Lithium battery diaphragm and preparation method therefor, and application of lithium battery diaphragm in lithium battery

A lithium battery separator and electrospinning technology, applied in the field of electrochemistry, can solve problems such as poor thermal stability, low electrolyte absorption rate, inability to guarantee lithium battery safety and stable cycle performance, etc., to improve wettability and benefit The effect of fast charge and discharge, good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a lithium battery separator, the method comprising the following steps:

[0027] (1) Preparation of electrospinning solution: mix soluble inorganic salt and solvent to form an inorganic salt solution with a mass fraction of 5%-20%, and mix the template polymer with a solvent to form a polymeric solution with a mass fraction of 5%-20%. compound solution, mixing the inorganic salt solution and the polymer solution to obtain an electrospinning solution, the mass ratio of the inorganic salt solution and the polymer solution is 4:1-1:4;

[0028] (2) Electrospinning: inject the electrospinning solution into the syringe of the electrospinning device for electrospinning to obtain a hybrid fiber membrane, set the injection speed to 50 μL / min-500 μL / min, and the rotational speed of the receiving drum 50r / min-100r / min, the reciprocating speed of the slide table is 0.5cm / min-5cm / min, the spinning voltage is 5kV-15kV, and the receiving d...

Embodiment 1

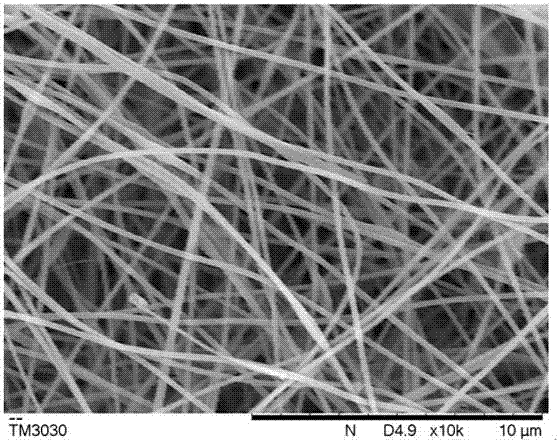

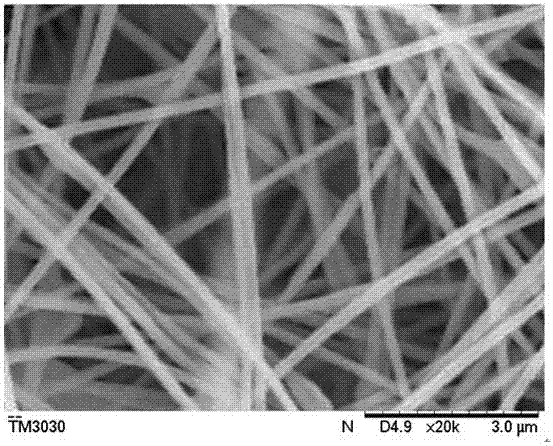

[0037] The lithium battery separator prepared in this example is SiO 2 nanofiber membrane

[0038] (1) Preparation of electrospinning solution: mix tetraethyl orthosilicate (TEOS) with deionized water to form a solution of orthoethyl silicate (TEOS) with a mass fraction of 5%, and mix polyvinyl alcohol (PVA) with deionized water Ionized water is mixed to form a polyvinyl alcohol (PVA) solution with a mass fraction of 5%, and tetraethyl orthosilicate (TEOS) solution and polyvinyl alcohol (PVA) solution are mixed to obtain an electrospinning solution, and tetraethyl orthosilicate ( The mass ratio of TEOS) solution and polyvinyl alcohol (PVA) solution is 4:1;

[0039] (2) Electrospinning: inject the electrospinning solution into the syringe of the electrospinning device for electrospinning to obtain a hybrid fiber membrane, set the injection speed to 100 μL / min, and the speed of the receiving drum to be 50 r / min. The reciprocating speed of the table is 1cm / min, the spinning vol...

Embodiment 2

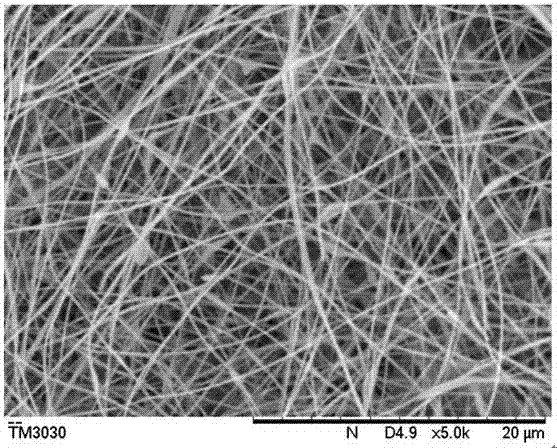

[0044] The lithium battery separator prepared in this example is Al 2 o 3 nanofiber membrane

[0045] (1) Preparation of electrospinning solution: aluminum nitrate (Al(NO 3 ) 3 ) mixed with deionized water to form aluminum nitrate (Al(NO 3 ) 3 ) solution, polyethylene oxide (PEO) and deionized water were mixed to form a polyethylene oxide (PEO) solution with a mass fraction of 11%, aluminum nitrate (Al(NO 3 ) 3 ) solution and polyethylene oxide (PEO) solution were mixed to obtain electrospinning solution, aluminum nitrate (Al(NO 3 ) 3 ) solution and the mass ratio of polyethylene oxide (PEO) solution is 2:1;

[0046] (2) Electrospinning: inject the electrospinning solution into the syringe of the electrospinning device for electrospinning to obtain a hybrid fiber membrane, set the injection speed to 200 μL / min, and the rotational speed of the receiving drum to be 80 r / min. The reciprocating speed of the table is 3cm / min, the spinning voltage is 15kV, and the receiving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com