Membrane containing active lithium sources, preparation method and lithium ion battery

A production method and lithium source technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of harsh environmental requirements, large loss of lithium sources, high production costs, etc., achieve low process environment requirements, and increase thermal stability resistance, heat shrinkage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

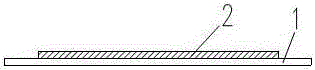

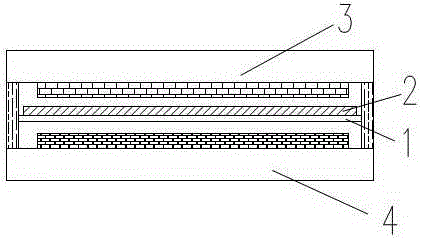

[0019] Such as figure 1 As shown, a diaphragm containing an active lithium source includes a diaphragm and a coating containing an active lithium source, and the coating containing an active lithium source is coated on the upper surface of the diaphragm. The active lithium source-containing coating used is a lithium iron phosphate layer. The separator used is a lithium compound such as polyethylene or polypropylene.

[0020] This embodiment also provides a method for manufacturing the above diaphragm containing active lithium source. The preparation method specifically includes the following steps:

[0021] (1) Lithium iron phosphate is selected as the active material containing the active lithium source, and the lithium iron phosphate material with a particle size D50 of 500nm is baked.

[0022] (2) Mix the dried lithium iron phosphate with the conductive agent and the binder according to a certain ratio, and then stir it to disperse it evenly, and make 100 kg of active mi...

Embodiment 2

[0028] A diaphragm containing an active lithium source, comprising a diaphragm and a coating containing an active lithium source, and the coating containing an active lithium source is coated on the upper surface of the diaphragm. The active lithium source-containing coating used is a lithium iron borate layer. The separator used is a lithium compound such as polyethylene or polypropylene.

[0029] This embodiment also provides a method for manufacturing the above diaphragm containing active lithium source. The preparation method specifically includes the following steps:

[0030] (1) Lithium iron borate is selected as the active material containing active lithium source, and the lithium iron borate material with a particle size D50 of 500nm is used for baking.

[0031] (2) Mix the dried lithium iron borate with the conductive agent and the binder according to a certain ratio, and then stir to make them fully mixed to make 100 kg of active mixed materials containing lithium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com