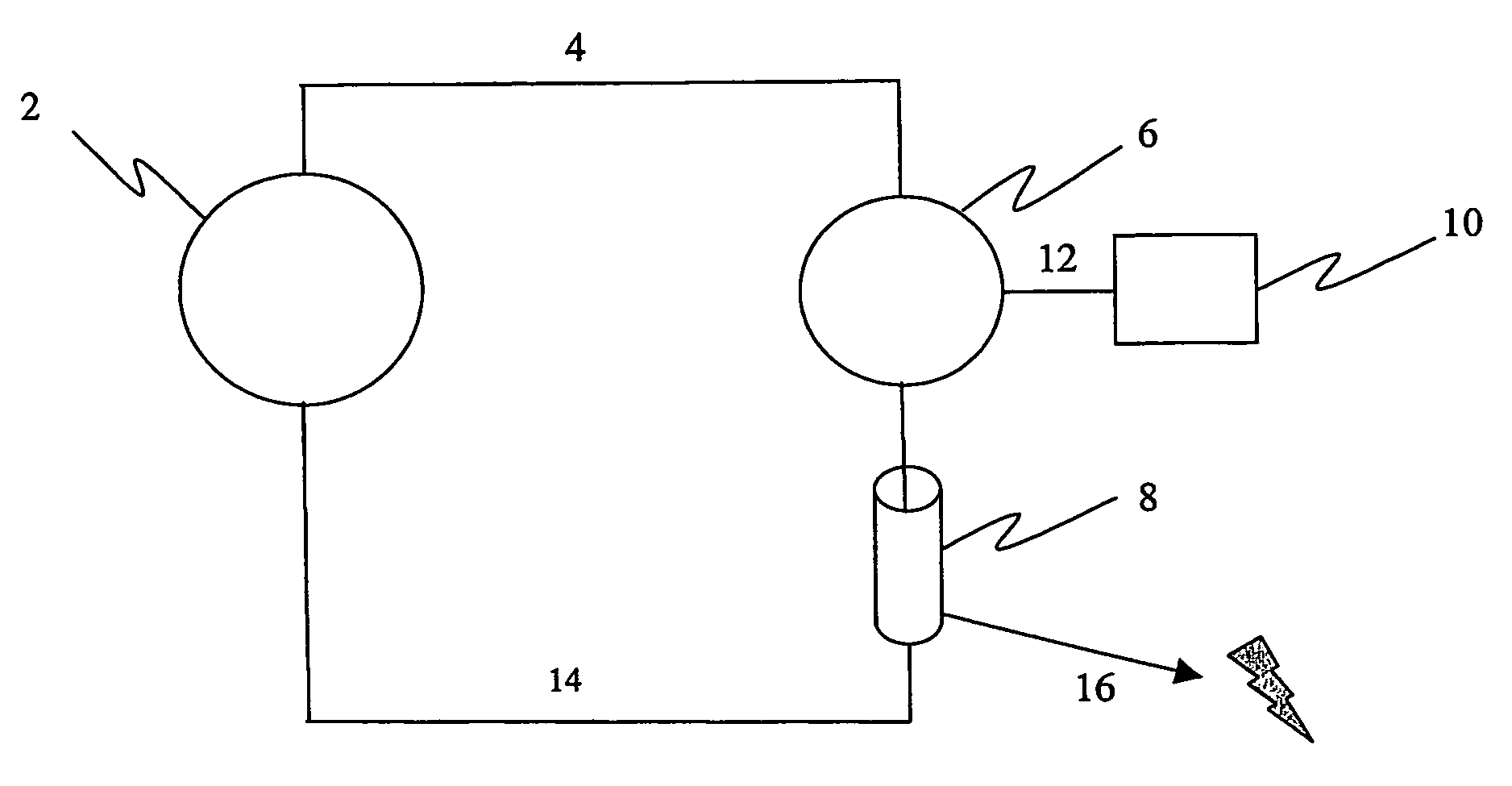

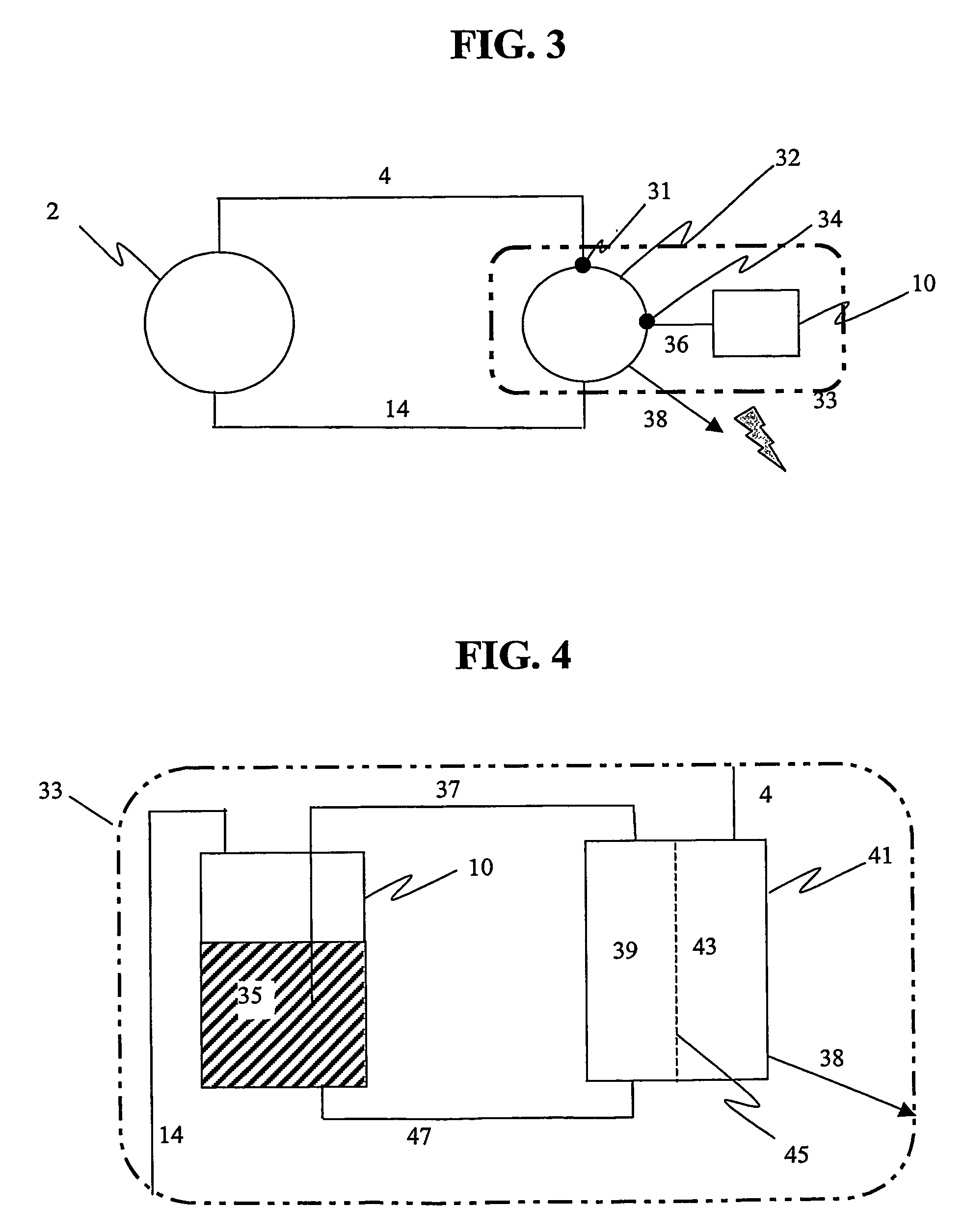

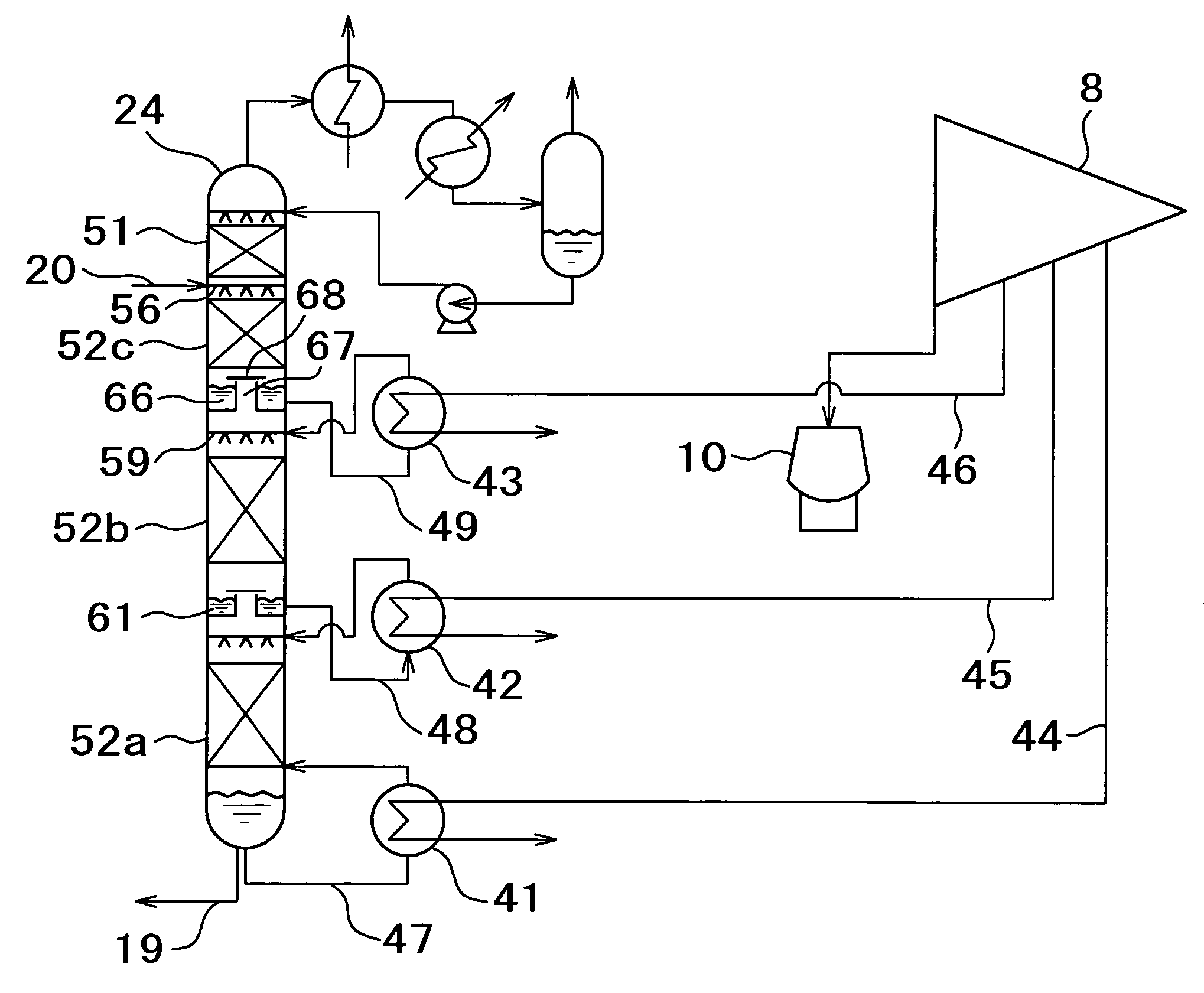

Carbon dioxide recovery and power generation

ActiveUS20060248890A1High outputIncrease pressureGas treatmentCarbon compoundsCombustionCo2 absorption

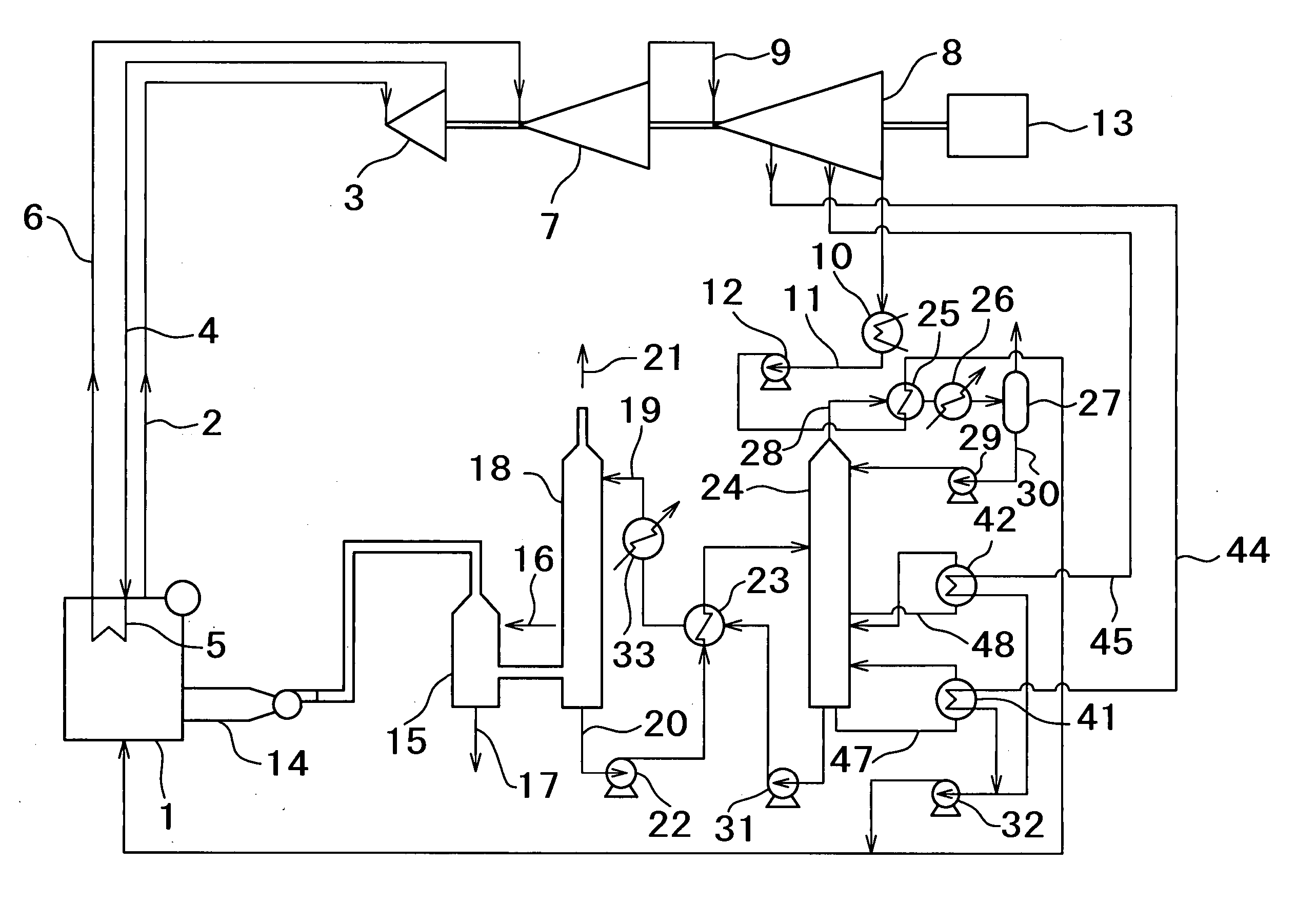

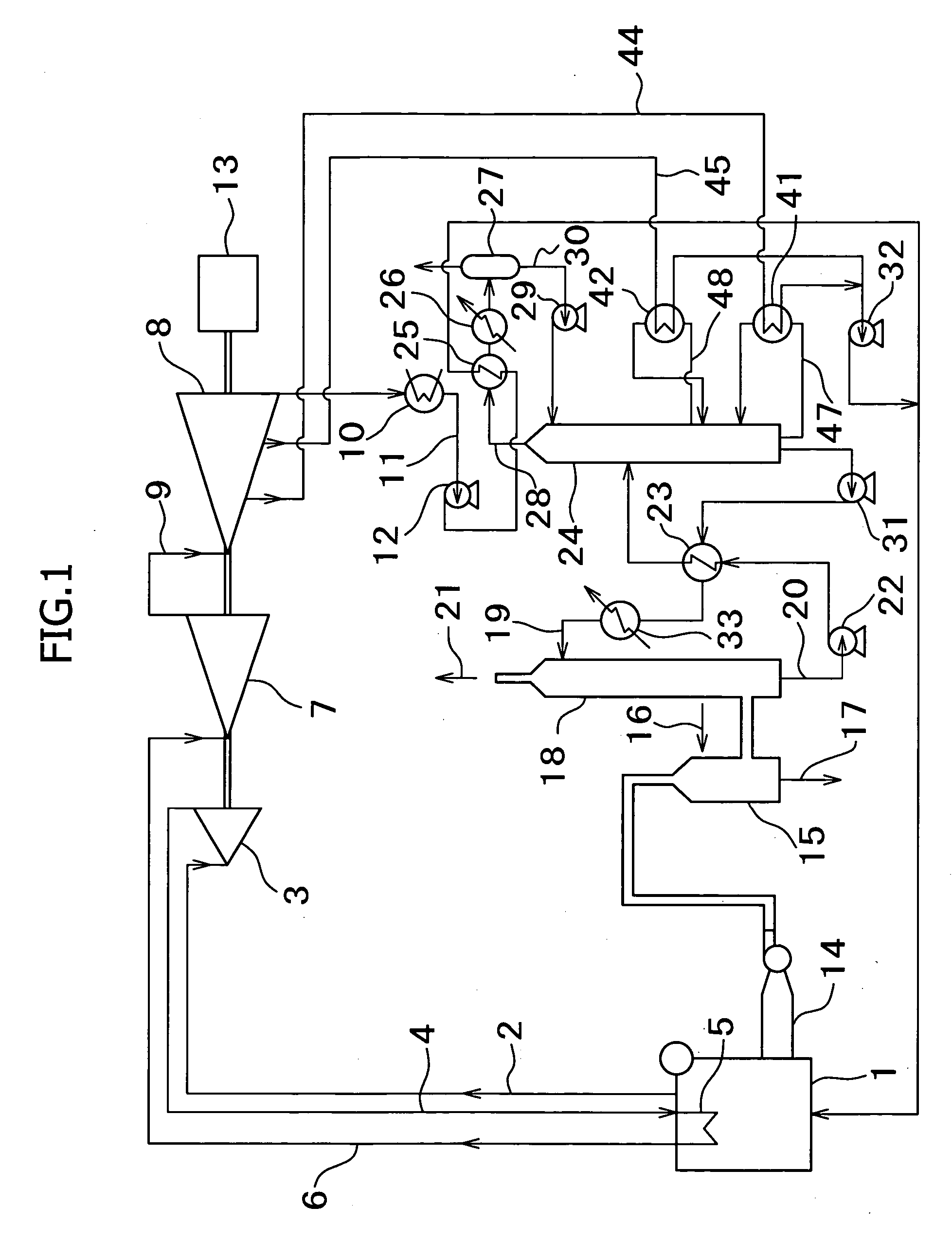

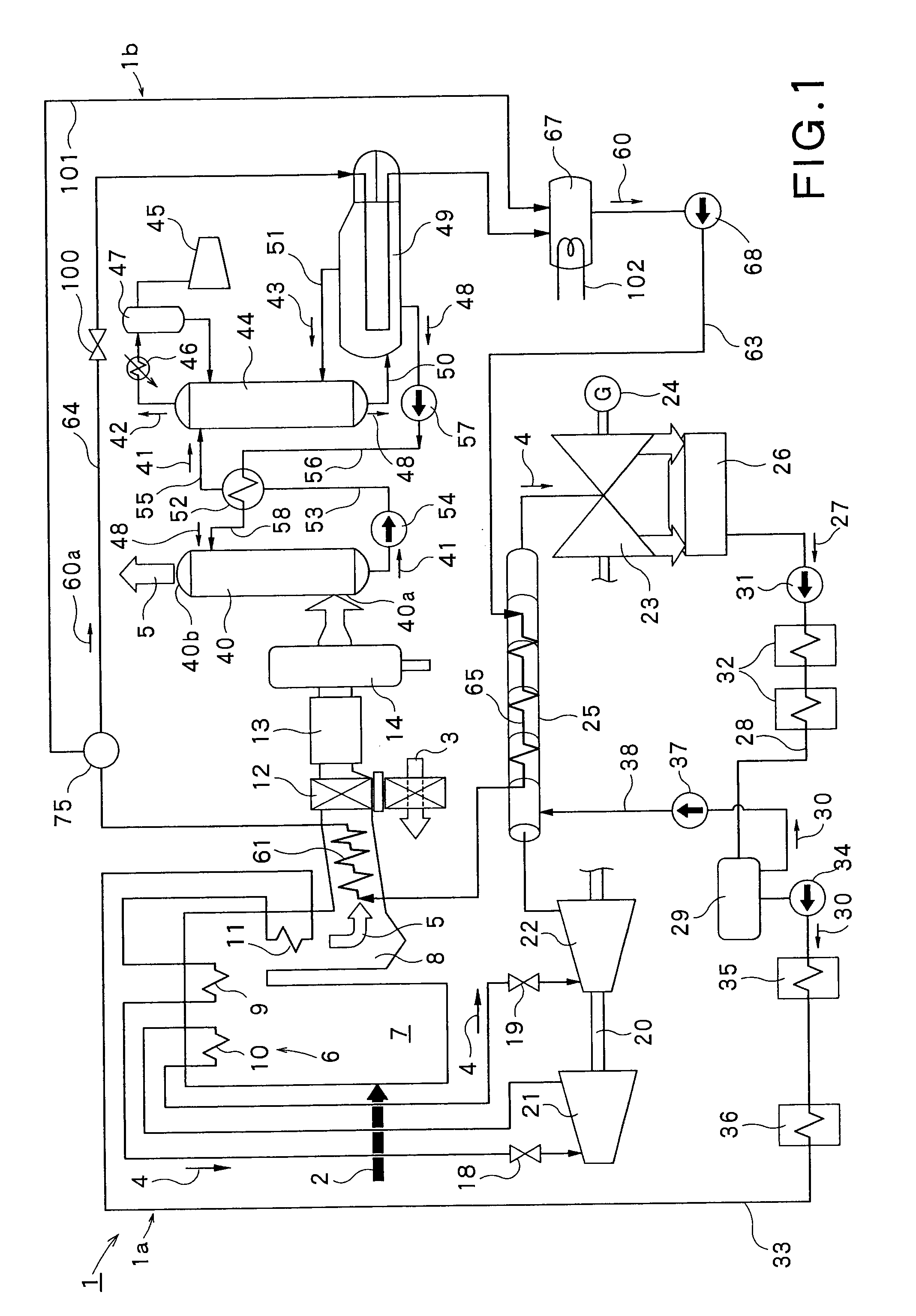

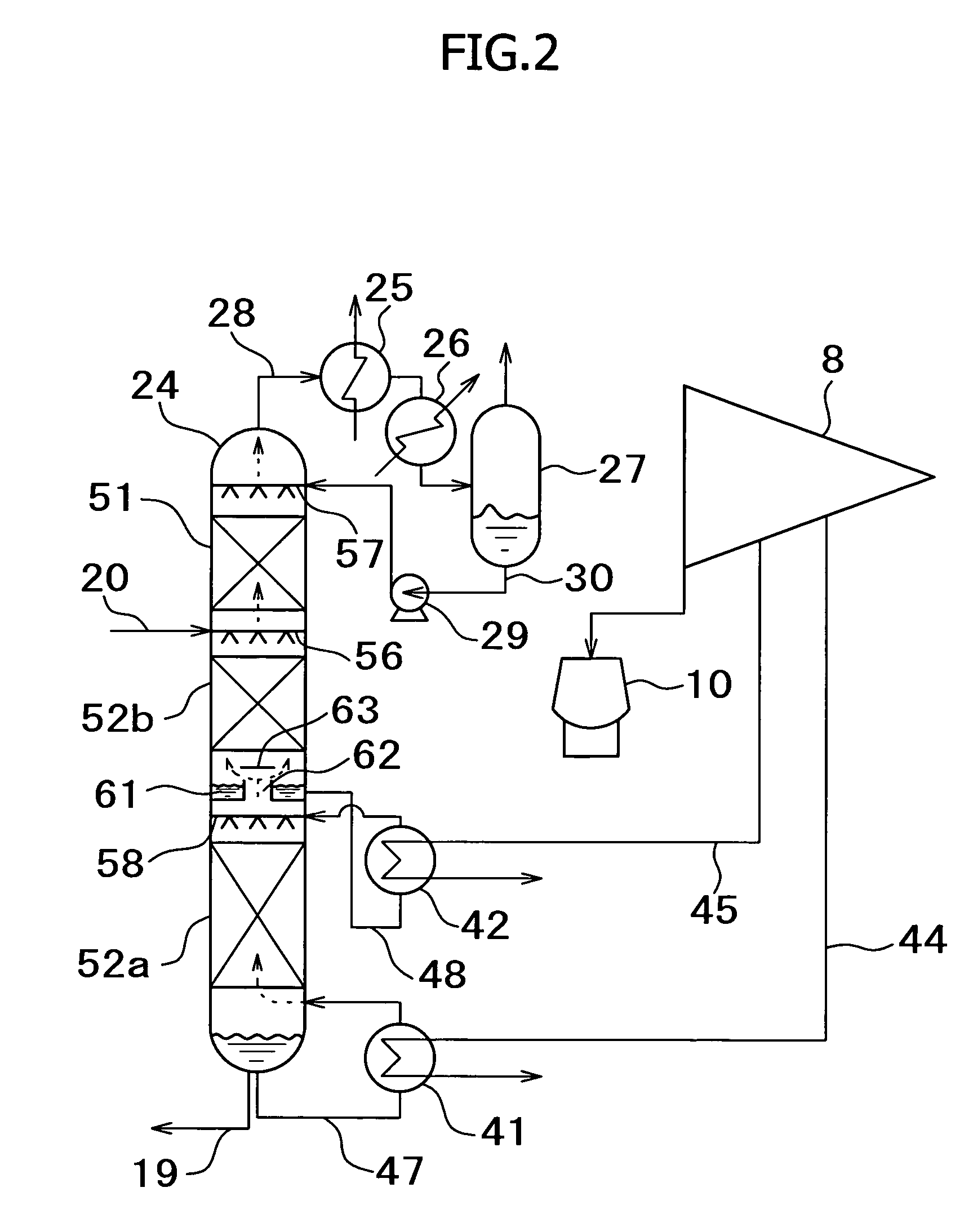

To provide a carbon dioxide recovery system capable of suppressing reduction in turbine output at the time of regenerating an absorption liquid with carbon dioxide absorbed therein, a power generation system using the carbon dioxide recovery system, and a method for these systems. The carbon dioxide recovery system including: a carbon dioxide absorption tower (18) which absorbs and removes carbon dioxide from a combustion exhaust gas of a boiler (1) by an absorption liquid; and a regeneration tower which heats and regenerates a loaded absorption liquid with carbon dioxide absorbed therein, is characterized in that the regeneration tower (24) is provided with plural loaded absorption liquid heating means (41, 42) in multiple stages, which heat the loaded absorption liquid and remove carbon dioxide in the load absorption liquid, in that a turbine (8) driven and rotated by steam of the boiler is provided with plural lines (44, 45) which extract plural kinds of steam with different pressures from the turbine and which supply the plural kinds of steam to the plural loaded absorption liquid heating means as their heating sources, and in that the plural lines are connected to make the pressure of supplied steam increased from a preceding stage (41) of the plural loaded absorption liquid heating means to a post stage (42) of the plural loaded absorption liquid heating means.

