Separator, production method for same and electrochemical device equipped with same

A diaphragm and halide technology, applied in the direction of circuits, electrical components, battery pack components, etc., can solve problems such as poor electrolyte wettability, short circuit between positive and negative electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

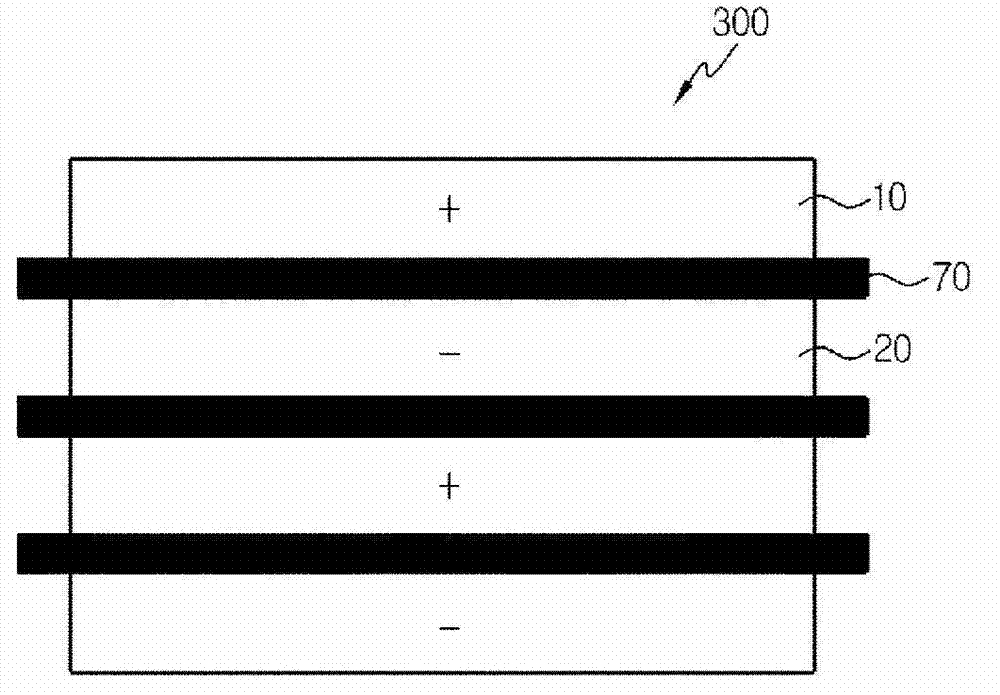

[0071] Example 1: Three-layer separator coated with polyamide for lithium ion battery

[0072] An aqueous solution of 2% by weight of m-phenylenediamine and a solution of isoparaffin and 0.1% by weight of trimesoyl chloride were prepared.

[0073] Then, the three-layer separator of Comparative Example 1 was immersed in an aqueous solution of 2% by weight of m-phenylenediamine for 2 minutes, and then the residual water was removed using a roller. The treated three-layer membrane was immersed in a solution of isoparaffin and 0.1 wt % trimesoyl chloride for 1 minute at room temperature.

[0074] The three-layer membrane with the polyamide coating was air-dried for 2 minutes, washed with water, and dried in an oven at 70°C for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com