Patents

Literature

34results about How to "High particle purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium hydride nano particle and preparation method and application thereof

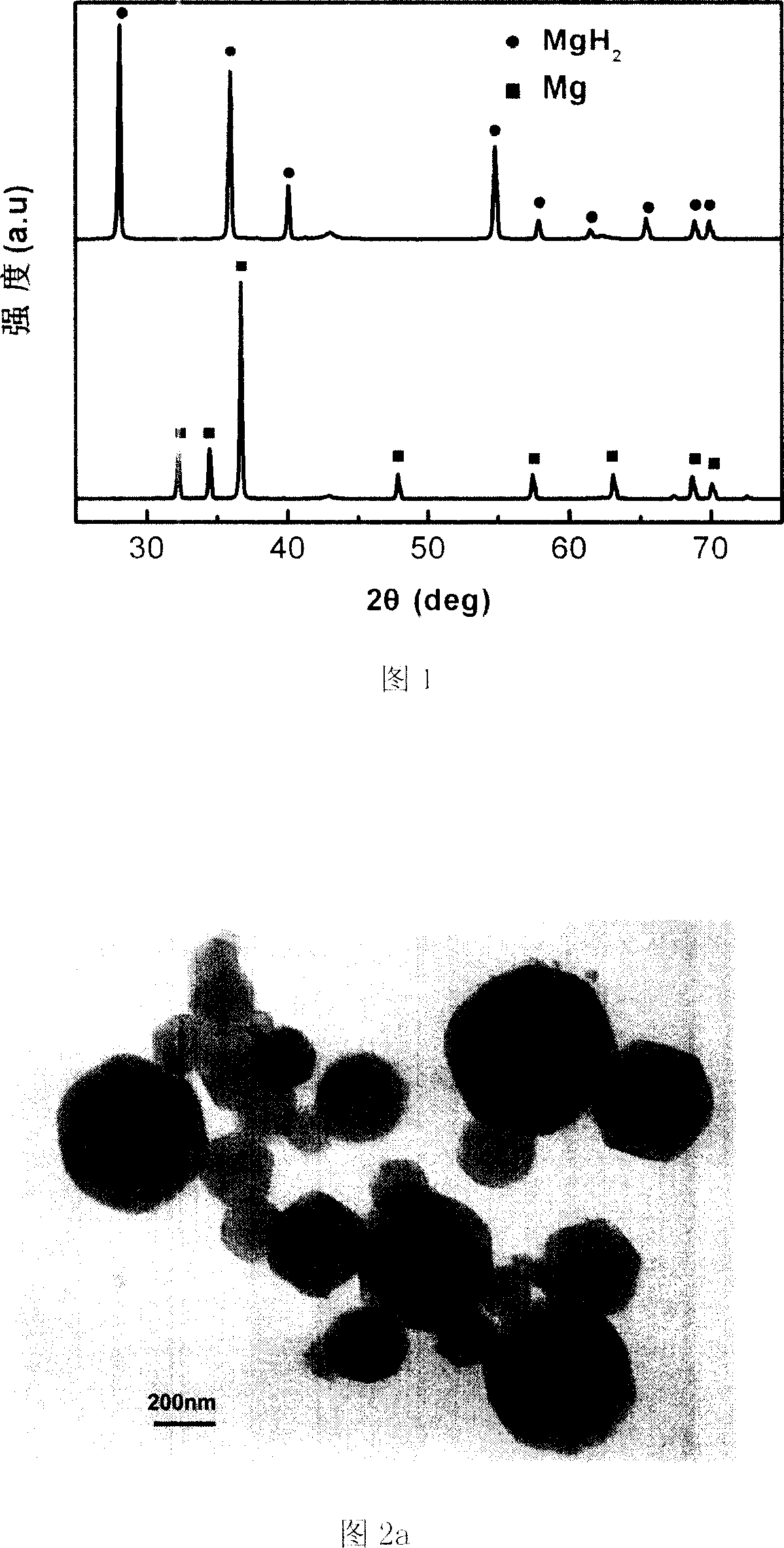

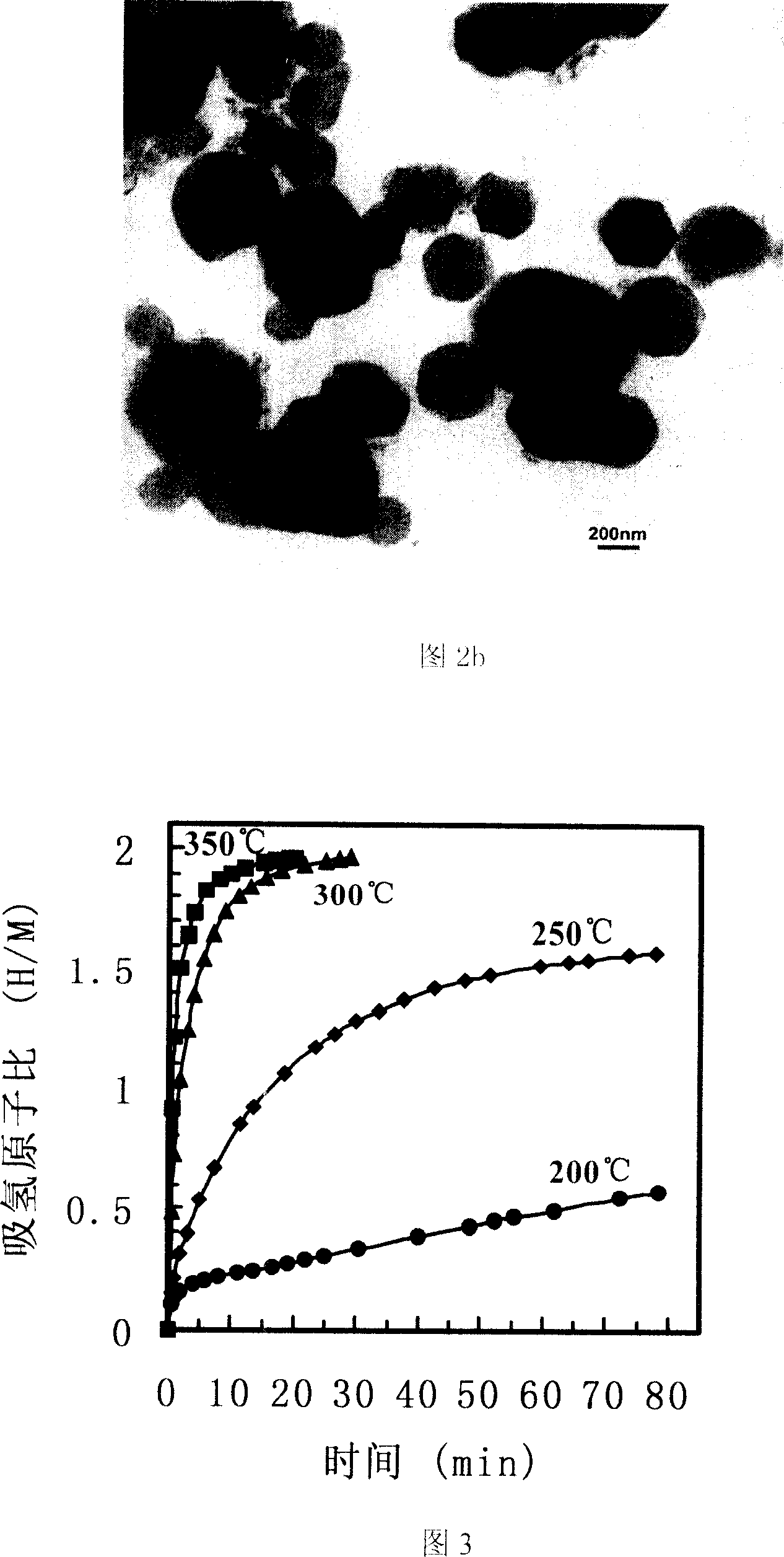

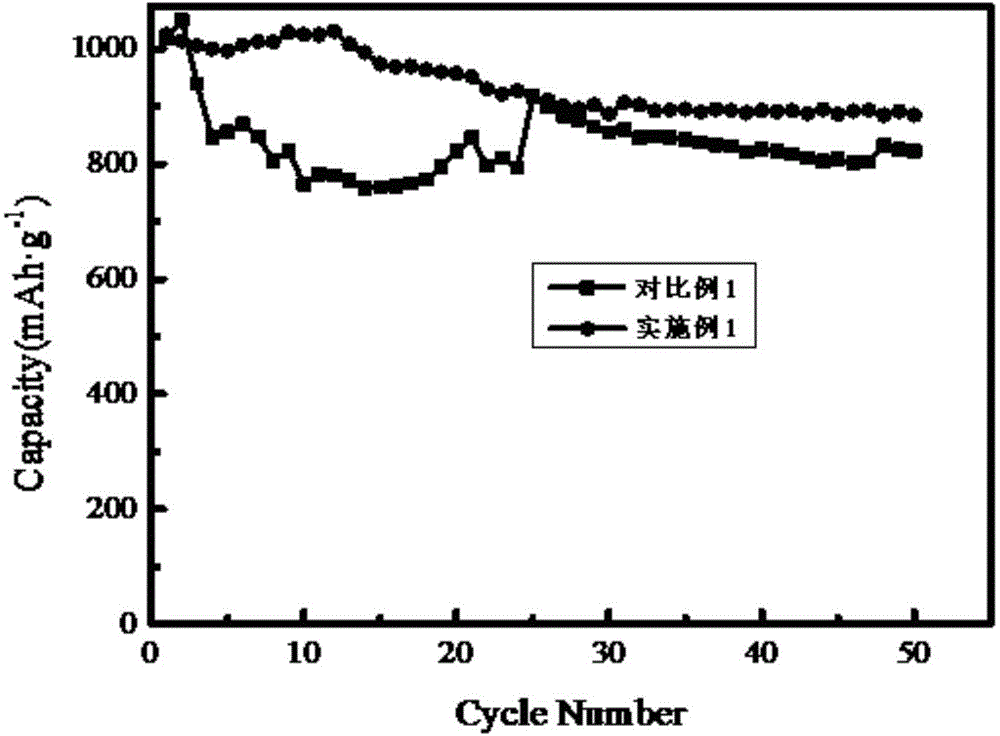

InactiveCN101117211ALarge specific surface areaShorten the diffusion distanceAlkali/alkaline-earth/beryllium/magnesium hydridesHydrogen absorptionNanotechnology

