Patents

Literature

266 results about "Nickel–lithium battery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The nickel–lithium battery, also known as Ni–Li, is an experimental battery using a nickel hydroxide cathode and lithium anode. The two metals cannot normally be used together in a battery, as there are no electrolytes compatible with both. The LISICON design uses a layer of porous glass to separate two electrolytes in contact with each metal. The battery is predicted to hold more than three and a half times as much energy per pound as lithium-ion batteries, and to be safer. However, the battery will be complex to manufacture and durability issues have yet to be resolved.

Method for improving environmental stability of cathode materials for lithium batteries

InactiveUS20090194747A1Good environmental stabilityQuality improvementConductive materialElectrode collector coatingCo2 absorptionNickel–lithium battery

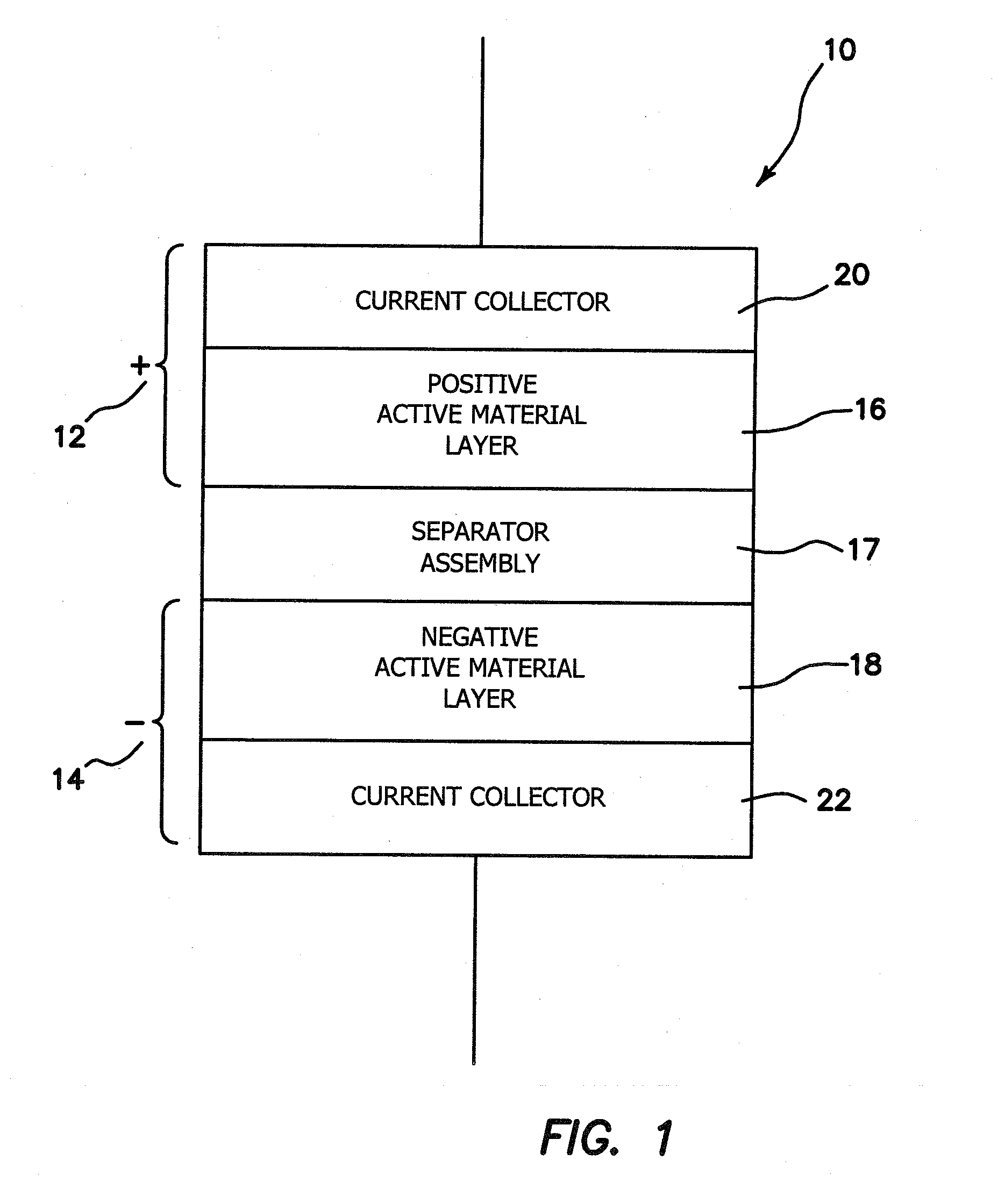

A method for improving the environmental stability of cathode materials used in lithium-based batteries. Most currently used cathode active materials are acutely sensitive to environmental conditions, e.g. leading to moisture and CO2 pickup, that cause problems for material handling especially during electrode preparation and to gassing during charge and discharge cycles. Binder materials used for making cathodes, such as PVDF and PTFE, are mixed with and / or coated on the cathode materials to improve the environmental sensitivity of the cathode materials.

Owner:TIAX LLC

Solid electrolyte material system for all solid state lithium battery and preparation method

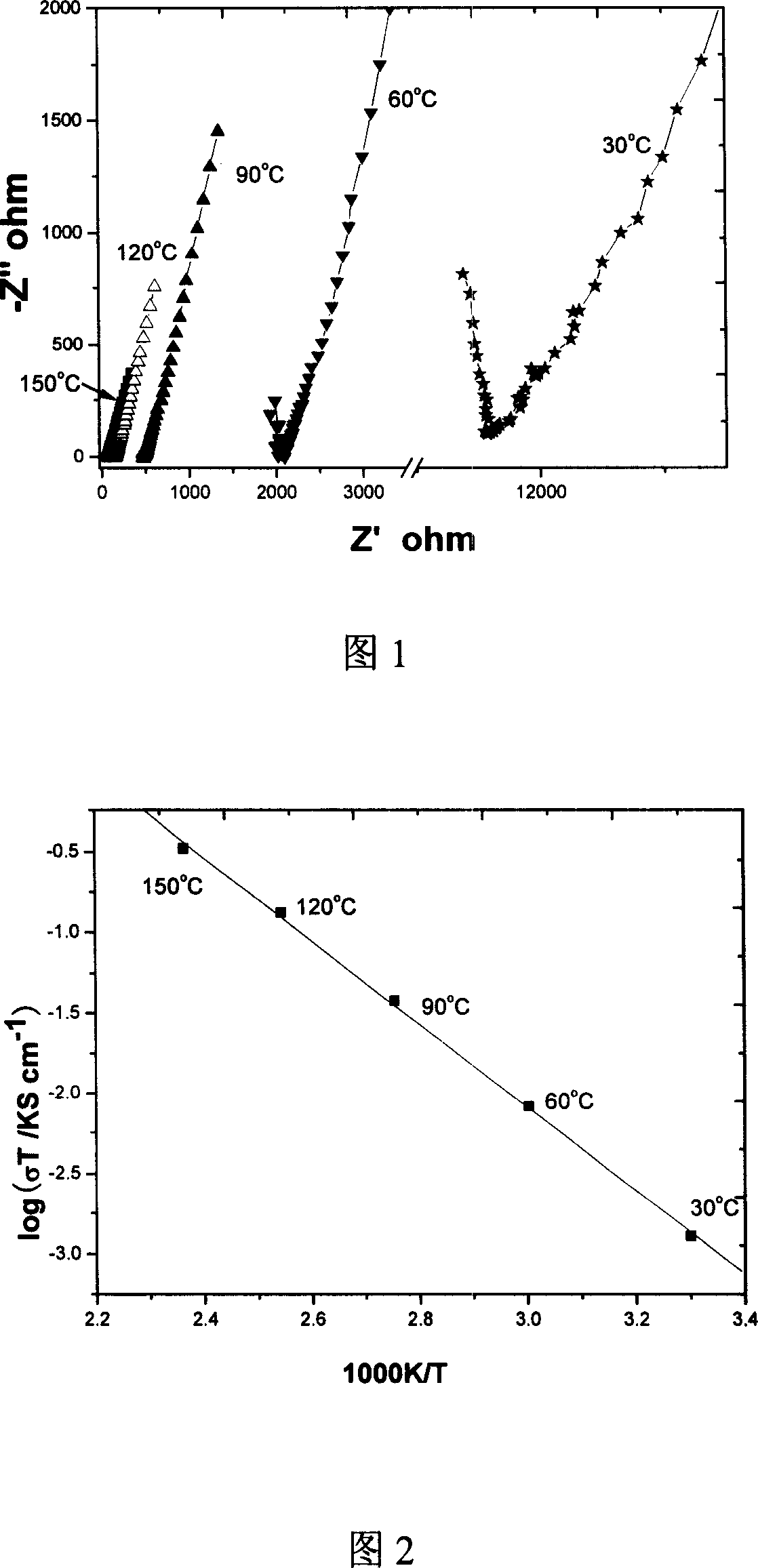

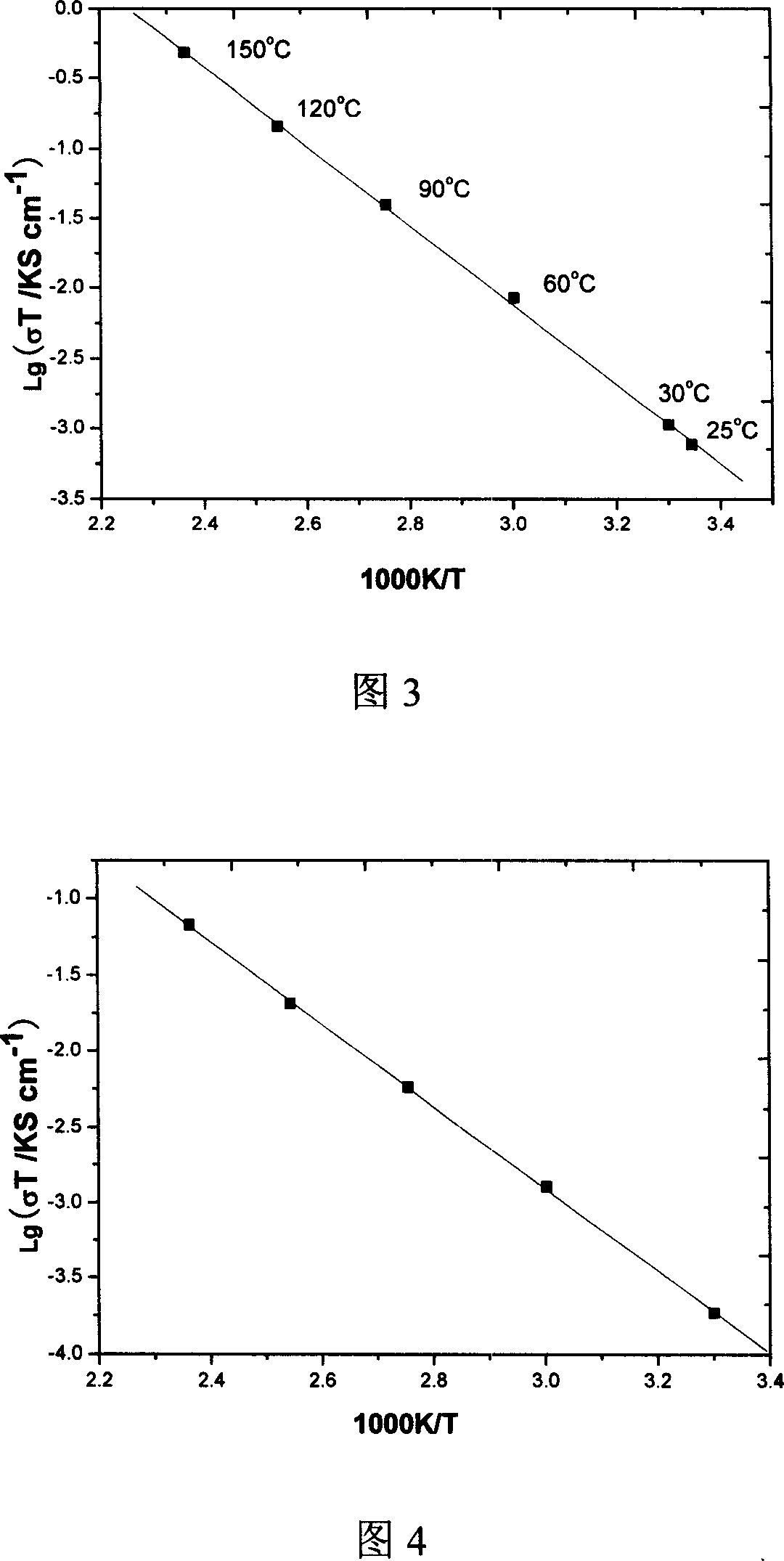

ActiveCN101013761AImprove conductivityImprove ionic conductivitySolid electrolyte cellsChemical/physical/physico-chemical processesCrystal systemAll solid state

The invention relates to one solid electrolyte materials and its process method for fix lithium battery, which is characterized by the following: Li2S and other sulfur compound B / S and A / I according to certain mole proportion for compounds to form non-crystal system to provide space for lithium ion transmission to get higher ion conductive rate, wherein, the materials have wider heat stable range to provide one ideal electrolyte prepare materials for solid lithium ion battery.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Lithium element supplementing method for electrode of lithium ion battery

InactiveCN103943825AImprove discharge capacityEasy to scale applicationCell electrodesSecondary cellsElectrical batteryNickel–lithium battery

The invention aims at providing a method for supplementing lithium element in a new lithium ion battery. A liquid solution method is used for supplementing lithium for an electrode which needs to supplement with lithium element, and the lithium element supplementing method has better process feasibility. The method comprises the following steps: preparing a solvent which can dissolve metal lithium, and dissolving the metal lithium to form a lithium solution; enabling an electrode sheet to be in full contact with the lithium solution and enabling the lithium solution to infiltrate into the electrode; removing the solvent in the electrode sheet to obtain the electrode sheet after lithium supplementation. By adopting the method provided by the invention, the lithium element can be added into the electrode sheet, and the discharge capacity of the lithium ion battery assembled by the electrode can be improved.

Owner:徐兆清

Negative pole piece for lithium battery, preparation method of negative pole piece and lithium battery with negative pole piece

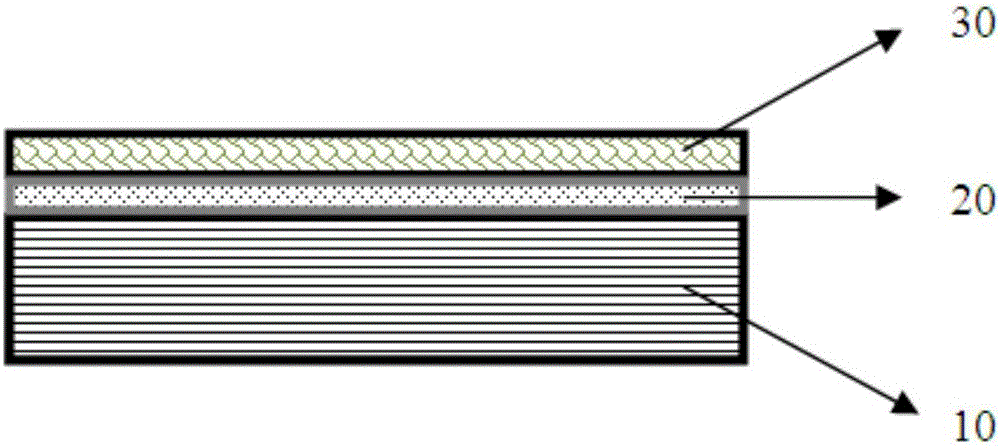

InactiveCN103022413AEvenly dispersedEffectively place the peelLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrical batteryNickel–lithium battery

The invention belongs to the technical field of lithium batteries, and in particular relates to a negative pole piece for a lithium battery. The negative pole piece comprises a current collector and a graphitic layer arranged on the current collector, and further comprises a protecting layer and a metal lithium layer, wherein the protecting layer is arranged on the graphitic layer; and the metal lithium layer is arranged on the protecting layer. Compared with the prior art, the negative pole piece is provided with the protecting layer on the surface of the graphitic layer, and the metal lithium layer on the surface of the protecting layer, when the negative pole piece is assembled into the lithium battery, metal lithium powder diffuses in the negative pole piece in an electrochemical manner, so that the first time efficiency of a negative pole is improved, and moreover, the energy density of the lithium battery is increased, and the capacity of the lithium battery is enhanced; and at the same time, the protecting layer is equivalent to a buffer layer which can effectively prevent the graphitic layer from internally peeling off, so that the stability of an SEI (Solid Electrolyte Interphase) membrane on the surface of the negative pole piece is improved, and the circulation performance of the battery is improved. In addition, the invention also discloses a preparation method of the negative pole piece and a lithium battery with the negative pole piece.

Owner:DONGGUAN AMPEREX TECH

Resource recycling method of waste battery cathode materials

InactiveCN106328927ALow costIncrease capacityCell electrodesWaste accumulators reclaimingRecovery methodElectric capacity

The invention relates to a resource recycling method of waste battery cathode materials. The resource recycling method comprises the following steps: performing high-temperature calcinating to the waste battery cathode materials so as to separate active powder in the cathode materials from aluminum foil; dissolving the obtained active powder into acid solution, and then filtering to obtain filtrate; determining the concentration of metal ions in the filtrate, and correspondingly supplementing nickel and / or cobalt and / or manganese ions into the solution, so that the molar concentration ratio of nickel, cobalt and manganese ions is 1:1:1; adding sodium hydroxide into the prepared nickel, cobalt and manganese mixture solution, and heating to lead the nickel, cobalt and manganese ions to be co-precipitated, then filtering the precipitate and washing and drying to obtain a nickel-cobalt-manganese precursor; adding sodium carbonate into the filtrate obtained in the step IV, and reacting to obtain lithium carbonate precipitate, filtering, washing and drying the lithium carbonate precipitate, to obtain lithium carbonate powder; and mixing the nickel-cobalt-manganese precursor with the lithium carbonate powder, and calcinating to obtain the lithium nickel cobalt manganese cathode materials. A ternary cathode material is prepared by resource recycling ofvarious battery materials, and batteries produced from the ternary cathode material are lower in cost, higher in electric capacity and better in performance compared with single cobalt-lithium batteries, manganese-lithium batteries and nickel-lithium batteries.

