Patents

Literature

95results about How to "Inhibit heat shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic/inorganic composite separator having porous active coating layer and electrochemical device containing the same

ActiveCN101542777AAvoid separationPrevent electrical short circuitSolid electrolytesLi-accumulatorsPorous substratePolyolefin

Owner:LG ENERGY SOLUTION LTD +1

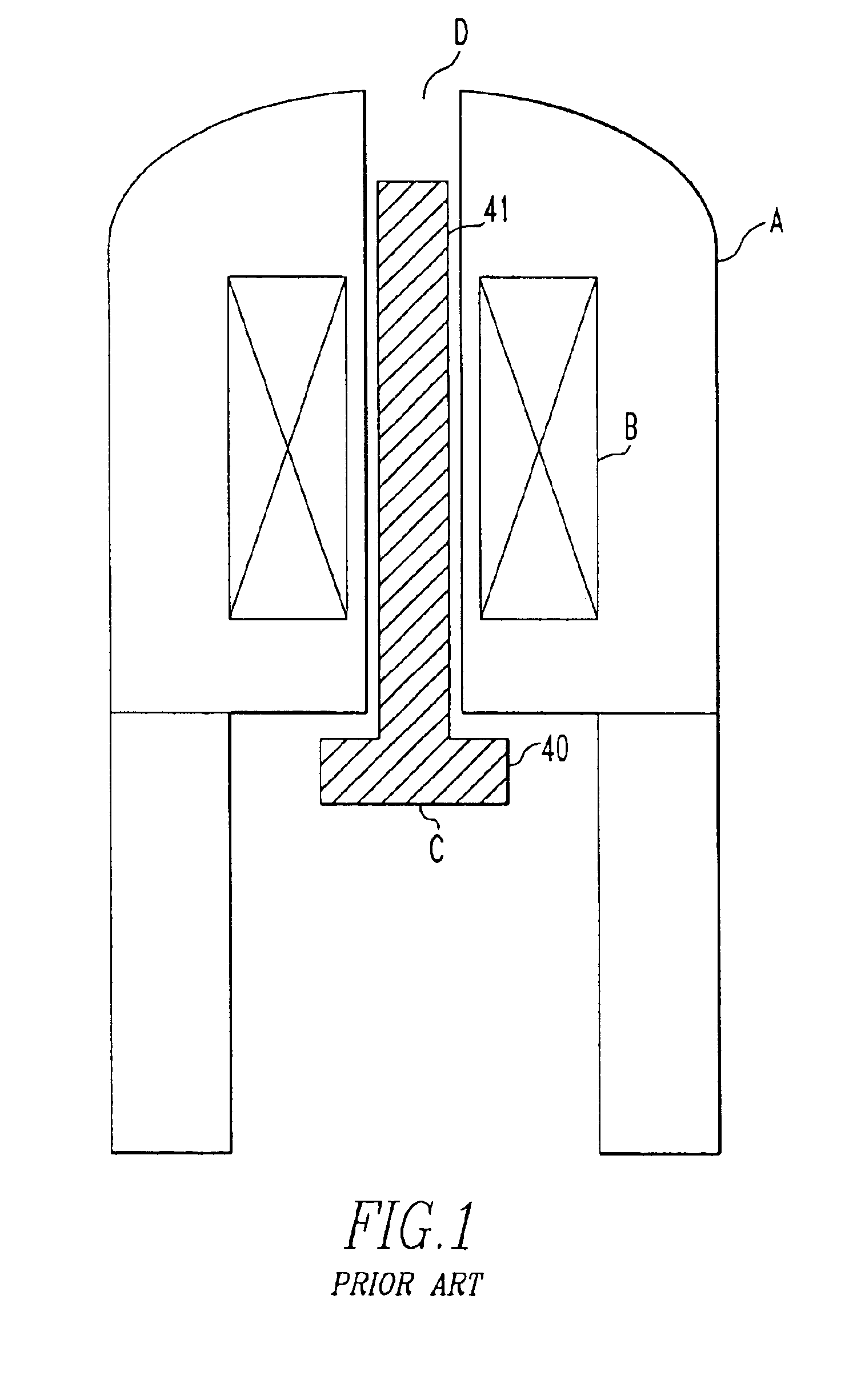

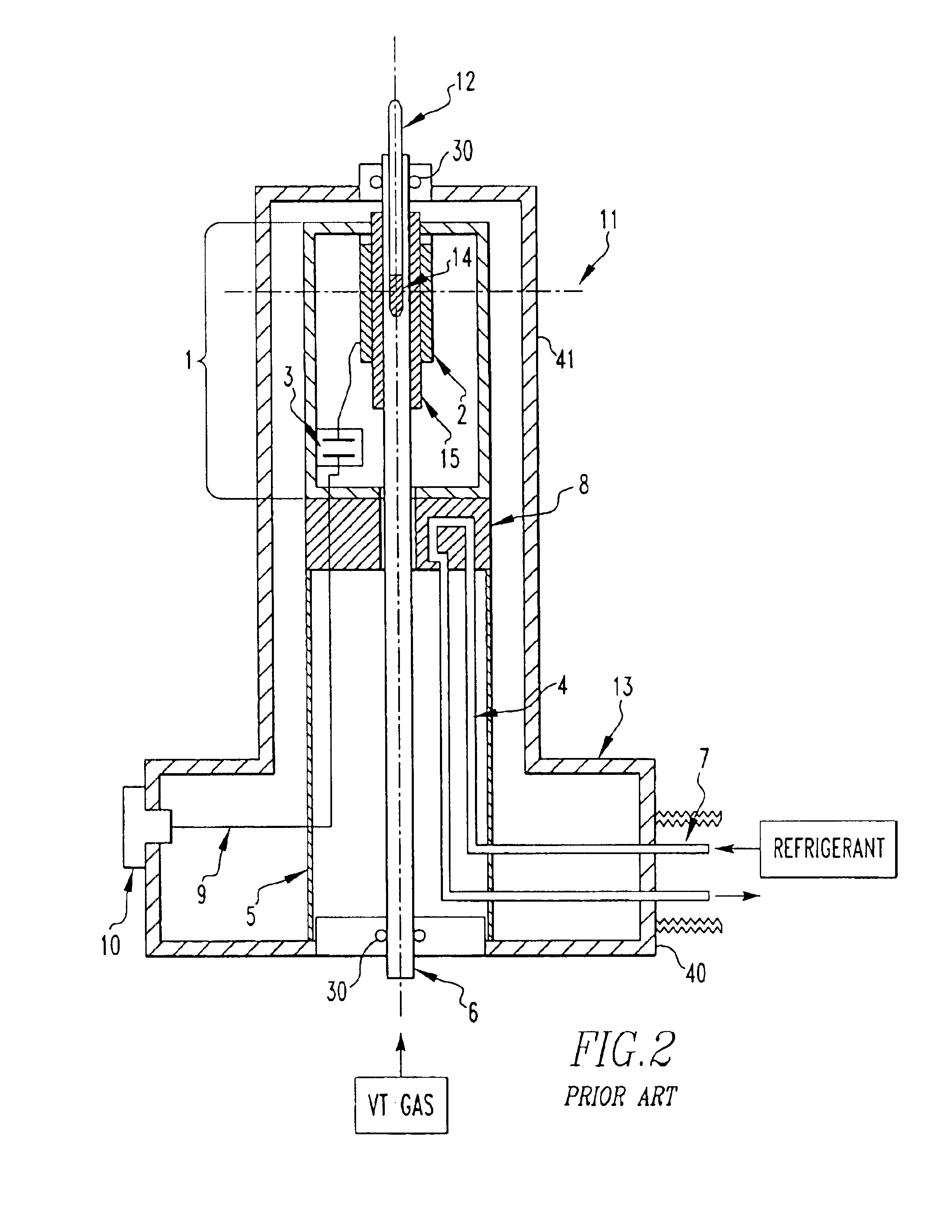

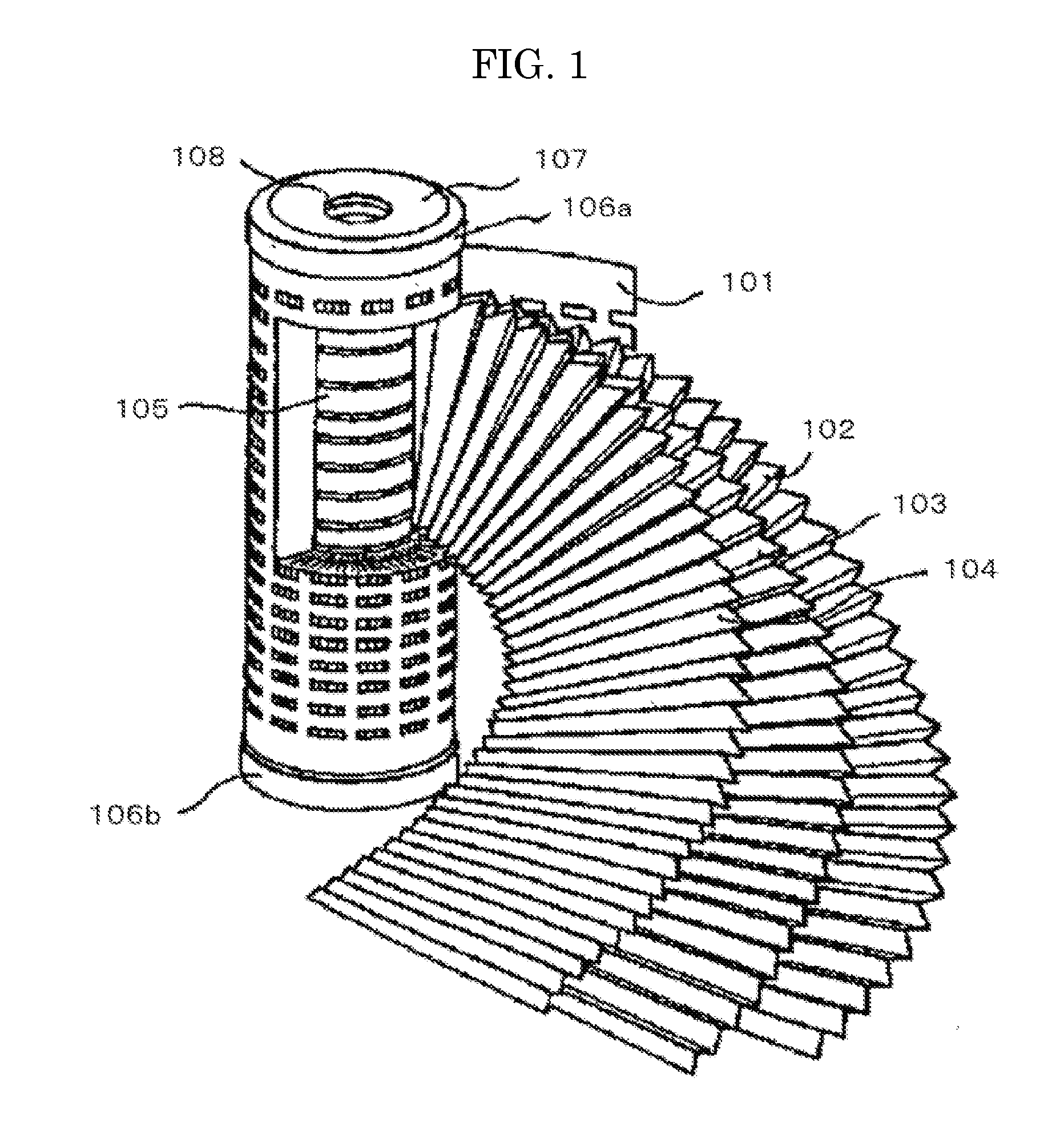

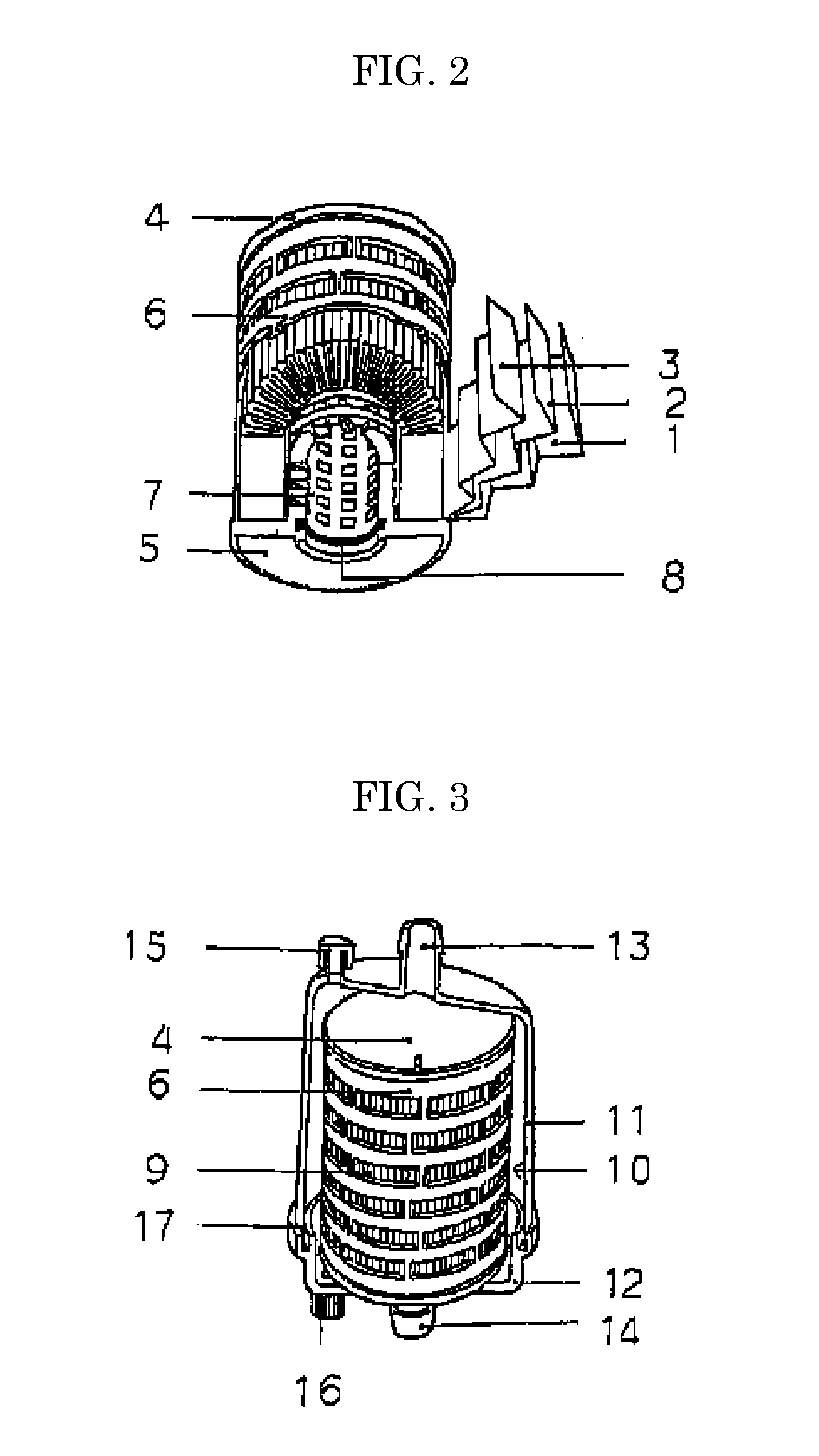

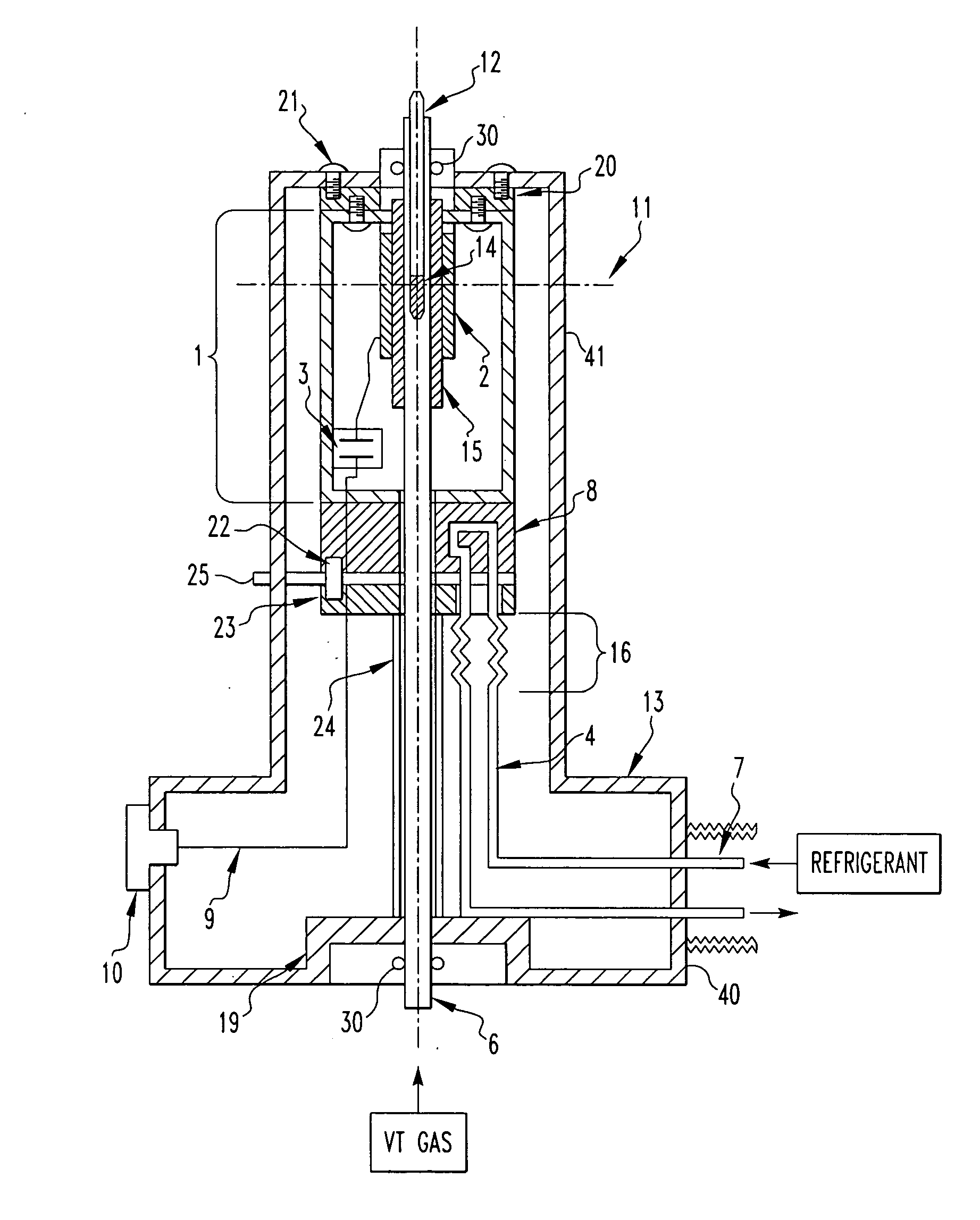

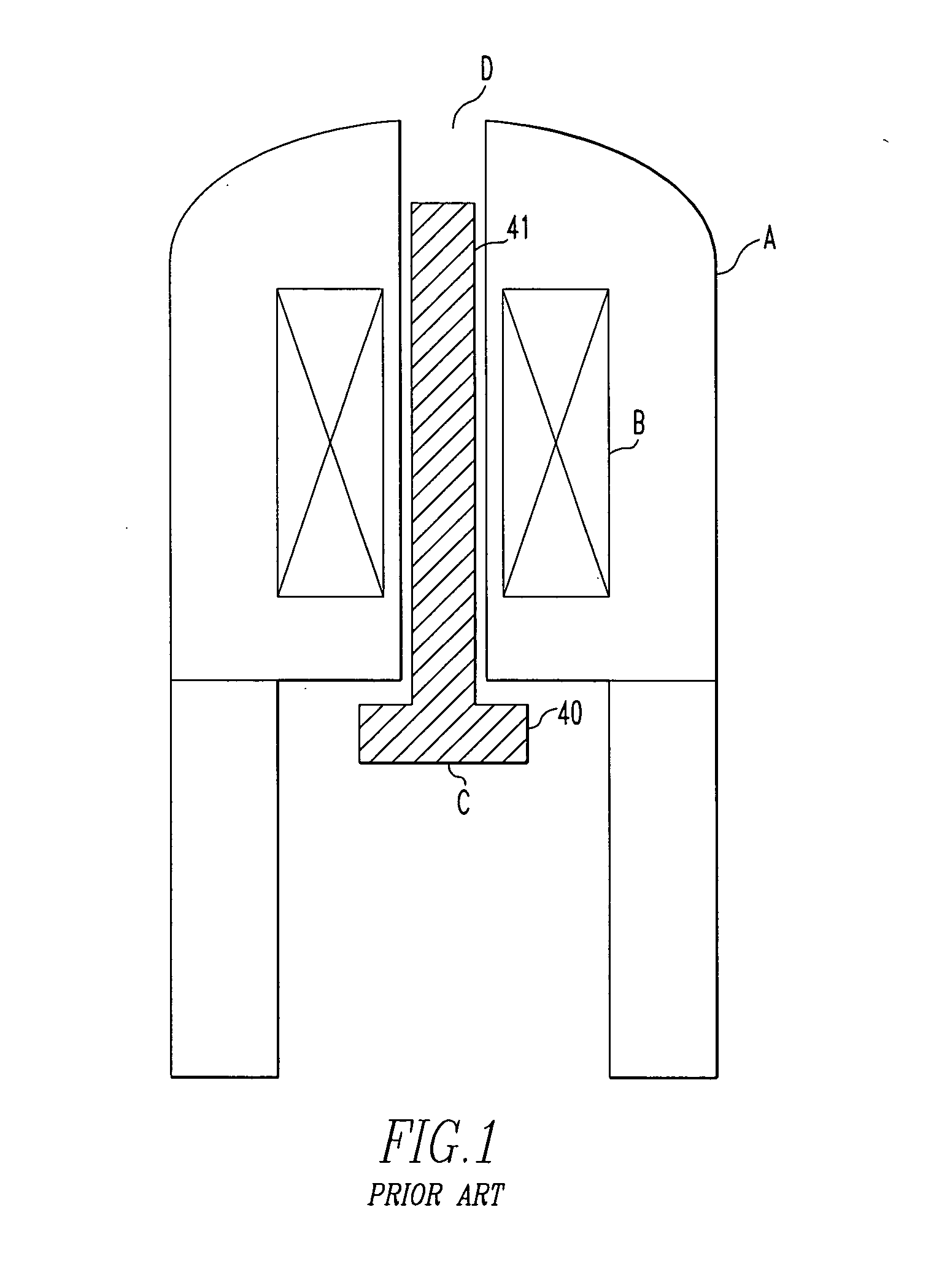

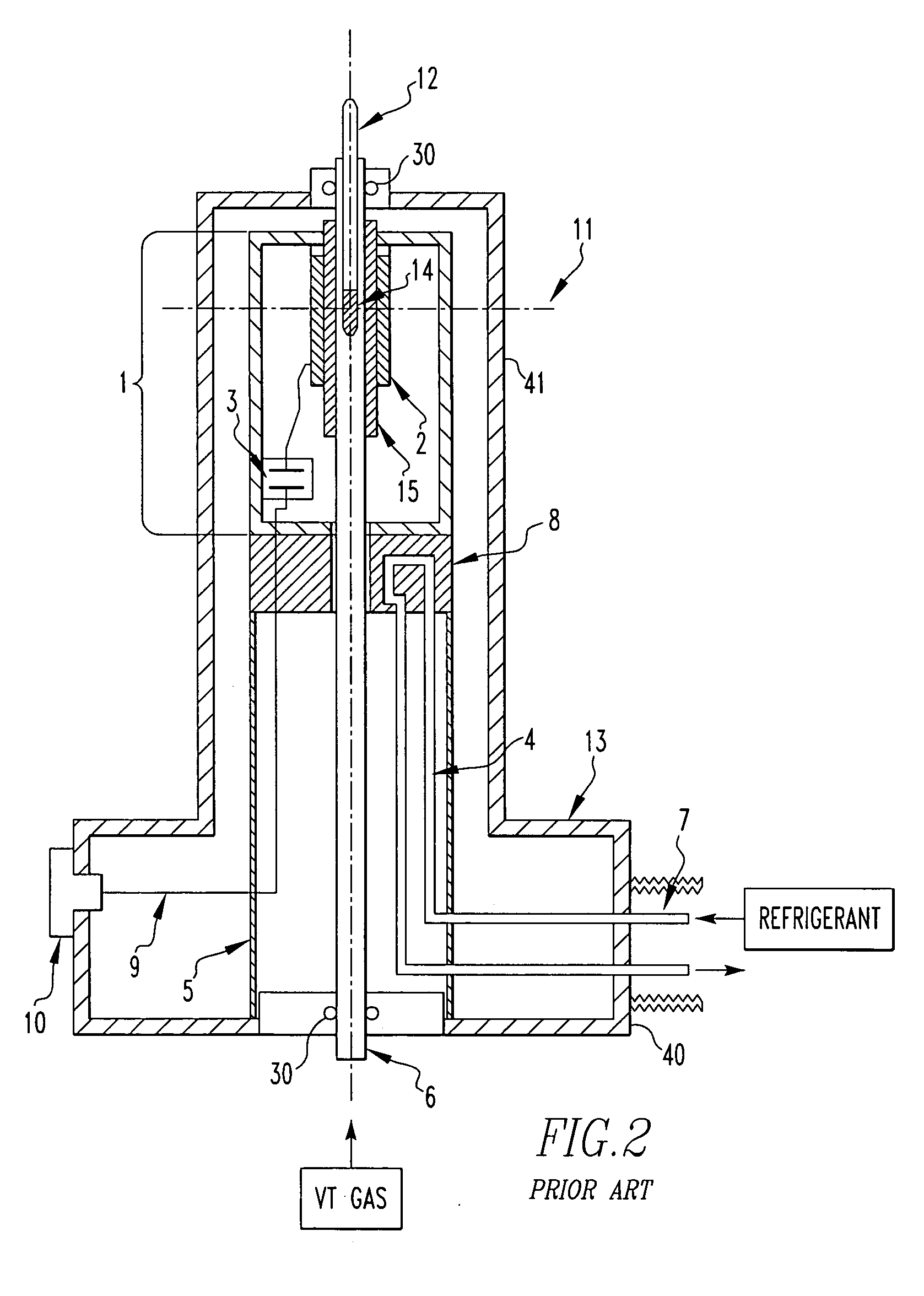

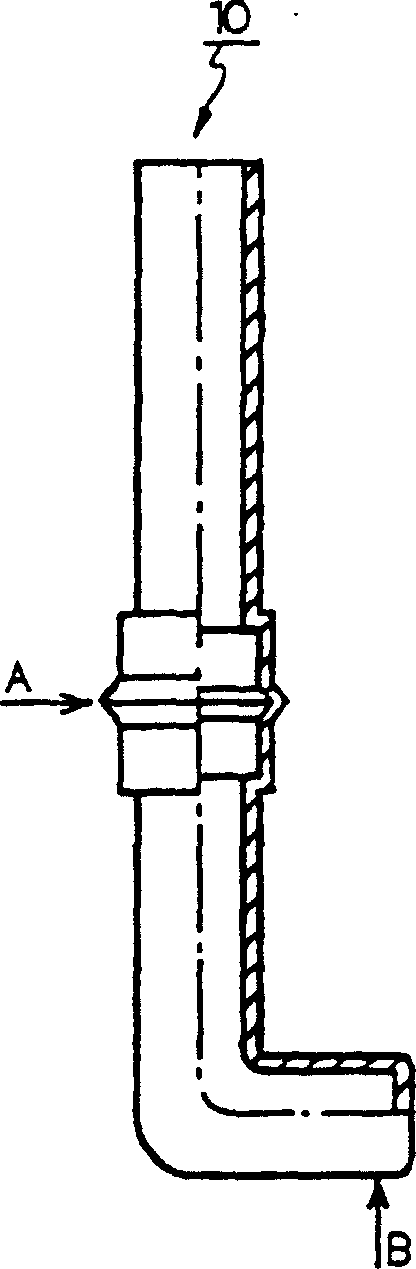

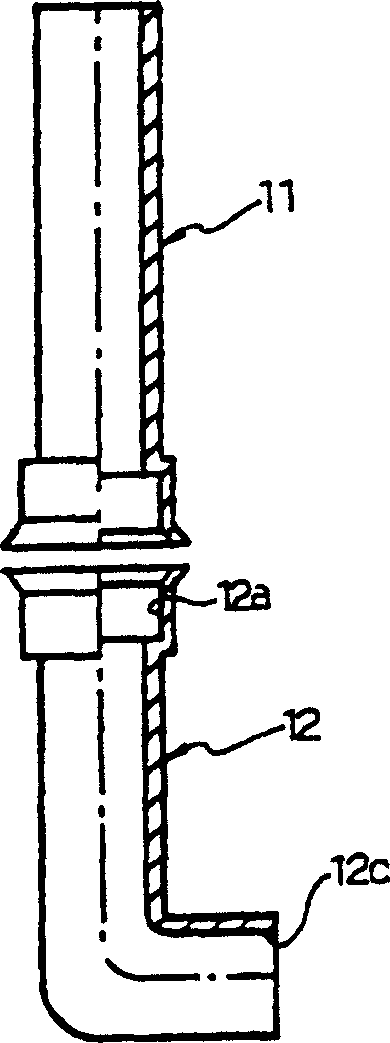

NMR probe

ActiveUS6914430B2Inhibit heat shrinkageHigh sensitivityElectric/magnetic detectionMeasurements using magnetic resonanceNMR - Nuclear magnetic resonanceMagnet

A nuclear magnetic resonance (NMR) probe is offered which can minimize positional shift of the detector portion caused by shrinkage of the support post due to cooling of the detector portion. The NMR probe has a vacuum-insulated container and the detector portion described above. The container has a cylindrical portion inserted in a magnet. The detector portion is made up of a detection coil and a tuning and matching circuit that are placed within the container. The detector portion is cooled by a cooling means such that NMR signals are detected with enhanced sensitivity. This probe is characterized in that the detector portion is mounted to the upper end surface or a side surface of the cylindrical portion.

