Patents

Literature

74results about How to "Crystal form controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

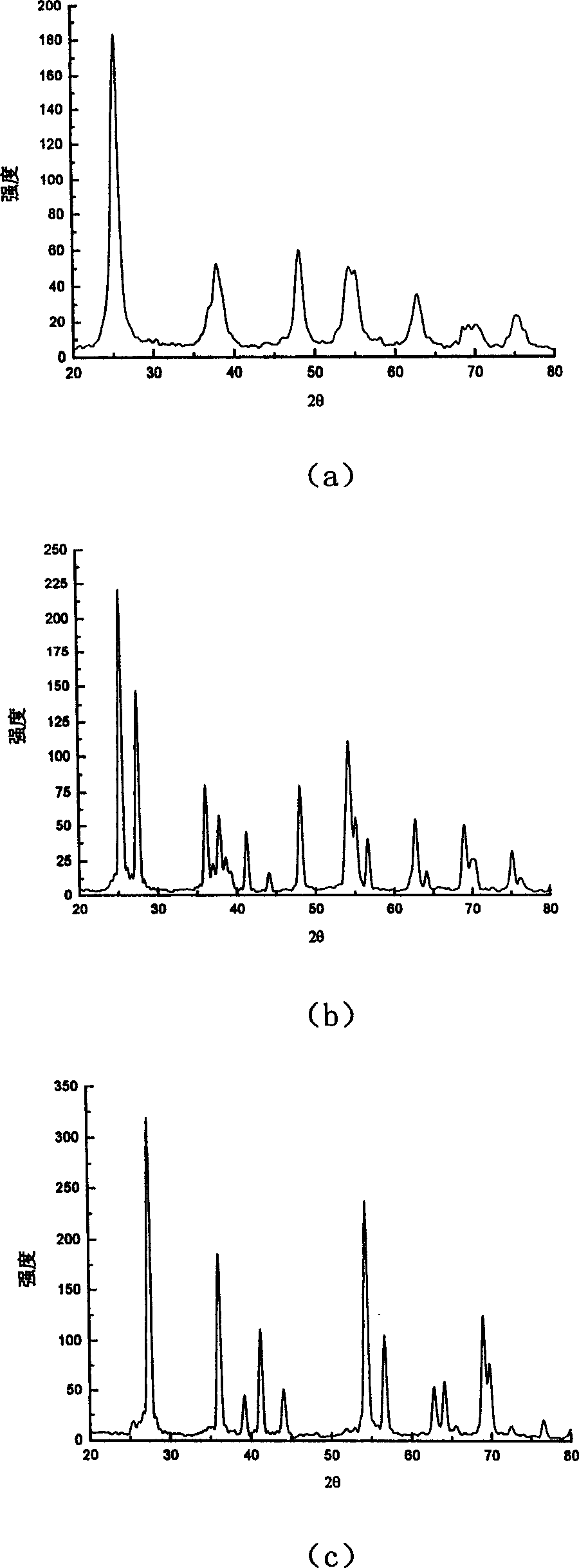

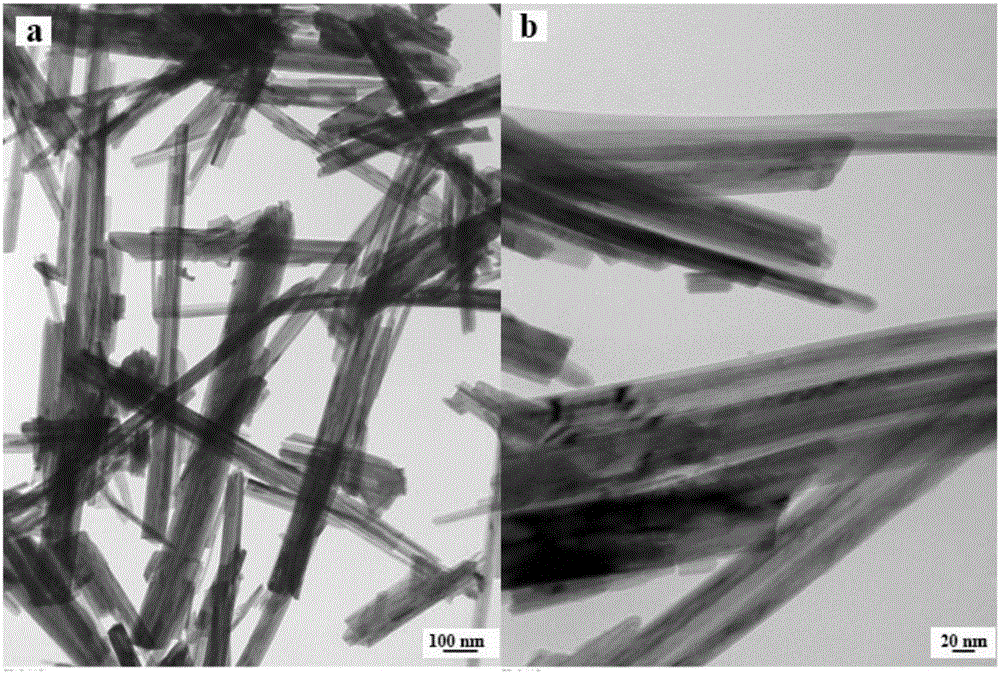

Method for preparing nano manganese dioxides with different appearances by hydrothermal synthesis process

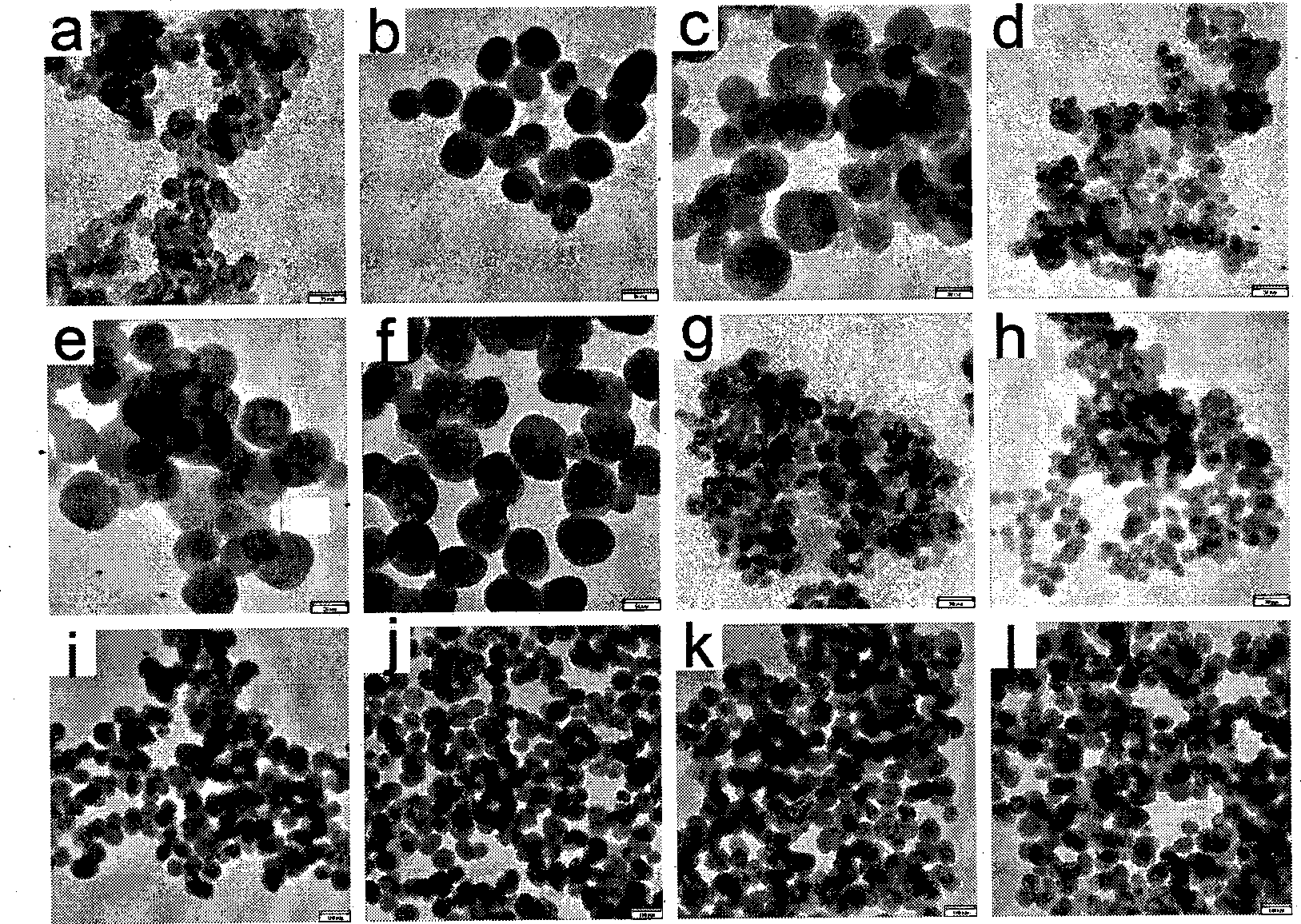

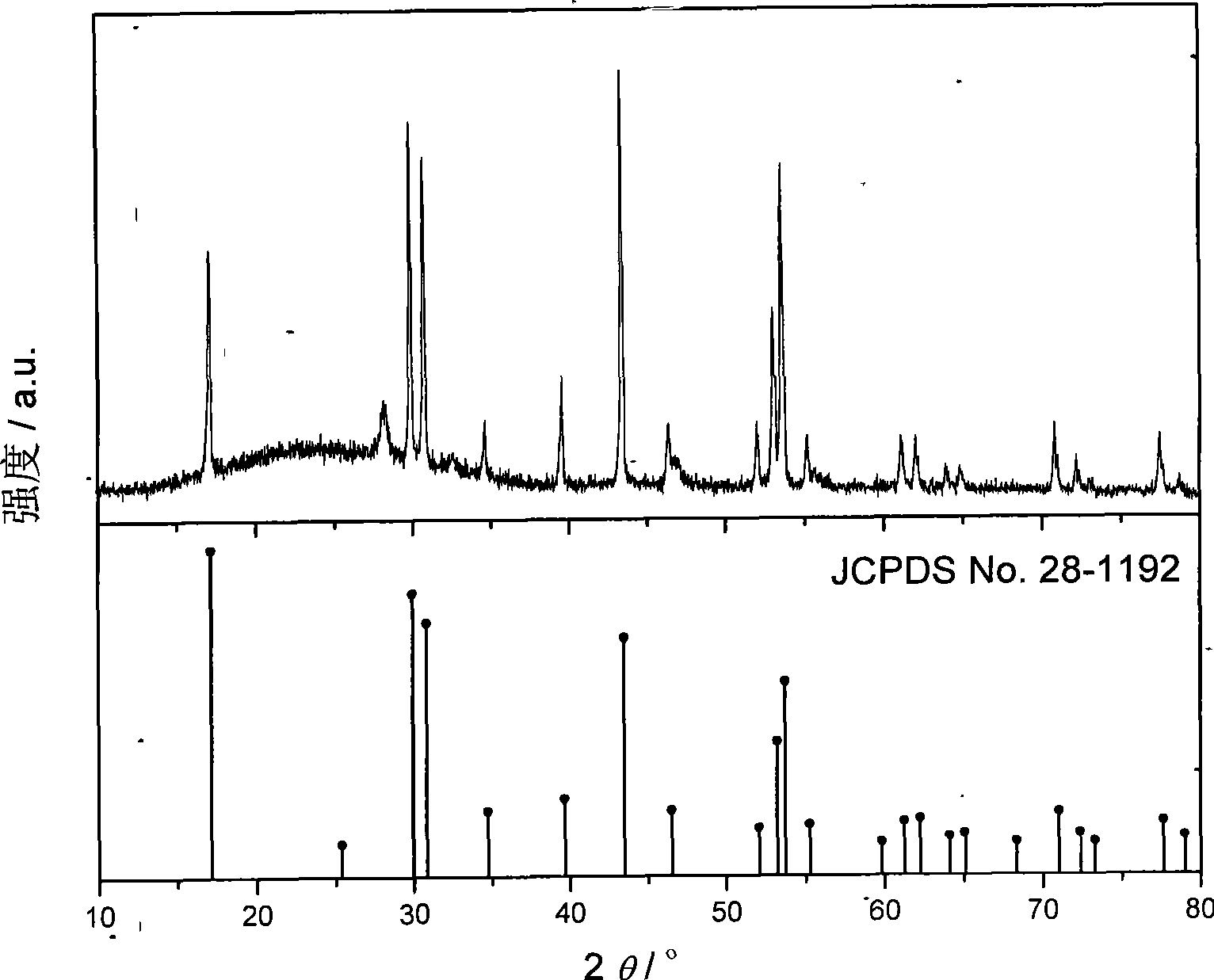

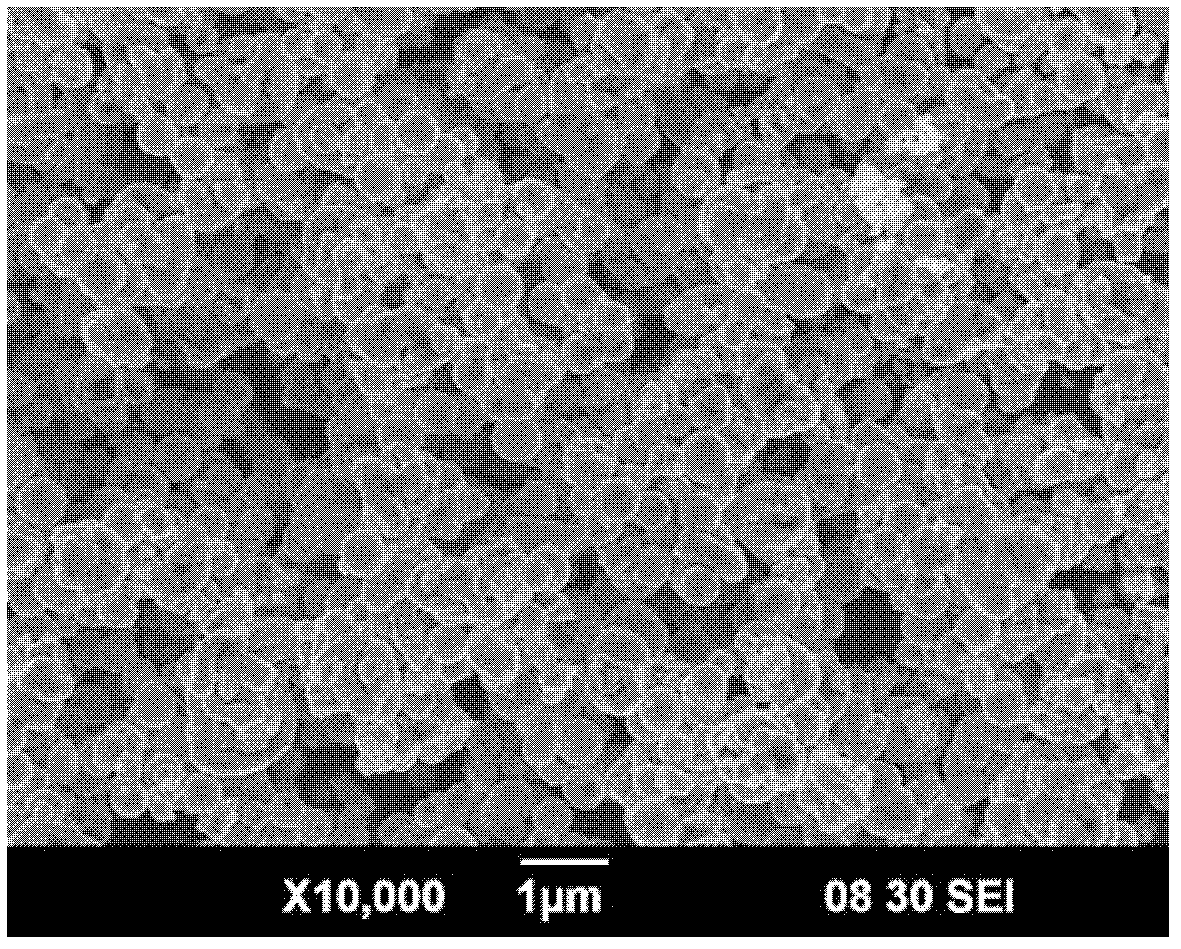

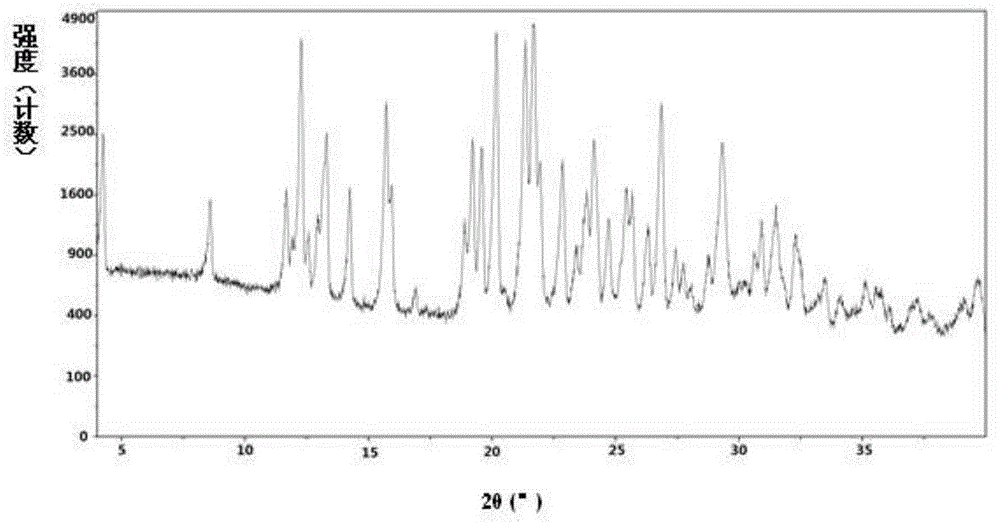

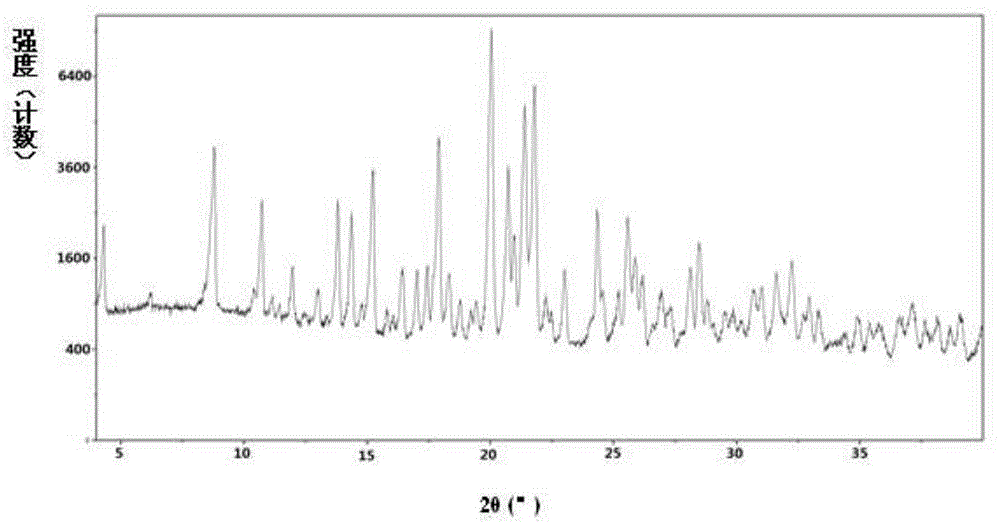

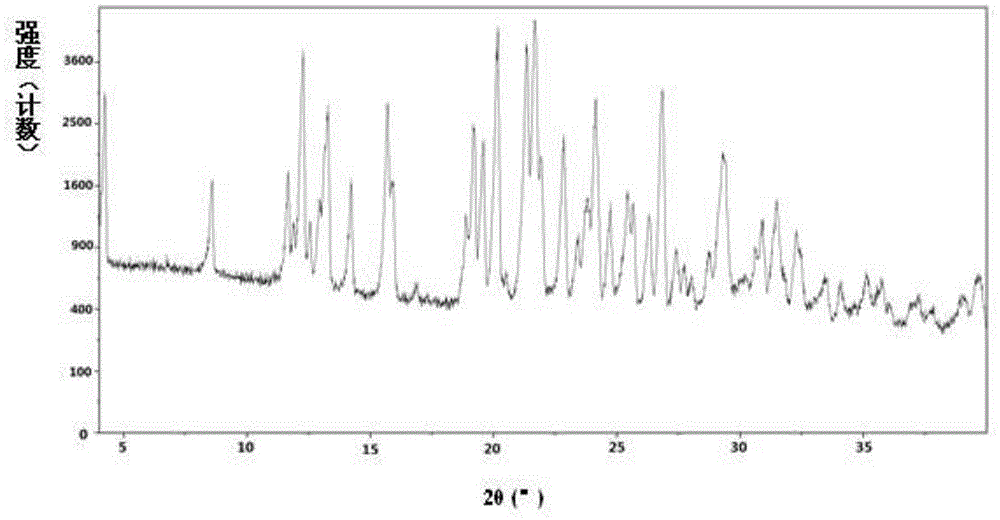

ActiveCN103553137AHigh catalytic electrochemical activityLow costMaterial nanotechnologyManganese oxides/hydroxidesElectric capacityManganese

The invention discloses a method for preparing nano manganese dioxides with different appearances by adjusting the reaction time only under exactly same other conditions. The method comprises the following steps of adding potassium permanganate into deionized water, and stirring to form a uniform solution in which the concentration of potassium permanganate is 0.3mol / L; then adding manganese sulfate, wherein the mass ratio of potassium permanganate to manganese sulfate is 5:2; then transferring the solution into a high-temperature high-pressure reaction kettle of which the inner container is a polytetrafluoroethylene inner container; reacting for 1-18 hours at 140 DEG C; cooling, filtering, flushing and finally drying to obtain a target product. In the method disclosed by the invention, the process is simple, the cost is relatively low, the reaction conditions are mild, and the appearance of the crystal form is controllable; the obtained product has stable quality, relatively high catalytic electrochemical activity, wide applicability and the like, and can be widely applied to lithium ion batteries, molecular sieves, catalysts, super capacitors and the like as well as the basic study of related fields.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

