Patents

Literature

538results about "Moulding machine components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

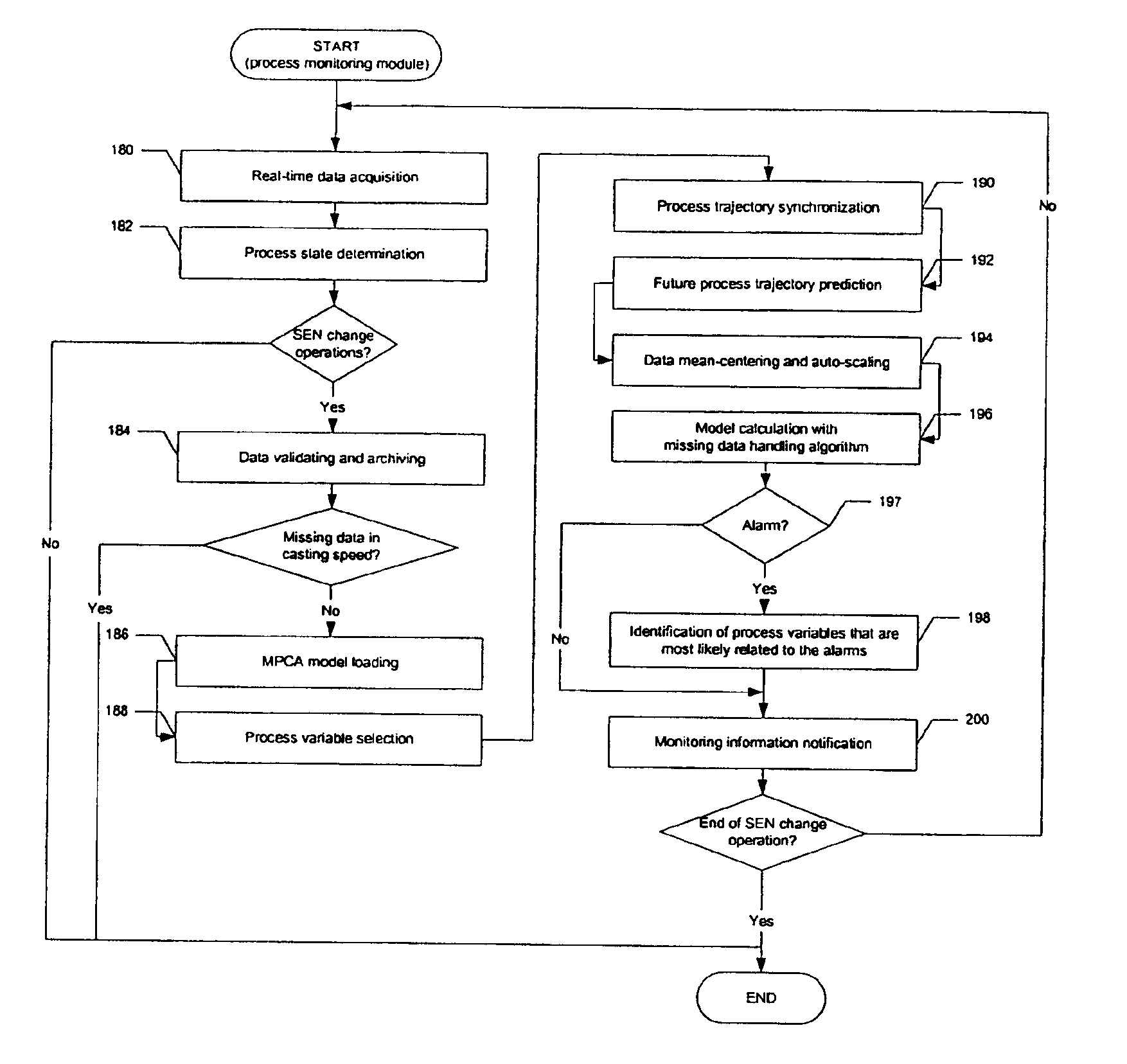

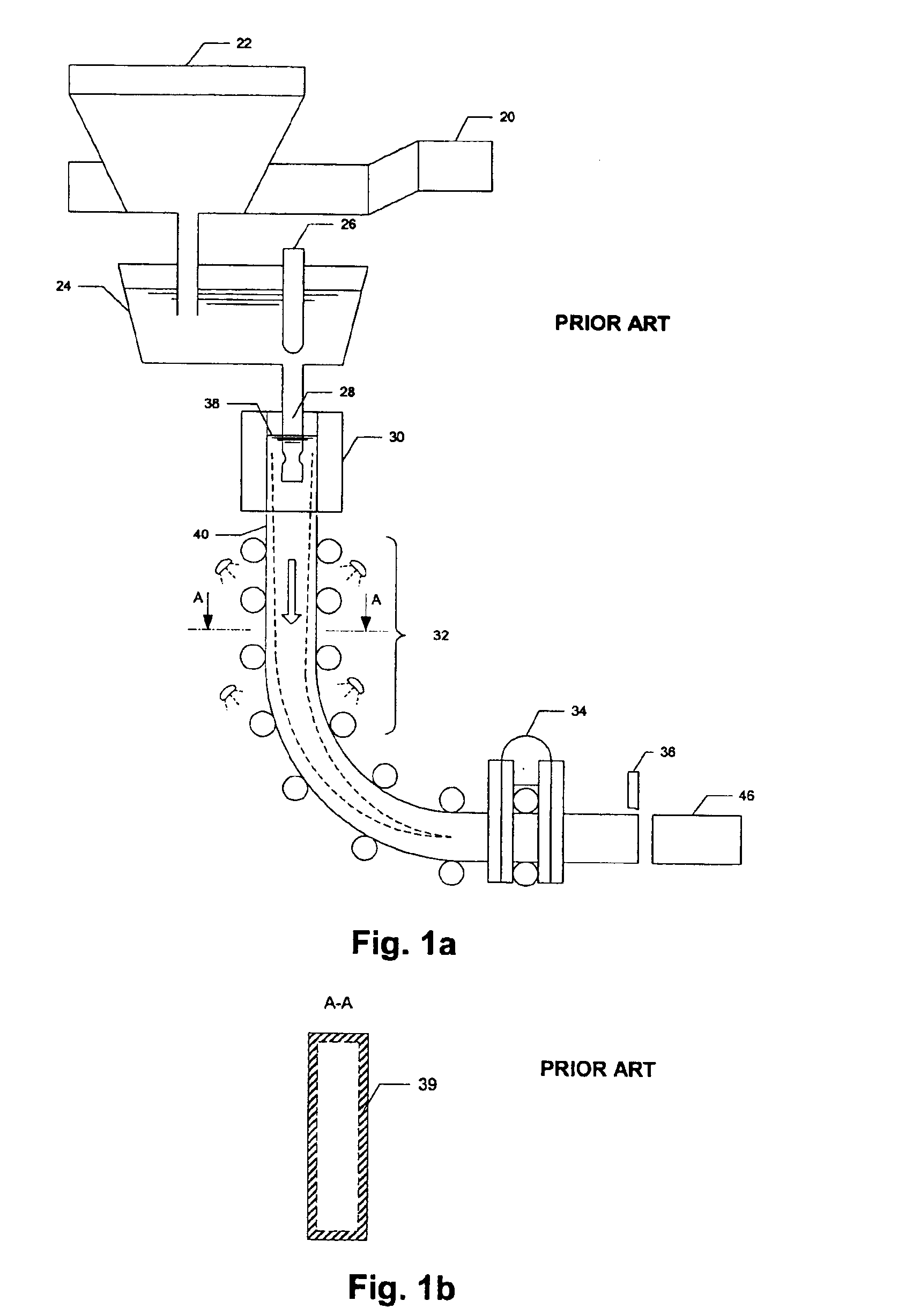

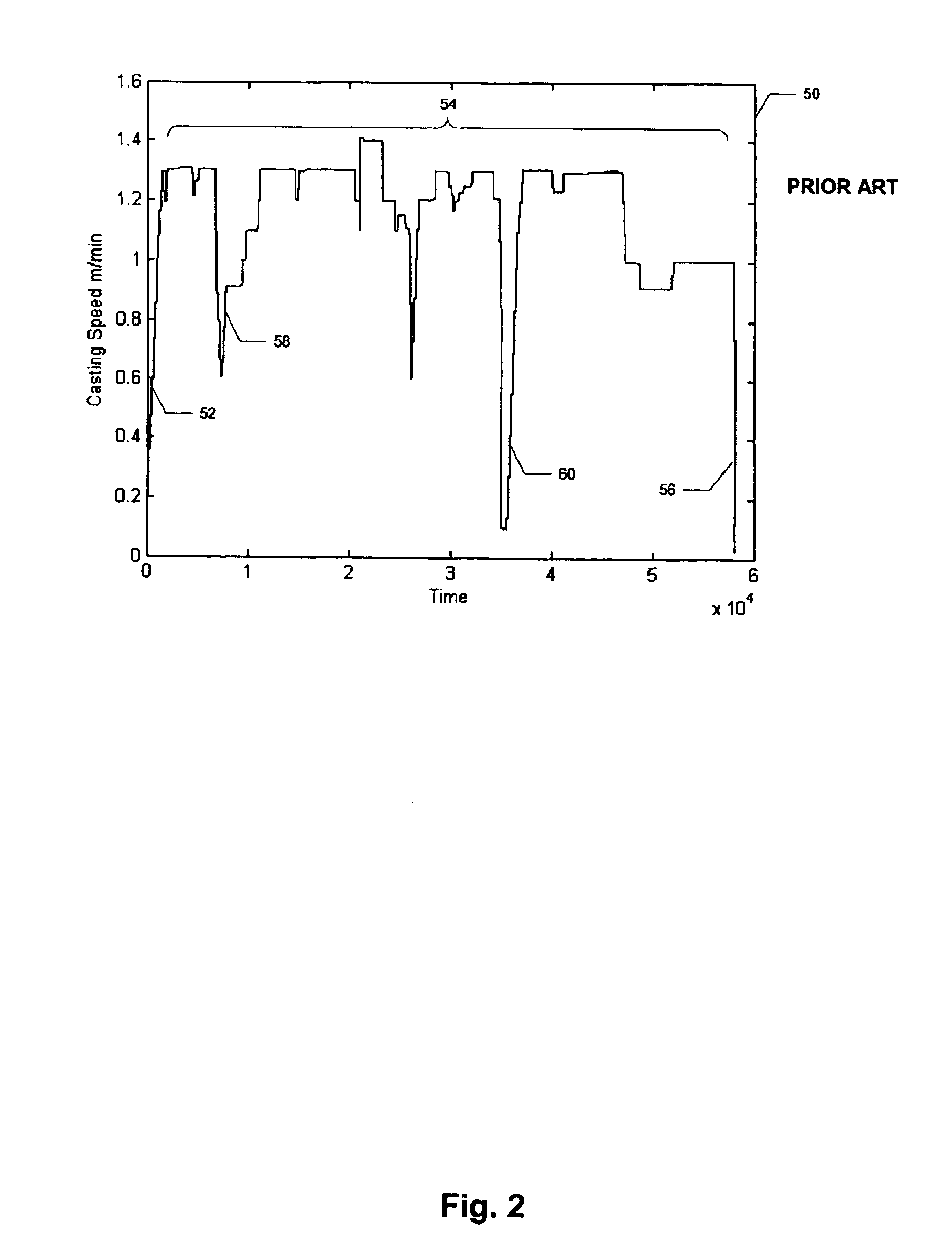

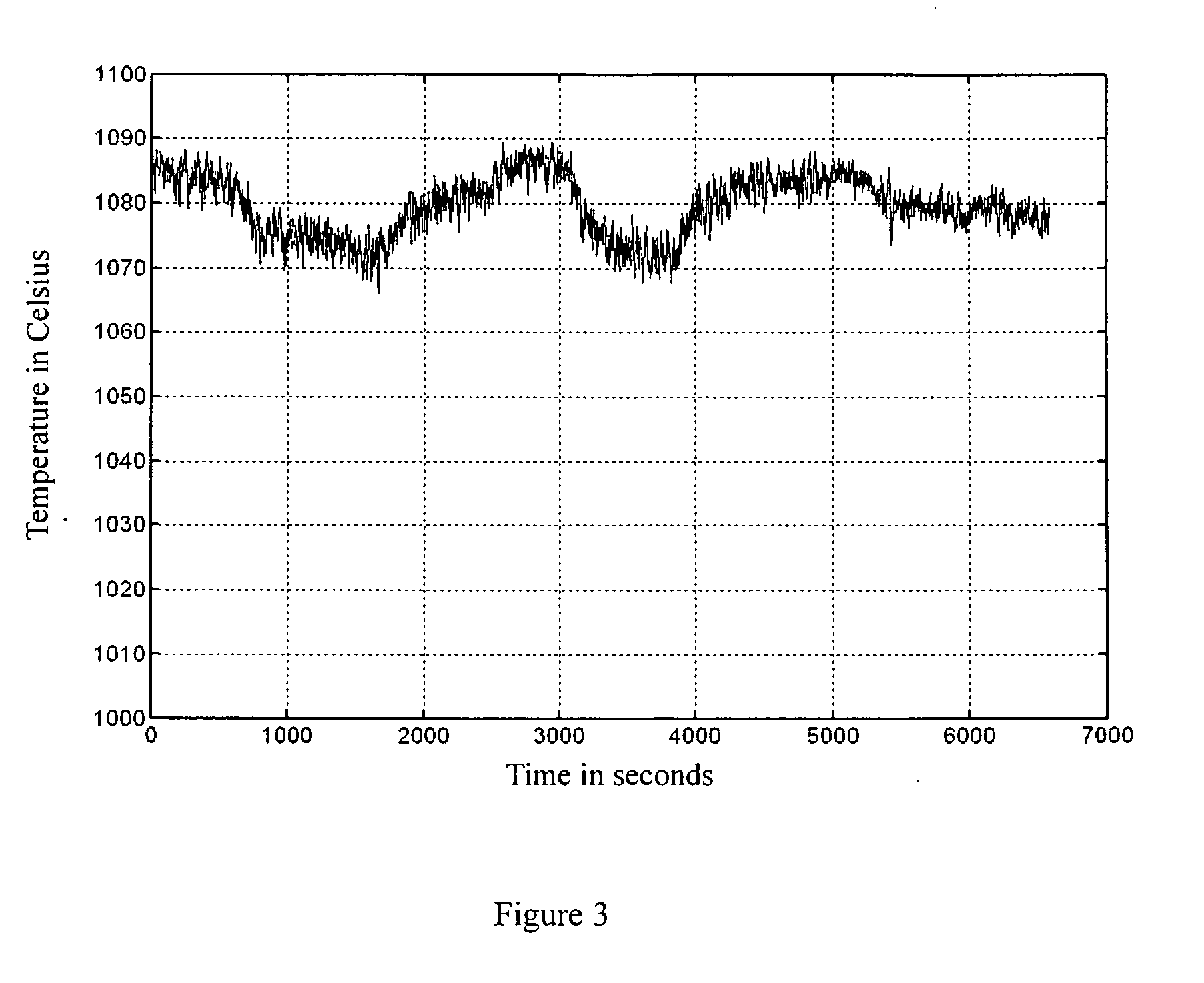

Real-time system and method of monitoring transient operations in continuous casting process for breakout prevention

ActiveUS6885907B1Testing/monitoring control systemsMoulding machine componentsPrincipal component analysisMultivariate statistical

A real-time system and method for online monitoring a transient operation in a continuous casting process. The transient operation refers to, but is not limited to, submerged entry nozzle changes, flying tundish changes, product grade changes, etc. This invention treats the aforementioned transient operations as batch processes and utilizes multiway principal component analysis to develop a multivariate statistical model to characterize normal process transitions based on carefully selected historical process data. Such a model is used by an online monitoring system to determine if a continuous caster transient operation is normal. This monitoring system can further be used to predict an impending breakout, one type of catastrophic process failures which may occur in a continuous casting process, during the transient operation. Process variables that are most likely related to the predicted breakout are identified by the system such that appropriate control actions can be taken to prevent an actual breakout occurrence.

Owner:DOFASCO INC

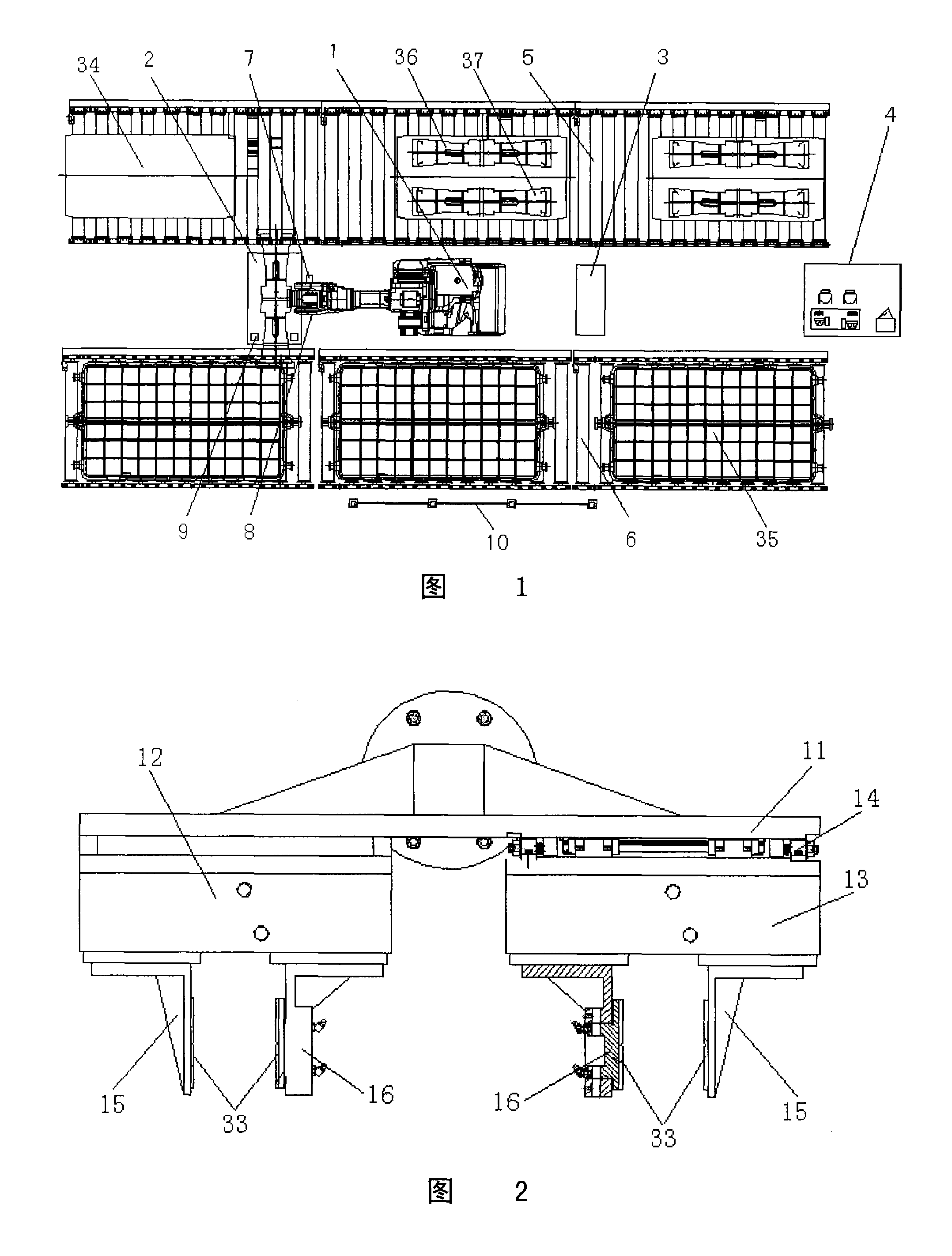

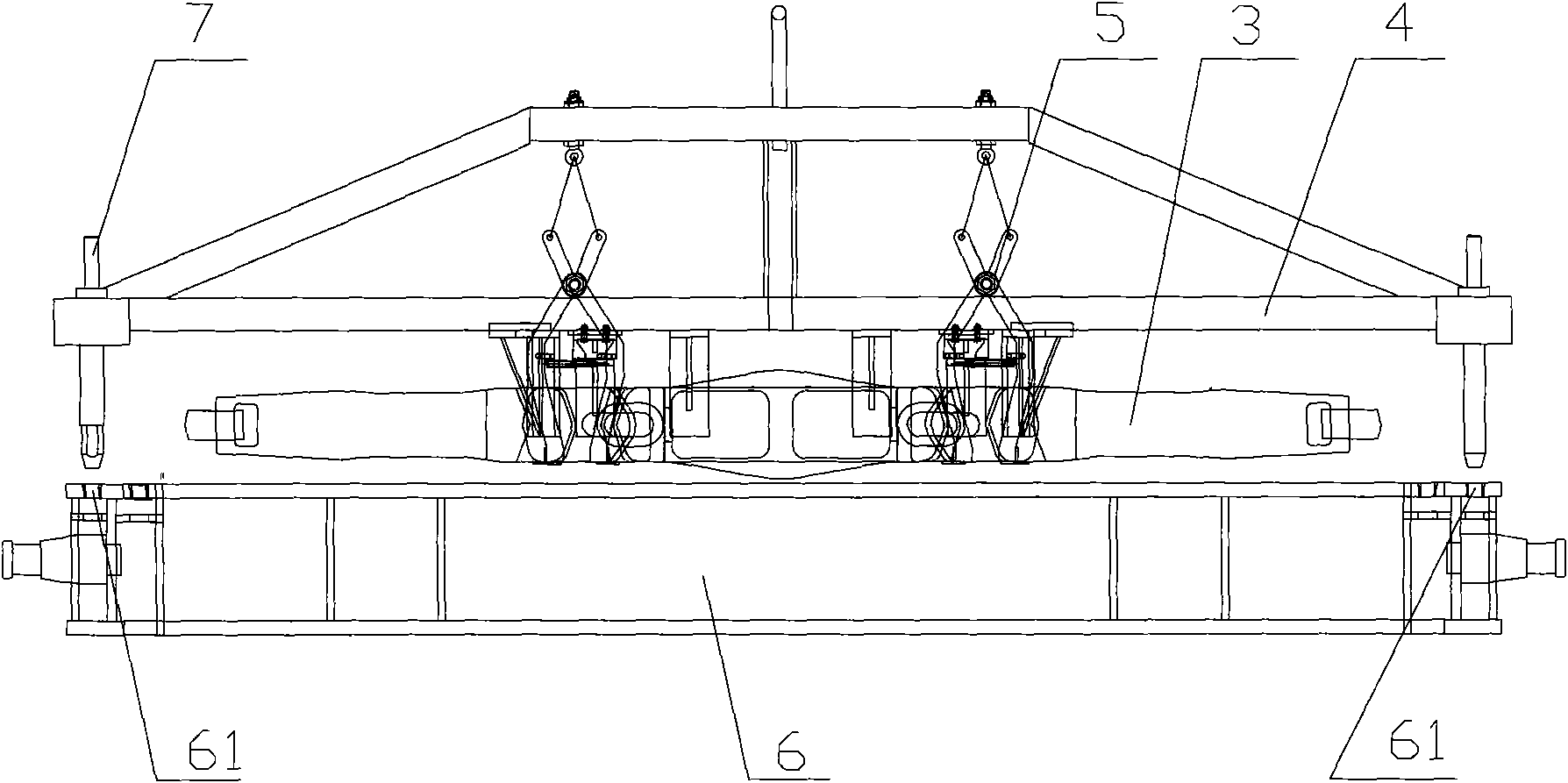

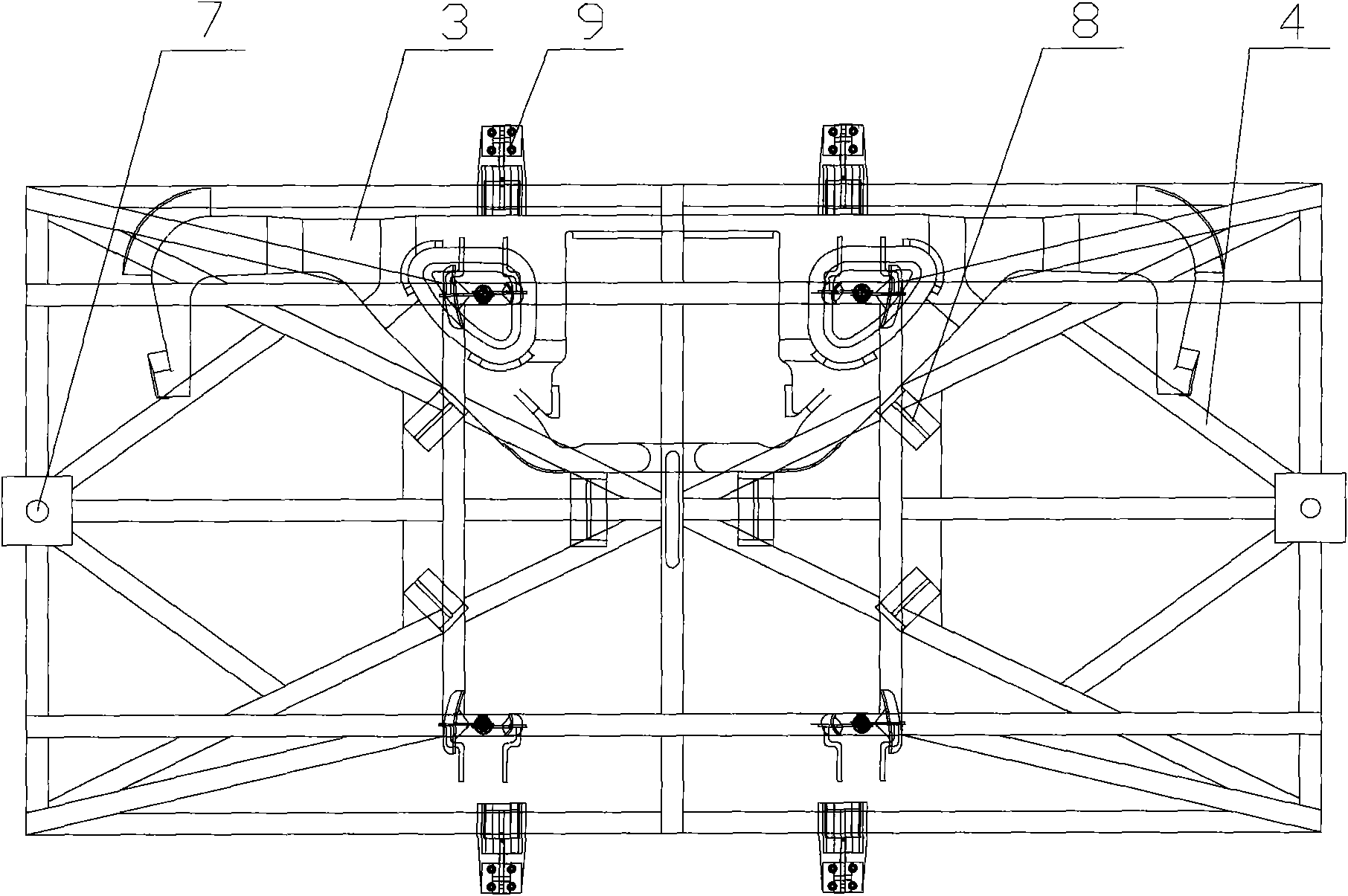

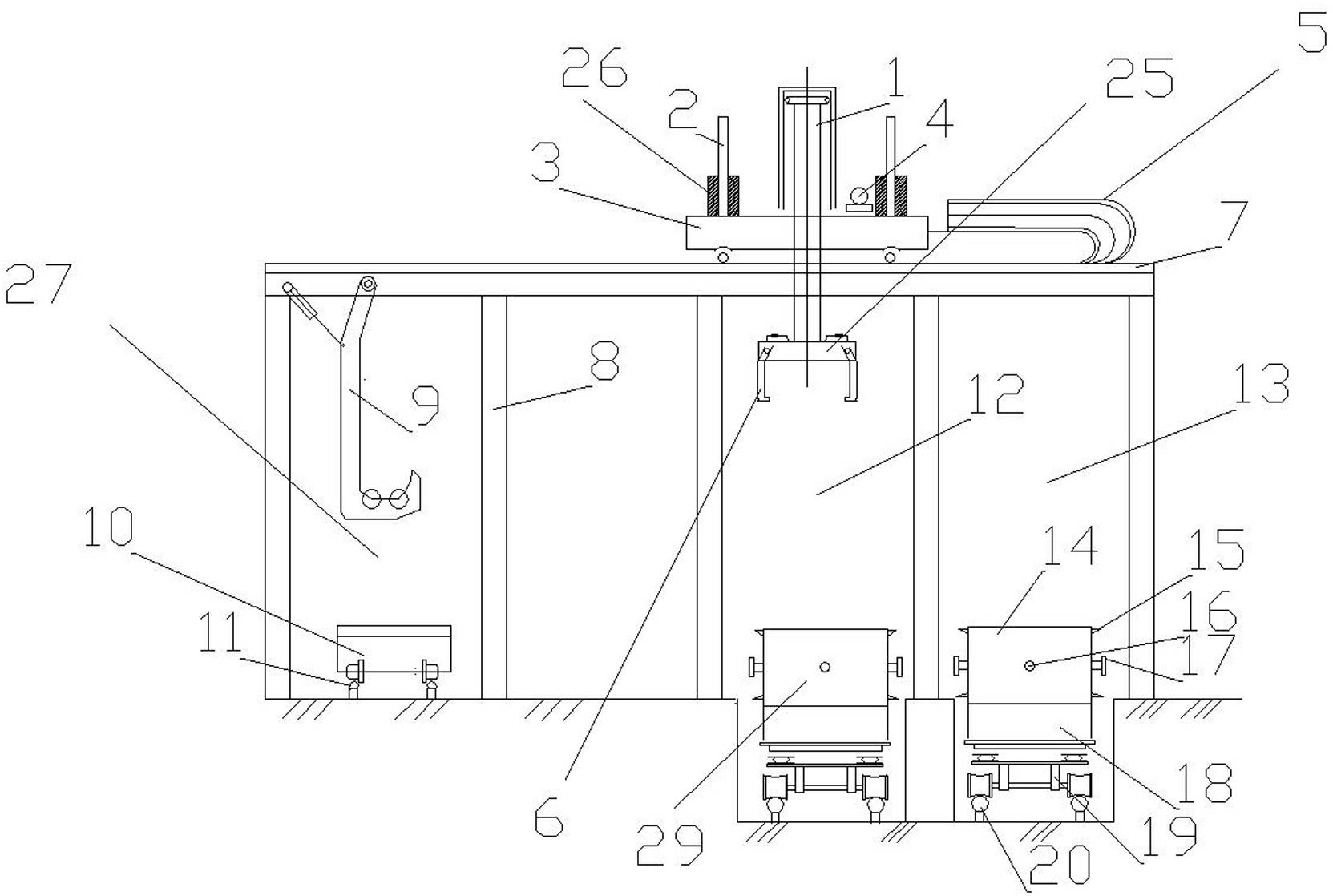

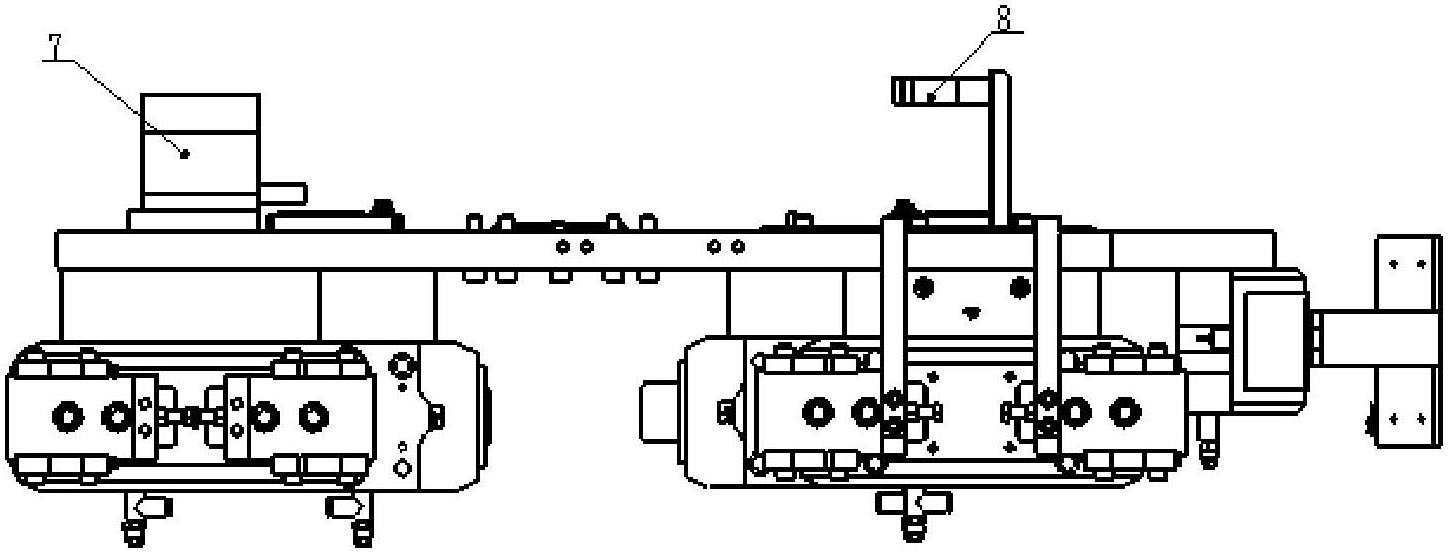

Robot sand core lock core, core setting method and system

ActiveCN101249548AQuality improvementImprove quality reliabilityProgramme-controlled manipulatorFoundry mouldsProduction rateControl room

The invention relates to a method and a system for locking and setting a sand core by a robot, which is characterized in that the system comprises the multi-degree-of-freedom industrial robot, a core locking platform and a central control room, wherein the robot actuator is connected with a 3D scanner and a flexible fixture at the tail end; the core locking platform is arranged on one side of the robot; and the central control room is arranged on the other side of the robot and comprises a computer as well as an auxiliary control unit for controlling and monitoring the robot, the core locking platform and the 3D scanner. The system can achieve automatic accurate gripping, conveying, locking and setting processes of the sand core, greatly improve labor production rate, lower labor intensity while ensuring high-accuracy core locking and setting processes and improving the quality of a final product.