Owner:JEOL LTD

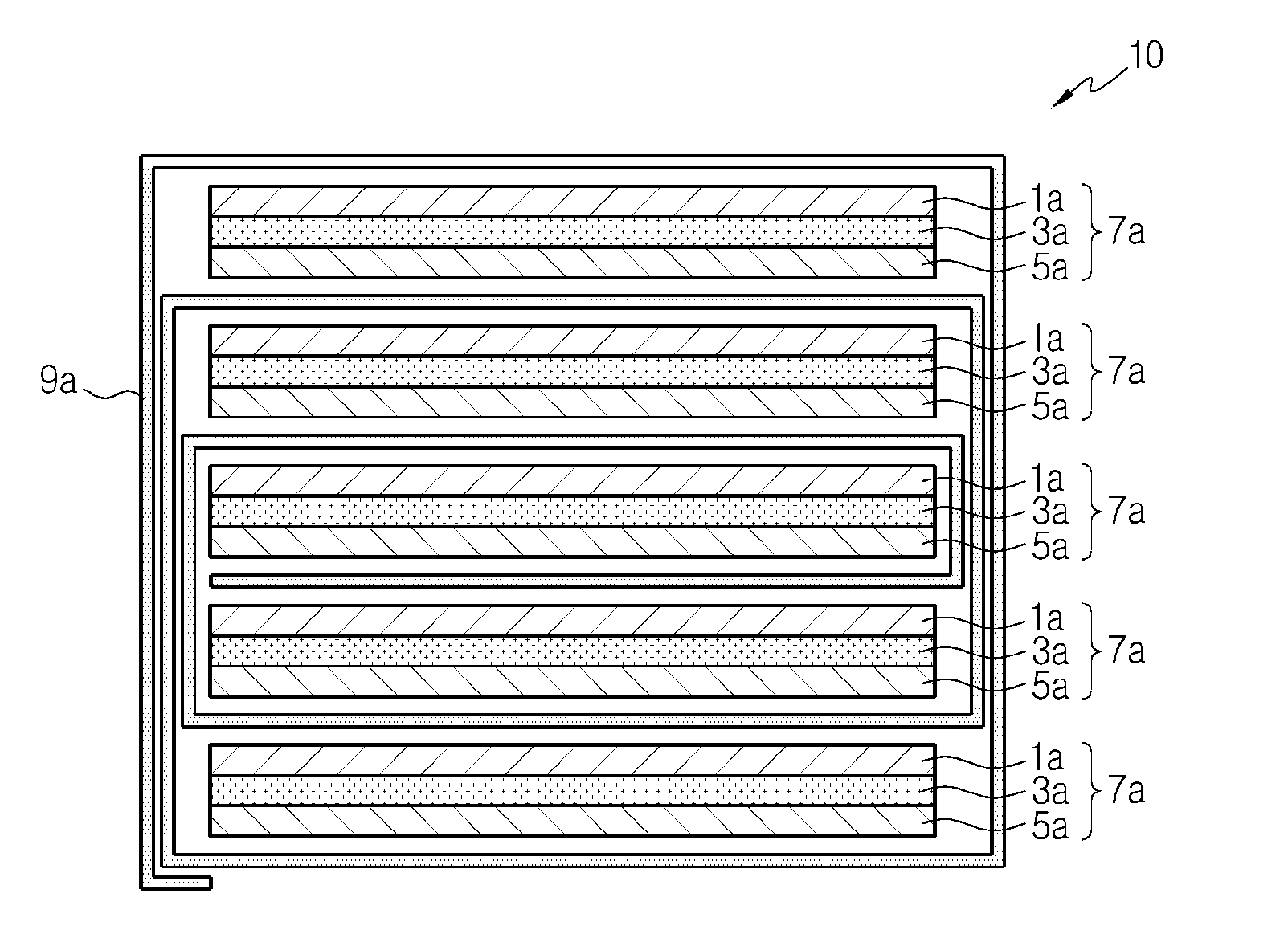

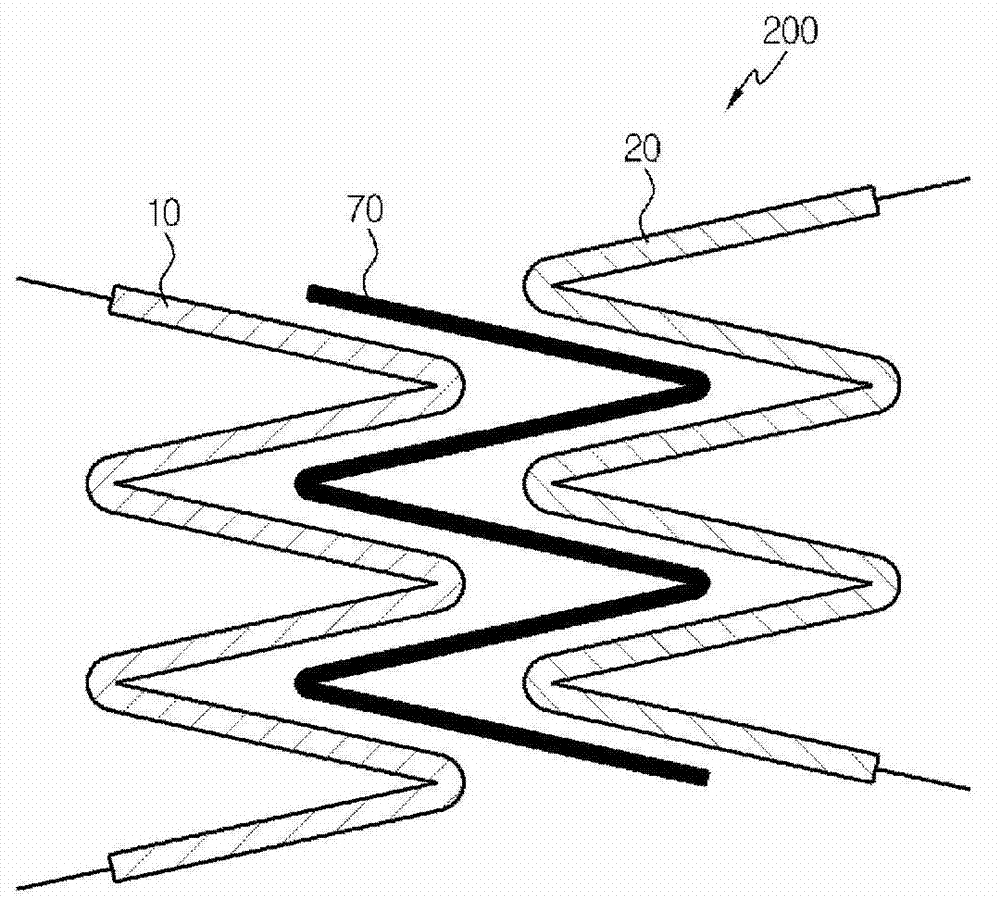

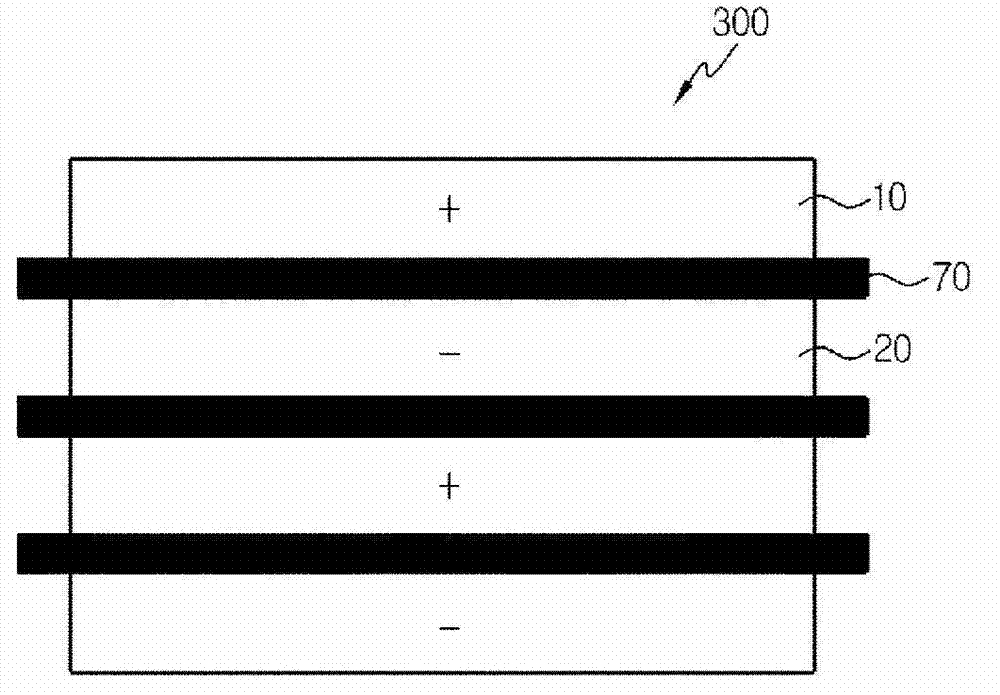

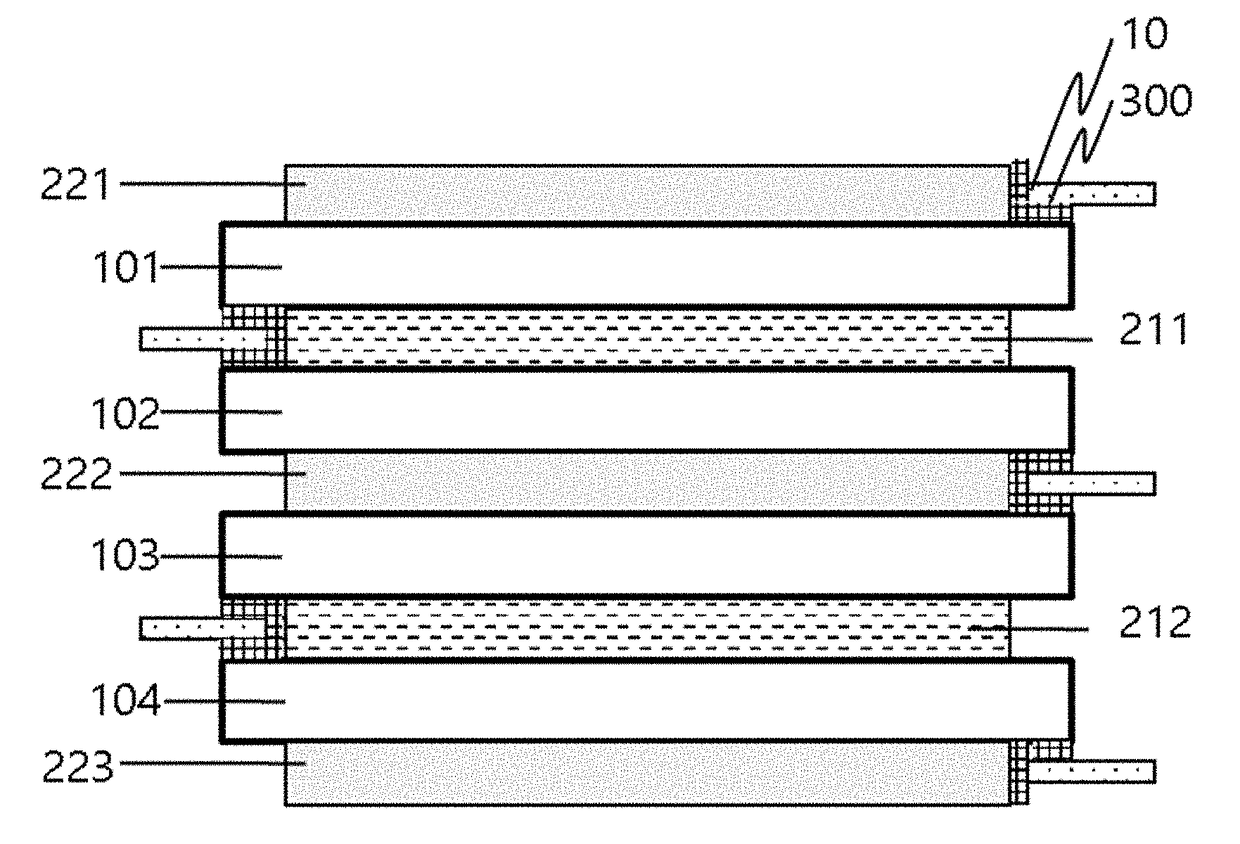

Electrochemical device having different kinds of separators

ActiveUS20100261047A1Prevent ignition and explosionReduce temperature increase rateFinal product manufactureJackets/cases materialsPolyolefinPorous coating

An electrochemical device includes a plurality of unit cells, each having a first separator and a cathode and an anode positioned at both sides of the first separator, and a continuous single second separator interposed between adjacent unit cells in correspondence with each other in a laminated pattern and arranged to surround each unit cell. The first separator includes a heat-resisting porous substrate having a melt point of 200° C. or above and a first porous coating layer formed on at least one surface of the heat-resisting porous substrate and made of a mixture of a plurality of inorganic particles and a binder polymer. The second separator includes a polyolefin porous substrate and a second porous coating layer formed on at least one surface of the polyolefin porous substrate and made of a mixture of a plurality of inorganic particles and a binder polymer.

