Preparation of upper conversion fluorescent nano particle

A technology of fluorescent nanoparticles and acid salts, which is applied in the field of materials, can solve the problems of increased particle size of nanoparticles and unfavorable biomolecular labeling applications, and achieve the effects of controllable crystal form, less demanding synthesis conditions, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

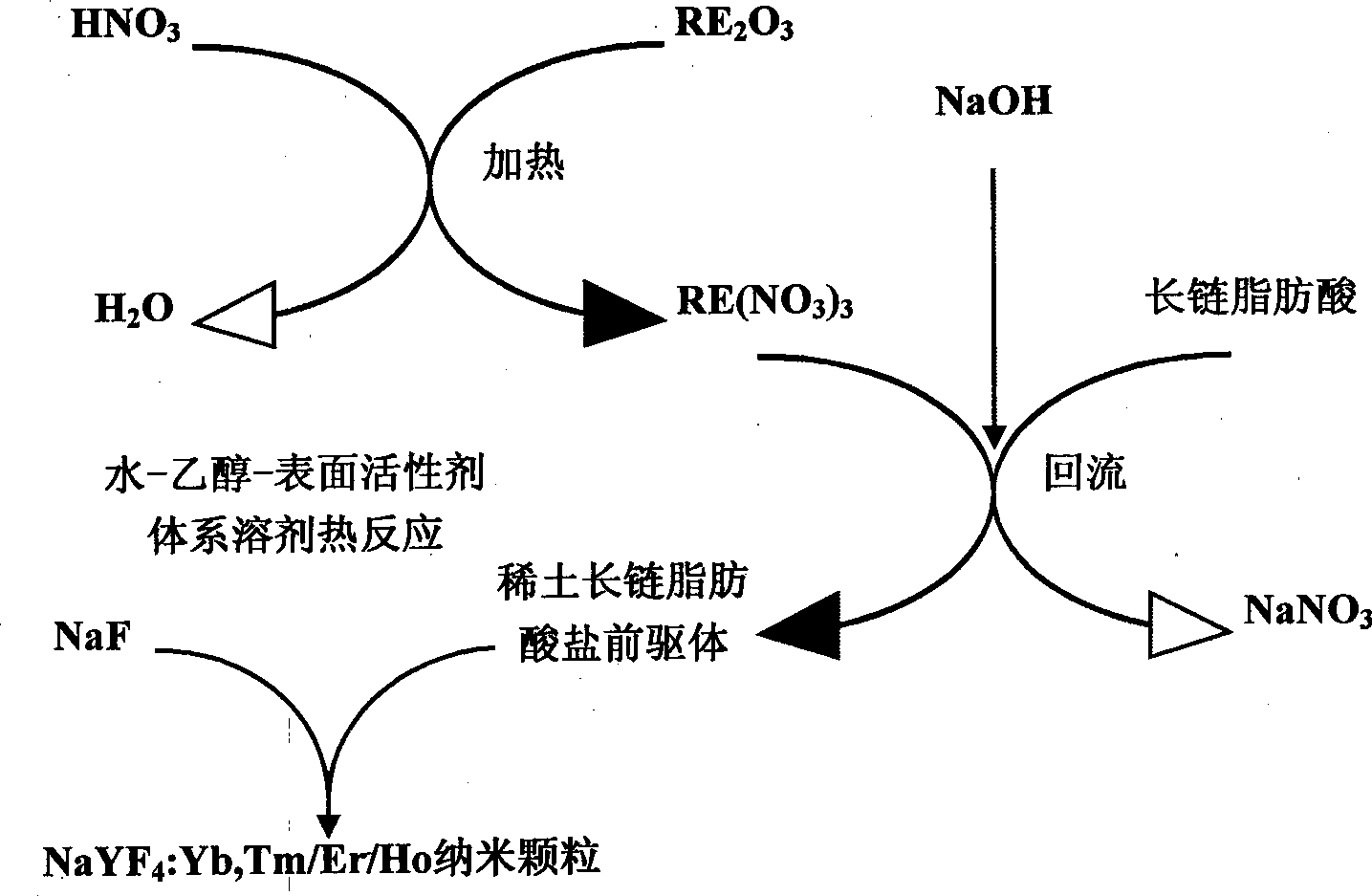

Method used

Image

Examples

Embodiment 1

[0045] Weigh 1.1291g (5mmol) of yttrium oxide, add concentrated nitric acid solution to it and heat to dissolve the yttrium oxide, and volatilize the remaining concentrated nitric acid to obtain rare earth nitrate powder. Dissolve the powder with 20 mL of ethanol to obtain an ethanol solution of yttrium nitrate.

[0046] Yttrium nitrate ethanol solution, 8.5344g (30mmol) stearic acid and 40mL ethanol are placed in a three-necked flask, reflux reaction under stirring conditions, the reaction temperature is 78 ° C, and the stirring speed is 300rpm, and the reaction is until the stearic acid is completely dissolved. Sodium hydroxide solution was slowly added dropwise to the reaction mixture until the pH of the reaction system rose to 7, and the stirring and reflux reaction was continued for 40 min. The reacted material was filtered under reduced pressure and washed twice with water, and dried to remove water to obtain the yttrium precursor.