Owner:廊坊智通机器人系统有限公司 +1

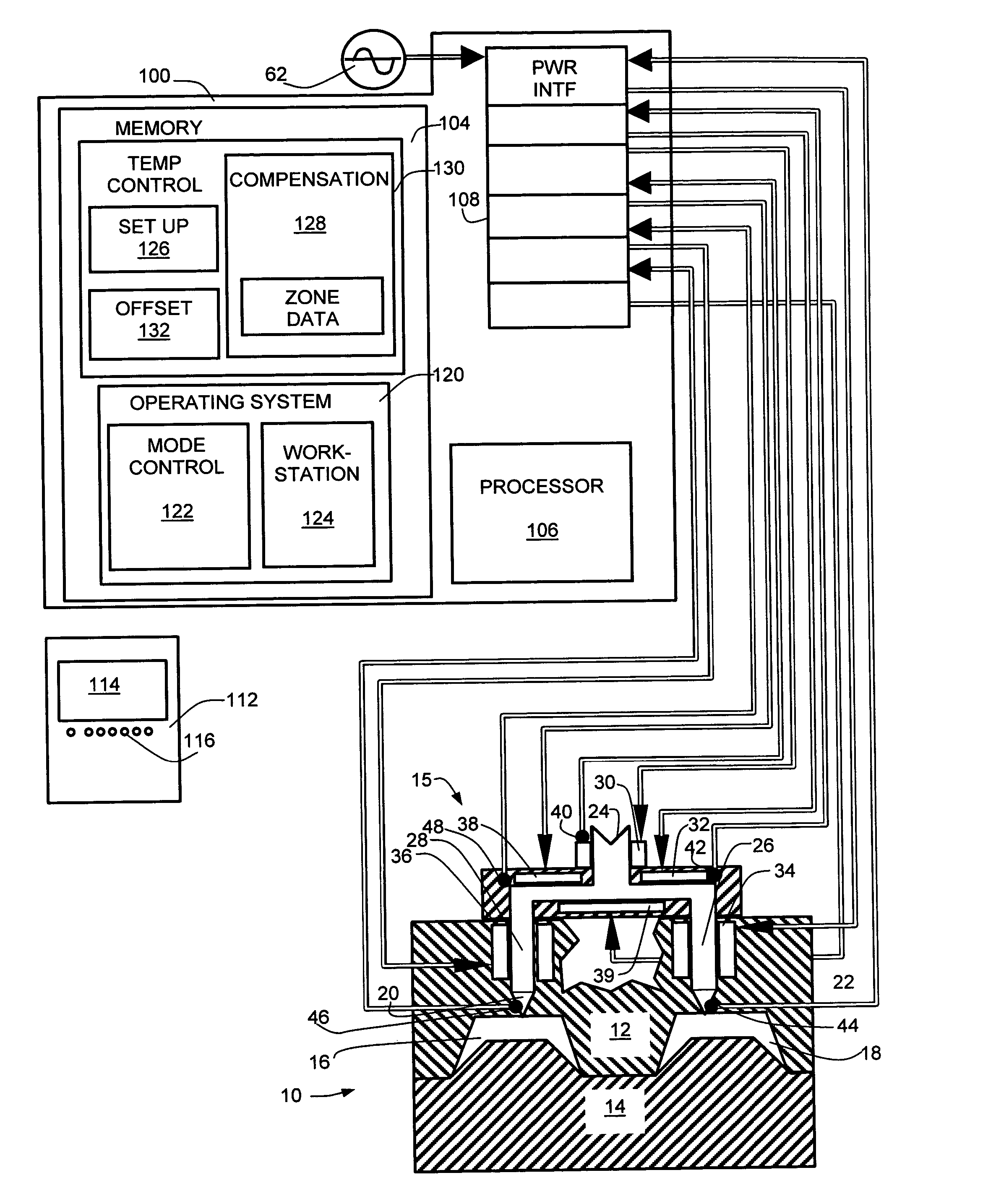

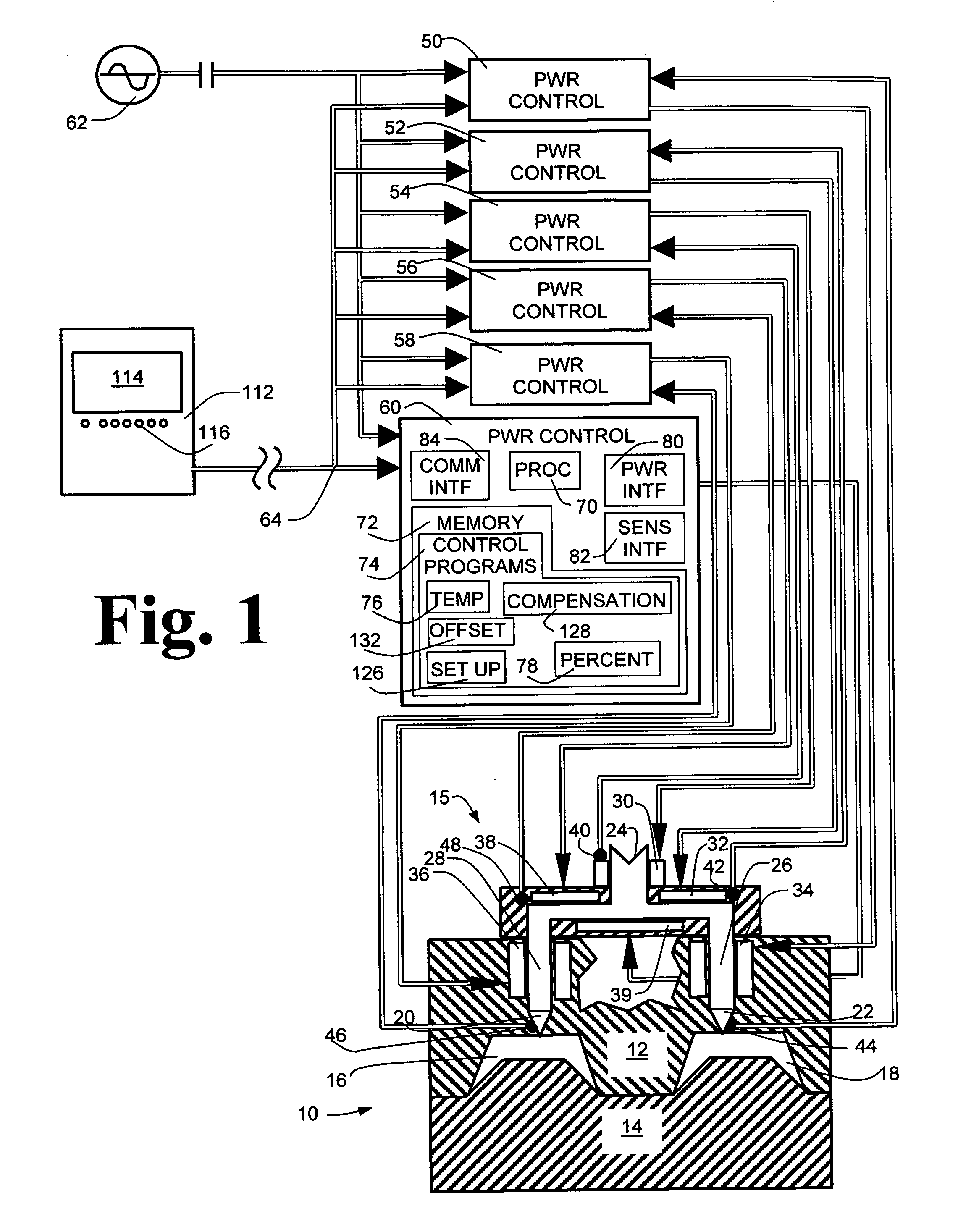

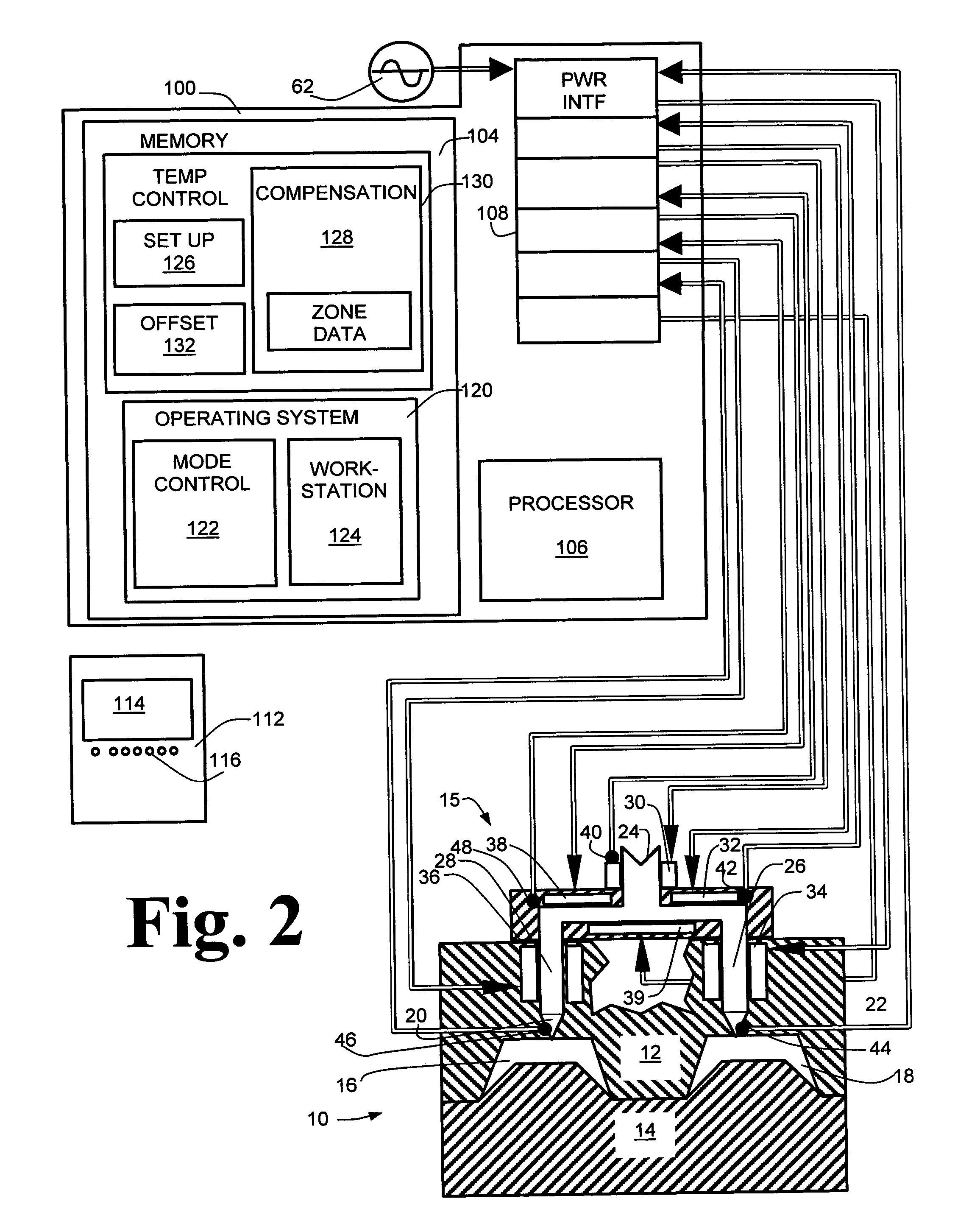

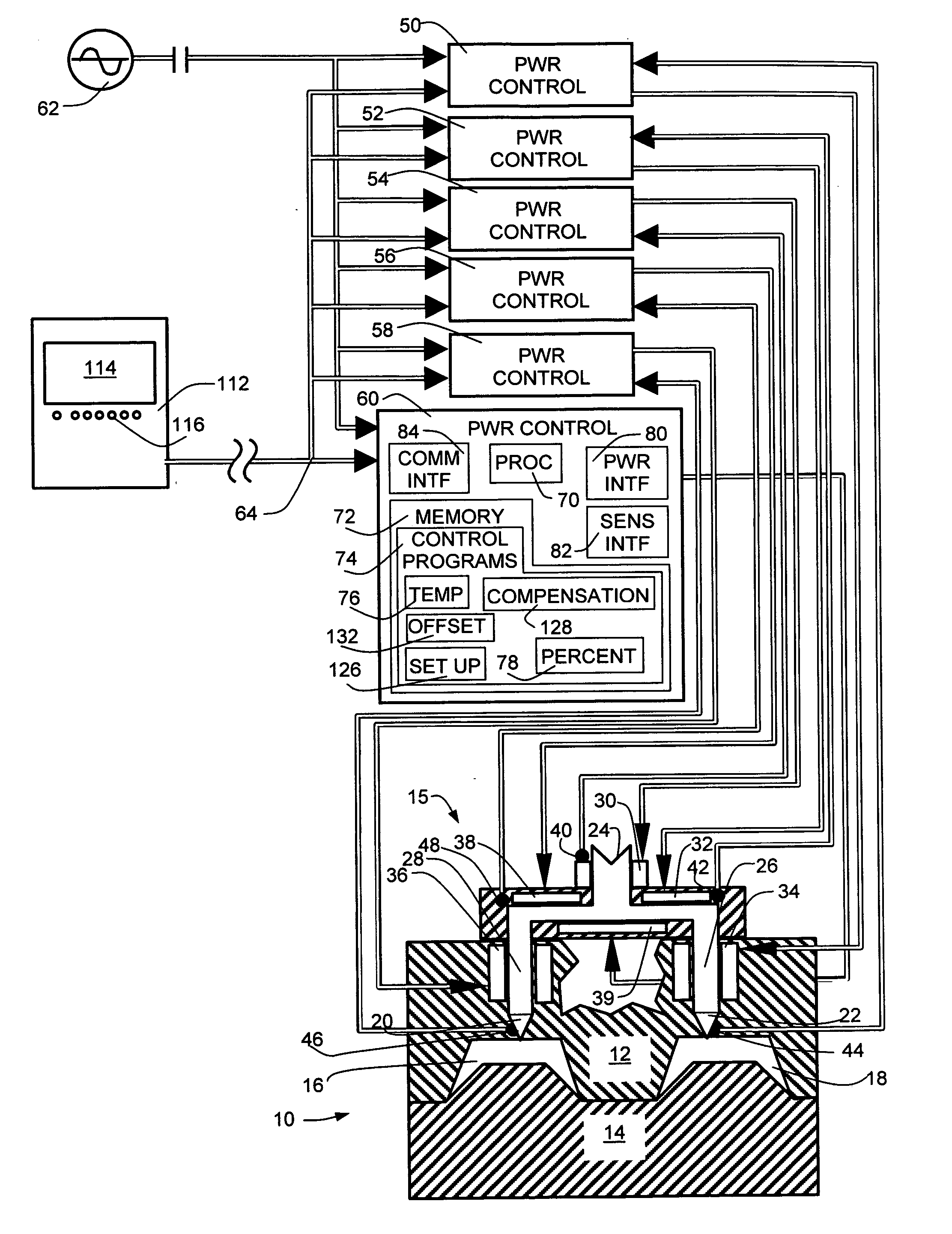

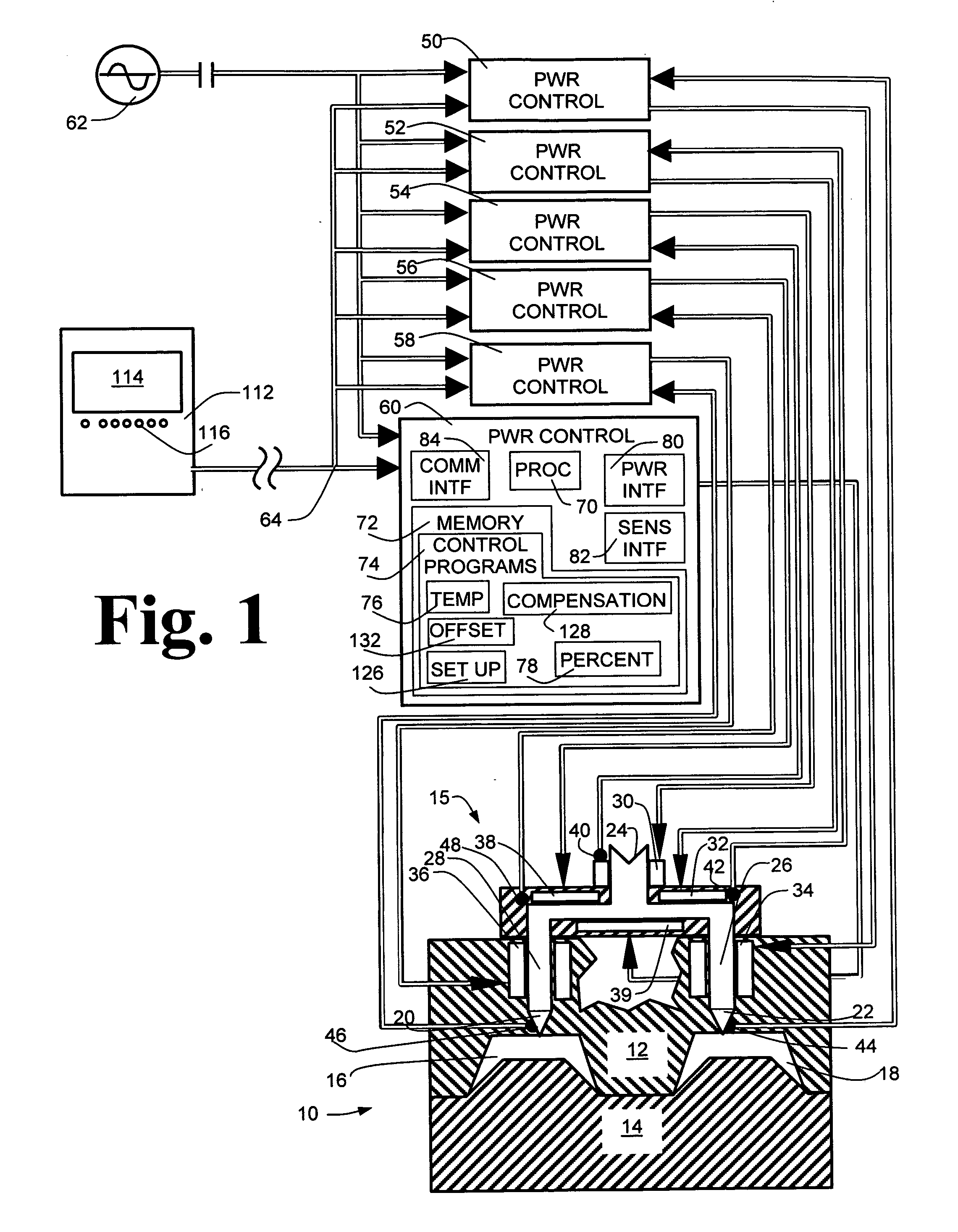

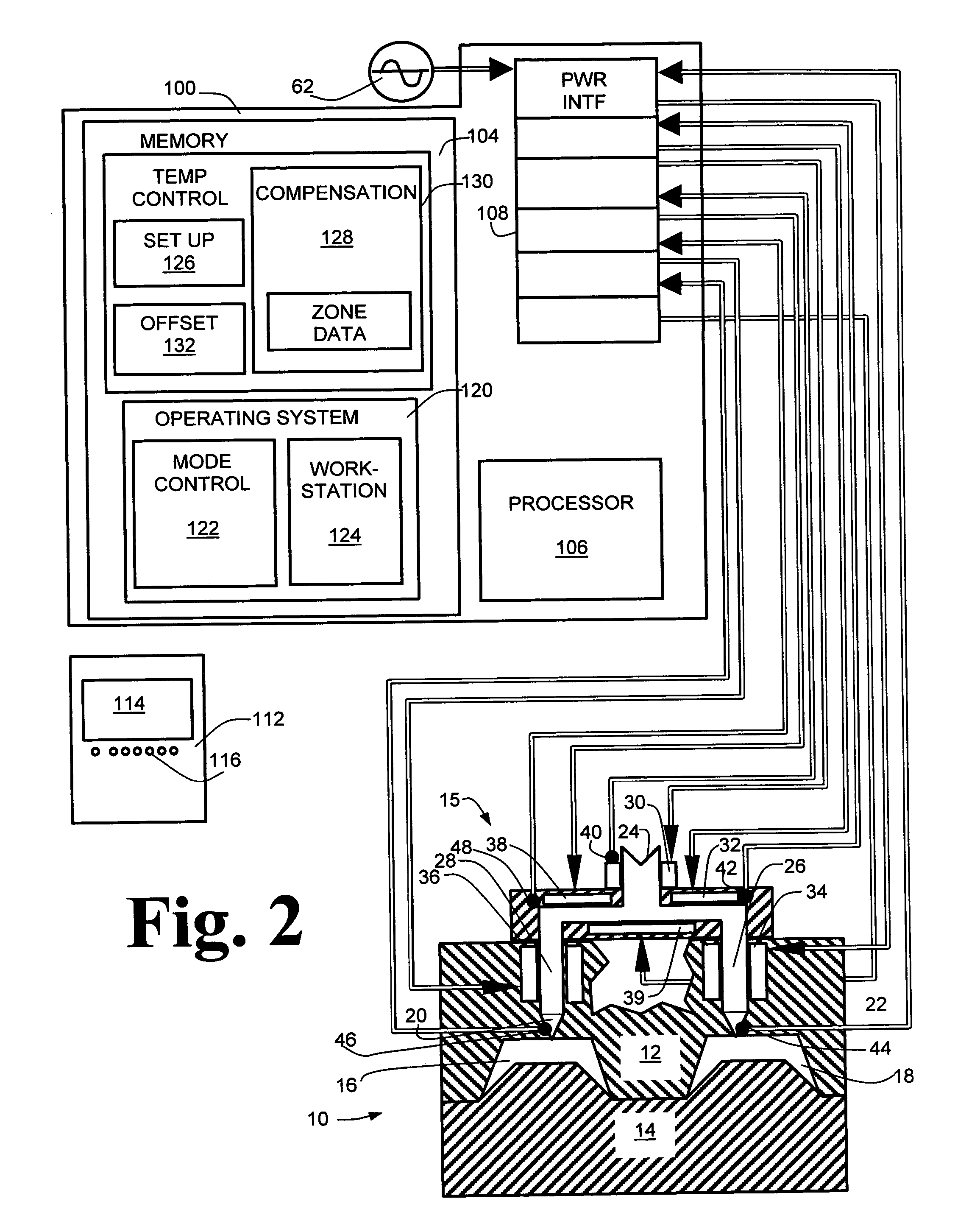

Temperature control

ActiveUS7020540B2Temperatue controlStatic/dynamic balance measurementTemperature controlControl zone

A method and apparatus are disclosed for controlling temperature of a plant comprising plural temperature control zones, wherein an effective control parameter for a first zone for which a signal representing measured temperature is available is produced according to an algorithm relating measured temperature, a desired temperature and a control parameter associated with a device affecting temperature in the first temperature control zone, the effective control parameter is summed with an offset value representing a proportional offset of the effective control parameter of a second temperature control zone relative to the effective control parameter of the first temperature control zone and the result is applied to control a device affecting temperature in the second temperature control zone. Advantageously, the offset value comprises a fixed amount and a variable amount, the variable amount accounting for dynamic differences in temperature control characteristics of the first and second temperature control zones.

Owner:D M E CO

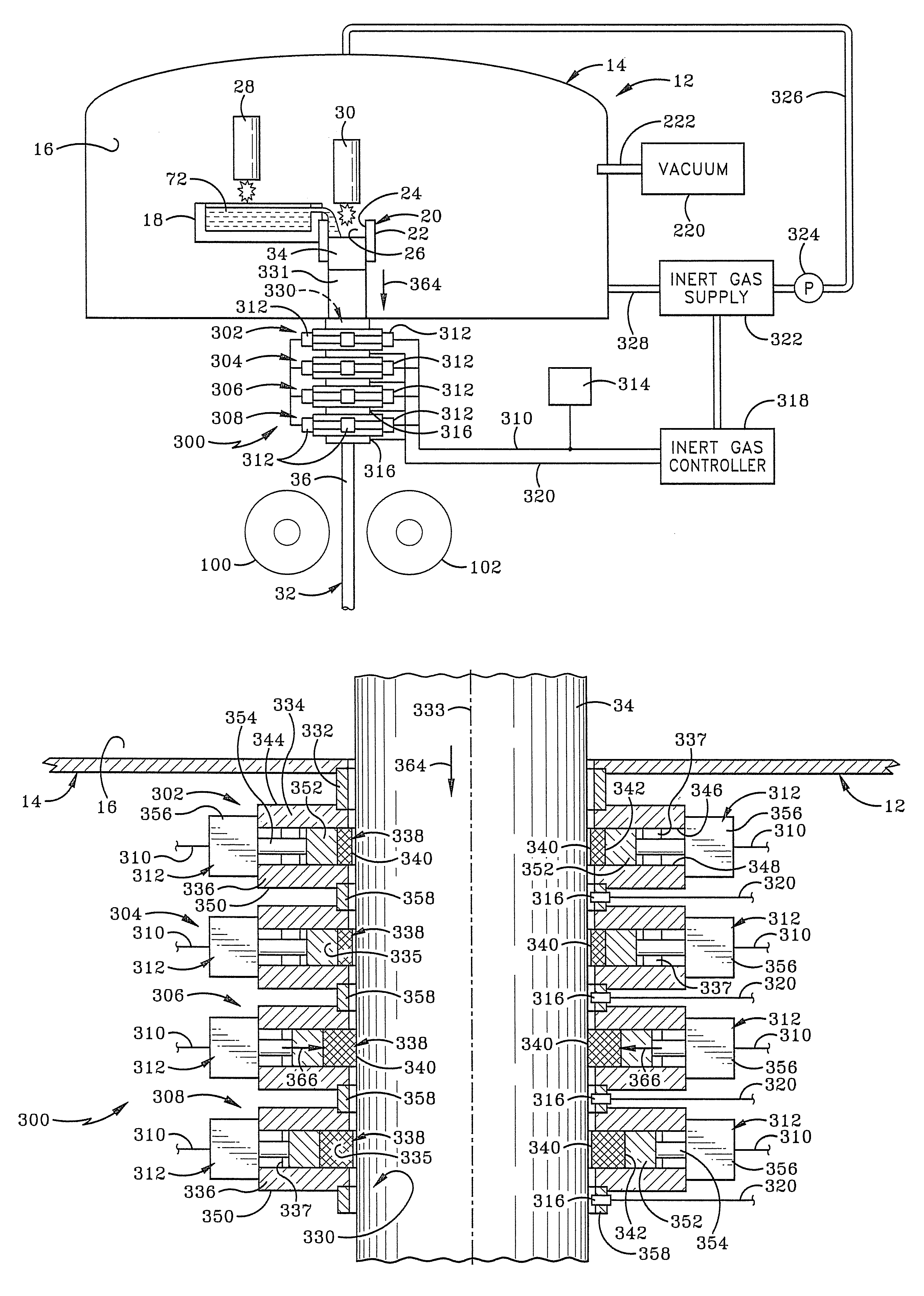

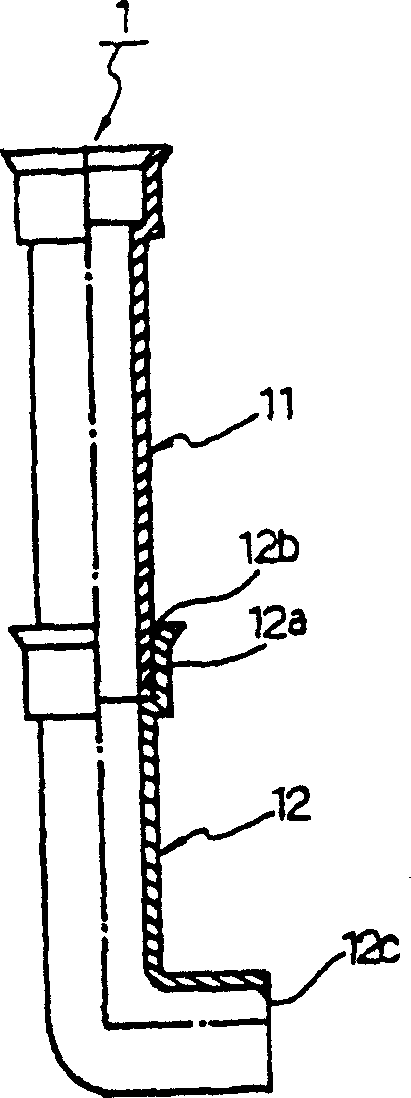

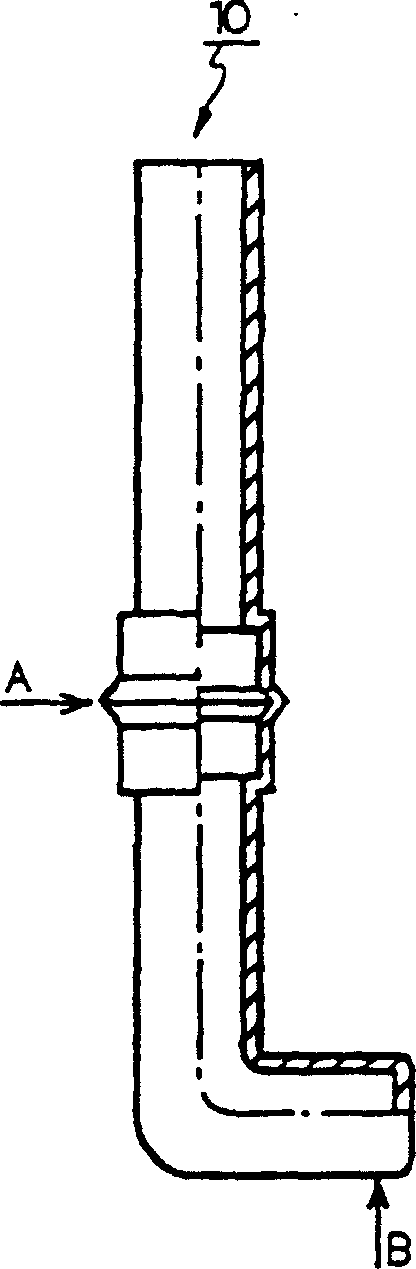

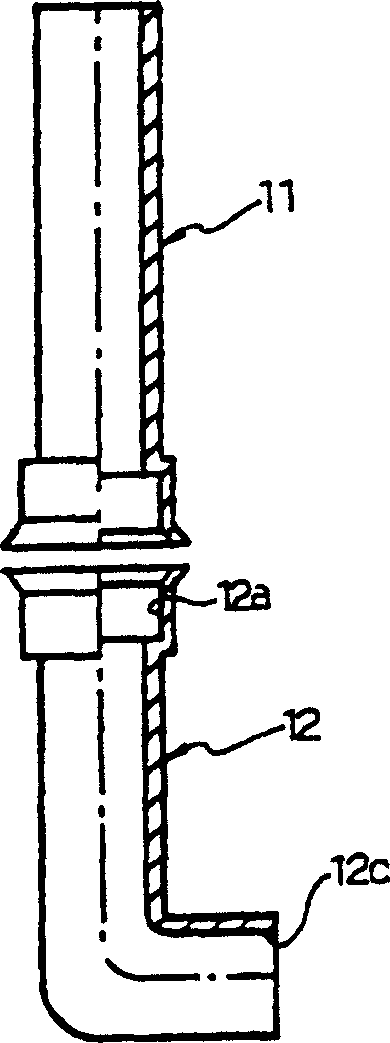

Continuous casting sealing method

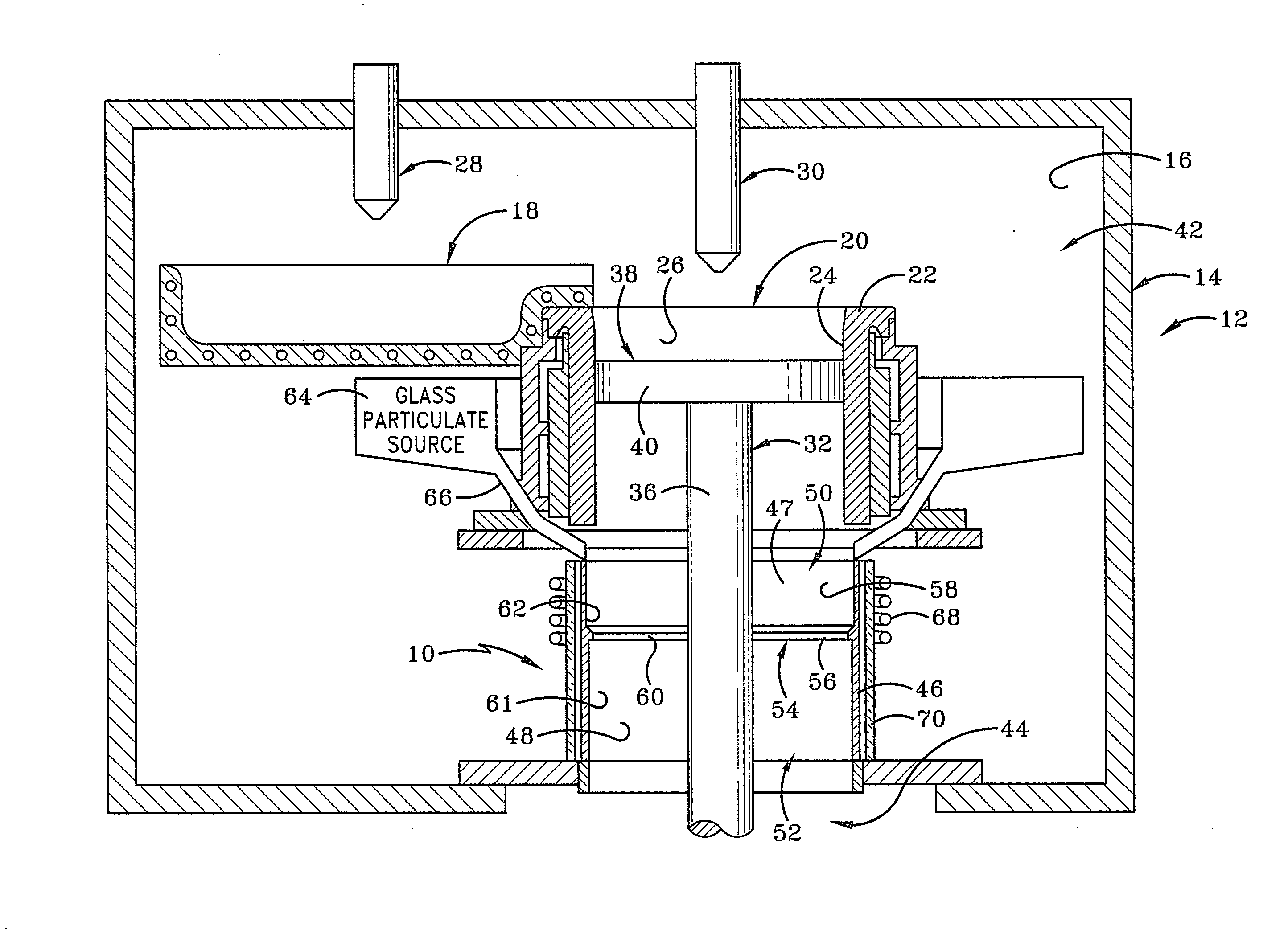

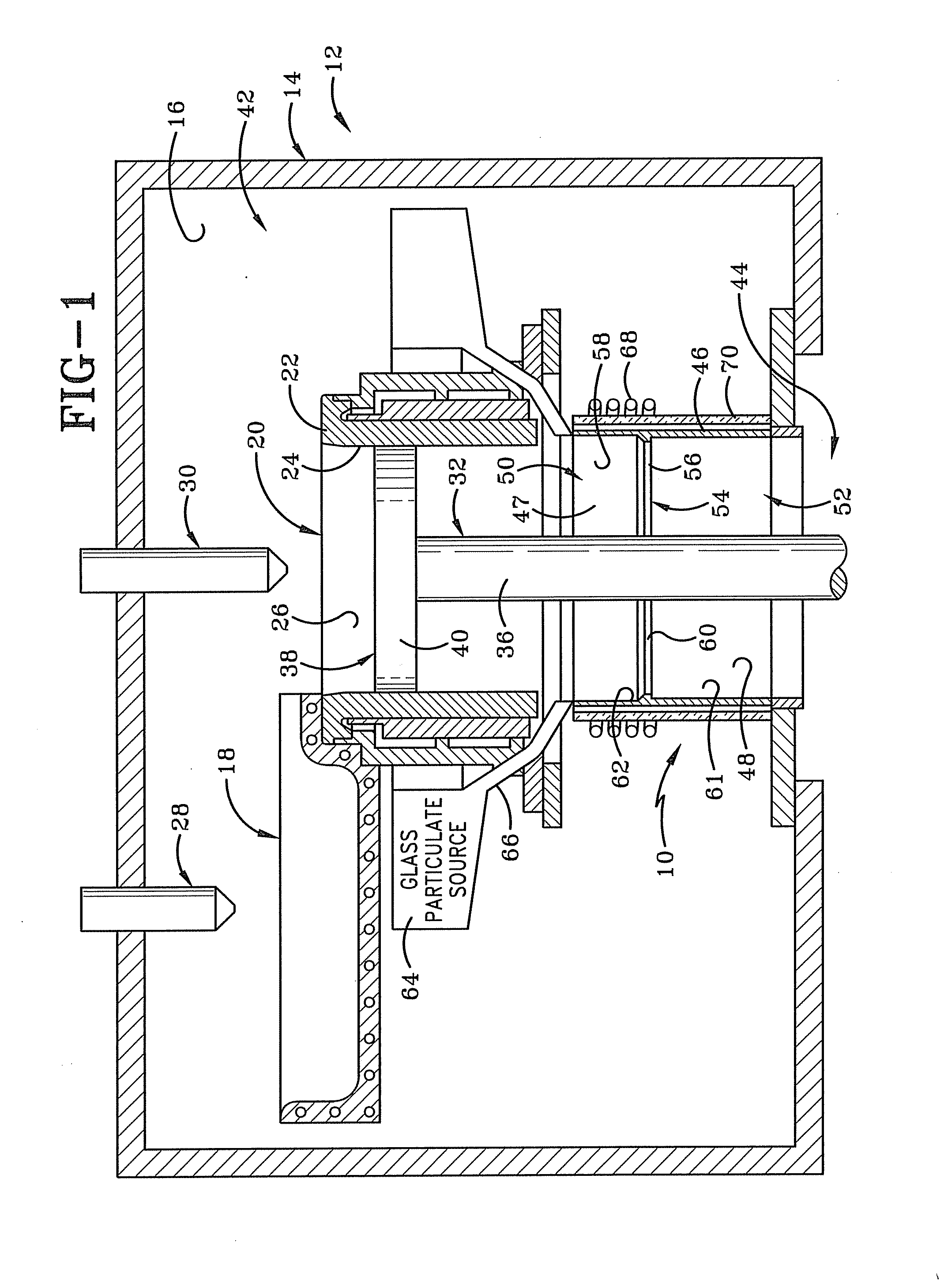

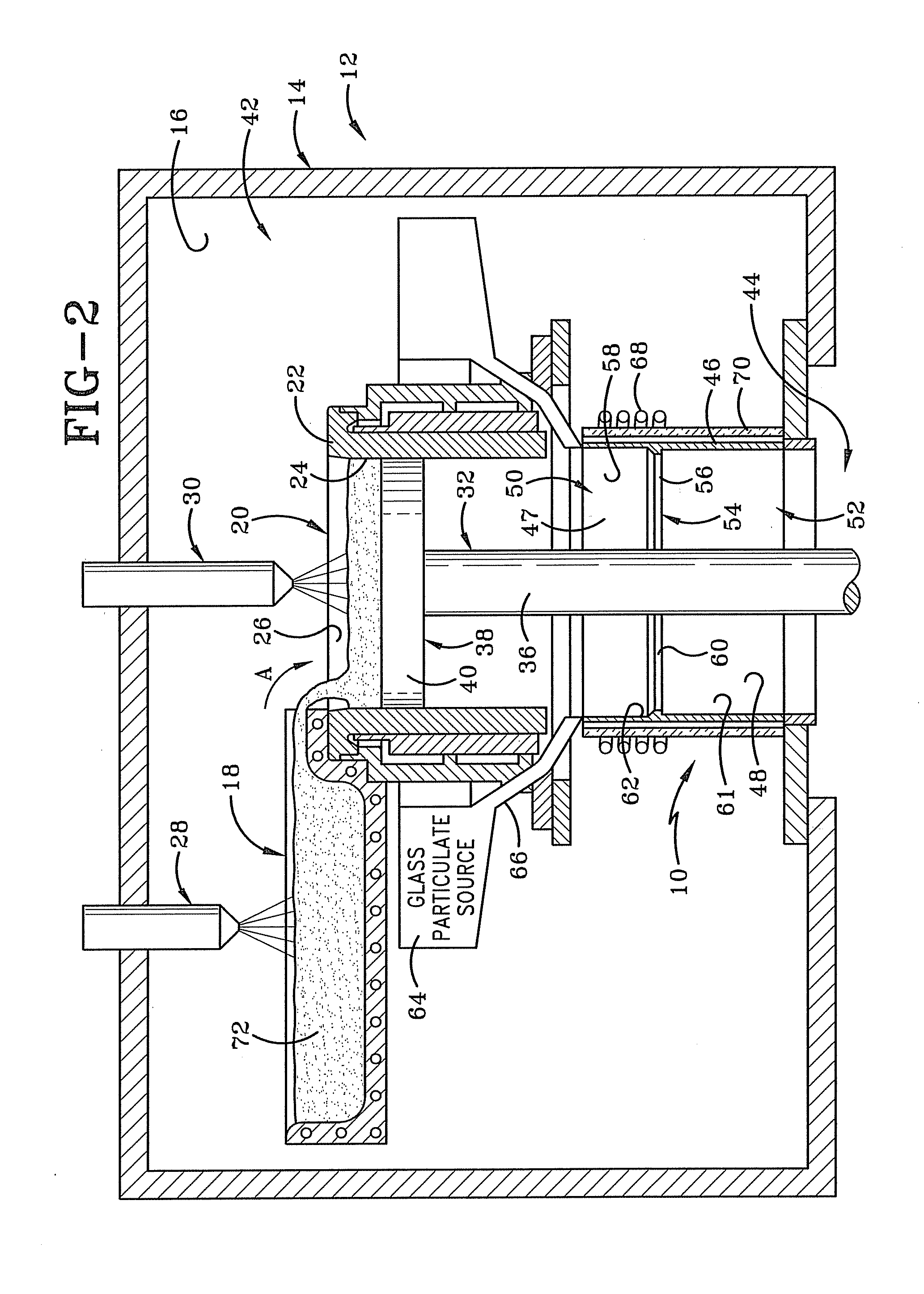

A casting furnace for manufacturing a metal casting comprises an interior chamber and a secondary chamber through which the metal casting passes from the interior chamber into external atmosphere. A seal along the secondary chamber surrounds and seals against the metal casting to separate the interior chamber from the external atmosphere in a manner which allows for an extended period of continuous casting. A force producing mechanism typically forces the seal against the metal casting. Multiple seals may be used sequentially to increase the duration of the sealing capability and the continuous casting process.