Owner:LG ENERGY SOLUTION LTD

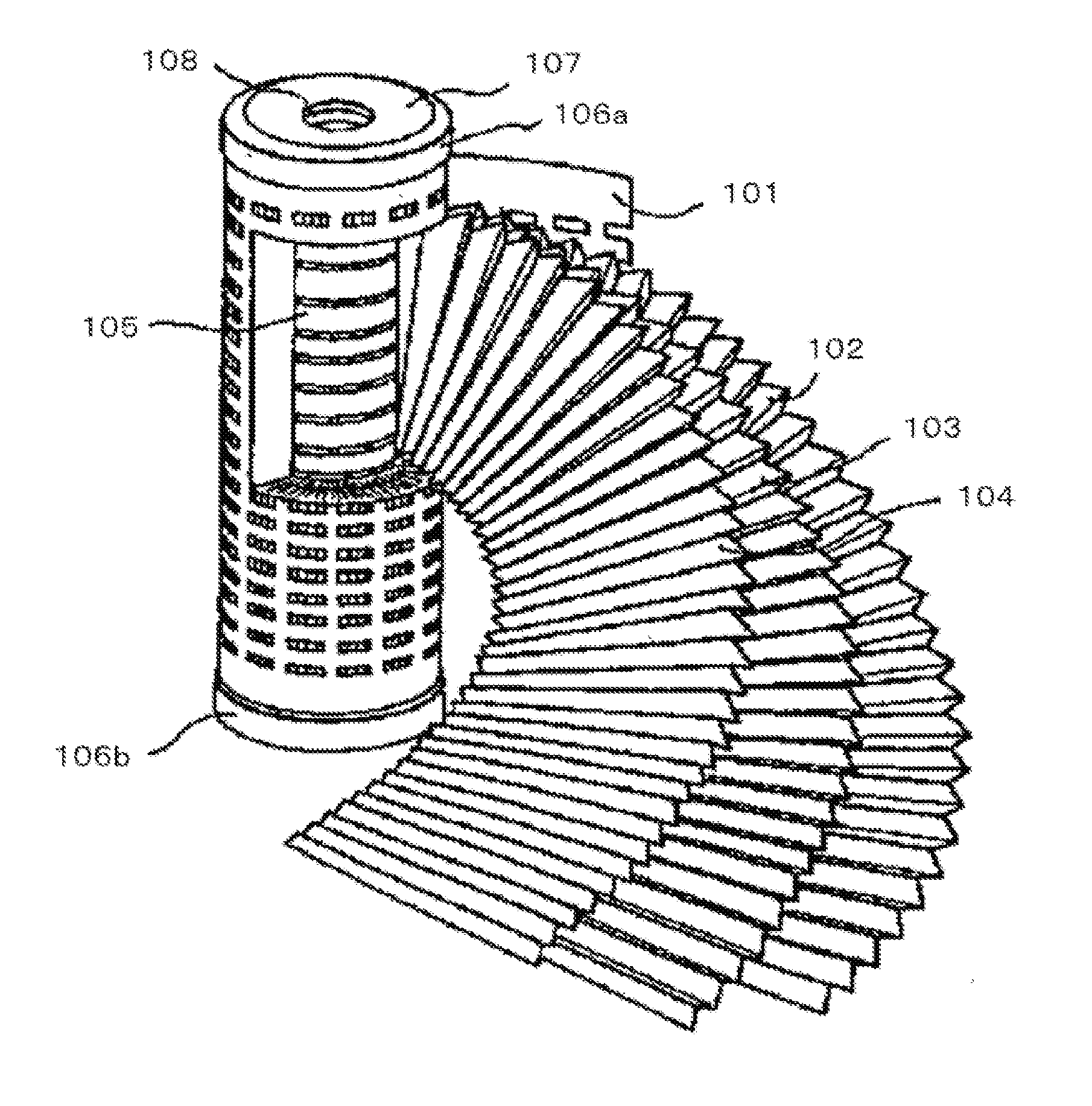

Filtration filter and method for producing the same

InactiveUS20110120937A1Improve water resistanceLong life-timeSemi-permeable membranesMembranesFiltrationPore diameter

A filtration filter including a cartridge, which contains a crystalline polymer microporous membrane having a plurality of pores, where the average pore diameter of a first surface of the crystalline polymer microporous membrane is larger than that of a second surface thereof, and the average pore diameter of the crystalline polymer microporous membrane continuously changes from the first surface thereof to the second surface thereof, wherein at least part of the crystalline polymer microporous membrane forming the cartridge is subjected to surface modification after the crystalline polymer microporous membrane is formed into the cartridge.

Owner:FUJIFILM CORP

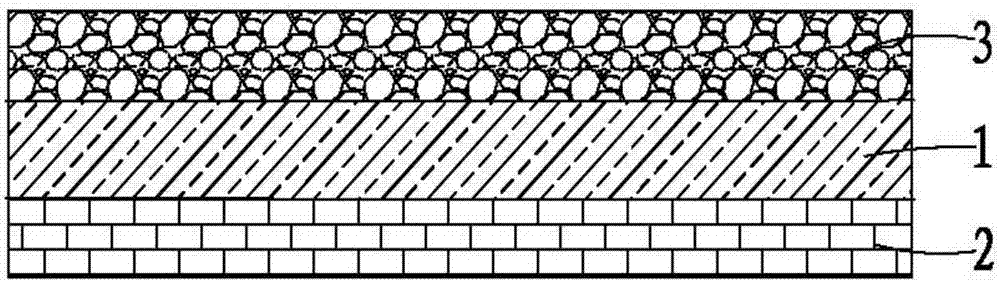

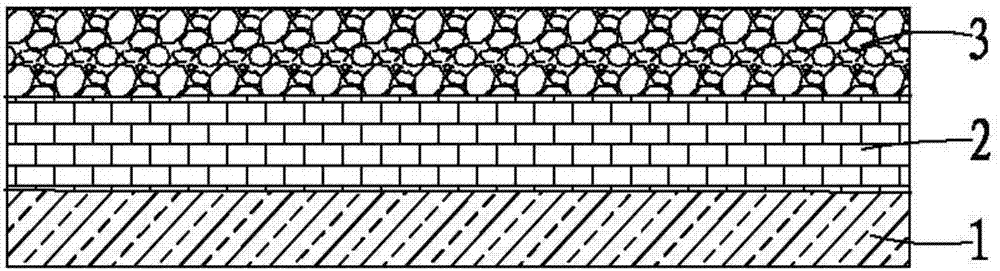

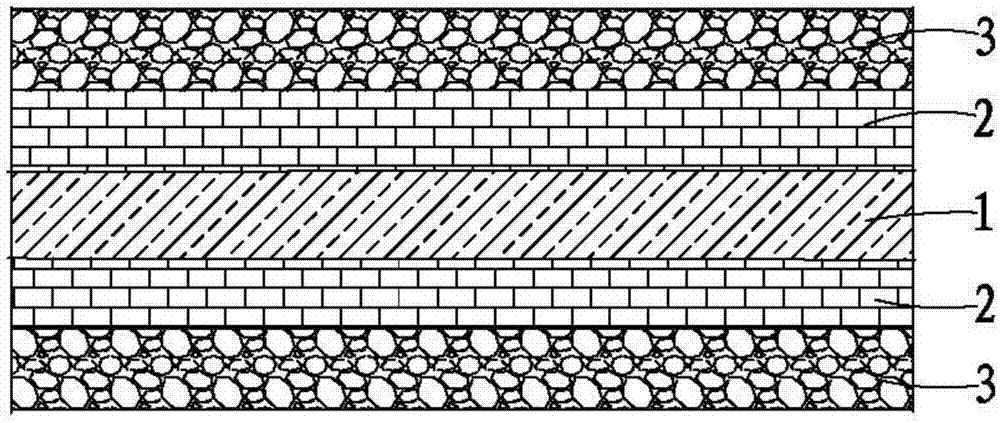

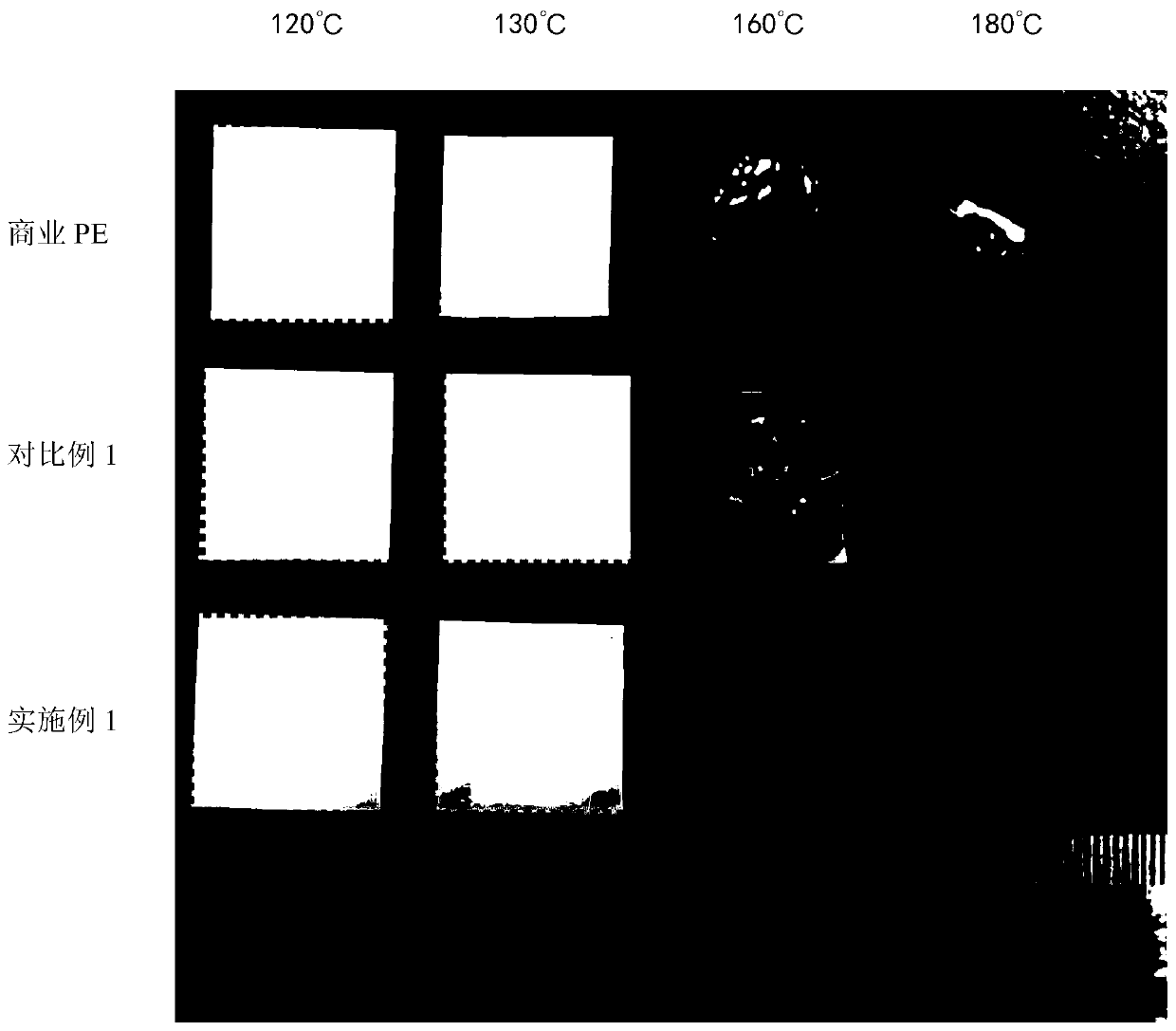

Polyethylene based composite material microporous diaphragm with hot-pressing adhesive characteristic

InactiveCN103178227AInhibit heat shrinkageImprove securityMembranesSemi-permeable membranesPolymer scienceWhole body

The invention relates to a polyethylene based composite material microporous diaphragm with a hot-pressing adhesive characteristic. According to the polyethylene based composite material microporous diaphragm, ethylene propylene monomer and polyisobutene rubbers with medium molecular weights are adopted to modify high-crystallinity high-density polyethylene, and fatty series dibasic acid ester of which the flashing point is more than 210DEG C is adopted as a process solvent and a pore forming agent of a diaphragm to obtain the diaphragm with the hot-pressing adhesive characteristic. The diaphragm with the hot-pressing adhesive characteristic and a positive pole piece are adhered into a whole body after hot-pressing lamination, so that the thermal contraction of the diaphragm is inhibited. The composite material diaphragm has high strength and high-temperature resistance, and can be applied to lithium ion power batteries with high safety and long cycle lives.

Owner:TIANJIN DG MEMBRANE

Glass substrate for flat panel display and method for manufacturing same

ActiveUS20130029830A1Inhibiting and avoiding erosion/wearPoint becomes highGlass drawing apparatusGlass forming apparatusMelting tankVitrification

Provided are: a glass substrate for p-Si TFT flat panel displays that is composed of a glass having high characteristic temperatures in the low-temperature viscosity range, typified by the strain point and glass transition point, having a small heat shrinkage rate, and being capable of avoiding the occurrence of the problem regarding the erosion / wear of a melting tank at the time of melting through direct electrical heating; and a method for manufacturing same. The present glass substrate is composed of a glass comprising 52-78 mass % of SiO2, 3-25 mass % of Al2O3, 3-15 mass % of B2O3, 3-25 mass % of RO, wherein RO is total amount of MgO, CaO, SrO, and BaO, 0.01-1 mass % of Fe2O3, and 0-0.3 mass % of Sb2O3, and substantially not comprising As2O3, the glass having a mass ratio (SiO2+Al2O3) / B2O3 in a range of 7-30 and a mass ratio (SiO2+Al2O3) / RO equal to or greater than 6. The present method for manufacturing a glass substrate involves: a melting step of obtaining a molten glass by melting, by employing at least direct electrical heating, glass raw materials blended so as to provide the aforementioned glass composition; a forming step of forming the molten glass into a flat-plate glass; and an annealing step of annealing the flat-plate glass.

Owner:AVANSTRATE INC

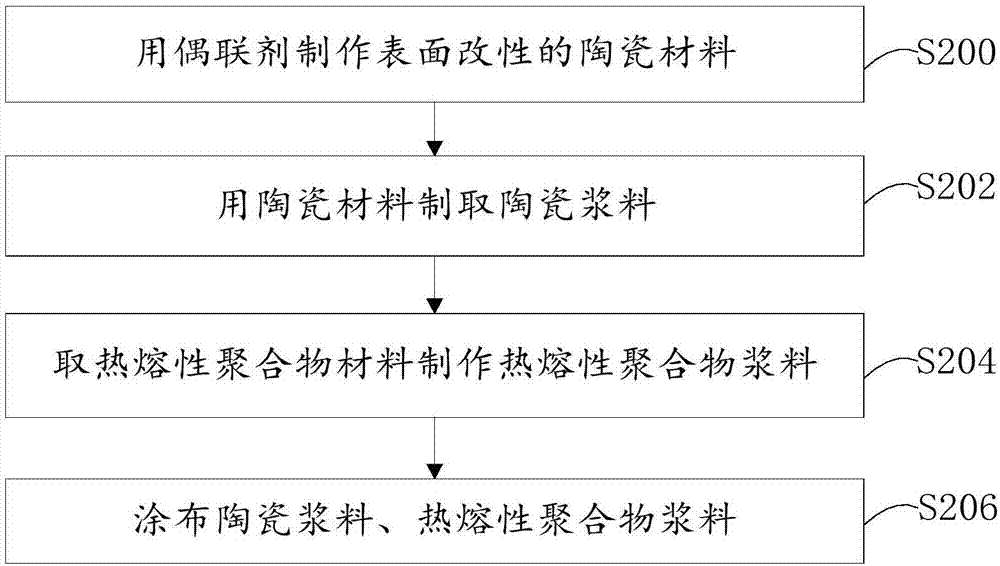

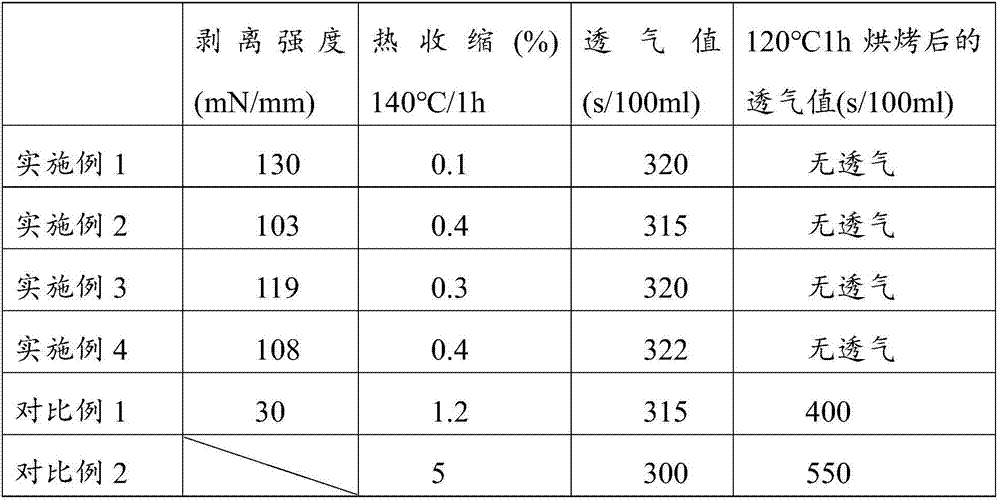

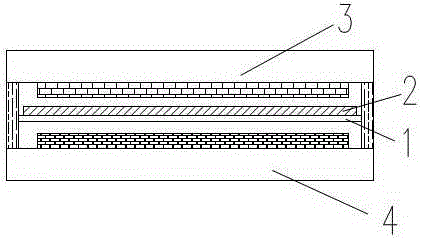

Diaphragm of lithium battery and preparation method thereof

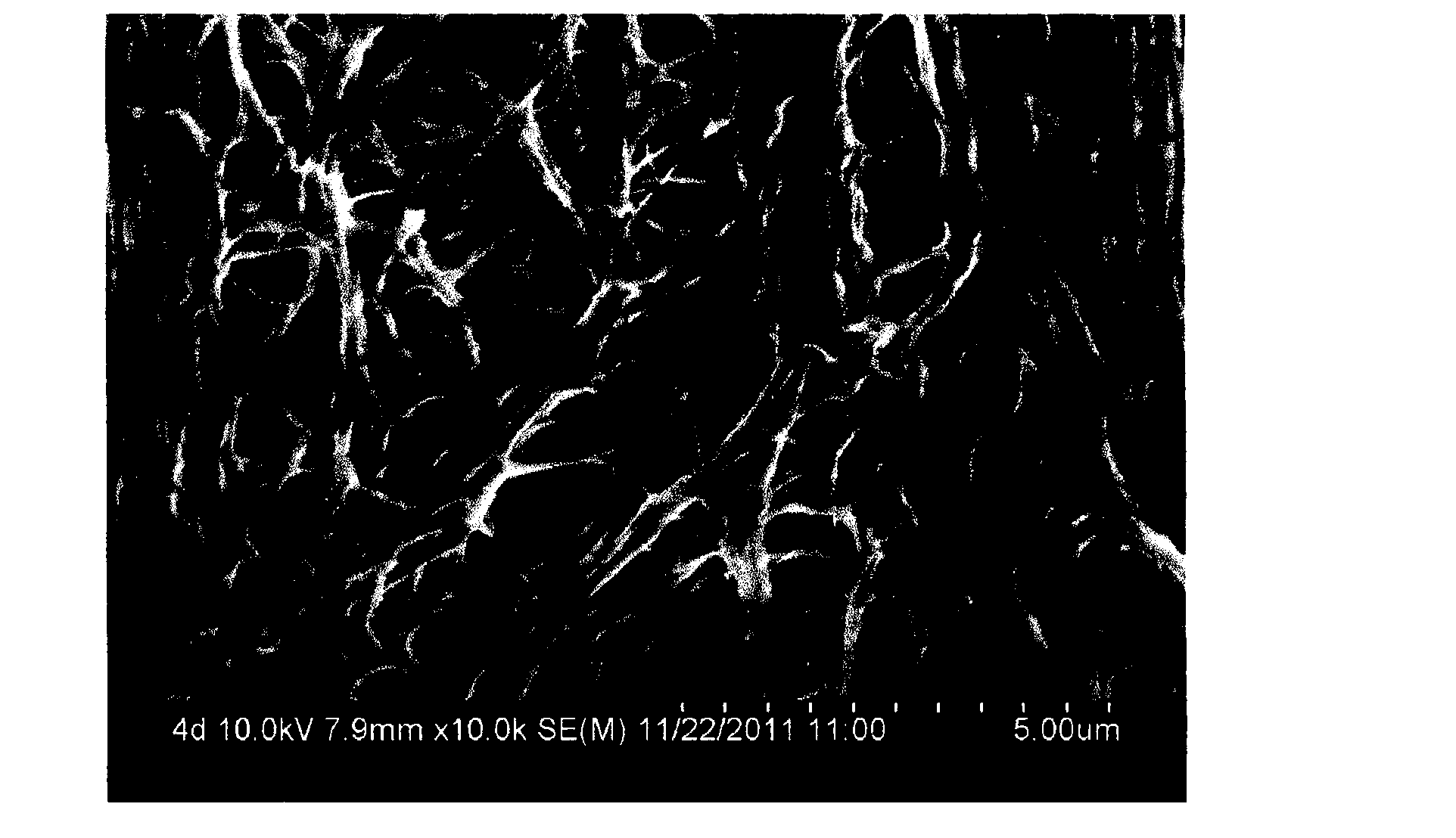

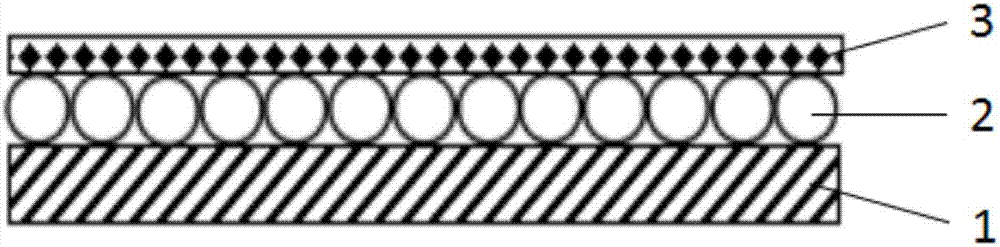

InactiveCN106887559AGood high temperature resistancePrevent heat shrinkageCell seperators/membranes/diaphragms/spacersCeramic coatingCeramic particle

The invention provides a diaphragm of a lithium battery and a preparation method thereof. The diaphragm of the lithium battery comprises a base diaphragm, a ceramic coating and a hot melted polymer coating. The ceramic coating and the hot melted polymer coating are located on the same side of the base diaphragm, and the ceramic coating comprises a ceramic particle material and a first adhesive; the hot melted polymer coating comprises hot melted polymer material particles and a second adhesive. The problem of thermal closing and thermal contraction of the diaphragm is solved.