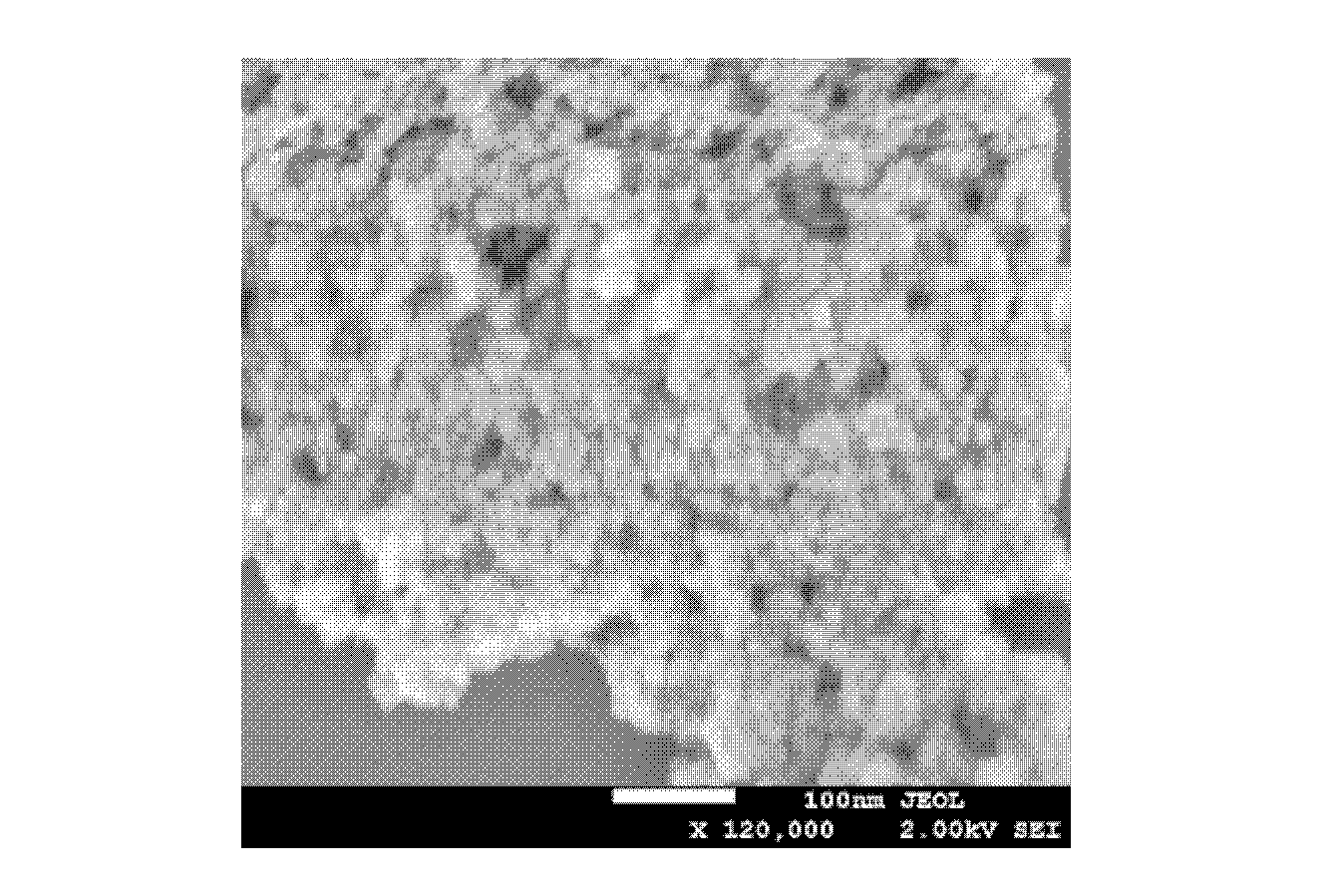

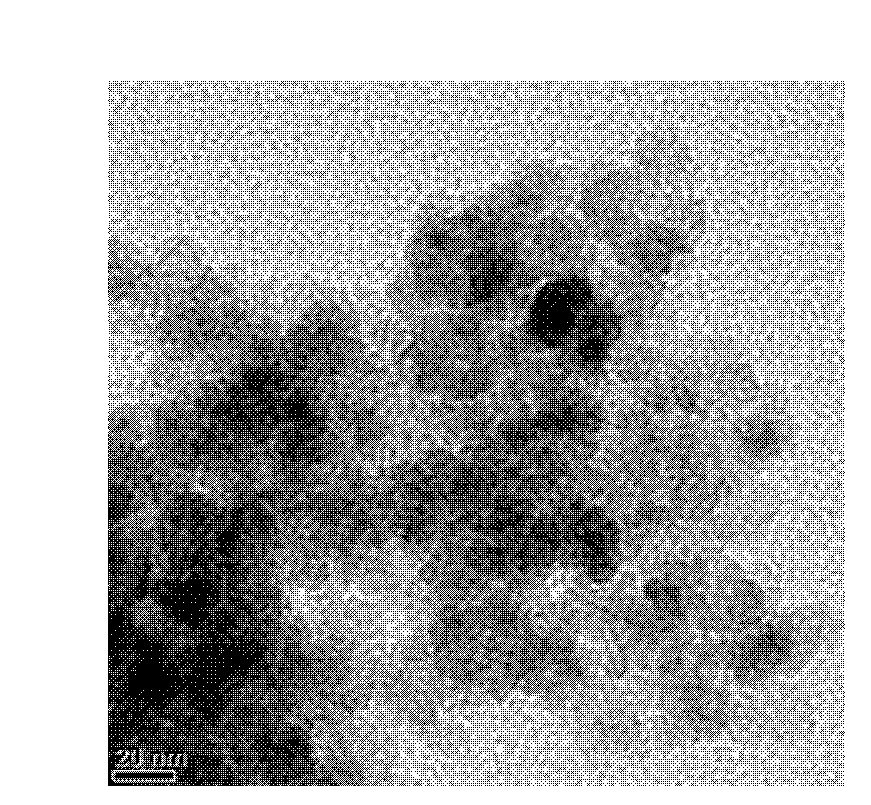

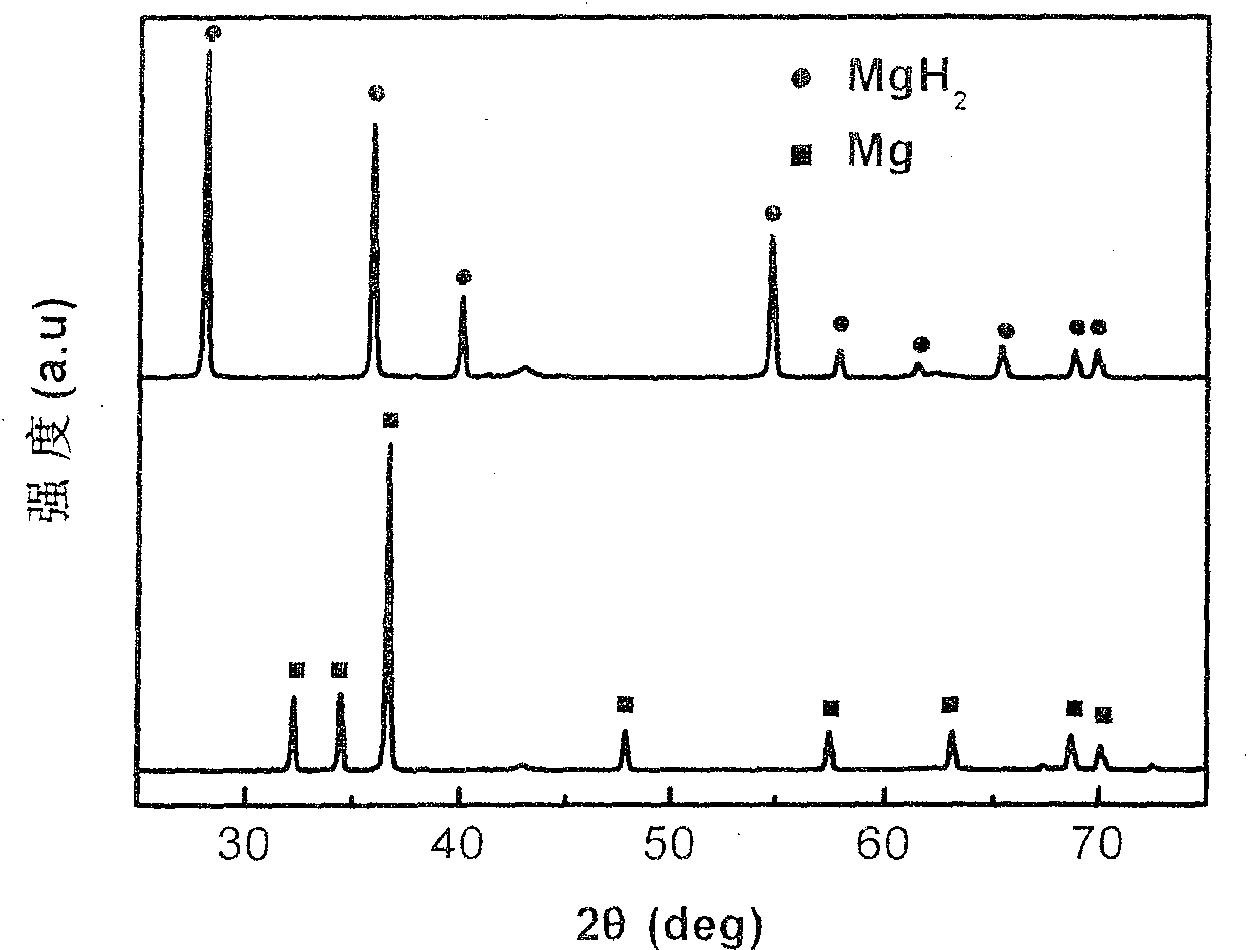

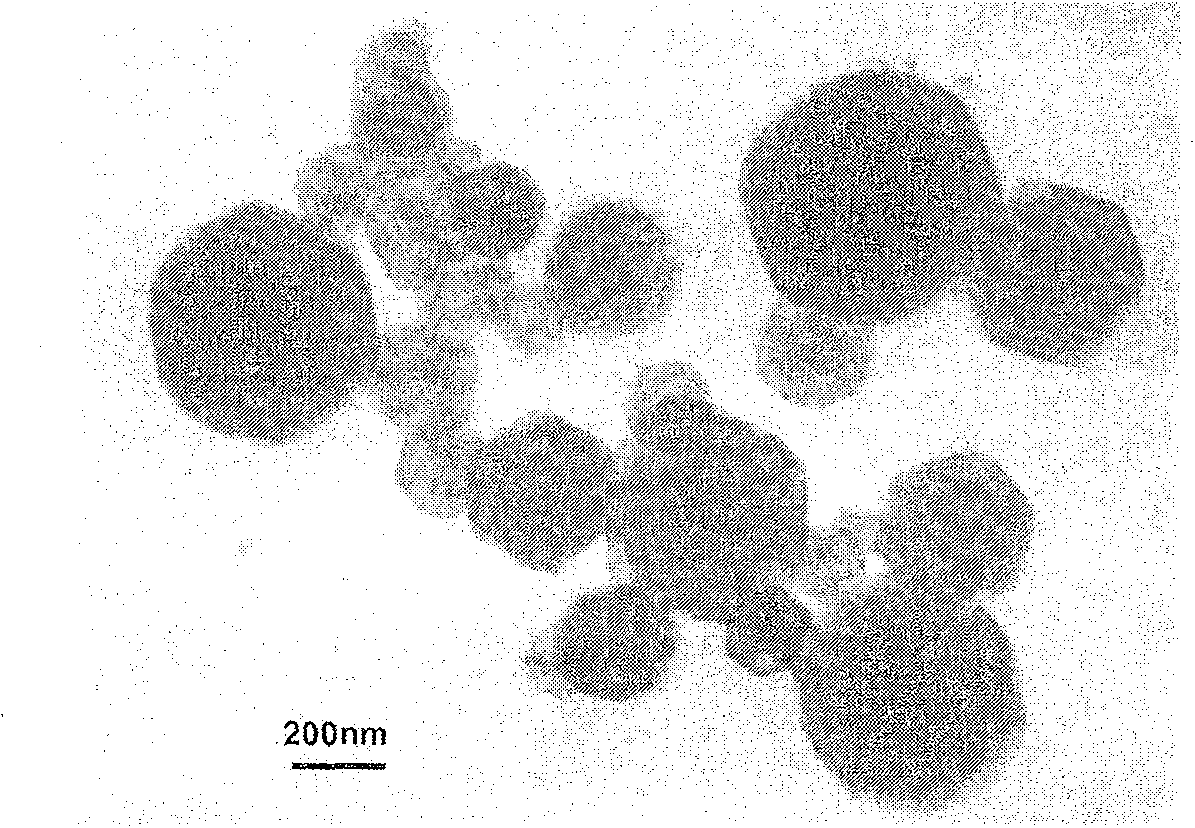

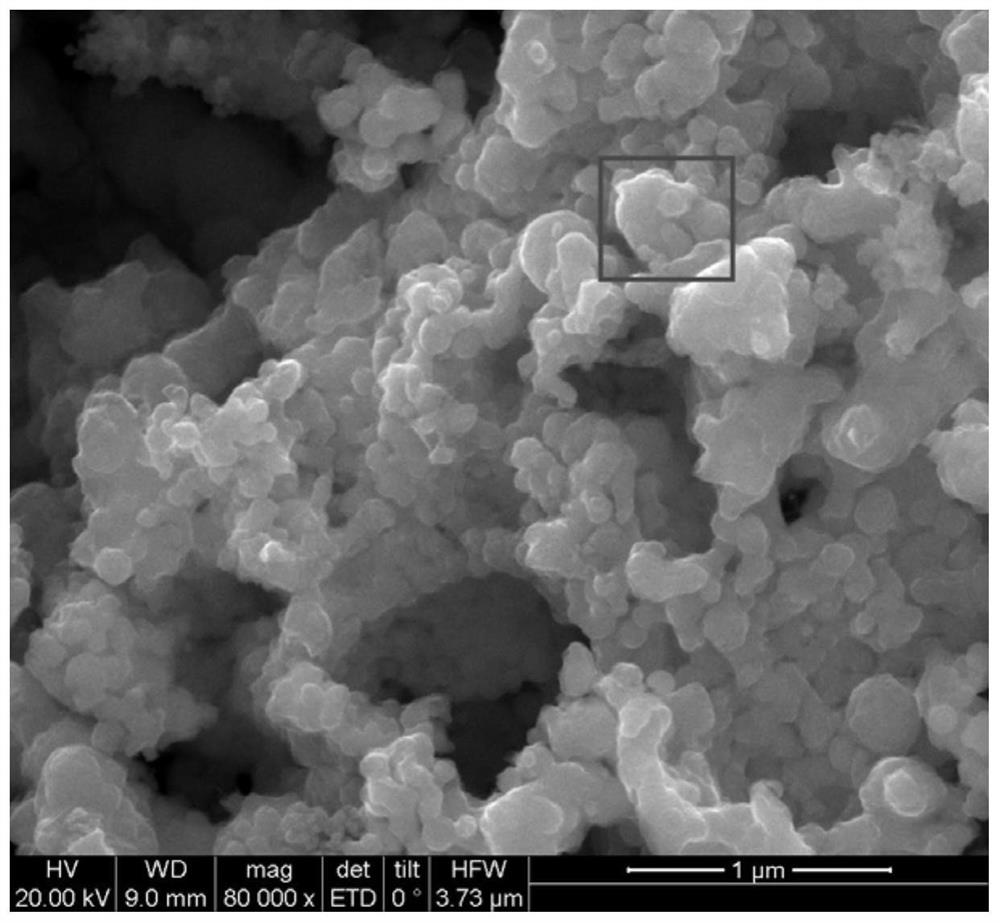

The invention discloses a magnesium hydride nanometer granular material and the preparing method and application, wherein nanometer magnesium powder is prepared through adopting arc heating method and then the magnesium powder is hydrogenated to obtain MgH2 granular product with the grain diameter being 50 nm to 600 nm. The nanometer MgH2 grain possesses high purity and outstanding kinetics property of hydrogen absorption and desorption during being used as hydrogen storage material, thereby possessing extremely important application value and extensive application potential in the hydrogen storage technical field.

Owner:PEKING UNIV

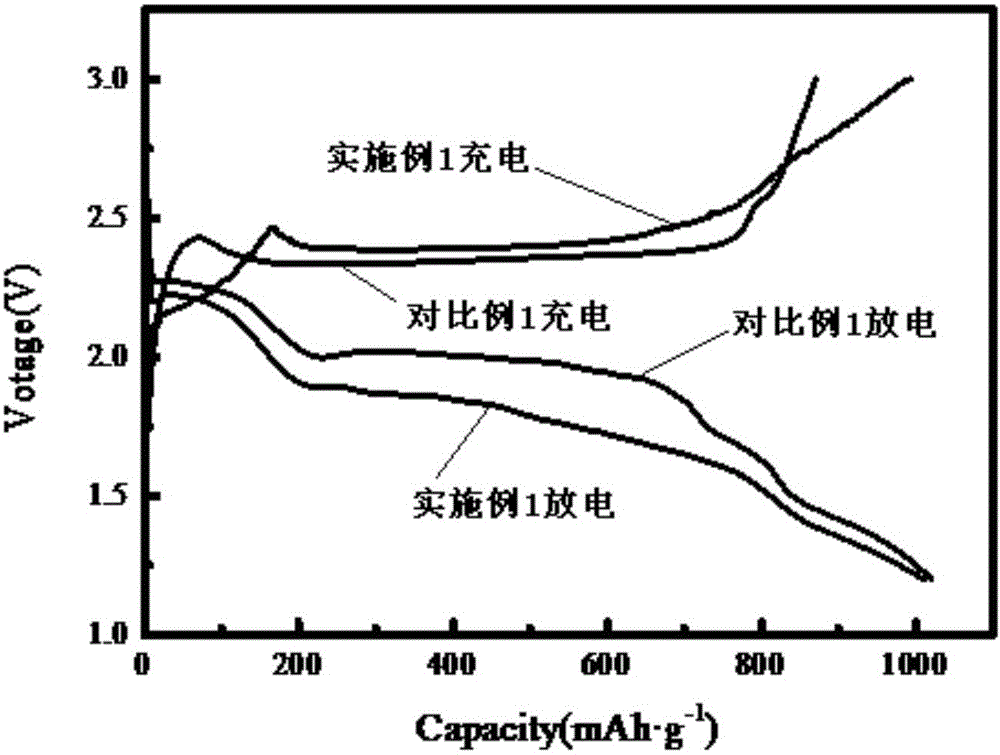

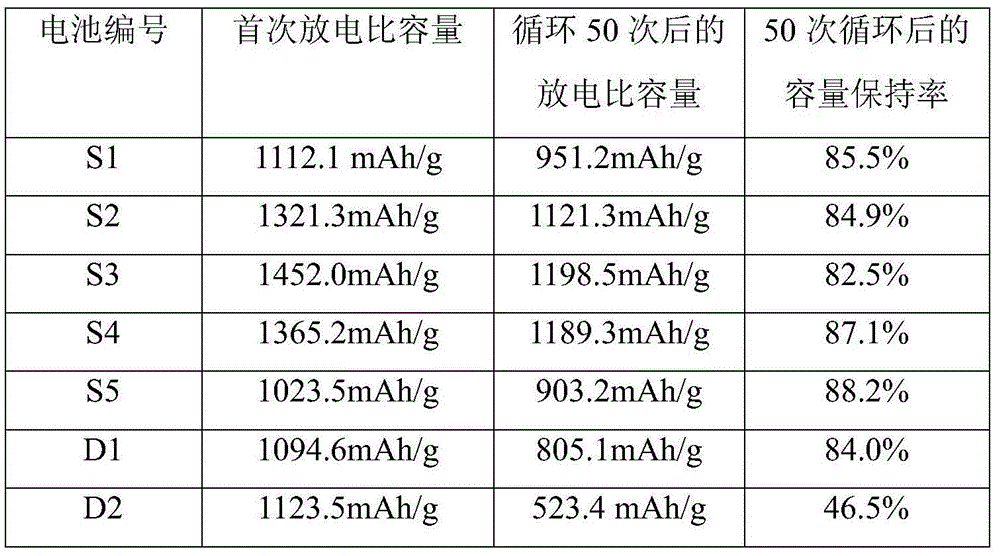

Preparation method of positive electrode material of lithium sulfur battery

InactiveCN104659338AGood dispersionCrystal form controllableMaterial nanotechnologyCell electrodesMass ratioFreeze-drying

The invention belongs to the technical field of lithium sulfur batteries, and particularly relates to a preparation method of a positive electrode material of a lithium sulfur battery. The preparation method comprises the following steps: adding a carbon nano tube into a nitrogen source substance solution with the mass concentration not less than 10%, mixing uniformly, transferring into a hydrothermal / solvent thermal reaction kettle for heat preservation, cooling, and washing and drying a reaction product so as to obtain a carbon nitride nano tube; dissolving sulfur into an organic solvent so as to obtain a sulfur contained organic solution, then adding the carbon nitride nano tube obtained in the step 1 into the sulfur contained organic solution, carrying out ultrasonic dispersion for more than 0.5 hour, and performing ultrasound treatment continuously while dropwise adding an extracting agent, wherein the mass ratio of the extracting agent to the organic solvent is (0.5-10) to 1; and then drying, and carrying out freeze drying on a product after the solvent is evaporated by more than a half. Compared with the prior art, the carbon-sulfur compound obtained by the method is good in circulation stability.

Owner:MCNAIR TECH +2

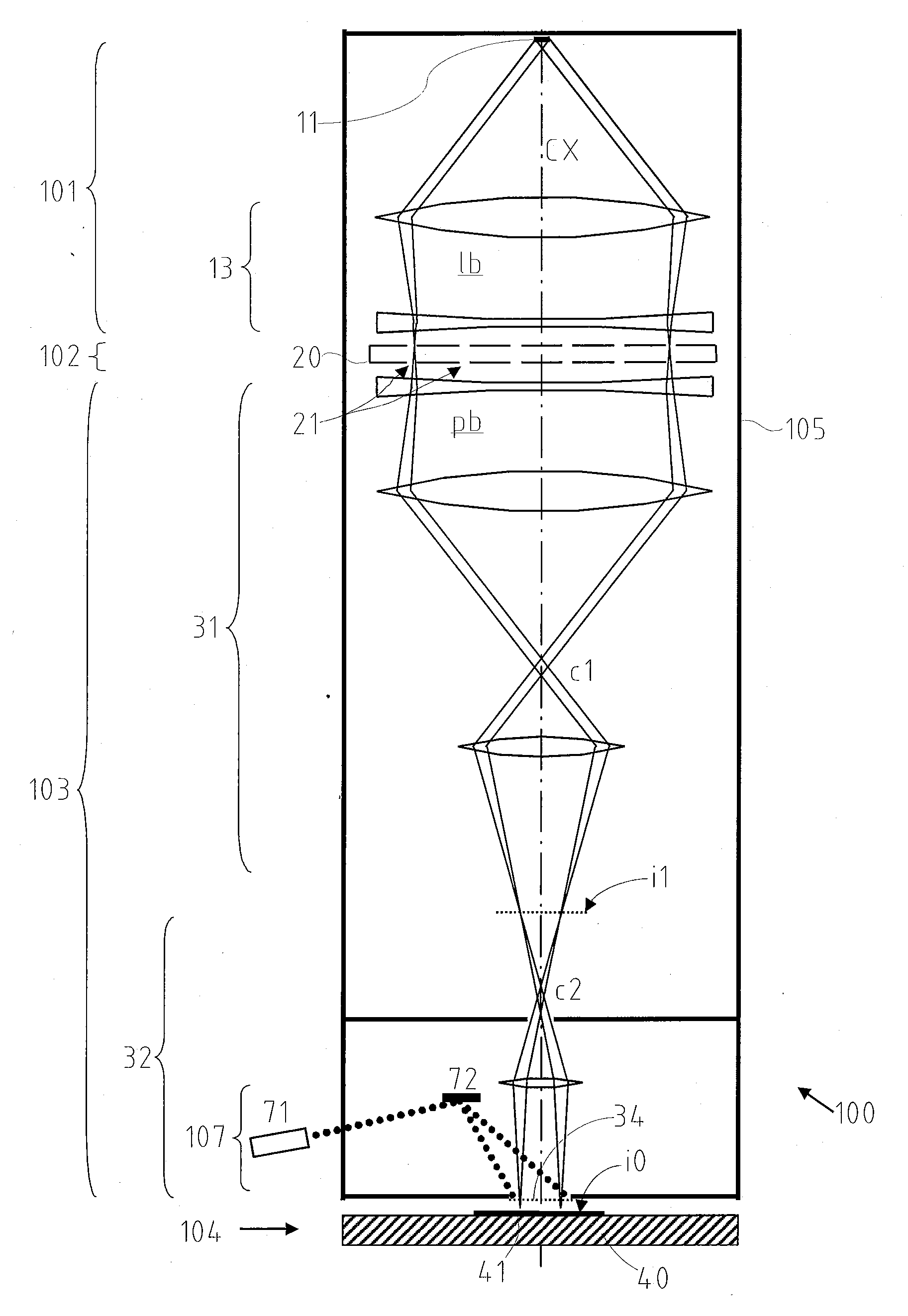

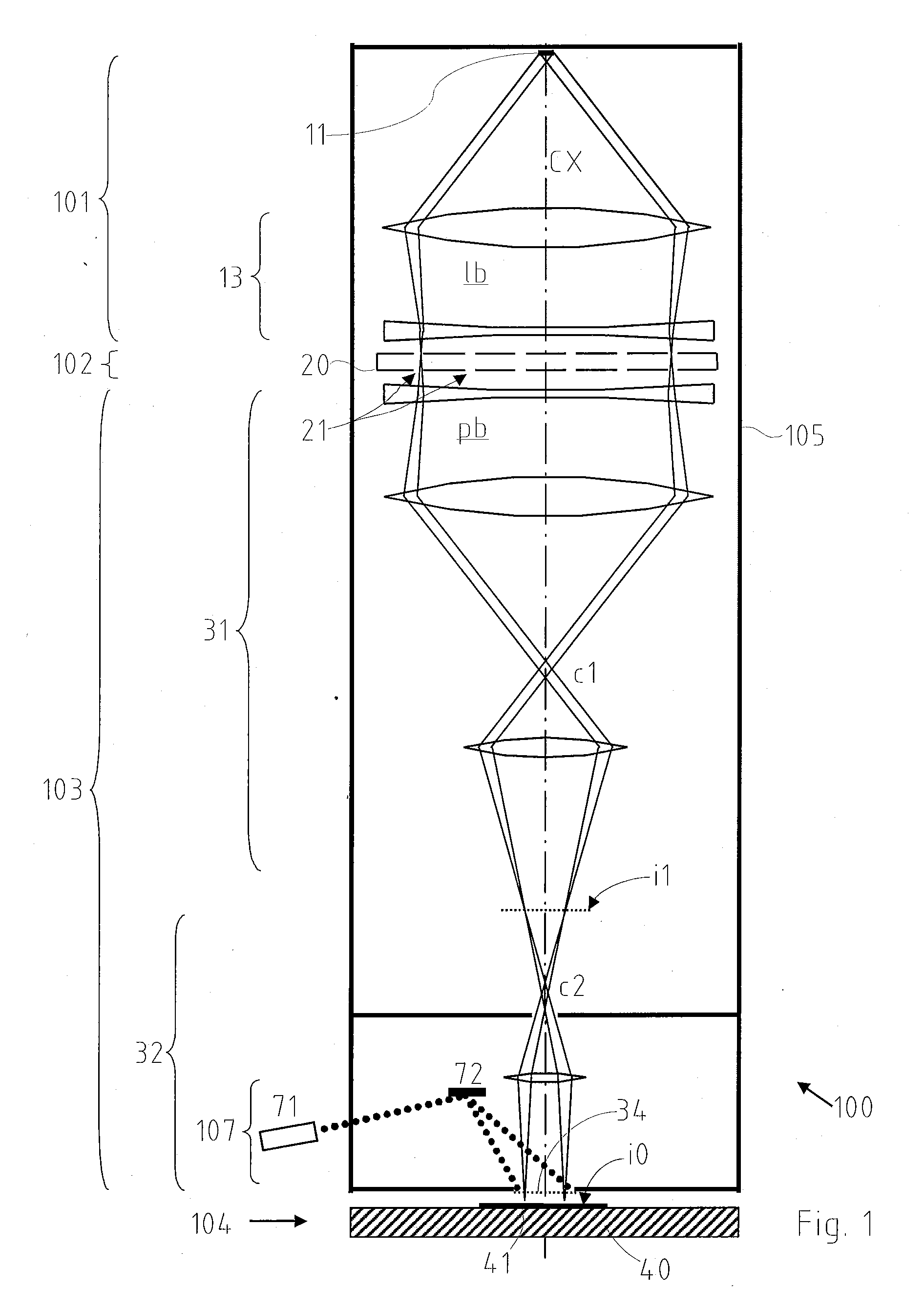

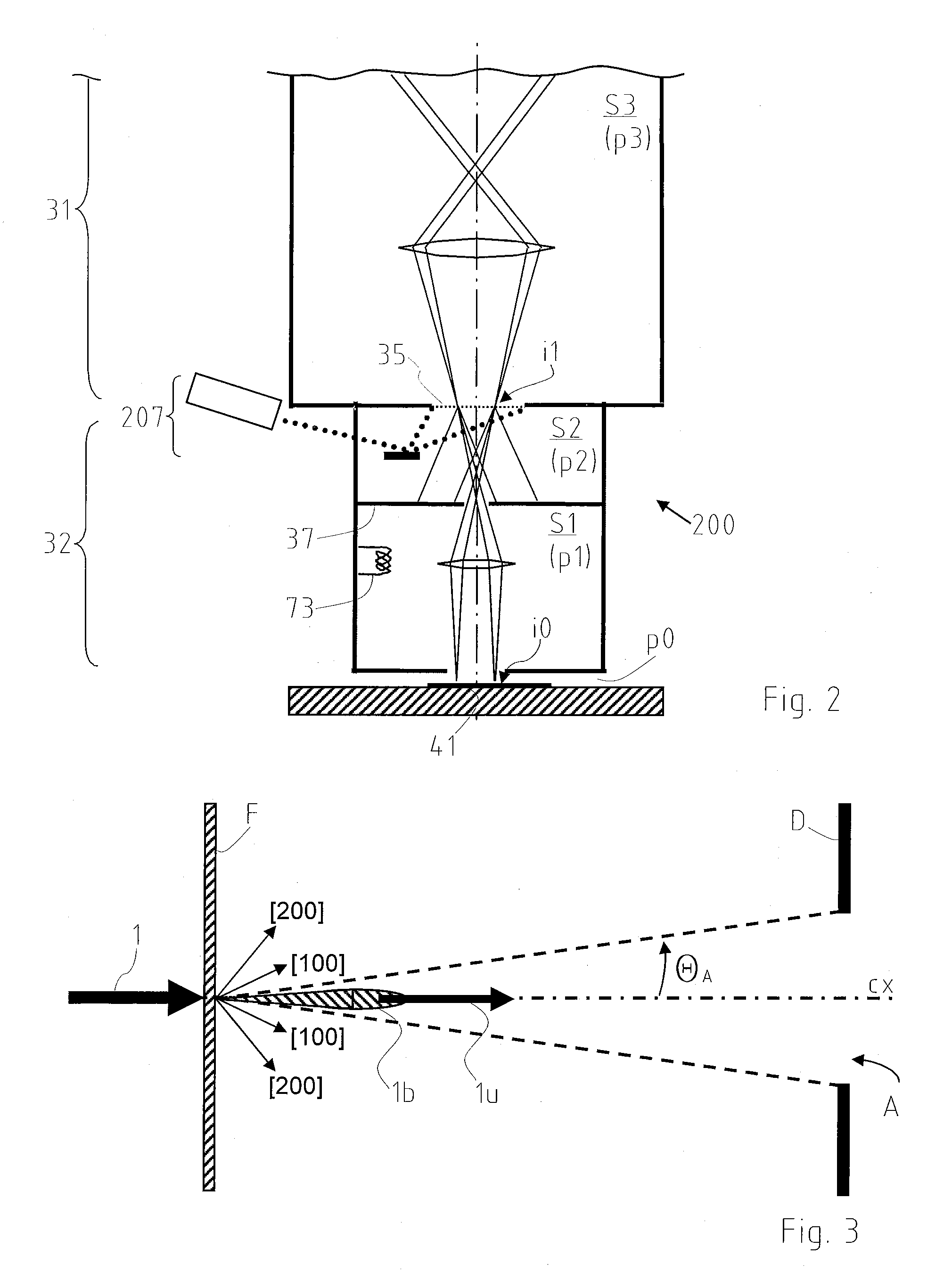

Charged-Particle Exposure Apparatus

ActiveUS20080258084A1High particle puritySevere contaminationElectric discharge tubesNanoinformaticsWide areaParticle beam

A particle-beam projection processing apparatus for irradiating a target, with an illumination system for forming a wide-area illuminating beam of energetic electrically charged particles; a pattern definition means for positioning an aperture pattern in the path of the illuminating beam; and a projection system for projecting the beam thus patterned onto a target to be positioned after the projection system. A foil located across the path of the patterned beam is positioned between the pattern definition means and the position of the target at a location close to an image of the aperture pattern formed by the projection system.