Owner:THE KANSAI ELECTRIC POWER CO +1

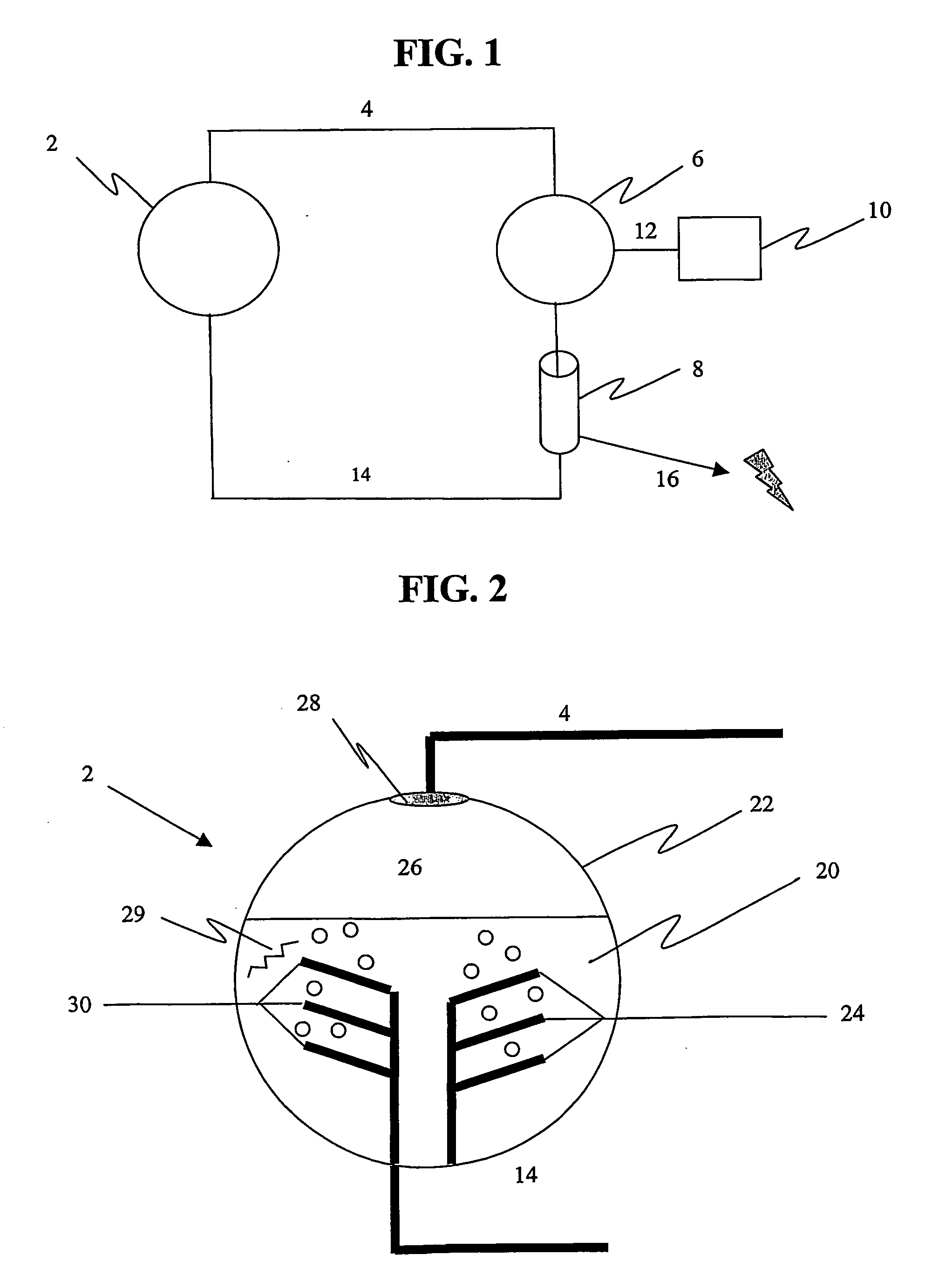

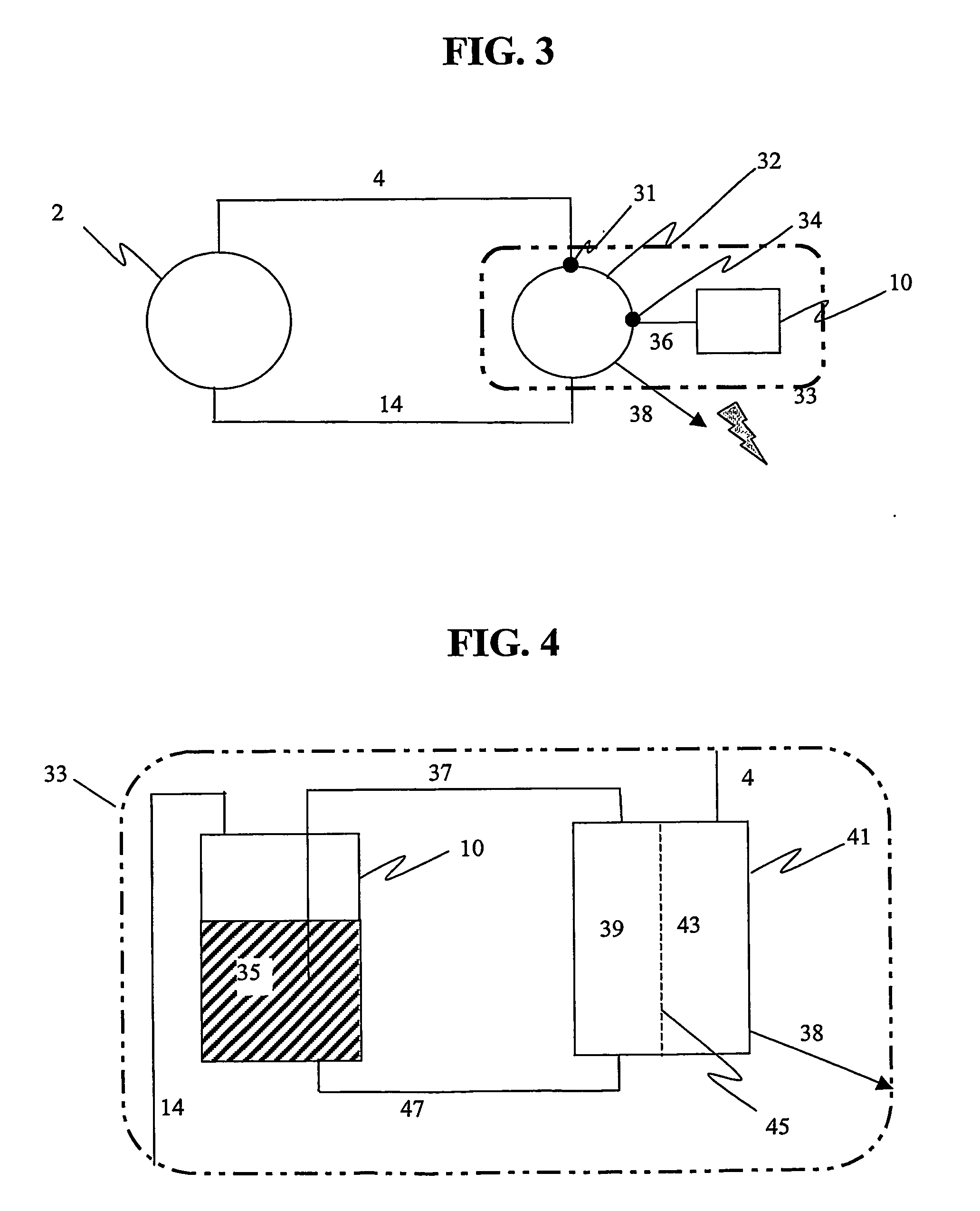

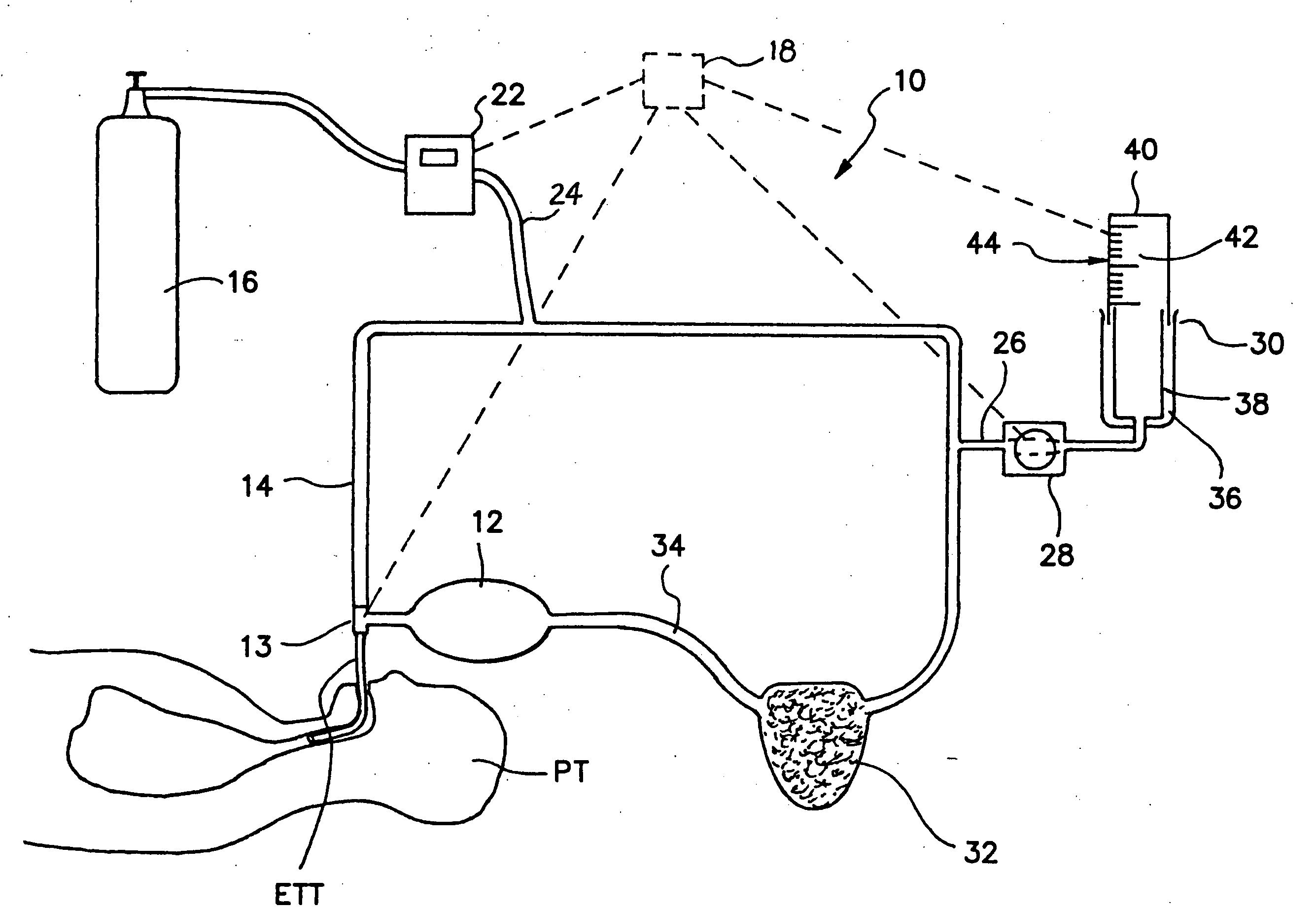

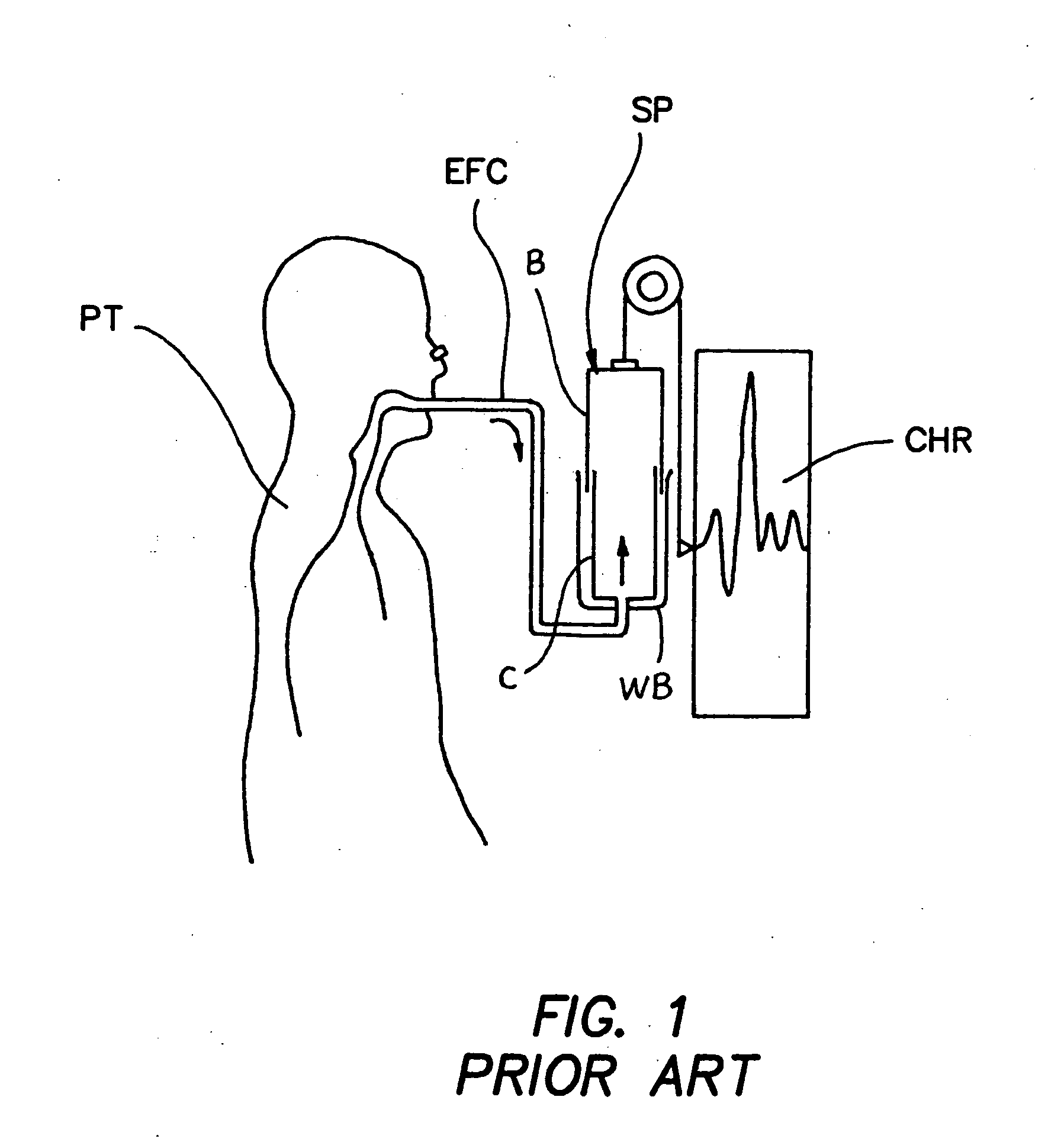

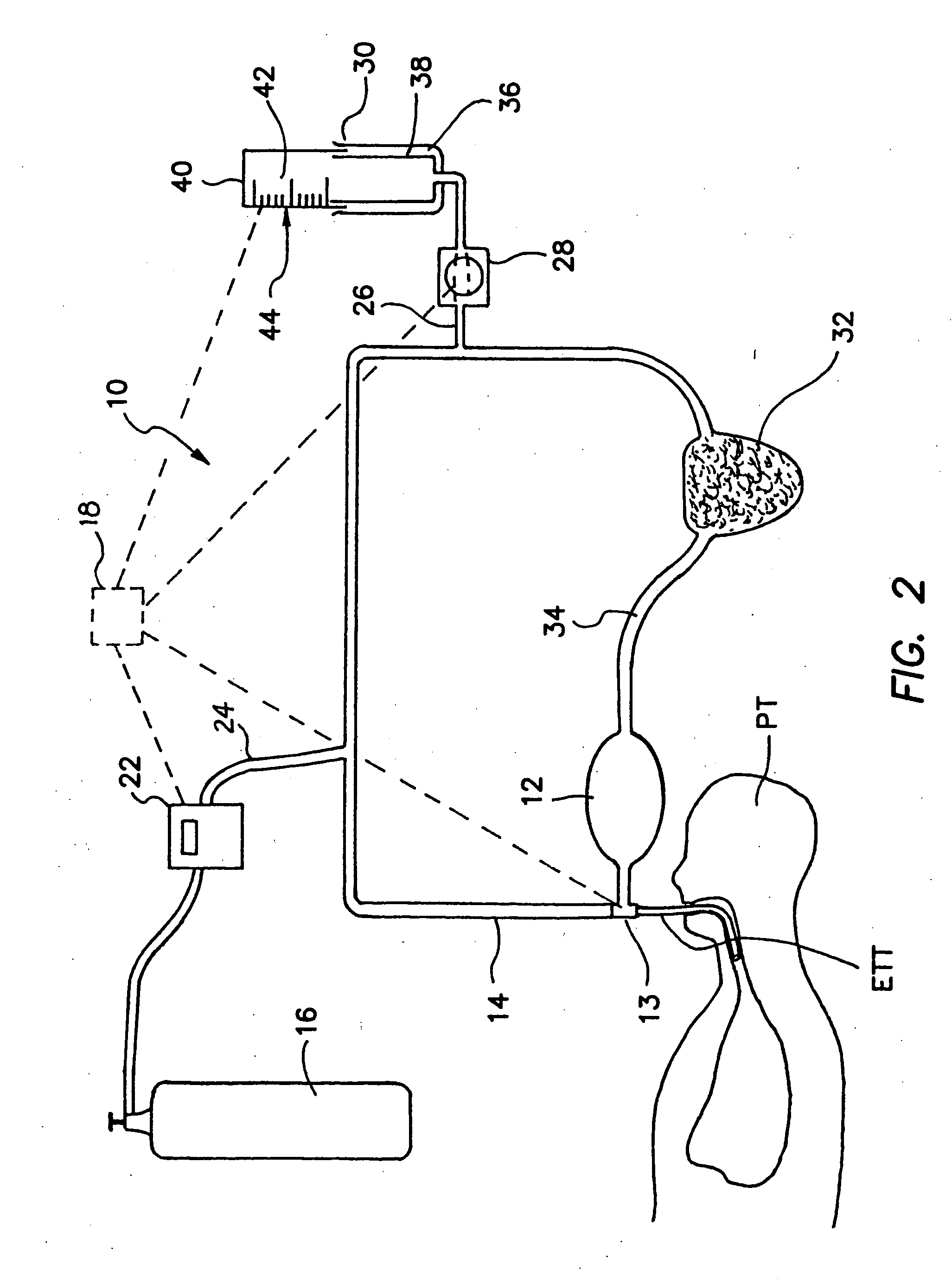

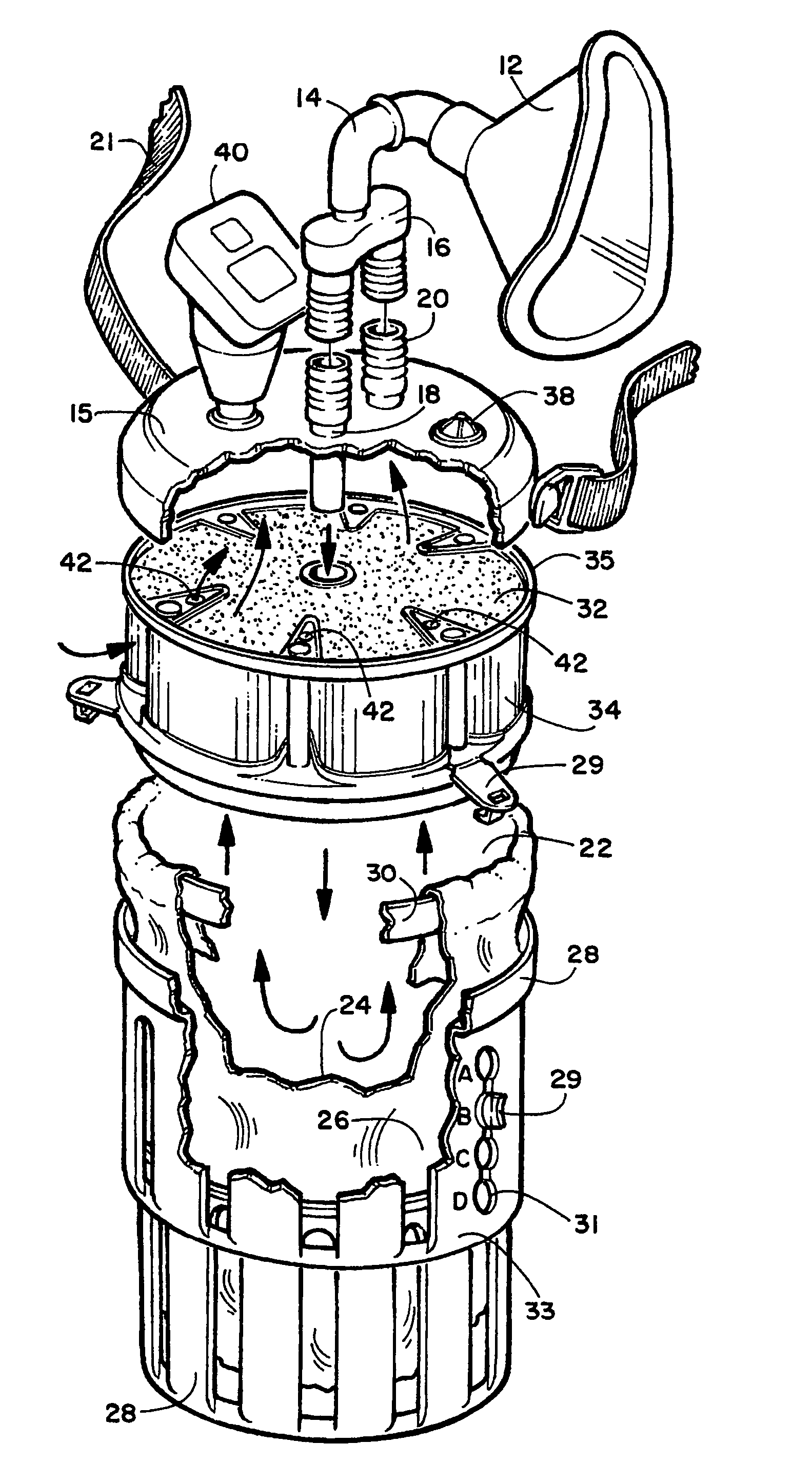

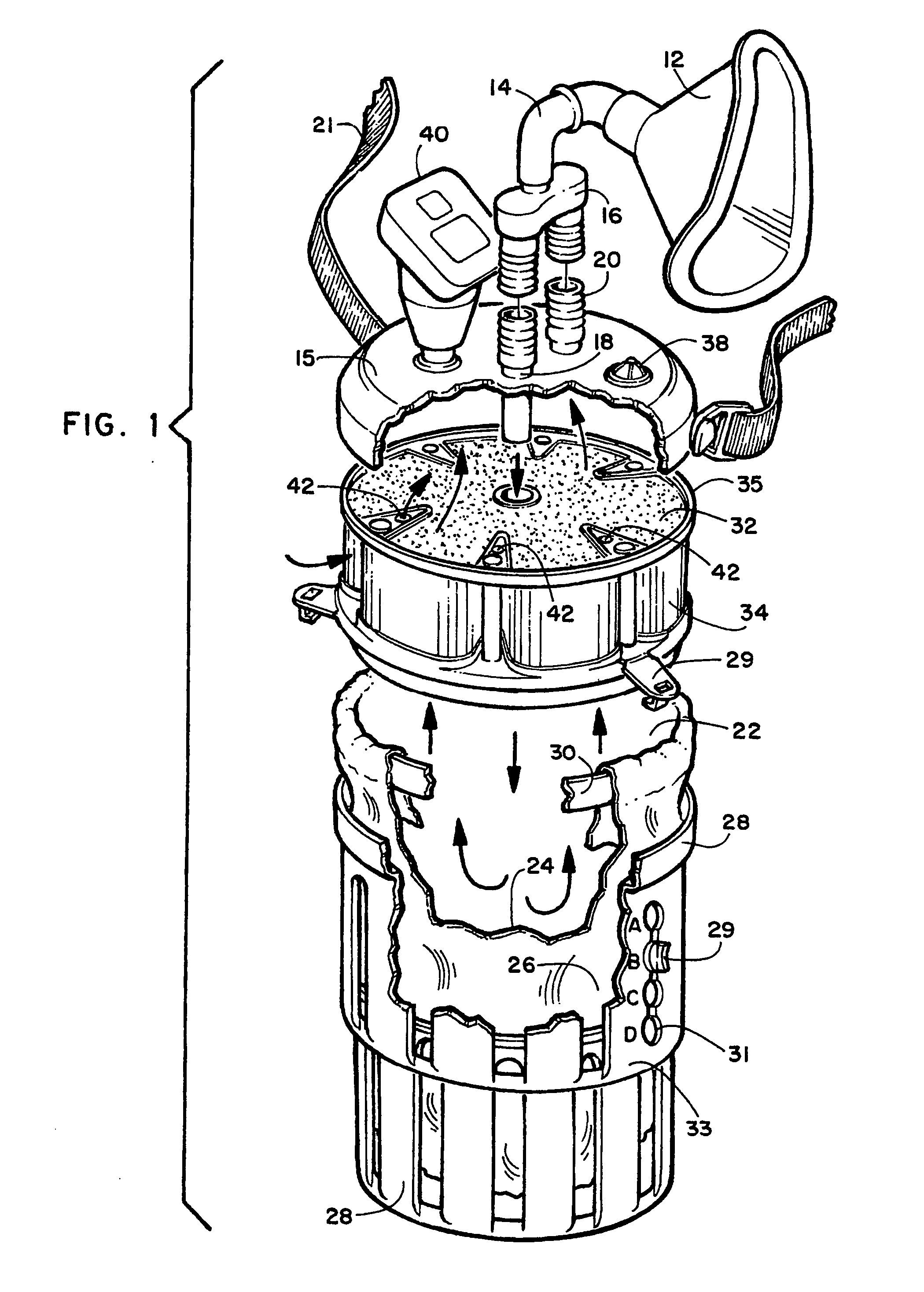

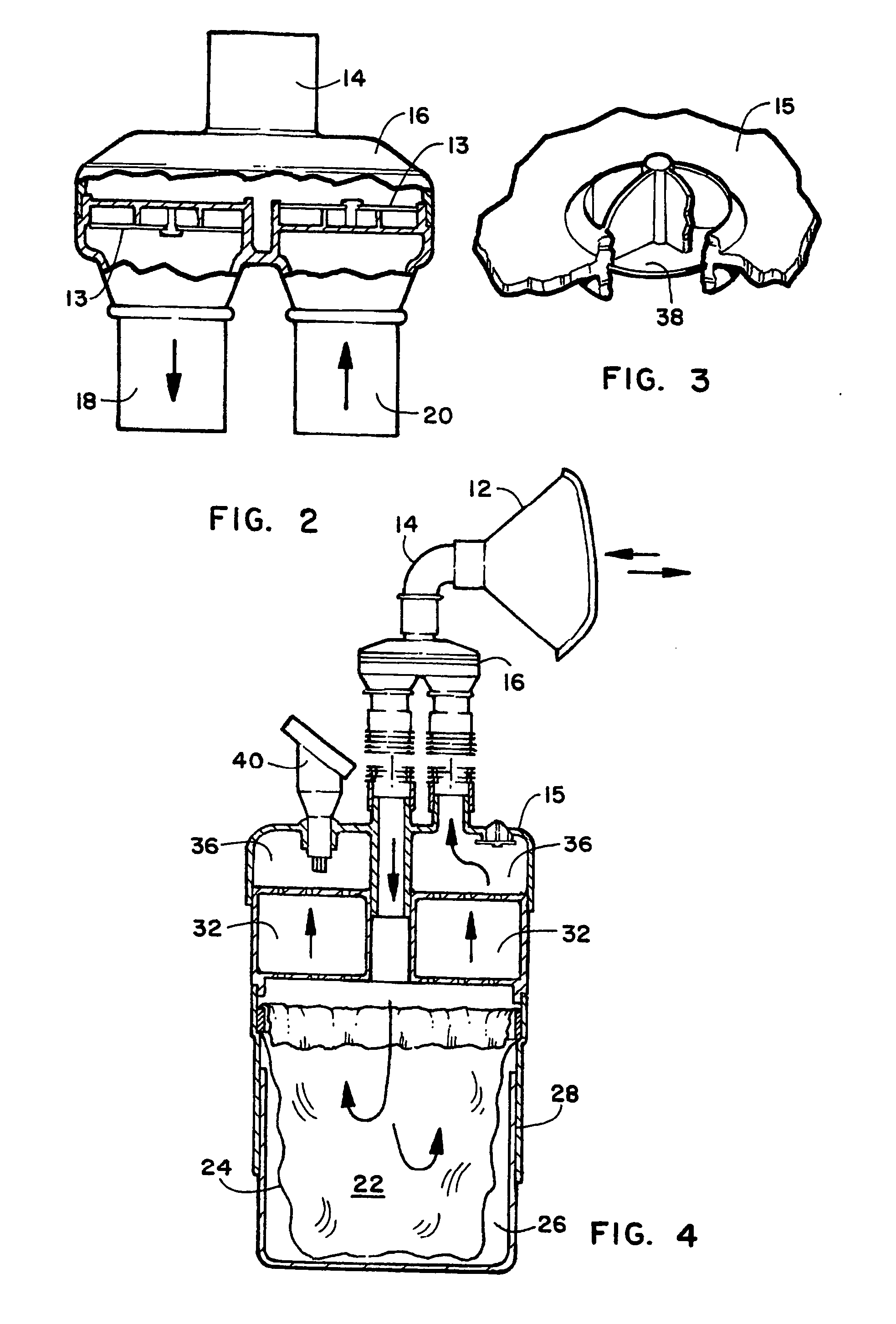

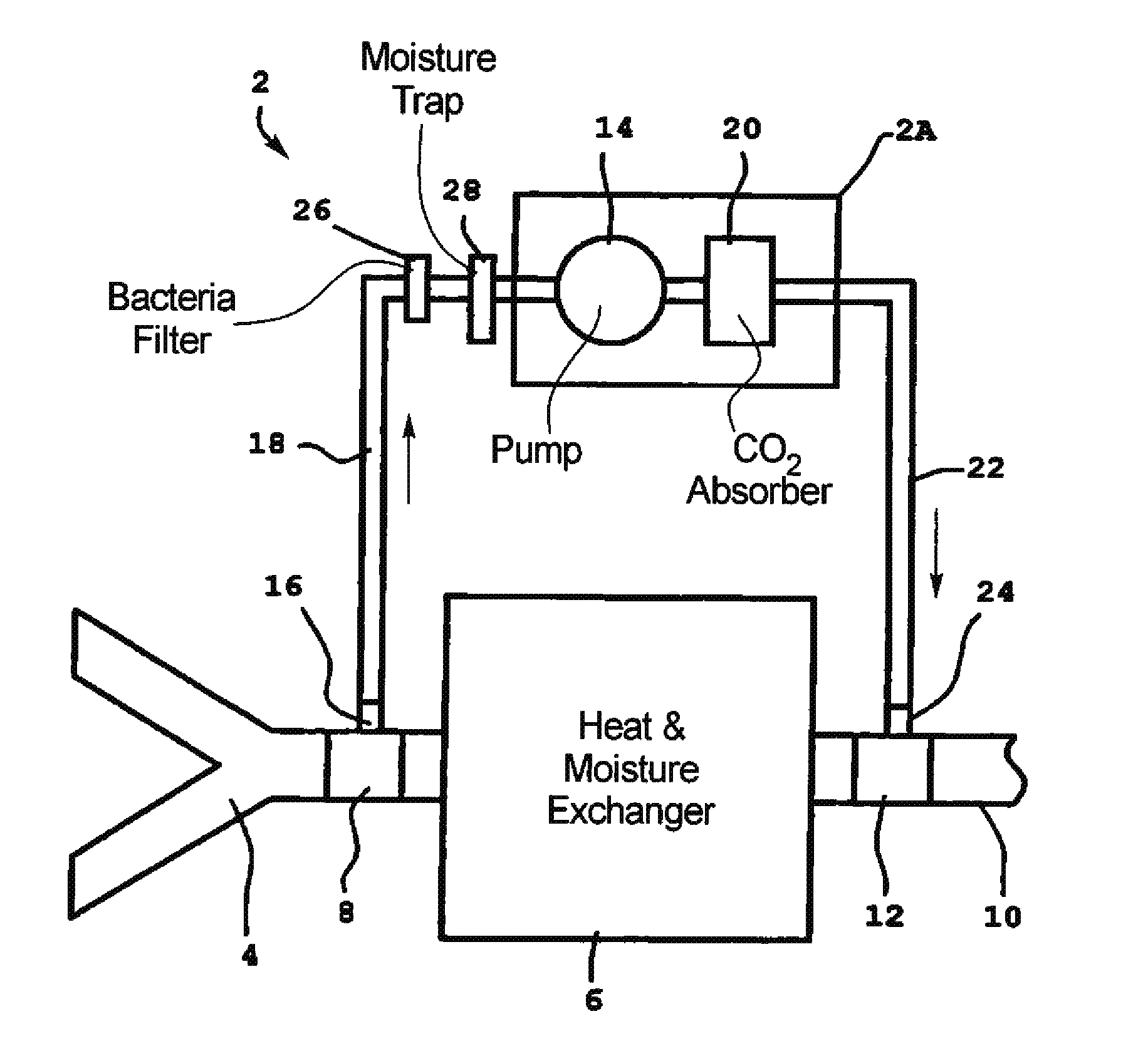

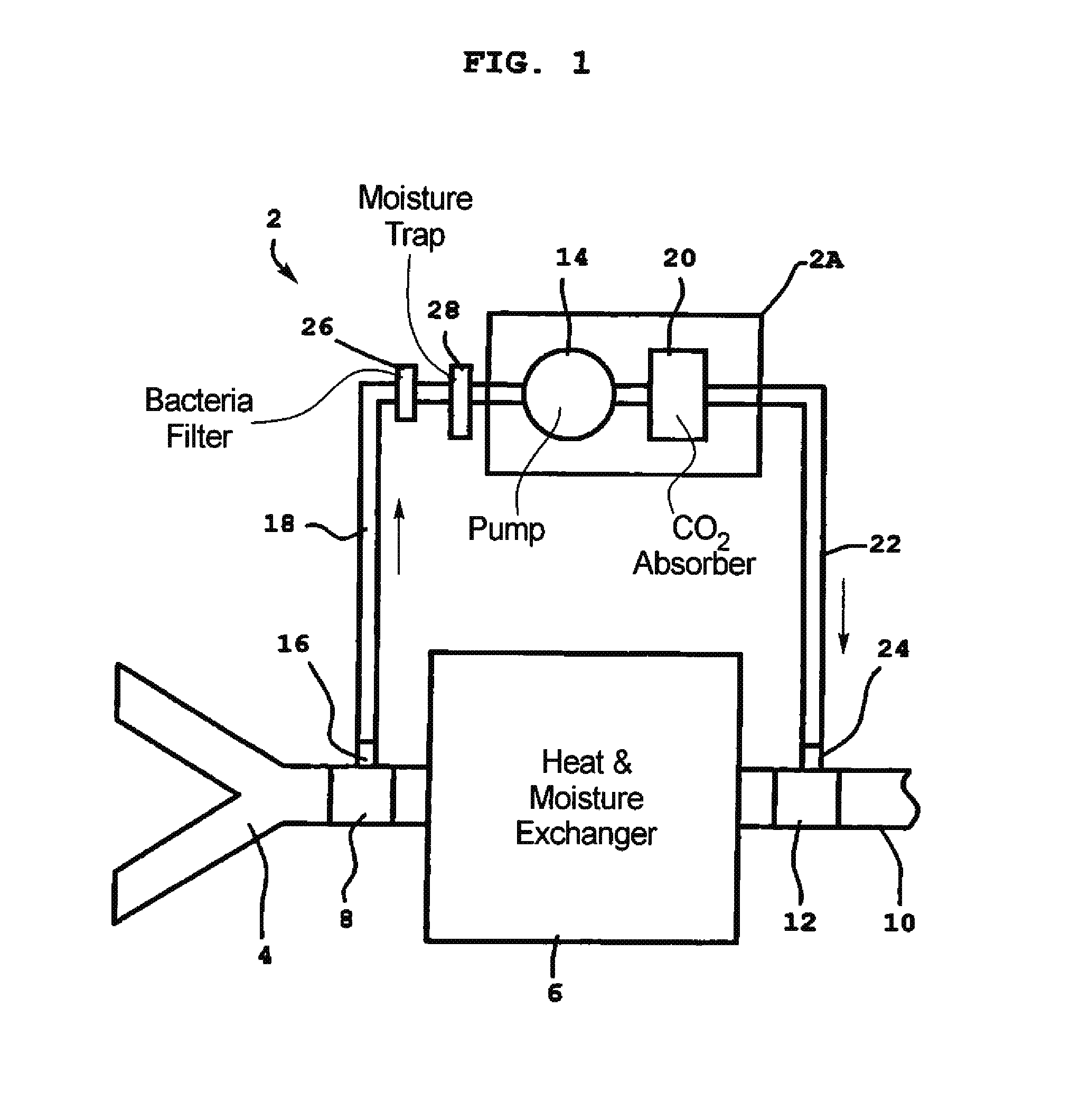

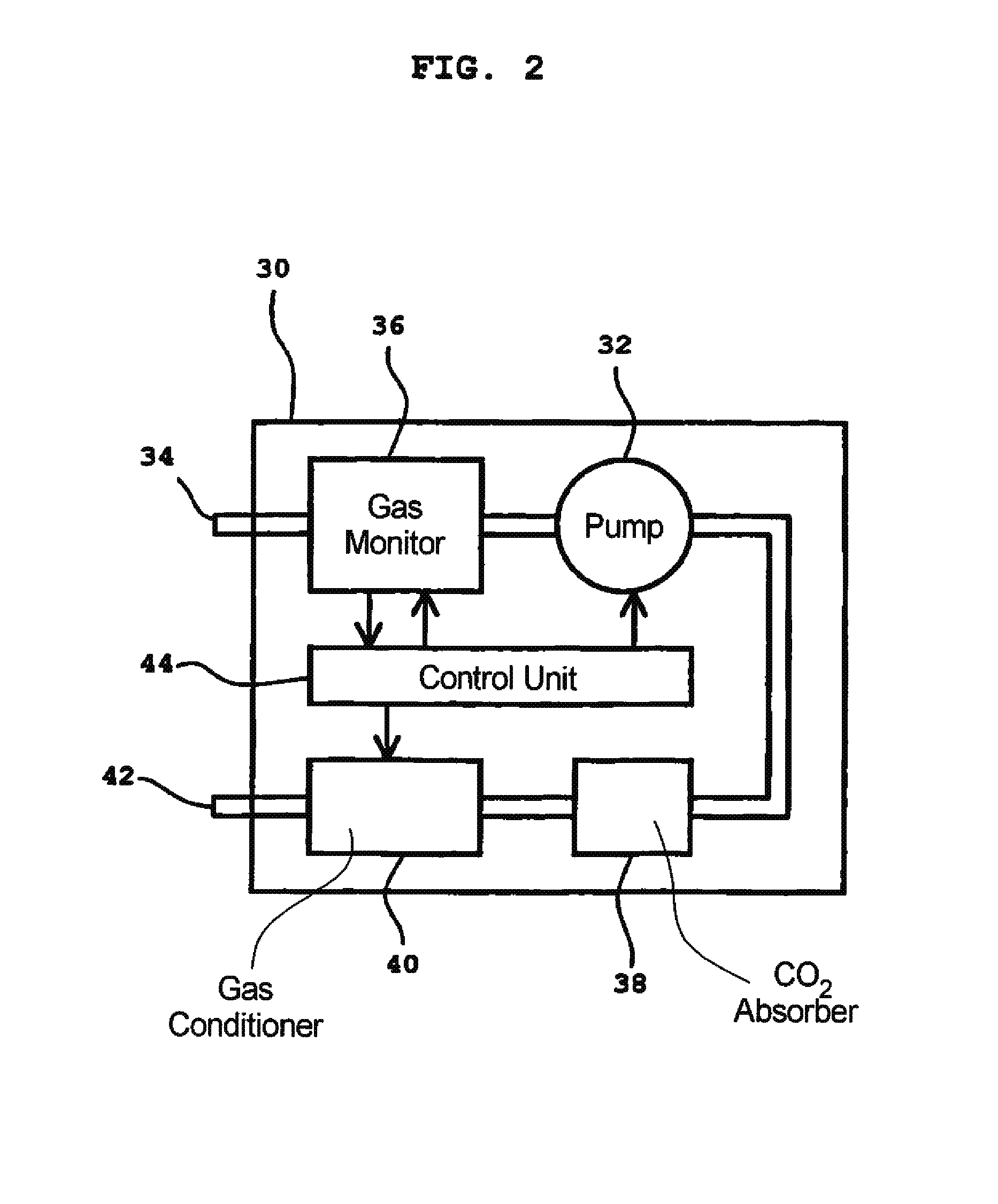

Stand-alone circle circuit with co2 absorption and sensitive spirometry for measurement of pulmonary uptake

InactiveUS20060201507A1Accurate and non-invasive and measurementPrevent backflowRespiratorsOperating means/releasing devices for valvesForced expiratory vital capacityLate expiratory

A system and method for determining the volume of oxygen taken up by the lungs of a human or veterinary patient. A closed ventilation circuit is connected to a spirometric device, which contains a quantity of oxygen. As oxygen is taken up by the patient, an equivalent volume of oxygen passes from the spirometric device into the ventilation circuit. The volume of oxygen that moves from the spirometric device may thus be measured as an indication of the volume of oxygen that has been taken up by the patient. In some embodiments, a source of make-up oxygen is connected to the ventilation circuit and the flow of make-up oxygen is adjusted as necessary to maintain a substantially constant volume of oxygen in the spirometric device. The volume of make-up