Owner:XUCHENG FUJIAN SCI & TECH

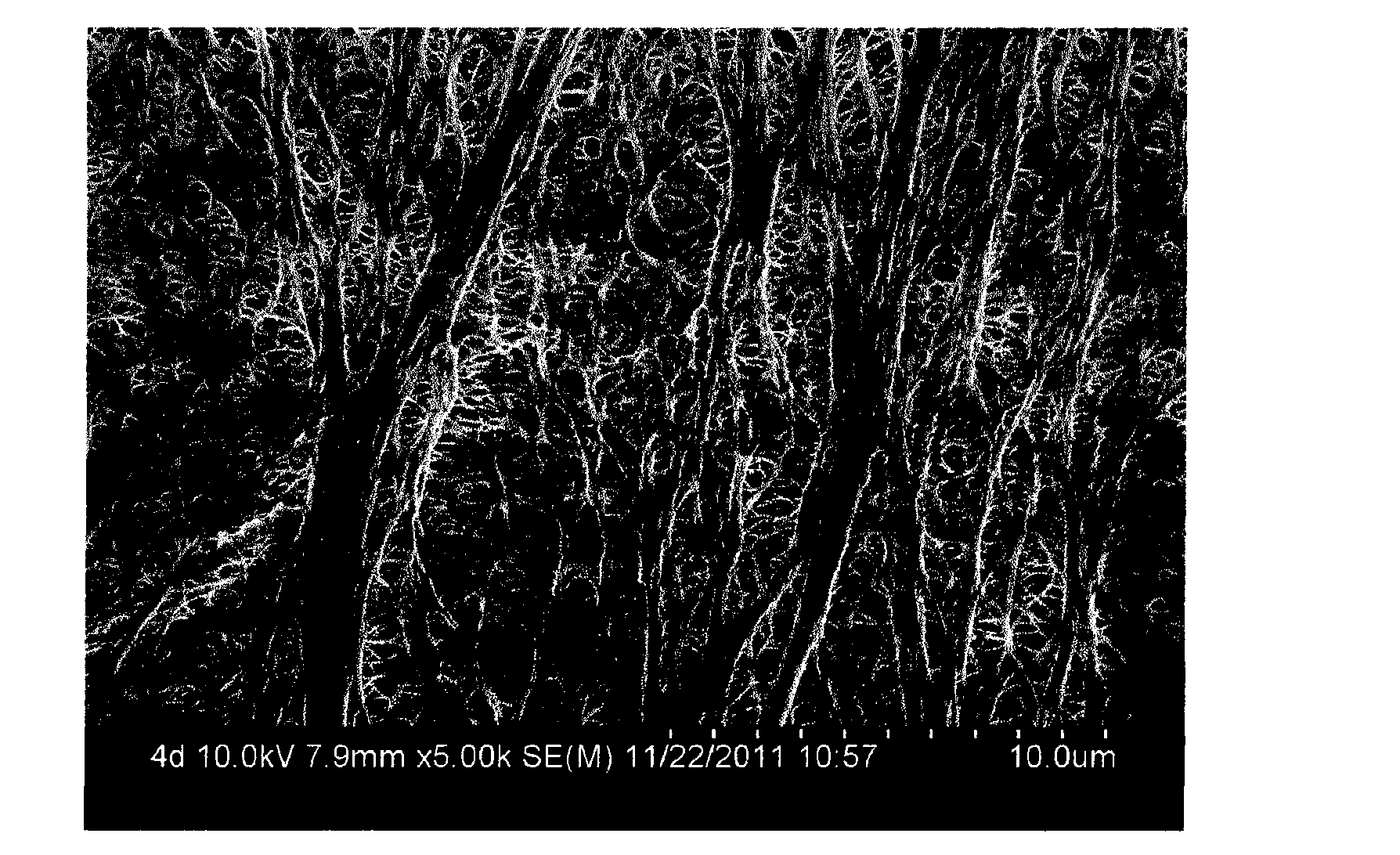

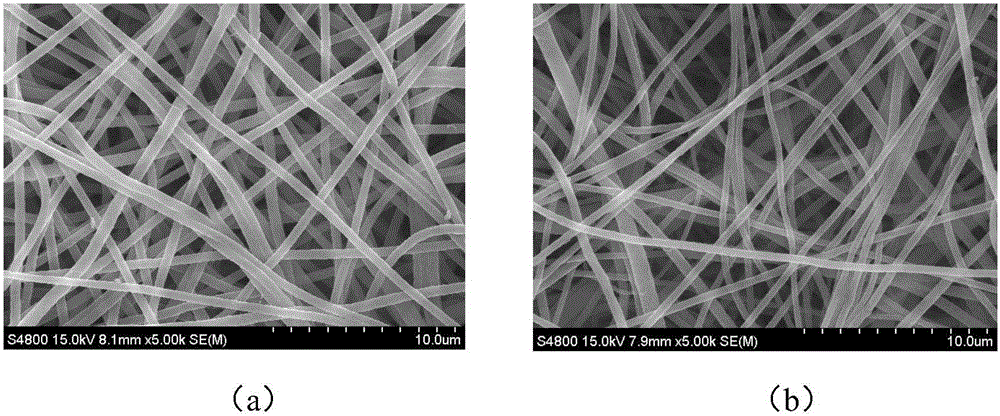

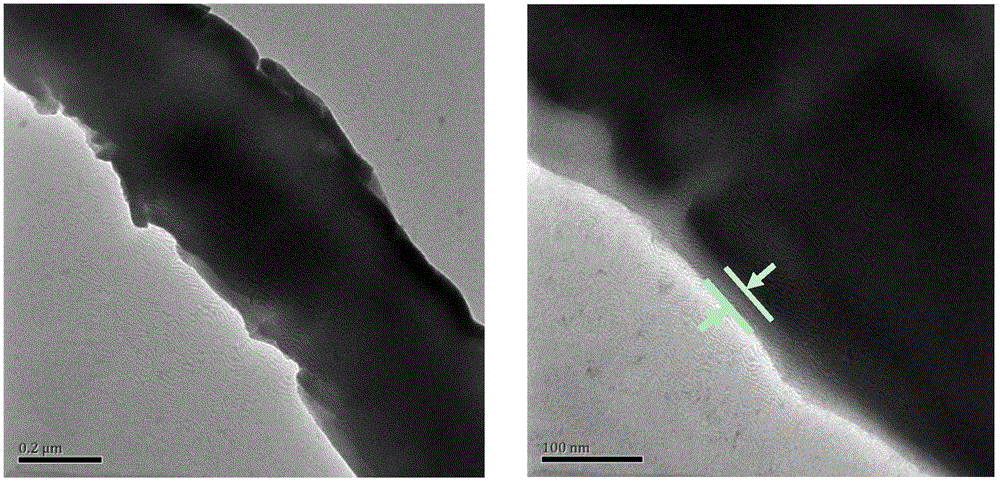

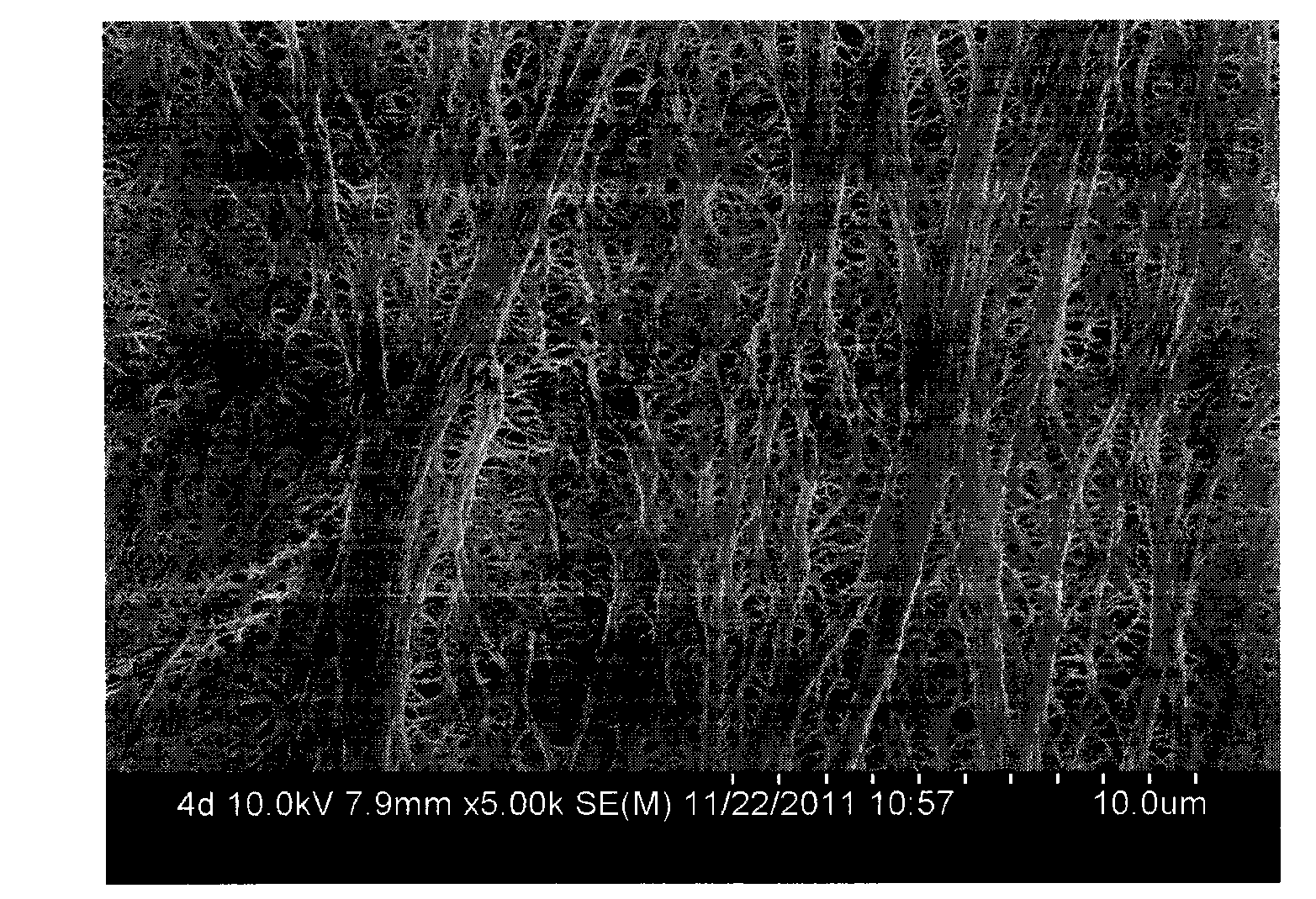

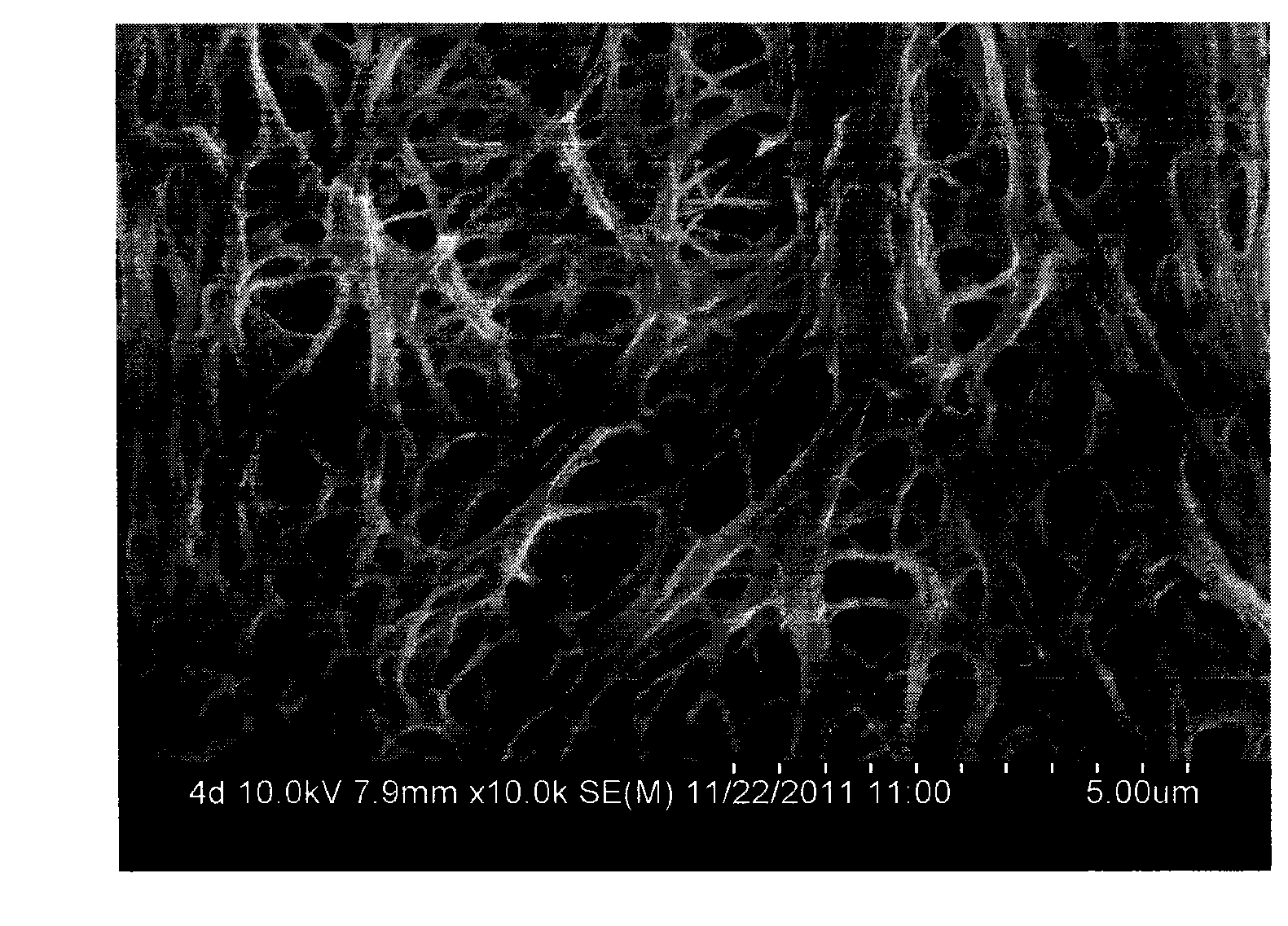

Nonwoven fabric ceramic separator, and preparation method and application thereof

InactiveCN106784539AImprove liquid absorption and retention capacityHigh porosityCell seperators/membranes/diaphragms/spacersSecondary cellsLayer thicknessNonwoven fabric

The invention provides a nonwoven fabric ceramic separator, and a preparation method and application thereof. The preparation method specifically comprises the following steps: preparing a nonwoven fabric fiber base membrane through an electrostatic spinning method; and performing atomic layer deposition on the surface through a plasma enhanced atomic layer deposition technology, so that inorganic matters are uniformly coated on the surface of the polymer fiber to form a core-shell structure taking the one-dimensional polymer fiber as the core and the inorganic matters as the shell. The nonwoven fabric ceramic separator is used in a secondary battery. The separator can be further endowed with a thermal shutdown function through a polymer layer compounding method. The nonwoven fabric ceramic separator obtained by the invention has high thermal shrinkage resistance, enhanced mechanical strength, small membrane ceramic layer thickness and favorable uniformity; and an assembled battery has high mass and volume specific energy and high safety. Thus, the separator provided by the invention can be used as a high safety separator material for lithium ion batteries and other secondary batteries.

Owner:XIAMEN UNIV

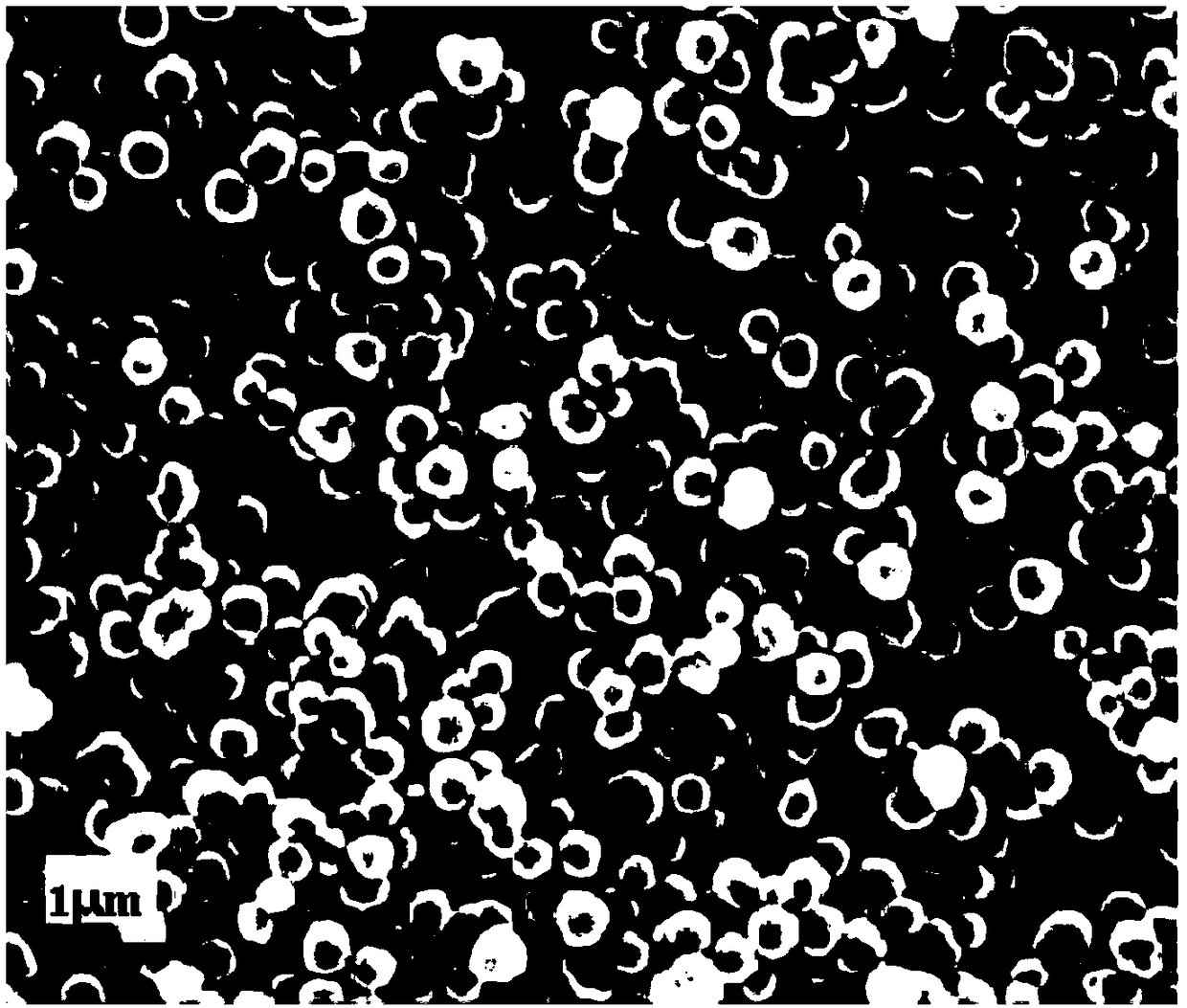

SiO2-PS nuclear shell structure ceramic coating diaphragm and preparation method and application thereof

ActiveCN108735953AImprove bindingGood dispersionCell seperators/membranes/diaphragms/spacersSecondary cellsPolyolefinSilanes

The invention relates to the technical field of the lithium ion battery diaphragm production, and specifically relates to a SiO2-PS nuclear shell structure ceramic diaphragm coating. A preparation method of the SiO2-PS nuclear shell structure ceramic diaphragm coating comprises the following steps: after modifying the monodispersed nanometer SiO2-particle in-situ grafted gamma-methacryloyloxy trimethoxy silane (MPS) prepared through the St-ber method, coating the monodispersed nanometer modified SiO2 particles by adopting the polyvinyl pyrrolidone ethanol solution and styrene-azodiisobutyronitrile mixed solution, thereby forming the nuclear shell structure with stable combination effect, and preparing the SiO2-PS nuclear shell structure ceramic diaphragm coating slurry; the nuclear shell SiO2-PS composite particle with good dispersibility can be uniformly dispersed in the coating slurry system and cannot produce excessive agglutination, and can form the coating not hindering the polyolefin porous diaphragm gap after being coated on the polyolefin porous diaphragm, and has good combining effect with the polyolefin porous diaphragm, and the membrane has good mechanical performance onthe whole; the diaphragm has stable membrane form under high-temperature state, the SiO2 of the nuclear layer is free from ceramic powder falling and blocking diaphragm duct under the coating of theglass-state polymer when the heat shrinkage phenomenon of the diaphragm caused by the high temperature is effectively blocked, and the security of the lithium ion battery is improved.