Owner:IMS NANOFABTION

Method for preparing BiFeO3 nano-particle and fine particle

InactiveCN101269842AHigh particle purityWide particle size distributionNanostructure manufactureIron compoundsScrapStoichiometry

The invention relates to a preparation method of BiFeO3 nano-particles and particles, and a mixed nitrate solution is prepared by Fe(NO3)3.9H2O and Bi(NO3)3.5H2O or Fe2O3 and Bi2O3 according to the stoichiometry of 1:1. Glycine is added to be used as fuel, and 5 to 10 millilitres of oxalic acid dehydration is added. The obtained solution is put into a microwave oven to be heated with 800 watt power and continuously heated for 10 to 20 seconds after the water is dried out, and the rapid combustion reaction of a mixture happens, thereby obtaining a loose nano-particle powder product. The obtained particle powder is suppressed into scraps by a preforming machine, and a bulk sample is obtained. Then, a bulk sample is arranged in the microwave oven to nodulize and to rapidly quench to the room temperature, and a massive particle product which is uniform in size is obtained. The BiFeO3 prepared by the method has the advantages of high purity, uniform particle size and adjustable granularity.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

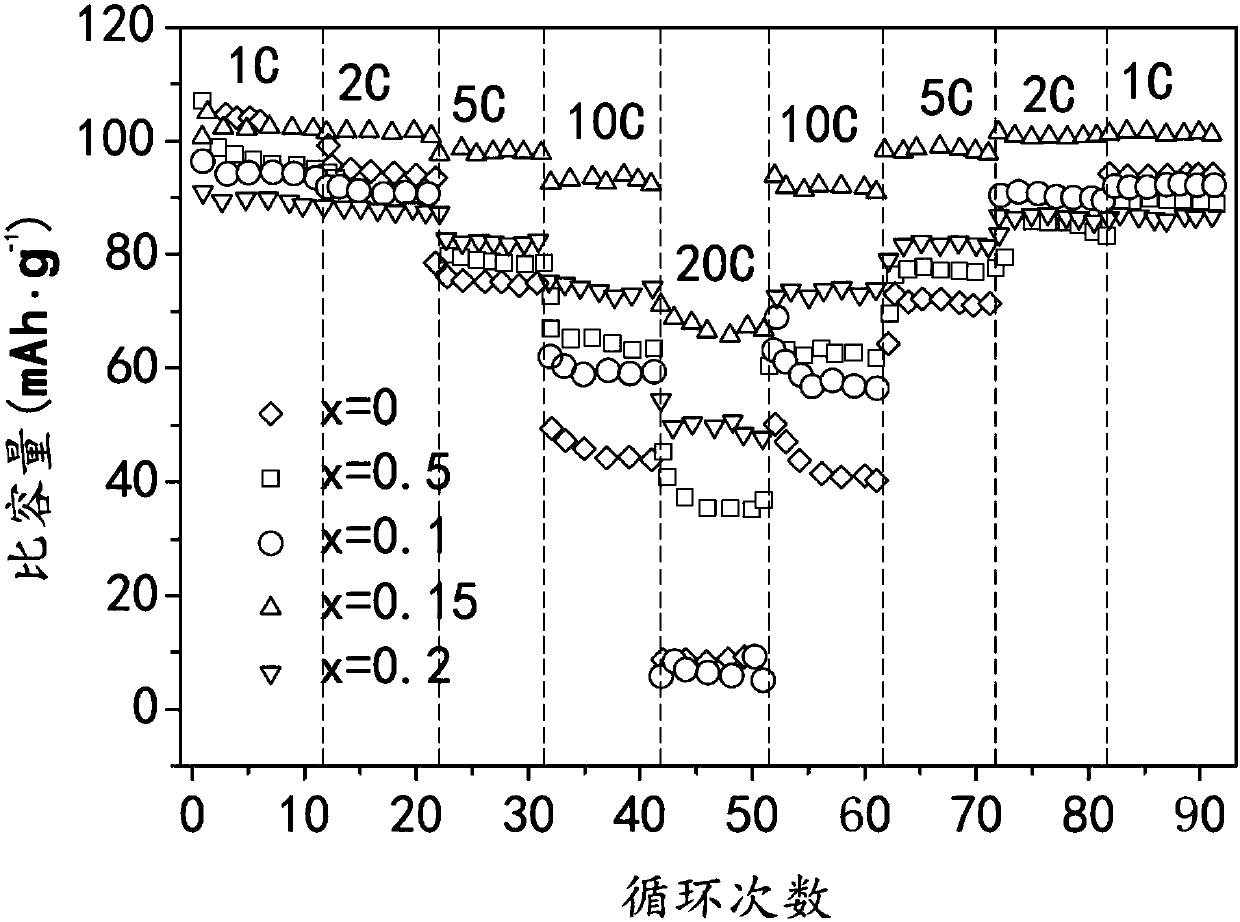

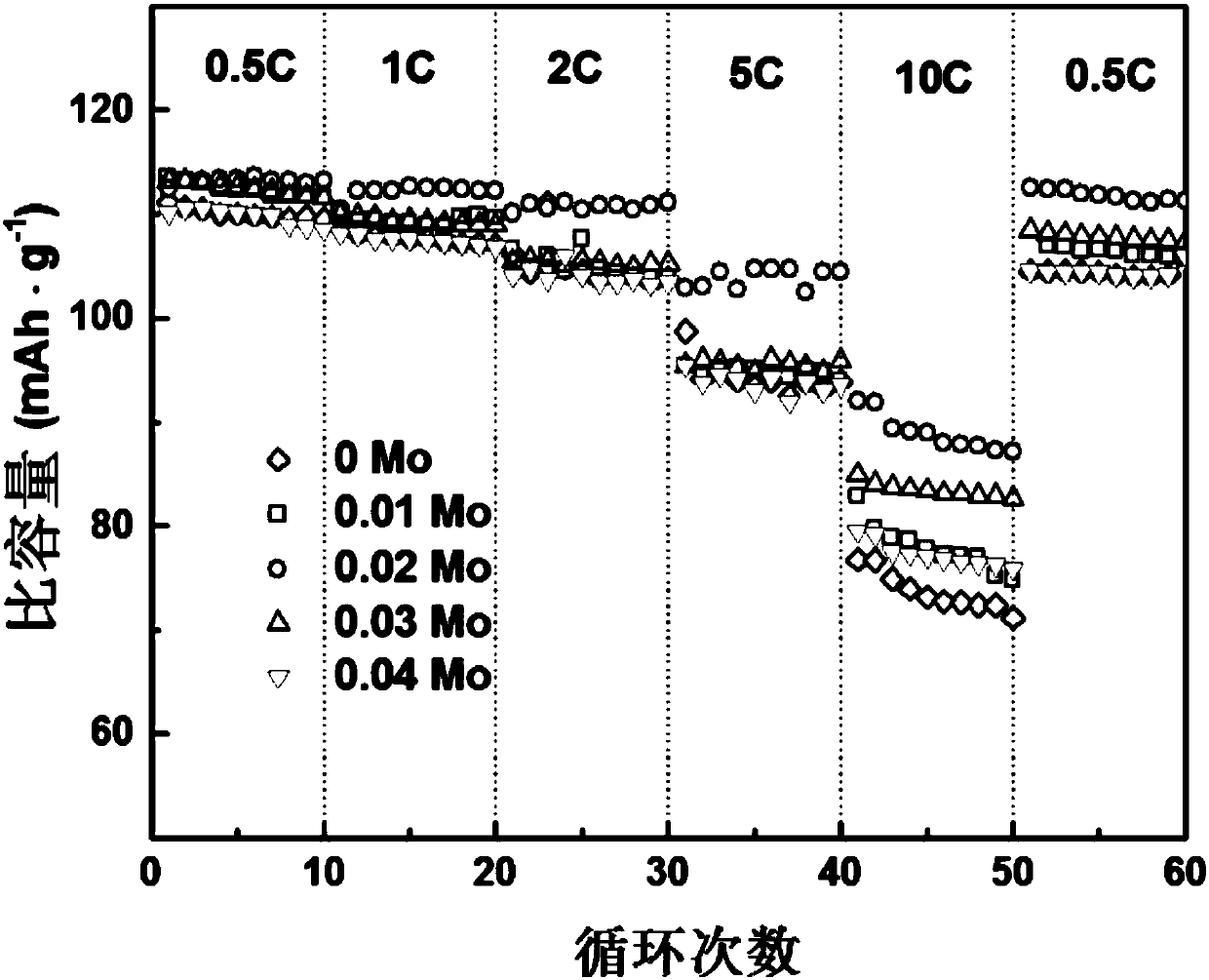

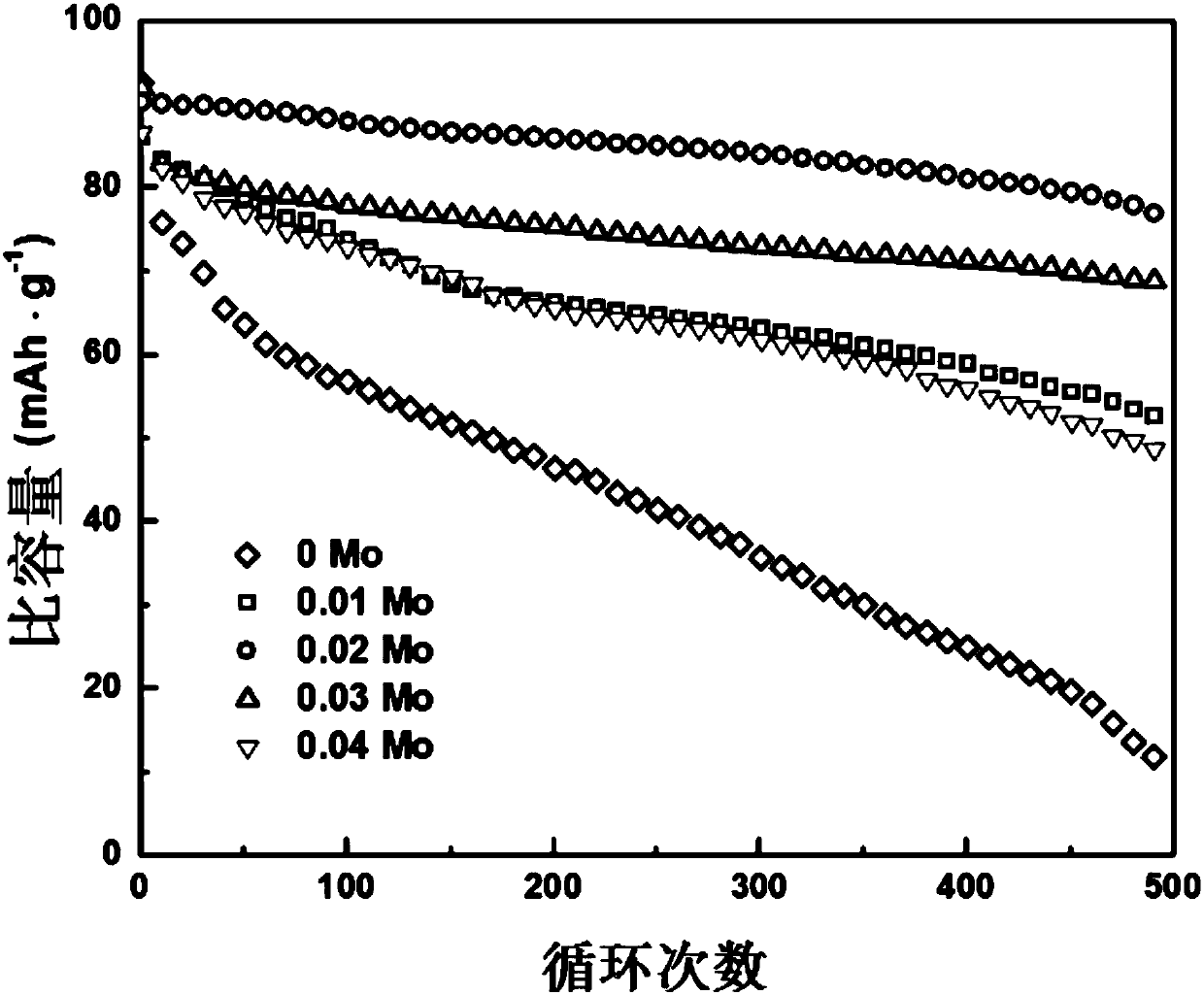

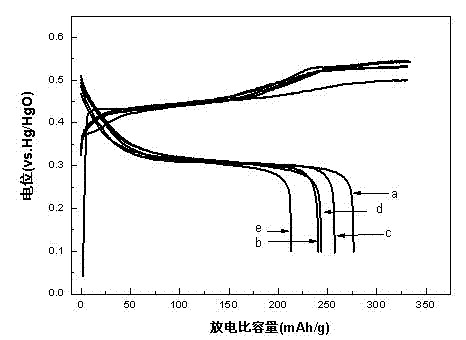

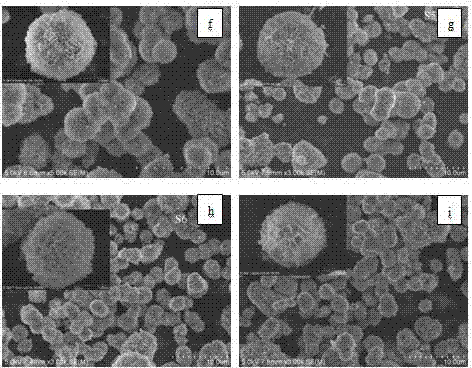

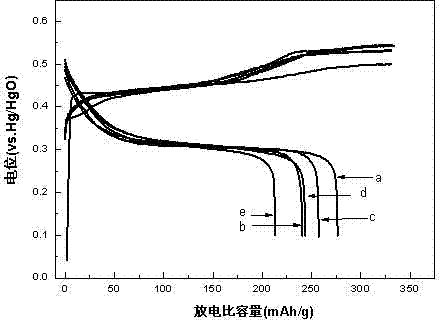

Preparation method for sodium ion battery positive electrode material doped with modified sodium vanadium phosphate

InactiveCN107871865ASimple processReduce energy consumptionCell electrodesSecondary cellsPhosphatePhosphoric acid

The invention relates to a preparation method for a sodium ion battery positive electrode material doped with modified sodium vanadium phosphate. The preparation method comprises the following steps of S1, precursor preparation, in which a sodium-containing raw material, a vanadium-containing raw material, a phosphate-containing raw material, an M doping element compound, an organic carbon material and a solvent are mixed and baked to prepare a precursor, wherein a doping element M is Ti or Mo; and S2, product sintering and preparation, in which the precursor is placed under a temperature of 750-900 DEG C for thermal processing to obtain a target product. By integral matching of the precursor preparation step and the product sintering and preparation step and by improving a precursor processing technology and a sintering technology, the product with a stable structure, high grain purity and uniform grain size is finally obtained, the prepared positive electrode material product doped with the modified sodium vanadium phosphate has favorable electrical property and favorable rate performance effect, and the preparation method is simple in process, low in energy consumption and low in cost.

Owner:HUAZHONG UNIV OF SCI & TECH

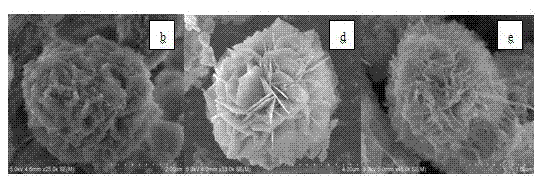

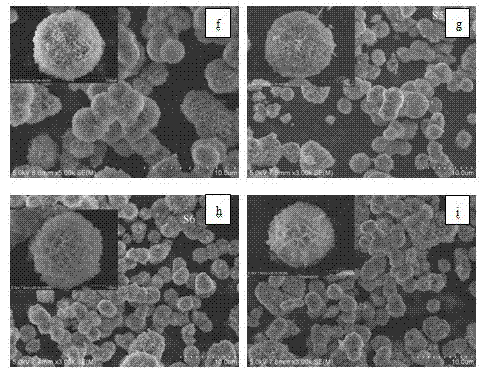

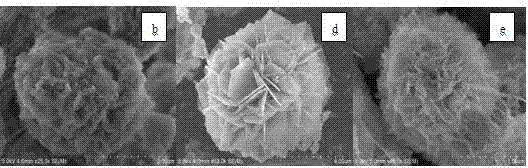

Preparation method of nano petaline Ni(OH)2

InactiveCN102774893AHigh particle purityUniform grain sizeNanotechnologyNickel oxides/hydroxidesMicrosphereSulfate

The invention discloses a preparation method of nano petaline Ni(OH)2. The method comprises the steps of taking nickel sulfate and urea as materials, preparing mixed solution of which the molar ratio of nickel to urea is 1:1 to 1:6 and then transferring the mixed solution to a 200mL of self-pressure lining polytetrafluoroethylene stainless steel reaction kettle, wherein the loading degree of a hydrothermal reaction kettle can be up to 80%; covering an inner cover and an outer cover to feed to an electric heating constant-temperature tank, heating the solution to 170 DEG C, reacting for 2-20 hours at constant temperature, then naturally cooling the solution to room temperature, filtering and washing the solution into a neutral state by deionized water; drying the solution into constant weight at 80 DEG C, and thinning the petals to prepare the nano petaline Ni(OH)2. According to the preparation method, the urea is taken as a precipitator, and a nano petaline Ni(OH)2 microsphere is directly prepared by hydrothermal syntheses; the method is simple in process, low in cost and easy to control without high-temperature sintering or a template agent, the obtained product crystal particle has the advantages that the size is uniform; the particle purity is high; the dispersity is good, and the crystalline form is good and controllable.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