Owner:王剑

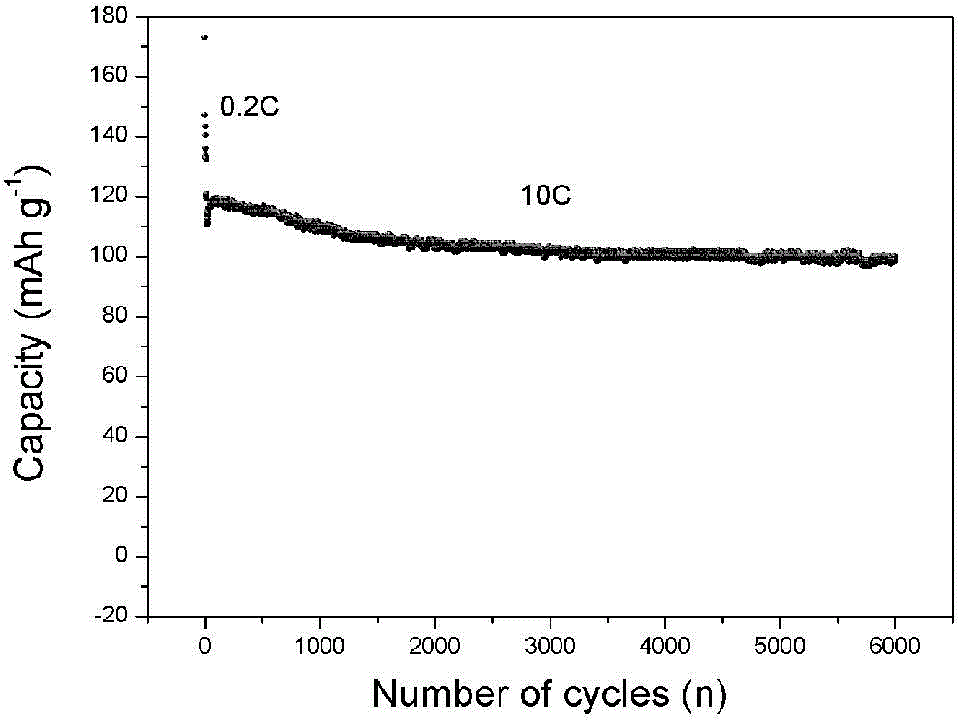

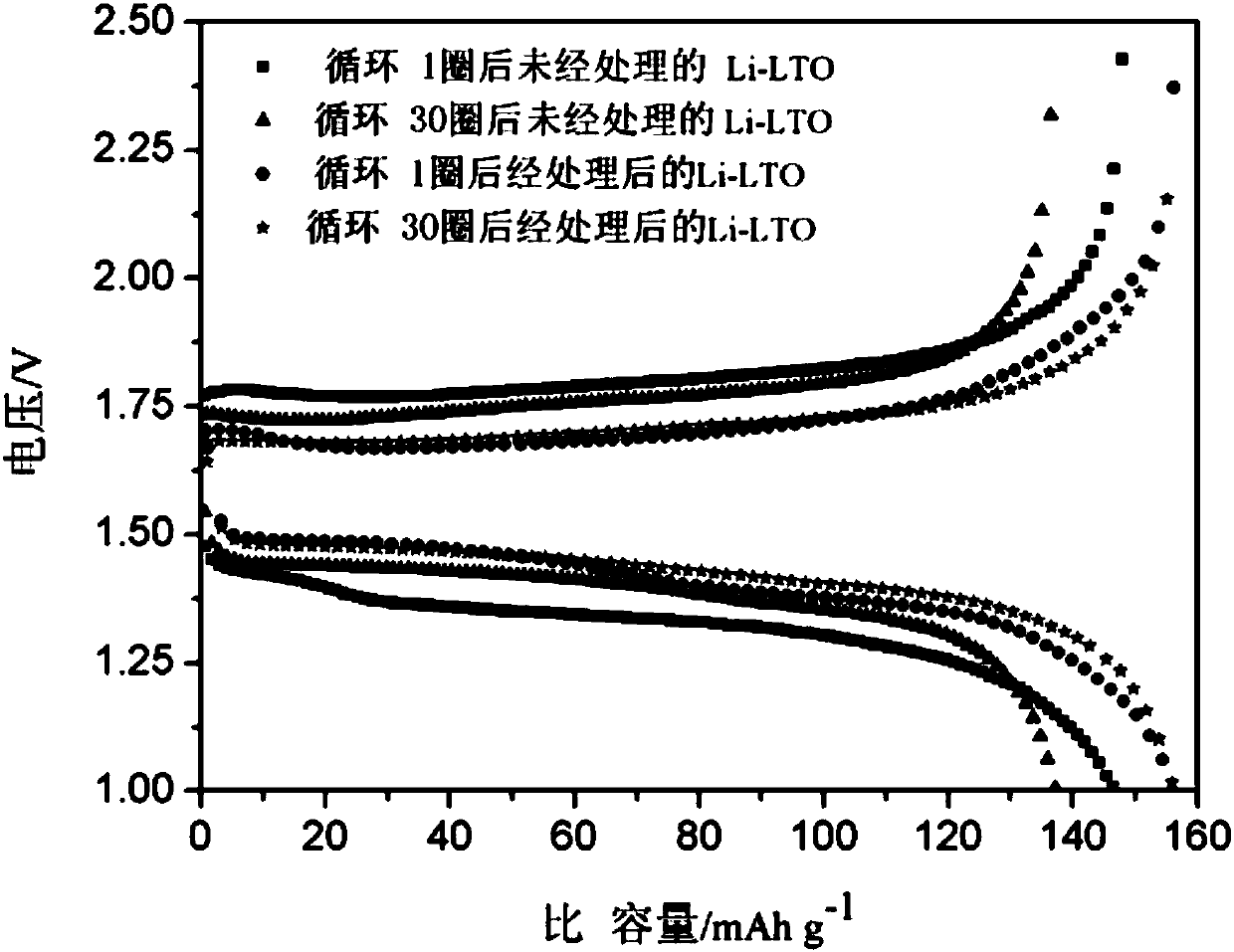

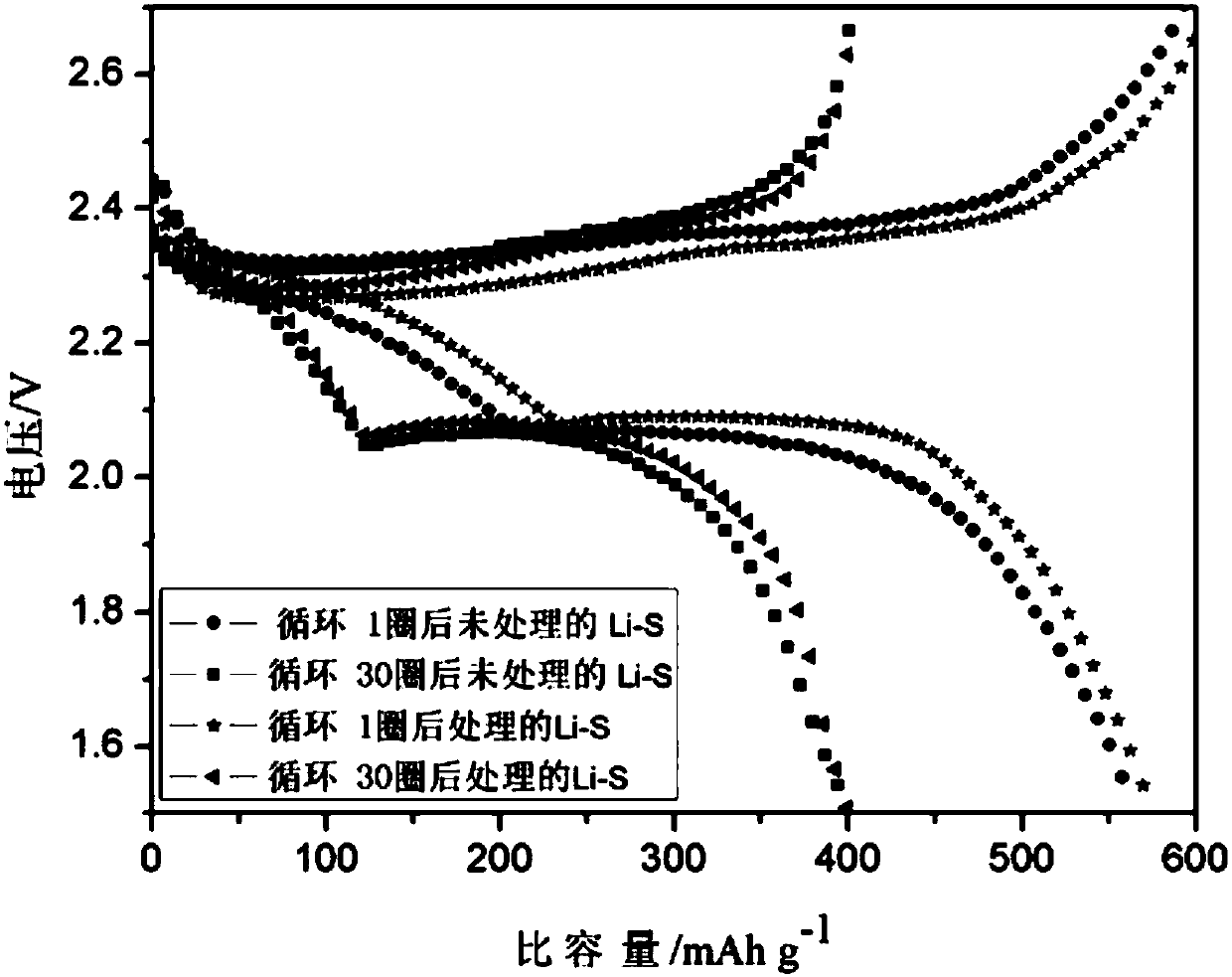

Method for solving flatulence of lithium titanate cathode of lithium battery by using double-boundary wrapping

ActiveCN103187562AImprove cycle stabilityImprove cycle lifeCell electrodesNickel–lithium batteryFlatulence

The invention relates to a method for solving flatulence of a lithium titanate cathode of a lithium battery by using double-boundary wrapping, and belongs to the technical field of energy materials. The method is characterized in that firstly, boundary stabilizing layer wrapping is carried out on a nitride of a lithium titanate cathode material, so as to establish an electrochemistry stable boundary between an electrode material and electrolyte, and subsequently hydrophobic surface layer wrapping is carried out by adopting a nitrogen-containing compound so as to establish a hydrophobic electrode boundary and prevent the crystal water in the electrode material from entering electrolyte; and at the same time the trace moisture of an electrolyte system is prevented from diffusing to the electrode boundary to cause catalysis reaction, and the electrolyte is prevented from decomposing to generate gas in the charging and discharging process, so that the problem that a lithium ion battery is swelled is solved, and the circulation service life of the battery is prolonged.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Solid electrolyte material for lithium battery and preparation method and application of solid electrolyte material

InactiveCN106532112ASimple methodSimple post-processingSolid electrolytesFuel and secondary cellsSolid state electrolyteHeat stability

The invention discloses a solid electrolyte material for a lithium battery and a preparation method and application of the solid electrolyte material, and belongs to the field of energy material preparation. The solid electrolyte material comprises a metal organic framework compound, a lithium salt, a film-forming additive and a filling. The solid electrolyte material for the lithium battery does not need polyoxyethylene or a derivative thereof; and compared with other inorganic solid electrolytes, the solid electrolyte material has the advantages of higher lithium ion containing capability, higher ionic conductivity and better heat stability, and the security of the battery can be greatly improved. The lithium-ion all-solid-state battery prepared by the method has the electrochemical properties equivalent to a liquid electrolyte. The solid electrolyte material for the lithium battery can be used for a lithium-ion battery, can be suitable for the systems of a lithium-sulfur battery, a lithium-air battery and the like, and is wide in application.

Owner:XIAMEN UNIV

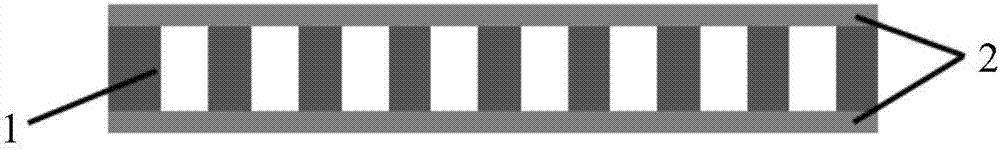

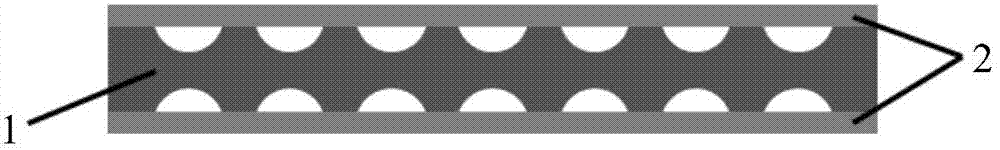

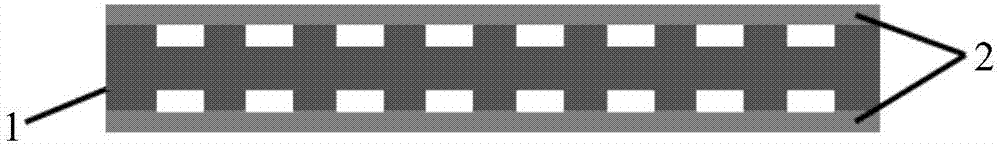

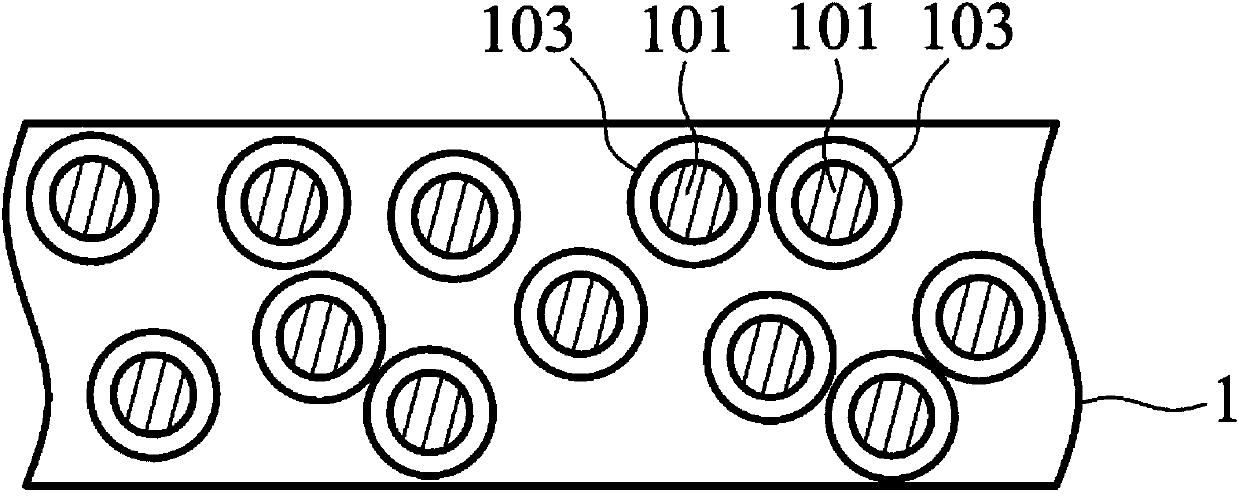

Negative plate, preparation method thereof and lithium battery

InactiveCN107482224AHigh specific surface areaIncrease energy densityElectrode carriers/collectorsSecondary cellsElectrical batteryNickel–lithium battery

The invention provides a negative plate, a preparation method thereof and a lithium battery. The negative plate comprises a current collector, wherein the current collector is copper with a hole structure, and a protective layer is arranged on the surface of the current collector. Copper with the hole structure is taken as the current collector of the negative plate, so that inside space of the current collector can serve as lithium storage space for storing lithium precipitated in a battery charging process, meanwhile, lithium metal precipitates between the copper current collector and the protective layer by means of the inorganic protective film on the surface of the current collector, and production of lithium dendrites is inhibited. Compared with a common lithium ion battery with a graphite cathode, a lithium secondary battery provided with the lithium-free negative plate has the advantage that the energy density of the lithium battery can be improved substantially under the precondition that higher safety performance and better cycle performance are guaranteed.

Owner:ZHUHAI COSMX BATTERY CO LTD

Lithium cathode used for lithium battery and provided with sandwich structure and preparation method thereof

ActiveCN106340616AImprove protectionUniform growthSecondary cellsNegative electrodesCyclic processNickel–lithium battery

The invention discloses a lithium cathode used for a lithium battery and provided with a sandwich structure and a preparation method thereof. The lithium cathode is provided with the sandwich structure formed by a conductive current collector, a metal lithium layer and a high polymer material layer. The method for preparing the lithium cathode comprises a first step of preparing an electrode precursor by compounding a high polymer material and the conductive current collector; and a second step of causing metal lithium to enter an intermediate layer of the electrode precursor to form the lithium cathode with the sandwich structure. By introduction of the high polymer material as a protective layer, growth of metal lithium dendrites can be inhibited, the safety of the lithium battery is improved, the volume expansion in the lithium battery cyclic process can be adapted, and an effect of stabilizing an interface is achieved. In addition, the conductive high polymer material can form a conductive network on the surface of the lithium cathode, lithium ions are induced to be deposited evenly, and a buffer effect on the lithium ions can also be achieved under the conditions of high-current charging and discharging. The method is simple to operate, low in cost, has easiness in large-scale production and has great potential application values in the lithium battery.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

