SiO2-PS nuclear shell structure ceramic coating diaphragm and preparation method and application thereof

A technology of core-shell structure and ceramic coating, which is applied in the direction of structural parts, separators/films/diaphragms/spacer components, electrical components, etc., can solve the problems of increasing the internal resistance of lithium batteries, uneven dispersion of ceramic powder, and thermal shutdown. Problems such as poor porosity, to achieve the effect of solving the negative impact of porosity, good bonding effect, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

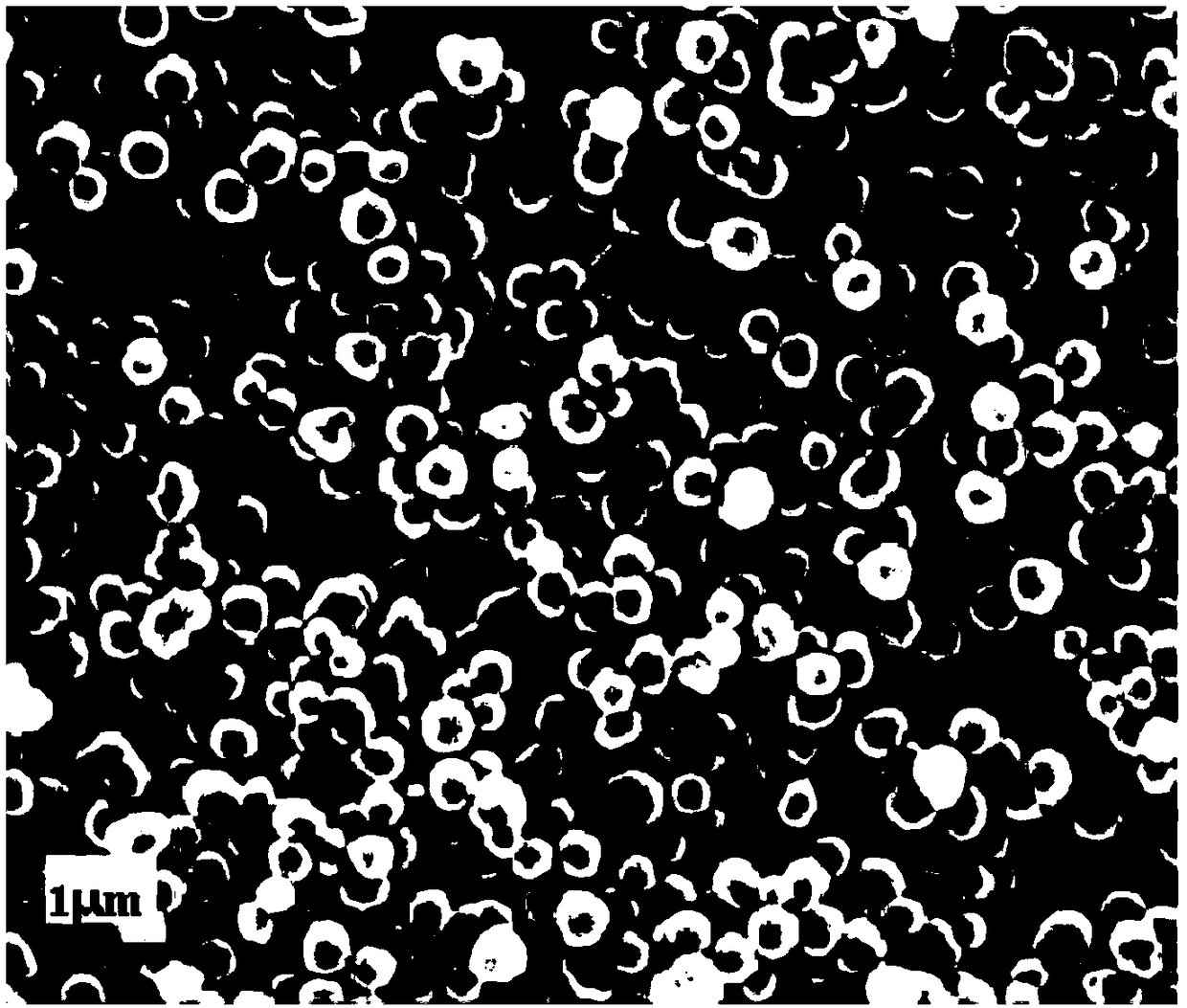

[0027] (1) Monodisperse nano-SiO 2 Preparation of granules: Mix 15mL concentrated ammonia water, 120mL ethanol solution and 12mL tetraethyl orthosilicate at the same time, react with Stöber method at room temperature, seal the bottle and carry out magnetic stirring for 18-24h, then centrifuge, and sieve the particle size Monodisperse nano-SiO of 50 nm and below 2 Particles are preserved in ethanol solution to form monodisperse nano-SiO 2 The particle dispersion is ready for use;

[0028] (2) Monodisperse nano-SiO 2 Modification of Particles: Using Monodisperse Nano-SiO 2 The ratio of particles to deionized water 0.85mg / mL, the monodisperse nano-SiO 2 Add the particle dispersion to the deionized water in the four-neck flask, mix 0.5mg of γ-methacryloxypropyltrimethoxysilane with 20mL of ethanol, and prepare γ-methacryloxypropyltrimethoxysilane ethanol The solution was added to a four-necked flask and 5-10 drops of ammonia water were added dropwise, and under the protection...

Embodiment 2

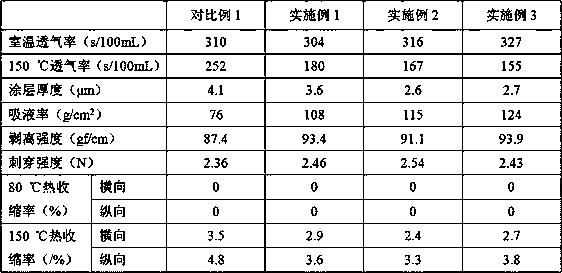