Owner:HOWMET AEROSPACE INC

Continuous casting sealing method

ActiveUS20100282427A1Easy to moveCasting safety devicesMoulding machine componentsInterior spaceMaterials science

A casting furnace for manufacturing a metal casting comprises an interior chamber and a secondary chamber through which the metal casting passes from the interior chamber into external atmosphere. A seal along the secondary chamber surrounds and seals against the metal casting to separate the interior chamber from the external atmosphere in a manner which allows for an extended period of continuous casting. A force producing mechanism typically forces the seal against the metal casting. Multiple seals may be used sequentially to increase the duration of the sealing capability and the continuous casting process.

Owner:HOWMET AEROSPACE INC

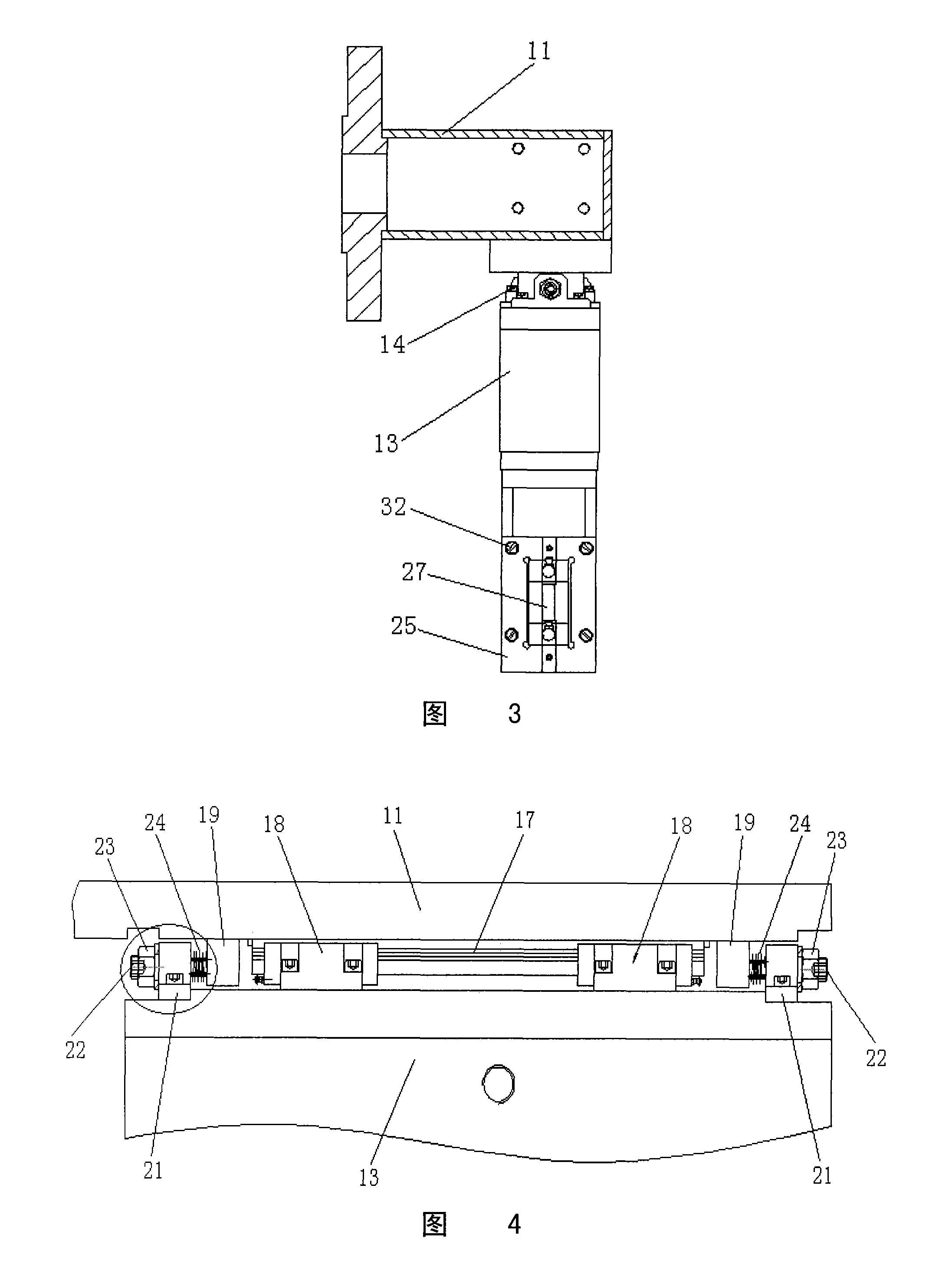

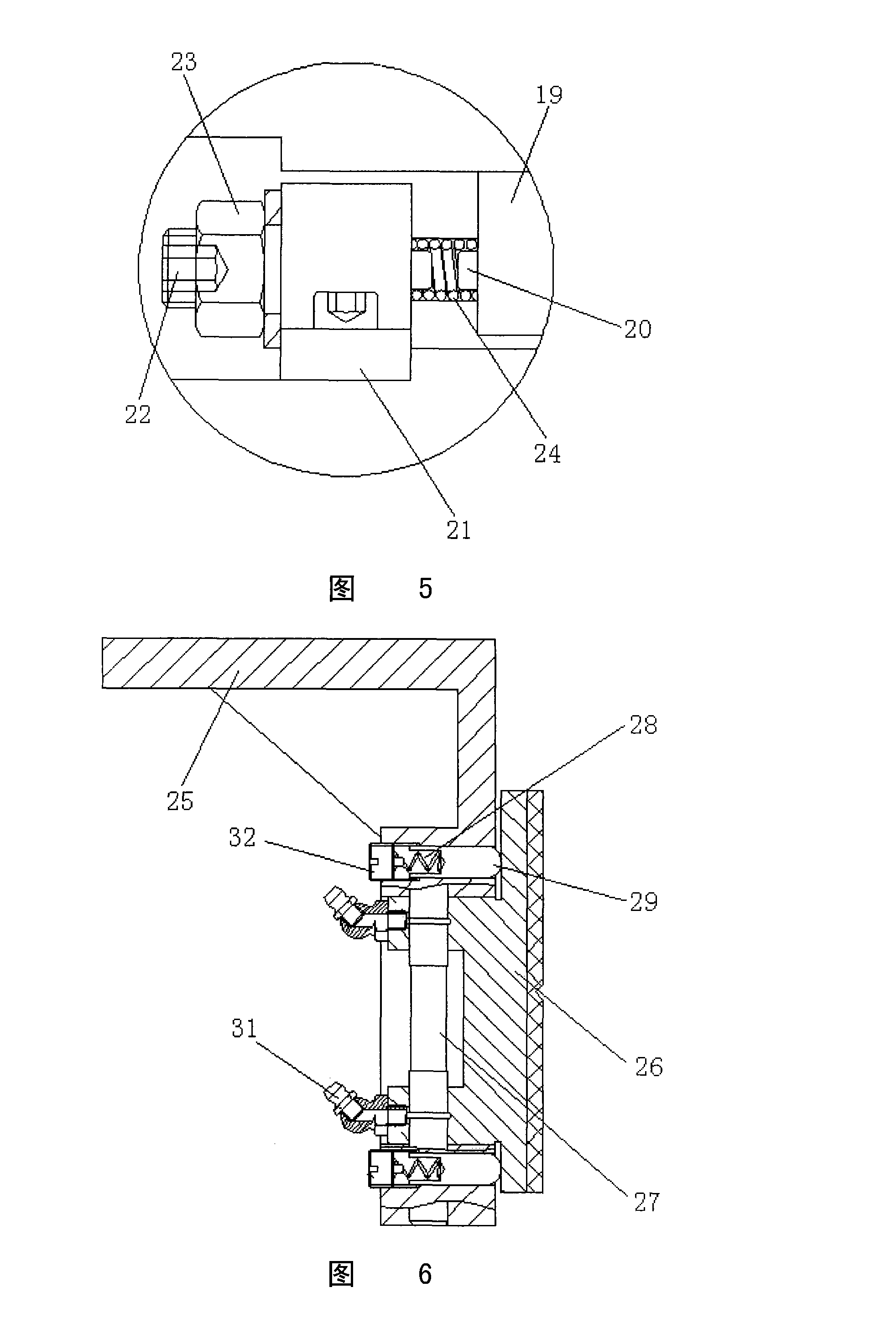

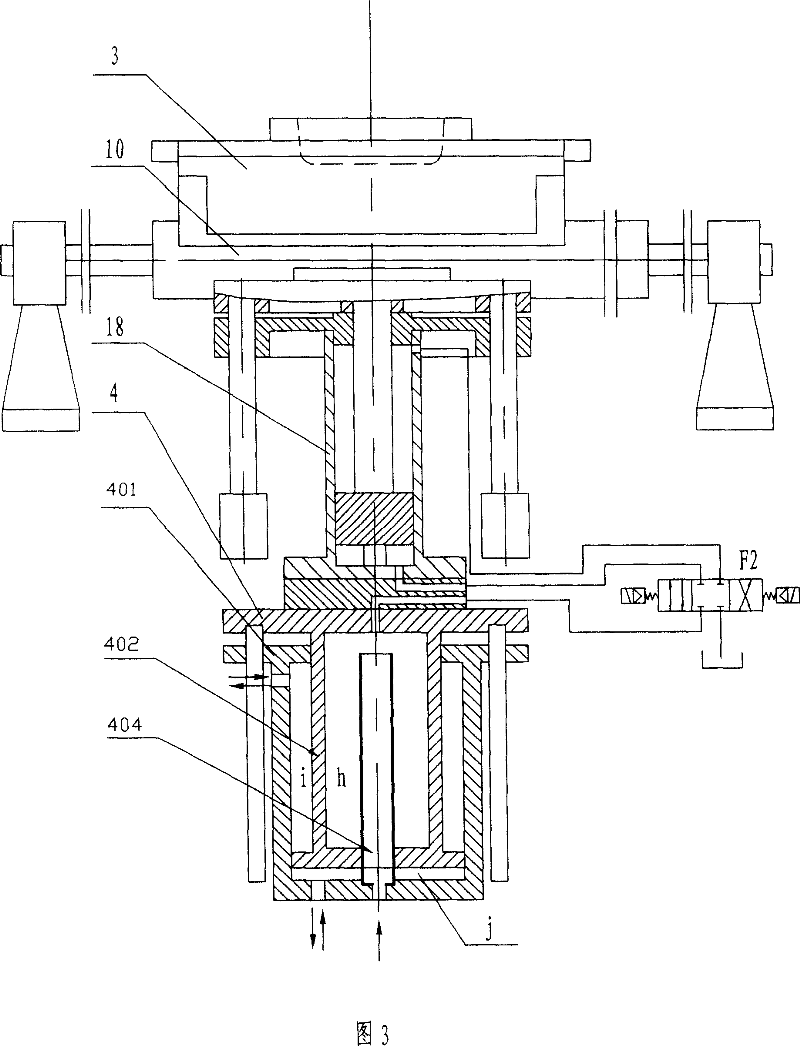

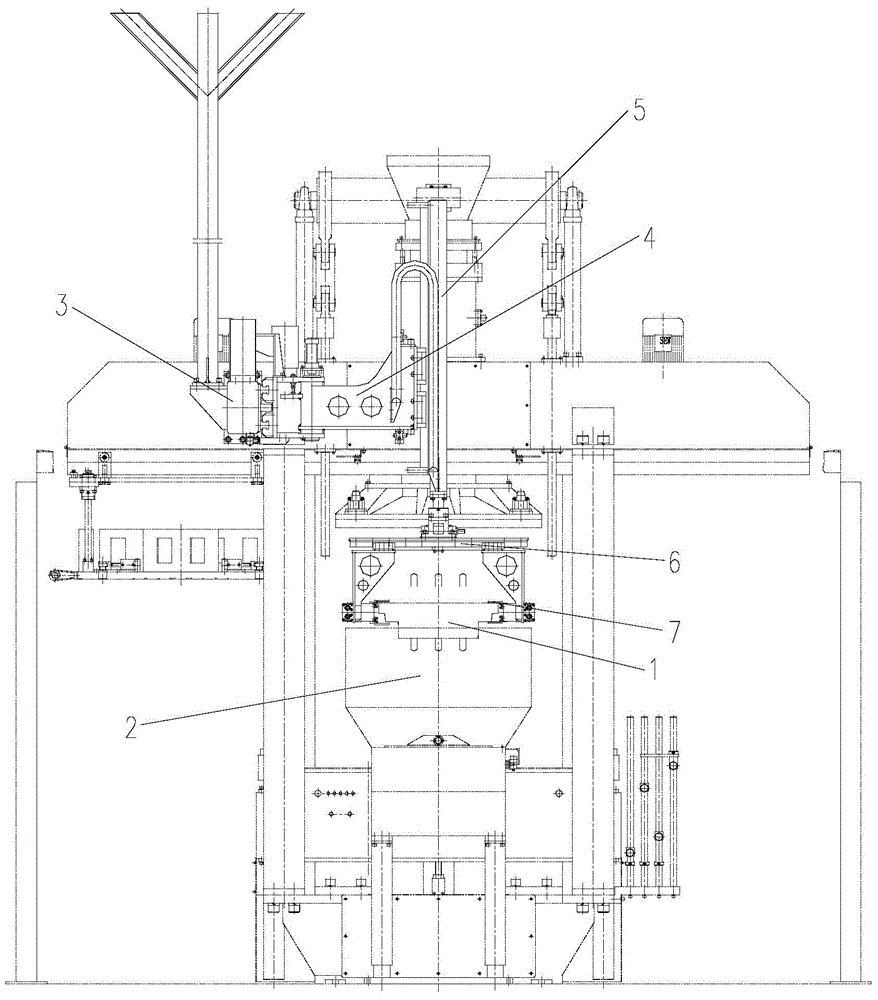

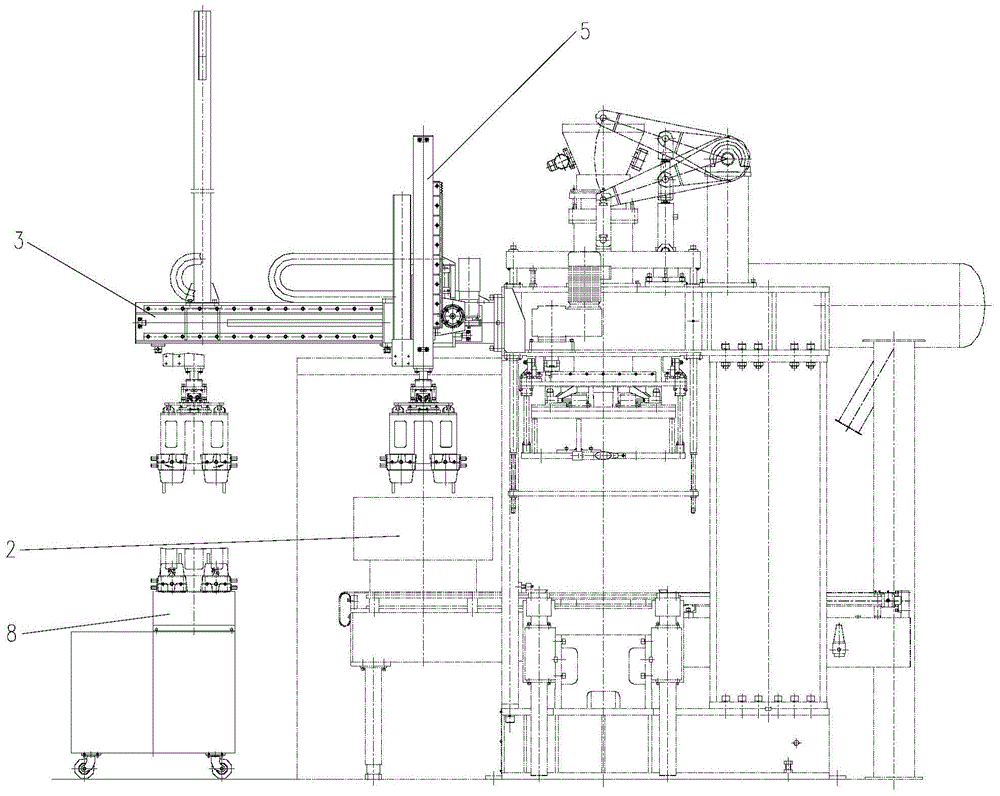

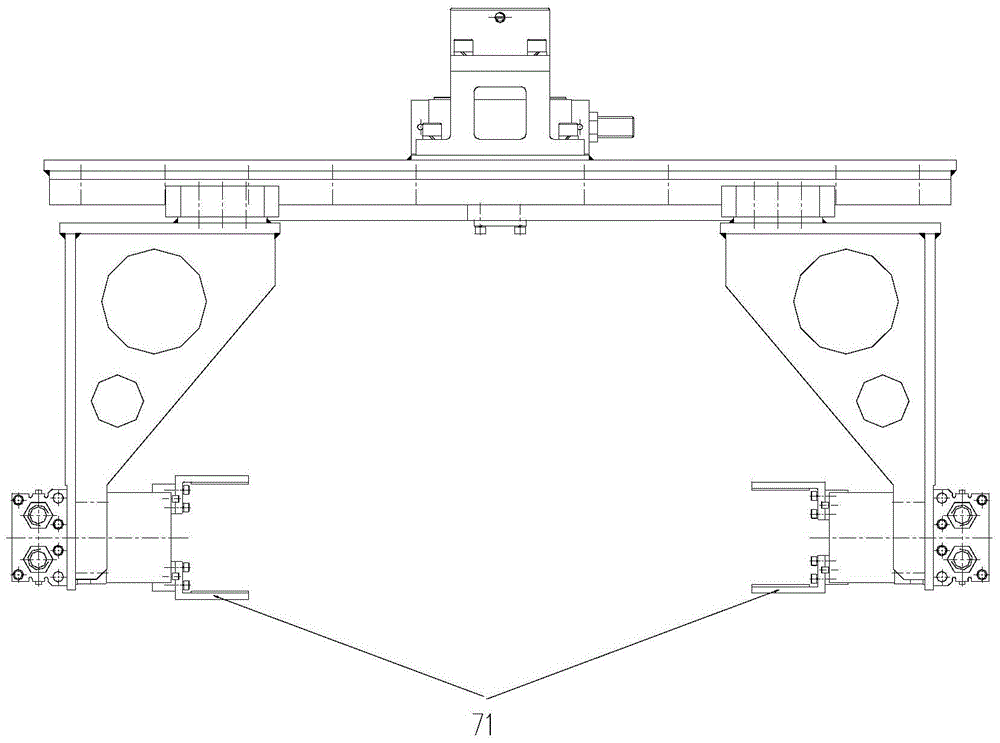

Core setting equipment for integral sand core

InactiveCN101602091AImprove securityWeight increaseFoundry mouldsMoulding machine componentsEngineeringElectrical and Electronics engineering

Owner:CRRC QIQIHAR ROLLING CO LTD +1

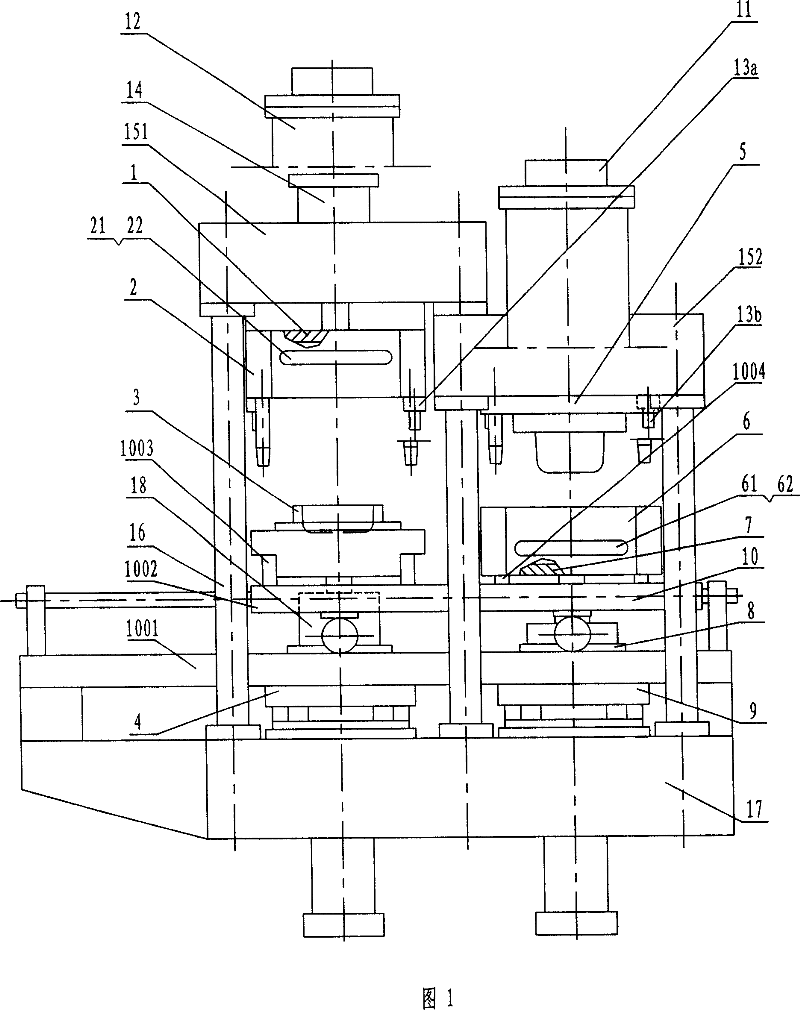

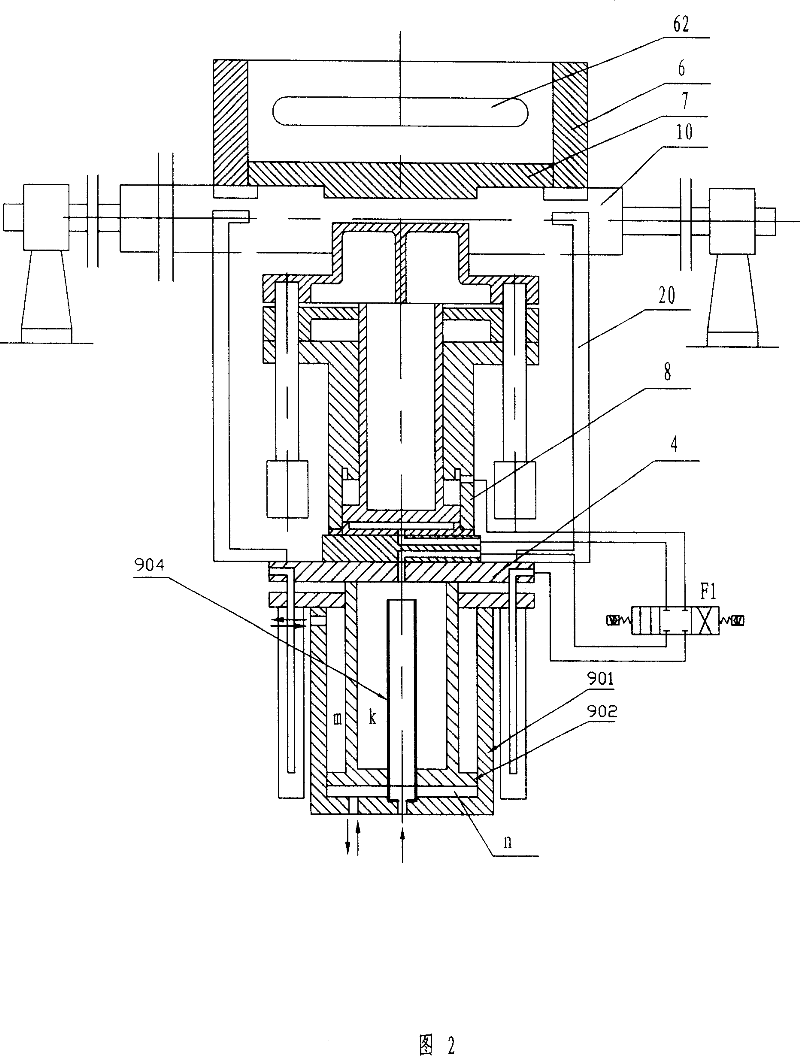

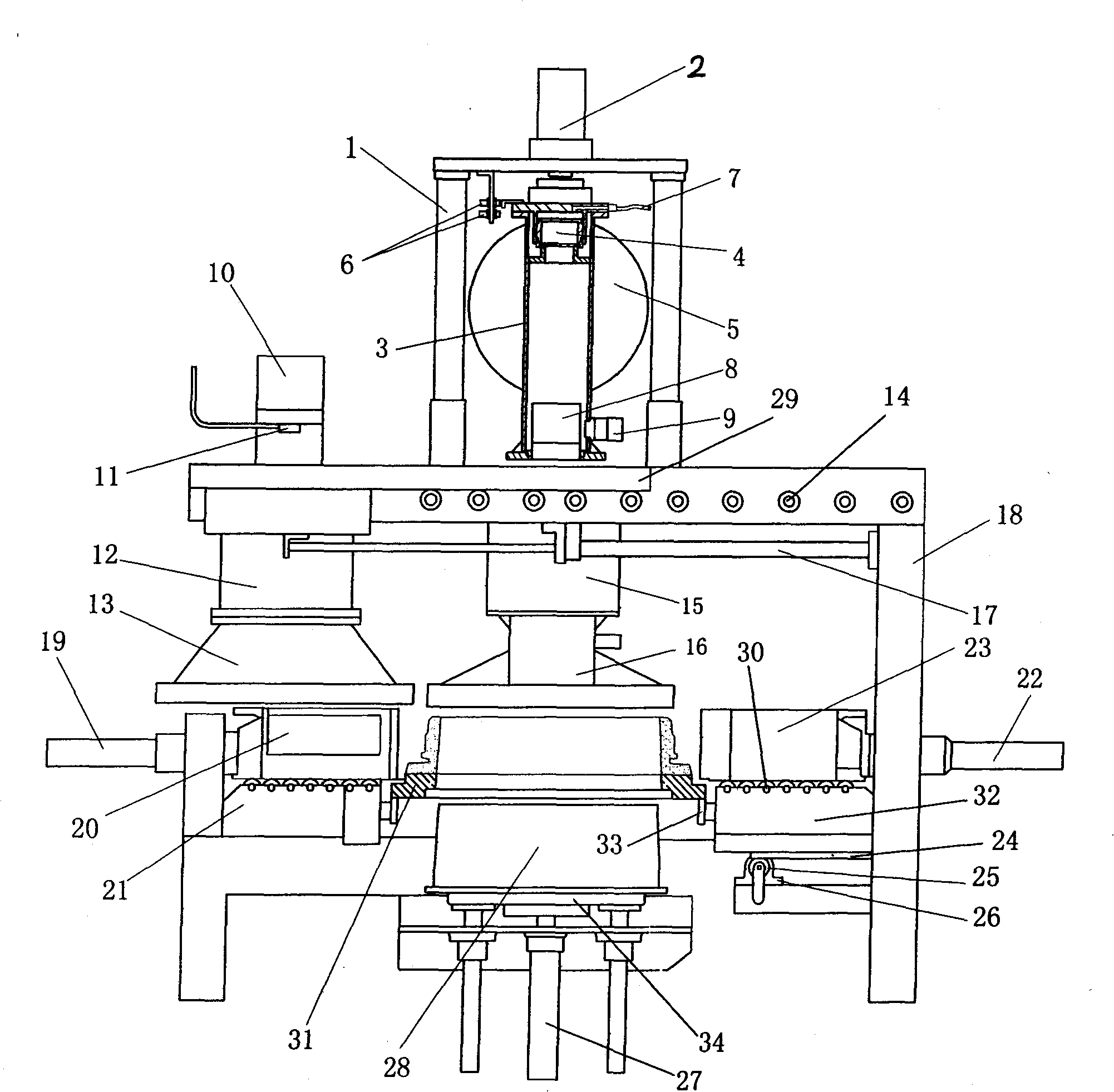

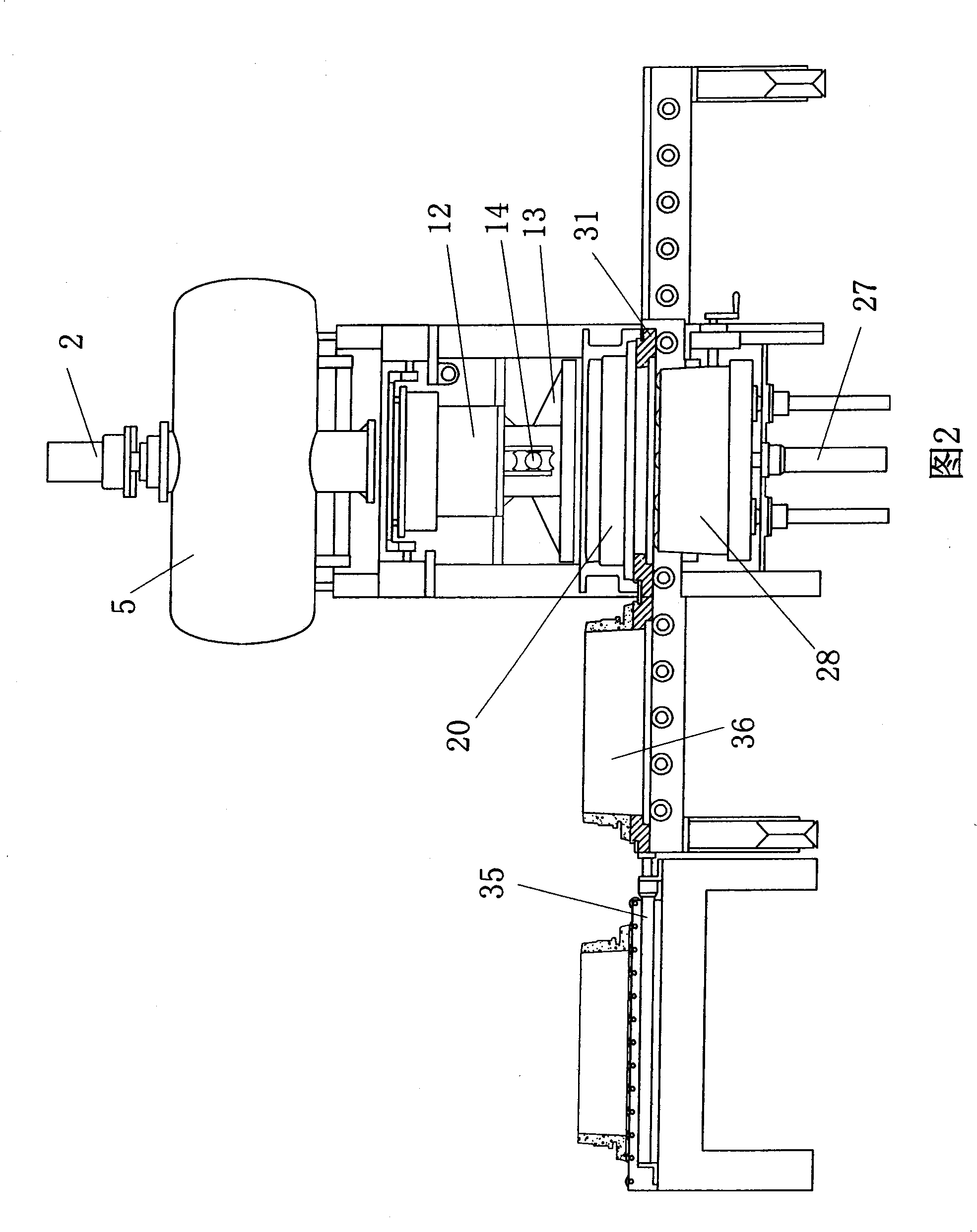

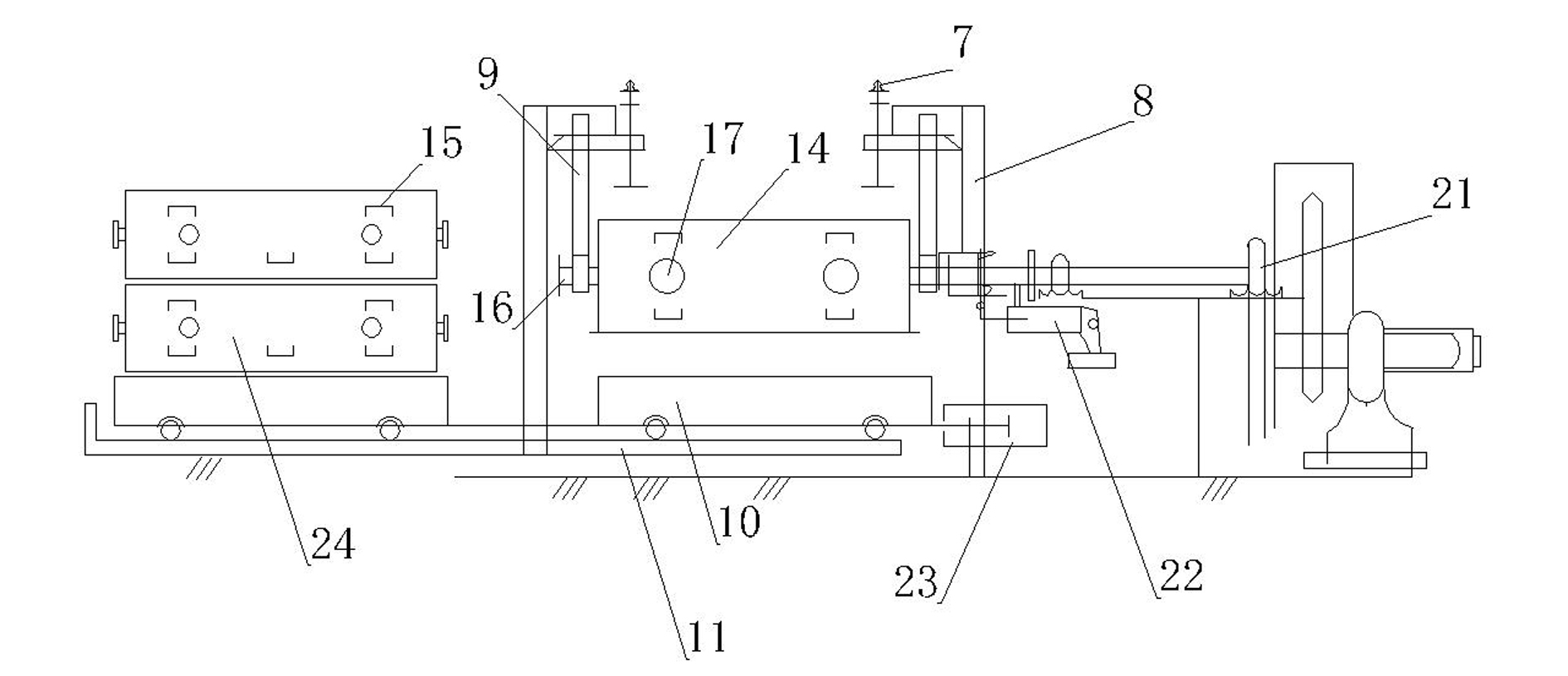

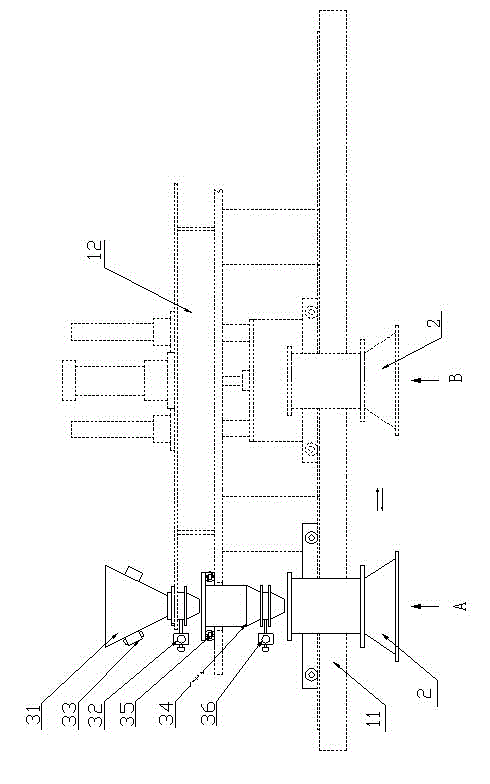

Double-station horizontal parting and removable flask shoot and squeeze molding machine

InactiveCN101036935ASimple structureCompact structureMoulding machine componentsMoulding machinesMolding machineShoot

The invention discloses a double station horizontal parting slip flask shoot-squeeze molding machine for producing sand mould, including base (17), a pillar (16) is provided on the base (17), two crossbeams (151, 152) are provided on the other end of the pillar (16), on one of which are provided with an upper sand mould compacting snapflask oil cylinder (14) and an upper box both sides shoot sand mechanism (12), an upper sand box (2) is connected on the crossbeam (151), the invention is based on horizontal parting slip flask shoot-squeeze molding technique, making the upper and lower molding divided on two stations of one machine, the upper and lower sand boxes respectively shoot sand on both sides for implementing both-way compaction and ensuring sand stream to max casting back area, which can ensure satisfied solidity for single mould of more than 200 mm, and with condition of producing high mould.