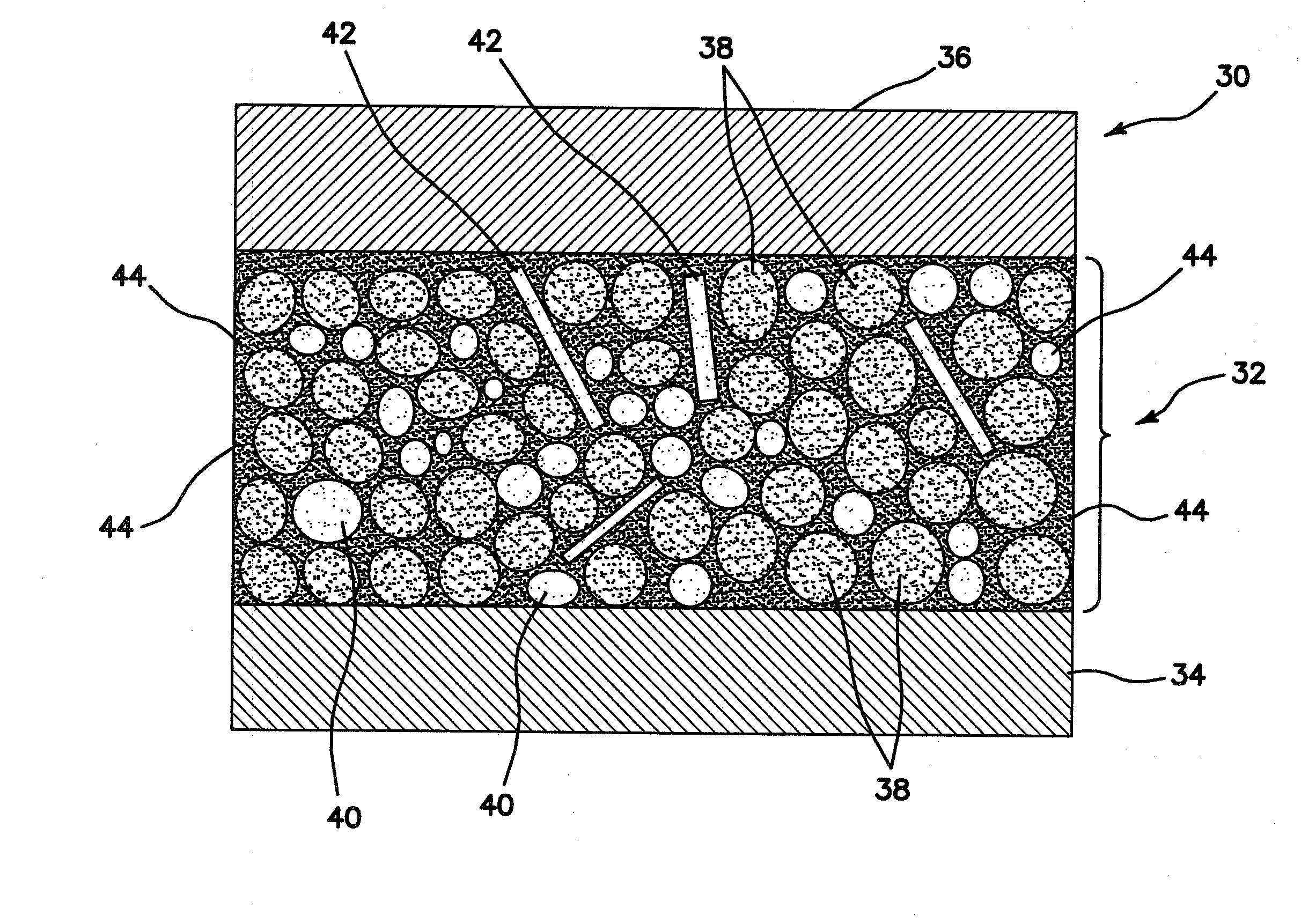

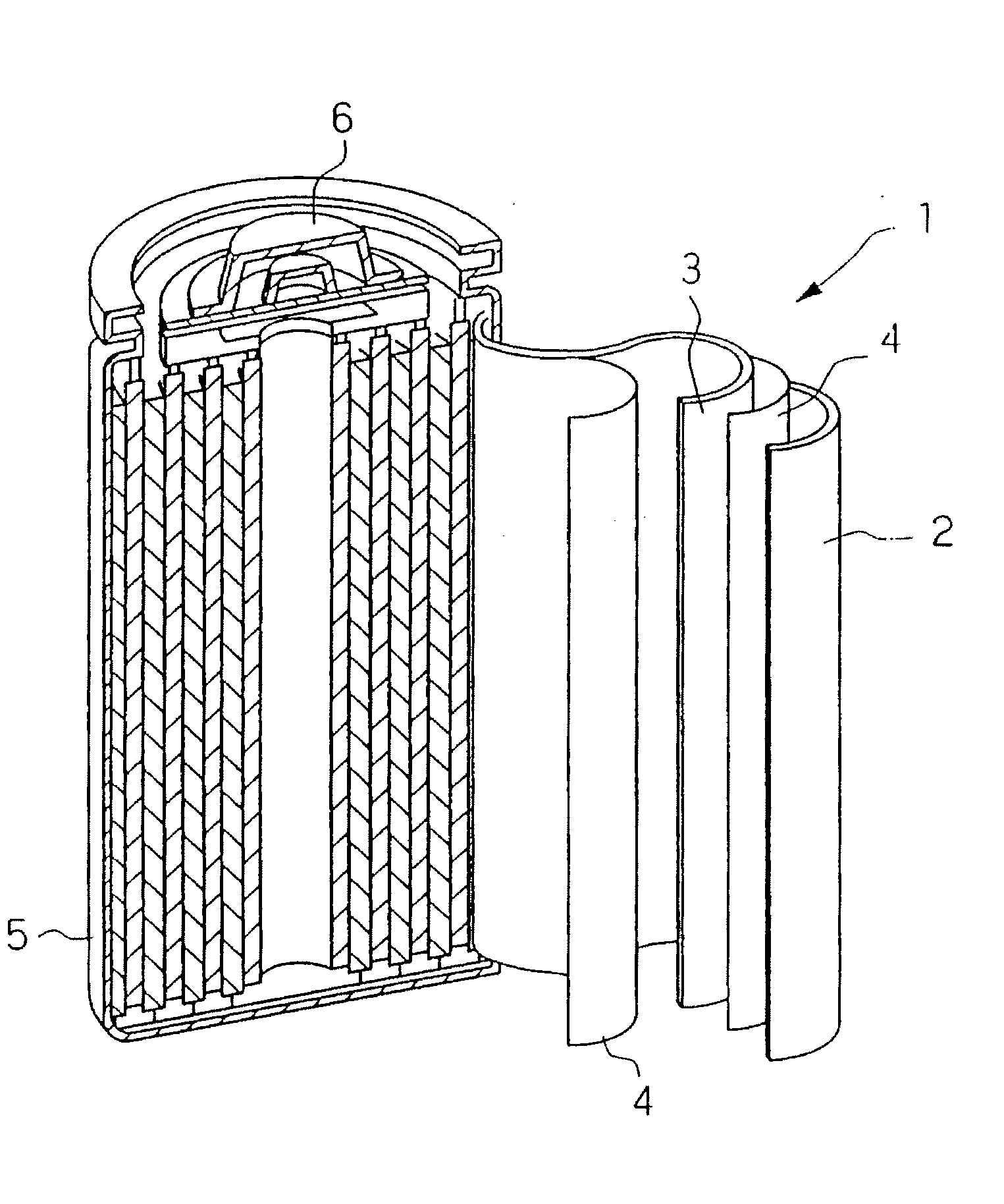

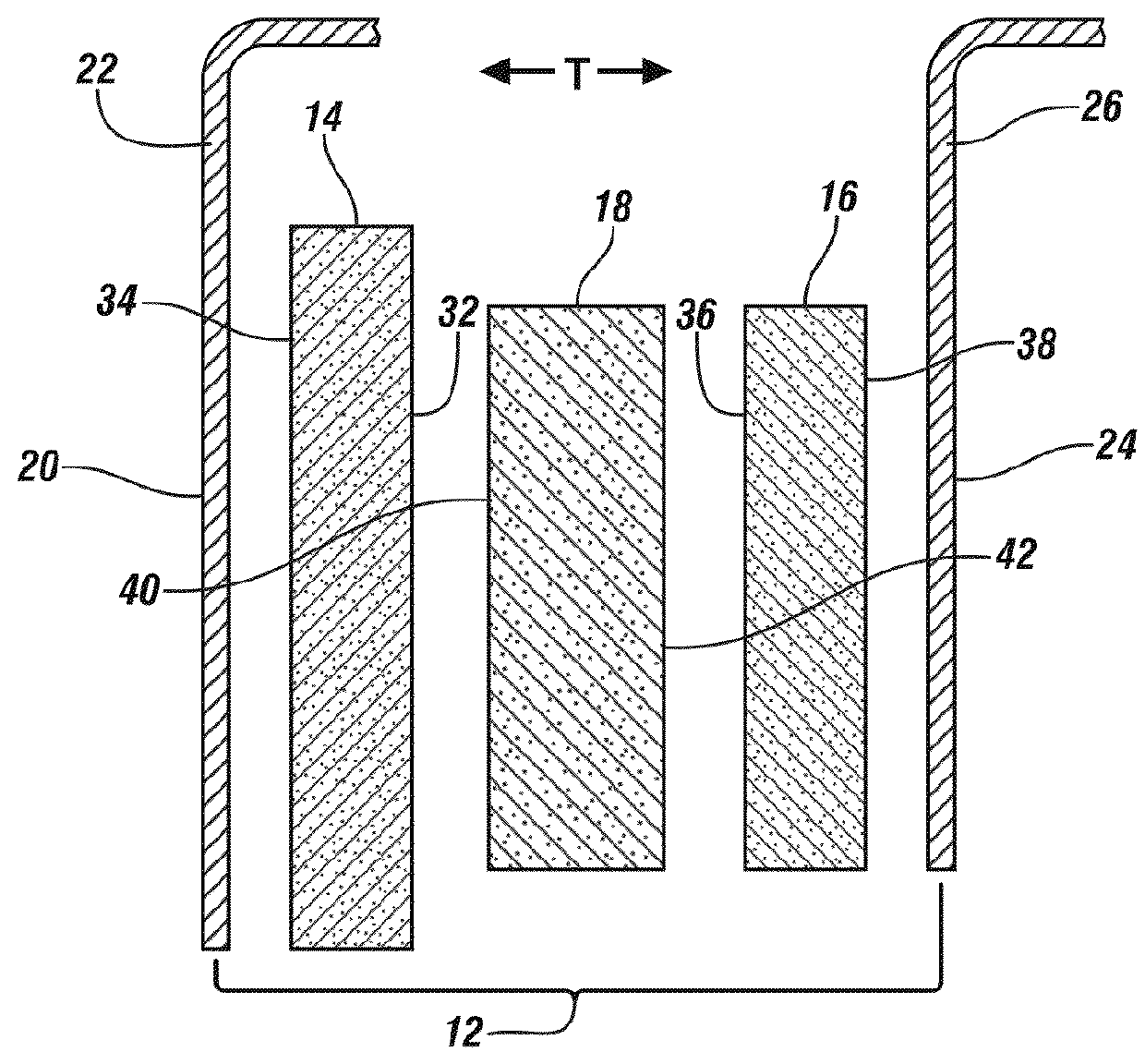

Enhanced Electrolyte Percolation in Lithium Ion Batteries

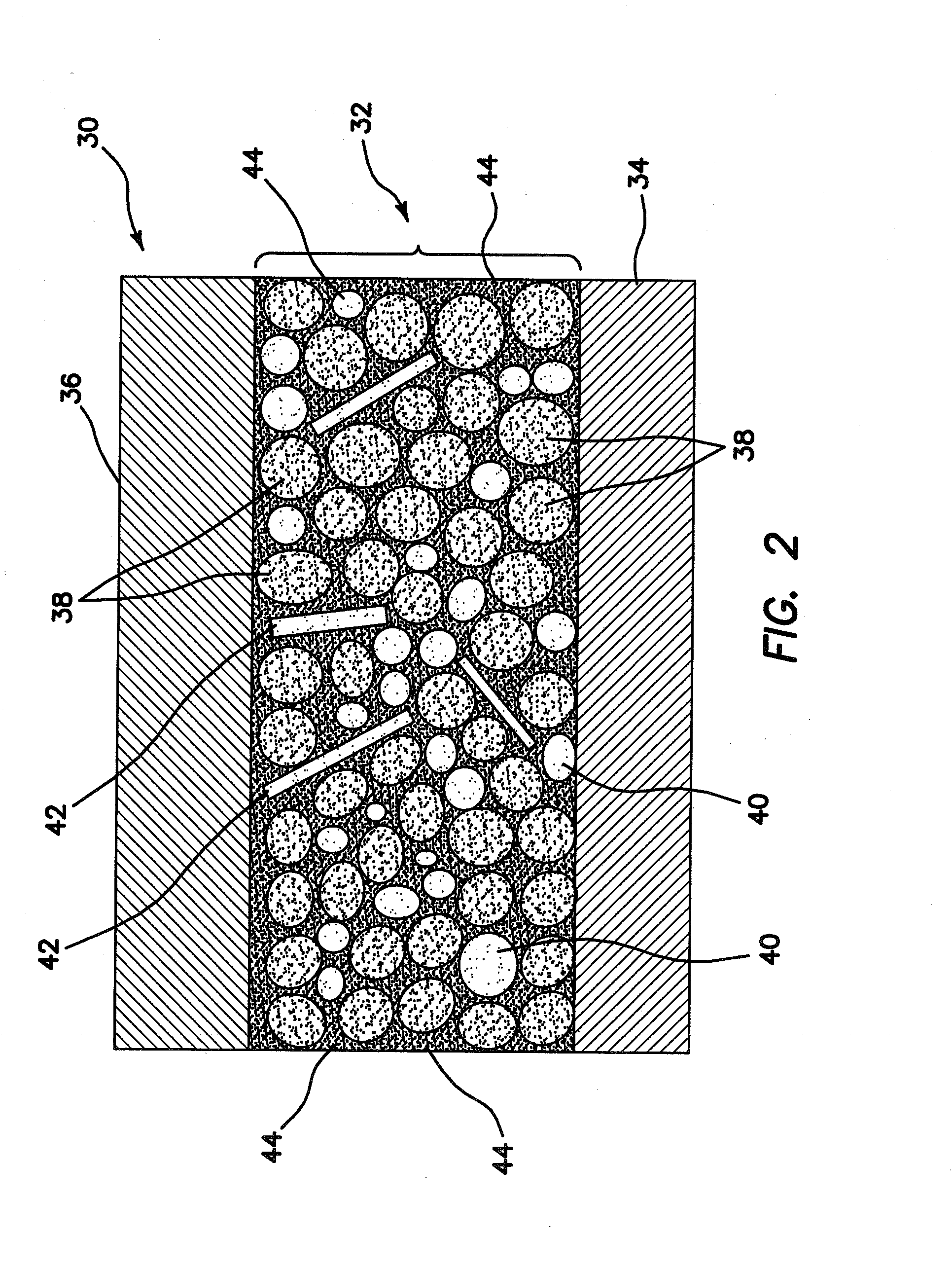

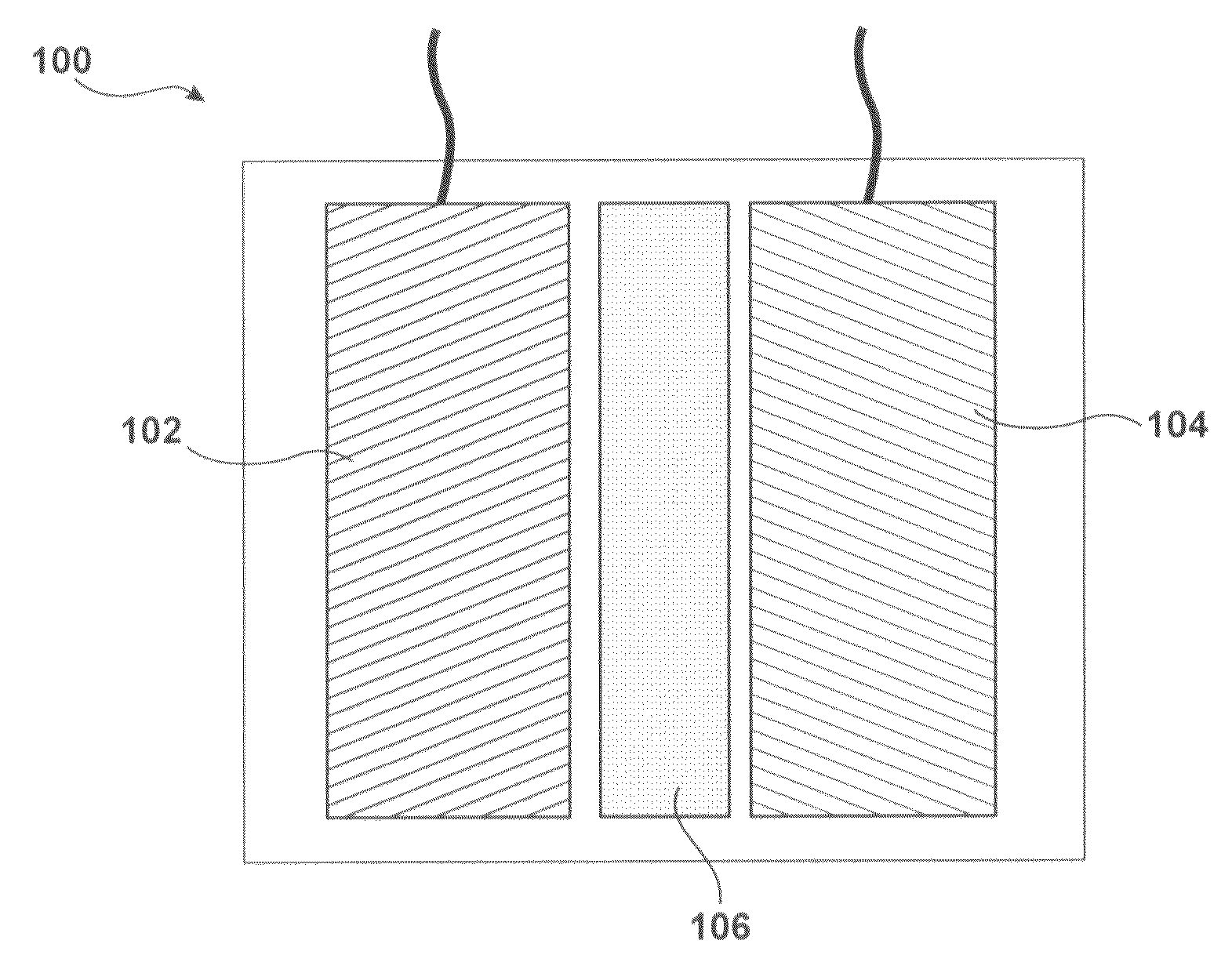

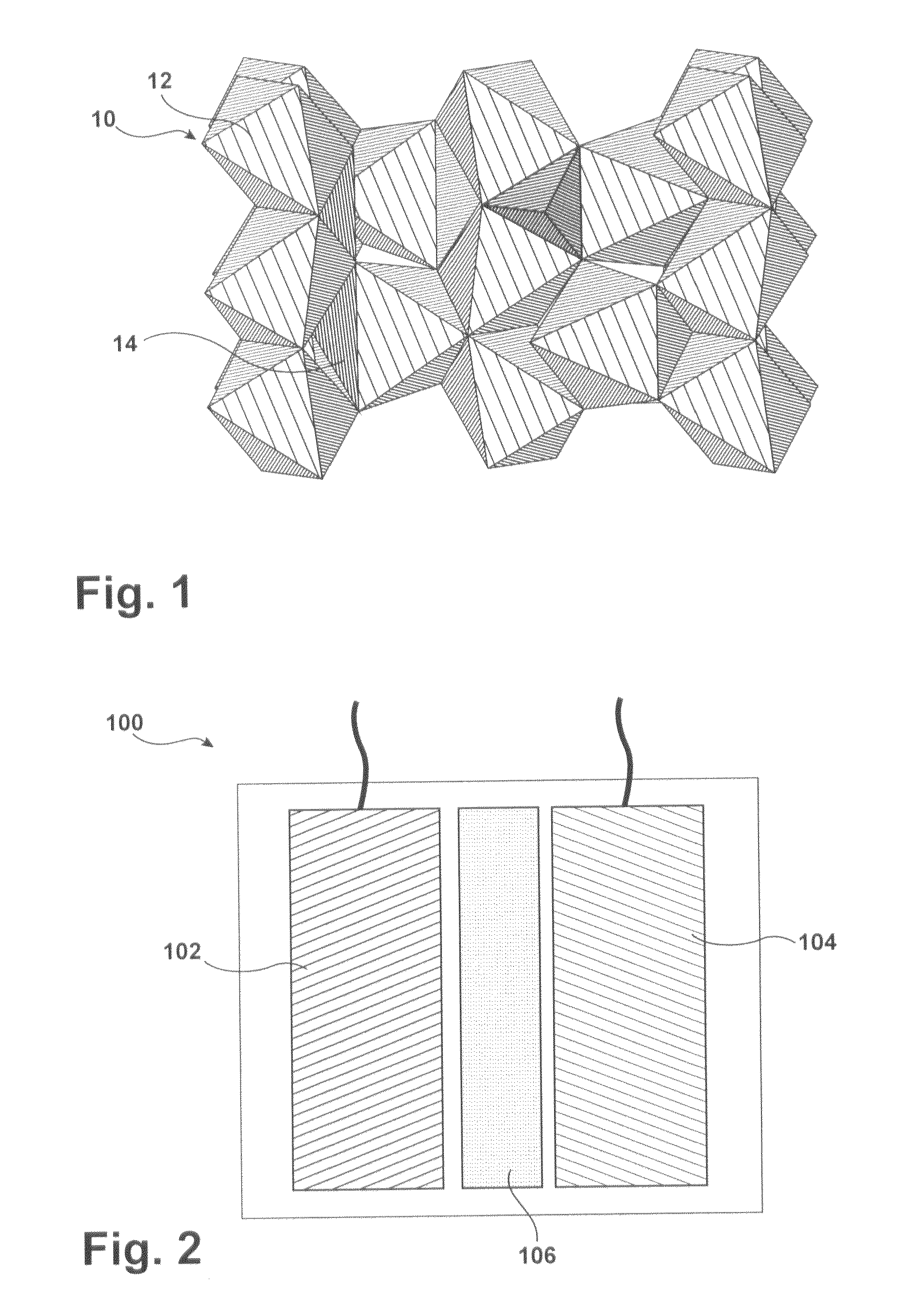

InactiveUS20100035141A1High porosityImprove abilitiesCell seperators/membranes/diaphragms/spacersActive material electrodesPorosityPresent method

New lithium ion batteries and methods useful in making lithium ion batteries and / or components thereof are provided. The present lithium ion batteries and / or components thereof are structured to allow enhanced ion diffusion into and out of an active material through an electrolyte and to provide enhanced heat transfer out of the active material. The present methods provide electrodes with enhanced porosity without employing a separate porosity additive or a separate electrolyte percolation additive.

Owner:GROSVENOR VICTOR

High energy density charge-discharge lithium battery

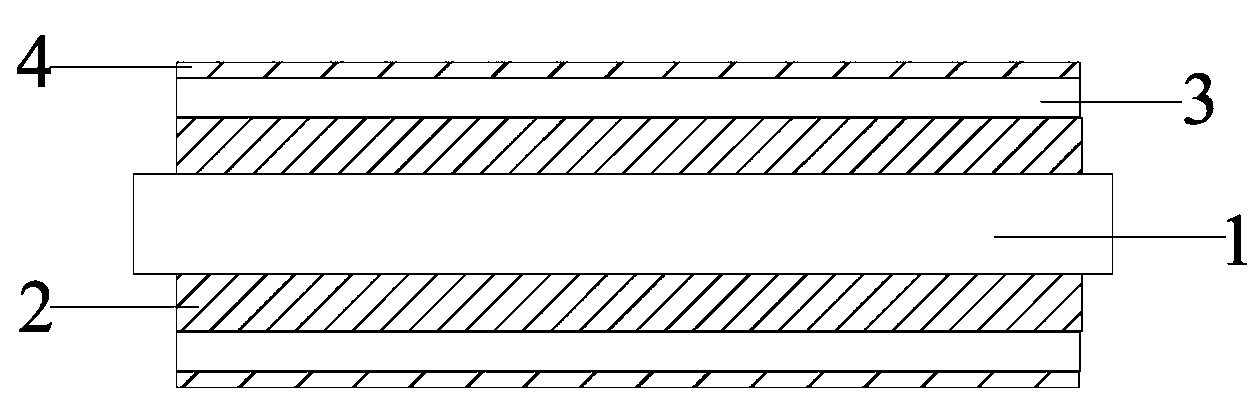

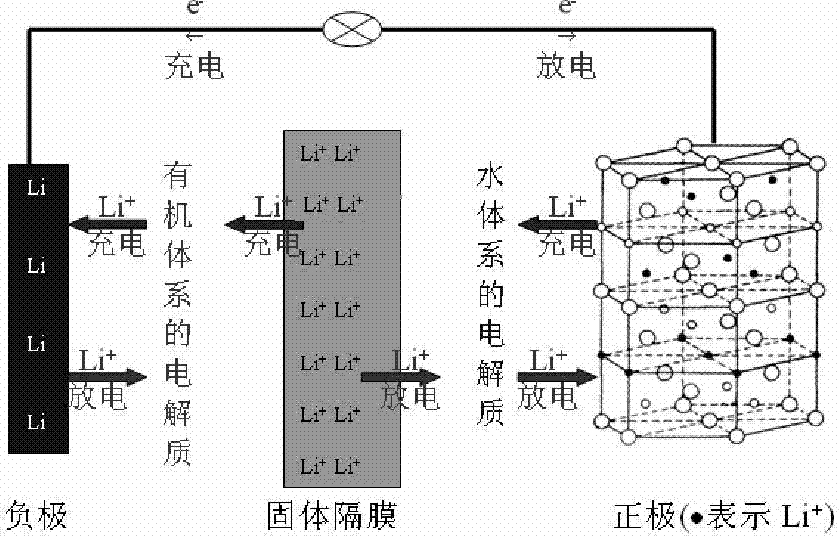

InactiveCN102738442ACell seperators/membranes/diaphragms/spacersCell electrodesLithium metalHigh energy

The invention, belonging to the technical field of electrochemistry, particularly discloses a high energy density charge-discharge lithium battery. The lithium battery comprises a separator, a cathode, an anode and an electrolyte, wherein the separator is solid, lithium ions can reversibly pass through the separator, the cathode is made of lithium metal or lithium alloy, the electrolyte of the cathode side comprises common organic electrolyte, polymer electrolyte, ionic liquid electrolyte or a mixture thereof, the anode is made of common cathode material of a lithium ion battery, and the electrolyte of the anode side comprises an aqueous solution containing lithium salt or a hydrogel electrolyte. Compared with the traditional lithium ion battery, the charge-discharge lithium battery disclosed by the invention has higher voltage, and the energy density of the charge-discharge lithium battery is more than 30% higher. The high energy density charge-discharge lithium battery can be used in the fields of electricity storage and release, etc.