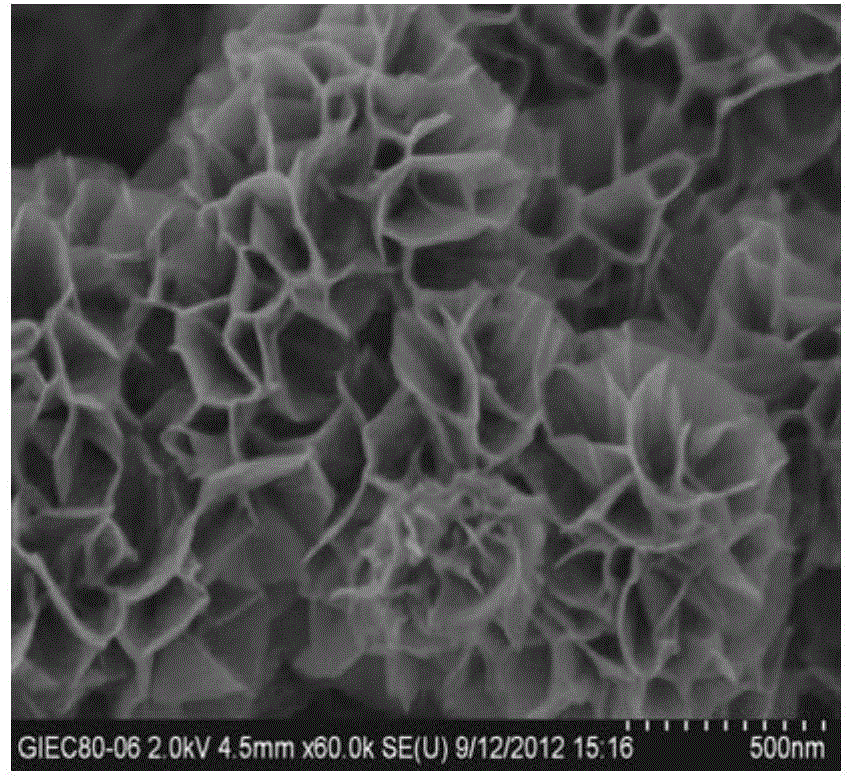

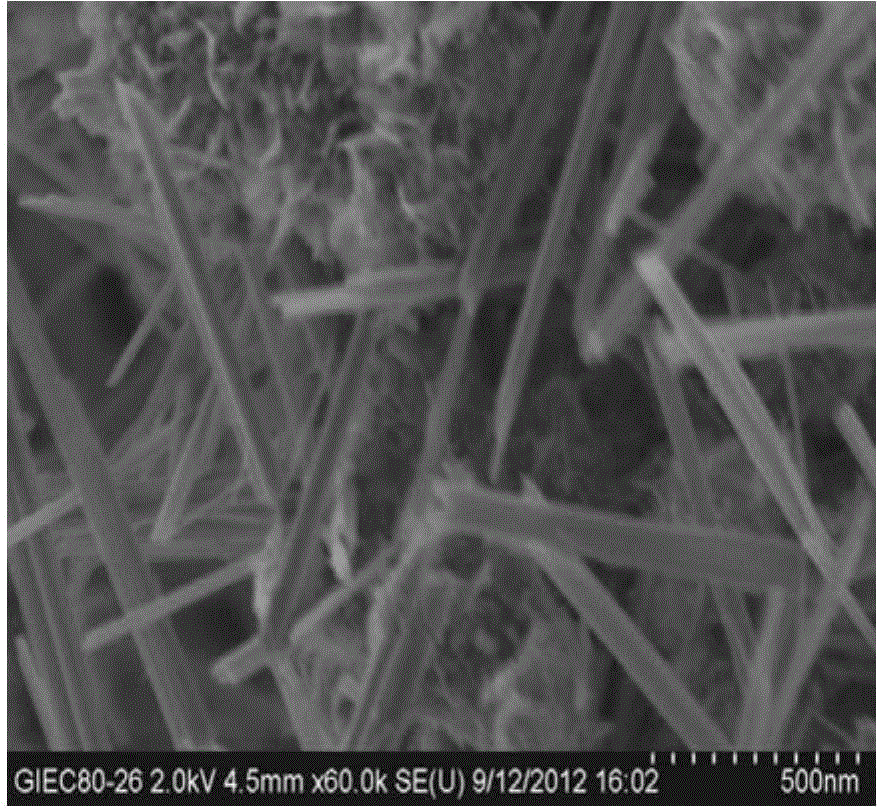

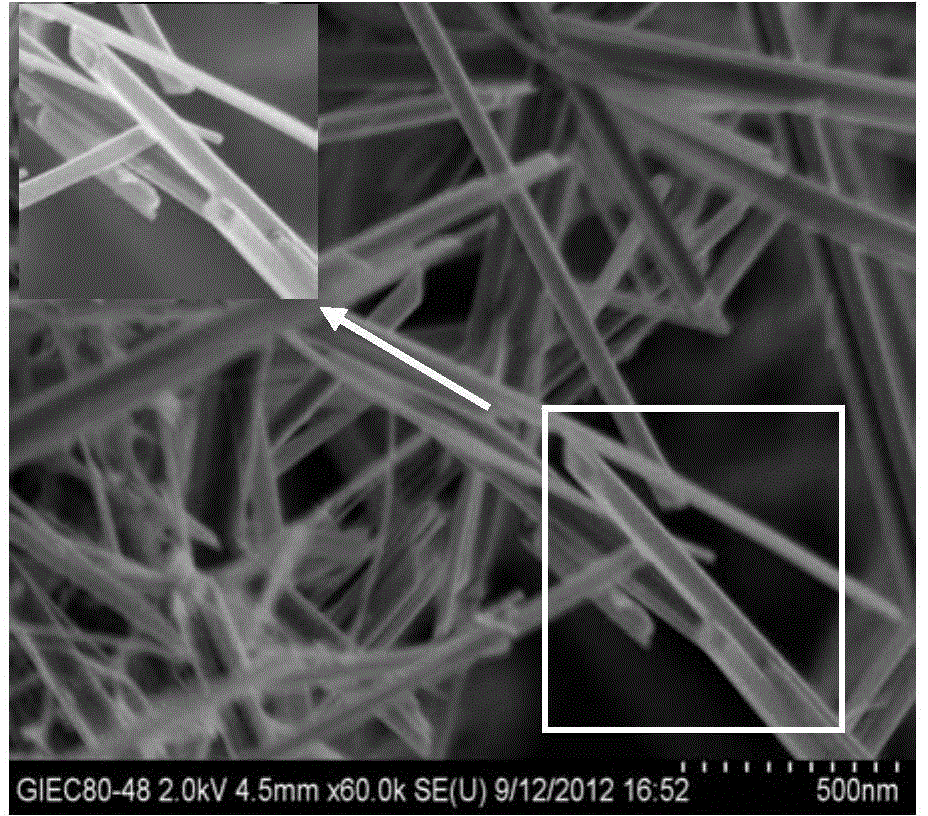

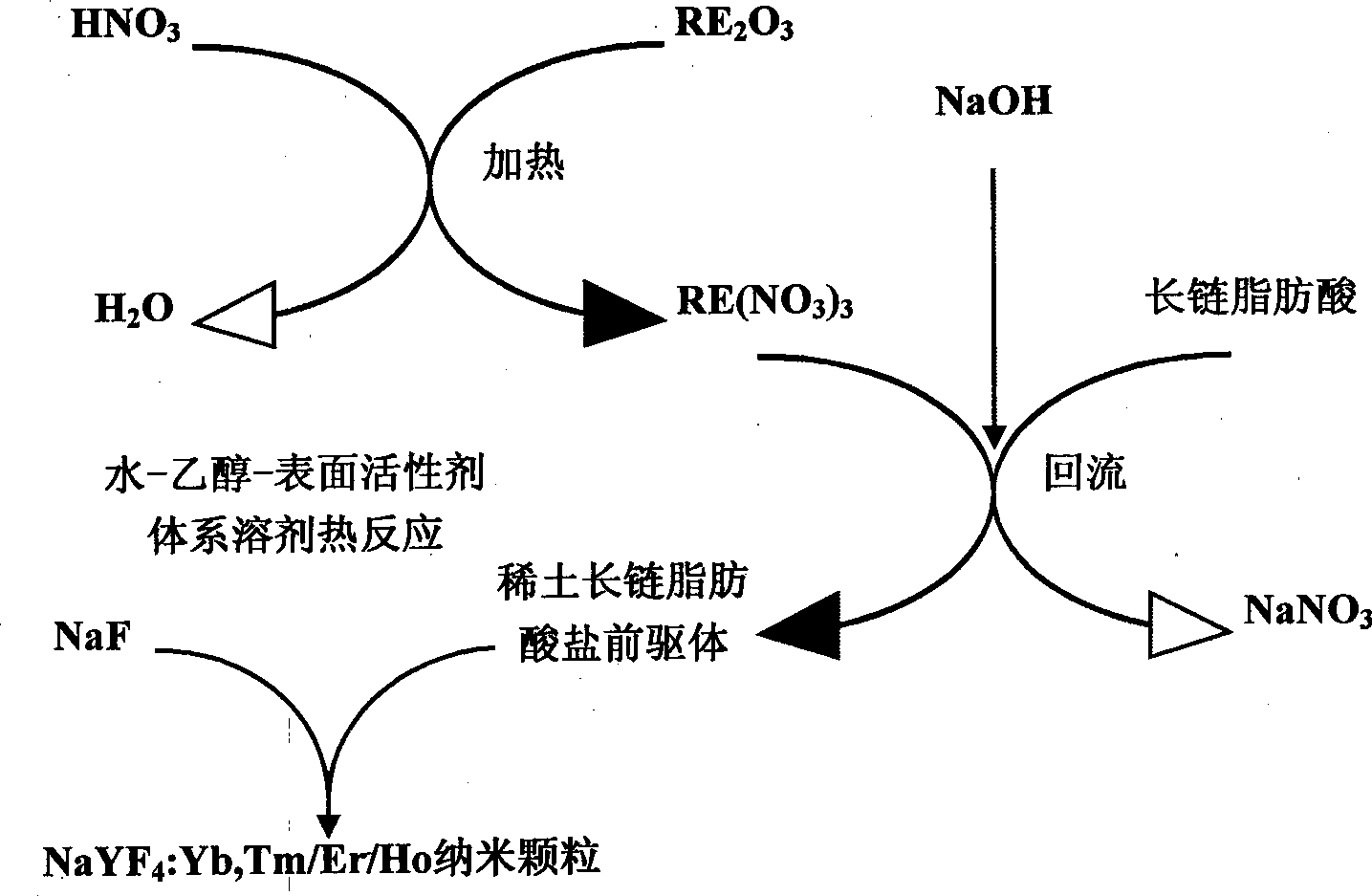

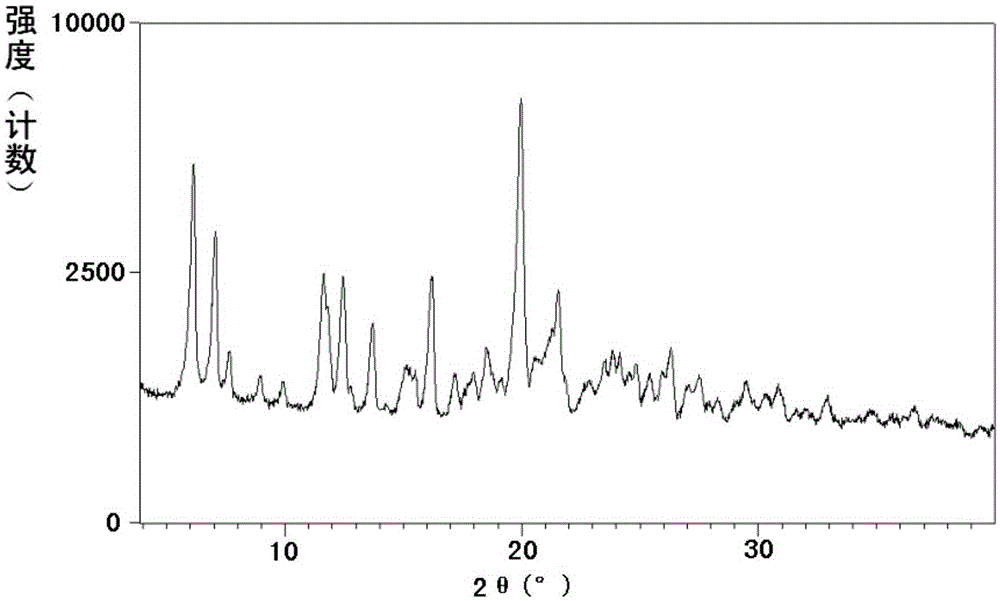

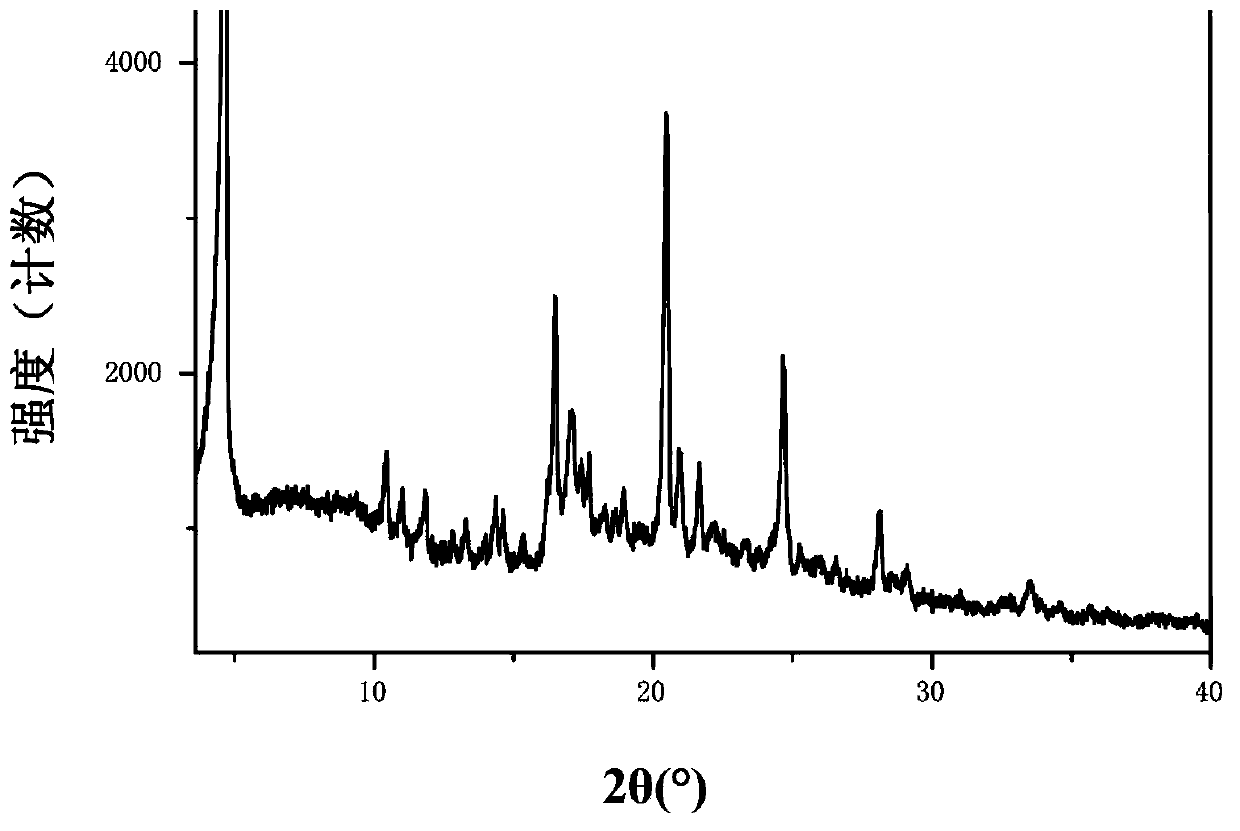

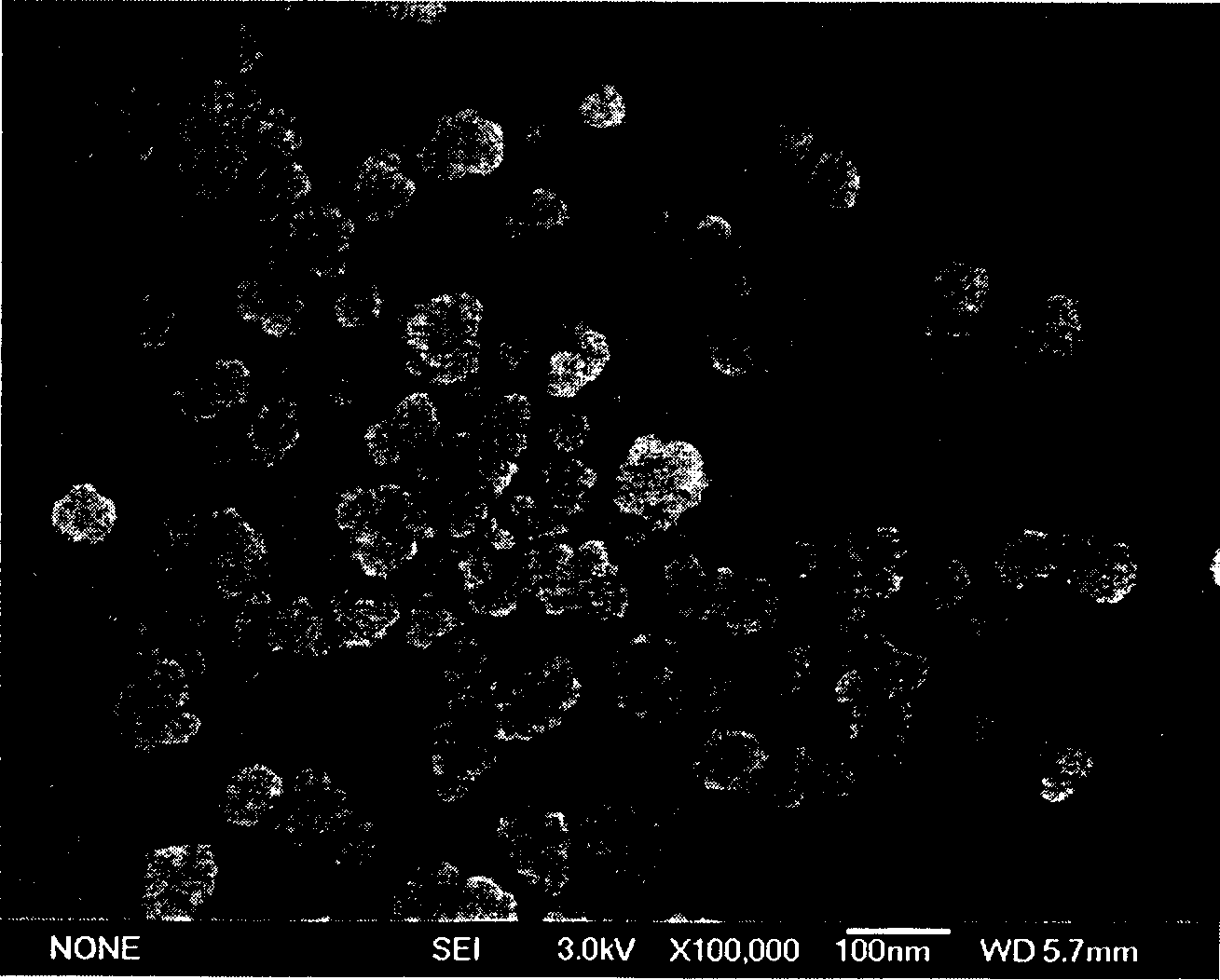

Preparation of upper conversion fluorescent nano particle

InactiveCN101497792ASmall and uniform particle sizeGood dispersionLuminescent compositionsRare earthSurface-active agents

A preparation method of up-conversion phosphor nanometer particles belongs to the technical field of materials and comprises the following steps: (1) dissolving rare-earth inorganic acid salt powder by ethanol to obtain rare-earth inorganic acid salt ethanol solution; (2) adding long-chain fatty acid, performing the reflux reaction under the mixing condition, and preparing a long-chain fatty acid precursor of rare-earth; (3) adding one of an erbium precursor, a thulium precursor and a holmium precursor as well as a yttrium precursor and a ytterbium precursor into a water-ethanol mixing system, adding and uniformly mixing sodium fluoride and surface active agent, and heating and reacting for 2-24h under the obturating condition; (4) adding organic solvent after lowering the temperature, centrifugalizing, and drying or naturally withering after washing white precipitate. The preparation method has simpler process, easy synthesis condition, good repetitiveness, low cost and higher productive rate.

Owner:NORTHEASTERN UNIV

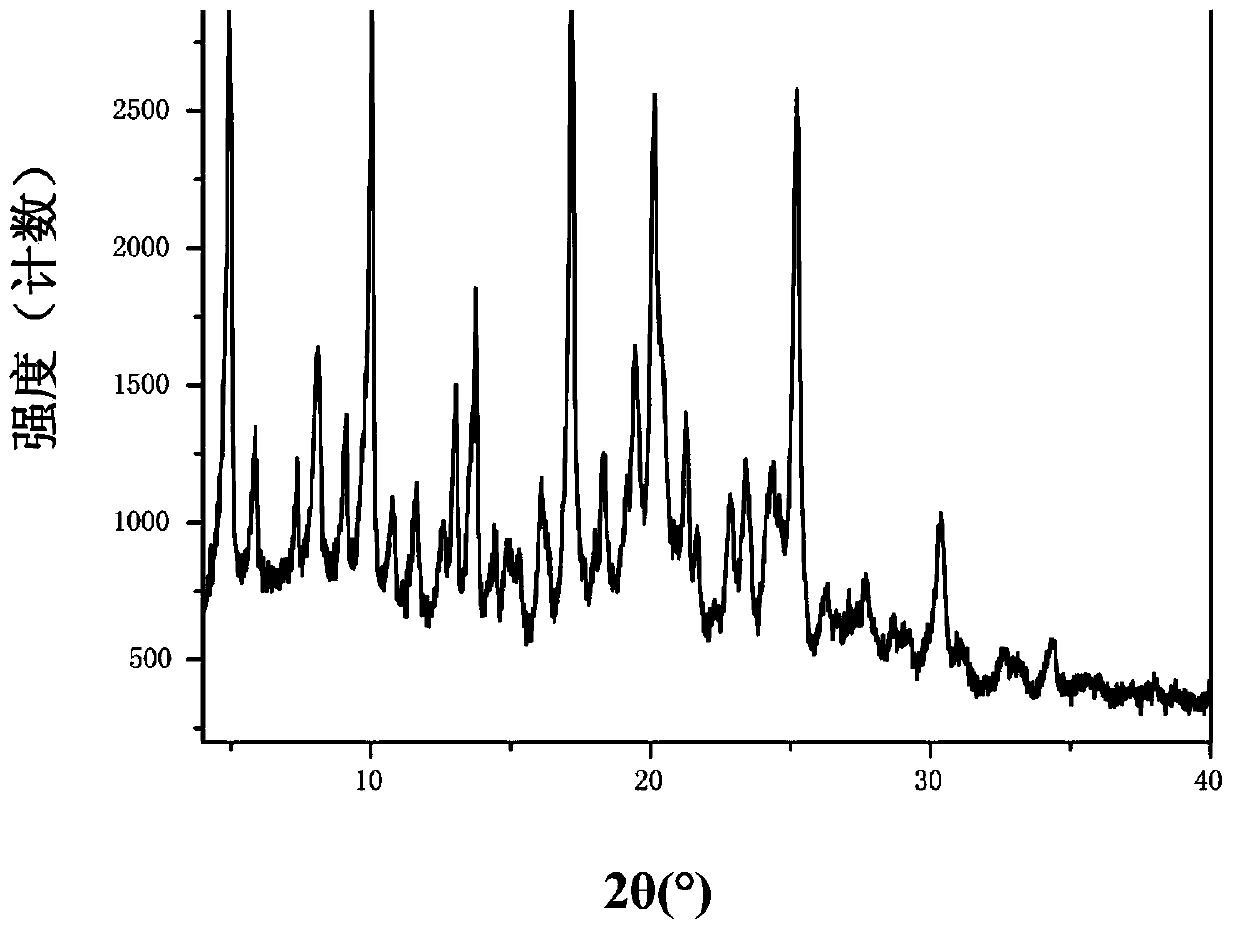

Sacubitril derivatives and medicine compositions, preparation methods and application thereof

ActiveCN105693543AEasy to prepareCrystal form controllableAmino compound purification/separationOrganic compound preparationEthylenediamineArginine

The invention provides sacubitril derivatives and medicine compositions, preparation methods and application thereof and belongs to the fields of medicine compounds and preparation thereof. The sacubitril derivatives comprise sacubitril lithium salt, sacubitril kali salt, sacubitril magnesium salt, sacubitril calcium salt, sacubitril strontium salt, sacubitril zinc salt, sacubitril ferric salt, sacubitril ammonium salt, sacubitril diethylamine salt, sacubitril ethylenediamine salt, sacubitril piperazine salt, sacubitril N-(2-ethoxyl)-pyrrolidine salt, sacubitril choline salt, sacubitril cholamine salt, sacubitril diethanol amine salt, sacubitril triethanolamine salt, sacubitril tromethamine salt, sacubitril meglumine salt, sacubitril diisopropylamine salt, sacubitril tert-butylamine salt, sacubitril N, N'-bis-benzyl ethylenediamine salt, sacubitril L-lysine salt, sacubitril L-arginine salt or sacubitril L-histidine salt.