[0047] Weigh 1.9704g (5mmol) of ytte...

Embodiment 2

[0052] The preparation method of yttrium precursor is with embodiment 1; The preparation method of ytterbium precursor is with embodiment 1; After the fatty acid was dissolved, sodium hydroxide was added to control the pH value of the solution to 6, and the reflux stirring was continued for 30 min.

[0053] Add 0.2100g (5mmol) sodium fluoride and 4mL oleic acid (surfactant), 0.78mmol yttrium-containing precursor, 0.20mmol ytterbium-containing precursor, 0.02mmol erbium-containing precursor in the mixed solvent of 10mL water and 15mL ethanol, Stir under ultrasonic conditions to form a homogeneous mixture without massive solids; the frequency of ultrasonic waves is 40-100kHz.

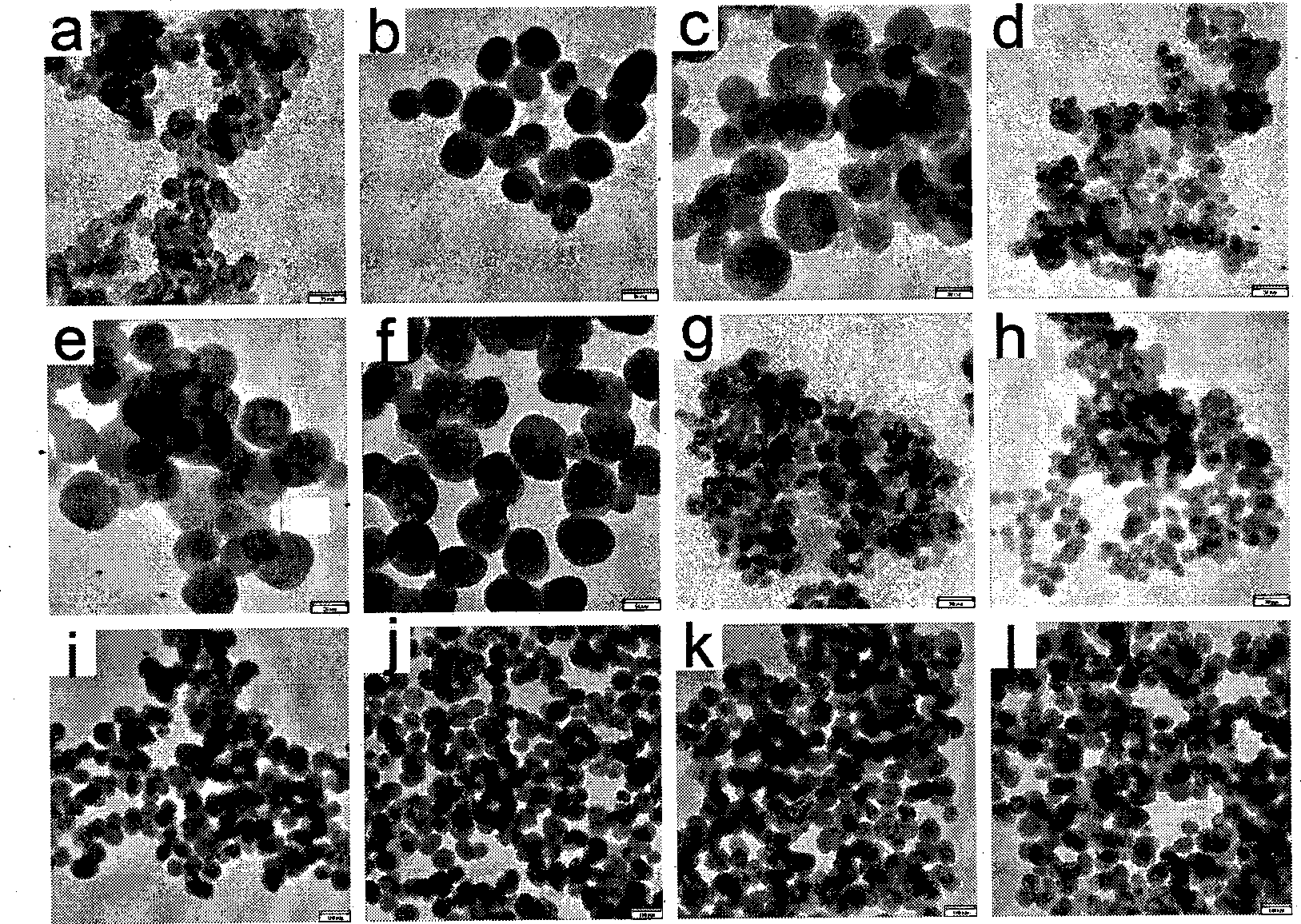

[0054] Transfer 4 batches of the mixture prepared by the above method to a hydrothermal synthesis reactor, set the reaction temperature at 100°C, 150°C and 200°C respectively, and react at constant temperature for 8h and 24h under closed conditions. Each batch of materials after the reaction finishes pre...

