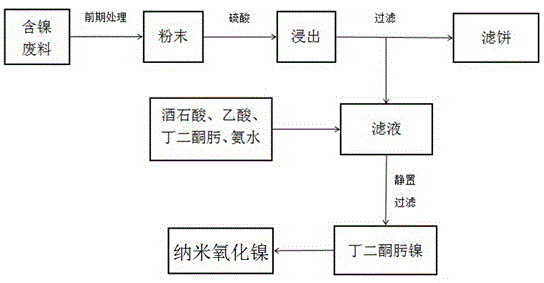

Method for preparing nano nickel oxide from nickeliferous waste materials

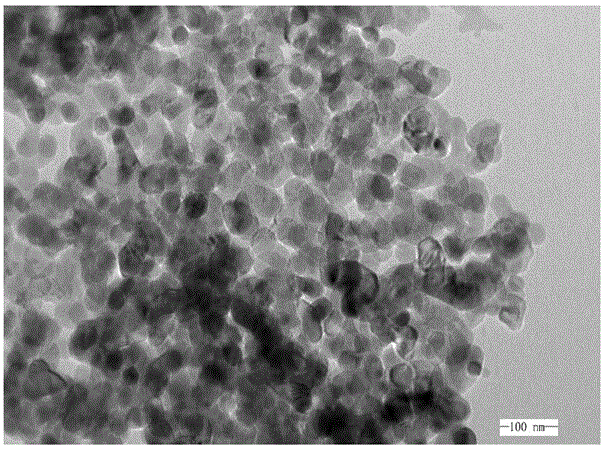

A nano-nickel oxide and waste technology, applied in the fields of nanotechnology for materials and surface science, nickel oxide/nickel hydroxide, nanotechnology, etc., can solve the problems of low nickel recovery rate, many influencing factors, and discharge of waste water, etc. To achieve the effect of short holding time, avoiding agglomeration and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The method for preparing nano-nickel oxide with nickel-containing waste described in this embodiment specifically comprises the following steps:

[0020] (1) Pre-treatment of nickel-containing waste: Nickel-containing waste is disassembled, dried (removing part of the moisture in the raw material so that the raw material can be crushed), and crushed for later use.

[0021] (2) Sulfuric acid leaching: The powdery nickel-containing waste is leached with sulfuric acid, wherein the mass percent concentration of sulfuric acid is 2mol / L, the stirring speed is 300r / min, and the leaching time is 150min. The solid-liquid ratio of powdery nickel-containing waste to sulfuric acid is It's 1:10.

[0022] (3) Treatment of sulfuric acid solution containing nickel:

[0023] ①Add tartaric acid solution to the nickel-containing sulfuric acid solution obtained in step (2), wherein the volume ratio of nickel-containing sulfuric acid solution to tartaric acid solution is 20:1, and the conc...

Embodiment 2

[0029] The method for preparing nano-nickel oxide with nickel-containing waste described in this embodiment specifically comprises the following steps:

[0030] (1) Pre-treatment of nickel-containing waste: Nickel-containing waste is disassembled, dried (removing part of the moisture in the raw material so that the raw material can be crushed), and crushed for later use.

[0031] (2) Sulfuric acid leaching: The powdery nickel-containing waste is leached with sulfuric acid, the mass percent concentration of sulfuric acid is 3mol / L, the stirring speed is 1000r / min, and the leaching time is 100min. The solid-liquid ratio of powdery nickel-containing waste to sulfuric acid is It is 1:8.

[0032] (3) Treatment of sulfuric acid solution containing nickel:

[0033] ①Add tartaric acid solution to the nickel-containing sulfuric acid solution obtained in step (2), wherein the volume ratio of nickel-containing sulfuric acid solution to tartaric acid solution is 35:1, and the concentrati...

Embodiment 3

[0039] The method for preparing nano-nickel oxide with nickel-containing waste described in this embodiment specifically comprises the following steps:

[0040] (1) Pre-treatment of nickel-containing waste: Nickel-containing waste is disassembled, dried (removing part of the moisture in the raw material so that the raw material can be crushed), and crushed for later use.

[0041] (2) Sulfuric acid leaching: leaching powdery nickel-containing waste with sulfuric acid, wherein the mass percent concentration of sulfuric acid is 4mol / L, the stirring speed is 1500r / min, and the leaching time is 70min. The solid-liquid ratio of powdery nickel-containing waste to sulfuric acid is It is 1:6.

[0042] (3) Treatment of sulfuric acid solution containing nickel:

[0043] ① Add tartaric acid solution to the nickel-containing sulfuric acid solution obtained in step (2), wherein the volume ratio of nickel-containing sulfuric acid solution to tartaric acid solution is 50:1, and the concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com