Composite lithium ion battery separator and preparation method thereof

A lithium-ion battery, composite technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as limited space occupation and performance impact of lithium-ion batteries, avoiding short circuits, increasing costs, and simple steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

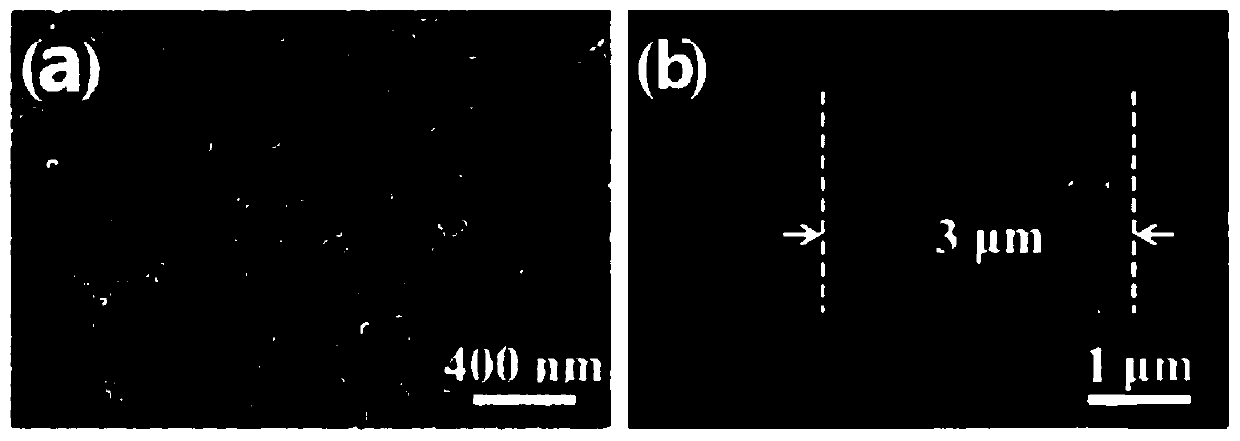

[0030] (1) Coating preparation: Add inorganic water-based dispersion liquid, organic water-based dispersion liquid and surfactant into deionized water and stir for 3 hours and mix uniformly to obtain coating; wherein, inorganic water-based dispersion liquid is water-based nano SiO with 50% solid content 2 Dispersion liquid; The organic water-based dispersion liquid is polyvinylidene fluoride (PVDF) dispersion liquid of 50% solid content; Surfactant is nonionic polyacrylamide; Wherein, the add-on of inorganic water-based dispersion liquid is 56wt%, organic water-based dispersion liquid The addition amount of the surfactant is 1wt%, the addition amount of the surfactant is 0.7wt%, and the addition amount of the deionized water is 42.3wt%. The particle diameter of the inorganic particles in the inorganic aqueous dispersion is 90-105nm; the particle diameter of the organic particles in the organic aqueous dispersion is 350-450nm.

[0031] (2) Pass the clean 12μm pure PE diaphragm ...

Embodiment 2

[0036] The preparation steps of embodiment 2 are basically the same as embodiment 1, and the only difference is that the water-based binder is acrylic acid ester (AE).