oxygen is measured and serves as an indication of the amount of oxygen taken up by the patient. A valve may be used to close the spirometric device off from the ventilation circuit during all but a part of the ventilation cycle (e.g., all but the late expiratory phase) to prevent substantial pressure or movement excursions within the spirometric device

Owner:RGT UNIV OF CALIFORNIA

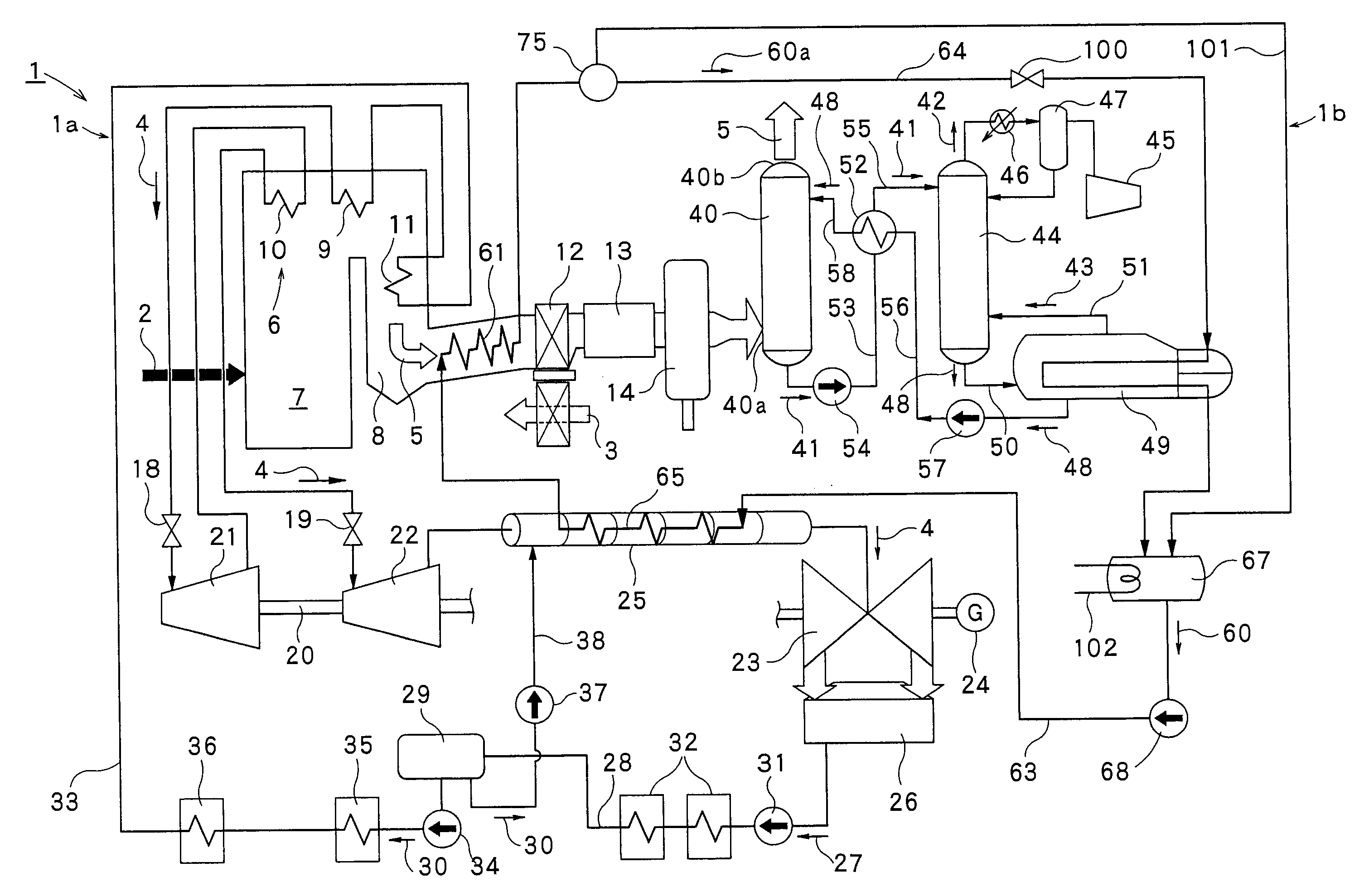

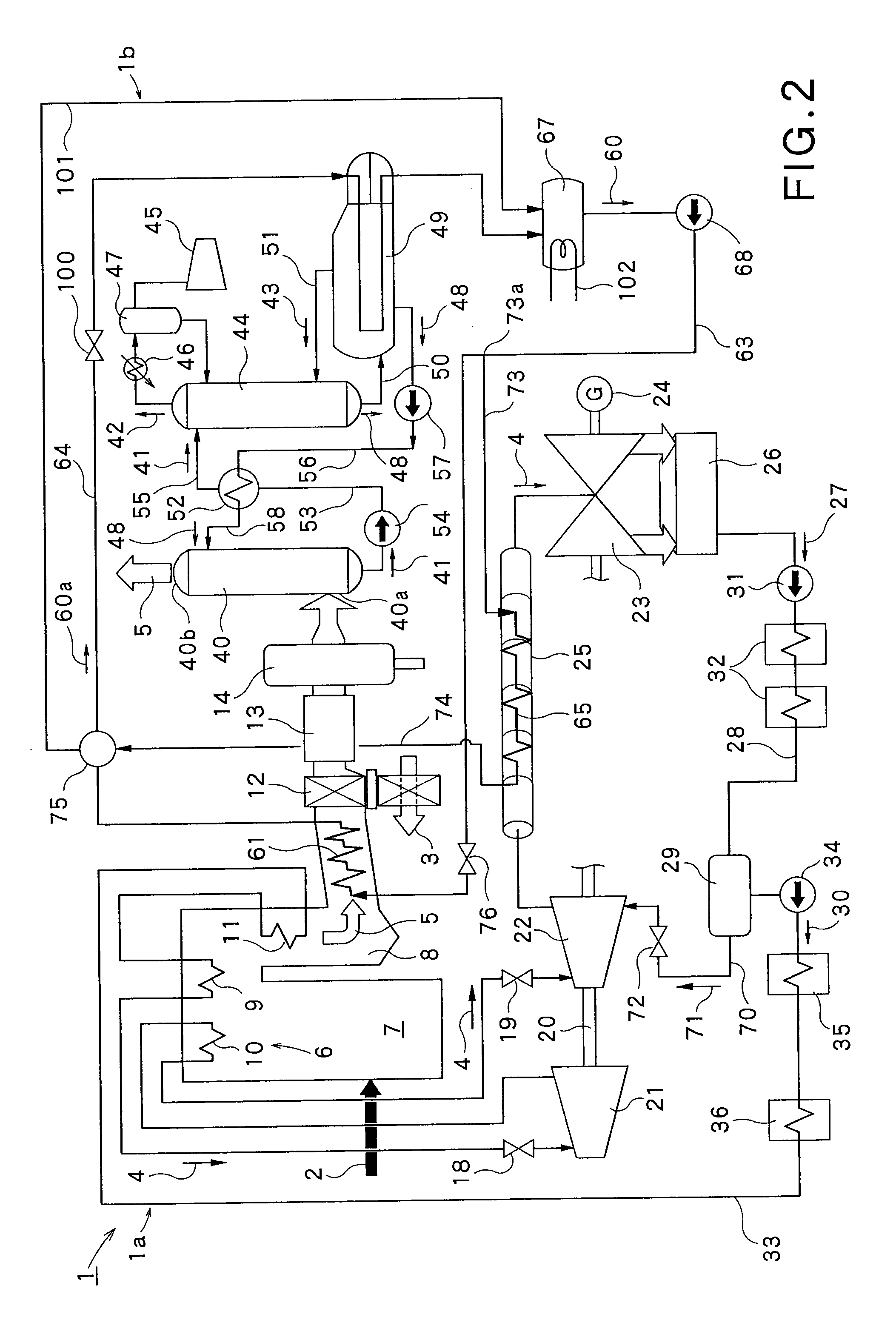

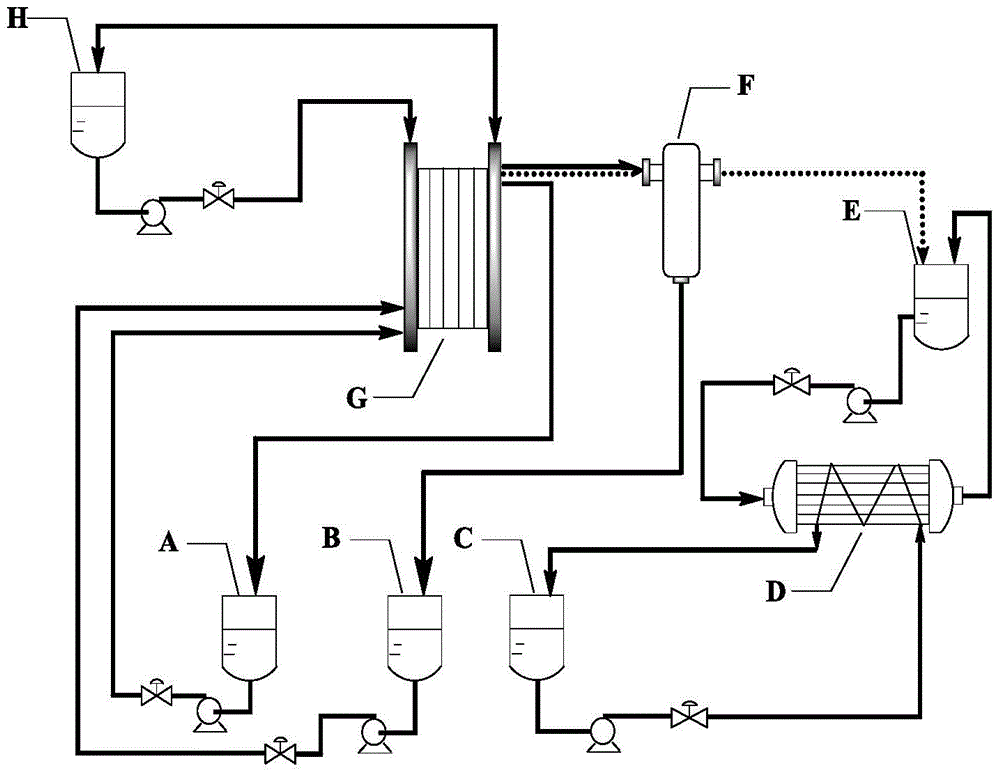

Carbon-dioxide-capture-type steam power generation system

InactiveUS20100050637A1Avoid power generation efficiencyImprove efficiencyLiquid degasificationCarbon compoundsCo2 absorptionReboiler

A carbon-dioxide-capture-type steam power generation system 1 according to the present invention comprises a boiler 6 producing an exhaust gas 5 by combusting a fuel 2 and having a flue 8; an absorbing unit 40 being configured to absorb the carbon-dioxide contained in the exhaust gas 5 into an absorbing solution; and a regenerating unit 44 being configured to release the carbon dioxide gas from the absorbing solution absorbing the carbon dioxide and discharge the released carbon dioxide gas. Further, in this system, a reboiler 49 is provided for receiving a heating-medium as heat source, producing a steam 43 and supplying the produced steam 43 to the regenerating unit 44. Additionally, in the flue 8 of the boiler 6, a boiler-side heat exchanger 61 is provided for heating the heating-medium by the exhaust gas 5 passing therethrough.