Owner:SICHUAN HAISCO PHARMA CO LTD

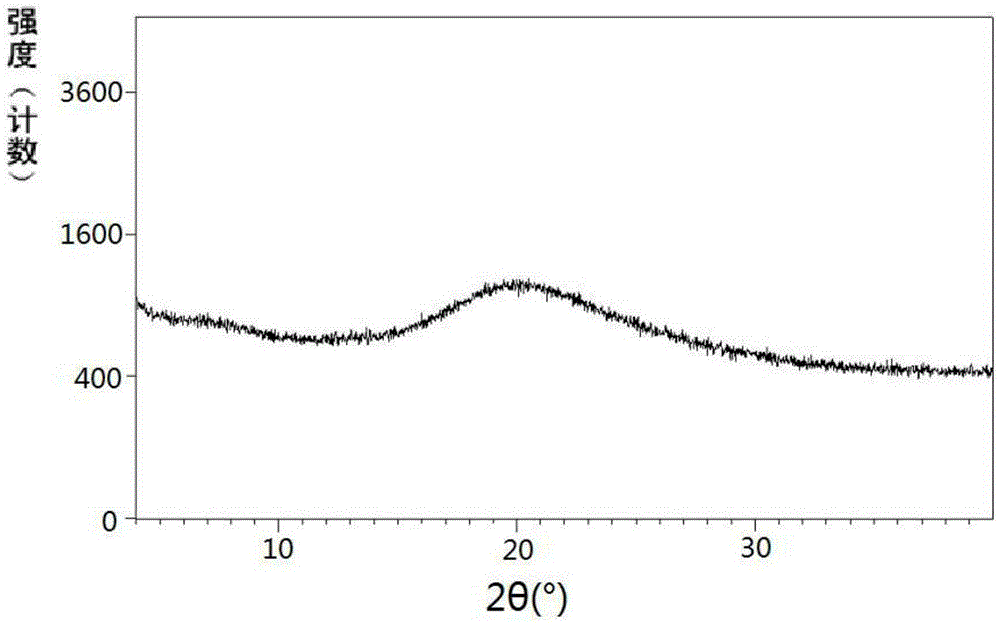

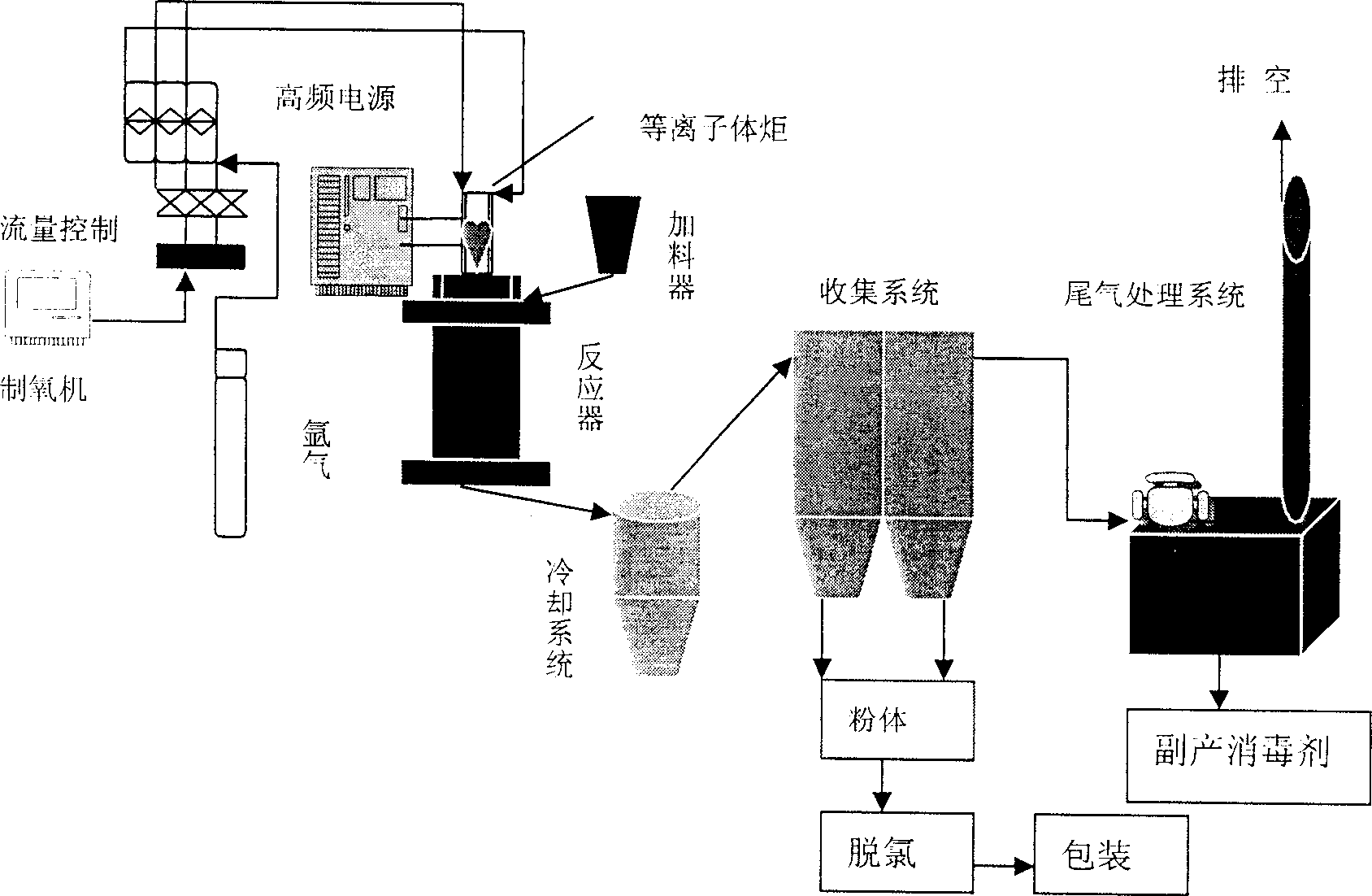

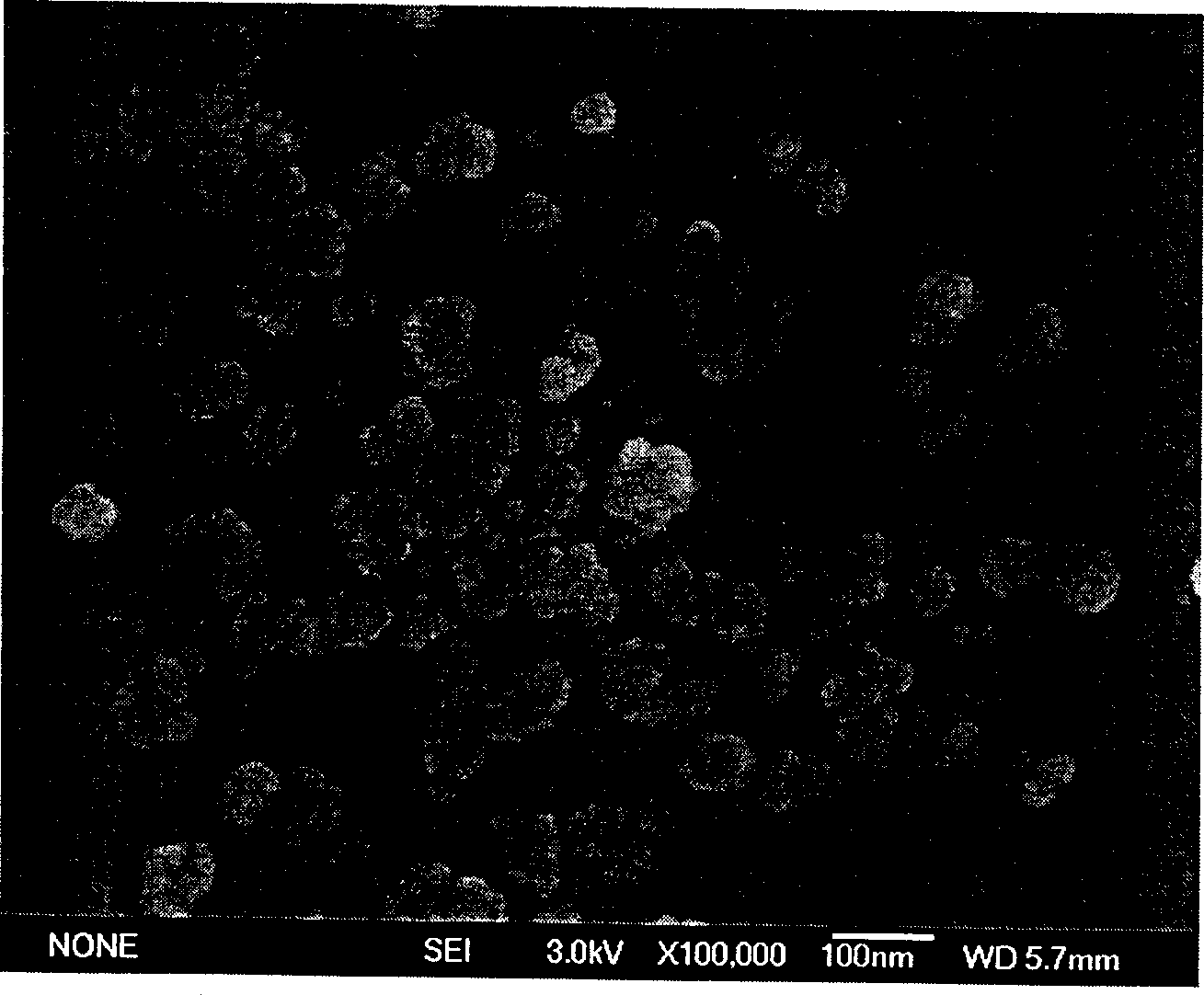

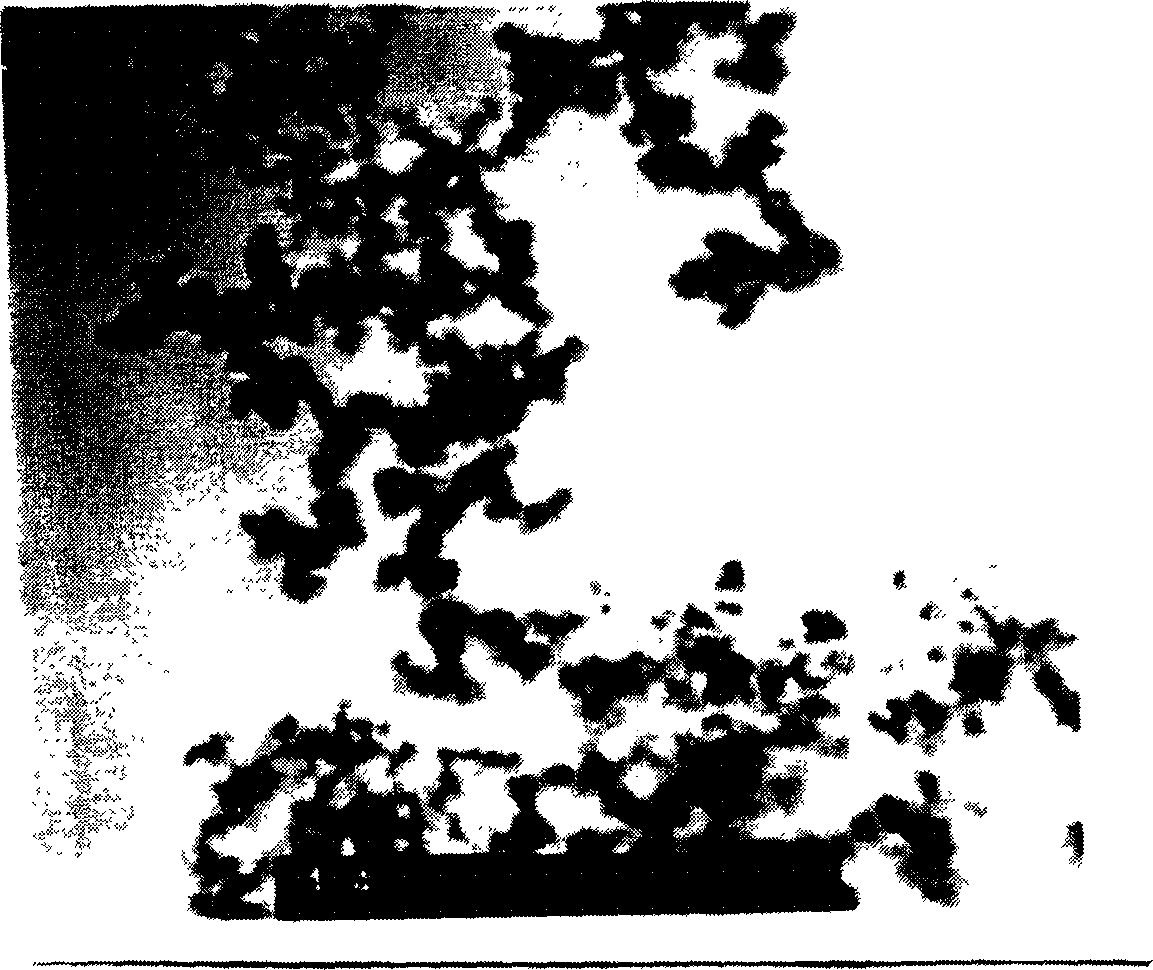

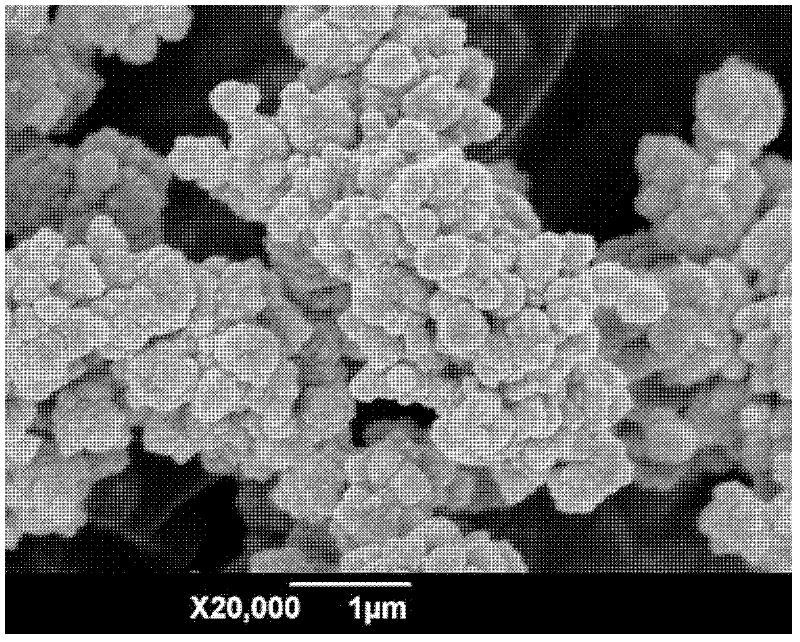

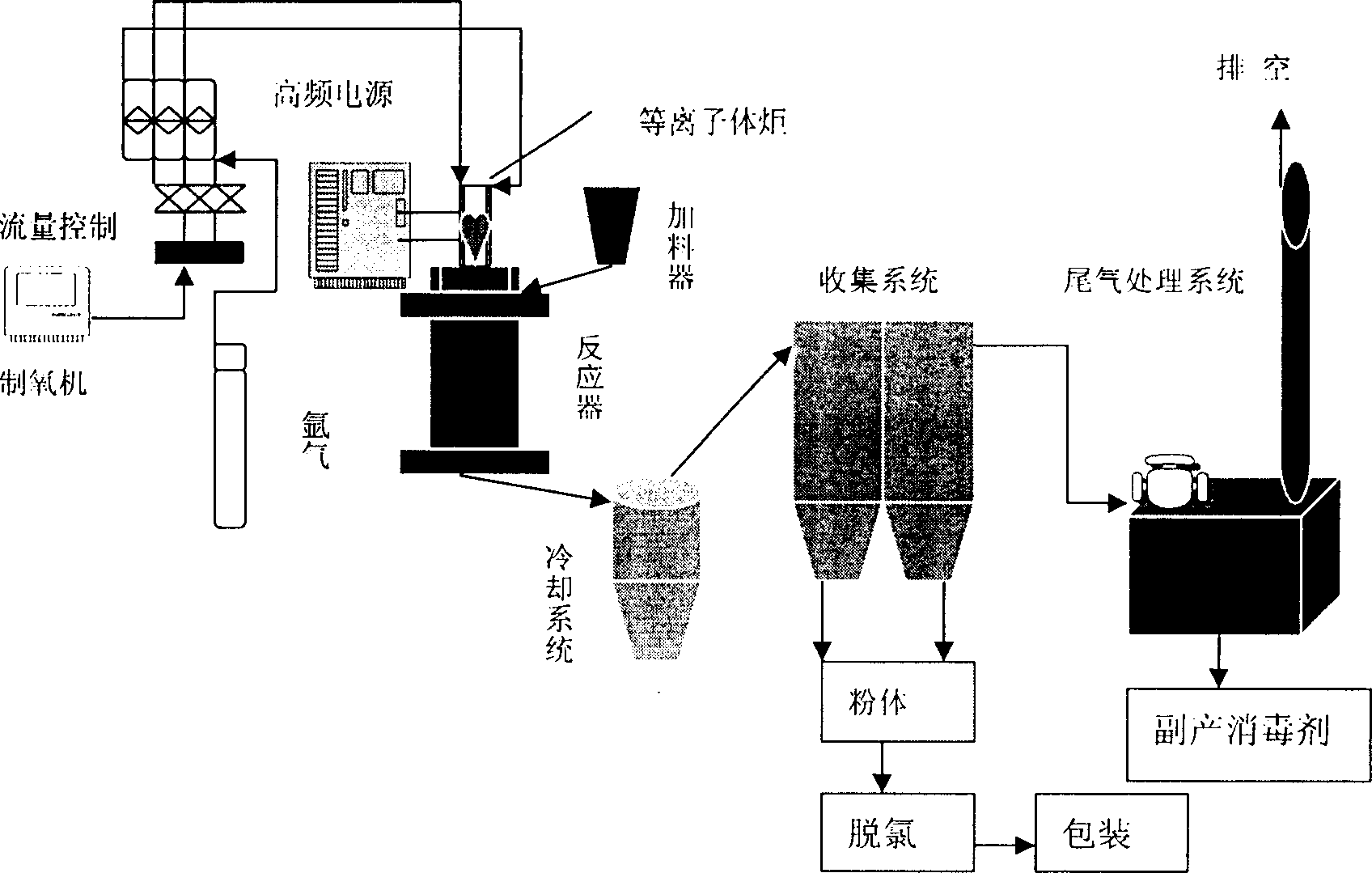

Preparation of high-purity nanometer silicon dioxide

Production of nanometer high-purity silicon dioxide in high-frequency plasma gas-phase oxidizing reactor is carried out by purifying air of oxygen and feeding it into high-frequency plasma generator, generating plasma oxygen at oscillating power 30KW and frequency 3í½4MHz, gasifying SiCl4 at 200í½300íÒC and delivering it plasma chemical reactor, reacting it with oxygen plasma at 1200í½1800íÒC, keeping the reactant in reactor for 0.15í½1s, removing scar with mol ratio of SiCl4 and oxygen: 1:1.2í½2, inducing dried air or N2 gas, quenching silicon dioxide crystal below 300íÒC, collecting powder, removing chlorine, and obtaining nanometer high-purity silicon dioxide. It achieves good dispersity, high output and simple process.

Owner:优美特(北京)环境材料科技股份公司

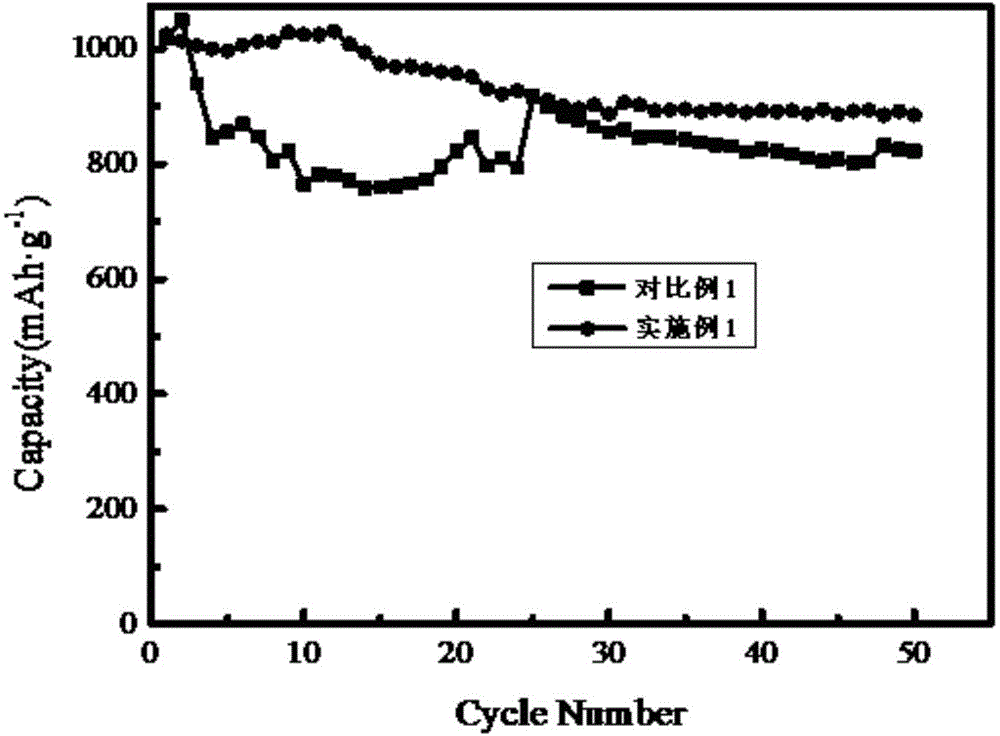

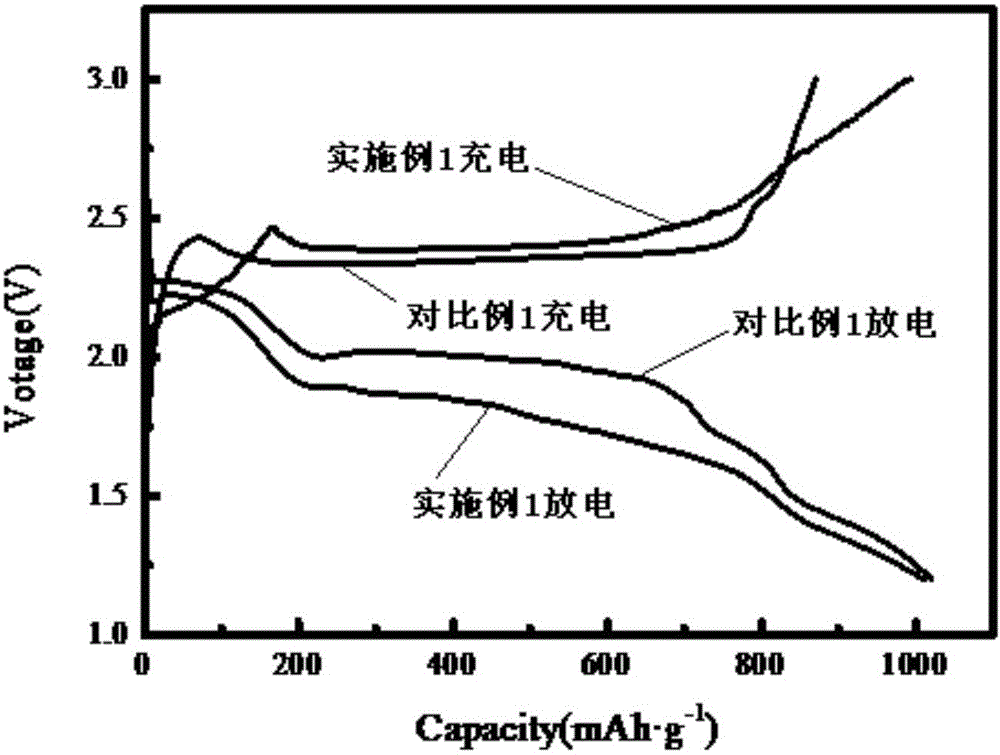

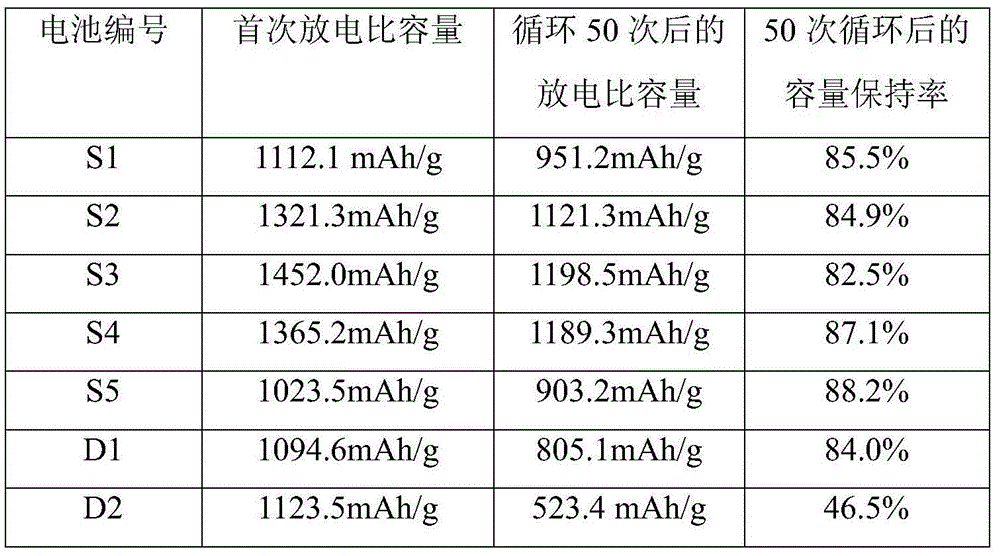

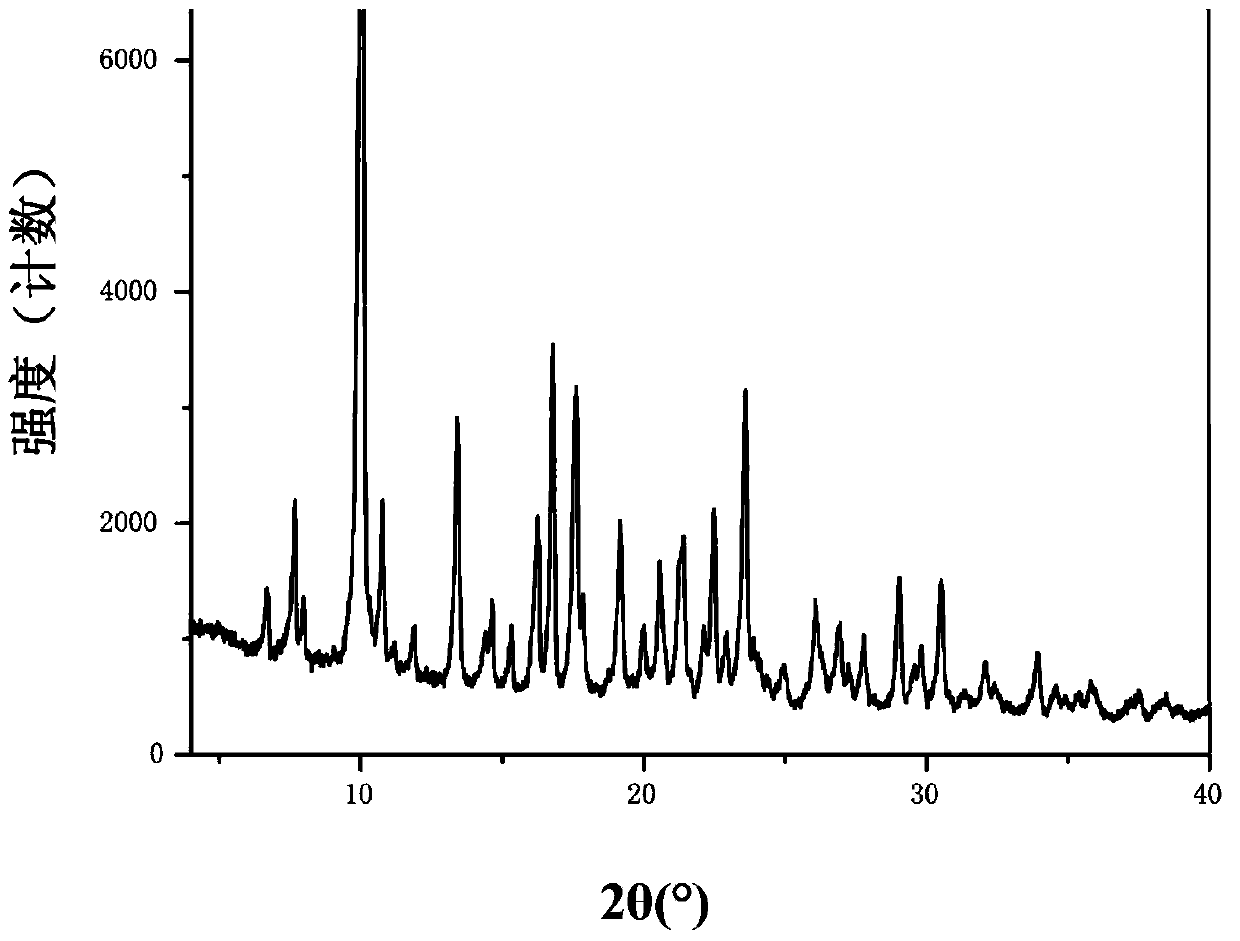

Preparation method of positive electrode material of lithium sulfur battery

InactiveCN104659338AGood dispersionCrystal form controllableMaterial nanotechnologyCell electrodesMass ratioFreeze-drying

The invention belongs to the technical field of lithium sulfur batteries, and particularly relates to a preparation method of a positive electrode material of a lithium sulfur battery. The preparation method comprises the following steps: adding a carbon nano tube into a nitrogen source substance solution with the mass concentration not less than 10%, mixing uniformly, transferring into a hydrothermal / solvent thermal reaction kettle for heat preservation, cooling, and washing and drying a reaction product so as to obtain a carbon nitride nano tube; dissolving sulfur into an organic solvent so as to obtain a sulfur contained organic solution, then adding the carbon nitride nano tube obtained in the step 1 into the sulfur contained organic solution, carrying out ultrasonic dispersion for more than 0.5 hour, and performing ultrasound treatment continuously while dropwise adding an extracting agent, wherein the mass ratio of the extracting agent to the organic solvent is (0.5-10) to 1; and then drying, and carrying out freeze drying on a product after the solvent is evaporated by more than a half. Compared with the prior art, the carbon-sulfur compound obtained by the method is good in circulation stability.

