Dual-Fuel Burning Gas Turbine Combustor

A technology for gas turbines and burners, applied in the directions of burners, combustion chambers, combustion methods, etc., can solve the problems of excessive thermal stress and leakage of welding parts, and achieve the effect of suppressing thermal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

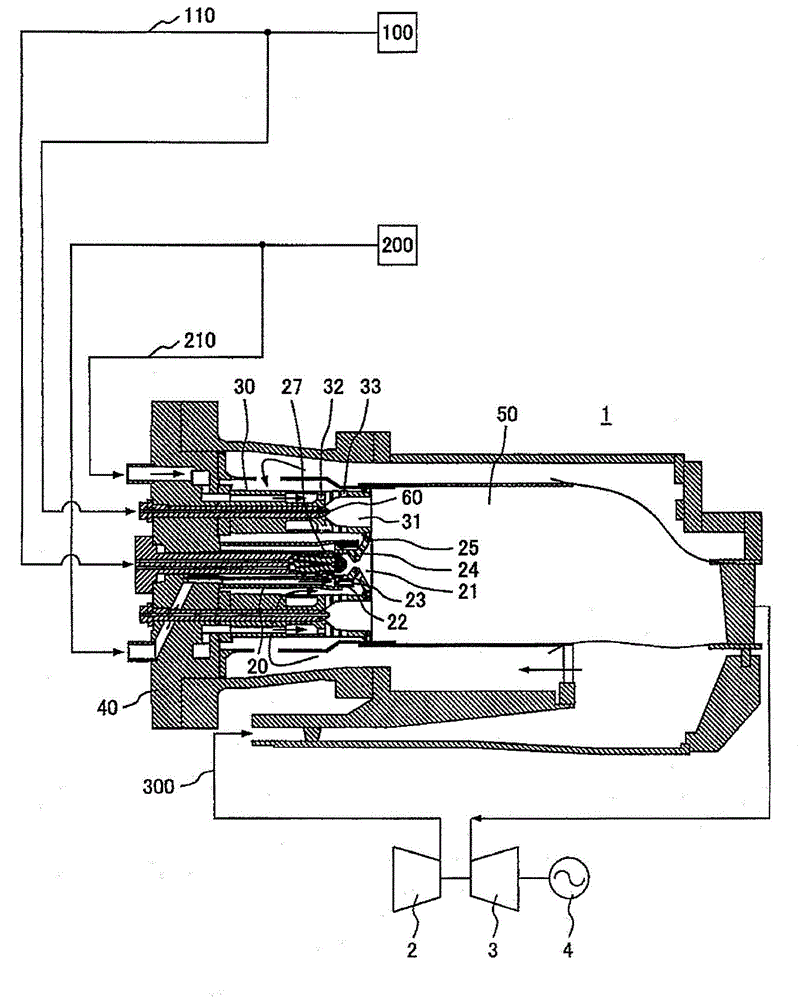

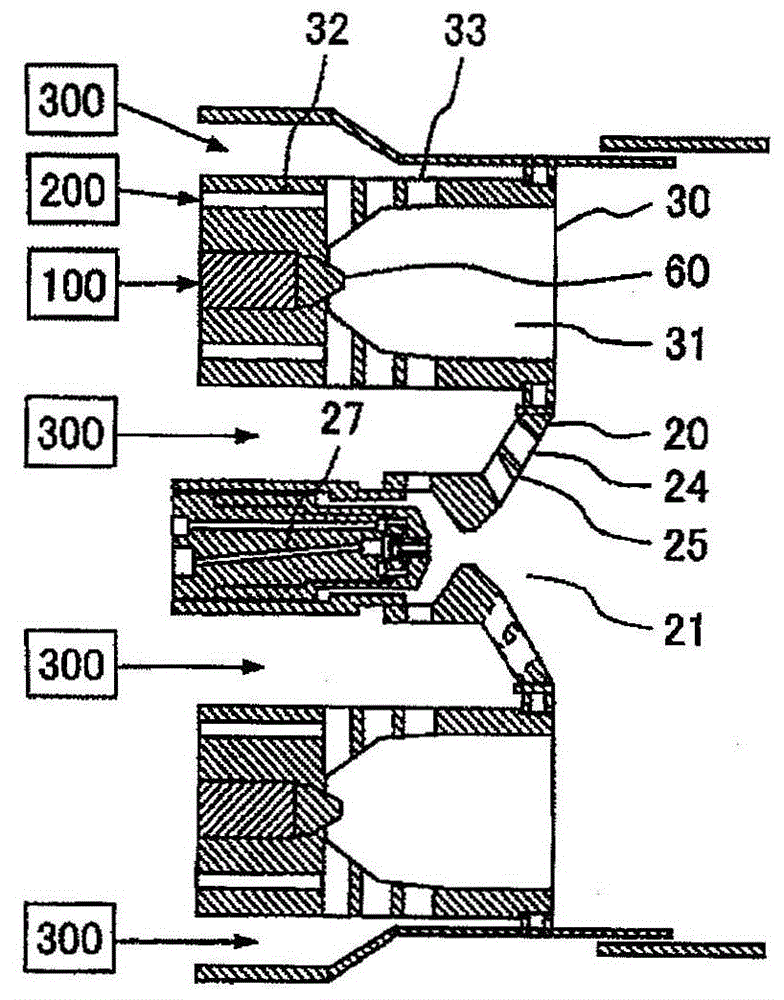

[0027] refer to Figure 1 ~ Figure 4 A dual fuel combustion gas turbine combustor using gas fuel and liquid fuel as fuel according to a first embodiment of the present invention will be described.