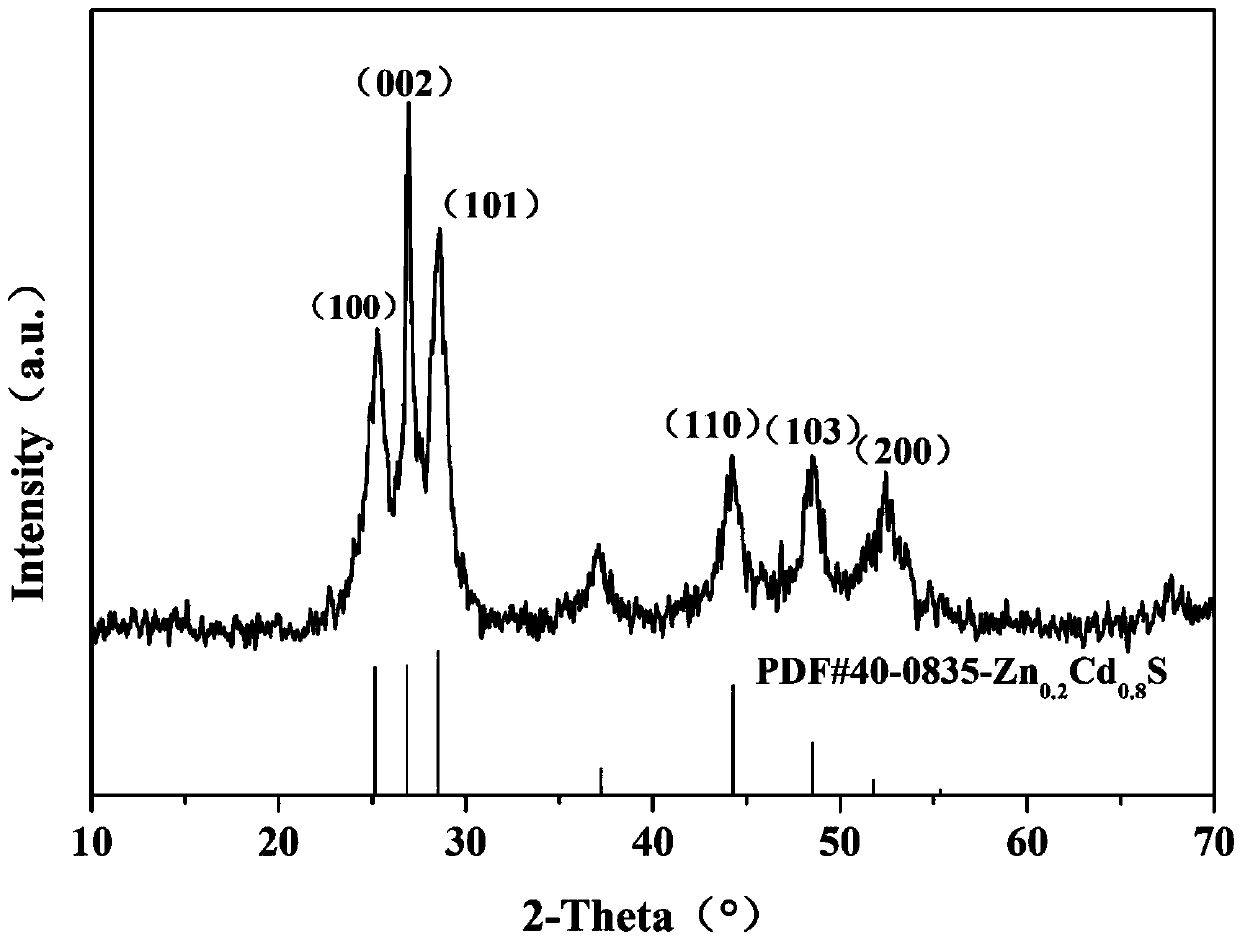

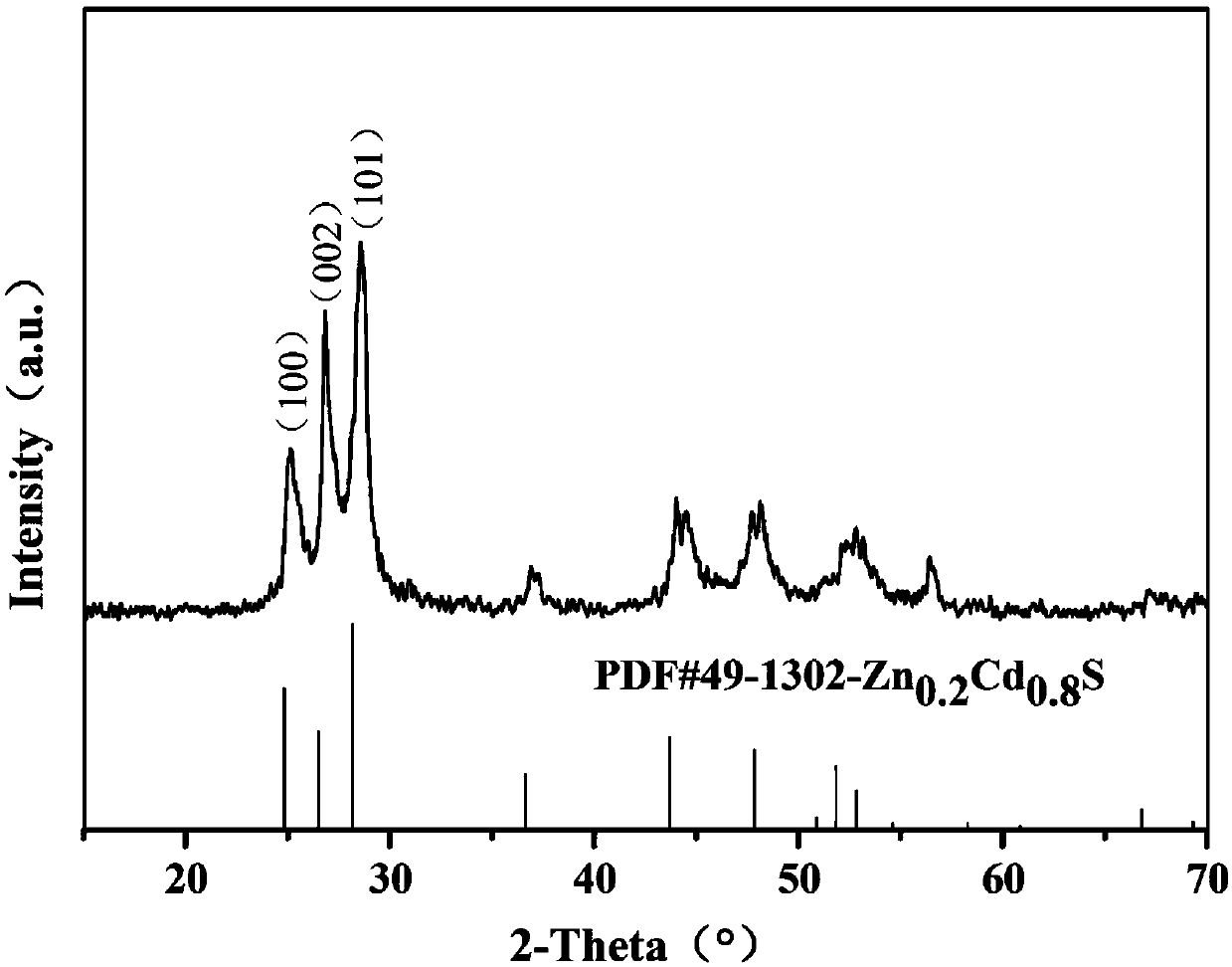

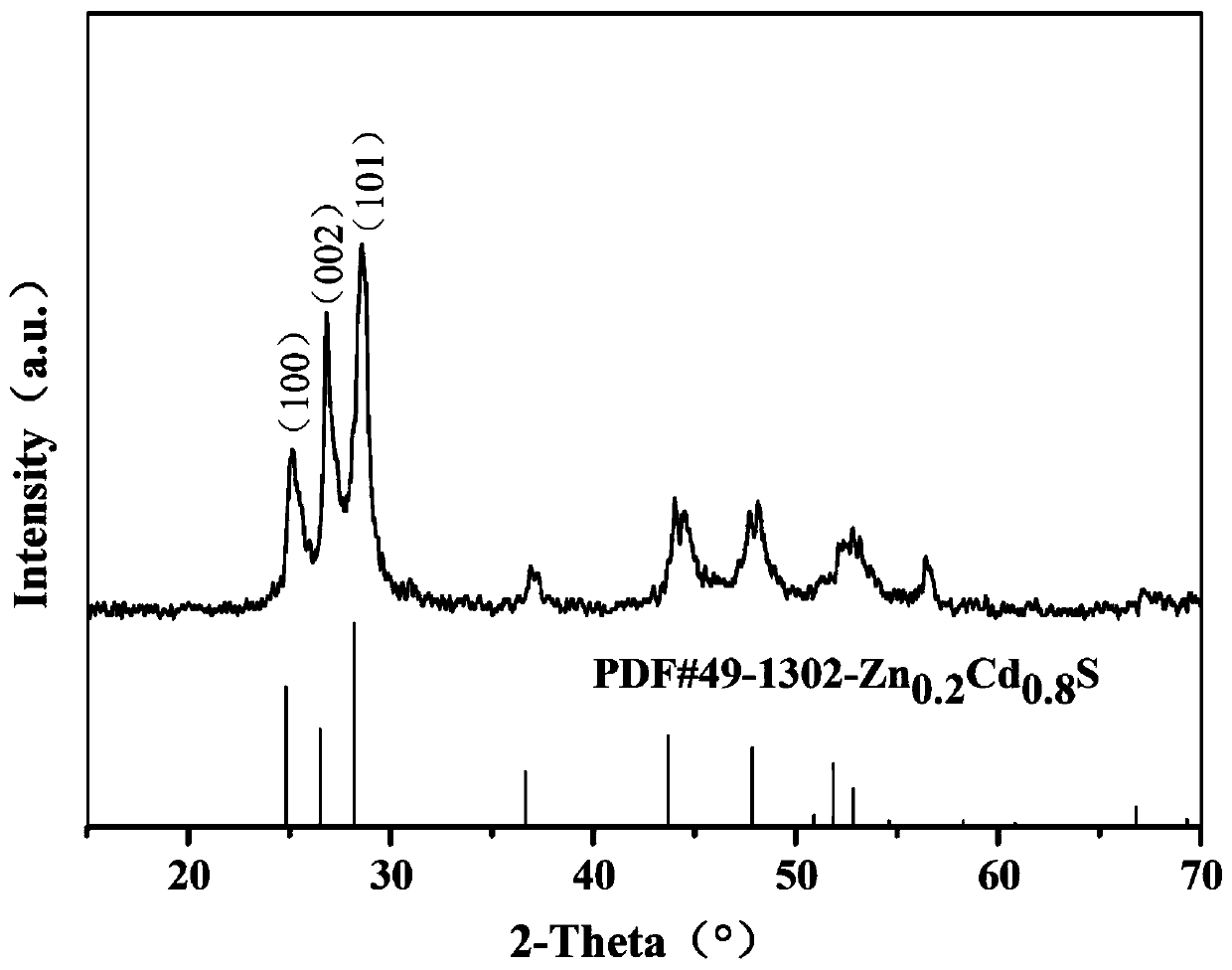

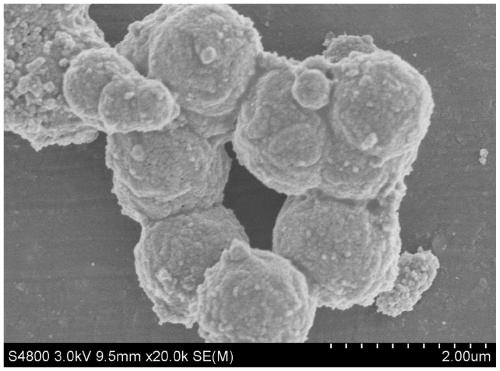

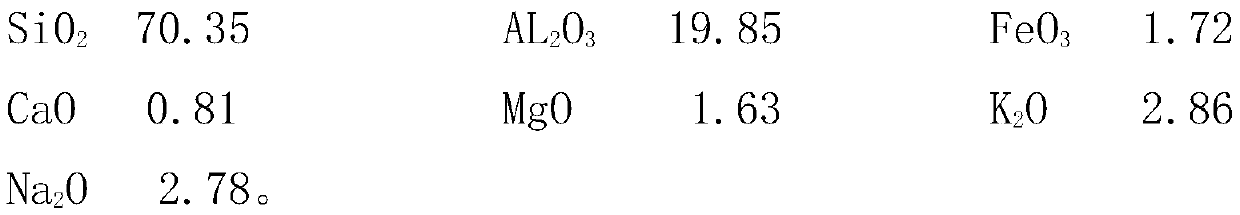

Preparation method of rod-shaped self-assembled spherical zinc-cadmium-sulfur solid solution material

ActiveCN108675339AImprove photocatalytic performanceImprove photocatalytic abilityPhysical/chemical process catalystsCadmium compounds preparationZinc Acetate DihydrateCadmium Cation

The invention discloses a preparation method of a rod-shaped self-assembled spherical zinc-cadmium-sulfur solid solution material. The preparation method comprises the following steps: measuring H2O with a measuring cylinder, adding 10mL of EN (ethylene diamine) to prepare a mixed solution, and performing magnetic stirring and ultrasonic treatment to form a mixed solution A; adding zinc acetate dihydrate and cadmium nitrate tetrahydrate which are taken as raw materials into the mixed solution A, and performing magnetic stirring and ultrasonic treatment to form a mixed solution B; adding L-cysteine which is taken as a sulfur source into the mixed solution B, and performing magnetic stirring and ultrasonic treatment to form a mixed solution C; adding the mixed solution C into an inner liningmade of polytetrafluoroethylene, and performing microwave hydrothermal reaction; and after the reaction is completed, performing centrifugal washing respectively with deionized water and ethanol forseveral times, and then performing drying and grinding to obtain zinc-cadmium-sulfur solid solution material powder.

Owner:SHAANXI UNIV OF SCI & TECH

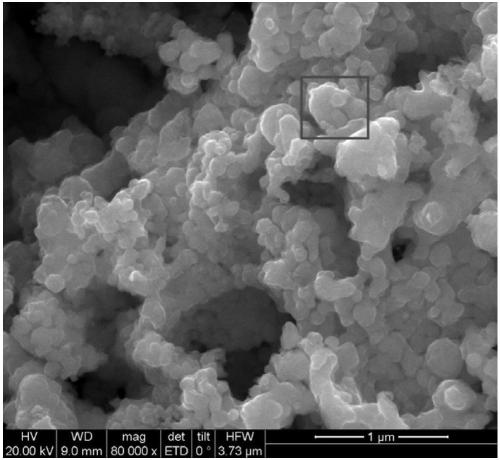

Modified iron-copper bimetallic nanoparticle and preparation method thereof

ActiveCN109205753AMitigate air oxidationFacilitates electron transferWater contaminantsContaminated groundwater/leachate treatmentChemistryNanometre

The invention discloses a modified iron-copper bimetallic nanoparticle and a preparation method thereof. The modified iron-copper bimetallic nanoparticle includes chitosan and iron-copper bimetallic nanoparticles, wherein chitosan is coated on the surfaces of the iron-copper bimetallic nanoparticles. The preparation method includes: mixing a chitosan solution with a ferrous sulfate solution, adding an NaHB4 solution dropwise for liquid phase reduction reaction, and adding a copper sulfate solution dropwise for in-situ displacement reaction to obtain the modified iron-copper bimetallic nanoparticle. The modified iron-copper bimetallic nanoparticle provided by the invention have the advantages of good dispersibility, strong reducibility, long service life and the like, and is an environment-friendly material that has good application prospects and can be applied to in-situ restoration of heavy metal polluted underground water. The preparation method of the modified iron-copper bimetallicnanoparticle provided by the invention has the advantages of simple operation, low cost, cleanness, no pollution, etc.

Owner:HUNAN UNIV

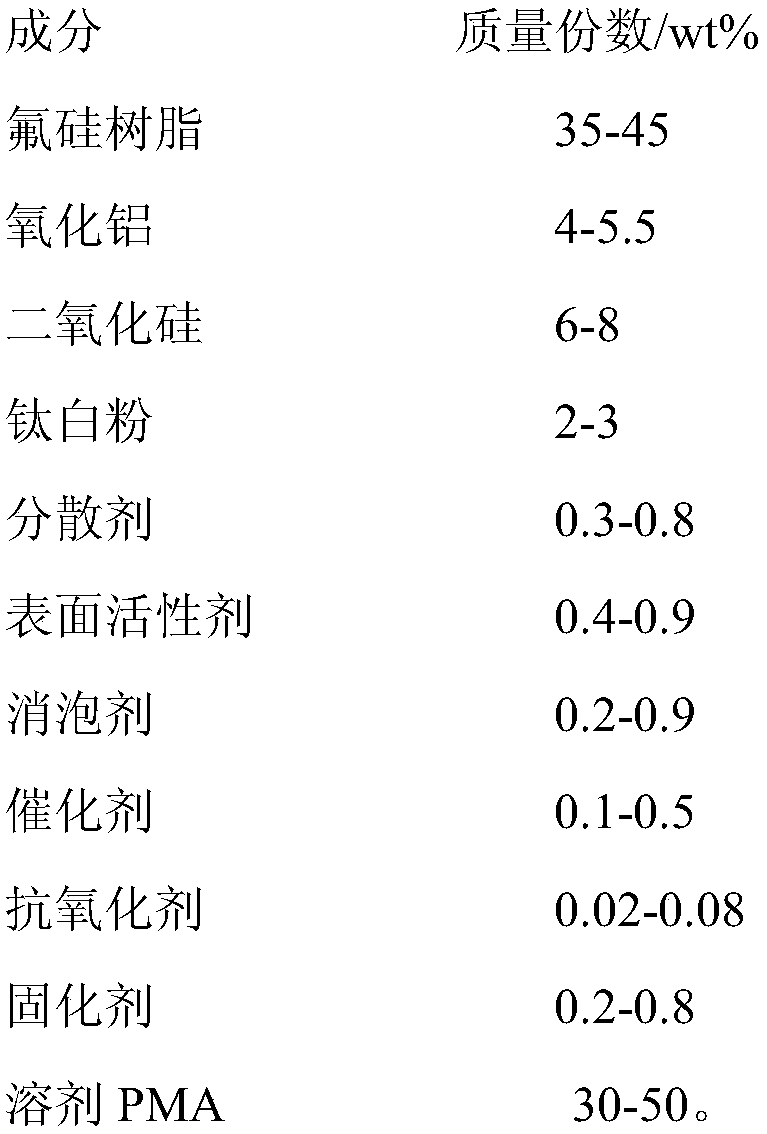

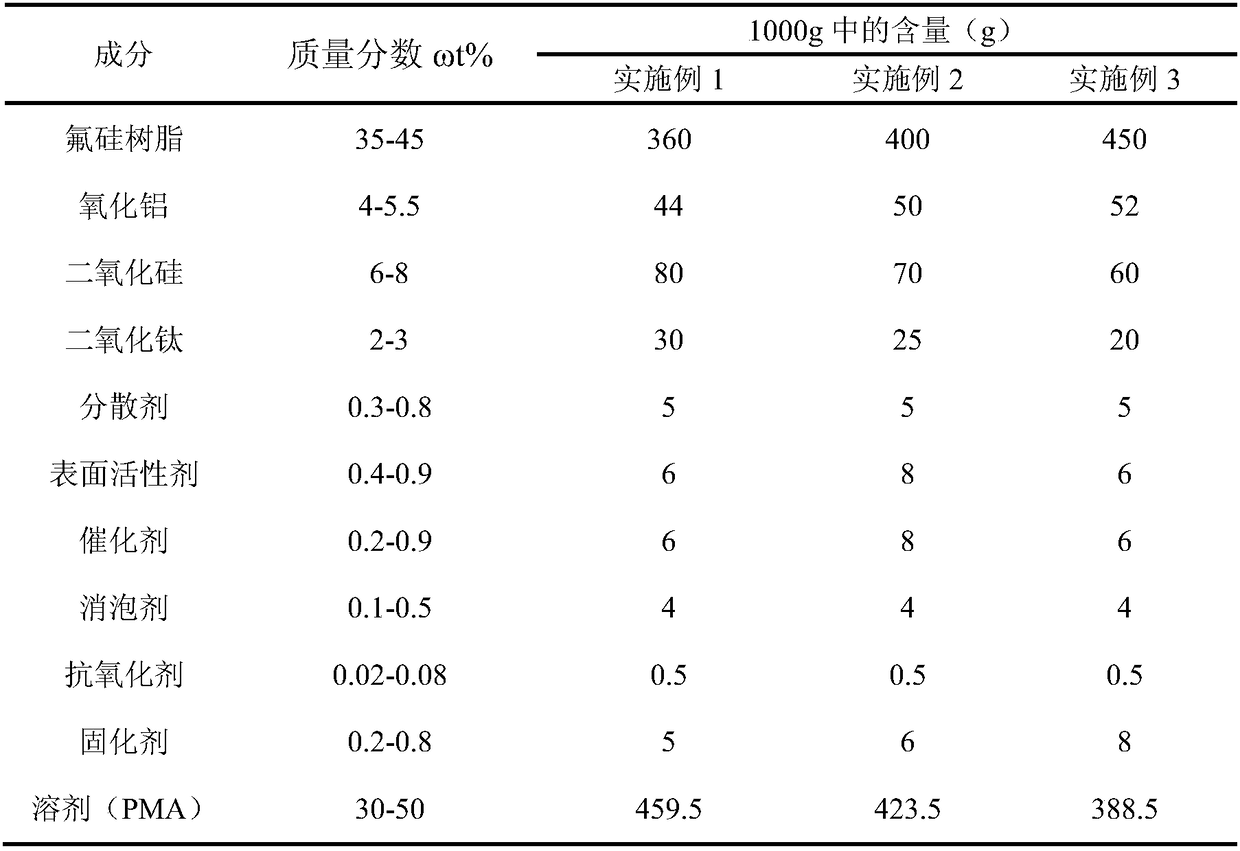

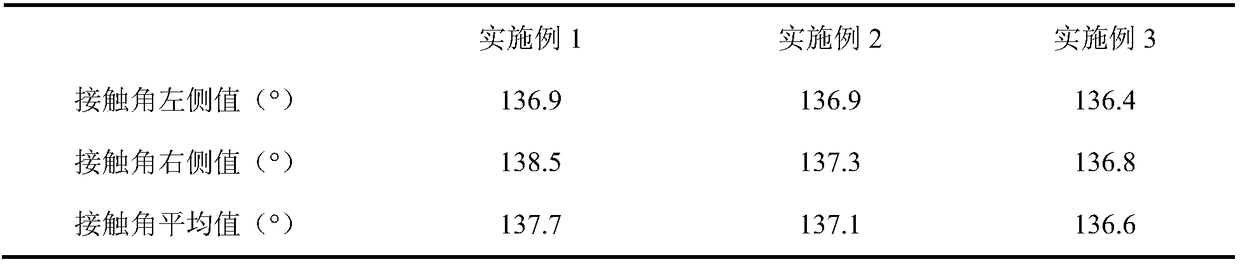

Insulator anti-icing coating and preparation method thereof

The invention discloses insulator anti-icing coating and a preparation method thereof. The anti-icing coating is prepared from the following components in parts by mass: 35-45 parts of fluorosiliconeresin, 4-5.5 parts of aluminum oxide, 6-8 parts of silicon dioxide, 2-3 parts of titanium dioxide, 0.3-0.8 part of dispersing agent, 0.4-0.9 part of surfactant, 0.2-0.9 part of de-foaming agent, 0.1-0.5 part of catalyst, 0.02-0.08 part of anti-oxidant, 0.2-0.8 part of curing agent and 30-50 parts of solvent PMA. The preparation method comprises the following steps: separately adding aluminum oxide, silicon dioxide and titanium dioxide into the surfactant, adding absolute ethyl alcohol, stirring until completely wet while adding, ultrasonically stirring and dispersing, drying, wetting and drying by distilling through PMA, stirring and dispersing after mixing fluorosilicone resin with residual PMA, pouring all system solution into a grinder to grind, pouring the de-foaming agent, the anti-oxidant and the catalyst into the grinder to disperse, adding the curing agent to disperse, thereby obtaining anti-icing coating. The anti-icing coating is remarkably improved in hydrophobicity performance, is good in anti-ice effect on a power transmission line, and has surface-drying time, volume resistivity and dielectric strength, which meet standards.

