Organic/inorganic composite separator having porous active coating layer and electrochemical device containing the same

一种无机复合、活性层的技术,应用在电化学发生器、电气元件、电池组零部件等方向,能够解决劣化热收缩的能力、粘附力弱、孔隙率降低等问题,达到抑制热收缩、防止电短路、提高稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

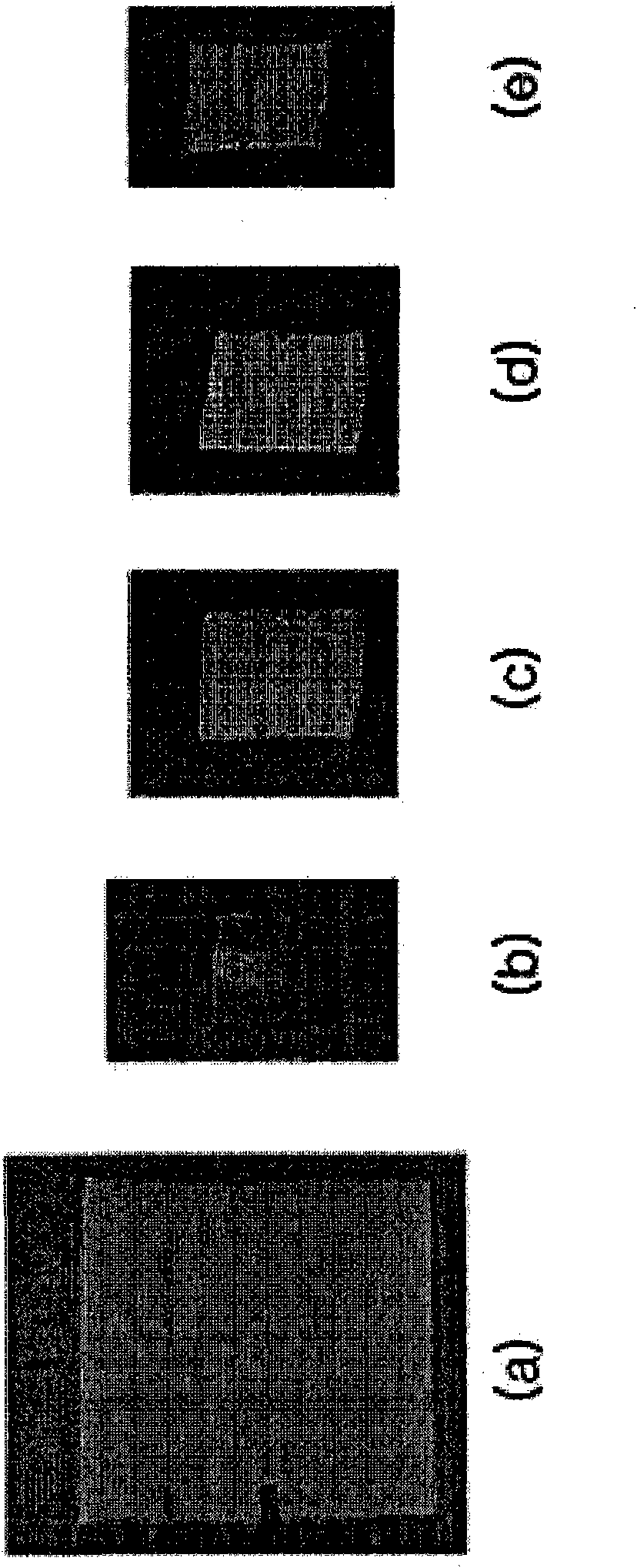

[0057] Preparation of organic / inorganic [(PVdF-HFP / cyanoethyl polyvinyl alcohol) / Al 2 o 3 ] Composite diaphragm

[0058] 5 wt% polyvinylidene fluoride-co-hexafluoropropylene (PVdF-HFP, the contact angle to water droplets is 100°) and 5 wt% cyanoethyl polyvinyl alcohol (the contact angle to water droplets is 30°) were added to in acetone and dissolved at 50°C for about 12 hours to prepare a binder polymer solution. Will Al 2 o 3 powder to polymer mixture / Al 2 o 3 = 10 / 90 weight ratio was added to the prepared binder polymer solution, and then the Al 2 o 3 The powder was pulverized and dispersed for more than 12 hours to prepare a slurry. In the prepared slurry, Al can be controlled according to the size (or diameter) of the beads used in the ball milling and the use time of the ball mill. 2 o 3 diameter, but in this example 1, the Al 2 o 3 The powder was pulverized to about 400 nm to prepare a slurry. The prepared slurry was applied to a polyethylene separator (por...

Embodiment 2

[0060] In addition to using polyvinylidene fluoride-co-trichloroethylene (PVdF-CTFE, the contact angle to water droplets is 95 °) instead of PVdF-HFP, prepare organic / inorganic [(PVdF-CTFE / cyanoethyl polyvinyl alcohol / Al 2 o 3 ] Composite diaphragm.

Embodiment 3

[0062] In addition to using BaTiO 3 Powder instead of Al 2 o 3 Except powder, prepare organic / inorganic [(PVdF-HFP / cyanoethyl polyvinyl alcohol / BaTiO in the same manner as in Example 1) 3 ) Composite diaphragm. The weight of the active layer is about 22g / m 2 ; Considering the size (400nm) and density (5.7g / cc) of the inorganic particles, the number of individual inorganic particles in the active layer is estimated to be about 4×10 19 / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat shrinkage ratio | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com