Owner:KK TOSHIBA

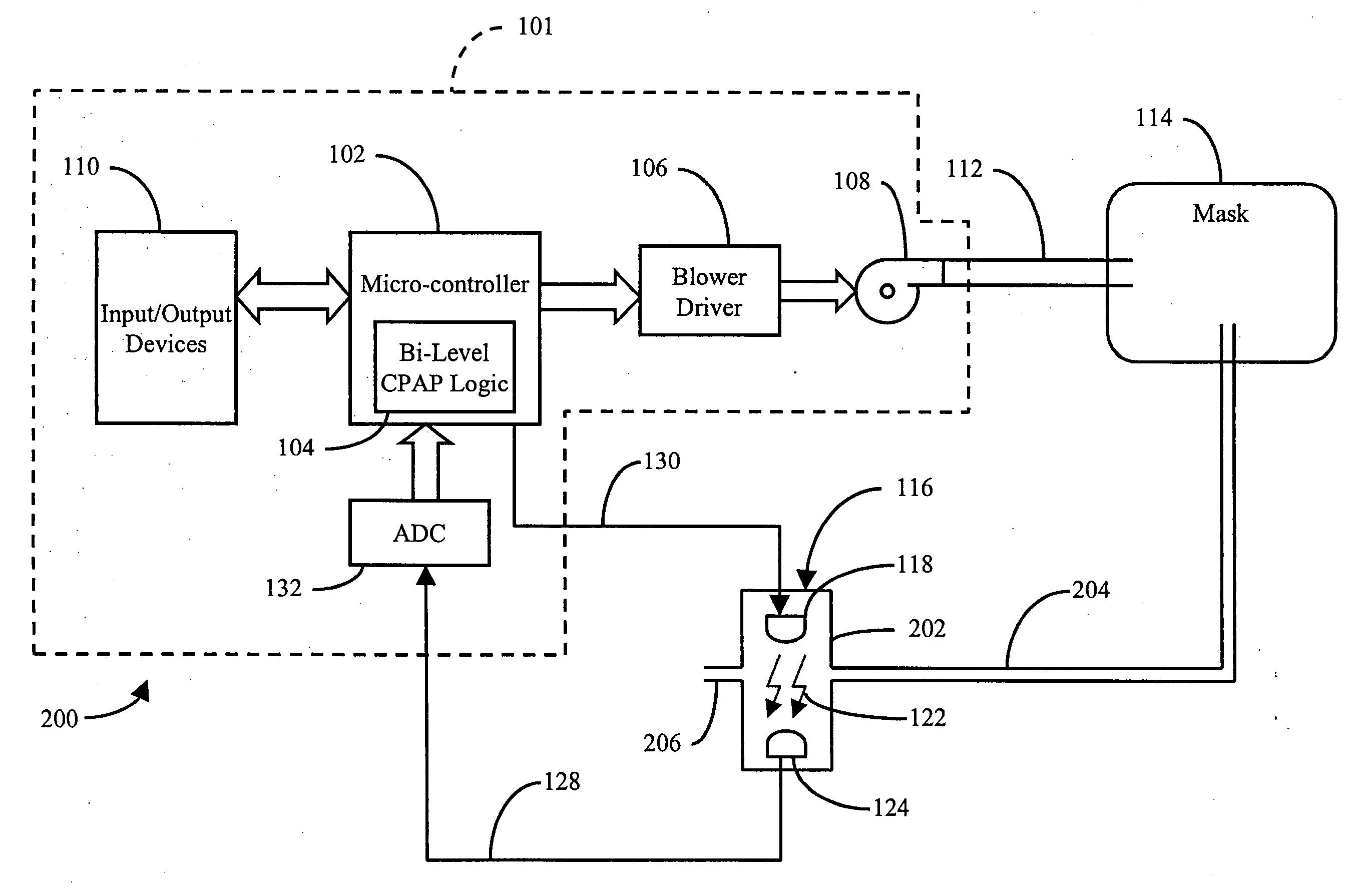

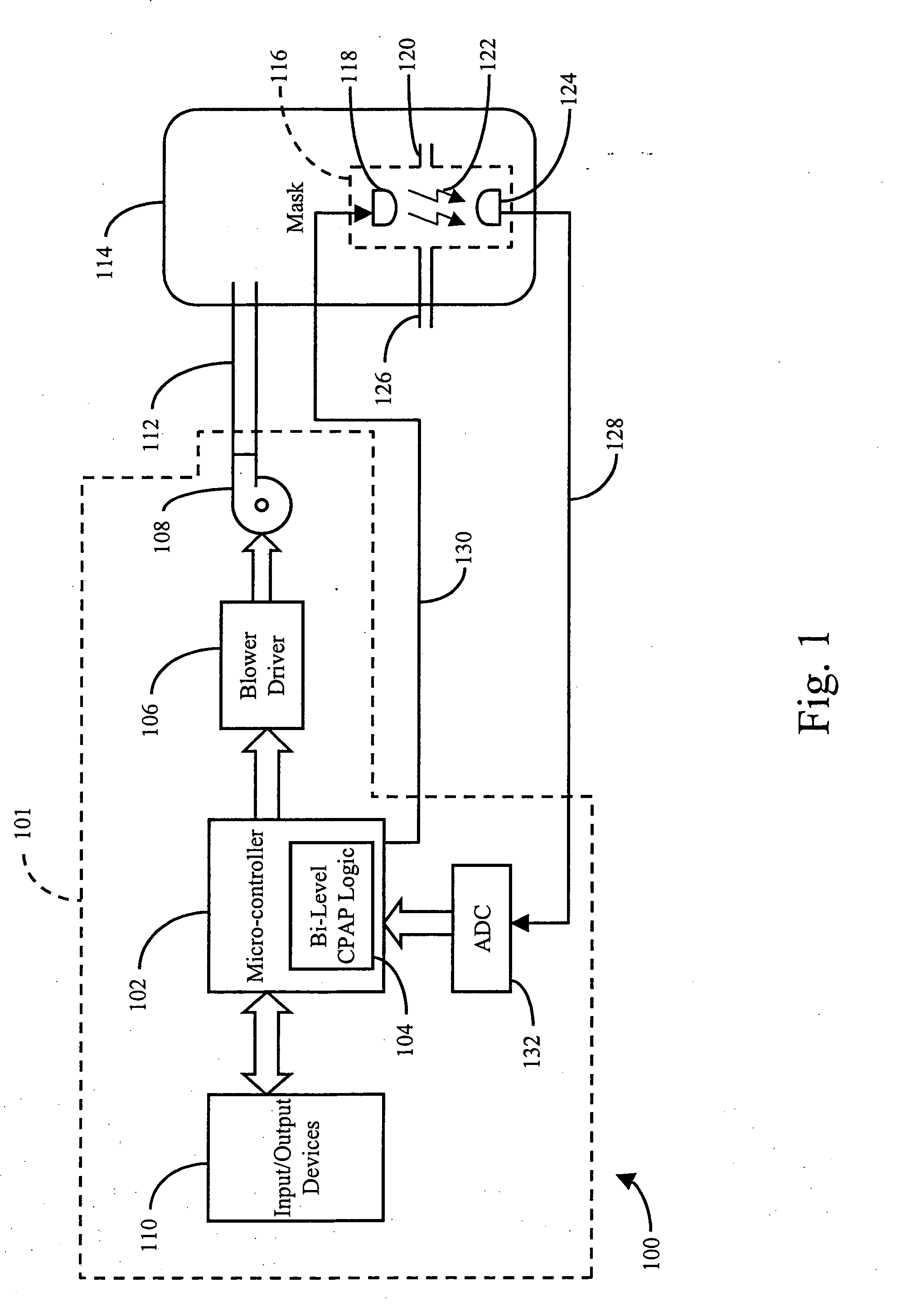

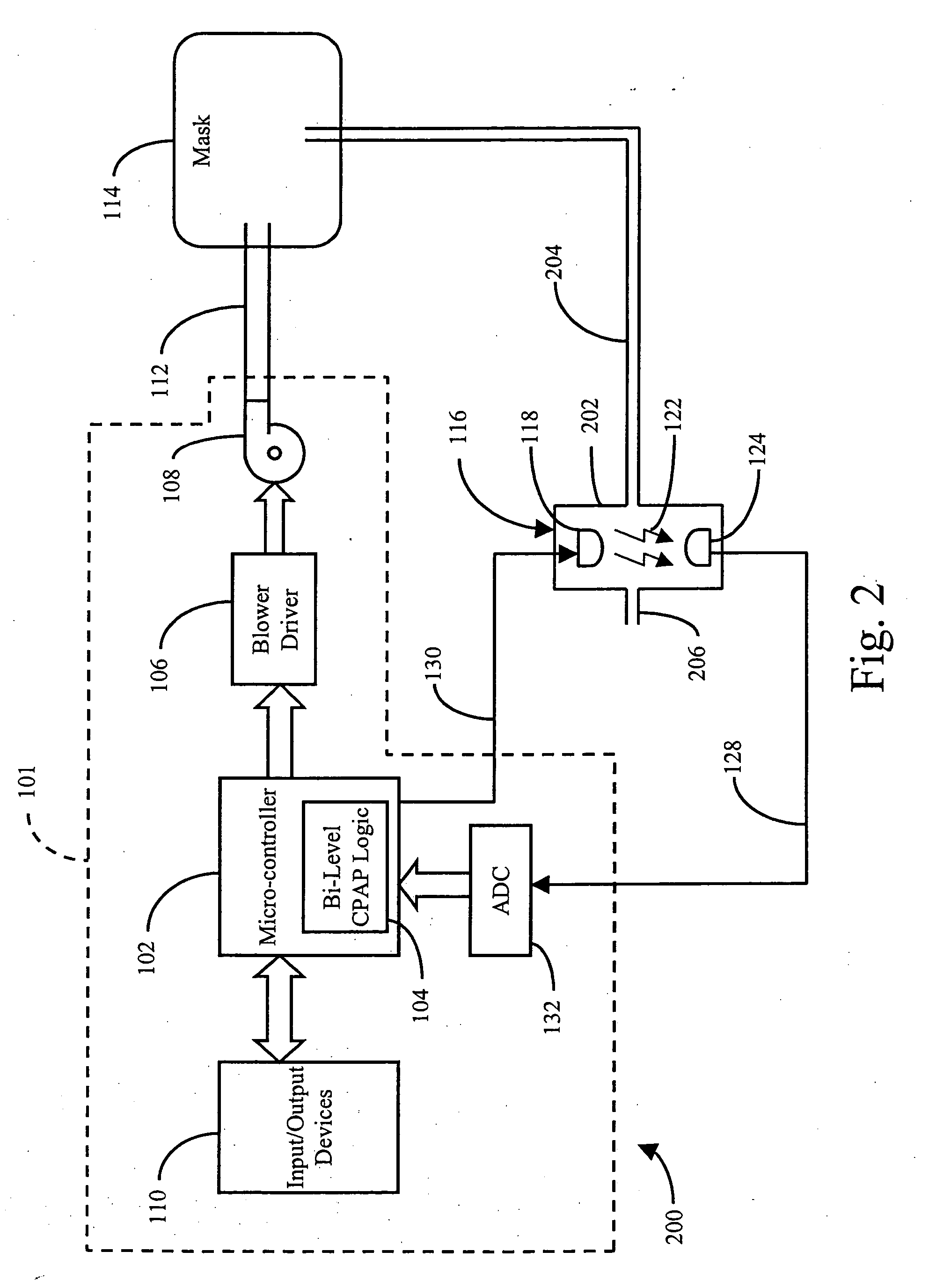

Carbon dioxide-based bi-level CPAP control

InactiveUS20050279358A1Few transmissionImprove pressure resistanceRespiratorsOperating means/releasing devices for valvesInhalationCo2 absorption

A system and method of providing bi-level CPAP therapy is provided that incorporates an infrared carbon-dioxide sensor to determine whether a patient is inhaling or exhaling. Patient exhalation causes the infrared light to be absorbed, while patient inhalation reduces the presence of carbon-dioxide causes little or no absorption of carbon-dioxide The level of carbon-dioxide in an associated patient breathing interface is monitored for thresholds that trigger higher CPAP pressure upon inhalation and lower CPAP pressure upon exhalation.

Owner:INVACARE CORP

Breathing apparatus for hypoxic pre-acclimatization and training

InactiveUS20060130839A1Reduce heatSmall sizeBreathing filtersBreathing masksReservoir bagCo2 absorption

A hand-held rebreather / breathing apparatus for high altitude pre-acclimatization and training. Air exhaled by a user is directed to a reservoir bag for cooling and condensate collection. At inhalation negative pressure created a mixing chamber forces the air stored in the reservoir bag to pass via CO2 absorption chamber where it may be mixed with a fresh portion of the ambient air that influxes via orifice(s) communicating with this chamber. Baseline of the minimum oxygen concentration in inspired air can be pre-set by means of adjustment of the maximum volume of the reservoir bag and / or by means of altering of the number or diameter of one or a plurality of orifices for commination of the ambient air. Biofeedback may be provided by an oxygen monitor.

Owner:BASSOVITCH OLEG

Integrated oxygen generation and carbon dioxide absorption method apparatus and systems

InactiveUS7427449B2Increase varietySmall sizeRegenerative fuel cellsFuel cell auxillariesChemical speciesCo2 absorption

A method for producing oxygen and absorbing carbon dioxide in a single operation using a solution that contains an oxygen source and a redox partner that can react to form oxygen and a chemical species that can form an insoluble carbonate to precipitate and chemically store carbon dioxide. Carbon dioxide is introduced into the solution and the carbonate precipitates as the oxygen is generated. In particular, the invention uses an aqueous solution of permanganate and hydrogen peroxide that react in the presence of a catalyst to produce oxygen and manganese (II) ions. Carbon dioxide gas introduced into the solution reacts with the manganese (II) ions to precipitate manganese carbonate. Other cations capable of reacting with carbon dioxide to form an insoluble carbonate, for example calcium, barium and magnesium, may also be added to the solution to precipitate carbonate salts. Calcium permanganate may used as a source of both calcium and permanganate.

Owner:CAPITAL MANAGEMENT +1

Method and Apparatus for the Removal of Carbon Dioxide from a Gas Stream

The invention provides methods and apparatuses for removing carbon dioxide from a gas stream. In particular, the invention provides methods and apparatuses for absorbing carbon dioxide from a coal-fired boiler flue gas stream using an absorbing solution and for regeneration of an alkaline component used in the absorbing solution. In one embodiment, the invention provides a method for removing carbon dioxide from a gas stream by contacting a gas stream containing carbon dioxide with an alkaline liquid stream; absorbing at least a portion of the carbon dioxide into the alkaline liquid stream to produce absorbed carbon dioxide; and catalyzing a reaction of the absorbed carbon dioxide to a form of carbonate.

Owner:FLUEGEN

Composite decarbonizing solution for recovering carbon dioxide in waste gas

InactiveCN101053751ALarge absorption capacityImprove the degree of purificationDispersed particle separationHigh concentrationReaction rate

The invention relates to a composite decarbonization solution for reclaiming the carbon dioxide in the exhaust gas, wherein the component and the mass percent of the composite are that: 20-60 percent of composite amines solution, wherein one or more fast reaction rate amines with a low concentration and one or more slow reaction rate amines with a high concentration are comprised; 5-10 percent of Polyxinolum; 1-5 percent of antioxidant; 1-5 percent of inhibitor; and the rest is water. The invention has the advantage of a large absorbing capability to CO2, a high degree of purification, a light causticity, a little consume of the solution and a lower recycling energy consumption. High concentration CO2 for gas injection oil-recovery can be obtained.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

CO2 absorption solution

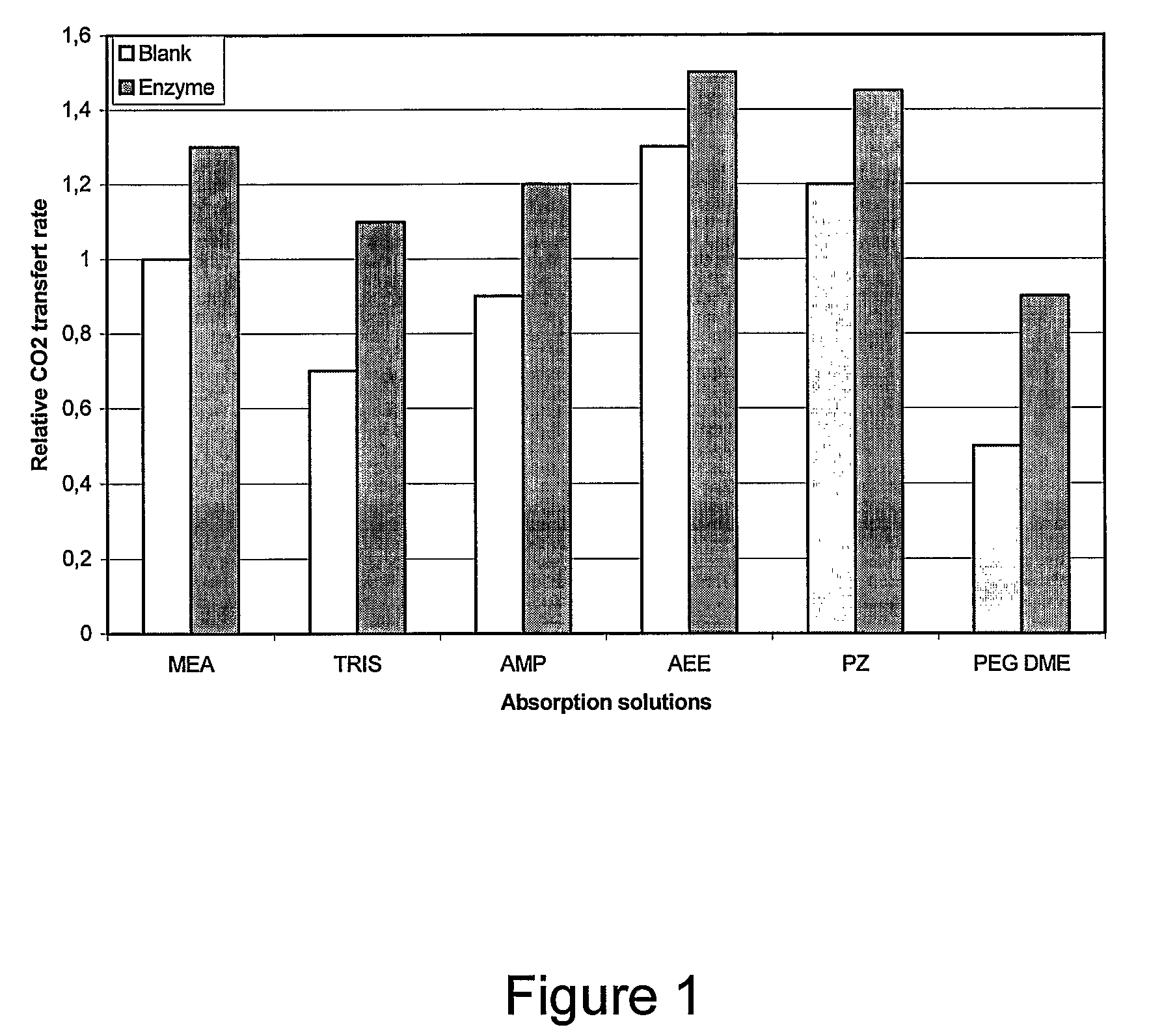

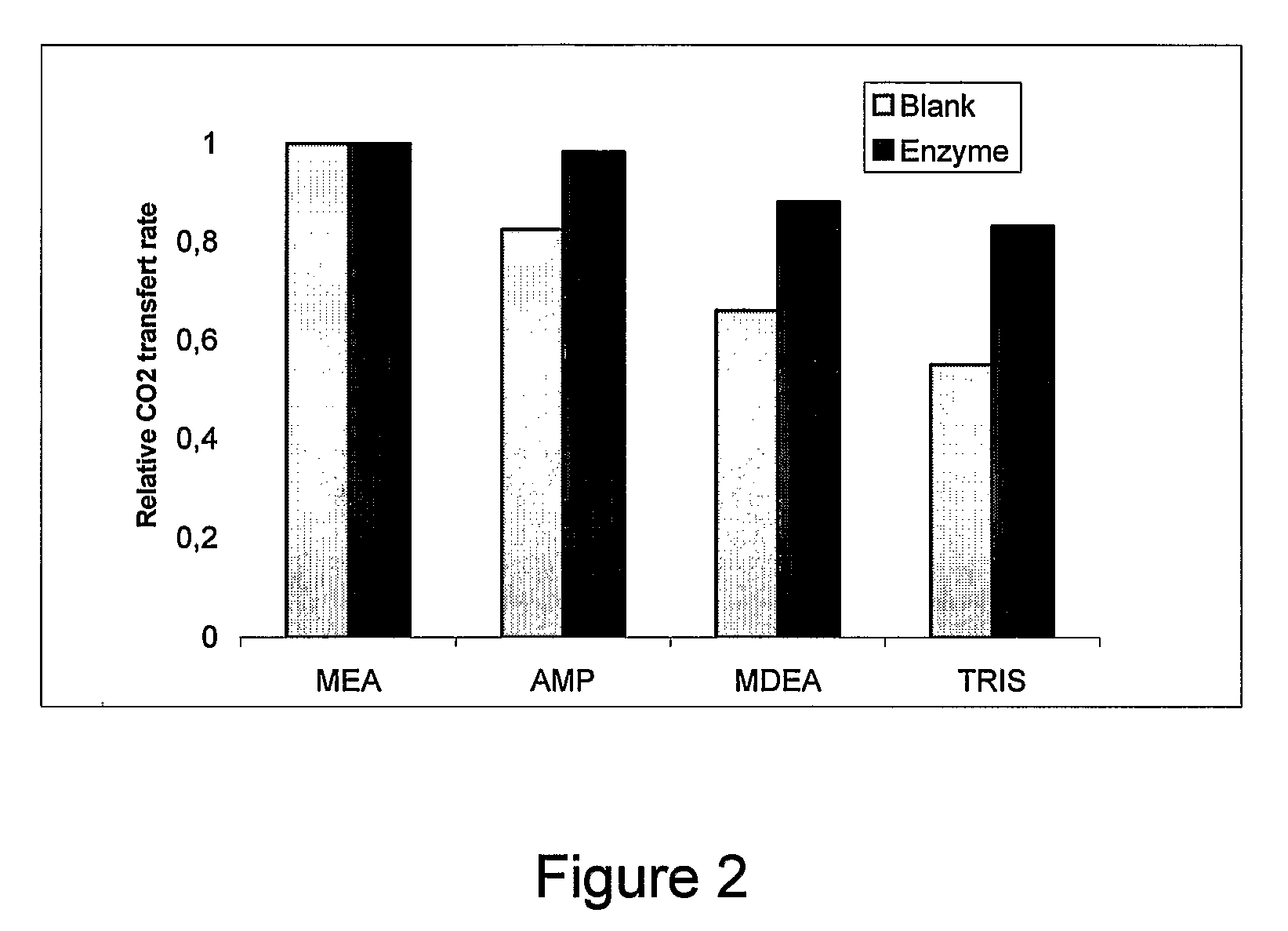

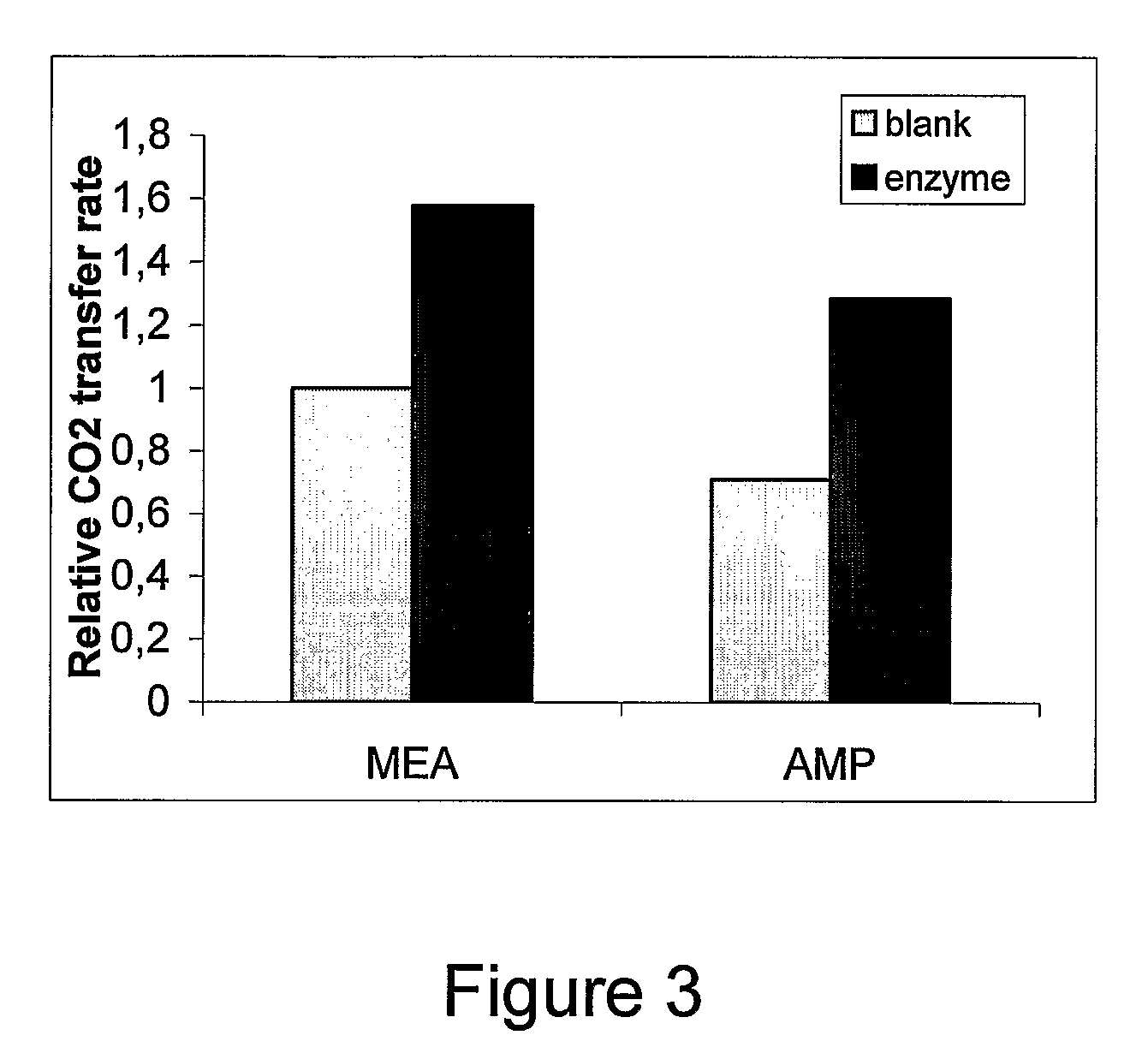

InactiveUS7740689B2Promote absorptionImprove performanceOther chemical processesUsing liquid separation agentCo2 absorptionAbsorption rate

Disclosed is a formulation for the absorption of CO2, which comprises water, at least one CO2 absorption compound and a carbonic anhydrase as an activator to enhance the absorption capacity of the CO2 absorption compound. The invention also concerns the use of carbonic anhydrase, in a CO2 absorption solution to increase the CO2 absorption rate of such solution.

Owner:CO2 SOLUTION

Method and device for reducing the carbon dioxide content in a dead volume

InactiveUS7814908B2Simple and effective of carbon dioxide contentEasy to installRespiratorsControlling ratio of multiple fluid flowsDead volumeMedicine

In a method and device for reducing the carbon dioxide content in a dead volume intended for connection to the respiratory system of a patient, and an anesthesia apparatus embodying such a device, a flow of gas is generated from an outlet associated with the dead volume and the gas is conducted through a carbon dioxide absorber, and the gas after passing through the carbon dioxide absorber is returned to an inlet associated with the dead volume.