[0033] In this example, on the basis of Example 1, in step (4), monodisperse core-shell SiO 2 -PS composite particles are fully washed with toluene, centrifuged at a speed above 8000rpm, and then fully washed with ethanol to monodisperse core-shell SiO 2 -PS composite particles, then centrifuged, and the monodisperse core-shell SiO 2 -PS composite particles, water-based adhesive, and solvent are mixed at a weight ratio of 70-100:1~5:500~1000, and then ultrasonic dispersion and mechanical stirring are carried out for 2-3 hours at the same time, so that each component is fully dispersed and uniform to form a uniform texture The mixed slurry; through the use of toluene washing, ethanol washing two processes, can effectively remove the monodisperse core-shell SiO 2 -Free PS and other impurities on the surface of PS composite particles can effectively reduce core-shell SiO in the subsequent process of making diaphragm coating slurry 2 - Adhesion between PS composite particles, ef...

Embodiment 3

[0035] This example is modified on the basis of Example 2. In the step (1), 20mL of concentrated ammonia water, 100mL of ethanol solution and 15mL of ethyl orthosilicate are mixed simultaneously, and 0.8mgγ - Mix methacryloxypropyltrimethoxysilane with 20mL ethanol to prepare ethanol solution of γ-methacryloxypropyltrimethoxysilane; step (4) uses styrene-butadiene rubber (SBR) and carboxymethyl The compound of cellulose-based cellulose (CMC) is used as a water-based binder, and 50% ethanol is used as a solvent. The compound of styrene-butadiene rubber and carboxymethyl cellulose is mixed in a ratio of 2-3:3. and modulated monodisperse core-shell SiO 2 -The weight ratio of PS composite particles, water-based adhesive, and solvent is 95-100:5-6:800-1000; in step (5), a porous PE film is used instead.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com