Owner:安徽美芯新材料有限公司

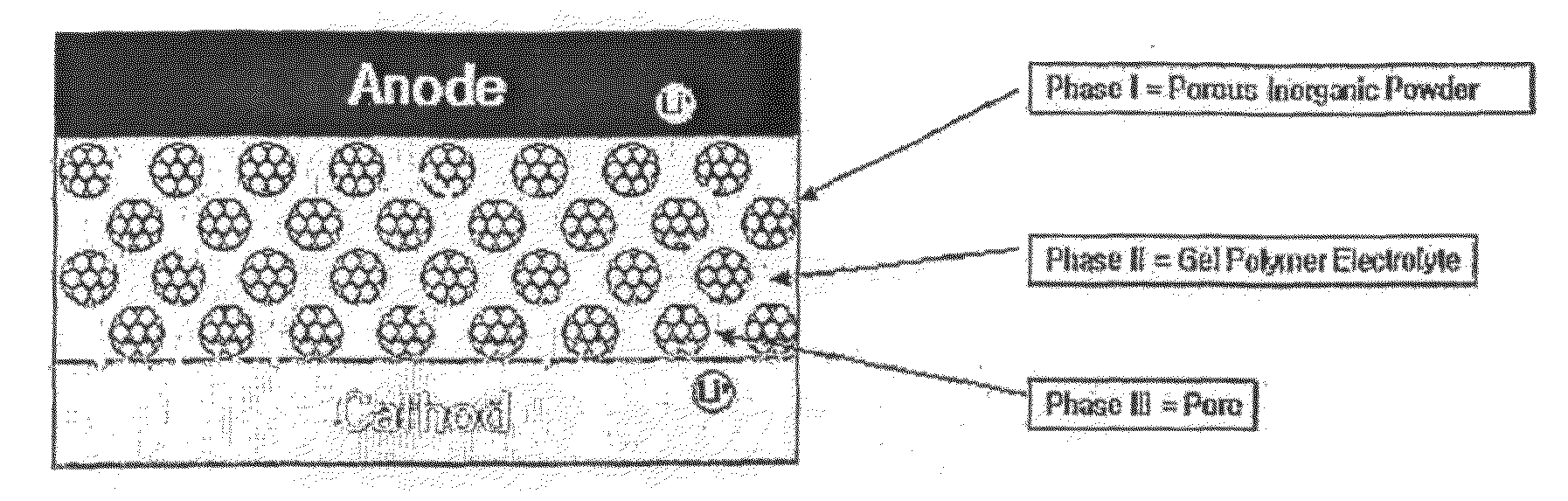

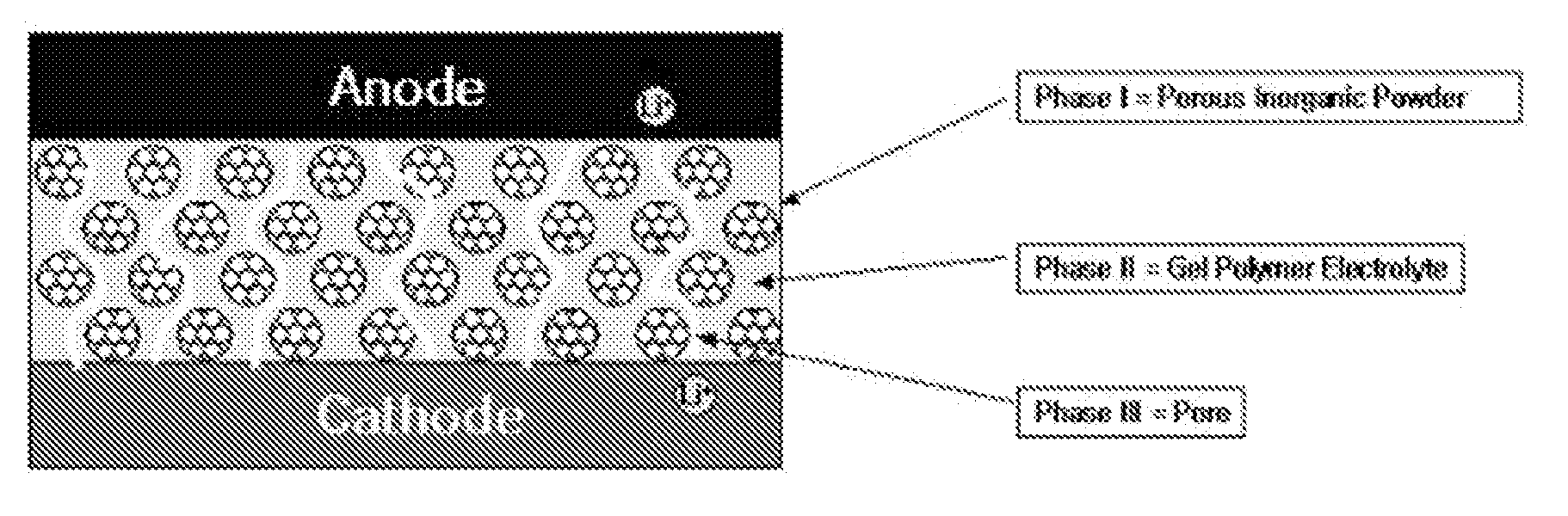

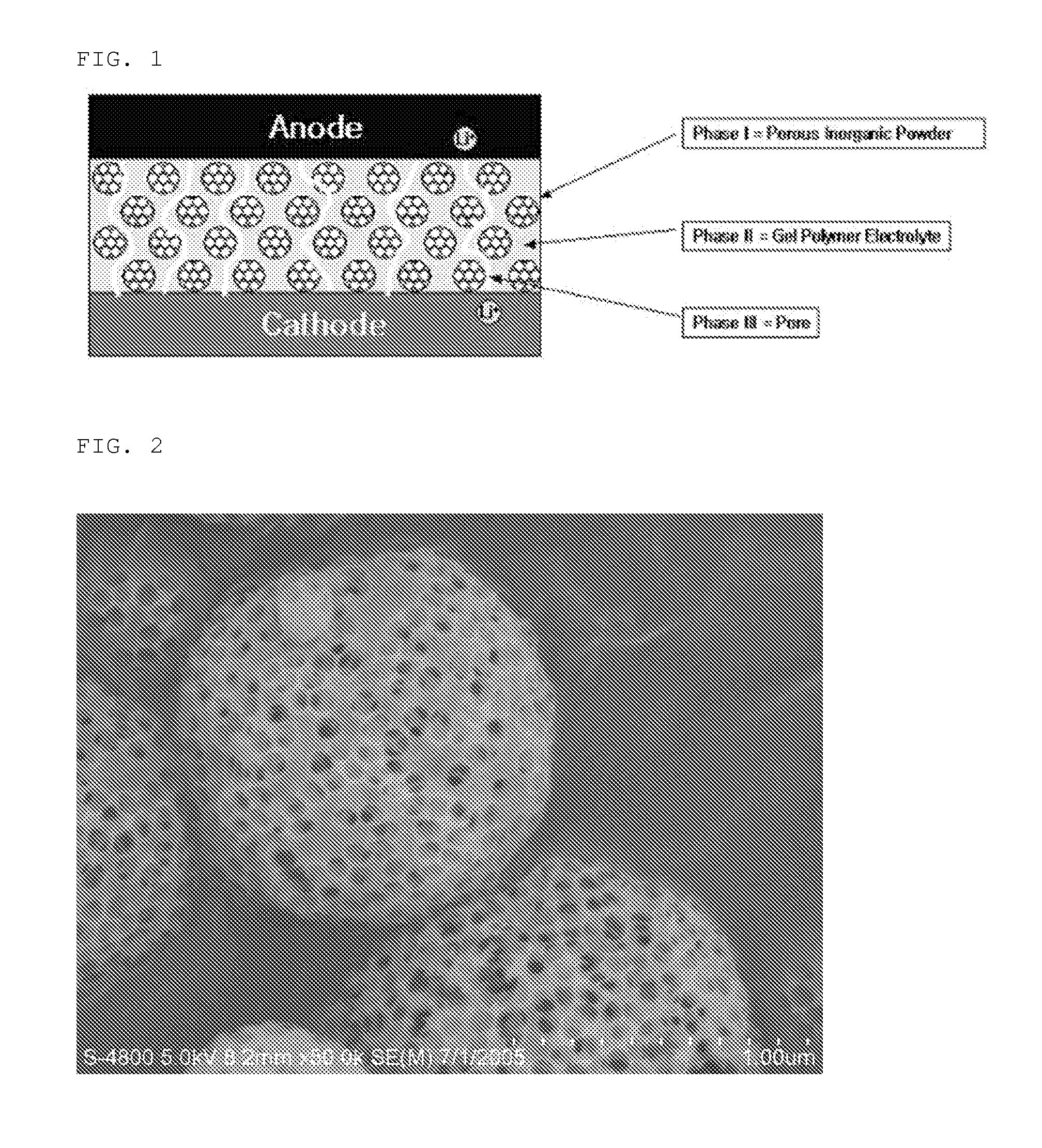

Organic/Inorganic Composite Electrolyte and Electrochemical Device Prepared Thereby

InactiveUS20100167124A1Improve securityInhibit heat shrinkageElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesPorous coatingComposite electrolyte

Disclosed is an electrode whose surface includes an organic / inorganic composite porous coating layer comprising porous inorganic particles and a binder polymer, wherein the porous inorganic particles have pores having such a size that lithium ions (Li+) solvated in an electrolyte solvent can pass therethrough. A method for manufacturing the electrode and an electrochemical device using the electrode are also disclosed. The organic / inorganic composite porous coating layer formed on the electrode according to the present invention provides an additional pathway for lithium ion conduction due to a plurality of pore structures present in the porous inorganic particles. Thus, when the organic / inorganic composite porous coating layer is used instead of a conventional polymer-based separator in a battery, the battery can provide improved quality and an increased energy density per unit weight due to a reduced weight of the organic / inorganic composite porous coating layer.

Owner:LG CHEM LTD

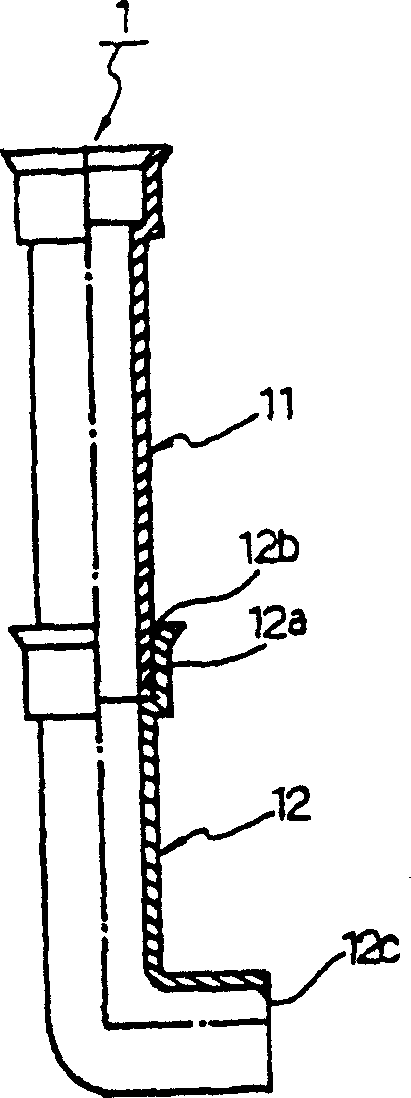

NMR probe

ActiveUS20050122107A1Inhibit heat shrinkageHigh sensitivityElectric/magnetic detectionMeasurements using magnetic resonanceNMR - Nuclear magnetic resonanceFree space

A nuclear magnetic resonance (NMR) probe is offered which can minimize positional shift of the detector portion caused by shrinkage of the support post due to cooling of the detector portion. The NMR probe has a vacuum-insulated container and the detector portion described above. The container has a cylindrical portion inserted in a magnet. The detector portion is made up of a detection coil and a tuning and matching circuit that are placed within the container. The detector portion is cooled by a cooling means such that NMR signals are detected with enhanced sensitivity. This probe is characterized in that the detector portion is mounted to the upper end surface or a side surface of the cylindrical portion.

Owner:JEOL LTD

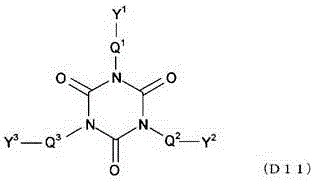

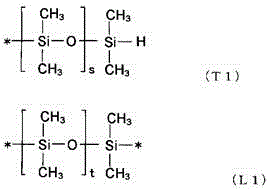

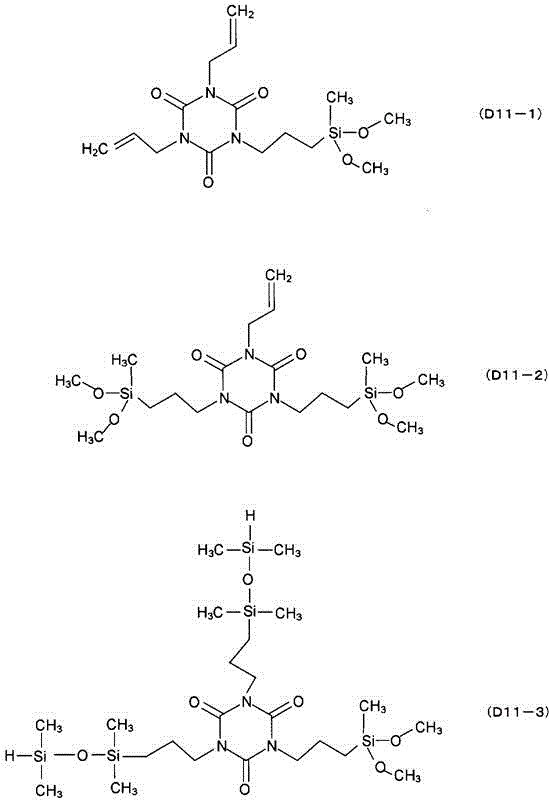

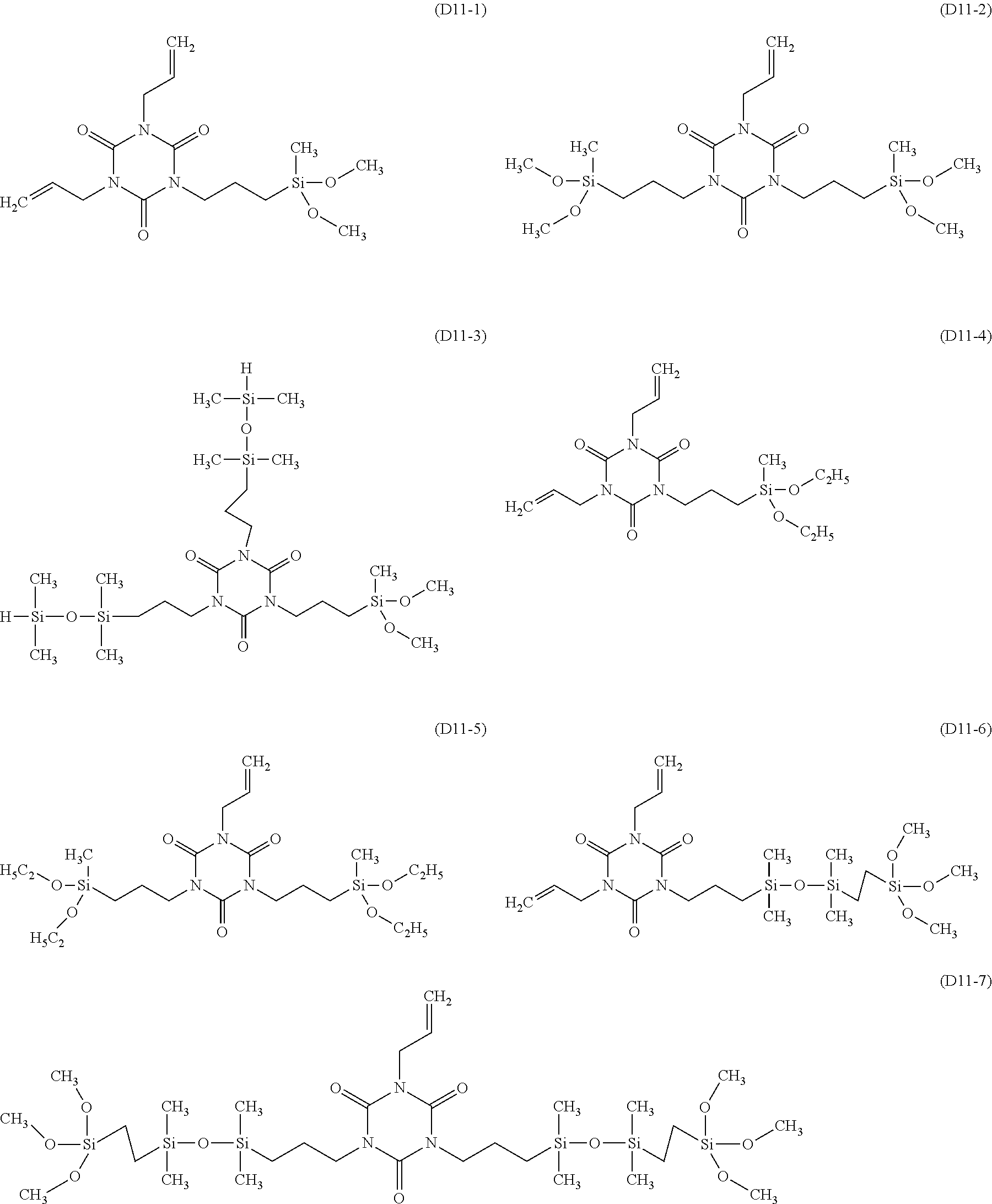

Addition-curable silicone composition

InactiveCN105814142AGood adhesionGood lookingSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceCarboxylic acid

Provided is an addition-curable silicone composition having little shrinkage or change in hardness due to heat, a cured silicone product of which obtained has excellent adhesiveness and appearance and makes it possible to protect metals, especially silver, from corrosion. An addition-curable silicone composition containing 100 parts by mass of polyorganosiloxane having an alkenyl group, polyorganohydrogensiloxane in an amount to make 0.9-3.0 mol of hydrogen atoms bonded to silicon atoms per 1 mol total amount of this alkenyl group, a catalytic amount of hydrosilylation catalyst, 0.01-10 parts by mass of adhesiveness-imparting agent, and 0.001-0.015 parts by mass, calculated in terms of metal atoms, of carboxylic acid metal salt indicated by (R<3>COO)kM (M indicates a metal atom selected from Ce, Fe, Cr, La, Nd, Pr, and Sm, k indicates a positive number of 2-4, and R<3> indicates a substituted or unsubstituted hydrocarbon group having 4-10 carbon atoms).

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

Ceramic diaphragm and preparation method therefor

InactiveCN106935778AImprove thermal conductivityReduced risk of short circuitsCell component detailsSecondary cells servicing/maintenanceCeramic coatingHeat conducting

The invention belongs to the technical field of a diaphragm of a lithium ion battery, and particularly relates to a ceramic diaphragm and a preparation method therefor. The ceramic diaphragm comprises a base diaphragm, and a heat-resistant ceramic coating layer which is coated on at least one surface of the base diaphragm, and also comprises a heat-conducting ceramic coating layer which is coated on the surface of the heat-resistant ceramic coating layer and / or the other surface of the base diaphragm. Compared with the prior art, by additionally arranging the heat-conducting ceramic coating layer on the base diaphragm comprising the heat-resistant ceramic coating layer, the heat conducting performance of the ceramic diaphragm is effectively improved; when the battery suffers form partial overheating caused by puncturing, collision, extrusion and the like, the heat-conducting ceramic coating layer can rapidly conduct and scatter the heat on the partial place of the diaphragm to the whole ceramic diaphragm, so that partial heat shrinkage of the ceramic diaphragm can be restrained, and risk of short circuit of the battery can be further lowered.