Owner:FUDAN UNIV

Negative electrode paste mixing process with pre-lithiation effect, and lithium battery

ActiveCN108417774AEasy to quantifyPromote formationElectrode manufacturing processesSecondary cellsConductive pasteNickel–lithium battery

The invention relates to a negative electrode paste mixing process with a pre-lithiation effect, and a lithium battery. In an environment with a dew point of minis 40 to minus 50 DEG C, a negative electrode active material, a conductive agent and other dry powder are stirred uniformly; next, conductive paste is added and then added into NMP in two times to be kneaded and mixed uniformly; and finally, a metal lithium sheet and a film-forming additive-containing electrolyte are added to carry out dispersion and pre-lithiation. The metal lithium sheet and the film-forming additive-containing electrolyte are added in the paste mixing process, so that quantification of the metal lithium sheet can be facilitated, formation of an SEI membrane can be promoted, and an obvious lithium supplementingeffect is realized; pre-lithiation is performed directly in the paste mixing process, and extra pre-lithiation equipment is not needed, so that production cost is lowered; and in the subsequent electrolyte injection of the lithium battery, the content of the additive in the electrolyte can be reduced, and electrical conductivity of the electrolyte can be improved, thereby improving safety, initialefficiency, rate capability and cycle performance of the battery.

Owner:江西安驰新能源科技有限公司

Lithium battery with silicon-based anode and silicate-based cathode

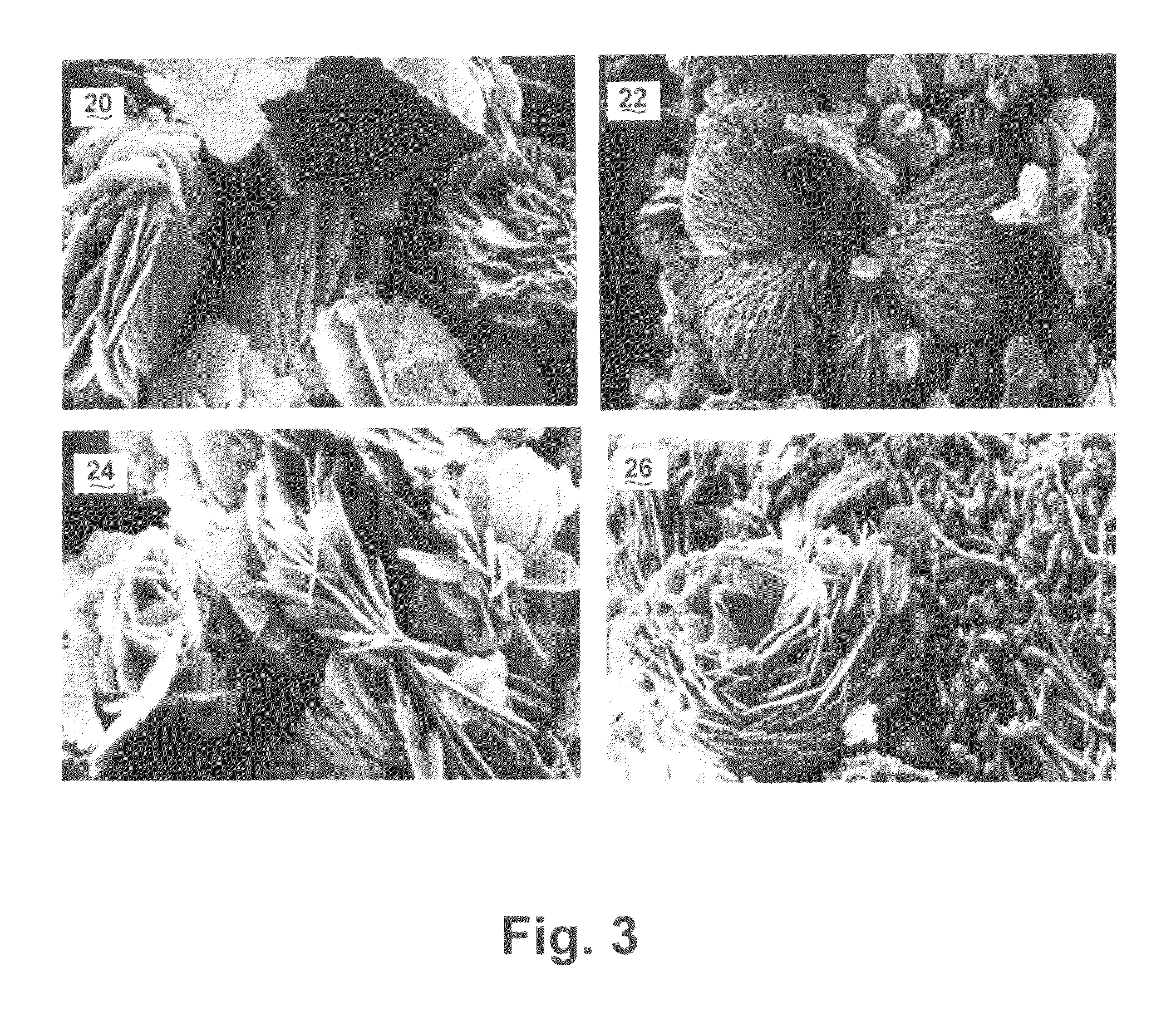

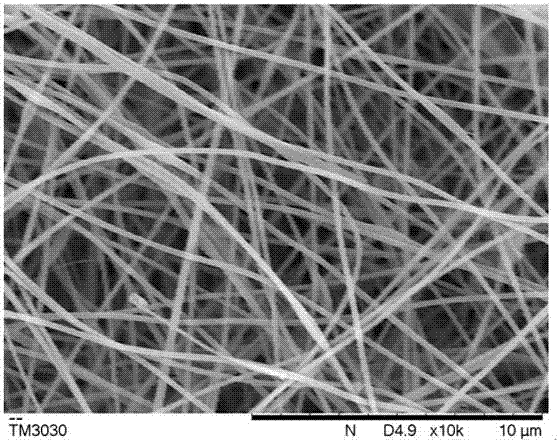

ActiveUS20130234674A1High energy capacityImprove cycle efficiencyMaterial nanotechnologyBatteries circuit arrangementsNickel–lithium batteryCarbon nanofiber

A lithium-ion battery is provided and related methods. The lithium-ion battery includes an electrode comprising an Olivine flake-like structure and an electrode comprising a plurality of coated carbon nanofibers. The Olivine flake-like structures form clusters through which the lithium ions are transported while reducing initial cycle irreversibility. The electrode comprising the coated carbon nanofibers additionally reduce initial cycle irreversibility by controlling expansion of the substrate forming the electrode comprising the coated carbon nanofibers.

Owner:GENERAL MOTORS COMPANY

Method for protecting lithium metal negative electrode, lithium metal negative electrode and lithium battery

ActiveCN108365178AUniform prolapseUniform depositionFuel and secondary cellsCell electrodesOrganic solventHigh energy

The invention provides a method for protecting a lithium metal negative electrode, the lithium metal negative electrode and a lithium battery. A protective layer is formed on the surface of the lithium metal negative electrode, an anionic polymer and boron nitride are dispersed in an organic solvent, and a dispersion solution is prepared; the surface of the lithium metal negative electrode is coated with the dispersion solution; the protective layer is formed on the surface of the lithium metal negative electrode after drying. Selective conduction of lithium ions can be achieved by the composite protective layer, the lithium ions can be uniformly deposited on the surface of the lithium metal negative electrode, lithium dendrites are prevented from penetrating out, and the stable lithium metal negative electrode is obtained and can improve cycle performance and safety performance of the lithium battery after being applied to the lithium battery, and high energy density is obtained.

Owner:ZHUHAI COSMX BATTERY CO LTD

Lithium battery diaphragm and preparation method therefor, and application of lithium battery diaphragm in lithium battery

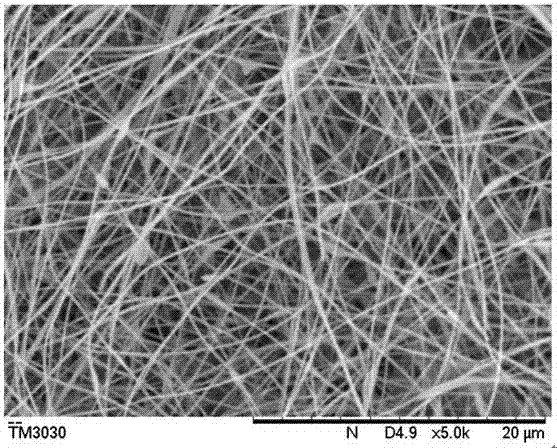

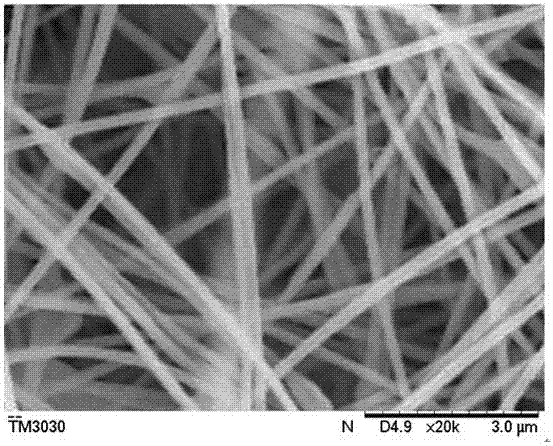

InactiveCN106876641AInhibit heat shrinkageHeat shrinkage does not occurLi-accumulatorsCell component detailsPorosityProduction rate

The invention discloses a lithium battery diaphragm and a preparation method therefor, and an application of the lithium battery diaphragm in a lithium battery. The lithium battery diaphragm is an inorganic nanofiber film; inorganic components can reinforce thermal dimensional stability of the lithium battery diaphragm, so that the lithium battery diaphragm can obtain relatively high heat resistance and stability; the inorganic components can improve wettability of the lithium battery diaphragm and an electrolyte; the inorganic nanofiber film is relatively high in porosity, so that the electrolyte absorptivity and ionic conductivity of the lithium battery diaphragm can be improved, and the cycling performance and the rate capability of the lithium battery can be enhanced; the lithium battery diaphragm prepared by an electrospinning technique has the advantages of high temperature resistance and high porosity, and the obtained lithium battery diaphragm can bear high temperature treatment for a relatively long time without causing an obvious thermal shrinkage phenomenon; the preparation method for the lithium battery diaphragm is simple in process and high in production efficiency; and the prepared lithium battery diaphragm can satisfy the safety requirement of a high-capacity lithium ion battery.

Owner:QINGDAO UNIV

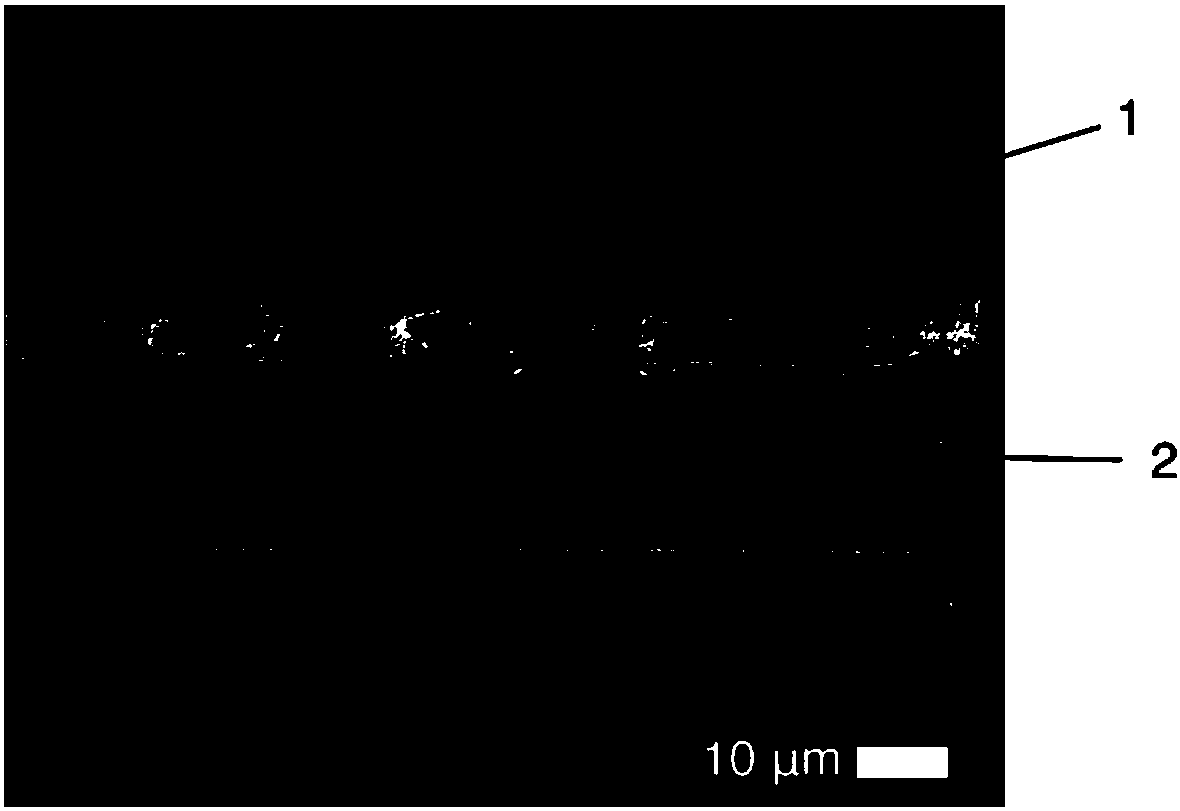

Composite separator for lithium battery

ActiveCN108365152AEvenly distributedGrowth inhibitionCell component detailsSecondary cells servicing/maintenanceElectrical conductorIon distribution

The invention discloses a composite separator for a lithium battery. The composite separator is applicable to a lithium ion battery or a metal lithium battery. The composite separator is formed by combining a substrate layer and an inorganic lithium ion conductor layer, wherein the inorganic lithium ion conductor layer employs an inorganic lithium ion conductor material with lithium ion conductivity larger than 1.0*10<-8>S cm<-1> under a temperature of 20-120 DEG C, the inorganic lithium ion conductor material exists in the substrate layer in a form of one or more of particle, cylinder, pipe and line, the substrate layer provides a basic separator framework, lithium ions can be induced to be uniformly deposited by the lithium ion conductor layer, and the mechanical property and the thermalstability of the separator are improved. The composite separator is simple in preparation method, lithium dendrites growth caused by non-uniform lithium ion distribution can be effectively suppressed, and the cycle efficiency and the safety of the battery within a wide temperature range are greatly improved; and by matching a high-capacity positive / negative electrode material, the cycle lifetimeof the lithium battery can be prolonged, the energy density and the safety of the lithium battery can be improved, and the industrial process is promoted.