Owner:GUIZHOU POWER GRID CO LTD

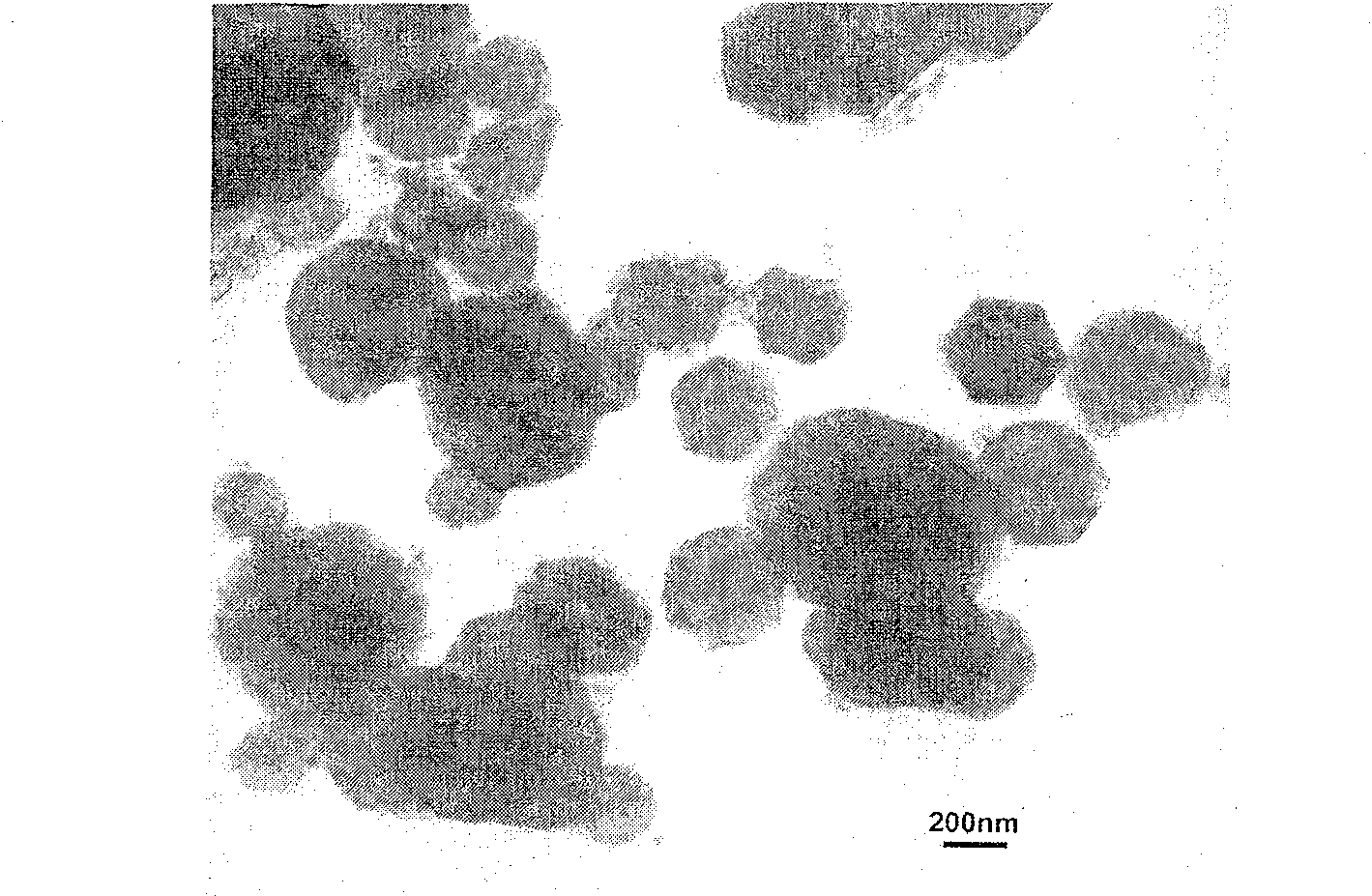

Preparation method of particulate self-assembling spherical zinc-cadmium-sulfur solid solution material

ActiveCN107697944AImprove photocatalytic performanceImprove photocatalytic abilityCadmium compoundsParticulatesSulfur

The invention discloses a preparation method of a particulate self-assembling spherical zinc-cadmium-sulfur solid solution material. The preparation method comprises the following steps: weighing CMC,preparing a solution, and then sequentially performing stirring and ultrasonic treatment to form a mixed solution A; weighing zinc acetate dihydrate and cadmium acetate dihydrate, adding the zinc acetate dihydrate and cadmium acetate dihydrate into the mixed solution A, and then sequentially performing stirring and ultrasonic treatment to form a mixed solution B; weighing thioacetamide as a sulfur source, and adding the thioacetamide into the mixed solution B; then sequentially performing stirring and ultrasonic treatment to form a mixed solution C; acidifying the mixed solution C with a HClsolution, and performing ultrasonic treatment to form a mixed solution D; adding the mixed solution D into a polytetrafluoroethylene lining, and performing a hydrothermal reaction; and after the reaction is completed, respectively performing centrifugal washing on the product through deionized water and ethanol for multiple times, and then performing drying and grinding to obtain powder of the required material.

Owner:SHAANXI UNIV OF SCI & TECH

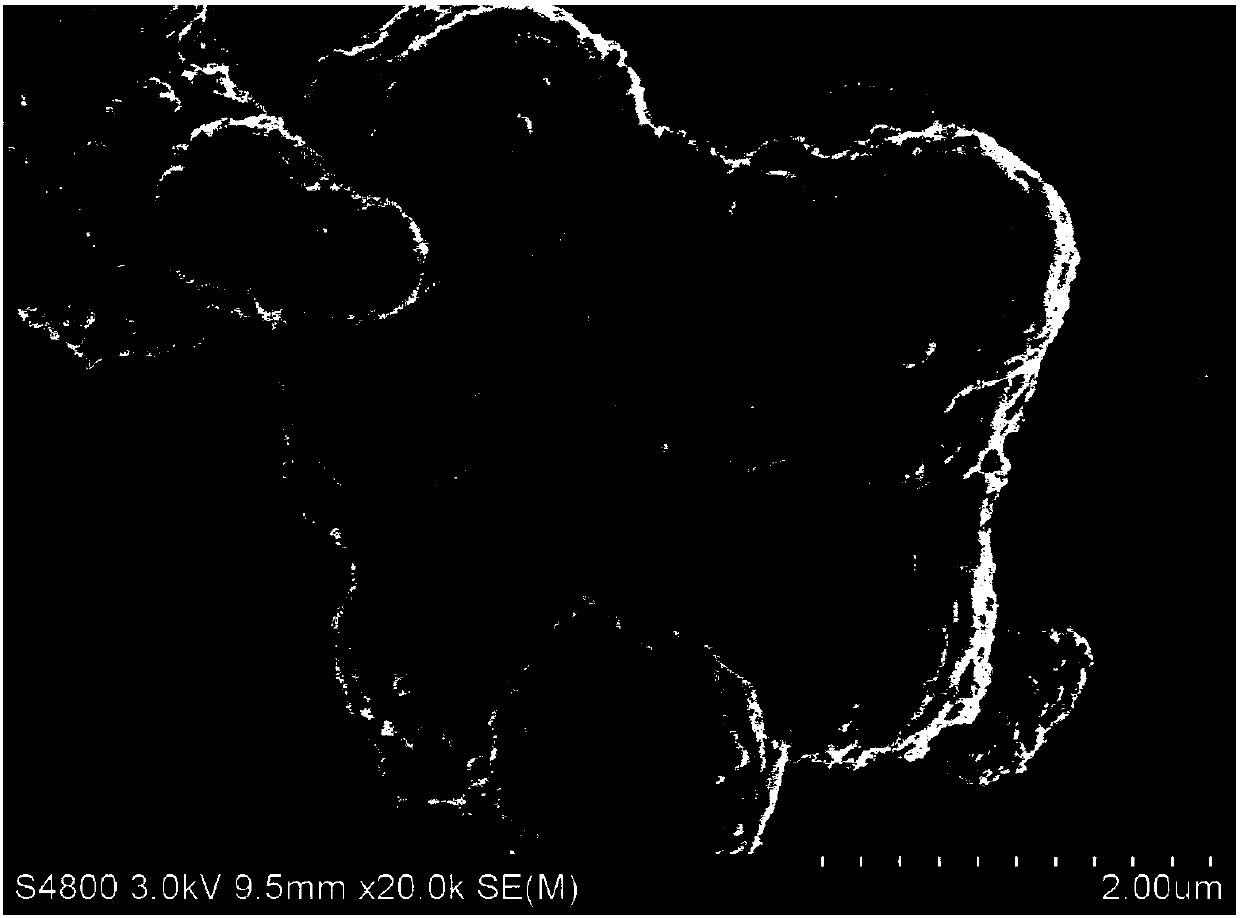

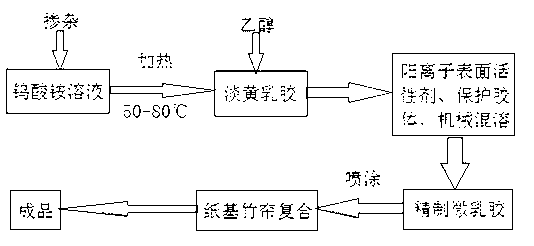

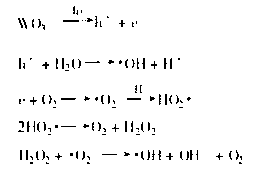

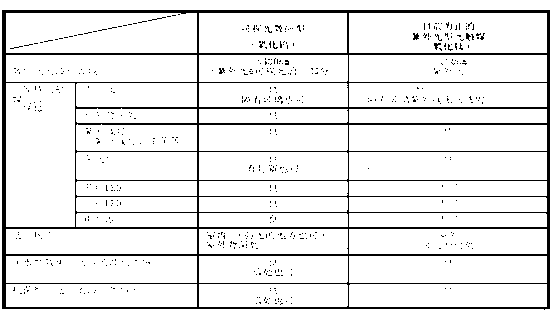

Nanometer tungsten oxide photocatalyst paper-base bamboo curtain manufacturing method and product thereof

InactiveCN103273544APromote degradationReduced band gapWood veneer joiningWood layered productsFiberSurface-active agents

The invention relates to a paper-base bamboo curtain manufacturing method and a product thereof, in particular to a nanometer tungsten oxide photocatalyst paper-base bamboo curtain manufacturing method and a product thereof. The method sequentially comprises the following steps that (1), ammonium tungstate solutions are heated under 50-80 DEG C and then are cooled, then ethyl alcohol is added into the ammonium tungstate solutions to form a first latex solution, then cationic surface active agents are added to protect colloid, and mechanical mixing dissolving and refining are used for obtaining a second latex solution; (2) paper-base fibers and a bamboo curtain are combined to obtain a paper-base bamboo curtain; (3) the second latex solution obtained in the step (1) is sprayed to the paper-base bamboo curtain obtained through in the step (2) to form a film, and a nanometer tungsten oxide photocatalyst paper-base bamboo curtain is obtained. The parameters of the manufactured bamboo curtain are that each clearance is smaller than 0.35mm in average, the bonding strength is larger than 0.20Mpa, formaldehyde emission is smaller than 0.5mg / L, antibacterial property is higher than 70%, and water content is 7-13%. According to the nanometer tungsten oxide photocatalyst paper-base bamboo curtain, tungsten oxide content in the paper-base bamboo curtain has good function effect in optic self-catalytic degradation Voc, deodorization, antibiosis and sterilization and the like, and cost can be lowered.

Owner:安吉汉洲竹制品有限公司

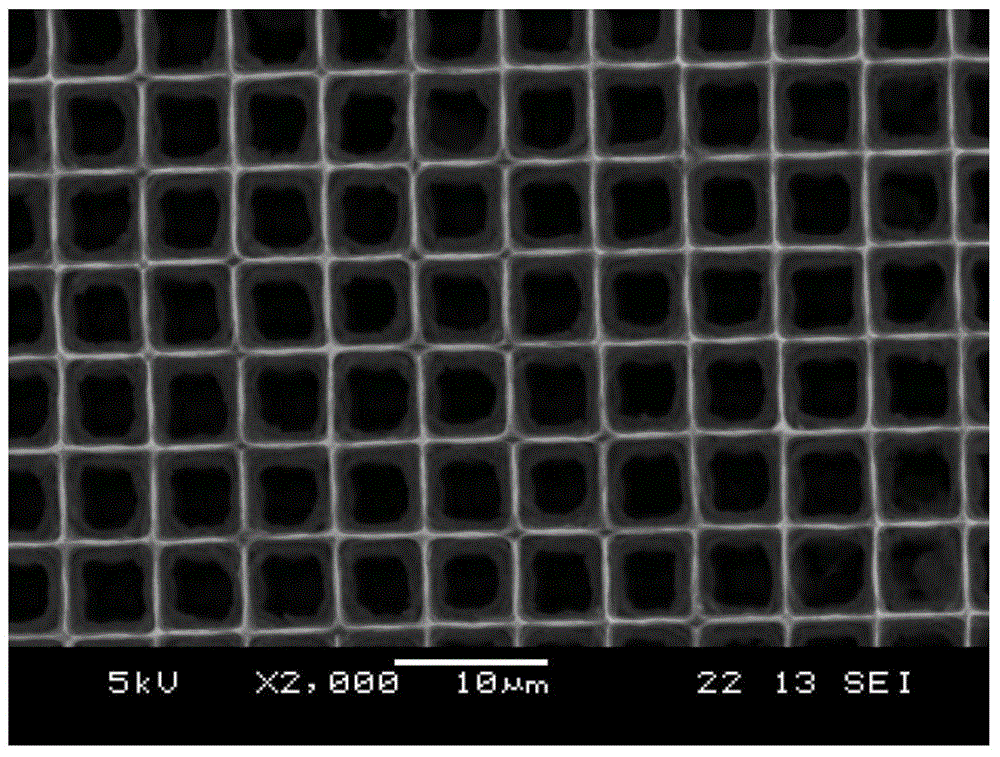

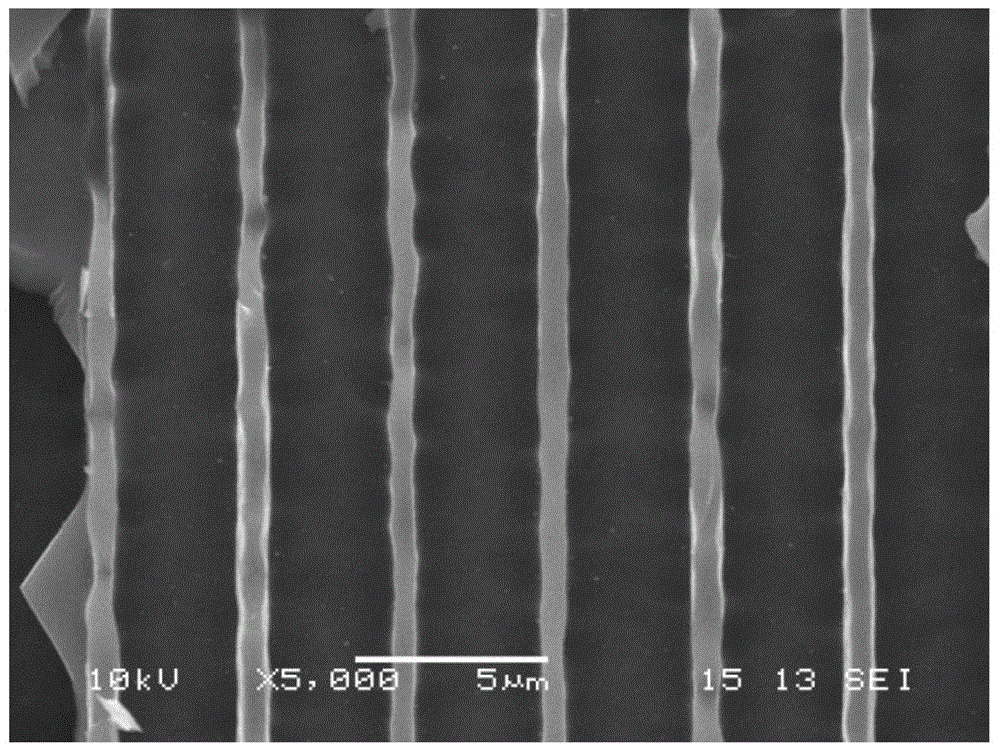

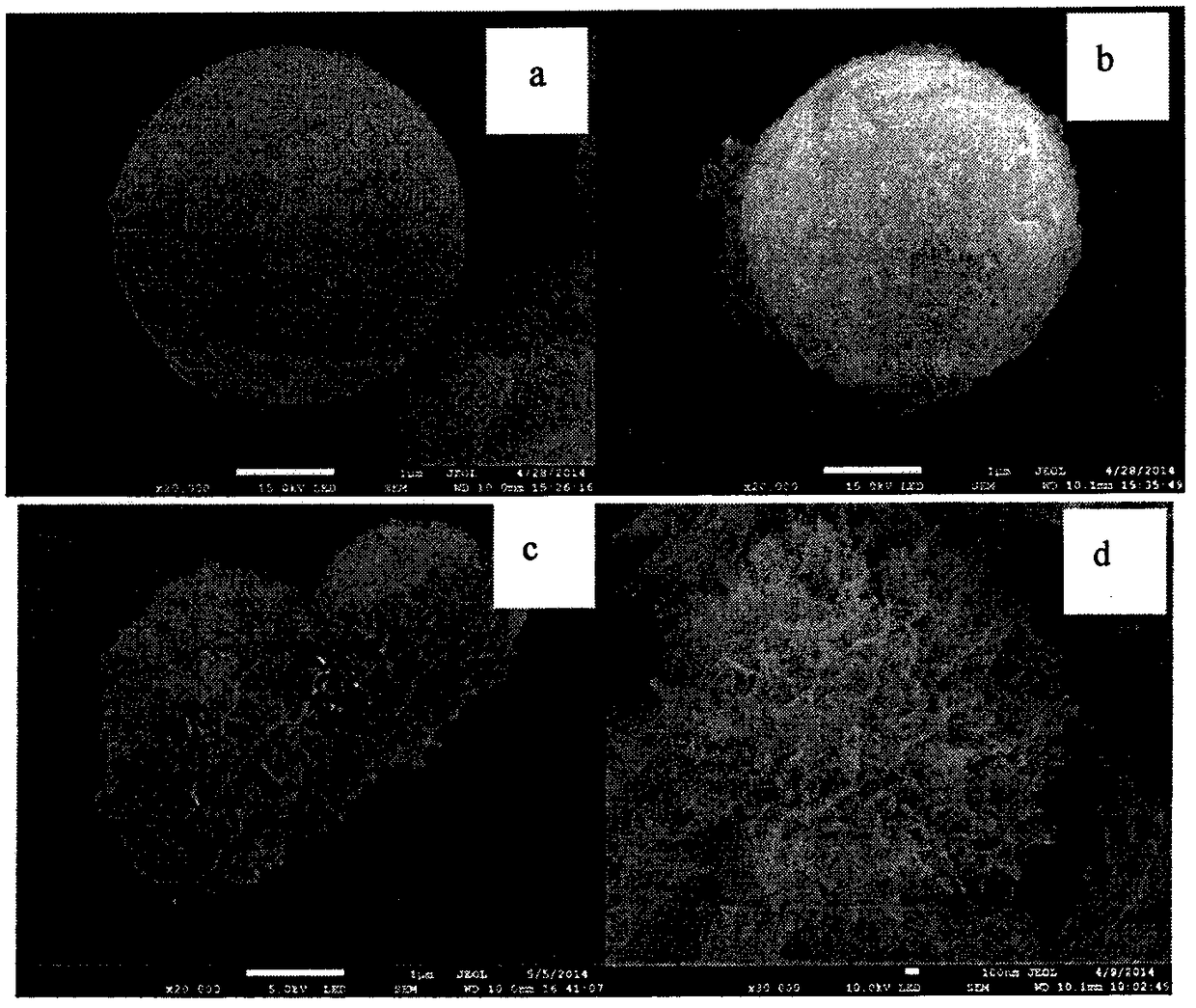

P-type silicon microchannel based surface uniform nano modification method

ActiveCN104828774AHigh particle purityGood dispersionMaterial nanotechnologyNanostructure manufactureMicrostructureOxide

The invention relates to the technical field of nano-grade material and microstructure, and discloses a method for uniformly growing a nanostructured material on a uniform chemically nickel-plated silicon microchannel substrate structure. The method comprises the following steps: silicon microchannels with a needed shape and separated from a silicon substrate are cut with laser; a uniform nickel conductive layer is grown on the surfaces of the microchannels with a chemical nickel-plating method; a nickel deposition time is adjusted, such that the resistance of the nickel-plated silicon microchannels is lower than 2ohm; a layer of nanostructure is grown on the surfaces of the nickel-plated microchannels with a hydrothermal method, wherein the nanostructure is composed of a composite metal oxide CoMoO4. According to the invention, the nanostructure is grown on the surfaces and insides of the nickel-plated silicon microchannels with micron-grade pore sizes with the hydrothermal method, such that the uniformity and stability of the structure are improved, and a problem of severe microchannel blockage caused by physically delivering materials to the inner sides of the microchannels is avoided. The material has good electrochemical activity, and has certain potential to be used in the field of new energy.