Owner:MAQUET CRITICAL CARE

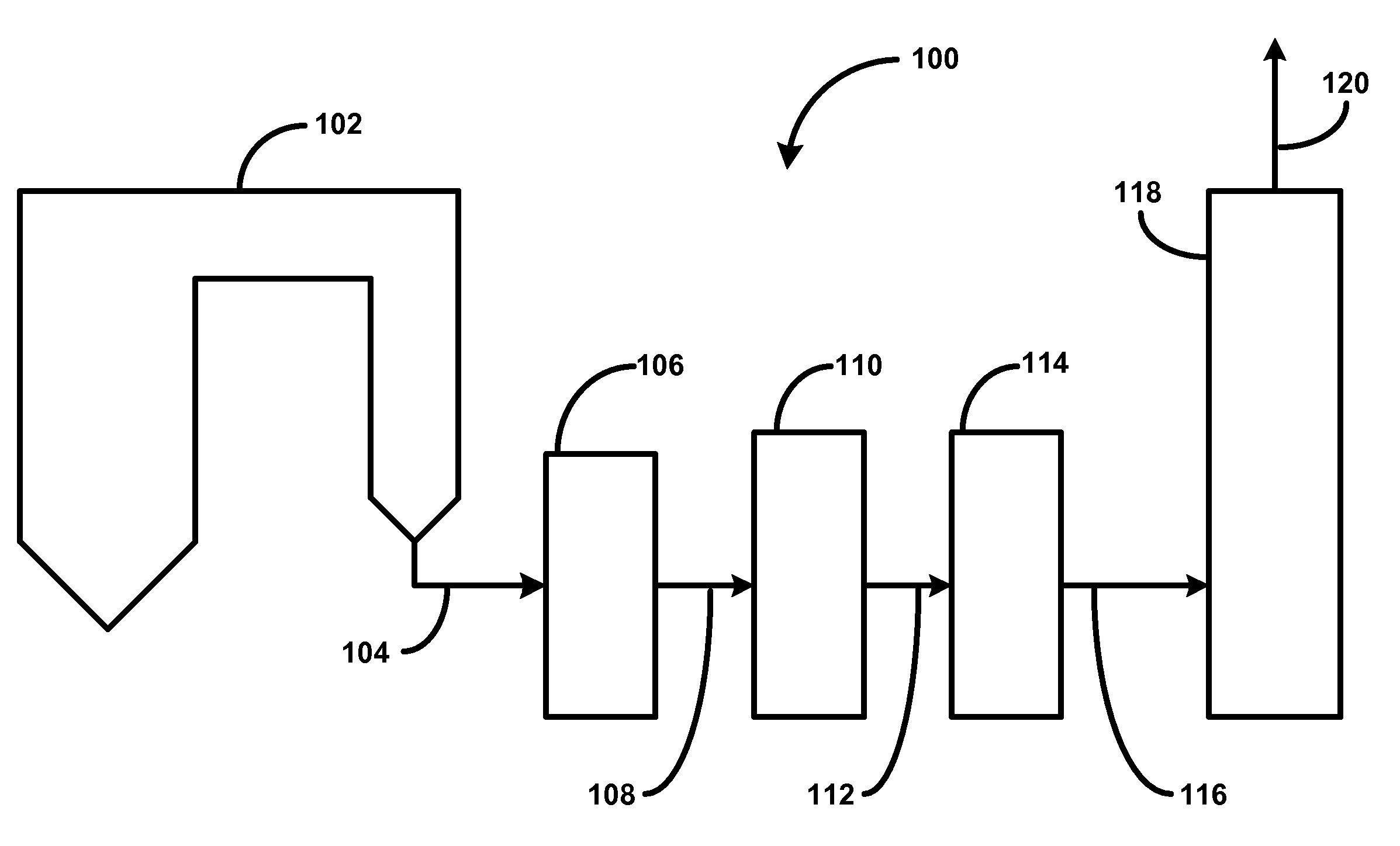

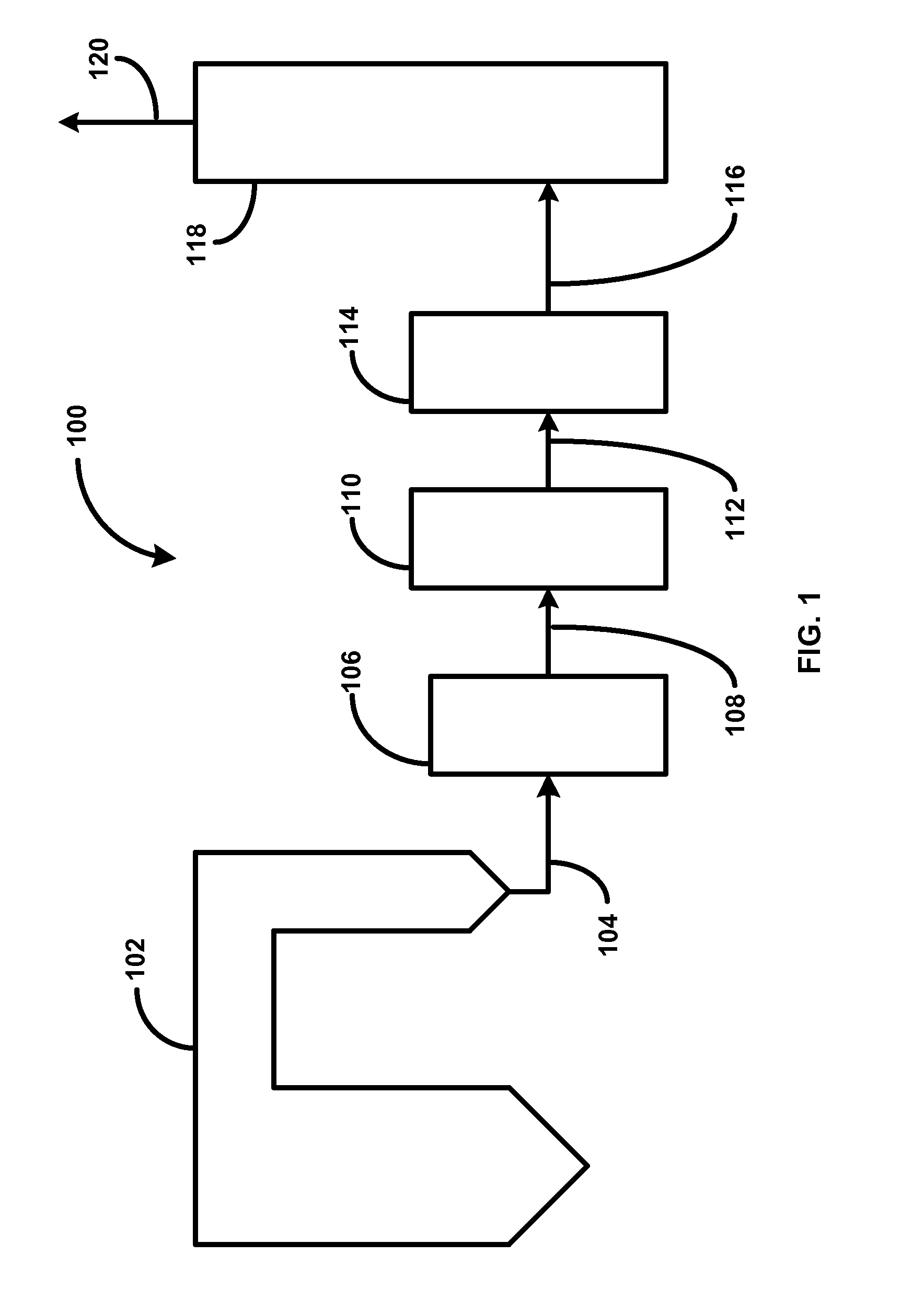

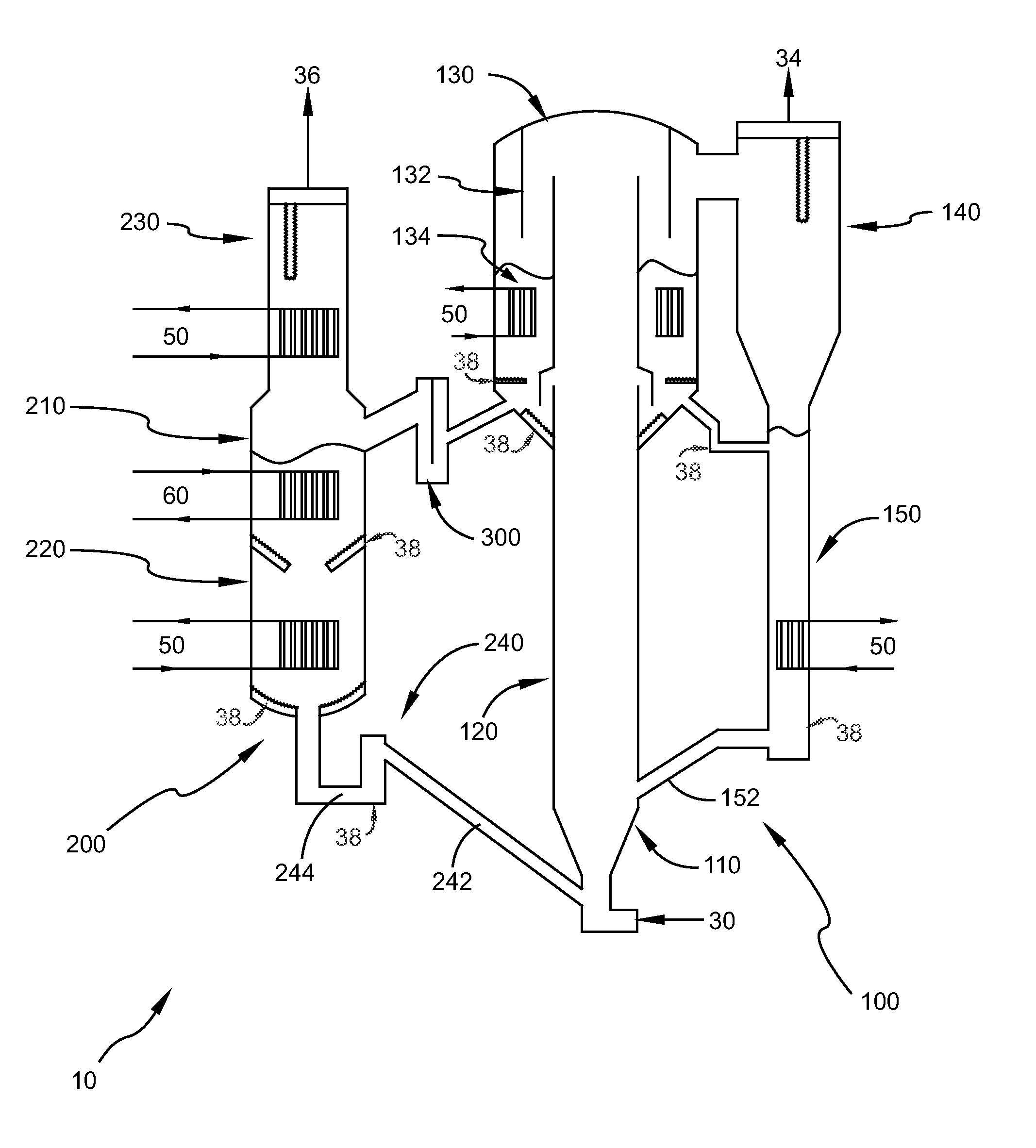

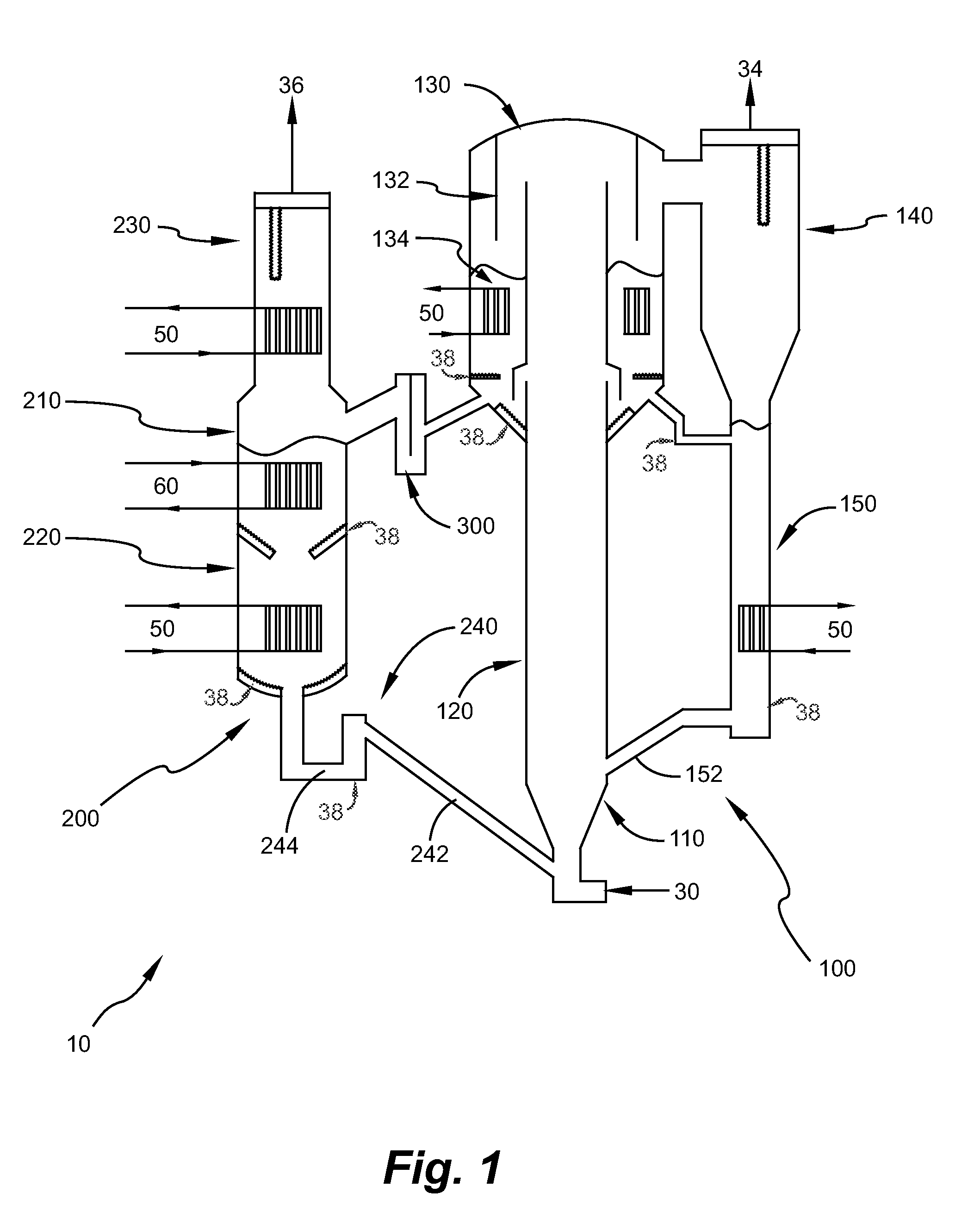

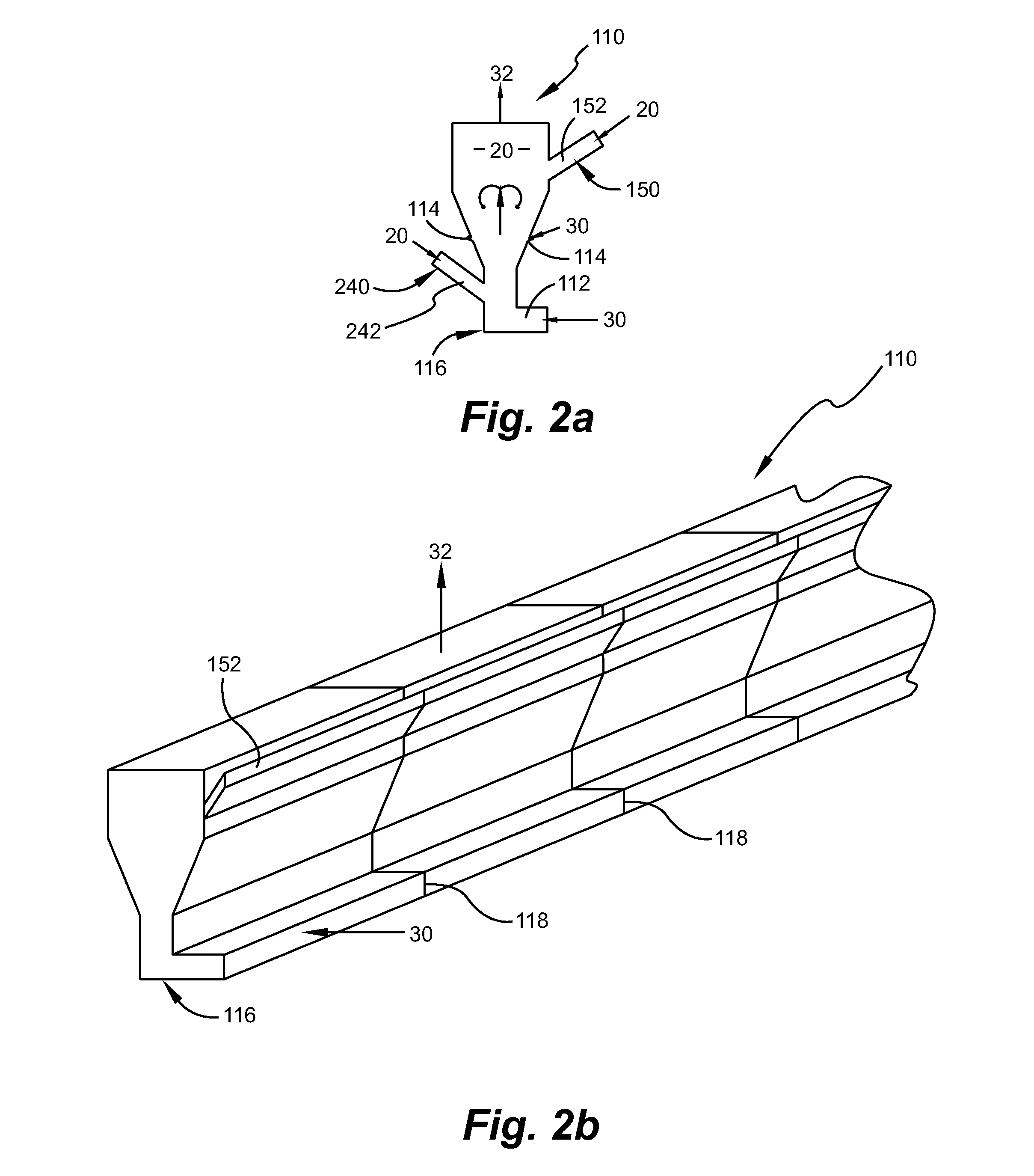

Carbon Dioxide Absorber And Regeneration Assemblies Useful For Power Plant Flue Gas

ActiveUS20110005395A1Limit and prevents any localized overheatingUniform bed temperatureGas treatmentEmission preventionSorbentCo2 absorption

Disclosed are apparatus and method to treat large amounts of flue gas from a pulverized coal combustion power plant. The flue gas is contacted with solid sorbents to selectively absorb CO2, which is then released as a nearly pure CO2 gas stream upon regeneration at higher temperature. The method is capable of handling the necessary sorbent circulation rates of tens of millions of lbs / hr to separate CO2 from a power plant's flue gas stream. Because pressurizing large amounts of flue gas is cost prohibitive, the method of this invention minimizes the overall pressure drop in the absorption section to less than 25 inches of water column. The internal circulation of sorbent within the absorber assembly in the proposed method not only minimizes temperature increases in the absorber to less than 25° F., but also increases the CO2 concentration in the sorbent to near saturation levels. Saturating the sorbent with CO2 in the absorber section minimizes the heat energy needed for sorbent regeneration. The commercial embodiments of the proposed method can be optimized for sorbents with slower or faster absorption kinetics, low or high heat release rates, low or high saturation capacities and slower or faster regeneration kinetics.

Owner:THE SOUTHERN CO

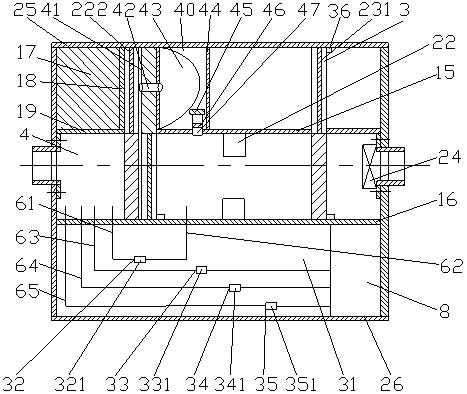

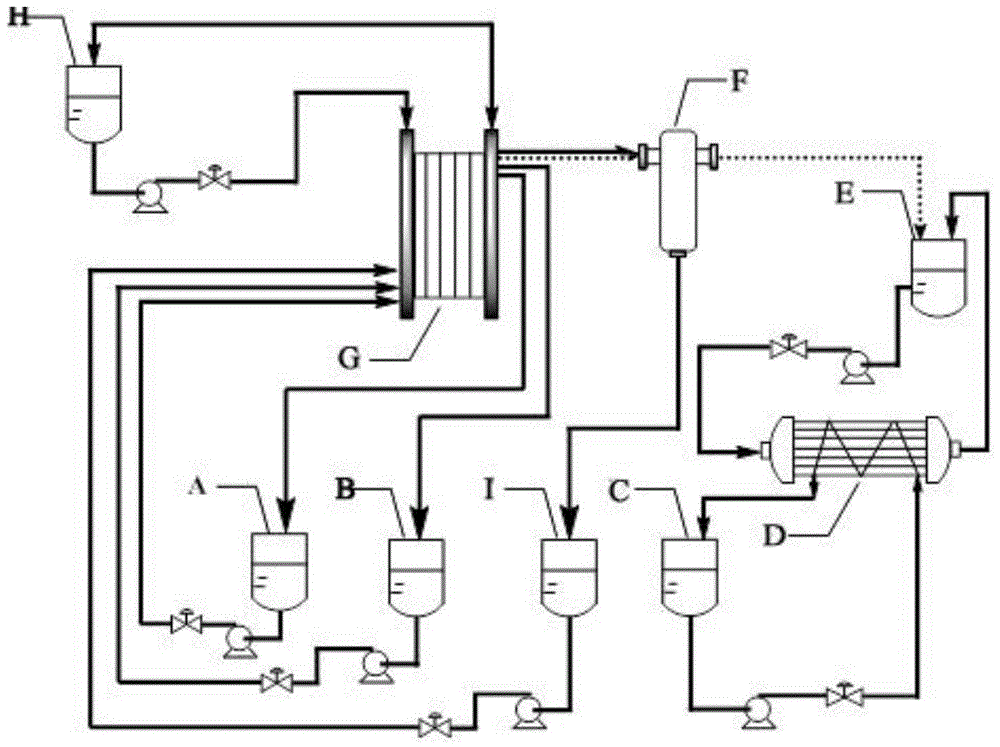

Multi-functional air purifier and energy conservation using method

InactiveCN101949562AImprove efficiencyLow energy operationDucting arrangementsSpace heating and ventilation safety systemsIndoor air qualityCo2 absorption

The invention discloses a multi-functional air purifier and an energy conservation using method thereof, belonging to the technical field of environmental protection devices. The multi-functional air purifier comprises a purifier body, a purification main air channel, a purification non-work area, a dust collecting air channel, a slideway, a detection and control device and other parts; the purifier body consisting of a stereometric frame structure comprises a front part, a middle part and a rear part; the purification main air channel is positioned in the middle of the purifier body; the purification non-work area and the dust collecting air channel are located at the front of the purifier body; the slideway positioned between the purification non-work area and the purification main air channel is installed in the purifier body; and the detection and control device is installed at the rear of the purifier body. The energy conservation using method of the multi-functional air purifiercan select different working modes to respectively carry out filter purification treatment, dust collecting treatment, toxic and harmful gas absorption and purification treatment and carbon dioxide absorption and purification treatment on indoor air according to the current indoor air quality condition, so as to ensure the air purifier to work at high efficiency with low energy consumption and achieve energy conservation effect.