Owner:TSINGHUA UNIV

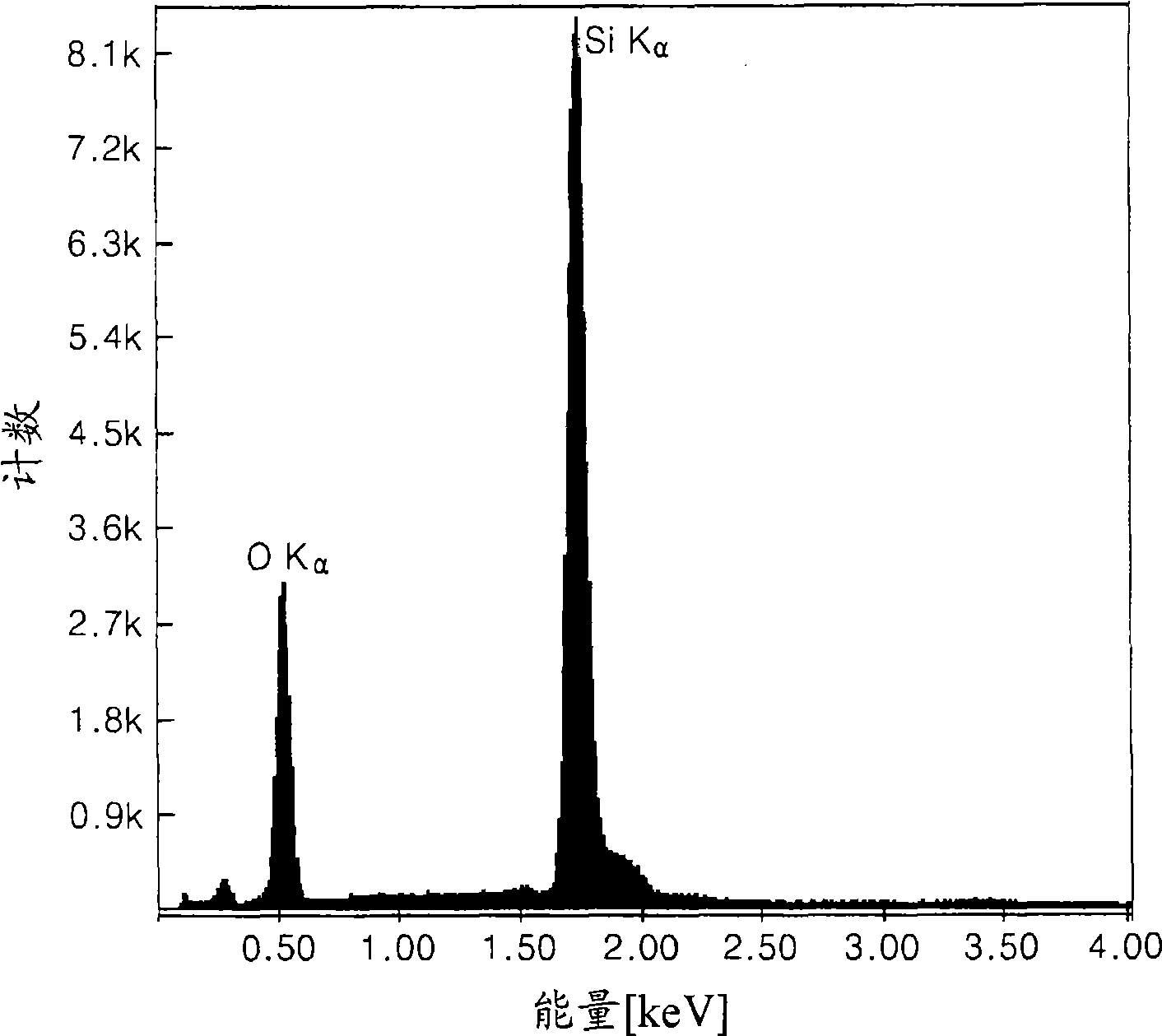

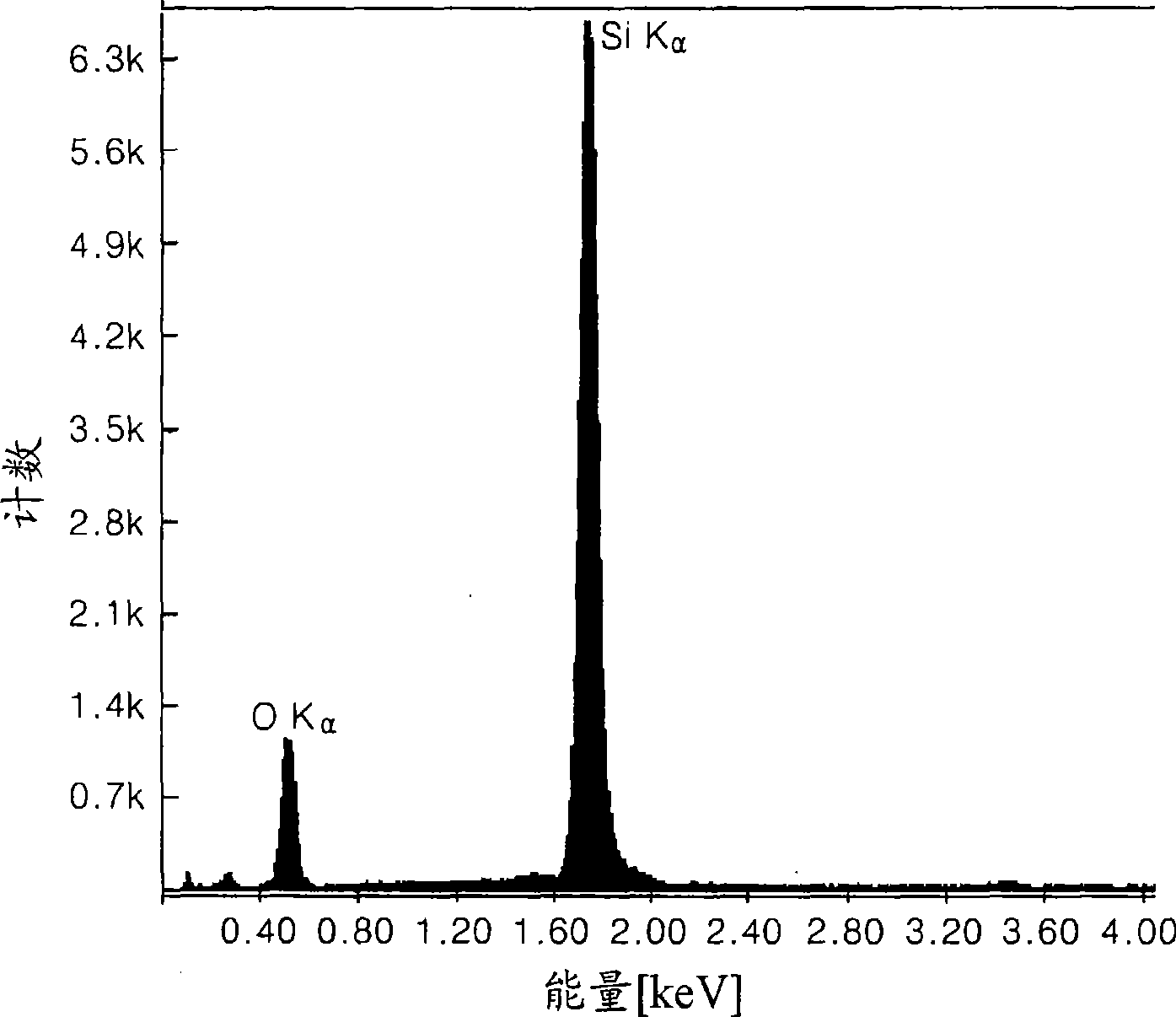

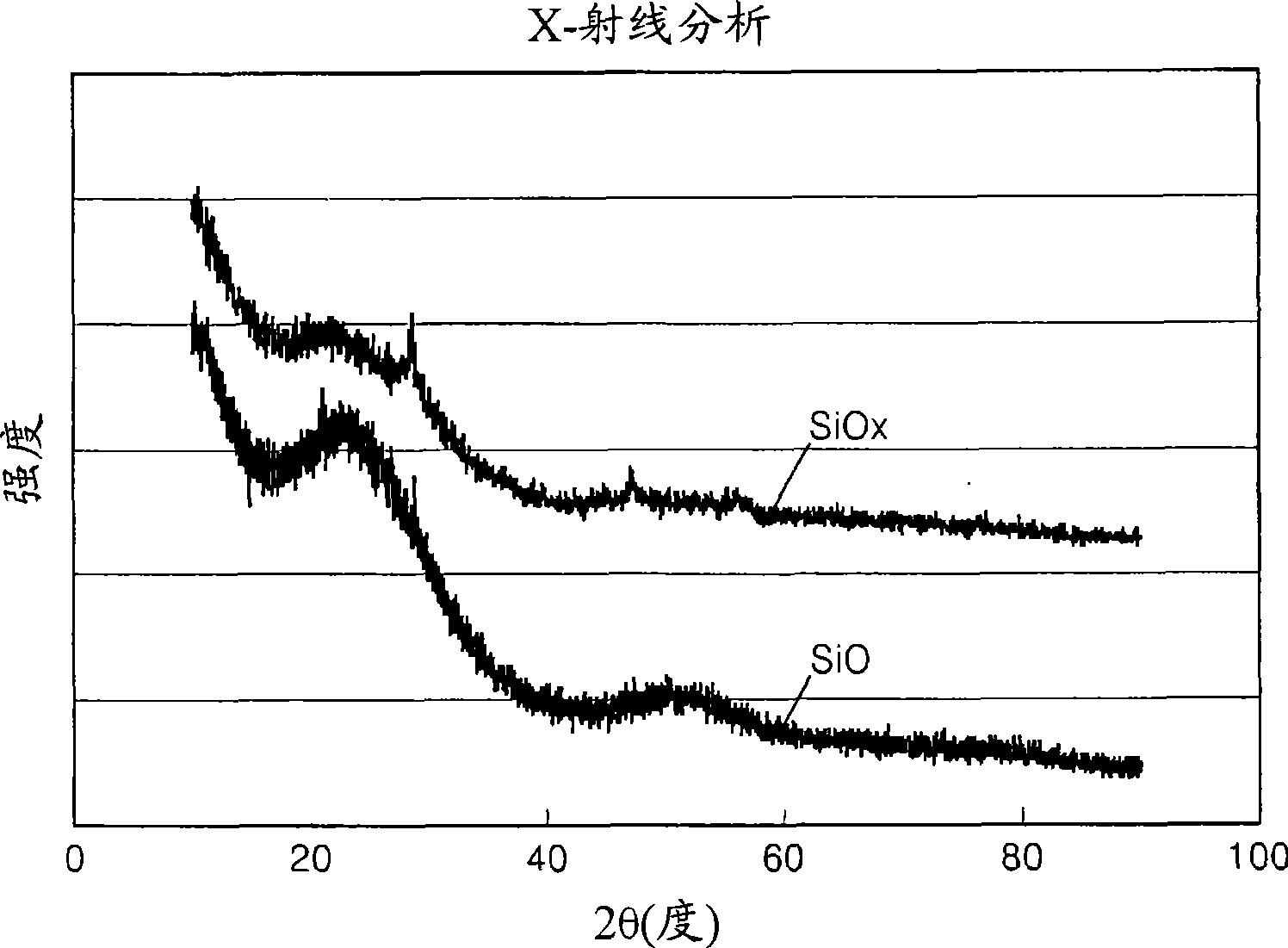

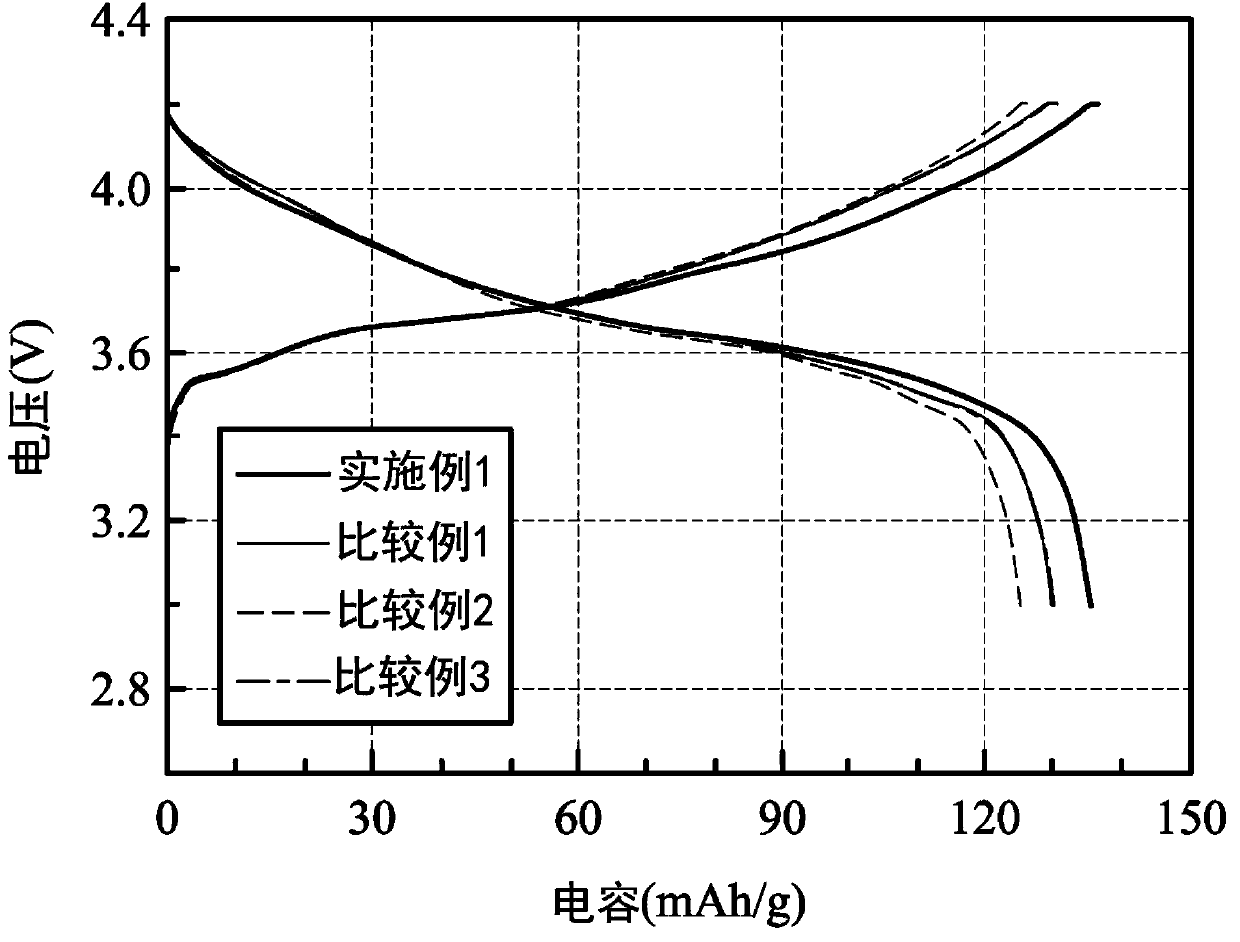

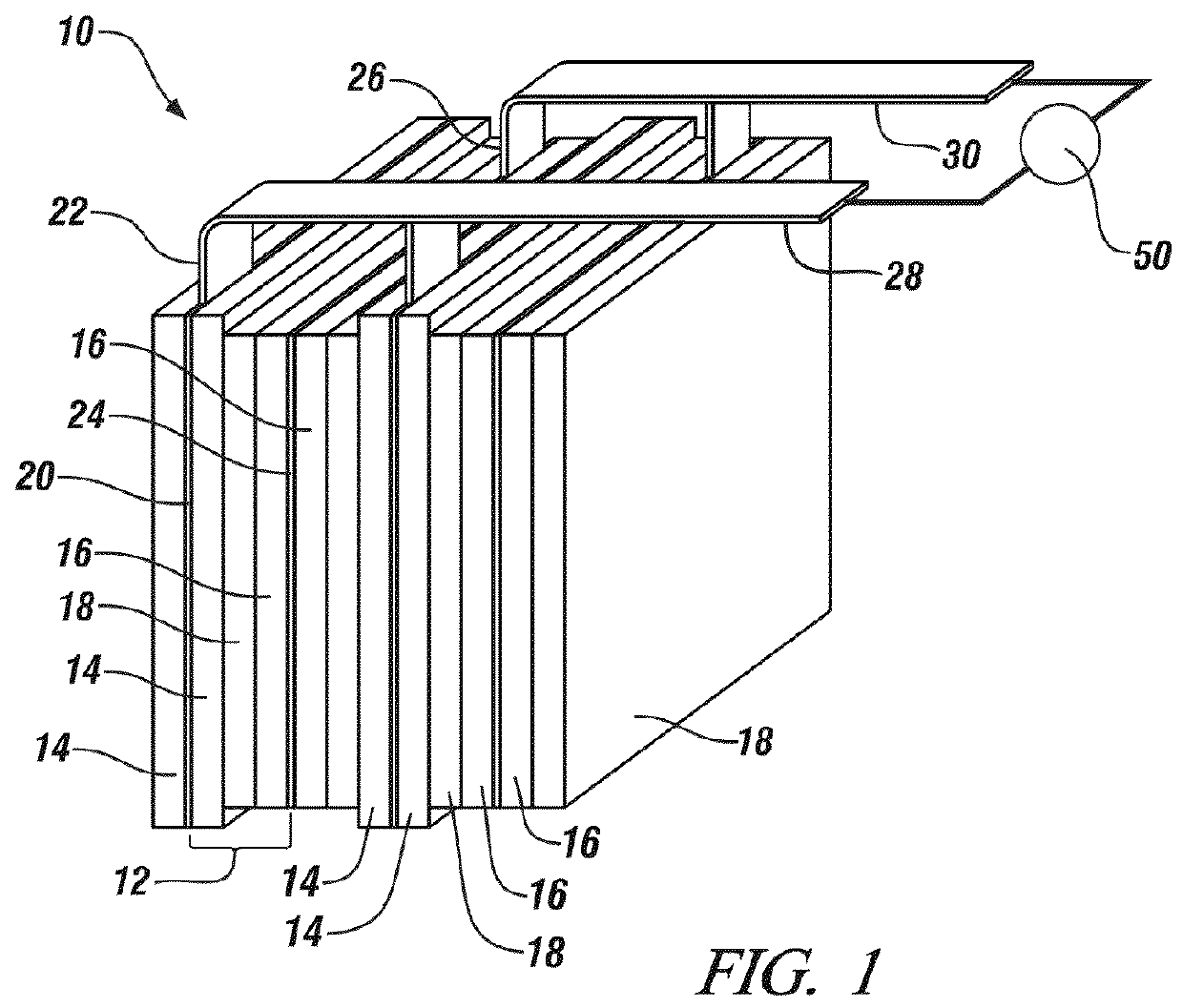

Anode active material, method of preparing the same, anode and lithium battery containing the material

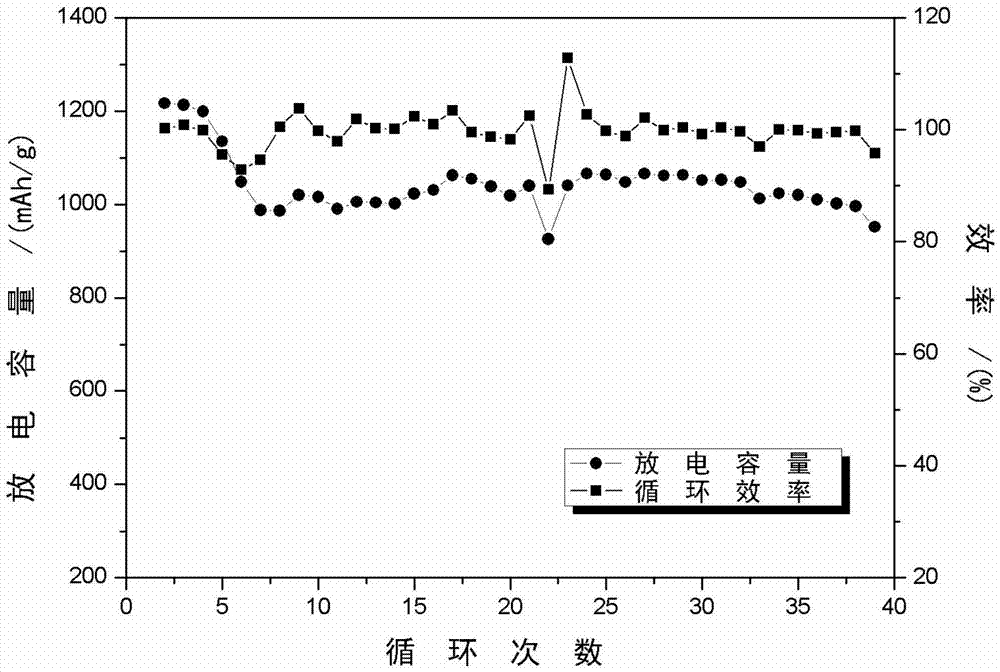

ActiveCN101510607AExcellent electrical propertiesImprove discharge characteristicsElectrode manufacturing processesNegative electrodesNickel–lithium batteryCharge discharge

Silicon oxide based anode active materials are provided. In one embodiment, the active materials include silicon oxides represented by the general formula SiOx, where 0<x<0.8. The anode active materials include silicon oxides having low oxygen contents. Further, anodes and lithium batteries employing such anode active materials have excellent charge-discharge characteristics.