Owner:MCNAIR TECH +2

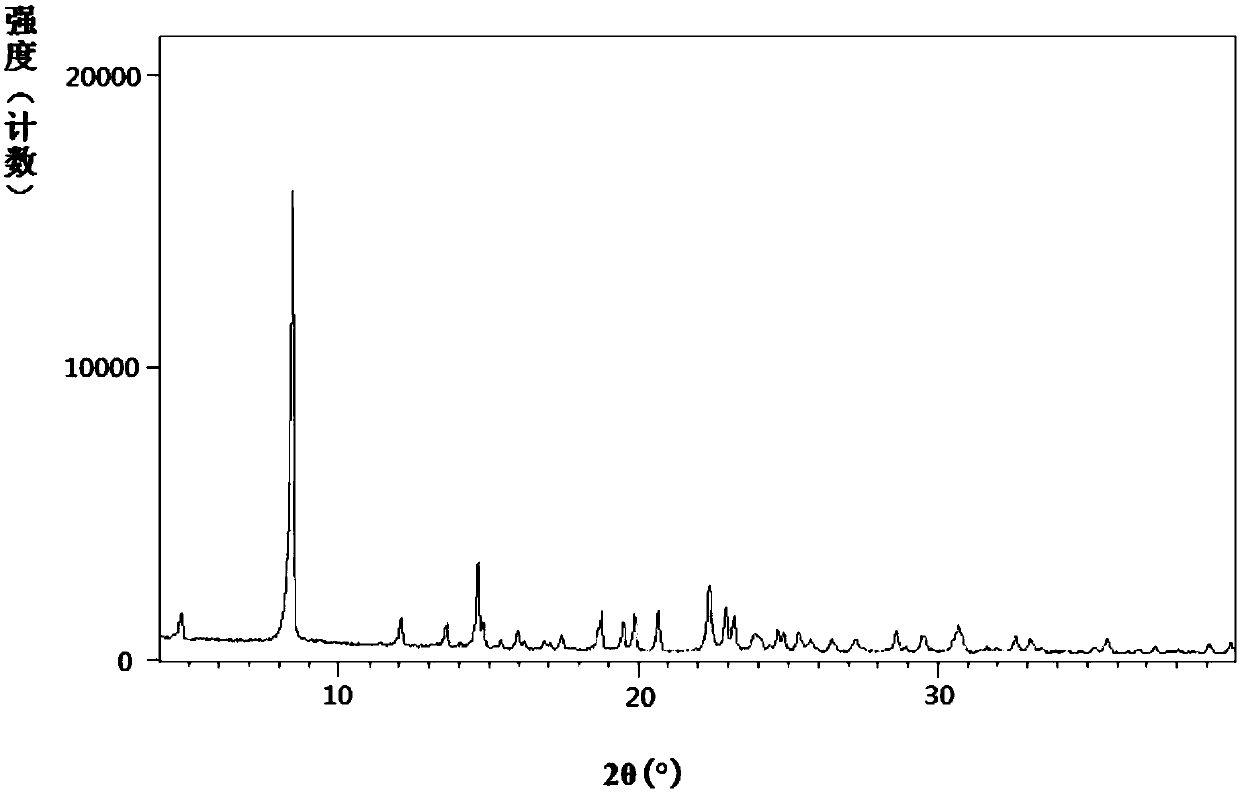

Solid of tenofovir disoproxil, and preparation method and application thereof

ActiveCN103626803AEasy to prepareCrystal form controllableOrganic active ingredientsGroup 5/15 element organic compoundsMedicineHepatitis B virus

The invention relates to a solid of tenofovir disoproxil. The solid is (1) a tenofovir disoproxil compound represented by a formula IV or (2) a tenofovir disoproxil cocrystal or salt represented by a formula V. The invention further relates to a preparation method for the solid of tenofovir disoproxil, a pharmaceutical composition containing the solid and application of the solid in preparation of drugs used for preventing and / or treating virus infection, especially hepatitis b virus (HBV) and / or human immunodeficiency virus (HIV) infection.

Owner:SICHUAN HAISCO PHARMA CO LTD

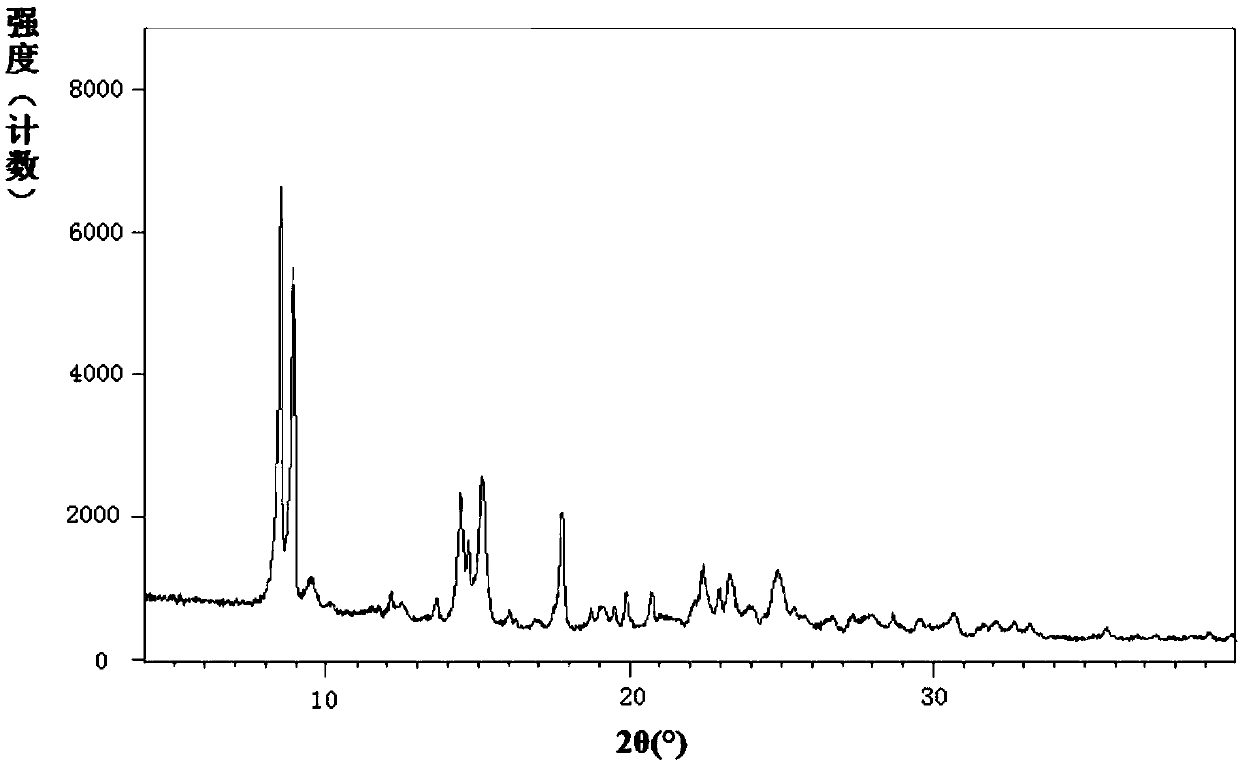

Vonoprazan salts and crystal forms, and preparation method and application thereof

InactiveCN107759568AEasy to prepareCrystal form controllableOrganic active ingredientsDigestive systemTartrateMedicinal chemistry

The invention relates to vonoprazan dihydrochloride, vonoprazan dihydrobromide, vonoprazan disulfate, vonoprazan nitrate, vonoprazan diphosphate, vonoprazan sulfonate, vonoprazan 1,4-hemibutanedisulfonate, vonoprazan 1,4-butanedisulfonate, vonoprazan 2-isethionate, vonoprazan L-tartrate and free alkali of vonoprazan, and crystal forms thereof. The salts and the crystal forms are simple to prepare,and the crystal forms are easy to control and has good dissolvability and stability. The invention further relates to preparation methods for the salts and the crystal forms, injections containing the salts, and application of the salts and the crystal forms to preparation of drugs used for treating and / or preventing diseases related to gastric acid.

Owner:SICHUAN HAISCO PHARMA CO LTD

Synthetic method of polynitrogen azole zinc/cadmium framework material

InactiveCN101830918AGreen preparationHigh yieldCadmium organic compoundsZinc organic compoundsOxideMetal

The invention relates to a synthetic method of a polynitrogen azole zinc / cadmium framework material. The method comprises the following steps of: mixing a polynitrogen azole ligand with a metering ratio of a metal polynitrogen azole framework chemical formula, an oxide or a hydroxide with a reaction liquid, carrying out an acid-base reaction after activation, and filtering, washing and drying after the reaction to obtain the polynitrogen azole zinc / cadmium framework material. The synthetic method has mild reaction conditions, and the polymerization process of the polynitrogen azole ligand and the solid oxide or the hydroxide is accelerated by utilizing the coordination buffer action of ammonia to enable the reaction to be rapidly and efficiently finished. The method has simple operation and low production cost and does not generate any other byproducts except a required product and water, the obtained product is easy to activate, and a residual mother liquid can be directly used as the reaction liquid for the next batch of synthesis, thereby realizing continuous production and being particularly suitable for large-scale industrialized production.

Owner:SUN YAT SEN UNIV

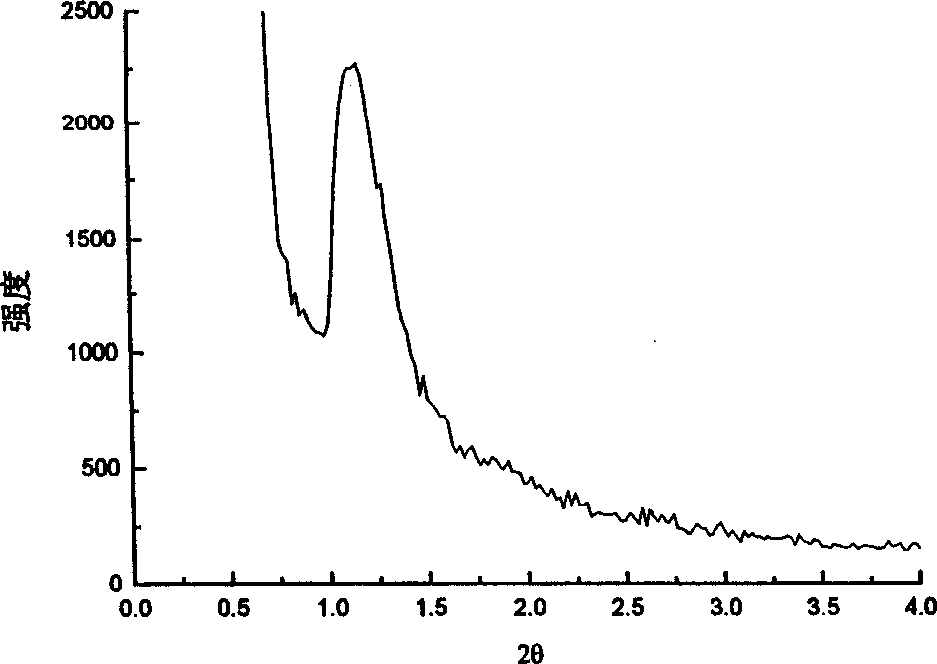

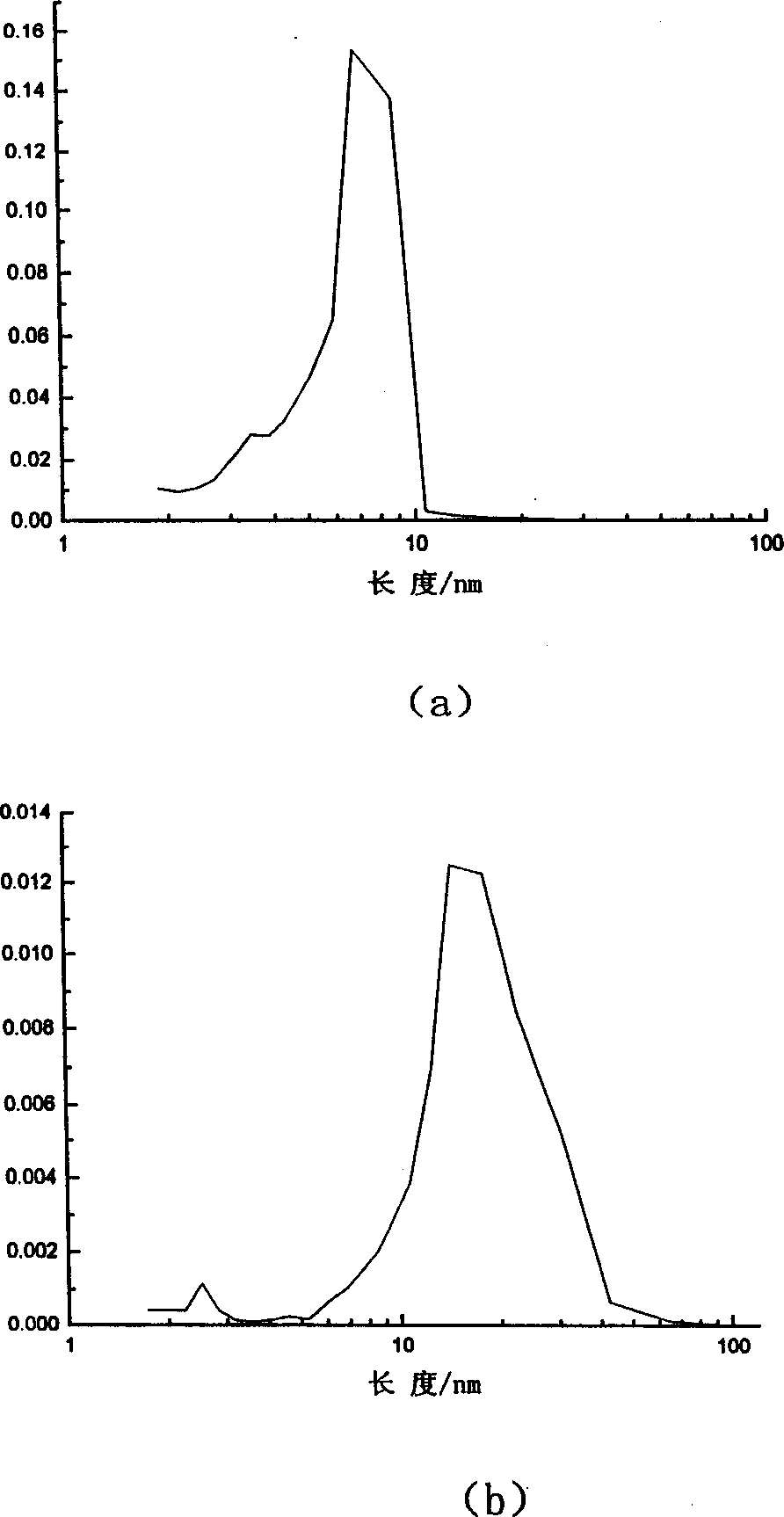

Method for preparing meso-porous nano hydroxyl phosphorite crystal

InactiveCN101254909AFully developedGood dispersionPhosphorus compoundsProsthesisChemical measurementOrganophosphate

A method for preparing mesoporous hydroxyapatite nanocrystal includes the following steps: weighing soluble calcium salt and phosphorus pentoxide or phosphate ester at a stoichiometric ratio of Ca / P of 1.67; respectively dissolving the phosphorus pentoxide or phosphate ester into the alcohol solution, and dissolving the soluble calcium salt into the aqueous solution, wherein the volume ratio of the aqueous solution / alcohol solution is of 2 / 3, 1 or 3 / 2; mixing the two solutions, adjusting the pH value of the mixed solutino to 9-10 with the ammonia water, and intensively mixing; feeding the solution into a reaction kettle, and carrying out the hydrothermal reaction at a temperature of 140-180 DEG C for 8 hours to obtain hydroxyapatite precipitate; washing with the distilled water, vacuum-filtering; and drying at a temperature of 200DEG C to obtain the mesoporous hydroxyapatite nanocrystal.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

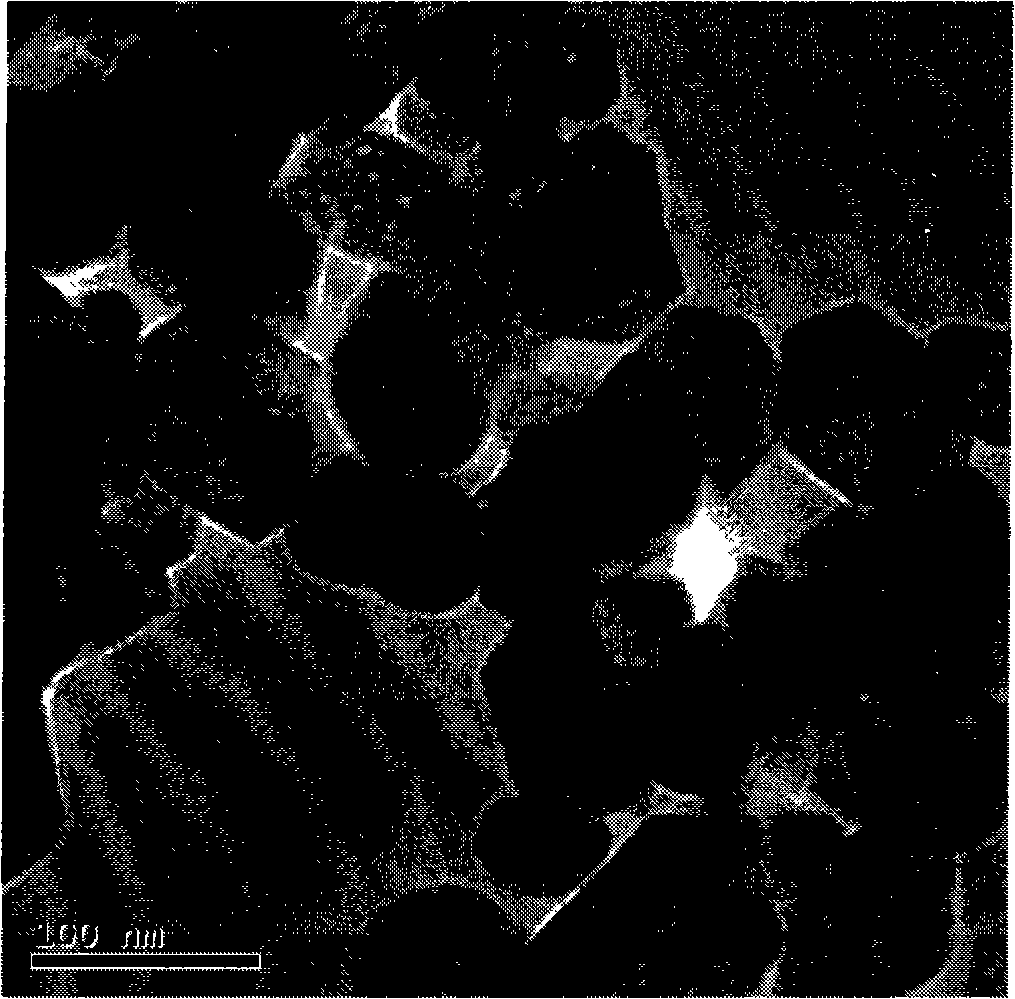

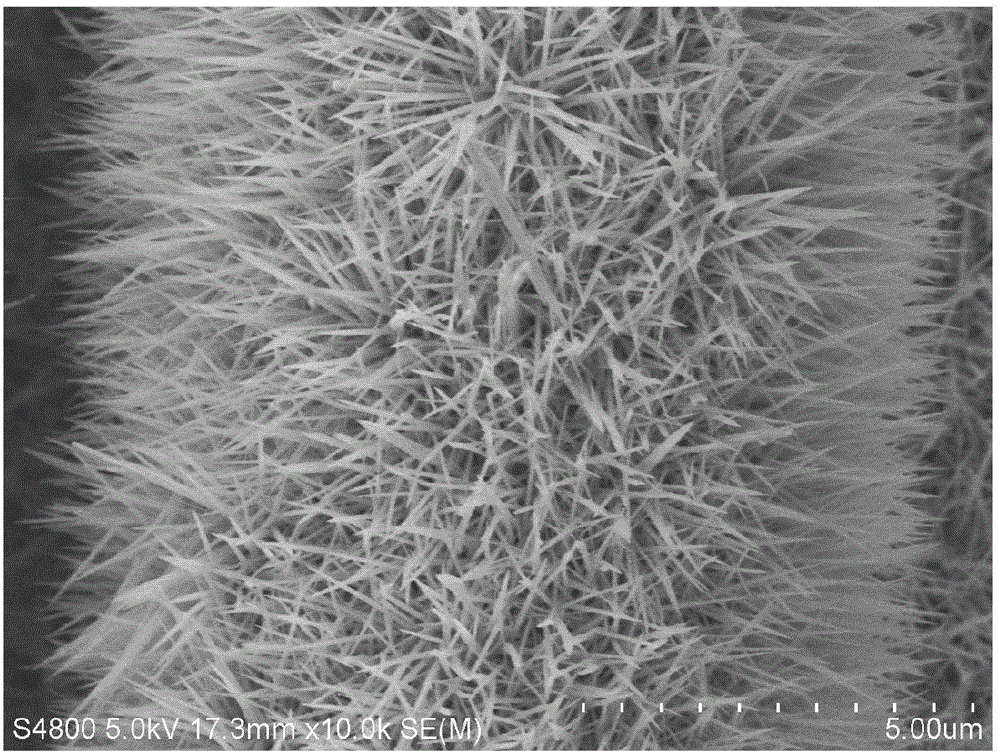

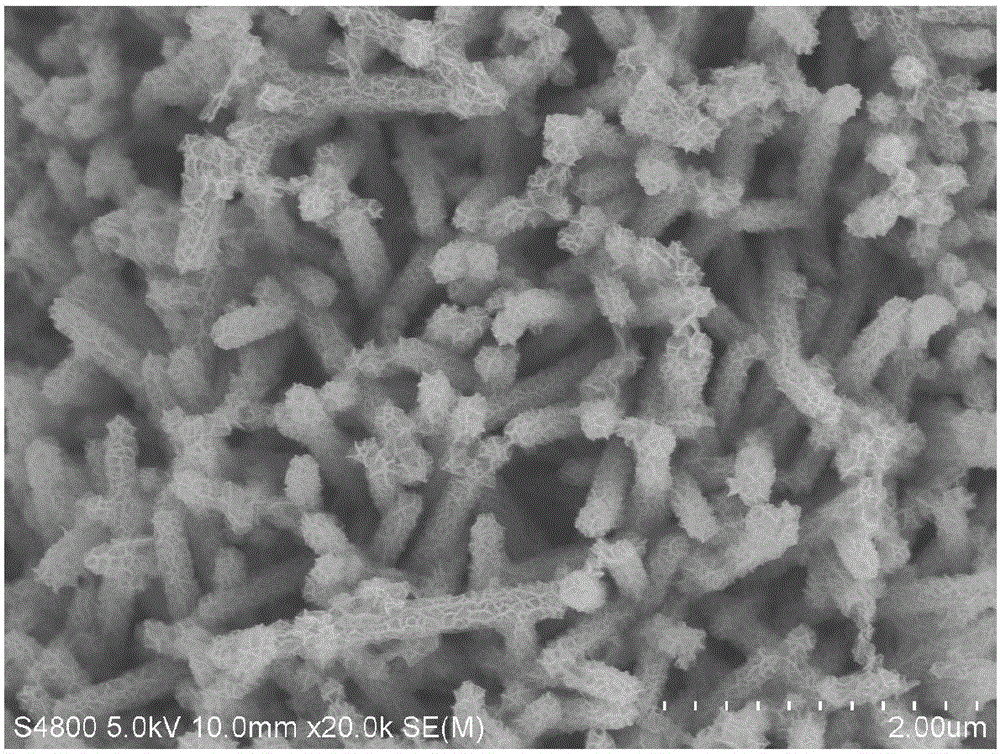

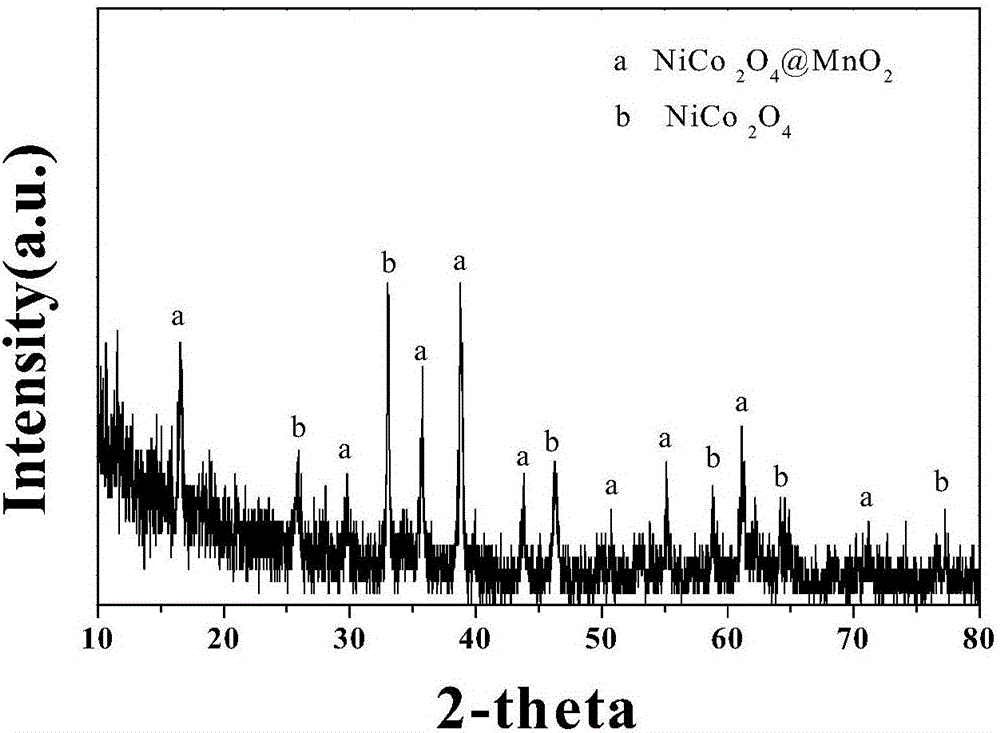

Nickel cobalt oxide<@>manganese dioxide nuclear shell heterostructure nanowire array grown on carbon cloth and preparation method and application thereof

InactiveCN106373785AHigh product purityGood dispersionHybrid capacitor electrodesHybrid/EDL manufactureCobalt oxideCapacitance

The invention provides a nickel cobalt oxide<@>manganese dioxide nuclear shell heterostructure nanowire array grown on carbon cloth and a preparation method and application thereof. Compared with the prior art, the product of the preparation method provided by the invention is high in purity, good in dispersibility, good and controllable in crystalline form, low in production cost and good in repeatability. The prepared nickel cobalt oxide<@>manganese dioxide nuclear shell heterostructure nanowire array grown on the carbon cloth can serve as an electrode material of a supercapacitor directly, long cycling stability, large specific capacitance, high energy density and power density are realized, and the nanowire array has a potential application value in the aspect of energy storage.