Owner:JIANGSU UNIV

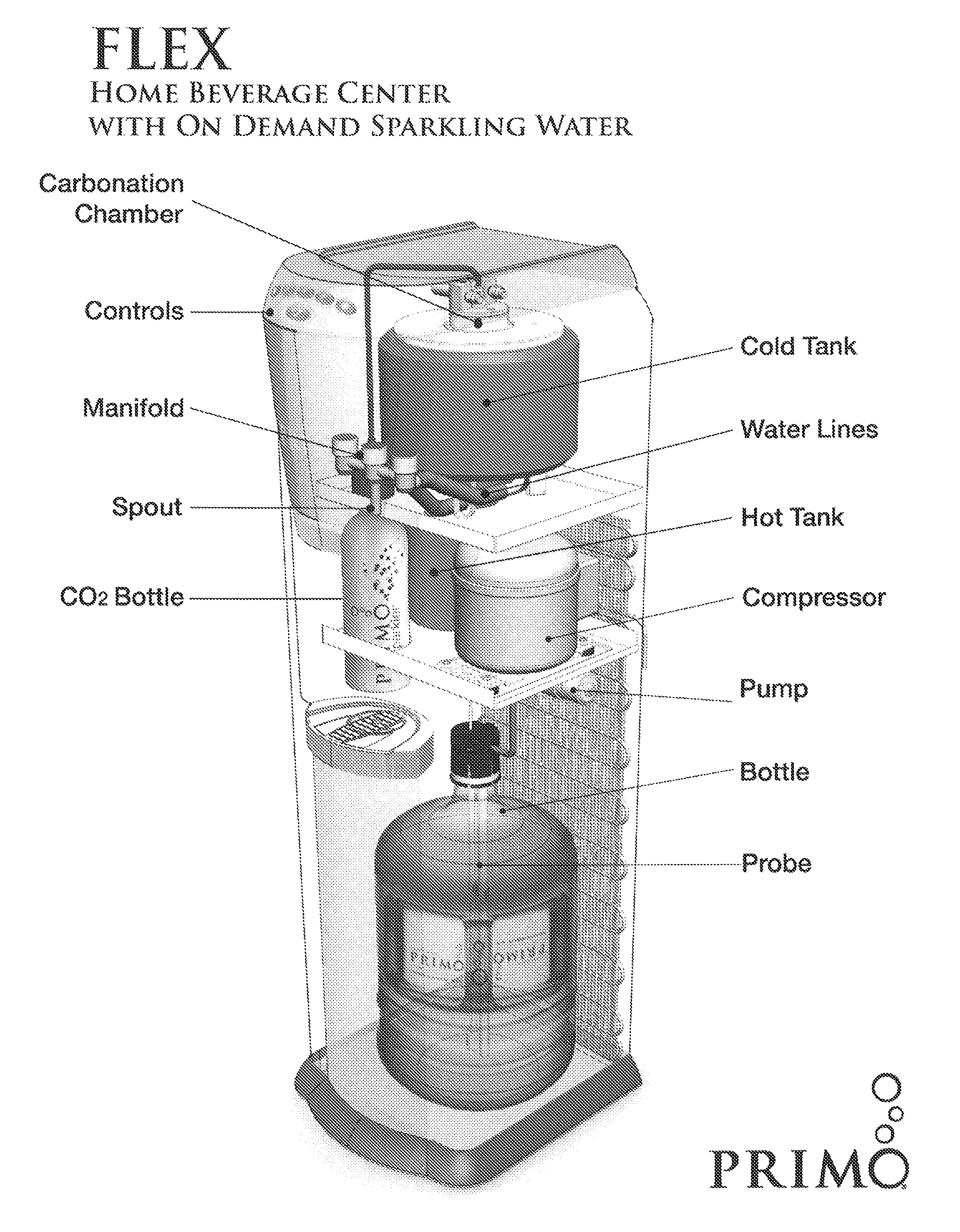

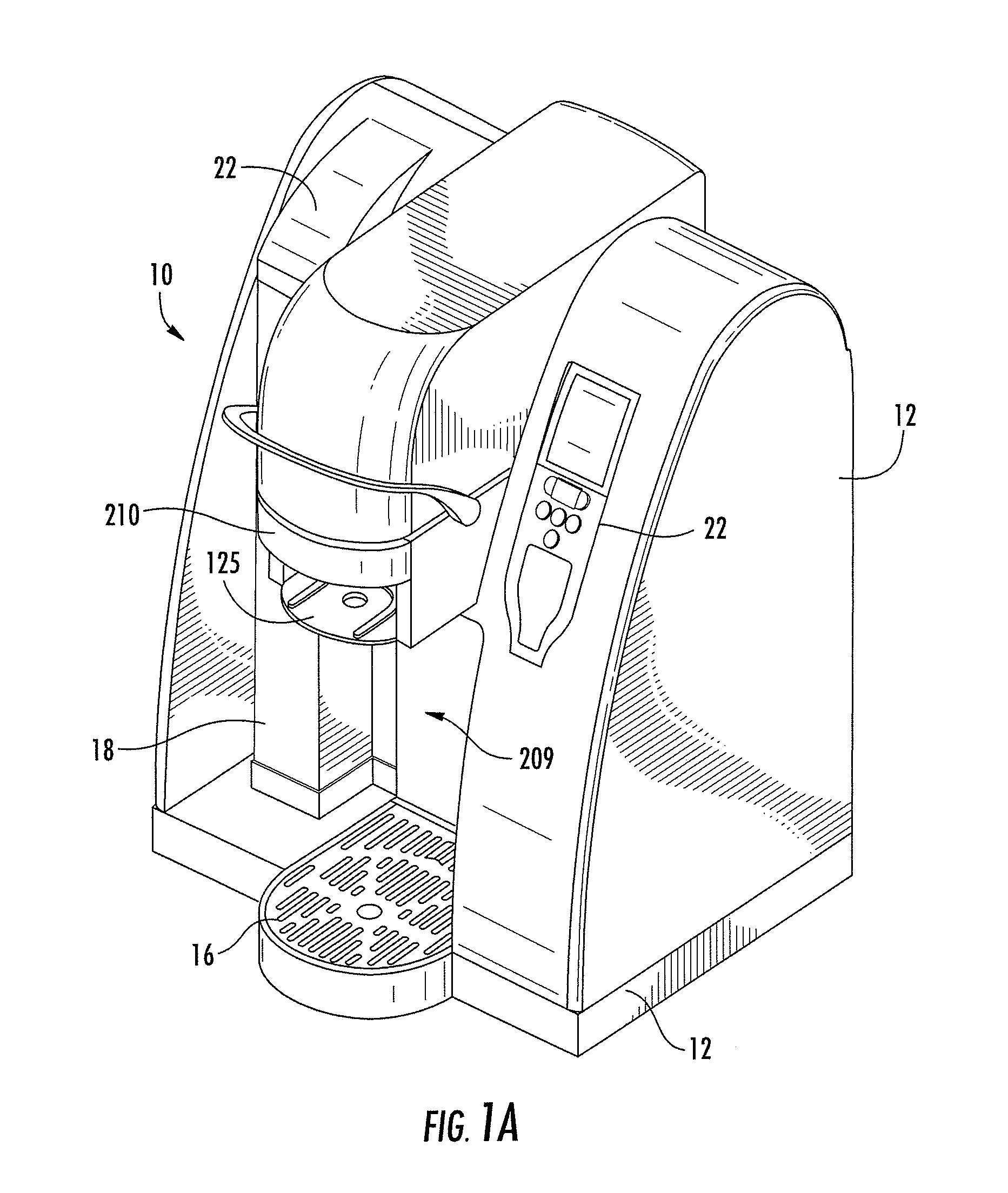

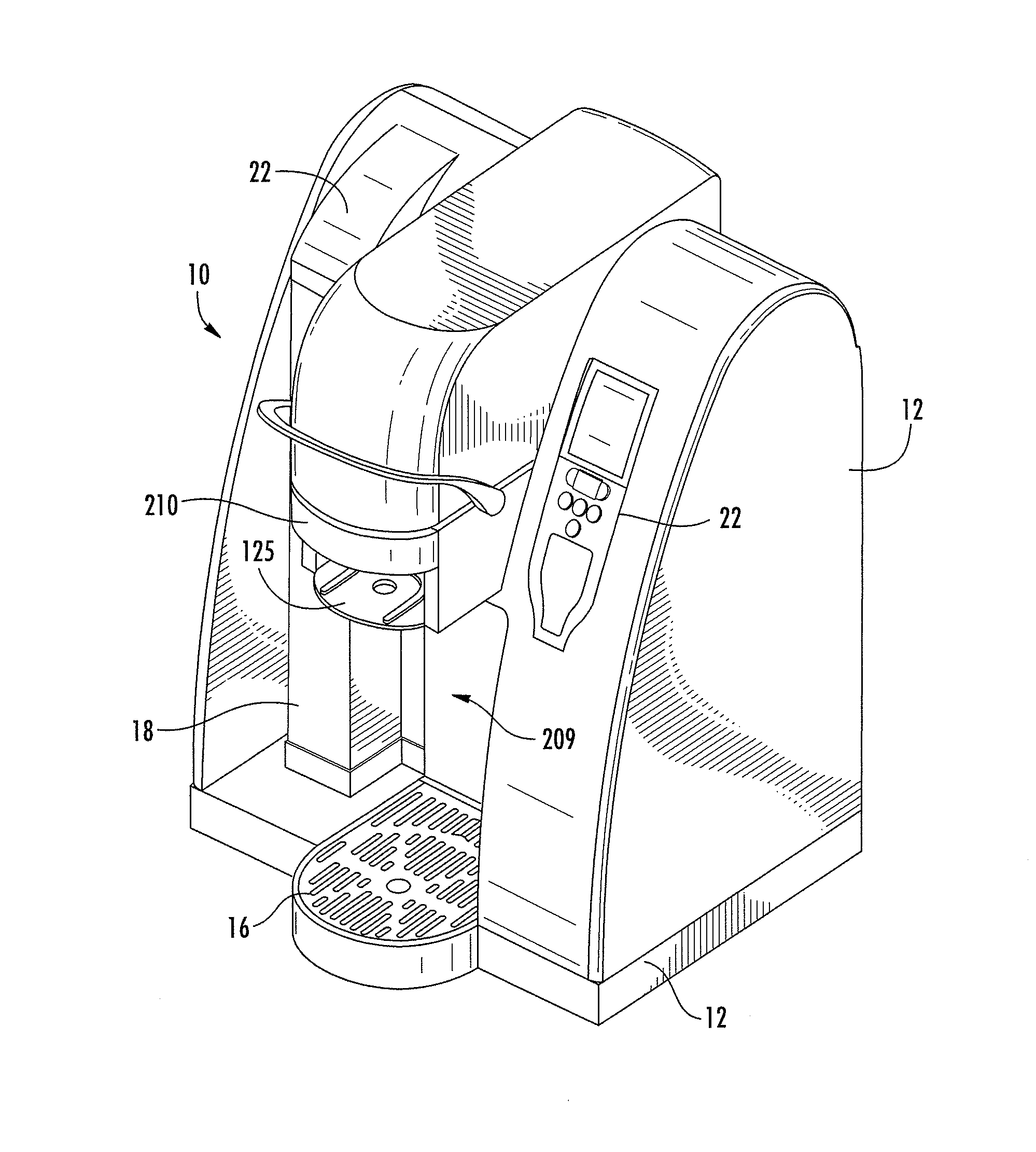

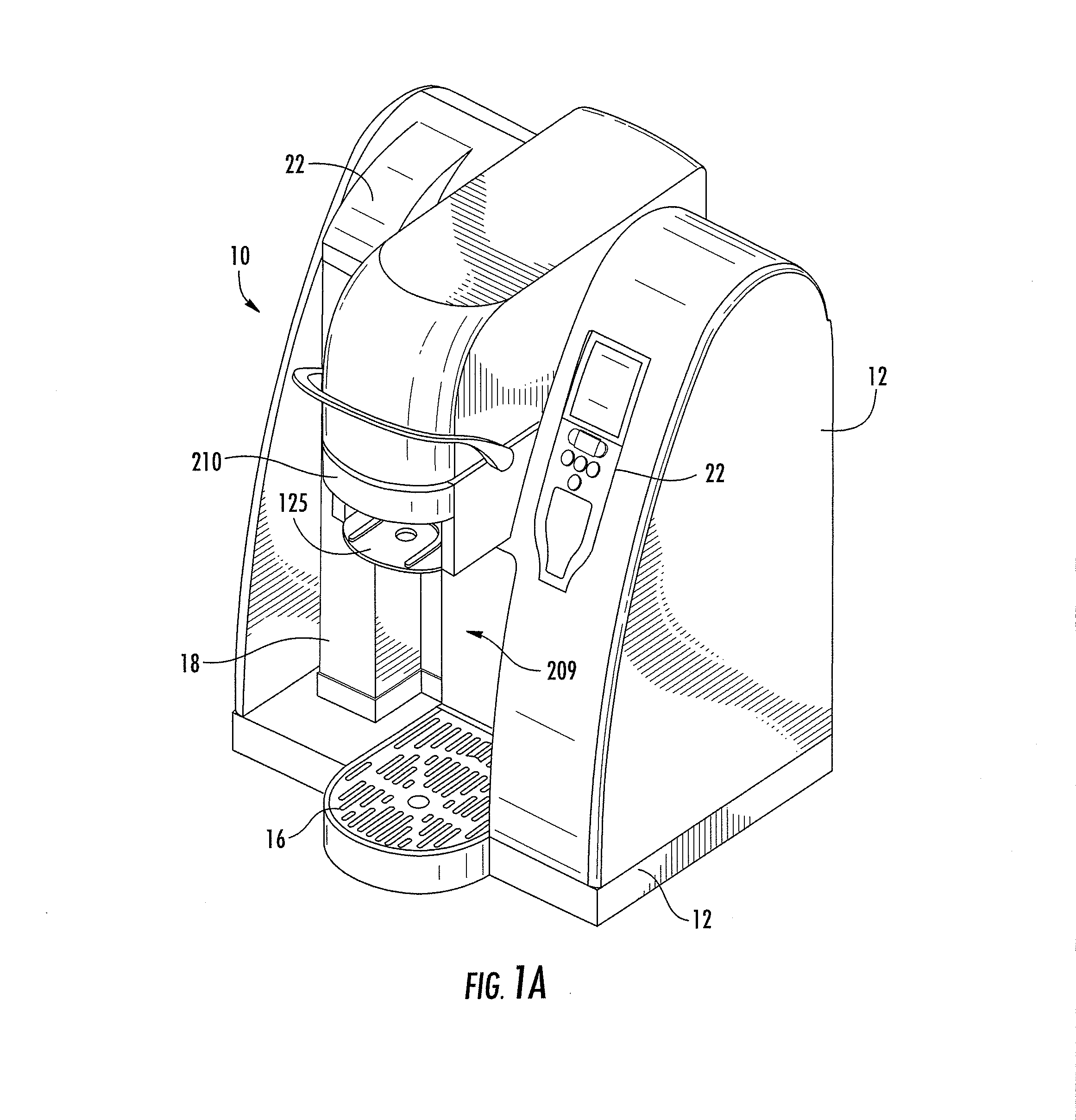

Select serving and flavored sparkling beverage maker system

A system with a beverage maker for making single serving customized beverages is provided herein. An example beverage maker includes a carbonation chamber for mixing a selected volume of fluid with carbon dioxide. The beverage maker also includes a pressurized carbon dioxide source in fluid communication with the carbonation chamber. The beverage maker is configured to receive an individually packed, single use disposable flavor cup containing a flavor and having a sealed cover that covers and seals the flavor cup. Additionally, the beverage maker includes a piercing mechanism for piercing the flavor cup and mixing the selected volume of fluid therein, and for discharging a blended fluid. The carbonation chamber comprises a pressure vessel assembly of a fixed volume such that carbon dioxide absorption can be performed and controlled. The system may also include a water dispenser fluidly connected to the beverage maker.

Owner:PRIMO PRODS

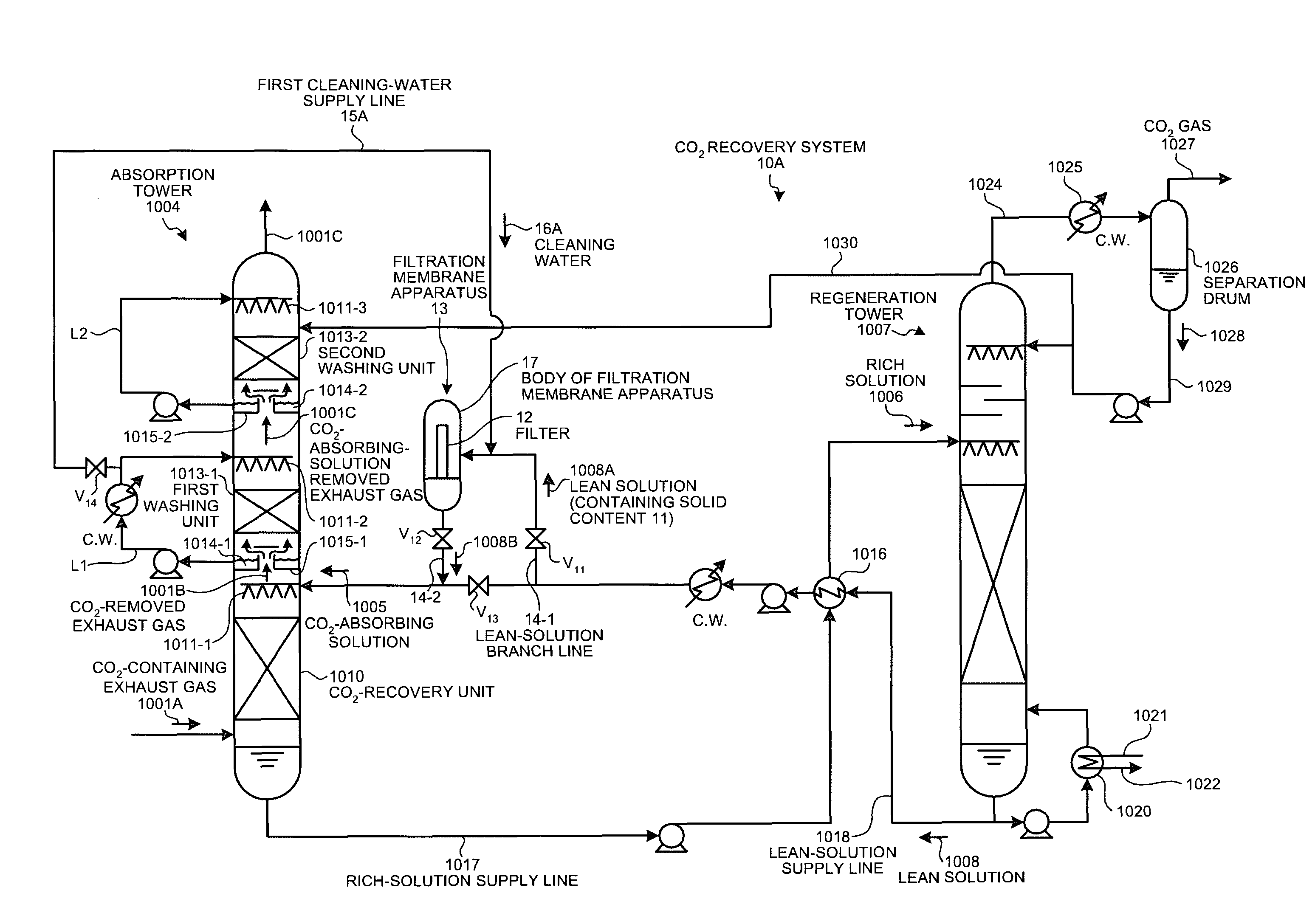

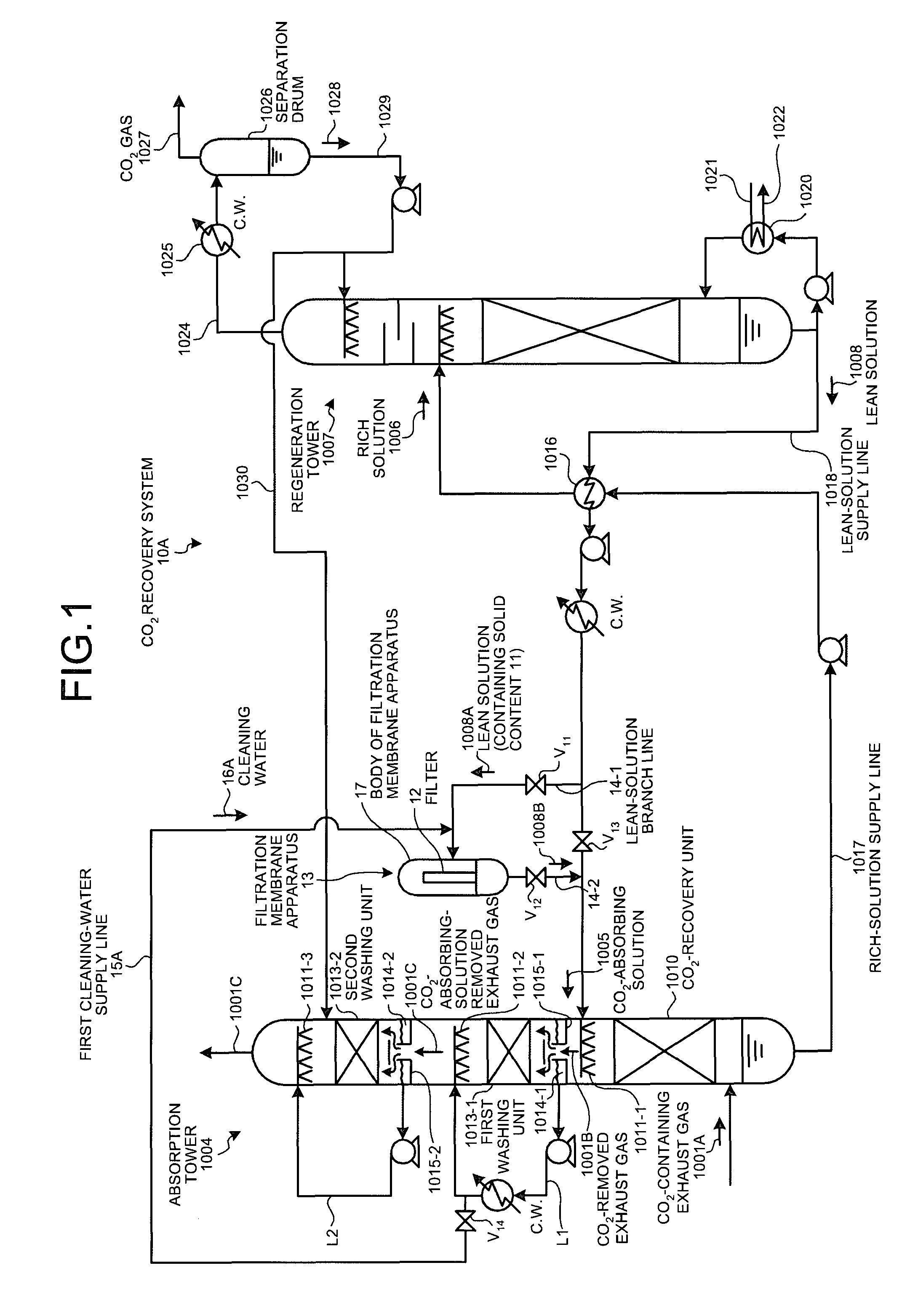

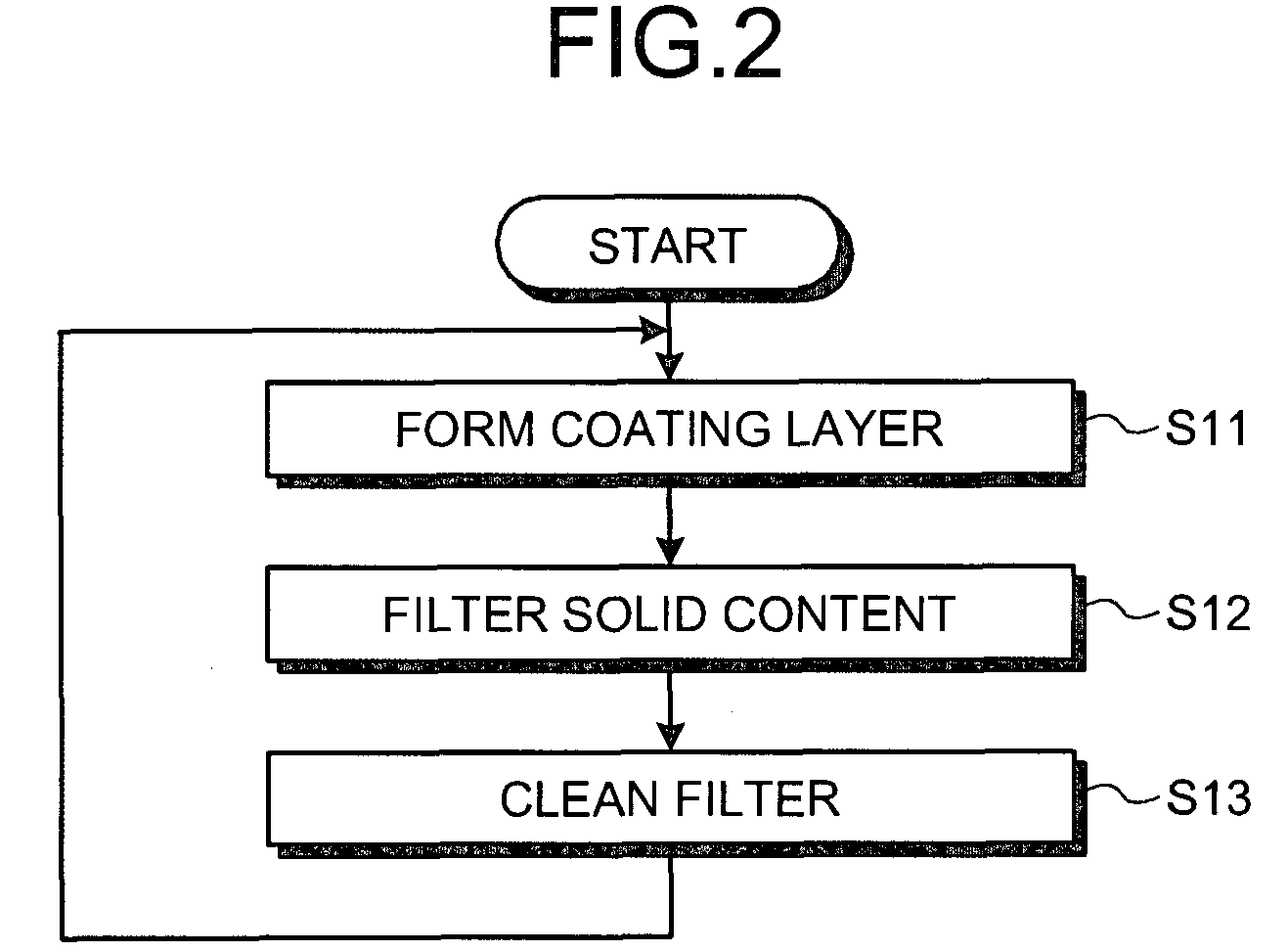

Co2 recovery system and method of cleaning filtration membrane apparatus

A CO2 recovery system includes an absorption tower that removes CO2 from exhaust gas, a regeneration tower that regenerates a rich solution, and a separation drum that condensates steam in CO2 gas released from the regeneration tower and separates water. The CO2 recovery system further includes a filtration membrane apparatus that filters solid content remaining in the lean solution using a filter, and cleans the filter using condensed water as cleaning water and again return the condensed water into the system. The CO2-absorbing solution attached to the filter is collected and the filter is cleaned without diluting the CO2-absorbing solution upon replacement of the filter.