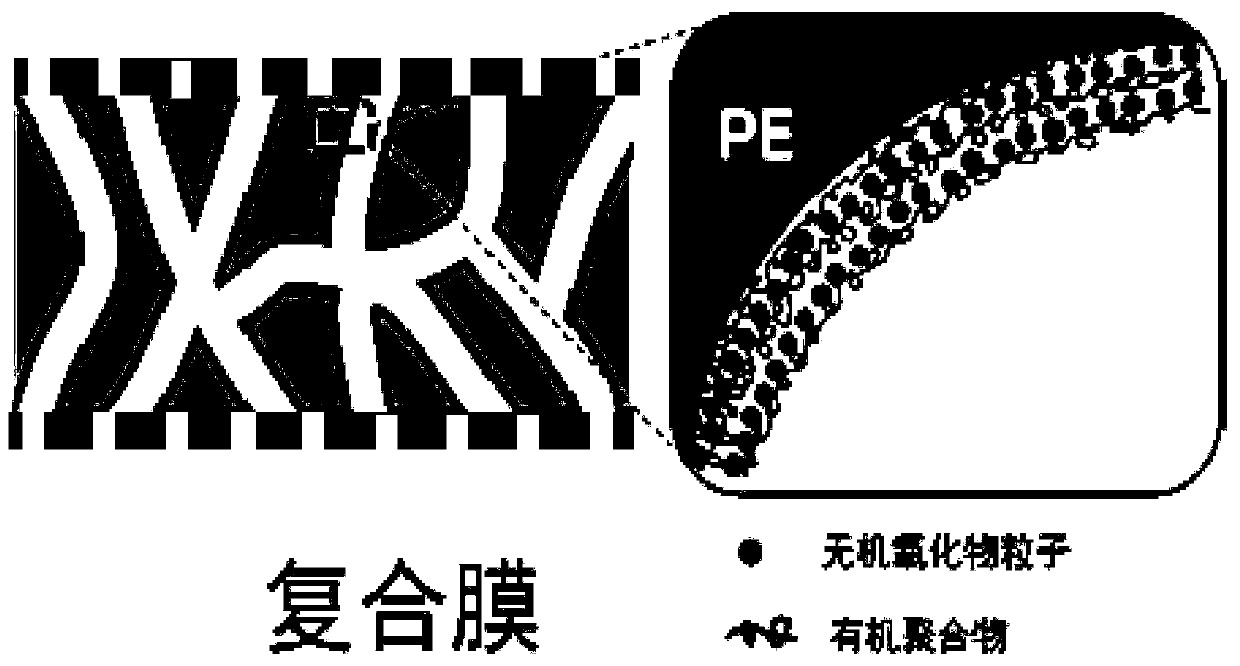

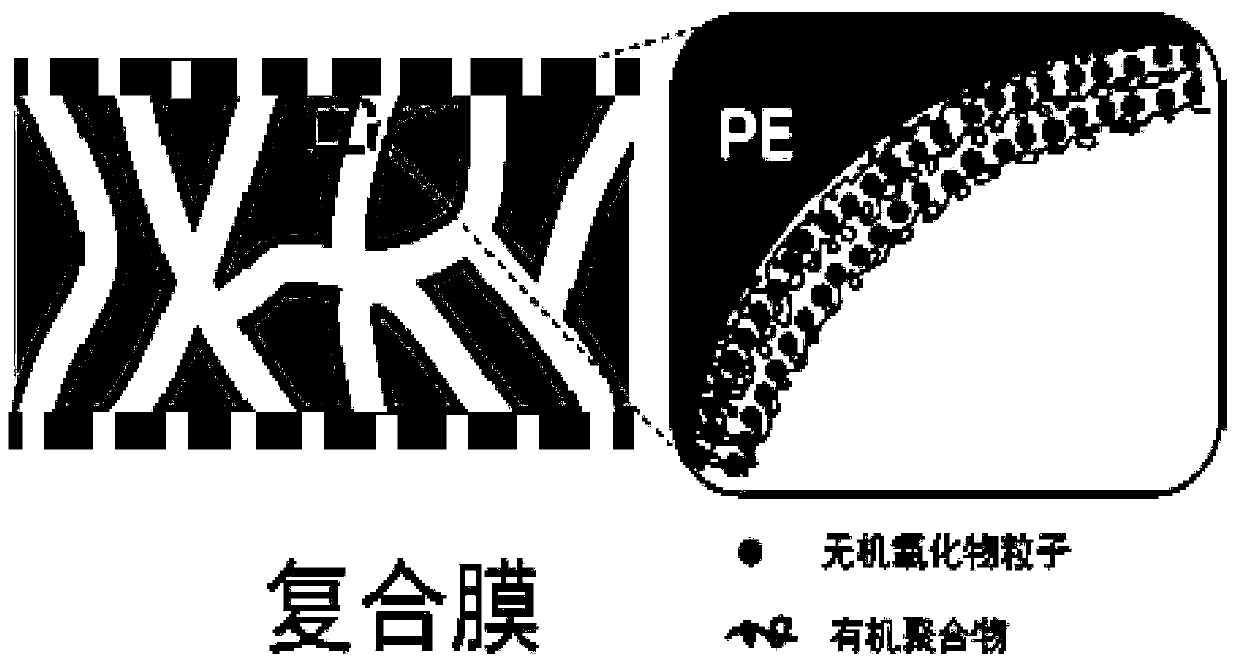

[0037] The composite lithium-ion battery diaphragm prepared by the above method is composed of a substrate layer and an inorganic / organic composite porous film layer arranged on the surface of the substrate layer, the substrate layer is a PE film; the inorganic / organic composite porous film layer is composed of inorganic SiO 2 The composite layer of nanoparticles and acrylate (AE), the thickness of the inorganic / organic composite porous film layer on one side of the substrate layer is about 3um.

Embodiment 3

[0039] The preparation steps of embodiment 3 are substantially the same as embodiment 1, and the only difference is that the water-based binder is polyurethane (PU).

[0040] The composite lithium-ion battery diaphragm prepared by the above method is composed of a substrate layer and an inorganic / organic composite porous film layer arranged on the surface of the substrate layer, the substrate layer is a PE film; the inorganic / organic composite porous film layer is composed of inorganic SiO 2 The composite layer of nanoparticles and polyurethane (PU), the thickness of the inorganic / organic composite porous film layer on one side of the substrate layer is about 3um.

[0041] Function detection:

[0042] (1) Test method:

[0043] a) air permeability

[0044] Air permeability is one of the important parameters to characterize the pore structure of lithium-ion battery separator, usually expressed by Gurley value, the unit is second (s). Its physical meaning is the time required...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com