Owner:王彤

Cold-box core blower

InactiveCN101352752AAvoid damageImprove pass rateFoundry mouldsMoulding machine componentsAir compressionEngineering

The invention provides a cold-box core shooter which comprises a frame, a lower air compression bag, a suspending movable shooting cavity and a suspension body, wherein, the lower air compression bag is arranged at the upper end of the frame, the upper part of the frame is provided with a race which is provided with a moving plate, the shooting cavity and the suspension body are arranged on the moving plate by spring in a suspension manner, either the shooting cavity or the suspension body is connected with a shifting cylinder on the frame, the left and right sides at the lower part of the frame are respectively provided with a mold opening and closing cylinder and a roller table frame, the upper end of the roller table frame is provided with a roller table and a baseplate race, the roller table frames at the two sides are provided with a race span adjusting mechanism, and a core box baseplate is arranged between the baseplate races at the two sides; the bottom of the frame is provided with a mold core lifting cylinder and a bearing plate, and the mold core lifting cylinder is connected with the bearing plate; the rear side of the frame at the bottom part is provided with a core outlet cylinder. The cold-box core shooter has the advantages of reasonable structure, realizing direct addition of sand to the shooting cavity by a sand mill, avoiding wall hanging and caking of wall, improving the qualification rate of the sand core and realizing upward air exhaust of the remaining air in the shooting cavity.

Owner:冯新林

Automatic mould assembling device

InactiveCN102078933AAvoid deformationOvercoming difficult and dangerous defectsFoundry mouldsMoulding machine componentsAgricultural engineeringManipulator

The invention relates to an automatic mould assembling device, comprising an elevated track, a lifter, a traveling trolley, an upper sand box and a lower sand box as well as a demoulding and disassembling mechanism and a mould turning-over and assembling system, wherein the demoulding and disassembling mechanism comprises a mould catching manipulator, a mould lug, a mould and a mould catching frame, the traveling trolley is arranged at a lower mould station or an upper mould station, the lifter is provided with the mould catching frame, and the mould catching frame is provided with the mould catching manipulator; the mould turning-over and assembling system comprises a mould turning-over and assembling station, a mould assembling trolley, a mechanical mould turning-over arm and a movable mould turning-over mechanism, the mechanical mould turning-over arm is connected with a mould lifting handle arranged on the lower sand box at the mould turning-over and assembling station in a catching way, a mould turning-over handle arranged on the lower sand box is rotatably connected with a clutch on an automatic mould turning-over mechanism, the upper sand box, the lower sand box after being turned over and the mould assembling trolley are respectively arranged at an upper position, a middle position and a lower position for assembling the mould. By applying the device in the invention, the mechanical automatic demoulding, mould turnover and mould assembling are realized, the mould abrasion and deformation of a sand match, which are caused during mould disassembling process and mould assembling process, can be avoided, and the working efficiency is improved.

Owner:山西华德冶铸有限公司

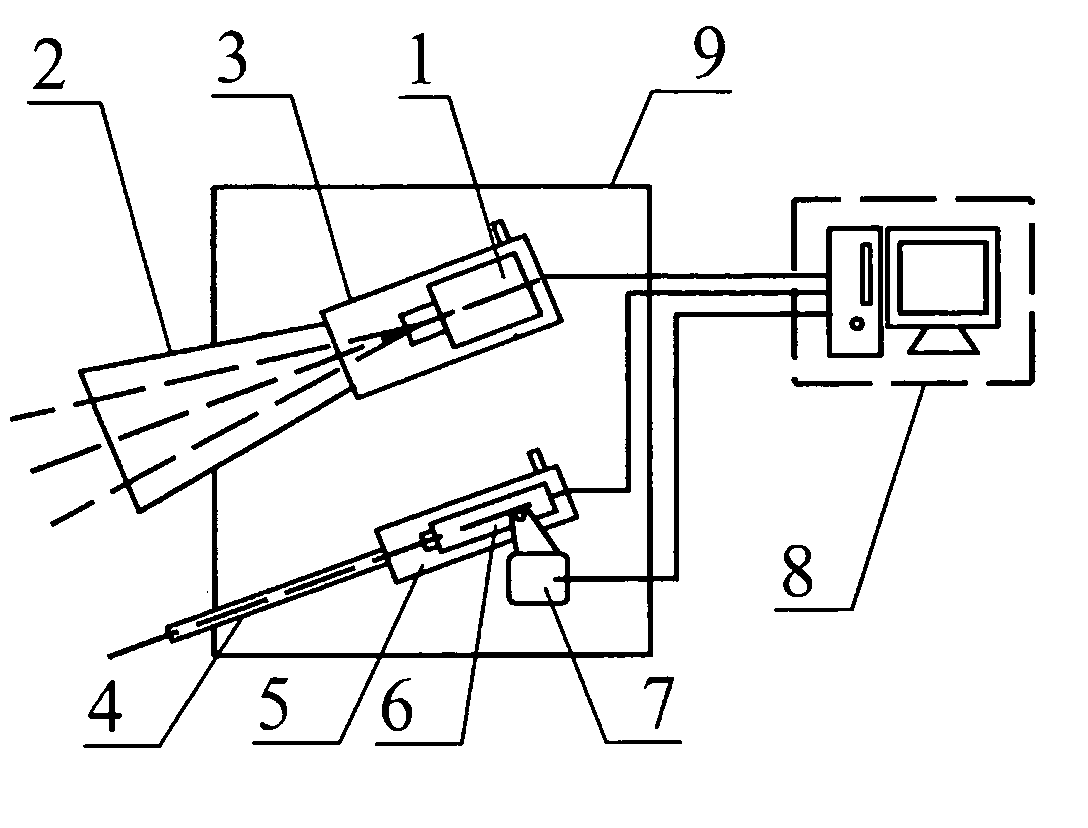

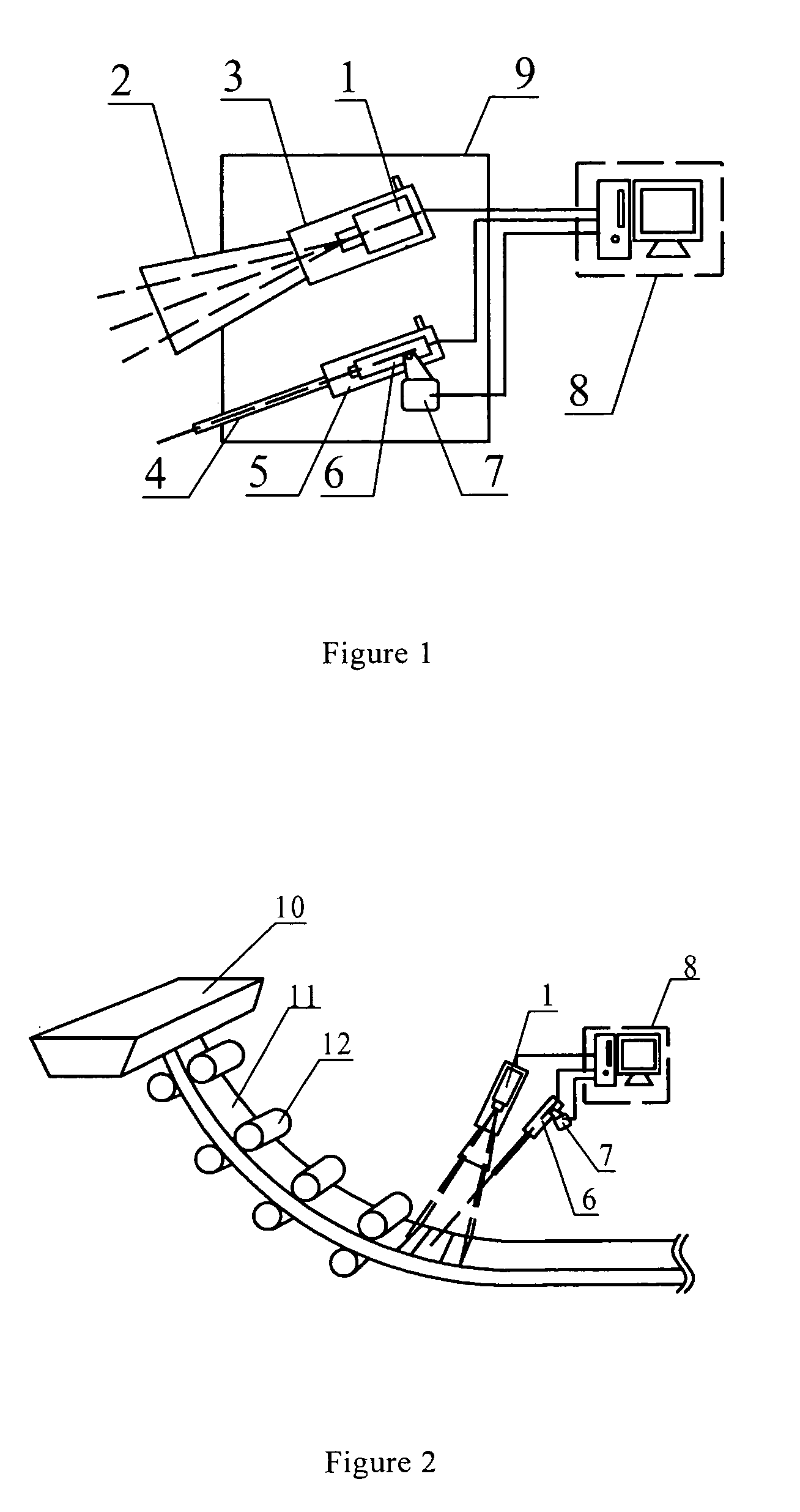

Apparatus and method for measuring the surface temperature of continuous casting billet/slab

ActiveUS20100236743A1Small geometryUneven thicknessThermometer detailsCasting safety devicesData processing systemRadiation thermometer

The present invention discloses a method and apparatus for measuring the temperature field on the surface of casting billet / slab, including: a thermal imager, an infrared radiation thermometer, a mechanical scanning unit, an image and data processing system; the thermal imager, the infrared radiation thermometer and the mechanical scanning unit are respectively connected to the image and data processing system; the infrared radiation thermometer is installed on the mechanical scanning unit and can measure the temperature of casting billet / slab surface by scanning; the thermal imager can measure the temperature of a certain area on the surface of casting billet / slab by thermal imaging. The present invention makes use of the combination of high-resolution thermal imager and scan-type infrared radiation thermometer, through the model-based filtering method, overcomes the influence of iron scales on the surface of casting billet / slab, and implements real-time stable measurement of surface temperature of casting billet / slab.

Owner:NORTHEASTERN UNIV +1

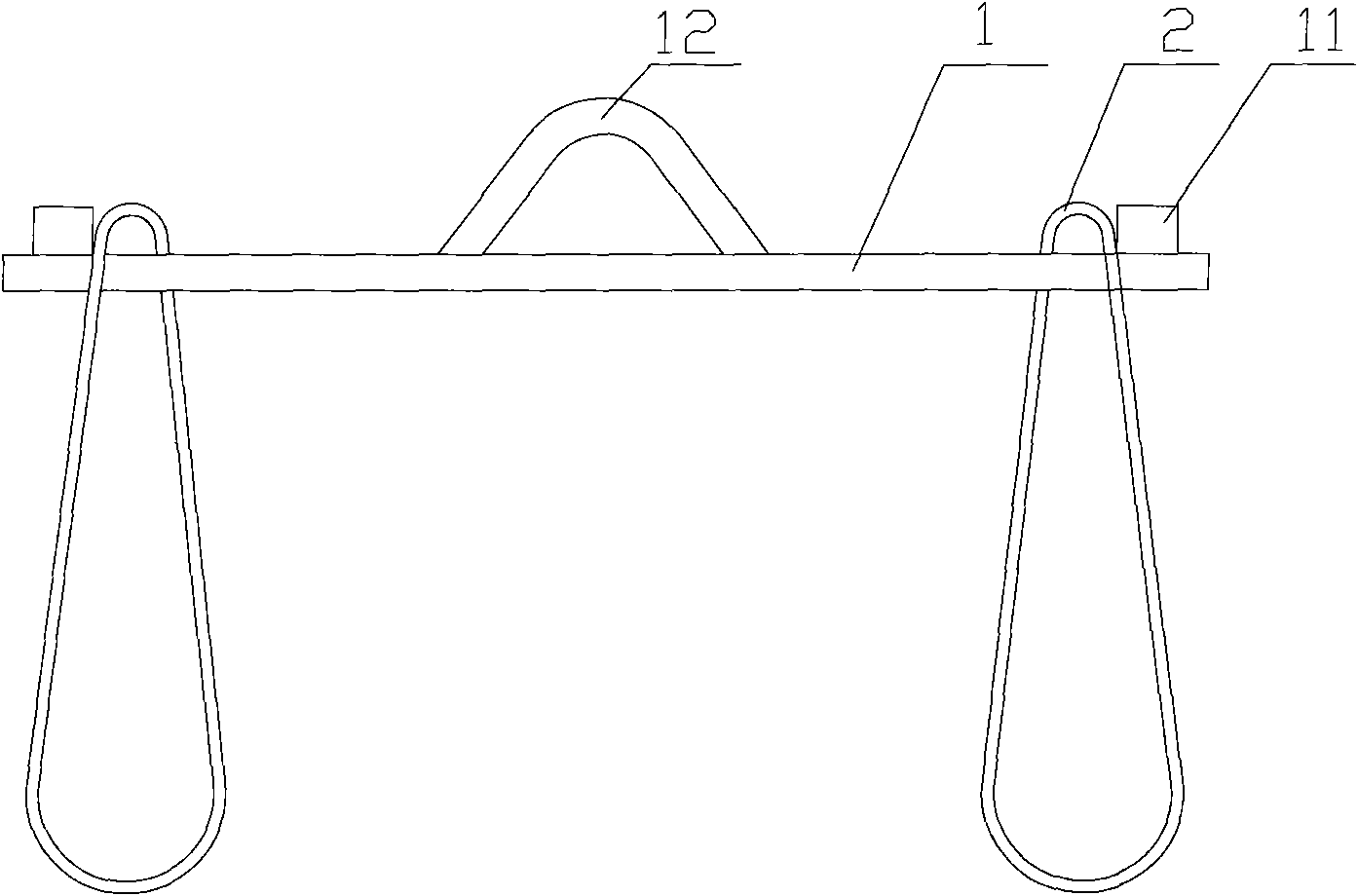

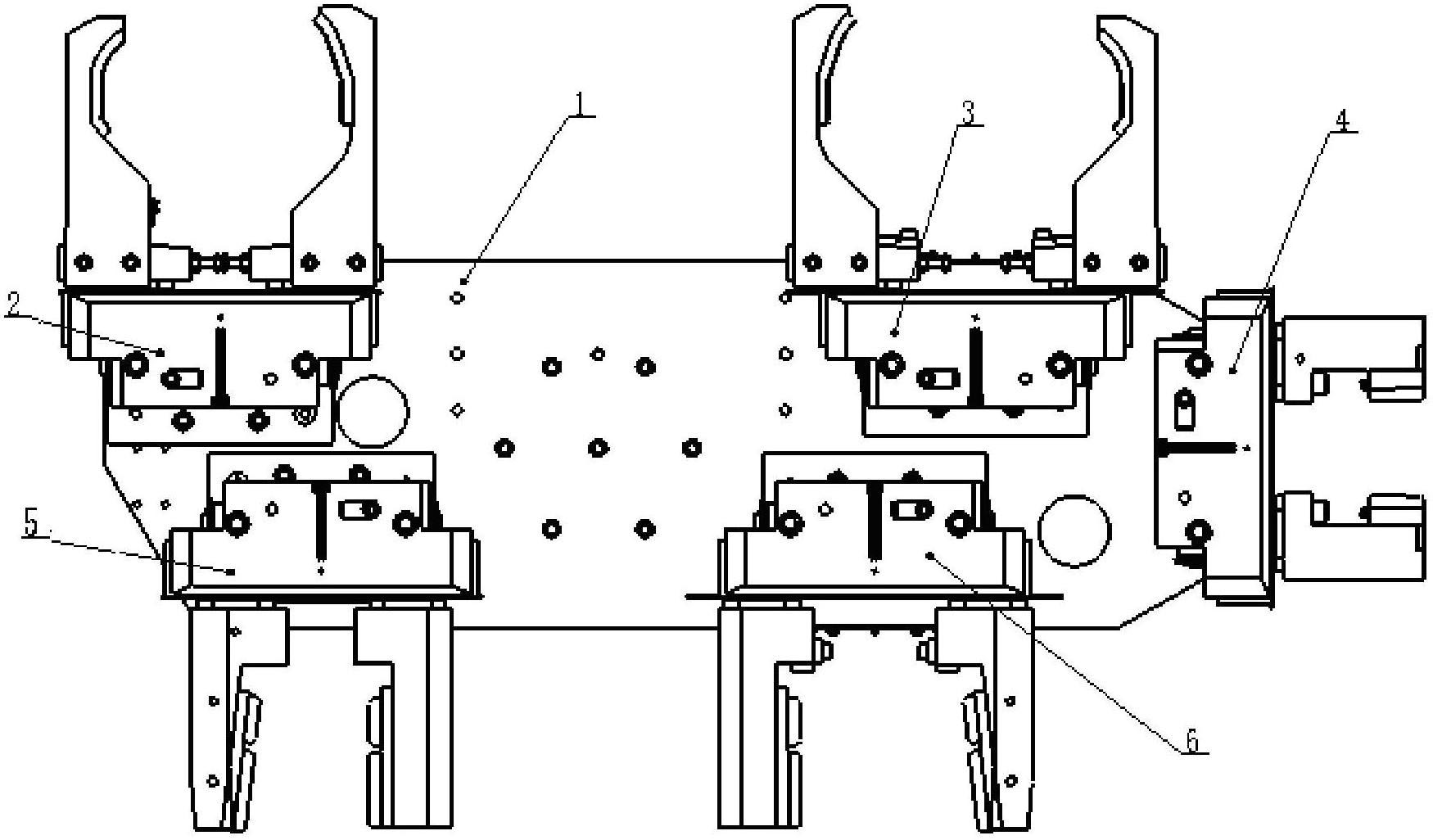

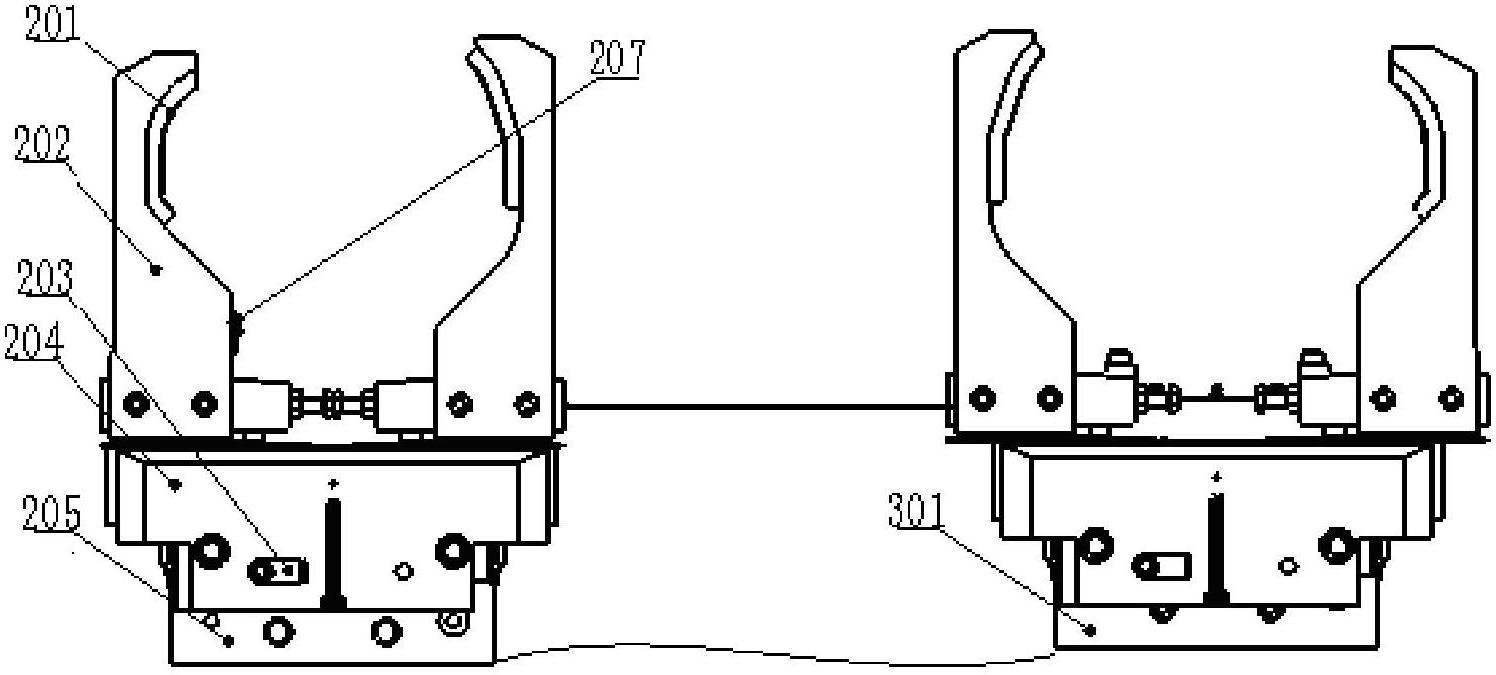

Three-in-one sealed flexible core setting fixture

The invention discloses a three-in-one sealed flexible core setting fixture, which is formed by combining three sets of fixtures, e.g., a swing bolster sand core fixture, a side frame sand core fixture and a box sand core fixture, wherein each of the swing bolster sand core fixture and the side frame sand core fixture consists of two sets of pneumatic clamping jaws, and a clamping structural form is that one set of pneumatic clamping jaw is fixed, and the other set of pneumatic clamping jaw is a flexible mechanism; and the flexible mechanism has a sealed structure, positive pressure is generated for dust prevention in the sealed structure, and the top of the sealed structure is oiled and lubricated. Compared with a fixture with the conventional structure, the swing bolster sand core fixture adopting the structure of clamping the positions of reinforcing ribs is more stable in clamping; and due to the adoption of internal clamping, a movable block required by the conventional external clamping is eliminated during the sand core manufacture of a customer to lower the sand core manufacture cost of the customer. By a mounting mode for abrasion-proof cushions of the side frame sand core fixture and the box sand core fixture, frictional contact areas are enlarged, the abrasion-proof cushions can be more firmly arranged, and the fixture can more stably and reliably work.

Owner:CHANGSHA CTR ROBOTICS

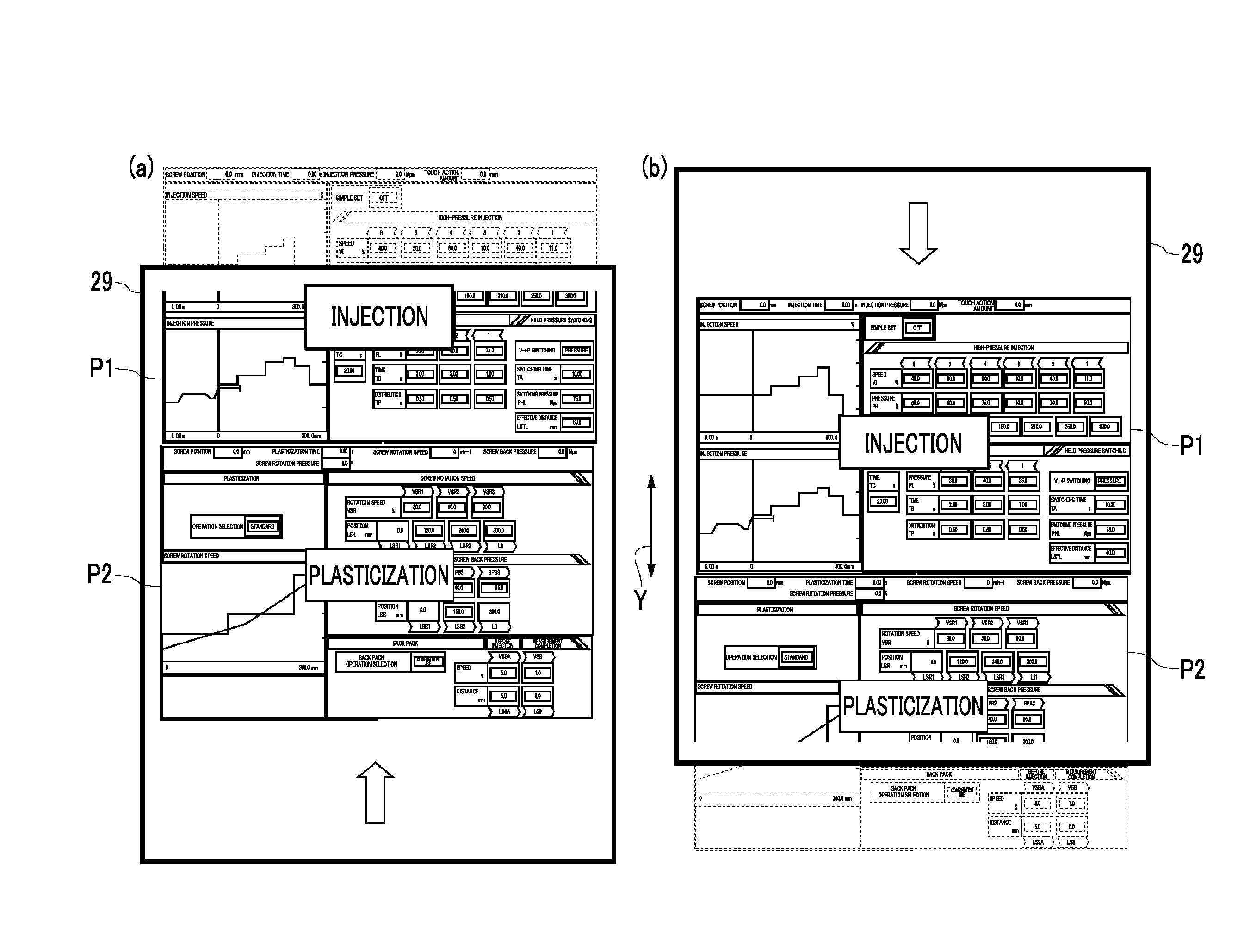

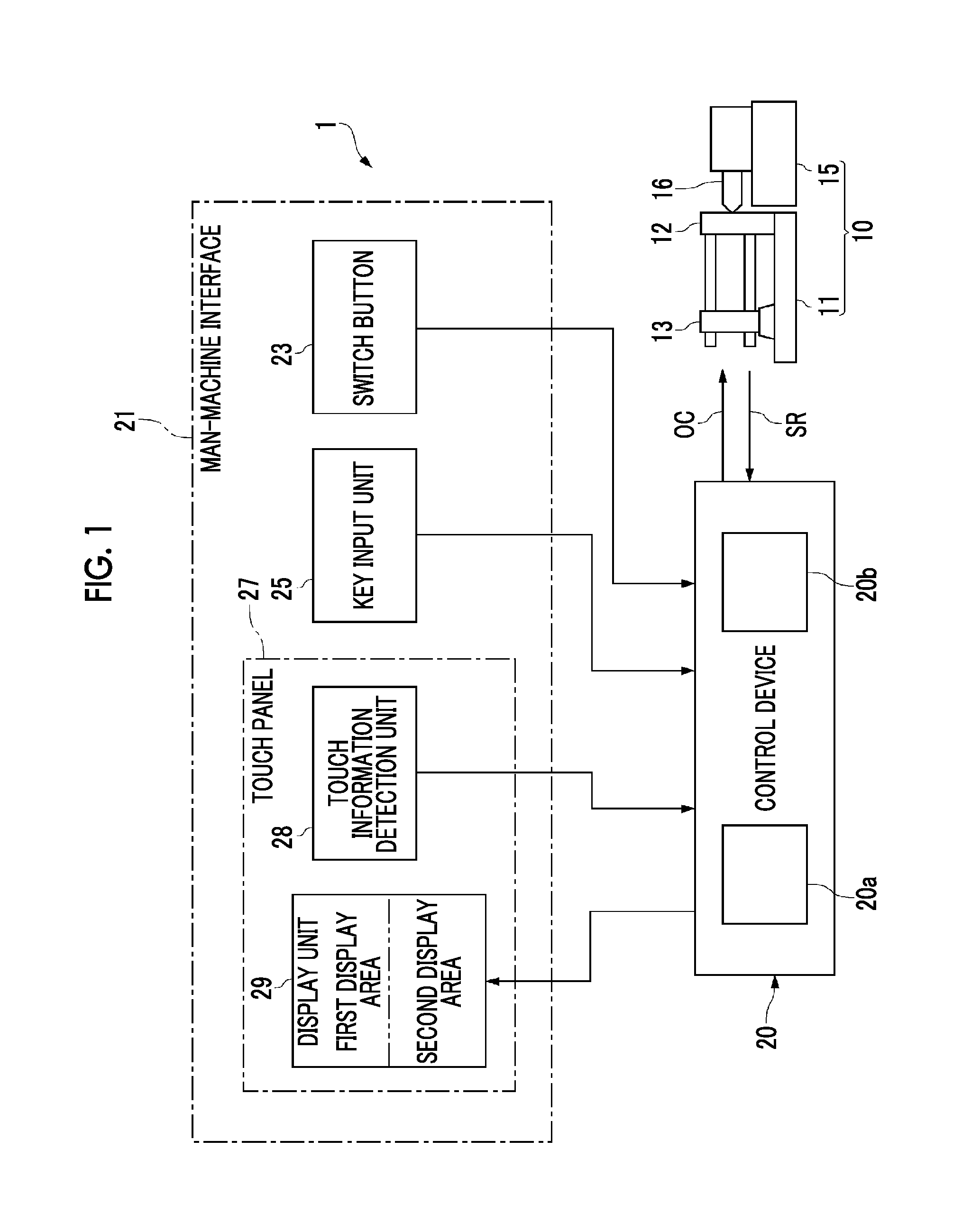

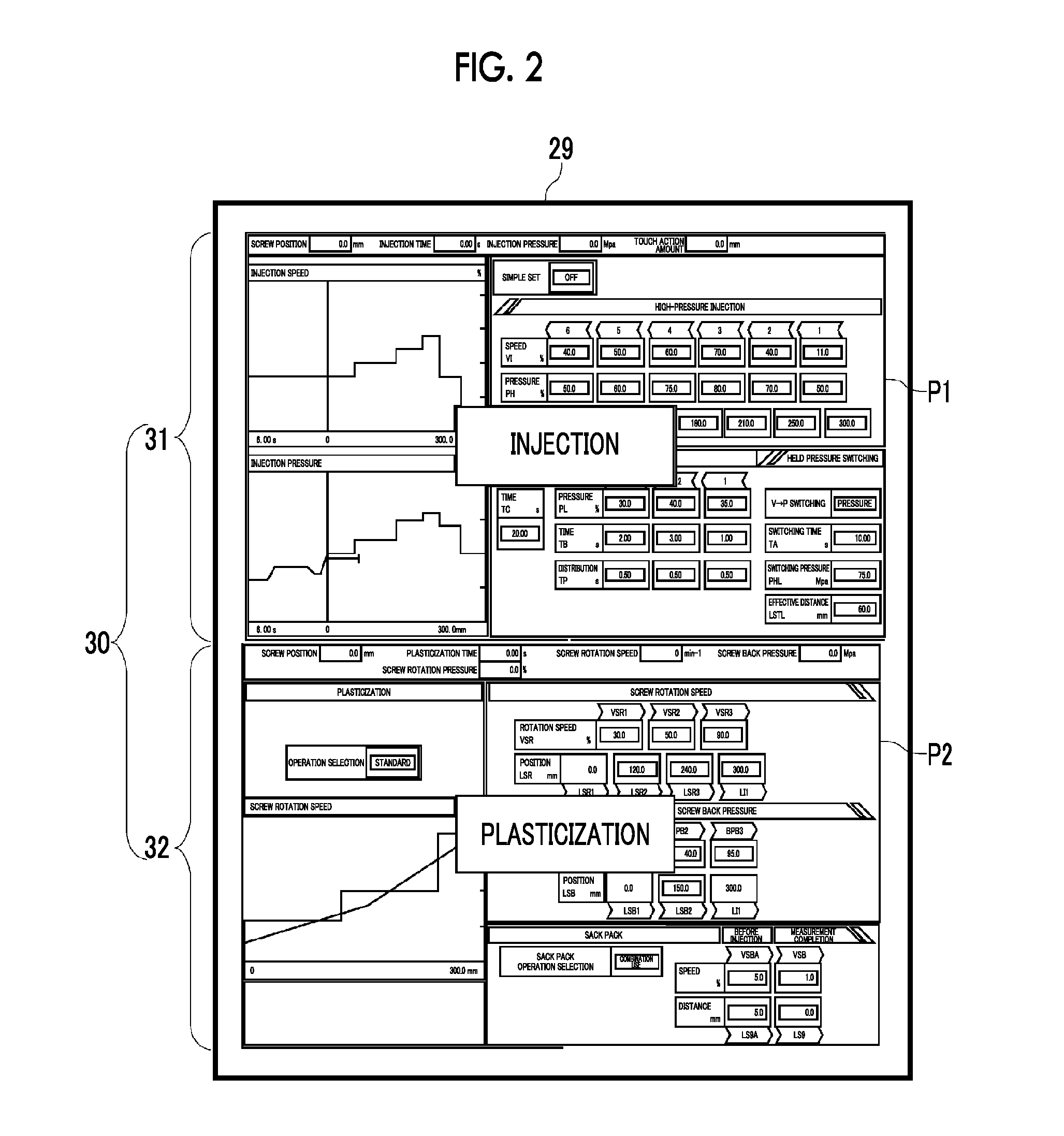

Control device for injection molding machine and screen display method

ActiveUS20160082504A1Reduce loadAuxillary shaping apparatusMoulding machine componentsHuman–machine interfaceInjection molding machine

Provided is a control device for an injection molding machine, capable of reducing the load on a user when re-displaying a previously displayed screen. The control device (20) for the injection molding machine (1) controls the display of display images on a display unit (29). This control device (20) divides the display unit (29) into a first display area (31) and a second display area (32) and, if an instruction to scroll in the vertical direction is received when a first display image (P1) is displayed in the first display area (31) and a second display image (P2) is displayed in the second display area (32), synchronously scrolls the first display image (P1) and the second display image (P2) whilst maintaining the relative positions of the first display image (P1) and the second display image (P2).