Owner:EAST CHINA NORMAL UNIVERSITY +1

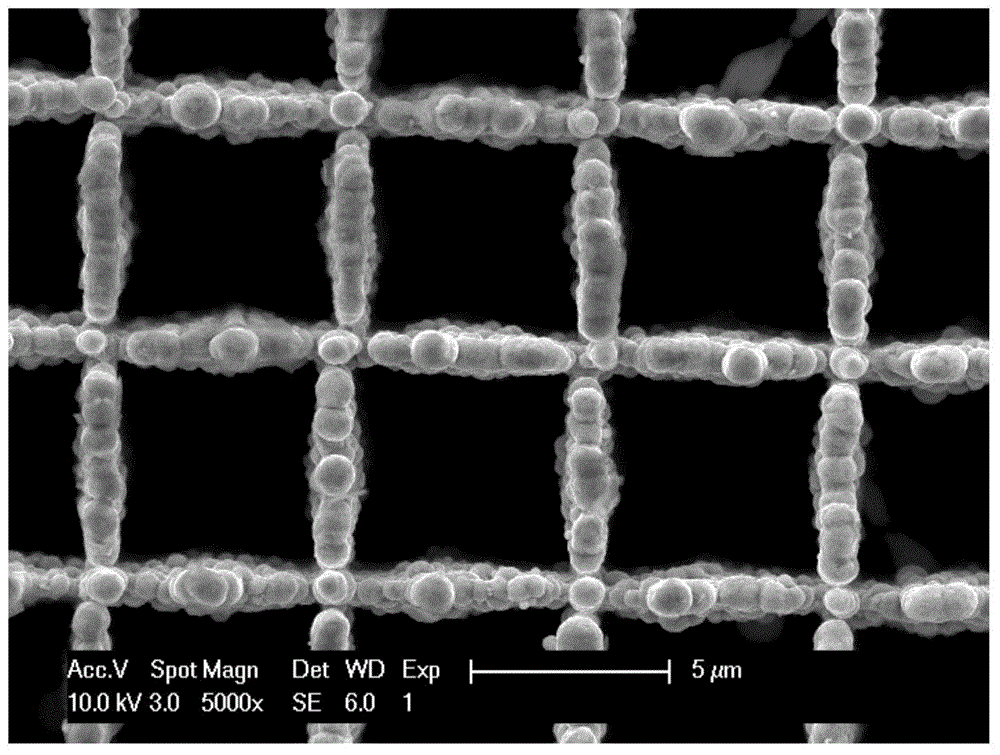

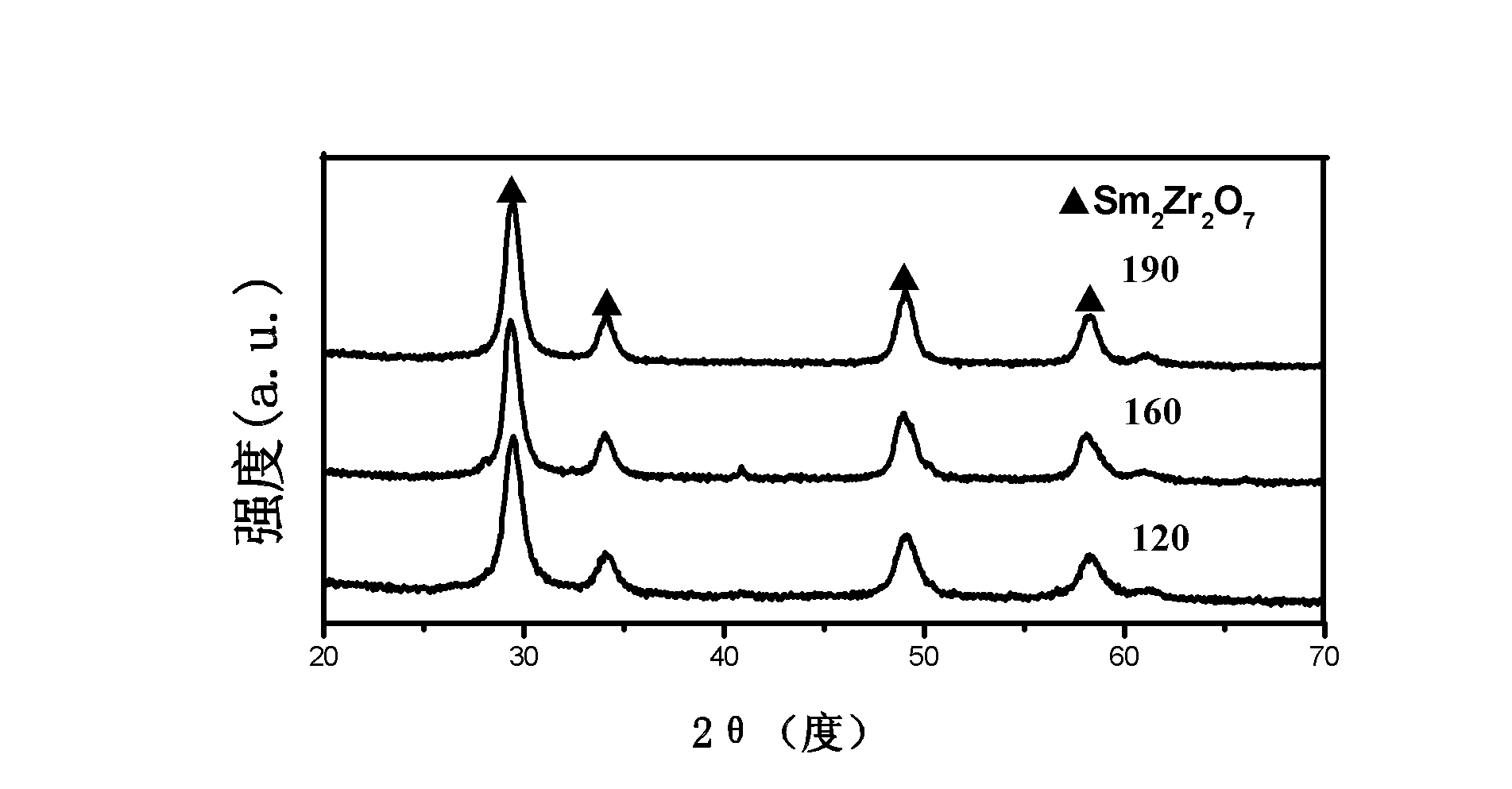

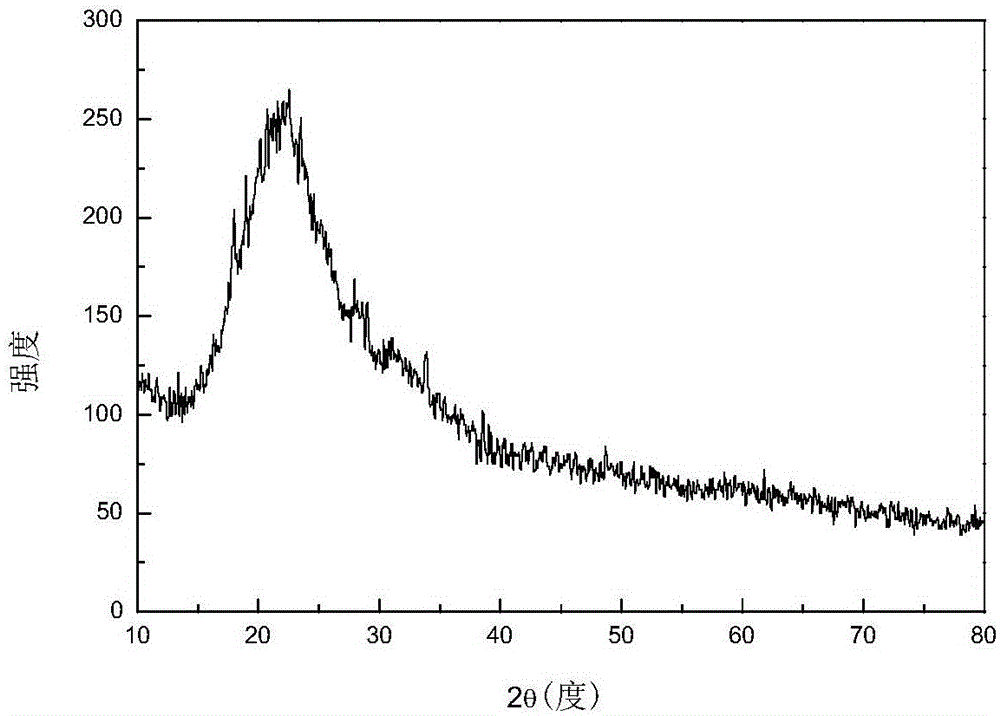

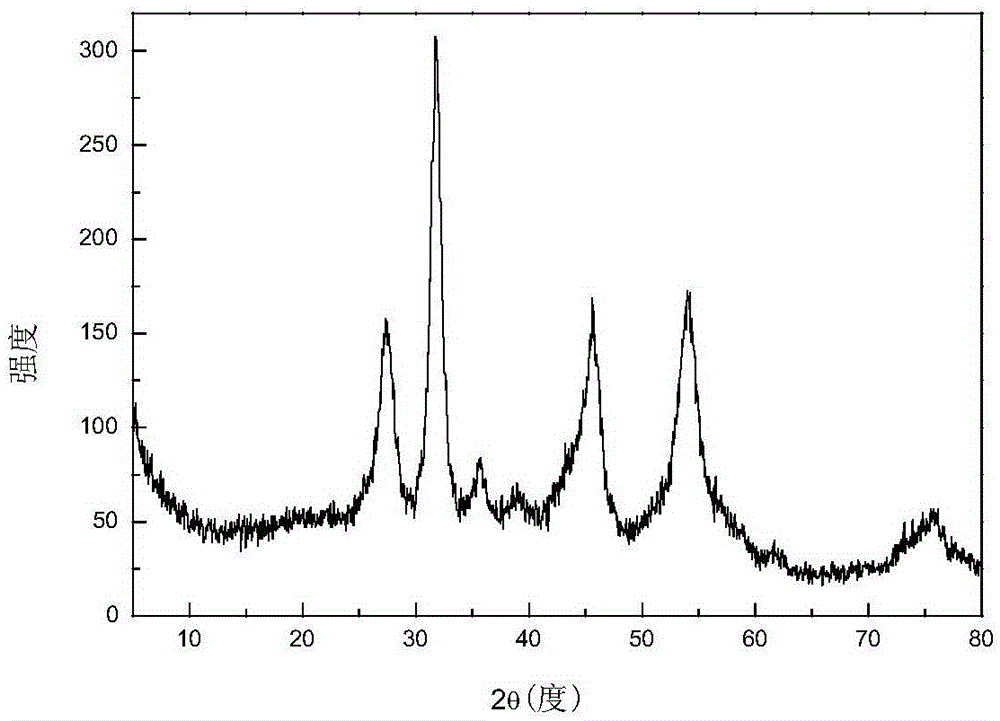

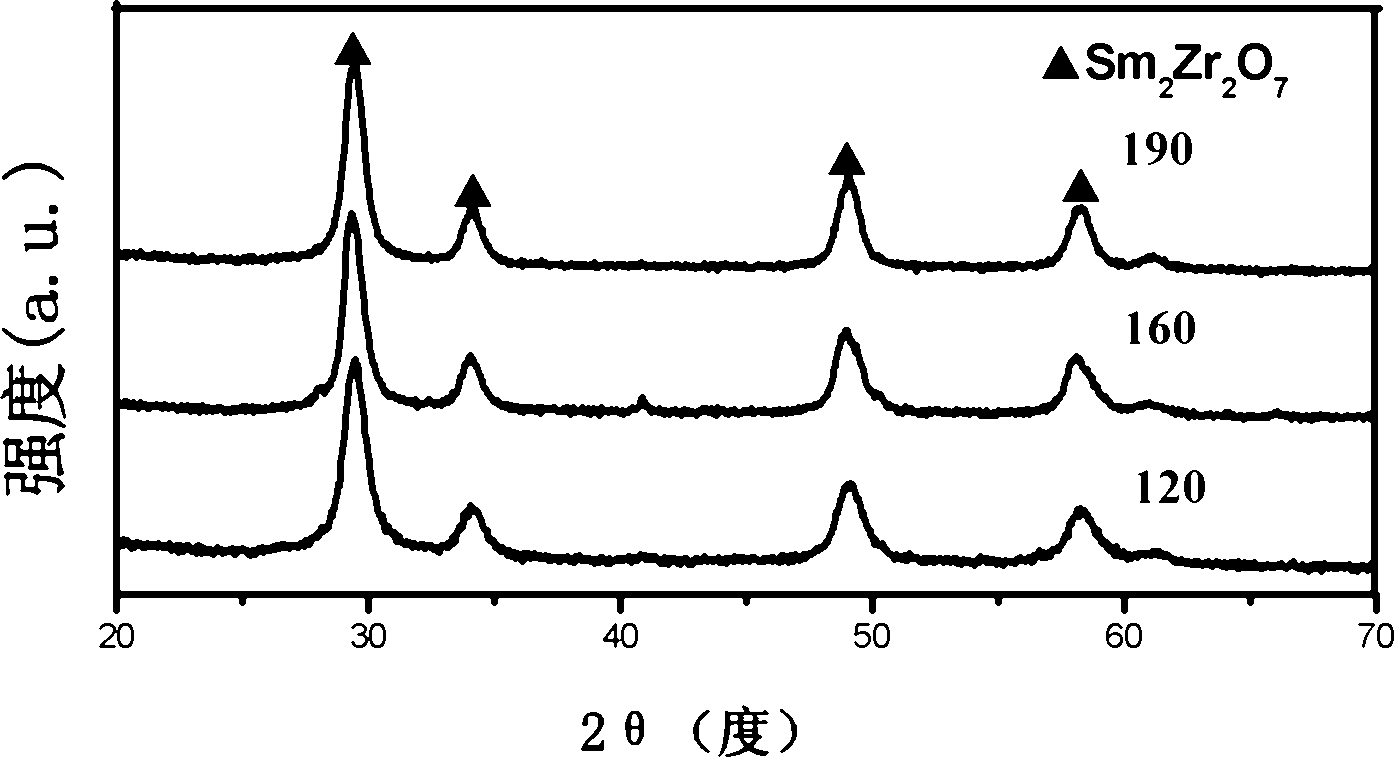

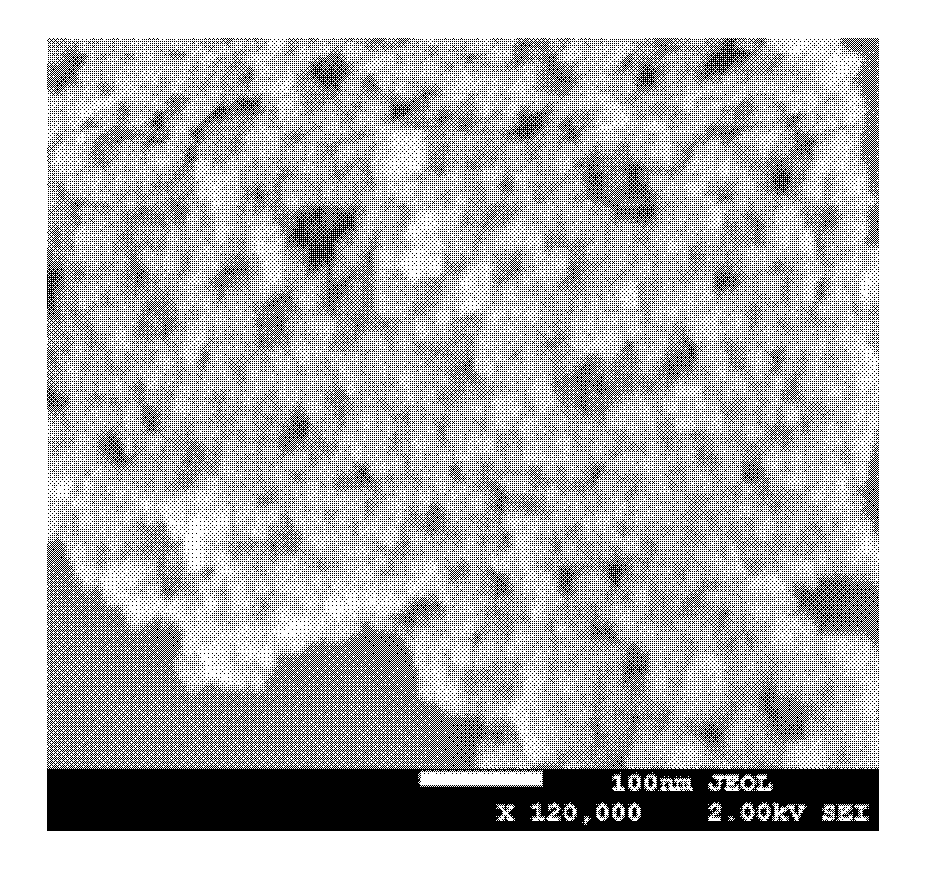

Rare earth samarium zirconate nano material and hydrothermal preparation method thereof

InactiveCN102674455AIncrease scatteringMean Free Path DecreaseZirconium compoundsNanotechnologySemiconductor materialsZirconate

The invention discloses rare earth samarium zirconate nano material and a hydrothermal preparation method of the rare earth samarium zirconate nano material. The rare earth samarium zirconate nano material adopts nanoscale rare earth samarium zirconate powder formed by directly performing hydro-thermal synthesis on coprecipitated precursors. The rare earth samarium zirconate powder prepared through the method has a low thermal coefficient and a good thermal barrier effect, and belongs to potential photocatalytic semiconductor material. The method comprises the following steps: firstly, dissolving a zirconium source in deionized water, and then mixing the zirconium source with samarium source solution, secondly, adding prepared strong alkali solution in the mixed solution of the step one, sufficiently stirring to obtain precursor products, and performing centrifugalization to obtain solid precipitate, thirdly, dispersing the solid precipitate of the step two in deionized water, adjusting the PH value of solution, and adding slurry in a high-pressure reaction kettle to be reacted; and fourthly, taking out powder after the reaction, and washing the powder obtain pour phase samarium zirconate nano powder.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Refining method of putty

InactiveCN102532973AHigh particle purityImprovement of anti-seepage functionFilling pastesClay processing apparatusDiaphragm pumpFiltration

The invention provides a refining method of putty, which is characterized in that the method comprises the following steps: introducing putty which is already stirred into slurry into material feeding filtration devices of an extruder, an extruding pump, a diaphragm pump, a filter press, and a screw pump during packaging, wherein inlets and outlets of the devices are equipped with filter screens, removing various impurities included in the putty to allow the putty to become a product with particle purity; the method greatly improves the construction performance, decorative effect and water seepage resistance of the putty; and the technology has marvelous key effect in the preparation process.

Owner:上海绿特丹保温工程有限公司

Holmium metal iodate fluorescent material and preparation method and applications thereof

InactiveCN103011236AHigh particle purityGood dispersionRare earth metal compoundsLuminescent compositionsLuminous intensityHolmium

The invention discloses a holmium metal iodate fluorescent material and a preparation method and applications thereof. The molecular formula of the compound is Ho(IO3)3, the space group is P21n, the parameters of unit cells comprise that a is equal to 8.7376 angstrom, b is equal to 5.9706 angstrom, c is equal to 15.0677 angstrom, alpha is equal to 90.000, beta is equal to 97.240, g is equal to 90.000, and Z is equal to 2; and the volume V of the unit cells is equal to 779.8(10) angstrom<3>. The material adopts hydrothermal reaction to obtain crystals; Ho<3+> fluorescence radiation intensity of the material can be enhanced through iodate ions; and the material is used for producing fluorescence radiation devices.

Owner:GUANGDONG UNIV OF TECH

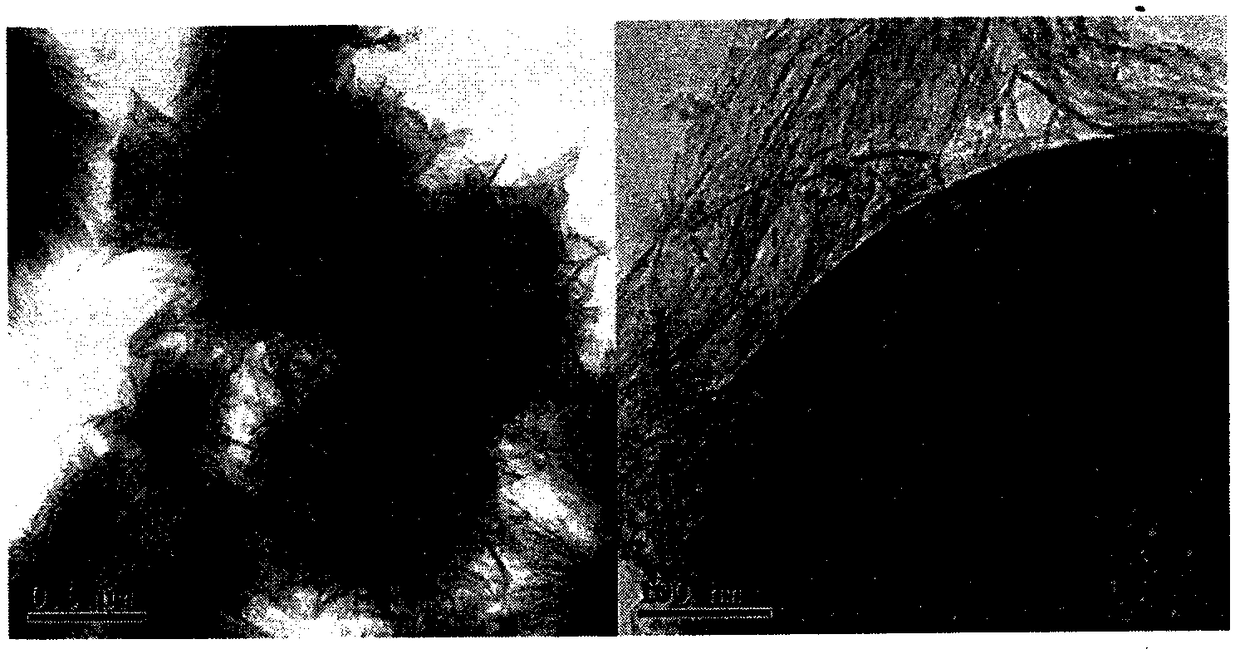

Magnesium hydride nano particle and preparation method and application thereof

InactiveCN100554142CLarge specific surface areaShorten the diffusion distanceAlkali/alkaline-earth/beryllium/magnesium hydridesNanoparticleHydrogen absorption

The invention discloses a magnesium hydride nano particle material, a preparation method and application thereof. The method of electric arc heating is used to prepare nano-sized magnesium powder, and then hydrogenated to obtain MgH2 particle products with a particle size of 50-600nm. The nano-scale MgH2 particle of the present invention has high purity, and has excellent kinetic properties of hydrogen absorption and desorption when used as a hydrogen storage material, so it has extremely important application value and broad application prospects in the field of hydrogen storage technology.