Owner:ANHUI NORMAL UNIV

Method for preparing medium pore molecular sieve of titanium dioxide

InactiveCN1686821ACrystal form controllableImprove photocatalytic activityPhysical/chemical process catalystsTitanium dioxideMolecular sieveAlcohol

The method for preparing nano titanium dioxide metaporous material includes the following steps: mixing titanium source and triethanolamine at room temp., uniformly stirring them, drop-adding one of water, propanetriol, glycol and ethyl alcohol as solvent, regulating pH value and making it be 7-9; drying for 2-48 hr, at 25 deg.C-180 deg.C to form homogeneous gel, making crystallization for 12-96 hr, at 25-180 deg.C in a closed reactor, heating to 300-800 deg.C, heat-insulating for 10-20 hr, or using alcohol solution to extract for 24-72 hr, and grinding so as to obtain the titanium dioxide metaporous molecular sieve.

Owner:BEIJING UNIV OF TECH

Metal halide perovskite quantum dot CsSnX3 and preparation method thereof

InactiveCN106634987AAdjust the emission wavelengthThe method is simple and controllableNanoopticsLuminescent compositionsN dimethylformamidePhosphate

The invention provides a preparation method of a metal halide perovskite quantum dot CsSnX3. The method comprises the following steps of providing CsX, a first main solvent and a first cosolvent; after mixing, performing first heating stirring; preparing a Cs precursor; providing SnX2, a second main solvent and a second cosolvent; after mixing, performing second heating stirring; preparing an Sn precursor; heating the Sn precursor; after the temperature rises to 100 to 200 DEG C, adding the Cs precursor; performing stirring treatment; performing constant-temperature reaction for 10 to 20 min; preparing and obtaining the metal halide perovskite quantum dot CsSnX3, wherein in the CsX and the SnX2, the X is at least one of Cl, Br and I; the first cosolvent is diethyl allyl phosphate or N, N-dimethylformamide; the second cosolvent is diethyl allyl phosphate or N, N-dimethylformamide.

Owner:TCL CORPORATION

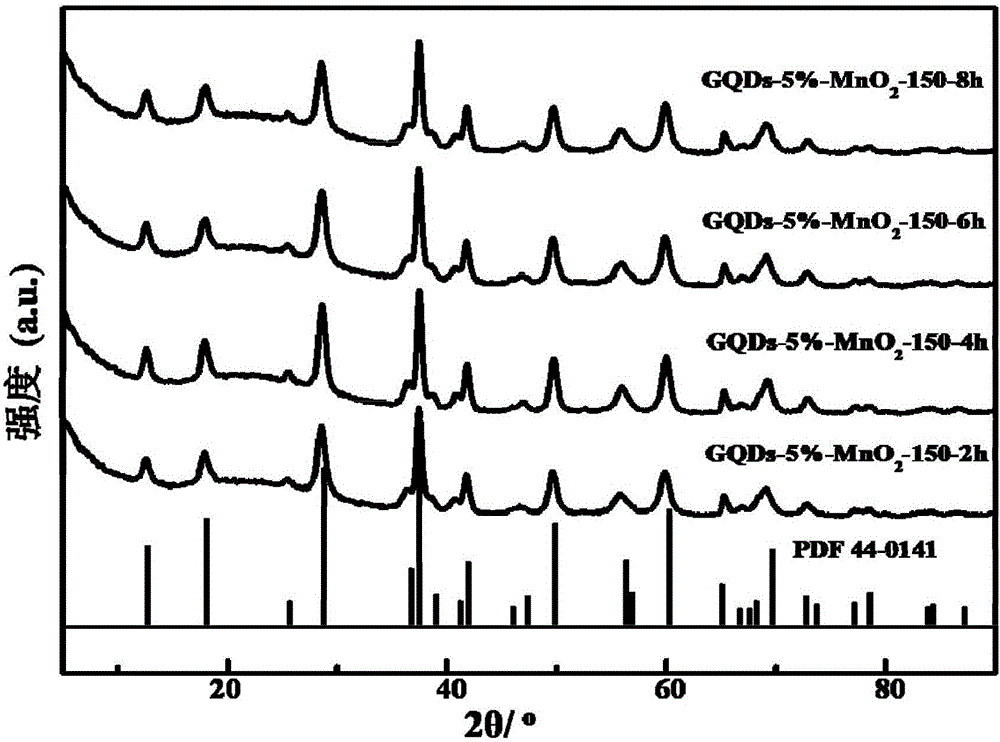

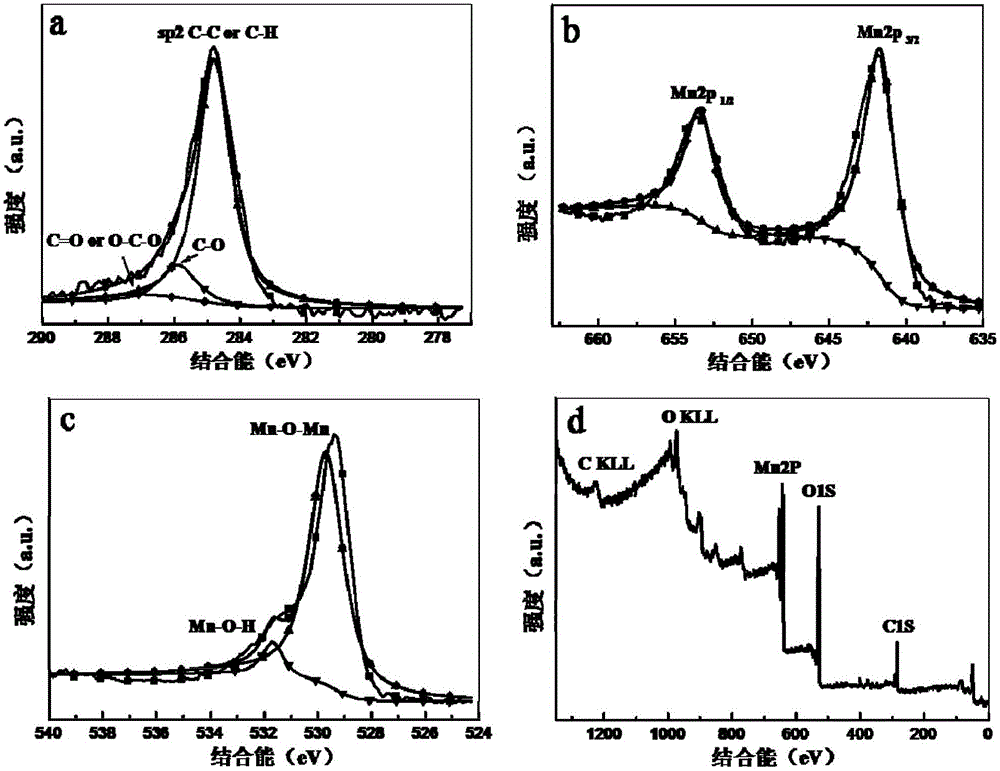

Preparation method and application of graphene quantum dots-MnO2 composite catalyst

InactiveCN104993158ALow costRich sourcesMaterial nanotechnologyCell electrodesPtru catalystFuel cells

The invention relates to a novel graphene quantum dots (GQDs)-MnO2 composite catalyst and a preparation method thereof. MnO2 is combined with GQDs to prepare the GQDs-MnO2 composite catalyst for the first time by using the physical and chemical characteristics of MnO2 and GQDs. The GQDs-MnO2 composite catalyst is prepared by adopting a hydrothermal technology, and structure of the composite catalyst can be regulated through regulating the content of GQDs and MnO2 and the crystal form and the nanometer dimension of MnO2 in order to change the electrocatalytic performances. The preparation method concretely comprises the following steps: 1, preparing and processing MnO2; 2, carrying out hydrothermal compounding on GQDs and MnO2; and 3, post-processing. The preparation method of the GQDs-MnO2 composite catalyst has the advantages of simplicity, economy and good repeatability. The composite catalyst has high catalysis activity on an oxygen reduction reaction, has good stability, and is suitable for being used as a fuel cell cathode catalyst.

Owner:DALIAN UNIV OF TECH

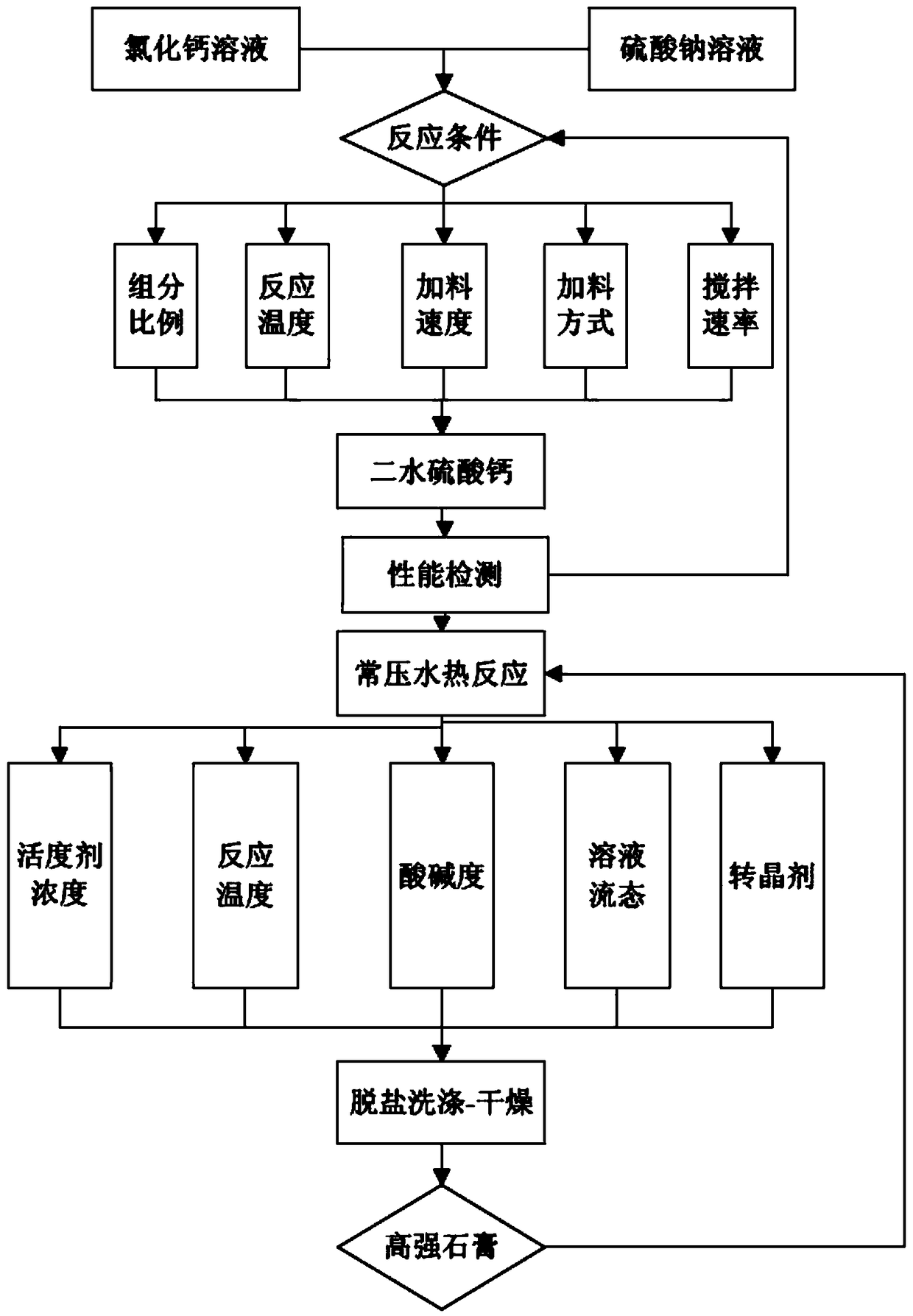

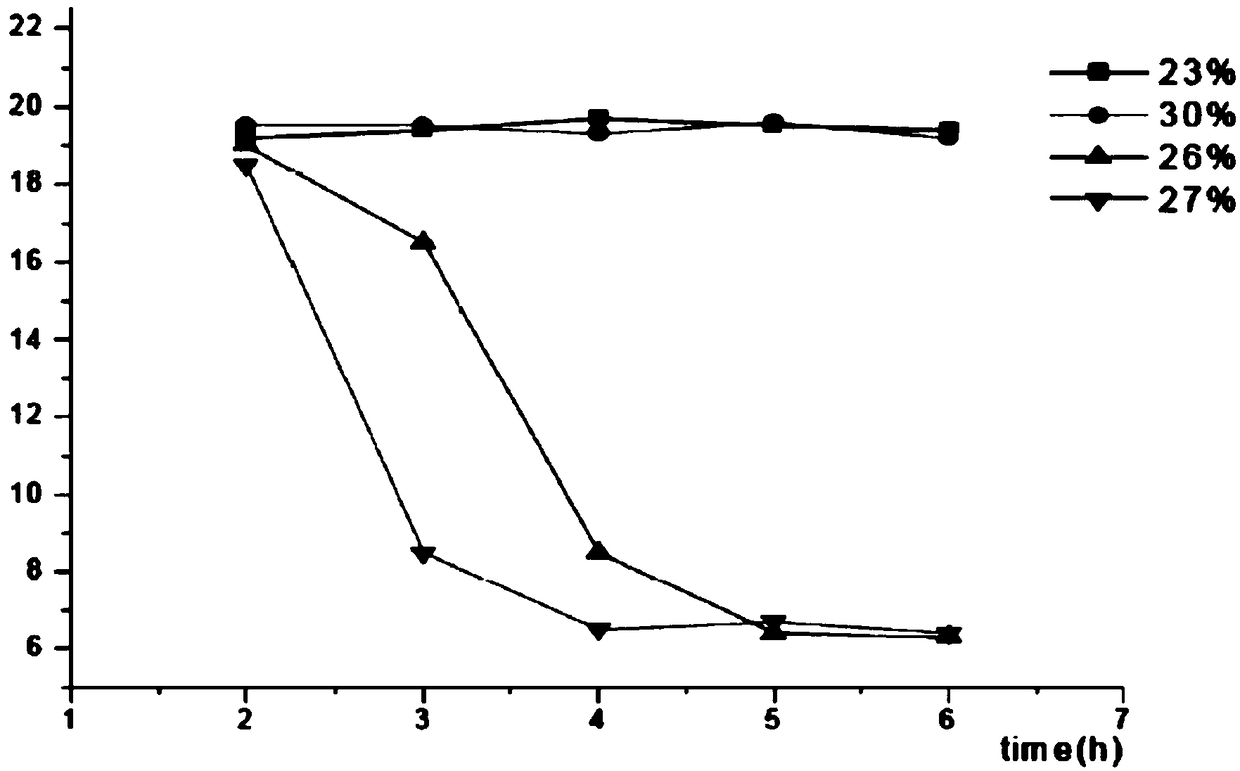

Process for preparing high-strength gypsum from salt chemical wastes

InactiveCN109369046AEffective control of aggressive growthHigh strengthCalcium/strontium/barium sulfatesSlurryChemical waste

The invention belongs to the technical field of reusing of salt chemical wastes, and discloses a process for preparing high-strength gypsum from salt chemical wastes. The process for preparing the high-strength gypsum from salt chemical wastes comprises the following steps: step 1, mixing a calcium chloride solution with old brine and stirring to obtain mixed slurry of sodium chloride and dihydrate gypsum; step 2, desalting and washing the mixed slurry to obtain purified dihydrate gypsum slurry; step 3, regulating the dihydrate gypsum slurry to be acidic, adding an activity agent and a crystalmodifier, and preparing alpha-hemihydrate gypsum by a normal-pressure hydrothermal method; step 4, carrying out solid-liquid separation; step 5, carrying out desalting, acid removal and washing; andstep 6, drying to obtain the high-strength gypsum finished product. The process for preparing the high-strength gypsum from the salt chemical wastes has the beneficial effects that active growth of the intermediate dihydrate gypsum crystals is controlled effectively, and the strength of the high-strength gypsum is improved; the normal-pressure hydrothermal method is adopted, energy consumption islow, investments are low, and a crystal form is easy to control; and the problem of solid wastes is solved effectively, and the requirements of industrial and green sustainable development are met.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD

High-quality high-purity semi-insulating silicon carbide single crystal, substrate and preparation method thereof

ActiveCN110396717AHigh purityReduce the temperaturePolycrystalline material growthFrom condensed vaporsSemiconductor materialsGas phase

The invention discloses a high-quality high-purity semi-insulating silicon carbide single crystal, a substrate and a preparation method thereof and belongs to the field of semiconductor materials. Thepreparation method of the high-quality high-purity semi-insulating silicon carbide single crystal comprises the following steps: putting a silicon carbide raw material into a crucible, performing sublimation so as to obtain a sublimation raw material, and conveying the sublimation raw material into a primary seed crystal through an axial temperature gradient gas phase in the crucible to implementprimary crystal growth, so as to obtain the high-quality high-purity semi-insulating silicon carbide single crystal, wherein at least one transition seed crystal is arranged between the silicon carbide raw material and the primary seed crystal; and with the transition seed crystal, at least a part of the sublimation raw material has a single crystal growth-resublimation process once. By adoptingthe preparation method disclosed by the invention, the semi-insulating silicon carbide single crystal of a very high purity can be prepared from the silicon carbide raw material of a low purity, meanwhile, the growth quality of the high-purity semi-insulating silicon carbide single crystal can be also taken into account, and the production cost is low; and in addition, the high-purity semi-insulating silicon carbide single crystal and the substrate thereof disclosed by the invention are free of or slight in defect, high in purity, high in quality and good in uniformity.