Owner:东莞市赛普克电子科技有限公司

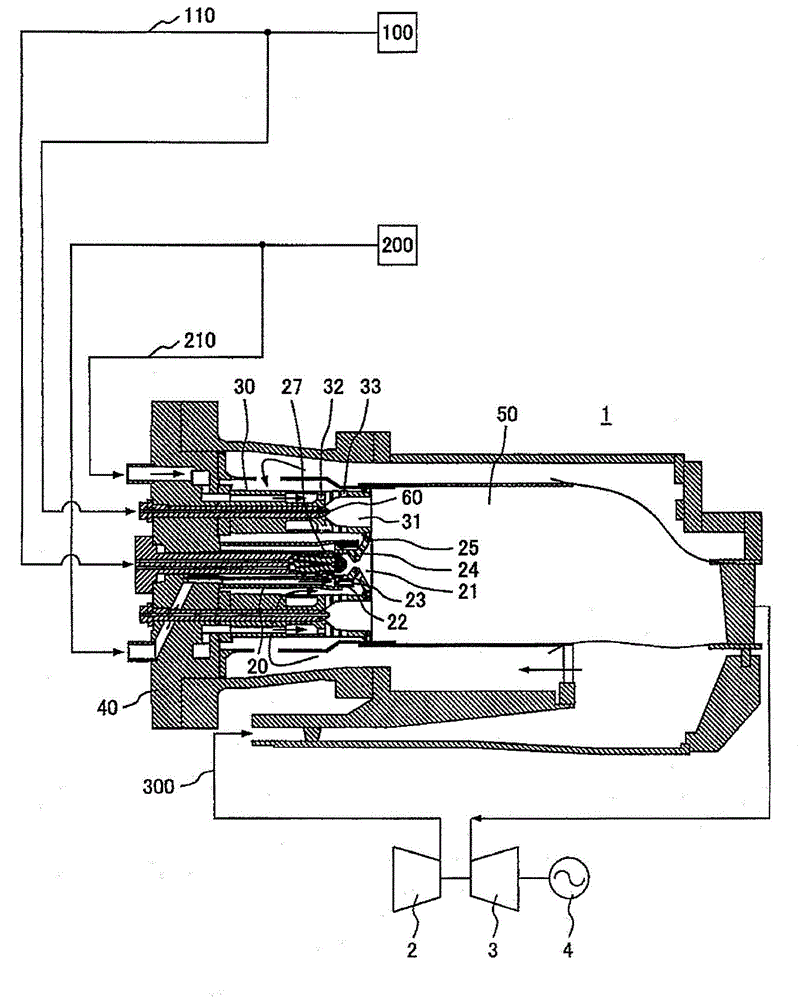

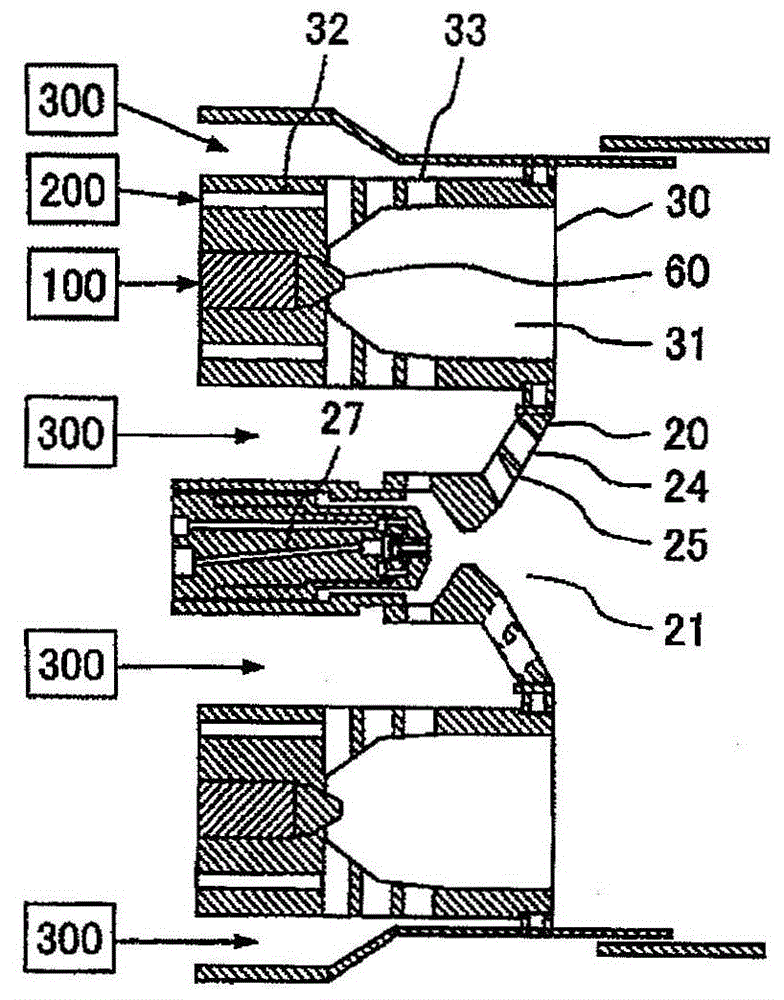

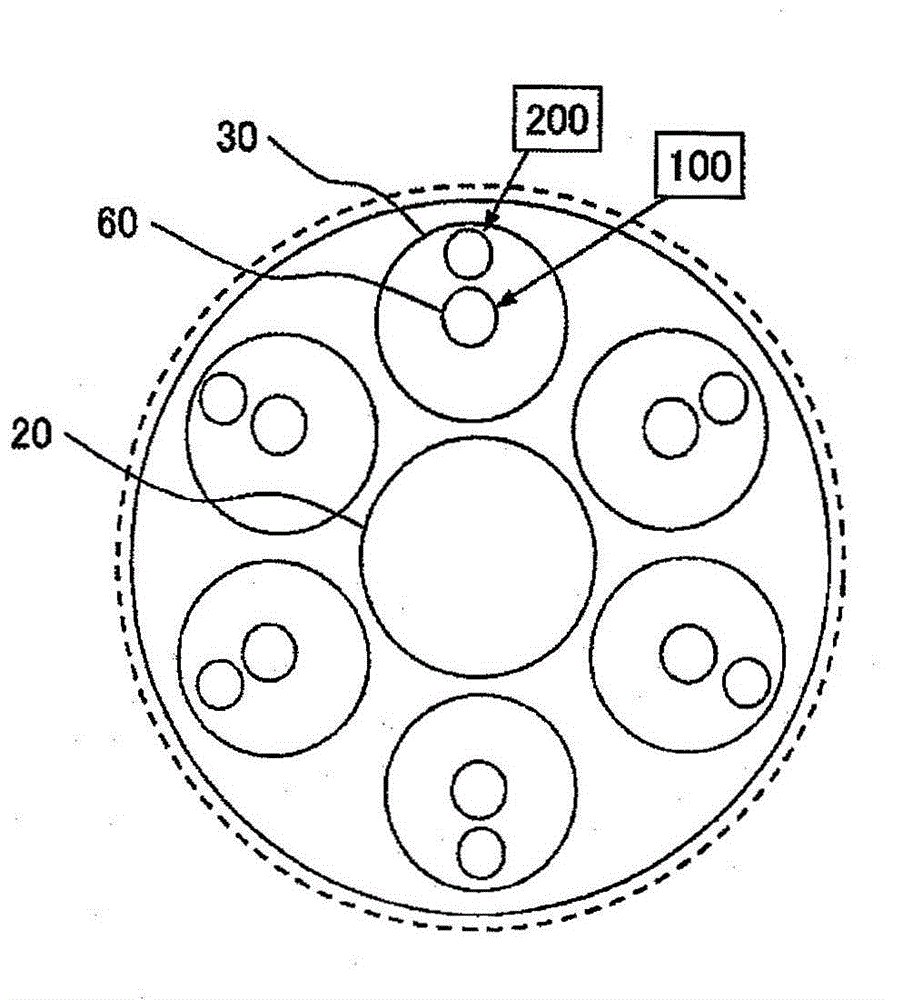

Dual-Fuel Burning Gas Turbine Combustor

ActiveCN104456629AInhibit heat shrinkageReduce stressBurnersContinuous combustion chamberCombustorLiquid fuel

A dual-fuel burning gas turbine combustor having a diffusive combustion burner to burn a liquid fuel and a gaseous fuel placed at the axis of the gas turbine combustor and a plurality of pre-mixing combustion burners to burn a liquid fuel and a gaseous fuel placed on an outer circumferential side of the diffusive combustion burner, each pre-mixing combustion burner having a liquid fuel nozzle, a plurality of gaseous fuel spray holes, a plurality of air holes, and a pre-mixing chamber to mix gaseous fuel and air, wherein each pre-mixing combustion burner has a double pipe sleeve at a connected portion between end cover and the pre-mixing combustion burner, and the double pipe sleeve has an inner sleeve having a gaseous fuel flow path, an outer sleeve positioned on an outer circumferential side of the inner sleeve, and a circular spacing formed between the inner sleeve and the outer sleeve.

Owner:MITSUBISHI POWER LTD

Thermal-resistant and flame-retardant membrane and preparation method thereof, and applications

ActiveCN110233224APrevent internal short circuitAvoid burning and explosionCell component detailsSecondary cells servicing/maintenancePhysical chemistryThermal stability

The present invention discloses a thermal-resistant and flame-retardant membrane and a preparation method thereof, and applications. According to the preparation method, the cost is controllable, theoperation of the preparation process is simple, and thus the preparation method is suitable for mass production. The prepared thermal-resistant and flame-retardant membrane has a double-layer composite structure with both thermal stability and flame retardancy, the membrane can prevent internal short circuit of a battery at a lower temperature, so that severe thermal runaway of the battery is prevented, and thus safety accidents, such as burning and explosion are prevented; the membrane can effectively prevent the battery from burning and exploding after the thermal runaway of the battery occurs under the conditions of overcharge, puncture and abuse; and the membrane has good applications in the chemical power supply system, especially in lithium ion batteries.

Owner:XIAMEN UNIV

Addition-curable silicone composition

InactiveUS20160280918A1Good adhesivenessExcellent external appearanceSemiconductor/solid-state device detailsSolid-state devicesHydrosilylationHardness

There is provide an addition-curable silicone composition from which a silicone cured product having excellent adhesiveness and external appearance, being able to protect metal, in particular, silver, from corrosion, and having less shrinkage and change in hardness due to heat, is obtained. The addition-curable silicone composition contains: 100 parts by mass of a polyorganosiloxane having alkenyl groups; an amount of a polyorganohydrogensiloxane such that an amount of Si—H groups is 0.9 to 3.0 mol relative to 1 mol of the alkenyl groups; a catalyst amount of a hydrosilylation reaction catalyst; 0.01 to 10 parts of an adhesiveness imparting agent; and 0.001 to 0.015 parts by mass, in terms of metal atoms of (R3COO)kM (where M is Ce, Fe, Cr, La, Nd, Pr or Sm, k is 2, 3 or 4, and R3 represents a substituted or unsubstituted hydrocarbon group having 4 to 17 carbon atoms).

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

Polyvinyl composite microporous membrane with thermocompression bonding characteristic

InactiveCN103184013AInhibit heat shrinkageImprove securitySemi-permeable membranesNon-macromolecular adhesive additivesMiddle molecular weightCrystallinity

The present invention relates to polyvinyl composite microporous membrane with thermocompression bonding characteristics. High-crystallinity and high-density polyethylene is modified by using ethylene-propylene methylene copolymer of the middle molecular weight and polyisobutylene rubber. The membrane with thermocompression bonding characteristics is obtained by using aliphatic dibasic acid ester with a flash point above 210 DEG C as a craft solvent and a pore forming agent. The membrane is hot pressed to bond integrally with a positive electrode sheet. The thermal shrinkage of the membrane is suppressed. The composite membrane has the characteristics of high strength and high temperature resistence, and can be used for lithium-ion batteries with high security and long cycle life.

Owner:TIANJIN DG MEMBRANE

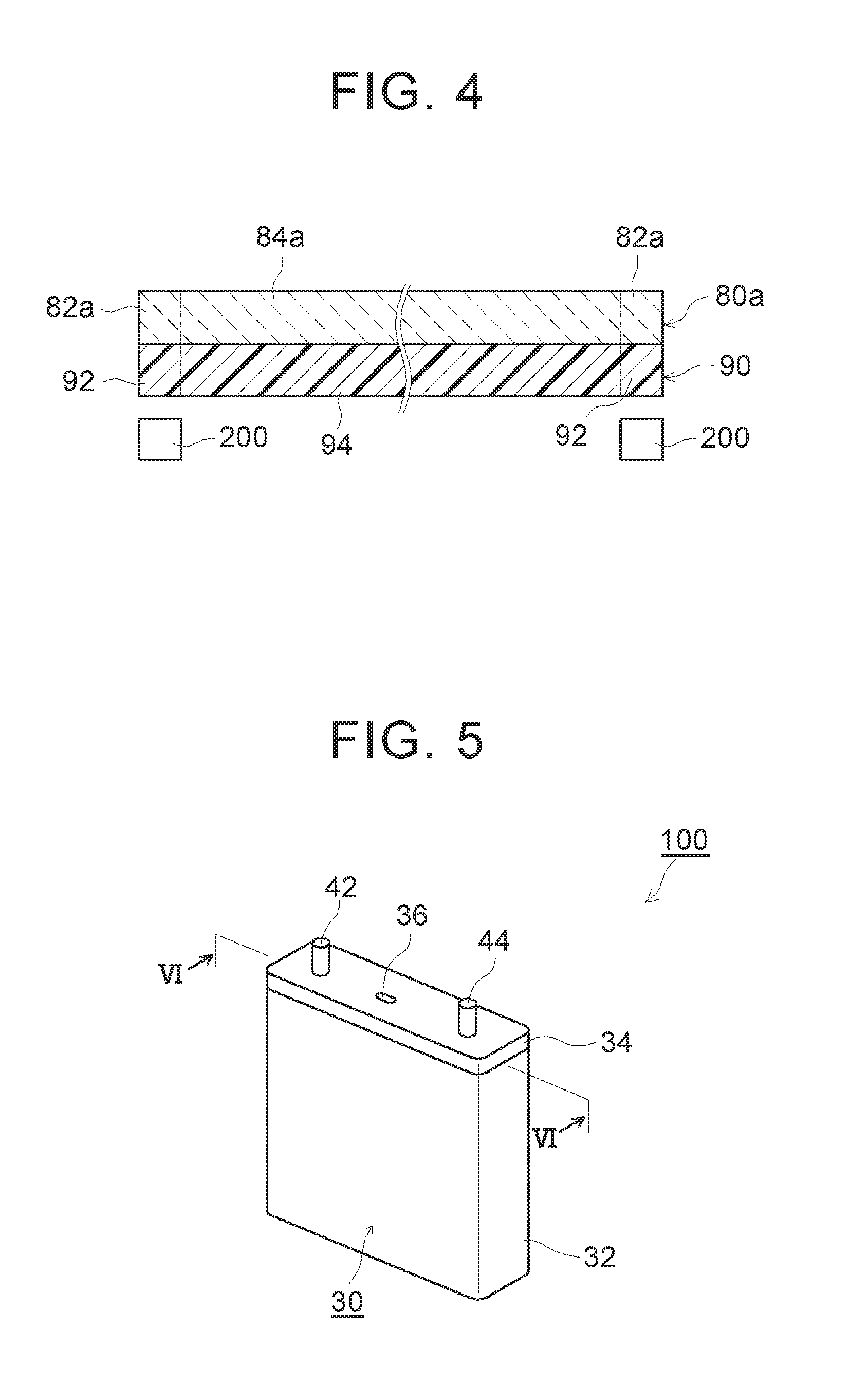

Separator, production method for same and electrochemical device equipped with same

ActiveCN103081172AReduce thicknessHigh porosityFinal product manufactureLi-accumulatorsCross-linkPorous substrate

Owner:LG ENERGY SOLUTION LTD

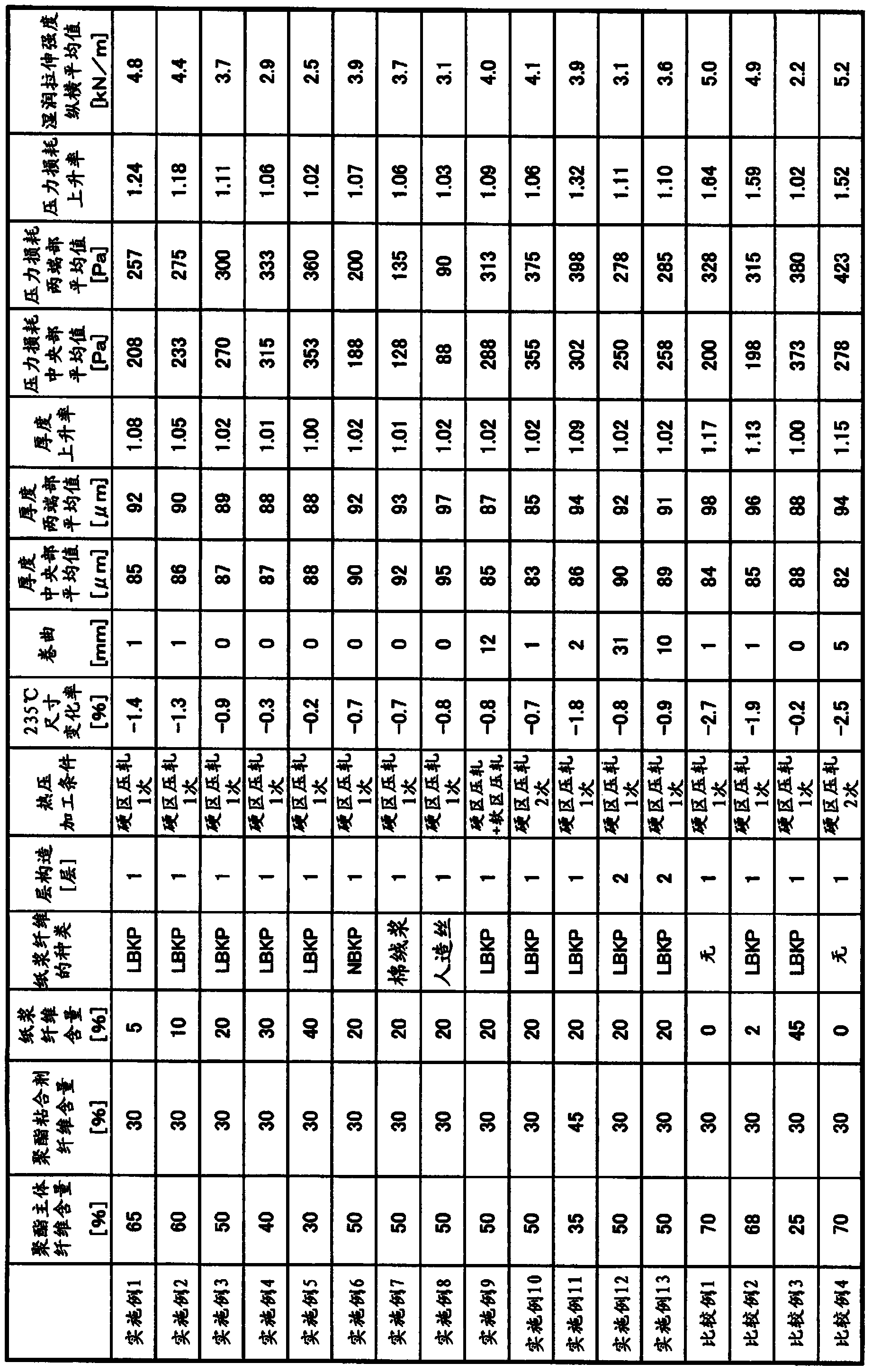

Part for cast production fabricated by wet type paper-making method

InactiveCN1671492AEasy to operateInhibit heat shrinkageFoundry mouldsMoulding machine componentsFiberDie casting

An element made by papermaking for use in the production of a die casting which comprises an organic fiber, an inorganic fiber, and a binder. The contents of the organic fiber, the inorganic fiber, and the binder are preferably 10 to 70 parts by weight, 1 to 80 parts by weight, and 10 to 85 parts by weight, respectively. The binder is preferably an organic binder. The organic fiber is preferably pulp fiber.

Owner:KAO CORP

Glass substrate for flat panel display and method for manufacturing same

ActiveUS20130059718A1Inhibiting and avoiding erosion/wearPoint becomes highGlass drawing apparatusGlass forming apparatusMelting tankFlat glass

A substrate for p-Si TFT flat panel displays made of a glass having a high low-temperature-viscosity characteristic temperature and manufactured while avoiding erosion / wear of a melting tank during melting through direct electrical heating. The glass substrate comprises 52-78 mass % of SiO2, 3-25 mass % of Al2O3, 3-15 mass % of B2O3, 3-20 mass % of RO, wherein RO is total amount of MgO, CaO, SrO, and BaO, 0.01-0.8 mass % of R2O, wherein R2O is total amount of Li2O, Na2O, and K2O, and 0-0.3 mass % of Sb2O3, and substantially does not comprise As2O3, wherein the mass ratio CaO / RO is equal to or greater than 0.65, the mass ratio (SiO2+Al2O3) / B2O3 is in a range of 7-30, and the mass ratio (SiO2+Al2O3) / RO is equal to or greater than 5. A related method involves melting glass raw materials blended to provide the glass composition; a forming step of forming the molten glass into a flat-plate glass; and an annealing step of annealing the flat-plate glass.

Owner:AVANSTRATE INC

Membrane containing active lithium sources, preparation method and lithium ion battery

InactiveCN105206780AImprove thermal stabilityInhibit heat shrinkageSecondary cellsCell component detailsSodium-ion batteryLithium-ion battery

The invention discloses a membrane containing active lithium sources. The membrane comprises a membrane body and a coating containing the active lithium sources. The coating containing the active lithium sources is arranged on one side or double sides of the membrane body. The invention discloses a preparation method of the membrane containing the active lithium sources. The invention further discloses a lithium ion battery. The membrane has a low requirement for the technology environment, the active material with which the surface of the membrane is coated can make the membrane store a certain quantity of lithium sources, the lithium sources are provided for a lithium ion secondary battery system to compensate for the lithium ion loss caused by primary charging and discharging, the utilization rate of the positive-pole active material can be increased to about 96-98%, and the gram volume of secondary battery positive-pole active substances can be made to reach the ideal level of half cells. Meanwhile, the active material containing the lithium sources forms a solid layer to cover the membrane after the lithium sources are lost, so that a solid substance layer for supporting the membrane structure is formed, the heat stability of the membrane is improved, heat shrinkage of the membrane is prevented, and the safety performance of the battery is improved.