Owner:PEKING UNIV

A kind of preparation method of granular self-assembled spherical zinc cadmium sulfur solid solution material

ActiveCN107697944BImprove photocatalytic performanceImprove photocatalytic abilityCadmium compoundsParticulatesCadmium acetate

Owner:SHAANXI UNIV OF SCI & TECH

A synthesis method of petal-shaped magnesia-aluminum spinel nanohollow spheres with high specific surface area

ActiveCN105366700BControl volumeMethod environmentally friendlyMaterial nanotechnologyAluminium oxides/hydroxidesPetalSpinel

The invention discloses a preparation method of petal-shaped MgAl2O4 hollow nanospheres. Glucose is used as a carbon source, and carbon spheres prepared by hydrothermal method are used as a template. 0.4g of carbon spheres is taken, and magnesium nitrate is weighed according to a molar ratio of 2:1. Dissolve with aluminum nitrate in water, disperse evenly by ultrasonication for 60 minutes at room temperature, transfer to a 100ml hydrothermal kettle, react at 180°C for 24 hours, naturally cool to room temperature, centrifuge and wash to obtain a dark brown precipitate, dry at 60°C for 12 hours, heat up to 1000°C Remove the carbon spheres and keep warm for 5 hours to obtain the hollow magnesia-aluminum spinel nanosphere material with a petal-like structure. The present invention uses carbon spheres as templates to directly hydrothermally synthesize petal-shaped magnesia-aluminum spinel nanospheres with high specific surface area, which has the advantages of simple process, low cost, easy operation, no precipitant, etc., and the obtained product has uniform size and crystal form. Nice and easy to control.