Owner:SAMSUNG SDI CO LTD

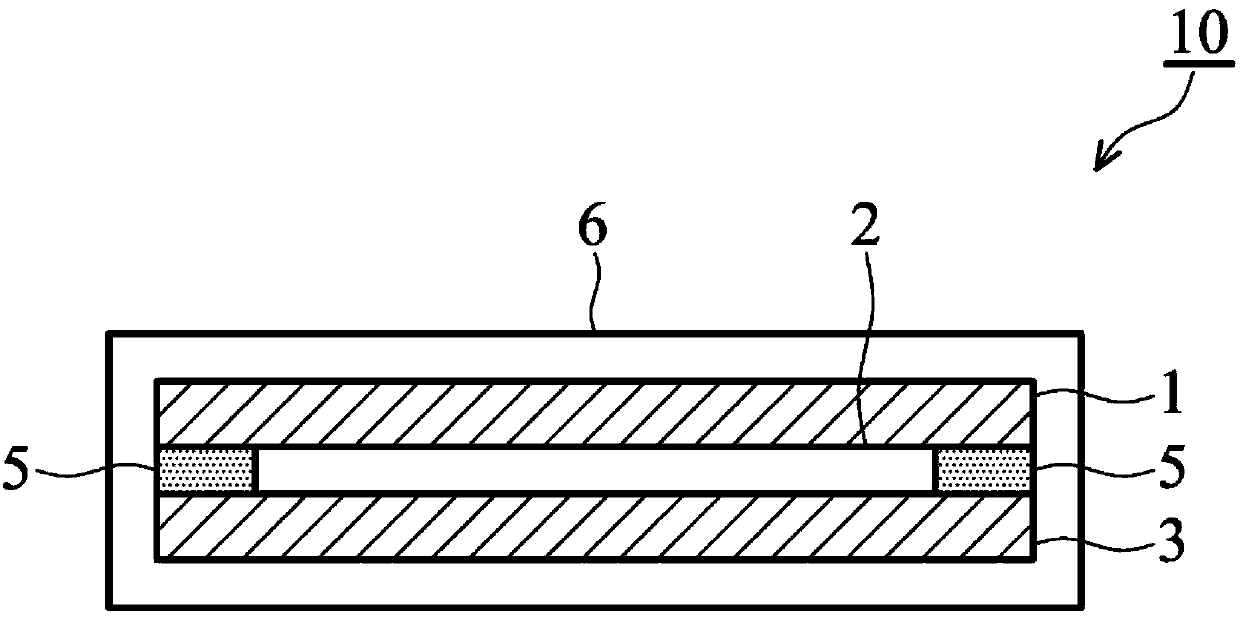

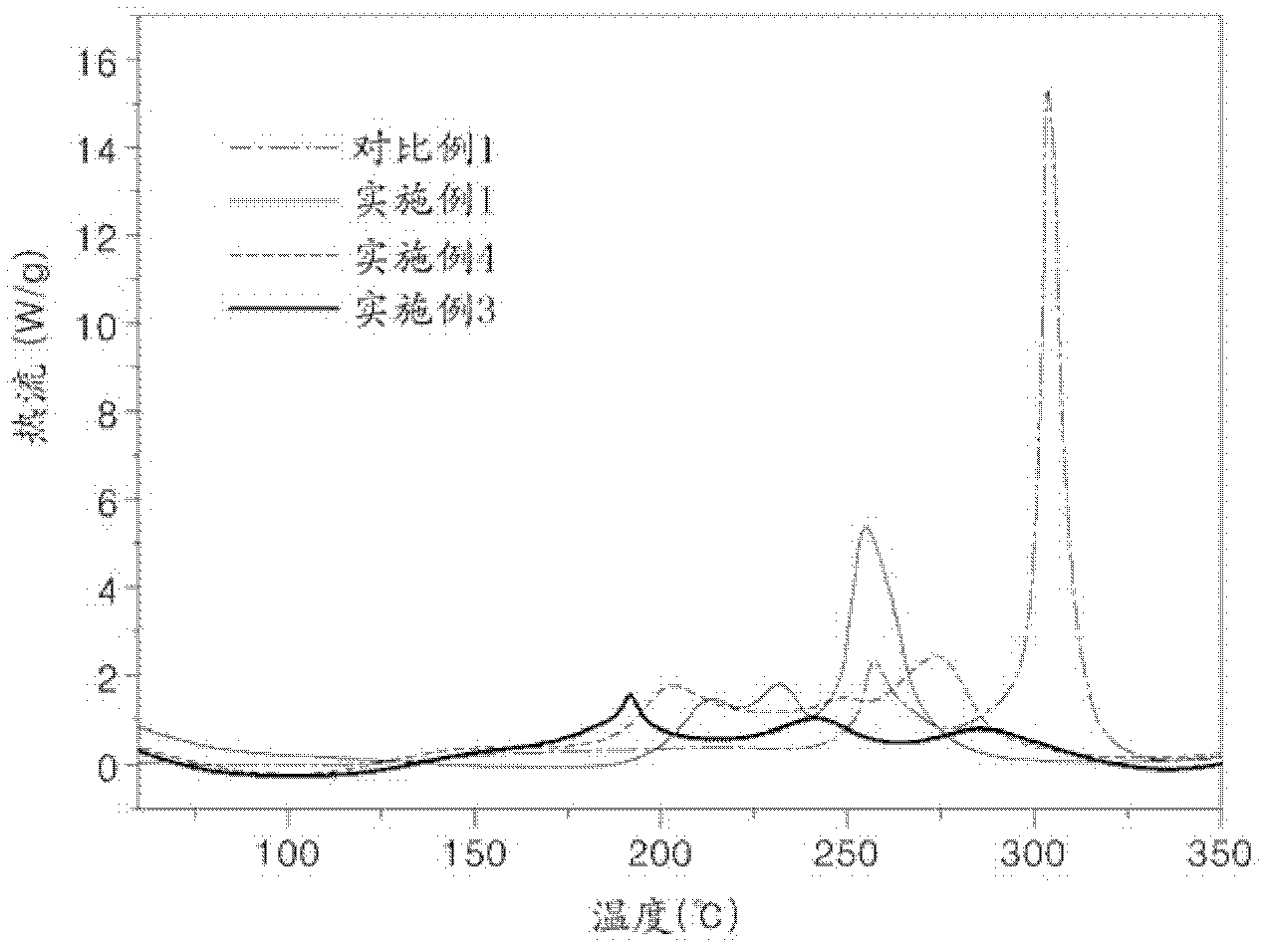

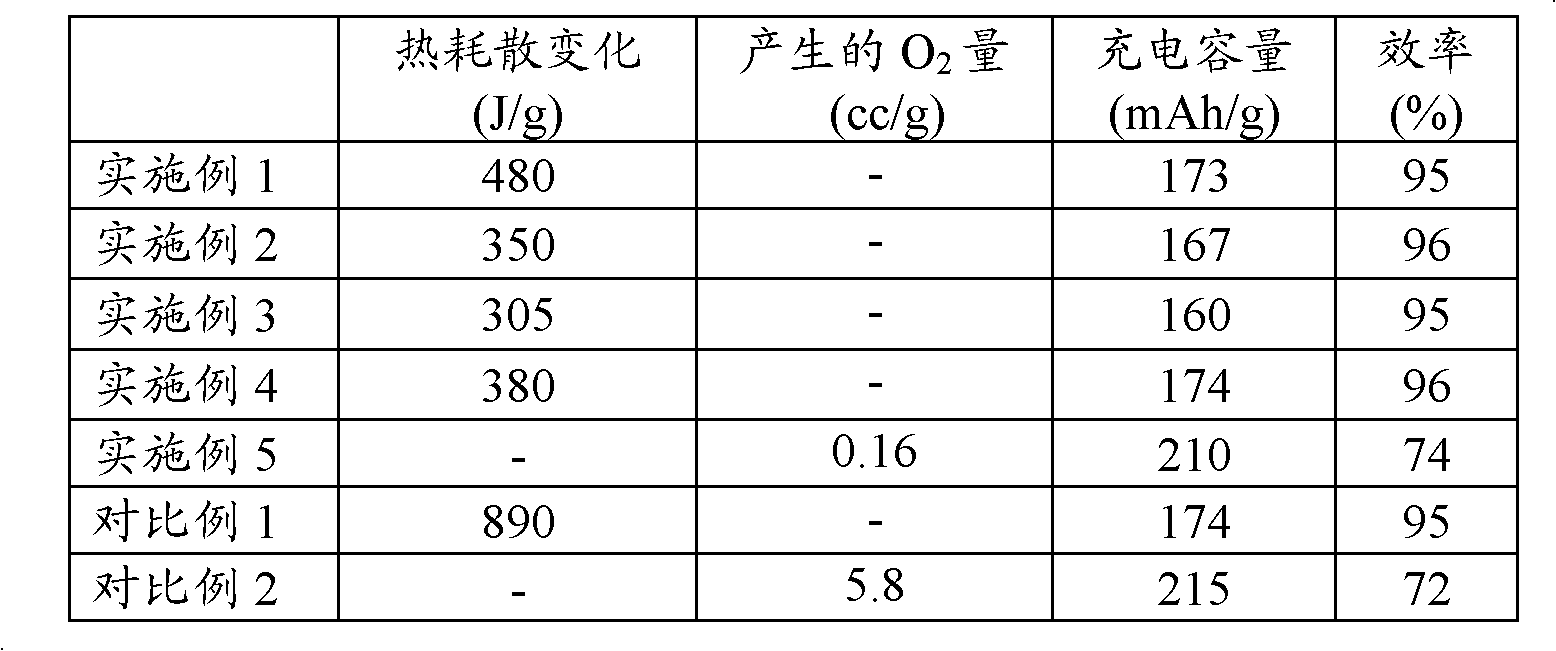

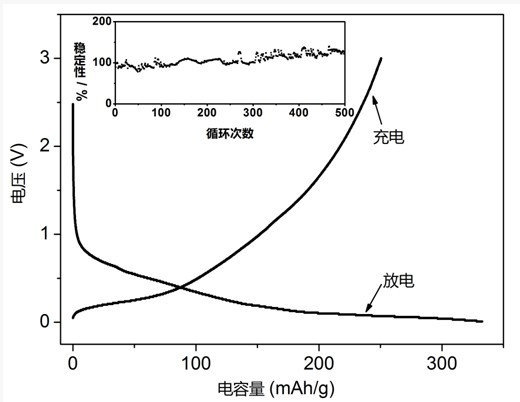

Lithium battery and forming method therefor

ActiveCN103872373AIncrease capacitanceLess heat releaseFinal product manufactureNon-aqueous electrolyte accumulator electrodesNitrogenPhysical chemistry

The invention provides a lithium battery. The lithium battery comprises a positive pole plate, a negative pole plate, an isolating membrane arranged between the positive pole plate and the negative pole plate for defining a holding region, and an electrolyte solution located in the holding region. The positive pole plate is a mixture of lithium transition metal oxides, binders and conducting particles. The surfaces of the lithium transition metal oxides are modified with nitrogen-containing macromolecules and transition-metal-containing cyano complexes. The invention relates to a forming method for the lithium battery.

Owner:IND TECH RES INST

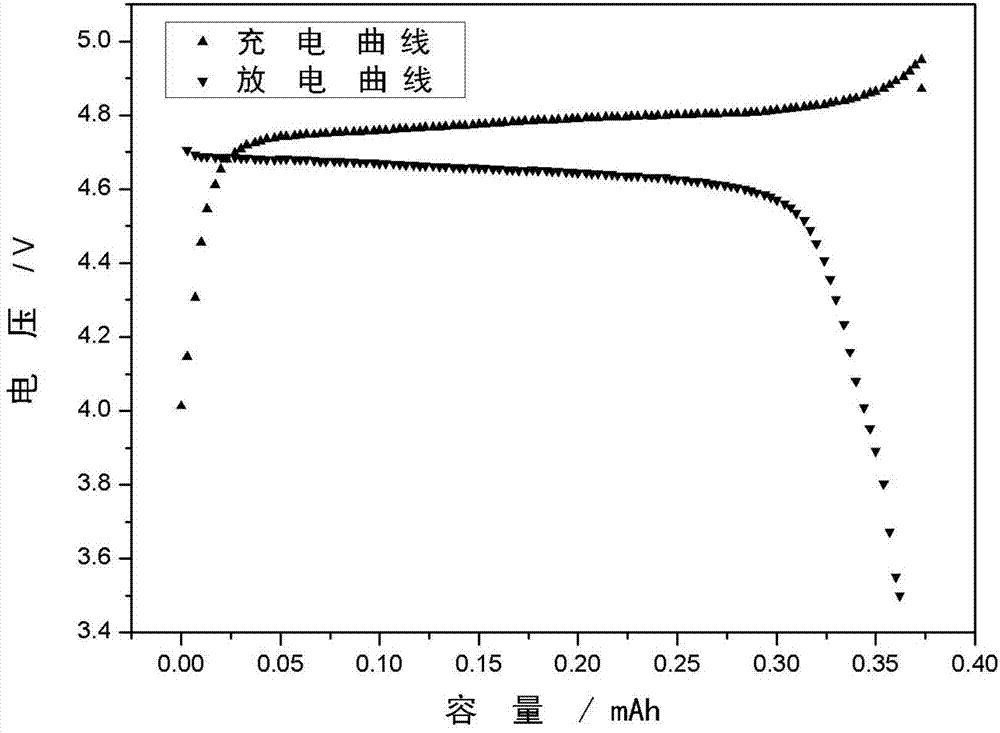

Electrolyte for high-voltage lithium battery and high-energy lithium battery including electrolyte

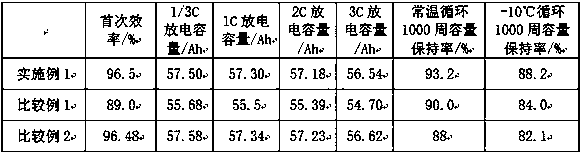

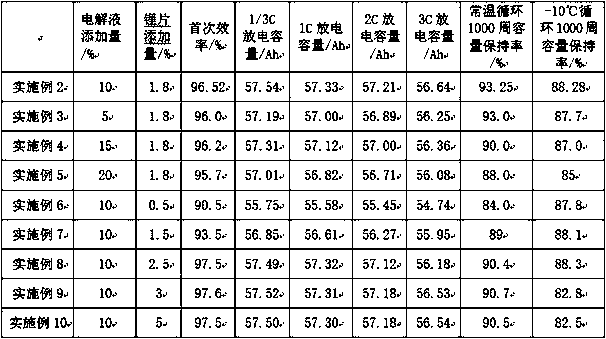

The invention belongs to the technical field of lithium ion batteries, and in particular relates to an electrolyte for a high-voltage lithium ion battery using silicon or a silicon-carbon composite material as a cathode. The electrolyte comprises a non-aqueous organic solvent, lithium salt and an additive and further comprises fluoro-ester and dinitrile organic compounds, wherein the dinitrile organic matter accounts for 0.01-10% of the total mass of the electrolyte. Compared with the prior art, the electrolyte has the advantages that LiDFOB and the dinitrile organic compound are added in the electrolyte, so that an SEI membrane can be formed on the surface of a high-voltage anode effectively, and the fluoro-solvent can effectively form an SEI membrane on the surface of a silicon or silicon-carbon cathode; meanwhile, the SEI membrane has relatively low resistance at low temperature, so that the cross-over resistance of lithium ions is reduced, and the high-voltage and low-temperature circulating performance of the battery including the electrolyte is significantly improved. Moreover, the invention also discloses a high-energy lithium ion battery including the electrolyte.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Continuous production method of carboxymethylcellulose lithium for lithium batteries

The invention discloses a continuous production method of carboxymethylcellulose lithium for lithium batteries in order to solve the problems that a lithium ion battery adhesion agent pollutes the environment, is single in function and high in price. The production method includes the steps that sodium carboxymethyl cellulose is prepared, and the carboxymethylcellulose lithium is obtained after the sodium carboxymethyl cellulose is acidized, alkalinized and purified. The prepared carboxymethylcellulose lithium breaks the pattern that autonomous mass production of carboxymethylcellulose lithium cannot be achieved domestically, according to the current condition of domestic production, on the basis that the performance of the carboxymethylcellulose lithium is guaranteed, continuous and large-batch production of the carboxymethylcellulose lithium can be achieved, and production cost is greatly reduced. A series of product performance testing preparation parameters are summarized in the method, and the parameters are quality control indexes of carboxymethylcellulose lithium and can also provide a reference for establishing standards of industrialized carboxymethylcellulose lithium in future.

Owner:CHONGQING LIHONG FINE CHEM +1

Lithium battery negative electrode sheet and preparation method thereof as well as lithium battery preparation method

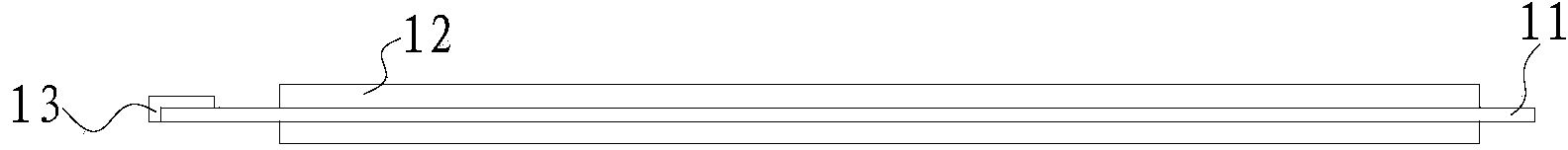

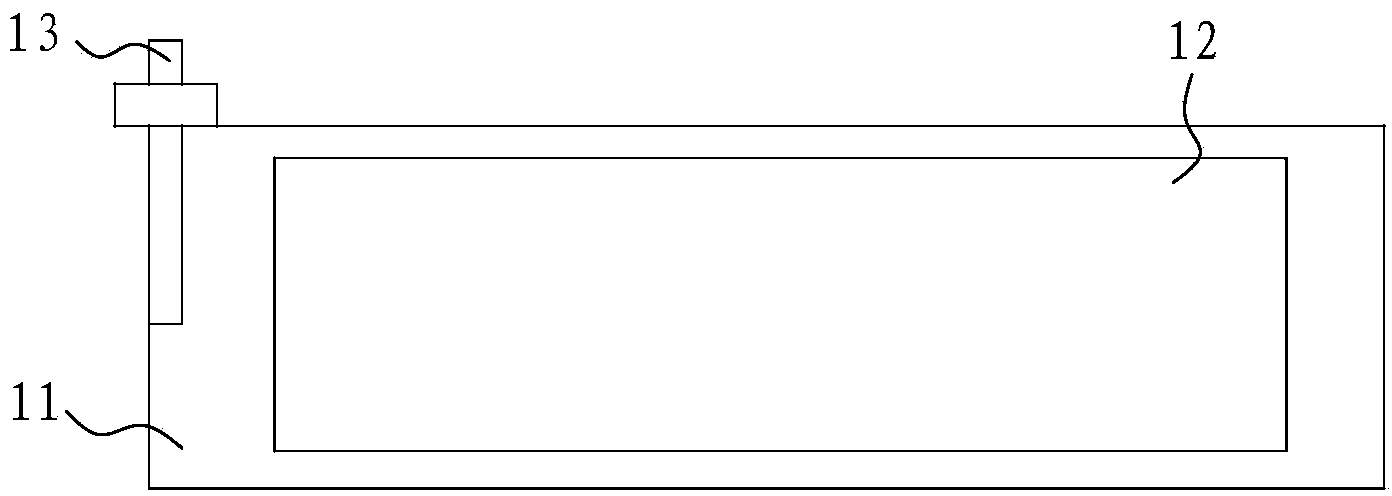

InactiveCN103779579AHigh tensile strengthSave spaceElectrochemical processing of electrodesElectrode carriers/collectorsMetal foilNickel–lithium battery

The invention discloses a lithium battery negative electrode sheet and a preparation method thereof as well as a lithium battery preparation method. The lithium battery negative electrode sheet comprises a negative electrode current collector manufactured by adopting a metal foil or a metal net, a lithium layer arranged on the surface of the negative electrode current collector and a negative electrode tab connected with the negative electrode current collector; a metal lithium layer is plated on the surface of the negative electrode current collector in an electroplating manner, and compared with the conventional lithium battery, the lithium battery disclosed the invention can greatly save the battery space and improve the energy density; the metal lithium layer is plated on the metal foil or the metal net in an electroplating manner, so that the negative electrode lithium layer is thinned and the tensile strength of the lithium layer is improved; compared with the primary lithium battery, the lithium battery achieves heavy current discharge and improves the power density; the difficulty that the primary lithium battery is required to be manufactured in a drying or inert atmosphere is avoided and the manufacture cost of the battery is reduced.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

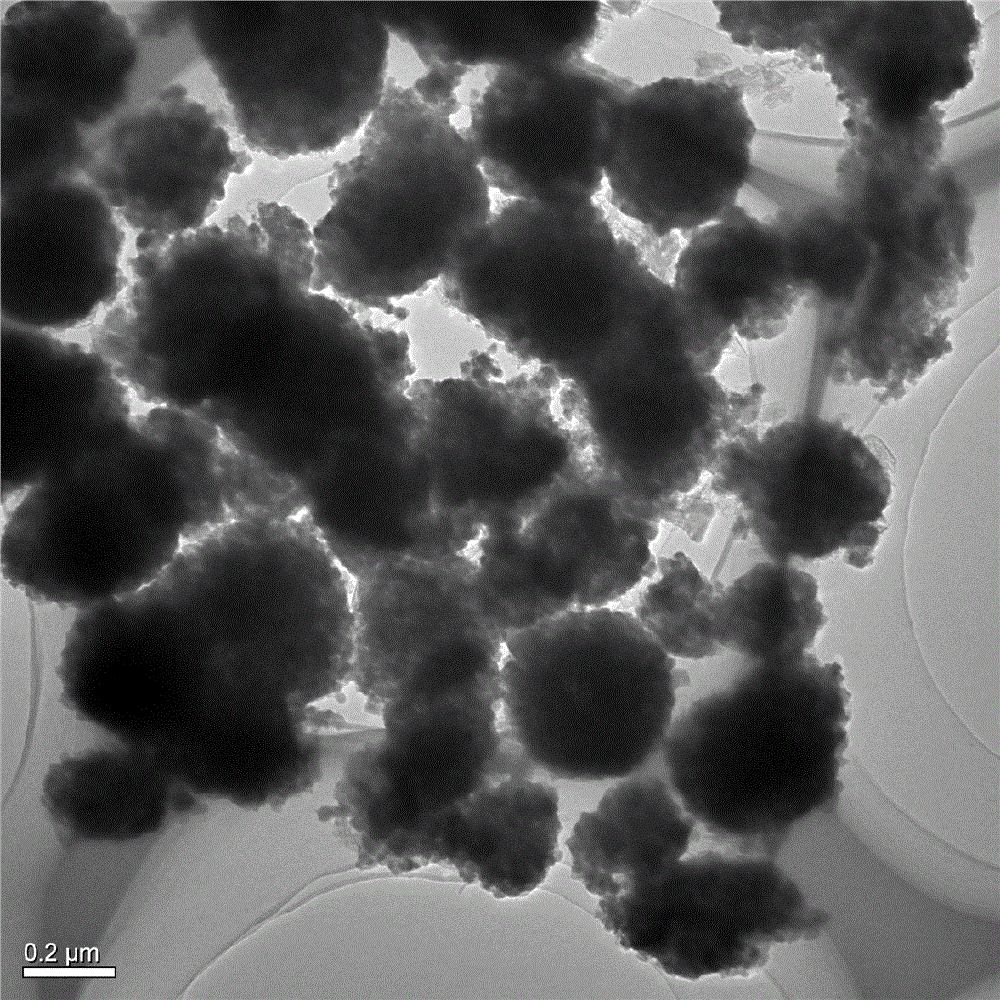

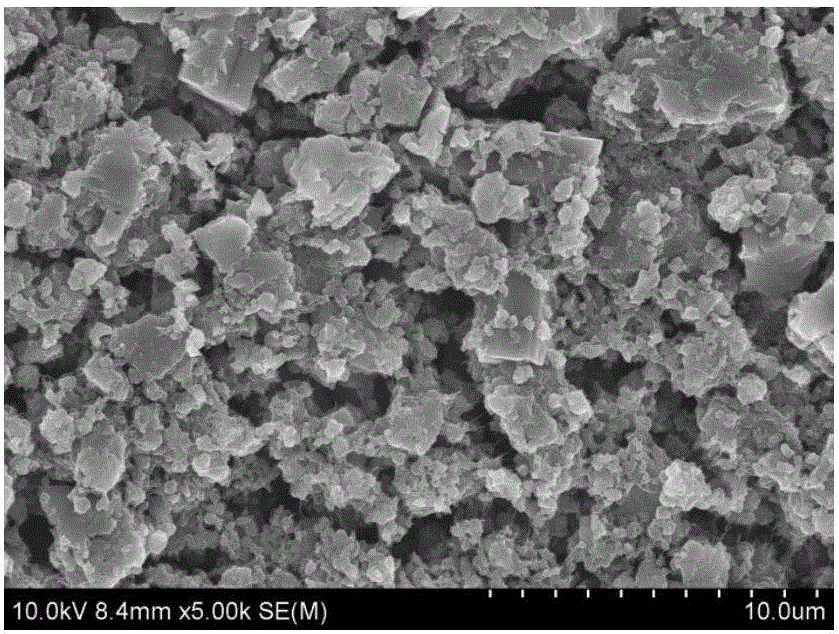

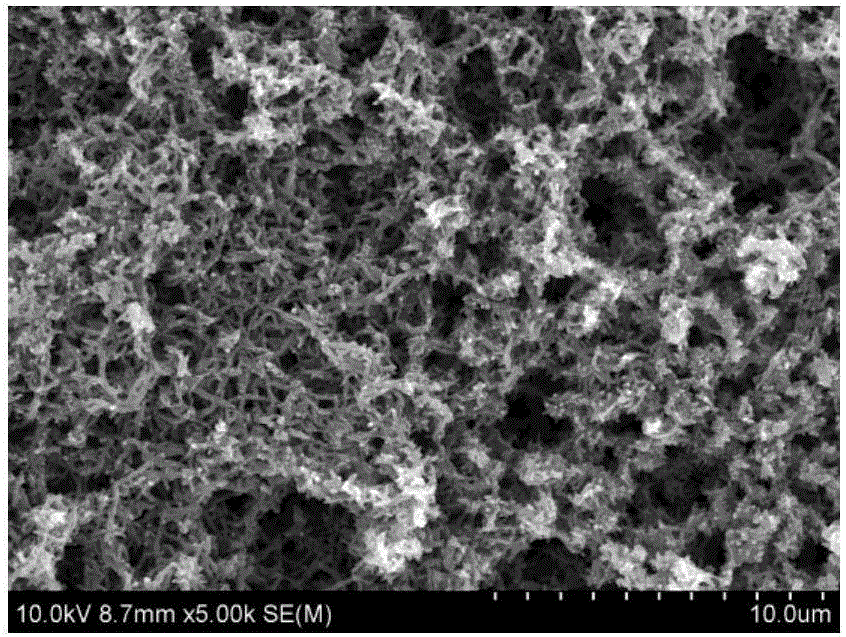

Lithium iron phosphate/carbon nano tube nanocomposite material for positive electrode material of lithium battery and preparation method of lithium iron phosphate/carbon nano tube nanocomposite material

ActiveCN107093732AImprove conductivityAvoid nudityMaterial nanotechnologyCell electrodesLithium iron phosphateNickel–lithium battery

The invention relates to a lithium iron phosphate / carbon nano tube nanocomposite material for a positive electrode material of a lithium battery and a preparation method of the lithium iron phosphate / carbon nano tube nanocomposite material. The composite material is prepared from lithium iron phosphate and a carbon nano tube shell, and is specifically prepared by the steps of fully stirring a lithium iron phosphate precursor and a catalyst precursor in a solvent evenly, adjusting the pH value by using alkali, adding the mixture to a hydrothermal reactor, heating the mixture to 500 DEG C and reacting for 12h to prepare catalyst-loaded lithium iron phosphate slurry; and atomizing the catalyst-loaded lithium iron phosphate slurry on CVD through a spray device, catalyzing a gas carbon source into a carbon nano tube under the conditions of a high temperature and an inert gas and coating on the surface of the lithium iron phosphate to obtain the lithium iron phosphate / carbon nano tube nanocomposite material. The material has relatively high electrochemical properties, such as the electrical conductivity, the specific capacity and the rate capability, and can be widely applied to the positive electrode materials of an electric vehicle lithium battery and a mobile phone lithium battery.