Owner:SICC CO LTD

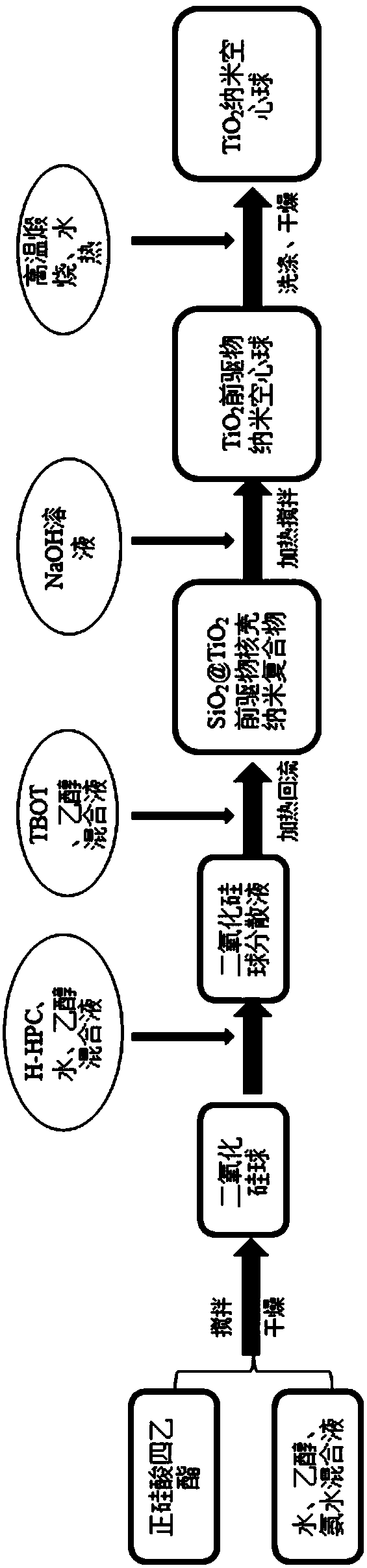

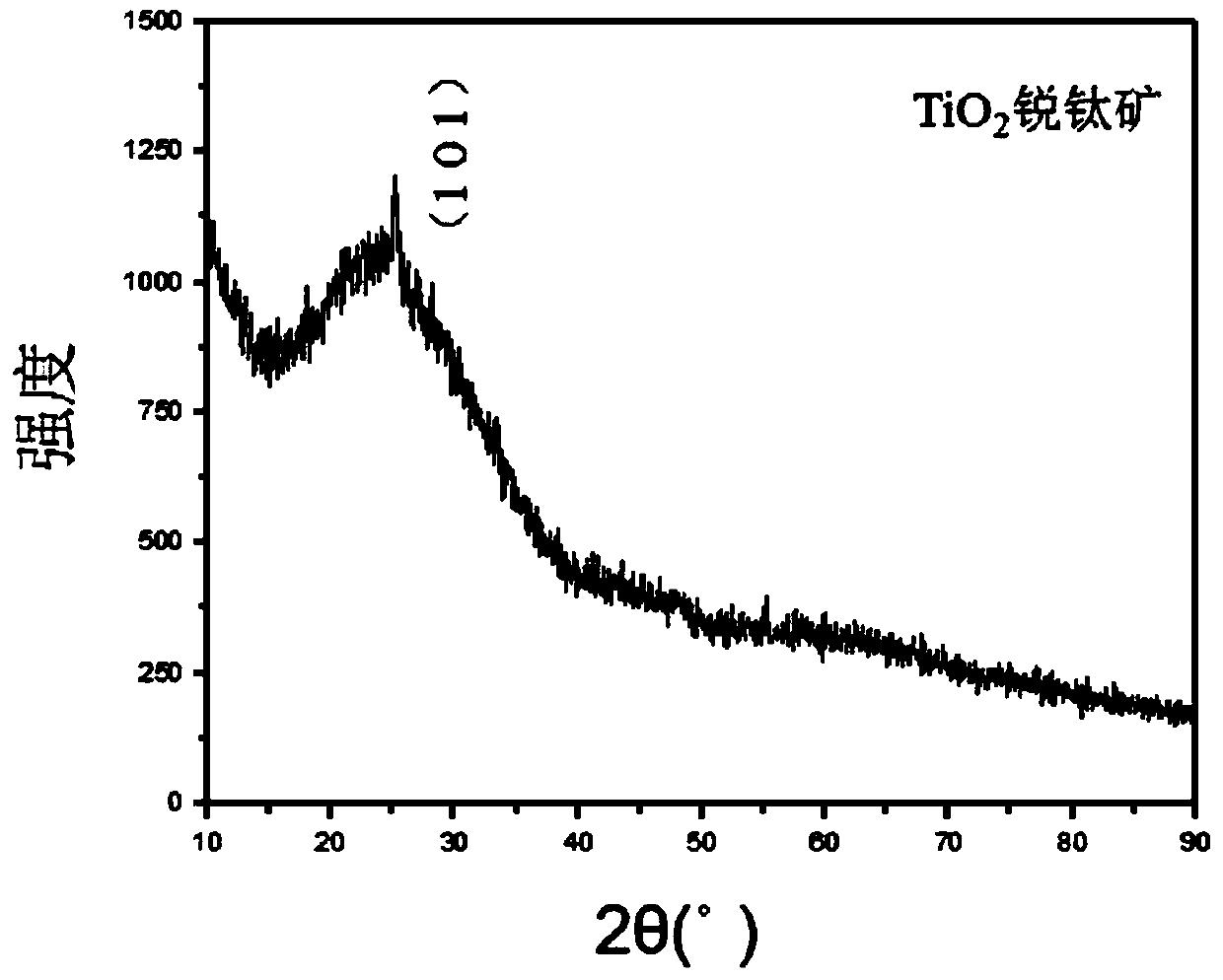

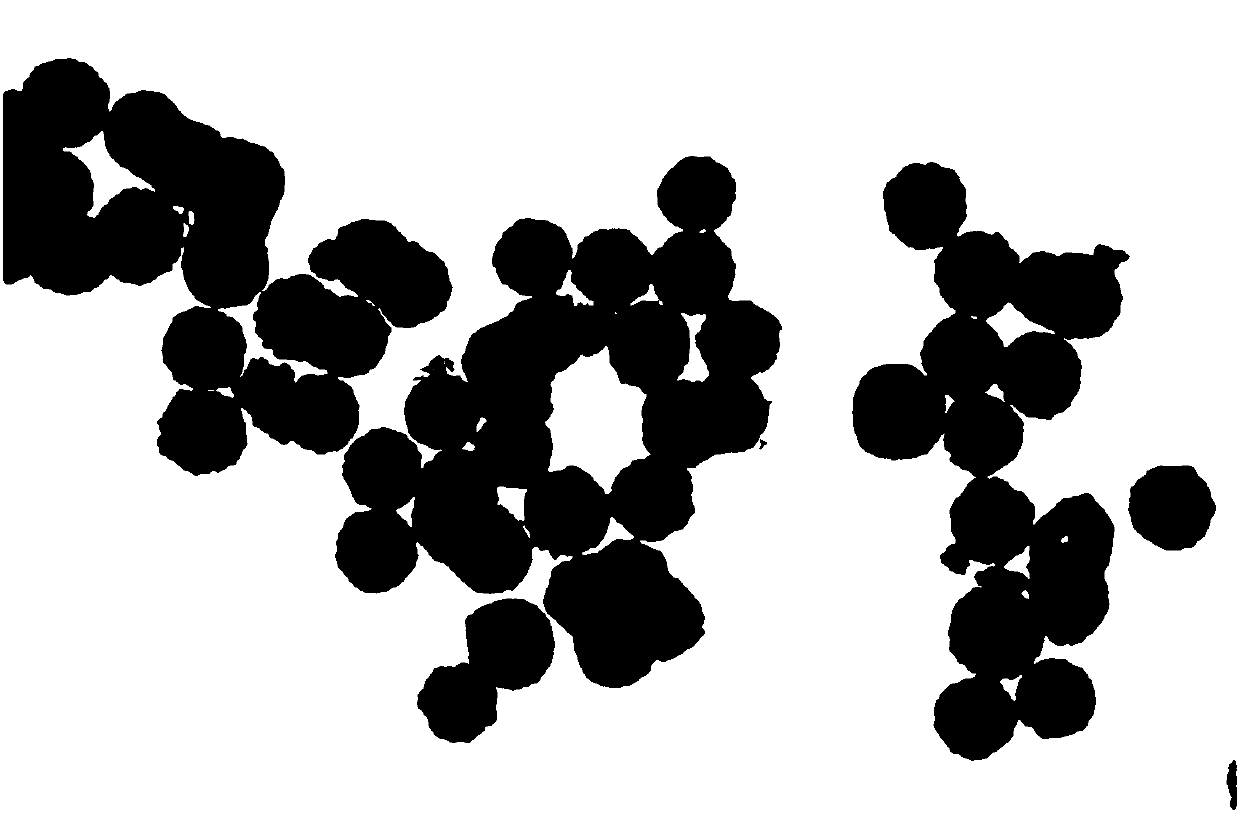

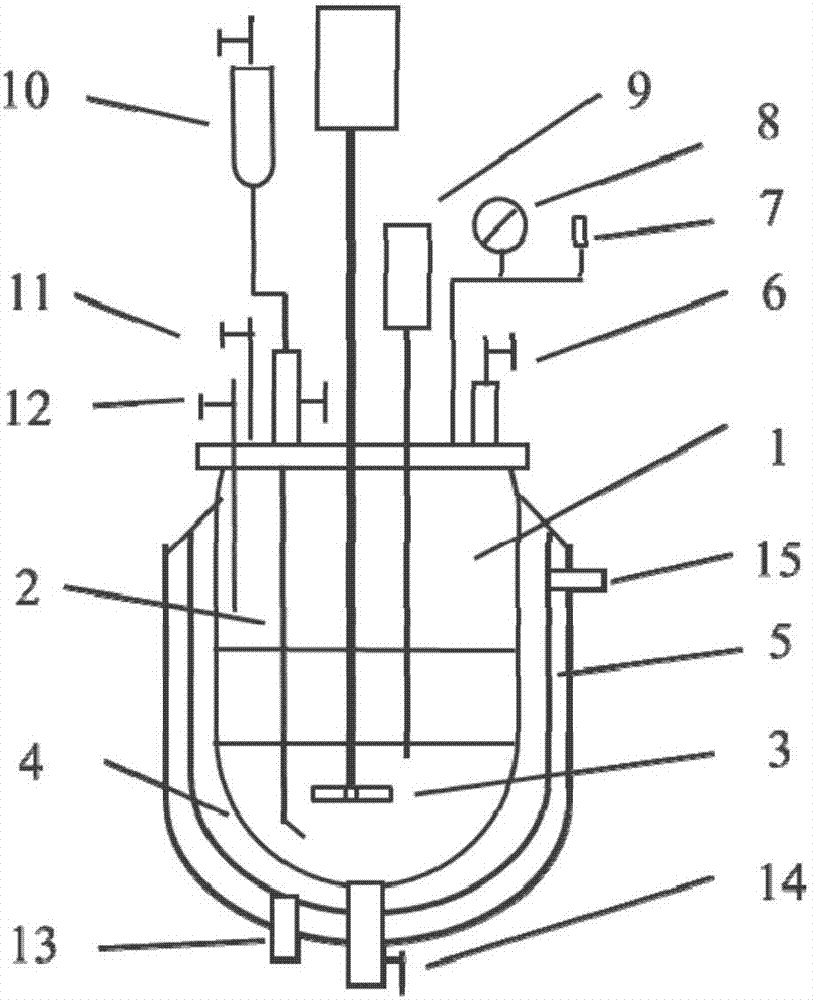

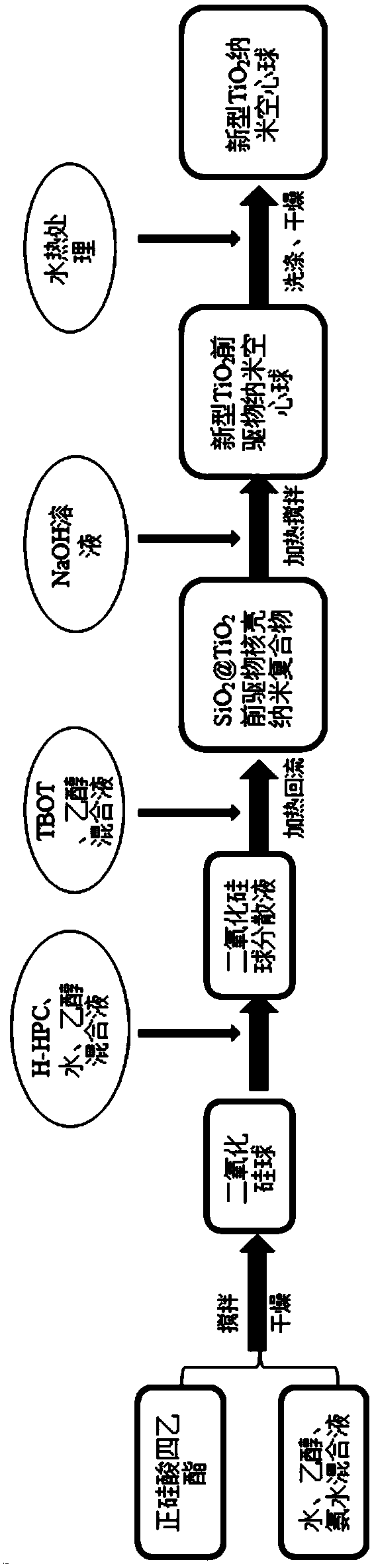

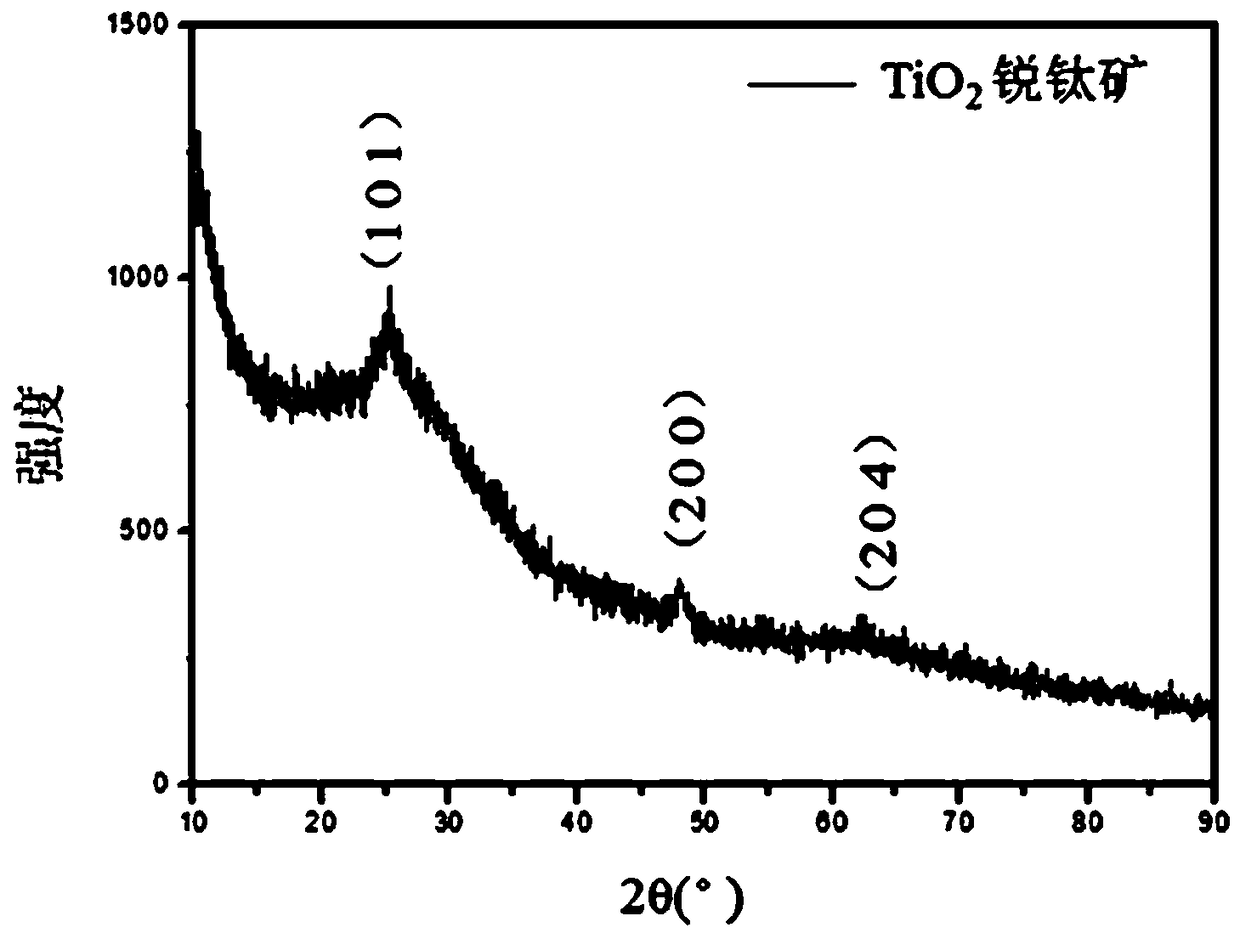

Titanium dioxide hollow nanospheres and preparation method thereof

InactiveCN108675345AGrowth inhibitionInhibition of coagulationSilicaPhysical/chemical process catalystsMicrosphereSilicon dioxide

The invention discloses a preparation method of titanium dioxide hollow nanospheres. The preparation method comprises the following steps: firstly, taking tetraethyl orthosilicate as a silicon sourceand preparing silicon dioxide microspheres by adopting a Stobe method; then cladding the surfaces of the silicon dioxide microspheres with a titanium dioxide precursor; then removing a silicon dioxideinner core by adopting strong alkali corrosion; finally, carrying out calcination and hydrothermal treatment to prepare anatase form titanium dioxide hollow nanospheres. The invention further discloses the titanium dioxide hollow nanospheres prepared by the preparation method provided by the invention. The method disclosed by the invention is simple to operate, low in production cost, small in process pollution, high in product yield, good in repeatability and suitable for large-scale production. A titanium dioxide nano-product prepared by the method has the advantages of high purity, good crystallization, controllable crystal form, fine particle granularity, uniform particles, good monodispersity, small particle size, large specific surface area and high photocatalytic activity.

Owner:NORTHEASTERN UNIV

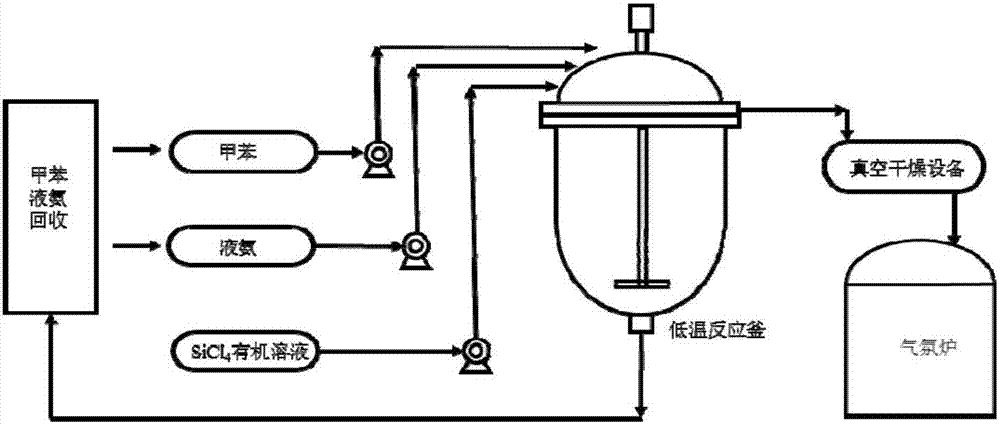

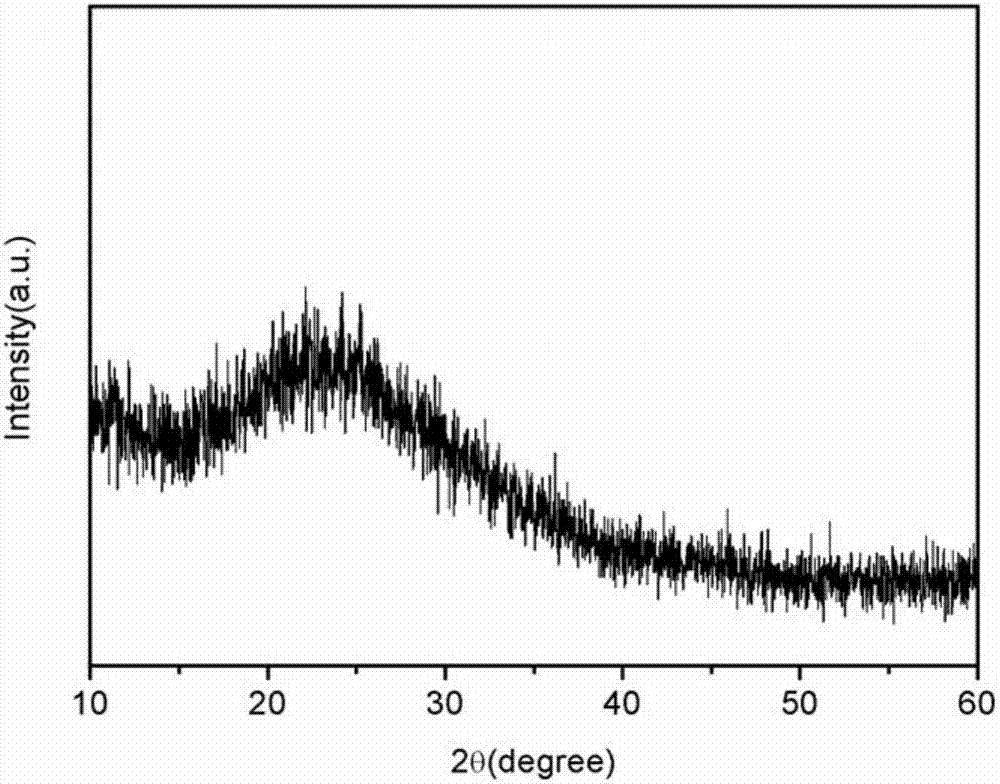

Preparation method of alpha-phase silicon nitride powder

ActiveCN107954723AEasy to cleanSimple internal structureNitrogen compoundsChemical/physical/physico-chemical stationary reactorsInterfacial reactionReaction rate

The invention discloses a preparation method of alpha-phase silicon nitride powder. The preparation method comprises the following steps: (1) reacting silicon tetrachloride with liquid ammonia in a two-liquid-phase interface of an organic solvent and the liquid ammonia to obtain a precursor which is silylimine, wherein the organic solvent is methylbenzene or a mixture of the methylbenzene and dimethylbenzene; (2) carrying out thermal decomposition on the silylimine to obtain non-shaped silicon nitride powder; and (3) carrying out crystallization treatment on the non-shaped silicon nitride powder in step (2) to obtain the alpha-phase silicon nitride powder. In the method, silicon tetrachloride reacts with the liquid ammonia on the two-liquid-phase interface of the organic solvent and the liquid ammonia, the silicon tetrachloride is diluted at low temperature, the reaction rate can be reduced by control over feeding speed, synthesis of the precursor can be controlled effectively, the circumstance that aggregates are formed by the precursor is avoided, the reaction area is expanded by interfacial reaction, and the speed of NH4Cl dissolved in the liquid ammonia is increased. The prepared alpha-Si3N4 powder is controllable in crystal form and morphology, grain sizes are distributed uniformly, a technological process is simple, and production requirements can be met.

Owner:浙江英德赛半导体材料股份有限公司

Titanium dioxide hollow nanospheres and preparation method thereof

ActiveCN108640149AHigh purityUniform particlesMaterial nanotechnologyPhysical/chemical process catalystsDispersityMicrosphere

The invention discloses a preparation method of titanium dioxide hollow nanospheres. The preparation method comprises the following steps: firstly, silicon dioxide microspheres are prepared from tetraethyl orthosilicate as a silicon source with a Stobe method, then, surfaces of the silicon dioxide microspheres are coated with a titanium dioxide precursor, silicon dioxide cores are removed by strong alkali corrosion, and finally, the crystalline titanium dioxide hollow nanospheres with flaky branch structures on the surface are prepared by hydrothermal treatment. The invention further disclosesthe titanium dioxide hollow nanosphere prepared with the preparation method. The method is simple to operate and good in repeatability, does not need high-temperature sintering, is suitable for large-scale production, avoids agglomeration of titanium dioxide powder, low in process pollution and achieves high product yield and low production cost; the obtained titanium dioxide hollow nanospheres have high purity, uniform particles, good crystallization, controllable crystal form, good dispersity, large specific surface area, high adsorption capacity and capture capacity for pollutants and highphotocatalytic efficiency, and a plurality of flaky branches are contained on the surface.

