Preparation method for SiC and graphite hybrid reinforced copper-based surface composite material

A surface composite material, copper-based technology, applied in the direction of manufacturing tools, molding machine parts, casting molding equipment, etc., can solve the problems of unfavorable large-scale material preparation, thin composite layer, etc., to achieve low production cost and design freedom Large, simple and flexible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

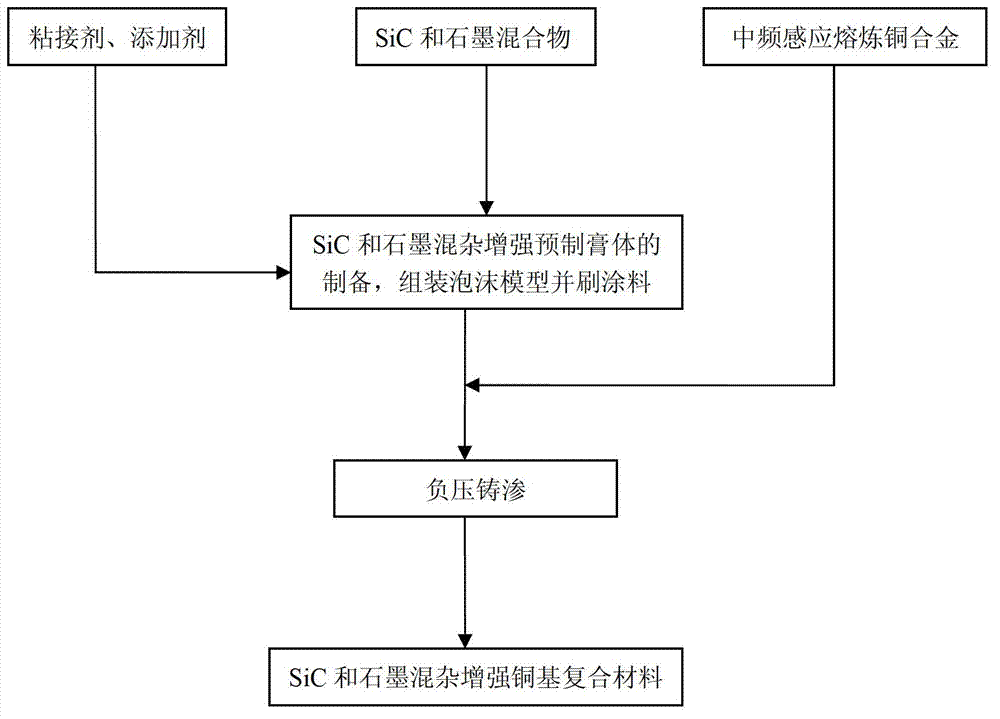

[0031] The invention provides a method for preparing a SiC and graphite hybrid reinforced copper-based surface composite material. The preparation method of SiC and graphite hybrid reinforced copper-based surface composite material is prepared by using the lost pattern negative pressure casting infiltration method, which is used to solve the problem of traditional copper alloy wear resistance. The problem of insufficiency. Such as figure 1 shown, specifically follow the steps below,

[0032] step 1

[0033] Surface pretreatment of SiC particles: put SiC particles in clean water, put them in an ultrasonic cleaner for 10-15 minutes to remove the dust doped in SiC particles; then place the washed SiC particles in a SHD electric drying oven , bake at a temperature of 200-300°C for one hour to remove volatile pollutants adsorbed on the surface of SiC particles; after SiC particles drop to room temperature, put SiC particles in acetone for ultrasonic cleaning for 10-15 minutes, re...

