Preparation method of catalyst for producing methyl methacrylate and application thereof

A methyl methacrylate and catalyst technology, which is applied in chemical instruments and methods, aldehyde redox preparation, physical/chemical process catalysts, etc., can solve the problem of unsatisfactory methacrolein MMA selectivity, harsh catalytic conditions, and impact on products Quality and other issues, to achieve the effect of a wide range of options, convenient operation, and low load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

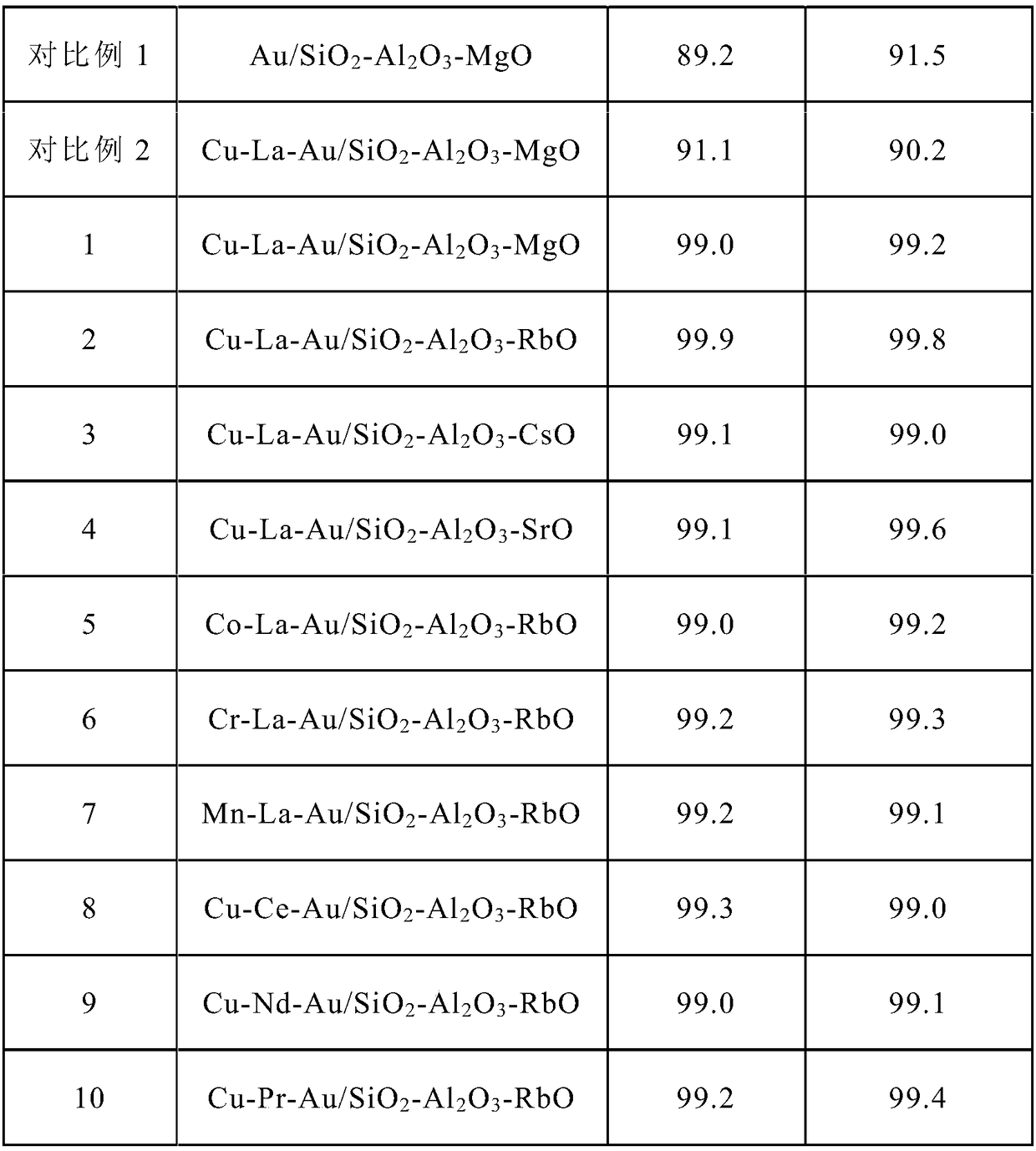

Embodiment 1

[0030] The preparation and molding conditions of the carrier are the same as in Comparative Example 1.

[0031] Under stirring condition, 250g chloroauric acid and 250g sodium citrate and 60L deionized water are fully mixed to obtain stable, uniform and single gold sol with a higher dispersion state, and 260g polyvinylpyrrolidone (PVP, PVP, Molecular weight 8000-10000), then add 935g lanthanum nitrate, 1170g copper nitrate successively, add 30kg above-mentioned prepared SiO after completely dissolving 2 -Al 2 o 3 -MgO powder, continue to stir and slowly raise the temperature to 75°C, continue to stir at this temperature for 14h and then cool down to room temperature, pour out the upper layer liquid after standing, wash the lower layer of precipitate with deionized water until no chloride ions are detected in the solution, 100°C After drying for 24 hours, bake in air at 300°C for 24 hours to obtain the catalyst Cu-La-Au / SiO 2 -Al 2 o 3 -MgO. The mass percentages of La, Ce...

Embodiment 2

[0033] The carrier molding conditions are the same as in Comparative Example 1, wherein magnesium nitrate is replaced by rubidium nitrate, and spherical SiO with a particle size of about 70 μm is obtained. 2 -Al 2 o 3 - RbO powder, and then roast the powder at 700° C. in an air atmosphere for 6 hours, and cool it down to room temperature for use.

[0034] Catalyst preparation condition is the same as embodiment 1, obtains catalyst Cu-La-Au / SiO 2 -Al 2 o 3 -RbO, wherein the mass percentages of La, Ce, and Au in the catalyst are 1%, 1%, and 0.48%, respectively.

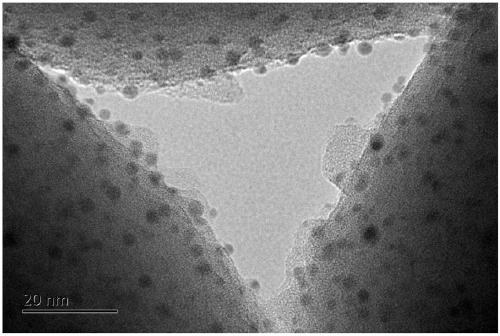

[0035] like figure 1 , is the electron micrograph of the catalyst prepared in this example. It can be seen from the figure that the particles of Au are uniform, highly dispersed on the surface of the carrier, and the particle size is 2nm; the particles of La and Ce are slightly larger than Au, but uniformly distributed, and the particle size is Around 4nm.

Embodiment 3

[0037] The carrier molding conditions are the same as in Comparative Example 1, wherein magnesium nitrate is replaced with cesium nitrate to obtain spherical SiO with a particle size of about 70 μm 2 -Al 2 o 3 -CsO powder, and then calcined the powder at 700° C. in an air atmosphere for 6 hours, and cooled it down to room temperature for use.

[0038] Catalyst preparation condition is the same as embodiment 1, obtains catalyst Cu-La-Au / SiO 2 -Al 2 o 3 -CsO, wherein the mass percentages of Cu, La, and Au in the catalyst are 1%, 1%, and 0.48%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com