Owner:HUIZHOU HENGTAI TECH

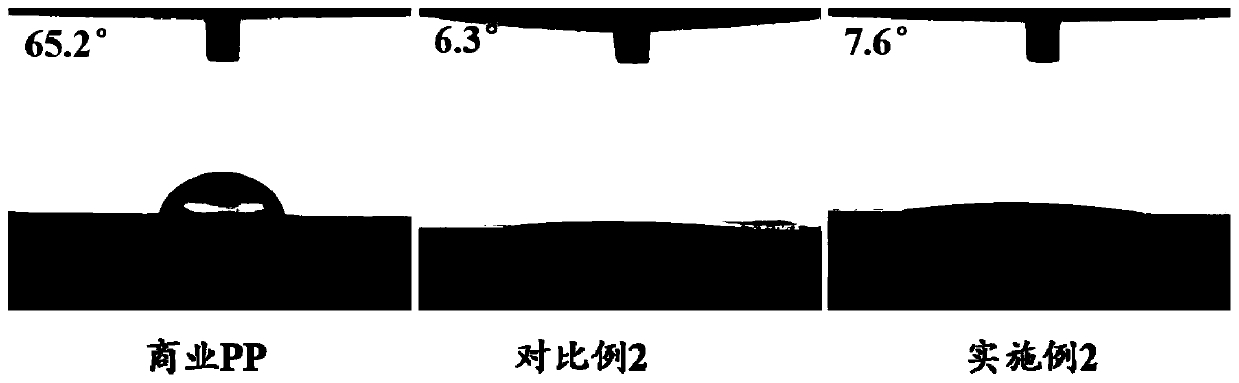

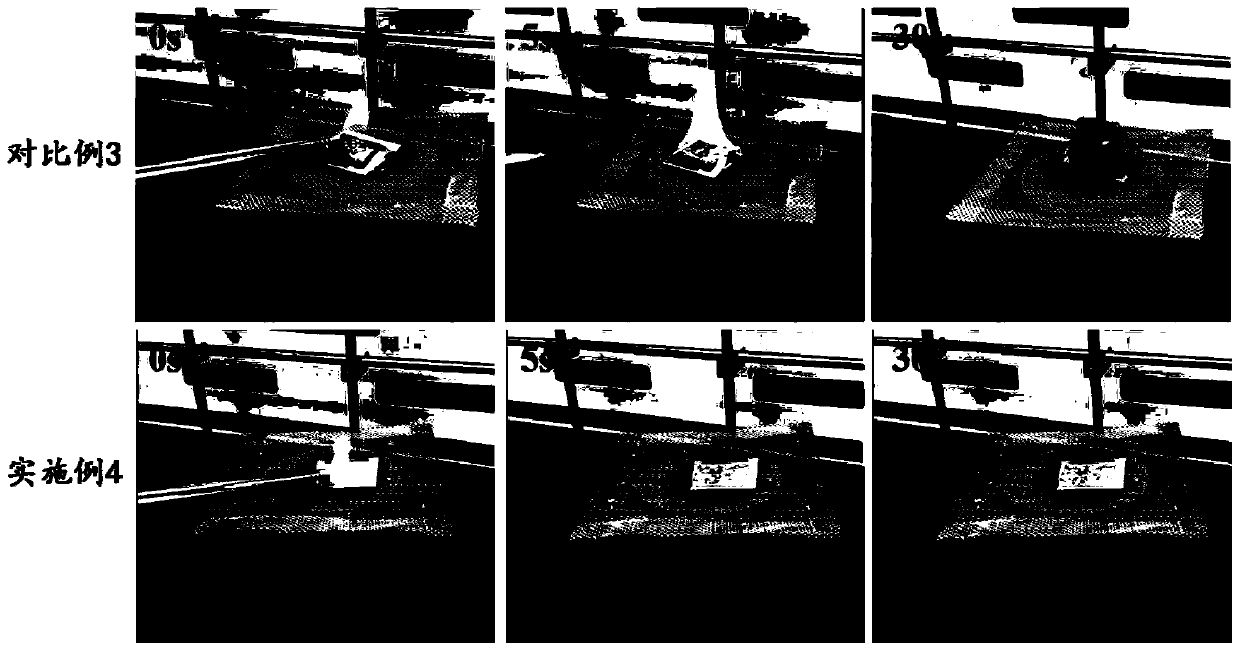

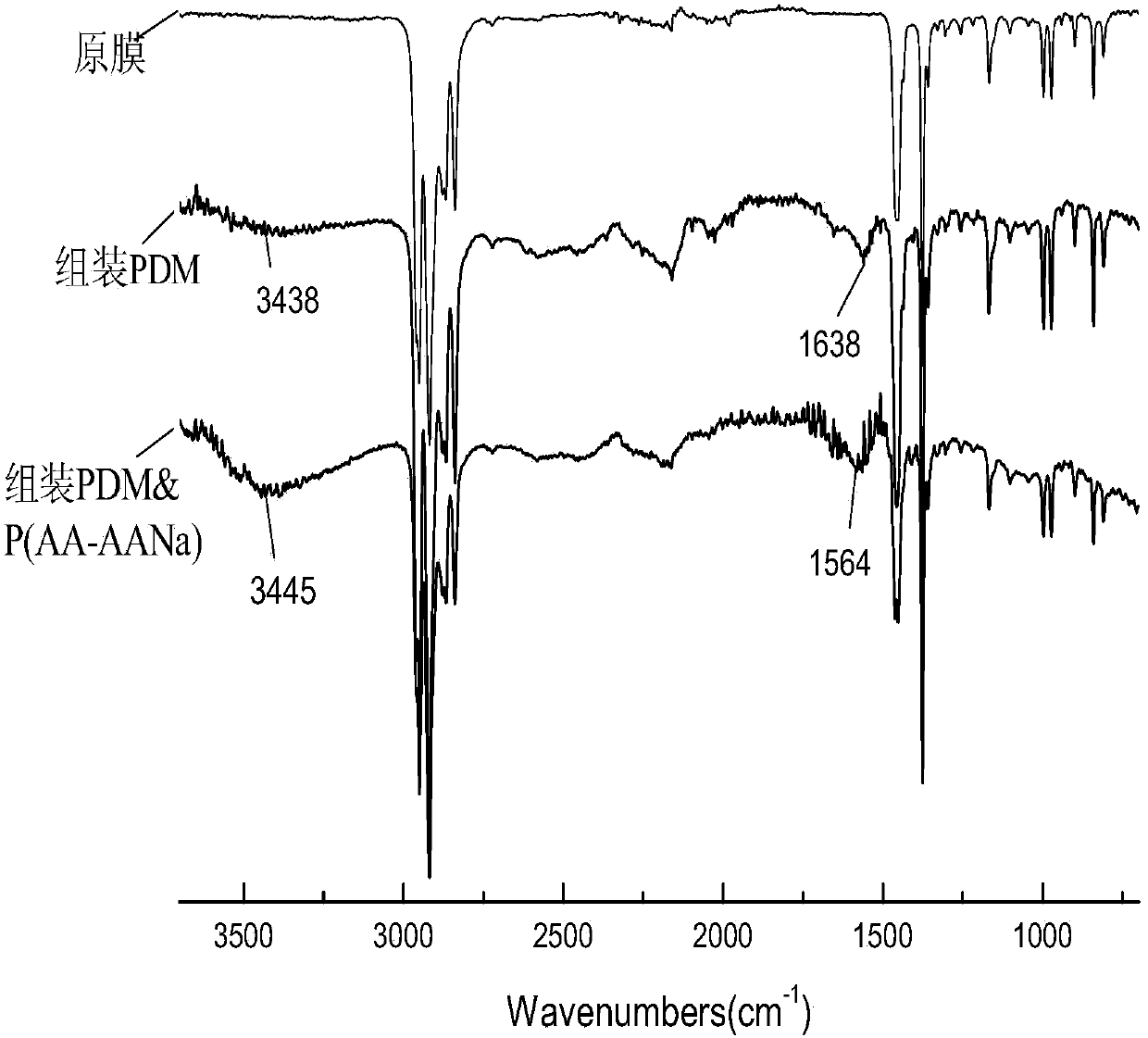

Method for improving hydrophilicity and thermal stability of polypropylene lithium-ion battery separator

ActiveCN103992505ANot easy to fall offInhibition of contractionCell component detailsCationic polyelectrolytesLayer by layer self assembly

Aiming at the problem that hydrophilicity and thermal stability of a polypropylene lithium-ion battery separator are poor, the invention provides a method for layer-by-layer self-assembly of polyelectrolyte on the surface of a separator so as to improve the hydrophilicity and thermal stability of the polypropylene lithium-ion battery separator. According to the technical scheme, an aqueous solution polymerization method is adopted for respectively preparing anion polyelectrolyte containing an anion structural unit and cation polyelectrolyte containing a cation structural unit, and a pretreated polypropylene separator is repeatedly and alternately soaked in two polyelectrolyte solutions, so that macromolecule polyelectrolyte is self assembled onto the surface of the polypropylene separator under the action of an electrostatic force; the polypropylene lithium-ion battery separator prepared by adopting the method provided by the invention has high hydrophilicity and thermal stability, a static water contact angle is as low as 30 degrees; after the polypropylene lithium-ion battery separator is treated for 4 hours at the temperature of 130 DEG C, thermal shrinkage of the polypropylene lithium-ion battery separator is about 15% only; the method is easy to operate and strong in practicability, the defects of chemical modification and a general coating method are overcome, and the method disclosed by the invention can be put into industrial production.

Owner:CHANGZHOU UNIV

Nonwoven fabric for eletrical insulation, prepreg and laminate

InactiveUS20040033746A1Improve reliabilitySmall roughnessPlastic/resin/waxes insulatorsPrinted circuit aspectsPolymer scienceNonwoven fabric

An electrically insulating non-woven fabric having a main component of poly-p-phenileneterephthalamide fibers bonded with each other by a binder of thermosetting resin and a second binder of one selected from fiber chops, fiber pulps and fibrids of thermoplastic resin having a softening point of 220° C. or higher, the poly-p-phenileneterephthalamide fibers being pulps or both of chops and pulps with a blend mass ratio of the chops to the pulps being 0 / 100 through 95 / 5 and preferably 50 / 50 through 90 / 10, a fiber length of the poly-p-phenileneterephathalamide fiber chops being preferably 3 to 6 mm, a content of the thermosetting resin binder in the non-woven fabric being 5 to 30 mass % and a content of the second binder being is 5 to 15 mass %.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD +1

Non-woven fabric for semipermeable membrane support

A purpose of the present invention is to provide a non-woven fabric for a semipermeable membrane support, which meets wet strength required by the non-woven fabric for the semipermeable membrane support, suppresses thermal contraction during hot press processing, and has uniform thickness and permeability. The non-woven fabric for the semipermeable membrane support provided by an embodiment is a non-woven fabric with pulp fibers having cellulose component as a main body and organic synthetic fibers as the main fibers. One side surface of the non-woven fabric supports the semipermeable membrane. The content of the pulp fibers having cellulose component as the main body is 5-40% by mass of a total mass of the non-woven fabric.

Owner:HOKUETSU KK

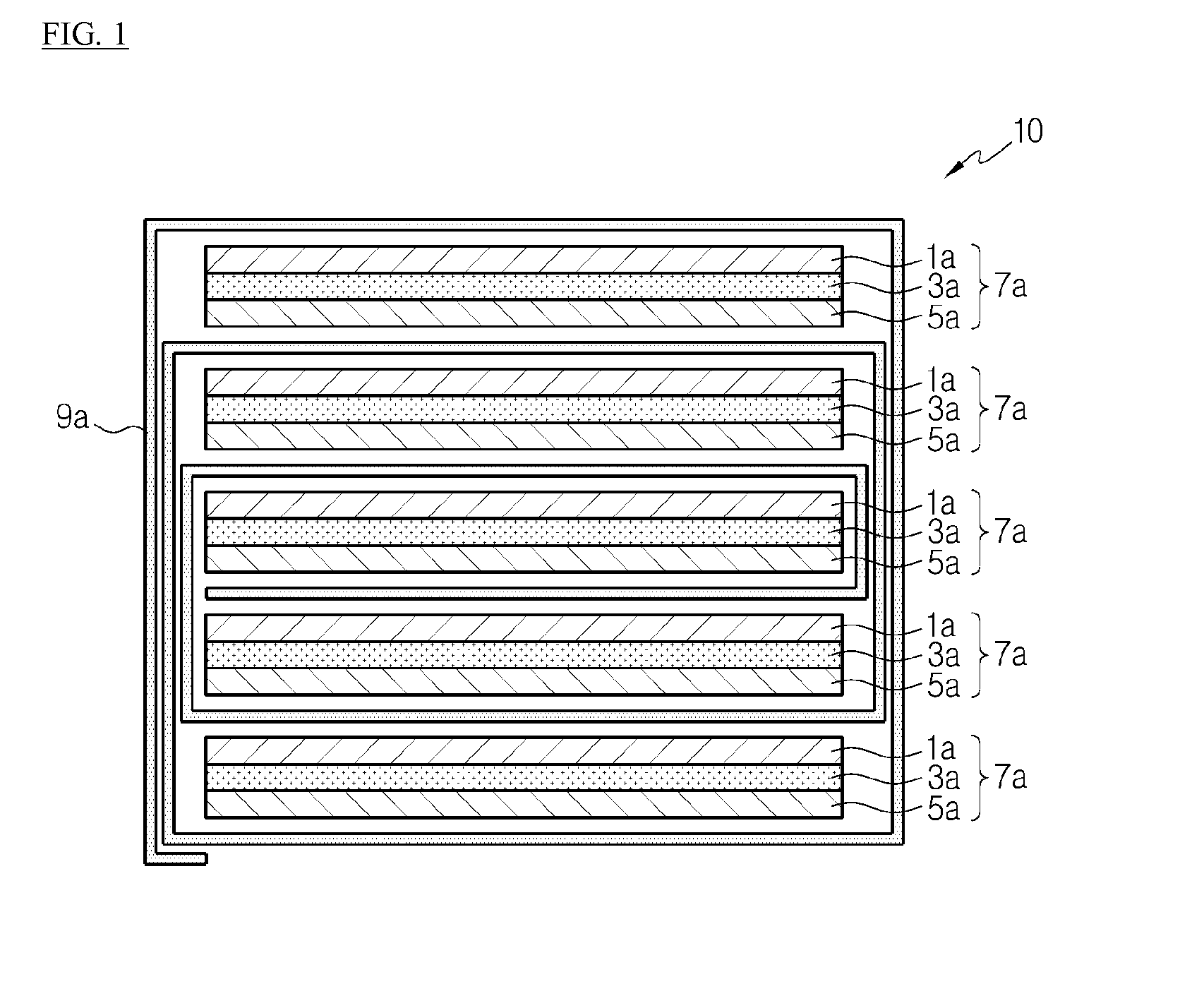

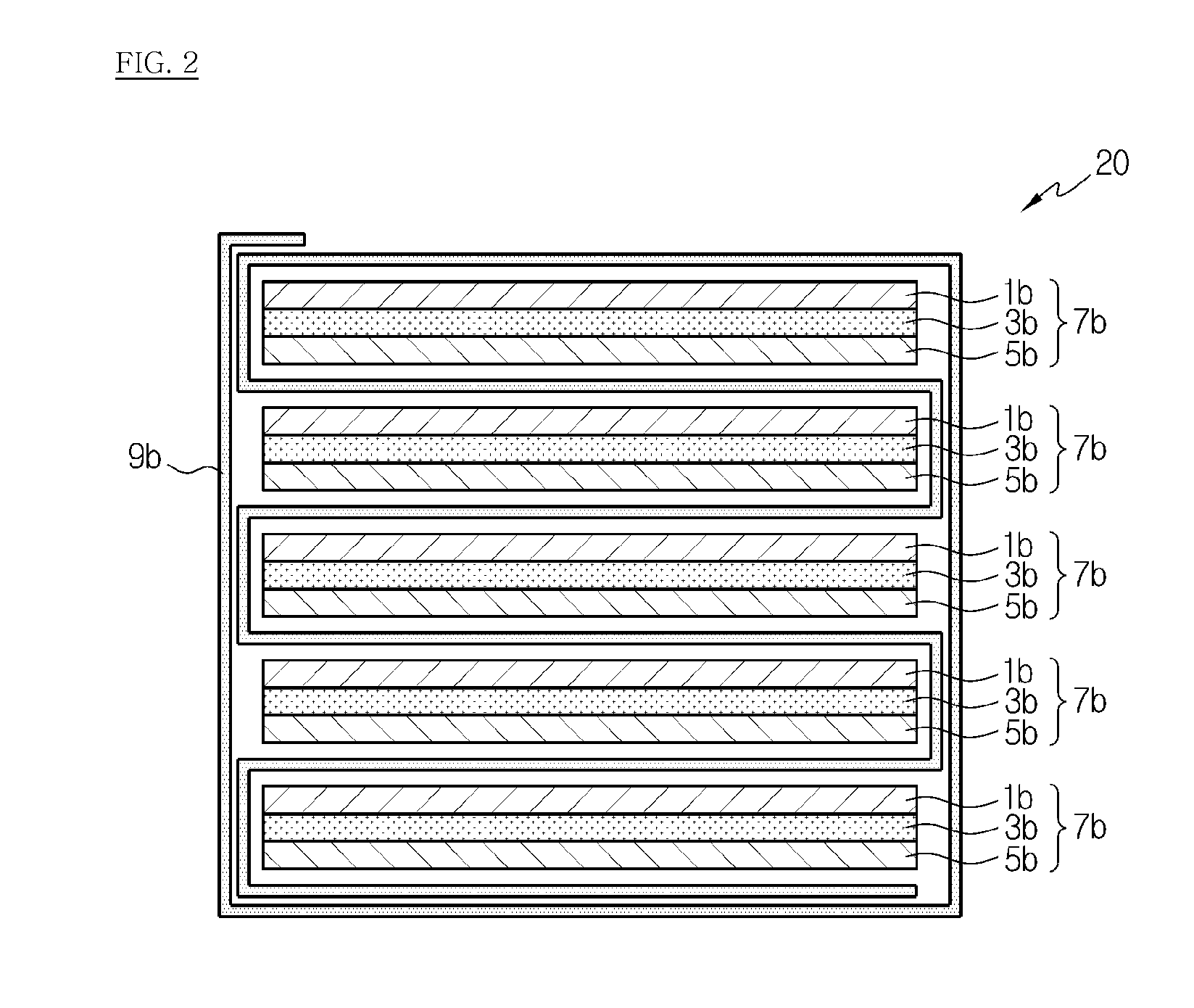

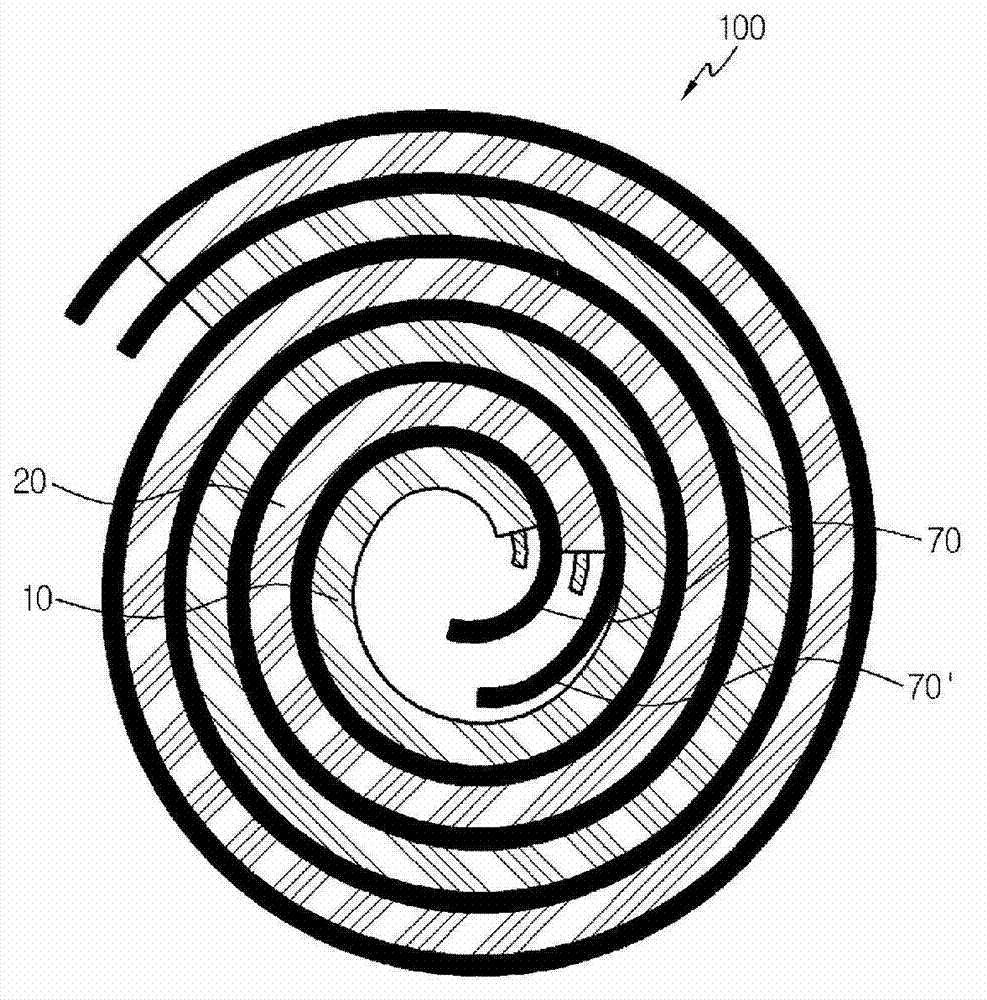

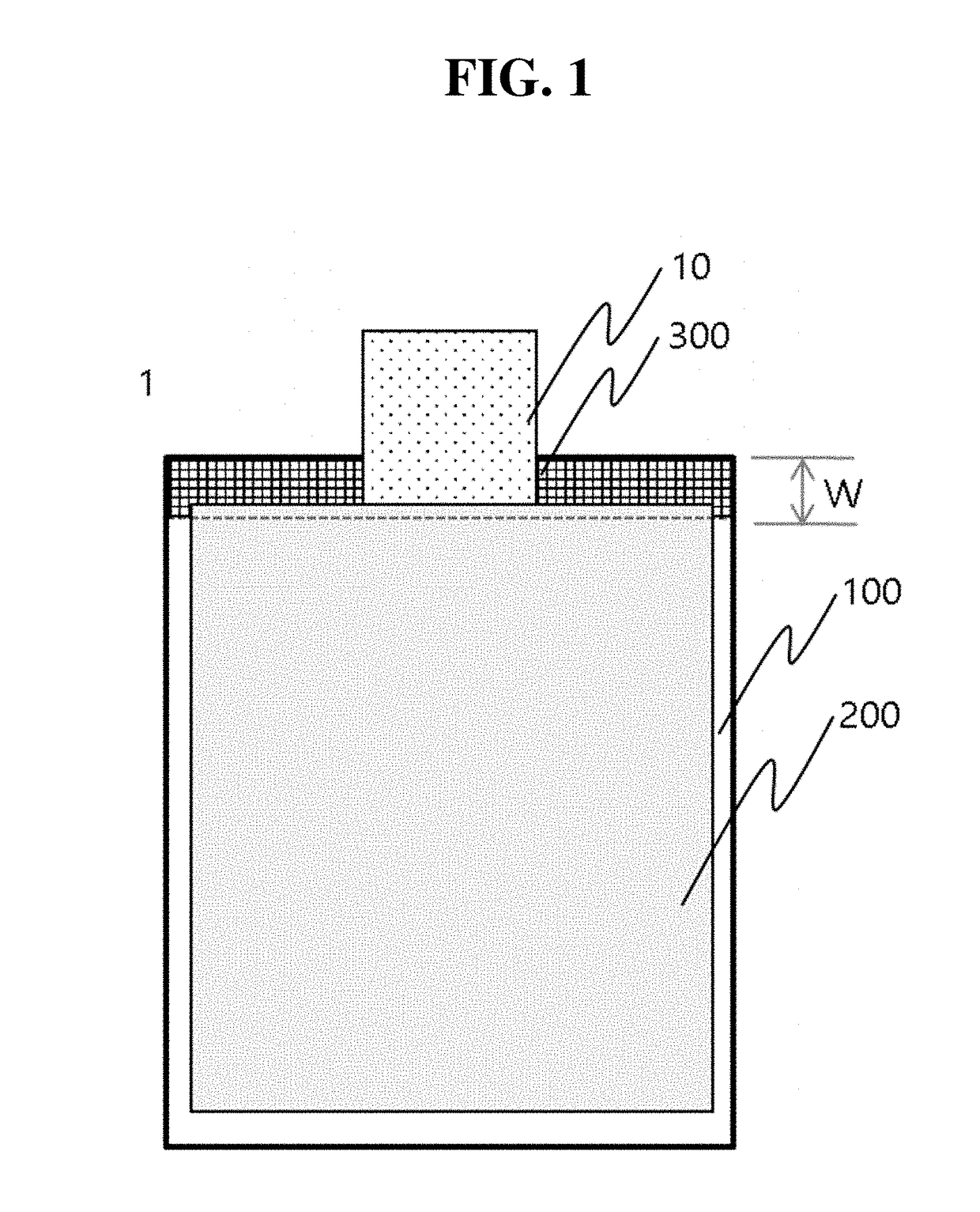

Electrode assembly comprising separator having insulation-enhancing part formed on edge portion of electrode

ActiveUS20180145376A1Inhibit heat shrinkageFinal product manufactureLi-accumulatorsEngineeringElectrode

An electrode assembly is provided. The electrode assembly has a plurality of electrode plates having one or both sides of each of the electrode plates that are coated with an electrode active material and are stacked with a separator interposed between the respective electrode plates. The separator includes a surplus outer periphery of a size greater than the outer periphery of an electrode plate, an electrode tab which extends from the outer periphery of the electrode plate and protrudes outwardly beyond the outer periphery of the separator is formed on each electrode plate, and at least some of the separators forming the electrode assembly have an insulation-enhancing part for suppressing heat shrinkage of a separator formed in the surplus outer peripheries thereof which are adjacent to the respective electrode tabs.