Embodiment 3

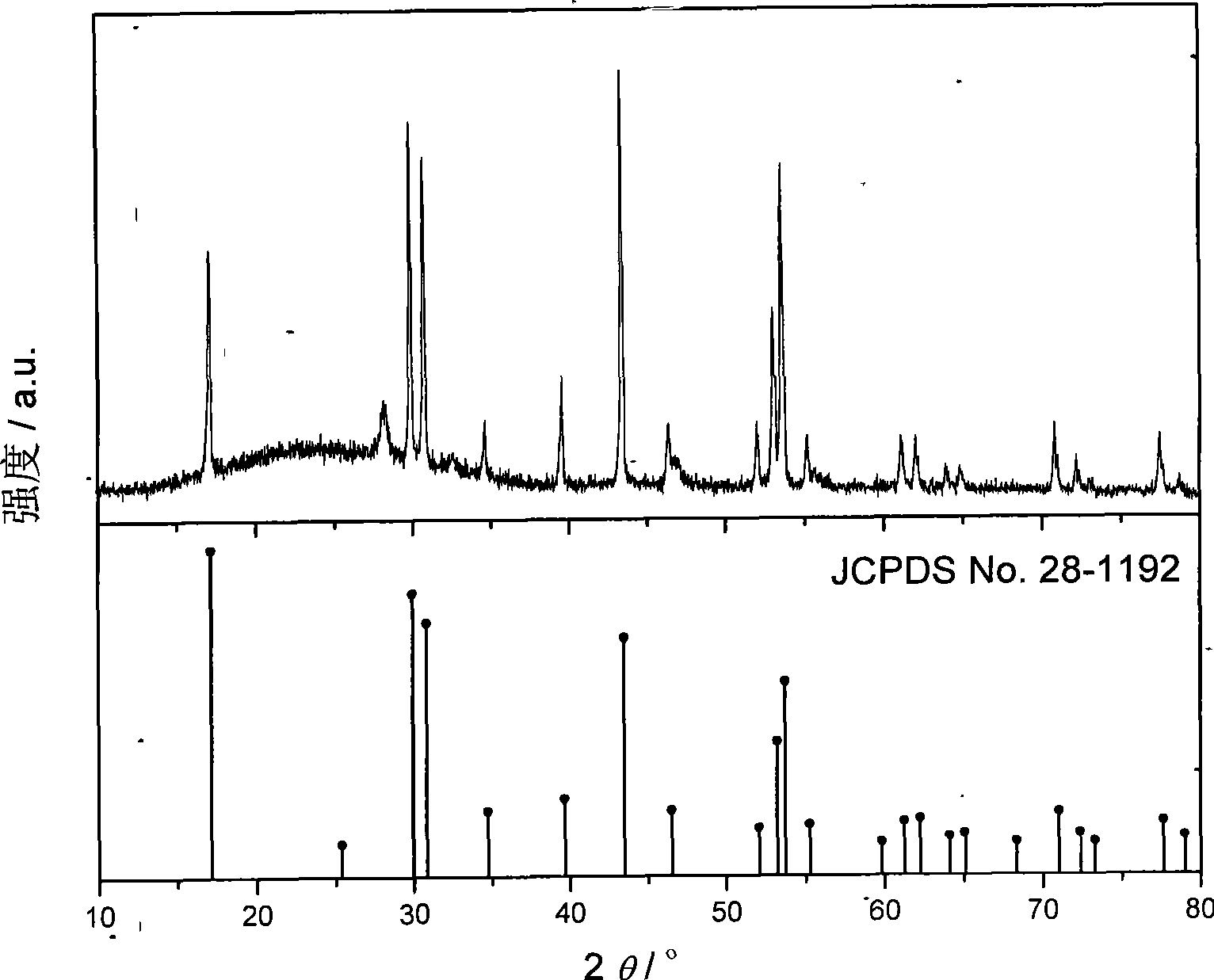

[0061] Palmitic acid was used instead of stearic acid in an amount of 7.6929 g (3.0 mmol); the yttrium precursor, the ytterbium precursor and the erbium precursor were prepared according to the method described in Example 1. And prepare NaY by the method described in Example 1 0.78 f 4 :Yb 0.20 , Er 0.02 Nanoparticles, the difference is that the reaction temperature in water and the reactor is 200°C, and the reaction time is 24h, to obtain NaY 0.78 f 4 :Yb 0.20 , Er 0.02 Up-conversion fluorescent nanoparticle 6# product.

[0062] Myristic acid was used instead of stearic acid in an amount of 6.8514 g (30 mmol); the method described in Example 1 was used to prepare yttrium precursor, ytterbium precursor and erbium precursor. And prepare NaY by the method described in Example 1 0.78 f 4 :Yb 0.20 , Er 0.02 Nanoparticles, the difference is that the reaction temperature in water and the reactor is 100°C, and the reaction time is 24h, to obtain NaY 0.78 f 4 :Yb 0.20 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com