Owner:湖南华佳纳米新材料科技有限公司

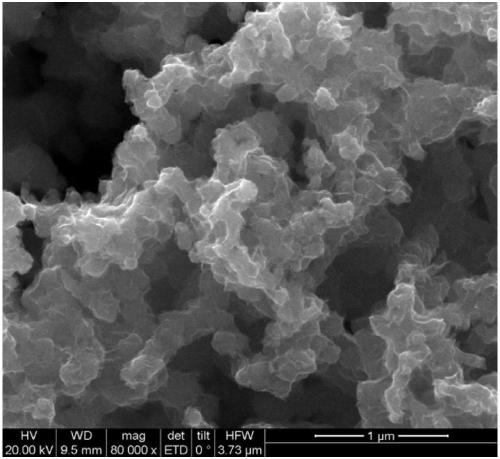

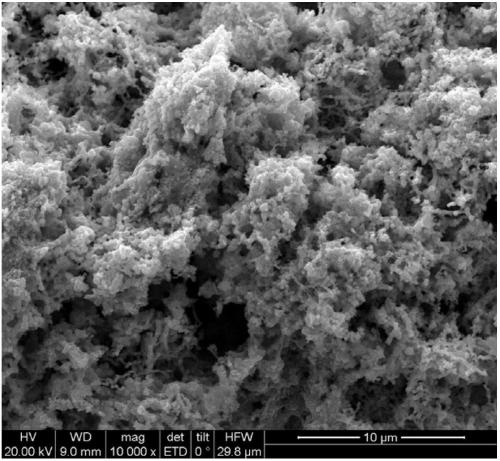

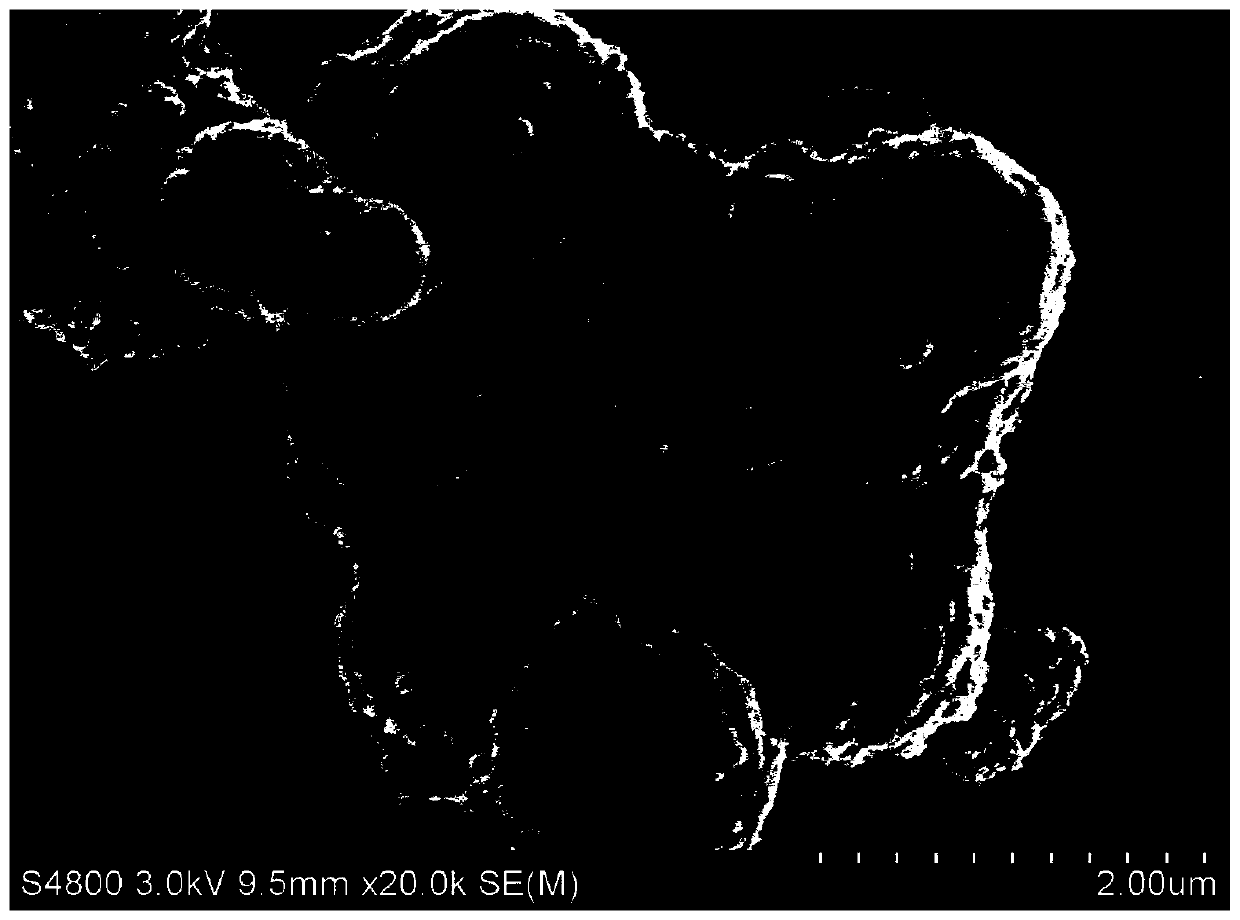

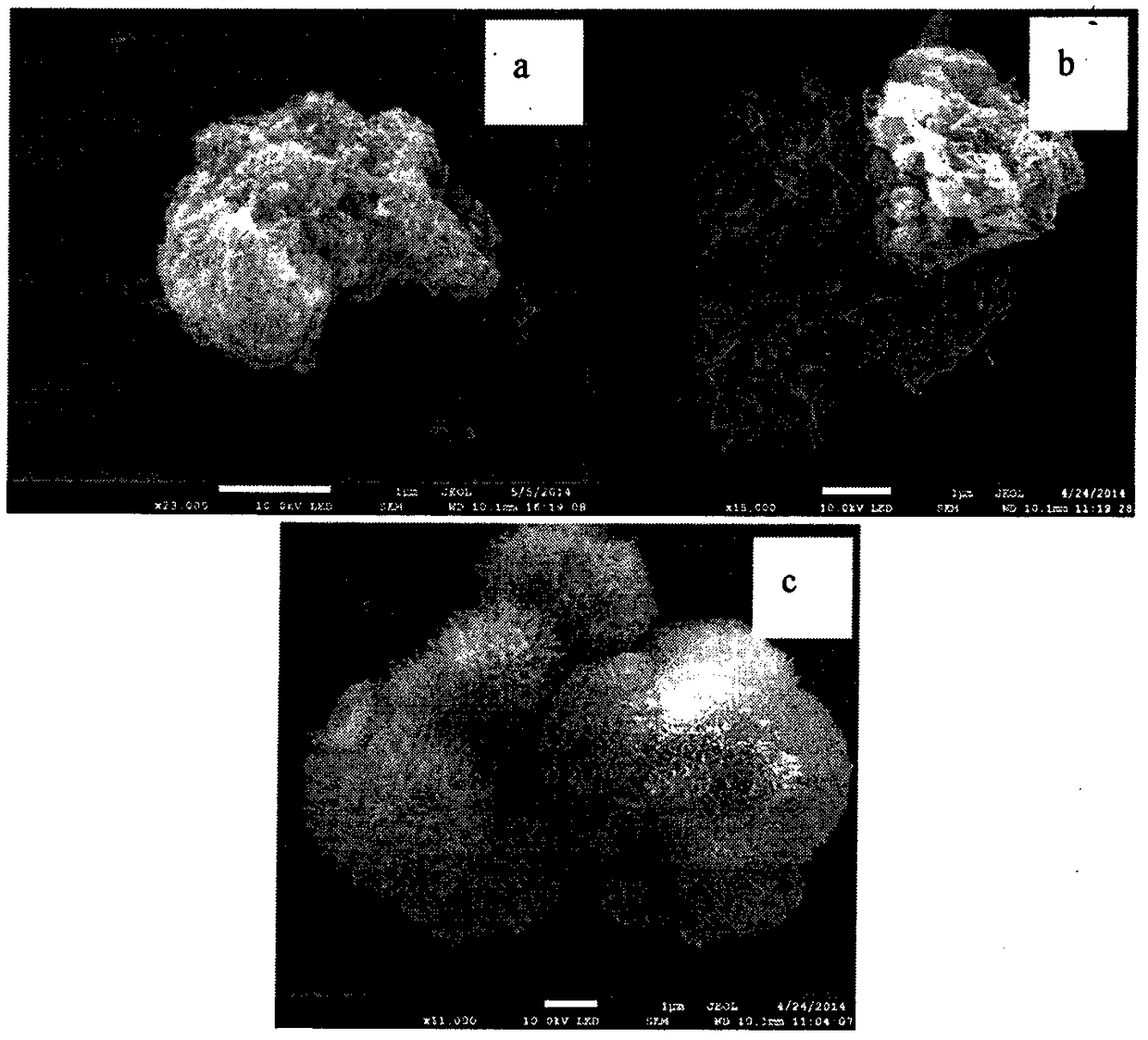

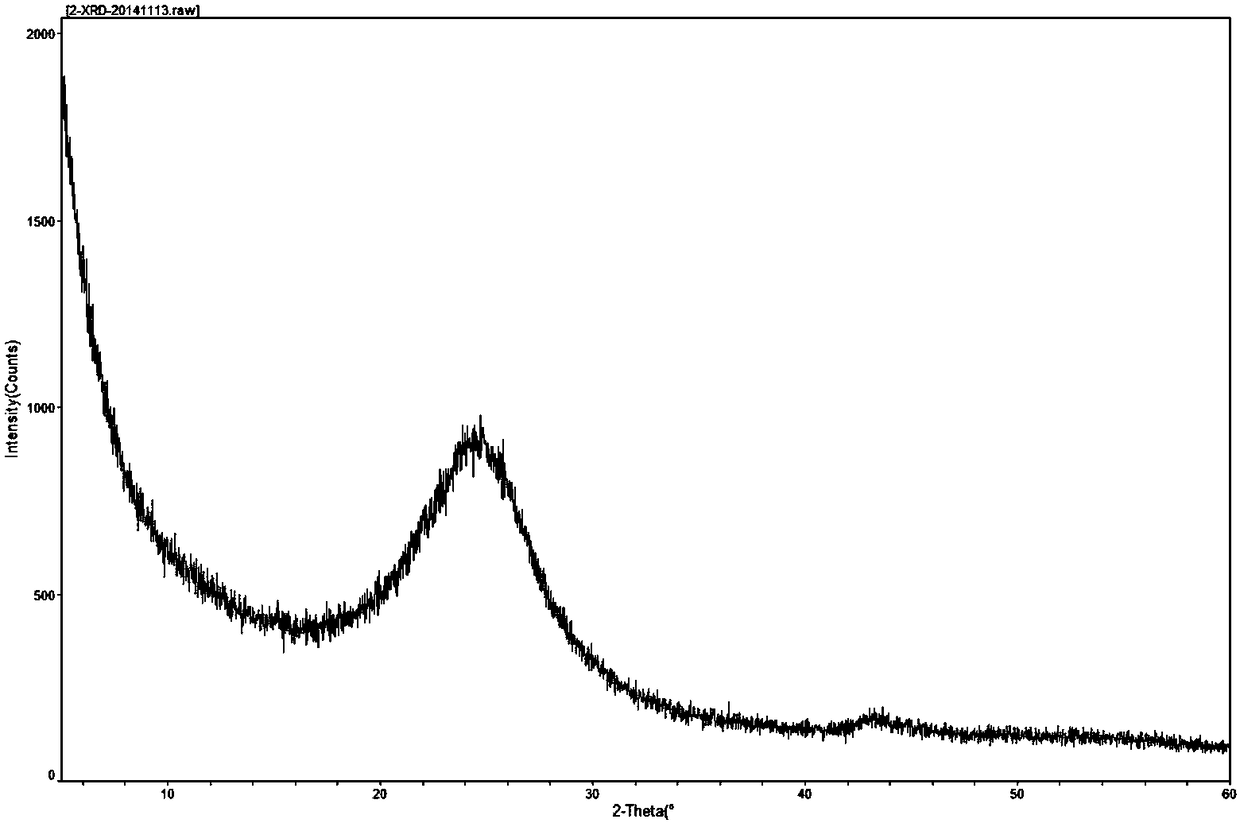

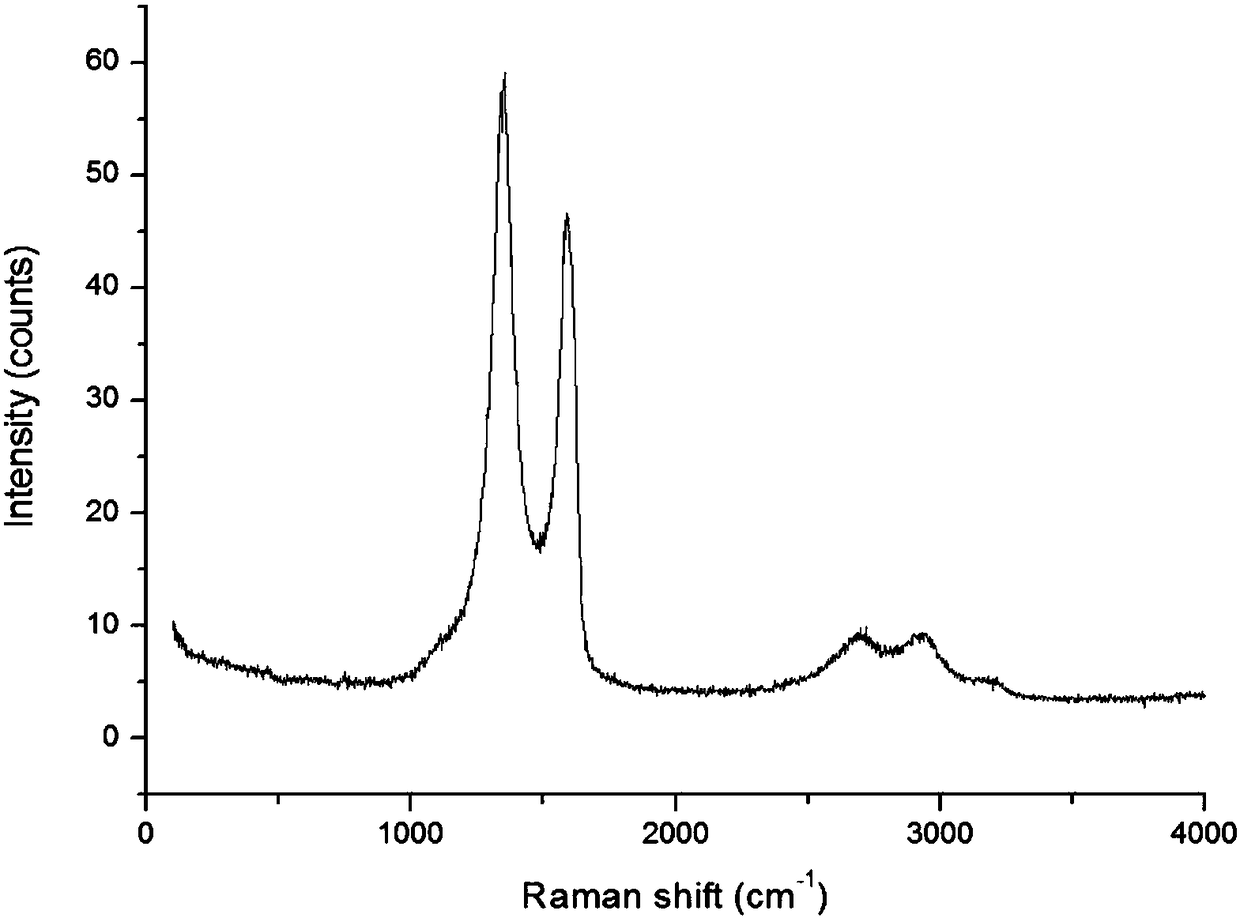

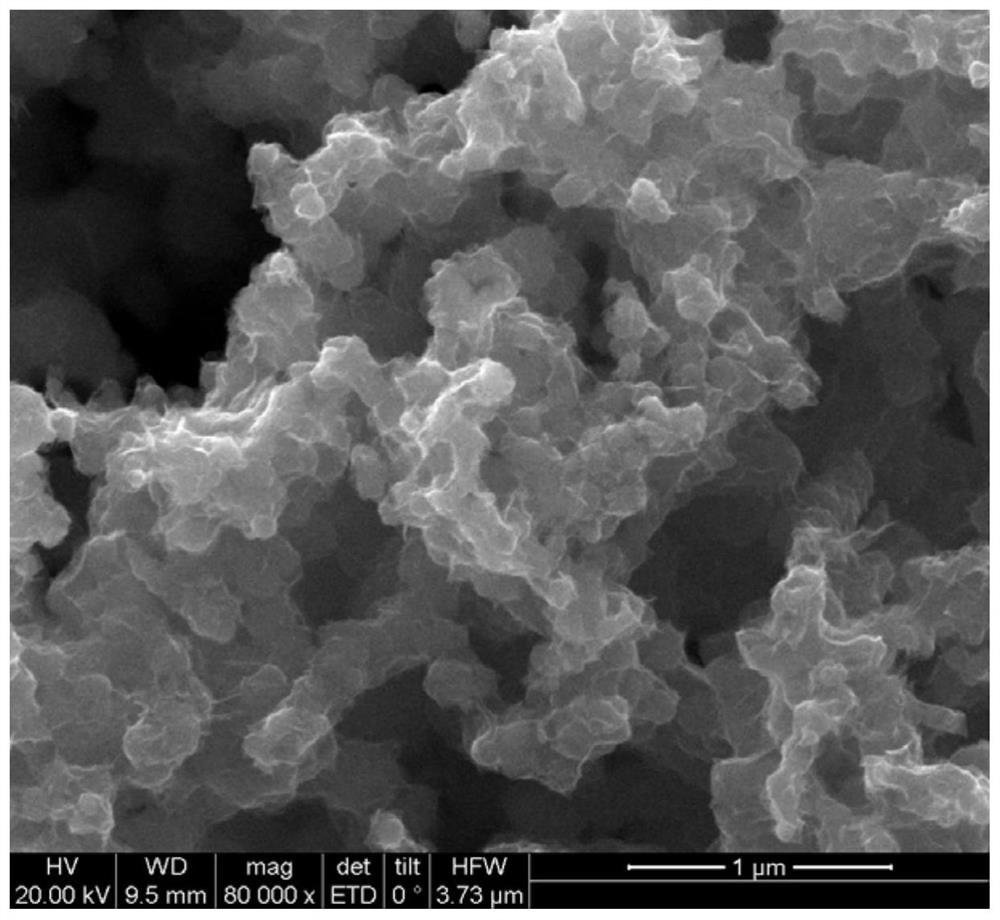

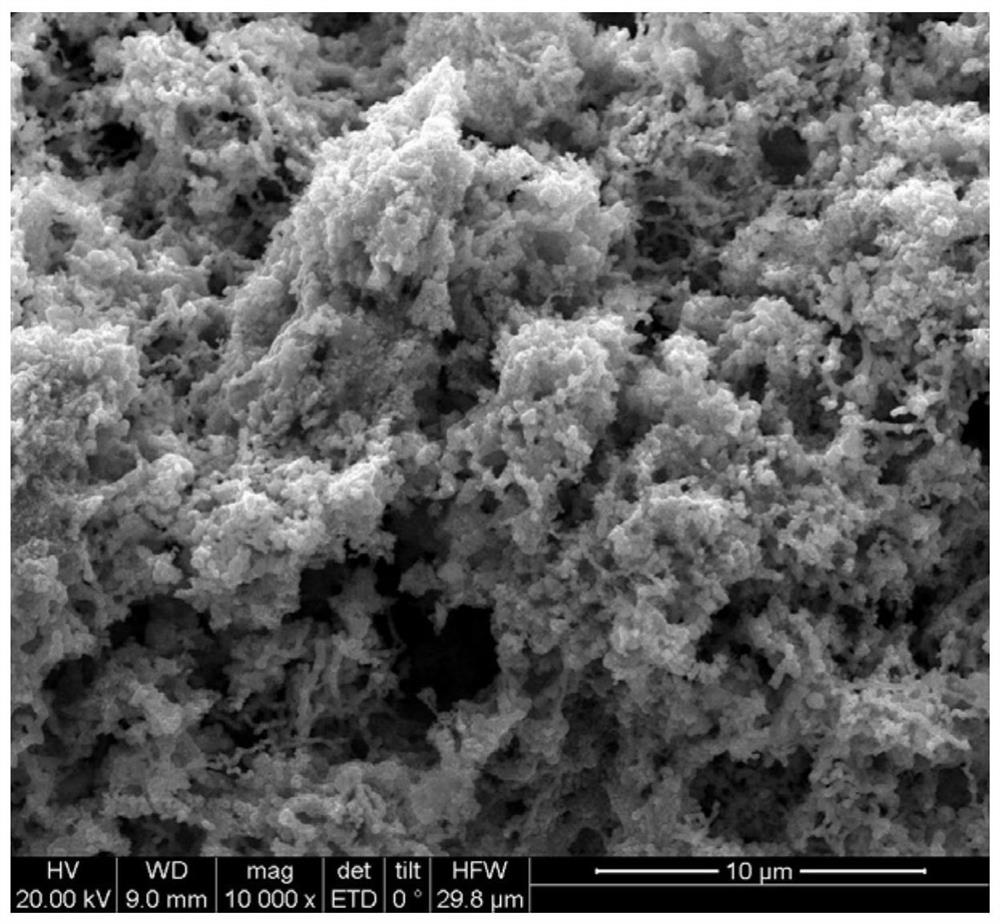

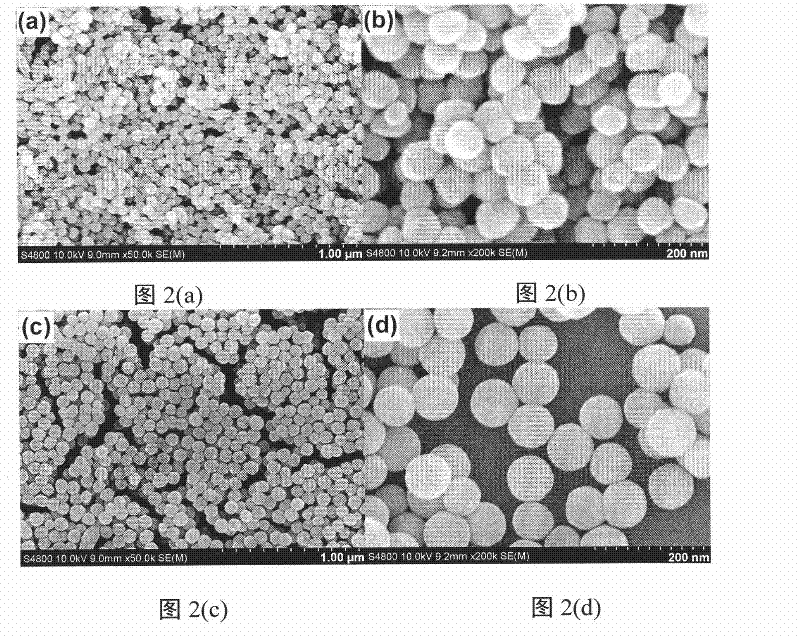

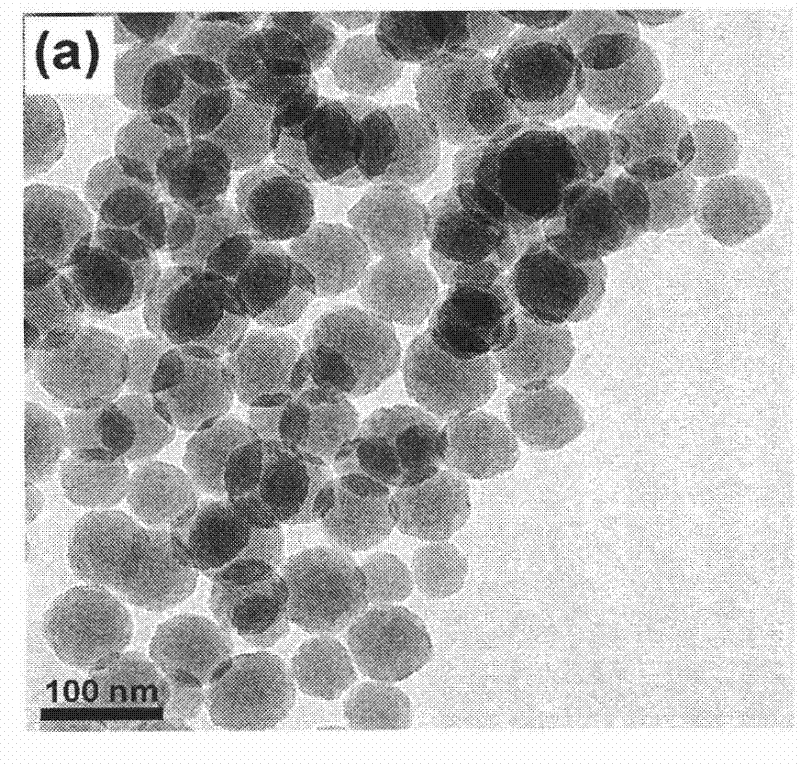

A kind of high saturation magnetization nano ferroferric oxide/graphene composite material with electromagnetic shielding function and preparation method thereof

ActiveCN105802579BUniform particle size distributionDimensionally stableMaterial nanotechnologyOther chemical processesMagnetizationElectromagnetic shielding

The invention discloses a nano Fe3O4 / graphene composite material with high saturation magnetization and an electromagnetic shielding function as well as a preparation method of the composite material. According to the method, Fe3<+> and Fe2<+> salts are used as iron sources, in combination with urea, reduced graphene oxide and water, the composite material is prepared with a hydrothermal method. The prepared nano Fe3O4 / graphene composite material is evenly distributed nanoparticles of 40-50 nm, the crystal form is complete, the specific saturation magnetization is 75 emu / g or above, and the electromagnetic shielding effectiveness of the composite material can reach 26 dB or above within 2-18 GHz when the filling amount is 50%. The preparation technology is simple, raw materials are wide in source, water is taken as a medium, and the production requirement of green chemistry is met. The composite material is a multifunctional nanomaterial and has broad application prospect in fields of biomedical materials, electromagnetic shielding materials, electrode materials, catalytic materials, sewage treatment and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Modified iron-copper bimetallic nanoparticles and preparation method thereof

ActiveCN109205753BImprove reducibilityStrong reductionWater contaminantsContaminated groundwater/leachate treatmentIn situ remediationFerrous sulfate iron

The invention discloses a modified iron-copper bimetallic nanoparticle and a preparation method thereof. The modified iron-copper bimetallic nanoparticle includes chitosan and iron-copper bimetallic nanoparticles, wherein chitosan is coated on the surfaces of the iron-copper bimetallic nanoparticles. The preparation method includes: mixing a chitosan solution with a ferrous sulfate solution, adding an NaHB4 solution dropwise for liquid phase reduction reaction, and adding a copper sulfate solution dropwise for in-situ displacement reaction to obtain the modified iron-copper bimetallic nanoparticle. The modified iron-copper bimetallic nanoparticle provided by the invention have the advantages of good dispersibility, strong reducibility, long service life and the like, and is an environment-friendly material that has good application prospects and can be applied to in-situ restoration of heavy metal polluted underground water. The preparation method of the modified iron-copper bimetallicnanoparticle provided by the invention has the advantages of simple operation, low cost, cleanness, no pollution, etc.

Owner:HUNAN UNIV

Preparation method of nano petaline Ni(OH)2

InactiveCN102774893BHigh particle purityUniform grain sizeNanotechnologyNickel oxides/hydroxidesMicrosphereSulfate

The invention discloses a preparation method of nano petaline Ni(OH)2. The method comprises the steps of taking nickel sulfate and urea as materials, preparing mixed solution of which the molar ratio of nickel to urea is 1:1 to 1:6 and then transferring the mixed solution to a 200mL of self-pressure lining polytetrafluoroethylene stainless steel reaction kettle, wherein the loading degree of a hydrothermal reaction kettle can be up to 80%; covering an inner cover and an outer cover to feed to an electric heating constant-temperature tank, heating the solution to 170 DEG C, reacting for 2-20 hours at constant temperature, then naturally cooling the solution to room temperature, filtering and washing the solution into a neutral state by deionized water; drying the solution into constant weight at 80 DEG C, and thinning the petals to prepare the nano petaline Ni(OH)2. According to the preparation method, the urea is taken as a precipitator, and a nano petaline Ni(OH)2 microsphere is directly prepared by hydrothermal syntheses; the method is simple in process, low in cost and easy to control without high-temperature sintering or a template agent, the obtained product crystal particle has the advantages that the size is uniform; the particle purity is high; the dispersity is good, and the crystalline form is good and controllable.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

The preparation method of binary rus2 heterogeneous catalyst

The invention discloses a preparation method of a binary RuS2 heterogeneous catalyst, and belongs to the technical field of preparation of a ruthenium catalyst. The catalyst consists of a carrier and an active ingredient, wherein the carrier is any one of ZSM-5, SBA-15, gamma-Al2O3 and SiO2, and the active ingredient is Ru; the preparation method comprises the steps of dissolving RuCl3.3H2O in ethanol, adding the carrier to the ethanol, stirring, uniformly mixing and drying, implementing temperature programming in a high-pressure reaction kettle to 200-220 DEG C, prevulcanizing and drying a prevulcanized black solid in a vacuum drying oven to obtain the binary RuS2 catalyst. The method is simple and feasible, and moderate in reaction condition; and the prepared binary RuS2 catalyst is relatively high in particle granularity and shows a relatively high catalytic activity in a thiofuran desulfurization process, so that binary RuS2 catalyst can realize industrial production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A rare earth samarium zirconate nanomaterial and its hydrothermal preparation method

InactiveCN102674455BIncrease scatteringMean Free Path DecreaseZirconium compoundsNanotechnologySemiconductor materialsRare earth

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Porcelain ceramic particle water scalpel sand and preparation method thereof

InactiveCN110202488ASimple preparation processNo pollution in the processOther chemical processesAbrasion apparatusBrickHigh pressure water

The invention relates to porcelain ceramic particle water scalpel sand and a preparation method thereof. A porcelain ceramic tile consists of the following components including, by weight,65%-75% of SiO2, 15%-25% of Al2O3, 1.0%-2.0% of FeO3, 0.5%-1.0% of CaO, 1%-2% of MgO, 1%-4% of K2O and 2%-4% of Na2O. The preparation method for the porcelain ceramic particle water scalpel sand comprises the following steps of(1) preparing, wherein after pug, sand and auxiliary materialadditives are added into a ball mill in proportion to prepare mud, powder is sprayed through a spray drying tower, and the mud is dried and is fed into a roller kiln to be fired; (2) crushing, wherein the porcelain ceramic tile is crushed and processed to obtain porcelain ceramic particles with a proper particle size; (3)grinding, wherein all particles are added into a grinding mill to be coarsely groundand then finely ground; (4) screening, wherein the particles pass through a screen to be separated to obtain porcelain ceramic particles, namely high-pressure water jet cut abrasive water scalpel sand; and (5) dust removal, wherein the porcelain ceramic particle water scalpel sand is subjected to dust removal to obtain porcelain ceramic particle water scalpel sand abrasive which meets requirements.

Owner:GUANGDONG JIA MEI CERAMIC +3

Dry powder granulation process for mica powder

The invention discloses a dry powder granulation process for mica powder. The process includes the steps of: S1, putting mica powder into a crusher for crushing treatment, S2, preparation of mica powder screening equipment; S3, installation of an induced draft fan; S4, screening treatment of mica powder; S5, ball-milling treatment of the mica powder in S4 in a ball mill to obtain dry mica powder;and S6, granulation treatment on the dry mica powder by a dry powder roller granulator, thus obtaining dry mica powder granules. The dry powder granulation process for mica powder provided by the invention is simple in operation method, the prepared mica powder granules have high purity, and the production cost is low, therefore the process is suitable for popularization and use.

Owner:ANHUI HENGHAO SCI & TECH

A preparation method of rod-shaped self-assembled spherical zinc-cadmium-sulfur solid solution material

ActiveCN108675339BImprove photocatalytic performanceImprove photocatalytic abilityPhysical/chemical process catalystsCadmium compounds preparationHydration reactionEthylic acid

The invention discloses a method for preparing a rod-shaped zinc cadmium sulfur solid solution material that self-assembles into a spherical shape. H is measured using a graduated cylinder. 2 OAdd 10 mL EN (ethylenediamine) into it to prepare a mixed solution, perform magnetic stirring and ultrasonic to form mixed solution A; use zinc acetate dihydrate and cadmium nitrate tetrahydrate as raw materials, add to mixed solution A, and perform magnetic stirring After mixing and ultrasonic, a mixed solution B is formed; L-cysteine is used as the sulfur source and added to the mixed solution B. After magnetic stirring and ultrasonic, a mixed solution C is formed; the mixed solution C is added to the inner lining of polytetrafluoroethylene. In the process, a microwave hydrothermal reaction is carried out; after the reaction is completed, the zinc cadmium sulfur solid solution material powder can be obtained by centrifugal washing with deionized water and ethanol several times, and then drying and grinding.

Owner:SHAANXI UNIV OF SCI & TECH

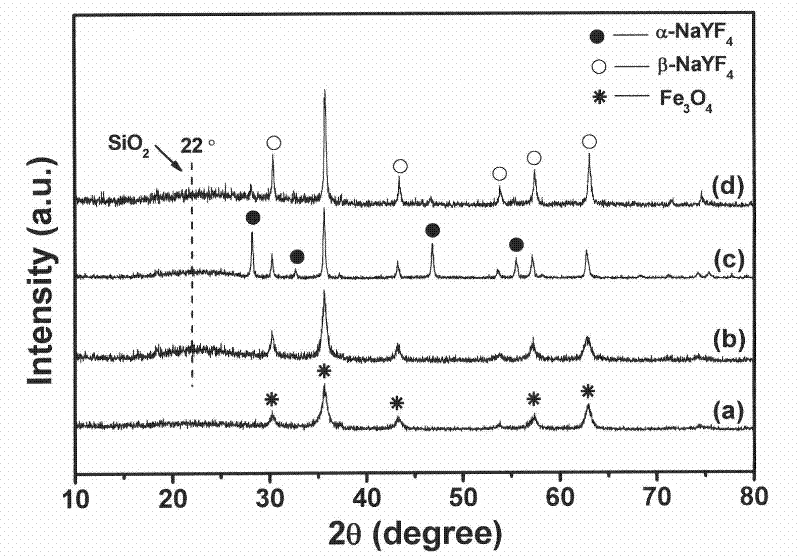

Membrane technology based preparation method of magnetic non-destructive testing material

InactiveCN105948136AHigh particle purityUniform particle size distributionMaterial nanotechnologyFerroso-ferric oxidesPolyvinylidene fluorideIon

The invention provides a membrane technology based preparation method of a magnetic non-destructive testing material. The preparation method comprises following steps: A, a1: ferric chloride and ferrous chloride are dissolved into a mixed solution S1 prepared from demineralized water, wherein an amount ratio of Fe<3+> to Fe<2+> is 1:1-3:2; a2, sodium hydroxide and a dispersing agent are dissolved into a mixed solution S2 prepared from the demineralized water, and an amount ratio of sodium hydroxide to the dispersing agent is 1:0.002-1:0.01; B, the mixed solution S1 and the mixed solution S2 are enabled to penetrate through a PVDF (polyvinylidene fluoride) membrane under the action of a pump, mixed in a reactor and subjected to a reaction, and a crude product of the magnetic non-destructive testing nanomaterial is produced; C, the produced crude product is subjected to water bath crystallization and magnetic separation and repeatedly washed with deionized water until the pH value of eluate is 7, ultrasonic oscillation is performed, and after drying, the magnetic non-destructive testing nanomaterial is obtained.

Owner:GUANGDONG INSPECTION & RES INST OF SPECIAL EQUIP ZHUHAI INSPECTION INST +1

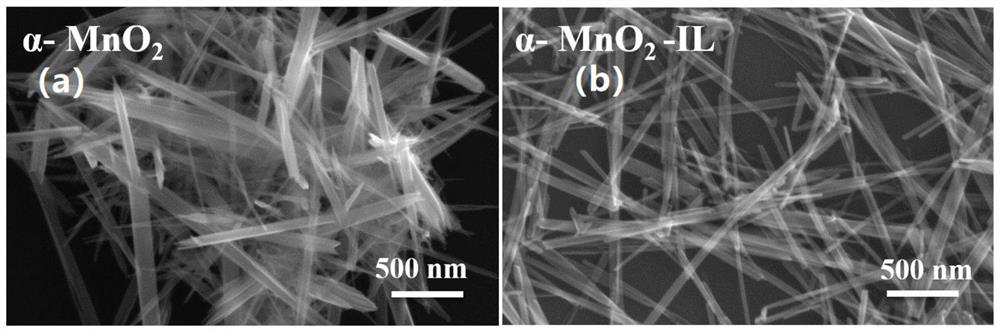

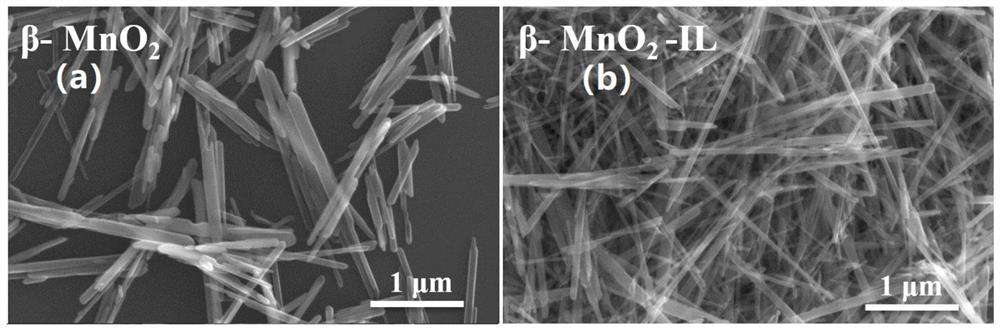

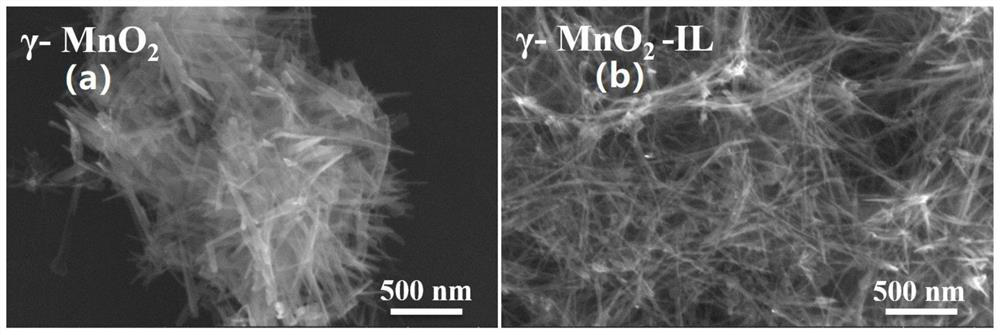

Preparation method of manganese oxide one-dimensional nanowire

The invention relates to a preparation method of a manganite one-dimensional nano wire. The preparation method of the manganite one-dimensional nano wire comprises the following steps of dissolving areducing agent, an oxidizing agent and an imidazolium-based ionic liquid into water, then carrying out hydrothermal reaction at 90 to 200 DEG C, and separating out a solid, wherein the solid is a manganese oxide crude product, the reducing agent is manganese sulfate, and the oxidizing agent is potassium permanganate or peroxysulphate, and preferably, hydrothermal reaction is carried out at 90 to 160 DEG C; roasting the manganite crude product in air at 300 to 450 DEG C, and obtaining the manganite one-dimensional nano wire, wherein manganite is manganese dioxide or manganic oxide, a crystal form of manganese oxide is an alpha crystal form, a beta crystal form or a gamma crystal form. The method provided by the invention is simple and easy to operate, low in raw material cost, applicable toindustrial production, and capable of preparing the manganite one-dimensional nano wire with a high draw ratio.

Owner:SUZHOU UNIV

A kind of preparation method of carbon particle/manganese dioxide composite electrode material

ActiveCN105405680BHigh particle purityGood dispersionHybrid capacitor electrodesHybrid/EDL manufactureGas phaseManganese

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com