Owner:U MHI PLATECH CO LTD

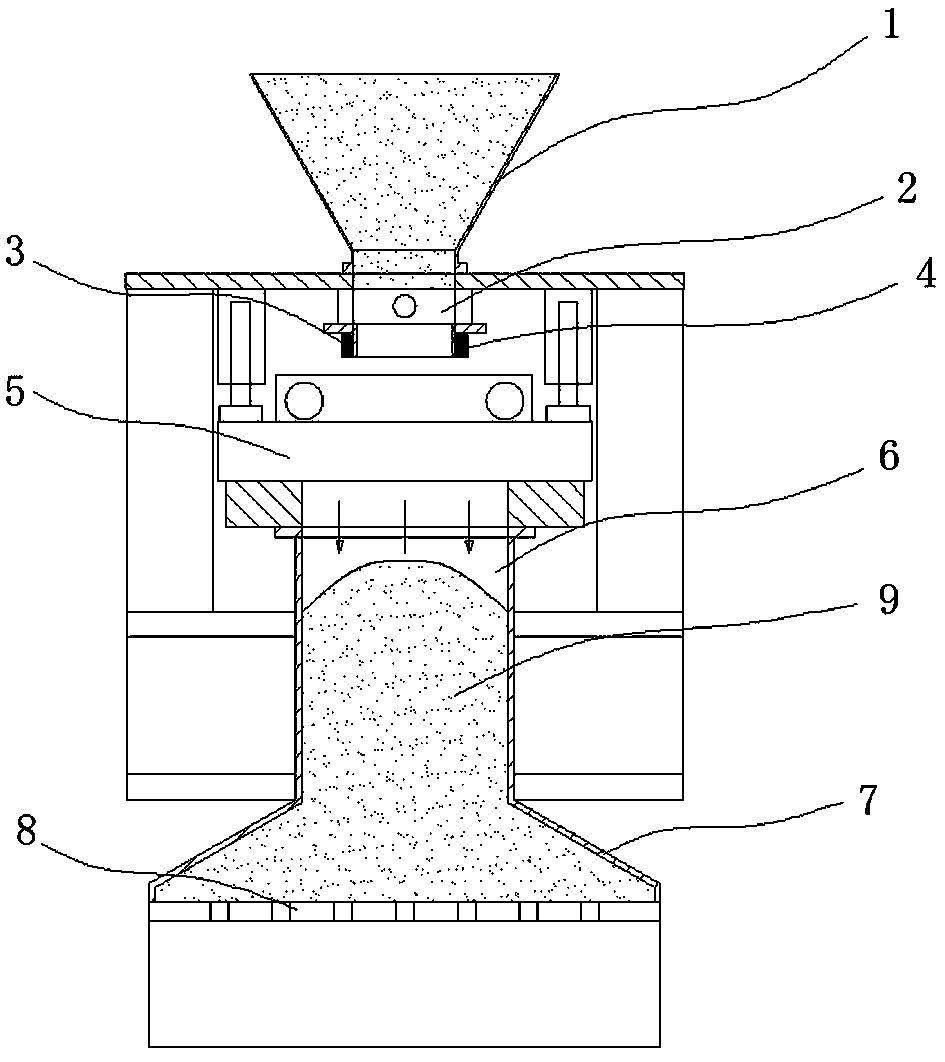

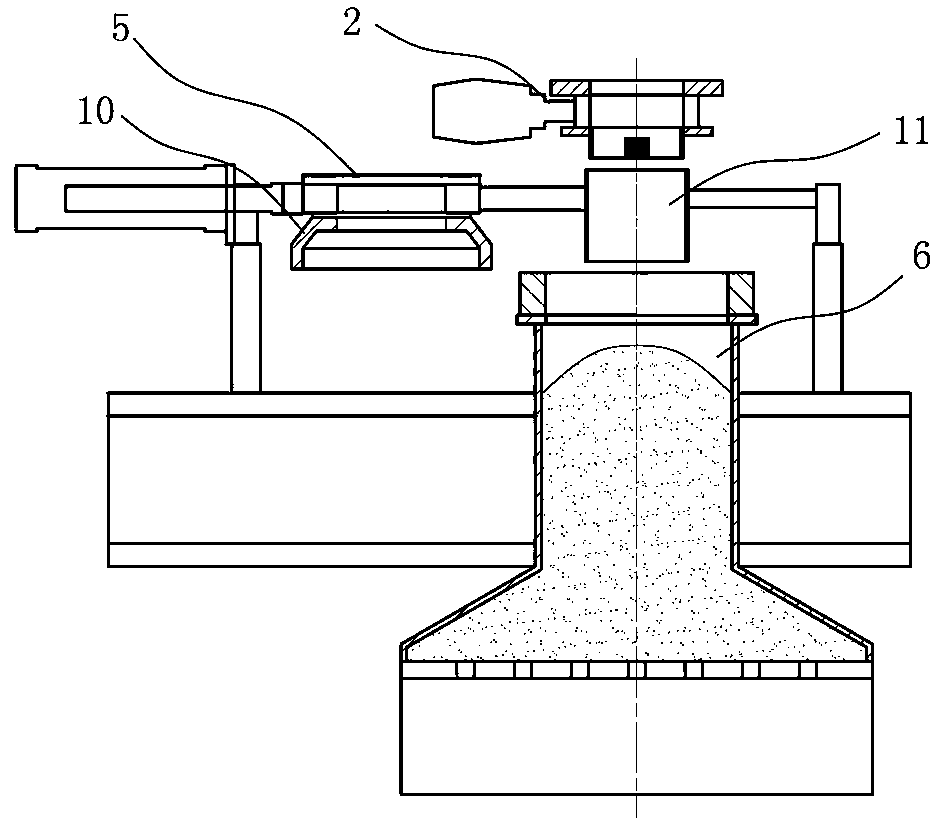

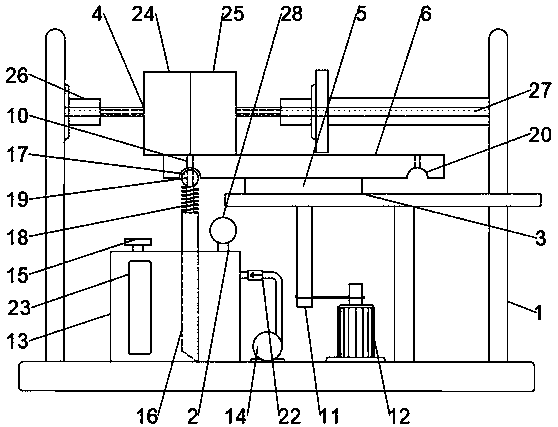

Quantitative sand adding mechanism and quantitative sand adding method of core shooter

ActiveCN104399906AReduce the impactUnaffected by stacked shapesMoulding machine componentsMould handling/dressing devicesEngineeringMolding sand

The invention discloses a quantitative sand adding mechanism of a core shooter. The core shooter comprises a lower rack and an upper rack located above the lower rack, wherein the lower rack is provided with a movable shooting head device. The quantitative sand adding mechanism comprises a sand storage hopper, a first sand adding valve, a vibrating motor and a quantitative hopper, wherein the sand storage hopper is mounted on the upper rack, the first sand adding valve is arranged at a sand outlet of the sand storage hopper, the vibrating motor is mounted on the outer wall of the sand storage hopper, the first sand adding valve is an adjustable valve, the quantitative hopper is connected onto the upper rack through a weighing component, a sand inlet of the quantitative hopper is connected with the sand outlet of the sand storage hopper through the first sand adding valve, a sand outlet of the quantitative hopper is provided with a second sand adding valve, the shooting head device is connected to the sand outlet of the quantitative hopper through the second sand adding valve when located in a sand adding position, and the sand adding process is not affected by the piling shape of molding sand and factors during valve closing. The invention further discloses a quantitative sand adding method of the core shooter adopting the quantitative sand adding mechanism.

Owner:SUZHOU MINGZHI TECH

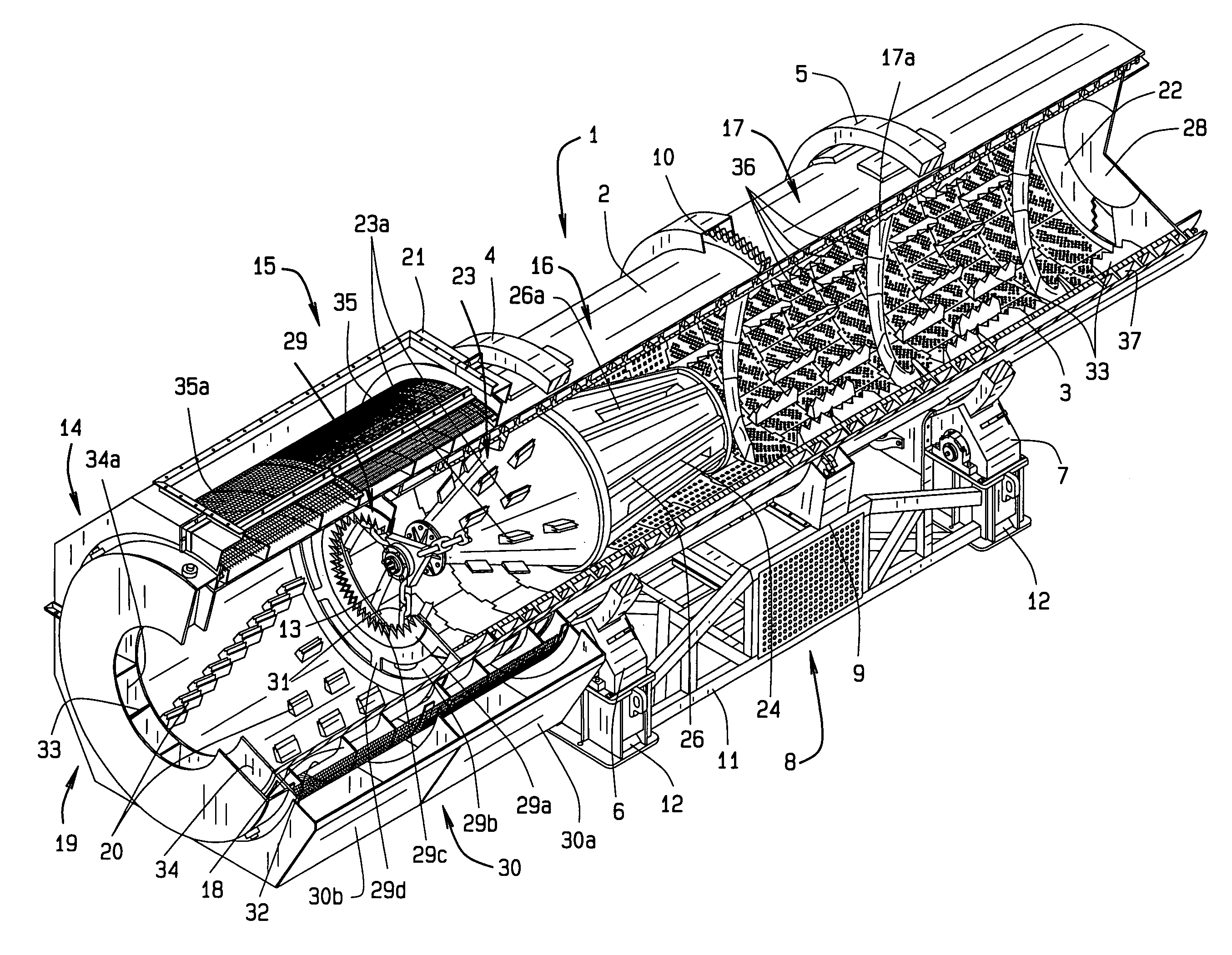

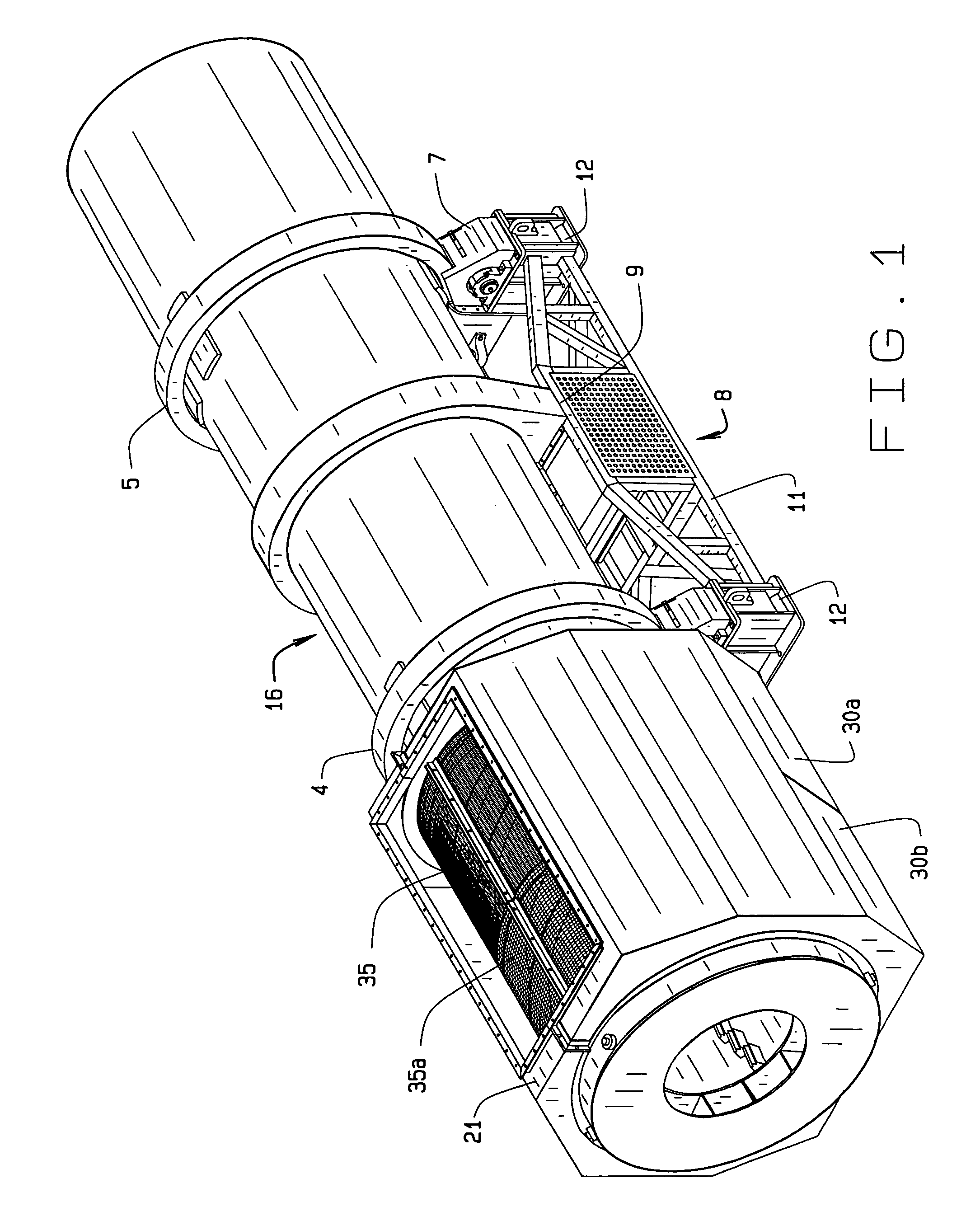

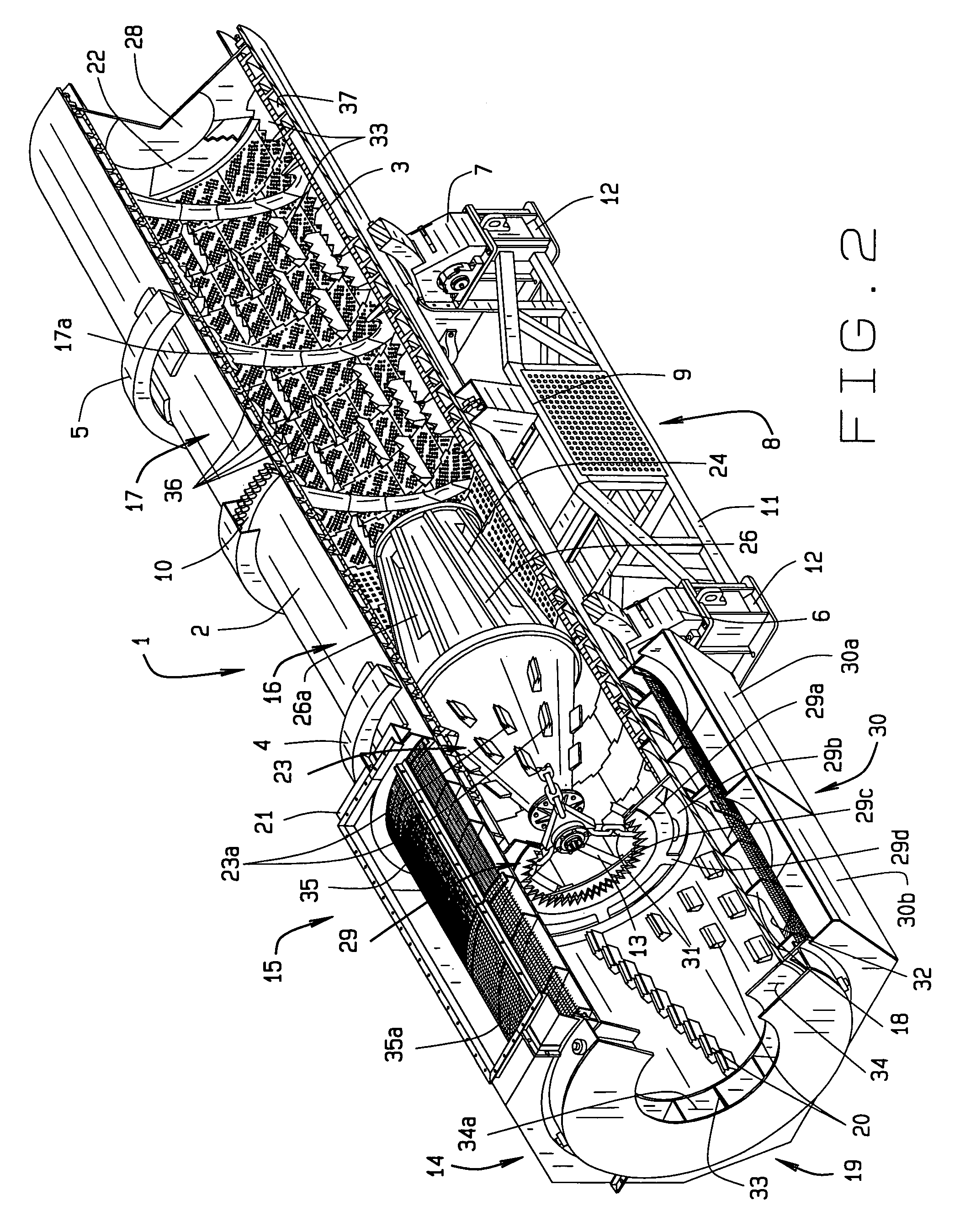

Rotary tumbler and metal reclaimer

ActiveUS7942354B2Small sizeLow costSolid waste disposalMoulding machine componentsEngineeringReclaimer

Owner:DIDION TECHNOLOGIES LLC

Part for cast production fabricated by wet type paper-making method

InactiveCN1671492AEasy to operateInhibit heat shrinkageFoundry mouldsMoulding machine componentsFiberDie casting

An element made by papermaking for use in the production of a die casting which comprises an organic fiber, an inorganic fiber, and a binder. The contents of the organic fiber, the inorganic fiber, and the binder are preferably 10 to 70 parts by weight, 1 to 80 parts by weight, and 10 to 85 parts by weight, respectively. The binder is preferably an organic binder. The organic fiber is preferably pulp fiber.

Owner:KAO CORP

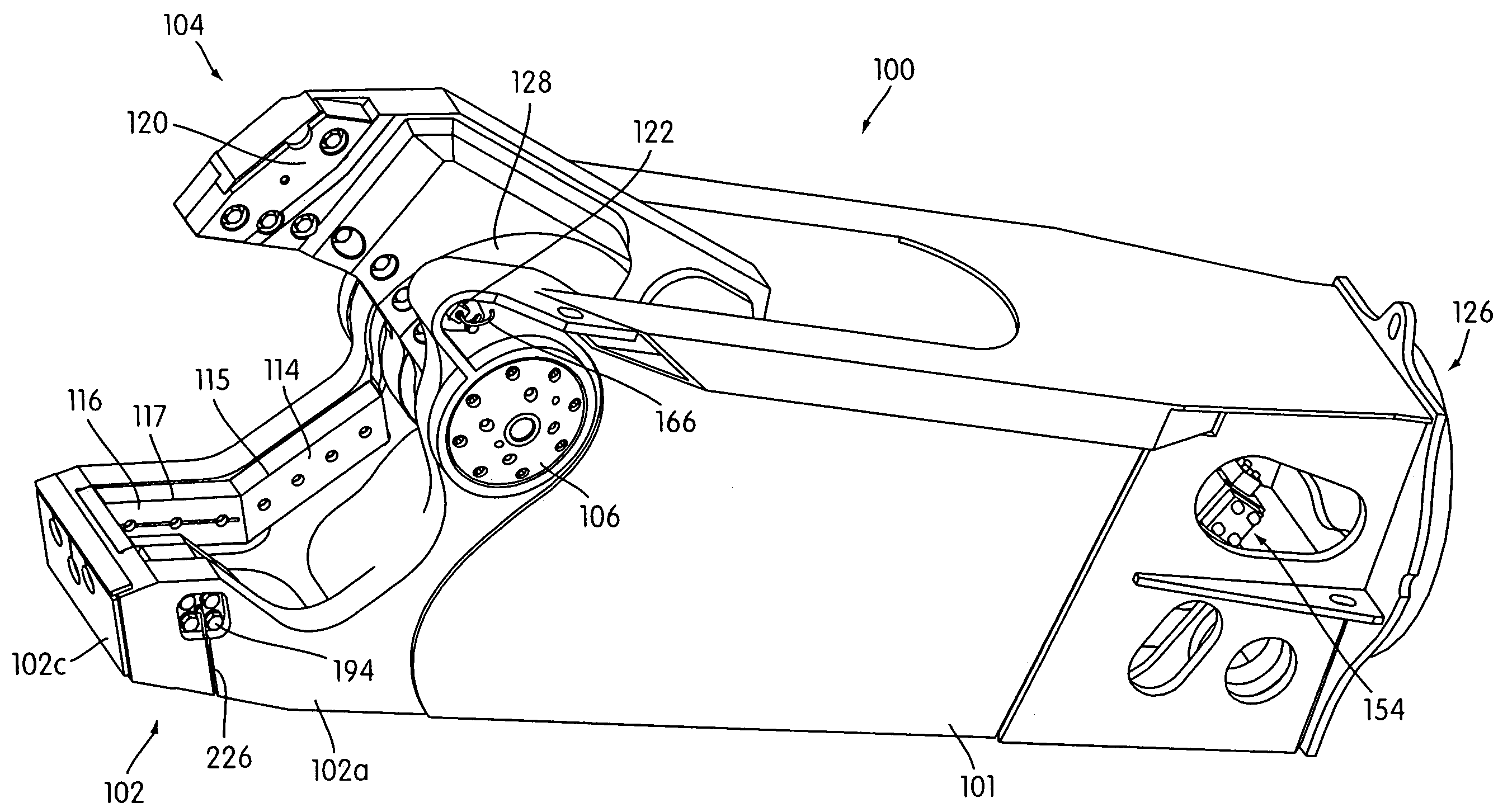

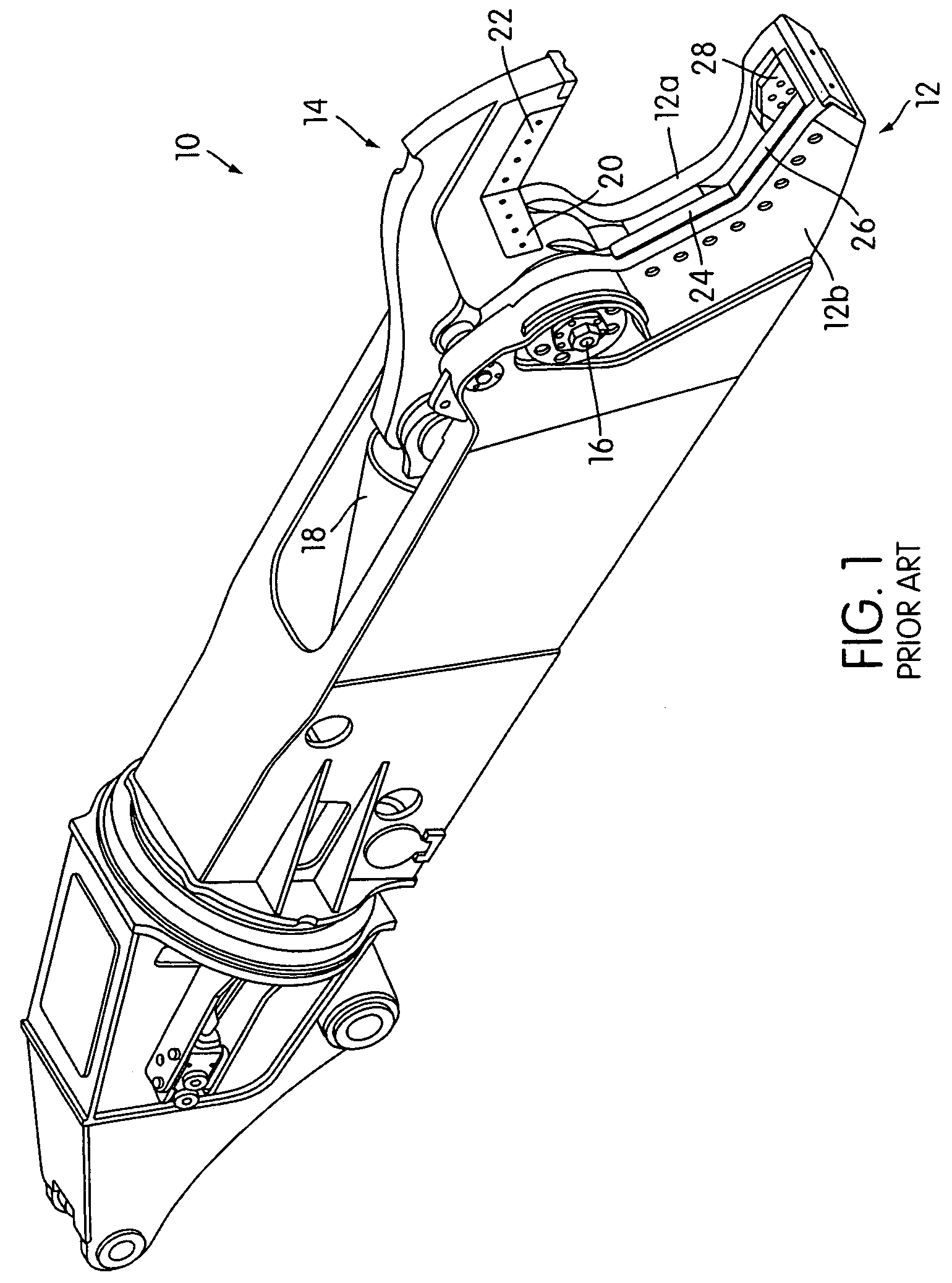

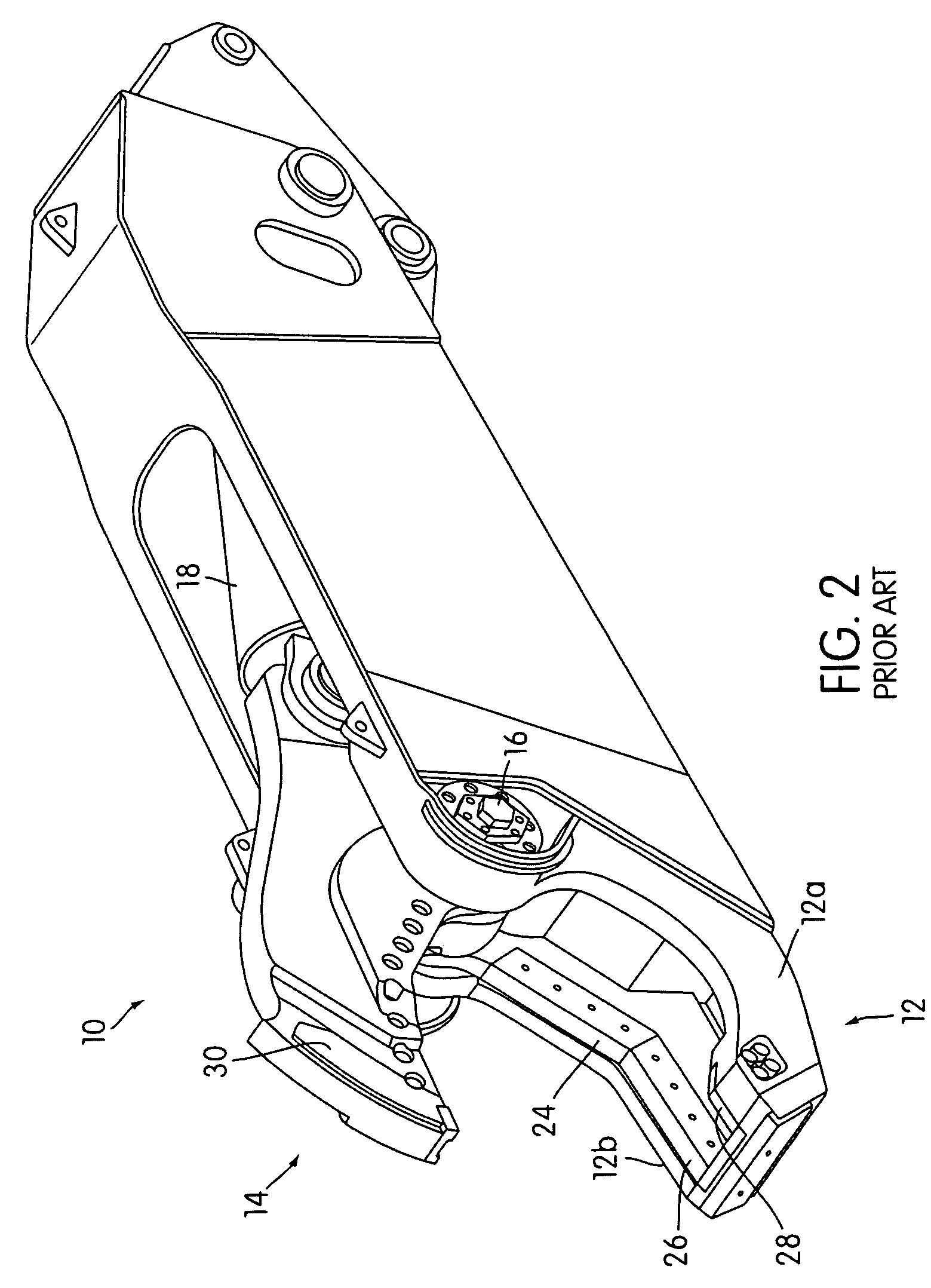

Lubricating system for metal-demolition shears

ActiveUS7487930B2Extended service lifePrecision lubricationMowersBuilding repairsHydraulic cylinderEngineering

A lubricating system for a heavy-duty metal demolition shears provides lubricant to one of more wear surfaces on one or more wear portions in the shears. The system includes a hydraulic lubricant pump that is actuated by the main hydraulic control system by means of which the jaws of the shears are opened and closed, and may include a sequential valve to distribute lubricant to various wear portions in sequential fashion. The lubricating system may lubricate one or more wear surfaces of the lateral blade stabilizers, primary and secondary blade(s) on the upper and / or lower jaws, pivotal connections between jaws and / or between the upper jaw and the hydraulic cylinder, and a forward wear plate. The lubricating system may be retrofitted onto a conventional non-lubricated shears by replacing a conventional upper jaw with a lubricated upper jaw and lubricating system.

Owner:STANLEY WORKS THE

Core machine ration sand adding method and device

ActiveCN103406498ASolving Scale ProblemsExtended service lifeMoulding machine componentsMoulding machinesButterfly valveMaterials science

The invention discloses a core machine ration sand adding method and device. The ration sand adding method comprises the following steps of additionally arranging a sand adding moving mechanism between a sand adding butterfly valve and a sand spraying cavity which are arranged below a sand storing hopper, and arranging a sand position height sensor; during the adding of sand, filling the sand in a sand storing hopper by utilizing a sand mixing system, moving the sand adding moving mechanism to a sand adding position, and communicating an outlet of the sand adding butterfly valve and the sand spraying cavity; detecting the sand position height in the sand spraying cavity by utilizing the sand position height sensor, judging whether the sand needs to be added, if so, switching on the sand adding butterfly valve, meanwhile, detecting whether the sand position in the sand spraying cavity achieves the setting height by utilizing the sand position height sensor, if so, closing the sand adding butterfly valve, shifting out the sand adding moving mechanism, and finishing the sand adding. The core machine ration sand adding method and device provided by the invention have the advantages that the ration sand adding is realized, a proportion problem of sand quantity to airflow in the sand spraying cavity of a core machine is solved, the service life of a core box is prolonged, the device and the method are used for manufacturing a complex sand core, meanwhile, the method is simple, a sand adding device structure does not need to be changed, and the realization is easy.