Owner:MITSUBISHI HEAVY IND ENG LTD

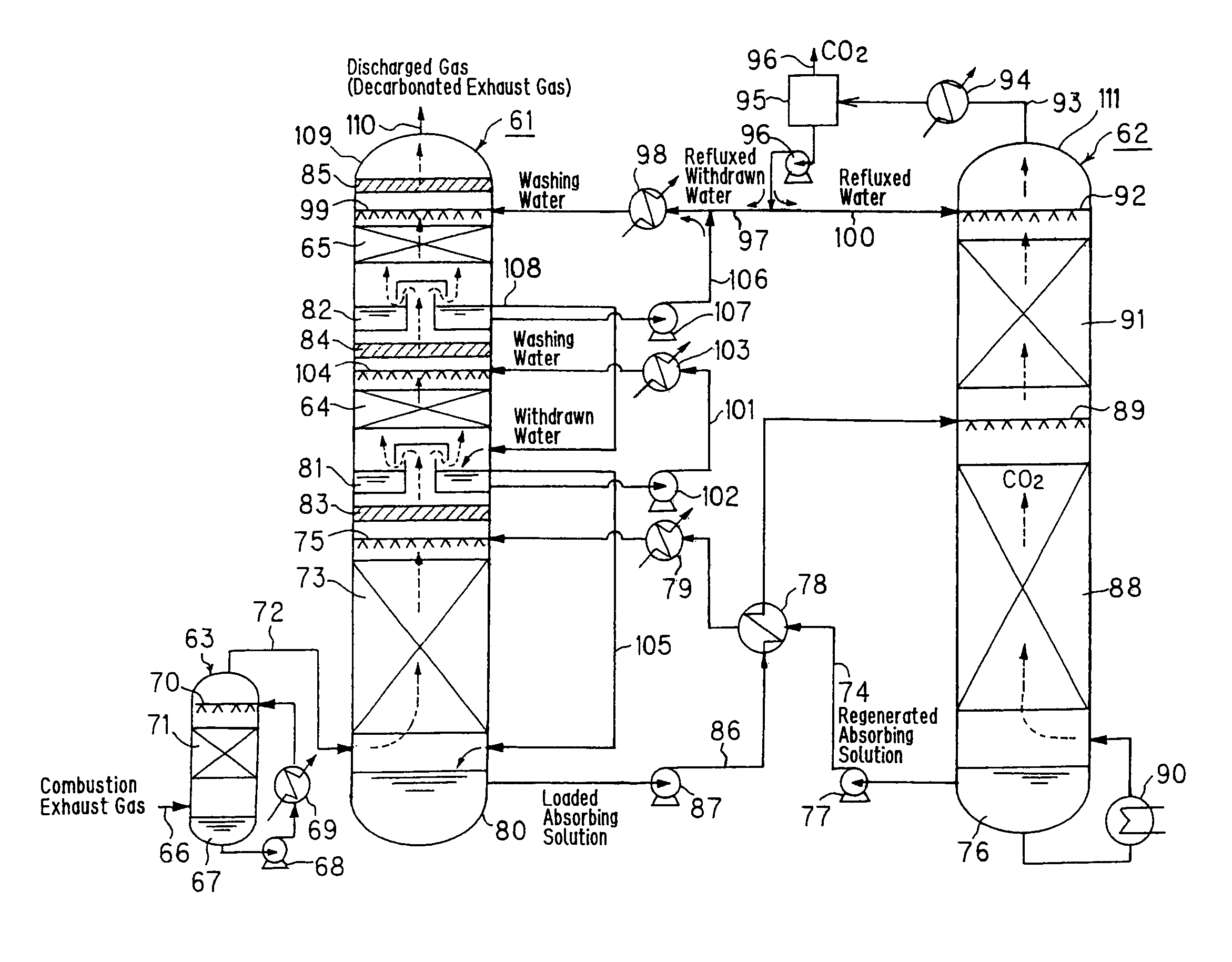

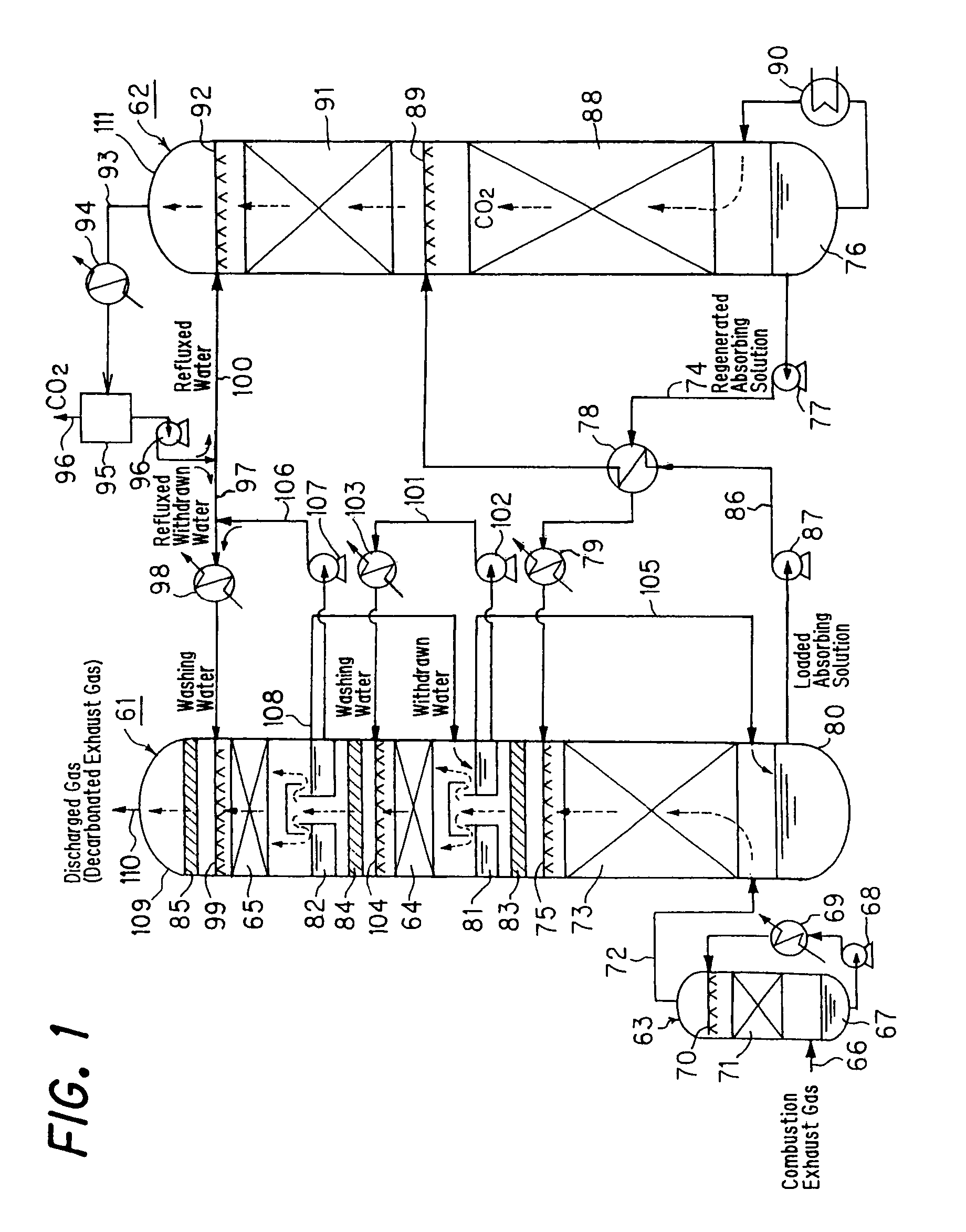

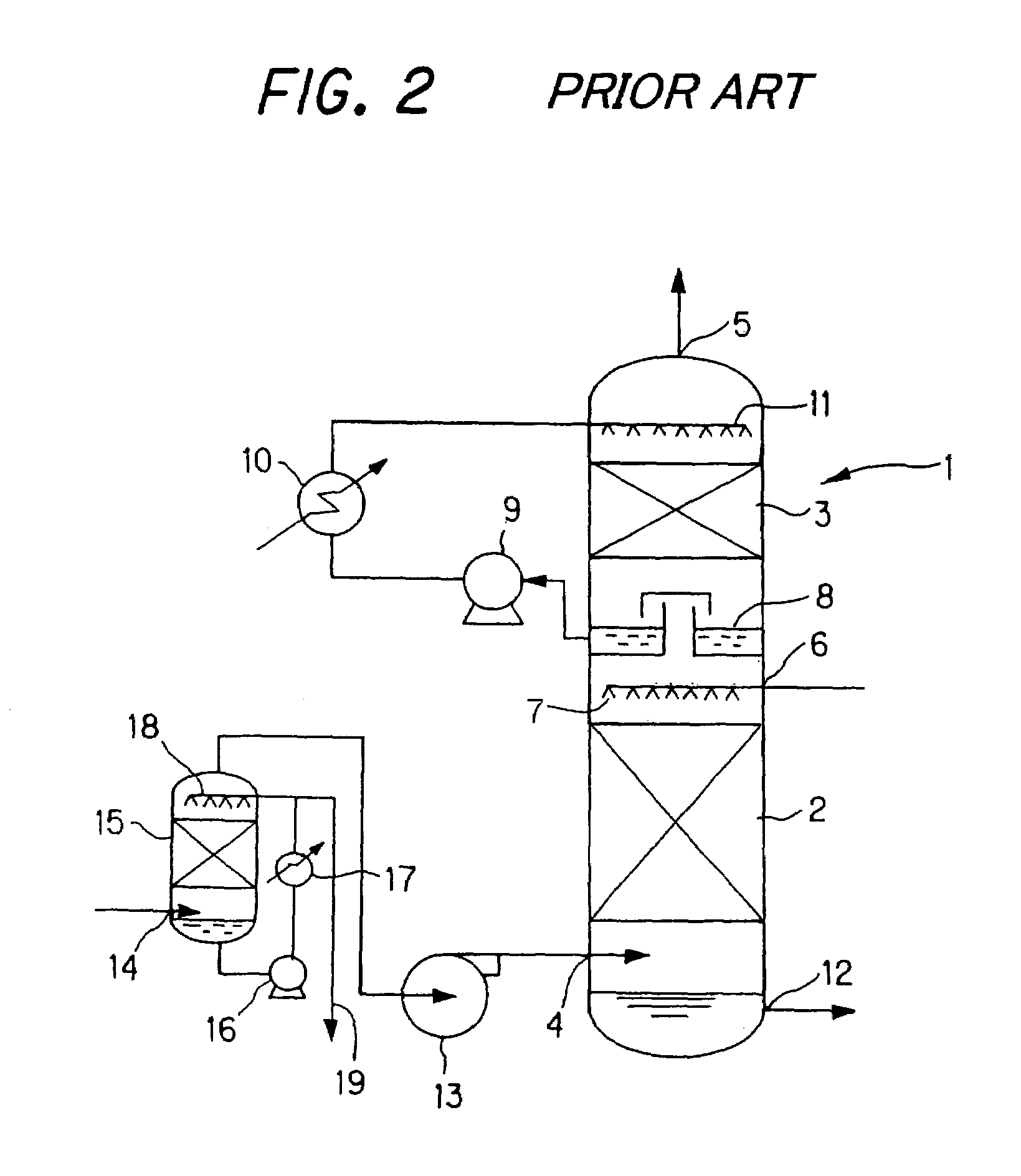

Amine recovery apparatus and decarbonation apparatus having same

InactiveUS7316737B2High ability to recover amine compoundReduce operating costsCombination devicesOrganic compound preparationVapor liquidCo2 absorption

An amine recovery apparatus includes a carbon dioxide absorption section and plural water washing sections. The carbon dioxide absorption section brings the exhaust gas into vapor-liquid contact with an absorbing solution containing an amine compound and produces decarbonated exhaust gas. The water washing sections bring the decarbonated exhaust gas into vapor-liquid contact with washing water and sequentially recover the amine compound accompanying the decarbonated exhaust gas, while the decarbonated exhaust gas passes through the water washing sections in sequence from inlet portions to outlet portions thereof, respectively. The water washing sections have plural liquid reservoirs provided at the inlet portions of the water washing sections, respectively, and the liquid reservoirs reserve the washing water which is transported to the outlet portions of the water washing sections and supplied to the water washing sections, respectively.

Owner:MITSUBISHI HEAVY IND ENG LTD

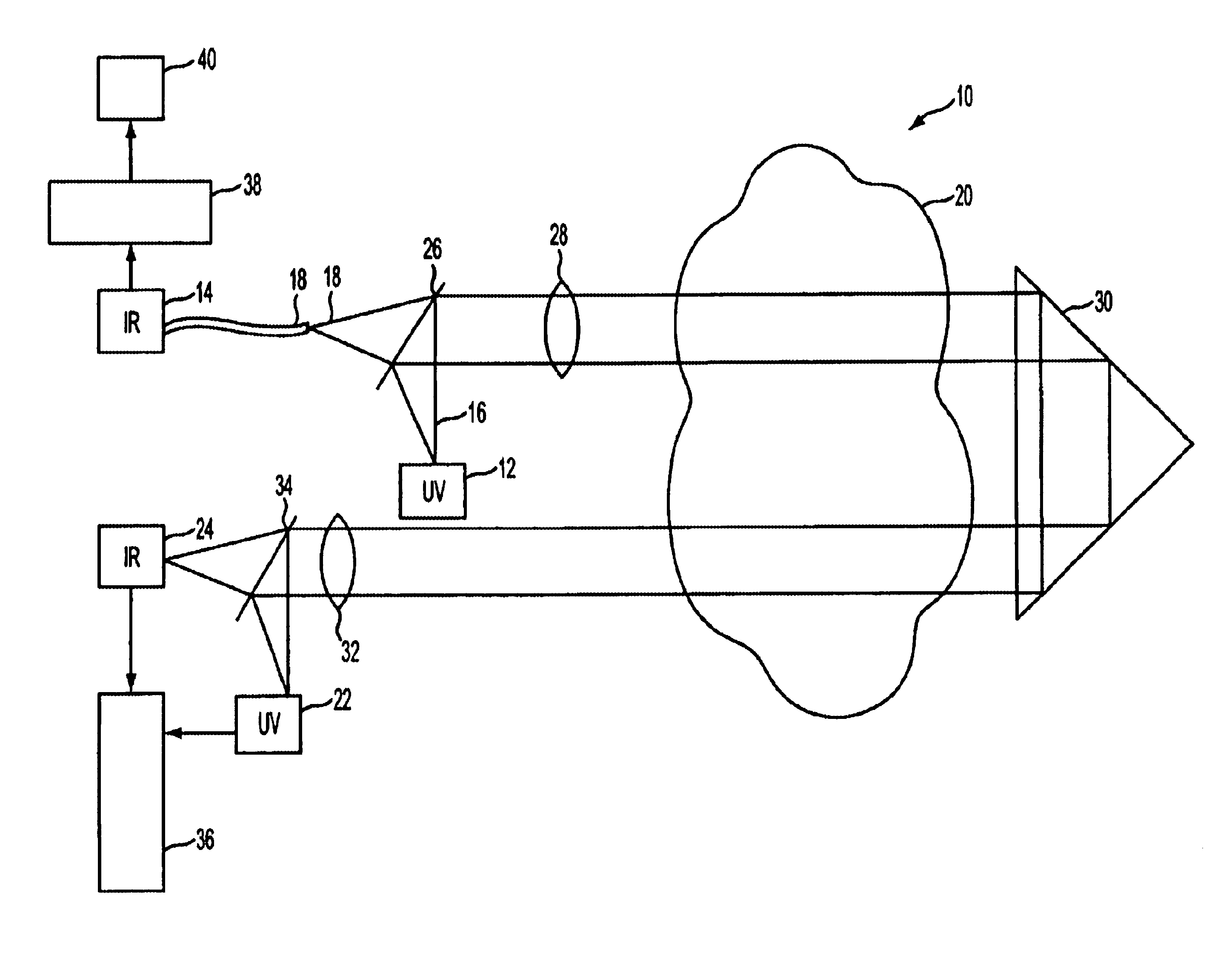

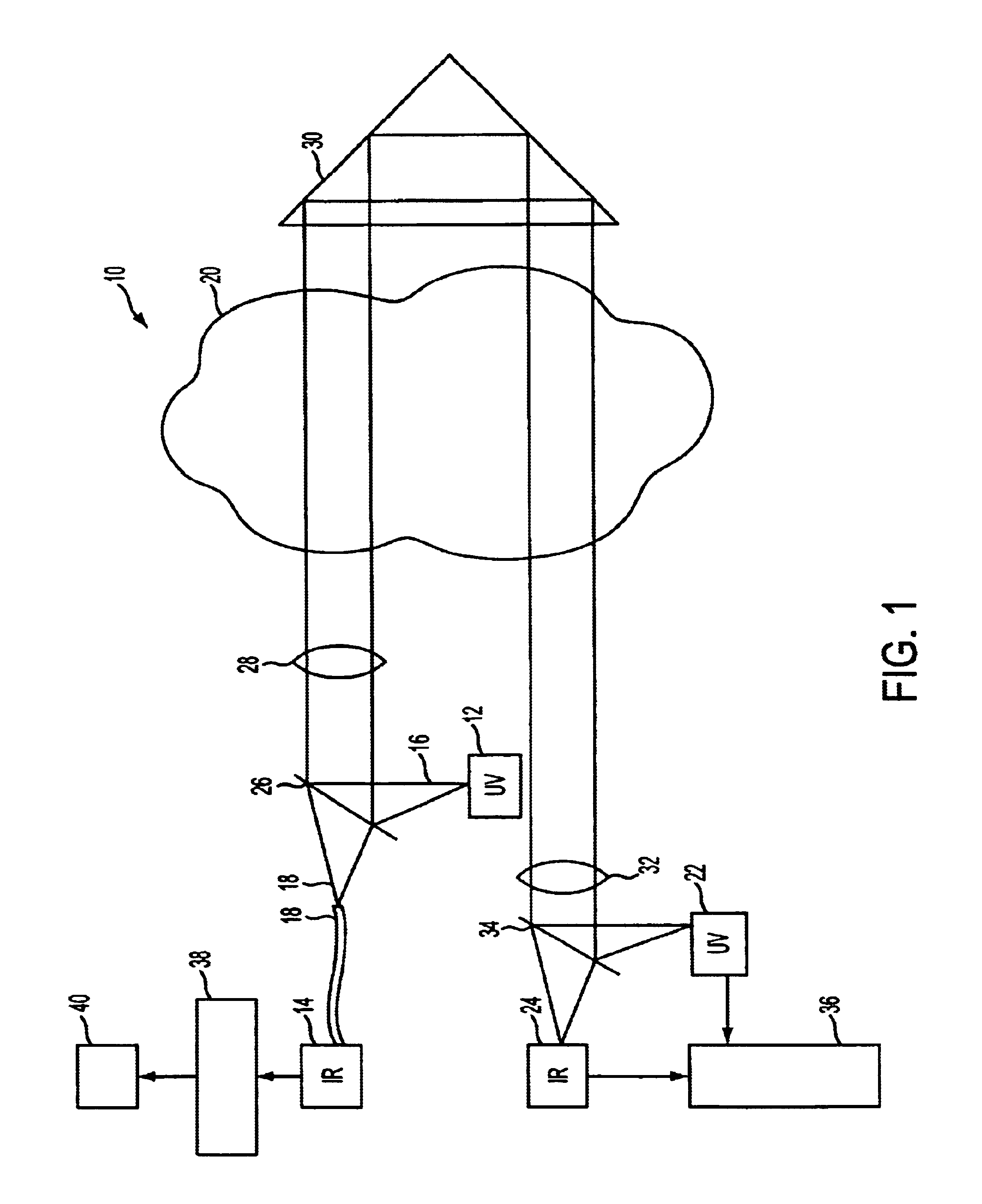

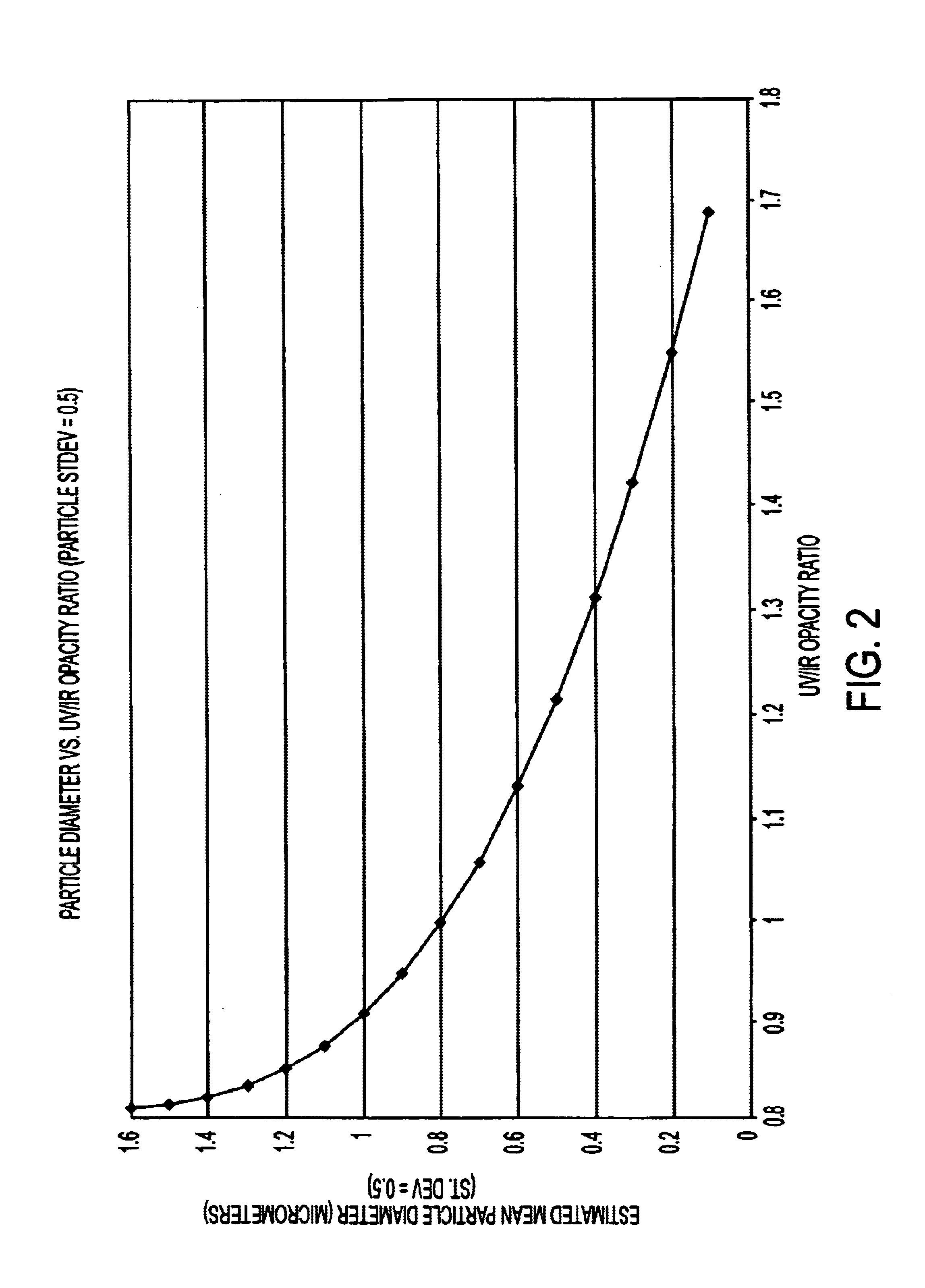

Method and apparatus for measuring particulates in vehicle emissions

InactiveUS6841778B1Accurate calculationRadiation pyrometryColor/spectral properties measurementsParticulatesCo2 absorption

A method and apparatus for measuring particulates in vehicle emissions. An ultraviolet light beam having a predetermined wavelength, and an infrared light beam having a predetermined wavelength are propagated through the exhaust plume of a vehicle that has passed on the road. The reduction in intensities of the light beams are measured. The reduction in intensity of the ultraviolet light is due to scattering of the light by particles in the exhaust. A portion of the reduction in intensity of the infrared light is due to absorption of the light by carbon dioxide in the exhaust and a portion of the reduction in intensity is due to the scattering of light by the particles in the exhaust. To distinguish between the two, a portion of the infrared light is run through a test cell with a known amount of carbon dioxide. The reduction in intensity is measured and compared with the reduction in intensity of the infrared light passing through the exhaust plume. As one measure of particulate content, the ratio of the particles in the exhaust whose diameter is greater than said predetermined wavelength of ultraviolet light to the density of the carbon dioxide in the exhaust plume is calculated. Another measure of particulate content is the ratio of the particles in the exhaust whose diameter is greater than said predetermined wavelength of infrared light to the density of the carbon dioxide in the exhaust plume. The average size of the particles is calculated from the ratio of the particles whose diameter is greater than the predetermined wavelength of ultraviolet light to the particles whose diameter is greater that the predetermined wavelength of infrared light is calculated. The average particle size is determined from the Mie efficiency using Mie scattering and absorption theory.

Owner:ENVIROTEST SYST HLDG CORP

Living environment control system in coal mine underground movable lifesaving cabin

InactiveCN101825000AIncrease effective spaceReduce volumeSafety equipmentsAir cycleOperating instruction

The invention discloses a living environment control system in a coal mine underground movable lifesaving cabin, comprising a lift support system and an air-conditioning system, wherein the life support system is composed of an air circulating system, an air purification system and an oxygen regenerator; the air-conditioning system has a refrigerating system, a phase-change material cold accumulation system and a heat exchange system; and the invention has simple structure and convenient use, miners can enter into the cabin to start the living environment control system of the movable lifesaving cabin according to the requirements of operating instructions when a mining accident happens, and the lift support system adopts a proven aerospace and submarine oxygen regeneration principle to work stably and reliably. High pressure oxygen cylinder with explosion risk can be saved in the cabin, thus reducing the shockproof requirement on the cabin and greatly reducing the volume of a CO2 absorption device; and the refrigerating system in the air-conditioning system is characterized by adopting no transmission parts (vortex tube refrigeration) or less transmission parts (turbo-expander refrigerator) and having no power demand, thus avoiding depending on power in the traditional refrigeration mode.