Owner:NORTHEASTERN UNIV

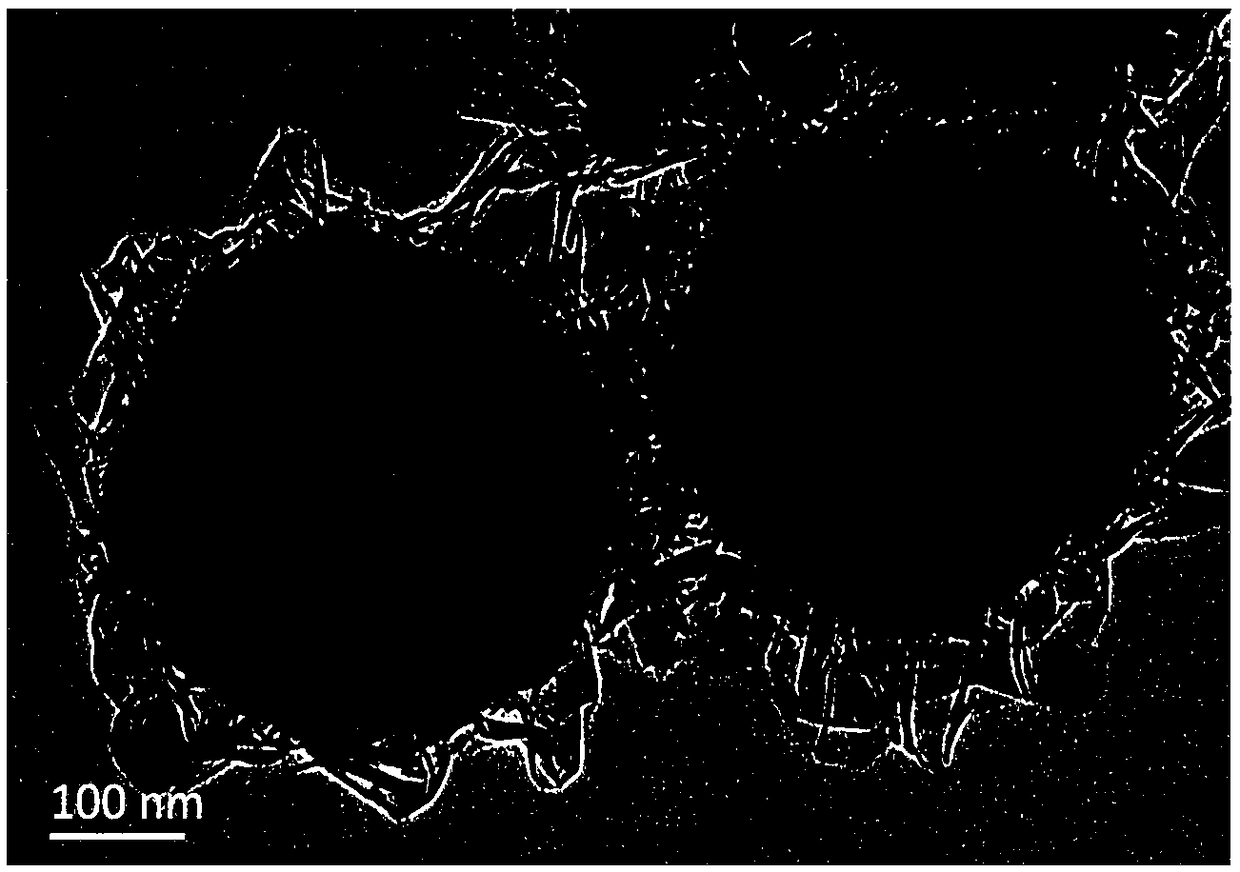

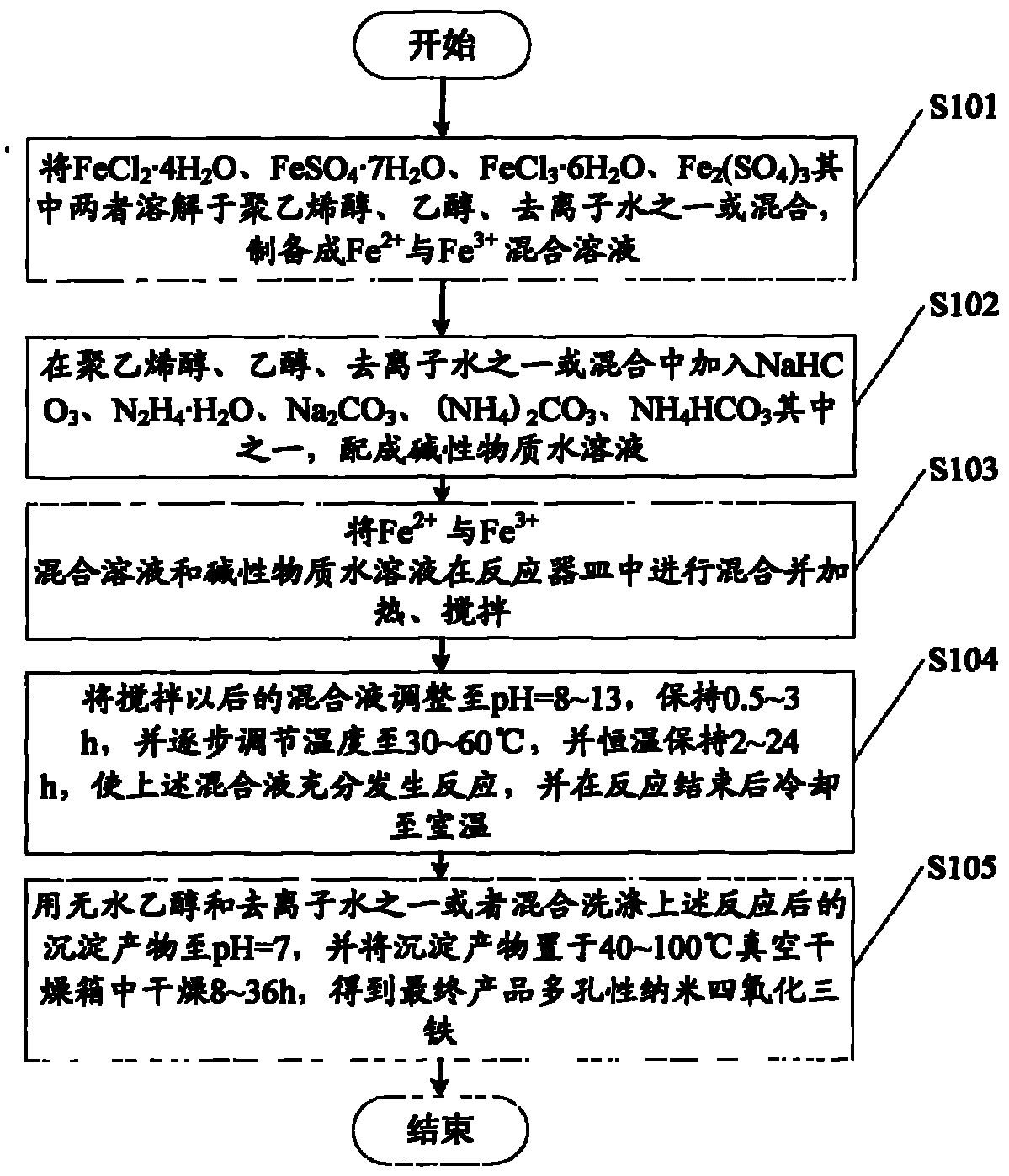

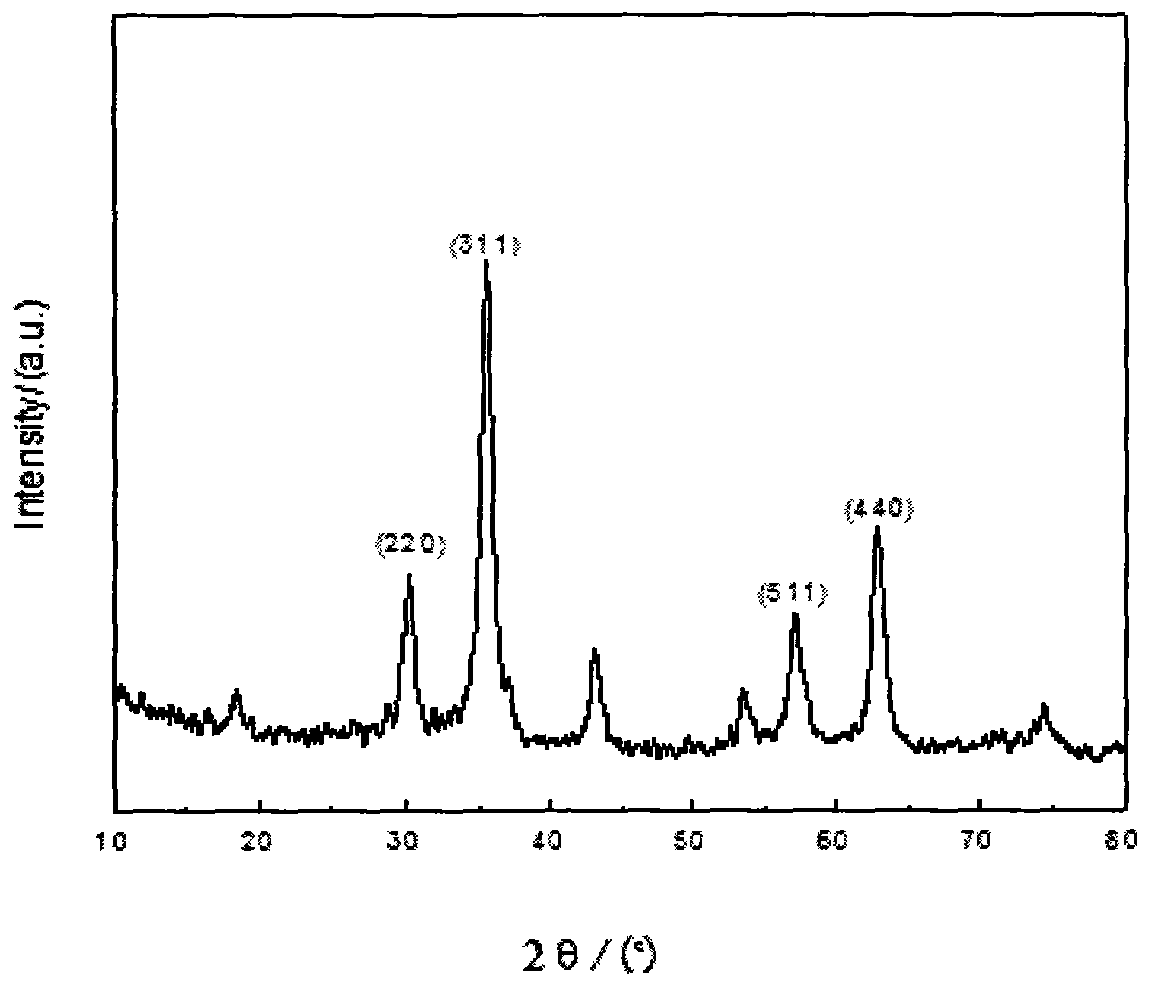

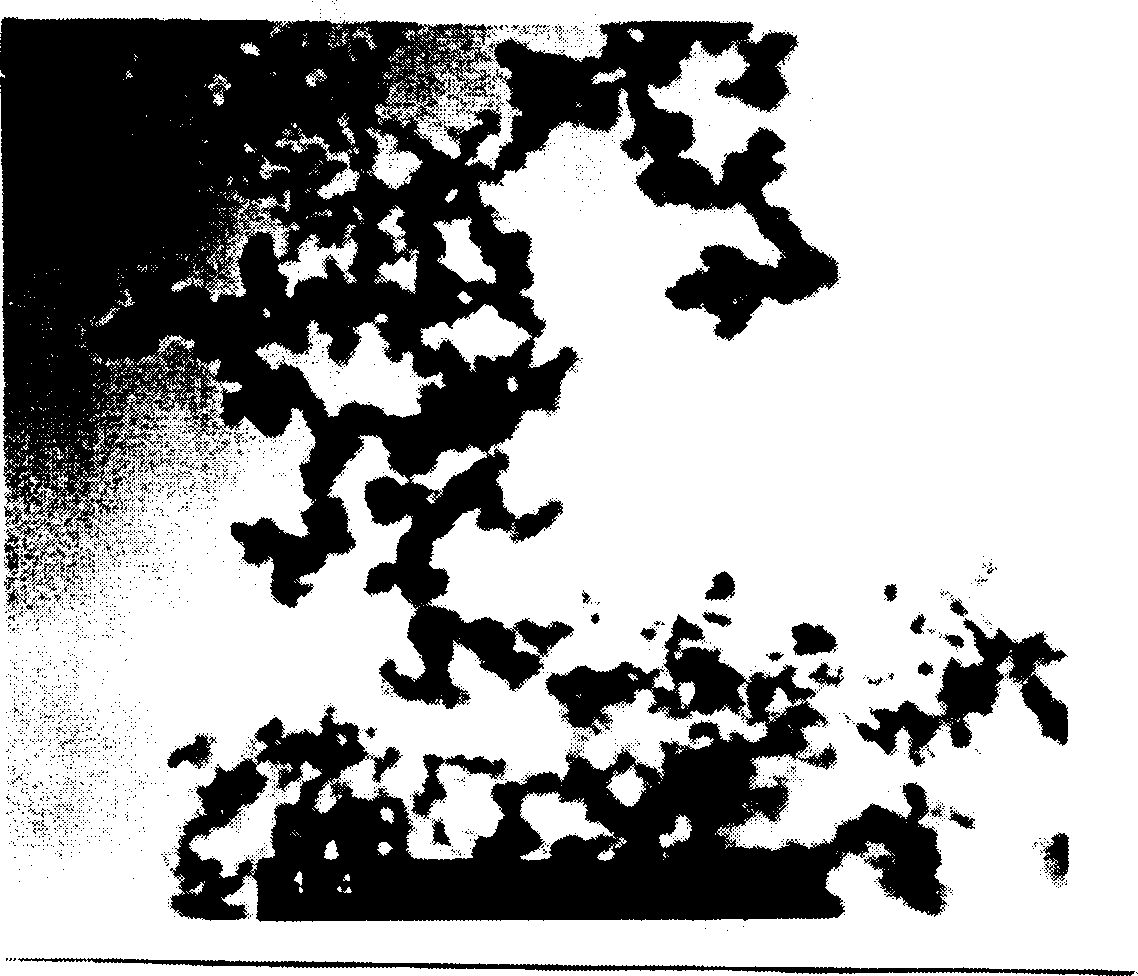

Method for preparing porous nano ferroferric oxide

ActiveCN103739020AHigh degree of crystallinityWell-developed pore structureMaterial nanotechnologyFerroso-ferric oxidesPolyvinyl alcoholRoom temperature

The invention discloses a method for preparing porous nano ferroferric oxide. The method comprises the steps: dissolving two of FeCl2.4H2O, FeSO4.7H2O, FeCl3.6H2O and Fe2(SO4)3 in one of polyvinyl alcohol, ethanol and deionized water or a mixture thereof to obtain a mixed solution containing Fe<2+> and Fe<3+>; adding one of NaHCO3, N2H4.H2O, Na2CO3, (NH4)2CO3 and NH4HCO3 in one of polyvinyl alcohol, ethanol and deionized water or the mixture thereof to obtain an alkaline substance aqueous solution; mixing the mixed solution containing Fe<2+> and Fe<3+> with the alkaline substance aqueous solution in a reaction vessel, heating, and stirring; adjusting the pH of the stirred mixed liquid to 8-13, keeping for 0.5-3 h, gradually adjusting the temperature to 30-60 DEG C, keeping the constant temperature for 2-24 h, allowing the mixed liquid to fully undergo a reaction, and after finishing the reaction, cooling to the room temperature; and washing the precipitate product after reaction with one of anhydrous ethanol and deionized water or a mixture thereof until the pH is 7, and drying for 8-36 h. The reaction process has no need of inert gas protection, and the industrialized production doorsill is low.

Owner:TAIYUAN UNIV OF TECH

Preparation method of zirconium silicate powder

ActiveCN102557055AQuality improvementNarrow particle size distributionSilicon compoundsProcess equipmentReaction temperature

The invention discloses a preparation method of zirconium silicate powder. The preparation method comprises the steps: adding ZrOCl2.8H2O, tetraethyl orthosilicate and NaF into distilled water to obtain a precursor solution A, adding hydrochloric acid into the precursor solution A to regulate a pH value to be 1-6.5 to obtain sol B, placing the sol B into an ultrasonic generator for ultrasonic reaction, and naturally cooling to room temperature after the reaction is finished; and taking out a reactant, leaching and collecting the reactant by using filter paper, then washing the reactant by using deionized water and absolute ethyl alcohol respectively, and drying in an electrothermal blowing dry box to obtain the zirconium silicate powder. According to the invention, the zirconium silicate power with high quality can be prepared by using a sol-gel assisted ultrasonic acoustochemical method. Because the reaction is completed in a liquid phase, annealing crystallization treatment is not needed in a later stage; the preparation method has the advantages of simple technological equipment, low reaction temperature, short period and good repeatability; and the obtained zirconium silicate grains are narrow in grain size distribution and controllable in crystal form.

Owner:路亚科消防车辆制造有限公司

Preparation of high-purity nanometer silicon dioxide

Owner:优美特(北京)环境材料科技股份公司

Spherical zirconium silicate nanometer crystal preparation method

ActiveCN102502675ASimple process equipmentEasy to operateNanotechnologySilicon compoundsIonUltrasonic generator

A spherical zirconium silicate nanometer crystal preparation method includes steps of adding ZrOCl2 8H2O, Na2SiO3 9H2O and PVP (polyvinyl pyrrolidone) into distilled water to obtain precursor liquid A, and adding LiF into the precursor liquid A to obtain liquor B; filling the liquor B in an ultrasonic generator to realize reaction under ultrasonic initiation, and naturally cooling to reach room temperature after reaction to obtain liquor C; pouring the liquor C into a hydrothermal reactor, then sealing the hydrothermal reactor, placing the hydrothermal reactor into a microwave hydrothermal reaction instrument, and naturally cooling to reach the room temperature after reaction to obtain liquor D; and collecting the liquor D by means of leaching of filter paper, then washing the collected liquor D by the aid of deionized water and anhydrous ethanol, and drying the washed liquor D in a draught drying cabinet to obtain spherical zirconium silicate nanometer crystals. Ultrasonic waves are adopted in a microwave hydrothermal method, so that the spherical zirconium silicate nanometer crystals with controllable crystalline forms and controllable sizes can be prepared at low temperature. Reactions are completed in liquid phase, accordingly, process equipment is simple, operation is convenient, raw materials can be obtained easily, preparation cost is low, distribution of grain sizes of the zirconium silicate crystals is narrow, the crystallize forms are controllable, reaction temperature is low, reaction period is short, and repeatability is good.

Owner:江苏华莱明新能源科技有限公司

Betrixaban salt, preparation method and application thereof

InactiveCN105085387AEasy to prepareHigh purityOrganic chemistry methodsRespiratory disorderSolubilityBetrixaban

The present invention relates to betrixaban salts as shown by formula II, wherein the method for preparing these salts is simple, the crystal form is easy to control, the stability and solubility are good, and the salts are suitable for preparing a variety of preparations. The present invention also relates to the method for preparing these salts, pharmaceutical compositions comprising these salts, and the use of these salts in the preparation of medicaments for the prevention and treatment of diseases characterized by adverse thrombus formation in mammals.

Owner:SICHUAN HAISCO PHARMA CO LTD

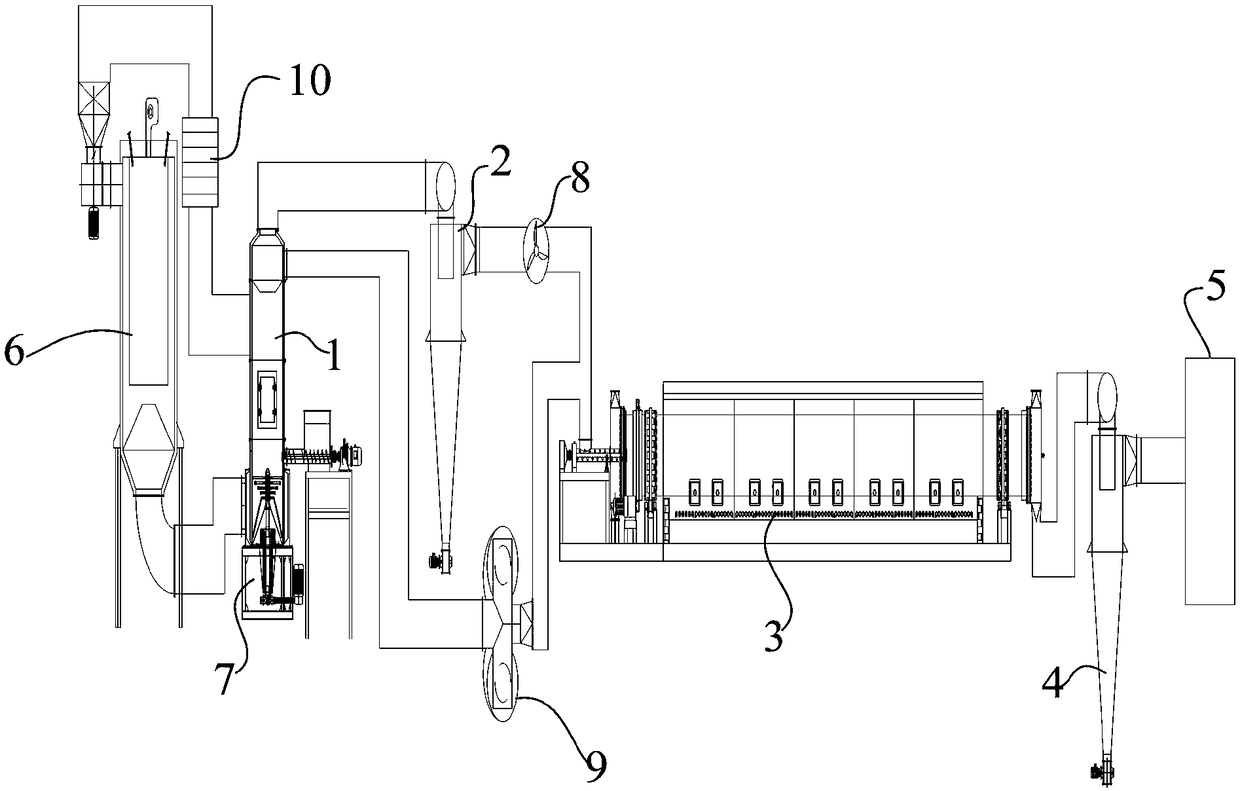

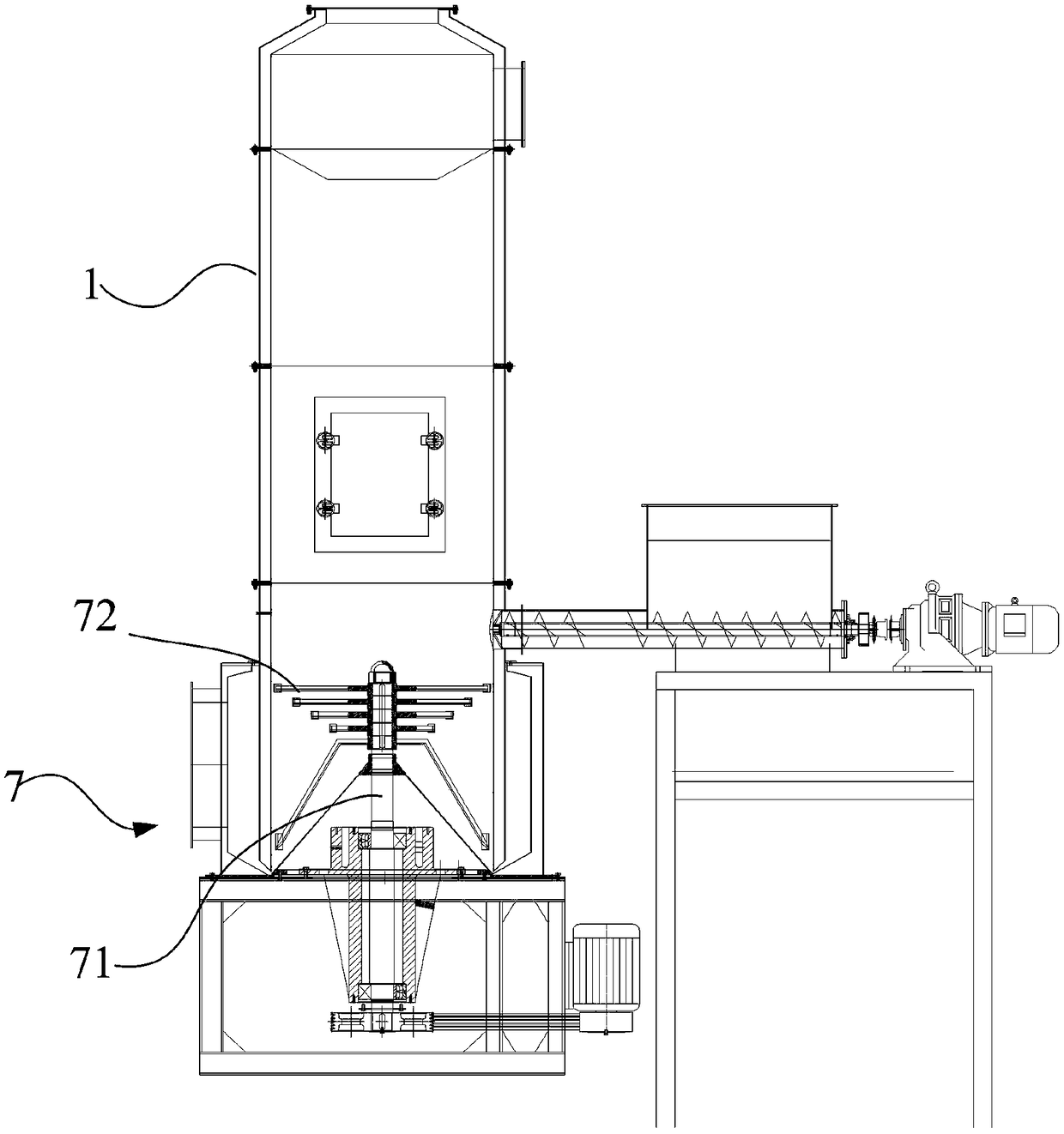

Iron phosphate continuous dehydration and crystal form controllable system and control method thereof

InactiveCN108731429AImprove sintering efficiencyCrystal form controllableRotary drum furnacesDrying gas arrangementsElectric heatingIron phosphate

The invention belongs to the field of iron phosphate preparation, and particularly relates to an iron phosphate continuous dehydration and crystal form controllable system and a control method thereof. The system comprises a flash steaming dryer, a cyclone dust collector, a rotary kiln, a second cyclone dust collector and a packaging machine, which are arranged in sequence along a logistical direction; a hot air blower which is used for supplying air to the flash steaming dryer is arranged at one side of the flash steaming dryer; the hot air blower is communicated with the bottom of the flashsteaming dryer; a beater which is used for beating the hot air and forming cyclone in the flash steaming dryer is arranged at the bottom of the flash steaming dryer; a second beater is arranged between the cyclone dust collector and the rotary kiln; the rotary kiln is an external electric heating type rotary calcining kiln; and a flash dry bag filter which is used for collecting free water tail gas not dehydrated by the cyclone dust collector is arranged between the flash steaming dryer and the rotary kiln. The iron phosphate continuous dehydration and crystal form controllable system and thecontrol method thereof are small in investment, low in energy consumption and suitable for large-scale popularization and application.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

Method for preparing flaky silicic acid zirconium nanocrystalline

ActiveCN102502673BNarrow particle size distributionCrystal form controllableNanotechnologySilicon compoundsFiltrationSilicic acid

The invention discloses a method for preparing flaky silicic acid zirconium nanocrystalline. ZrCl4, ethyl orthosilicate and CTAB are added into distilled water for obtaining a precursor liquid A, hydrochloric acid is added into the precursor liquid A to adjust the PH value to be 1 to 5, and a gelatin D is obtained at the room temperature through ageing; the gelatin D is put into a constant temperature drying box for drying, and then put into a mortar box for grinding after being dried, and powder E is obtained; the power E is prepared into a suspending liquid, then the suspending liquid is poured into a hydrothermal reaction kettle, then the hydrothermal reaction kettle is sealed and placed into a microwave hydrothermal reaction instrument for reaction, after reaction, and then through natural cooling to the room temperature, a cooling solution F is obtained; the solution F is collected through suction filtration of filter paper, then both deionized water and absolute ethyl alcohol are adopted for washing, and then the flaky silicic acid zirconium nanocrystalline is obtained through drying in an electric heating blast drying box. In the invention, sol-gel is adopted for assisting a microwave hydrothermal method to prepare the flaky silicic acid zirconium nanocrystalline, since the reaction is accomplished in liquid phase, later annealing crystallization treatment is not required, the particle size distribution of obtained silicic acid zirconium nanocrystalline is narrow, the crystal formation is controllable, the reaction temperature is low, the period is short, and the repetitiveness is excellent.

Owner:临沂市高新汽车租赁服务有限公司

Preparation method of zinc oxide nano film, sensor electrode and electrochemical sensor

InactiveCN103575780ALarge specific surface areaHigh purityNanostructure manufactureZinc oxides/hydroxidesZincNanometre

The invention relates to a preparation method of a zinc oxide nano film, an electrochemical sensor electrode and an electrochemical sensor. According to the preparation method, the zinc oxide nano film can be controllably prepared by virtue of a hydrothermal method; as being adhered to the surface of a zinc sheet, the prepared ultrathin zinc oxide nano film can be directly taken as the electrode and the sensor to be directly applied to matter detection.