Owner:SUZHOU MINGZHI TECH

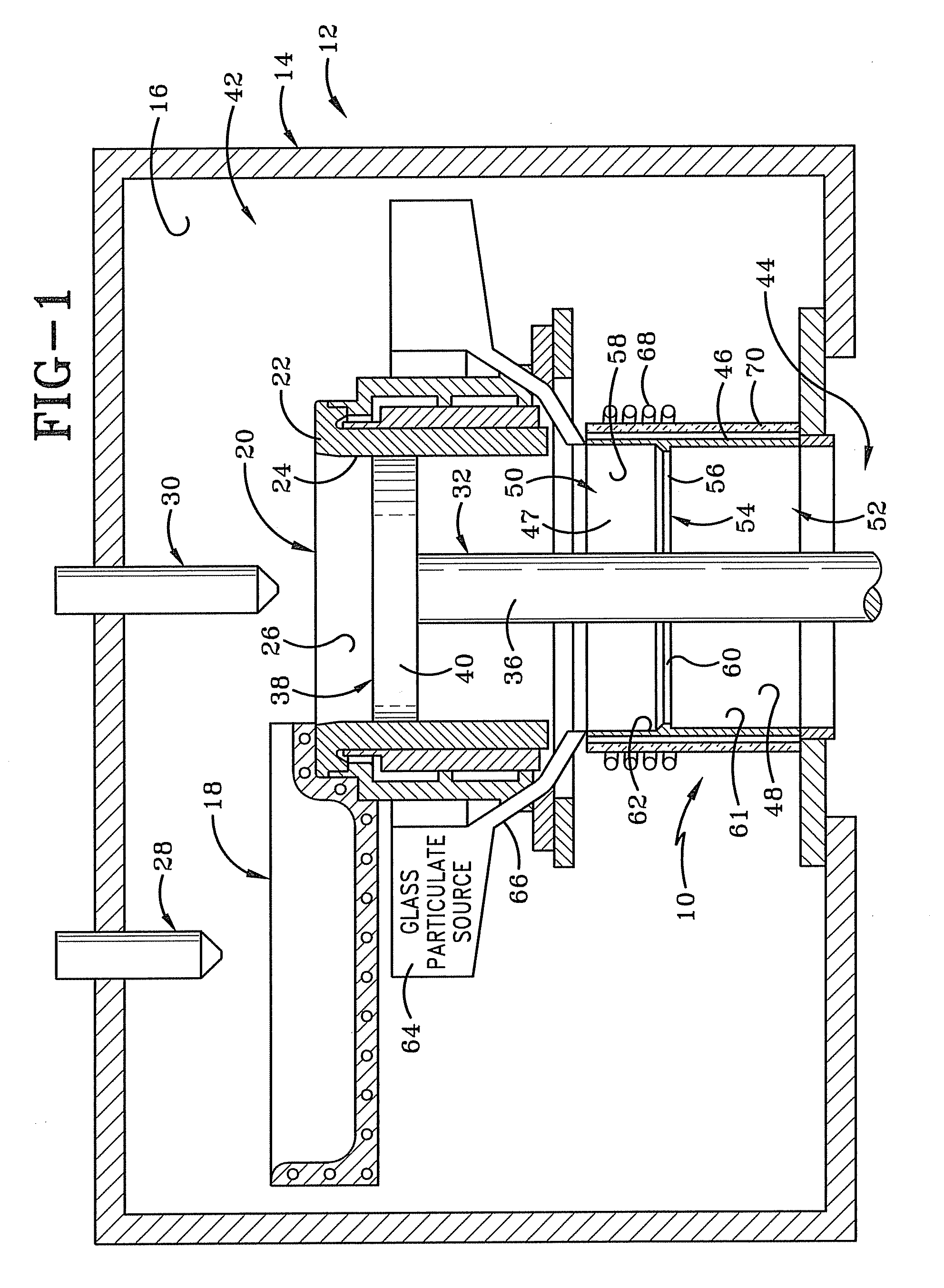

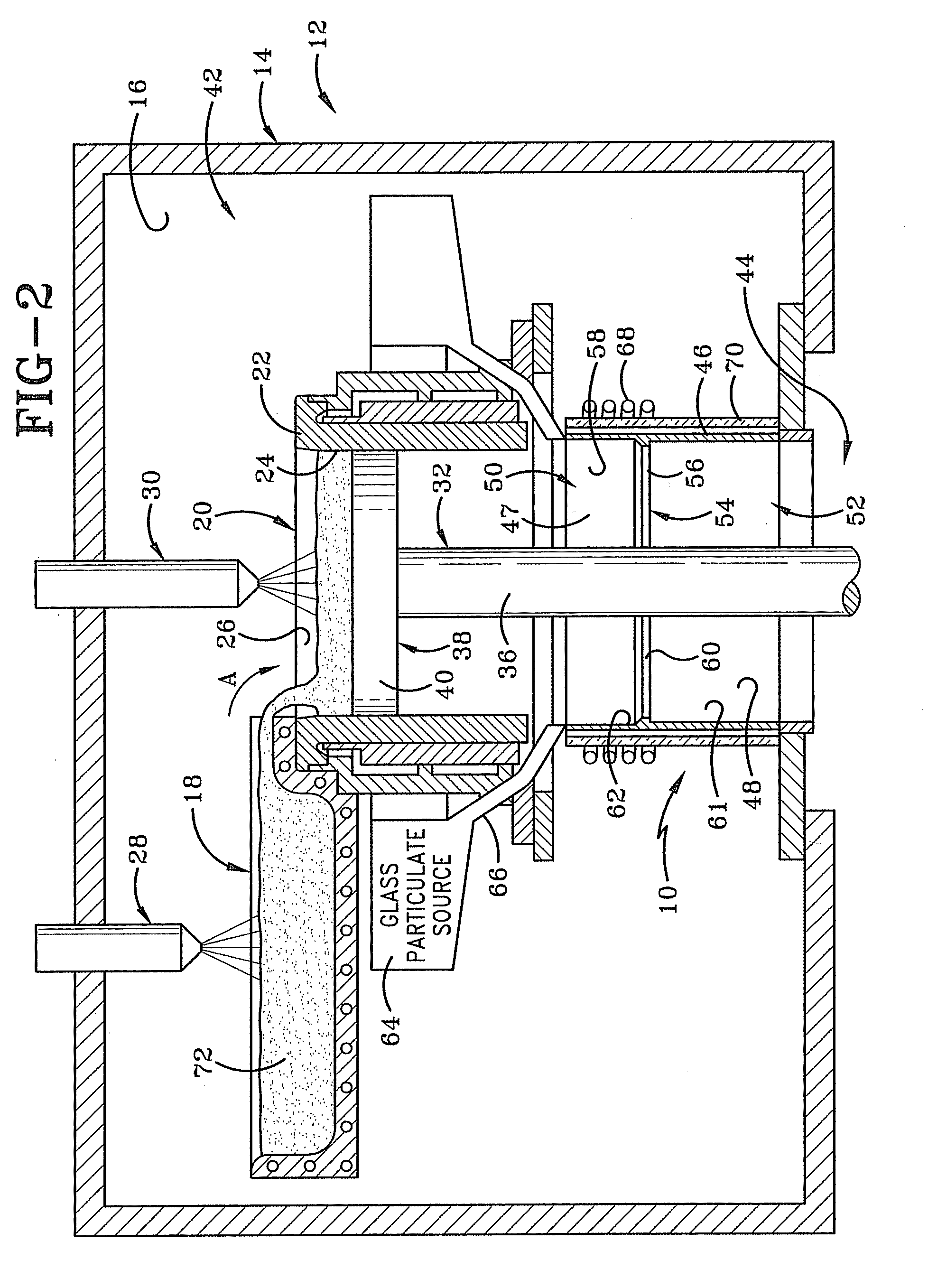

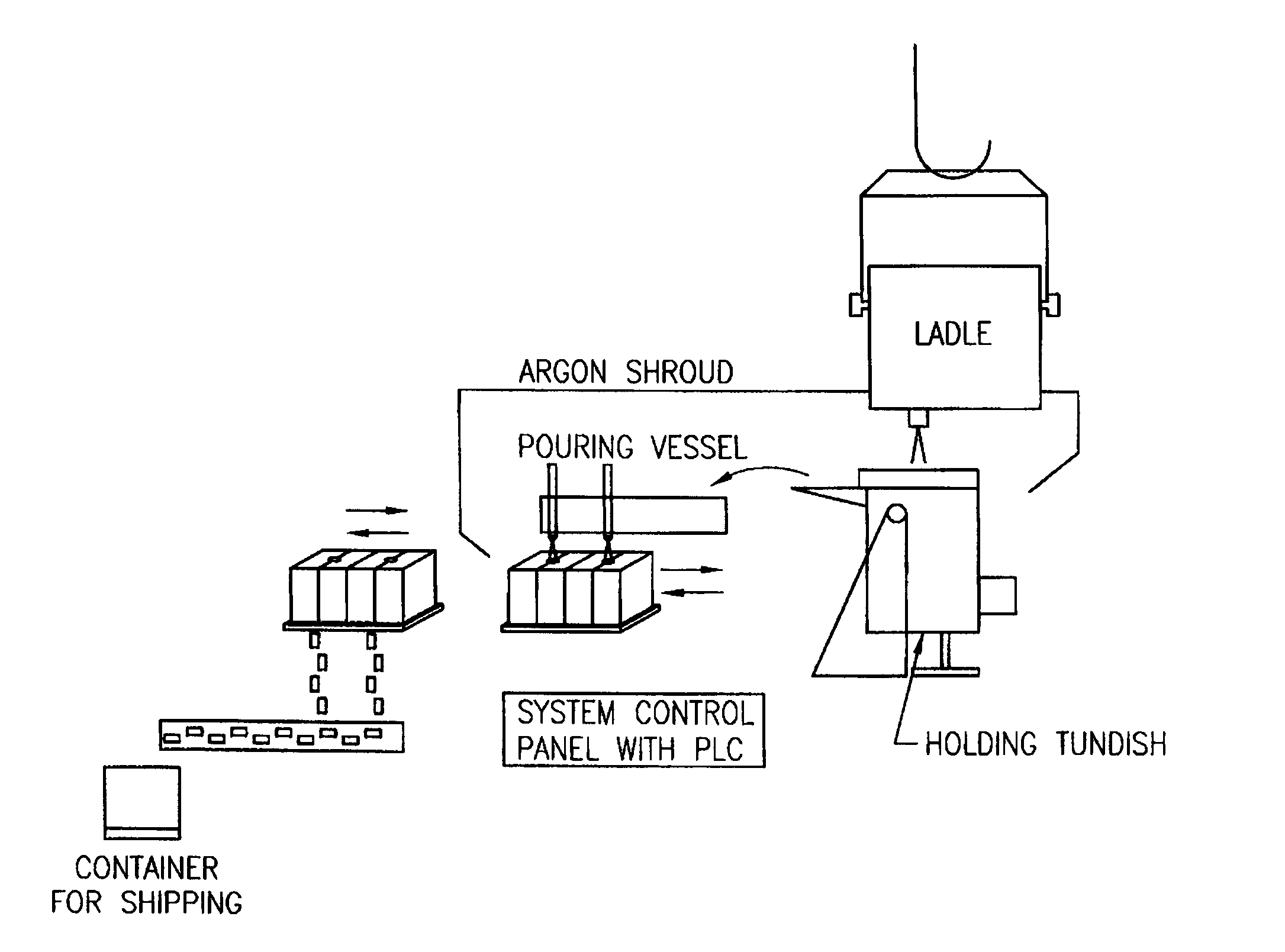

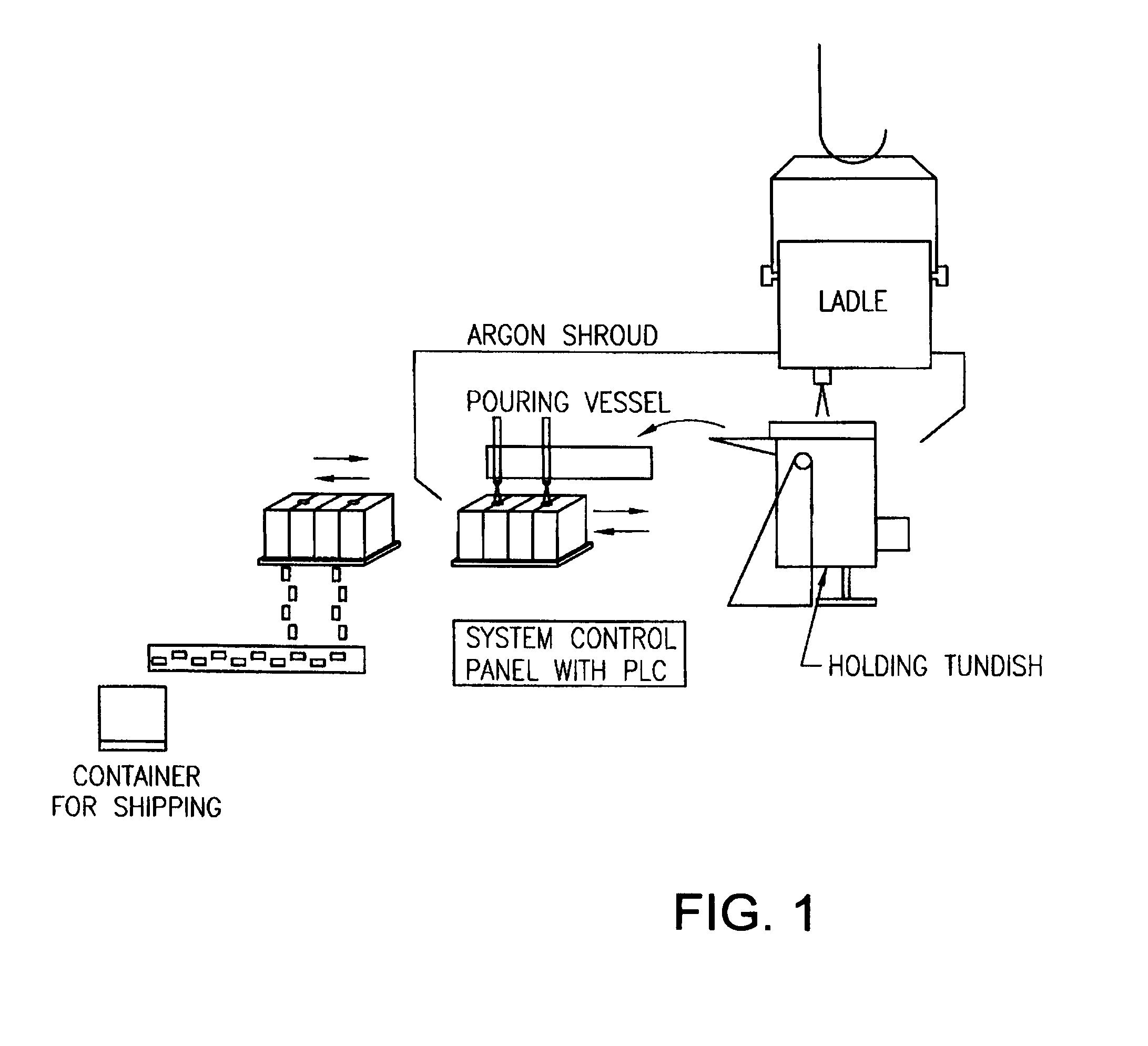

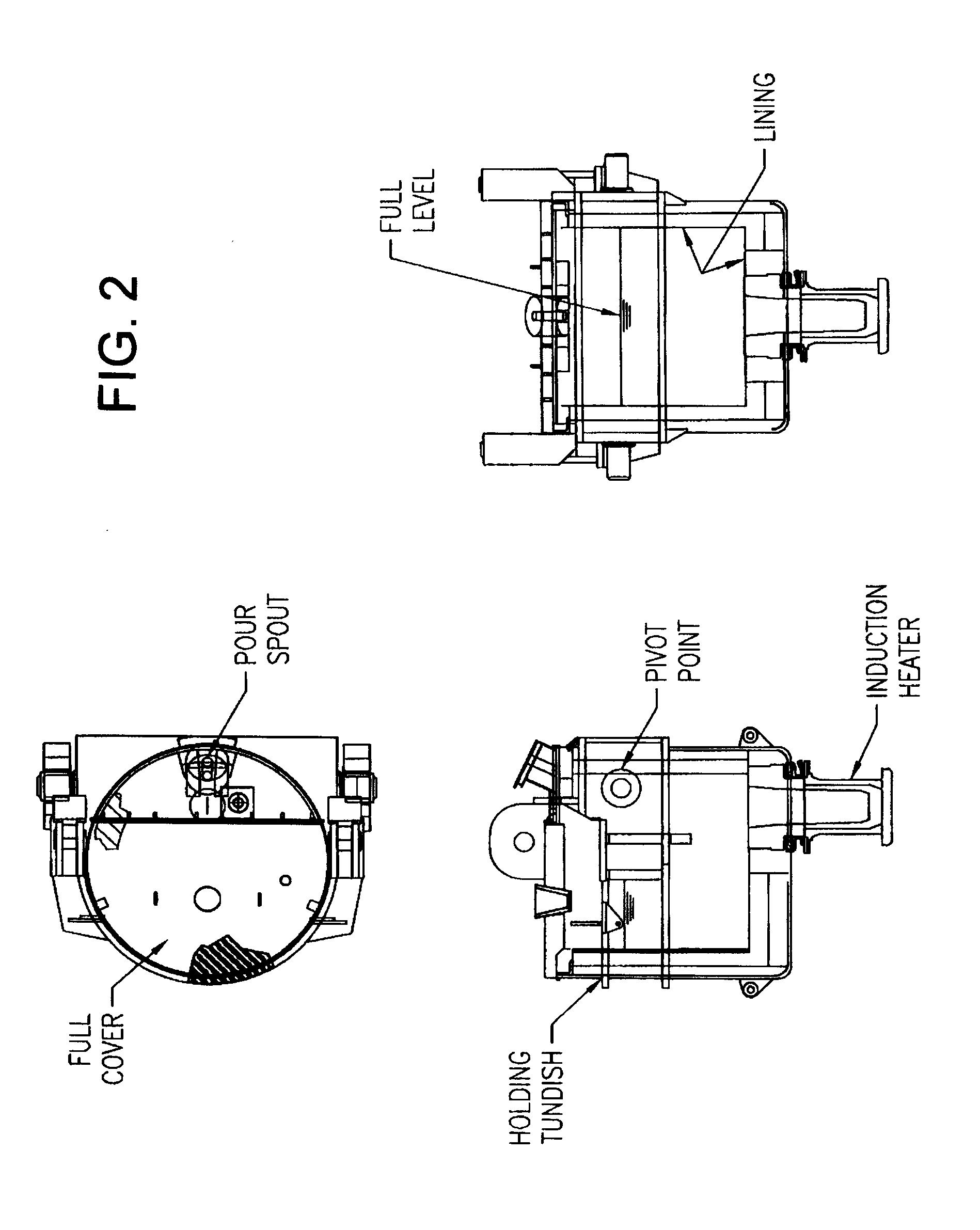

Method and apparatus for manufacturing metal bars or ingots

InactiveUS20090288794A1Increased operating costReduce environmental problemsPig casting plantsCasting safety devicesTrademarkEngineering

Method and apparatus for manufacturing metal bars or ingots. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:PRIME METALS & ALLOYS

Temperature control

ActiveUS20050256612A1Temperatue controlStatic/dynamic balance measurementTemperature controlEngineering

A method and apparatus are disclosed for controlling temperature of a plant comprising plural temperature control zones, wherein an effective control parameter for a first zone for which a signal representing measured temperature is available is produced according to an algorithm relating measured temperature, a desired temperature and a control parameter associated with a device affecting temperature in the first temperature control zone, the effective control parameter is summed with an offset value representing a proportional offset of the effective control parameter of a second temperature control zone relative to the effective control parameter of the first temperature control zone and the result is applied to control a device affecting temperature in the second temperature control zone. Advantageously, the offset value comprises a fixed amount and a variable amount, the variable amount accounting for dynamic differences in temperature control characteristics of the first and second temperature control zones.

Owner:D M E CO

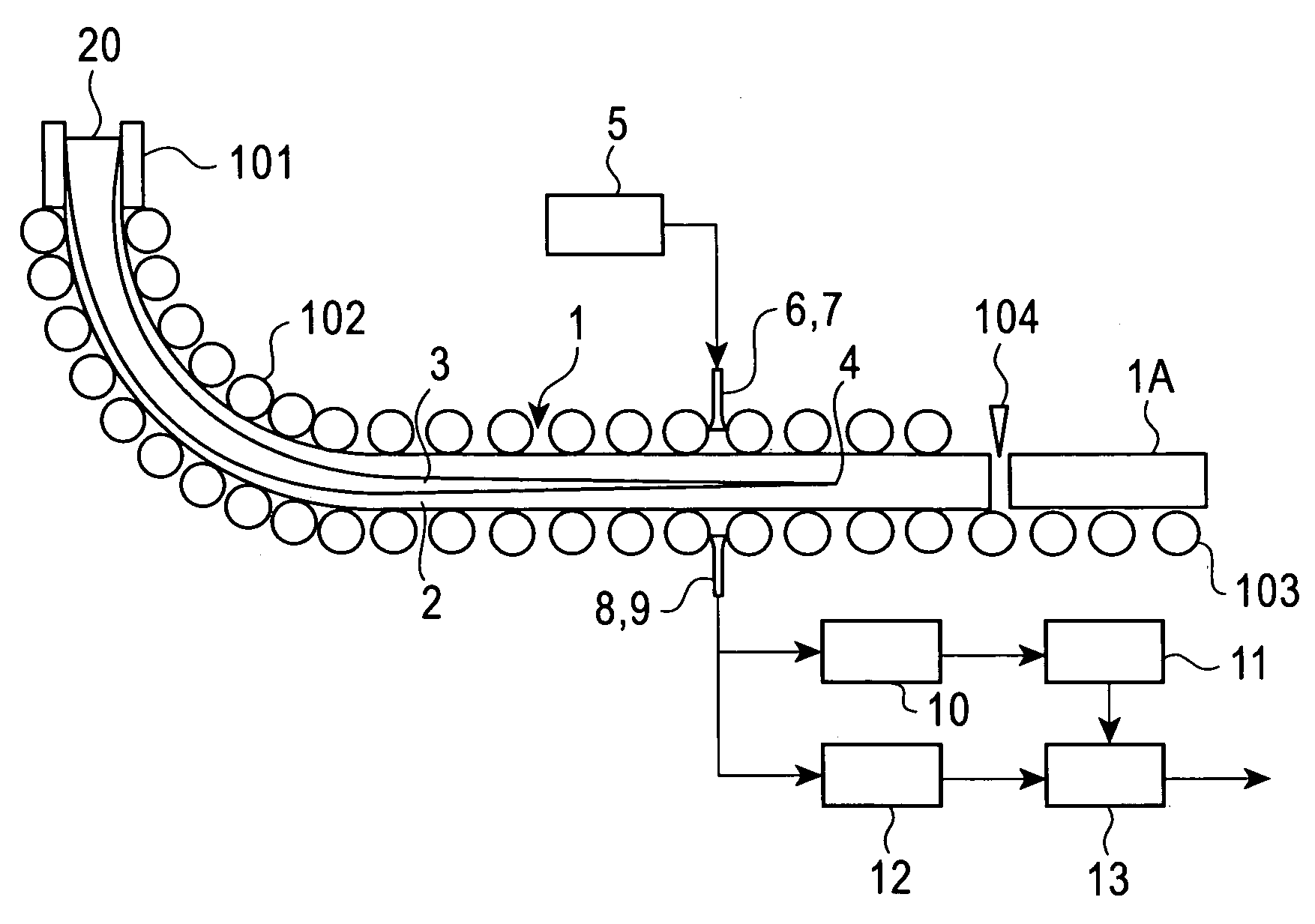

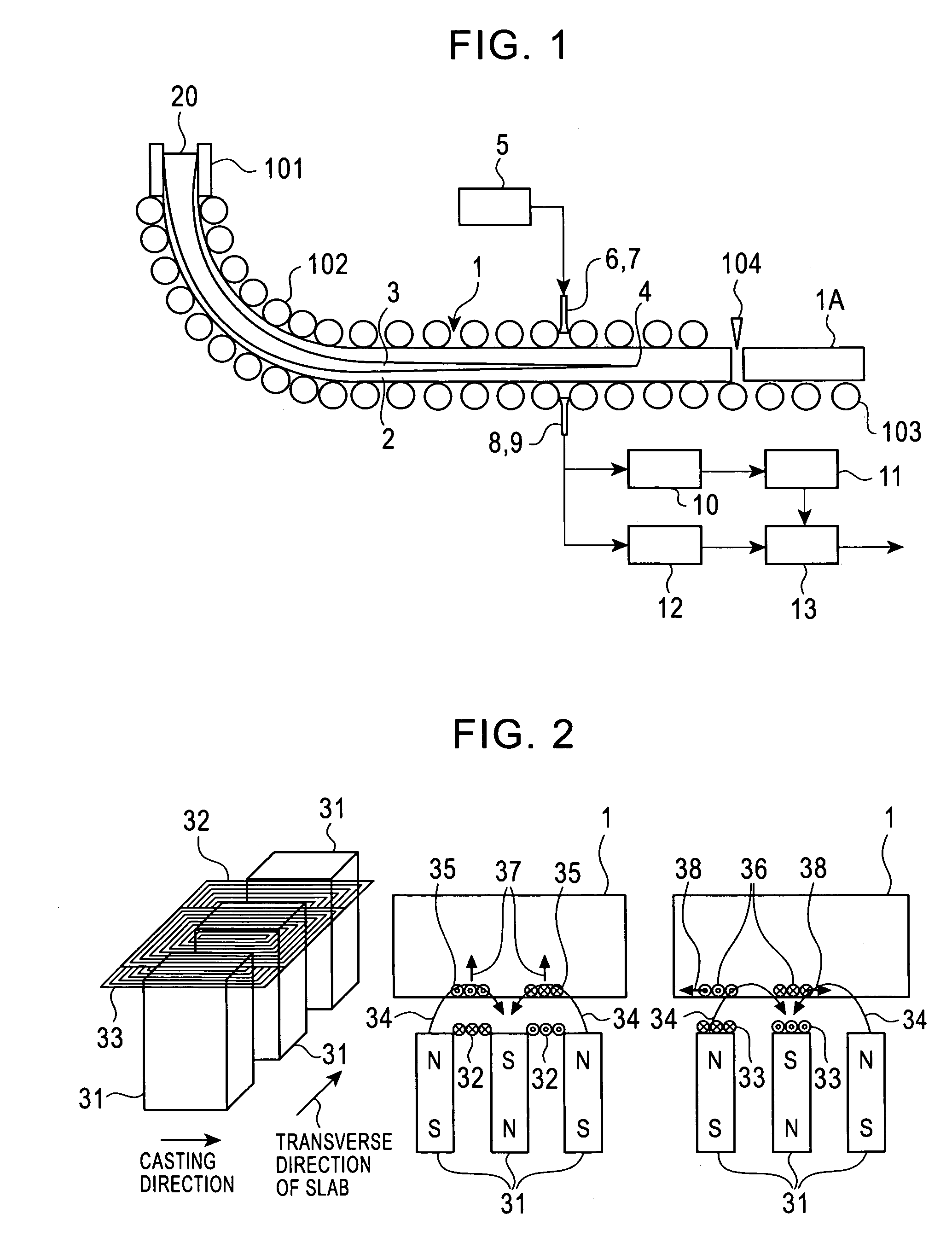

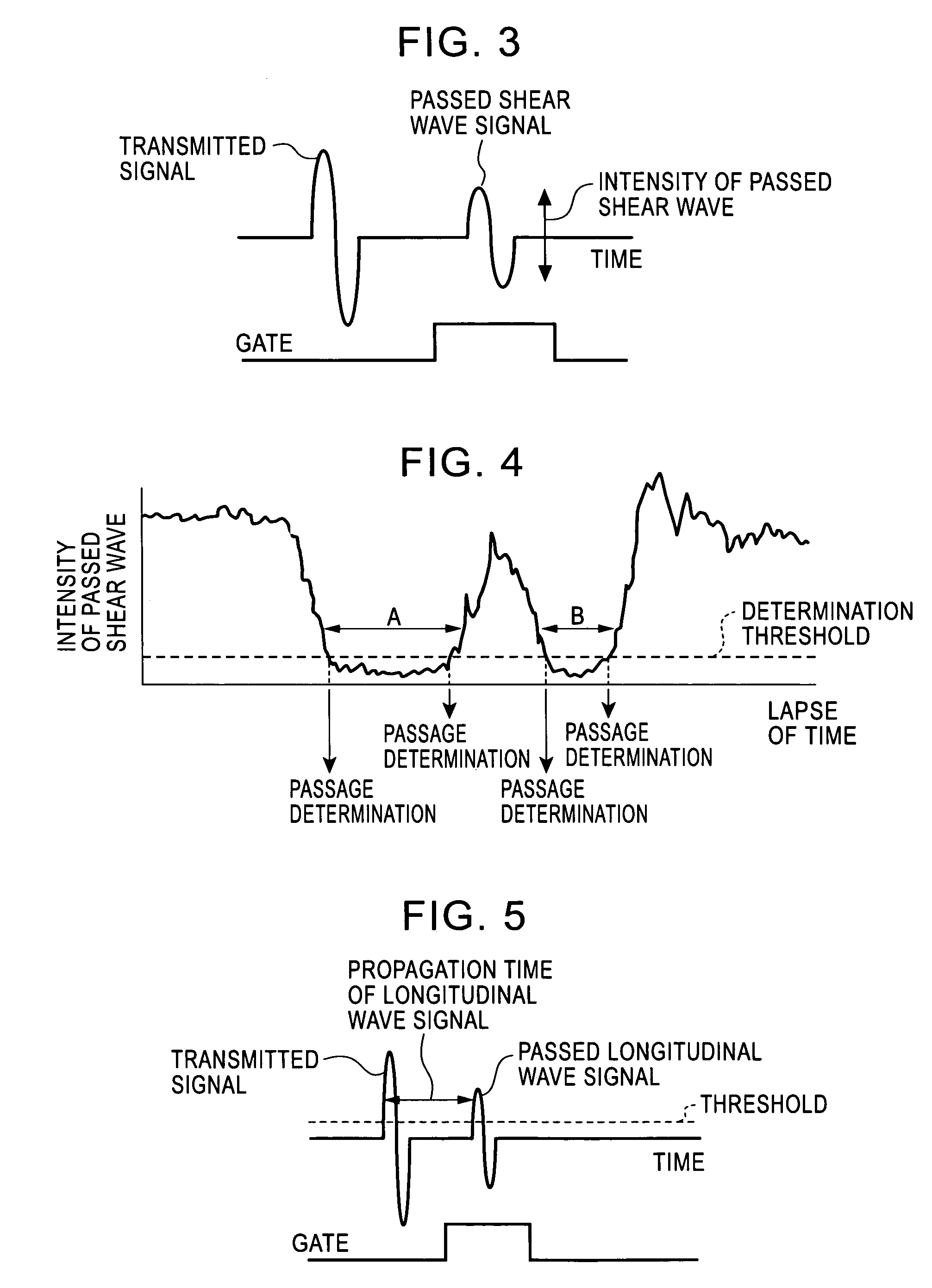

Method and apparatus for detecting crater end of continuously cast product, and method for producing continuously cast product

ActiveUS7740051B2Accurate detectionIncrease productivityMaterial analysis using sonic/ultrasonic/infrasonic wavesCasting safety devicesLongitudinal waveShear waves

A method for detecting a crater end of a continuously cast product including installing an ultrasonic shear wave sensor for transmitting an ultrasonic shear wave to a cast product and receiving the transmitted ultrasonic longitudinal wave and an ultrasonic longitudinal wave sensor for transmitting an ultrasonic longitudinal wave to the cast product and receiving the transmitted ultrasonic longitudinal wave at the same position in a continuous casting machine or at positions apart from each other in a casting direction, but at the same position in a transverse direction of the cast product, detecting based on variations of an ultrasonic signal received by the ultrasonic shear wave sensor that the crater end of the cast product is matched with the installed position of the ultrasonic shear wave sensor, calibrating a calculation formula for determining the crater end and determining the crater end.

Owner:JFE STEEL CORP

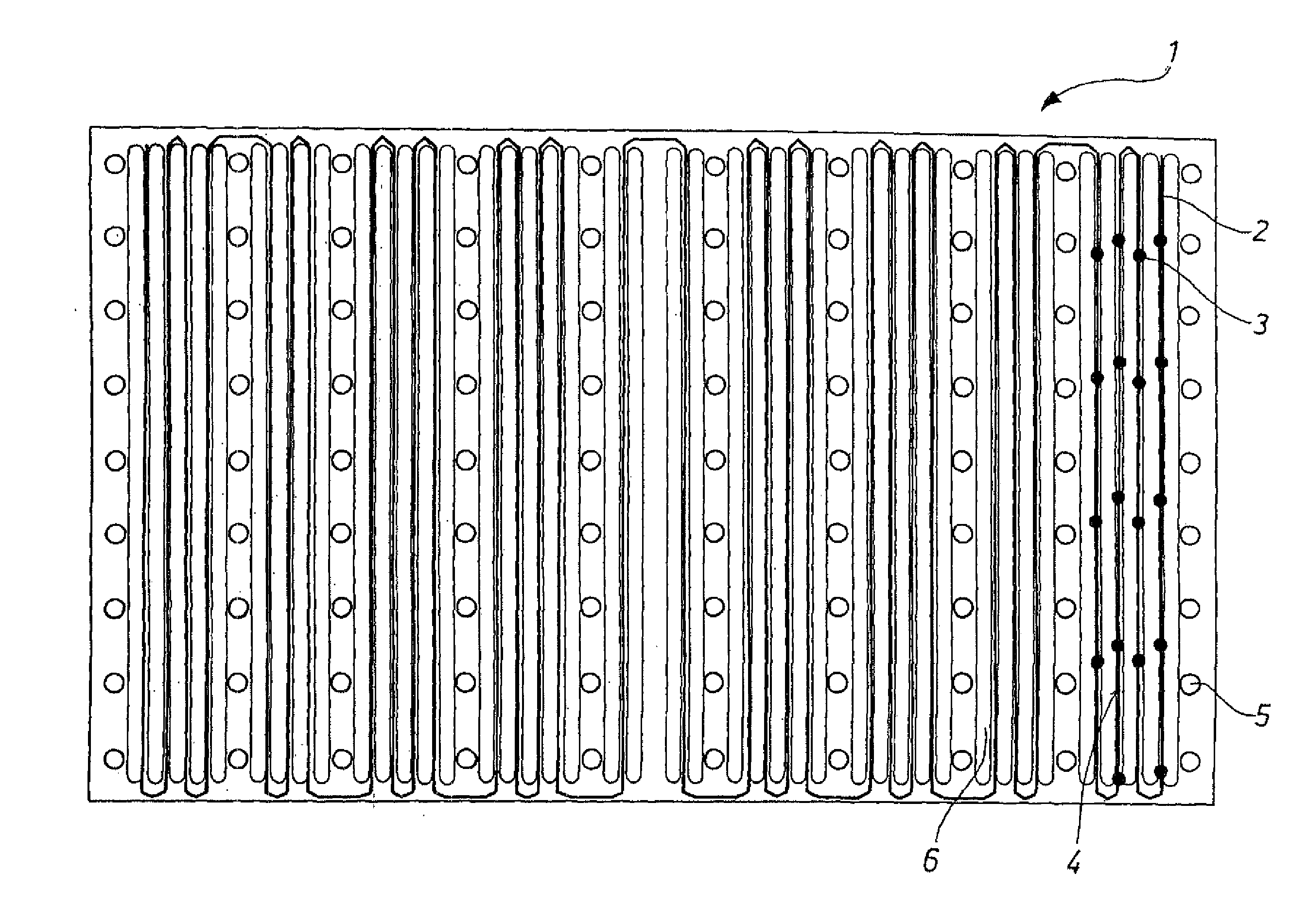

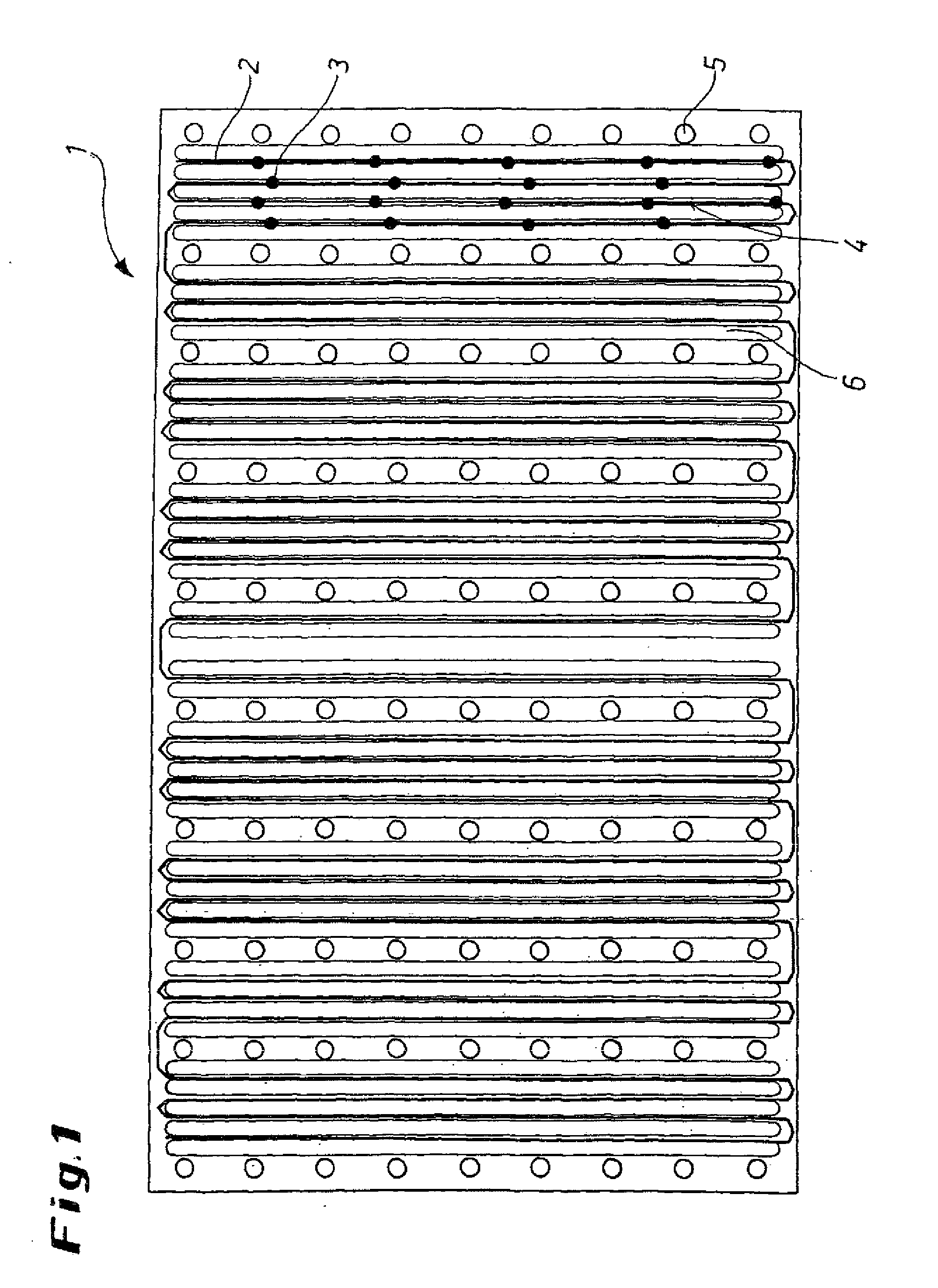

Aerogenerator of triethylamine

InactiveCN101347821AFast hardeningPollution controlFoundry mouldsMoulding machine componentsAtmospheric airEngineering

The invention provides a triethylamine gas generator, comprising a carburetor and an enclosed quantitative amine adding device; the carburetor comprises a heat accumulation body, a heating pipe and a vaporization pipe; the heating pipe and the vaporization pipe are arranged inside the heat accumulation body; the vaporization pipe is distributed in a snake shape in a circuitous way; the heating pipes are arranged between the gaps of the vaporization pipe at intervals; the vaporization pipe is provided with an amine adding mouth, a vaporization amine outlet and a gas inlet; the enclosed quantitative amine adding device is connected with the amine adding mouth of the carburetor. The carburetor of the invention has enough heat source, heat accumulation quantity and good heat exchange conditions, therefore, the flowing liquid amine can be ensured to be sufficiently vaporized, the hardening speed of the sand core can be effectively improved, the amine consumption can be reduced, the environmental pollution can be controlled radically, the production efficiency and the sand core quality can be improved; meanwhile, the enclosed quantitative amine adding device is an enclosed system, therefore, the control is simple and convenient, the quantification is exact, as well as the device is separated from the atmosphere and has no volatilization pollution.