Owner:HENAN UNIV OF URBAN CONSTR

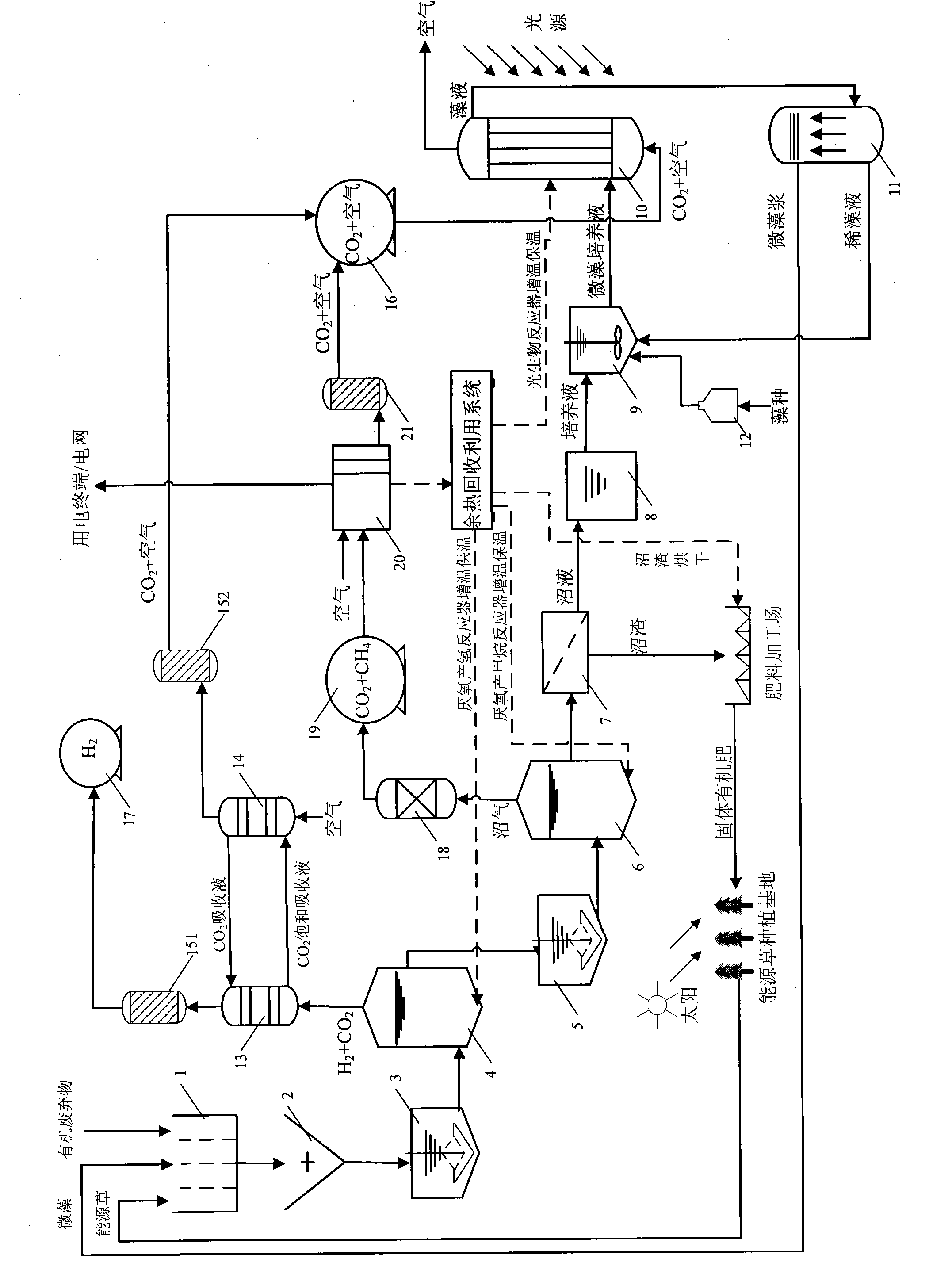

Energy utilization system of organic wastes with zero emission of carbon dioxide

ActiveCN101920258ARealize processingEliminate pollutionWaste processingSolid waste disposalSludgeCo2 absorption

The invention provides an energy utilization system of organic wastes with zero emission of carbon dioxide, which organically combines anaerobic fermentation hydrogen production, methane fermentation, CO2 absorption, microalgae fixation CO2, biogas liquid treatment and energy grass planting. The system is suitable for treating various types of organic wastes, can be applied to the treatment of agricultural organic wastes, industrial organic wastes, domestic organic wastes, slurry and the like, and the industries, such as new energy development. Through the application of the invention, the specific application demonstration of recycling economy can be carried out, clean energy is obtained while eliminating environmental pollution, no greenhouse gas emits in the process, and the triple effects of wastes treatment, production of clean and renewable energy sources and reduction of carbon dioxide emission can be realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

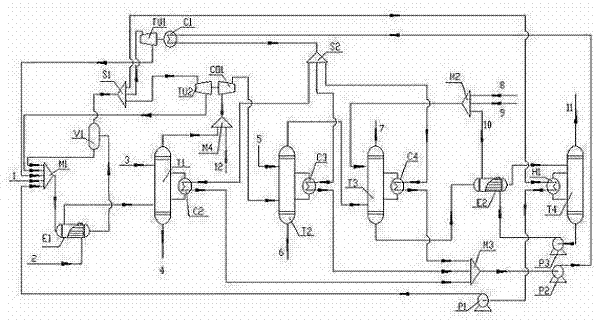

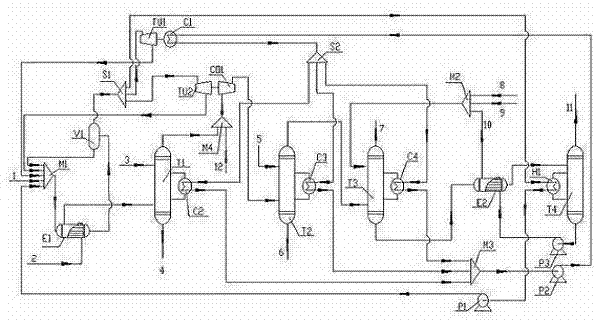

Process for removing acid gas from flue gas by using residual heat of flue gas

InactiveCN102343201AComply with energy saving requirementsLess integrated technology researchNitrous oxide captureGas treatmentSteam pressureCo2 absorption

The invention discloses a process for removing acid gas from flue gas by using residual heat of the flue gas. The process comprises the following steps of: introducing flue gas into a heat exchanger I; lowering the temperature of the flue gas; making the flue gas enter a desulfurizing-absorbing tower; heating and gasifying water in the tube pass of the heat exchanger and making the heated and gasified water enter a phase splitter; combining the heat exchanger and the phase splitter into a waste heat boiler, wherein the generated steam pressure is 3-6 Pa; partitioning the water steam into three streams for entering a low-pressure steam turbine I, a low-pressure steam turbine II and a heater respectively; driving the low-pressure steam turbine I with the water steam for supplying a power source to a refrigerator to obtain chilled water, wherein the chilled water is taken as cooling media of the desulfurizing-absorbing tower, a denitrifing-absorbing tower and CO2 absorbing tower respectively to keep the temperatures of the towers at respective needed temperatures; driving the low-pressure steam turbine II with the second stream of water steam; compressing desulfurized flue gas; making the desulfurized flue gas enter the denitrifing-absorbing tower to remove NOx and generate dilute nitric acid simultaneously; and supplying a heat source to a CO2 regeneration tower through a heater H1 by using the third stream of water steam to regenerate a CO2 absorption liquid, using the water steam circularly, and generating and collecting CO2 simultaneously.

Owner:NANJING UNIV

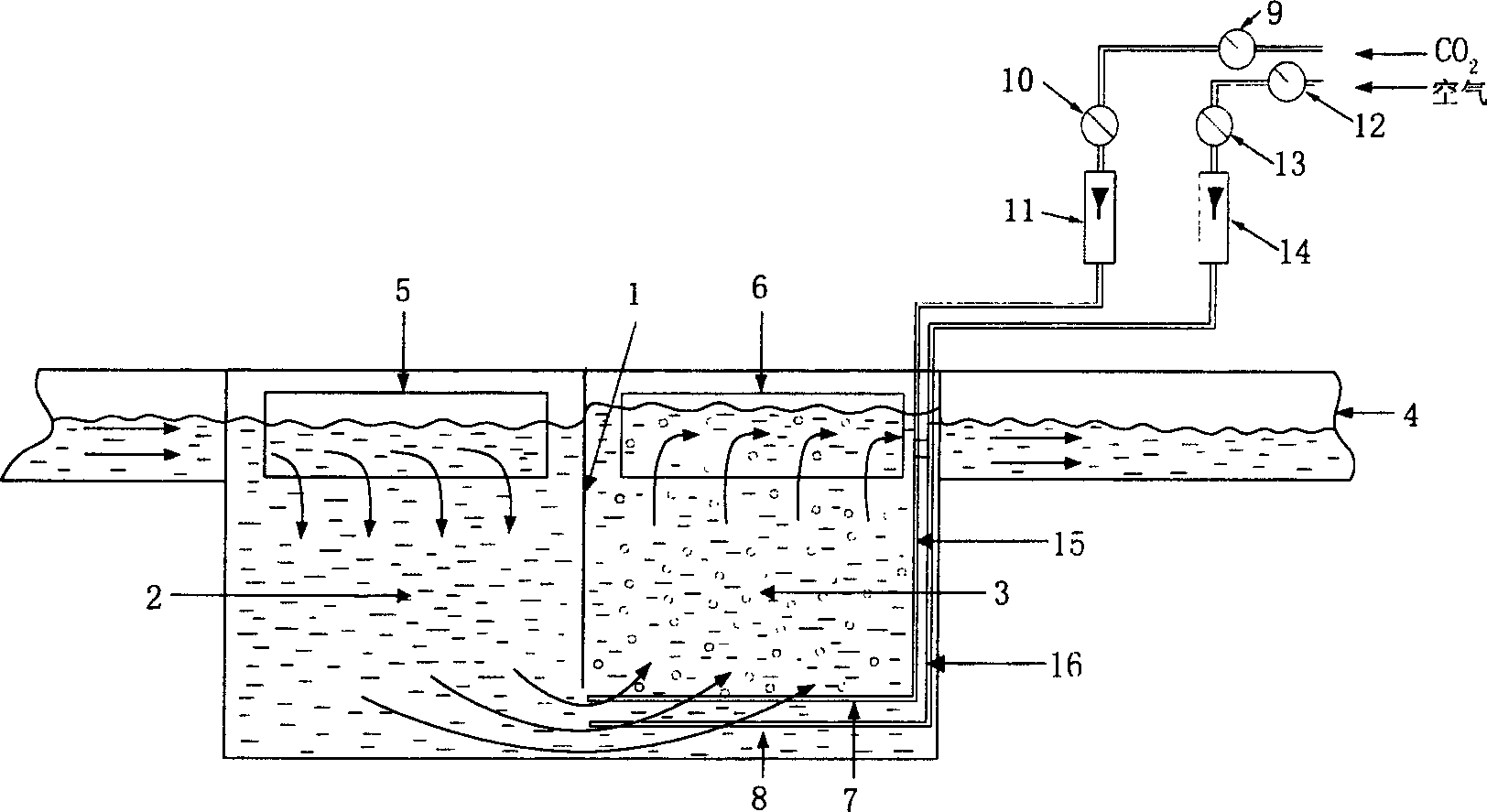

Arrangement for supplementing CO2 to micro-algae culture pond

InactiveCN1837350AImprove absorption and utilizationReduce consumptionUnicellular algaeRing cultureCo2 absorption

The invention discloses a carbon dioxide supplementary device of microalgae culture pond, which comprises the following parts: aerating groove area I, aerating groove area II, carbon dioxide aerating pipe, air aeration pipe, carbon dioxide supplying system, air supplying system and brack, wherein the aerating groove is next to the culture pond; the aerating groove area I connects the culture pond through channel as well as the aerating groove area II; one end of carbon dioxide aeration pipe connects the carbon dioxide supplying pipe; one end of air aeration pipe connects the air supplying pipe with a block of baffle in the aeration groove. The invention improves the carbon dioxide absorbance and utilizes the carbon dioxide effectively, which possesses obvious economical and environmental benefit.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

Select serving and flavored sparkling beverage maker system

A system with a beverage maker for making single serving customized beverages is provided herein. An example beverage maker includes a carbonation chamber for mixing a selected volume of fluid with carbon dioxide. The beverage maker also includes a pressurized carbon dioxide source in fluid communication with the carbonation chamber. The beverage maker is configured to receive an individually packed, single use disposable flavor cup containing a flavor and having a sealed cover that covers and seals the flavor cup. Additionally, the beverage maker includes a piercing mechanism for piercing the flavor cup and mixing the selected volume of fluid therein, and for discharging a blended fluid. The carbonation chamber comprises a pressure vessel assembly of a fixed volume such that carbon dioxide absorption can be performed and controlled. The system may also include a water dispenser fluidly connected to the beverage maker.

Owner:PRIMO PRODS

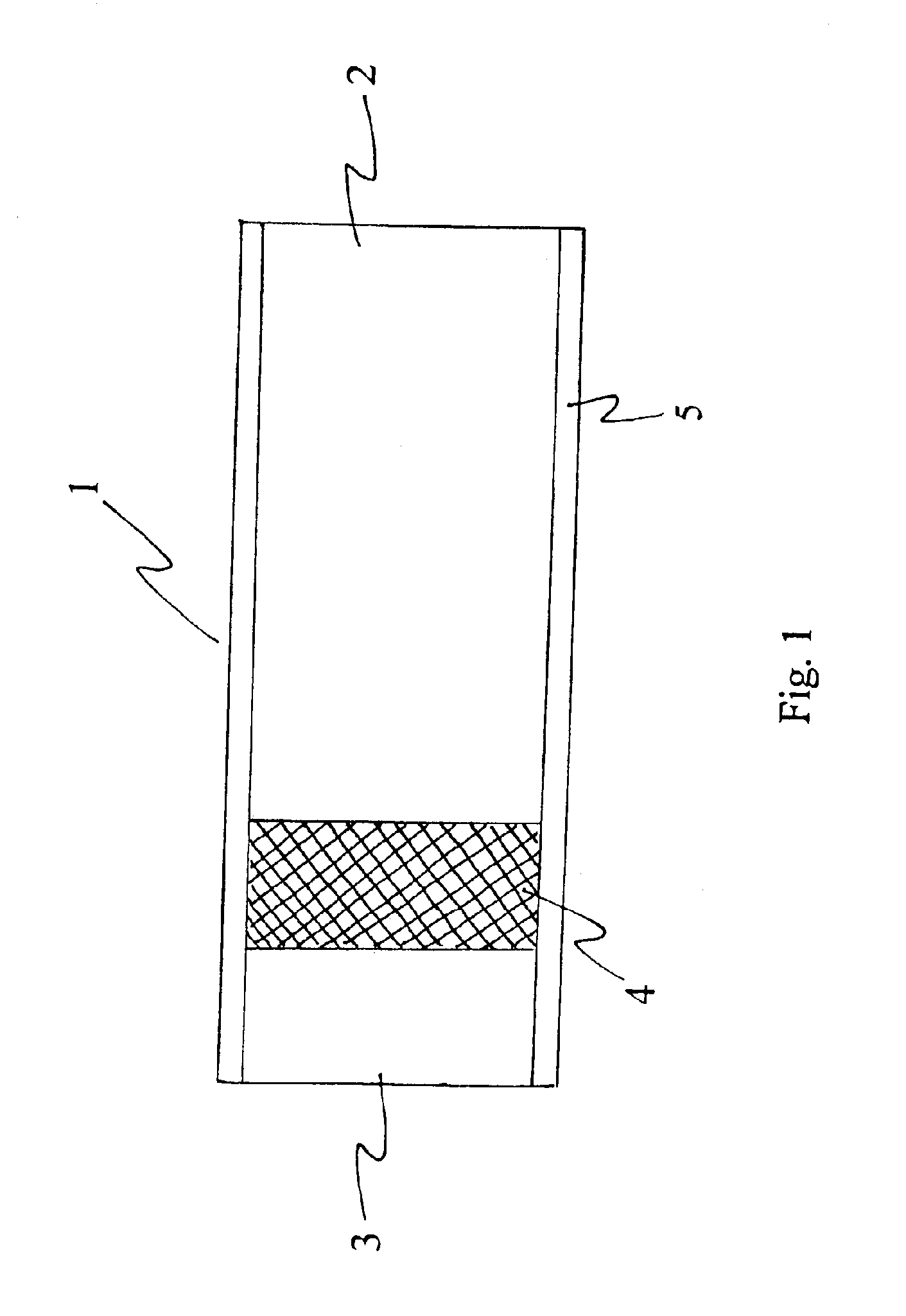

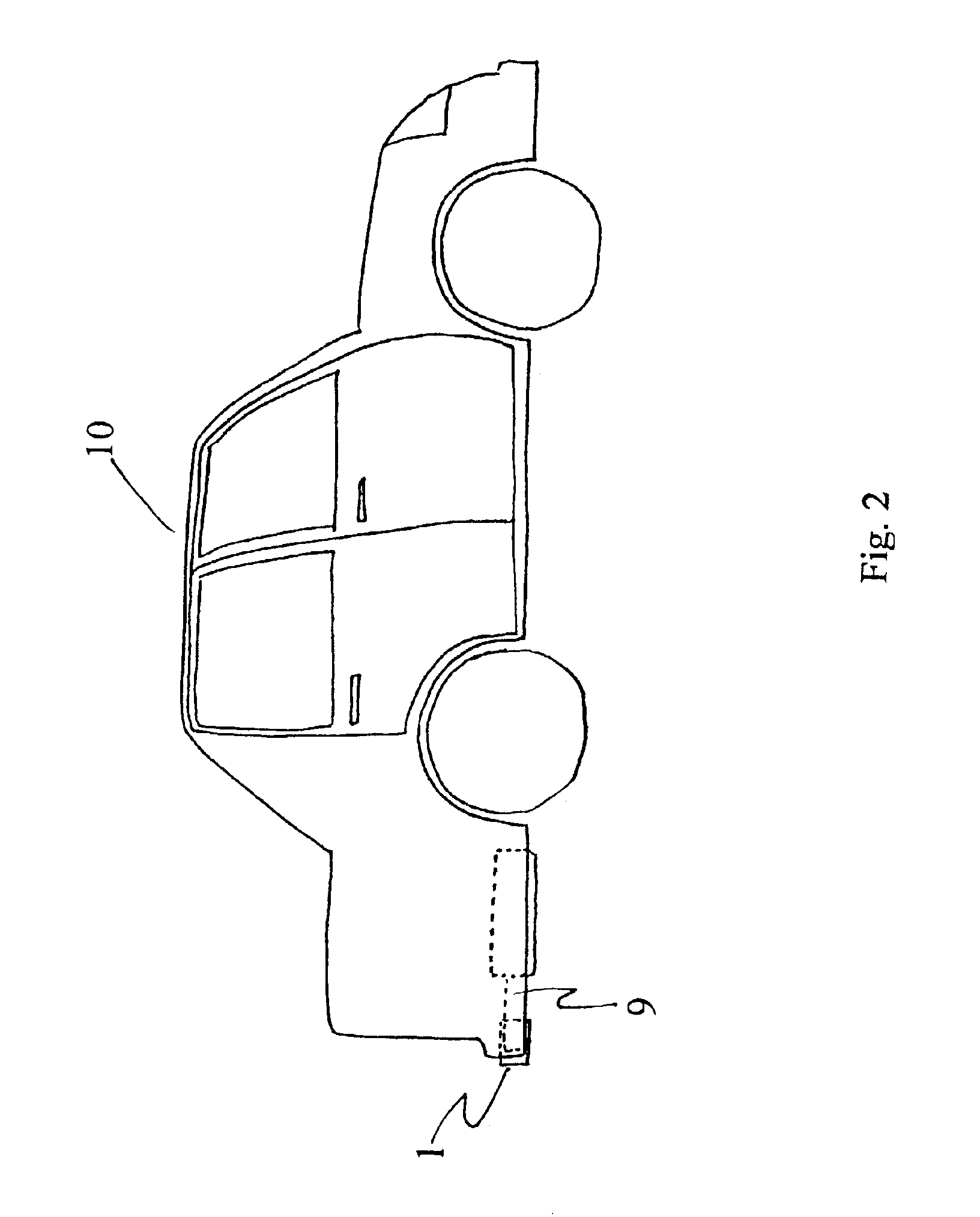

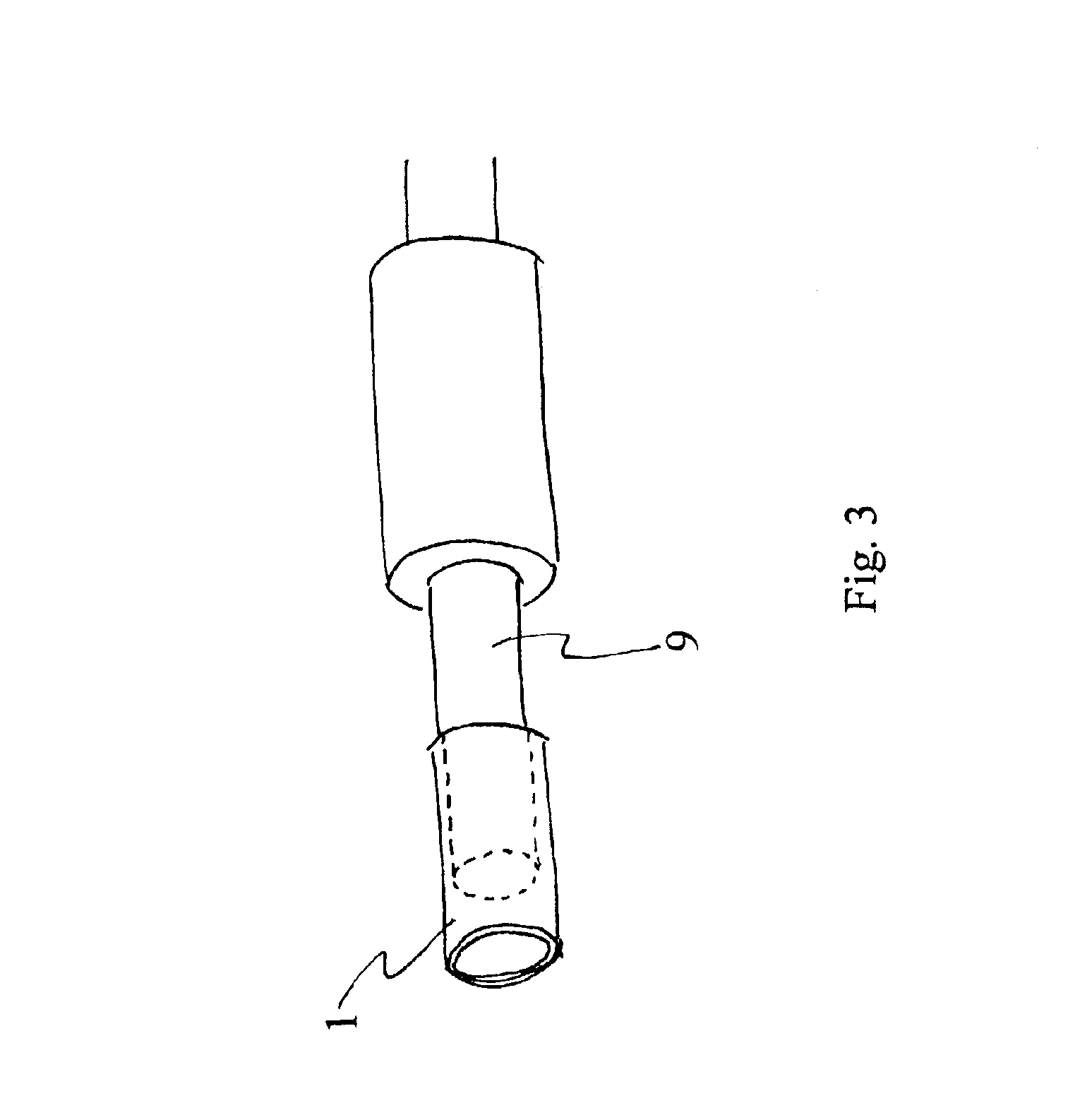

Device for absorbing carbon dioxide, and a method for absorbing carbon dioxide

The present invention relates to a device for absorbing carbon dioxide, which is equipped along an automobile exhaust pipe and a factory chimney. The present invention also relates to a method for absorbing carbon dioxide. According to the present invention, there is provided a device for absorbing carbon dioxide, comprising a housing 4 of a material having air permeability; a cement composition for absorbing carbon dioxide, enclosed inside the housing 4; and a pipe 5 across the housing, the pipe having an inlet 2 and an outlet 3. According to the present invention, when a gas is introduced from the inlet 2, carbon dioxide in the gas is absorbed by the carbon dioxide absorbing materials such as a cement composition enclosed in the housing 4. The gas is discharged from the outlet 3.

Owner:INT ENVIRONMENTAL CONSERVATIVE ASSOC

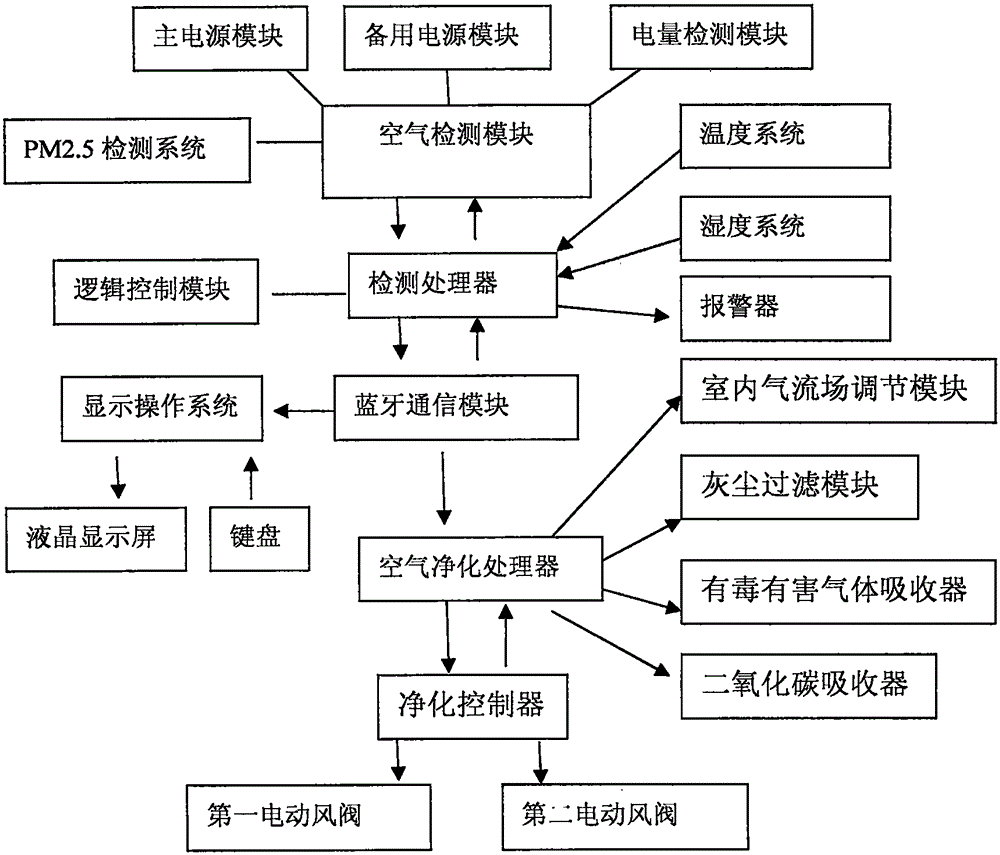

Multifunctional indoor air purification and detection system

InactiveCN105066337ANon-stop workAccurate detectionMechanical apparatusSpace heating and ventilation safety systemsCo2 absorptionEngineering

The invention relates to a multifunctional indoor air purification and detection system. The multifunctional indoor air purification and detection system comprises an air detection module, a detection processor, an air purification processor, a Bluetooth communication module, a logic control module and a display operating system. Three systems are adopted by the air detection system for detecting a first PM 2.5 content value outdoors, a second PM 2.5 content value at an indoor air inlet and a third PM 2.5 content value at an indoor air outlet respectively. The air purification processor is connected with an indoor airflow field conditioning module, a dust filtering module, a hazardous gas absorber, a carbon dioxide absorber and a purification controller. According to the multifunctional indoor air purification and detection system, the categories of pollutants can be detected, and if the concentration of various pollutants exceeds the national standard, different draught fans are hierarchically driven to achieve segmental purification; multiple types of air detection modules are integrated, so that the system size is reduced, indoor air can be detected accurately and indoor detection cost is reduced.

Owner:YANCHENG INST OF TECH

Method and device for preparing methionine and recovering by-product-carbon dioxide

ActiveCN105671587ARealize cleaner productionReduce energy consumptionElectrolysis componentsElectrolytic organic productionHydantoin derivativesCo2 absorption

The invention discloses a method for preparing methionine and recovering a by-product-carbon dioxide. The method comprises the steps that a methionine salt and carbonate mixed solution obtained by hydrolyzing methylmercapto-ethyl hydantoin with alkali is filtered through a microporous membrane, and then filtrate is delivered to a bipolar membrane electrodialysis system to be subjected to electrodialysis treatment, so that acid liquor A and alkali liquor A are obtained; the alkali liquor A is treated continuously and cyclically, and the acid liquor A is subjected to gas-liquid separation, so that gaseous carbon dioxide and acid liquor B are obtained; the acid liquor B is delivered back into the bipolar membrane electrodialysis system to be subjected to cyclic treatment till the pH value of the acid liquor B is 3.8-4.5, the reaction is completed, a methionine solution is prepared, and the methionine is prepared through concentration and crystallization of the methionine solution; the gaseous carbon dioxide is introduced into an absorption cell, and carbon dioxide on the upper portion of the absorption cell absorbs mother liquor, is subjected to membrane distillation and concentration and then is circulated back to the absorption cell; carbonate crystals are grown at the bottom of the absorption cell and guided out from the bottom of the absorption cell; and carbonate is recovered through solid-liquid separation. According to the method for preparing the methionine and recovering the by-product-carbon dioxide, the gaseous carbon dioxide is recycled, so that carbon emission is reduced, and energy resources are saved through the membrane distillation technique.

Owner:浙江佰辰低碳科技有限公司

Carbon dioxide recovery and power generation

ActiveUS7488463B2Preventing reduction in turbine outputReduce outputCombination devicesCarbon compoundsCombustionCo2 absorption

Owner:THE KANSAI ELECTRIC POWER CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com