Owner:JIANGXI DIBIKE

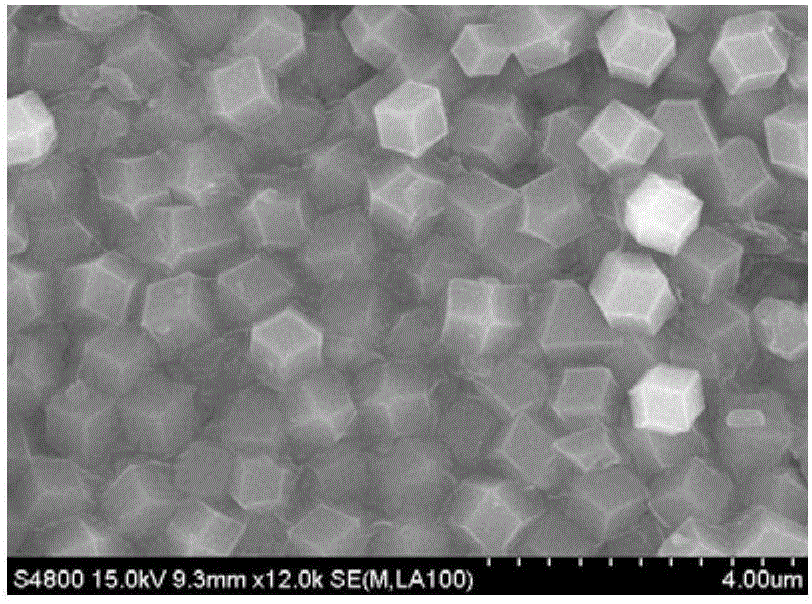

Double-oxide co-coated high-nickel lithium battery positive electrode material and preparation method thereof

InactiveCN108390039ASuppresses the problem of high alkali contentImprove cycle performanceCell electrodesSecondary cellsDecompositionLithium hydroxide

The invention provides a double-oxide co-coated high-nickel lithium battery positive electrode material and a preparation method thereof. A high-nickel ternary precursor material is prepared through aco-precipitation method; and then, vacuum pre-sintering is carried out after fully mixing and ball-milling with lithium hydroxide and calcium hydroxide; later, sulfate, metal oxide titanium oxide, cerium oxide and the like are added into gel synthesized in an organic solvent; and the high-nickel lithium battery positive electrode material coated by a double-oxide layer is obtained after sintering. According to the method in the invention, the problem that the alkali content of the traditional high-nickel ternary material is excessively high in the precursor preparation process is solved; theprepared double-oxide-layer coated high-nickel lithium battery positive electrode material forms a physical isolation layer, so that the corrosion of HF in the electrolyte and the generation of side reactions are inhibited, the high-nickel lithium battery positive electrode material is protected; therefore, the cycling performance of the battery is improved; meanwhile, the introduced sulfate ionsform a stable electrolyte layer, so that the decomposition of the electrolyte is inhibited, and the cycling performance of the battery is further improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Anode active material and lithium battery comprising anode active material

Owner:SAMSUNG SDI CO LTD

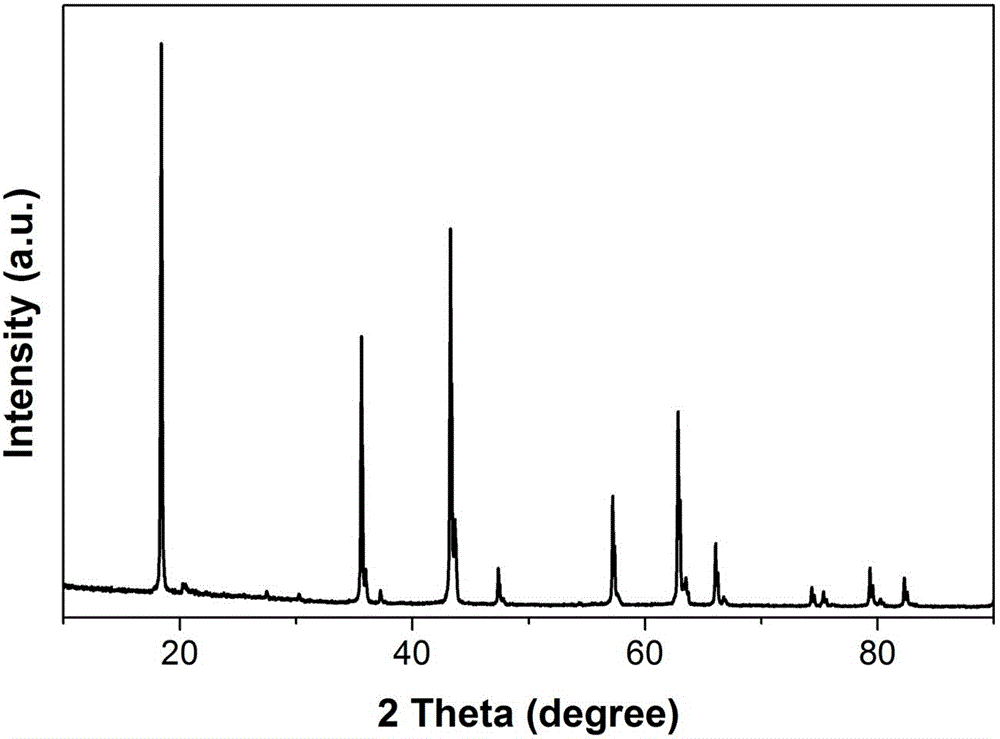

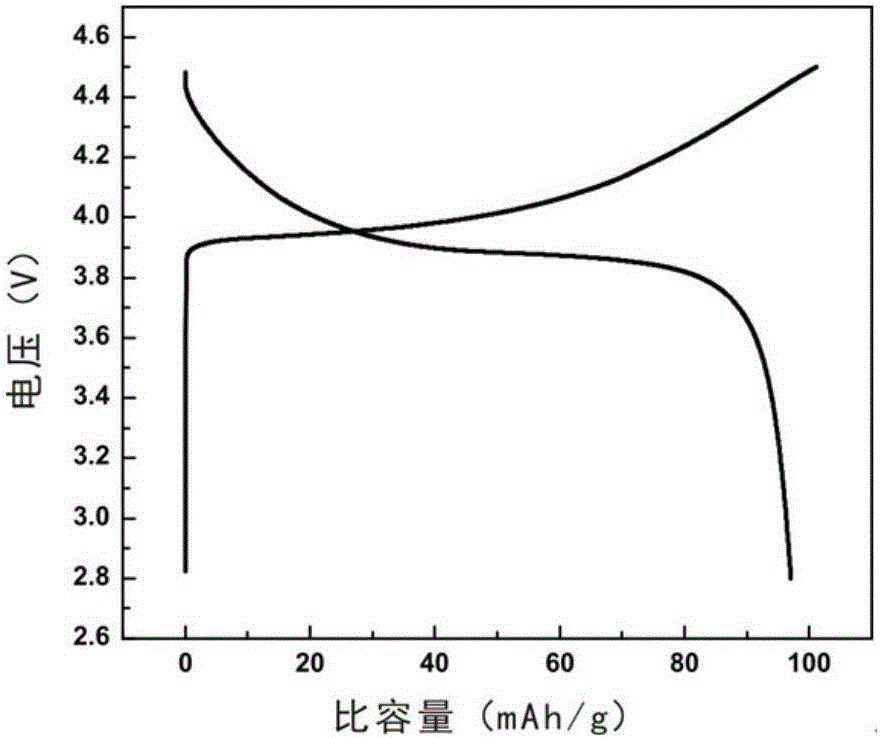

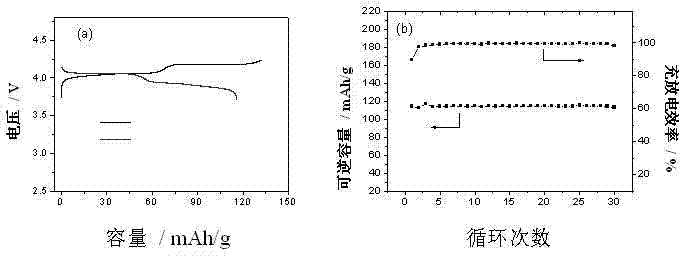

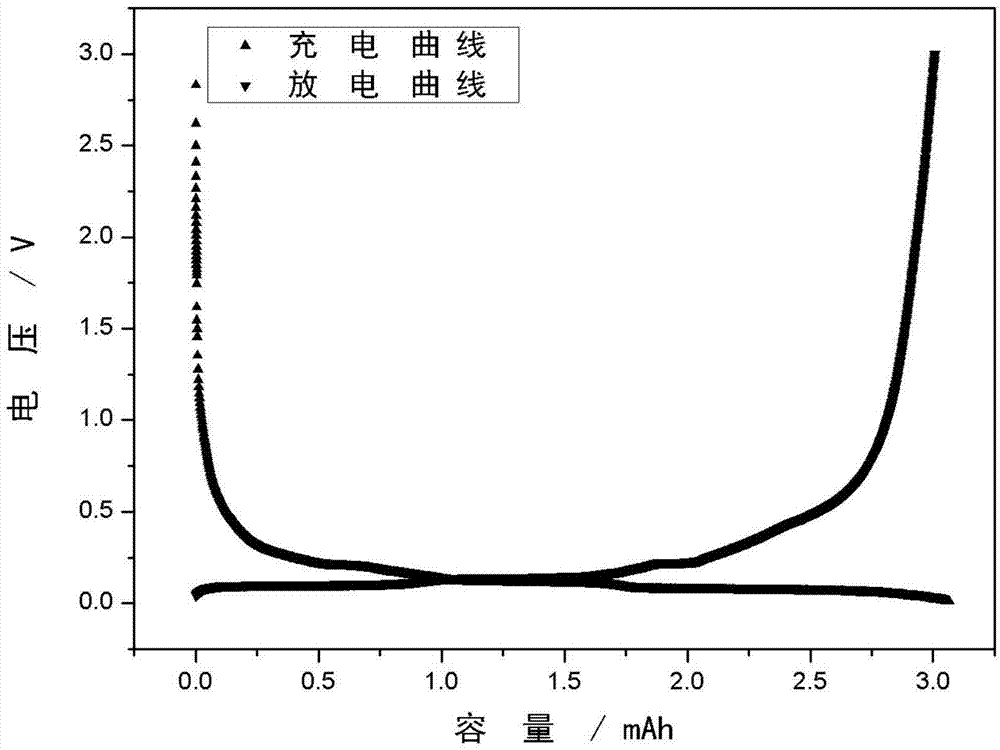

Titanium lithium silicate, preparation method thereof and use of the same serving as electrode material of lithium battery

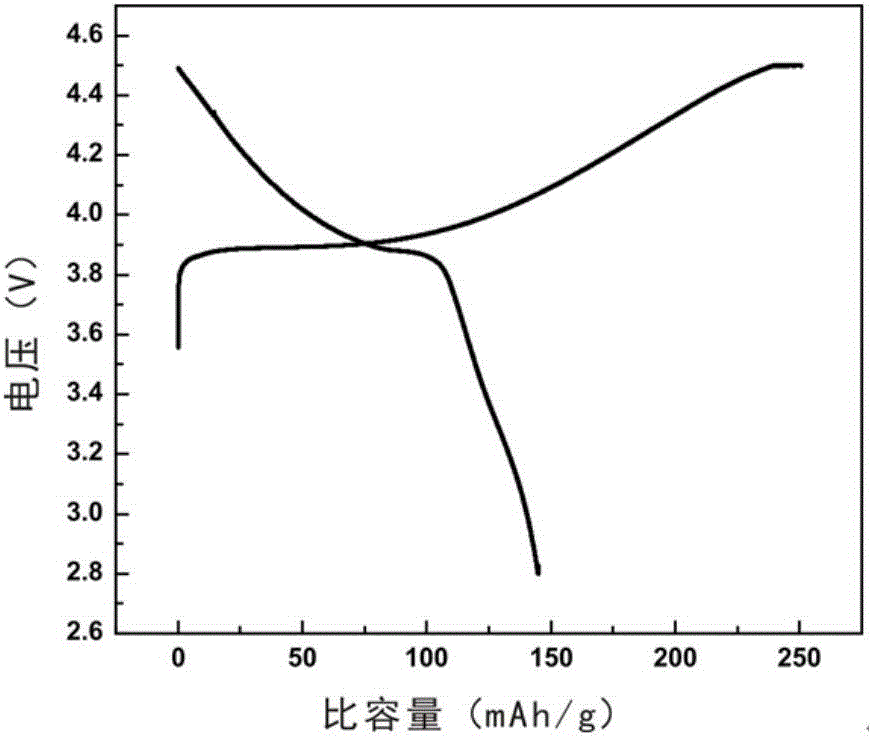

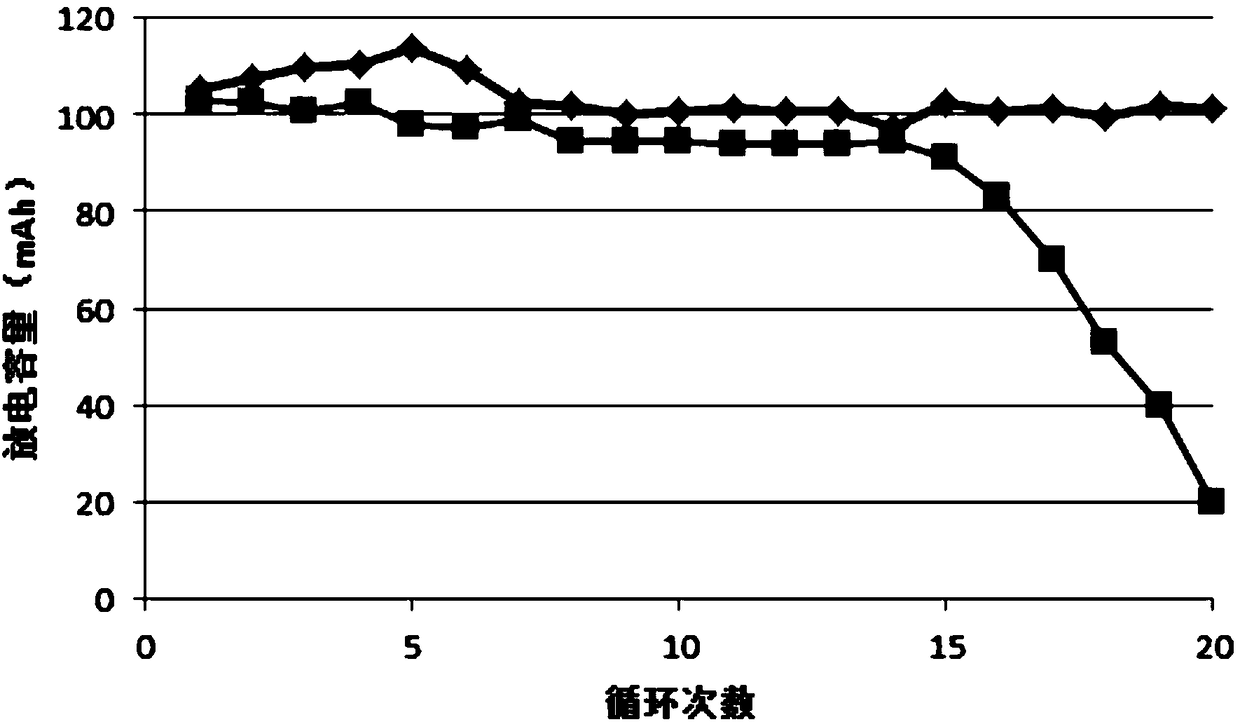

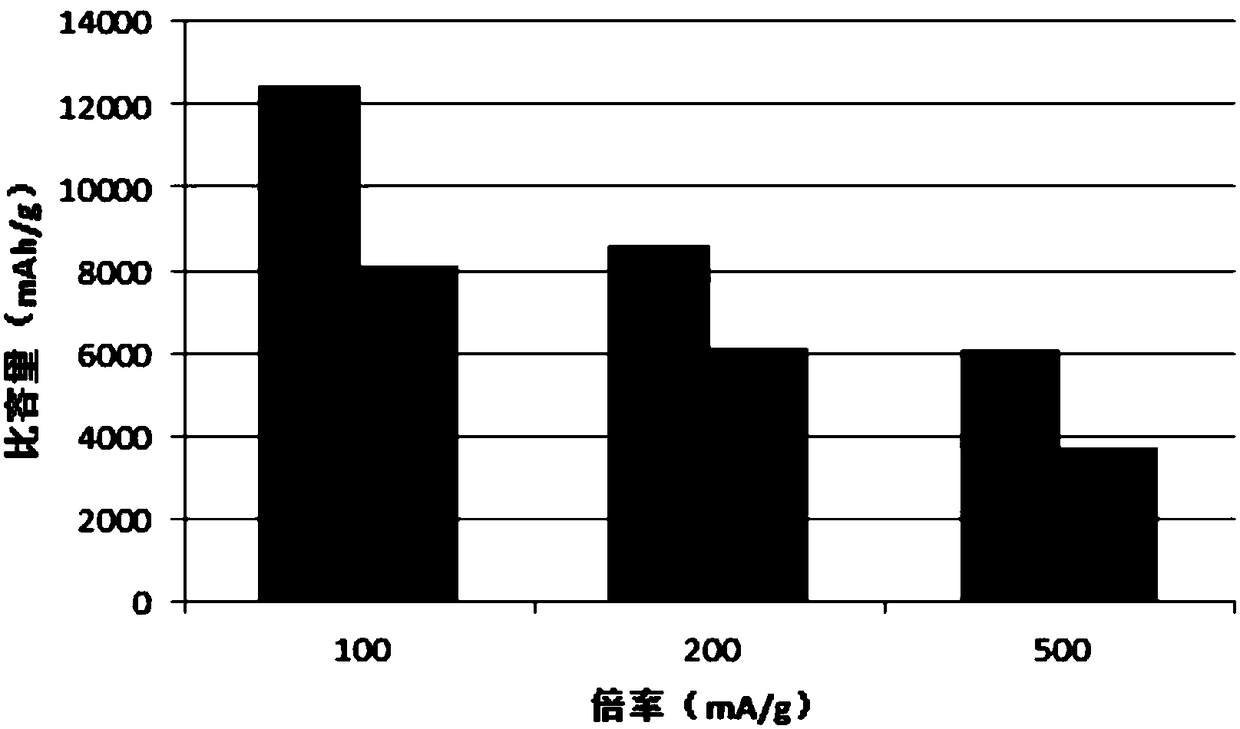

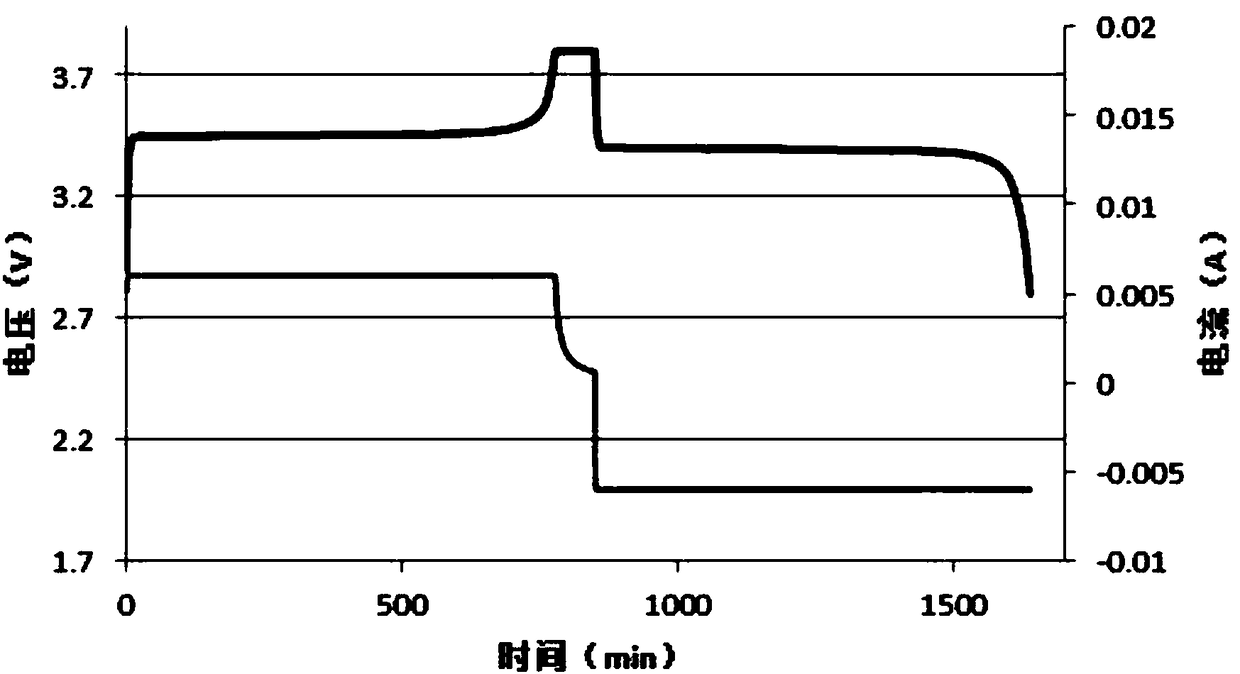

InactiveCN102623698ALow discharge platformIncrease capacityCell electrodesNickel–lithium batteryCharge discharge

The invention provides titanium lithium silicate serving as an electrode material of a lithium battery. The titanium lithium silicate serving as the electrode material of the lithium battery is manufactured through the exchange of a metal titanium silicate precursor with a two-dimensional layered structure or a three-dimensional framework structure with lithium ions. The titanium lithium silicate can be used for preparing a negative electrode material of the lithium ion battery. The titanium lithium silicate material provided by the invention has a low discharge plateau, high electric capacitance, good cyclic charge-discharge performance, and the like when serving as the negative electrode material of the lithium ion battery. The invention provides a preparation method of the titanium lithium silicate electrode material, and the titanium lithium silicate electrode material provided by the invention is simple to easy to prepare, has high repeatability and is a superior electrode material. The invention discloses the preparation method of the titanium lithium silicate.