Owner:LG ENERGY SOLUTION LTD

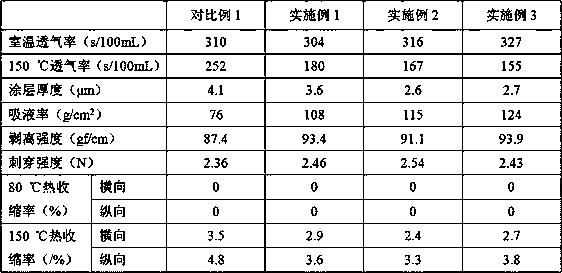

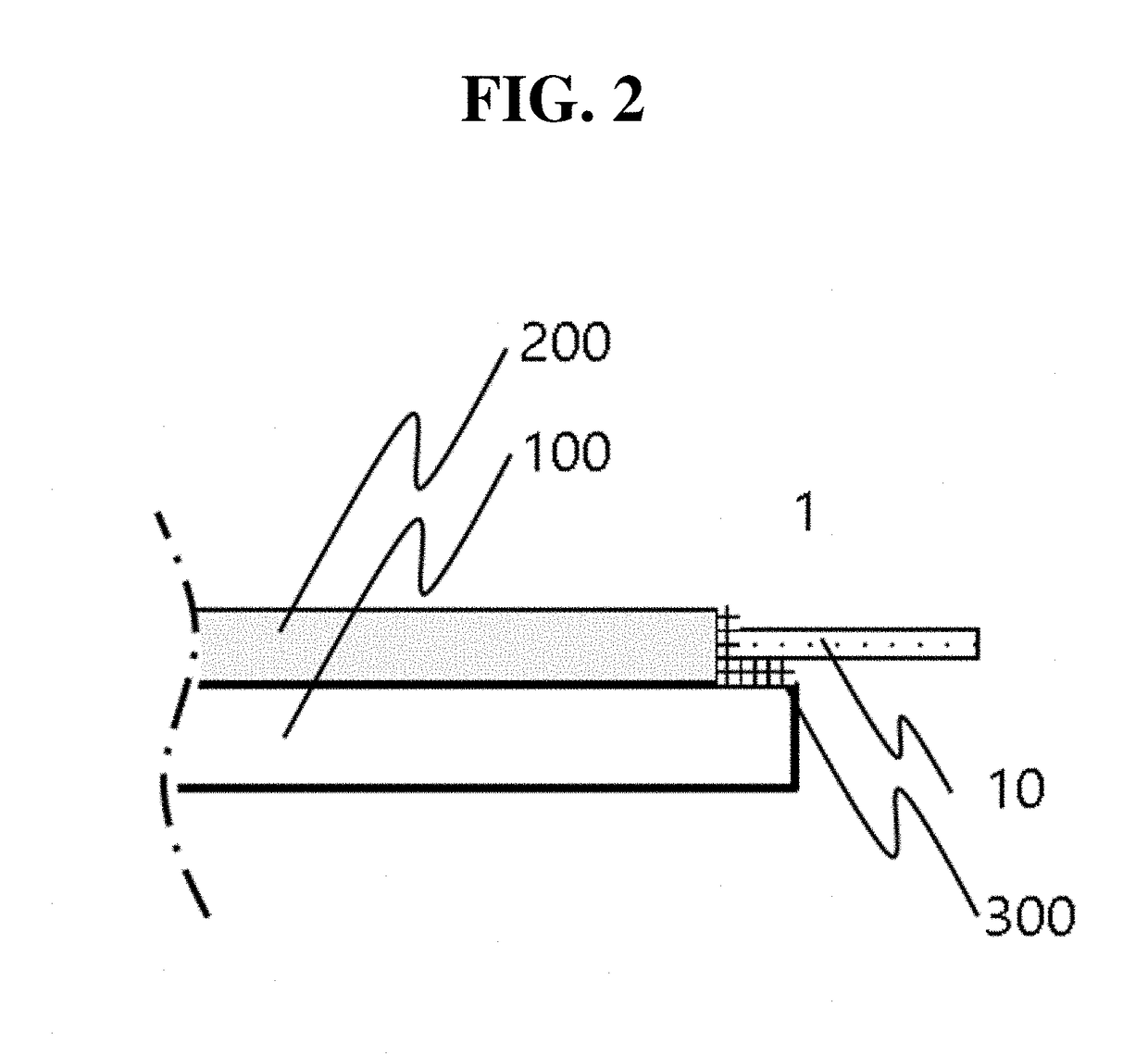

Separator for non-aqueous electrolyte secondary battery and manufacturing method thereof

ActiveUS20160308185A1Peel strengthIncrease volumeNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersPhysical chemistryAqueous electrolyte

A separator includes a substrate layer made of a resin and a heat resistance layer. The heat resistance layer contains heat-resistant fine particles and a binder. An amount of the binder contained per unit volume in the heat resistance layer positioned at an end portion in a width direction perpendicular to a longitudinal direction of the separator is higher than the amount of the binder contained per unit volume in the heat resistance layer (84) positioned at a center portion which includes the center in the width direction of the separator. In the heat resistance layer at the end portion, the amount of the binder contained per unit volume in a substrate layer side region is higher than the amount of the binder contained per unit volume in a surface region which includes a surface of the heat resistance layer.

Owner:TOYOTA JIDOSHA KK

Glass substrate for flat panel display and manufacturing method thereof

ActiveUS20140249019A1Inhibiting and avoiding erosion/wearPoint becomes highGlass drawing apparatusGlass forming apparatusFlat glassDisplay device

Owner:AVANSTRATE INC

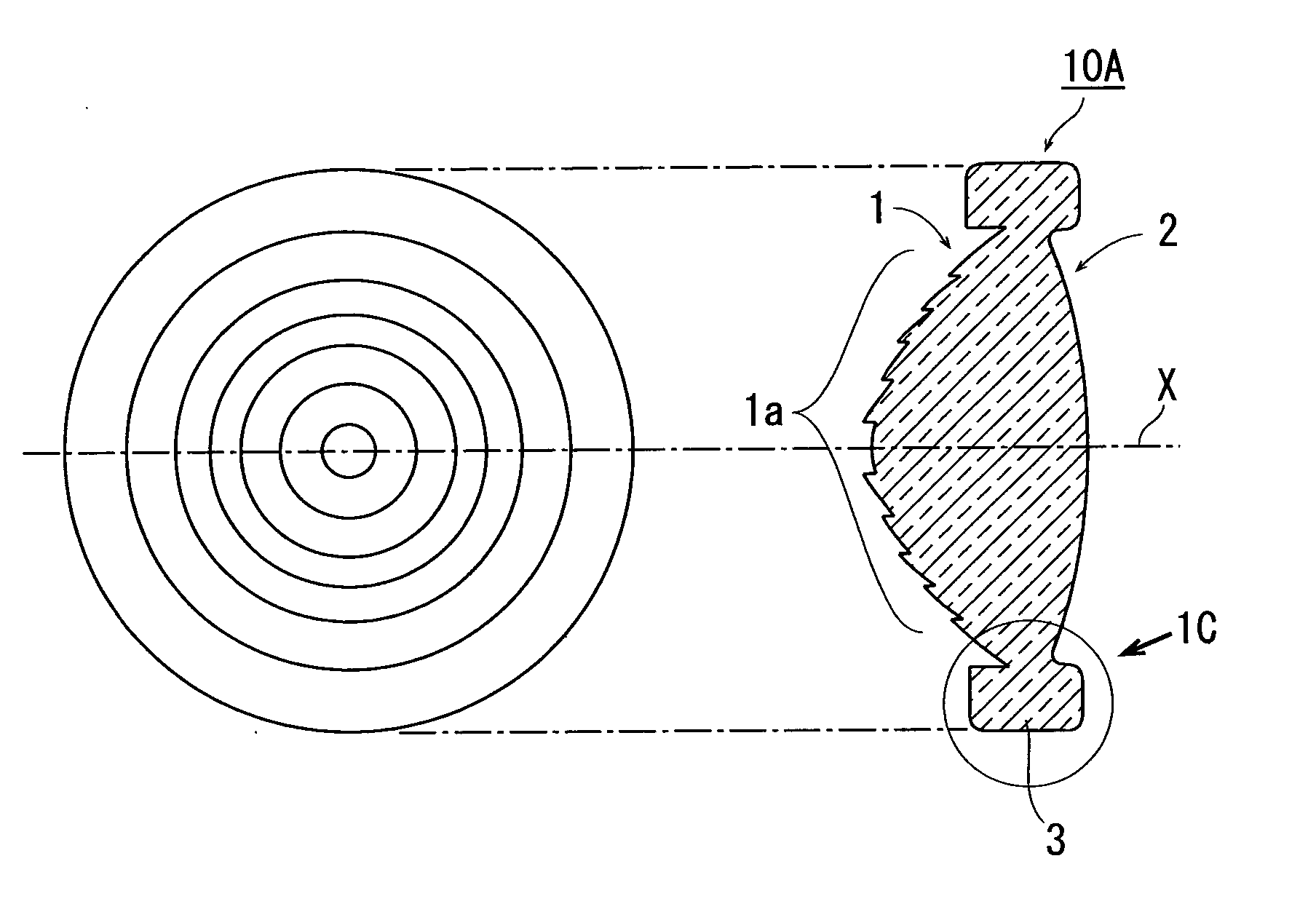

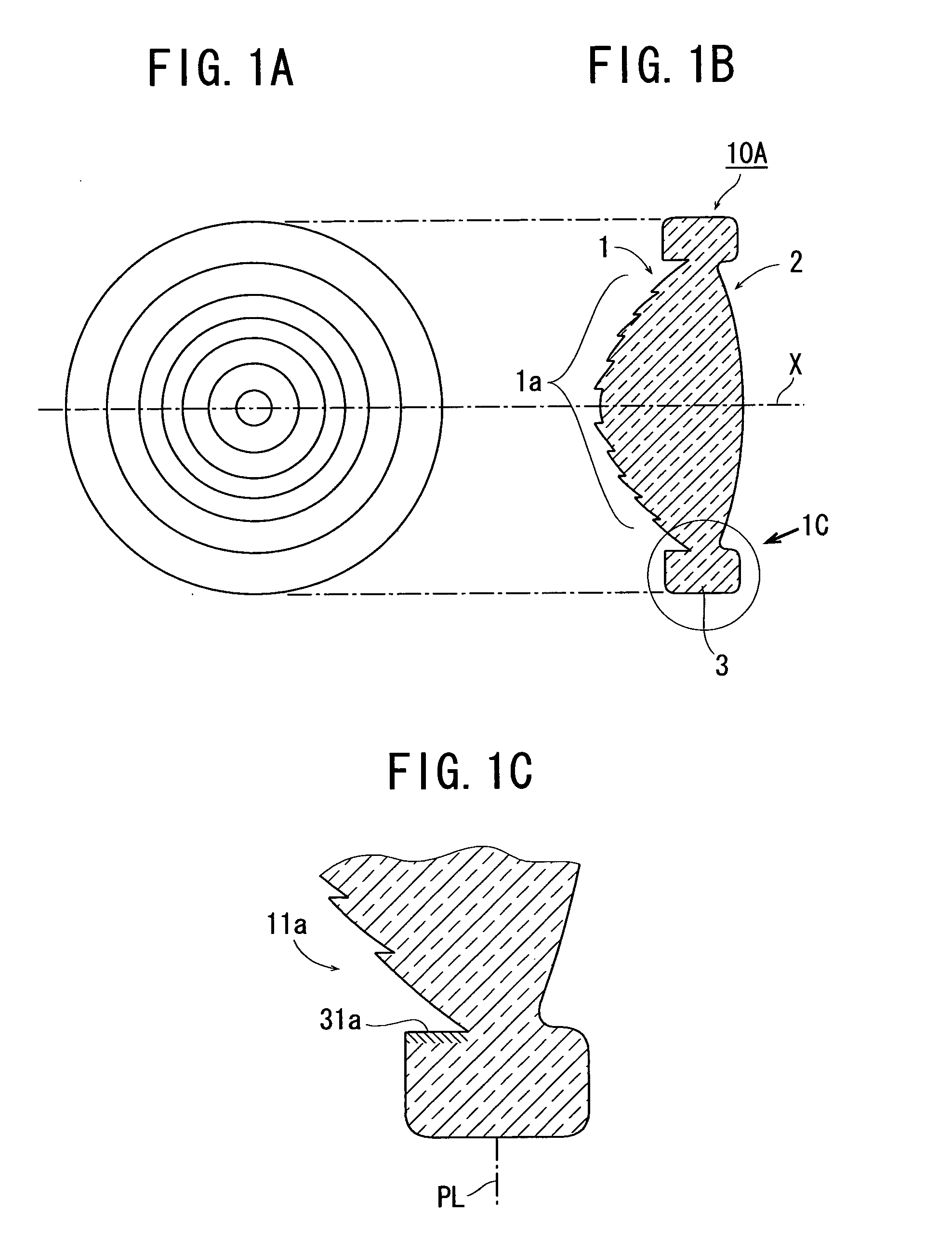

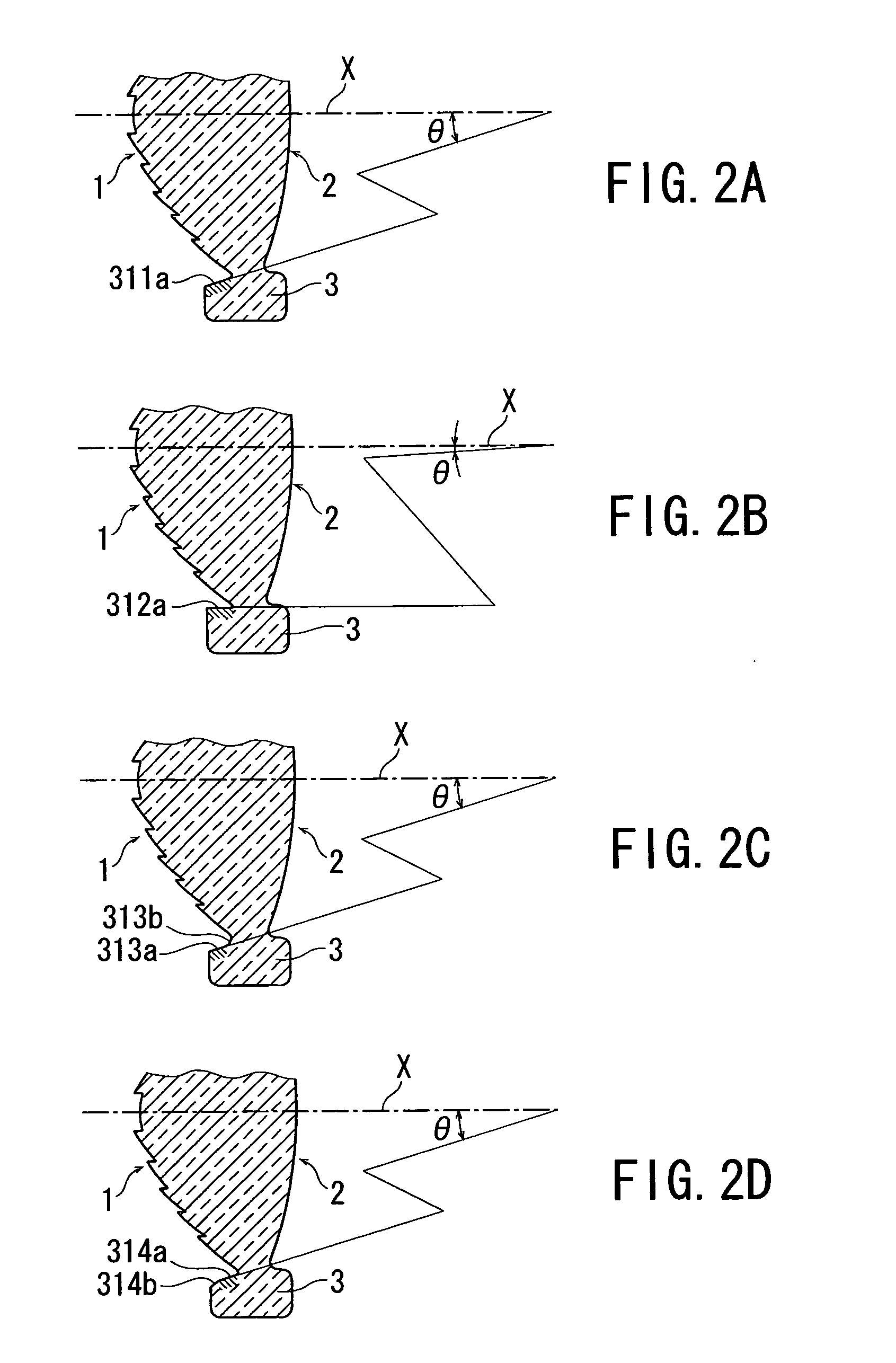

Optical element, method of molding optical element, and mold

ActiveUS20050094294A1Improve accuracyInhibit heat shrinkageOptical articlesMountingsFine structureOptical axis

This invention provides an optical element comprising: an optical functional section on a first surface of the optical element, the optical functional section having a fine structure; and a flange section formed on a periphery of the optical functional section, wherein the flange section has a heat shrinkage-inhibiting portion, which inhibits heat shrinkage of the optical element during molding in a direction perpendicular to an optical axis of the optical element. The invention further provides a method of molding the optical element, and a mold.

Owner:KONICA MINOLTA OPTO

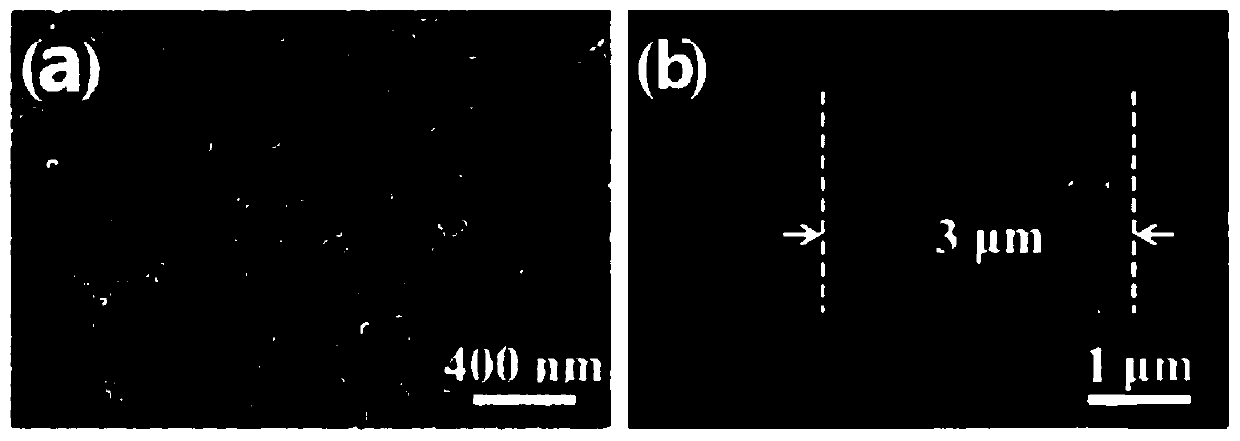

Composite lithium ion battery separator and preparation method thereof

InactiveCN110048058AImprove securityImprove thermal stabilitySecondary cellsCell component detailsPolyolefinDip-coating

The present invention relates to a composite lithium ion battery separator and a preparation method thereof. The composite lithium ion battery separator is composed of a substrate layer and an inorganic / organic composite porous film layer arranged on the surface of the substrate layer. The substrate layer is polyolefin porous film and the inorganic / organic composite porous film layer is a composite layer containing inorganic nanoparticles and waterborne binder. The preparation method of the composite lithium ion battery separator is as follows: inorganic waterborne dispersion liquid, organic waterborne dispersion liquid and surfactant are added into deionized water, stirred and mixed uniformly to prepare coating; the substrate layer is immersed into the prepared coating, subjected to dip coating, dried at a room temperature and then dried in vacuum to prepare the composite lithium ion battery separator. The invention aims at the problem that the safety performance of the separator is unstable; an organic-inorganic uniform hybrid porous film is cured and formed on the surface of the separator; and the improvement of the separator thermostability and the safety and the chemical corrosion resistance of the lithium ion battery is realized.

Owner:SHANGHAI NANOTECH PROMOTION CENT

Organic/inorganic composite electrolyte and electrochemical device prepared thereby

ActiveUS20120088029A1Improve securityInhibit heat shrinkageFinal product manufactureLi-accumulatorsPolymer dissolutionPorous coating

The present invention relates to a method for manufacturing an electrode having an organic / inorganic composite porous coating layer comprising porous inorganic particles and a binder polymer, wherein the porous inorganic particles have pores having such a size that lithium ions (Li+) solvated in an electrolyte solvent can pass therethrough. The method comprises the steps of dispersing inorganic precursors and heat-decomposable compounds in a dispersion medium, misting the inorganic precursor solution, and performing a thermal decomposition and a crystallization processes, to thereby prepare porous inorganic particles, adding and mixing the porous inorganic particles to a polymer solution in which a binder polymer is dissolved, and coating the mixture onto a preliminarily formed electrode and drying the coating layer.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com