Owner:冯新林

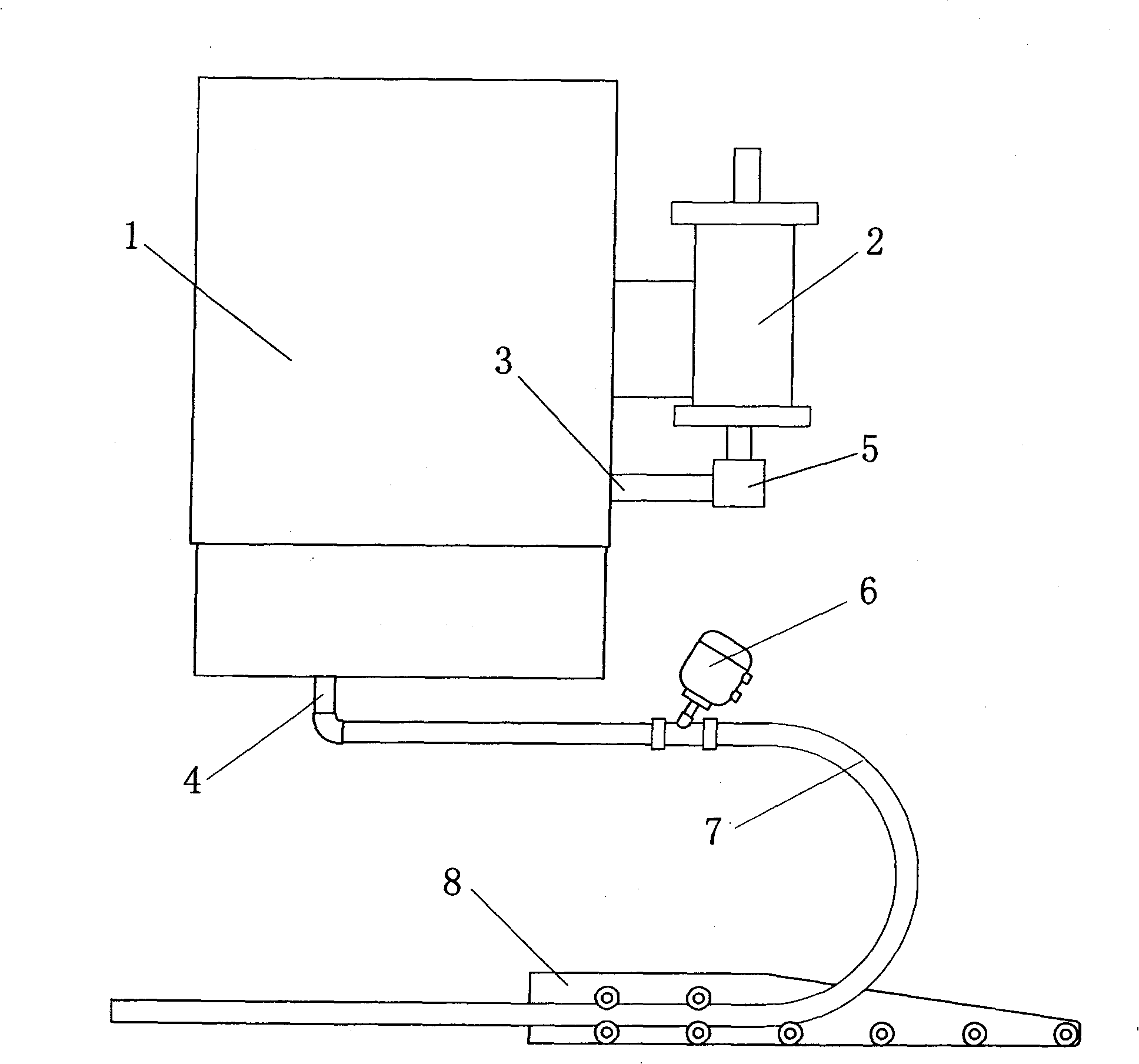

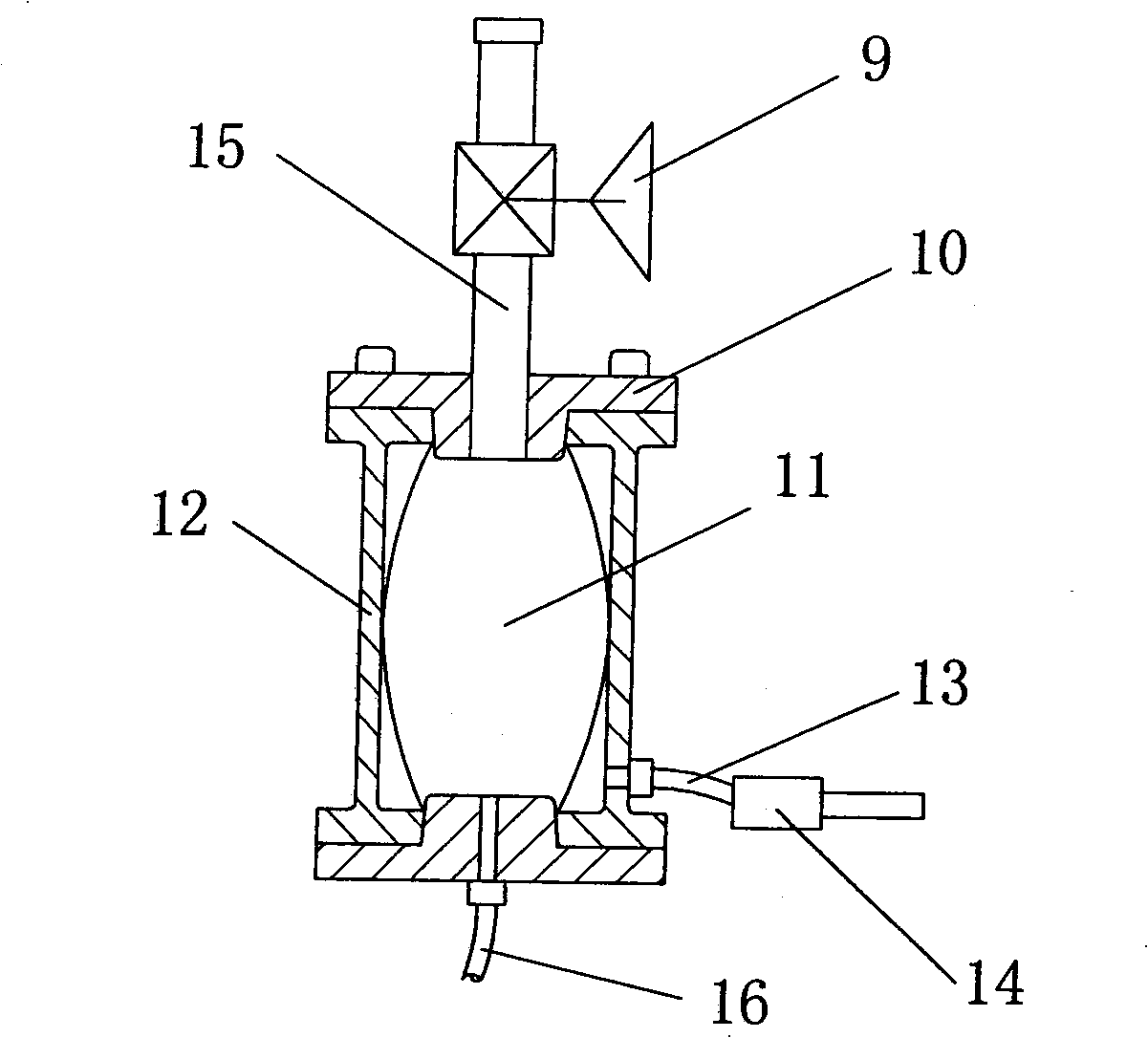

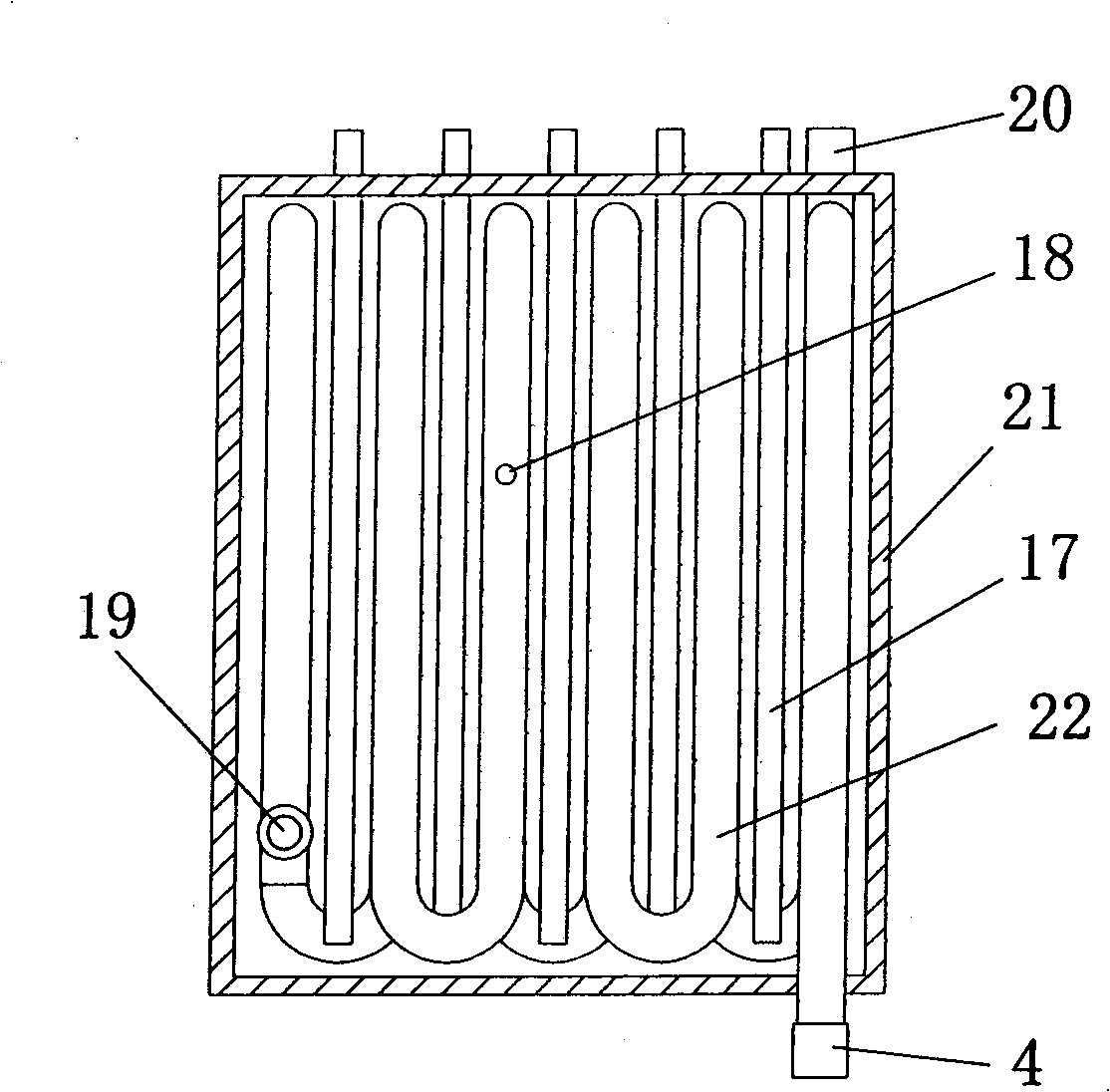

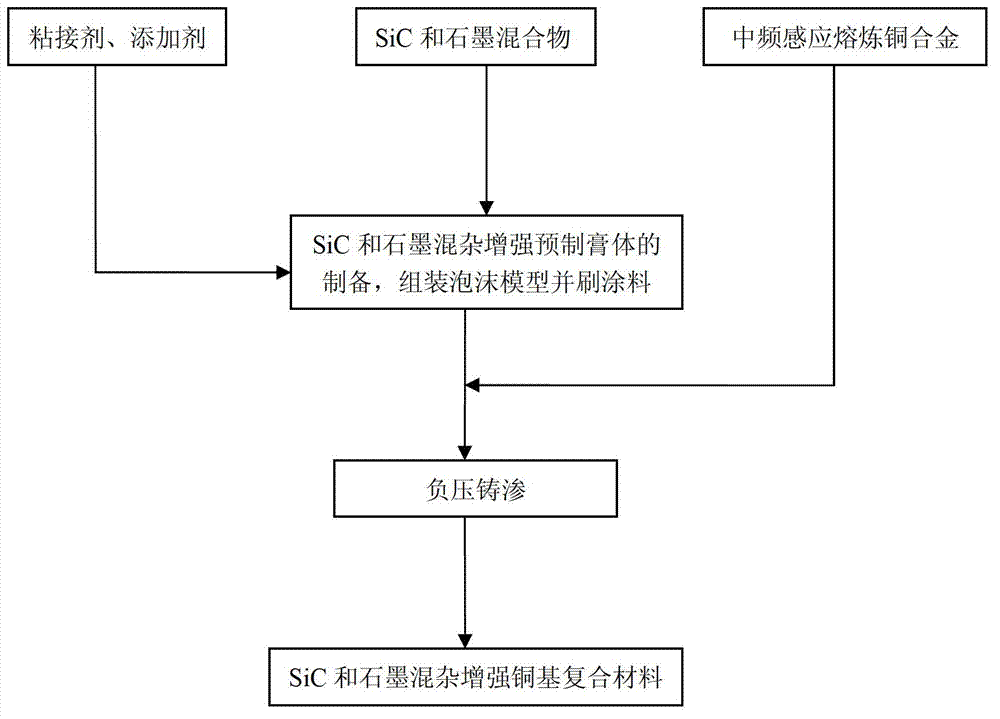

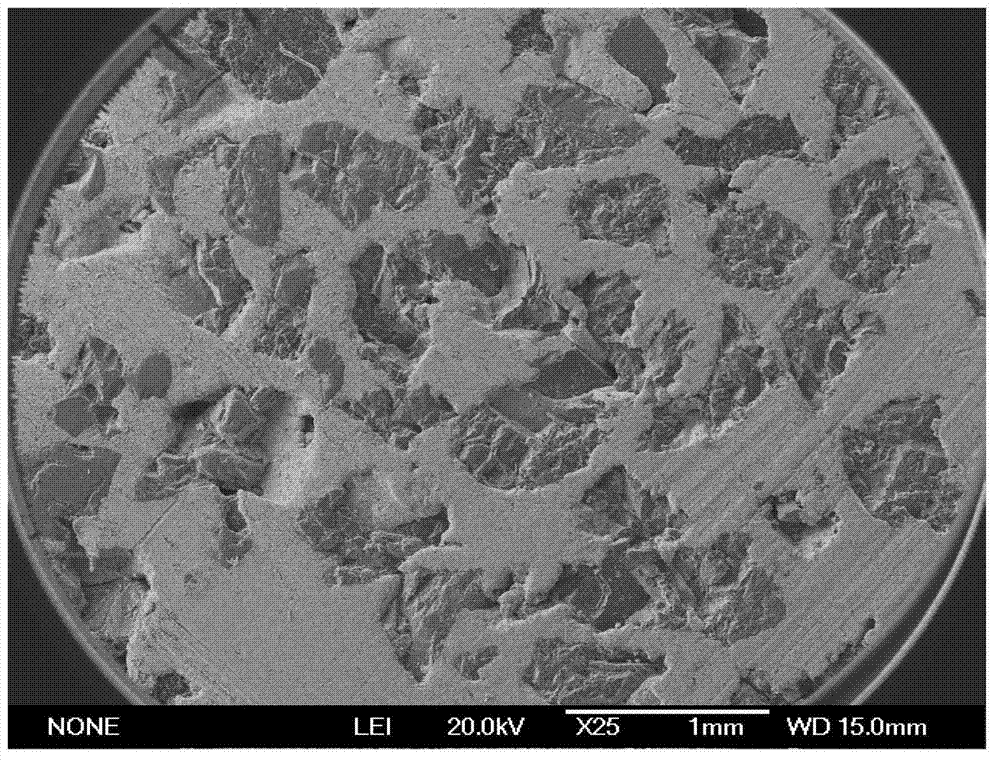

Preparation method for SiC and graphite hybrid reinforced copper-based surface composite material

InactiveCN102787253ASolve the problem that thinner is not conducive to the preparation of bulky large materialsSolve the problem that thinness is not conducive to the preparation of bulky large materialsFoundry mouldsMoulding machine componentsSodium fluorideInterfacial bonding

The invention discloses a preparation method for a SiC and graphite hybrid reinforced copper-based surface composite material. The method comprises the following steps: mixing SiC particles with graphite particles after pretreatment of the SiC particles, adding a binder, boric acid and sodium fluoride to prepare prefabricated paste, coating the prefabricated paste on the surface of foam, drying the coated foam and assembling an obtained complex with a gating system; then brushing lost foam on the paste to cast a refractory coating and roasting and drying the refractory coating at a low temperature; and putting the prepared gating system and a complex model into a sand model pouring, smelting brass after vacuumization, carrying out deoxidation with phosphor copper, using charcoal as a covering agent, accomplishing pouring at a vacuum degree after copper is thoroughly molten and reaches a set pouring temperature, maintaining vacuum infiltration for a certain period of time, carrying out cooling and then carrying out cutting and grinding to obtain the composite material. For the SiC and graphite hybrid reinforced copper-based surface composite material prepared by using the method provided in the invention, a composite layer has a smooth surface, reinforced particles are uniformly distributed, thickness of the composite layer can reach 2 to 2.5 mm, interfacial bonding of the composite layer and a substrate is good, and no obvious agglomeration occurs.

Owner:XIAN UNIV OF TECH

Cold core machine pickup device and cold core machine pickup method

InactiveCN104815968AReduce labor intensityImprove production safetyMoulding machine componentsMoulding machinesControl systemEngineering

Owner:KOLBENSCHMIDT PIERBURG SHANGHAI NONFERROUS COMPONENTS

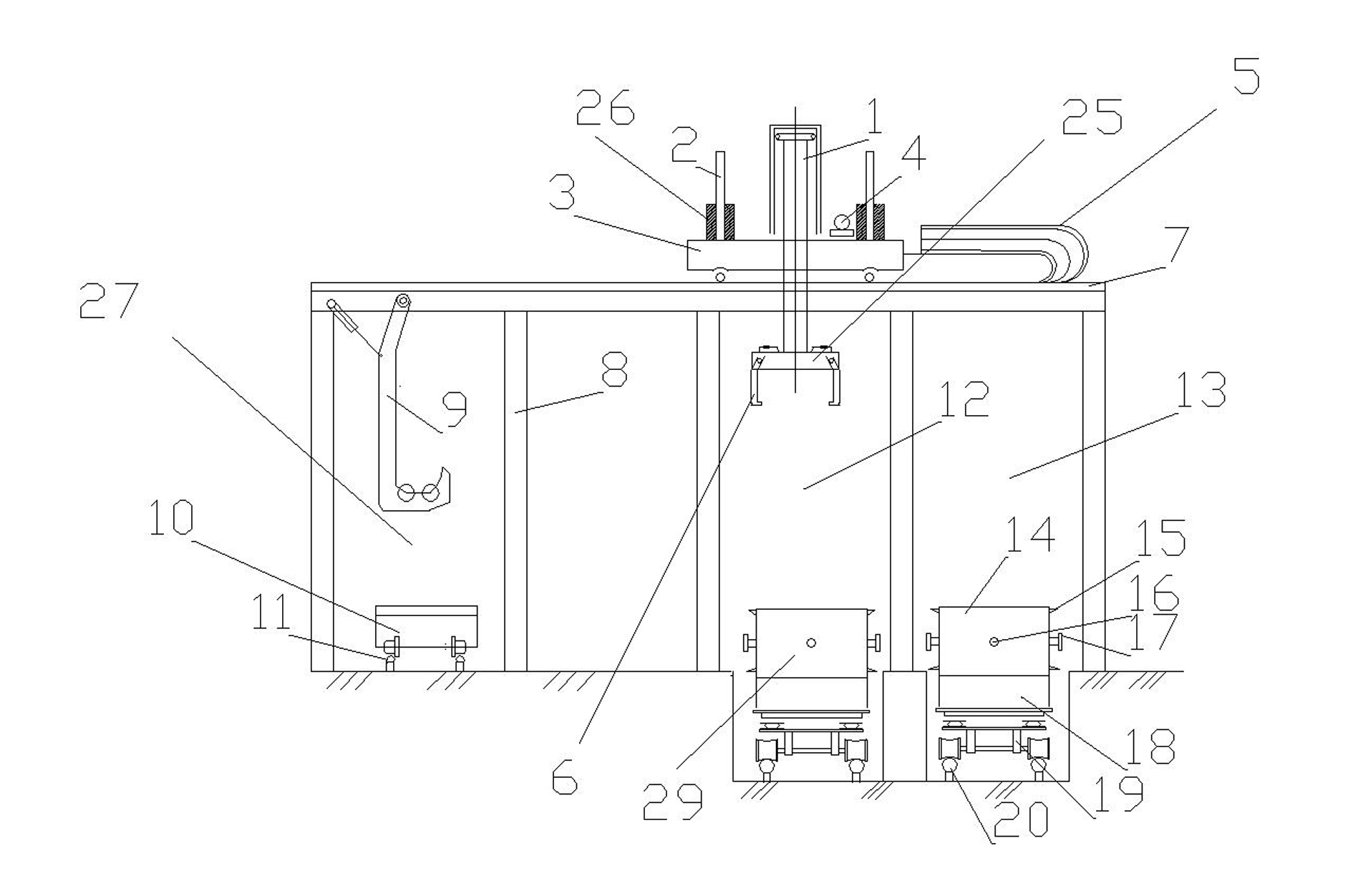

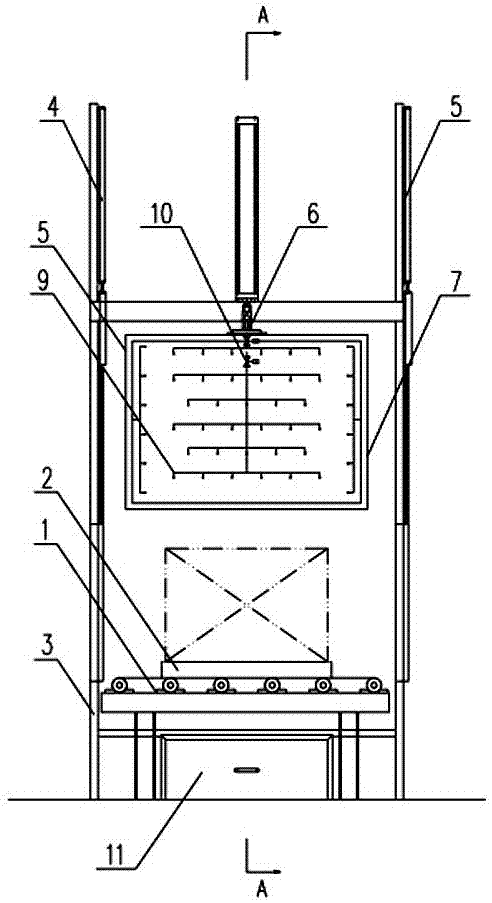

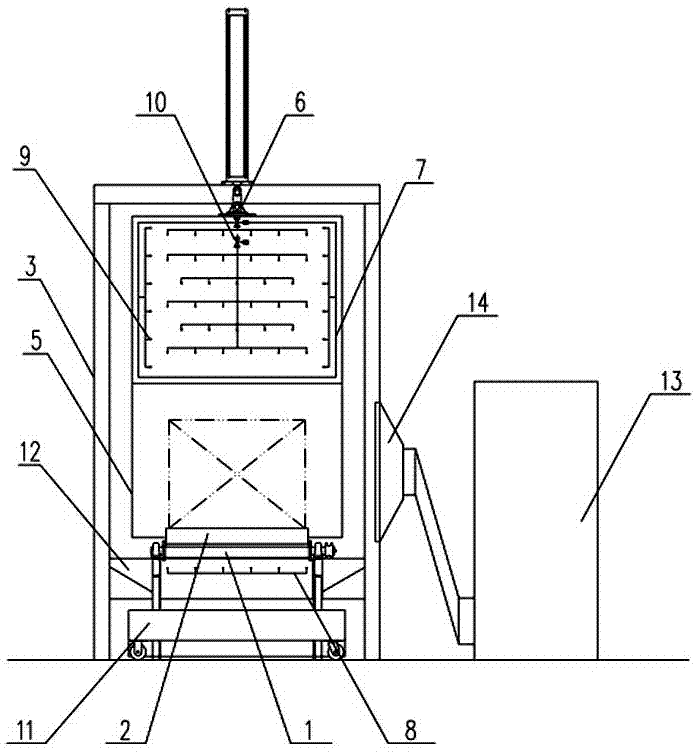

3D printing sand mold continuous type six-face automatic sand cleaning machine and sand cleaning method

InactiveCN107876710AReduced post-processing timeHigh degree of automationAdditive manufacturing apparatusMoulding machine componentsSolenoid valvePhysical well being

The invention discloses a 3D printing sand mold continuous six-sided automatic sand cleaning machine, which includes a sand cleaning machine shell straddling a roller conveyor, and the front and rear sides of the sand cleaning machine shell are respectively provided with an entrance closed door and a The exit closed door, the top of the shell of the sand cleaning machine is provided with a lift-type sand blowing cover, the middle of the shell of the sand cleaning machine is provided with a bottom blowing frame below the roller conveyor, the top surface of the sand blowing cover, the surrounding side walls and The bottom blowing frame is equipped with blowing nozzles, which are connected to the solenoid valve controlled by PLC. The bottom of the sand cleaning machine shell is equipped with a mobile sand collecting box, and the side of the sand cleaning machine shell is equipped with a dust collector. A connected vacuum hood; at the same time, a continuous six-sided automatic sand cleaning method for 3D printing sand molds is disclosed. The invention not only improves the automation of sand cleaning work, greatly shortens the post-processing time of 3D printing sand molds, but also greatly improves the working environment of the sand cleaning process, which is beneficial to the health of operators.

Owner:SIPPR ENG GROUP

Continuous production-type coated sand core shooting machine

ActiveCN109746400AReasonable structural designRealize continuous productionMoulding machine componentsMoulding machinesDrive shaftSand blasting

The invention discloses a continuous production-type coated sand core shooting machine. The continuous production-type coated sand core shooting machine comprises a machine frame, a sand shooting assembly arranged at the bottom of the machine frame, a rotating supporting assembly in sliding and communicating connection with the sand shooting assembly and a die splicing assembly in sliding contactwith the rotating supporting assembly, wherein the rotating supporting assembly comprises a rotating disk and a supporting disk movably arranged on the machine frame through the rotating disk, the rotating disk comprises a rotating bearing, an upper supporting sleeve is fixedly arranged on an outer ring of the rotating bearing, a lower supporting sleeve is fixedly arranged on an inner ring of therotating bearing, a plurality of feeding channels for conveying coated sand are evenly arranged on the supporting disk, the feeding channels are circumferentially distributed on the supporting disk, atransmission shaft is fixedly arranged at the central position of the bottom surface of the supporting disk, a driving motor is connected to the transmission shaft in a transmission mode, and the driving motor is fixedly arranged on the machine frame. The continuous production-type coated sand core shooting machine has reasonable structural design, realizes continuous coated sand blasting operation, improves the working efficiency of the core shooting machine, and greatly reduces the labor cost.

Owner:LIYANG WANSHENG CASTING

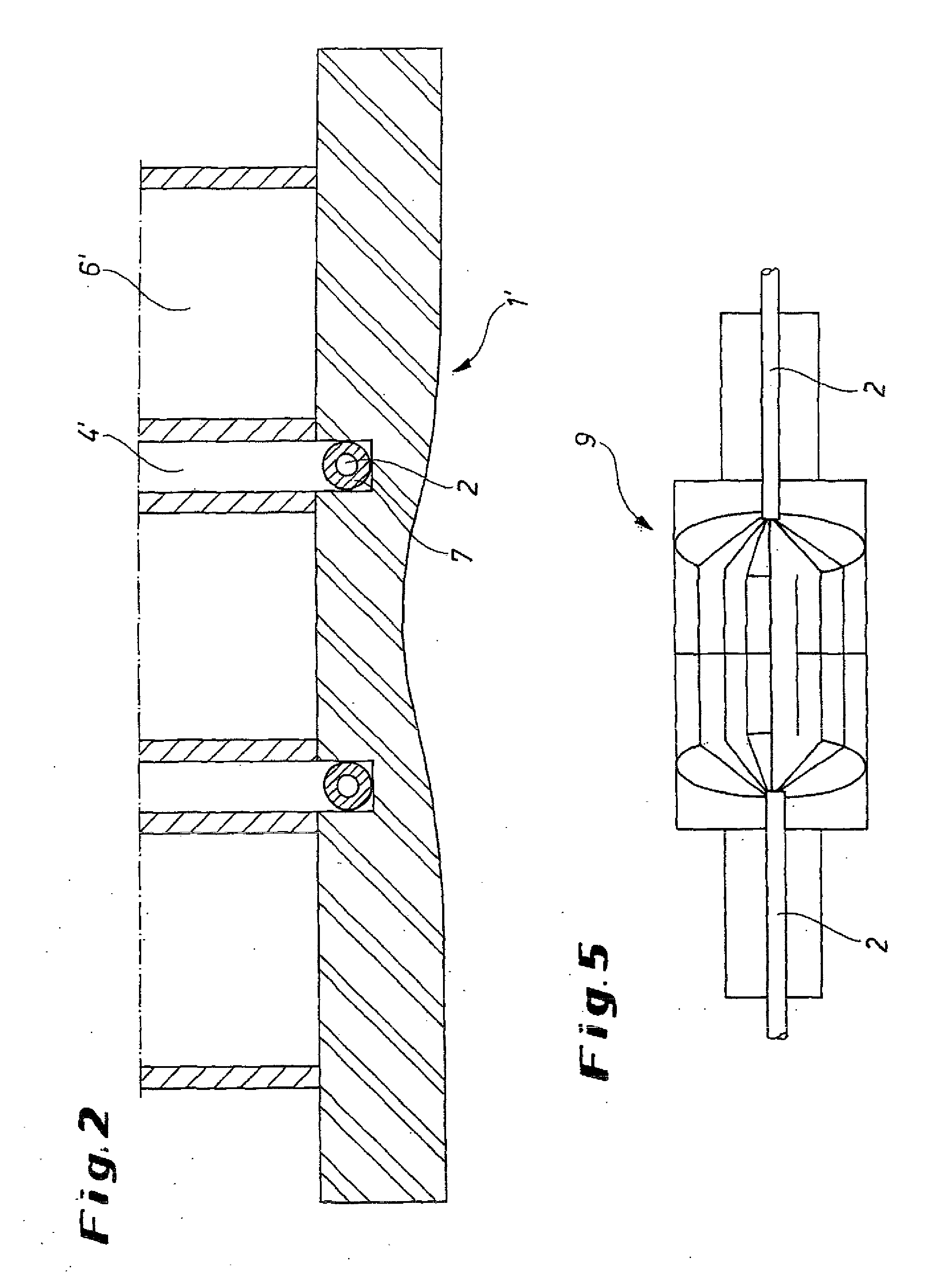

Temperature measurement in a chill mold by a fiber optic measurement method

InactiveUS20110139392A1Reduce the amount requiredWork lessCasting safety devicesThermometers using physical/chemical changesFiberImage resolution

The invention presents a method for measuring the temperature in a mold by means of a fiber-optic measurement method and a correspondingly designed mold. For this purpose, light waveguides, through which laser light is conducted, are arranged in grooves in the outside surface of the copper mold plate. The temperature at several measurement points along the measurement fiber is determined by a temperature detection system. In particular, the method makes it possible to achieve much greater local resolution of the temperature measurements than that achieved by thermocouples.

Owner:SMS DEMAG AG

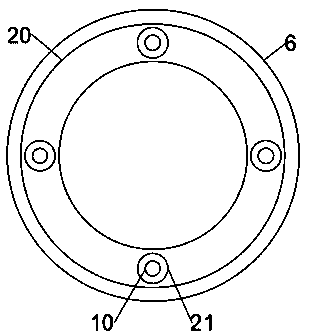

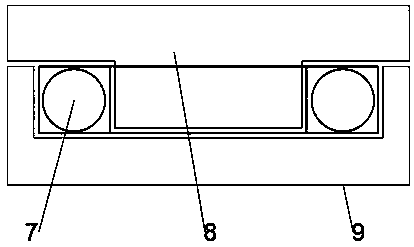

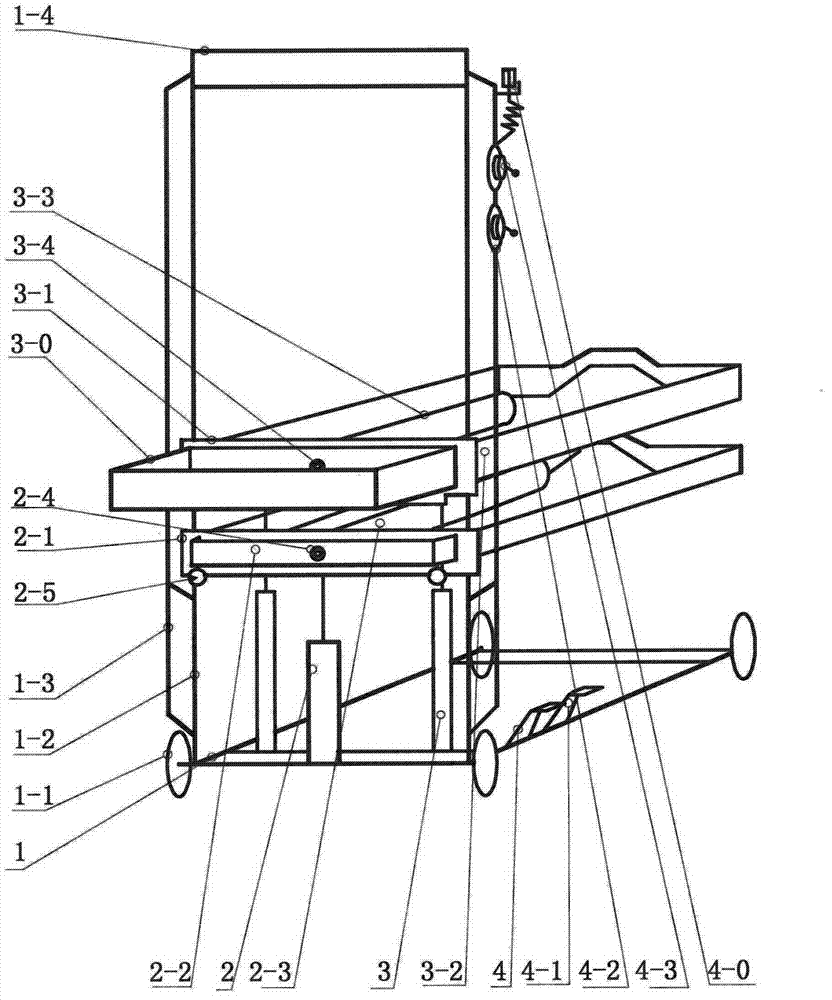

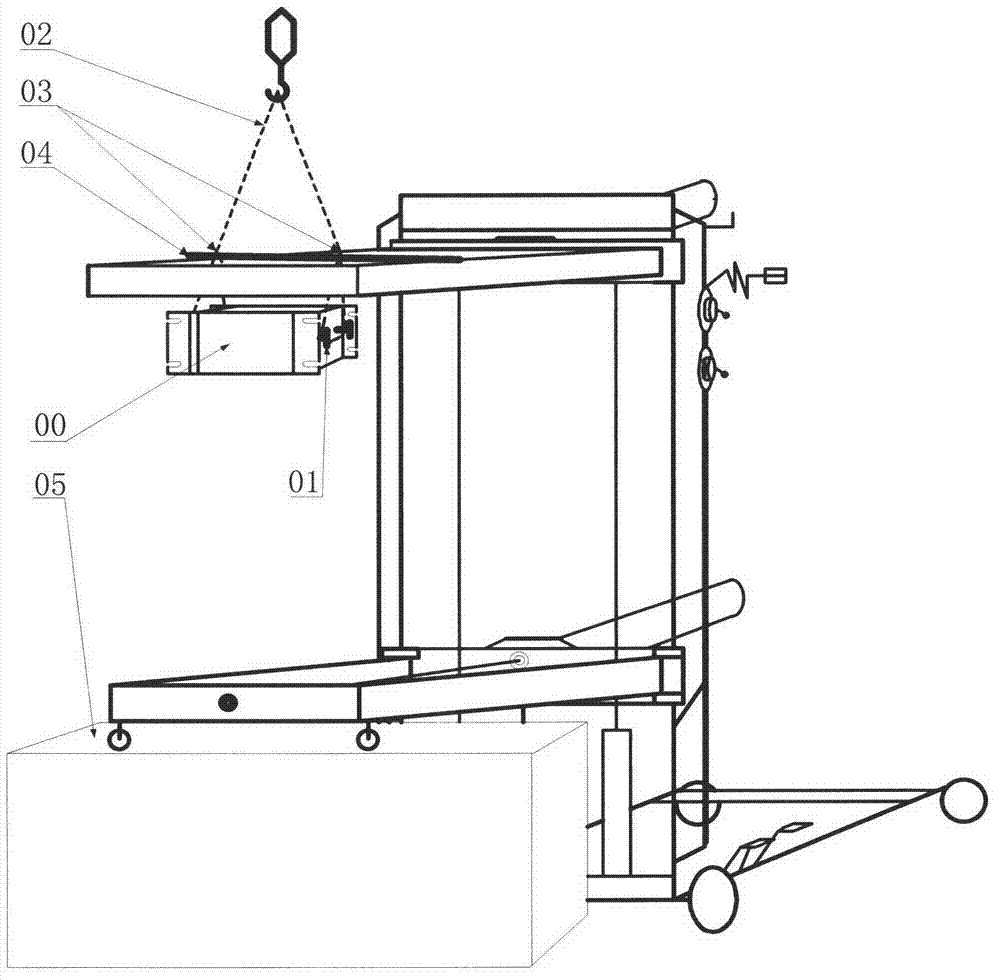

Switching trolley for mold for core making machine

The invention provides a switching trolley for a mold for a core making machine. The switching trolley comprises a frame mechanism, a stretching frame mechanism, a moving lifting frame mechanism, a control mechanism and a lifting device, wherein the frame mechanism comprises a base frame, braking wheels, a vertical guide rail, a vertical frame and a cross beam; the stretching frame mechanism comprises a stretching frame hydraulic cylinder, a stretching frame lifting frame, a stretching frame, a stretching frame cylinder and stretching frame wheels; the moving lifting frame mechanism comprises a lifting frame hydraulic cylinder, a lifting frame elevating frame, a lifting frame and a lifting frame cylinder; the control mechanism comprises a stretching frame hydraulic pedal, a lifting frame hydraulic pedal, a stretching frame flexible control valve, a lifting frame flexible control valve and a rapid air connector; and the lifting device comprises a mold lifting rod, a long mold lifting cable, a short mold lifting cable and a mold lifting pole. The switching trolley has the advantages that the stretching frame stretched from the stretching frame mechanism is inserted into a base frame platform of the core making machine, supporting points are provided for the core making machine, receiving of the mold for the lifting frame is facilitated, the mold is horizontally placed in the core making machine for positioning installation, the operation is safe, and the working efficiency is improved.

