Preparation method of positive electrode material of lithium sulfur battery

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problem of poor cycle stability, poor electronic conductivity and ionic conductivity of carbon-sulfur complexes , Unfavorable battery high rate performance and other issues, to achieve good conductivity, low production cost, and good crystal shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

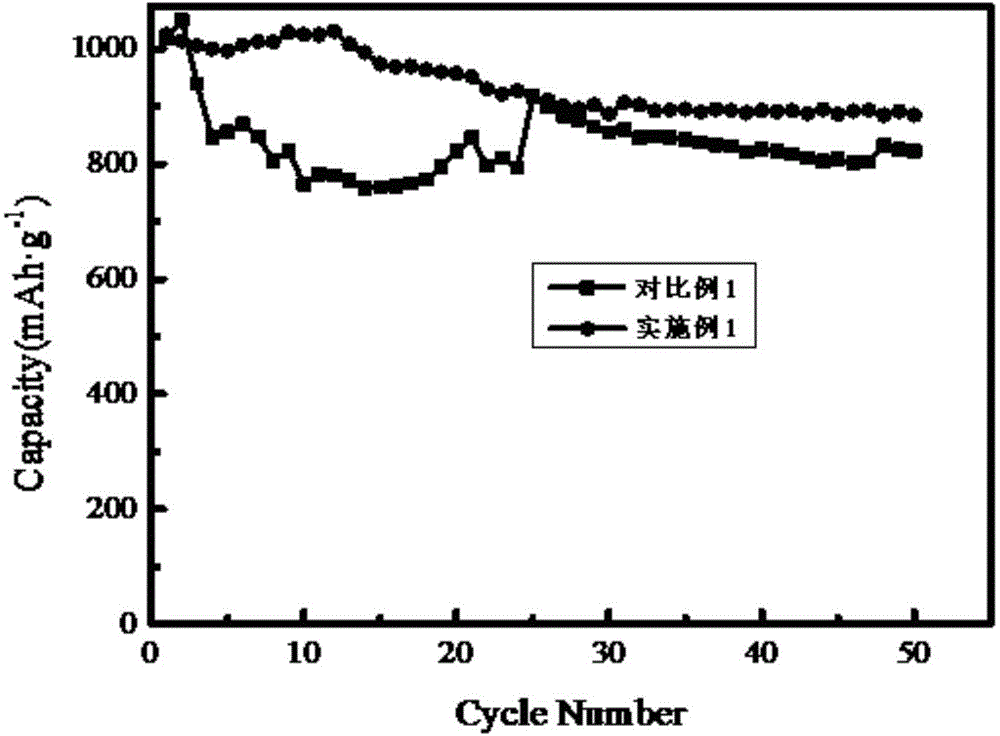

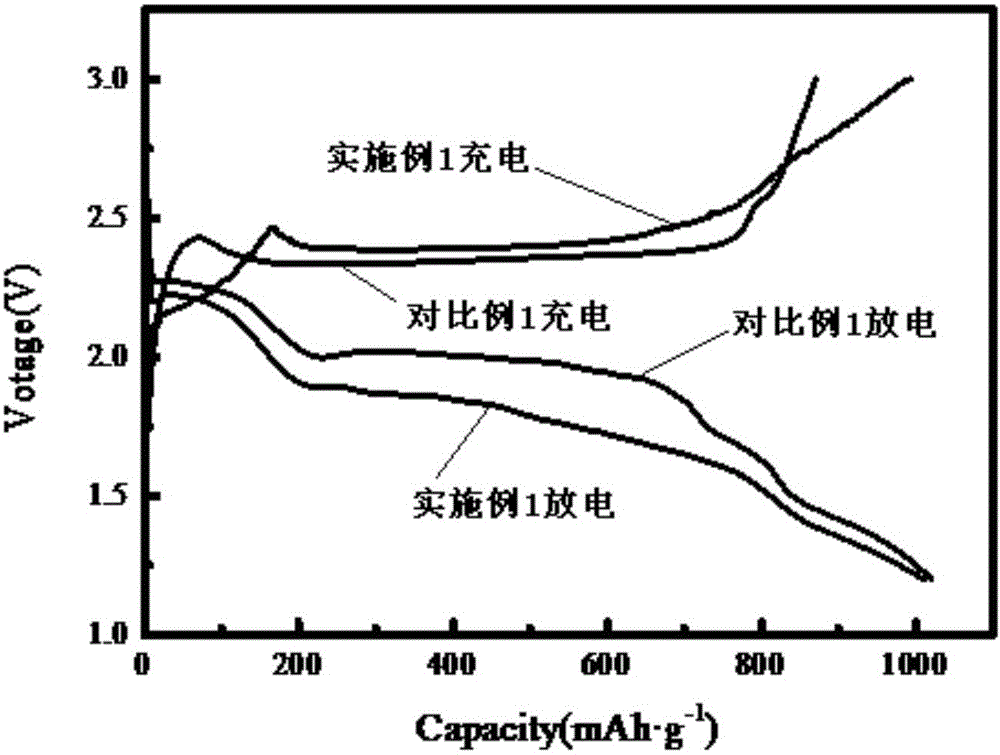

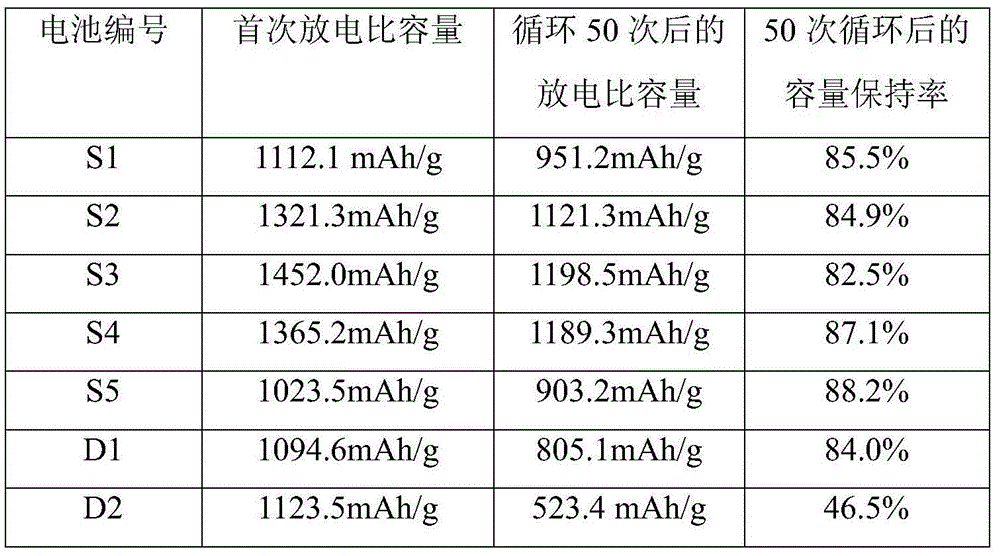

Embodiment 1

[0031] The preparation method of a lithium-sulfur battery cathode material provided in this embodiment comprises the following steps:

[0032] The first step, the preparation of carbon nanotubes nitride: carbon nanotubes with an average diameter of 100nm were added to ammonia water with a mass concentration of 15%, after mixing evenly, transferred to a hydrothermal reaction kettle, and kept at 250°C for 3h , after cooling, wash the reaction product with dilute nitric acid, then wash the reaction product 3 times with distilled water, and dry at 60° C. for 2 hours to obtain carbon nitride nanotubes;

[0033] The second step, the preparation of carbon-sulfur composite material: dissolving sulfur in ethanol to obtain a sulfur-containing organic solution with a mass concentration of 10%, and then adding the carbon nitride nanotubes obtained in step 1 to the sulfur-containing organic solution, Make the mass ratio of carbon nitride nanotubes and sulfur to be 1:1, ultrasonically dispe...

Embodiment 2

[0035] The preparation method of a lithium-sulfur battery cathode material provided in this embodiment comprises the following steps:

[0036] The first step, the preparation of nitrided carbon nanotubes: carbon nanotubes with an average diameter of 150nm are added to an aqueous solution of ethylenediamine with a mass concentration of 20%, and after mixing evenly, they are transferred to a hydrothermal reaction kettle and heated at 200 Insulate at ℃ for 5h, after cooling, first wash the reaction product with dilute hydrochloric acid, then wash the reaction product with ethanol for 3 times, and dry at 70°C for 1h to obtain carbon nitride nanotubes;

[0037] The second step, the preparation of carbon-sulfur composite material: dissolving sulfur in carbon disulfide to obtain a sulfur-containing organic solution with a mass concentration of 20%, and then adding the carbon nitride nanotubes obtained in step 1 to the sulfur-containing organic solution, Make the mass ratio of carbon ...

Embodiment 3

[0039] The preparation method of a lithium-sulfur battery cathode material provided in this embodiment comprises the following steps:

[0040] The first step, the preparation of nitrided carbon nanotubes: carbon nanotubes with an average diameter of 70nm are added to an ethanol solution of pyrrole with a mass concentration of 30%, after mixing evenly, transfer to a solvothermal reaction kettle, and heat at 180°C Keeping it warm for 4 hours, and after cooling, wash the reaction product with dilute sulfuric acid, then wash the reaction product 4 times with ethanol, and dry at 80° C. for 2 hours to obtain carbon nitride nanotubes;

[0041] The second step, the preparation of carbon-sulfur composite materials: dissolve sulfur in carbon tetrachloride to obtain a sulfur-containing organic solution with a mass concentration of 12%, and then add the carbon nitride nanotubes obtained in step 1 to the sulfur-containing organic solution. In the solution, make the mass ratio of carbon nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com