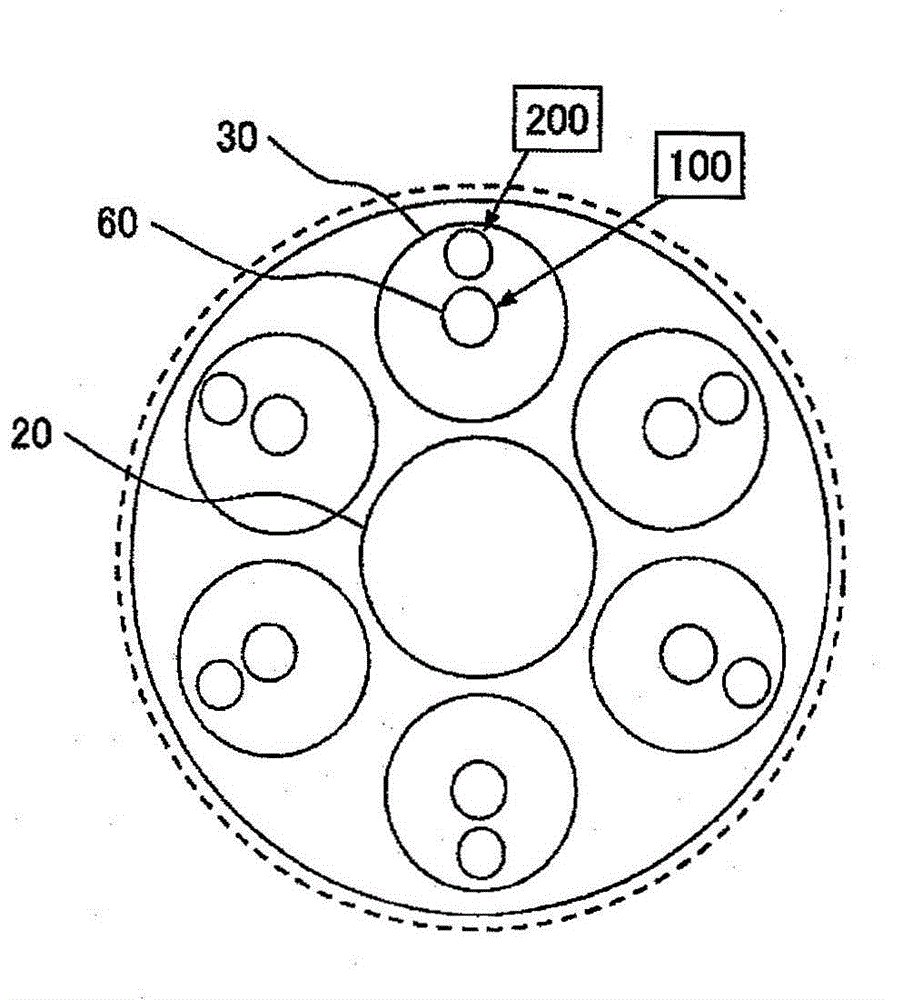

[0028] exist figure 1 And in the dual fuel combustion gas turbine combustor 1 using gaseous fuel and liquid fuel as fuel in the first embodiment of the present invention shown in FIG. 2 , the dual fuel combustion gas turbine combustor 1 of the present embodiment One diffusion burner 20 for injecting liquid fuel 100 and gaseous fuel 200 into the combustion chamber 50 for combustion is arranged on the central side in the axial direction of 1, and a plurality of premixing burners 30 are arranged on the outer peripheral side of the diffusion burner 20, For example, six premix burners 30 are respectively arranged on the outer peripheral side of the diffuser burner 20 at a distance from each other, and the liquid fuel 100 and the gas fuel 200 are injected into the combustion chamber 50 ...

Embodiment 2

[0077] Next refer to Figure 5 A dual fuel combustion gas turbine combustor using gas fuel and liquid fuel as fuel according to a second embodiment of the present invention will be described.

[0078] because Figure 5 The dual-fuel incineration gas turbine combustor 1 using gaseous fuel and liquid fuel as fuel of the present embodiment shown in FIG. Figure 1 ~ Figure 4 The basic structure of the dual-fuel combustion gas turbine combustor using gaseous fuel and liquid fuel as fuel in the first embodiment shown is the same, so the description common to both will be omitted below, and only the different structures will be described.

[0079] exist Figure 5 In the dual-fuel combustion gas turbine combustor 1 of the present embodiment shown, as far as the double-pipe sleeve 80 provided relative to the end cover 40 and the premixing burner 30 is concerned, the inner side sleeve of the above-mentioned double-pipe sleeve 80 is constituted. 81 abuts against the upstream side end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com