Owner:WUXI LIHU PRESSURIZE TECH CO LTD

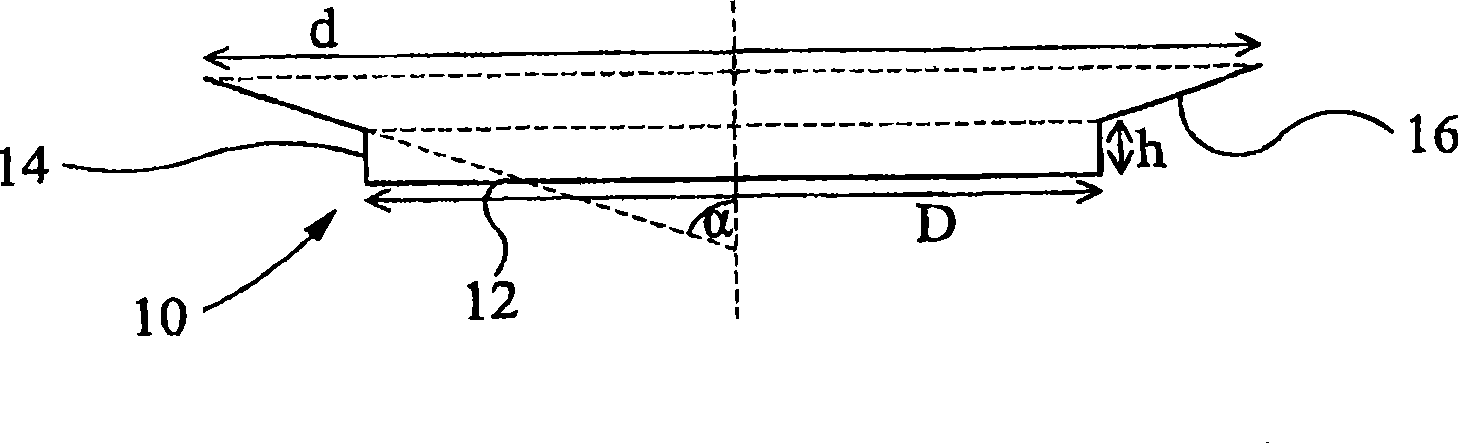

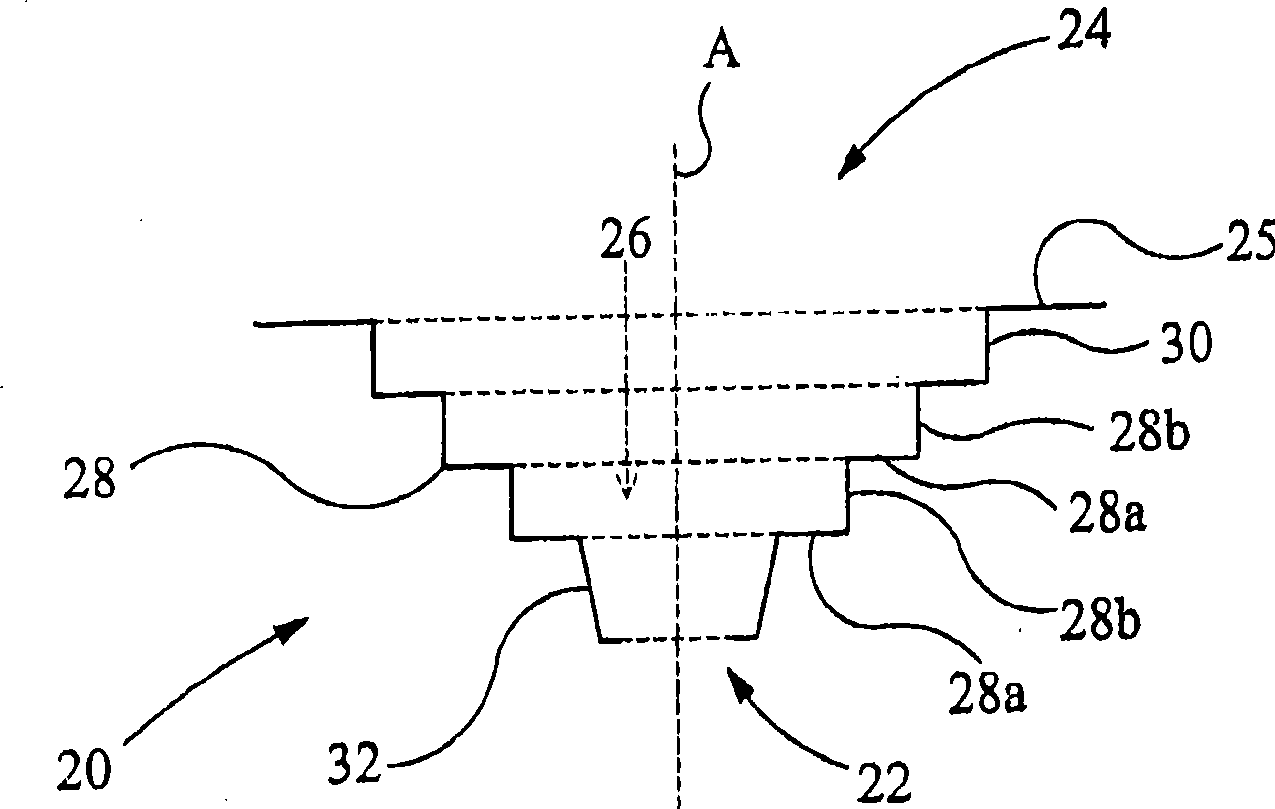

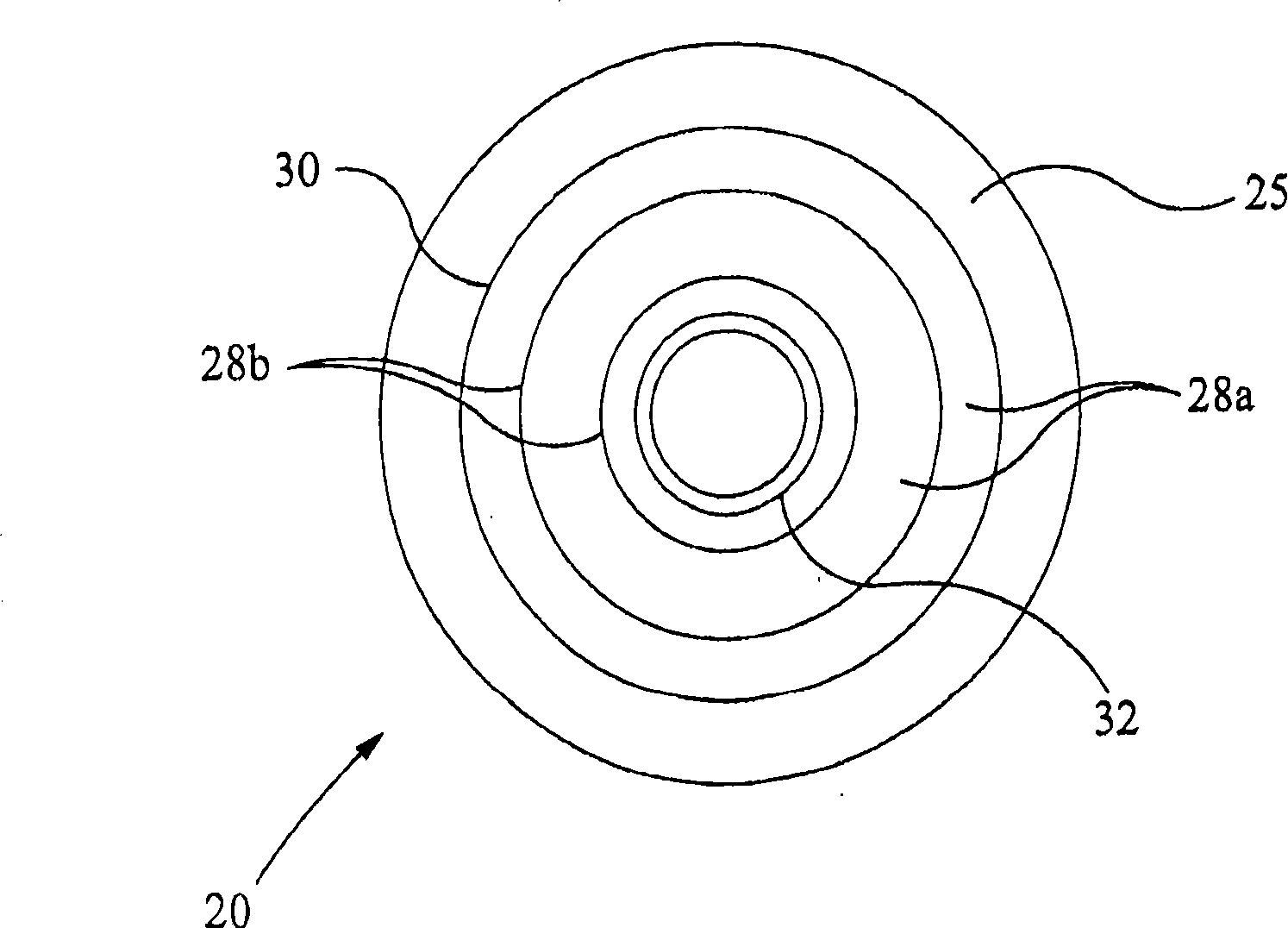

Feeder element for metal casting

The present invention provides a feeder component used in metal casting, which comprises the following components: (i) a first end which is used for being installed on the molded foundry mould; (ii) an opposite second end which is used for accommodating the feeder sleeve; and (iii) a hole which is restrained by the step-shaped side wall and is positioned between the first end and the second end. The feeder component is condensable in using thereby reducing the distance between the first end and the second end, wherein the step-shaped side wall is provided with a first side wall area and a second side wall area. The first side wall area limits the second end of component and an installation surface (54) which is used for the feeder sleeve in using. The first side wall area inclines with an angle less than 90 DEG relatively to the axial line of hole. The second side wall area is adjacent with the first side wall area, and inclines parallelly with the axial line of hole or with an angle different from the first side wall area relatively to the axial line of hole thereby limiting step in the side wall. The feeder component provides an improvement of component disclosed in the patent document WO 2005 / 051568.

Owner:FOSECO INT LTD

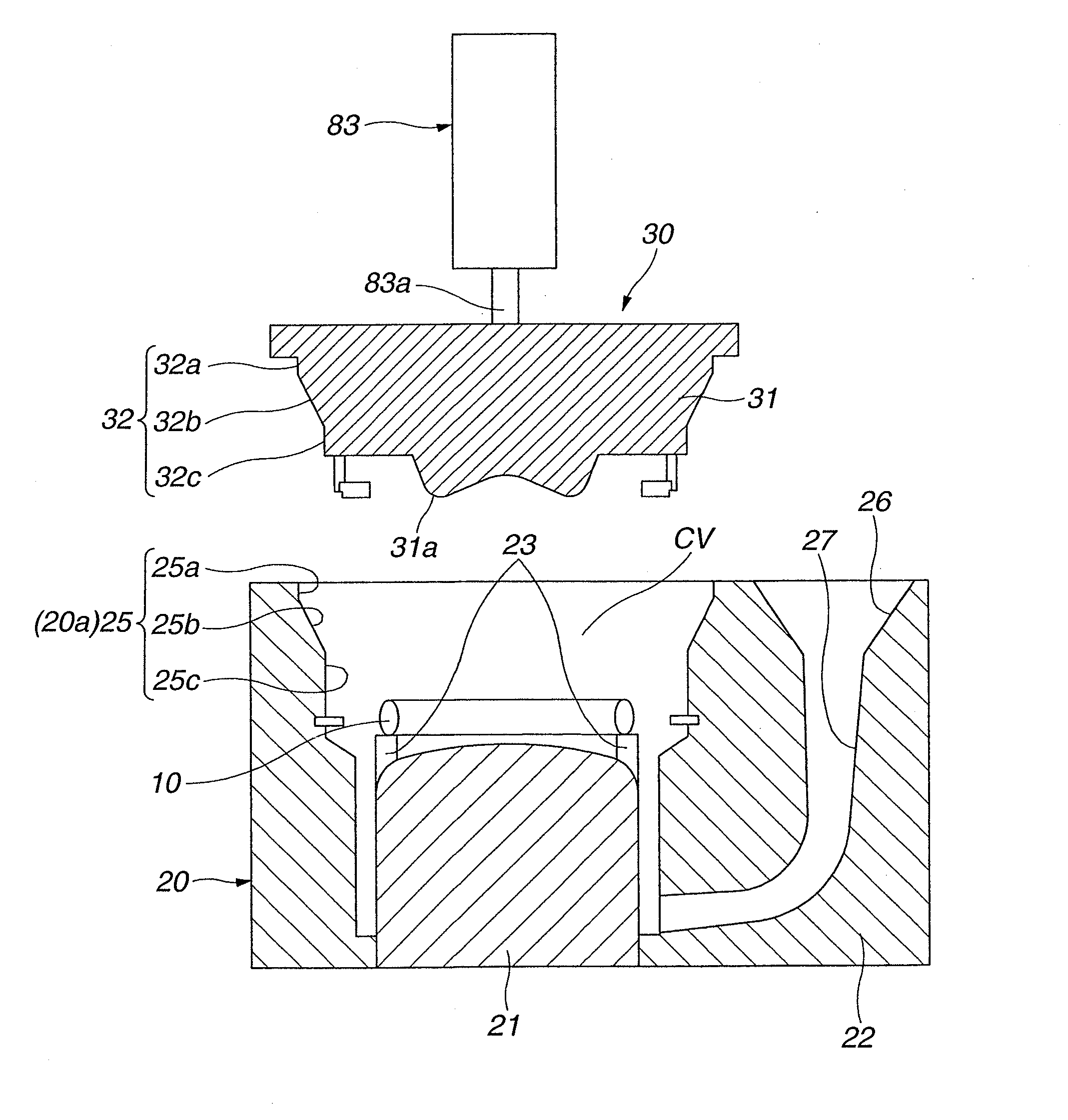

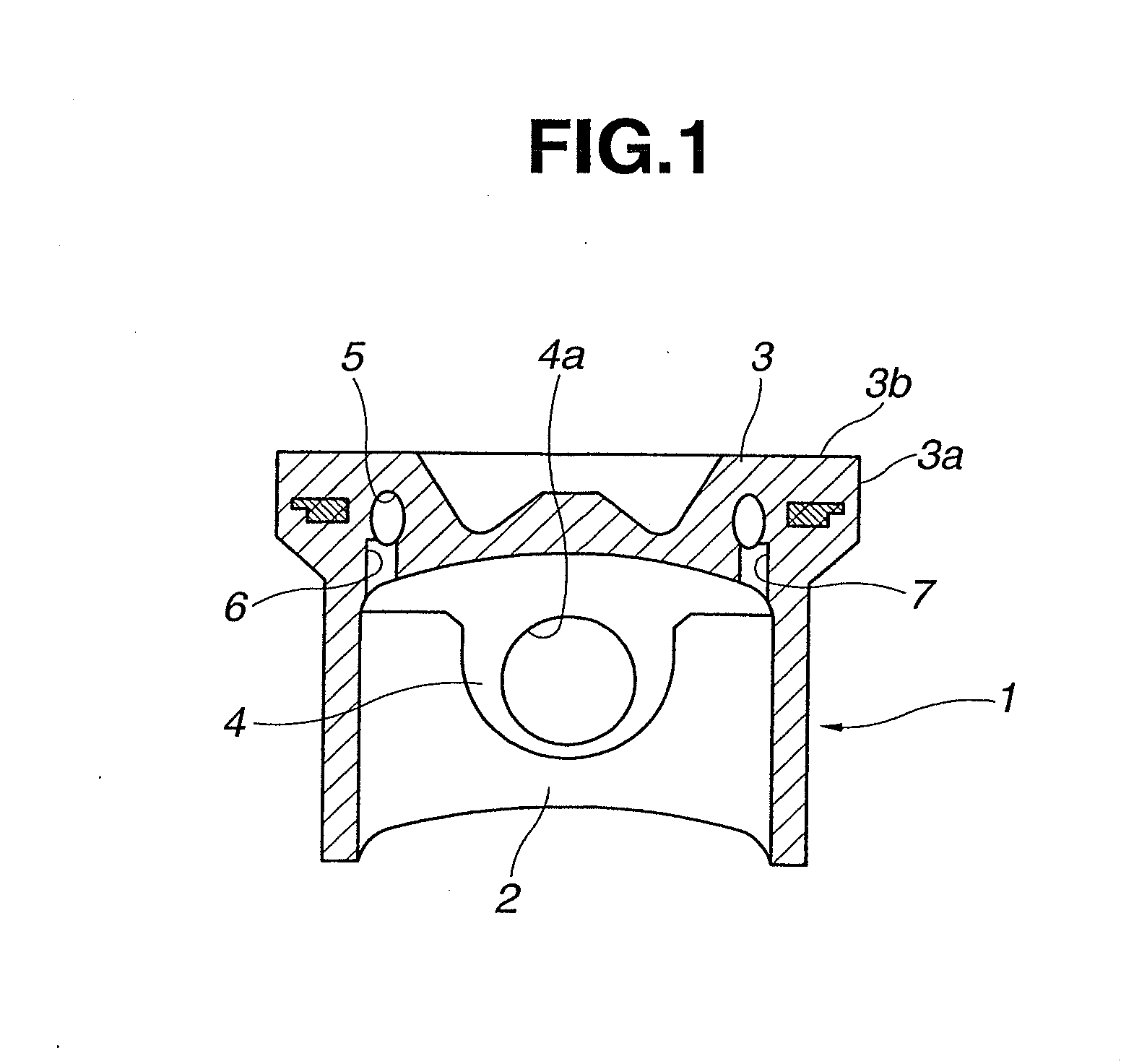

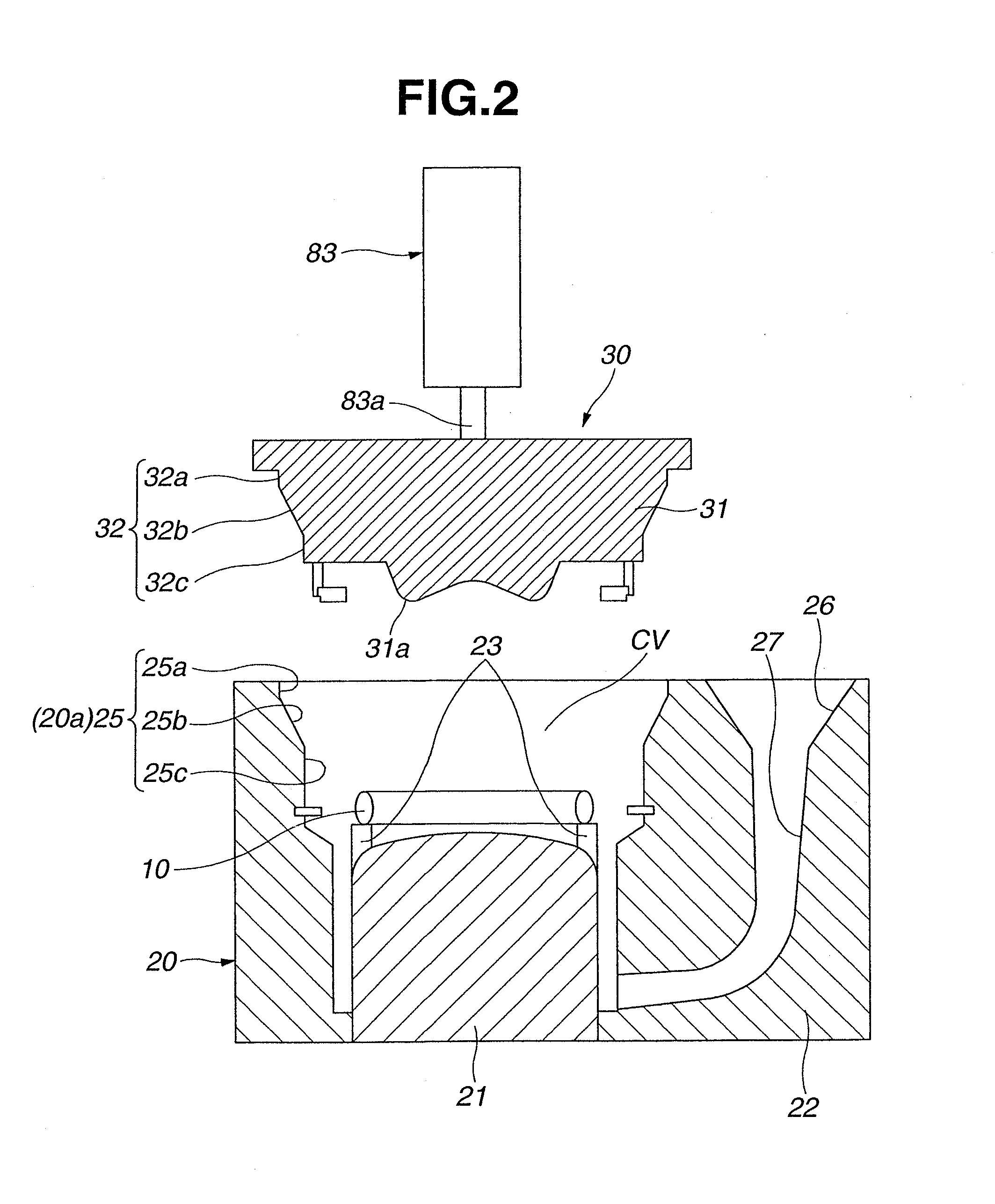

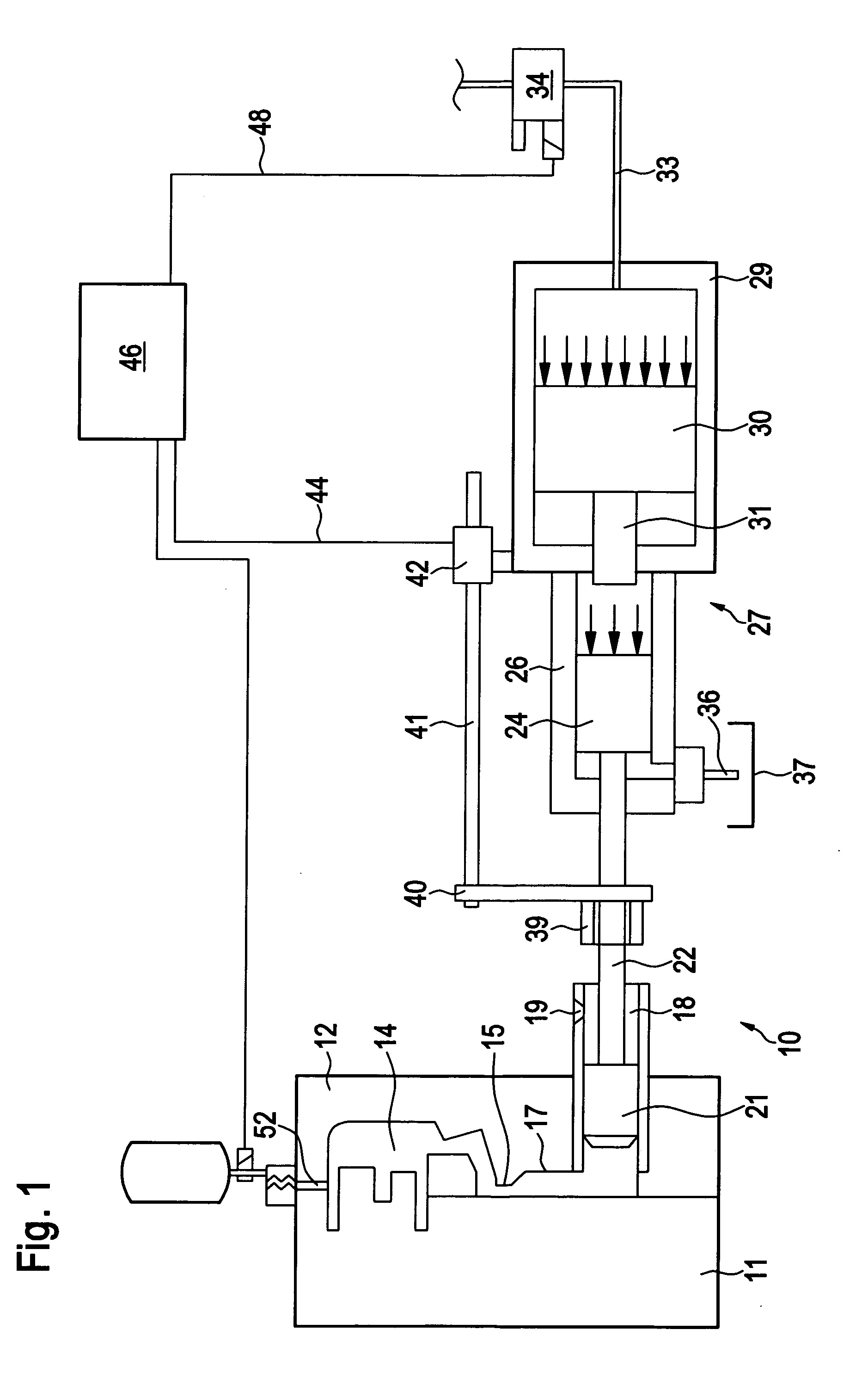

Apparatus and Method for Producing Piston for Internal Combustion Engine

ActiveUS20130277005A1Easy to operateGood insertion and engagementFoundry mouldsCombustion enginesInternal combustion engineCooling channel

An apparatus for producing a piston for an internal combustion engine by casting, the piston having a cooling channel therein, the apparatus including a fixed die with an upwardly opened cavity in which a core serving to form the cooling channel is to be disposed, a moveable die moveably disposed relative to the fixed die in a vertical direction and including a predetermined engaging portion, a guide die including an engaging portion engageable with the fixed die and having a same shape as that of the engaging portion of the moveable die, and a core retaining mechanism disposed in the guide die to retain the core in a predetermined position.

Owner:HITACHI ASTEMO LTD

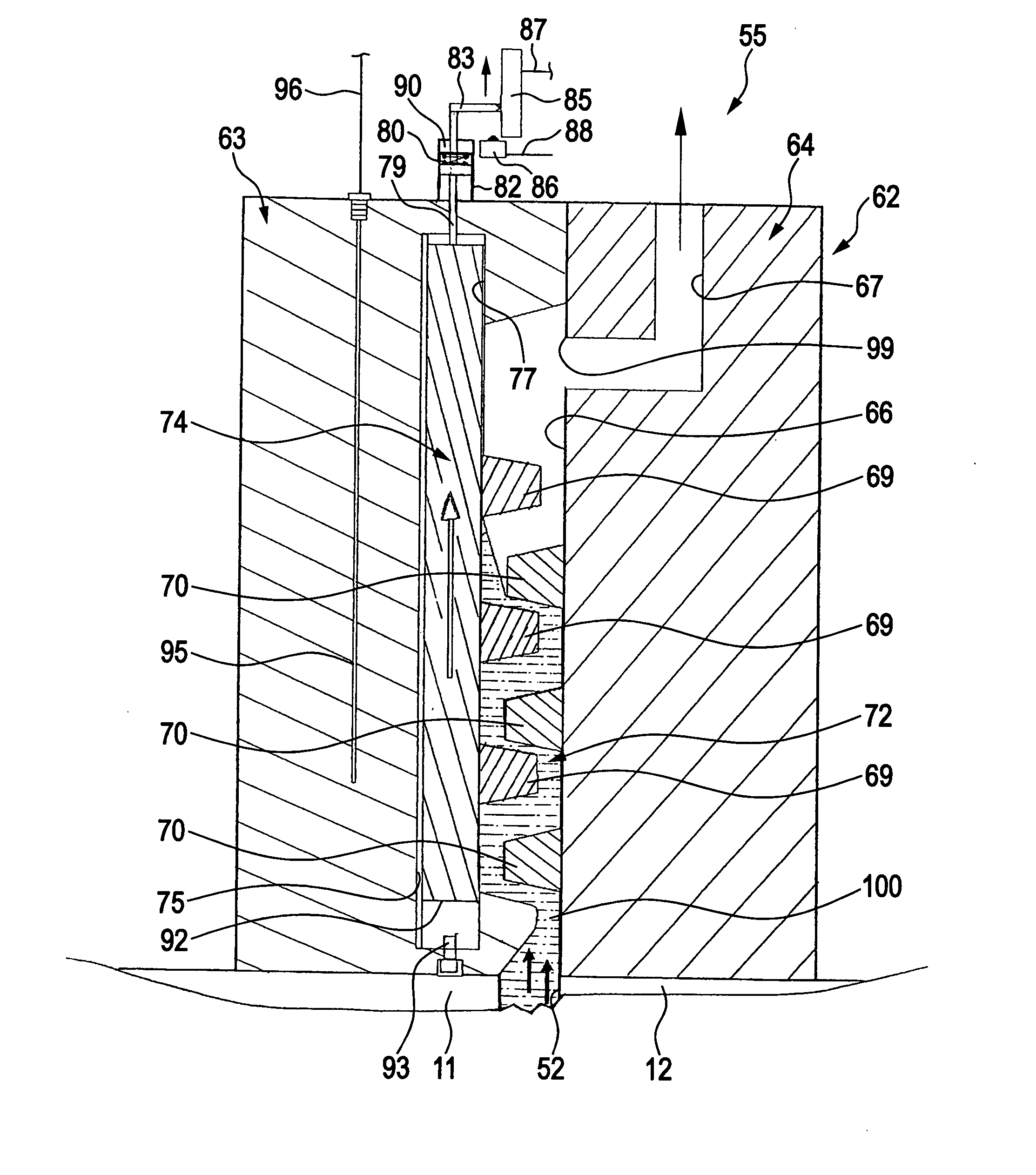

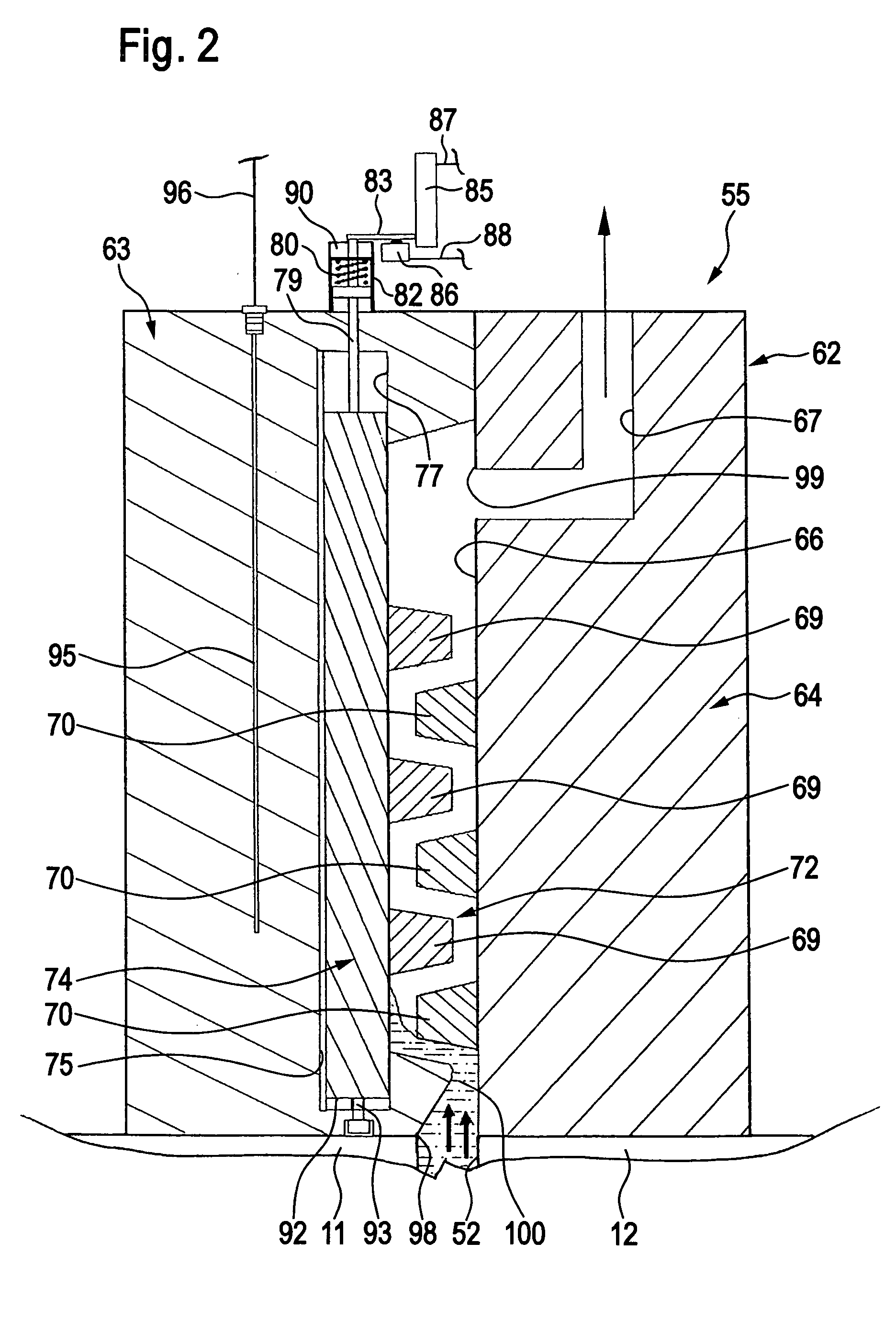

Venting unit for a Die Casting device

InactiveUS20100276107A1Reduce traffic lossLarge flow cross sectionFoundry mouldsMoulding machine componentsDie castingProduct gas

The invention relates to a venting unit for a die casting device which has a mold cavity that is adapted to be filled with liquid casting material and a gas suction device that is connected to the mold cavity for extracting gas from the mold cavity by suction, the venting unit comprising a flow labyrinth, the inlet of which is adapted to be connected to the mold cavity and the outlet of which is adapted to be connected to the gas suction device. In order to develop the venting unit in such a way that it makes improved evacuation of the mold cavity possible without the risk that liquid casting material can escape from the venting unit, it is proposed according to the invention that the flow cross-section of the flow labyrinth is variable. Furthermore, a die casting device with a venting unit of this kind is proposed.

Owner:ELECTRONICS GMBH VERTRIEB ELEKTRONISCHER GERATE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com