Owner:NANJING UNIV

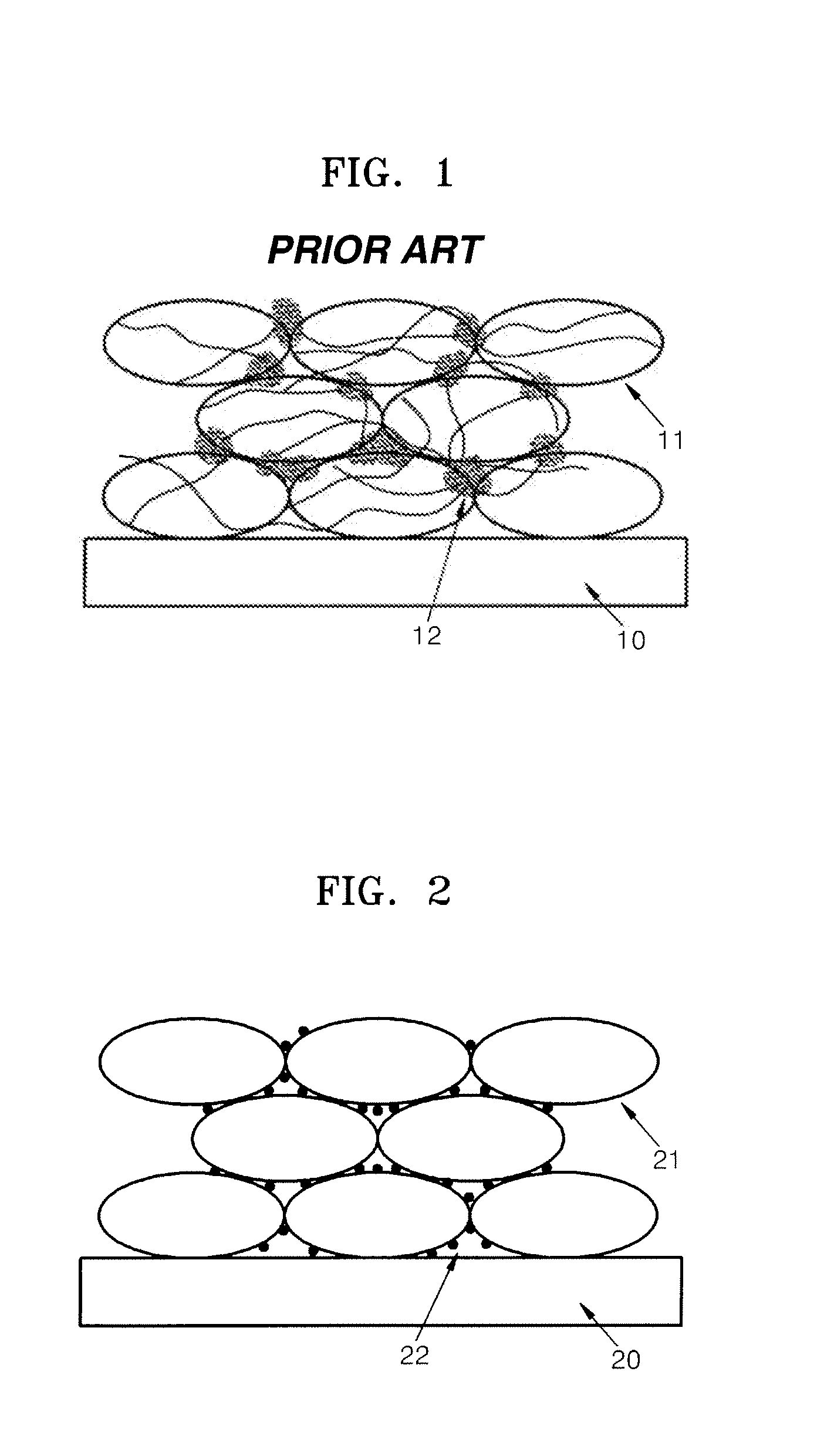

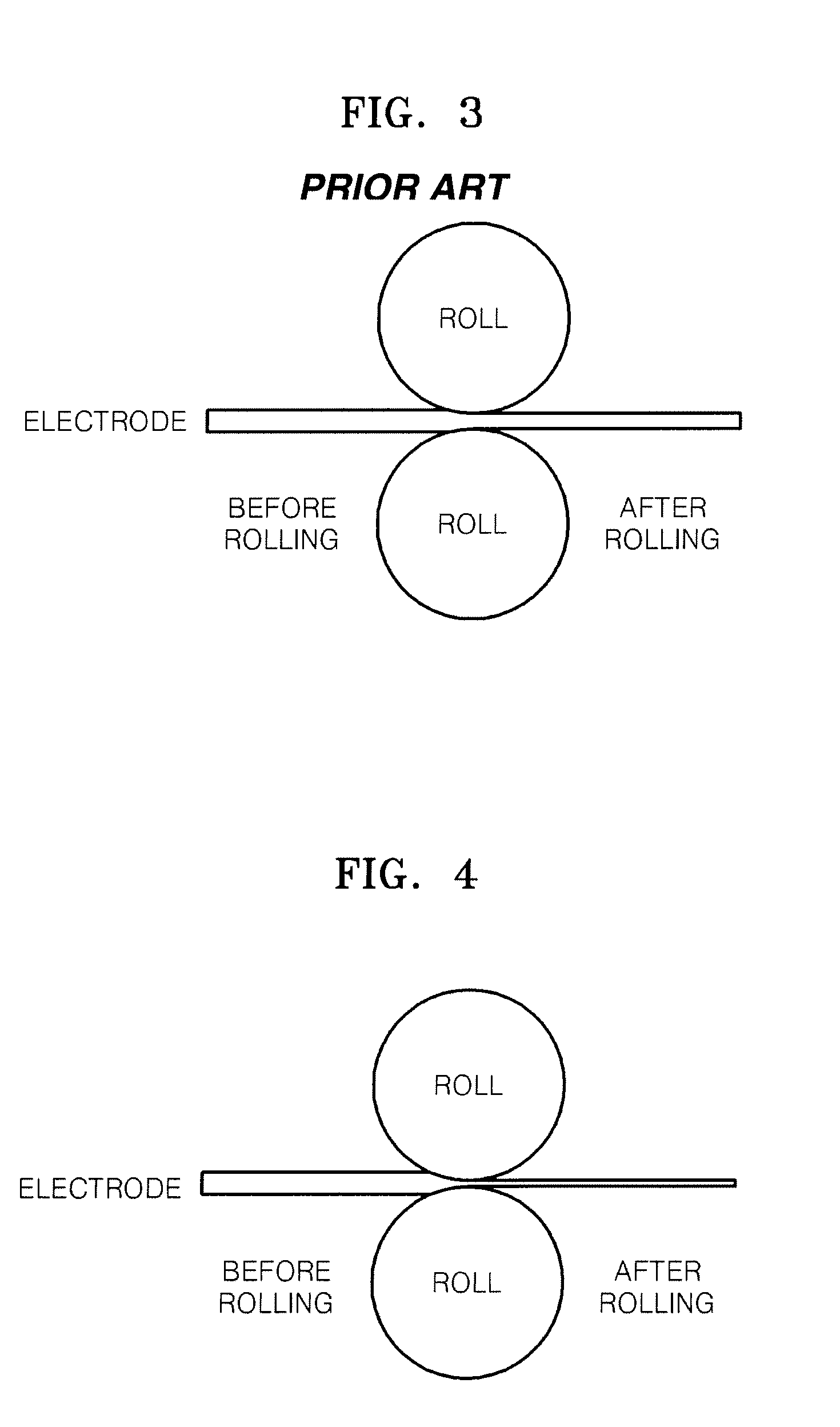

Anode for lithium battery and lithium battery employing the same

InactiveUS20080166633A1Increased assembly density and electrode energy densityExcellent binding force and elasticityElectrode rolling/calenderingNegative electrodesHigh energyNickel–lithium battery

Anodes for lithium batteries and lithium batteries employing the anodes are provided. In one embodiment, an anode includes an anode active material, and a binder including a waterborne acrylic polymer and a water-soluble polymer. The binder permeates the anode active materials to provide binding force between the anode active materials through point binding. The binder has excellent binding force and elasticity, and does not experience the spring-back phenomenon during electrode manufacture. The anodes have improved assembly density, high capacity and high energy density. Further, the anodes have improved lifetime characteristics since the anode structure is maintained long term over repeated charge / discharge cycles.

Owner:SAMSUNG SDI CO LTD

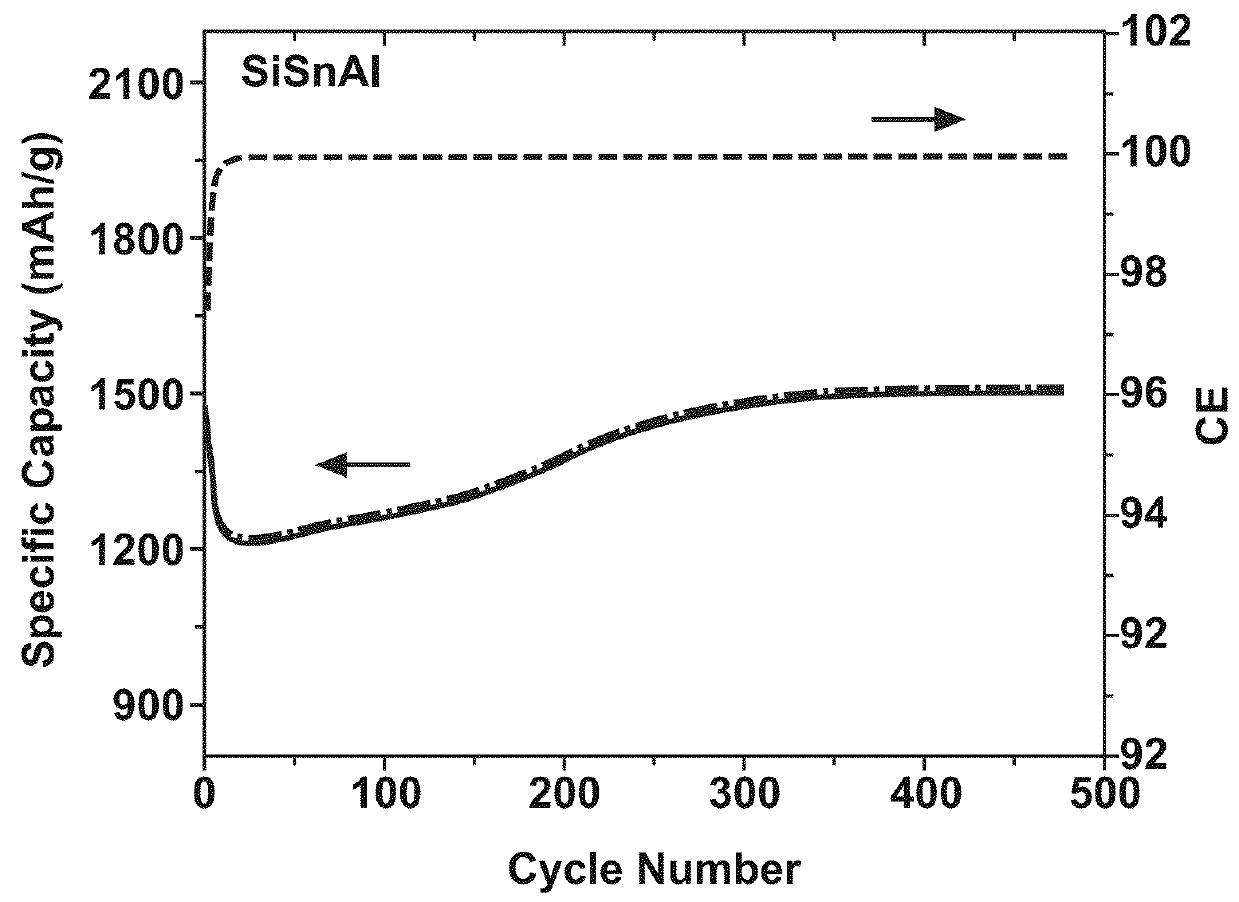

Multi-phase separated silicon based alloys as negative electrode material for lithium batteries

ActiveUS8859144B2Reduce concentrationReduce fracturesMaterial nanotechnologyElectrode melt handlingNickel–lithium batteryAlloy

A particulate composite of silicon, tin, and aluminum (or other suitable metal) is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery or a lithium-sulfur battery. This electrode material is formed such that the silicon is present as a distinct amorphous phase in separate matrix phases of crystalline tin and crystalline aluminum. While the distinct tin and aluminum phases provide electron conductivity, each phase accommodates the insertion and extraction of lithium in the operation of the cell and all phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. Other suitable metals for use in the composite with silicon and tin include copper and titanium.

Owner:GM GLOBAL TECH OPERATIONS LLC

Lithium supplementing method for the lithium ion battery positive electrode

InactiveCN110120493ANo protectionIncrease energy densityElectrode manufacturing processesSecondary cellsElectrical batteryNickel–lithium battery

The invention relates to a lithium supplementing method for a lithium ion battery positive electrode. The method is used for supplementing lithium for the lithium ion battery positive electrode. In apositive electrode pulping process, a lithium supplementing material is uniformly mixed with a positive electrode main material, a conductive agent, a binding agent, a solvent and other materials, andthen the lithium battery is prepared through the procedures of coating, rolling, assembling, liquid injecting, formation, capacity grading and the like. Compared with the prior art, the process doesnot need to be changed, and operation is easy; inert atmosphere protection is not needed; no special requirement on the environment is needed; the existing production process and equipment do not needto be improved; the lithium supplementing material is uniformly mixed with materials such as a main material, a binder and a conductive agent in the positive electrode pulping process under the existing production environment, equipment and process conditions; and the additional equipment cost does not need to be increased. The method belongs to 'wet processes for lithium supplement', and dust pollution and safety problems caused by dry processes for lithium supplement are avoided. After the lithium ion battery is supplemented with lithium, the initial efficiency and the battery capacity canbe improved, so that the energy density of the battery is increased.

Owner:湖北猛狮新能源科技有限公司

Lithium metal negative pole preparation method, lithium metal negative pole and lithium battery

InactiveCN108039454APromote circulationSimple methodCell electrodesLi-accumulatorsLithium metalButton battery

The invention discloses a lithium metal negative pole preparation method, a lithium metal negative pole and a lithium battery. The preparation method comprises the steps: step 1, utilizing carbon fluoride as a positive pole active material to prepare positive pole plate slurry, coating a current collector with the positive pole plate slurry and punching to prepare carbon fluoride pole pieces; step2, utilizing a lithium metal sheet, a carbon fluoride pole piece and a lithium ion conductive solution to assemble a button battery, wherein the lithium metal sheet and the carbon fluoride pole piecedirectly contact each other; step 3, standing for a period, disassembling the button battery and taking the lithium metal sheet out, wherein a lithium metal protecting layer is formed on the surfaceof the lithium metal sheet. According to the preparation method disclosed by the invention, lithium fluoride is introduced to the surface of the lithium metal in an in-situ reaction mode, so that stable lithium metal can be prepared; the preparation method has the advantages of no addition of any extra technology, simpleness, easiness and practicability in method, strong industrial feasibility andindustrial application value and potential. The lithium metal negative pole prepared by the preparation method disclosed by the invention has excellent circulation performance in all kinds of lithiumbatteries and has a good application prospect and universality in lithium secondary batteries.

Owner:SHANGHAI POWER ENERGY STORAGE BATTERY SYST ENG TECH +1

Positive active material and lithium battery including the same

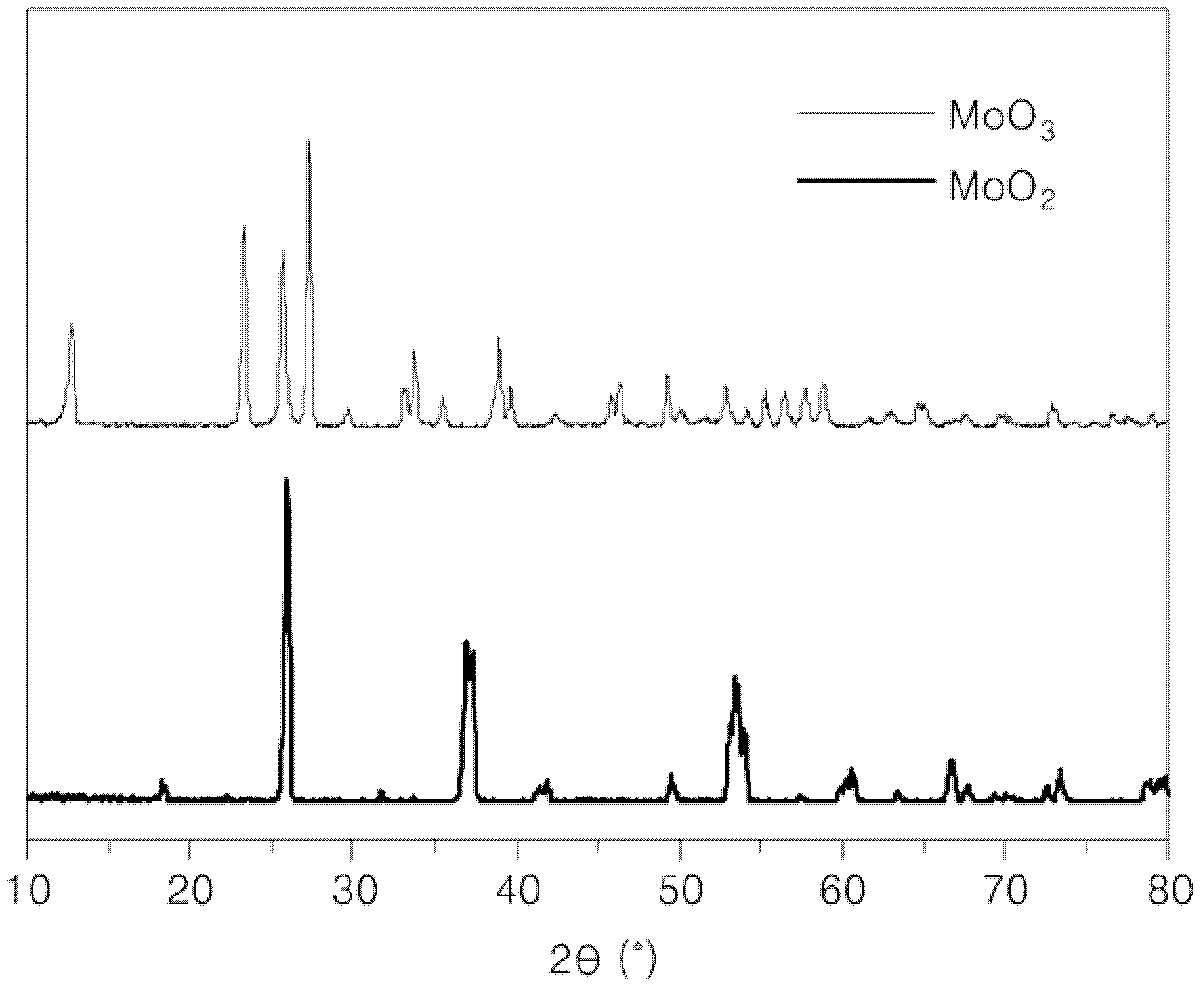

ActiveUS20120037846A1Improve stabilityAvoid it happening againTungsten oxides/hydroxidesCell electrodesStable statePhysical chemistry

A positive active material including a lithium composite oxide and a transition metal oxide including a transition metal having an oxidation number smaller than an oxidation number when the transition metal is in the most stable state hinders generation of oxygen occurring during charging and provides a lithium battery with high-temperature preservation characteristics and high stability.

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com