Owner:ANHUI NORMAL UNIV

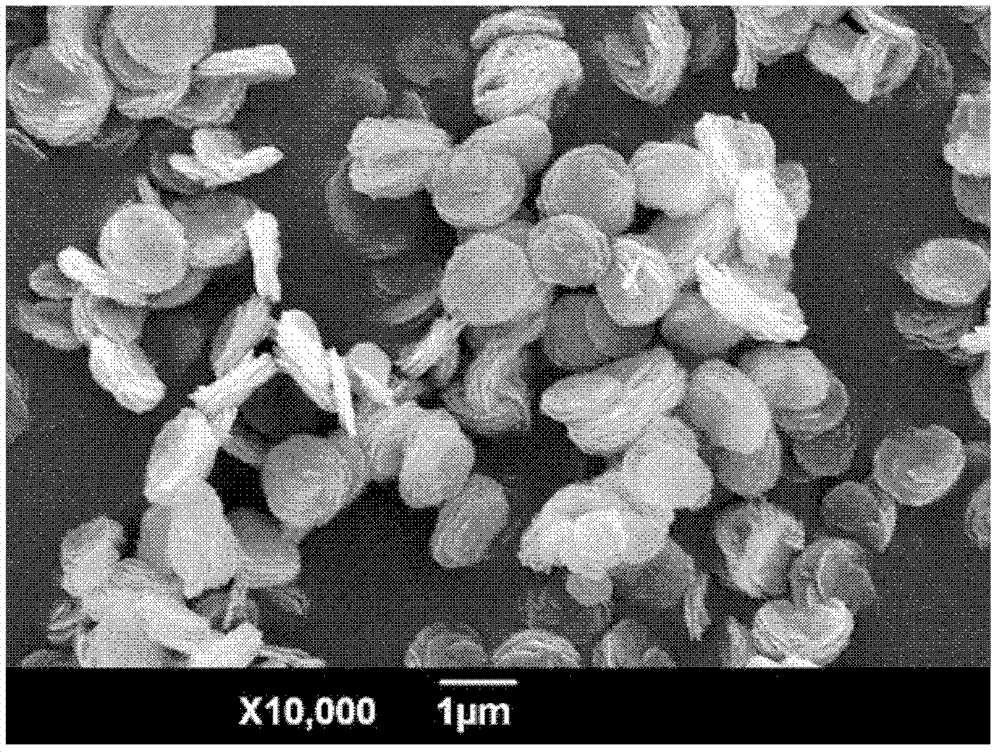

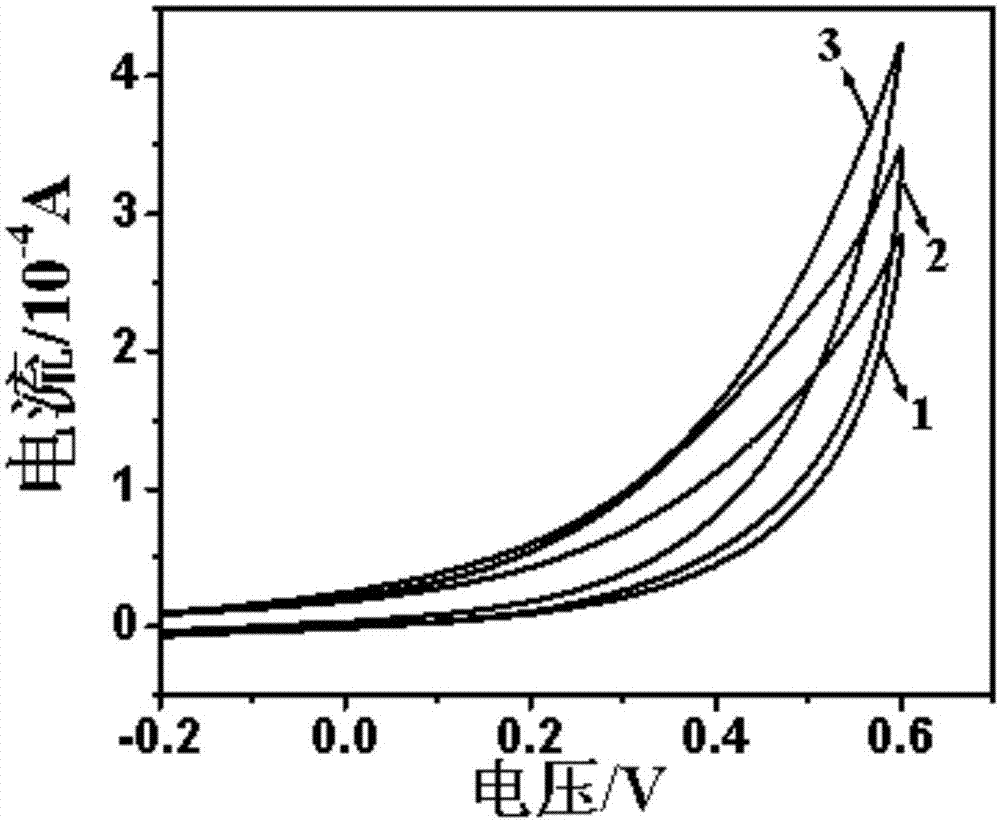

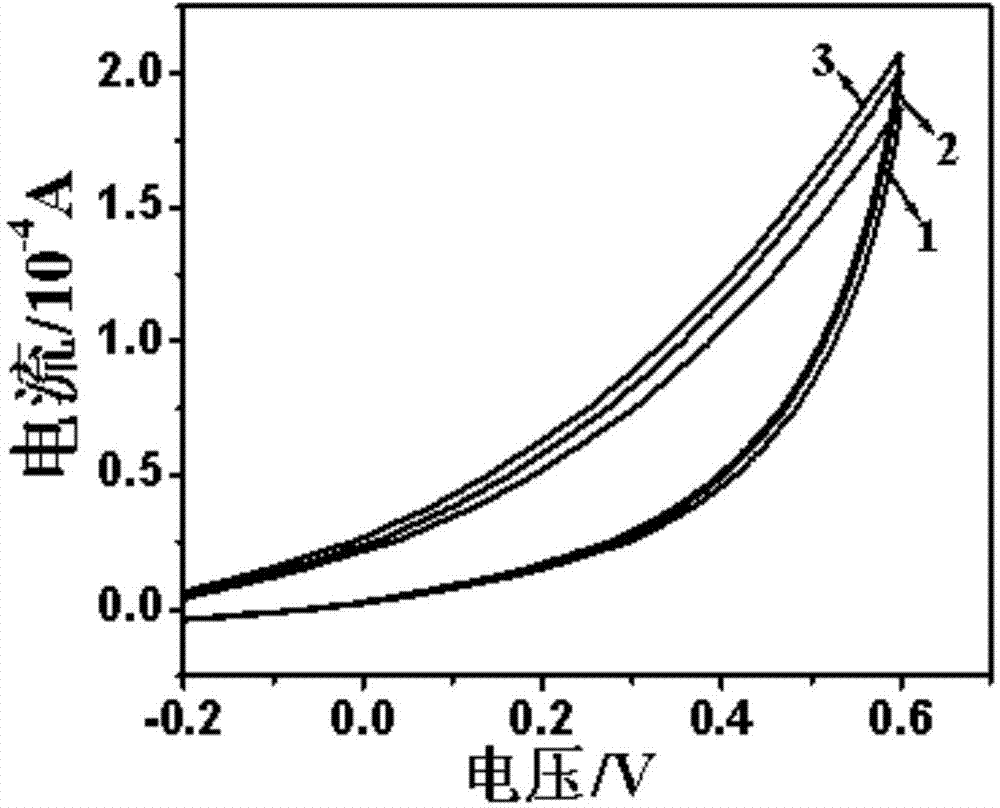

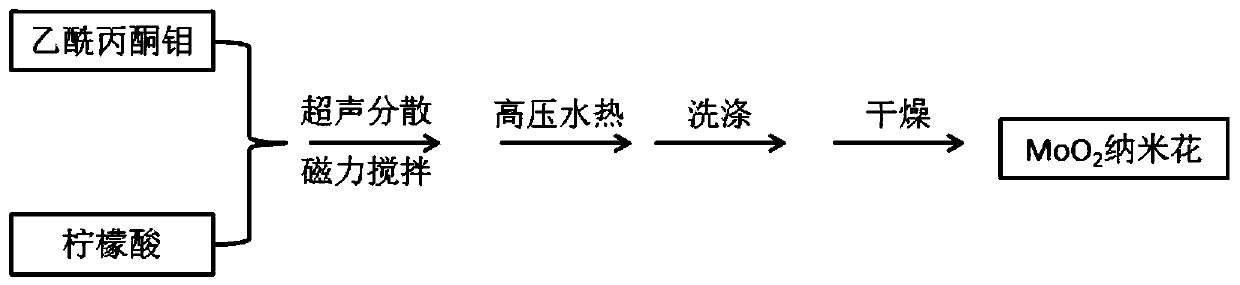

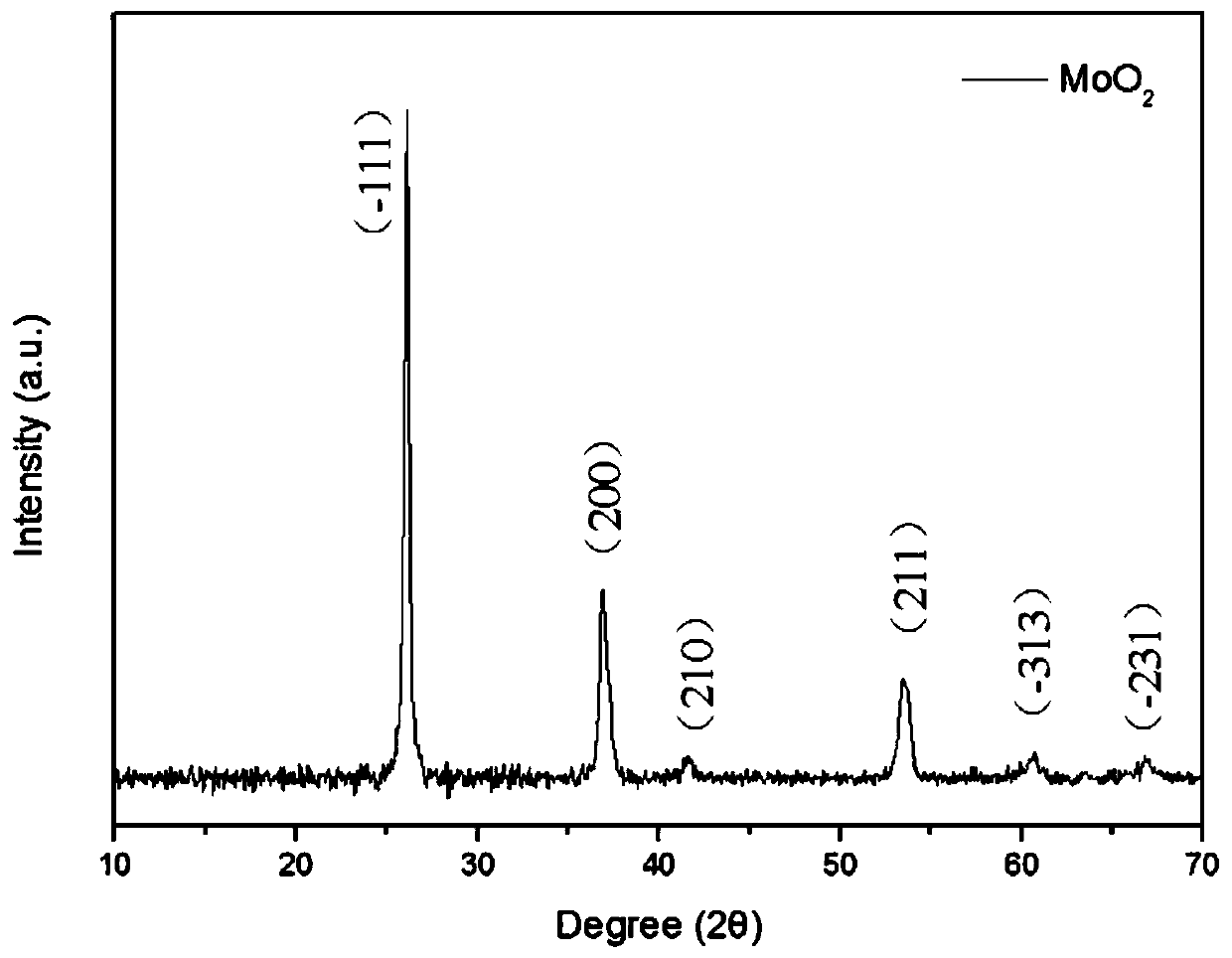

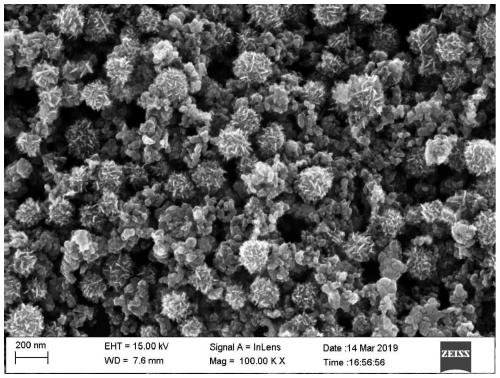

Preparation method of flower-like MoO2 (Molybdenum dioxide) nano material

InactiveCN110182847AUniform particlesHigh purityNanotechnologyMetal/metal-oxides/metal-hydroxide catalystsHigh pressureUltrasonic dispersion

The invention relates to the technical field of metal oxide catalytic materials, in particular to a preparation method of a flower-like MoO2 (Molybdenum dioxide) nano material. The method comprises the following steps: S1, adding citric acid to suspension of molybdenyl acetylacetonate, and completely dissolving the molybdenyl acetylacetonate by at least one way of ultrasonic dispersion, stirring or oscillation to obtain a reaction system; S2, placing the reaction system in a high-pressure reaction kettle for a hydrothermal reaction to obtain black gray precipitates; S3, collecting the precipitates. According to the method provided by the invention, flower-like MoO2 nanoparticles with the particle diameter of 100 to 200 nm can be obtained; the microscopic morphology of the flower-like MoO2nanoparticles is a spherical surface with flake-like branches / fins; the flower-like MoO2 nanoparticles show photocatalytic activity and organic matter degradation ability far superior to existing spherical MoO2 nanoparticles.

Owner:NORTHEASTERN UNIV

Solar cell backboard

ActiveCN105789358AHigh UV reflectivityHigh glossPhotovoltaic energy generationSemiconductor devicesPolyolefinWeather resistance

The invention relates to a solar cell backboard. The backboard comprises a weather resistance layer, a base material layer and a polyolefin layer. A weather resistance coating is obtained by coating and drying a weather resistance coating liquid. An inorganic filler in the weather resistance coating liquid is formed by 5-90% titanium dioxide coating shape silicate composite particles and 10-95% titanium dioxide. The backboard in the invention maintains a high-efficiency ultraviolet absorption ability, and simultaneously water resistance performance, insulation performance, salt-fog resistance performance and the like can be improved so that overall performance of the backboard is increased.

Owner:乐凯胶片股份有限公司

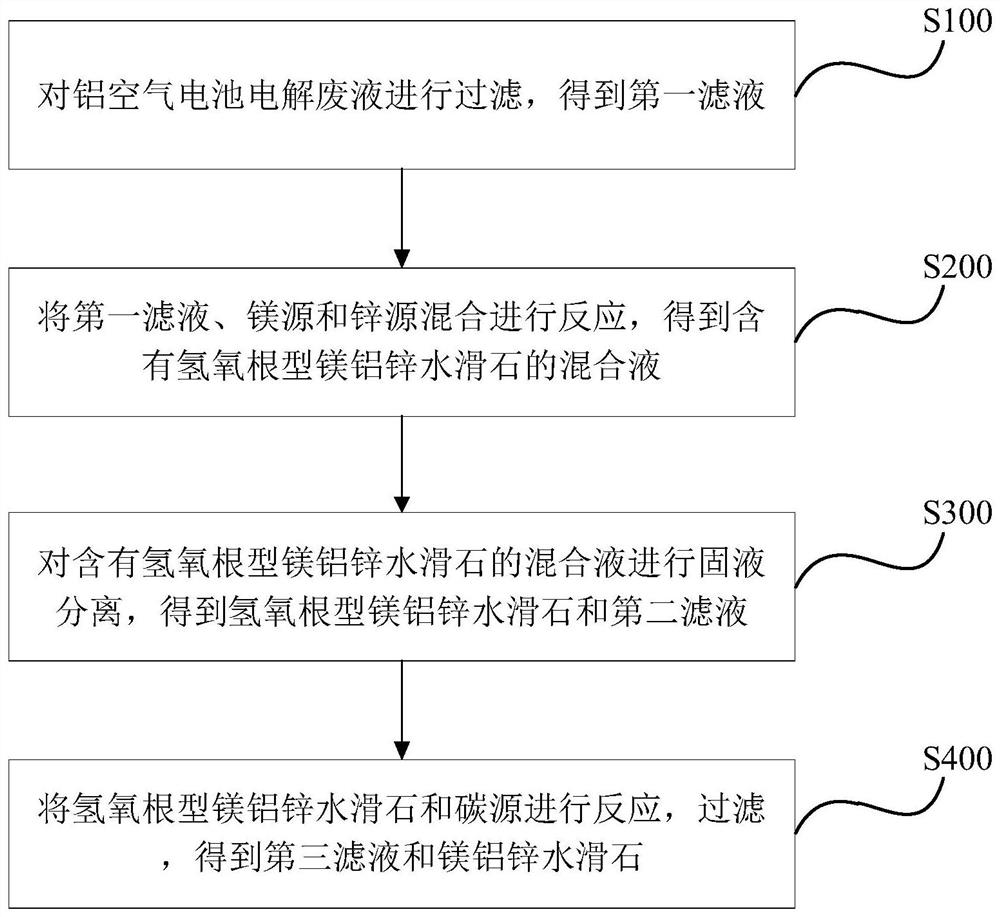

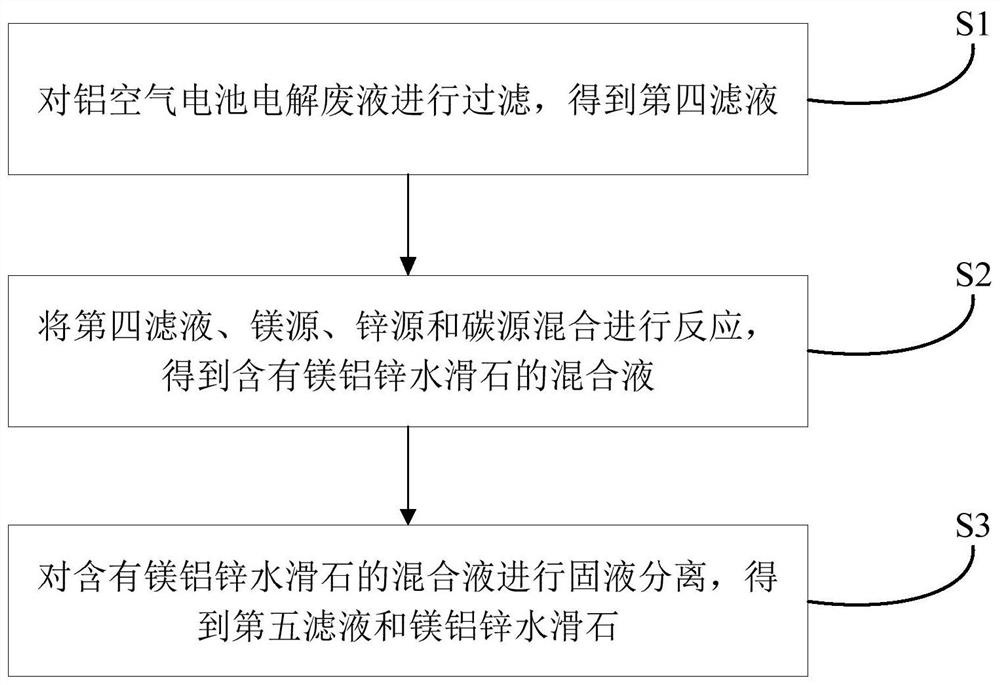

Method for preparing magnesium-aluminum-zinc hydrotalcite from aluminum-air battery electrolytic waste liquid, and application thereof

InactiveCN113620326AEnable recyclingLow impurity contentAluminium compoundsAlkali metal carbonatesElectrolysisPhysical chemistry

The invention discloses a method for preparing magnesium-aluminum-zinc hydrotalcite from aluminum-air battery electrolytic waste liquid, and application thereof. The preparation method comprises a scheme 1 or a scheme 2, and the scheme 1 comprises the following steps: filtering the aluminum-air battery electrolytic waste liquid in advance, reacting filtrate with a magnesium source and a zinc source, carrying out solid-liquid separation to obtain hydroxyl type magnesium-aluminum-zinc hydrotalcite, reacting the hydroxyl type magnesium-aluminum-zinc hydrotalcite with a carbon source, and filtering to obtain magnesium-aluminum-zinc hydrotalcite; and the scheme 2 comprises the following steps: directly reacting filtrate obtained by filtering the aluminum-air battery electrolytic waste liquid with the magnesium source, the zinc source and the carbon source, and performing solid-liquid separation to obtain magnesium-aluminum-zinc hydrotalcite. By adopting the method, resource utilization of the aluminum-air battery electrolytic waste liquid can be realized, the magnesium-aluminum-zinc hydrotalcite with a relatively high additional value can be obtained, the production cost of the hydrotalcite can be reduced, and the prepared magnesium-aluminum-zinc hydrotalcite is relatively low in impurity content, easy in crystal form control, simple in equipment operation, relatively low in production cost, energy-saving and environment-friendly, and is easy to realize industrial production.

Owner:云南创能斐源金属燃料电池有限公司

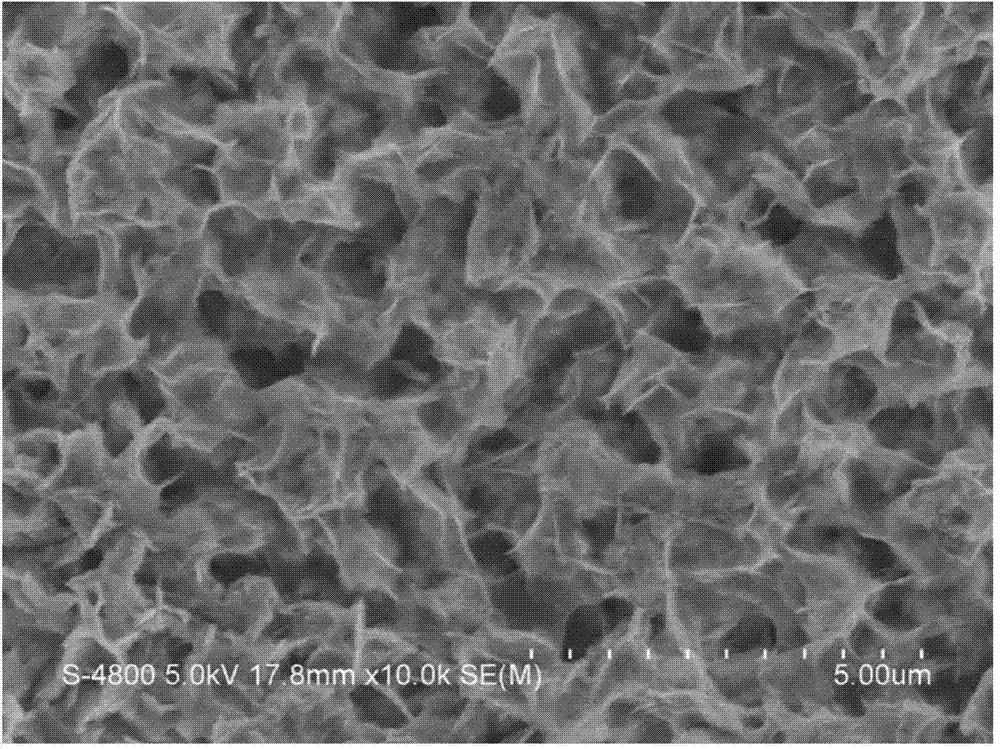

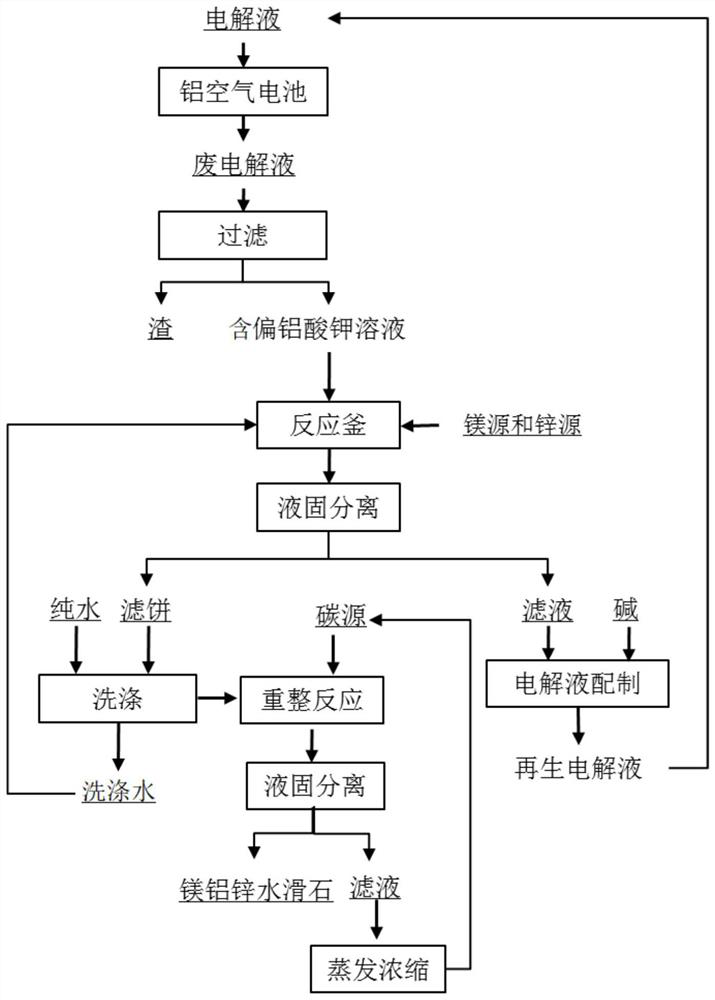

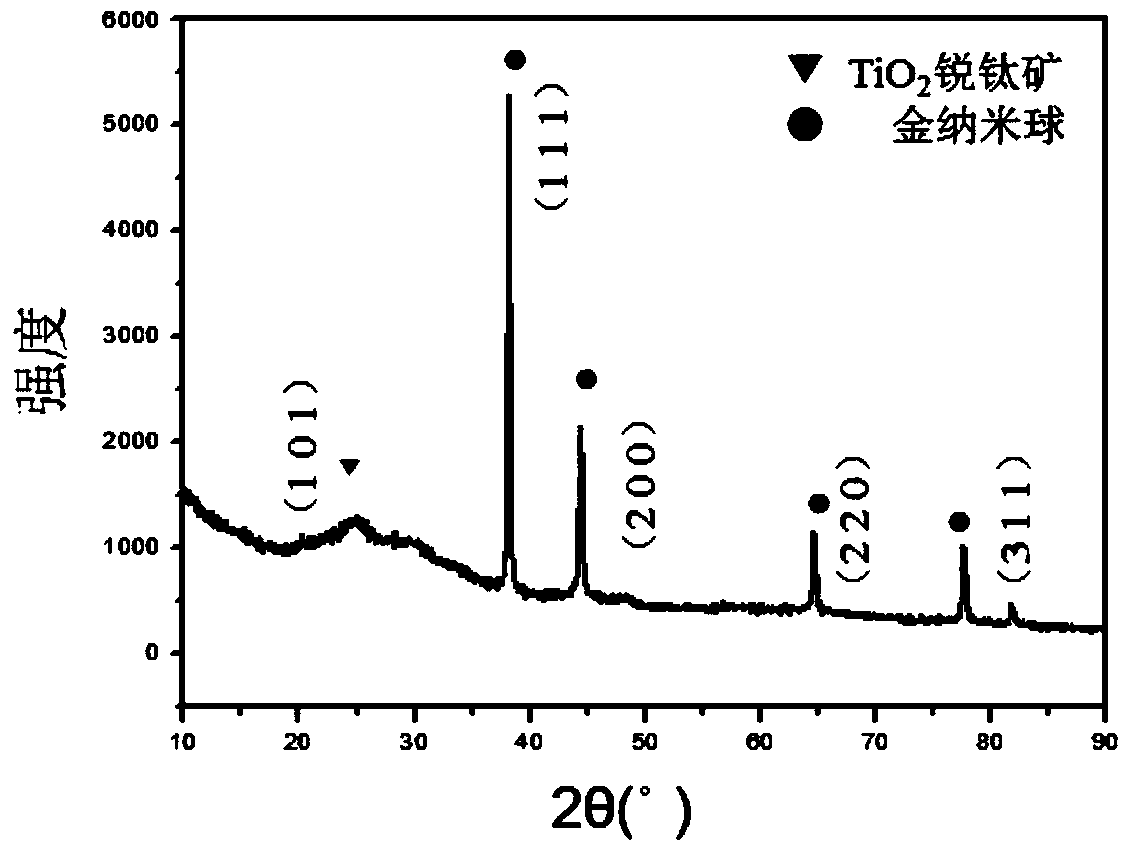

Au-TiO2 yolk-structured nanocomposite material and preparation method thereof

ActiveCN108906038AChanging the spectral absorption rangePlay a regulating roleWater/sewage treatment by irradiationWater contaminantsYolkMesoporous material

The invention relates to an Au-TiO2 yolk-structured nanocomposite material and a preparation method thereof. The preparation method comprises the following steps: firstly preparing a gold nanosphere;then coating the surface of the gold nanosphere with a silicon dioxide layer; coating the surface of the silicon dioxide layer with a titanium dioxide precursor mesoporous material layer; then removing the silicon dioxide layer; and finally carrying out hydro-thermal treatment to obtain the Au-TiO2 yolk-structured nanocomposite material with a sheet-like branch structure on the surface. The preparation method of the invention is simple in process, easy to operate, low in production cost, small in process pollution and suitable for large-scale production; and the prepared Au-TiO2 yolk-structured nanocomposite material has a unique movable core and has the sheet-like branch structure on the surface, which can increase the specific surface area of the material, greatly enhance the photocatalytic performance of the material and realize high utilization rate of solar energy.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com