Embodiment 1

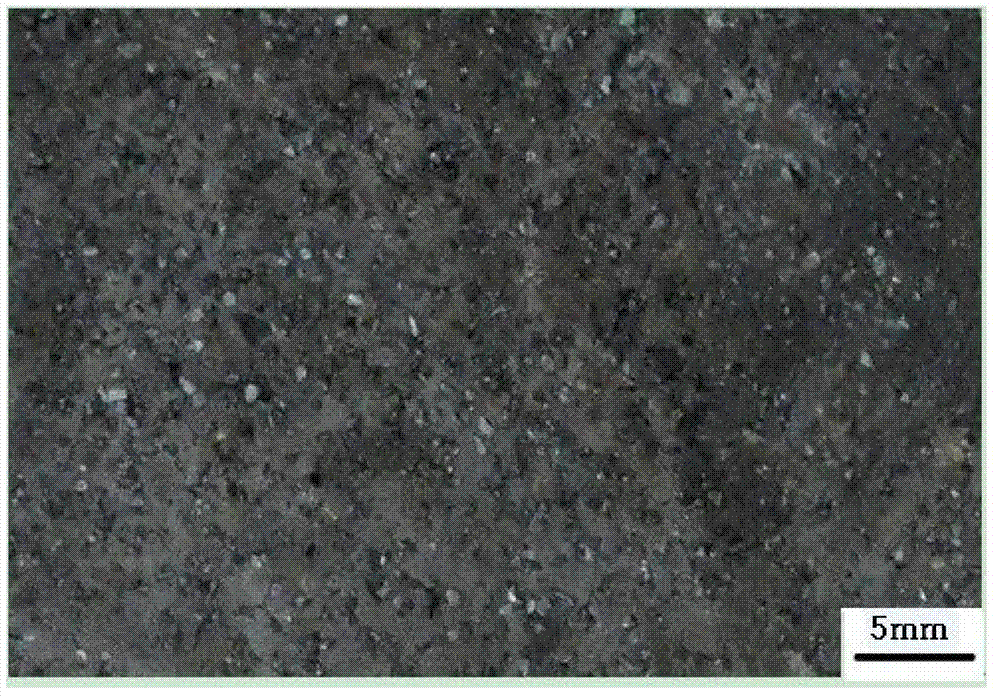

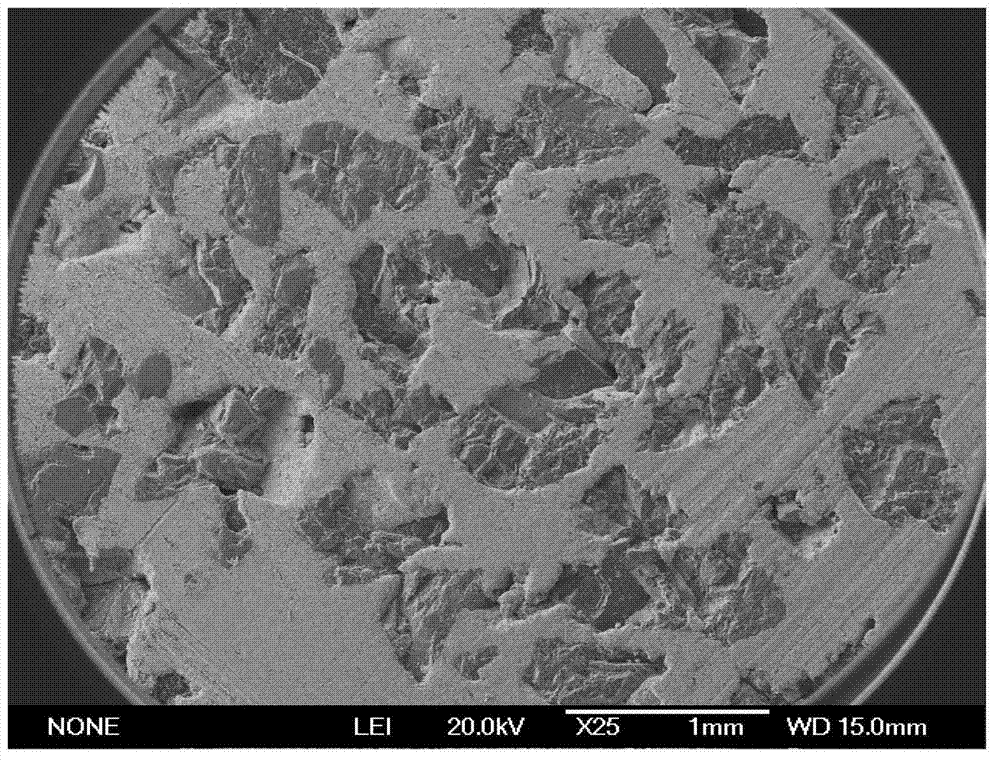

[0042] Select 600μm SiC particles for surface pretreatment. The treatment method is: put SiC particles in clean water, put them in an ultrasonic cleaner for cleaning for 10-15 minutes, and rough wash to remove the dust doped in SiC particles; then wash the SiC particles The particles are placed in an SHD electric drying oven and baked at 200-300°C for 1 hour to remove the volatile pollutants adsorbed on the surface of the particles; when the temperature is lowered to room temperature, put the SiC particles in acetone for ultrasonic cleaning for 10-15 minutes, repeat 2~3 times, using the principle of similar compatibility of organic solvents to wash off impurities such as residual organic matter on the surface of SiC particles, and then drying at 120~150°C. A mixture of 90% surface-treated 600 μm SiC particles, 4% 425 μm graphite particles, 2% boric acid, 2% sodium fluoride, 2% clay and 20% water in the total mass of the mixture was stirred evenly , to prepare the required pref...

Embodiment 2

[0044] Select 400μm SiC particles for surface pretreatment. The treatment method is: put SiC particles in clean water, put them in an ultrasonic cleaner for cleaning for 10-15 minutes, and rough wash to remove the dust doped in SiC particles; then wash the SiC particles The particles are placed in an SHD electric drying oven, and baked at 200-300°C for about 1 hour to remove volatile pollutants adsorbed on the surface of the particles; when the temperature is lowered to room temperature, put the SiC particles in acetone for ultrasonic cleaning for 10-15 minutes, Repeat 2 to 3 times, use the principle of similar compatibility of organic solvents to wash off impurities such as residual organic matter on the surface of SiC particles, and then dry at 120~150°C. Mix surface-treated 400 μm SiC particles with a mass fraction of 88%, 6% 450 μm graphite particles, 2% boric acid, 2% sodium fluoride, and 2% clay, and add 25% water to the total mass of the mixture, Stir evenly to prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com